Ramie fibre decorticating method and transverse feeding type ramie raspador thereof

A ramie fiber and manufacturing method technology, which is applied in the directions of fiber mechanical separation, fiber treatment, mechanical treatment, etc., can solve the problems of low hemp stripping work efficiency and high labor intensity, so as to improve the work efficiency of hemp stripping, reduce labor intensity, and solve the problem of low work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The ramie fiber peeling method of the present invention is: the ramie stalk is fed horizontally during peeling, and the ramie stalk is peeled off in two sections, the section near the tip is first stripped, and then the section near the base is stripped.

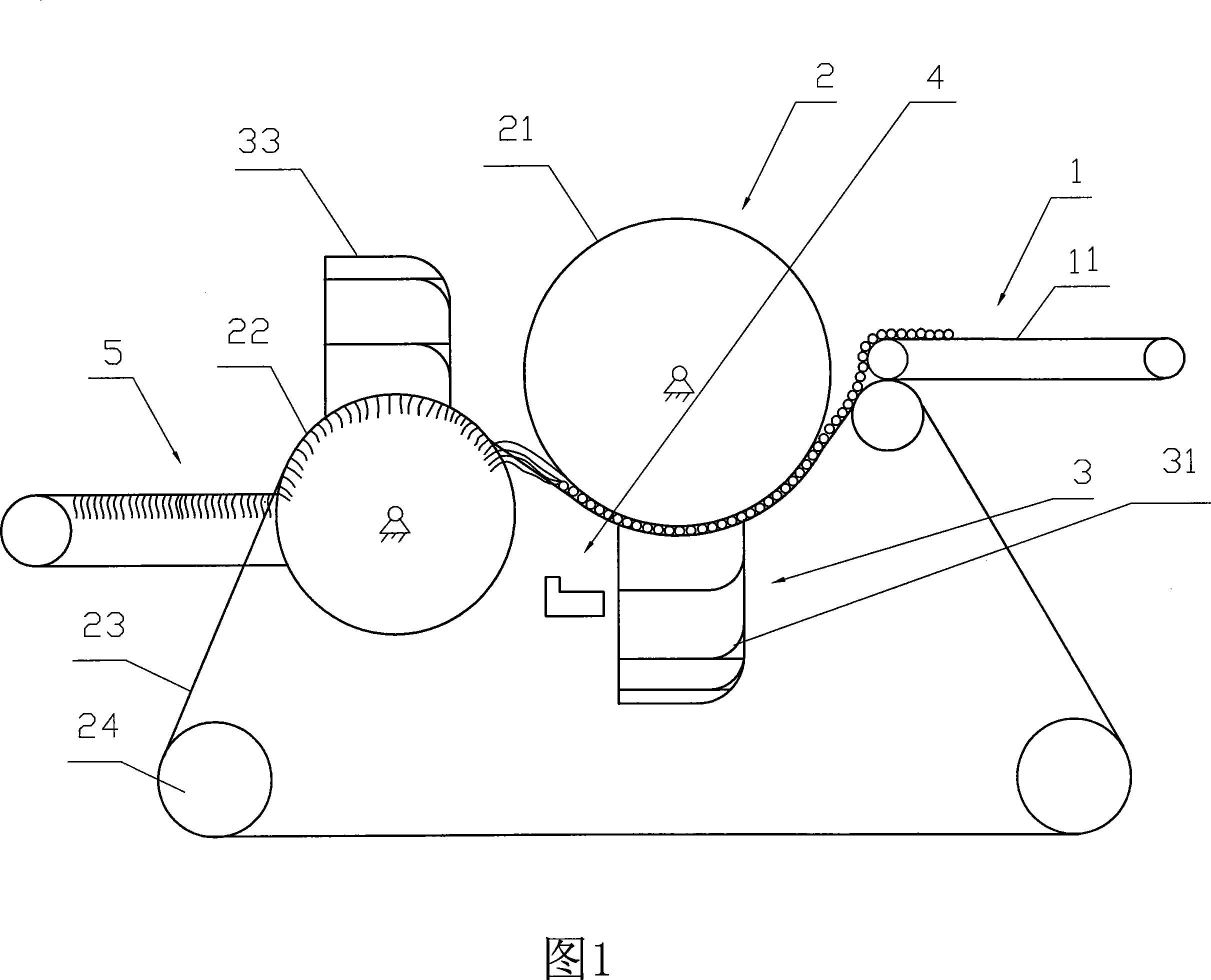

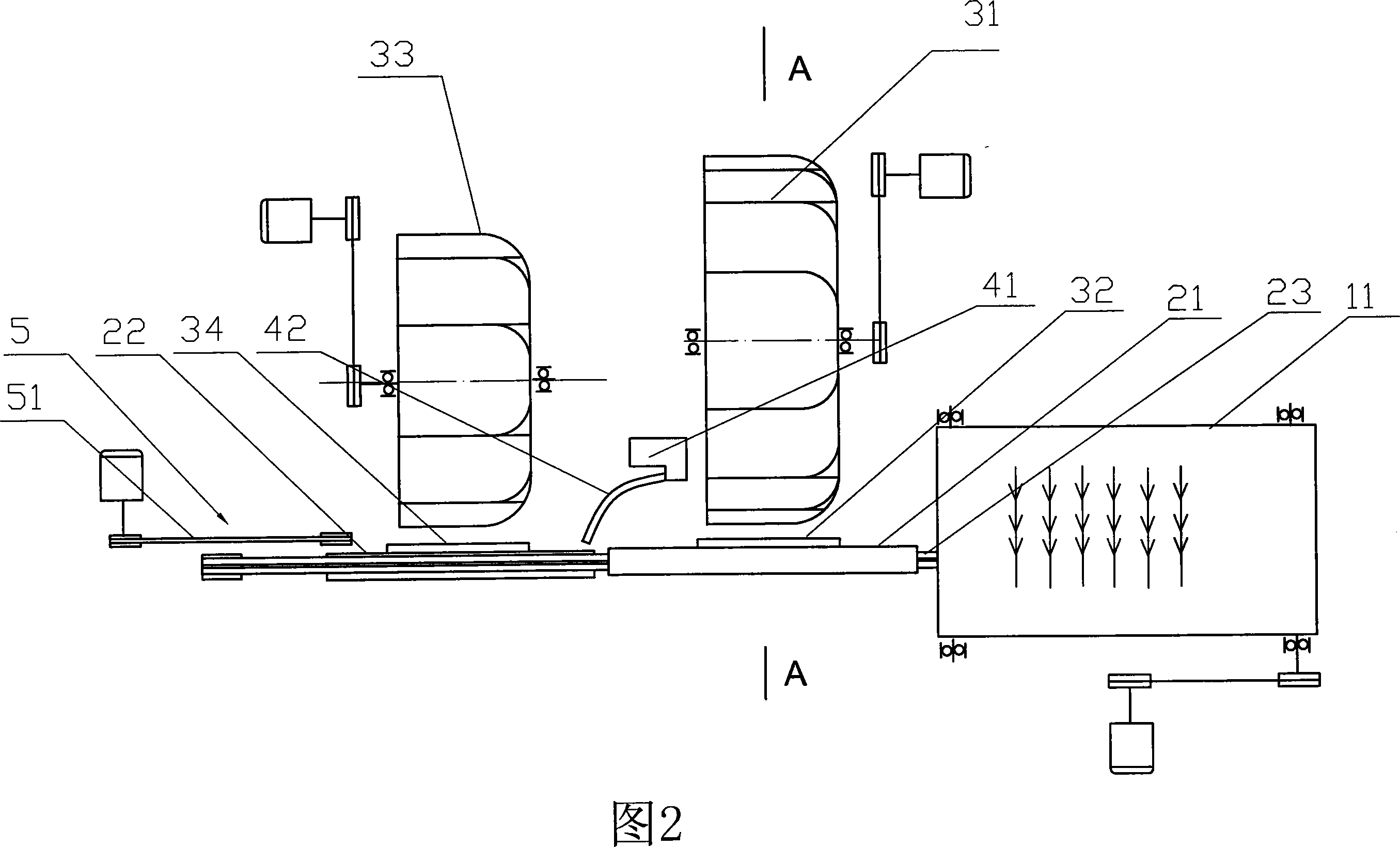

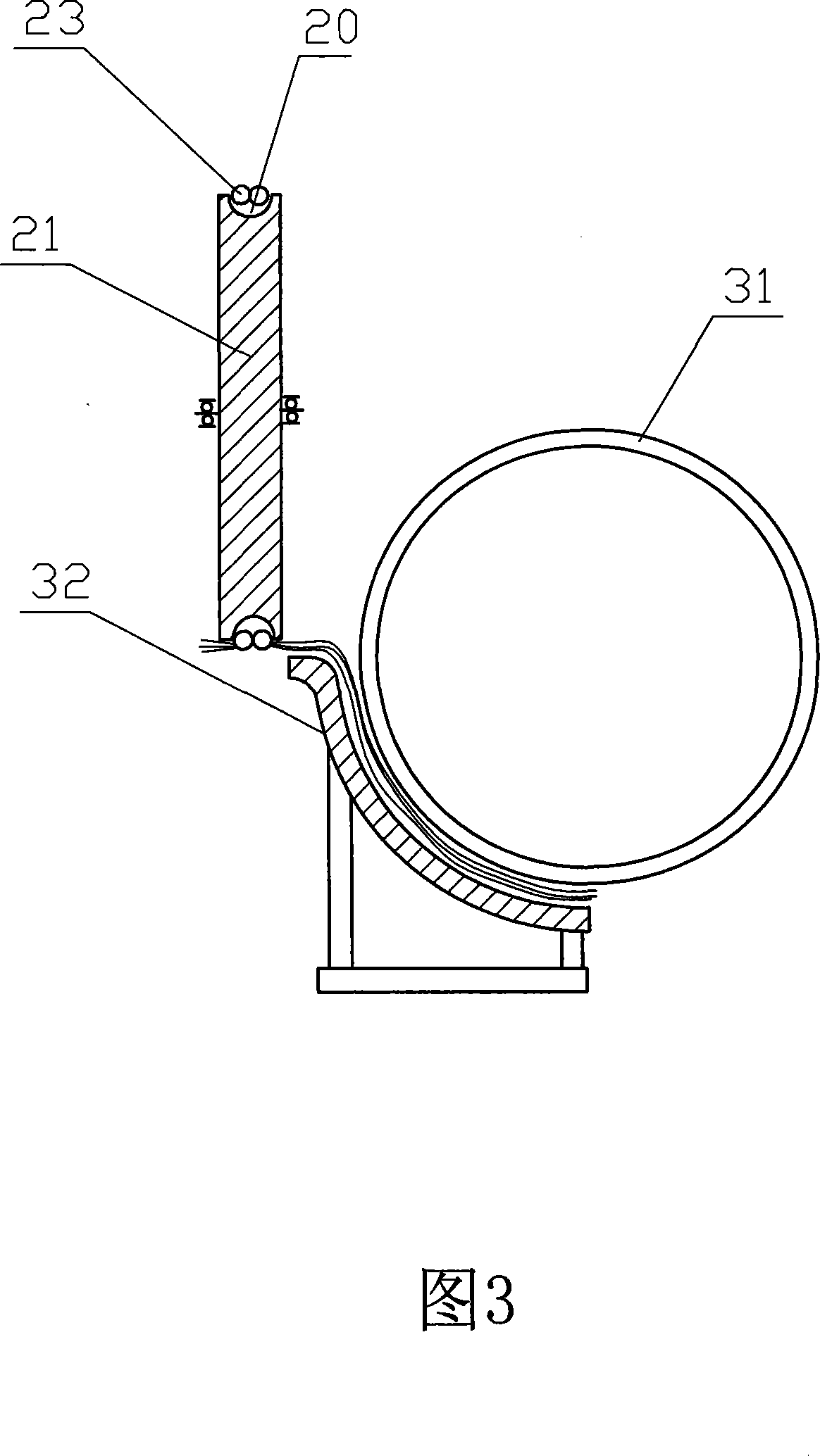

[0011] Fig. 1-Fig. 3 has reflected a kind of horizontal feeding type ramie peeling hemp machine that realizes above-mentioned method.

[0012] It can be seen from Fig. 1-Fig. 3 that the present invention comprises a transverse hemp feeding mechanism 1, a hemp clamping mechanism 2, a hemp scraping mechanism 3, a guiding mechanism 4, and a hemp receiving mechanism 5. Wherein the horizontal hemp feeding mechanism is mainly made up of conveyer belt 11, and the fresh stem of ramie adopts the horizontal feeding mode, and the stalk is horizontally laid on the conveyer belt 11, and the base is fed laterally towards the hemp clamping mechanism one end, so that it can ensure The continuity of feeding fresh ramie stems greatly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com