Melt nano fiber super-high-efficiency oil absorbent cotton

A nanofiber and oil-absorbing cotton technology, applied in the field of ultra-efficient oil-absorbing cotton and melt nanofiber ultra-efficient oil-absorbing cotton, can solve the problem that oil pollution cannot be recycled and reused, there is no high oil absorption rate and oil absorption efficiency, and the oil absorption cotton cannot be too much. Repeated use and other problems to achieve high oil absorption rate, improve oil absorption efficiency, and reduce oil discharge rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

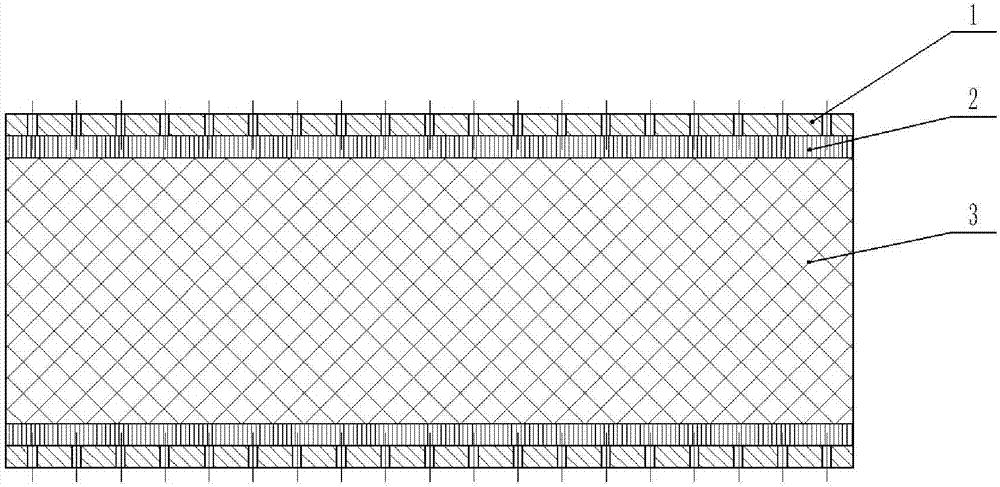

[0016] A kind of melt nanofiber ultra-efficient oil-absorbing cotton of the present invention, as figure 1 As shown, it is a schematic diagram of ultra-high-efficiency oil-absorbing cotton. The middle area is the folds formed by the porous cotton layer and the oriented fiber oil-absorbing layer, which increases the contact area with oil stains and increases the oil-absorbing efficiency.

[0017] A kind of melt nanofiber ultra-efficient oil-absorbing cotton of the present invention, as figure 1 As shown, it mainly includes: porous cotton cloth layer 1, oriented nanofiber oil-absorbing layer 2 and nanofiber oil-holding layer 3. The oil is in contact with the wrinkled outer surface formed by the cotton layer 1 and the oriented nanofiber oil-absorbing layer 2 , and the oil is directly absorbed into the nanofiber oil-holding layer 3 through the capillary effect and adsorption of the oriented fiber oil-absorbing layer 2 . The nanofiber oil-retaining layer 3 adopting the hot-pressin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com