Patents

Literature

196results about "Evaporators with forced circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

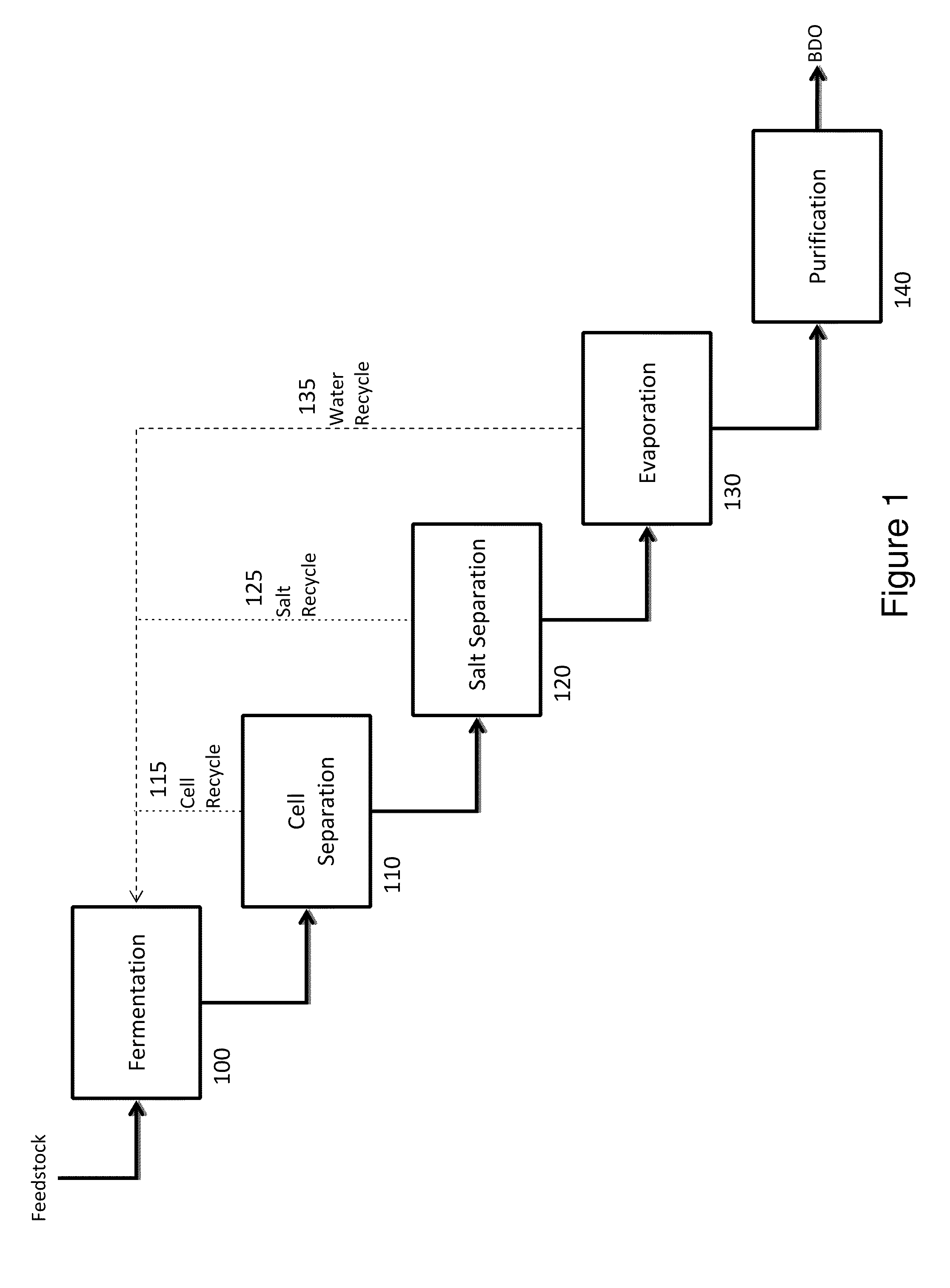

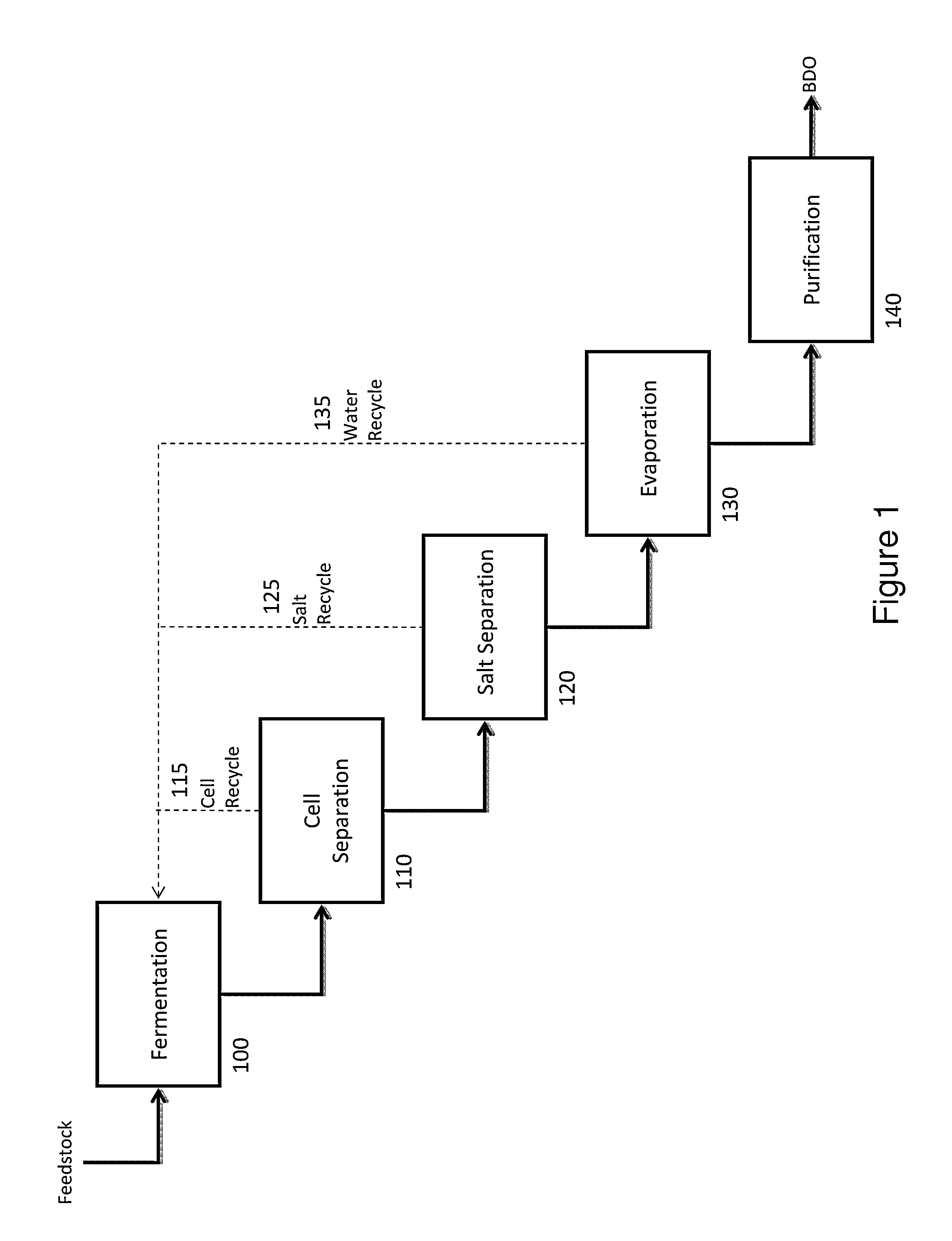

Process of separating components of a fermentation broth

ActiveUS20110003355A1Produce lotFermented solutions distillation/rectificationOrganic compound preparation1,4-ButanediolMicroorganism

A process of isolating 1,4-butanediol (1,4-BDO) from a fermentation broth includes separating a liquid fraction enriched in 1,4-BDO from a solid fraction comprising cells, removing water from said liquid fraction, removing salts from said liquid fraction, and purifying 1,4-BDO. A process for producing 1,4-BDO includes culturing a 1,4-BDO-producing microorganism in a fermentor for a sufficient period of time to produce 1,4-BDO. The 1,4-BDO-producing microorganism includes a microorganism having a 1,4-BDO pathway having one or more exogenous genes encoding a 1,4-BDO pathway enzyme and / or one or more gene disruptions. The process for producing 1,4-BDO further includes isolating 1,4-BDO.

Owner:GENOMATICA INC

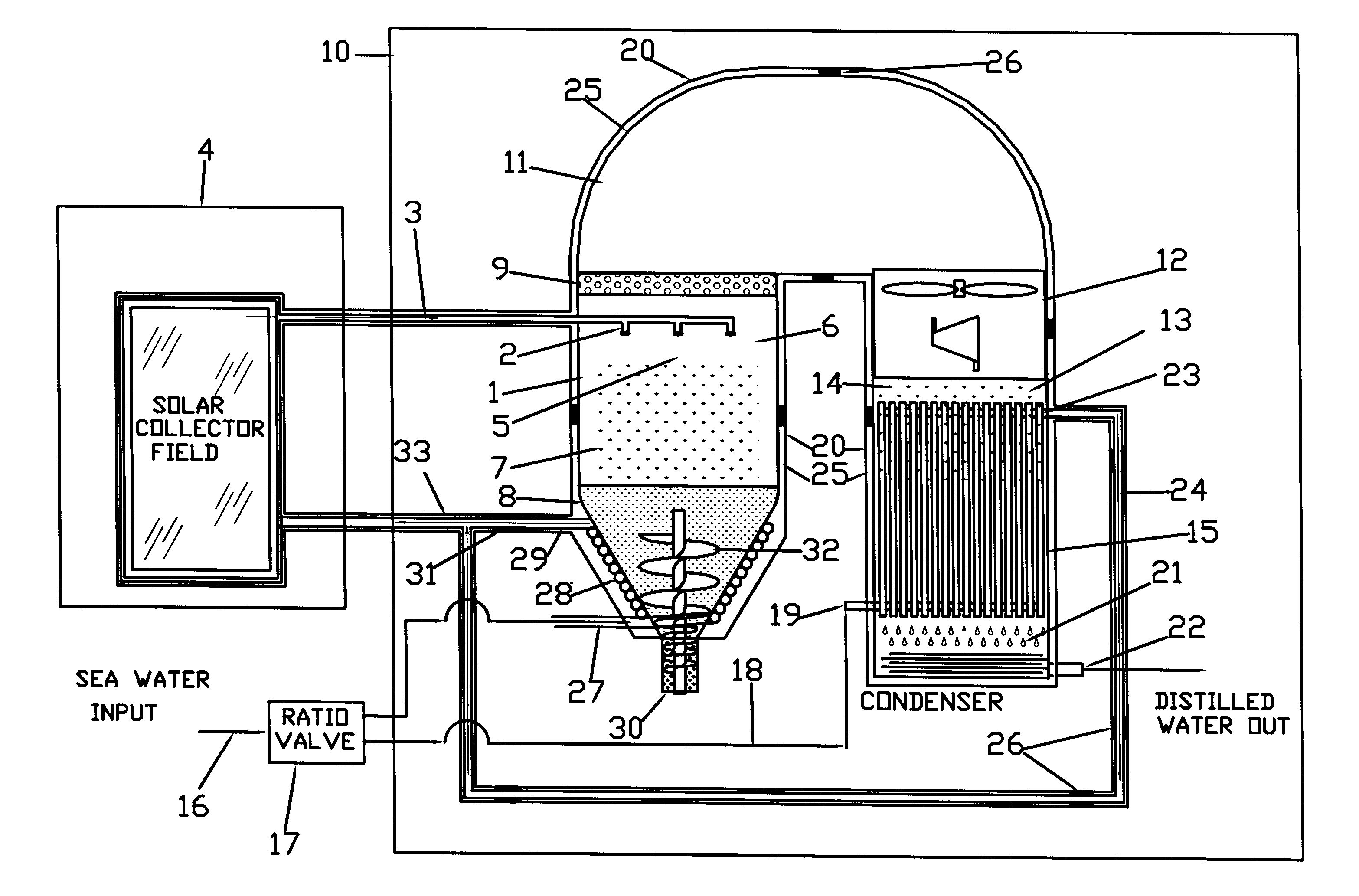

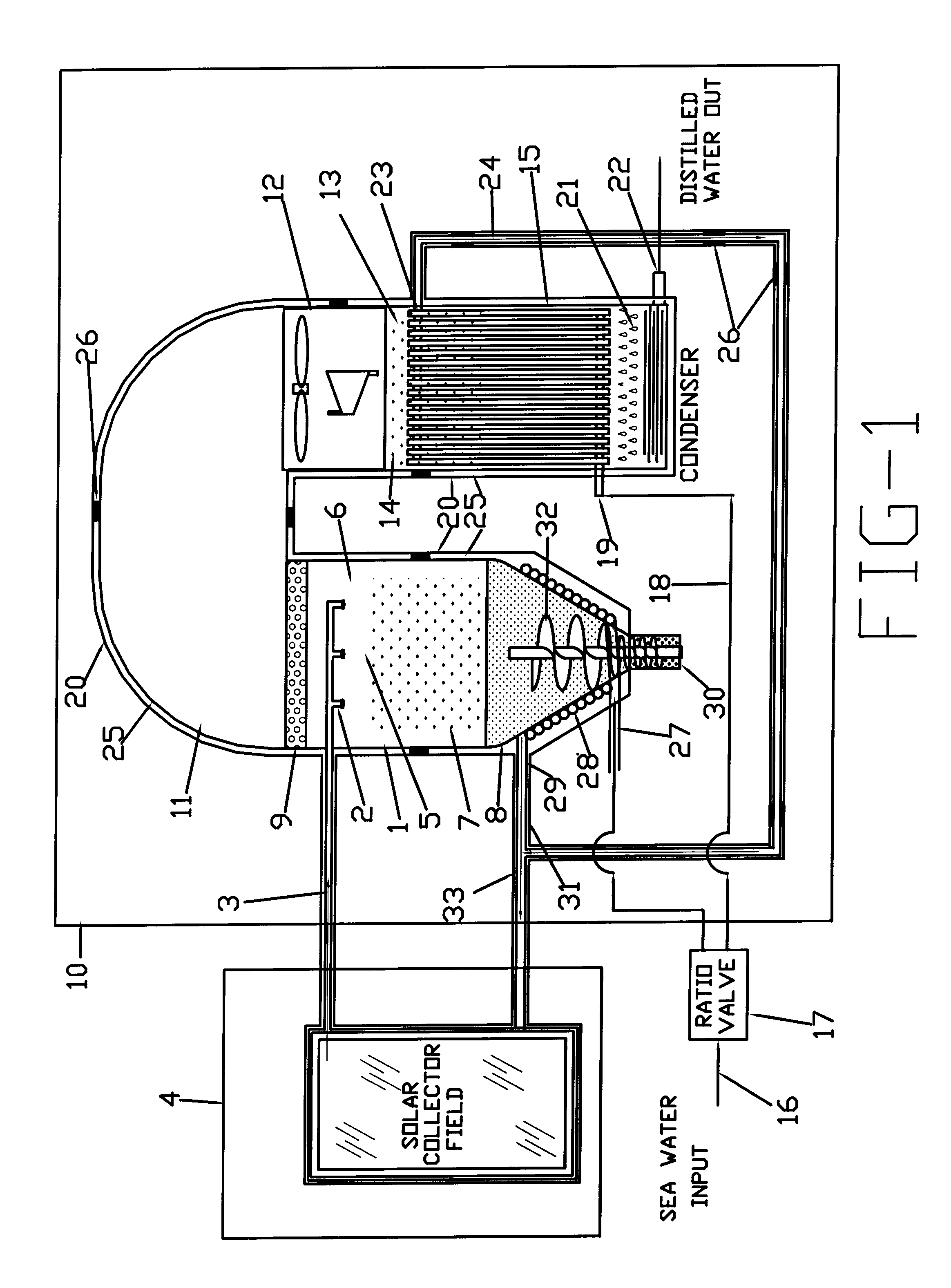

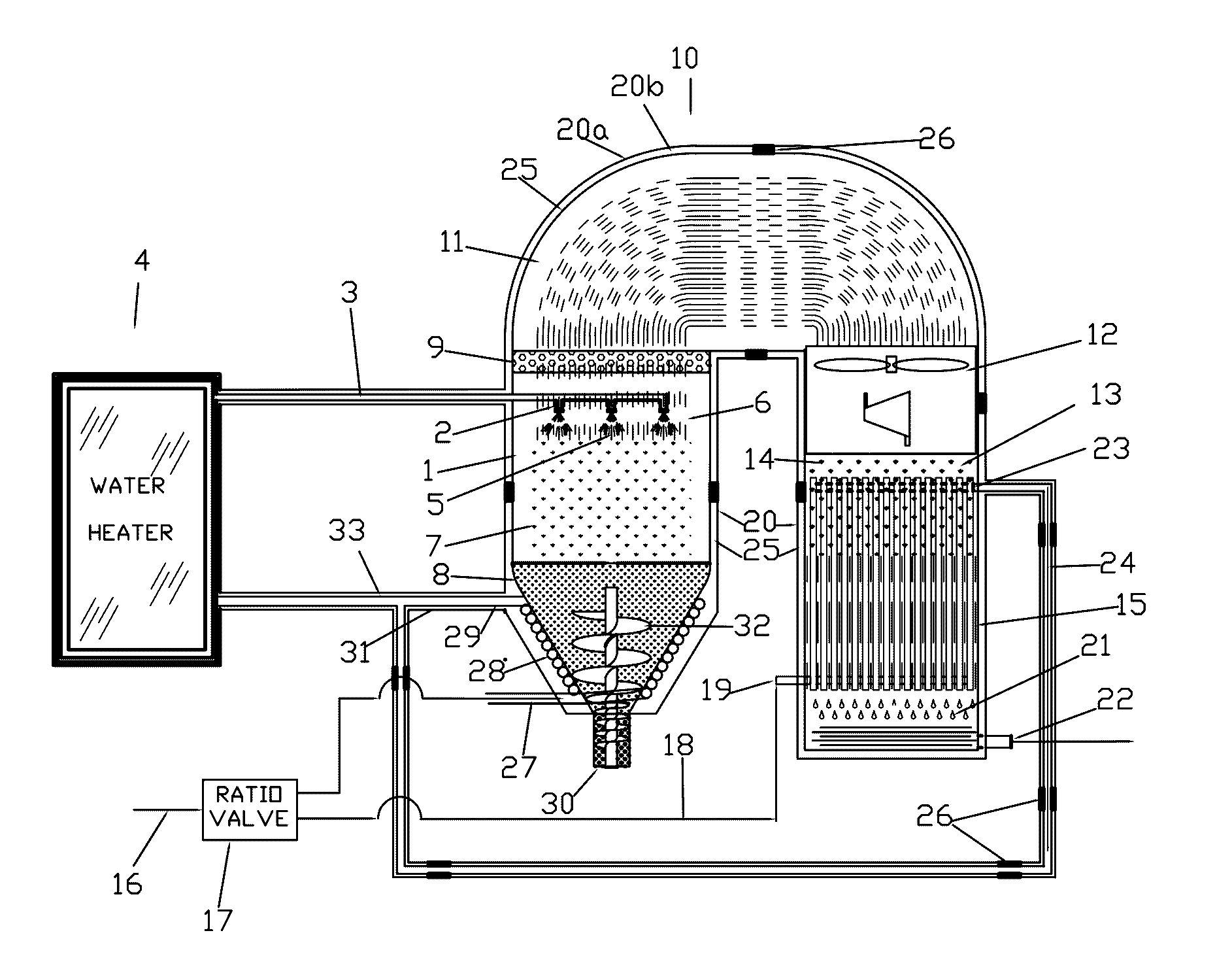

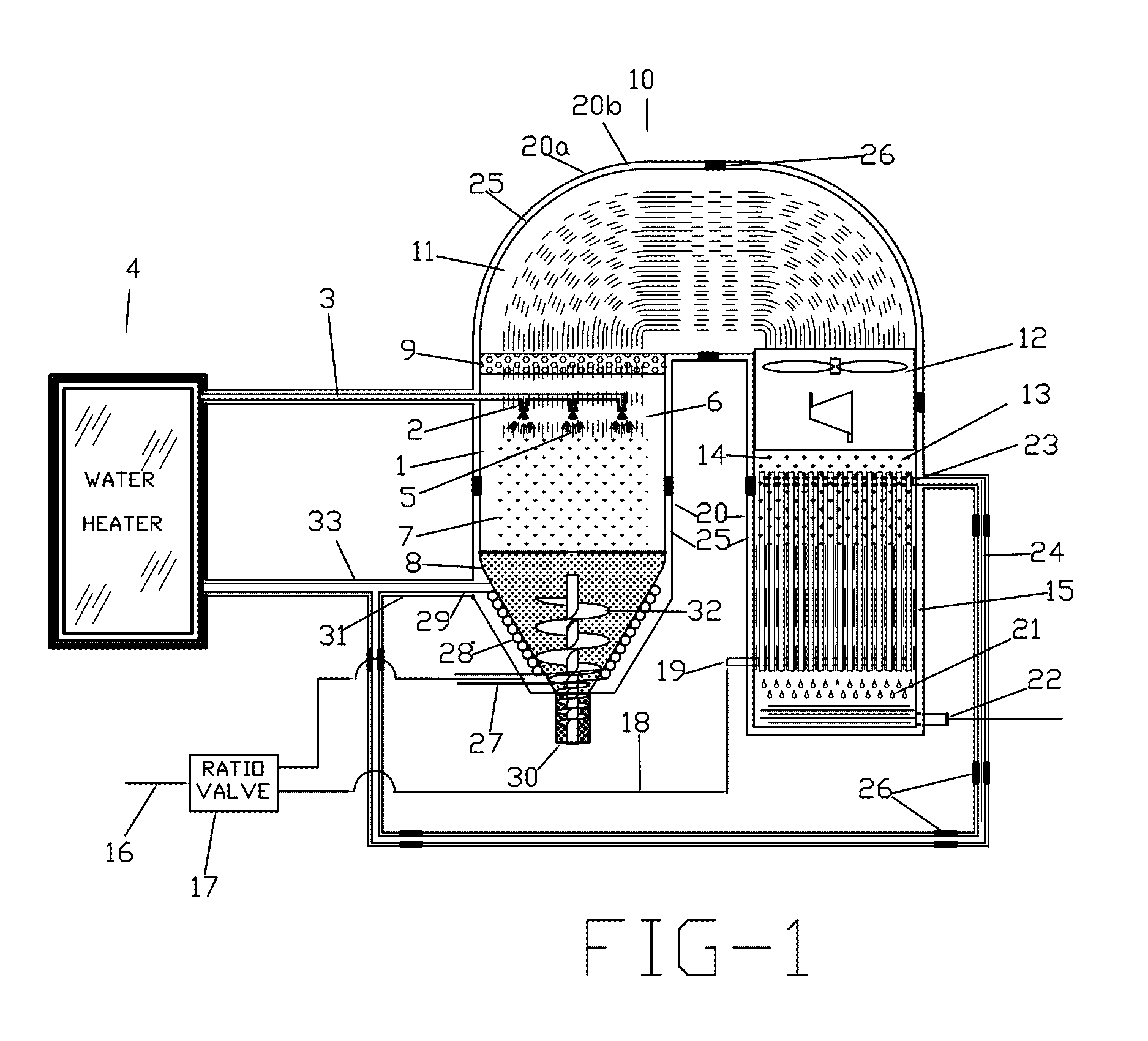

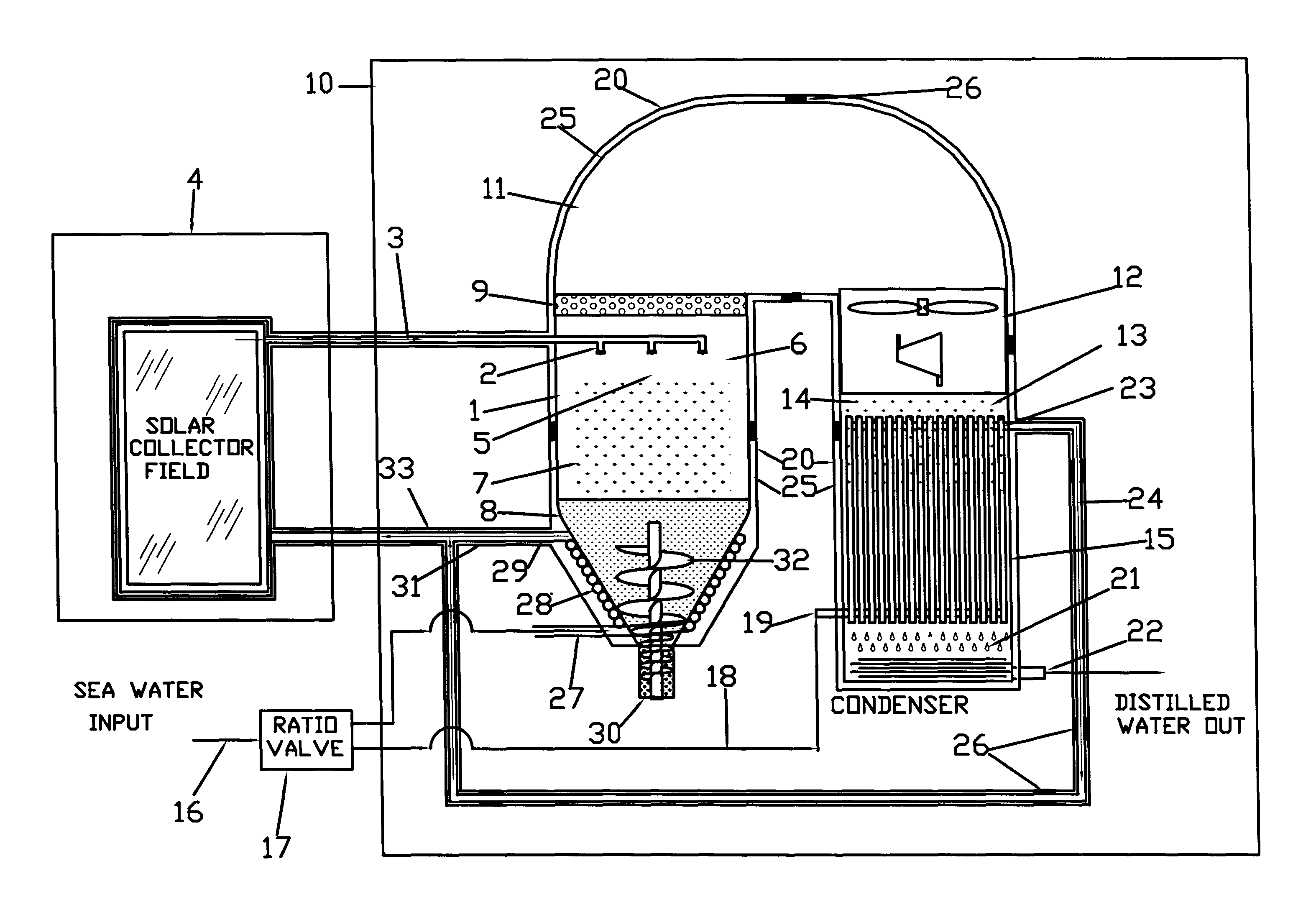

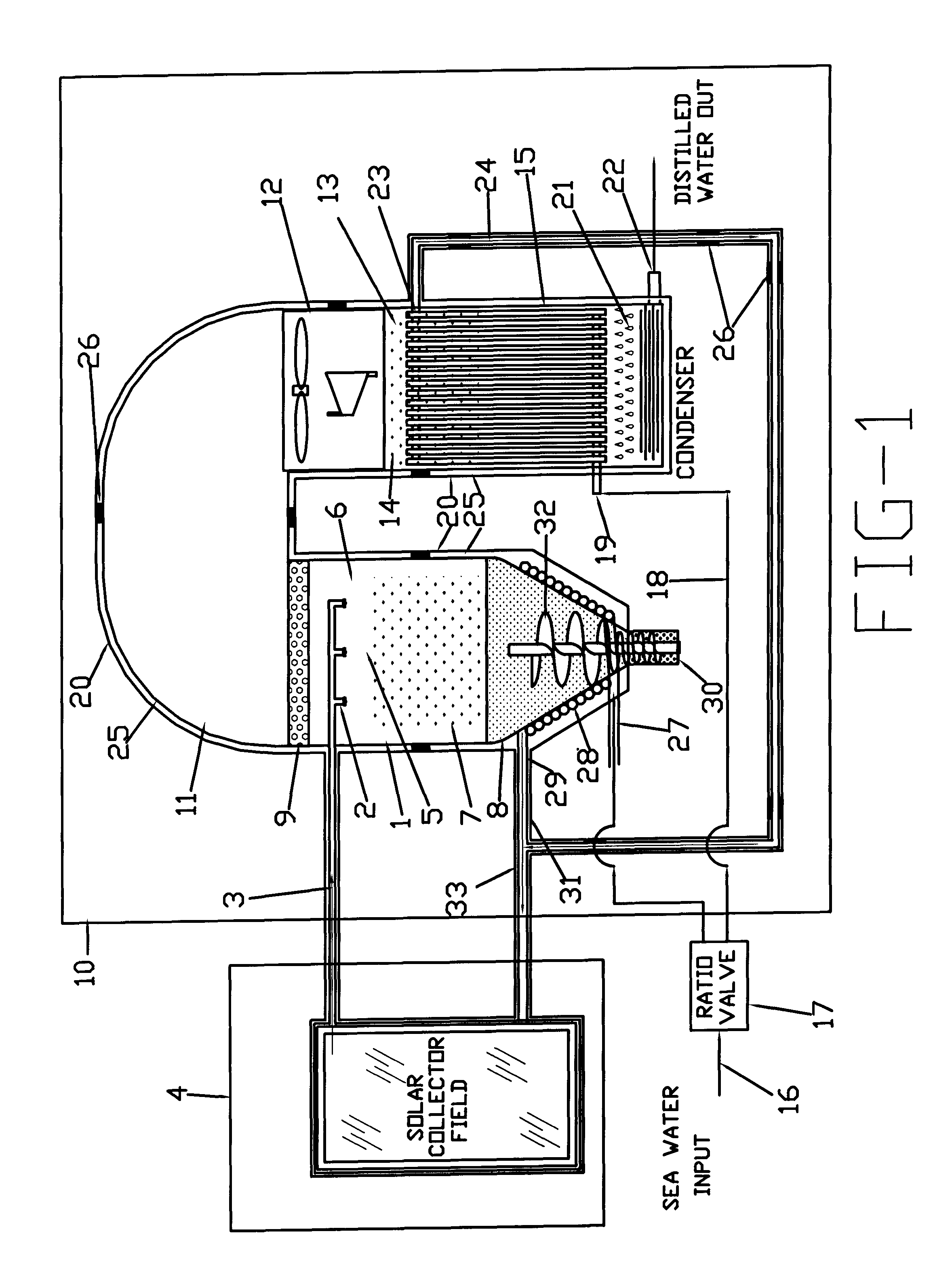

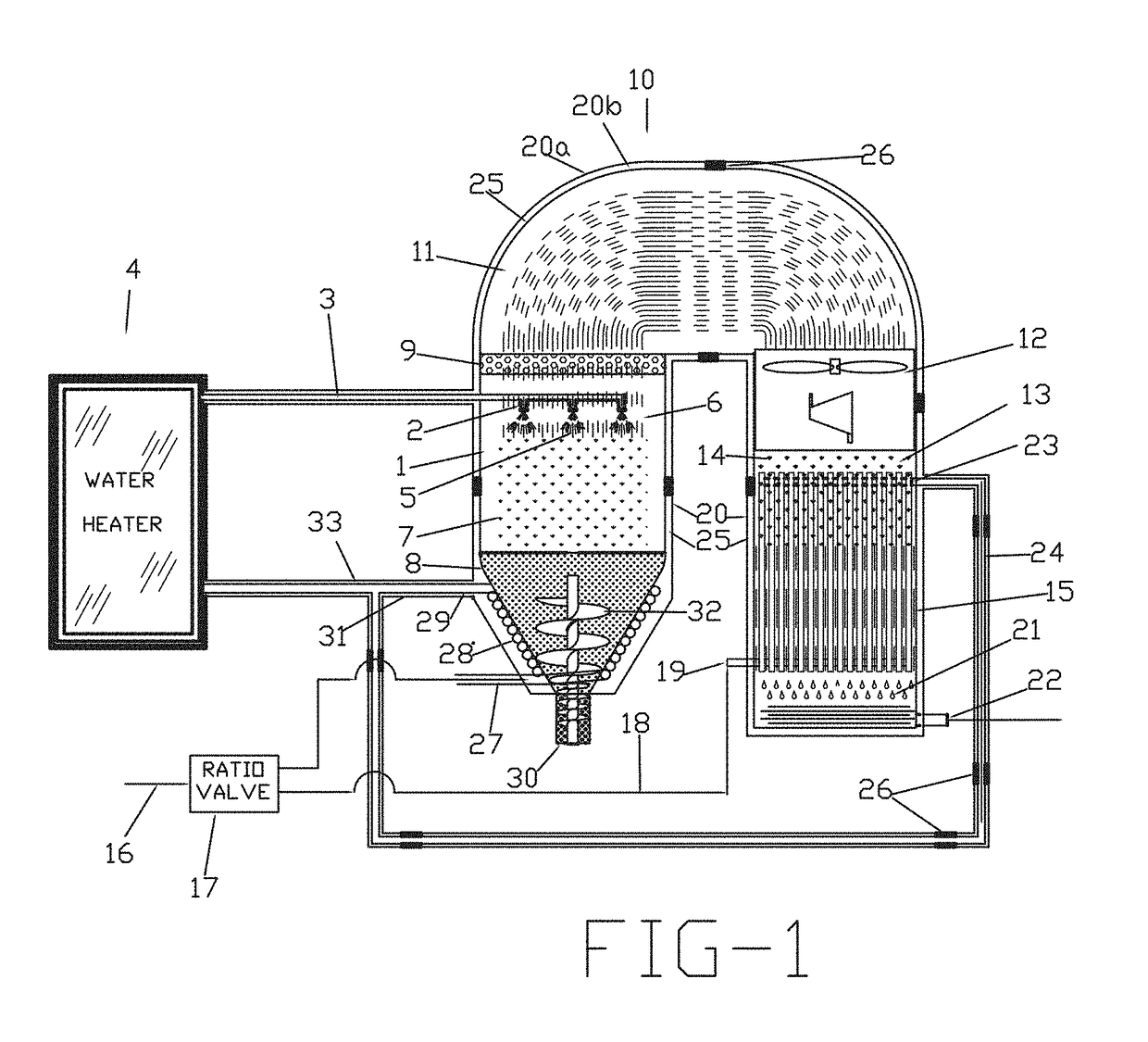

Large scale insulated desalination system

ActiveUS20120085635A1Improve distillation efficiencyLower energy requirementsGeneral water supply conservationAuxillariesDistillationBrackish water

An apparatus and method for the distillation of ocean and brackish water that includes insulation means for preventing heat from escaping to the atmosphere is disclosed. The insulation means comprises a second wall surrounding the basic assemblies of a desalination system in which the space between the second wall and basic assemblies is under low partial vacuum and is partially or totally filled with an insulation material for structural support. The system provides a means for flash evaporation of heated input water and condensing the resultant vapors into pure distilled water. A means for recapturing and using the heat of condensation as well as heat from the salt byproduct to preheat the input contaminated water is also disclosed.

Owner:FLO ONICS LLC

Closed loop cleaning system

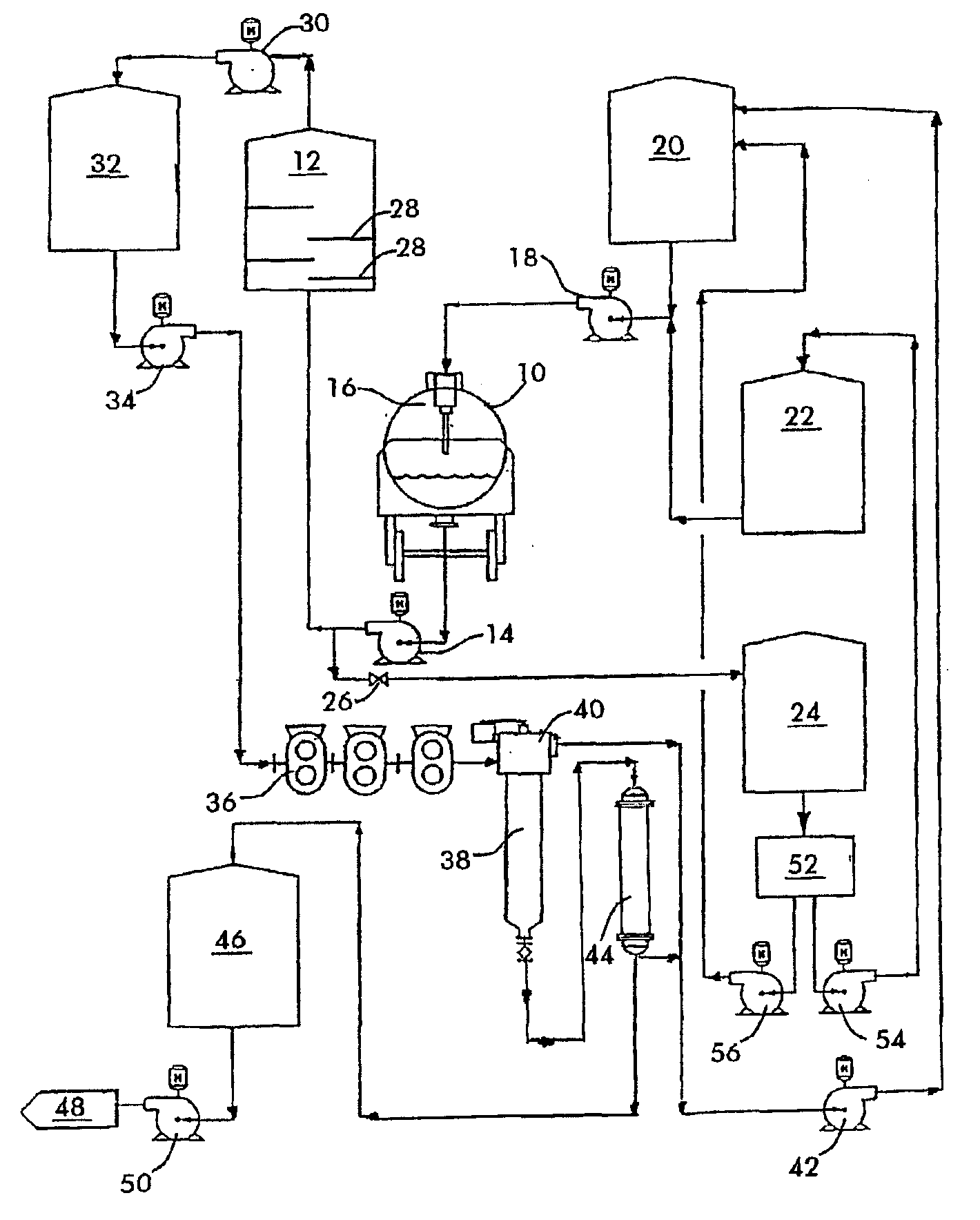

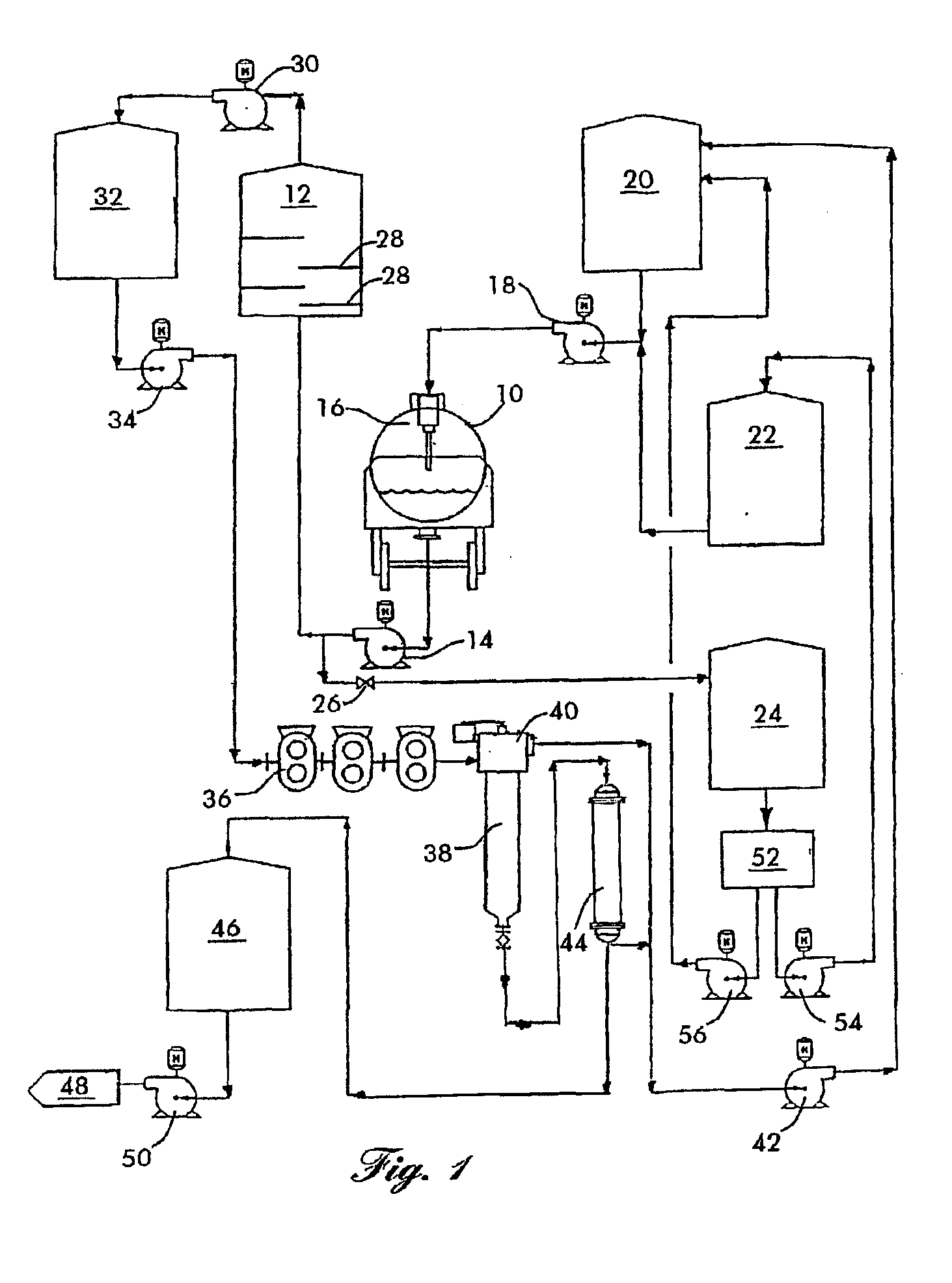

InactiveUS6858090B2Hollow article cleaningLiquid hydrocarbon mixture productionDistillationPetroleum product

Railroad tank cars that have contained petroleum products are cleaned of asphalt residues by a closed cleaning system. An initial spray of terpene-based solvent is followed by a water rinse. The solvent extracts hydrocarbons from the asphalt residue. The solvent and hydrocarbon are separated by filtration, stratification, and distillation, allowing reuse of clean solvent and sale of marketable oil products. The rinse water is cleaned by filtration and evaporation of solvent residues, allowing reuse of the water. The asphalt solids such as residual inorganics are removed by filtration as a dry product suited for disposal in a landfill.

Owner:HEBERT SHIRLEY A

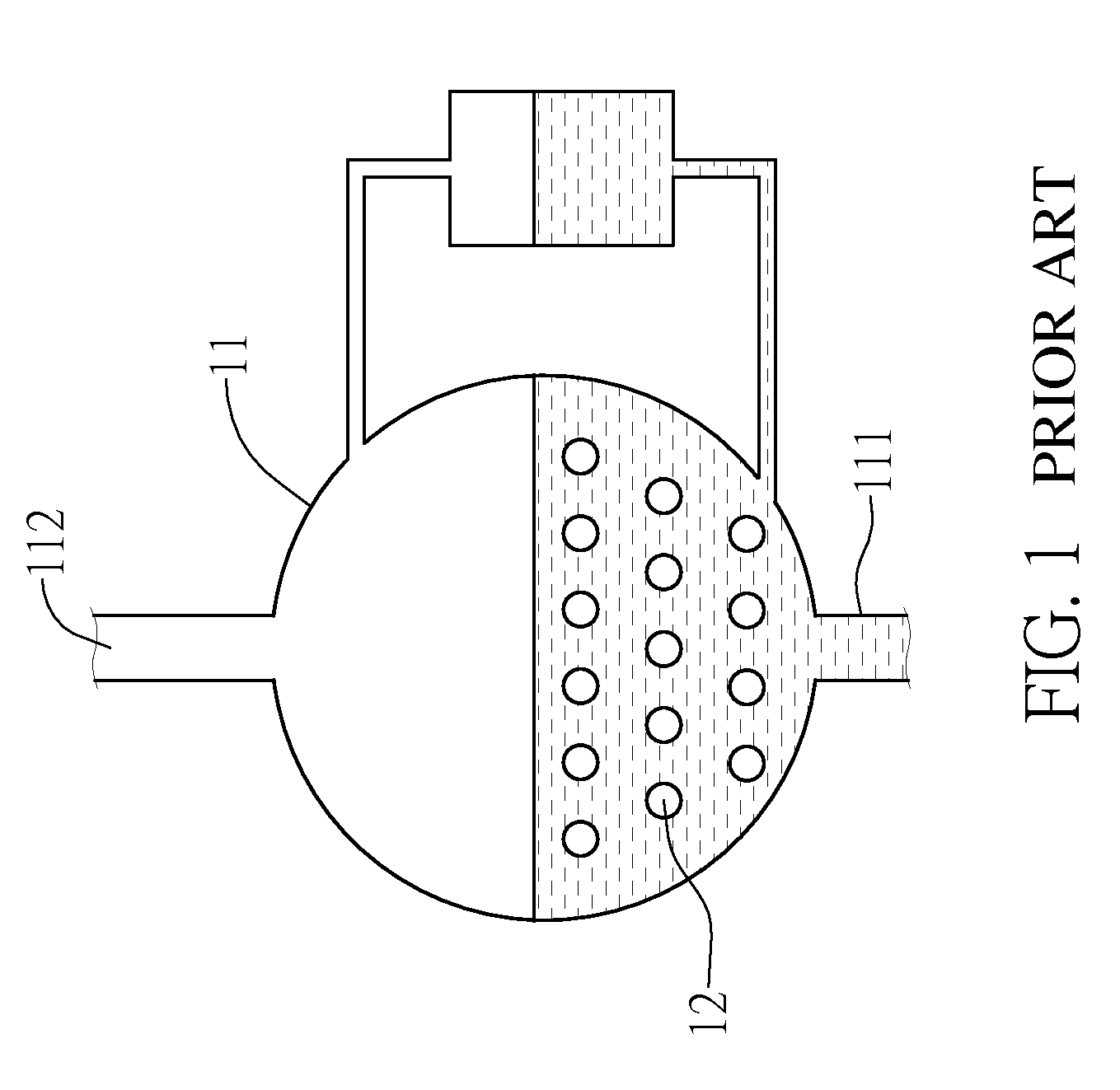

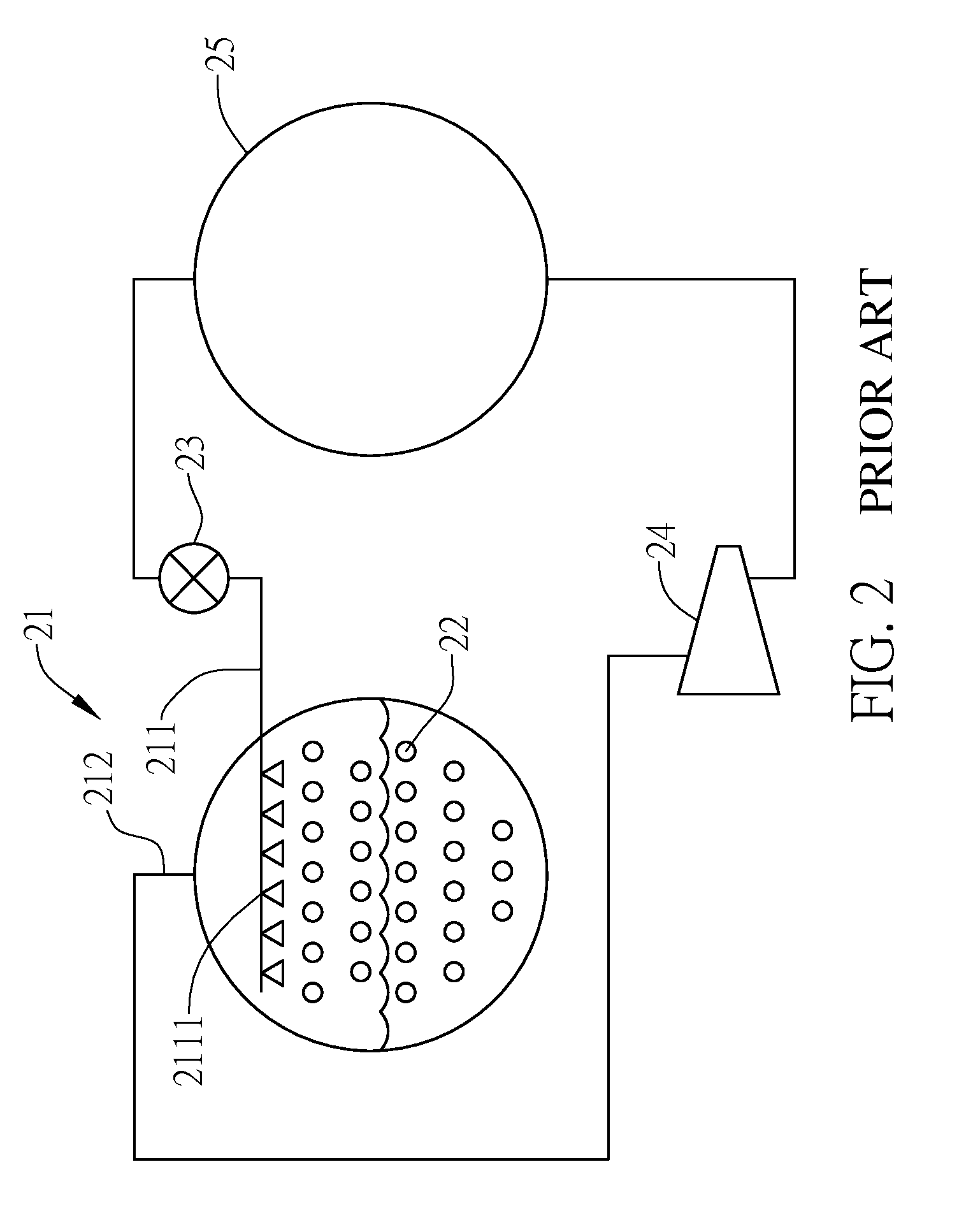

Solar distilling apparatus for alcohol

InactiveUS20060037853A1Reduce the temperatureFermented solutions distillation/rectificationGeneral water supply conservationAlcoholSteam condensation

A distilling apparatus for alcohol includes an evaporation tank having a compartment for receiving fermented alcoholic liquid. A heating tube is mounted in the compartment for heating the fermented liquid into steam. A condensing device is communicated with the evaporation tank for receiving and condensing steam from the evaporation tank. A collecting tank is communicated with the condensing device for collecting condensed liquid from the condensing device. A negative pressure creating device creates a negative pressure in the evaporation tank, allowing the fermented alcoholic liquid in the evaporation tank to evaporate at a low temperature. A solar energy collecting device includes a solar energy collector and a water tank containing water heated by the solar energy collector. Hot water in the water tank flows into the heating tube for heating the fermented alcoholic liquid in the evaporation tank.

Owner:ROAN TONY +1

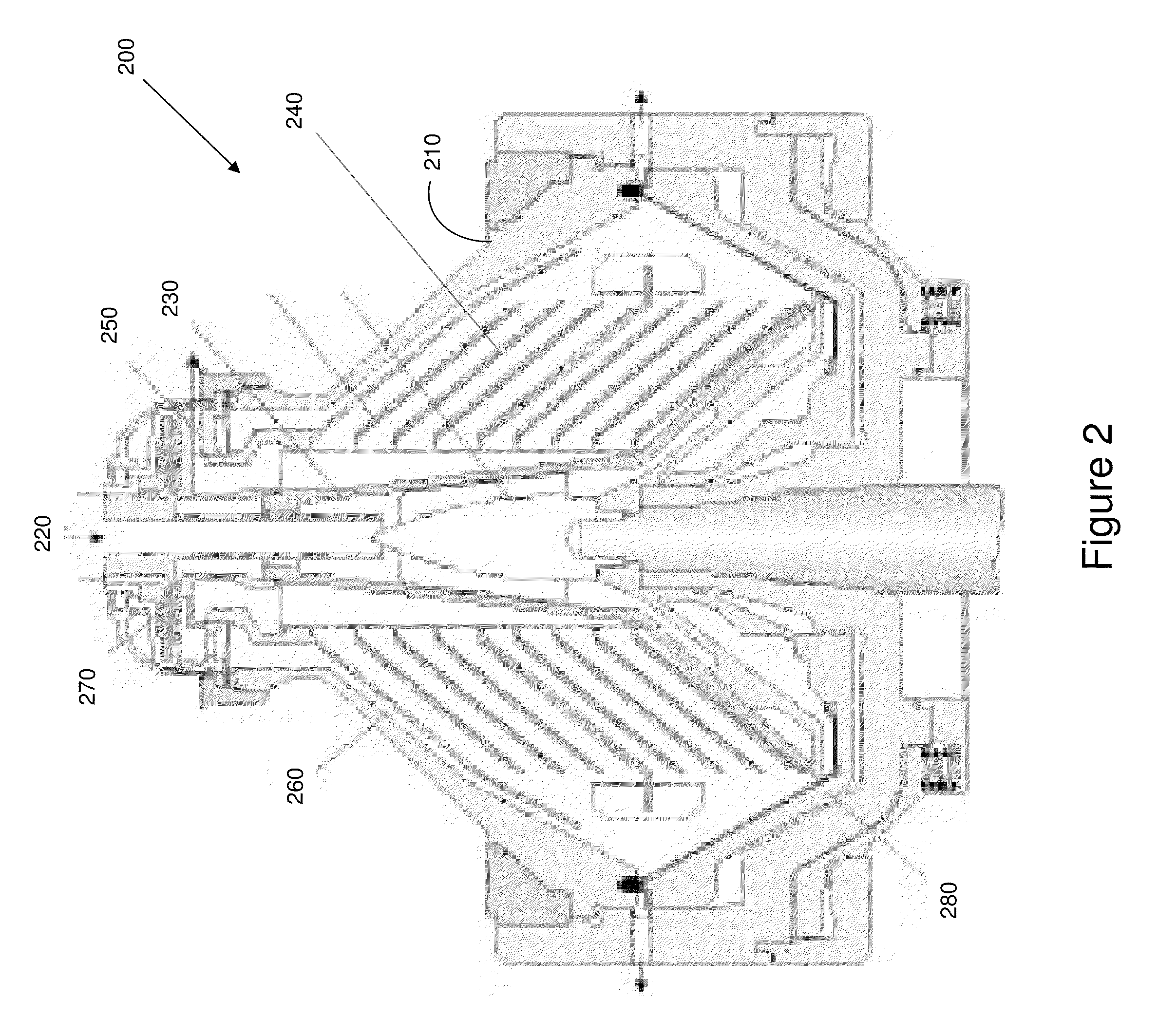

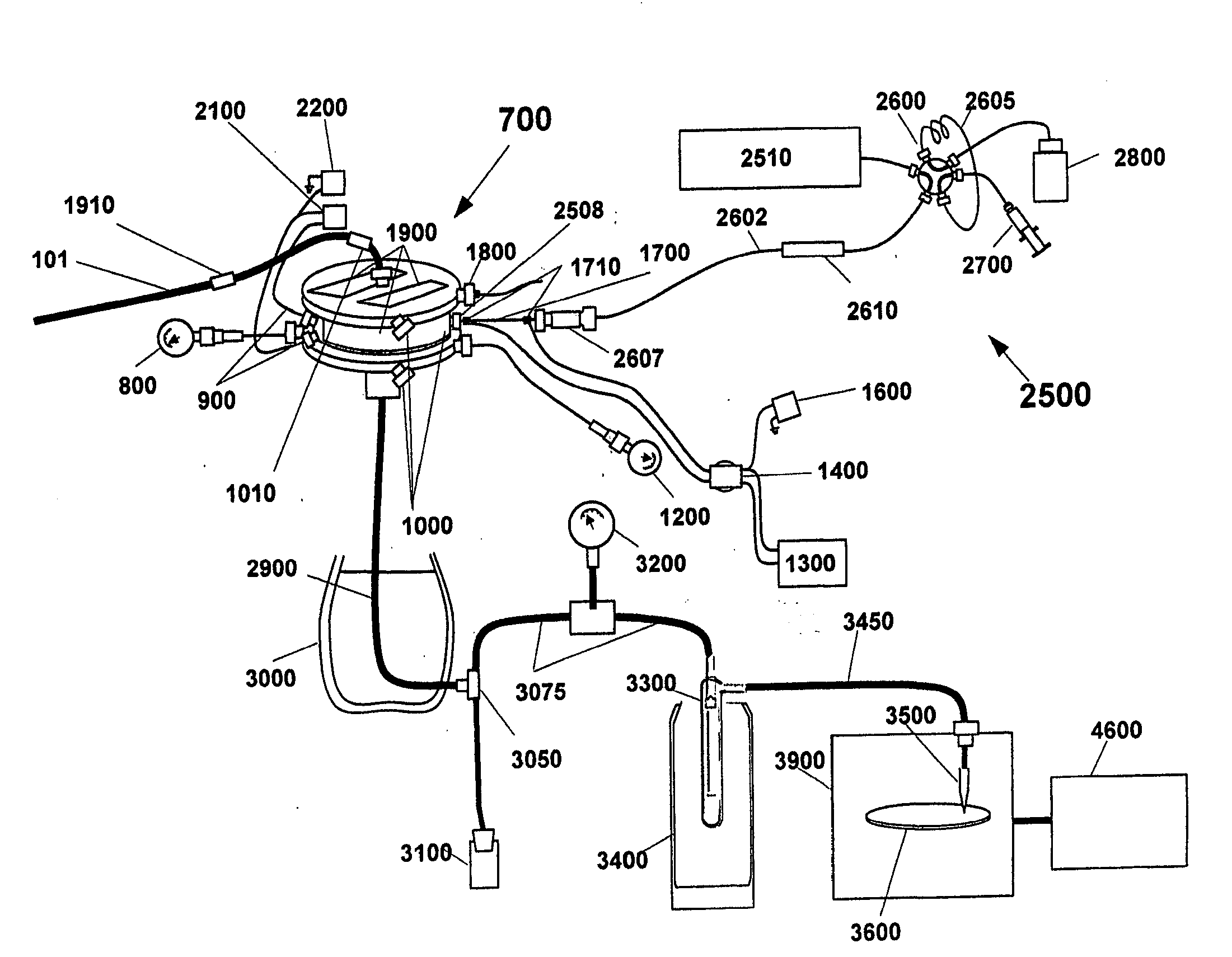

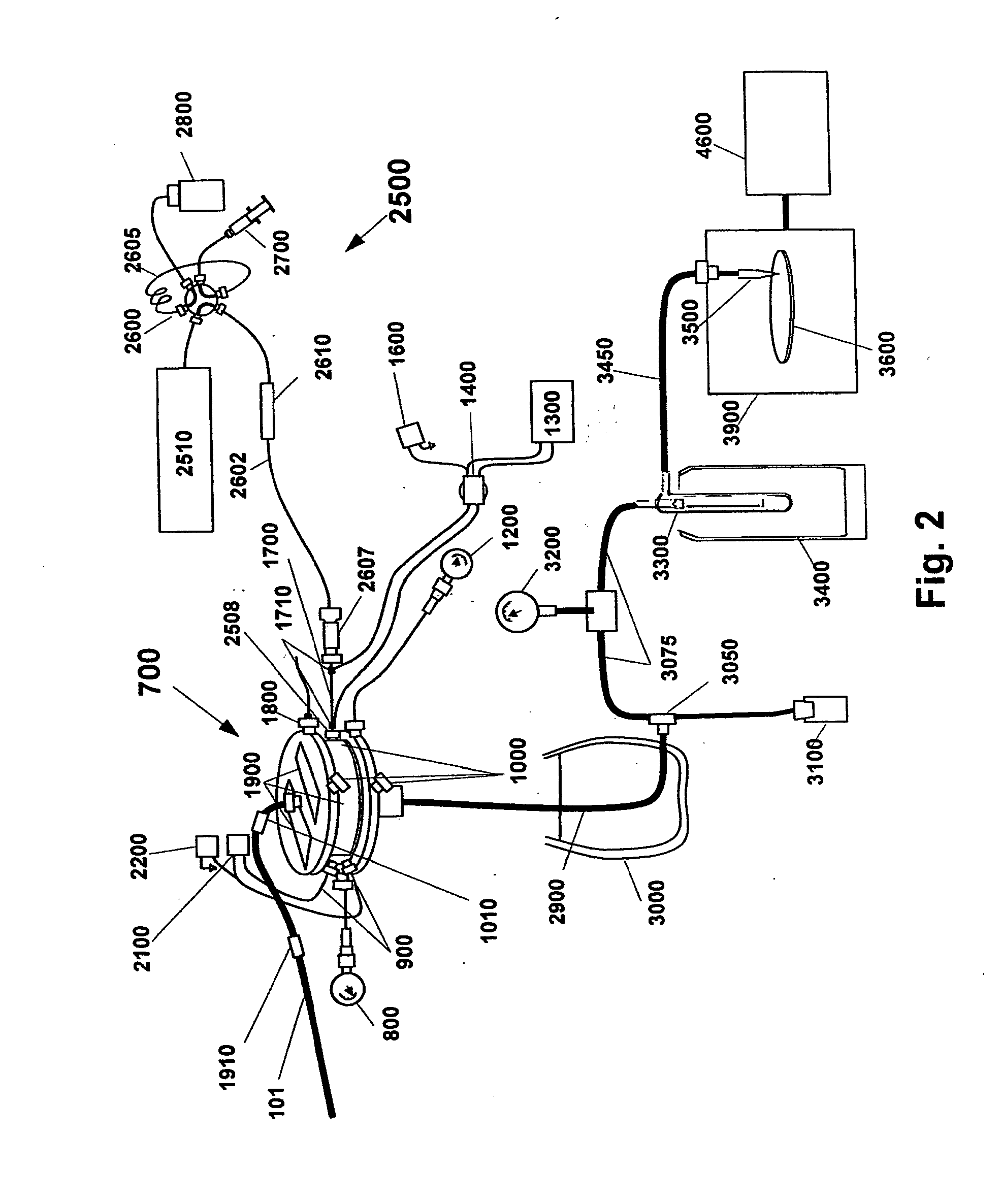

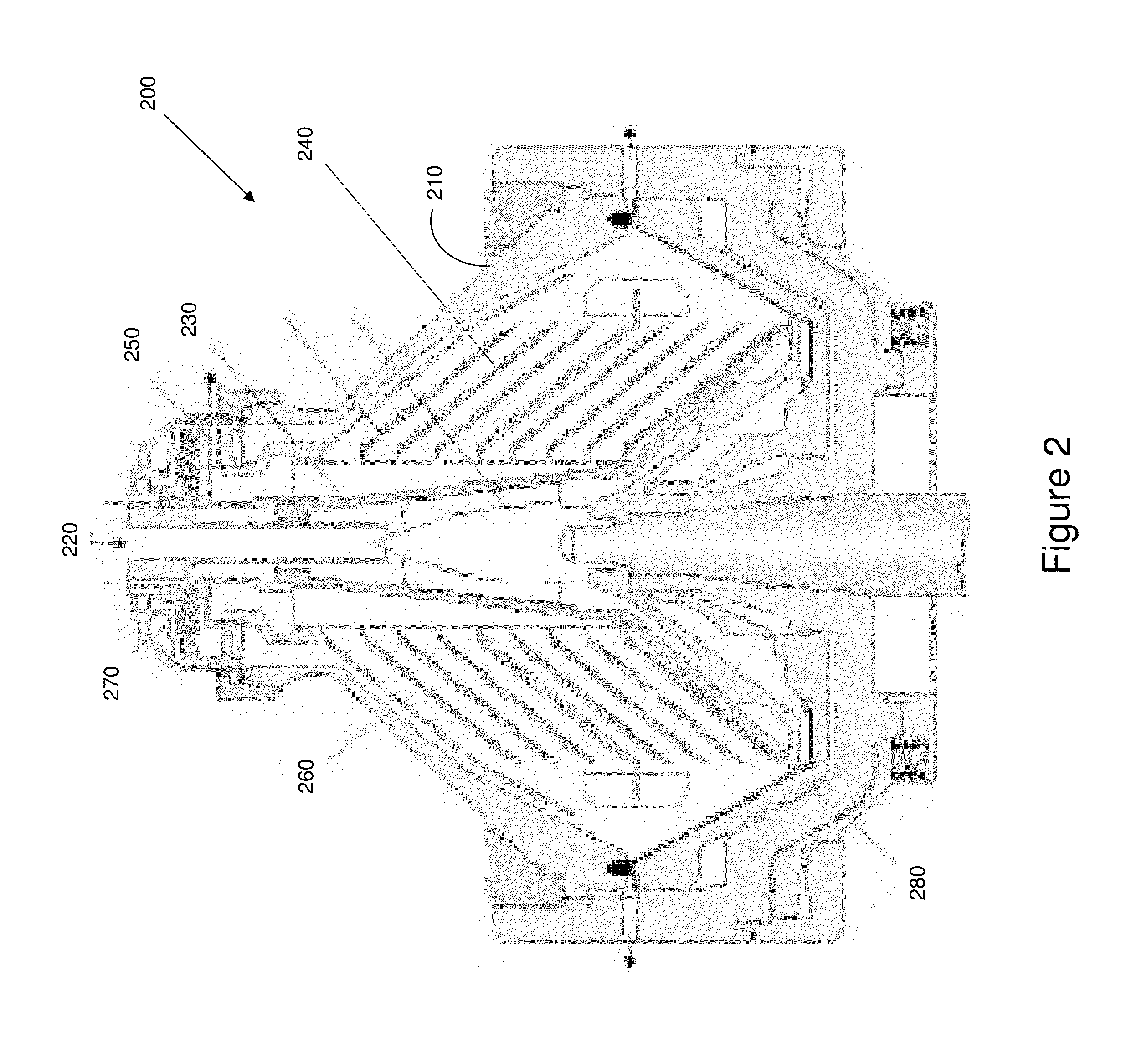

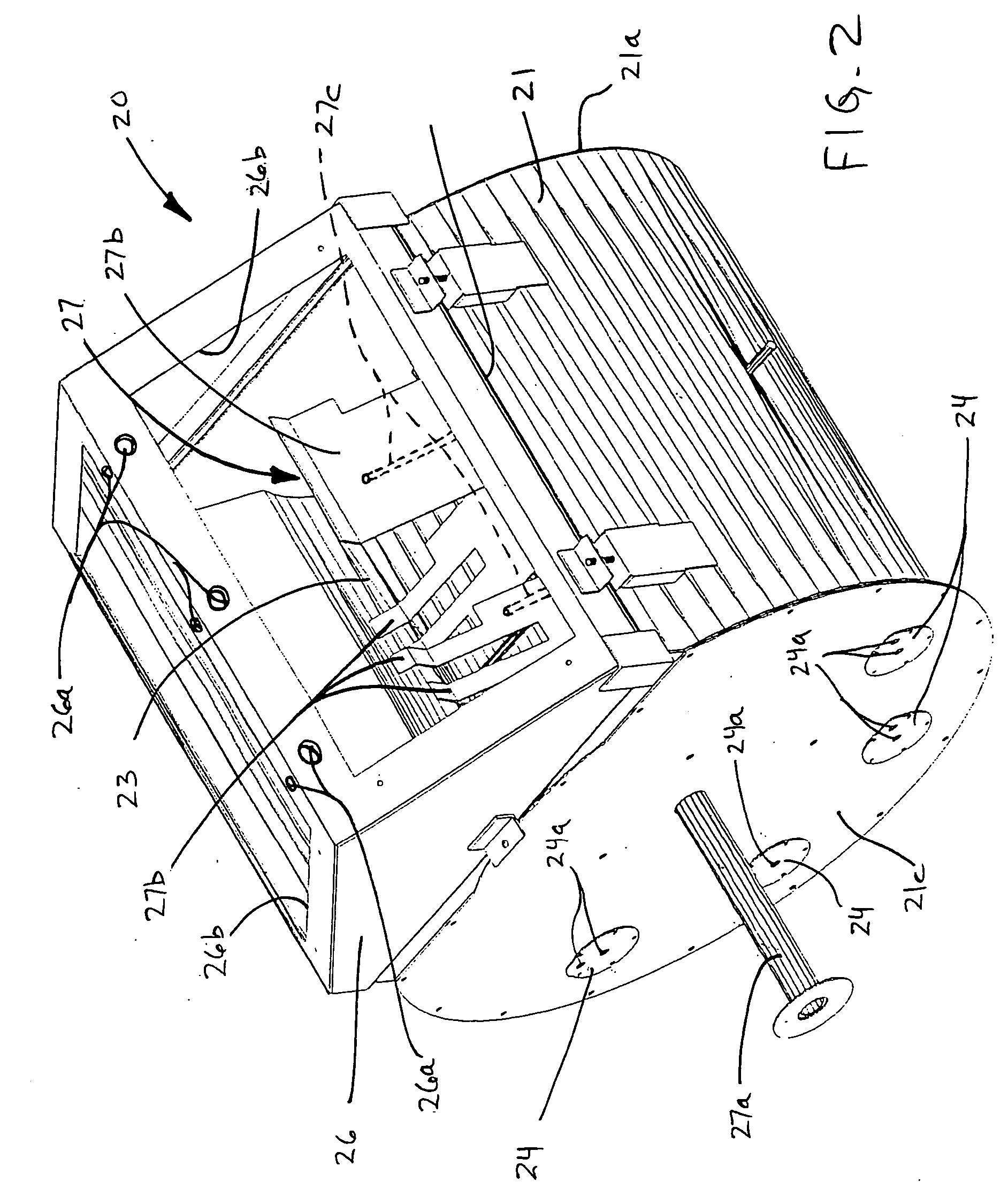

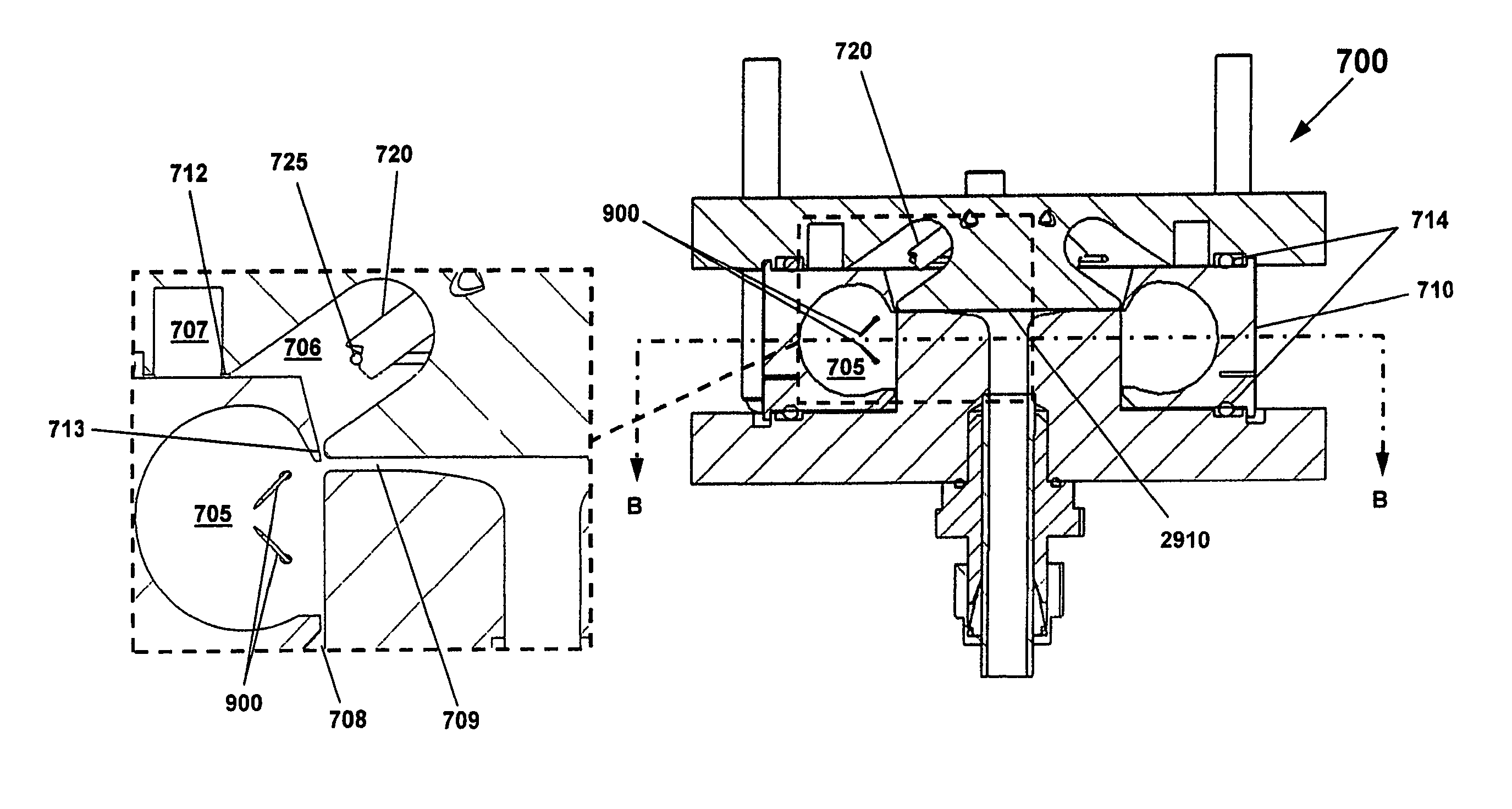

Method and apparatus for desolvating flowing liquid

ActiveUS20100000943A1Quick releaseAvoid contactLiquid degasificationComponent separationTemporal resolutionSolvent vapor

Methods and apparatus for desolvating flowing liquid streams while retaining temporal resolution of dissolved substrates are disclosed. A novel small-scale self-regulating spray dryer preserves temporal resolution while desolvating a liquid chromatography eluent stream and depositing the solute onto an optical surface for infrared spectrographic analysis. The liquid eluent is pumped through a heated nebulizer to create a high-speed jet of solute containing liquid and solvent vapor. This jet is directed circumferentially inside a hot cylindrical cavity. Centrifugal force causes the larger liquid droplets to travel along the outer diameter of the cavity. The cavity surface is heated to cause the droplets to film boil. Film boiling reduces droplet contact with the cavity surface thereby retaining the solute in the droplets. The solute temperature is limited by controlling the pressure into which the solvent evaporates from the droplets. When the droplets are sufficiently small, Stokes drag from the exiting solvent vapor carries the droplets out through the center of the cylindrical cavity. After exiting, the superheated solvent vapor further dries the droplets. Solvent vapor is removed by condensation onto a cooled surface. A freezing point reducing agent may be added to improve removal of solvent condensate. Stokes drag from a non-condensable gas maintains the dried droplets in suspension. This suspension travels through an orifice that focuses the impaction of the dried droplets onto the optical surface for infrared analysis. The deposition surface is in an evacuated chamber and is temperature controlled to freeze liquid solutes yet allowing sublimation of residual solvent.

Owner:SPECTRA ANALYSIS INSTR

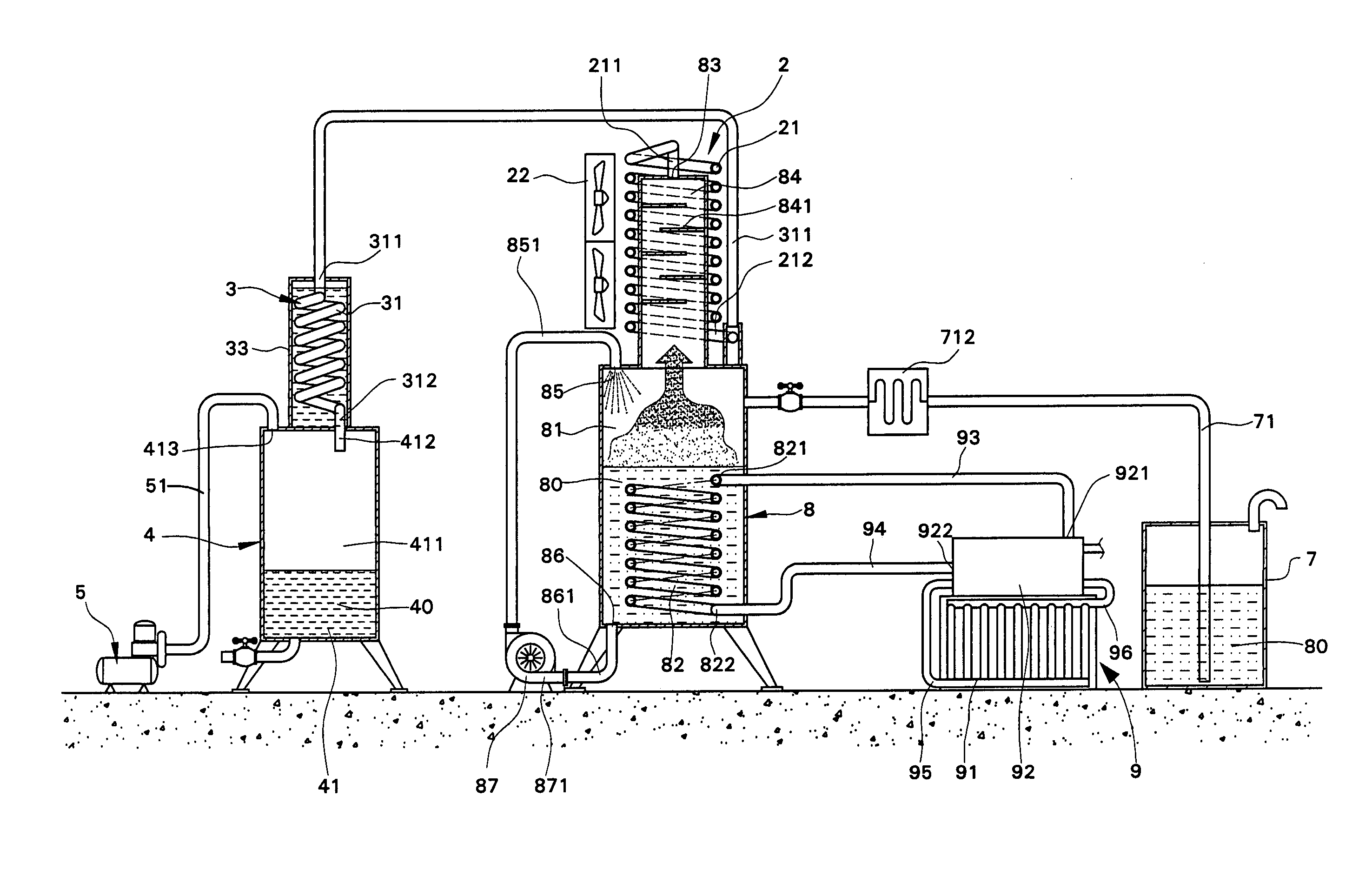

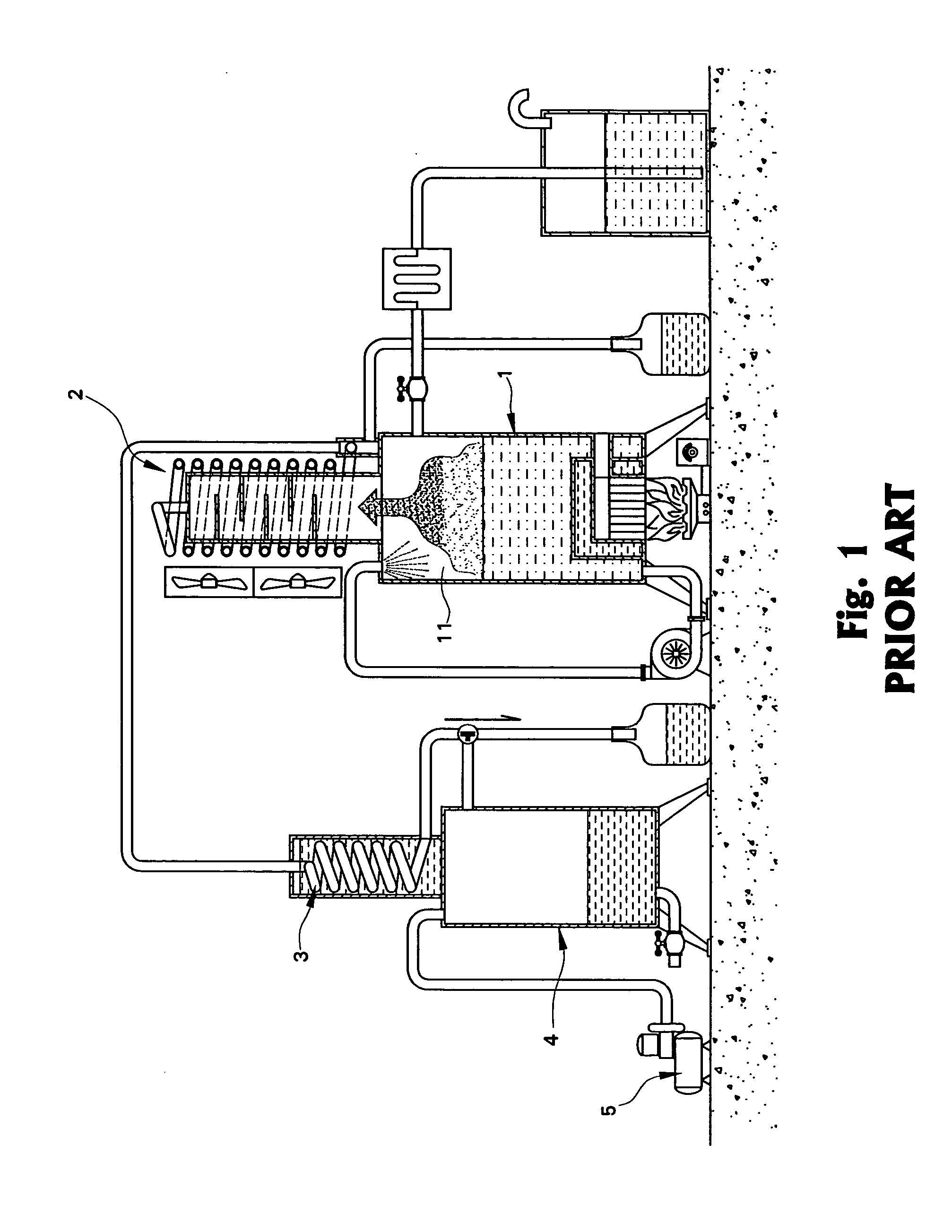

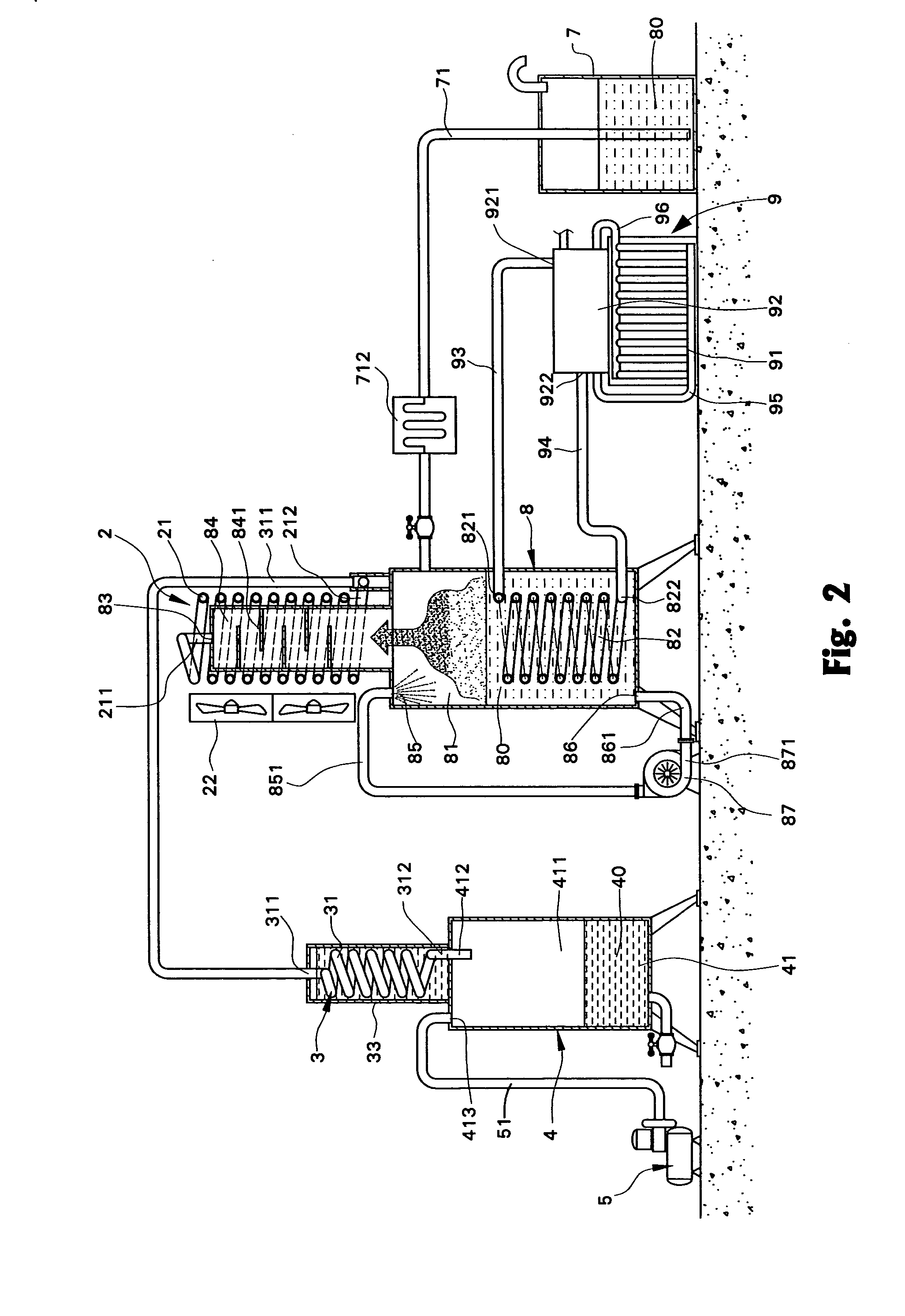

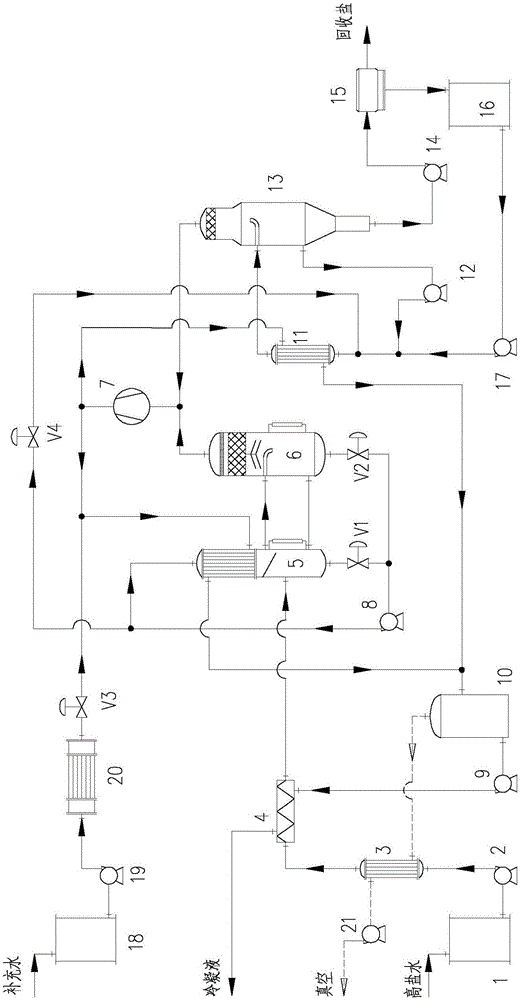

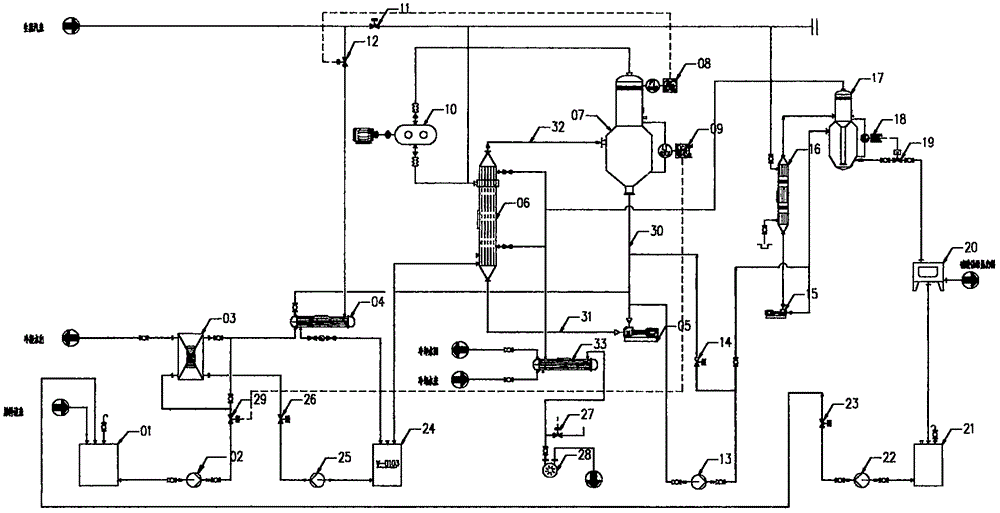

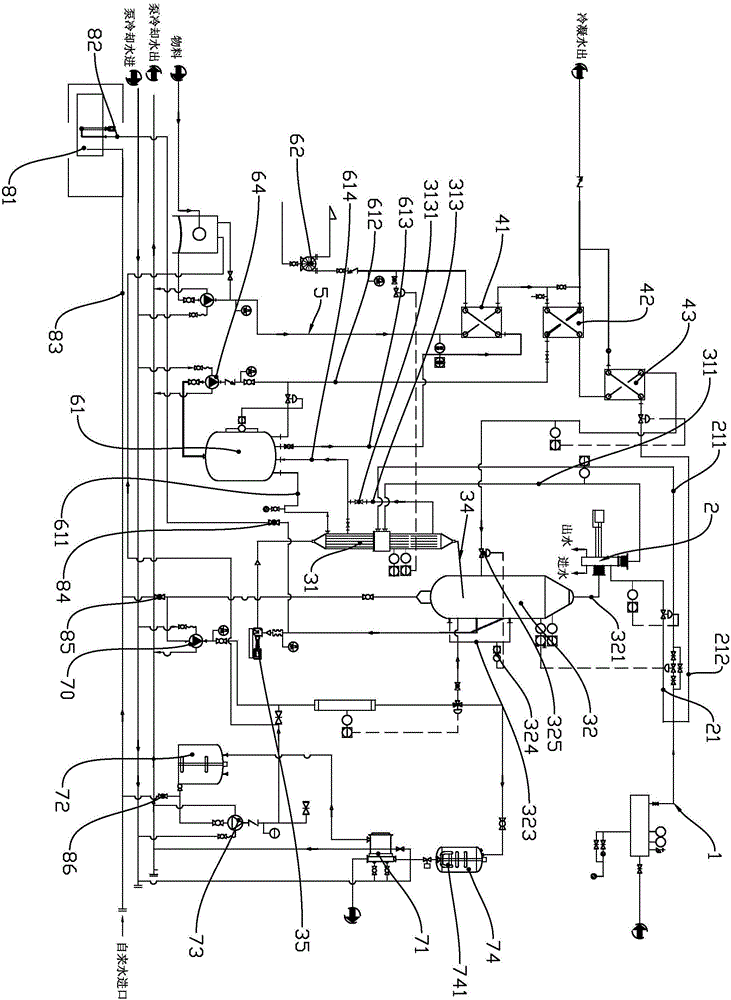

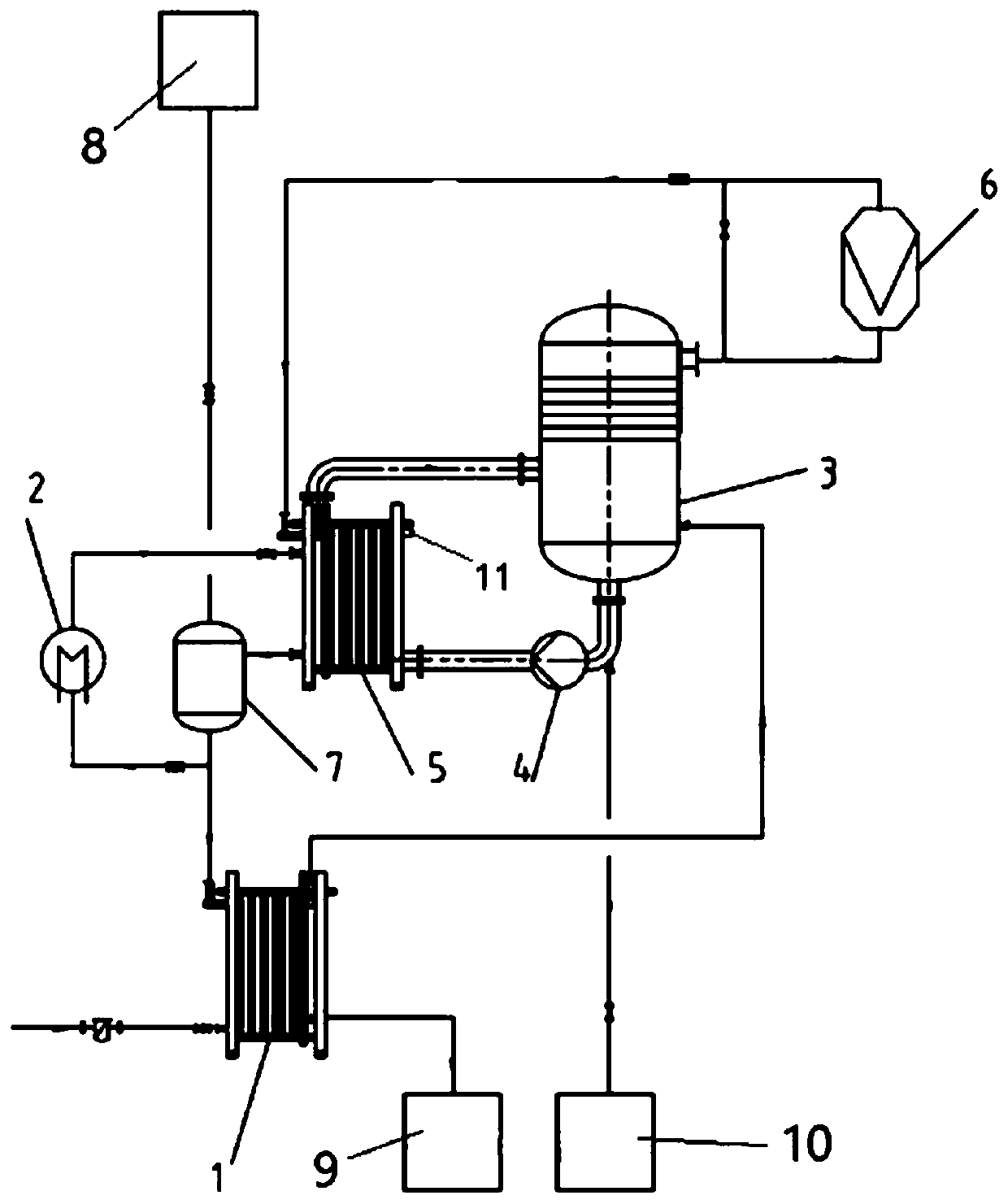

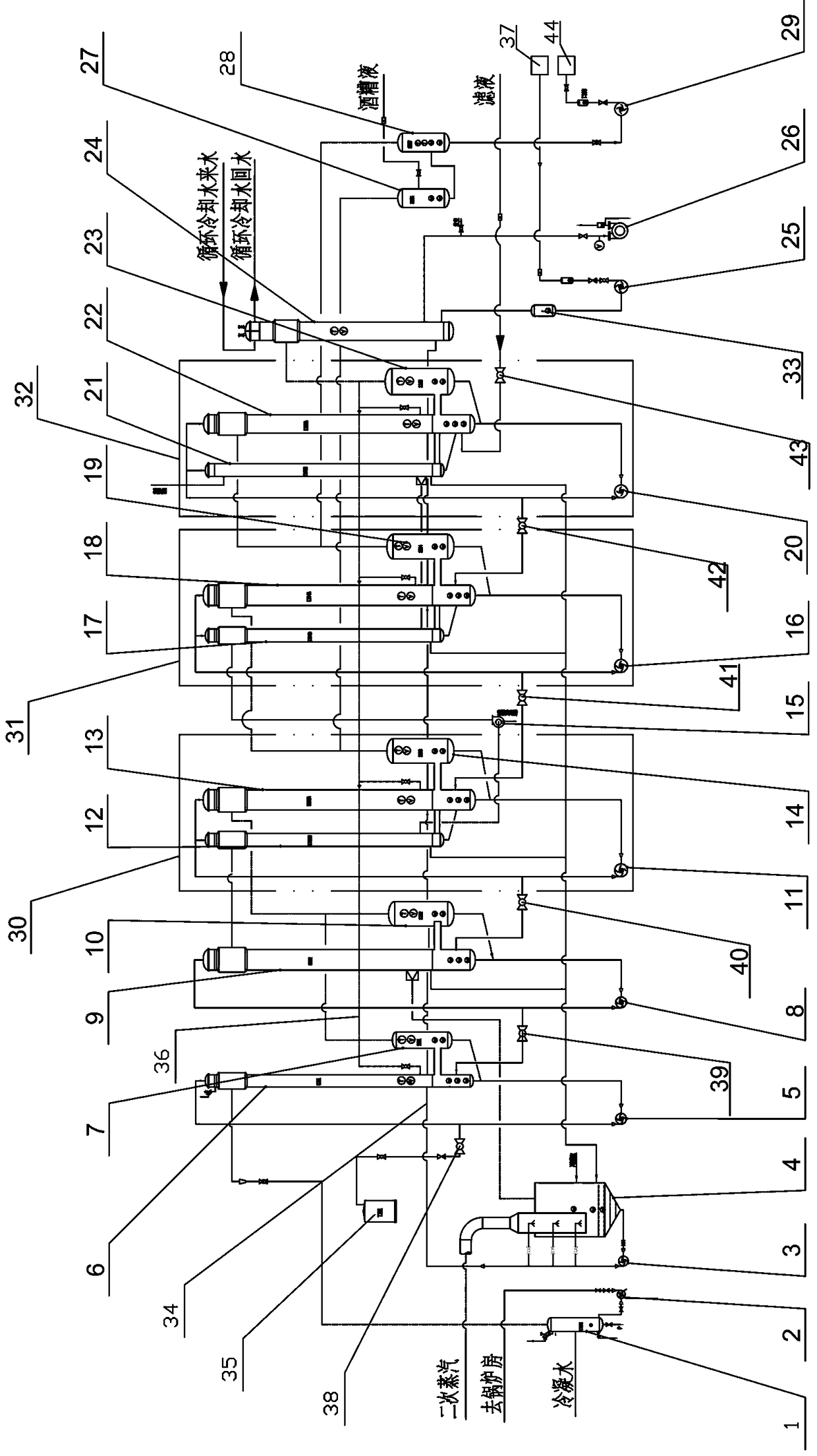

MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater

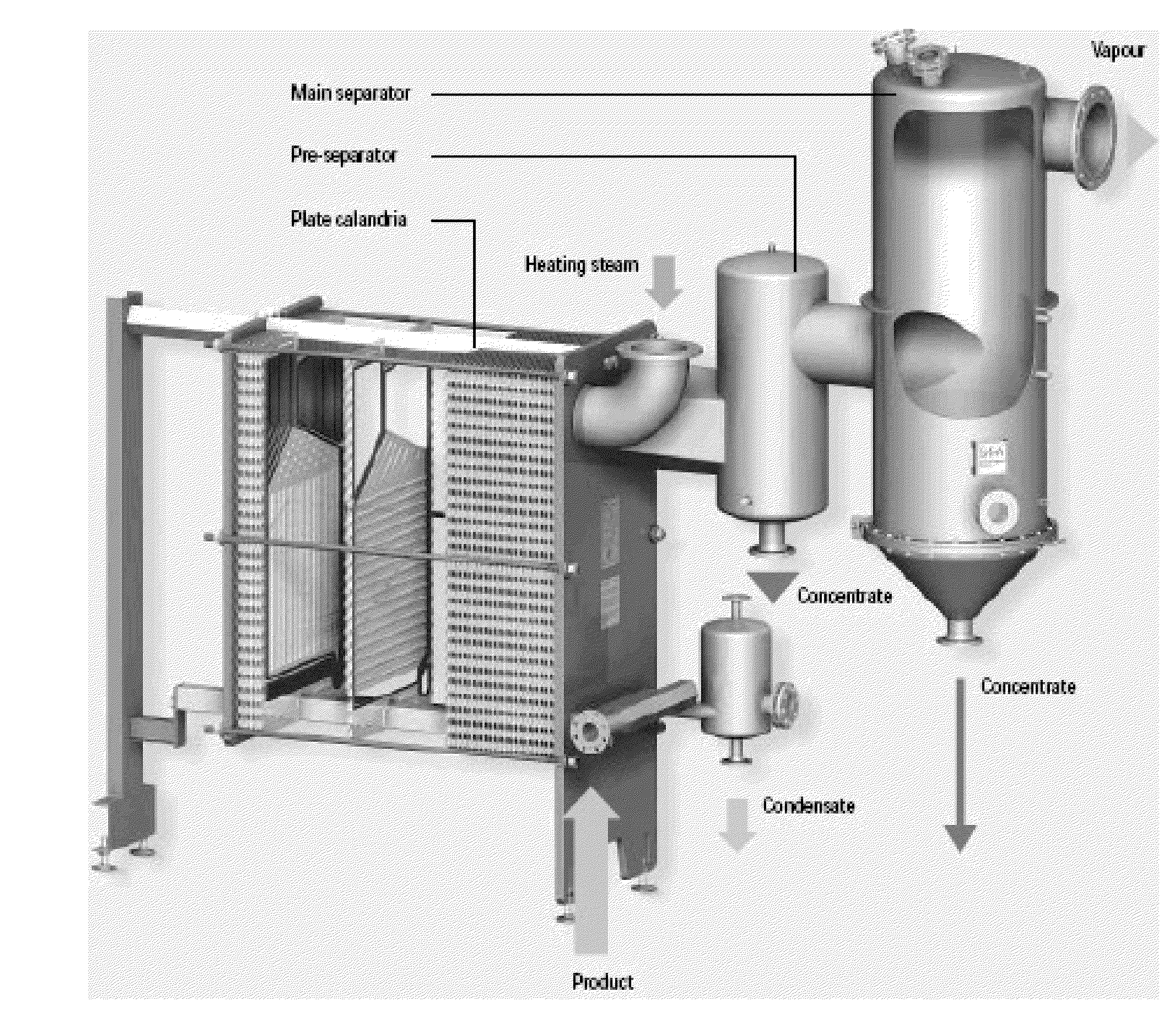

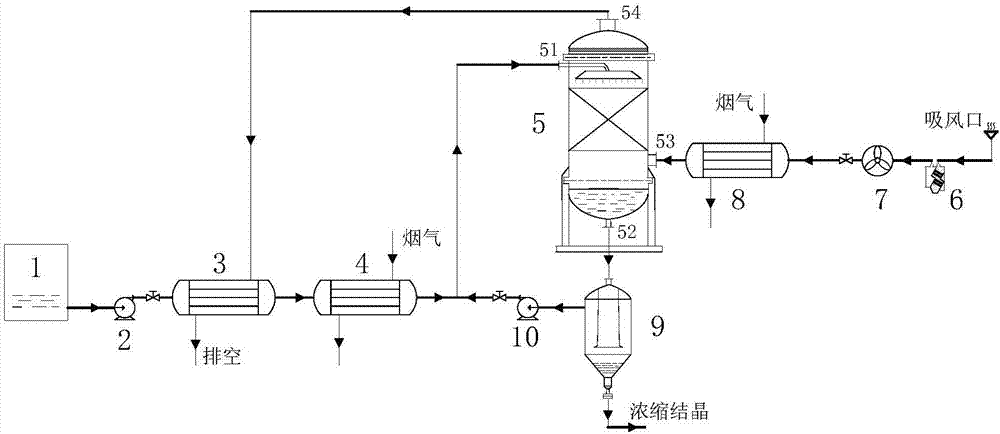

PendingCN106669207ATake advantage ofAchieve recyclingEvaporator accessoriesEvaporators with forced circulationVapor–liquid separatorEvaporation

The invention discloses an MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater[0]. The system comprises a raw material tank, a first preheater, a second preheater, an MVR evaporator, a gas-liquid separator, a compressor, a first circulating pump, a condensate tank, a forced circulation evaporator, a second circulating pump, a crystallizer, a centrifuge and a vapor generator. The full utilization of secondary vapor is realized after high-salinity wastewater is treated with the system, and the system has the advantages that the cost is low, the continuity and the energy saving effect are good, and the crystal salt quality is high.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

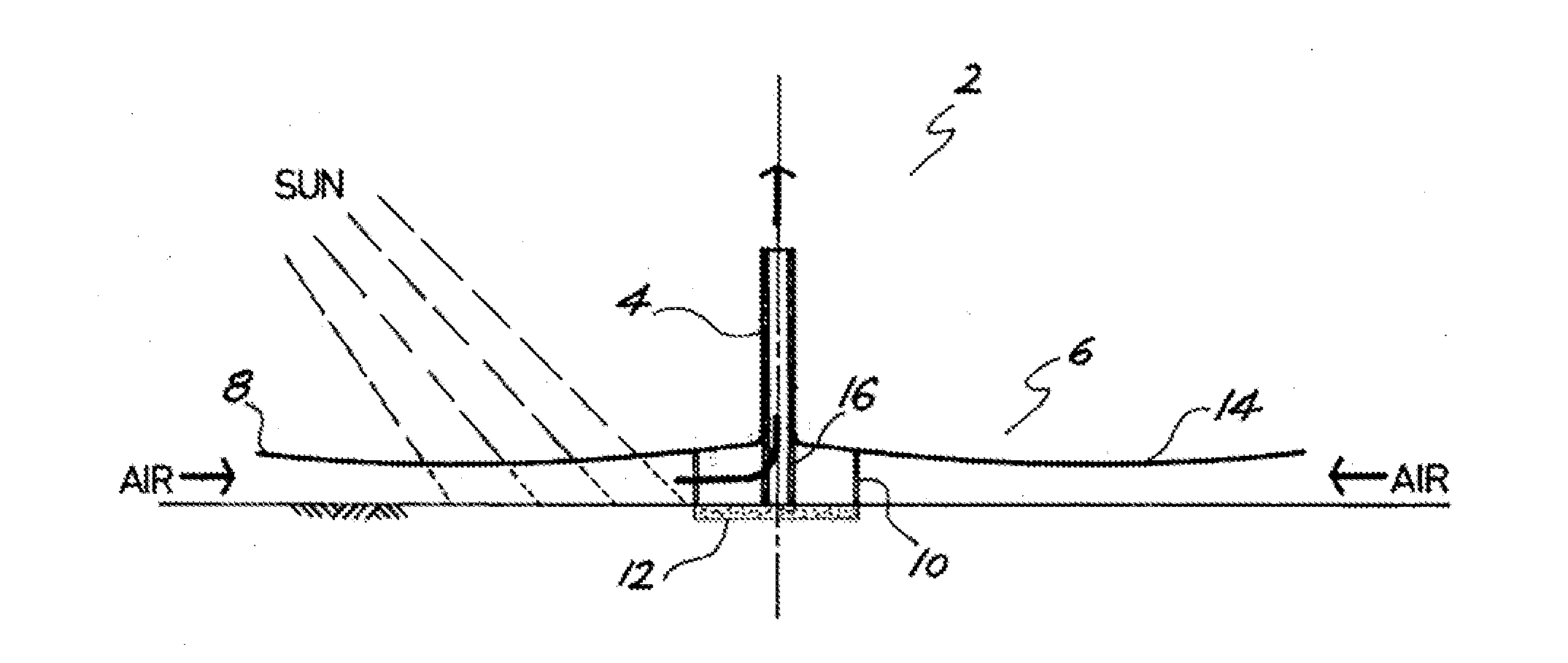

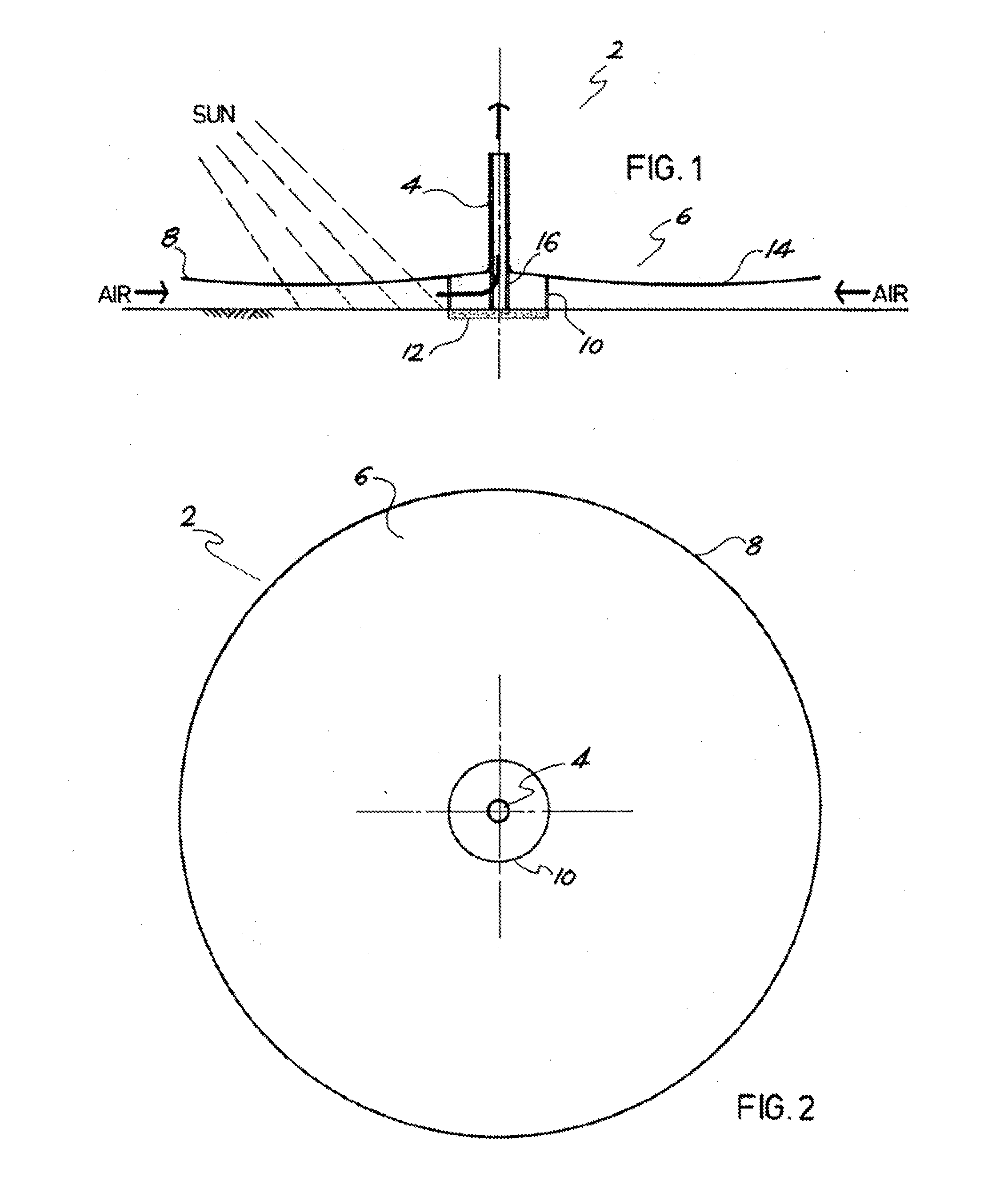

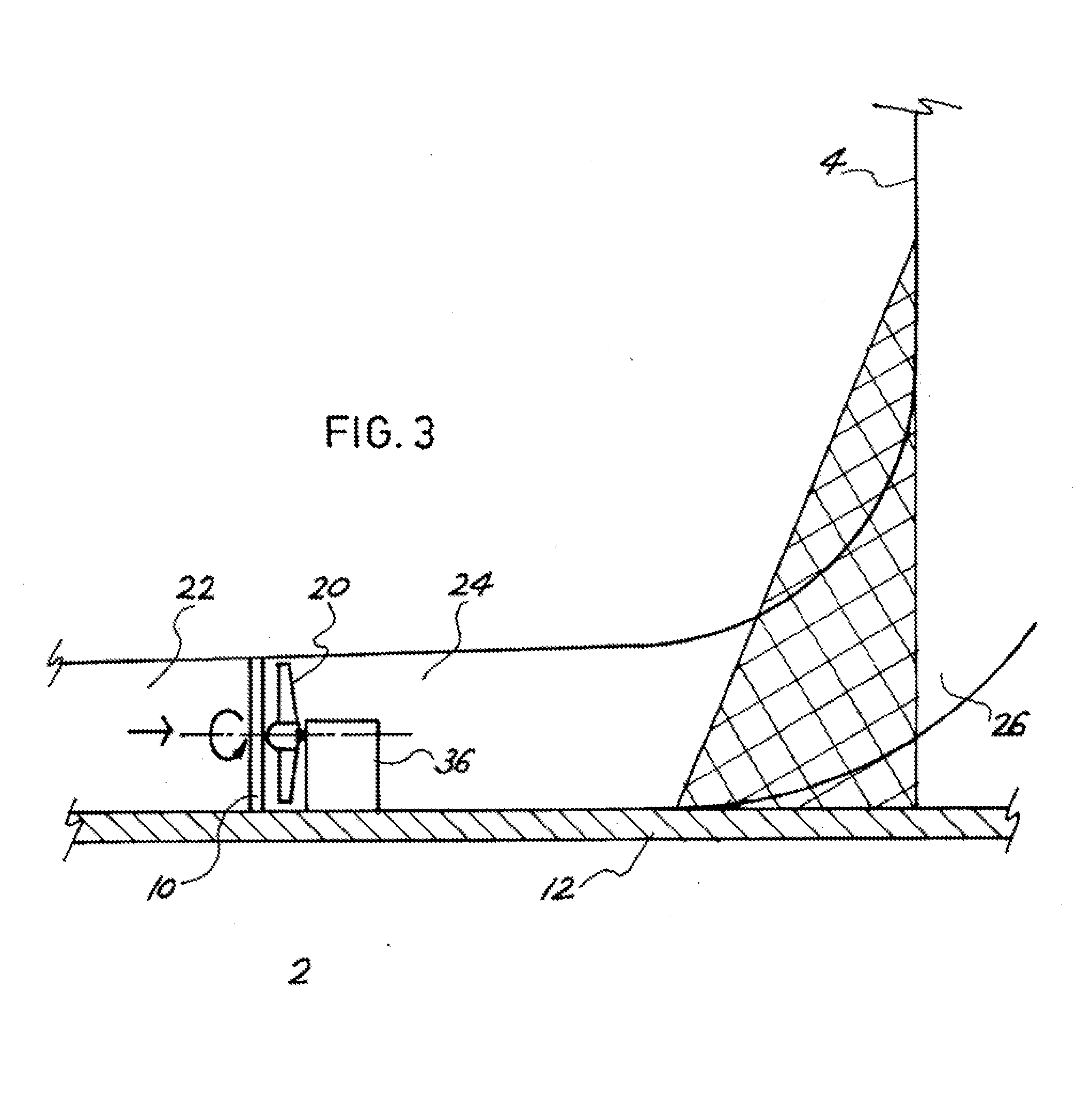

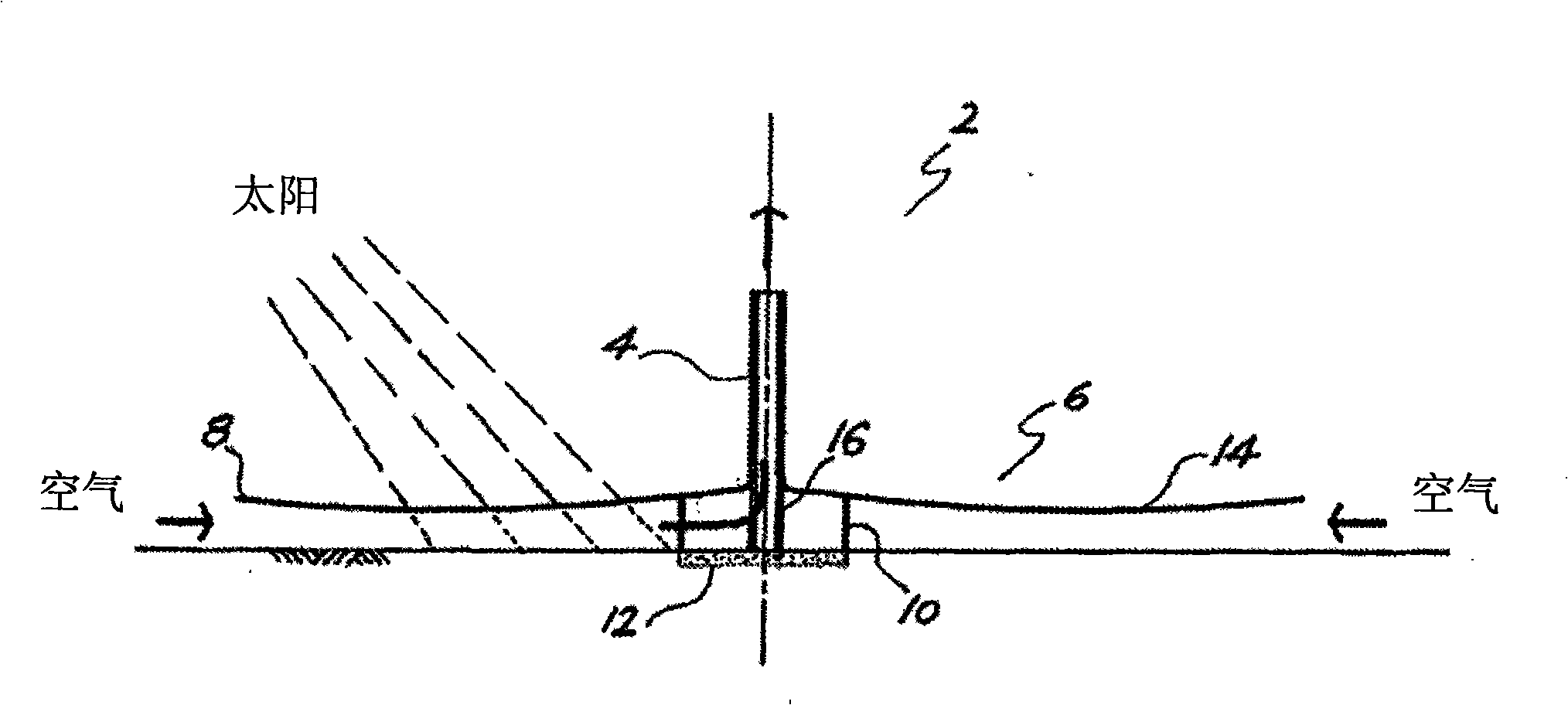

Solar Atmospheric Water Harvester

InactiveUS20080314058A1Cooling effectImprove condensation efficiencyGeneral water supply conservationVapor condensationSurface coolingAtmospheric air

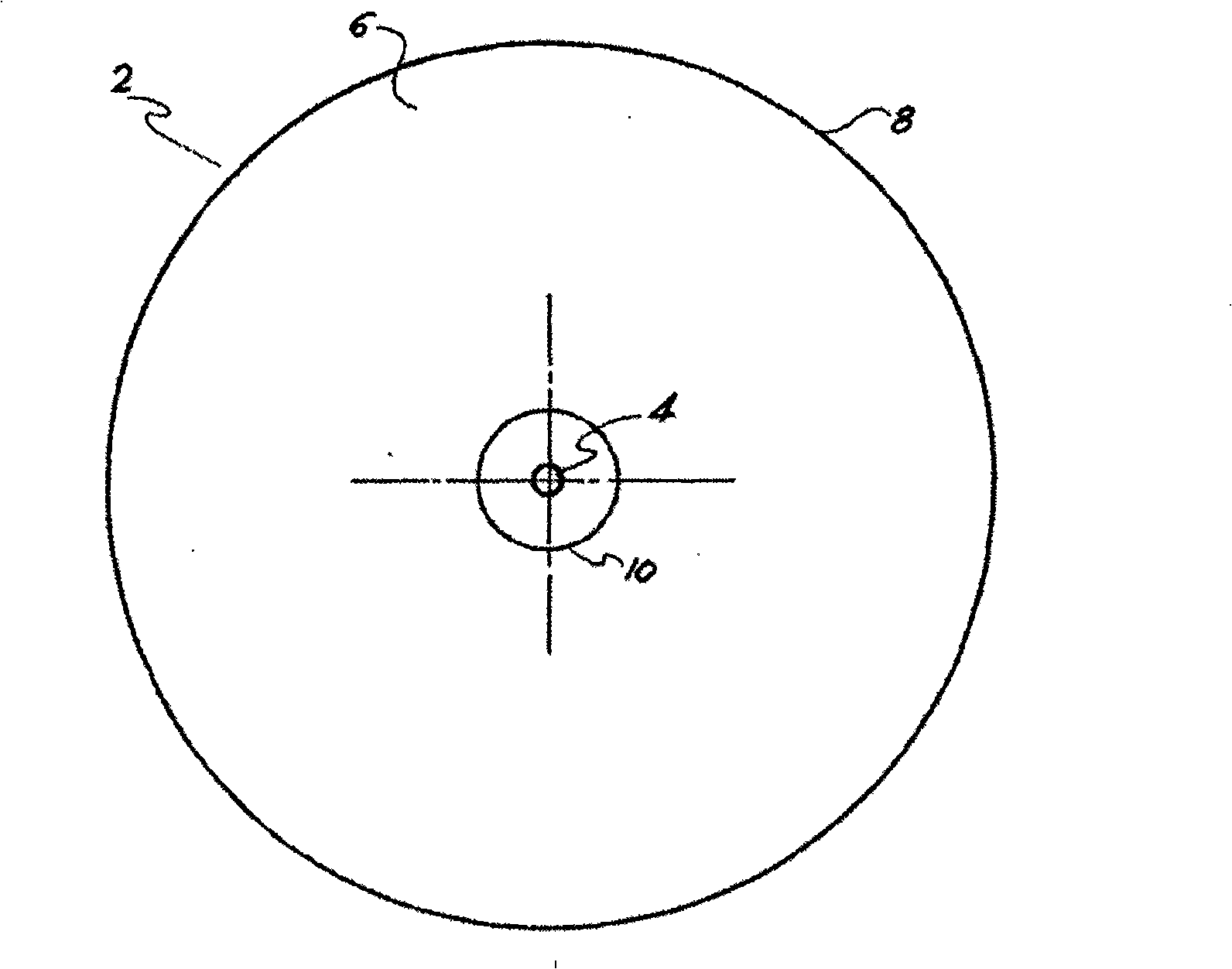

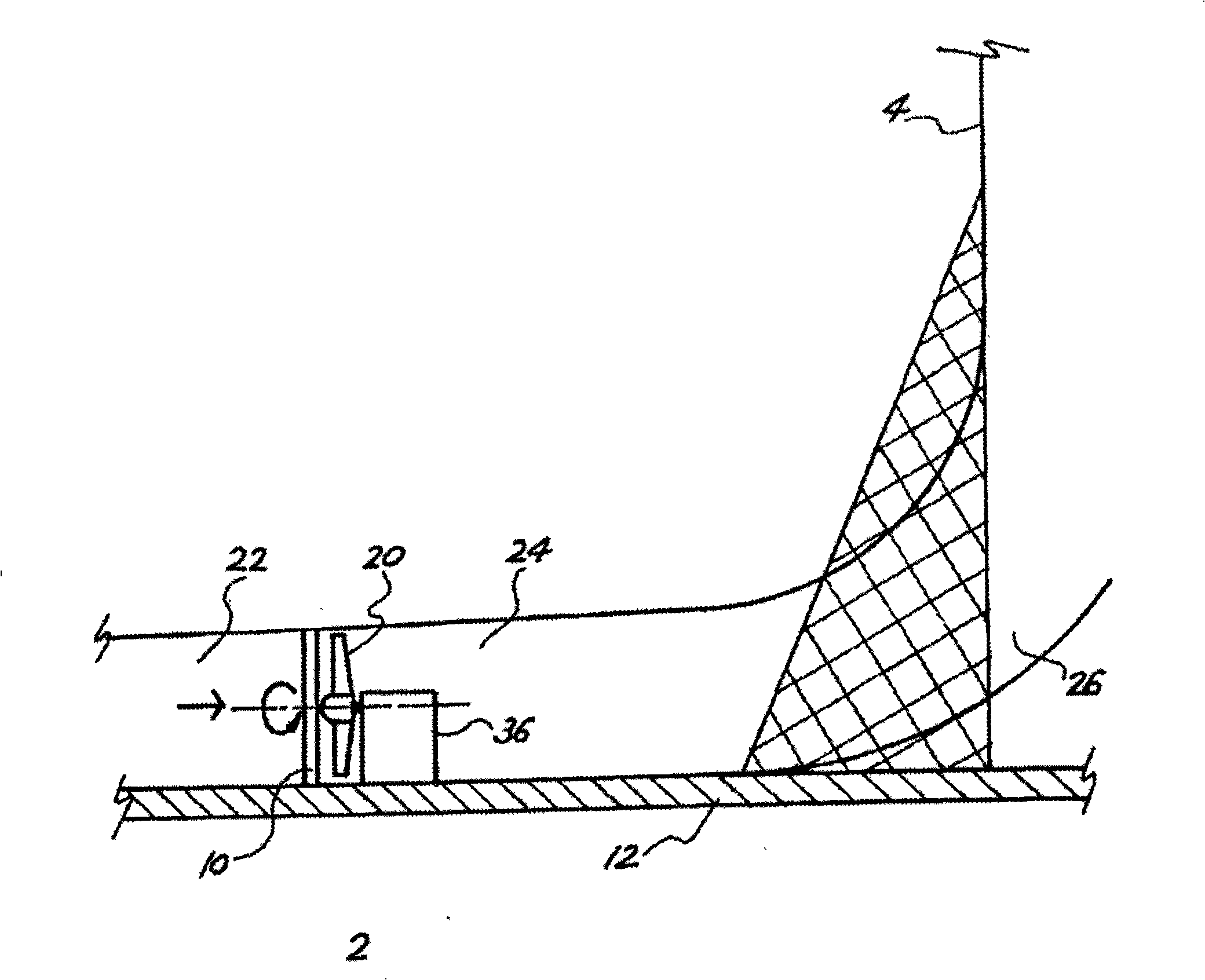

The atmospheric water harvester (2) shown in FIG. (1) comprises a centrally located flue in the form of a tower 4 and a surrounding heating enclosure (6) for collecting incident solar energy to heat air which enters its periphery (8). With heating of the air in the heating enclosure (6), an updraught is created within tower (4) as the air from the heating enclosure (6) returns to the atmosphere from the open end of the tower A base structure (10) housing a plurality of wind turbines is provided around the base of the tower. As the heated air flows from the heating enclosure (6) into the tower it is harnessed to rotate the wind turbines. Each wind turbine (20) is provided with associated water collection apparatus (94) comprising a refrigeration system for cooling condensation surfaces to, or below, the dew point of the air to effect the condensation of water from the air onto condensation surfaces of the water collection apparatus for collection. The refrigeration system comprises a compressor (46) for compressing a refrigerant vapour for the cooling of the condensation surfaces and which is driven by the wind turbine (20).

Owner:HYDROTOWER PTY LTD

Land Based and Pontoon Based Forced Air Thermal Evaporator

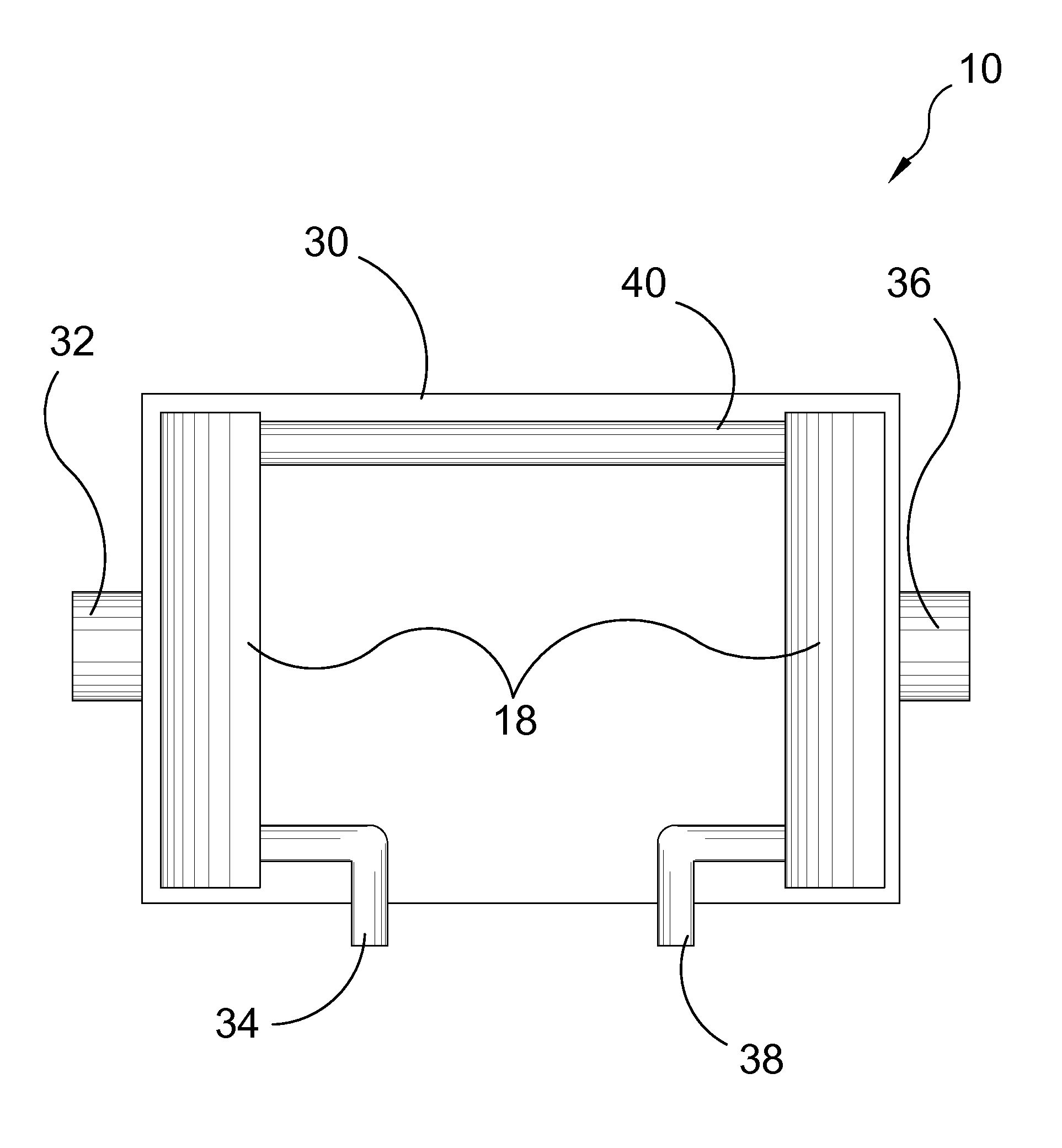

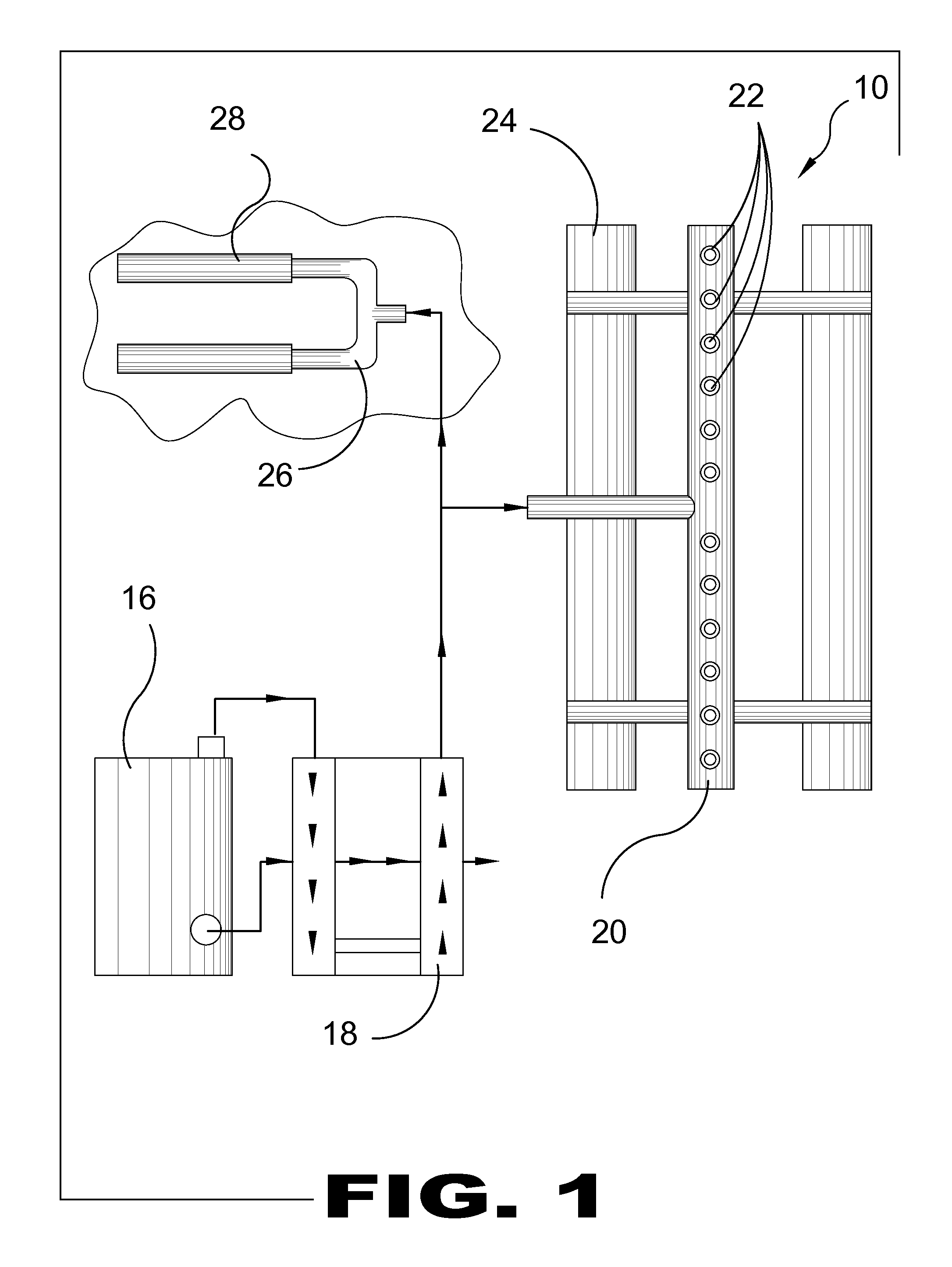

InactiveUS20110168646A1Great evaporation rateImprove efficiencyEvaporators with forced circulationWater/sewage treatment by heatingCold airWater source

A method of evaporating waste water utilizing waste heat employs a forced air thermal evaporator system having an air heat exchanger with: a waste heat inlet, a waste heat outlet, a cold air inlet and a hot air outlet; a compressor connected with the cold air inlet to force air into the cold air inlet; and a distribution header having a hot air inlet connected with the hot air outlet, a waste water inlet connected to a waste water source, and air / water mixing nozzles connected with the hot air inlet and the waste water inlet. Engaging the compressor forces air through the heat exchanger and into the distribution header where the waste water is admixed with the hot air which then exits through spray nozzles as water vapor.

Owner:TAFOYA JAMES

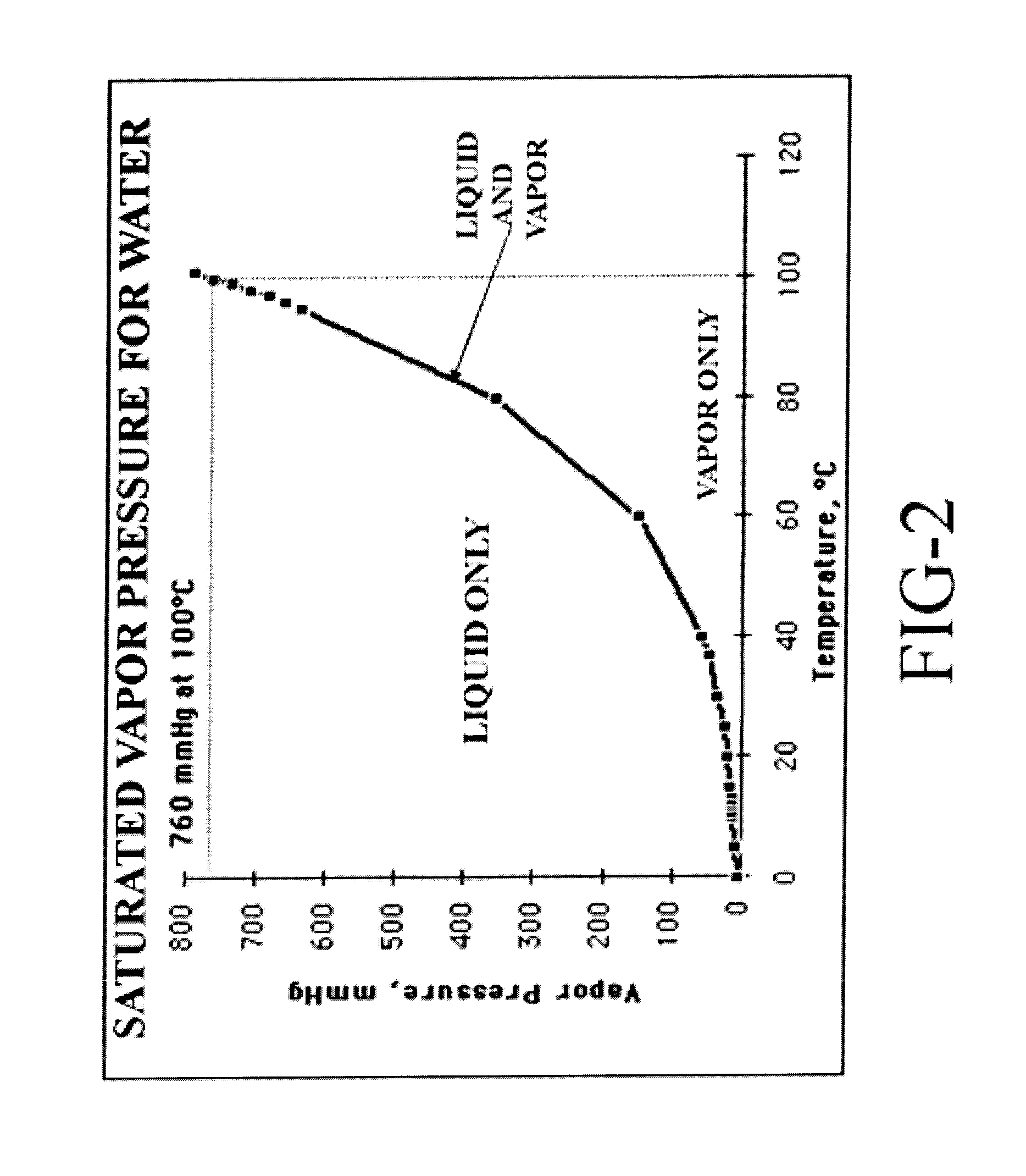

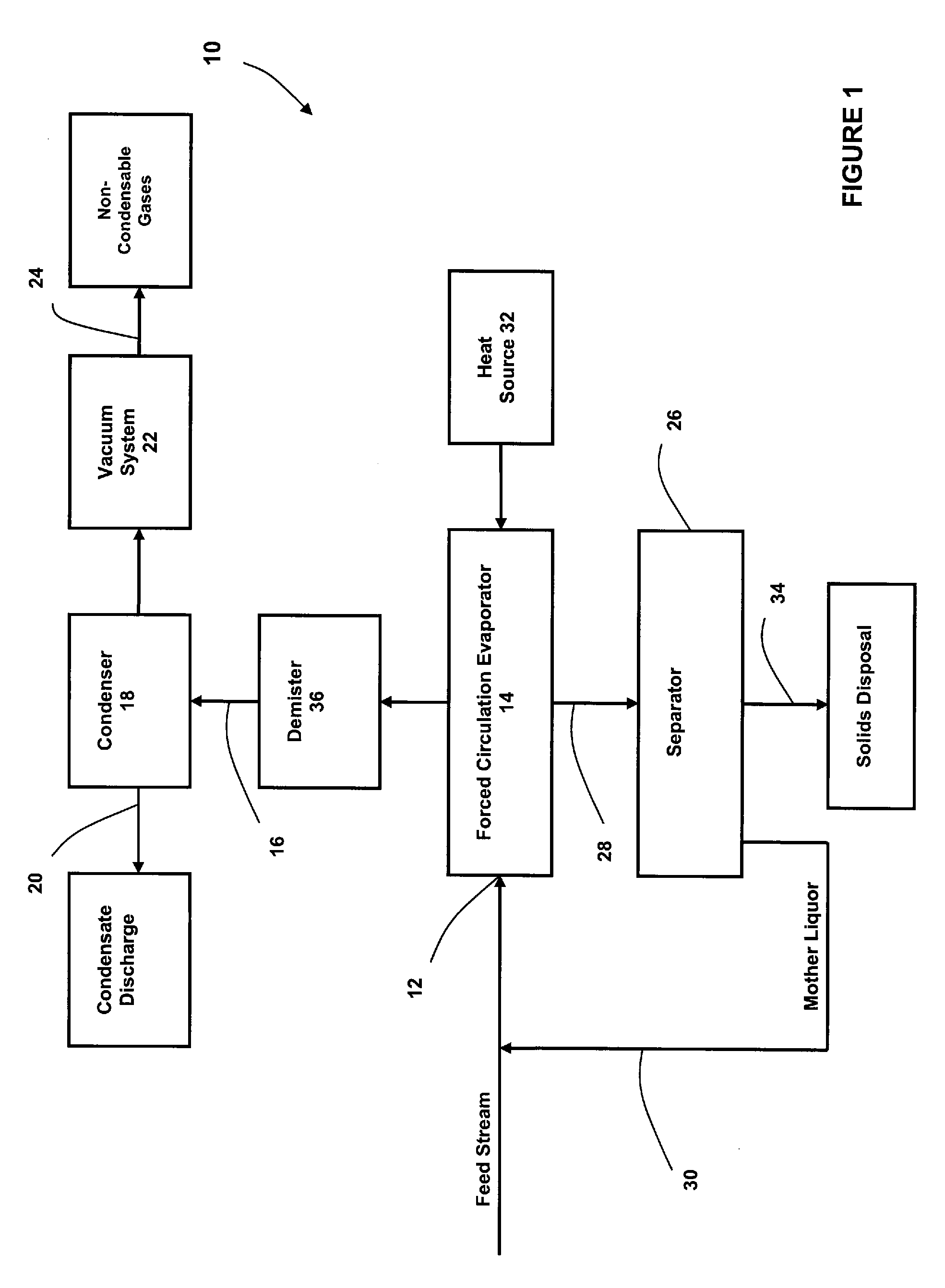

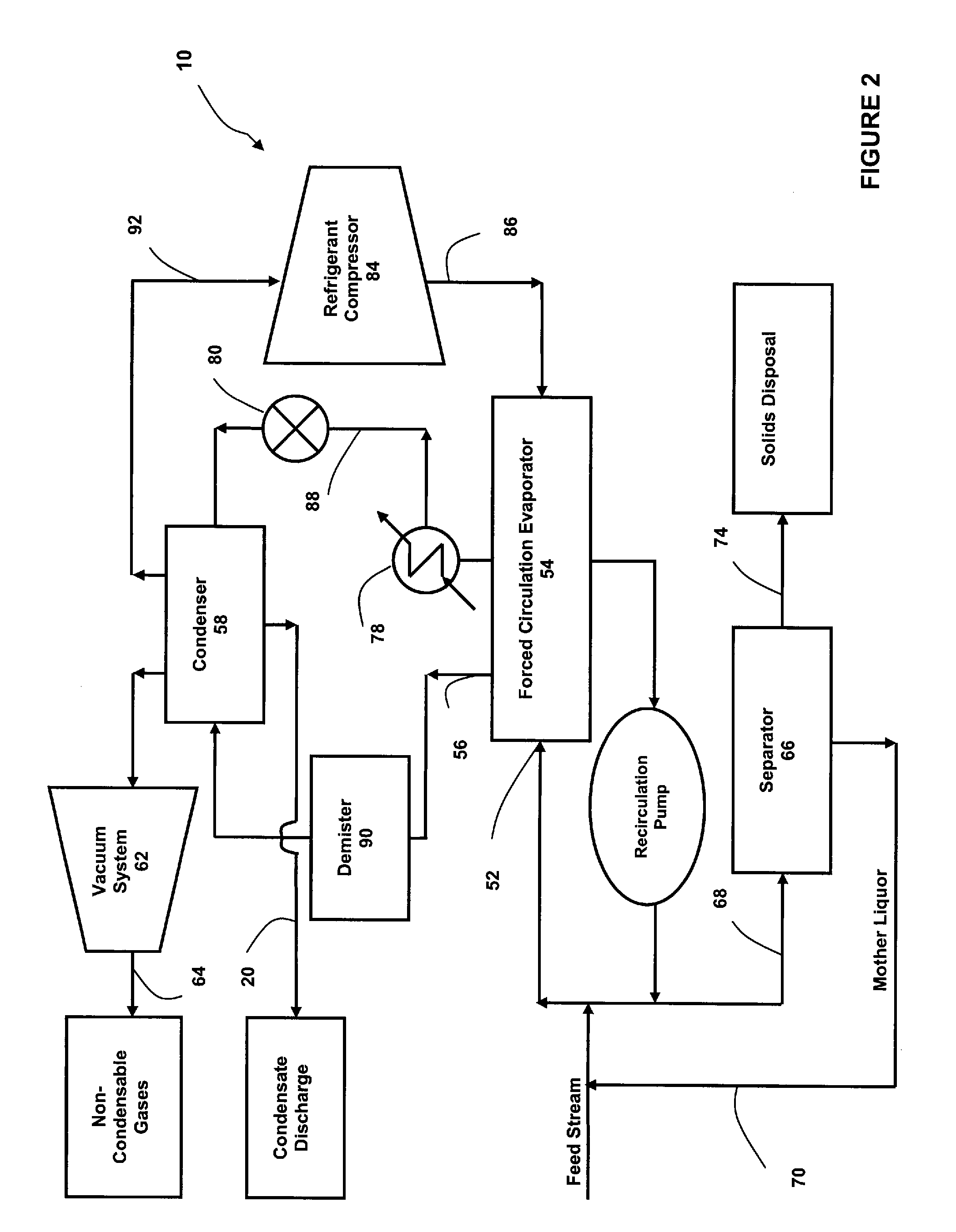

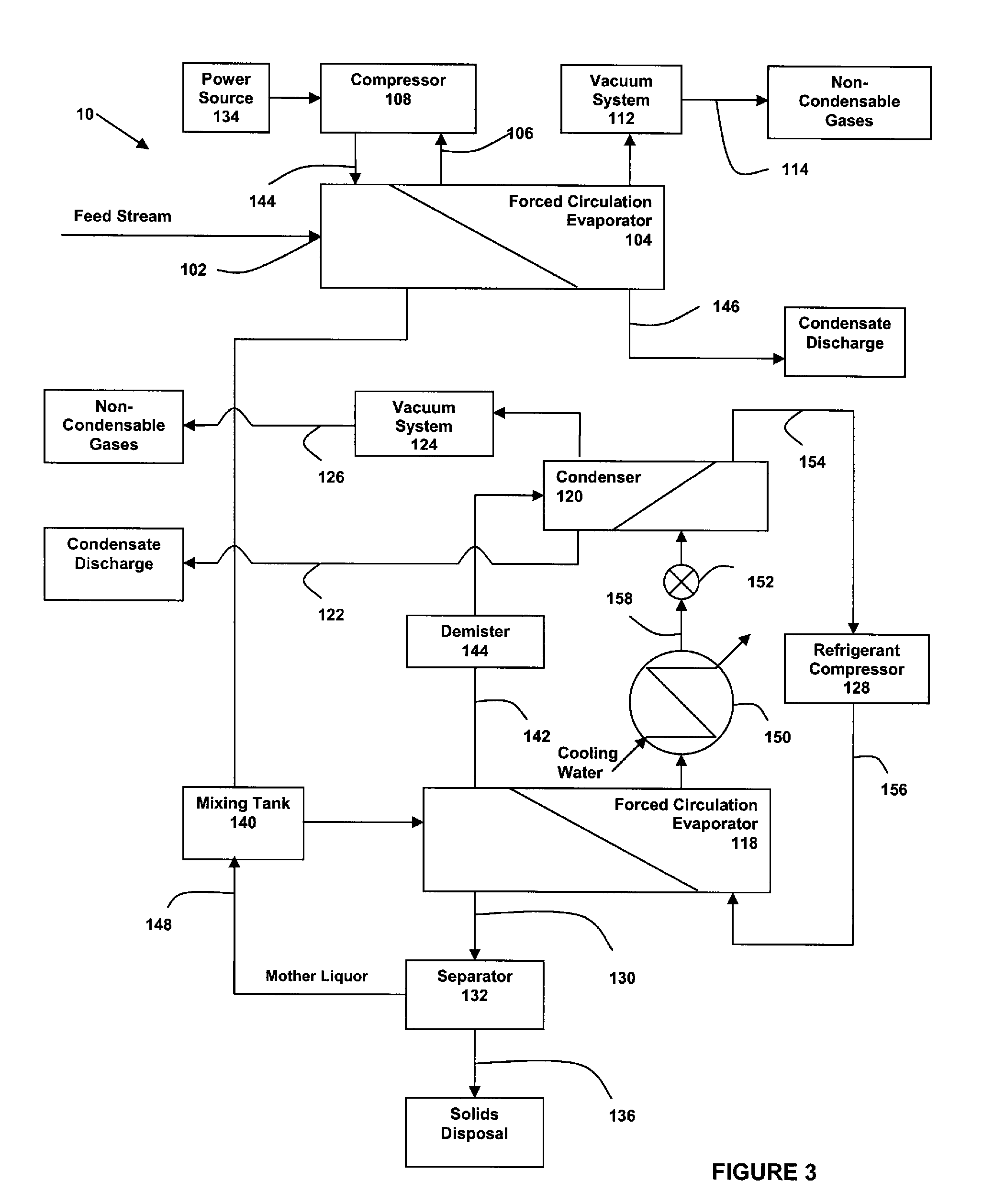

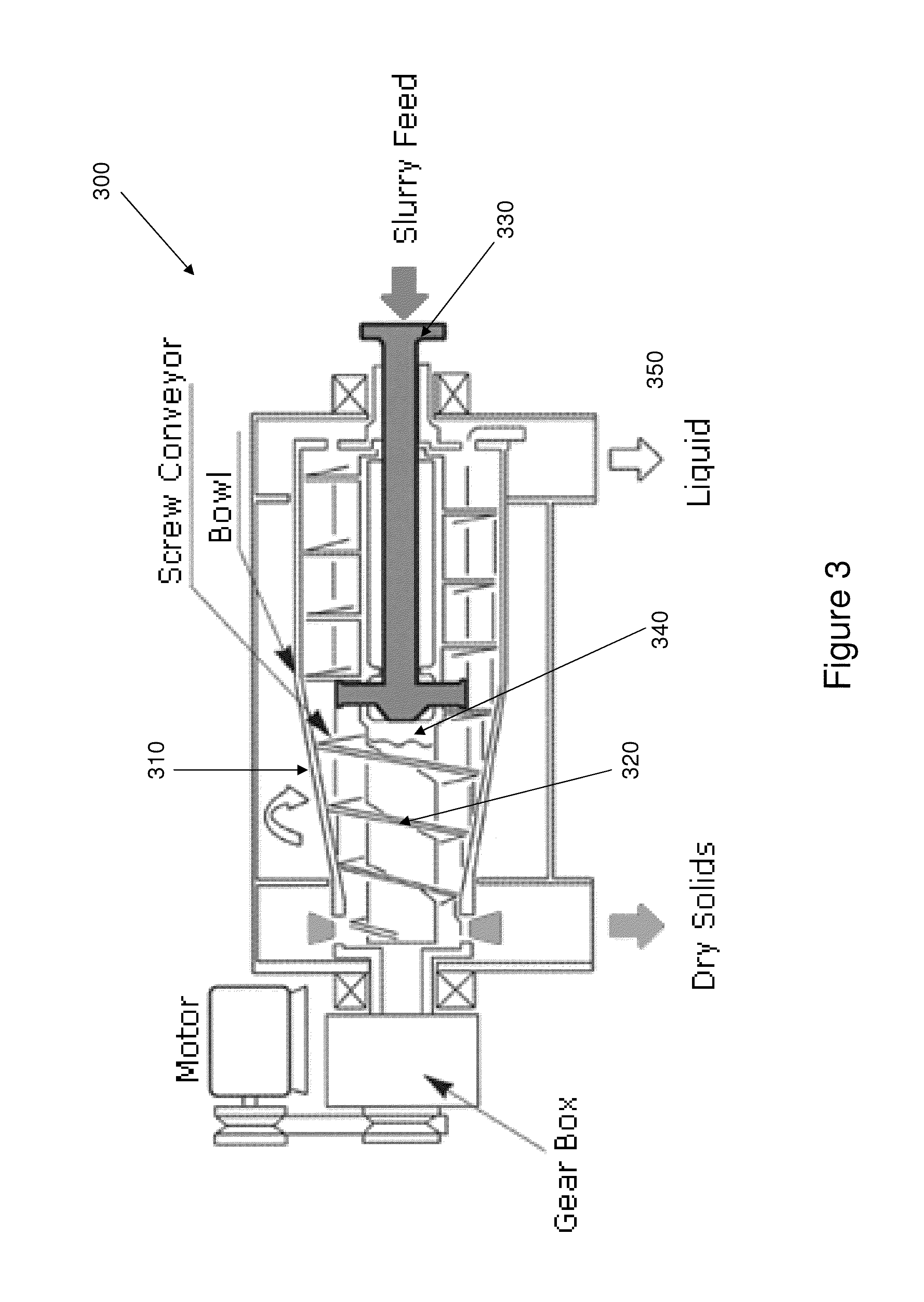

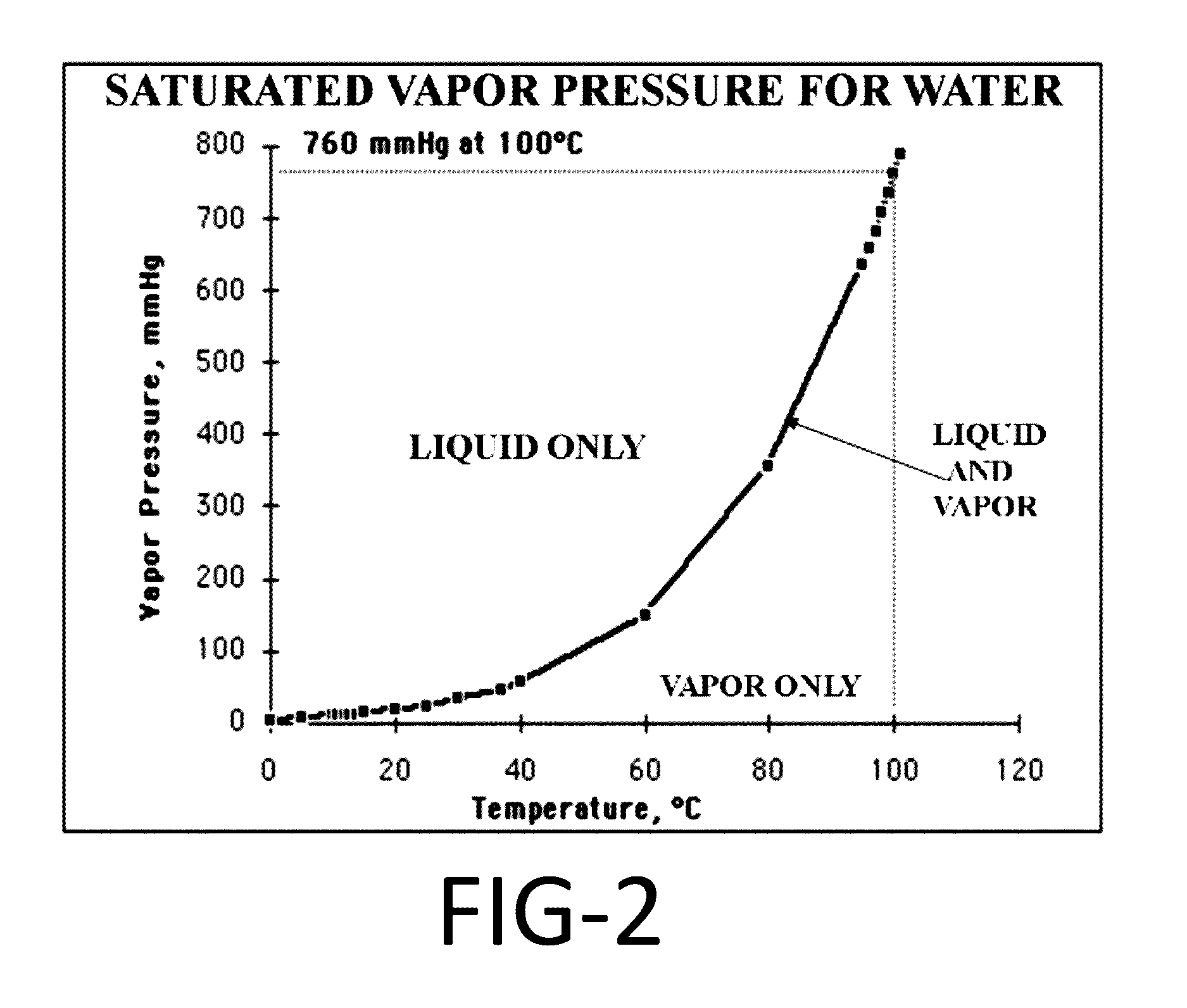

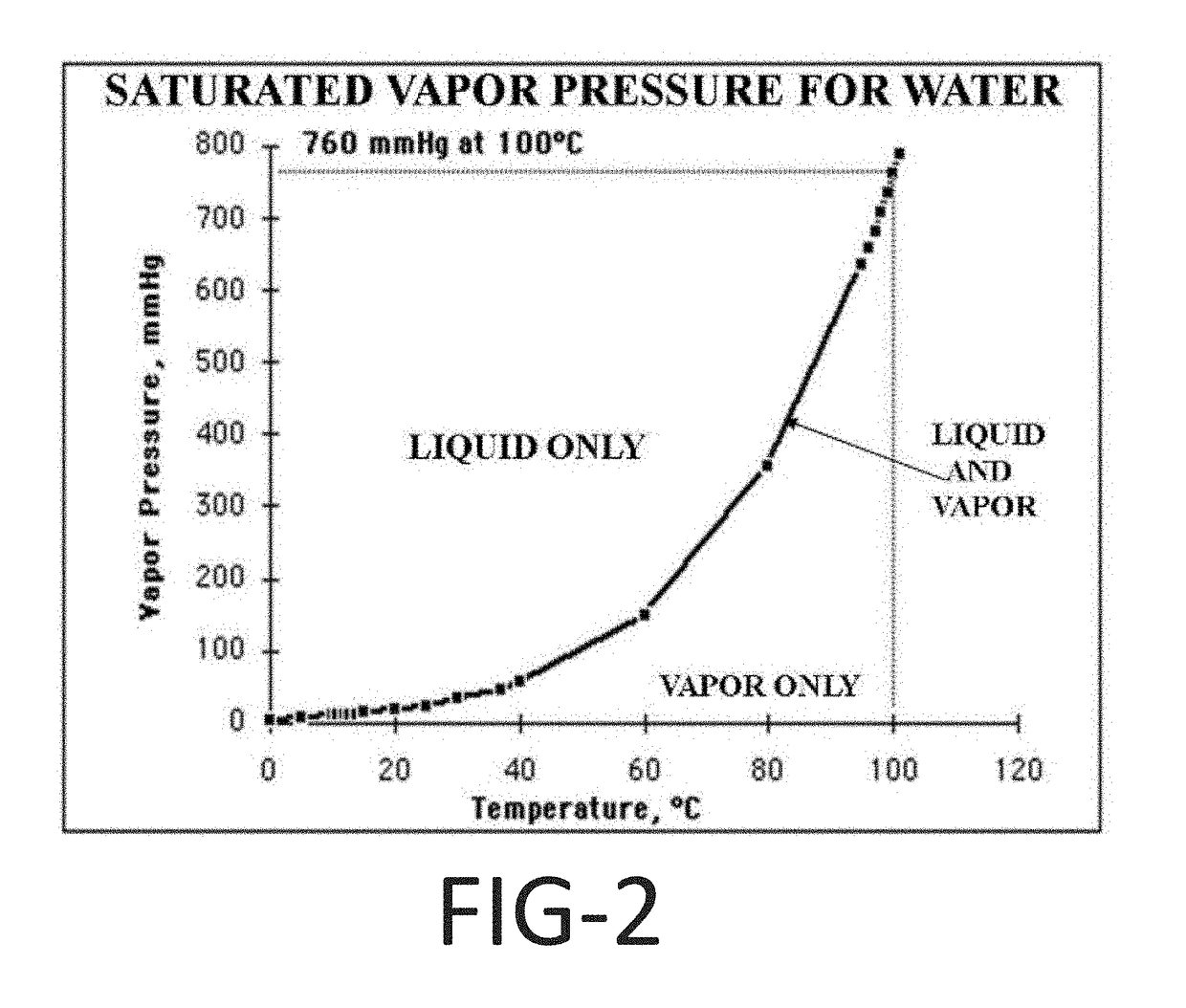

Method for removing dissolved solids from aqueous waste streams

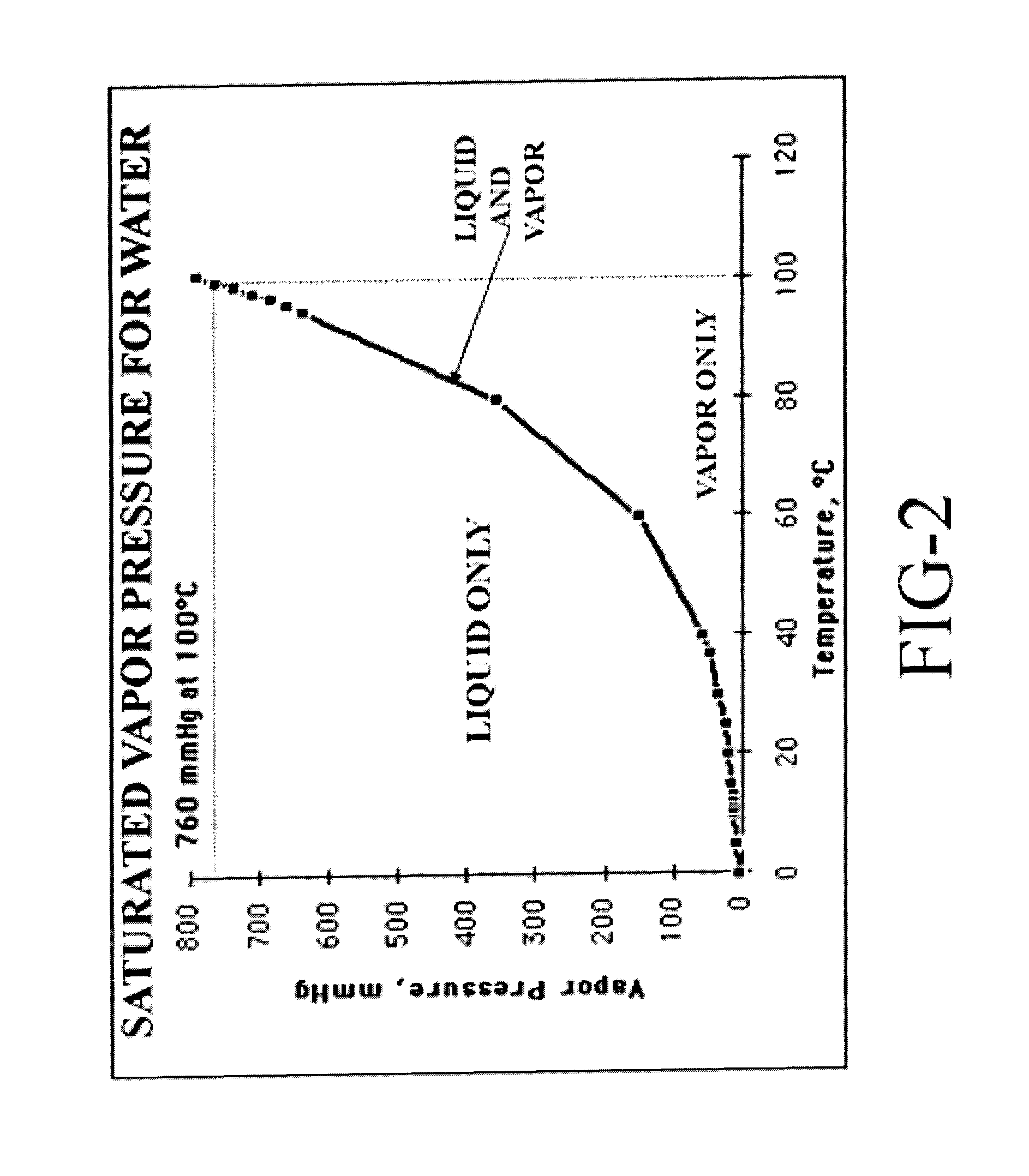

ActiveUS8052763B2Sedimentation separationWaste water treatment from gaseous effluentsWaste streamBoiling point

A method for removing dissolved solids from a waste stream, such as that produced in flue gas scrubbing, through an evaporation-crystallization process operated at relatively low temperature. A waste stream is directed into an evaporator and heated at a temperature of less than 60° C. at a pressure below atmospheric pressure. The waste stream is concentrated through the evaporation process and forms a slurry stream having crystallized solids. At the low temperature of evaporation, the solids crystallize at substantially lower temperature and the solution has a substantially lower boiling point elevation than at atmospheric pressure. The slurry stream is directed to a solid-liquid separator where the crystallized solids in the slurry stream are separated, producing a solid cake and mother liquor.

Owner:VEOLIA WATER TECH INC

Process of separating components of a fermentation broth

A process of isolating 1,4-butanediol (1,4-BDO) from a fermentation broth includes separating a liquid fraction enriched in 1,4-BDO from a solid fraction comprising cells, removing water from said liquid fraction, removing salts from said liquid fraction, and purifying 1,4-BDO. A process for producing 1,4-BDO includes culturing a 1,4-BDO-producing microorganism in a fermentor for a sufficient period of time to produce 1,4-BDO. The 1,4-BDO-producing microorganism includes a microorganism having a 1,4-BDO pathway having one or more exogenous genes encoding a 1,4-BDO pathway enzyme and / or one or more gene disruptions. The process for producing 1,4-BDO further includes isolating 1,4-BDO.

Owner:GENOMATICA INC

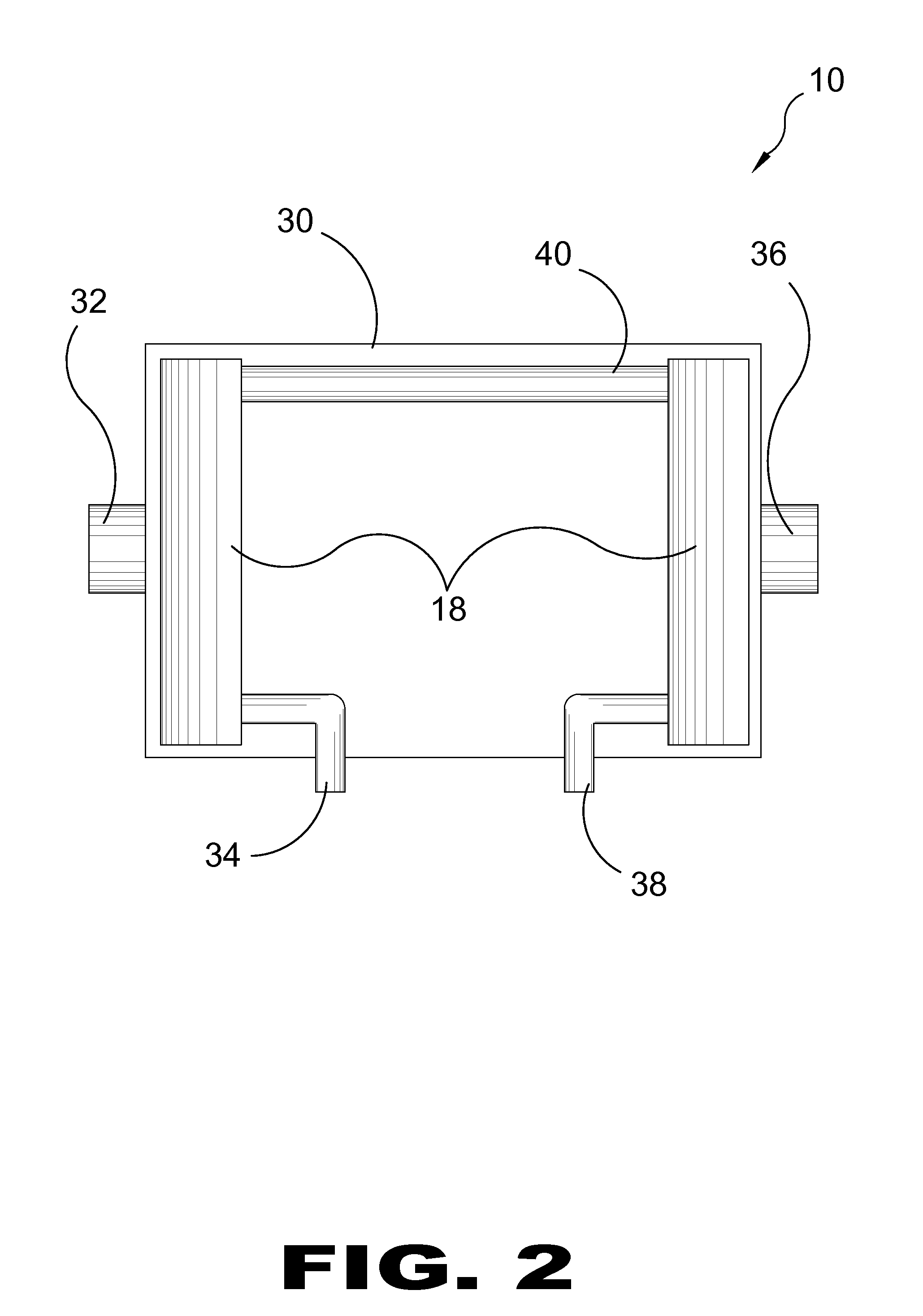

High Efficiency, Large Scale Desalination System

ActiveUS20160368784A1Improve distillation efficiencyLower energy requirementsGeneral water supply conservationSeawater treatmentAtmospheric airDistillation

An apparatus and method for the distillation of ocean and brackish water that includes a means for using the ambient temperatures of seawater and air to continually transfer the heat energy, from the outer perimeters of the system, back into the, centrally located, evaporation chamber and insulation for preventing heat from escaping to the atmosphere. The insulation comprises a first and second wall surrounding the basic assemblies of a desalination system in which the space between the first and second wall is under low partial vacuum and is partially filled with an insulation material for structural support. The system provides a feed through means that prevent heat transfer through the structural connections between the first and second walls. The system provides an evaporation system for flash evaporation by atomizing the input contaminated water, preheated by the heat of condensation into very small liquid droplets, which are then sprayed into a stream of hot dry air. The liquid rapidly evaporates leaving behind hot dry solids that is recaptured and used to preheat the input contaminated water.

Owner:FLO ONICS LLC

Device system for efficient cobalt sulfate concentration and continuous crystallization

ActiveCN106115804AGuaranteed cooling temperatureReduce dosageVacuum condensationEvaporation with vapour compressionEvaporationStock solution

The invention relates to a device system for efficient cobalt sulfate concentration and continuous crystallization. The device system provided by the invention comprises an evaporation heater (06), an evaporation separator (07), an OSLO vacuum crystallizer (17), a fine grain eliminating heater (16), a steam compressor (10), a condensate water preheater (03), a steam preheater (04), a centrifugal machine (20) and a pump. A stock solution enters the evaporation heater through the preheater, and the heater is connected with the separator and the circulating pump; the separator is connected with the OSLO vacuum crystallizer; a material liquid drop device is arranged in the middle of the OSLO vacuum crystallizer, a flash chamber is arranged at the top of a pipe, a circulating liquid outlet is formed in the side part, a secondary steam outlet is formed in the top of the flash chamber and is connected with a condenser and a fine grain eliminator, the crystallizer is connected with the centrifugal machine, and the centrifugal machine is connected with a mother liquid tank and a stock solution buffer tank to realize overall material liquid circulation. The system has the characteristics of energy conservation, continuity, automation and high efficiency, and obtained products are large in grain size and high in quality.

Owner:湖州惠鹏达节能环保科技有限公司

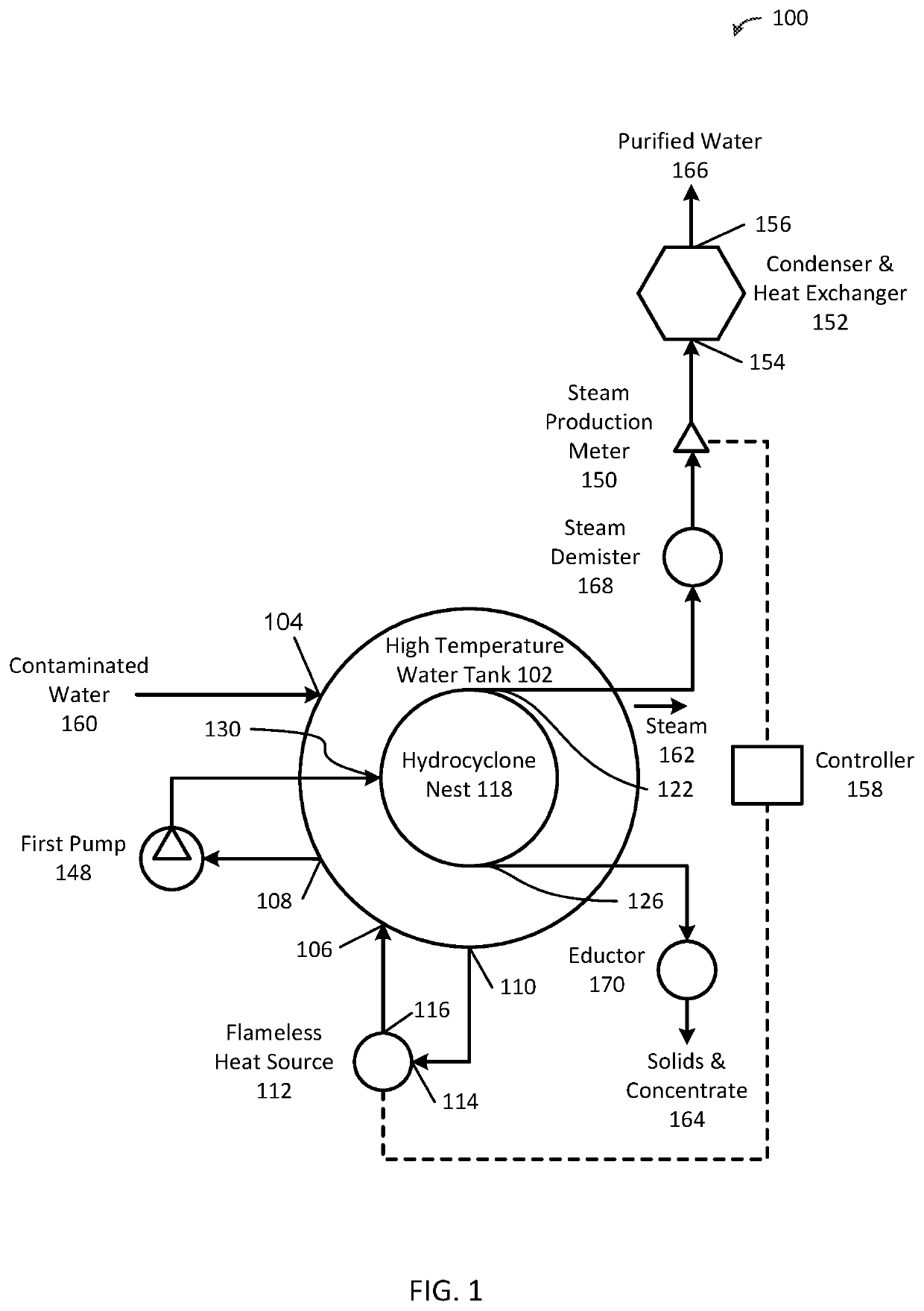

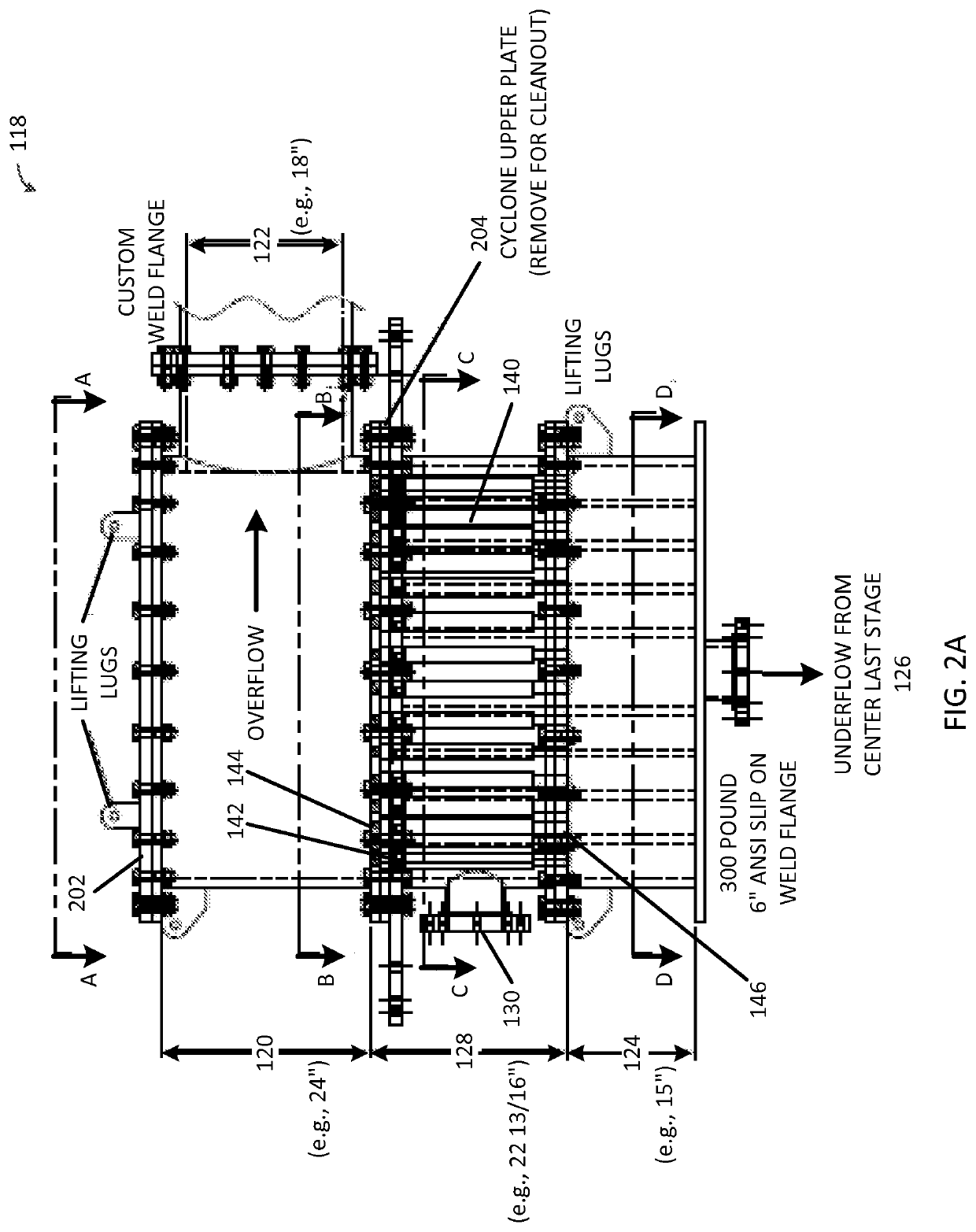

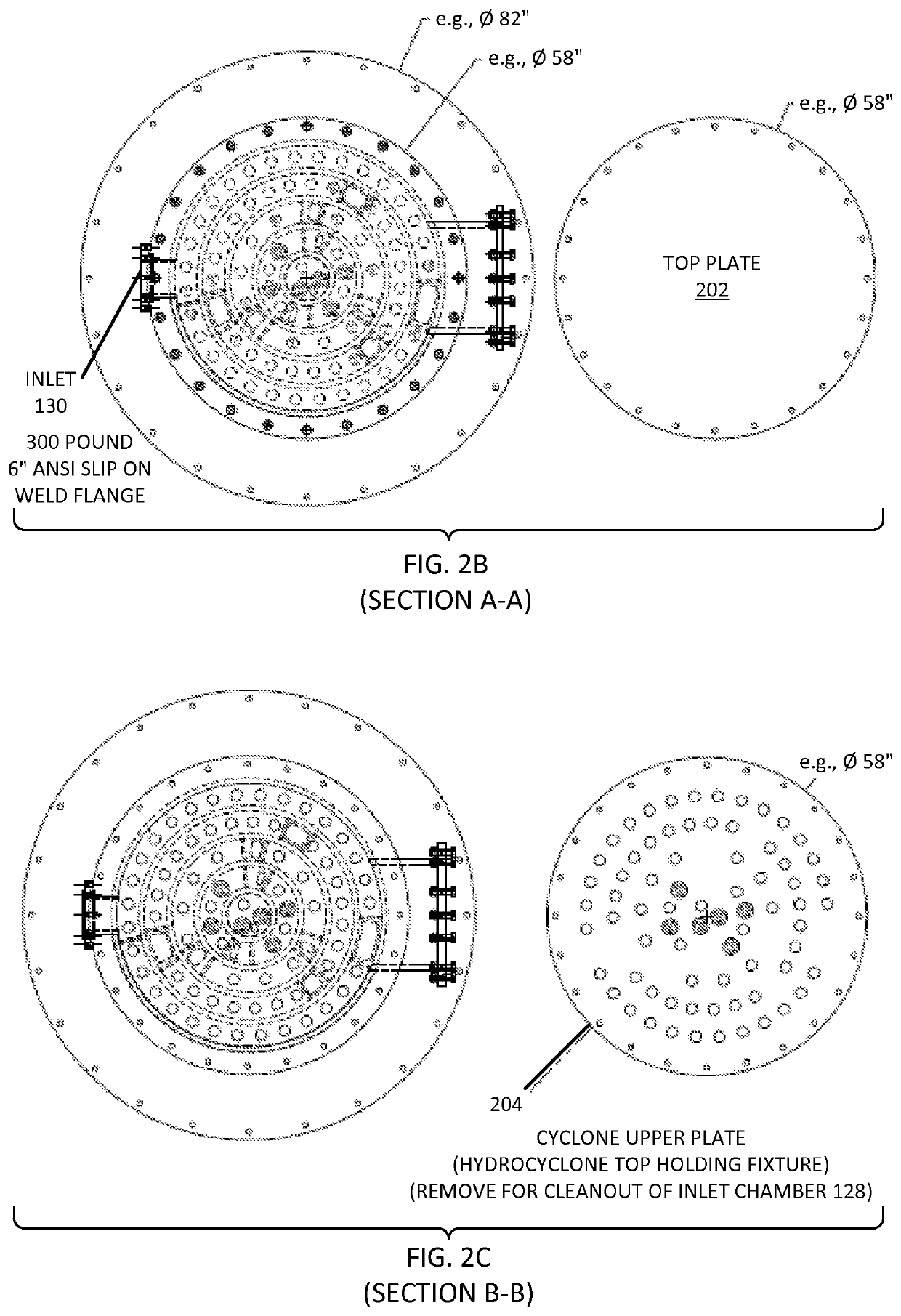

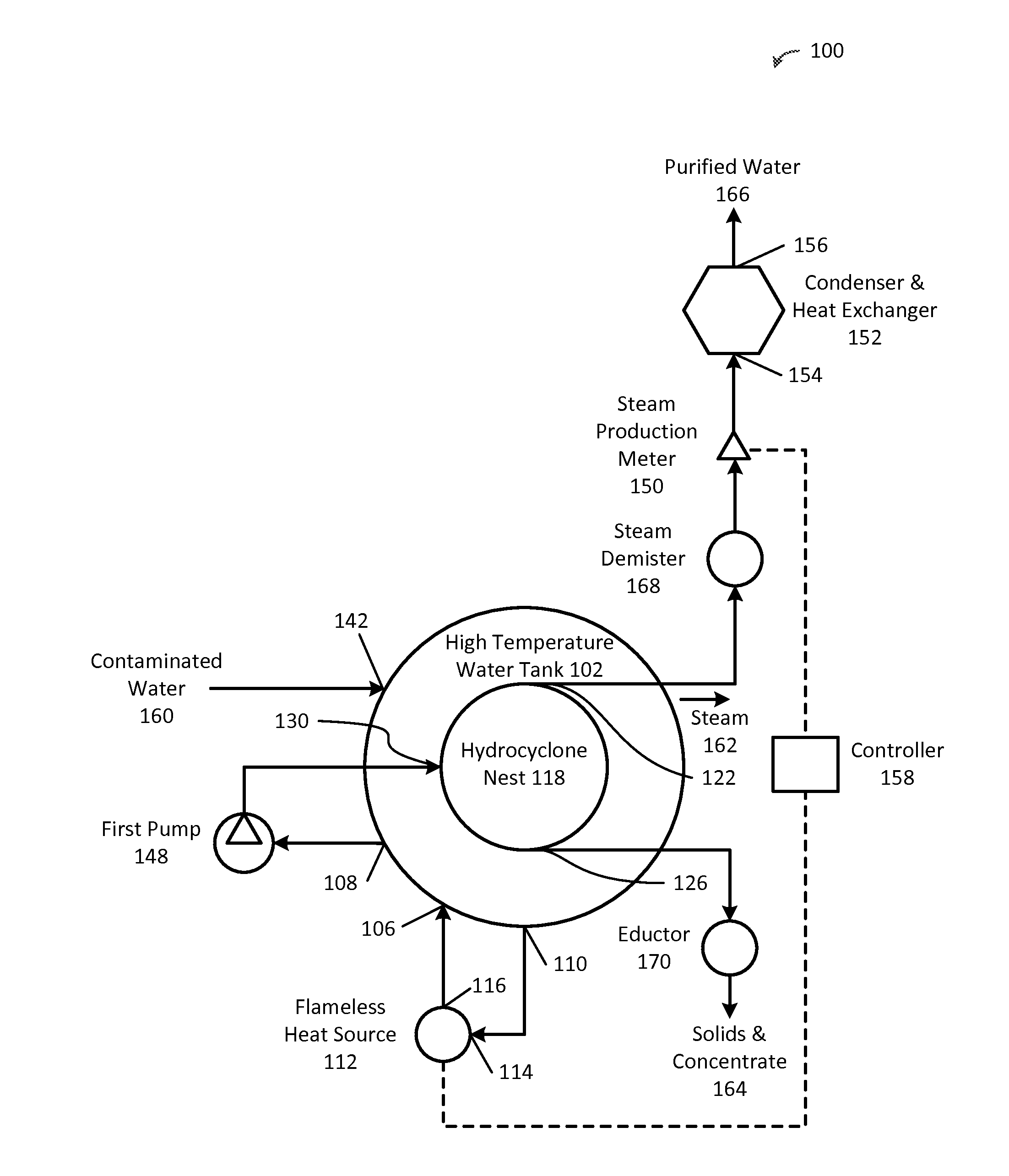

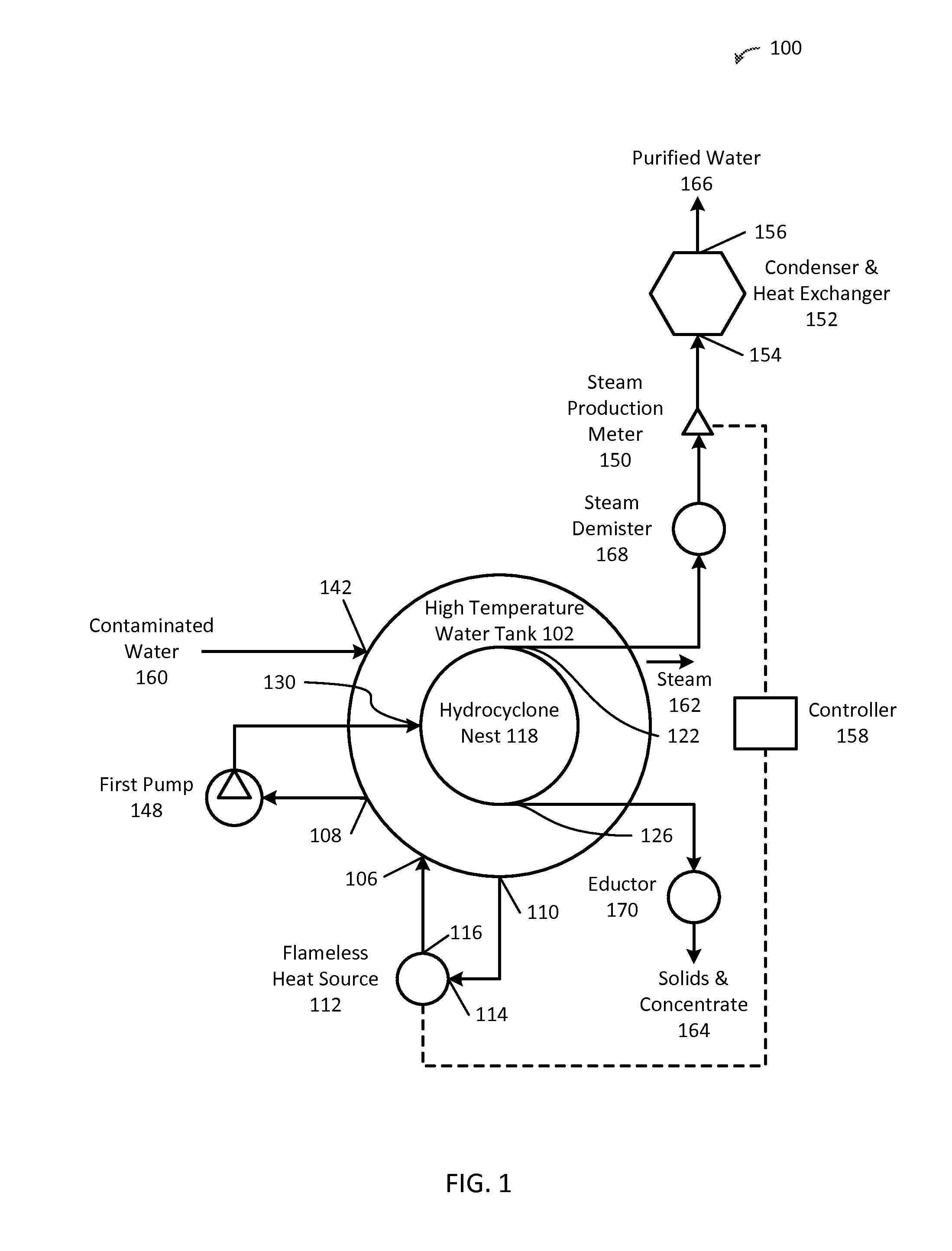

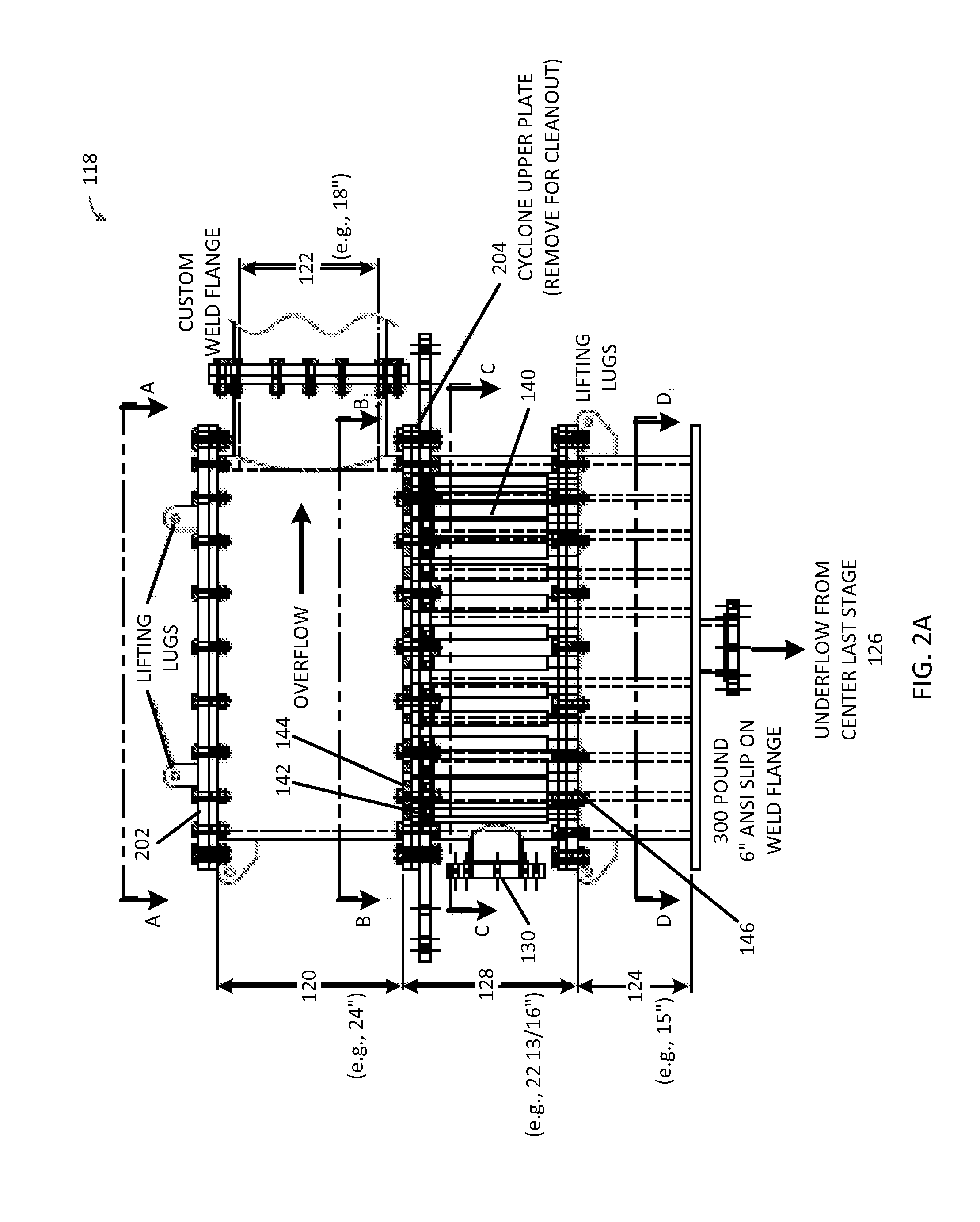

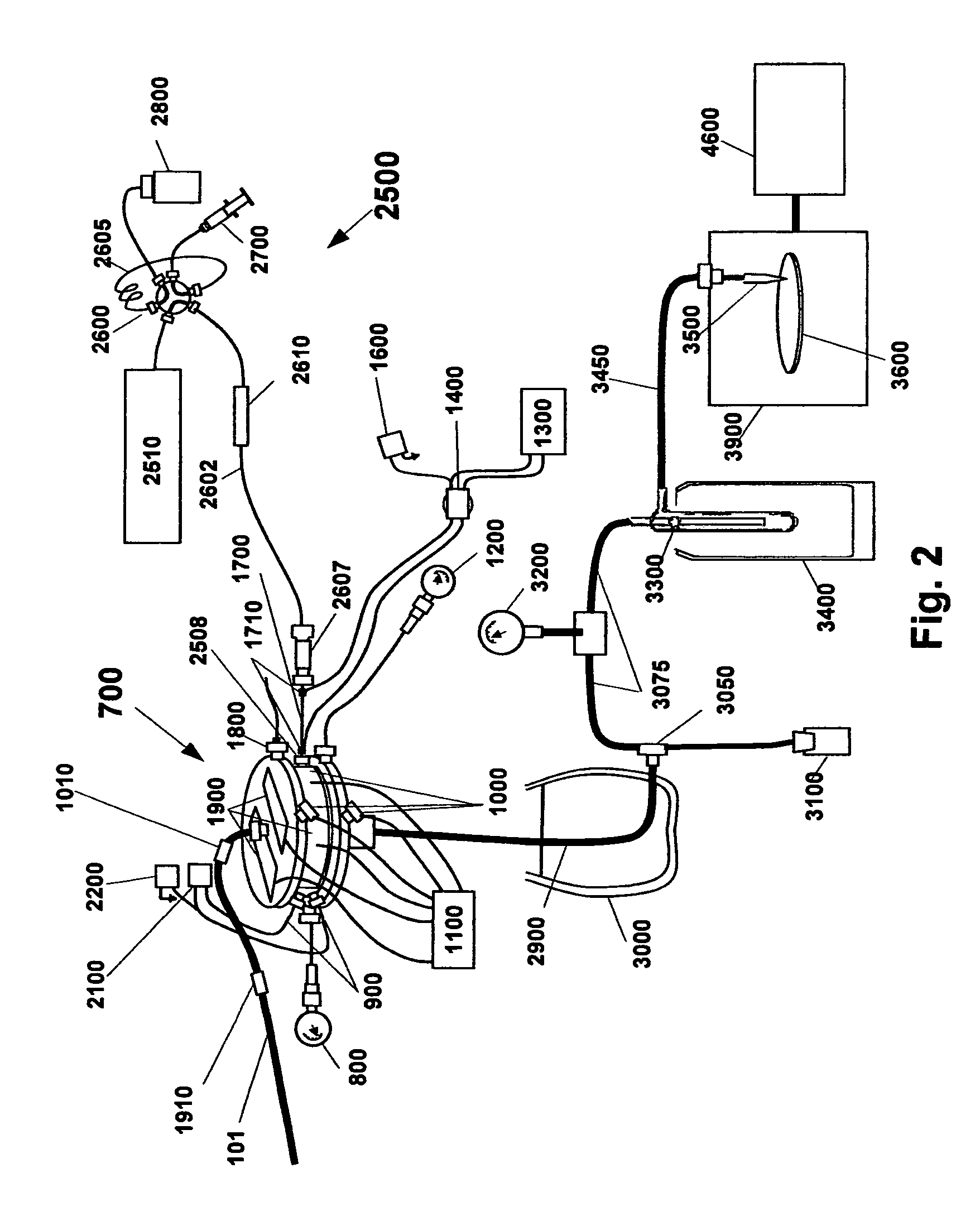

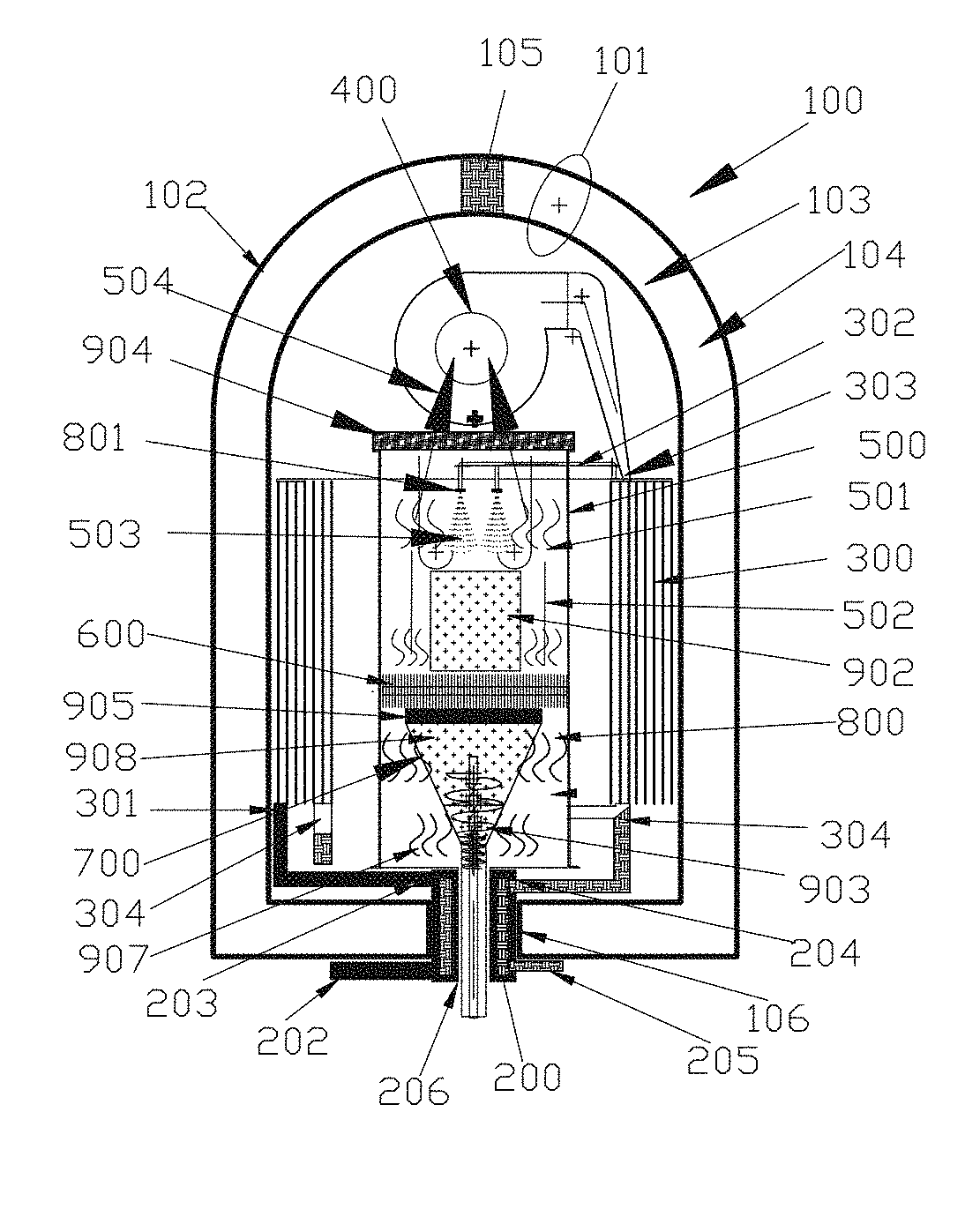

System and method for water purification

A water purification system includes a high temperature water tank, a flameless heat source, a cylindrical vessel (hydrocyclone nest), a first pump, a steam production meter, and a steam condenser and heat exchanger. The contaminated water is heated within the high temperature water tank using the flameless heat source. The heated contaminated water heats the cylindrical vessel and one or more sets of hydrocyclones. The heated contaminated water is pumped into the cylindrical vessel such that the heated contaminated water enters a tangential inlet of the hydrocyclones, the hydrocyclones separate the heated contaminated water into steam and solids / concentrate, the steam exits through an overflow of the hydrocyclones and a first outlet of the cylindrical vessel, the solids / concentrate exit through an underflow of the hydrocyclones and a second outlet of the cylindrical vessel. The steam is condensed into purified water using the steam condenser and heat exchanger.

Owner:CLOUDBURST SOLUTIONS

Large scale insulated desalination system

ActiveUS9428403B2Improve efficiencyReduced energy input requirementsAuxillariesGeneral water supply conservationAtmospheric airDesalination

An apparatus and method for the distillation of ocean and brackish water that includes insulation for preventing heat from escaping to the atmosphere is disclosed. The insulation comprises a second wall surrounding the basic assemblies of a desalination system in which the space between the second wall and basic assemblies is under low partial vacuum and is partially or totally filled with an insulation material for structural support. The system allows for flash evaporation of heated input water and condensing the resultant vapors into pure distilled water. The heat of condensation as well as heat from the salt byproduct may be recaptured and used to preheat the input contaminated water.

Owner:FLO ONICS LLC

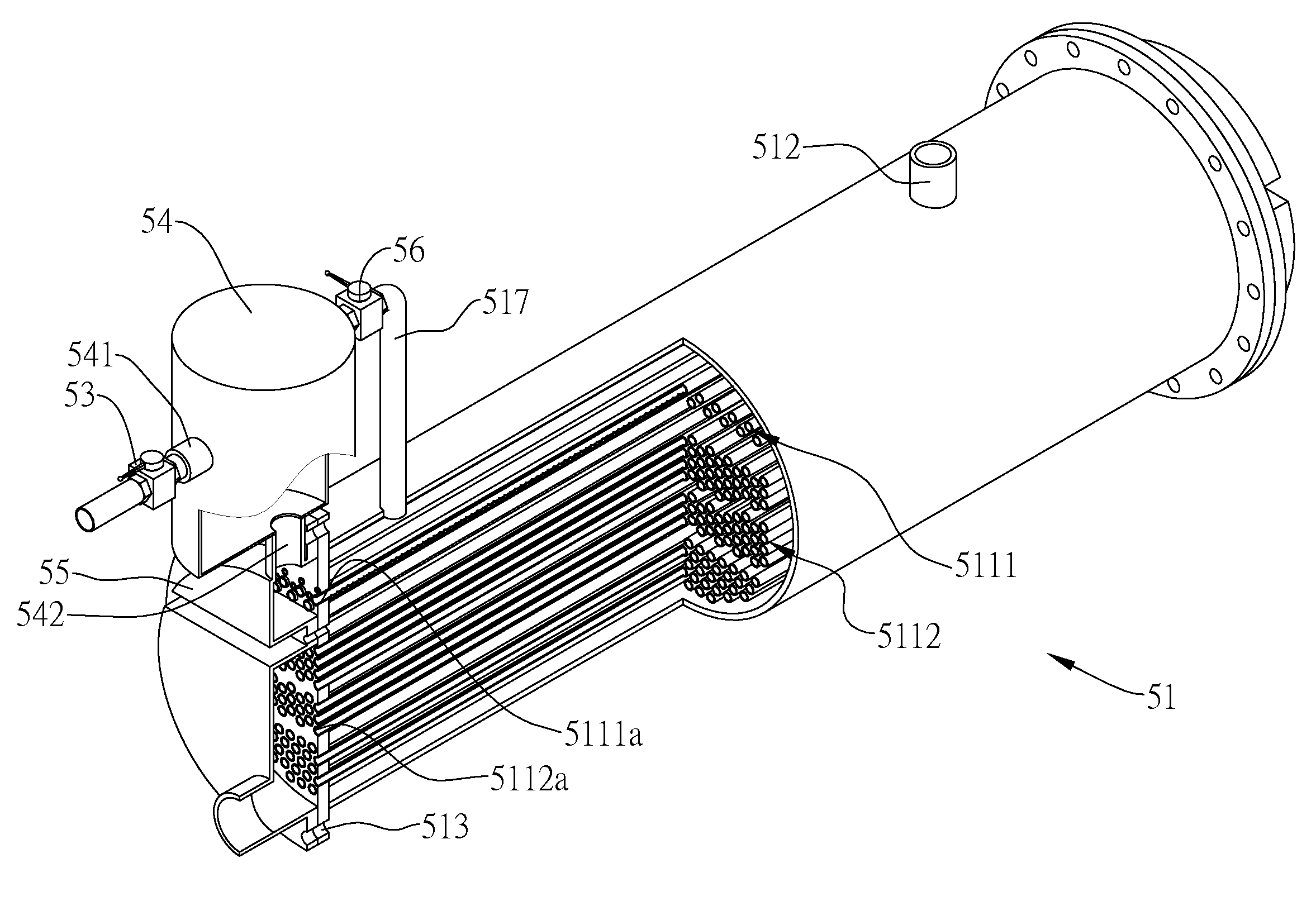

Pressure-adjustable multi-tube spraying device

InactiveUS20100139898A1Spray evenlySimple pressure controllingLiquid surface applicatorsEvaporators/condensersRefrigerantMechanical engineering

A multi-tube spraying device is provided. The multi-tube spraying device includes a body having a closed vessel, wherein a plurality of spraying tubes are disposed in the upper part of the closed vessel and a plurality of heat exchanging tubes are disposed in the lower part of the closed vessel. The device further includes an outlet pipe for discharging refrigerant vapor contained therein and a connecting pipe for introducing the refrigerant vapor from a source to the vessel. In addition, a liquid-vapor separator connected to the refrigerant source separates the refrigerant into vapor and liquid for introducing the liquid refrigerant to the spraying tubes in the vessel while introducing the refrigerant vapor into the vessel. Therefore, a heat exchange is performed between the refrigerant and the heat exchanging tubes.

Owner:IND TECH RES INST

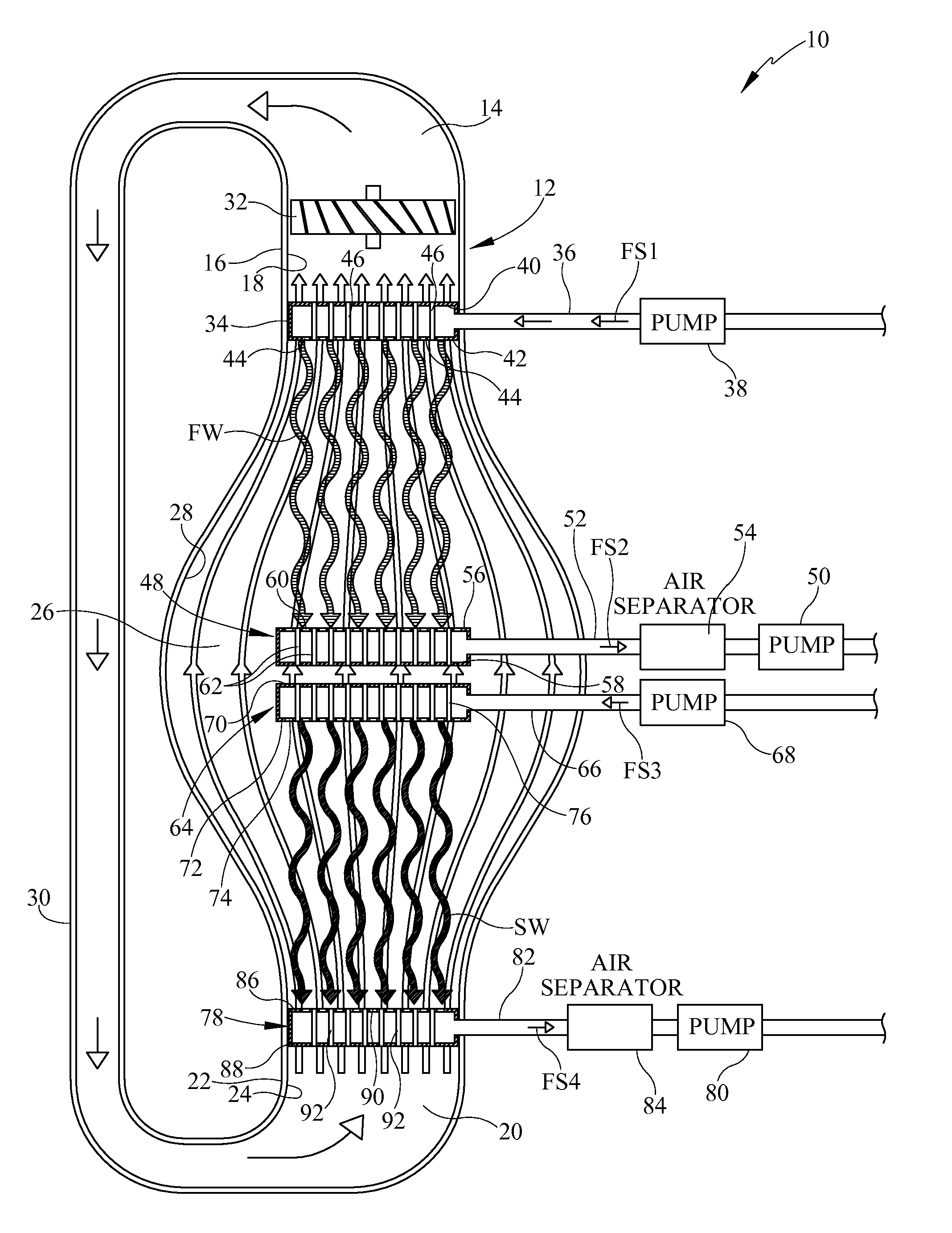

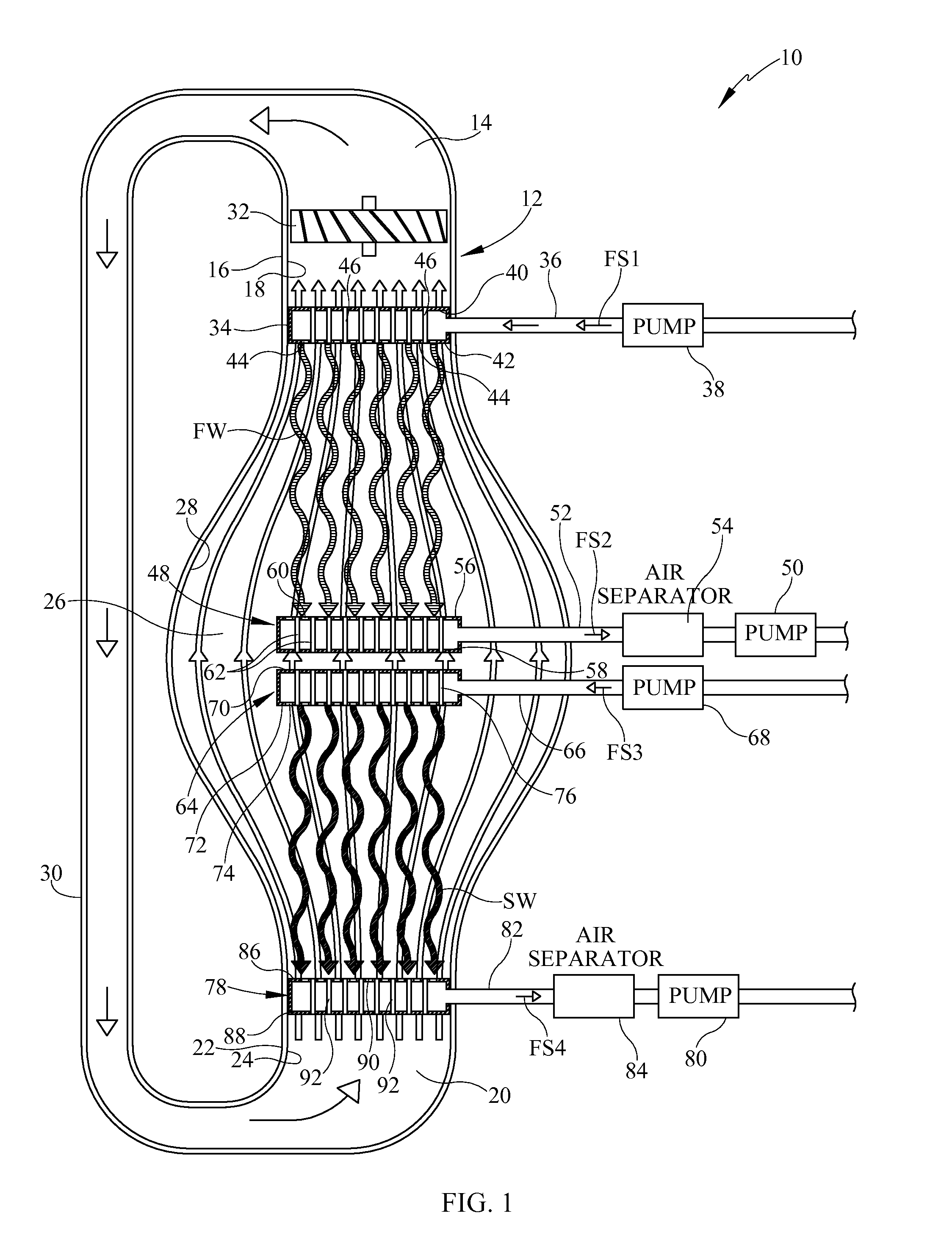

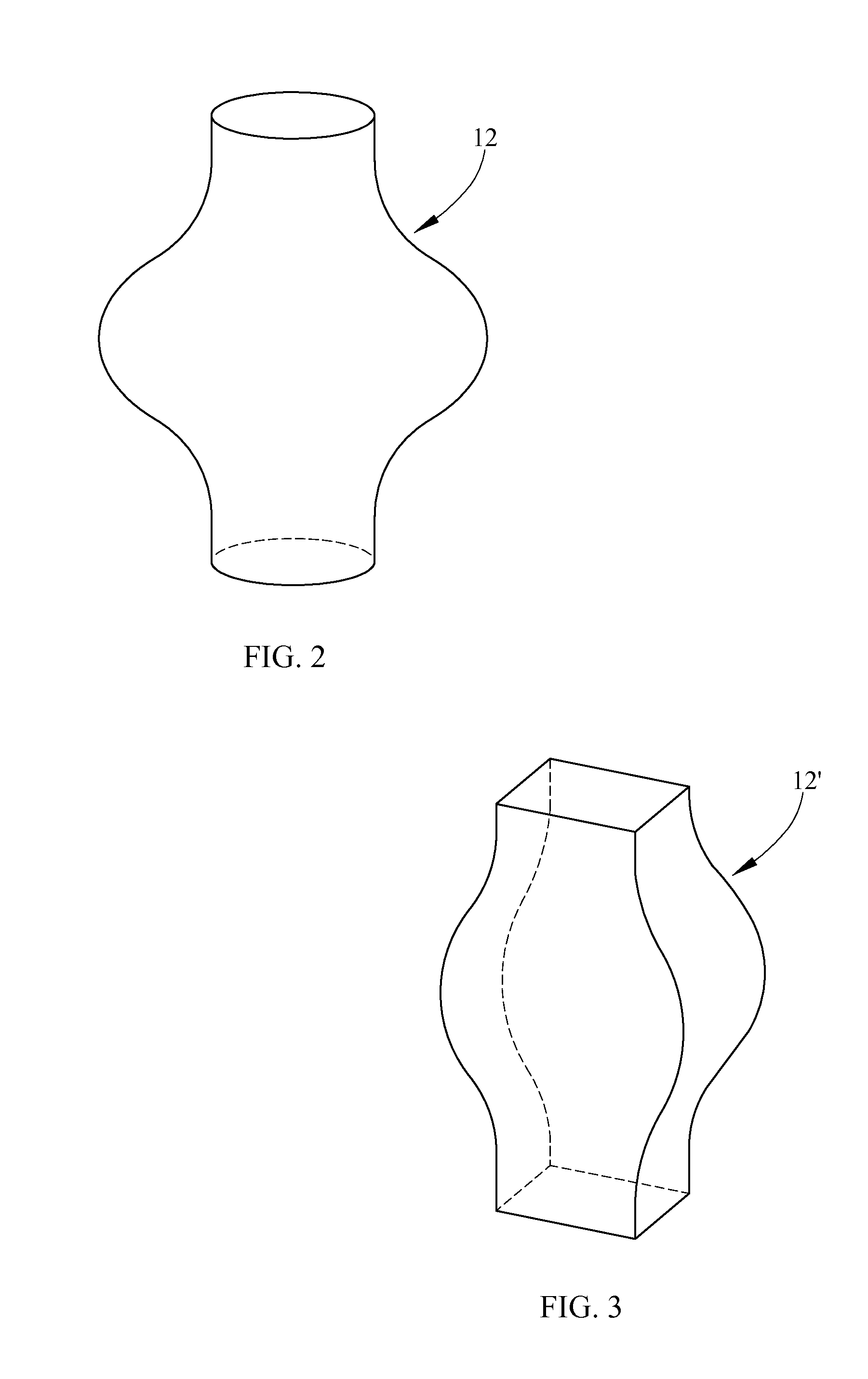

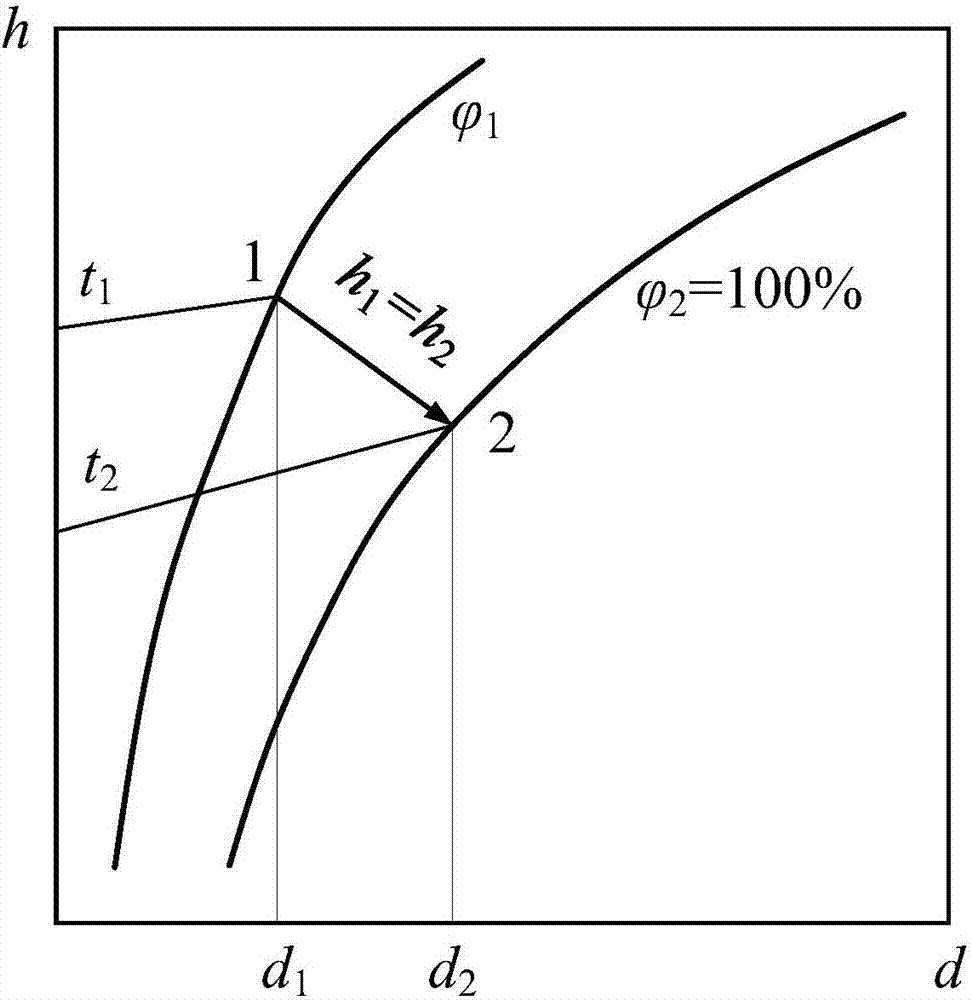

Contoured humidification-dehumidification desalination system

InactiveUS20140291137A1Improve energy efficiencySacrificing energy efficiencyGeneral water supply conservationVapor condensationCondensation processWater desalination

A humidification-dehumidification water desalination system uses a contoured interior chamber, essentially onion shaped, in order to balance the thermodynamics of the evaporation / condensation process completely by facilitating the needed fluid bypass with air and the contoured shape of the interior chamber so that the desalination can occur energy efficiently in a single stage humidification-dehumidification system. The contour of the internal wall of the interior chamber is loosely proportional to the differential of the percentage of water vapor that can be carried by air as a function of temperature, with the interior chamber being essentially symmetrical about a horizontal midplane through the interior chamber.

Owner:MOLECULE SORTING SERVICES

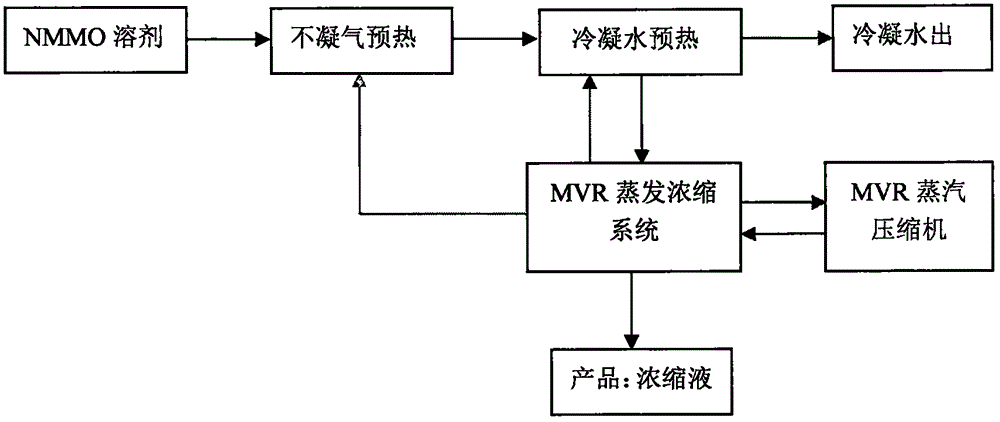

MVR evaporation and concentration process of NMMO solvent

InactiveCN105854319AEasy to implementImprove production continuityOrganic chemistryEvaporation with vapour compressionEvaporationProcess engineering

A MVR evaporation and concentration process of an NMMO solvent includes a preheating part and an MVR evaporation and concentration system, wherein the preheating part includes a non-condensable gas preheating part and a condensed water preheating part, waste heat of the system is fully utilized without additionally supplemented heat energy, and the heat energy consumption is reduced; the MVR evaporation and concentration system includes a vacuum system utilizing secondary steam heating, evaporative concentration, secondary steam re-compression and independence, can reasonably utilize the effective temperature difference of the system to reduce energy consumption, and can also ensure the stable operation of the system. The process adopts an MVR evaporation and concentration mode, greatly reduces the energy consumption, reduces the operation costs and can also meet the high-vacuum requirement of the system.

Owner:BEIJING PUREN MEIHUA ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH

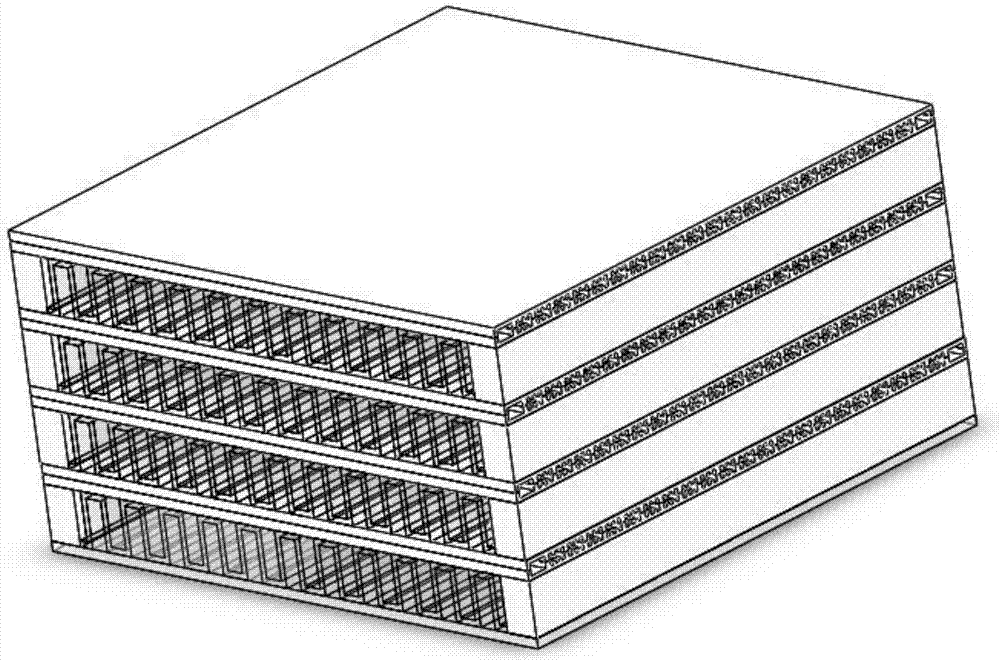

Vaporization system based on air heat insulation and humidification process

ActiveCN107376384AHigh thermal efficiency utilizationImprove heat utilizationEvaporator accessoriesDispersed particle separationWater vaporEngineering

The invention discloses a vaporization system based on an air heat insulation and humidification process. The process comprises the following steps: enabling hot air to directly contact a solution to transfer heat and mass, transferring the apparent air heat to the solution, enabling the water to be vaporized after absorbing the heat, latent heat is returned into the air in a water vapor form, i.e., the air is humidified in an isenthalpic process, so that a vaporization effect can be achieved. By controlling the temperature of the hot air entering a vaporization chamber, a vaporization temperature of the solution and the outlet temperature of the humidified air can be controlled, and the system is simple in control; and by continuously adding materials and discharging concentrated solutions, the continuous vaporization operation is realized.

Owner:NANJING UNIV OF TECH

Solar atmospheric water harvester

InactiveCN101304950AGeneral water supply conservationVapor condensationSurface coolingAtmospheric air

The atmospheric water harvester (2) shown in fig (1) comprises a centrally located flue in the form of a tower 4 and a surrounding heating enclosure (6) for collecting incident solar energy to heat air which enters its periphery (8). With heating of the air in the heating enclosure (6), an updraught is created within tower (4) as the air from the heating enclosure (6) returns to the atmosphere from the open end of the tower. A base structure (10) housing a plurality of wind turbines is provided around the base of the tower. As the heated air flows from the heating enclosure (6) into the tower it is harnessed to rotate the wind turbines. Each wind turbine (20) is provided with associated water collection apparatus (94) comprising a refrigeration system for cooling condensation surfaces to, or below, the dew point of the air to effect the condensation of water from the air onto condensation surfaces of the water collection apparatus for collection. The refrigeration system comprises a compressor (46) for compressing a refrigerant vapour for the cooling of the condensation surfaces and which is driven by the wind turbine (20).

Owner:HYDROTOWER PTY LTD

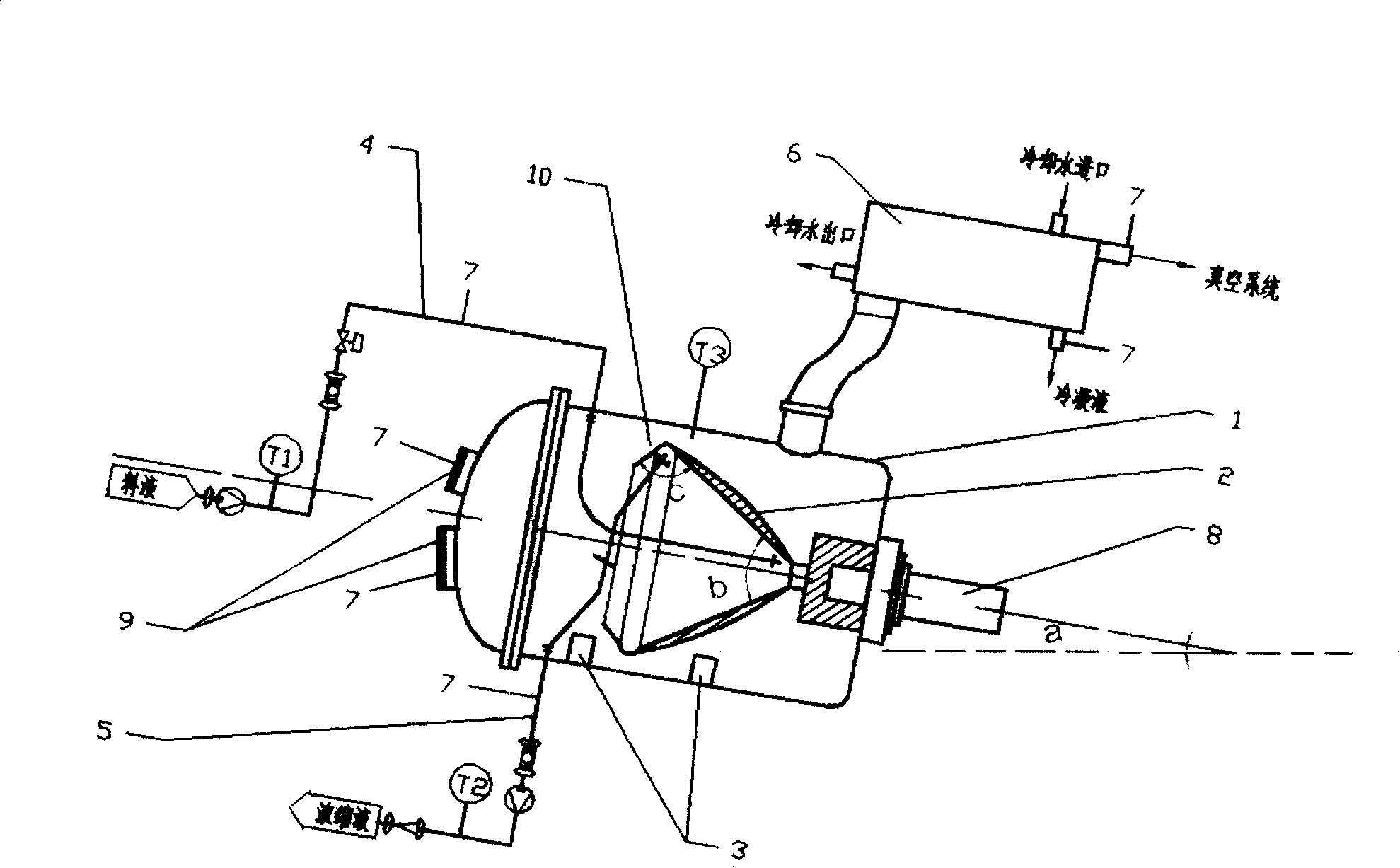

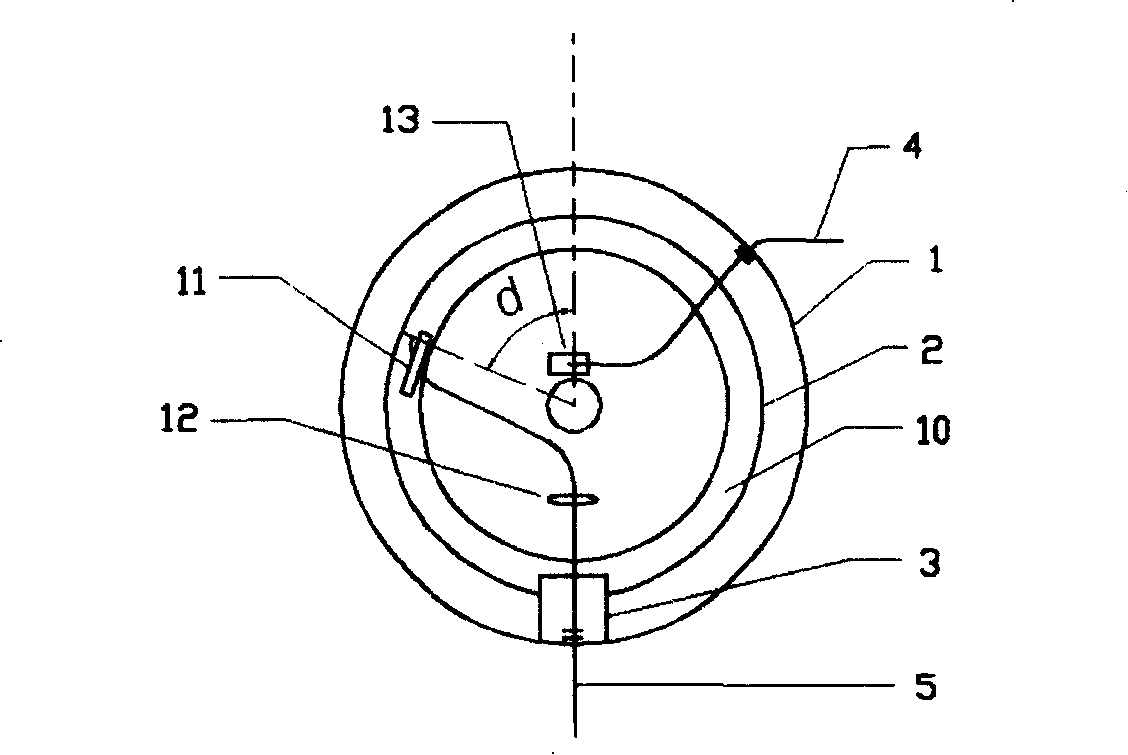

Microwave rotating thin film concentrator

InactiveCN101234257AReduce volumeAvoid efficiencyDrying solid materials without heatEvaporators with forced circulationMagnetic tension forceDecomposition

The invention discloses a microwave rotating film concentration device, comprising a sealing tank body (1), a rotating evaporator (2), a microwave device (3), a solution feeding tube (4), a concentrated liquid discharging tube (5), condenser (6), a microwave shielding device (7), a stirring motor (8) and a vacuum system; wherein the evaporating surface of the rotating evaporator (2) is conical or round, the angle a between the axis of the evaporator and the horizontal plane is 0 to 90 degree, the rotating evaporator (2) adopts a magnetic stirring device to be connected with the external stirring motor (8), which is arranged in the center of the sealing tank body which is provided with a cover which can be opened and closed, the cover is provided with a sight glass (9). The concentration device solves the problems of the present equipments in the process of concentrating extraction liquid, such as the low evaporating speed, the high concentrating temperature, the decomposition of feed solution caused by long-term heating, decompression operation being impossible because of the blasting boiling of feed solution, the low energy utilization ratio, the large size of equipment, and the equipment being difficult to be cleaned, thus the invention has a wide applied prospect.

Owner:PHARM TECH TIANJIN

MVR continuous evaporative crystallization system

InactiveCN105879426AIncrease profitImprove energy savingEvaporator accessoriesSolution crystallizationEngineeringVacuum pump

The invention relates to a MVR continuous evaporative crystallization system which comprises a heating system, an evaporative crystallization system, a crystallization separation system and a condensation system. The heating system comprises a live steam compensation pipeline, a steam compressor and a material preheating device. The evaporative crystallization system comprises a circulation evaporator and a crystallizer. The crystallization separation system comprises a centrifugal machine. The condensation system comprises a condensate collection tank. The circulation evaporator comprises is connected with the condensate collection tank through a condensate water inlet pipe. The material preheating device comprises a primary preheater, a secondary preheater and a tertiary preheater. A second branch pipe, used for conveying live steam, connected to the steam compressor is connected into the tertiary preheater. The condensate collection tank is connected with the secondary preheater through a condensate water outlet pipe. The condensate collection tank is connected with the primary preheater through a non-condensation gas pipe. A non-condensation gas outlet of the primary preheater is connected with a vacuum pump. The MVR continuous evaporative crystallization system has the advantages of being high in heat utilization rate, good in energy-saving performance, low in pollution, high in efficiency and stable in work.

Owner:WENZHOU TAIKANG EVAPORATOR

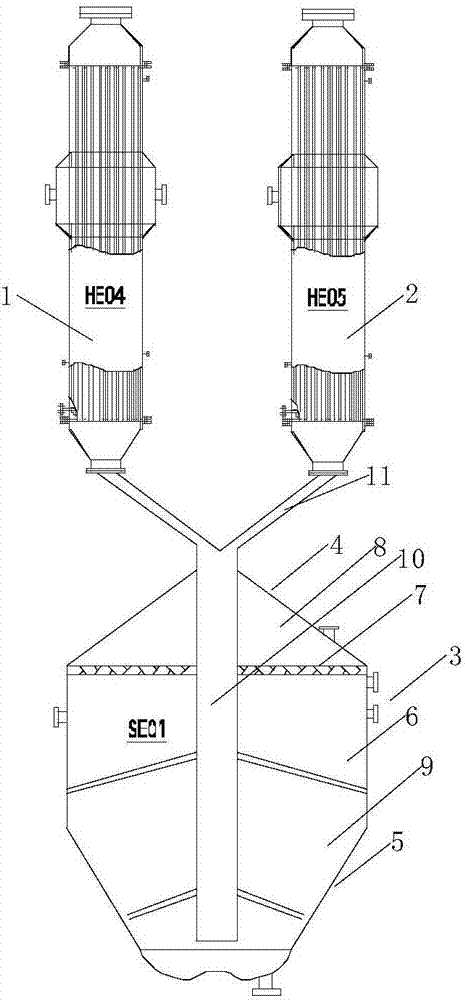

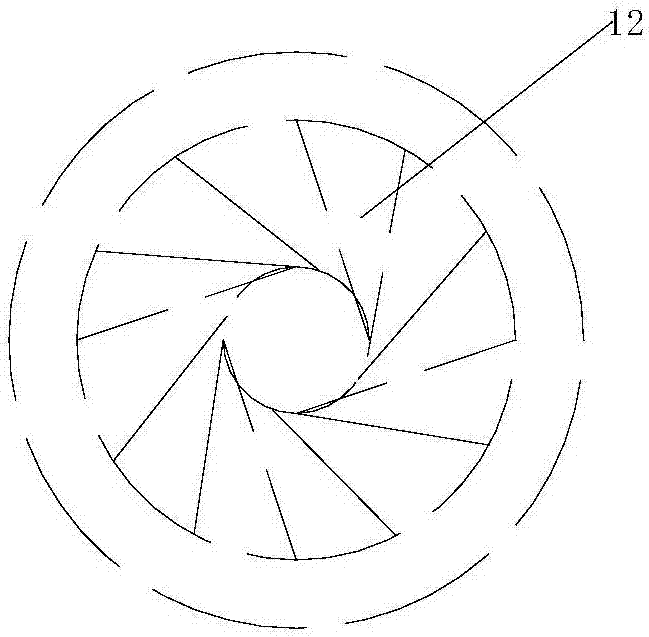

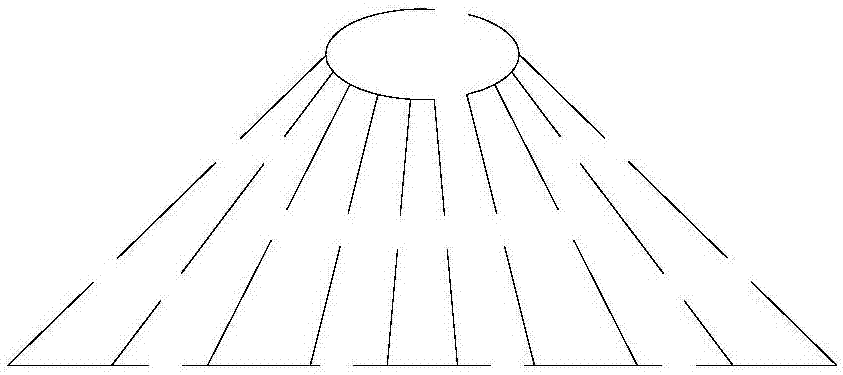

Integrated forced circulation crystallizing evaporator for producing large-grained ammonium sulfate and device

The invention relates to the technical field of devices for producing large-grained ammonium sulfate, in particular to an integrated forced circulation crystallizing evaporator for producing large-grained ammonium sulfate and a device. The integrated forced circulation crystallizing evaporator comprises a first evaporator, a second evaporator and a crystallizer, the crystallizer is sequentially connected with a first conical portion, a cylinder portion and a second conical portion from top to bottom, a wire mesh demister is arranged at a joint of the first conical portion and the cylinder portion, the crystallizer is divided into a vaporizing chamber and a crystallizing chamber by the wire mesh demister, the taper of the second conical portion is larger than that of the first conical portion, a first 'Y'-shaped flow guide pipe is arranged in the crystallizer, extends out the top end of the crystallizer and is connected with material outlets of the first evaporator and the second evaporator through two second 'Y'-shaped flow guide pipes, a first rotational flow device and a second rotational flow device are sequentially connected on the outside of the first flow guide pipe below the wire mesh demister from top to bottom, so that the integrated forced circulation crystallizing evaporator for producing the large-grained ammonium sulfate is small in occupied area, and the layering effect of different crystal sizes is good.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

System and method for water purification

ActiveUS20160145122A1Waste water treatment from quariesLiquid degasificationSteam condensationSewage

A water purification system includes a high temperature water tank, a flameless heat source, a cylindrical vessel (hydrocyclone nest), a first pump, a steam production meter, and a steam condenser and heat exchanger. The contaminated water is heated within the high temperature water tank using the flameless heat source. The heated contaminated water heats the cylindrical vessel and one or more sets of hydrocyclones. The heated contaminated water is pumped into the cylindrical vessel such that the heated contaminated water enters a tangential inlet of the hydrocyclones, the hydrocyclones separate the heated contaminated water into steam and solids / concentrate, the steam exits through an overflow of the hydrocyclones and a first outlet of the cylindrical vessel, the solids / concentrate exit through an underflow of the hydrocyclones and a second outlet of the cylindrical vessel. The steam is condensed into purified water using the steam condenser and heat exchanger.

Owner:CLOUDBURST SOLUTIONS

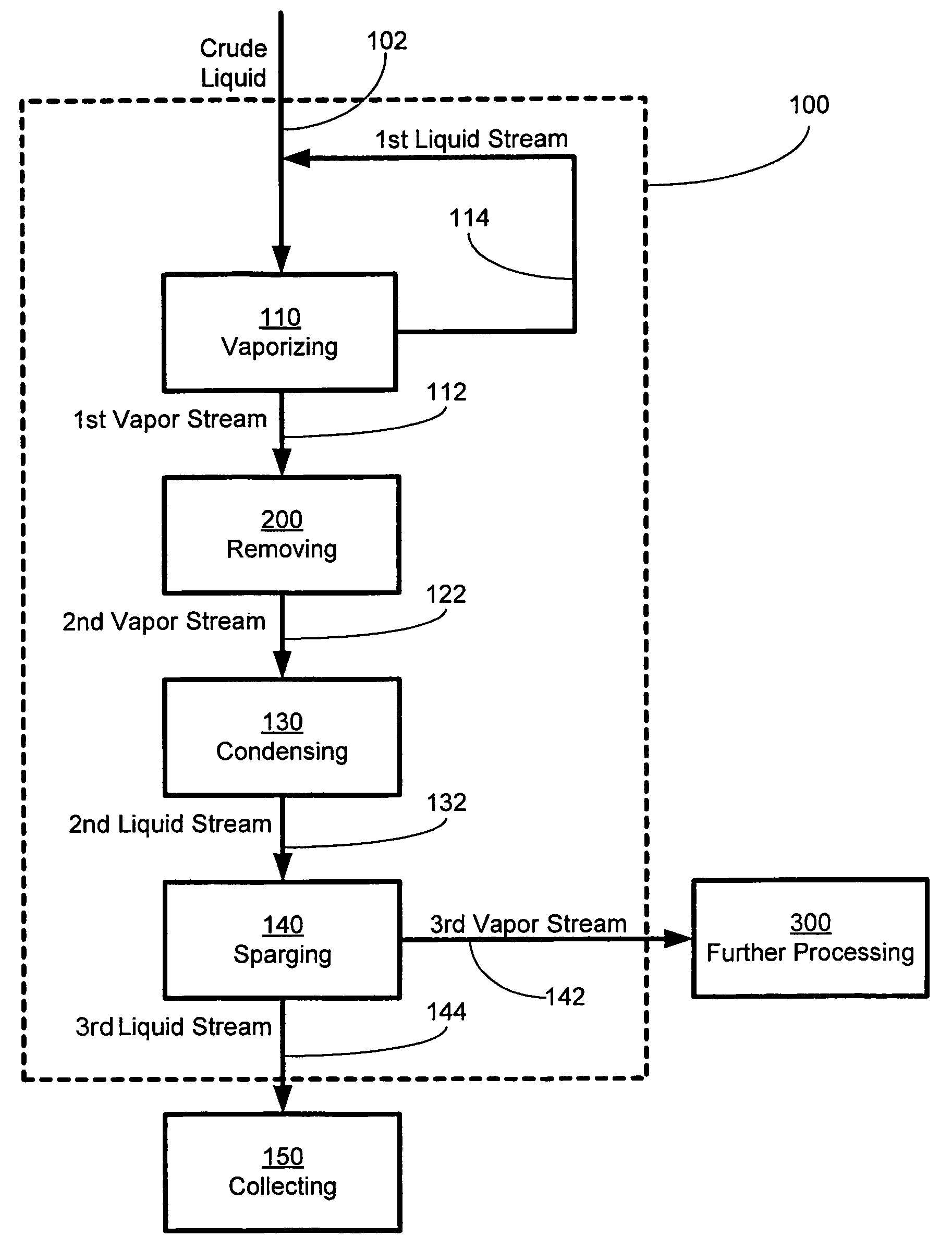

Method and apparatus for corrosive gas purification

ActiveUS7175696B2Good removal effectHigh purityUsing liquid separation agentEvaporator accessoriesParticulatesSorbent

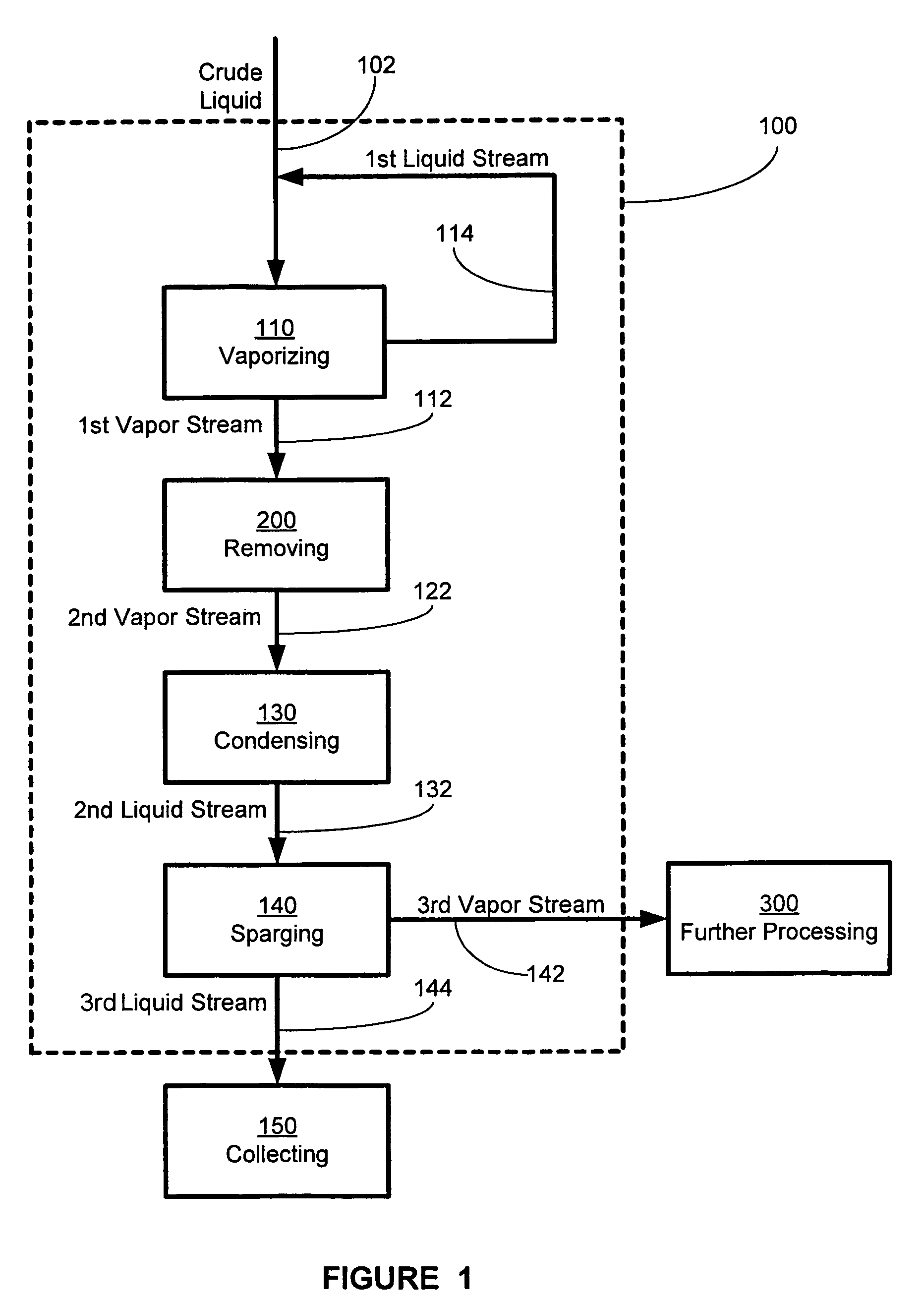

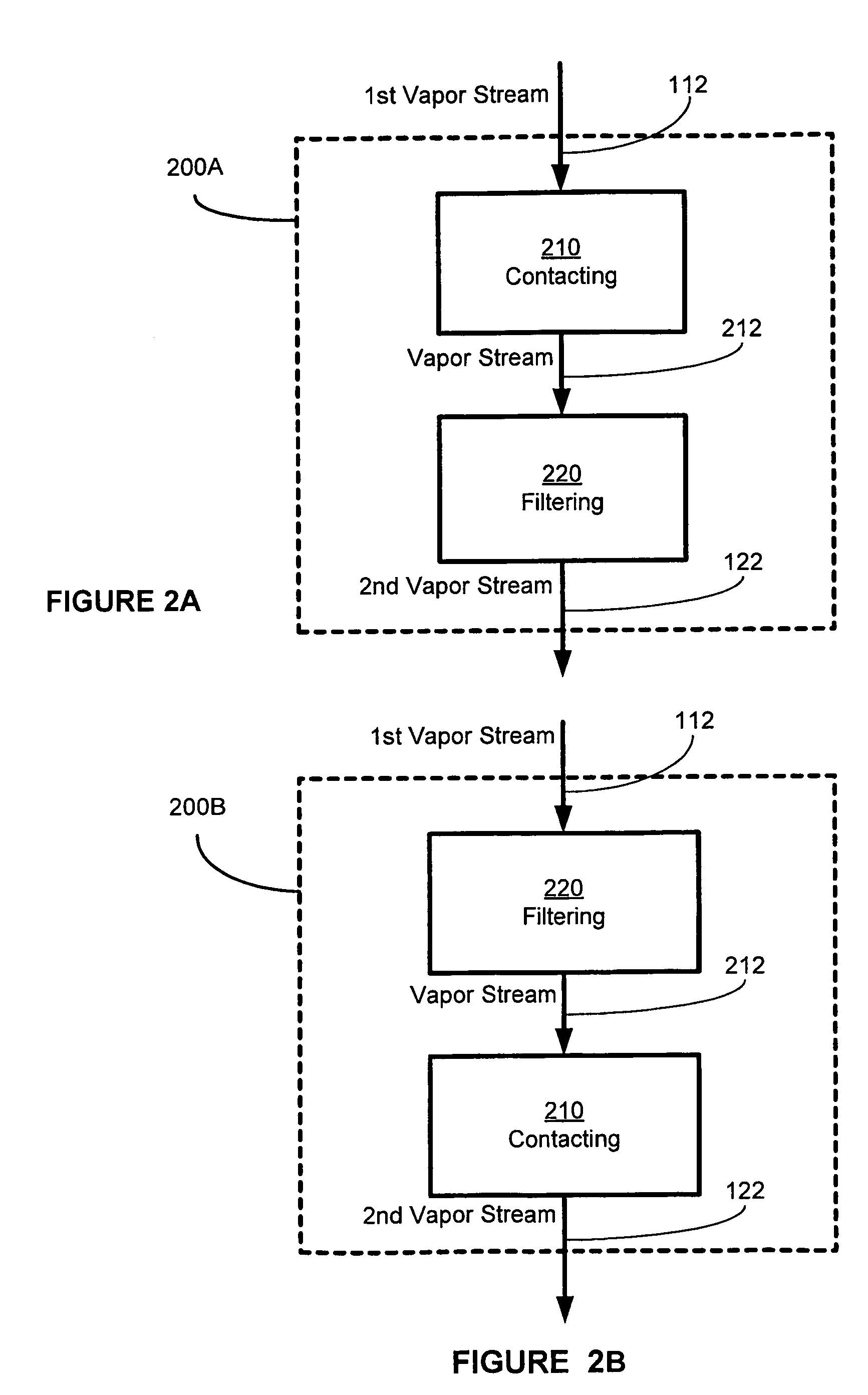

Herein is disclosed a method and an apparatus for preparing a highly purified gas from a crude liquid comprising the gas and one or more of a metal, particulates, water vapor, or a volatile impurity. The method comprises: (a) vaporizing the crude liquid, to yield (i) a first vapor stream comprising the gas and (ii) a first liquid stream comprising the gas; (b) removing water vapor, particulates, or both from the first vapor stream, to yield a second vapor stream comprising the gas; (c) condensing the second vapor stream, to yield a second liquid stream comprising the gas; and (d) sparging the second liquid stream with an inert gas, to yield (i) a third vapor stream comprising the gas and (ii) a third liquid stream comprising the highly purified gas. Also disclosed is a method for preparing an adsorbent to effectively remove water vapor from the gas, as well as an adsorbent so prepared.

Owner:AIR LIQUIDE AMERICA INC +1

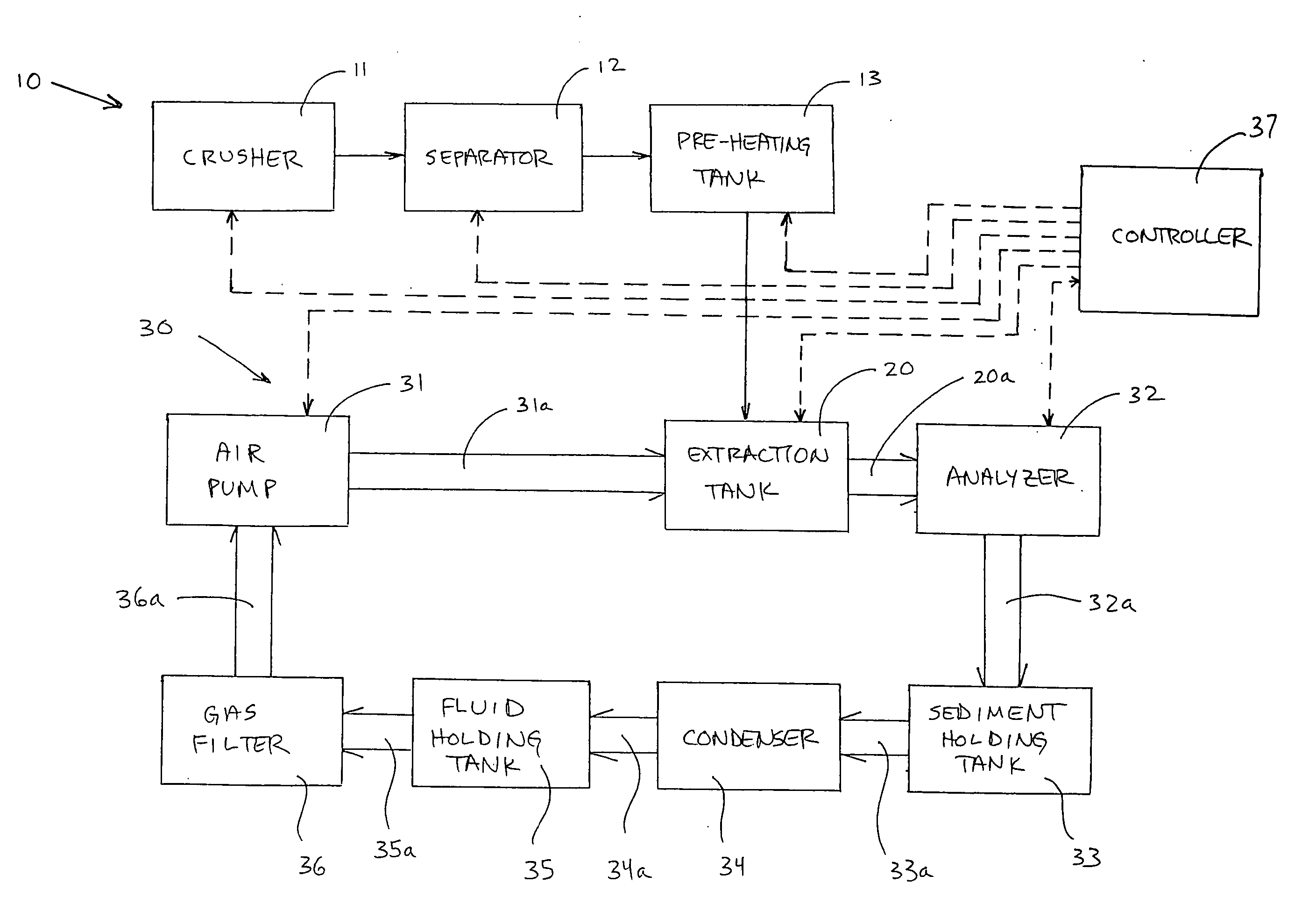

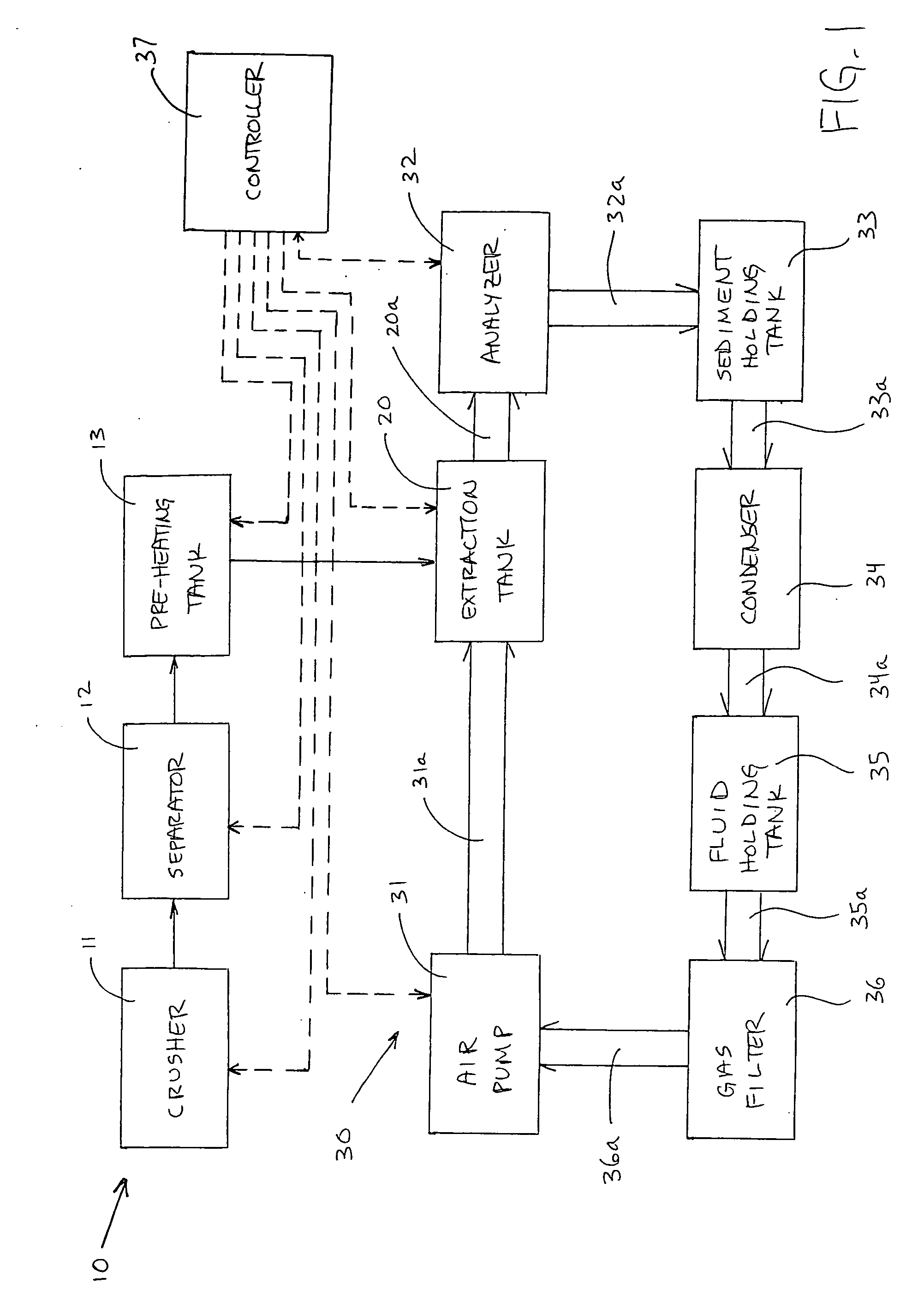

Method and apparatus for extracting contaminants from soil and from animal manure

ActiveUS20060228231A1Positive displacement pump componentsDistillation regulation/controlPositive pressureClosed loop

An apparatus for extracting contaminants from a contaminated material, such as contaminated soil and animal manure, includes an extraction tank having an interior, a heating element that is adapted heat the contaminated material to a temperature where contaminants in the contaminated material are released therefrom to the interior of the extraction tank, and an agitator that is adapted to agitate the contaminated material as it is being heated by the heating element. The apparatus also includes an air pump that generates a series of positive pressure air pulses at an outlet thereof and a series of negative pressure air pulses at the inlet thereof. The apparatus further includes one or more contaminant retaining mechanisms, such as a sediment holding tank, a fluid holding tank, and a gas filter. The interior of the extraction tank, the air pump, and the contaminant retaining mechanisms are connected in a closed loop air circulation system such that the contaminants that are released from the contaminated material are stored in the contaminant retaining mechanisms.

Owner:WINZELER DENNIS D +1

Method and apparatus for desolvating flowing liquid

ActiveUS8695813B2Quick releaseAvoid contactParticle separator tubesIon-exchanger regenerationTemperature controlTemporal resolution

Methods and apparatus for desolvating flowing liquid streams while retaining temporal resolution of dissolved substrates are disclosed. A novel small-scale self-regulating spray dryer preserves temporal resolution while desolvating a liquid chromatography eluent stream and depositing the solute onto an optical surface for infrared spectrographic analysis. The liquid eluent is pumped through a heated nebulizer to create a high-speed jet of solute containing liquid and solvent vapor. This jet is directed circumferentially inside a hot cylindrical cavity. Centrifugal force causes the larger liquid droplets to travel along the outer diameter of the cavity. The cavity surface is heated to cause the droplets to film boil. Film boiling reduces droplet contact with the cavity surface thereby retaining the solute in the droplets. The solute temperature is limited by controlling the pressure into which the solvent evaporates from the droplets. When the droplets are sufficiently small, Stokes drag from the exiting solvent vapor carries the droplets out through the center of the cylindrical cavity. After exiting, the superheated solvent vapor further dries the droplets. Solvent vapor is removed by condensation onto a cooled surface. A freezing point reducing agent may be added to improve removal of solvent condensate. Stokes drag from a non-condensable gas maintains the dried droplets in suspension. This suspension travels through an orifice that focuses the impaction of the dried droplets onto the optical surface for infrared analysis. The deposition surface is in an evacuated chamber and is temperature controlled to freeze liquid solutes yet allowing sublimation of residual solvent.

Owner:SPECTRA ANALYSIS INSTR

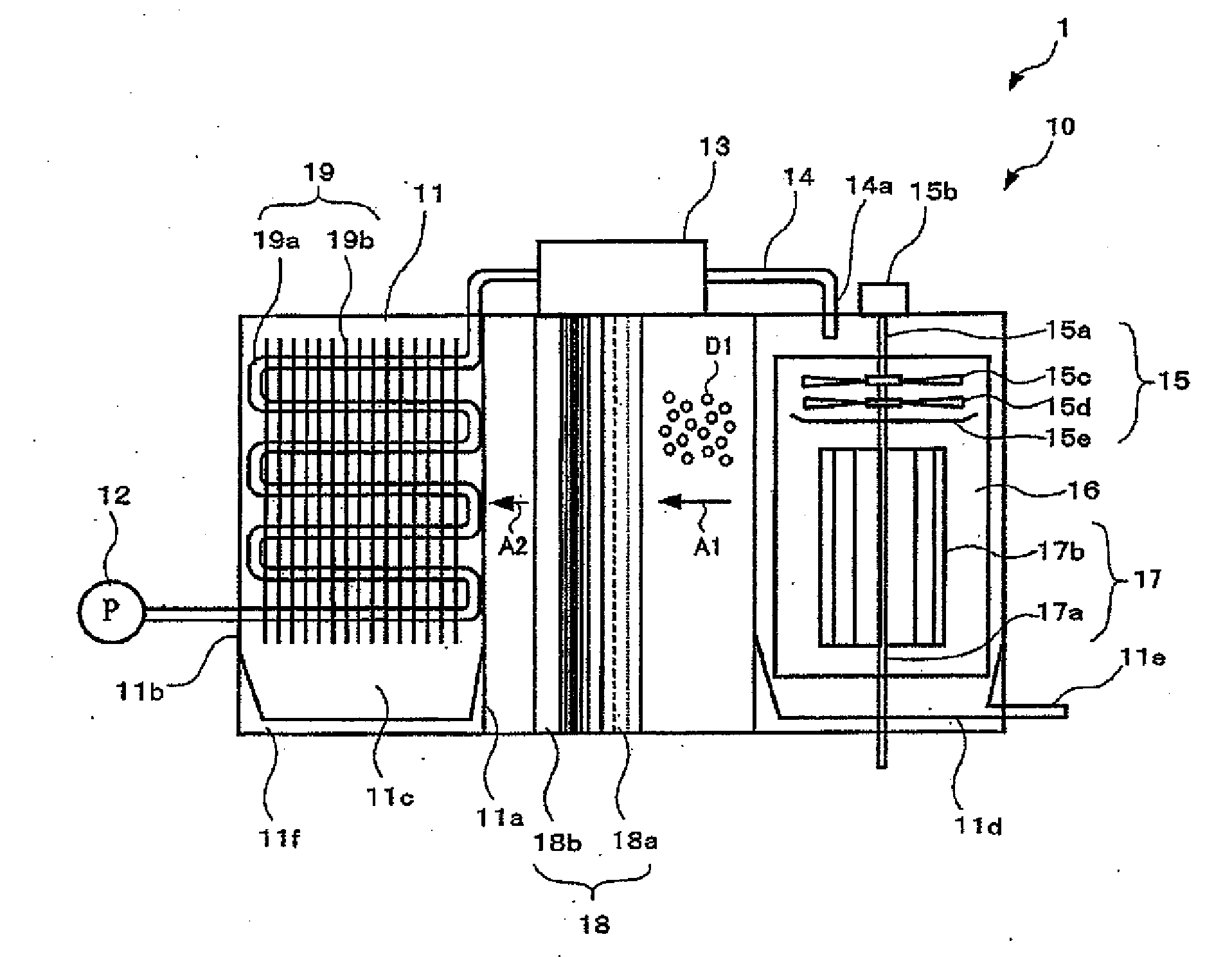

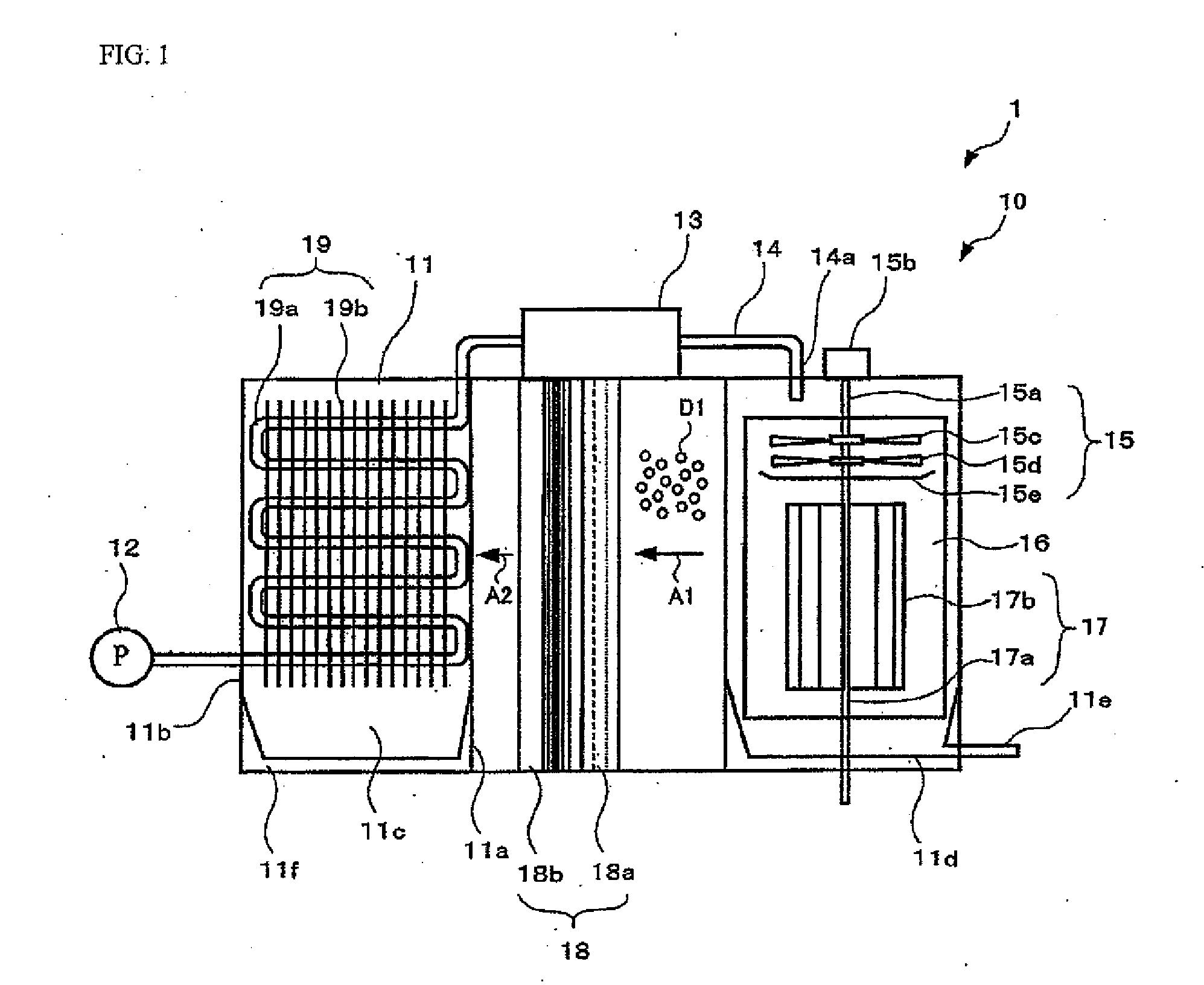

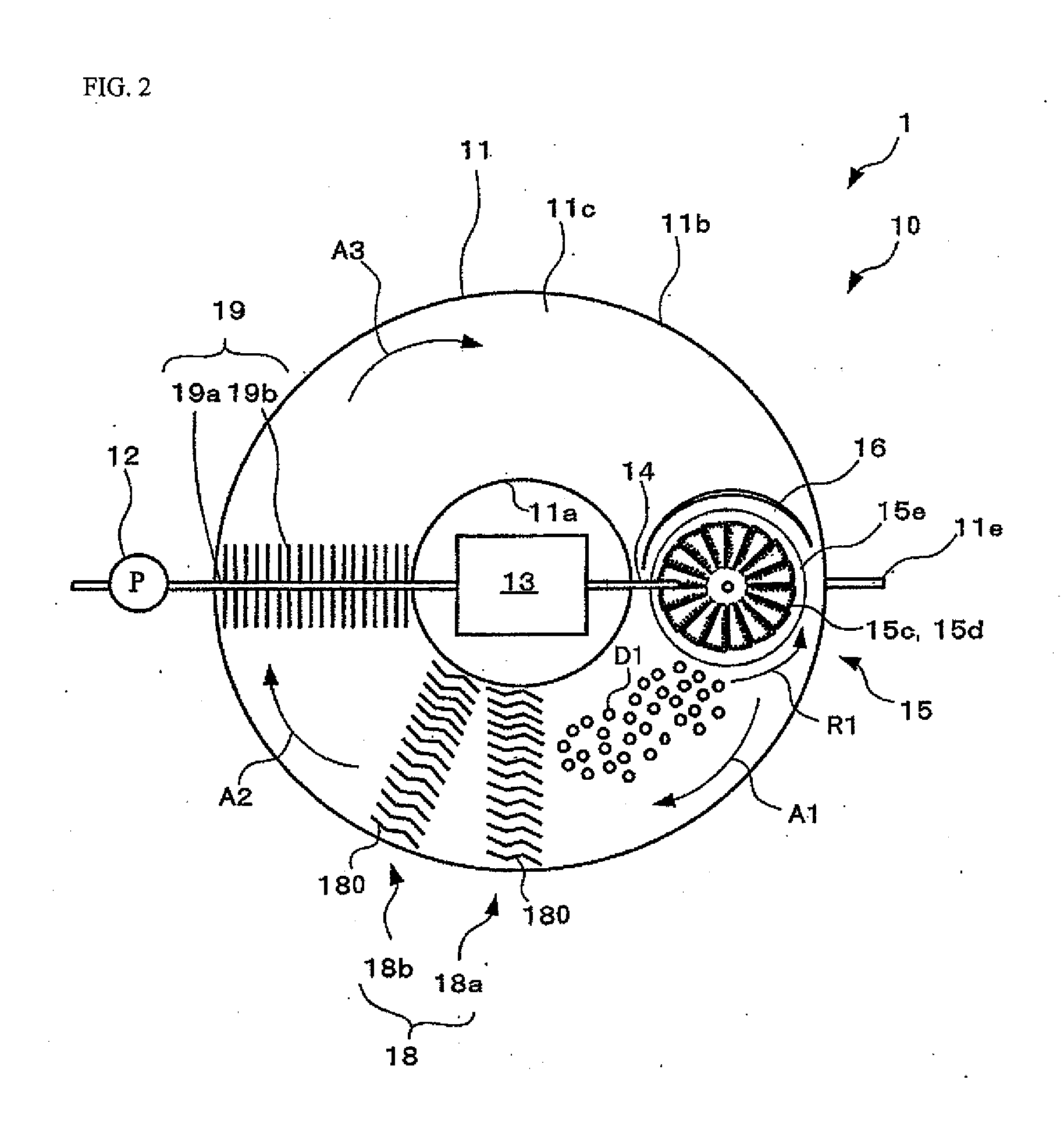

Water Purifying Apparatus

InactiveUS20120175237A1Improve deformationImprove efficiencySeawater treatmentVapor condensationWater vaporPurified water

Provided is a water purifying apparatus capable of efficiently producing purified water from raw water. The water purifying apparatus comprises: a casing (11) having a circulation path; a splitter device (15) disposed within the casing (11) and adapted to split raw water into droplets and create a carrier airflow (A1) capable of circulating along the circulation path and carrying water vapor evaporated from the droplets (D1); and a condenser (19) disposed within the casing (11) at a position downstream of the splitter device (15) in a direction of the carrier airflow and adapted to condense the water vapor to create purified water. The splitter device (15) comprises a rotary shaft (15a) extending in an up-down direction of the casing (11), and a blade (152A to 152Q) radially attached to the rotary shaft (15a) and having irregularities (152p, 152q, 152r, 152s, 152t).

Owner:CIP SOFTWARE

MVR evaporation system for radioactive waste liquid in nuclear power station and operation method thereof

ActiveCN110648775AGuaranteed low temperature evaporationDecompression guaranteeEvaporation with vapour compressionEvaporator accessoriesThermodynamicsNuclear engineering

The invention discloses an MVR evaporation system for radioactive waste liquid in a nuclear power station. The MVR evaporation system comprises a preheater, an evaporation tower, a circulating pump, aheater, a steam compressor, an electric heating device and a distillation tank, wherein the heater is located out of the evaporation tower; an inlet and an outlet in one side of the heater are communicated with the evaporation tower; the evaporation tower is communicated with the steam compressor; an outlet of the steam compressor is communicated with an inlet in the other side of the heater; anoutlet in the other side of the heater is communicated with the distillation tank; and two ends of the electric heating device are respectively connected with the other-side inlets of the distillationtank and the heater. An operation method based on the evaporation system comprises the following steps: step a, starting a liquid inlet pump, and adding to-be-treated feed liquid to the evaporation tower until a specified liquid level is reached; step b, starting the circulating pump, the electric heating device and a distillation pump; step c, starting the steam compressor and a liquid sprayingpump; and step d, turning off the electric heating device and the distillation pump. According to the invention, radioactive waste liquid of the nuclear power station is efficiently treated, radioactive pollution is reduced, and latent heat of secondary steam generated by the waste liquid is recycled.

Owner:湖南汉华京电清洁能源科技有限公司

Energy-saving environment-friendly DDGS (Distillers Dried Grains with Solubles) waste heat vaporization system

PendingCN109432808AAchieve primary recyclingSolve problems such as pollutionEvaporator accessoriesVapor condensationEvaporationVaporization

The invention relates to an energy-saving environment-friendly DDGS (Distillers Dried Grains with Solubles) waste heat vaporization system which comprises a condensate water flash tank, a high-temperature condensate pump, a waste gas washing tower, a washing water pump, a first effective heater, a first effective separator, a second effective heat exchanger, a second effective separator, evaporators, a surface condenser, a condensate water collecting tank and a condensate pump, wherein the quantity of the evaporators is three, namely, a third effective evaporator, a fourth effective evaporatorand a fifth effective evaporator. According to the invention, secondary steam generated by a tube bundle dryer is washed by the washing tower and then is fed into a multi-level vaporization system; the condensate water generated by the tube bundle dryer is treated by the flash tank to generate steam and then the generated steam is fed into the multi-level vaporization system; the secondary steamafter washing and the steam generated by the flash tank are utilized to perform evaporation concentration on a filtrate formed after solid-liquid separation of distiller liquor; the secondary steam generated by the tube bundle dryer and heat in the condensate water are fully recovered; the recovery ratio of waste heat is high; dust pollutants in the secondary steam are absorbed; and the purpose ofsaving energy and reducing emission is achieved.

Owner:郑州博大浓缩干燥设备有限公司

High efficiency, large scale desalination system

ActiveUS9771278B2Improve distillation efficiencyLower energy requirementsGeneral water supply conservationEvaporation with vapour compressionThermal energyAtmospheric air

An apparatus and method for the distillation of ocean and brackish water that includes a means for using the ambient temperatures of seawater and air to continually transfer the heat energy, from the outer perimeters of the system, back into the, centrally located, evaporation chamber and insulation for preventing heat from escaping to the atmosphere. The insulation comprises a first and second wall surrounding the basic assemblies of a desalination system in which the space between the first and second wall is under low partial vacuum and is partially filled with an insulation material for structural support. The system provides a feed through means that prevent heat transfer through the structural connections between the first and second walls. The system provides an evaporation system for flash evaporation by atomizing the input contaminated water, preheated by the heat of condensation into very small liquid droplets, which are then sprayed into a stream of hot dry air. The liquid rapidly evaporates leaving behind hot dry solids that is recaptured and used to preheat the input contaminated water.

Owner:FLO ONICS LLC

Popular searches

Oxygen compounds purification/separation Fermentation Hydroxy compound separation/purification Vacuum distillation separation Water treatment installations Evaporation by spraying Cleaning using liquids Multiple-effect/fractional condensation Evaporators with heating coils Solid sorbent liquid separation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com