Patents

Literature

454results about How to "The method flow is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrogenation method for producing diesel oil in low sulphur

ActiveCN101092573AHigh activityLow operating pressureRefining to eliminate hetero atomsLiquid productHydrogen

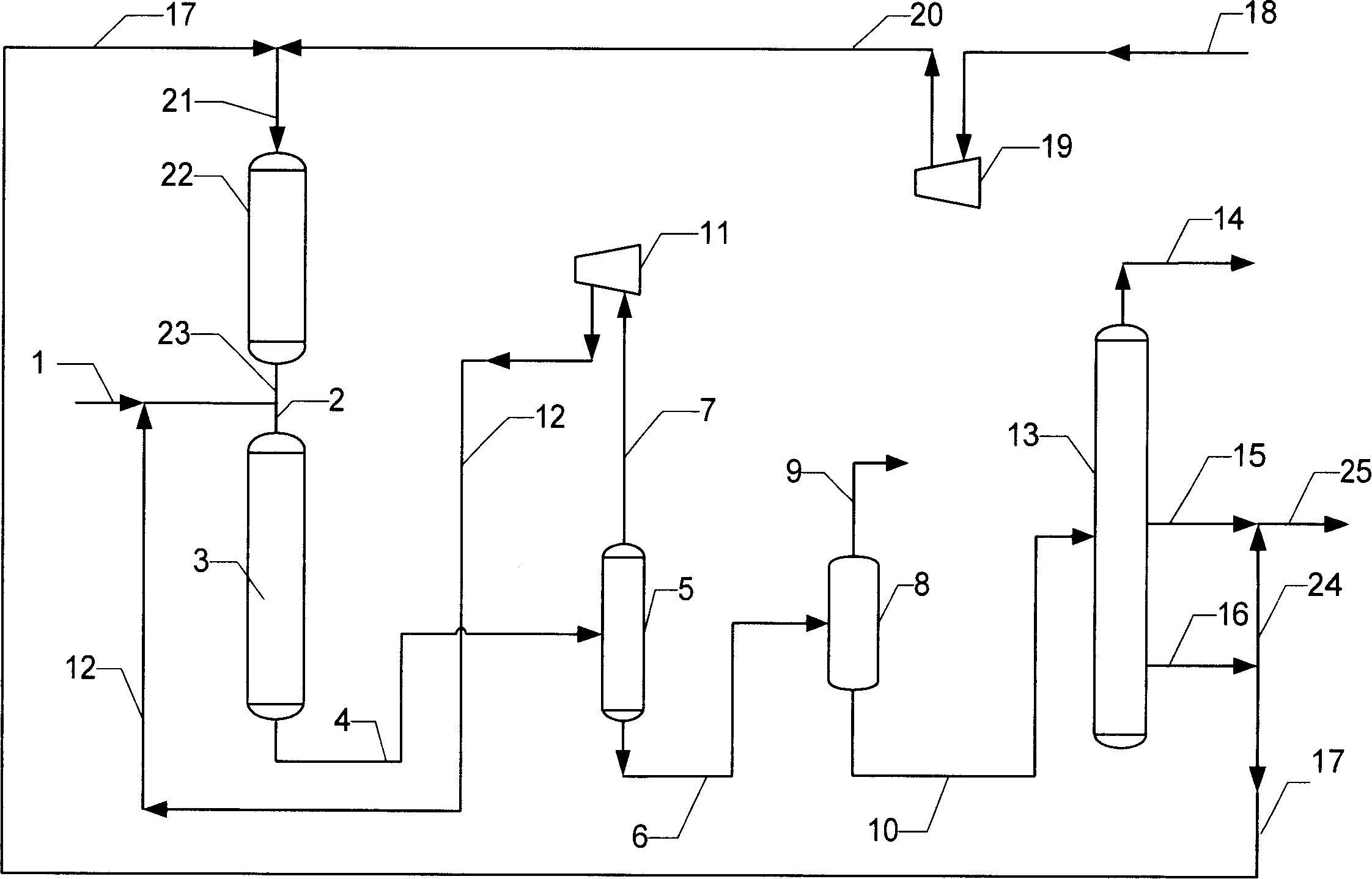

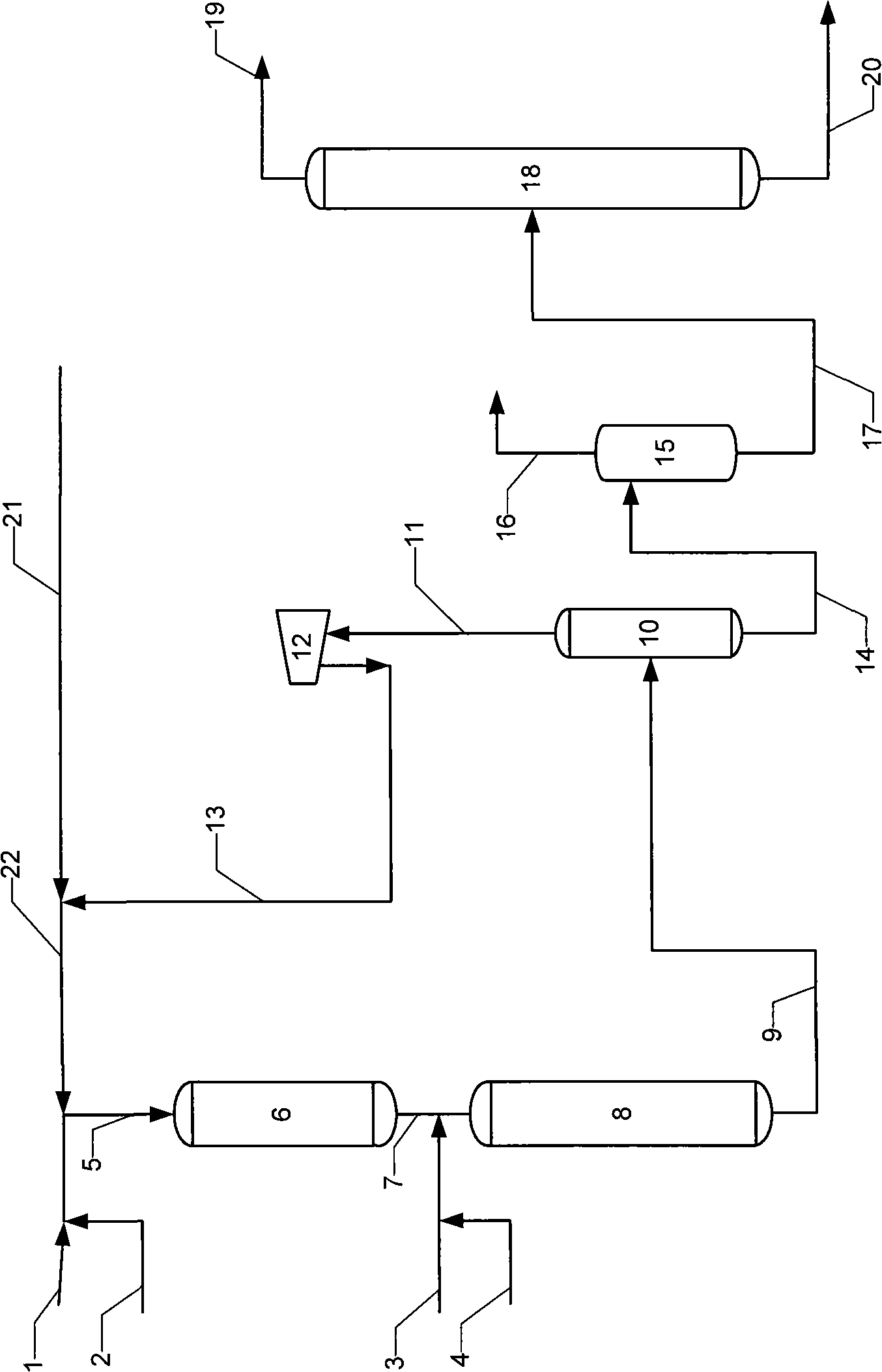

This invention discloses a hydrogenation method for producing low-sulfur diesel oil. The method comprises: mixing base oil with hydrogen, introducing into a hydrogenation reactor to orderly contact hydrogenation protecting agent, hydrorefining catalyst I, hydrorefining catalyst II and freely selected hydrorefining catalyst III for reactions, cooling the effluent, and separating to obtain hydrogen-rich gas and liquid product. With the synergism of the catalysts, the whole catalyst activity is improved. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and low-sulfur diesel oil that can meet Europe III standard and Europe IV standard can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

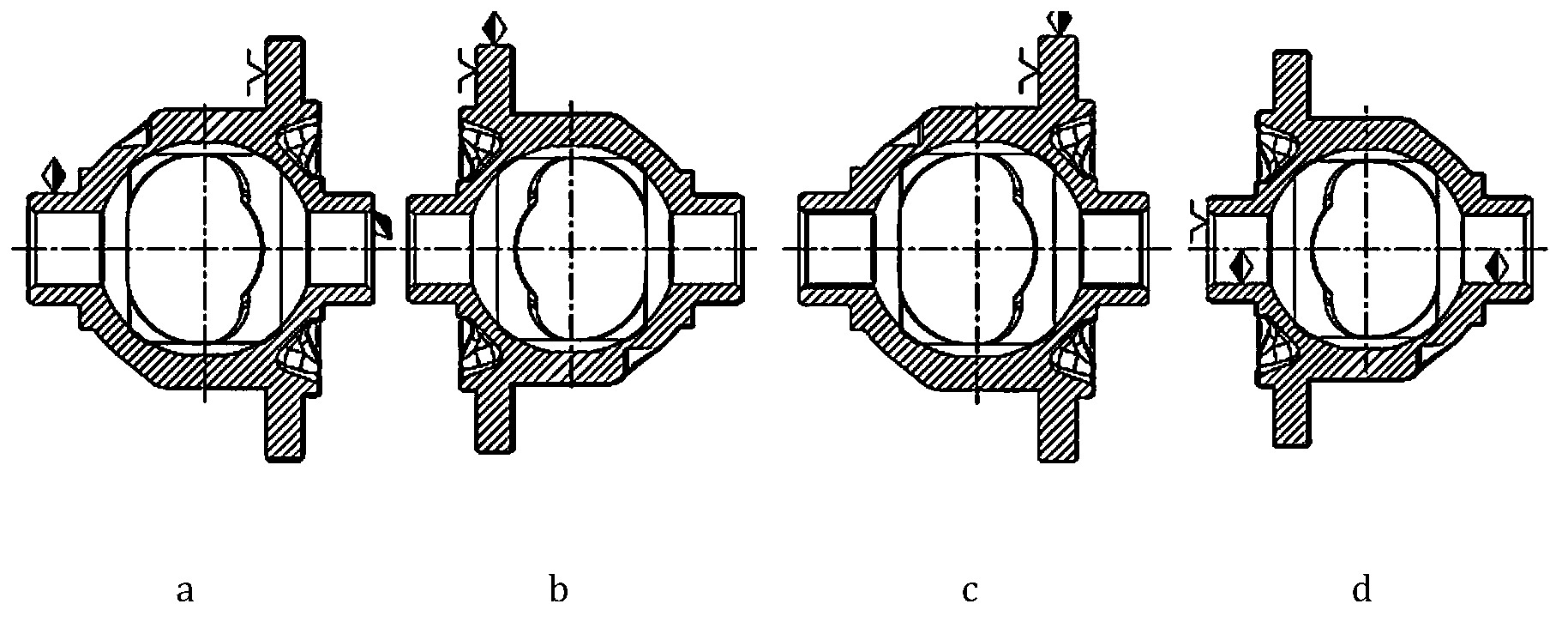

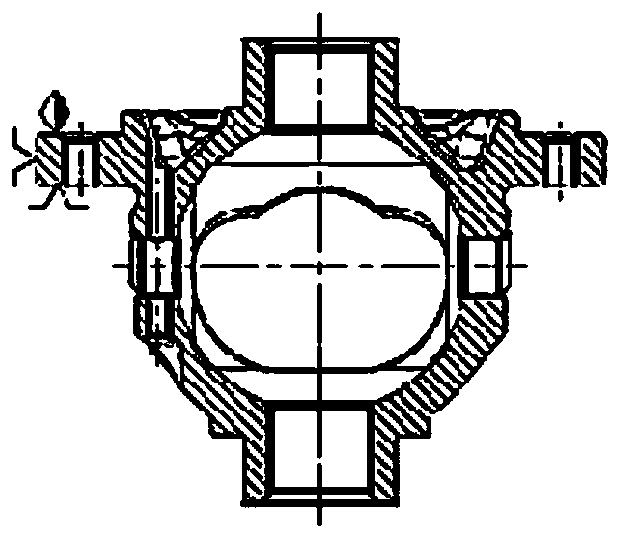

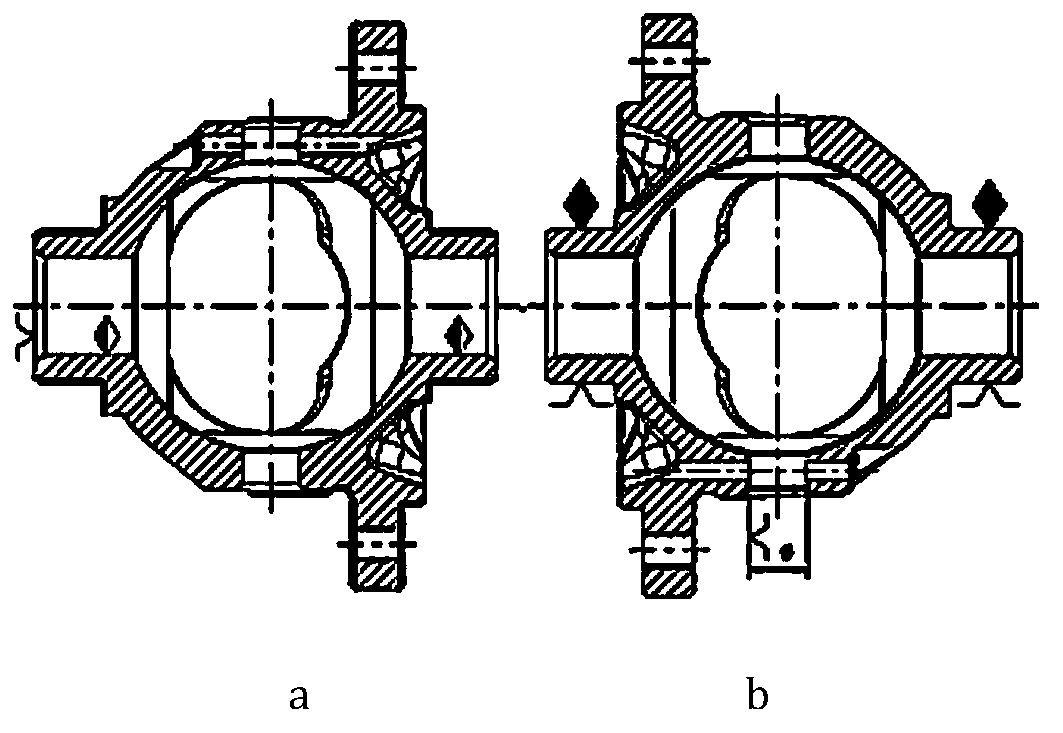

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

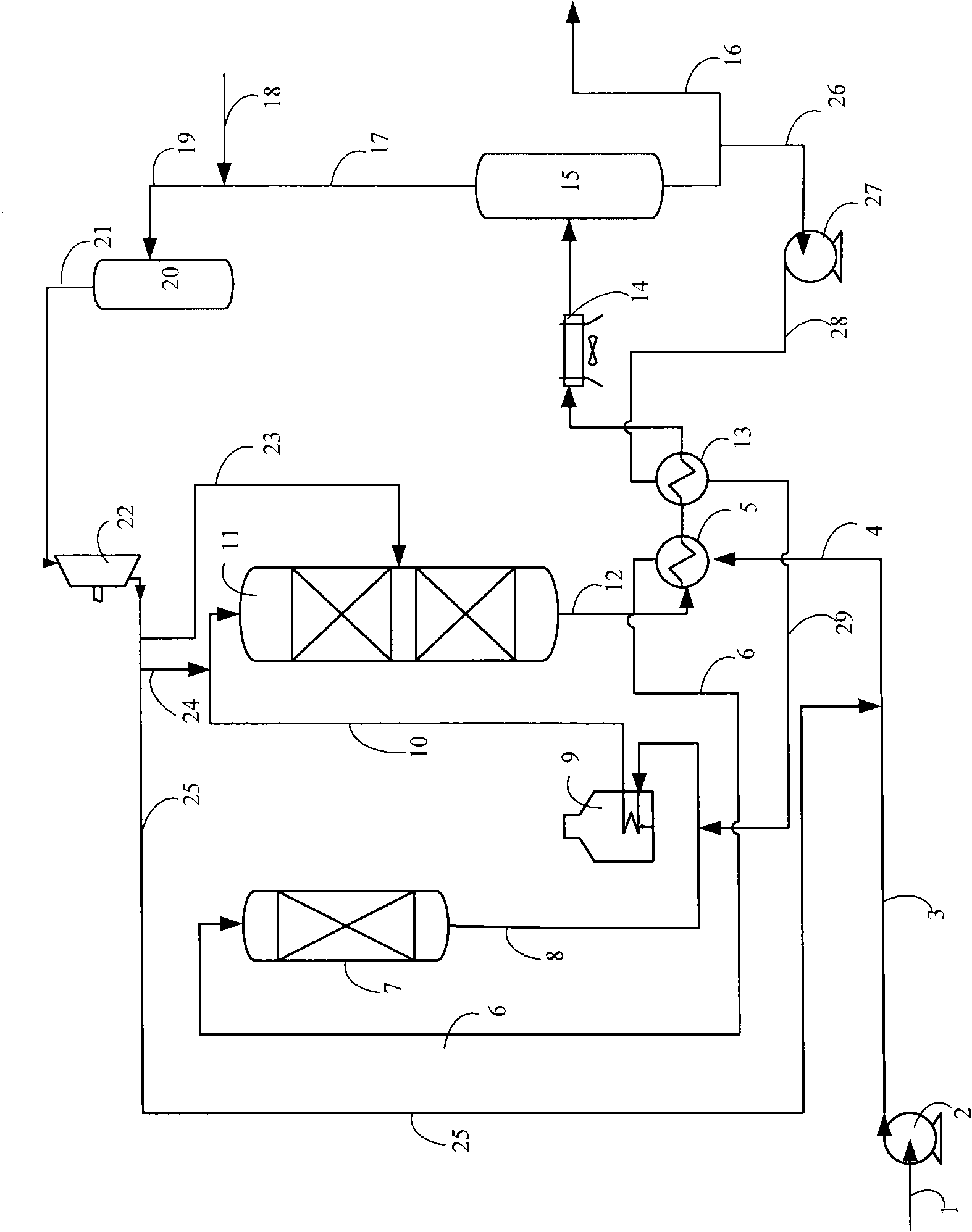

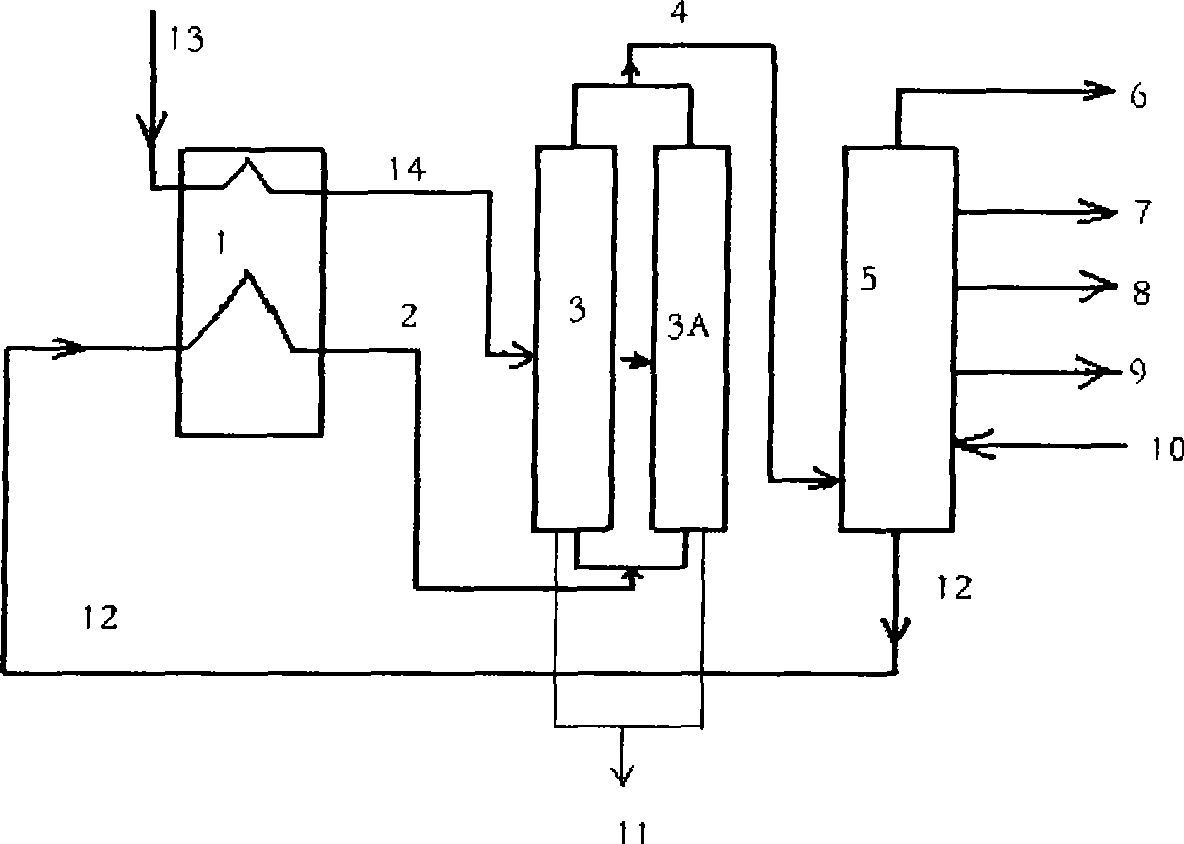

Hydrogenation and refining method of gasoline with poor quality

ActiveCN101591565AThe method flow is simpleEasy and flexible operationTreatment with hydrotreatment processesSolventPoor quality

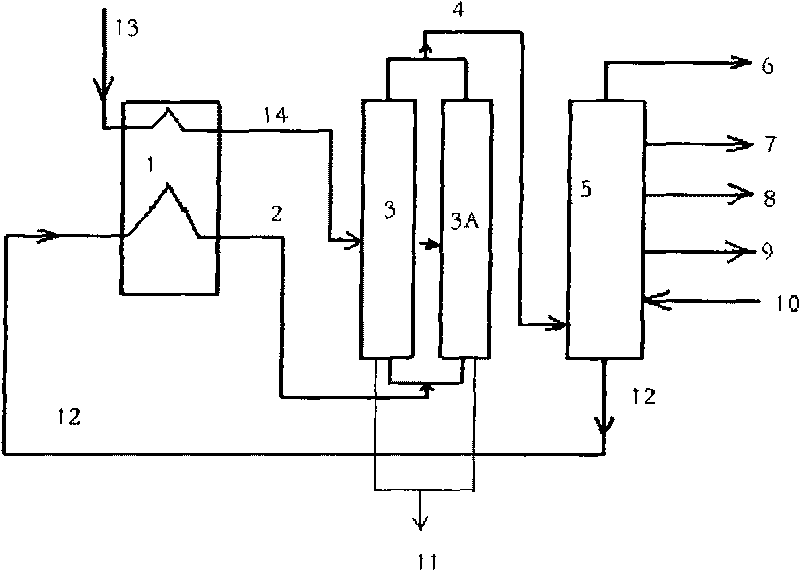

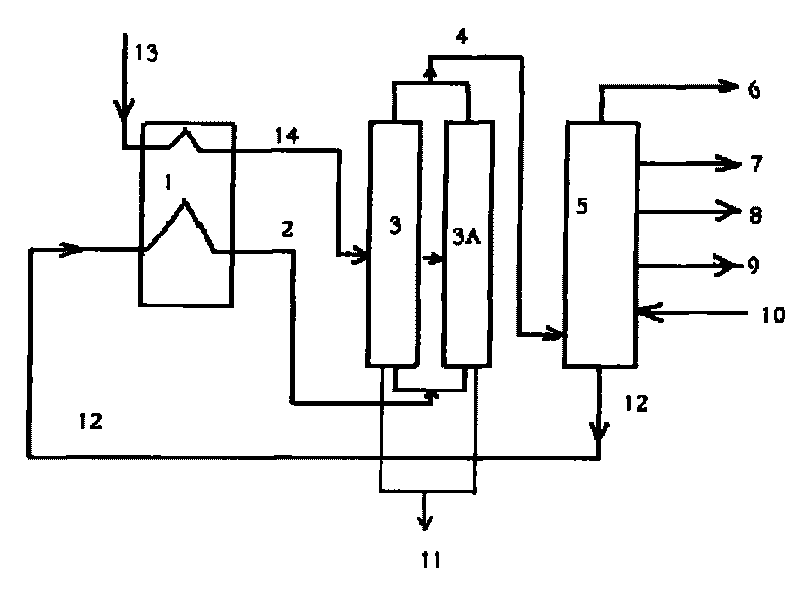

The invention discloses a hydrogenation and refining method of gasoline with poor quality, comprising the following steps: the base oil of gasoline contacts and reacts with hydrogenation protective agent at low temperature; after reaction effluent is mixed with circulation oil, the mixture sequentially contacts and reacts with hydrogenation desilication solvent and hyrorefining catalyst at high temperature; the reaction product is cooled and separated to obtain hydrogen-rich gas and refined gasoline fraction; and parts of refined gasoline fraction serves as circulation oil to return to the outlet of a first hydrogenation reaction area. The method can handle coker gasoline with high content of sulphur, nitrogen and olefin, and refined gasoline fraction can satisfy charging requirements of reforming pre-hydrogenation devices and steam cracking ethene preparing devices. The method of the invention can effectively slow coking speed of heating furnace tubes, greatly lowers pressure drop generation frequency of a main hydrogenation reactor, improves the operating severity of the main hydrogenation reactor and retards the deactivation speed of catalyst at the bottom of a refined reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing clean diesel oil

The present invention relates to a hydrogenation method for producing clean diesel oil, after the raw material oil is mixed with circulating hydrogen, the mixture enters into a second hydrogenating reactor area, under the action of hydrogenation refining catalyst, the reaction is performed, after the reaction effusion is cooled, separated and fractionated, naphtha distillate, light diesel oil distillate and heavy diesel oil distillate are got, after a part or whole heavy diesel oil distillate is mixed with new hydrogen, the mixture enters into a first hydrogenating reactor area, and contacts with the hydrogenating reforming catalyst to perform reaction, the reactant enters into the second hydrogenating reactor area directly without separation, the left heavy diesel oil distillate and the light diesel oil distillate are mixed to get the diesel oil product. The adoption method of the present invention can treat high sulpher, high nitrogen and high drying point diesel oil distillate, under the relaxer operation condition, 2 type and 3 type of standard clean diesel oil which meet the requirement of the World Fuel Oil Code can be got. The present invention has simple flow and low operation pressure, the investment for equipments and the operation cost are all comparatively lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ion-exchange separation method for tungsten and molybdenum in tungstate and molybdate mixed solution

InactiveCN102162030AEasy to parsePromote regenerationMolybdeum compoundsProcess efficiency improvementTungstate ionMOLYBDATE ION

The invention discloses an ion-exchange separation method for tungsten and molybdenum in a tungstate and molybdate mixed solution, technically characterized by comprising the following steps of: adjusting the pH of the tungstate and molybdate mixed solution by mineral acid to be appropriate, so that the tungstate ions in the solution are polymerized into paratungstate ions, while molybdenum still exists in the form of tungstate ions; adjusting the concentration of Cl<-> in the solution to be appropriate, enabling the solution to flow through ion exchange columns loaded with macroporous strong base anion exchange resin, so that the tungsten in the solution is absorbed firstly, thereby separating the tungsten from the molybdenum; rinsing a small amount of MoO4<2-> ions absorbed by the resin in the ion exchange columns by a solution with an appropriate concentration of Cl<->; and finally resolving the tungsten absorbed on the resin by using an alkali solution with an appropriate concentration of Cl<-> as a resolving agent to regenerate the resin.

Owner:CENT SOUTH UNIV

Organic waste gas purifying method

ActiveCN101143282ASimple equipmentStable operationDispersed particle separationPorous solidsPolyester

The invention provides a purification method of an organic waste gas, in particular to a purification method of organic water gases containing aldehydes, ethylene glycol, PTA dust and so on, polyester waste gas processing method for example. After being discharged from the discharge port, polyester waste gas firstly enters into an adsorption homogenization tank filled with porous solid adsorbent, and then is processed catalytic combustion treatment. In adsorption homogenization tank, the components of ethylene glycol and so on are fully absorbed, and the PTA dust is filtrated, and at the same time the concentrations of components of aldehydes and so on are homogenized under adsorption-desorption effect. The concentration homogenized waste gas enters into catalytic combustion reactor, and is totally oxidized into carbon dioxide and water under the effect of catalyst, and standard-met discharge is achieved. The function of the special typed active carbon used in the invention is not condensation but adsorption, filtering and homogenizing. The invention can prolong the service life of catalytic combustion catalyst, has good purification effect, safe and stable arrangement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing diesel oil with low sulphur and low arene

ActiveCN101092575ASimple processLow operating pressureTreatment with hydrotreatment processesHydrogenGasoline

This invention discloses a method for producing low-sulfur low-arene diesel oil. The method comprises: mixing base oil and hydrogen, introducing into a hydrogenation reactor, reacting in the first hydrogenation region by contacting hydrorefining catalyst I, directly introducing the reaction product into the second hydrogenation region without separation, reacting by contacting hydrorefining catalyst II, cooling and separating the reaction product to obtain hydrogen-rich gas and liquid substance, circulating the hydrogen-rich gas for repeated use, introducing the liquid substance into a fractionating system, fractionating to obtain crude gasoline fraction, light diesel oil fraction and heavy diesel oil fraction, introducing part or all of the heavy diesel oil fraction bake to the hydrogenation reactor. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and clean diesel oil (with low sulfur content and low arene content) can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing ultralow sulfur diesel fuels

ActiveCN101311252AReduce sulfur contentReduce PAH contentTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonNaphtha

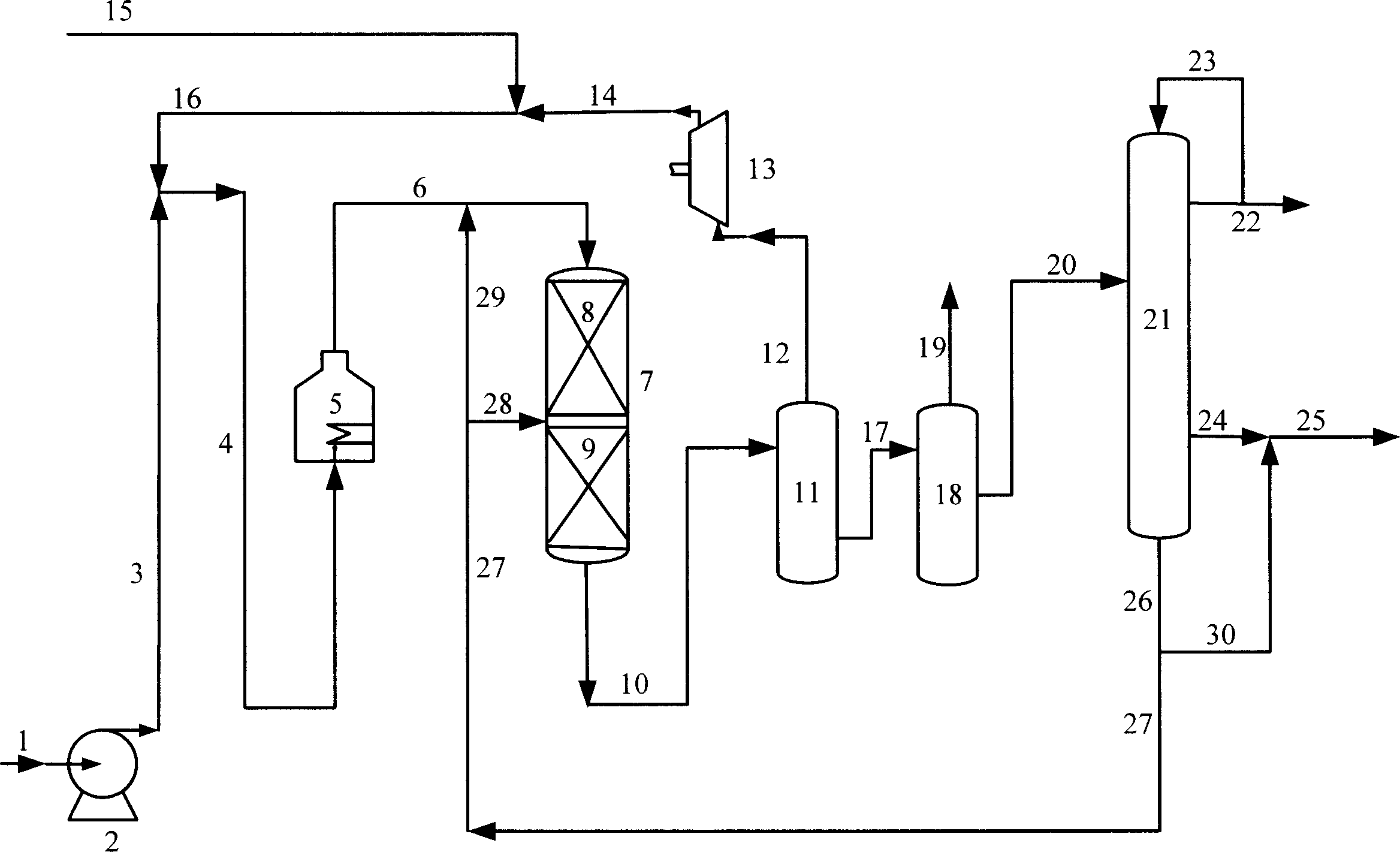

The invention relates to a production method for ultra-low sulfur diesel oil; wherein, after mixed with hydrogen, straight-run atmosphere 3rd side cut distillate and (or) diesel oil heavy distillate enter(s) a first hydrogenation reaction zone and reacts under the action of hydro-upgrading catalyst and hydrofining catalyst; after mixed with the reaction effluent of the first hydrogenation reaction zone, straight-run atmosphere 2nd side cut distillate and (or) diesel oil light distillate enter(s) a second hydrogenation reaction zone and reacts under the action of the hydrofining catalyst; the reaction effluent of the second hydrogenation reaction zone is cooled, separated and distilled to obtain naphtha fraction and diesel products. The method provided by the invention can treat the diesel distillate with high sulfur, high nitrogen and high final boiling point, and under mild operating conditions, obtain clear diesel products with low content of sulfur and polycyclic aromatic hydrocarbons as well as high cetane number; meanwhile, the product quality can reach the indexes of the IV European emission standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent red light running identifying system and vehicle behavior detecting and capturing method

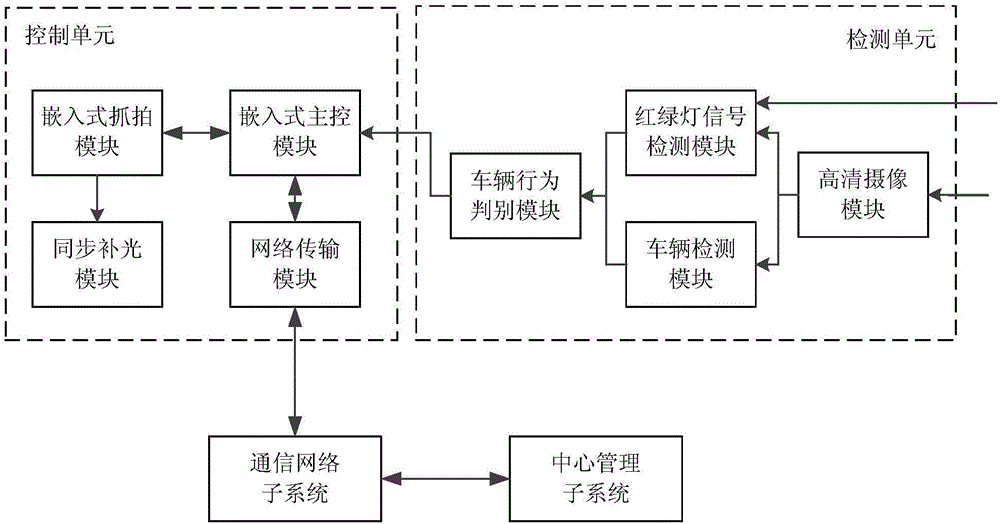

InactiveCN105788286AImprove the level of intelligenceImprove work efficiencyRoad vehicles traffic controlVideo monitoringData acquisition

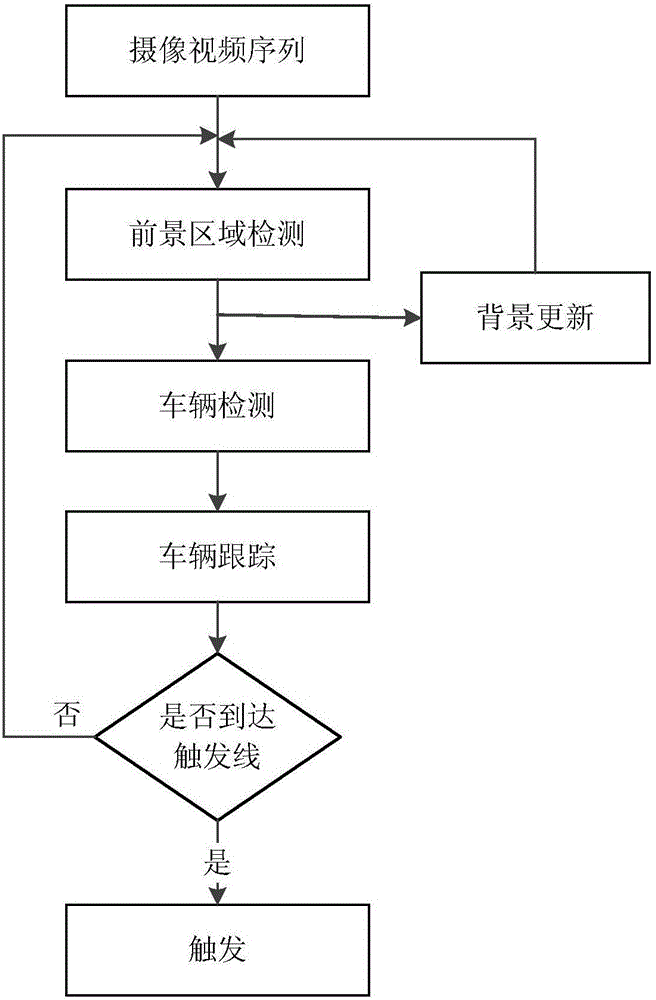

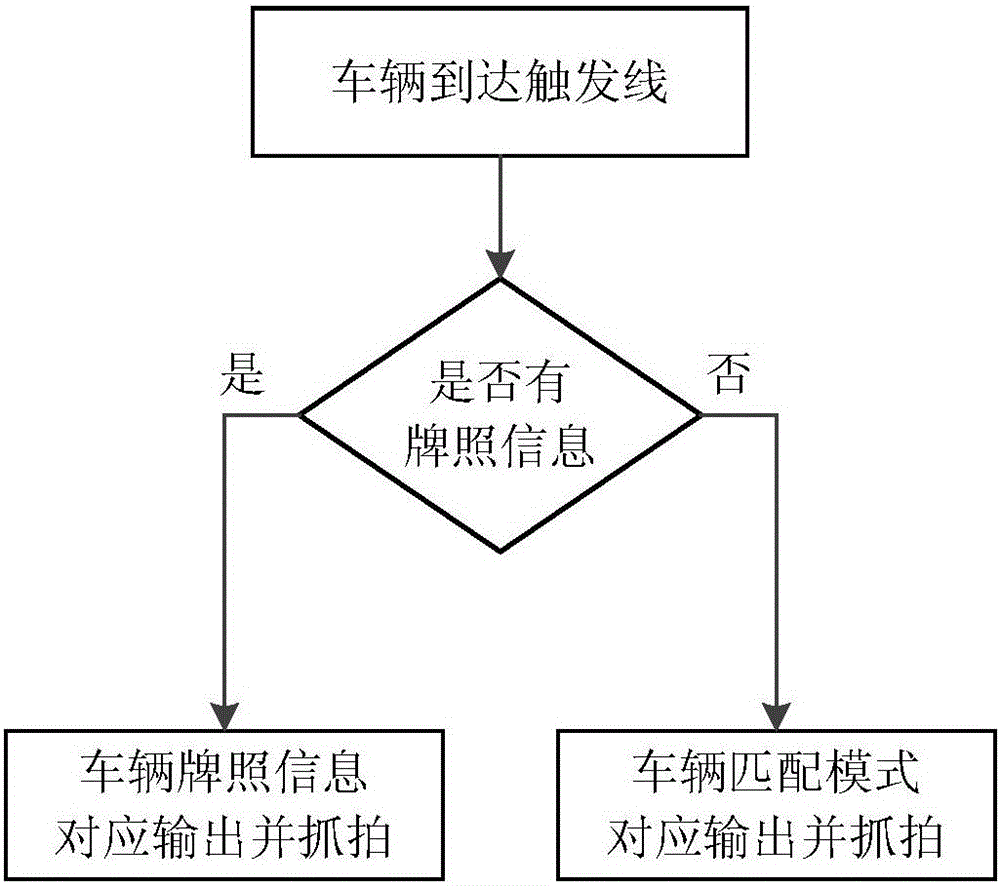

The invention belongs to the technical field of video monitoring and discloses an intelligent red light running identifying system which is characterized by comprising a data collection sub-system, a communication network sub-system and a central management sub-system, wherein the data collection sub-system is used for video stream collection, traffic light state detection, motor vehicle traffic violation behavior detection, traffic violation picture capturing, fill light control, local storage of traffic violation records and network uploading task of related information. The invention also discloses a vehicle behavior detecting and capturing method which is characterized by comprising the following steps: acquiring a camera video sequence; carrying out foreground area detection; carrying out vehicle detection; carrying out vehicle tracking; judging whether the vehicle reaches the trigger line position or not; and if so, sending a trigger signal. In the invention, the intelligence level of electronic traffic management is raised, the efficiency of traffic violation vehicle detecting, identifying and capturing is improved, and intelligent integration of collection, identifying and recording in electronic traffic management can be realized.

Owner:HUNAN BOGUANG INFORMATION TECH CO LTD

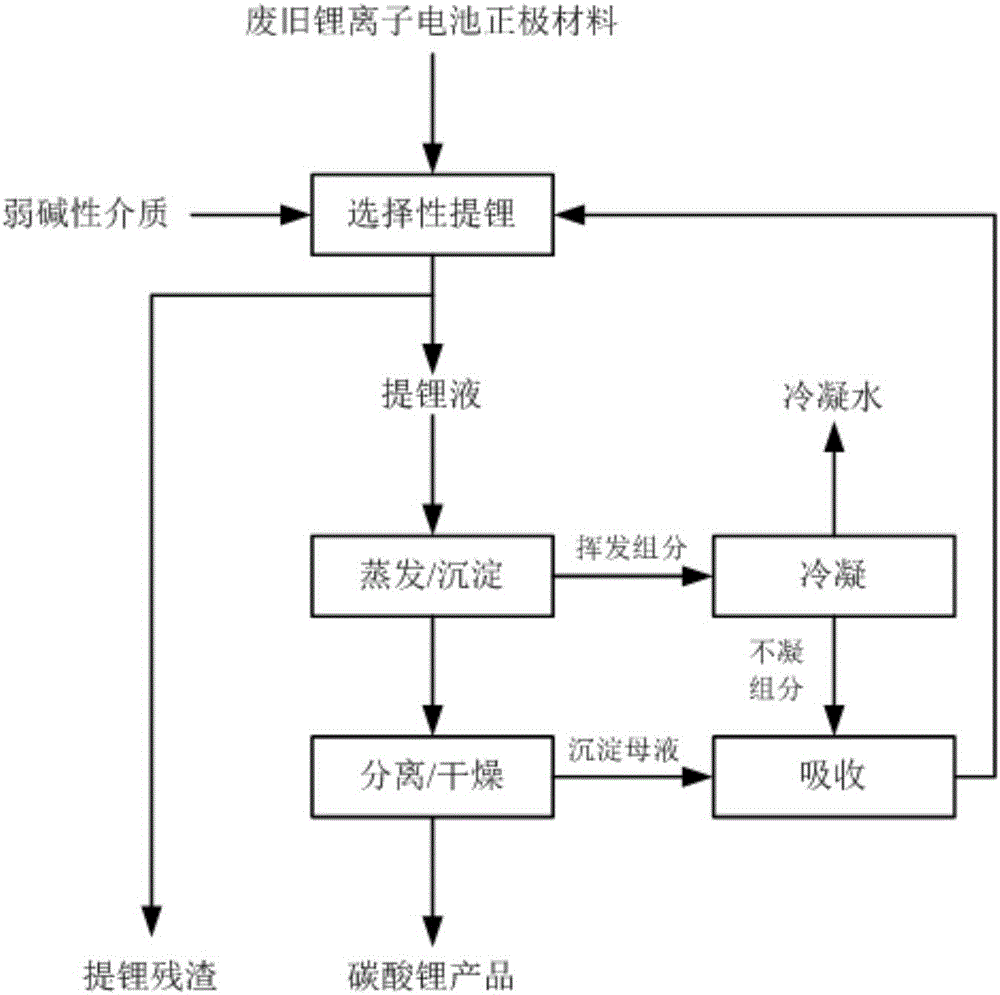

Green method for recycling lithium in cathode materials

ActiveCN106340692AImprove conversion efficiencyWeak base selectivityWaste accumulators reclaimingBattery recyclingLithium carbonateCarbon dioxide

The invention provides a green method for recycling lithium in cathode materials, and the method comprises the following steps of 1, using cathode materials containing lithium and mixture of weak base and water as the reaction raw materials, carrying out reaction at the temperature of 5 DEG C-90 DEG C and at the pressure of 0.2 MPa-1.0 MPa, proceeding liquid-solid separation on the materials remaining after the reaction and then obtaining lithium and residue; 2, carrying out postprocessing on the extraction solution of lithium to obtain lithium carbonate. The green method for recycling lithium in cathode materials has simple procedures and green reaction process, during which, the leaching efficiency of lithium is larger than 95 WT%, the purity of lithium carbonate is larger than 98.5 WT%, and the impurity content satisfies national standard GB / T11075 2013.

Owner:北京中科百特科技有限公司

Method for synthesizing anatase type crystallizing titanium dioxide nano nuclear-shell or shell structure material by water phase one-step method

InactiveCN101077792AThe method flow is simpleEasy to operateTitanium dioxidePhotonic crystalPolystyrene

The present invention relates to preparation process of core-shell material and hollow material, and is especially water phase one-step synthesis process for preparing nanometer crystallized anatase type titania material in core-shell and hollow structure. Water soluble titanium peroxide precursor is treated through a sol-gel process so as to coat a nanometer titania layer onto the surface of polystyrene, and the nanometer titania layer in the shell is crystallized directly at relatively low temperature to form nanometer anatase type titania without needing sintering. Furthermore, the precursor may be controlled properly, so that the polystyrene core serving as the template may be dissolved spontaneously after the shell is formed and crystallized and nanometer hollow titania may be obtained directly in water phase. The present invention is simple, easy to operate, low in cost and suitable for batch production, and may find wide application in different aspects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

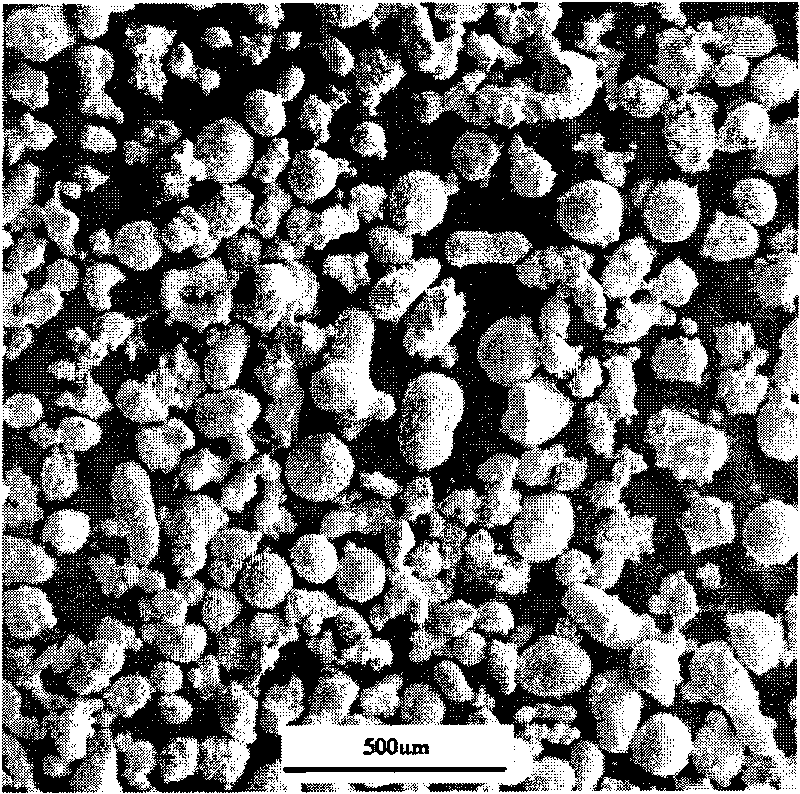

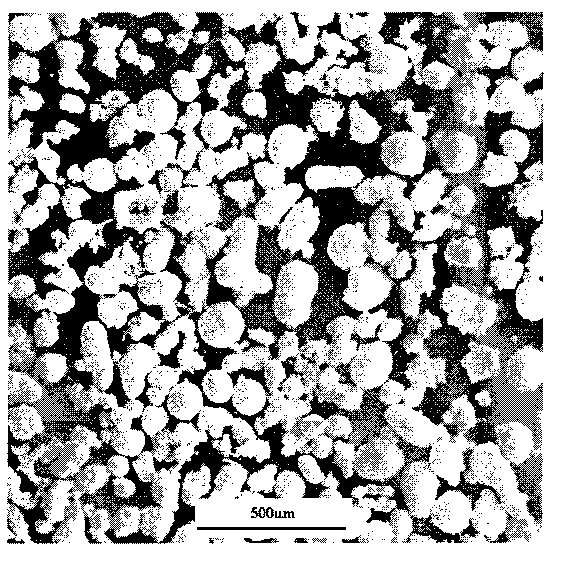

Preparation method of low-apparent-density copper tin alloy powder for micro oil-retaining bearing

The invention discloses a preparation method of low-apparent-density copper tin alloy powder for a micro oil-retaining bearing, and belongs to the technical field of copper tin alloy powder for the micro oil-retaining bearing. The alloy powder comprises the following component phases in percentage by weight: 65-95 percent of Cu and 5-35 percent of Sn. The preparation method comprises the following steps of: after atomized pulverizing of the copper tin alloy, dynamically oxidizing the prepared alloy powder; and then obtaining the alloy powder with proper apparent density by using a high-temperature hydrogen reduction technology. The method has a simple flow, low equipment investment and high technical content; the copper tin alloy powder is not mechanically mixed so as to easily cause the phenomenon of segregation during use and storage; meanwhile, the specific surface area of the powder is increased; and the press sintering performance of the powder is improved. The prepared alloy powder is particularly suitable for producing the micro oil-retaining bearing.

Owner:有研科技集团有限公司 +1

Method for beneficiating high-peat copper sulphide ore

The invention discloses a method for beneficiating high-peat copper sulphide ore and relates to a method for beneficiating nonferrous metals, which specifically relates to a method for beneficiating high-peat copper sulphide ore; regulating agent and composite inhibitor are added before floating ore pulp and after graining raw ore; flotation environment and mineral surface state in ore pulp are improved in the method disclosed by the invention; the inhibition capacity of inhibitor on easily-floated gangue mineral and selective collection of collecting agent on mineral are enhanced; compared with the traditional method for beneficiating pre-deslimed peat, a technical procedure is simplified by the invention; the loss of available mineral caused by pre-deslimed peat is avoided; and the recycle rate of copper is increased by about more than 18%.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Production method of needle coke raw material

ActiveCN101724420BHigh reactivityExpand sourceThermal non-catalytic crackingCoking carbonaceous materialsCoke rateDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

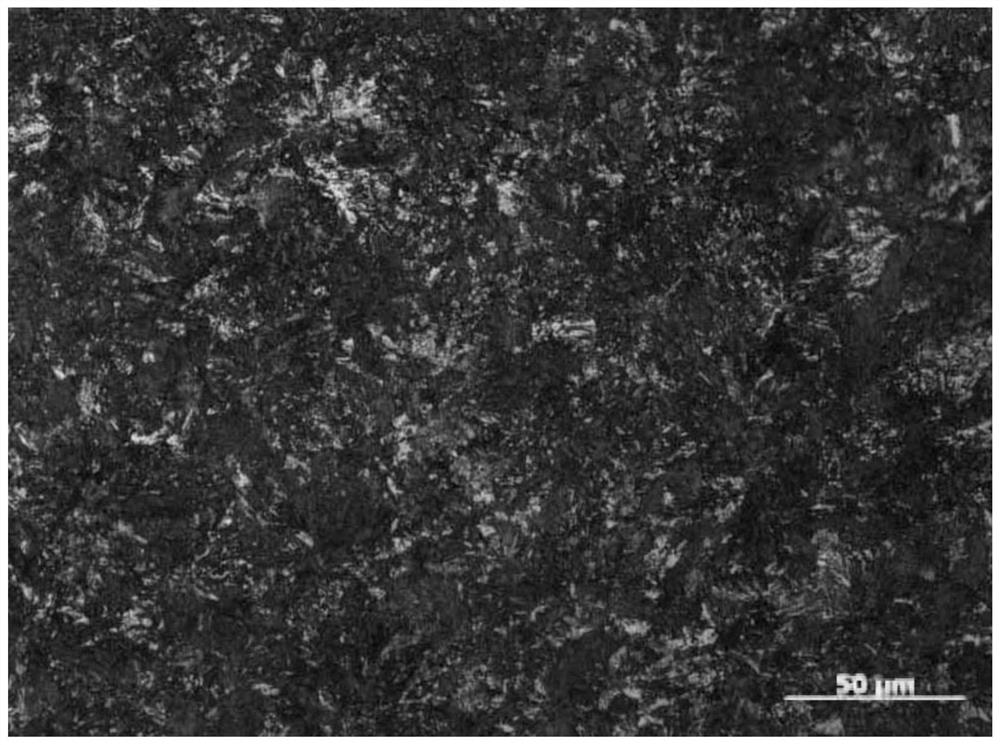

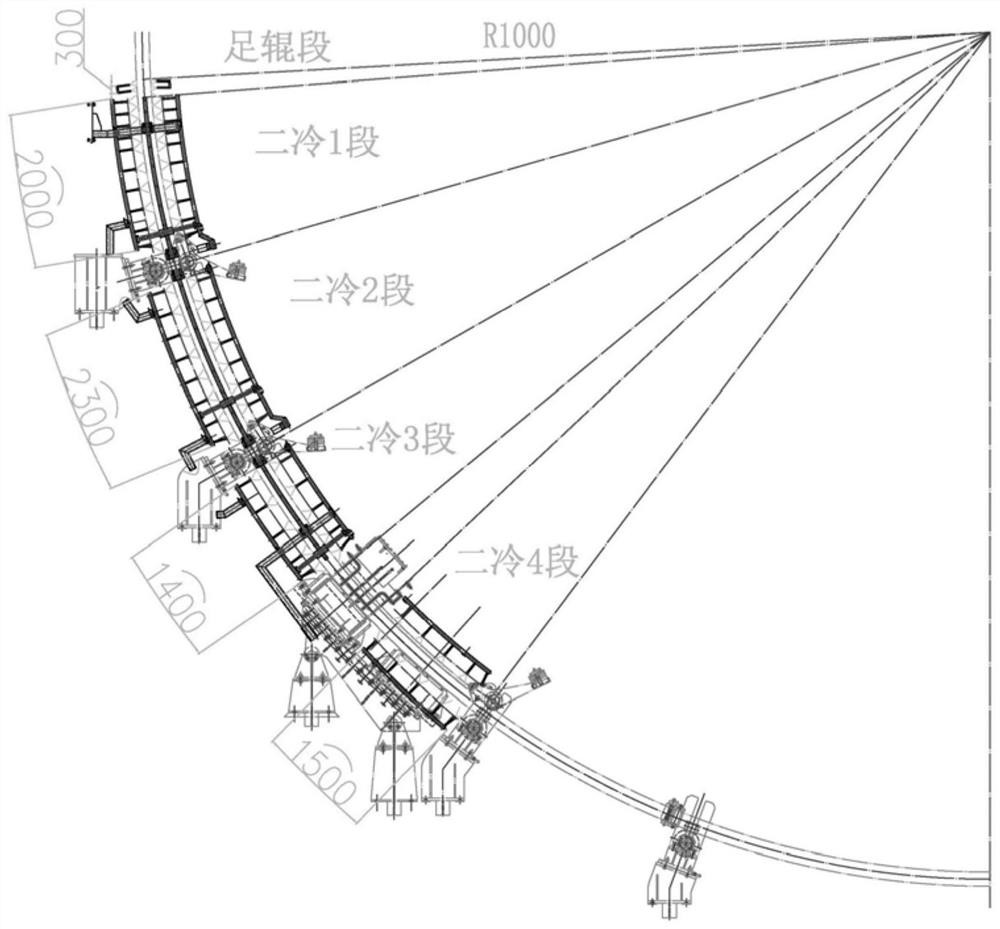

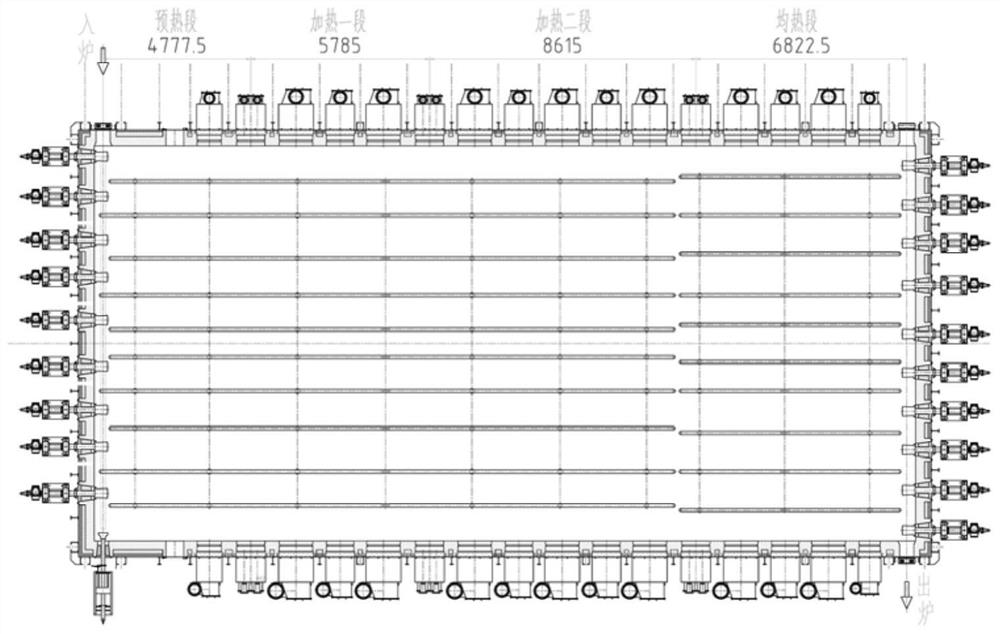

Control method for segregation and net carbon of 86-grade high-strength cord steel wire rod

ActiveCN112359277AImprove segregationImprove mesh carbonProcess efficiency improvementWire rodContinuous casting

The invention discloses a control method for segregation and net carbon of an 86-grade high-strength cord steel wire rod. The control method comprises the following steps of: KR molten iron pre-desulfurization, BOF converter smelting, LF furnace refining, continuous casting CC, casting blank surface treatment, casting blank heating, controlled rolling and controlled cooling procedures which are carried out in sequence. The 86-grade high-strength cord steel wire rod comprises the following components in percentage by weight: 0.85-0.90% of C, 0.15-0.35% of Si, 0.40-0.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.010% of Cr, less than or equal to 0.005% of Al and the balance Fe. According to the control method, the segregation and netcarbon of the wire rod are improved by combining continuous casting of small square billets with wire rolling, the period and cost are greatly reduced, the sorbitizing rate of the prepared wire rod is larger than or equal to 90%, the center segregation of the wire rod is slight, no net-shaped cementite exists in the center, and the drawing use requirements of users are met.

Owner:ZENITH STEEL GROUP CORP +1

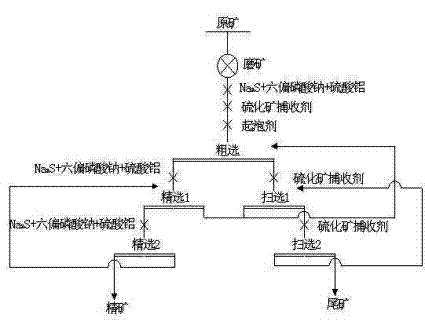

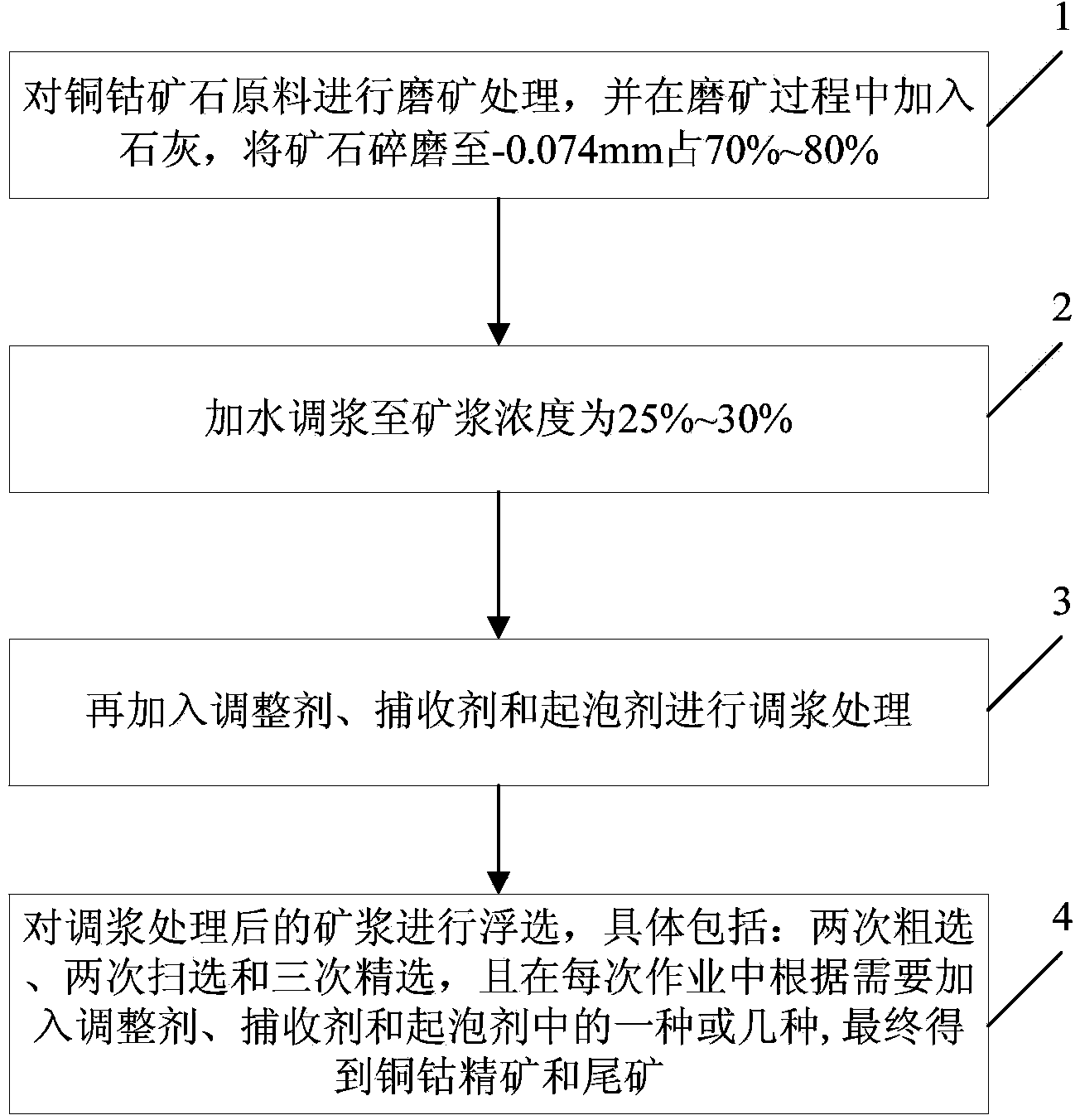

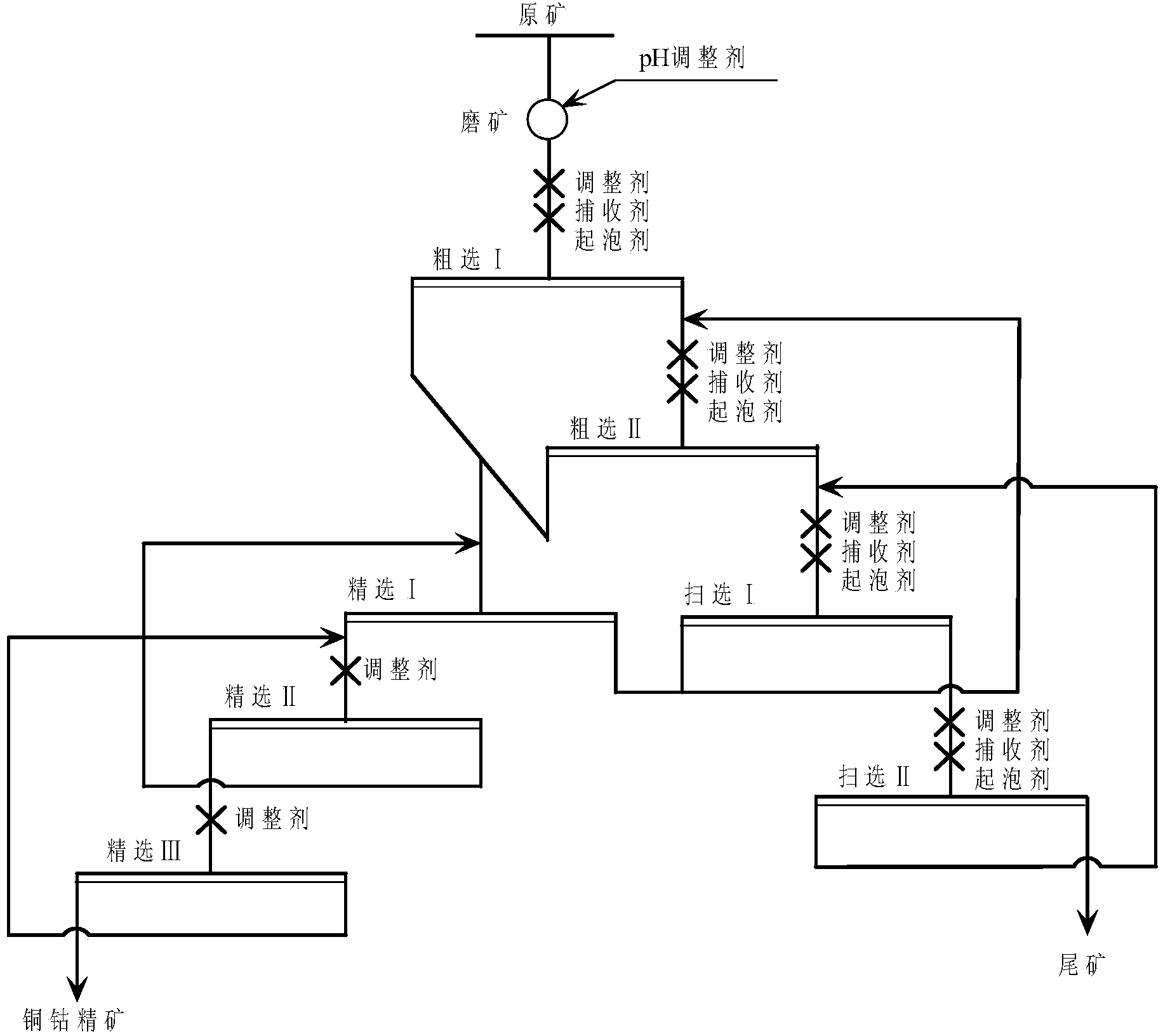

Flotation method for carbonaceous copper-cobalt ore

InactiveCN103480500AImprove concentrate qualityThe method flow is simpleFlotationFoaming agentCopper

The invention discloses a flotation method for carbonaceous copper-cobalt ore. The flotation method includes firstly, performing ore grinding on copper-cobalt core raw materials, adding lime during ore grinding, and grinding the ore until the ore is -0.074mm in size and accounts for 70%-80%; adding water and preparing ore pulp until concentration of the ore pulp reaches 25%-30%; adding a regulating agent, a collecting agent and a foaming agent again for ore pulp preparation; performing flotation, including two-time rougher flotation, two-time scavenging and three-time concentration, on the ore pulp subjected to ore pulp preparation; adding one or more of the regulating agent, the collecting agent and the foaming agent during each operation according to needs to finally obtain copper-cobalt concentrates and tailings. The flotation method is simple in procedure, convenient to control, high in separation efficiency and good in index, and the obtained copper-cobalt concentrates have good quality.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Bayer process dissolving-out method

InactiveCN101117230ASimple processEasy to implementCarbon captureAluminium oxides/hydroxidesAluminium oxideSolid content

The invention provides a dissolving method with Bayer process, relating to a preparation method used in the dissolving process, in which diasporic bauxite is used as a raw material and aluminum oxide is produced with Bayer process. The invention is characterized in that: in the dissolving process, sodium ferrate, lime and the lye is added into bauxite, the amount of sodium ferrate and lime is calculated according to silicon content in bauxite which can be completely changed into molten iron garnet(3CaO.Fe2O3.nSiO2.(6-2n)H2O); the lye concentration NK is 100g / L to 450g / L, aluminium oxide concentration is less than 5g / L, the solid content of the dissolved preparation ore pulp is 50g / L to 300g / L, the temperature is 80 DEG C to 180 DEG C the dissolving time is 0.5 hour to 12 hours., and then the solid and the liquid are separated, the solid is dissolved in the condition of the conventional Bayer process. Through the invention, the existing form of silicate mineral of the dissolved red mud is mainly molten iron garnet instead of the usual sodium-silicon residue. The invention reduces the alumina-silicon ratio A / S and the sodium-silicon ratio N / S of the dissolved red mud. The invention is adapted to process diasporic bauxite source of Chinese high alumina-silicon.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for improving quality of bio-oil

ActiveCN104560102ARaise the pHImprove qualityBiofuelsEfficient propulsion technologiesAlkaneNitrogen atmosphere

The invention relates to a method for improving the quality of bio-oil. The method comprises the following steps: adding bio-oil produced by the pyrolysis into an autoclave, adding calcium oxide and reacting for 1-4 hours at 30-80 DEG C under nitrogen atmosphere, heating to 160-180 DEG C, reacting for 0.5-2 hours, and finally cooling to 80-120 DEG C, and further carrying out heat preservation and reacting for 0.5-2 hours to obtain precursors of C7-C15 alkane fuels. By the method, the content of acid in the bio-oil can be well decreased, the pH and stability of the bio-oil are increased and meanwhile, produced ketone substances and aldehyde substances in the bio-oil can be reacted to obtain the precursors of the C7-C15 alkane fuels and thus the quality of the bio-oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

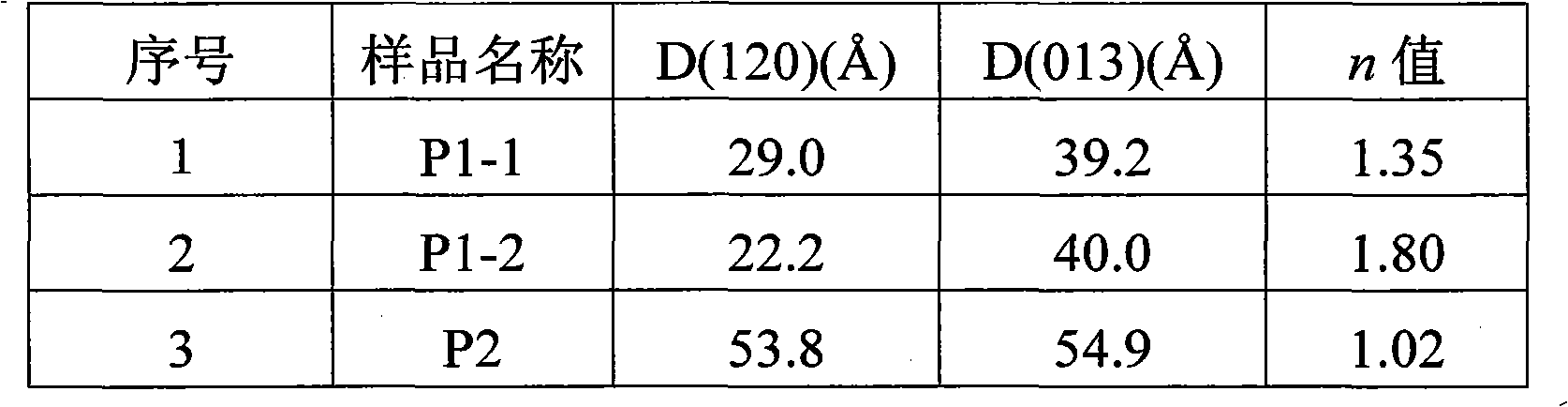

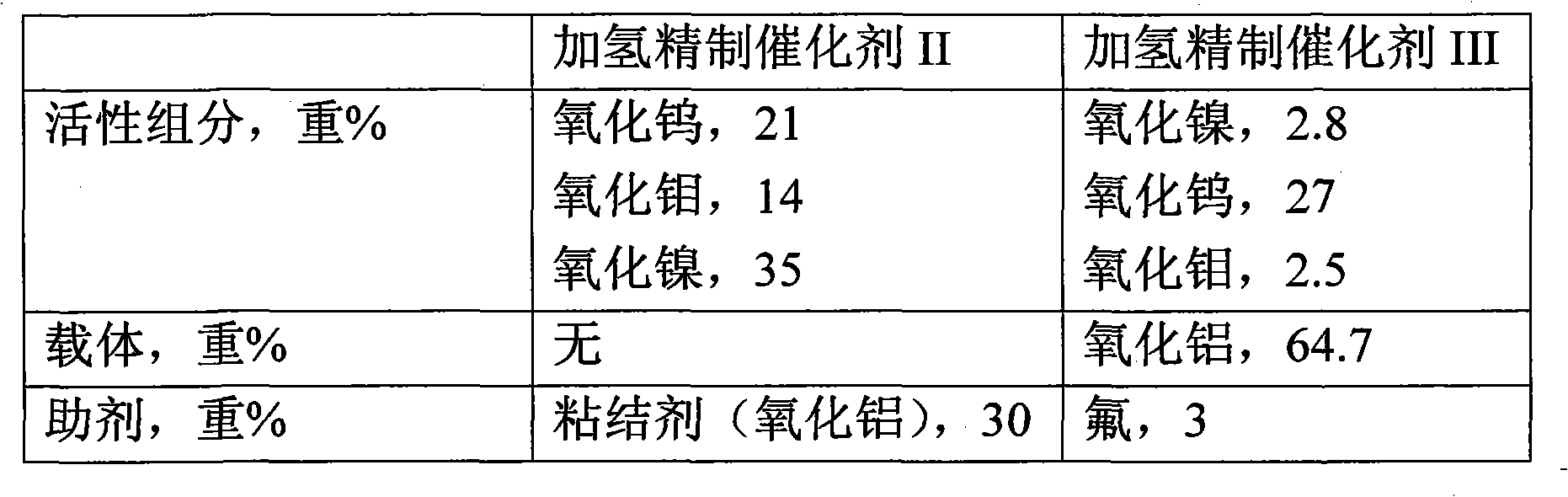

Method for production of ultralow-sulfur diesel oil

ActiveCN102851070AReduce partial pressureReduce inhibitionTreatment with hydrotreatment processesHydrogenTungsten

Disclosed is a method for production of ultralow-sulfur diesel oil. Raw oil of diesel oil fraction enters a reactor from the top, make-up hydrogen and circulating hydrogen are mixed and then enter the reactor from the bottom, the raw oil of diesel oil fraction sequentially contacts a hydrofining catalyst I and a hydrofining catalyst II for reaction under the hydrofining reaction conditions, and the reaction products are separated and fractionated to obtain diesel oil product. The hydrofining catalyst I is a loaded hydrofining catalyst using nickel-molybdenum or nickel-molybdenum-tungsten as active metal component, and the hydrofining catalyst II is a bulk hydrofining catalyst. The invention can solve the problems of harsh operating conditions and low space velocity in prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

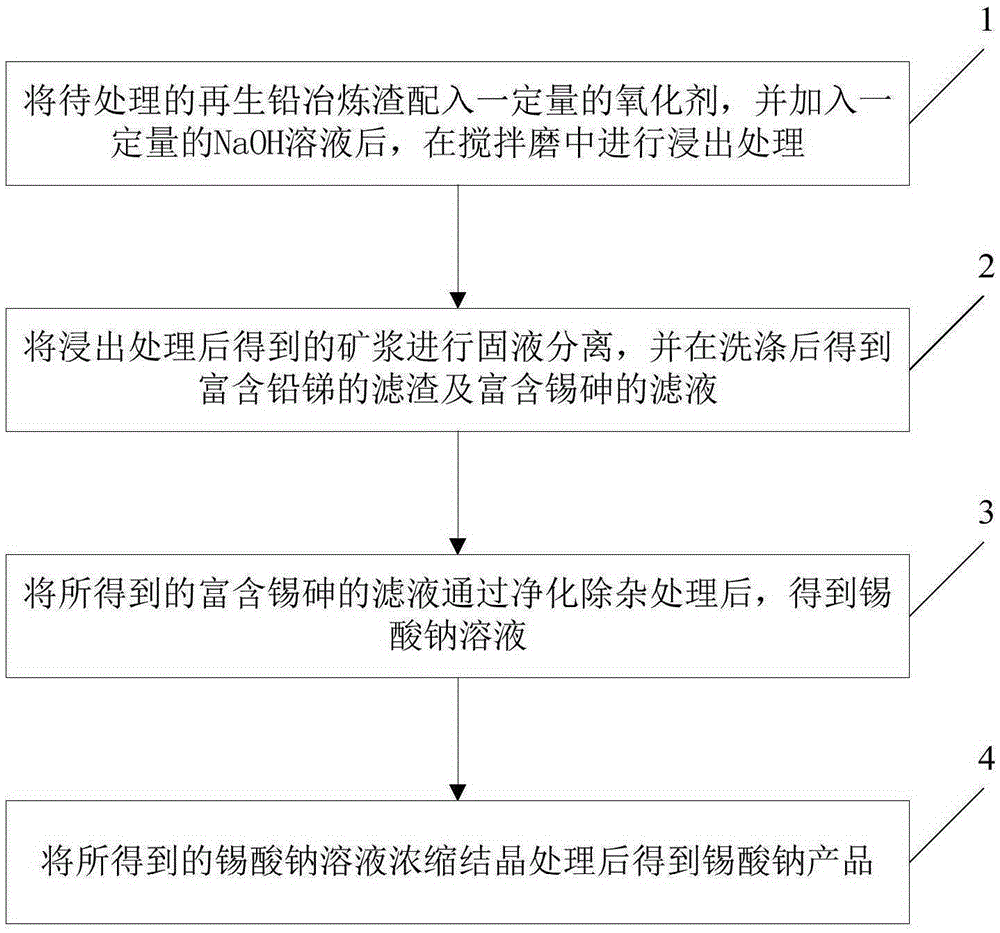

Method for extracting and separating valuable metal from secondary lead smelting slag

The invention discloses a method for extracting and separating valuable metal from secondary lead smelting slag. The method includes the steps that a certain amount of oxidizing agent is mixed in the secondary lead smelting slag to be treated; after a certain amount of NaOH solution is added, leaching treatment is conducted in a stirring mill; pulp obtained through leaching treatment is subjected to solid-liquid separation, and filter residues rich in lead and antimony and filtrate rich in tin and arsenic are obtained after washing; the obtained filtrate rich in tin and arsenic is subjected to impurity purifying treatment, and a sodium stannate solution is obtained; and the obtained sodium stannate solution is condensed and crystallized to obtain a sodium stannate product. The method is simple in process and easy to adopt, valuable metal such as tin, antimony and arsenic can be directly separated under the alkaline condition, a qualified sodium stannate product is obtained through subsequent purifying and impurity removing, and the recycling rate of the valuable metal is increased.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Microarc oxidation treatment method for high strength casting rare earth magnesium alloy

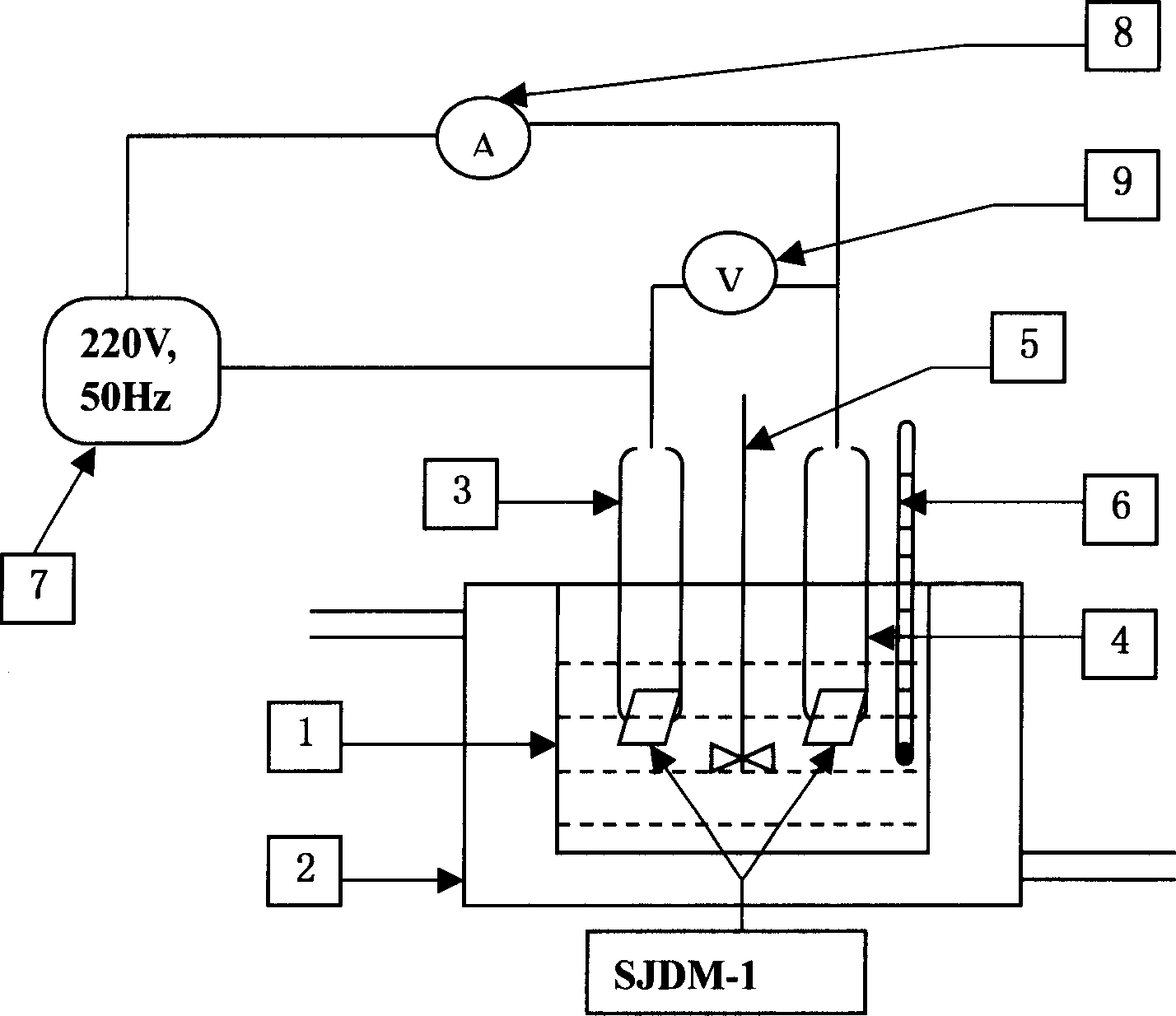

InactiveCN1844484AThe method flow is simpleIncrease productivityAnodisationMicro arc oxidationPlasma electrolytic oxidation

This invention relates to the casting rare earth magnetism alloy micro-arc oxidation dealing method with high intensity. This invention has follows steps: (1) Preparing electrolyte; (2) preprocessing SJDM-1 high -intensity casting rare earth magnetism alloy; (3) micro-arc oxidation; (4) after-processing SJDM-1 high -intensity casting rare earth magnetism alloy. the ceramic film thickness can get to 10-50um,the erosion resistance is well, if the reaction time prolongs for 30-60 min, then the ceramic film thickness can increase to 150, which improves the ceramic surface rigidity up to 500Hv. This invention has broad application value especially in the filed that needs light and good erosion-bearing material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

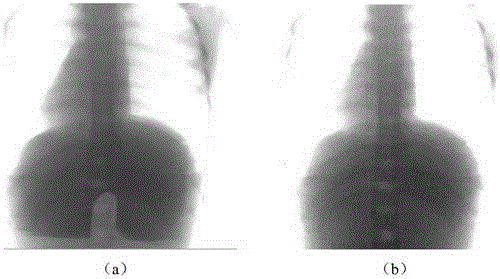

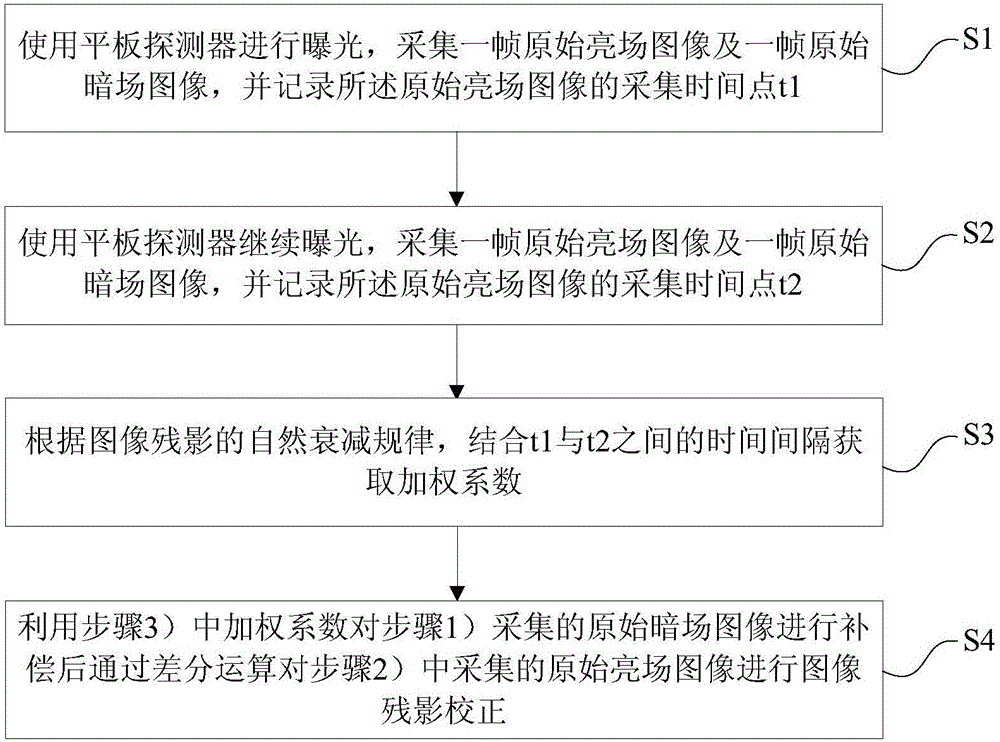

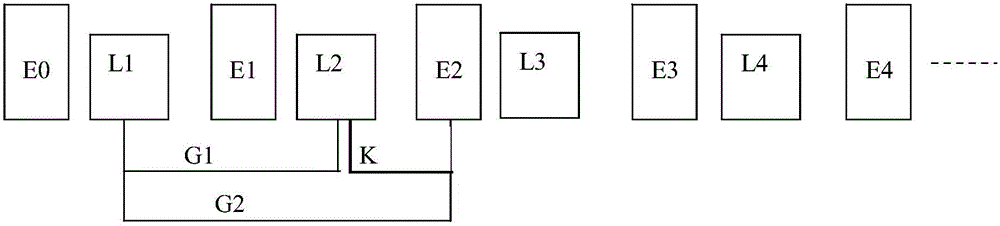

Method for eliminating image persistence of vision of flat panel detector and flat panel detector

ActiveCN106097282AAchieve no visible afterimageEliminate image afterimagesImage enhancementFlat panel detectorUltrasound attenuation

The invention provides a flat panel detector and a method for eliminating image persistence of vision of the flat panel detector. The method comprises that 1) the flat panel detector is used for exposure, a frame of original bright-field image and a frame of original dark-field image are collected, and a collection time point t1 of the original bright-field image is recorded; 2) the flat panel detector is used to continue exposure, another frame of original bright-field image and another frame of original dark-field image are collected, and a collection time point t2 of the original bright-field image is recorded; 3) according to a natural attenuation rule of the image persistence of vision as well as a time interval between t1 and t2, a weighting coefficient is obtained; and 4) the weighting coefficient obtained in the step 3) is used to compensate the original dark-field image collected in the step 1), and then implement persistence of vision correction on the original bright-field image collected in the step 2) by difference operation. The method of the invention is simple in process and simplified in algorithms, is highly practically and is high in the system integrated level.

Owner:SHANGHAI IRAY TECH

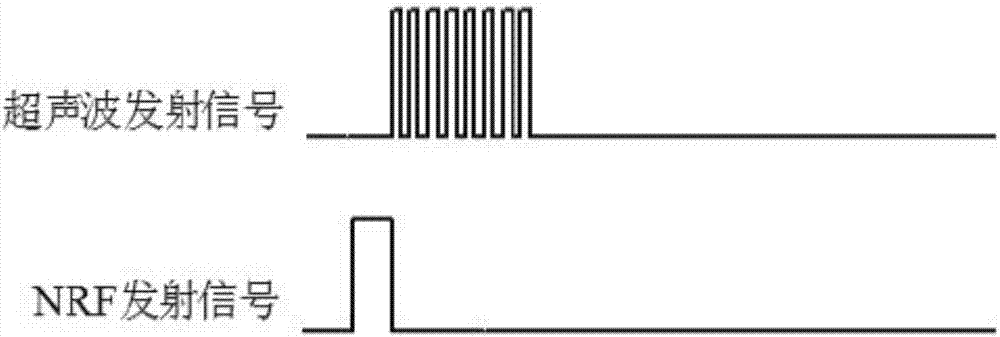

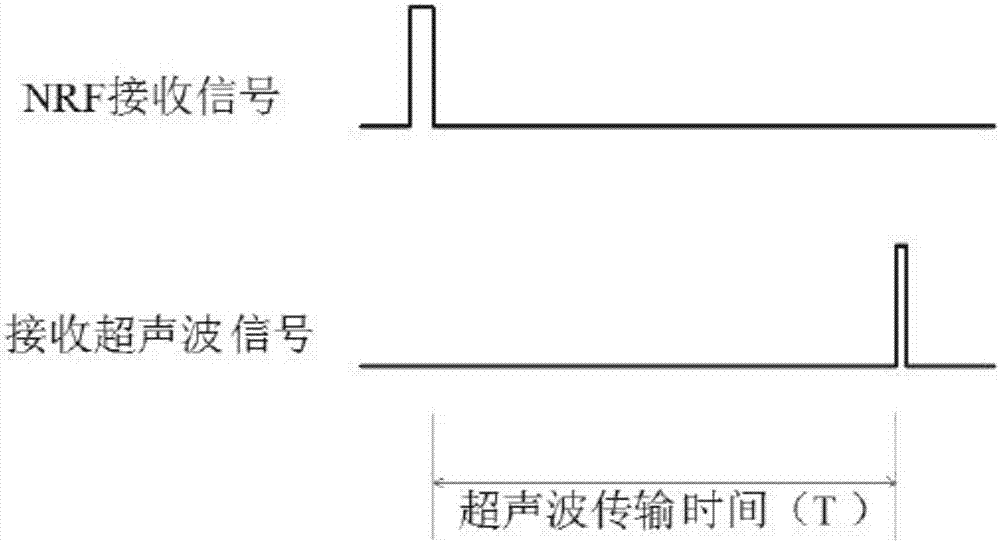

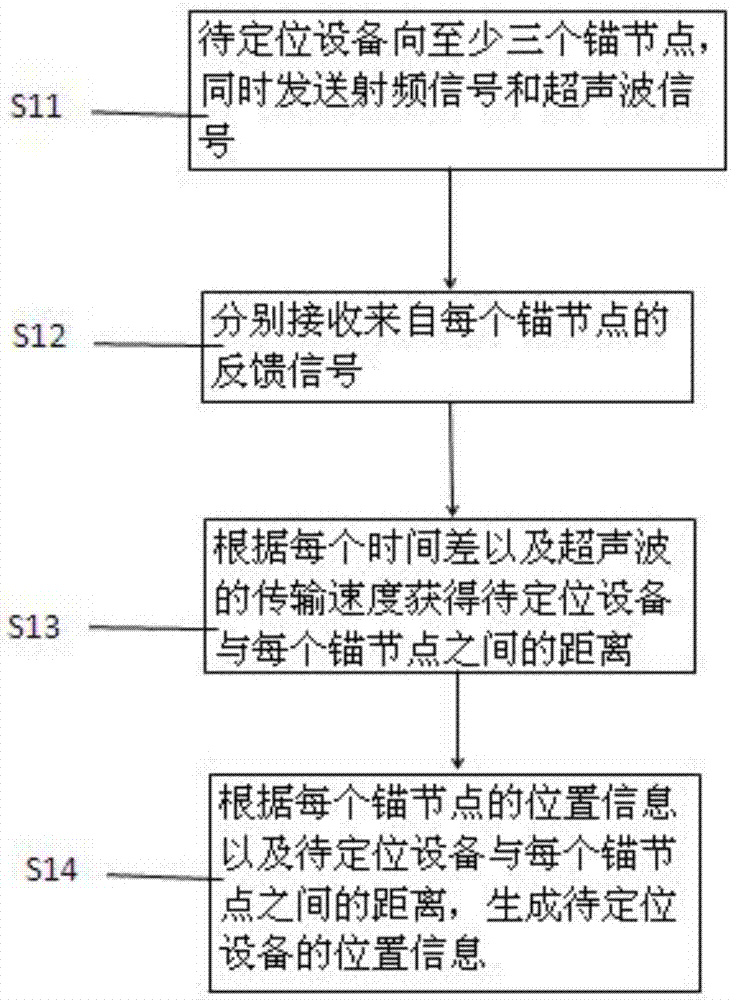

Indoor navigation positioning method, system, to-be-positioned device and anchor nodes

InactiveCN106895838AAvoid defectsEasy to implementNavigational calculation instrumentsPosition fixationRadio frequency signalLocation Equipment

The invention relates to an indoor navigation positioning method, a system, a to-be-positioned device and anchor nodes. The method comprises the following steps: simultaneously sending a radio frequency signal and an ultrasonic signal to the anchor nodes distributed along different directions by the to-be-positioned device, and then calculating distances between the to-be-positioned device and the anchor nodes and generating position information of the to-be-positioned device, according to the time difference of the received radio frequency signal and ultrasonic signal and the ultrasonic transmission rate. Compared with the prior art, the indoor navigation positioning method, the device and the system thereof provided by the invention have the advantages of simple and easy operation, low power consumption, high positioning precision, large navigation area and low cost.

Owner:上海器魂智能科技有限公司

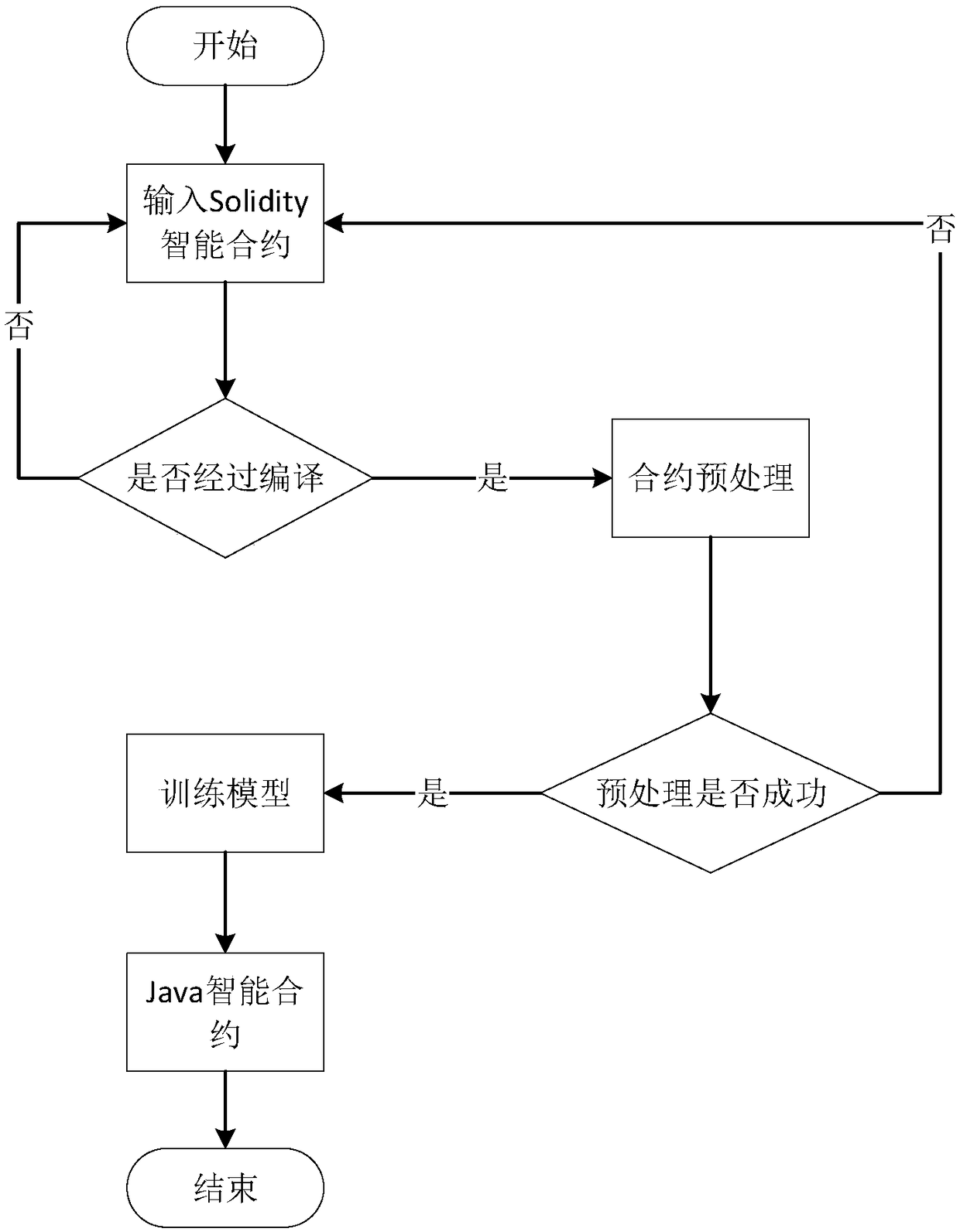

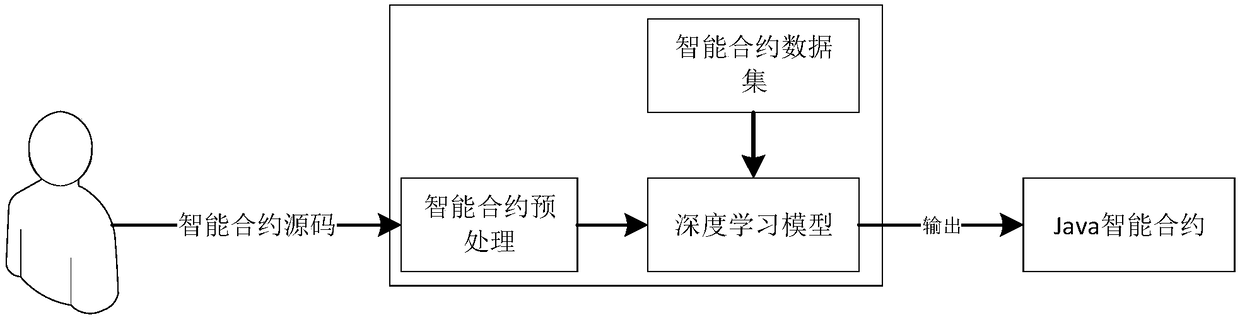

Method for converting ethereum intelligent contracts into hyperledger intelligent contracts

ActiveCN108595185ARapid production landingIncrease productivityNeural learning methodsSource to sourceMathematical modelAlgorithm

The invention discloses a method for converting ethereum intelligent contracts into hyperledger intelligent contracts. The method comprises the following steps of: carrying out training by using a machine learning method so as to obtain a conversion model; inputting a Solidity source code and preprocessing an intelligent contract code, compiled by using Solidity, on an ethereum; and carrying out high-class recognition work such as object recognition, algorithm recognition, module recognition and interface recognition by using a trained mathematic model, and converting an intelligent contract of a Solidity language into an intelligent contract of a Java language on a hyperledger. The method is capable of realizing rapid conversion from ethereum intelligent contracts to hyperledger intelligent contracts, so that the development time and development cost of the developers are saved.

Owner:JINAN UNIVERSITY

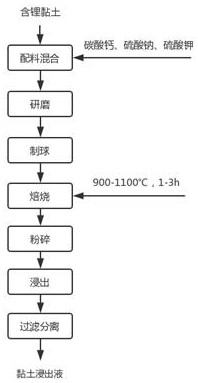

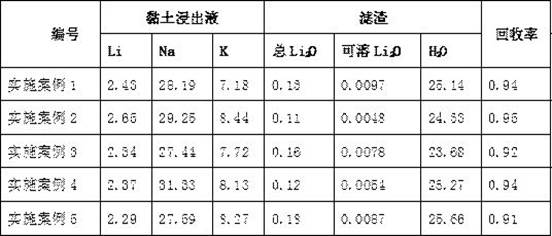

Method for extracting lithium from clay containing lithium

The invention provides a method for extracting lithium from clay containing lithium. The method for extracting the lithium from the clay containing the lithium includes the steps that (1) the clay containing the lithium, calcium carbonate, sodium sulfate, and potassium sulfate are mixed to obtain a paste after adding water; (2) the paste is ground to obtain a ground material; (3) the ground material is made into a plurality of spherical materials; (4) the spherical materials are put into a furnace and roasted to obtain a roasted material; (5) the roasted material is crushed to obtain a crushedmaterial; (6) the crushed material and pure water are mixed and stirred for leaching to obtain a leached solution; (7) the leached solution is filtered to obtain a clay leached solution. The method for extracting the lithium from the clay containing the lithium fires the clay containing the lithium, the calcium carbonate, the sodium sulfate, and the potassium sulfate in a certain proportion, which is simple in technique, low in cost, high in recovery of the lithium, simple in impurity removal and no pollution in later stages.

Owner:GANFENG LITHIUM CO LTD

High-luster scratching-resistant ABS (Acrylonitrile-Butadiene-Styrene) resin and preparation method thereof

The invention belongs to the technical field of polymer materials, and discloses ABS (Acrylonitrile-Butadiene-Styrene) resin and a preparation method thereof. The ABS resin comprises the following components in parts by weight: 80-40 parts of ABS resin, 20-60 parts of polymethacrylate, 1-6 parts of compatilizer, 1-5 parts of scratching-resistant agent, 0.1-1 part of main antioxidant, 0.1-1 part of auxiliary antioxidant, and 0.1-1 part of lubricant. The preparation method of the ABS resin comprises the following steps of: firstly adding the ABS resin, polymethacrylate, compatilizer, scratching-resistant agent, main antioxidant, auxiliary antioxidant, and lubricant to a high-speed stirrer for uniformly mixing, after mixing is finished, conveying the materials to a double-screw extruder by a precision metering conveying device, sufficiently fusing the materials under the shearing, milling and conveying of the screws, finally extruding, drawing and cooling to obtain granules. The high-luster scratching-resistant ABS resin not only retains the original excellent performances of the ABS resin, but also has the outstanding advantages of high luster, environmental friendliness, scratching resistance and the like.

Owner:滁州格美特科技有限公司

Method of preparing vanadium-containing clinker by using TiCl4 refined tailings

ActiveCN103911517AThe method flow is simpleLess investmentProcess efficiency improvementTitanium tetrachlorideWater soluble

The invention provides a method of preparing a vanadium-containing clinker by using TiCl4 refined tailings. The method comprises the steps of carrying out water soaking treatment on the titanium tetrachloride refined tailings, controlling the mass ratio of water and the titanium tetrachloride refined tailings no less than 10:1, and then carrying out solid-liquid separation; uniformly mixing a solid obtained after solid-liquid separation and a sodium-containing additive according to the mass ratio of 100:(17-21), wherein the sodium-containing additive comprises alkali or slat of sodium; and roasting a mixture of the solid and the sodium slat in the air environment at the temperature of 780-900 DEG C, and cooling to obtain the water-soluble vanadium-containing clinker. The method has the advantages that the method and procedure are simpler, subsequent water soaking and vanadium precipitating devices does not need to be established, the investment is little, and the production cost is low; with the adoption of the process, the vanadium yield is high (for example, the vanadium yield can reach above 90 percent), the quality of the prepared vanadium-containing clinker is high, and the application condition is wide; and the titanium tetrachloride refined tailings with the characteristic of high pollution can be effectively utilized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Copperizing solvent and preparation method thereof

ActiveCN101736285AGood formabilityImprove infiltration efficiencySolid state diffusion coatingHydrogenSteel ball

The invention discloses a copperizing solvent and a preparation method thereof, belonging to the technical field of powder metallurgy. The copperizing solvent comprises the following components in percentage by weight: 0.5-10% of one or a plurality of Fe, Zn, Mn, Sn, P and Cr, and 90-99.5% of Cu The preparation method is as follows: weighting raw materials at ratio, adding ceramic balls or stainless steel balls and diffusion accelerating agent; after mixing, sending powder into a hydrogen reduction furnace for diffusion at the diffusion temperature of 300-1000 DEG C for 0.5-25h; cooling, discharging, breaking, screening and collecting; and adding lubricant for blending. The copperizing solvent prepared with the preparation method has the characteristics of favourable forming property, high infiltration efficiency, no erosion and small residue and obviously improves material density and mechanical property. The method has simple flow, required equipment is easy to operate and the coppering solvent can be produced in batch.

Owner:GRIPM ADVANCED MATERIALS CO LTD

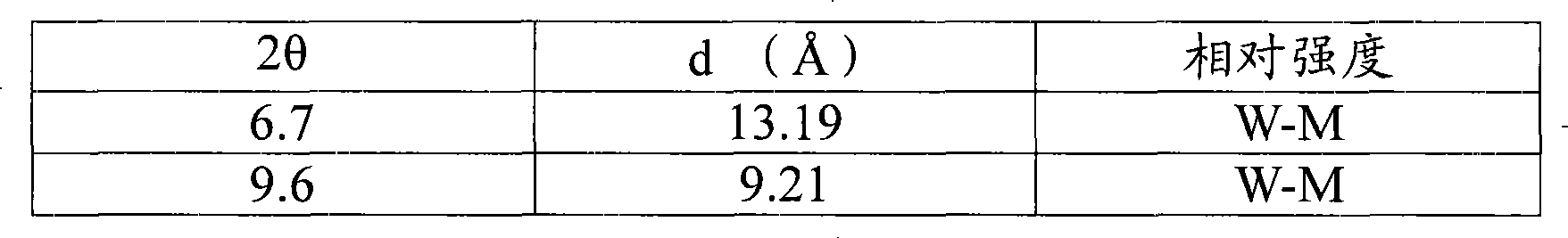

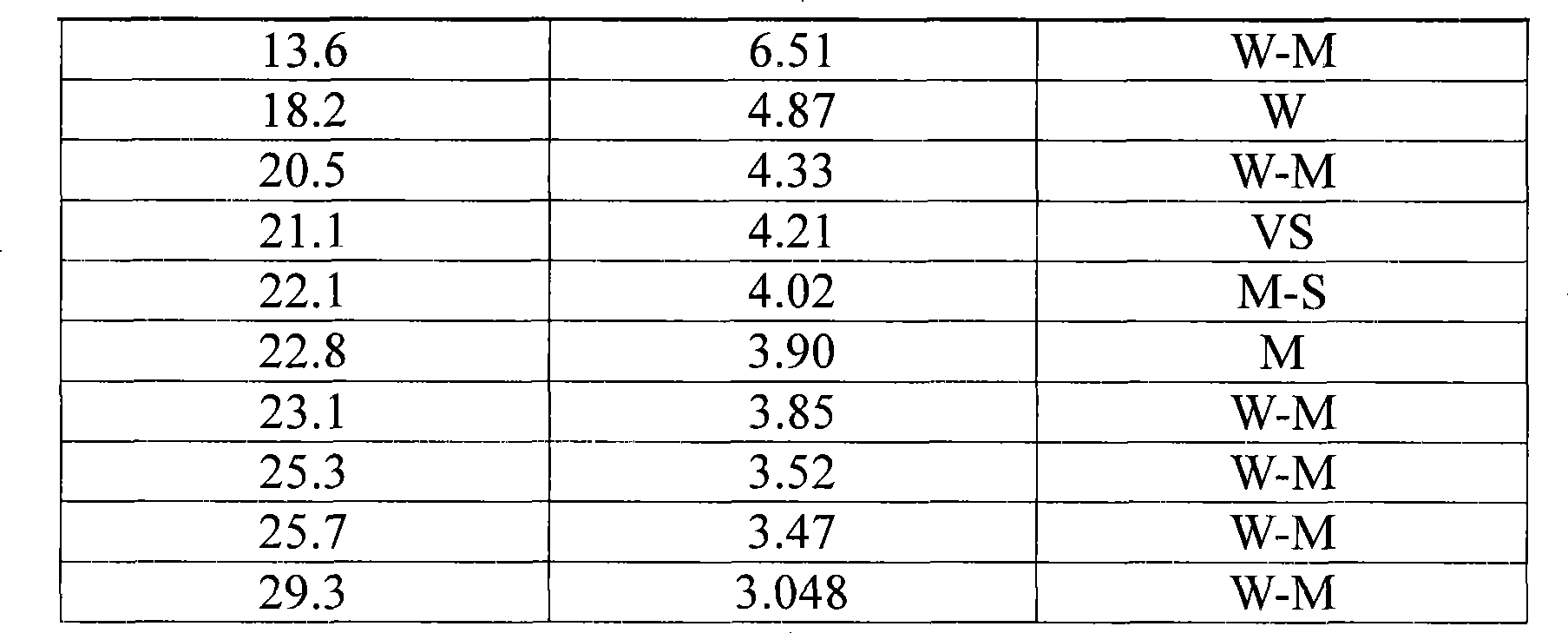

Metal silicon-aluminum phosphate molecular sieve with AFO structure and synthesis method thereof

ActiveCN101367530AReduce dosageThe method flow is simpleMolecular sieve catalystsMolecular-sieve aluminophosphatesSynthesis methodsPhosphate

The invention relates to a metal aluminum-silicon phosphate molecular sieve MeAPSO-41; the water-free chemical formula of the molecular sieve is nMe(SixAlyPz)O2, wherein, n is the mole number of the metal corresponding to the (SixAlyPz)O2 per mole, and x, y and z respectively represent the molar fraction of silicon atom, aluminum atom and phosphorous atom, and n is equal to 0.001 to 0.60, x is equal to 0.001 to 0.60, y is equal to0.001 to 0.70, z is equal to 0.001 to 0.70, and x plus y plus z is equal to 1. The MeAPSO-41 molecular sieve has good water heating stability, and can be used as the ion exchanging agent and the absorption agent, and also can be used for catalyzing the transforming reaction of the hydrocarbon. The molecular sieve is synthesized in the method: aluminum source, silicon source, phosphorous source and the template agent are mixed to gel; AFO structural molecular sieve is adopted as the inoculating crystal; the mixture is heated in the water and crystallized more than one hour at the temperature of 110 to 250 DEG C; during the crystallization process, the mixture is added with metal oxide to produce the reaction compound with the mole compositions of aR2:Al2O3:bP2O5:cSiO2:dMeOx:eH2O, wherein, a is equal to 0.05 to 2.5, b is equal to 0.1 to 2.0, c is equal to 0.01 to 1.5, d is equal to 0.01 to 1.0 and e is equal to 5 to 150; after the crystallization is completed, the product is recycled. The method has simple flow procedures, consumes less template and has low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com