Ballast water treatment apparatus and method

一种处理装置、压载水的技术,应用在水处理装置、水/污水处理、自然水体处理等方向,能够解决环境不利影响、难细菌杀灭至满足等问题,达到减轻环境的影响的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

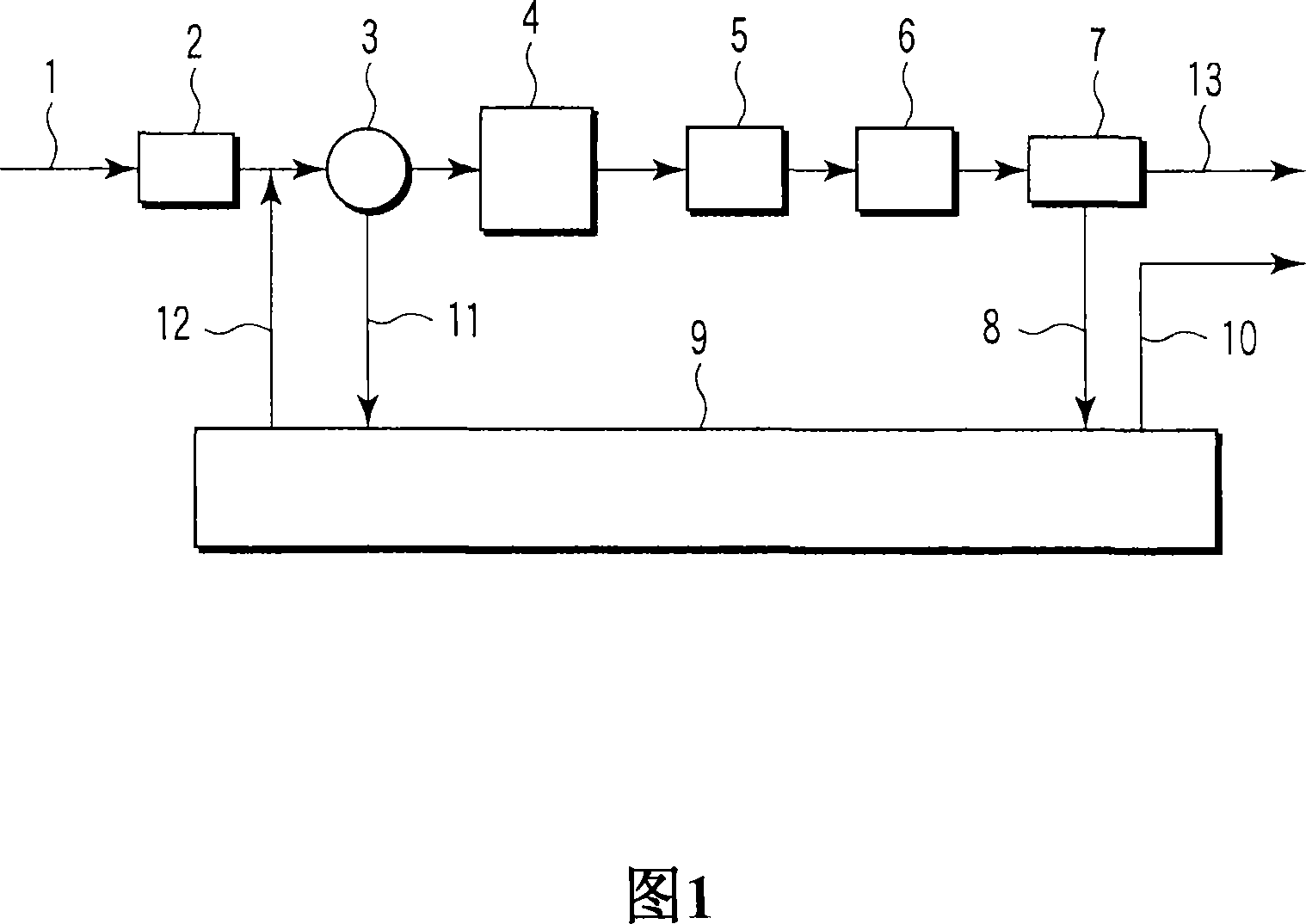

[0125] An example of embodiment of the ballast water treatment device according to the present invention will be described in detail with reference to the drawings.

[0126] FIG. 1 is a block diagram of a ballast water treatment apparatus according to a first embodiment of the present invention. This ballast water treatment device has the following structure. The seawater inlet pipeline 1 that introduces seawater into the container. The coarse filter 2 removes coarse matter in the seawater introduced by the seawater inlet pipeline 1 . The pump 3 introduces sea water or ballast water in the ballast tank 9 (described later) to the filter 4 (described later). The filter 4 removes the plankton present in the sea water from which the coarse matter has been removed by the coarse filter 2 . The bactericide supply device 5 supplies a bactericide to the seawater filtered through the filter 4 to kill bacteria and plankton. The fungicide decomposing agent supply device 6 supplies the...

Embodiment approach 2

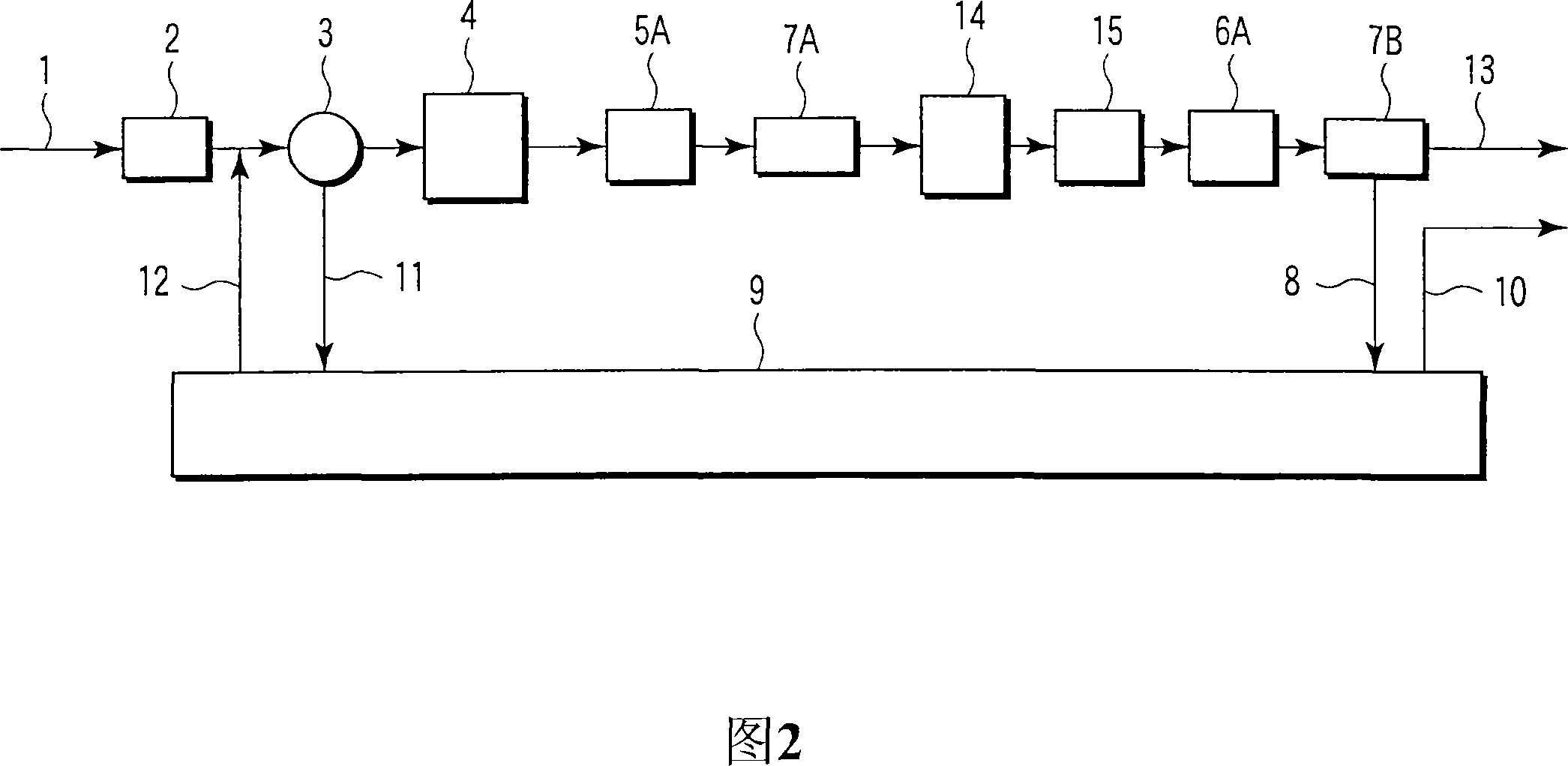

[0199] Fig. 2 is a schematic view according to a second embodiment of the present invention. The same symbols are attached to the same components as those of Embodiment 1. This embodiment differs from Embodiment 1 in that seawater is preserved after supplying the chlorine bactericide to the seawater, treated with hydrogen peroxide, and uses a second venturi. Specifically, a chlorine bactericide is supplied to the filter-filtered seawater before it is introduced into the first venturi. Chlorine bactericide is diffused in seawater by the cavitation generated in the venturi tube, so that the bactericidal effect is improved. Then, the seawater is stored in the storage tank for a predetermined period of time, after which hydrogen peroxide is supplied to the seawater, and then the seawater is introduced into the second venturi tube. Hydrogen peroxide is diffused in seawater by cavitation created in the second venturi.

[0200] In this embodiment, after the chlorine sterilizer is ...

Embodiment approach 3

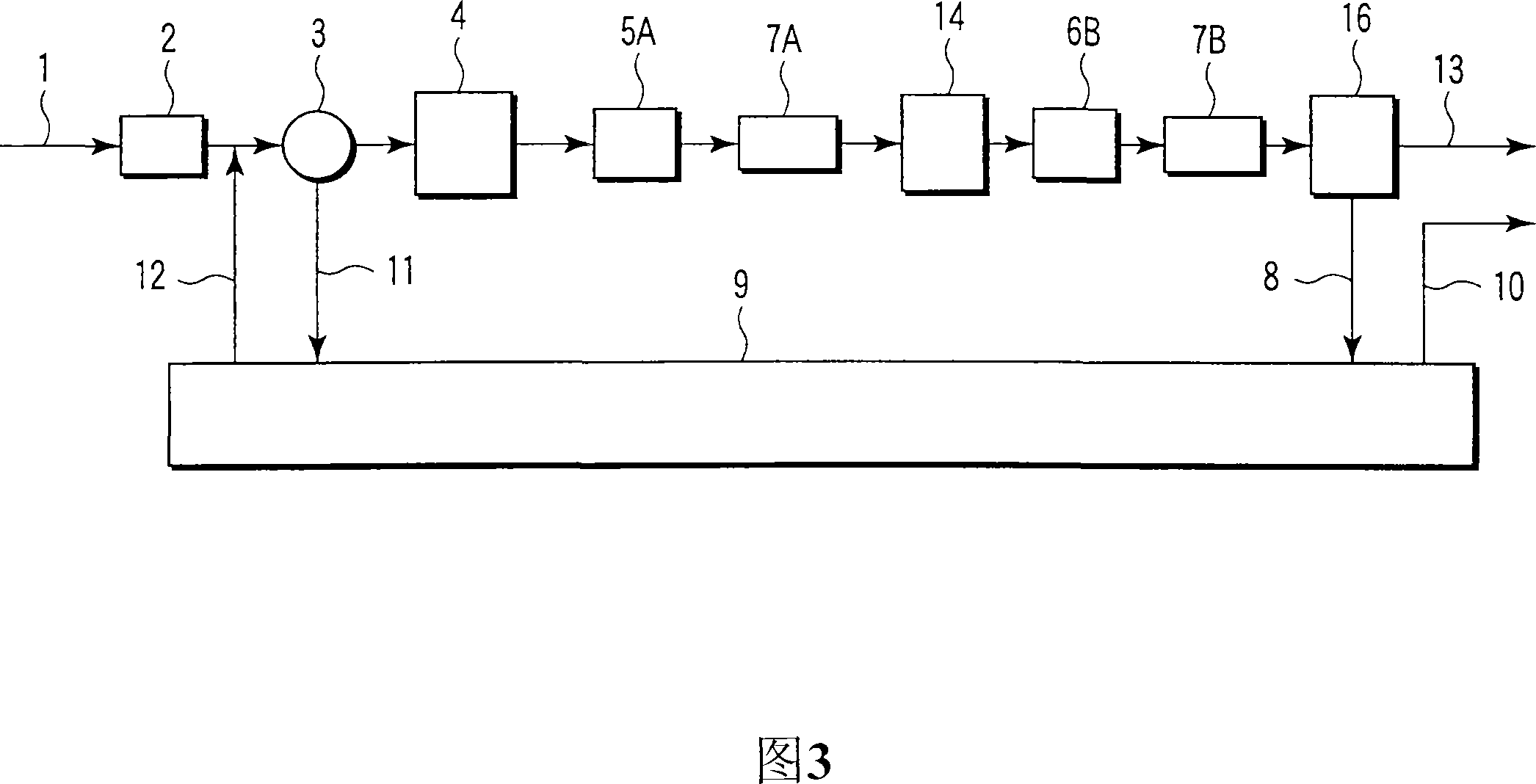

[0232] Fig. 3 is a schematic view according to a third embodiment of the present invention. The same symbols are attached to the same components as those of Embodiment 1. This embodiment differs from Embodiment 1 in that seawater is preserved after supplying chlorine bactericide to seawater, chlorine reducing agent is supplied, a second venturi is used, and activated carbon treatment is performed. Specifically, a chlorine bactericide is supplied to the filter-filtered seawater before it is introduced into the first venturi. The chlorine biocide is diffused in the seawater by the cavitation created in the first venturi. Then, the seawater is stored in the storage tank for a predetermined period of time, after which the chlorine reducing agent is supplied to the seawater, and then the seawater is introduced into the second venturi tube. The chlorine reducing agent is diffused in seawater by cavitation created in the second venturi. The seawater discharged from the second vent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction potential | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com