Patents

Literature

91results about How to "High oil absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

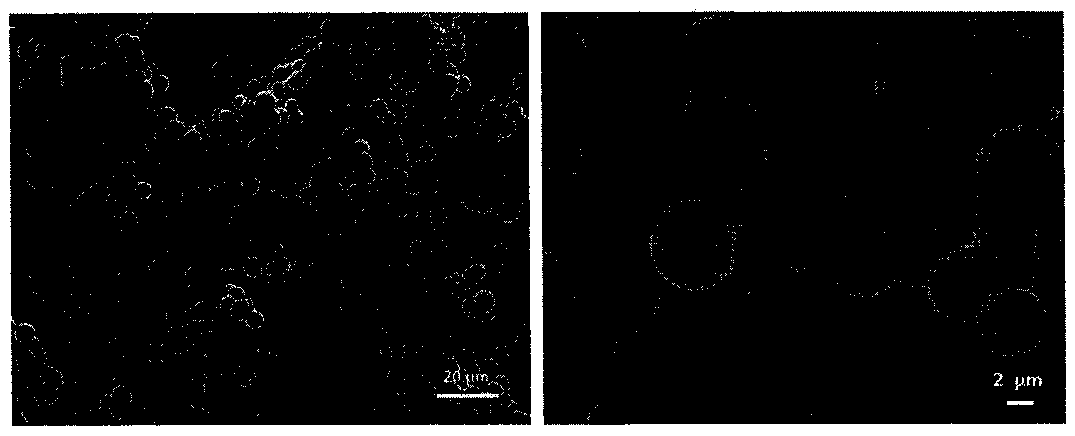

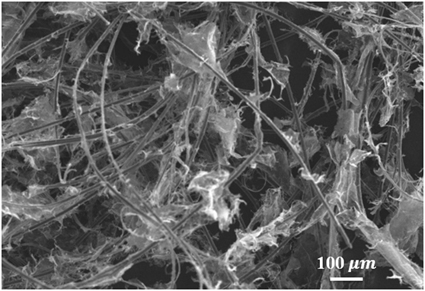

Preparation method of ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption

InactiveCN103756006ASolve the defect of strong hydrophilicityLow densityCoatingsEnvironmental resistanceCellulose

The invention discloses a preparation method of an ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption, and relates to a preparation method of cellulose aerogel. The method disclosed by the invention aims to solve the problem that existing cellulose aerogel which is lower in oil absorption multiplying power and strong in hydrophilicity is not suitable for oil-water separating materials. The method comprises the following steps: I, preparing cellulose aqueous liquor; II, preparing a nano fibrillated cellulose aqueous dispersion liquid; III, preparing a strongly gelatinous nano fibrillated cellulose aqueous dispersion liquid; IV, freezing and drying; and V, carrying out hydrophobic modification to obtain the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption. The preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption is simple in preparation process, wide in source of raw materials, low in cost and environment-friendly and green. The invention relates to the preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption.

Owner:NORTHEAST FORESTRY UNIVERSITY

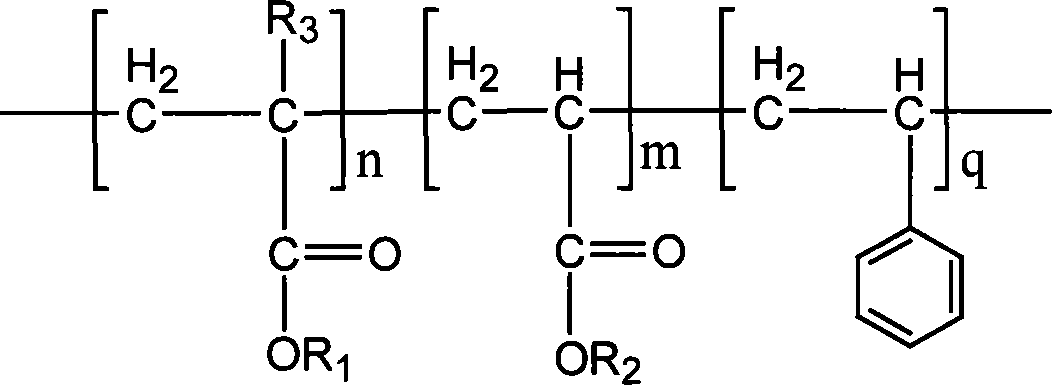

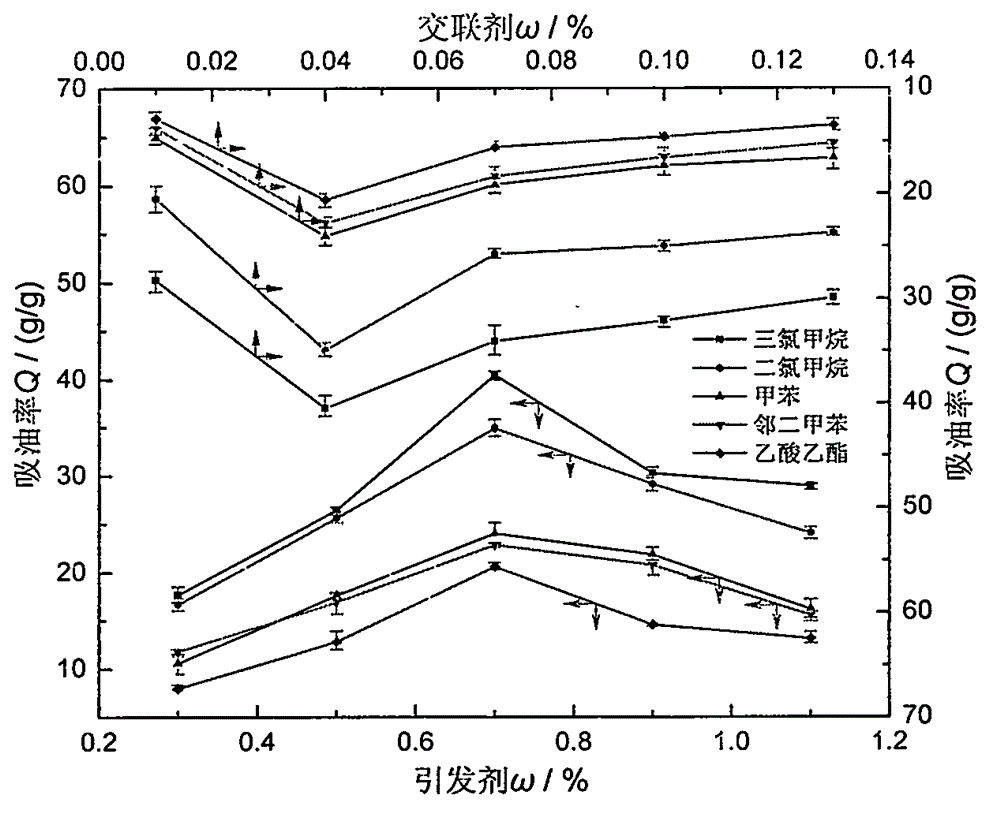

High oil absorption resin and synthetic method thereof

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

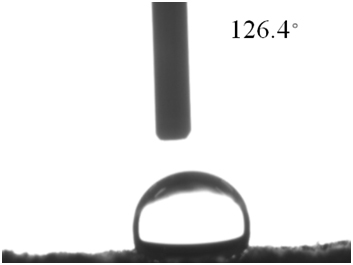

Preparation method of super-hydrophobic, super-oleophylic and ultralight sponge

ActiveCN104324524ASmall surface areaHigh oil absorption rateLiquid separationSurface energyOrganic chemicals

The invention relates to a preparation method of super-hydrophobic, super-oleophylic and ultralight sponge. The preparation method comprises two steps of performing functionalized processing on melamine sponge by using an impregnation method and performing a curing reaction after processing. The melamine sponge used by the invention has a large quantity of active functional groups such as hydroxyl groups and amino groups on the surface, the content of the hydrophobic active functional groups on the surface of the sponge is remarkably reduced after the active groups are chemically functionalized, which causes a result that the surface energy of the material is reduced, thus the sponge is endowed with super-hydrophobic and super-oleophylic effects, and a contact angle between the sponge and water exceeds 150 degrees; and the modified melamine sponge belongs to an ultralight material due to density. The method disclosed by the invention has the advantages that raw materials are low in price and easy to available, the process is simple and easy to operate, the large-scale preparation is easily realized, and the like. The sponge prepared according to the preparation method has the advantages of low density, excellent compression resistance, high oil absorbing speed, high oil absorbing rate, high oil and water separation selectivity and the like, is a novel and efficient ultralight-density oil and water separating material, and has a wide application prospect in the fields such as organic chemical reagent treatment, oil-containing wastewater treatment, and leaking crude oil recovery.

Owner:中科瑞丽分离科技无锡有限公司

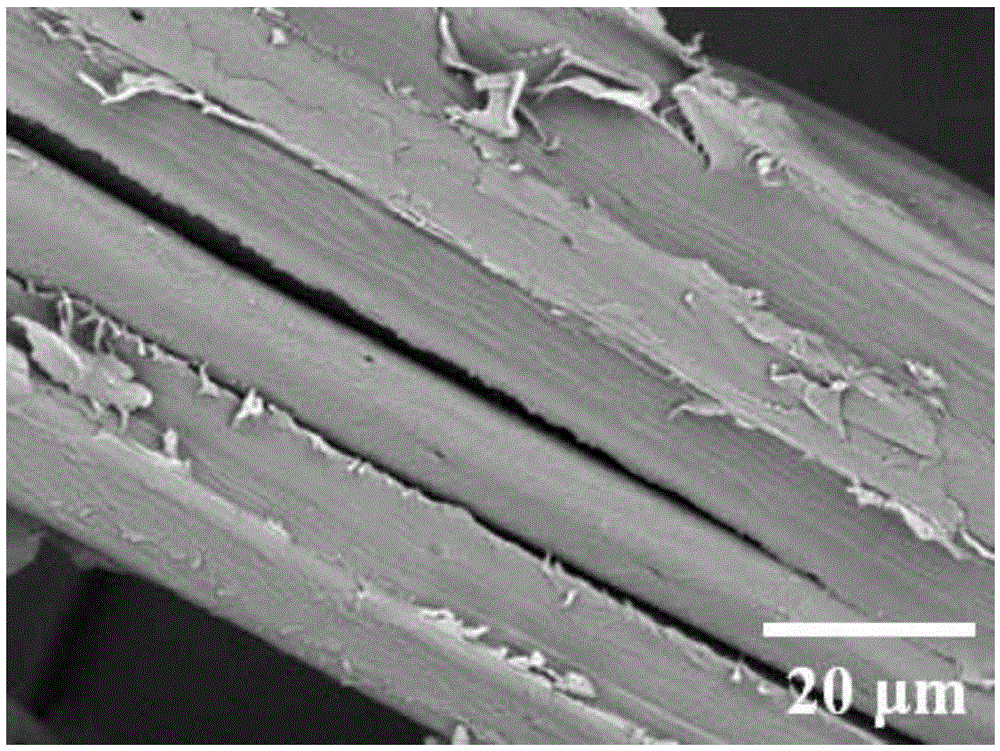

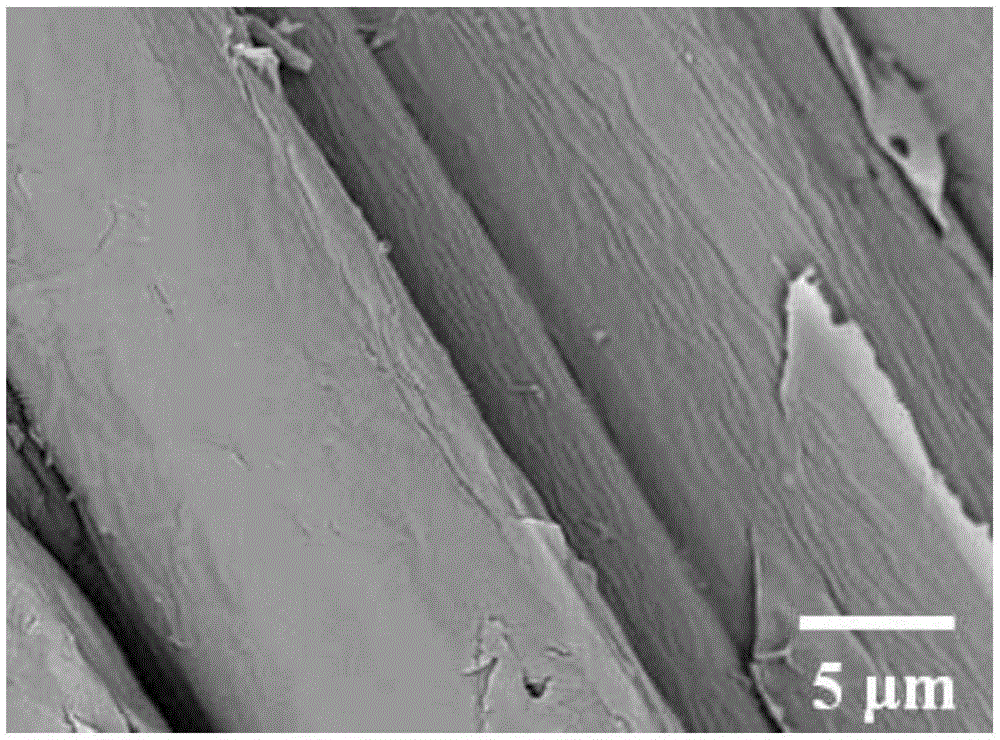

Preparation method for superhydrophobic superoleophilic straw fiber

ActiveCN105107468AEfficient use ofAvoid secondary pollutionFatty/oily/floating substances removal devicesOther chemical processesFiberSolvent

The invention discloses a preparation method for superhydrophobic superoleophilic straw fiber, belonging to the technical field of functional materials. The objective of the invention is to provide the preparation method for the superhydrophobic superoleophilic straw fiber which has cheap and easily-available raw materials, high oleophilic property and biodegradability. The method in the invention comprises the following steps: step 1, crushing straw, soaking the crushed straw in an alkali solution and carrying out pretreatment, and carrying out washing and drying; step 2, with tetraethyl orthosilicate as a silicon source, ammonia water as a catalyst and absolute ethyl alcohol as a solvent, carrying out in-situ synthesis so as to obtain straw fiber with surface loaded with silicon dioxide particles; step 3, dissolving zinc nitrate in a sodium hydroxide aqueous solution, and carrying out vigorous stirring, centrifugal separation and drying so as to obtain zinc oxide particles; step 4, preparing octyltriethoxysilane modified liquid; and step 5, taking the straw fiber in the step 2 and zinc oxide in the step 3, adding the straw fiber and the zinc oxide into the above-mentioned modified liquid, carrying out uniform mixing and dispersing, carrying out filtering separation so as to obtain the straw, and carrying out drying. The superhydrophobic superoleophilic straw fiber prepared by the method in the invention has excellent superoleophilic property and wide application space in the field of marine spilled oil cleaning.

Owner:NORTHEAST FORESTRY UNIVERSITY

Kapok fiber-based three-dimensional network oil absorption material

The invention discloses a kapok fiber-based three-dimensional network oil absorption material. According to the invention, activation-treated kapok fibers are used as base materials, and the three-dimensional network oil absorption material is prepared by grafting copolymerization, crosslinking, washing, drying, and crushing in the presence of an initiator. The dry oil absorption material can absorb diesel oil with a mass being 40-50 times of the mass of the material, can absorb gasoline with a mass being 40-47 times of the mass of the material, and can absorb chloroform with a mass being 60-67 times of the mass of the material. The oil absorption material of the invention is simple in preparation operation, is characterized by high oil absorption rate and high oil absorption speed, and is applicable to fields such as sea, river, lake surface oil pollution, kitchens, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

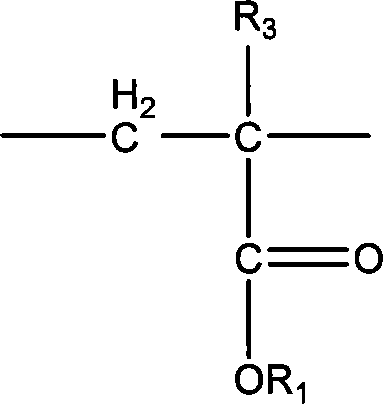

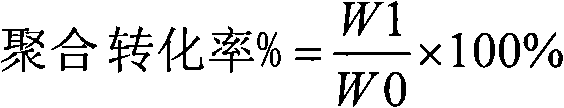

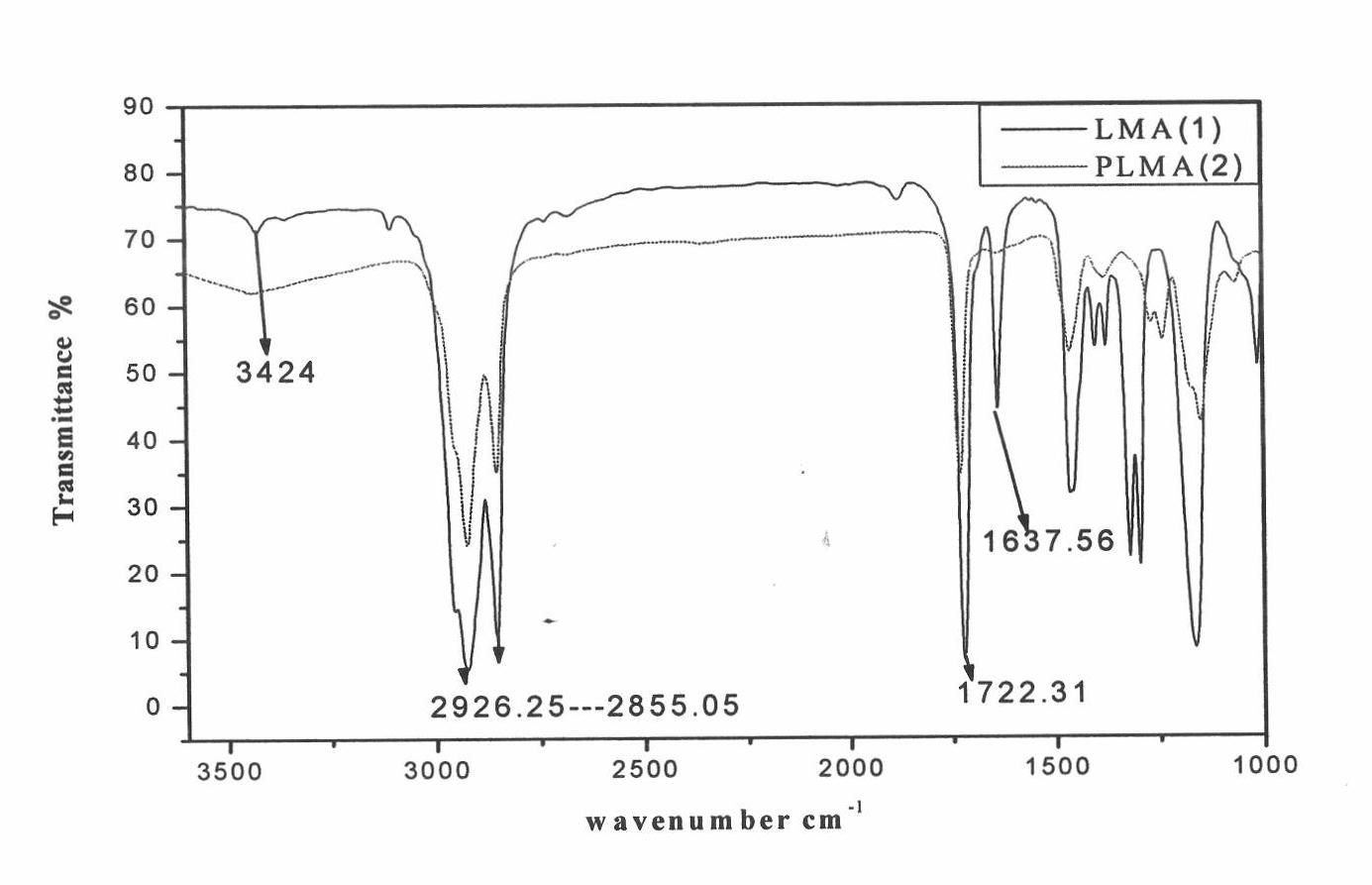

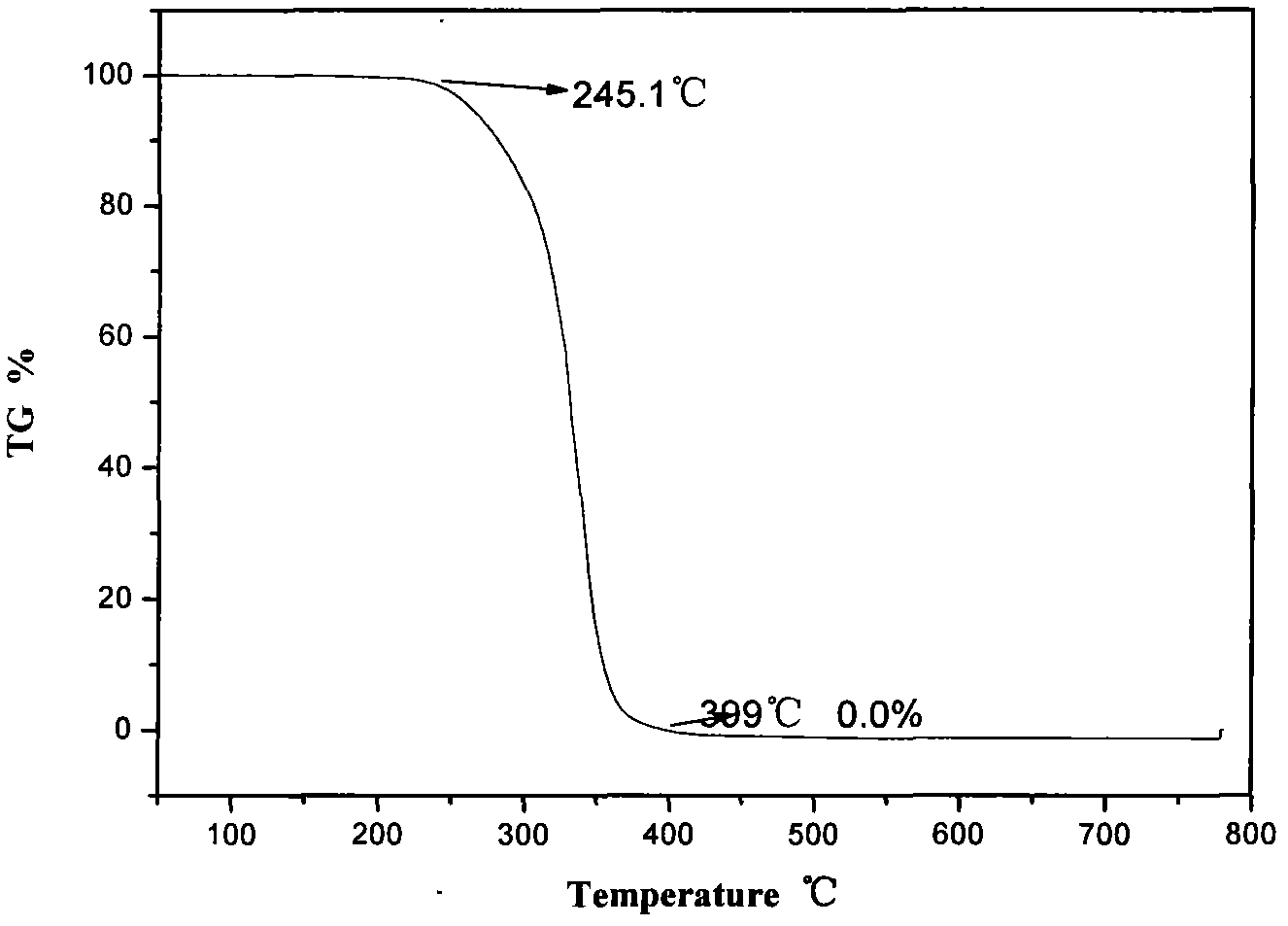

Preparation method for copolymethacrylate/polypropylene composite oil-absorbing material

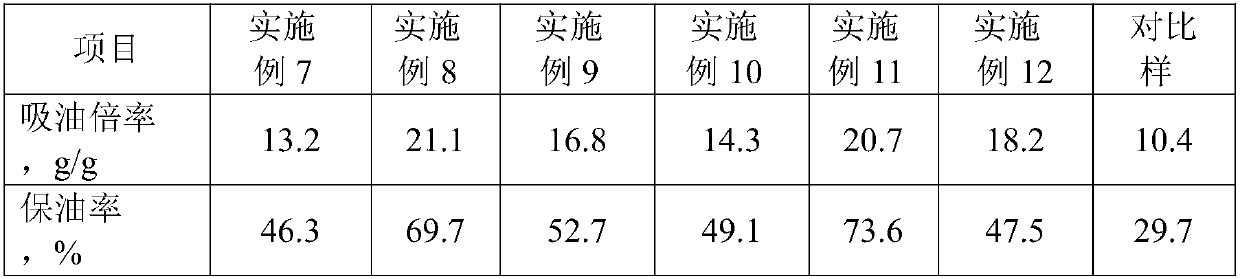

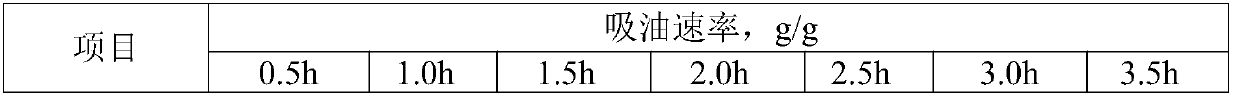

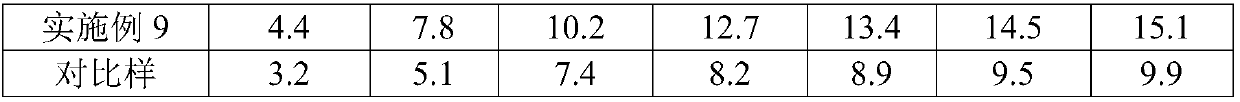

InactiveCN104693592AHigh oil absorption rateGood oil retentionMelt spinning methodsConjugated synthetic polymer artificial filamentsBenzoyl peroxideDibenzoyl Peroxide

The invention relates to a preparation method for a copolymethacrylate / polypropylene composite oil-absorbing material. The method comprises the following steps: adding a dispersant and deionized water into a polymerization kettle, adding a mixed solution and carrying out polymerization so as to obtain copolymethacrylate, wherein the dispersant is polyvinyl alcohol, and the mixed solution comprises 85 to 90% of alkyl methacrylate substances and styrene, 0.5% of benzoyl peroxide and 10 to 15% of beta-hydroxylethyl methacrylate; mixing copolymethacrylate with polypropylene master batch so as to obtain modified polypropylene master batch; and applying the modified polypropylene master batch to manufacturing of a melt-blown non-woven fabric so as to obtain the composite oil-absorbing material. To diesel oil No. 0, the oil absorption rate of the composite oil-absorbing material prepared in the invention is increased to 12.2 g / g from 11.2 g / g before compositing, the oil holdup rate is increased to 96.8% from 83.1% before compositing, and the water absorption rate is decreased to 6.6% from 18.2% before compositing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method for oil absorption material made of polypropylene non-woven cloth

The invention discloses a preparation method for an oil absorption material made of polypropylene non-woven cloth. The preparation method comprises the steps of treatment of the polypropylene non-woven cloth, preliminary grafting reaction, grafting reaction and final treatment so as to obtain the oil absorption material made of the polypropylene non-woven cloth. In the preliminary grafting reaction and the grafting reaction, a monomer drop addition method or a monomer infusion method is adopted. The process of the drop addition method is as follows: adding an oleophylic monomer dropwise in preliminary grafting reaction solution, and conducting the grafting reaction for 30 minutes to 120 minutes under constant-temperature agitation so as to obtain a graft polymerization product, wherein the oleophylic monomer belongs to methacrylic acid alkyl esters, and the adding amount of the oleophylic monomer is 3%-6% of the total mass of the preliminary grafting reaction solution. The process of the infusion method is as follows: taking out a product of the grafting reaction, putting the product into the oleophylic monomer, conducting constant-temperature agitation, and conducting the grafting reaction for 30 minutes to 120 minutes so as to obtain the graft polymerization product, wherein the oleophylic monomer belongs to methacrylic acid alkyl esters, and the adding amount of the oleophylic monomer is 3%-6% of the total mass of the preliminary grafting reaction solution.

Owner:河北维嘉无纺布有限公司

Super-hydrophobic-oleophylic porous material, and preparation method and application thereof

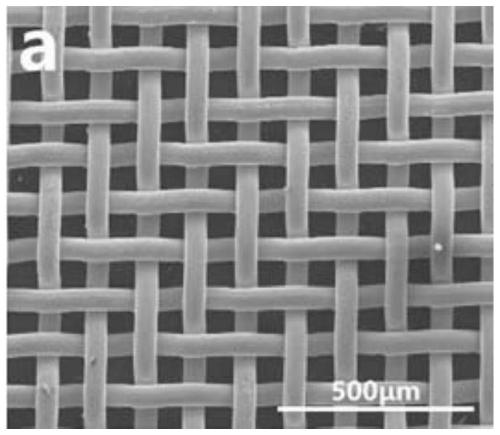

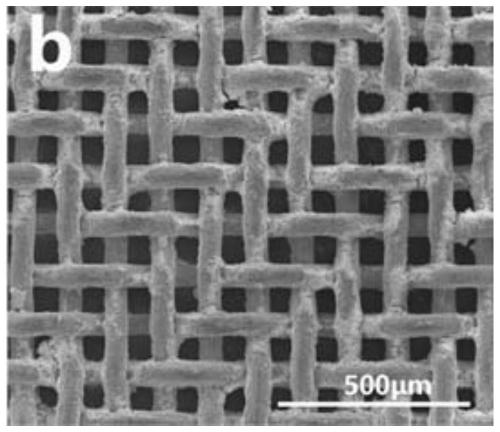

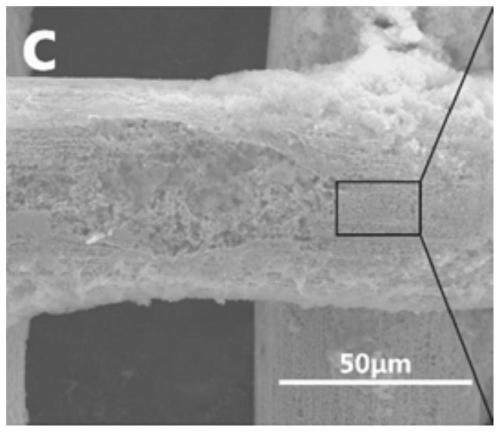

InactiveCN110280222ASimple processLow costFatty/oily/floating substances removal devicesOther chemical processesMicro nanoSilanes

The invention provides a super-hydrophobic-oleophylic porous material, and a preparation method and application thereof. The super-hydrophobic-oleophilic porous material comprises a metal grid structure and an organic-inorganic hybrid coating covering the metal grid structure, wherein the organic-inorganic hybrid coating is mainly formed by the reaction of phytic acid and fluorine-containing silane. According to the super-hydrophobic-oleophylic porous material, and the preparation method and application thereof, through the cocondensation of the phytic acid and the fluorine-containing silane, and the chelation of the phytic acid and the metal grid structure, an organic-inorganic hybrid micro-nano structure is formed on the surface of the metal grid structure, and the super hydrophobic-oleophilic modification of the surface of the metal grid structure is realized. The super-hydrophobic-oleophilic porous material provided by the invention can float on a water surface, can recover different kinds of floating oil on water efficiently, and has stable super hydrophobicity and corrosion resistance in a high salt spray environment; the oil absorption rate and oil-water separation efficiency are high; meanwhile, the preparation method is simple, the cost is low, large-scale preparation can be realized, and a very good industrial application prospect is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

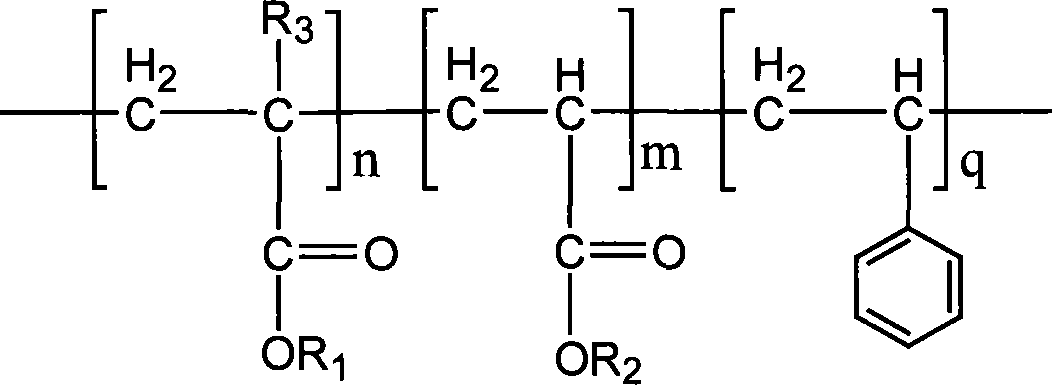

Acrylate polymer high oil absorption resin and preparation method and application thereof

ActiveCN101967212AHigh purityHigh oil absorption rateOther chemical processesWater/sewage treatment by sorptionCross-linkOil retention

The invention relates to acrylate polymer high oil absorption resin and a preparation method and application thereof. The oil absorption resin comprises the following components in part by weight: 50 to 95 parts of flexible chain segment monomer, 5 to 50 parts of rigid chain segment monomer, a cross-linking agent in an amount which is 0.2 to 5 percent of the total weight of the monomers, and a solvent in an amount which is 1.5 to 4 times the total weight of the monomers. The high oil absorption resin is prepared by free radical solution polymerization at room temperature under the initiation of gamma rays. The preparation process is simple, the reaction condition is easy to control, energy consumption is saved, and the method is safe and environmental-friendly and is more suitable for industrial production. The prepared high oil absorption resin has the advantages of high purity, complete hydrophobicity, wide application range, capacity of absorbing multiple types of oil, high oil absorption multiplying power, high oil retention performance, recyclability and the like, and can be widely applied to the absorption of floating oil on the sea surface, scattered oil, cooled emulsified oil on lathes of factories, and oil and organic substances in industrial production and domestic sewage.

Owner:SHANGHAI FINETAC PRECISION TECH CO LTD

Preparation method and application of three-element siloxane sponge

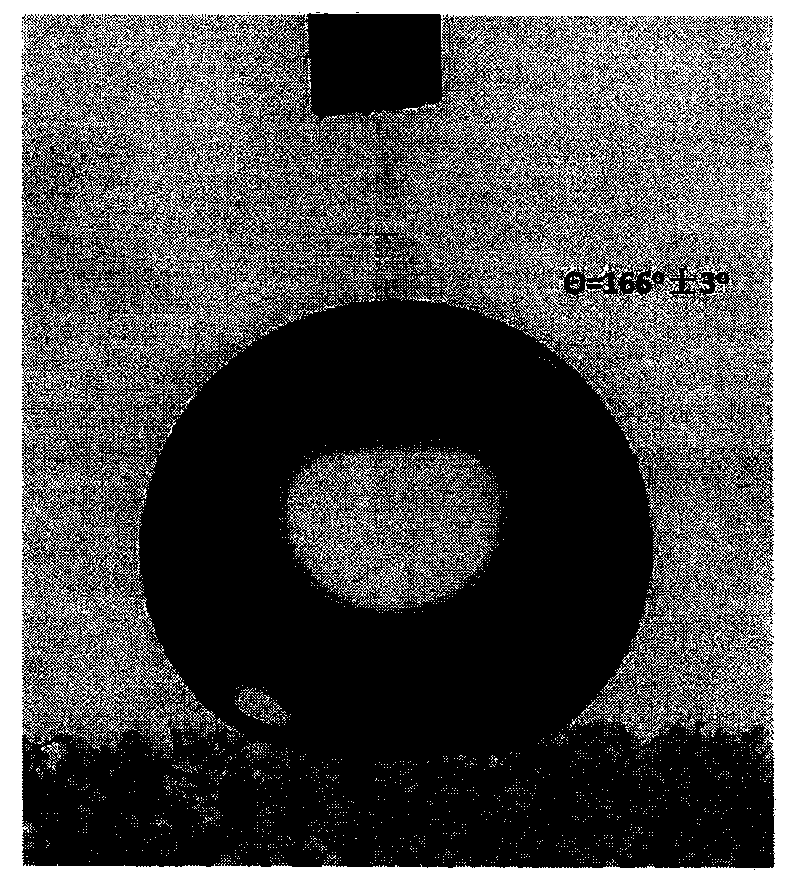

ActiveCN104194028ALow densityExcellent compression resistanceFatty/oily/floating substances removal devicesLiquid separationSilanesHydrolysis

The invention relates to a preparation method and application of three-element siloxane sponge, belonging to the technical field of preparation and application of environmental functional materials. The method comprises the following steps: alkoxy silane hydrolysis, gelation, product washing and drying. Compared with the traditional two-element siloxane sponge, the three-element siloxane sponge contains abundant non-polar groups and higher roughness on the surface, and is endowed with the superhydrophobic and superoleophylic effects; the contact angle with water exceeds 160 degrees; and the material has excellent mechanical properties. The preparation method is simple to operate, has the advantages of cheap raw materials and the like, and can easily implement large-scale preparation. The three-element siloxane sponge has the advantages of low density, excellent compression resistance, high oil absorption speed, high oil absorption power and the like, has wide application prospects in the fields of organic chemical solvent treatment, oily wastewater treatment, oil spillage treatment and the like, and is a novel efficient oil-water separation material.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

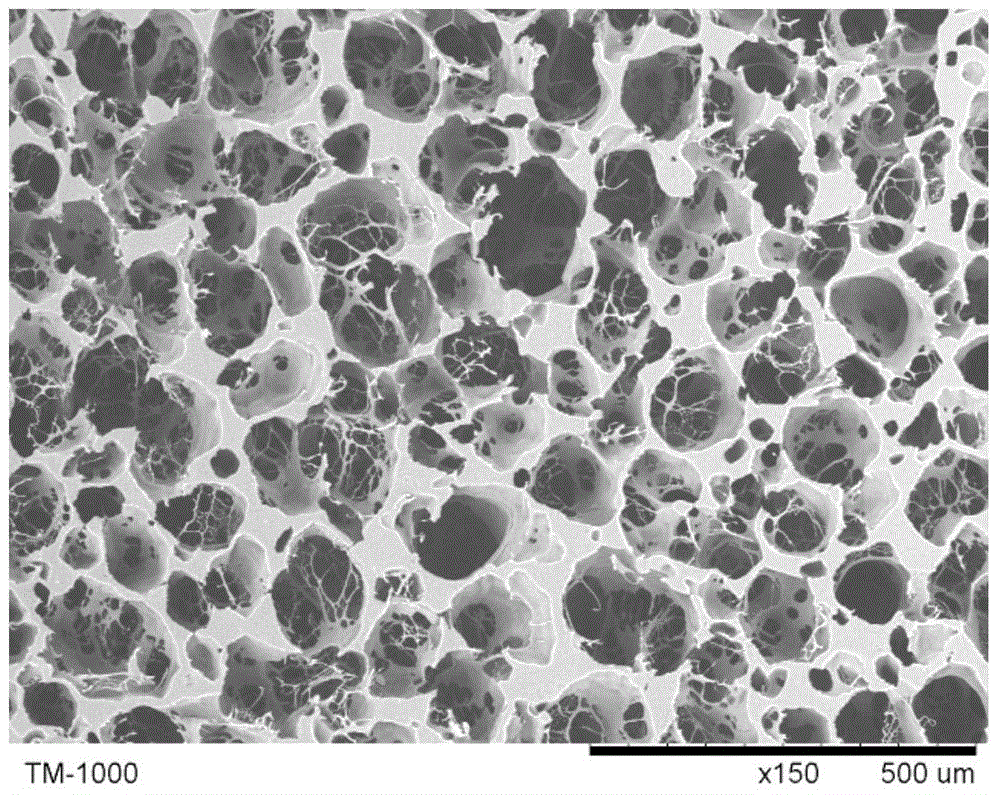

Open-cell polymer foam material and preparation method therefor

The present invention provides a preparation method for an open-cell polymer foam material. The preparation method comprises the following steps of: a, weighing the following materials in parts by weight: 100 parts of polypropylene, 0.5-5 parts of a nucleating agent, 10-100 parts of ethylene-containing polyolefin and 1-30 parts of open-cell fillers; b, uniformly mixing polypropylene, the nucleating agent, ethylene-containing polyolefin and the open-cell fillers to obtain a mixture; adding the mixture into an extruder, and introducing supercritical-state carbon dioxide at a 1 / 5-1 / 3 part of a screw rod of the extruder; extruding and carrying out foaming to obtain the open-cell polymer foam material containing the open-cell fillers, wherein the open-cell polymer foam material contains the open-cell fillers comprising a plurality of first openings; and c, immersing the open-cell polymer foam material containing the open-cell fillers into an etching solution so as to etch the open-cell fillers to form a plurality of second openings, thereby obtaining the open-cell polymer foam material. The present invention further provides the open-cell polymer foam material. The open-cell polymer foam material has the advantages of a high open-cell ratio and good oil absorption ratio.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

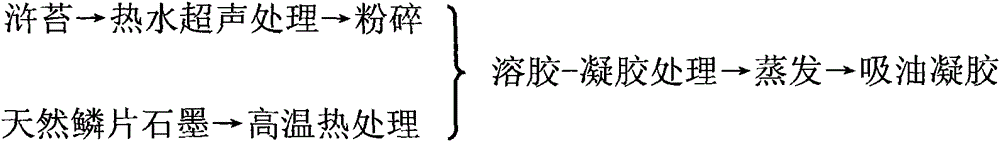

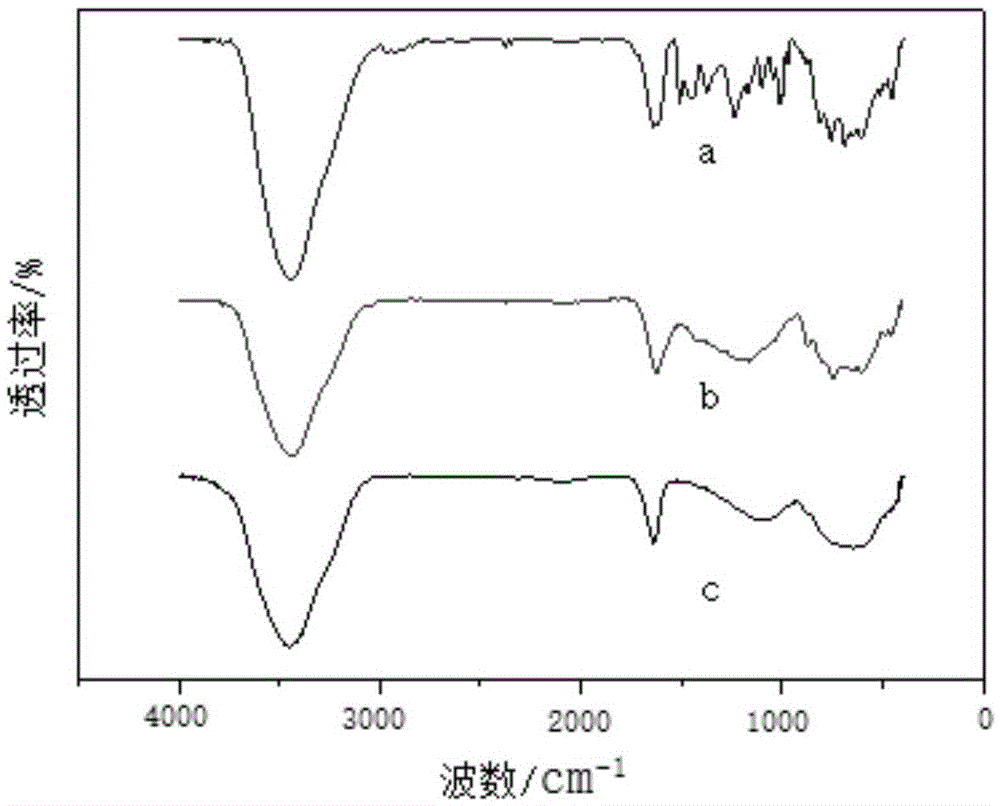

Enteromorpha gel oil suction material and preparation method thereof

The invention relates to an enteromorpha gel oil suction material and a preparation method thereof, the gel oil suction material comprises the following components: 60-70% of enteromorpha extract product, 10-15% of expandable graphite, 2-4% of ferric nitrate, 5-8% of cobalt nitrate, 8-12% of citric acid and 2-4% of ammoniacal liquor. According to the invention, enteromorpha with abundant output in sea is taken as a raw material, sugar alcohol, aliphatic acid and crude fiber extracted in enteromorpha are taken as base, and are mixed with expandable graphite by using a sol-gel method, the gel oil suction material can be recovered and used with high efficiency and environmental protection, the molecular structure of three-dimensional fiber mesh can greatly absorb oil molecule. The oil suction material has good oil adsorption performance, oil suction can reach saturation in 60-80 minutes under dynamic state, the saturation adsorption multiple is 40-60 which is higher than that of the current resin oil suction material and biomass oil suction material, and the enteromorpha gel oil suction material has the advantages of fast oil suction speed, good oil binding capacity and low cost.

Owner:QINGDAO UNIV

Natural oil adsorbing material made of maize straw

InactiveCN105126774AHigh oil absorption rateGood regeneration effectOther chemical processesCorn stoverCellulose

The invention relates to a natural oil adsorbing material made of maize straw, and belongs to the field of novel material preparing. The natural oil adsorbing material is characterized in that the maize straw serves as raw materials, cellulose in the straw is extracted through sodium hydroxide and sodium hypochlorite and then chemically modified through acetic anhydride, hydroxide radical is replaced by acetyl, lipophilic groups on the surfaces of the cellulose are increased, and the natural oil adsorbing material is prepared. The preparing materials come from pure natural plants and can be biodegraded, the material prepared after modification is high in oil adsorption rate and good in regeneration effect, and the adsorption effect is still remarkable after the material is repeatedly used five to six times.

Owner:CHANGZHOU DINGRI ENVIRONMENTAL PROTECTION TECH

Oil absorbing resin, preparation method and application thereof

InactiveCN105153342AFast oil absorptionIncrease elasticityOther chemical processesCross-linkFoaming agent

The invention relates to an oil absorbing resin, which comprises, by mass part, 40-60 of a water phase and 5.25-7.5 of an oil phase. The water phase is composed of, by volume, 30-45 of water and 10-25 of a dispersing agent. The oil phase is composed of, by mass, 3-8 parts of a polymer monomer, 0.045-0.095 part of an initiator, 0.03-0.2 part of a cross-linking agent, and 0.5-2 parts of a pore-foaming agent. The invention also discloses a preparation method of the oil absorbing resin, and the method includes: adding the oil phase into the water phase, performing heating to 78-82DEG C and conducting mixing, maintaining the temperature at 78-82DEG C for 1-6h till liquid drops shape; raising the temperature to 88-90DEG C, carrying out heat preservation for 0.5-2h and performing cooling, thus obtaining the resin. The invention discloses application of the oil absorbing resin in edible oil, gasoline, kerosene or diesel oil adsorption. And the oil absorbing resin has the advantages of high elasticity, high swelling speed, high strength, and fast oil absorption rate.

Owner:HEILONGJIANG UNIV

High-oil-absorbency resin

InactiveCN103396507AHigh oil absorption rateGood reversibilityOther chemical processesChemistryAcrylate

The invention discloses a high-oil-absorbency resin which is mainly prepared from the following ingredients in parts by weight: 100 parts of a acrylic monomer, 0.5-1.5 parts of a dispersing agent, 0.5-1.5 parts of an initiating agent, 3-5 parts of a chemical cross-linking agent and 4-8 parts of a physical cross-linking agent. Compared with other oil-absorbency resins prepared in a single chemical cross-linking mode in the prior art, the high-oil-absorbency resin has the advantages that oil absorption multiplying power for diesel oil is improved by 18-20%, the oil absorption multiplying power for engine oil is increased by 14-16%, the oil absorption multiplying power is remarkably increased, and the oil absorption reversibility is remarkably improved.

Owner:南京市荣达树脂有限公司

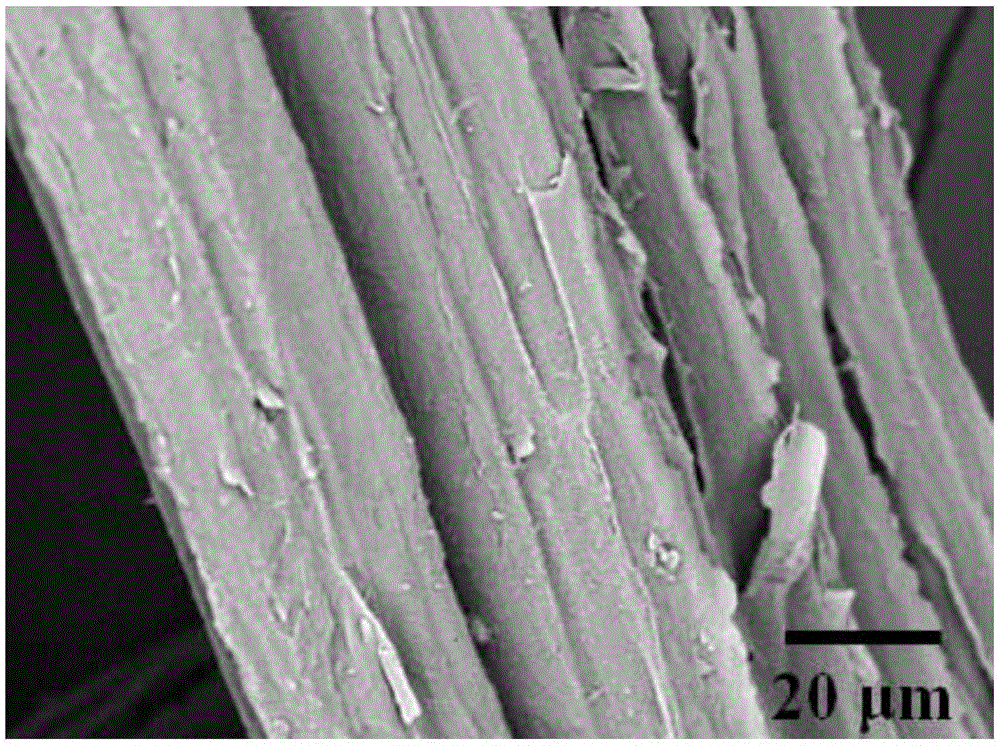

High oil-absorbing polyacrylonitrile hollow activated carbon fiber and preparation method thereof

InactiveCN105544019AHigh oil absorption rateLarge adsorption capacityOther chemical processesHollow filament manufactureCarbon fibersNitrogen gas

The invention belongs to the technical field of functional materials, and discloses a high oil-absorbing polyacrylonitrile hollow activated carbon fiber and a preparation method thereof. The method is as below: dissolving polyacrylonitrile in DMF to obtain a polyacrylonitrile / DMF solution; degassing the solution and conducting a dry-wet spinning to obtain polyacrylonitrile hollow fibers; soaking the fibers in deionized water for pretreatment, heating the polyacrylonitrile hollow fibers after pretreatment to 230-250 DEG C, pre-oxidizing for 1-3 h, then heating to 550-600 DEG C under a nitrogen atmosphere, and carbonizing for 1-1.5 h; and finally heating to 800-1100 DEG C in a carbon dioxide atmosphere and activating for 1-4 h to obtain the high oil-absorbing polyacrylonitrile hollow activated carbon fiber. The obtained polyacrylonitrile hollow activated carbon fiber has high oil absorption rate, is easy to recycle and reuse, can be widely used in oil spill treatment, waste oil recovery and floating oil treatment.

Owner:SOUTH CHINA UNIV OF TECH

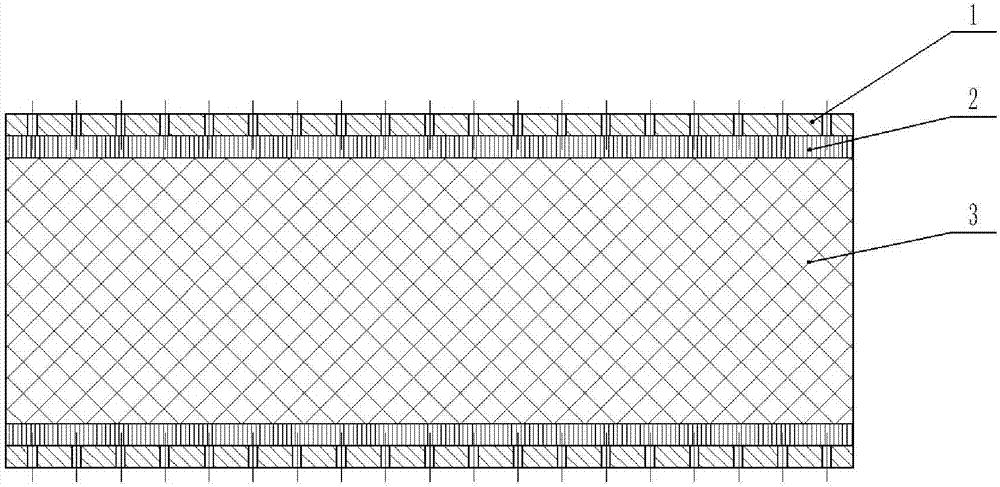

Oil absorption felt material with skin/core composite structure

InactiveCN104441854AImprove oil absorption capacityGood oil retentionSynthetic resin layered productsCleaning equipmentPolyesterNonwoven fabric

The invention relates to an oil absorption felt material with a skin / core composite structure. A compact non-woven material forms a skin layer, and a core layer material is composed of multilayers of loose non-woven materials. The skin layer material is a polypropylene melt-blown non-woven material with a gram weight of 15-50g / m<2>, the core layer material is a polypropylene / polyester mixed melt-blown non-woven material with a thickness of 3-5cm, the core layer material is coated by the skin layer material hermetically, and the periphery is sealed by means of hot pressing. For the oil absorption felt material, the skin layer material has high oleophylic and hydrophobic effects, when the oil absorption felt contacts oil, oil molecules can be led into the oil absorption felt inner core to be adsorbed by the inner core layer material, and water molecules cannot enter the core layer through the skin layer material, the core layer material can adsorb oil products with a self weight of 10-15 times, the oil products are sealed and stored in the oil absorption felt core layer and do not leak. The oil absorption felt provided by the invention has high oil absorption and oil holding performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

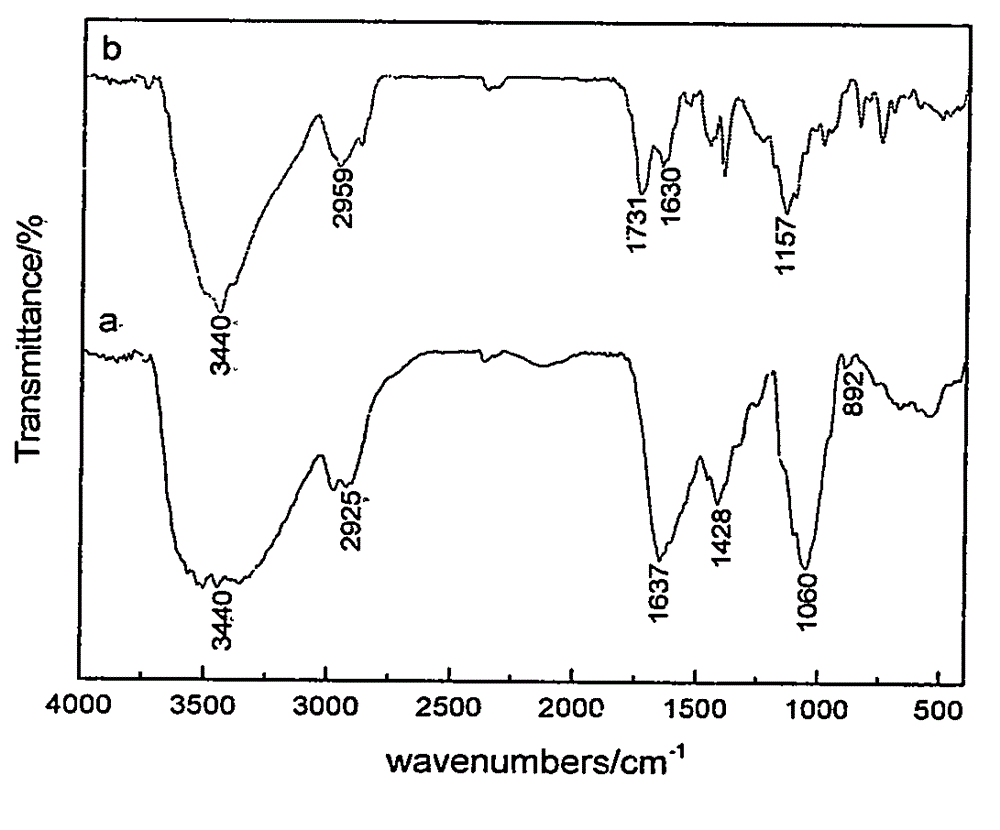

High oil absorption resin and preparation method thereof

The invention provides high oil absorption resin. The high oil absorption resin is prepared form the following raw materials in parts by weight: 1.6-9.4 parts of rapeseed meal, 90.7-96.9 parts of a graft monomer, 0.3-1.1 parts of an initiator and 0.01-0.13 part of a crosslinking agent. The invention also provides a preparation method of the high oil absorption resin. The preparation method comprises the following step: with the rapeseed meal as a substrate, MMA and BA as monomers and BPO as the initiator, carrying out graft copolymerization to synthesize RSM-g-P (MMA-co-BA) high oil absorption resin successfully. The high oil absorption resin has the inherent lipophilic performance of RSM and is also added with the characteristics of BA and MMA after crosslinking, and thus the oil absorption performance of the high oil absorption resin is greatly improved.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Method for preparing graphene high-oil absorption resin

ActiveCN107617427AExcellent hydrophobic and lipophilic propertiesHigh oil absorption rateOther chemical processesLiquid separationIonCvd graphene

The invention relates to a method for preparing a graphene high-oil absorption resin. The method comprises the following steps: 1, putting modified porous graphene or modified porous graphene antibacterial composition into deionized water, and performing ultrasonic dispersion for 1-24 hours so as to obtain a modified porous graphene suspension; 2, stirring deionized water and an emulsifier in a reaction container, sufficiently dissolving, and adding an acrylic monomer so as to obtain a stable emulsion; 3, putting the modified porous graphene suspension into the emulsion in the step 2, performing continuous stirring emulsification for 30-60 minutes, further adding a chemical cross-linking agent and a pore-forming agent, and continuously stirring for 10-30 minutes; 4, heating to 40-70 DEG C,performing a reaction for 2-20 hours with an initiator so as to obtain porous high-oil absorption resin gel; 5, pelletizing the porous high-oil absorption resin gel, and drying in an oven at 105-180DEG C till a constant weight, so as to obtain the graphene high-oil absorption resin.

Owner:浙江卫星新材料科技有限公司

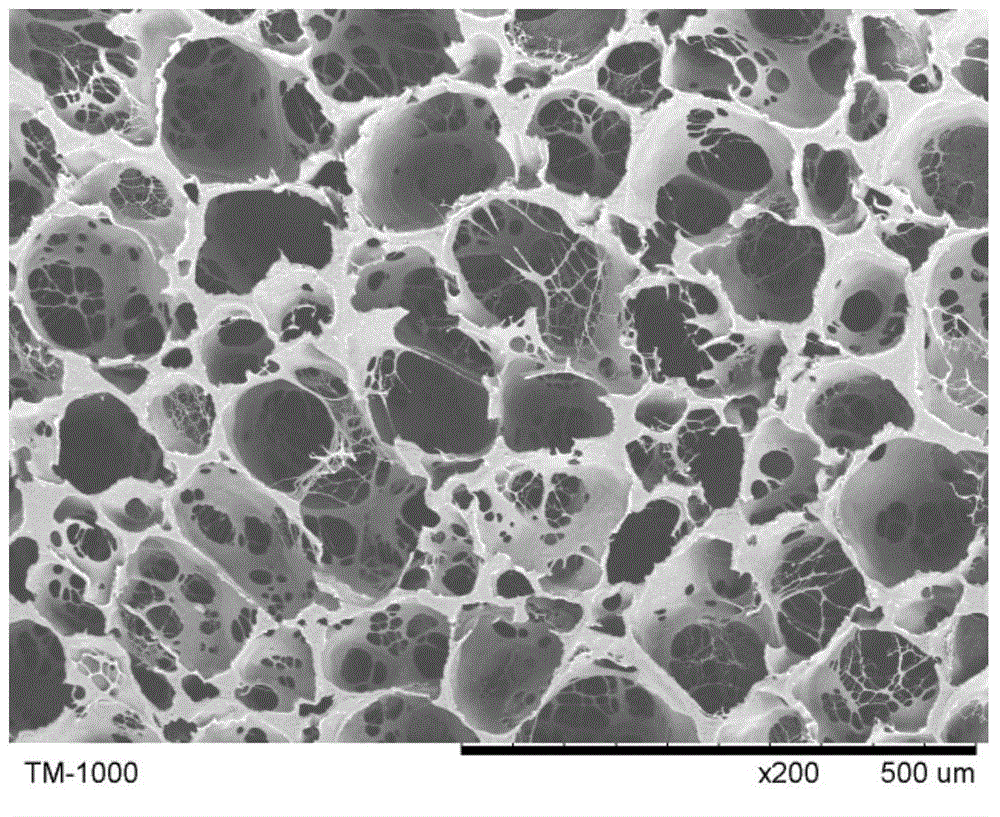

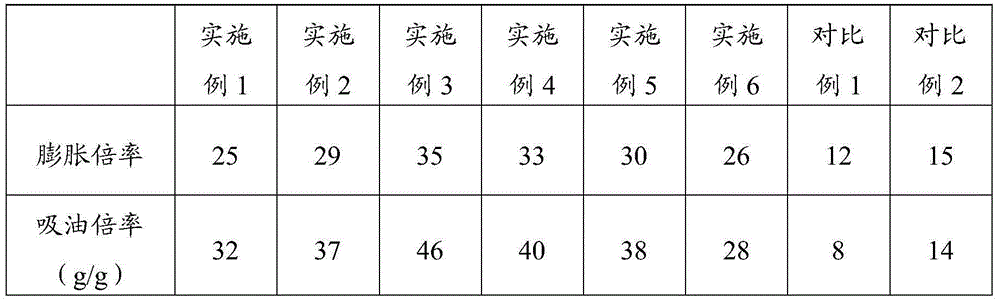

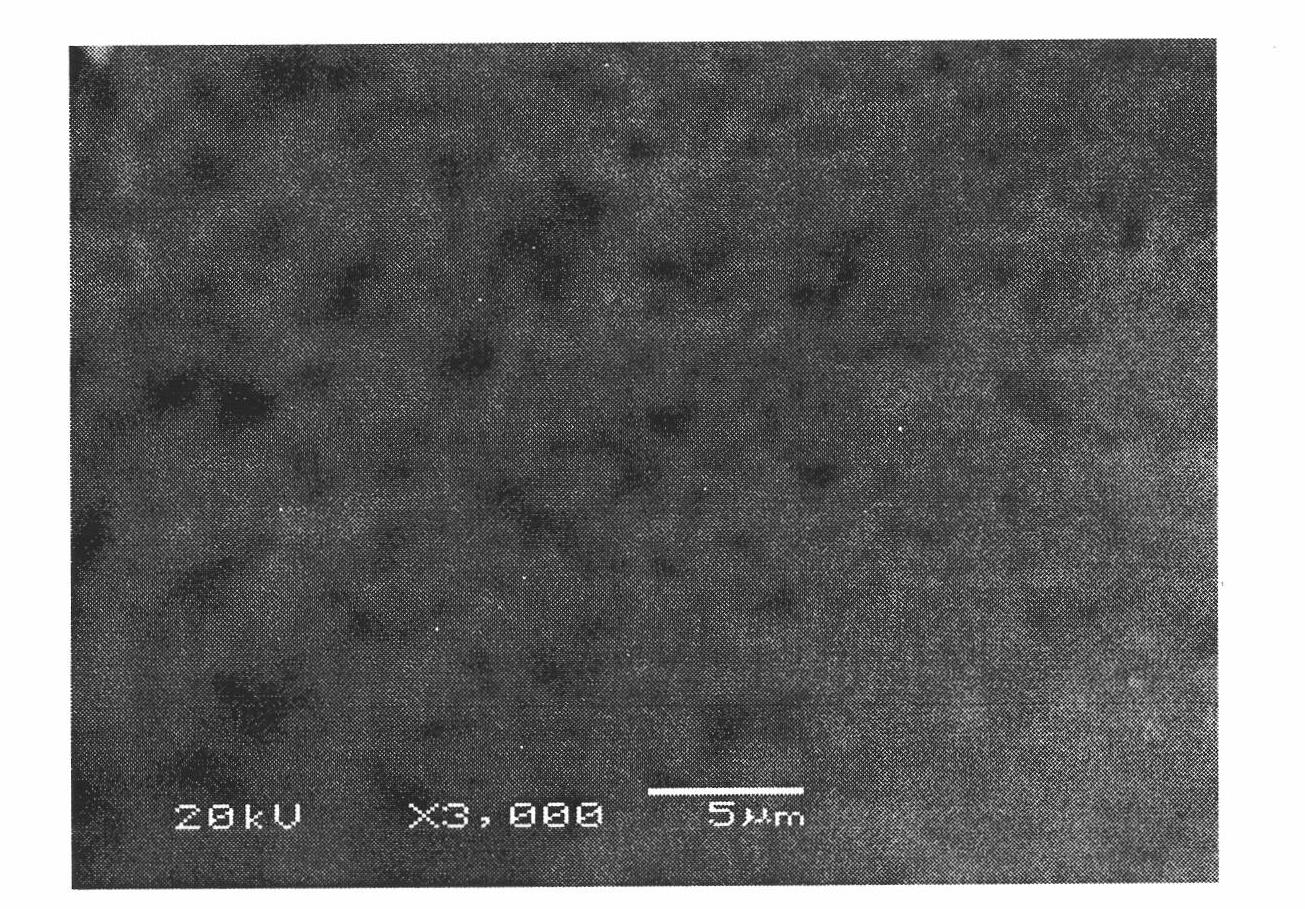

Preparation method of ultrahigh-porosity polyacrylate porous oil absorption material

InactiveCN111054317AGood water and oil separation efficiencyHigh oil absorption rateOther chemical processesAlkali metal oxides/hydroxidesOil separationOil phase

The invention discloses a preparation method of an ultrahigh-porosity polyacrylate porous oil absorption material. Acrylate is used as a monomer, and a solution obtained by dissolving an emulsifier inthe monomer is used as an oil phase; an aqueous solution containing an electrolyte and an initiator is used as a water phase; and the water phase is added into the oil phase during stirring to obtaina high internal phase emulsion, the obtained emulsion is transferred into a mold, the mold is put into a constant-temperature water tank for polymerization, and an obtained material is dried to obtain the polyacrylate porous material with an open pore structure, high water-oil separation efficiency and porosity of 97.5%. The material has an adjustable pore structure, and compared with the material obtained in the prior art, the material has higher oil absorption rate and speed.

Owner:EAST CHINA UNIV OF SCI & TECH

Melt nano fiber super-high-efficiency oil absorbent cotton

InactiveCN107042024AImprove oil absorption efficiencyUltra-high specific surface area and porosityLayered productsLiquid separationAbsorption rateCotton cloth

The invention discloses a melt nano fiber super-high-efficiency oil absorbent cotton. The melt nano fiber super-high-efficiency oil absorbent cotton mainly comprises porous cotton cloth layers, oriented nano fiber oil absorbing layers, and a nano fiber oil storage layer; the porous cotton cloth layers are arranged on the outermost layers; the oriented nano fiber oil absorbing layers and the nano fiber oil storage layer are arranged and combined in different sequences; the external surface of each oriented nano fiber oil absorbing layer is coated by the corresponding porous cotton cloth layer firmly, winkles on the external layers of the melt nano fiber super-high-efficiency oil absorbent cotton are formed by the porous cotton cloth layers and the oriented nano fiber oil absorbing layers; the porous cotton cloth layers and the oriented nano fiber oil absorbing layers are relatively thin; the nano fiber oil storage layer is arranged on the internal surfaces of the two oriented nano fiber oil absorbing layers; each of the two surfaces of the nano fiber oil storage layer and the corresponding surface of the oriented nano fiber oil absorbing are contacted with and embedded into each other. According to the melt nano fiber super-high-efficiency oil absorbent cotton, the porous cotton cloth layers with elasticity are taken as the outermost layers, and winkle surfaces are formed by the porous cotton cloth layers with the oriented nano fiber oil absorbing layers, so that the contact area of oriented oil absorbing fiber with oil stain is increased effectively; oil absorbed by the melt nano fiber super-high-efficiency oil absorbent cotton can be recycled via squeezing the melt nano fiber super-high-efficiency oil absorbent cotton, and oil stain absorption rate is maintained.

Owner:BEIJING UNIV OF CHEM TECH

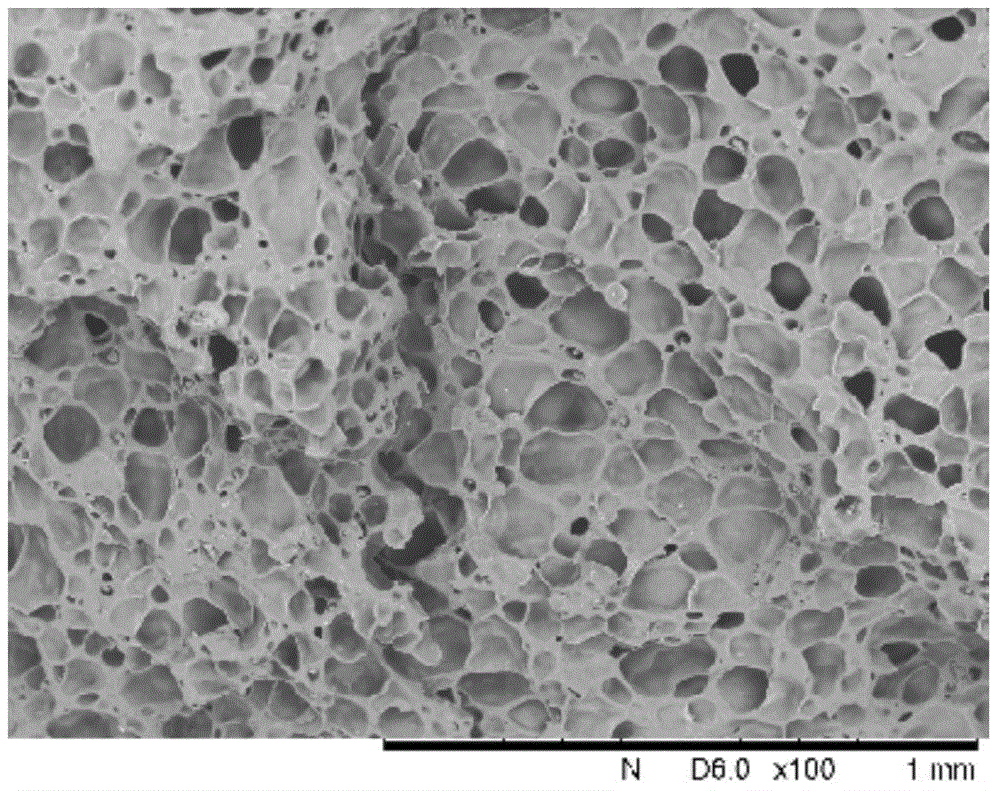

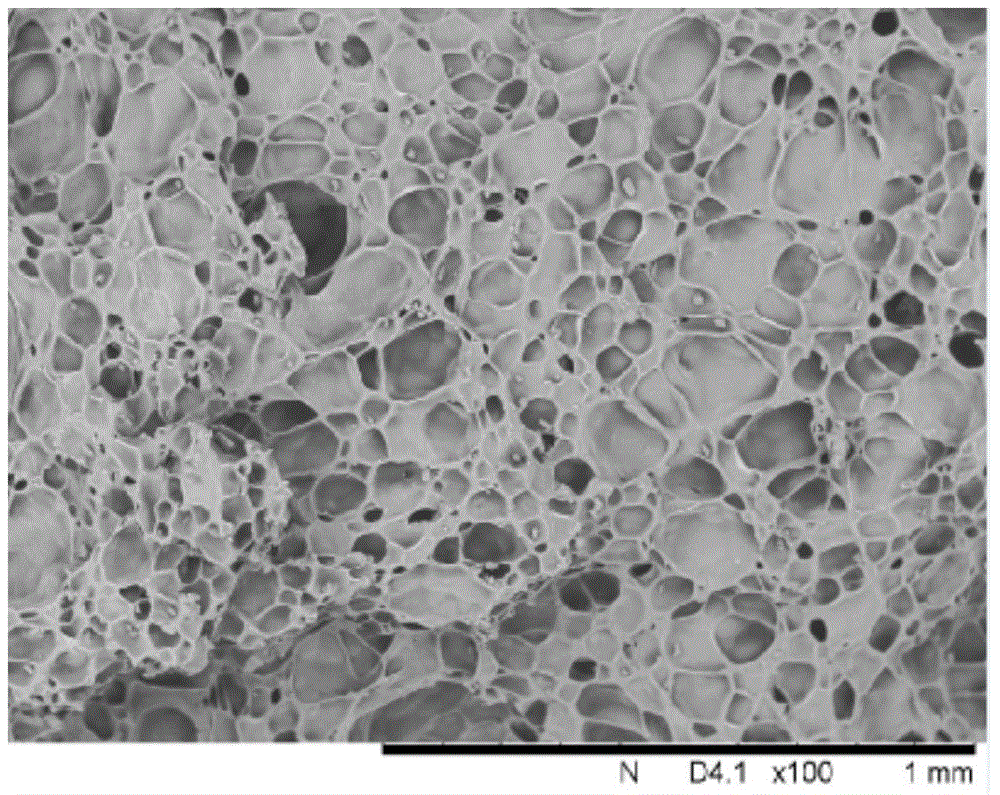

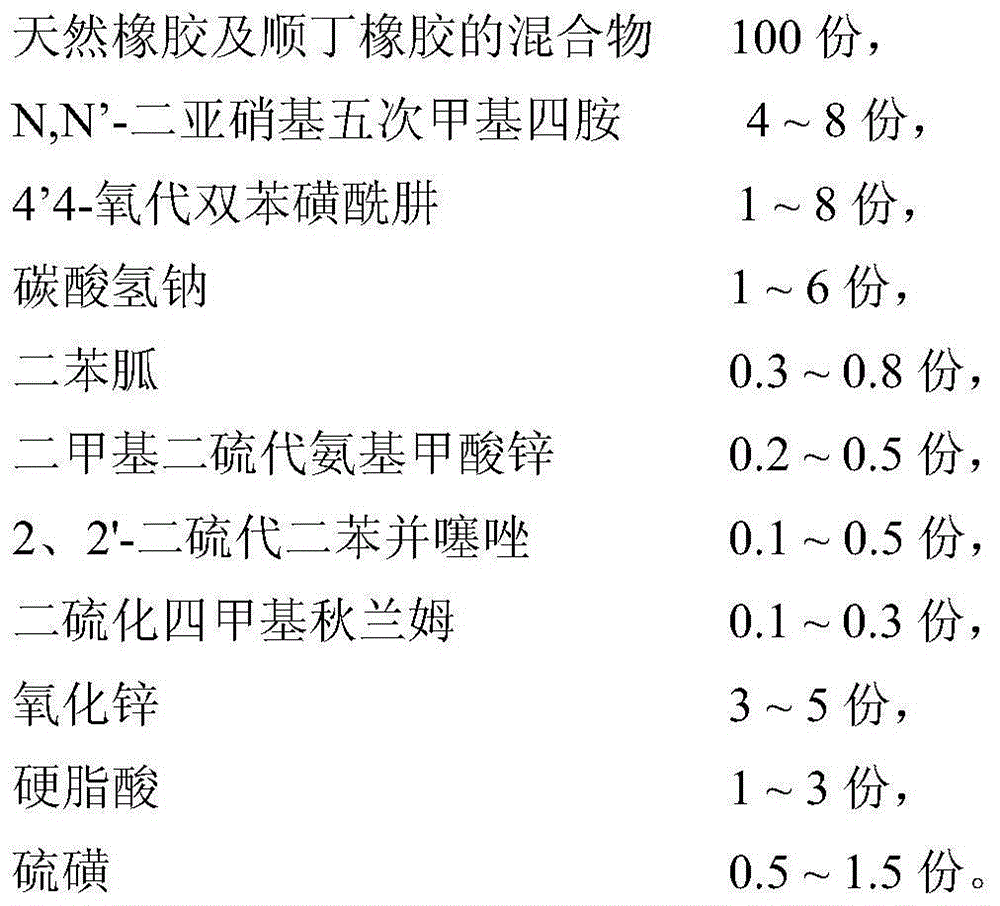

A rubber foaming oil-adsorbing material and a preparing method thereof

InactiveCN105585745AGood oil retentionImprove adsorption capacityOther chemical processesOxygenStearic acid

The invention relates to a rubber foaming oil-adsorbing material and a preparing method thereof. The material comprises 100 parts by weight of a mixture comprising natural rubber and polybutadiene, 4-8 parts by weight of N,N'-dinitrosopentamethylenetetramine, 1-8 parts by weight of 4,4'-oxybis(benzenesulfonyl hydrazide), 1-6 parts by weight of sodium hydrogen carbonate, 0.3-0.8 part by weight of diphenylguanidine, 0.2-0.5 part by weight of zinc dimethyldithiocarbamate, 0.1-0.5 part by weight of 2,2'-dithiobis(benzothiazole), 0.1-0.3 part by weight of tetramethylthiuram disulfide, 3-5 parts by weight of zinc oxide, 1-3 parts by weight of stearic acid and 0.5-1.5 parts by weight of sulfur. The material adopts the mixture comprising the natural rubber and the polybutadiene as a substrate and is lower in cost and higher in oil adsorbing rate. The oil adsorbing rate of the material for xylene is 48.6 g / g, and the oil adsorbing rate of the material for gasoline is 30 g / g or above. The method is simple in process and prone to industrial production.

Owner:NINGBO UNIV

Porous high-oil-absorption resin and preparation method thereof

InactiveCN102504072AHigh oil absorption rateNo pollution in the processOther chemical processesWater/sewage treatment by sorptionCross-linkEmulsion polymerization

The invention relates to a porous high-oil-absorption resin and a preparation method thereof. The high-oil-absorption resin is prepared by radical-triggered composite emulsion polymerization of a monomer in the presence of a cross-linking agent, a trigger and an emulsifier and in a protective atmosphere of nitrogen. The high-oil-absorption resin in a small volume has high oil absorption rate and can absorb only oil but not water; after absorbing oil, the resin becomes a block and is easy to recover; with a density smaller than that of water, the resin can float on water and thus can well treat floating oil; and the resin has a certain application value in fields of petroleum, chemicals, environment protection and medicines.

Owner:NORTHWEST NORMAL UNIVERSITY

Antistatic flame-retardation and high-oil-adsorption functional material and preparation method thereof

The invention discloses an oil adsorption material. The oil adsorption material is prepared through a polymerization reaction of polyether polyol, a lipophilic assistant, a responsive flame retardant, a flame retardation smoke suppressor, a responsive antistatic agent, a composite catalyst, diisocyanate, a foam stabilizer and a foaming agent; and the density of the oil adsorption material is 8-20Kg / m<3>, the crude oil adsorption rate is 30-50 times, and the oxygen index is greater than 26%. The oil adsorption material has the advantages of antistatic property, flame retardation, high oil adsorption rate, non-toxicity, no pollution, low cost and onsite foaming. The oil adsorption material can be used to adsorb overflow oil on the water surface as an antistatic flame-retardation oil adsorption material, is especially suitable for emergency treatment of overflow oil on the water surfaces of rivers, lakes and seas, and is also suitable for kitchen range hoods, factory oil-containing exhaust gas recovery devices and other oil waste absorption or recovery occasions.

Owner:江苏瑞丰科技实业有限公司

Synthetic method for modified carbon nanotube and acrylate composite high-oil-absorption resin

InactiveCN105968254ALow costThe synthesis method is simpleOther chemical processesWater contaminantsPolymer scienceBenzoyl peroxide

The invention belongs to the field of synthesis of polymeric nanocomposites, and relates to modification of carbon nanotubes, in particular to a preparation method for acrylate / carbon nanotube composite resin with high oil absorption performance. The acrylate / carbon nanotube composite resin is synthesized by polymeric monomer butyl acrylate and butyl methacrylate, modified carbon nanotubes MWNTs-KH570, N-N methylene bisacrylamide, purified benzoyl peroxide and ethyl acetate at constant pressure and under the protection of nitrogen. The acrylate / carbon nanotube composite resin has the advantages that the oil and water selectivity is favorable, various oil products can be absorbed, the oil absorption rate can reach tens to dozens of times, the mass is low, the size is small, and the transportation and the storage are easy.

Owner:JIANGSU UNIV

Inorganic filling material modified high-molecular absorbent, and preparation method thereof

InactiveCN105037638AHigh oil absorption rateImprove thermal stabilityOther chemical processesButyl methacrylateChemistry

The invention discloses an inorganic filling material modified high-molecular absorbent. The inorganic filling material modified high-molecular absorbent is prepared from, by weight, 3 to 4 parts of bentonite, 2 to 3 parts of calcium carbonate, 1 to 2 parts of hexadecyl trimethyl ammonium bromide, 0.3 to 0.5 parts of liquid paraffin, 0.2 to 0.3 part of titanate coupling agent TC-F, 23 to 25 parts of butyl methacrylate, 22 to 24 parts of tetradecyl acrylate, 4 to 5 parts of tetradecyl acrylate, 21 to 23 parts of ethyl acetate, 1 to 1.2 parts of azodiisobutyronitrile, 0.15 to 0.2 part of ethylene glycol dimethacrylate, 0.9 to 1.2 parts of p-methylstyrene, 1.8 to 2.5 parts of divinyl benzene, 1 to 2 parts of nano aluminium hydroxide, 0.05 to 0.07 part of silane coupling agent kh450, 1 to 1.2 parts of di(isooctyl) phosphate, 0.5 to 0.6 part of silicone oil, and an appropriate amount of distilled water. The inorganic filling material modified high-molecular absorbent is wide in application range, rapid in absorption speed, and convenient and efficient for application.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

Method for modified preparation of high-oil-absorption gel through human hair keratin

InactiveCN103382239AHigh oil absorption rateHigh reuse rateConnective tissue peptidesPeptide preparation methodsDimethyl formamideChloroform

The invention discloses a method for modified preparation of high-oil-absorption gel through human hair keratin. The method is characterized by comprising the steps of firstly, using a reducing solution to extract the keratin from human hair, then using 2-bromoisobutyryl bromide to modify and obtain keratin macroinitiator, dissolving the keratin macroinitiator in N,N-dimethyl-formamide, adding monomers, a cross-linking agent, a catalyst and ligands sequentially, performing single electron transfer living radical polymerization, and obtaining the high-oil-absorption gel. By the aid of the preparation method, the high-oil-absorption gel with the oil absorption rate of 44 times on chloroform can be obtained.

Owner:LUDONG UNIVERSITY

Macromolecule absorbent with modified high thermal stability based on nanosilicon dioxide polylactic acid and preparation method thereof

InactiveCN104987464AImprove the three-dimensional network structureHigh oil absorption rateOther chemical processesPhosphateFire resistance

The invention discloses a macromolecule absorbent with modified high thermal stability based on nanosilicon dioxide polylactic acid and a preparation method thereof. The macromolecule absorbent is characterized in that the macromolecule absorbent comprises, by weight, the following raw materials of 26-28 parts of cyclohexyl acrylate, 17-20 parts of butyl acrylate, 3-4 parts of polylactic acid, 3-4 parts of nanosilicon dioxide, 0.3-0.4 part of gamma-methacrylamide acyloxy propyl trimethoxy silane, 0.16-0.2 part of acrylic ester, 4-5 parts of carboxymethylcellulose, 22-24 parts of ethyl acetate, 1-1.2 parts of benzoyl peroxide, 0.9-1.2 parts of p-methylstyrene, 1.8-2.5 parts of divinyl benzene, 1-2 parts of nano aluminum hydroxide, 0.05-0.07 part of silane coupling agent kh450, 1-1.2 parts of di (isooctyl) phosphate, 0.5-0.6 part of silicone oil and moderate distilled water. The macromolecule absorbent with modified high thermal stability based on the nanosilicon dioxide polylactic acid is of a double-layer porous structure, a big volume expansion ratio is achieved, the thermal stability is high, and certain fire resistance is achieved.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

High-power oil absorption gel material and preparation method therefor

The invention discloses a high-power oil absorption gel material. According to the high-power oil absorption gel material, polyether polyol, a composite catalyst, a foam stabilizer, organic low-molecule gel, deionized water and a foamer serve as raw materials, and the high-power oil absorption gel material is firstly obtained through one-step-method polymerization reaction. The high-power oil absorption gel material has the crude oil absorption power of 60-100g / g and the oil retention rate higher than 90%. The high-power oil absorption gel material has the advantages of high oil absorption power, good oil retention property, no toxicity, no pollution, low cost, foaming-in-place and the like, can be applied to the adsorption of water surface spillover oil and is particularly applicable to the emergency treatment of water surface spillover oil of rivers and lakes.

Owner:江苏瑞丰科技实业有限公司

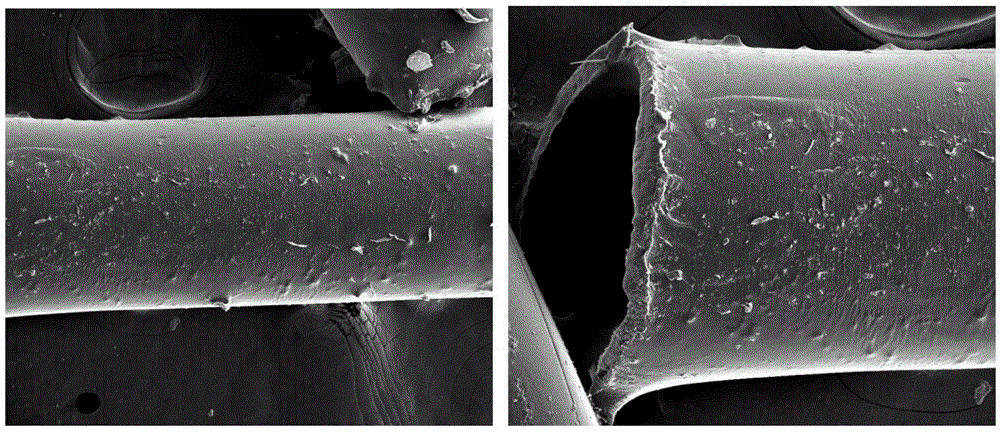

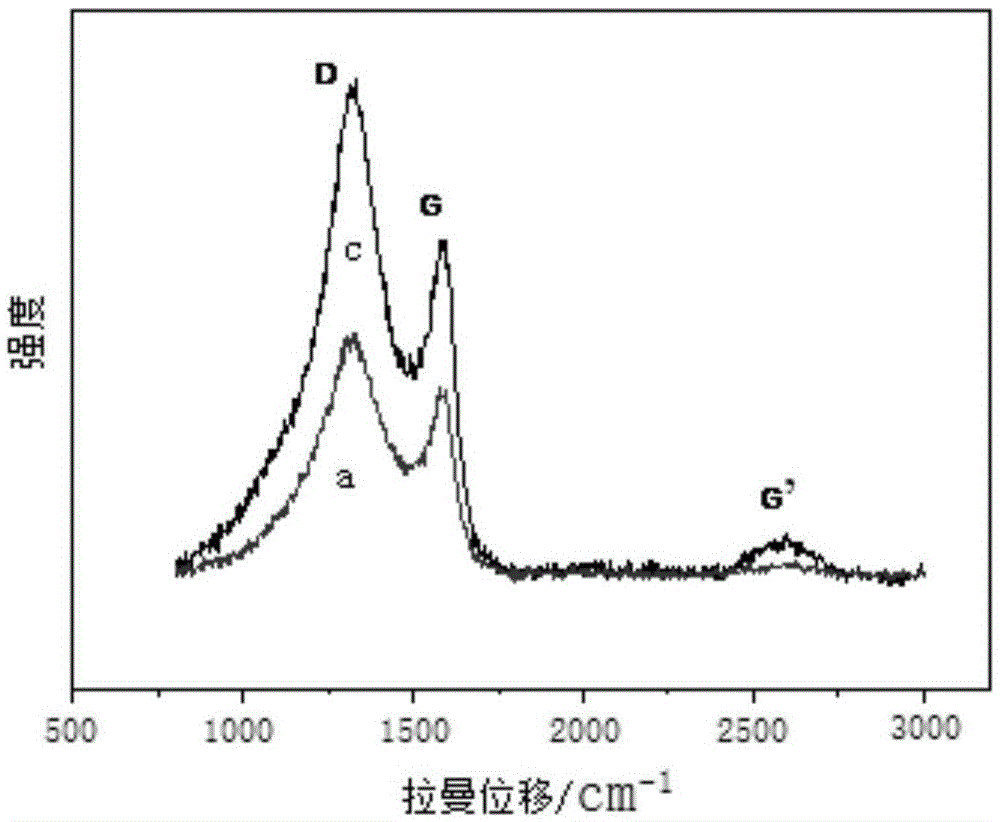

Preparation method of polyacrylonitrile/reduced graphene oxide composite oil absorption material

ActiveCN111888799AImprove thermal stabilityIncrease inertiaGeneral water supply conservationLiquid separationFreeze-dryingOxide composite

The invention discloses a preparation method of a polyacrylonitrile / reduced graphene oxide composite oil absorption material, belongs to the field of oil absorption materials, and aims to solve the problems that an existing polymer porous oil absorption material is low in oil absorption rate and complex in preparation process. The preparation method comprises the following steps of: chopping polyacrylonitrile fibers to 3-5mm; putting the chopped polyacrylonitrile fibers into a crusher; uniformly dispersing and infiltrating the chopped polyacrylonitrile fibers into a reduced graphene oxide aqueous solution; carrying out ultrasonic treatment for 10-30min; sealing an obtained product in a container; putting the container into a drying oven; carrying out hydrothermal reaction; cooling to roomtemperature; washing a reaction product with distilled water; freezing the reaction product in a refrigerator; and finally drying the reaction product in a freeze dryer to obtain the polyacrylonitrile / reduced graphene oxide composite oil absorption material. According to the preparation method, the polyacrylonitrile fibers are taken as a framework, and the reduced graphene oxide is taken as a reinforcing phase; the oil absorption material which is ultra-light, high in saturated oil absorption rate, high in oil absorption rate, stable in structure and capable of being recycled for multiple times is prepared through the hydrothermal method and freeze drying, and the oil absorption material is widely applied to the fields of oil stain leakage and the like.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com