Production method for two-sided heterochromous self-cleaning jean fabric

A denim fabric, double-sided heterochromatic technology, applied in the processing of textile materials, liquid/gas/steam textile material processing, fabrics, etc., can solve the problems of deviation from the user's wearing needs, waste of resources, etc., and achieve a good denim style. , less cleaning, and the effect of ensuring the internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

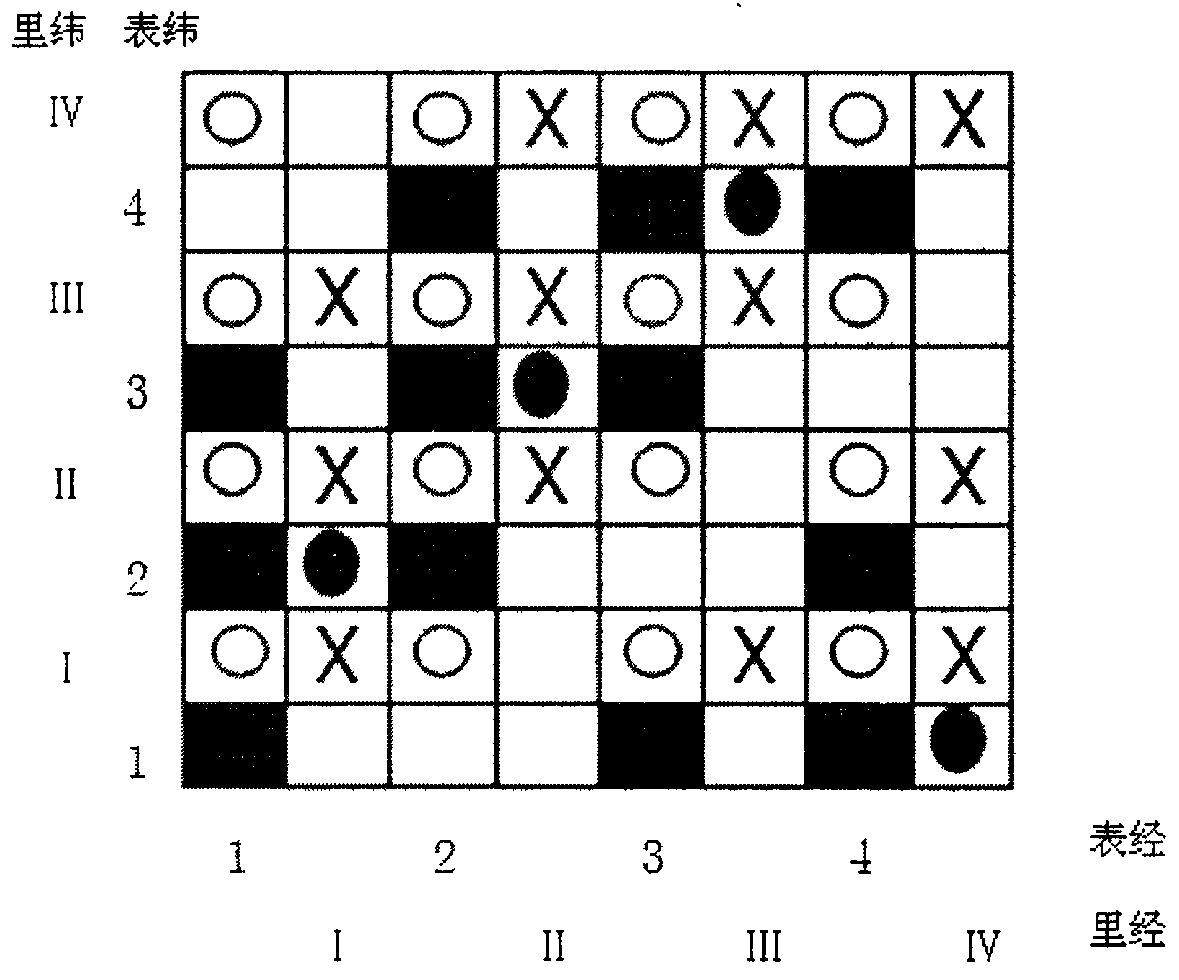

[0019] A double-sided different-color self-cleaning denim fabric is characterized in that the warp yarn adopts ring-spun combed cotton yarn, the yarn count is 21S, and the warp yarn twist is controlled at 350-380 twists / meter; the weft yarn adopts natural antibacterial hemp fiber or bamboo Fiber, yarn count 24S; two colors of warp yarn, white weft yarn, double-layer weave with the same basic structure: the surface layer and the inner layer are 3 up and 1 down right twill, and the inner layer is connected to the surface by the method of bottom connection and top; one cycle of weaving There are 4 joints in the weave, the weave arrangement of the surface weft and the inside warp is 1 up and 3 down right twill, the arrangement ratio of the surface warp and the inside warp is 1:1, and the arrangement ratio of the surface weft and the inside weft is 1:1. (specifically as figure 1 shown)

[0020] The production method of the double-sided different-color self-cleaning denim fabric is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com