Patents

Literature

939results about "Water treatment installations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

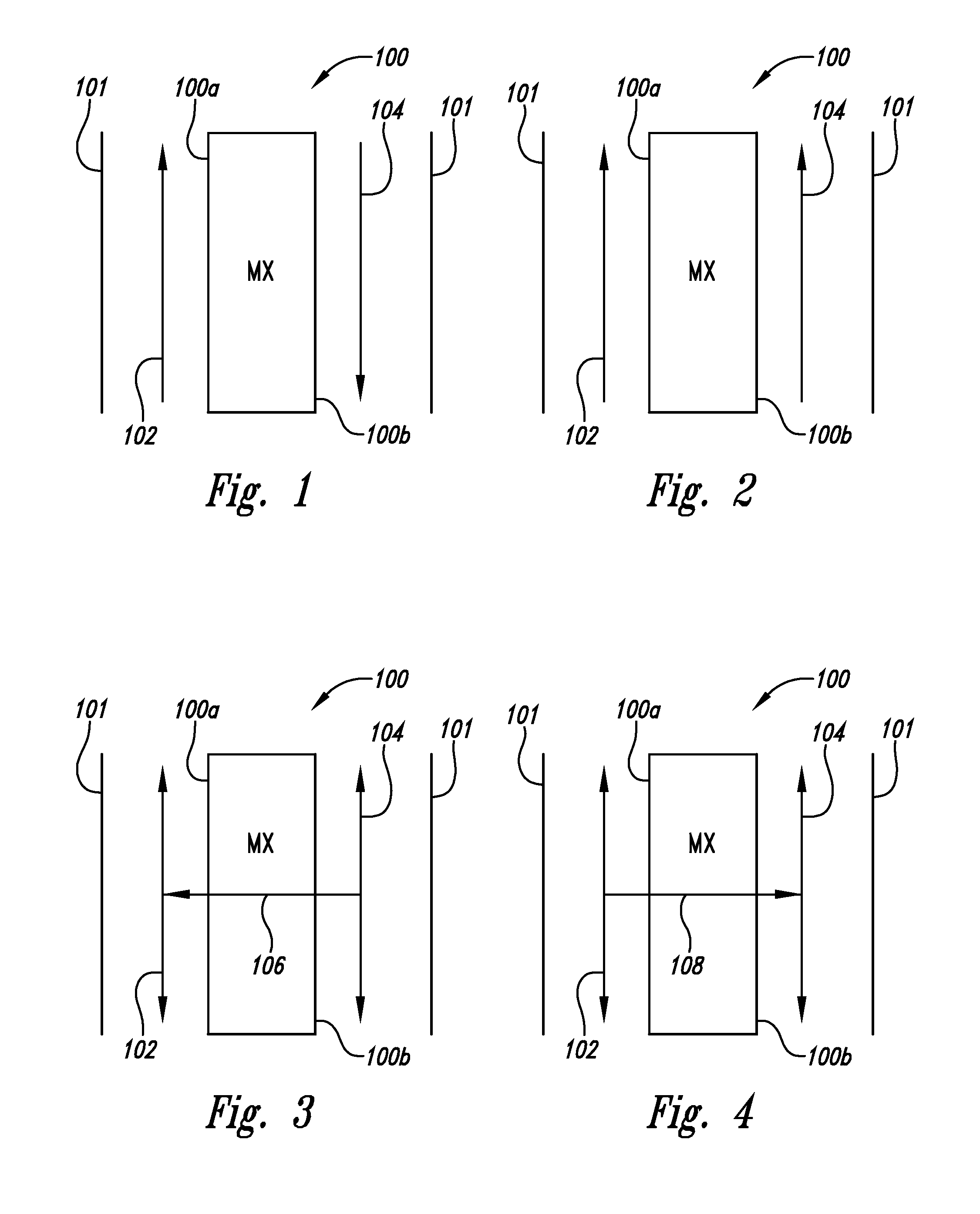

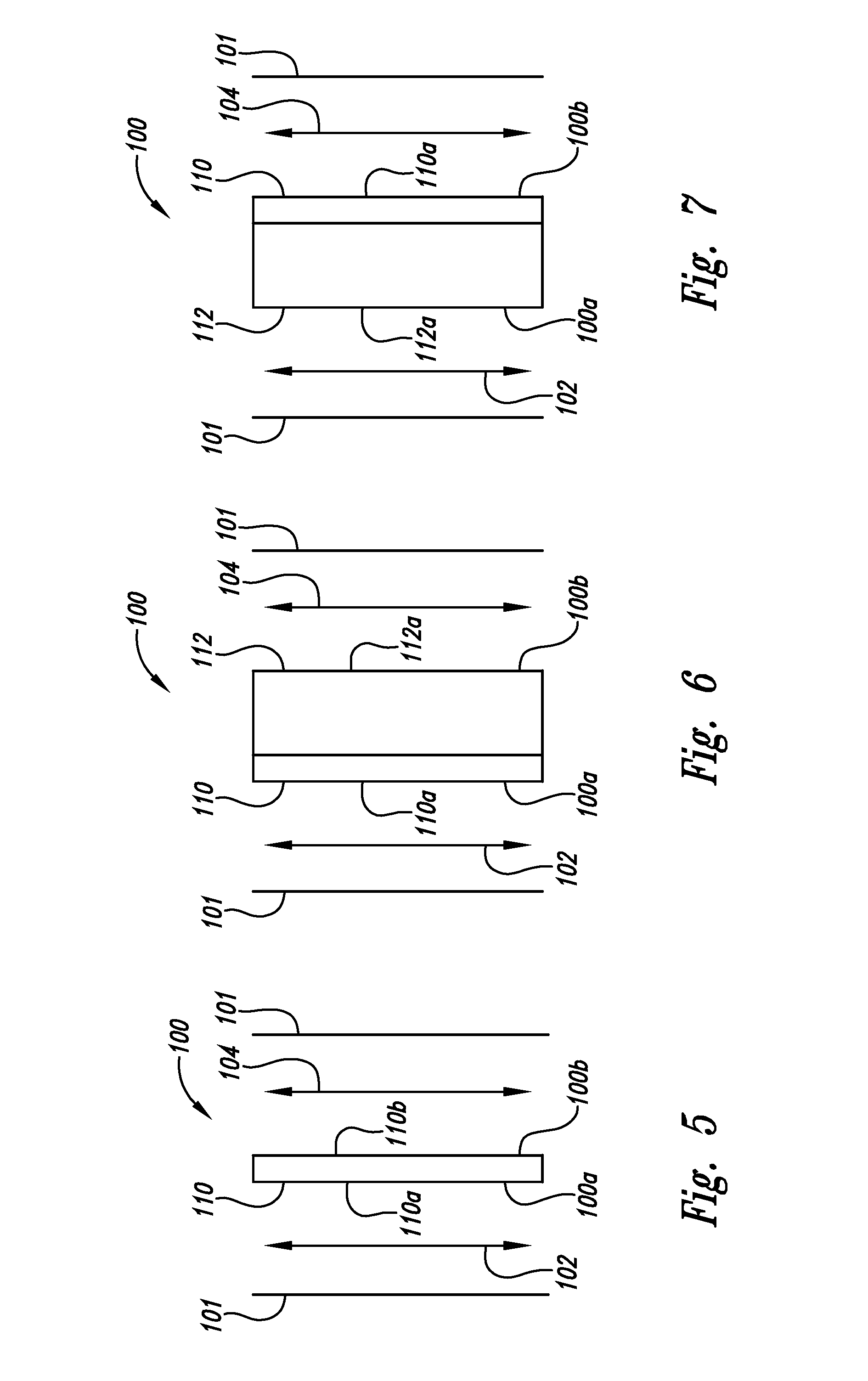

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

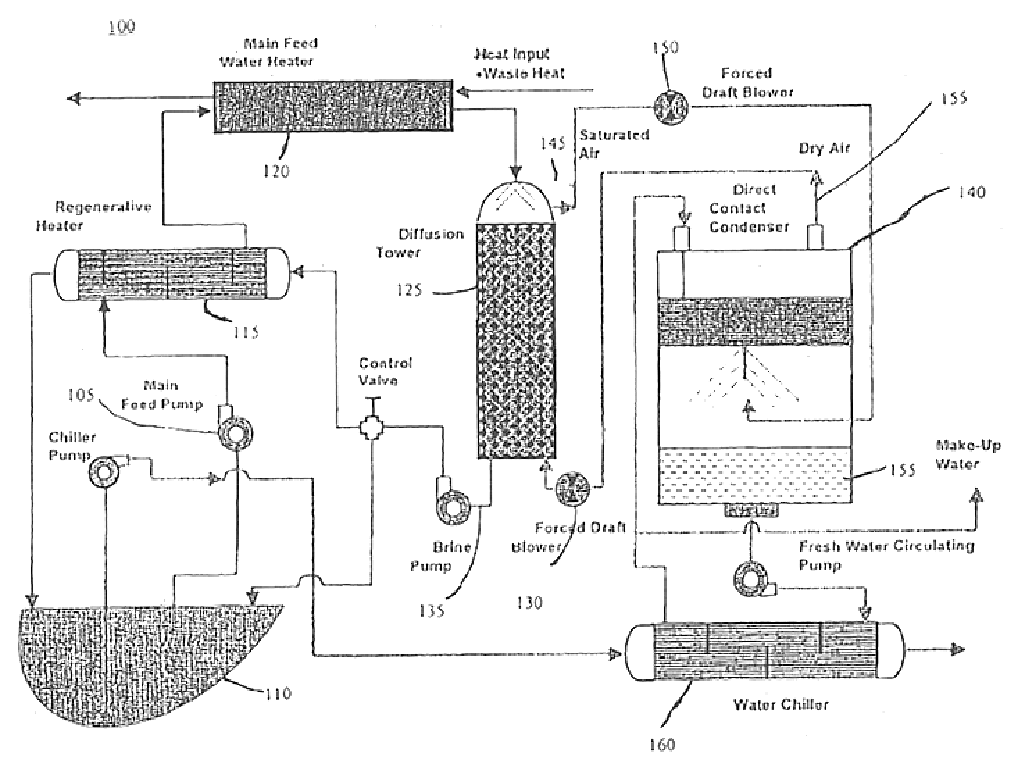

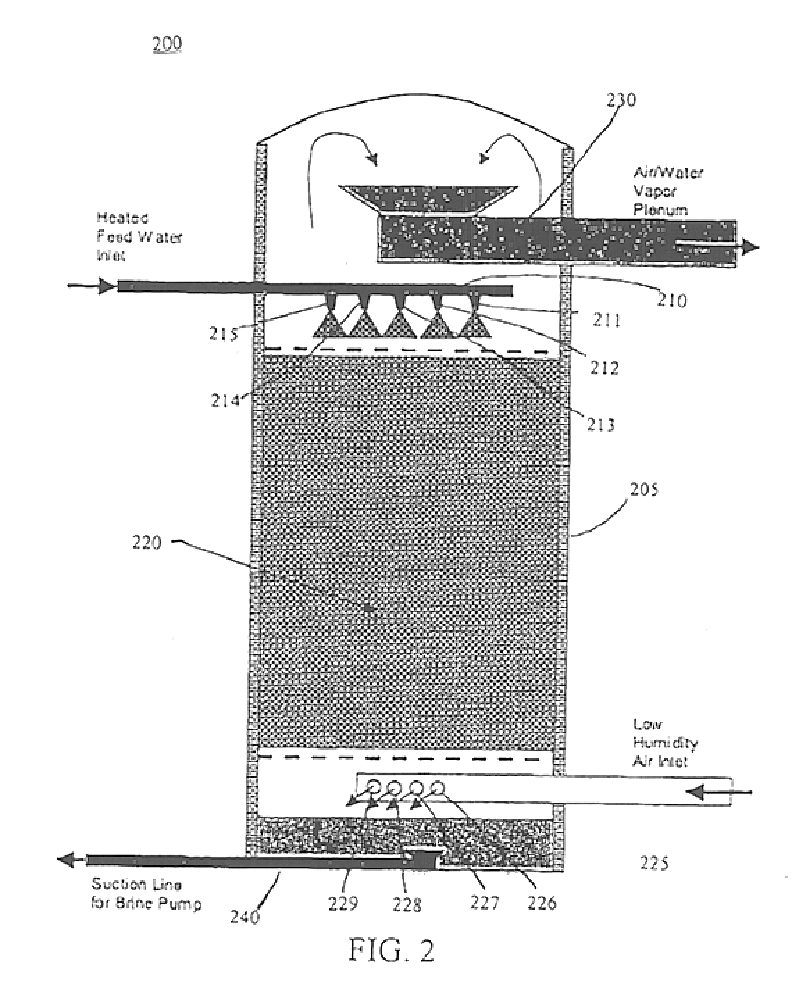

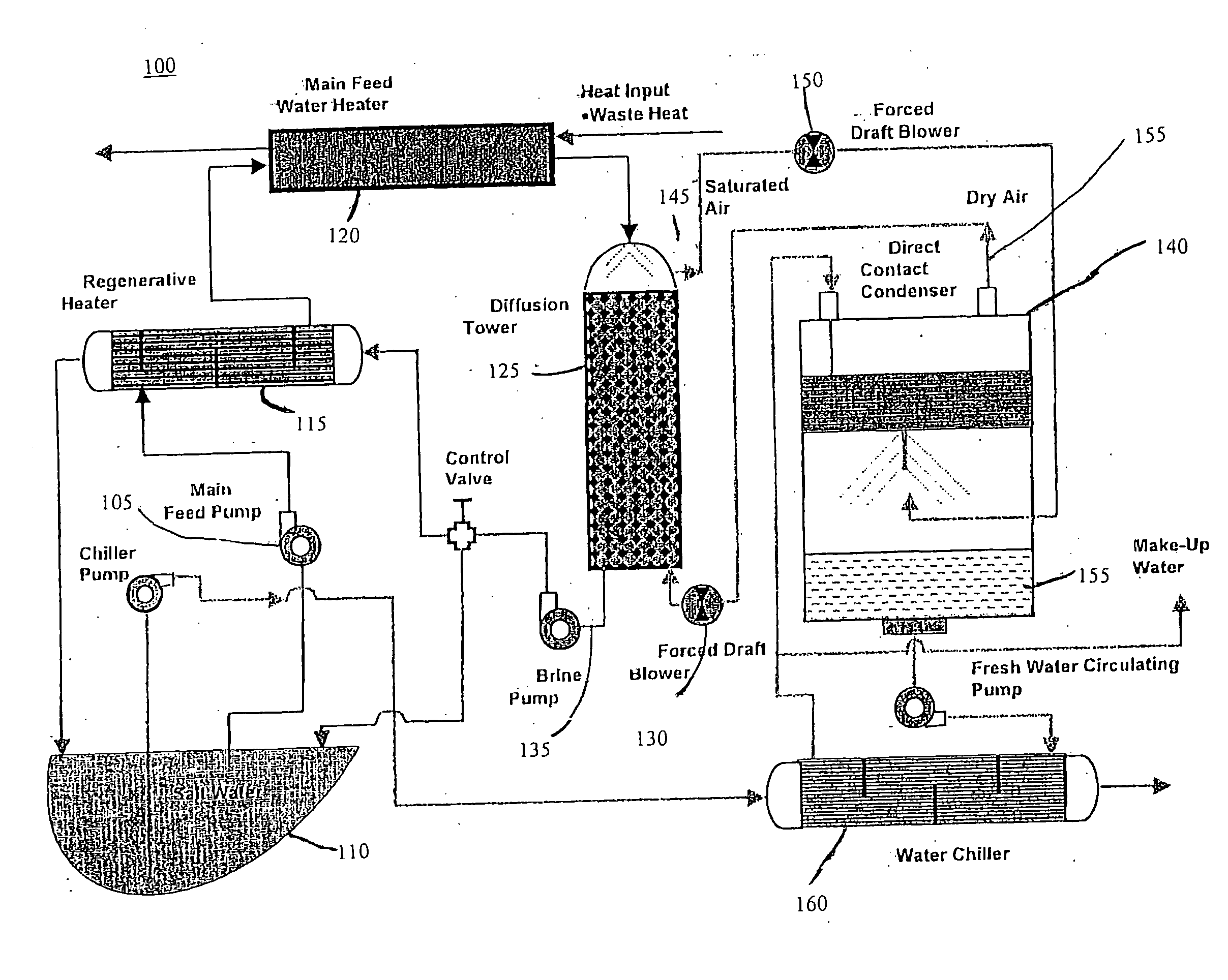

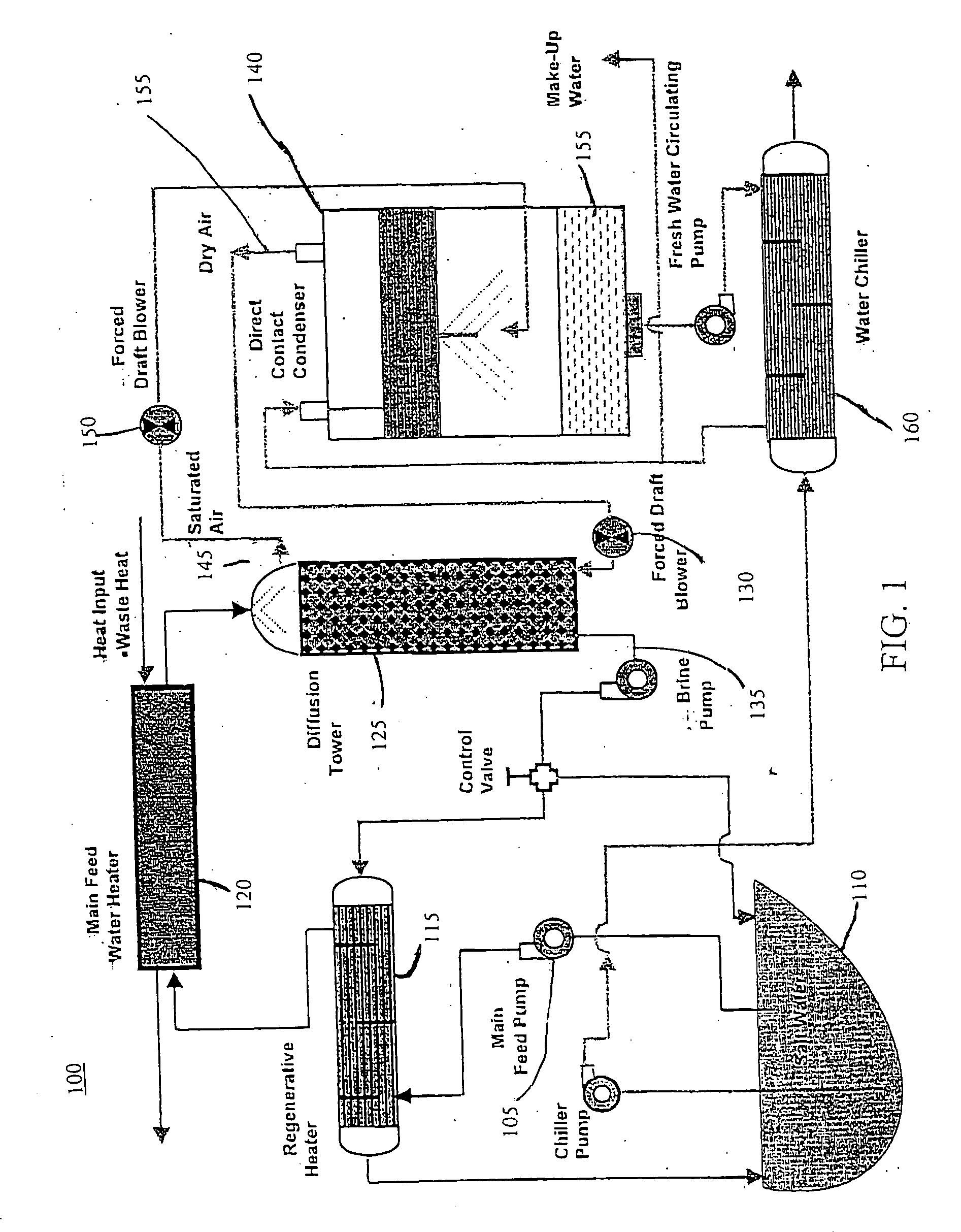

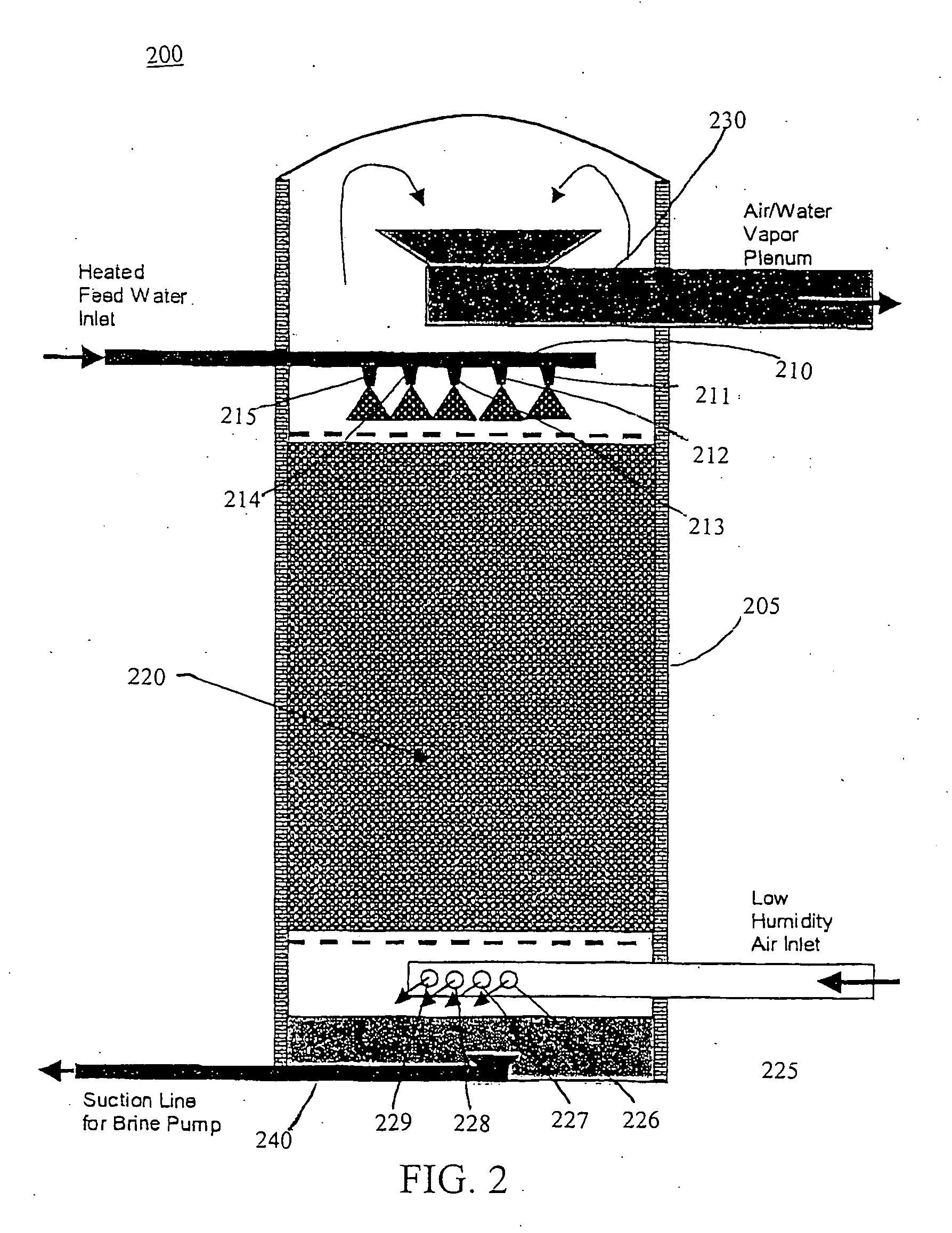

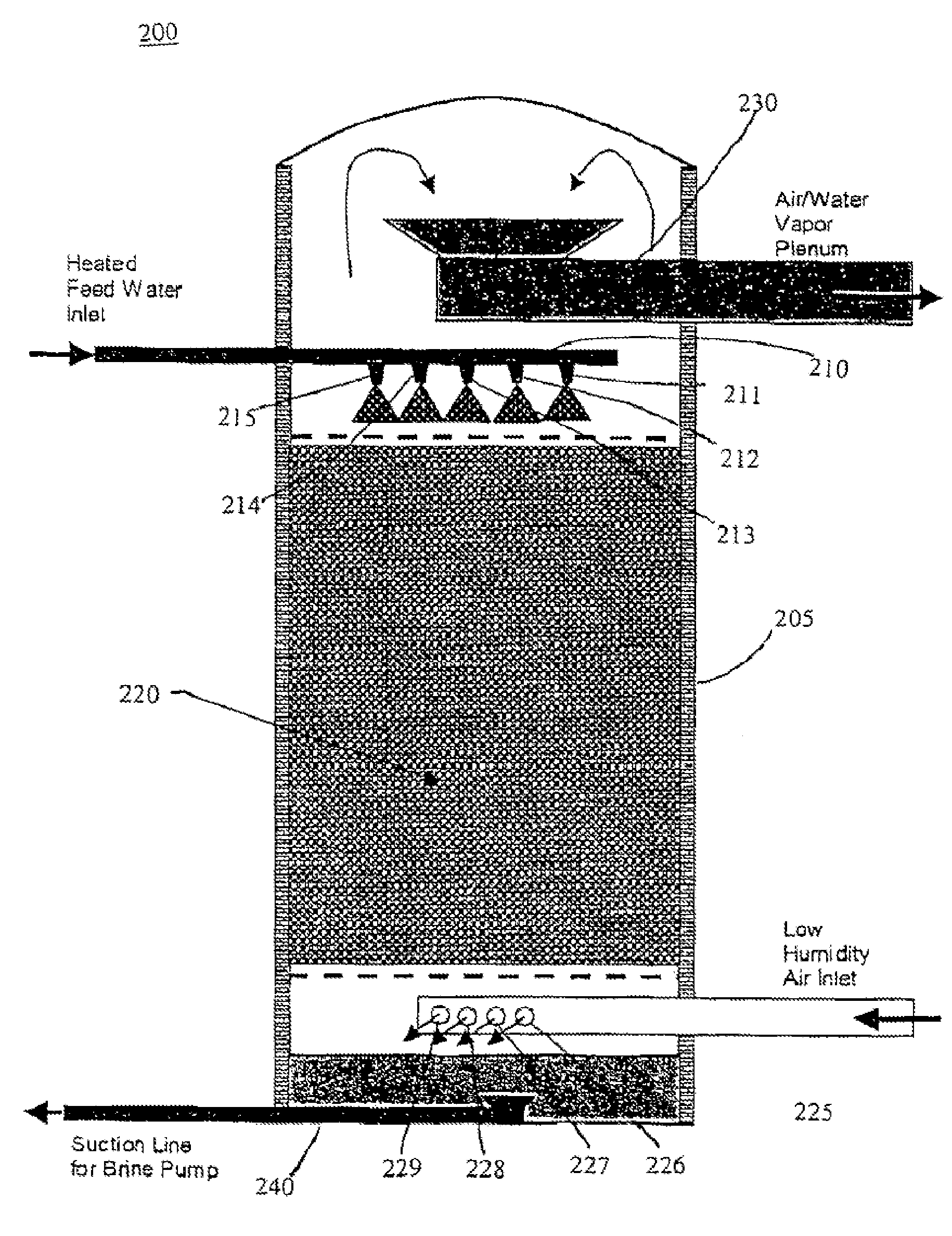

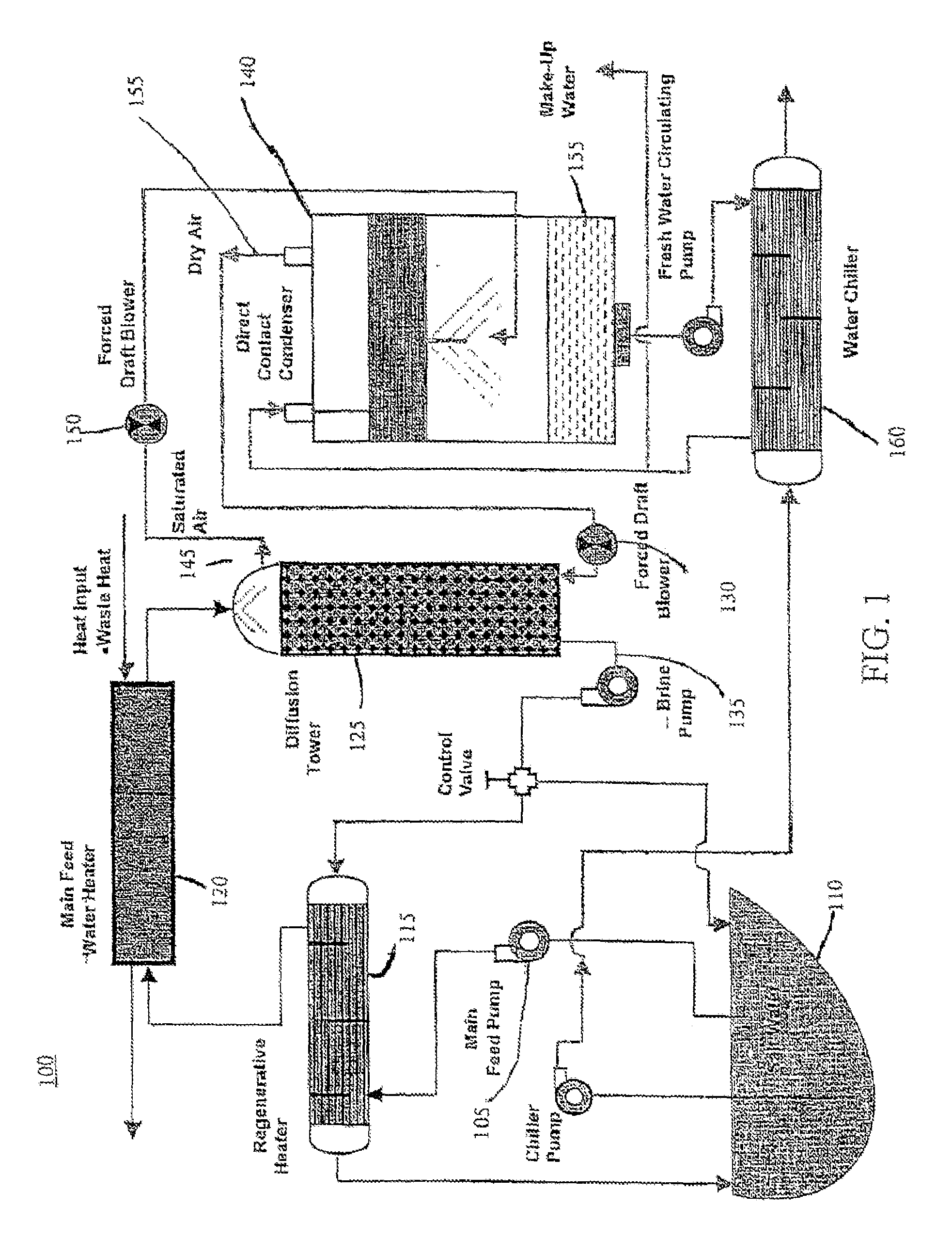

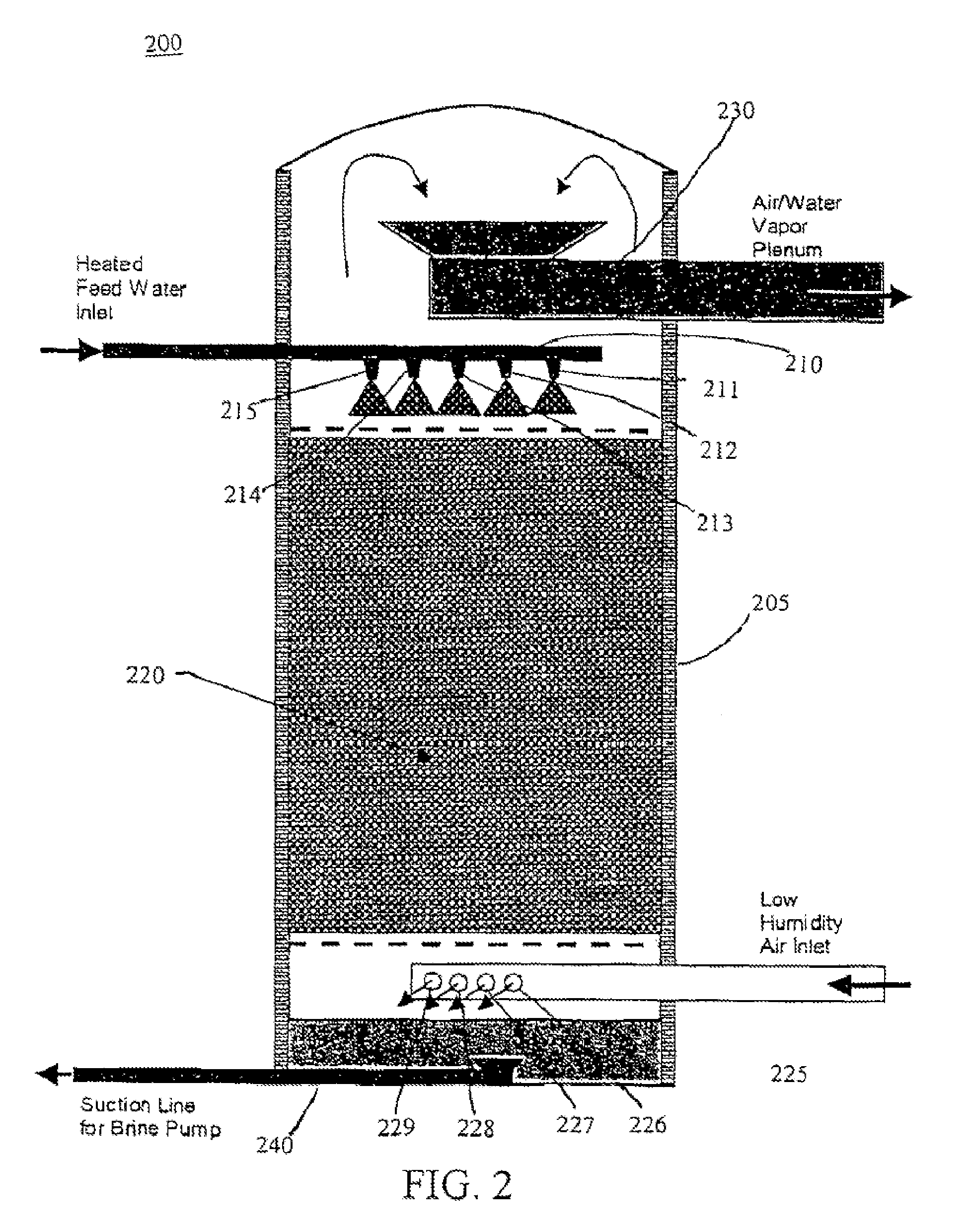

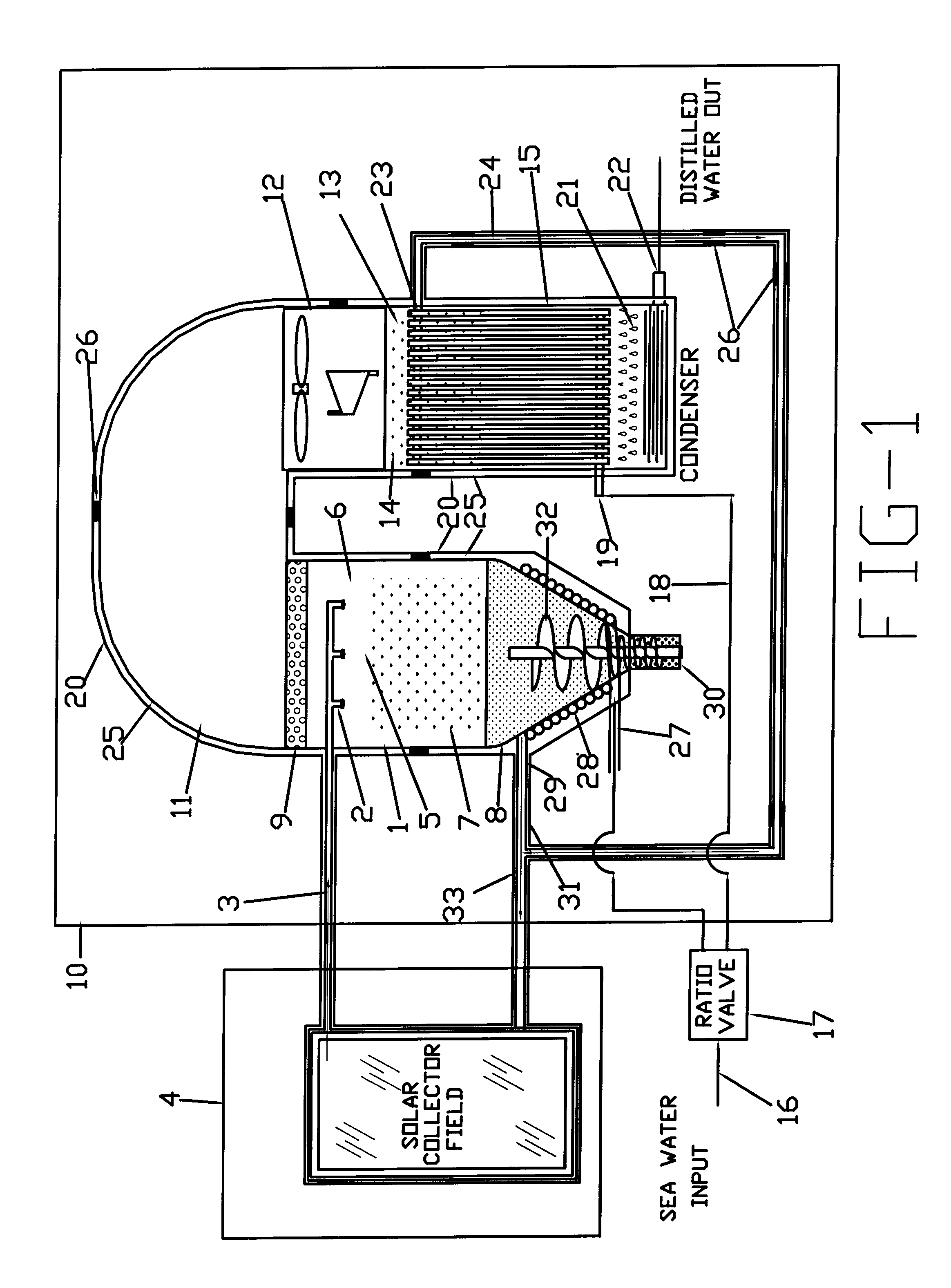

Diffusion driven desalination apparatus and process

A diffusion driven desalination apparatus and related method includes structure for receiving a heated water stream and creating at least one region having a thin film of water and structure for forcing a low humidity air stream over the thin film of water, wherein water from the thin film of water evaporates and diffuses into the air stream to create a humidified air stream. A diffusion tower including at least one plenum can be used to create and transfer the humidified air stream. At least one condenser, such as a direct contact condenser, condenses the humidified air stream, wherein purified water is produced. Waste heat from a power plant can be used to provide the heated water stream and power plants can use the waste heat generated to inexpensively provide purified water.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

Diffusion driven water purification apparatus and process

An apparatus for purifying water, such as for desalinization, includes a source of a heated air stream, the heated air stream having a temperature above an ambient temperature. A diffusion tower having high surface area material therein receives a water stream including at least one impurity and creates at least one region having thin films of water therein from the water stream. The heated air stream is directed over the thin films of water to create a humidified air stream that is at least substantially saturated. At least one direct contact condenser is in fluid communication with the humidified air stream for condensing the humidified air stream, thus producing purified water. A power plant can include the apparatus for purifying water, where energy to heat the air stream is provided by low pressure condensing steam.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

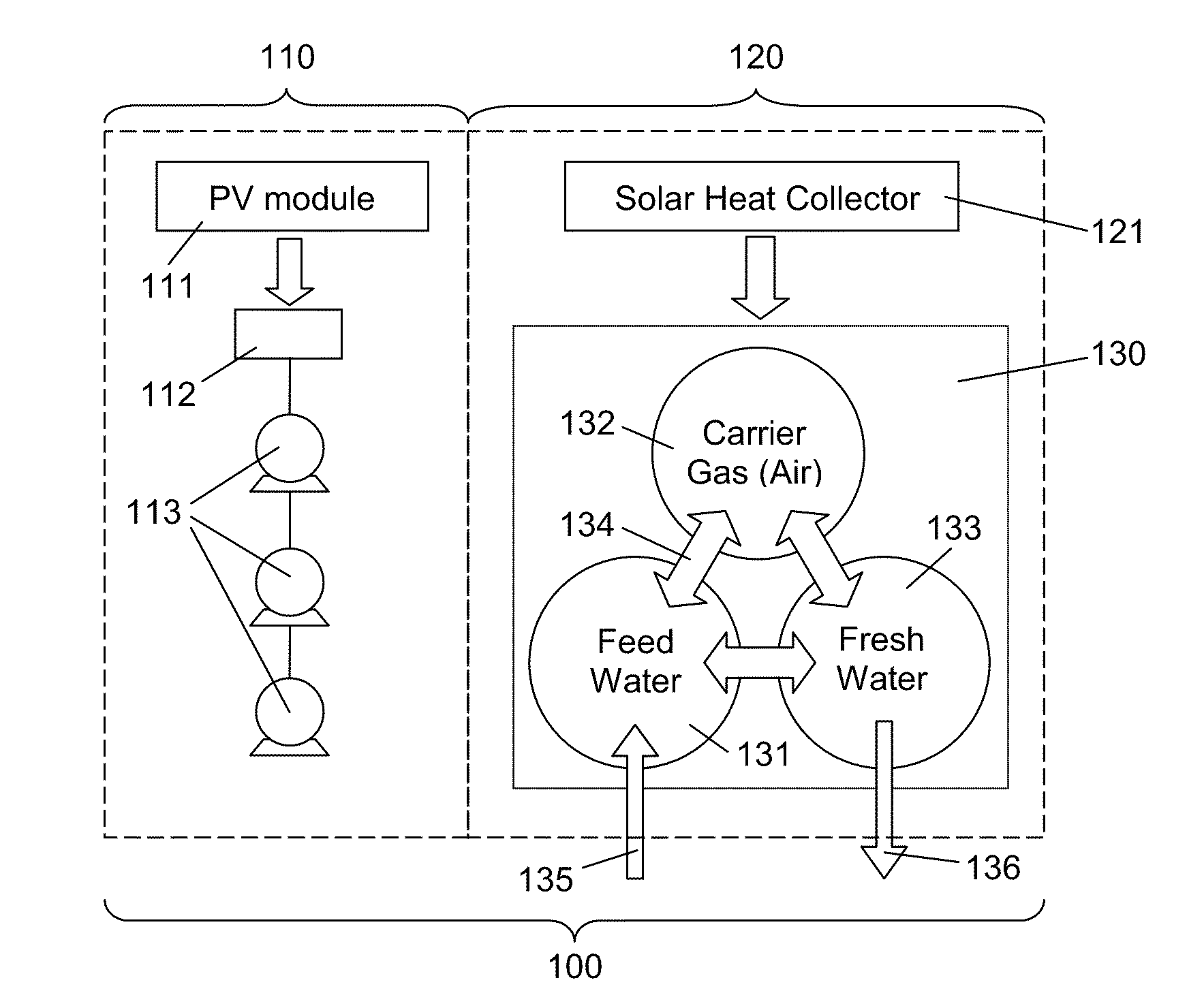

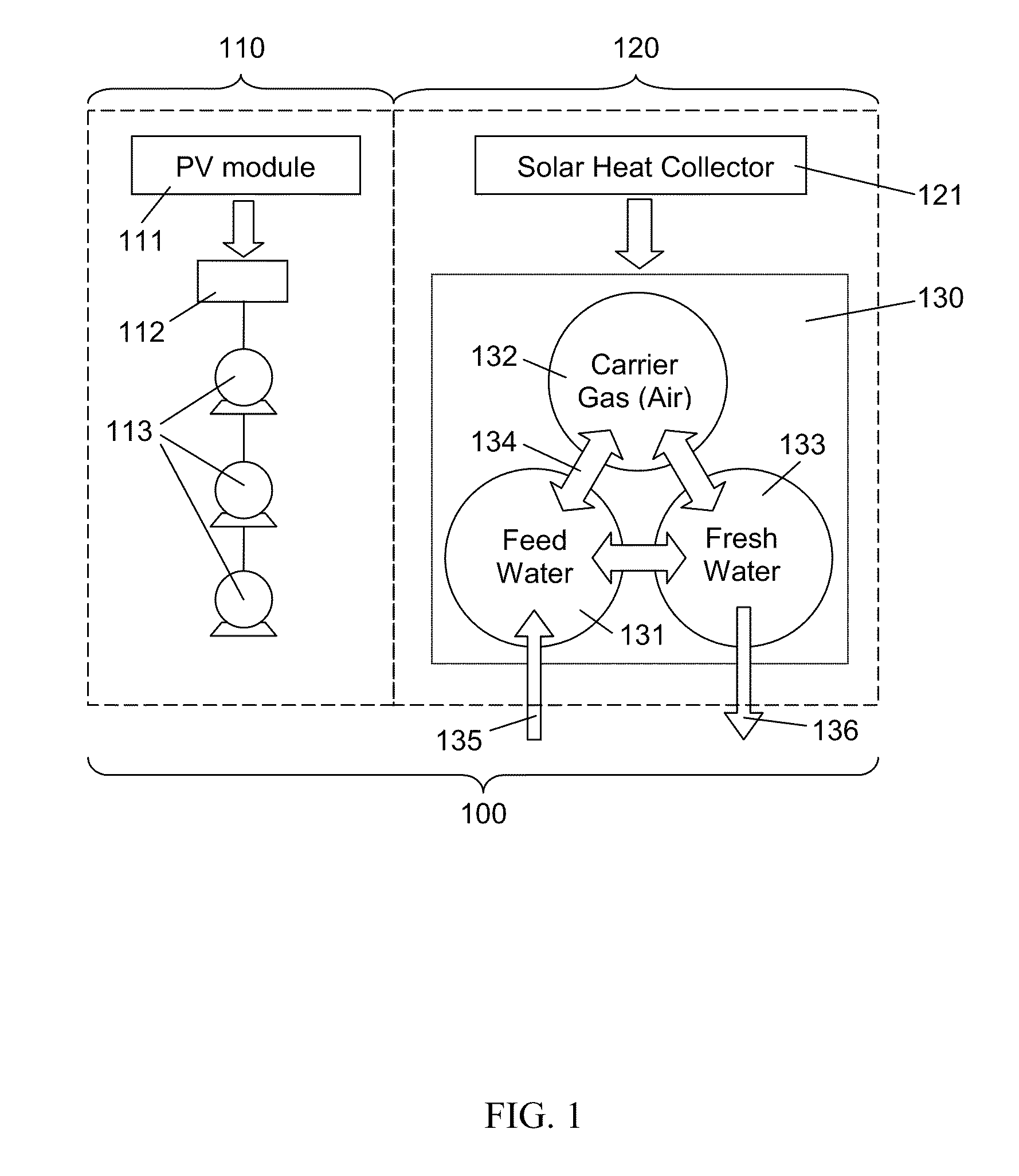

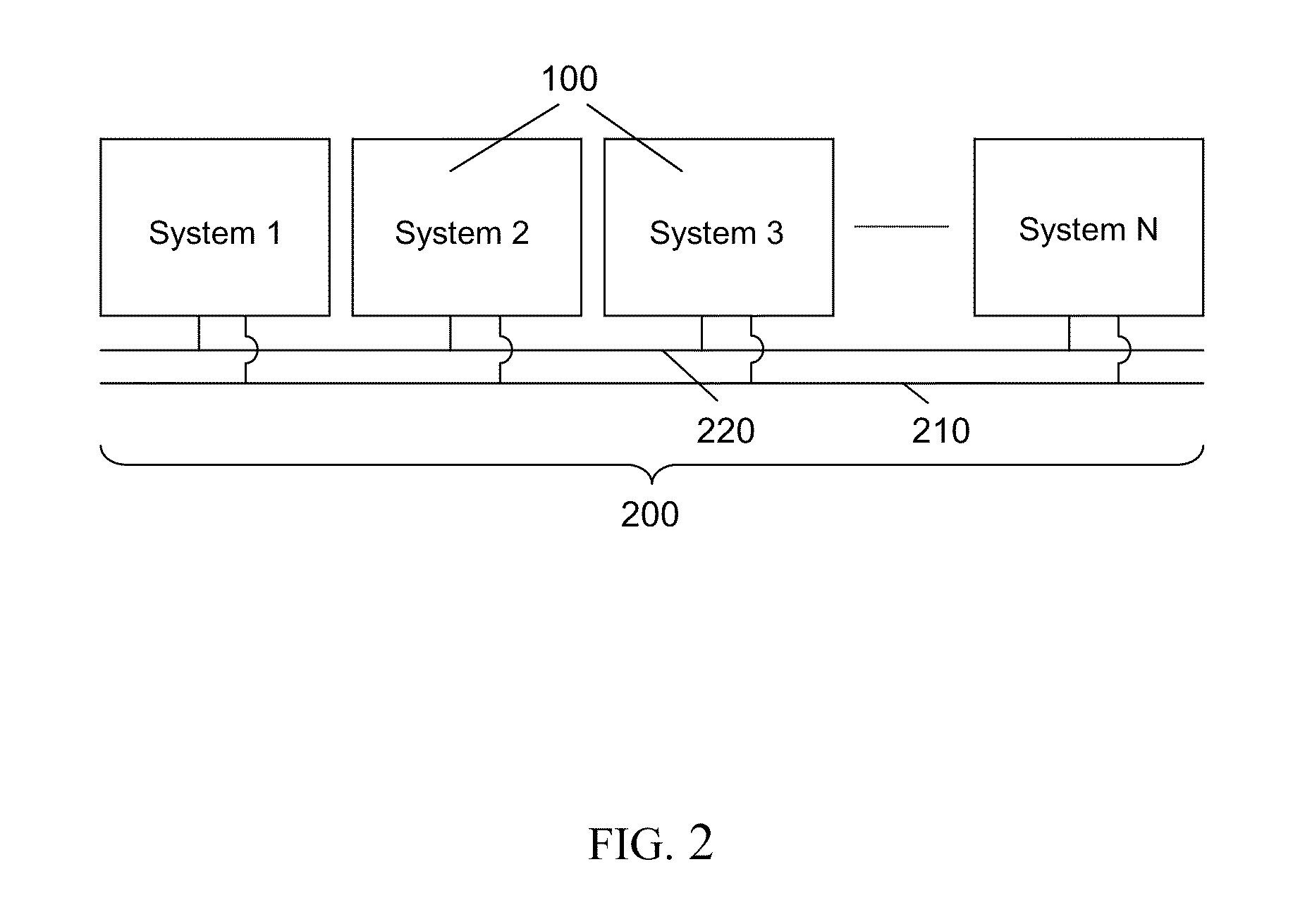

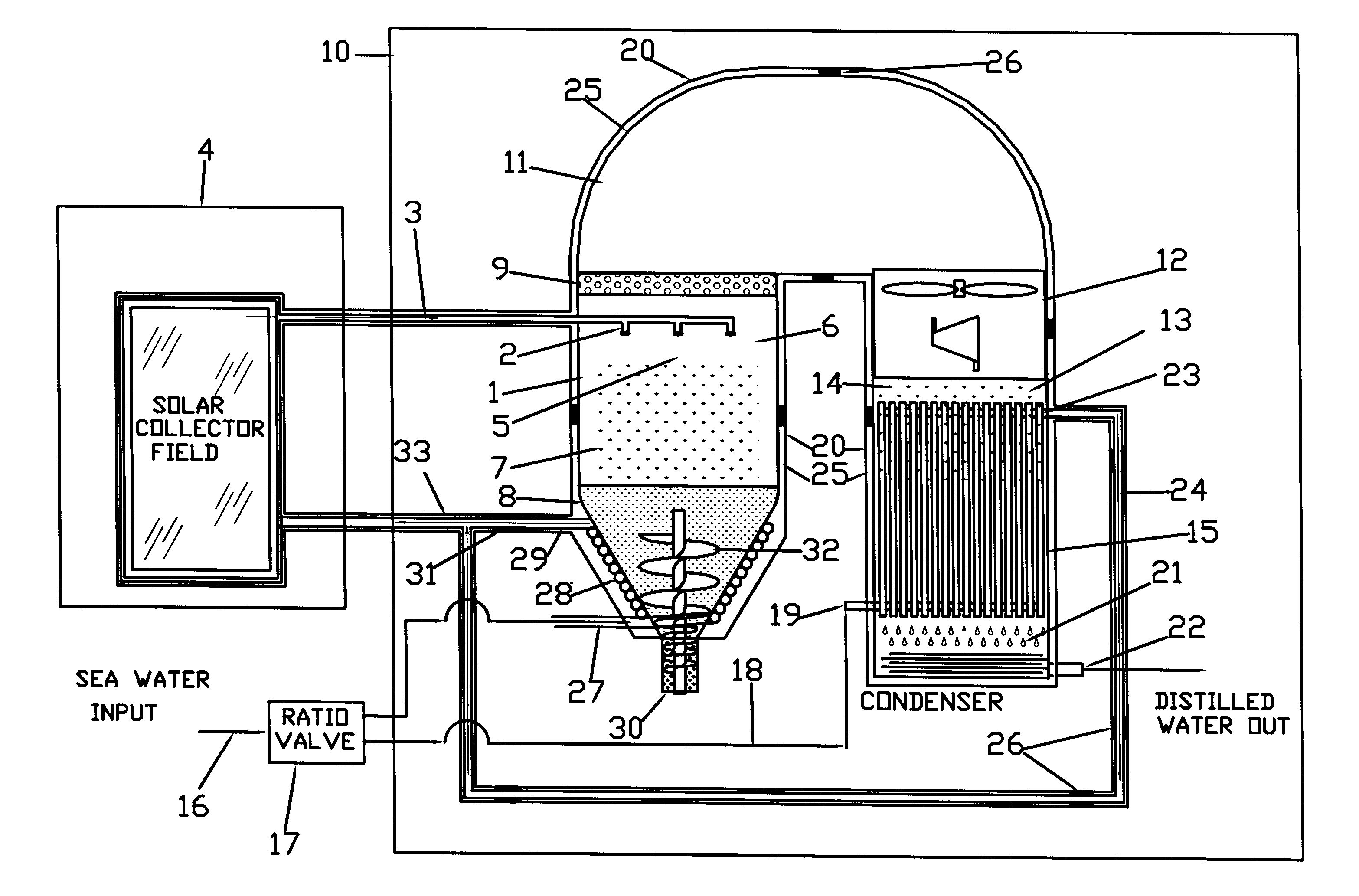

Hybrid solar desalination system

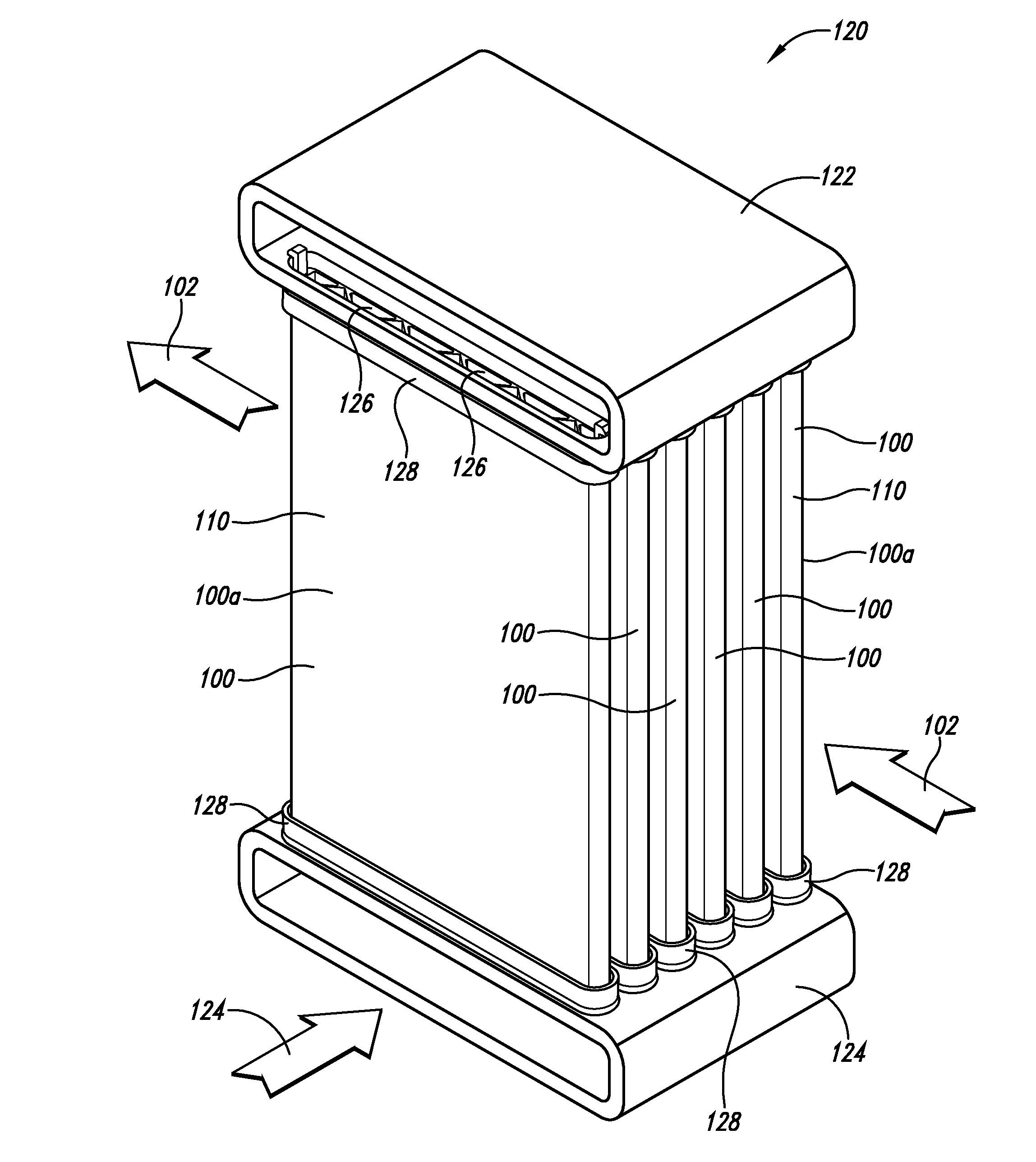

A hydro-thermal exchange unit (HTEU) for desalinating feed water in accordance with a humidification-dehumidification includes feed water, fresh water and gas conduit circuits for transporting feed water, fresh water, and gas, respectively. The unit also includes an evaporator through which a portion of the feed water conduit and the gas conduit pass. The evaporator causes evaporation of a portion of the feed water to produce vapor that is transported through the gas conduit. The unit also includes a condenser through which a portion of the gas conduit and the fresh water conduit pass. The condenser has input and output ports for coupling the gas and fresh water conduit circuits. The condenser extracts moisture from the vapor transported therethrough by the gas conduit. The extracted moisture is discharged through the fresh water conduit. The unit also includes a heat exchanger through which a portion of the fresh water conduit and the feed water conduit pass to thereby extract residual heat from the fresh water such that the residual heat heats the feed water.

Owner:SUNLIGHT PHOTONICS

Diffusion driven water purification apparatus and process

Owner:UNIV OF FLORIDA RES FOUNDATION INC

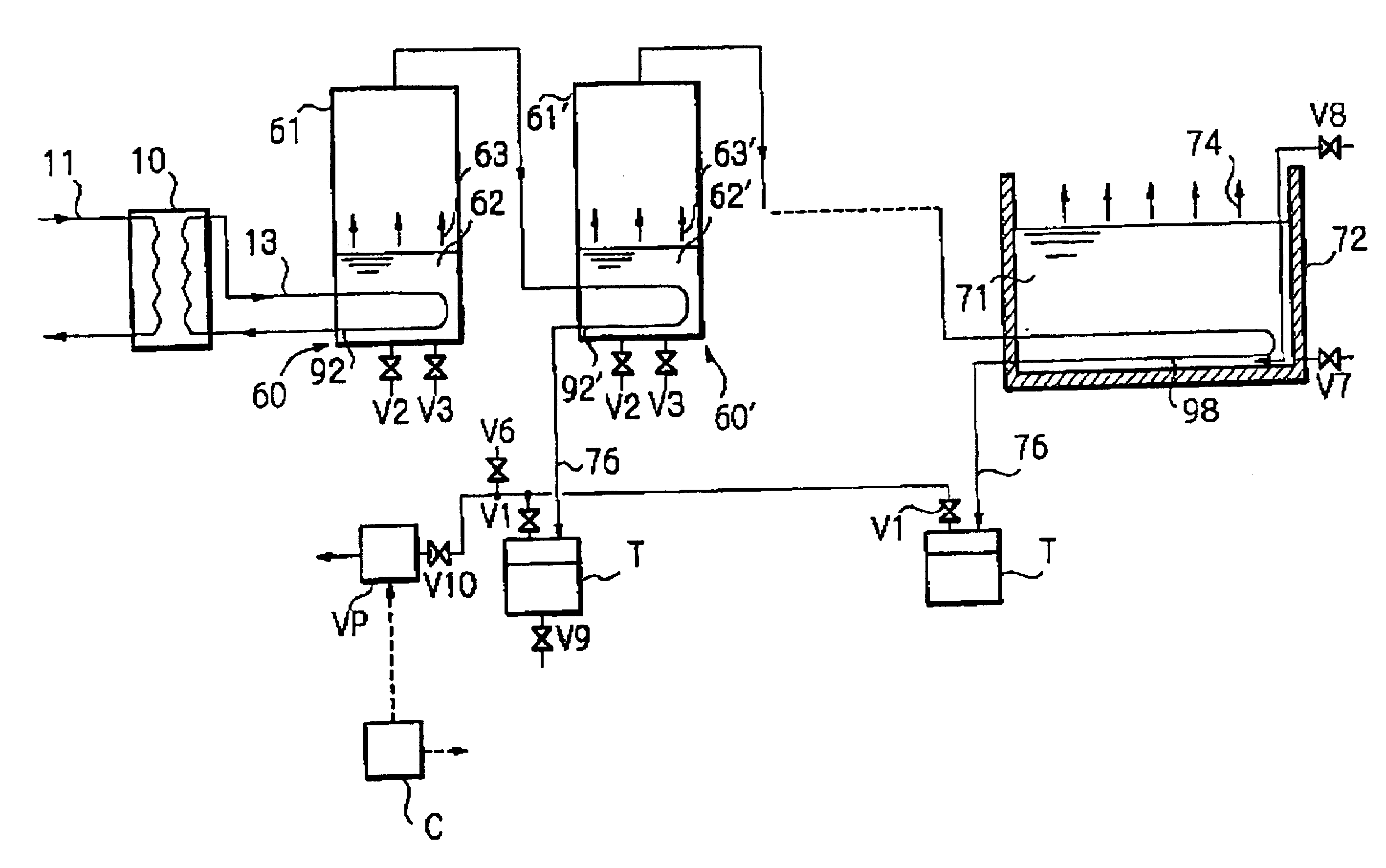

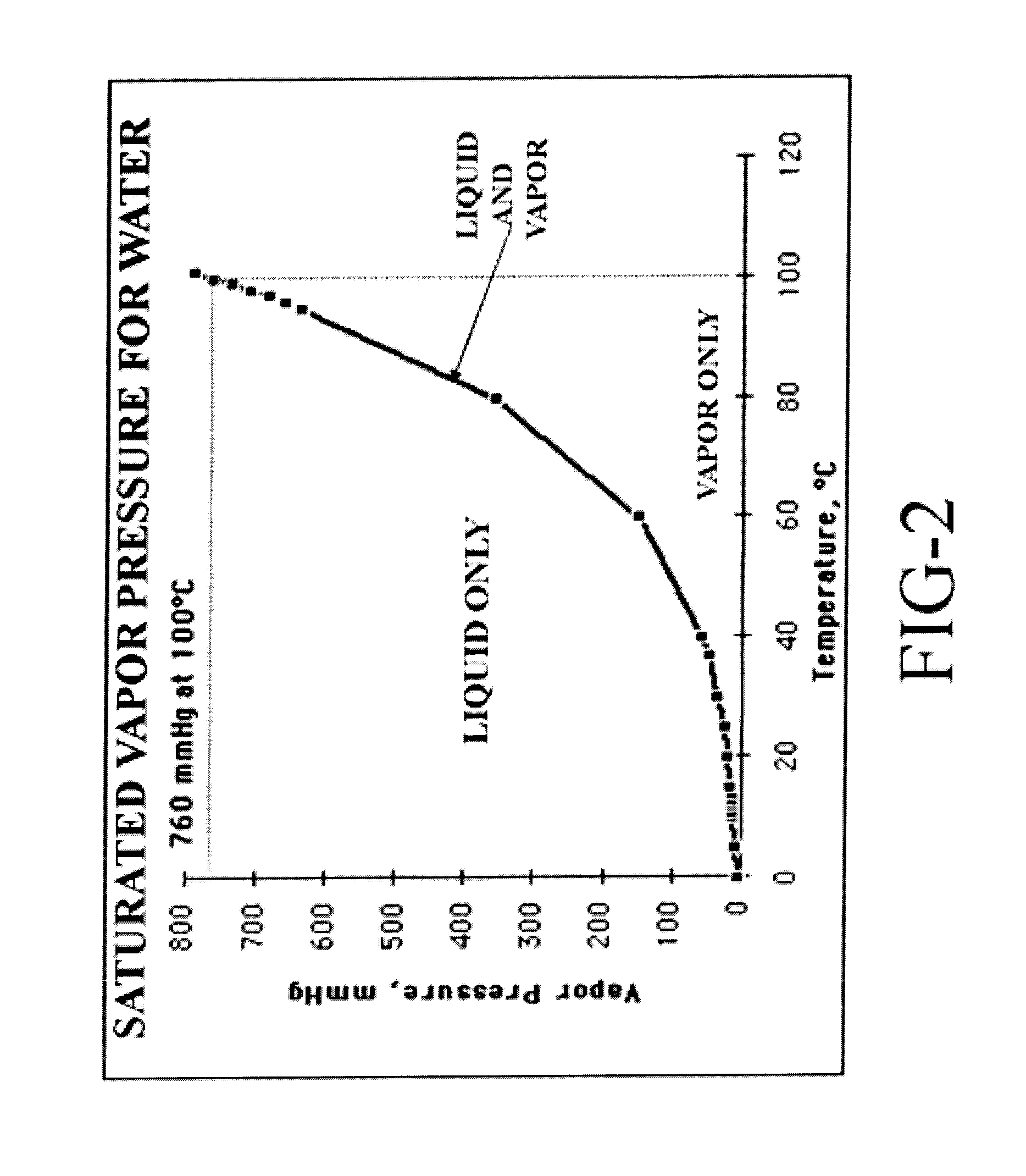

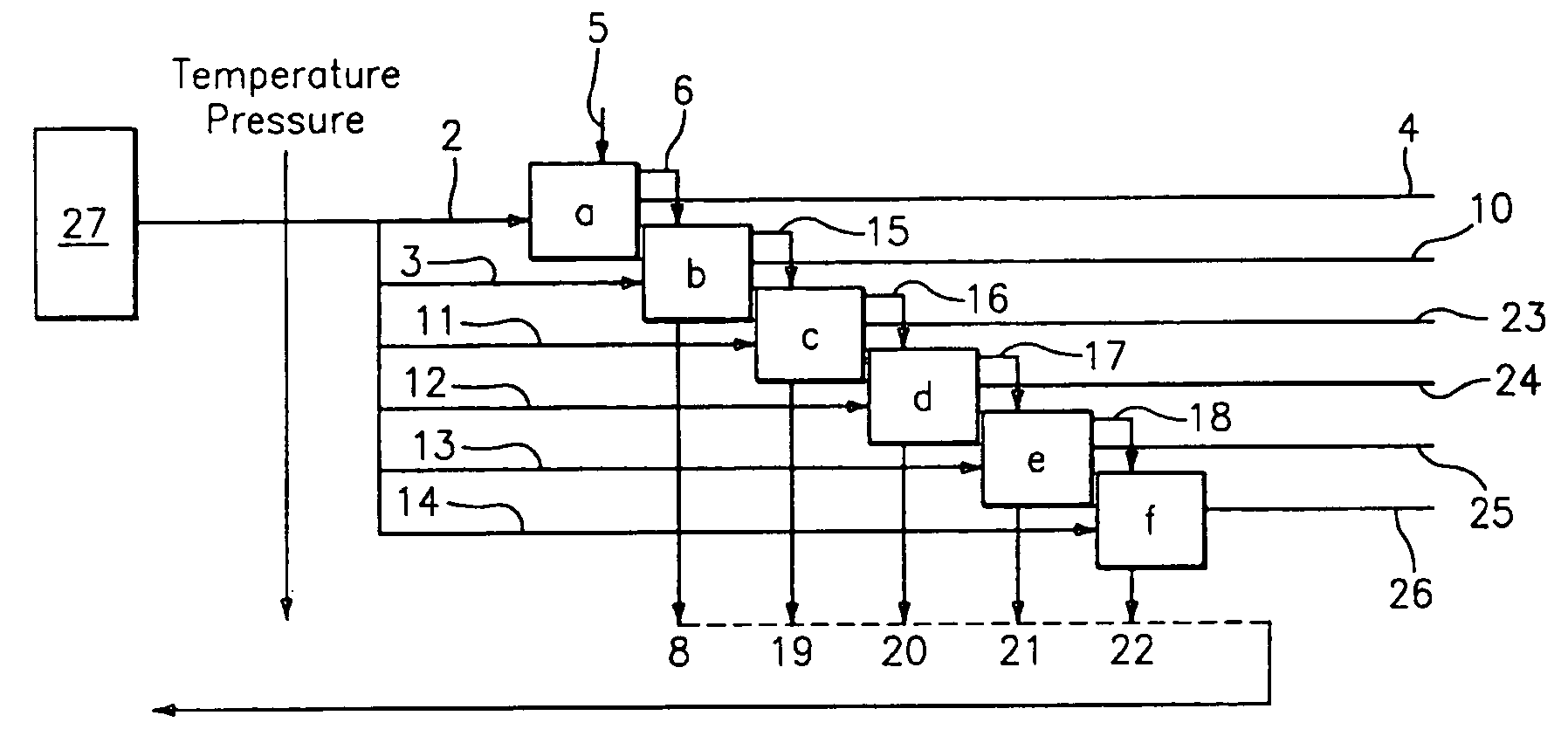

Desalination method and desalination apparatus

InactiveUS6833056B1Number of stage increasingIncrease the number ofAuxillariesGeneral water supply conservationDesalinationDistilled water

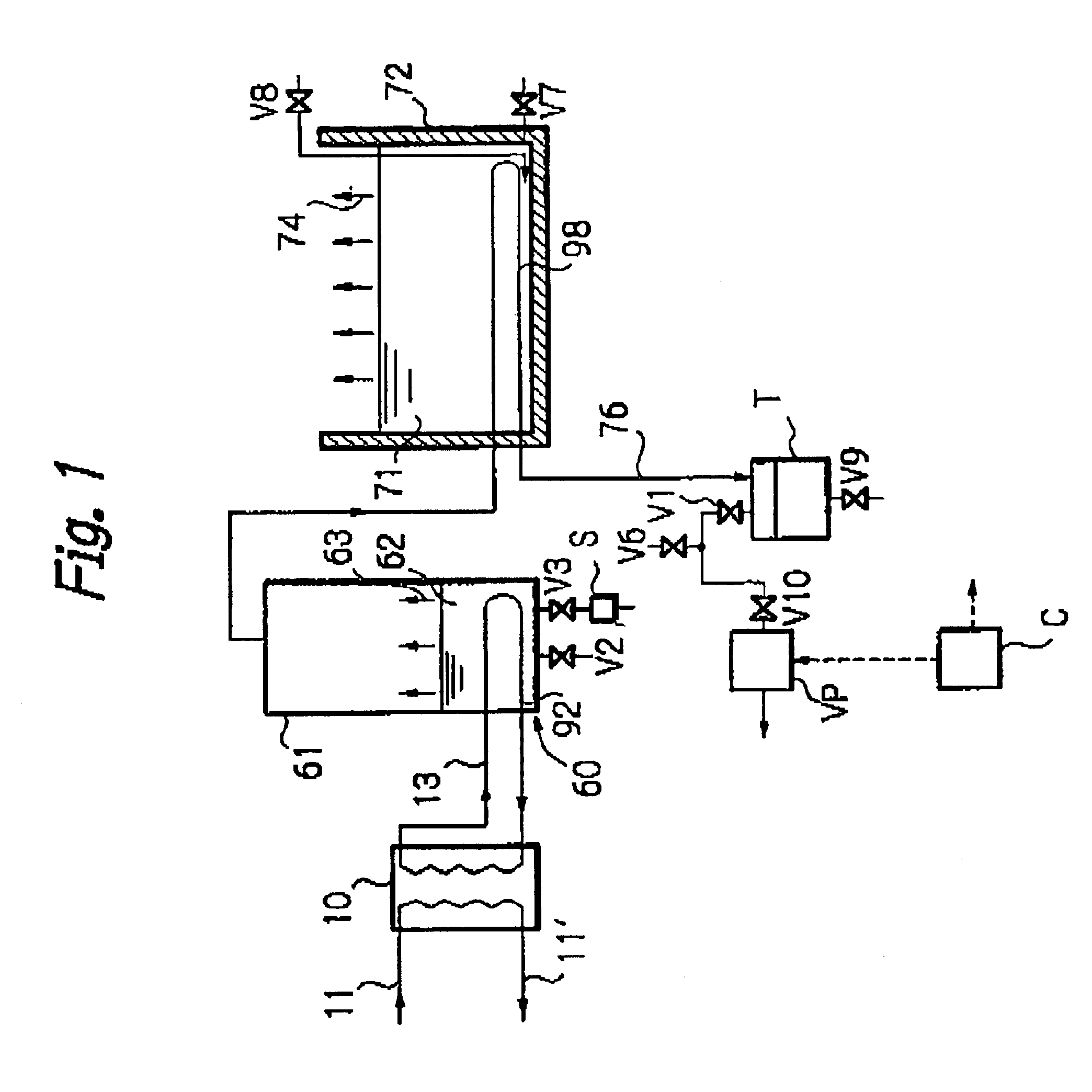

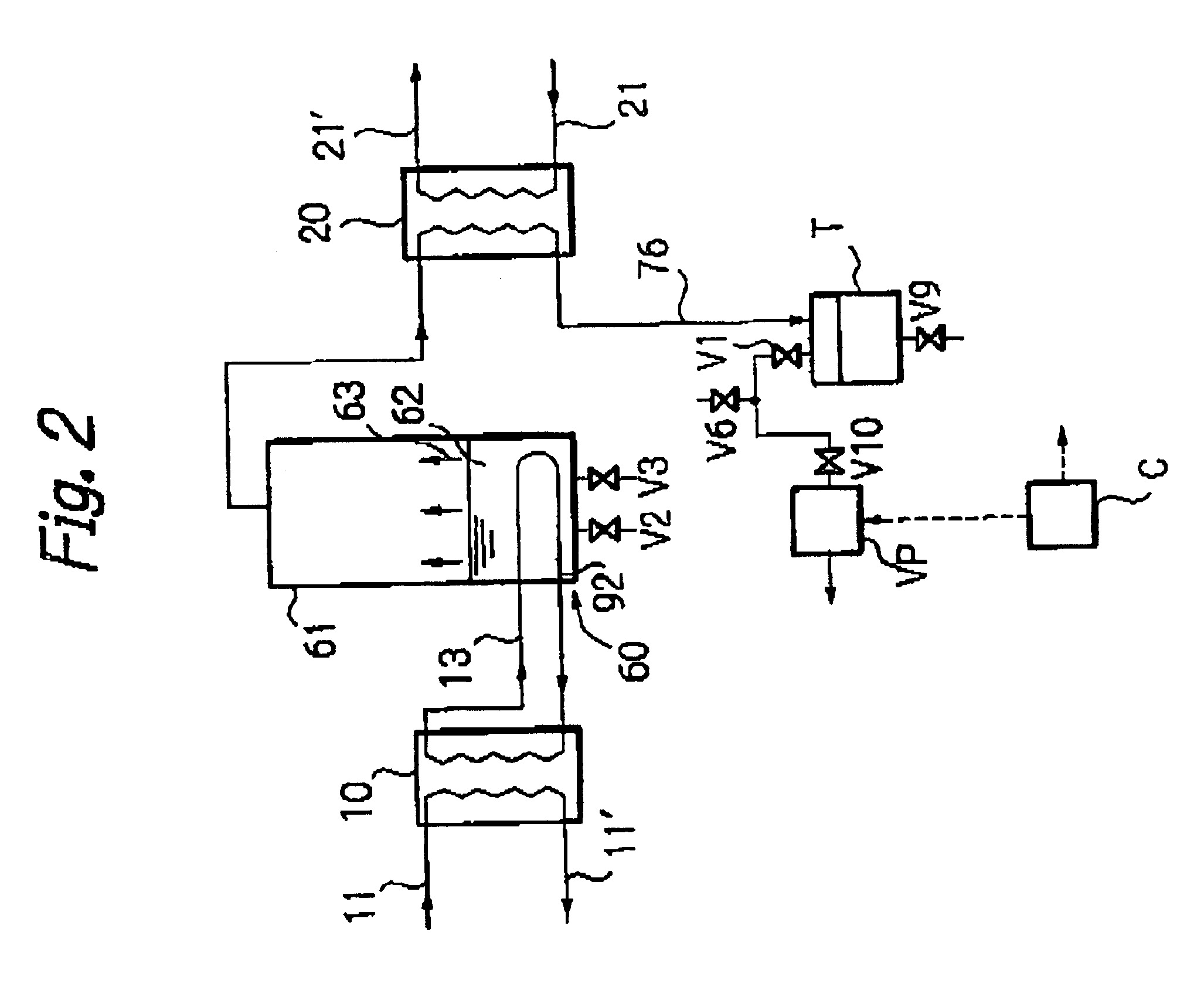

A desalination apparatus capable of obtaining fresh water stably at low cost by utilizing low-temperature waste, wherein the desalination apparatus including a heat exchanger 92 cooperating with an evaporation can 60 so as to subject a low-temperature waste heat 11 and raw water 62 in the evaporation can 60 to heat exchange and generate water vapor 63 in the evaporation can 60; a condenser 98 cooperating with a raw water tank 72 so as to receive the water vapor 63 from the evaporation can 60, cool the water vapor 63 by subjecting the water vapor 63 and raw water 71 in the raw water tank 72 to heat exchange and obtain distilled water 76; a distilled water tank for storing the distilled water 76; vacuum means for evacuating the evaporation can 60 and depressurizing the inside thereof so as to promote generation of water vapor 63 in the evaporation can 60; and raw water supply means for supplying raw water to the evaporation can.

Owner:EBARA CORP

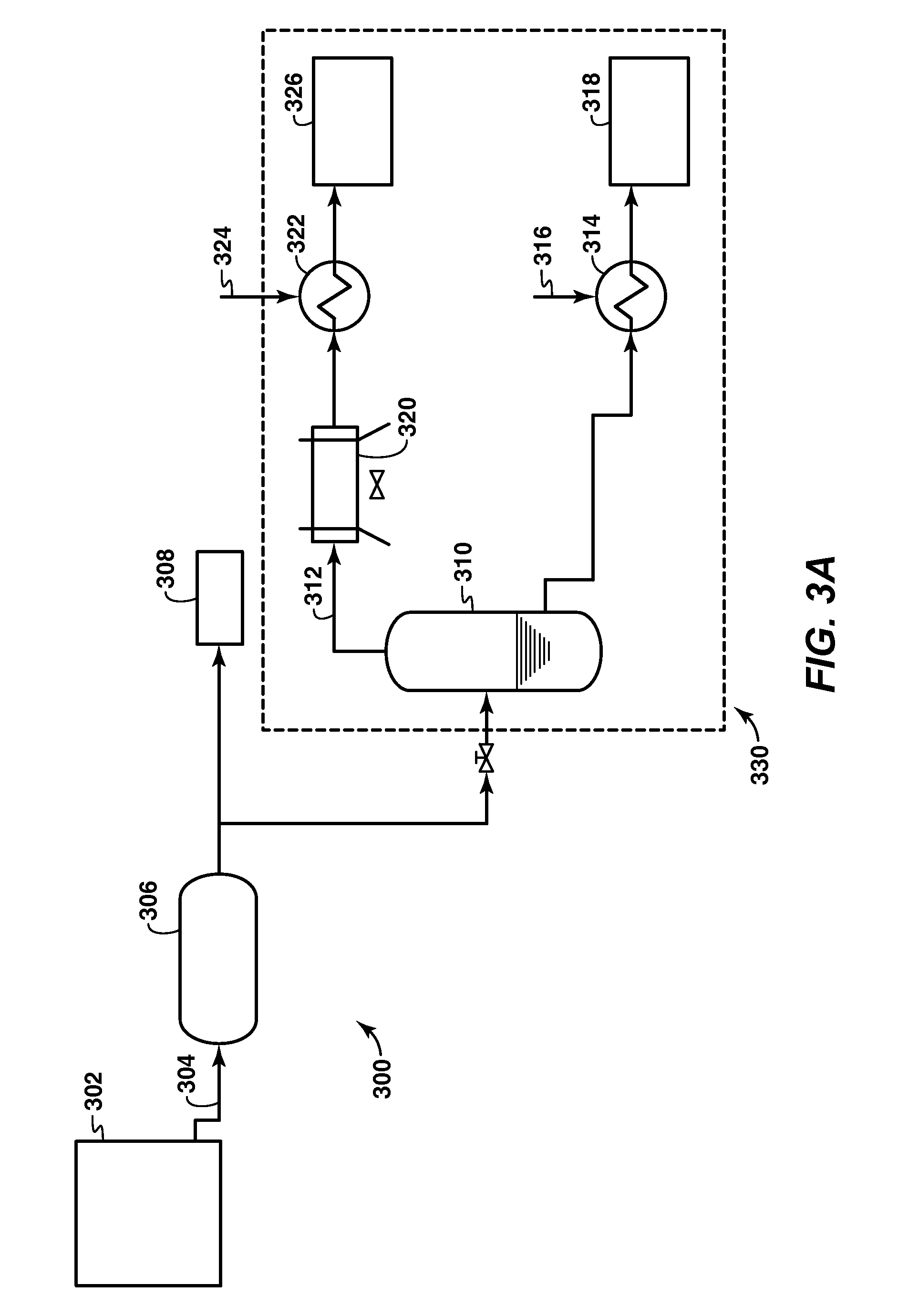

Recovery of high water from produced water arising from a thermal hydrocarbon recovery operation using vaccum technologies

InactiveUS20100282593A1High purityImprove purification effectAuxillariesEvaporation with vapour compressionWater flowVaporization

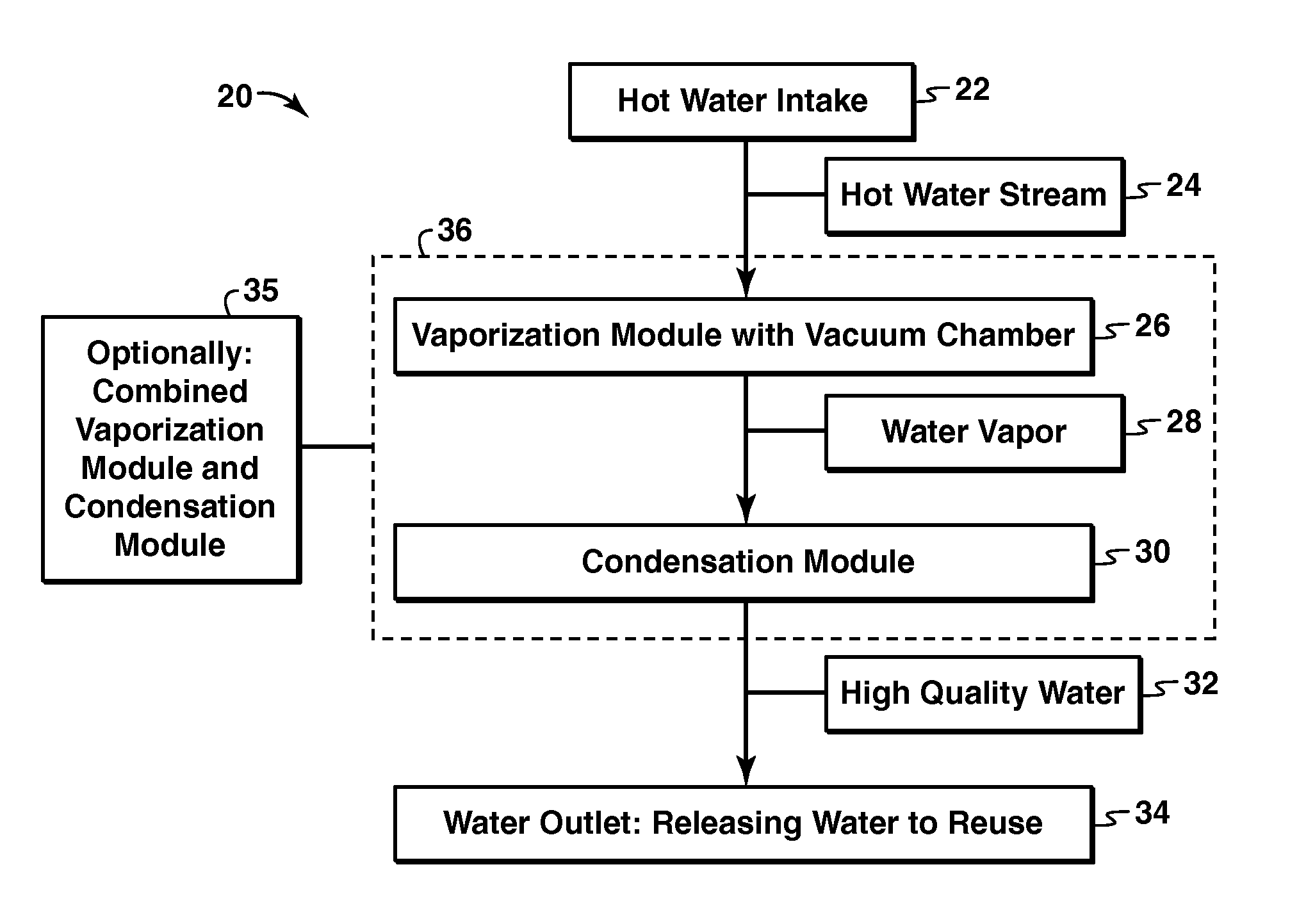

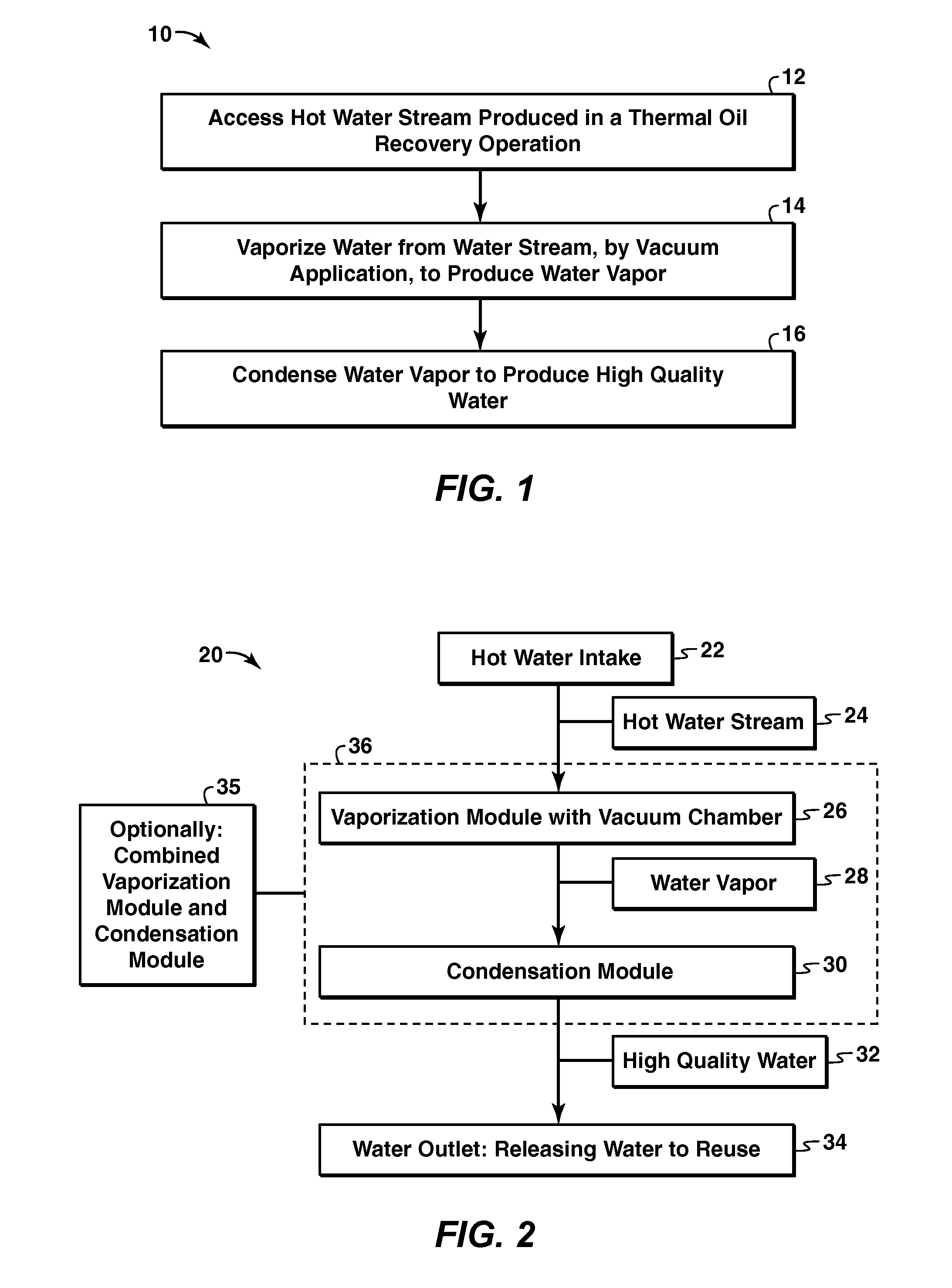

A method for reducing and re-using waste heat and water resulting from thermal hydrocarbon recovery operations involving accessing a hot water stream produced in a thermal hydrocarbon recovery operation; vaporizing water from the water stream by applying a vacuum, thereby producing water vapor; and condensing the water vapor to produce high quality water. A system is described including a hot water intake interfacing with a hot water stream from a thermal hydrocarbon recovery operation; a vaporization module receiving the hot water stream from the hot water intake, comprising a vacuum chamber in which a vacuum is applied to produce water vapor from the hot water stream; a condensation module in which water vapor produced in the vaporization module is condensed to form high quality water; and a water outlet for releasing the high quality water from the condensation module for re-use within the thermal hydrocarbon recovery operation.

Owner:EXXONMOBIL UPSTREAM RES CO

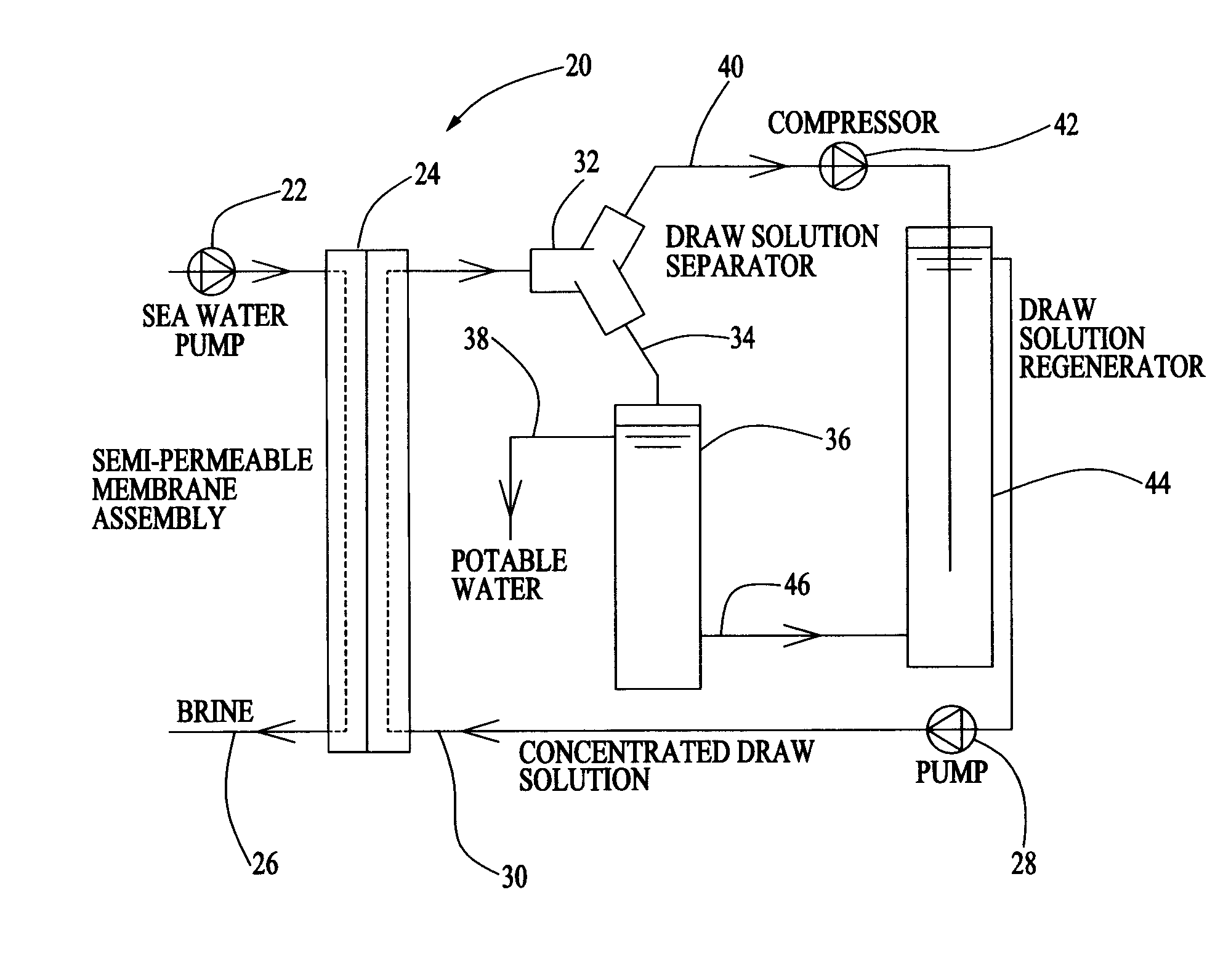

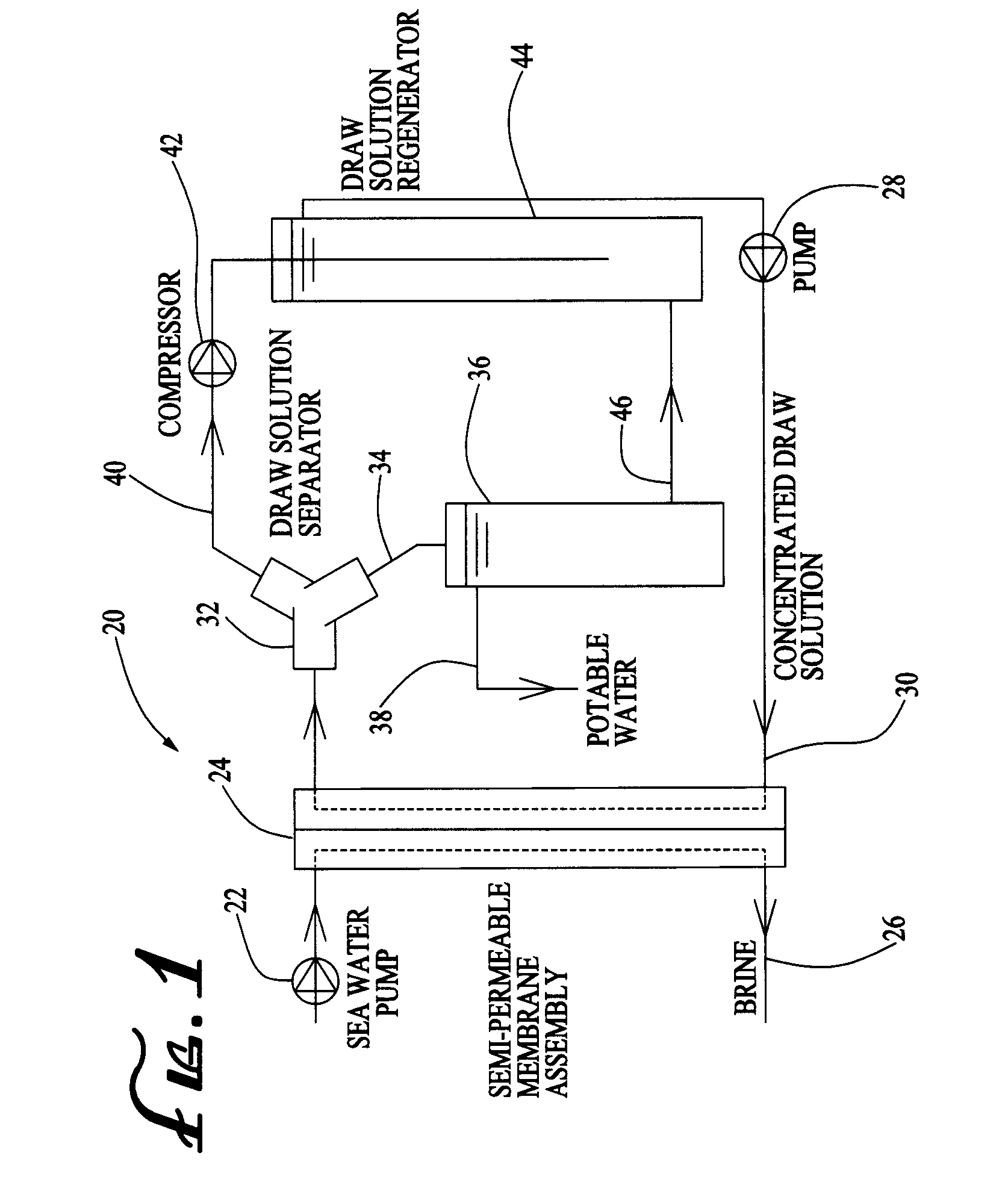

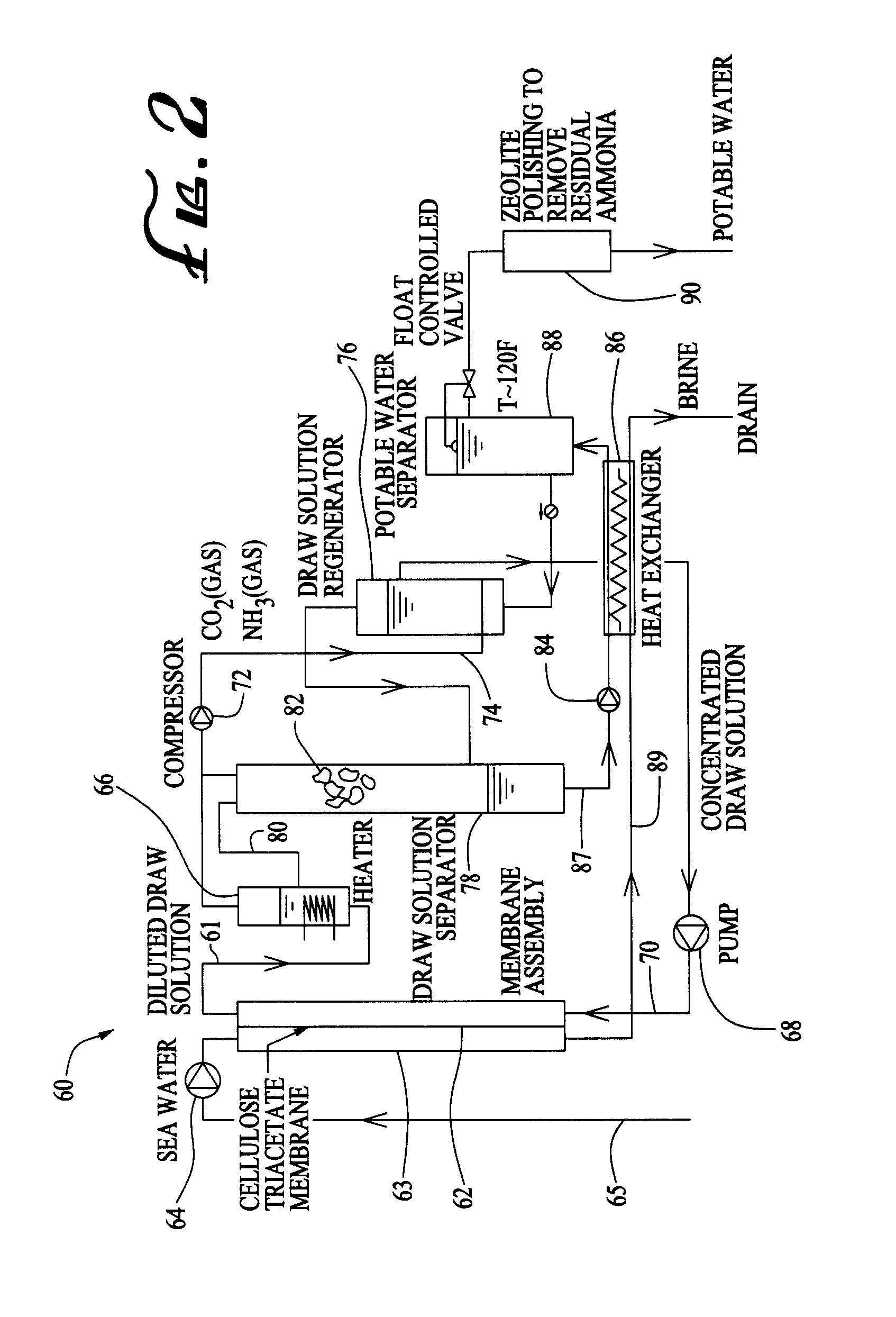

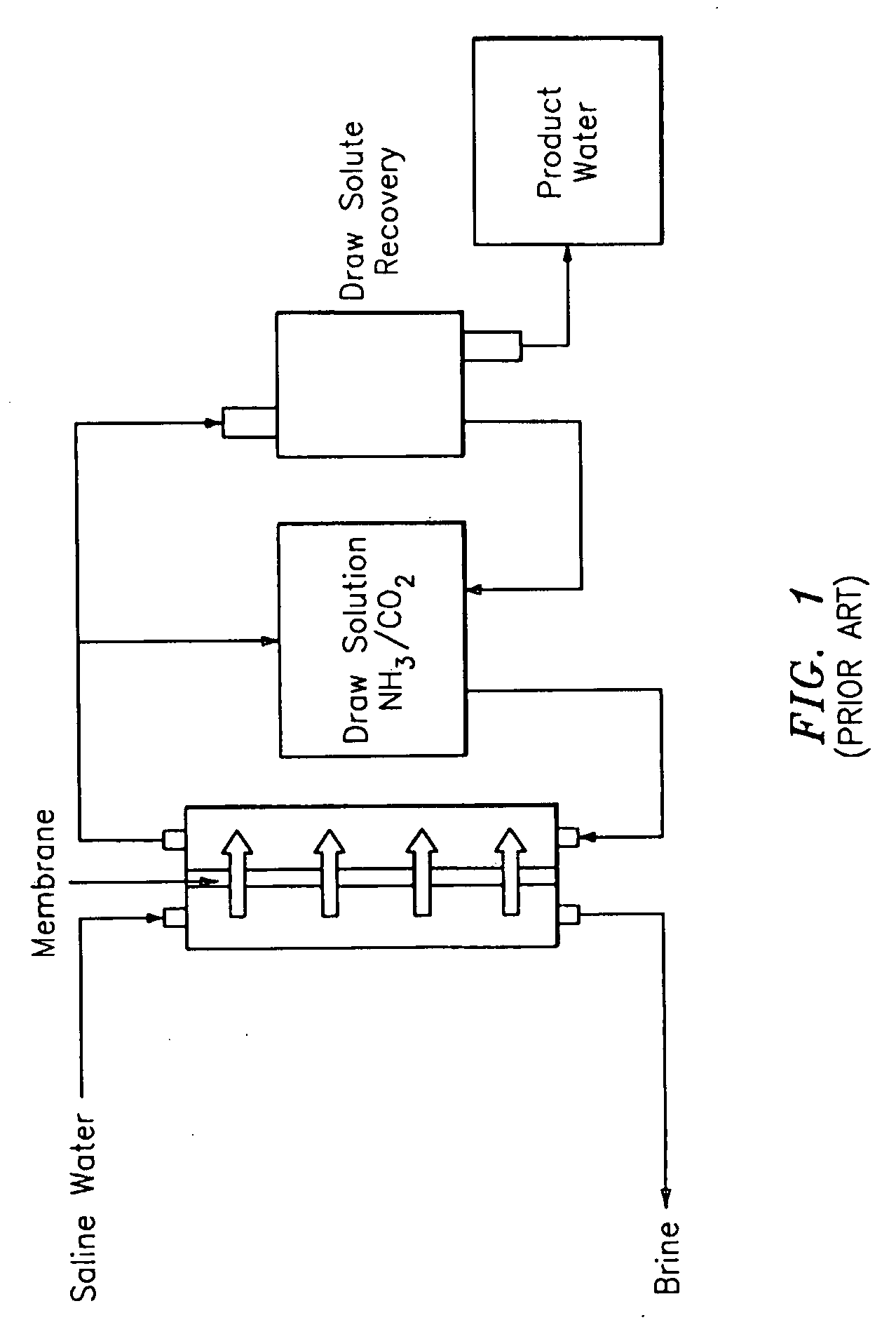

Method and Apparatus for Producing Potable Water from Seawater Using Forward Osmosis

ActiveUS20090308727A1Efficient and effectiveAuxillariesGeneral water supply conservationDesalinationPotable water

A method and apparatus for desalinating seawater which uses an ammonia bicarbonate forward osmosis desalination process. Seawater is pumped through one side of a membrane assembly. A draw solution is pumped through the other side of the membrane assembly. The draw solution withdraws water molecules from the seawater through the membrane into the draw solution. A draw solution separator receives a heated draw solution which then decomposes into ammonia, carbon dioxide and water. Potable water is separated from ammonia has and carbon dioxide gas. The ammonia gas and carbon dioxide gas are recombined with a portion of the potable water stream to reform the ammonium bicarbonate draw solution.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

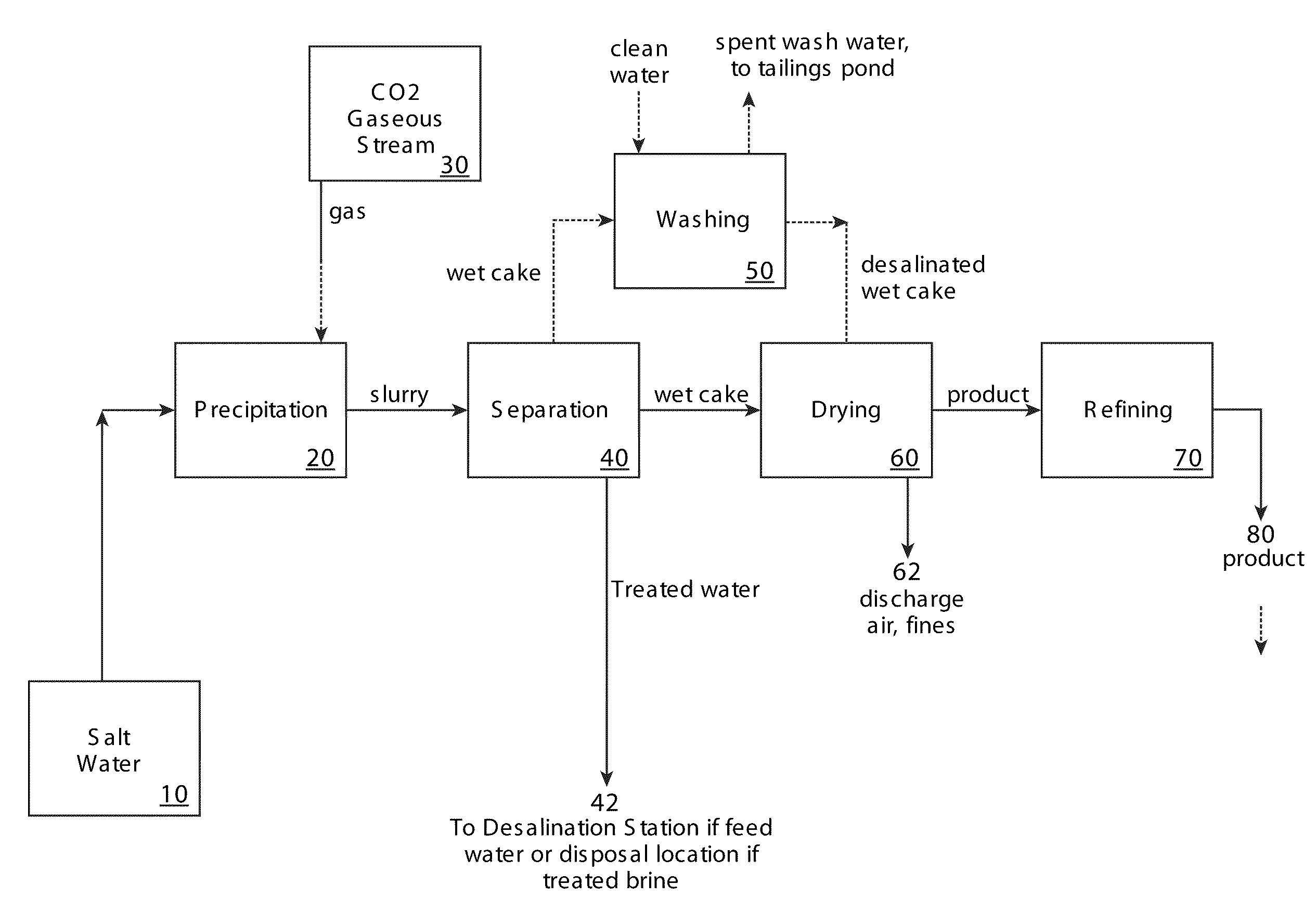

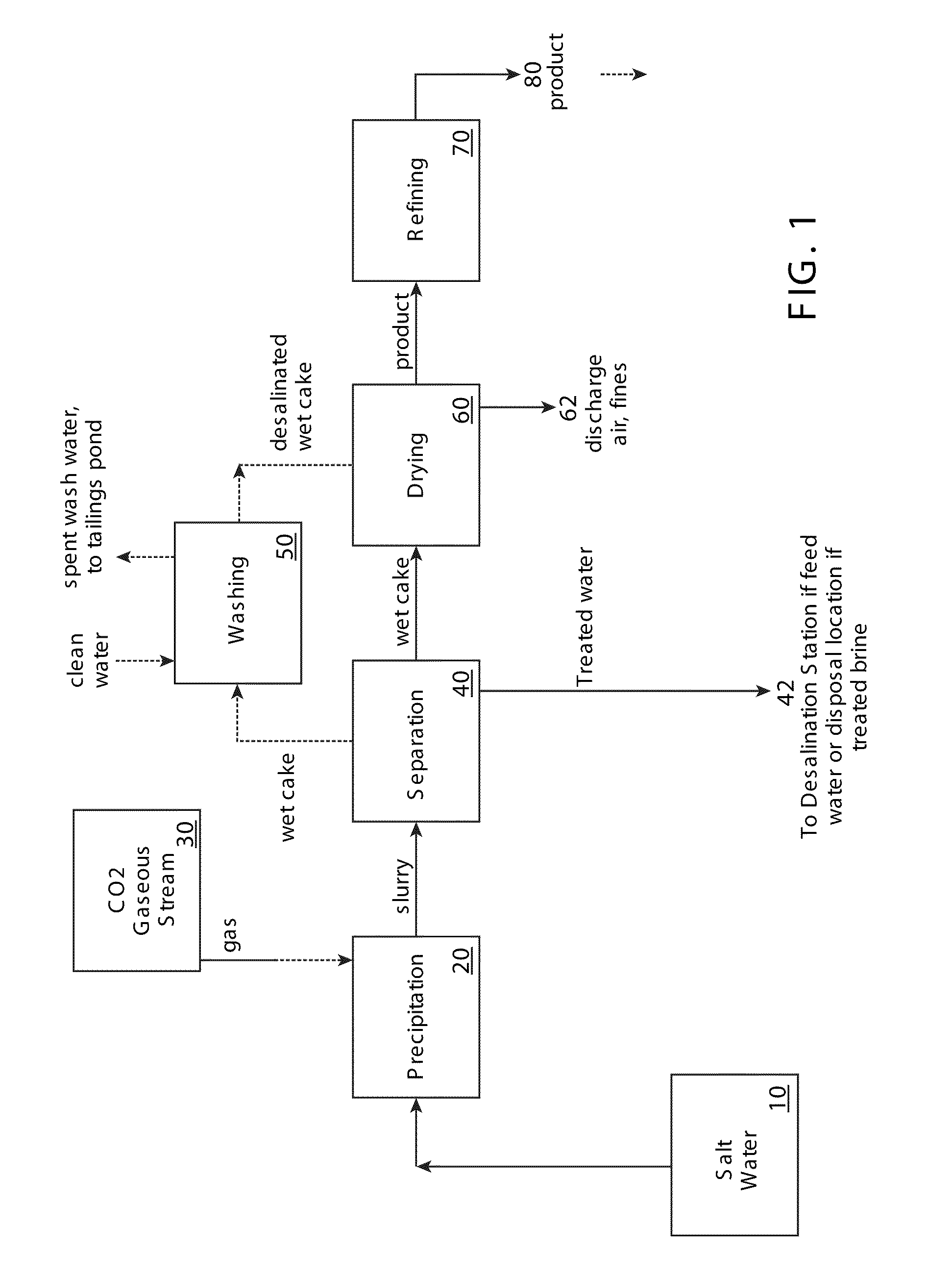

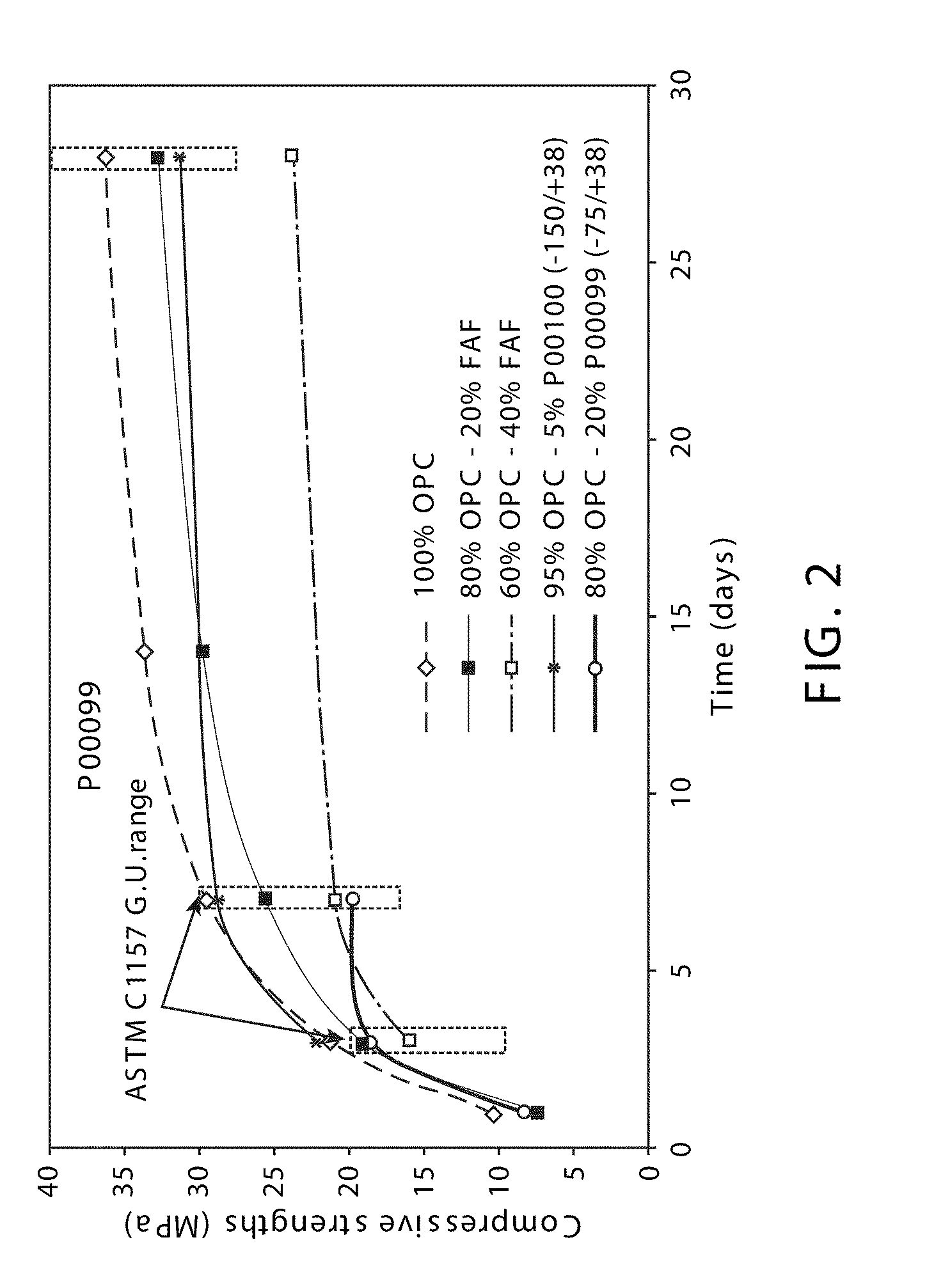

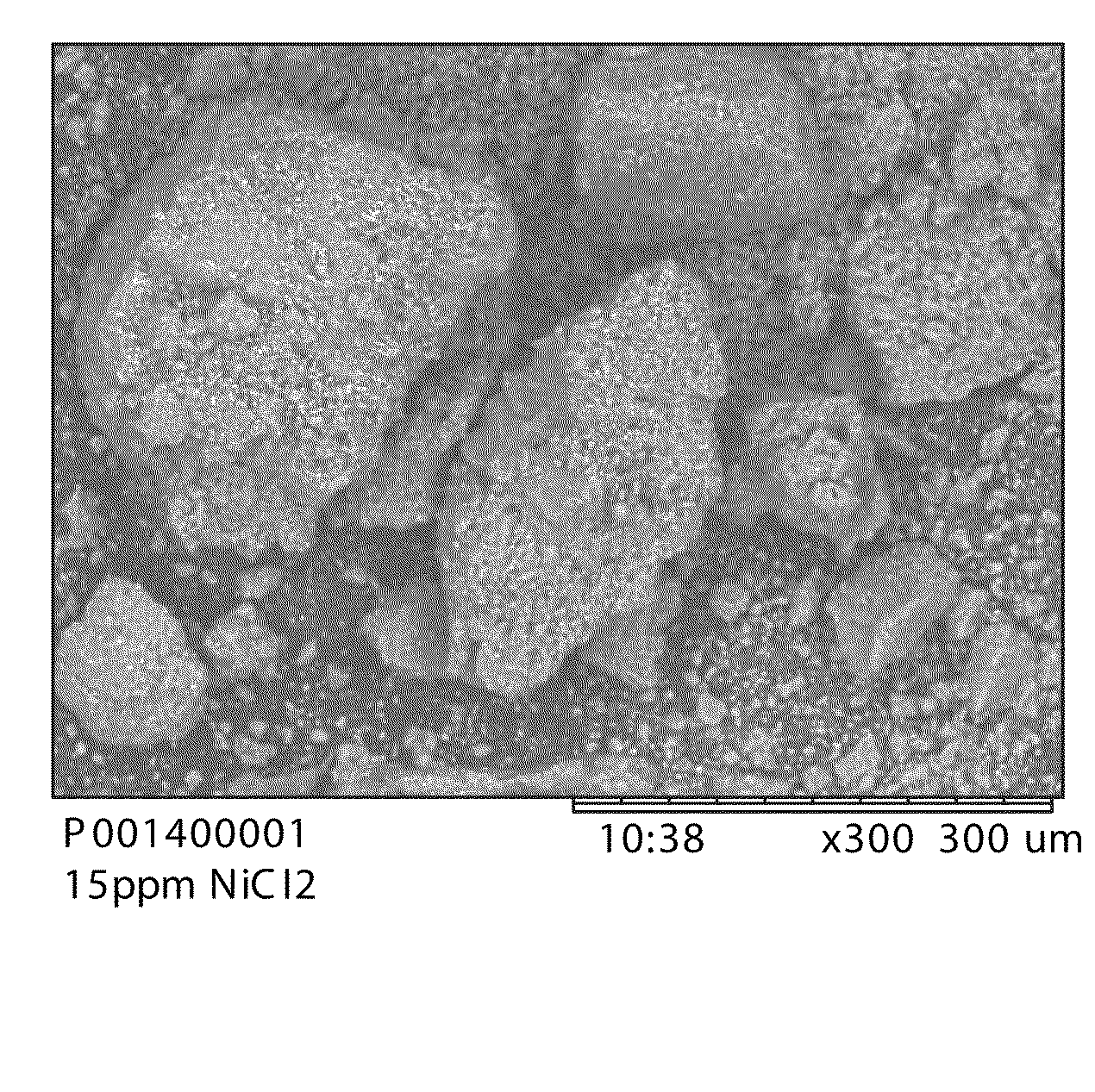

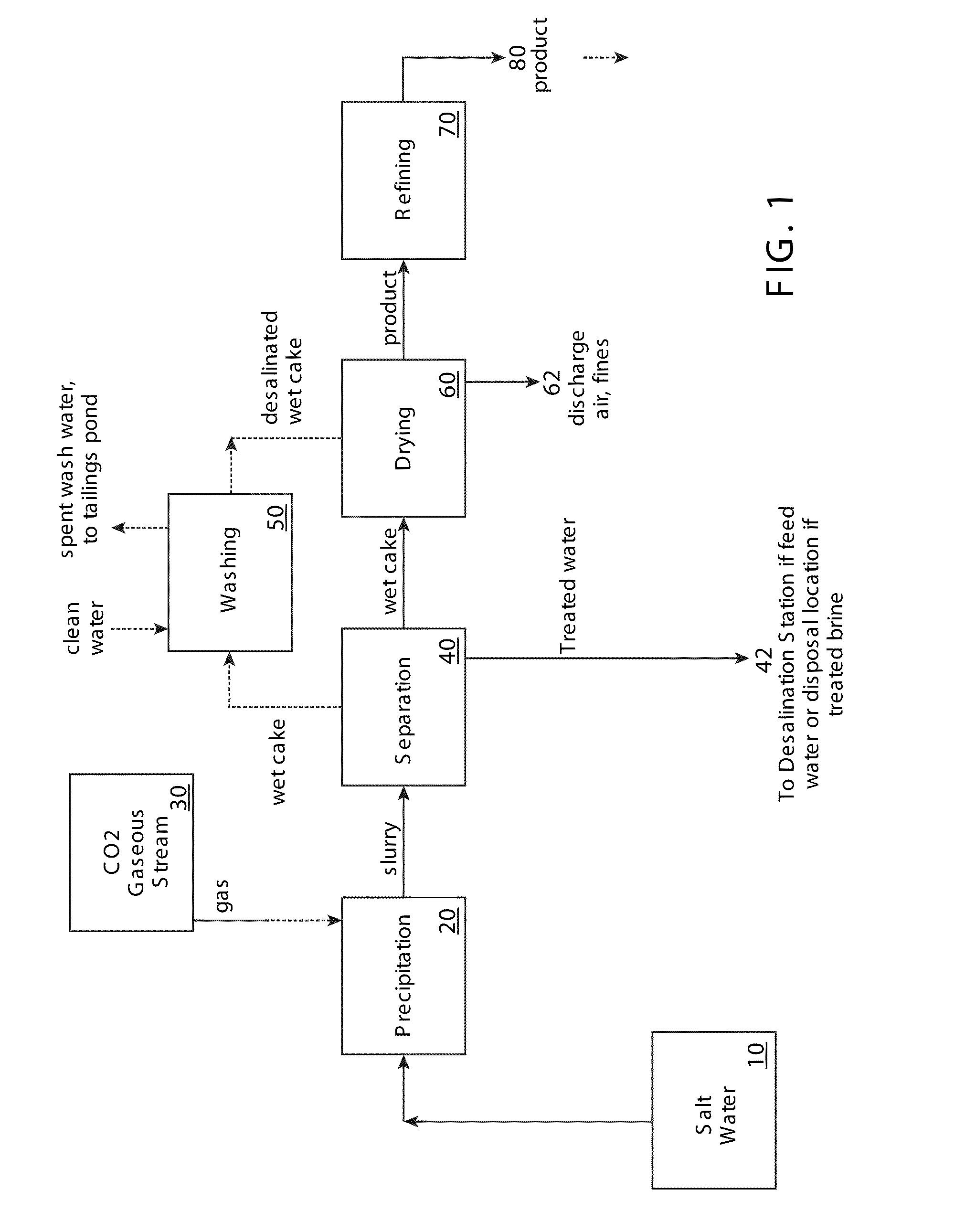

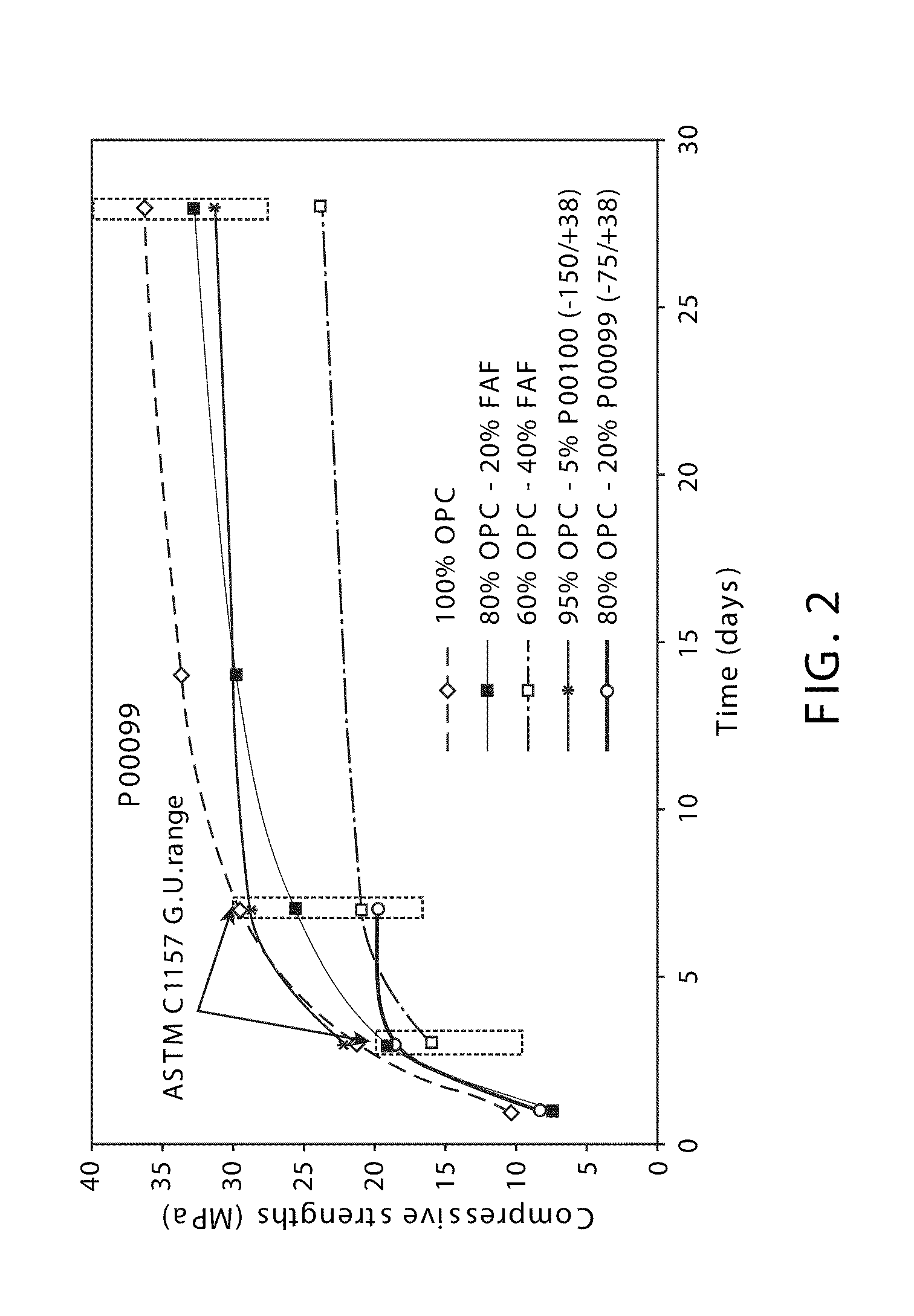

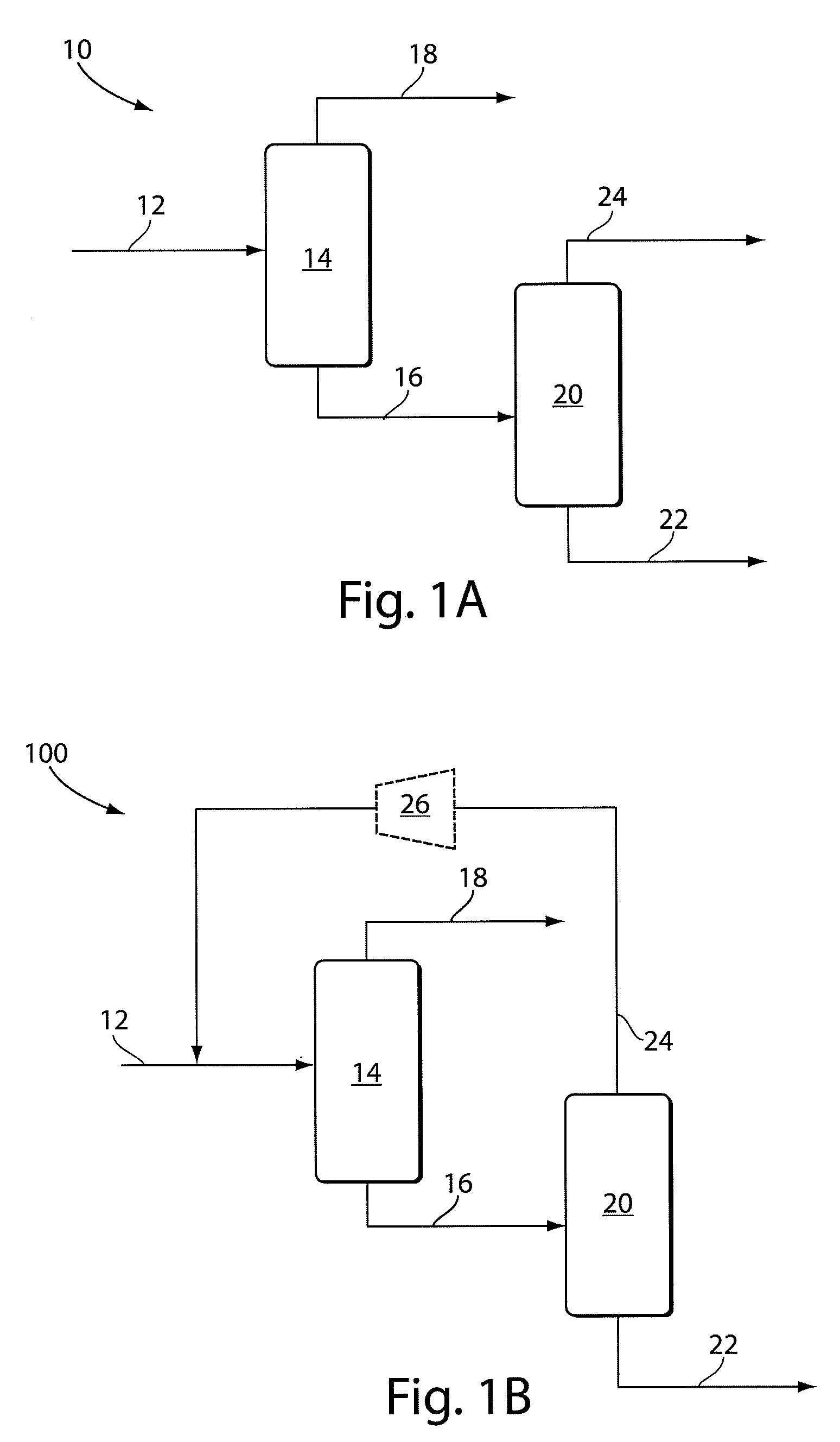

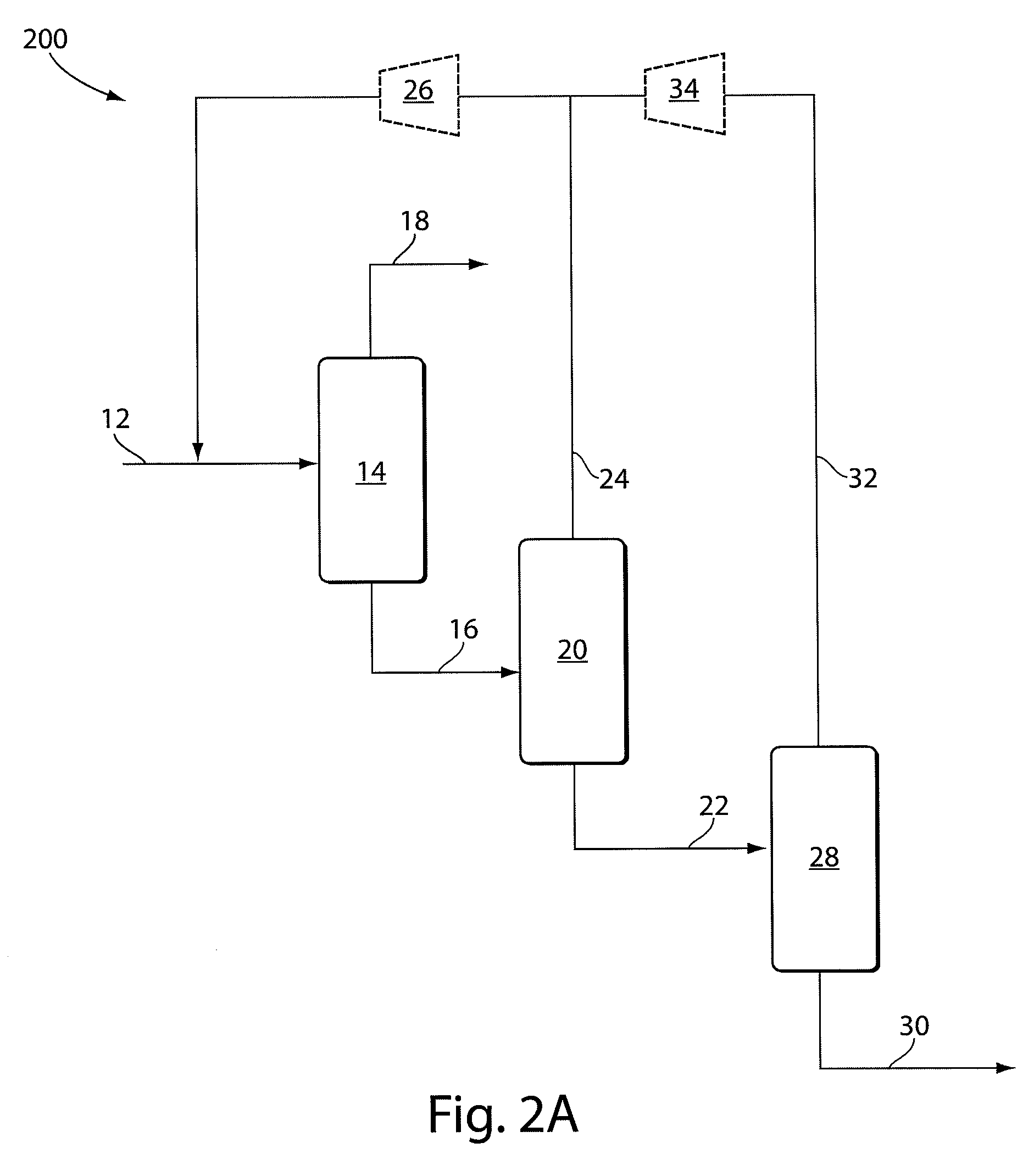

Desalination methods and systems that include carbonate compound precipitation

InactiveUS20100154679A1Easy complianceImprove desalination efficiencyAuxillariesGeneral water supply conservationSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbon dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:CALERA CORP

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20100158786A1Easy complianceImprove desalination efficiencyCalcium/strontium/barium carbonatesAuxillariesSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

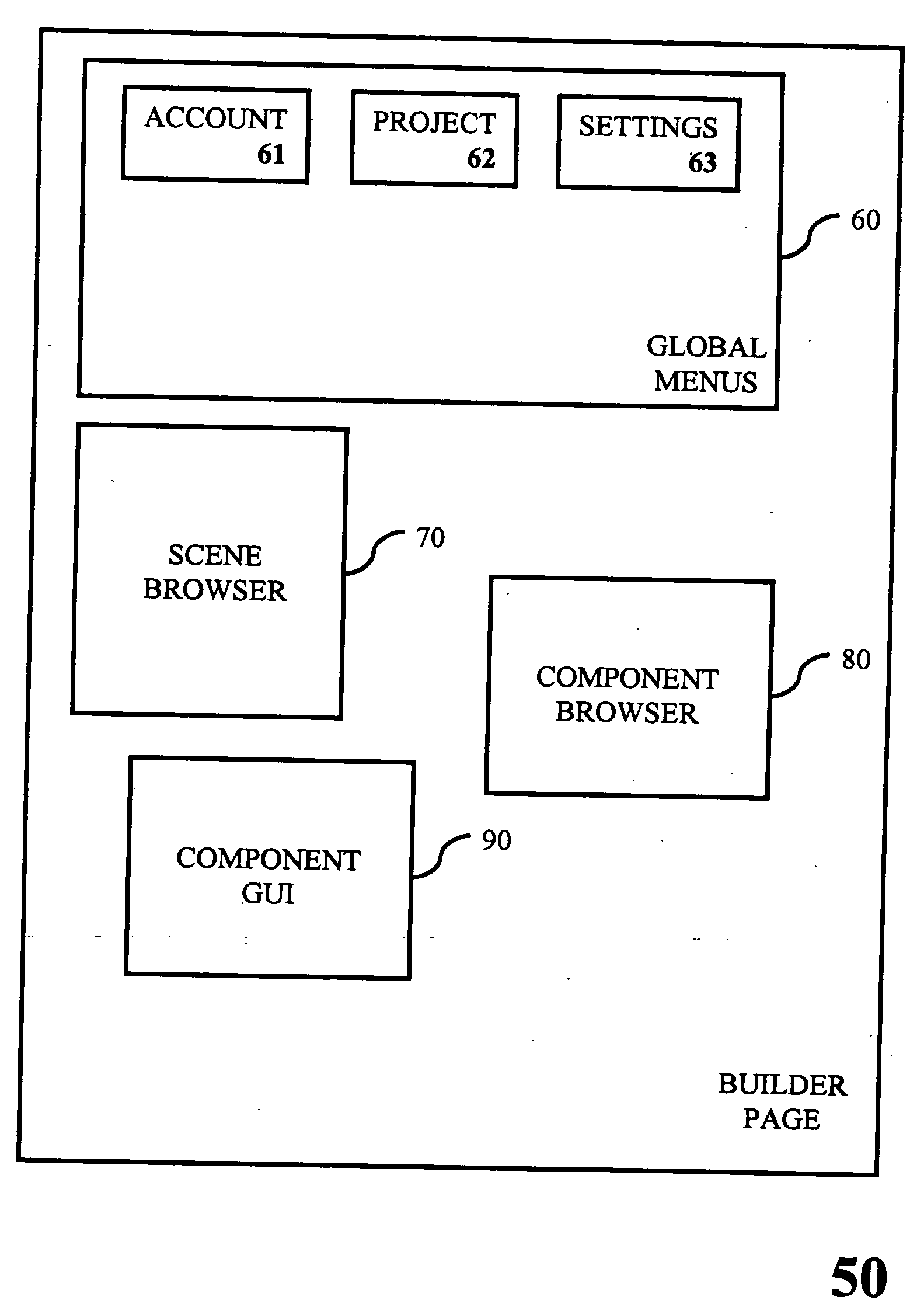

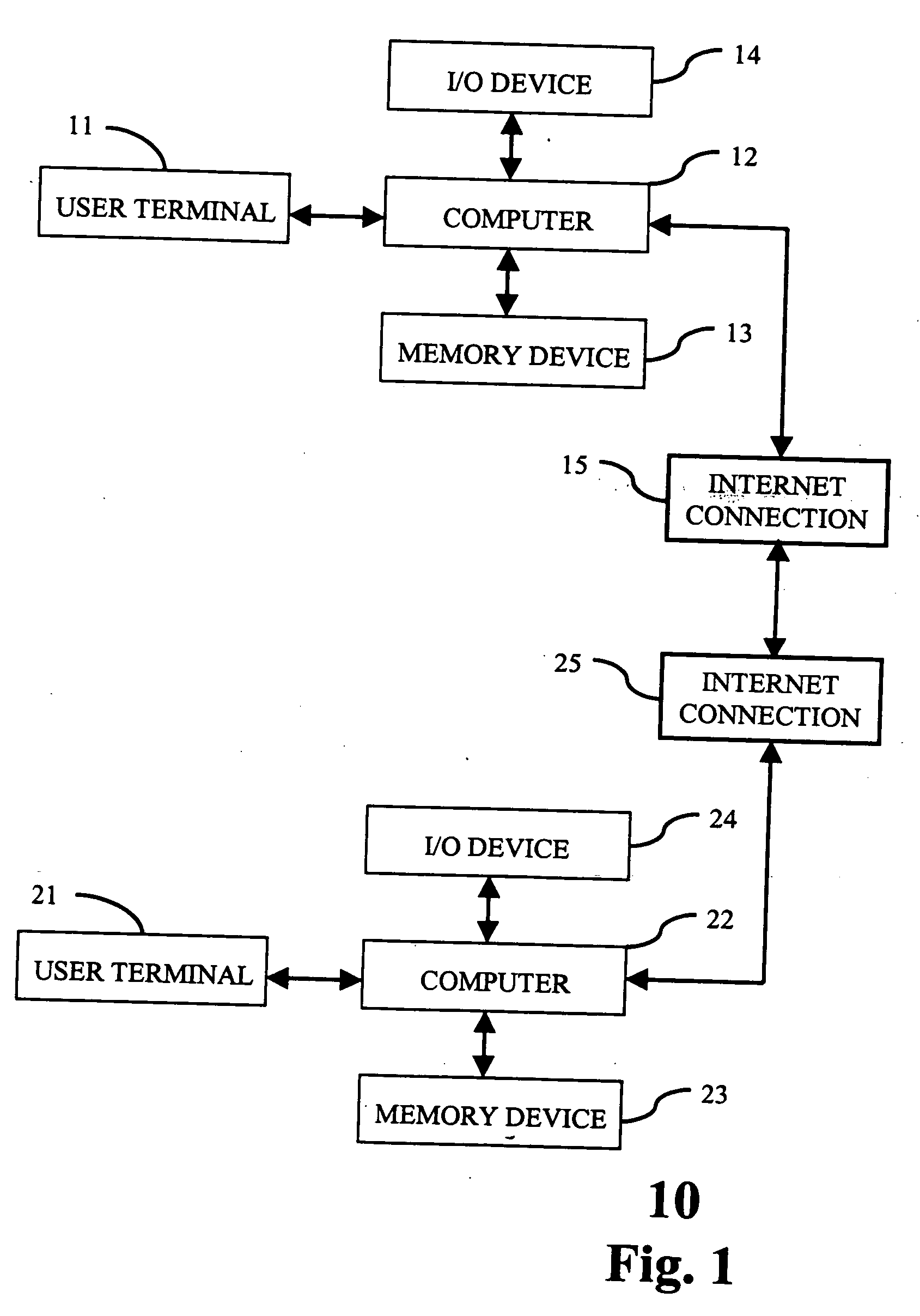

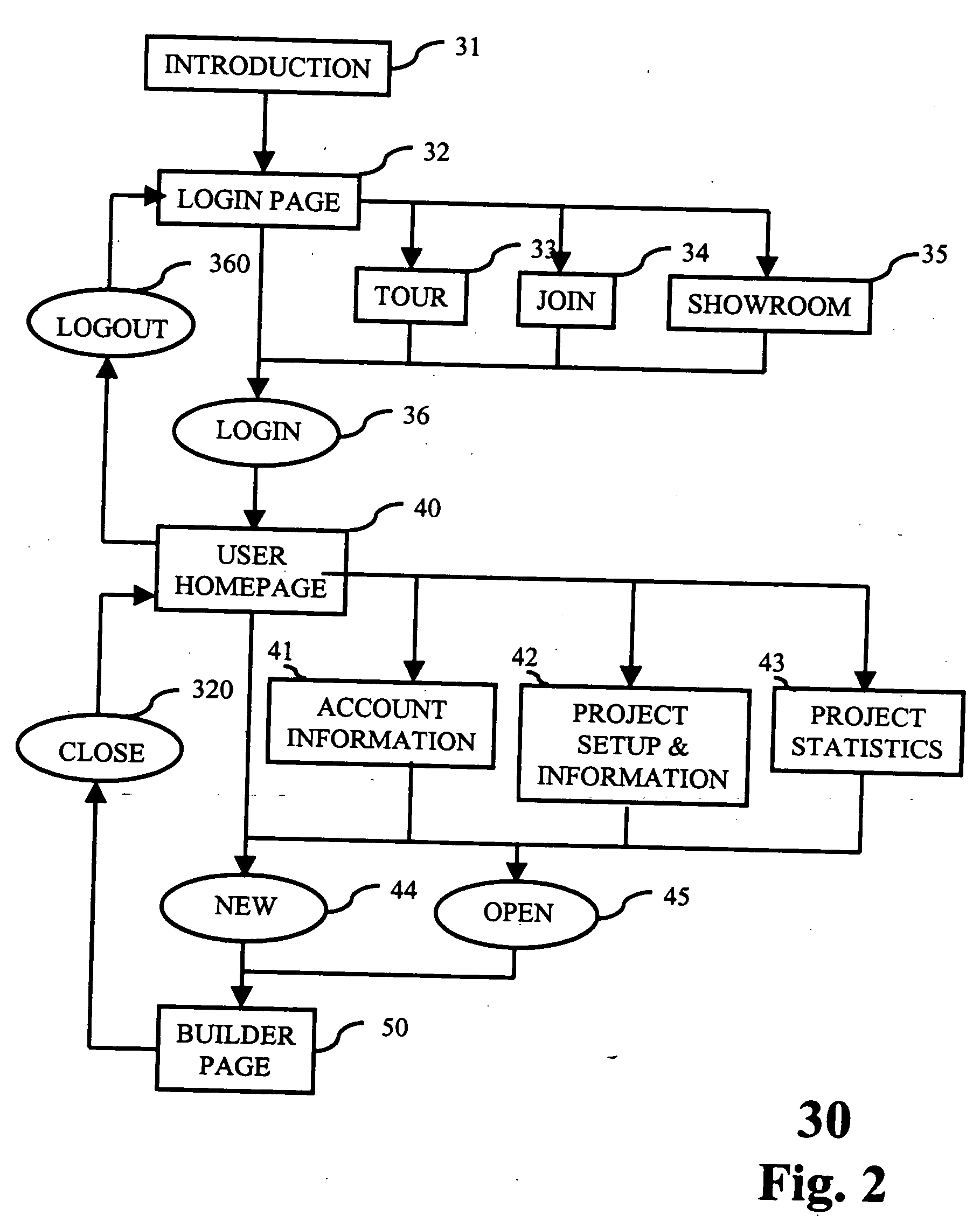

Methods, systems, and processes for the design and creation of rich-media applications via the Internet

Rich-media applications are designed and created via the Internet. A host computer system, containing processes for creating rich-media applications, is accessed from a remote user computer system via an Internet connection. User account information and rich-media component specifications are uploaded via the established Internet connection for a specific user account. Rich-media applications are created, deleted, or modified in a user account via the established Internet connection. Rich-media components are added to, modified in, or deleted from scenes of a rich-media application based on information contained in user requests. After creation, the rich-media application is viewed or saved on the host computer system, or downloaded to the user computer system via the established Internet connection. In addition, the host process monitors the available computer and network resources and determines the particular component, scene, and application versions, if multiple versions exist, that most closely match the available resources.

Owner:BALTHASER NEIL

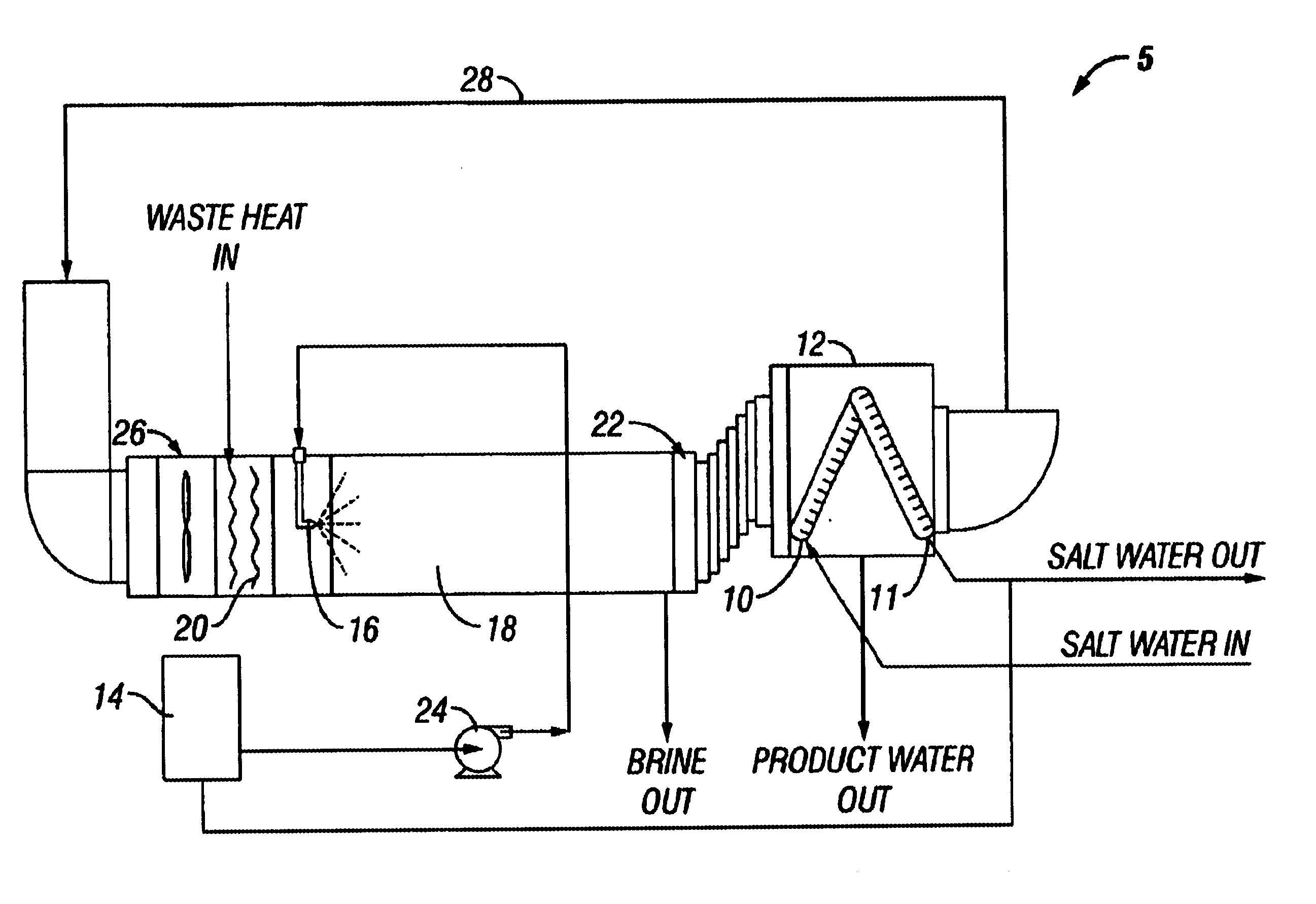

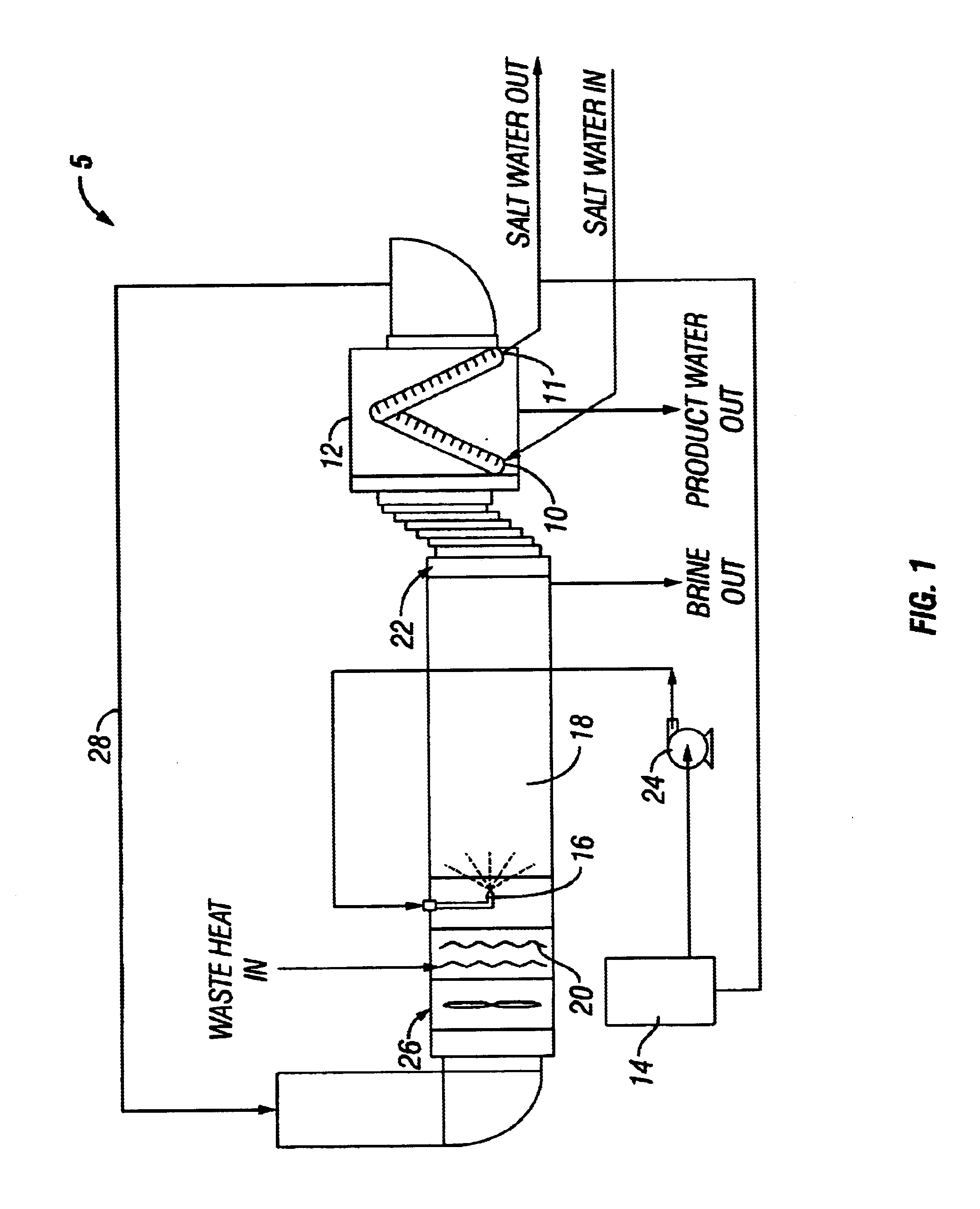

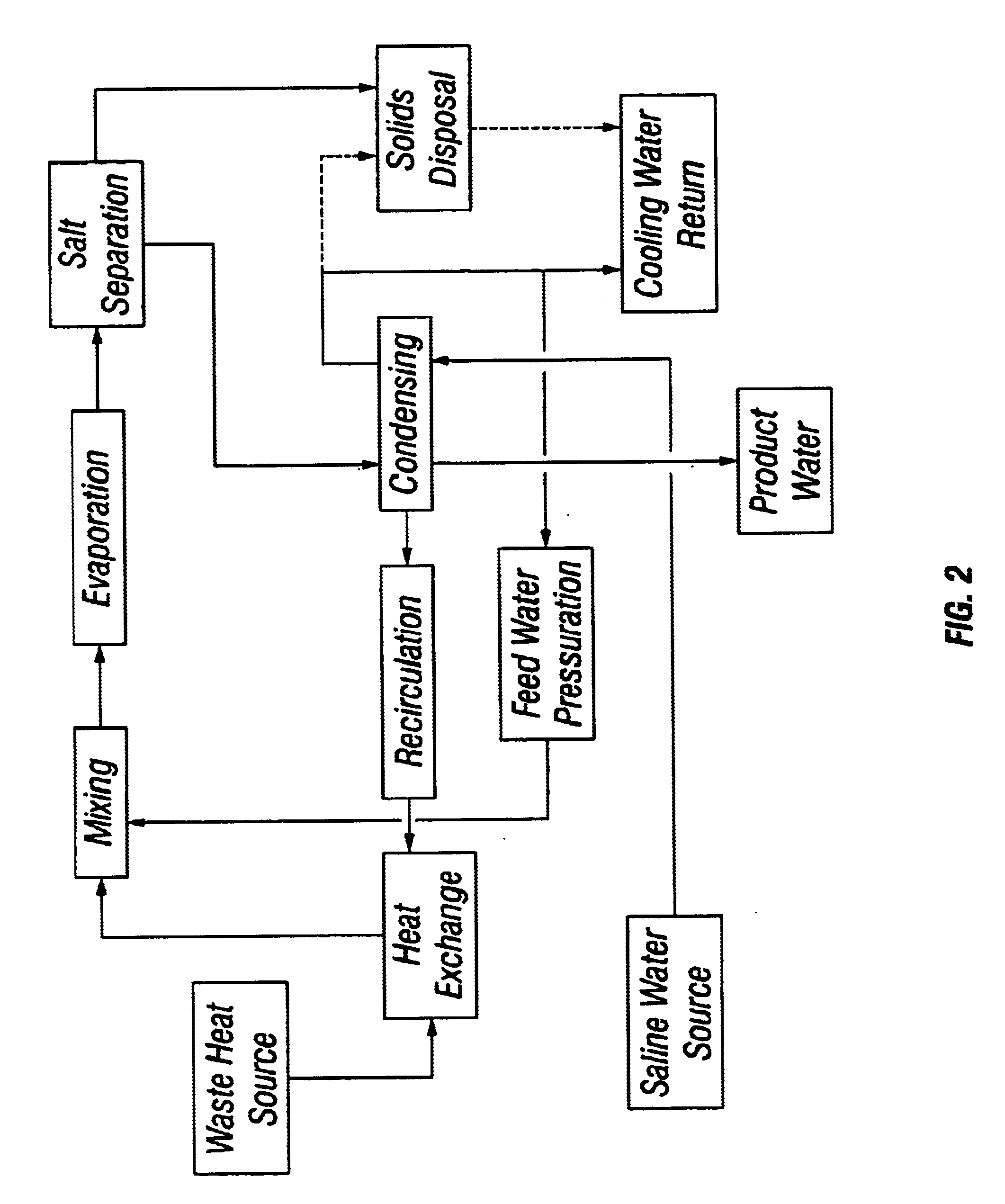

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

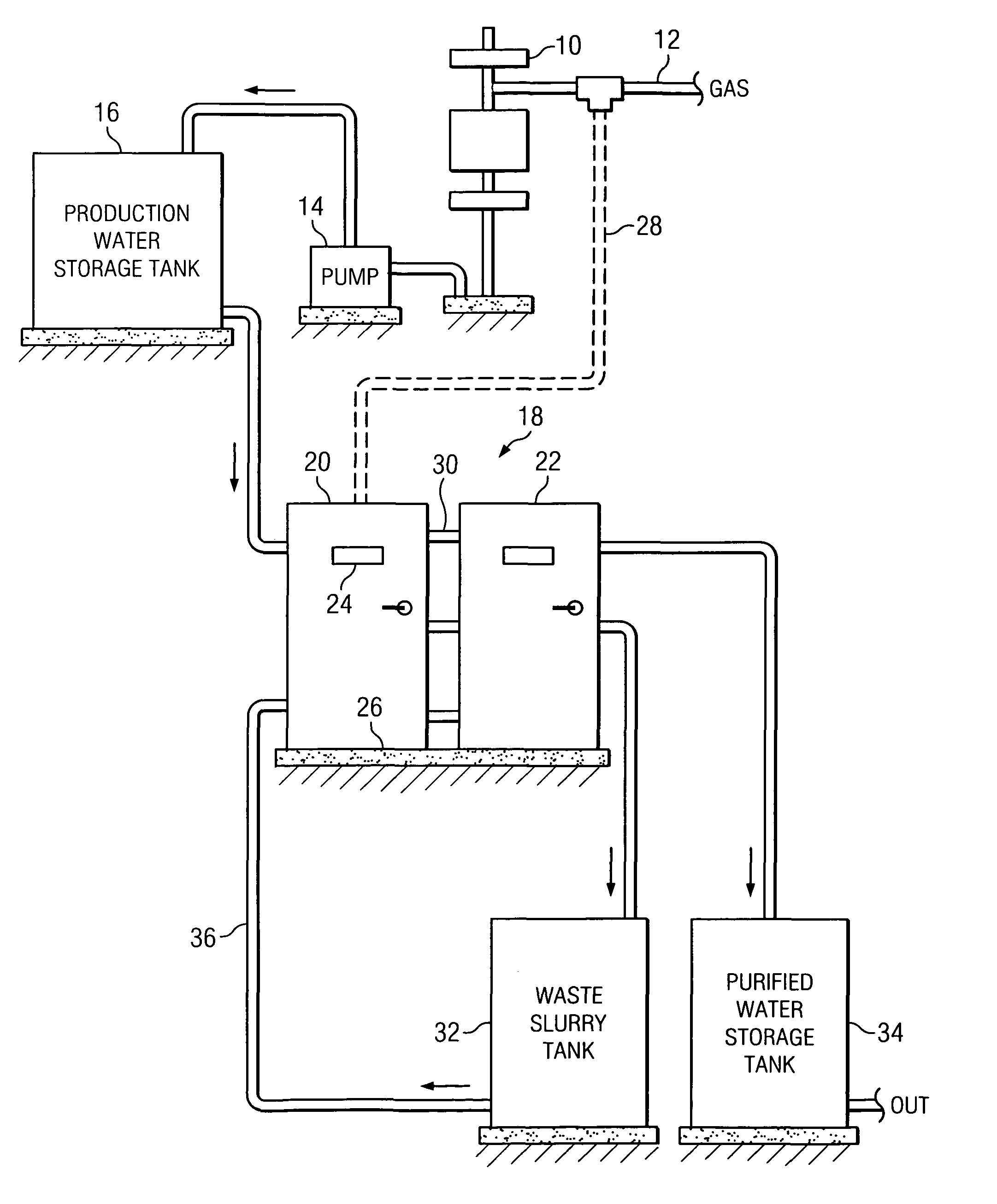

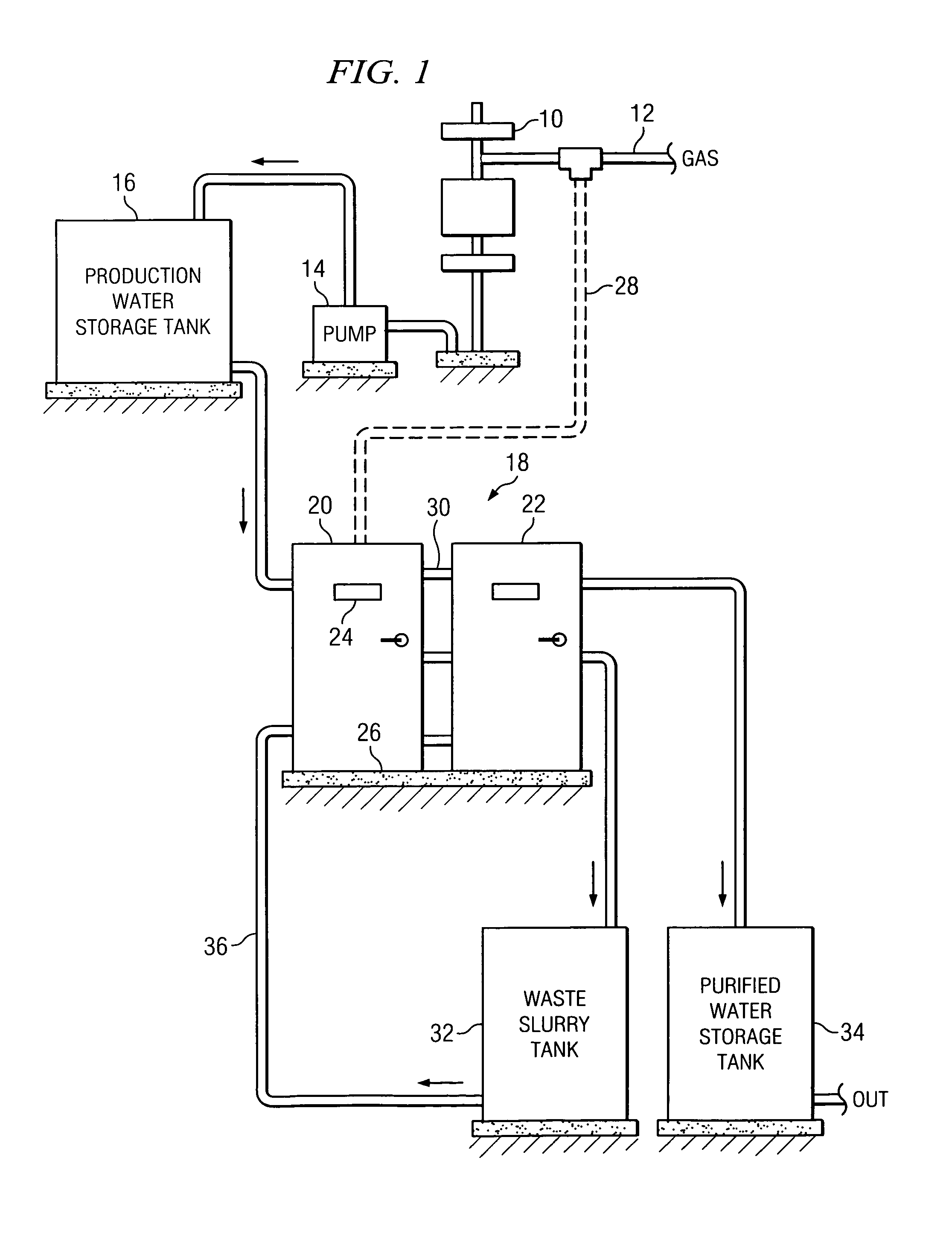

Bilge water reclamation system and process

InactiveUS6902678B2Reduce pollutantsEasy to processLiquid separation by electricityAuxillariesOil retentionBilge

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

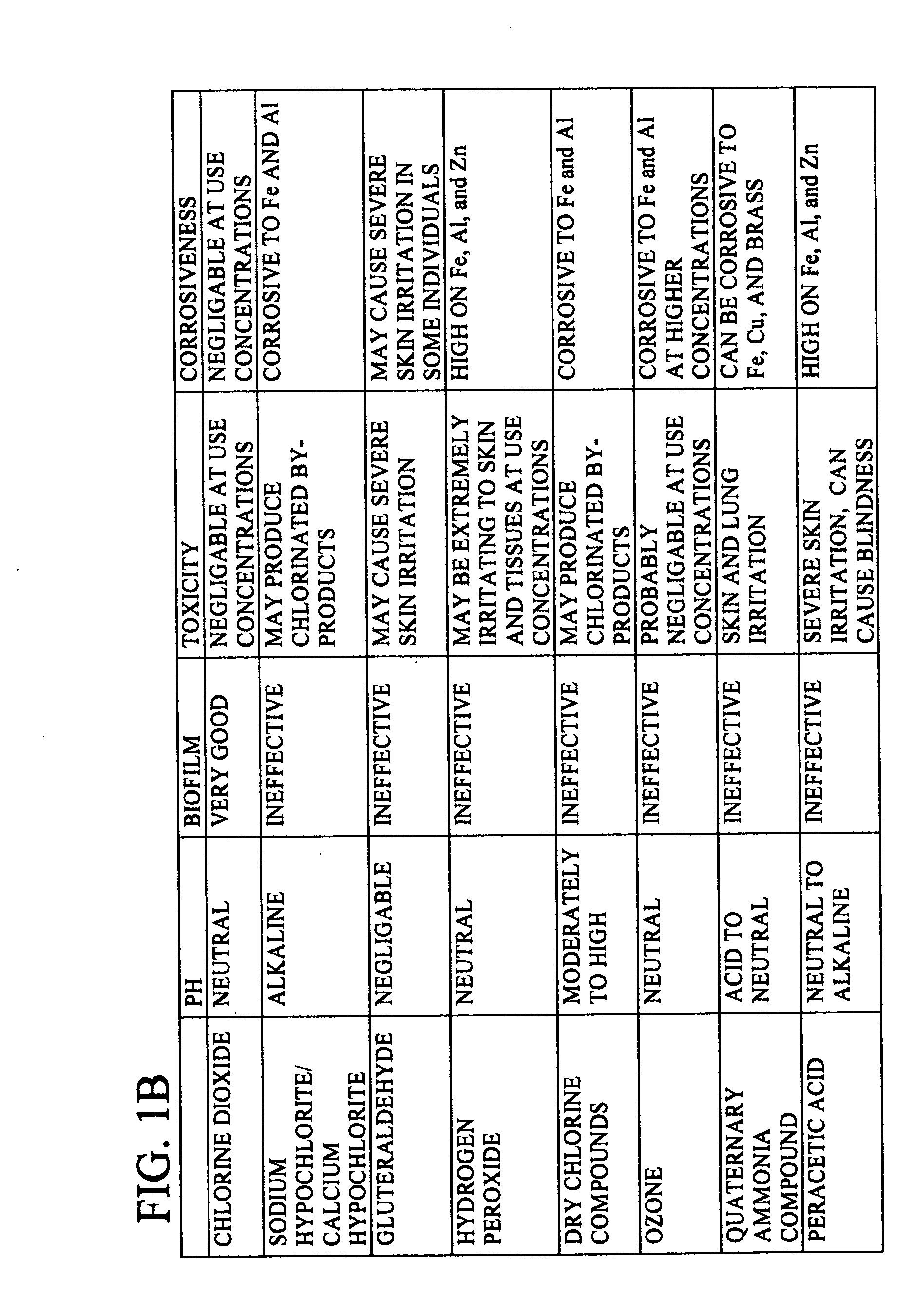

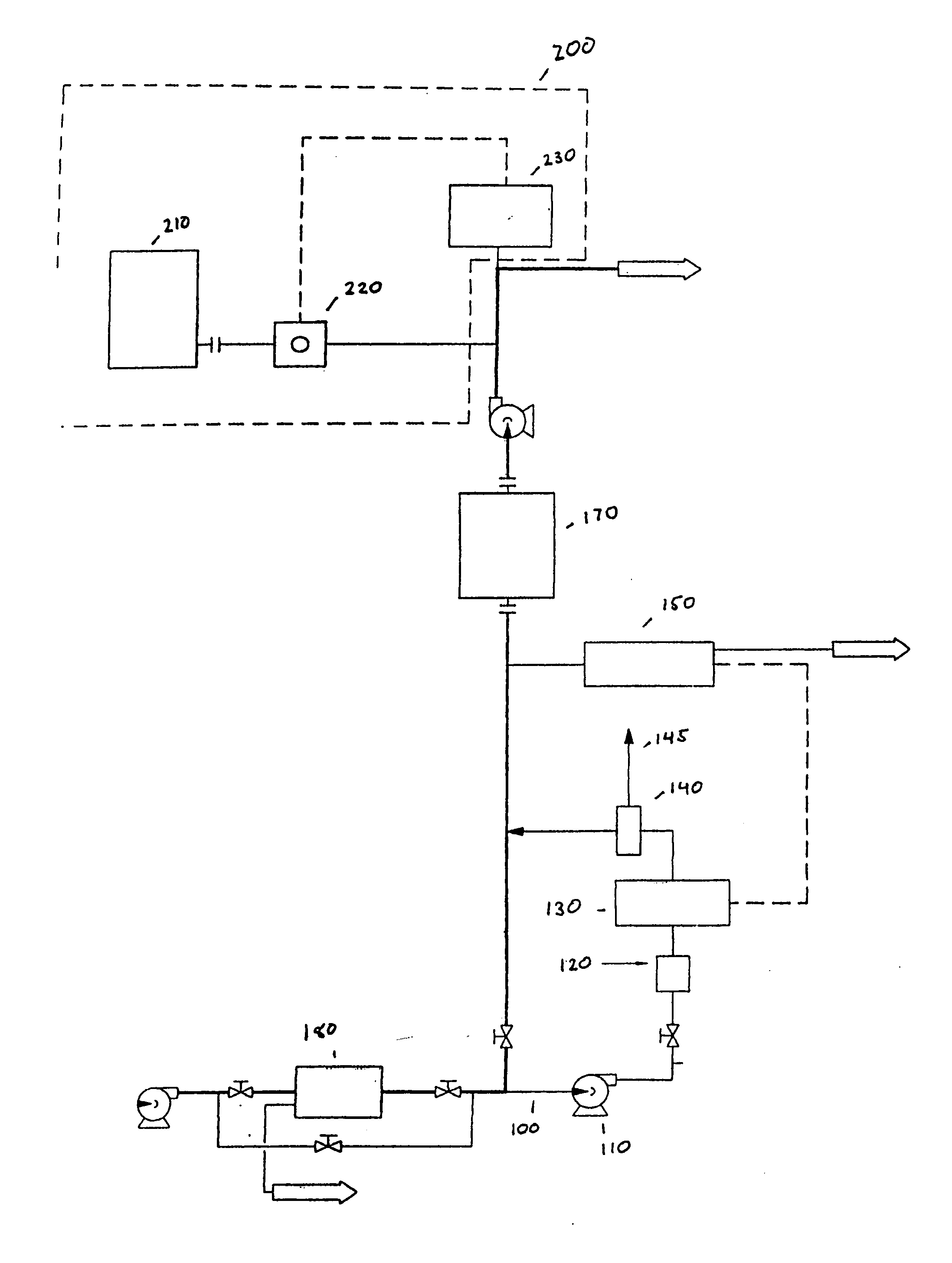

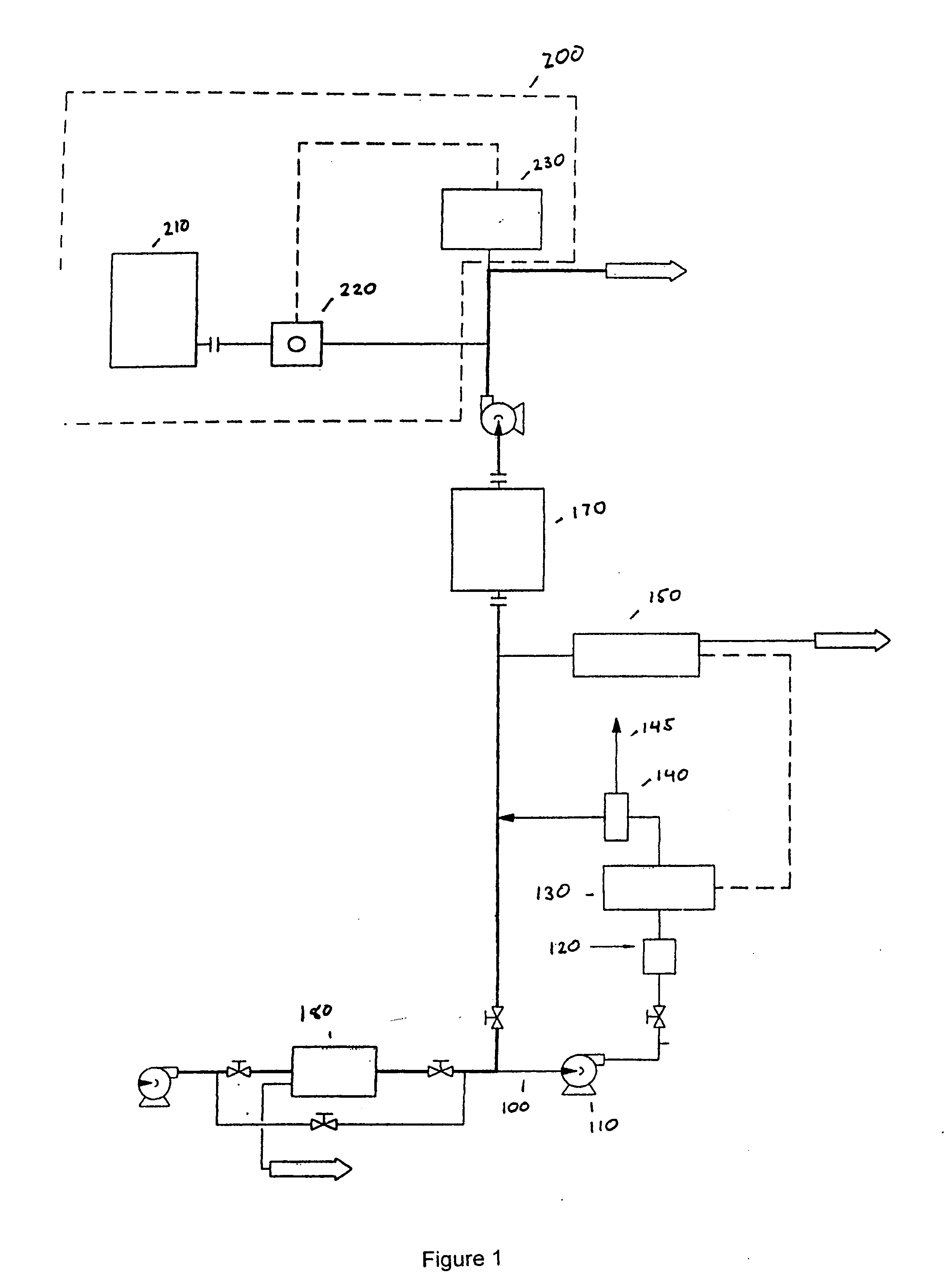

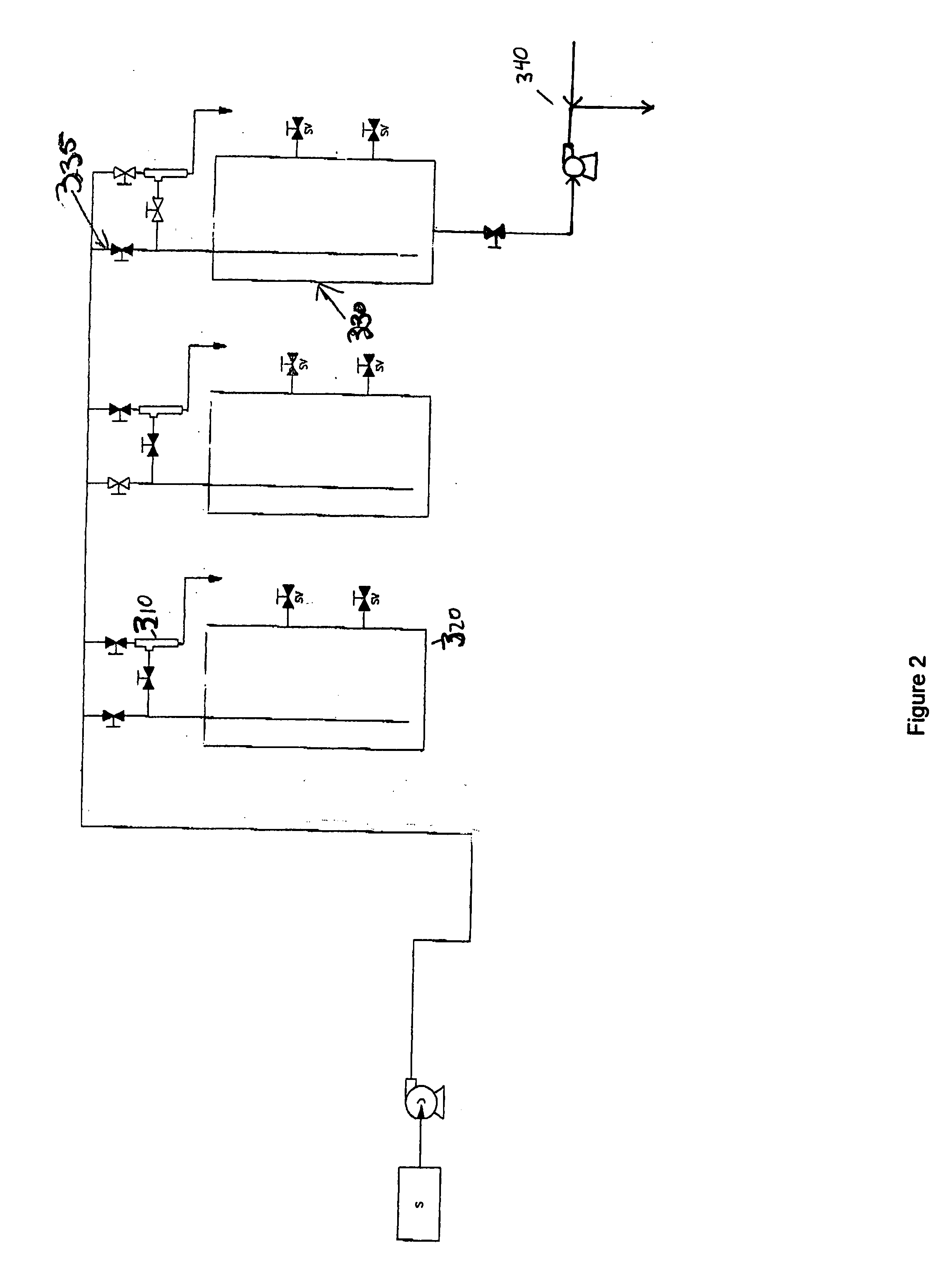

Methods, apparatus, and compositions for controlling organisms in ballast water

InactiveUS20050016933A1Water treatment parameter controlAuxillariesChlorine dioxideWater treatment system

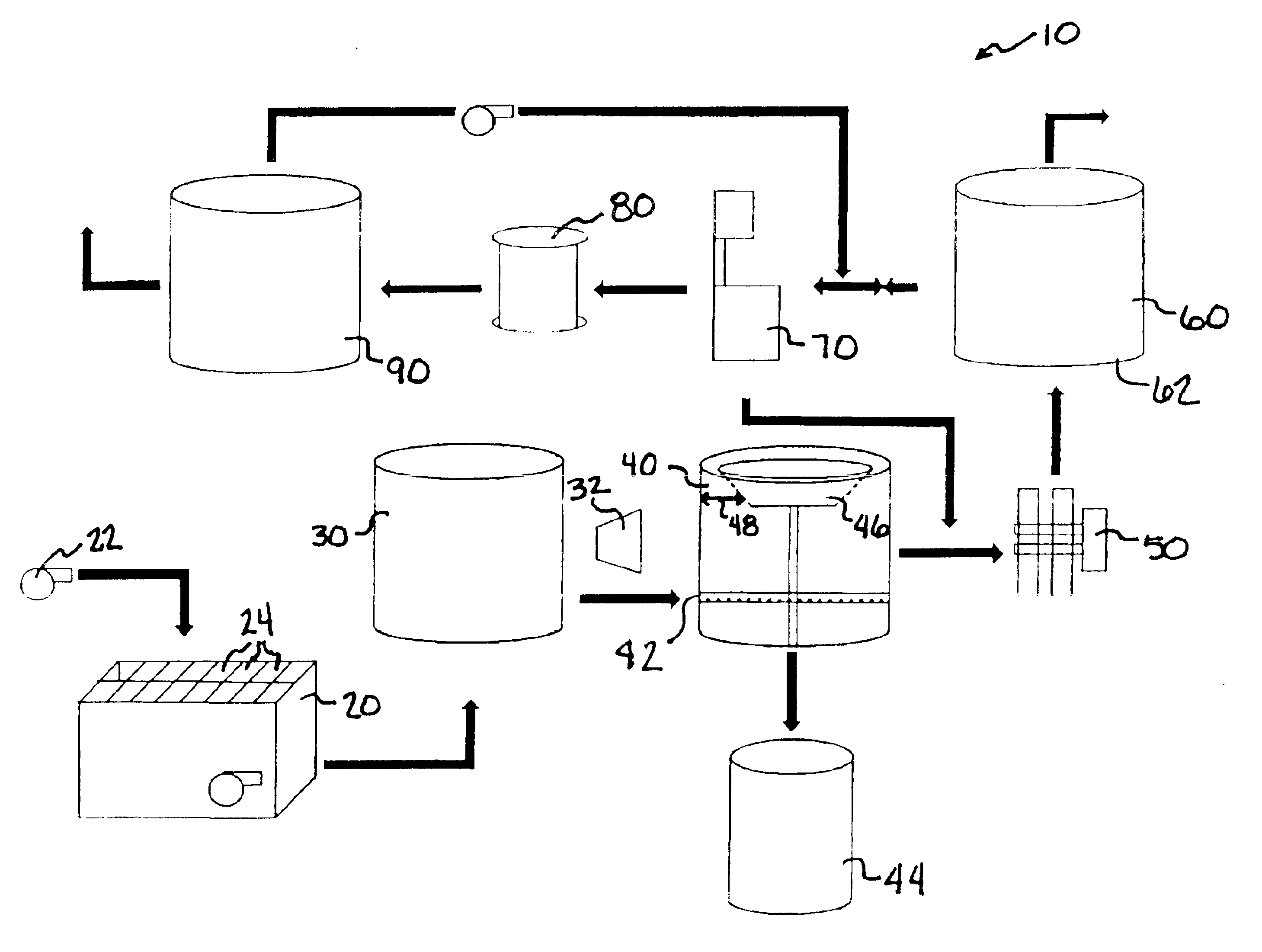

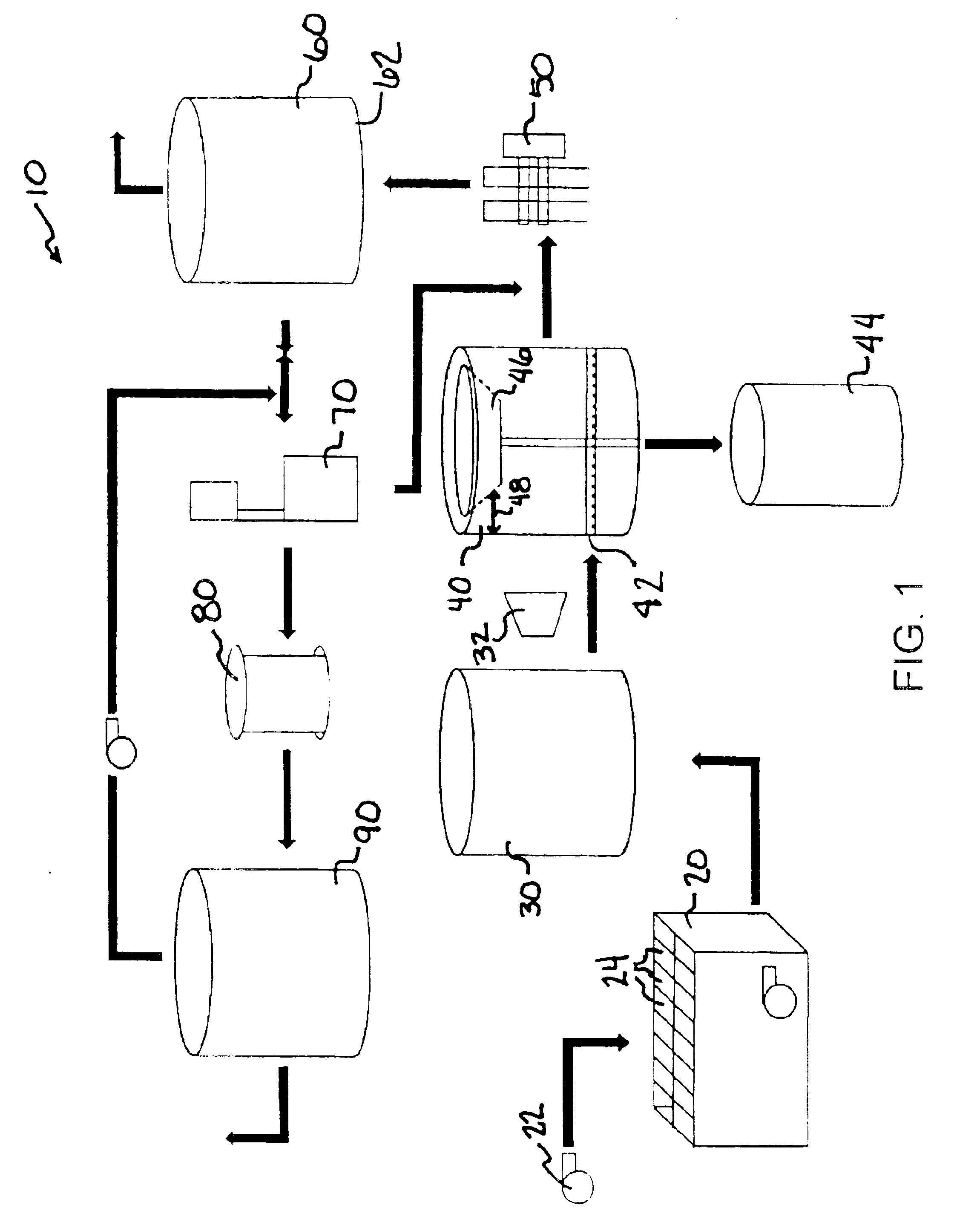

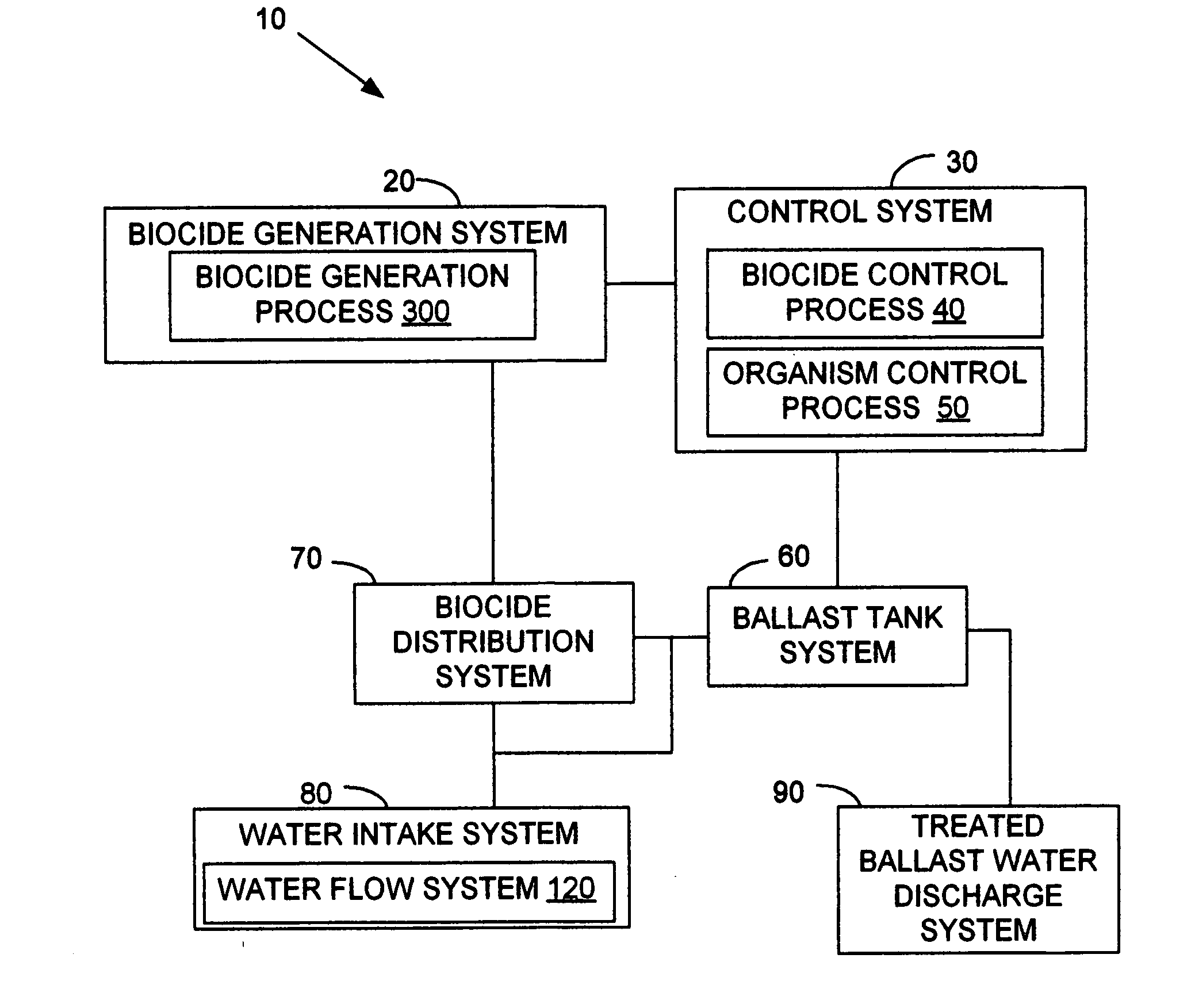

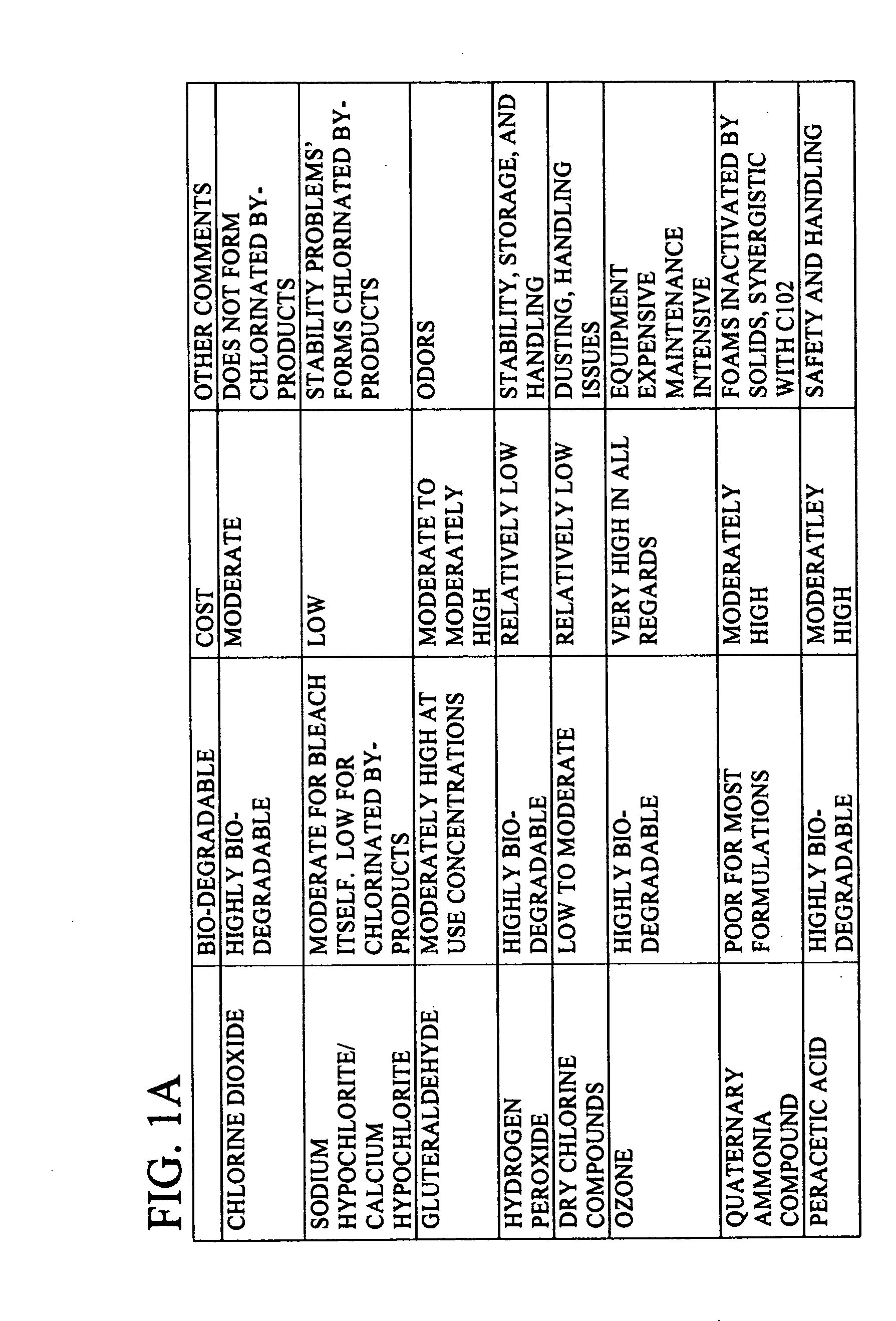

Apparatuses and methods of a ballast water treatment system are disclosed. The ballast water treatment system includes a control system and a ballast tank system. The control system controls the concentration of a biocide in the ballast tank system. In addition, the ballast water treatment system can be implemented in a vessel. The ballast water treatment system includes a control system, a biocide generation system, and a ballast tank system. The control system is capable of controlling the concentration of a biocide in the ballast tank system by controlling the amount of the biocide feed into the ballast tank system from the biocide generation system. Further, the ballast water treatment system involves methods for controlling organisms in ballast water of a vessel. A representative method includes providing the ballast water, and treating the ballast water with chlorine dioxide.

Owner:PERLICH TOM +1

System and method for treatment of ballast water

ActiveUS20060113257A1Prevent outbreakLiquid separation by electricityAuxillariesHypochloriteHydrogen

A system and method for treating ballast water within an ocean going vessel by generating hypochlorite for treating the ballast water. The system comprises one or more hypochlorite electrolytic cells in fluid communication with a stream of ballast water. A chlorine analyzer is positioned downstream from the electrolytic cells to determine the chlorine concentration of the treated ballast water. A hydrogen separator is connected to the hypochlorite electrolytic cells for venting hydrogen. In the method of this invention, water is taken aboard the ship for ballast in one port. A treatment stream is separated from the ballast water stream and piped to hypochlorite electrolytic cells. Hypochlorite is generated into the treatment stream and the hydrogen byproduct is separated by the hydrogen separators. The treatment stream is then reintroduced to the ballast water to eliminate marine species and pathogenic bacteria from ballast water. The ballast water undergoes de-chlorination prior to being discharged into a new port.

Owner:DE NORA WATER TECH

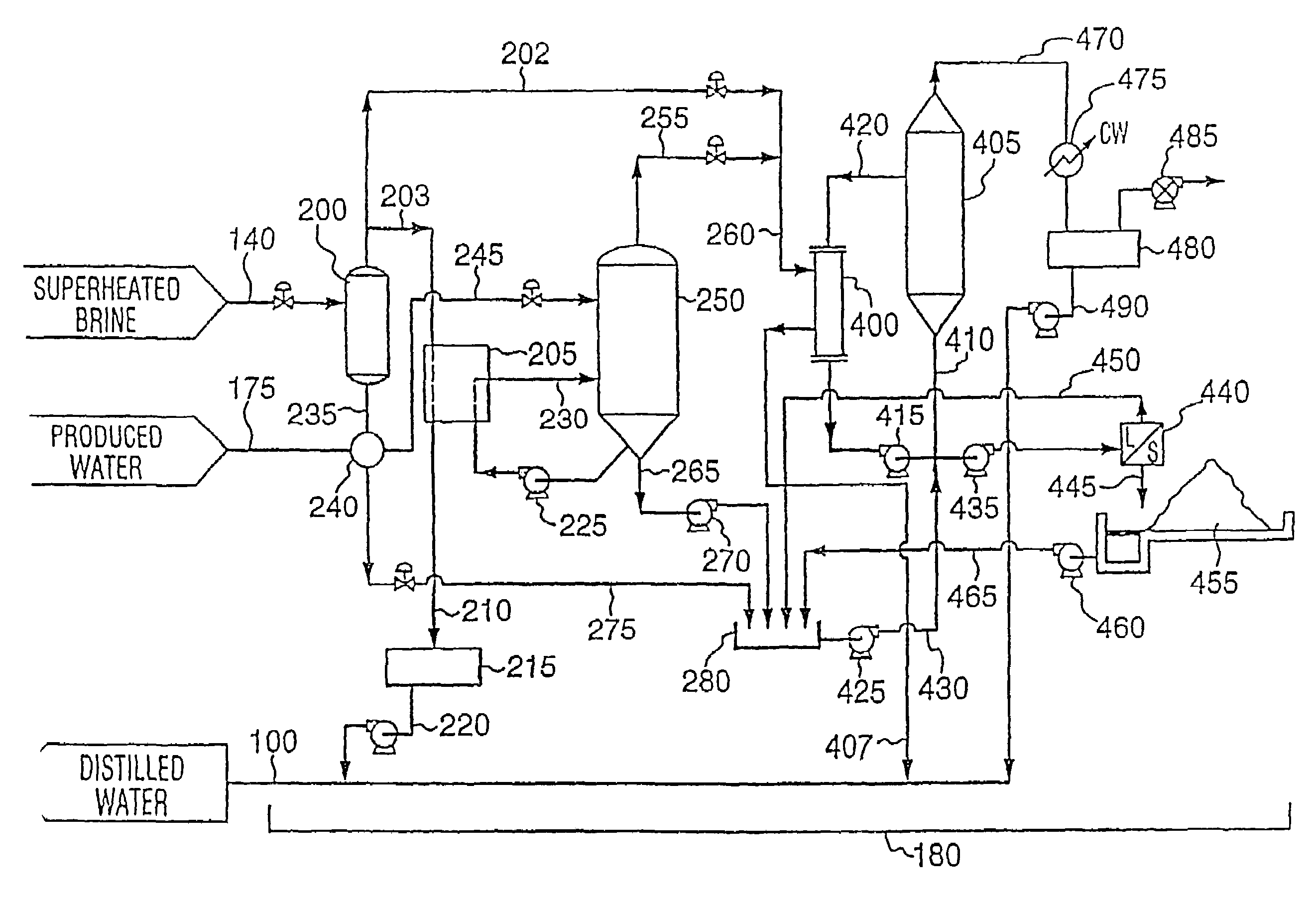

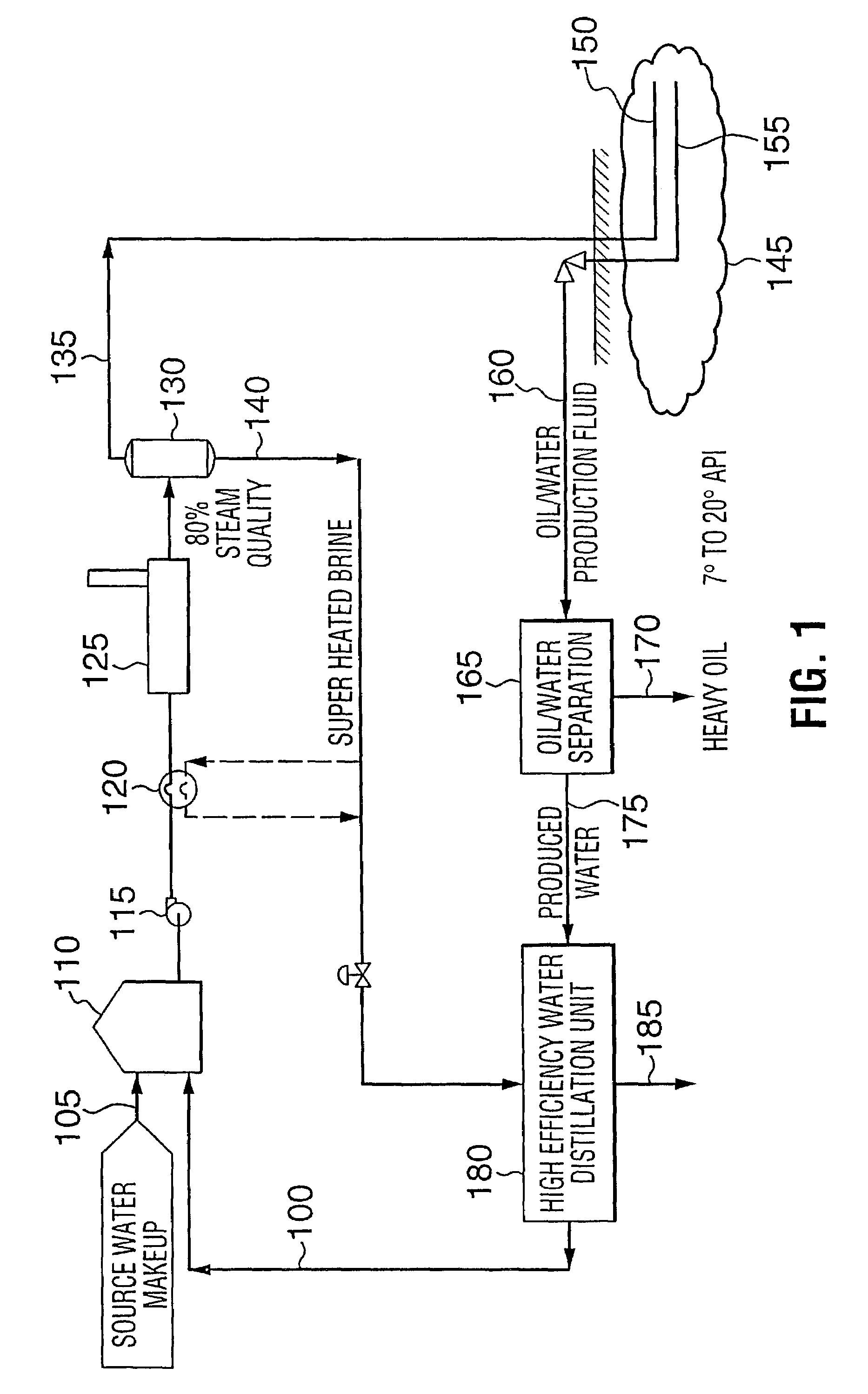

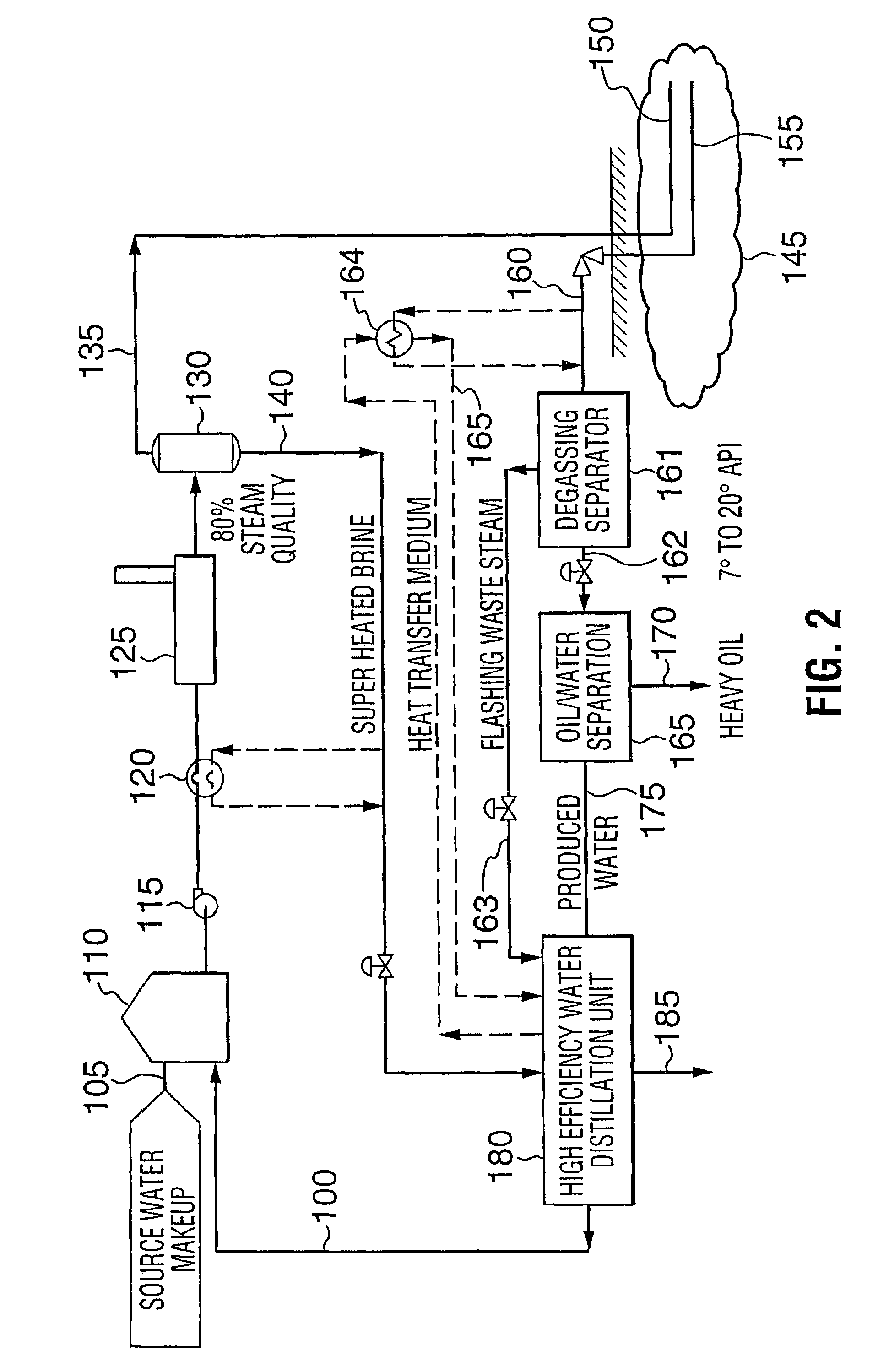

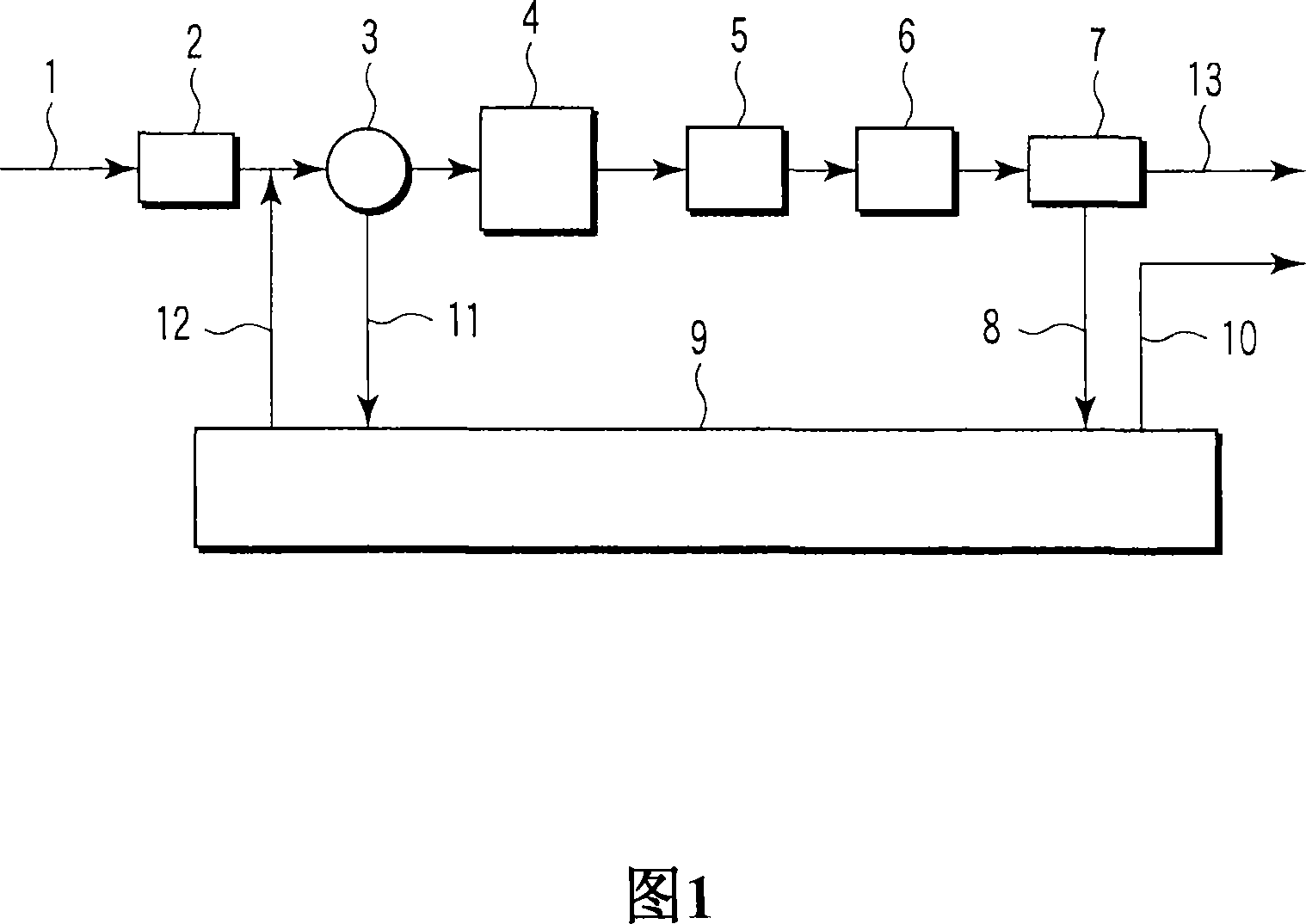

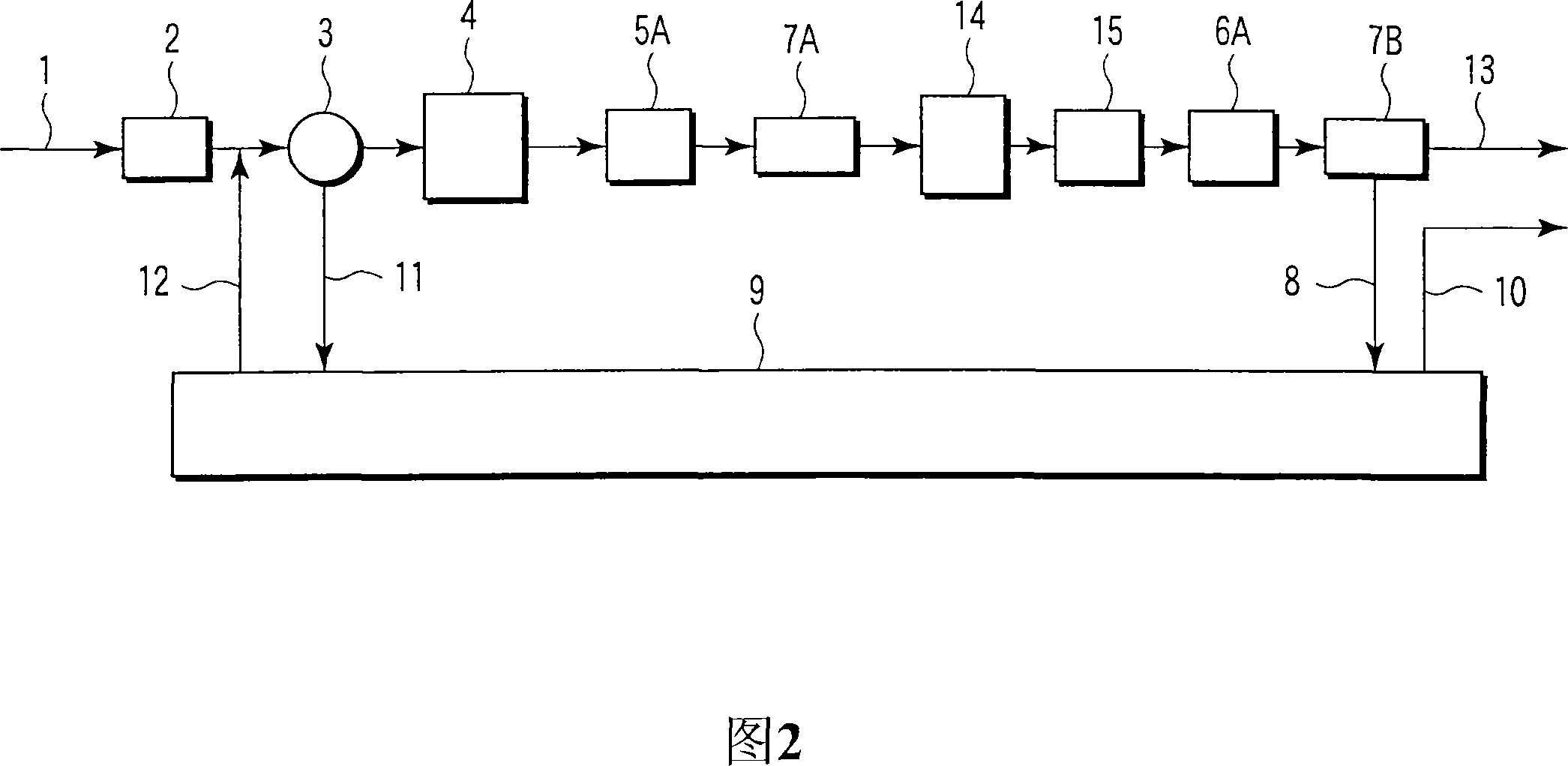

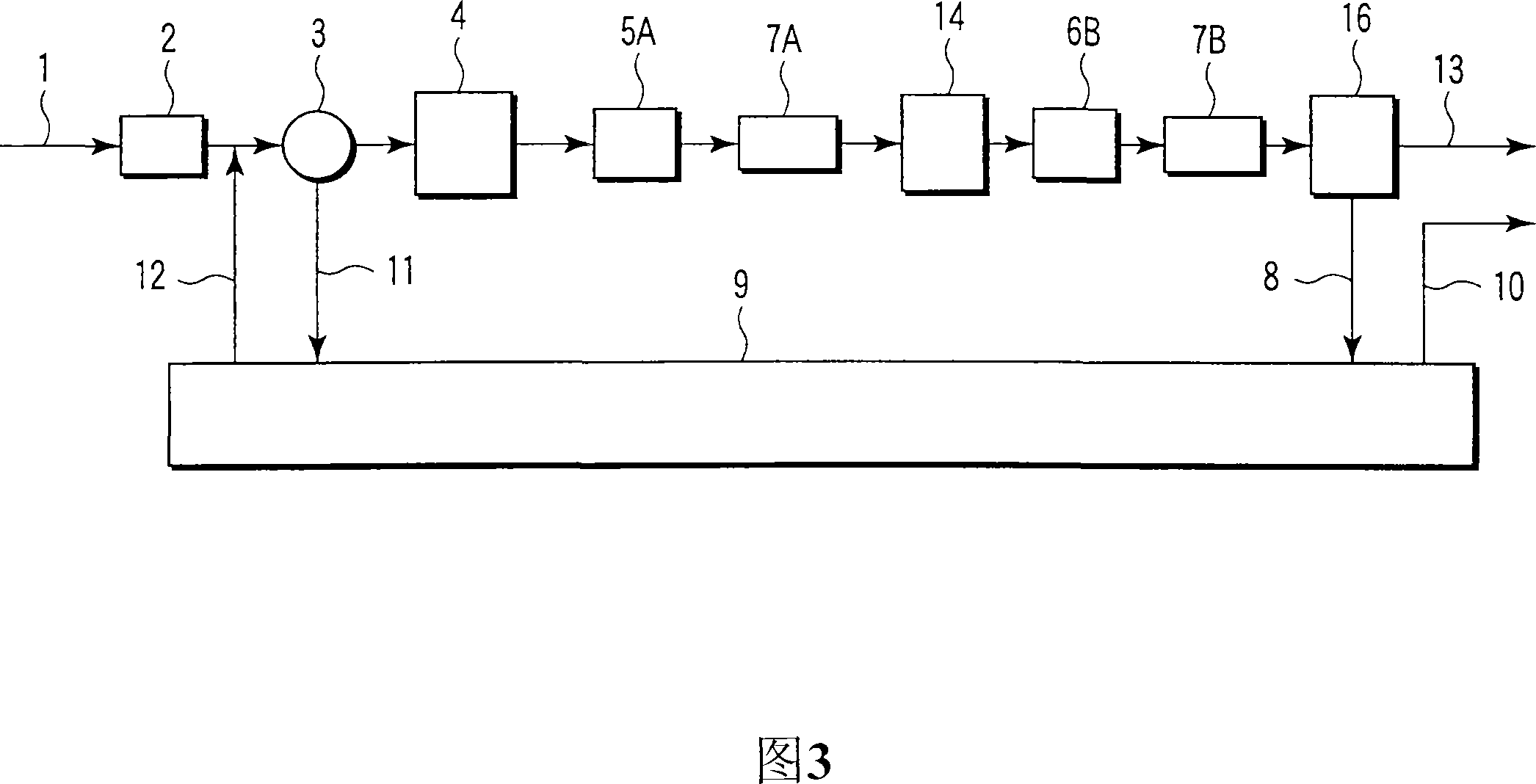

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

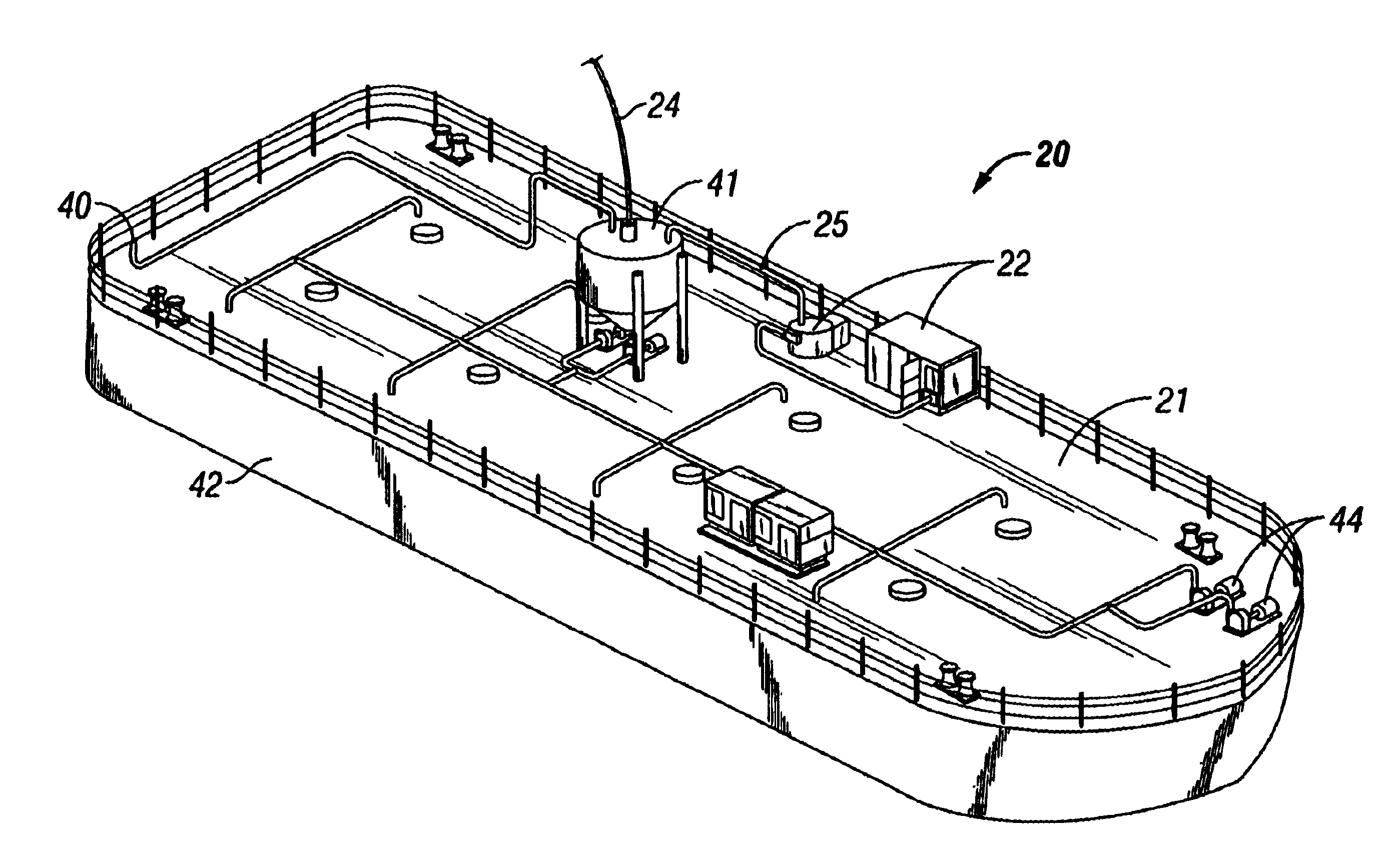

Methods and apparatus for disposing of deleterious materials from a well

InactiveUS6745856B2Save spaceSave equipmentCargo handling apparatusAuxillariesDrill siteHazardous substance

An improved method and apparatus for processing deleterious material on a floating vessel during transportation from a well to a disposal site. The vessel contains equipment for the slurrification and agitation of the deleterious material. Such equipment includes storage tanks, slurrification units, and agitation units, as well as transfer equipment such as flow lines and vacuum or pump means. The deleterious material is transferred from the drill site to the storage tanks on the vessel. The vessel then transports the material to a disposal site, such as an injection well. During transportation, the deleterious material is processed. Such processing can include slurrification and / or agitation of the deleterious material to maintain the slurry, adding fluid if necessary. Once at the disposal site, the deleterious material slurry is then transferred from the vessel to the disposal site.

Owner:MI

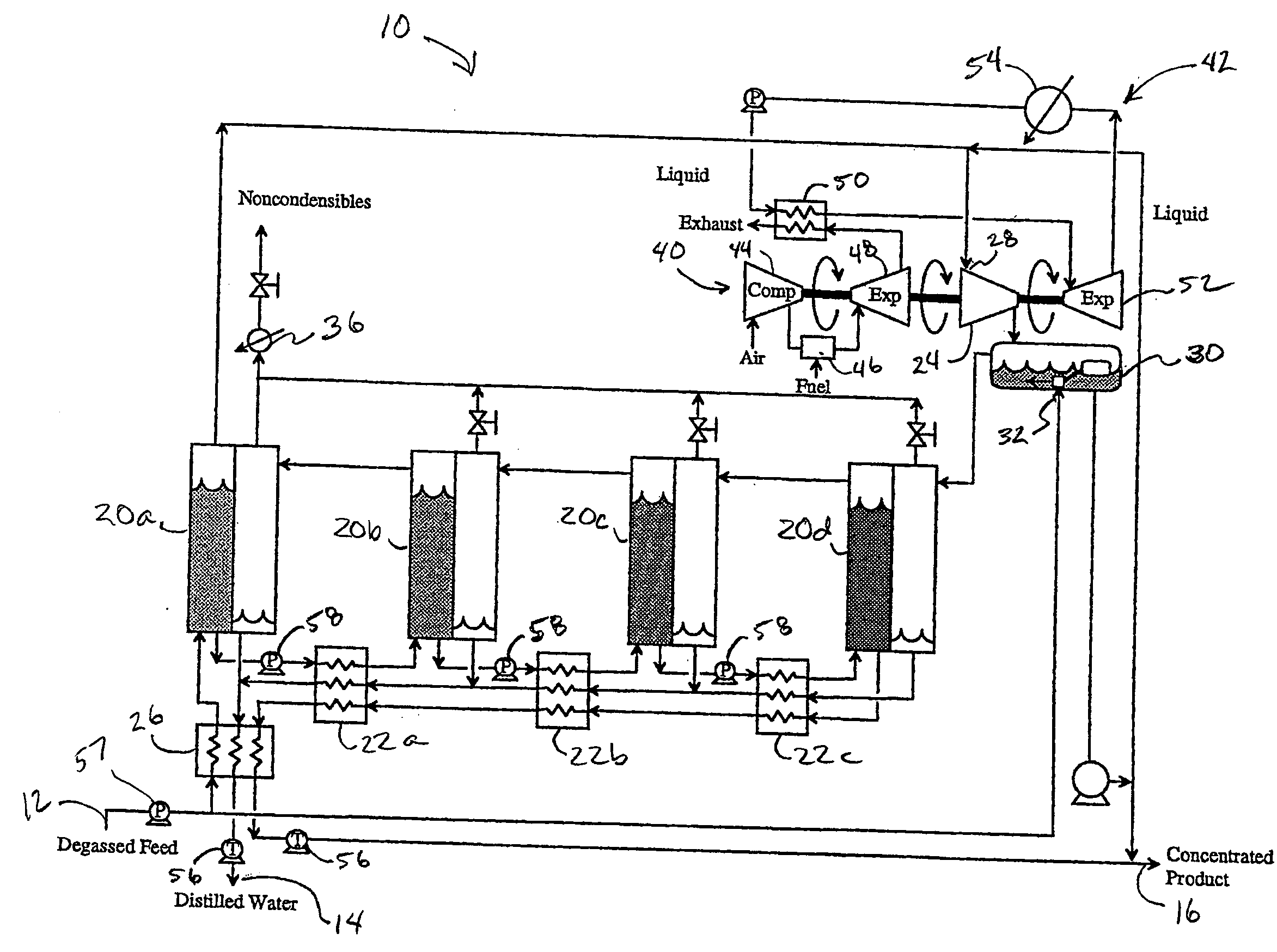

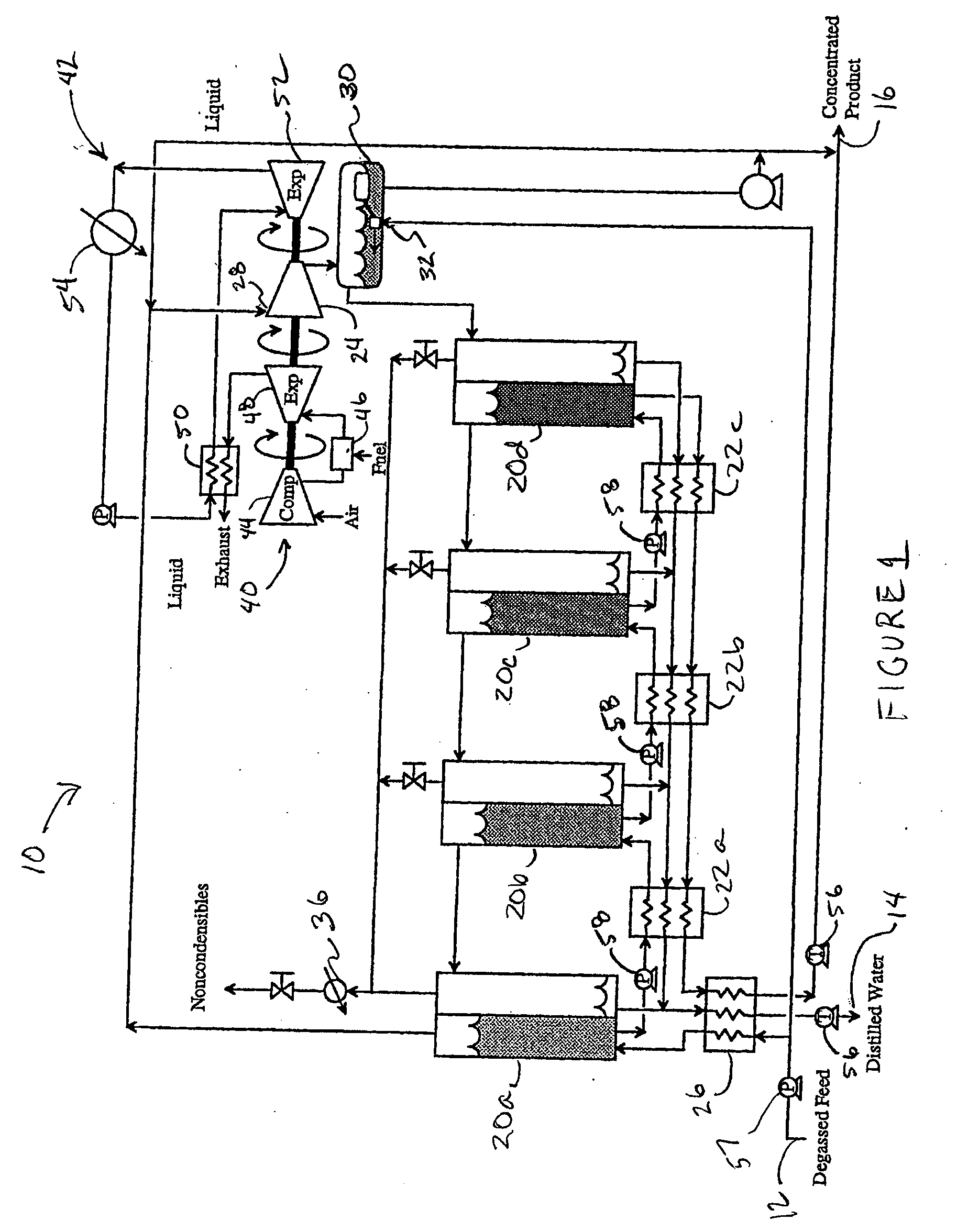

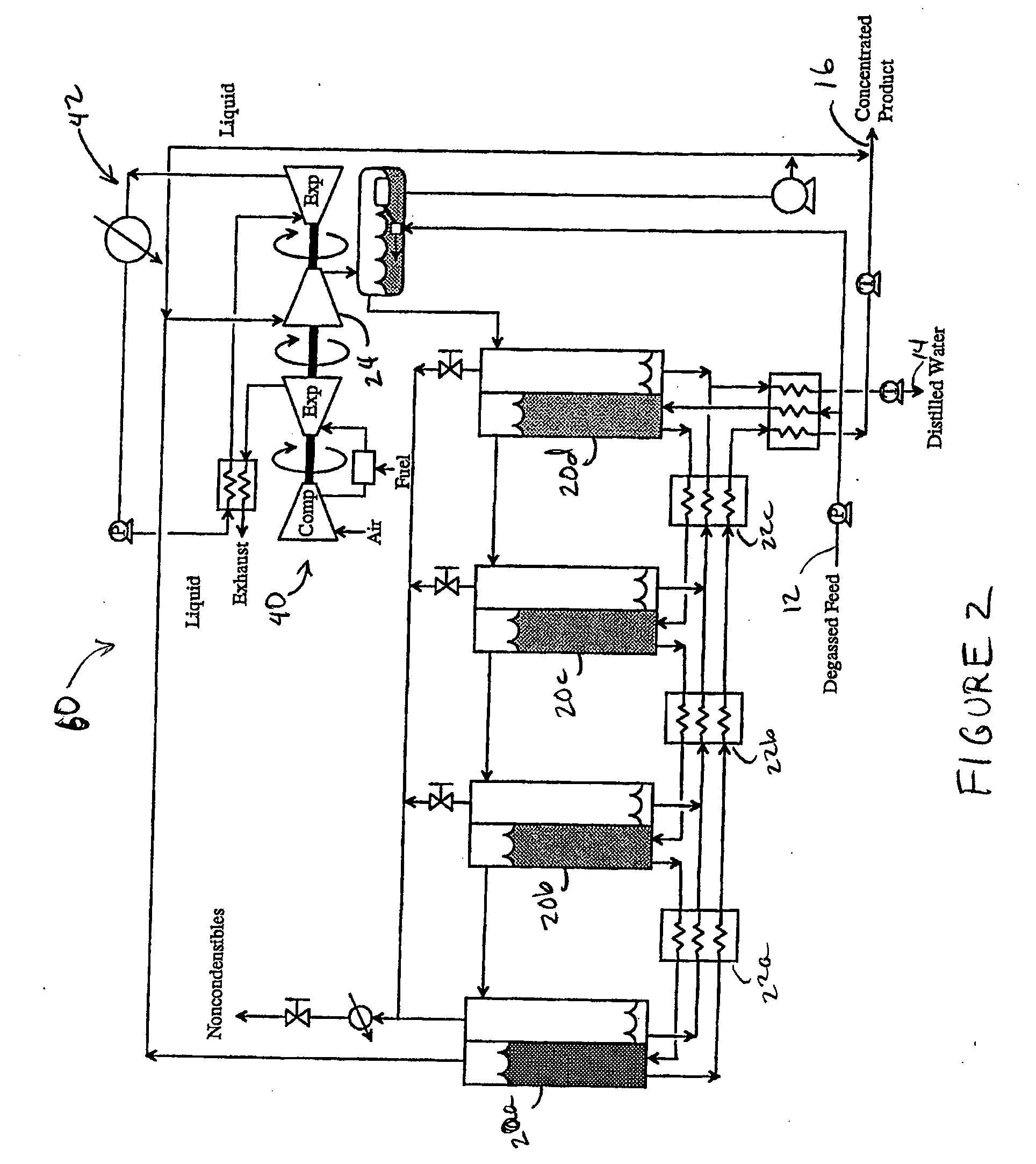

Desalination System

InactiveUS20080083605A1EfficientlyReduce workloadAuxillariesGeneral water supply conservationDesalinationEngineering

In accordance with particular embodiments, a desalination system includes a plurality of evaporators. The plurality of evaporators includes at least a first evaporator and a last evaporator. The plurality of evaporators are arranged in cascading fashion such that a concentration of salt in a brine solution increases as the brine solution passes through the plurality of evaporators from the first evaporator towards the last evaporator. The desalination system also includes a plurality of heat exchangers. An input of each evaporator is coupled to at least one of the plurality of heat exchangers. The system also includes a vapor source coupled to at least one of the plurality of evaporators.

Owner:TERRABON ADVE +1

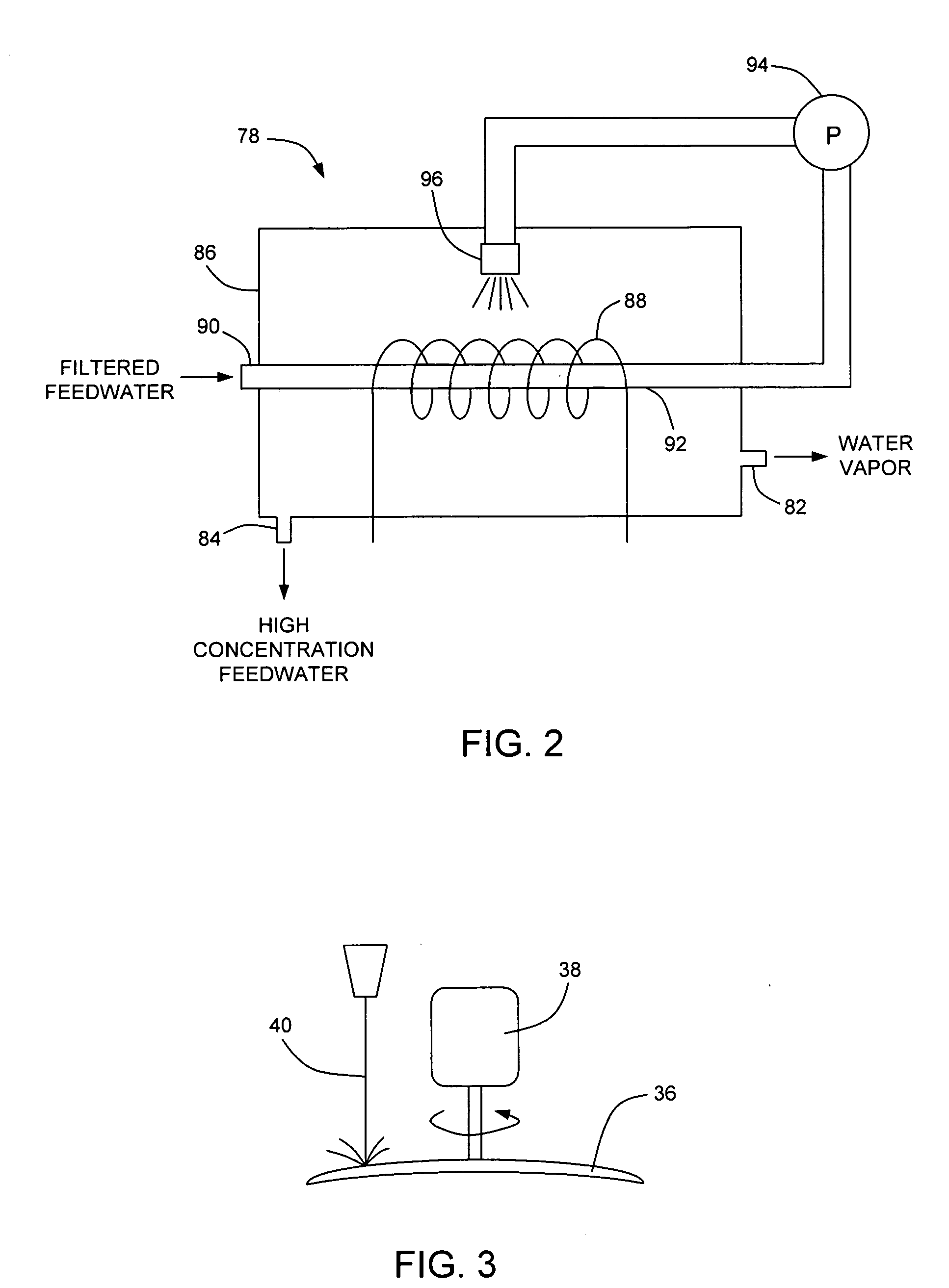

Salt water distillation system

The salt water distillation system includes a sprinkler to form a mist of salt water over a distillation plate. The distillation plate is heated by applying electrical current to a heating coil. The steam is transferred to a condensation chamber and condensed fresh water is collected. During the desalination process, salt impurities are deposited on the hot distillation plate. A sludge remover, i.e., a steam head and movable ram, is provided to clean the distillation plate of the salt impurities. An exhaust fan is provided to cool fresh water condensate and lower air pressure in the system. Heat transferred from the steam during condensation is used to pre-heat the salt water to increase efficiency of the system.

Owner:RIVES MICHAEL L +1

Bilge water reclamation system and process

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

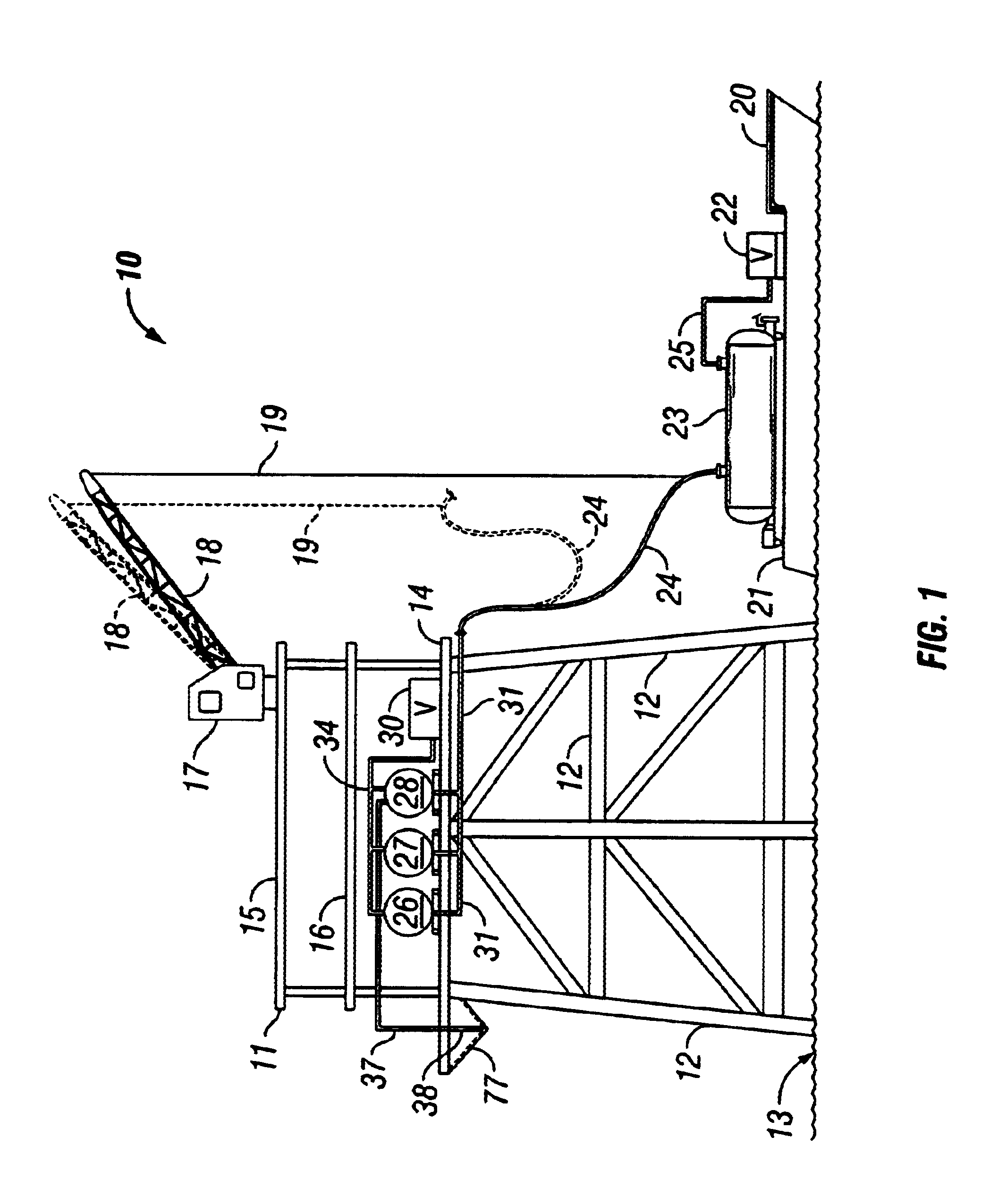

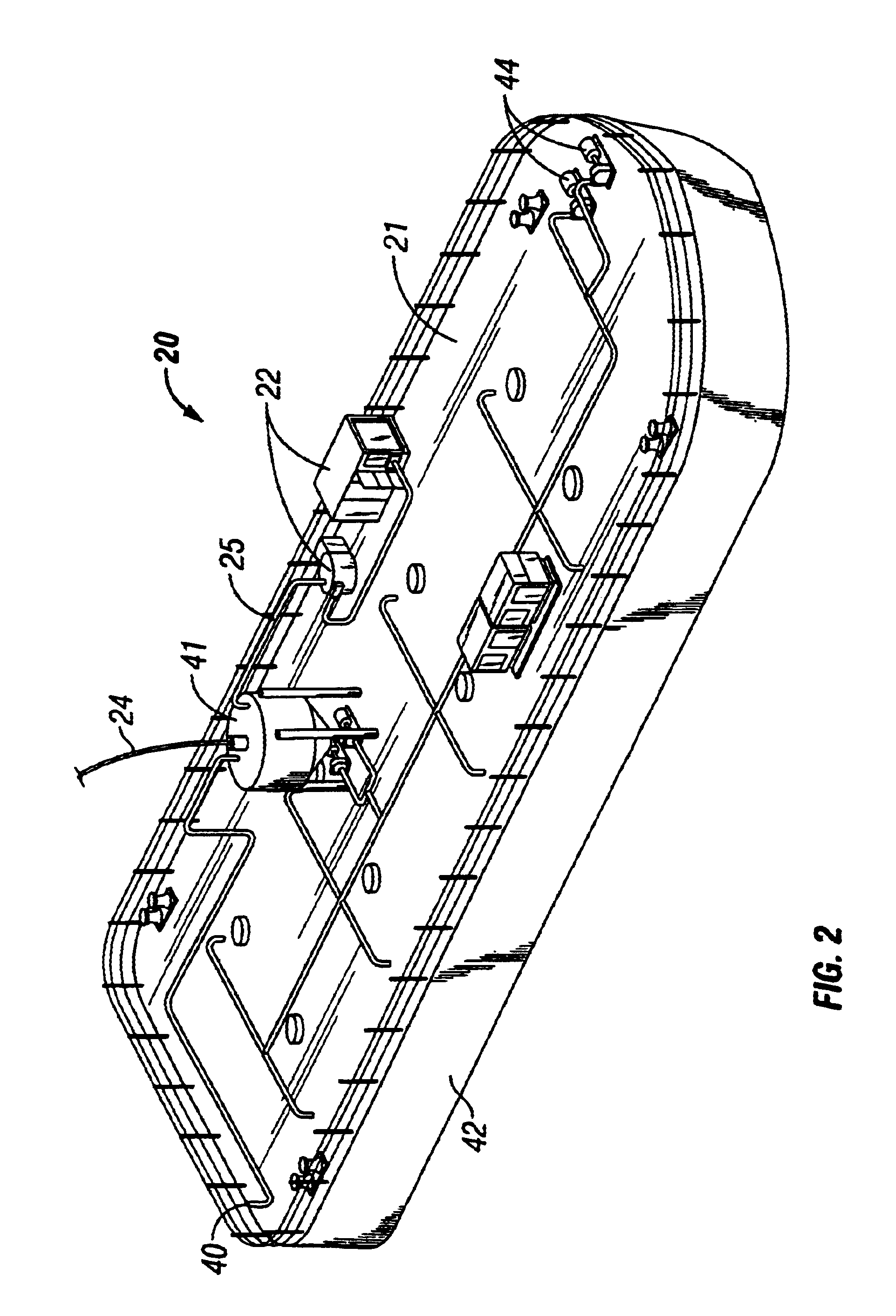

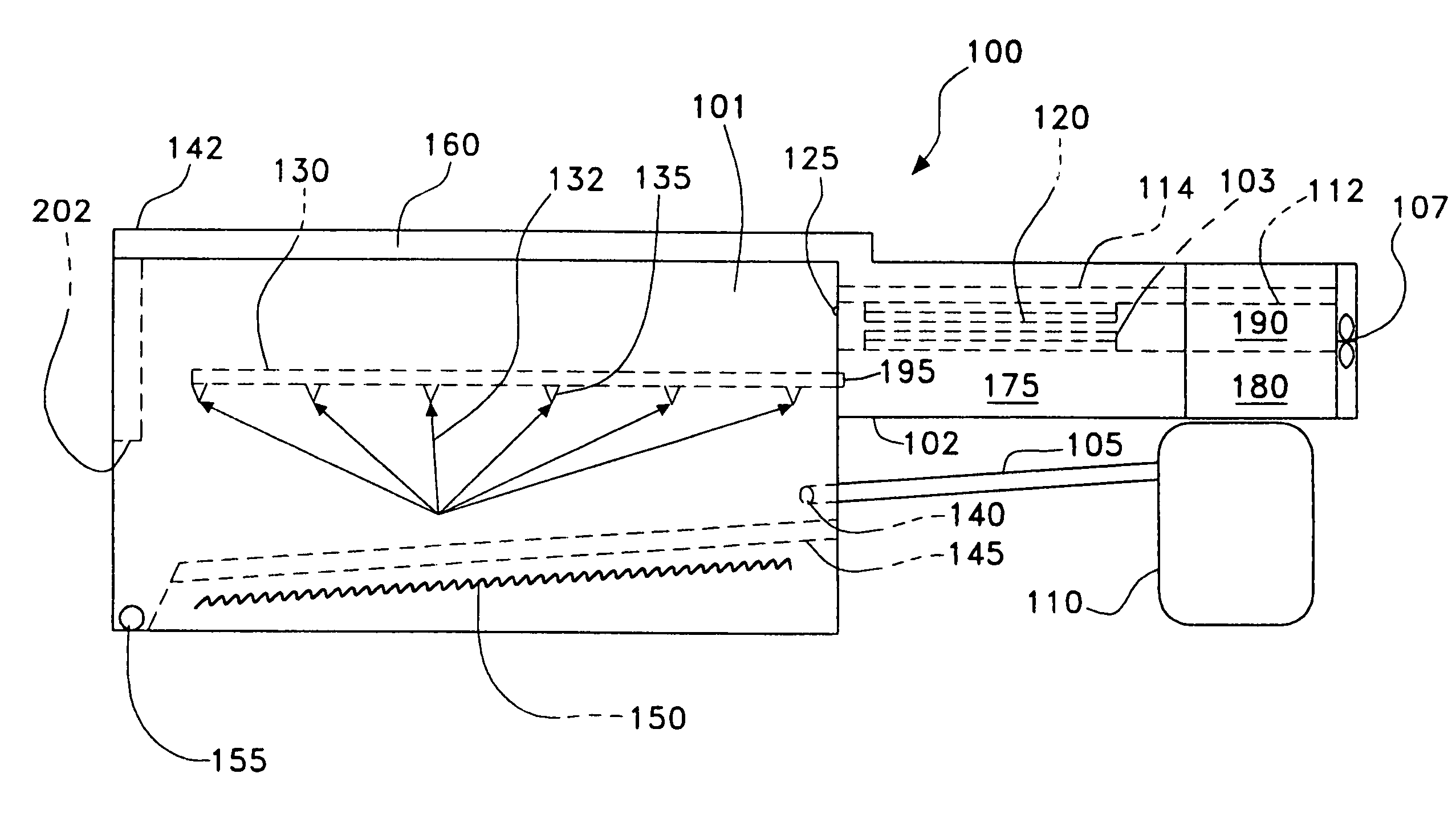

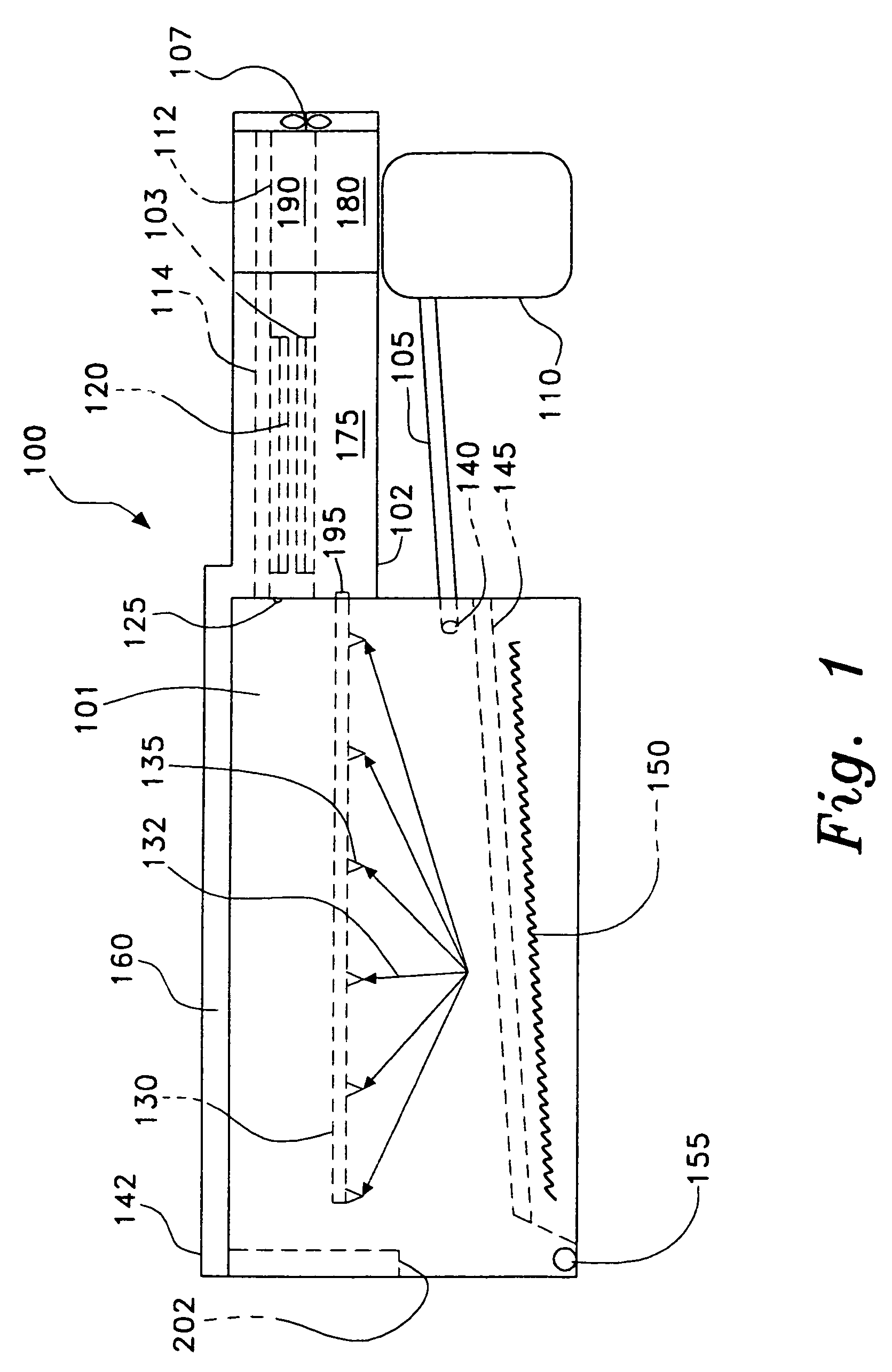

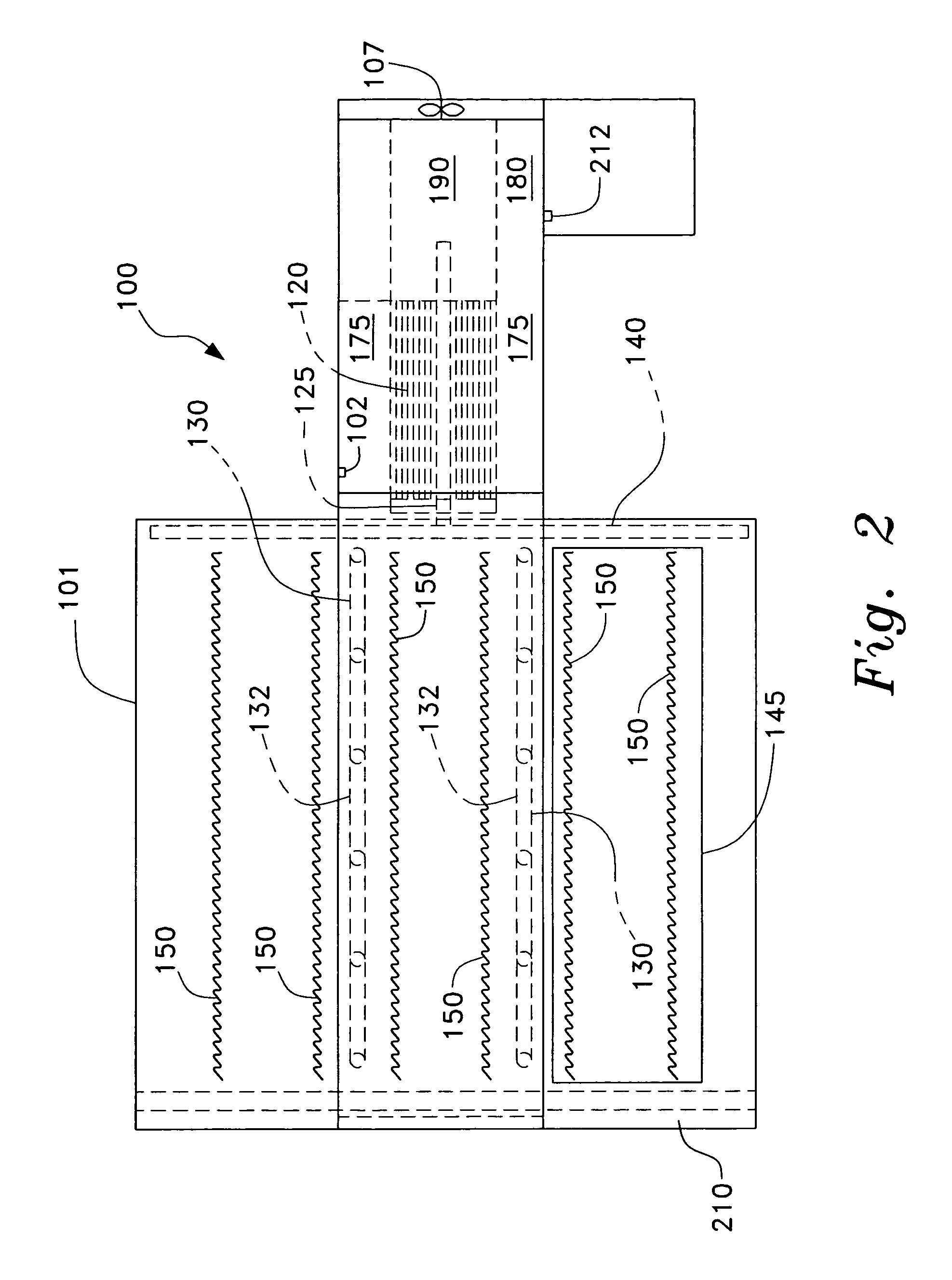

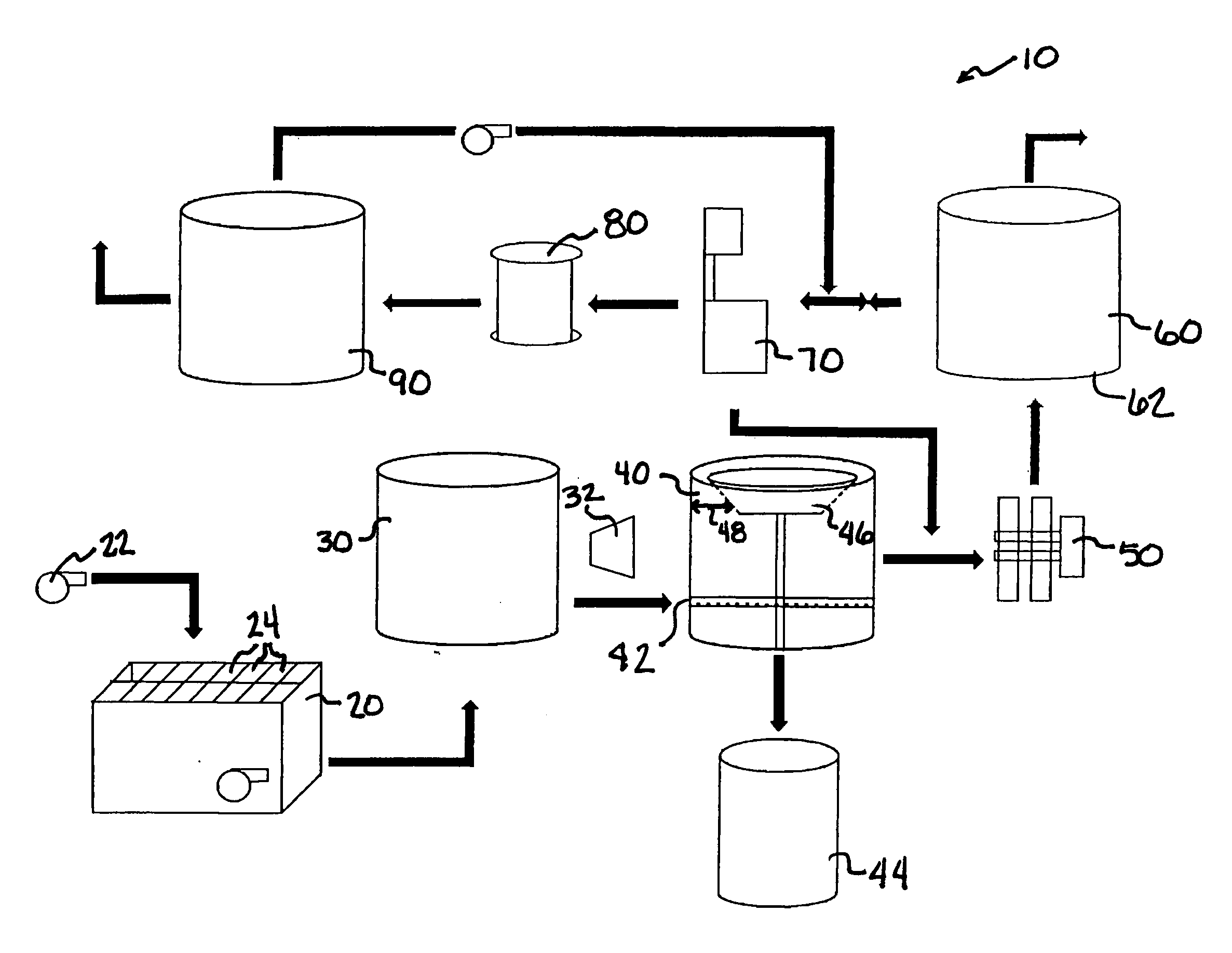

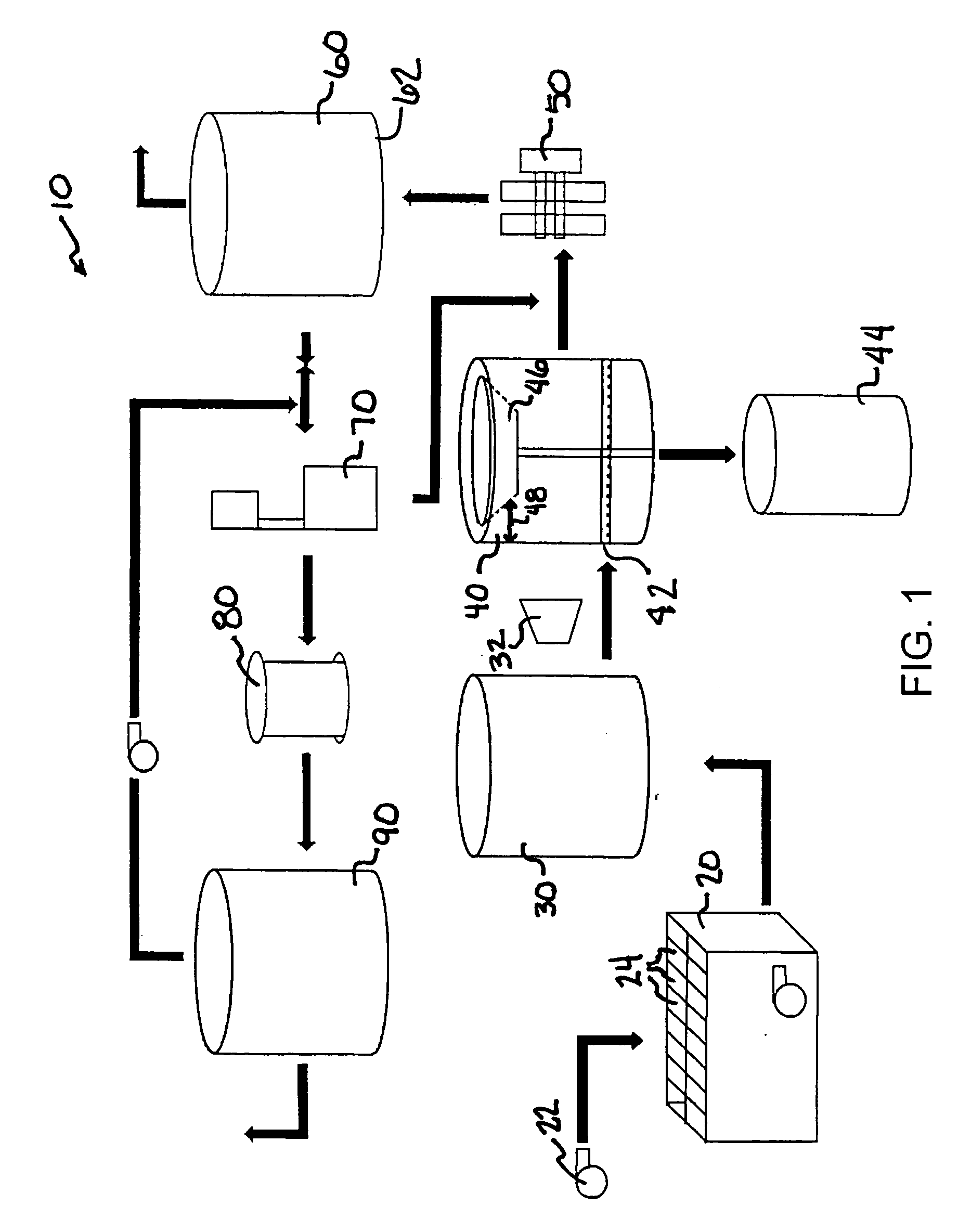

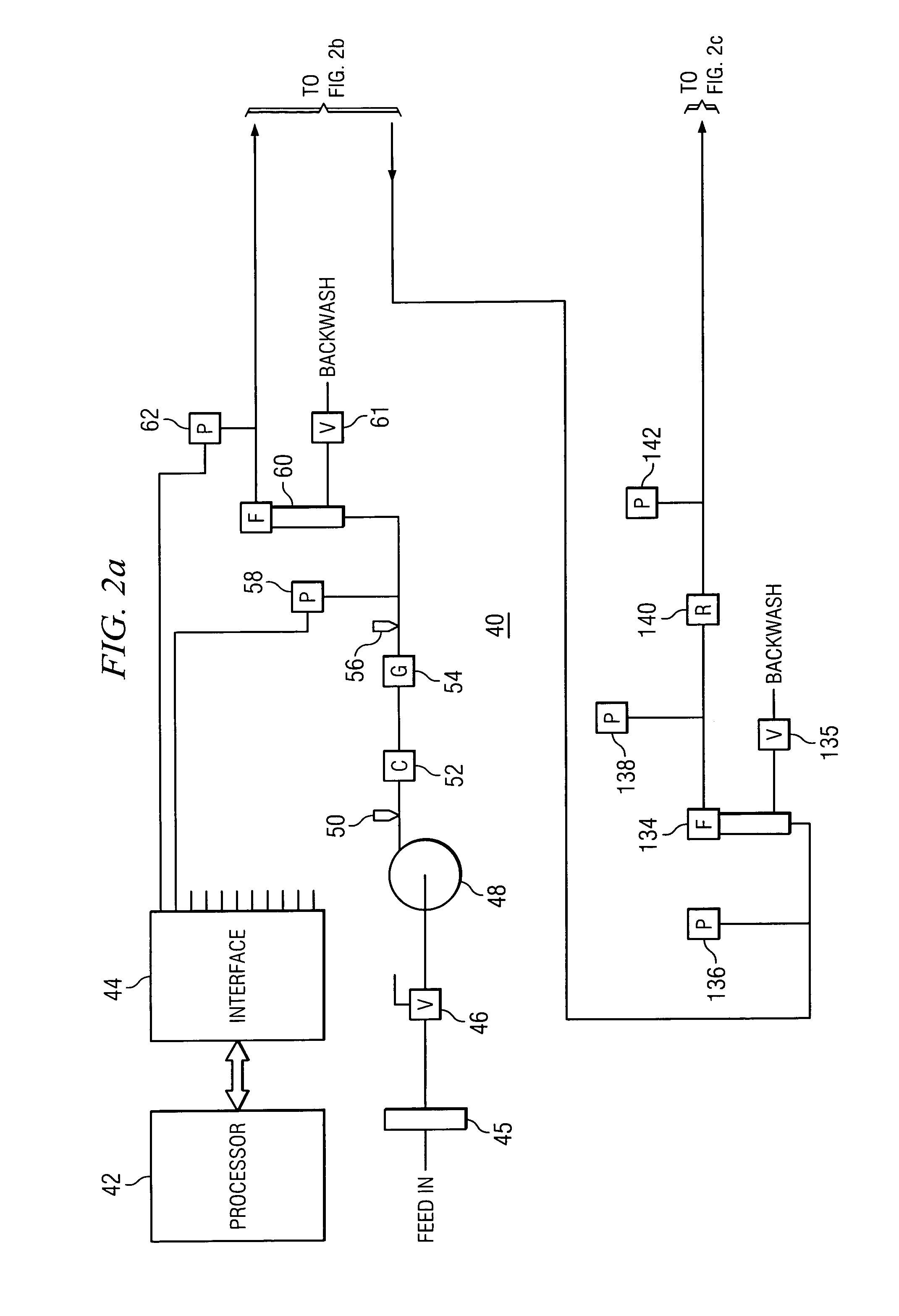

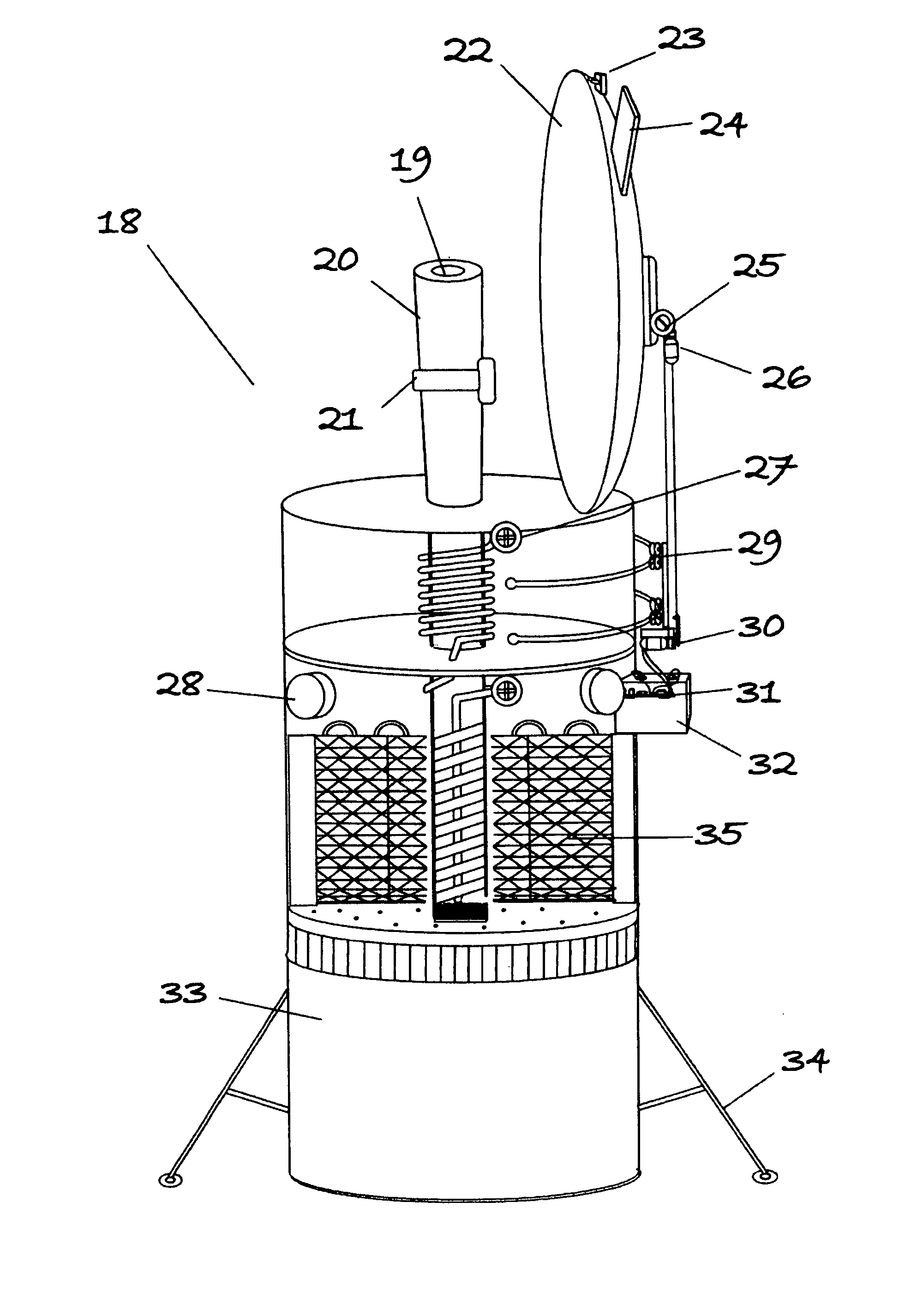

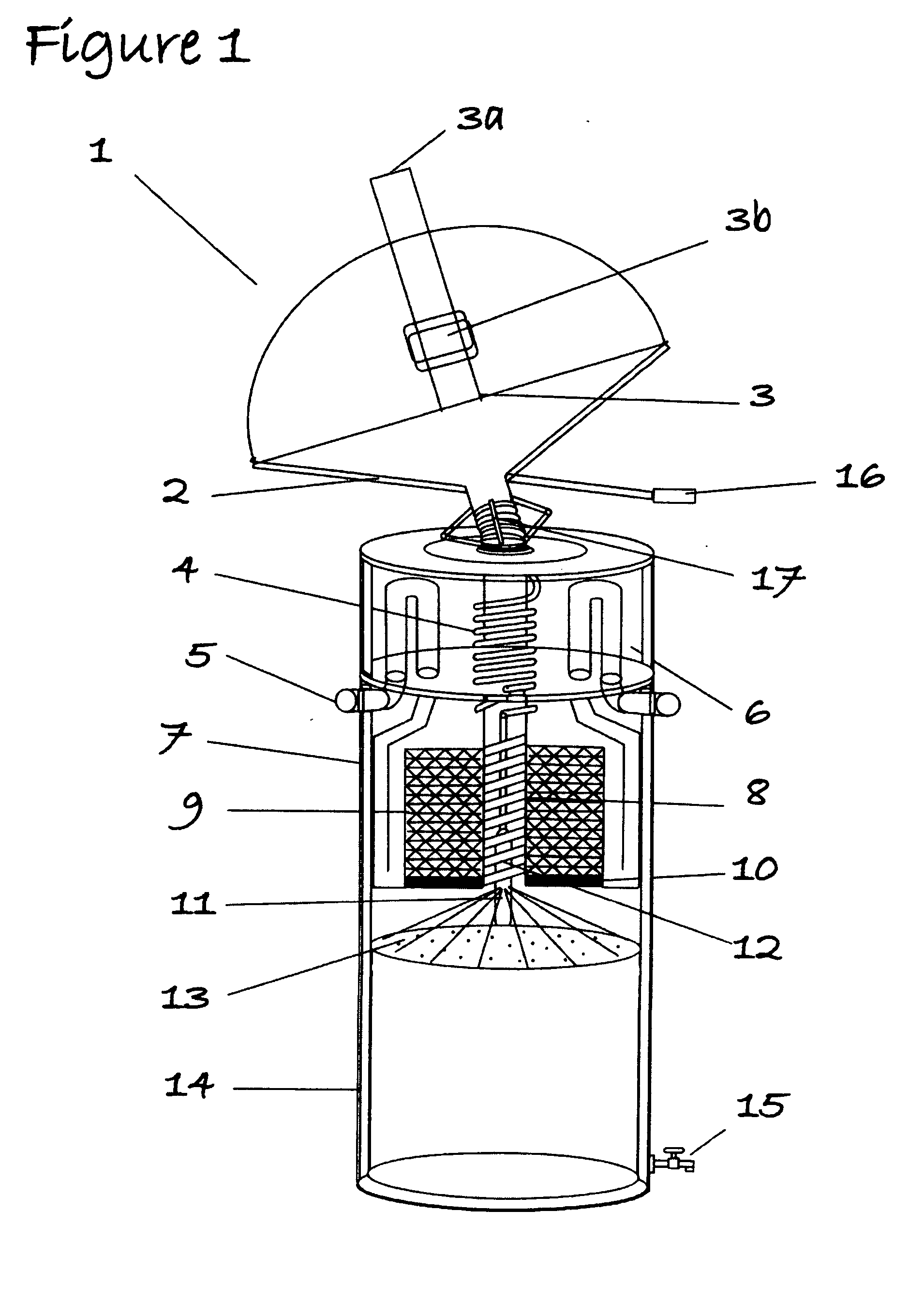

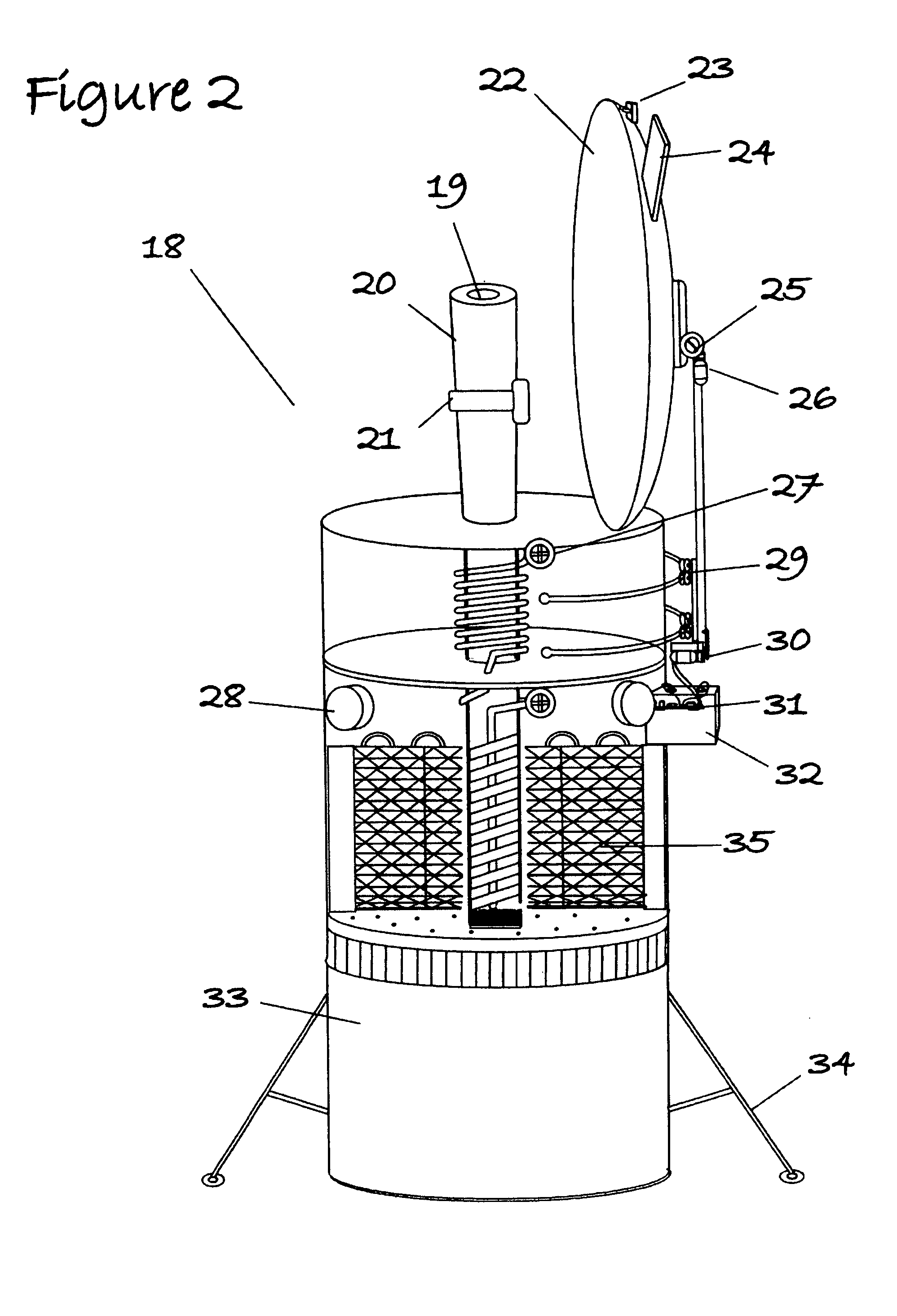

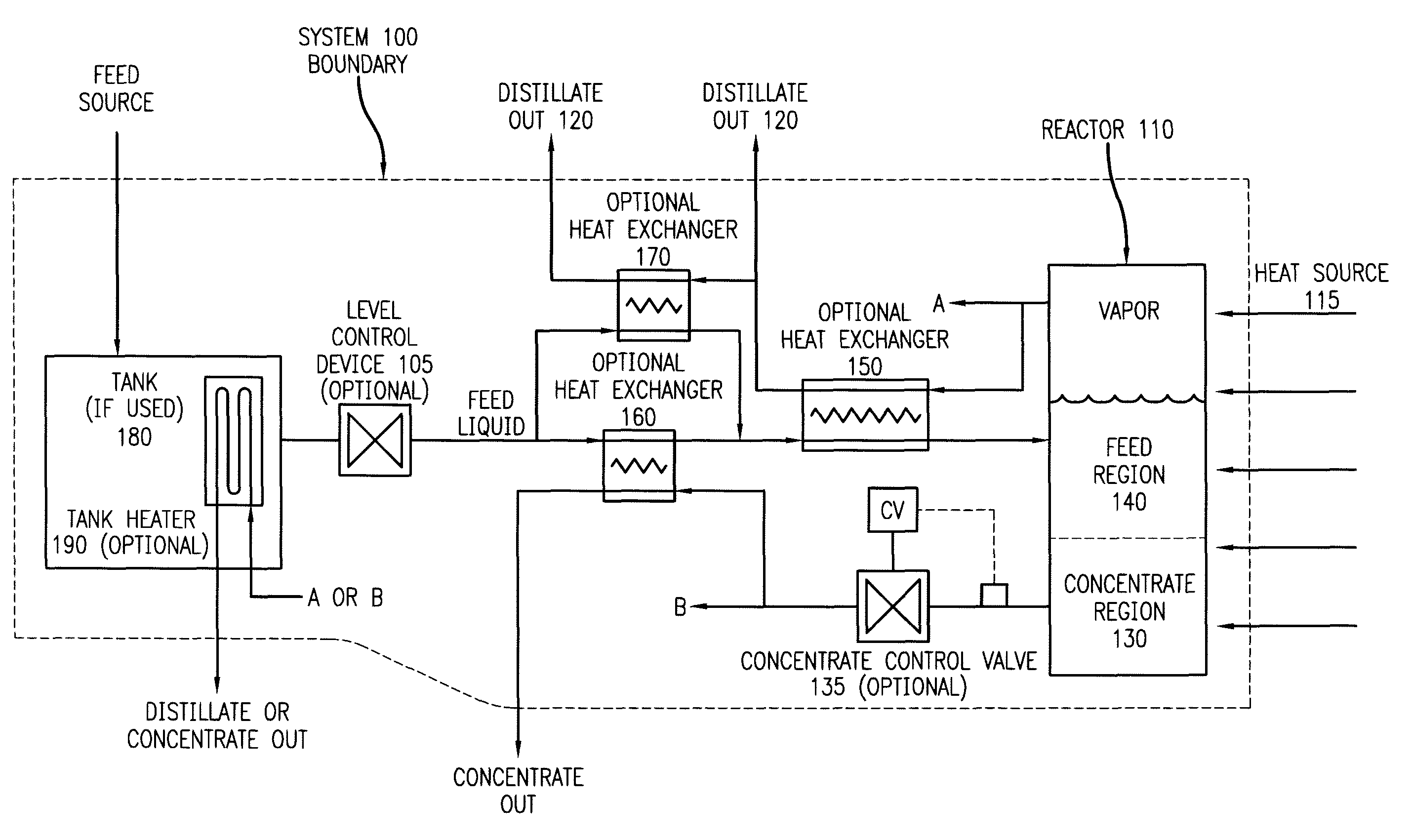

Method and apparatus for purifying water

ActiveUS8097128B1Improve efficiencyImprove throughputLiquid degasificationAuxillariesThermal energyInternal combustion engine

An efficient flash evaporation water purification system located at a hydrocarbon well site. An internal combustion engine uses hydrocarbon fuel from the well and drives a pump to pressurize production water from the well. The engine also generates thermal energy used to preheat the production water. An electrical generator is also driven by the engine to produce electrical power for the water purification system, as well as produce AC power for off-site consumers.

Owner:SHERRY RAYMOND C

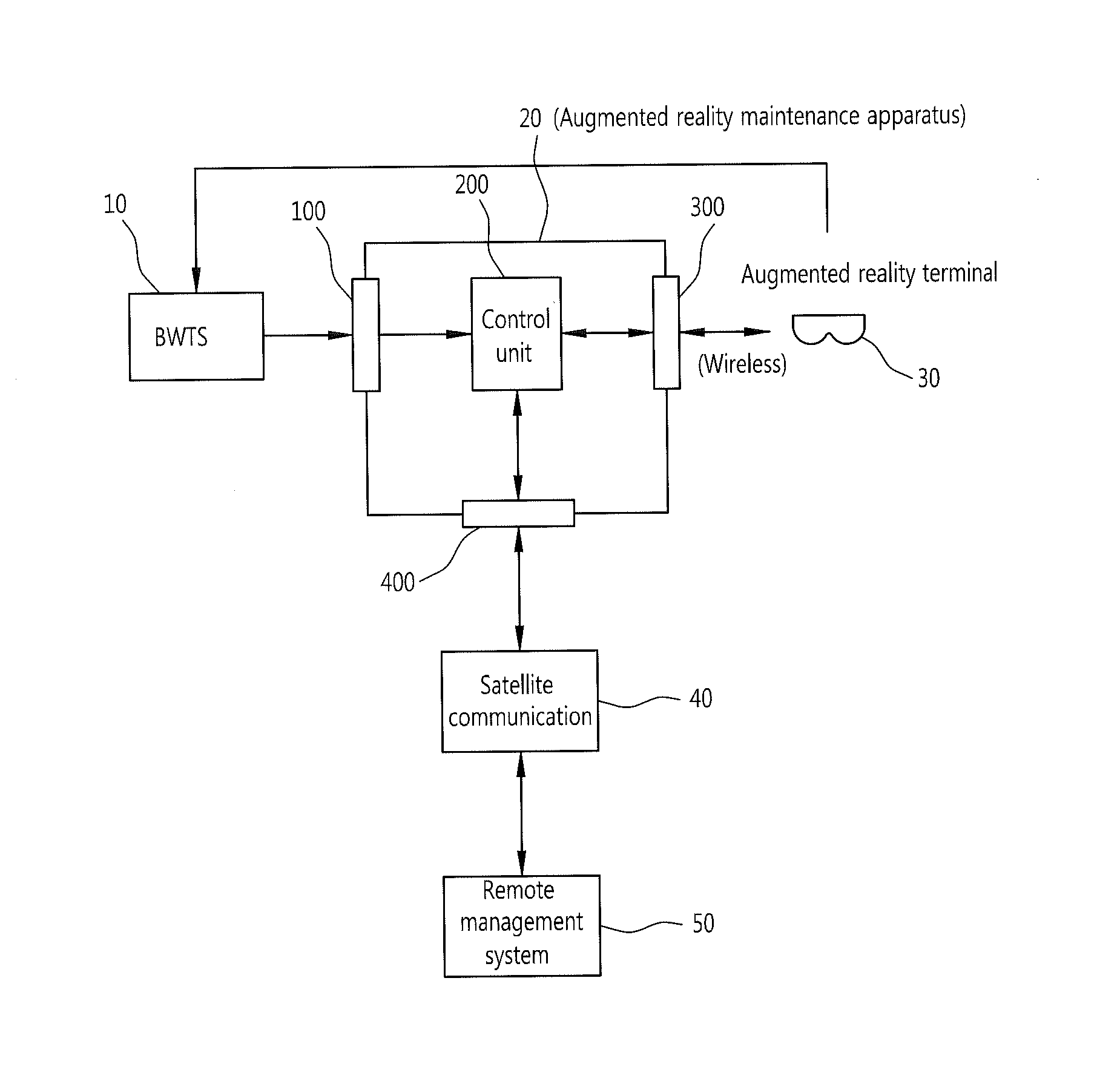

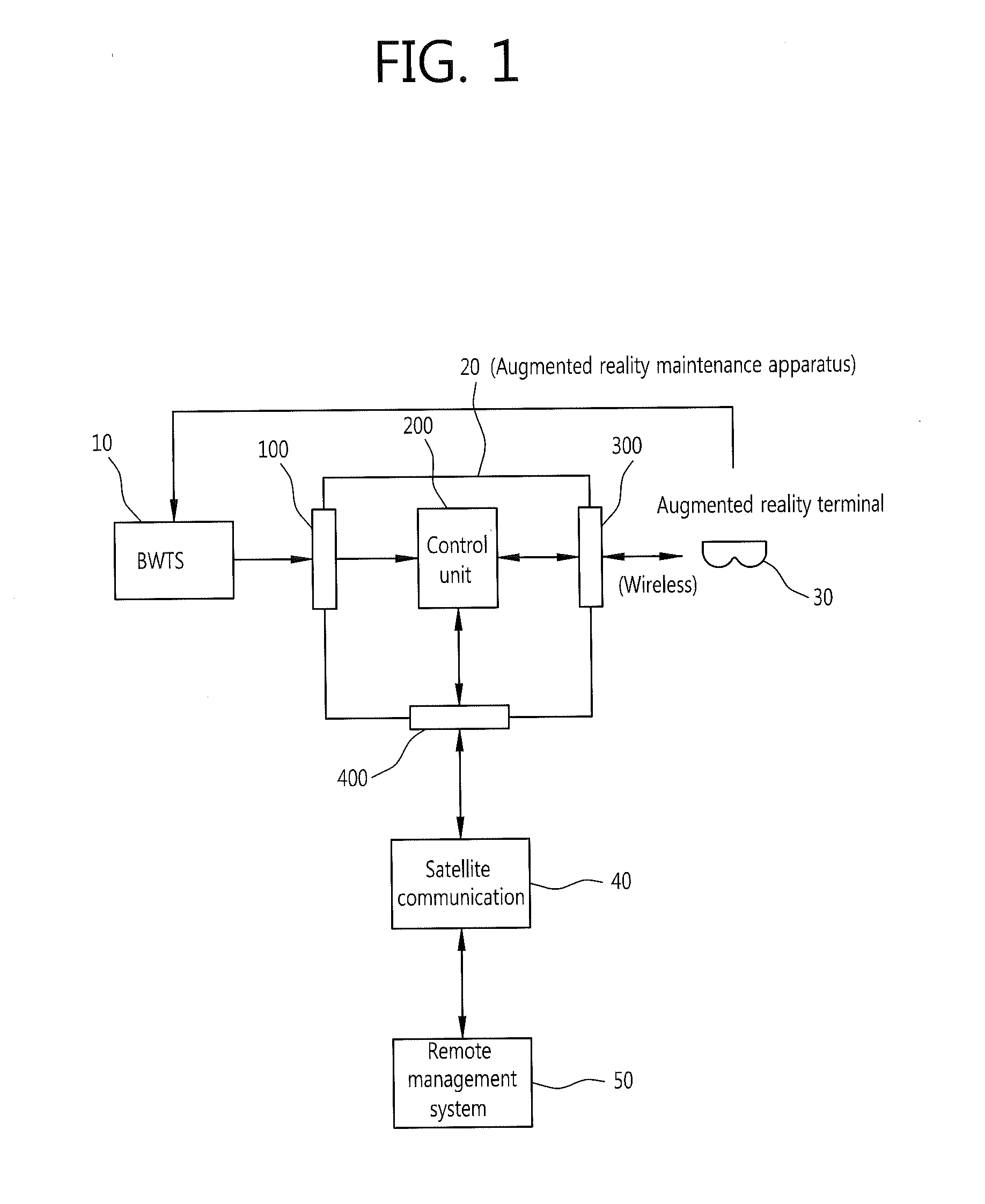

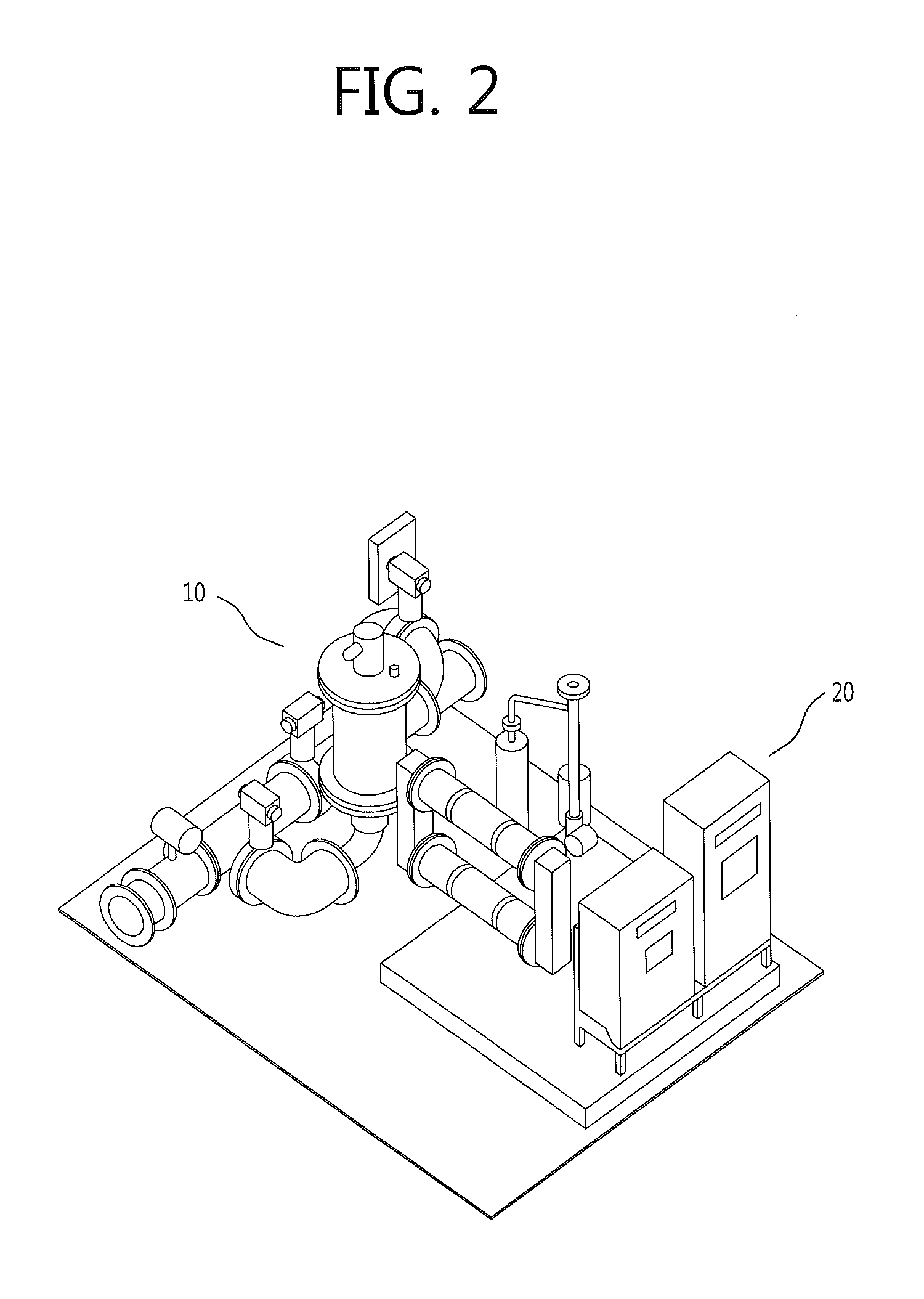

Remote managed ballast water treatment system using augmented reality

ActiveUS20160176724A1Reduce maintenanceReducing failure repair costProgramme controlWater treatment parameter controlBallast water treatmentEngineering

The present invention relates to a remote managed ballast water treatment system using augmented reality, in particular, a ballast water treatment system (hereinafter, referred to as “BWTS”) which receives operation and failure information from various sensors installed in each component within a device, the remote managed ballast water treatment system comprising: an augmented reality terminal having a software application installed therein, which can recognize each component of the BWTS through shape information in a shot image while shooting a real-time image and provides information on a state of the BWTS and information required for the BWTS (provides augmented reality information), through a computer graphic image, in addition to a real-time image of reality; an augmented reality maintenance apparatus for the BWTS, the apparatus comprising a BWTS interface, an augmented reality interface, a satellite communication interface, and a control unit; and a remote management system of a terrestrial base station which shares sensing information of the BWTS and real-time image information of the augmented reality terminal with satellite communication through the satellite communication interface, wherein, when BWTS maintenance information has been sent from the remote management system of the terrestrial base station during a BWTS failure, the control unit outputs a failure point and repair information as augmented reality image information to the augmented reality terminal, a failure treatment method is guided to a user as a real-time augmented reality image, and the terrestrial base station supervises a failure treatment process of the BWTS through a real-time image.

Owner:HANLA IMS CO LTD

Atmospheric water collection device

InactiveUS20050103615A1Simple economicalPractical and convenientSolar heating energyAuxillariesAtmospheric airEngineering

The present invention is directed at a solar powered heat exchange system preferably used to drive a water collection device, which condenses water vapour in atmospheric air to water. The device comprises means for drawing the atmospheric air into the device; means for condensing the moisture vapour in the atmospheric air into water; and means for collecting the water.

Owner:FREEDOM WATER CO LTD

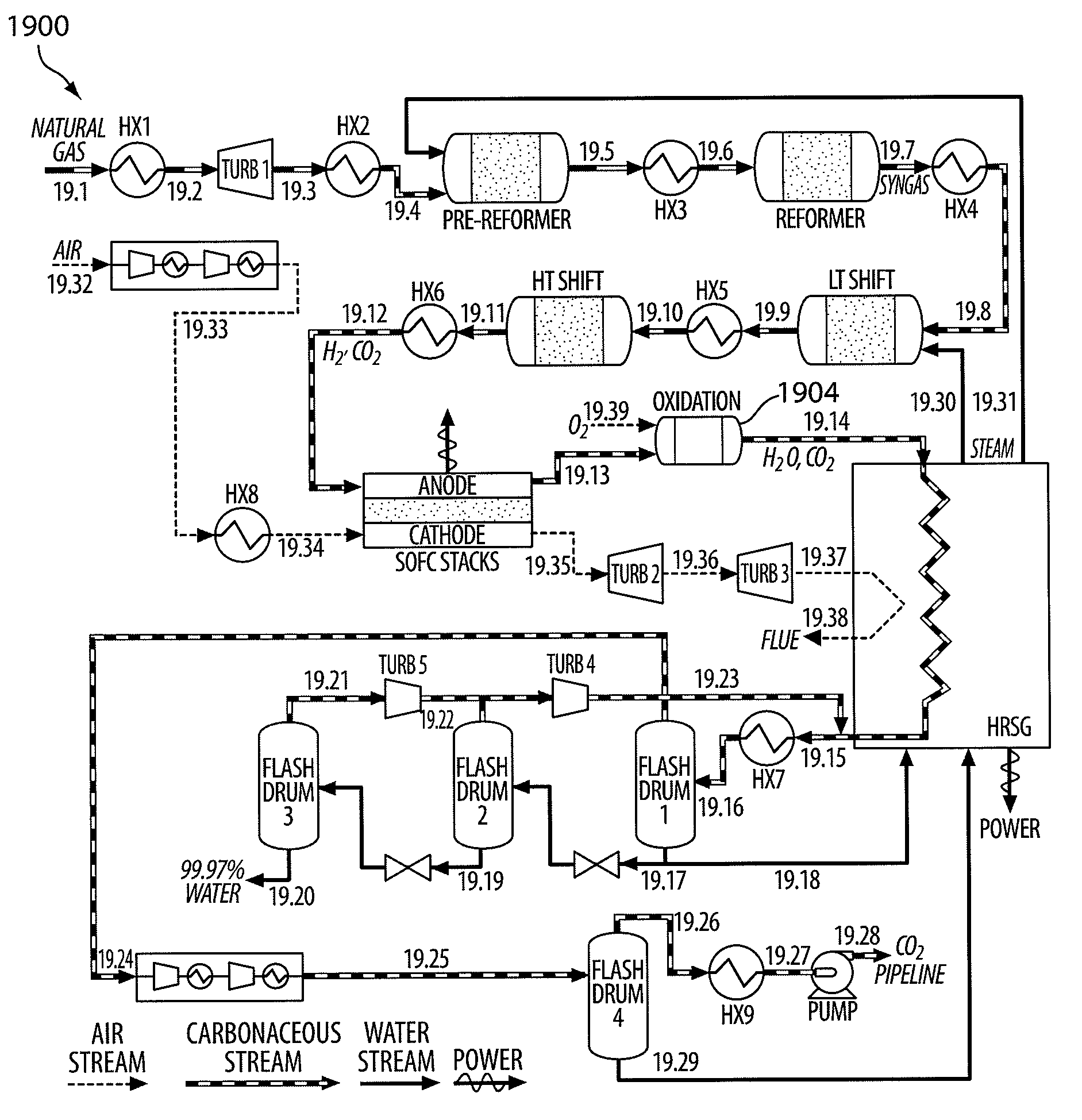

Systems and methods for the separation of carbon dioxide and water

Systems and methods for the separation and capture of carbon dioxide from water are generally described. In some embodiments, a vapor stream containing carbon dioxide and water is separated using a cascade of at least two flash drums. Additional flash steps may be incorporated to remove atmospheric gases, such as nitrogen and argon, from the feed. Carbon dioxide may be condensed and pressurized at purities suitable for pipeline transport and eventual storage in geological formations. In addition, water may be recovered at high purity.In some embodiments, fuel cells may be used in combination with fuel reforming or gasification to produce syngas. Certain aspects of the invention involve innovations related to the combined reforming and fuel cell process, that, in certain embodiments, do not depend upon water and carbon dioxide separation. It should be understood, however, that the invention is not limited to the applications described above, and may be used with any suitable system in which the separation of carbon dioxide and water is desired.

Owner:MASSACHUSETTS INST OF TECH

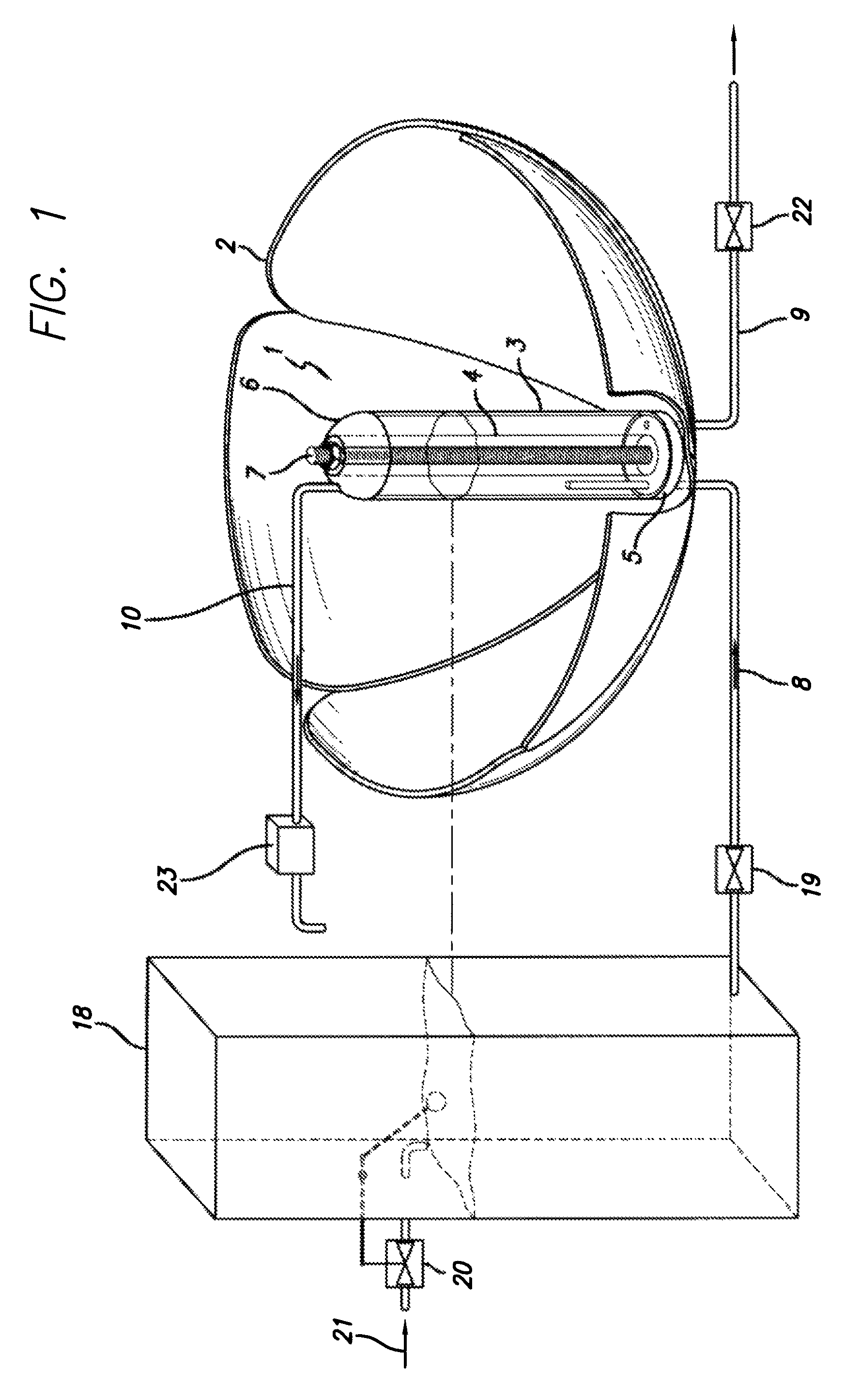

Solar distillation device

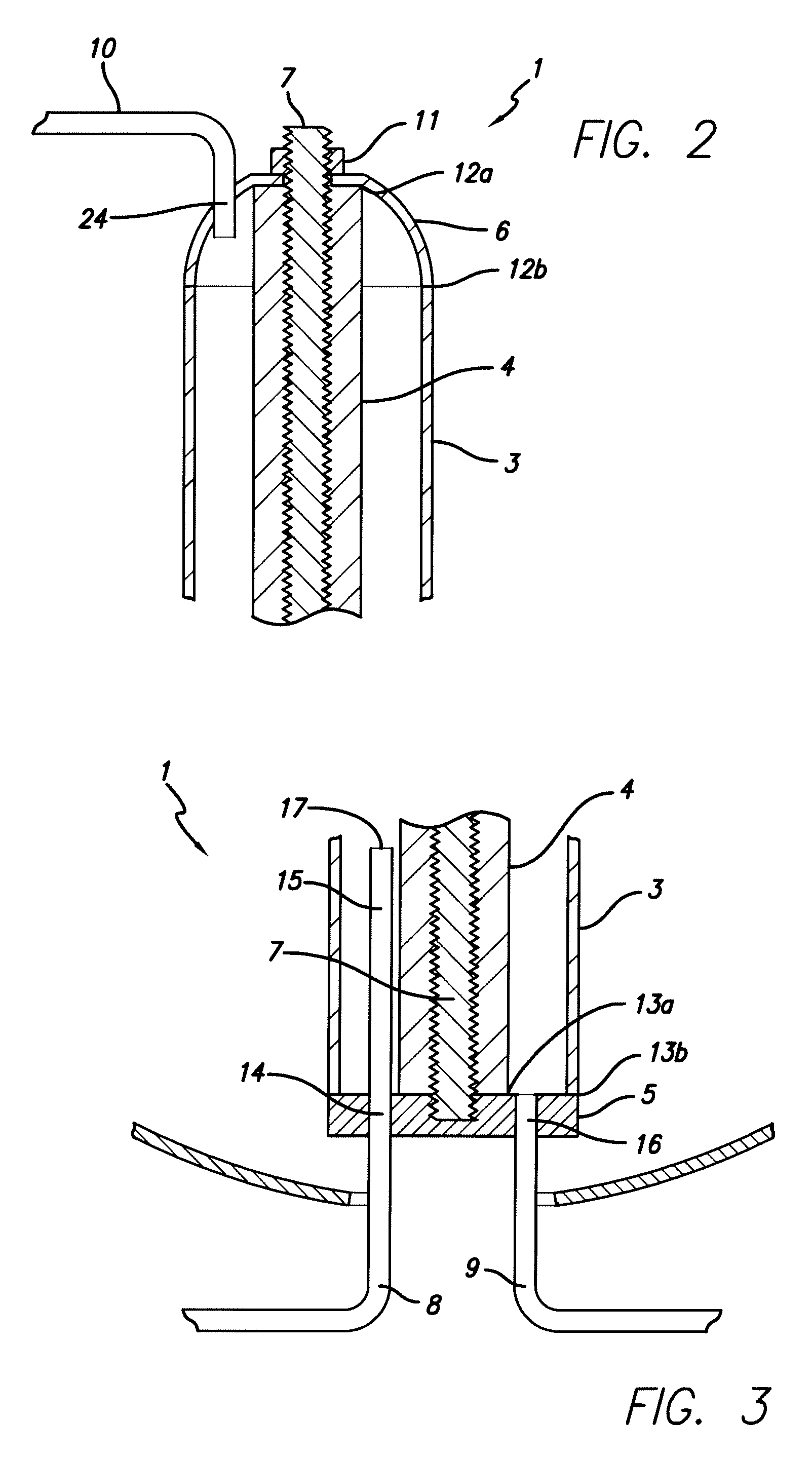

A solar distillation apparatus utilizing a substantially vertical reactor assembly is disclosed. The reactor includes a tubular outer shell, a base, a cap, and a central tension member. The annular space between the outer tube and the central tension member forms the reactor chamber. Seawater or other feed liquid enters the reactor chamber through the base plate. Reflected or direct solar energy heats the feed liquid, generating low pressure vapor. The vapor exits the reactor through the cap structure or the base. The concentrate left behind settles by gravity to the bottom region of the reactor's liquid column. Extension tubes on the feed openings allow feed liquid to enter the liquid column above the concentrate layer and avoid excessive mixing of the feed liquid and the concentrate. The concentrate exits the reactor through one or more openings in the base.

Owner:MCCLURE MILES

Large scale insulated desalination system

ActiveUS20120085635A1Improve distillation efficiencyLower energy requirementsGeneral water supply conservationAuxillariesDistillationBrackish water

An apparatus and method for the distillation of ocean and brackish water that includes insulation means for preventing heat from escaping to the atmosphere is disclosed. The insulation means comprises a second wall surrounding the basic assemblies of a desalination system in which the space between the second wall and basic assemblies is under low partial vacuum and is partially or totally filled with an insulation material for structural support. The system provides a means for flash evaporation of heated input water and condensing the resultant vapors into pure distilled water. A means for recapturing and using the heat of condensation as well as heat from the salt byproduct to preheat the input contaminated water is also disclosed.

Owner:FLO ONICS LLC

Ballast water treatment apparatus and method

InactiveCN101193824AImprove permeabilityStrong toleranceAuxillariesSelf-bailing equipments/scuppersFungicideCavitation

A ballast water treatment device which can meet the ballast water standard stipulated by IMO at low cost with certainty. Provided is a ballast water treatment device comprising: a filter unit (4) for filtering seawater to capture aquatic organisms; a bactericide supply unit (5) for supplying a bactericide to the filtered seawater; And Venturi tube (7), this tube is used for introducing the seawater that adds bactericide, and produces cavitation in seawater, thus has not only diffused bactericide but also kills or kills the aquatic organisms of seawater.

Owner:JFEENGINEERING CORP

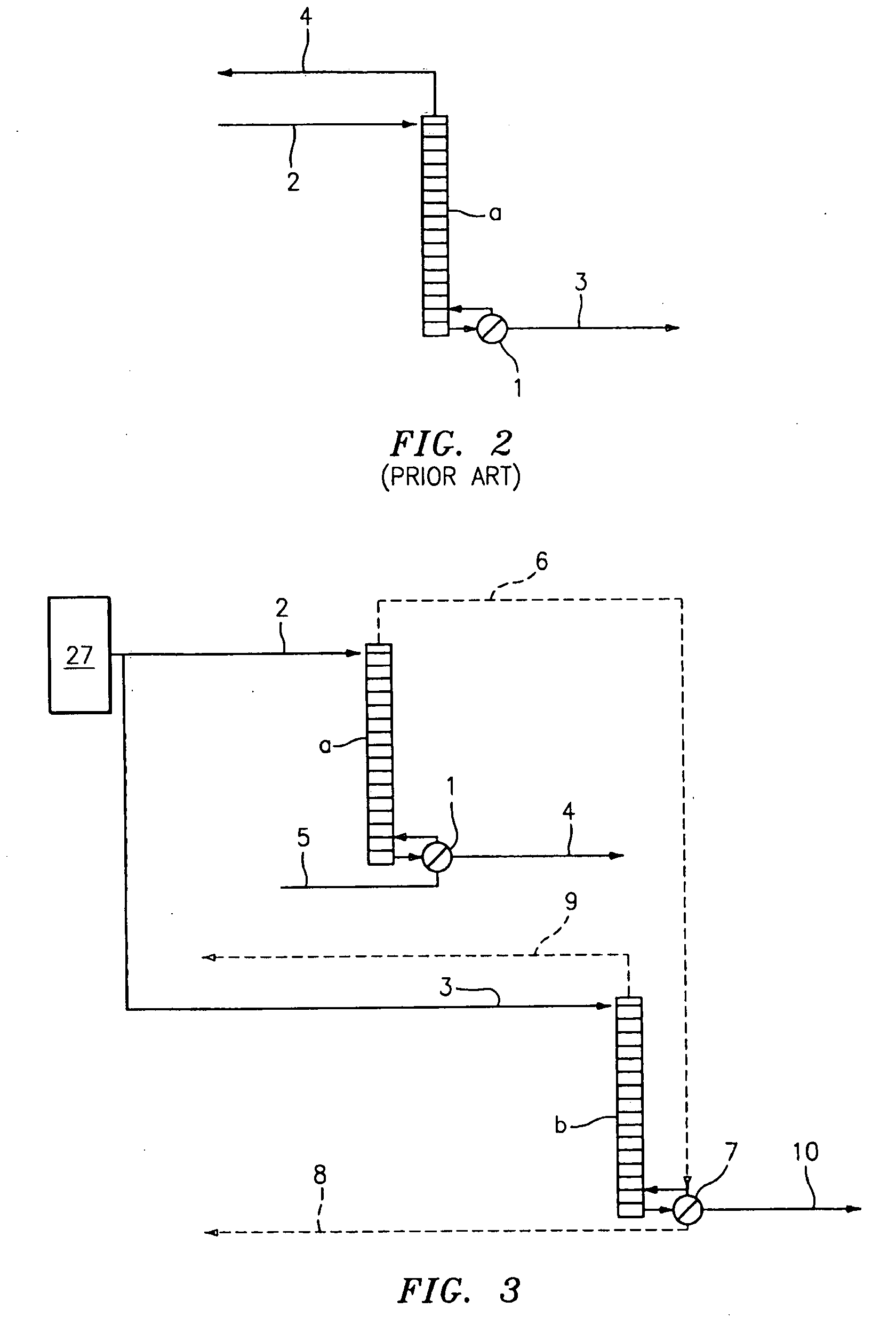

Multi-Stage Column Distillation (MSCD) Method for Osmotic Solute Recovery

ActiveUS20090297431A1Improve heating efficiencyImprove efficiencyLiquid separation auxillary apparatusCyanogen compoundsWater desalinationFractionating column

A method and apparatus for separating draw solution solutes and product solvent from a draw solution using a plurality of distillation columns. In one embodiment, the draw solution is used in a Forward Osmosis (FO) water desalination process. In this embodiment, the draw solution is directed to the plurality of distillation columns in parallel while the energy stream (heat) is directed to the plurality of distillation columns in series such that the efficiency of heat use is improved and in turn the cost of the heat is reduced.

Owner:YALE UNIV

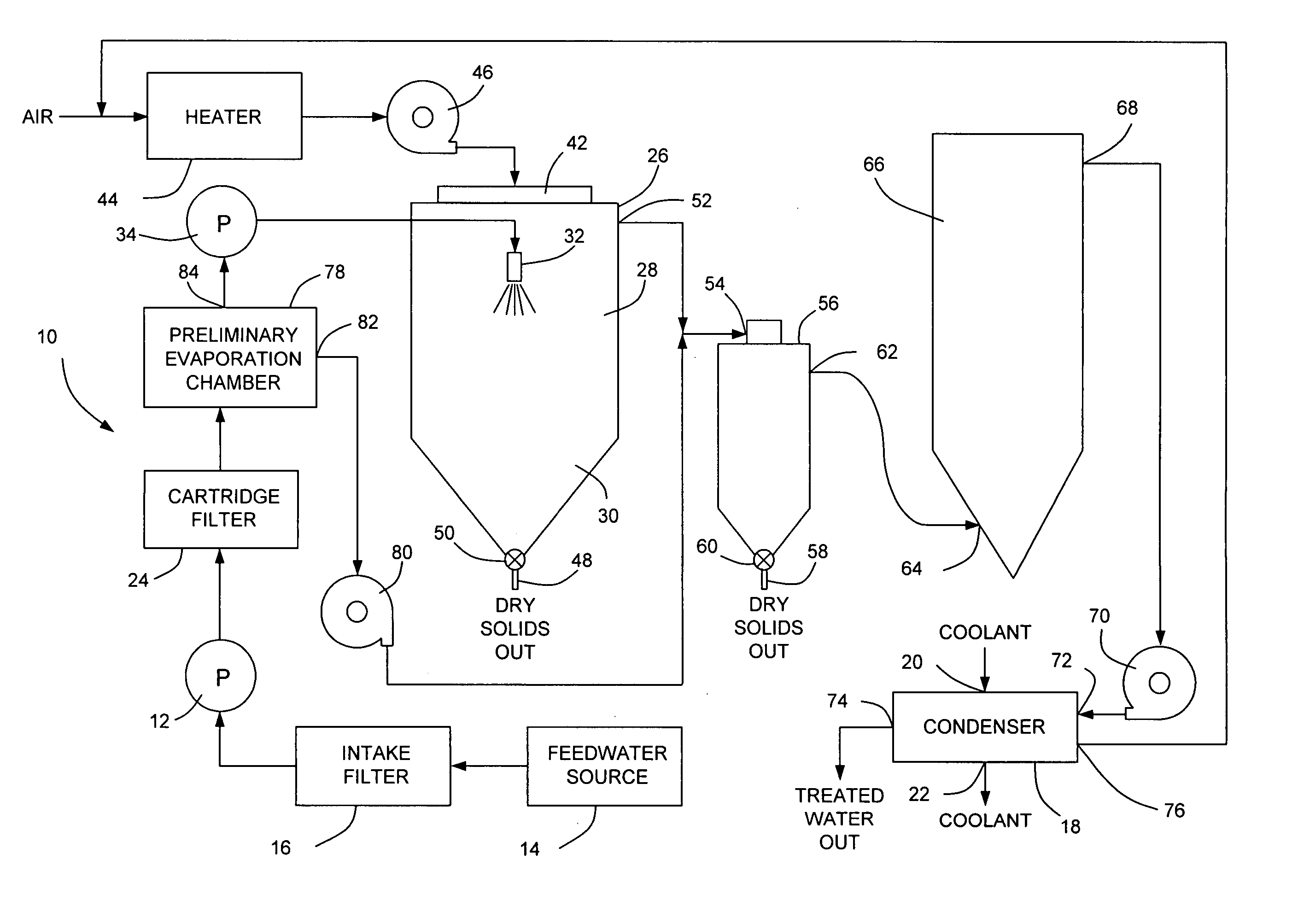

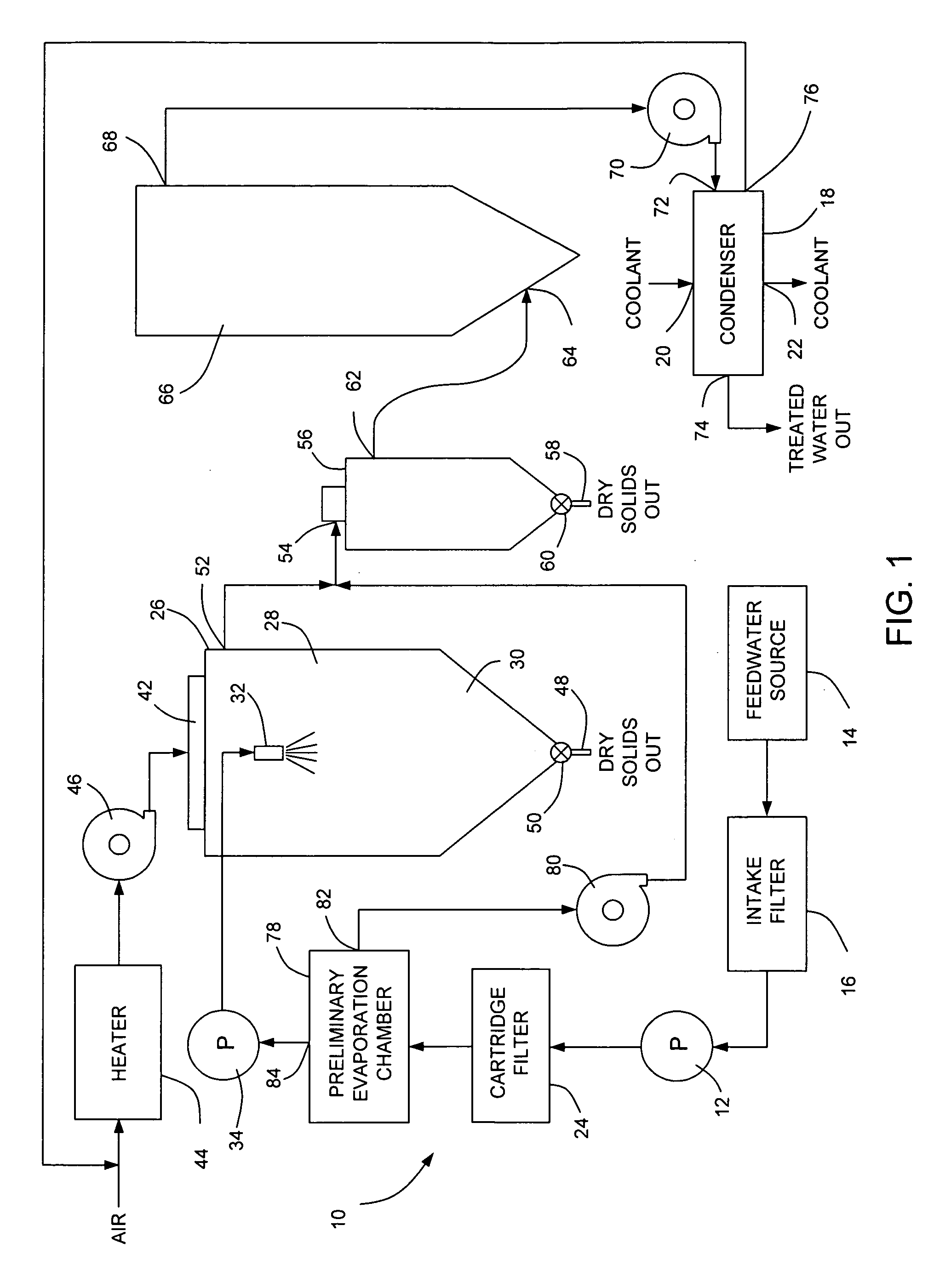

Method and system for separating solids from liquids

A method and system for treating feedwater includes evaporating a portion of the feedwater in a first evaporation chamber so as to separate water vapor from the remaining feedwater. Droplets of the remaining feedwater are dispersed into a stream of hot air produced in a second evaporation chamber. The droplets evaporate and solids in the feedwater precipitate. The precipitated solids are collected in the lower section of the second evaporation chamber. Water vapor discharged from both evaporation chambers can be treated in a cyclone separator to remove residual solids therefrom. The cleansed water vapor output from the cyclone separator can be condensed to recover clean water. Dry solids can be discharged from the second evaporation chamber and the cyclone separator for recovery.

Owner:WATERVAP

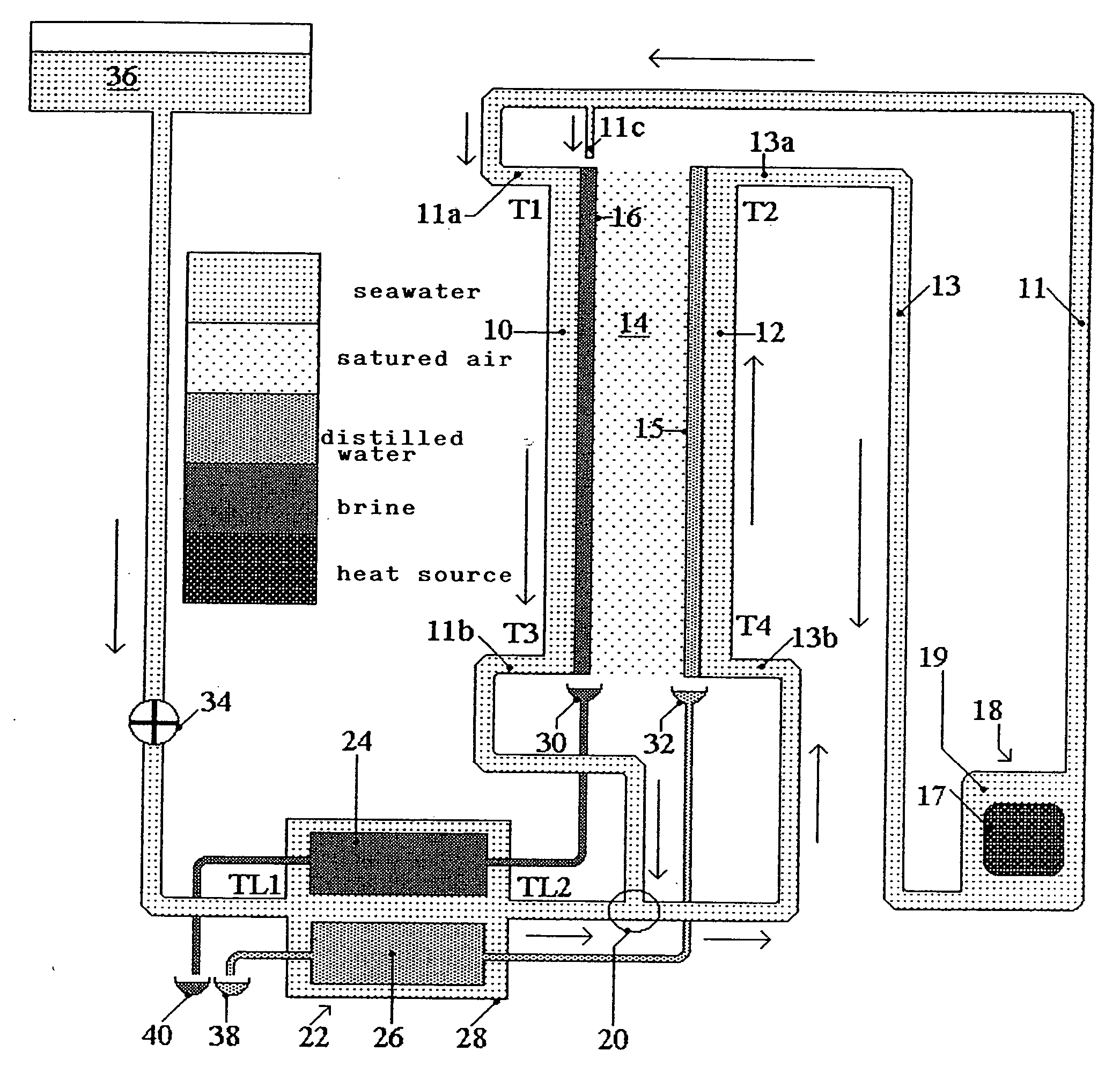

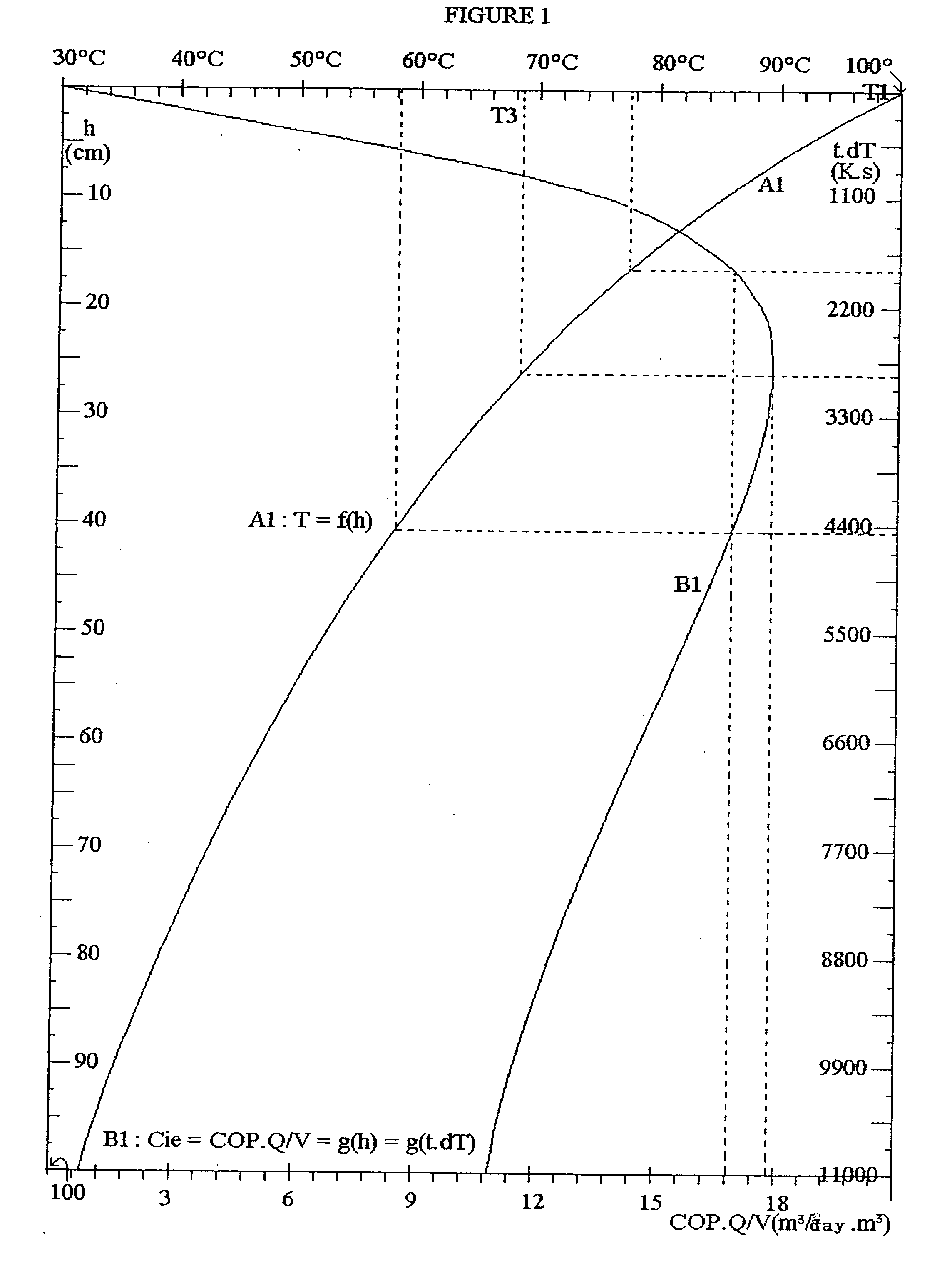

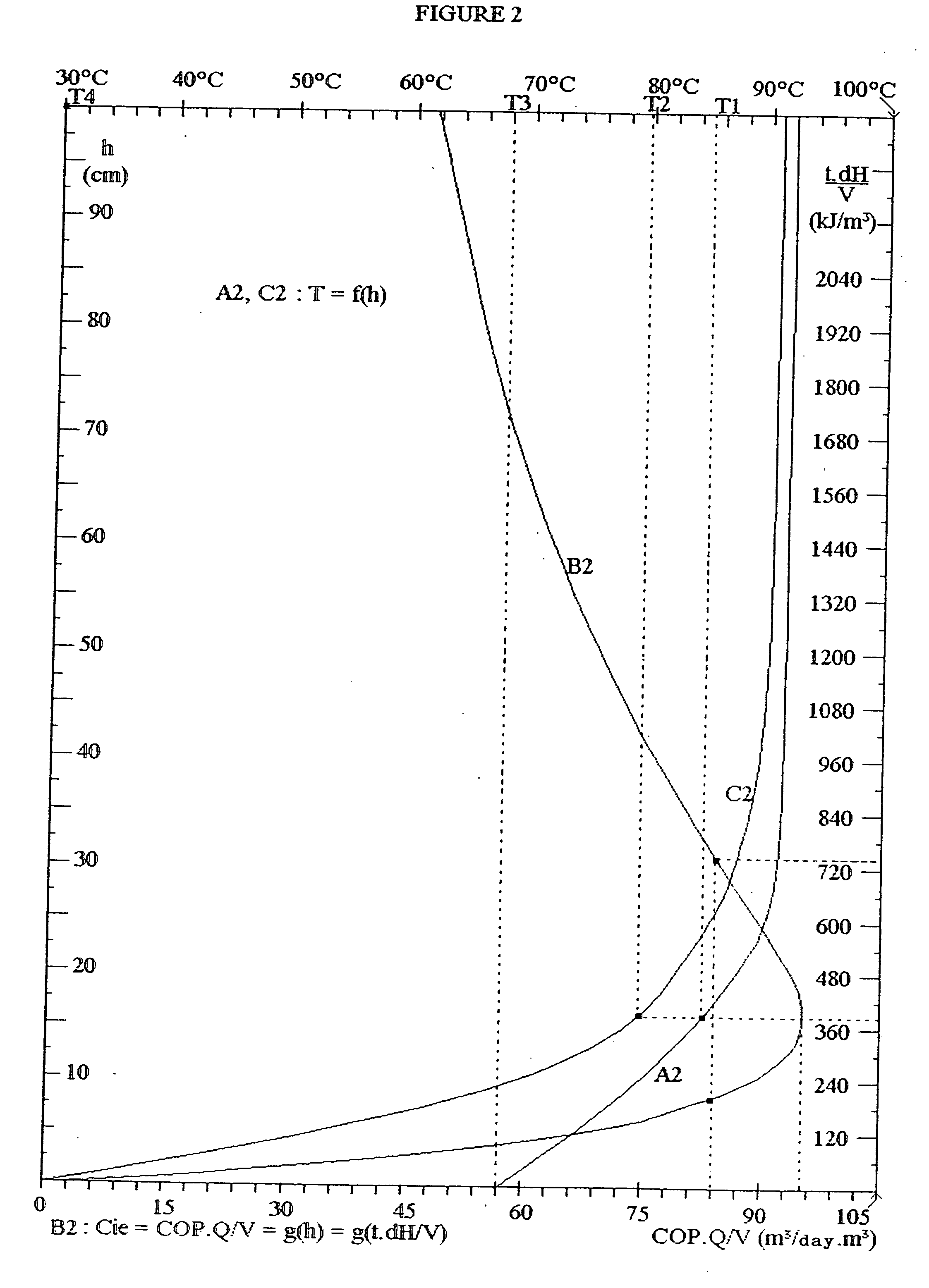

Distillation methods and devices in particular for producing potable water

InactiveUS20060272933A1Improve efficiencyHigh densityGeneral water supply conservationAuxillariesEngineeringSeawater

The inventive device is embodied in the form of a chamber-oven for diffusing vapour and saturated hot air which circulate in a closed circuit by natural convection. Said device is embodied in the form of a domestic-use solar energy collecting device provided with a greenhouse whose surface is equal to 1 m2 and produces from 50 to 100 litres / day of distilled water. The device comprises a distillation unit arranged between two furnaces (59′, 79′) in a temperature-controlled container (48′). Said distillation unit comprises 100 flat thin hollow plates having a surface of 20 dm2 by face and an active volume of 200 dm3. The fine and tensioned walls (54) of said plates are provided with a hydrophilic coating (60′) and internal (56′) and inter-plate (58′) spaces. The lower chimney (59′) comprises a greenhouse (118′, 119′) whose bottom is embodied in the form of an impermeable black layer provided with a thin hydrophilic carpet on the rear part thereof. Saturated hot air at a temperature of 80° C. enters inside (56′) hollow plates from bellow and exits from the top at a temperature of 50° C. A high chimney (79′) is provided with a monoblock heat exchanger (84′) which is transversed by a non-potable water to be distilled which, afterwards is spread warm (40° C.) over the hydrophilic coating (60′). During passage through the heat exchanger (84) the air is cooled to 30° C. and moved down by gravity to the inter-plate spaces (58′) and exits therefrom at a temperature of 78° C. The distilled water condensed in the plates and by the heat exchanger is collected and removed. Brine is received in the bottom of the inter-plate space and distributed along the thin hydrophilic carpet of the bottom (122′) of the greenhouse. An air current passes along said hot carpet is heated and saturated and enters the plates. The brine liquor finally flows in an air-preheating tank (63′) which is emptied each morning. The greenhouse can be substituted by a heating tube transversed by a heating fluid or associated with another steam-jet tube. The more powerful chamber-ovens can produce at least 200 m3 / day of distilled water for collective consumption. Said invention can be used for salt removal from seawater, co-generating electricity and potable water and for producing food concentrates.

Owner:THE THIRD MILLENIUM WATER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com