Superhydrophobic cotton cellulose aerogel, and preparation method and application thereof

A technology of cellulose airgel and cotton cellulose, applied in the field of airgel, can solve the problems of high preparation cost, cumbersome preparation process, and low density of cellulose airgel, and achieve low preparation cost, simple process, high The effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

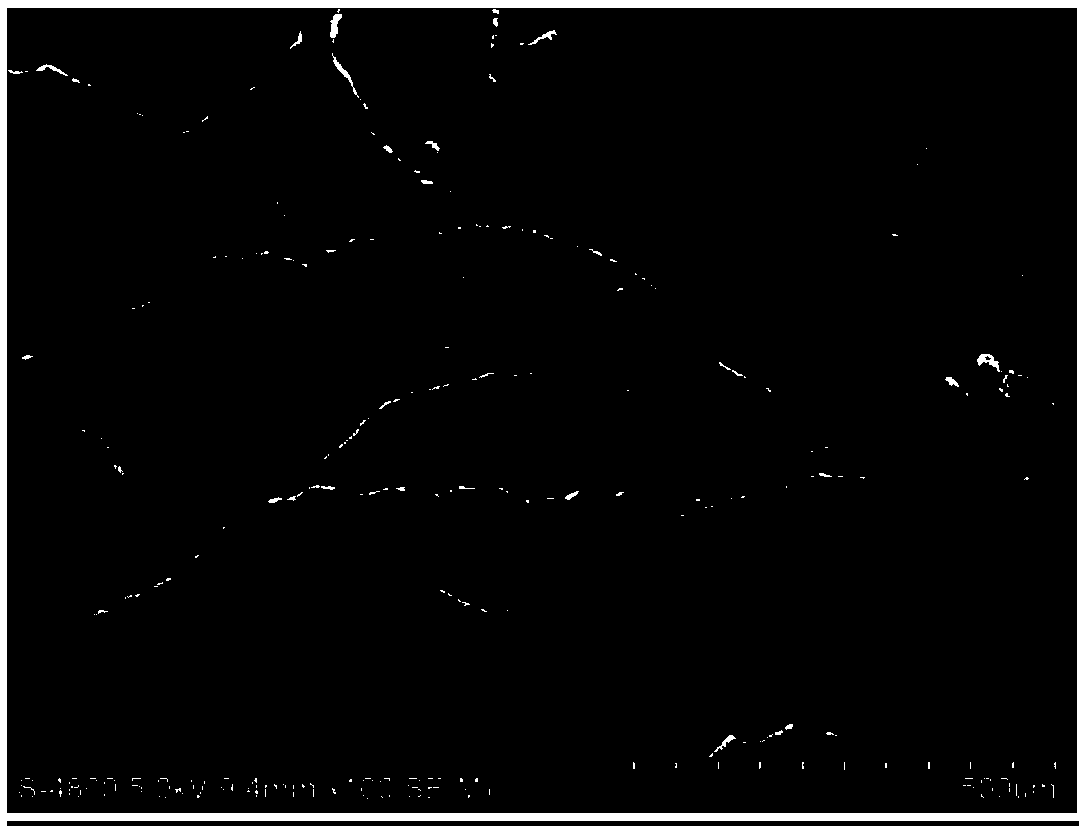

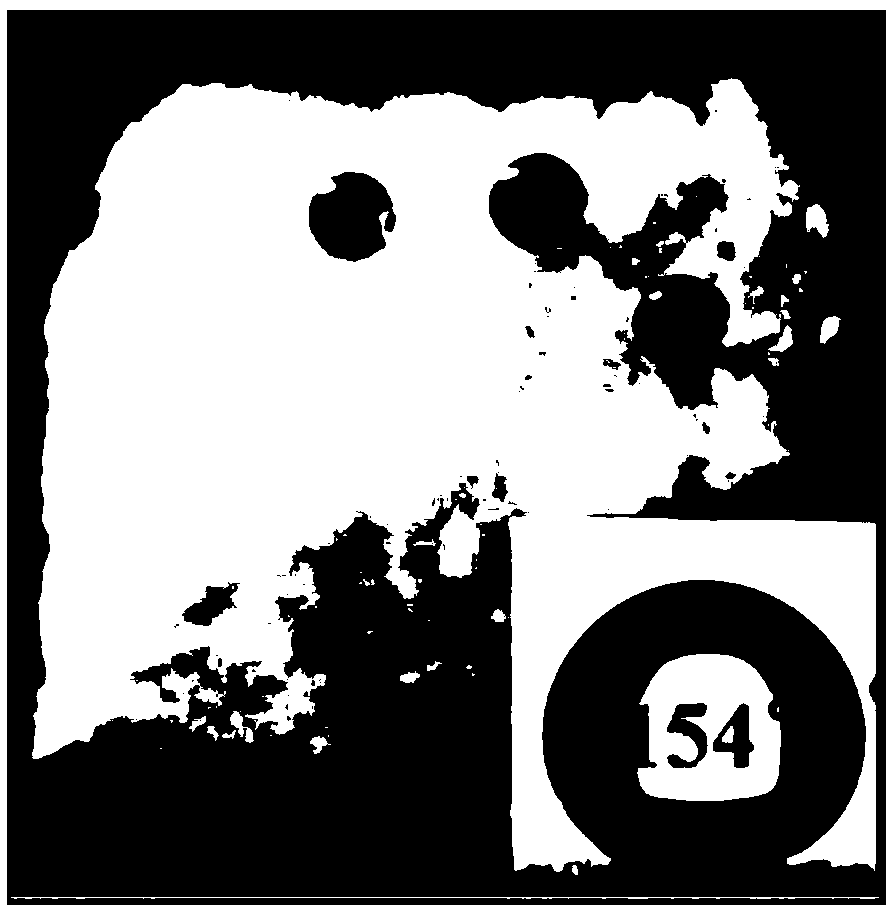

Image

Examples

Embodiment 1

[0045] 1. Add cotton fiber into 12wt% sodium hydroxide solution, pretreat at 80°C for 1 hour, wash with distilled water, and fully dry. 3.0 g of pretreated cotton fiber was added to 98.5 mL of NaOH solution (14 wt %) precooled at -20° C. for 25 min. Stir at 800 rpm for 5 min, then add a mixed solution (98.5 mL) containing 3.0 wt% urea and 1.0 wt% thiourea into the cotton fiber dispersion, and stir evenly to obtain a cotton cellulose solution. Subsequently, the resulting cotton cellulose solution is transferred to the desired mold.

[0046] 2. Put the cotton cellulose solution at 80°C for 3 hours, after it is completely gelled, soak it in 6wt% hydrochloric acid solution for 24 hours, and finally replace it with distilled water until it is neutral, and you can get cotton cellulose water gel.

[0047] 3. The obtained cotton cellulose hydrogel was frozen at -15°C for 32 hours to obtain cotton cellulose jelly, and then the sample was freeze-dried at -80°C for 48 hours to obtain h...

Embodiment 2

[0054] 1. Add the cotton fiber into 6wt% sodium hydroxide solution, pretreat it at 80°C for 4 hours, wash it with distilled water, and dry it fully. 5.0 g of pretreated cotton fiber was added to 97.5 mL of NaOH solution (10 wt %) precooled at -20° C. for 25 min. Stir at 800 rpm for 5 min, then add a mixed solution (97.5 mL) containing 4.5 wt% urea and 0.5 wt% thiourea into the cotton fiber dispersion, and stir evenly to obtain a cotton cellulose solution. Subsequently, the resulting cotton cellulose solution is transferred to the desired mold.

[0055] 2. Put the cotton cellulose solution at 50°C for 36 hours, after it is completely gelled, soak it in 2wt% hydrochloric acid solution for 48 hours, and finally replace it with distilled water until it is neutral, and you can get cotton cellulose water gel.

[0056] 3. The obtained cotton cellulose hydrogel was frozen at -15°C for 32 hours to obtain cotton cellulose jelly, and then the sample was freeze-dried at -80°C for 48 hou...

Embodiment 3

[0060] 1. Add cotton fiber to 16wt% sodium hydroxide solution, pretreat at 40°C for 0.5 hour, wash with distilled water, and fully dry. 7.0 g of pretreated cotton fiber was added to 96.5 mL of NaOH solution (14 wt %) precooled at -20° C. for 25 min. Stir at 800 rpm for 5 min, then add a mixed solution (96.5 mL) containing 3.0 wt% urea and 1.0 wt% thiourea into the cotton fiber dispersion, and stir evenly to obtain a cotton cellulose solution. Subsequently, the resulting cotton cellulose solution is transferred to the desired mold.

[0061] 2. Put the cotton cellulose solution at 80°C for 30 hours, after it is completely gelled, soak it in 10wt% hydrochloric acid solution for 48 hours, and finally replace it with distilled water until it is neutral, and you can get cotton cellulose water gel.

[0062] 3. The obtained cotton cellulose hydrogel was frozen at -15°C for 24 hours to obtain cotton cellulose jelly, and then the sample was freeze-dried at -40°C for 48 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com