Method for producing fine sand concrete gel containing waste stone dust through concrete mixing device

A mixing device and concrete technology, applied in the field of concrete, can solve the problems of insufficient concrete strength and uneven mixing, etc., and achieve the effects of ensuring strength, uniform mixing of raw materials, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

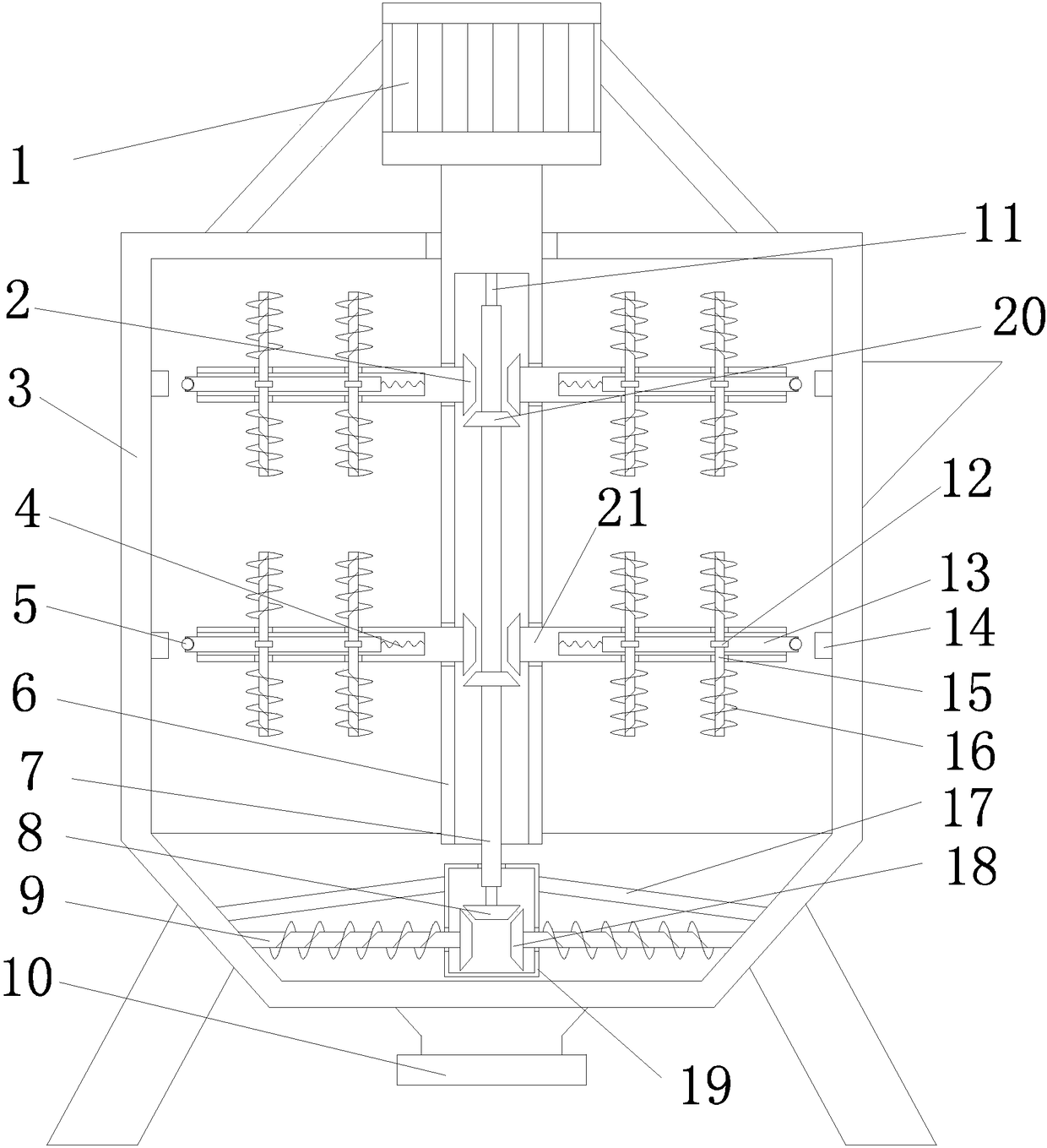

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0019] refer to figure 1 , a concrete mixing device, comprising a mixing bucket 3 and legs fixed on its bottom, one side of the mixing bucket 3 is connected with a feed hopper, the bottom of the mixing bucket 3 is connected with one end of a discharge pipe, and the other end of the discharge pipe One end is detachably connected with a material cover 10, and the end of the discharge pipe away from the mixing tank 3 is threadedly connected with a material cover 10, which is convenient for disassembly. The top of the mixing tank 3 is connected with a motor 1 through a support rod, and the output end of the motor 1 is connected with a hollow shaft 6. One end, the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com