Antibacterial water supply pipe, antibacterial PE composite material and preparation method thereof

A technology of composite materials and water supply pipes, applied in chemical instruments and methods, pipes, rigid pipes, etc., can solve the problems of life and health risks, poor shading effect, easy to breed bacteria, etc., and achieve good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

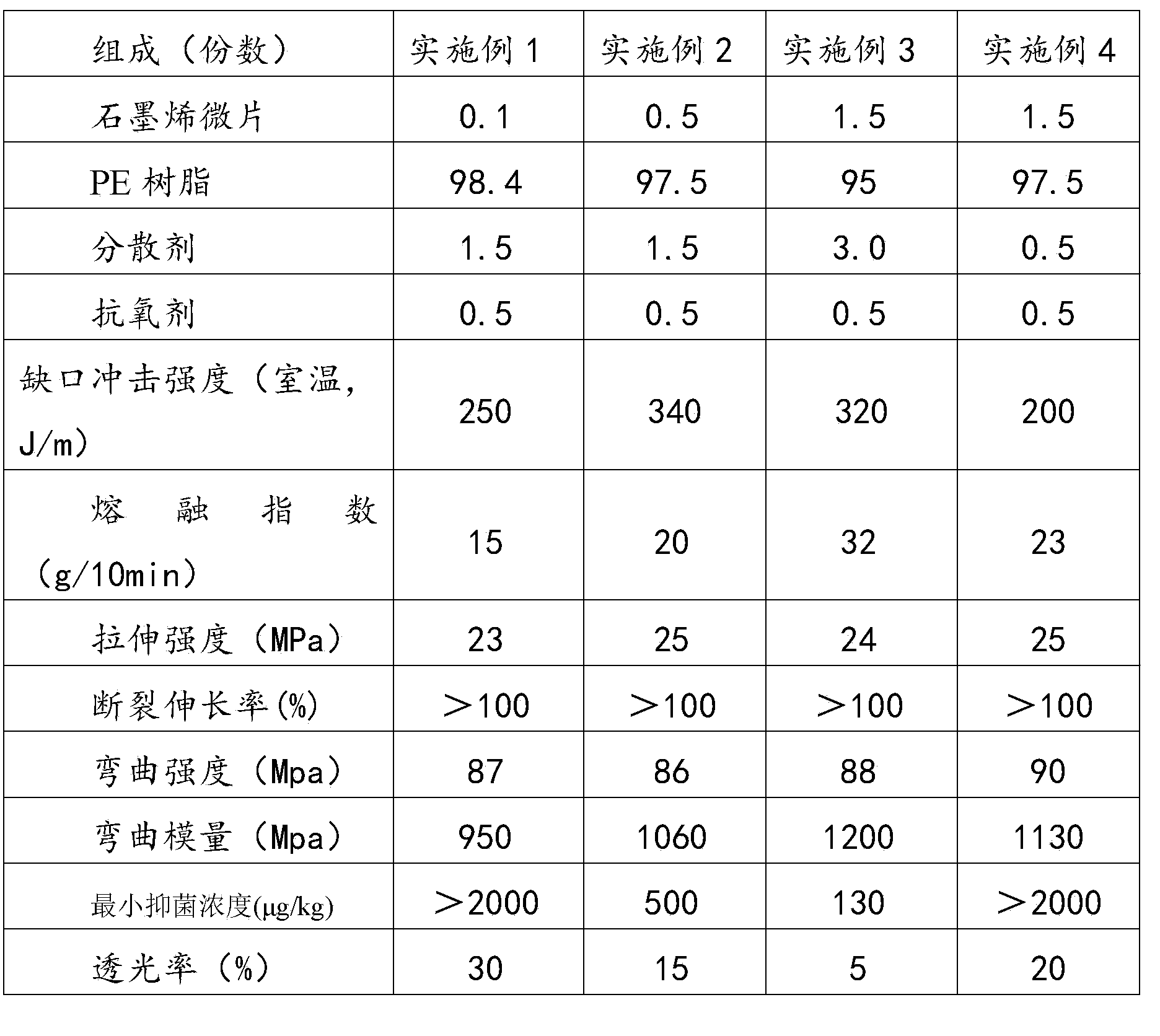

Examples

Embodiment 1

[0029] a: Take the following parts by weight according to the required formula;

[0030] Graphene microflakes 0.1 parts

[0031] PE resin 98.4 parts

[0032] Dispersant 1.0 parts

[0033] Antioxidant 0.5 parts

[0034] b: The components are placed in a high mixer and stirred for 5-8 minutes;

[0035] c: The mixture obtained in step b is placed in a twin-screw machine, melted and extruded, and granulated. The process conditions are: the temperature of the first zone is 130°C, the temperature of the second zone is 140°C, the temperature of the third zone is 145°C, and the temperature of the fourth zone is 150°C ℃, the temperature of the fifth zone is 140 ℃, the temperature of the sixth zone is 140 ℃, the temperature of the seventh zone is 130 ℃, the temperature of the die head is 140 ℃, the speed of the main machine during extrusion: 480r / min; the feeding speed: 35r / min.

[0036] d: The ordinary PE outer layer and the antibacterial inner layer are co-extruded through a co-ex...

Embodiment 2

[0039] a: Take the following parts by weight according to the required formula;

[0040] Graphene microflakes 0.5 parts

[0041] PE resin 97.5 parts

[0042] Dispersant 1.5 parts

[0043] Antioxidant 0.5 part

[0044] b: The components are placed in a high mixer and stirred for 10 to 15 minutes;

[0045] c: The mixture obtained in step b is placed in a twin-screw machine, melted and extruded, and granulated. The process conditions are: the temperature of the first zone is 130°C, the temperature of the second zone is 140°C, the temperature of the third zone is 145°C, and the temperature of the fourth zone is 150°C ℃, the temperature in the fifth zone is 140 ℃, the temperature in the sixth zone is 140 ℃, the temperature in the seventh zone is 130 ℃, the temperature of the die head is 140 ℃, the speed of the main machine during extrusion: 430r / min; the feeding speed: 32r / min.

[0046] d: The ordinary PE outer layer and the antibacterial inner layer are co-extruded through a c...

Embodiment 3

[0049] a: Weigh the following parts by weight according to the required formula;

[0050] Graphene microflakes 1.5 parts

[0051] PE resin 95.0 parts

[0052] Dispersant 3.0 parts

[0053] Antioxidant 0.5 part

[0054] b: The components are placed in a high mixer and stirred for 15 to 20 minutes;

[0055] c: The mixture obtained in step b is placed in a twin-screw machine, melted and extruded, and granulated. The process conditions are: the temperature of the first zone is 160°C, the temperature of the second zone is 160°C, the temperature of the third zone is 165°C, and the temperature of the fourth zone is 165°C. ℃, the temperature of the fifth zone is 150 ℃, the temperature of the sixth zone is 150 ℃, the temperature of the seventh zone is 140 ℃, the temperature of the die head is 150 ℃, the main engine speed during extrusion: 500r / min; feeding speed: 30r / min.

[0056] d: The ordinary PE outer layer and the antibacterial inner layer are co-extruded through a co-extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com