Patents

Literature

353 results about "Bilge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The bilge /bɪldʒ/ of a ship or boat is the part of the hull that would rest on the ground if the vessel is unsupported by water. The "turn of the bilge" is the transition from the bottom of a hull to the sides of a hull.

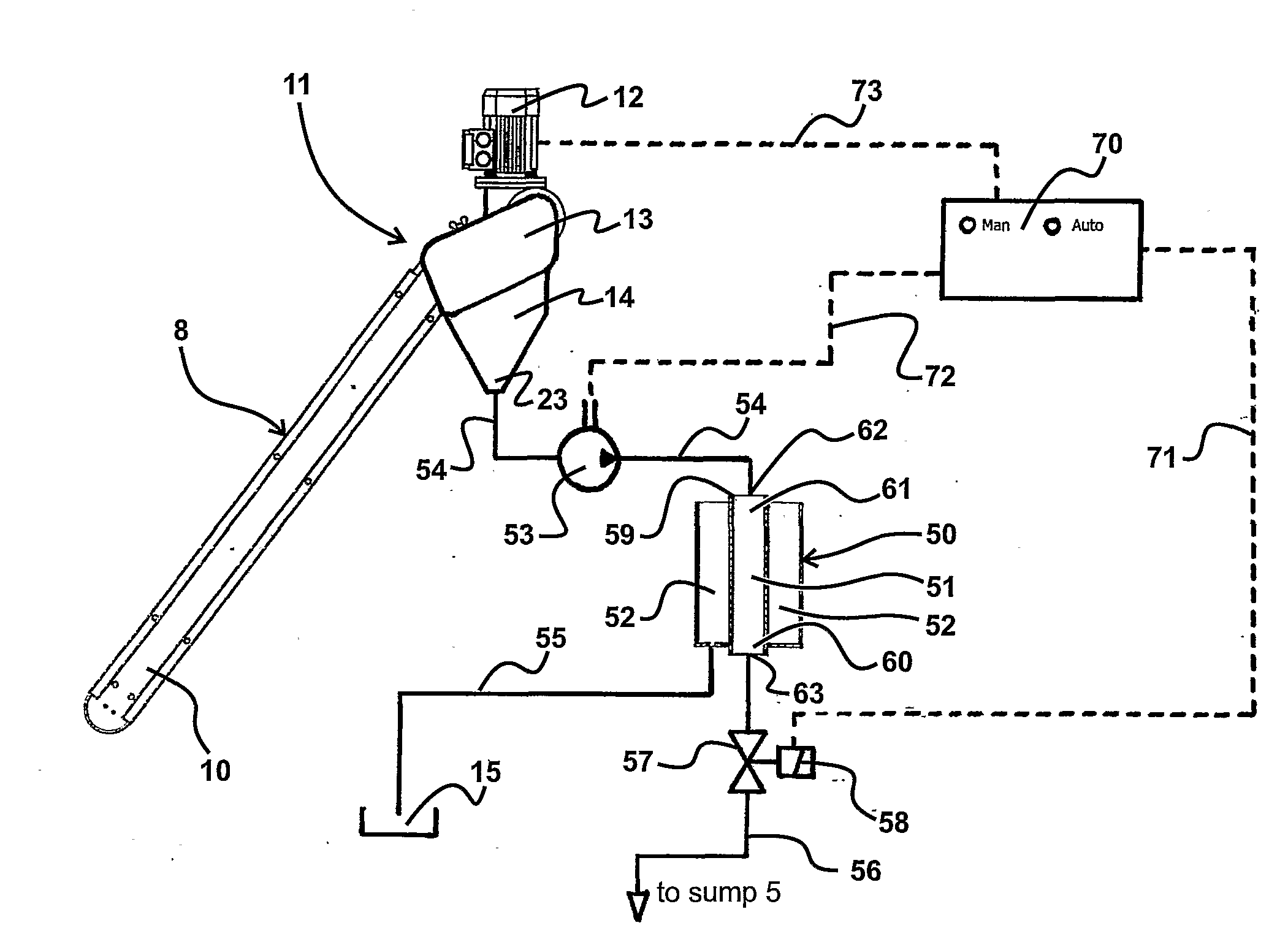

Bilge water reclamation system and process

InactiveUS6902678B2Reduce pollutantsEasy to processLiquid separation by electricityAuxillariesOil retentionBilge

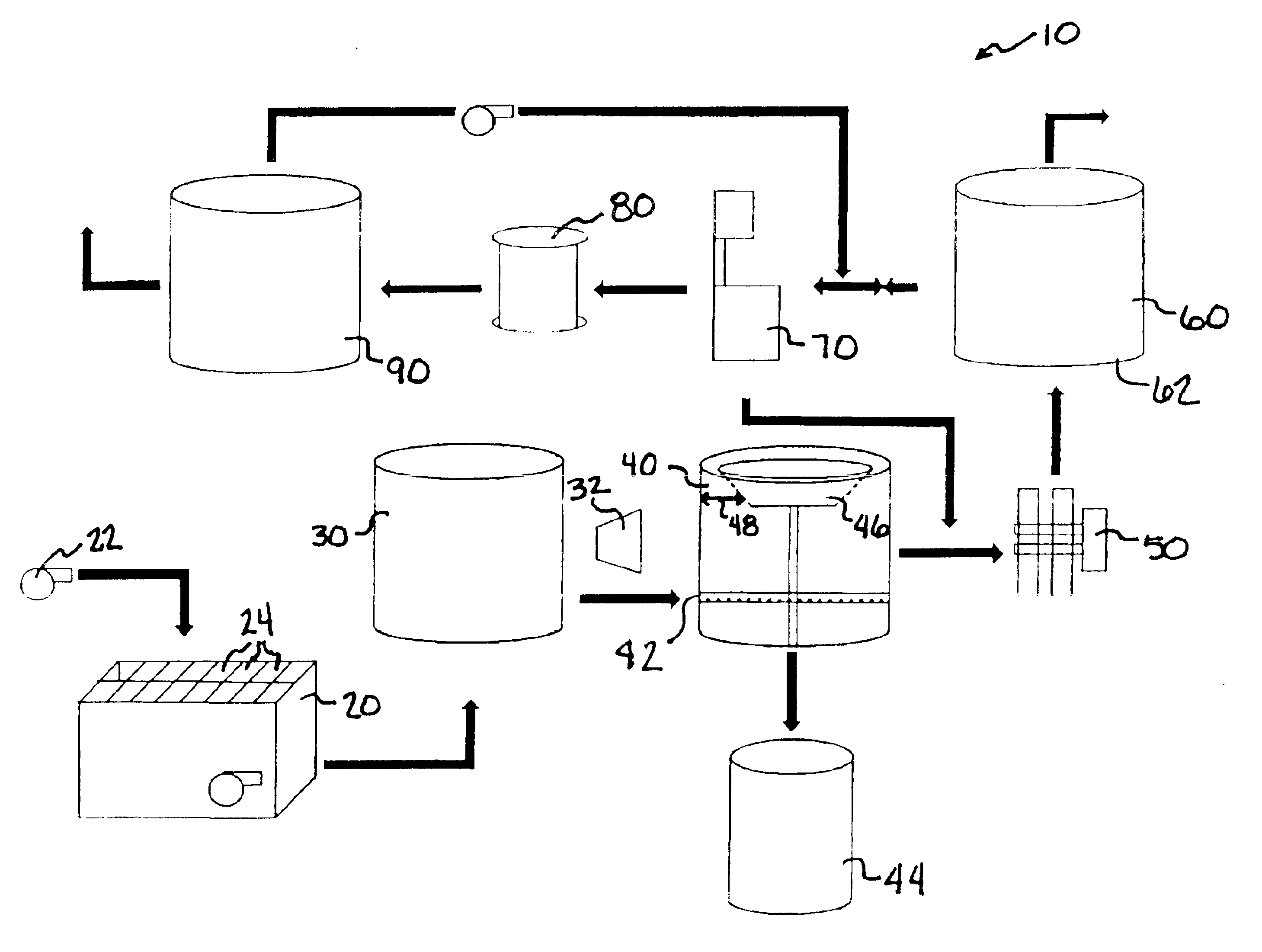

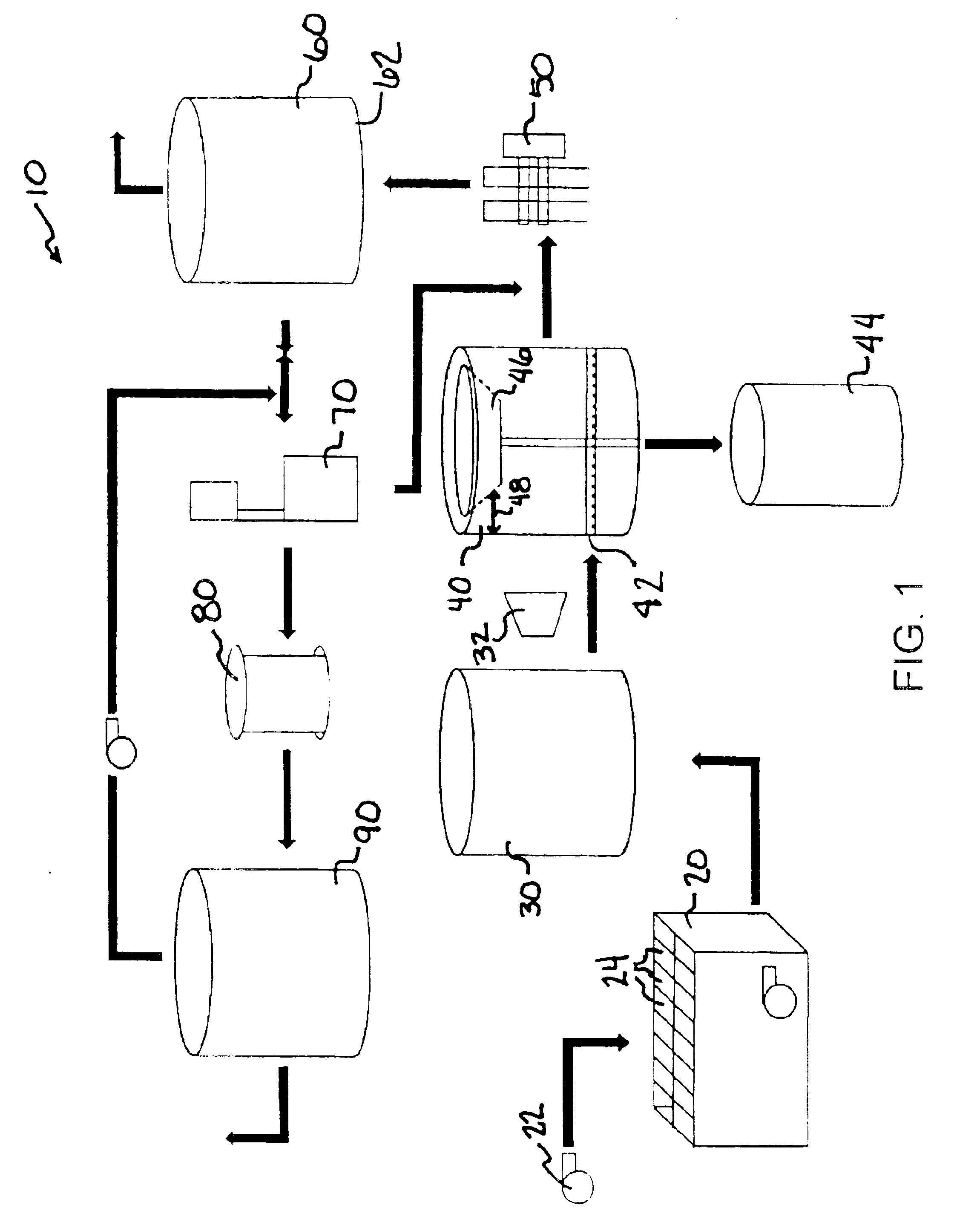

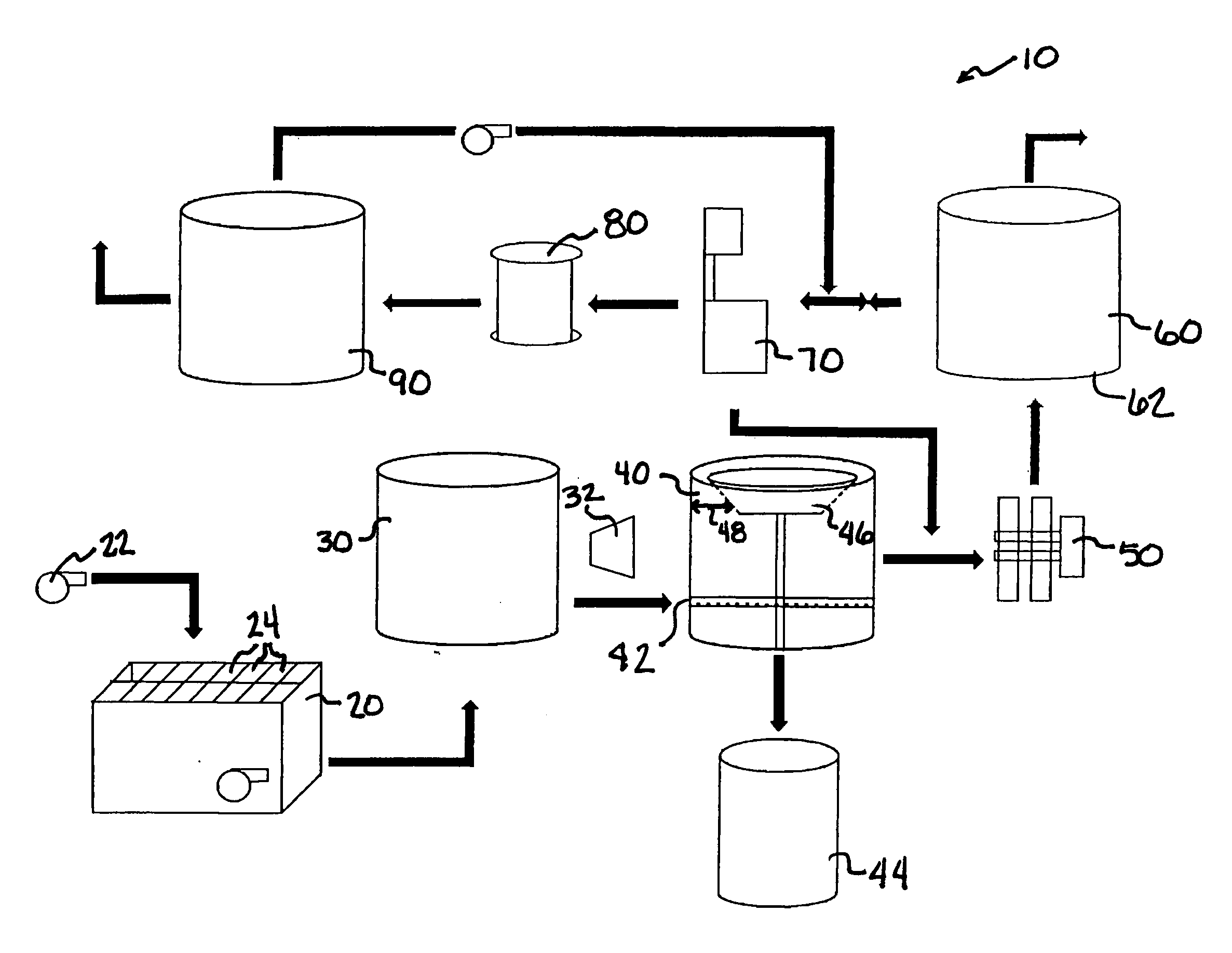

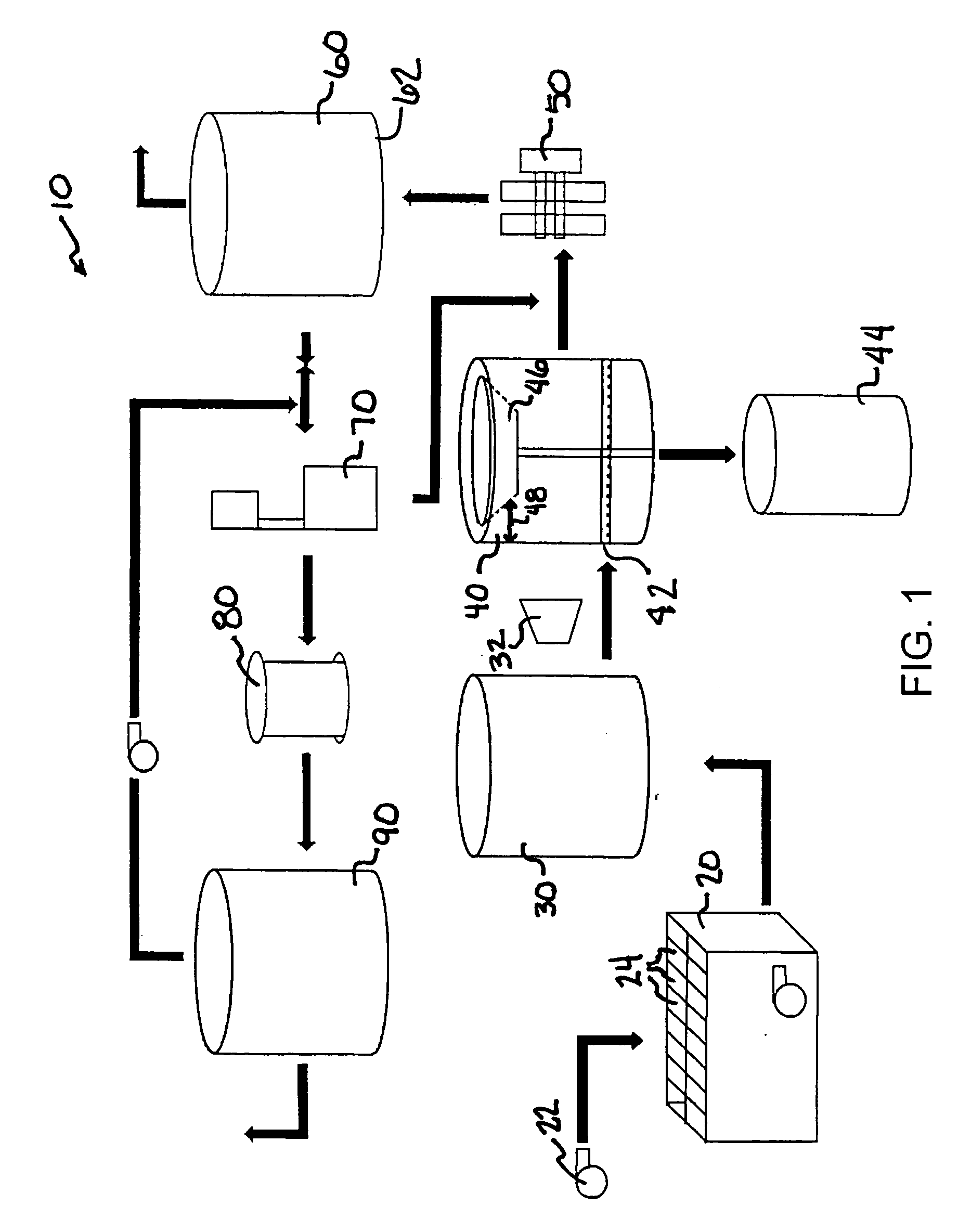

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

Bilge water reclamation system and process

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

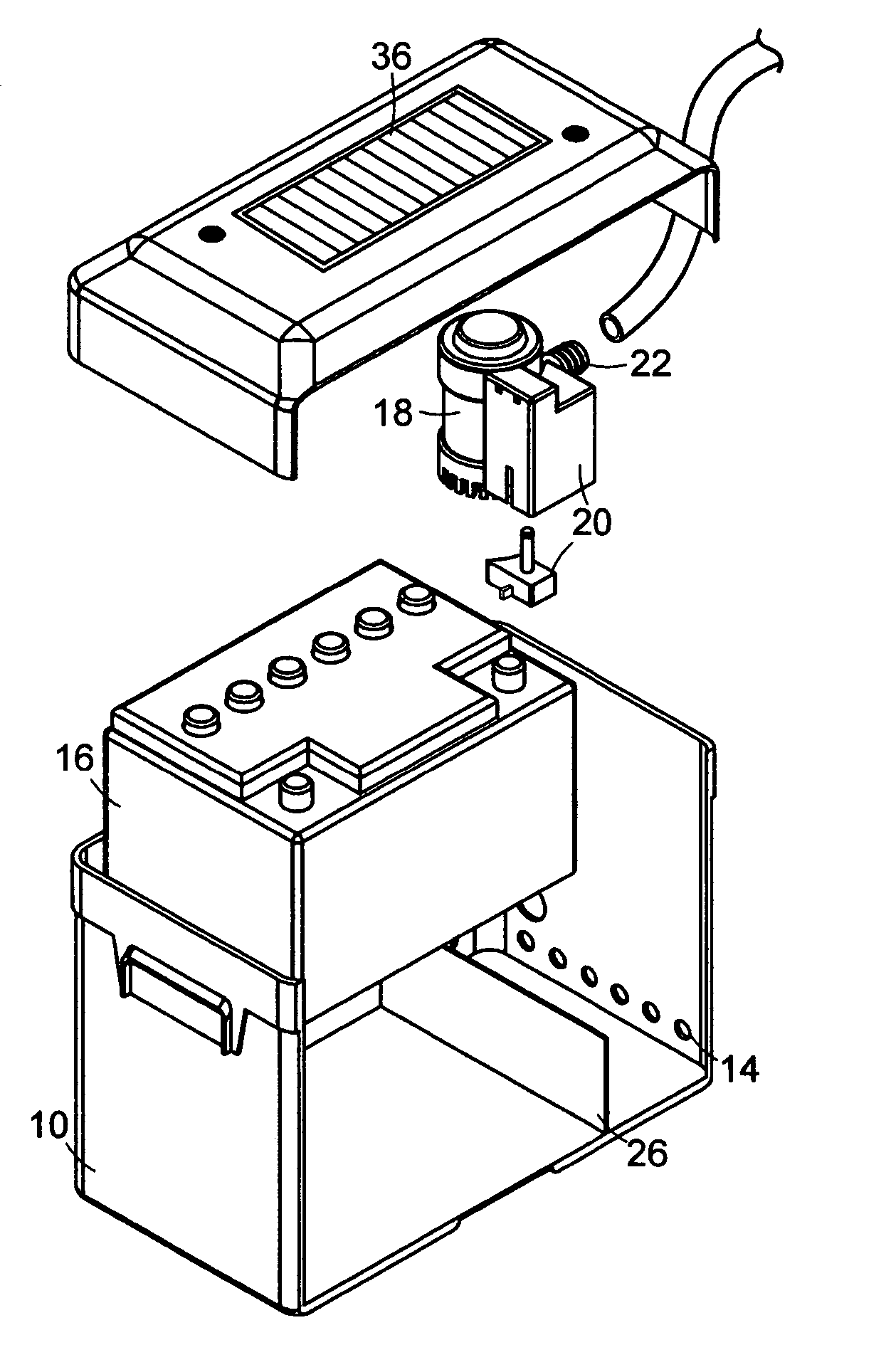

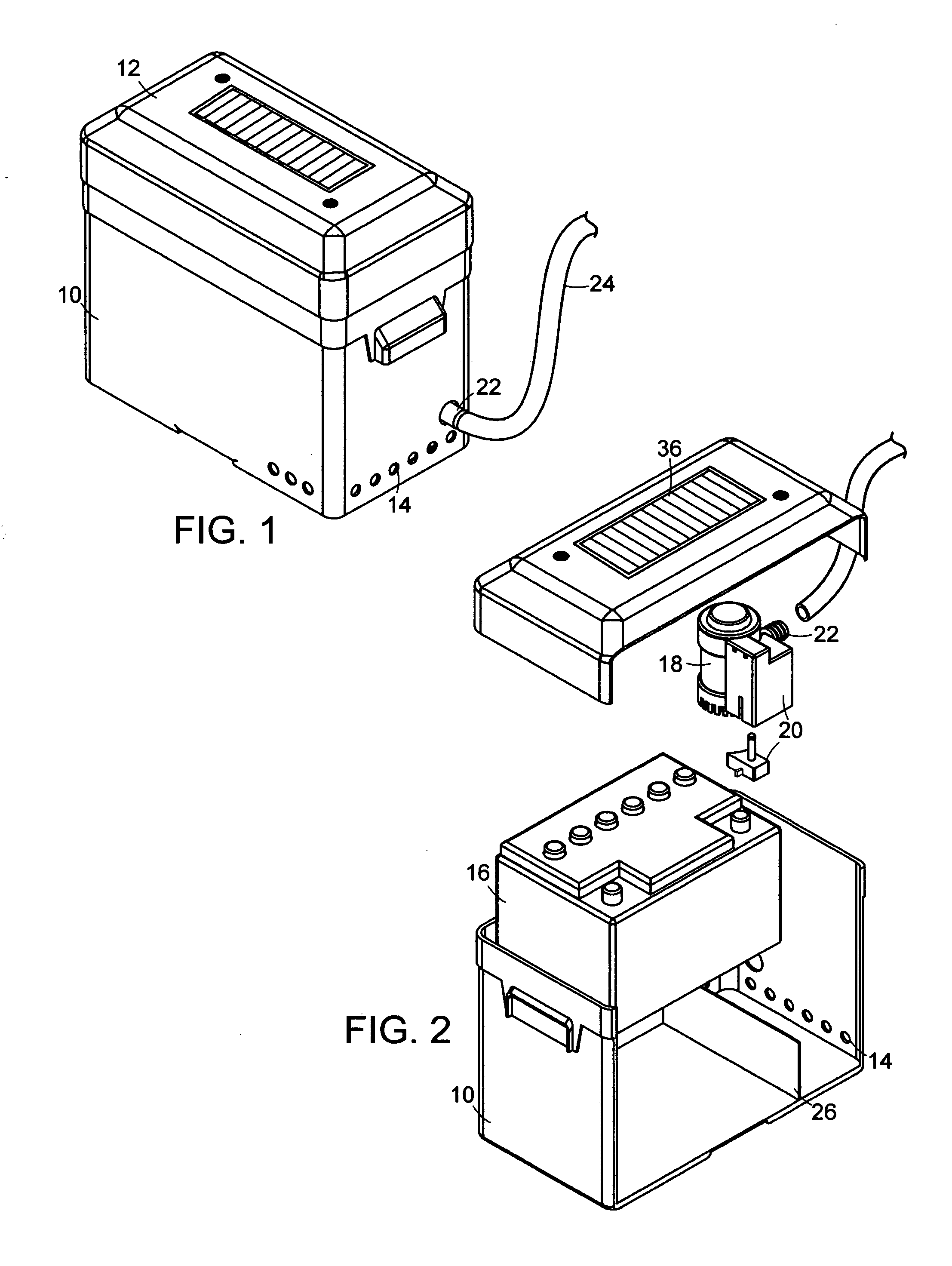

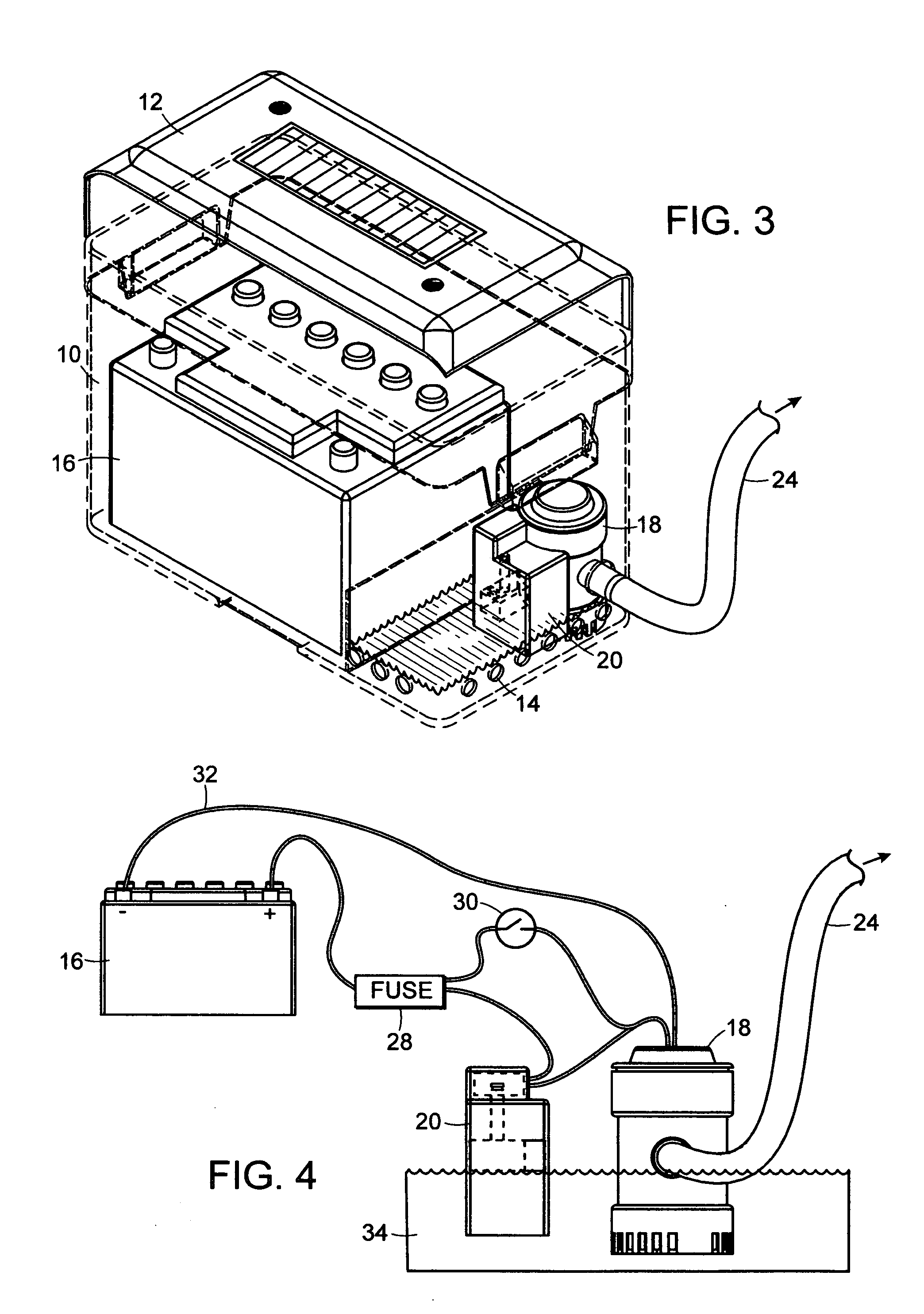

Portable battery powered automatic pump

InactiveUS20060269426A1Easy to assembleEliminate needSelf-bailing equipments/scuppersVessel partsBilgeElectrical battery

Owner:LLEWELLYN DANIEL M

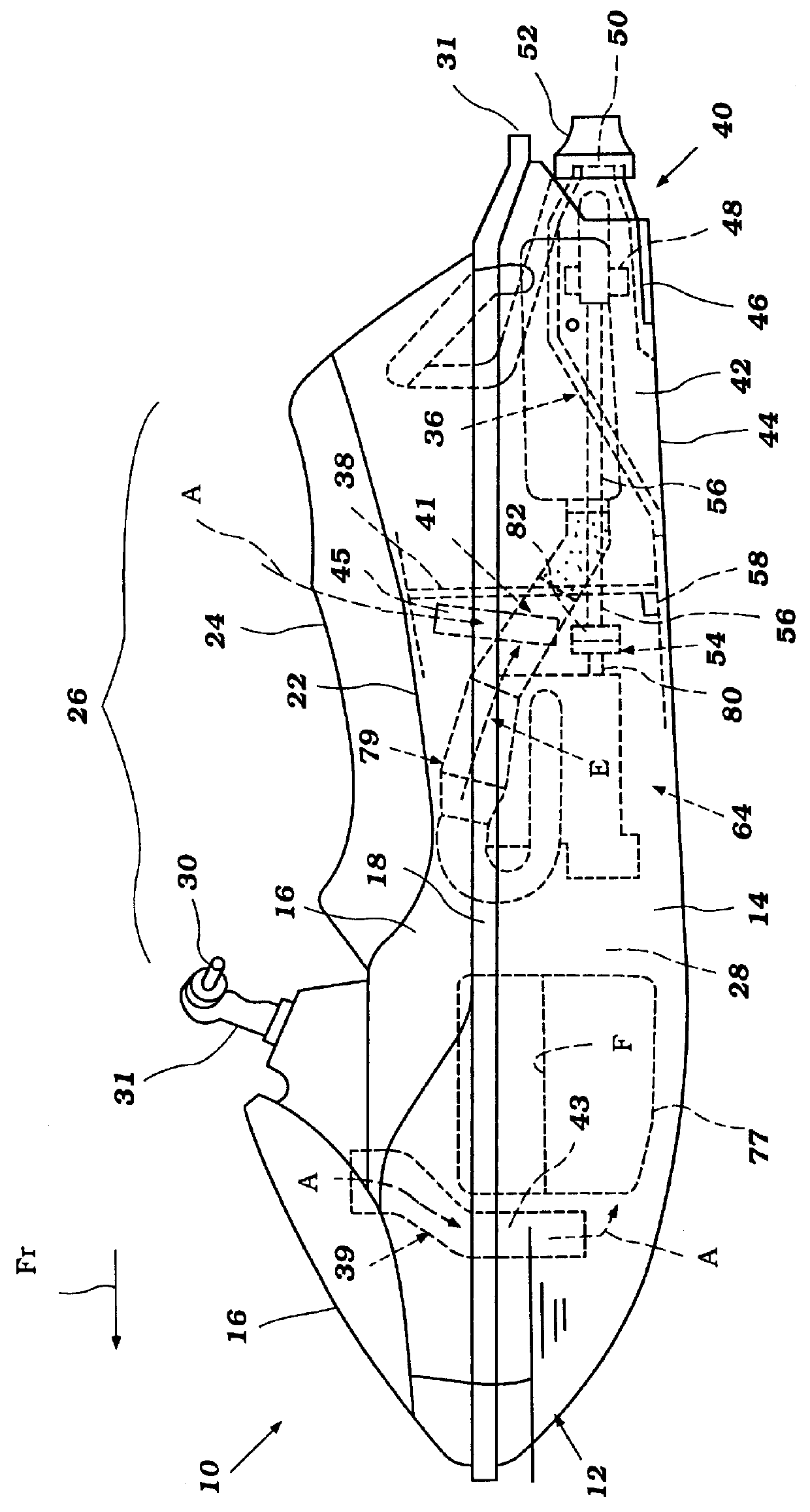

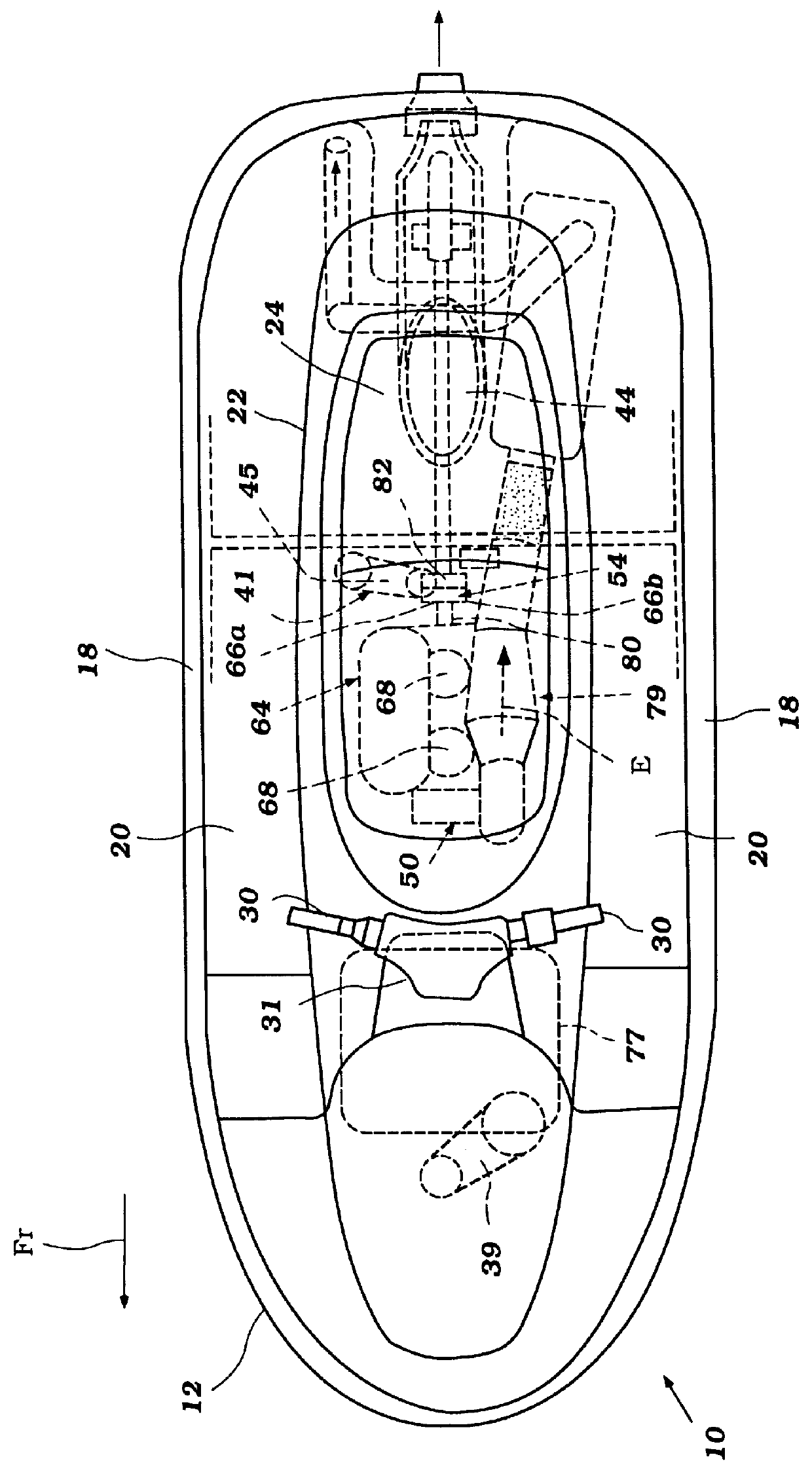

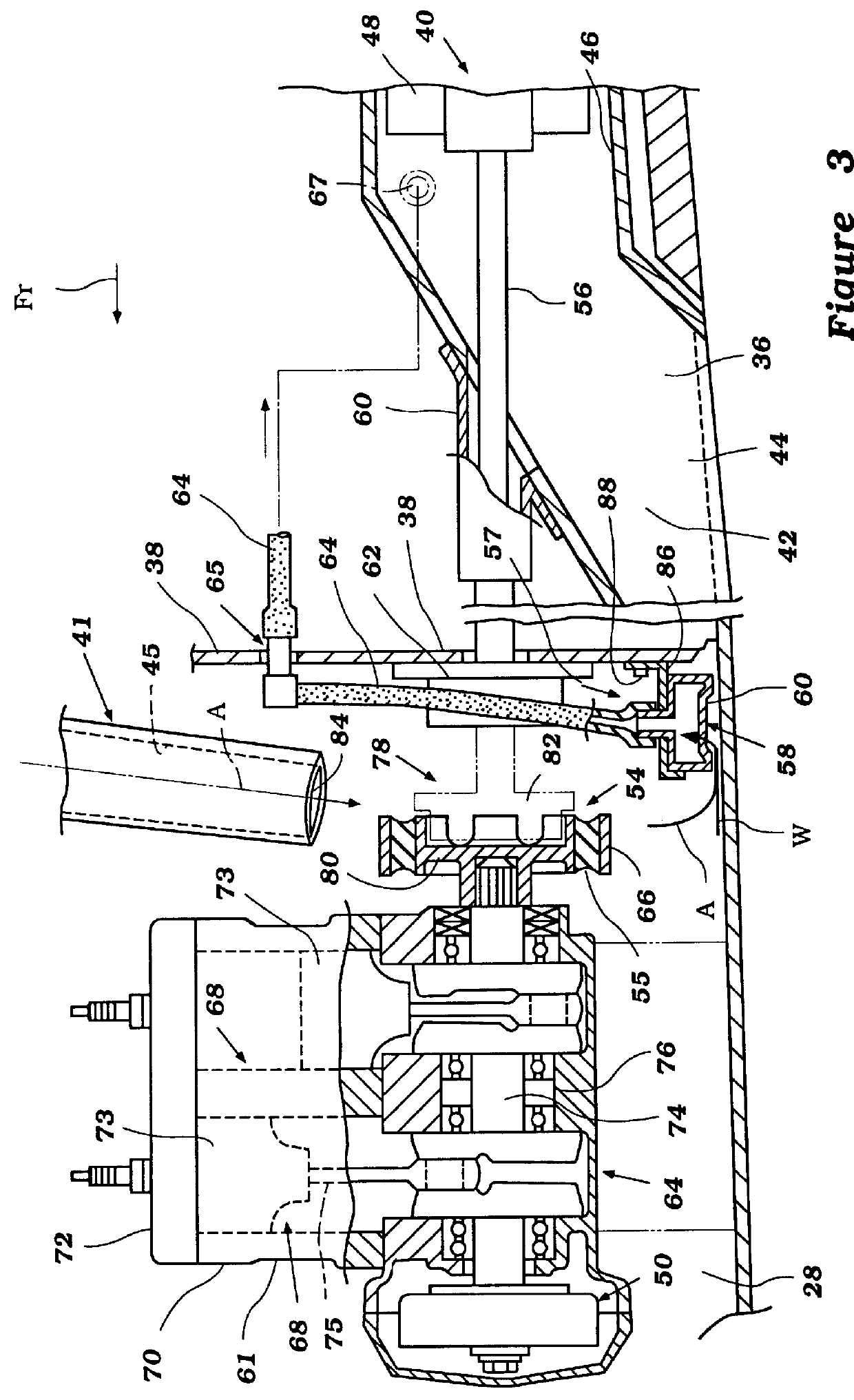

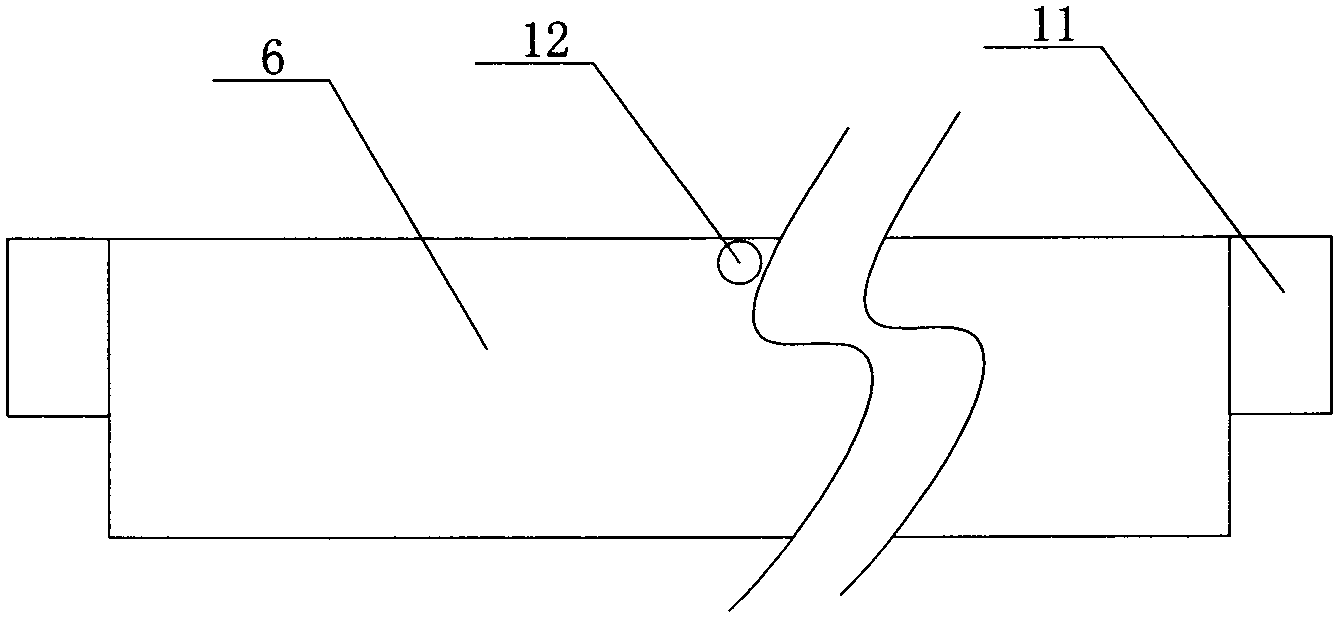

Torsional damper for watercraft propulsion system

A vibrational damper reduces torsional vibration within a crankshaft of a marine engine. The vibrational damper is located on an end of the crankshaft opposite of the flywheel and includes an inertia ring that adds additional mass to this opposite end. In addition, the vibrational damper includes an elastic member that suspends the inertia ring about the crankshaft. The elastic member effectively dampens torsional vibrations. The torsional damper desirably is cooled by an air flow so as to maintain it's dampening efficiency. A ventilation duct, which is positioned directly above the vibrational damper, supplies the cooling air. Cooling is enhanced by locating a bilge system inlet below and slightly behind the vibrational damper. An air flow stream occurs between the duct and the bilge inlet and across the torsional damper to cool the torsional damper.

Owner:YAMAHA MOTOR CO LTD

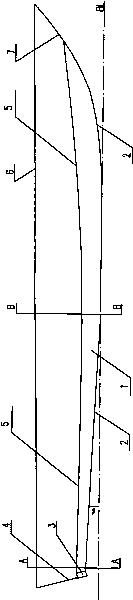

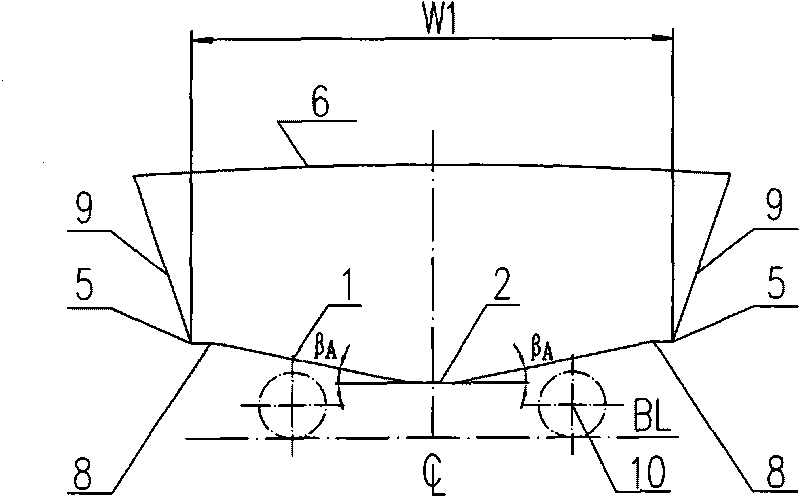

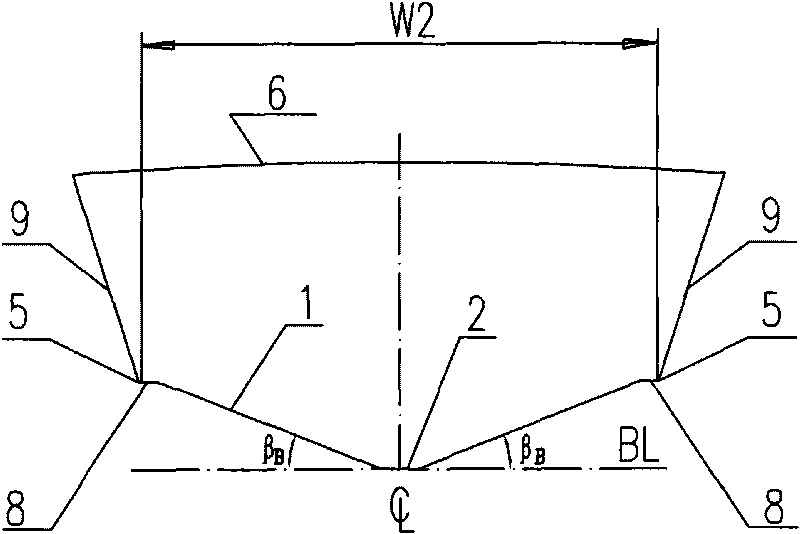

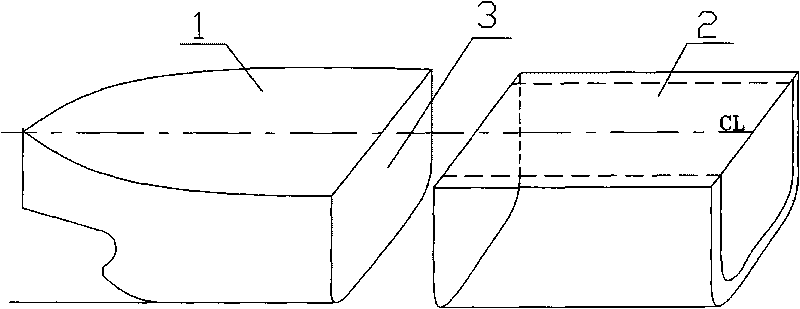

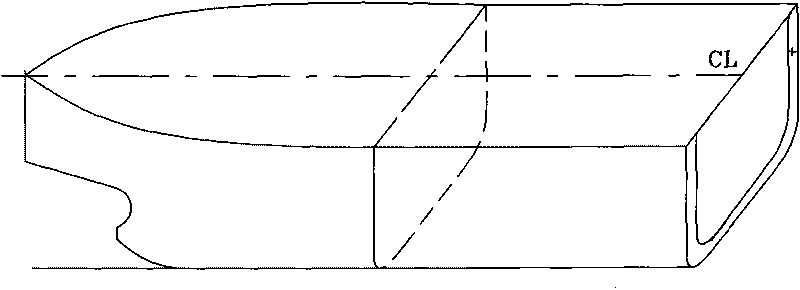

Boat type of deep V skimming boat

ActiveCN101704401AImprove propulsion efficiencySolve the problem of large thrust lossHull partsHydrodynamic/hydrostatic featuresBilgePropeller

The invention relates to a boat type of a deep V skimming boat, which comprises a boat body. The transverse directions of a boat bottom and the boat body are V-shaped. The boat type of the deep V skimming boat is characterized in that an oblique ascending angle beta B of left and right sides of the waist of the boat bottom is 20 to 25 degrees, a transverse oblique ascending angle beta A of the left and right sides of the stern of the boat bottom is 10 to 15 degrees, and the oblique ascending angles of the left and right sides from the waist of the boat bottom to the stern of the boat bottom are in smooth transition and are reduced gradually. Built-in horizontal bilge plates are arranged at the outside break angles of the left and right sides of the boat bottom. The boat type of the deep V skimming boat has the following advantages that: 1, on the premise of volume Fourier coefficient, not only the sailing resistance is reduced, the sailing speed is improved or the host power is reduced, but also the seakeeping property is obviously improved; 2, the longitudinal sailing inclination angle during skimming can be reduced, and the problems of over-large resistance crest, driving sight improvement and the like are solved; and 3, when the conventional propellers are adopted for propelling, the axis included angle is reduced, the problem of larger propeller thrust loss is solved, and the propelling efficiency of the propeller is improved.

Owner:CHINA SHIP DEV & DESIGN CENT

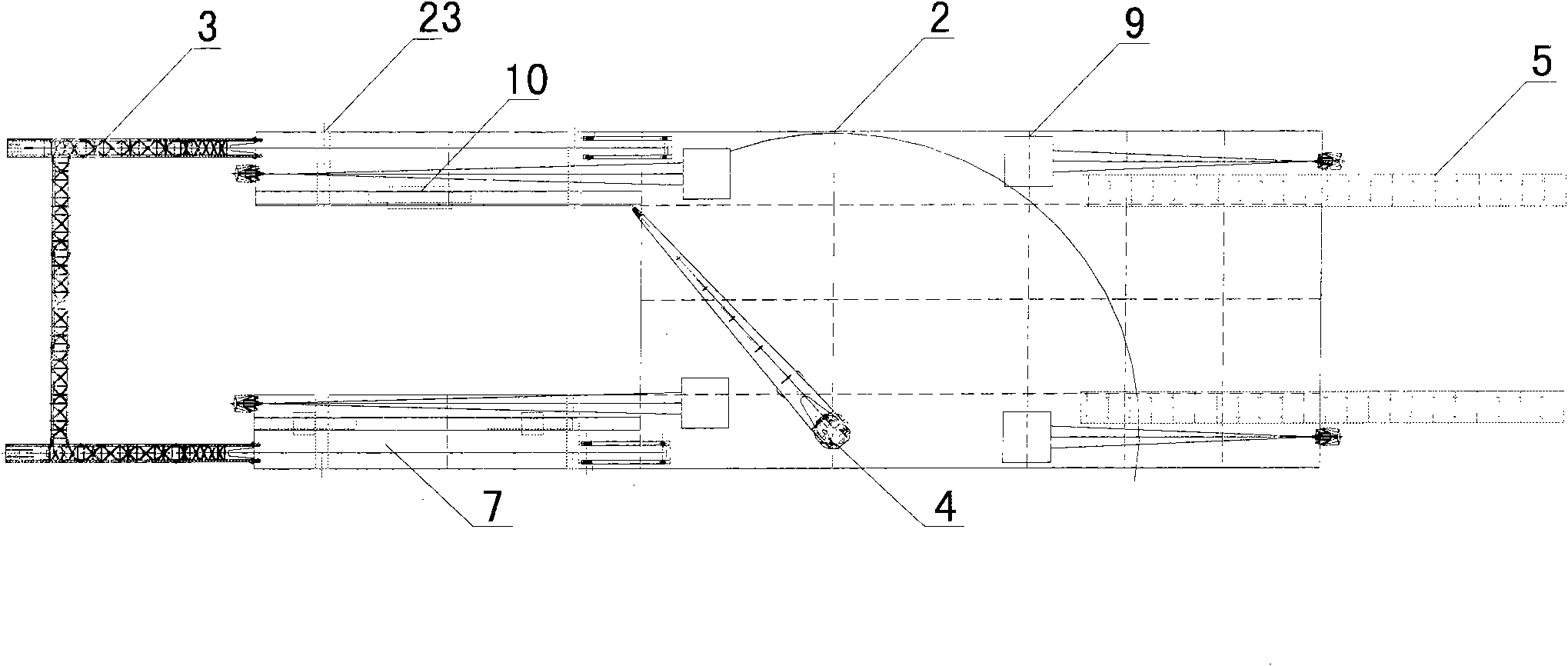

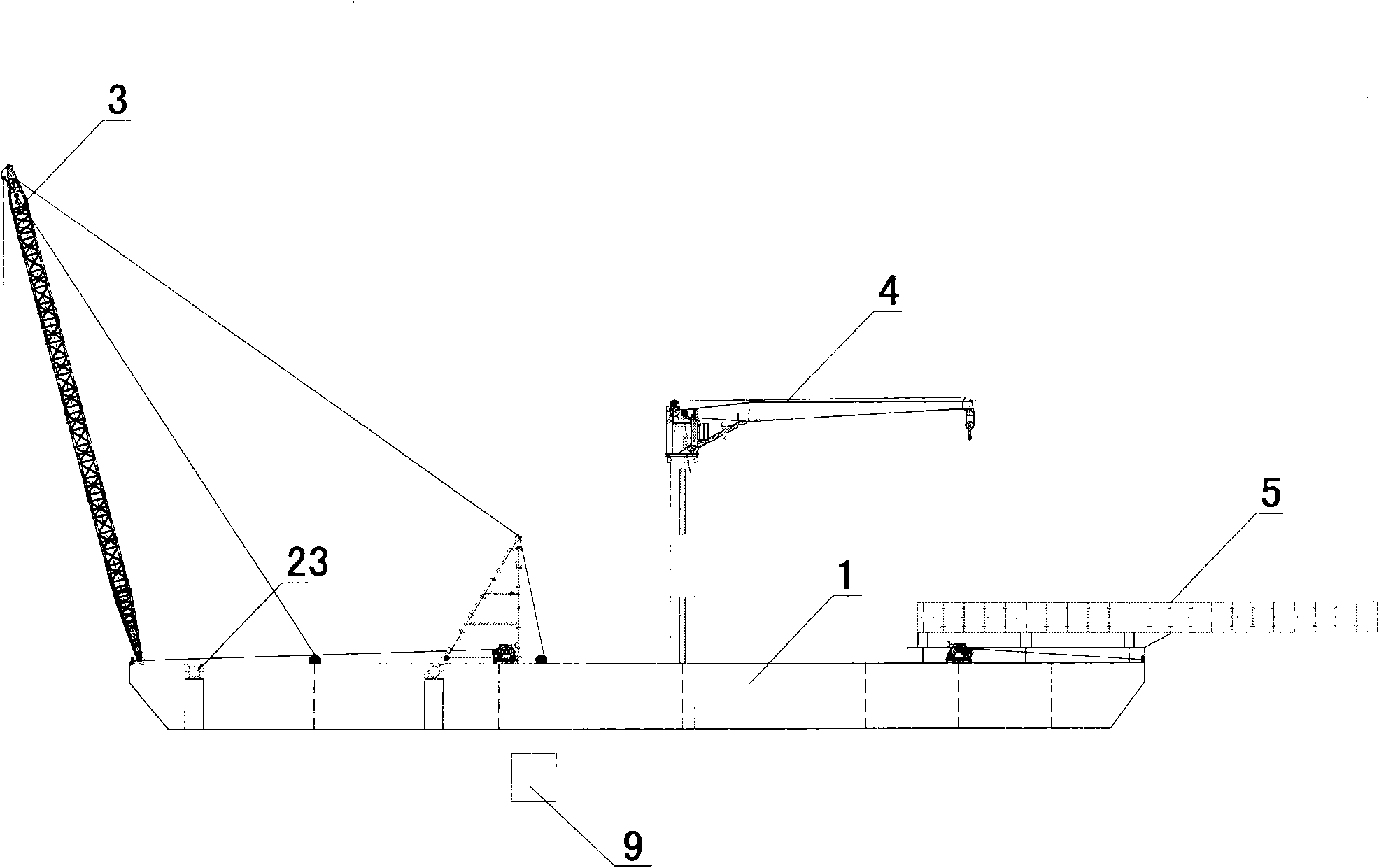

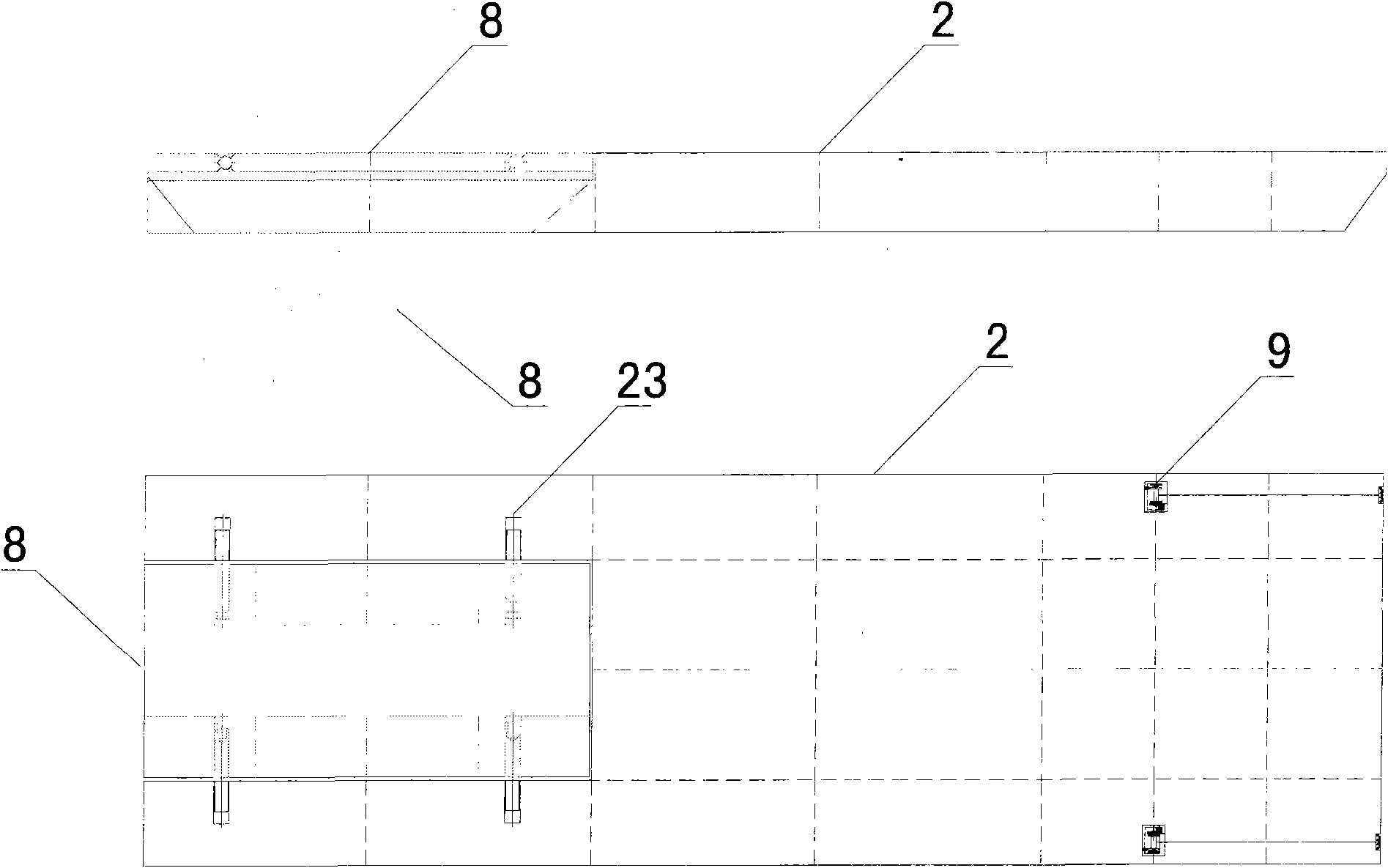

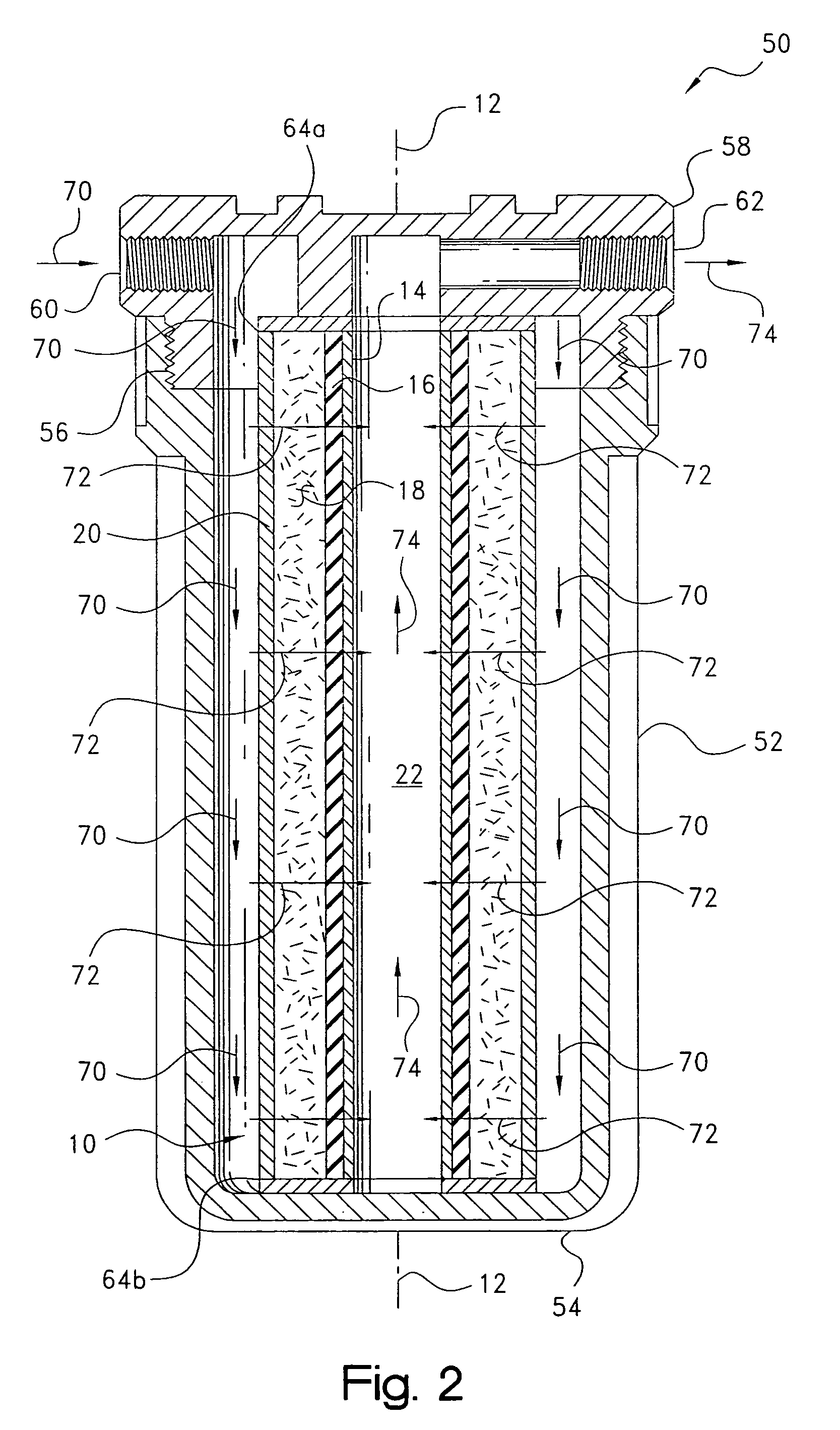

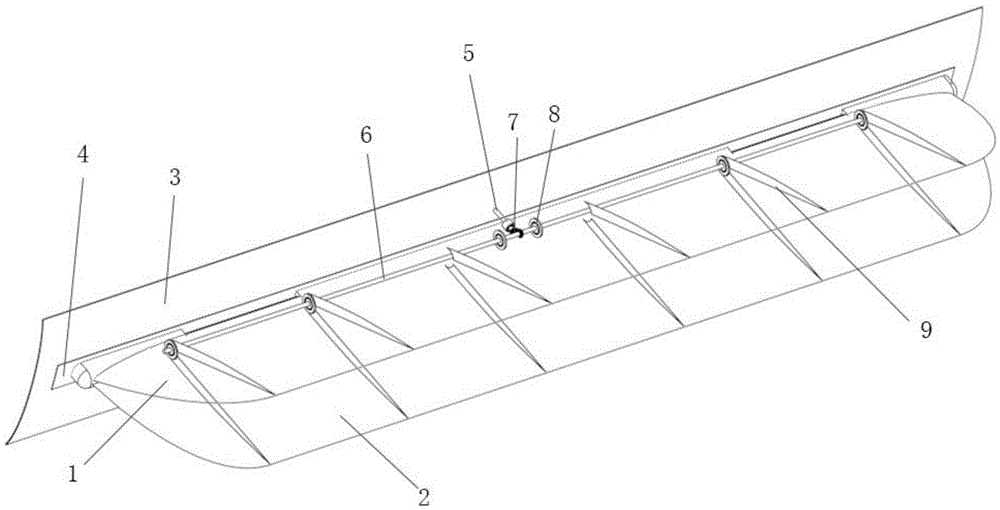

Novel offshore installation construction resource-combined type pontoon barge

InactiveCN101774422ARealize shipmentRealize transportationCargo handling apparatusPassenger handling apparatusBilgeFuel tank

The invention provides an offshore installation construction resource-combined type pontoon barge. The combined type pontoon barge (1) comprises a flat plate ship body (2), a portal jib crane (3), a crane (4), a cantilever beam (5), an awler crane (6), a slide rail (7) and a removable deck (8), wherein the portal jib crane (3), the crane (4), the cantilever beam (5), the awler crane (6), the slide rail (7) and the removable deck (8) are arranged on the flat plate ship body, and at the same time, a left and right water ballast tanks (11), a fresh-water tank (12), a bilge tank (13), a hydraulic motive power station tank (generator tank) (14), a fuel oil tank (15), a ballast tank control tank (16), a dust tank (17) and a living tank (18) for meeting the living and residing requirements of 60 persons are arranged on the flat plateship body (2). The pontoon barge is mainly used for the transportation and the installation operation of large structures of ocean engineering, and can also be used for the installation of expansion bend parts, offshore pipe pavement construction operation and the like. The invention has the advantages that the shipping, the transportation and the offshore installation can be realized at the same time, the risk of offshore installation construction is reduced, the offshore construction resources are reduced, and the time is saved.

Owner:NEPTUNE OFFSHORE ENG DEV

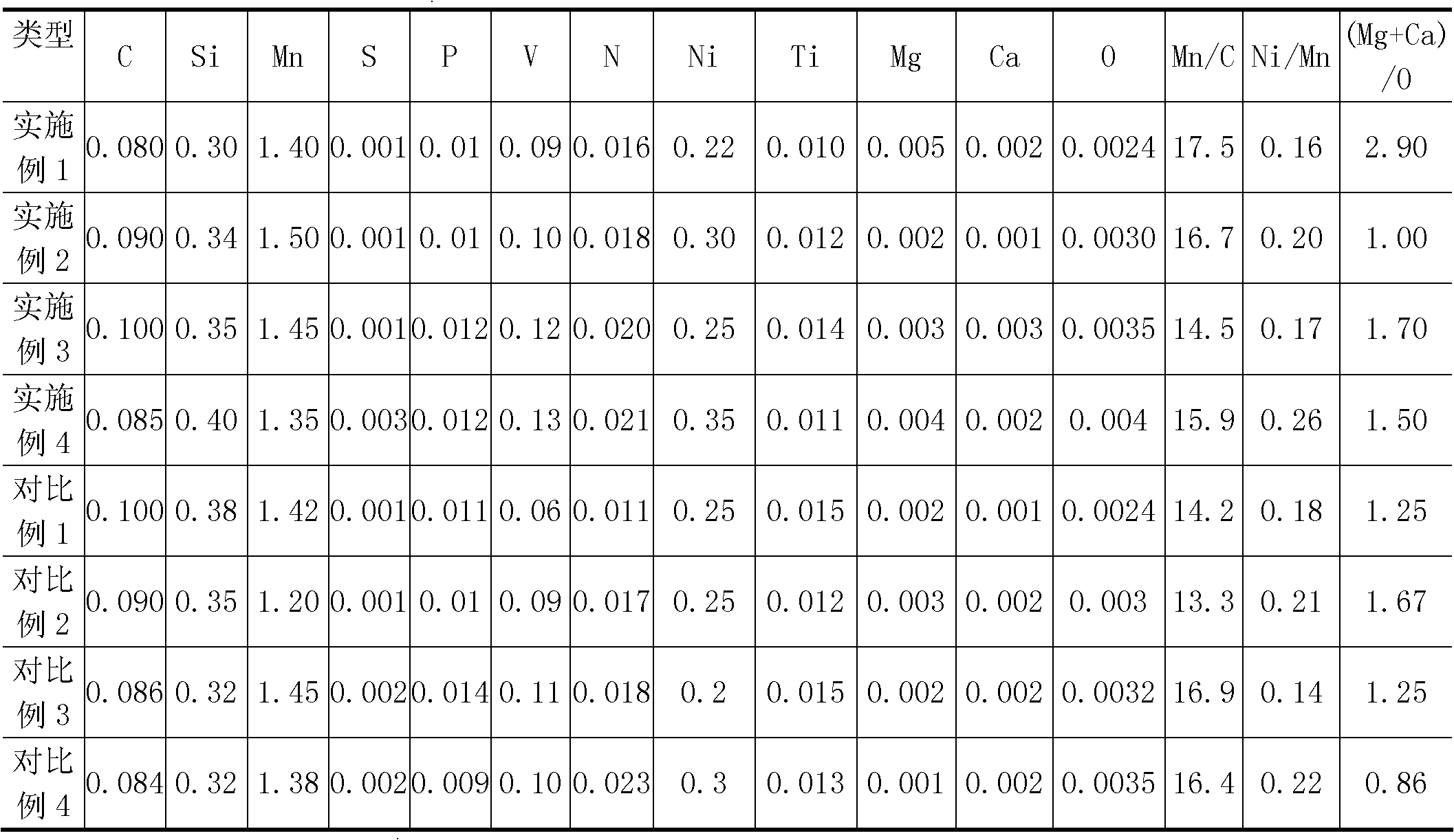

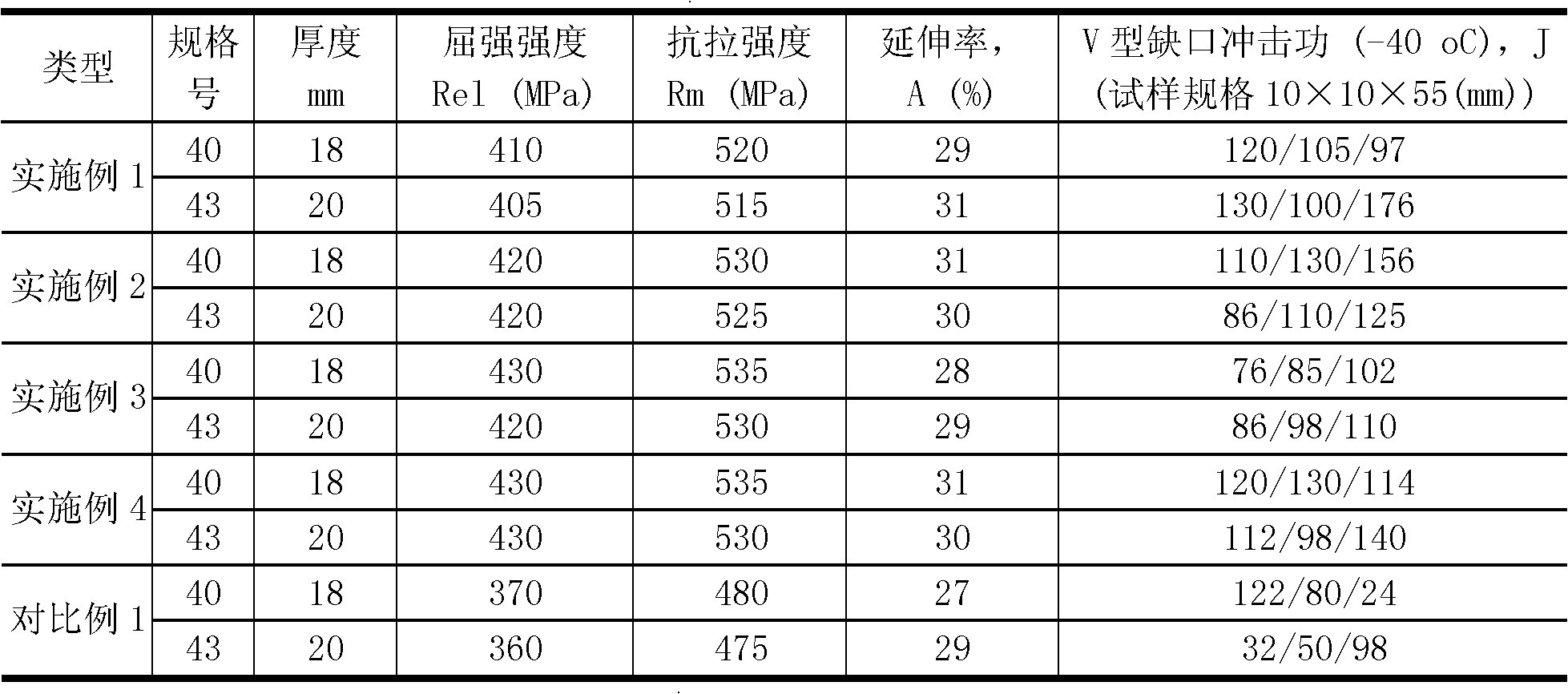

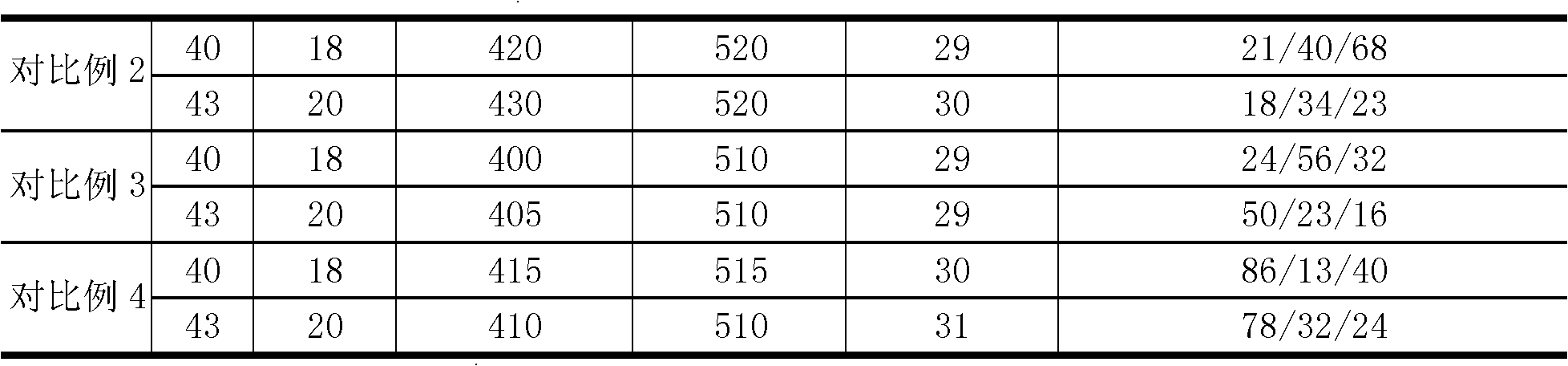

Large-specification and high-strength D40 hot-rolled flat-bulb steel for ships and production process for hot-rolled flat-bulb steel

The invention relates to large-specification and high-strength D40 hot-rolled flat-bulb steel for ships and a production process for the hot-rolled flat-bulb steel, and belongs to the technical field of marine structural steel. The large specification of the large-specification and high-strength hot-rolled flat-bulb steel is No. 40 and over No.40. The steel comprises the following chemical ingredients in percentage by weight: 0.08 to 0.15 percent of C, 0.10 to 0.50 percent of Si, 1.15 to 1.75 percent of Mn, less than or equal to 0.020 percent of S, less than or equal to 0.020 percent of P, 0.08 to 0.15 percent of V, 0.10 to 0.50 percent of Ni, 0.01 to 0.03 percent of Ti, 0.001 to 0.01 percent of Mg, 0.001 to 0.01 percent of Ca, 0.001 to 0.01 percent of O, 0.016 to 0.025 percent of N and the balance of Fe and inevitable impurities, wherein Mn / C is more than or equal to 14.0, Ni / Mn is more than or equal to 0.15, and (Mg+Ca) / O is more than or equal to 1.0. The production process comprises the following steps of: feeding a vanadium nitrogen alloy wire with the diameter of 13 millimeters and a Mg-Ca alloy wire with the diameter of 10 millimeters into molten steel after vacuum is finished, and blowing argon and stirring at the bottom; and in the hot rolling process, heating a low-temperature blank, performing final rolling for large deformation and cooling after rolling. The large-specification and high-strength D40 hot-rolled flat-bulb steel has the advantages that: the requirements of yield strength and impact toughness at the low temperature of -40 DEG C can be met, the flat-bulb steel is used for stiffeners at bilge keels of large-scale ships, and the rigidity of the ships and the safety coefficients of the ships used at the low temperature are improved obviously under the condition that the weight of the ships is not improved.

Owner:CENT IRON & STEEL RES INST

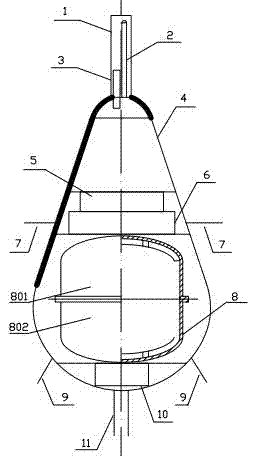

Abysmal sea communication relay buoy

The invention discloses an abysmal sea communication relay buoy which comprises a shell body. A wall-collision device and an antenna are symmetrically arranged at one end of the shell body and a cable guide tube is connected with the other end of the shell body. A conductance temperature depth (CTD) sensor, an acoustic transponder main machine, a pressure resistant tank and an acoustic transponder transducer are arranged sequentially in the shell body from top to bottom. Upper shake-reducing boards are symmetrically arranged at the periphery of the middle portion of the shell body. Lower shake-reducing boards are further symmetrically arranged at the periphery of the bilge portion of the shell body. According to the abysmal sea communication relay buoy, a shell is designed in a water-drop-shaped solid of revolution with the size gradually increased from top to bottom, devices with large weight are arranged at the bottom of the shell, so that in serious sea environment, the abysmal sea communication relay buoy is high in moving stability, capable of maintaining an efficient and long working state, compact in structure and convenient to process. The cable guide tube is arranged at the bottom of the shell body, a cable used for connection can be arranged in the cable guide tube, and therefore the abysmal sea communication relay buoy is rapid and convenient to arrange and recycle and high in work efficiency.

Owner:中国船舶重工集团公司第七〇二研究所

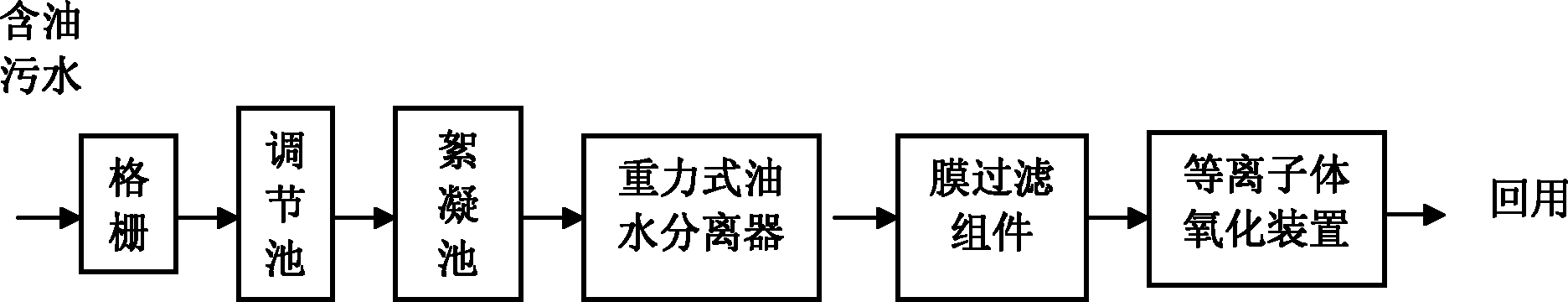

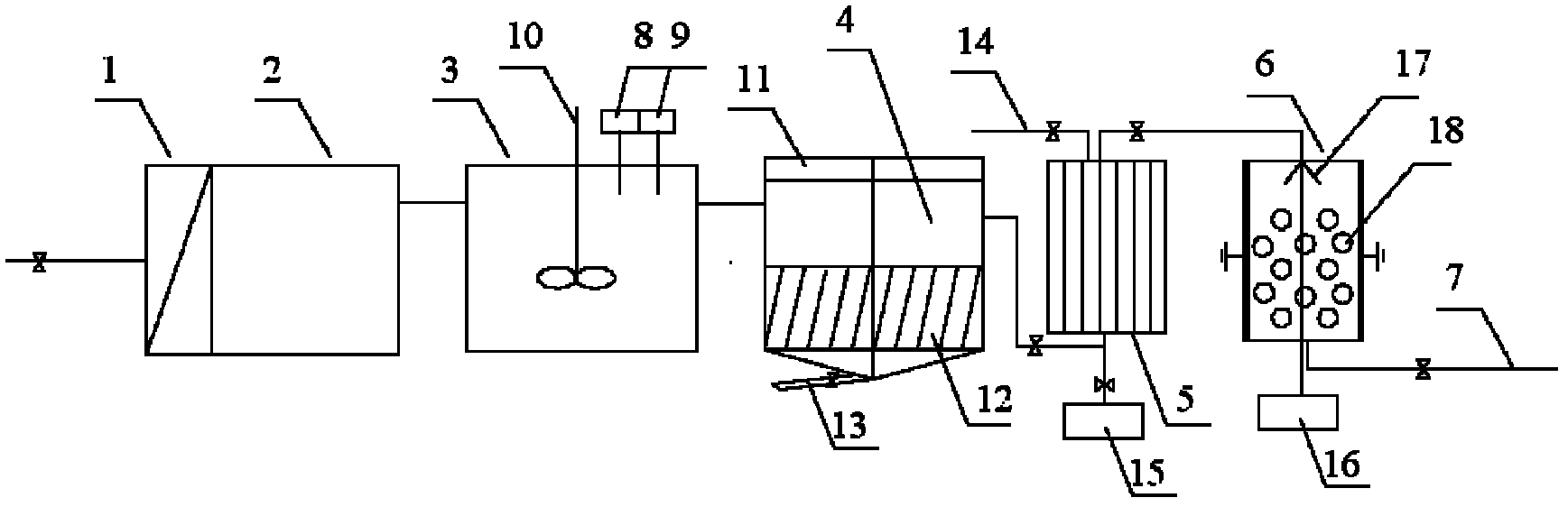

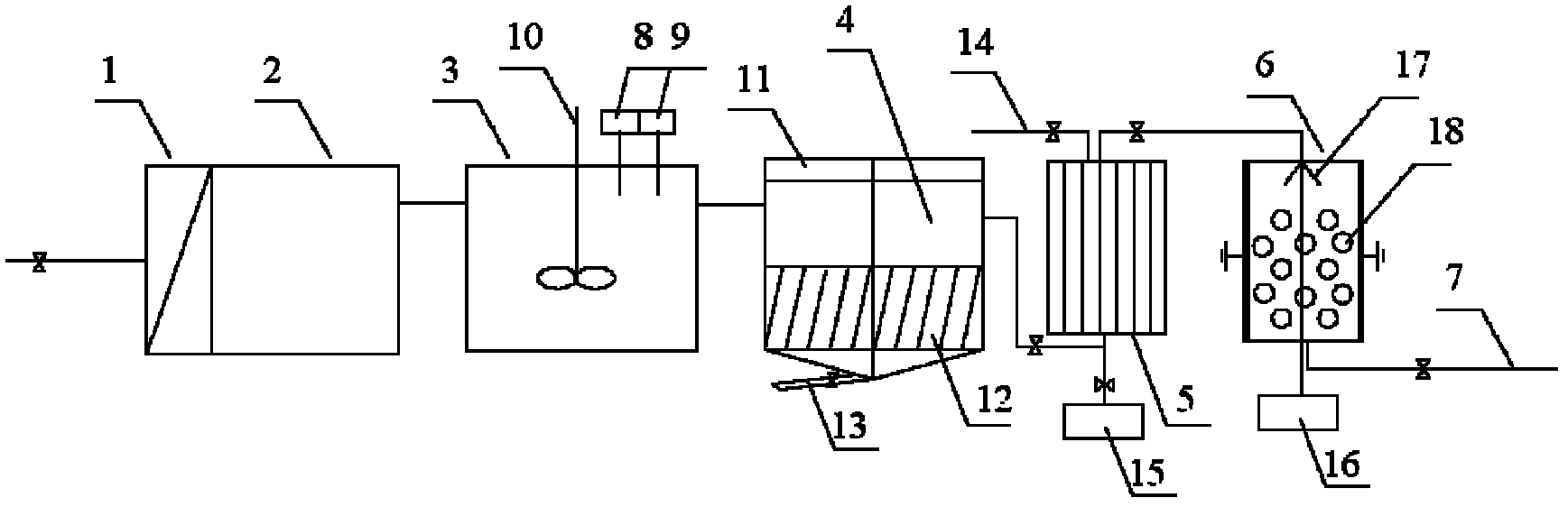

Device and method for integrally treating oily sewage at bilge of ship

InactiveCN102633390AReduce loadImprove efficiencyFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFlocculationContinuous use

The invention provides a device and a method for integrally treating oily sewage at the bilge of a ship. Oily sewage at the bilge enters into a regulating pool by passing through a collection pipeline and a grid and then enters into a flocculation reaction pool, coagulant polymerization and coagulant aids are respectively fed into the flocculation reaction pool by a reagent feeder, an agitator is arranged on the flocculation reaction pool, the oily sewage enters into a gravity type oil-water separator after being flocculated, an oil scraper is arranged on the upper part of the gravity type oil-water separator, an oblique plate structure is arranged on the lower part, the oily sewage at the bottom is collected by a sewage hopper and discharged by a blowdown pipe controlled by a blowdown valve, the oily sewage to be treated after being subjected to separation action of the gravity type oil-water separator enters into a membrane separation unit, ultrafiltrated concentrated water is discharged by a drain pipe, and a backwashing device is arranged on the membrane separation unit. By using the device and the method, the volume of a sewage storage cabinet in the ship can be saved, consumption of raw materials can also be reduced, recovery of oil resources and continuous use of treated sewage are realized, and the purposes of saving energy and reducing emission are achieved.

Owner:HARBIN ENG UNIV

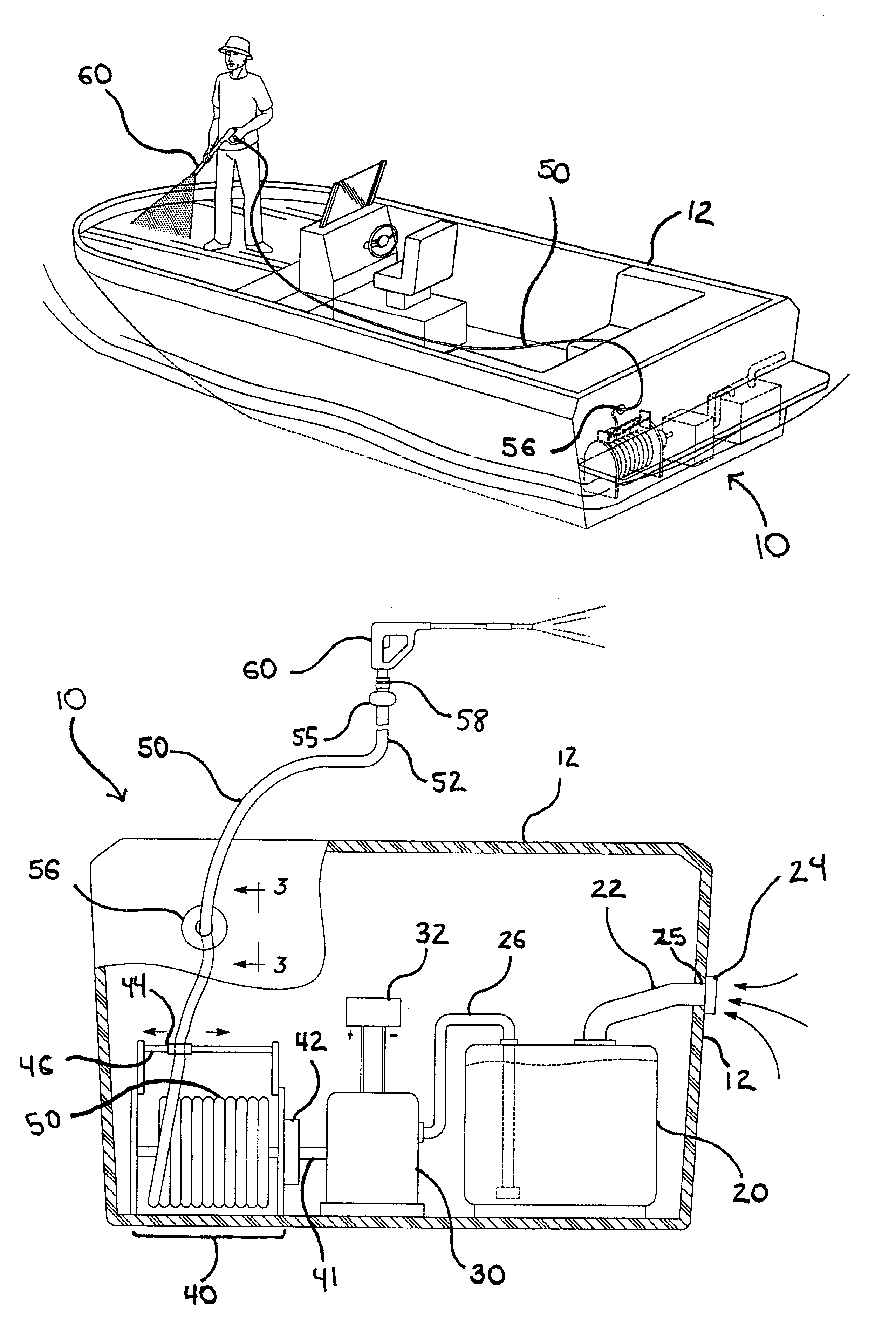

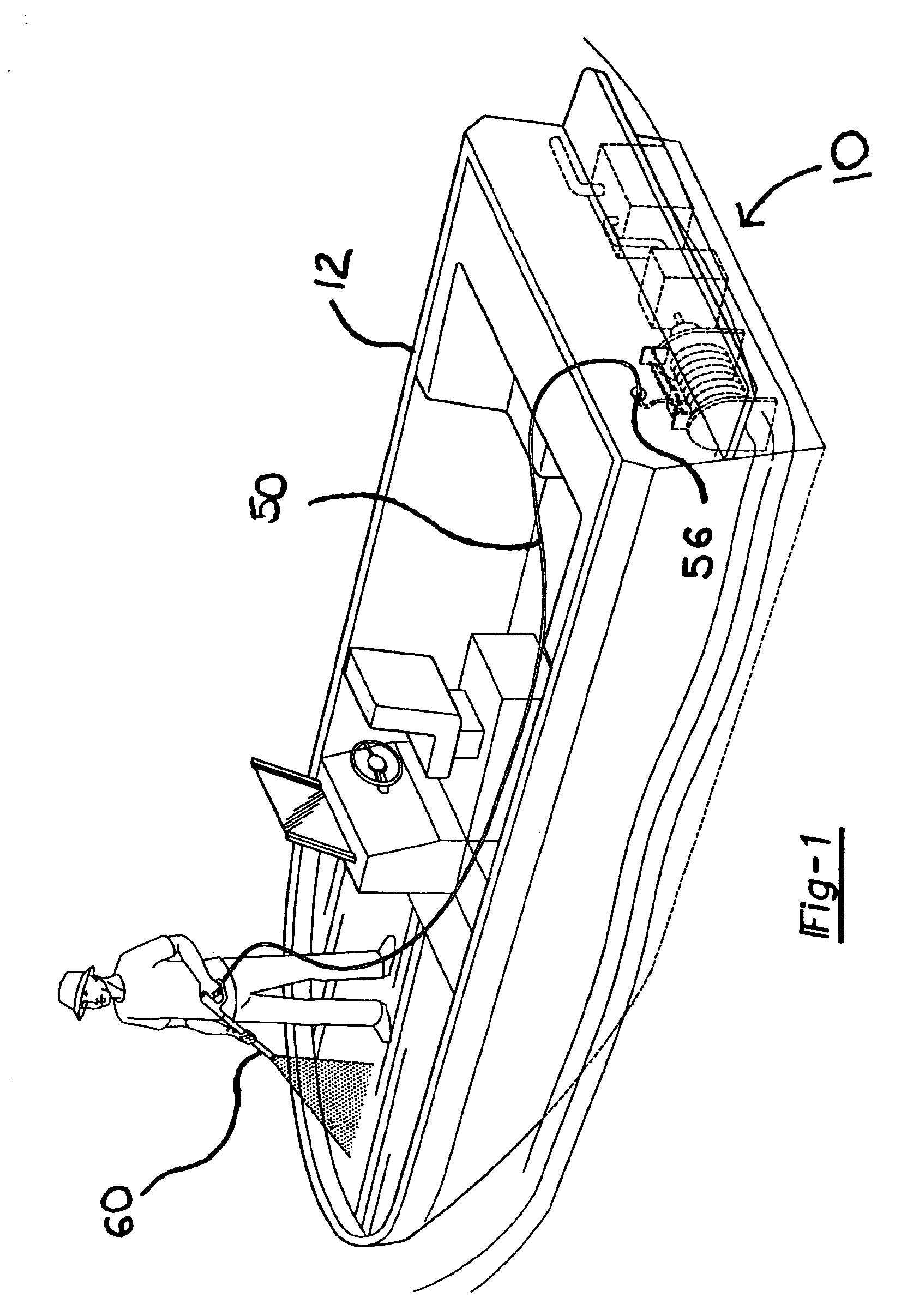

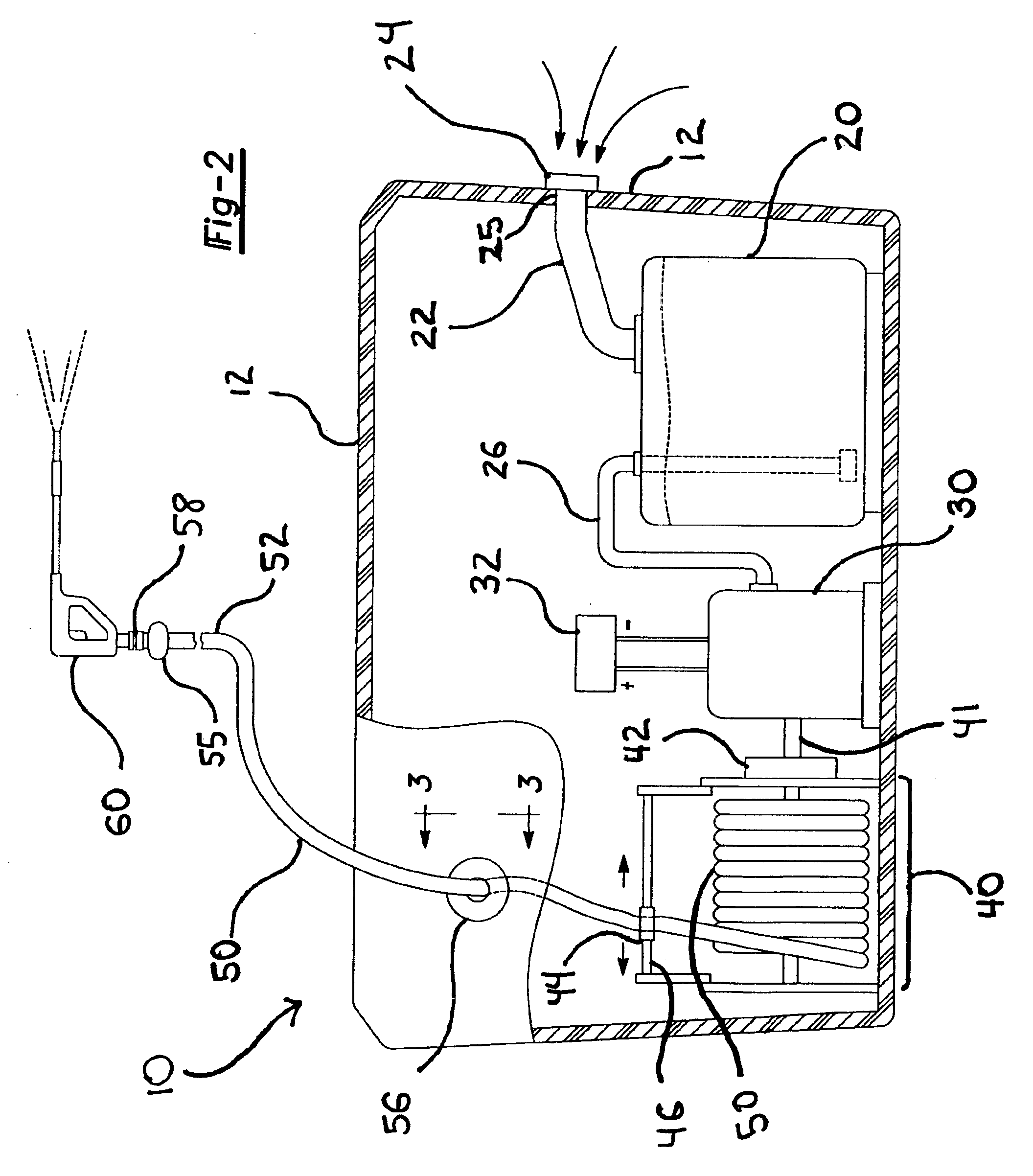

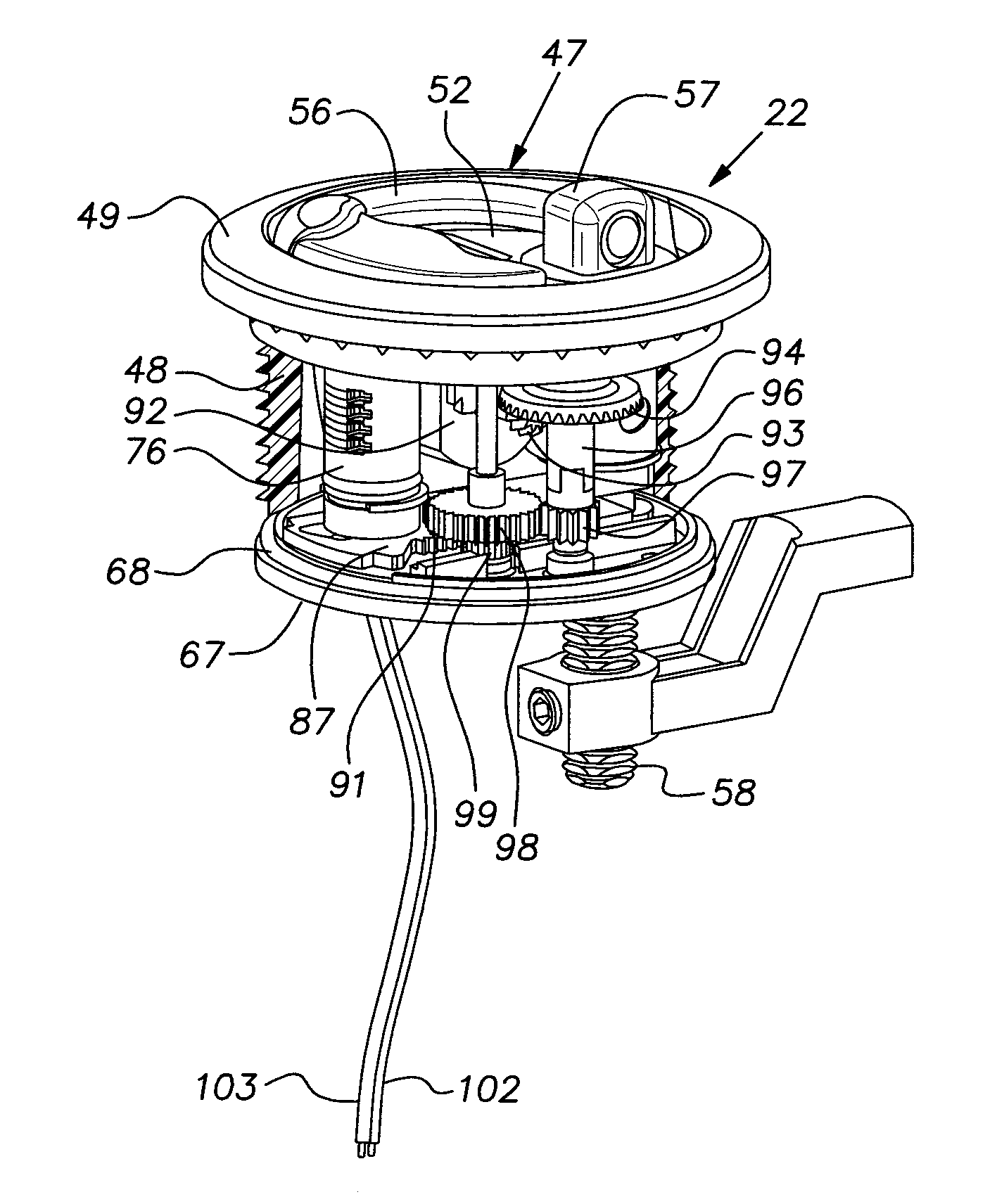

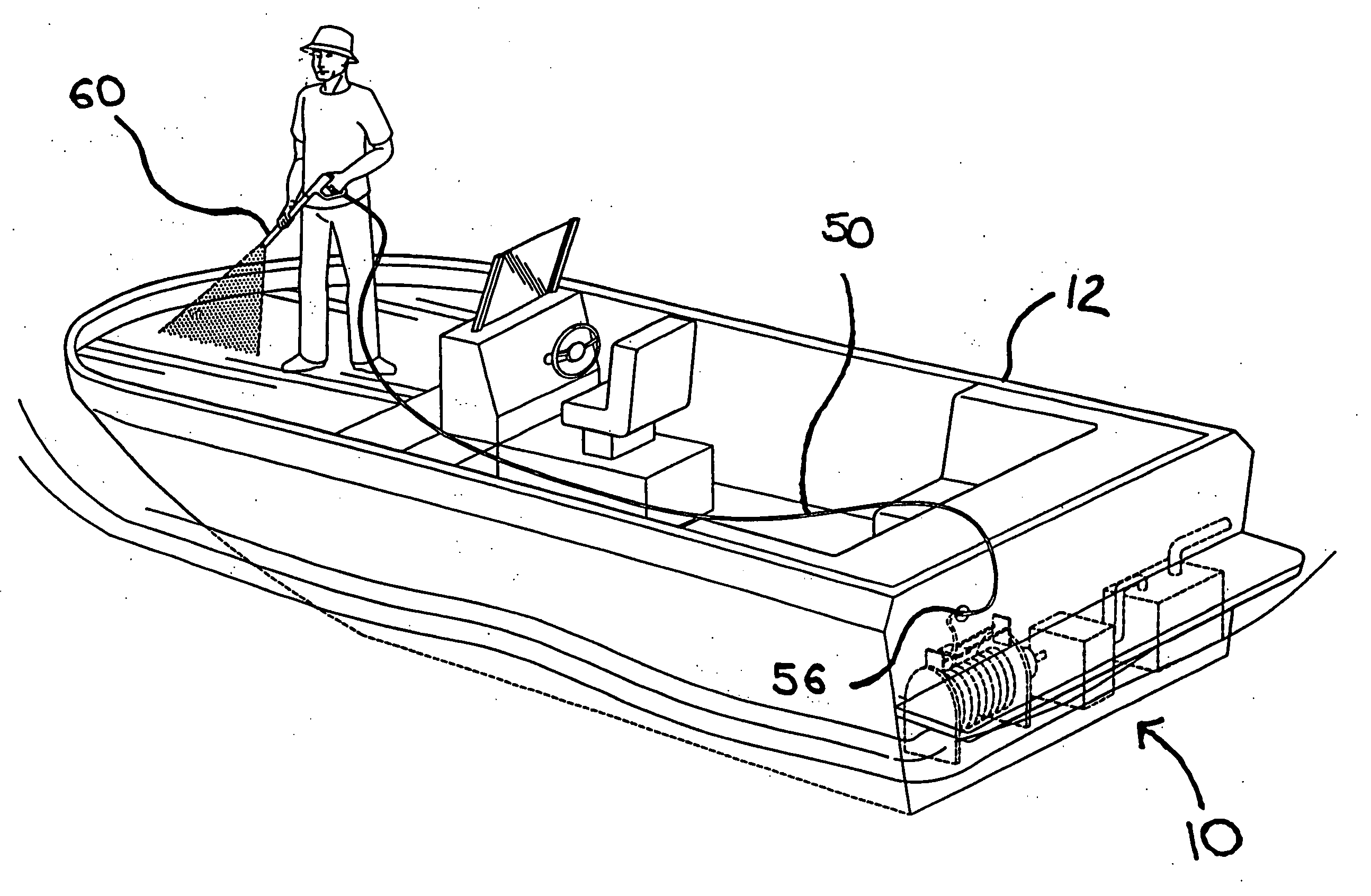

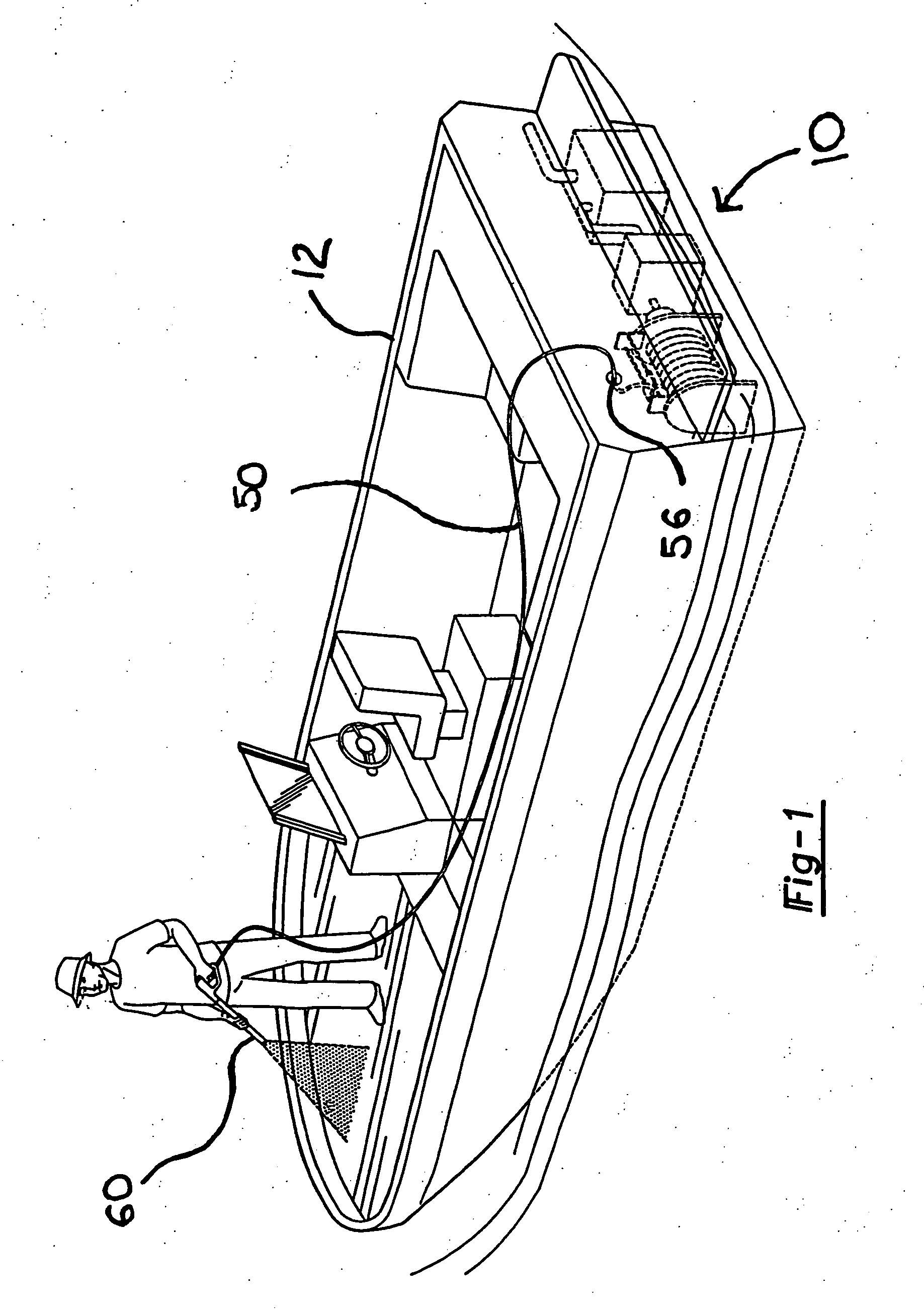

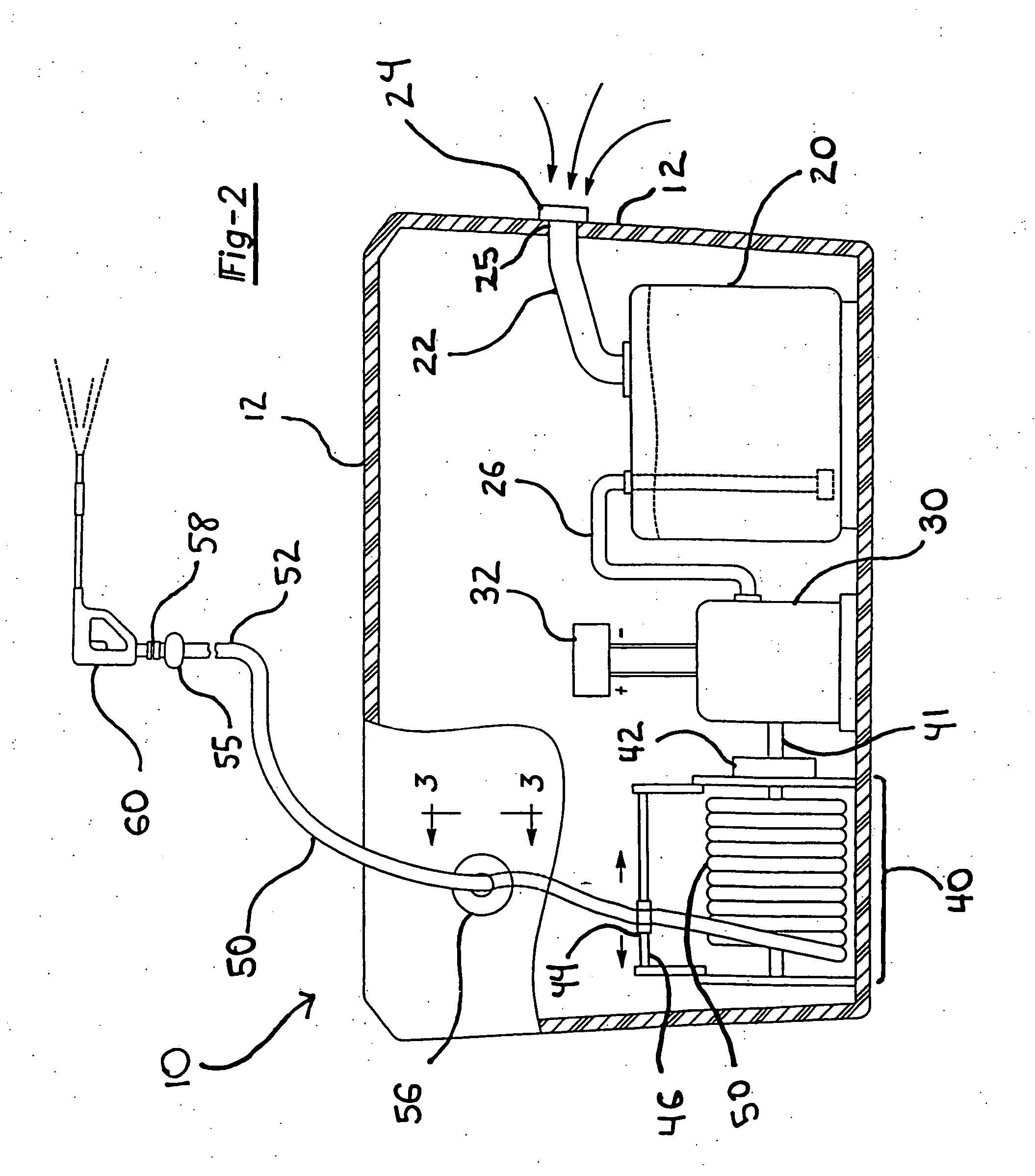

Boat/RV mounted pressure-wash system

A boat or recreational vehicle (RV) mounted pressure washing system fully plumbed and integrated electrically with the boat or RV, and located remotely therewithin according to user's preferred mounting location such as the bilge, engine compartment or a supply cabinet. The system provides the user with a high pressure supply of water for washing, rinsing, etc. by means of a pump, water reservoir and fully retractably high pressure hose, to which a nozzle of choice may be quickly attached or removed when not in use. The pressure hose is of significant length to provide for the pressure washing of the entire vehicle and surrounding areas by the user, whereby when not in use is fully retractable into the boat or RV for storage.

Owner:ATTAR ROBERT A

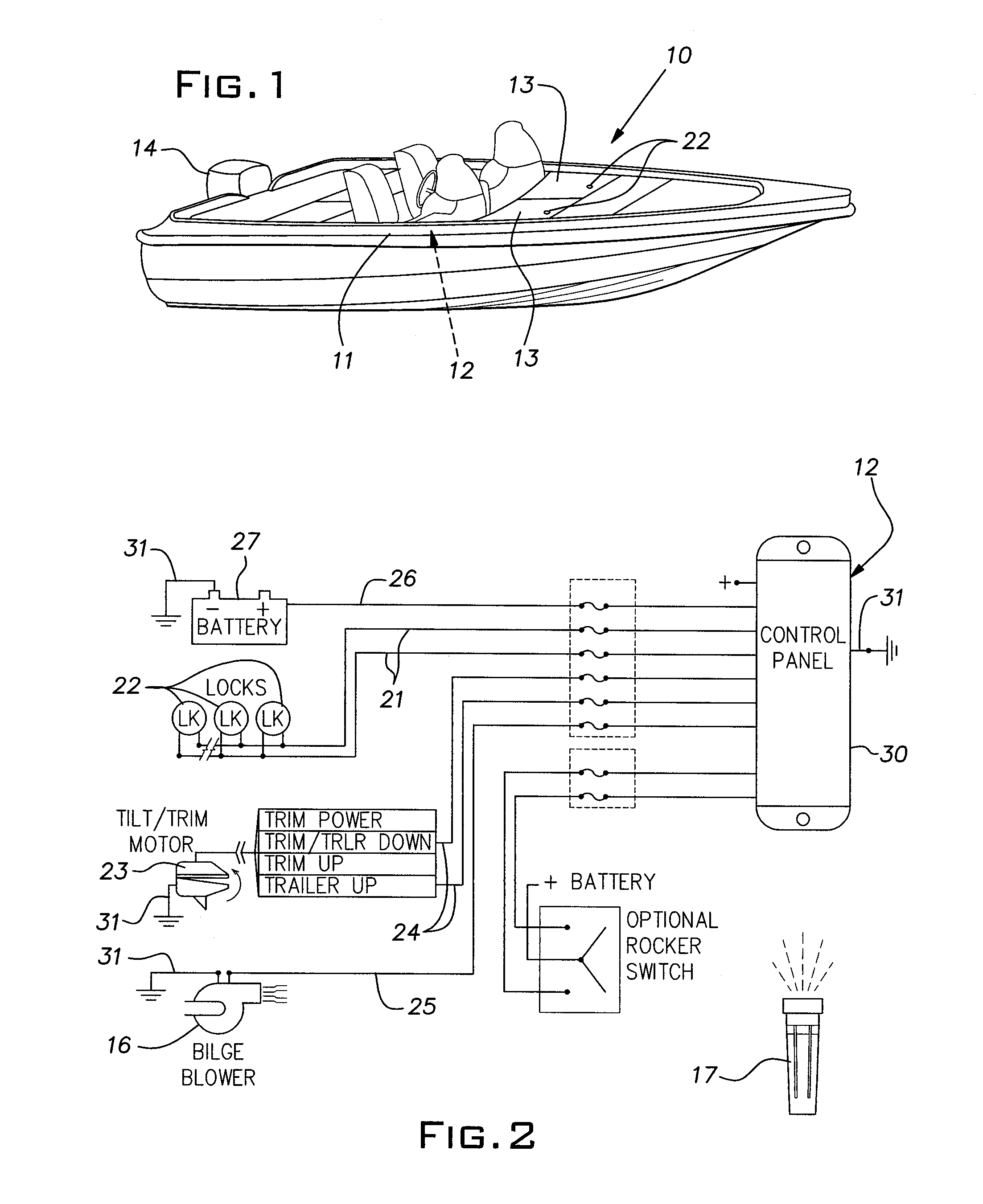

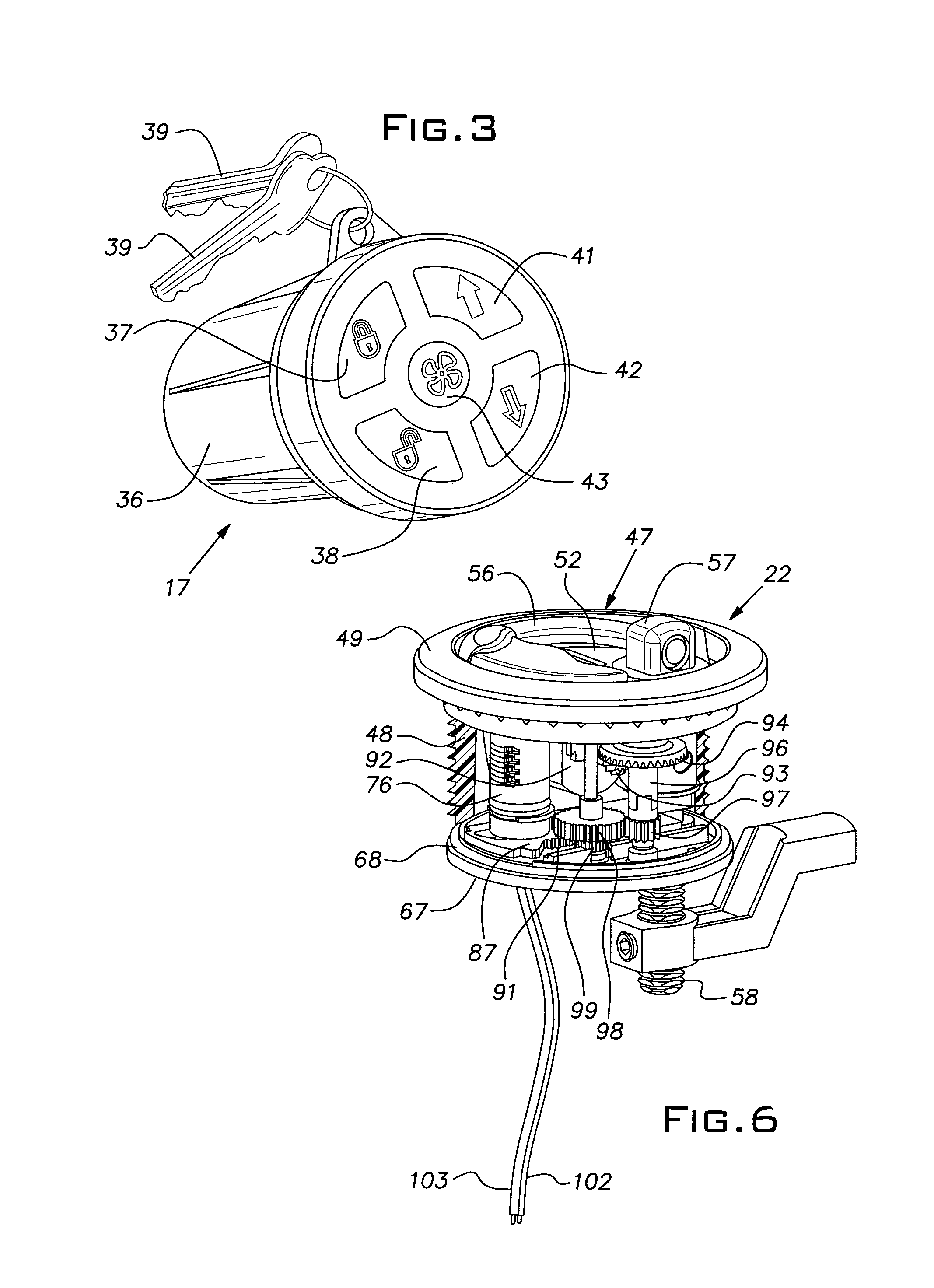

Remote control marine lock system

ActiveUS8272240B1Shorten the timeReduce effortAnti-theft cycle devicesWing handlesBilgeRadio reception

A system for simplifying launching and storage procedures for a recreational boat comprising a radio receiver / controller adapted to be permanently installed onboard the boat, a hand-held radio transmitter for sending a plurality of different signals to the receiver / controller, the receiver / controller including a plurality of separate control circuits, said circuits being connectable to a plurality of power-operated locks on the boat and a set of other electrically operated devices on the boat such as electric lights, an engine tilt actuator, and a bilge blower, the receiver / controller being arranged to be powered by an electrical power circuit serving electrically operated devices on the boat separate from those controlled by the transmitter and receiver / controller, the locks being integrated with manually operated latches and having a manual key override feature.

Owner:SCHILENS JAMES A

Method of installing ship bilge equipment

The process of manufacturing outfitting for ship engine room bottom floor includes the following steps: drawing midship line, rib site line, longitudinal line and inner bottom plate edge line in the internal field with the longitudinal line as datum, and setting height line on wall or upright to determine the grille height and base height; erecting uprights for the grille frame, splicing grille plane and welding to the uprights; locating the apparatus base and maintenance platform on the grille; installing apparatus on the base and maintenance platform; mounting pipe supports, pipes, valves and accessories; and hoisting the installed outfitting onto the ship. The process can shorten the operation period in dock, raise operation efficiency, improve operation condition, raise safety and lower ship building cost.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

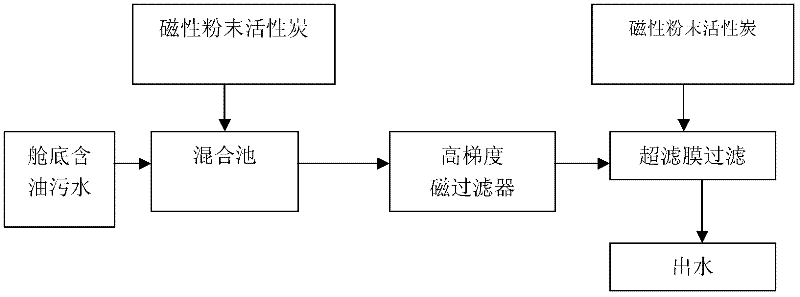

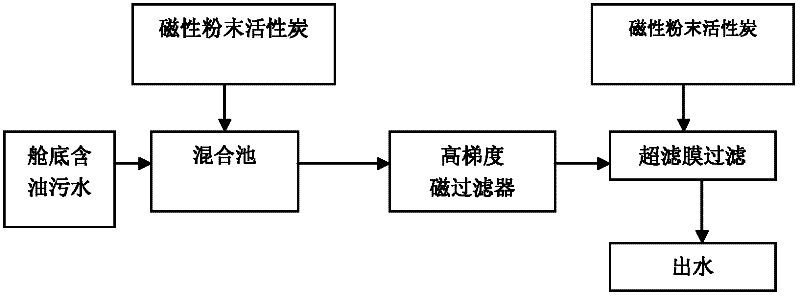

Method for treatment of oily sewage at bottom of bilge of vessel and method for preparation of magnetic activated carbon for decontamination of oily sewage

InactiveCN102381800AImprove adsorption capacityInnovativeFatty/oily/floating substances removal devicesOther chemical processesActivated carbonBilge

The invention provides a method for treatment of oily sewage at the bottom of a bilge of a vessel and a method for preparation of magnetic activated carbon for decontamination of the oily sewage. The method for treatment of oily sewage at the bottom of the bilge of the vessel includes steps of feeding magnetic activated carbon into a mixing tank, filtering and retaining suspended particles in sewage at the bottom of the bilge and the magnetic powdered activated carbon with partial oil adsorbed by means of a high-gradient magnetic filter, feeding magnetic powdered activated carbon into an ultra-filtration membrane reaction tank, and deoiling by means of the magnetic powdered activated carbon and an ultra-filtration membrane. The method for preparation of magnetic activated carbon includes the steps of soaking powdered activated carbon into clean water for more than twenty-four hours, taking out the powdered activated carbon and drying the powdered activated carbon for two hours at a temperature higher than 105 DEG C, ultrasonically dispersing the dried powdered activated carbon with ferroferric oxide at the ambient temperature, and filtering by means of a filter screen and drying the filtered activated carbon for more than two hours at a temperature higher than 105 DEG C. More loosened mud cake layers are formed on the surface of the ultra-filtration membrane, filterability is greatly improved, membrane flux is improved, and membrane pollution can be effectively prevented.

Owner:HARBIN ENG UNIV

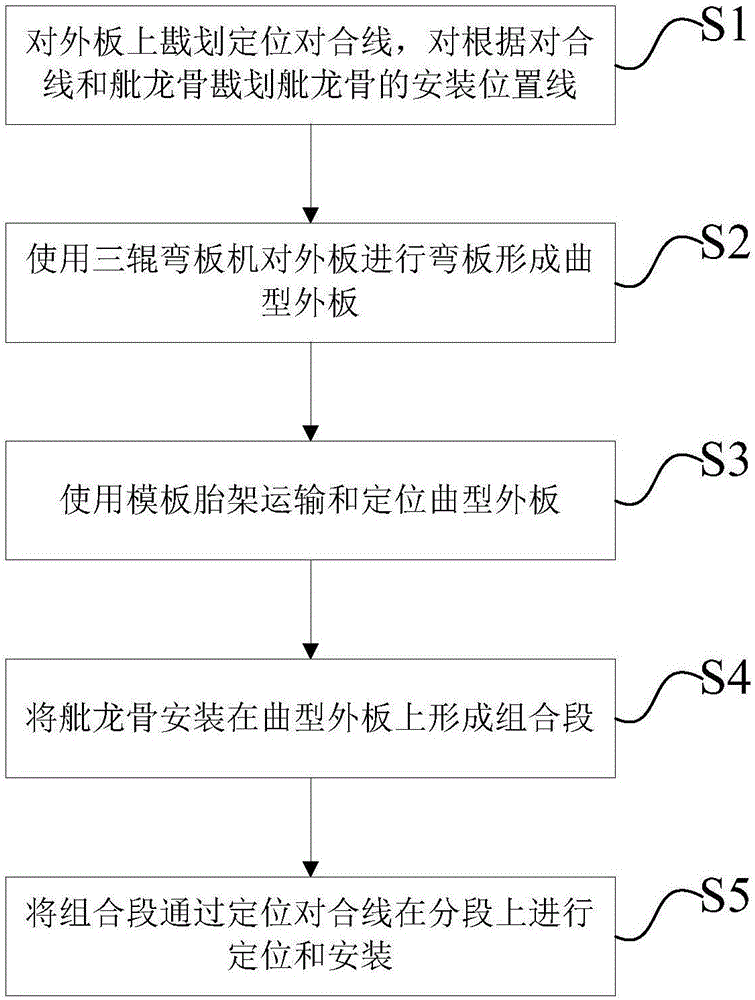

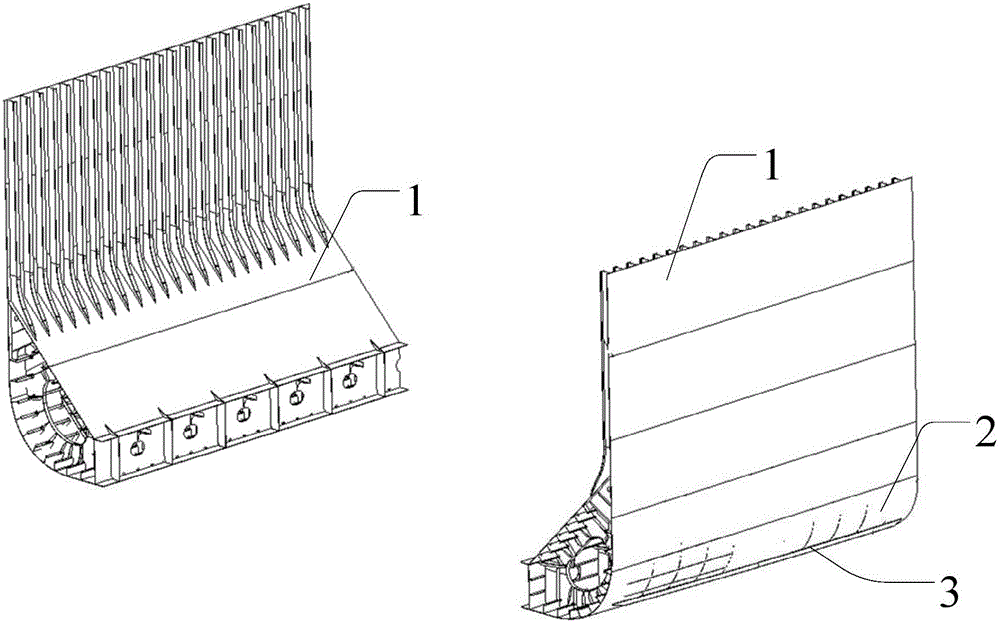

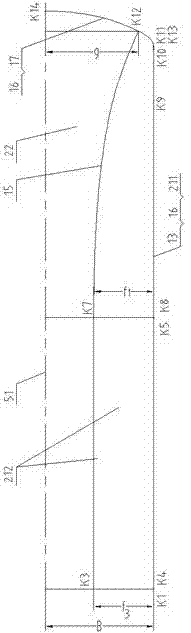

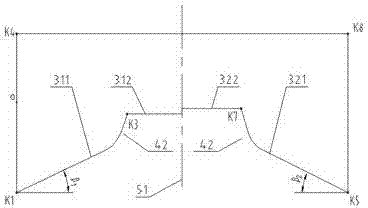

Ship bilge keel positioning and mounting method

ActiveCN106516001AOptimize the segmented construction processReduce installation difficultyVessel designingBilgeKeel

The invention provides a ship bilge keel positioning and mounting method. A bilge keel is mounted on an outer curved plate which is positioned in a bilge section. The method includes steps: S1, marking a positioning joining line on the outer plate, and marking a bilge keel mounting position line according to the positioning joining line and the bilge keel; S2, adopting a three-roll plate bending machine for linear curvature processing of the outer plate to form the outer curved plate; S3, using a moulding bed for transporting and positioning the outer curved plate; S4, mounting the bilge keel on the outer curved plate to form a combined section; S5, positioning and mounting the combined section on the bilge section according to the positioning joining line. At a bilge keel mounting stage, after completion of a large section group, curvature processing of the outer plate of the bilge section is performed before mounting of the bilge keel. A normal-posture faceup installation way of the bilge keel is optimized into a horizontal faceup installation way to lower installation difficulty. Bilge keel installation precision is optimized from rough installation to accuracy control, subsequent reworking is avoided due to angle control of the bilge keel, and the moulding bed guarantees linear precision of the outer curved plate in a placement and transport process to avoid subsequent reworking.

Owner:JIANGNAN SHIPYARD GRP CO LTD

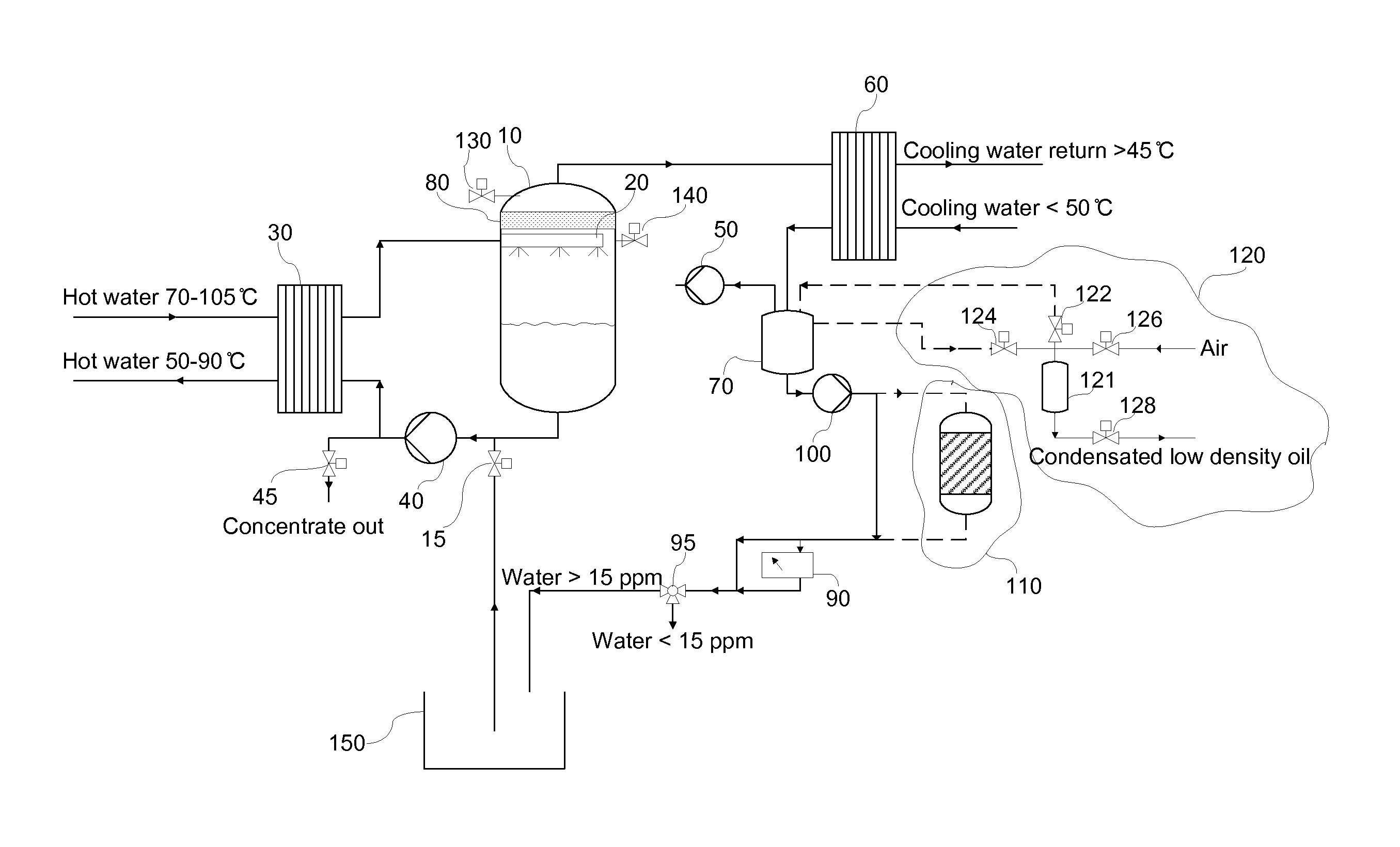

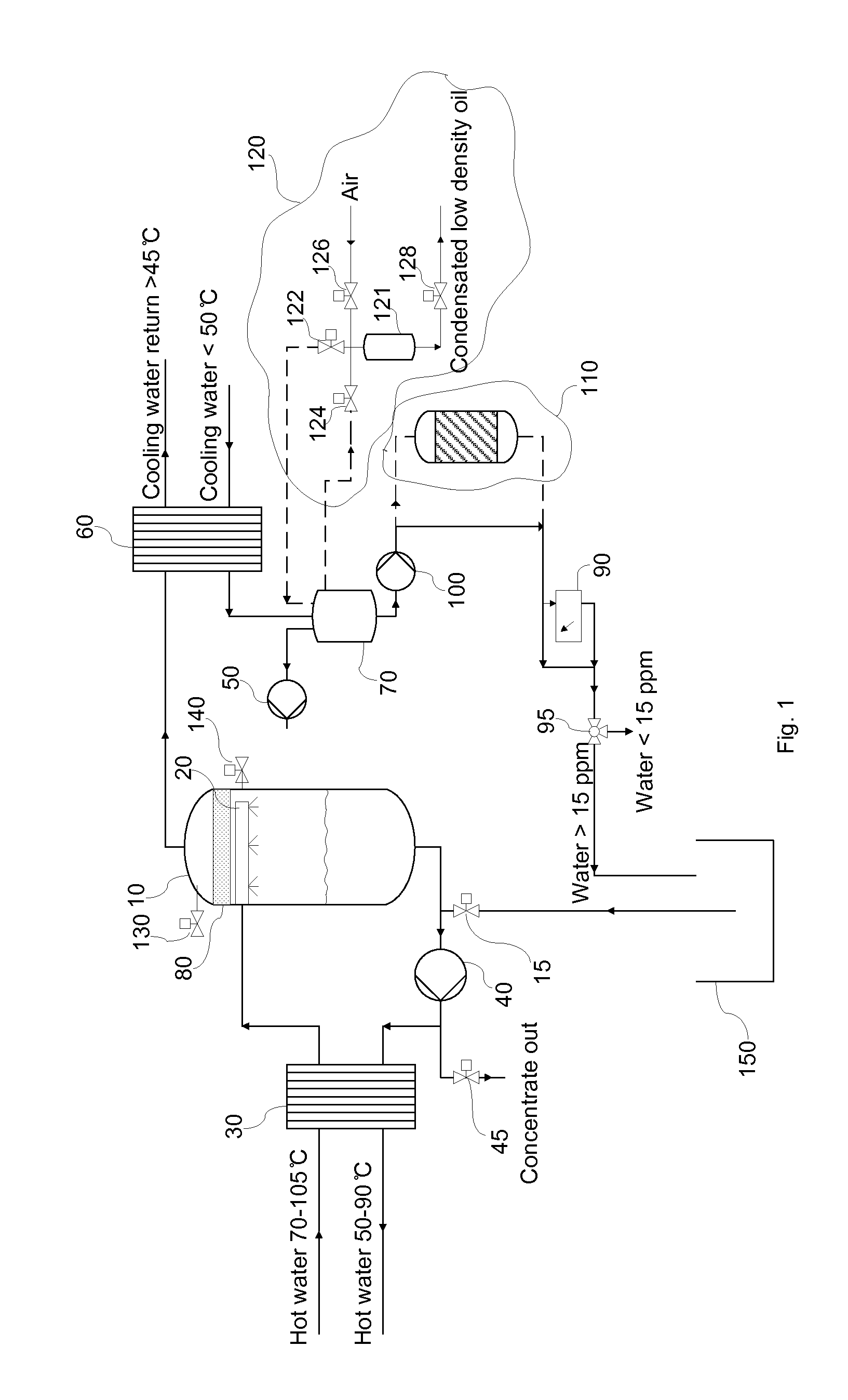

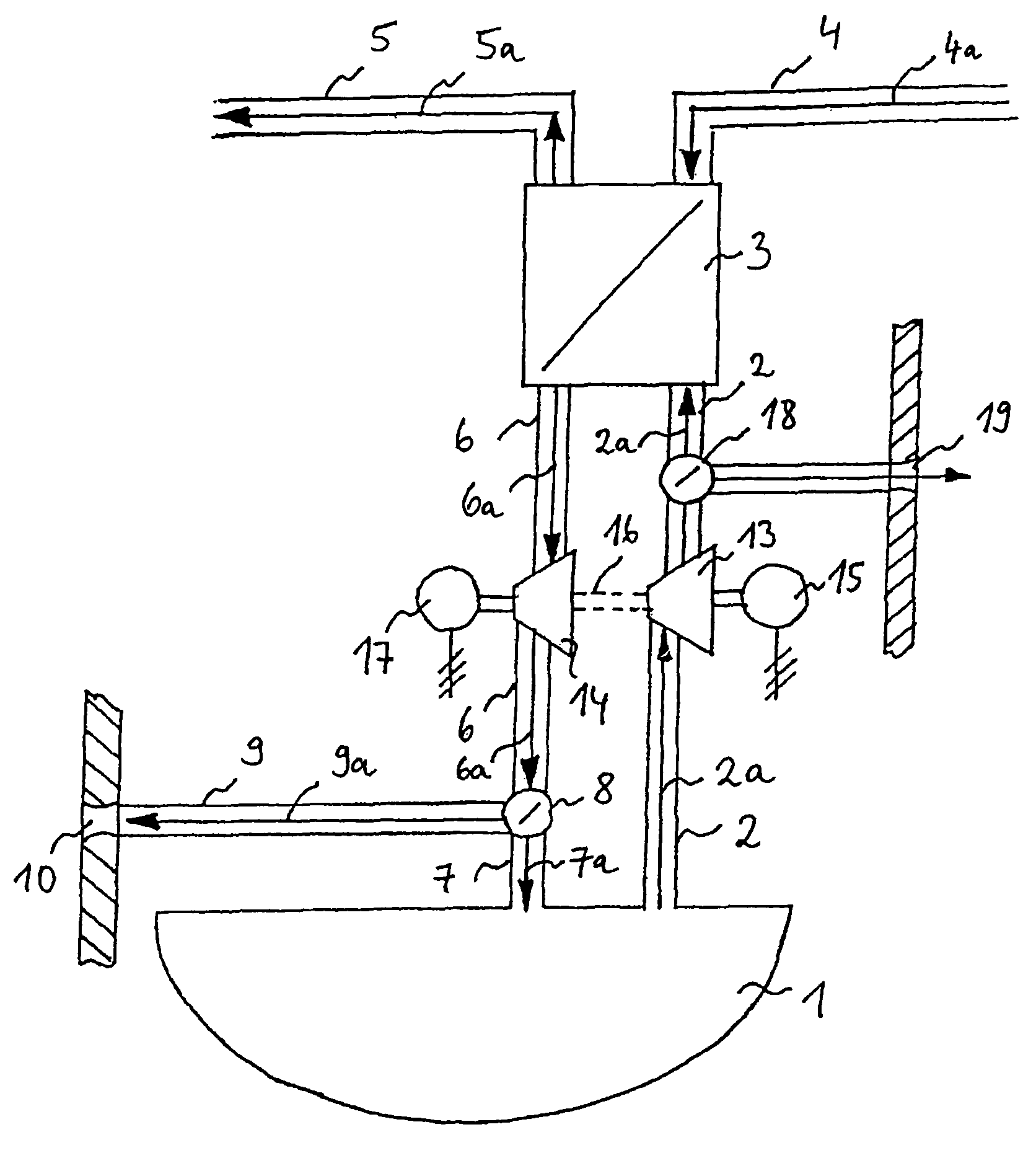

Method and plant for purification of oil-contaminated bilge and sludge water on a ship, and ship equipped with such plant

ActiveUS20120160660A1Control flowInhibition formationFatty/oily/floating substances removal devicesAuxillariesSludgeBilge

The present invention relates to a method for purification of bilge and sludge water on a ship, especially at sea, using excess heat from the ship's engine(s) to a level of oil contamination of less than 15 ppm. The invention also relates to a plant for carrying out the method, and a vessel including such plant, as well as the use of the method and plant.

Owner:PPMCLEAN

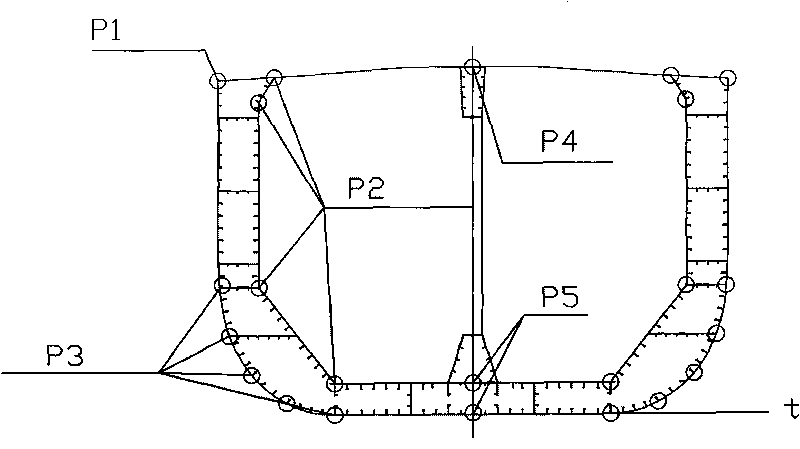

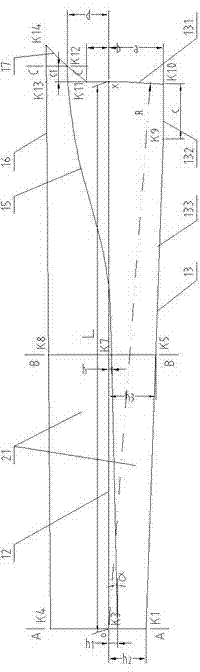

Method for positioning butt joint of two total sections in large dock shipbuilding

The invention discloses a method for positioning butt joint of two total sections in large dock shipbuilding. The method comprises the following steps: firstly, measuring the following data of the butt joint surface of a first total section: a molded breadth or molded depth measuring point (P1), a deck centre measuring point (P4), each measuring point (P3) of an outside plate of a bilge, centre measuring points (P5) of an inner bottom plate and an outer bottom plate, and points (P2) for measuring heights from each break angle of an inner shell plate to the centre and a base line; and secondly, feeding the data back to a second total section so as to provide positioning reference data for the subsection positioning at the close seam when subsequently positioning the second total section. In the method, in order to reduce cutting and repairing work, a set of positioning process requirements on the subsection at butt point close seam of the two total sections in the large dock shipbuilding is provided, which realizes the butt joint of the two total sections effectively, improves work efficiency, and reduces working cost and working difficulty.

Owner:DALIAN SHIPBUILDING IND

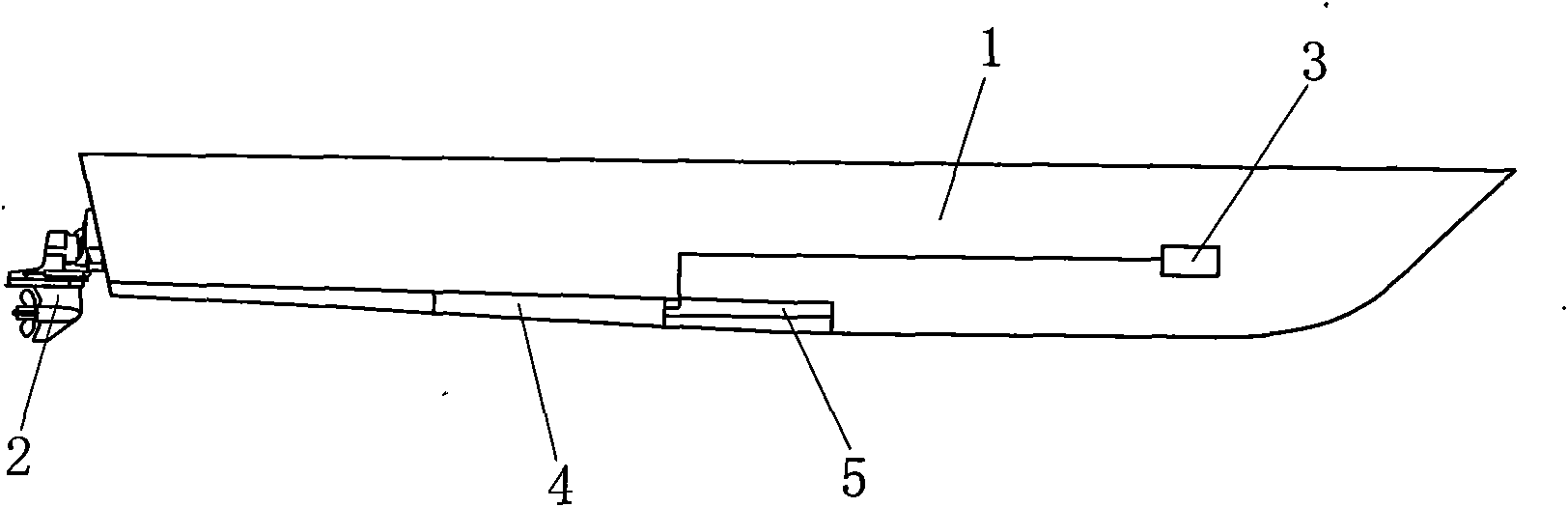

High-speed rounded bilge type boat utilizing air cavity to reduce resistance

InactiveCN101891006AEnsure drag reductionAir stabilizationWatercraft hull designVessel stability improvementBilgePropulsive efficiency

The invention relates to a high-speed rounded bilge type boat utilizing an air cavity to reduce resistance. The high-speed bilge type boat of the invention comprises a boat body, a propulsion system and a gas supply system arranged in the boat body, and is characterized in that the bottom surface of the boat body is provided with an inward concave air cavity; the air cavity is composed of two arcboard lateral fins; the width of the air cavity gradually increases from the head part to the tail part of the boat body, the front part of the air cavity is provided with a head platform, and the rear part of the air cavity is provided with a wedge bulge; and an air inlet used in the gas supply system to supply gas to the air cavity is arranged at the fault-step position of the head platform. The high-speed rounded bilge type boat of the invention is provided with the reasonable air cavity structure, the head platform is arranged at the front part of the air cavity, and the wedge bulge is arranged at the rear part of the air cavity, thus ensuring the stability of inlayer air in the air cavity and the resistance reducing function of the air cavity, being capable of effectively reducing frictional resistance in the sailing process of the boat body, saving fuel materials and effectively improving the propulsive efficiency.

Owner:中国船舶重工集团公司第七〇二研究所

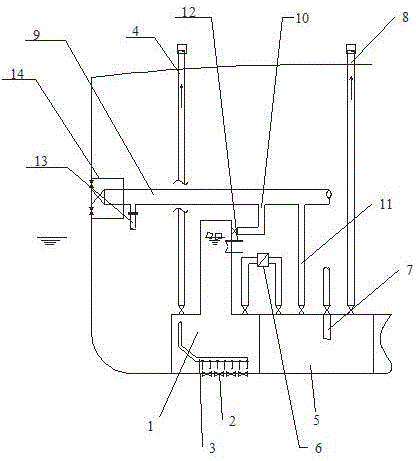

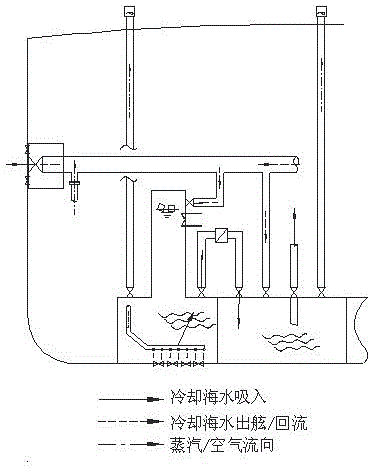

Sea chest device suitable for arctic navigation vessel

ActiveCN106184619ASmooth dischargeGuarantee unimpededSelf-bailing equipments/scuppersVessel partsOcean bottomIce water

The invention discloses a sea chest device suitable for an arctic navigation vessel of which the structure can be arranged at a proper position from broadside bilge to the center line of the bottom of the vessel. The sea chest device comprises an ice storing tank, and an ice and water separating structure for separating ice from seawater, wherein filters are arranged between the ice storing tank and a seawater partition; the seawater partition is connected with a suction of a cooling seawater pump; the seawater partition is provided with a vent pipe; and the vent pipe and a shut off valve are directly connected to the broadside. Before being drained outboard through an outboard drainage pipe, a part of the heated seawater can recurrently flow to the seawater partition and the ice storing tank for melting floating ice. Measures are provided by the seawater partition, the ice storing tank, the broadside valve and the components to prevent freezing. According to the sea chest device disclosed by the invention, trash ice can be separated from the seawater, so that the situation that a sea chest is blocked by the ice, the working of each seawater system is influenced, and a main engine fails and the vessel is suspended, is avoided.

Owner:NANTONG COSCO KHI SHIP ENG

Boat/RV mounted pressure-wash system

InactiveUS20050156060A1Eliminate needEasy to storePower plants using condensersVessel cleaningBilgeHigh pressure

A boat or recreational vehicle (RV) mounted pressure washing system fully plumbed and integrated electrically with the boat or RV, and located remotely there within according to user's preferred mounting location such as the bilge, engine compartment or a supply cabinet. The system provides the user with a high pressure supply of water for washing, rinsing, etc. by means of a pump, water reservoir and fully retractably high pressure hose, to which a nozzle of choice may be quickly attached or removed when not in use. The pressure hose is of significant length to provide for the pressure washing of the entire vehicle and surrounding areas by the user, whereby when not in use is fully retractable into the boat or RV for storage.

Owner:ATTAR ROBERT A

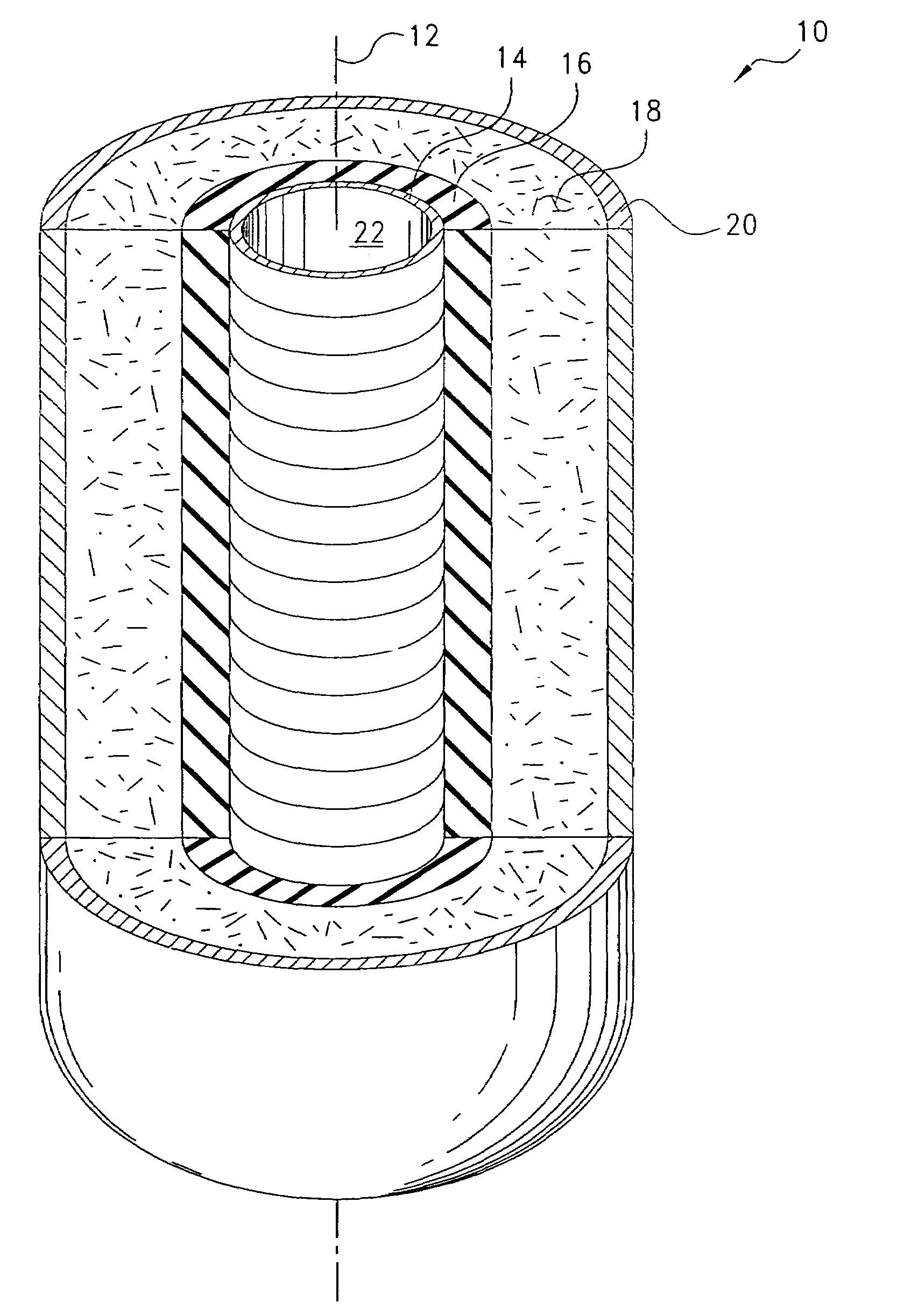

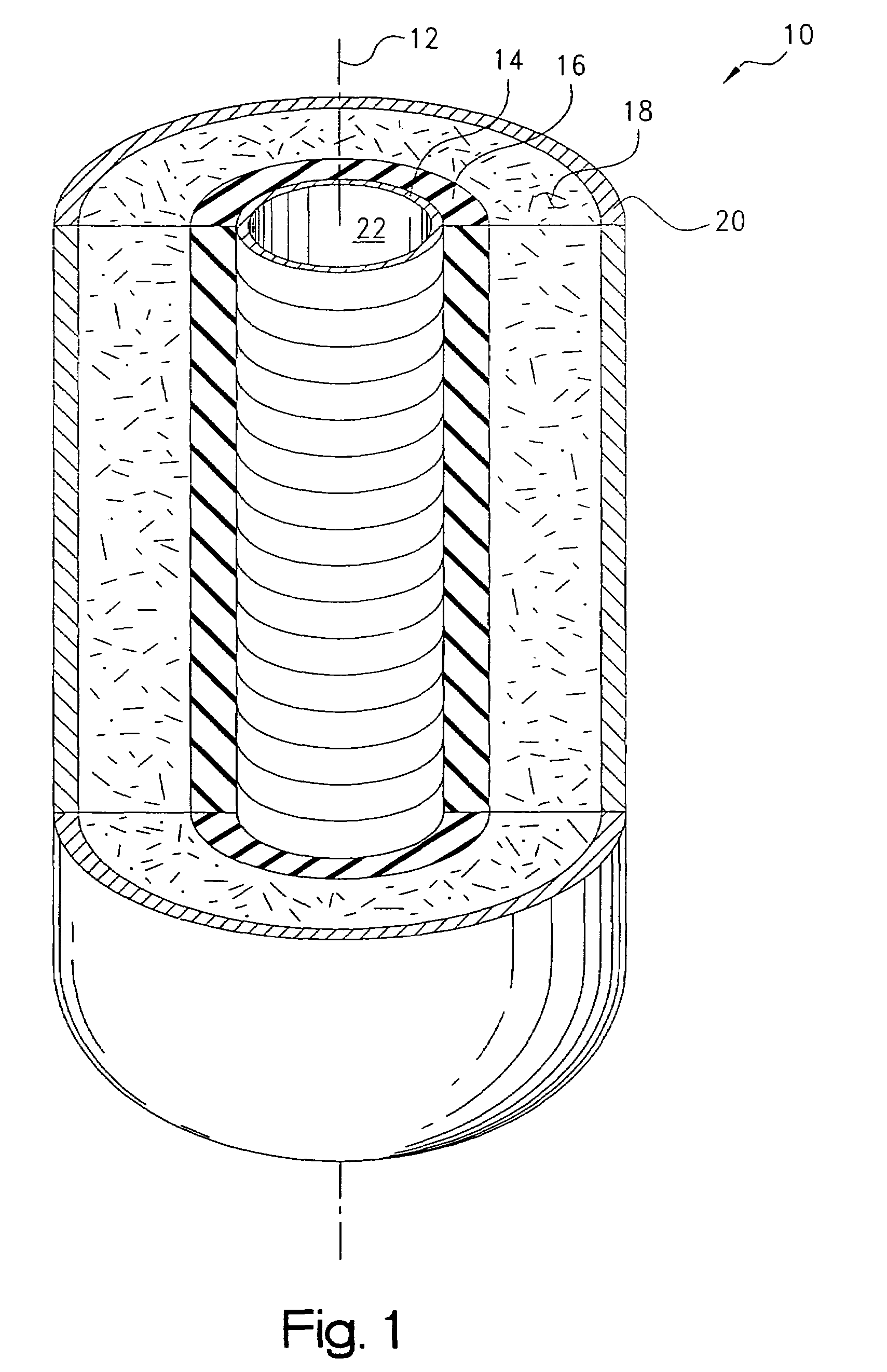

Oil-sorbing filter element

ActiveUS7297267B2Improve performanceEasy to useFatty/oily/floating substances removal devicesOther chemical processesBilgeWater flow

An oil-sorbing filter element for removing oil from an aqueous flow such as the bilge water of a watercraft. The element includes a first stage which is formed of a consolidated permeable mass of a oleophilic polymeric material such as styrenic mid-block copolymer.

Owner:PARKER INTANGIBLES LLC

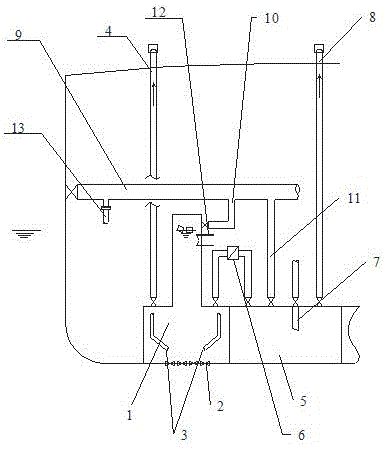

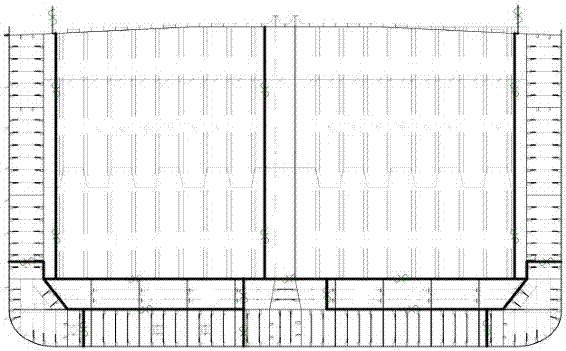

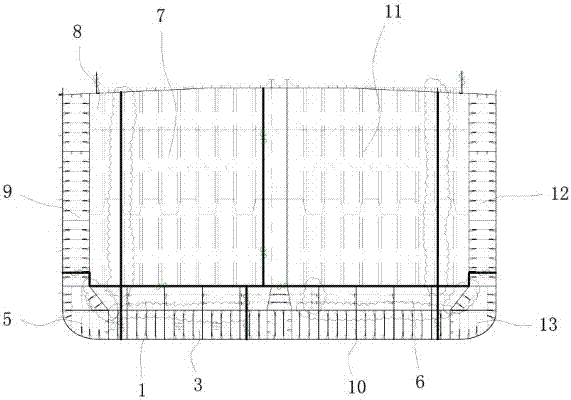

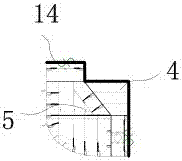

Bilge mechanism of bulk cargo ship

InactiveCN104309761AImprove stabilityImprove space utilizationHull interior subdivisionFor bulk goodsBulk cargoBilge

The invention discloses a bilge mechanism of a bulk cargo ship and relates to the technical field of shipbuilding, wherein a top side tank and a bottom side tank are connected by a ship side frame, the bottom side tank is connected with a double-layer bilge, the middle part of the double-layer bilge is respectively provided with a plurality of rib plates, an upper stool is arranged on the top side tank, the upper stool is connected with the lower stool by a transverse bulkhead, the bottom of the upper stool is arranged in a bilge way, the top of the lower stool is arranged in a glide path, both sides of the upper and lower stools are respectively provided with a clamping block, and the middle parts of the upper and lower stools are respectively provided with a height detector; the bilge mechanism adopts the fixing rib plate so as to greatly increase bearing capacity of the bilge, the flexibility of the bilge is improved by the movable internal structure and the upper and lower stools and the triangular bottom side tank has the excellent steadiness.

Owner:JIANGSU ROKEE HEAVY IND TECH

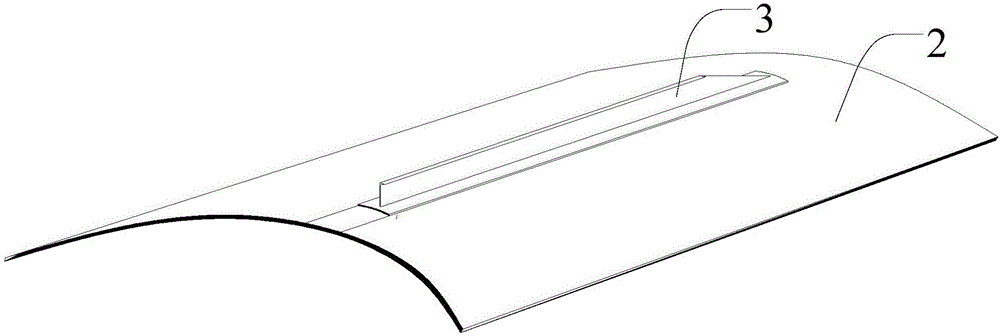

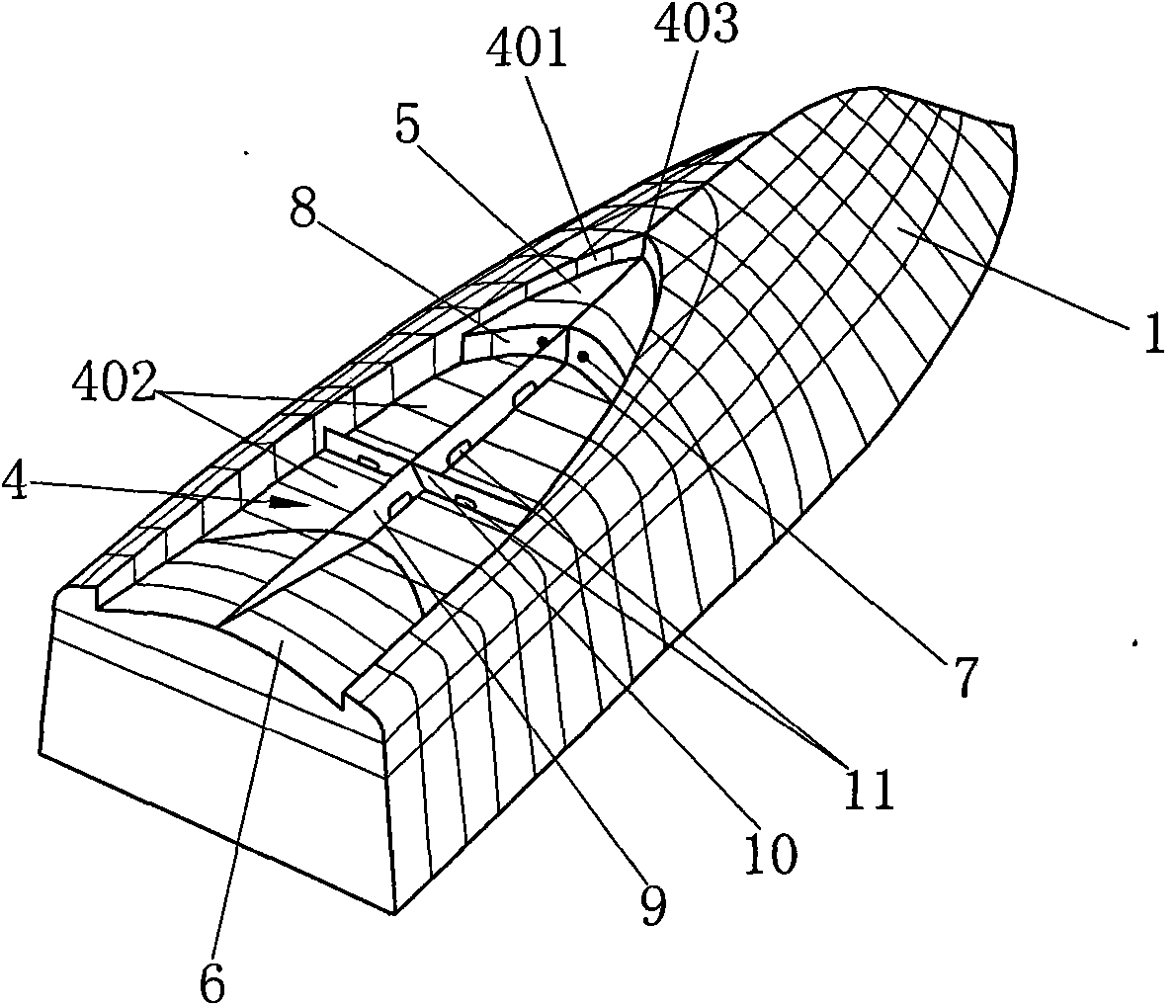

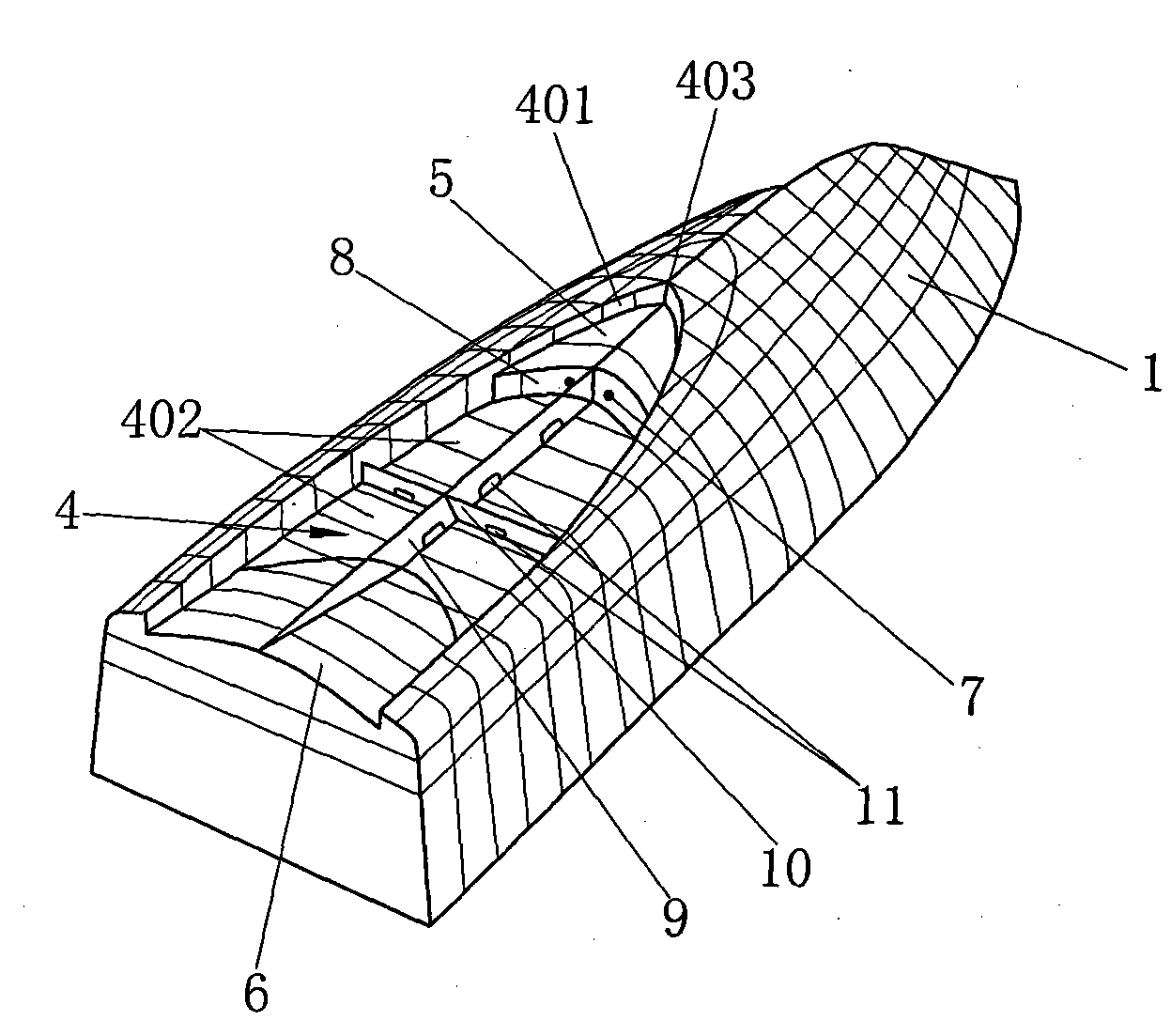

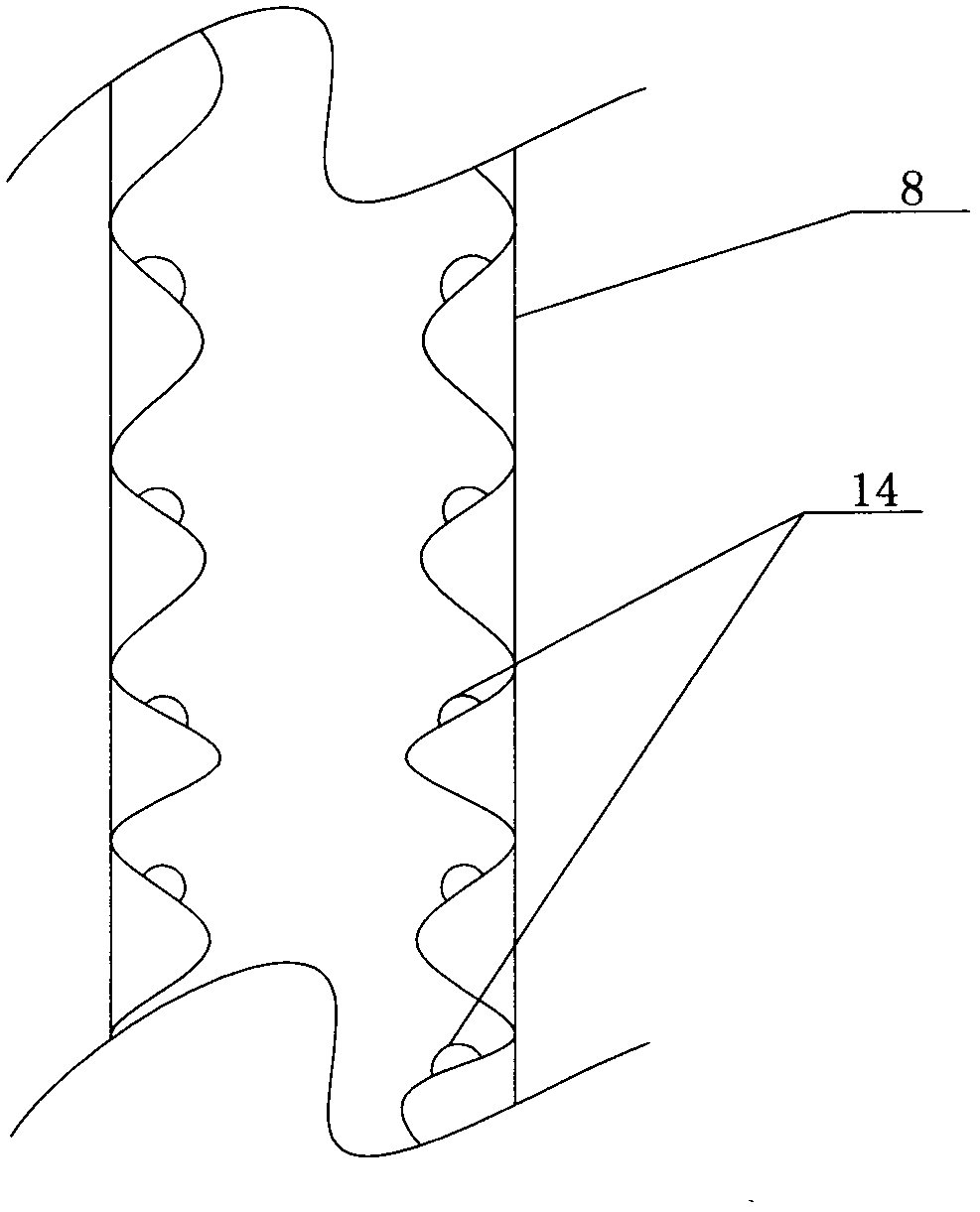

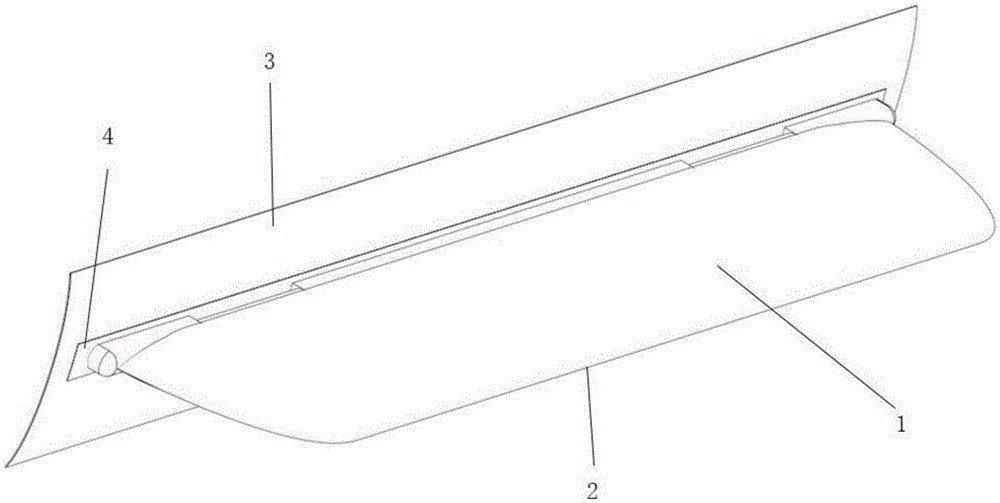

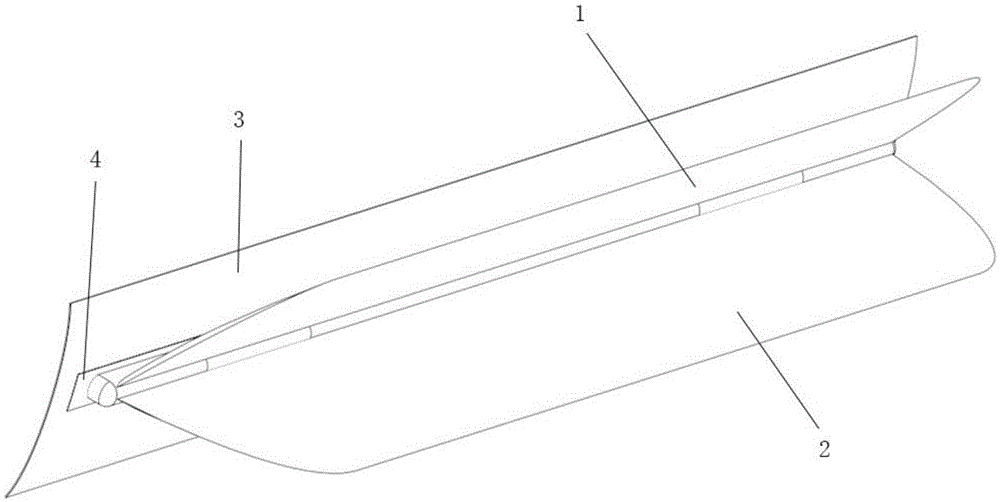

External-opened retractable bilge keel

InactiveCN105539757ADoes not affect speedIncrease dampingVessel movement reduction by foilsStrakeBilge

The invention relates to an external-opened retractable bilge keel. A main body structure comprises two parts of a fixed shell structure (2) and a rotary shell structure (1), wherein after being closed, the two parts are in a flat shape; front and tail ends of the main body structure is shaped like a streamline; the fixed shell structure (2) is fixedly connected with a bilge strake (3); the rotary shell structure (1) is connected with the fixed shell structure (2) through a rotating shaft system; and the rotating shaft system is used for opening and closing the shell structure (1). The external-opened retractable bilge keel provided by the invention is advantaged in that the rolling damping of a ship can be increased, the rolling of the ship is effectively reduced and the rolling stability is enhanced.

Owner:TIANJIN UNIV

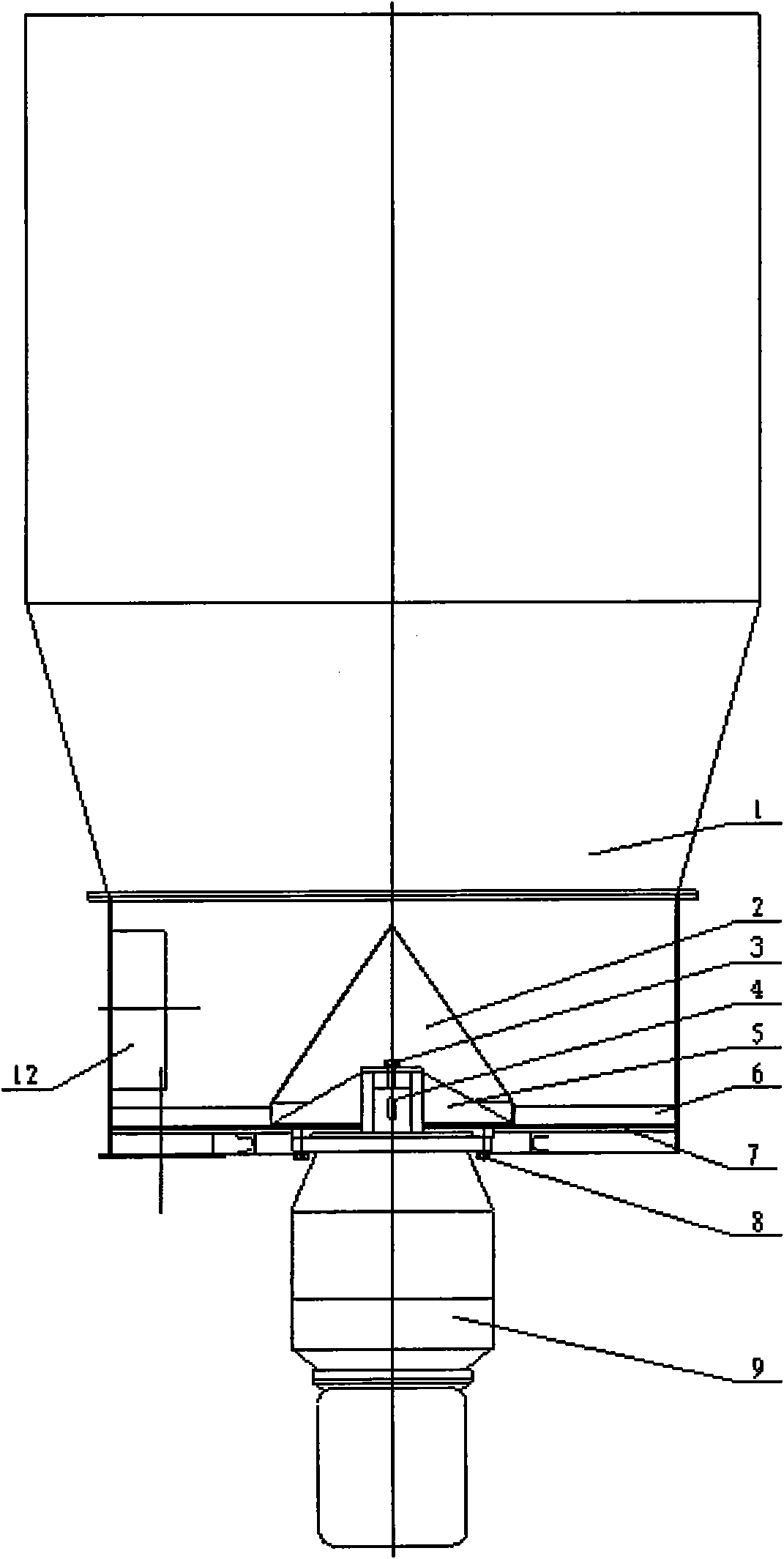

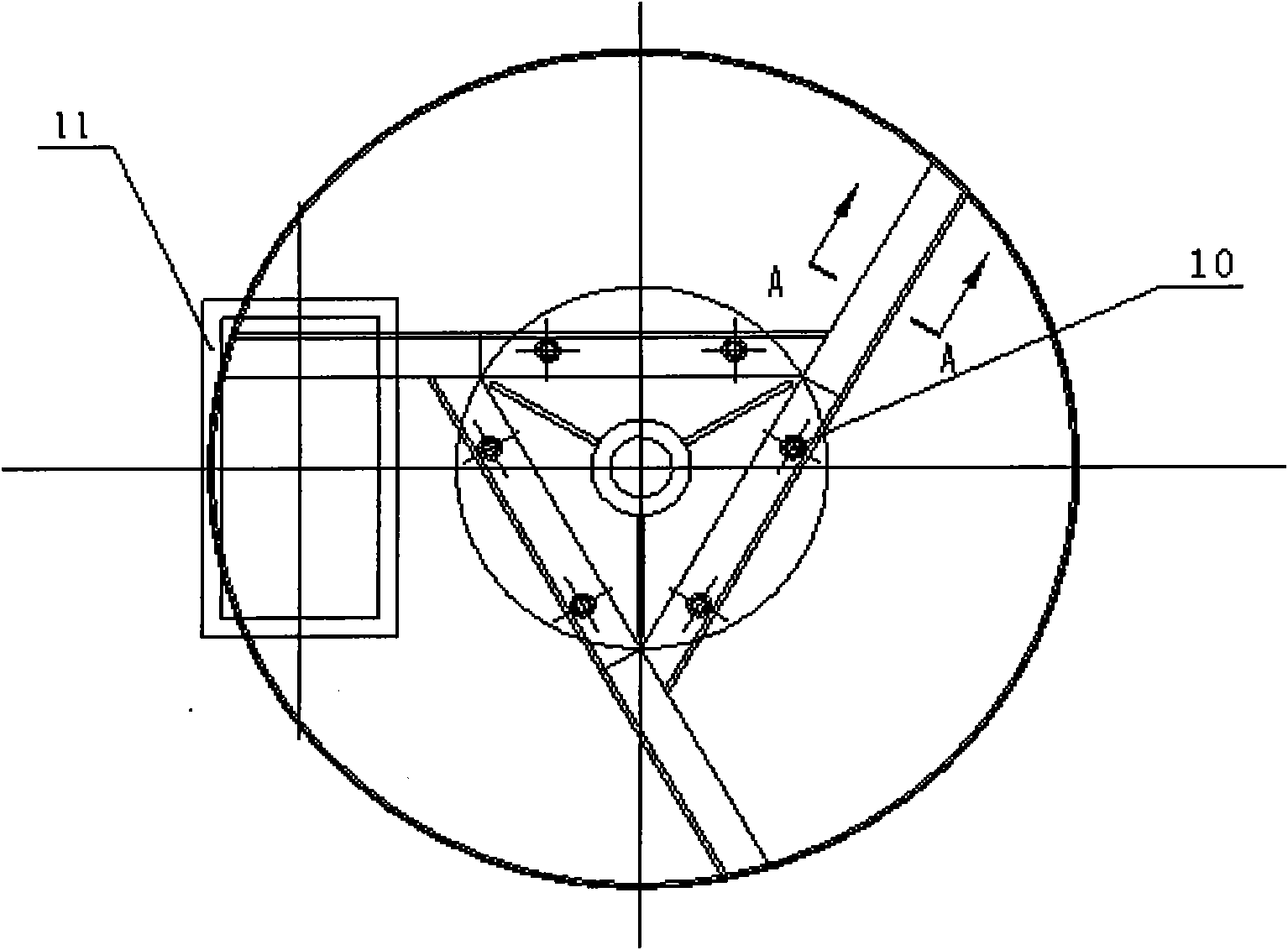

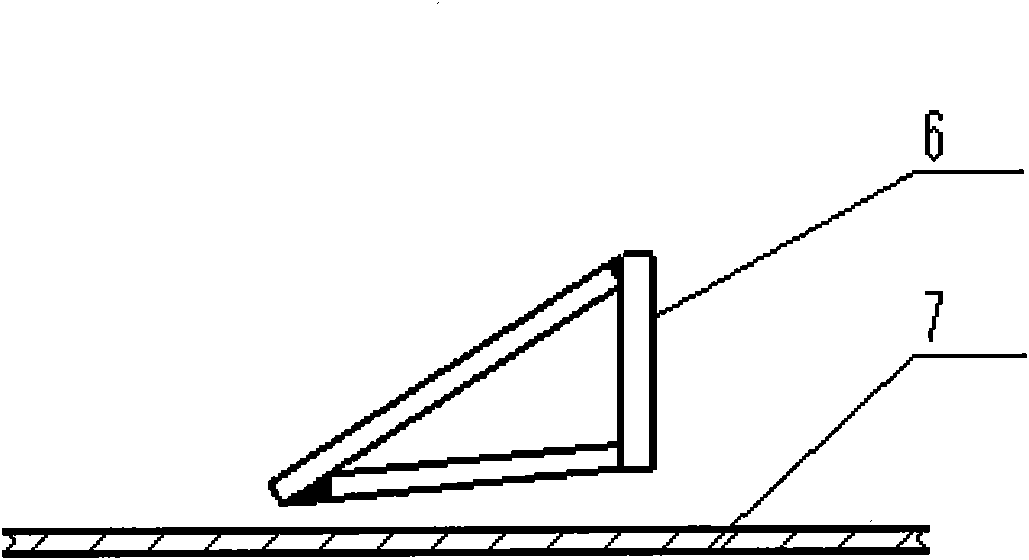

Disc-type discharging machine

InactiveCN101927906ASmooth dischargeReduce vibrationLarge containersLoading/unloadingLow noiseLow speed

The invention discloses a disc-type discharging machine for bilge discharging equipment, which comprises a bin body, a bottom plate, a discharging scraper and a drive device thereof. The bin body is arranged on the bottom plate; the discharging scraper is arranged in the bin body and is driven to rotate by the drive device thereof, and rotating axial direction is vertical; and the bottom of the bin body is provided with a discharge hole which is formed below a plane formed when the discharging scraper is rotated. The disc-type discharging machine has the advantages that: due to no limitation of the size of the discharge hole, the disc-type discharging machine can be used for the large-scale bin capacity and can discharge materials with different specific gravities smoothly, particularly the lightweight material. A conical cover is arranged on a cutter to play a role in guiding the materials to the discharge hole and reducing rotating resistance of the cutter; the disc-type discharging machine avoids material buildup and material blocking due to a scraper stripping mode of the discharge hole, and has the advantages of enough power, small vibration and low noise due to a low speed operating mode; and the equipment is more stable and reliable.

Owner:LIYANG YUDA MASCH CO LTD

Assembling method for broadside section and bilge section of oil ship

The invention relates to an assembling method for a broadside section and a bilge section of an oil ship. A left wall pier and a right wall pier are respectively divided into two sections and the two divided sections are respectively integrated with the bilge section and the bottom section on the corresponding side, so that the wall pier used as an independent section is cancelled, the welding of the wall pier and the bilge and bottom is reduced, the difficulty in large folding operation is reduced, the assembling steps are simplified and the working efficiency is increased. The divided broadside section and the divided bilge section are assembled in advance on the ground by taking an external plate as a base bottom, so that the precise control difficulty of the original vertical overlapping hoisting without assembling is greatly reduced. The divided broadside section and the divided bilge section are butt-jointed on the ground, so that the original horizontal welding is converted into common flat welding, the welding quality is promoted, the piling block used for adjusting and aligning is avoided, the repairing rate is greatly reduced, the working efficiency is increased, the time and labor are saved, the manufacturing cost is greatly saved and the quality and beautiful appearance of the external plate are guaranteed.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

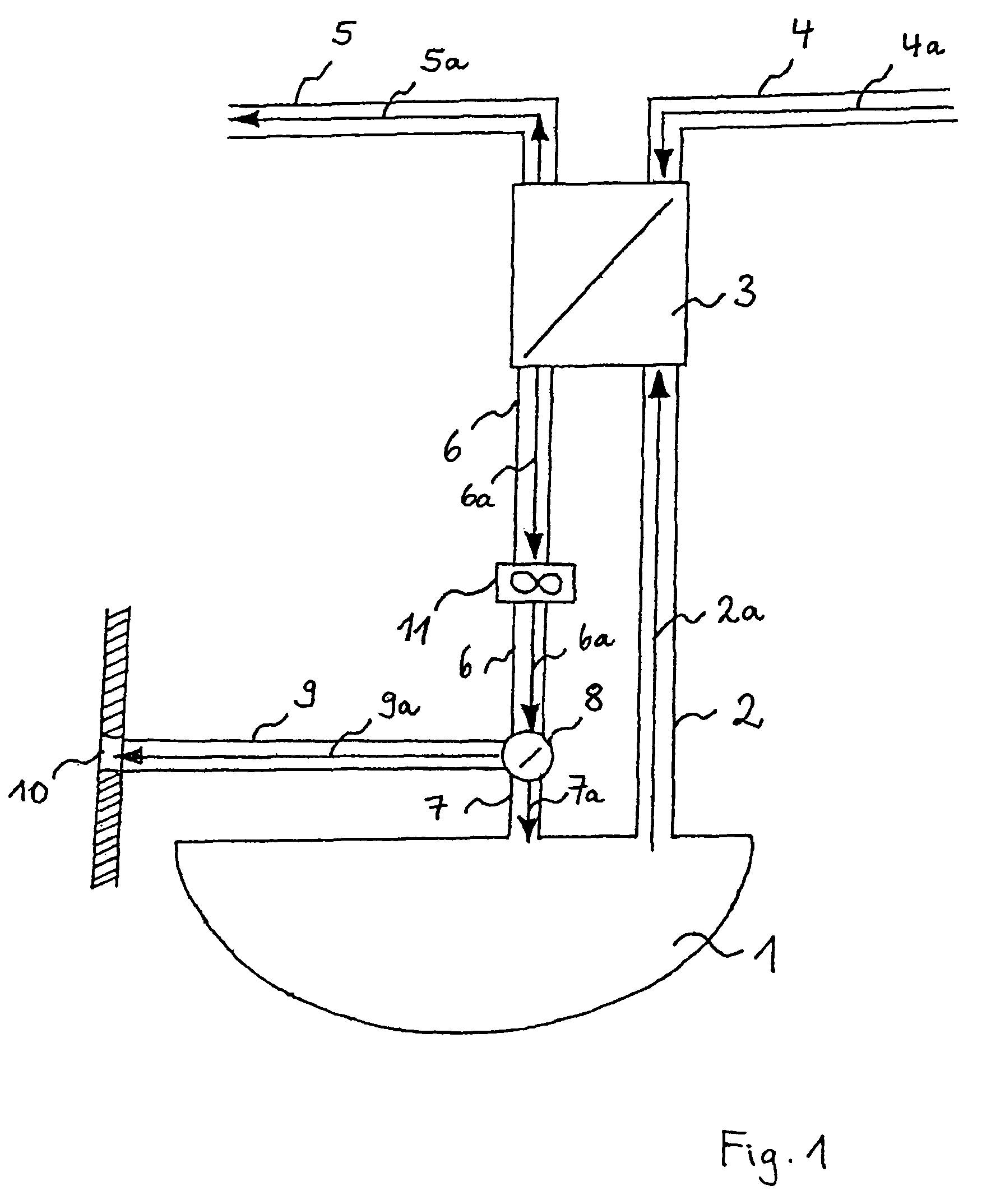

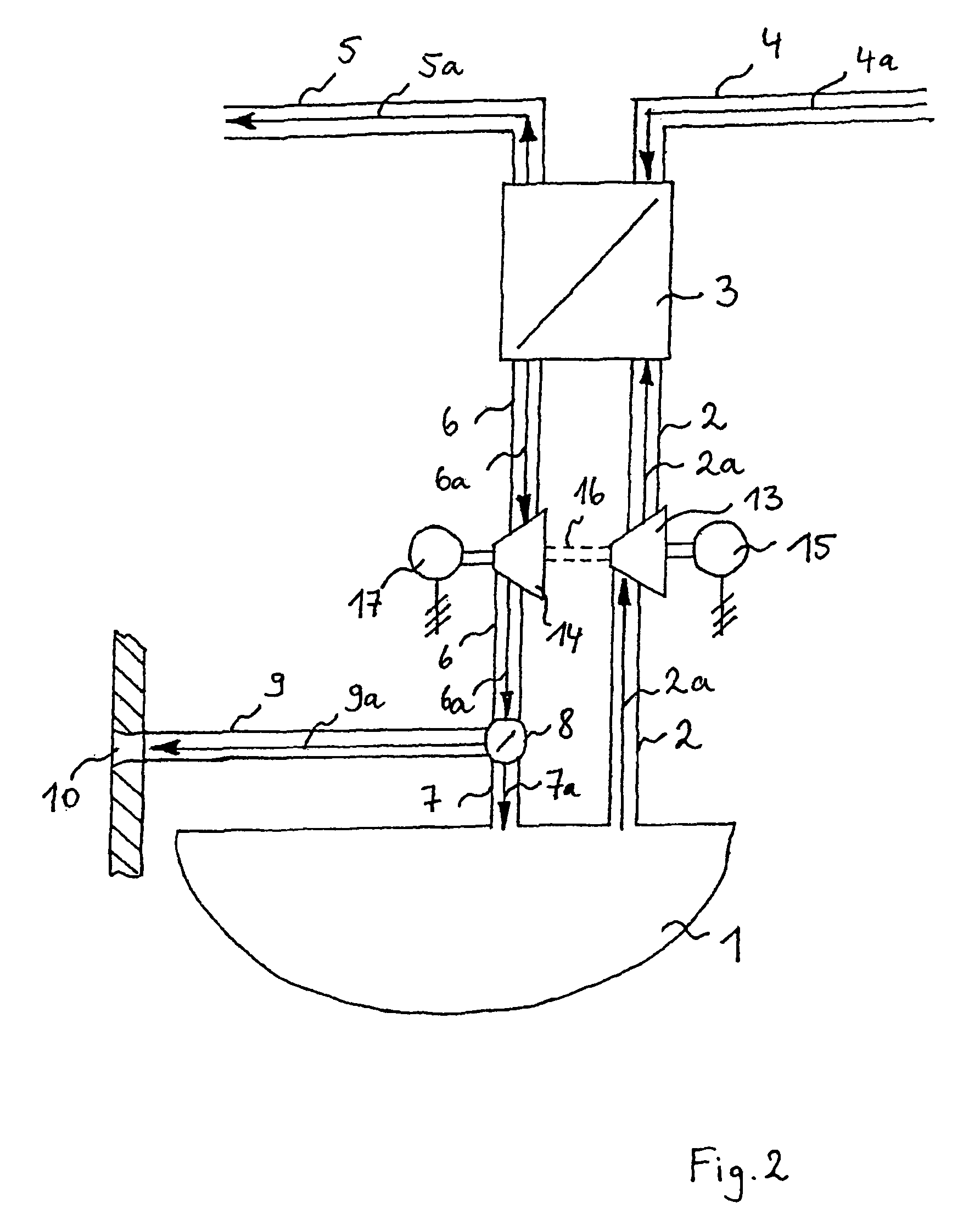

Arrangement and method for utilizing the heat of waste air for heating the bilge area of aircraft

InactiveUS7980928B2Improved and effective heatingReduce expenditureAir-treating devicesAir-treatment apparatus arrangementsHeat flowBilge

The present application describes an arrangement and a method for utilizing the heat of waste air for heating the bilge area of aircraft, wherein the bilge area is connected to a heat transfer unit via a first air supply pipe, through which a bilge air flow drawn in from the bilge area flows into the heat transfer unit, wherein the heat transfer unit comprises a second air supply pipe, through which a waste air heat flow to be cooled that is created at another location in the aircraft flows into the heat transfer unit in order to heat the drawn-in bilge air flow, wherein the heat transfer unit comprises a first air discharge pipe, through which the cooled waste air heat flow is discharged, and a second air discharge pipe with a bilge inlet section, and wherein at least a portion of the heated bilge flow is returned to the bilge area via the air discharge pipe and the bilge inlet section.

Owner:AIRBUS OPERATIONS GMBH

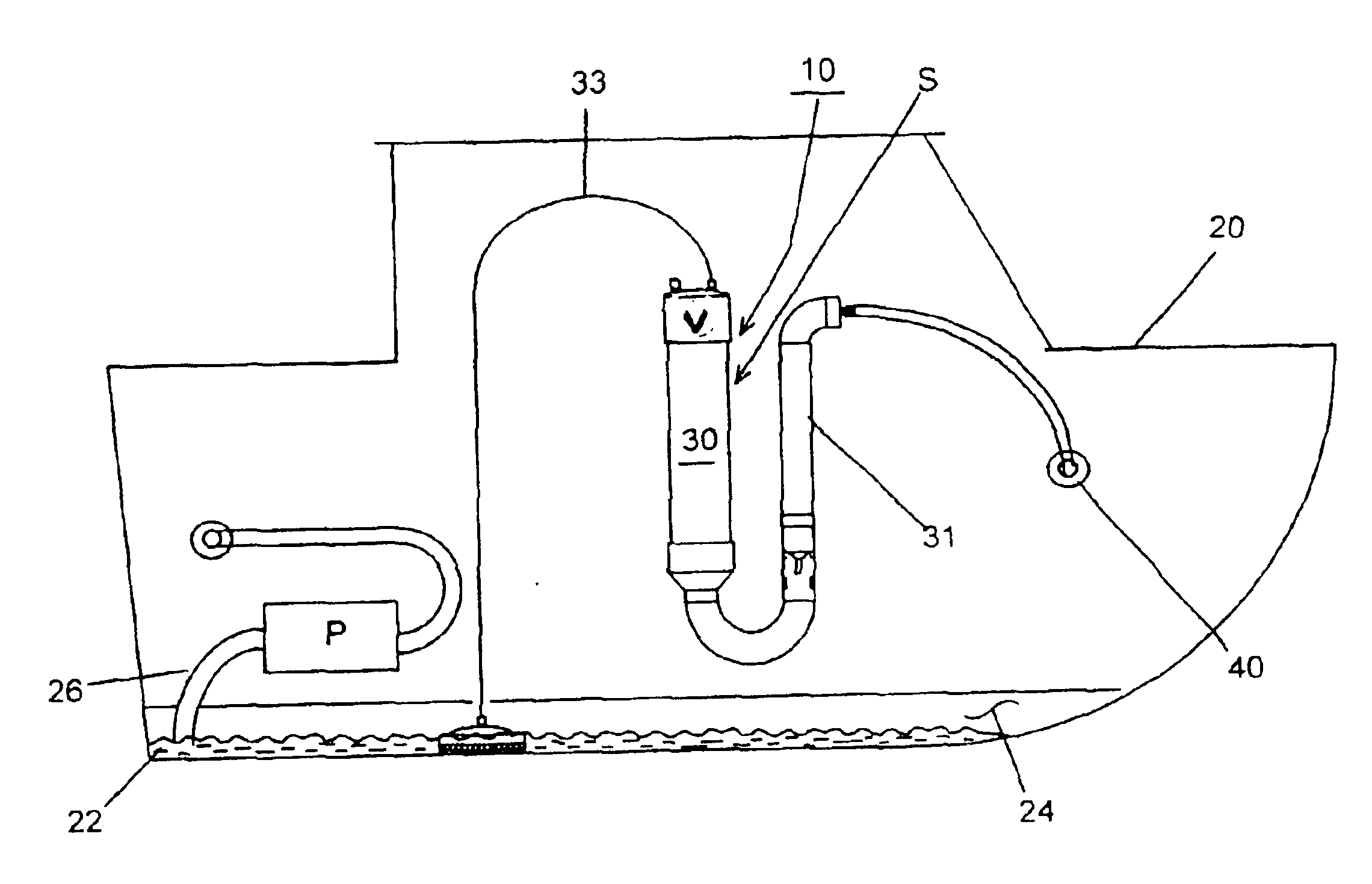

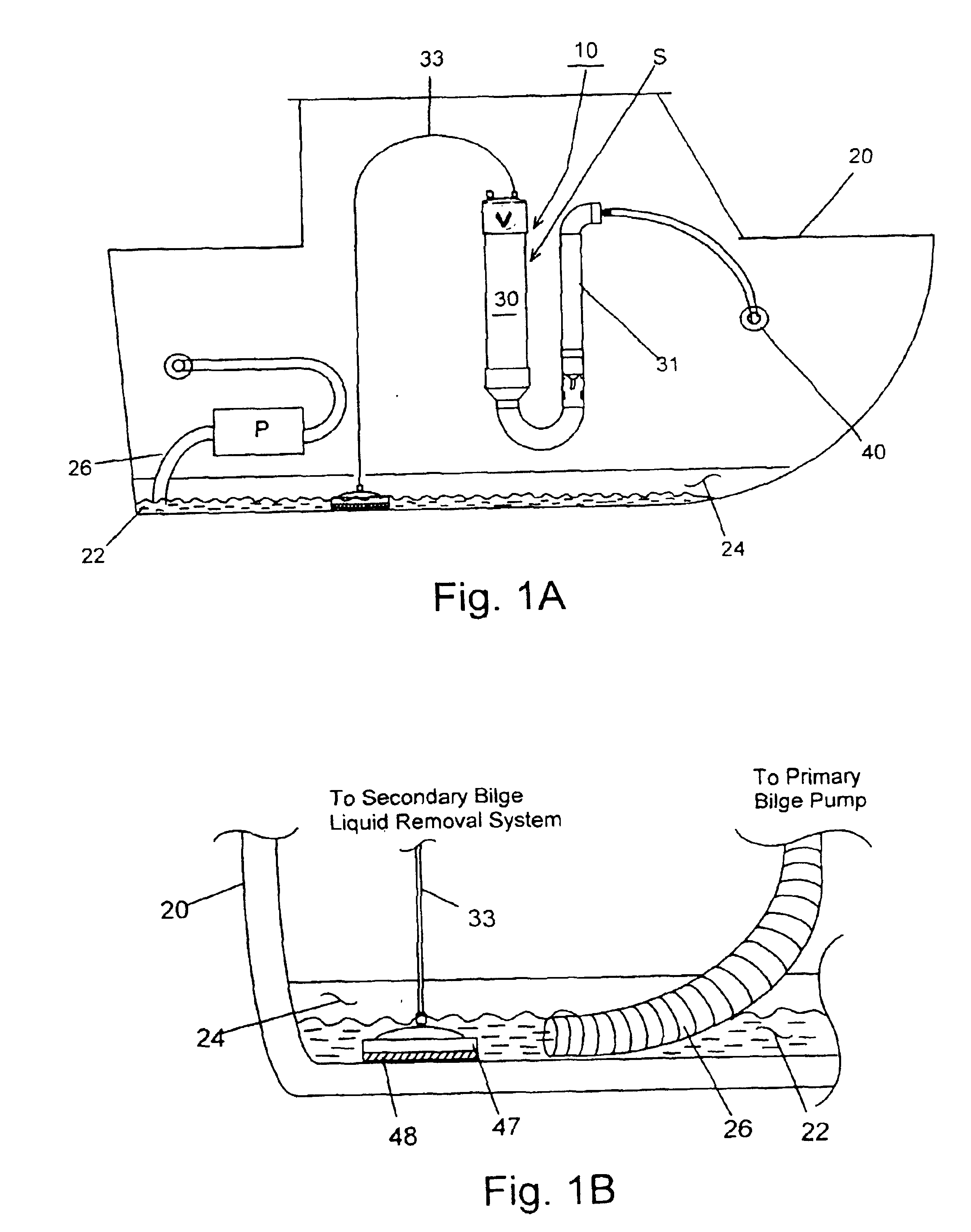

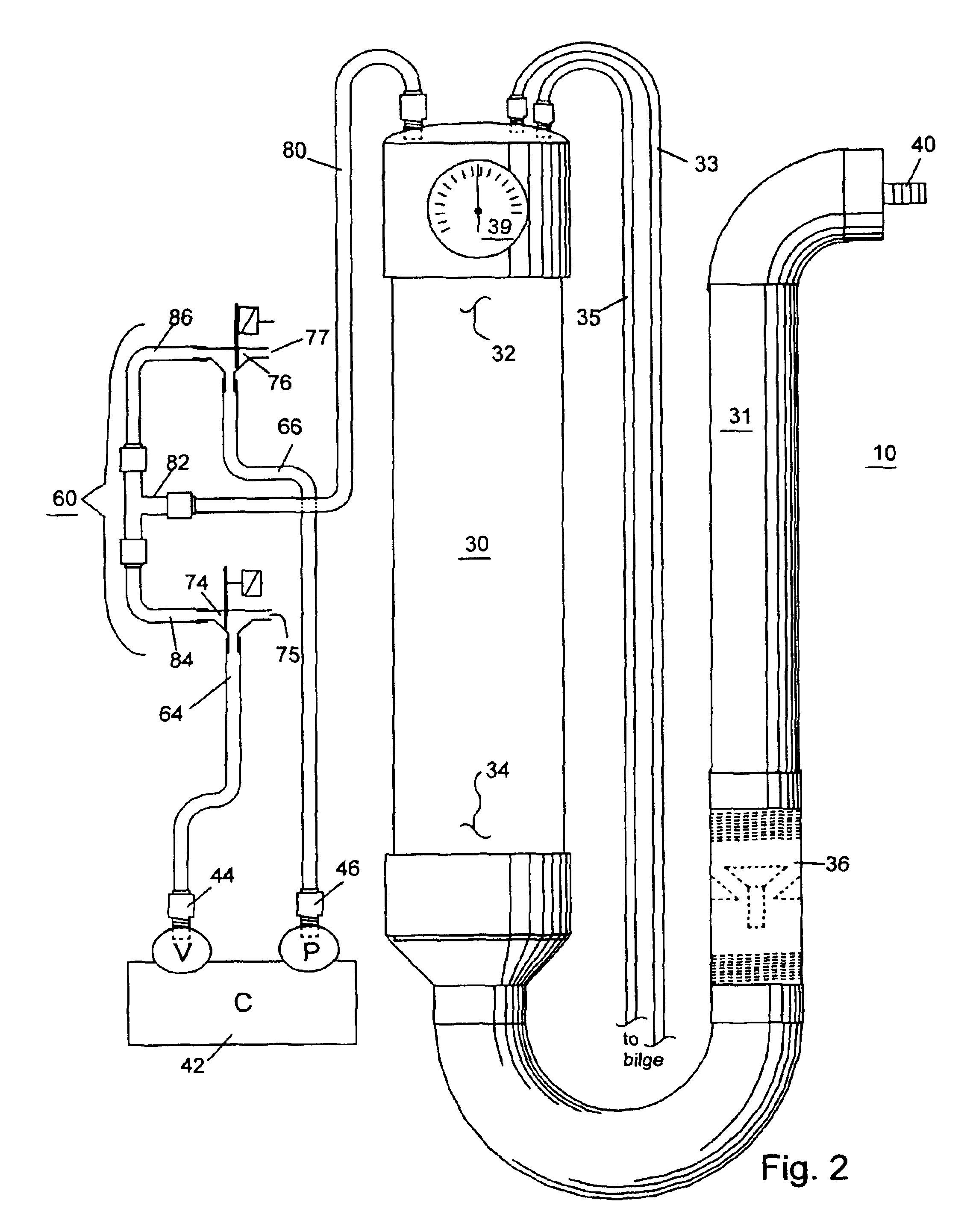

Pneumatic bilge liquid removal system and method therefor

The invention relates to a pneumatic bilge liquid removal system including an air compressor having inlet and outlet ports pneumatically coupled to a valve system, a collection chamber with the top segment coupled to the valve system, at least one collection tube extending from the bilge to the collection chamber, a discharge tube coupled to the collection chamber, and a control system for the air compressor and valve system. The air compressor pressurizes the collection chamber via the outlet port for a first time interval causing the bilge liquid in the collection chamber to discharge through the discharge tube, and the air compressor creates a negative pressure in the collection chamber via the inlet port for a second time interval causing any the bilge liquid in the bilge to be drawn into and accumulate in the collection chamber via the collection tubes. A bilge liquid removal method is also provided.

Owner:BAURLEY ALFRED RUDOLPH

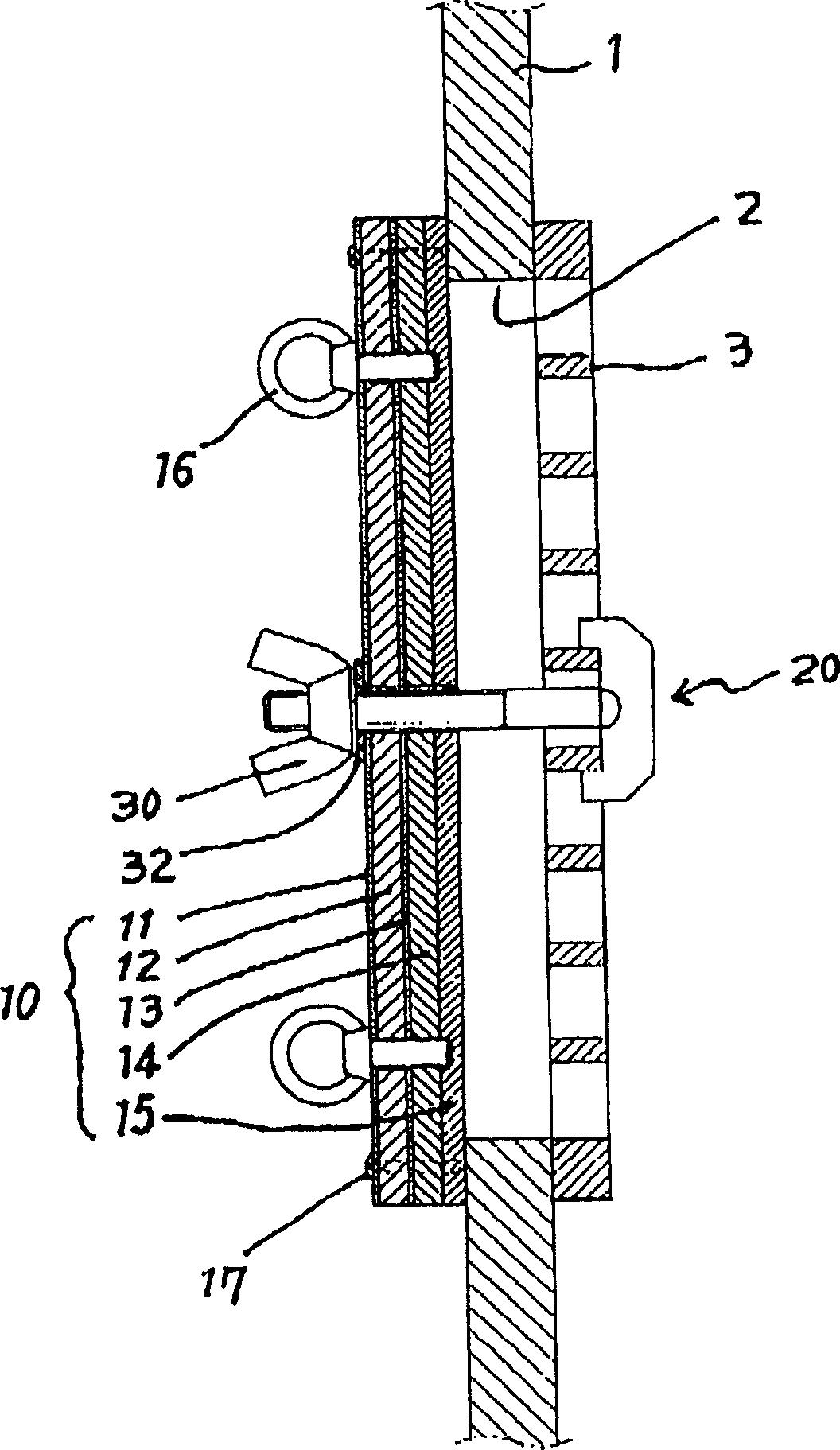

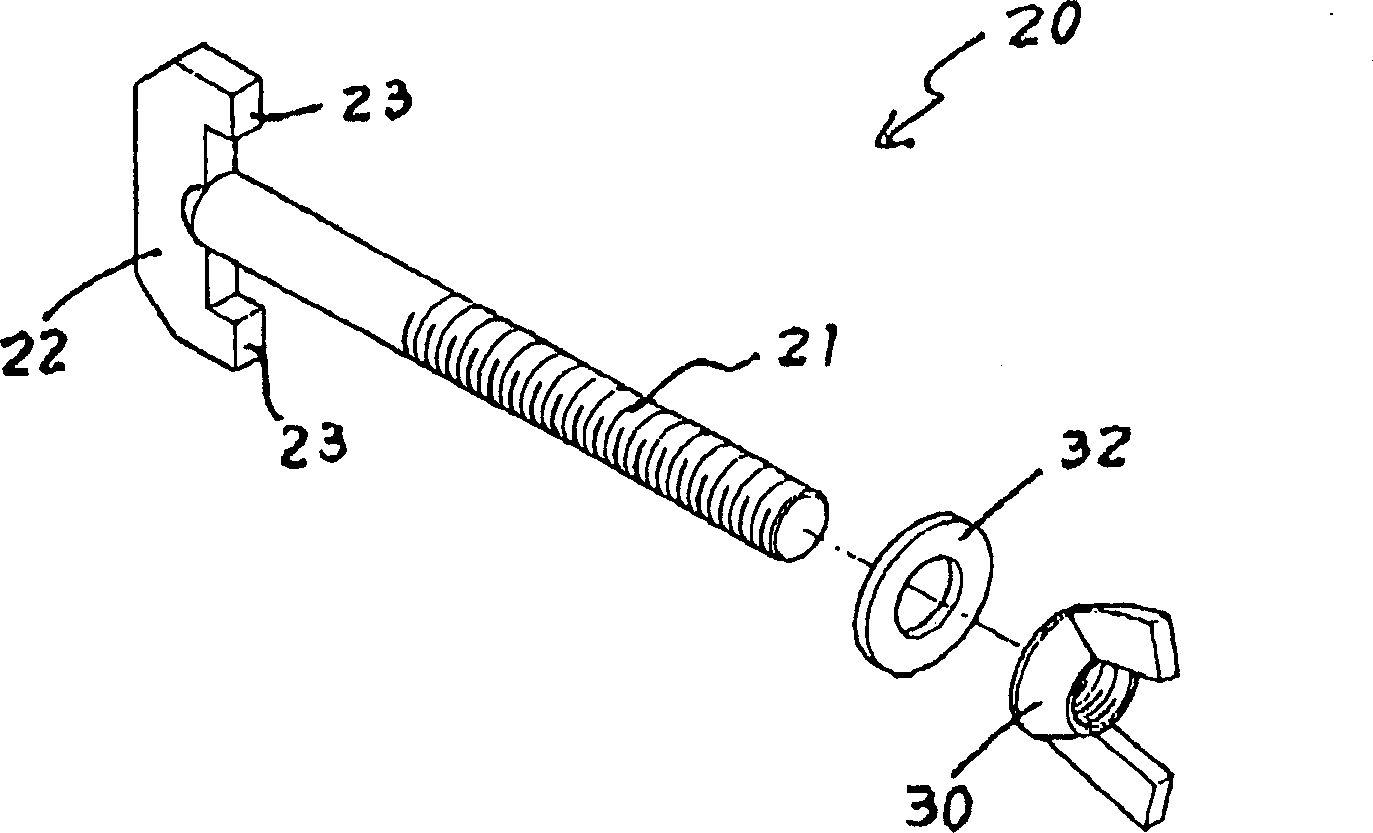

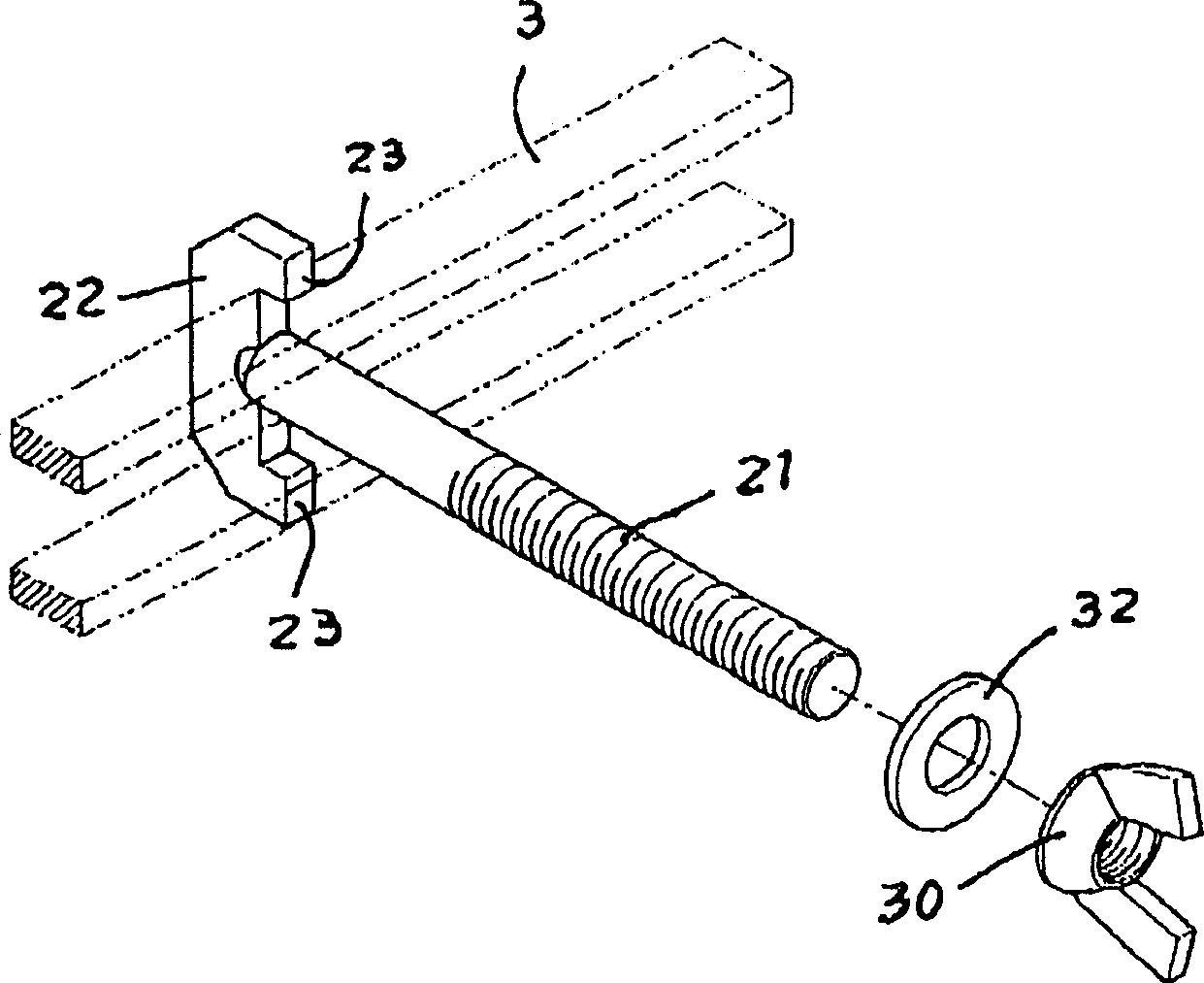

Seawater hole plate of gate at low holds of ship

InactiveCN1680168APrevent disengagementAvoid lossSelf-bailing equipments/scuppersVessel partsBilgeEngineering

The invention provides a sheathing board for closing the seawater inflow hole of the bilge door of a ship, including: a baffle, bolts for fixing rope which are mounted on one or two points on the baffle, fixing bolts, rubber filler, and fixing nuts which are mounted on the fixing bolts, the baffle is provided with elasticity filler, a hole for the fixing bolts penetrating is formed in the middle, a second reinforcing plate which has the same size and shape with the elasticity filler and a hole for the fixing bolts penetrating formed in the middle, an intermediate plate having the same size and shape with the second reinforcing plate and a hole for the fixing bolts penetrating formed in the middle, a first reinforcing plate having the same size and shape with the intermediate plate and a hole for the fixing bolts penetrating formed in the middle, a surface plate having the same size and shape with the first reinforcing plate and a hole for the fixing bolts penetrating formed in the middle, and fixing screw which is mounted on the margin to fix all the materials.

Owner:DOO YANG

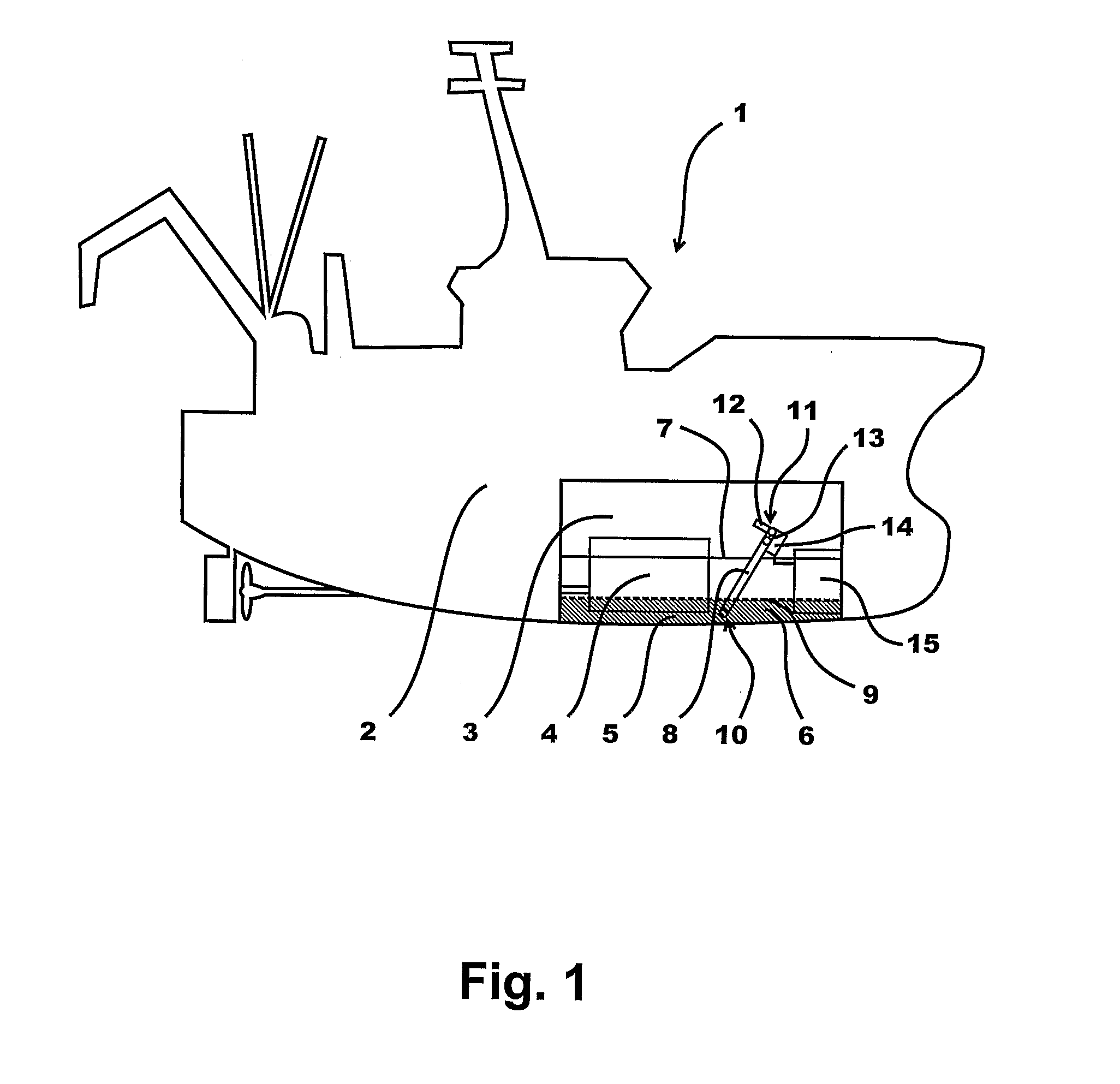

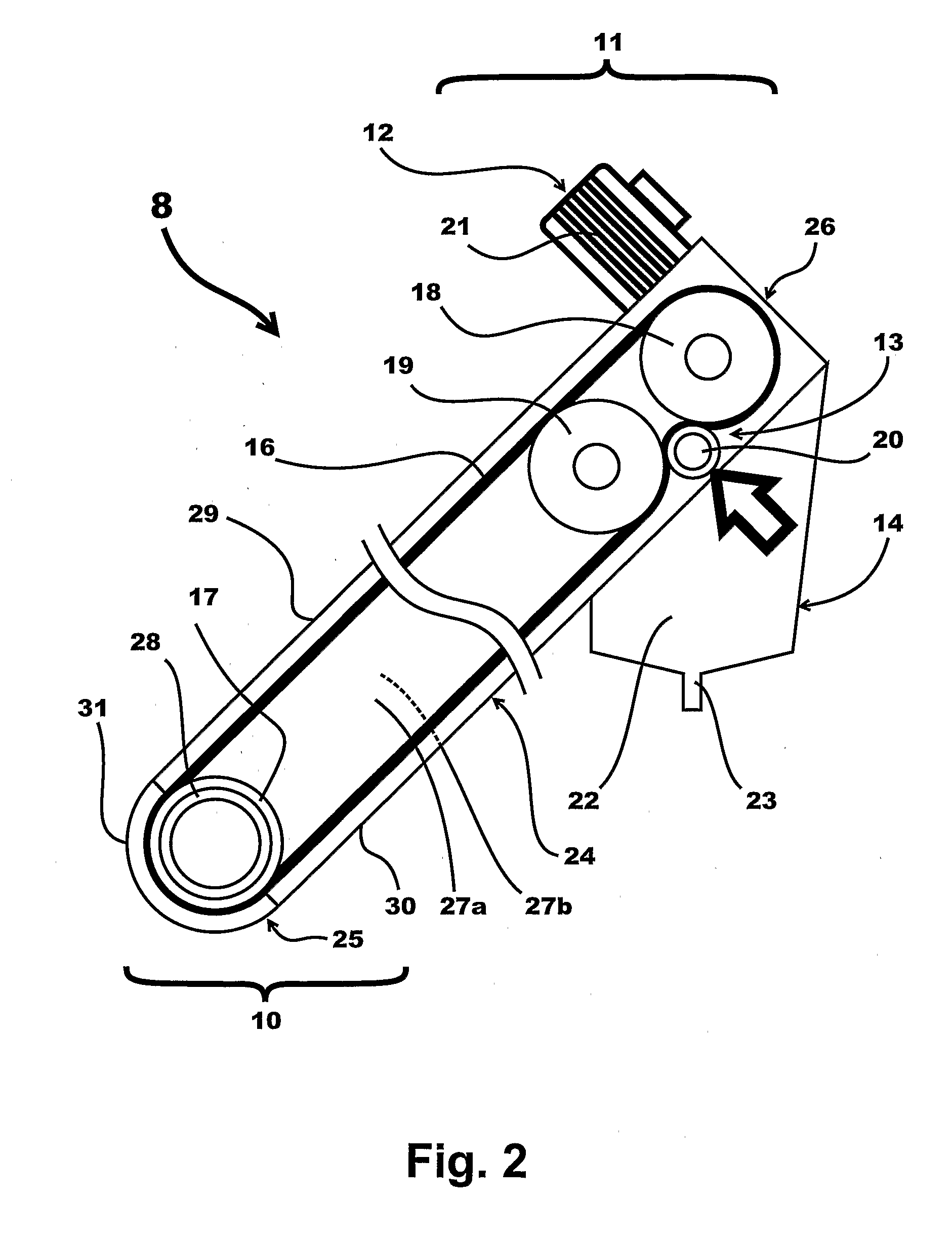

Ship with a contaminant separation device

InactiveUS20100213132A1Reduce the amount requiredDurable systemLiquid separation auxillary apparatusAuxillariesBilgeAbsorbent material

A ship comprises a bilge water sump collecting bilge water and contaminants. A first contaminant separation device is provided comprising a conveyor arrangement with an endless belt comprising adsorbing / absorbing material. The conveyor arrangement has a first portion submergible into the bilge water and contaminants in the bilge water sump, and a second portion being spaced from the first portion and provided with means for releasing adsorbed / absorbed contaminants from the conveyor belt and means for collecting the contaminants released. The conveyor arrangement is further provided with means for driving the endless belt along a moving path defined by guiding means.

Owner:P F FAROE MARITIME TECHNIC

Straight wall constant wetted length slideway type round bilge speed boat shape

InactiveCN103612707AImprove stabilityImprove airworthinessWatercraft hull designHydrodynamic/hydrostatic featuresBilgeOperability

The invention discloses a straight wall constant wetted length slideway type round bilge speed boat shape which is characterized in that a boat body comprises two straight wall constant wetted length round bilge lateral bodies in left-right symmetry, slideway tops and slideways, the straight wall constant wetted length round bilge lateral bodies are formed by straight wall contour lines, slideway contour lines, stern cross section lines, stern bottom oblique ascensions, midship cross section lines and midship bottom oblique ascensions. The straight wall constant wetted length slideway type round bilge speed boat shape has the advantages that the wetted length is constant, during sailing, waves and flying foams on the outer side of the boat body are reduced greatly, the waves, flying foams and air flows on the inner side of the boat body flow through the slideways and flow out towards the rear of the boat at high speed, parts of the energy of the waves and flying foams on the inner side of the boat body are recycled by the slideways (equals to wave and foam elimination) and converted into the dynamic lifting force of the boat body along with the air flows, the operability, navigability and seakeeping performance of the boat shape are increased greatly, and the boat shape is applicable to sea conditions 1-2 levels higher than those which traditional speed boats are applicable to. In addition, due to the fact that the wetted length of the boat shape is constant, the performance of the boat shape can be favorably and theoretically analyzed and researched by using length Froude number.

Owner:JIANGSU UNIV OF SCI & TECH

Anti-splash single-hull planing boat

InactiveCN102923245AImprove lateral stabilityReduce rollingOutboard propulsion unitsVessel movement reduction by foilsAcute angleBilge

The invention discloses an anti-splash single-hull planing boat which comprises a boat body, a propelling device and a composite stabilizing wing, wherein the composite stabilizing wing is arranged at the bottom of a stem; the composite stabilizing wing comprises a vertical stabilizing wing and a horizontal stabilizing wing; downwardly inclined longitudinal anti-splash bodies are symmetrically arranged on two sides of the boat body from the front bilge part of a boat middle part to a stem bilge part; the widths of the longitudinal anti-splash bodies are gradually narrowed from the front part of the boat middle part to the stem; the head part of the boat body is gradually transitional from a shallow V-shaped cross section with an acute angle between the two side surfaces to the shallow V-shaped cross section with an obtuse angle between two side surfaces of the front part of the boat middle part; and the front part of the boat middle part is gradually transitional from a shallow V-shaped cross section with an obtuse angle between two side surfaces to a horizontal cross section, on which V-shaped edge strips extend downwards from two sides of the bottom of the stem, or an inverted shallow V-shaped cross section with an obtuse angle between two side surfaces. According to the invention, the splashing of lateral water flow of the sliding surface of the boat body can be effectively prevented, so that the rapidness, transverse stability, longitudinal stability, directional stability, seakeeping quality and so on are greatly improved, convenience for mounting propellers with larger diameters is achieved, and the propelling efficiency is increased.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com