Synthesis method of porous magnetic metal oxide/carbon composite wave-absorbing material

A technology of magnetic metal and wave absorbing material, applied in chemical instruments and methods, magnetic/electric field shielding, other chemical processes, etc., to achieve the effects of excellent microwave absorption performance, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

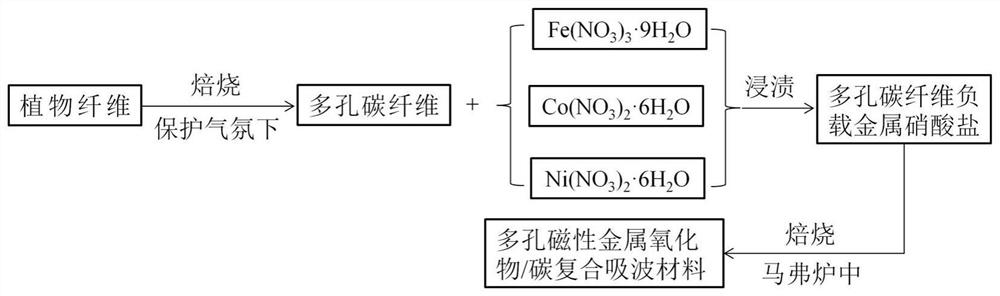

Method used

Image

Examples

Embodiment 1

[0041] A porous Fe 3 o 4 The synthetic method of / carbon composite wave-absorbing material is characterized in that, its steps are as follows:

[0042] Step 1, prepare porous carbon fiber: put 11.5 g absorbent cotton gauze at 700 o C, N 2 Calcined under the atmosphere for 2 h, the heating rate was 4 o C / min, obtain cotton-based porous carbon fiber;

[0043] Step 2, porous carbon fiber loaded iron nitrate:

[0044] Take 0.7 g of porous carbon fiber and soak it in 50 ml of 0.5 mol / L Fe(NO 3 ) 3 9H 2 O solution, after soaking for 24 hours, use tweezers to clamp out the wet porous carbon fiber, and when there is no solution dripping, put it in an evaporating dish at 60 o C and dried for 12 h to obtain a porous carbon fiber loaded ferric nitrate sample;

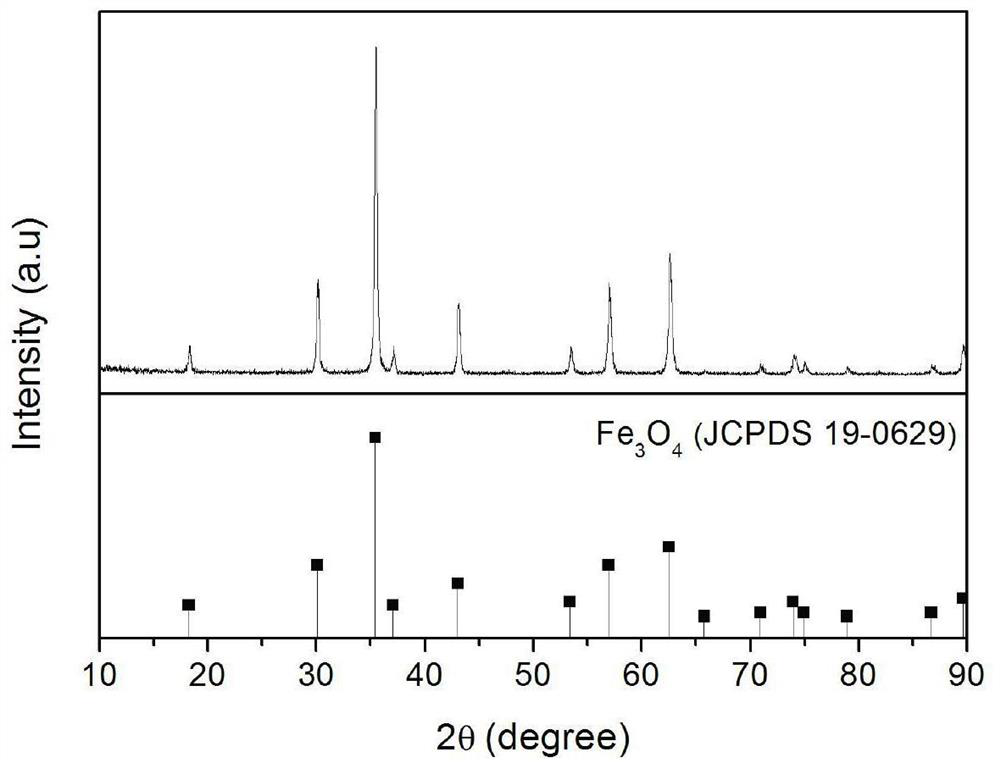

[0045] Step 3, porous carbon supported α-Fe 2 o 3 :

[0046] The product obtained in step 2 is placed in a muffle furnace with a heating rate of 2 o C / min, 300 o Calcined at C for 2 h to obtain porous carbon-supporte...

Embodiment 2

[0061] A kind of preparation method of porous NiO / carbon composite wave-absorbing material, it is characterized in that, its steps are as follows:

[0062] Step 1, preparing porous carbon fibers: 12.5 g bamboo fibers were prepared at 700 o C, N 2 Calcined under the atmosphere for 2 h, the heating rate was 4 o C / min to obtain bamboo-based porous carbon fibers.

[0063] Step 2, porous carbon fiber loaded with nickel nitrate

[0064] Take 0.8 g of porous carbon fiber and soak in 50 ml of 0.5 mol / L Ni(NO 3 ) 2 ·6H 2 O solution, after soaking for 24 h, use tweezers to clamp out the wet porous carbon fiber, and when there is no solution dripping, put it into an evaporating dish at 60 o Dry for 15 h at C to obtain a porous carbon fiber loaded ferric nitrate sample;

[0065] Step 3, porous carbon supported NiO

[0066] The product that step 2 makes is in muffle furnace, 300 o C for 2 h at a heating rate of 2 o C / min, that is, supporting NiO on porous carbon.

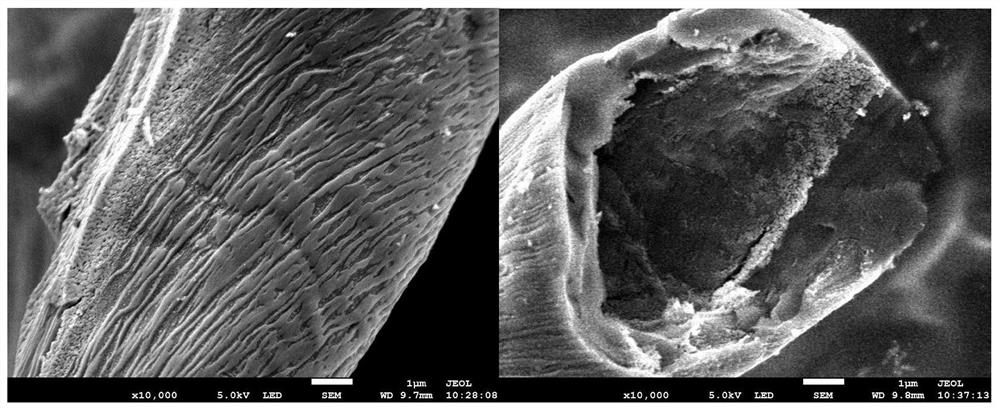

[0067] Figure...

Embodiment 3

[0071] A kind of preparation method of porous NiO / carbon composite wave-absorbing material, it is characterized in that, its steps are as follows:

[0072] Step 1, preparing porous carbon fibers: 12.5 g bamboo fibers were prepared at 700 o C, N 2 Calcined under the atmosphere for 2 h, the heating rate was 4 o C / min to obtain bamboo-based porous carbon fibers.

[0073] Step 2, porous carbon fiber loaded with nickel nitrate

[0074] Take 0.8 g of porous carbon fiber and soak in 50 ml of 0.2 mol / L Ni(NO 3 ) 2 ·6H 2 O solution, after soaking for 24 h, use tweezers to clamp out the wet porous carbon fiber, and when there is no solution dripping, put it into an evaporating dish at 60 o Dry for 15 h at C to obtain a porous carbon fiber loaded ferric nitrate sample;

[0075] Step 3, porous carbon supported NiO

[0076] The product that step 2 makes is in muffle furnace, 300 o C for 2 h at a heating rate of 2 o C / min, that is, supporting NiO on porous carbon. The NiO loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com