Patents

Literature

775results about "Self-bailing equipments/scuppers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

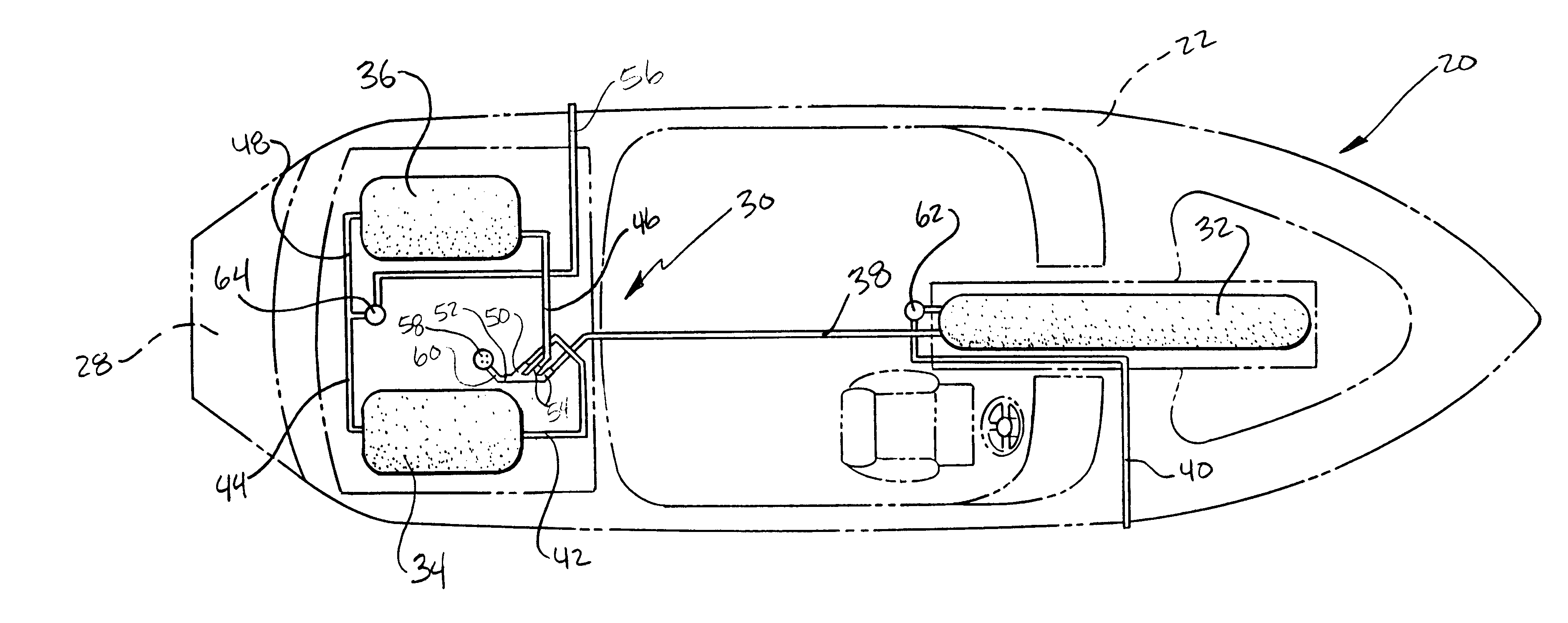

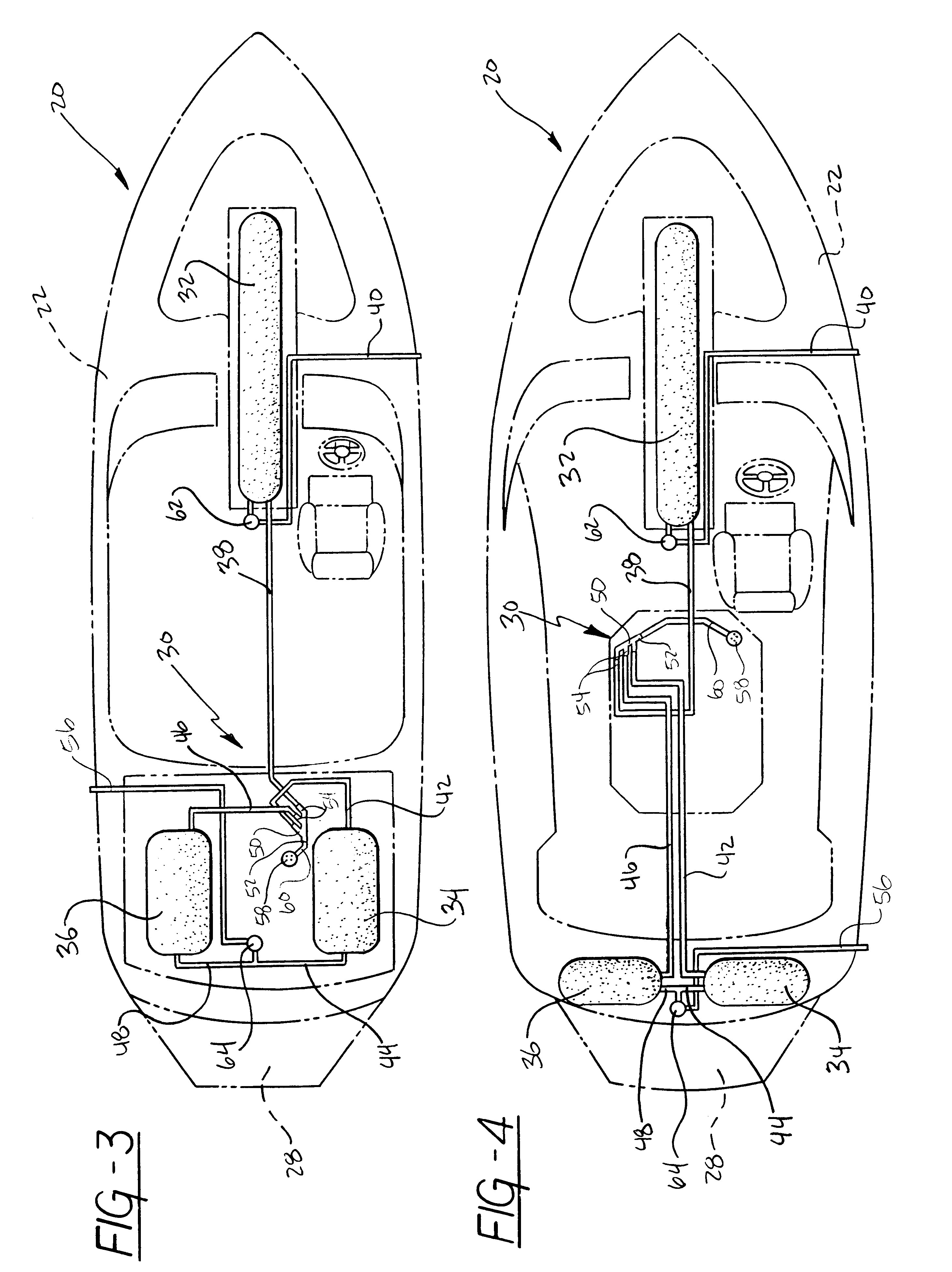

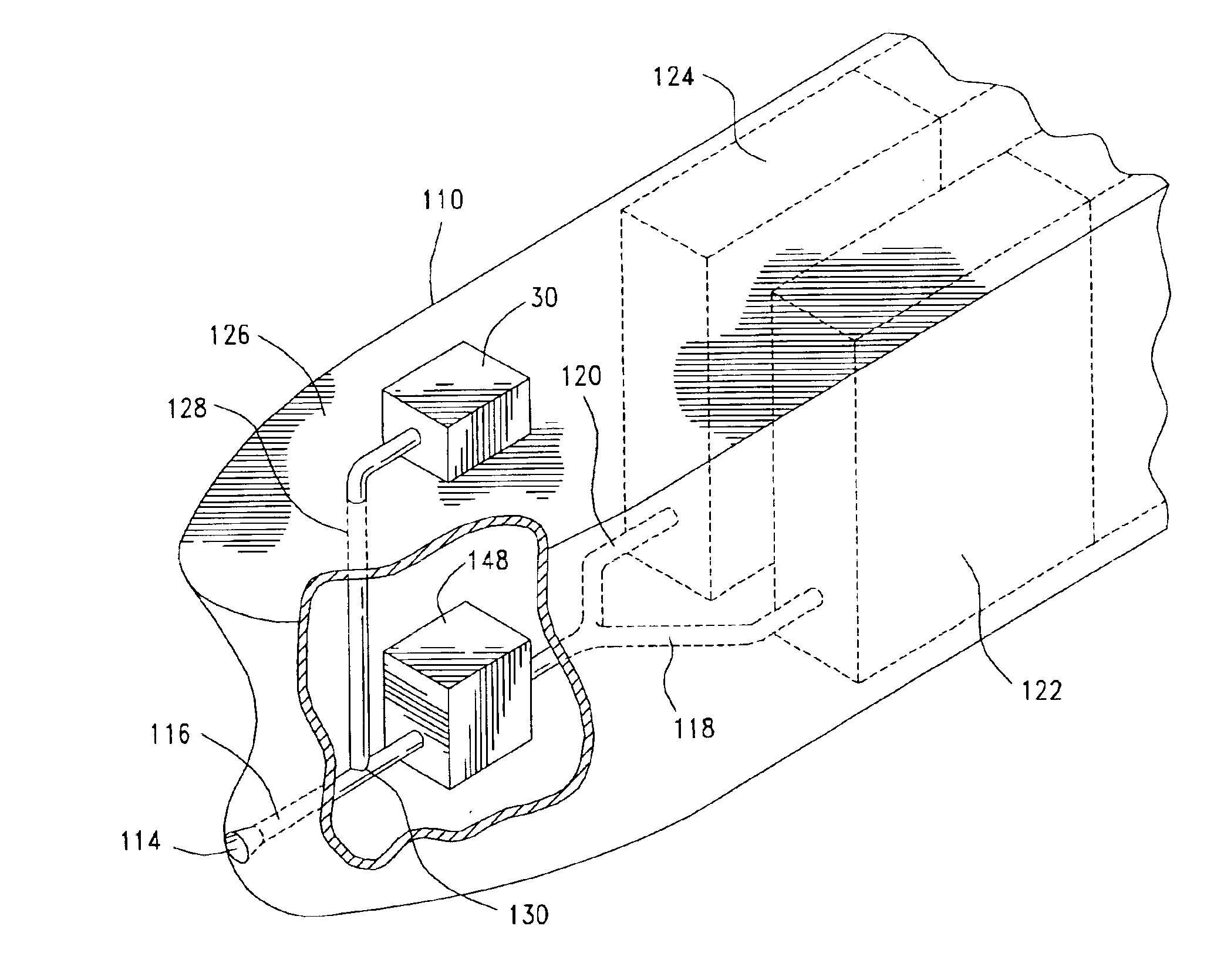

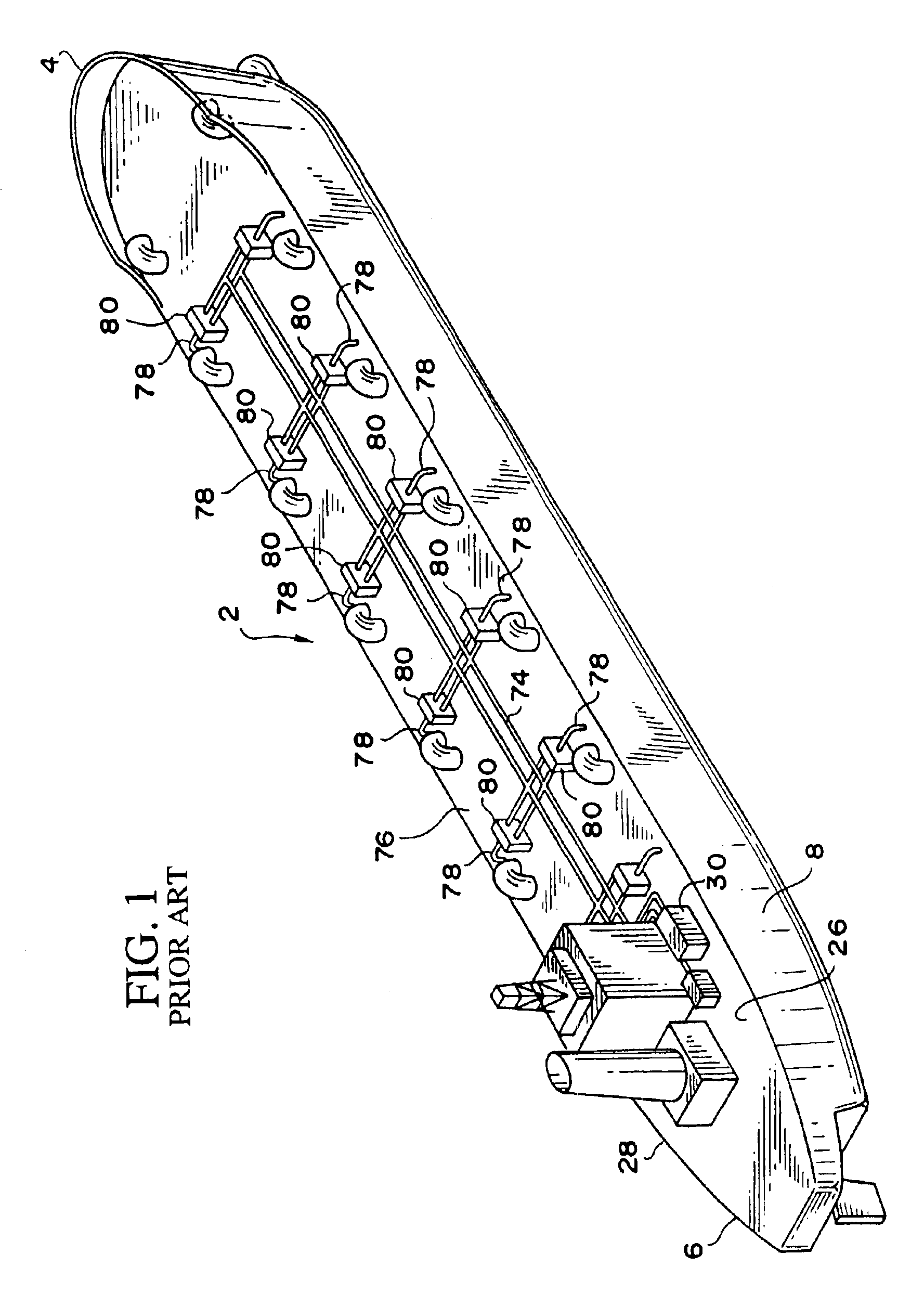

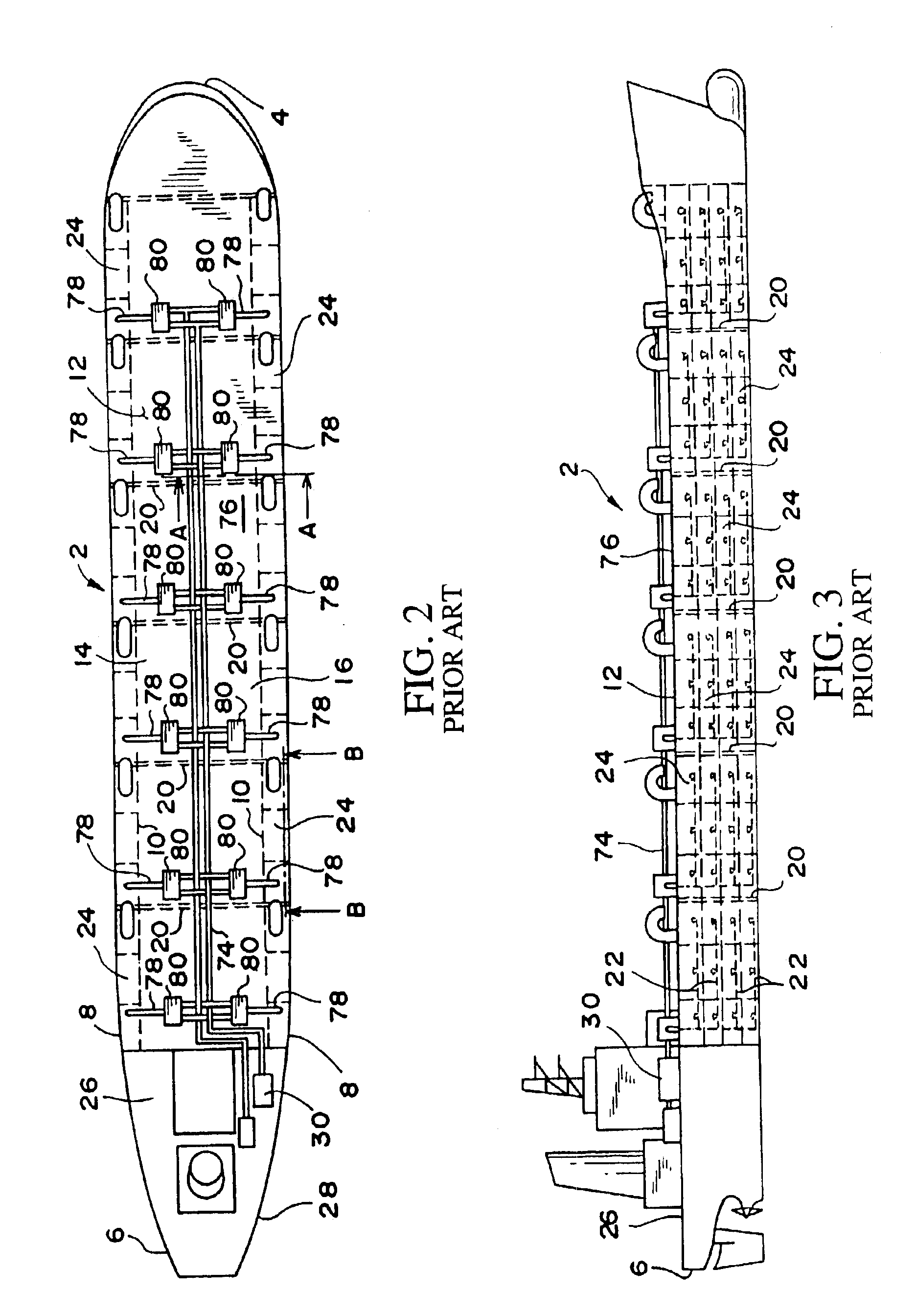

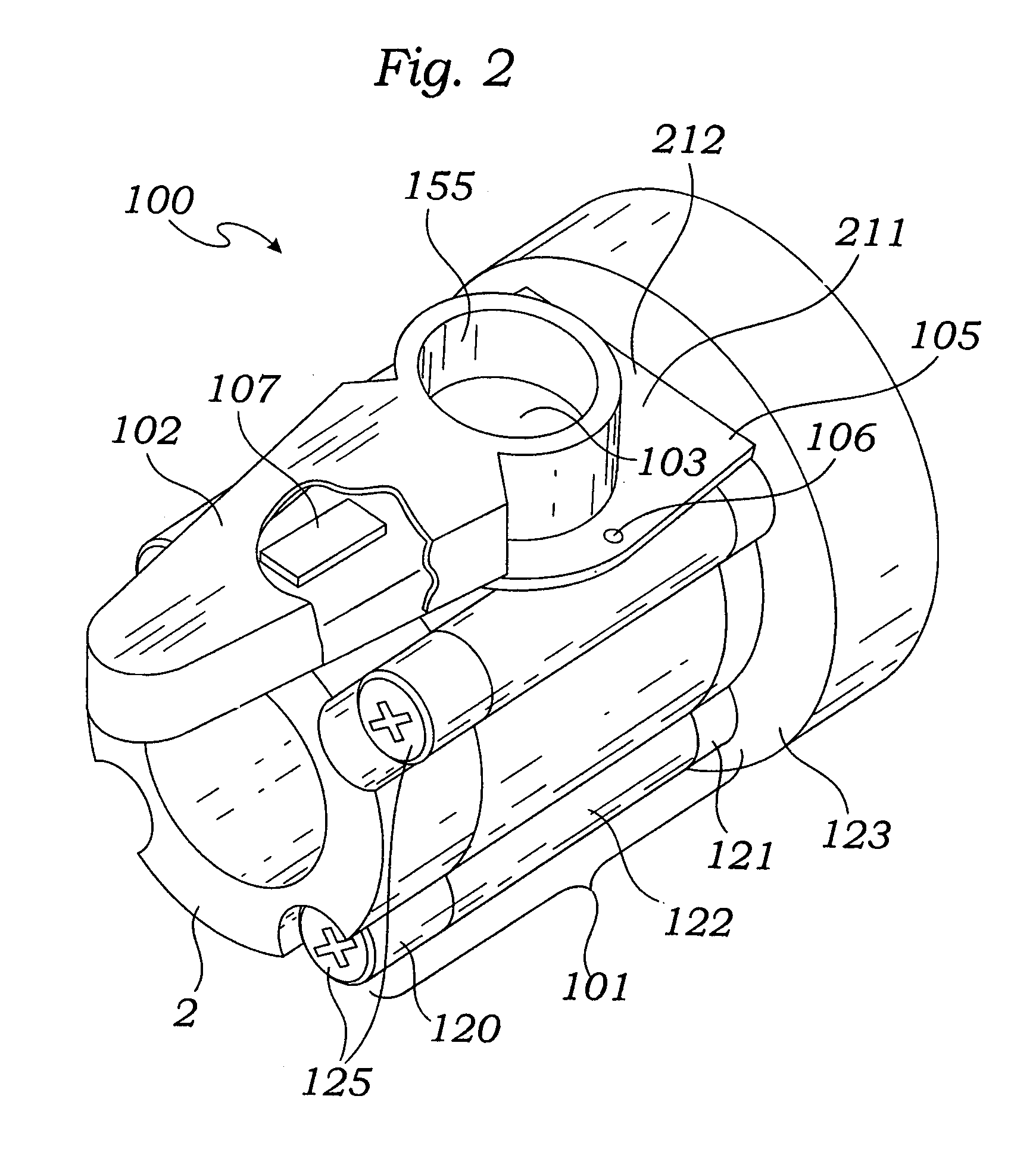

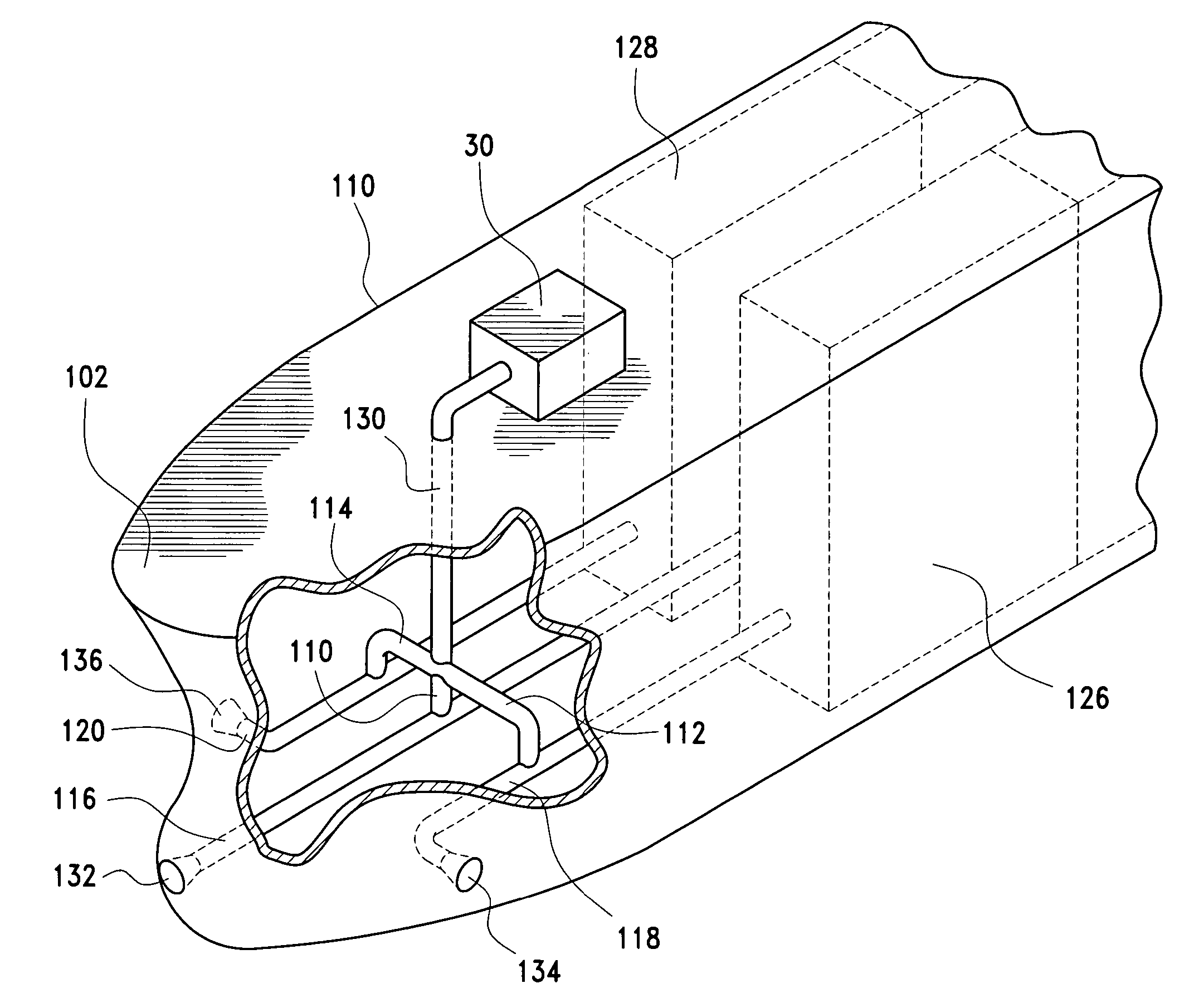

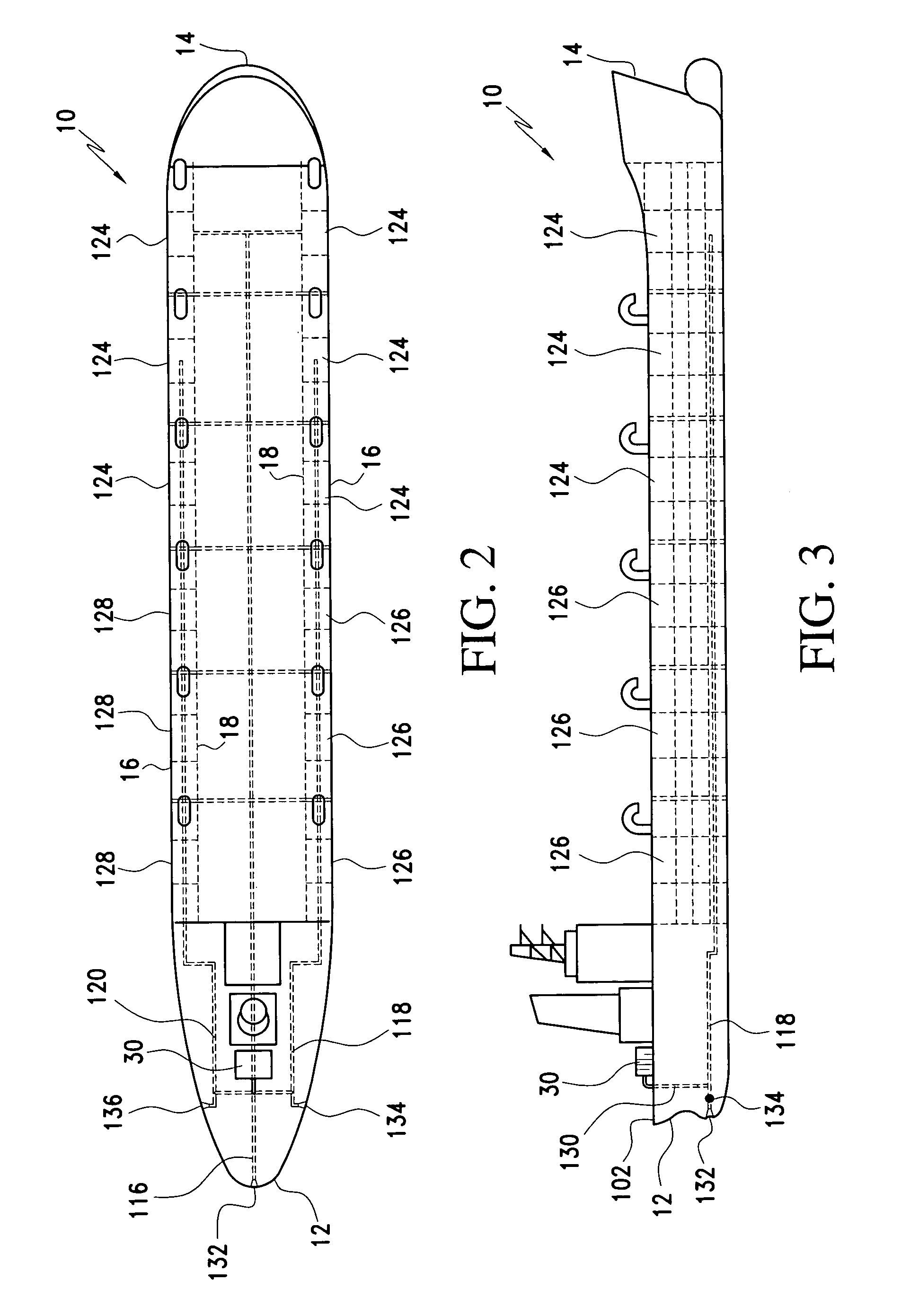

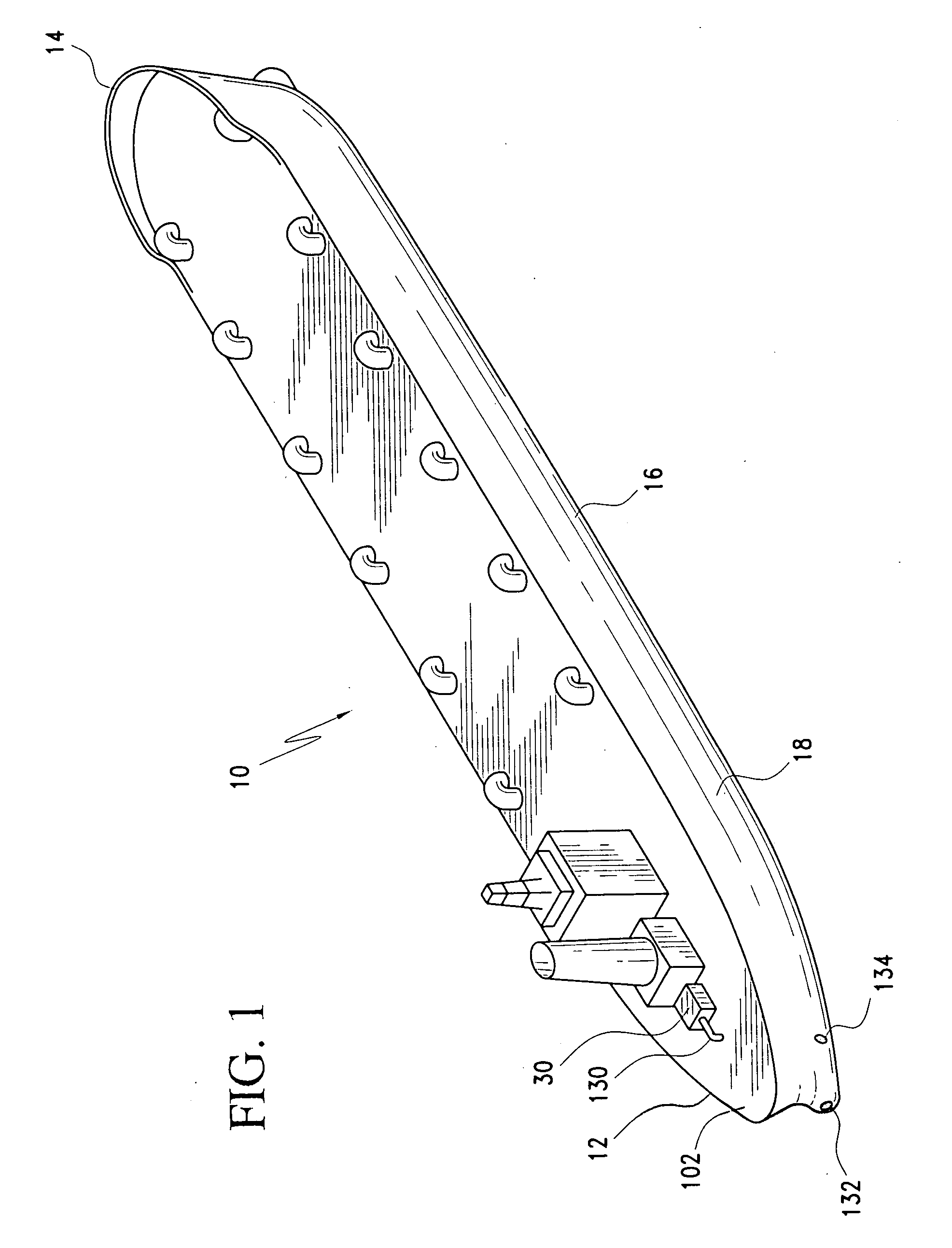

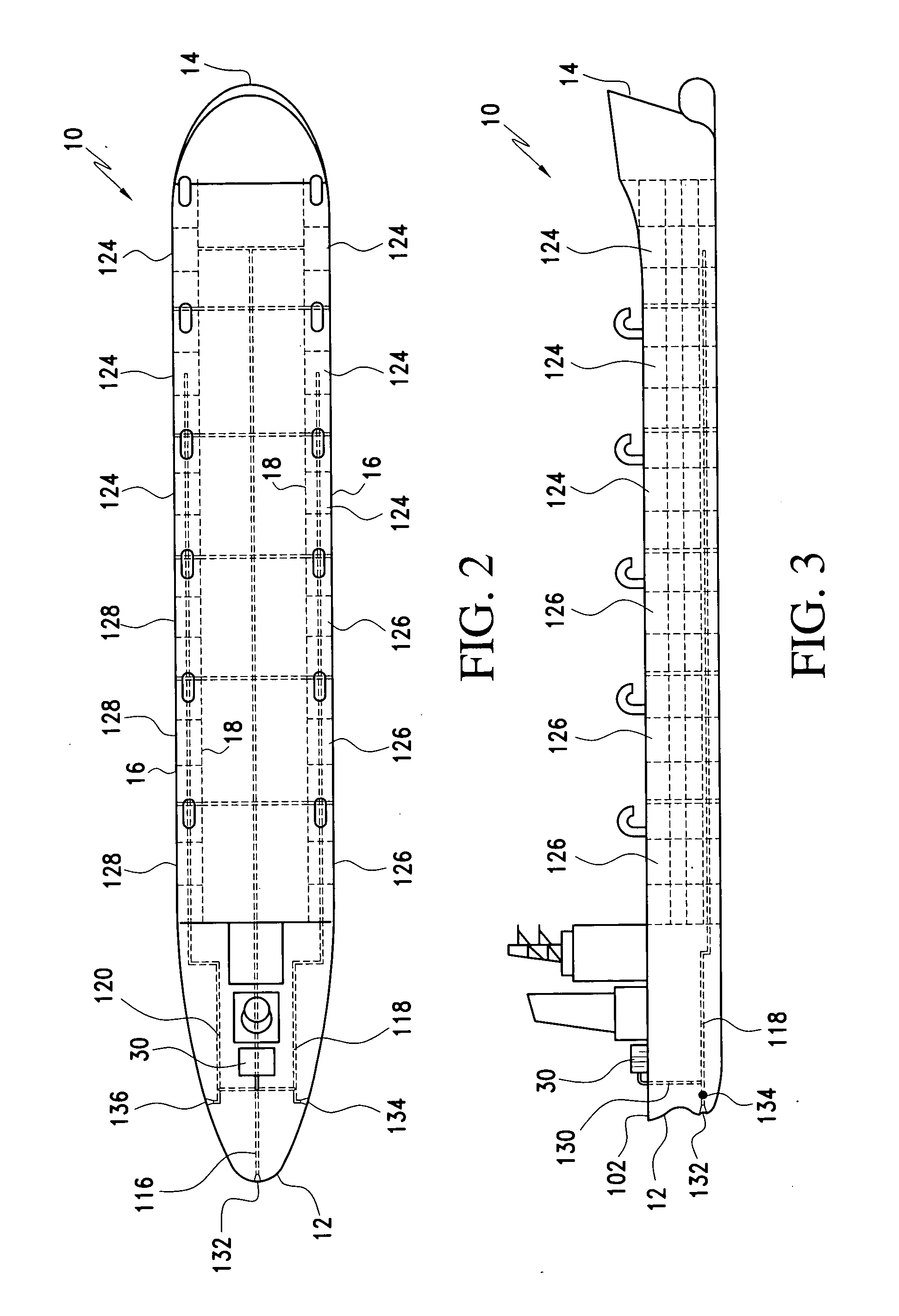

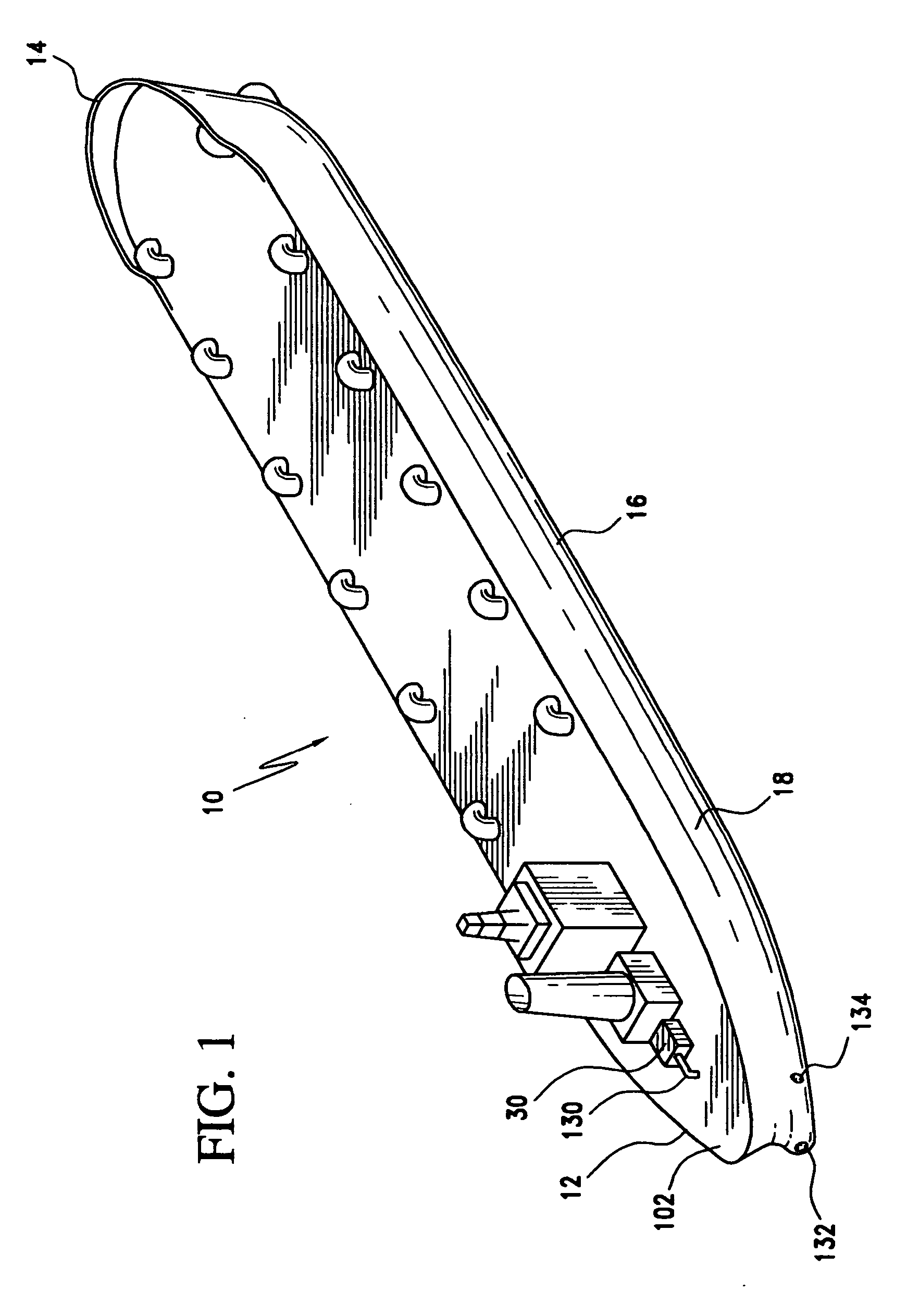

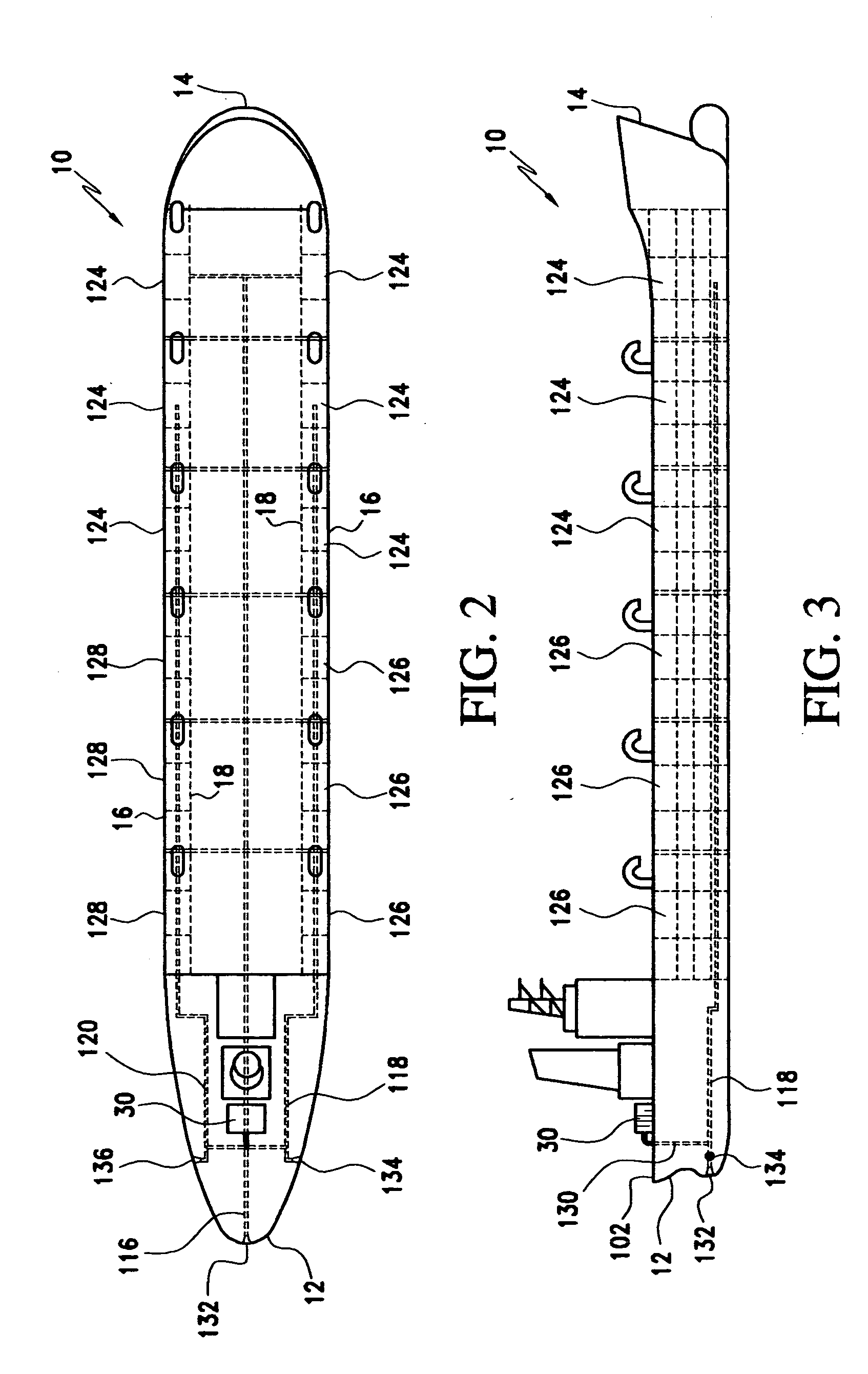

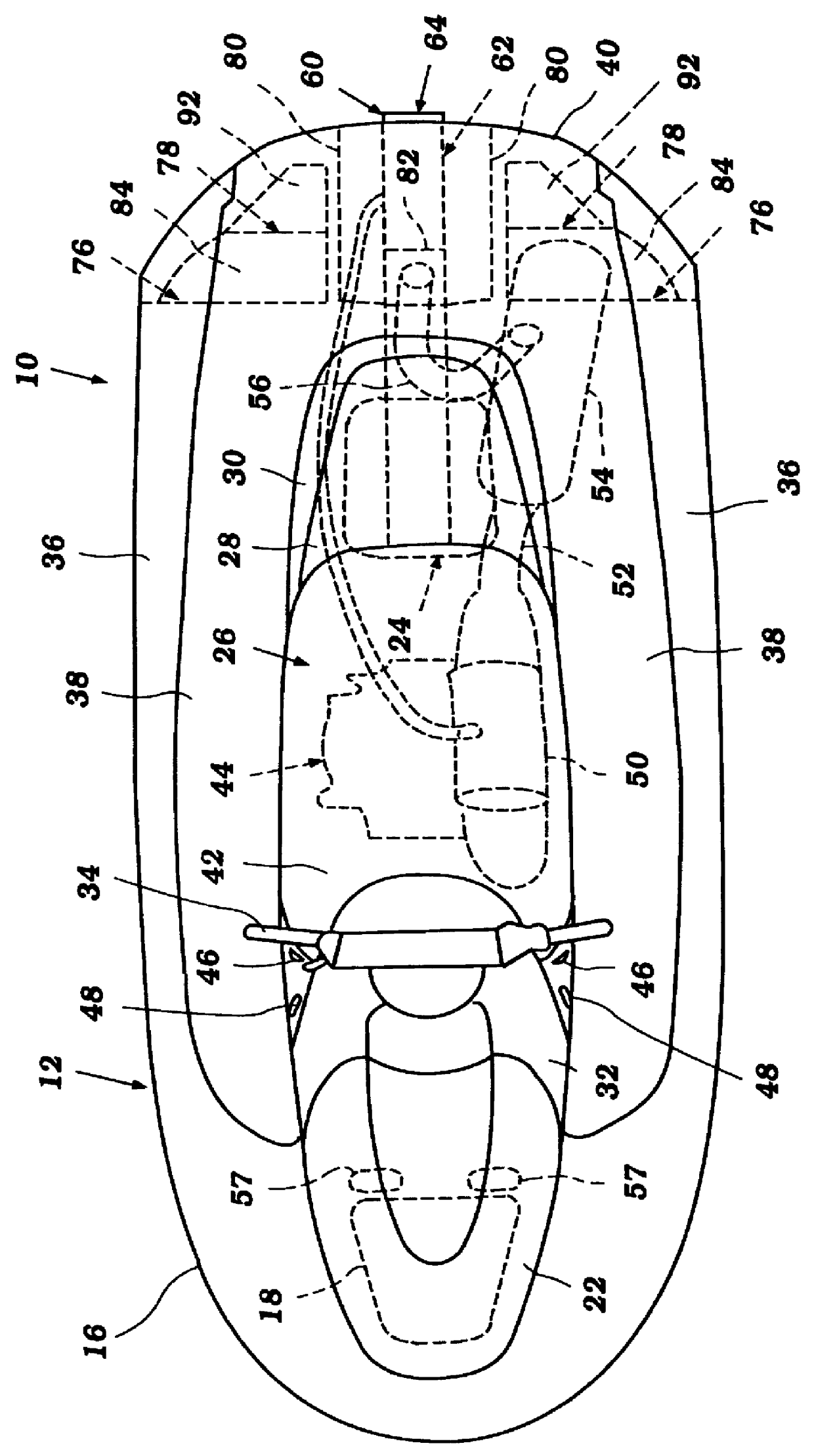

Wake enhancement assembly

InactiveUS6427616B1Inexpensively retrofittedLarge weighting factorWave generating vesselsWater sport boardsBiomedical engineeringVALVE PORT

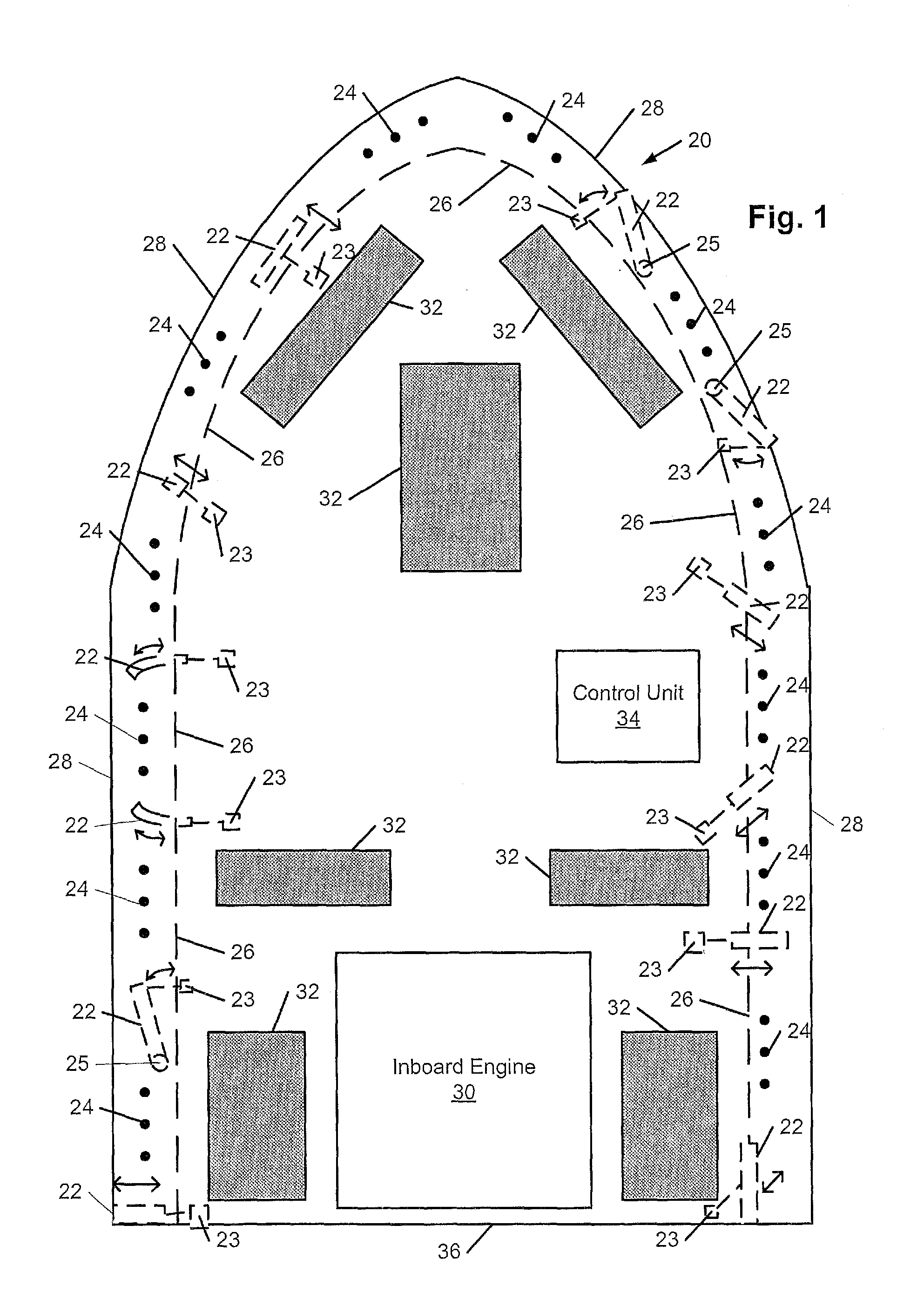

The subject invention is a wake enhancement assembly to vary a configuration of a wake produced by the hull of a boat. The assembly preferably includes three or four fluid chambers adapted to be disposed within the hull of the boat. The fluid chambers can be filled to provide added weight in selected areas of the hull. The added weight alters how the hull rides within a body of water and as such will alter the wake of the boat. A plurality of hoses are mounted to and in fluid communication with the fluid chambers for selectively filling and draining the fluid chambers. The assembly is characterized by a manifold having an inlet and a plurality of outlets. Each of the outlets has a valve disposed in fluid communication therewith. The filling hoses are connected to the outlets such that the valves of the manifold control a flow of fluid to and from the fluid chambers independently of each other. The valves and manifold electronically and remotely control the selective filling and draining of the fluid chambers.

Owner:HAGEN TONI LYNN

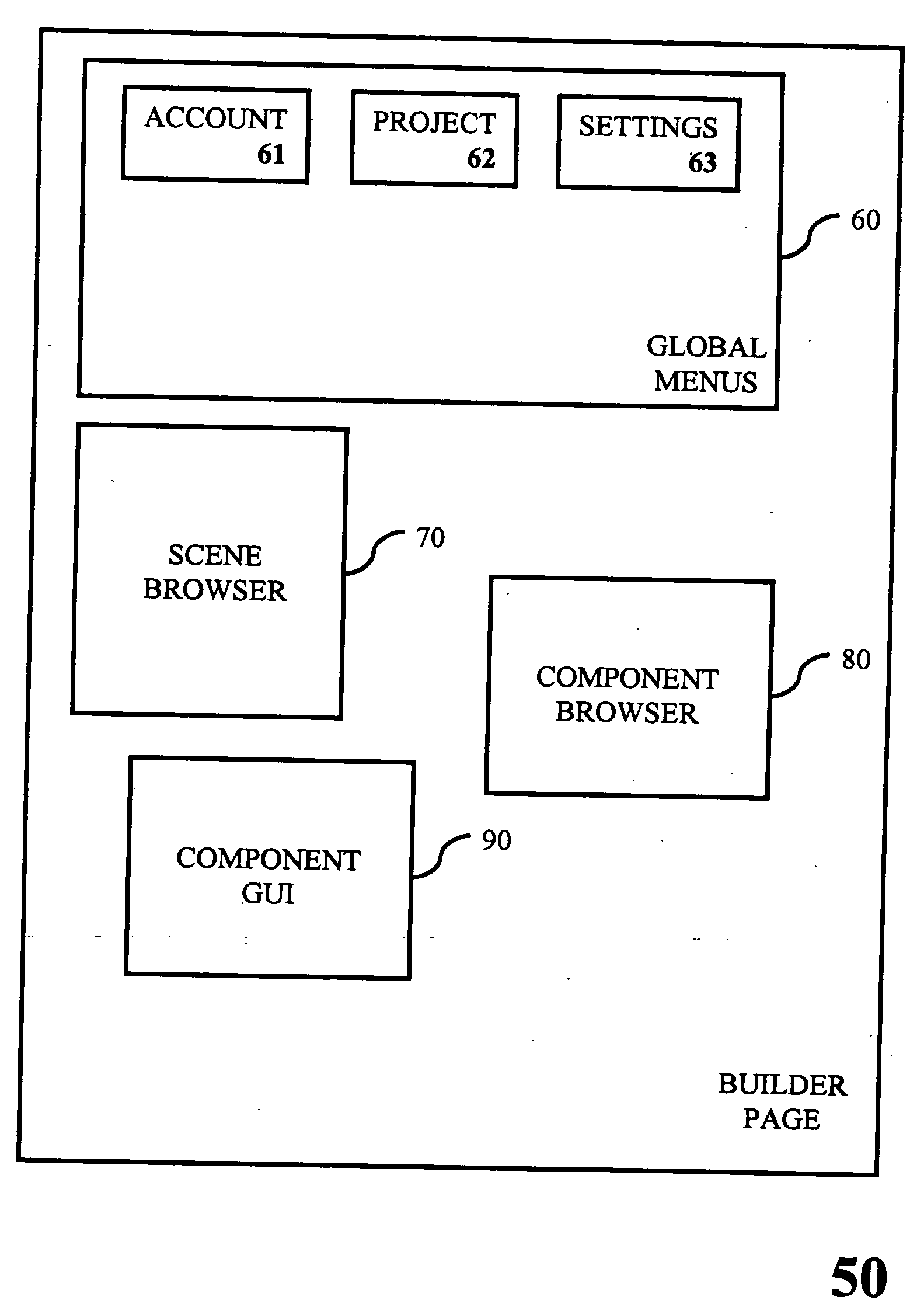

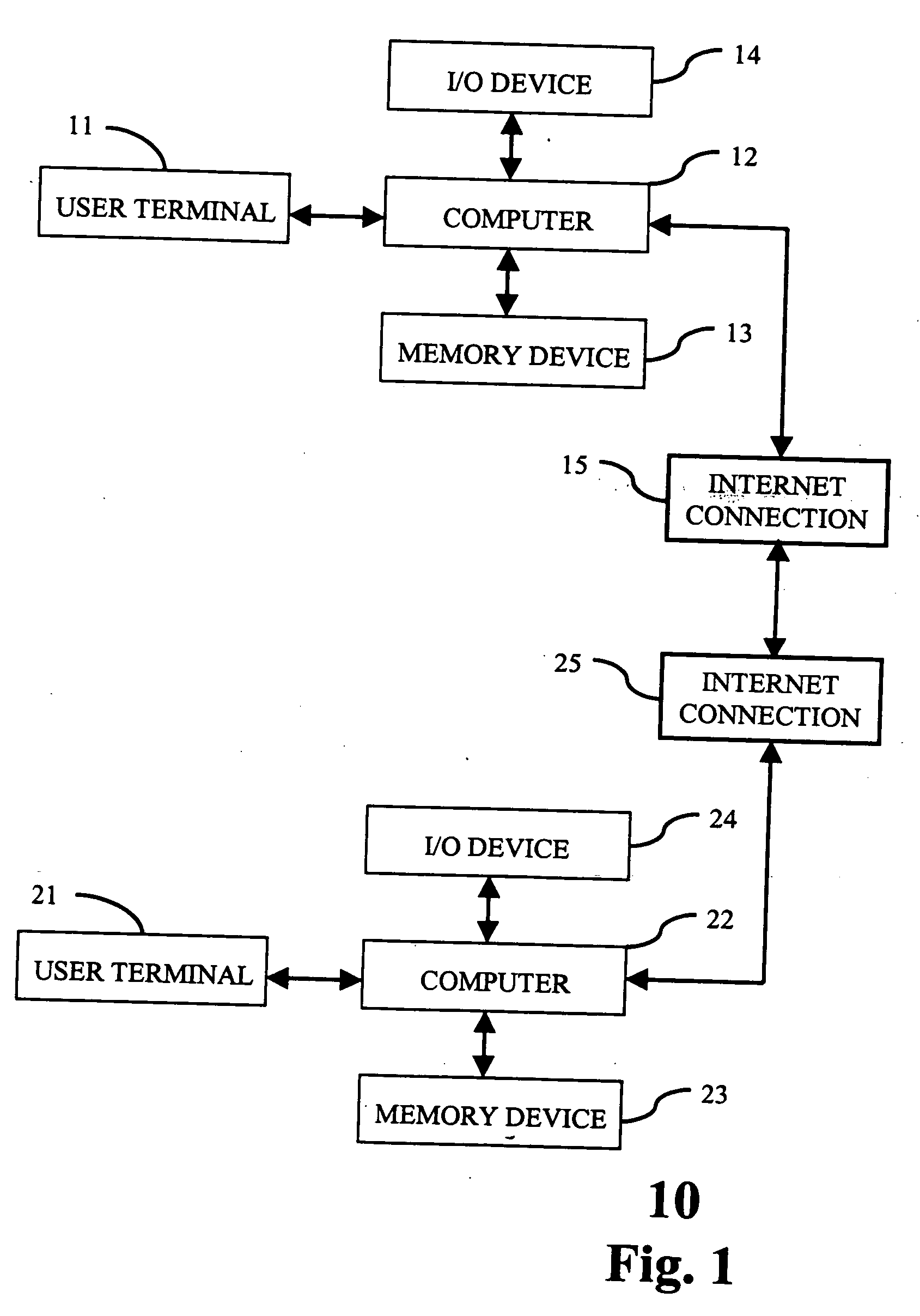

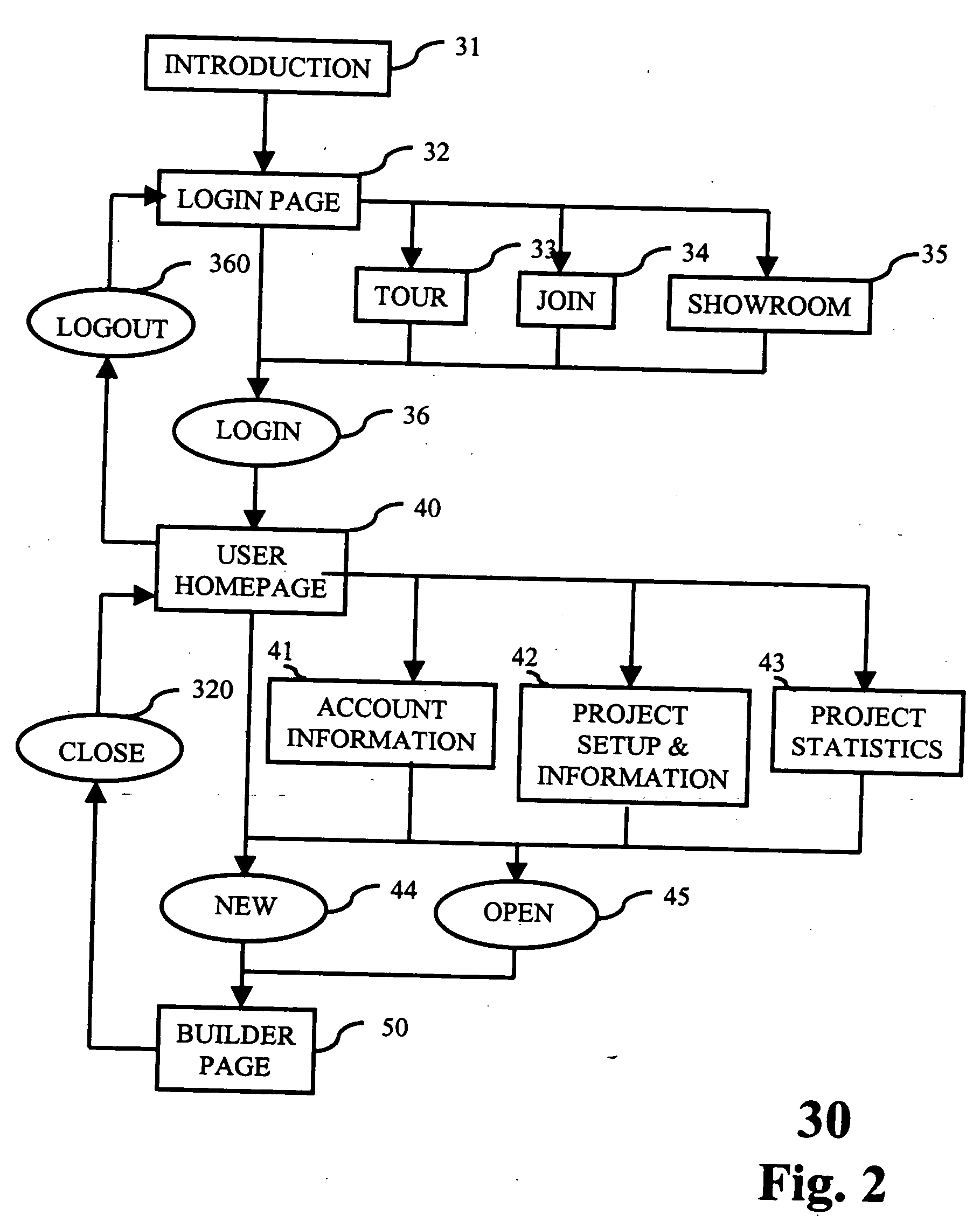

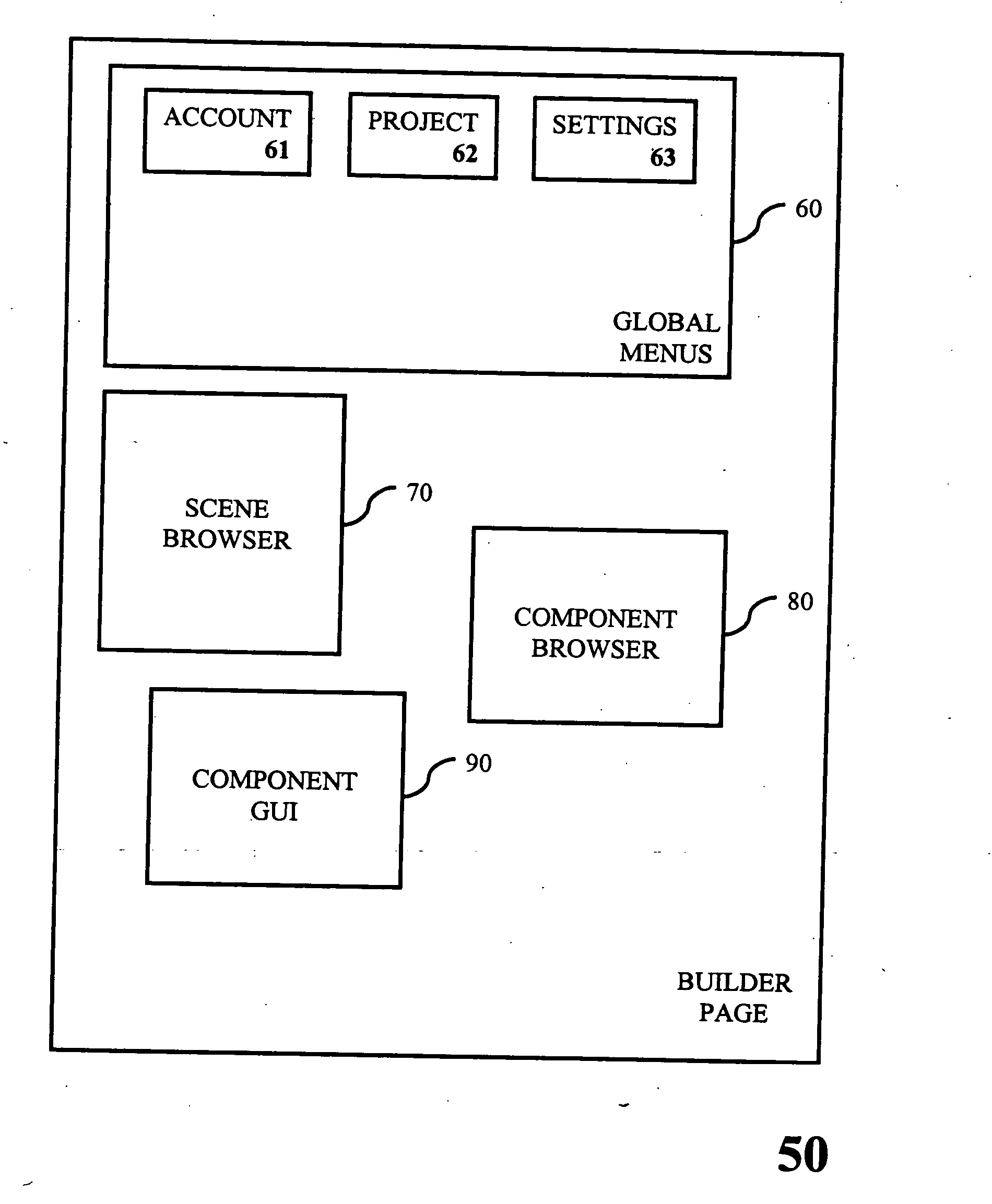

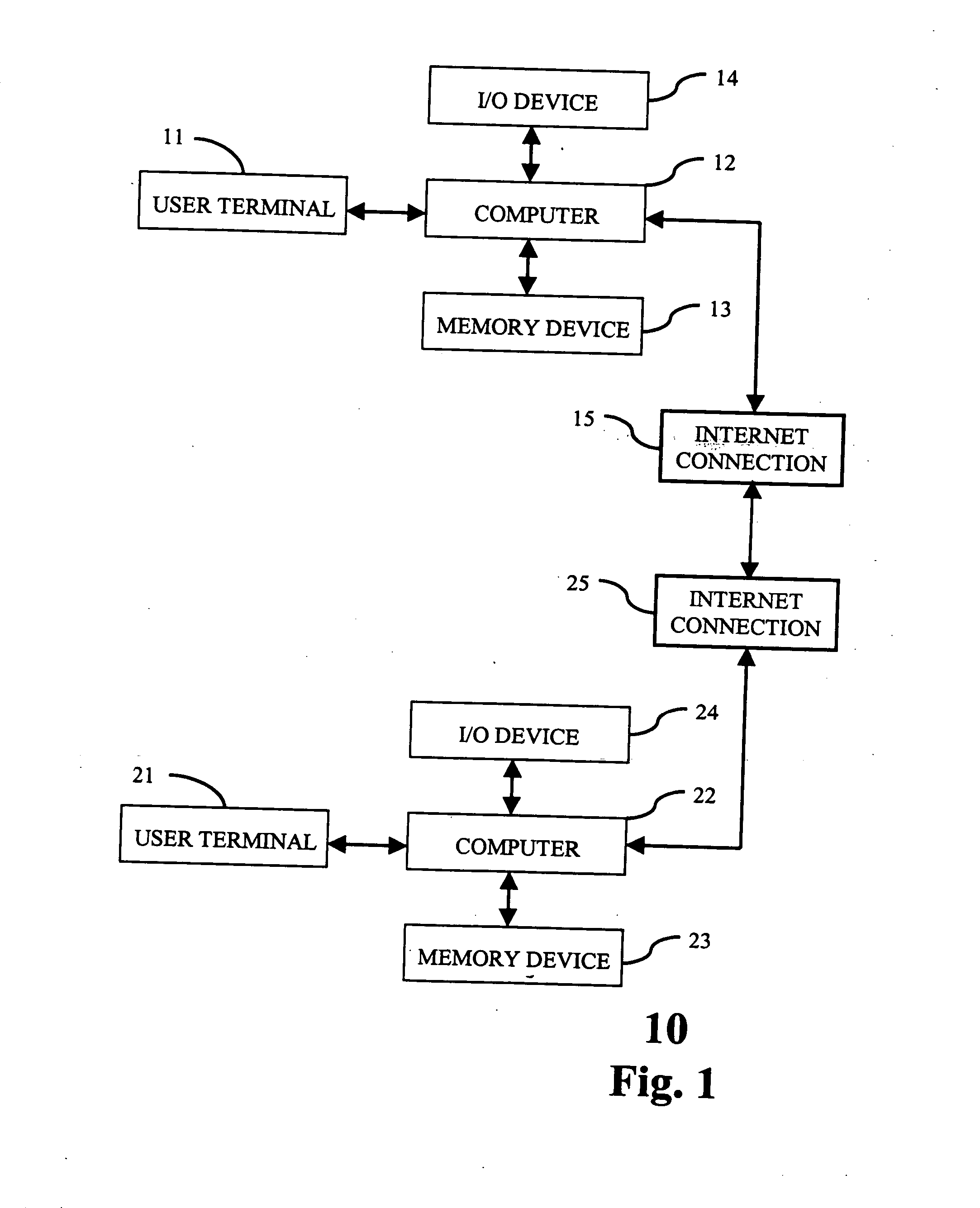

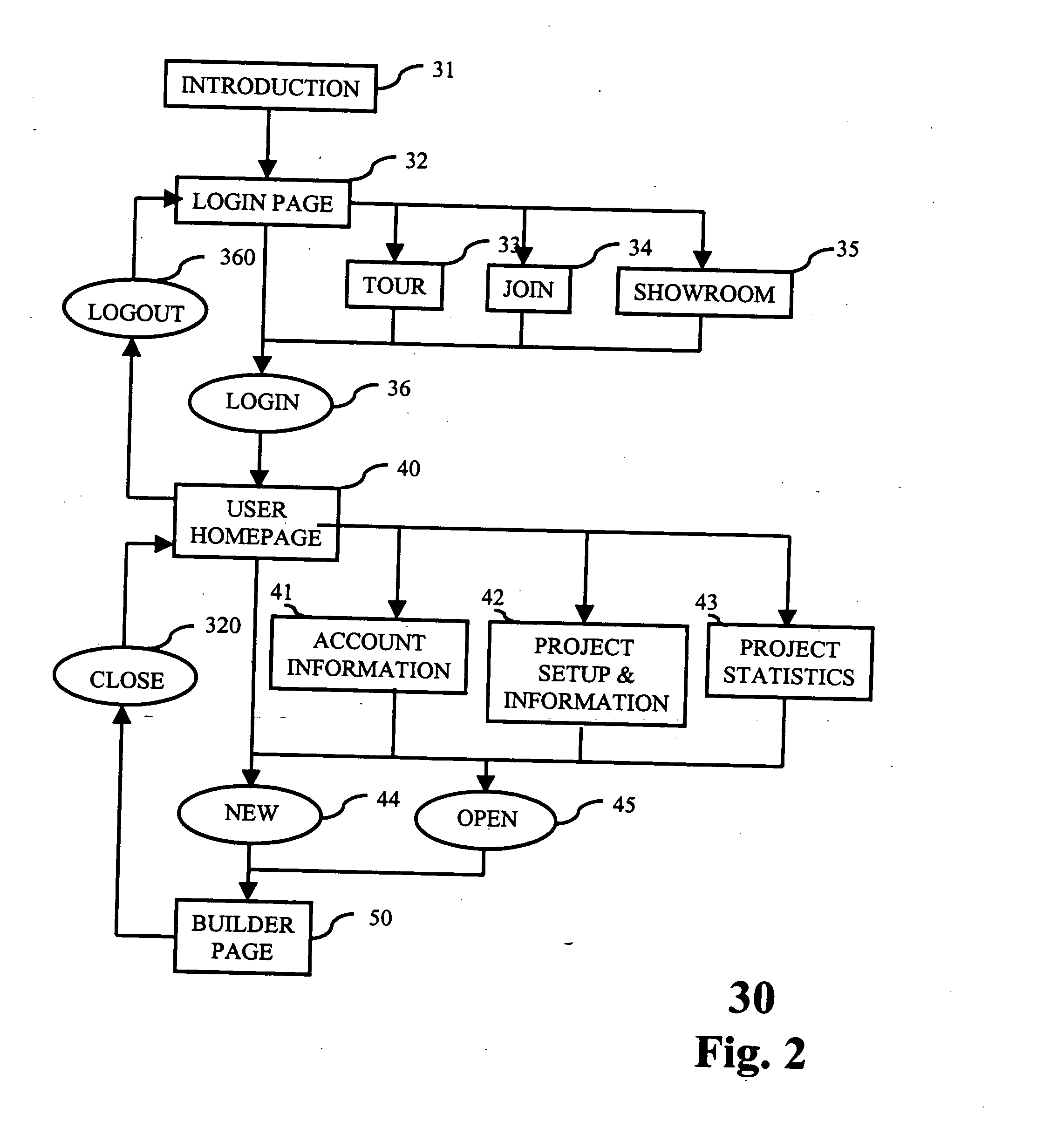

Methods, systems, and processes for the design and creation of rich-media applications via the Internet

Rich-media applications are designed and created via the Internet. A host computer system, containing processes for creating rich-media applications, is accessed from a remote user computer system via an Internet connection. User account information and rich-media component specifications are uploaded via the established Internet connection for a specific user account. Rich-media applications are created, deleted, or modified in a user account via the established Internet connection. Rich-media components are added to, modified in, or deleted from scenes of a rich-media application based on information contained in user requests. After creation, the rich-media application is viewed or saved on the host computer system, or downloaded to the user computer system via the established Internet connection. In addition, the host process monitors the available computer and network resources and determines the particular component, scene, and application versions, if multiple versions exist, that most closely match the available resources.

Owner:BALTHASER NEIL

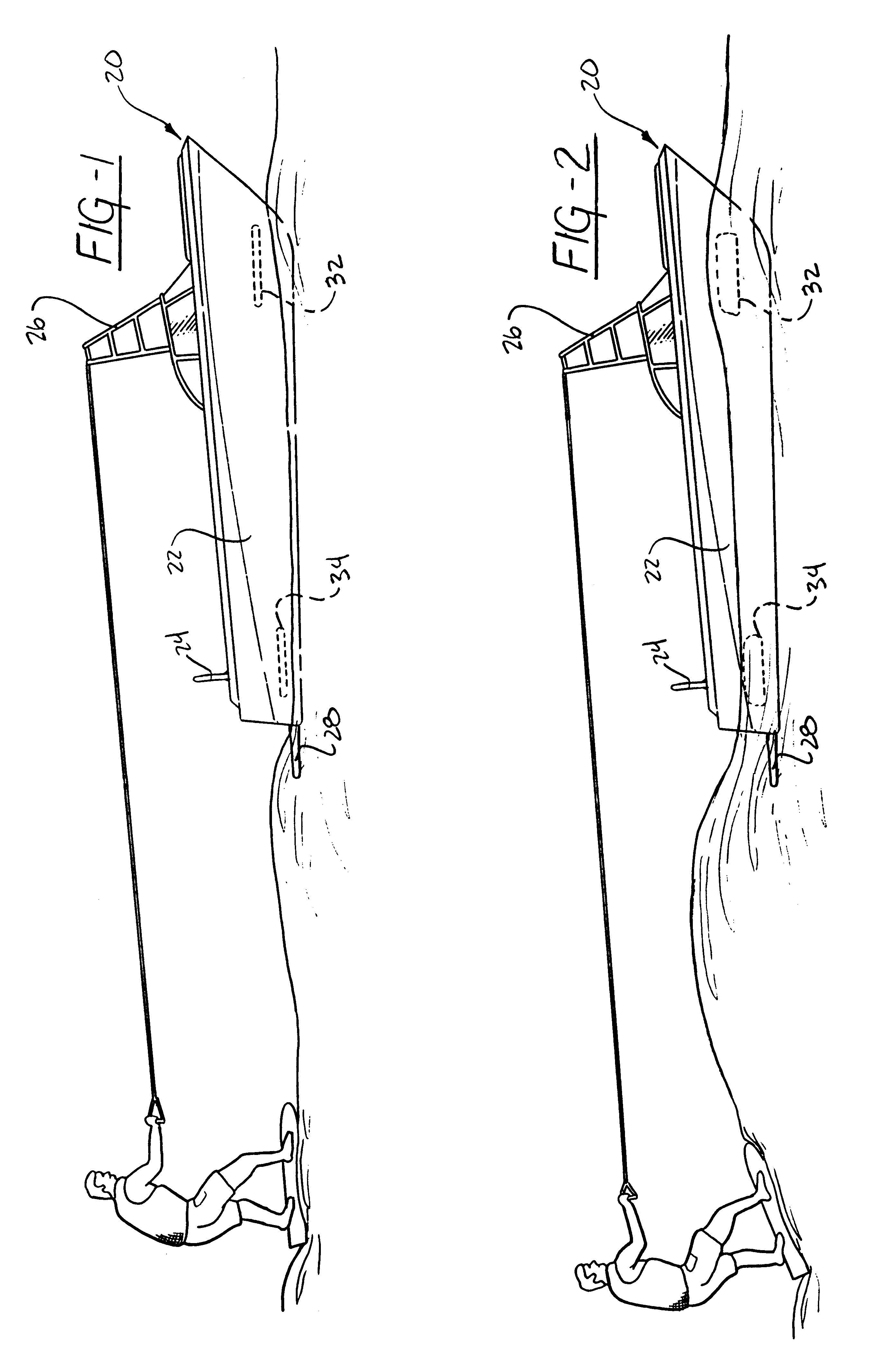

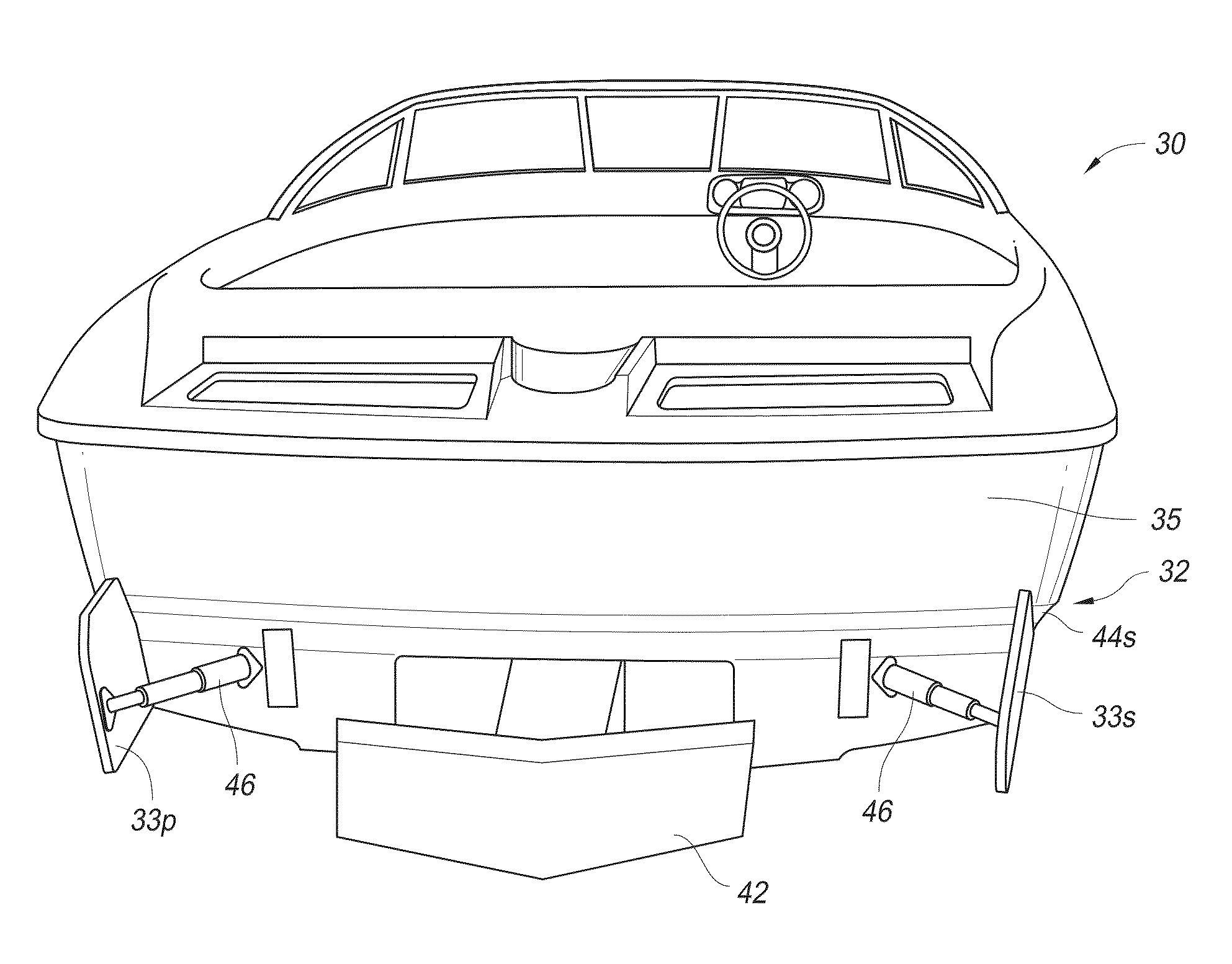

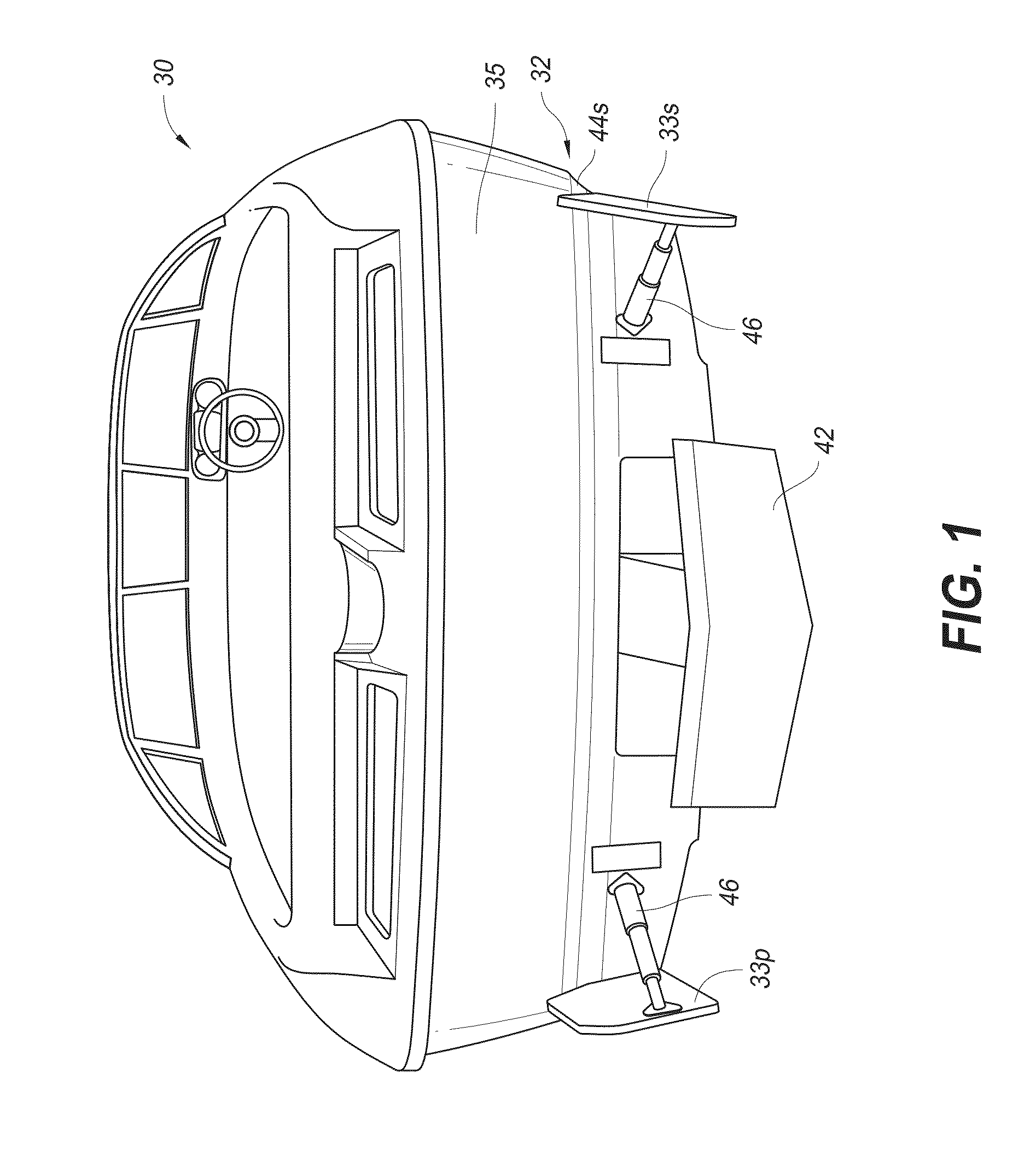

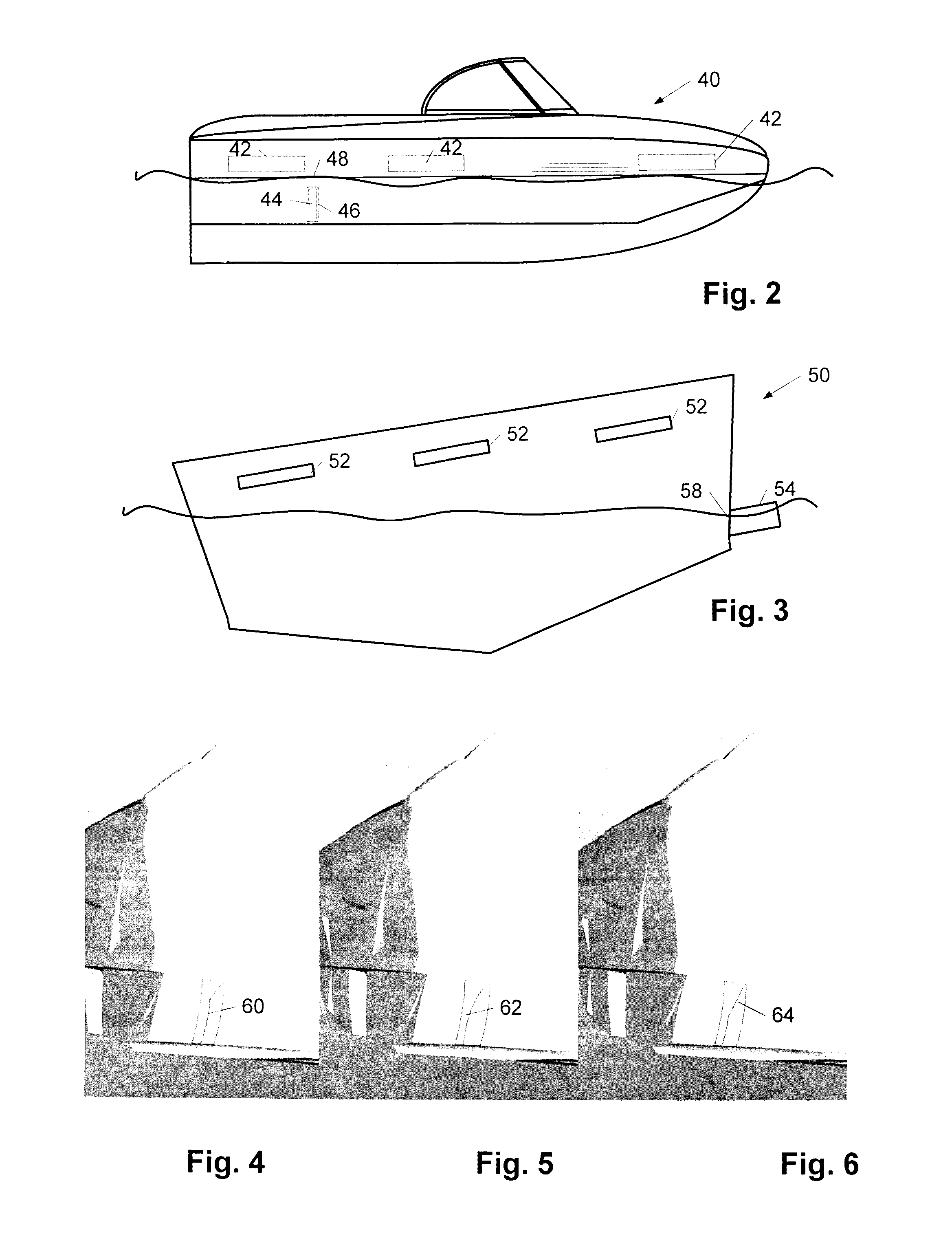

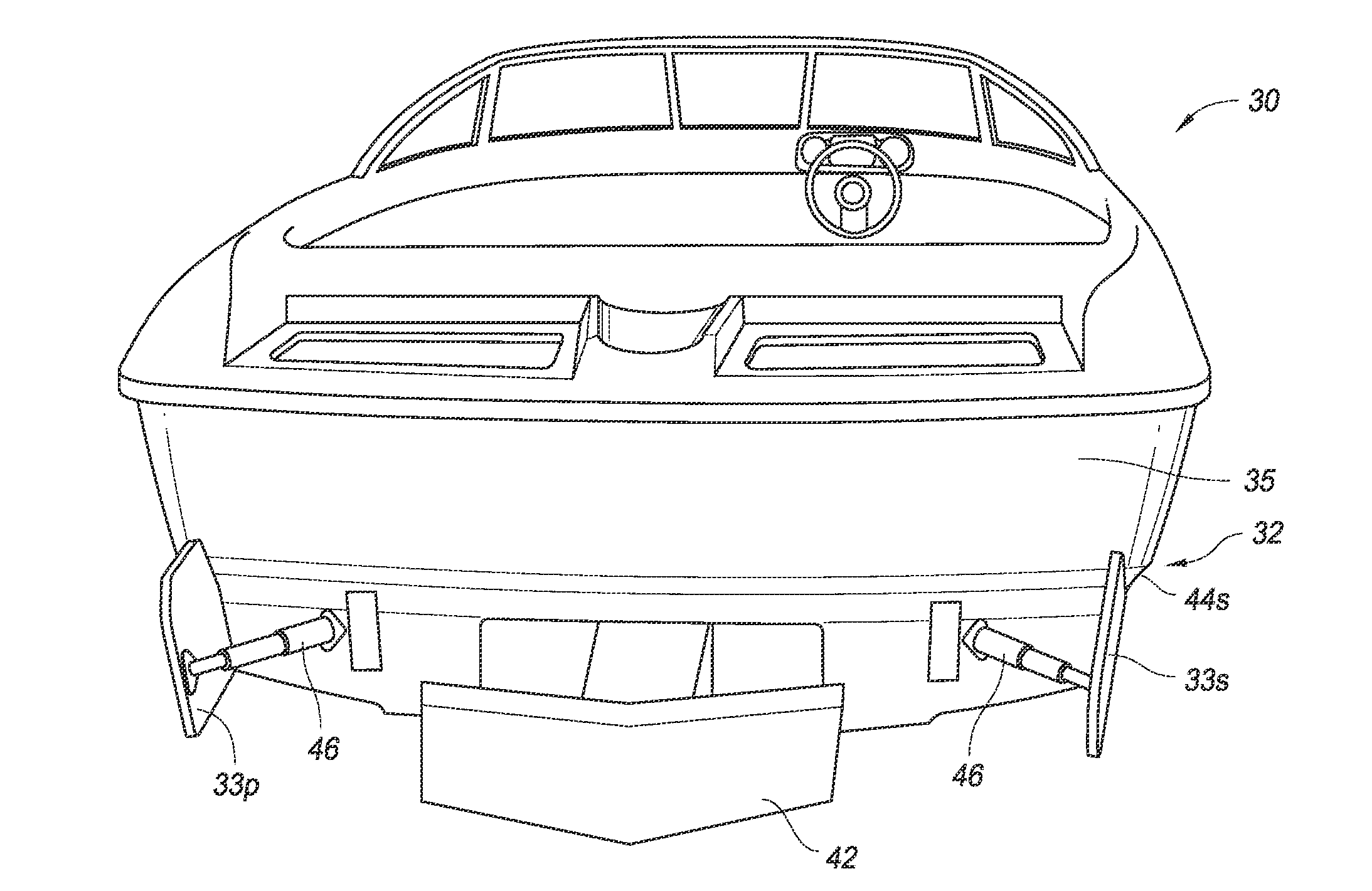

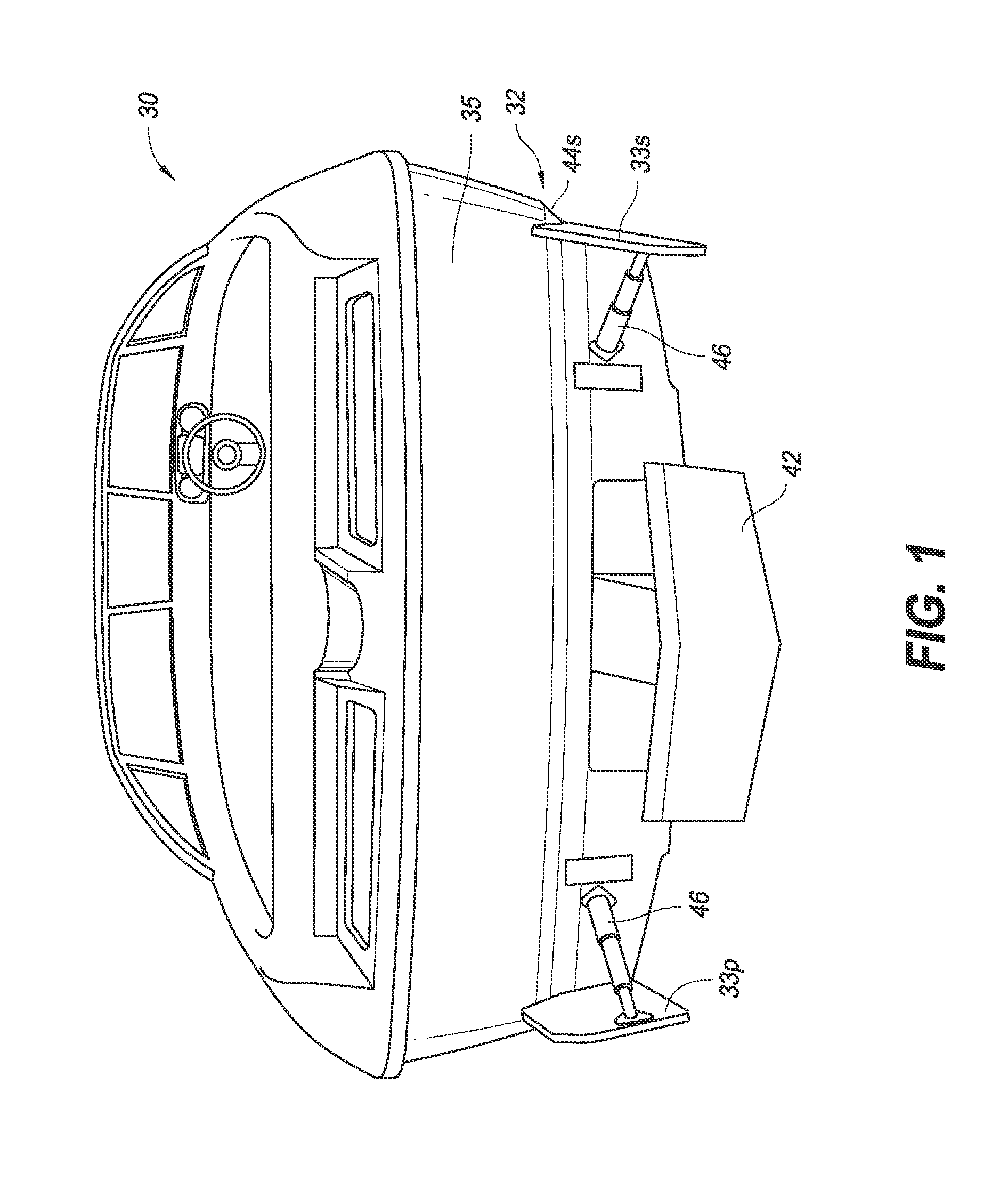

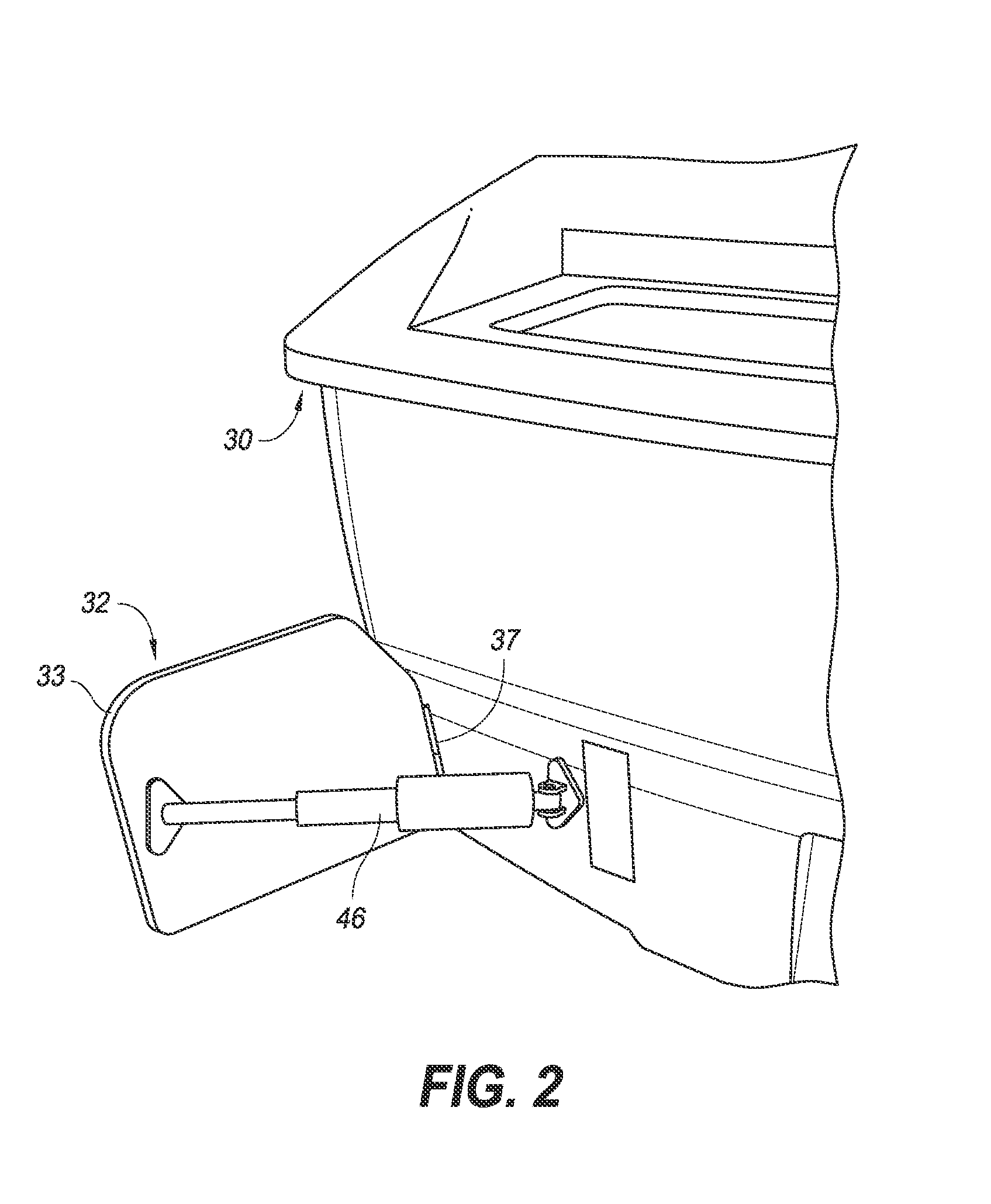

Surf wake system for a watercraft

An adjustable surf wake system enhances a wake formed by a watercraft travelling through water. The system may include a flap for deflecting water traveling past the stern of the watercraft, and / or a positioner operably connected to the flap for positioning the flap relative to a longitudinal axis of the watercraft between a neutral position and an outward position. Positioning a port flap in its extended position enhances a starboard surf wake, and positioning the starboard flap in its extended position enhances a port surf wake.

Owner:MALIBU BOATS

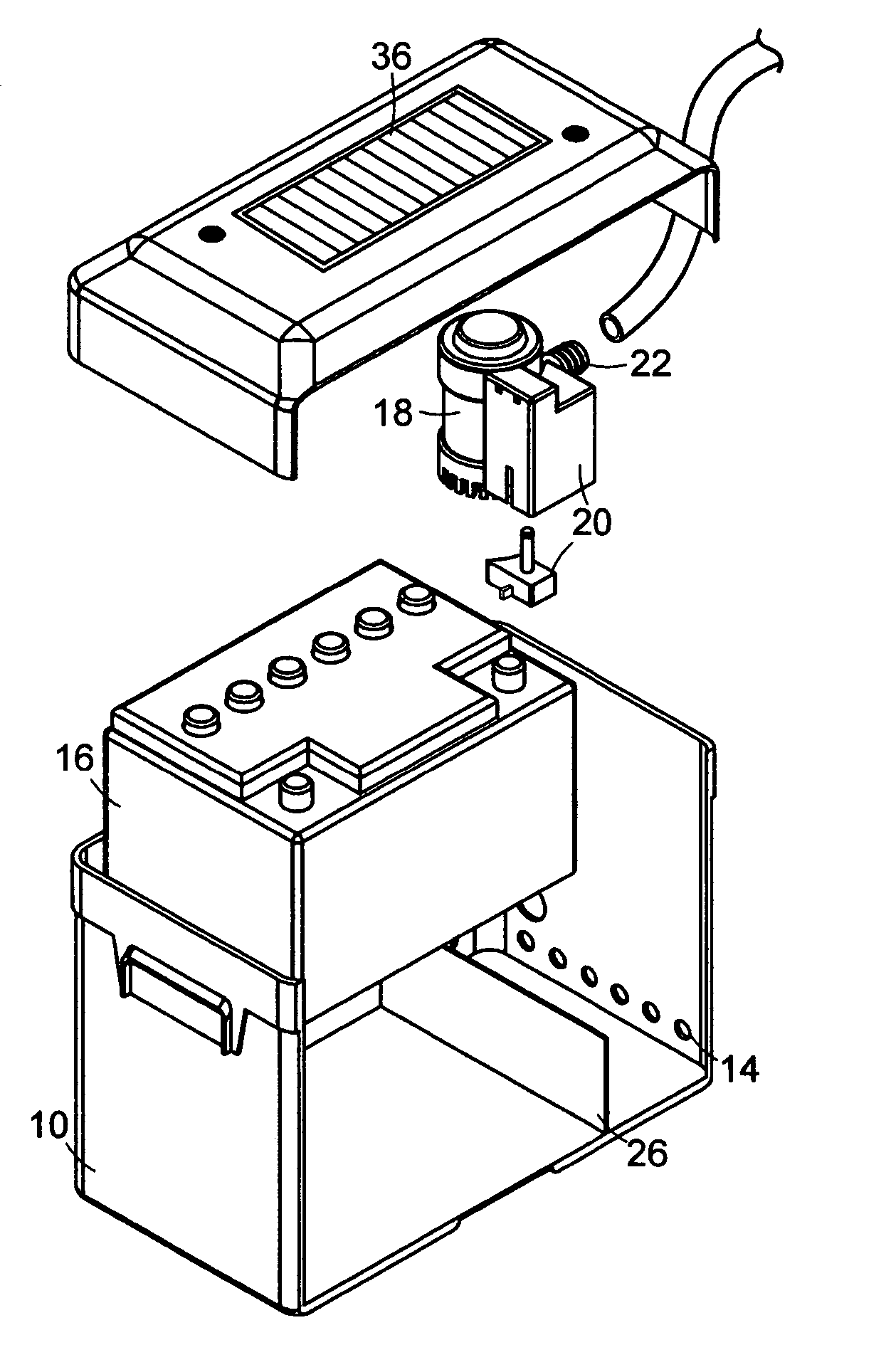

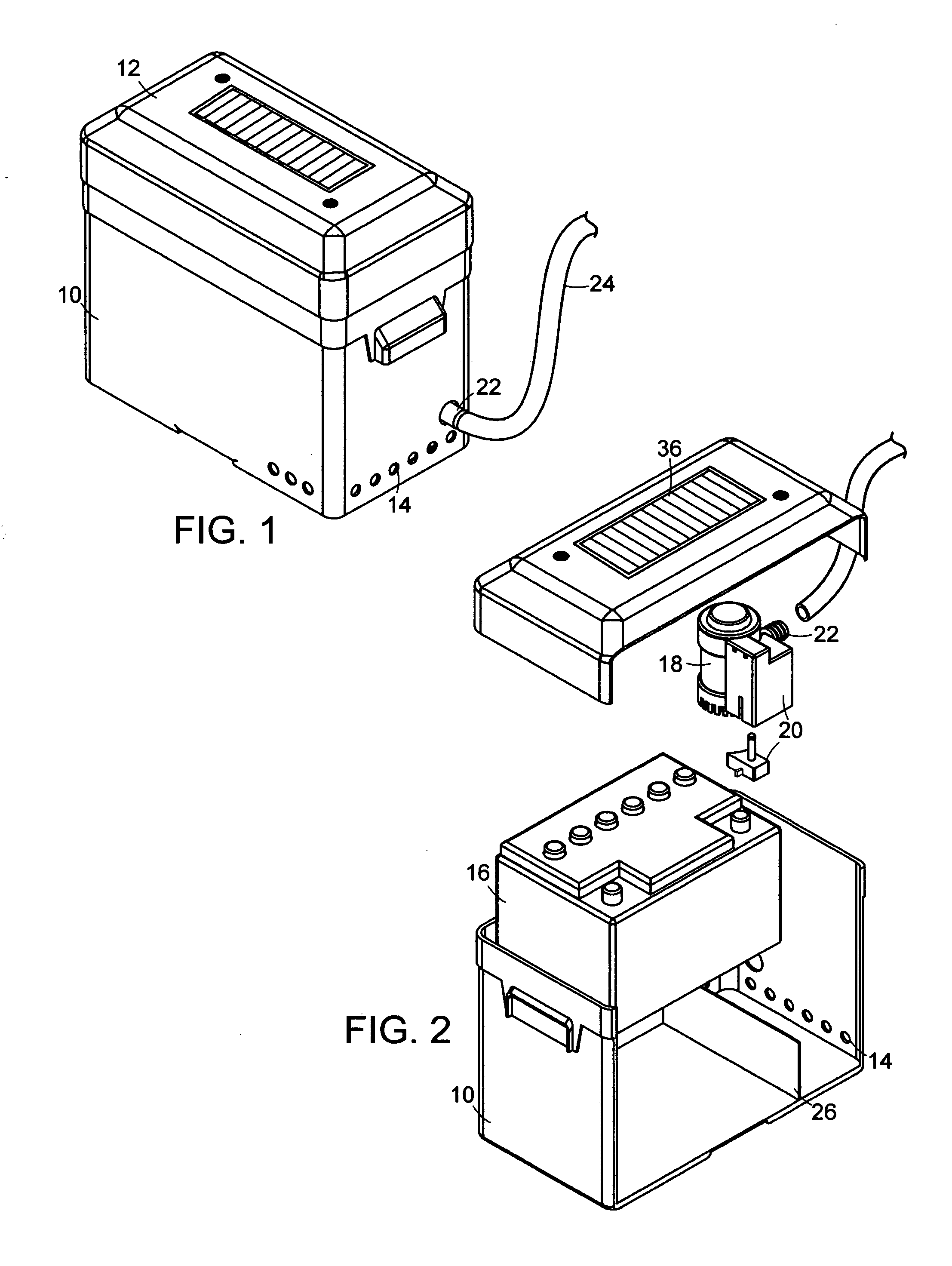

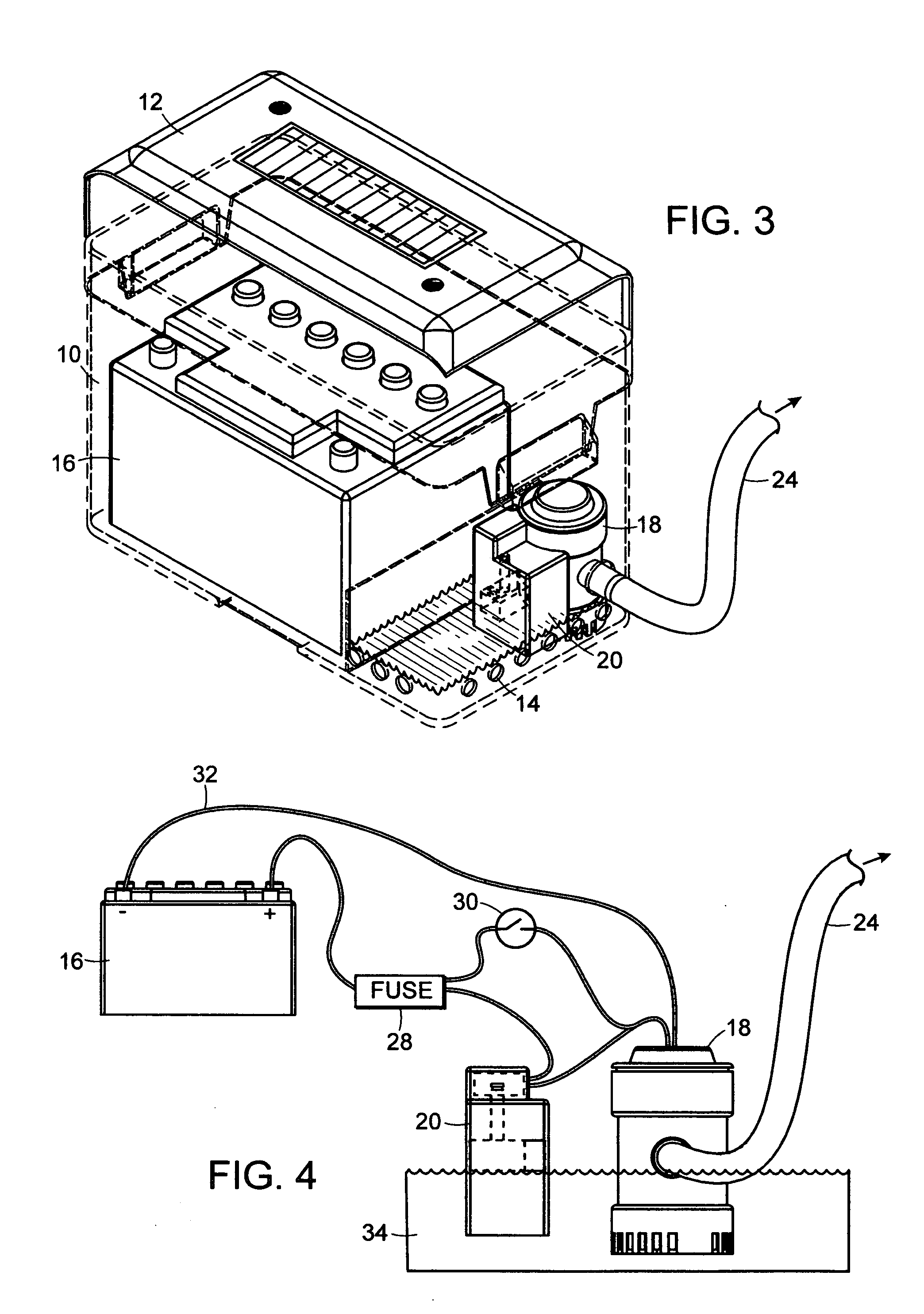

Portable battery powered automatic pump

InactiveUS20060269426A1Easy to assembleEliminate needSelf-bailing equipments/scuppersVessel partsBilgeElectrical battery

Owner:LLEWELLYN DANIEL M

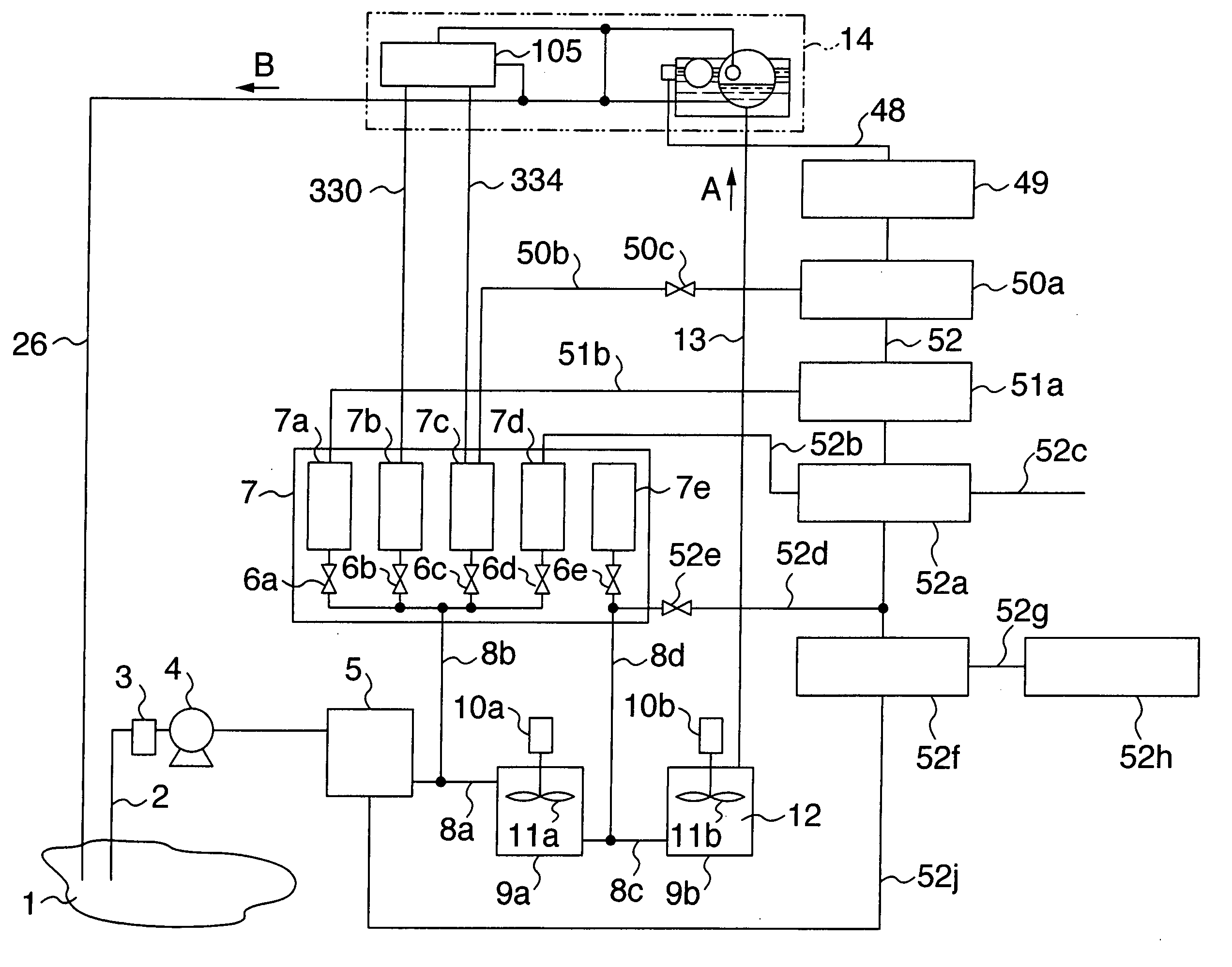

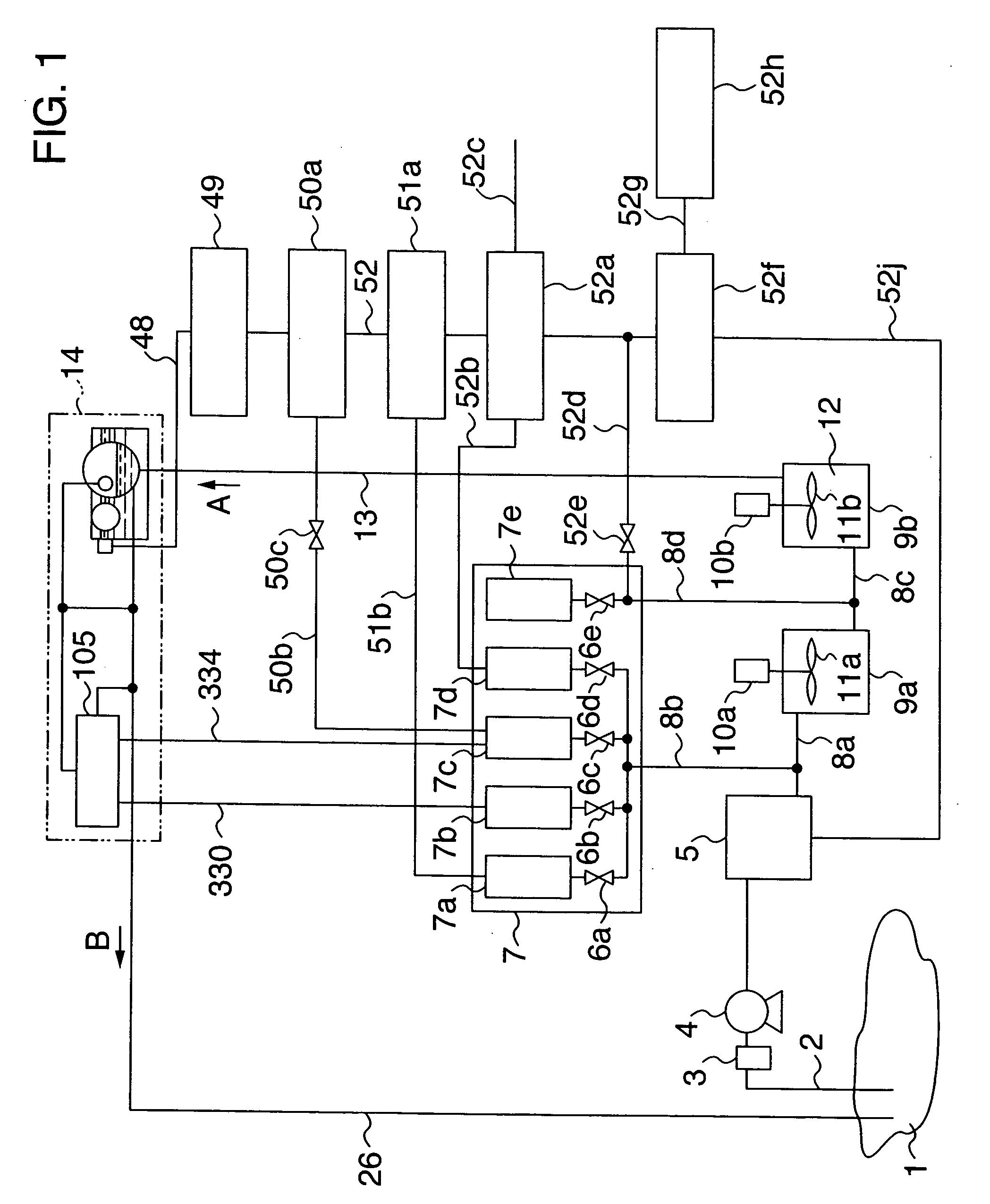

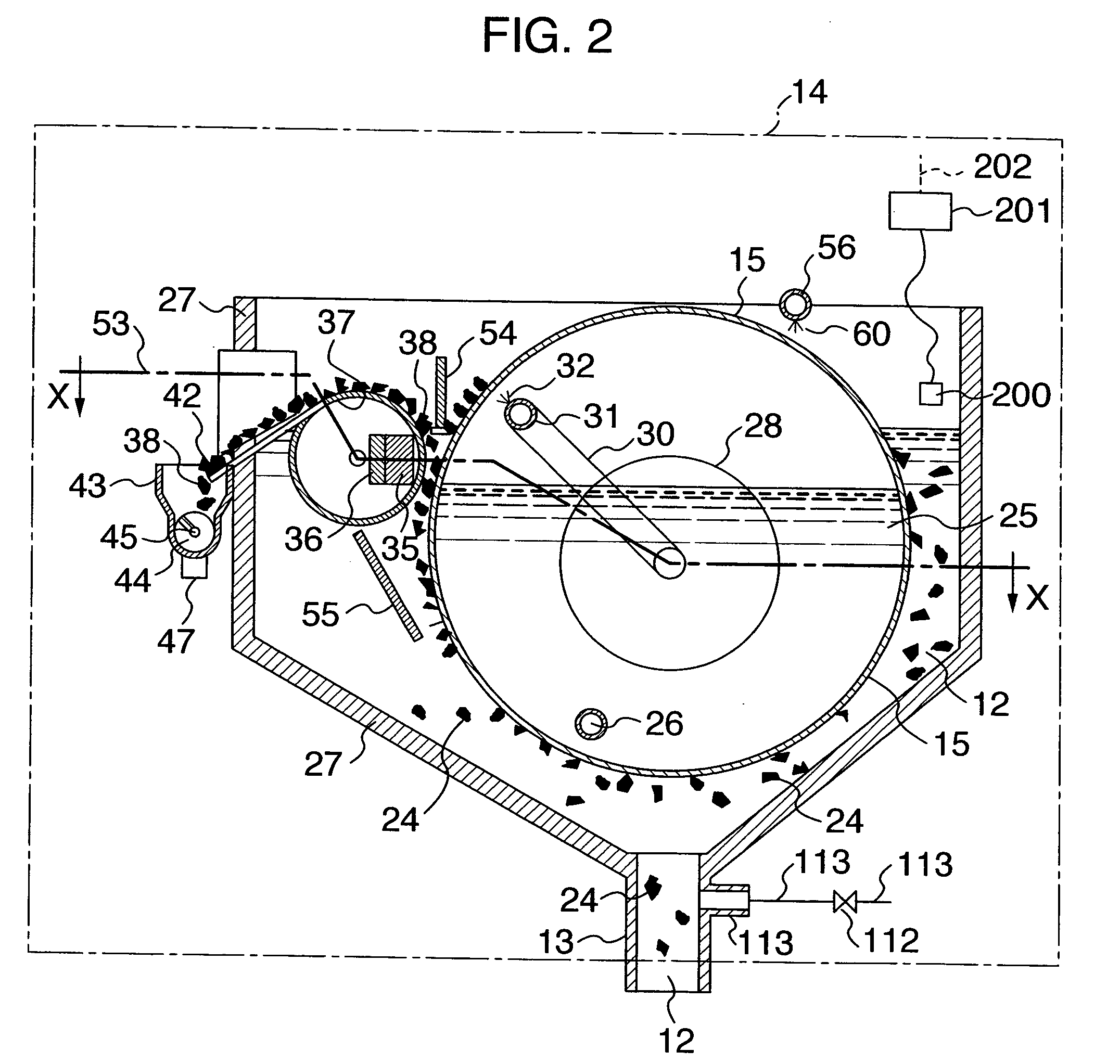

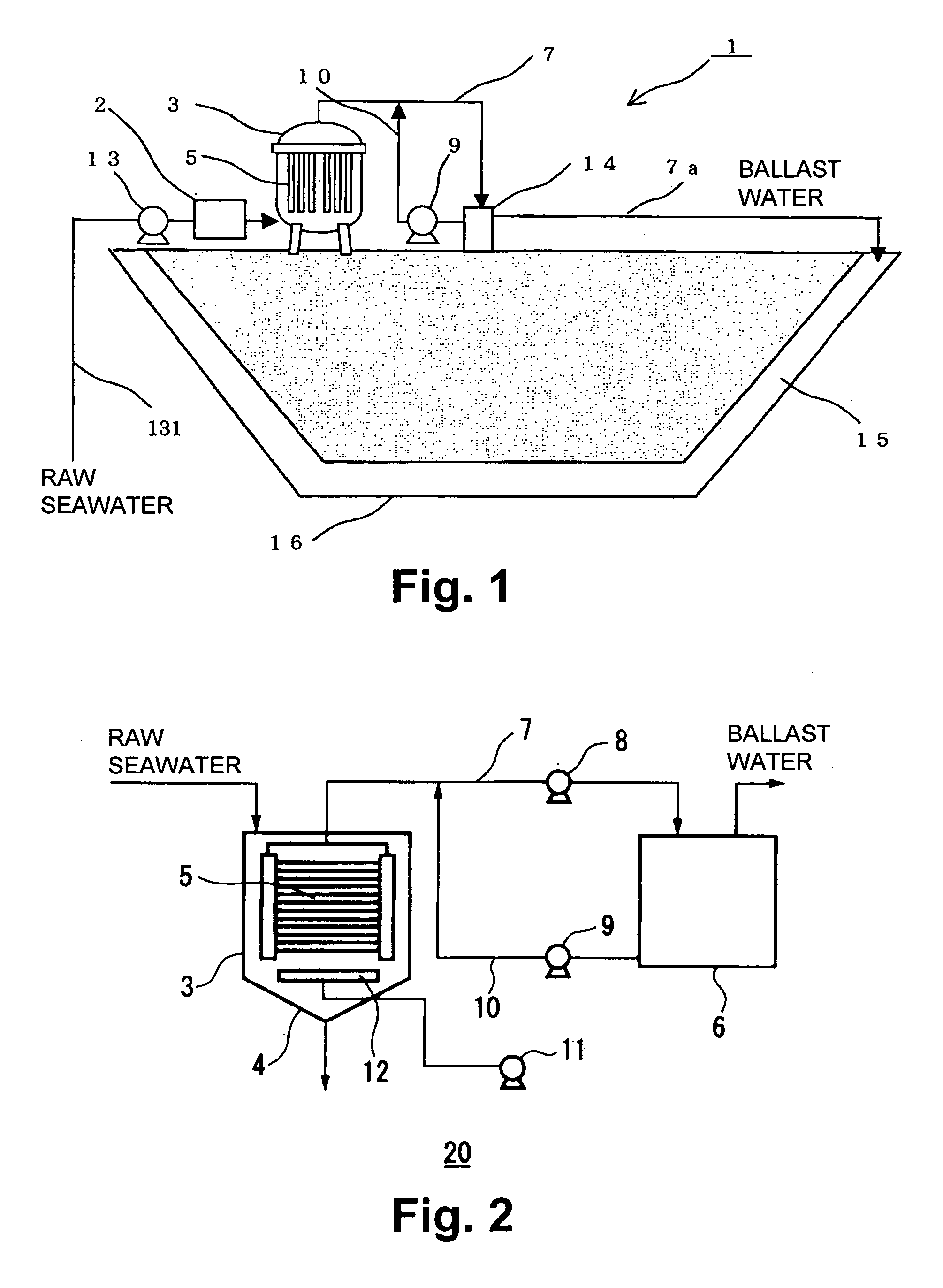

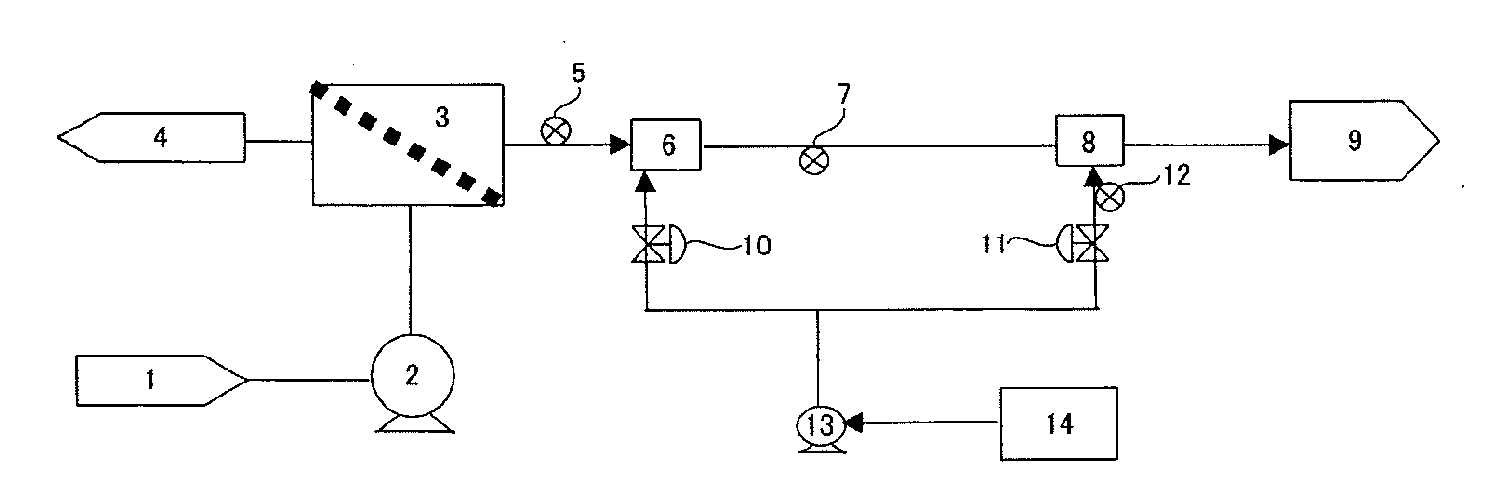

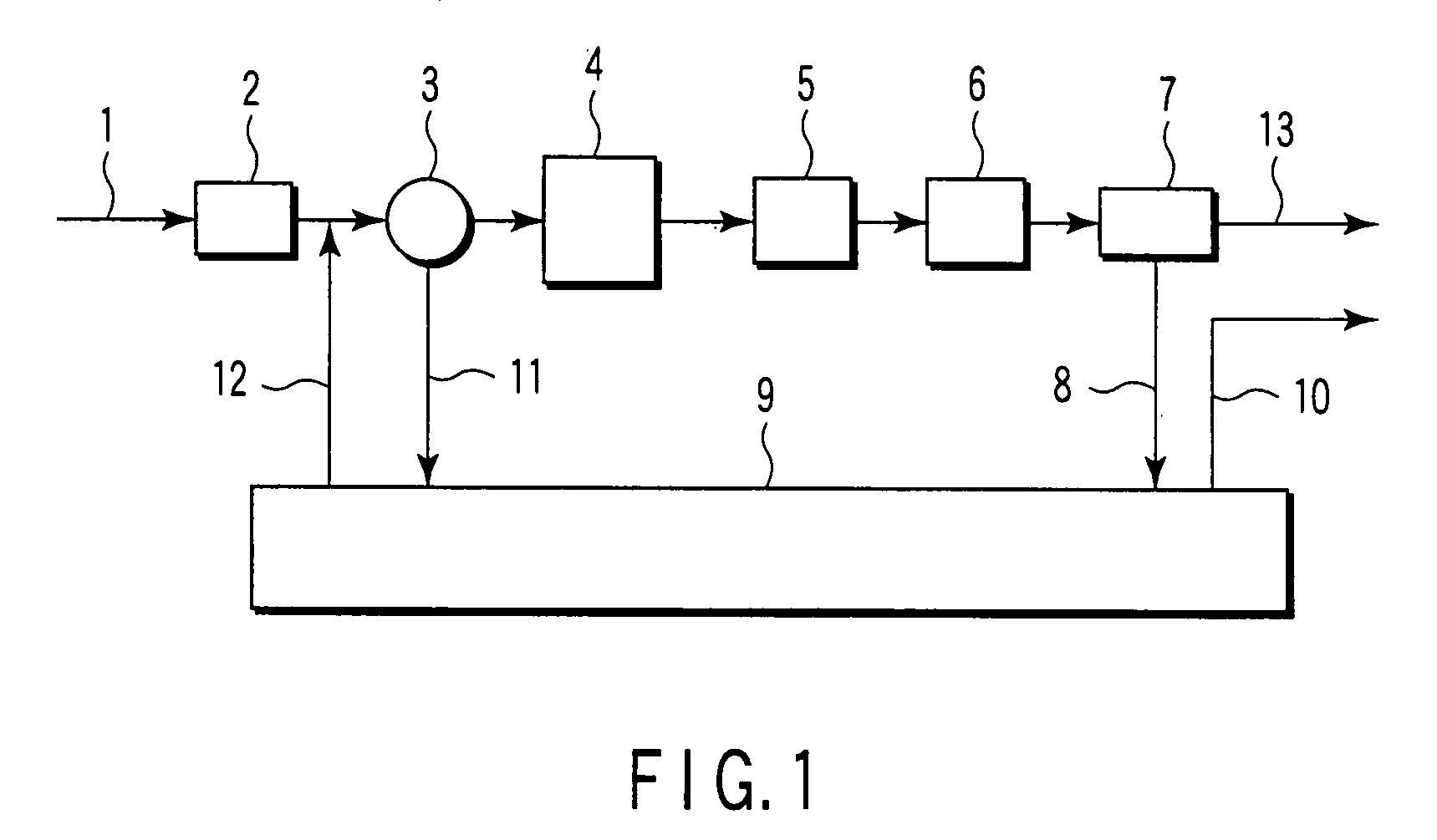

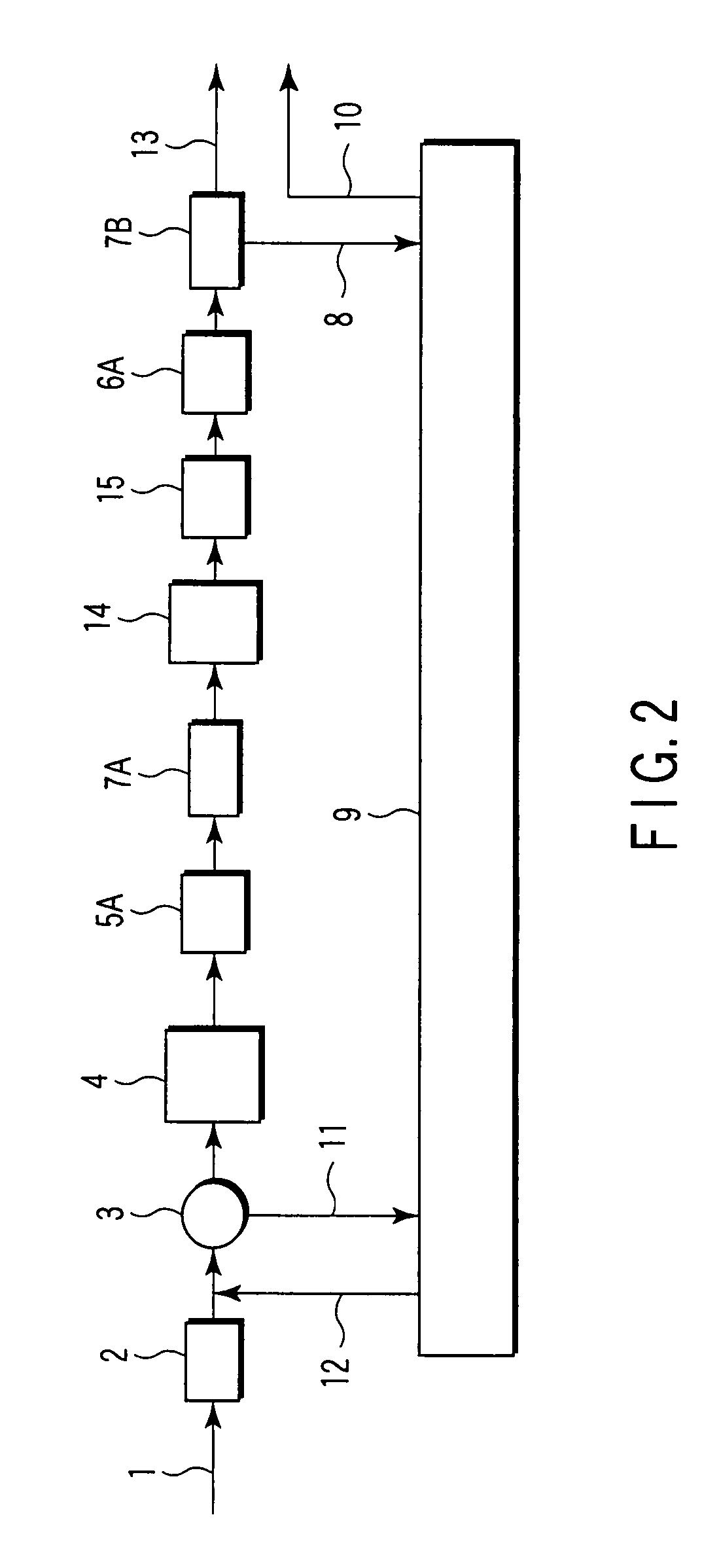

Ballast water treatment apparatus and method

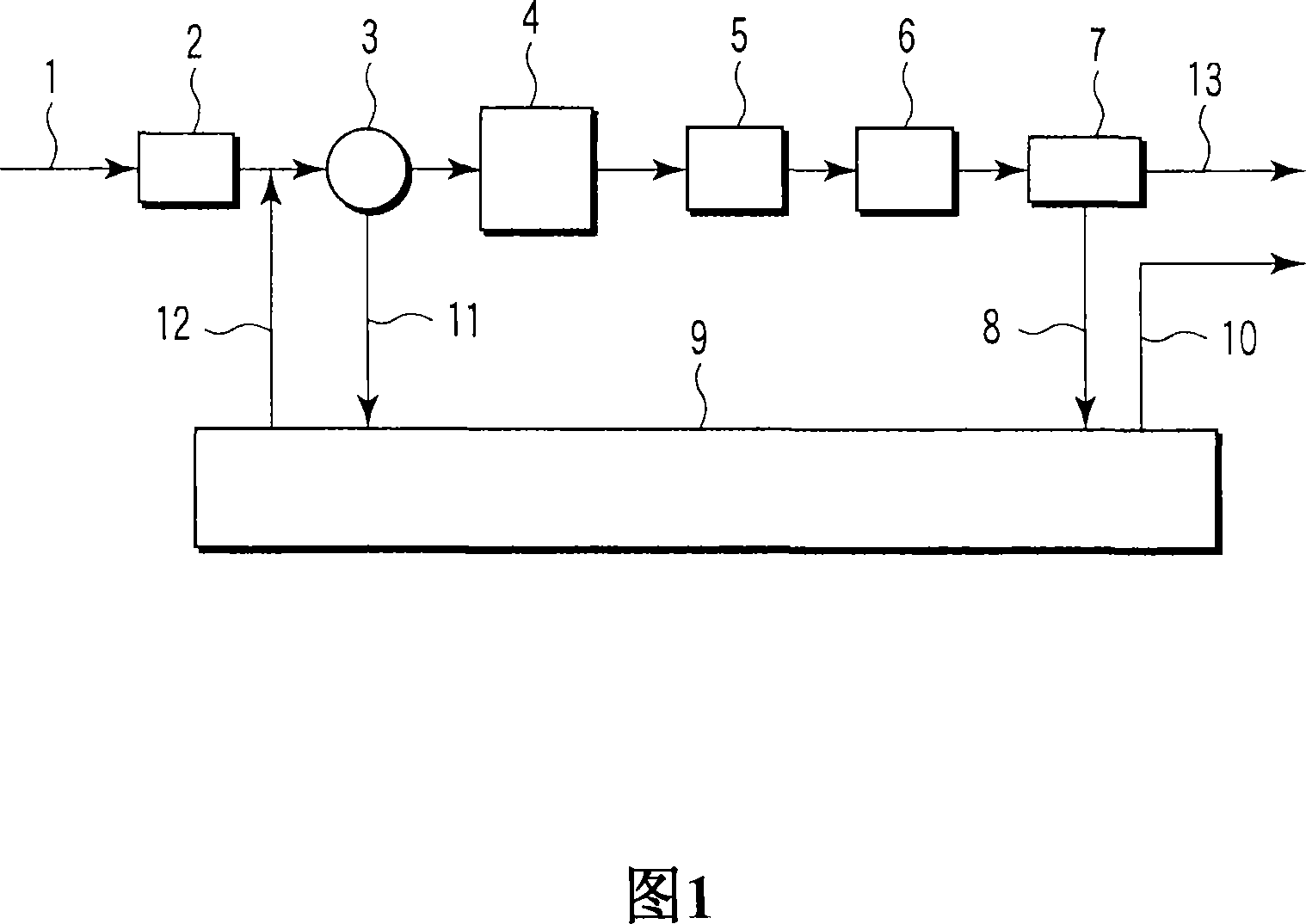

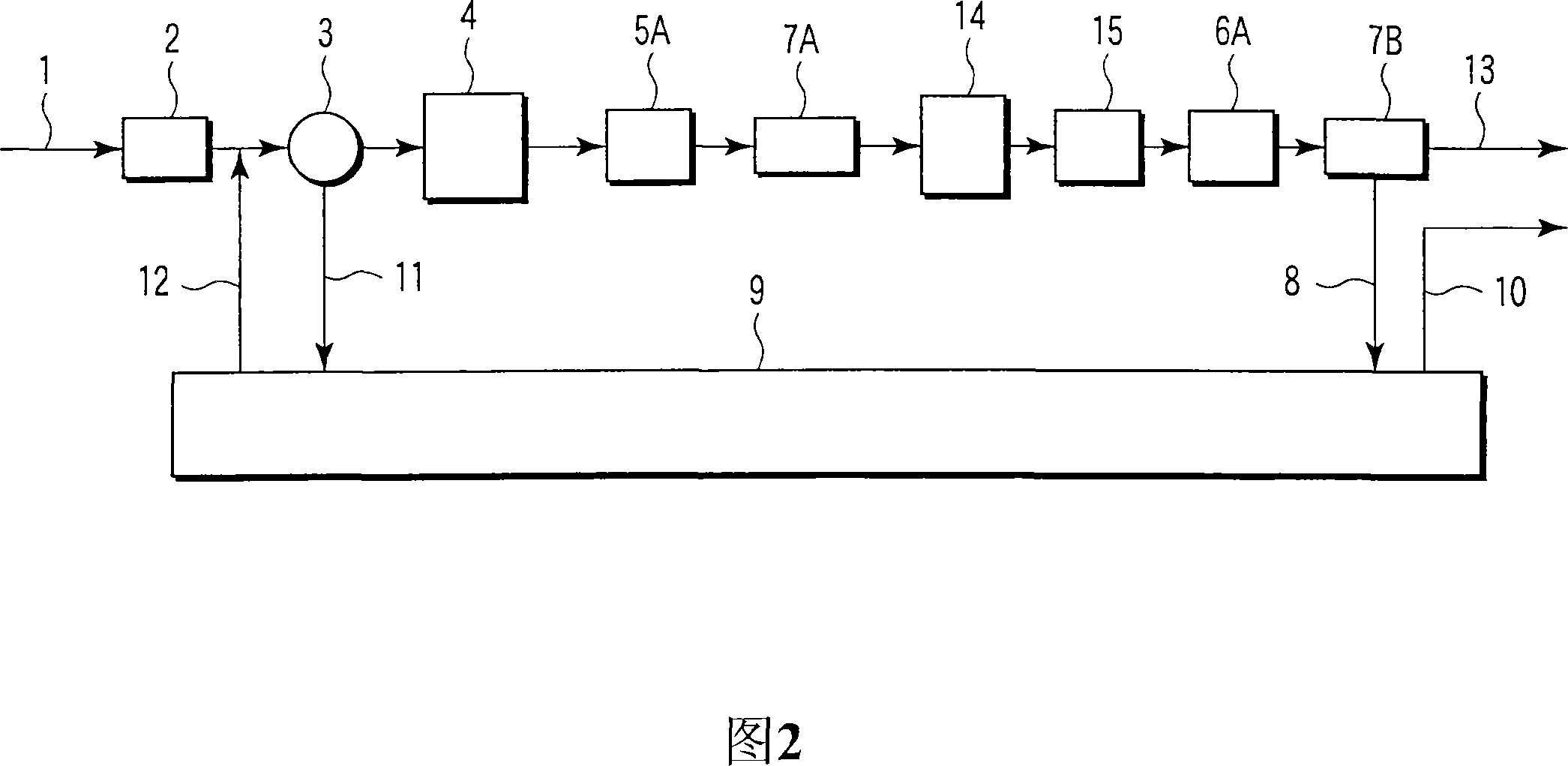

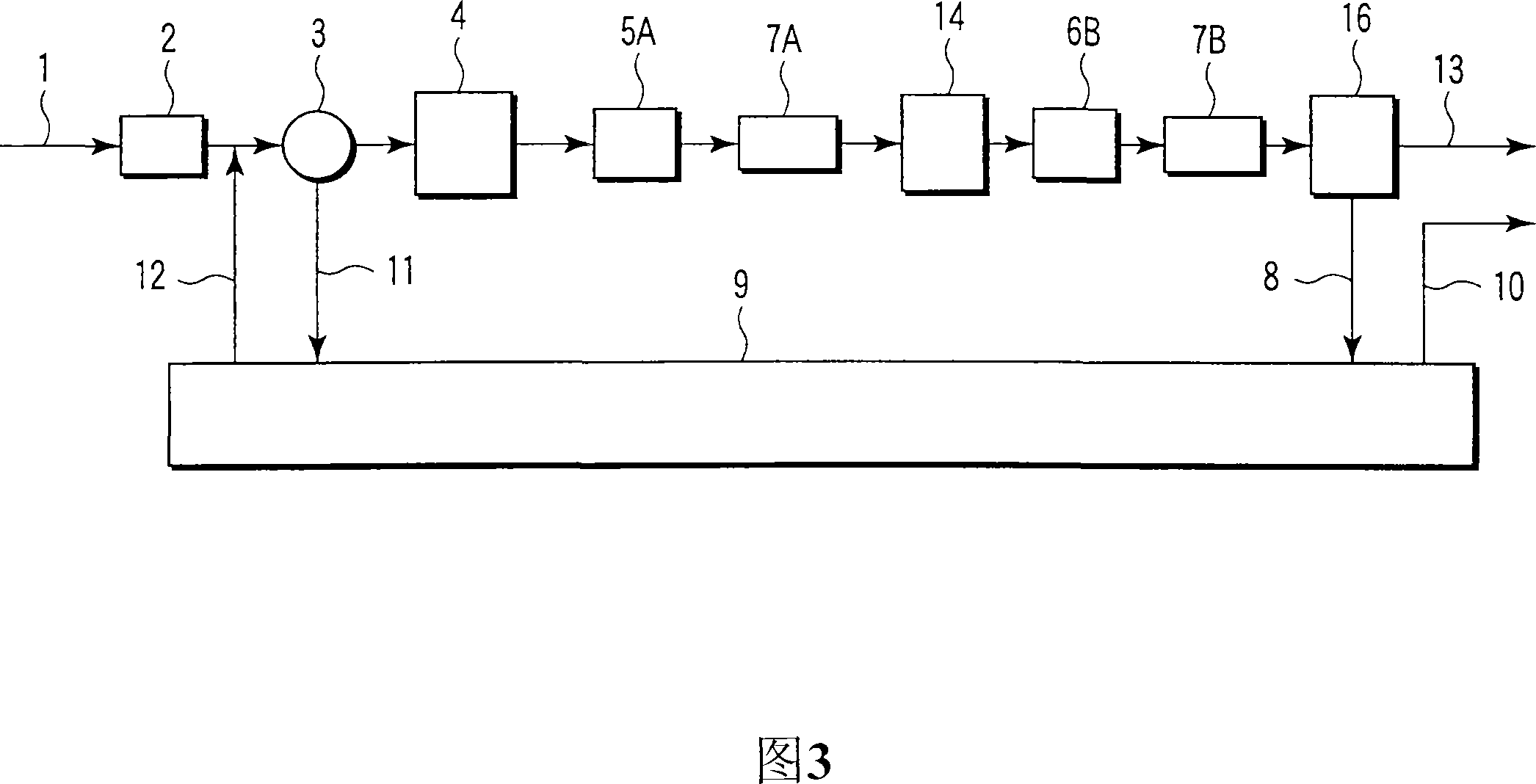

InactiveCN101193824AImprove permeabilityStrong toleranceAuxillariesSelf-bailing equipments/scuppersFungicideCavitation

A ballast water treatment device which can meet the ballast water standard stipulated by IMO at low cost with certainty. Provided is a ballast water treatment device comprising: a filter unit (4) for filtering seawater to capture aquatic organisms; a bactericide supply unit (5) for supplying a bactericide to the filtered seawater; And Venturi tube (7), this tube is used for introducing the seawater that adds bactericide, and produces cavitation in seawater, thus has not only diffused bactericide but also kills or kills the aquatic organisms of seawater.

Owner:JFEENGINEERING CORP

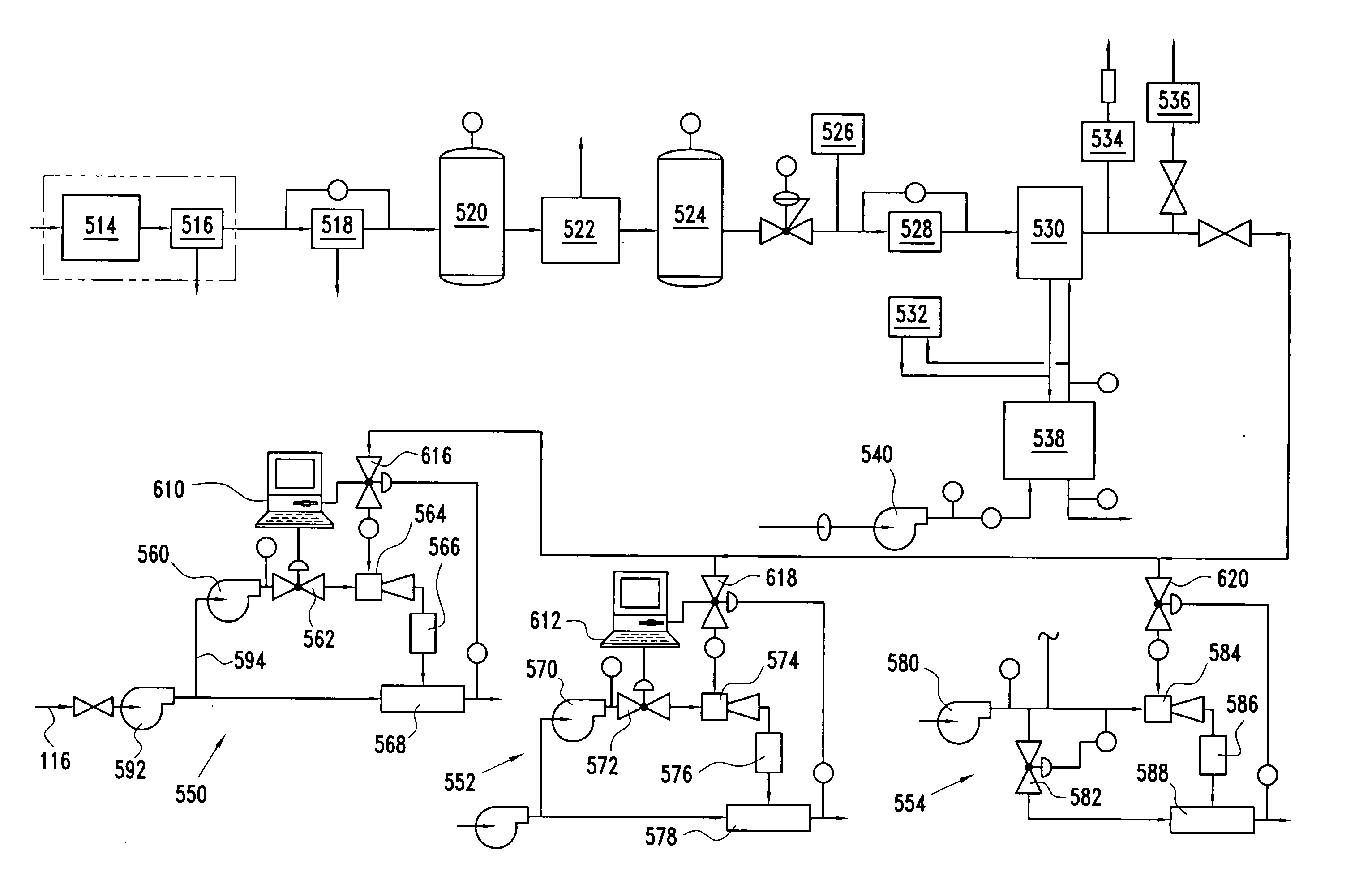

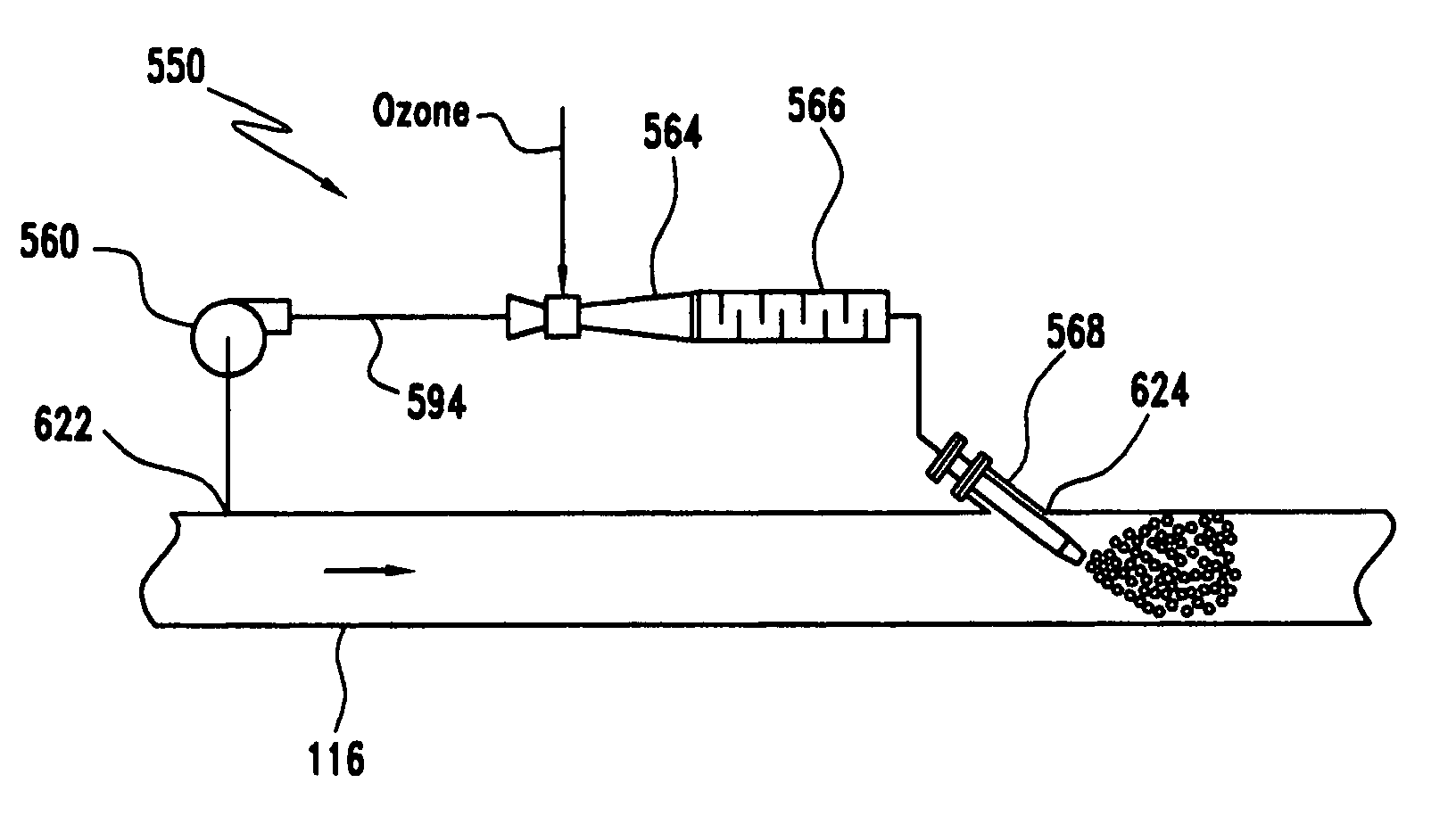

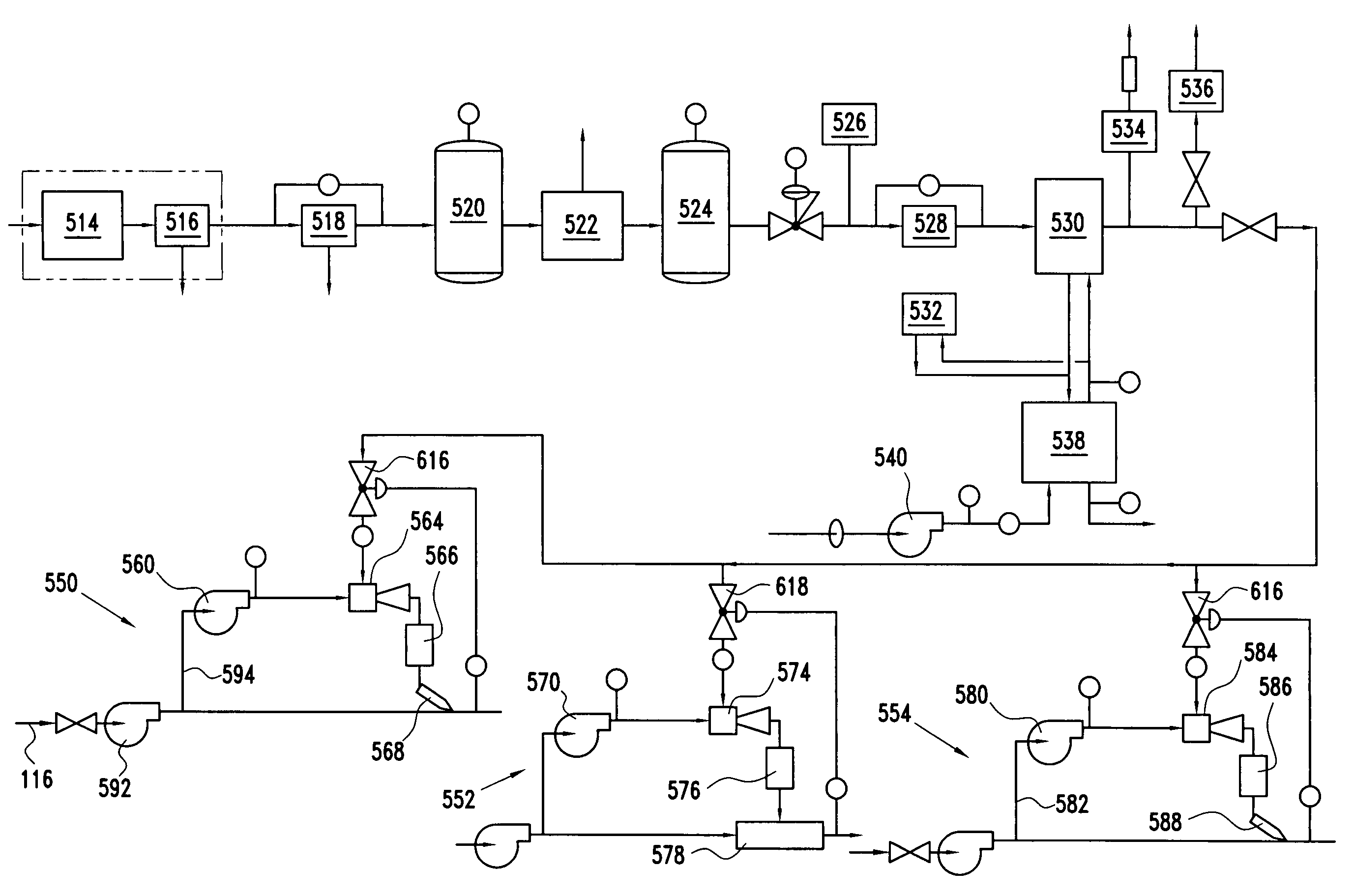

Ballast water ozone injection method and system

InactiveUS6869540B2Method securityAuxillariesSelf-bailing equipments/scuppersOzone generatorInjection point

A method to treat ballast water comprises injecting ozone into water loading into a sea faring vessel prior to charging the water into a ballast tank; and charging the ozone injected water into the ballast tank. A system for treating ballast water comprises a sea faring vessel including at least one ballast tank; an ozone generator that generates ozone, a ballast water conduit that uptakes water through a loading port of a sea faring vessel and conducts the water to load the ballast tank; and an ozone feed line that injects ozone from the generator into water in the conduit at an injection point located upstream to an intersection of the conduit with the ballast tank.

Owner:NUTECH O3 INC

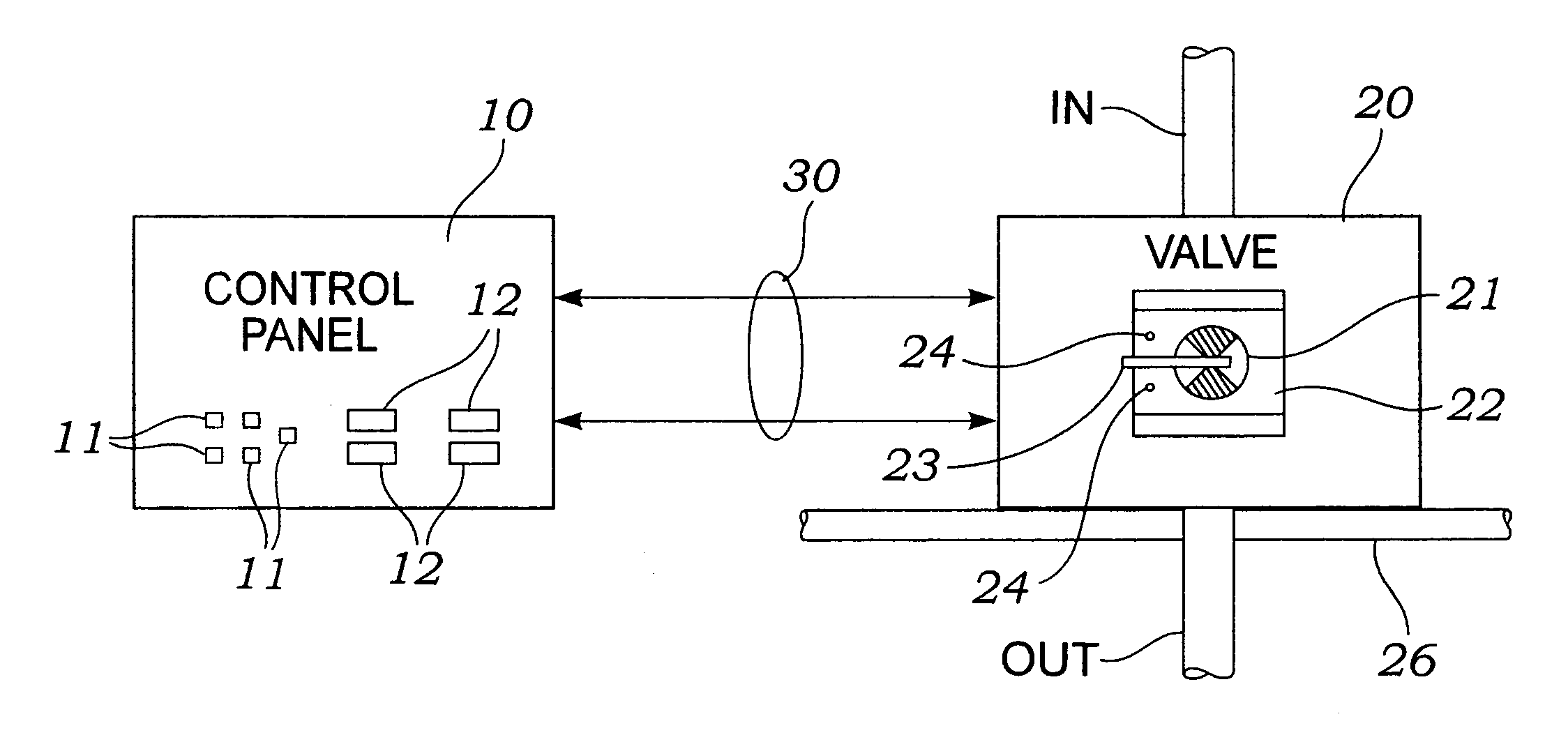

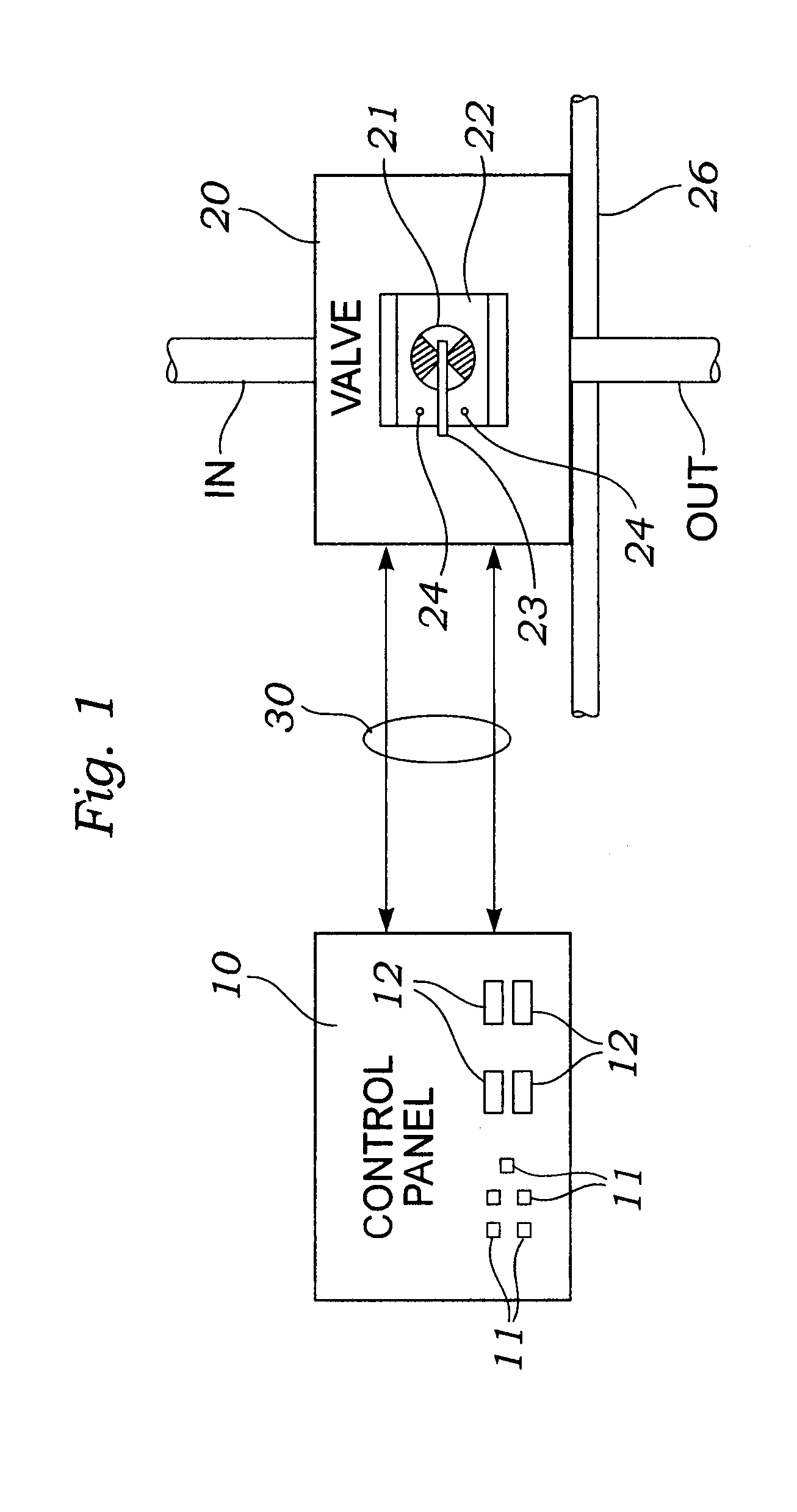

Valve monitoring and controlling system

InactiveUS7784490B1Operating means/releasing devices for valvesSelf-bailing equipments/scuppersMonitoring systemEngineering

A valve monitoring system including at least one valve having a movable handle with an activator therein mounted adjacent to a support panel on which are disposed a plurality of sensor devices responsive to the activator and a separate indicator panel for displaying the position of the valve handle. The activator at the handle and the sensor devices interact to selectively indicate operational conditions of the valve. In addition, a motor can be used to move the handle, and reconfigure the valve, as desired.

Owner:FORESMAN ROBERT

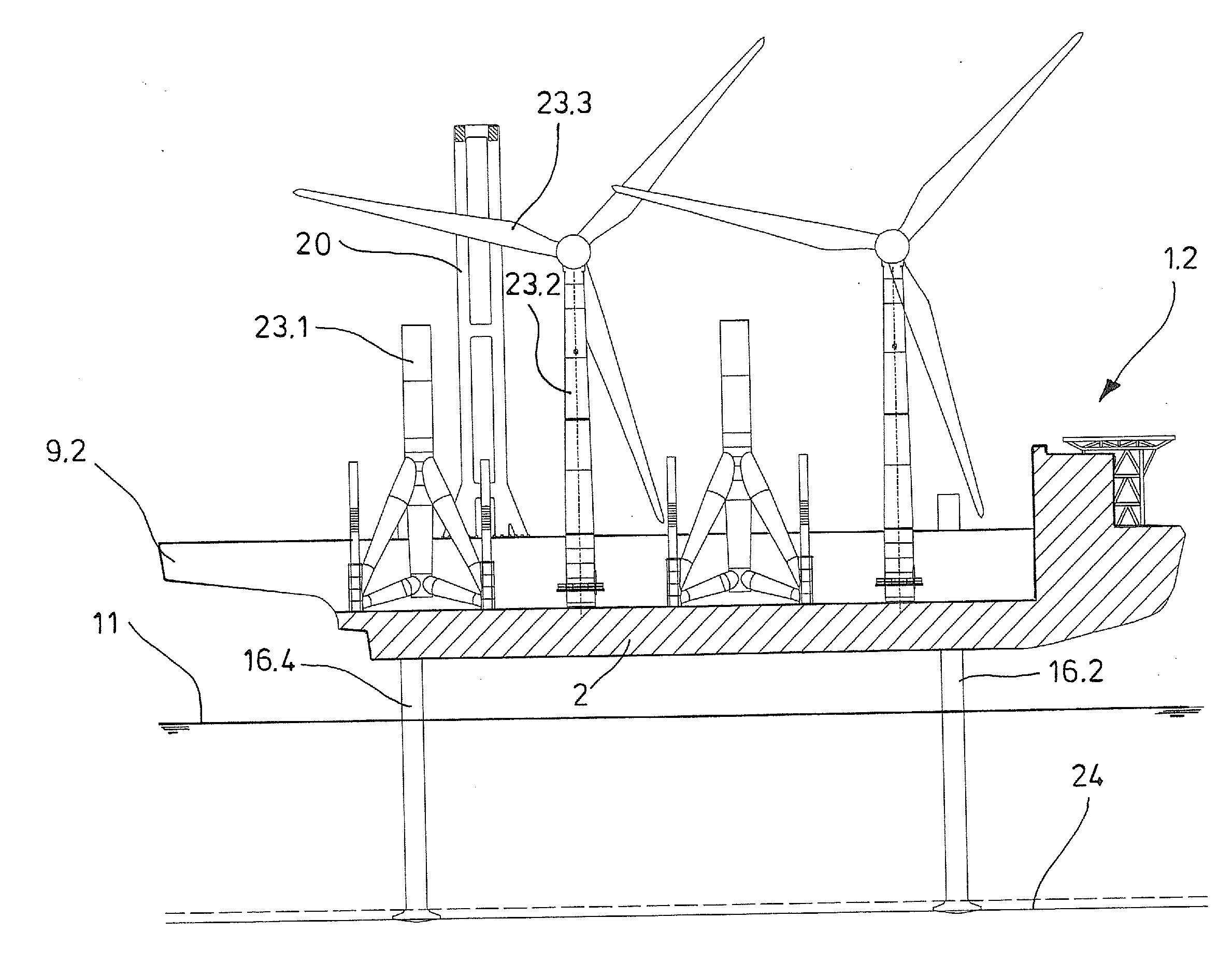

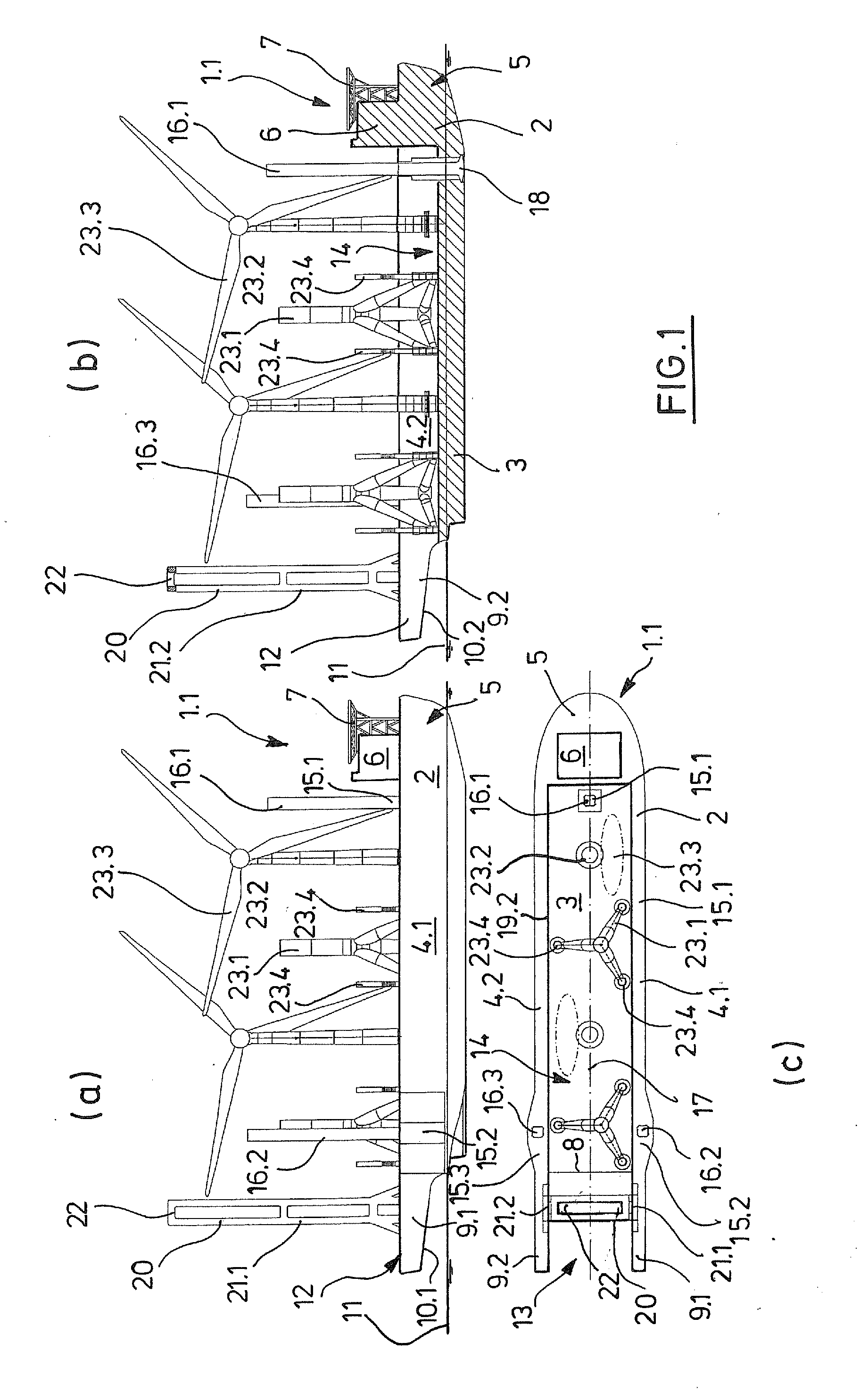

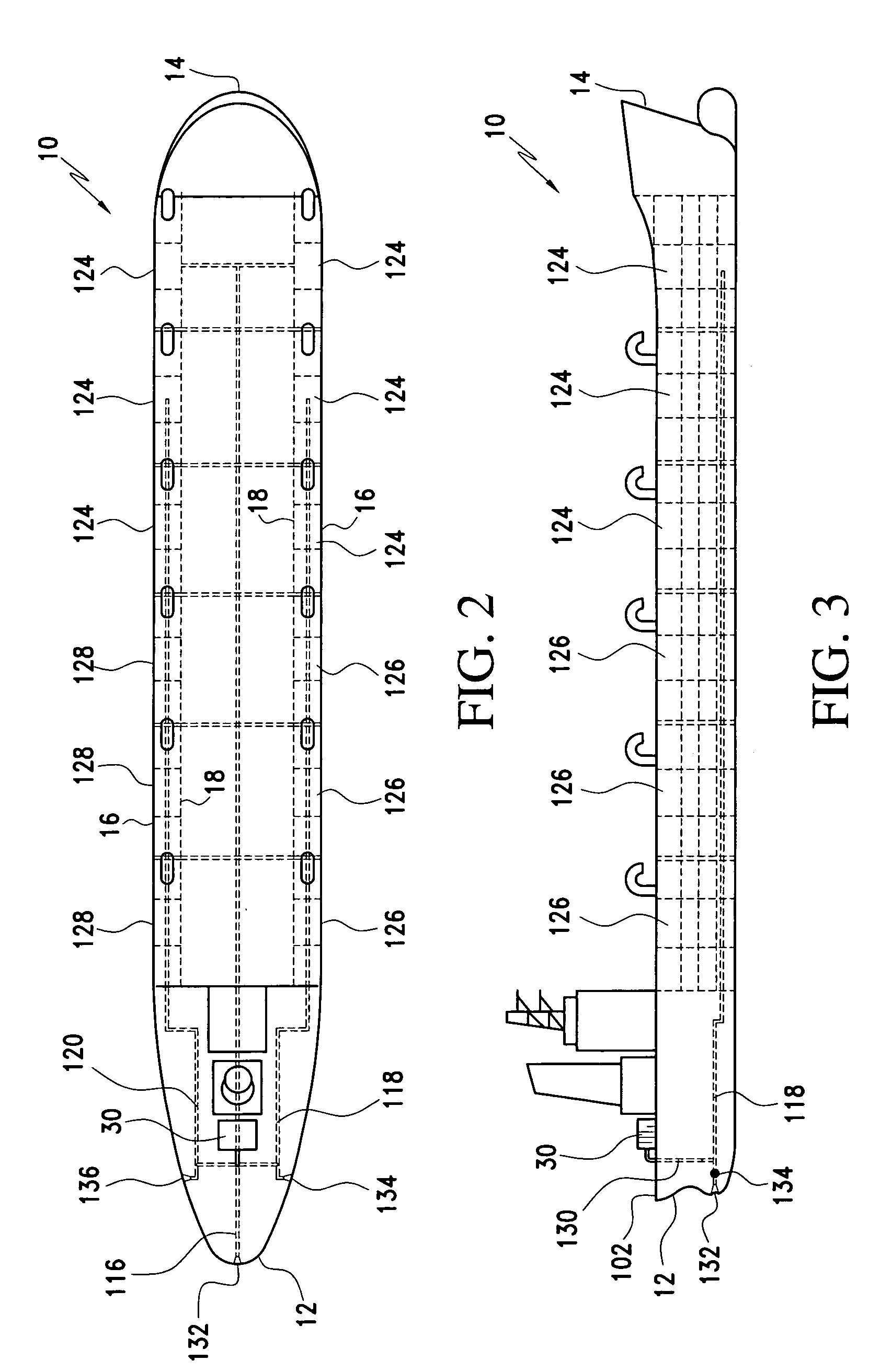

Ship and Method for Conveying and Setting Up Offshore Structures

A ship according to the invention for conveying and setting up offshore structures having:a hull with a U-shaped cross-section having an open stern and projections of the side walls extending at the rear beyond the rear edge of the floor,jack-up leg systems with jack-up legs integrated in the hull that are movable in a vertical direction with their bottom ends in positions below the floor, anda crane that can move on the top edges of the side walls.

Owner:NORDIC YARDS HLDG

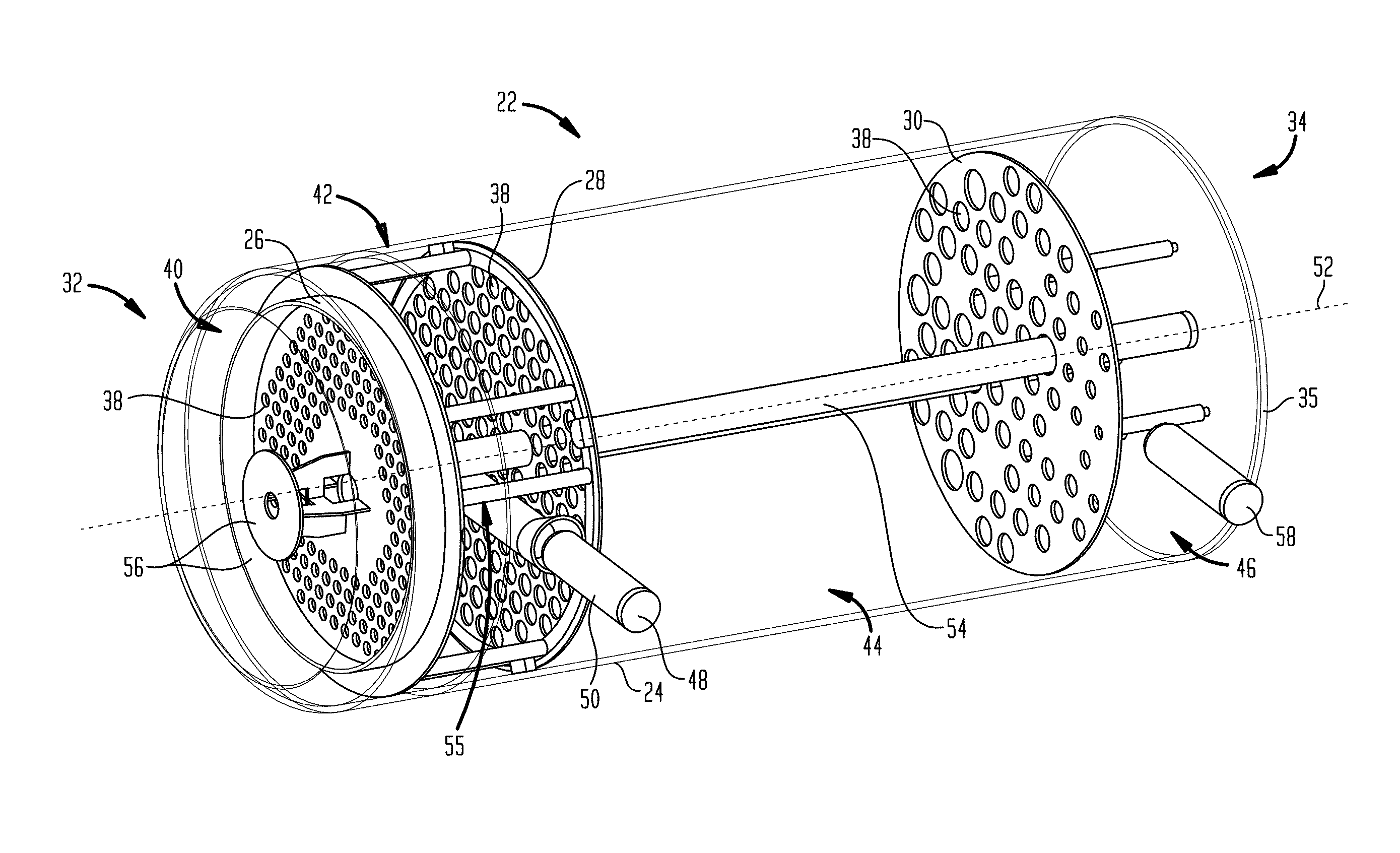

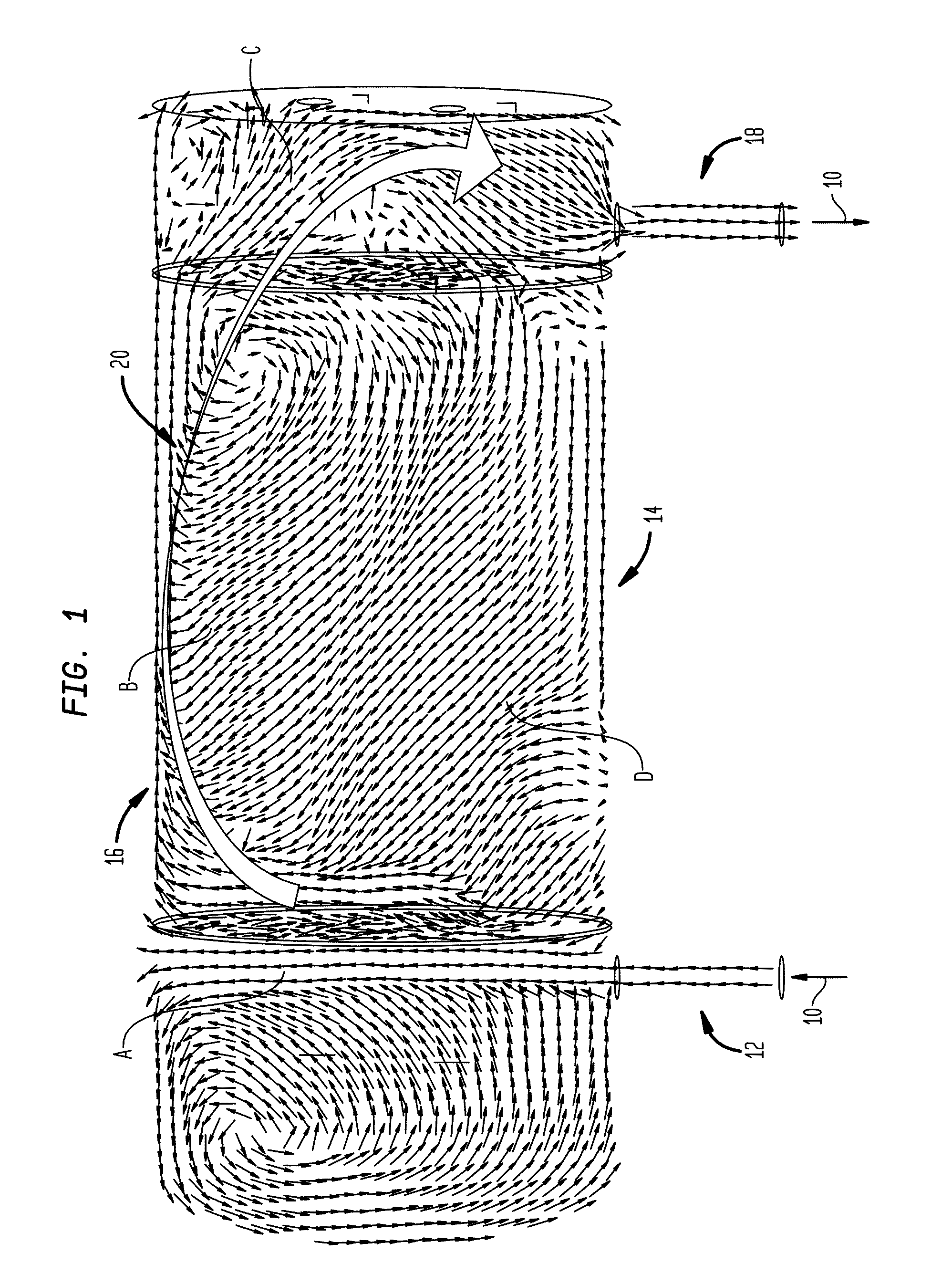

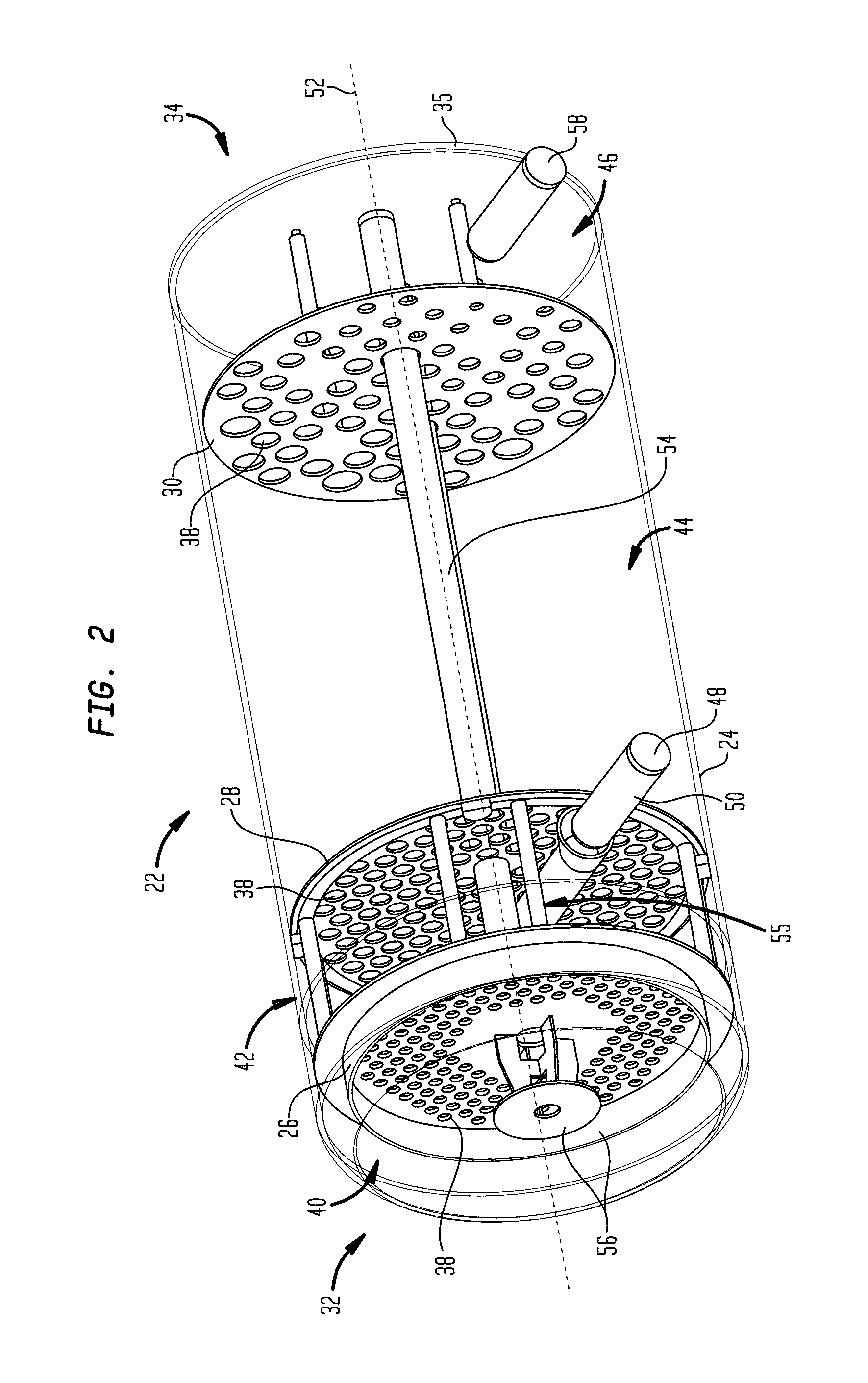

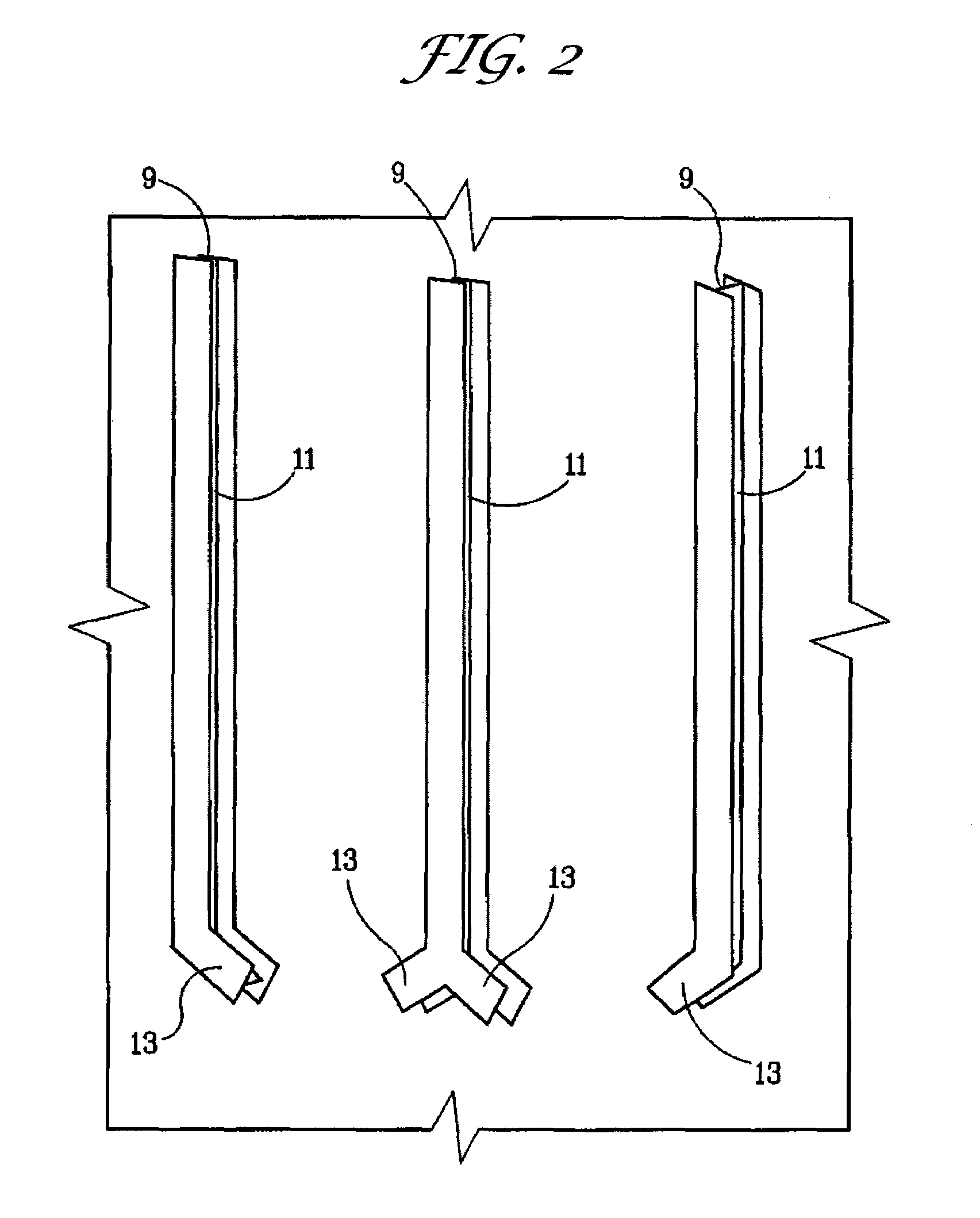

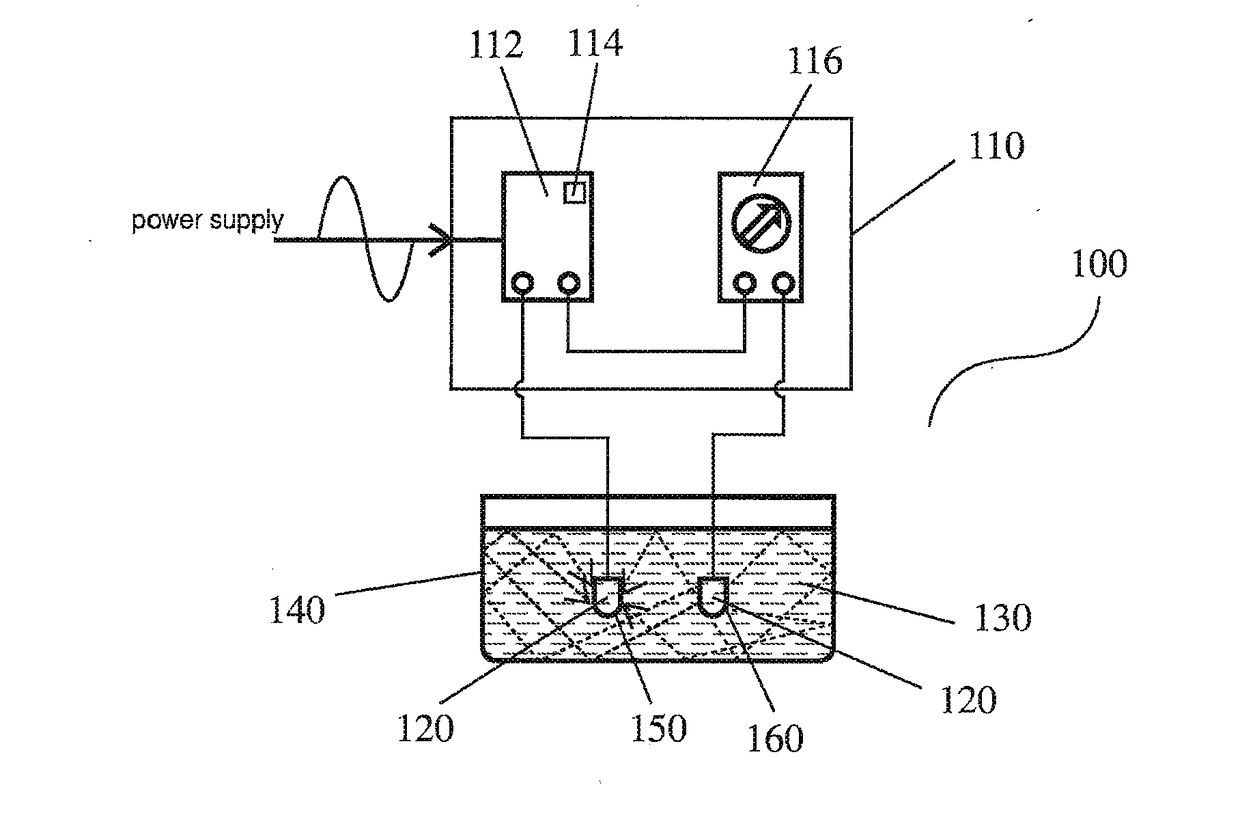

Baffle plates for an ultraviolet reactor

InactiveUS20110024365A1Electrolysis componentsSelf-bailing equipments/scuppersUltraviolet lightsEngineering

An ultraviolet reactor for treating a fluid. The reactor includes a vessel having an inlet for receiving fluid and an outlet for discharging fluid. The reactor further includes an ultraviolet light source and baffle plates. The baffle plates include holes arranged in a predetermined pattern for providing plug flow in areas in the reactor near the ultraviolet light source.

Owner:EVOQUA WATER TECH PTE LTD

Methods, systems, and processes for the design and creation of rich-media applications via the Internet

Rich-media applications are designed and created via the Internet. A host computer system, containing processes for creating rich-media applications, is accessed from a remote user computer system via an Internet connection. User account information and rich-media component specifications are uploaded via the established Internet connection for a specific user account. Rich-media applications are created, deleted, or modified in a user account via the established Internet connection. Rich-media components are added to, modified in, or deleted from scenes of a rich-media application based on information contained in user requests. After creation, the rich-media application is viewed or saved on the host computer system, or downloaded to the user computer system via the established Internet connection. In addition, the host process monitors the available computer and network resources and determines the particular component, scene, and application versions, if multiple versions exist, that most closely match the available resources.

Owner:BALTHASER NEIL

Ozone injection method and system

A target biokill of species for water to be discharged from a ballast tank of a sea faring vessel is determined. A diverted portion of sea water is regulated prior to charging the water into the ballast tank. Regulation of the diverted portion of water and a rate of injection of the ozone into the portion are adjusted to attain the target biokill. Then ozone at the determined rate into the regulated diverted portion to attain the target biokill when the portion is recombined into the water for charging to the ballast tank.

Owner:NUTECH O3 INC

Waste water purification apparatus and waste water purification method including the regeneration of used coagulant

InactiveUS20050230299A1Disinfect the pollutant mattersSelf-bailing equipments/scuppersLiquid displacementPurification methodsOperational costs

Conventional purification apparatuses and operation methods therefor require continuous addition of coagulants as expendables in every operation, and the coagulants are expensive, thereby causing increase in operation cost, and furthermore, the operators have to convey and resupply the coagulant at regular intervals which further increases the operation cost owing to the personnel cost to be increased accordingly. The invention provides a purification apparatus and an operation method therefor, for coagulating and separating particularly the pollutant matter in sea water including oil and the like, which can regenerate and reuse the coagulant within the apparatus, without scarcely resupplying the coagulant and acid / alkali solutions. For disintegrating coagulated flocs and regenerating the coagulant from the sludge, a strong alkali solution and a strong acid solution are required. According to the invention, an alkali water enriched in sodium hydroxide and an acidic aqueous solution containing hydrochloric acid and the like are generated by electrolyzing sea water and collecting sodium ion and chloride ion respectively in the cathode and anode sections, and also by including hydroxide ion and hydrogen ion in sea water; the flocs in the sludge are disintegrated by use of the alkali water; pollutant matter is removed from the aqueous solution subjected to disintegration; and the strongly acidic solution containing hydrochloric acid is added to the acidic solution from which pollutant matter has been separated and removed, and a ferric chloride aqueous solution is generated. The ferric chloride aqueous solution is the coagulant, and thereby the coagulant can be regenerated from the recovered sludge.

Owner:HITACHI LTD

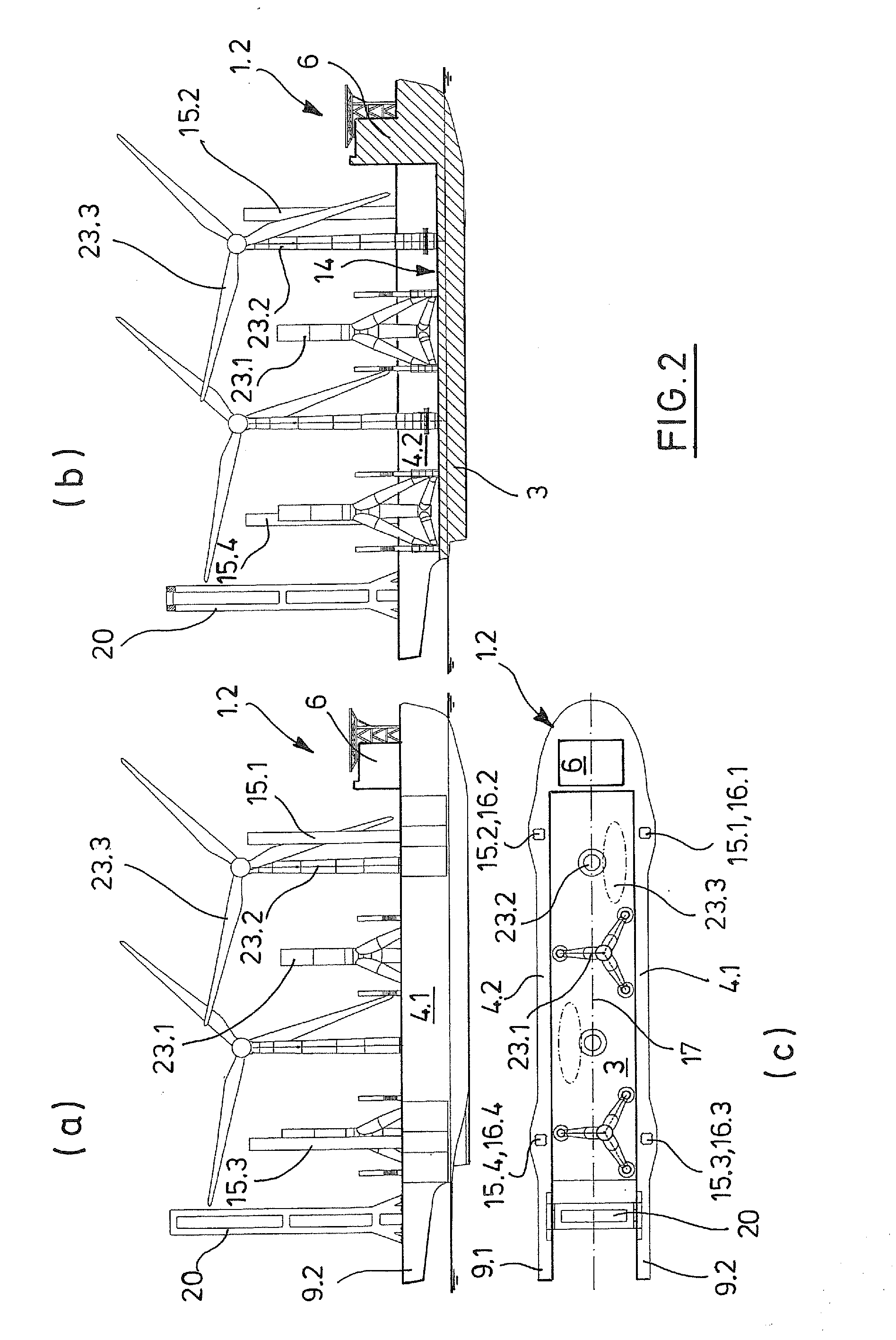

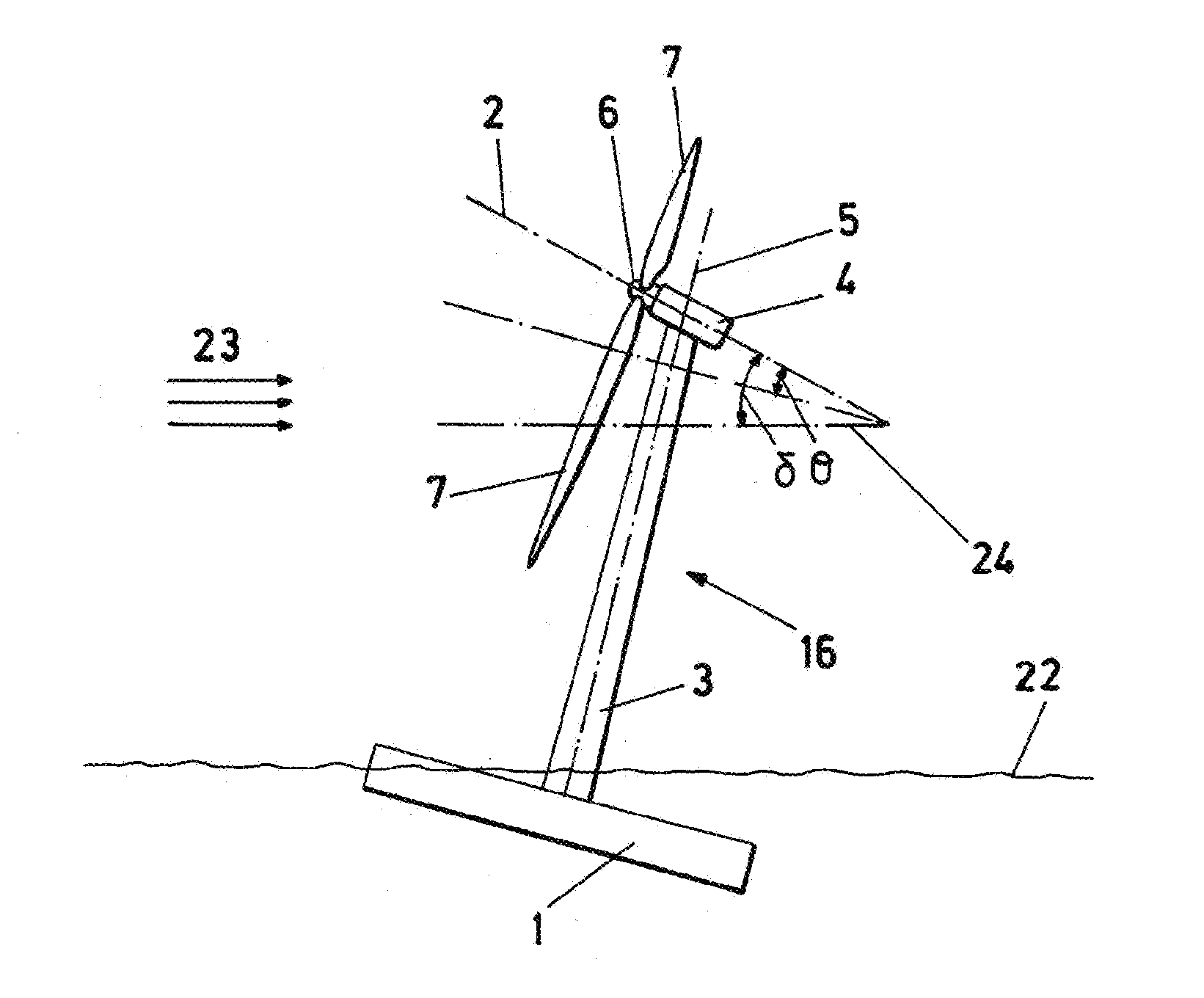

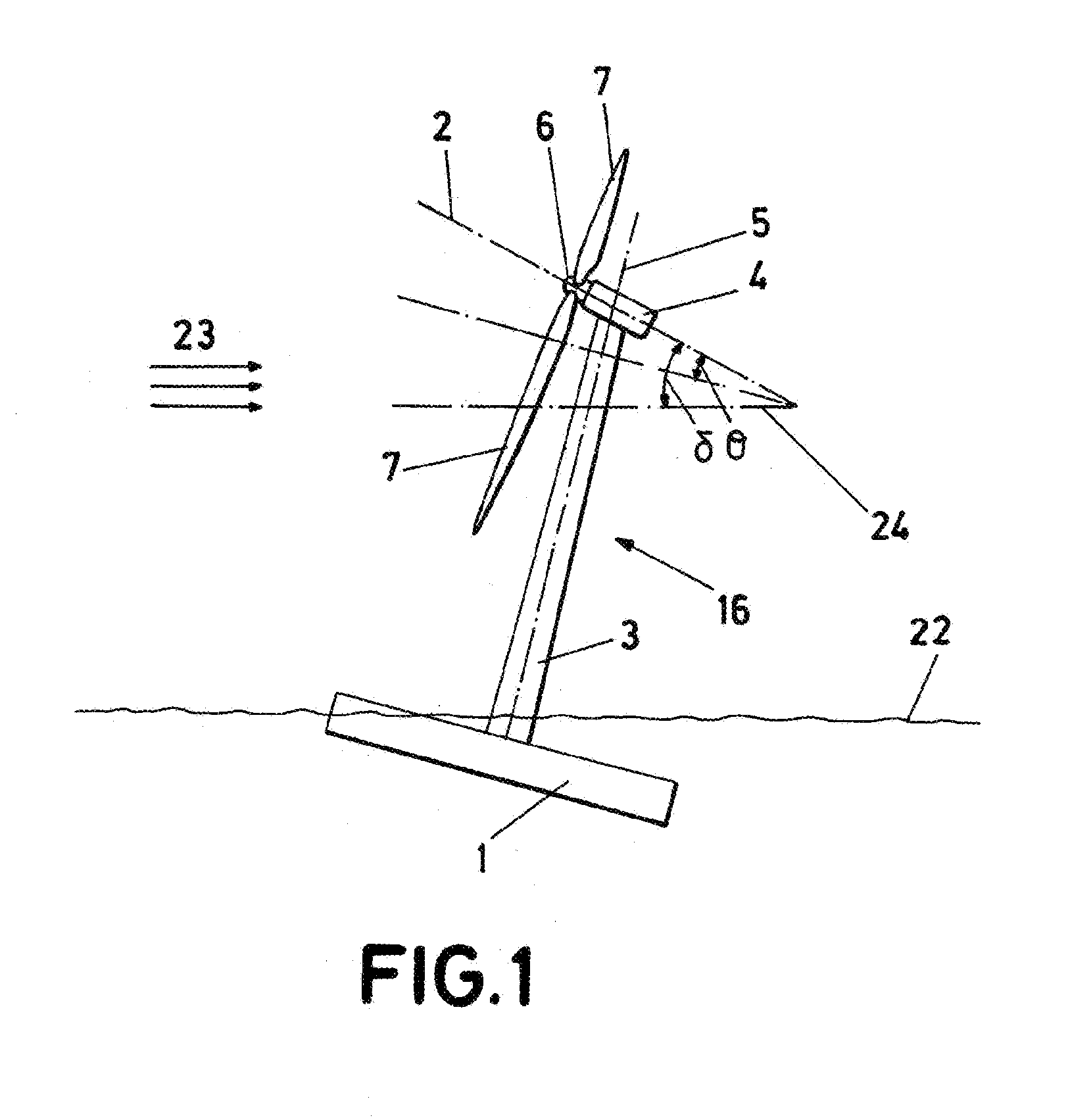

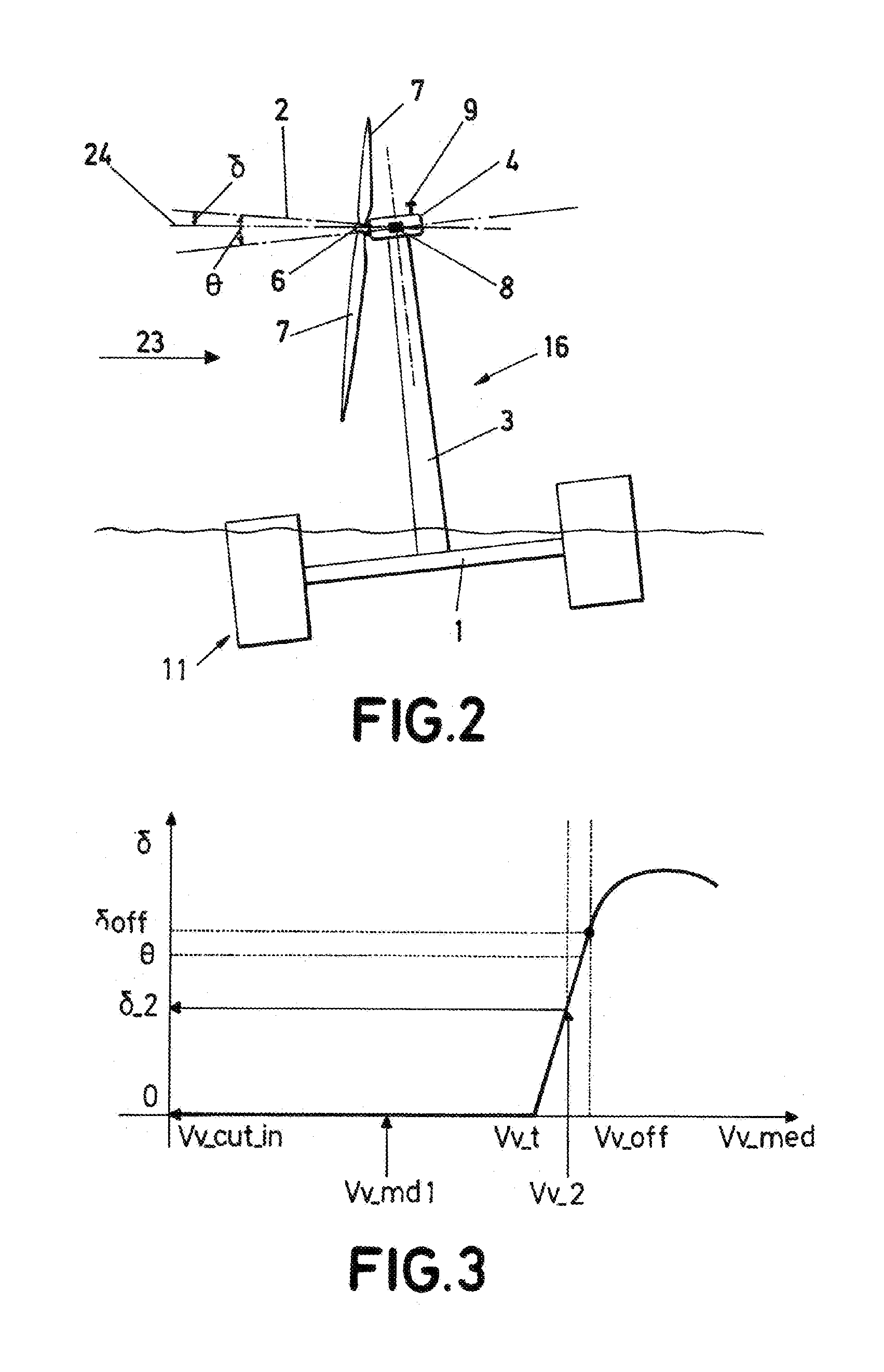

Wind turbine - floating platform assembly and method for orienting said assembly description

ActiveUS20120171034A1Low costMost efficientPropellersWind motor controlAxis–angle representationFloating platform

The invention allows orientation of the platform (1) in order to obtain conditions of maximum efficiency in the wind turbine (16). It comprises first sensors (8) for detecting an effective rotation axis angle (δ) formed between the rotation axis (2) and a horizontal plane (24); second sensors (9) for detecting wind direction (23); platform orientation means (11) for modifying the effective rotation axis angle (δ); and at least one control unit (12) adapted for receiving a first input (13) from the first sensors (8) and a second input (14) from the second sensors (9) and, based on said inputs (13, 14), transmitting orders to the platform orientation means (11) and yaw mechanism.

Owner:NORDEX ENERGY SPAIN SA

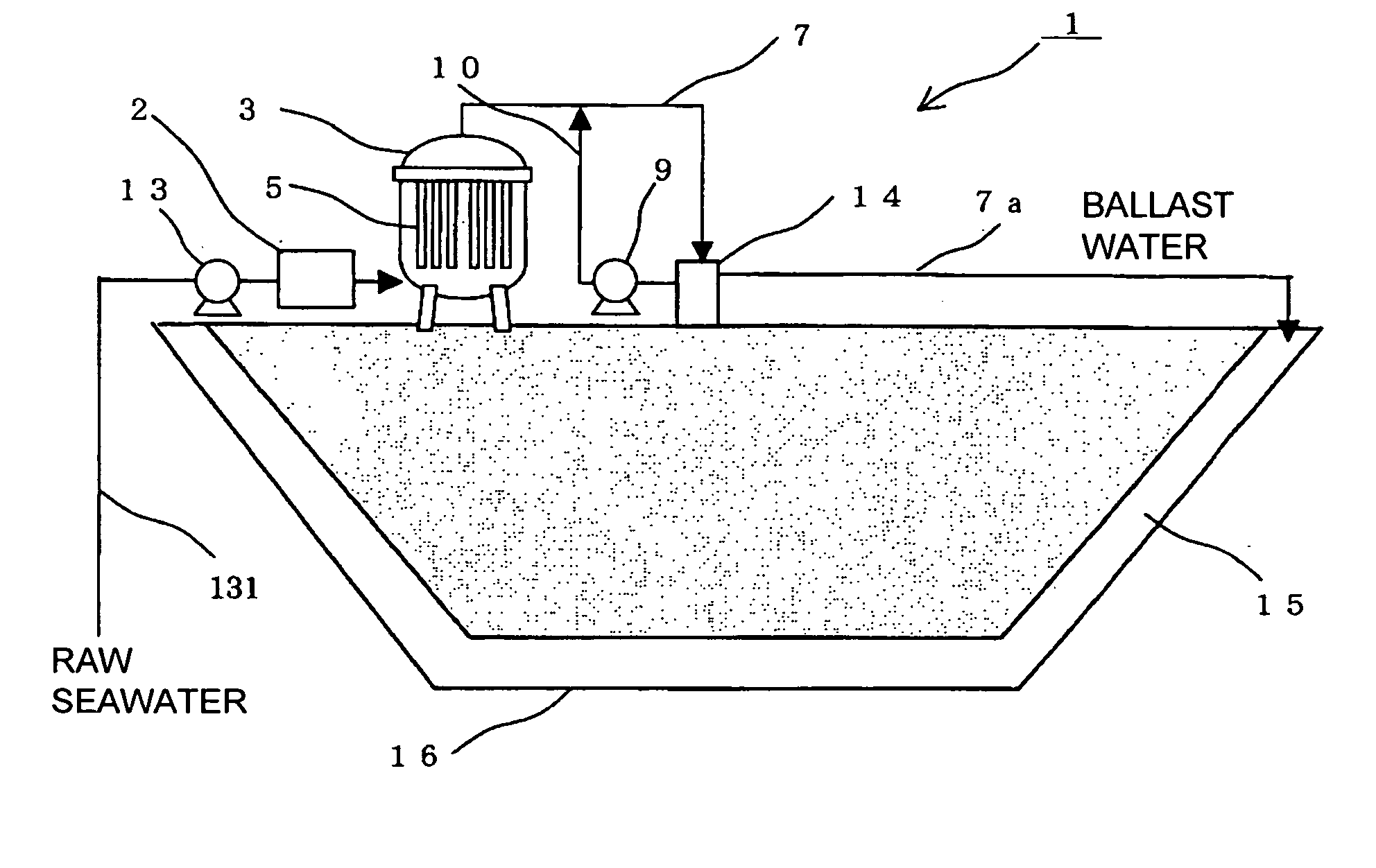

Process For Producing Ship Ballast Water, Ship Ballast Water Producing Apparatus And Use Thereof

InactiveUS20070246424A1Cost effectiveIncrease flow rateGeneral water supply conservationAuxillariesFiltration membraneSeawater

A process for producing ship ballast water includes removing microorganisms from seawater by passing the seawater through a microorganism filtration membrane, and backwashing the microorganism filtration membrane to clean the microorganism filtration membrane. Microorganisms living in seawater can be removed in a manner which does not kill the microorganisms.

Owner:MITSUBISHI RAYON CO LTD +1

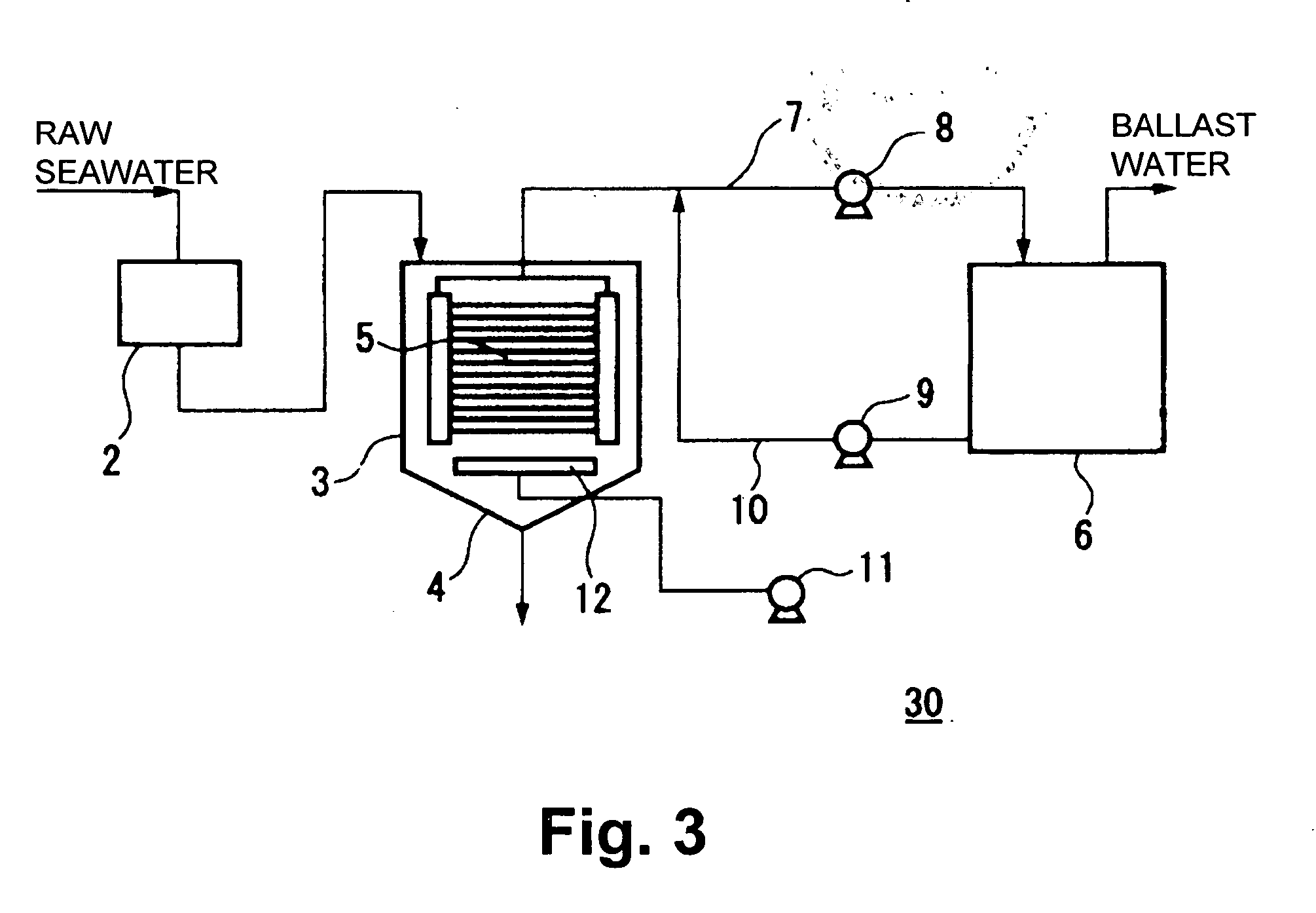

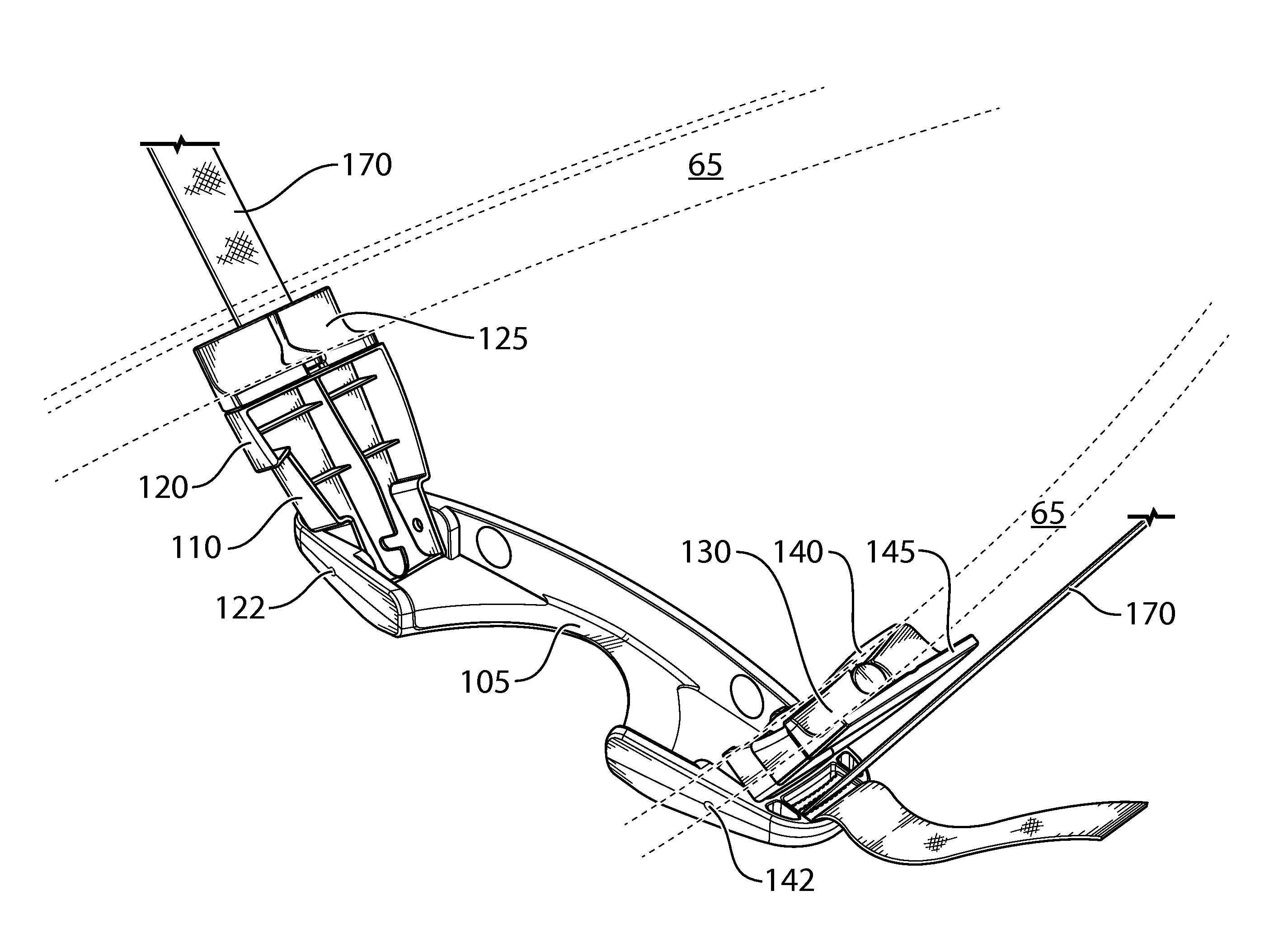

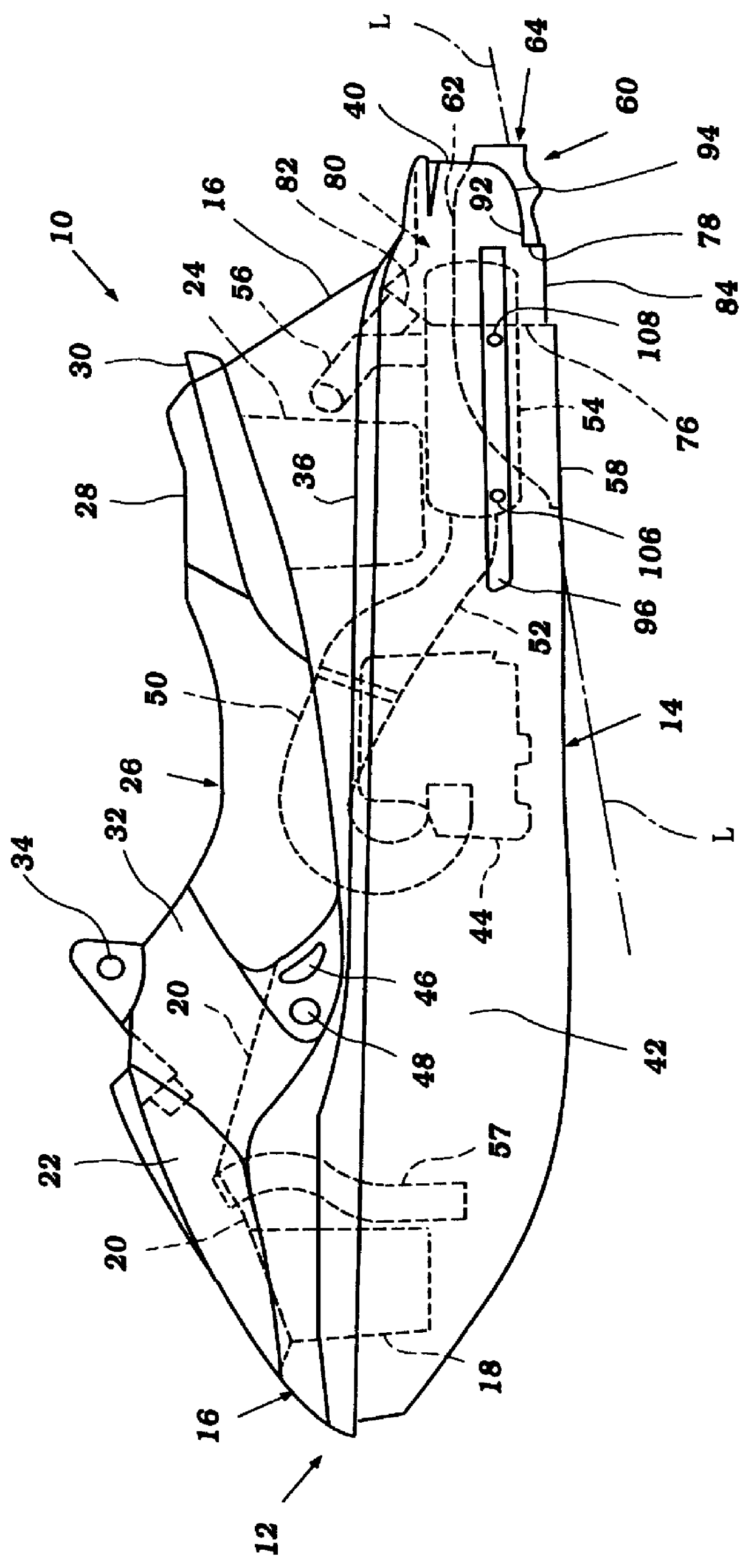

Personal boat carrying apparatus

ActiveUS9254901B2Not easy to damageRapid deploymentTravelling sacksWater sport boardsGunwaleEngineering

A personal boat carrying apparatus is provided for supporting a kayak or similar boat on a user during a portage to make portaging a kayak easier and less uncomfortable. The apparatus is lightweight but durable and has a body with a curved and arched center portion for resting on the shoulders of a user carrying the kayak, and two opposite body ends. Each body end has a support arm which pivots from a closed position to one or more open positions. The pivoting support arm provides multiple open positions to allow the apparatus to support kayaks and similar boats of different widths and configurations. Each support may have a swiveling bracket for engaging the gunwale of the cockpit of the kayak or similar boat. When the support arms are in the closed position, the apparatus may be compactly stored in the boat or elsewhere.

Owner:GILL SCOTT

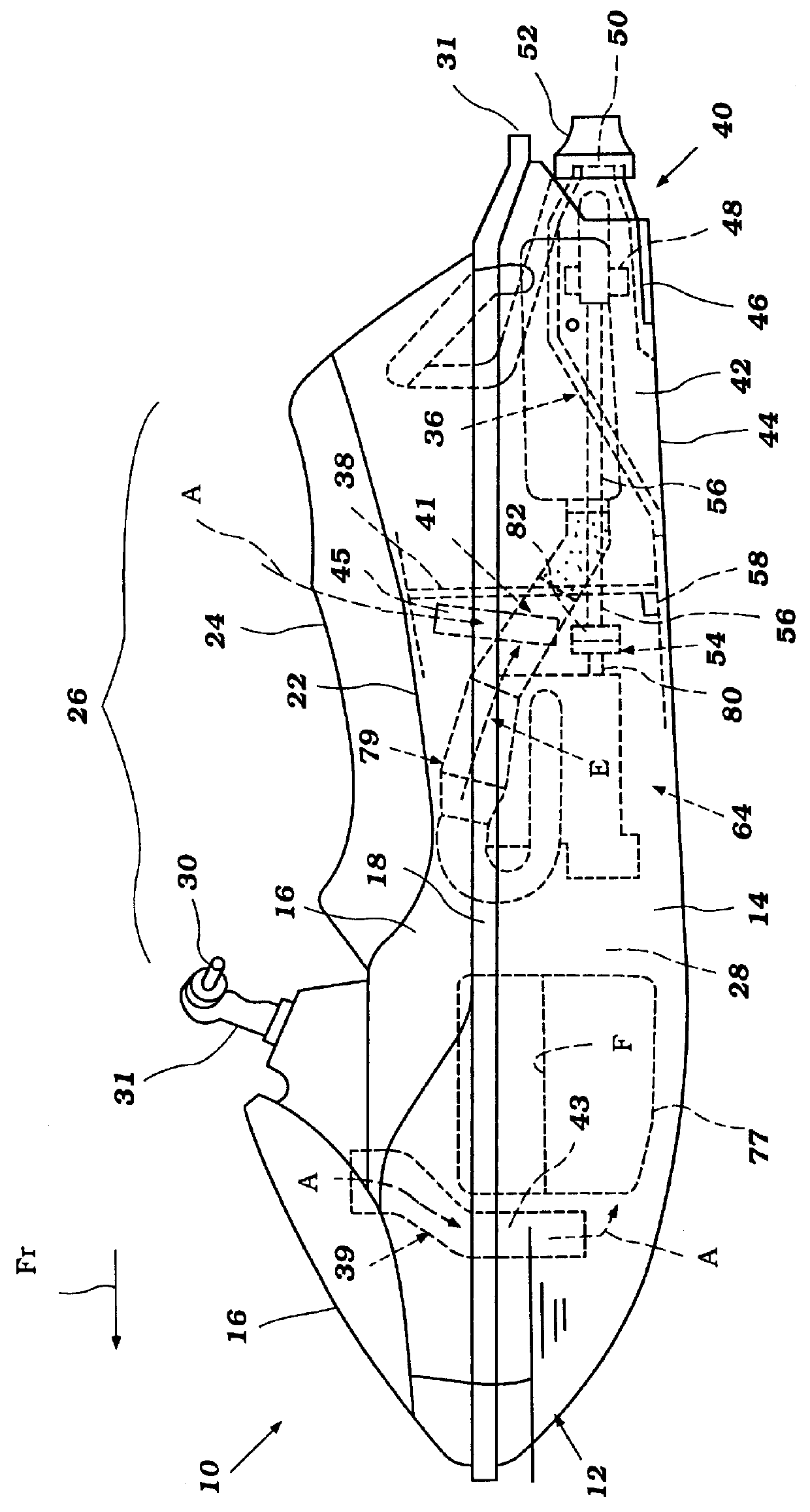

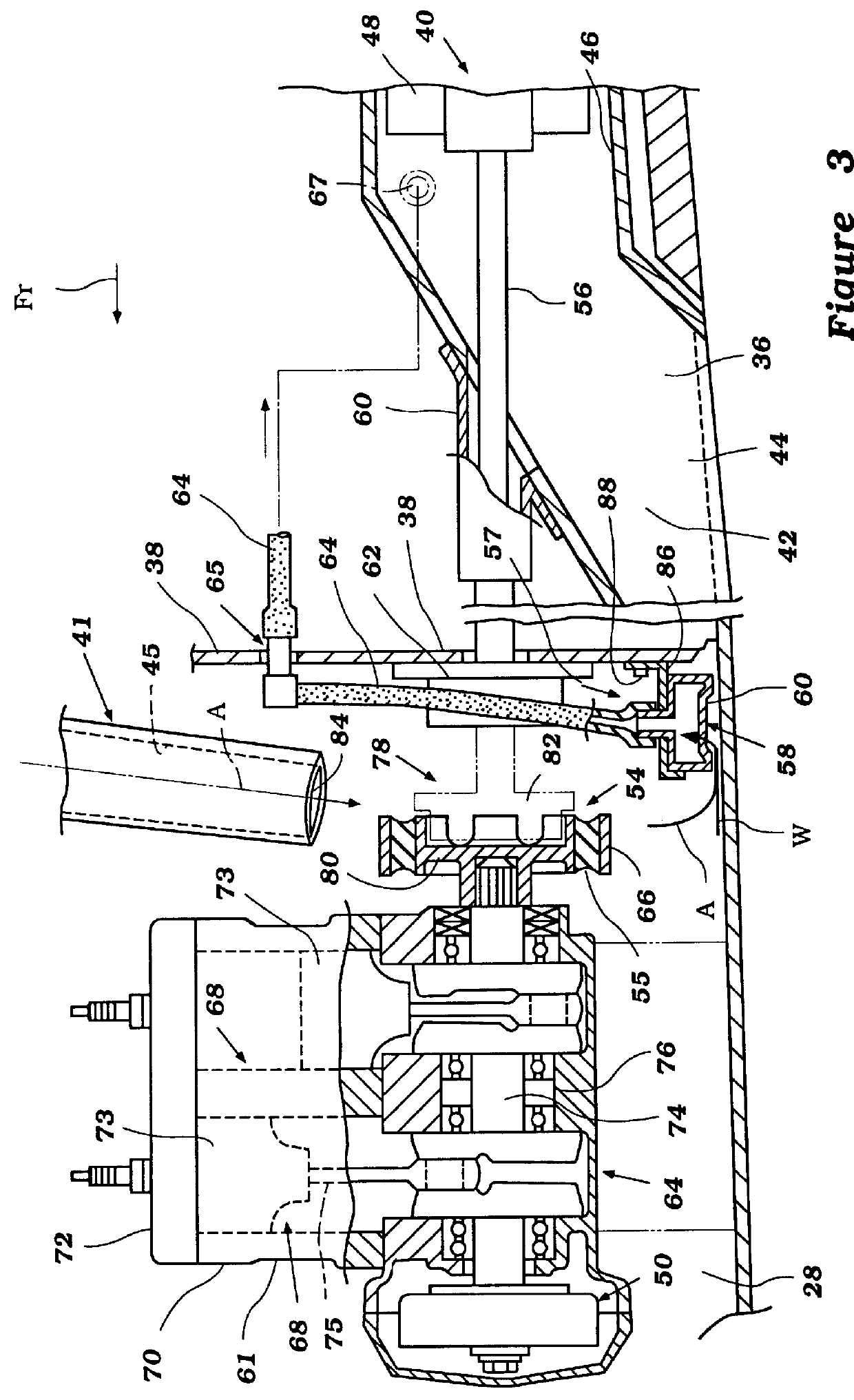

Torsional damper for watercraft propulsion system

A vibrational damper reduces torsional vibration within a crankshaft of a marine engine. The vibrational damper is located on an end of the crankshaft opposite of the flywheel and includes an inertia ring that adds additional mass to this opposite end. In addition, the vibrational damper includes an elastic member that suspends the inertia ring about the crankshaft. The elastic member effectively dampens torsional vibrations. The torsional damper desirably is cooled by an air flow so as to maintain it's dampening efficiency. A ventilation duct, which is positioned directly above the vibrational damper, supplies the cooling air. Cooling is enhanced by locating a bilge system inlet below and slightly behind the vibrational damper. An air flow stream occurs between the duct and the bilge inlet and across the torsional damper to cool the torsional damper.

Owner:YAMAHA MOTOR CO LTD

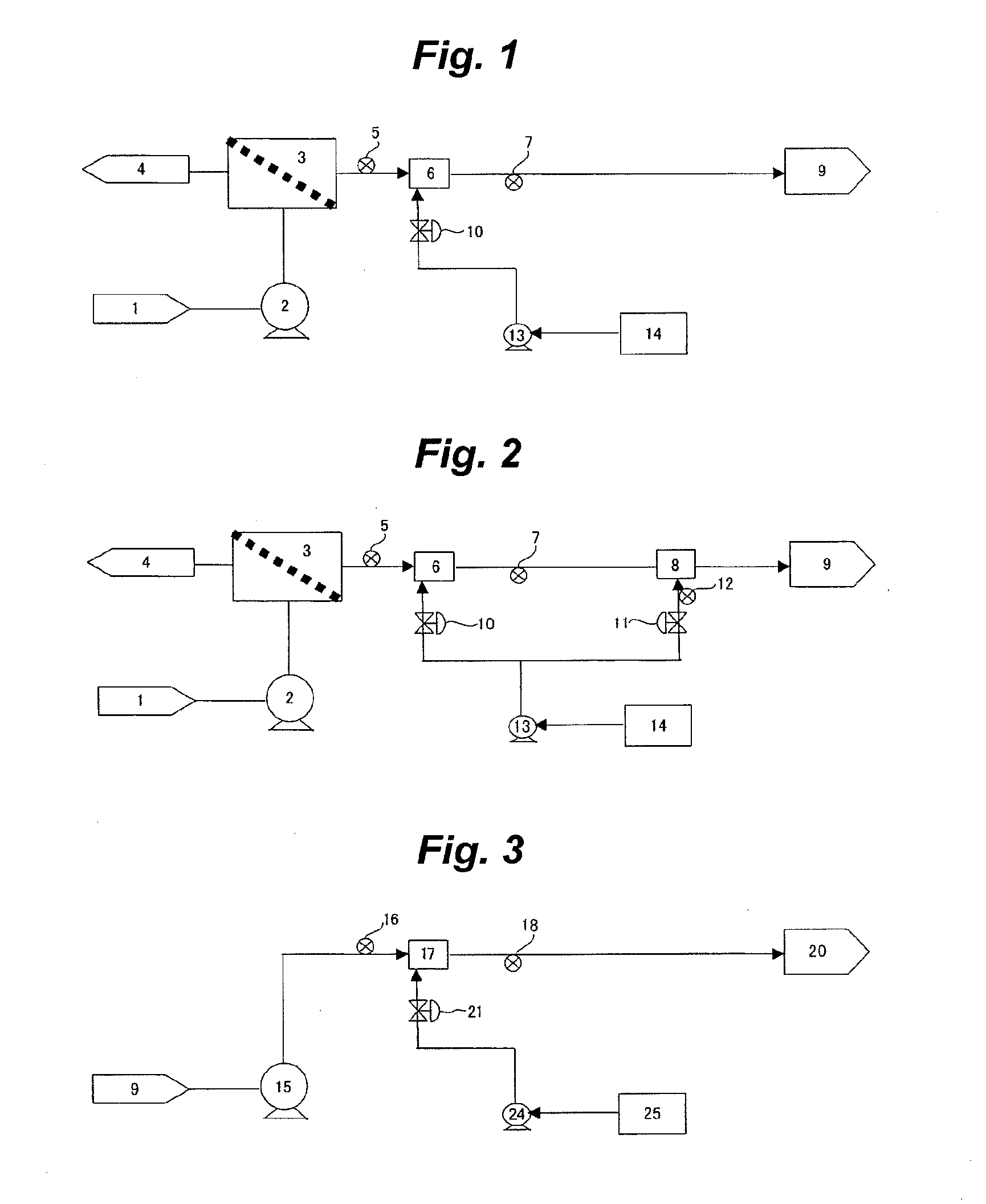

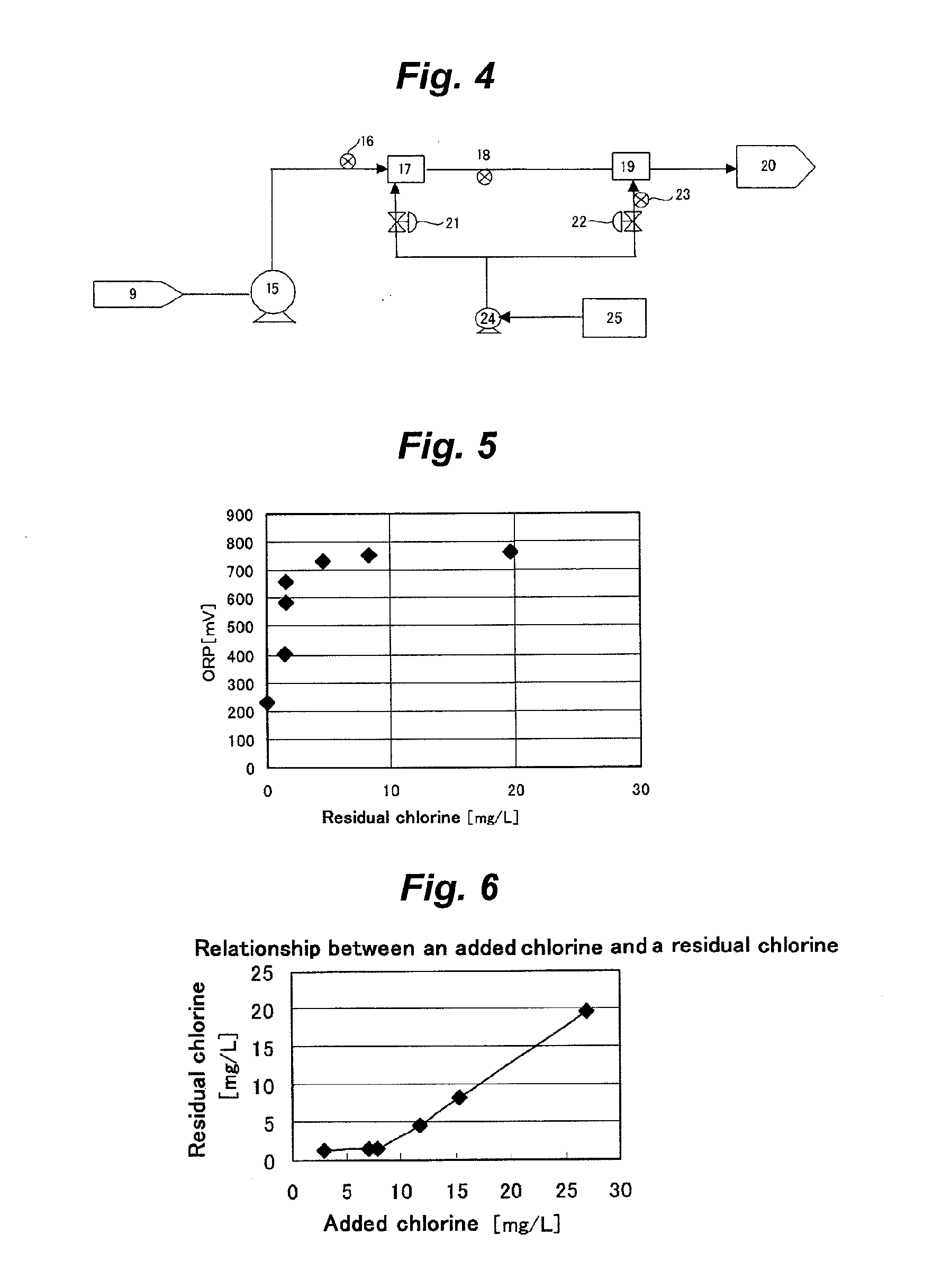

Method of treating ballast water of ship

InactiveUS20100072144A1Water treatment parameter controlSelf-bailing equipments/scuppersBiological bodyHypochlorite

A method of treating a ballast water for sterilizing bacteria, microorganisms or organisms in the ballast water in a hold or ballast tank of a ship, has the steps of: sterilizing the bacteria, microorganisms or organisms by adjusting a residual chlorine concentration in the ballast water to 1 mass ppm or more and 1000 mass ppm or less with a hypochlorite, and removing the residual chlorine in the ballast water with a sulfite.

Owner:TGCORP +2

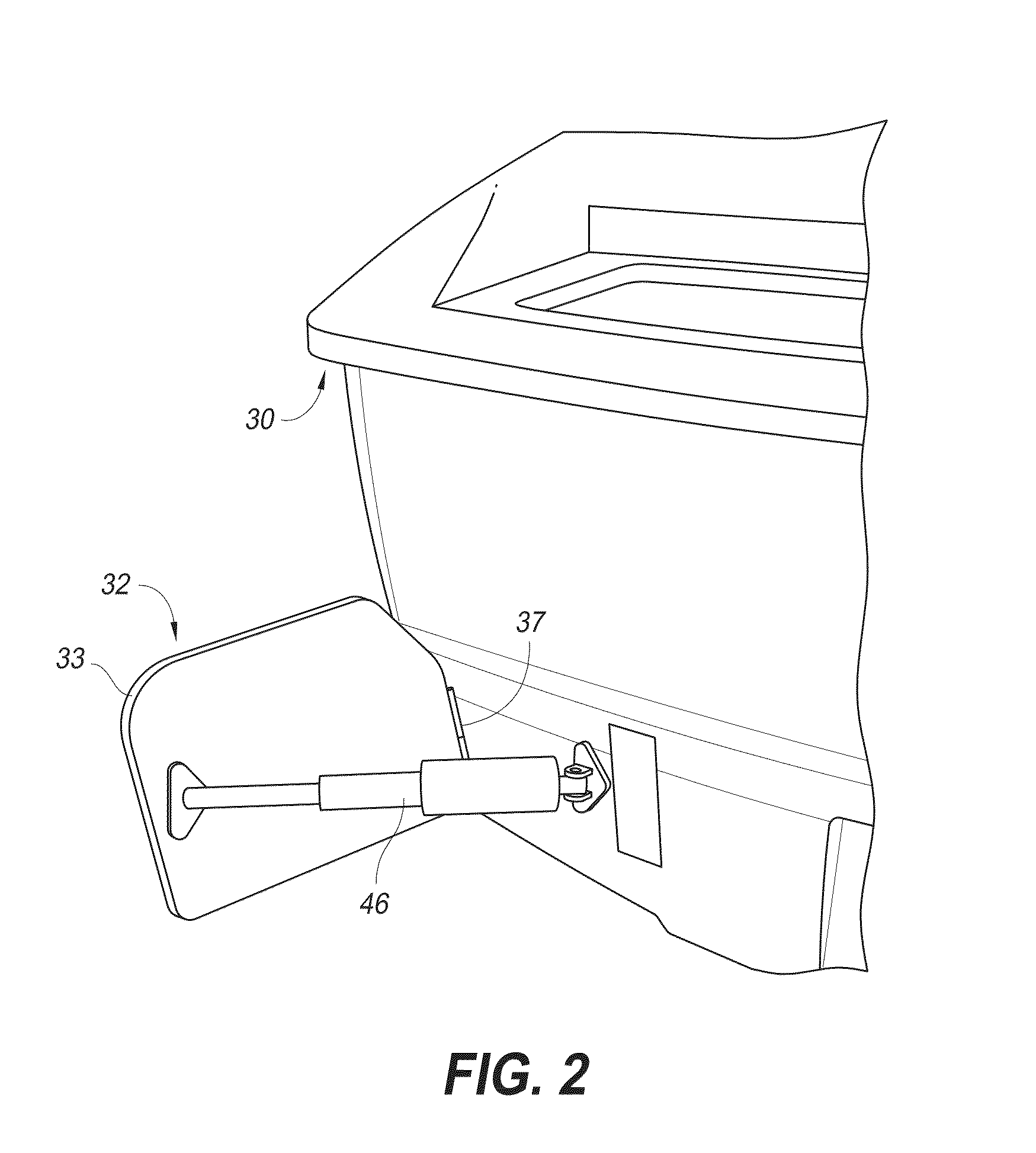

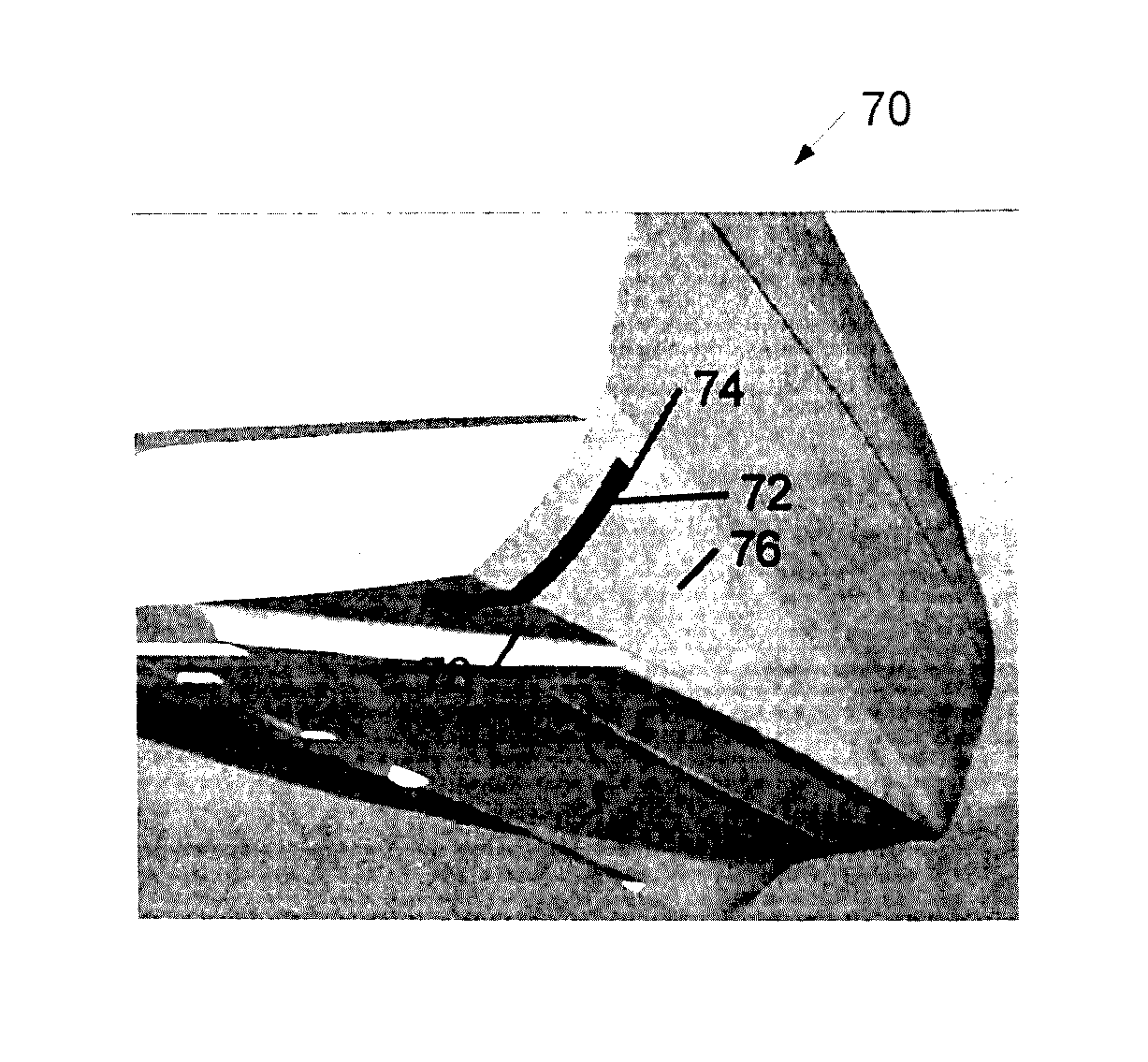

Devices mounted within and/or on boat hulls for manipulating wakesurf and wakeboard wakes

Wakesurf and wakeboard boats are provided which include a component positioned along and / or within the hull and an actuator coupled to the component for moving an end of the component outward from the hull and retracting the end of the component to be in proximity with the hull. In some embodiments, the component is spaced forward of a vertical plane comprising the forwardmost point of the transom. Methods for creating a wake behind a boat are also provided which include listing a boat to one side via a listing component disposed on such a side and moving a component disposed within or coupled to an exterior surface of the hull on the opposing side of the boat. The component is moved outwardly from the exterior surface of the hull such that a distal free end of the component is spaced from the exterior surface when the boat is listed.

Owner:TIGE BOATS

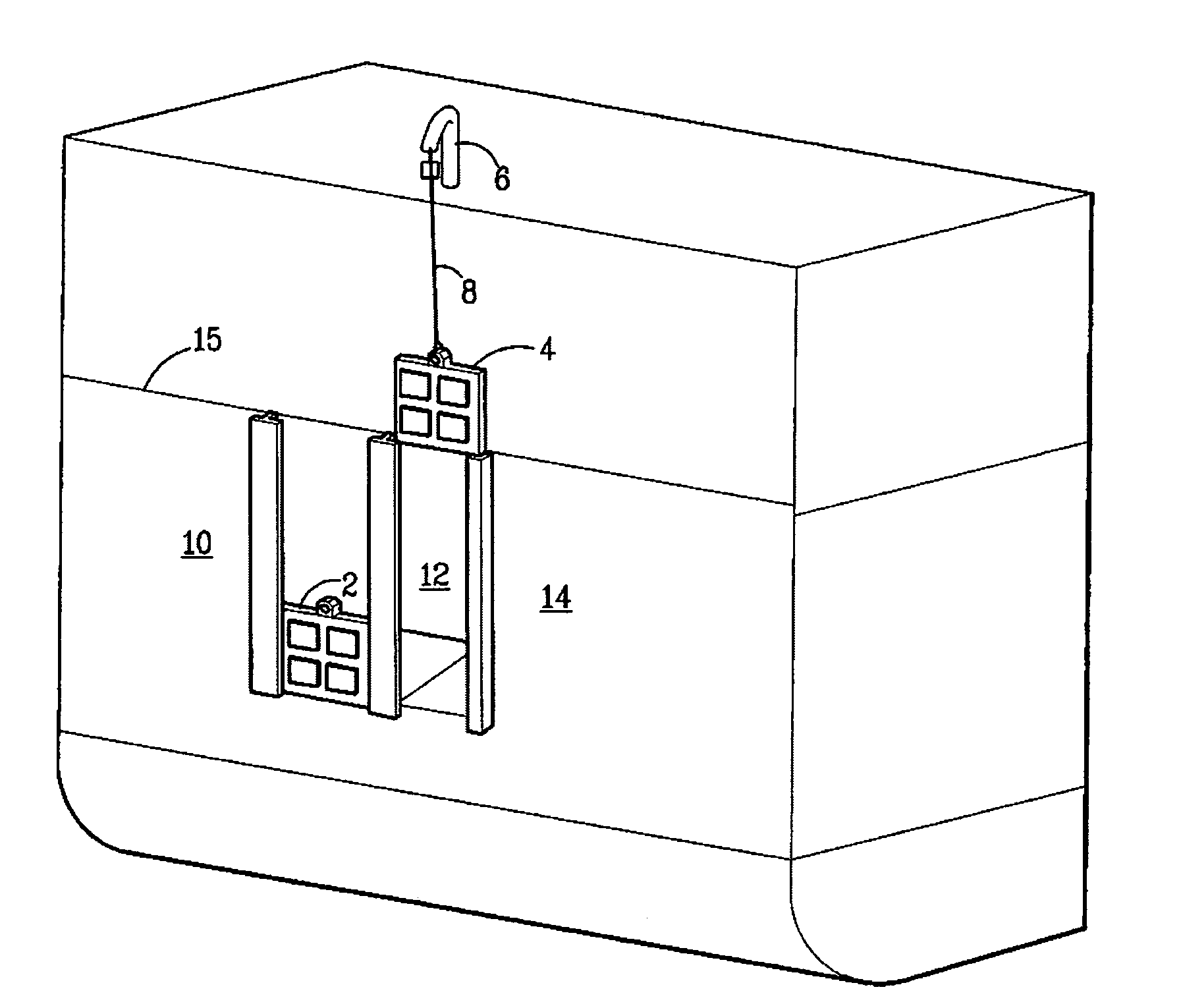

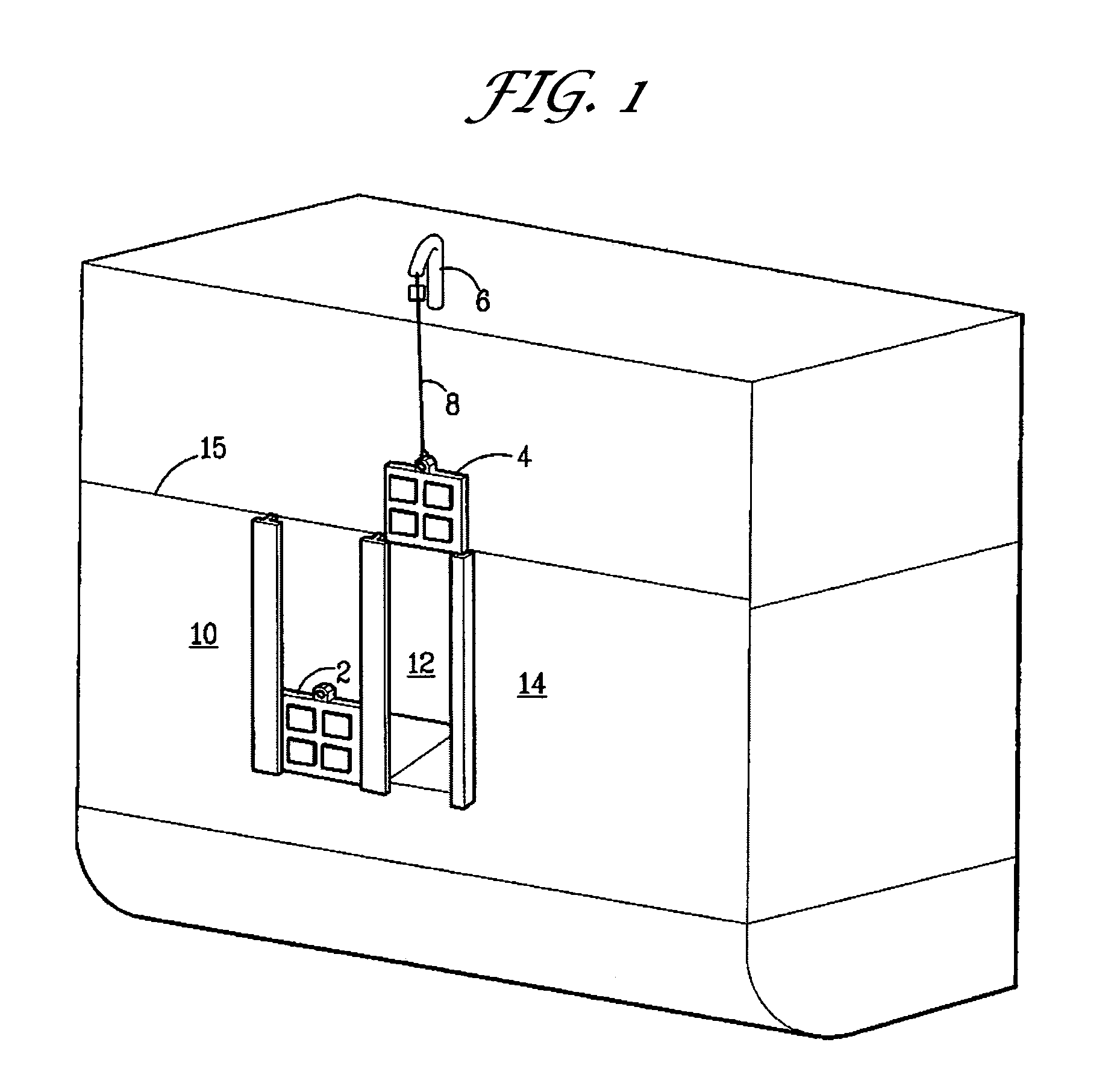

Systems and processes for covering openings of marine vessel hulls

InactiveUS7451717B1Promote repairEasy maintenanceSelf-bailing equipments/scuppersVessel designingGlass fiberMarine engineering

Systems and processes for closing openings in marine vessel hulls are provided. The systems and processes facilitate repairs and maintenance of marine vessels by closing openings in the marine vessel hulls to permit dry access to compartments in communication with the openings. The processes and systems incorporate a cover constructed from a lightweight material such as fiberglass, a viscoelastic material such as polyethylene or polyurethane, and blends thereof. The cover is guided in place to effectuate closure of the opening by a track device that receives at least two of the peripheral edges of the cover and directs the cover to the proper position to close the hull opening. The cover may be lowered into place by use of a hoisting device such as a davit.

Owner:CONOCOPHILLIPS CO

Ozone injection method and system

ActiveUS20050167369A1Method securityAuxillariesSelf-bailing equipments/scuppersEnvironmental engineeringBallast tank

A target biokill of species for water to be discharged from a ballast tank of a sea faring vessel is determined. A diverted portion of sea water is regulated prior to charging the water into the ballast tank. Regulation of the diverted portion of water and a rate of injection of the ozone into the portion are adjusted to attain the target biokill. Then ozone at the determined rate into the regulated diverted portion to attain the target biokill when the portion is recombined into the water for charging to the ballast tank.

Owner:NUTECH O3 INC

Ozone retention method and system

A method and system of ozone treatment diverts a portion of water from a flow of water in a conduit, injects ozone into the portion to provide an ozonated portion, and recombines the ozonated portion with the flow of water in the conduit. Another method and system identifies a species-destructive reaction product of ozone with a water constituent, determines a life of the reaction product, and contacts ozone with a water containing the species for a period determined according to the determined life of the reaction product.

Owner:NUTECH O3 INC

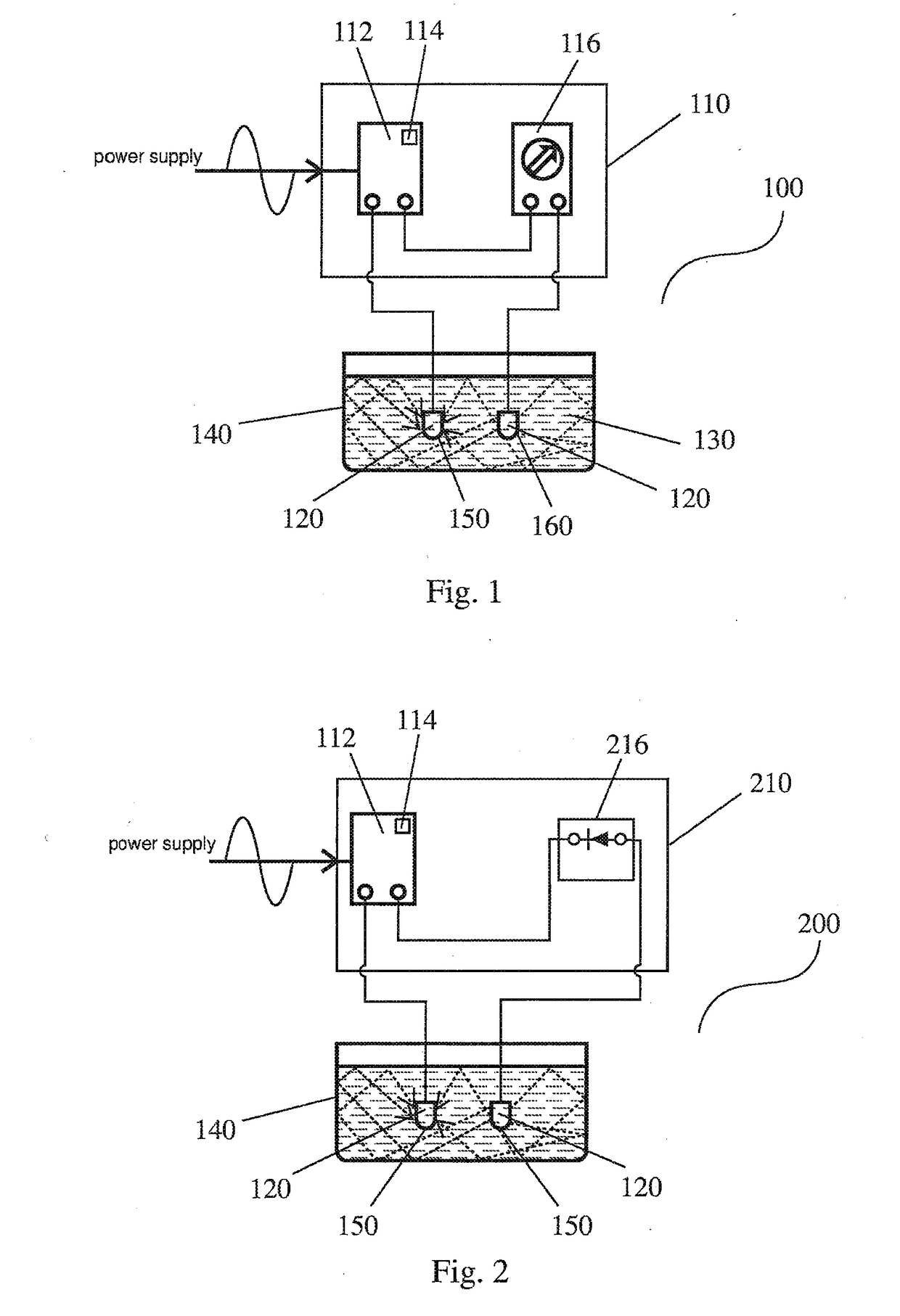

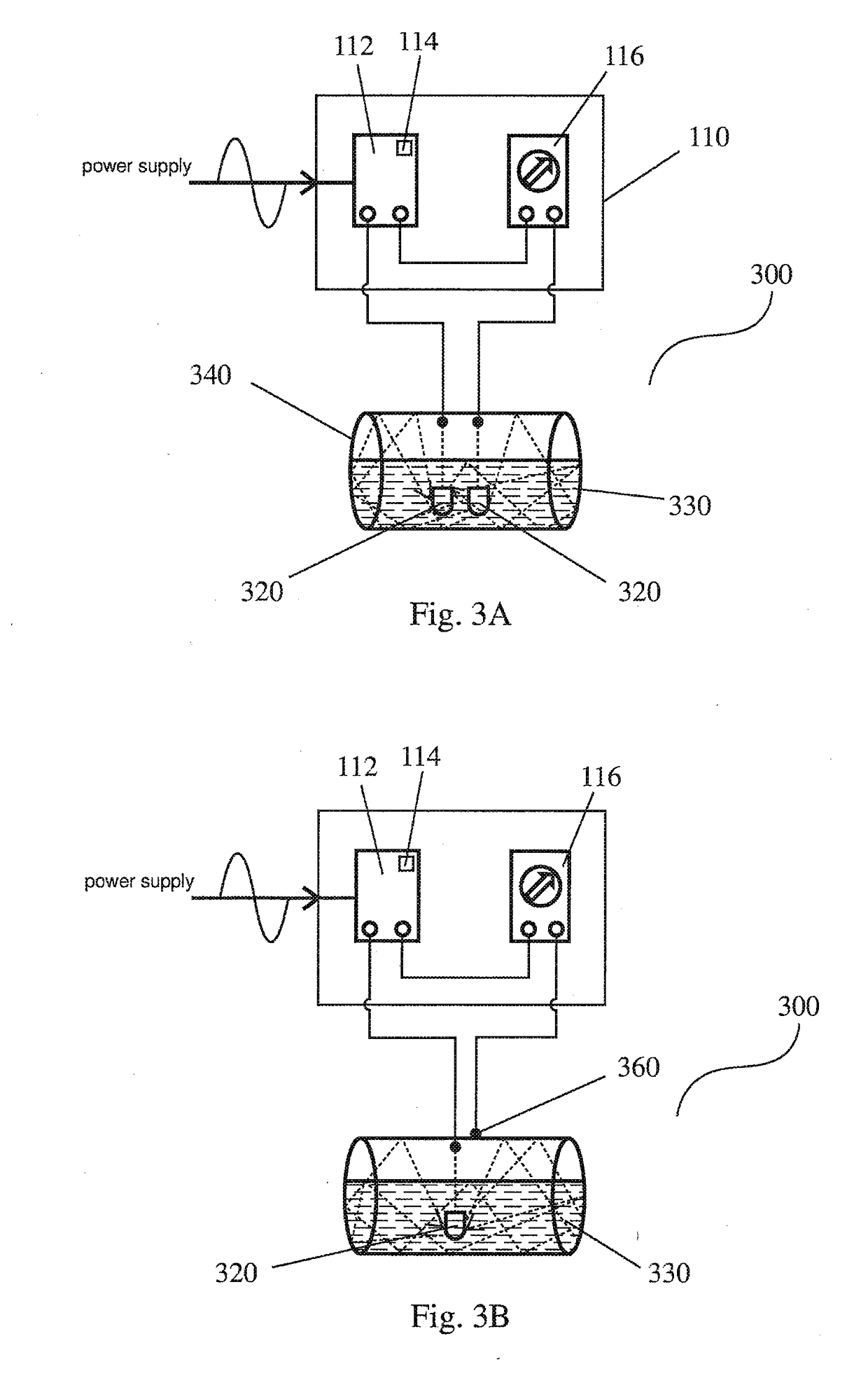

Method and system for applying superimposed time-varying frequency electromagnetic wave for corrosion protection of submerged and/or buried structures

ActiveUS20180216246A1Economical and convenient to utilizeAvoid structureAnodisationChromatisationReturn currentAcoustics

The invention relates to a method and system for preventing corrosion of at least one metallic structure in an electrolyte medium, comprising applying a superimposed time-varying frequency electromagnetic wave to the structure, the method comprising the steps of generating a superimposed time-varying frequency electromagnetic wave (DAC wave) where an AC driving signal with time-varying frequency is riding on a DC output with a predefined DC bias voltage, transmitting the DAC wave current to one or more emitters, emitting the DAC wave via the one or more emitters, placing the one or more emitters at a spaced distance from the metallic structure, subjecting the metallic structure to the DAC wave current, controlling the negative return current of the DAC wave from the metallic structure, such that the DAC wave is distributed across the structure surface and directly excites a target region of the metallic structure, and wherein the excitation induces a flow of ionic current having a DC component travelling in a pulsating and time-varying manner in the target region and effects induced vibration of electrons and molecules in the target region. The method and the system of the invention significantly reduce capital costs and require very low energy, they avoid environmentally unfriendly final products, and are able to result in effective corrosion protection of metallic structures in different surrounding conditions.

Owner:SEMB ECO R&D PTE LTD

Surf wake system for a watercraft

An adjustable surf wake system enhances a wake formed by a watercraft travelling through water. The system may include a flap for deflecting water traveling past the stern of the watercraft, and / or a positioner operably connected to the flap for positioning the flap relative to a longitudinal axis of the watercraft between a neutral position and an outward position. Positioning a port flap in its extended position enhances a starboard surf wake, and positioning the starboard flap in its extended position enhances a port surf wake.

Owner:MALIBU BOATS

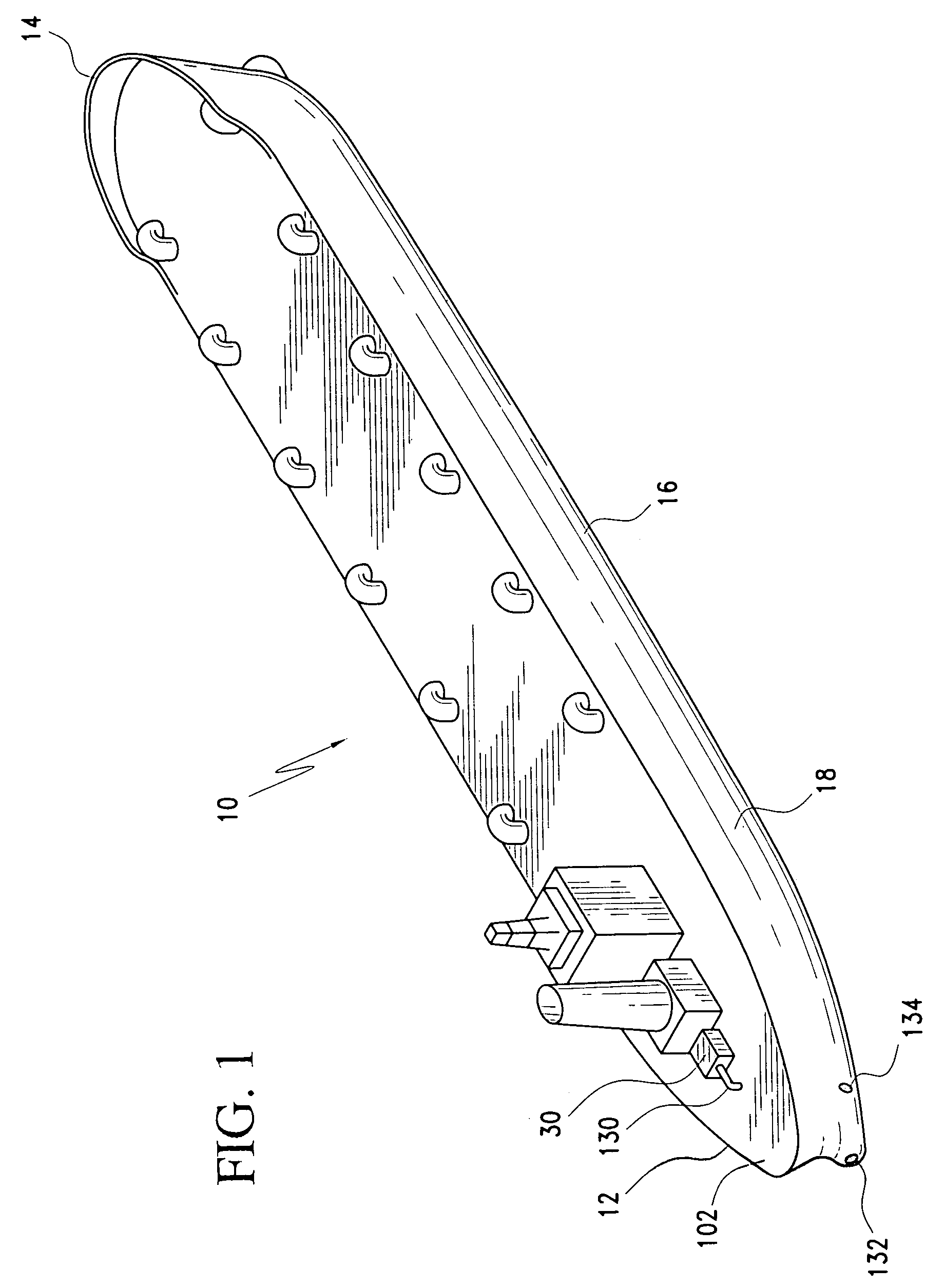

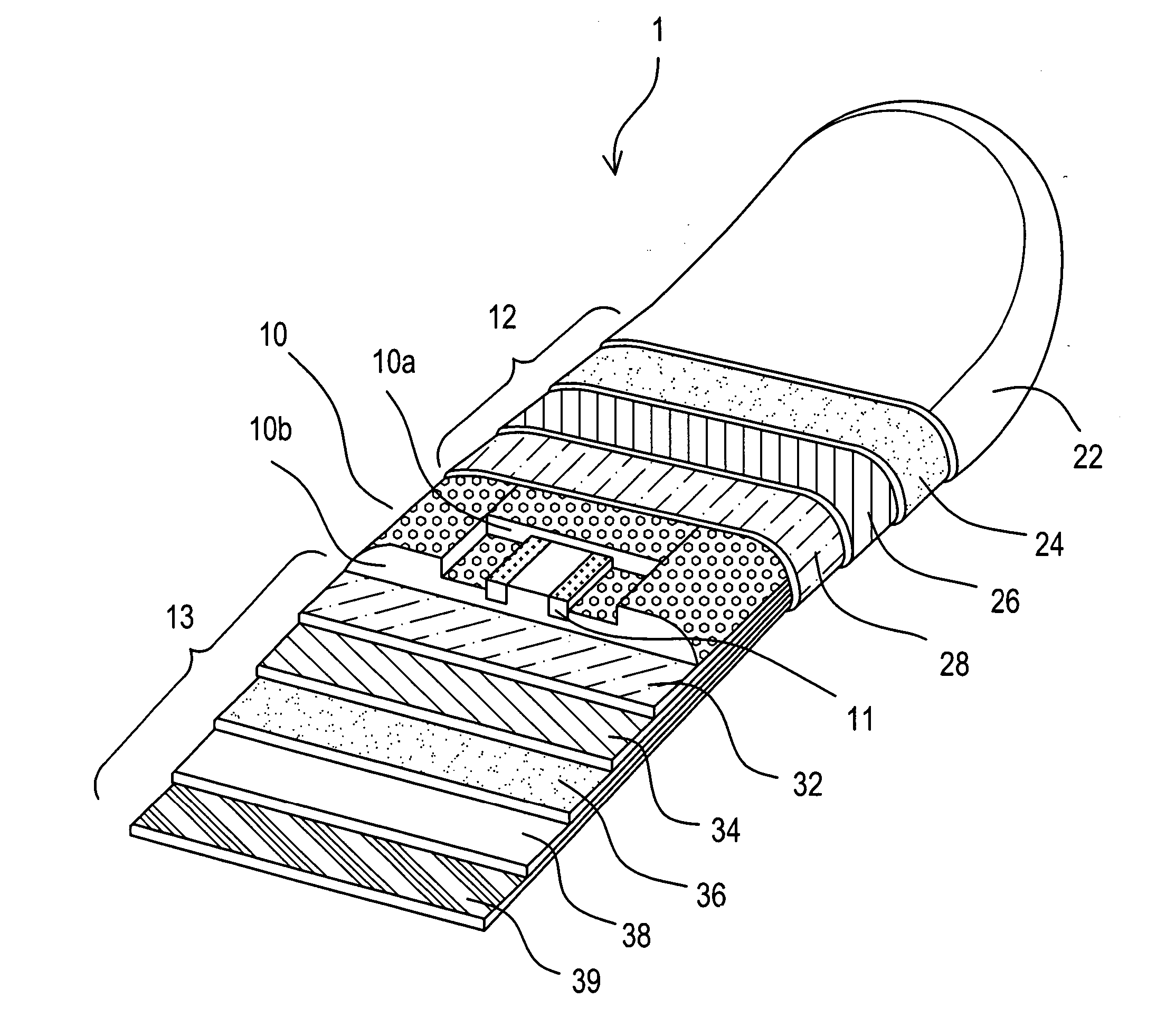

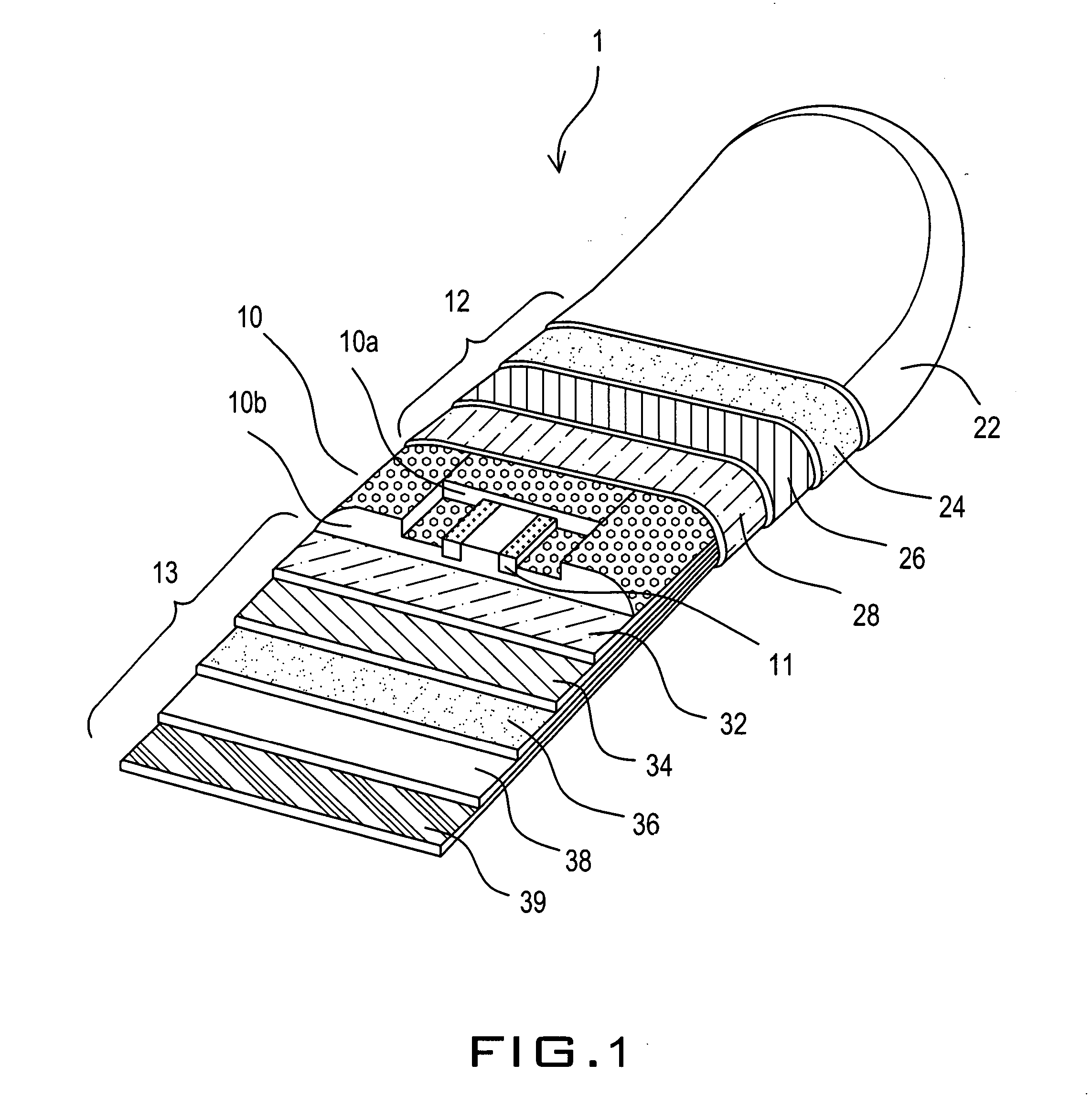

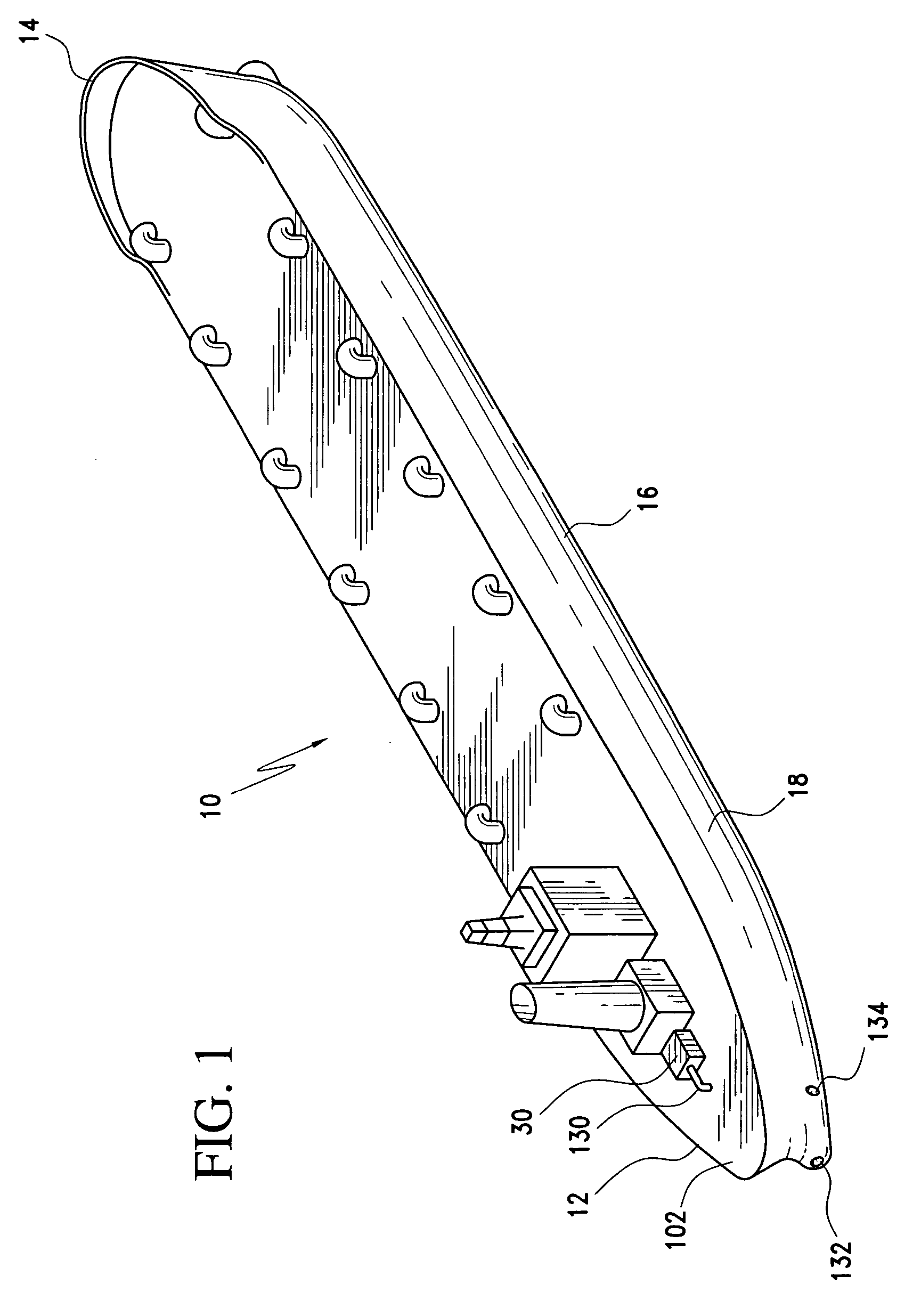

Foam deck composite surfboard

A polyethylene foam composite surfboard comprises a longitudinally extending foam core having a top surface, a bottom surface and rail surfaces. A top laminate is bonded to the top surface and rail surfaces. A bottom laminate bonded to the bottom surface. The top laminate or the bottom laminate comprises (a) a polyolefin foam layer having an inner surface and outer surface;(b) a non-woven fabric layer having a first hot melt resin coated surface and a second uncoated surface opposed to the resin coated surface, of which the hot melt resin coated surface is bonded to the inner surface of the polyolefin foam; and (c) a reinforcement layer comprising fiberglass laminate impregnated with polymer resin and having an inner surface and outer surface. The outer surface is bonded to the uncoated surface of the non-woven fabric and the inner surface is bonded to the foamed surface of the core.

Owner:CHEUNG WAH KAN

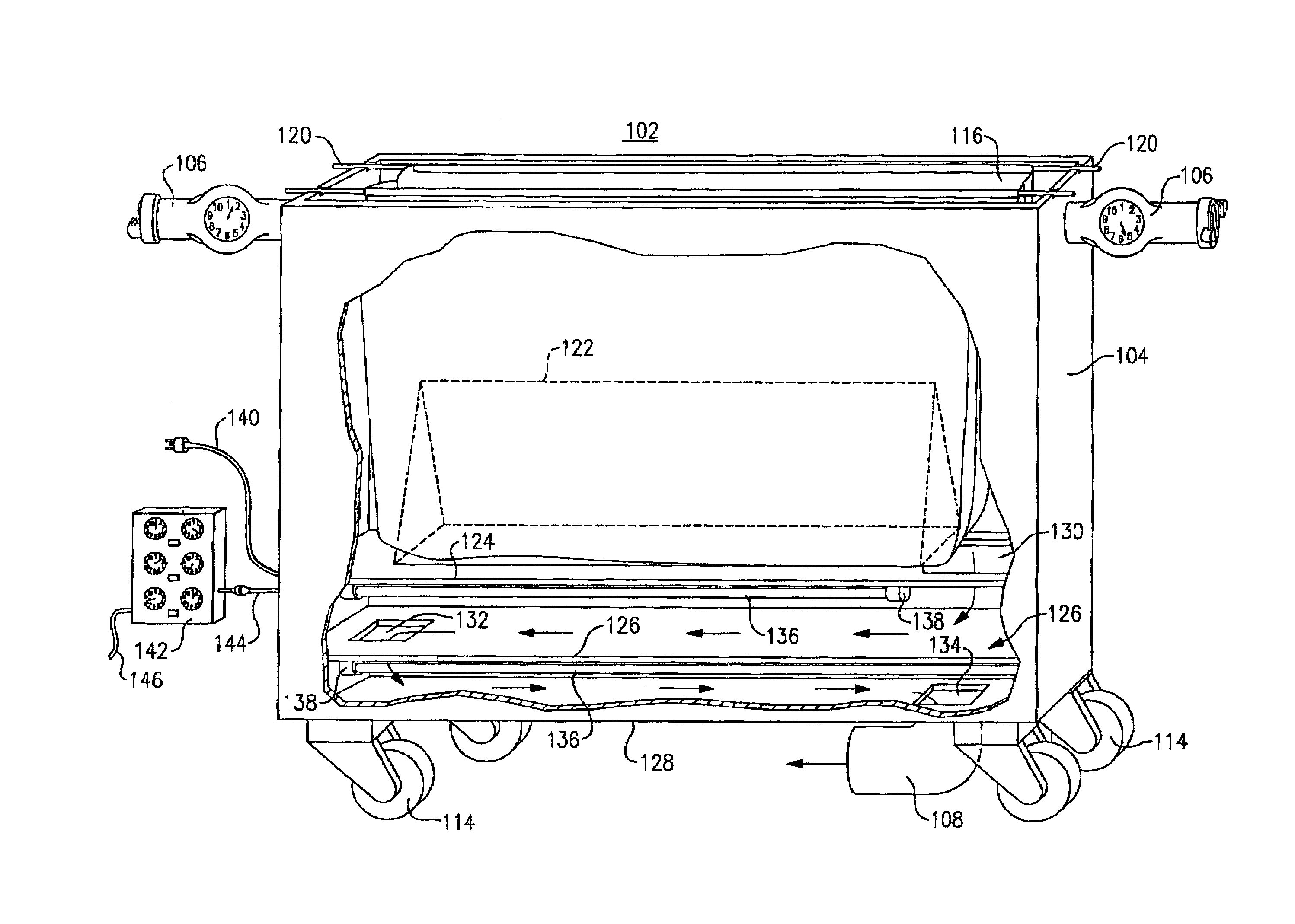

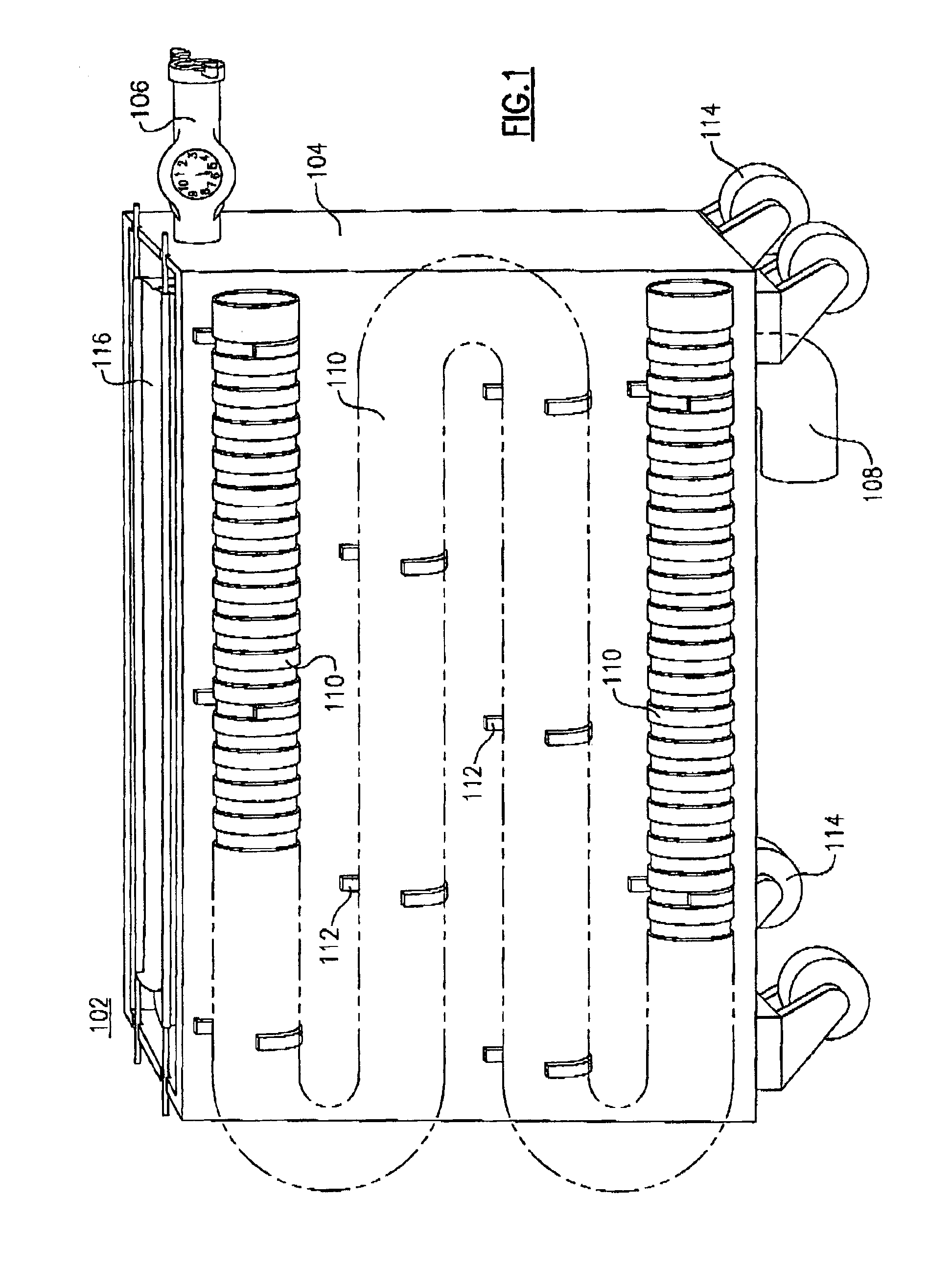

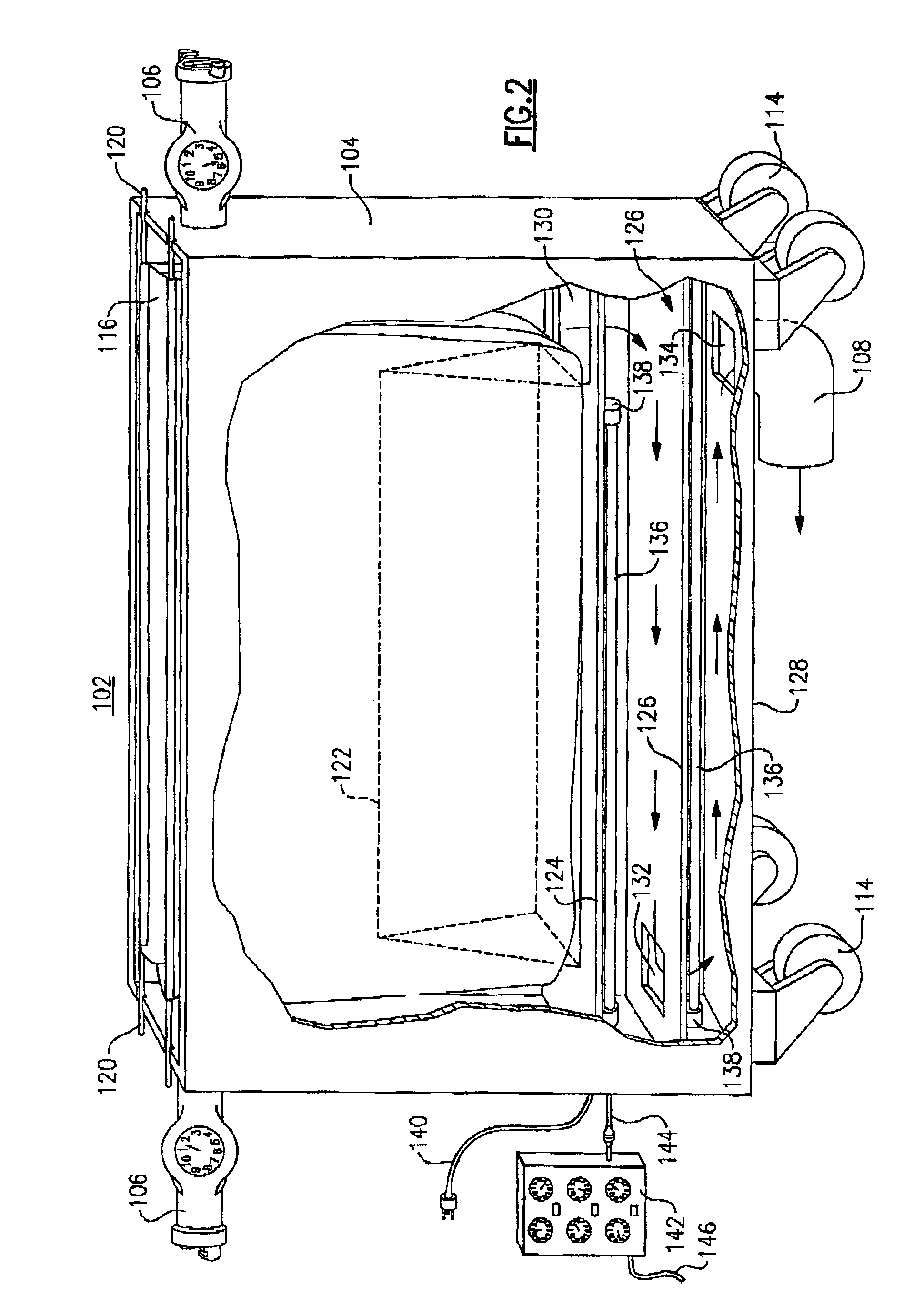

Ballast water treatment systems including related apparatus and methods

Ballast water treatment apparatus and methods for preventing foreign aquatic invasive species form entering marine ecological zones by translocation in ship's ballast water. The apparatus includes a housing, a filter member, and UV water treatment chambers. Methods include use of a ship's fire hydrant system for moving ballast water from the ship's ballast tanks into the apparatus for filtration and treatment. In-port service vessels and dock-side service vehicles are equipped with the treatment and filtration apparatus to provided in-port or dock-side ballast water treatment services. Related methods are also provided.

Owner:MARENCO TECH GROUP

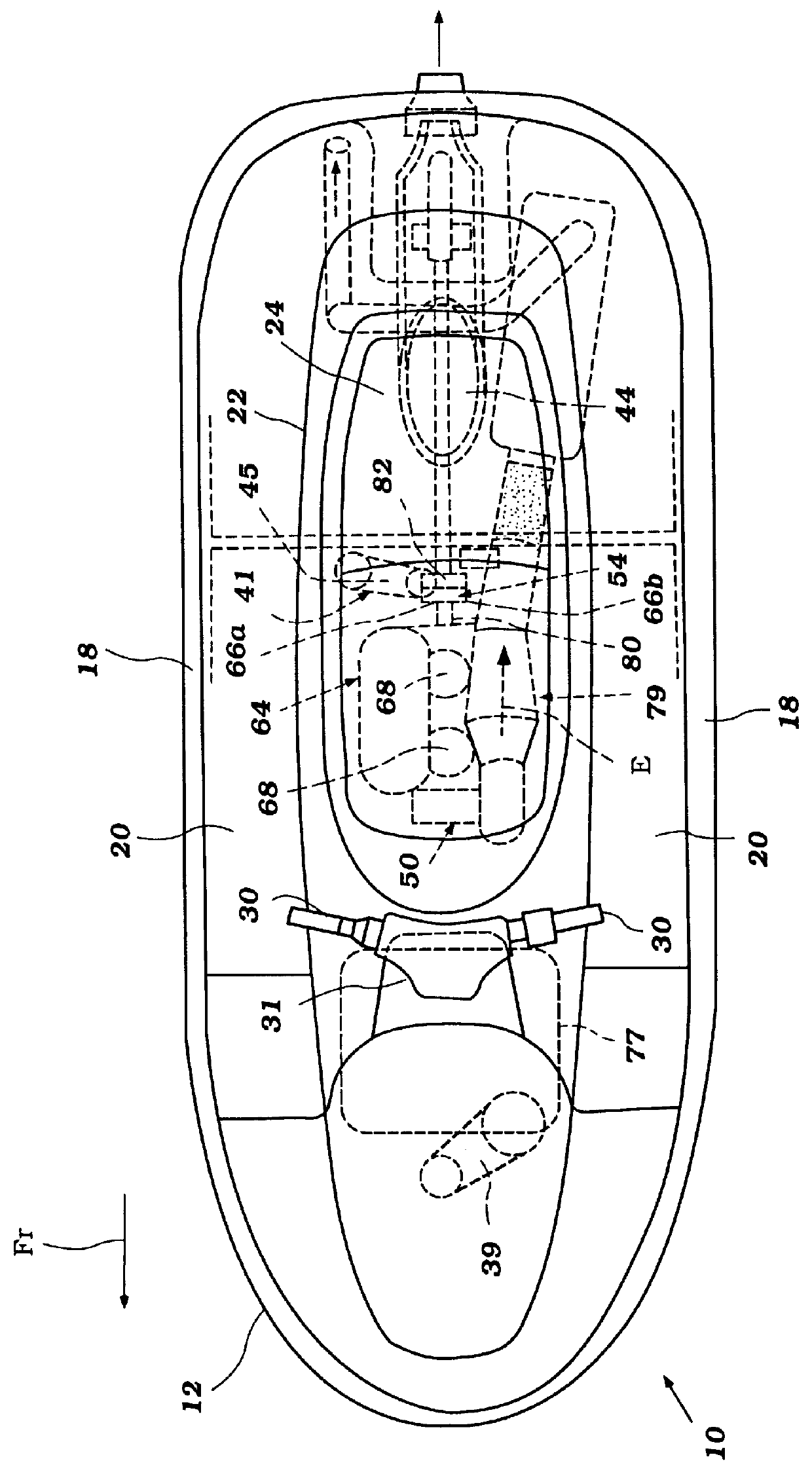

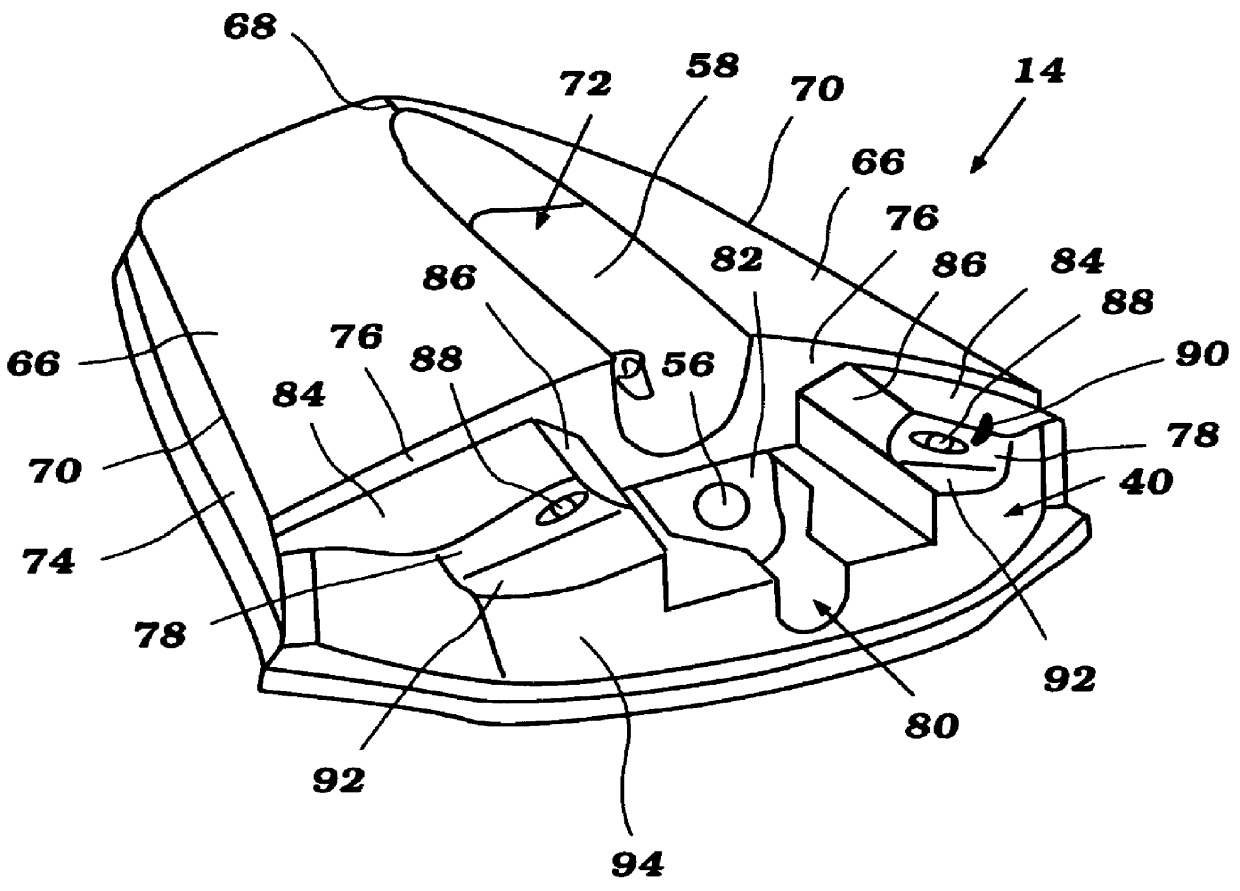

Hull construction for small watercraft

InactiveUS6058873ASelf-bailing equipments/scuppersVessel movement reduction by foilsHull structureWetted area

A personal watercraft includes an improved hull design which reduces drag on the watercraft and inhibits porpoising of the watercraft at high speeds, while providing adequate buoyancy when the watercraft is at rest. The watercraft hull includes a pair of steppers positioned toward the aft end of the watercraft hull. The rear stepper has a greater height than the front stepper. This design reduces the wetted area of the hull when the watercraft is up on plane. The second stepper, however, provides additional surface contact should the watercraft to porpoise in order to stabilize the watercraft. The hull design also includes improved foot steps and adjustable sponsons. The foot steps are sloped upwardly in order to provide greater control of the watercraft when leaning the watercraft in a turn.

Owner:YAMAHA MOTOR CO LTD

Ballast water treatment system and method without off-gas

A method and system treat ballast-water with ozone without release of detrimental off-gas into the atmosphere.

Owner:NUTECH O3 INC

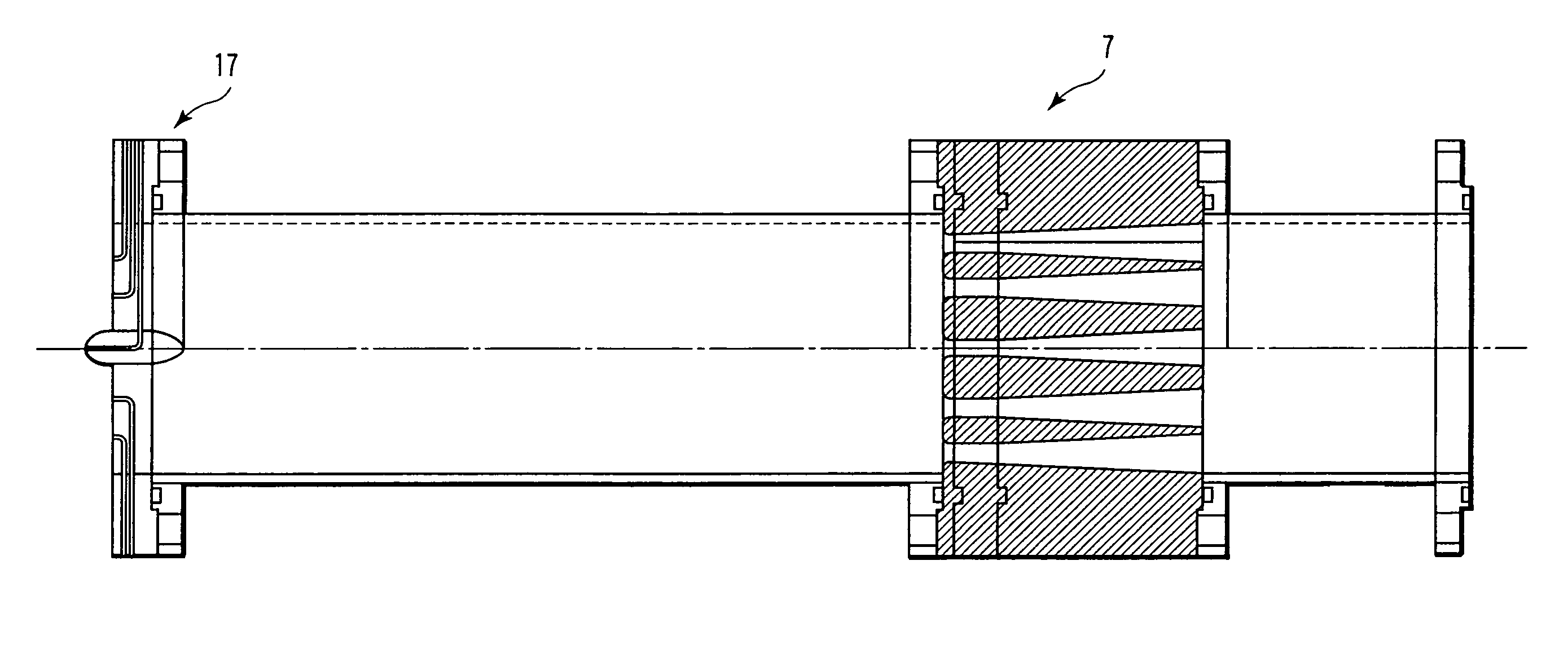

Apparatus for treating ballast water and method for treating ballast water

InactiveUS7776224B2Avoid dischargeSelf-bailing equipments/scuppersSolid sorbent liquid separationCavitationEnvironmental engineering

The present invention relates to an apparatus for treating ballast water, the apparatus being capable of treating ballast water so as to meet the ballast water standard established by the IMO exactly at low costs. The treatment apparatus of the present invention comprises a filter (4) that filters sea water to trap aquatic organisms, a bactericide supply apparatus (5) that supplies bactericide to the filtrate sea water, and a venturi tube 7 that introduces the sea water to which the bactericide is added, to produce cavitation in the sea water, thereby diffusing the bactericide and also damaging and destroying aquatic organisms in the sea water.

Owner:JFEENG CORP

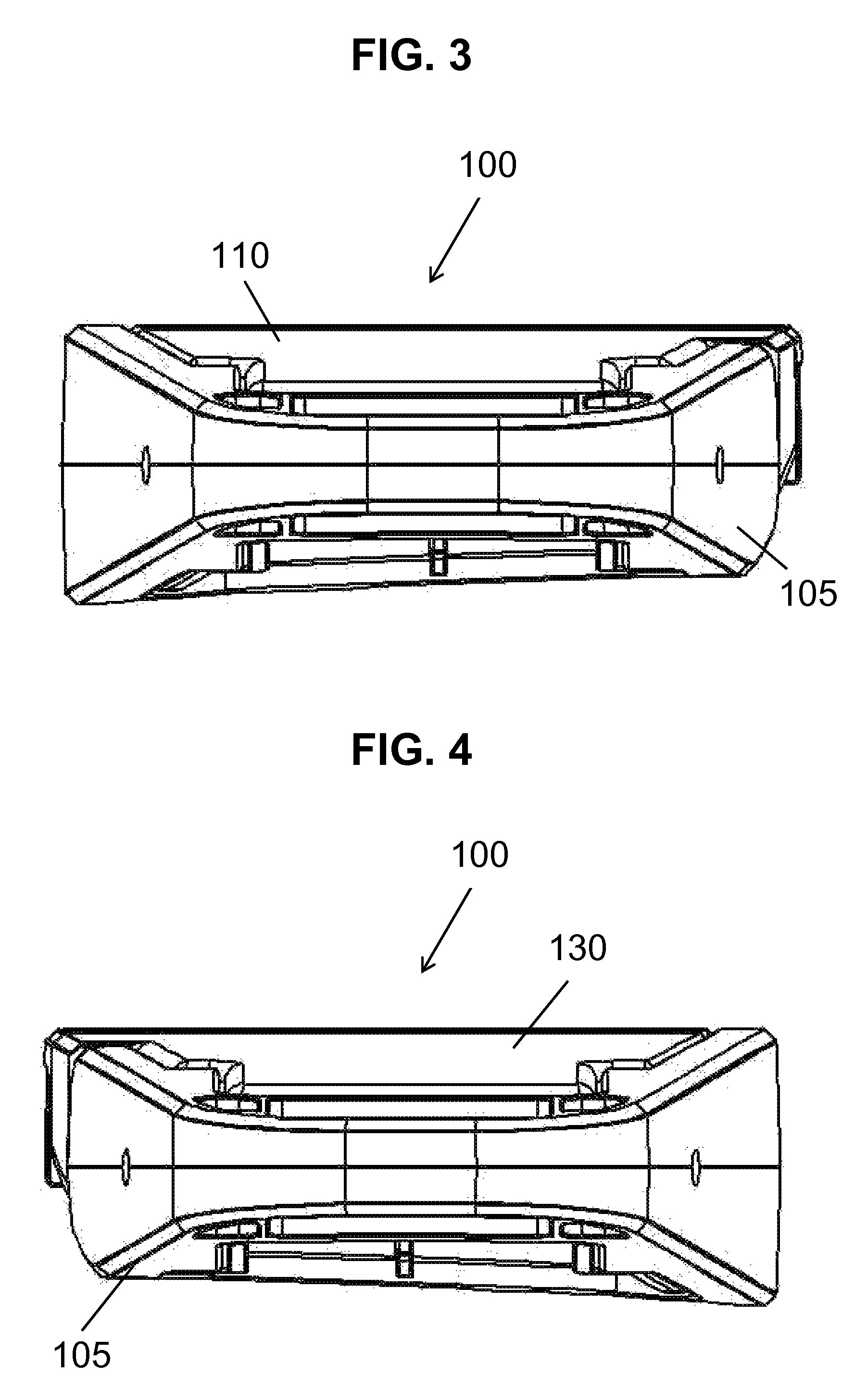

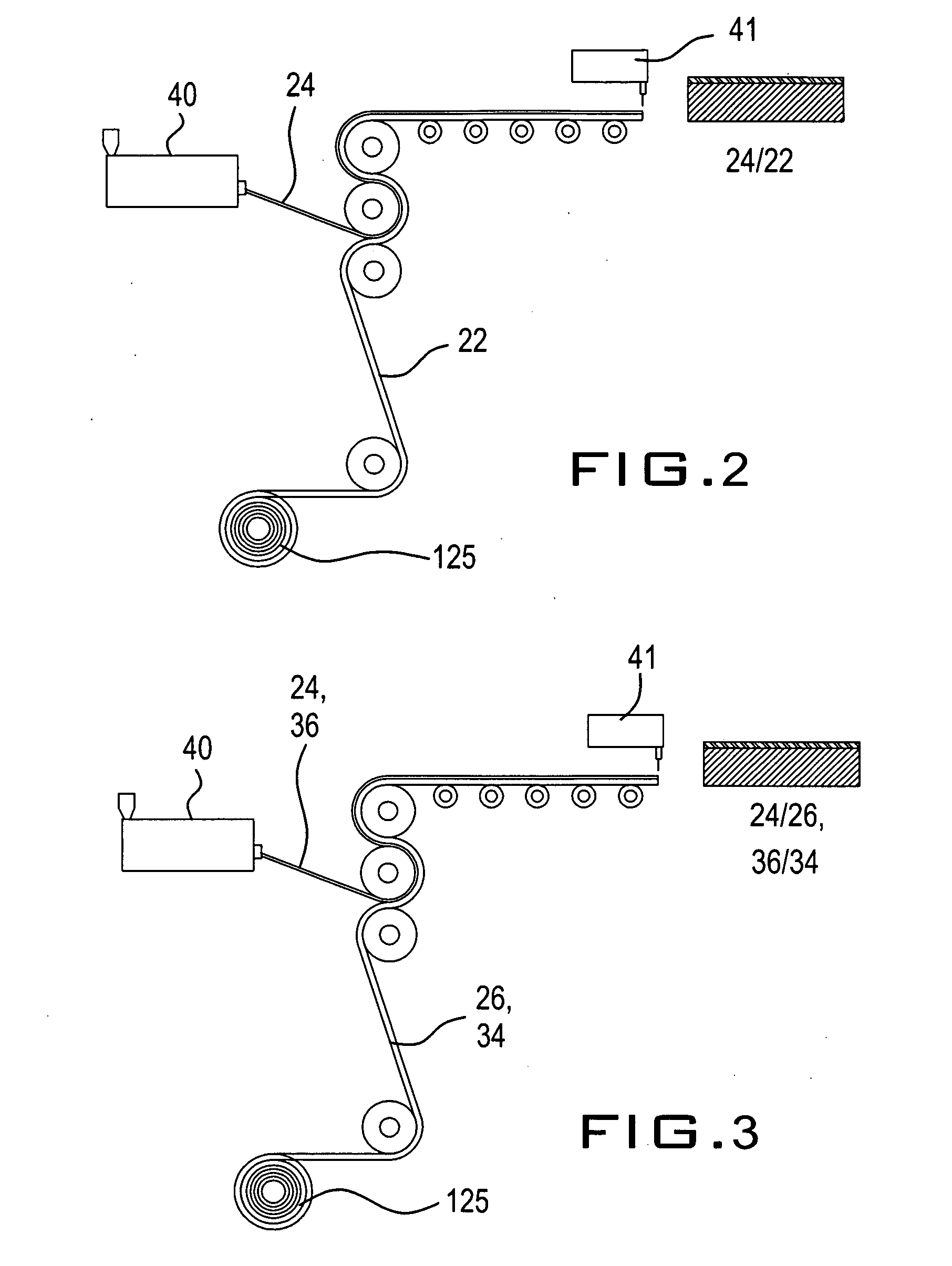

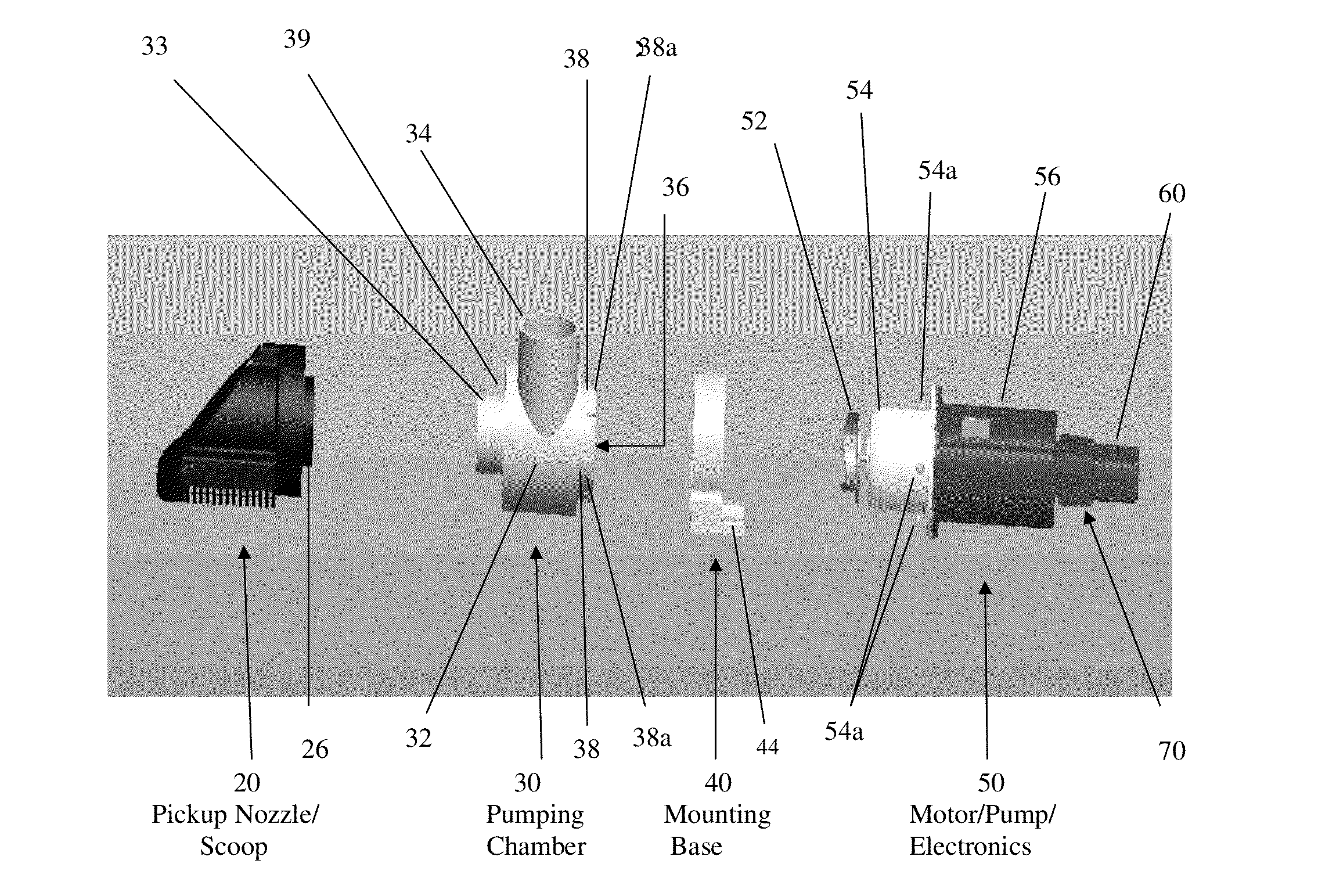

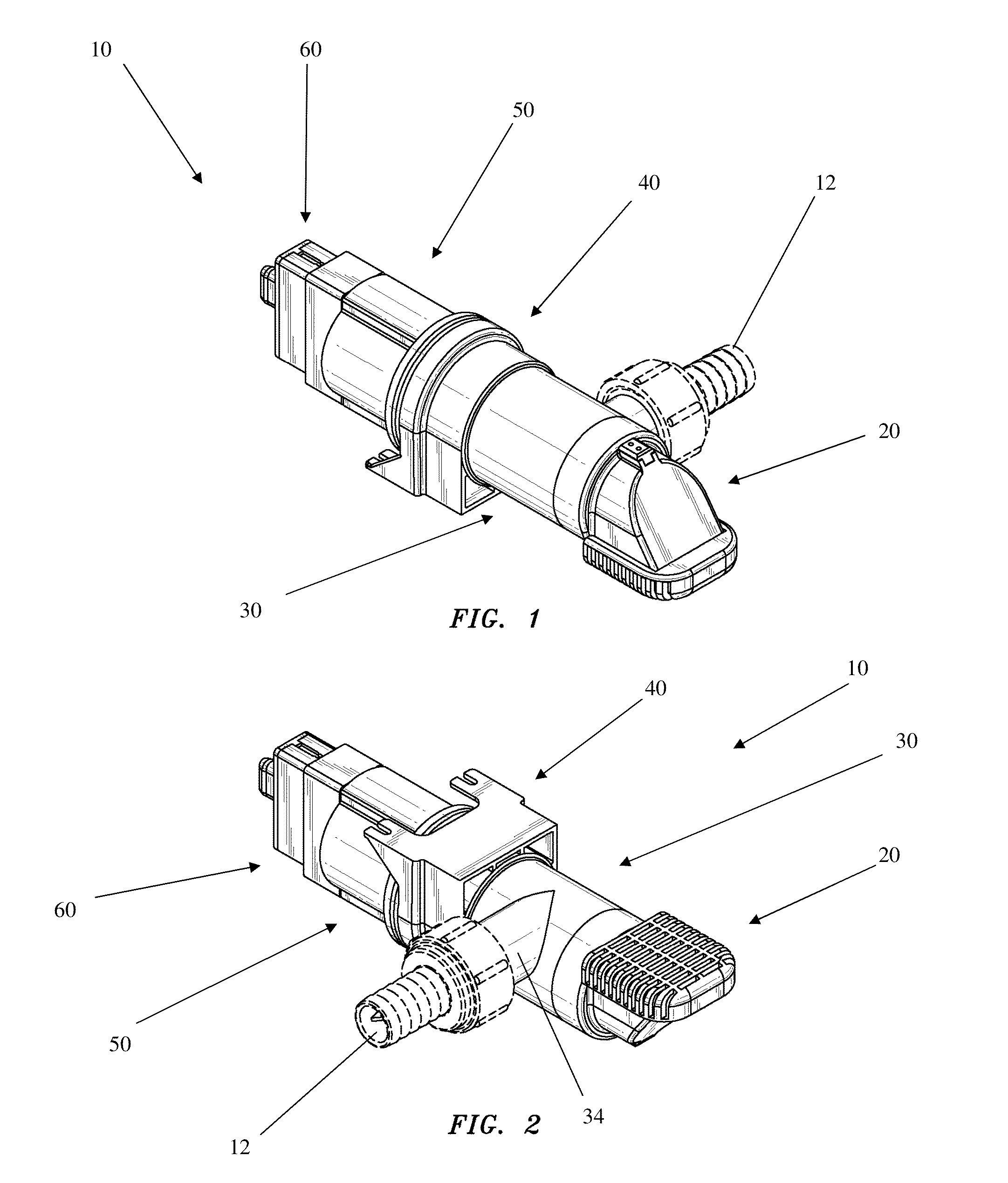

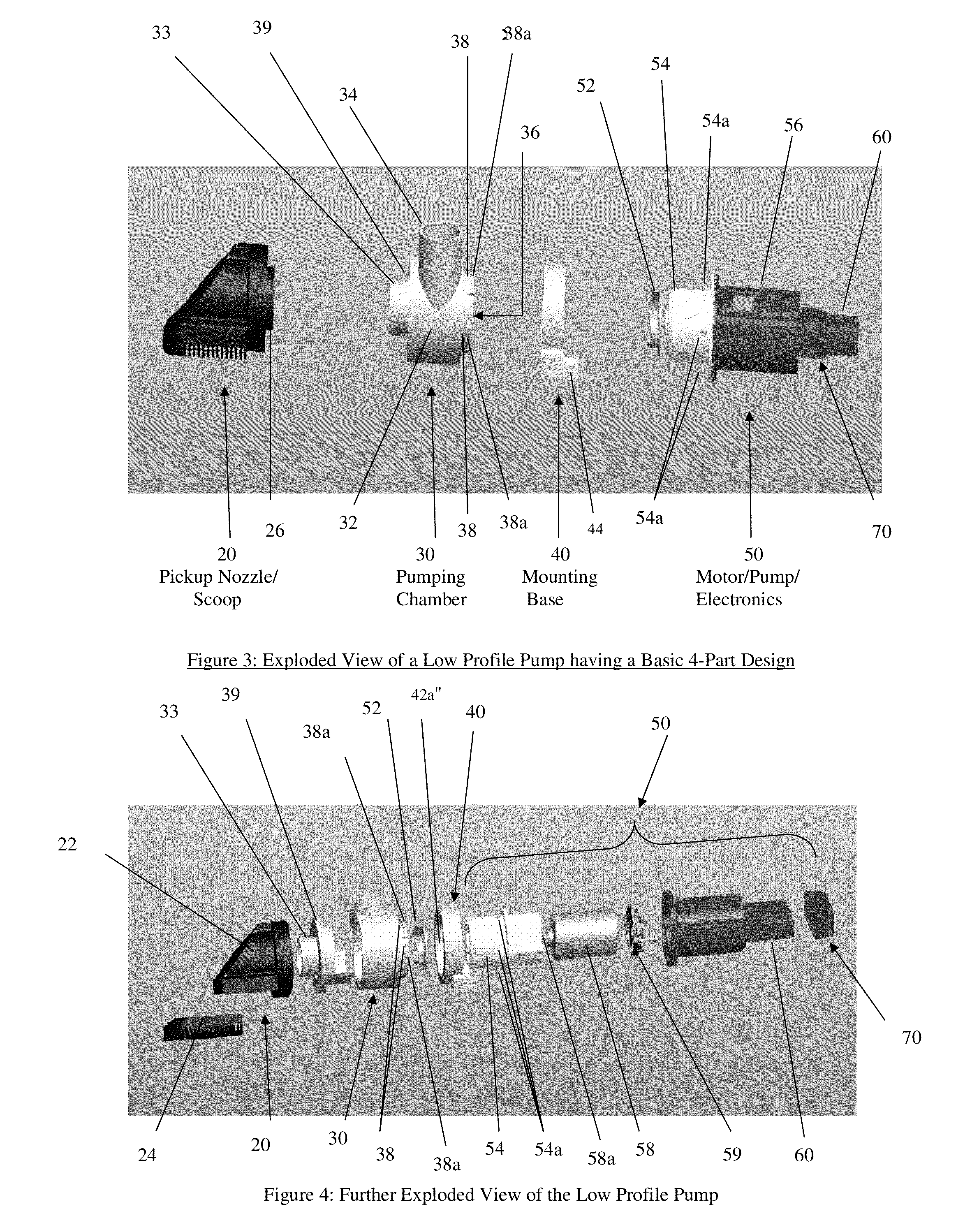

Low profile pump with the ability to be mounted in various configurations

ActiveUS20140341752A1Lower the water levelPump componentsSelf-bailing equipments/scuppersPump chamberCoupling

A pumping system featuring a pump chamber configured with a central portion having a tangential outlet, and configured with a tubular coupling end portion having inwardly flexible rim portions on one side; and a mounting base, having a circular portion with an inner circumferential rim configured to receive and engage the inwardly flexible rim portions of the tubular coupling portion of the pump chamber so as to be rotationally coupled to the pumping chamber so that the pumping chamber may be rotated 360° in relation to the mounting base.

Owner:FLOW CONTROL LLC

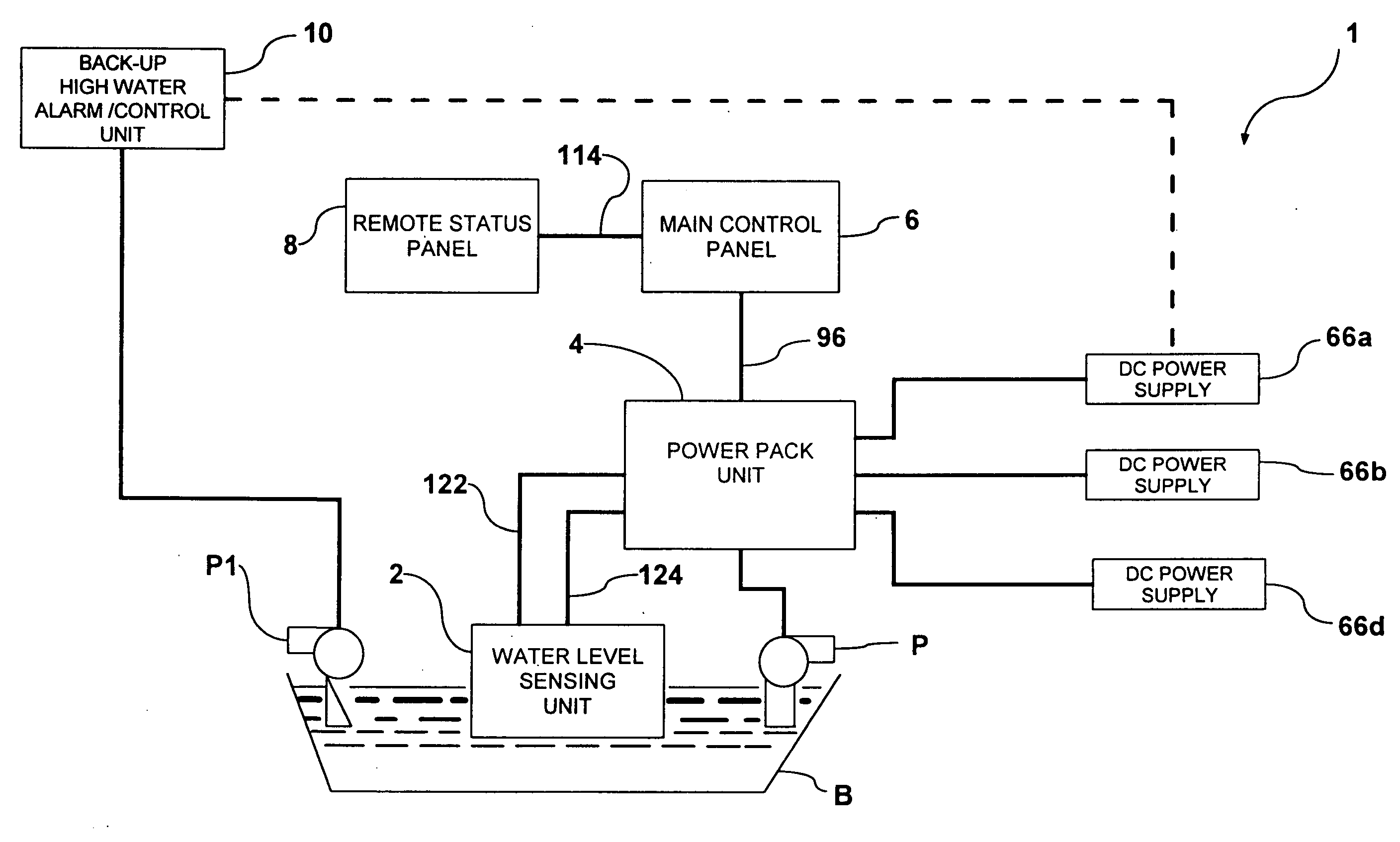

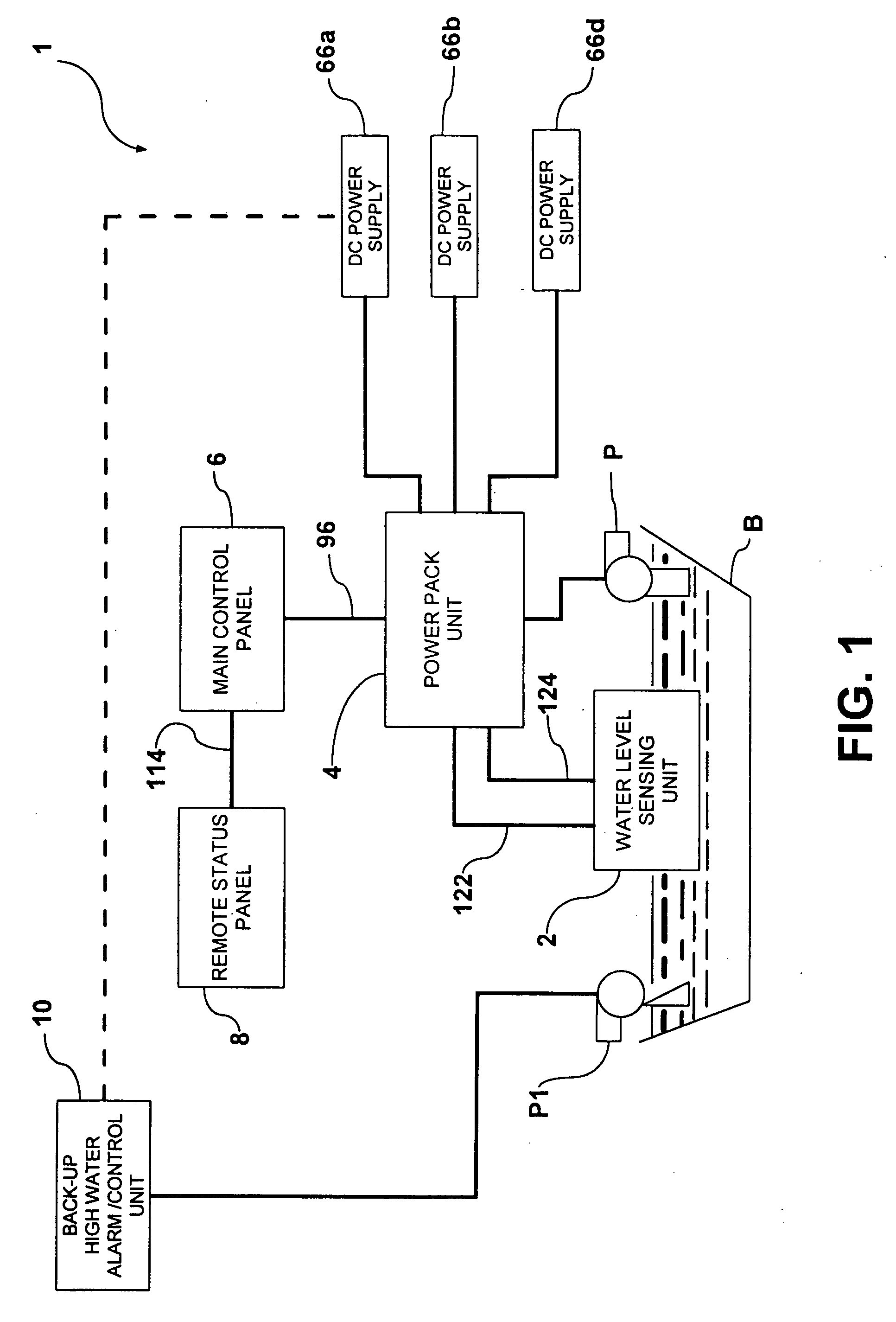

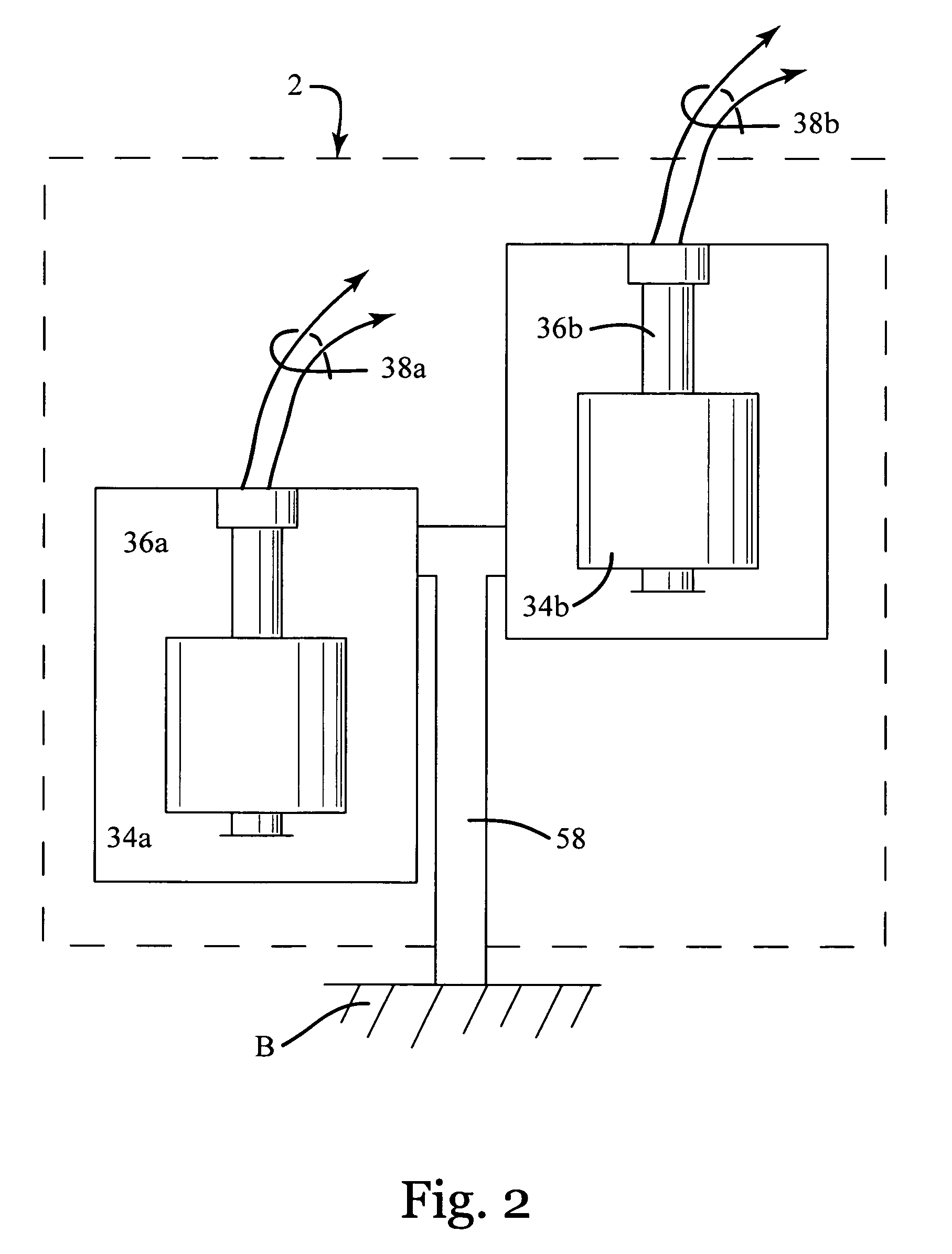

Method of and apparatus for detecting and controlling bilge water in a sea vessel

InactiveUS20090050042A1Reduce the possibilityAuxillariesSelf-bailing equipments/scuppersEngineeringSeawater

An improved bilge water level monitor, alert and control system for boats and other vessels. The system provides a method of detecting excessive leakage of water into the bilge and in response to the excessive water in the bilge, triggering an alarm to notify the operator and others and energizes bilge pumps to remove the excessive water. The system is designed with many redundancies in the sub elements and subsystems for safety. The system provides a means for reducing the likelihood of exhausting battery power in the event of a significant seawater leakage problem. The electrical power rating of the monitoring circuitry components is relatively low, thereby reducing the size and weight of those components relative to prior bilge pump monitoring and alert systems. There is no electrical wiring exposed to bilge water during system operation thereby reducing damage to the wiring components. The water level detection and control circuitry operates with sufficiently low amperage to substantially eliminate the hazard of spark-induced combustion.

Owner:WALDECKER DONALD E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com