Patents

Literature

184 results about "Hemp fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hemp is traditionally known as a fiber plant and most historical cultivation of the plant in the United States from the 17th to mid-20th centuries was with fiber use in mind. Two kinds of fibers are derived from the hemp plant’s stalk. These are long (bast) fibers and the short (core fibers).

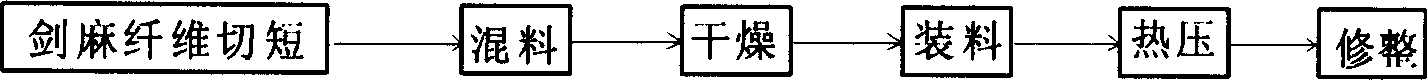

Method for polishing wheet from sisal fiber

InactiveCN1562570ARich varietyVarious ventilation structuresFlexible-parts wheelsPlant fibreSisal fiber

A polishing wheel is made up of short sisal hemp fibres, synthetic resin, plant fibres and inorganic compound through proportionally mixing, drying, hot die pressing and trimming.

Owner:黄焕仪 +1

Manufacturing method of bast fiber nonwoven fabric

InactiveCN101324012AEasy to manufactureAvoid breakingNon-woven fabricsAdhesivesNonwoven fabricMaterials science

The invention discloses a production method of a fibrilia non-woven fabric and comprises following steps: (1) opening and mixing: the fibrilia is opened once, bonding fiber and other fibers are opened for two or more times, and the opened fibrilia, bonding fiber and other fibers are mixed; (2) the mixed fibers are processed into a meshwork; (3) prickling shaping: the fiber meshwork that is obtained from step (2) is prickled by a needle machine; (4) hot rolling shaping: the fiber meshwork that is obtained after the prickling is transmitted onto a roll squeezer to be rolled, and the hot rolling shaping is implemented. The production method of the fibrilia non-woven fabric is simple, and the opening times of the fibrilia is limited, thus avoiding fibrilia break that is caused by a plurality of opening times, and consequently ensuring the length of the fibers and being convenient for the production of the non-woven fabric; simultaneously the opening of other fibers excluding the fibrilia is implemented for two or more times, thus ensuring full opening of the fibers and being convenient for the production of the non-woven fabric.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Natural vegetable fiber reinforced fully-degradable polymer composite material and preparation method thereof

The invention refers to a full-degradable polymer composite material strengthened by the natural plant fiber and the preparing method. It adopts India plant fiber-Hildegardia populifolia, sisal fiber, ramee, wood fibre and so on as the fiber raw material, tand the degradable plastic-the poly-methyl ethyl carbonic acid resin as the basic body, and smelts and commixes the filling and the basic body on the existent / nonexistent condition of the coupling agent to make the composite material. The weight percent content of the fiber is 5-80%, the better fiber 10-40%.

Owner:SUN YAT SEN UNIV

Natural green health care knitwear and its mfg. method

A health-care knitting fabric is made up of hemp fibre, color cotton fibre, bamboo fibre, soybean protein fibre, chitin fibre, and natural wooden pulp fibre through twisting, knitting, boiling, softening, baking and high-pressure ironing.

Owner:王新文

Boiling-off method for bast fibre and bast fibre produced by the same

InactiveCN1772976AAchieve economyFully reflect the scientific concept of developmentVegetable materialEngineeringWater content

The present invention discloses a degumming method of bast fibre. Said method includes the following steps: soaking bast fibre in water for 40-80 min, making its water content is 60-100%, then placing the water-contained bast fibre into a steam explosion tank, making steam explosion under the condition of that its pressure is 1.3-1.7 MPa and the pressure-retaining time is 3-8 min, taking out the bast fibre, washing said bast fibre with water and drying so as to obtain the invented degummed bast fibre.

Owner:北京赛特瑞科技发展有限公司

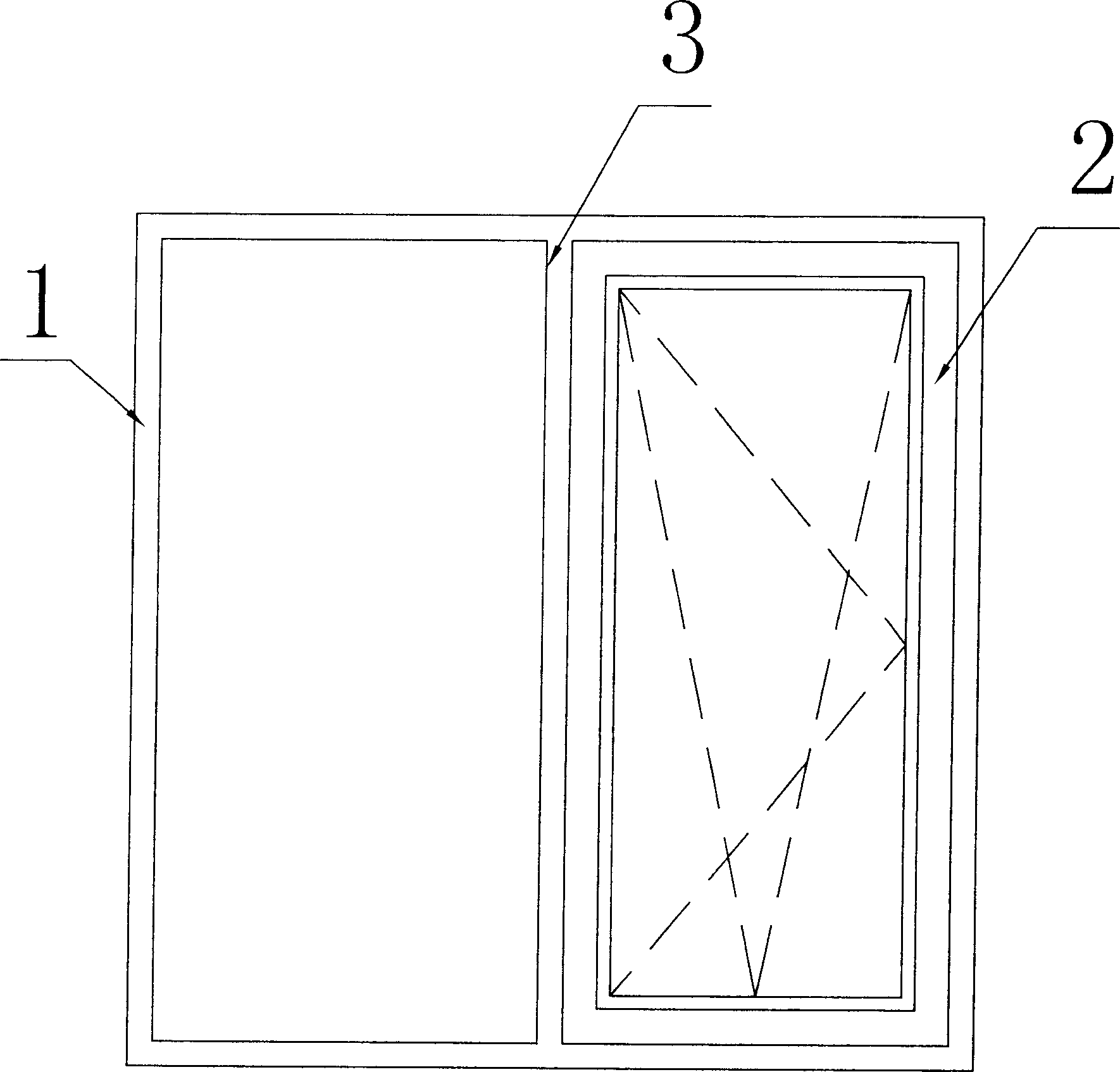

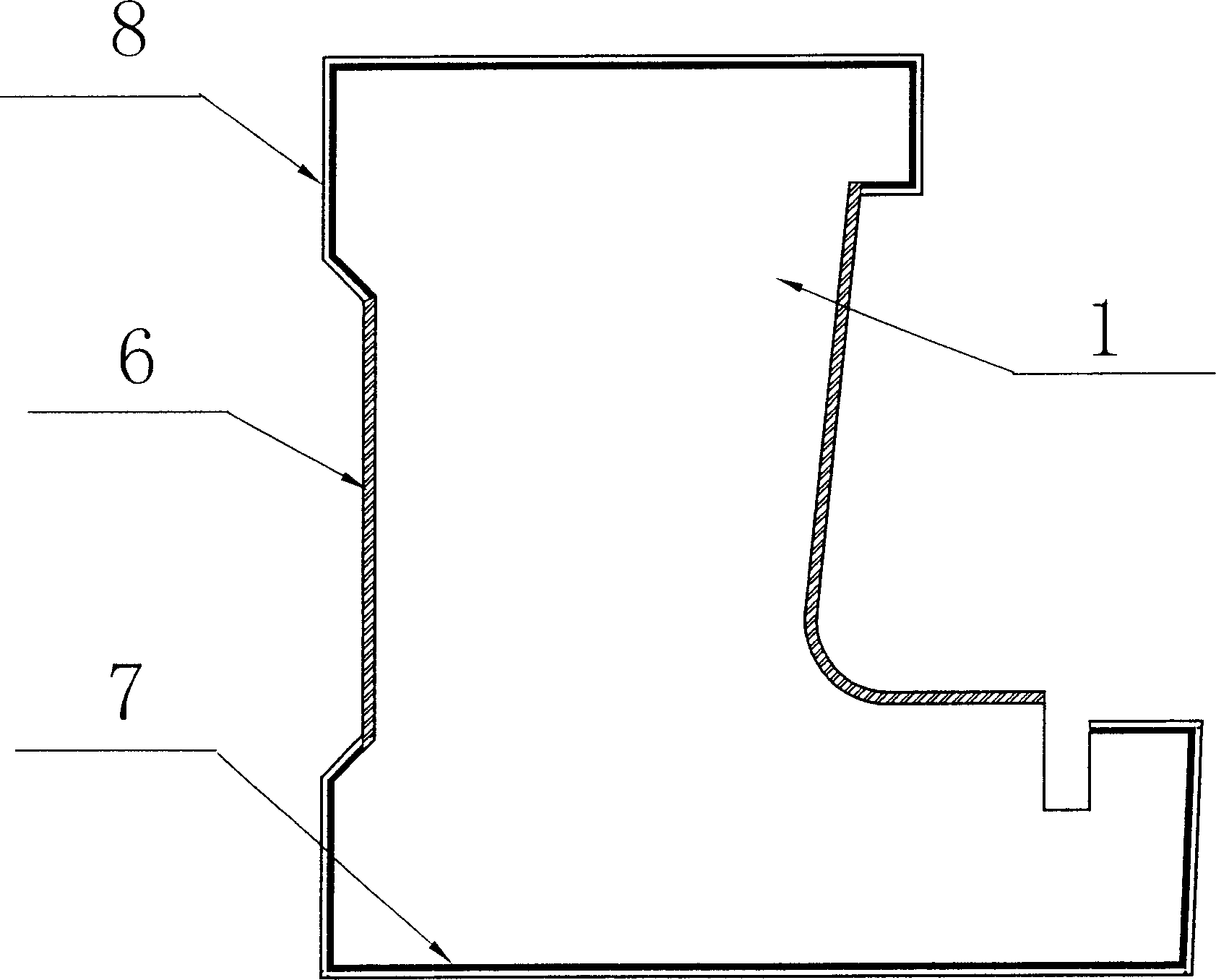

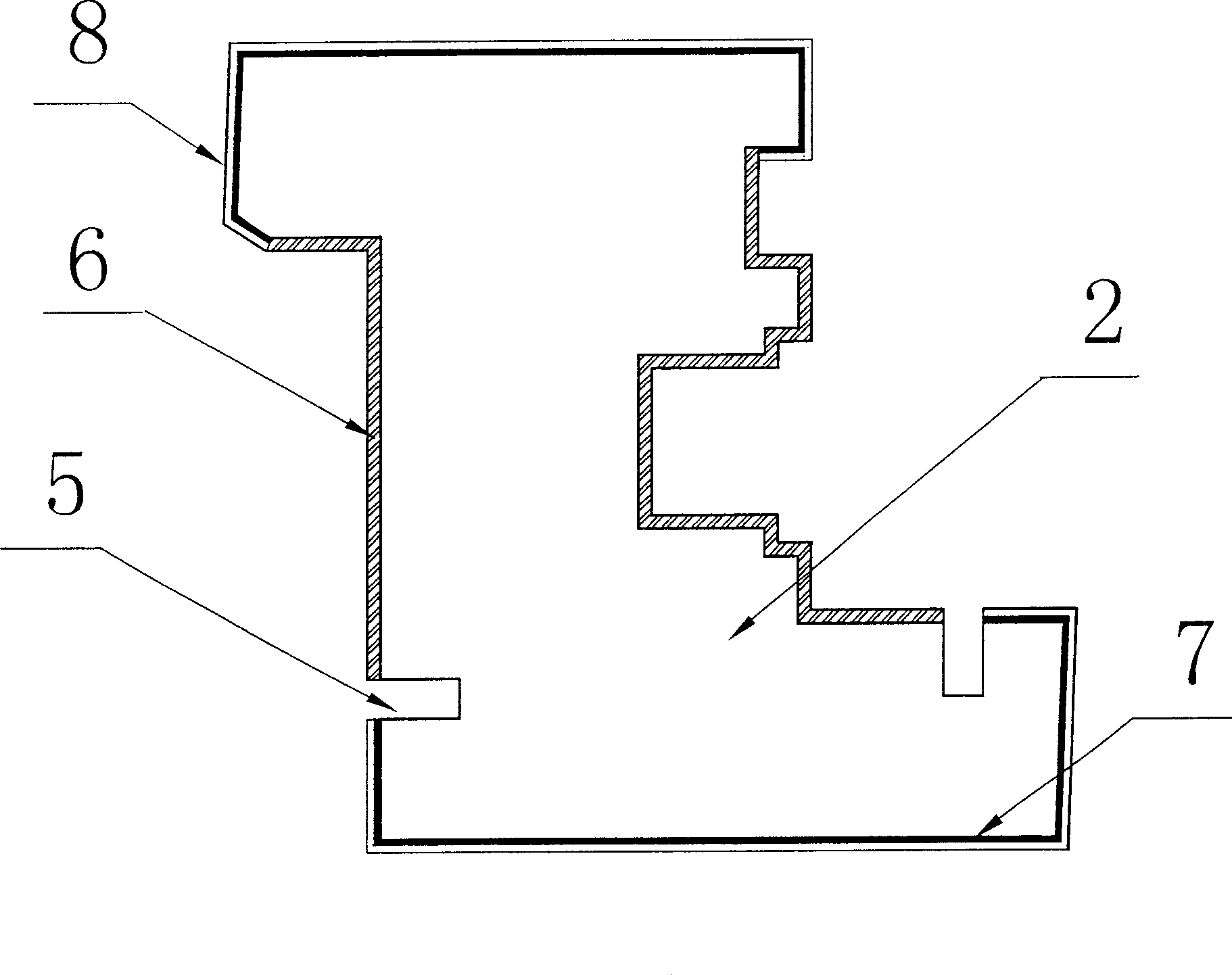

Environmental-protective and regenerative solid wooden plastic door and window and its production

This invention is a kind of regenerative environmental protecting type solid core wooden door and window. It is combined with frame structural section, sector structural section, middle frame structural section and sealing strips. The structural sections are solid core structural section. Their side faces are coated with plastic layer. The indoor face and outdoor face are coated with aluminum-coated layer through glue line. The main raw materials of the said solid core structural sections are regenerative polyolefine resin, plant fiber filler and auxiliary agent. The said regenerative polyolefine resin is the mixture of regenerative polypropylene and regenerative polyethylene. The plant fiber filler is wood fiber powder, hemp fiber powder, bamboo fiber powder, grass fiber powder, chaff powder or straw fiber powder. This invention decreases environmental pollution. It will not generate harmful gas when being heated. It also increases the anti-ultraviolet radiation, aging resistance and heat insulating performances.

Owner:北京大龙东升门窗幕墙工程有限公司

Tourmaline-containing sheath-core composite fibers

ActiveCN104451940AHas antibacterial and antibacterial effectImprove itchingPhysical treatmentConjugated cellulose/protein artificial filamentsGlycerolSlurry

The invention relates to fibers, in particular to tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers are prepared through the following steps: (1) tourmaline processing; (2) core layer material processing, that is, bast fibers and palm fibers after degumming processing are combed and cut into short bast fibers and short palm fibers, the short bast fibers and the short palm fibers are then soaked in a mixed manner in a lignocellulose aerogel solution for 15 to 20 minutes according to a formula, the short bast fibers and the short palm fibers after the mixed soaking are then taken out for draining, the short bast fibers and the short palm fibers after the draining are sent to an opener for opening and mixing, the short bast fibers and the short palm fibers after the opening and mixing pass through airflows and are arranged through a roller groove to form meshed semi-products with S-shaped section structures, and the meshed semi-products go through spunlace to form non-woven needled bast-palm fiber aerogel core layer materials; (3) sheath layer material processing, that is, a first pulp is prepared from processed tourmalines and ethylene glycol, phthalic acid and glycerol are used for esterification reaction, the first pulp, magnesium oxide and calcium hydroxide are added after the reaction for condensation polymerization, and polyester chip sheath layer materials are obtained through strip casting and sized dicing; (4) composite melt spinning for obtaining of the tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers provided by the invention achieve the antibacterial and healthcare effects, high degree of comfort, as well as environment friendliness.

Owner:HEYE HEALTH TECH CO LTD

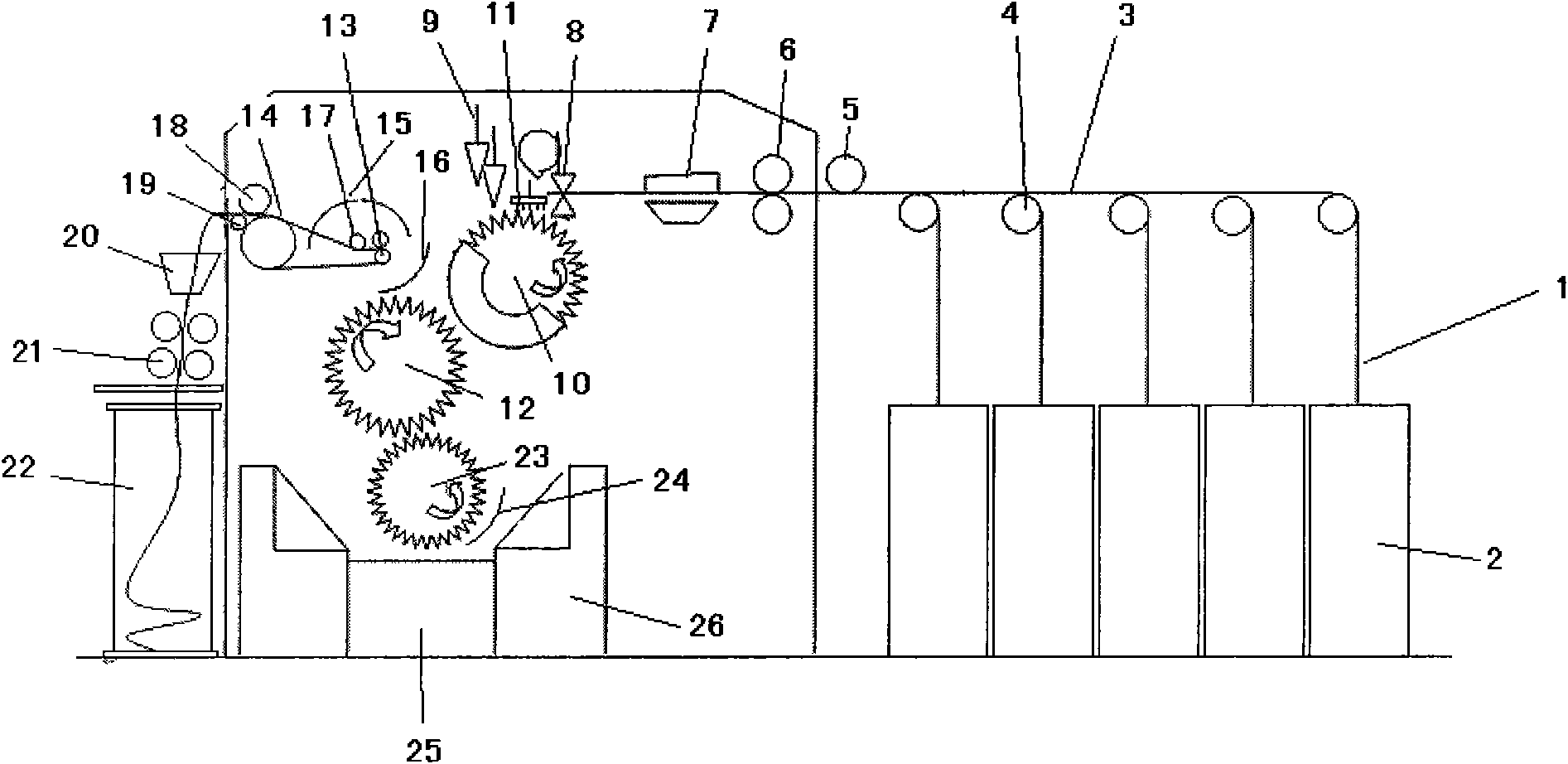

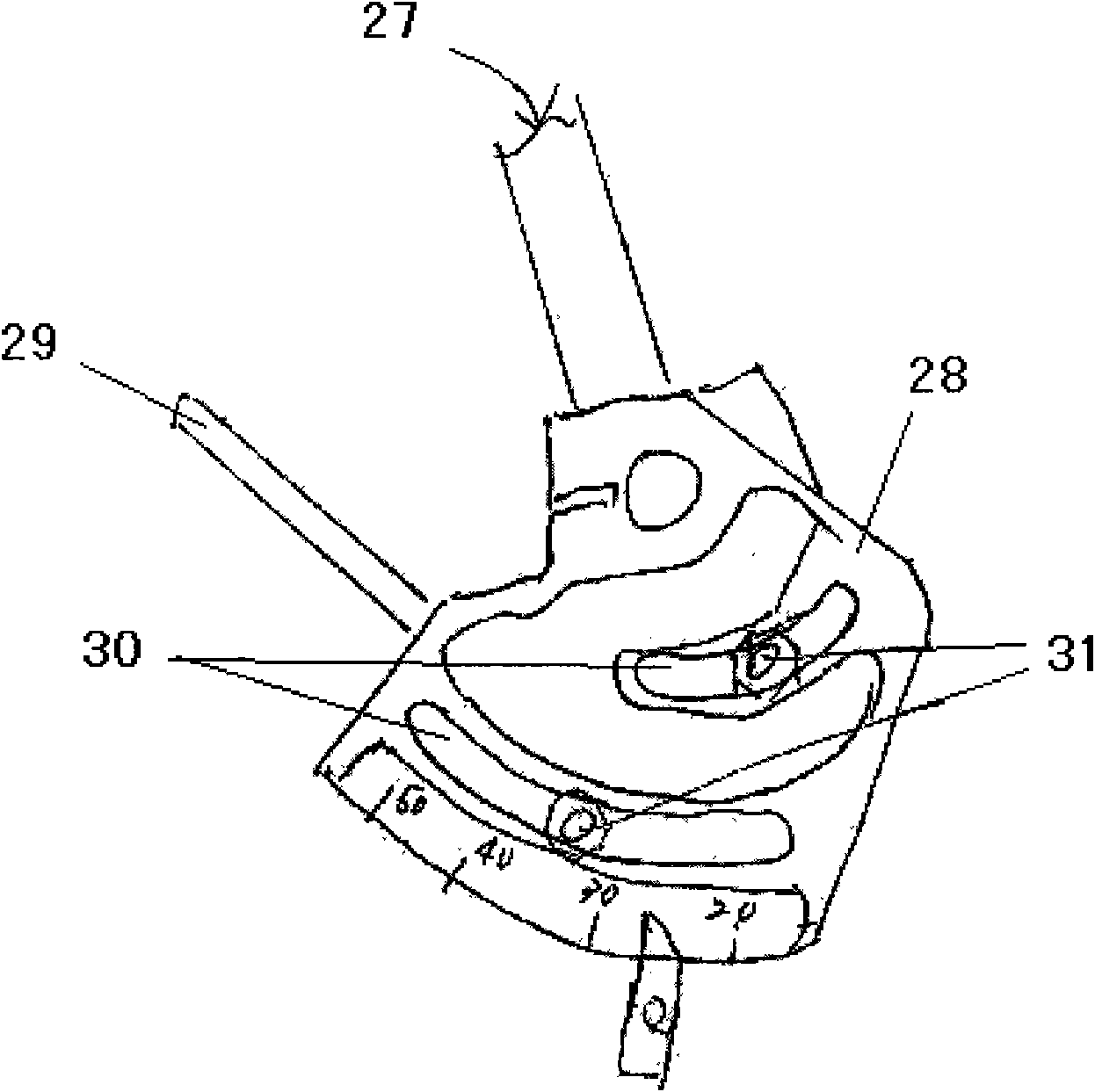

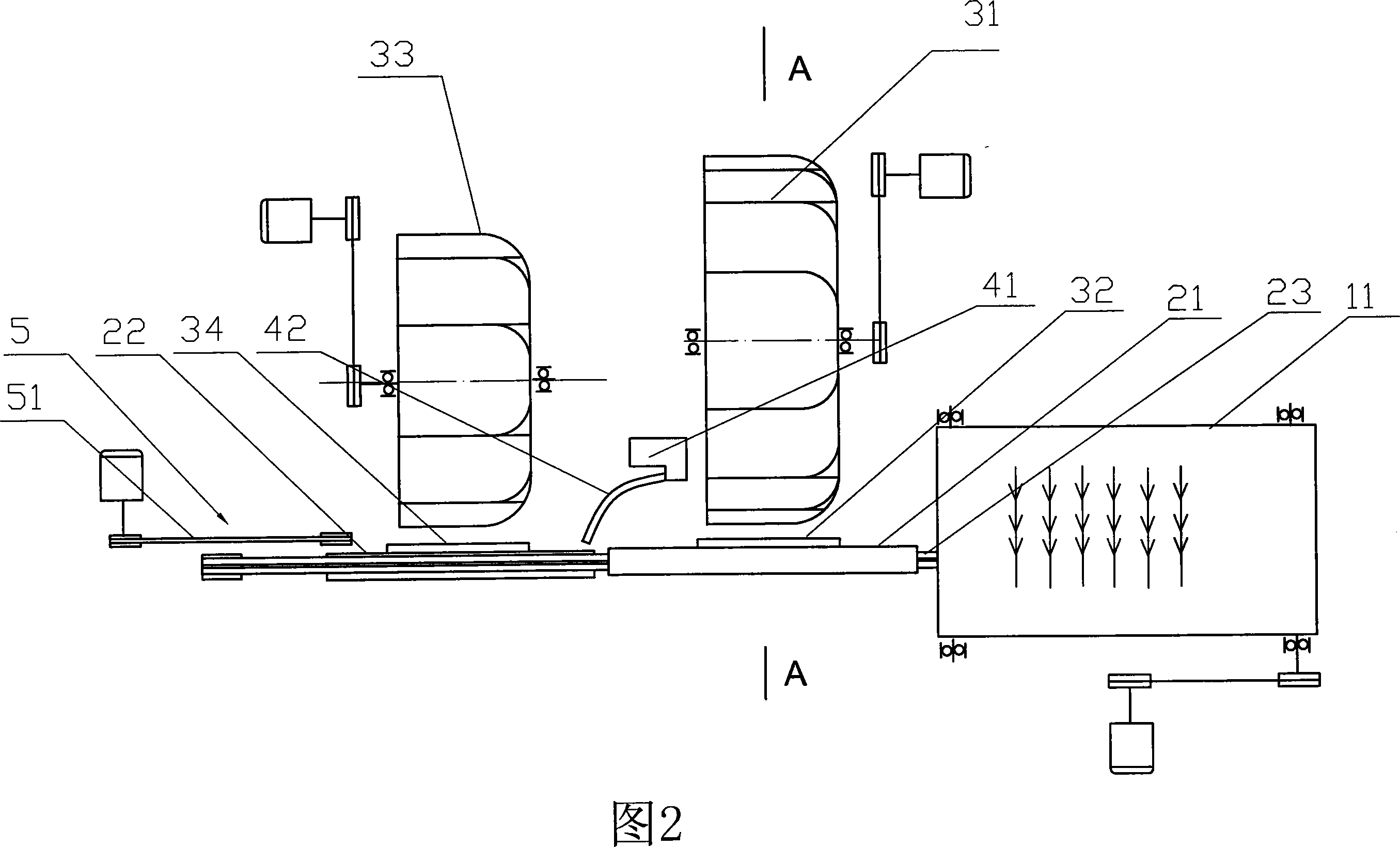

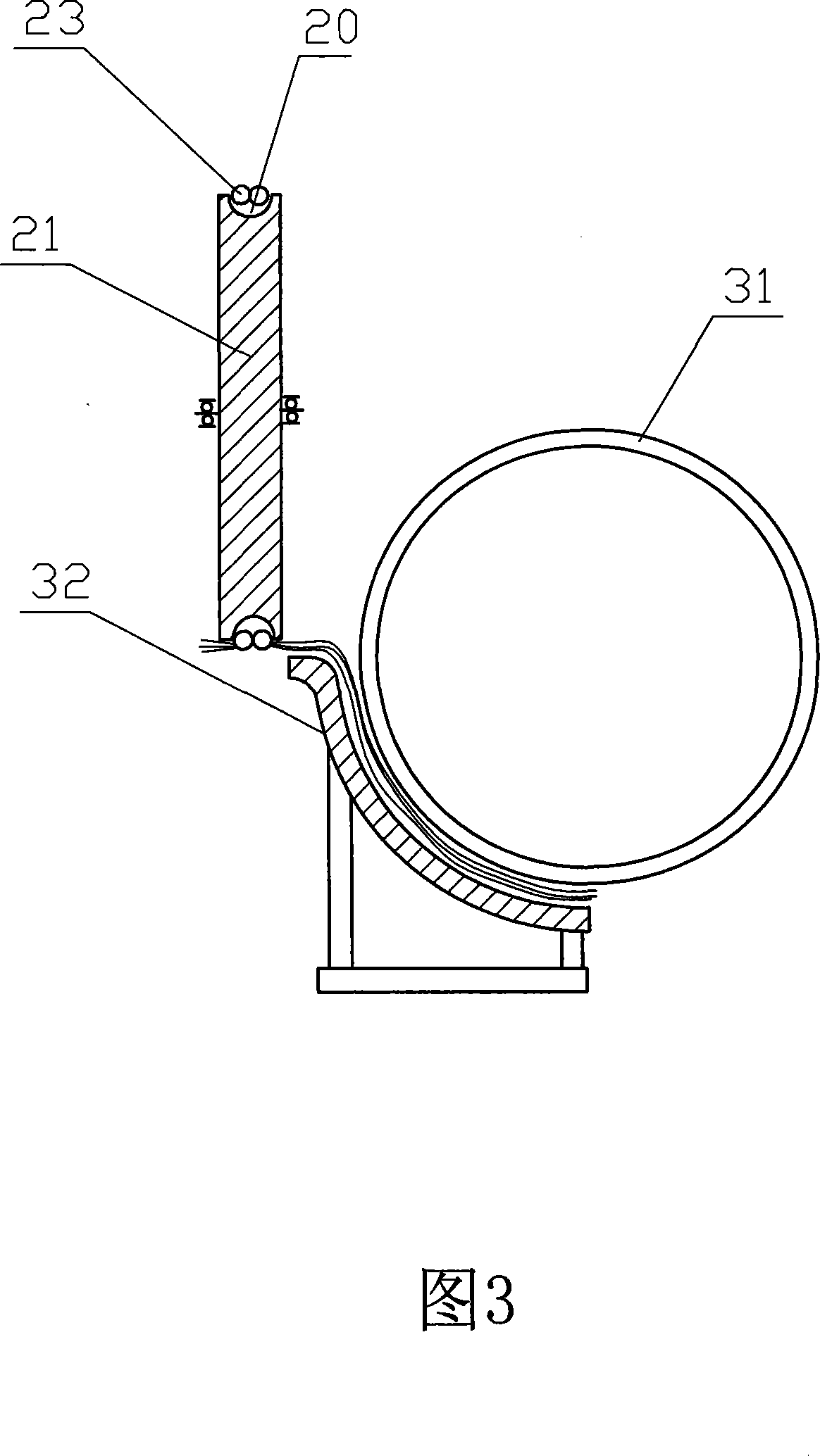

Sesaron combing and sorting method and device

ActiveCN101824676AEfficient removalIncrease the degree of splittingSafety devices for fibre treatmentCombing machinesCombingEngineering

The invention relates to a sesaron combing and sorting method and a device; combed ramie stripes with different specifications and lengths are obtained through a plurality of layers of combing; the split degree of the ramie stripes is decided by comb needle models used in all the layers of combing; and the lengths of the ramie stripes are changed by adjusting a pulling vehicle. In a combing and sorting mechanism of the device, circular comb needle strips are lined in a circumference of 0 to 270 degrees respectively through a rack method and a rack and needle row combined method, and top combs are in a single row or a plurality of rows. A pulling separation mechanism comprises the pulling vehicle, the pulling vehicle is arranged on a regulation frame, the regulation frame is provided with a rod and a circular arc-shaped chute, a bolt is inserted into the circular arc-shaped chute, the bolt is fastened on a frame, the bolt is loosened, and the regulation frame can slide along the circular arc-shaped chute by triggering the rod. At least two pairs of curl rollers are arranged in a strip discharge mechanism. The ramie stripe fibers processed by the method and the device are even and uniform, have short fiber rate, uniform fiber length and low ultra-long length fiber content, so that the fibers are more parallel and straighter, the operation is convenient, the efficiency is high, and the labor intensity is low.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

Ramie hemp and usage and extraction and preparation method for the same

InactiveCN101037808AMolecular orientation is smallReduce crystallinityYarnFibre treatment to obtain bast fibreYarnOxygen

The invention relates to a high-count ramie fabric of high quality, which can reach to 2500-4500 metric count, even above 4500 metric count, and technique for extration and preparation of ramie fabric, abbreviated as twice-boiling and twice-bleaching high-temperature splicing method. The features of the method are that during the extration and preparation of ramie fabric, the steps are twice boiling, twice bleaching and high-temperature splicing. The twice bleaching are chlorine bleaching and oxygen bleaching. The chlorine bleaching uses 3-8G / L of sodium hypochlorite for 40-80 minutes, at the use temperature of 35-45 degree. The oxygen bleaching uses 4-6G / L of hydrogen peroxide for 40-80 minutes, at the use temperature of 80-100 degree. Soda boiling performs twice. The high-temperature splicing performs after twice boiling and twice bleaching, and uses 100-140G / L of soda for 1.5-2.5 hours, at the use temperature of 100-140 degree. The invention also relates to pure ramie yarn, commingled yarn and blended yarn obtained during preparation of ramie fabric.

Owner:徐梅荣

Spinning method of spun-dyed hemp/cotton blended yarn

InactiveCN102021702AGood moisture absorption and perspirationSolve the problem that the length becomes shorter and the strength dropsYarnYarnCotton fibre

The invention discloses a spinning method of spun-dyed hemp / cotton blended yarn. The blended yarn is prepared by spinning the yarn which is formed by blending the dyed hemp fibre and cotton fibre at a ratio of (40-50):(50-60). The spinning method specifically comprises an opening picking process, a cotton carding process, a drawing process, a roving process and a spinning process, wherein the opening picking process is as follows: the dyed hemp fibre and the cotton fibre are manufactured into lap or cotton stream; and the cotton carding process is as follows: the lap or cotton layer is fed into a carding machine to be prepared into cotton strips, five-point gauge between a cylinder and a cover board is 0.22mm, 0.2mm, 0.18mm, 0.18mm, 0.2mm respectively, the rotation speed of the cylinder is 330-360r / min, and the speed of discharging strips is 65-75m / min. The blended yarn produced by the spinning method has bright color and has the advantages of good sterilization bacteriostasis and good wet-absorbing sweat-discharging property, and is a novel generation environment-friendly product.

Owner:SUNVIM GROUP

Preparation method of sisal hemp cellulose nanowhisker/polylactic acid biological composite material

The invention discloses a preparation method of a sisal hemp cellulose nanowhisker / polylactic acid biological composite material. The preparation method comprises the following steps: grafting a polylactic oligomer on the surface of the sisal hemp cellulose nanowhisker through adopting a grafting treatment method; and forming good interfacial adhesion by means of compatibility between the polylactic oligomer which is grafted on the surface of the sisal hemp cellulose nanowhisker and polylactic acid and preparing the sisal hemp cellulose nanowhisker / polylactic acid biological composite material by adopting an in-situ composite technique. The preparation method disclosed by the invention is simple in preparation process and green and environmental friendly, and the prepared sisal hemp cellulose nanowhisker / polylactic acid biological composite material has excellent mechanical properties and biocompatibility.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

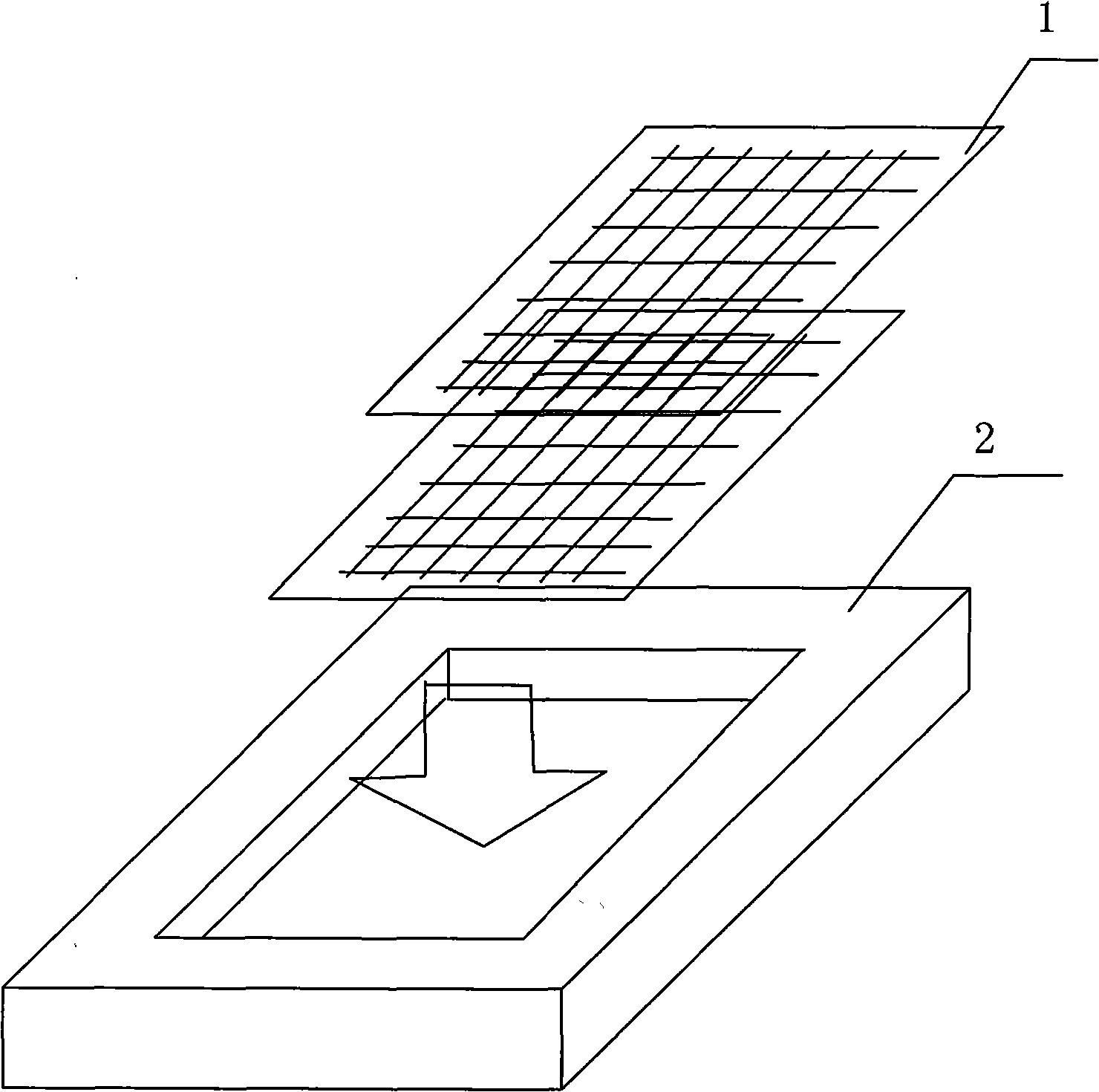

Manufacture technology of hemp woven fabric reinforced composite material sheet

ActiveCN101491947AHigh strengthHigh specific strengthFlat articlesManufacturing technologyTransfer molding

The invention discloses a method for manufacturing a composite material, in particular a process for manufacturing a hemp woven fabric reinforced composite material plate in the automobile industry. The process for manufacturing the hemp woven fabric reinforced composite material plate is characterized in that the hemp woven fabric is one of flax, jute and ambary; the hemp woven fabric is paved in a prefabricated mould layer by layer; each layer of the hemp woven fabric has a paving angle; each layer of the hemp woven fabric is crossed and paved; the volume content of hemp fibre is more than or equal to 40 percent; a resin transfer molding forming process is adopted to carry out mould filling; the mixture ratio of epoxy resin to a polyamide curing agent to a reactive diluent is 10:(1.2 to 2.4):(0.6 to 0.8); the curing time is four hours; and after mould filling is completed, the fabric is cured at the temperature of 130 DEG C, cooled, demoulded and subjected to surface treatment. The manufactured composite material plate has good strength and excellent impact resistance, can design strength, can be recycled and belongs to an environment-friendly material.

Owner:黑龙江金达麻业有限公司

Method for producing worsted cloth by mixed spinning hemp and wool

InactiveCN1431346AWith ecological health functionMeet consumer demandBiochemical fibre treatmentYarnWorstedEngineering

Owner:凯诺科技股份有限公司

Method for preparing heavy metal ion exchange fibers by virtue of roundpod jute capable of being modified by microwave and application

ActiveCN104562632AComplete efficientlyShort manufacturing timePhysical treatmentWater/sewage treatment by ion-exchangePolymer scienceMicrowave oven

The invention discloses a method for preparing heavy metal ion exchange fibers by virtue of roundpod jute capable of being modified by microwave and application. The method comprises the following steps: I. firstly boiling roundpod jute fibers by boiled water, then soaking the roundpod jute fibers by using a sodium hydroxide solution and drying and storing; and II. adding the roundpod jute fibers pretreated in the step I and a complexing group active monomer into the solution, carrying out reaction in a microwave oven, after reaction, taking out the material, and after cleaning, putting the product in the oven to be dried until constant weight is achieved to obtain a roundpod jute-base modified adsorption material which can be used for sudden heavy metal pollution and conventional heavy metal wastewater treatment, so that the hardness of water is effectively reduced. According to the invention, the matrix is rapidly grafted and modified by virtue of a microwave radiation technology in the preparation process to prepare fibers with complexing functions, so that the advantages of non-thermal effect of microwaves and strong grafting penetrating power are fully utilized, chemical grafting reaction can be quickly and efficiently accomplished, the preparation time is greatly shortened, and the method is simple to operate and convenient and feasible.

Owner:HARBIN INST OF TECH

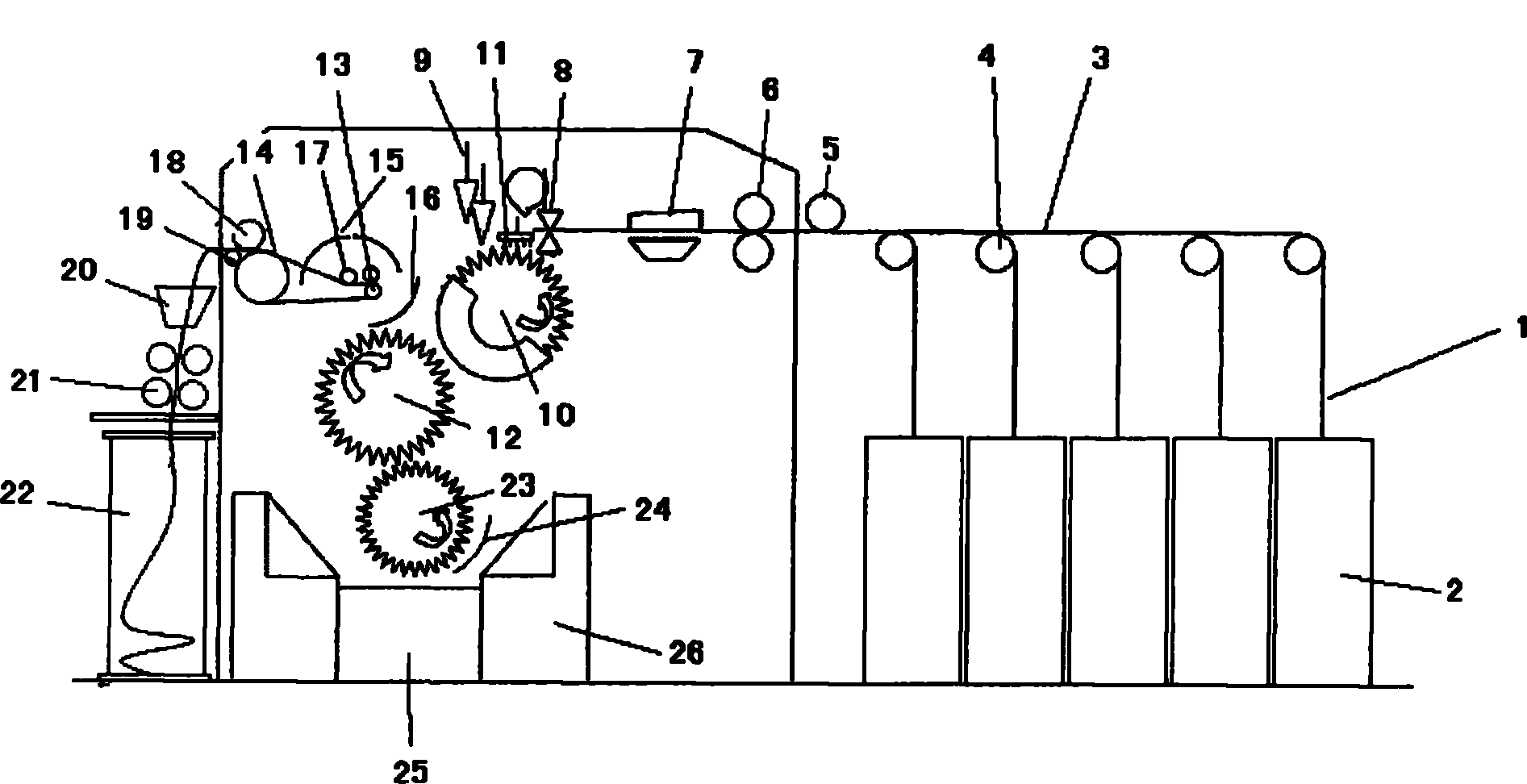

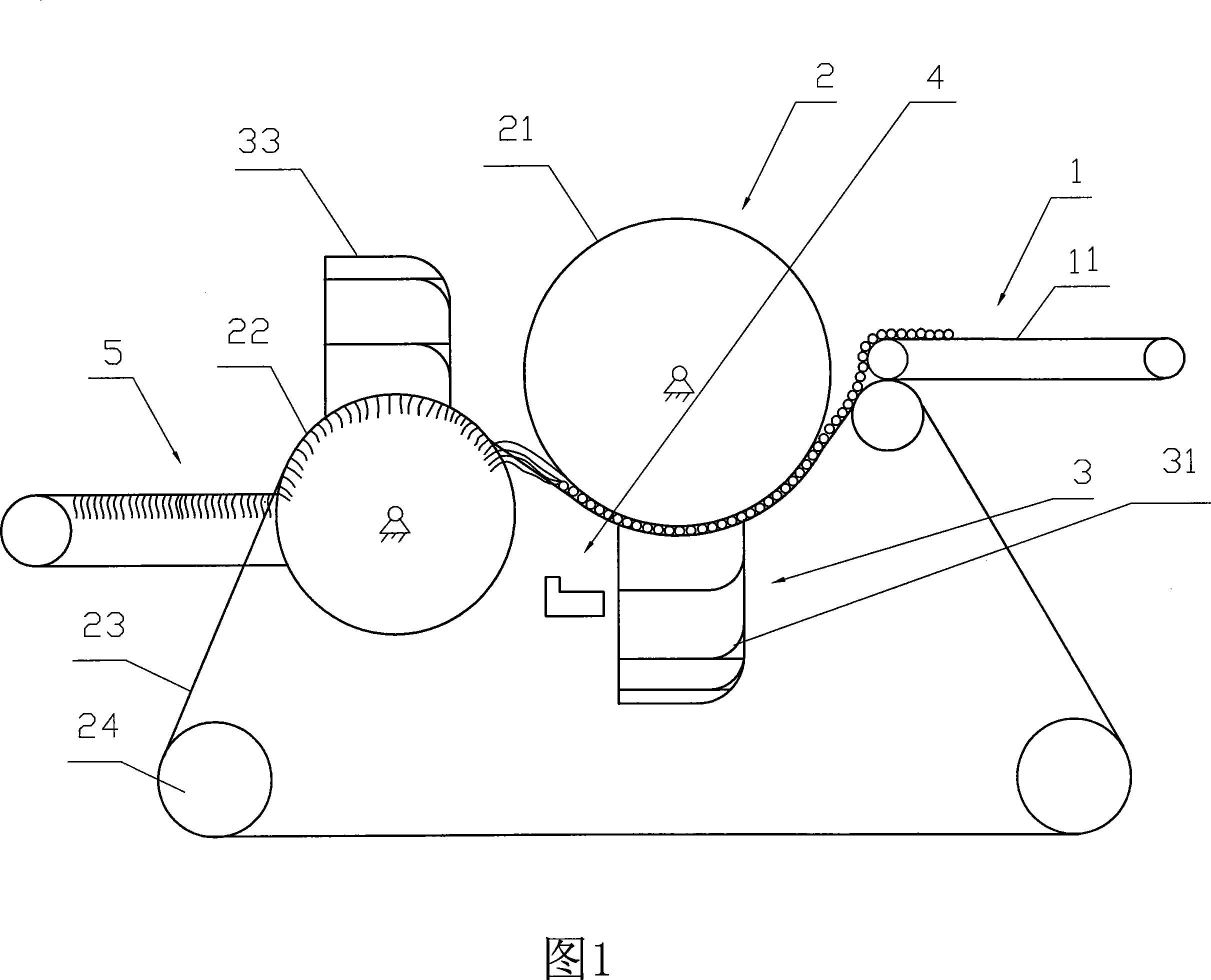

Ramie fibre decorticating method and transverse feeding type ramie raspador thereof

ActiveCN101168853ALow work efficiencyRealize automatic feedingMechanical fibre separationDecortication procedureEngineering

The invention discloses a ramie fiber stripping method and a transverse feeding type ramie stripping machine. The method is as follows: the ramie stems are stripped by transverse feeding, and the ramie stems are stripped in two stages. Make a section near the tip, and then peel off a section near the base. The ramie stripping machine includes a horizontal hemp feeding mechanism, a hemp clamping mechanism, a hemp scraping mechanism, a guiding mechanism, and a hemp receiving mechanism; wherein the horizontal hemp feeding mechanism is mainly composed of a conveyor belt; the hemp clamping mechanism is mainly composed of a primary hemp clamping wheel, a secondary Clamping wheel and clamping hemp rope are composed, and clamping hemp rope forms an S shape between the two clamping hemp wheels and bypasses the two clamping hemp wheels; The secondary hemp stripping hob and its matching concave plate are composed of the primary hemp clamping wheel corresponding to the position of the primary hemp stripping hob, and the secondary hemp clamping wheel is corresponding to the position of the secondary hemp stripping hob; the guide mechanism is mainly composed of The slightly end of the hemp stripped by the hob is blown to the blower on the secondary hemp wheel and the corresponding hemp guide plate; the hemp receiving mechanism is mainly composed of a conveyor belt. The invention can automatically feed and strip, thereby greatly reducing the labor intensity and improving the work efficiency of stripping hemp.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

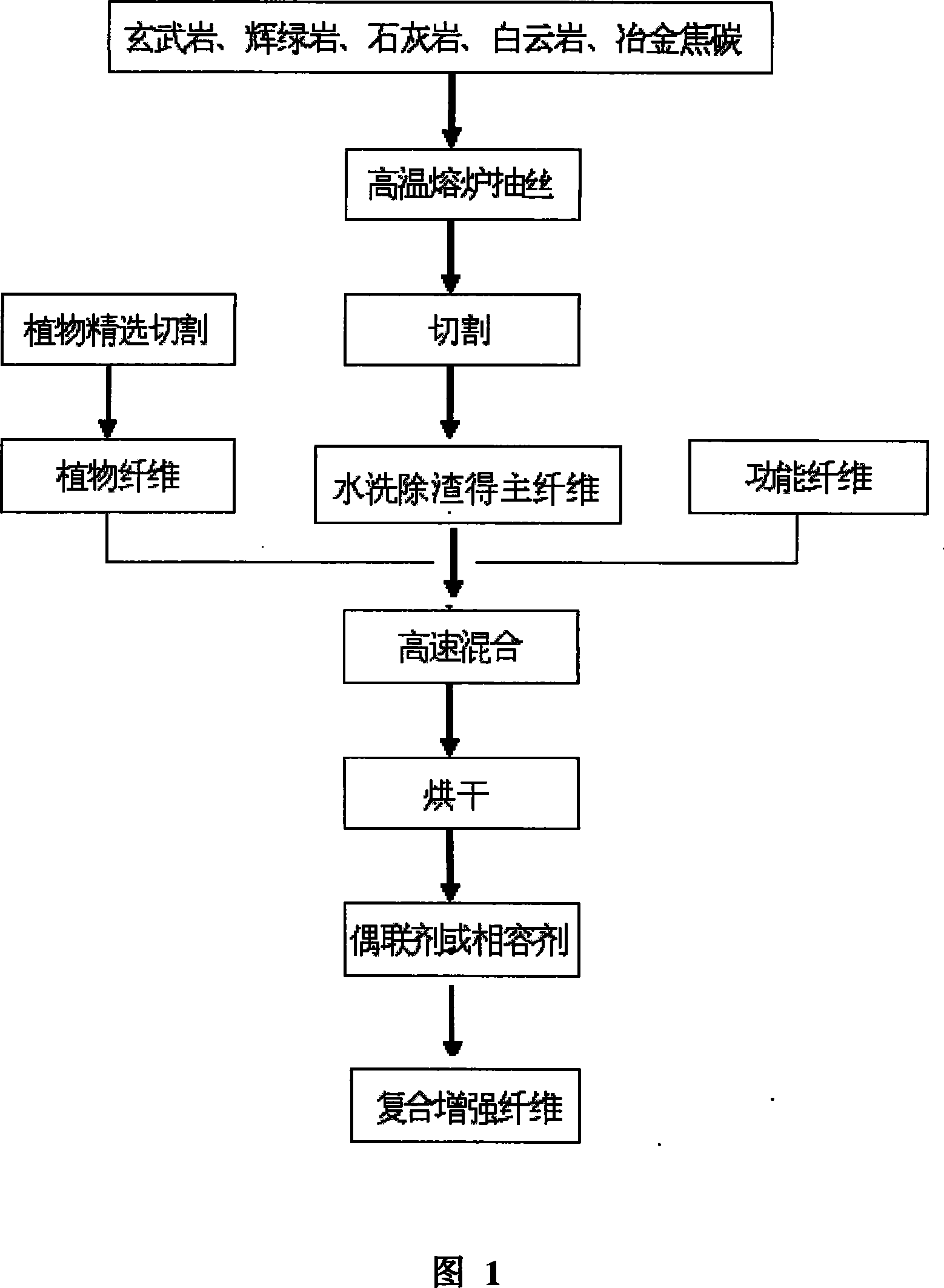

Asbestos-free composite enhancement fibre for friction material and producing technique thereof

InactiveCN101235153AAchieve high performanceRealize environmental protectionOther chemical processesFiberCoupling

The invention provides a new non-asbestos composite reinforced fiber of friction material with low cost and a relative production method, wherein the fiber is environment-friend, degradable and non-pollution, which can improve the impact strength of friction material. When in use at high temperature, the friction factor is stable with low abrasion. The production method is simple, cheap and suitable for producing friction material. The non-asbestos composite reinforced fiber of friction material is composed of mine rock wool or gravel-shaped wool of 50-80 accounts, fibrilia of 2-10 accounts, wood fiber of 3-8 accounts, mica powder or ceramic powder of 2-20 accounts, coupling agent or compatibilizer of 1-5 accounts. The production method comprises preparing the materials, cutting mine rock wool or gravel-shaped wool, washing via centrifugal machine, removing slag to obtain main fiber, controlling the slag content lower than 0.5-1%, adding fibrilia, wood fiber and mica powder or ceramic powder to be mixed at high speed, drying and spraying coupling agent or compatibilizer, while the drying temperature is 105-150DEG C and the drying time is 1-2h, to obtain composite reinforced fiber.

Owner:韩德忠

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

Car brake block mixed with piemarker fiber and preparing method of car brake block

InactiveCN103836098AHigh melting pointModerate hardnessOther chemical processesFriction liningRare earthRenewable resource

The invention discloses a car brake block with a piemarker fiber and a preparing method of the car brake block. The car brake block comprises the natural piemarker fiber, aramid fiber pulp, rare-earth modified phenolic resin, a friction performance modifier, padding and the like, and comprises, by weight, 30-35 parts of reinforced fiber, 13-16 parts of binding agent, 9-12 parts of friction performance modifier and 40-45 parts of padding. The piemarker fiber on which the alkali treatment and ultrasonic treatment are carried out is low in price, light, high in specific strength, specific modulus and tensile strength and good in abrasion resistance and has other superior properties, and belongs to renewable resources. The car brake block prepared under the optimal technological condition and mixed with the piemarker fiber has a stable friction coefficient, a good brake effect and brake smoothness, is low in noise, good in comfort and friendly to the environment and is an ideal environment-friendly friction material.

Owner:QINGDAO UNIV

Explosion and supercritical carbon dioxide fluid combined degumming method for apocynum venetum

InactiveCN103835005ALow residual glue rateSoft touchFibre treatment to obtain bast fibreFiberApocynum venetum

The invention relates to an explosion and supercritical carbon dioxide fluid combined degumming method for apocynum venetum, aiming at the problems of severe environment pollution and large fiber damage in a present degumming process of apocynum venetum, and the problems of uneasy control of quality and non-ideal degumming effect in a single degumming method. The method comprises the steps of firstly pre-treating apocynum venetum with explosion under a relatively low temperature and pressure so as to prevent the fiber damage and remove most of colloid structure change; then extracting residual colloid in apocynum venetum by using the supercritical carbon dioxide fluid; and at the same time, degrading partial of lignin in the fibers by using a laccase solution. The method has the characteristics of high degumming efficiency, soft fiber handfeel, good product quality of degummed ramie, and energy conservation and environment protection. Besides, no chemicals are used in the method.

Owner:姜著川

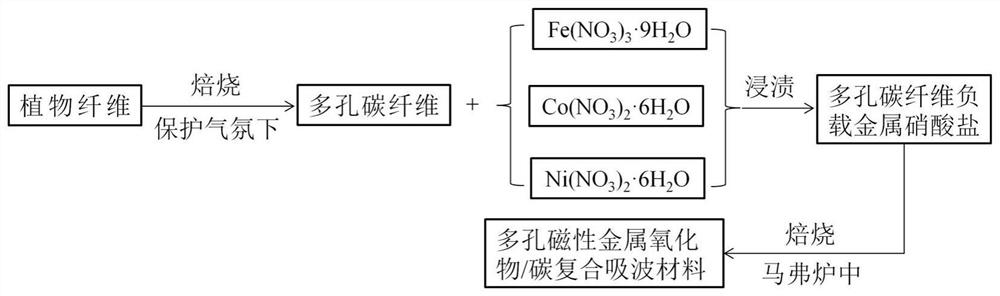

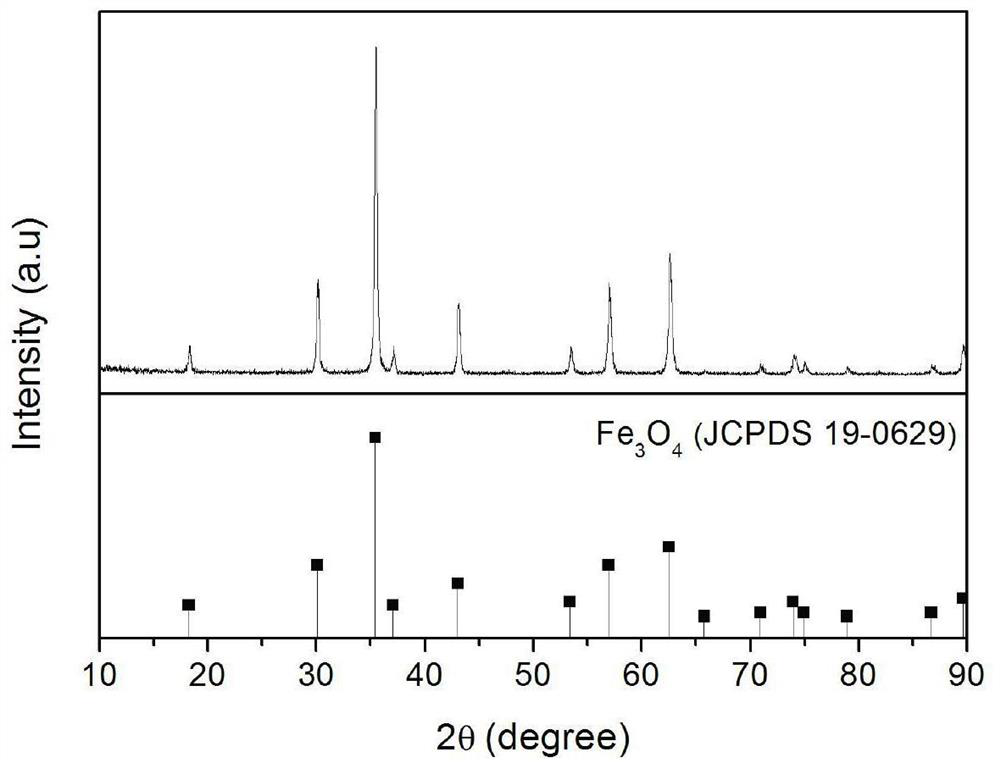

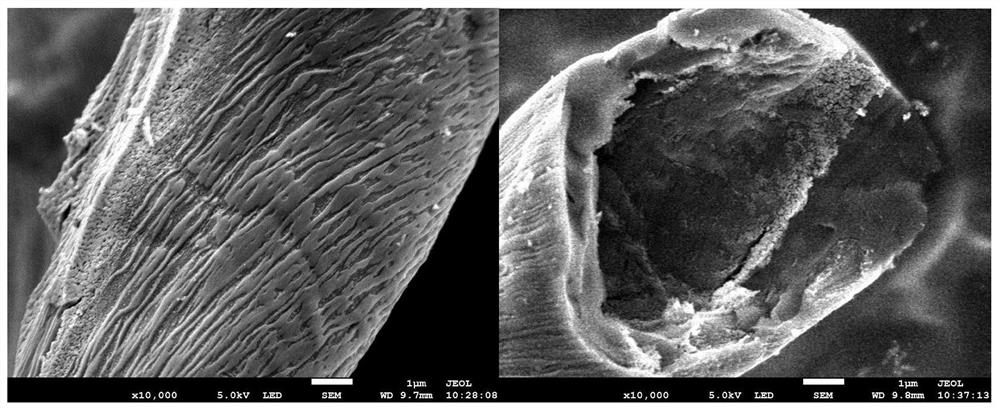

Synthesis method of porous magnetic metal oxide/carbon composite wave-absorbing material

ActiveCN112195013AWide variety of sourcesLow costOther chemical processesMagnetic/electric field screeningCarbon compositesCarbon fibers

The invention discloses a synthesis method of a porous magnetic metal oxide / carbon composite wave-absorbing material. The method comprises the following steps of: using porous carbon fibers obtained by roasting plant fibers with stable structures like cotton fibers, hemp fibers, bamboo fibers and the like in a high-temperature protective atmosphere as a carbon source and a template, impregnating nitrates of metals like Fe, Co, Ni and the like, and then performing roasting, thus obtaining the porous magnetic metal oxide / carbon composite wave-absorbing material, and further realizing regulationand control of the loading capacity of Fe3O4, Co3O4, NiO and other magnetic metal oxides in a wide range. The method disclosed by the invention has the advantages that: (1) the raw materials are widein source, renewable and low in cost; (2) the process is simple, the synthesis cost is low, complex synthesis equipment and chemical reagents are not needed, and the method is suitable for industrialproduction; (3) the magnetic components are loaded on the porous carbon, so that the material density is very low; (4) by controlling process conditions, the ratio of the magnetic components to the porous carbon can be regulated and controlled in a relatively wide range; and (5) the composite material has multiple electromagnetic loss mechanisms and is a novel light efficient microwave absorbent.

Owner:JINZHONG UNIV

Textile towel fabric

ActiveCN107268157AGood drapabilityEffective antibacterial and antifungalLayered productsFibre treatmentYarnPolyester

The invention provides a textile towel fabric. The fabric comprises a three-layer composite fabric layer, its upper layer fabric and lower layer fabric are consistent in fabric structure, both the upper layer fabric and the lower layer fabric comprise warp and weft, the warp is made of cotton fiber and polyester in a blending mode, while the weft is made of Chinese hemp fiber, and abaca fiber and cotton fiber in a blending mode, the average width of the gap between the yarns of the warp is greater than 100 micro meters, and the average width of the gap between the yarns of the weft is greater than 80 micro meters; the middle layer fabric is formed between the upper layer fabric and the lower layer fabric, and the three-layer composite fabric layer is woven into one body through cotton threads, the middle fabric layer is made of fiber-forming polymer and cotton fiber in a blending mode, a net surface is formed on the middle layer, fiber holes are formed in the net surface, and a layer of bamboo fiber or seaweed fiber is formed on the two sides of the middle layer fabric by spunlace. The textile towel fabric has the advantages of being puffy, full and thick in appearance, comfortable in hand feel, good in water absorption, and effective in improving wool effect and further improving hand feel and product quality.

Owner:YUEYANG BAOLI TEXTILE

Synthesizing type friction material

InactiveCN103045163AHigh mechanical strengthIncrease frictionOther chemical processesMetal powderHemp fibre

The invention discloses a synthesizing type friction material which is prepared from the following raw materials in parts by weight: 20-40 parts of inorganic bond, 10-20 parts of organic bond, 20-30 parts of bastose, 5-10 parts of coke and 5-15 parts of metal powder. The synthesizing type friction material has high mechanical strength, favorable friction property and heat resistance, can be used for stabilizing and reducing the shrinkage and expansion of the material to improve the brake performance, avoiding surface corrosion of the friction material, greatly dispersing the acting force on the friction from the environment so as to have a good buffer and a rebound effect, and acquiring a breaking effect immediately, does not harm the dual, and can reduce noise.

Owner:殷国忠

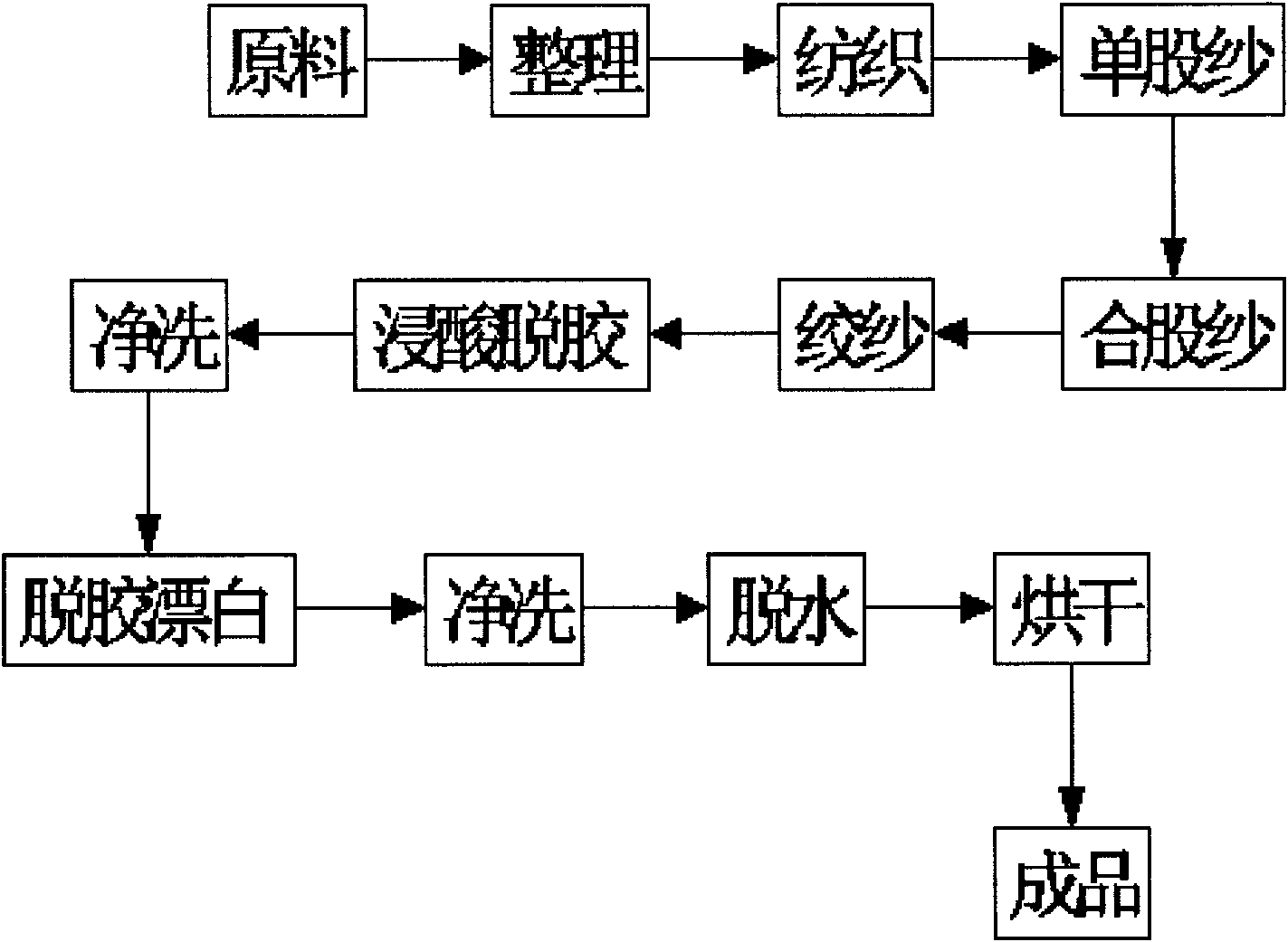

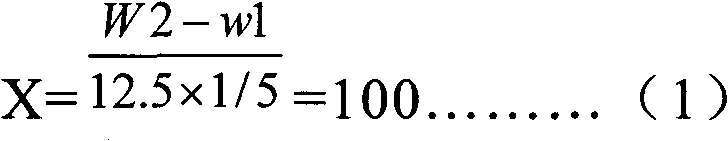

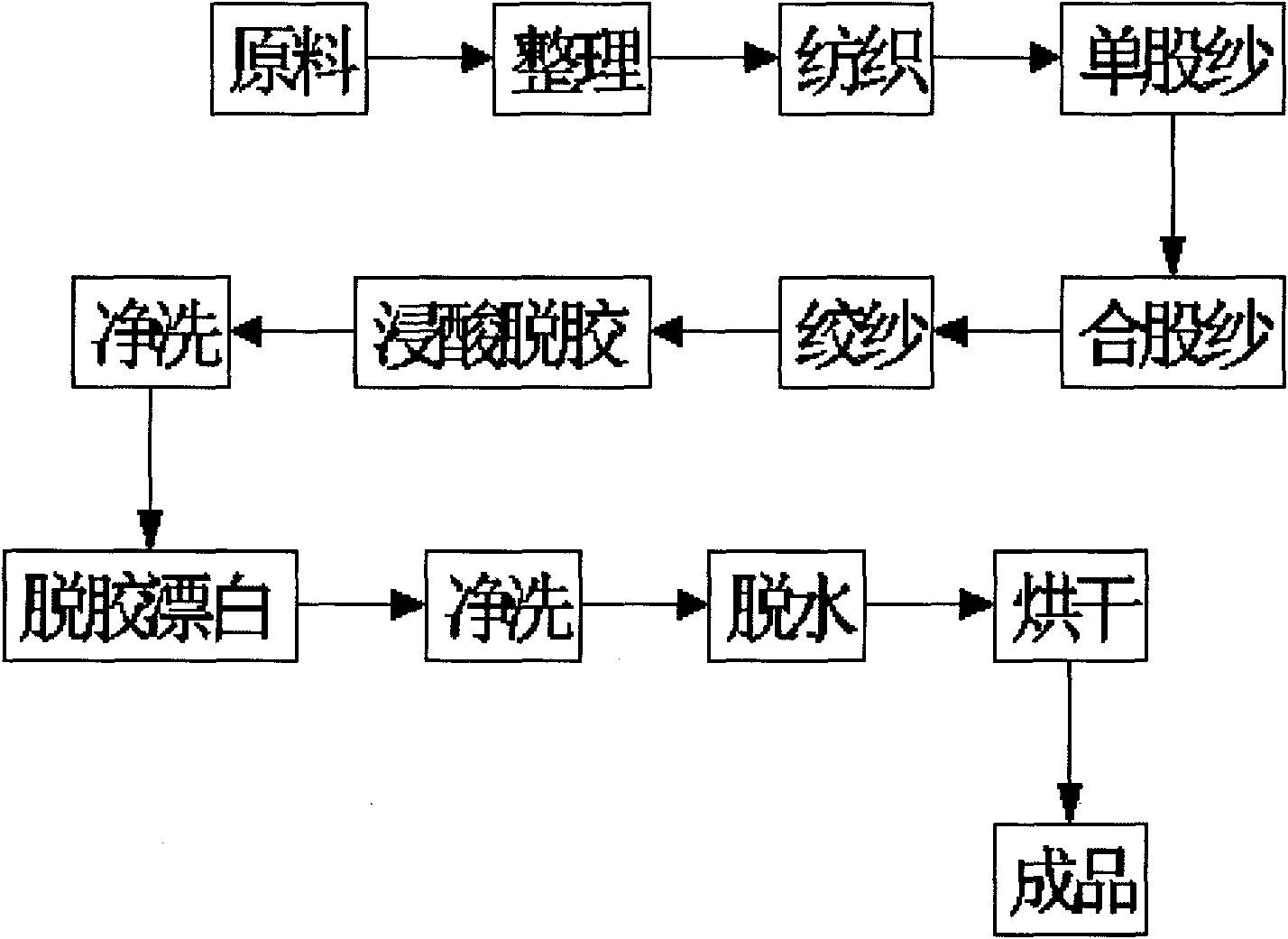

Hemp fibre filter wire and preparation method thereof

InactiveCN101884859AUnique anti-mold and bactericidal functionGood inhibition effectFiltration separationVegetable materialChemical industryYarn

The invention relates to a filter material for water treatment, in particular discloses a hemp fibre filter wire and a preparation method thereof. The hemp fibre filter wire is characterized by being prepared by using hemp fibres as raw materials, spinning the hemp fibres into yarns through hemp spinning equipment and then degumming, bleaching, drying and forming. The invention is mainly used for the purification and the filtering of various liquids; a wire-wound filter core prepared by the hemp fibre filter wire is used for the precise filtering of the liquids in a petroleum industry, a chemical industry, an electron industry, a pharmaceuticals industry, a food industry, a domestic water industry, and the like; and in addition, the invention can bring new vitality for the water treatment industry due to excellent performance and complete green environmentally-friendly quality.

Owner:郭淼

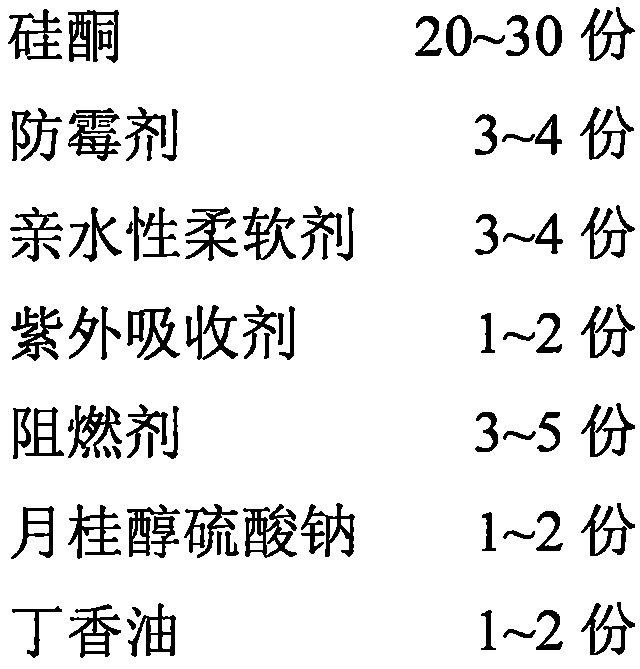

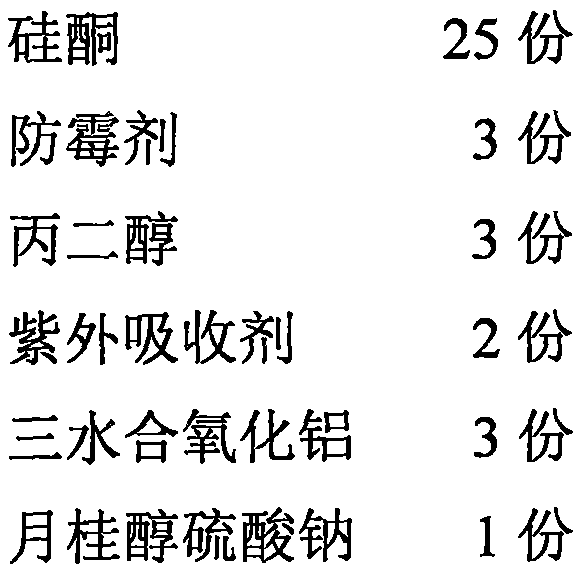

Degumming flame-proof process technique for Han fibrilia

The invention discloses a Chinese bast fiber degumming flame retardant treatment technique. The technique carries out ultraviolet radiation, quencher and heating treatments after hot water bath, pre-pickling and pre-chlorination treatments; then carries out alkali oxygen-machine combined degumming treatment and finally carries out flame retardant treatment for twice repeatedly. The surface of the Chinese bast fiber treated by the technique has excellent degumming effect and is better than degumming with a normal alkali oxygen method and a mechanical method; the flame retardant effect is better than the effect of flame retardant post treatment aimed at a Chinese bast fabric and a better white content is obtained; a special blanching working procedure and a flame retardant working procedure are not needed to be arranged in post finishing, thus shortening the flow and saving the cost; the length and the fineness of the fiber are also improved after treatment; less polluting waste water is discharged. The invention is a green and environment protective technical method.

Owner:TAIYUAN UNIV OF TECH

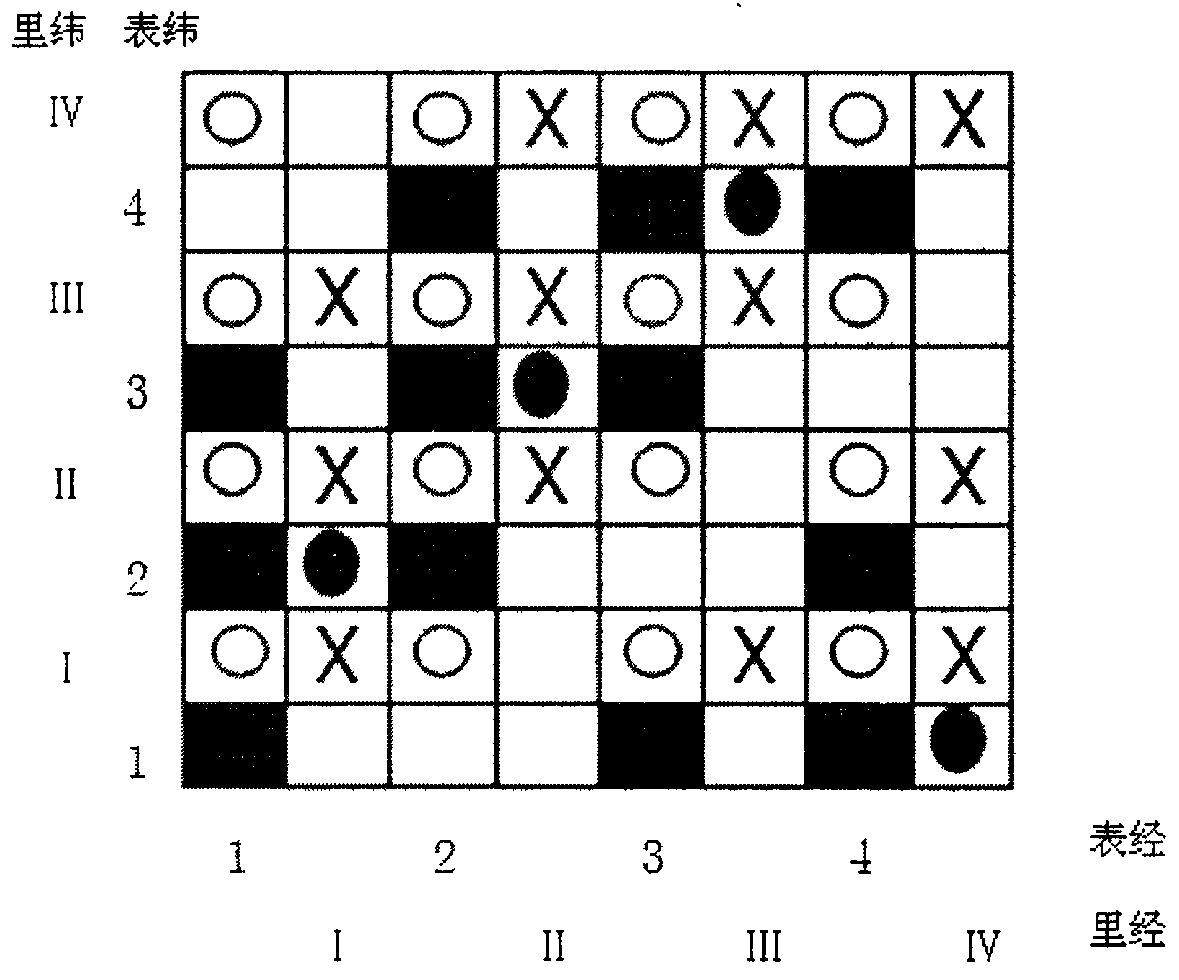

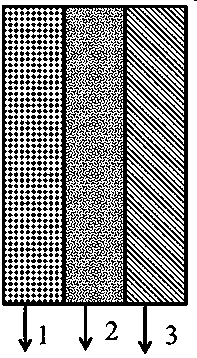

Production method for two-sided heterochromous self-cleaning jean fabric

ActiveCN104047090AAvoid breedingMeet individual needsSolvent-treatmentWoven fabricsPolymer scienceCombing

A production method for a two-sided heterochromous self-cleaning jean fabric is characterized in that warp is ring spun combed cotton yarn with the yarn count of 21S, and the twist of the warp is controlled at 350-380 twists per meter; weft is fibrilia or bamboo fiber with natural antibacterial properties, and the yarn count of the weft is 24S; the warp has two colors, the weft is raw white, and a double-layer organization formed on the same basis is adopted, wherein the surface layer and the lining layer are both right twills with three up and one down, and the lining layer is connected with the surface layer through a down-to-up method; four binding places are formed in one woven circulation organization, wherein the organization arrangement mode of the surface weft and the lining warp is that the right twills are arranged with one up and three down, the arrangement rate of the surface warp to the lining warp is 1:1, and the arrangement rate of the surface weft to the lining weft is 1:1. According to the production method, the warp is subjected to spooling, beaming, dyeing, sizing, drying and drafting, and then the warp and the weft are jointly subjected to weaving, singeing, inclining, preshrinking, drying, inspection and packing. The two-sided heterochromous self-cleaning jean fabric can meet the demand that jeans wear is worn in a personal style, and the jeans wear has no peculiar smell after being worn for a long time.

Owner:ZHEJIANG JIE GAO TEXTILE

Plant fiber-based composite lawn nursery strip coiled material for vegetation recovery and manufacturing method for coiled material

ActiveCN102440100AHigh tensile strengthEvenly distributedWood working apparatusDomestic articlesAgricultural sciencePlant fibre

The invention discloses a plant fiber-based composite lawn nursery strip coiled material for vegetation recovery and a manufacturing method for the coiled material. The method comprises the following steps of: preparing agriculture and forestry residues into wood fibers by chipping and pulping; conveying at least one of degradable synthetic fibers and natural jute fibers to a fiber opener, and performing opening treatment; mixing the two obtained raw materials in a weight percentage of 85:15-95:5, performing mixed opening by a mixed fiber opener, and blowing air to a bin of a natural plant fiber non-woven airflow paver; paving a latticed mesh liner material layer on the surface of a conveying curtain of the airflow paver; and uniformly paving the prepared fiber mixture to form a compositemesh blank under the action of negative pressure through the airflow paver, covering the formed mesh blank on the mesh liner material, and preparing a basic plant fiber-based composite lawn nursery strip. By adopting an airflow non-woven forming technology, the raw materials for the lawn nursery strip are distributed uniformly and have good interweaving property, and the tearing resistance of thecoiled material is superior to that of the lawn nursery strip coiled material produced by other technology.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Production method of copper ammonia/viscose/linen cotton fiber blended fabric

The invention discloses a production method of a copper ammonia / viscose / linen cotton fiber blended fabric. According to the production method, selected warp and weft materials are as follows in parts by mass: 30-50 parts of copper ammonia fibers, 15-25 parts of linen fibers, 40-90 parts of viscose fibers, 20-40 parts of combed cotton and 8-18 parts of ultrafine fine denier polyester. A step of slashing in the production process comprises the specific steps: (1) mixing size: adding water into a size mixing bucket and raising the temperature of the water to 50 DEG C, adding a pre-dyeing agent, wherein the adding mass of the pre-dyeing agent is 15-18% of that of water, starting a stirrer and adding solid PVA (Polyvinyl Acetate) at the mass ratio of the solid PVA to the water of (1-4) to 80, raising the temperature to 90 DEG C, and stirring and dissolving to prepare slurry; and (2) sizing: sizing by adopting a slashing machine, wherein size in a size tank does not need to be heated. The yarns of the sizing procedure are subjected to sizing by adopting the PVA with the concentration which is not higher than 4%; the sizing rate is low, size skins are not easy to form by a sizing agent and desizing is easy to carry out by post-finishing; and meanwhile, the sizing agent can be stored after being prepared and can be used at any time in future, and does not need to be prepared when being needed, so that the energy and time are saved.

Owner:SUZHOU CHENHENG WEAVING

All-natural raw material wood fiber composite dalle and manufacture method thereof

InactiveCN102501292ARich sourcesCheap sourceSynthetic resin layered productsLaminationFiberManufacturing technology

The invention discloses an all-natural raw material wood fiber composite dalle, which completely adopts natural and degradable raw materials comprising 30-40% of wood fiber, 20-30% of natural gum rosin resin, 20-30% of limestone and 5-10% of hemp fabric. Compared with the traditional fiber plate, the all-natural raw material wood fiber composite dalle is characterized in that no formaldehyde is discharged in the production and use process, and the all-natural raw material wood fiber composite dalle belongs to the environment-friendly plate. The all-natural raw material wood fiber composite dalle has the texture of the natural marble and also has the elasticity of the wood. The product can be completely degraded after reaching a use service life. The product manufactured by the technology has better performance in the aspects of hardness, bendability and abrasive resistance if being compared with the common plate. Meanwhile the all-natural raw material wood fiber composite dalle has the functions of preventing sliding, resisting cigarette firing, resisting pollution, bearing pressure, resisting idler wheels, silencing, lowering noise, resisting static electricity, and the like. The production and manufacture technology is simple, and the all-natural raw material wood fiber composite dalle can be produced by the traditional fiber plate production equipment. No waste water, waste slag and waste gas are discharged in the production process so as not to cause pollution to the environment. The raw material has the abundant resources and is cheap, the production process has low energy consumption, and the environment is protected while resources are saved.

Owner:湖北格丽特新材料科技股份有限公司

Green ventilated felt for forming composite material and preparation method of green ventilated felt

InactiveCN106400306AImprove mechanical propertiesImprove breathabilityNon-woven fabricsFiberRoom temperature

The invention relates to the technical field of composite material formation auxiliary materials and in particular to a green ventilated felt for forming a composite material and a preparation method of the green ventilated felt. The novel green ventilated felt is prepared by adopting natural bast fibers or blending 20-100 percent of the natural bast fibers and 0-80 percent of chemical fibers by mass percentage, and carrying out procedures of opening and carding the fibers, laying a fiber net, needling, and carrying out post trimming, wherein the feeding frequency of a carding machine is 1-30Hz, the cylinder rotation frequency is 10-30Hz, and the doffer rotation frequency is 5-25Hz; the felting needle setting density of a needling machine is 1000-5000 needles / m, the needling frequency is 400-500 times / min, the needling depth is 2-10mm, and the needling pass is 1-3 passes. According to the ventilated felt prepared by the method, the performance is close to that of the common chemical fiber ventilated felt, the air permeation rate at room temperature is about 350-3000L / m<2>.s, and formation of a composite material product can be guaranteed to be good. The preparation method is low in raw material cost, simple in process and lower in cost and can lower the whole cost of the composite material product.

Owner:ACC BEIJING SCI & TECH CO LTD

Preparation method and application of ramie fiber / epoxy resin composite material

InactiveCN107936483AAvoid the process of direct modificationImprove the bonding strength of the interfaceEpoxyRoom temperature

The invention belongs to the field of bullet-proof armor plates, and discloses a preparation method and application of a ramie fiber / epoxy resin composite material. Ramie fiber is cut into segments, and placed in a mold cavity, the mold cavity is placed in a mechanical vibration table, the vibration power is set to 1.2 to 1.8 KW, the vibration frequency is 300 to 600 HZ, the amplitude is 1 to 5 mm, and the vibration time is 10-30 min; liquid epoxy resin, a curing agent and a silane coupling agent are uniformly mixed in a mass ratio (1 to 1.2) : 1 : (0.01 to 0.066) to obtain an epoxy resin glueliquid; the mold cavity is taken out from the mechanical vibration table, the epoxy resin glue liquid is injected into the mold cavity to soak the ramie fiber; the soaked ramie fiber is first dried at room temperature, pressurized for forming, and finally cured to obtain the ramie fiber / epoxy resin composite material. The method avoids the problems of long period for dispersion of the ramie fiberby a solution method and performance reduction caused by modification of the surface of the fiber, and the obtained ramie fiber / epoxy resin composite material can be applied to a sandwich material ofthe bullet-proof armor plates.

Owner:西安锐思博创应用材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com