Patents

Literature

148 results about "Oil retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil retention enema. oil re·ten·tion en·e·ma. a rectal injection of mineral oil, introduced at low pressure and retained for several hours before expelling, to soften feces.

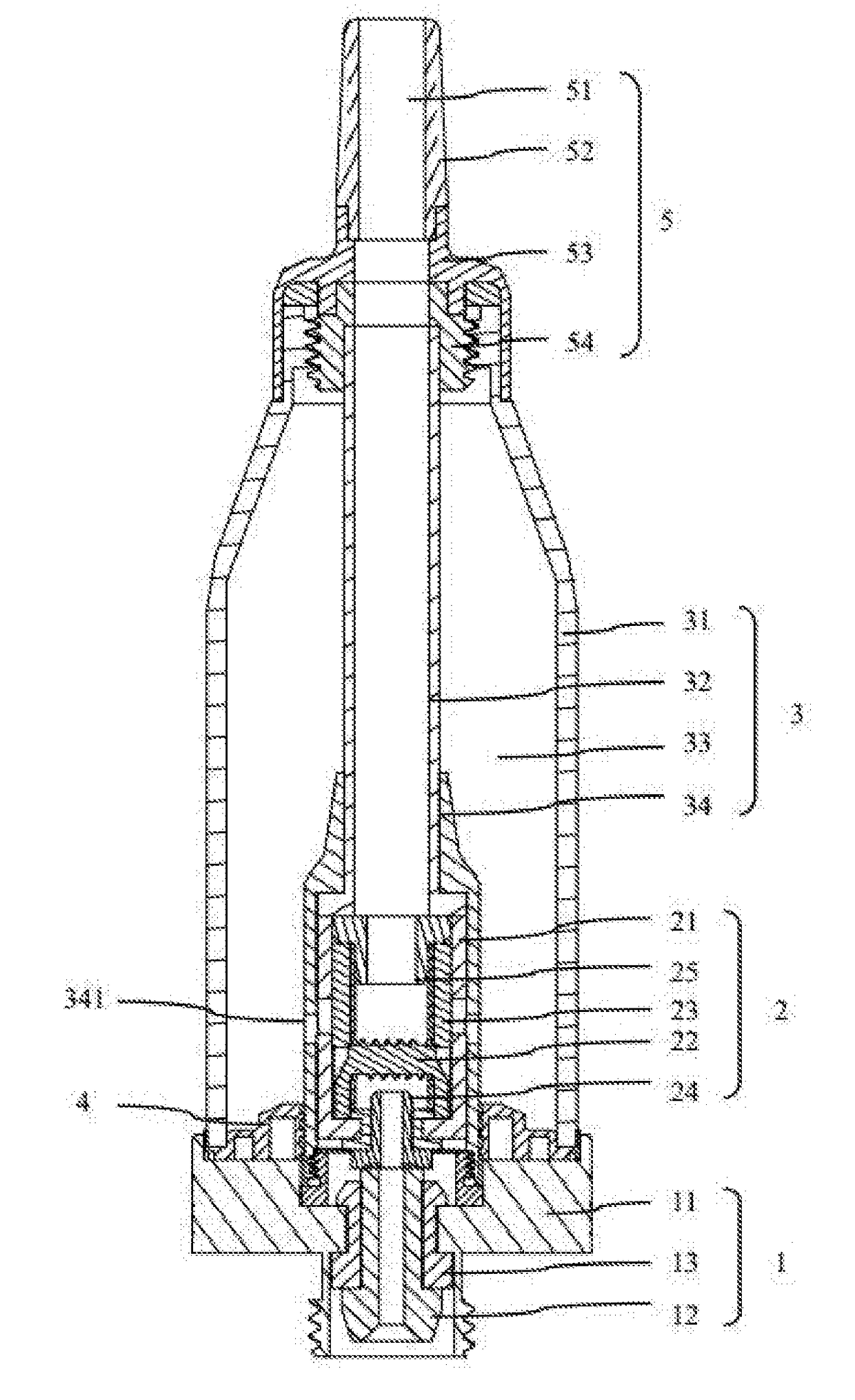

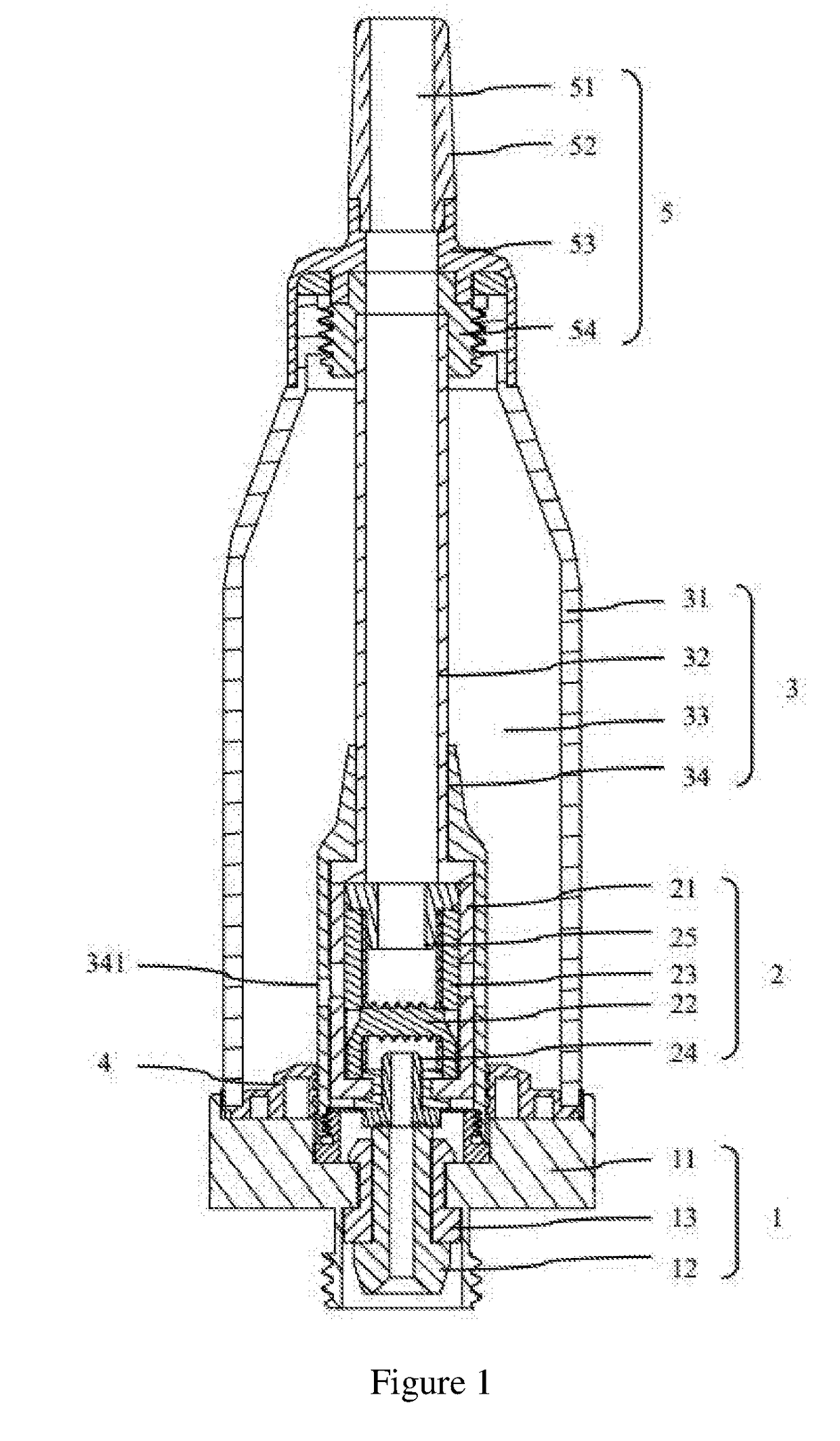

Atomizing component and electronic cigarette

ActiveUS20170273359A1Ensure electrical connection reliabilityImprove seismic performanceTobacco devicesMedical atomisersElectricityOil retention

The present application discloses an atomizing assembly and electronic cigarette. The atomizing assembly comprises a connecting assembly, an atomizing core, an oil cup assembly and a sealing gasket. The connecting assembly comprises a connecting base and a lower electrode. The oil cup assembly comprises an oil storage sleeve, a vent pipe, and a mounting sleeve which enclose to form an oil storage chamber for storing smoke oil. The connecting base and the oil storage sleeve are either abutted against or expandedly fitted with each other. The connecting base is cappingly provided on an oil filler of the oil storage sleeve. The atomizing core comprises an atomizing sleeve, a heating wire assembly, a smoke oil retention member and an inner electrode. The inner electrode is abutted against and electrically connected to the lower electrode. The atomizing core is slidably sleeved in the mounting sleeve.

Owner:HUIZHOU KIMREE TECH

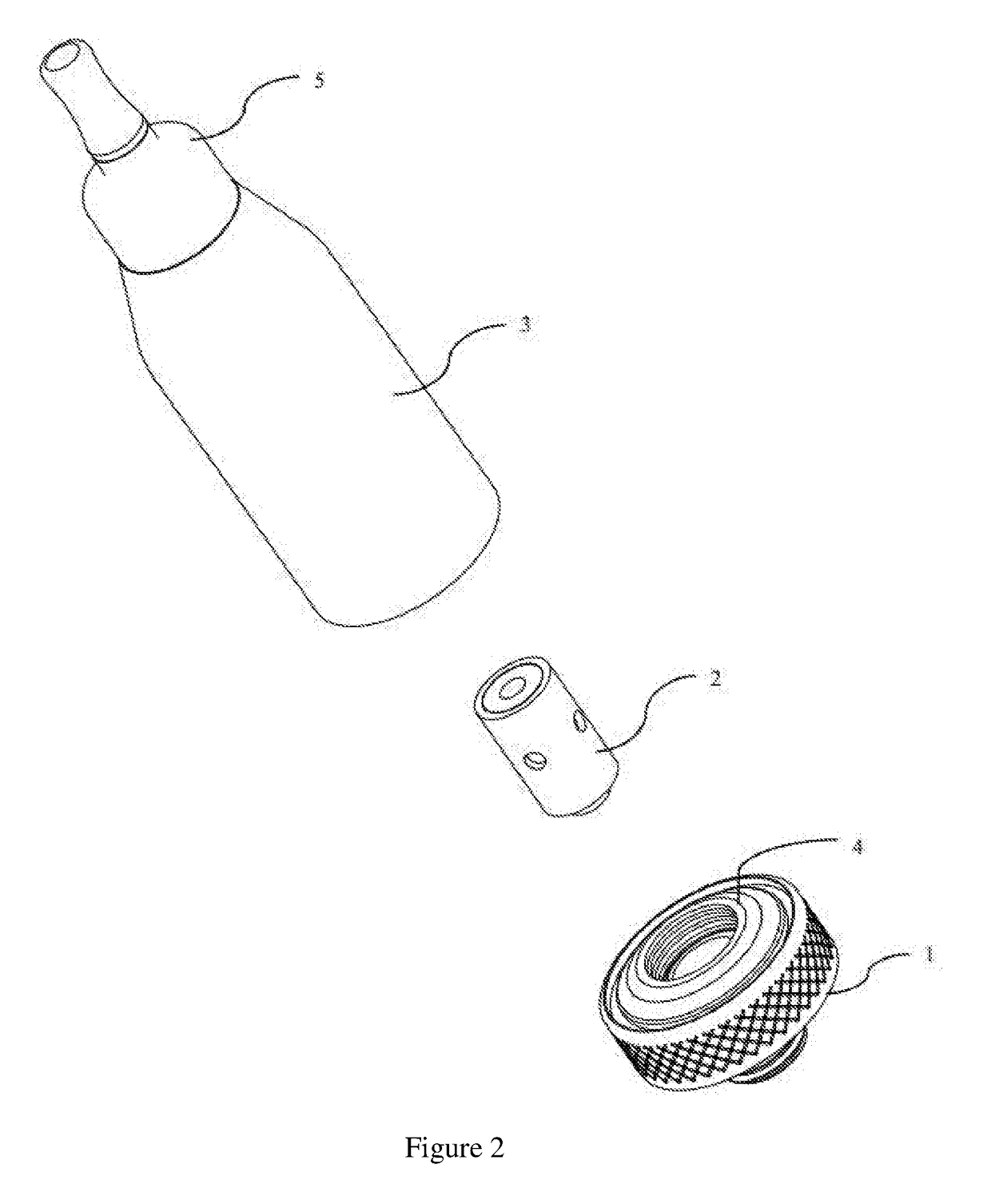

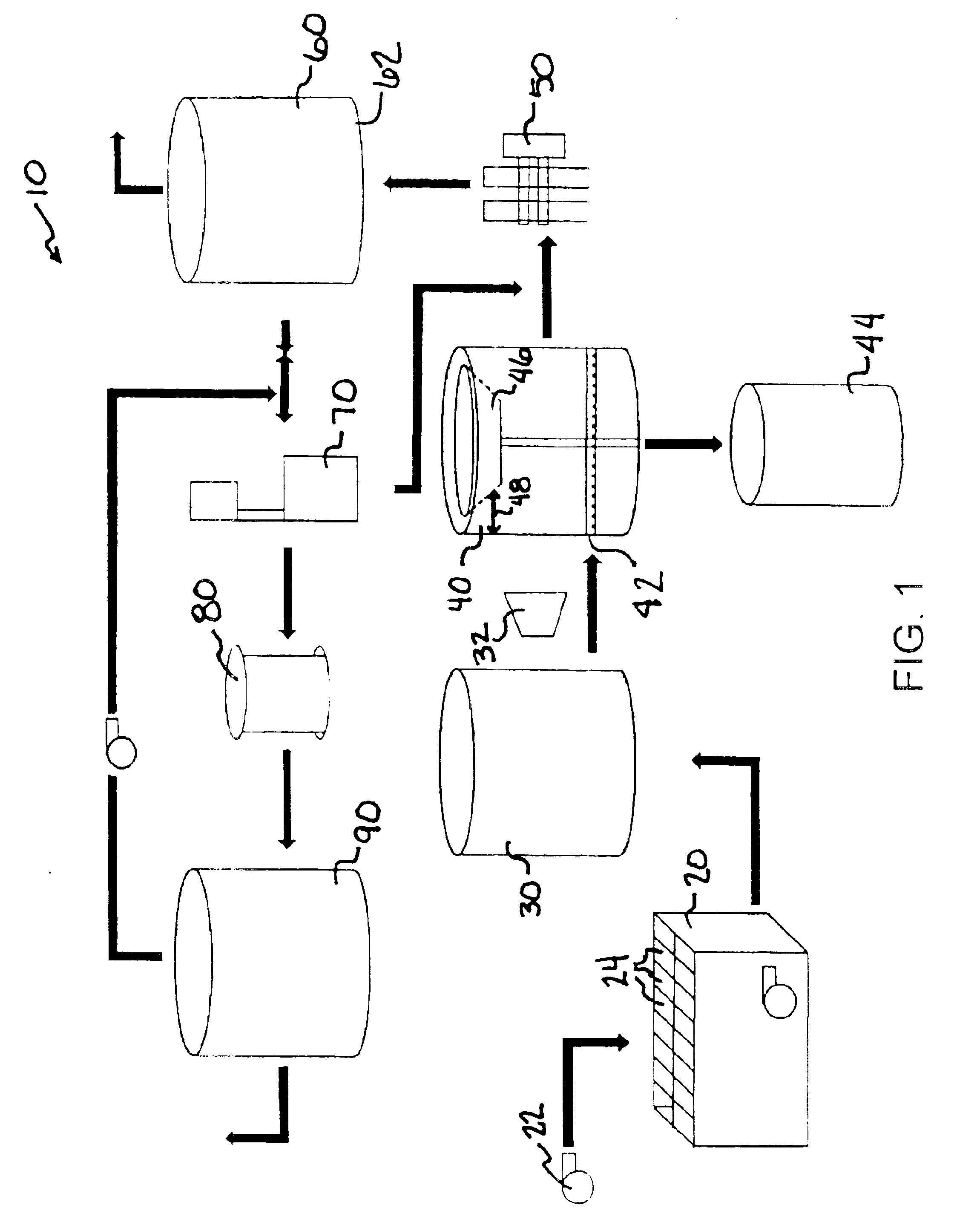

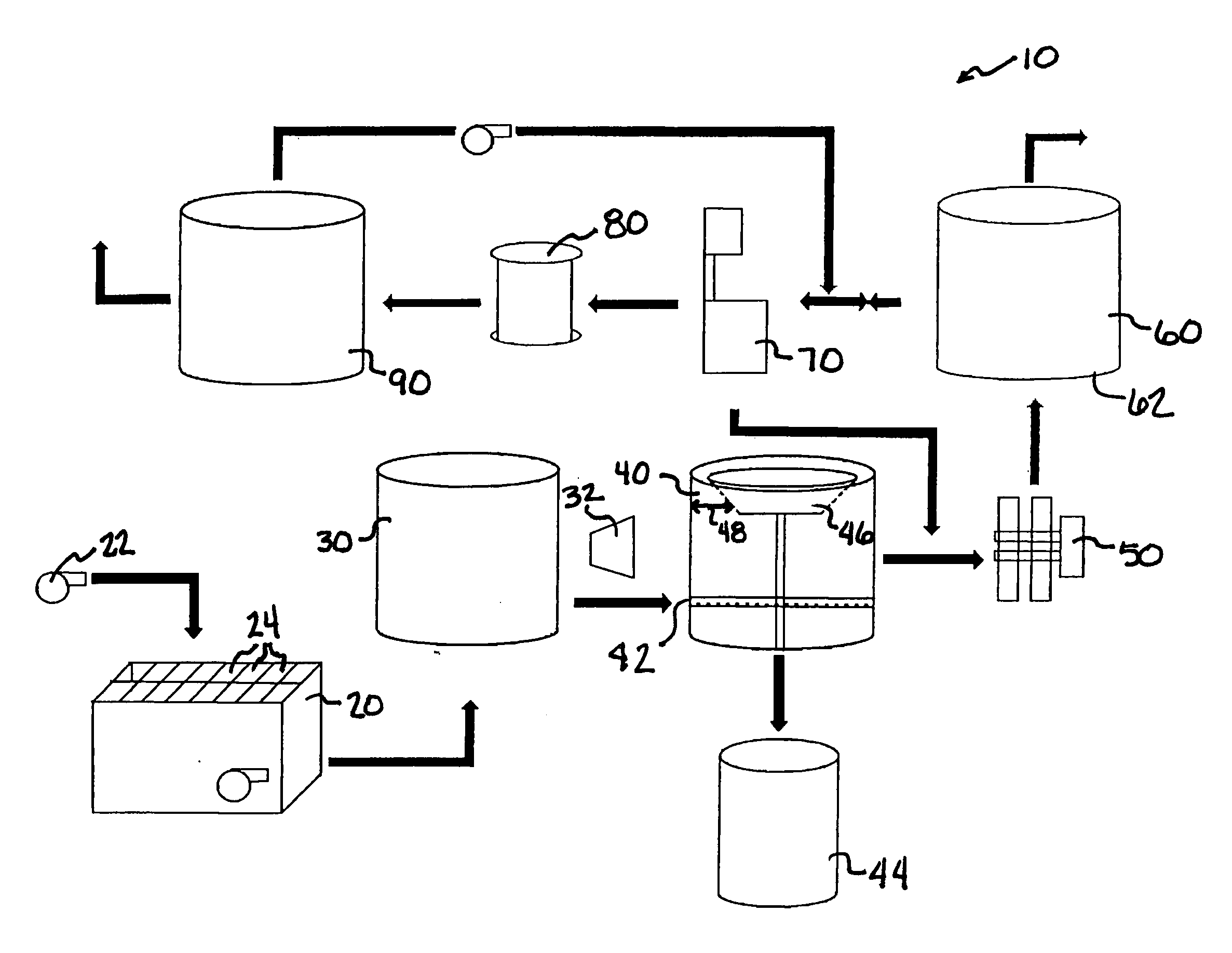

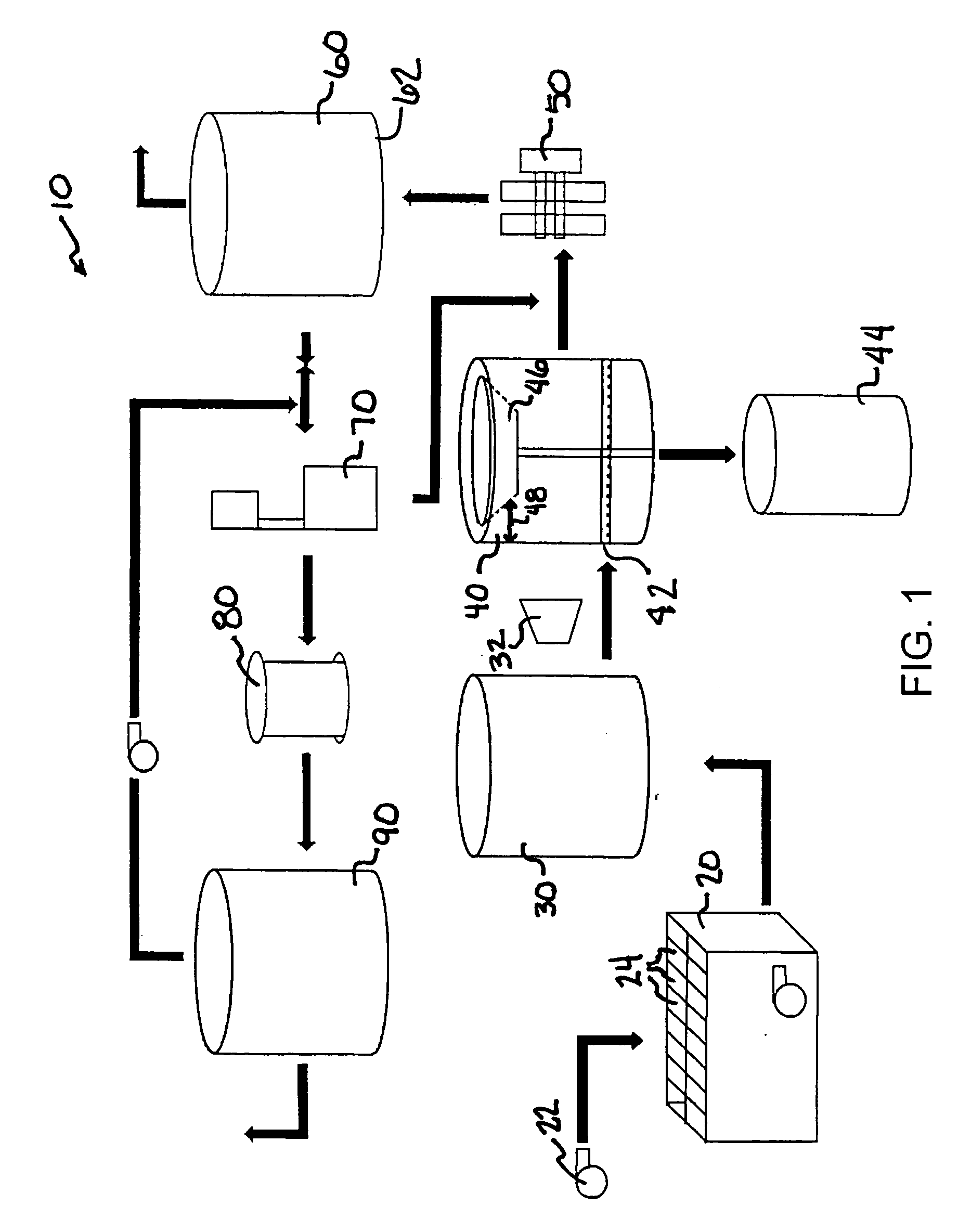

Bilge water reclamation system and process

InactiveUS6902678B2Reduce pollutantsEasy to processLiquid separation by electricityAuxillariesOil retentionBilge

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

Bilge water reclamation system and process

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

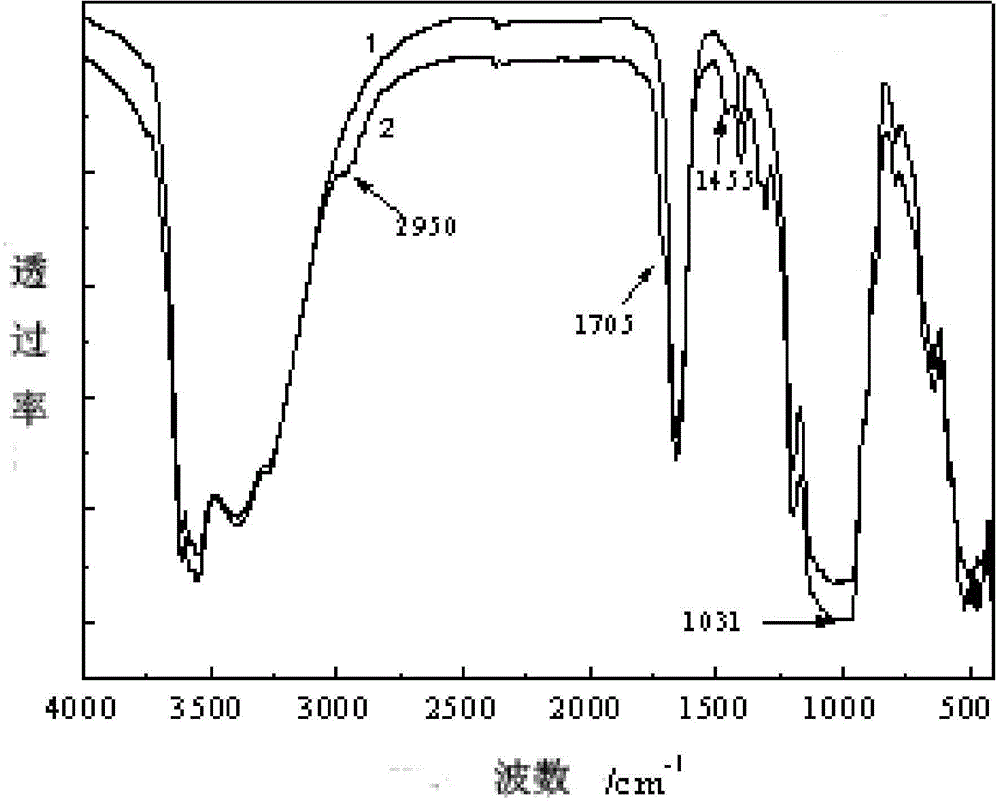

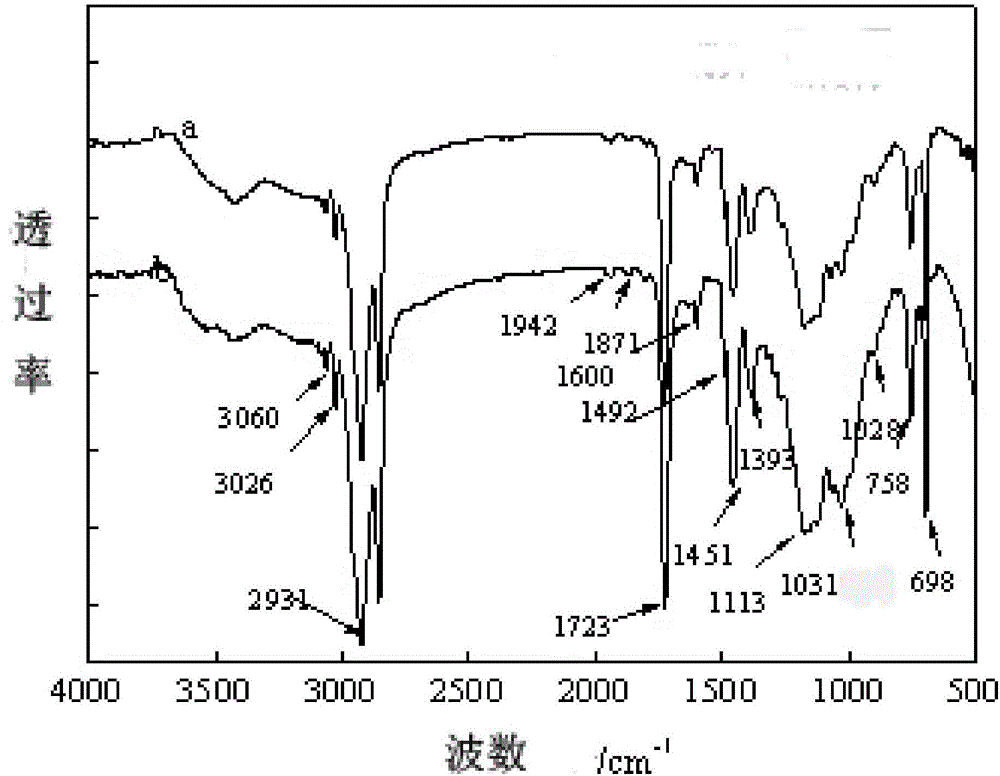

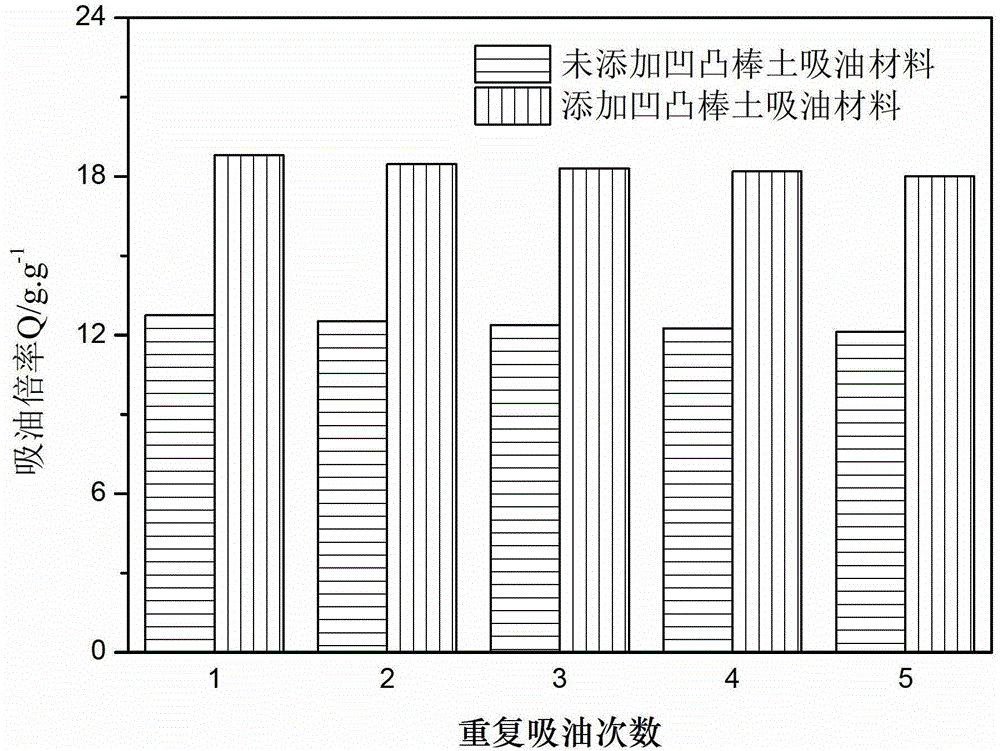

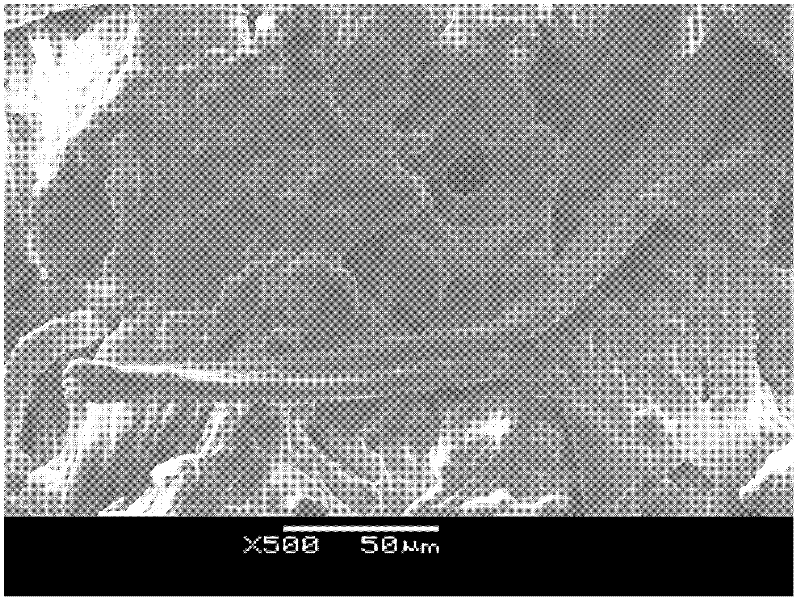

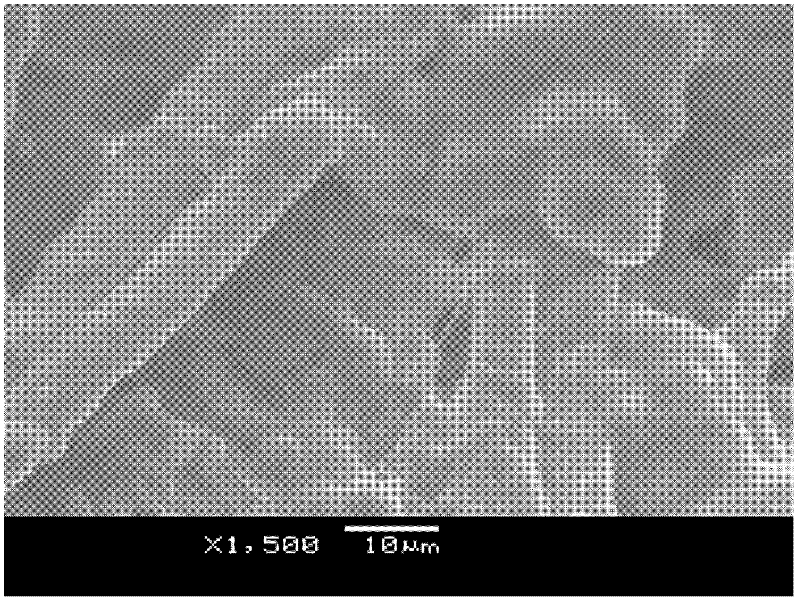

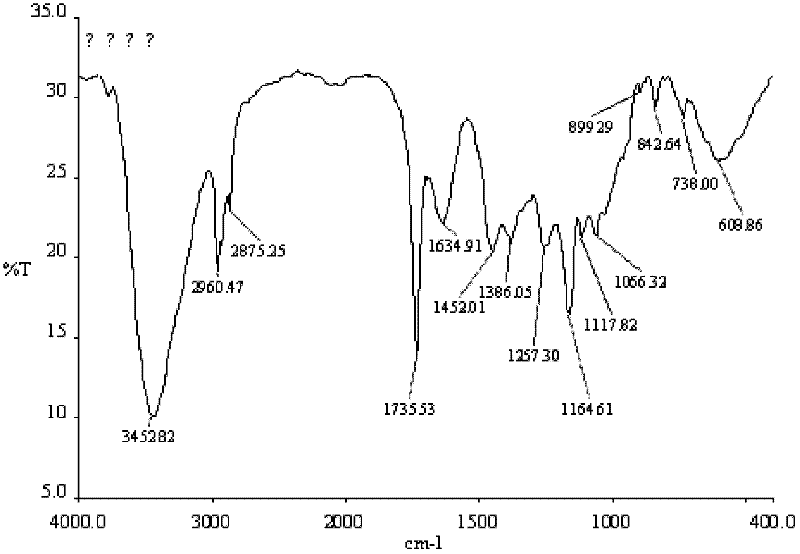

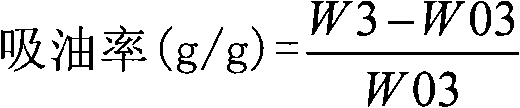

Acrylic ester-attapulgite composite oil-absorbing material and preparation method thereof

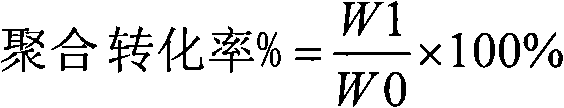

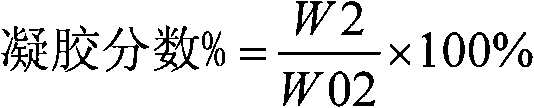

The invention relates to an organic-inorganic composite oil-absorbing material formed by compounding an acrylic ester monomer with attapulgite, and a preparation method thereof. The oil-absorbing material takes the following components as raw materials in parts by weight: 50-60 parts of acrylic ester, 35-50 parts of styrene, 0.5-2 parts of initiator, 0.2-1 part of cross-linking agent, 1-5 parts of dispersant and 1-10 parts of the attapulgite. The preparation method comprises the following steps of: based on a polyvinyl alcohol water solution as a reaction system, adding a mixed solution formed by uniformly mixing butyl methacrylate, styrene, the initiator, the cross-linking agent, and attapulgite under the protection of inert gas to react; and then washing to obtain the product. Compared with the traditional oil-absorbing material, the organic-inorganic composite oil-absorbing material has the advantages of high oil-absorbing multiplying power, oil retention rate and repeated oil-absorbing times, and has a potential application prospect on the aspect of environmental protection.

Owner:常熟紫金知识产权服务有限公司

Method for preparing oil absorption material by adopting straws as base materials

InactiveCN102344531AEfficient recyclingHigh oil absorptionOther chemical processesChemical recyclingCross-linkOil retention

The invention relates to a method for preparing an oil absorption material by adopting straws as base materials, which comprises the following steps of: grinding crop straws (maize straws, wheat straws, sorghum straws and the like) into block shapes; adding sodium hydroxide solution or dilute sulphuric acid solution; reflowing and stewing for 10min under the action of microwave, or reflowing in anormal pressure reactor for 3h; filtering, rinsing and drying to obtain straw powder; adding the straw powder into water; warning up under the protection of nitrogen; adding an initiating agent, a reaction monomer and a cross-linking agent; stirring and reacting; and filtering and drying to obtain the oil absorption material. According to the invention, the straws of agricultural solid residues are utilized as the base materials, suspension polymerization is adopted, and graft copolymerization is carried out on acrylic ester or styrene and the like, so that the biodegradable oil absorption material is prepared. The oil absorption material not only has the biodegradability of the straws, but also has the high oil absorption performance of long-chain acrylic ester, so that not only can the production cost be greatly reduced and the solid waste be effectively utilized, but also the density is low, and the effects of oil absorption and oil retention are good due to a special porous structure of the raw straw materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

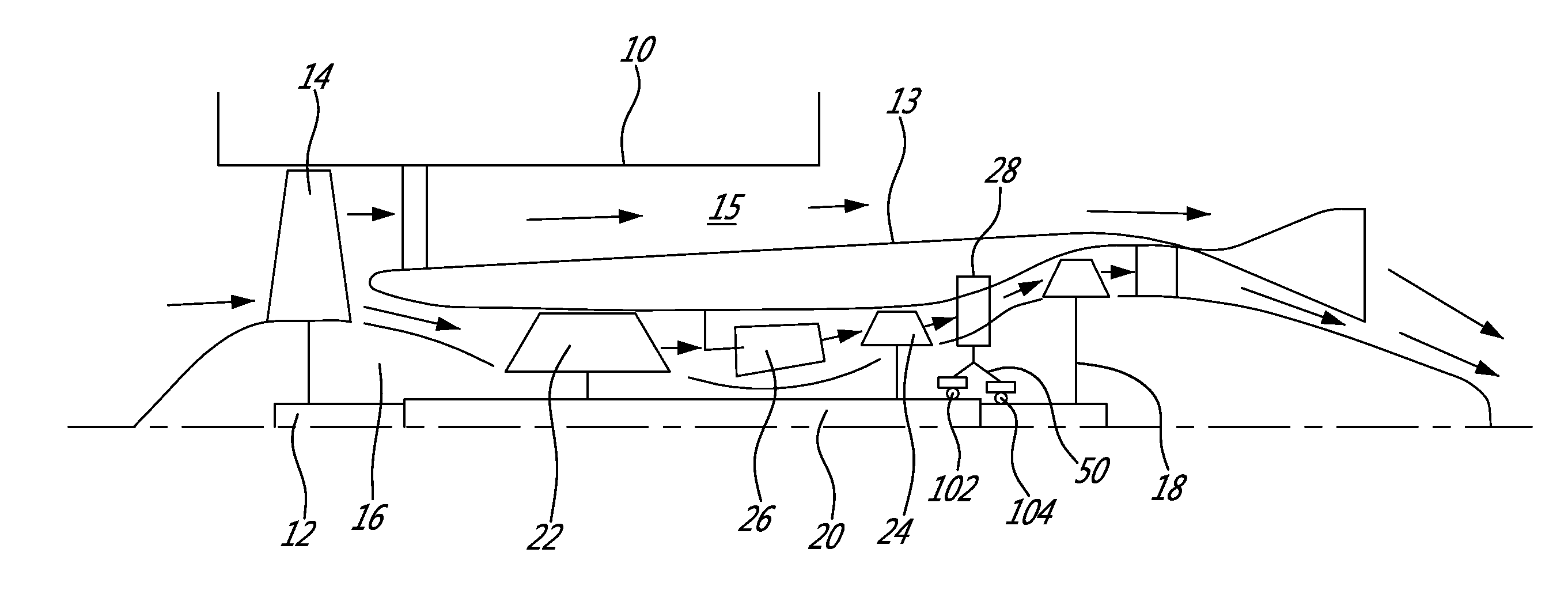

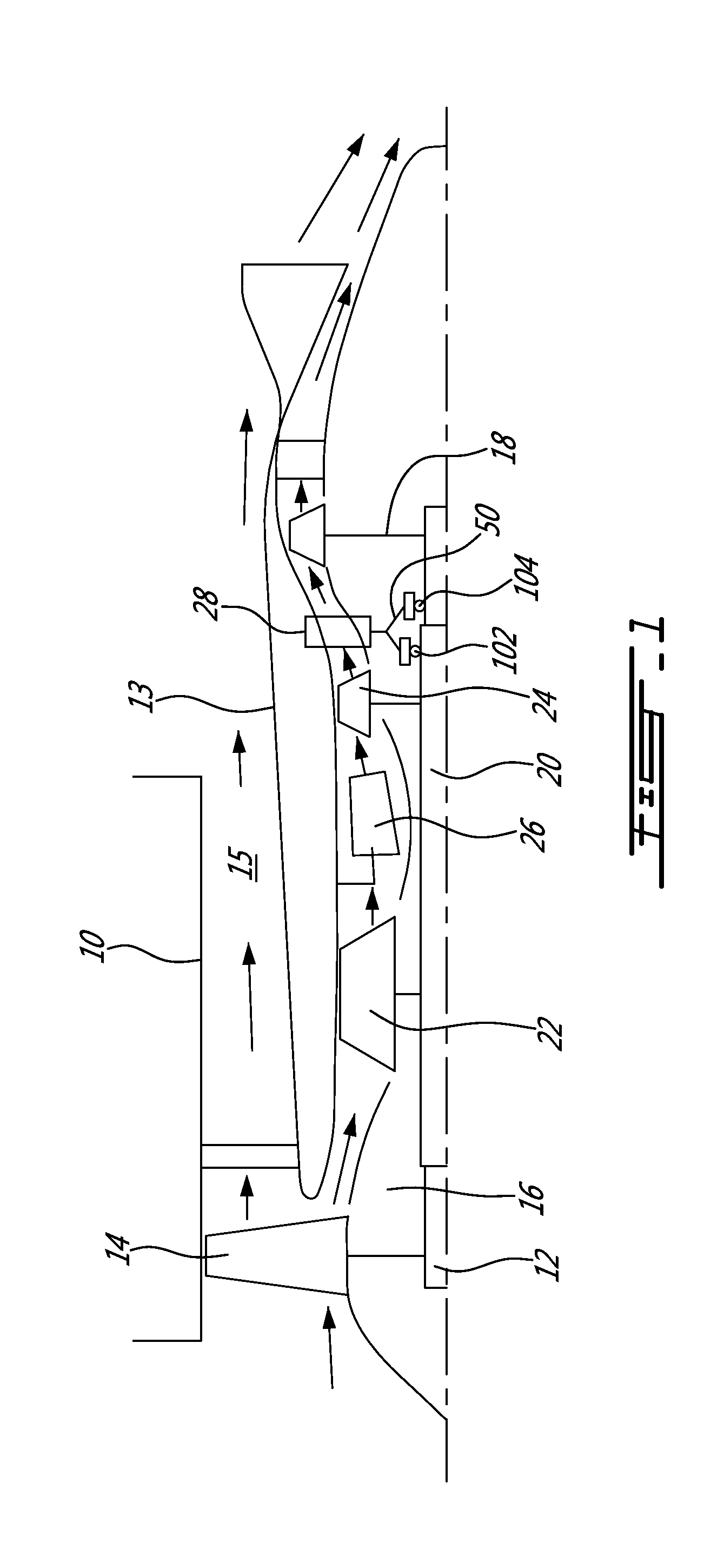

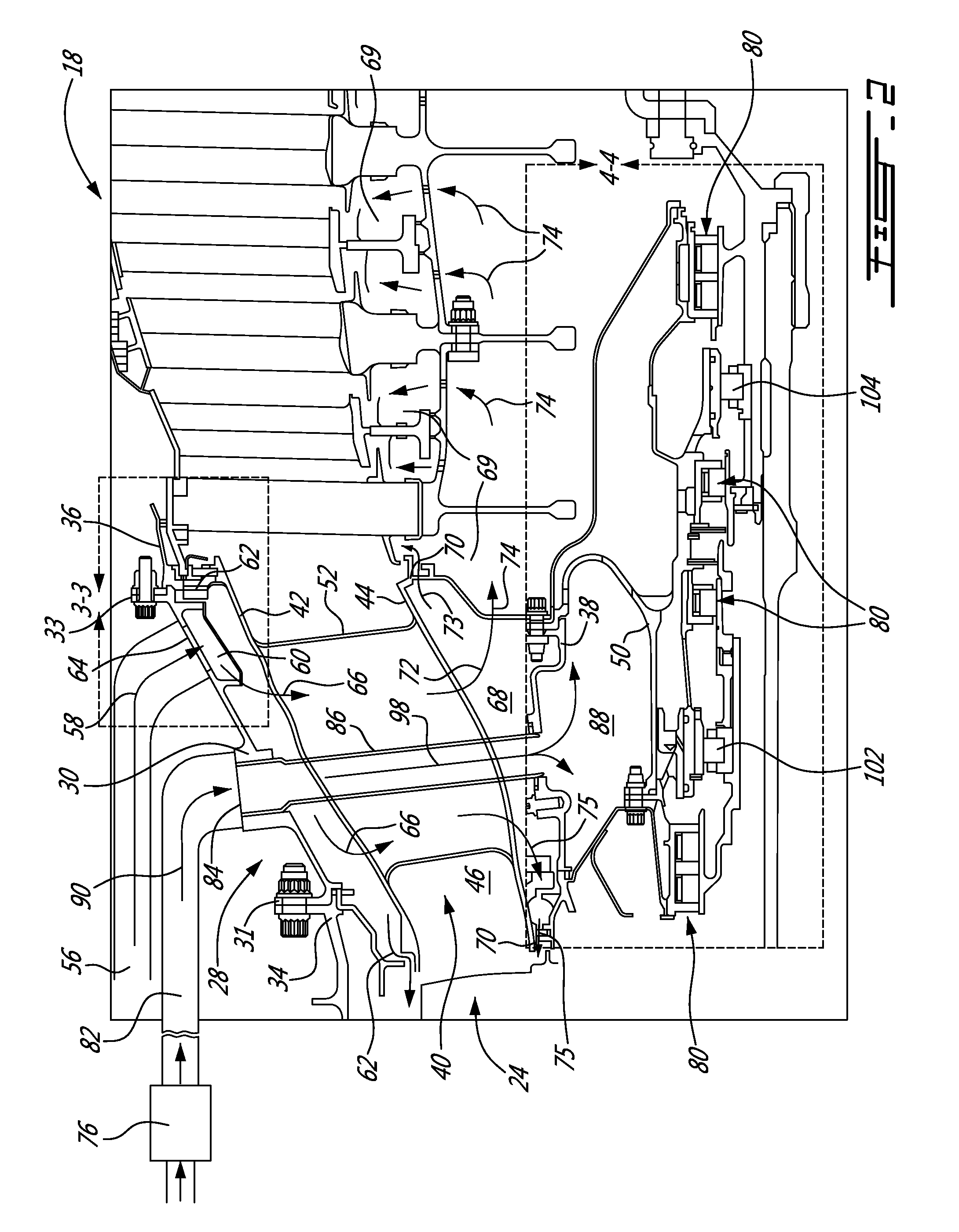

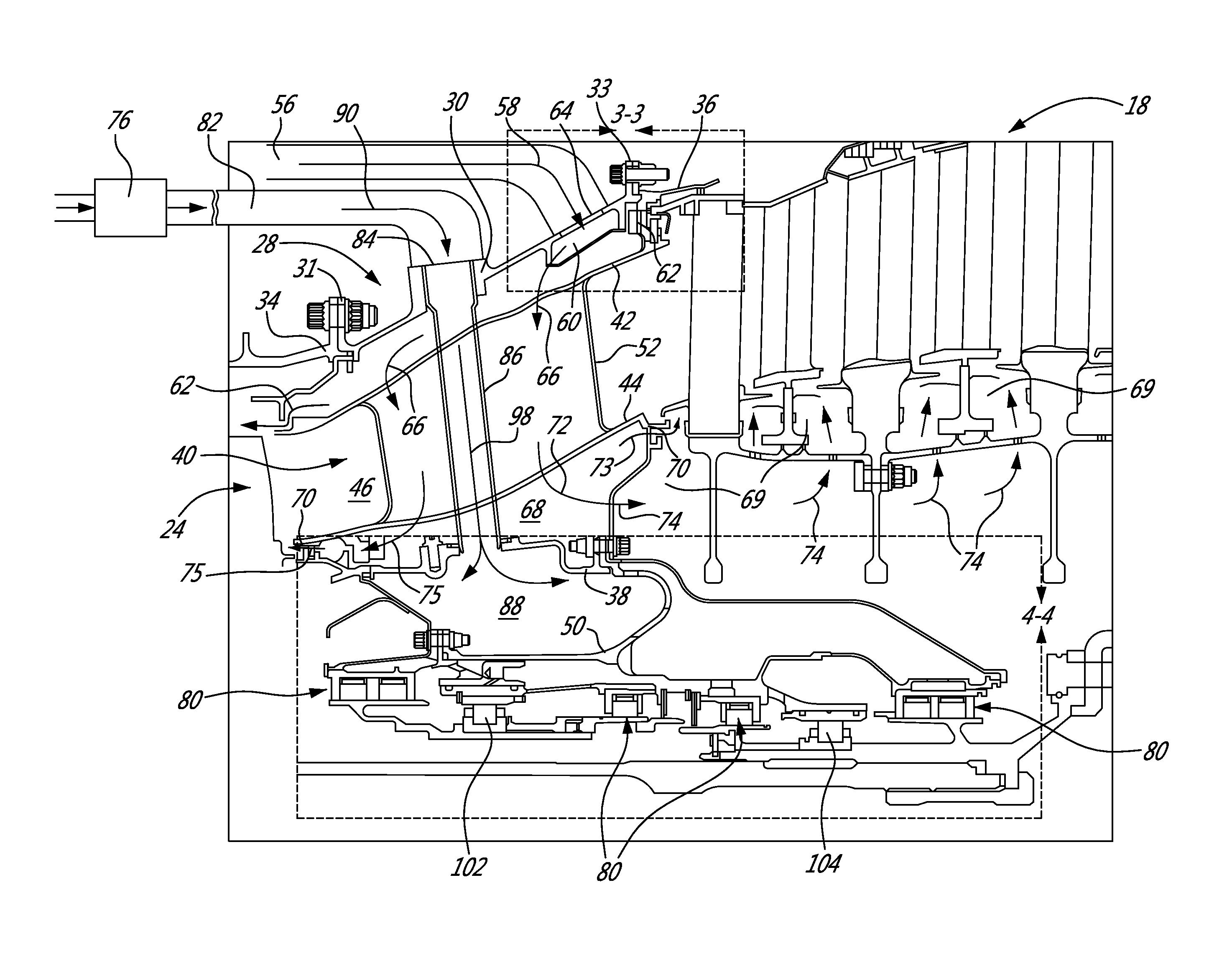

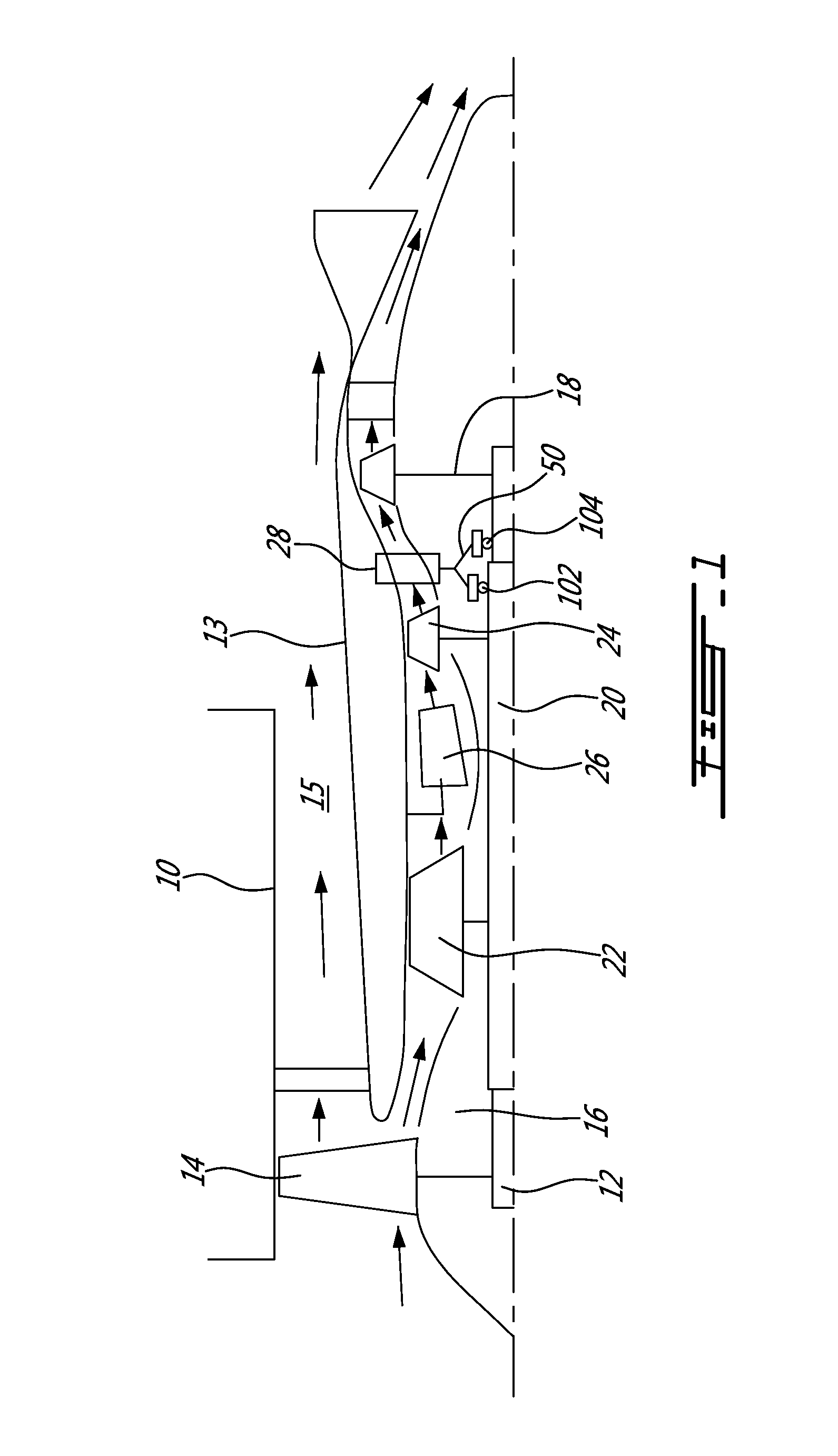

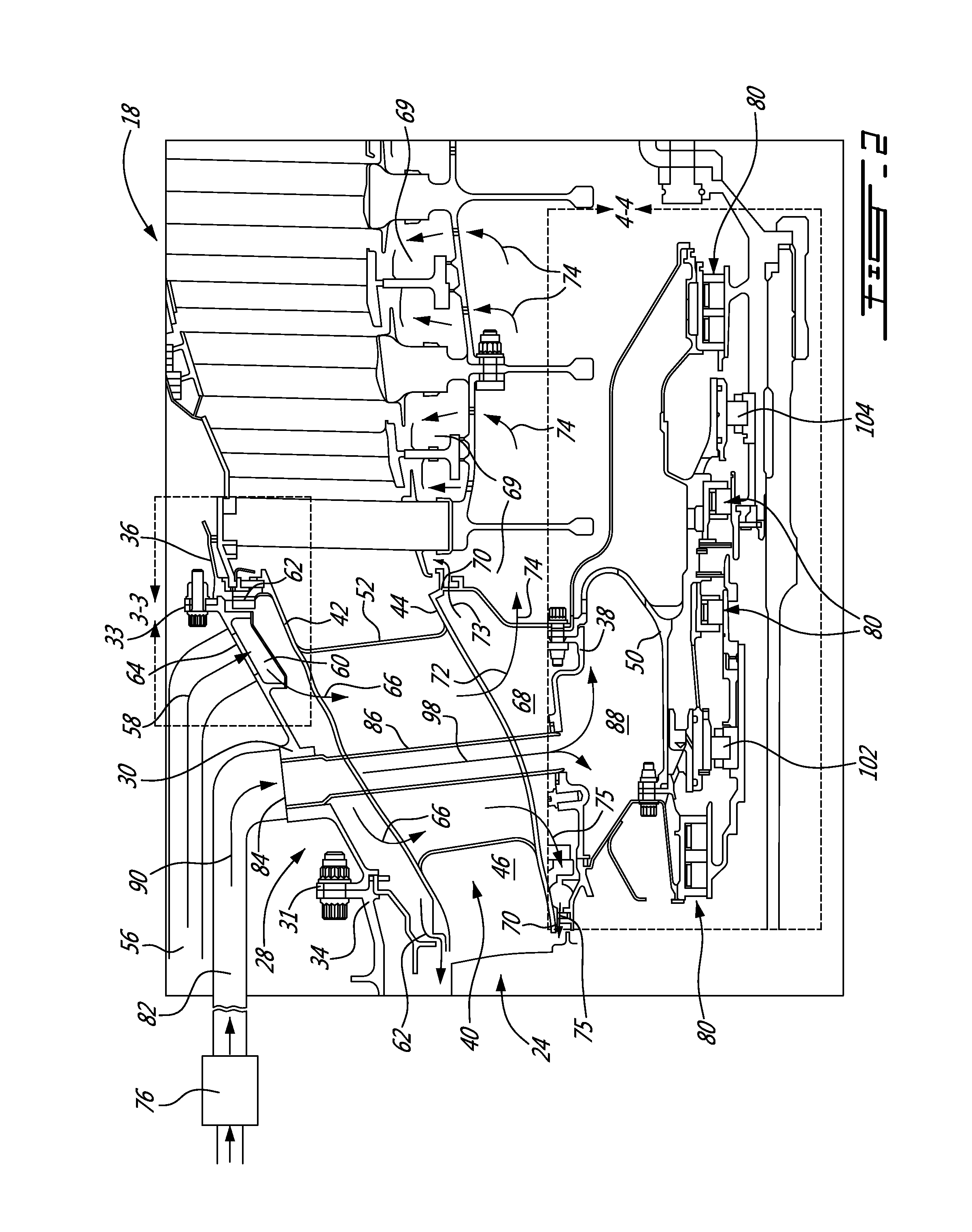

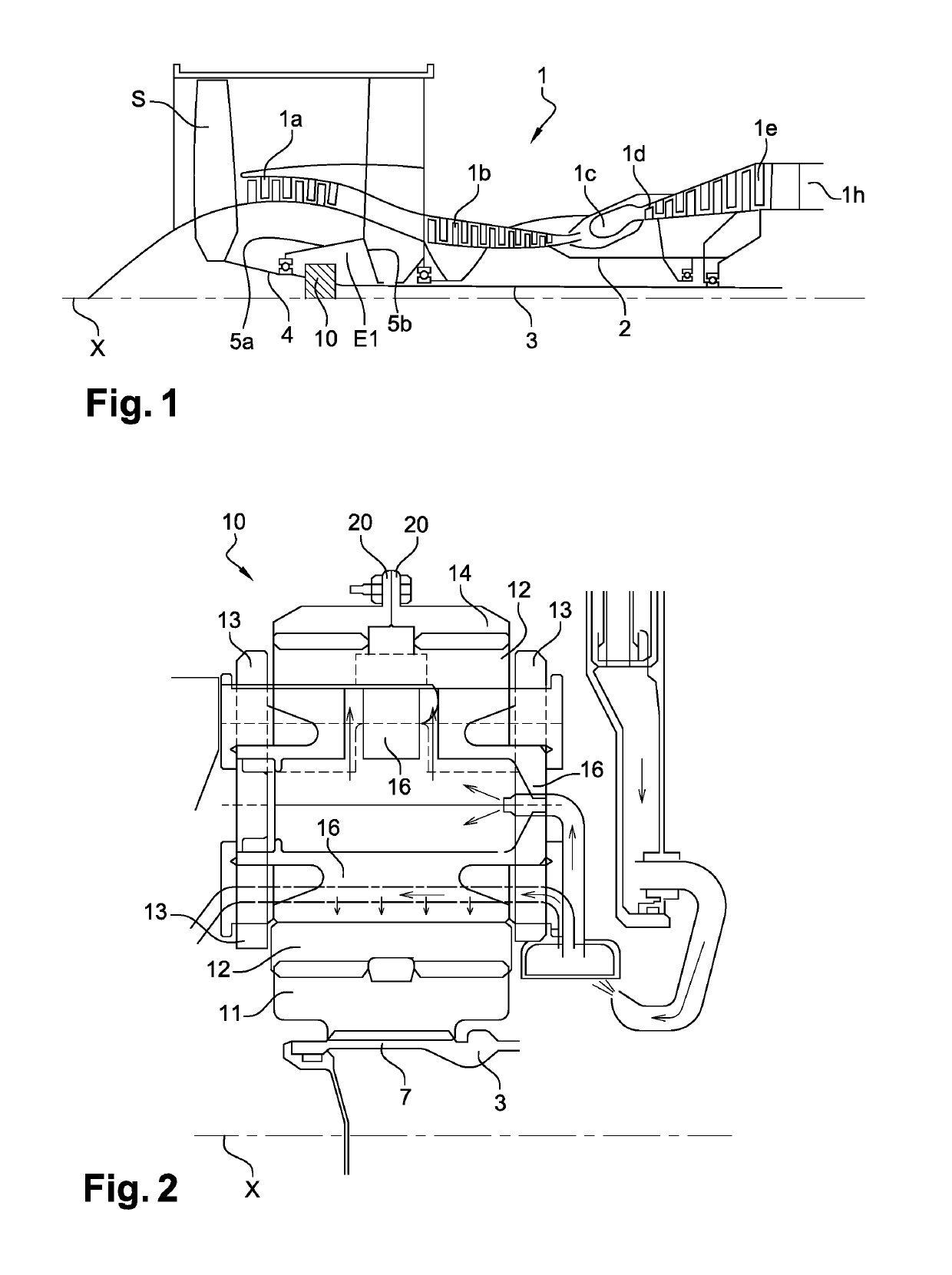

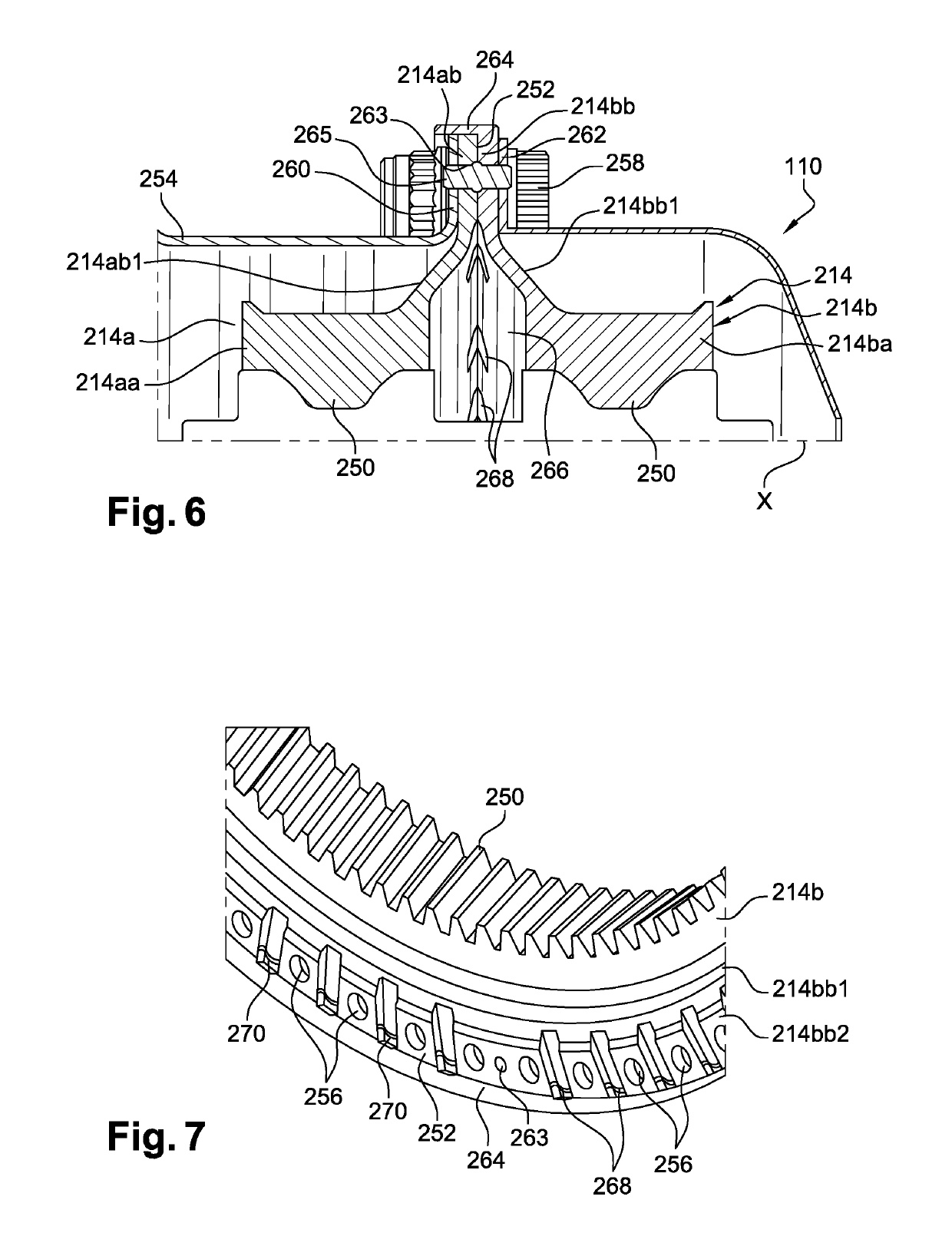

Air system architecture for a mid-turbine frame module

A mid-turbine frame is disposed between high and low pressure turbine assemblies. A secondary air system is defined in the mid-turbine frame (MTF) to provide cooling to the turbine section of the engine. The secondary air system may be used to cool and pressurize seals to assist with oil retention in bearing cavities. The temperature gain of the secondary air may be reduced by flowing the secondary air through one or more external lines and then generally radially inwardly through air passages defined in the MTF.

Owner:PRATT & WHITNEY CANADA CORP

Air system architecture for a mid-turbine frame module

A mid-turbine frame is disposed between high and low pressure turbine assemblies. A secondary air system is defined in the mid-turbine frame (MTF) to provide cooling to the turbine section of the engine. The secondary air system may be used to cool and pressurize seals to assist with oil retention in bearing cavities. The temperature gain of the secondary air may be reduced by flowing the secondary air through one or more external lines and then generally radially inwardly through air passages defined in the MTF.

Owner:PRATT & WHITNEY CANADA CORP

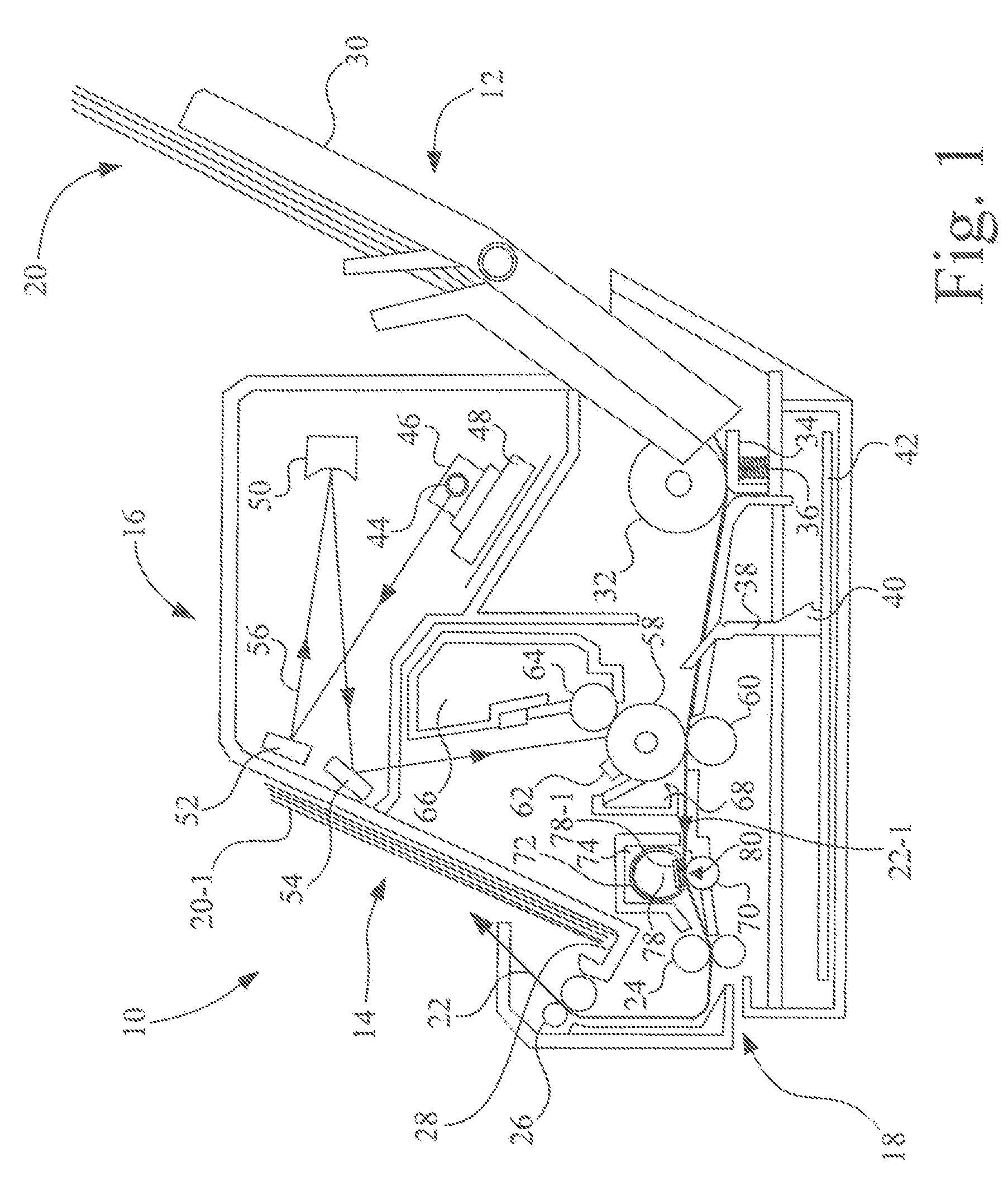

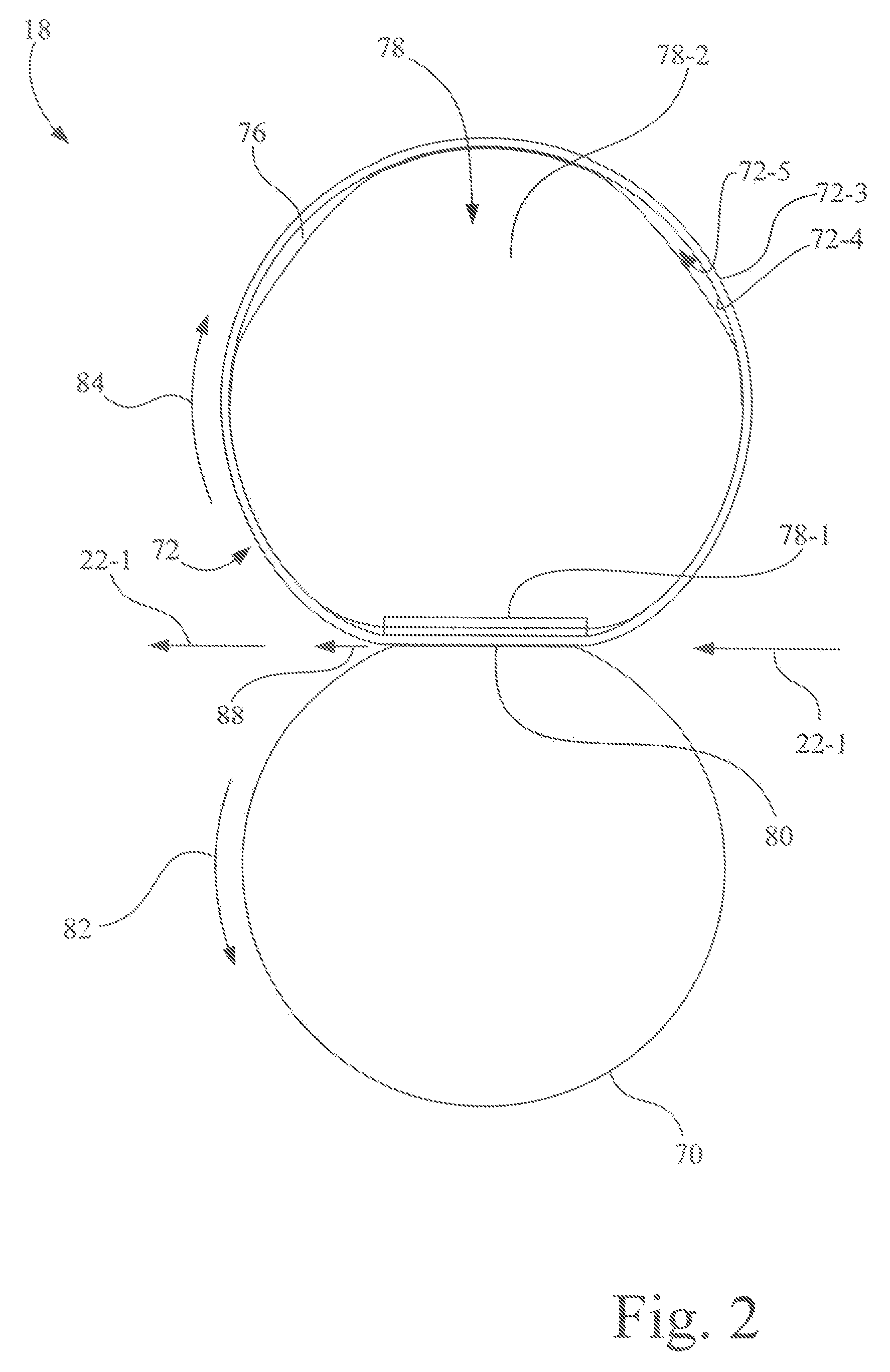

Fuser assembly having oil retention features

A fuser assembly includes a first end cap, and a second end cap spaced apart from the first end cap along an axis orthogonal to a sheet feed direction. A fuser belt is positioned between and supported by the first end cap and the second end cap to rotate around the axis in a belt moving direction at the nip corresponding to the sheet feed direction. A heater assembly is located in the hollow interior of the fuser belt. A plurality of ribs is positioned to contact the interior surface of the fuser belt. A first rib is connected to one of the first end cap and the heater assembly. A second rib is connected to one of the second end cap and the heater assembly. Each of the plurality of ribs is oriented to longitudinally extend at an acute angle with respect to the belt moving direction.

Owner:LEXMARK INT INC

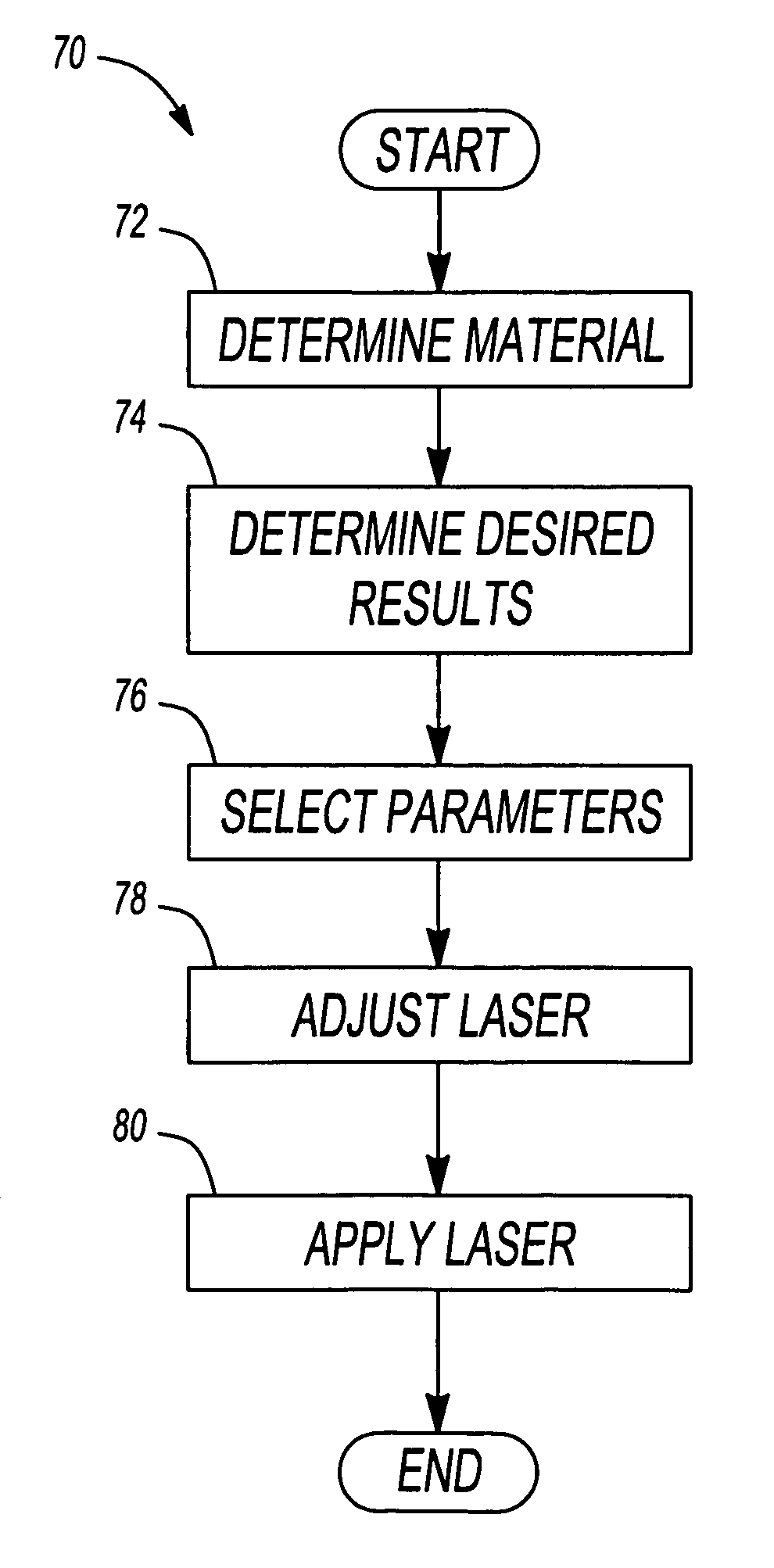

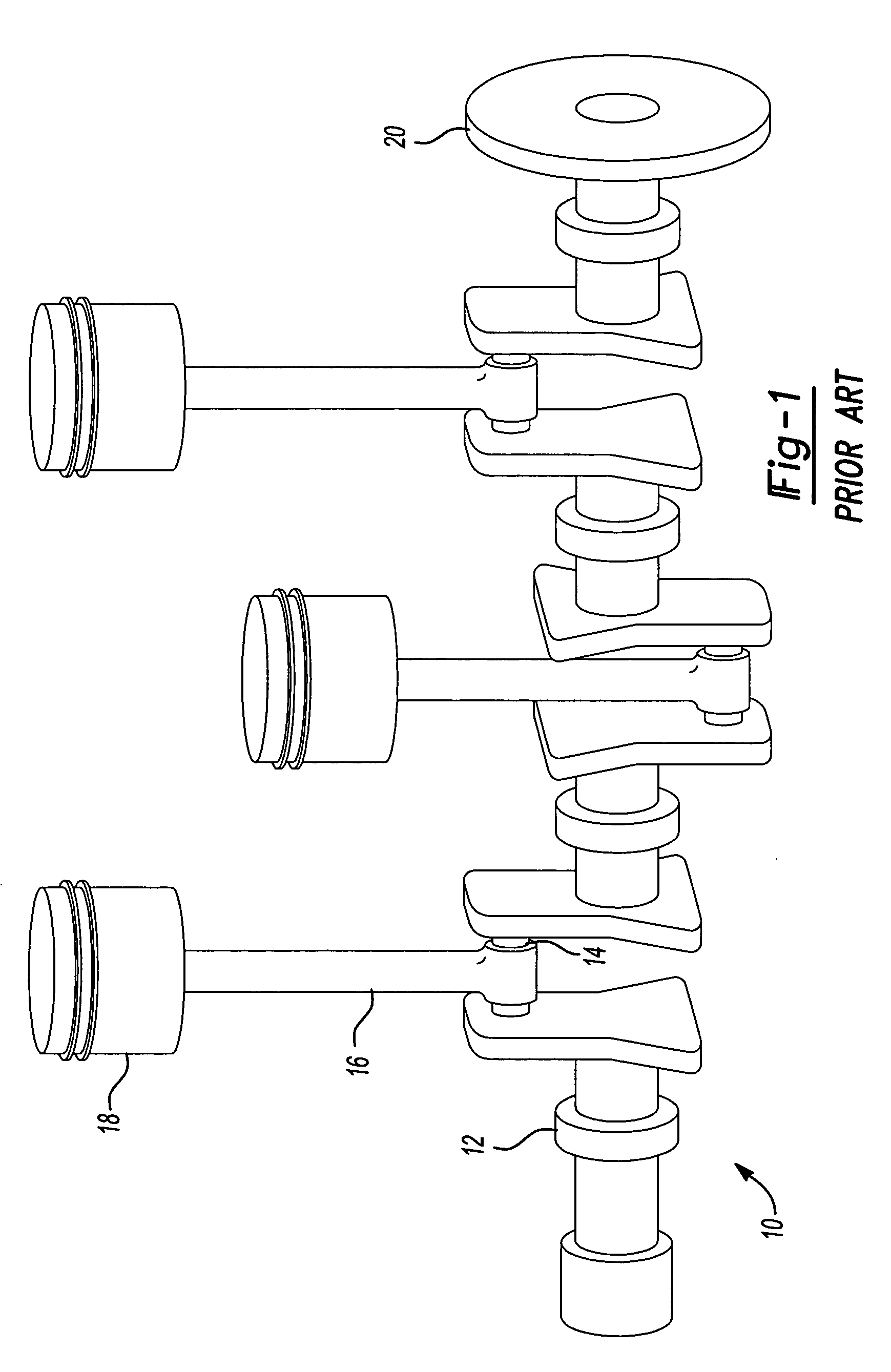

Manufacturing method that uses laser surface transformation to produce new and unique surface profiles for rotating bearings

ActiveUS20060138100A1Semiconductor/solid-state device manufacturingPhotosensitive material processingOil retentionEarth surface

A laser ablation method is used to polish a bearing surface of an automotive crankshaft. A laser ablation device generates a laser according to parameters such as wavelength, pulse duration, pulse repetition rate, and beam quality. The laser is applied to the surface of a rotating engine component, such as a crankshaft, as the component is rotated in order to polish the surface according to the parameters. The laser substantially improves tribological performance of the bearing surface by changing the waviness and form of the surface profile. Further, oil-retention reservoirs are formed in the surface. As a result, the friction coefficient of the crankshaft surface is reduced while the roughness of the crankshaft surface is maintained, reduced, or increased.

Owner:ADCOLE CORP +1

Sugar free / non-cariogenic encapsulation matrix

InactiveUS20120231122A1Improve performanceIncrease loadDough treatmentConfectioneryOil retentionCarba mix

Provided herein are emulsifier and non-digestible carbohydrate mixtures for sugar free / non-cariogenic encapsulation applications. A multi-component matrix that provides superior performance including emulsification, viscosity, and processability for spray drying is utilized. The resulting microcapsules with high loading showed high oil retention, low surface oil, and good oxidation resistance.

Owner:CORN PROD DEV INC

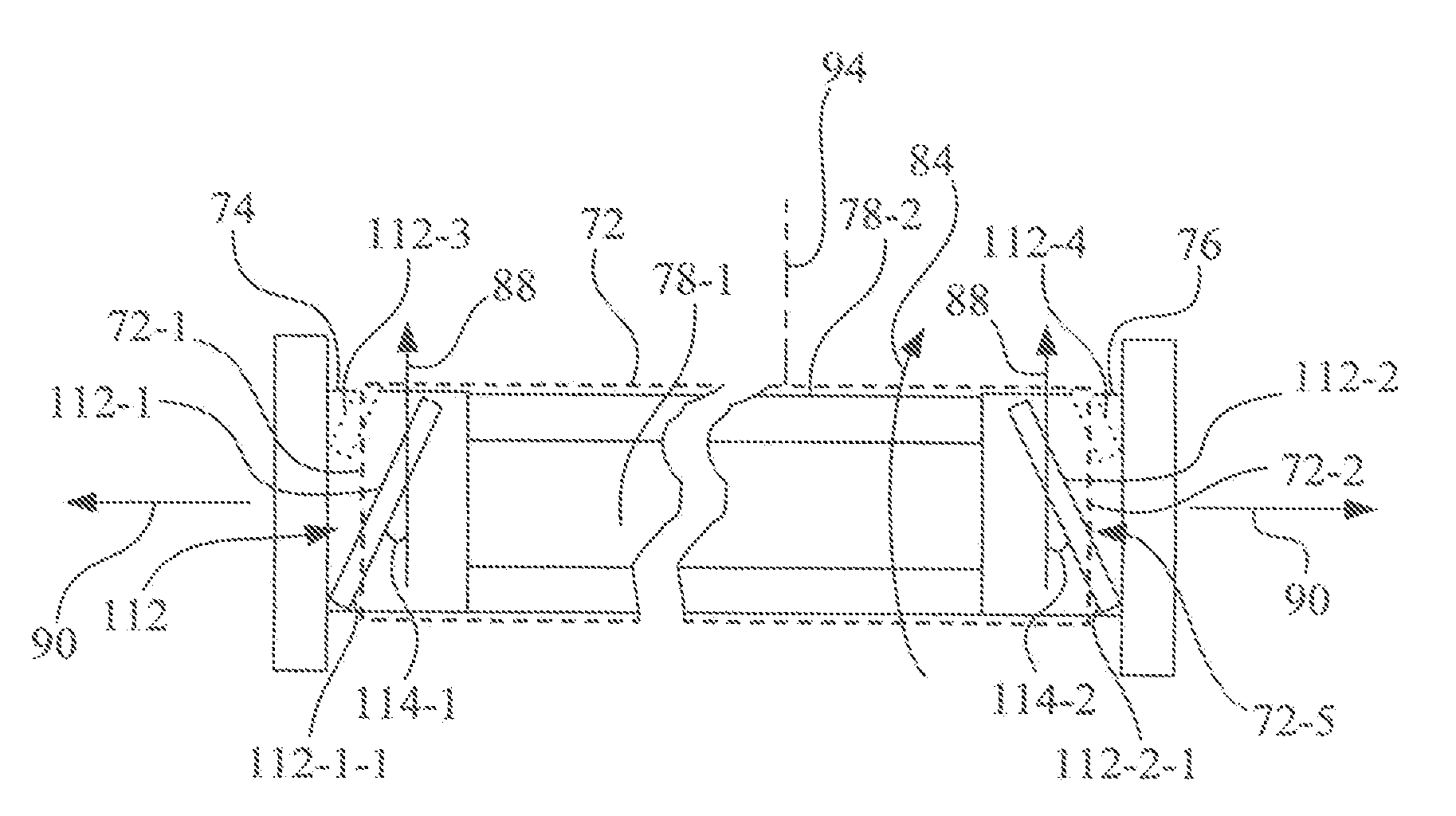

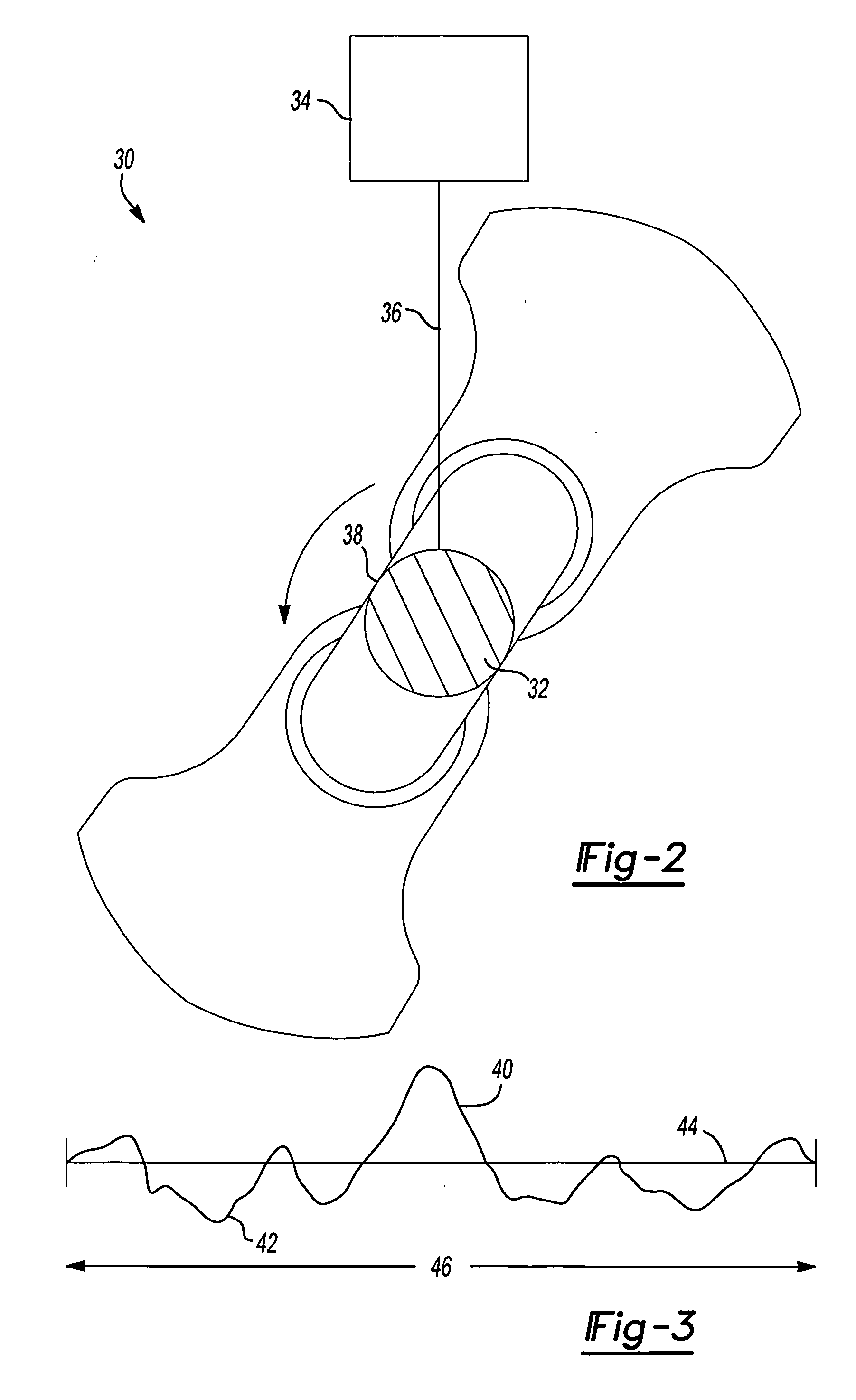

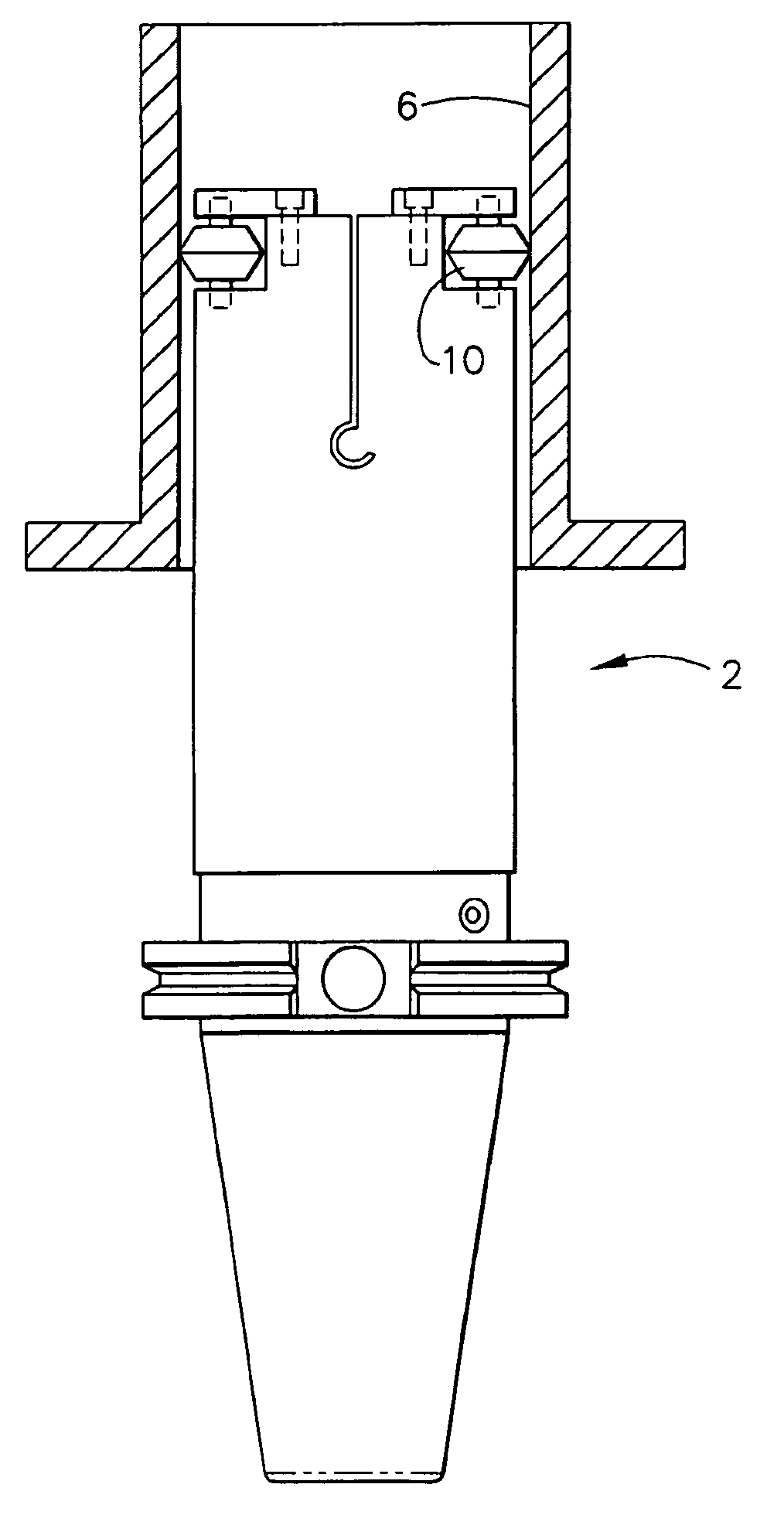

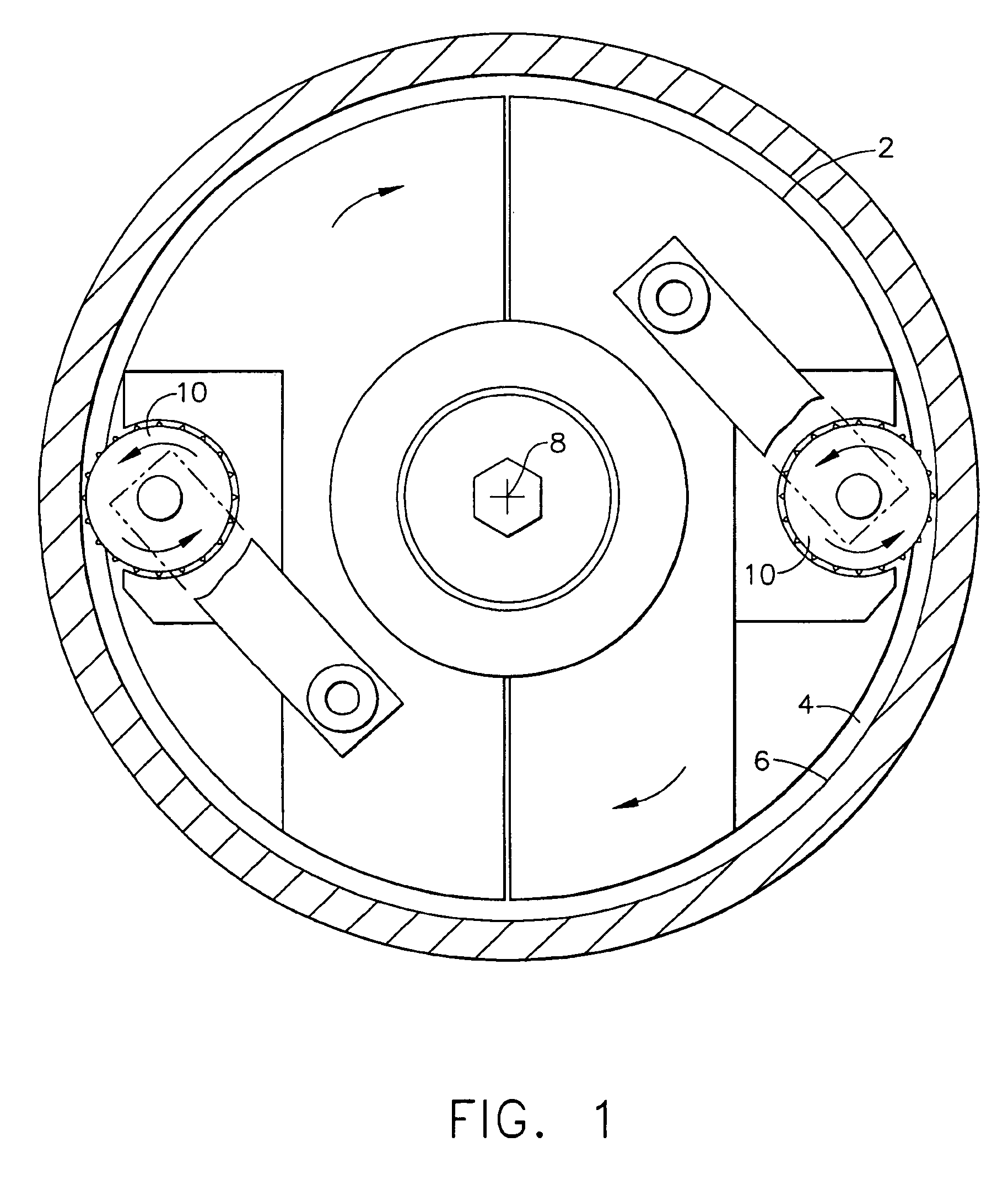

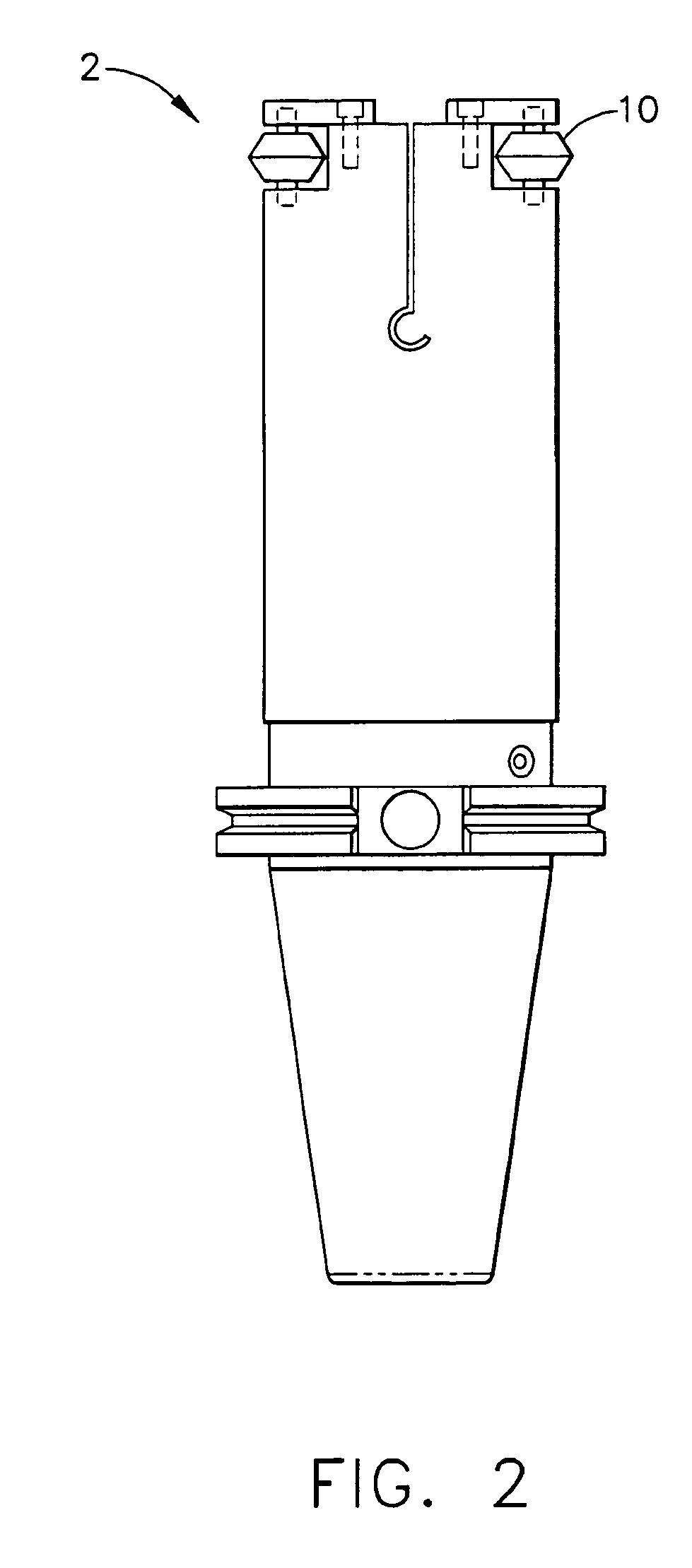

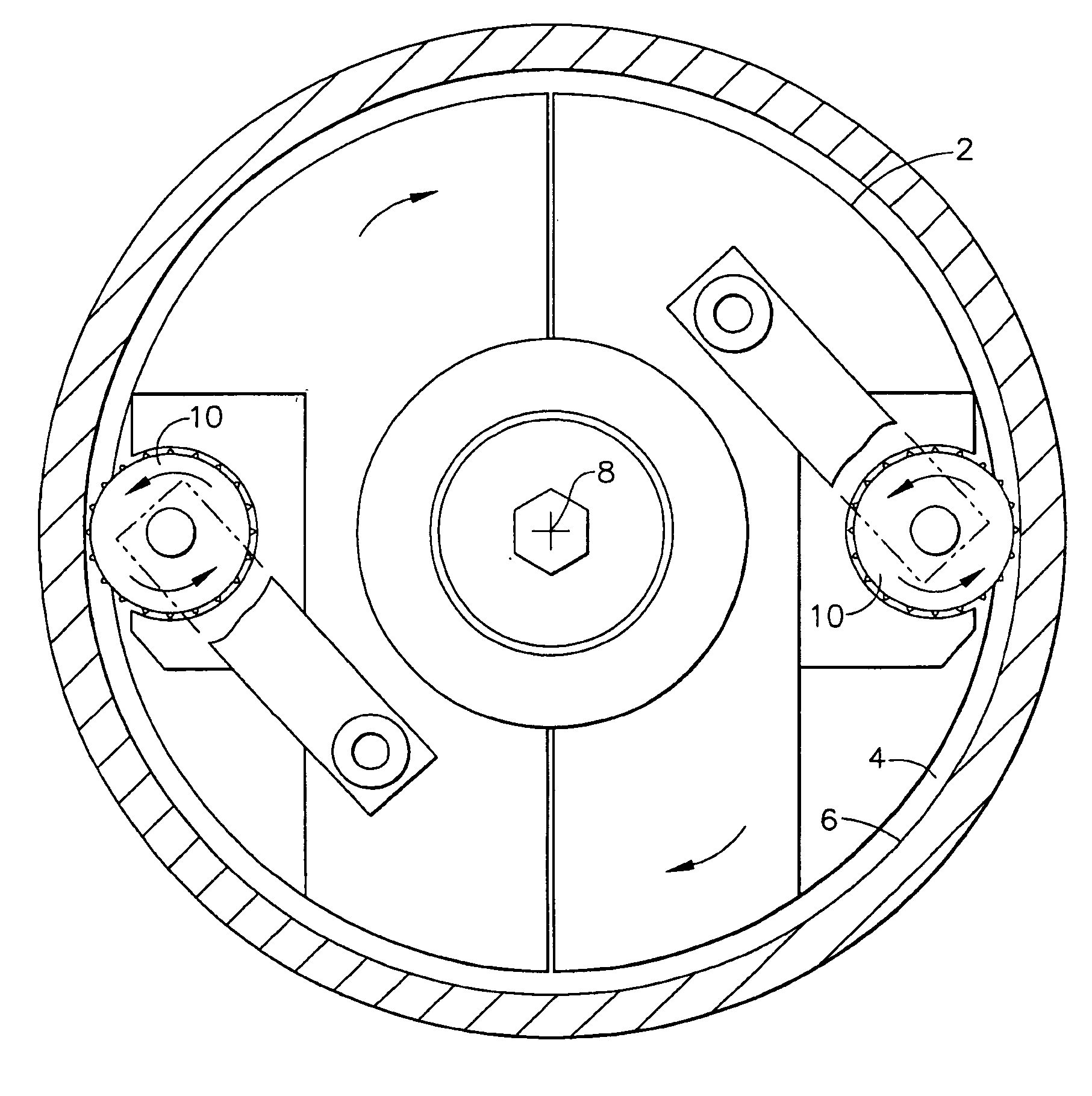

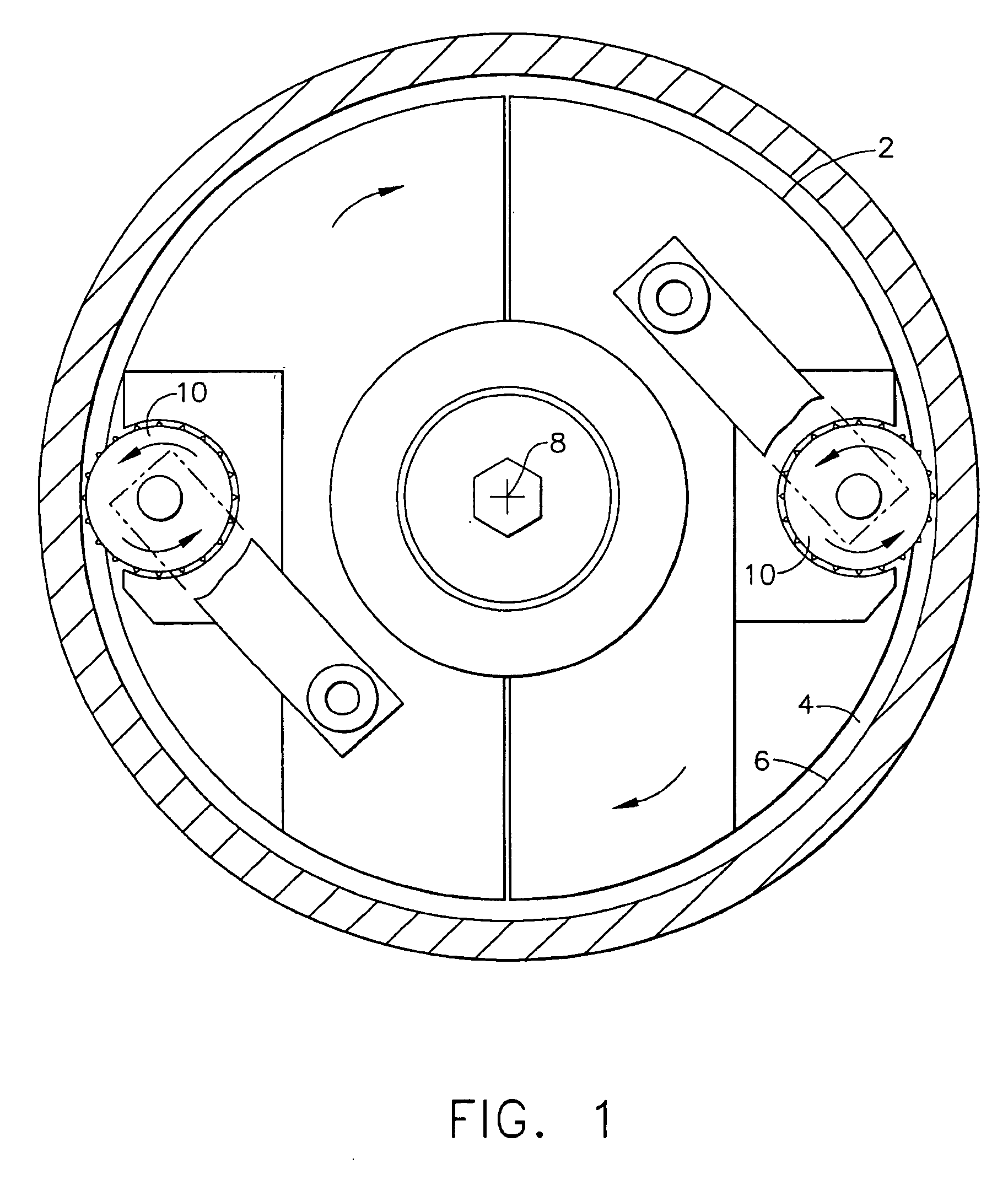

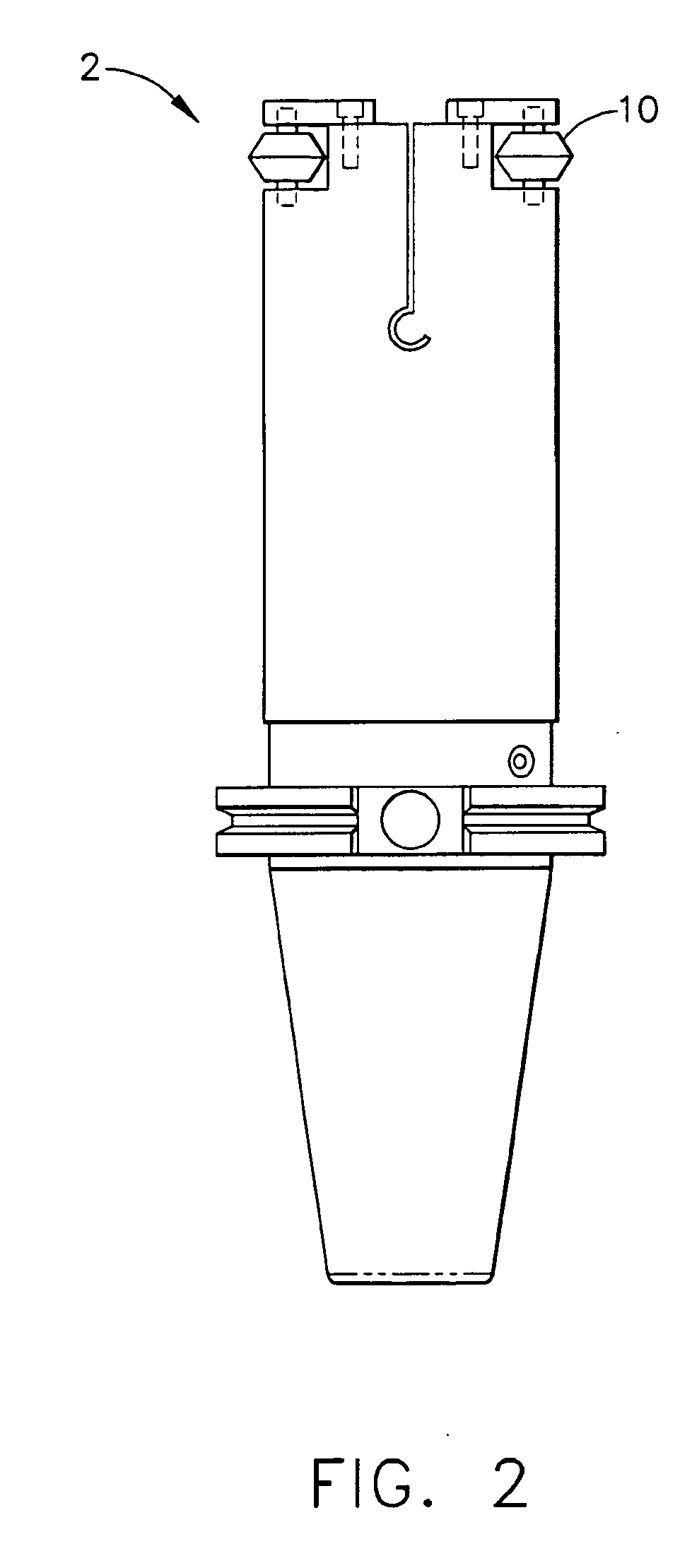

Method and apparatus for patterning of bore surfaces

An apparatus comprises a rotating member having one or more rollers. The one or more rollers have a plurality of protuberances. The rollers may be advanced toward a surface during rotation of the rotating member, such as toward a bore surface. The protuberances are configured to make a pattern of discrete indentations in the surface upon engagement of the protuberances with the surface. The apparatus is particularly suited for creating oil-retention pockets in the surface of an engine cylinder and other uses. The apparatus may be used to create a pattern of oil-retention pockets or other pockets in a cylinder with varying pocket density in a single pass.

Owner:MAKINO MILLING MASCH CO LTD

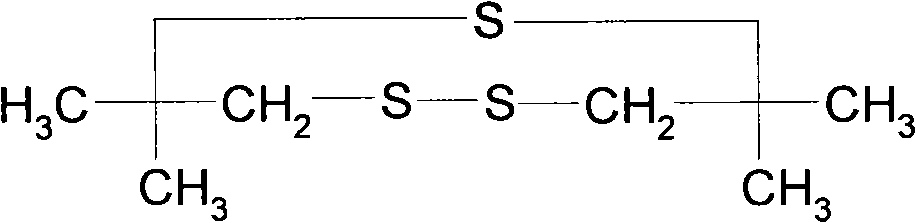

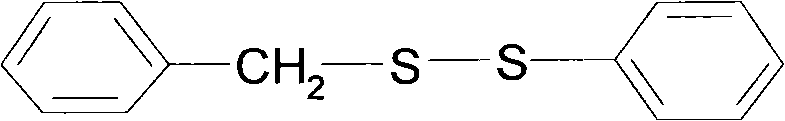

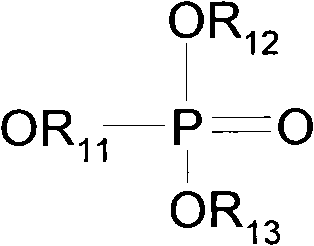

Refrigerator oil composition

InactiveCN102485871ALow content of non-ideal componentsImprove stabilityLubricant compositionOil retentionRefrigerated temperature

The invention relates to a refrigerator oil composition. According to the invention, deep hydrorefined cycloalkane-based base oil and / or paraffin-based mineral oil is adopted as a base oil; a sulfur type, a phosphorus type or a sulfur-phosphorous type anti-scuff agent which takes 1.0-2.5% of every gram of the base oil by weight, and a silicon type, a non-silicon type or a composite type anti-foaming agent which takes 5-25mug of every gram of the base oil by weight are added to the base oil. The refrigerator oil composition provided by the invention has a good pour point depression and dewaxing effect, an excellent fluidity, and a low wax precipitation tendency. A pour point of the base oil with a kinematical viscosity of 35-45mm<2> / s under a temperature of 40 DEG C can be lower than -45 DEG C, and a floc point can be reduced to a value below -42 DEG C. Therefore, heat transferring efficiency reduction caused by refrigerator oil retention at low-temperature positions such as a compressor expansion valve or an evaporator can be prevented. The refrigerator oil composition has sulfur and nitrogen content below 10ppm, a %CA value close to 0, arene content below 1%, and excellent heat / chemical stability and corrosion resistance. With the refrigerator oil composition, a high-power air-conditioner compressor with R22 (monochlorodifluoromethane) as a refrigeration agent can stably operate for a long time.

Owner:PETROCHINA CO LTD

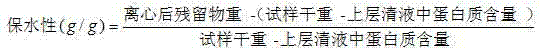

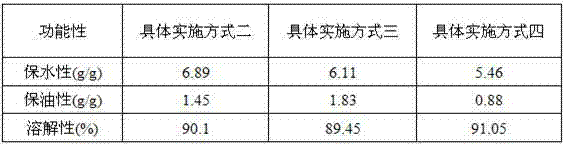

Method of improving solubility, water retention and oil retention of soy protein isolate by utilizing ultra-high pressure homogenization combined with enzymatic modification

InactiveCN104489240AEnsure safetyKeep the flavorVegetable proteins working-upSolubilityOil retention

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

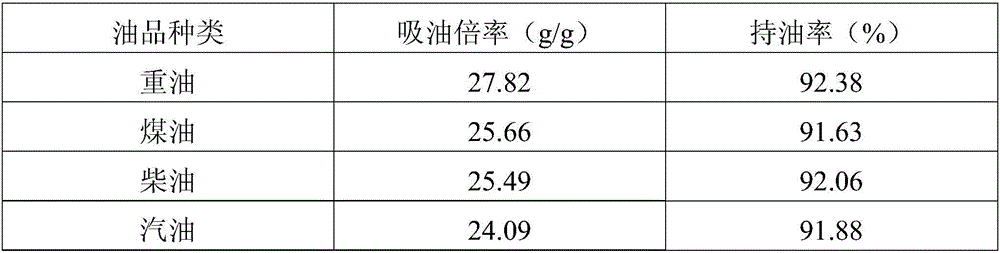

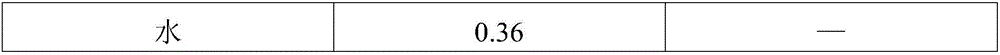

Acrylate polymer high oil absorption resin and preparation method and application thereof

ActiveCN101967212AHigh purityHigh oil absorption rateOther chemical processesWater/sewage treatment by sorptionCross-linkOil retention

The invention relates to acrylate polymer high oil absorption resin and a preparation method and application thereof. The oil absorption resin comprises the following components in part by weight: 50 to 95 parts of flexible chain segment monomer, 5 to 50 parts of rigid chain segment monomer, a cross-linking agent in an amount which is 0.2 to 5 percent of the total weight of the monomers, and a solvent in an amount which is 1.5 to 4 times the total weight of the monomers. The high oil absorption resin is prepared by free radical solution polymerization at room temperature under the initiation of gamma rays. The preparation process is simple, the reaction condition is easy to control, energy consumption is saved, and the method is safe and environmental-friendly and is more suitable for industrial production. The prepared high oil absorption resin has the advantages of high purity, complete hydrophobicity, wide application range, capacity of absorbing multiple types of oil, high oil absorption multiplying power, high oil retention performance, recyclability and the like, and can be widely applied to the absorption of floating oil on the sea surface, scattered oil, cooled emulsified oil on lathes of factories, and oil and organic substances in industrial production and domestic sewage.

Owner:SHANGHAI FINETAC PRECISION TECH CO LTD

Method and apparatus for patterning of bore surfaces

An apparatus comprises a rotating member having one or more rollers. The one or more rollers have a plurality of protuberances. The rollers may be advanced toward a surface during rotation of the rotating member, such as toward a bore surface. The protuberances are configured to make a pattern of discrete indentations in the surface upon engagement of the protuberances with the surface. The apparatus is particularly suited for creating oil-retention pockets in the surface of an engine cylinder and other uses. The apparatus may be used to create a pattern of oil-retention pockets or other pockets in a cylinder with varying pocket density in a single pass.

Owner:MAKINO MILLING MASCH CO LTD

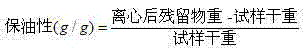

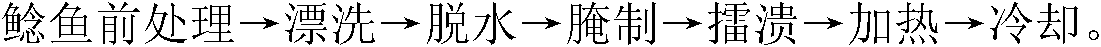

Processing method of catfish luncheon meat

The invention relates to a processing method of catfish luncheon meat, belonging to the technical field of foods. The processing method of the catfish luncheon meat is characterized by comprising thefollowing steps: preprocessing: removing the abodominal organs, the skin and the head of a catfish, cleaning and cutting the catfish into blocks; rinsing: using a 0.1-1.0 percent of NaCl solution or a0.1-1.0 percent of NaHCO3 solution to rinse the catfish at 2-12 DEG C; dewatering: dewatering the catfish by using a centrifuger or using gauze to extrude; pickling: using a curing agent to pickle the catfish at 1-10 DEG C for 3-20 hours; mixing and kneading: adding spices to the pickled catfish and mixing and kneading the catfish at 2-10 DEG C for 2-10 minutes; heating: canning mixed and kneadedminced fillet into a die and cooking at 60-95 DEG C for 1-6 hours; and cooling: cooling the die to a room temperature. The invention has the advantages of simple process, economy, practicability, high production efficiency, good water and oil retention, emulsifying property, excellent strength, tastes, texture and shape of gel and the like, and the luncheon meat has tender fiber and fresh tastes,stimulates the appetite, is digestible and particularly suitable for eating by old people and children.

Owner:天津市宽达水产食品有限公司

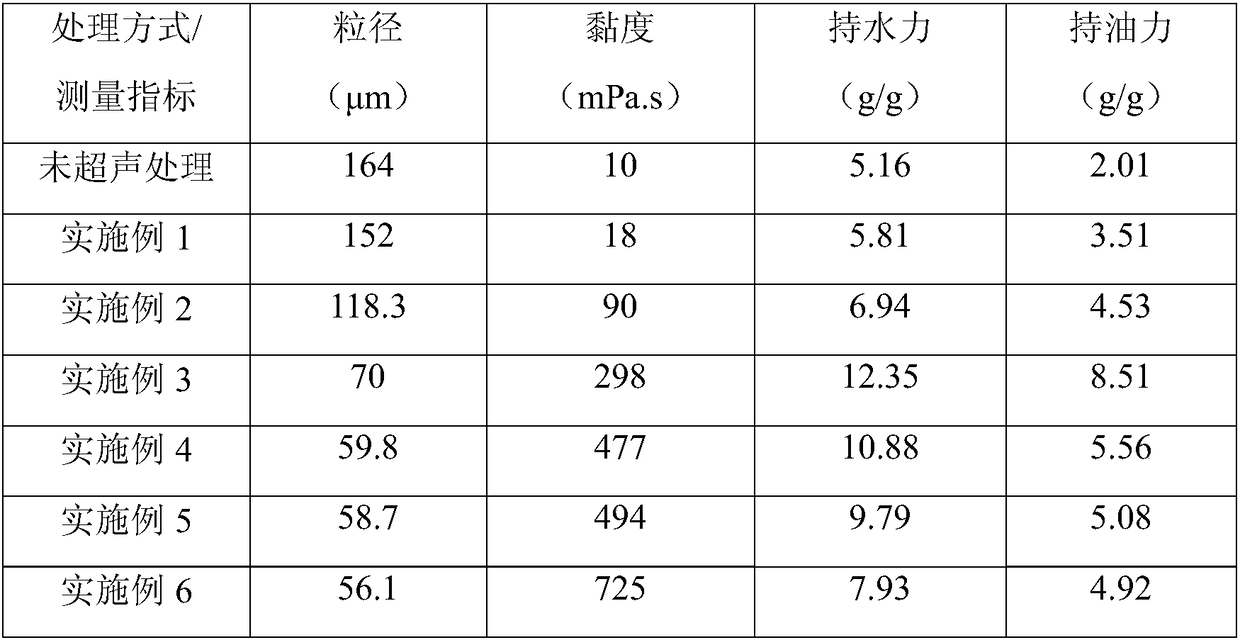

Method for preparing citrus fibers through ultrasonic treatment

InactiveCN108433113AImprove water holding capacityGood oil retentionFood ingredient as thickening agentNatural extract food ingredientsWater bathsFood additive

The invention belongs to the field of food additives, and discloses a method for preparing citrus fibers through ultrasonic treatment. The method comprises the following steps of crushing citrus fiberresidues, performing screening with an 80-120-mesh sieve, preparing a citrus fiber solution of which the mass concentration is 0.1-1% with deionized water, then performing treatment under ultrasonicpower of 250-450W for 1-20min, regulating the pH to 3.0-7.0, performing heating in a water bath in a water bath pot of 45-60 DEG C for 1-2h, adding an ethanol solution, performing centrifugation, removing a supernatant, and drying solid precipitate under 45-70 DEG C to constant weight to obtain the citrus fibers. The citrus fibers are treated with ultrasonic waves, so that the prepared citrus fibers have good water retention ability, good oil retention ability, and good physicochemical properties of stickiness, particle diameter and the like, can well achieve the effects of stabilizing, thickening and water retention, and can widen the application range of the citrus fibers in food industry.

Owner:SOUTH CHINA UNIV OF TECH

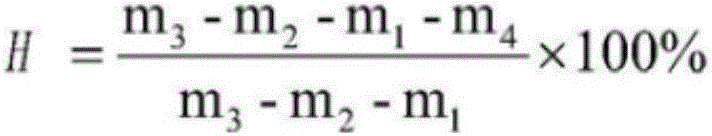

Quick high-efficiency oil-adsorbing resin and preparation method thereof

InactiveCN104558385AImprove lipophilicityLarge adsorption ratioOther chemical processesOil retentionGasoline

The invention relates to a quick high-efficiency oil-adsorbing resin and a preparation method thereof. According to the preparation method, a monomer, a crosslinking agent, an initiator, a dispersing agent and other raw materials are proportionally subjected to suspension polymerization to prepare the quick high-efficiency oil-adsorbing resin. The quick high-efficiency oil-adsorbing resin has higher adsorptivity and higher oil retention property, and can be repeatedly regenerated and reused. More importantly, the oil adsorptivity of the prepared oil-adsorbing resin for carbon tetrachloride within 10 minutes is 19.52 g / g, the oil adsorptivity for gasoline is 12.62 g / g, the oil adsorptivity for paraxylene is 11.19 g / g, the oil adsorptivity for machine oil is 9.39 g / g, and the oil adsorptivity for diesel is 9.2 g / g. The quick high-efficiency oil-adsorbing resin is suitable for treating oil slick in the fishing boat centralized mooring area, and can also be used for quick treatment of oil leakage accidents.

Owner:BEIJING FORESTRY UNIVERSITY

Food gum for meat products and preparation method thereof

InactiveCN106213239AIncrease elasticitySuitable for industrial productionFood ingredient as thickening agentFood ingredient as gelling agentOil retentionSulfate

The invention discloses a food gum for meat products, which consists of the following materials in parts by weight: 45 to 55 parts of sodium alginate, 20 to 25 parts of calcium sulfate, 10 to 15 parts of glucono- Delta -lactone, 5 to 10 parts of sodium pyrophosphate, 5 to 10 parts of calcium carbonate and 1 to 5 parts of guar gum. Also disclosed is a preparation method for the food gum for meat products. The food gum for meat products and the preparation method thereof which are disclosed by the invention have the advantage that the food gum for meat products is low in cost, is easy to use, has a good emulsification, water retention and oil retention effect, and cannot be softened due to high temperature.

Owner:河南隆霄生物科技有限公司

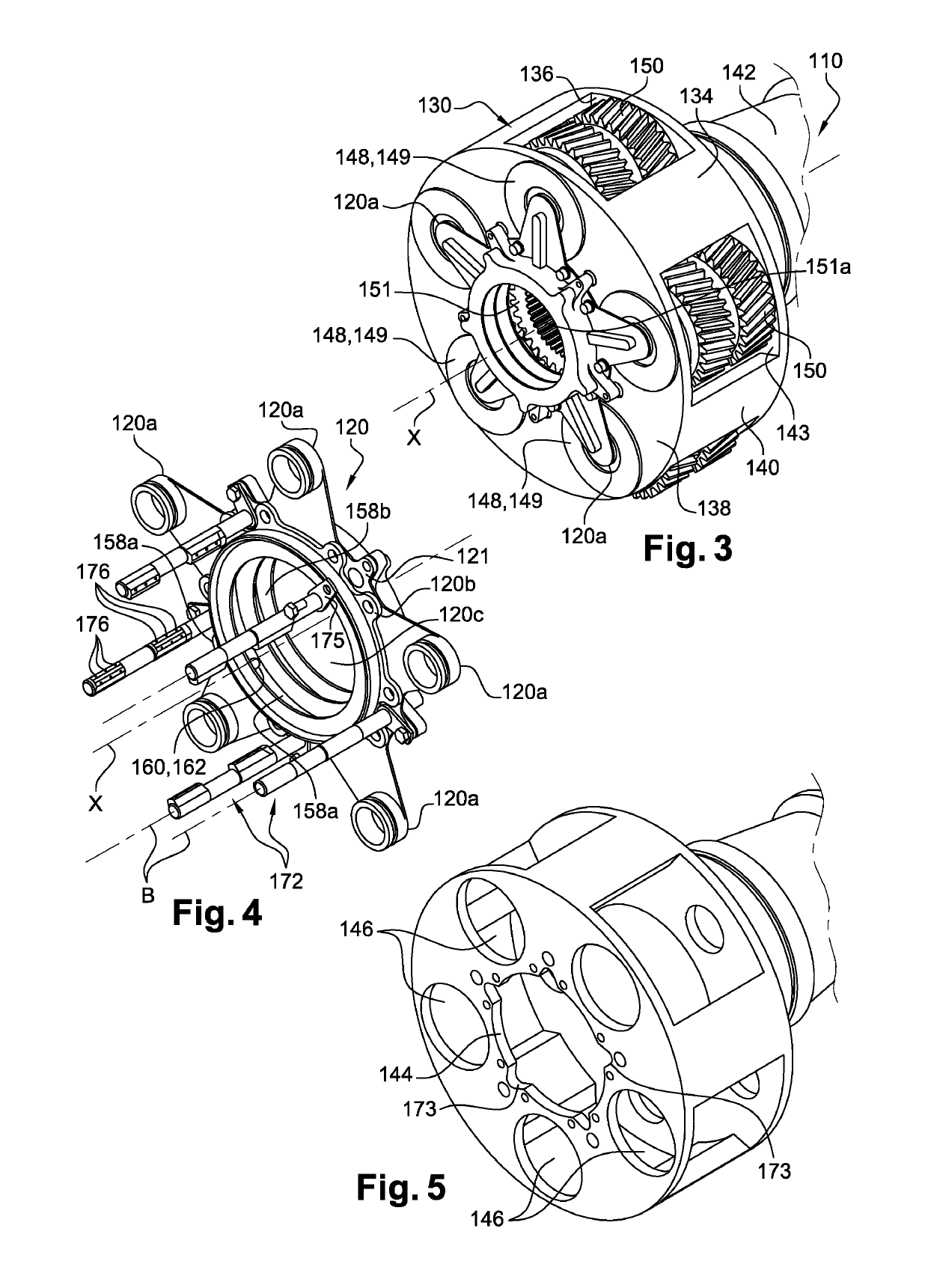

Planetary reduction gear ring gear for a turbine engine

ActiveUS20190170240A1Avoid turningKeep properlyEngine fuctionsGear lubrication/coolingOil retentionCentrifugation

A planetary reduction gear ring gear for a turbine engine, in particular of an aircraft, the ring gear extending about an axis (X) and including first and second coaxial annular elements and respectively two inner annular teeth oriented differently. The first and second annular elements include respectively first and second radially external annular flanges to secure the first and second elements to one another, the teeth of the first and second annular elements being axially spaced from one another and from a joint plane (P) of the first and second flanges, and defining between them an annular space externally delimited by two annular rims supporting respectively the flanges. At least one of the flanges includes joint plane notches that are substantially radial for the oil to pass through by centrifugation. The ring gear further includes an annular row of oil-retention walls protruding from the rims in the space.

Owner:SAFRAN TRANSMISSION SYST

Method for obtaining oil absorption material by adopting melamine resin foam as matrix

InactiveCN106215904APorousLarge specific surface areaOther chemical processesWater/sewage treatment by sorptionOil retentionPolymer science

The invention discloses a method for obtaining an oil absorption material by adopting melamine resin foam as a matrix, and belongs to the technical field of oil pollution treatment. The method comprises the following steps that the melamine resin foam is placed in a hydrophobing agent solution, and vacuum impregnation is carried out for 20-60 minutes at the temperature of 25 DEG C to 100 DEGC; the melamine resin foam containing a hydrophobing agent is taken out and dried fast, a hydrophobing agent infusion with the melamine resin foam as the matrix is obtained, and the oil absorption material is obtained. According to the oil absorption material prepared by adopting the melamine resin foam as the matrix, the modifying method that the hydrophobing agent is loaded in a dipping mode is adopted, the method is a simple physical modifying method, the process is simple, cost is low, and the advantages of being porous, large in specific surface area, low in density, high in oil absorption performance and good in oil retention effect are achieved.

Owner:郑州峰泰纳米材料有限公司

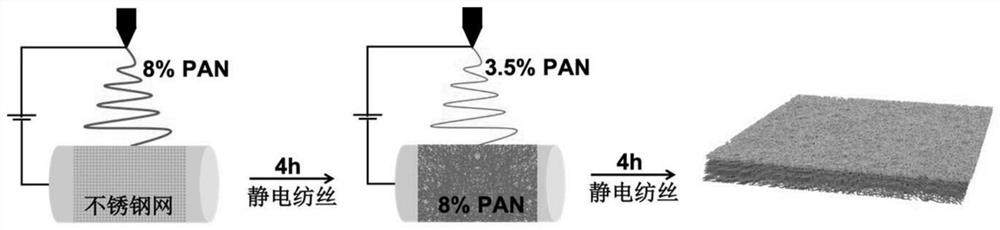

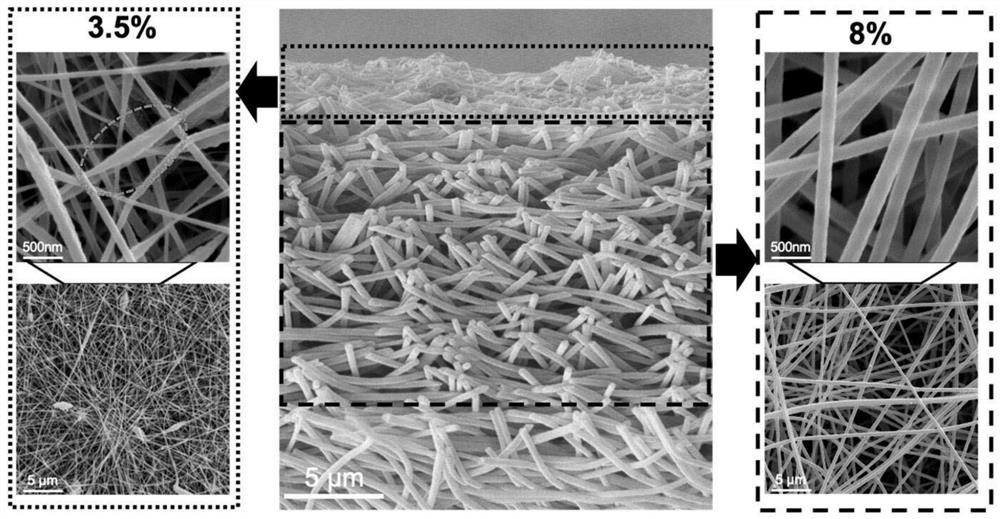

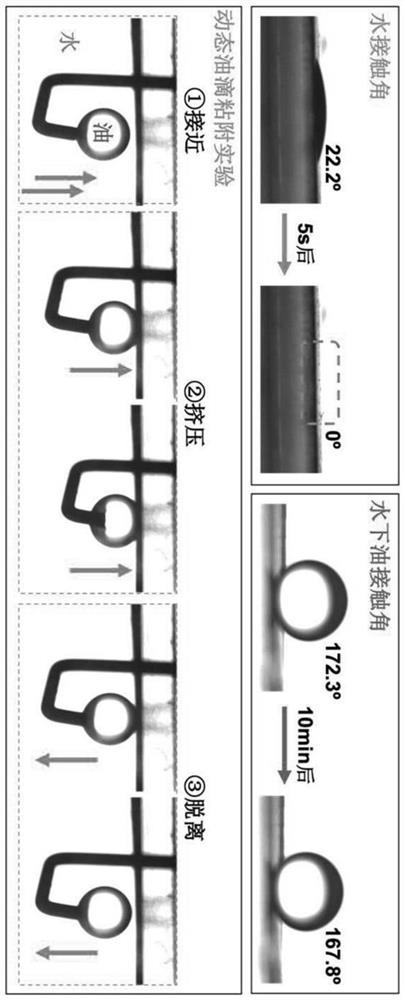

Method for efficiently treating oil-in-water emulsion by using super-hydrophilic nanofiber membrane with gradient structure

ActiveCN112777689AGood compatibilityReduce dosageSemi-permeable membranesMembranesOil retentionSpinning

The invention provides a method for efficiently treating an oil-in-water emulsion by using a super-hydrophilic nanofiber membrane with a gradient structure, which comprises the specific preparation steps of preparing the super-hydrophilic nanofiber membrane with the gradient structure by electrostatic spinning, filtering distilled water for pre-wetting only under the action of gravity, and then directly filtering the oil-in-water emulsion for oil-water separation, wherein the filter membrane is directly reused after being simply cleaned by clean water. According to the invention, efficient oil-water separation can be achieved for oil-in-water emulsion with the liquid drop particle size ranging from the micron level to the nano level, the extremely high treatment flux can be achieved through low-pressure driving, the oil retention rate ranges from 92.51% to 99.52%, and the effect is not remarkably attenuated after the oil-water separation device is reused for 6 times; and the super-hydrophilic nanofiber membrane material with a gradient structure is used for realizing efficient oil-water separation on various nanoscale oil-in-water emulsions, and the material is convenient to prepare, mild in operation condition, high in oil retention rate and treatment flux, high in anti-pollution performance and wide in applicable treatment object range.

Owner:TONGJI UNIV

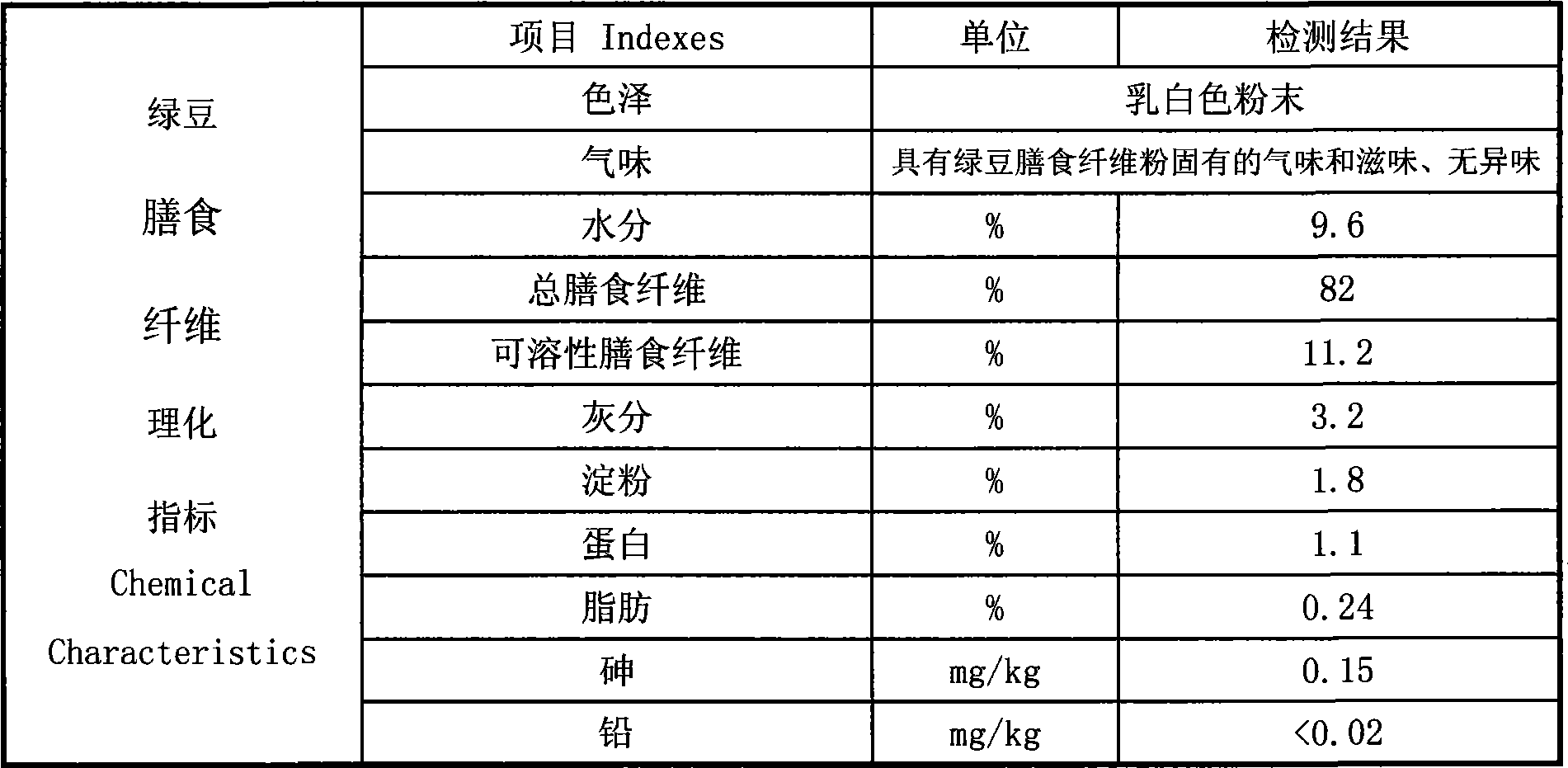

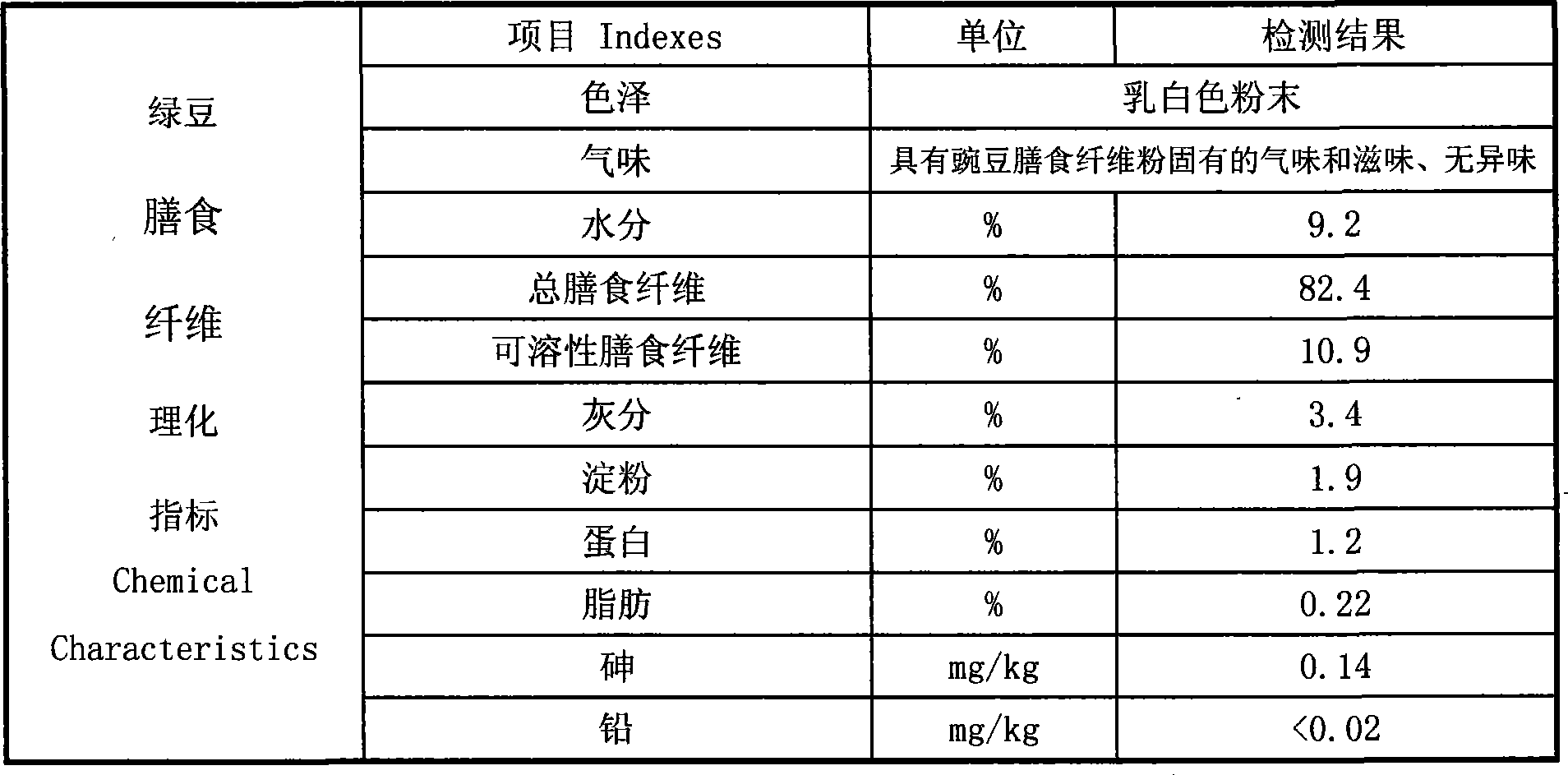

Mung bean or pea dietary fiber and method for producing the same

The invention relates to dietary fibers and a method for producing the same, and belongs to the technical field of dietary fibers and a method for producing the same. A method for producing mung bean or pea dietary fibers is characterized by comprising the following steps of: 1, bean dreg separation; 2, plate pressure filtration; 3, flash streaming drying; 4, microwave sterilization; 5, superfine crushing; and 6, screening and packing. The dietary fibers are made by the method for producing the bean or pea dietary fibers. The invention provides dietary fibers and a method for producing bean or pea dietary fibers. The method processes dietary fibers by using bean dregs from starch process as a raw material and adopting a superfine crushing and extraction technique to achieve a granularity of certain fineness, and improves the prior production process. The dietary fibers are used to be added into foods to bring a fine mouth feel for the foods, have a health-care effect, modify the water retention, oil retention, color and taste of the foods, and have an active effect on environmental protection.

Owner:王雪源

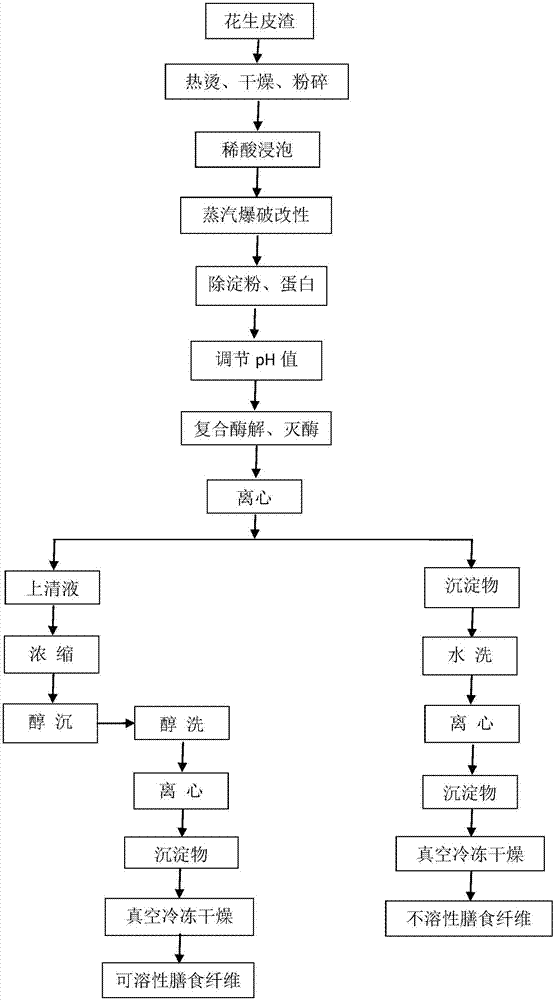

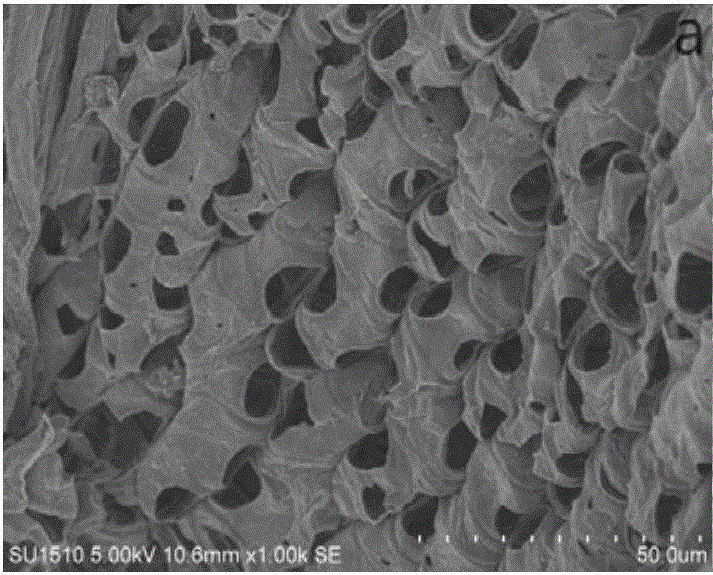

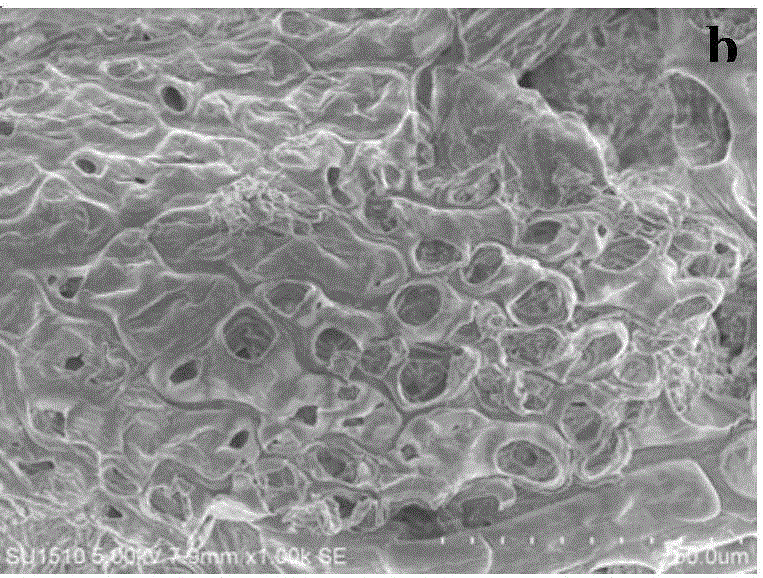

Method for extracting peanut dietary fibers through steam explosion modification and enzymatic hydrolysis coupling

The invention discloses a method for extracting peanut dietary fibers through steam explosion modification and enzymatic hydrolysis coupling and belongs to the field of agricultural byproduct deep processing. The method comprises the following steps of taking peanut skin dregs as a raw material, performing steps of blanching, drying, crushing, soaking with dilute acid, steam explosion modification, starch and protein removal, complex enzymatic hydrolysis and the like, and treating a filtrate and precipitates to obtain water-soluble dietary fibers and insoluble dietary fibers respectively. For the method, by combining the extraction process with the modification process, the extraction rate of the water-soluble dietary fibers is increased, the composition and the structure of the dietary fibers are changed, more binding sites are exposed, and the adsorption performance and the dispersion performance of dietary fibers are improved; the water retention ability, the oil retention ability and the expansive force of the insoluble dietary fibers are improved, the adsorption ability of the water-soluble dietary fibers is strengthened, and thus the functionality of the peanut dietary fibers is strengthened; and by taking the skin dregs, which are a processing byproduct of peanuts, as the raw material, fine and deep processing of agricultural byproducts is realized, and a new way is provided for comprehensive utilization of the peanut agricultural byproducts.

Owner:唐山润泽粮油食品有限公司 +1

Modified natural plant fiber oil absorbent and preparation and application methods thereof

ActiveCN106637968AHigh oil absorptionWide variety of sourcesFatty/oily/floating substances removal devicesOther chemical processesOil and greaseFiber

The invention discloses a modified natural plant fiber oil absorbent and preparation and application methods thereof. The preparation method comprises providing a natural plant fiber substrate, and then performing physical modification on the natural plant fiber substrate to form a hydrophobic natural high-polymer membrane on the surface of the natural plant fiber substrate and further to obtain the modified natural plant fiber oil absorbent, wherein the hydrophobic natural high-polymer membrane is in a hierarchical nano microstructure. The physical modification comprises crushing grinding, pulping, drying, first impregnating and second impregnating. The preparation method of the modified natural plant fiber oil absorbent is simple and easy to operate, wide in source of raw materials which are all natural products, and low in cost; the obtained modified natural plant fiber oil absorbent has the advantages of being high in hydrophobicity, lipophilicity and oil absorption rate and velocity, good in oil and water selectivity, easy to convey and store, good in buoyancy, high in oil retention rate, good in biodegradability and the like, and can be applied to treatment on leakage of petroleum and organic solvent, kitchen oily dirt and the like. Meanwhile, the modified natural plant fiber oil absorbent can keep afloat before and after absorption, thereby being convenient to recover and postprocess and avoiding secondary pollution to the environment.

Owner:JIANGNAN UNIV

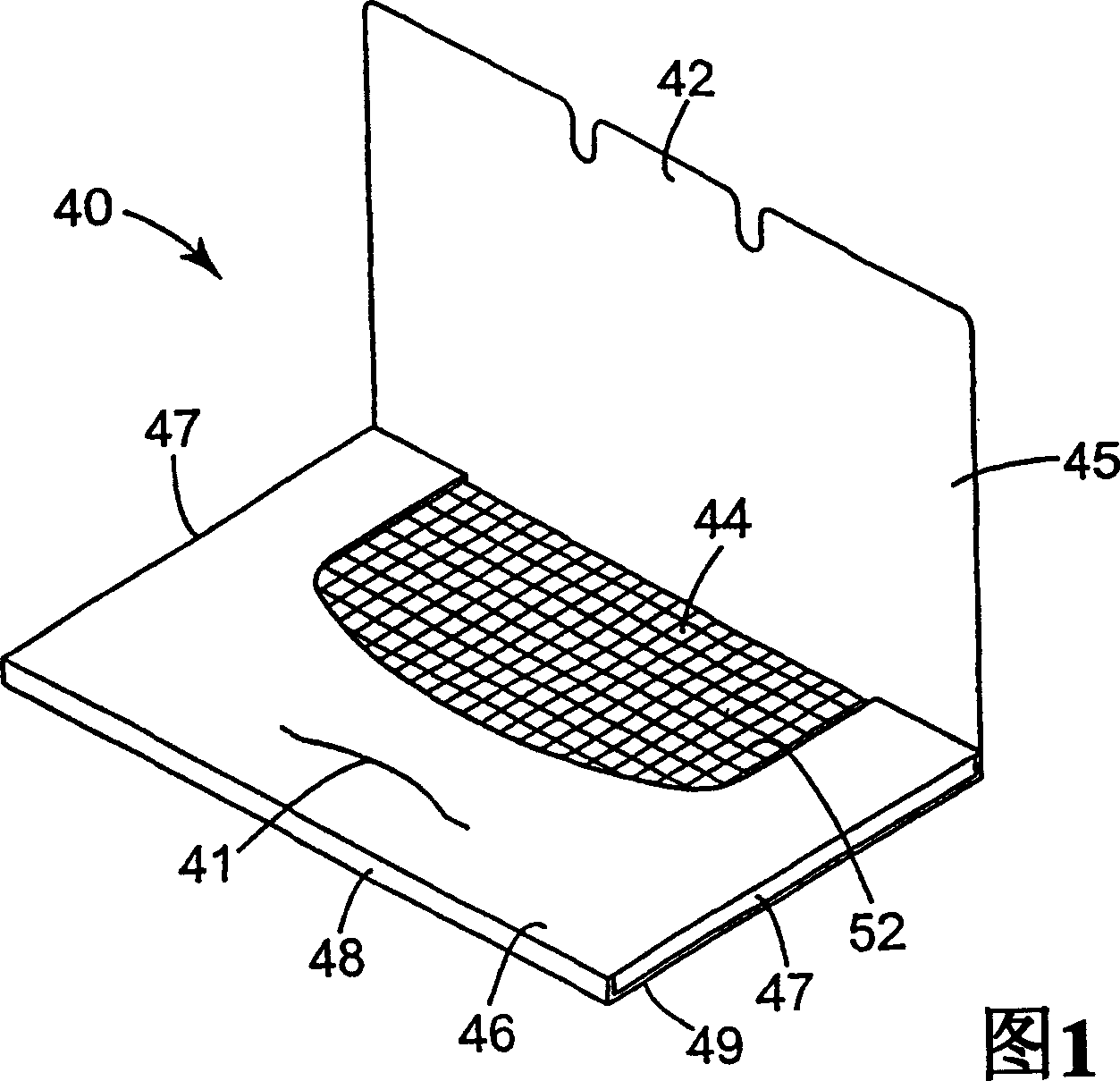

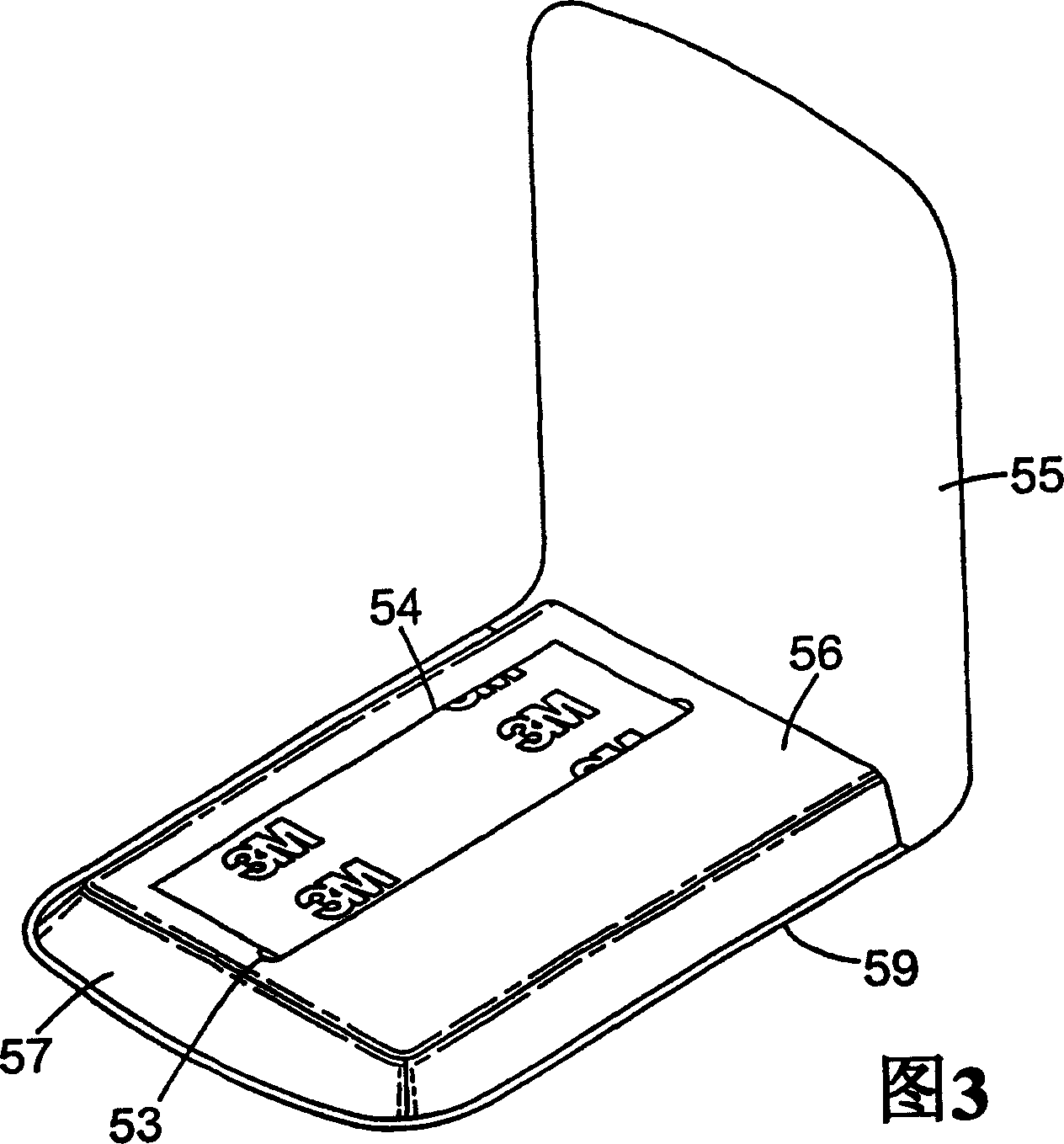

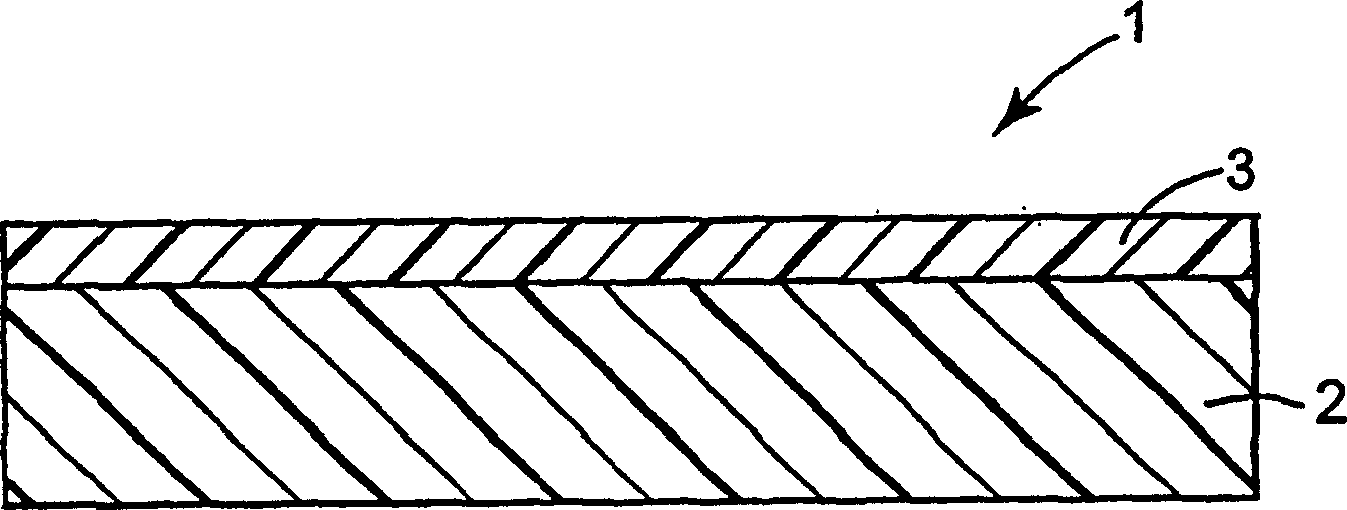

Package of multiple oil wipes

InactiveCN1538821AHigh transparencyImprove distributabilityCosmetic preparationsLayered productsPorous substrateOil retention

There is provided a package 40 of multiple oil absorbing wipes 44 suitable for wiping a users skin or hair. The invention wipes comprise an oil absorbing porous film of a thermoplastic material having a transparency of less than 65 which porous substrate changes transparency when loaded with oil. The porous substrate has directly on one face an oil contaminable layer, without any intermediate oil impermeable layer or film. The porous film has a percent oil retention of from 50 to 100 percent.

Owner:3M INNOVATIVE PROPERTIES CO

Oil-retention and water-retention sausage emulsifying agent

InactiveCN103549468AReduce the phenomenon of oil and waterEasy to useFood preparationOil retentionSodium Caseinate

The invention relates to an oil-retention and water-retention sausage emulsifying agent and belongs to the field of food processing. The oil-retention and water-retention sausage emulsifying agent is characterized by being compounded by the following components in mass percentage: 25%-35% of soy isolate protein, 15%-20% of sodium caseinate, 20%-40% of guar gum and 10%-30% of glycerin monostearate. The oil-retention and water-retention sausage emulsifying agent has the beneficial effects that 1 one efficient oil-retention and water-retention agent is provided for low-temperature emulsified sausage products and a phenomenon of discharging oil and water from a product is reduced effectively; 2 the oil-retention and water-retention sausage emulsifying agent is convenient to use and can be directly added into the product to be used when fat is chopped; affiliated adding conditions are not needed; 3 the application is wide and the oil-retention and water-retention sausage emulsifying agent can be applied to the current low-temperature emulsified sausages and can also be applied to quickly-frozen roasting sausage; 4 under the condition that an existing formula of each low-temperature emulsified sausage is not changed, 0.2%-0.8% of the oil-retention and water-retention sausage emulsifying agent is added so that the oil and water discharging effect of the product is inhibited well and the quality of the product is improved greatly.

Owner:HENAN ZHONGPIN FOOD IND

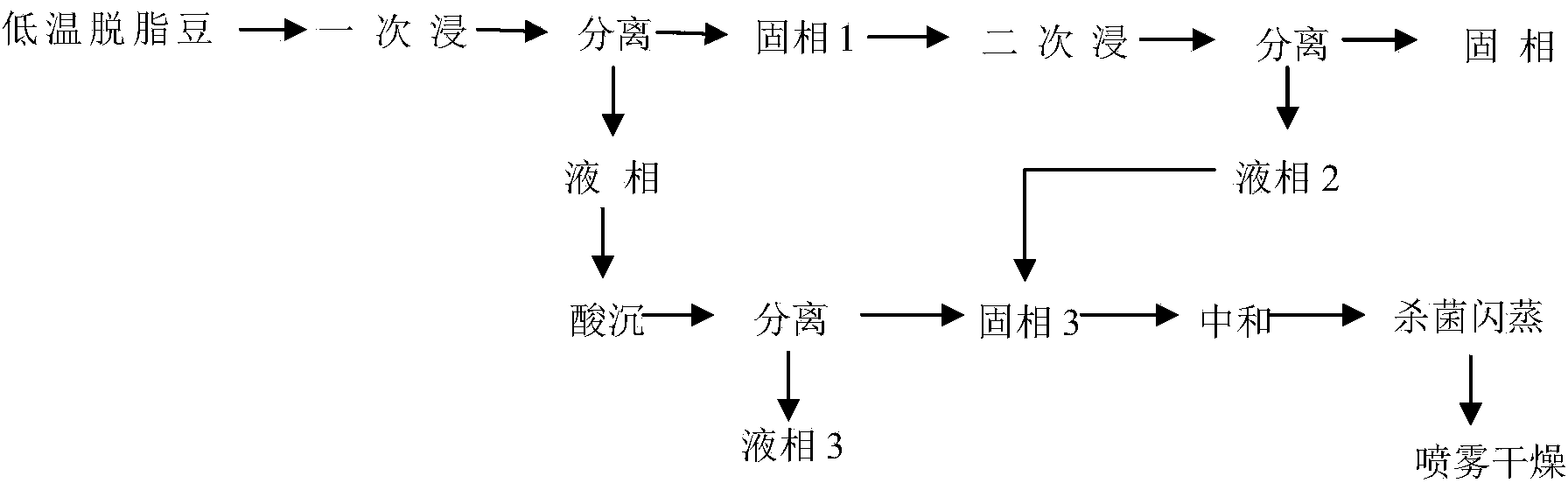

Production method for soybean protein

InactiveCN104256050AImprove water retentionGood oil retentionProtein composition from vegetable seedsOil retentionSoybean protein

The invention discloses a production method for soybean protein. The production method comprises the following steps: performing primary leaching, primary separation, secondary leaching and secondary separation on a raw material, i.e., low-temperature defatted soybean meal, regulating the pH value of a liquid phase 1 obtained through the primary separation to 4.4-4.7, performing sedimentation, and then performing centrifugal separation to obtain a solid phase 3; mixing the solid phase 3 and a liquid phase 2 obtained through the secondary separation, adding water for smashing, and regulating the pH value of smashed liquid to 7.0-7.5 until solid phase granules are completely dissolved; performing disinfection and flash evaporation, and performing the disinfection and the flash evaporation on neutralized liquid at the temperature of 130-150 DEG C; drying, performing spray drying on feed liquid on which the flash evaporation and the disinfection are performed, and recovering the feed liquid on which the spray drying is performed through a recovery system to obtain the soybean protein. According to the separation method provided by the invention, through the secondary leaching and the secondary separation, the solid phase 3 and the liquid phase 2 are smashed and neutralized, so that the obtained soybean protein has higher water retention and oil retention, the usage amount of the soybean protein in food is increased, and the texture of the food can be better improved.

Owner:LINYI YUWANG VEGETABLE PROTEIN

Superhydrophobic cotton cellulose aerogel, and preparation method and application thereof

PendingCN110575794AEasily available in large quantitiesEasy to degradeWater cleaningFatty/oily/floating substances removal devicesCelluloseFiber

The invention belongs to the field of aerogels, and discloses superhydrophobic cotton cellulose aerogel, and a preparation method and an application thereof. The superhydrophobic cotton cellulose aerogel is prepared from a cotton fiber, the superhydrophobic cotton cellulose aerogel has a three-dimensional network porous structure, the surface of the superhydrophobic cotton cellulose aerogel contains hydrophobic groups, and the water contact angle of the superhydrophobic cotton cellulose aerogel is 140-155 DEG. A cotton cellulose solution is prepared from the cotton fiber, then a cotton cellulose hydrogel and a hydrophilic cotton cellulose aerogel are sequentially obtained, and the hydrophilic cotton cellulose aerogel undergoes hydrophobic modification to obtain the superhydrophobic cottoncellulose aerogel. Compared with organically synthesized oil absorption materials, the aerogel has the advantages of super-light weight, superhydrophobicity, high oil absorption rate and high oil retention performance. The preparation method has the characteristics of simple process, low cost, environmental friendliness and greenness, is suitable for industrial mass production, and makes the product widely applied to treatment of oily wastewater discharged in the industries of chemical processing, food production, kitchens, automobile repair and the like.

Owner:BEIFANG UNIV OF NATITIES

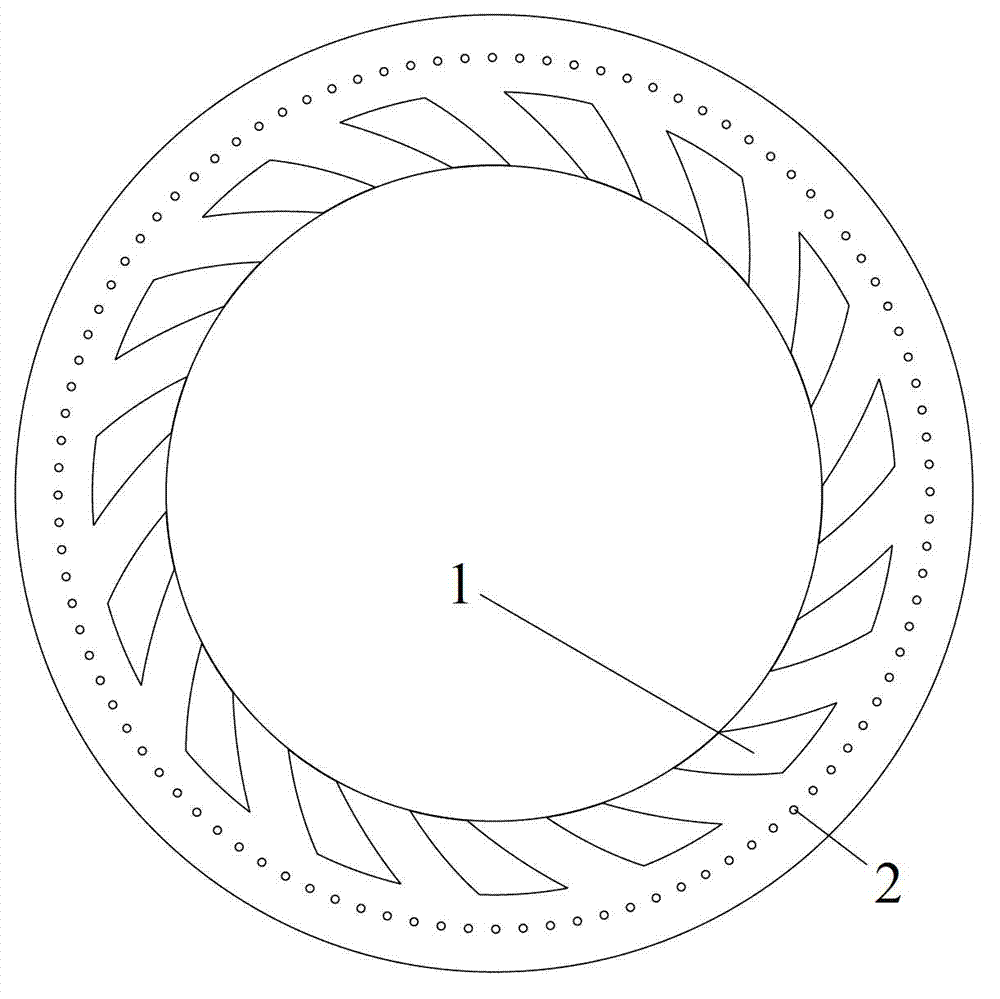

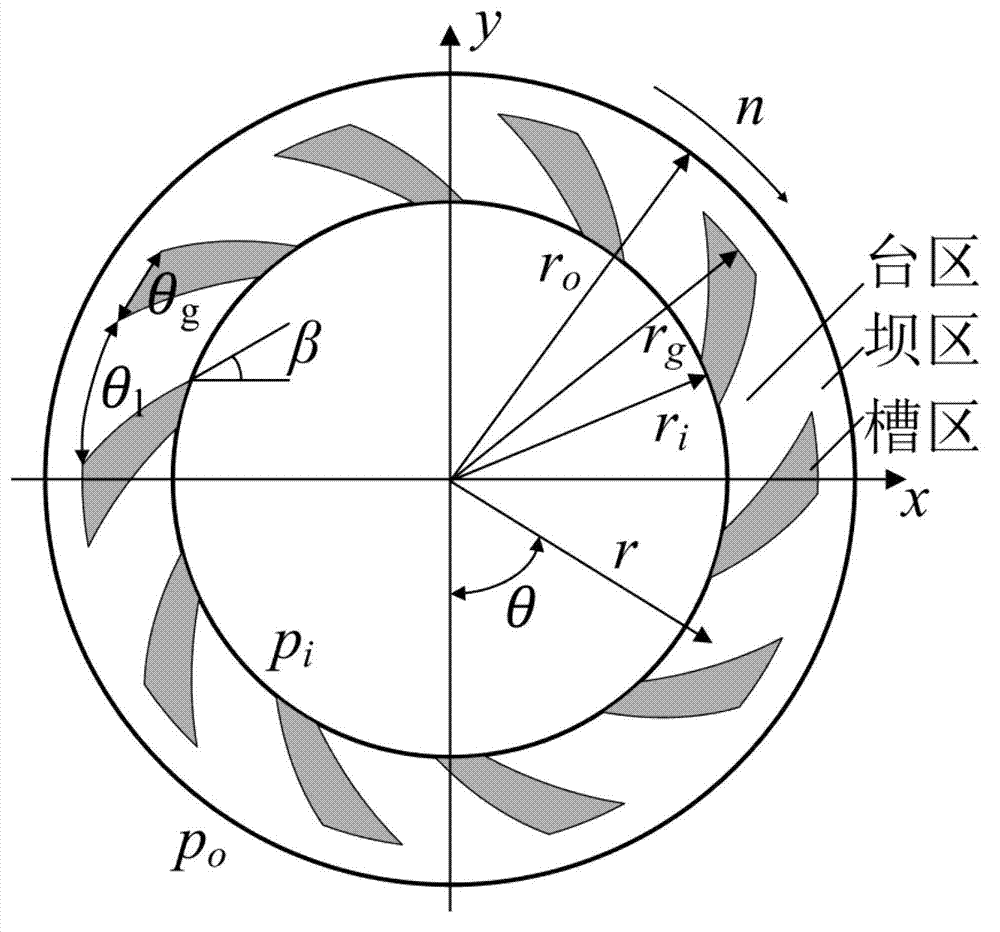

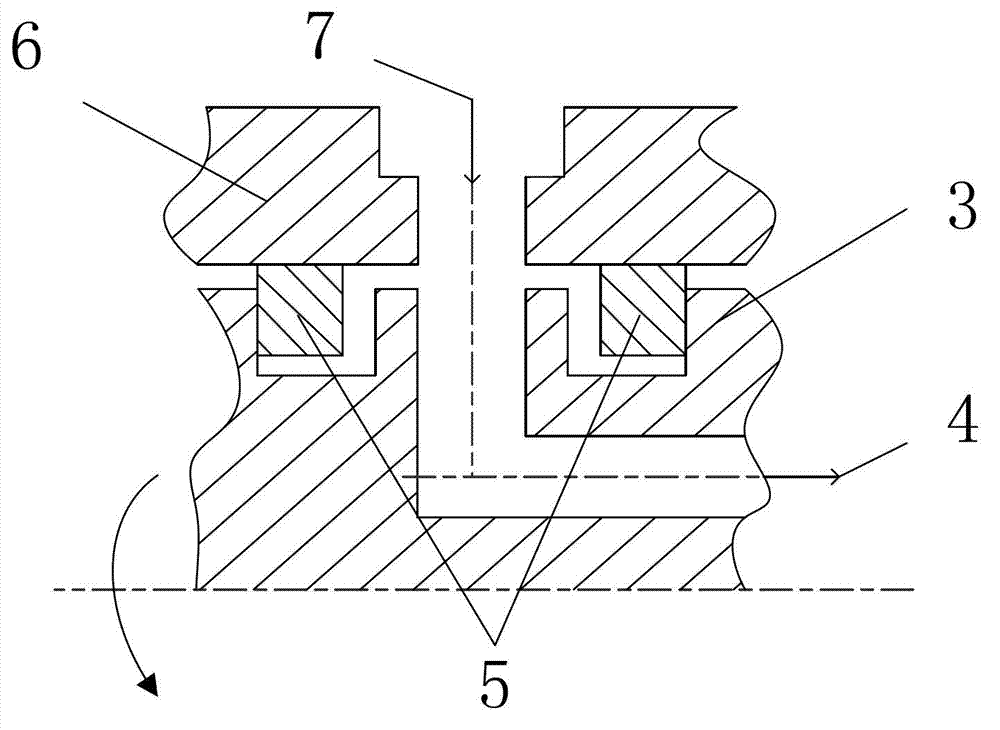

Spiral groove rotary sealing ring with porous end surface for vehicle

The invention provides a spiral groove rotary sealing ring with a porous end surface for a vehicle and belongs to the technical field of sealing engineering of automobile transmission devices. 10-20 spiral grooves and 60-90 micropores are uniformly distributed on the end surface of the rotary sealing ring along the circumferential direction, each spiral groove extends from an inner circle of the sealing ring to an outer circle of the sealing ring, and the micropores are uniformly distributed in a barrage area of the sealing ring along the circumferential direction. By means of a structural design of the micropores and the spiral grooves which are formed in the end surface of the rotary sealing ring, the spiral grooves can produce hydrodynamic pressure under high-speed and high-pressure working conditions and achieve non-contacting lubrication, the oil retention function of the micropores under a low-speed working condition guarantees the lubrication of an oil film, thus friction and abrasion of an oil distribution sleeve are reduced, the using performance of the oil distribution sleeve is improved, and the service life of the oil distribution sleeve is prolonged.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com