Preparation method and application of ramie fiber / epoxy resin composite material

A ramie fiber and epoxy resin technology, which is applied in the field of preparation of ramie fiber/epoxy resin composite materials, can solve the problems of fiber surface structural state pollution, long production process, etc., and achieves shortened preparation cycle, low cost, and shortened dispersion cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

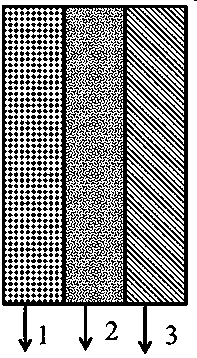

Image

Examples

Embodiment 1

[0021] A preparation method of ramie fiber / epoxy resin composite material, the steps are as follows:

[0022] (1) Cut the ramie fibers into 10 mm length sections, place them in the mold cavity, and then place them on a mechanical vibration table. Set the vibration power to 1.5 KW, the vibration frequency to 600 HZ, the vibration amplitude to 3 mm, and The time is 10 min;

[0023] (2) Mix liquid bisphenol A epoxy resin with curing agent triethylenetetramine and silane coupling agent A-151 in a mass ratio of 1:1:0.02 to obtain epoxy resin glue;

[0024] (3), the mold cavity is taken out from the mechanical vibration table, and then the above-mentioned epoxy resin glue is injected into the mold cavity to soak the ramie fiber, and the mass concentration of the ramie fiber in the final system is 30%;

[0025] (4) Dry the impregnated ramie fibers in step (3) at room temperature, press them into shape at 100 MPa, and cure them in an oven at 60 °C for 24 h to obtain ramie fiber / epoxy...

Embodiment 2

[0028] A preparation method of ramie fiber / epoxy resin composite material, the steps are as follows:

[0029] (1) Cut the ramie fibers into sections with a length of 15 mm, place them in the mold cavity, and then place them on a mechanical vibration table, set the vibration power to 1.2 KW, the vibration frequency to 300 HZ, the amplitude to 5 mm, and the vibration The time is 30 min;

[0030] (2) Mix liquid phenolic epoxy resin with curing agent diethylenetriamine and silane coupling agent A151 at a mass ratio of 1.1:1:0.063 to obtain epoxy resin glue;

[0031] (3), the mold cavity is taken out from the mechanical vibration table, and then the above-mentioned epoxy resin glue is injected into the mold cavity to soak the ramie fiber, and the mass concentration of the ramie fiber in the final system is 40%;

[0032] (4) Dry the impregnated ramie fibers in step (3) at room temperature, press them into shape at 120 MPa, and cure them in an oven at 70 °C for 30 h to obtain ramie ...

Embodiment 3

[0035] A preparation method of ramie fiber / epoxy resin composite material, the steps are as follows:

[0036] (1) Cut the ramie fiber into a 20 mm length section, place it in the mold cavity, and then place it in a mechanical vibration table. Set the vibration power to 1.8 KW, the vibration frequency to 400 HZ, the amplitude to 2 mm, and the vibration The time is 20 min;

[0037] (2) Mix liquid bisphenol A epoxy resin with curing agent polyamide and silane coupling agent at a mass ratio of 1.2:1:0.044 to obtain epoxy resin glue;

[0038] (3), the mold cavity is taken out from the mechanical vibration table, and then the above-mentioned epoxy resin glue is injected into the mold cavity to soak the ramie fiber, and the mass concentration of the ramie fiber in the final system is 50%;

[0039] (4) Dry the ramie fibers impregnated in step (3) at room temperature, press them at 150 MPa, and cure them in an oven at 80 °C for 36 h to obtain ramie fiber / epoxy resin composites.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com