Patents

Literature

802results about How to "Avoid investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

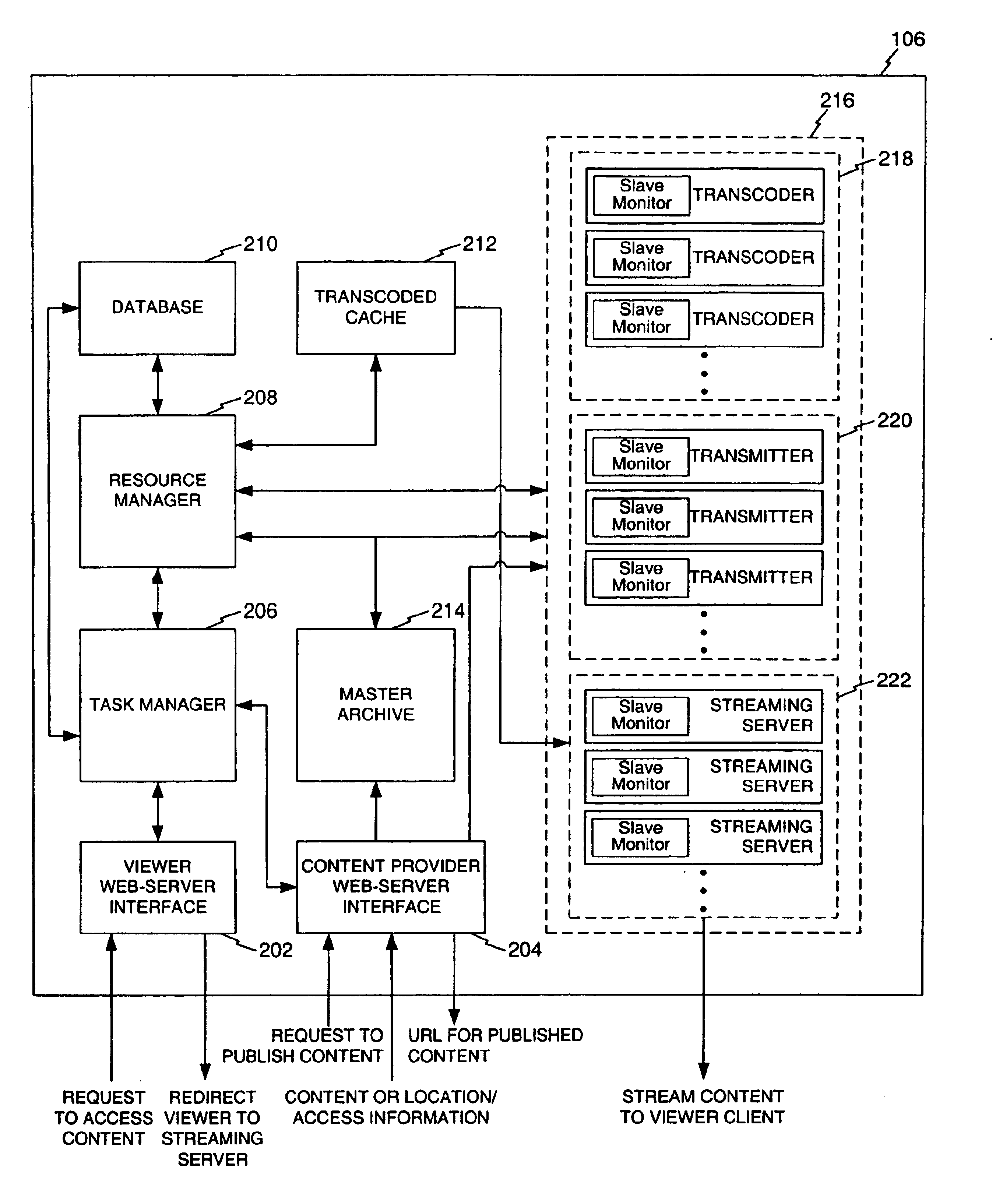

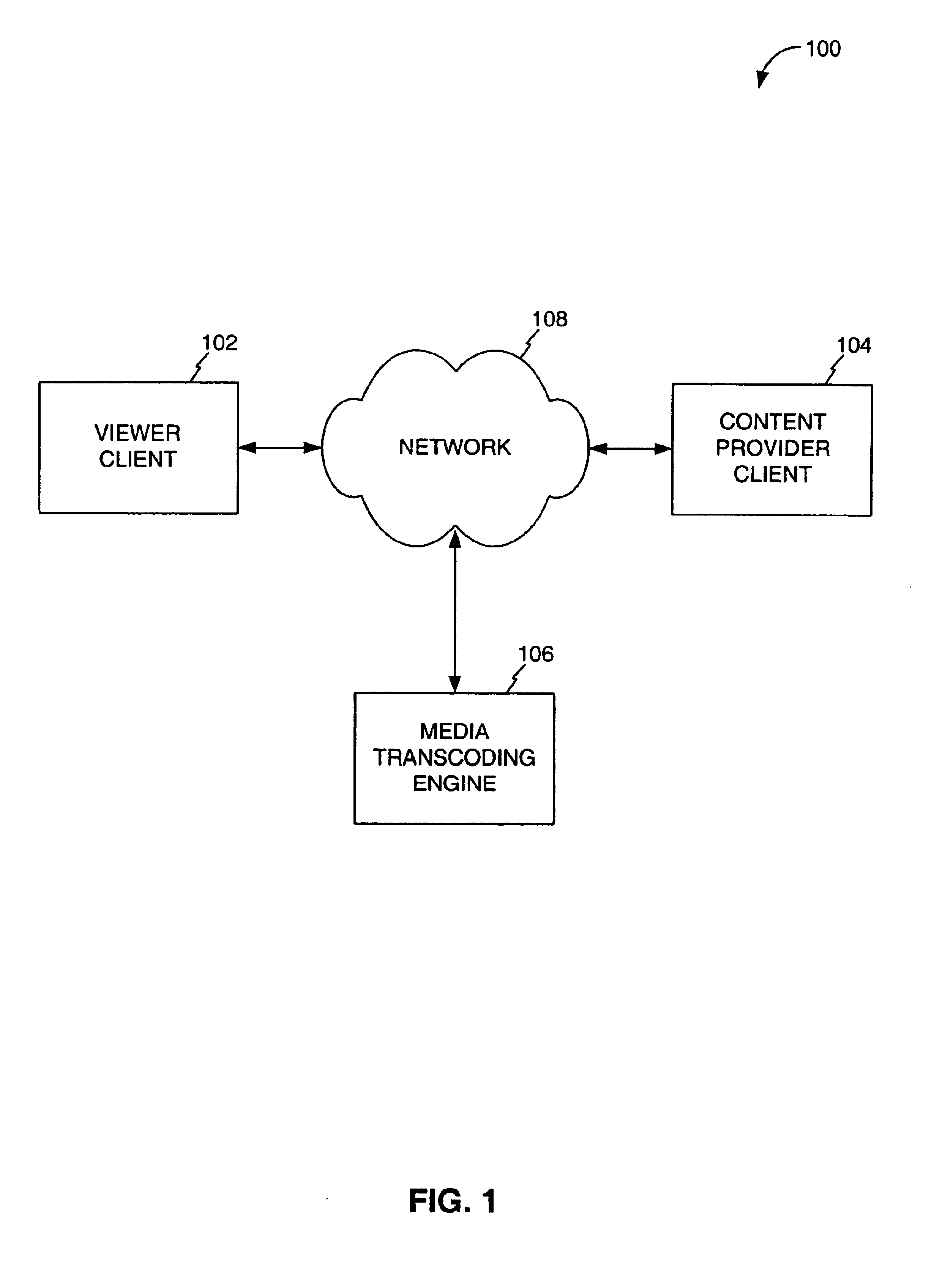

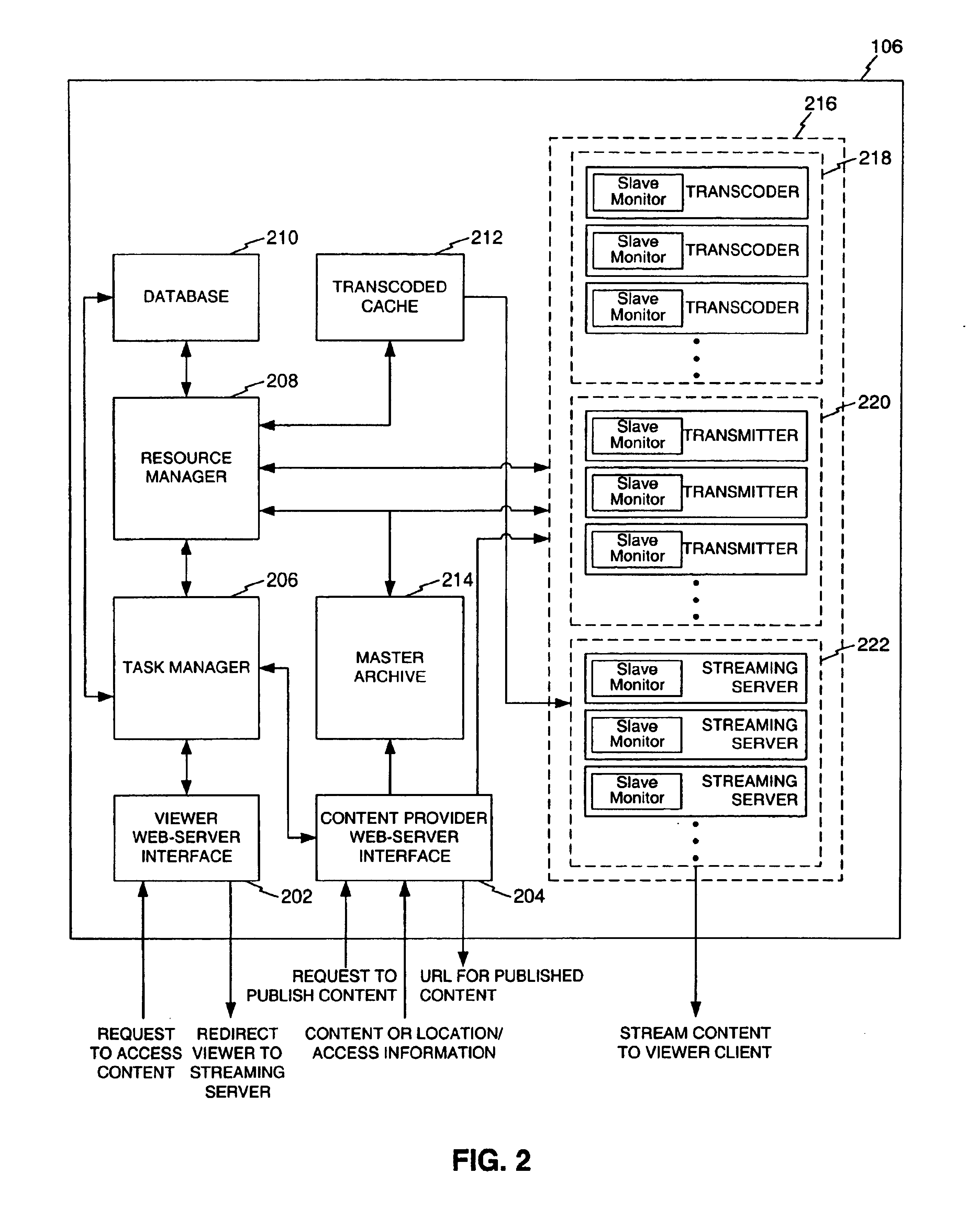

Distributed on-demand media transcoding system and method

InactiveUS6888477B2Eliminate needExpedites publishing processTransmission control/equalisingIndividual digits conversionDigital dataSource type

A system and method for the on-demand transcoding of media content from a source type to a destination type is provided, wherein the system includes a plurality of transcoders for transcoding from a plurality of source types to a plurality of destination types, and wherein the system receives a transcoding request for media content, fetches the media content in response to the transcoding request, sends the media content to one of the plurality of transcoders based on the source type and destination type, transcodes the media content from the source type to the destination type, thereby generating transcoded media content, and transmits the transcoded media content. The system fetches, sends, and transcodes the media content and transmits the transcoded media content in a pipelined fashion. The system also provides for the publication of media content as a file or stream of digital data, for the archiving of media content, and the caching of transcoded media content to improve system efficiency.

Owner:SONY CORP

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

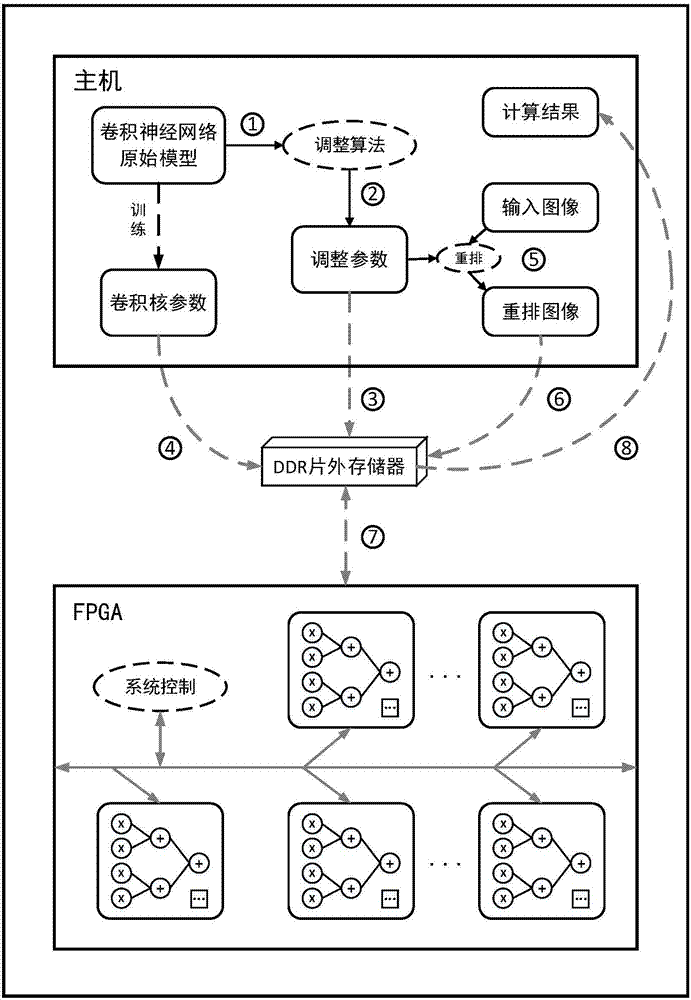

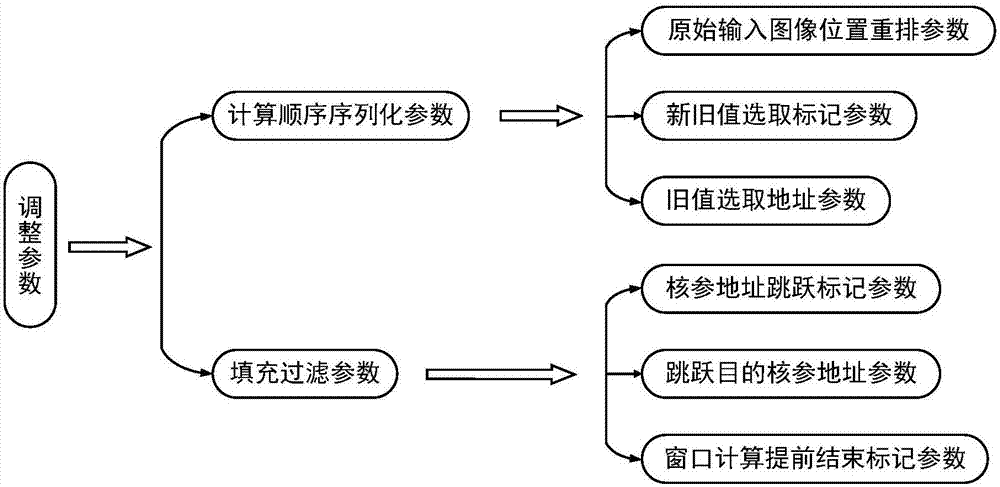

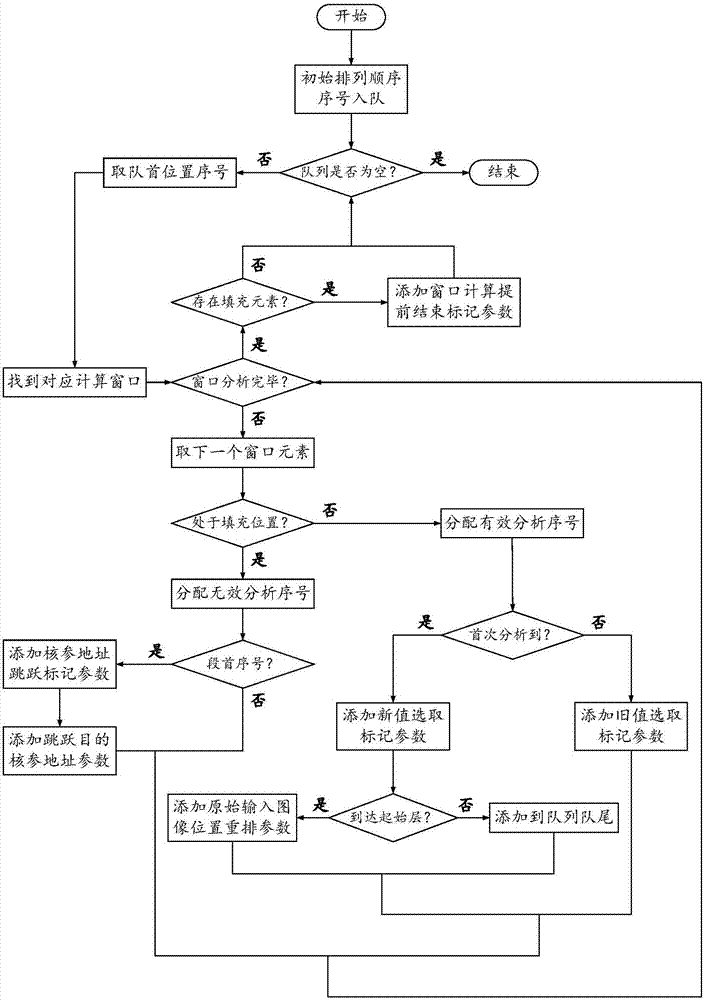

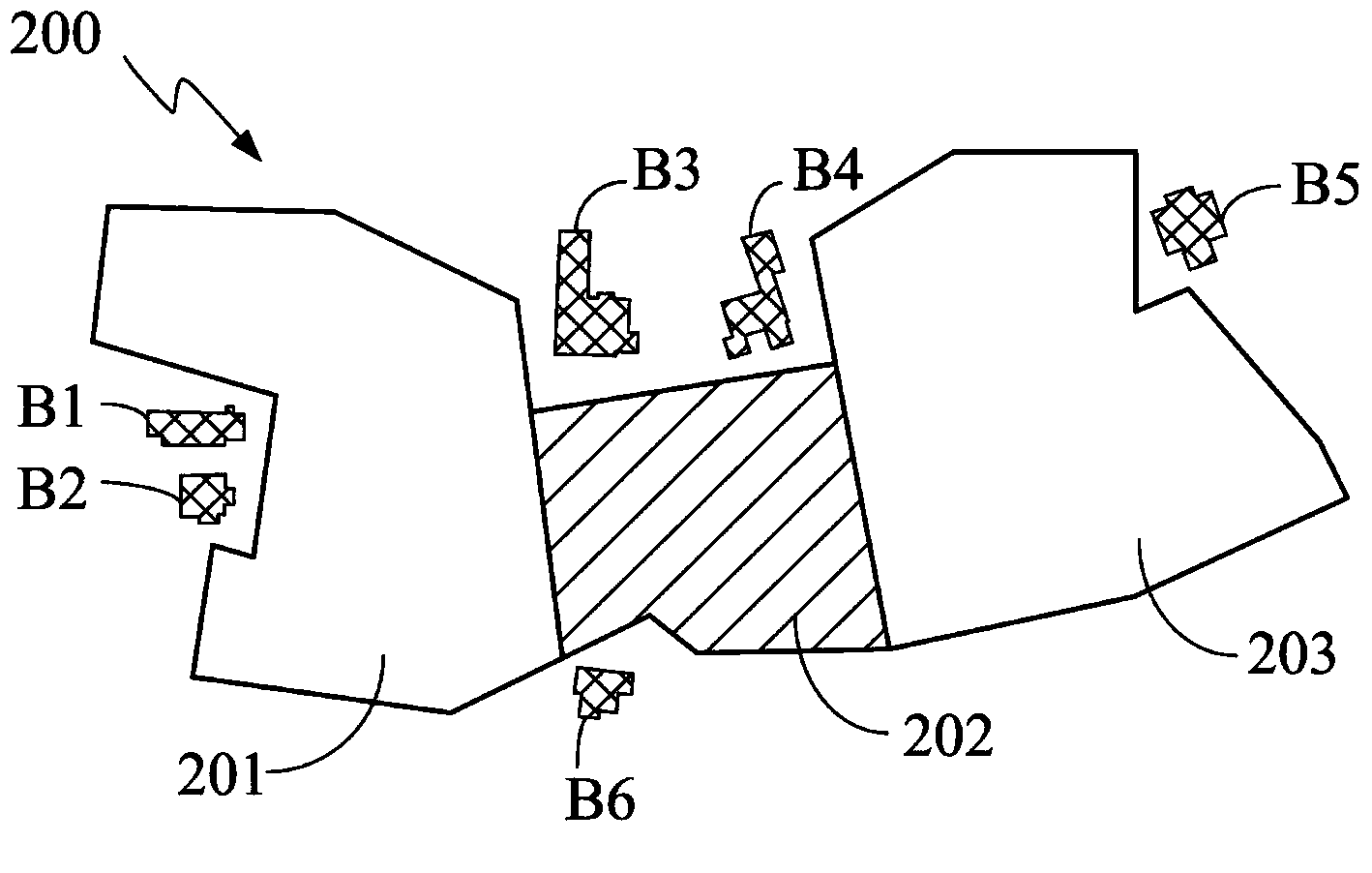

Streamlined acceleration system of FPGA-based depth convolution neural network

ActiveCN106875012AProcessing speedHighly integratedPhysical realisationNeural learning methodsComputer science

The invention brings forward a streamlined acceleration system of an FPGA-based depth convolution neural network. The streamlined acceleration system is mainly formed by an input data distribution control module, an output data distribution control module, a convolution calculating sequence serialization realizing module, a convolution calculating module, a pooling calculating sequence serialization realizing module, a pooling calculating module, and a convolution calculating result distribution control module. Moreover, the streamlined acceleration system comprises an internal system cascade interface. Through the streamlined acceleration system designed by the invention, highly efficient parallel streamlined realization can be conducted on an FPGA, problems of resource waste and effective calculation delays caused by filling operations during calculation are effectively solved, the power consumption of the system is effectively reduced, and the operation processing speed is greatly increased.

Owner:武汉魅瞳科技有限公司

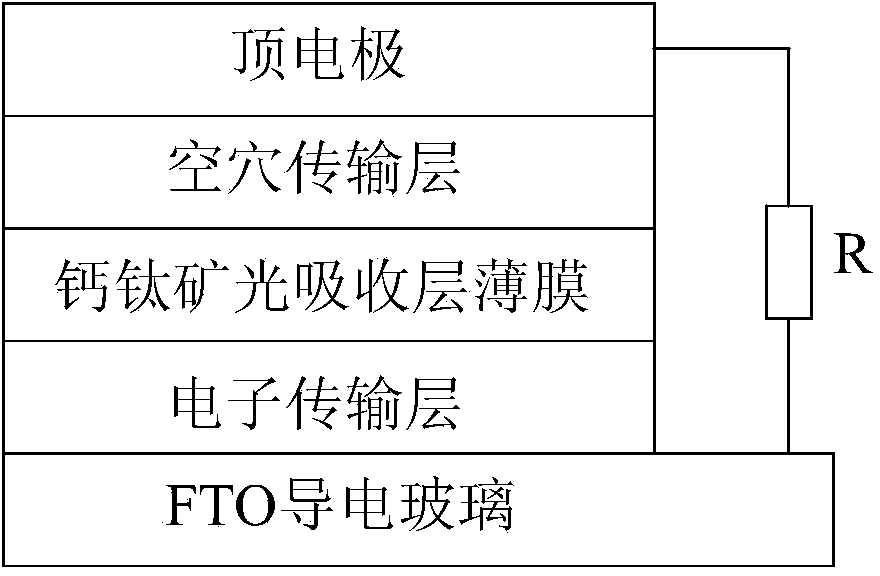

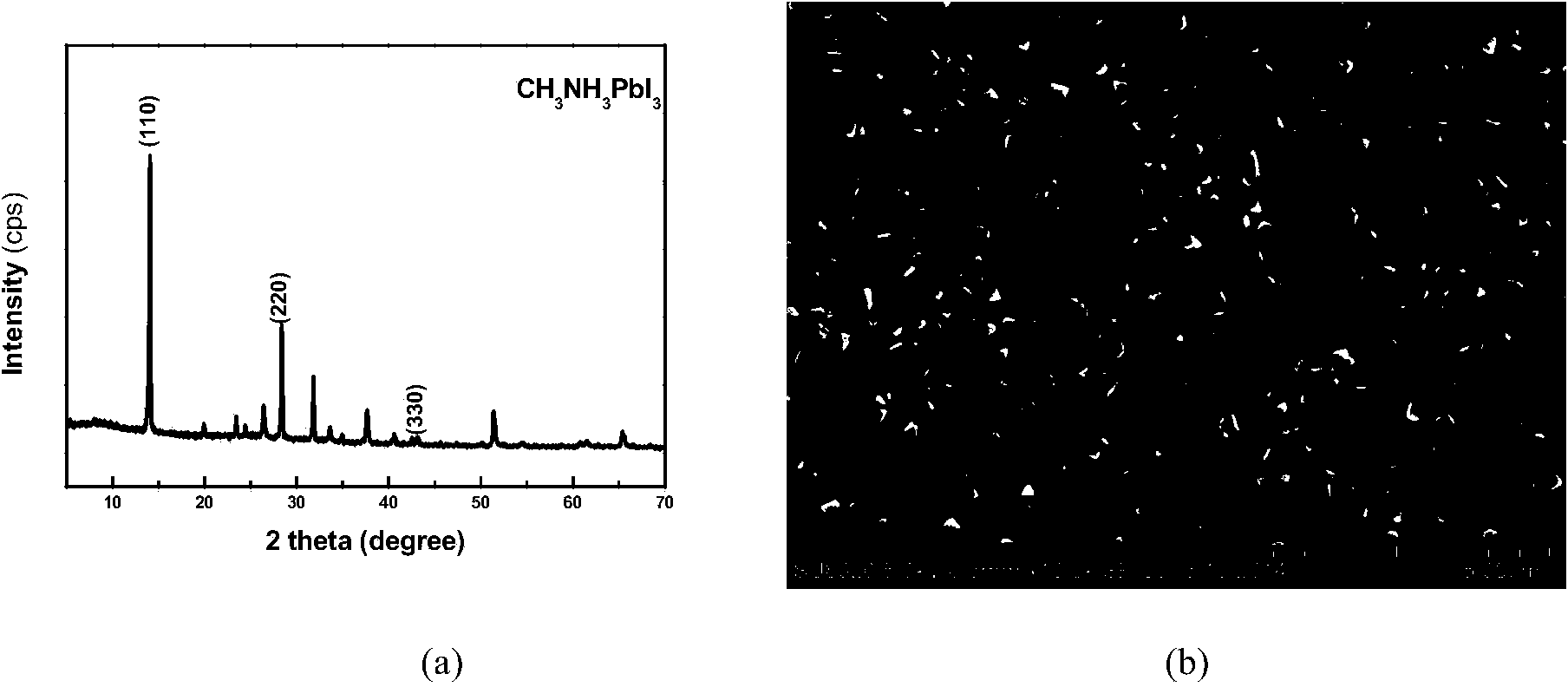

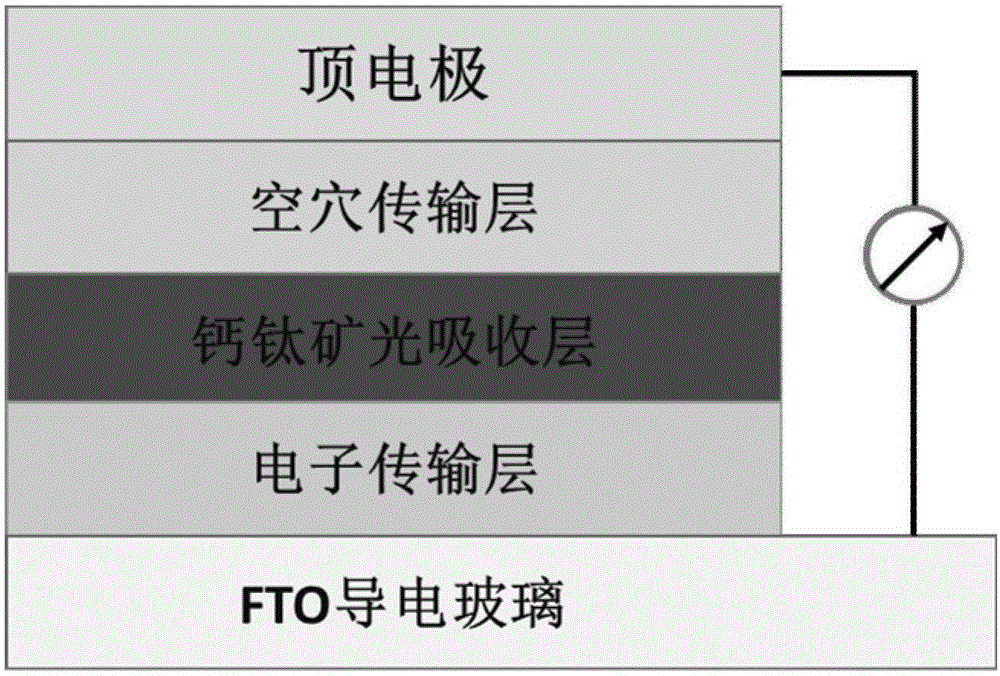

Chemical vapor deposition preparation method for perovskite solar cell

ActiveCN104393109AEasy to operateImprove film qualityFinal product manufactureChemical vapor deposition coatingHeterojunctionPerovskite solar cell

The invention discloses a chemical vapor deposition preparation method for a perovskite solar cell. The preparation method is characterized in that a compact layer TiO2 thin film is deposited on a surface on which the FTO thin film of FTO conductive glass is positioned so as to act as an electron transmission layer; a perovskite light absorption layer thin film is prepared on the electron transmission layer via a chemical vapor deposition method; a hole transmission layer is prepared on the perovskite light absorption layer thin film; and an Ag electrode or an Au electrode is vapor-deposited on the hole transmission layer to act as a top electrode so that the perovskite solar cell is obtained. The preparation method is simple and low in cost. The prepared perovskite light absorption layer thin film is high in quality, excellent in substrate coverage and great in stability and repeatability. Preliminary conversion efficiency of the prepared planar heterojunction perovskite solar cell can be 11%.

Owner:HEFEI UNIV OF TECH

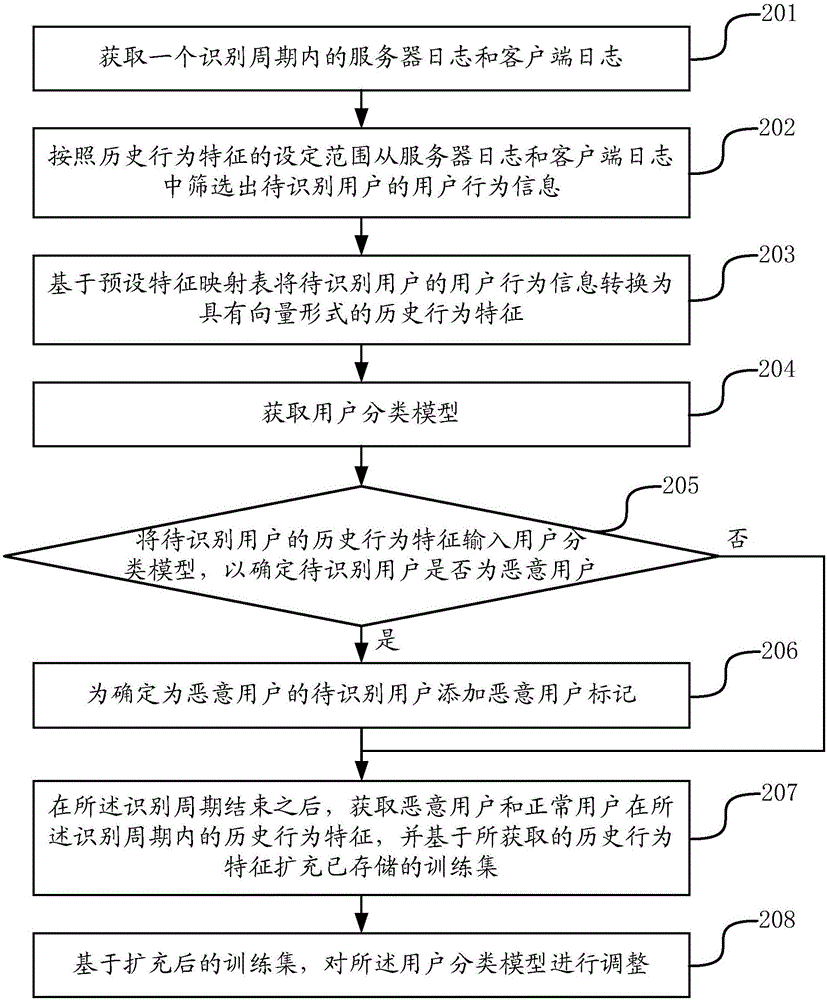

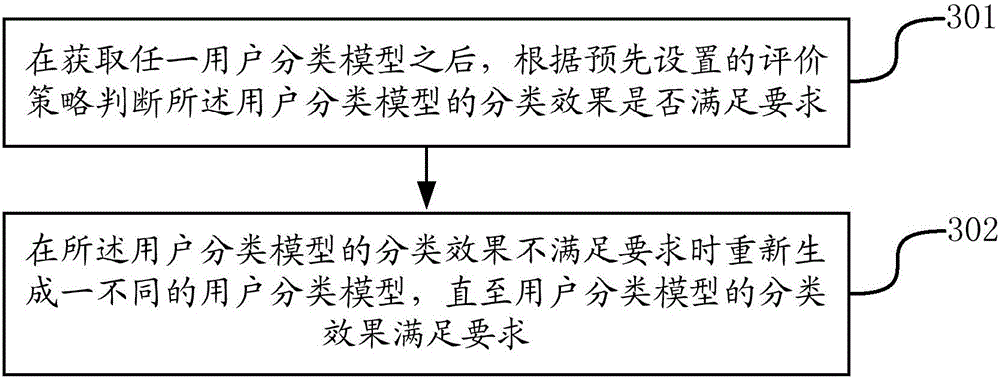

Method and device for recognizing malicious users

PendingCN106777024AImprove accuracyWide coverageWeb data indexingMachine learningPattern recognitionCognition.knowledge

The invention provides a method and device for recognizing malicious users, and belongs to the field of network technology. The method includes the steps that historical behavior characteristics of a user to be recognized are acquired; a user classification model is acquired, wherein the user classification model is generated through classifier model training based on historical behavior characteristics of malicious users and historical behavior characteristics of normal users; the historical behavior characteristics of the user to be recognized are input into the user classification model to determine whether the user to be recognized is a malicious user or not. Through the user classification model obtained through classifier model training, the behavior characteristics of malicious users can be automatically analyzed according to the characteristics of a machine learning algorithm; compared with the prior art, the method and device have the advantages that the recognition process is independent of the subjective cognition of the human, and the coverage scope of behavior characteristics is wider, so that misjudgment and missed judgment are effectively reduced, and the accuracy of recognizing malicious users is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

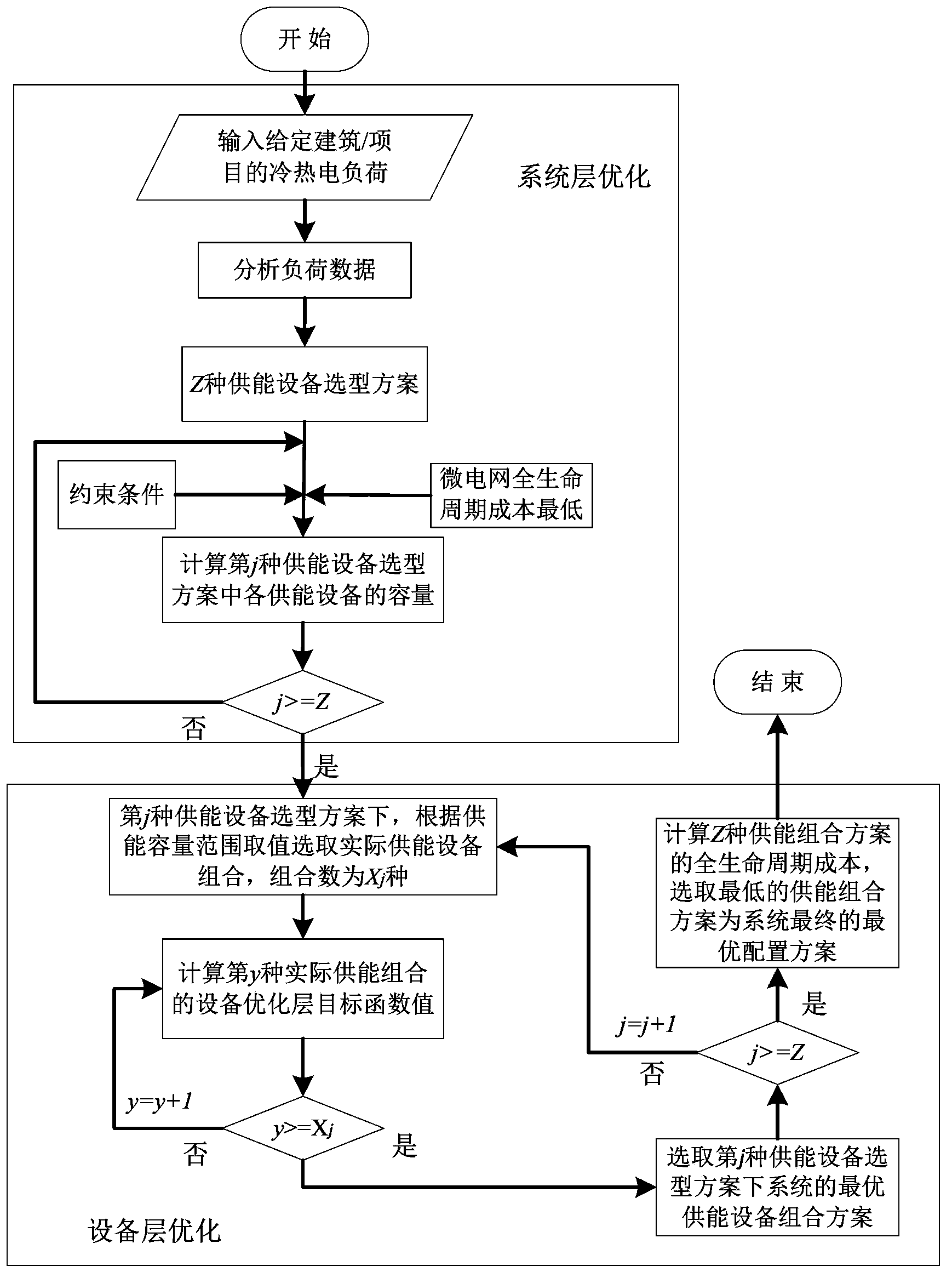

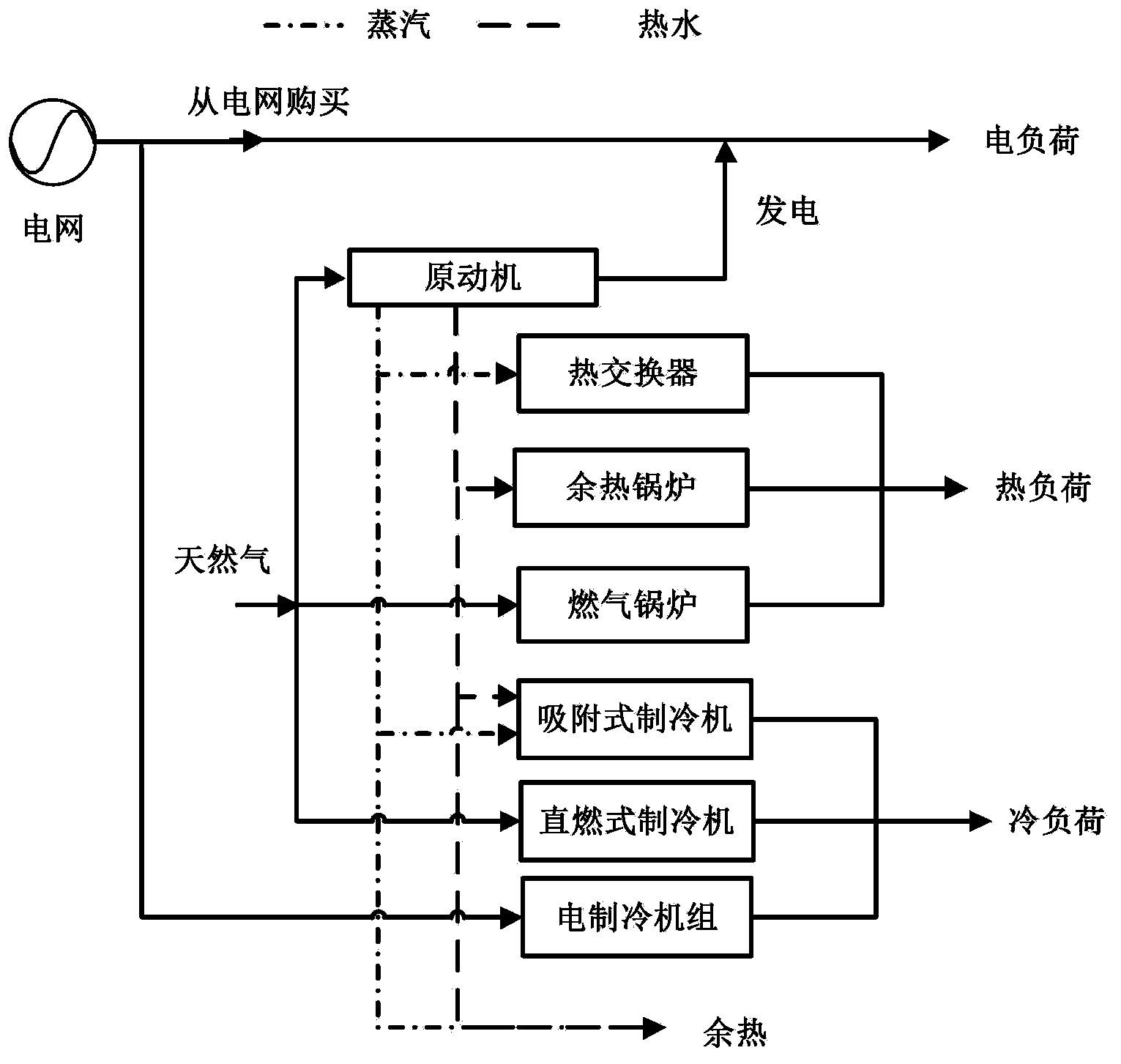

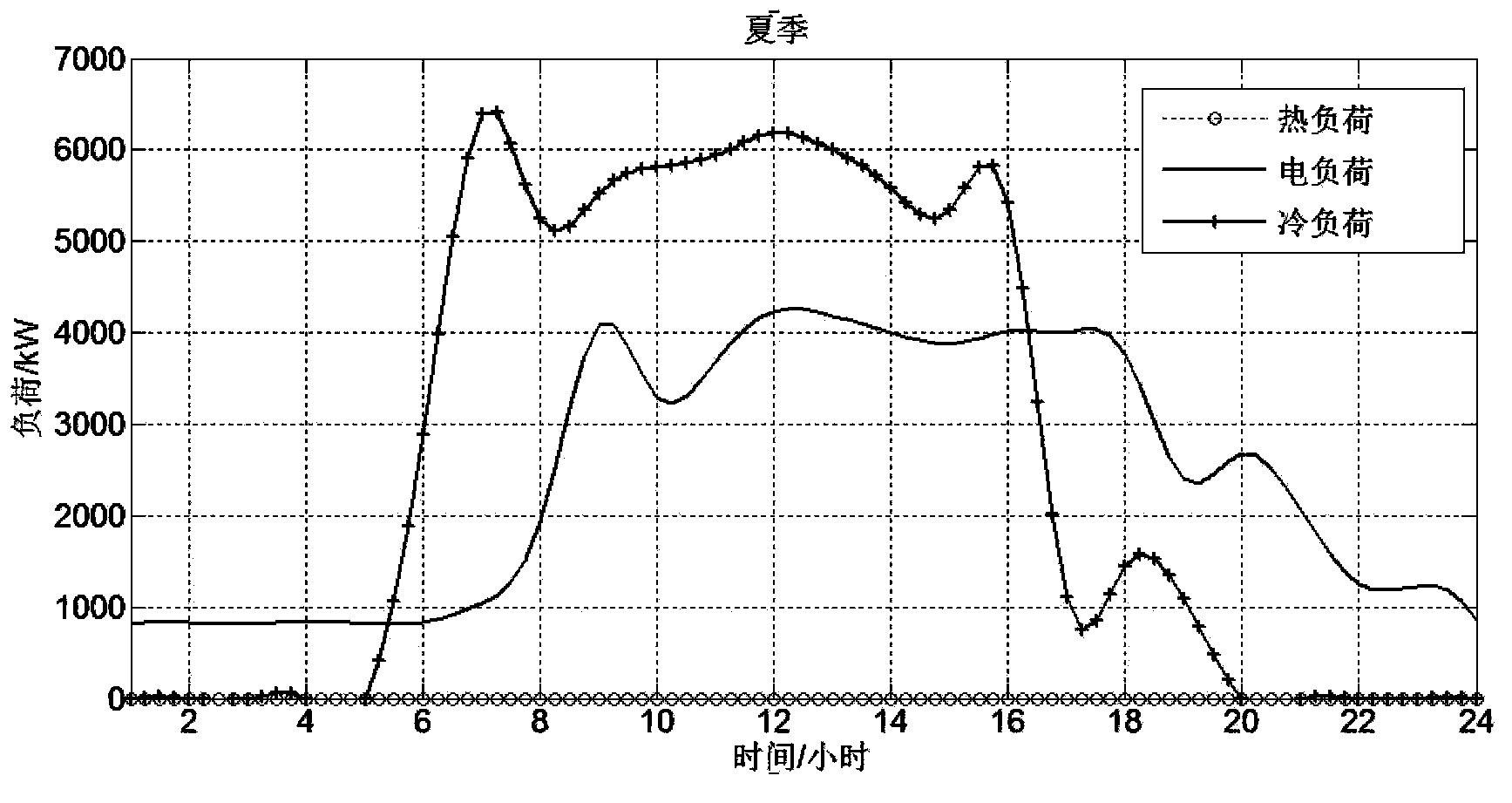

Cool-heat-electricity cogeneration type microgrid optimal configuration method

InactiveCN103400042AImprove utilization efficiencyImprove economyEnergy industrySpecial data processing applicationsElectricity priceMicrogrid

The invention discloses a cool-heat-electricity cogeneration type microgrid optimal configuration method. The method includes the steps of system level optimization and equipment level optimization. Safe and stable operation of electricity, heat and cool generation systems of a system is used as the constraint condition of system level optimization, load data, electrovalence policies and fuel cost in a microgrid region to be planned are used as input, energy supply equipment categories are selected on the basis of load data analysis, the lowest full life circle cost of a microgrid is used as an objective function, the objective function is solved by the adoption of a mixed integer programming approach, and then equipment capacity in the microgrid is acquired. Equipment level optimization is based on a cool-heat-electricity cogeneration equipment scheme library, the capacity value ranges of equipment are set on the basis of the result of system level optimization, solution is calculated in a weighted mode, and then the optimal configuration scheme of the system is obtained. According to the method, capacity of the generation systems can be balanced, utilization efficiency of primary energy and the utilization rate of the equipment are improved, unnecessary investment is avoided, meanwhile, overall economy of the system is improved, and annual operation cost is reduced.

Owner:SOUTHEAST UNIV

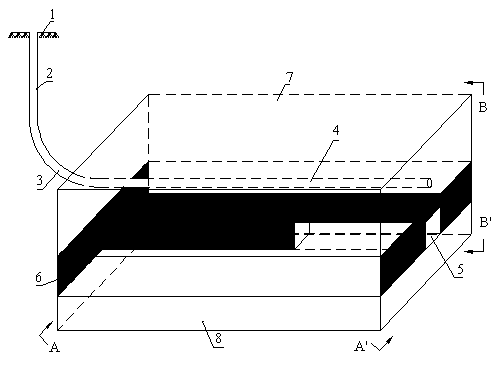

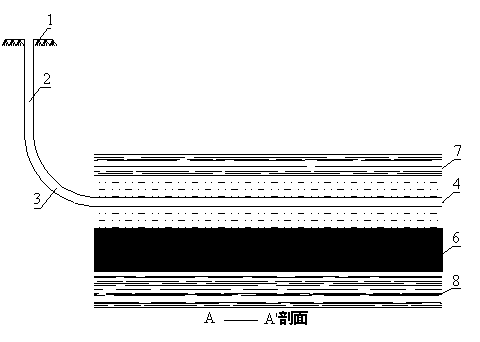

Solution preparing method for CsPbI3 film and application of photovoltaic device thereof

ActiveCN106159087AAvoid investmentQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingElectrical batteryThin membrane

The invention discloses a solution preparing method for a CsPbI3 film and application of a photovoltaic device thereof. The solution preparing method for the CsPbI3 film includes the steps that a CsPbI3 pecursor solution is prepared through an ageing method, a CsPbI3 pecursor film is prepared through spin coating and drying, and finally the CsPbI3 film is prepared through a solvent annealing method. Inert atmosphere protection is not needed, an inorganic perovskite battery is high in stability under the atmosphere condition, and the photoelectric efficiency in the earlier stage reaches 3.19% already. The preparing method is simple in process, low in cost and easy to industrially enlarge and is expected to promote development and application of the inorganic perovskite battery.

Owner:HEFEI UNIV OF TECH

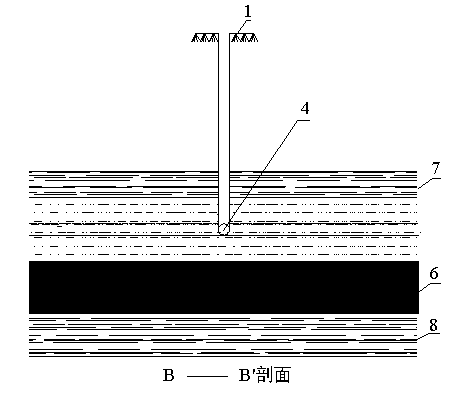

Method for pre-pumping coal roadway stripe gas of single soft protruded coal seam of unexploited area

InactiveCN102852546AAvoid investmentIncrease the lead timeFluid removalDrainageMining engineeringHorizontal wells

The invention provides a method for pre-pumping coal roadway stripe gas of a single soft protruded coal seam of an unexploited area and relates to the technical field of gas pumping. Through the method, outburst removal of the area with a single soft hypotonic protruded coal seam coal roadway stripe can be achieved. The method for pre-pumping the coal roadway stripe gas of the single soft protruded coal seam of the unexploited area comprises building a concordant layer horizontal well which is 3-6m away from the coal seam from the ground to a top plate and a base plate of the single soft protruded coal seam of the unexploited area, performing segmented fracturing after oriented perforating, enabling top plate and base plate rock terrane where coal seam gas is sealed and stored originally to be transformed into a pumping liberation layer with developed fracture networks, enabling the pumping liberation layer to be communicated with the coal seam in a large-area mode through the fracture networks, performing decompression and aerogenesis by dewatering, determining whether to perform negative pressure pumping according to water production conditions, enabling the coal seam gas to be desorbed and diffused continuously, and pumping the gas massively by pumping a horizontal well opening in the liberation layer. By pumping the gas massively, the outburst prevention index in the coal roadway stripe can be reduced to below the safety standard in the outburst prevention rules, and safe and speedy drivage is achieved.

Owner:HENAN COAL CHEM IND GROUP INST

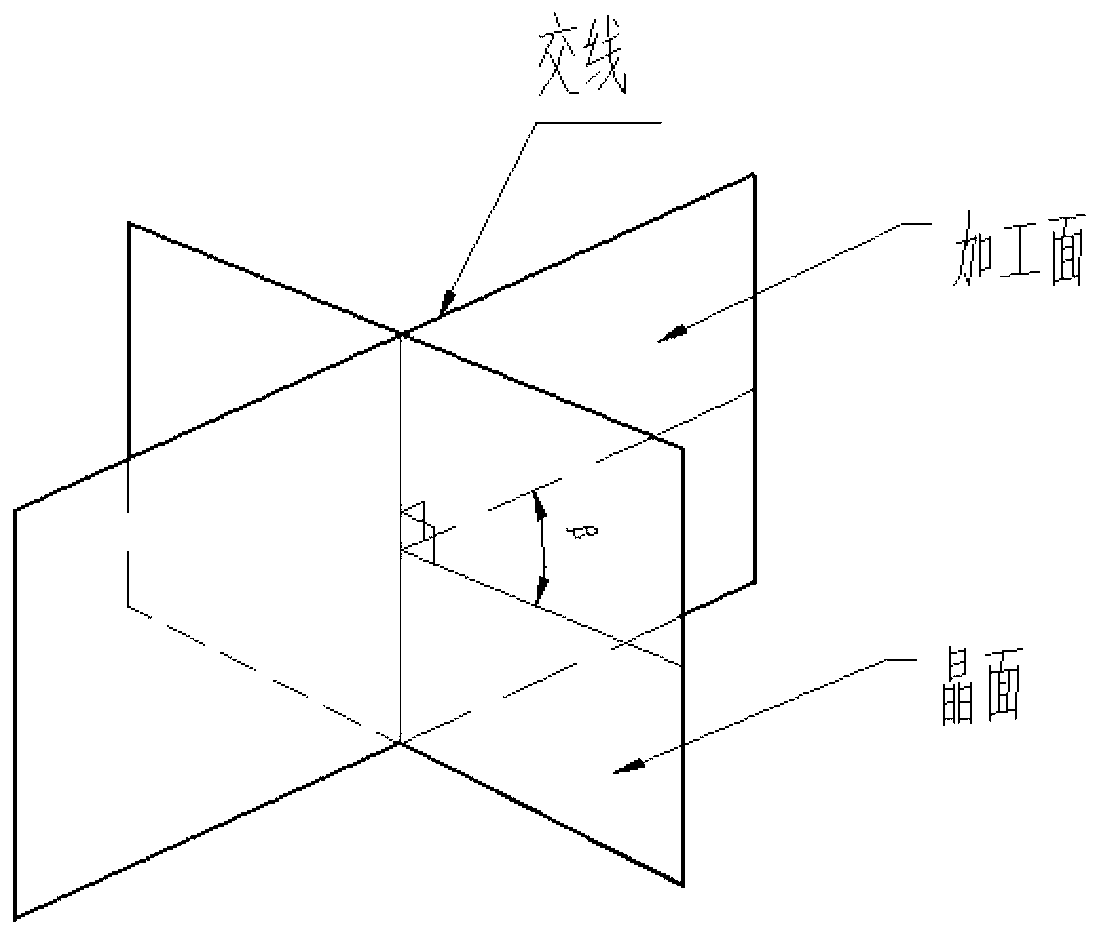

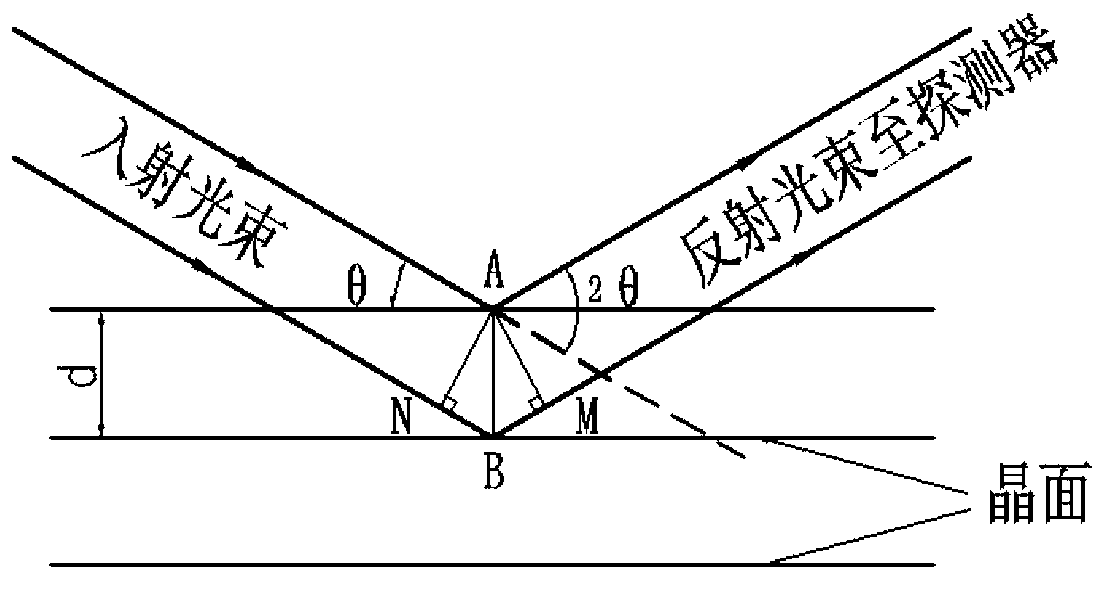

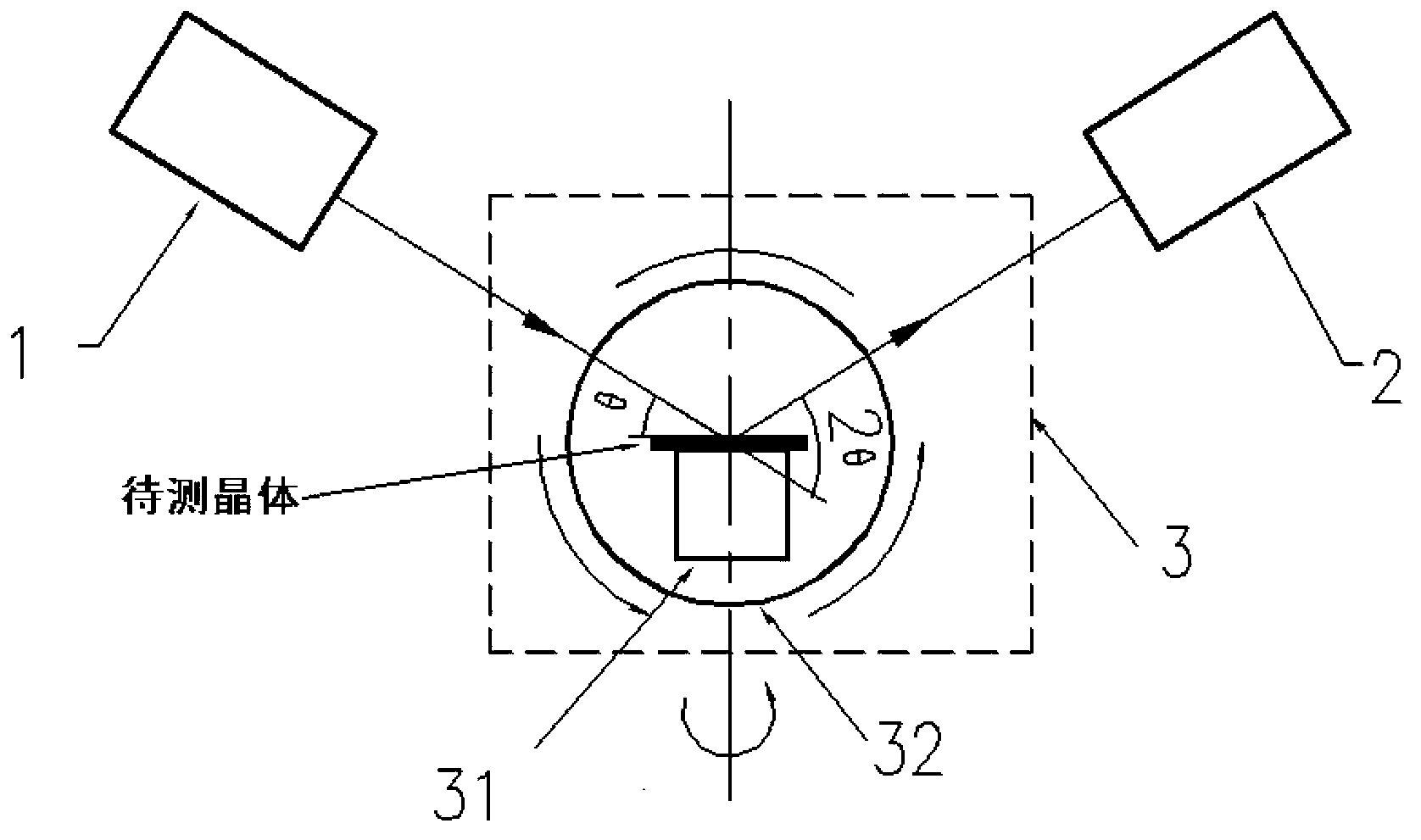

Crystal direction finder for directly measuring deflecting angle in crystal orientation and measurement method thereof

InactiveCN103257150APrevent leakageAvoid duplicationMaterial analysis using wave/particle radiationRotary stageMachined surface

The invention provides a crystal direction finder for directly measuring deflecting angle in crystal orientation, which is characterized in that one side of an objective table is connected with an X-ray generator, and the other side is connected with an X-ray detector, and an objective table is provided with a horizontal revolving bench, and the horizontal revolving stage can revolve a crystal to be measured parallely to the light propagation surface, and the center of the horizontal revolving bench is fixed with a vertical revolving stage, and the vertical revolving stage can revolve the crystal to be measured on the plane which is perpendicular to the light propagation surface; the crystal direction finder is used for directly finding the intersection line of the machined surface and the crystal face, and an angle measuring instrument of the objective table can be used for directly reading the deflecting angle beta in crystal orientation. The invention overcomes the defects that the present X-ray crystal direction finder has a complex operating method, wherein, the measurement process needs multiple times of rotations, dismountings and fixations of the detected crystal with low measurement efficiency, which is easy to induce cumulative errors and X-ray leakage.

Owner:YUNNAN KIRO CH PHOTONICS

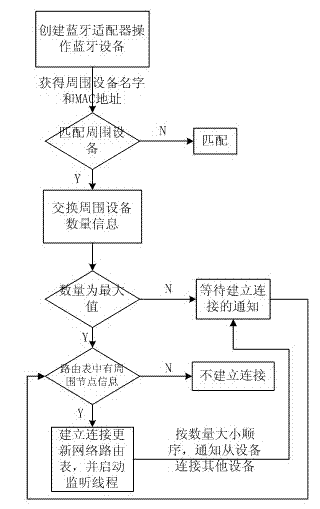

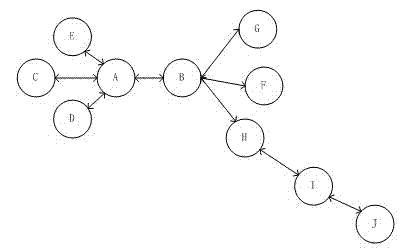

Bluetooth based networking and communication methods for Anddroid mobile equipment

InactiveCN103179635AAutomatic and fast buildAvoid investmentNetwork topologiesRouting tableEngineering

The invention relates to a bluetooth based networking and communication methods for Anddroid mobile equipment . A networking method includes (1), searching and acquiring surrounding bluetooth device names and Media Access Control addresses; (2), matching connection and exchanging found surrounding device number information; and (3), connecting surrounding devices and forming an original routing list. A communication method includes that the mobile devices detects information of the routing list and calculates the distance from a target device; and if the target device is directly connected with the mobile device, then message information can be directly sent out; and if not, the message information can be sent to devices adjacent to the mobile device, and then be sequentially sent to the target device. Compared with the prior art, preset network facilities are not required with the new message-sending method based on the bluetooth; the method has good adaptability and practicability rebuilding processes, and the rebuilding process is totally transparent without manual parameter configuration or setup; and communicating distance range is broadened.

Owner:NANJING UNIV OF POSTS & TELECOMM

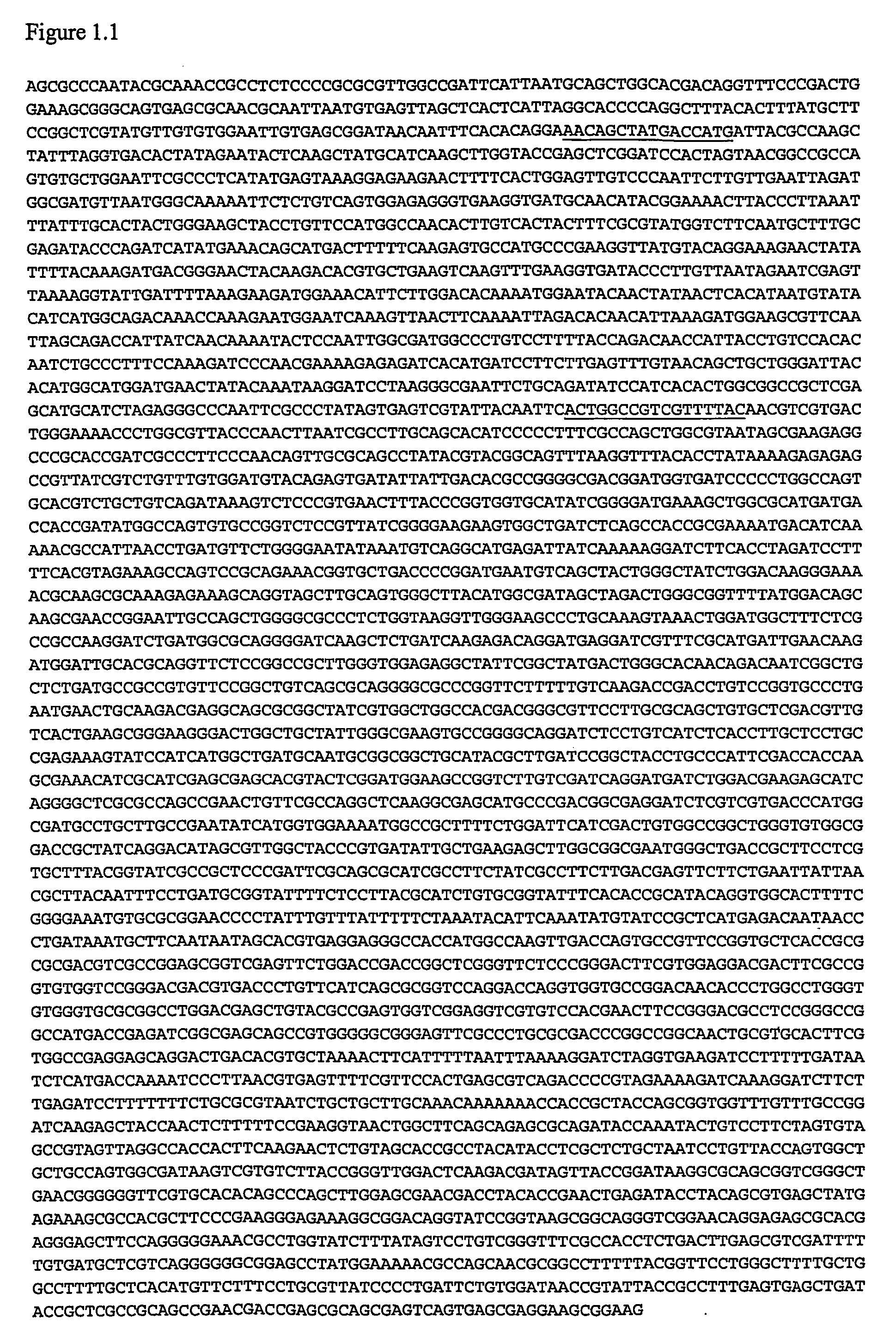

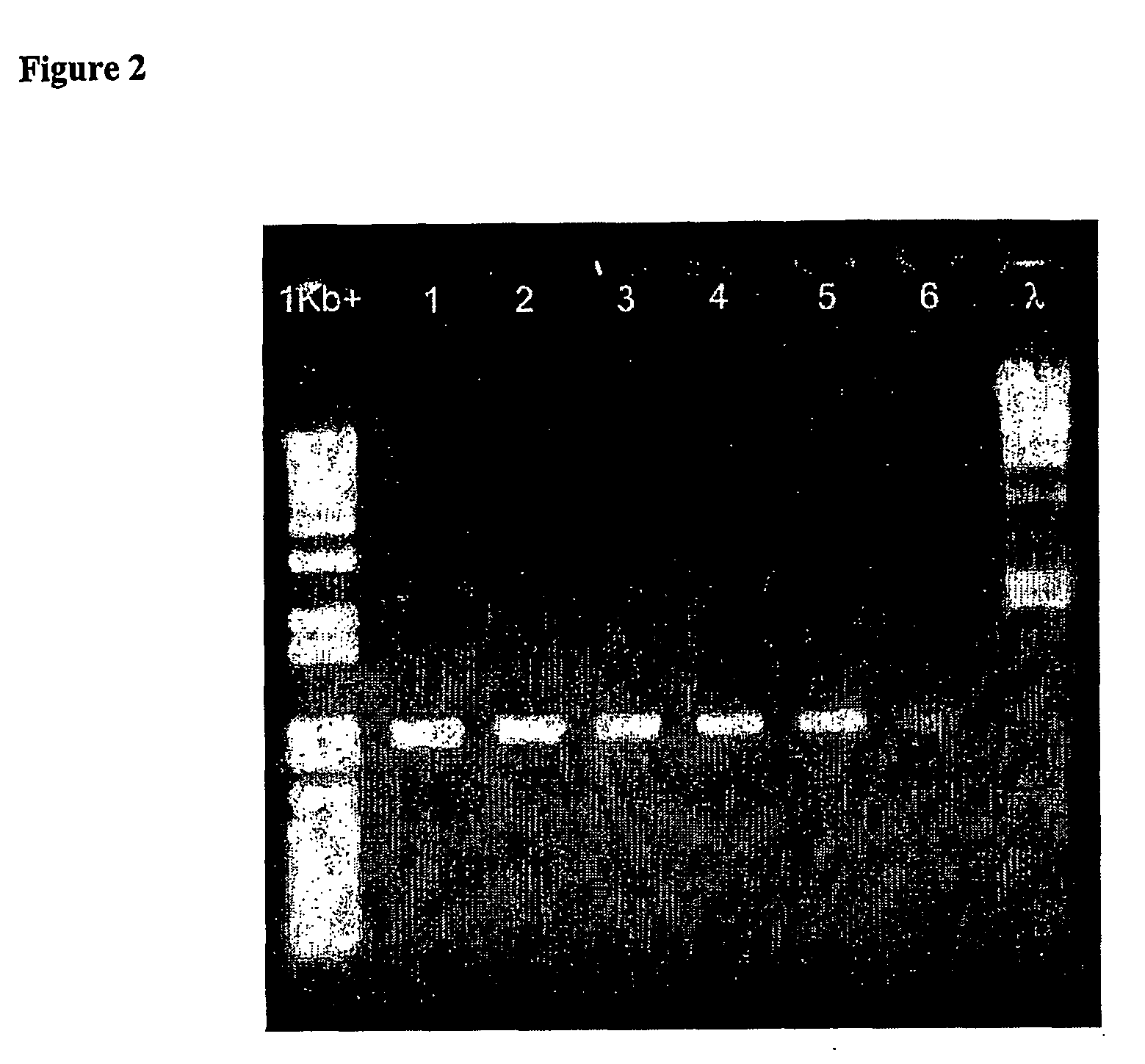

Dna amplification and sequencing in collapsible emulsions

InactiveUS20060068390A1Avoid difficultyAvoid investmentMicrobiological testing/measurementFermentationEmulsionChemical reaction

The present invention relates to a method of performing a chemical reaction, in particular a small-scale chemical reaction. The method involves the use of two (or more) phases which, when formed into an emulsion, have the characteristic of being subject to “collapse” under certain physical or chemical conditions such that the discontinuous phase dispersed in the emulsion becomes a substantially continuous phase—the chemical reaction taking place in the newly-formed continuous phase.

Owner:NUCLEICS

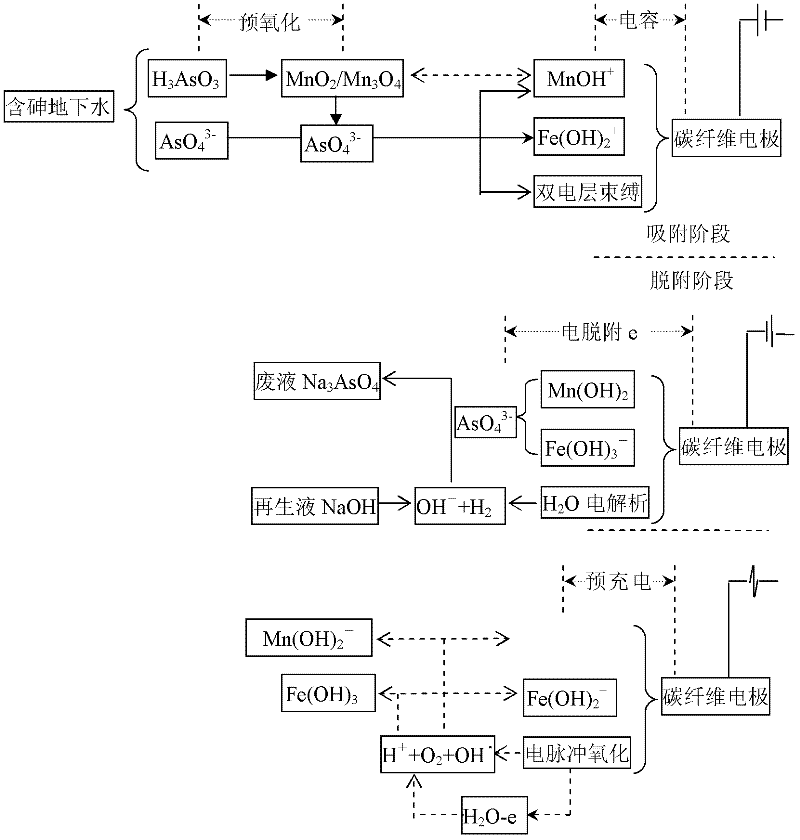

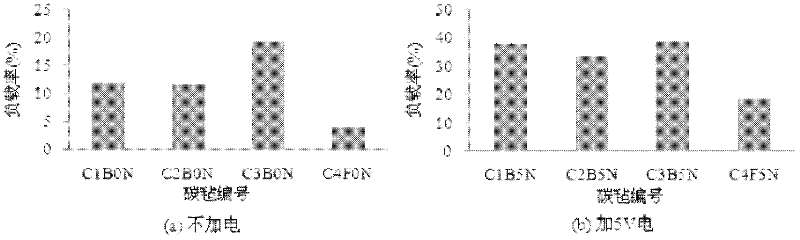

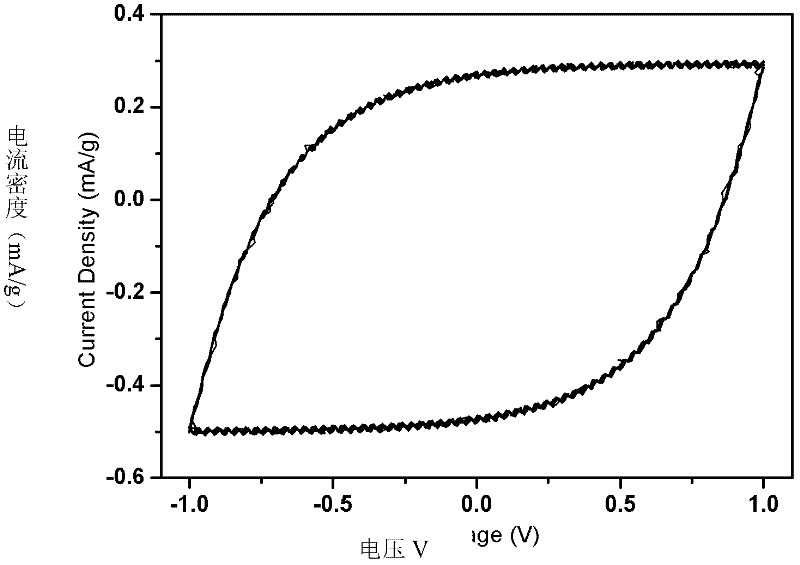

Arsenic removal material by adsorption of electrochemistry strengthened nano ferro-manganese loaded carbon fiberand arsenic removal method by using same

ActiveCN102641722AReduce dosageIncreased Electrosorption CapacityOther chemical processesDispersed particle separationReverse currentOxide

The invention discloses arsenic removal material by adsorption of electrochemistry strengthened carbon fiber loaded nano ferro-manganese and an arsenic removal method by using the material. The material comprises a substrate material and nano ferro-manganese oxidesloaded on the substrate material through electrochemistry and electro-deposition; the substrate material can be carbon fiber yarns, carbon fiber felts or graphite carbon fiber felts, and the shape of the substrate material is cylindrical or flat-shaped; and when a three-dimensional electrode is used, the substrate material is activecarbon. The arsenic removal material is prepared by performing ferro-manganese metal salt surface electro-deposition on the substrate material by electrifying. The arsenic removal method comprises the following steps of: carrying out coupling electro-absorption in the process of arsenic removal by chemical absorption, and strengthening the arsenic removal effect by using the electro-absorption action of a charging capacitor in the absorption process; applying reverse current to facilitate arsenic desorption on a surface of ferro-manganese hydrated oxide in a regeneration process, and simultaneously applying high voltage to perform hydrolysis, hydrogen generation and oxygen evolution so as to facilitate activity regeneration of the ferro-manganese oxide. With the adoption of the material and the method, the high absorption effect and the quick regeneration capability can be achieved.

Owner:TSINGHUA UNIV

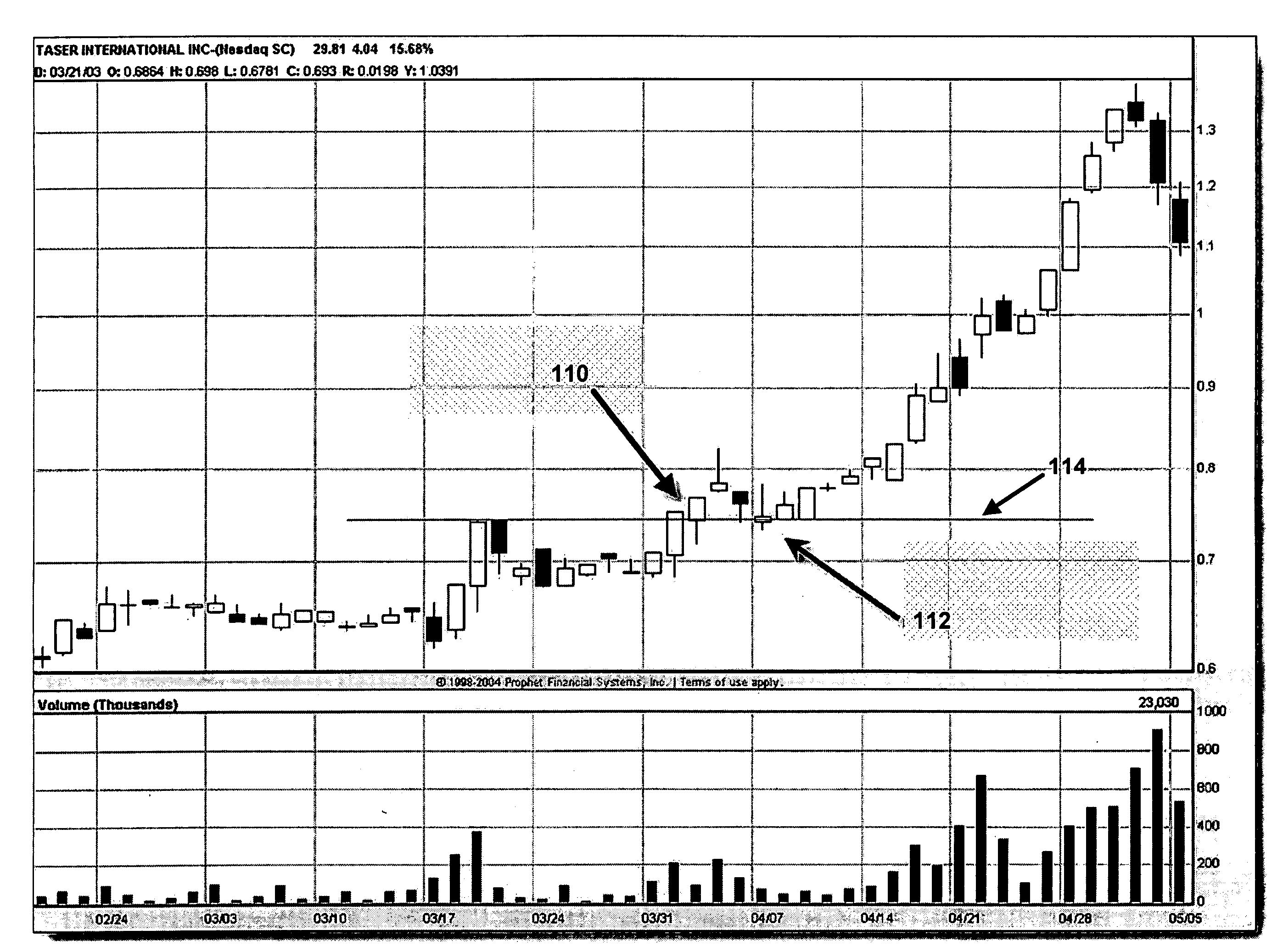

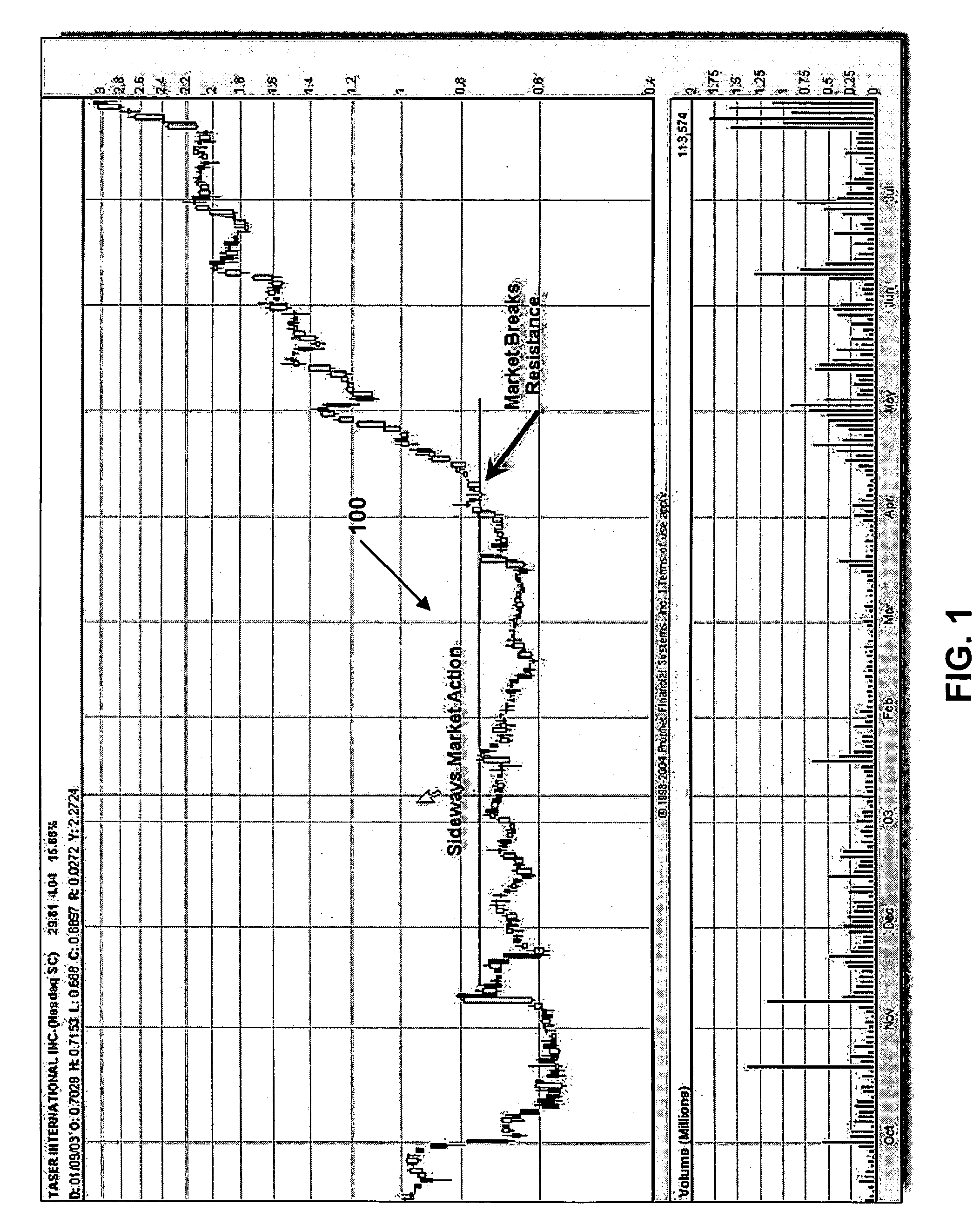

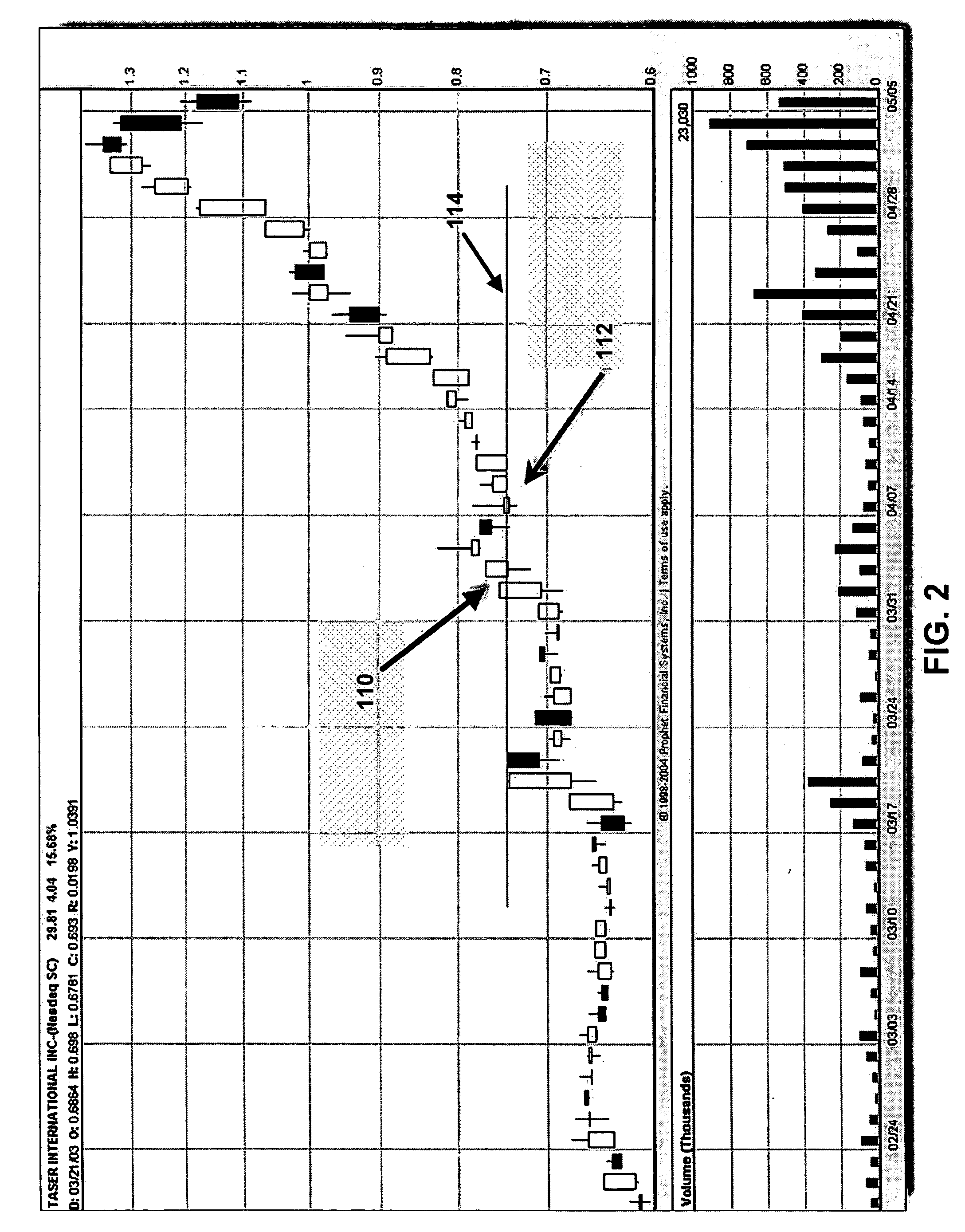

Threshold trading method

Owner:EDUTRADES

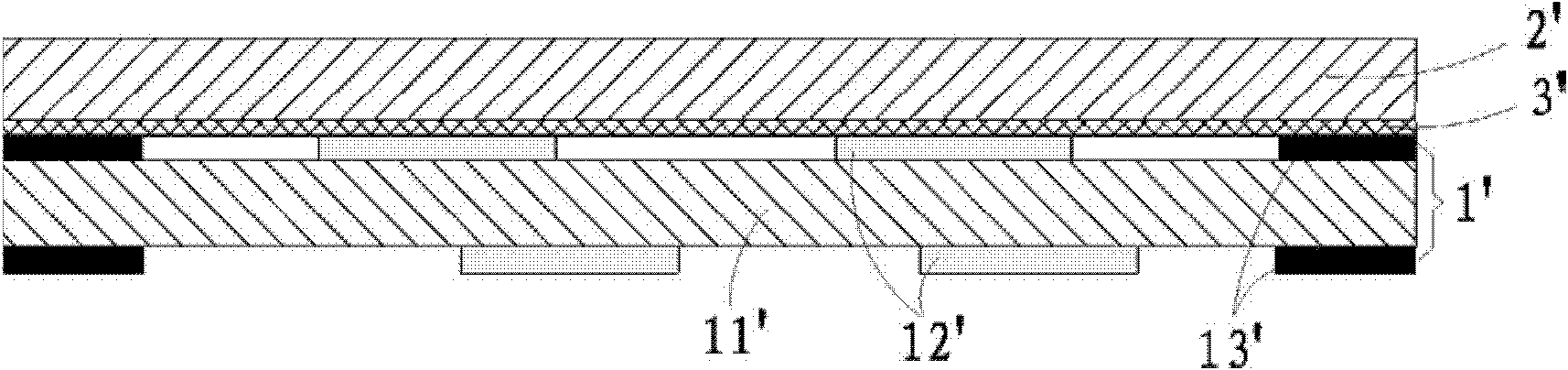

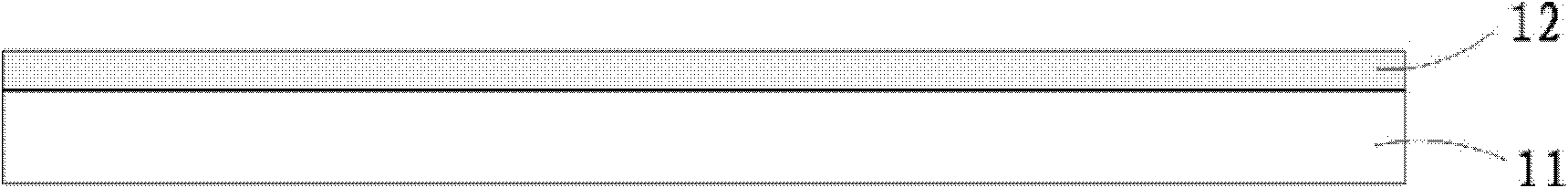

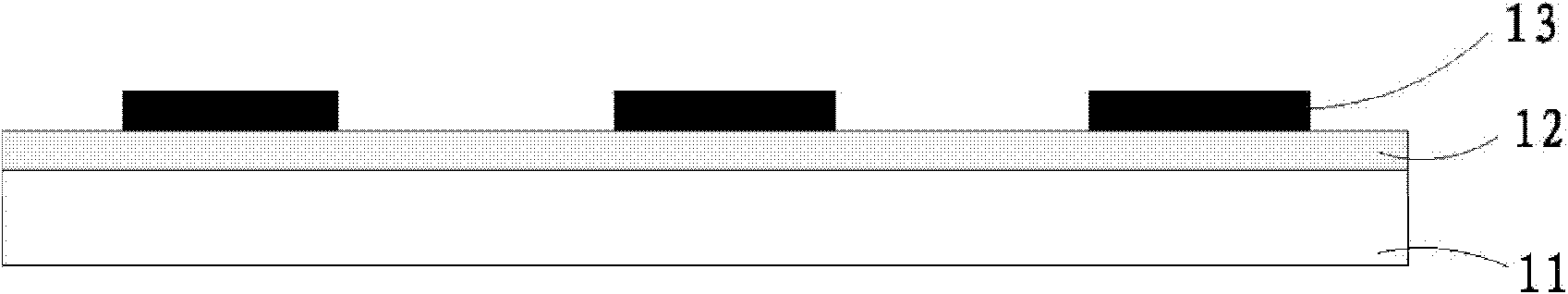

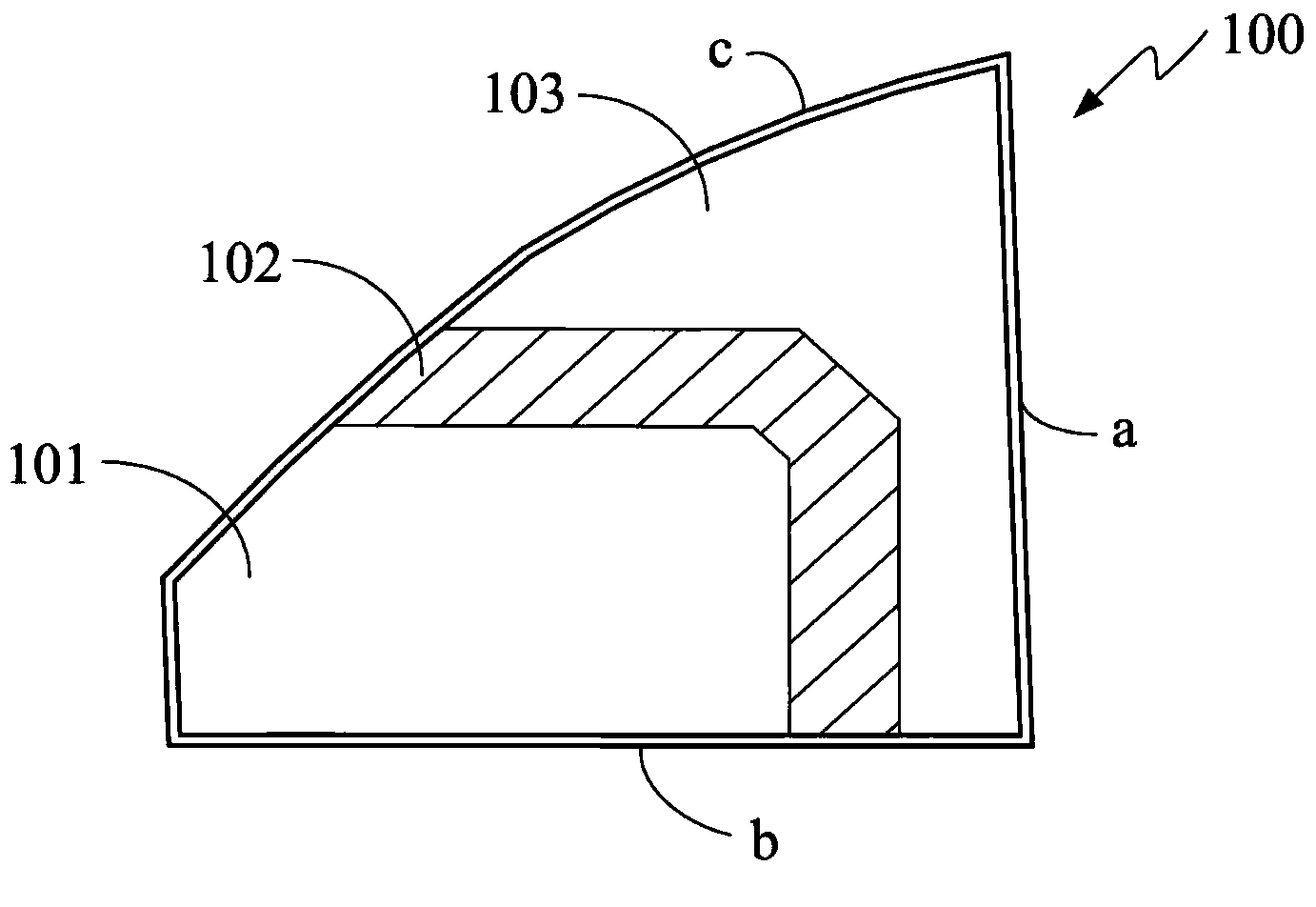

Novel capacitive touch screen, manufacturing method thereof, and touch screen terminal

ActiveCN102279682AAvoid investmentAvoid equipment debugging difficultiesInput/output processes for data processingFilm structurePhotolithography

The invention is applicable to the technical field of touch screen production, and provides a novel capacitive touch screen and its manufacturing method and touch screen terminal; the novel capacitive touch screen includes a layer of panel glass, and also includes two layers coated with ITO conductive pattern layers and silver paste electrodes The PET film structural part, two layers of the PET film structural part and one layer of the panel glass are sequentially bonded together by optical glue; the capacitive screen manufacturing process of this structure does not need to be used when making ITO patterns and peripheral leads. The yellow light manufacturing process can greatly reduce equipment investment and process costs, and is conducive to the popularization and application of capacitive touch screens, thereby replacing resistive touch screens on a large scale.

Owner:深圳豪威显示科技有限公司

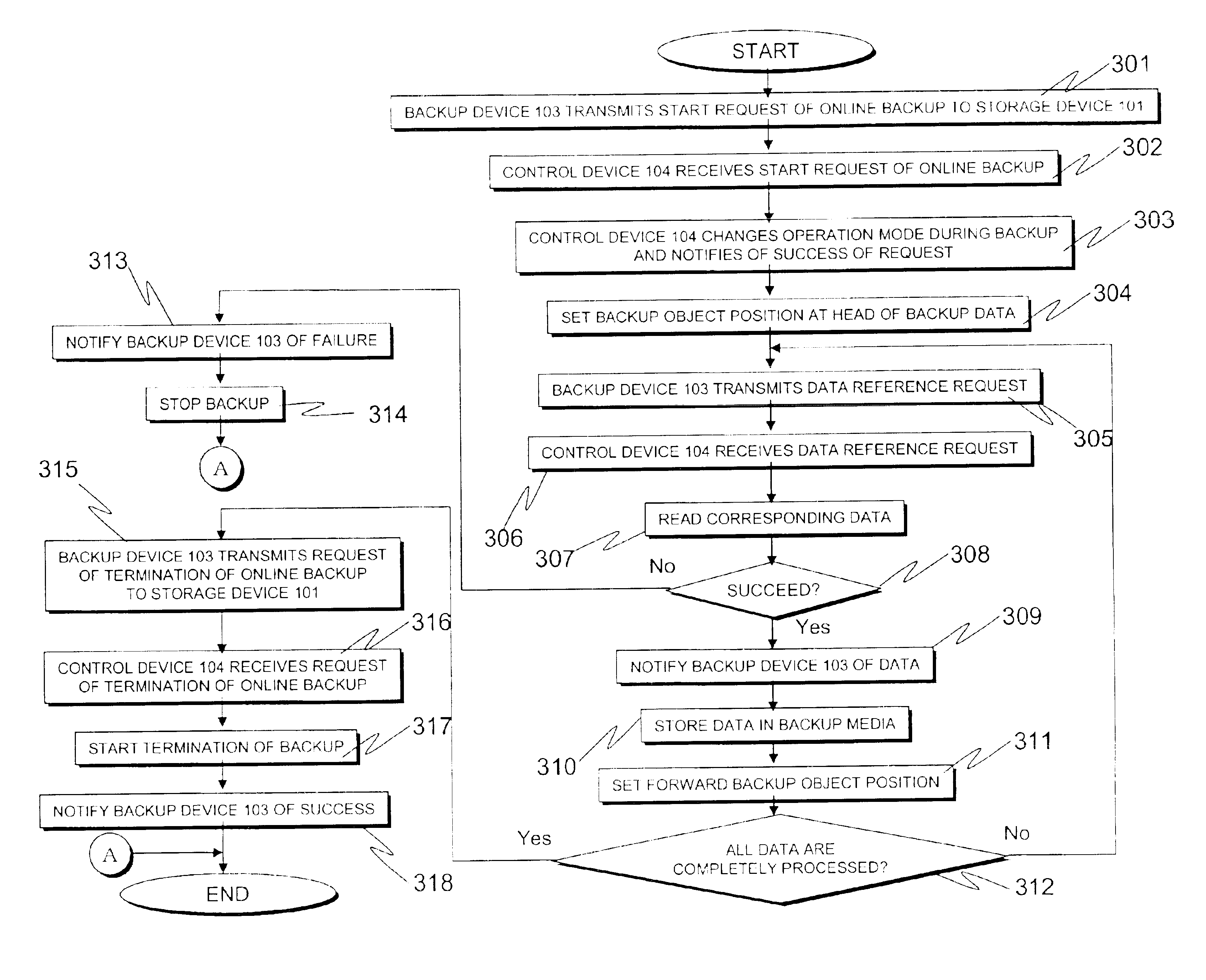

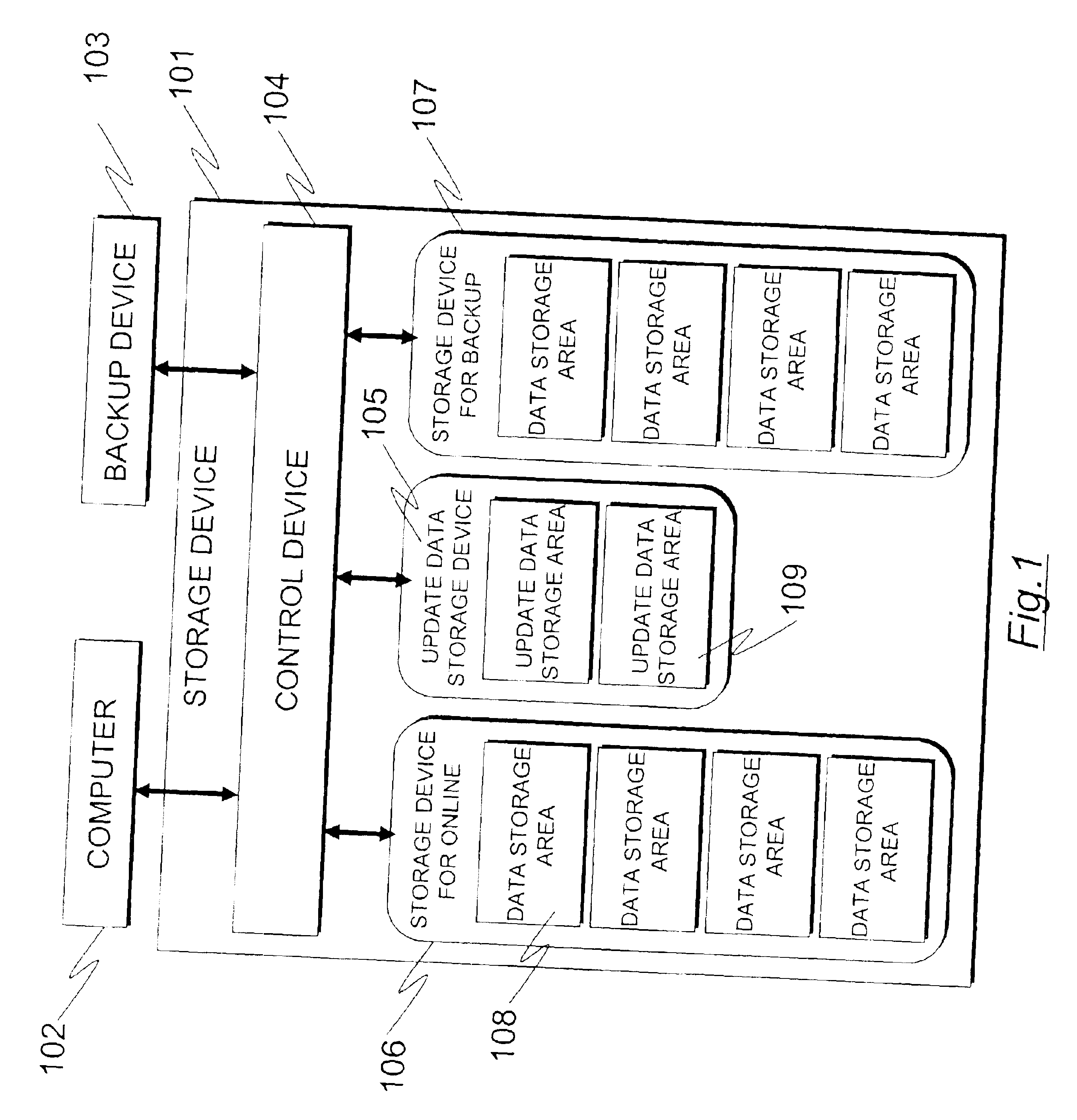

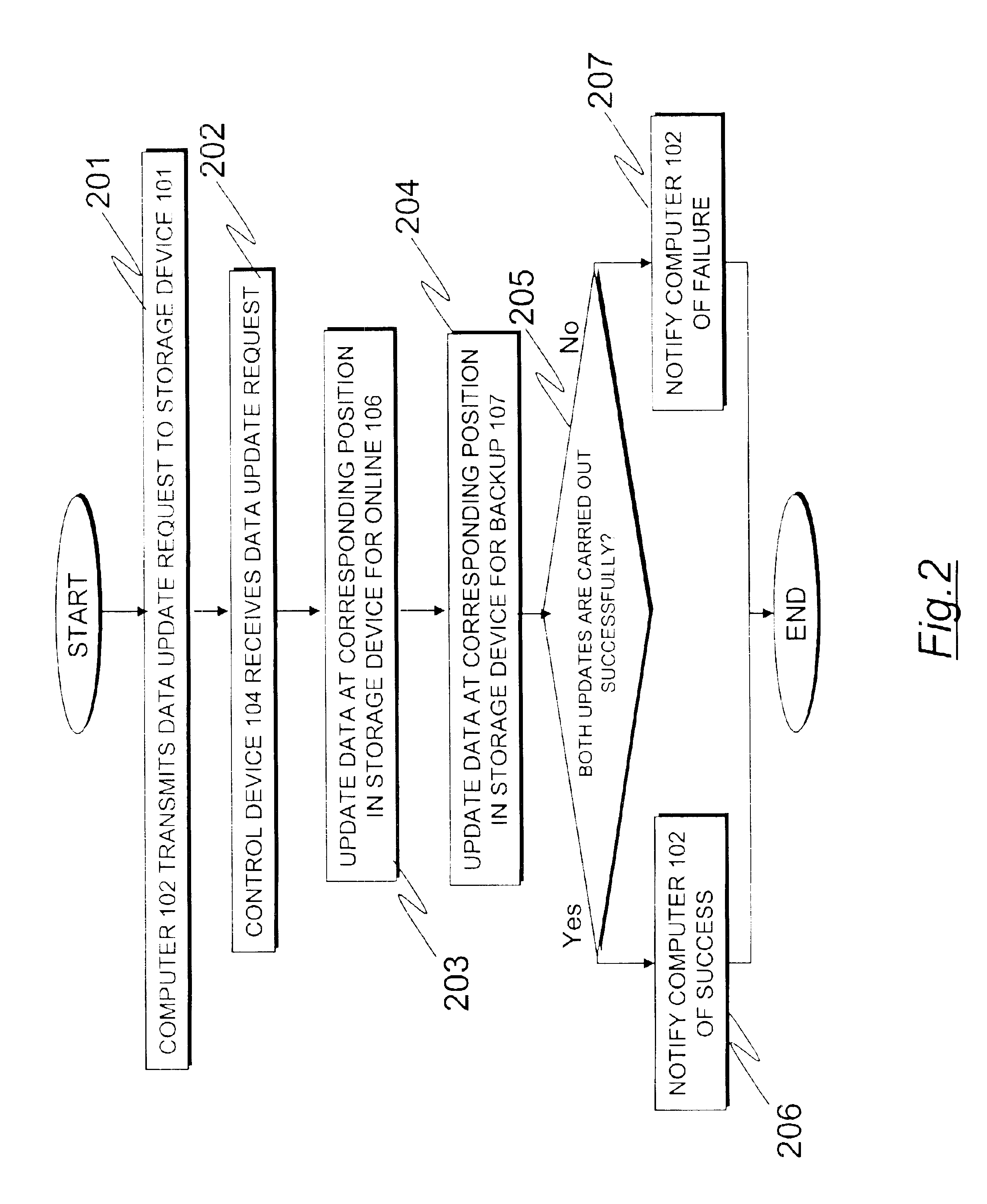

Storage device, backup and fault tolerant redundant method and computer program code of plurality storage devices

ActiveUS6883112B2Avoid investmentInput/output to record carriersData processing applicationsData storeData application

A storage device for which restoration of data is possible without the need for excess equipment includes mirrored storage units for online use and for backup, and is capable of performing a data backup while continuing input and output of data. The storage device is further provided with an update data storage unit for storing update data. According to the storage device, even if the information stored in a storage unit for online use is not capable of being read because of a fault in the storage unit, it is possible to restore the data in the backup storage unit to the state that existed in the storage unit for online use immediately before the fault by applying the update data to the information stored in the storage device for backup.

Owner:KK TOSHIBA

Method for controlling temperature in the production process of seaweed polysaccharide plant empty capsules

The invention discloses a temperature control technology and temperature control parameters for all production processes which have significant influences on the production quality of enterprises engaged in the production of hardshell empty capsules, in particular to a method for controlling the temperature in the production process of seaweed polysaccharide plant empty capsules. The method adopts cellulose hydroxypropyl methyl ether as film forming agent, seaweed polysaccharide as film assisting agent, hydrolyzed starch as thermal reversible colloid and calcium citrate as coagulant aid; the dissolution temperature of all raw materials in capsule material is controlled at 70-90 DEG C; the balanced reaction time of solution is within 2-4 hours, and the reaction temperature is 70-80 DEG C; the adhesive film-forming temperature is 45-55 DEG C; the adhesive time is controlled at 3-7 seconds; the humidity of a film forming workshop is controlled to be 30-45 percent, and the temperature in the film forming workshop is 30-36 DEG C; the temperature of a drying channel is controlled at 30-40 DEG C, and the humidity of the drying channel is controlled to be 30-45 percent; and the temperature of a plastic plate is controlled at 32-37 DEG C.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

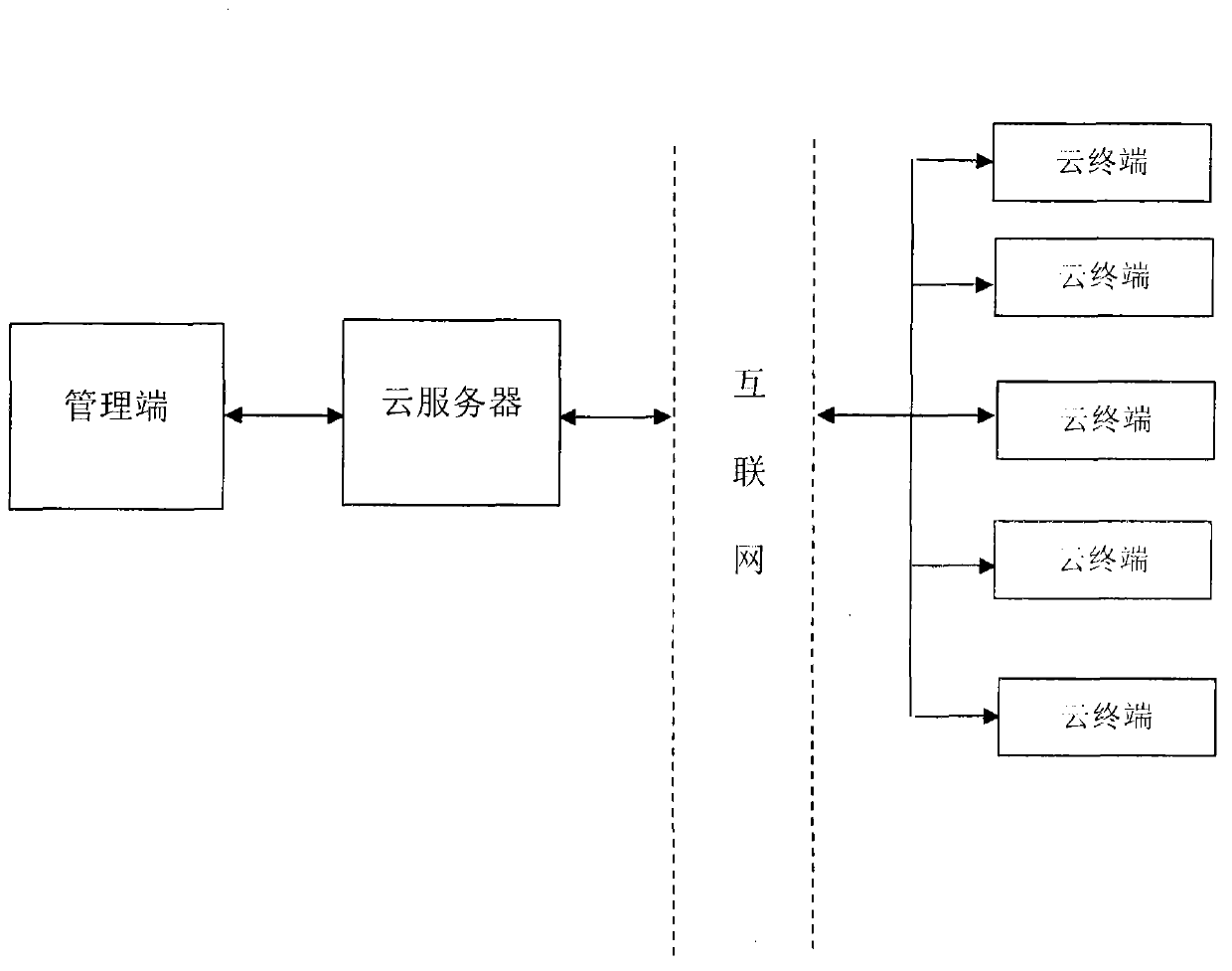

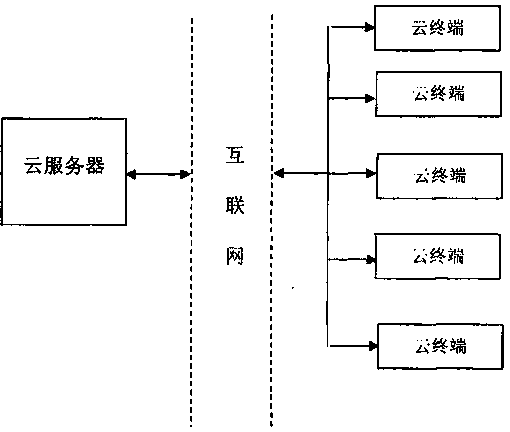

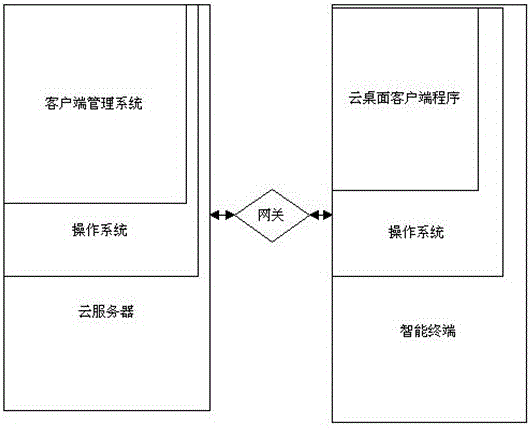

Cloud desktop system and operating method

InactiveCN103281359AReduce operating costsLow failure rateTransmissionSoftware simulation/interpretation/emulationOperating pointOperational costs

A cloud desktop system comprises a management end, a cloud server and cloud terminals; the cloud server forms a physical machine for a plurality of virtual machines, and the cloud terminals correspond to the virtual machines on the cloud server. An operating method for the cloud desktop system includes the following steps: users are connected with the cloud server through the cloud terminals, each user corresponds to a different virtual machine, and when the users use the cloud terminals to work, data are actually processed by the cloud server, while the local cloud terminals only assume the work of data transmission and display. Compared with the conventional working mode, the cloud infrastructure can more sufficiently utilize resources, excessive hardware investment on the local end is avoided, the operating cost of work is saved, the pressure of hardware upgrading is avoided, and since the structure of the cloud terminal is relatively simple and the fault rate is low, the cost of later maintenance is further reduced as well.

Owner:北京启创卓越科技有限公司

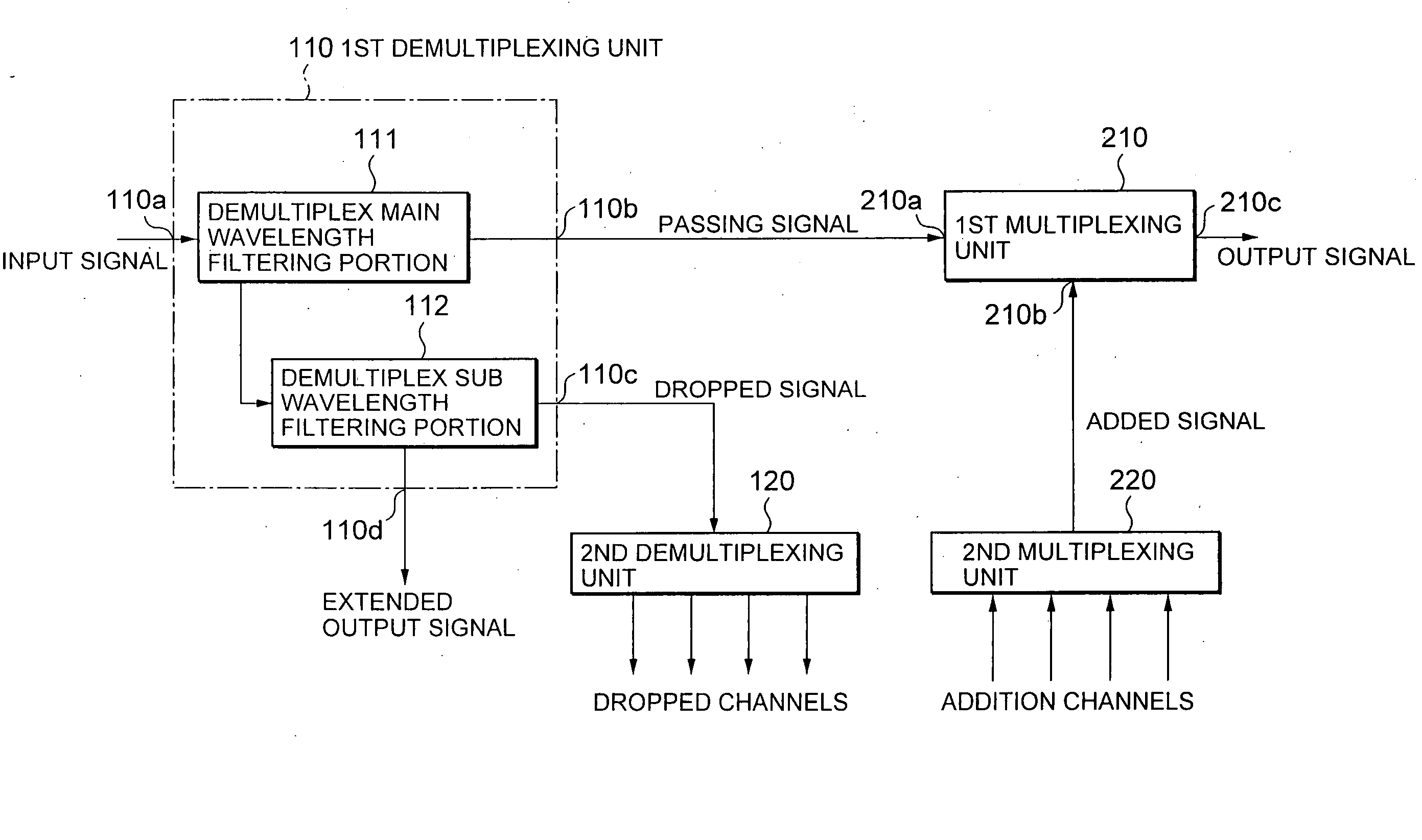

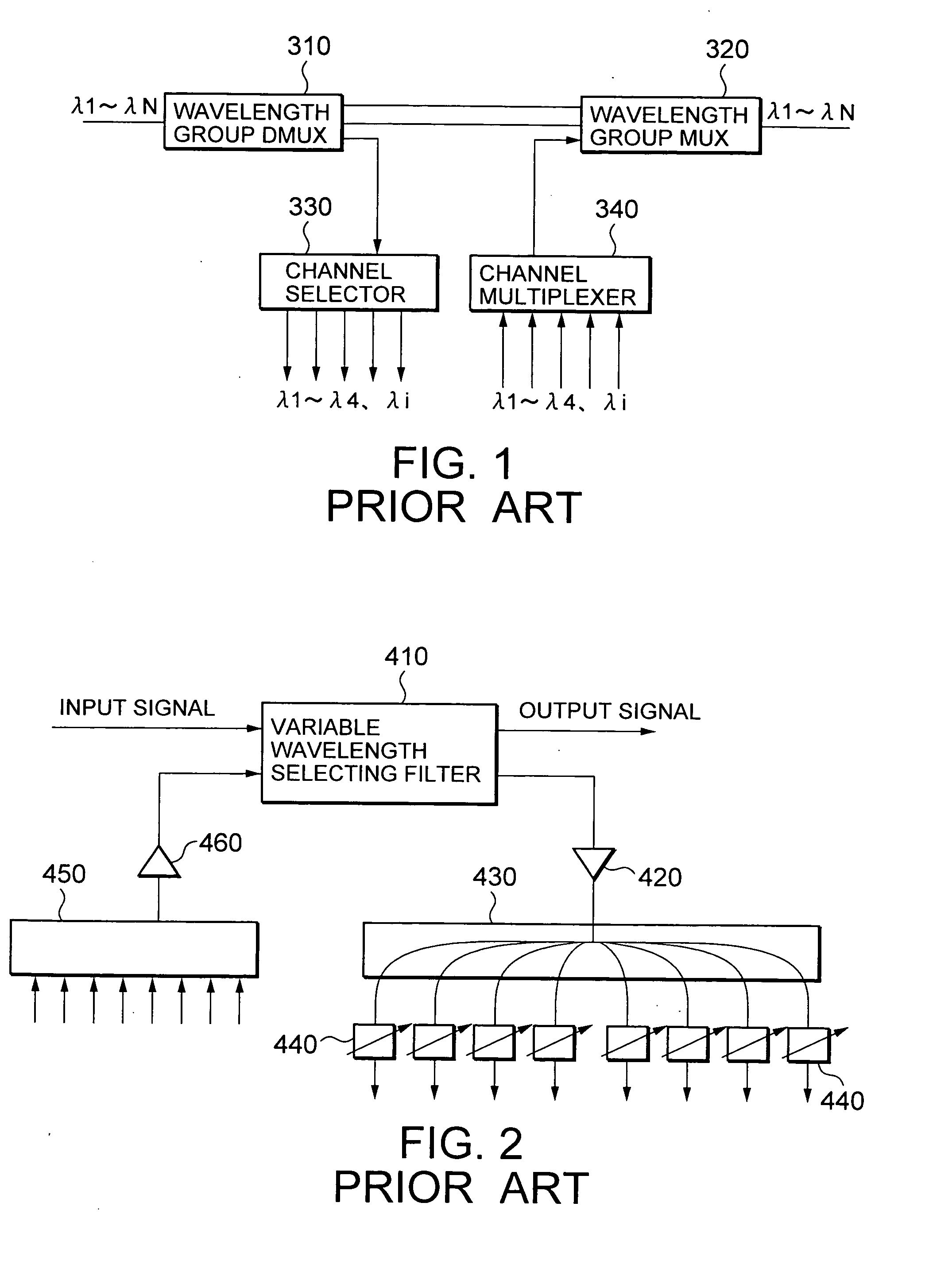

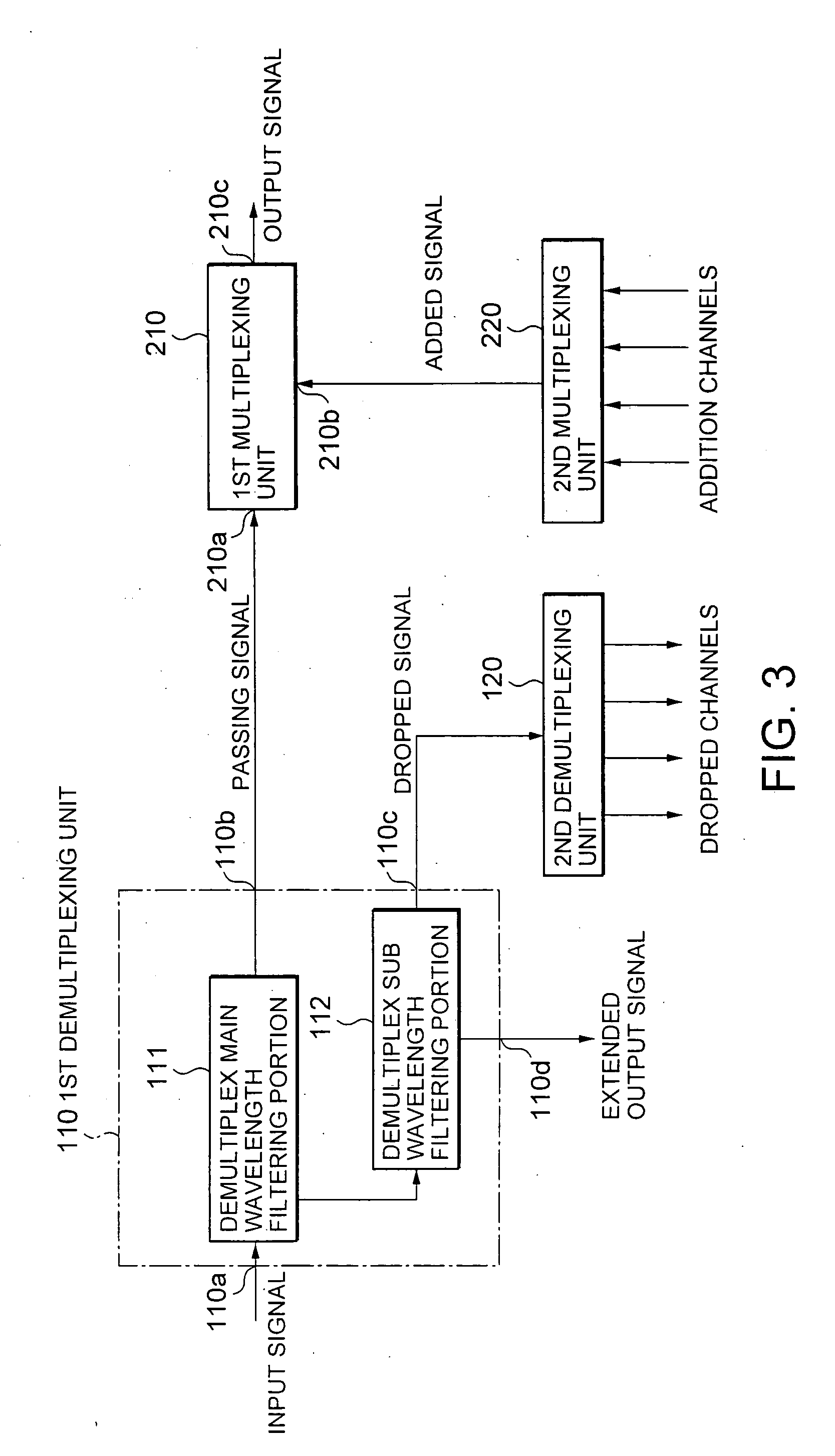

Optical add-drop apparatus and method

InactiveUS20050013615A1Reduce five filterReduce in quantityWavelength-division multiplex systemsElectromagnetic network arrangementsLength waveSignal multiplexing

A wavelength variable filter (111) separates an input signal into a passing signal and an intermediate output signal. A wavelength variable filter (112) separates the intermediate output signal into a dropped signal and an extended output signal. An interleaver (120) separates the dropped signal into individual dropped channels. An intrerleaver (220A) multiplexes a plurality of addition channels into an added signal. A wavelength variable filter (212) multiplexes the added signal and an extended input signal to produce an intermediate input signal. A wavelength variable filter (211) multiplexes the passing signal and the intermediate input signal into an output signal. A wavelength setting portion (100) sets a wavelength of each wavelength variable filter in accordance with operation of an operator.

Owner:NEC CORP

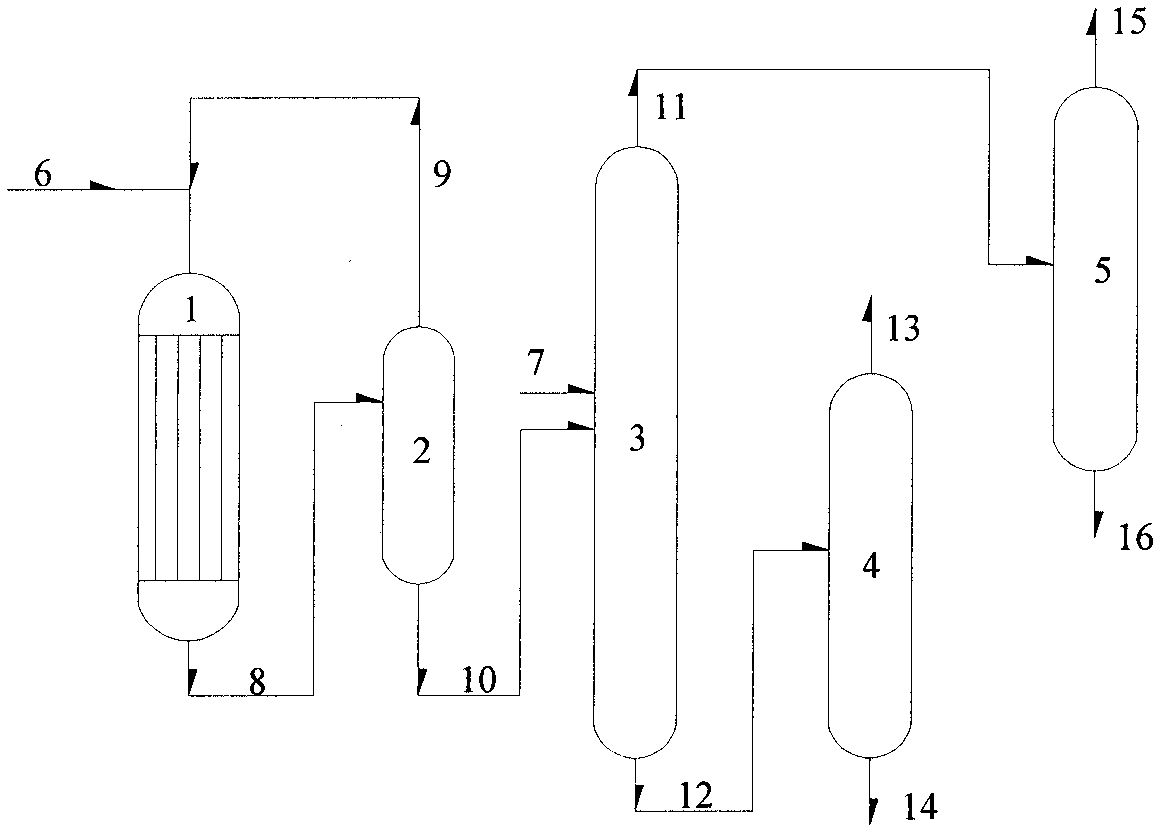

Method for producing isopropanol by acetone hydrogenation

InactiveCN102690172AReduce water contentImprove cleanlinessOrganic compound preparationHydroxy compound preparationEconomic benefitsDiisopropylamine

The invention aims at solving the problems of isopropanol production by acetone hydrogenation and impurity removal, especially water removal from isopropanol, and provides a method for producing qualified isopropanol products by converting acetone into isopropanol through hydrogenation, entraining water in the isopropanol by using diisopropylamine as an entrainer, and removing heavy components. The method for producing isopropanol in the invention has a short production flow, is easy to master, and has high economic benefits. Isopropanol can be produced in an isopropylamine production device; diisopropylamine is used as an entrainer; no new substance is introduced; not only the cleanness of the device system is guaranteed, but also the increase of investment for separation equipment and storage tank equipment is not necessary; and the production cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing silicon dioxide aerogel by normal pressure drying method using rice hull ash as raw material

A method for dry producing the silica dioxide aerogel from rice husk ash as raw material in atmosphere pressure, belongs to the technical field of chemical industry materials producing, which comprises the following steps: leaching the rice husk ash formed by rice husk burning in the inorganic strongly basic aqueous solution and inorganic corrosive acid neutralizing basic solution to get the silica dioxide hydrosol, treating the hydrosol with organo-silicon compound to get the hydrogel, then ageing, water scrubbing, replacing the moisture in hydrogel with a organic solvent, and drying in atmosphere pressure to get the silica dioxide aerogel with the specific surface area about 400-800 m.

Owner:TSINGHUA UNIV

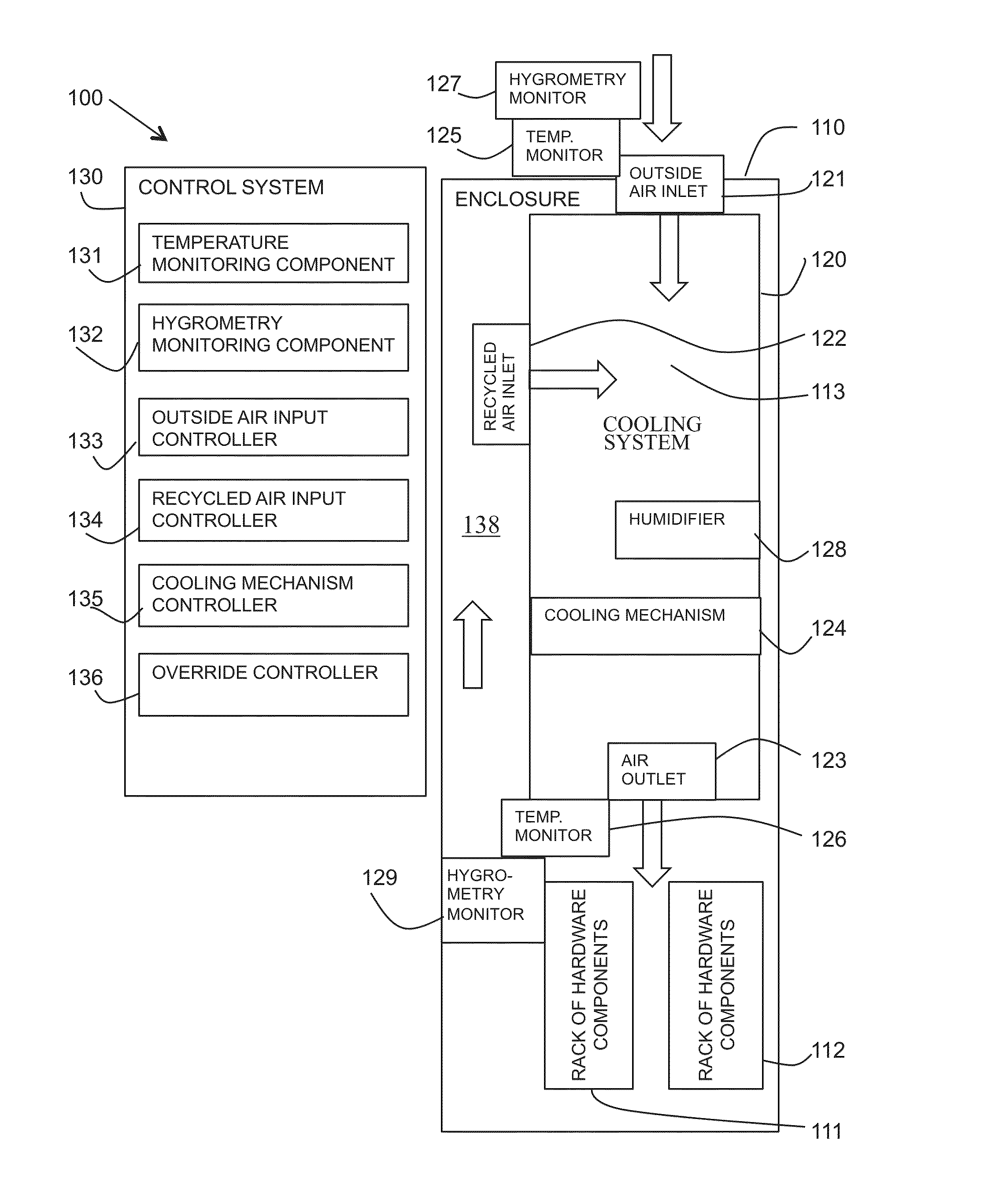

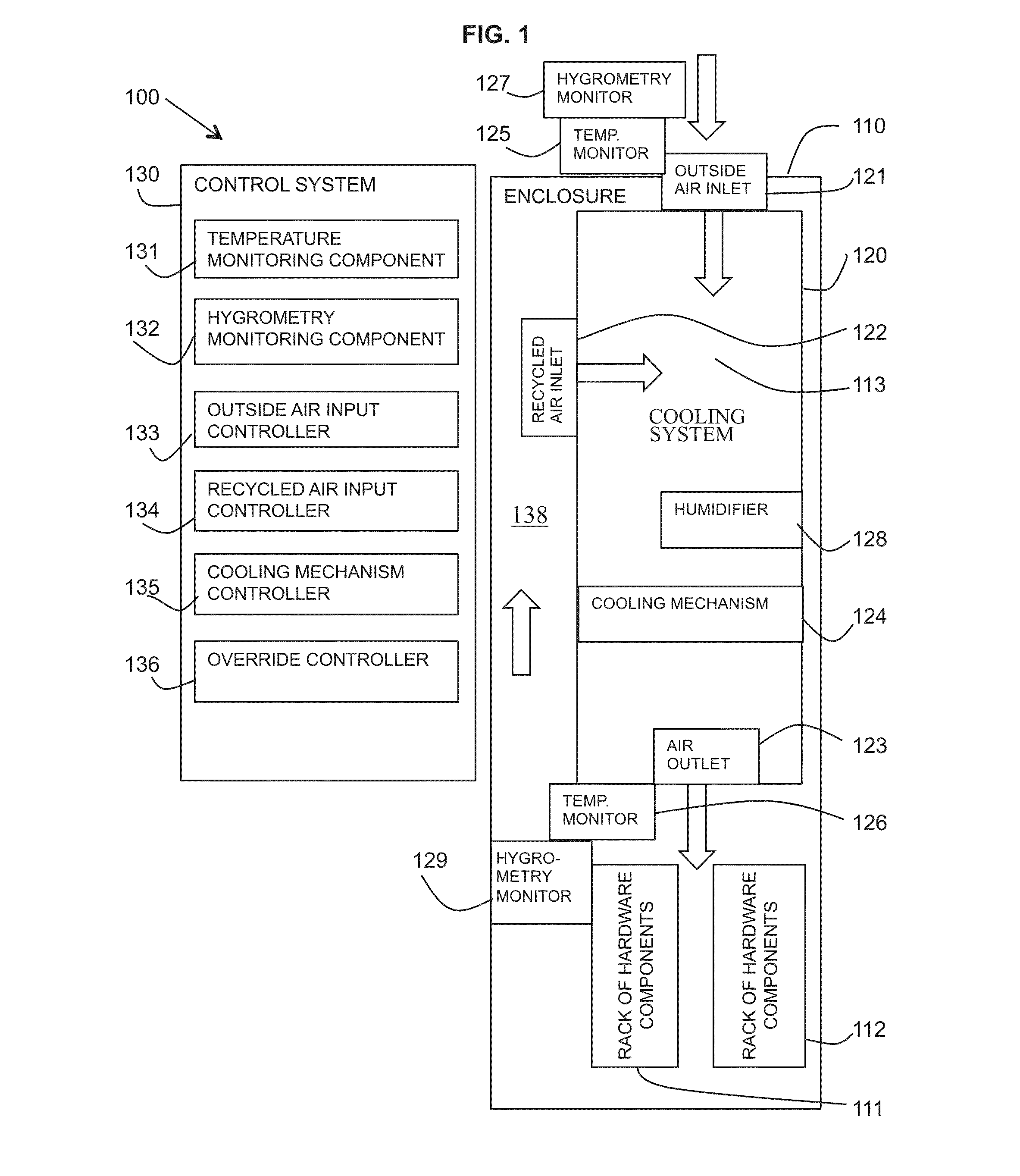

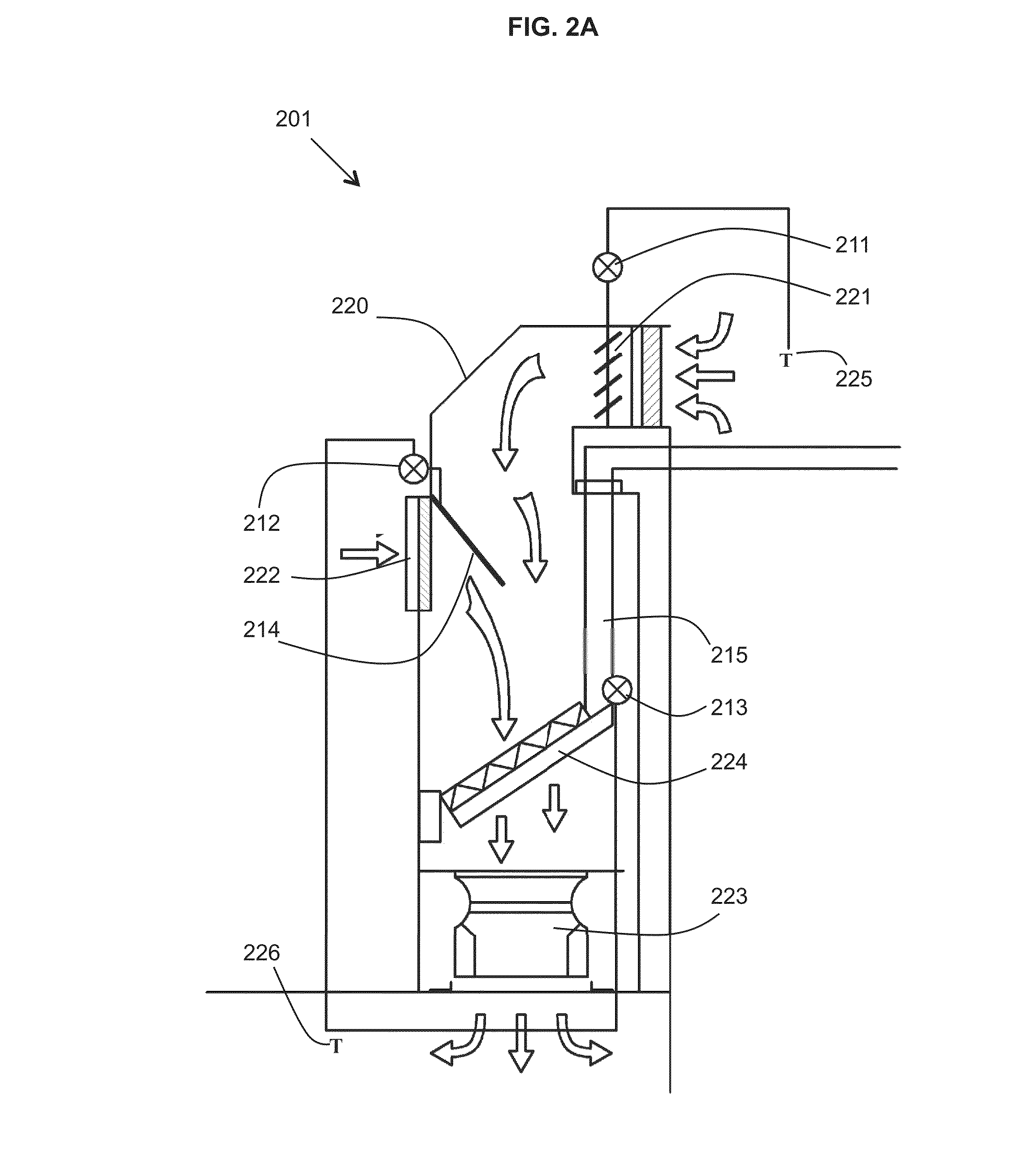

Variable air cooling system for data centers

ActiveUS20150208553A1Avoids infrastructure investmentEnergy efficiencyMechanical apparatusSpace heating and ventilation safety systemsTemperature controlData center

A method and system for variable air cooling for data centers. The system may include: an enclosure to be cooled suitable for housing hardware components; a cooling system including: a first air input for controllably allowing input of outside air from outside the enclosure; a second air input for controllably allowing input of recycled air from the enclosure; a selectively activatable cooling mechanism; an air output for allowing output of air into the enclosure; a first temperature monitor for monitoring an outside air temperature of air outside the enclosure; a second temperature monitor for monitoring a blowing air temperature of air at the air output; and a control mechanism for controlling an operation of the first air input, the second air input, and the cooling mechanism dependent on a monitored outside air temperature at the first temperature monitor and a monitored blowing air temperature at the second temperature monitor.

Owner:KYNDRYL INC

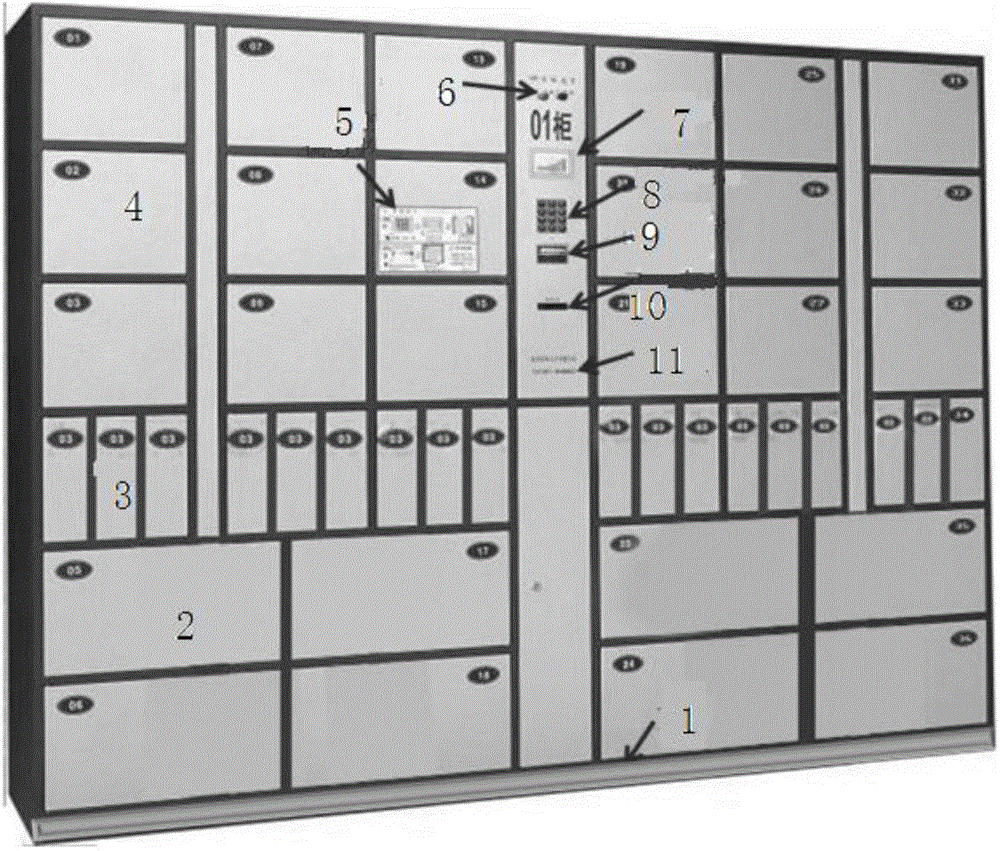

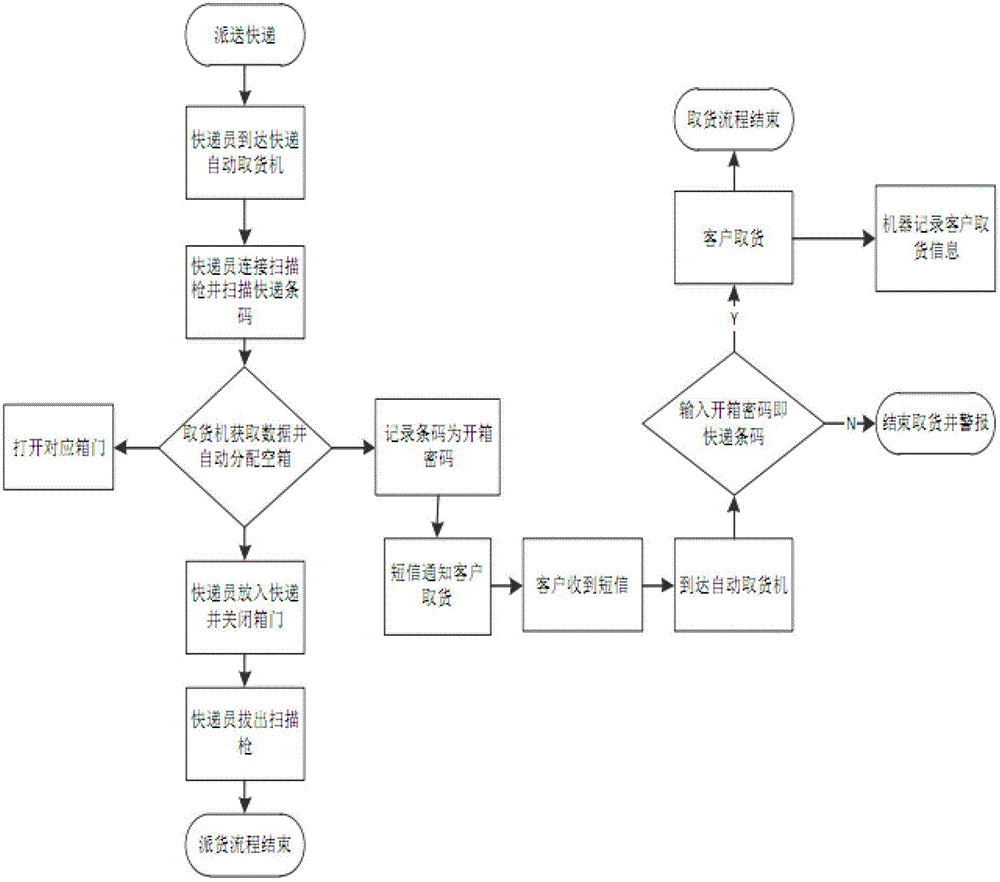

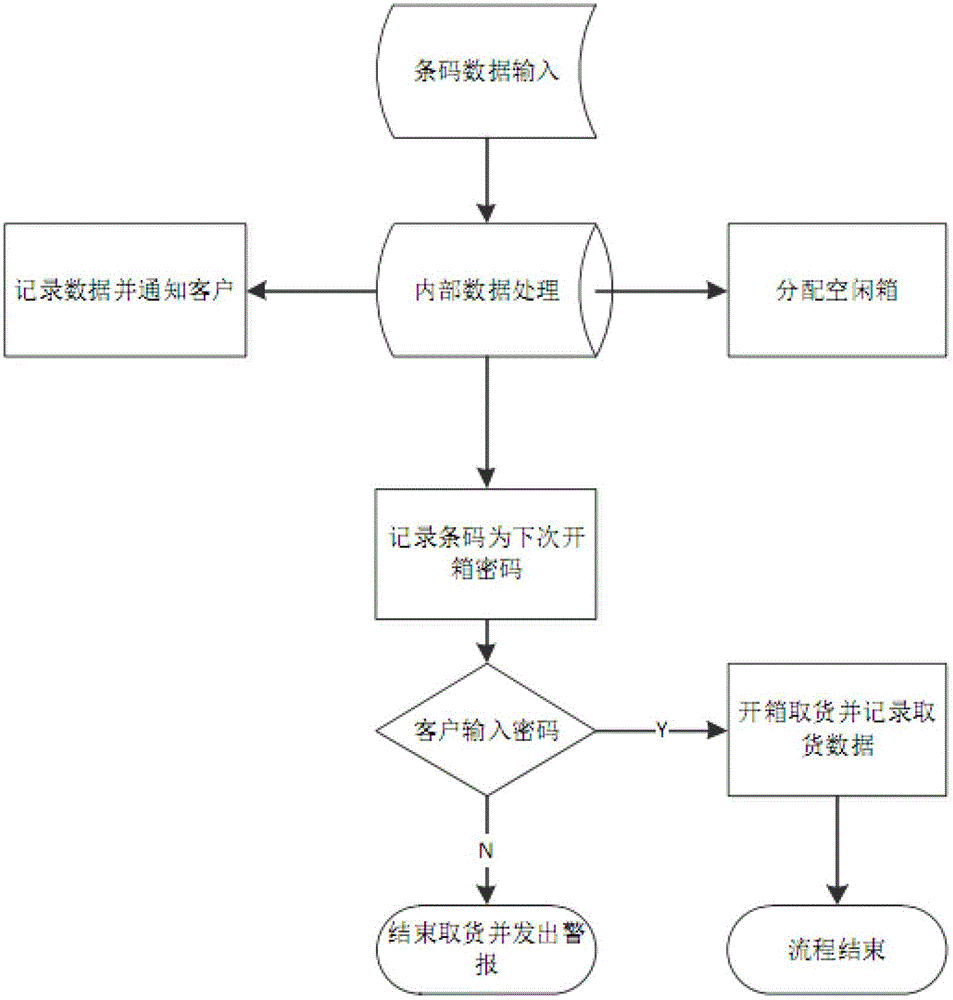

Automatic goods fetching system for terminal express delivery and implementation method thereof

InactiveCN102750779AReduce workloadReduce in quantityCoin-freed apparatus detailsApparatus for dispensing discrete articlesMicrocomputer systemPassword

The invention discloses an automatic goods fetching system for terminal express delivery and an implementation method thereof. The automatic goods fetching system for terminal express delivery comprises a box body, the box body is divided into three storage boxes at least, a microcomputer system is arranged in the box body, the box body is provided with a USB (universal serial bus) interface or a wireless communication network, a keyboard, a red prompting light, a green prompting light, a display screen, a power source, a voice prompting device and the like, one side of the bottom of the box body is provided with a weighing device, and the top of the box body is provided with a camera; the structure of the automatic goods fetching device for express is in a no-interlayer design; and the implementation method based on the device is introduced in detail. The automatic goods fetching device for express is combined with technologies of bar codes, short message feedback, password memory and identification and the like, entire intact operation of an express enterprise is realized, and the problems that time conflict exists between a courier and a customer and goods safety in terminal express delivery can not be guaranteed can be effectively solved, so that the service quality and the entire benefit of the enterprise are improved.

Owner:SHANDONG JIAOTONG UNIV +4

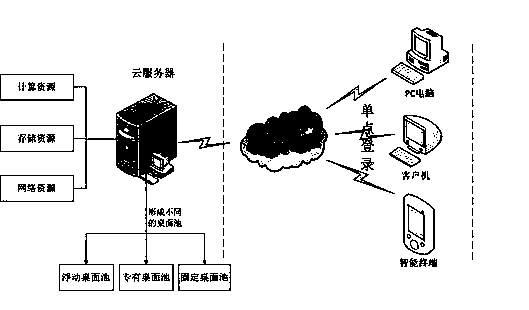

Remote cloud desktop operation system

The invention provides a remote cloud desktop operation system which comprises a cloud server and a cloud terminal, wherein the cloud server consists of computing resources, storage resources and network resources which are registered on an Internet, thus a physical machine for control and data exchange among a plurality of cloud terminals is formed; the cloud server supposes different virtual machines according to demands of different cloud terminals, thus the cloud terminals are enabled to accomplish corresponding operation; the cloud terminals comprise user computers and client programs which are arranged on the computers and are connected with the cloud servers; and a user can access to the cloud servers through the Internet by using the client programs of the computers, and the cloud terminals correspond to the virtual machines on the cloud servers. The operation system can effectively solve the technical problems that the operation is inconvenient and the security is relatively poor as computer terminal hardware is not reliable and the operation system is relatively poor in compatibility.

Owner:JIANGSU LUHAI IOT SCI & TECH

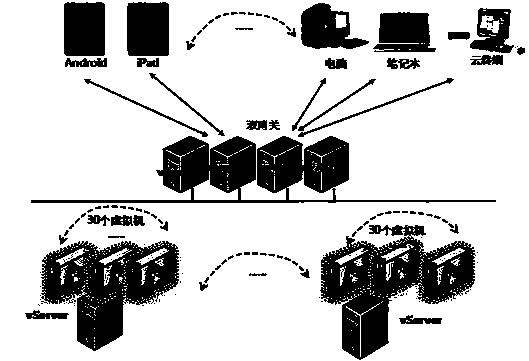

Cloud desktop intelligent terminal management system

InactiveCN106506620AReduce operating costsSimple structureTransmissionOperational systemOperational costs

The invention relates to the field of cloud computing, and particularly relates to a cloud desktop intelligent terminal management system. The system comprises a cloud server, a gateway and an intelligent terminal. The cloud server and the intelligent terminal are connected through the gateway. The cloud server comprises a server host, and an operating system and a client side management system which are installed on the server. The intelligent terminal comprises a terminal, and an operating system and a cloud desktop client side program which are installed on the terminal. The beneficial effects of the cloud desktop intelligent terminal management system are that the resources can be more fully utilized by the cloud framework so that excessive hardware input of the local side can be avoided, the office operation cost can be saved, the pressure of hardware upgrading can be avoided and the cost of subsequent maintenance can also be further reduced due to relatively simple structure and low fault rate of the cloud terminal; and the configuration of the terminal is simplified, the data security is enhanced, centralized management of the resources is also facilitated and maintenance of the system is more convenient.

Owner:HENAN ZHIYE TECH DEV

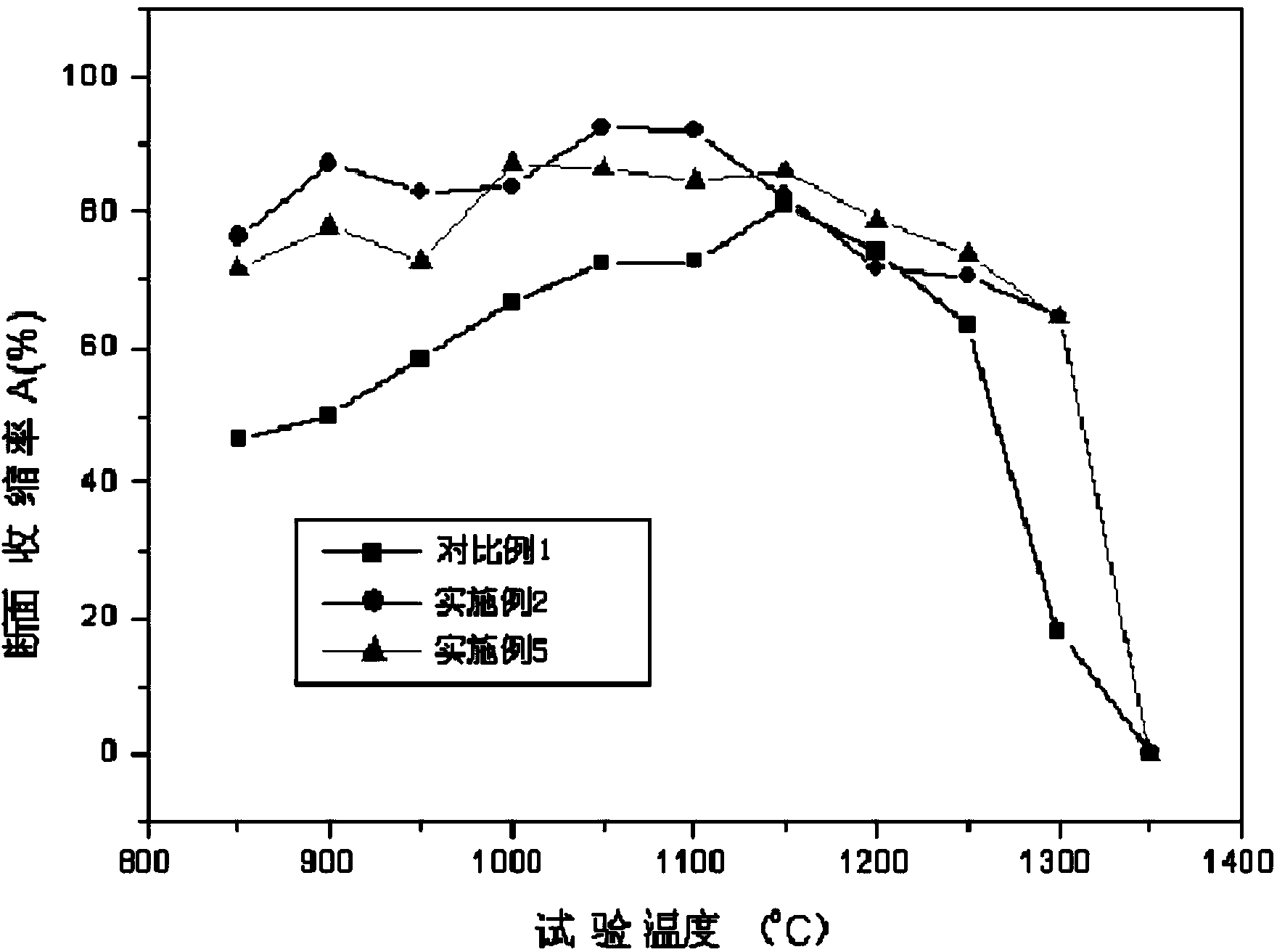

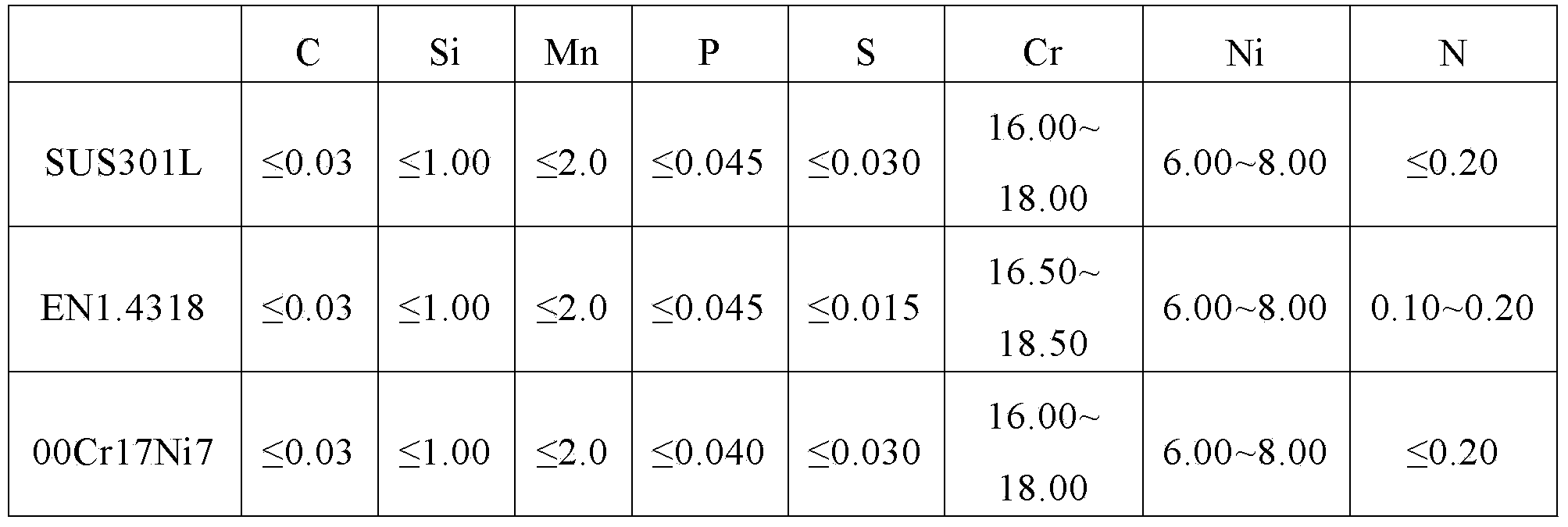

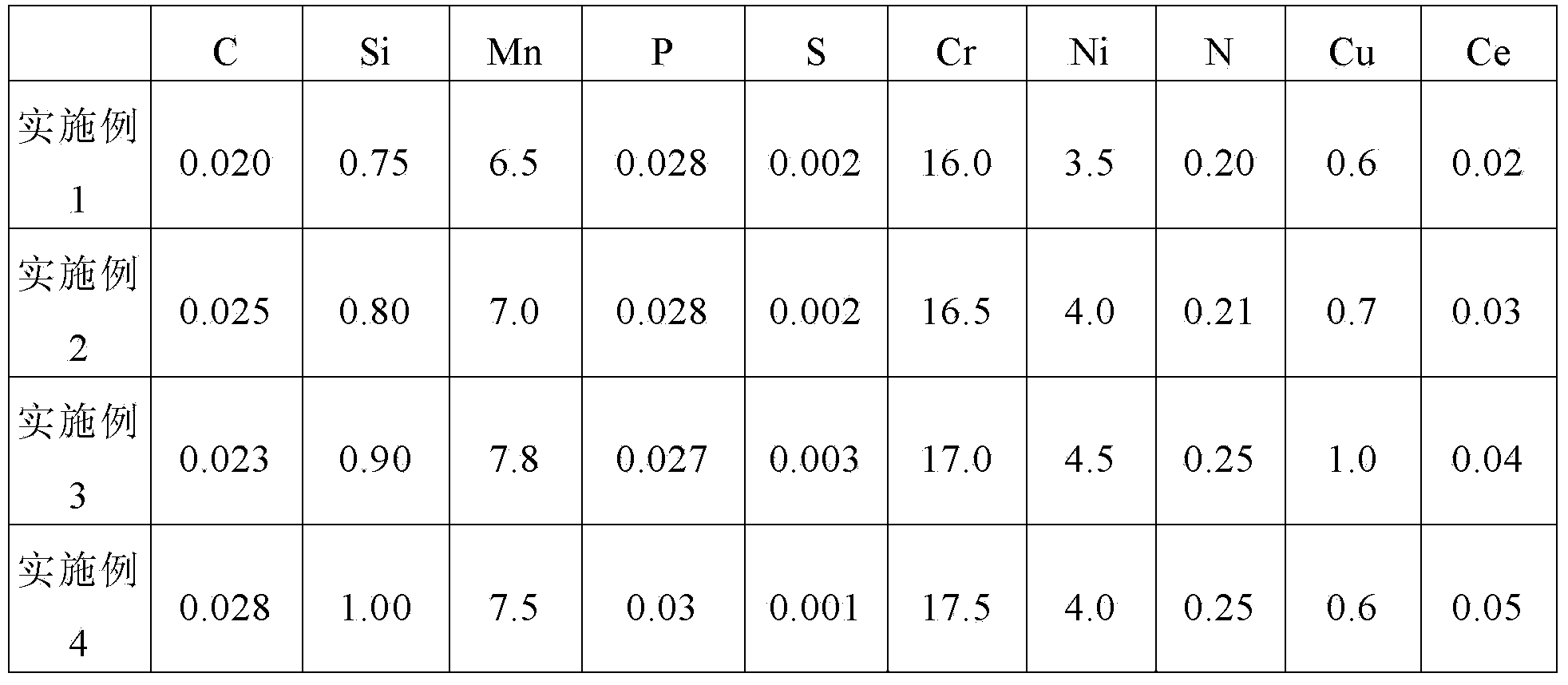

Austenitic stainless steel for urban rail vehicle face plates and manufacturing method of austenitic stainless steel

The invention discloses austenitic stainless steel for urban rail vehicle face plates and a manufacturing method of the austenitic stainless steel. The austenitic stainless steel comprises the following chemical compositions inpercentage by weight: less than 0.03% of C, 0.75-1.0% of Si, 6.5-8.0% of Mn, 16.0-17.5% of Cr, 3.0-4.5% of Ni, 0.15-0.25% of N, 0.5-1.0% of Cu, 0.02-0.05% of Ce, no greater than 0.040% of P, no greater than 0.03% of S, and the balance of Fe and inevitable impurities; the manufacturing method of the austenitic stainless steel comprises the following steps: through the operations of smelting, continuous casting, refining, tombarthite mixture block feeding, and soft stirring, continuous casting slabs are obtained by continuous casting, and the continuous casting slabs are heated; after hot rolling, cooling, reeling, air cooling, solution treating, shot blasting, acid cleaning, cold rolling and annealing acid cleaning are conducted, the finished product austenitic stainless steel is manufactured. According to the austenitic stainless steel for the urban rail vehicle face plates and the manufacturing method of the austenitic stainless steel, the oxidation of the edge part grain boundary caused by overheating of the slab edge part can be avoided; in the process of heating, a layer of dense chromium oxidation film with high adhesion is formed on the surface, the surface quality of the continuous casting slabs is protected, and the guarantee about surface quality control of stainless steel material used for the urban rail vehicle face plates can be provided.

Owner:BAOSTEEL STAINLESS STEEL

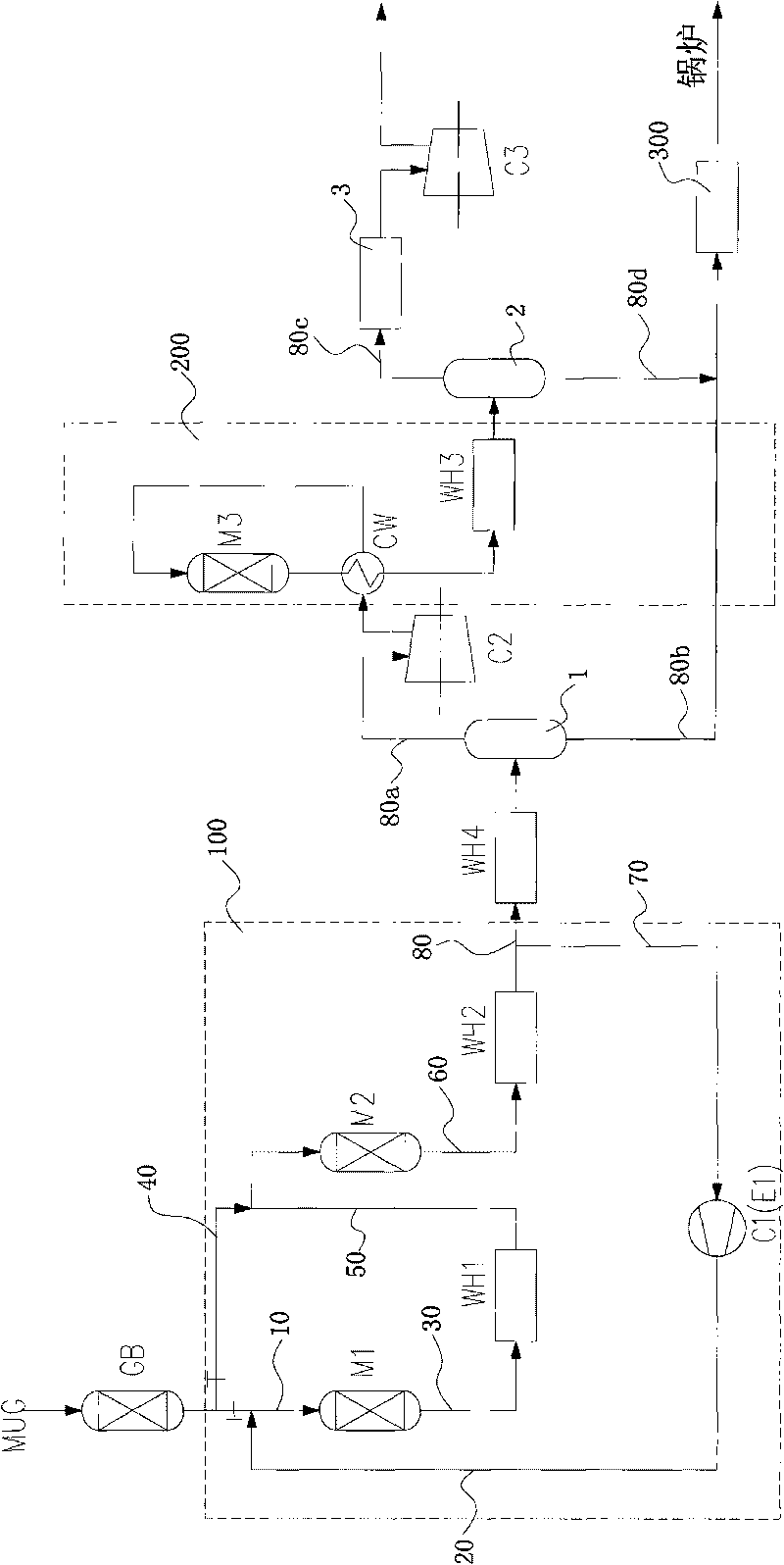

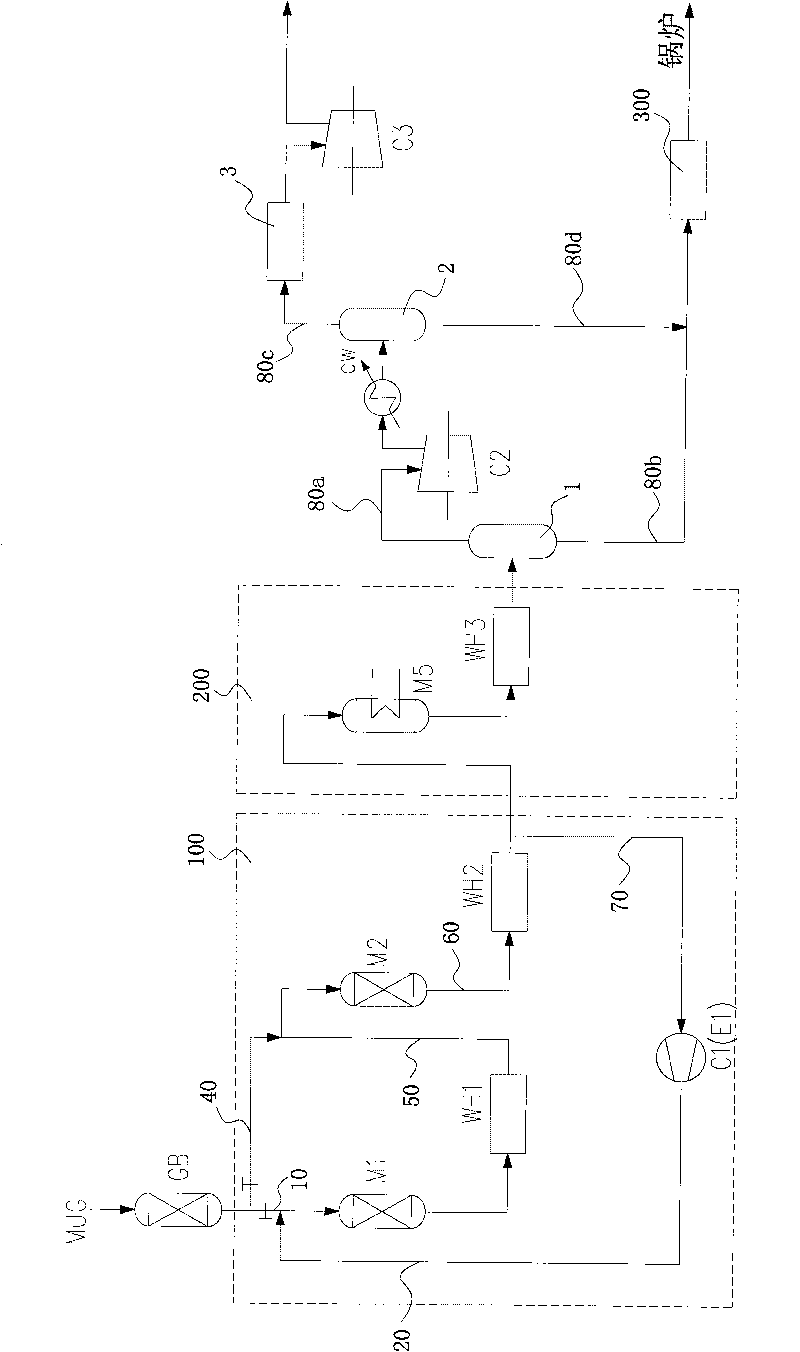

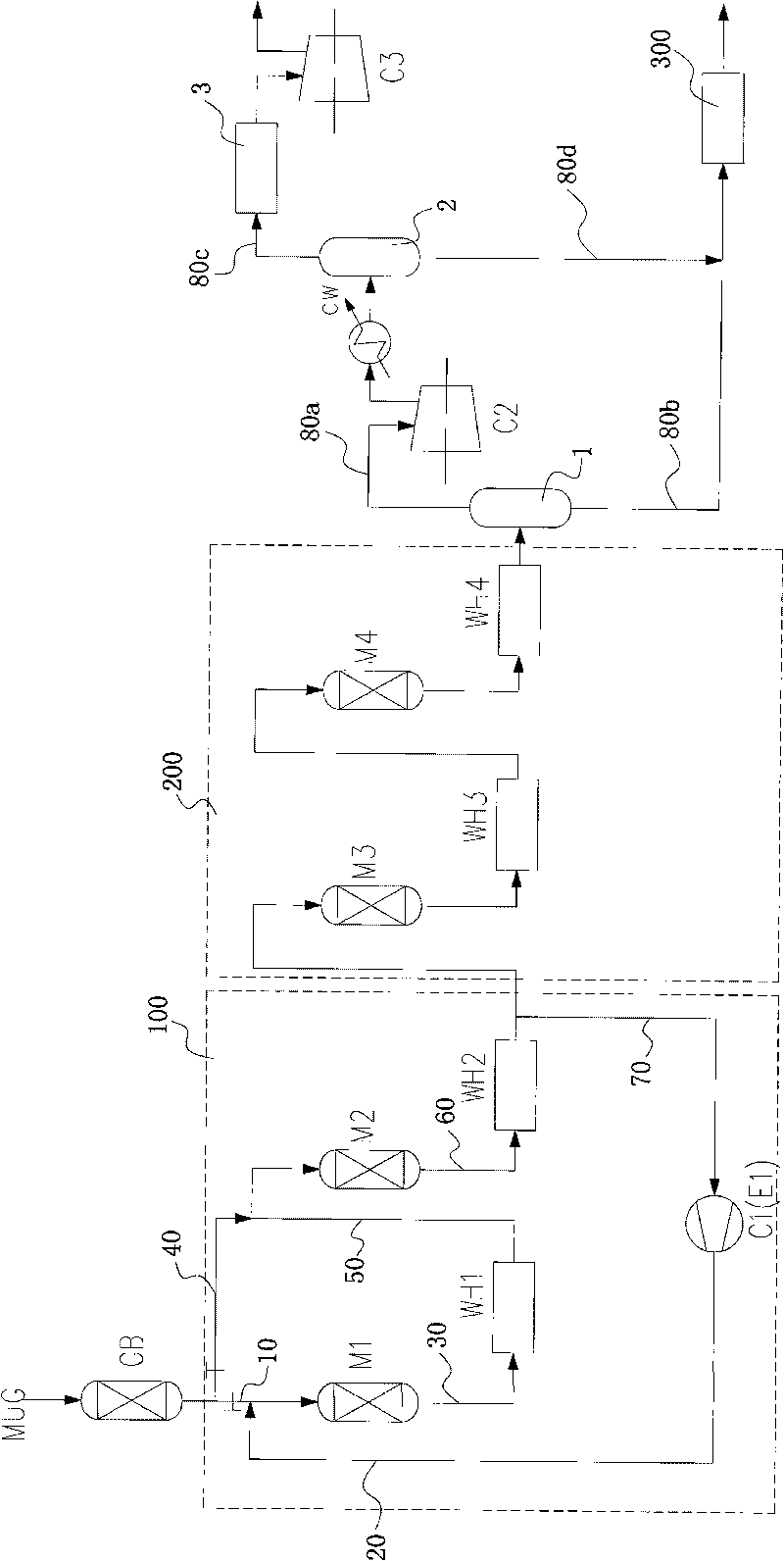

Adiabatic methanation process and device for preparing synthetic natural gas

The invention discloses an adiabatic methanation process for preparing synthetic natural gas, which comprises the following steps of: carrying out methanation; carrying out methanation heat recovery to prepare steam; and processing a condensate, wherein purified synthesis gas enters the methanation step to carry out methanation. The process is characterized in that: the methanation step adopts atleast one adiabatic methanation reactor to carry out methanation and also comprises a methanation refining step; and the methanation refining step is arranged between the methanation step and the step of methanation heat recovery to prepare the steam or arranged in the step of the methanation heat recovery to prepare the steam. The invention also discloses an adiabatic methanation device used foran isothermal methanation process for preparing the synthetic natural gas. The process and the device have the advantages of energy saving, environmental protection and less investment.

Owner:SHANGHAI INT ENG CONSULTING

Sectionalized construction method of deep and large foundation pit

InactiveCN103510520AIncrease stiffnessOptimizing the supporting structure systemExcavationsEngineeringBuilding construction

The invention provides a sectionalized construction method of a deep and large foundation pit, and relates to the technical field of engineering construction of deep and large foundation pits. According to an existing construction method of the deep and large foundation pit, due to the negative factors that the excavation area of the foundation pit is overlarge, and the flat shape is irregular, or a lot of important buildings exist in the influence range of excavation of the foundation pit, the problems that influence of construction of the deep and large foundation pit on the surroundings is excessively high, and the construction period is long are caused. The sectionalized construction method of the deep and large foundation pit comprises the steps of (1) selecting the sectionalized construction method according to the engineering geological conditions of a construction field of the deep and large foundation pit, the nature of the foundation pit and the surroundings of the foundation pit; (2) dividing the deep and large foundation pit into a first foundation pit body, a second foundation pit body and a third foundation pit body, wherein the first foundation pit body, the second foundation pit body and the third foundation pit body are arranged in sequence, and the first foundation pit body and the third foundation pit body are arranged on the two sides of the deep and large foundation pit, and are not adjacent to each other.

Owner:上海市建工设计研究总院有限公司

Ultra-thin broad-width wear-resistant steel plate and method for producing steel plate in large compression ratio

The invention discloses an ultra-thin broad-width wear-resistant steel plate and a method for producing the steel plate in large compression ratio. The method comprises the following steps: a continuous casting billet is heated, wherein the heating temperature is between 1,180 DEG C and 1,250 DEG C, and the soaking time is not less than 40 min; rough rolling and finish rolling are performed on the heated continuous casting billet, so that the steel plate with the thickness of 5-8 mm and the width of 3,000-4,000 mm is obtained, in coarse rolling, under the condition that the temperature is higher than 1,110 DEG C, perfect re-crystallization rolling is performed, and the thickness of the continuous casting billet to be heated is 5-10 times bigger than that of a finished product; in the finish rolling, initial rolling temperature is more than or equal to 1,000 DEG C, the finish rolling temperature is more than or equal to 800 DEG C, the rolling is performed at 5-11 gates, and the ratio of the thickness of the continuous casting billet to the thickness of the steel plate is 30-35; air cooling is performed on the rolled steel plate; quenching treatment and tempering treatment are performed on the cooled steel plate, in the quenching treatment, the steel plate is heated to Ac3+(0-70) DEG C and between 860-950 DEG C, heat preservation is performed for 5-20 min, water quenching is performed, and Ac3 refers to the temperature after austenitic transformation during the heating; in the tempering treatment, the steel plate is heated to 150-350 DEG C, heat preservation is performed for 10-20 min, and then air cooling is performed. The method is high in processing efficiency, and the product with HBW330-510 grade can be obtained.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

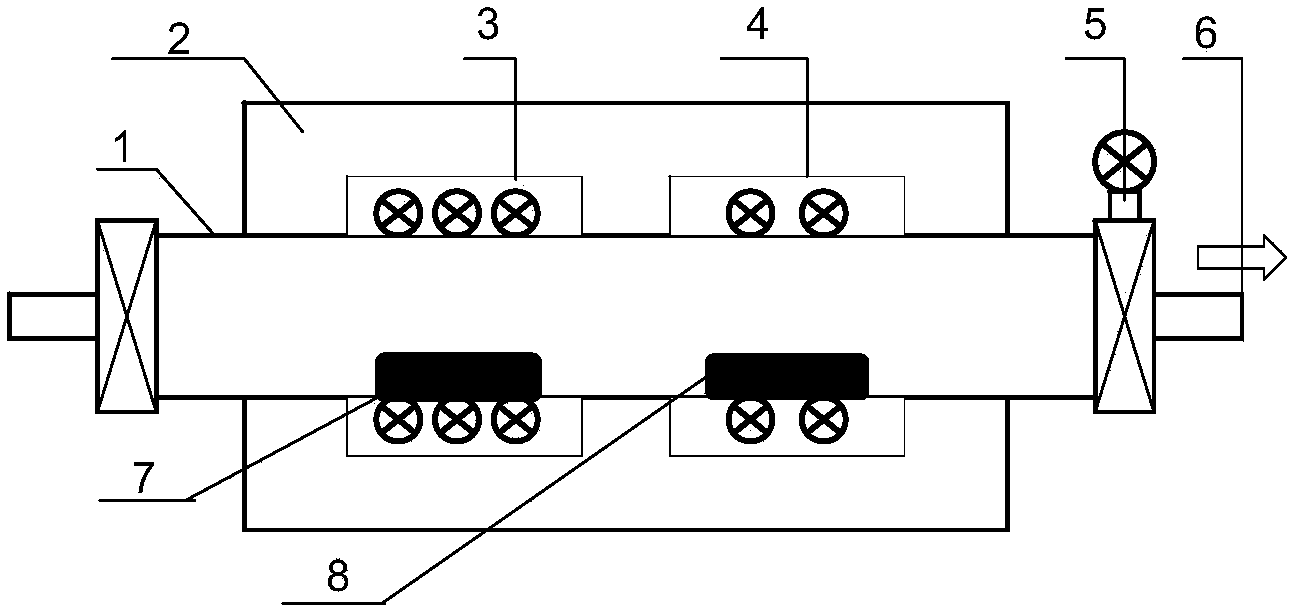

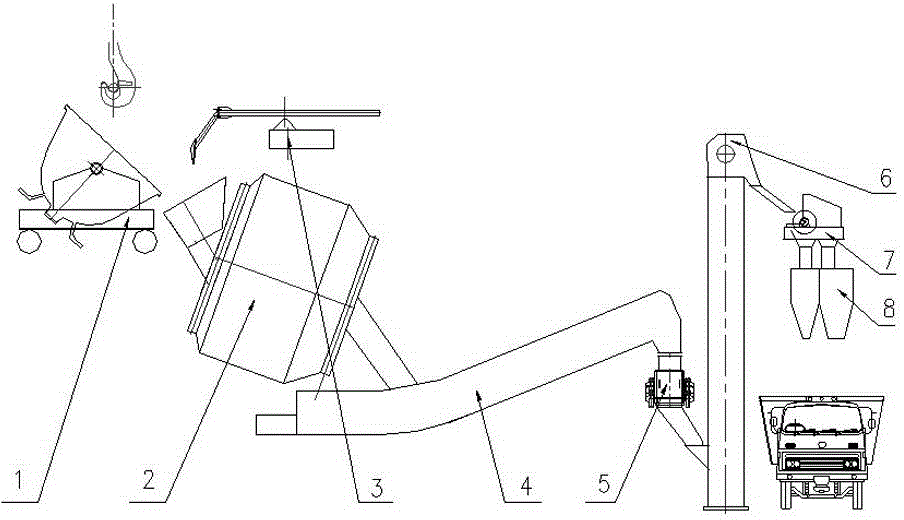

Rotating-drum method based full flow processing system and rotating-drum method based full flow processing technique

InactiveCN104894309AImprove processing rateImprove securityRecycling and recovery technologiesElectrical controlSlag

The invention discloses a rotating-drum method based full flow processing system and a rotating-drum method based full flow processing technique. The system mainly comprises a tipping device, a slagging-off device, a rotating drum device, a finished-product conveying device, a vibratory separation device, a bucket-type lifting device, an online magnetic separation device, a storage device, a dust removal device, a water system device and an electrical control device. The tipping device and the slagging-off device are used for assisted feeding. The rotating drum device is used for core processing of steel slags. The rotating-drum method based full flow processing system and the rotating-drum method based full flow processing technique have the advantages that rotating-drum processing rate of the steel slags can be increased remarkably, slag feeding safety and reliability of a rotating drum can be improved, and travelling crane occupancy rate can be reduced; the steel slags processed by the rotating drum can be subjected to online separation and initial magnetic separation; materials can be stored in a overhead bunker, and environmental pollution and surplus input both caused by secondary and multiple loading and unloading of finished slags are avoided.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

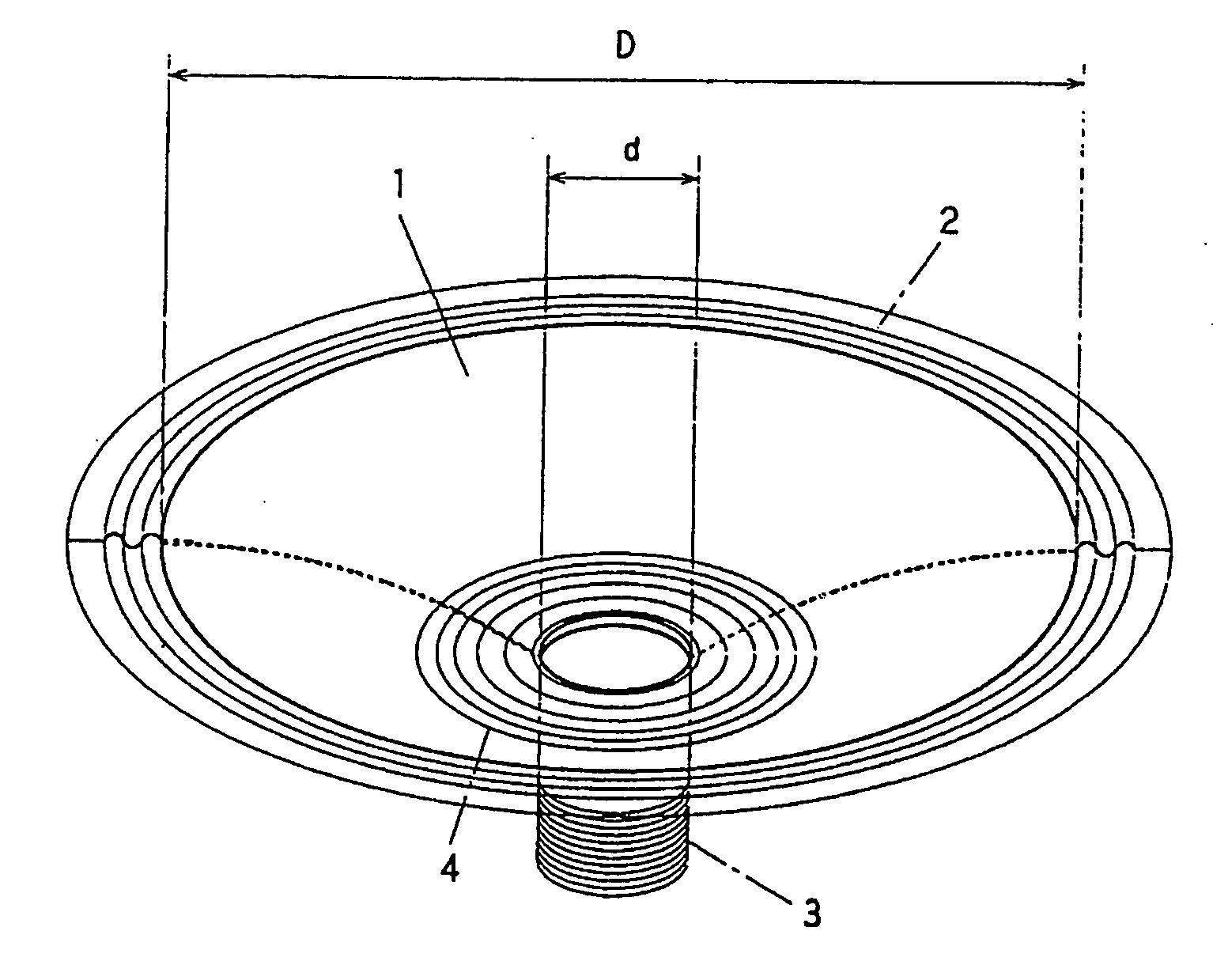

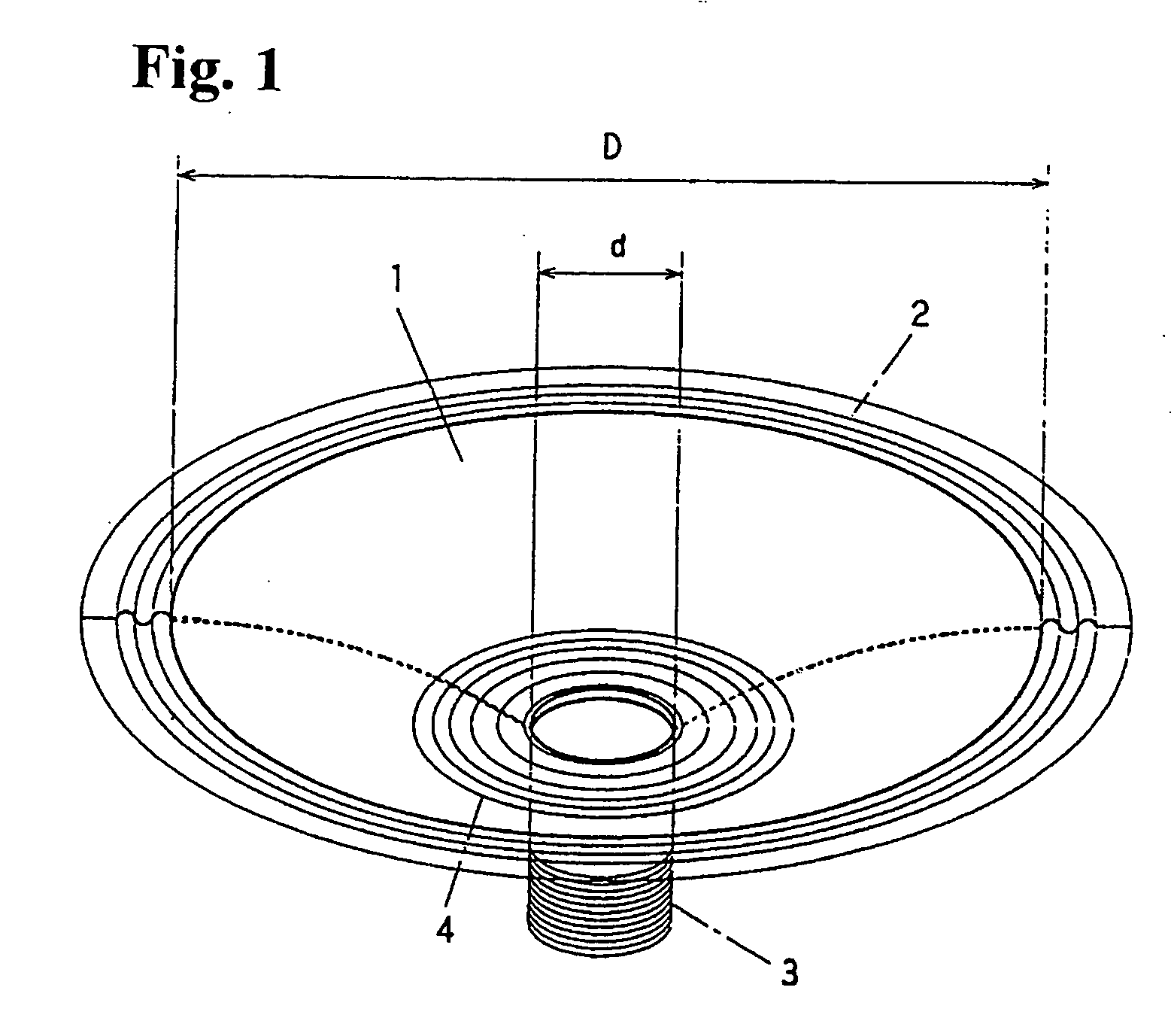

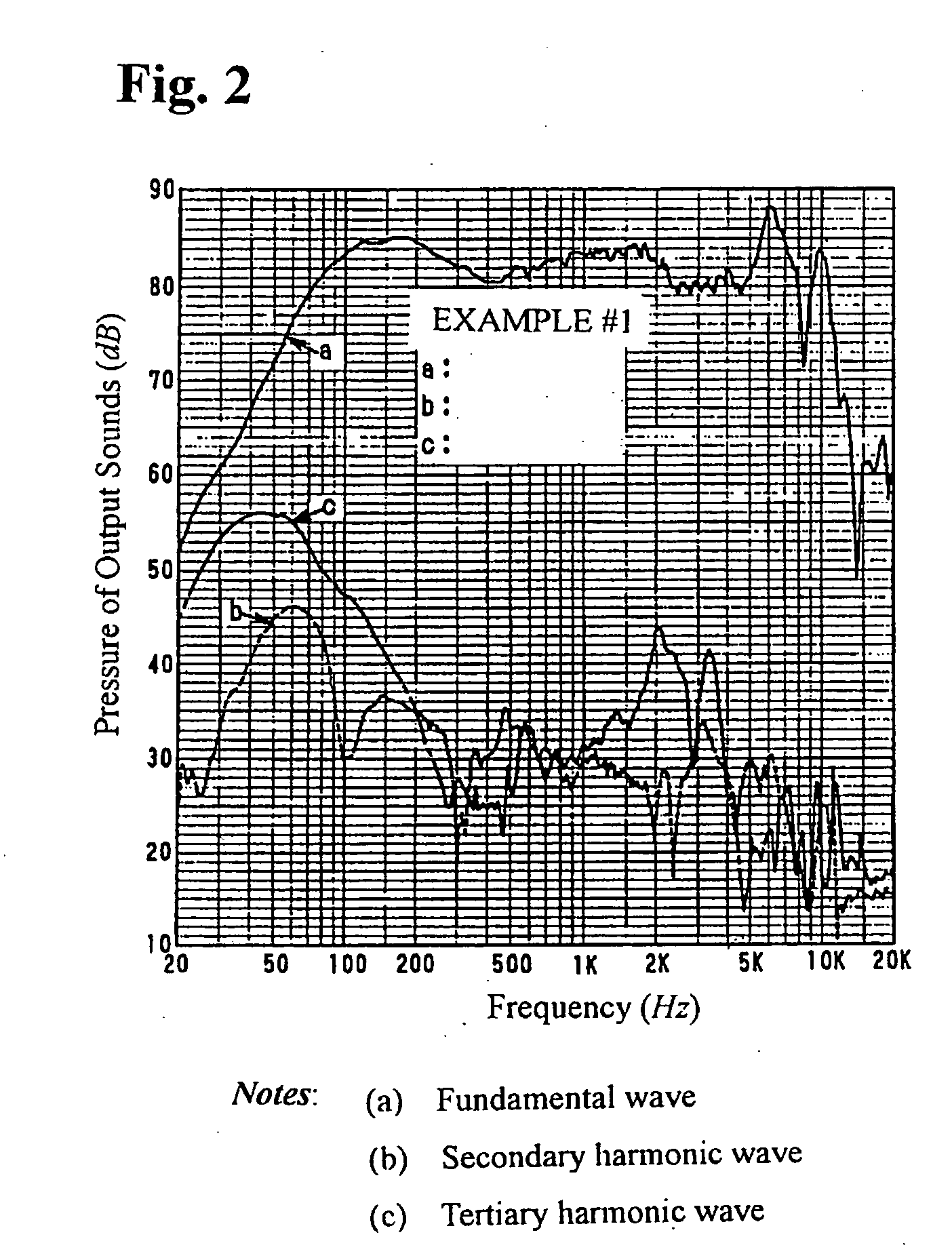

Speaker Diaphragm

InactiveUS20080027158A1High affinityIncrease valueFibre diaphragmsNon-planar diaphragms/conesCelluloseLoudspeaker

A smaller-sized and acoustically excellent speaker diaphragm is inexpensively provided using the mixture of a specially surface-coated woody material and a mass-producible synthetic resin.The mixture is composed of a non-chlorinated synthetic resin and a powdery cellulose material whose particle size falls within a range of from 5 μm to 500 μm. The cellulose material has been subjected to a surface treatment to enhance its affinity to the non-chlorinated synthetic resin, and 30% to 70% by weight of the cellulose material is contained in the mixture.

Owner:PANASONIC CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com