Patents

Literature

52results about How to "Good capillary effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

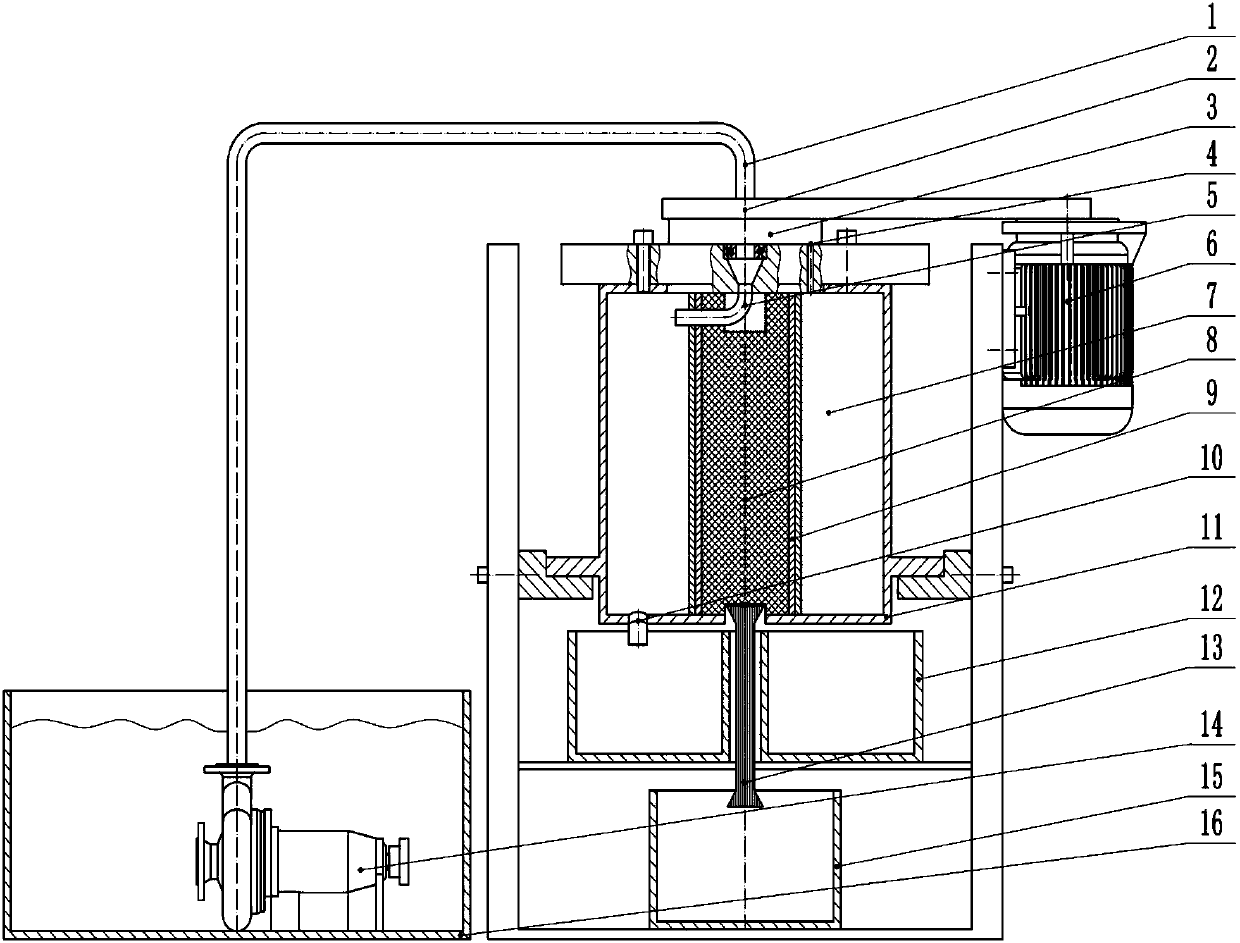

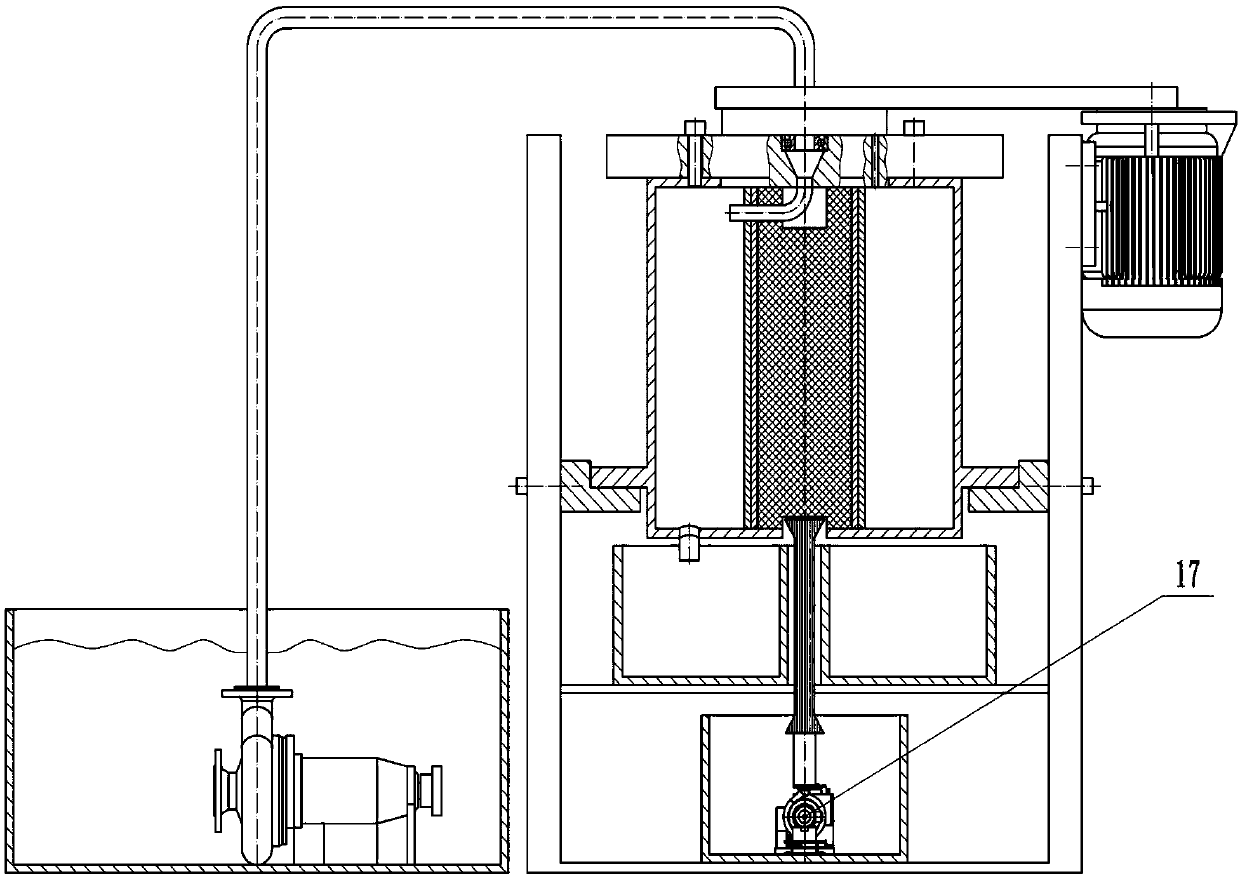

Centrifugation and dynamic adsorption combination oil-water separation device

PendingCN107804893AImprove separation efficiencyEasy to useWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesFiberCentrifugation

The invention relates to a centrifugation and dynamic adsorption combination oil-water separation device, and belongs to the field of oil pollution treatment. The centrifugation and dynamic adsorptioncombination oil-water separation device mainly comprises a motor, a rotating device, an oil-water separation device, an oriented nanofiber oil conveying pipe and a collection device. According to thecentrifugation and dynamic adsorption combination method, by use of the principle that oil is light and water is heavy and combination of oleophylic and hydrophobic modification of a fiber membrane,efficient oil-water separation of oil-containing sewage is realized under the action of centrifugal force. The oil-containing sewage in an emulsified state is demulsified through a demulsification filter net membrane, and then enters nanofiber oil adsorption cotton which is of a fluffy space structure, is irregularly arrayed and has high oil adsorption rate, with water blocked outside; the oriented nanofiber oil conveying pipe is embedded into the fiber cotton, so that the adsorbed oil dirt can be sucked out in time under the action of the gravity or external suction, and is conveyed into an oil storage barrel, and then the oil adsorption capacity of the nanofiber oil adsorption cotton is recovered. According to the centrifugation and dynamic adsorption combination oil-water separation device disclosed by the invention, oil-containing sewage treatment which has high separation efficiency and separation capacity and can repeatedly use oil is finally realized.

Owner:BEIJING UNIV OF CHEM TECH

Chromatic high-wet conductivity anti-bacterial fiber and spinning method thereof

InactiveCN101158054AHas antibacterial functionGood for healthMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a colorful antibacterial fiber with high-wet conductivity and the corresponding spinning method. The antibacterial fiber is made of 85 to 95 polyester slices, four to six color masterbatches and four to five nano-silver ion antibacterial masterbatches through processes of drying, mixing and melting treatment, pre-filtering, spinning, oiling and winding, etc., base on which, the spun fiber has relatively high filling rate in unit area; the weaved fabrics has good capillary effect, air permeability, little contact area with skin and relatively high wearing comfort when wearing, thus being favorable to the health of people.

Owner:唐敏

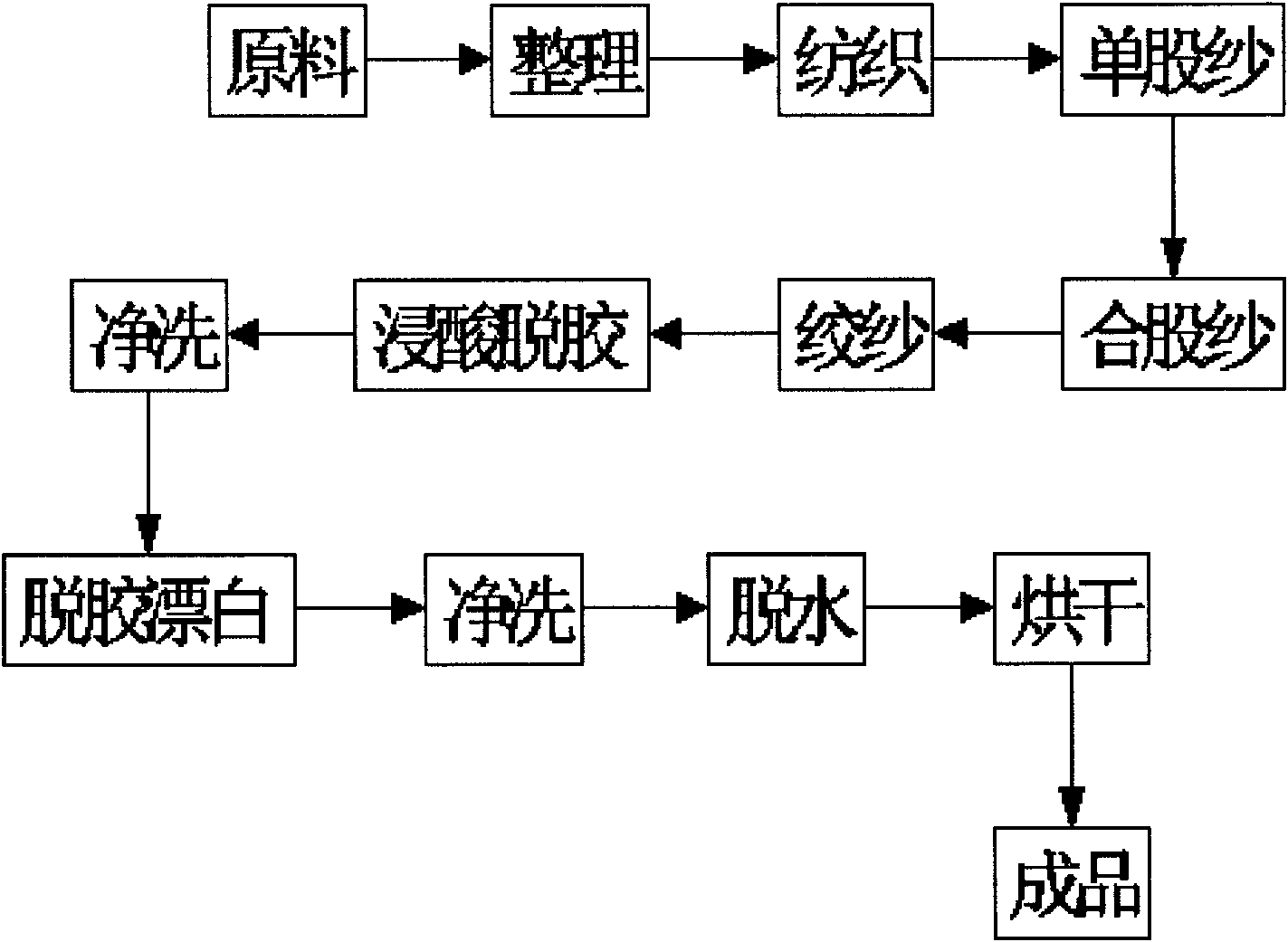

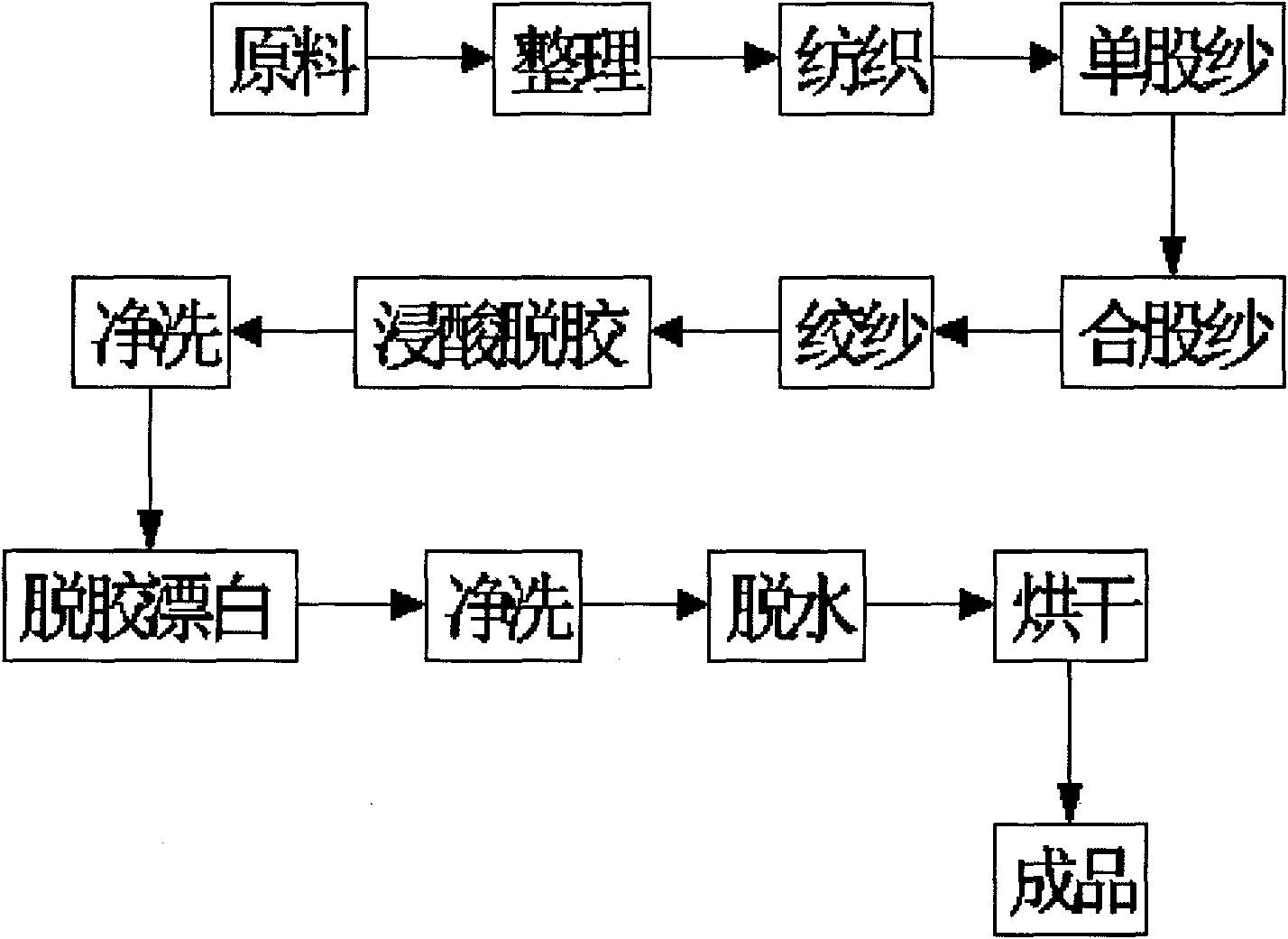

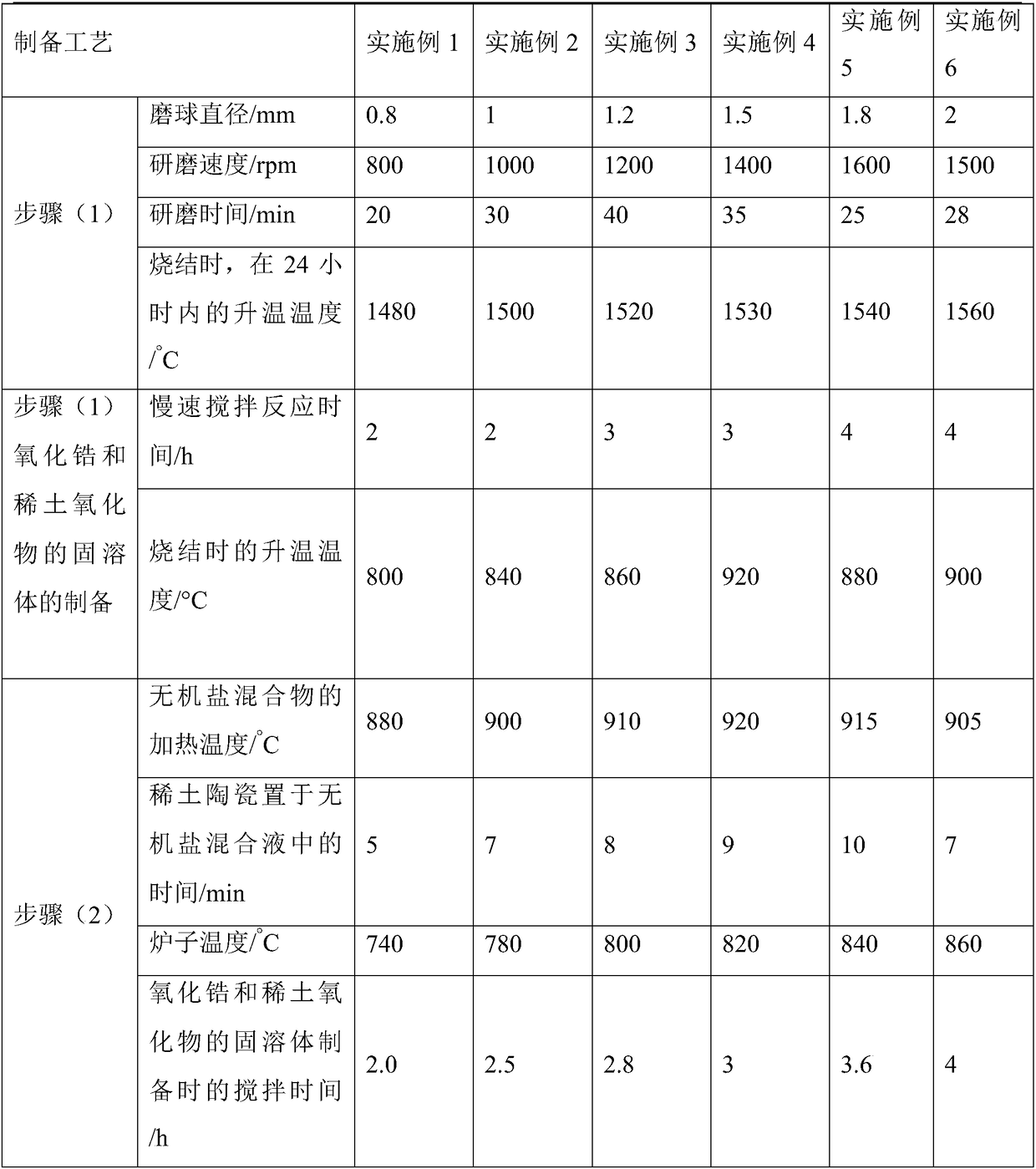

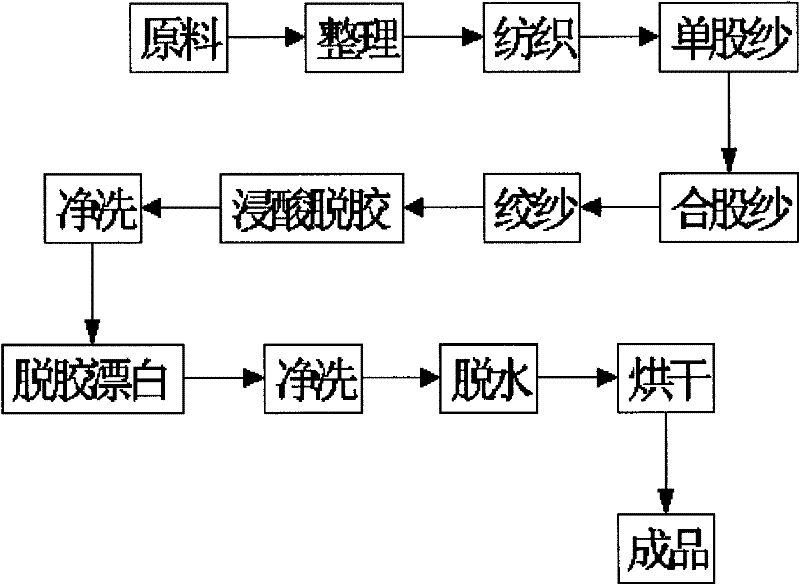

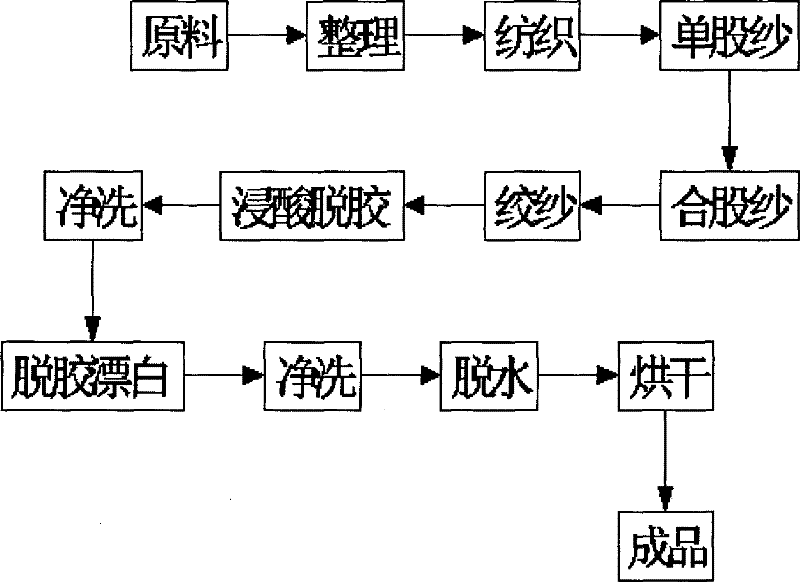

Hemp fibre filter wire and preparation method thereof

InactiveCN101884859AUnique anti-mold and bactericidal functionGood inhibition effectFiltration separationVegetable materialChemical industryYarn

The invention relates to a filter material for water treatment, in particular discloses a hemp fibre filter wire and a preparation method thereof. The hemp fibre filter wire is characterized by being prepared by using hemp fibres as raw materials, spinning the hemp fibres into yarns through hemp spinning equipment and then degumming, bleaching, drying and forming. The invention is mainly used for the purification and the filtering of various liquids; a wire-wound filter core prepared by the hemp fibre filter wire is used for the precise filtering of the liquids in a petroleum industry, a chemical industry, an electron industry, a pharmaceuticals industry, a food industry, a domestic water industry, and the like; and in addition, the invention can bring new vitality for the water treatment industry due to excellent performance and complete green environmentally-friendly quality.

Owner:郭淼

Blended yarn of terylene, rabbit hair and silkworm pupa protein fiber

The invention provides blended yarn of terylene, rabbit hair and silkworm pupa protein fiber. The blended yarn comprises the following components: 65-75 weight parts of terylene, 25-35 weight parts of rabbit hair and 10-20 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of terylene, rabbit hair and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

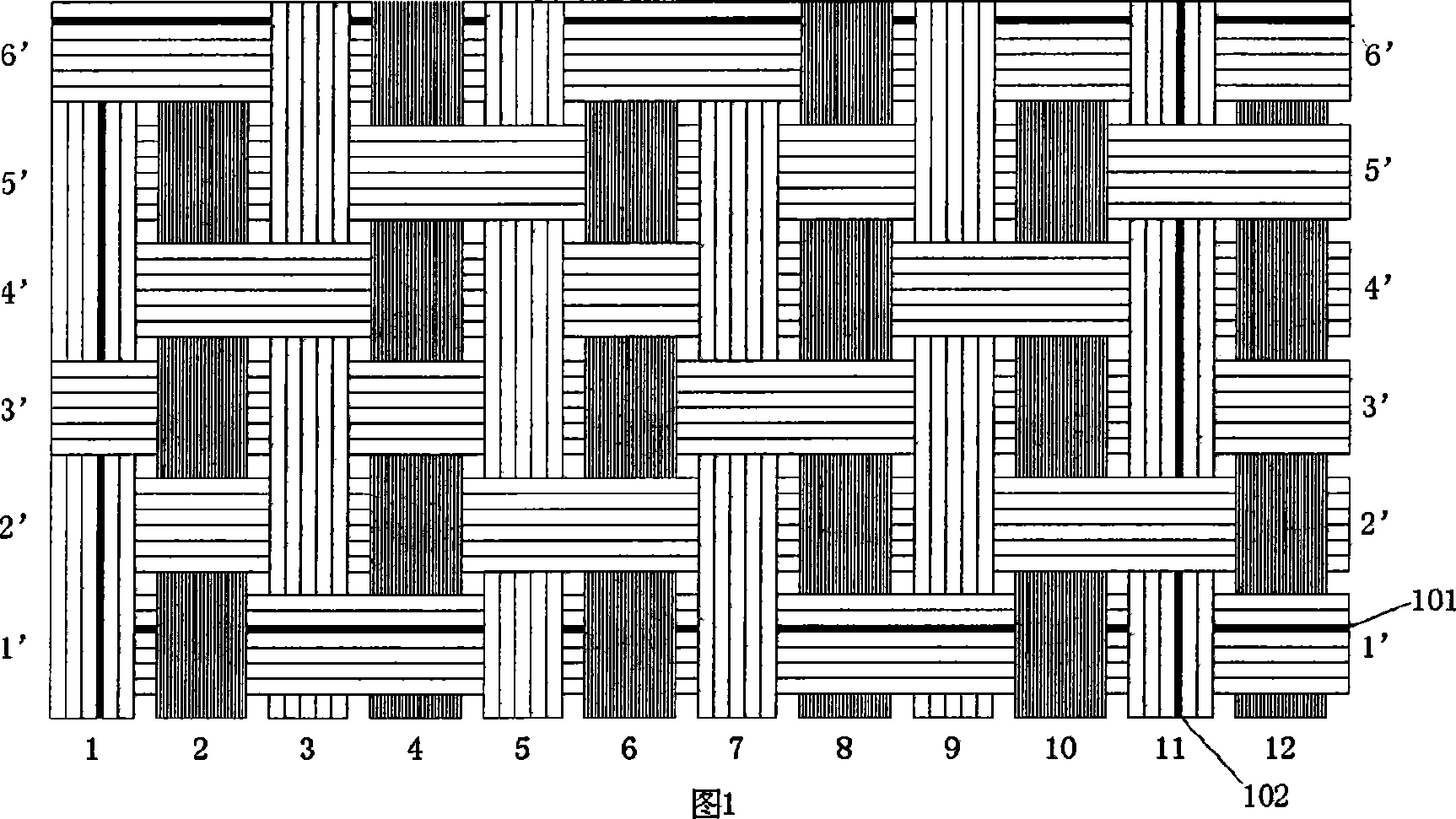

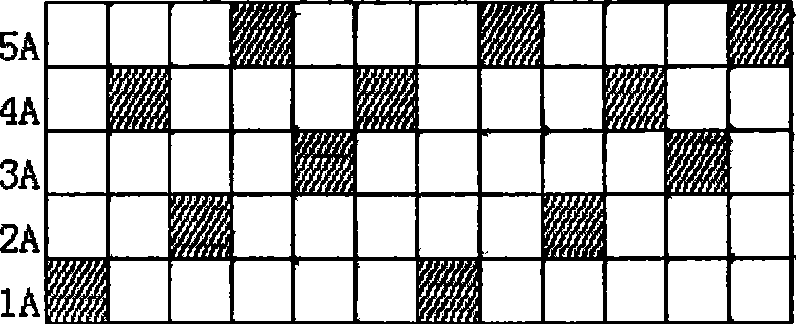

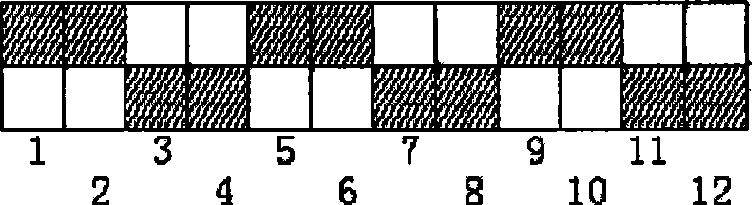

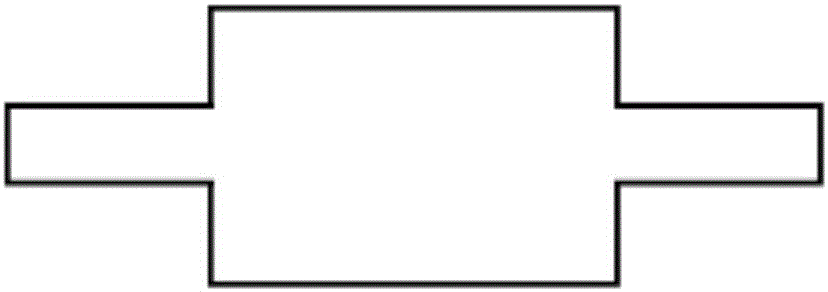

Moisture absorption and perspiration antistatic fabric

InactiveCN101413168AGood hygroscopicityLower specific resistanceWoven fabricsFiberMoisture absorption

The invention discloses an antistatic fabric for moisture absorption and sweat elimination, which is formed by interweaving warps and wefts. The fabric has rib weave consisting of back weave and face weave, wherein odd warps are back warps which are interwoven with the wefts to form the back weave, even warps are face warps which are interwoven with the wefts to form the face weave, the back warps are common fiber back warps, the face warps are superfine fiber face warps, and the fabrics are embedded into conductive yarns at intervals in the warp direction and in the weft direction respectively. The invention provides the antistatic fabric for the moisture absorption and the sweat elimination, which has good effects on moisture absorption and sweat elimination, good antistatic effect, and comfort.

Owner:苏州新纶超净技术有限公司 +1

Coolplus moisture-absorption sweat-releasing and warming Raschel woolen blanket

ActiveCN107419423ARaw material composition is simpleLow costFibre typesWarp knittingPolyesterEngineering

The invention discloses a Coolplus moisture-absorption sweat-releasing and warming Raschel woolen blanket. The Coolplus moisture-absorption sweat-releasing and warming Raschel woollen blanket is woven on a two-needle bar Raschel warp knitting machine by using blended yarns of Coolplus fibers and acrylic fibers as nap yarns and using polyester silk as basic silk. Special-shaped polyester fibers can be acquired by using a +-shaped herringbone or Chinese character mi-shaped spinning assembly; air plasma and alkali peeling treatment is performed on the polyester fibers; regular micro grooves and micro holes are formed in surfaces of the polyester, and the grooves and the holes can generate a significant capillary effect, moisture and sweat excreted by a human body are diffused and transmitted, and then are discharged out, and skins can keep dry; and noncurrent static air is stored in the regular micro grooves and micro holes, and the static air can significantly improve the warming performance of the Raschel woolen blanket.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

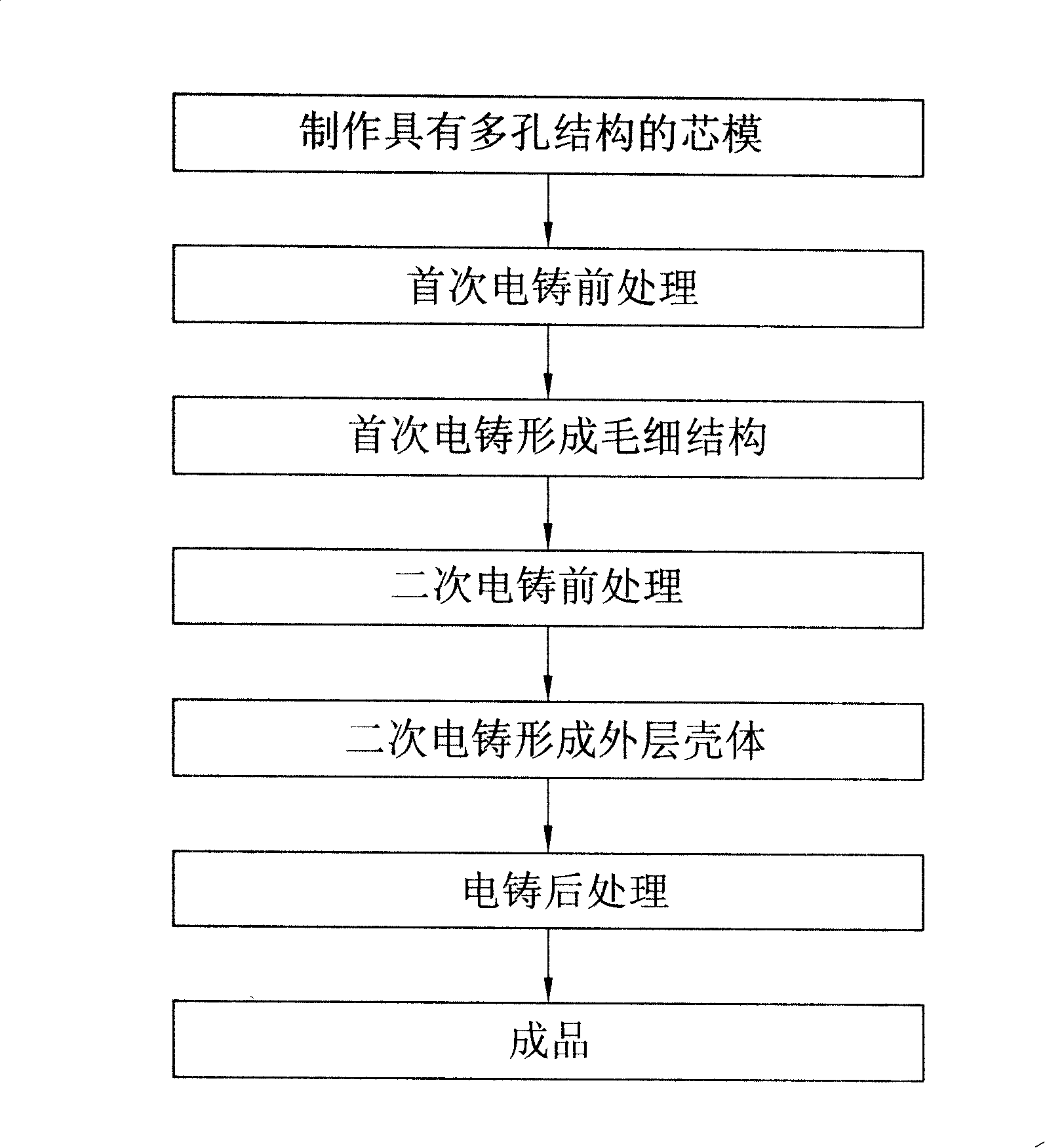

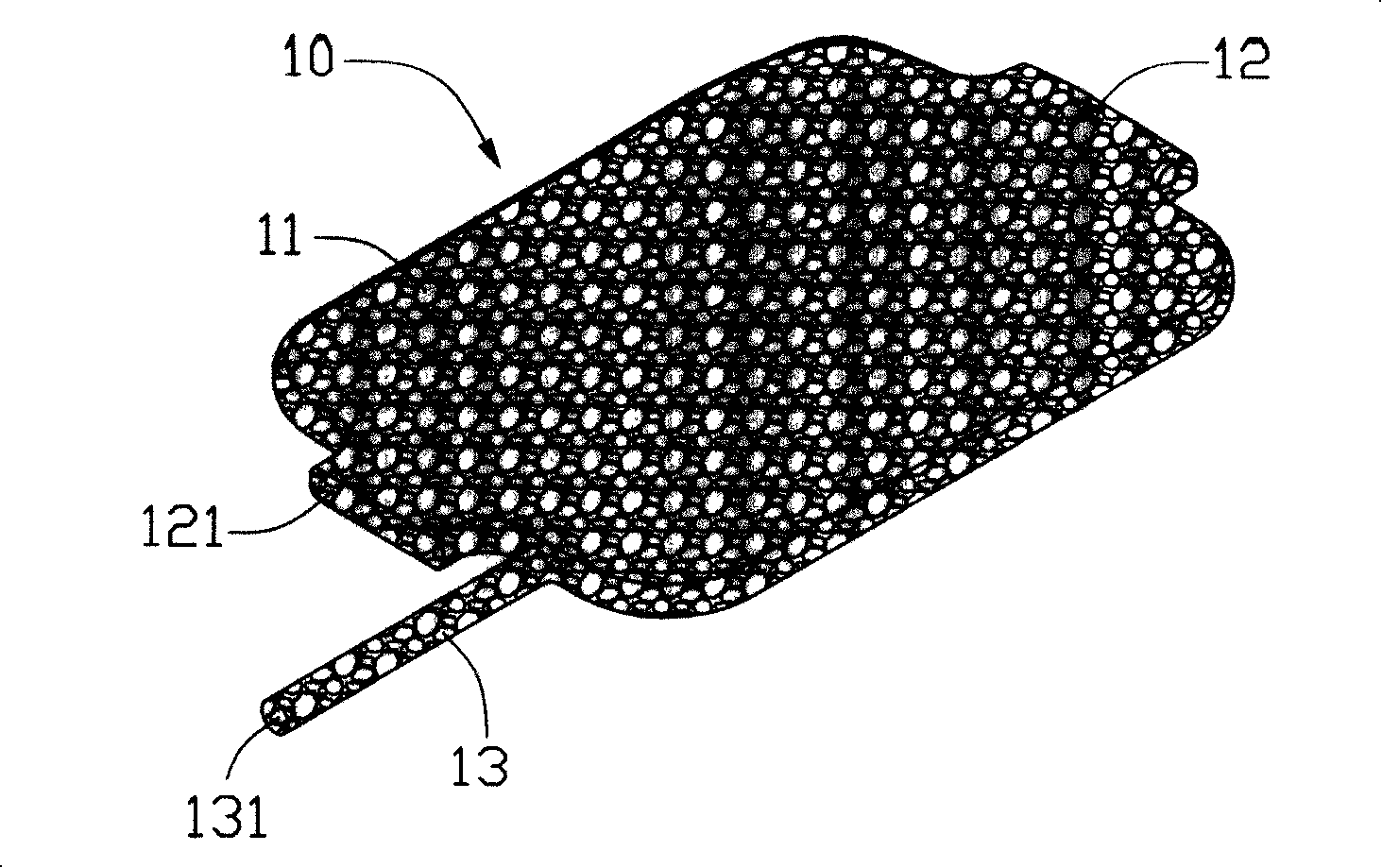

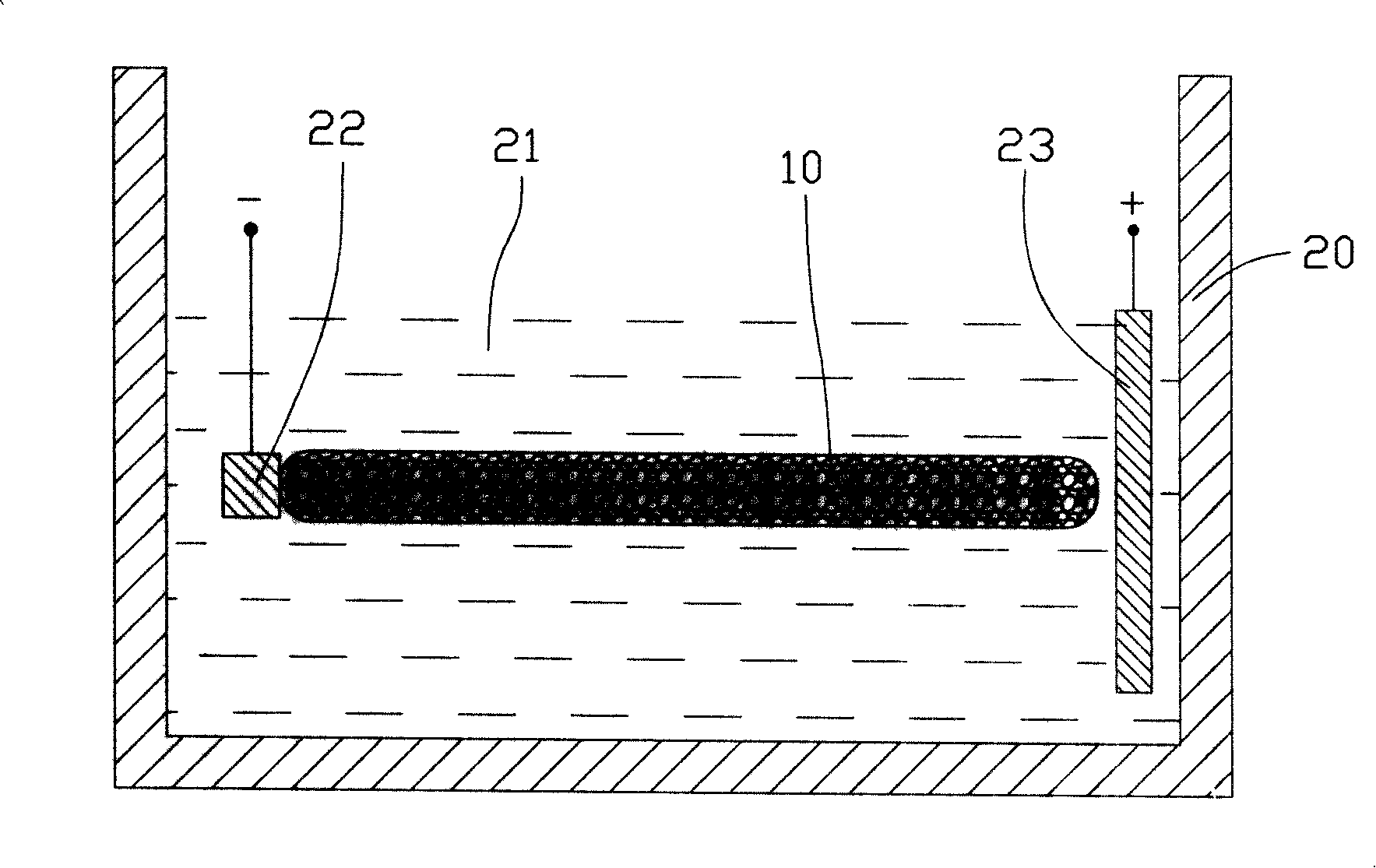

Method for manufacturing airtight cavity structure

InactiveCN101230472ASimplify the processGood capillary effectElectroforming processesMetalMaterials science

The invention relates to a method of manufacturing an airtight cavity structure and includes the following steps: firstly, a mandrel with a porous structure is manufactured, that is, a porous foam plastic framework is manufactured; secondly, an electric conduction treatment is conducted to the pore wall of the foam pore on the surface of the mandrel and at a predetermined depth under the surface of the mandrel; thirdly, the mandrel is electroformed for the first time and a first metal cast layer is formed on the surface of the mandrel and in the foam pore at the predetermined depth; fourthly, a surface polishing treatment is conducted to the mandrel electroformed for the first time to flatten and smooth the surface; fifthly, the mandrel is electroformed for the second time and a second metal cast layer is formed on the outer surface of the mandrel; sixthly, the mandrel is eliminated and a cavity body with the first metal cast layer as the capillary structure and the second metal cast layer as the shell body is obtained; and finally, an operating fluid is injected into the cavity body and an airtight cavity structure is thus obtained. The manufacturing method has simple manufacturing procedures and can mold an airtight cavity structure with preferable capillary effect.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber

The invention provides a blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber. The blended yarn is characterized by comprising the following components: 60-70 weight parts of acrylic fiber, 15-25 weight parts of jute fiber and 15-25 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of acrylic fiber, jute fiber and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:JIANGSU TONGHAI THREAD

Nylon-acrylon-pupa azelon blended yarn

The invention provides a nylon-acrylon-pupa azelon blended yarn which comprises the following components in parts by weight: 40-50 parts of nylon, 40-50 parts of acrylon and 15-25 parts of pupa azelon. The invention complements the mutual characteristics of the nylon, acrylon and pupa azelon, and displays the advantages of the nylon, acrylon and pupa azelon.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

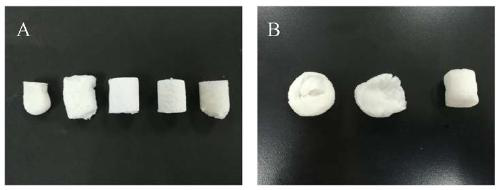

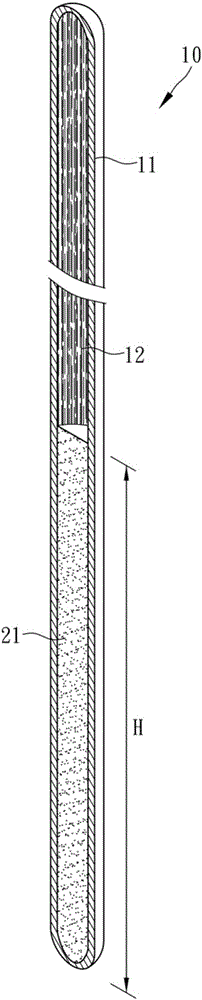

Melt nano fiber super-high-efficiency oil absorbent cotton

InactiveCN107042024AImprove oil absorption efficiencyUltra-high specific surface area and porosityLayered productsLiquid separationAbsorption rateCotton cloth

The invention discloses a melt nano fiber super-high-efficiency oil absorbent cotton. The melt nano fiber super-high-efficiency oil absorbent cotton mainly comprises porous cotton cloth layers, oriented nano fiber oil absorbing layers, and a nano fiber oil storage layer; the porous cotton cloth layers are arranged on the outermost layers; the oriented nano fiber oil absorbing layers and the nano fiber oil storage layer are arranged and combined in different sequences; the external surface of each oriented nano fiber oil absorbing layer is coated by the corresponding porous cotton cloth layer firmly, winkles on the external layers of the melt nano fiber super-high-efficiency oil absorbent cotton are formed by the porous cotton cloth layers and the oriented nano fiber oil absorbing layers; the porous cotton cloth layers and the oriented nano fiber oil absorbing layers are relatively thin; the nano fiber oil storage layer is arranged on the internal surfaces of the two oriented nano fiber oil absorbing layers; each of the two surfaces of the nano fiber oil storage layer and the corresponding surface of the oriented nano fiber oil absorbing are contacted with and embedded into each other. According to the melt nano fiber super-high-efficiency oil absorbent cotton, the porous cotton cloth layers with elasticity are taken as the outermost layers, and winkle surfaces are formed by the porous cotton cloth layers with the oriented nano fiber oil absorbing layers, so that the contact area of oriented oil absorbing fiber with oil stain is increased effectively; oil absorbed by the melt nano fiber super-high-efficiency oil absorbent cotton can be recycled via squeezing the melt nano fiber super-high-efficiency oil absorbent cotton, and oil stain absorption rate is maintained.

Owner:BEIJING UNIV OF CHEM TECH

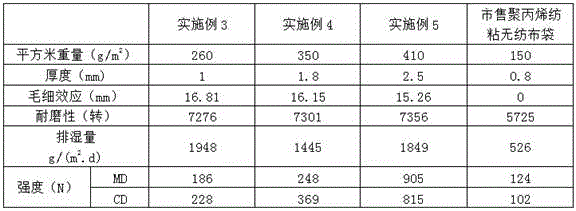

Grain storage bag and preparation method thereof

ActiveCN105755674AImprove preservation qualityNatural bacteriostasisBio-packagingDomestic containersGrain storageNonwoven fabric

The invention discloses a grain storage bag and a preparation method thereof and relates to the field of packaging. The grain storage bag is prepared from polylactic acid fibers and jute fibers. The preparation method of the grain storage bag comprises the following steps: preparing a lower layer polylactic acid filament fiber web by adopting a polylactic acid chip; unwinding jute fiber woven roving cloth and directly laying on the lower layer polylactic acid filament fiber web; preparing an upper layer polylactic acid filament fiber web by adopting the polylactic acid chip, and laying on the jute fiber woven roving cloth to form three layers of fiber webs; pre-reinforcing the three layers of fiber webs to obtain polylactic acid filament non-woven fabric; compounding the polylactic acid filament non-woven fabric through an ultrasonic method, cutting according to a certain specification and then sewing and thermally-sealing to obtain the grain storage bag. According to the grain storage bag disclosed by the invention, point-like compounding is performed by using the degradable polylactic acid fibers, the jute fibers with unique fiber cavity structures and the ultrasonic method, so that the grain storage bag has the advantages that the grain quality deterioration is delayed, the grain storage period is prolonged, and the damage due to collision in the grain transporting process is buffered.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

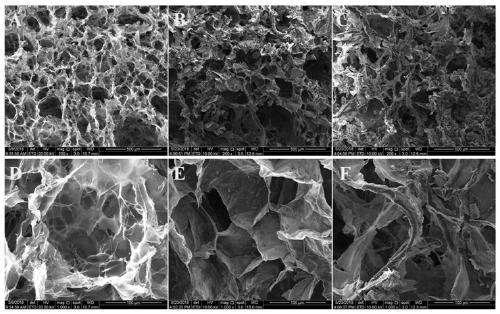

Preparation method of drug-loading hemostatic sponge as well as drug-loading hemostatic sponge prepared from same

ActiveCN109111591AHigh porosityImprove fluffinessSurgical adhesivesPharmaceutical delivery mechanismCelluloseMedicine

The invention discloses a preparation method of drug-loading hemostatic sponge. The preparation method comprises the following steps: (1) preparing lignocelluloses sponge; and (2) loading the lignocelluloses sponge with chitosan and a hemostatic drug in a spraying or immersion manner, and freeze drying to obtain the drug-loading hemostatic sponge. A preparation method of the lignocelluloses spongecomprises the following steps: (1) freezing an alkali urea solution, forming icy slurry, adding lignocelluloses into the icy slurry, and obtaining a lignocelluloses solution; (2) adding a surfactantinto the lignocelluloses solution, stirring, and forming a foam body; (3) freezing the foam body into foam icy slurry, adding a pore forming agent into the foam icy slurry, injection molding, freezing, aging, and obtaining gel; and (4) soaking to remove the surfactant and the pore forming agent in the gel, freeze shaping, freeze drying, and obtaining the lignocelluloses sponge. By adopting the drug-loading hemostatic sponge prepared by the invention, by virtue of the synergistic effect of the chitosan and hemostatic drug, the blood on the surface of a wound can be rapidly absorbed, the blood coagulation of the wound can be effectively promoted, and the bleeding can be rapidly stopped.

Owner:ZHENGZHOU UNIV

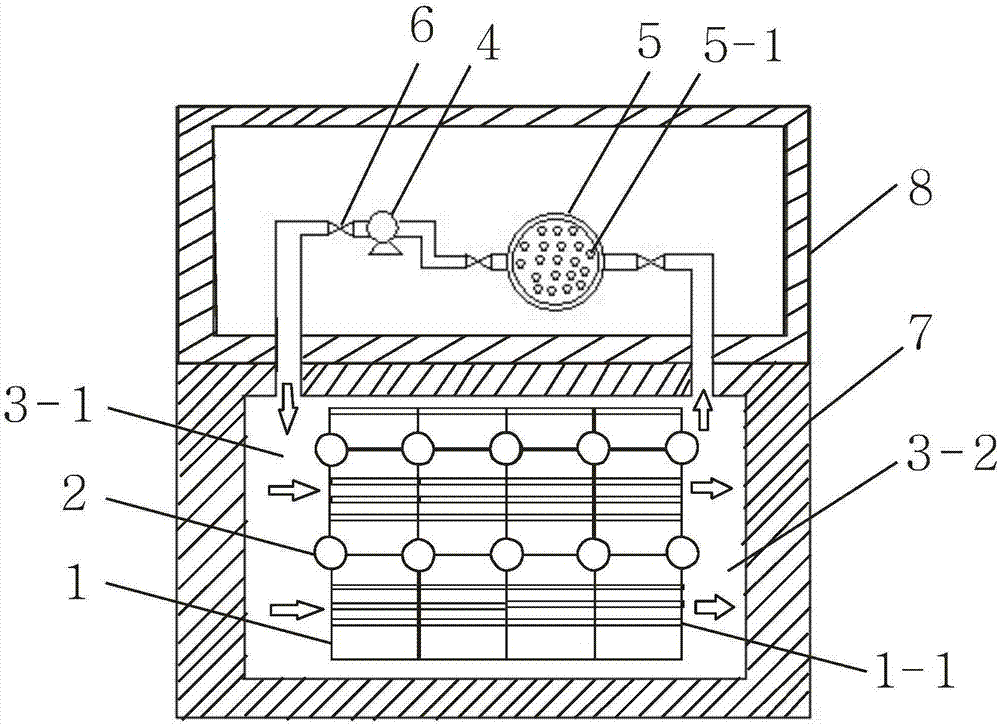

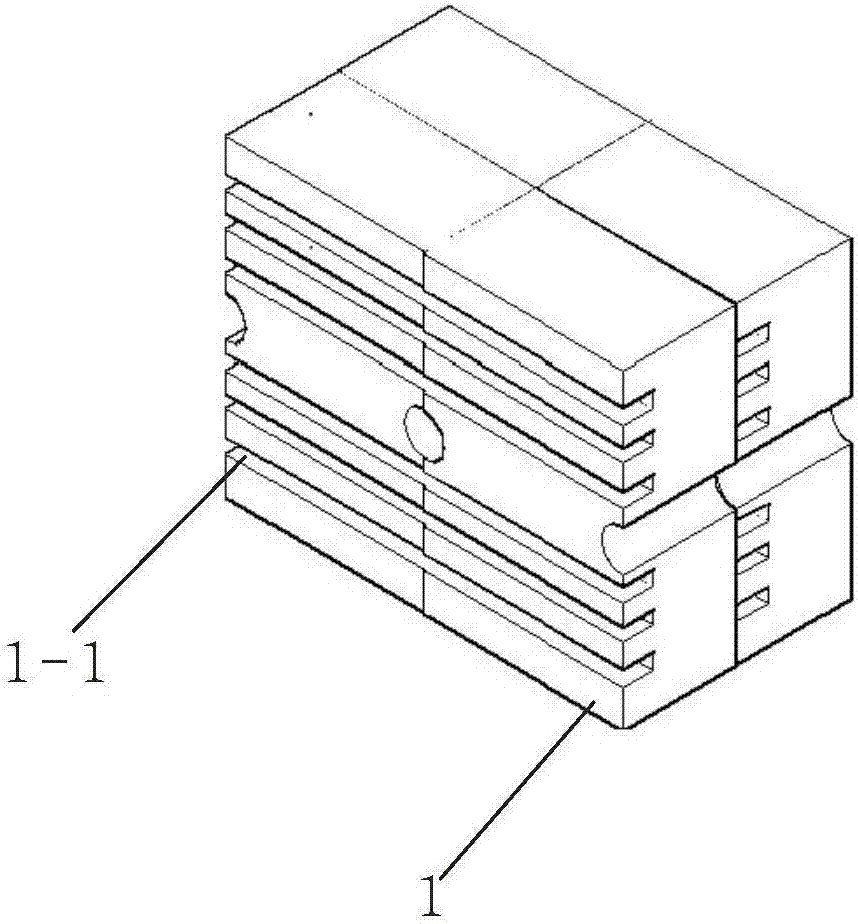

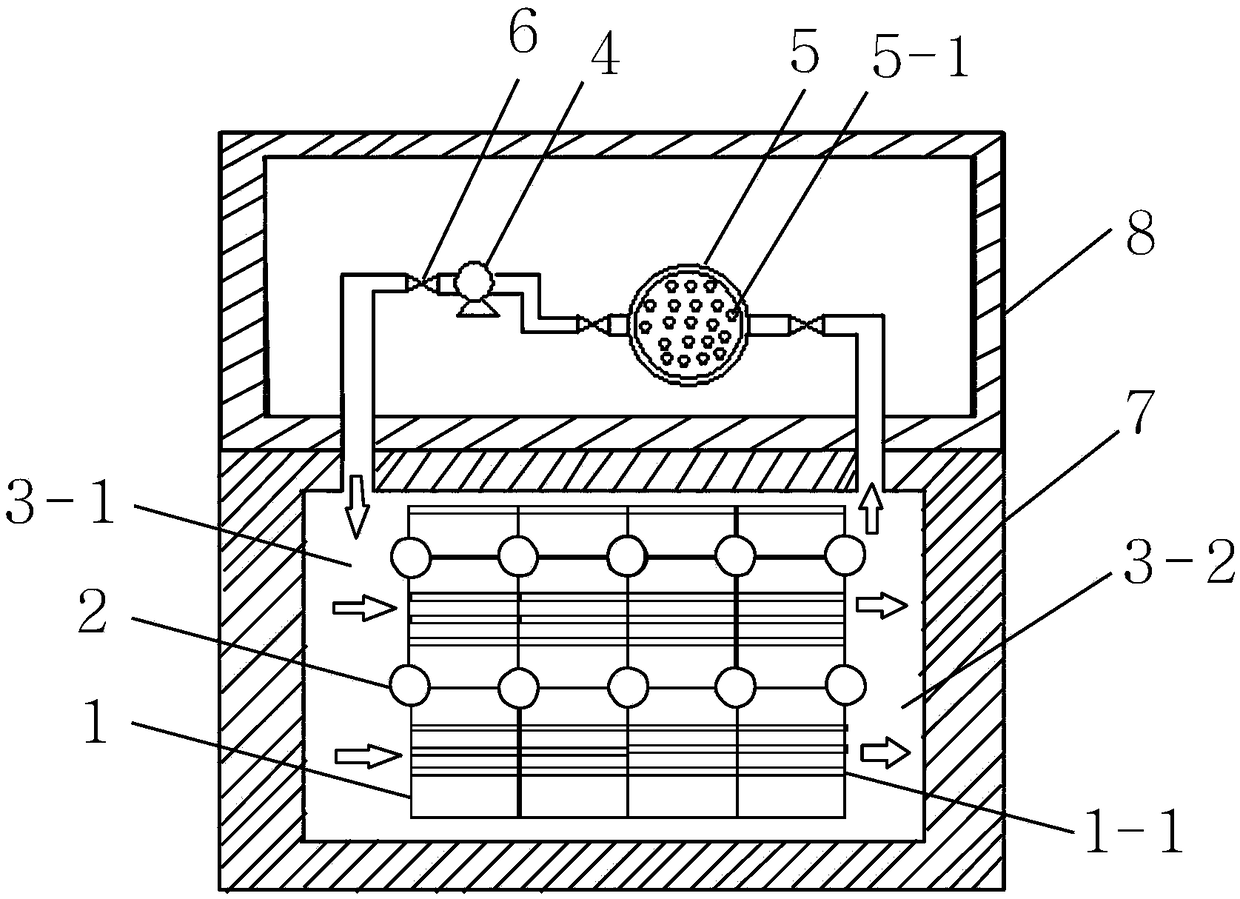

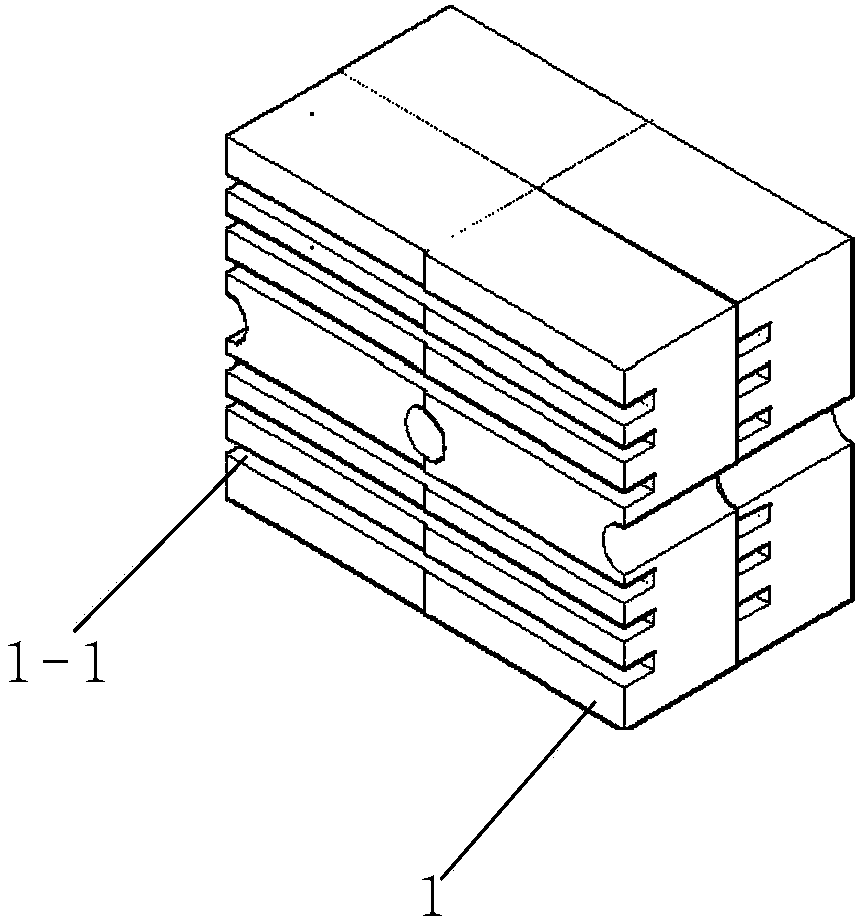

Energy-storage heat exchange device

ActiveCN107167013ARealize the purpose of energy storage and heat exchangeLow melting pointHeat storage plantsCold airElectricity

The invention relates to an energy-storage heat exchange device. The energy-storage heat exchange device comprises an energy storage pile, a heat exchanger, a heating tube and a fan, wherein a thermal insulation layer A is arranged at the periphery of the energy storage pile; a gap between the energy storage pile and the thermal insulation layer A is taken as an air flue; a ventilating groove is formed in the energy storage pile; the fan is connected with the heat exchanger through a pipeline; the other end of the fan is accessed into the air flue A through a pipeline; the other end of the heat exchanger is accessed into an air flue B through a pipeline; the air flue A and the air flue B refer to air flues formed between opposite two ends in the energy storage pile and the thermal insulation layer A; an electric heating tube is arranged in the energy storage pile in a penetrating mode for heating the energy storage pile; under driving of the fan, air flow enters the energy storage pile through the air flue A; and air flow is heated by the energy storage pile. The energy-storage heat exchange device utilizes off-peak electricity to heat the energy storage pile, and utilizes the energy storage pile to slowly release heat for heating air flow to form hot air; and after entering the heat exchanger to exchange heat, hot air is changed into cold air for being blown into the fan, and re-enters the air flue A under driving of the fan in a circulating mode, so that the energy-storage heat exchange purpose is realized.

Owner:天津朗华科技发展有限公司

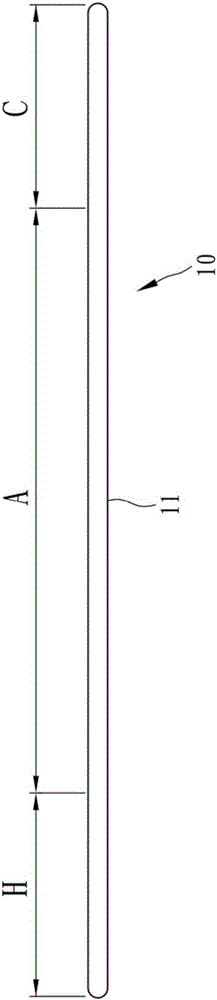

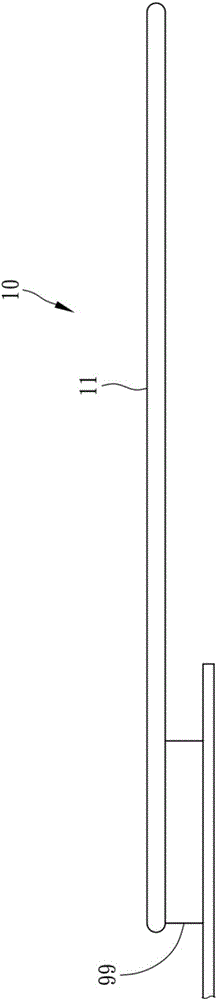

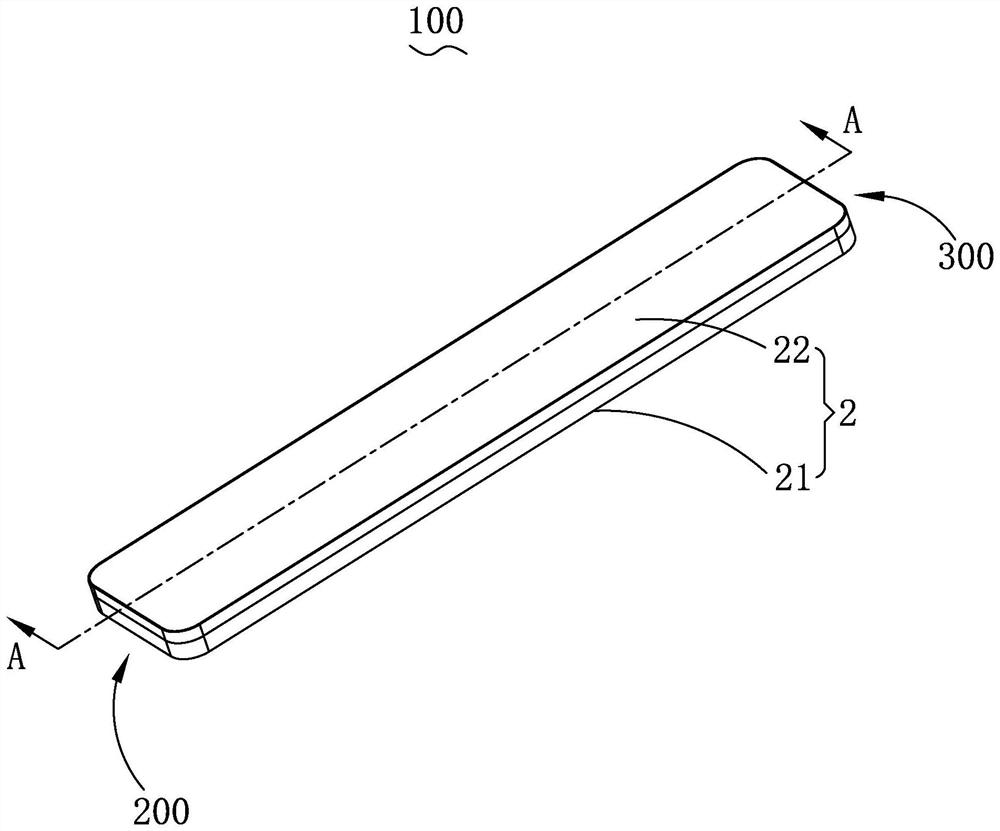

Micro heat pipe and manufacturing method of micro heat pipe

InactiveCN106323061AAvoid occupyingAvoid attenuationIndirect heat exchangersMicro-loop heat pipeEngineering

The invention discloses a micro heat pipe. The micro heat pipe comprises a pipe body, a second capillary structure and acting liquid, wherein the two ends of the pipe body are closed, a heated section, a heat insulation section and a condensation section are defined from one end to the other end of the pipe body along the body part of the pipe body; an etching line which is formed after etching is arranged on the inner wall of the pipe body, and the etching line is defined as a first capillary structure and distributed all over the heated section, the heat insulation section and the condensation section; the second capillary structure is arranged in the pipe body and located on the heated section of the pipe body, and the heated section is filled with the second capillary structure which has a liquid adsorbing capillary effect; and the acting liquid is injected into the pipe body. The invention further discloses a manufacturing method of the micro heat pipe. The manufacturing method of the micro heat pipe mainly comprises the steps that the inner wall surface of the pipe body is etched for forming the first capillary structure, liquid injection, vacuumizing and sealing are conducted after the heated section is filled with the second capillary structure and sintered, and then the micro heat pipe is obtained.

Owner:ACMECOOLS TECH

Vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn

The invention provides vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn which is composed of, by weight, 55-65 parts of vinylon, 20-30 parts of bamboo fibers and 10-30 parts of silkworm pupa protein fibers. The vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn integrates characteristics of the vinylon, the bamboo fibers and the silkworm pupa protein fibers to bring advantages of the same into play.

Owner:NANTONG MEIMING CHINLON

Spandex, flax fiber and silkworm pupa protein fiber blended yarn

The invention provides a spandex, flax fiber and silkworm pupa protein fiber blended yarn. The spandex, flax fiber and silkworm pupa protein fiber blended yarn comprises, by weight, 75-85 parts of spandex, 10-20 parts of flax fibers and 5-10 parts of silkworm pupa protein fibers. The spandex, flax fiber and silkworm pupa protein fiber blended yarn has the advantages that characteristics of the spandex, the flax fibers and the silkworm pupa protein fibers are complementary to one another, and accordingly merits of the spandex, the flax fibers and the silkworm pupa protein fibers can be played.

Owner:南通市京山锦纶有限公司

Blended yarn formed by cotton fibers, delustering fibers and silkworm pupa protein fibers

The invention provides blended yarn formed by cotton fibers, delustering fibers and silkworm pupa protein fibers. The blended yarn formed by the cotton fibers, the delustering fibers and the silkworm pupa protein fibers comprises, by weight, 65-75 parts of the cotton fibers, 10-20 parts of the delustering fibers and 15-25 parts of the silkworm pupa protein fibers. The blended yarn formed by the cotton fibers, the delustering fibers and the silkworm pupa protein fibers has the technical advantages that complementation is carried out on the characteristics of the cotton fibers, the characteristics of the delustering fibers and the characteristics of the silkworm pupa protein fibers, the cotton fibers are good in moisture absorption performance and breathability, soft and good in heat insulation; the delustering fibers are also known as matt fibers, are chemical fibers without surface gloss, are made by adding delustering agents to a spinning solution or a fondant before spinning is carried out, and are formed through spinning, so that the fibers can scatter light to eliminate the gloss so as to reduce the transparency and improve the whiteness; the silkworm pupa protein fibers have the advantages that softness and fineness are achieved, the fineness of the silkworm pupa protein fibers is about 1.0-1.8 dtex, and the handfeel of the silkworm pupa protein fibers is soft like the handfeel of cashmere, and is smooth and exquisite like the handfeed of real silk; the blended yarn formed by the cotton fibers, the delustering fibers and the silkworm pupa protein fibers can have the advantages of the cotton fibers, the advantages of the delustering fibers and the advantages of the silkworm pupa protein fibers.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

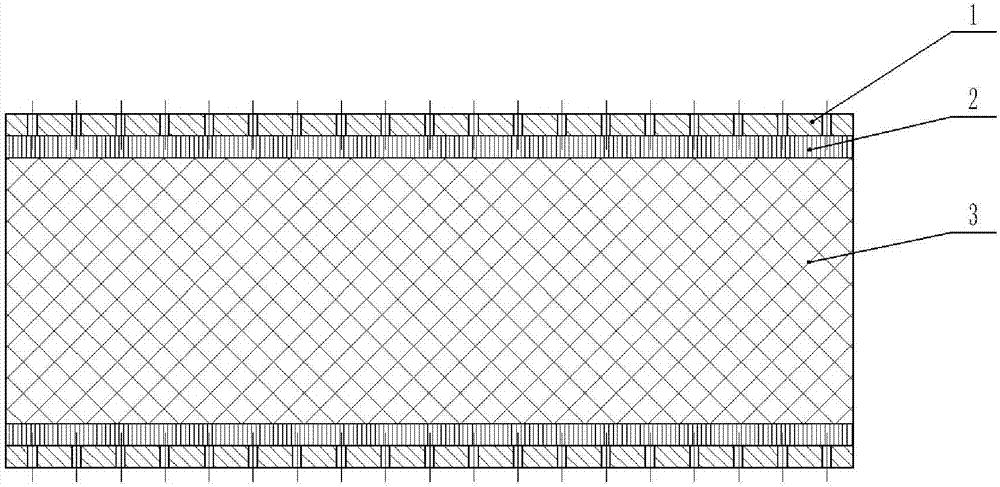

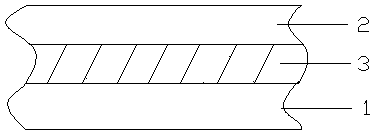

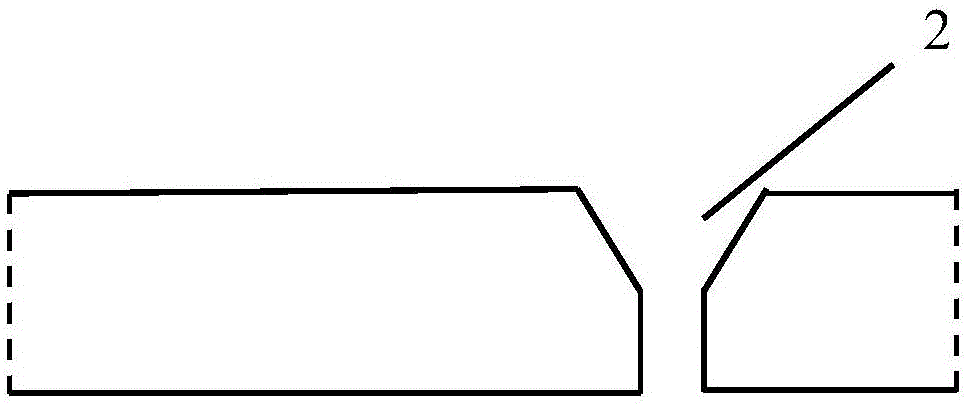

Mosquito repelling, moisture absorption and sweat releasing fabric

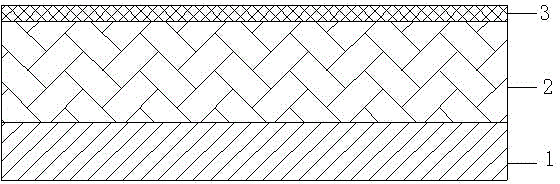

InactiveCN104195714AKeep drivingFree from bitesHollow filament manufactureSynthetic resin layered productsFiberEngineering

The invention relates to a mosquito repelling, moisture absorption and sweat releasing fabric. The mosquito repelling, moisture absorption and sweat releasing fabric comprises a basic fabric layer (1) and a shell fabric layer (2), a mosquito repelling interlayer (3) is arranged between the basic fabric layer (1) and the shell fabric layer (2), the mosquito repelling interlayer is composed of mosquito repellents, and the mosquito repellents are wrapped in a thin film, and are arranged between the basic fabric layer (1) and the shell fabric layer (2) in order. The basic fabric layer is formed by interweaving warp yarn and weft yarn, the warp yarn is environment-friendly yarn, the weft yarn is a hollow fiber, the surface of the weft yarn is of a microcellular structure, and the cross section of the weft yarn is in a four-pipe shape. The mosquito repelling, moisture absorption and sweat releasing fabric has the function of slowly releasing the mosquito repelling flavor, and can continuously repel mosquitoes, and therefore the human body is protected against mosquito biting. According to the fabric, the moisture absorption and sweat releasing functions are achieved.

Owner:WUXI TEBO ELECTRONICS TECH

An energy storage heat exchange device

ActiveCN107167013BRealize the purpose of energy storage and heat exchangeLow melting pointHeat storage plantsCold airInsulation layer

The invention relates to an energy-storage heat exchange device. The energy-storage heat exchange device comprises an energy storage pile, a heat exchanger, a heating tube and a fan, wherein a thermal insulation layer A is arranged at the periphery of the energy storage pile; a gap between the energy storage pile and the thermal insulation layer A is taken as an air flue; a ventilating groove is formed in the energy storage pile; the fan is connected with the heat exchanger through a pipeline; the other end of the fan is accessed into the air flue A through a pipeline; the other end of the heat exchanger is accessed into an air flue B through a pipeline; the air flue A and the air flue B refer to air flues formed between opposite two ends in the energy storage pile and the thermal insulation layer A; an electric heating tube is arranged in the energy storage pile in a penetrating mode for heating the energy storage pile; under driving of the fan, air flow enters the energy storage pile through the air flue A; and air flow is heated by the energy storage pile. The energy-storage heat exchange device utilizes off-peak electricity to heat the energy storage pile, and utilizes the energy storage pile to slowly release heat for heating air flow to form hot air; and after entering the heat exchanger to exchange heat, hot air is changed into cold air for being blown into the fan, and re-enters the air flue A under driving of the fan in a circulating mode, so that the energy-storage heat exchange purpose is realized.

Owner:天津朗华科技发展有限公司

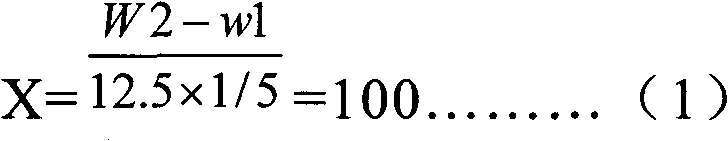

Hemp fibre filter wire and preparation method thereof

InactiveCN101884859BBeyond moisture absorption and breathabilityGood capillary effectFiltration separationVegetable materialYarnChemical industry

The invention relates to a filter material for water treatment, in particular discloses a hemp fibre filter wire and a preparation method thereof. The hemp fibre filter wire is characterized by being prepared by using hemp fibres as raw materials, spinning the hemp fibres into yarns through hemp spinning equipment and then degumming, bleaching, drying and forming. The invention is mainly used forthe purification and the filtering of various liquids; a wire-wound filter core prepared by the hemp fibre filter wire is used for the precise filtering of the liquids in a petroleum industry, a chemical industry, an electron industry, a pharmaceuticals industry, a food industry, a domestic water industry, and the like; and in addition, the invention can bring new vitality for the water treatmentindustry due to excellent performance and complete green environmentally-friendly quality.

Owner:郭淼

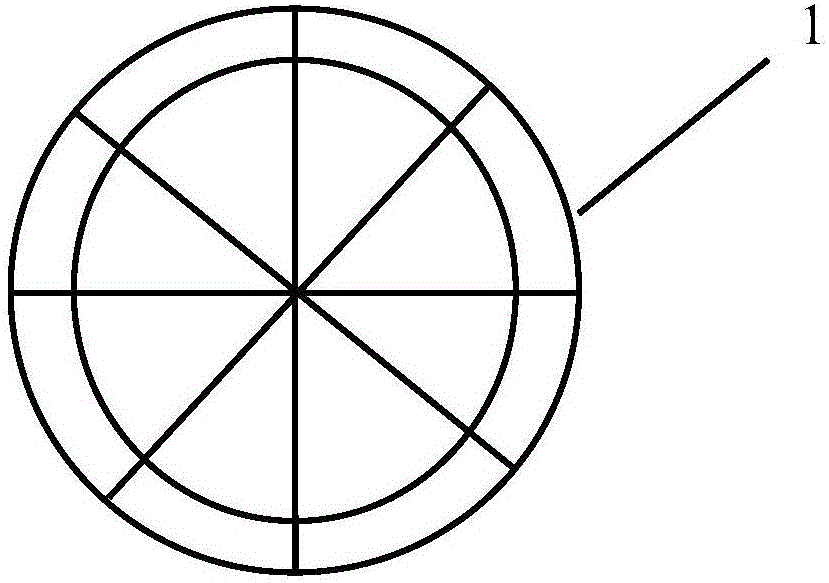

Acrylic fiber with flying saucer-like cross section and production method thereof

InactiveCN106498529AFluffy goodImprove fluffinessArtificial filament washing/dryingArtificial filament heat treatmentFiber bundleAcrylonitrile

The invention discloses an acrylic fiber with a flying saucer-like cross section. The acrylic fiber with the flying saucer-like cross section mainly comprises, by mass, 91 to 94% of acrylonitrile and 6 to 9% of vinyl acetate, and is prepared through extrusion by a spinneret plate; and the cross section of the acrylic fiber has a length-breadth ratio of (6-9): 2. The invention also discloses a production method for the acrylic fiber with the flying saucer-like cross section. The production method comprises the following steps: allowing acrylonitrile and vinyl acetate to form a spinning solution in a solvent after copolymerization; heating the spinning solution to 82 to 90 DEG C, extruding the spinning solution from the spinneret plate and forming nascent fibers in a coagulation bath; and subjecting the nascent fibers to washing and drafting so as to form fiber bundles and carrying out oiling, drying and sizing on the fiber bundles so as to prepare the acrylic fiber with the flying saucer-like cross section. According to the invention, the prepared acrylic fiber has excellent performance by adjusting the contents of acrylonitrile and vinyl acetate in a copolymer and the molecular weight of the copolymer, reasonably designing the spinneret plate and adjusting a production process.

Owner:NINGBO ZHONGXIN ACRYLIC FIBERS

Moisture absorption and sweat releasing anti-stain work suit

InactiveCN104082881AFree from pollutionReduce cleaning timesSynthetic resin layered productsProtective garmentYarnFiber

The invention relates to a moisture absorption and sweat releasing anti-stain work suit. The moisture absorption and sweat releasing anti-stain work suit is composed of a fabric layer (1) and a waterproof fabric layer (2), the waterproof fabric layer (2) is formed by a polytetrafluoroethylene film and cloth in a compound mode, the surface of the waterproof fabric layer (2) is coated with a waterproof coating (3), and the waterproof coating (3) is a plastic modified asphalt coating layer. The fabric layer is formed by interweaving warps and wefts, the warps are environment-friendly yarns, the wefts are hollow fibers, the surfaces of the fibers are of a cellular structure, and the cross section of the fibers is in a four-tube shape. Under joint protection of the waterproof fabric layer and the waterproof coating, the anti-stain work suit will not be stained with sewage, liquid and other sundries, and therefore it is ensured that the anti-stain work suit is prevented from being stained. The fabric of the anti-stain work suit has the moisture absorption and sweat releasing functions.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

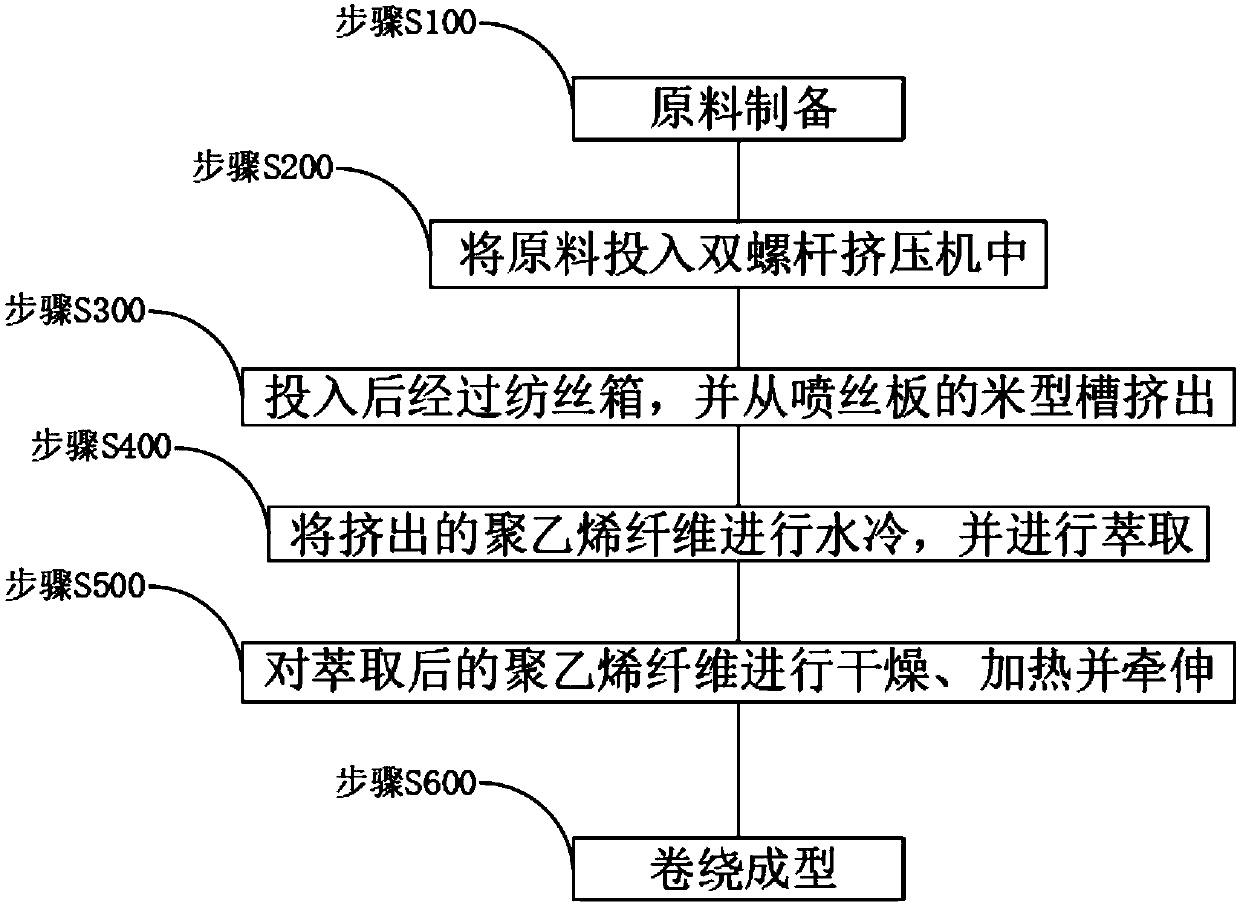

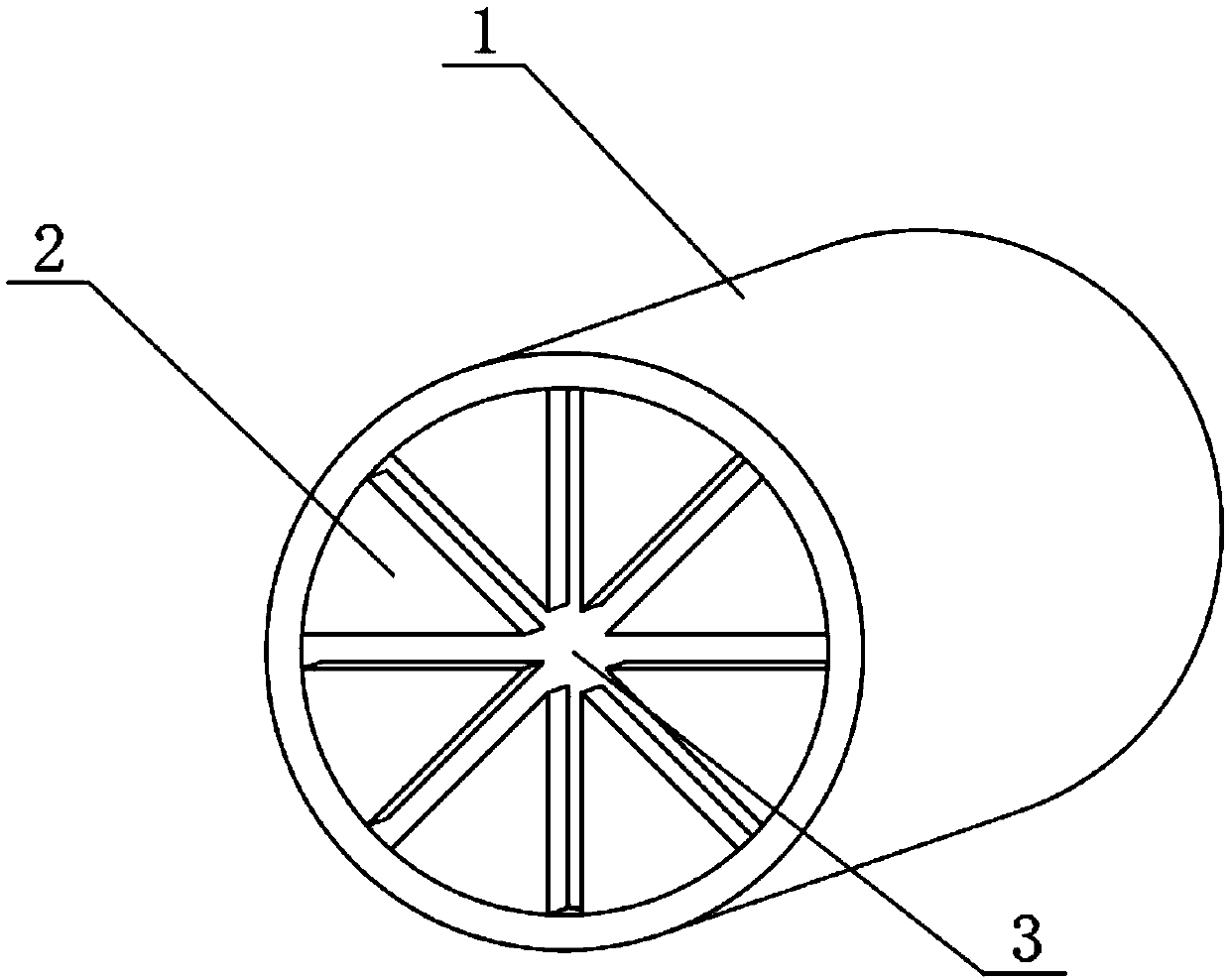

Production method for moisture-absorbing sweat-releasing high-strength high-modulus polyethylene

InactiveCN109097847AGood hygroscopicityLarge specific surface areaFilament/thread formingSingle fibreWater cooling

The invention discloses a production method for moisture-absorbing sweat-releasing high-strength high-modulus polyethylene. The production method for the moisture-absorbing sweat-releasing high-strength high-modulus polyethylene comprises the following steps: S100, preparing a raw material; S200, putting the raw material into a twin-screw extruder; S300, after the raw material is put into the twin-screw extruder, enabling the raw material to pass through a spinning box, and extruding the raw material from *-shaped slots of a spinning plate; S400, performing water cooling on the extruded polyethylene fibres, and extracting; and S500, drying, heating and drawing the extracted polyethylene fibres; and after the raw material is extruded from the spinning plate, extruding the polyethylene fibreraw material into * shapes, wherein the ultrafine high-strength polyethylene fibres with the *-shaped cross sections are provided with eight grooves, are large in specific surface area, can guide moisture and are breathable; the specific surface area of a single fibre of 0.4 to 0.5 dpfp is 2 to 3 times that of the single fibre of 2 dfp; and a good capillary effect can be achieved by the spaces among the fibres, so that the moisture absorbing property of the fibres is enhanced. Therefore, the ultrafine high-strength polyethylene fibres with the *-shaped cross sections has good moisture absorbing property and sweat releasing property when the ultrafine high-strength polyethylene fibres with the *-shaped cross sections are applied in the fields of home textile and underwear.

Owner:盐城优和博新材料有限公司

Hygroscopic and sweat releasing antibacterial fabric

InactiveCN105252838AQuick killComfortable to wearSynthetic resin layered productsCellulosic plastic layered productsDiseaseCellulose

The invention discloses hygroscopic and sweat releasing antibacterial fabric which comprises a silkworm pupa protein fiber layer and a hygroscopic and sweat releasing layer. The hygroscopic and sweat releasing layer is arranged below the silkworm pupa protein fiber layer, and according to the silkworm pupa protein fiber layer, after silkworm pupa protein and natural cellulose are blended and when fibers are formed, protein can be enriched on the surfaces of the fibers, and protein fibers of a skin-core structure are formed. The hygroscopic and sweat releasing layer is formed by blending and knitting polyester fibers and polyamide fibers, the polyester fibers are adopted as a skin layer, the polyamide fibers are adopted as a core layer, the polyamide fiber sections of the polyamide fibers are in a pentagram shape, a groove is formed between every two adjacent points of the pentagram, nano-silver ions are added to the grooves, and the silkworm pupa protein fiber layer and the hygroscopic and sweat releasing layer are bonded through glue. The nano-silver ions are added to hygroscopic quick-dry yarn with the special-shaped section, cocci and disease bacteria can be fast killed, and meanwhile it is guaranteed that clothes made of the fabric is comfortable to wear.

Owner:JIESHOU SHUANGXIN TEXTILE

Capillary structure of heat dissipation element, heat dissipation element and preparation method of capillary structure

PendingCN114543570AThickness is easy to controlGood size controlHot-dipping/immersion processesSemiconductor/solid-state device detailsActive agentPhysical chemistry

The invention relates to the technical field of heat dissipation, and particularly provides a capillary structure element of a heat dissipation element, which is characterized in that a capillary structure is prepared from copper metal slurry, and the copper metal slurry comprises copper powder, a binder, a solvent, a pore forming agent, a dispersant, a stabilizer, a surfactant and an antioxidant. The invention further provides a heat dissipation element comprising the capillary structure element and a preparation method of the heat dissipation element. The capillary structure element provided by the invention has the characteristics of simple preparation process, convenience in operation, controllable thickness, controllable size, controllable aperture, excellent capillary effect and the like, and is particularly suitable for preparing ultra-thin heat dissipation elements.

Owner:AAC TECH NANJING

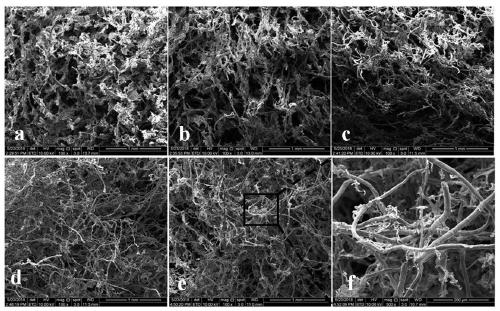

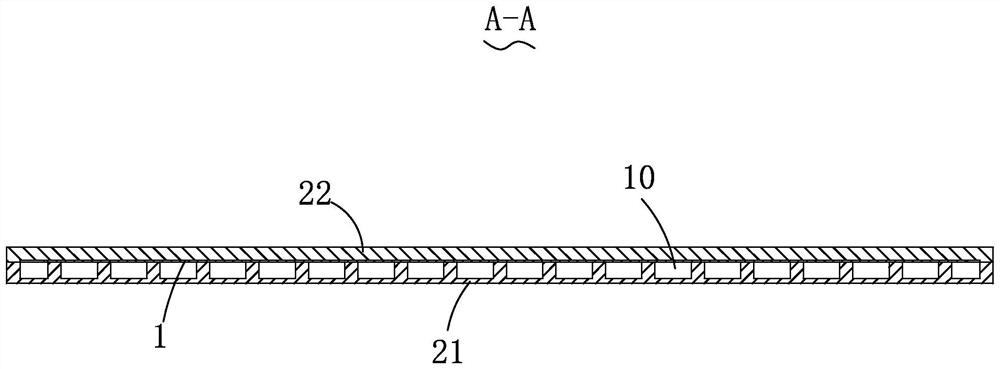

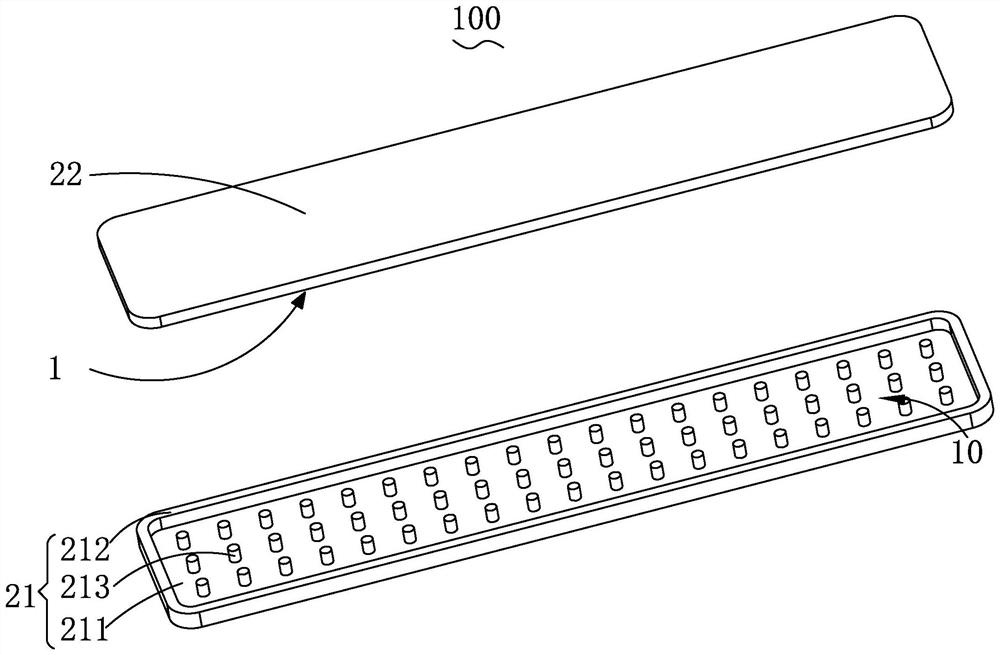

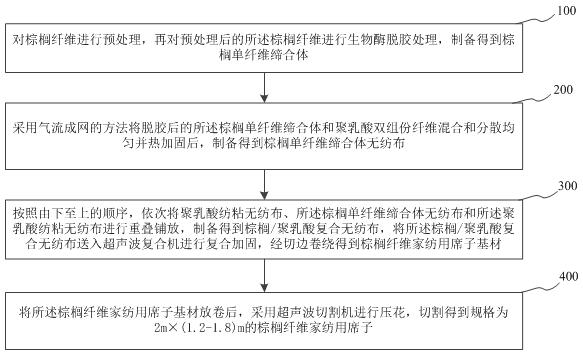

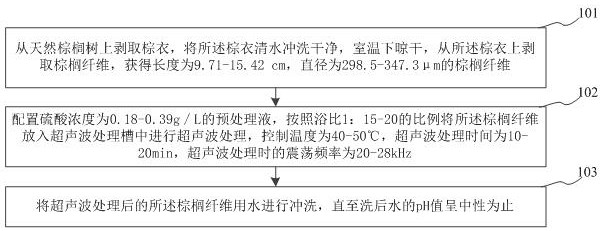

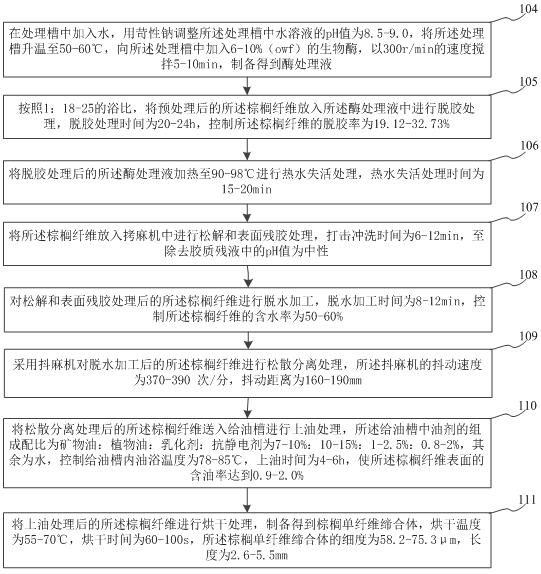

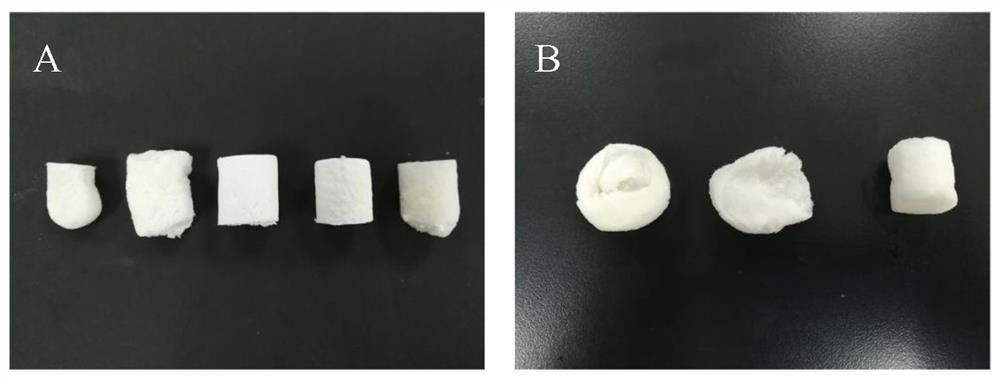

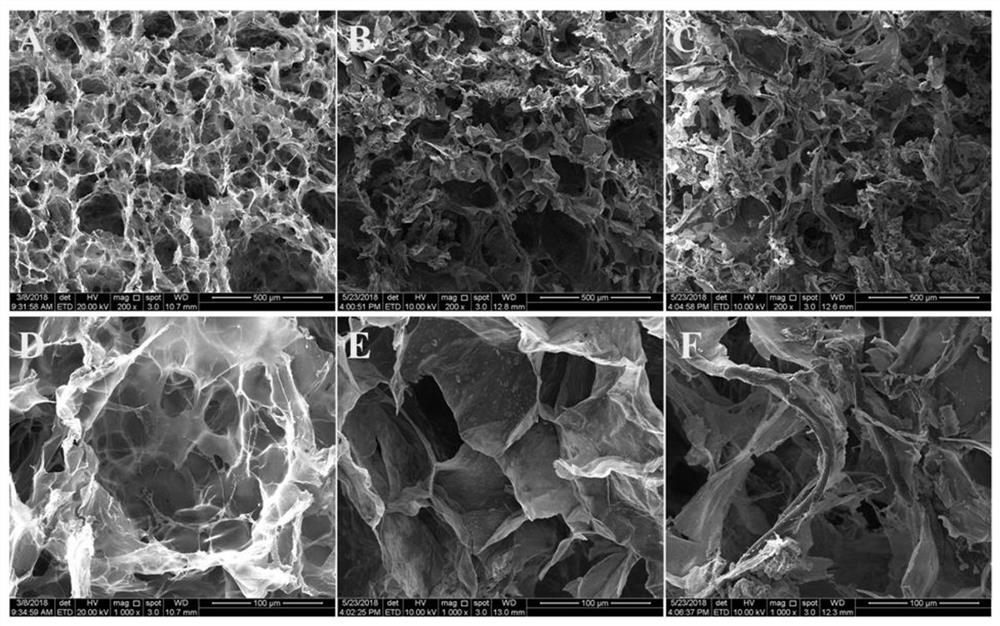

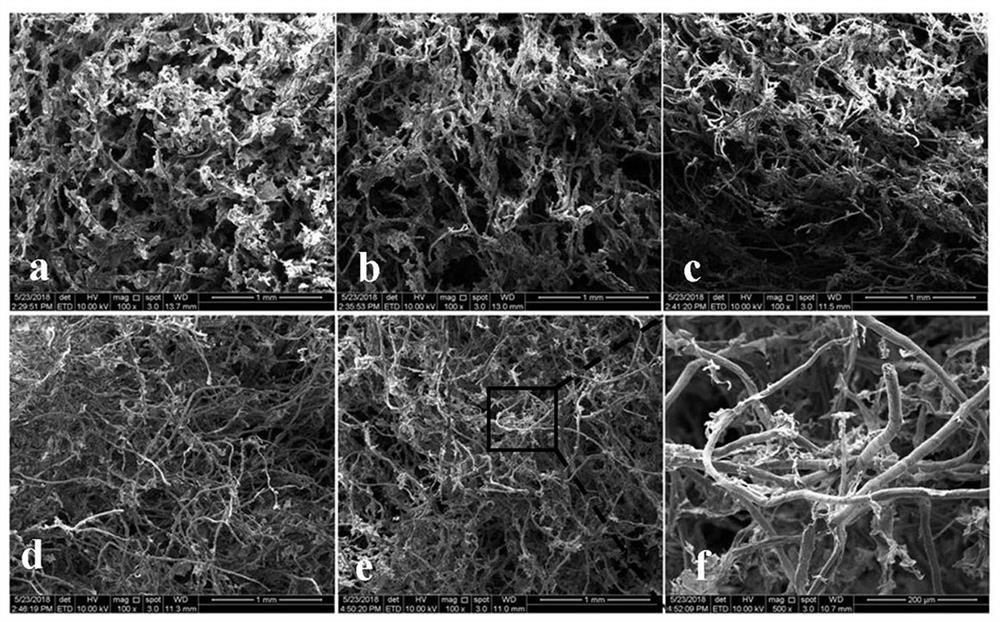

A kind of palm fiber home textile mat and preparation method thereof

ActiveCN110509630BShorten the lengthGood moisture conductivityLamination ancillary operationsBlanketPolymer scienceSingle fibre

The invention discloses a palm fiber home textile mat and a preparation method thereof, and relates to the technical field of home textile materials. The present invention provides a palm fiber home textile mat and a preparation method thereof. The natural palm fiber is partially degummed by a composite method combining ultrasonic pretreatment and biological enzymes to obtain a palm single fiber in which multiple palm single fibers are glued together. The association, and then adopt the air-laid method to control the weight of the air-carrying palm fiber and the polylactic acid bicomponent fiber to make a palm monofilament nonwoven fabric containing the polylactic acid bicomponent fiber, and then pass through the upper layer and the polylactic acid bicomponent fiber. The lower polylactic acid spun-bonded non-woven fabric is compounded to make a palm fiber home textile mat base material, and then cut and welded by an ultrasonic cutting machine to make a semi-durable palm fiber home textile mat. The palm fiber home textile mat utilizes the high hollowness of the palm single fiber and the excellent capillary effect formed by internal folds to achieve good moisture absorption, moisture conduction and air permeability.

Owner:JIAXING UNIV

A kind of preparation method of drug-loaded hemostatic sponge and prepared drug-loaded hemostatic sponge

ActiveCN109111591BHigh porosityImprove fluffinessSurgical adhesivesPharmaceutical delivery mechanismCelluloseActive agent

Owner:ZHENGZHOU UNIV

A coolplus moisture-wicking and warm-keeping raschel blanket

ActiveCN107419423BPromote popularizationSimple compositionFibre typesWarp knittingPolyesterChinese characters

The invention discloses a Coolplus moisture-absorption sweat-releasing and warming Raschel woolen blanket. The Coolplus moisture-absorption sweat-releasing and warming Raschel woollen blanket is woven on a two-needle bar Raschel warp knitting machine by using blended yarns of Coolplus fibers and acrylic fibers as nap yarns and using polyester silk as basic silk. Special-shaped polyester fibers can be acquired by using a +-shaped herringbone or Chinese character mi-shaped spinning assembly; air plasma and alkali peeling treatment is performed on the polyester fibers; regular micro grooves and micro holes are formed in surfaces of the polyester, and the grooves and the holes can generate a significant capillary effect, moisture and sweat excreted by a human body are diffused and transmitted, and then are discharged out, and skins can keep dry; and noncurrent static air is stored in the regular micro grooves and micro holes, and the static air can significantly improve the warming performance of the Raschel woolen blanket.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

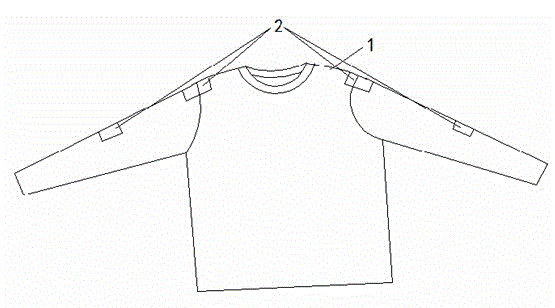

Cooldry garment for treating arthritis

InactiveCN104126890AGood capillary effectGood moisture absorptionGarmentsMedical devicesFiberHuman body

The invention relates to a cooldry garment for treating arthritis. The comprises a garment body (1), wherein medicine accommodating interlayers (2) are arranged at the positions of joints of the garment body, rubber is arranged on the surface, close to the garment, of each medicine accommodating interlayer (2), gauze is arranged on the surface, close to the human body, of each medicine accommodating interlayer (2), the garment body is made of the fabric which is formed by interweaving of warp and weft, the warp is environment-friendly yarn, the weft is hollow fiber with cellular structures on the surface, and the cross section of the weft is in a four-tube shape. When treatment is needed, medicine is placed on the medicine accommodating interlayers and makes contact with tissue of the joints after permeating through the gauze, and then the arthritis treating effect is realized. The garment has the cooldry property.

Owner:JIANGYIN YINGXIN WEAVING

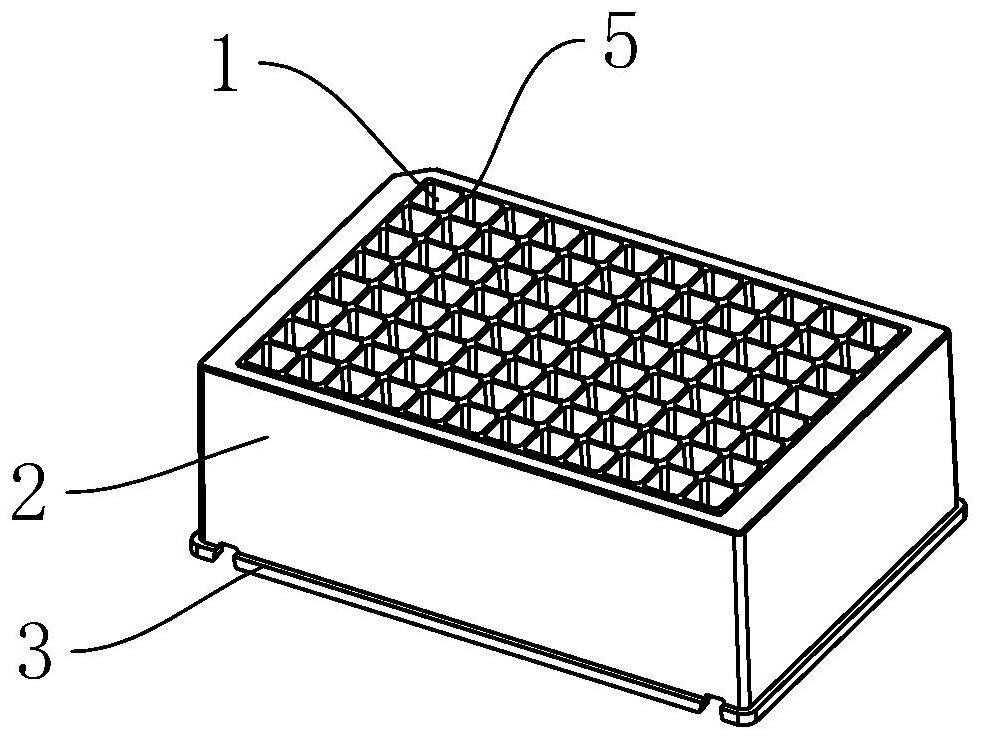

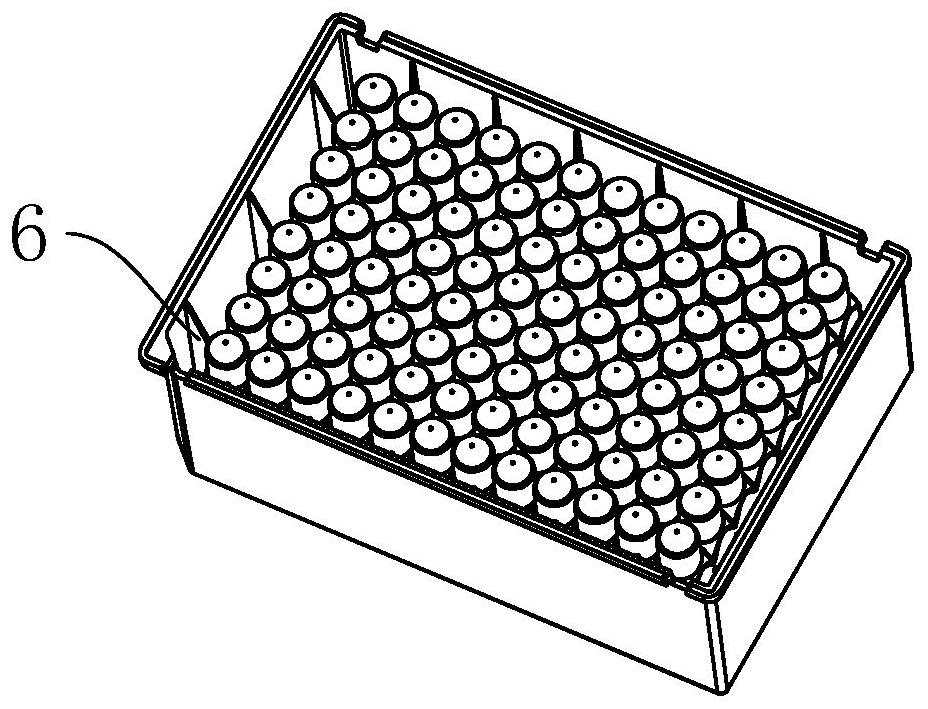

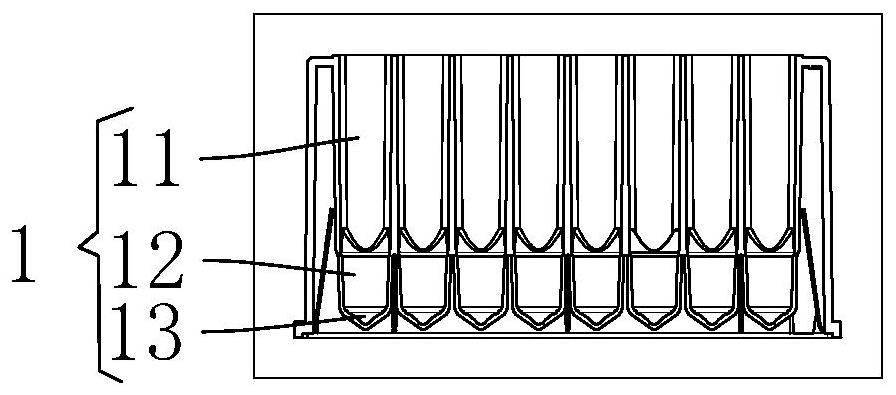

Deep-well plate with high nucleic acid extraction rate and preparation method of deep-well plate

PendingCN114437904AReasonable structural designWill not polluteBioreactor/fermenter combinationsBiological substance pretreatmentsBiocompatibilityMaterials science

The invention provides a deep-well plate with a high nucleic acid extraction rate and a preparation method of the deep-well plate. The deep-hole plate with the high nucleic acid extraction rate comprises a containing cavity, and a plurality of deep-hole plate holes are formed in the containing cavity; the deep hole plate skirt edge is fixedly connected to the side edge of the accommodating cavity; the base is formed by extending the bottom of the skirt edge of the deep-hole plate towards the direction far away from the accommodating cavity; wherein an inner corner is arranged on the inner side of the deep hole plate hole. The deep well plate with high nucleic acid extraction rate has the characteristics of good biocompatibility and low nucleic acid adsorption.

Owner:浙江博毓生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com