Device and process for machining differential housing

A differential and casing technology is applied in the field of processing devices for differential casings, which can solve the problems of low automation and processing efficiency, difficult to meet industrial needs, long processing cycle, etc., and achieves reasonable clamping and positioning design. The effect of low processing cost and high turning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

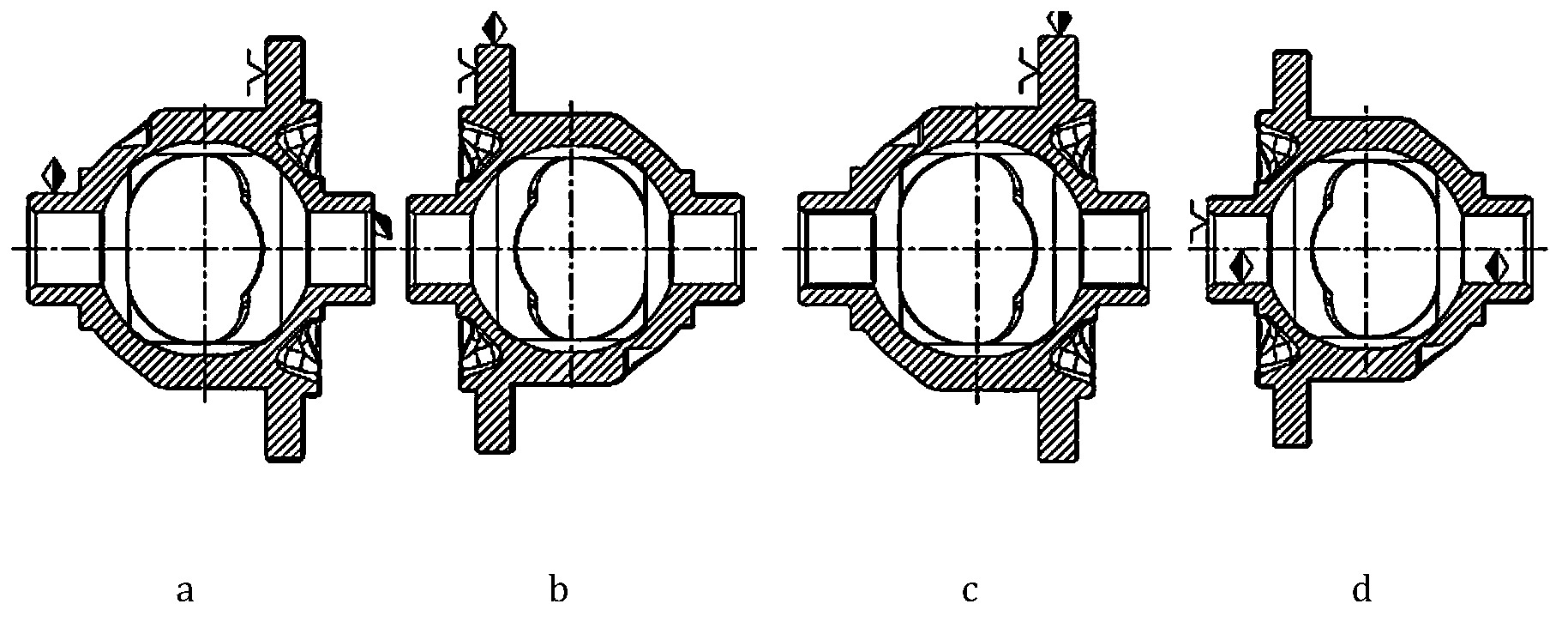

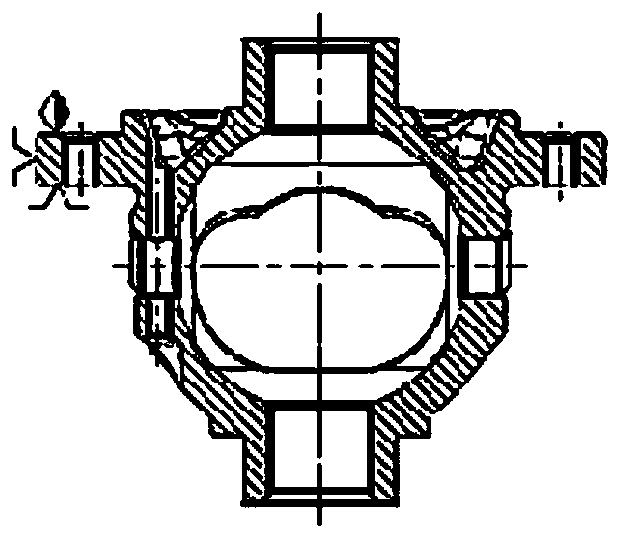

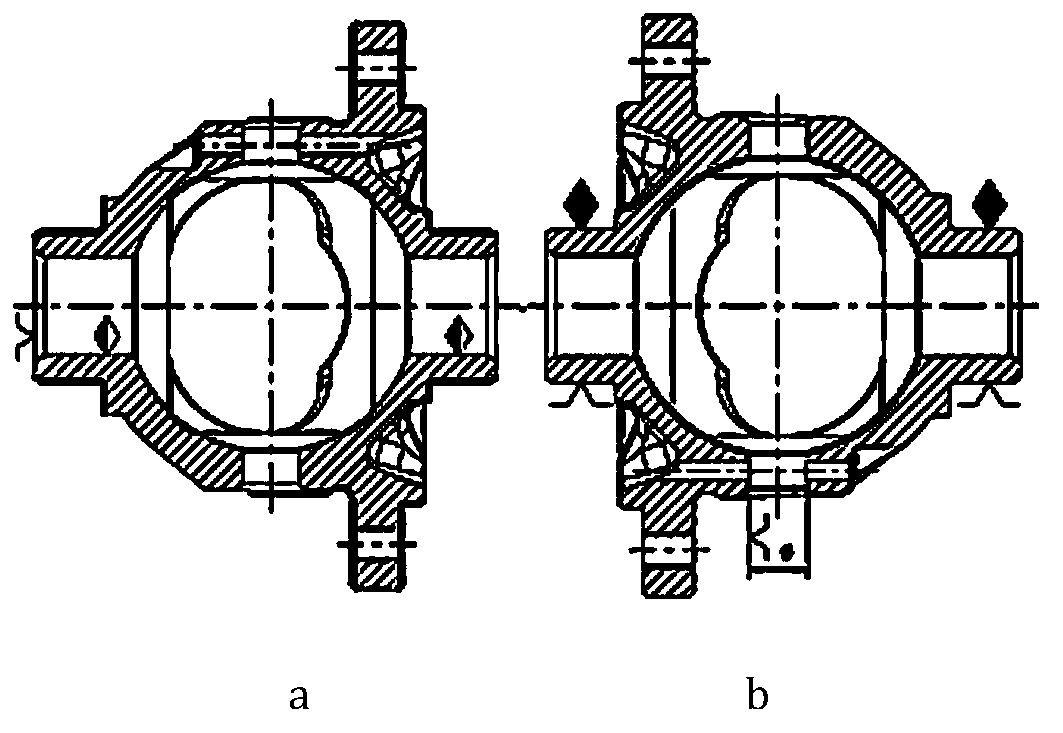

[0037] Such as Figure 4 , Figure 5 with Image 6 As shown, the processing device for the differential case of this embodiment is composed of a rotary fixture set on the machining center 2, an inner turning fixture set on an ordinary numerical control lathe, and a turning spherical fixture set on an ordinary numerical control lathe ,in:

[0038]The rotary fixture includes: two ends of the operating part 3 arranged on the machining center 2 through the rotating assembly 1, wherein:

[0039] The operating part 3 includes: a number of hydraulic angle cylinders 5, 6 fixedly arranged on the front and back sides of the fixture seat 4, an operating table 7, and a positioning wrench 8 rotatably arranged on the fixture seat 4, wherein: located on the fixture seat 4 Each console 7 on the front side is evenly distributed with three oil hydraulic corner cylinders 5 for positioning, and the opposite side of the fixture seat 4 corresponding to each console 7 is provided with a hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com