Hydraulic vertical hinge shaft dismantling device

A hinged shaft, hydraulic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of shortening disassembly steps, convenient operation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

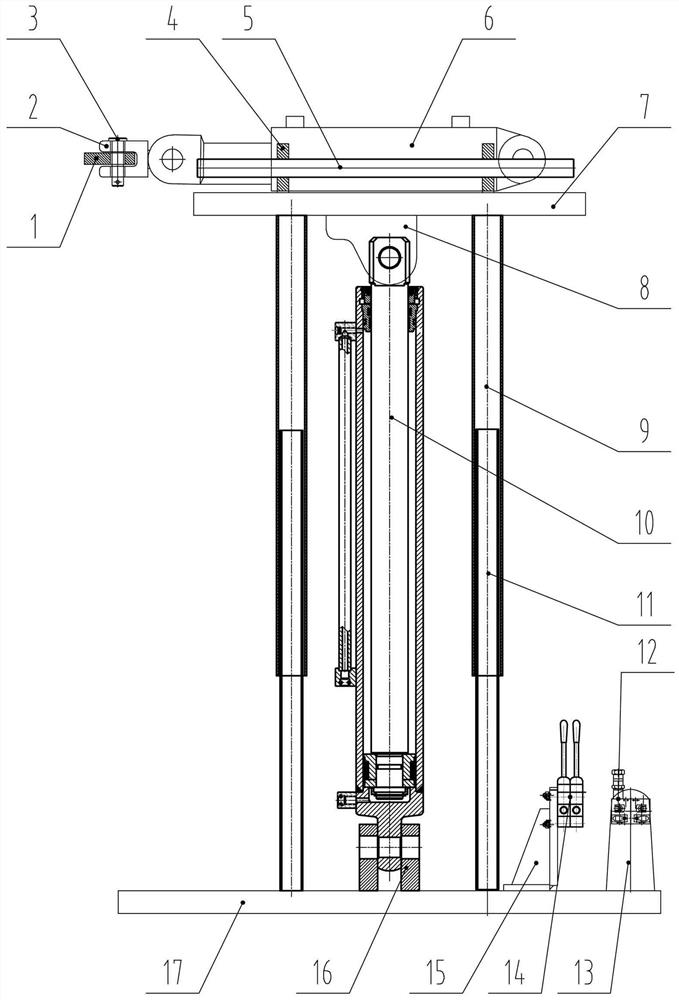

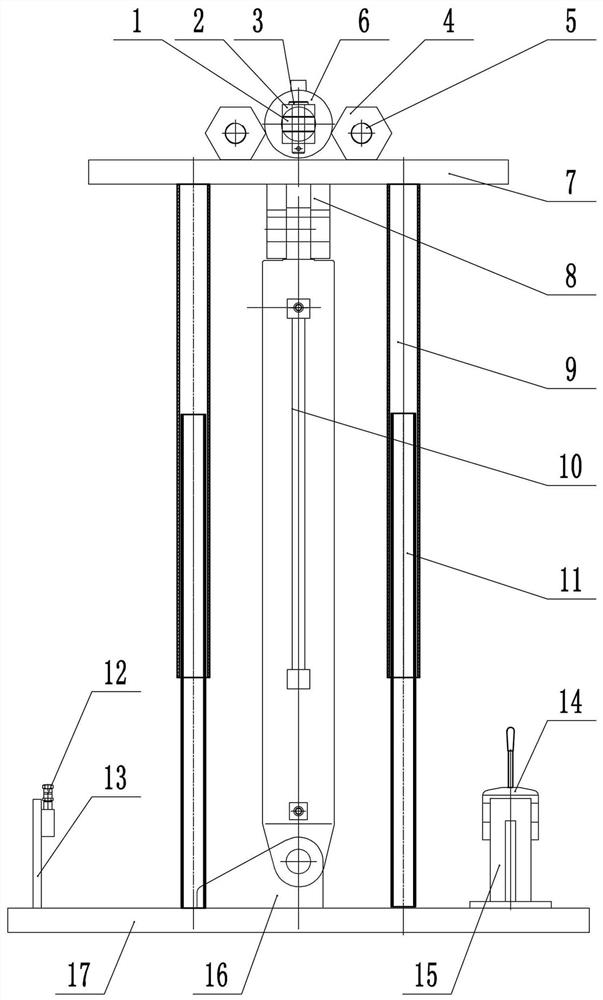

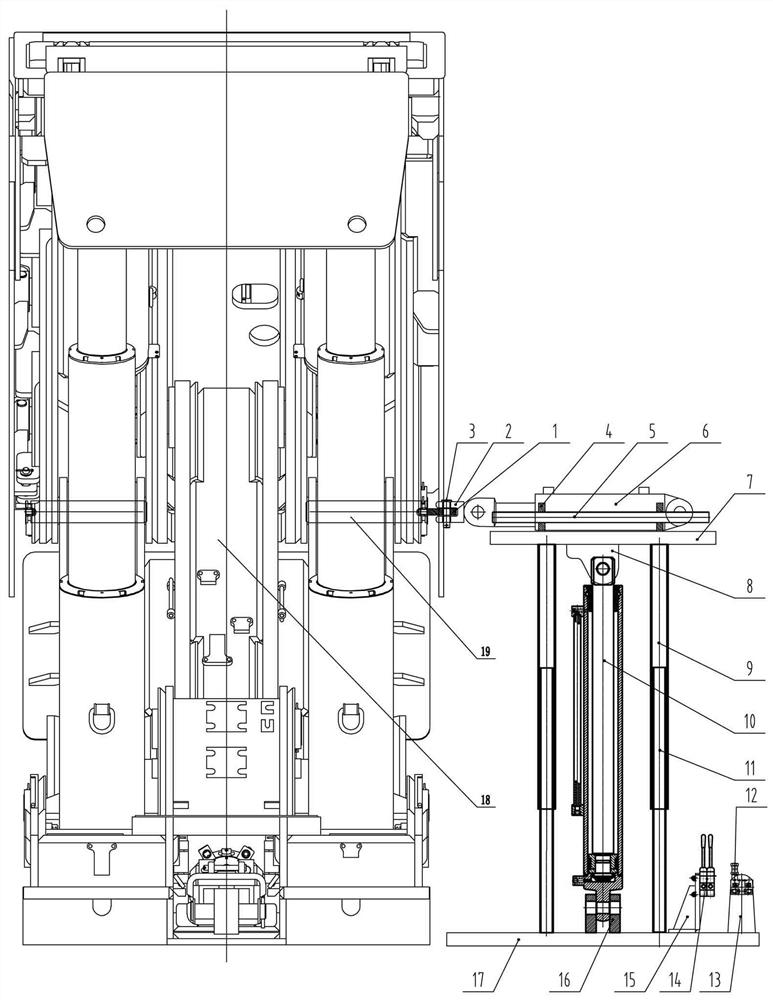

[0009] The invention is attached figure 1 , 2 As shown, it includes a coupling block 1, a series connection block 2, a pin shaft 3, four hexagonal rectangular nuts 4, two adjustable top support screw screws 5, a push-pull jack 6, an upper platform 7, an upper ear seat 8, four Group sliding connection device, telescopic jack 10, two-way lock 12, valve seat plate 13, control valve group 14, control valve frame 15, lower ear seat 16, lower platform 17, the sliding connection device consists of upper casing 9 and lower casing 11 Composition; the overall weight of the device is about 215Kg, the static height is about 1050mm, and it can reach 1900mm after being raised, which is suitable for dismantling of multi-position hinged shafts; the upper platform is a square plate of 520mm×520mm, and the lower platform is a square plate of 750mm×750mm. To ensure the stability of the device; the push-pull jack 6 on the upper platform 7 chooses a large bore specification model (φ140 / 105-542), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com