Sea chest device suitable for arctic navigation vessel

A technology for submarine doors and ships, which is applied in the direction of pipelines, hulls, and ship parts for emptying/ballasting, and can solve problems such as ship shutdown and suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

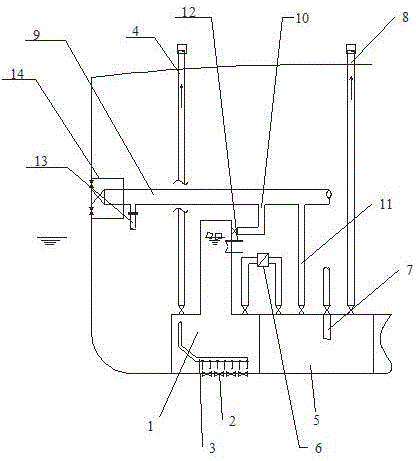

[0025] Such as figure 1 As shown, the submarine door device disclosed by the present invention is suitable for polar navigation ships, and can be arranged at a certain distance below the ballast waterline of the lowest ice area on the side of the hull, and at an appropriate position between the side bilge and the bottom of the centerline of the hull. It includes a storage bin 1, the lower end of the storage bin 1 is provided with a seawater suction port, and a ship side filter plate 2 is installed outside the suction port, and the filter plate 2 can be a grid or a plate with holes. A steam pipe 3 is arranged near the filter plate 2. The steam pipe 3 is arranged along the filter plate 2. A certain number of holes are opened on the steam pipe 3 at the grille of the filter plate 2 to release steam to blow off floating ice or marine organisms. Wait.

[0026] The storage bin 1 adopts a variable section design, and the upper section is smaller than the lower section. Using the prin...

Embodiment 2

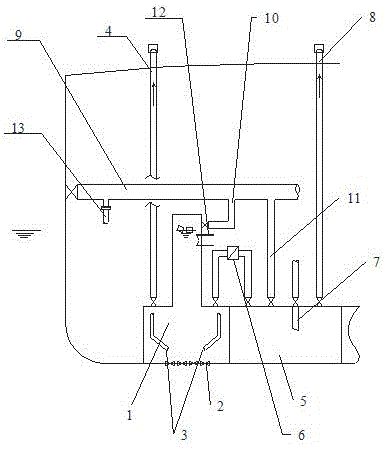

[0031] The second embodiment is as image 3 As shown, the steam pipe in the storage bin 1 is arranged along the side wall, and the mouth of the steam pipe faces the filter plate 2 at the same time, so as to blow off crushed ice or marine organisms. This method is convenient for opening the filter plate 2 during later docking repairs, and entering into the interior of the seabed door for inspection and maintenance. The overboard discharge pipe 9 is provided with a steam heating pipe 13 near the contact with the outer plate to melt or blow off crushed ice to ensure that the seawater is discharged smoothly.

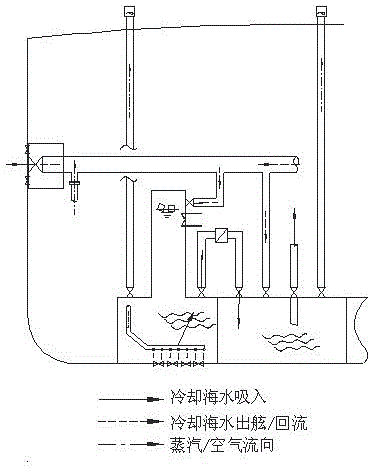

[0032] The flow of sea water or steam is shown as Figure 4 shown.

Embodiment 3

[0034] The third embodiment is as Figure 5 As shown, the storage bin 1 and the seawater compartment 5 are combined and arranged. Comprising a storage bin 1, the lower end of the storage bin 1 is a seawater suction port, and a ship side filter plate 2 is installed outside the suction port, and the filter plate 2 can be a grid or a plate with holes. A steam pipe 3 arranged along the side wall is arranged near the filter plate 2 to release steam to blow off crushed ice or marine organisms and the like. The storage bin 1 adopts a variable section design, and the upper section is smaller than the lower section. Using the principle that the density of ice is lower than that of seawater, floating ice accumulates on the upper part of the storage bin, forming a stratification of seawater and ice. The first ventilation pipe 4 is installed on the storage bin, and the first ventilation pipe 4 extends above the deck. The head of the ventilation pipe can be equipped with a heating device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com