Patents

Literature

70results about How to "Reduce capillary force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

Continuous aluminium oxide base ceramic fibre preparation method

ActiveCN101381225AAvoid instabilityAvoid cracking tendenciesInorganic material artificial filamentsFiberSilicon dioxide

The invention provides a method for preparing a continuous alumina-based ceramic fiber, which relates to an alumina-based ceramic fiber, in particular to a method for preparing a continuous alumina-based ceramic fiber which takes alumina as a main component and adds a second component as a crystalling phase inhibitor. The invention provides a method for preparing the continuous alumina-based ceramic fiber, which is simple in technique and low in cost. The method comprises the steps: preparing alumina sol; preparing silicon dioxide sol; mixing the alumina sol and the silicon dioxide sol to obtain biphase sol, and adding a spinning addition agent into the biphase sol; condensing the biphase sol added with the addition agent and spinning by a dry method to obtain the gel fiber; pyrolyzing the gel fiber to obtain the ceramic fiber; and sintering the ceramic fiber to obtain the continuous alumina-based ceramic fiber.

Owner:FUJIAN ESTABLISHED YATE TAO CO LTD

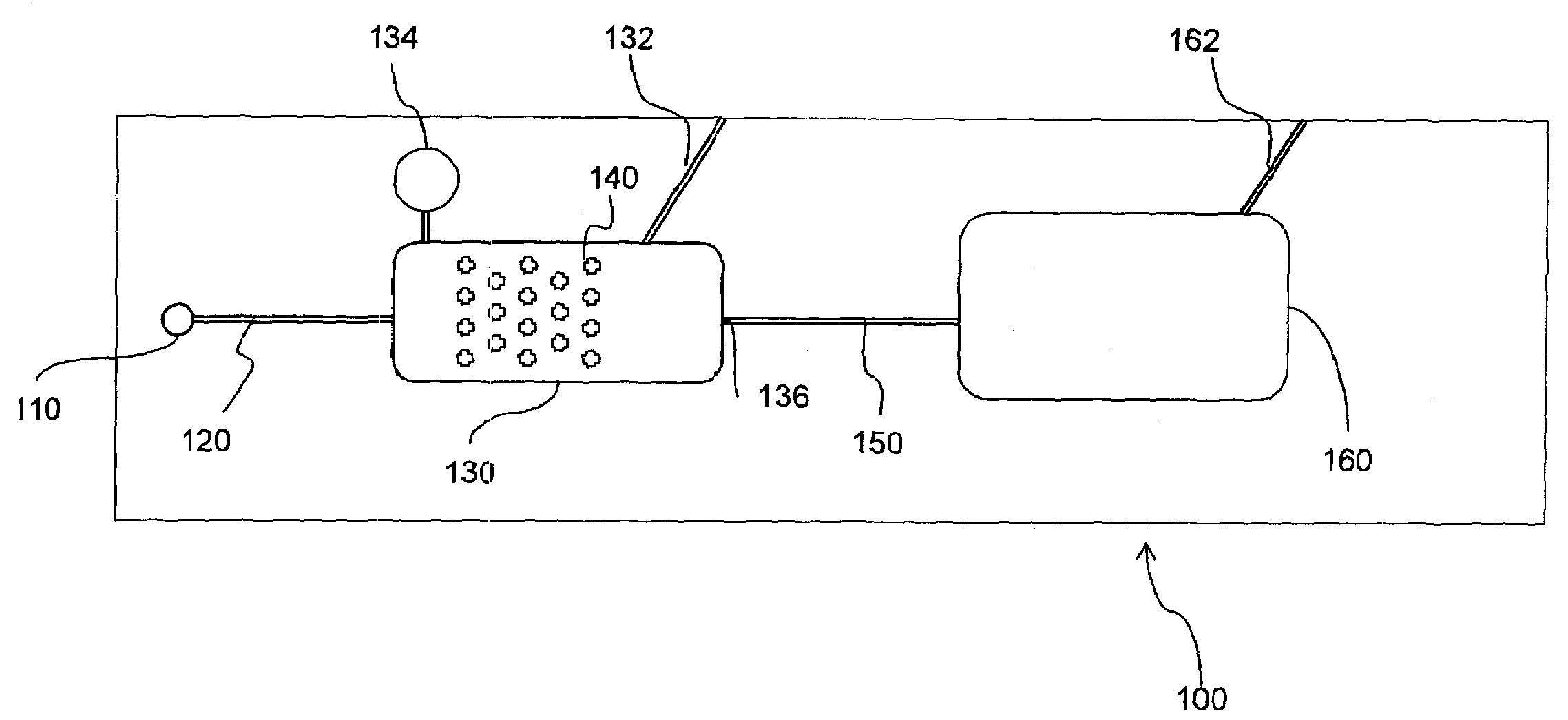

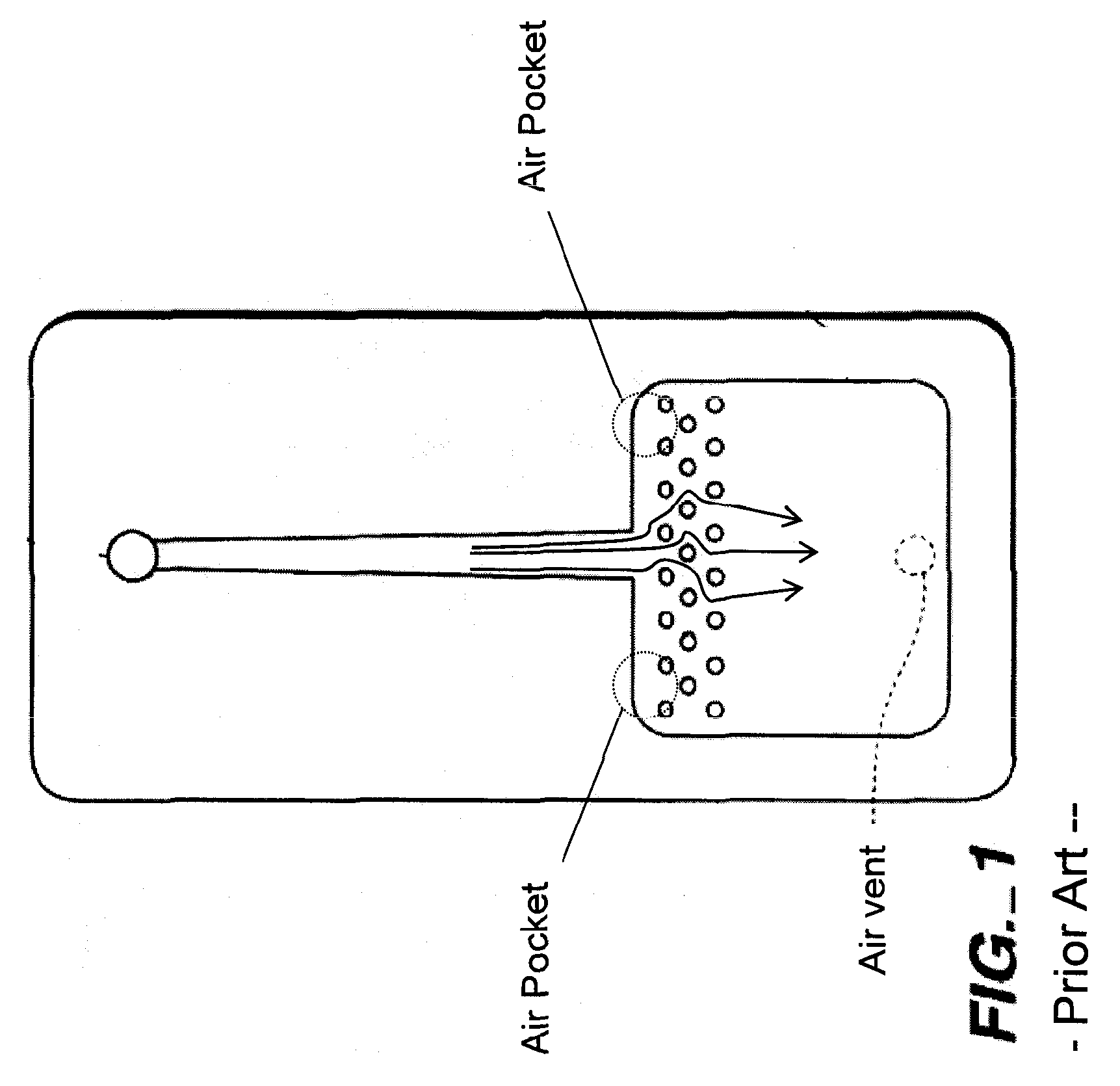

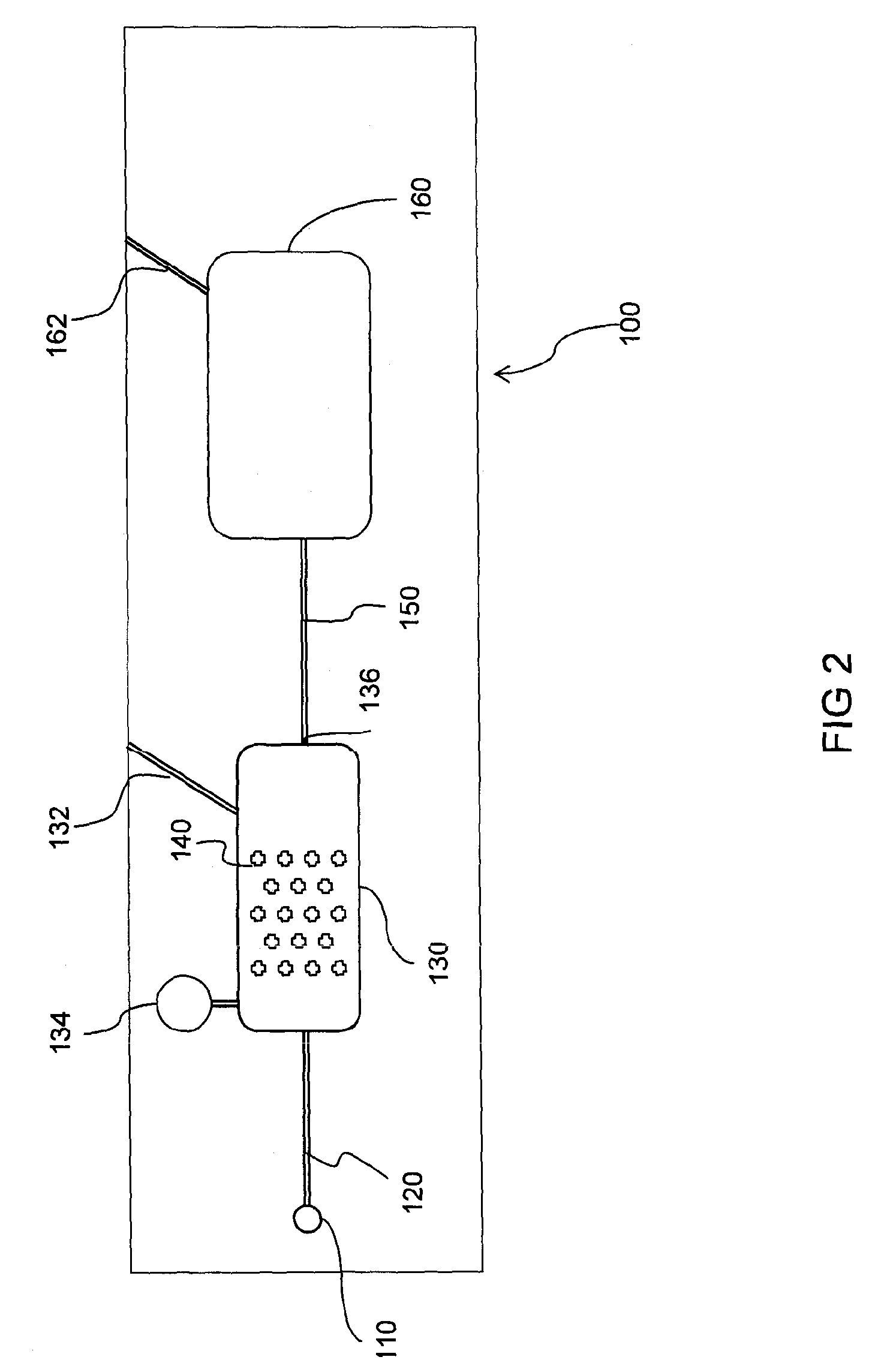

Method and apparatus for entry of specimens into a microfluidic device

InactiveUS20080257754A1Accurate and repeatable assayEvenly distributedImmobilised enzymesBioreactor/fermenter combinationsEngineeringCapillary channel

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

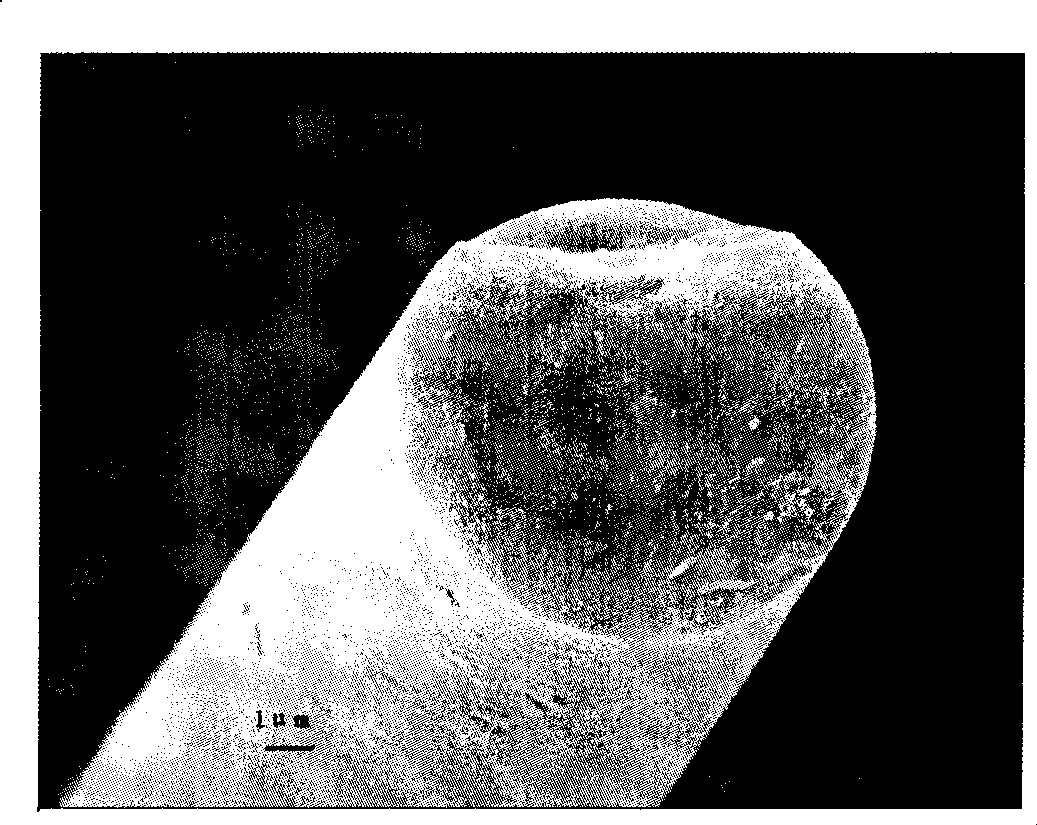

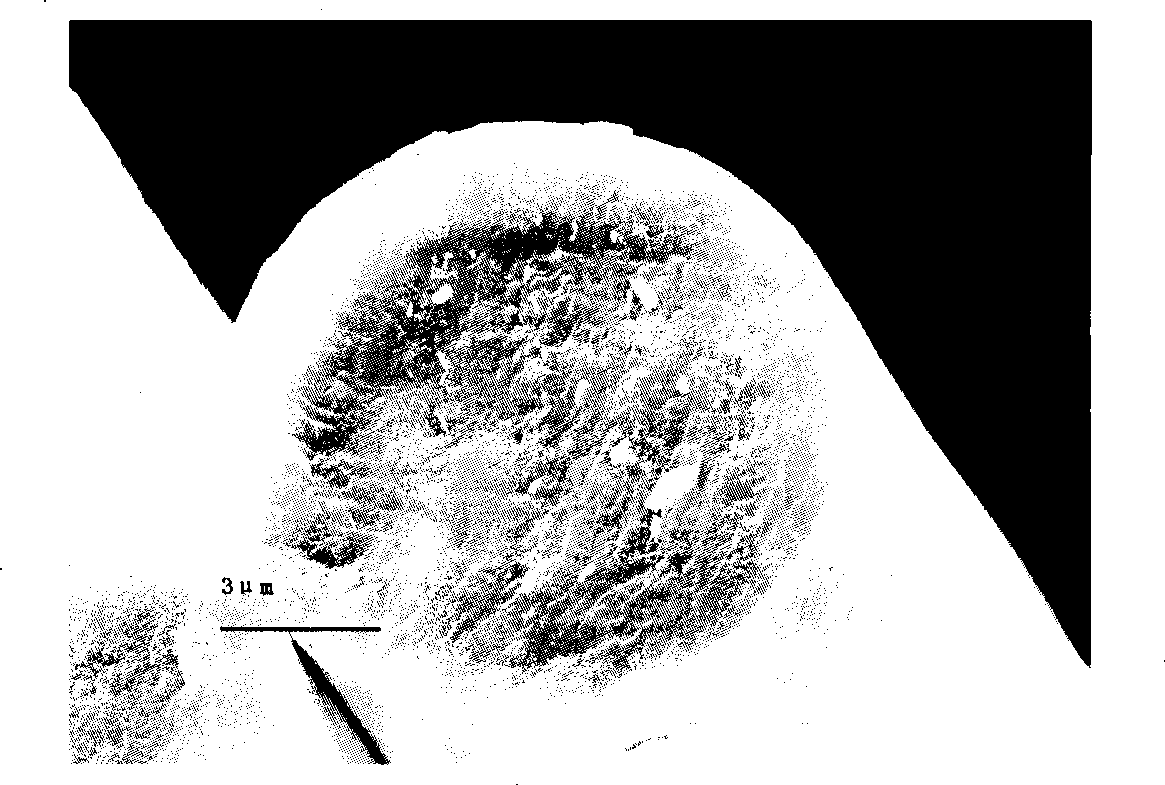

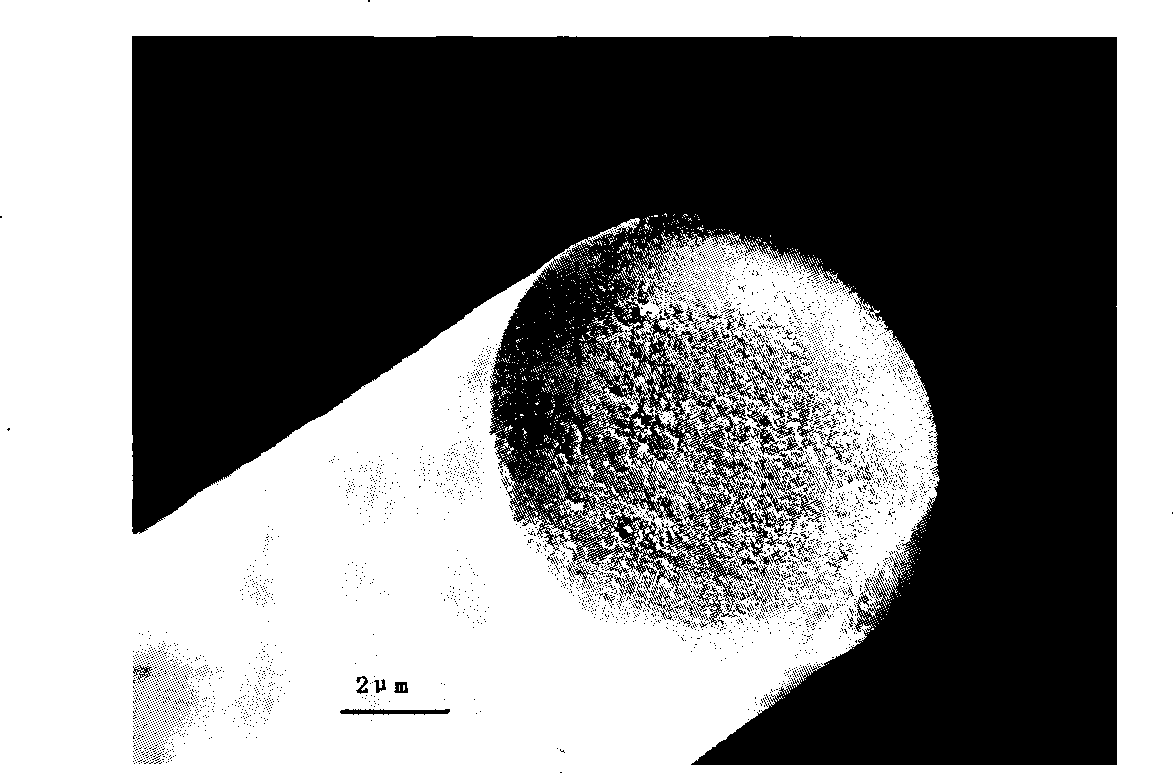

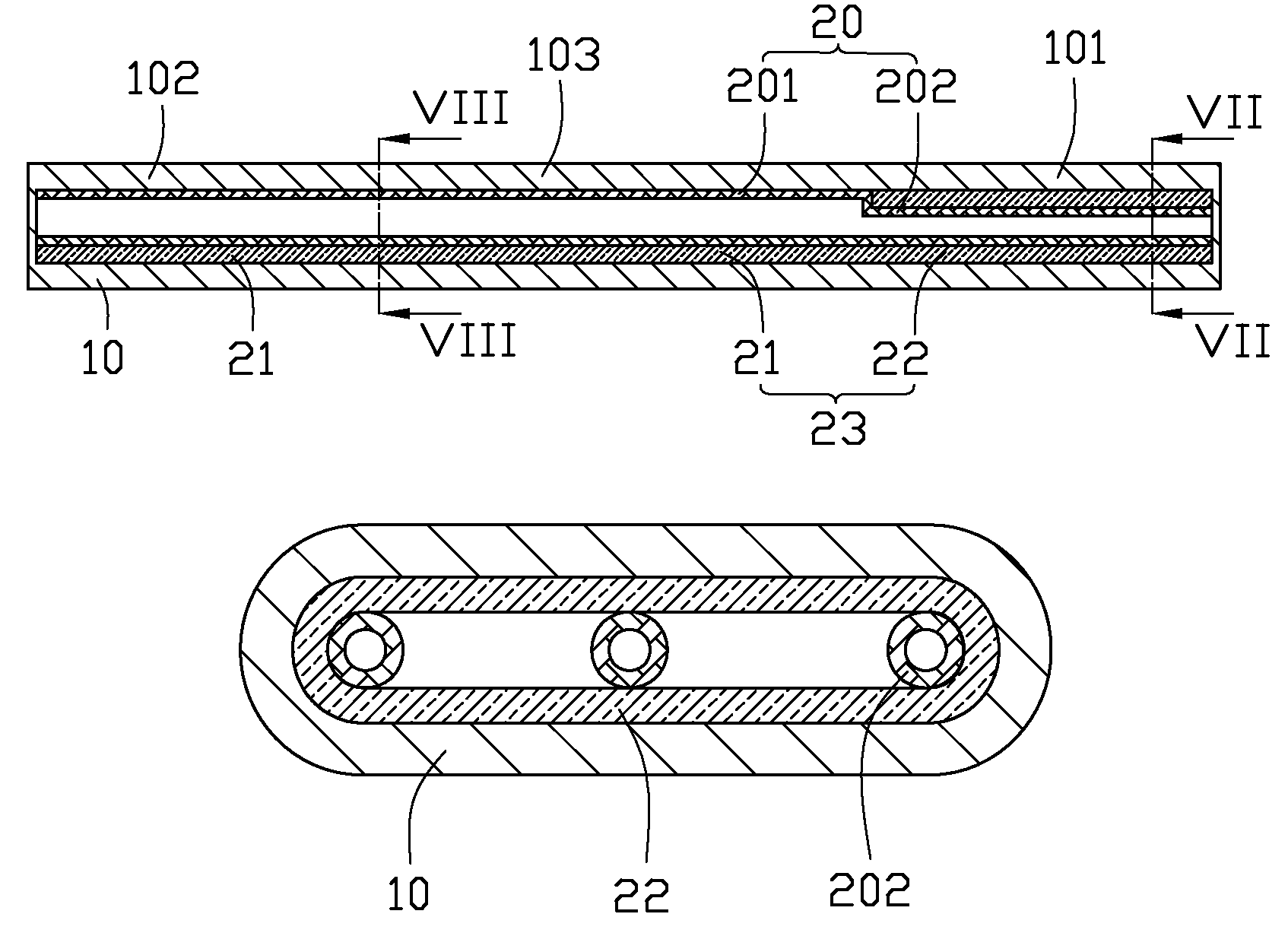

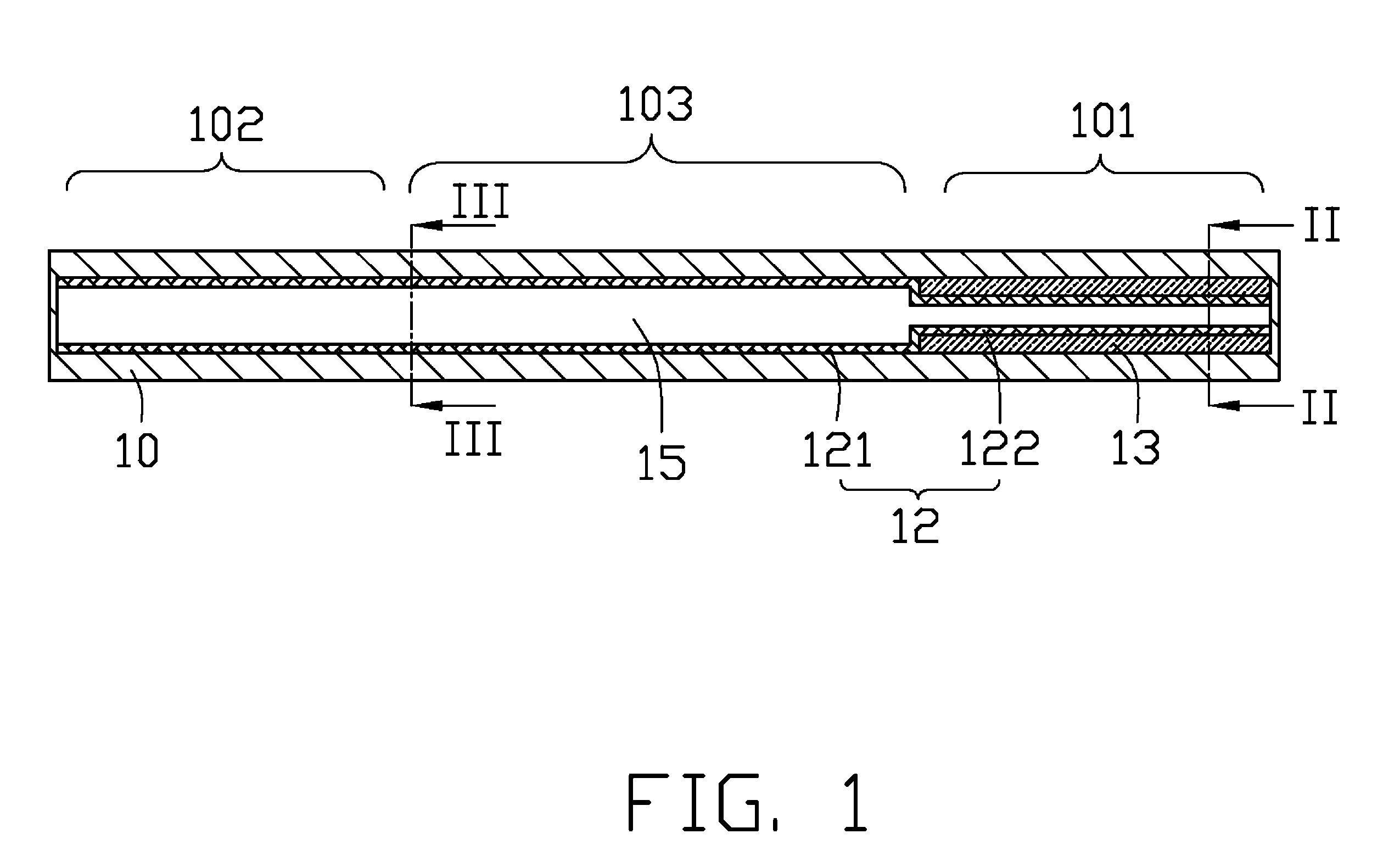

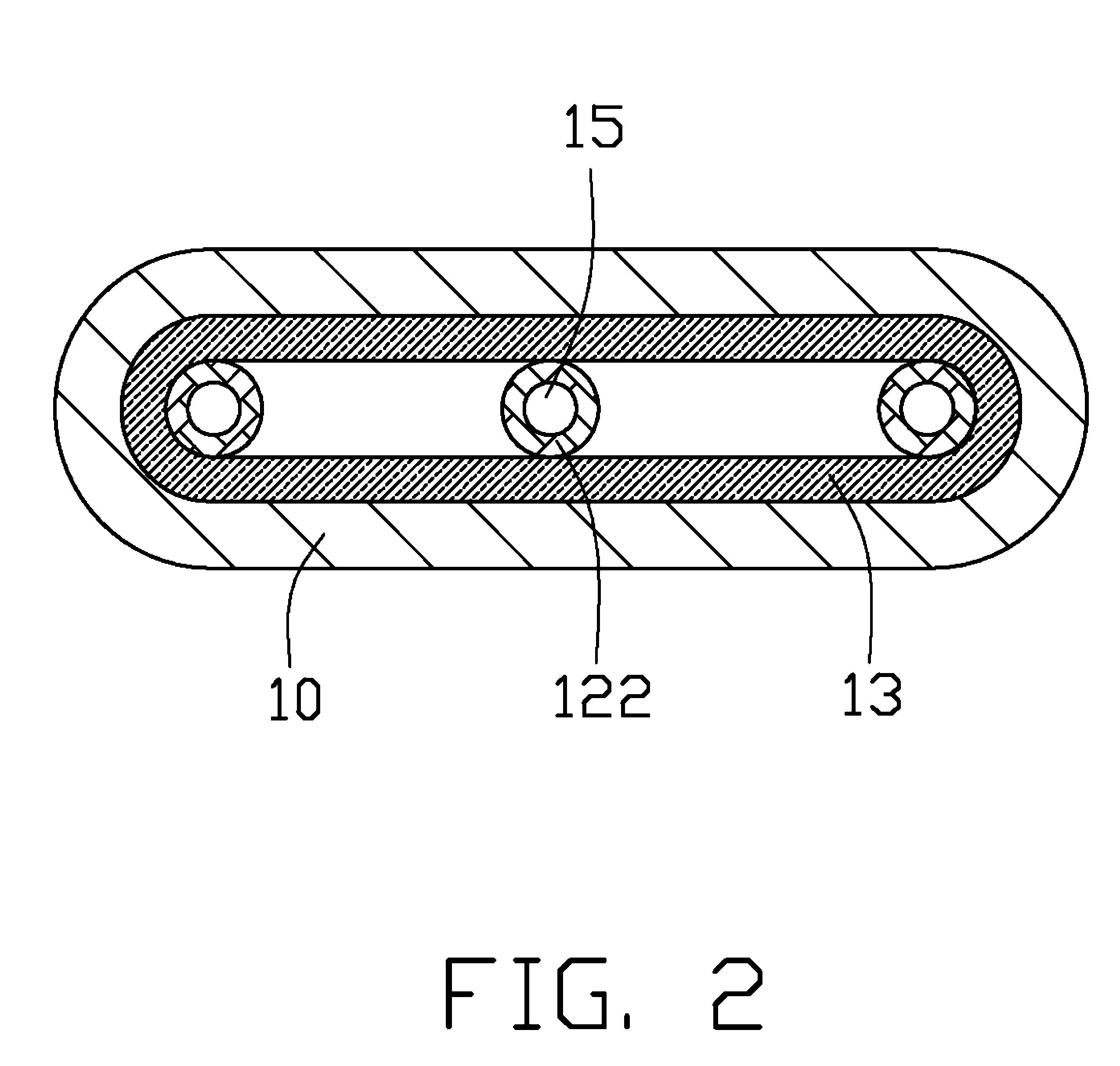

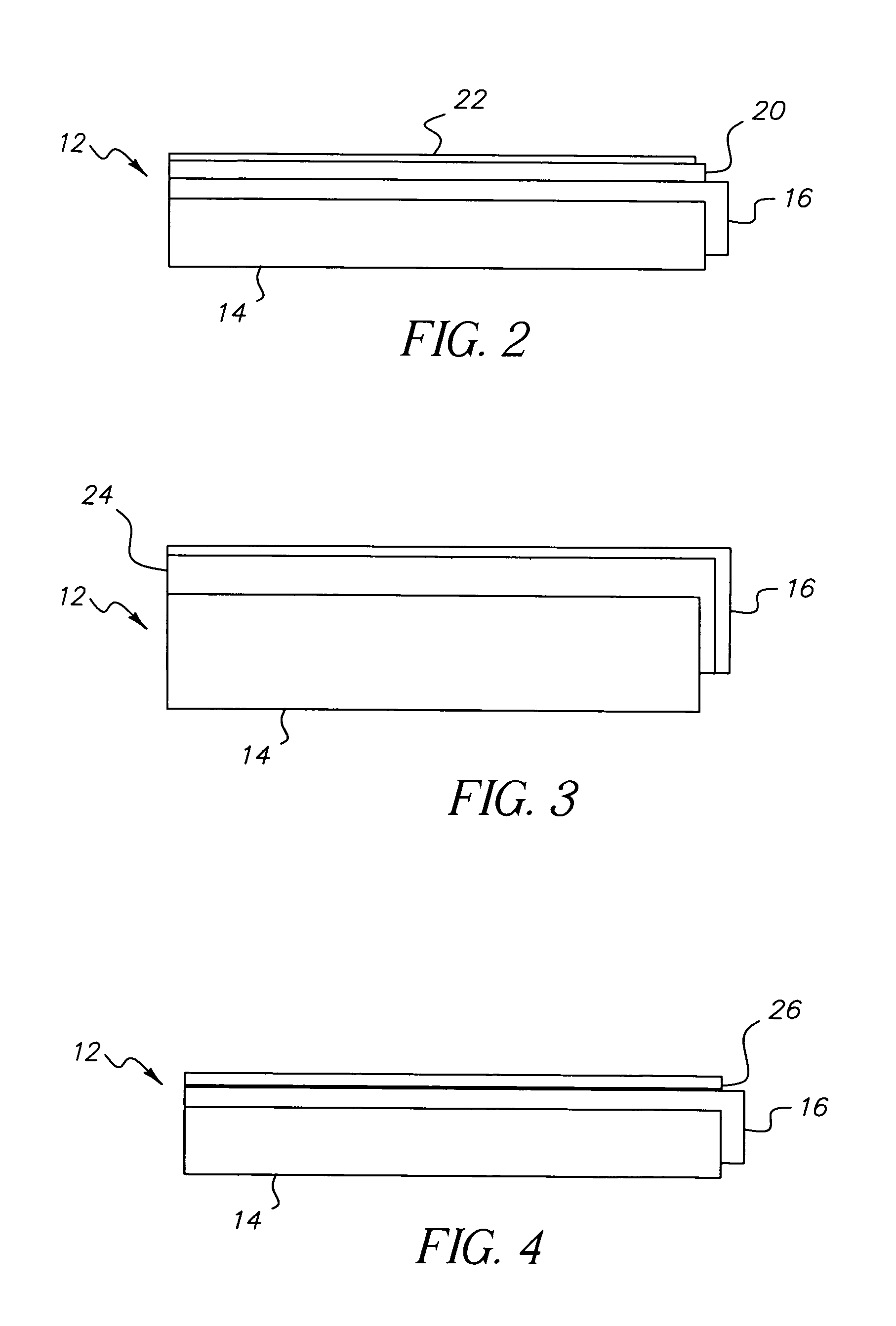

Heat pipe with composite wick structure

InactiveUS7845394B2Lower overall flow resistanceReduce heat transferSolid-state devicesIndirect heat exchangersMechanical engineeringHeat pipe

A heat pipe includes an elongated casing (10), a wick (13), at least one artery mesh (12), and working medium filling in the casing. The casing has an evaporating section (101) and a condensing section (102). The wick is disposed on an inner wall of the evaporating section. The at least one artery mesh includes a large portion (121) and a small portion (122) with an outer diameter smaller than that of the large portion. The small portion is located within and contacts with the wick, and the large portion contacts with the inner wall of the condensing section of the casing. The working medium saturates the wick and the at least one artery mesh.

Owner:HON HAI PRECISION IND CO LTD

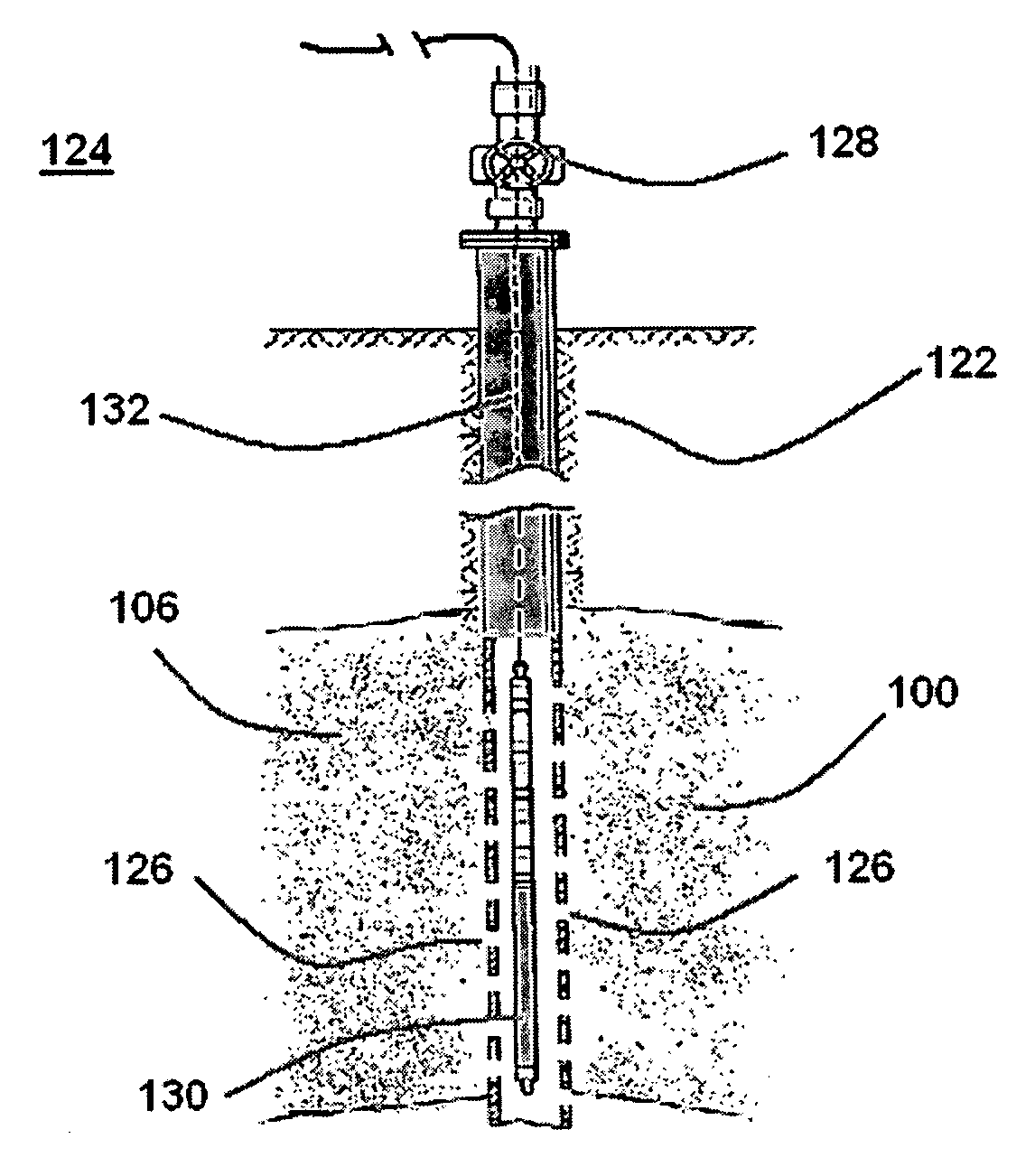

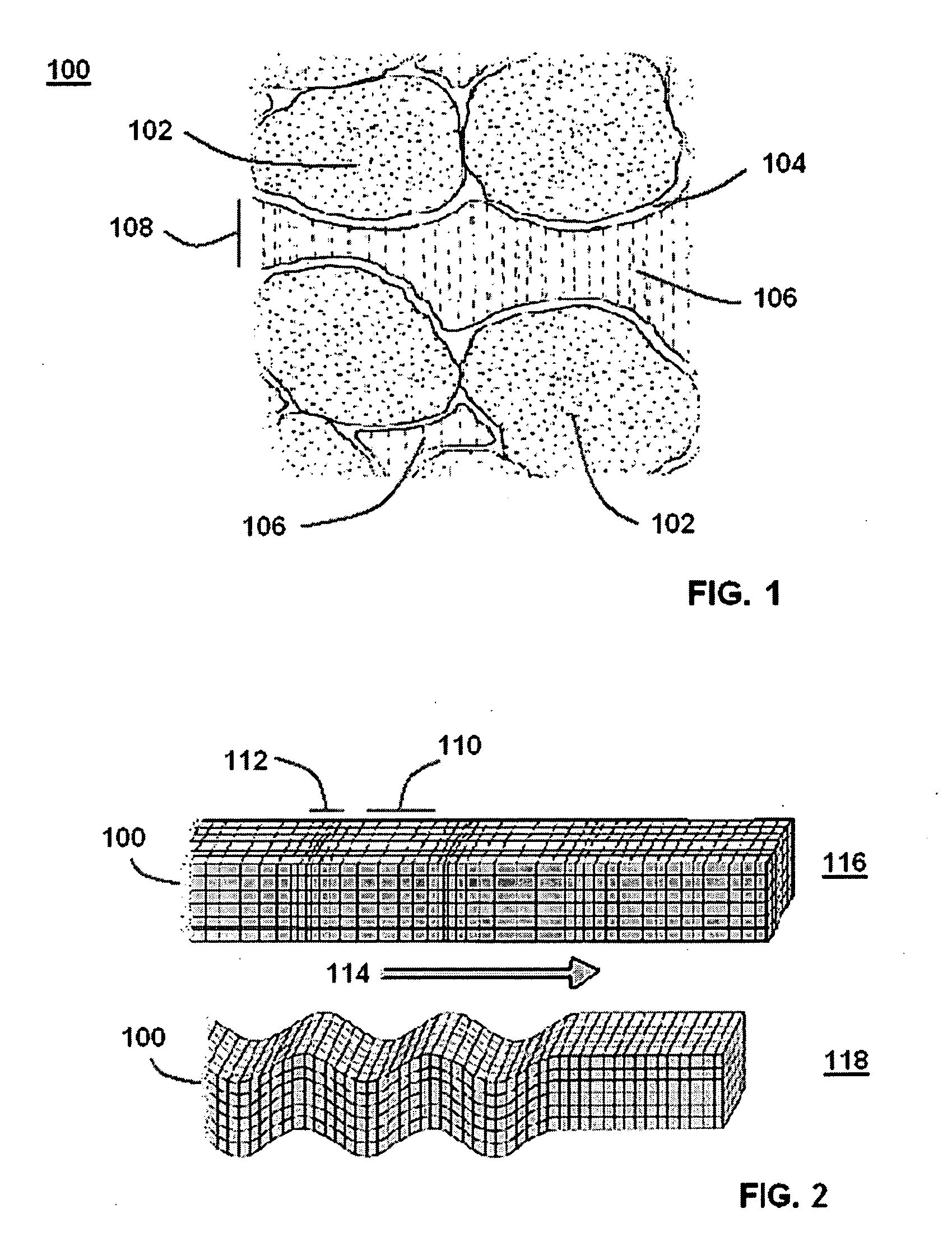

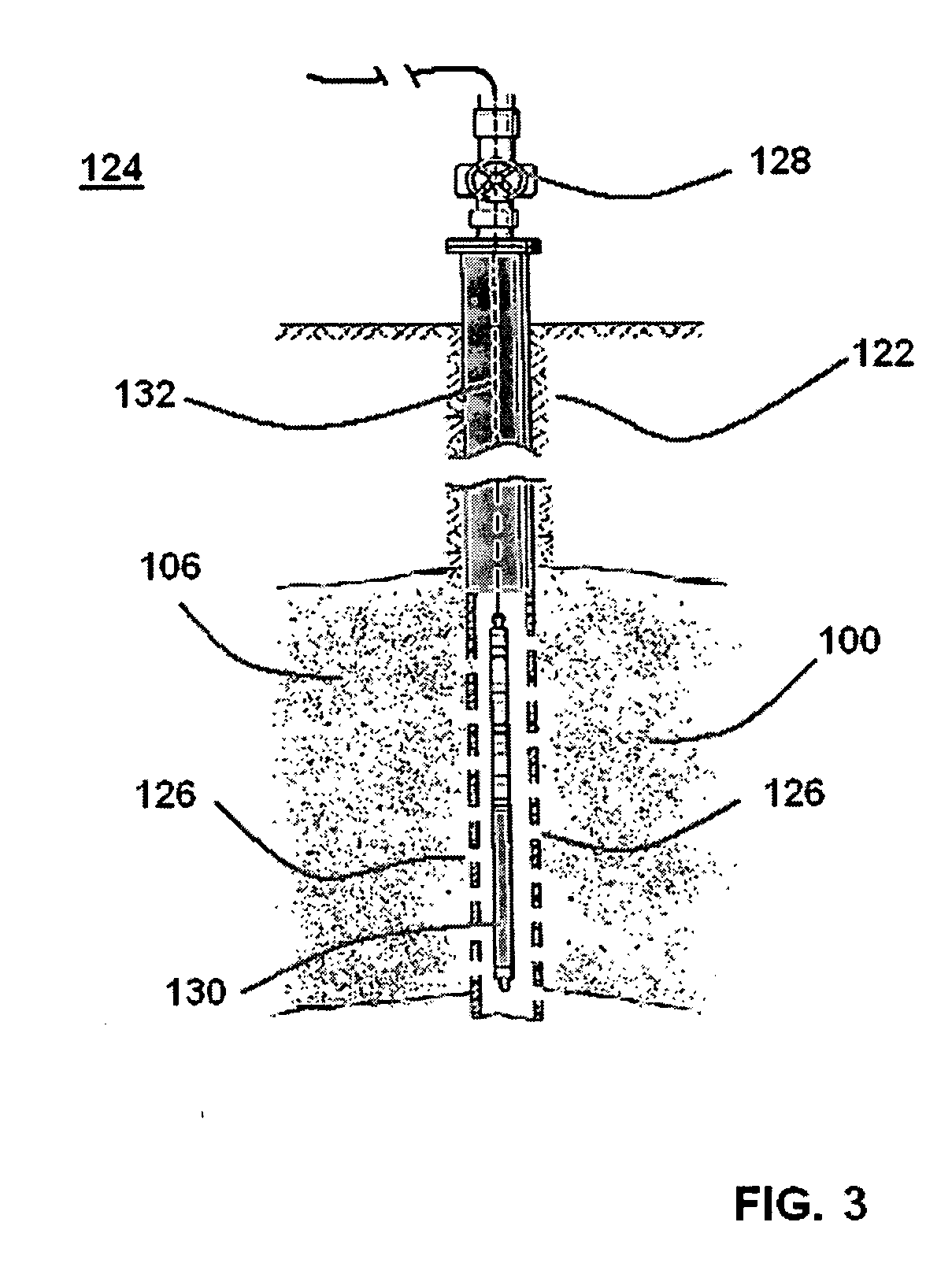

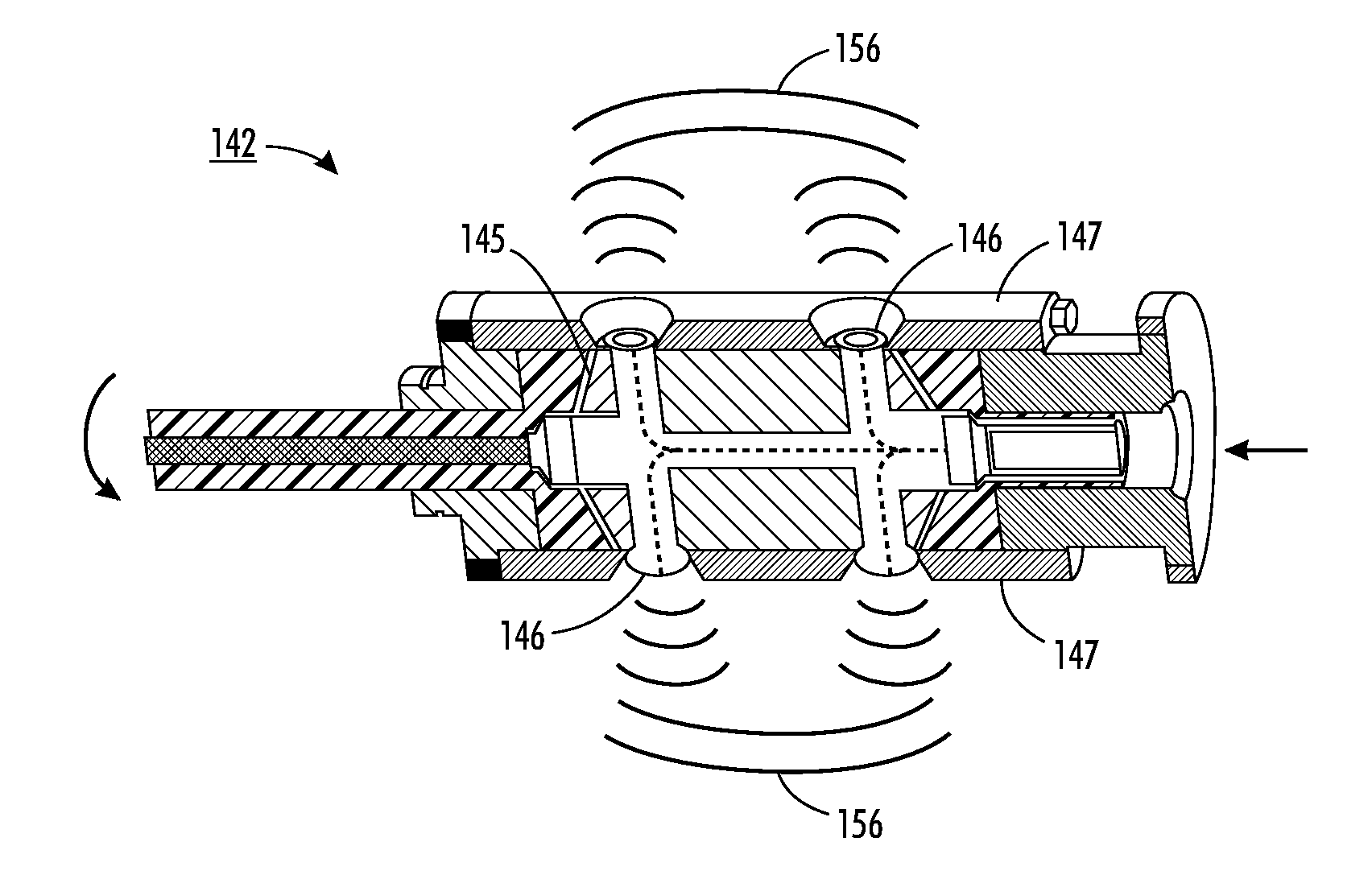

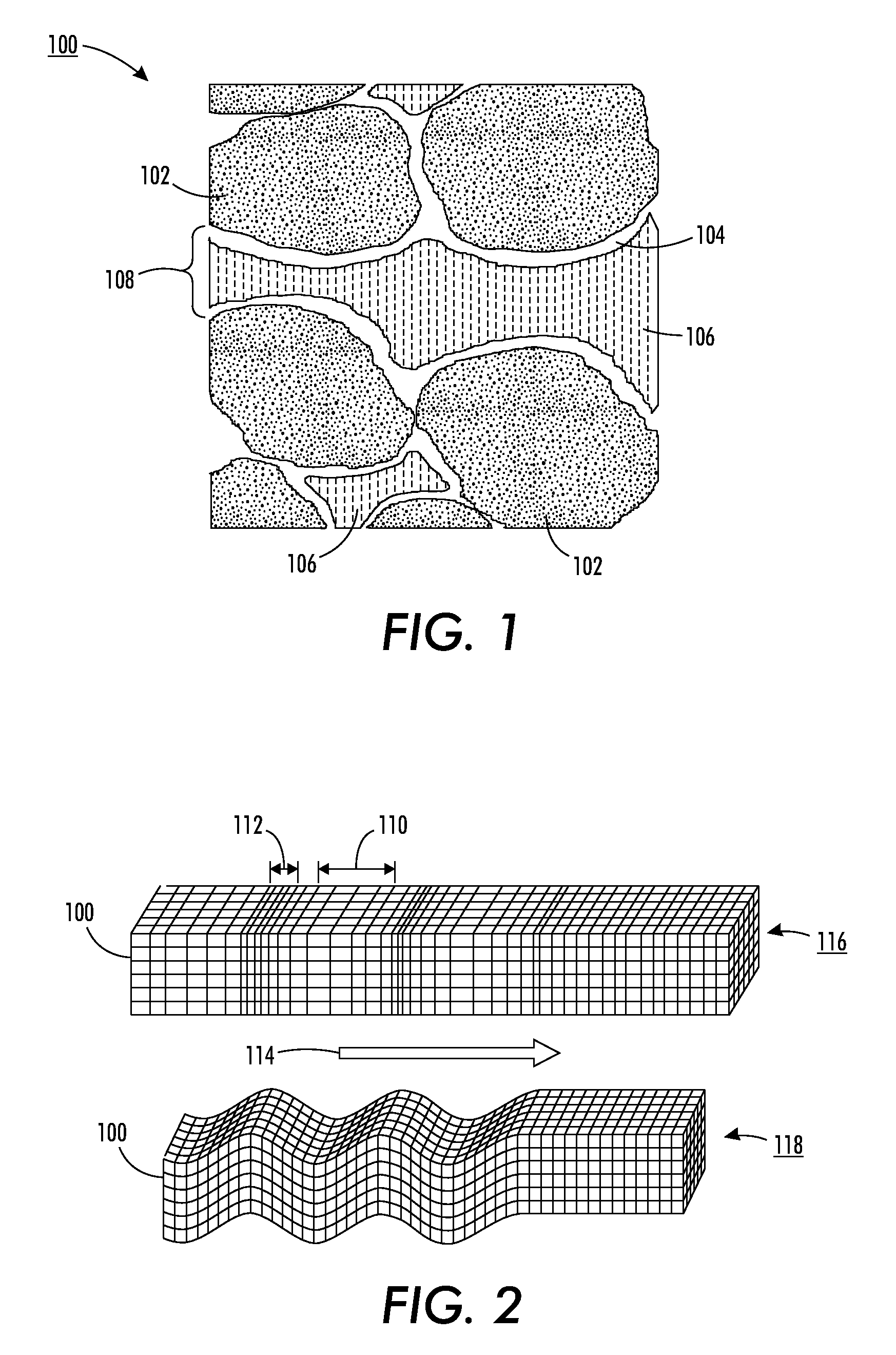

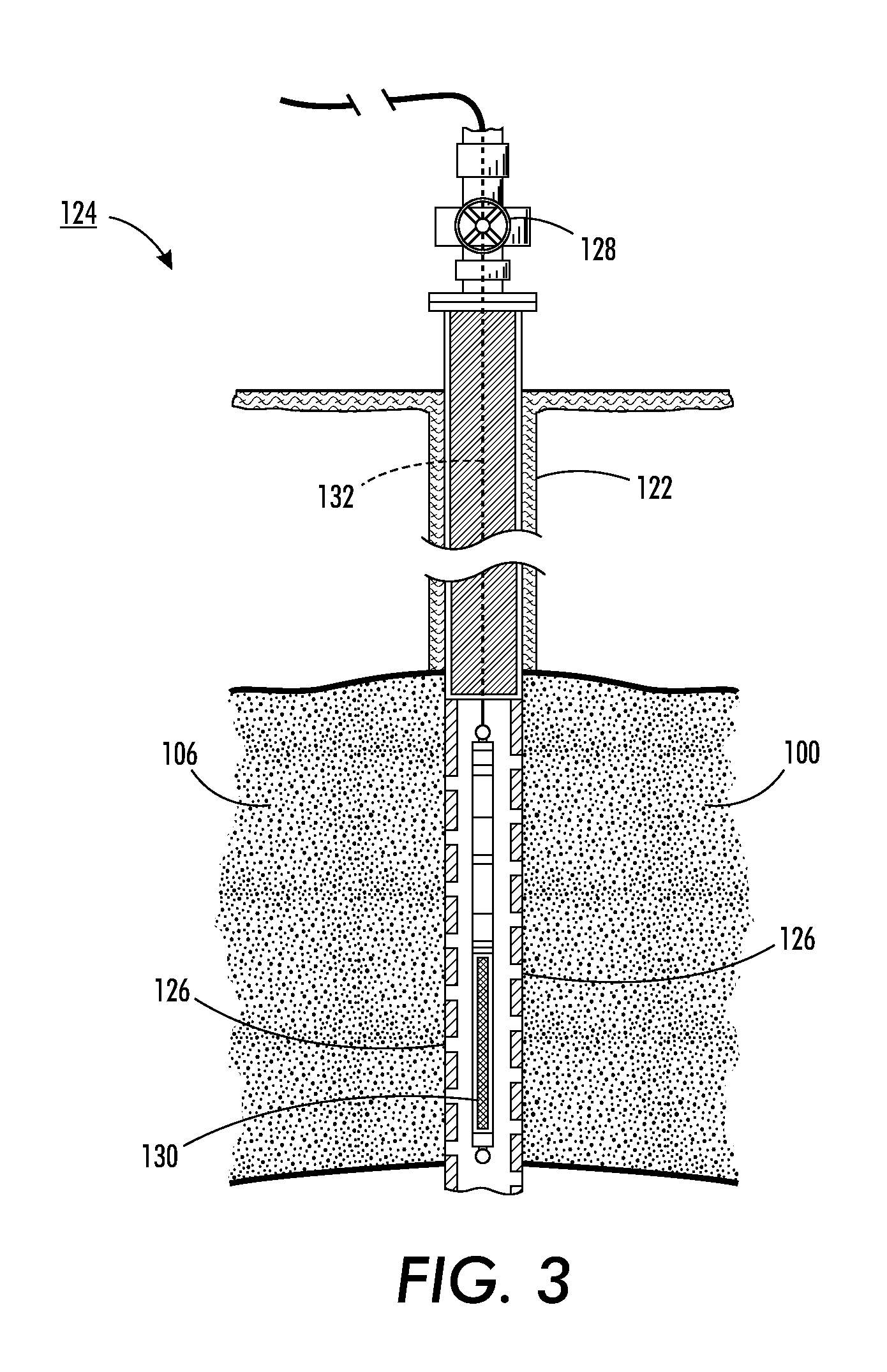

System and method for enhanced oil recovery using an in-situ seismic energy generator

ActiveUS20090200019A1Encourage rate of migrationEnhanced overall recoveryFluid removalVibration devicesElectricityElectro hydraulic

Disclosed are systems and methods for generating seismic acoustic waves, and more particularly a downhole electro-hydraulic seismic pressure wave source to enhance oil recovery.

Owner:HYDROACOUSTICS INC

System and method for enhanced oil recovery using an in-situ seismic energy generator

ActiveUS8113278B2Encourage rate of migrationEnhanced overall recoveryFluid removalVibration devicesElectro hydraulicAcoustic wave

Disclosed is a system and method for enhanced oil recovery using at least one in-situ seismic energy generator for generating seismic acoustic waves. More particularly the system and method employ a downhole electro-hydraulic seismic pressure wave source to enhance the recovery of oil from reservoirs.

Owner:HYDROACOUSTICS INC

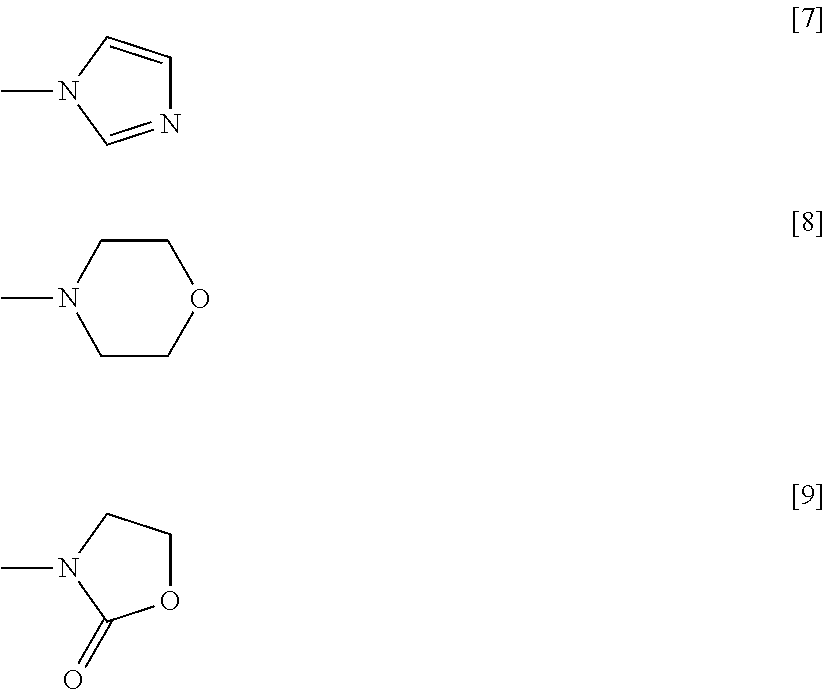

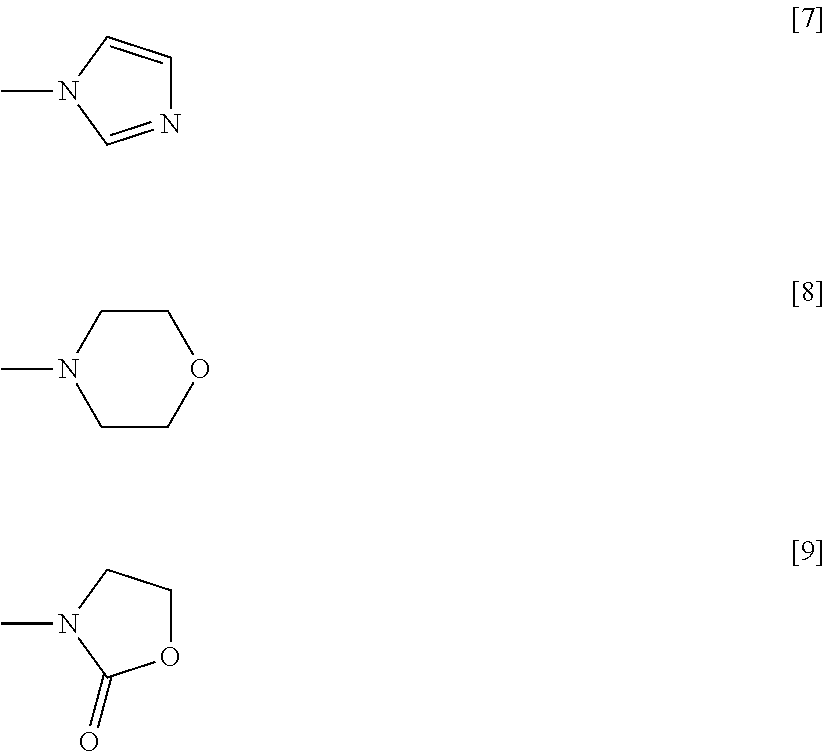

Liquid Chemical for Forming Protecting Film

ActiveUS20120017934A1Improve waterproof performanceReduce capillary forceNon-ionic surface-active compoundsOther chemical processesTrimethylsilyl trifluoromethanesulfonateCompound a

Disclosed is a liquid chemical for forming a water-repellent protecting film at least on a surface of a recessed portion of an uneven pattern at the time of cleaning a wafer having a finely uneven pattern at its surface and containing silicon at least a part of the uneven pattern. This liquid chemical contains a silicon compound A represented by the general formula: R1aSi(H)bX4-a-b and an acid A, the acid A being at least one selected from the group consisting of trimethylsilyl trifluoroactate, trimethylsilyl trifluoromethanesulfonate, dimethylsilyl trifluoroactate, dimethylsilyl trifluoromethanesulfonate, butyldimethylsilyl trifluoroactate, butyldimethylsilyl trifluoromethanesulfonate, hexyldimethylsilyl trifluoroacetate, hexyldimethylsilyl trifluoromethanesulfonate, octyldimethylsilyl trifluoroactate, octyldimethylsilyl trifluoromethanesulfonate, decyldimethylsilyl trifluoroacetate and decyldimethylsilyl trifluoromethanesulfonate.

Owner:CENT GLASS CO LTD

Chemical for Forming Protective Film

ActiveUS20130056023A1Excellent water-repellencyReduce wettabilityOther chemical processesSemiconductor/solid-state device manufacturingChemistryCompound (substance)

Disclosed is a liquid chemical for forming a water repellent protective film on a wafer that has at its surface a finely uneven pattern and contains silicon element at least at a part of the uneven pattern, the water repellent protective film being formed at least on surfaces of recessed portions of the uneven pattern at the time of cleaning the wafer. The liquid chemical contains: a silicon compound (A) represented by the general formula R1aSi(H)b(X)4−a−b and an acid; or a silicon compound (C) represented by the general formula R7gSi(H)h(CH3)w(Z)4−g−h−w and a base that contains no more than 35 mass % of water. The total amount of water in the liquid chemical is no greater than 1000 mass ppm relative to the total amount of the liquid chemical. The liquid chemical can improve a cleaning step that easily induces pattern collapse.

Owner:CENT GLASS CO LTD

Method of Preparing Liquid Chemical for Forming Protective Film

InactiveUS20130255534A1Reduce capillary forceGood for persistenceOther chemical processesSemiconductor/solid-state device detailsOrganic solventCompound (substance)

Disclosed herein is a method for preparing a liquid chemical for forming a water-repellent protective film, the liquid chemical being for forming the water-repellent protective film at the time of cleaning a wafer having at its surface an uneven pattern and containing silicon element at least at a part of the uneven pattern at least on surfaces of recessed portions of the uneven pattern, the liquid chemical containing a nonaqueous organic solvent, a silylation agent, and an acid or a base. The method includes (i) adjusting a water content of the nonaqueous organic solvent to 200 mass ppm or less by dehydration; and (ii) mixing the nonaqueous organic solvent, the silylation agent, and the acid or the base after the adjusting step.

Owner:CENT GLASS CO LTD

Liquid Chemical for Forming Protecting Film

ActiveUS20110162680A1Reduce capillary forceEasy to operateOrganic chemistryAnionic surface-active compoundsWater insolubleTitanium nitride

Disclosed is a liquid chemical for forming a water-repellent protecting film on a wafer. The liquid chemical is a liquid chemical containing a water-repellent-protecting-film-forming agent for forming the water-repellent protecting film, at the time of cleaning the wafer which has a finely uneven pattern at its surface and contains at least at a part of a surface of a recessed portion of the uneven pattern at least one kind of matter selected from the group consisting of titanium, titanium nitride, tungsten, aluminum, copper, tin, tantalum nitride, ruthenium and silicon, at least on the surface of the recessed portion. The liquid chemical is characterized in that the water-repellent-protecting-film-forming agent is a water-insoluble surfactant. The water-repellent protecting film formed with the liquid chemical is capable of preventing a pattern collapse of the wafer, in a cleaning step.

Owner:CENT GLASS CO LTD

Preparation method of zirconium oxide aerogel

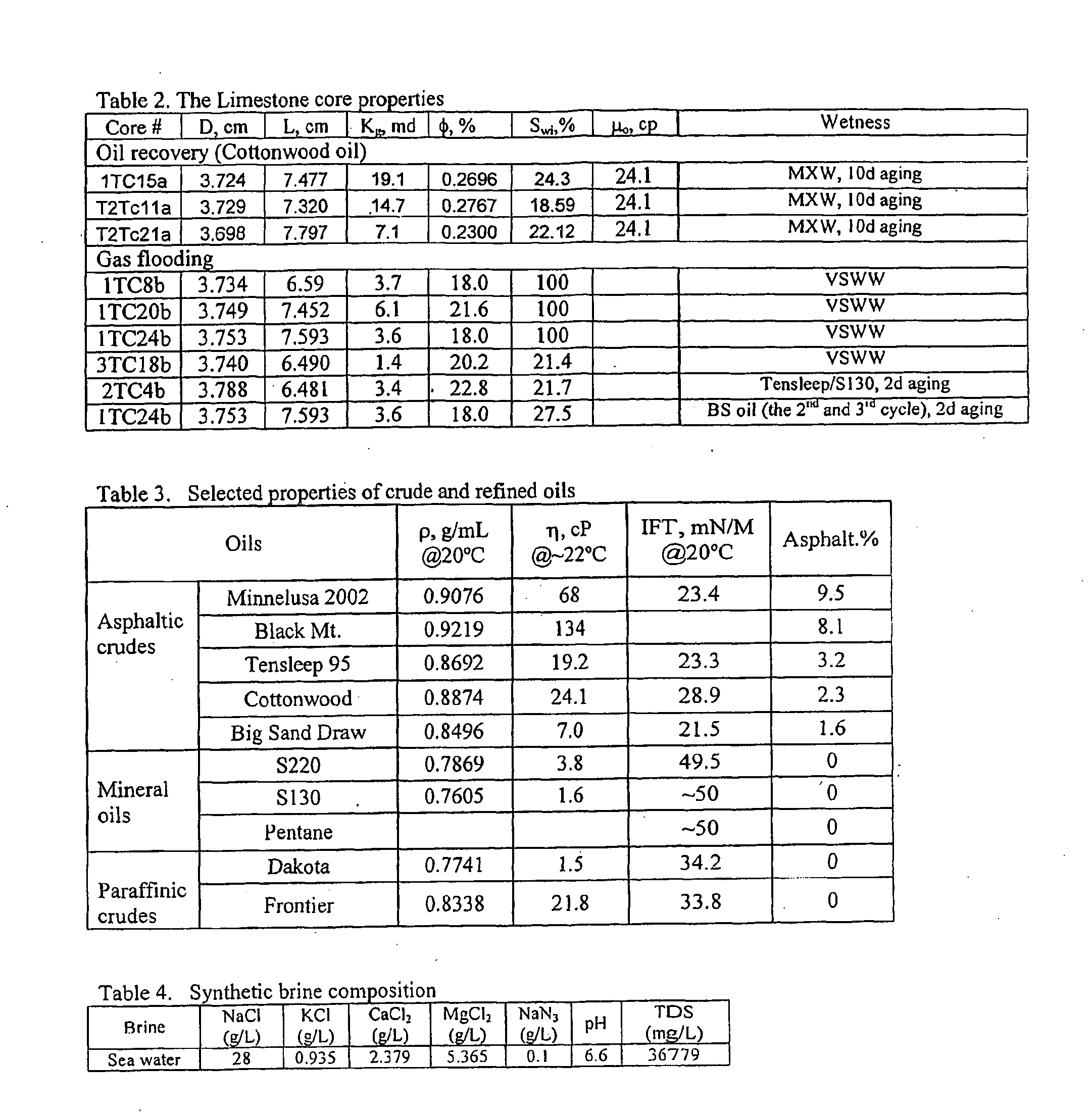

The invention provides a preparation method of zirconium oxide aerogel, which comprises the following steps of: dissolving alkoxide into anhydrous ethanol, and stirring and mixing to obtain an ethanol solution containing the alkoxide; dropwise adding concentrated nitric acid, then adding a mixed solution containing deionized water, formamide and epoxy propane, and continuously stirring for 20-60 minutes to obtain clear transparent sols; transferring the sols into a mould, and standing and ageing to obtain ZrO wet gels; respectively soaking the ZrO wet gels at 35-100 DEG C by using ageing liquids; and finally supercritically drying an object obtained by soaking with a drying medium solvent for 2-5 times to obtain a complete block-shaped ZrO aerogel. The method provided by the invention realizes the preparation of the block-shaped ZrO aerogel and solves the technical problem of preparing a low-density medium-intensity block-shaped zirconium oxide; and in addition, the block-shaped zirconium oxide aerogel has the density of 100-250 kg / m<3>, the normal-temperature heat conductivity of 0.018-0.031 w / mk and the compressive strength of 100-300 KPa.

Owner:蓝烟新材料科技有限公司

Fast drilling fluid and preparation technique thereof

InactiveCN101186813AIncrease drilling speedLower drilling costsDrilling compositionWater basedWell drilling

The invention discloses a rapid drilling fluid, of which the component proportion according to mass parts comprises 3-5 parts of sodium soil, 0.2-0.3 part of organosilicate semipermeable membrane agent, 1-3 parts of modified starch filtrate reducer, 1.5-2.5 parts of sulfonated-methyl brown coal, 0.2-0.3 part of zwitterions encrusting agent, 0.2-0.5 part of rapid drilling agent and 90-100 parts of water. The rapid drilling fluid is water based drilling fluid by which drilling speed is greatly increases. Simultaneously, the drilling cost is low, no mud drum is produced in drilling process, and the drilling performance and the well wall are stable.

Owner:CNPC DRILLING RES INST

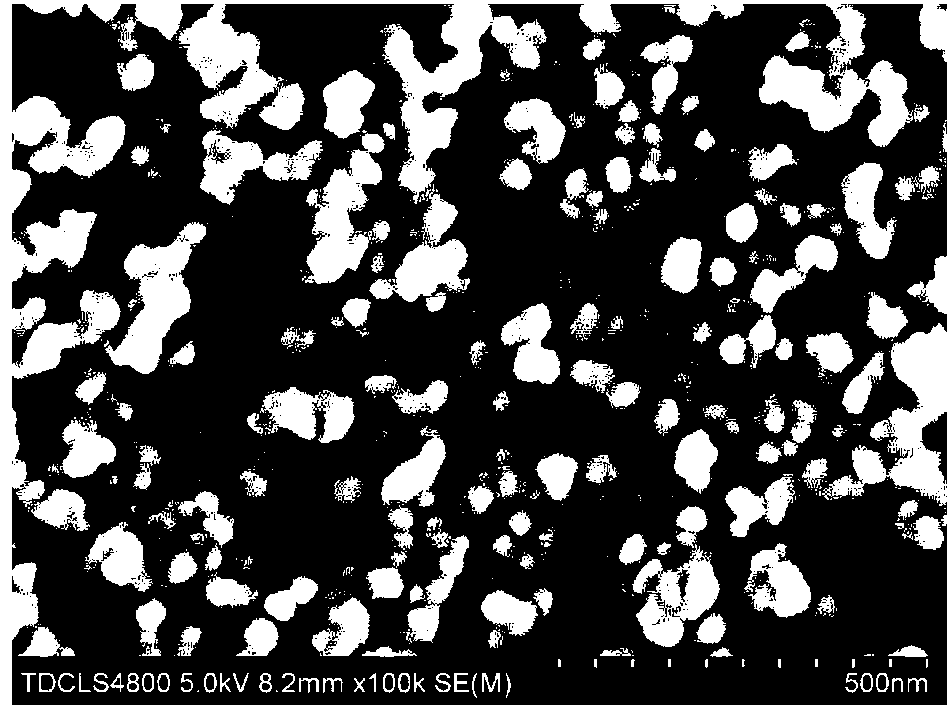

Dispersible dielectric particles and methods of forming the same

InactiveUS20030215606A1Reduce agglomerationInhibition formationLayered productsFixed capacitor dielectricSolventAgglomerate

Methods of forming dispersible dielectric particles, as well as articles and compositions that include the dispersible dielectric particles, are provided. The methods involve forming an aqueous mixture of dielectric (e.g., barium titanate-based) particles and replacing at least a portion of water in the mixture with a non-aqueous solvent (e.g., ethanol). According to one set of methods, the particles are then dried. The limited, or lack, of water present in the mixture during drying reduces capillary forces that otherwise may draw the particles together to cause formation of strong agglomerates. Thus, particle agglomeration during drying may be reduced which increases particle dispersibility. According to another set of methods of the invention, the particles are not dried after non-aqueous solvent replacement, thus, avoiding formation of agglomerates during drying and increasing dispersibility. In both sets of methods, particles (or mixtures thereof) may be further processed, for example, to form composite layers. As a result of the increased particle dispersibility, the particles are relatively uniformly distributed throughout the polymeric material. This uniform distribution improves properties of the composite layers which may be used as an embedded capacitor in electronic applications including printed circuit boards.

Owner:CABOT CORP

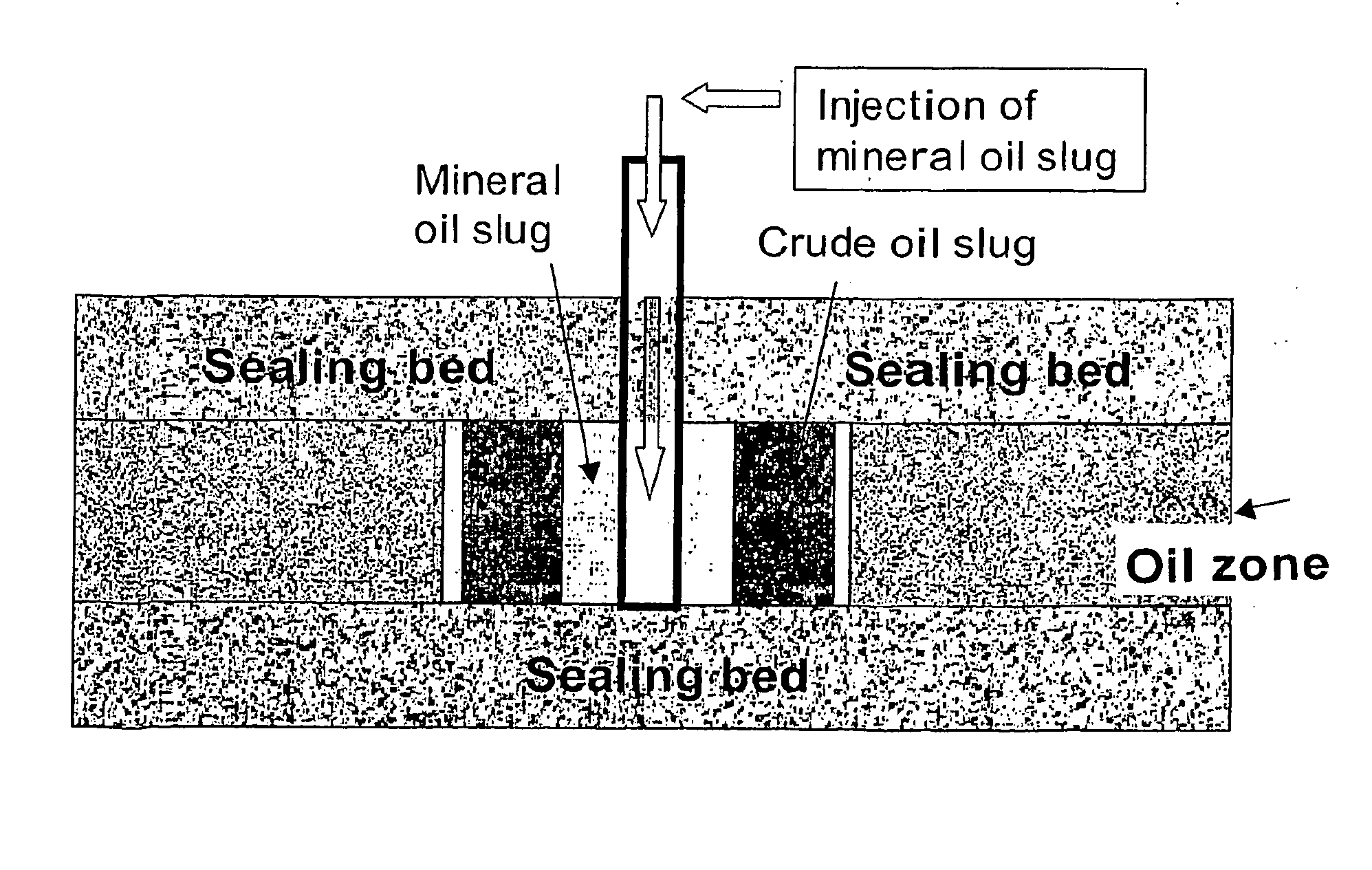

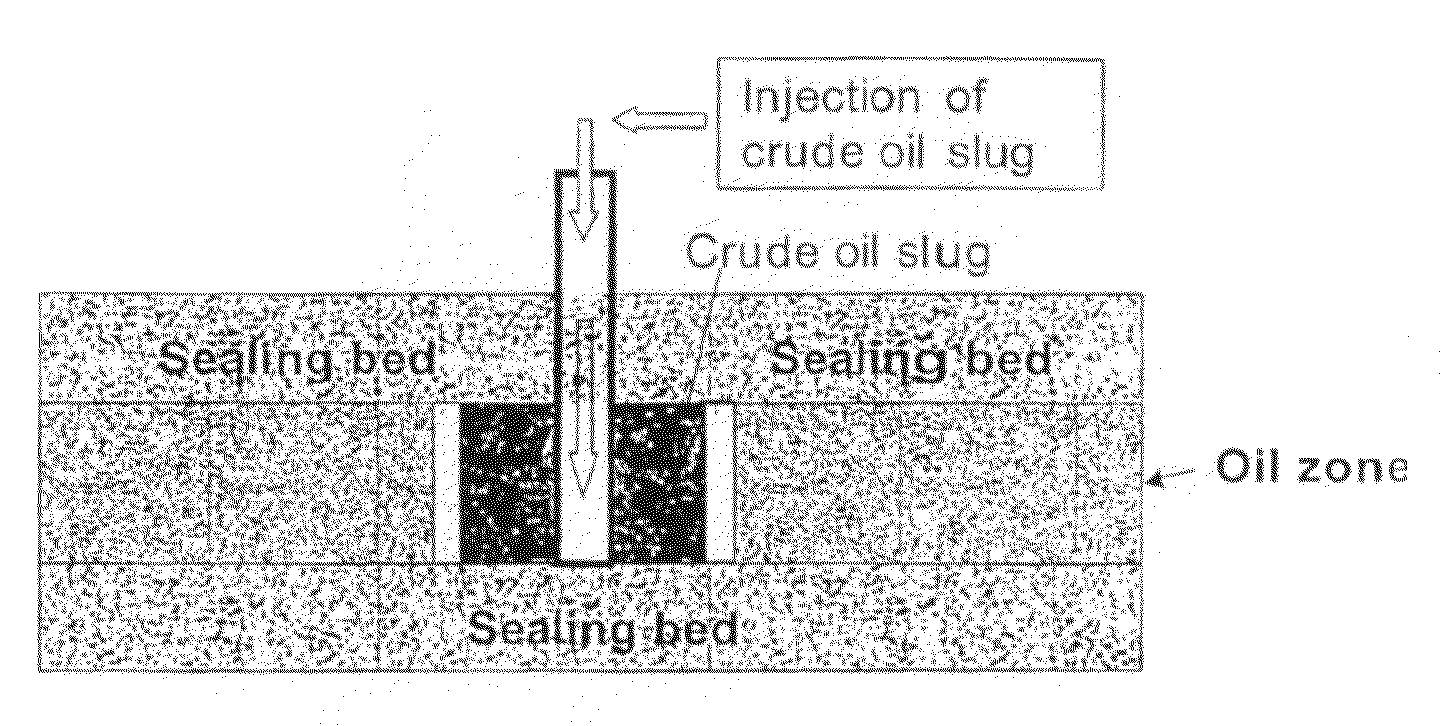

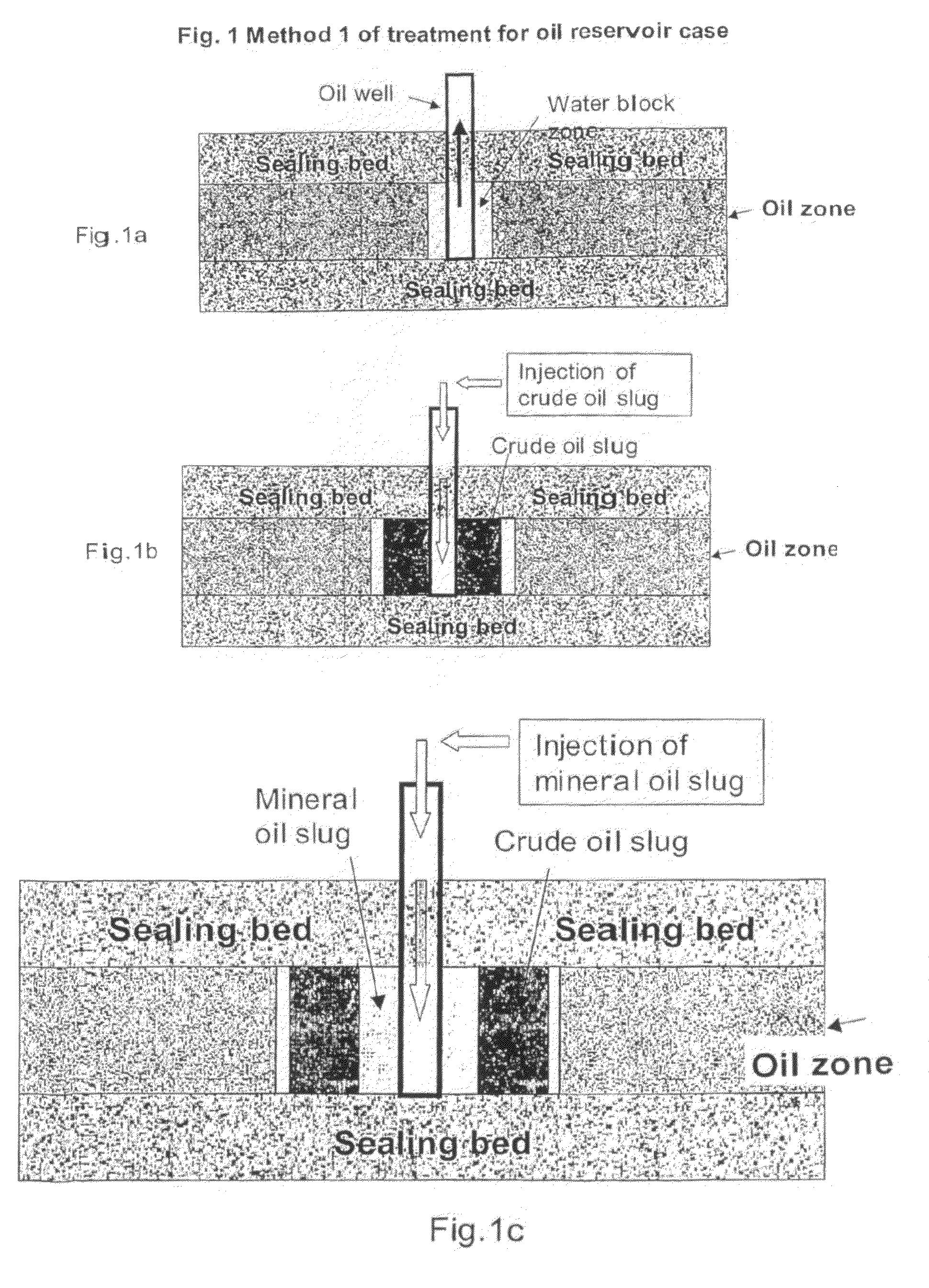

Method for Increasing the Production of Hydrocaarbon Liquids and Gases

InactiveUS20080236845A1Reduce eliminateAltering formation wettabilityFluid removalDrilling compositionWater blockAsphaltene

A method for reducing or climinating water block around a well bore of a well bore region in a reservoir is provided. The method comprises removing the water from around the well bore, injecting crude oil around the well bore, and injecting precipitants causing surface precipitation of asphaltenes thereby altering formation wettability in the well bore and decreasing capillary forces of retention for water and / or gas condensates and increasing the flow of hydrocarbon fluids from the reservoir.

Owner:UNIVERSITY OF WYOMING

Preparation method of blocky hybrid aerogel

InactiveCN105413626AReduced time for hydrolysisLow quality scoreOther chemical processesWater contaminantsWater bathsOXALIC ACID DIHYDRATE

The invention belongs to the technical field of new material preparation and relates to a preparation method of blocky hybrid aerogel which specifically refers to blocky aerogel fast prepared under the normal pressure condition and has an efficient removing effect on Cd2+ in waste water. The preparation method includes the steps that firstly, tetraethyl orthosilicate, deionized water, acetonitrile and an oxalic acid solution are measured and taken and are mixed, and the mixture is placed in a water bath kettle to react; after reaction, a beaker is taken out, 3-aminopropyltriethoxysilane is transferred into the beaker through a pipette when temperature returns to room temperature, and acetonitrile is added for aging after gelation; then gel is soaked in an acetonitrile solution containing isophorone diisocyanate and is placed in the water bath kettle for crosslinking; finally, acetonitrile is added, after standing performed under room temperature, the gel is sealed through a preservative film with needle holes and placed in a normal-pressure drying oven to be dried, and the silicon dioxide blocky hybrid aerogel is obtained. In the preparation process of the blocky hybrid aerogel, no solvent exchange or surface modification exists, consumed time is short, consumed energy is little, operation is easy, and the blocky hybrid aerogel has an efficient adsorbing effect on Cd2+ in waste water.

Owner:JIANGSU UNIV

Ambient pressure drying method of silsesquioxane aerogel

ActiveCN110822816AImprove solvent replacement efficiencyReduce capillary forceDrying solid materials with heatDrying solid materials without heatSolventActive agent

The invention discloses an ambient pressure drying method of silsesquioxane aerogel. According to the ambient pressure drying method of the silsesquioxane aerogel, methyltrimethoxysilane is taken as aprecursor, water is taken as a solvent to be combined with a surfactant, silica wet gel with a large aperture size can be prepared through a sol-gel process, after solvent replacement by ethanol is carried out, the silica wet gel is directly and slowly dried at high temperature, and a silsesquioxane aerogel material can be prepared. According to the ambient pressure drying method of the silsesquioxane aerogel, the methyltrimethoxysilane is selected as the precursor, so that the in-situ modification of a gel skeleton surface is realized, the aperture structure is controlled by the surfactant content, the solvent replacement efficiency can be improved, the capillary force during drying can be reduced, the use amount of organic solvent in the ambient pressure drying process is greatly reduced, and the large-scale production is facilitated.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for increasing the production of hydrocarbon liquids and gases

InactiveUS7549472B2Altering formation wettabilityReduce capillary forceFluid removalDrilling compositionWater blockAsphaltene

A method for reducing or eliminating water block around a well bore of a well bore region in a reservoir is provided. The method comprises removing the water from around the well bore, injecting crude oil around the well bore, and injecting precipitants causing surface precipitation of asphaltenes thereby altering formation wettability in the well bore and decreasing capillary forces of retention for water and / or gas condensates and increasing the flow of hydrocarbon fluids from the reservoir.

Owner:UNIVERSITY OF WYOMING

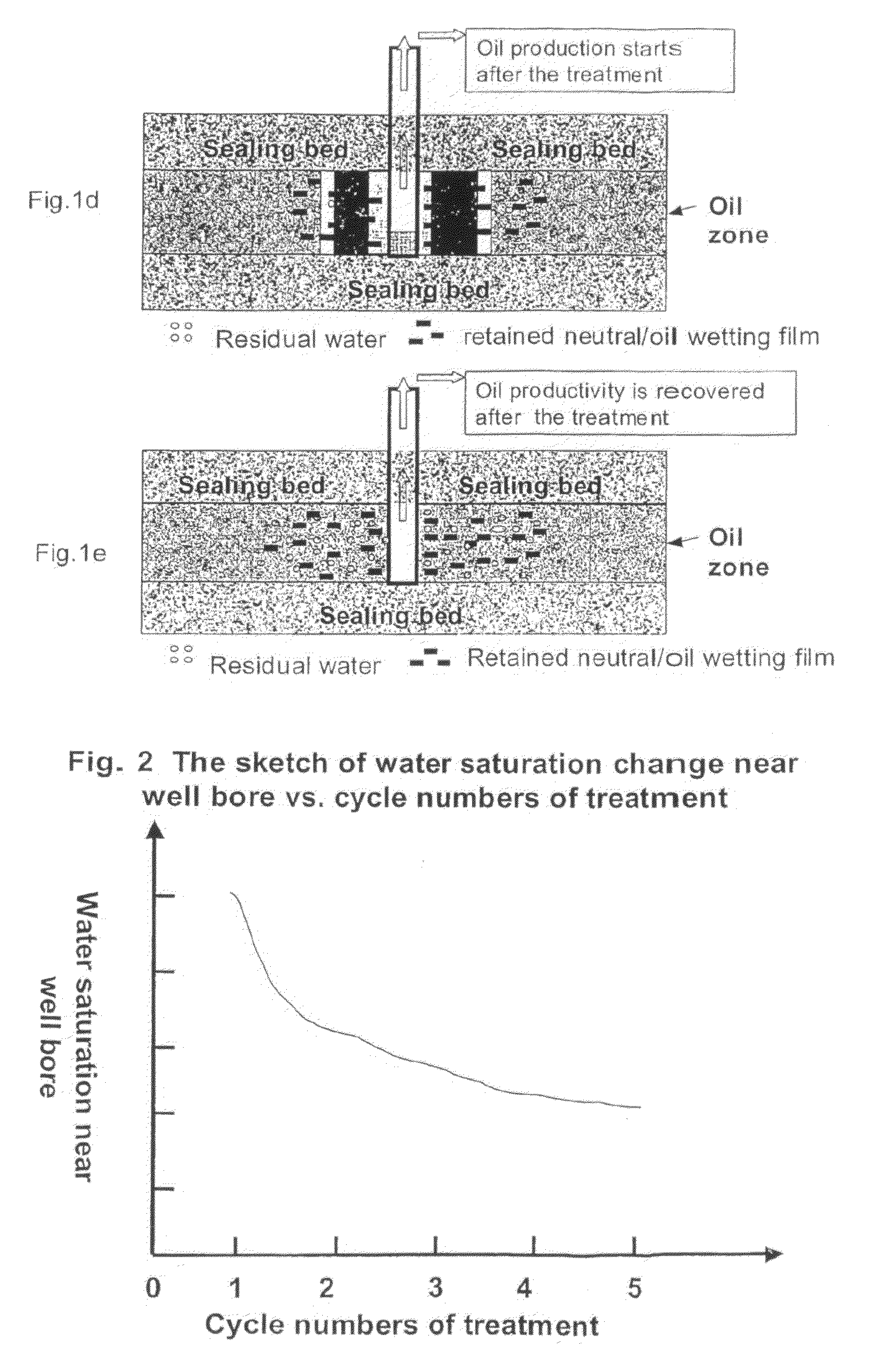

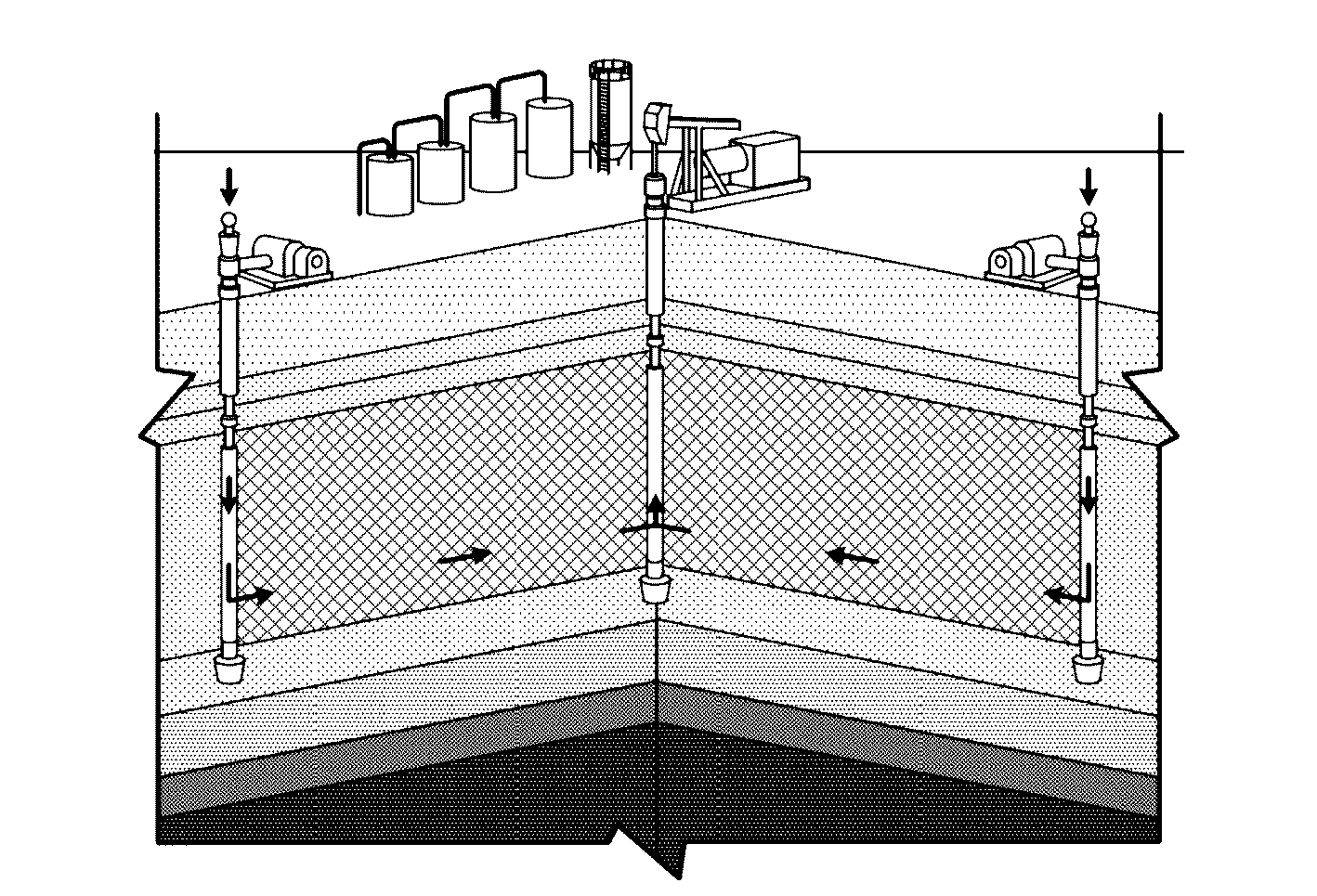

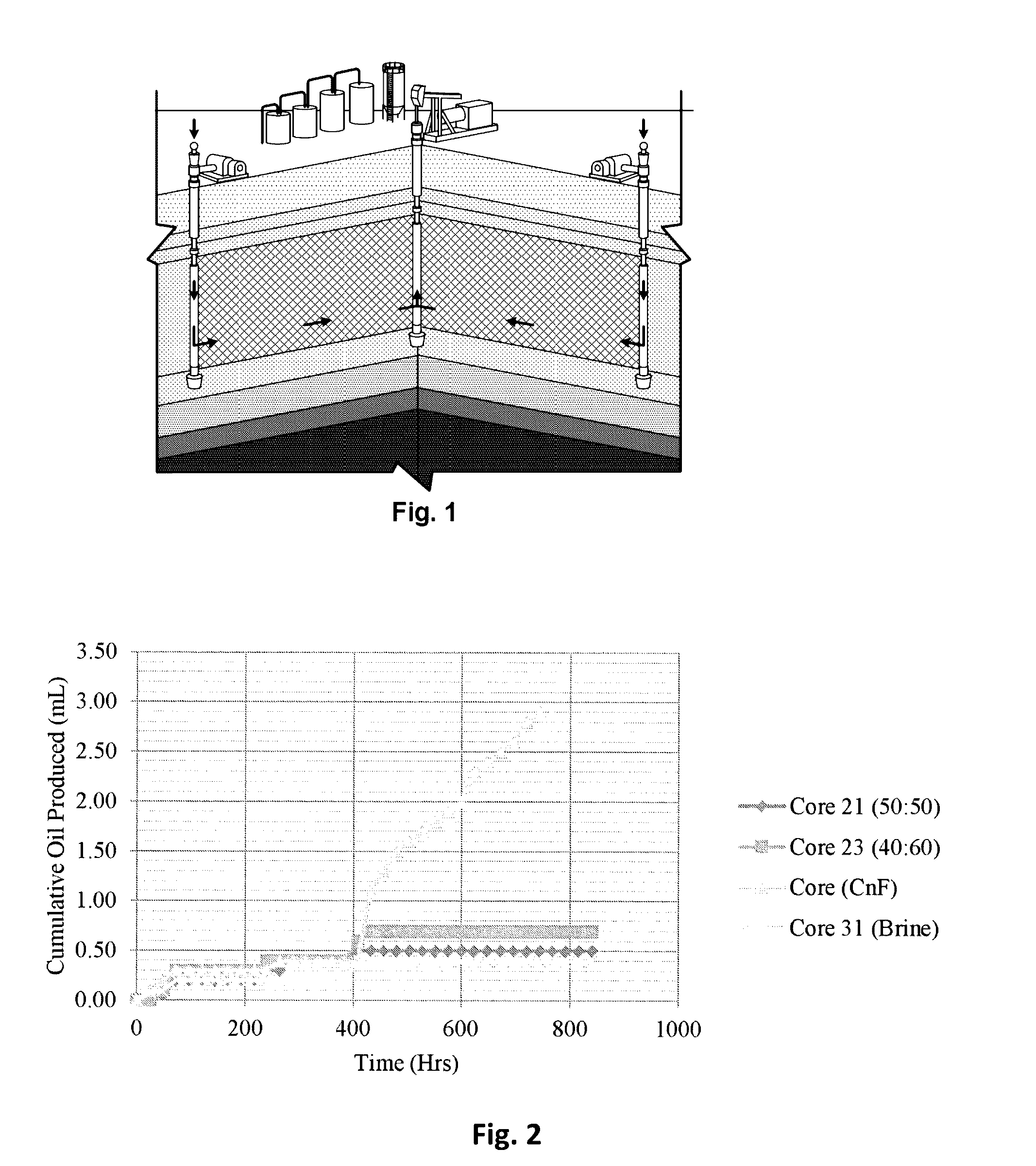

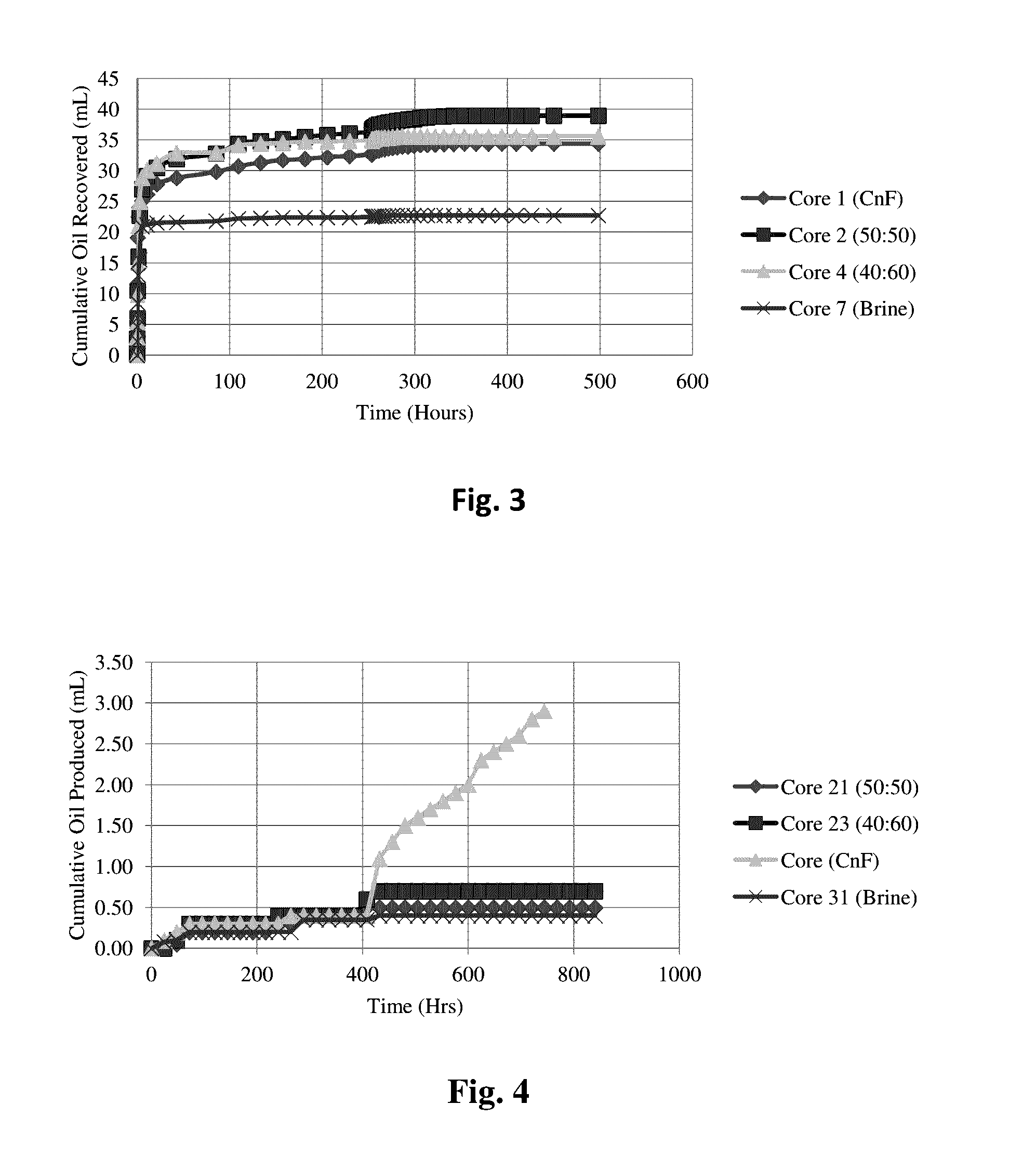

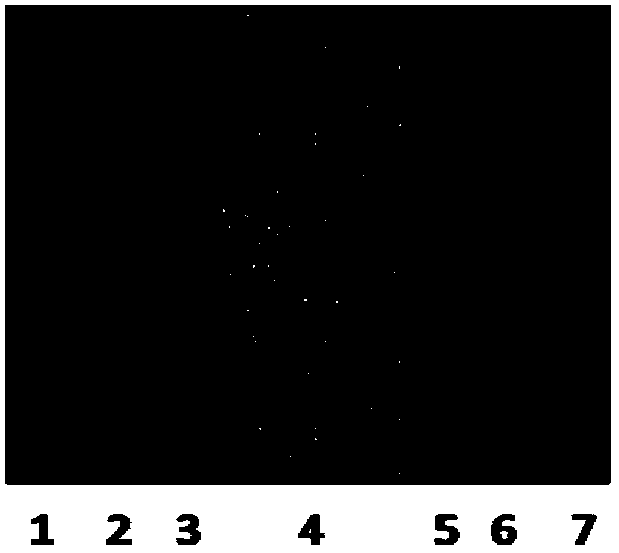

Methods for enhancing oil recovery using complex nano-fluids

InactiveUS20170009128A1Increase oil extractionSpeed up recoveryFluid removalDrilling compositionOil productionInjection well

The inventions described herein relate generally to novel methods for increasing oil extraction using complex nano-fluids and, in at least one embodiment, to a method of increasing the recovery during oil extraction by injecting complex nano-fluids into an injection well in order to increase oil production yields.

Owner:UNIVERSITY OF WYOMING

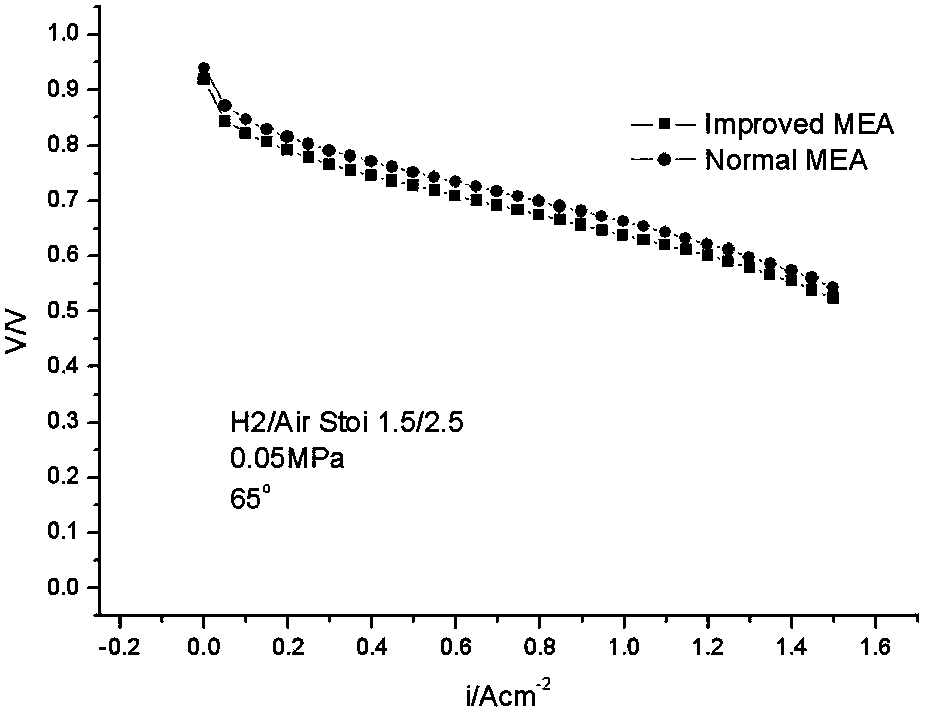

Membrane electrode for improving anode water management of proton exchange membrane fuel cell

ActiveCN103855408ARelieve stressImprove water resistanceCell electrodesWater management in fuel cellsOxideHigh conductivity

An anode of a proton exchange membrane fuel cell does not generate water, but water generated by a cathode can enter the anode through concentration diffusion, and the water needs to be carried out of the cell by hydrogen to ensure stable cell performance, so that the burden of anode water management is increased and the hydrogen utilization rate is reduced. The invention relates to a membrane electrode capable of improving the anode water management of a proton exchange membrane fuel cell. According to the membrane electrode, water-locking substances such as SiO2 and other oxides are added into a membrane and a catalyst layer on the anode side to lock a large quantity of anode water in the catalyst layer and the membrane; an anode micropore layer is made from carbon materials, such as graphite powder, with relatively good hydrophobicity, relatively high conductivity and relatively large particle size, so that the water resistance of the anode micropore layer can be improved, a large quantity of water is prevented from entering an anode flow field, and the anode water management burden is reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

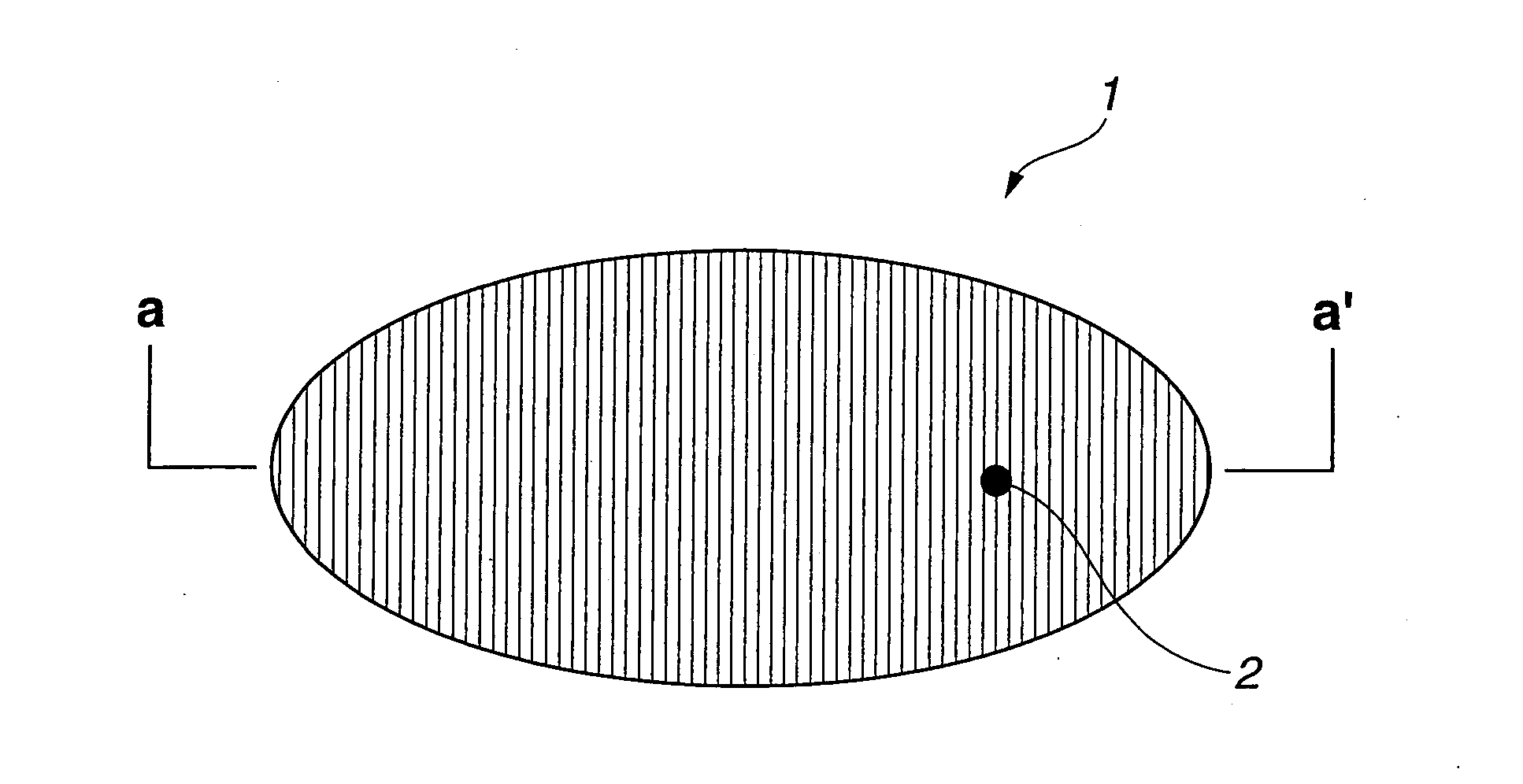

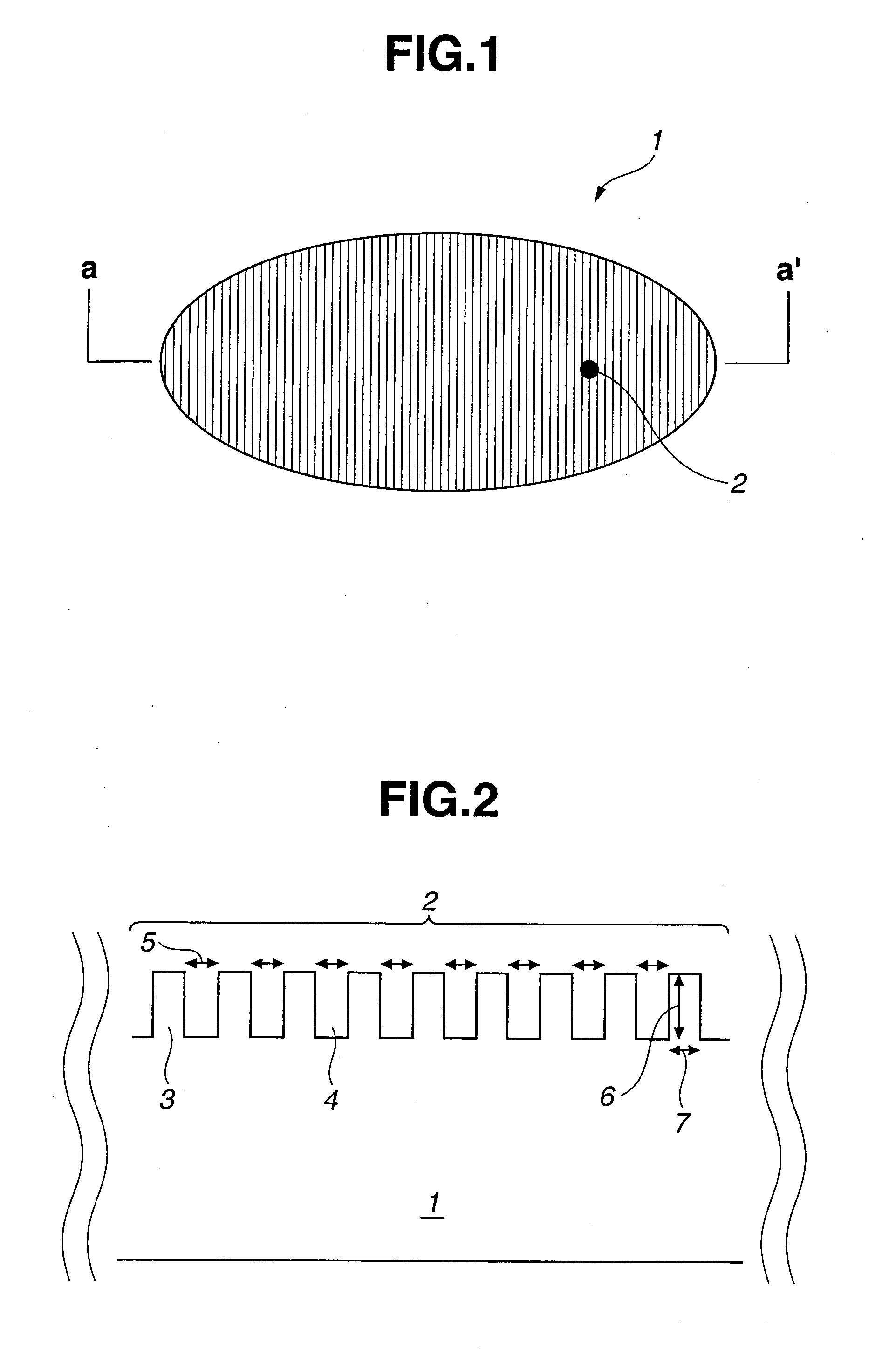

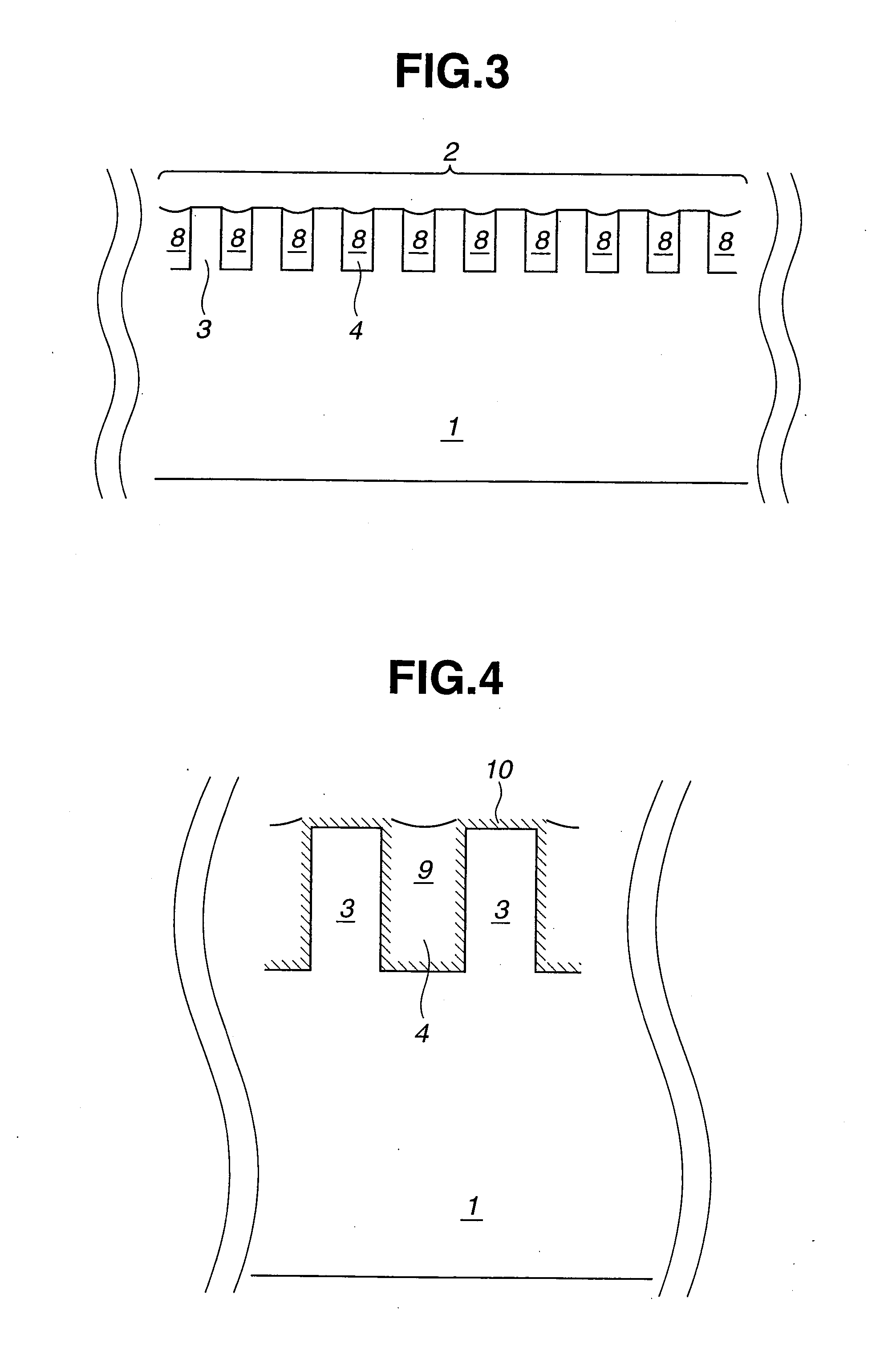

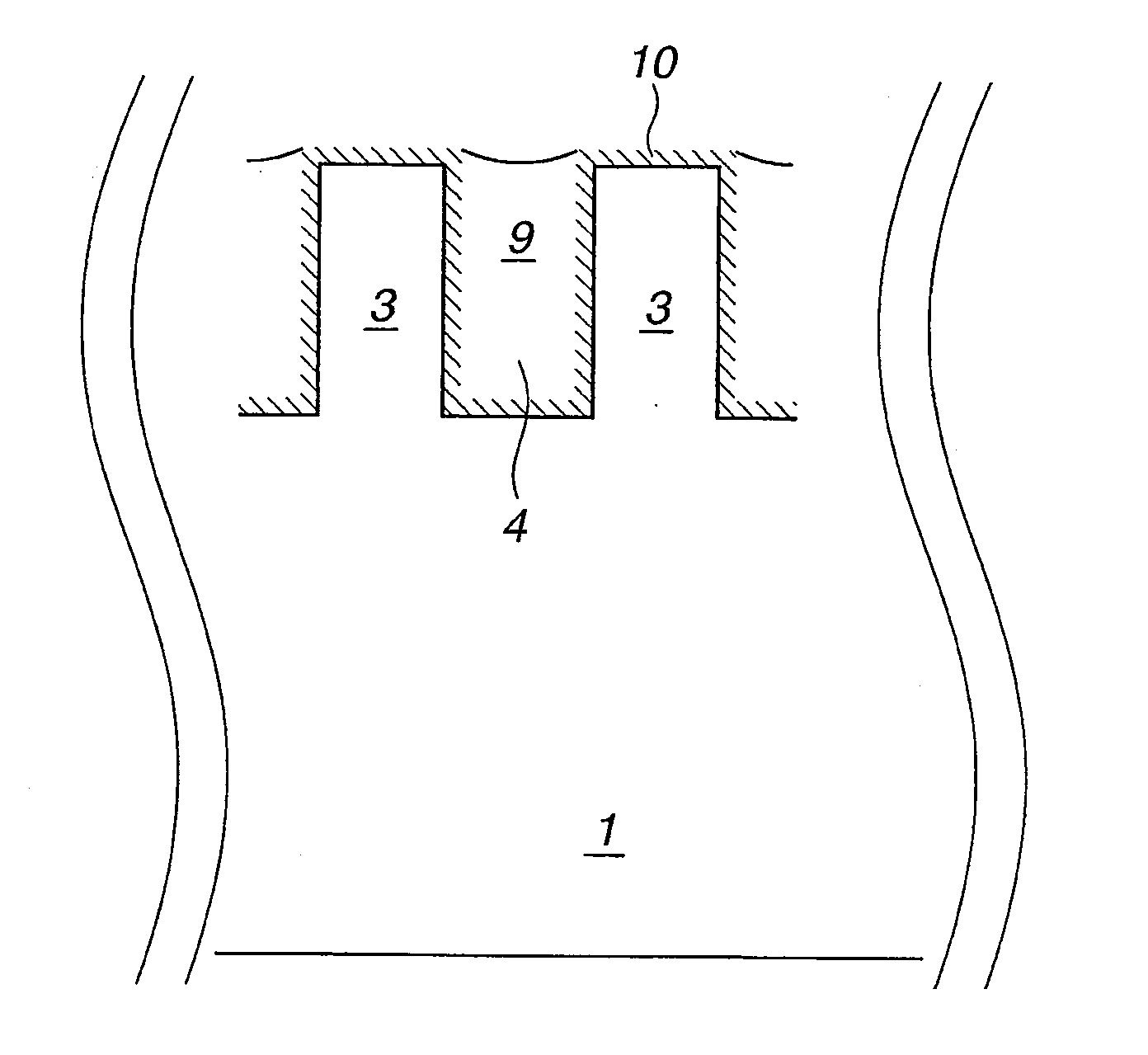

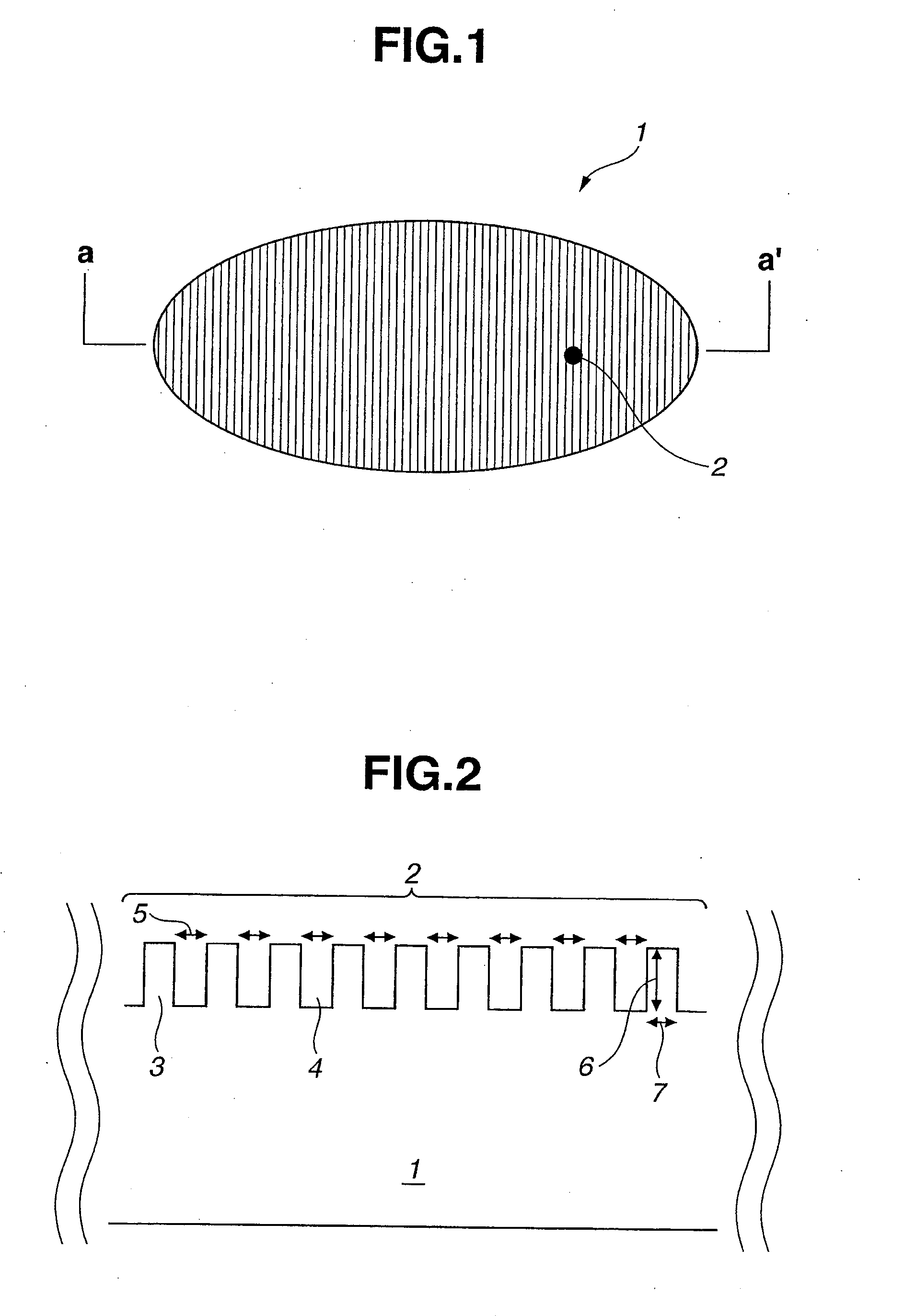

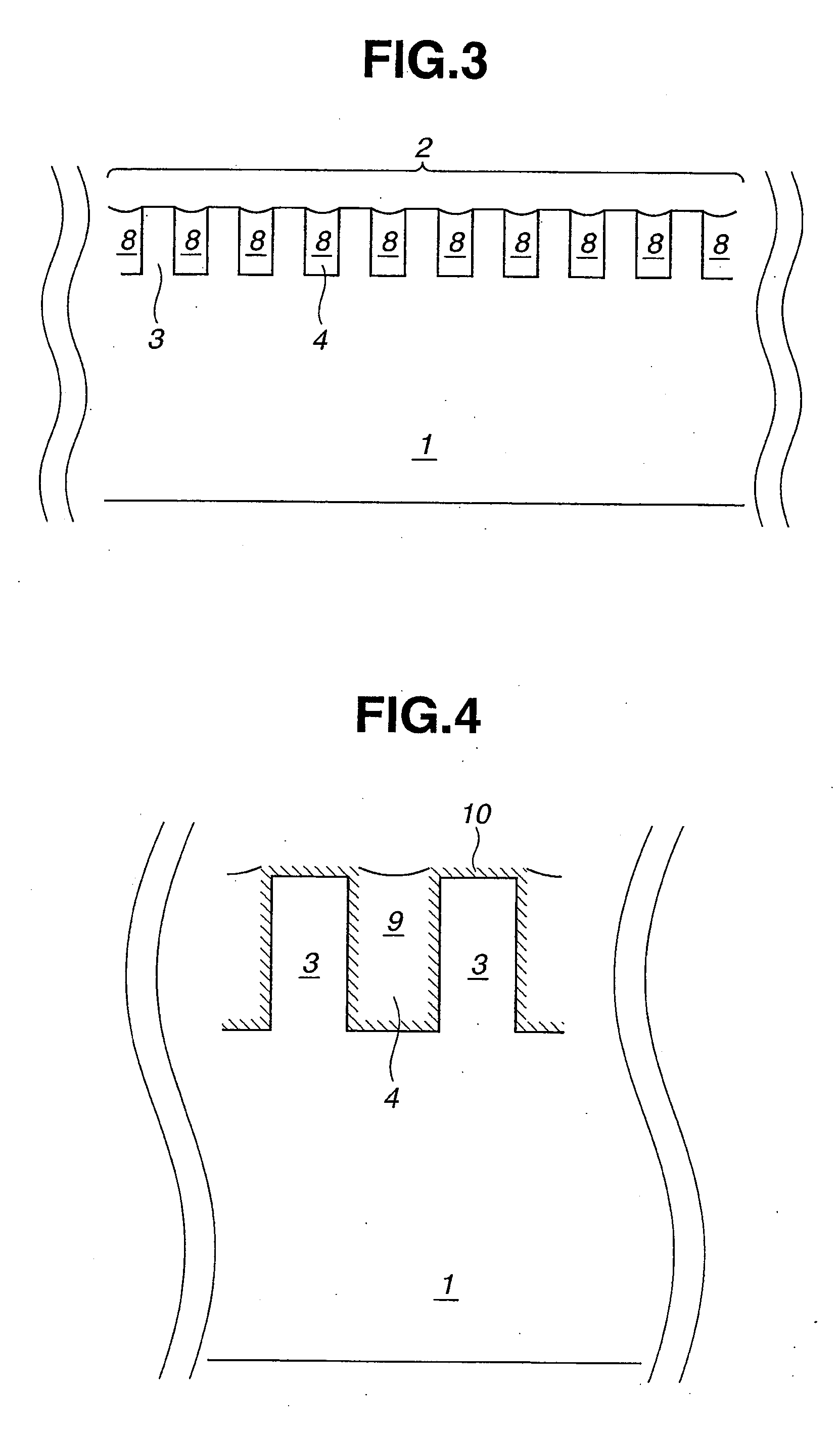

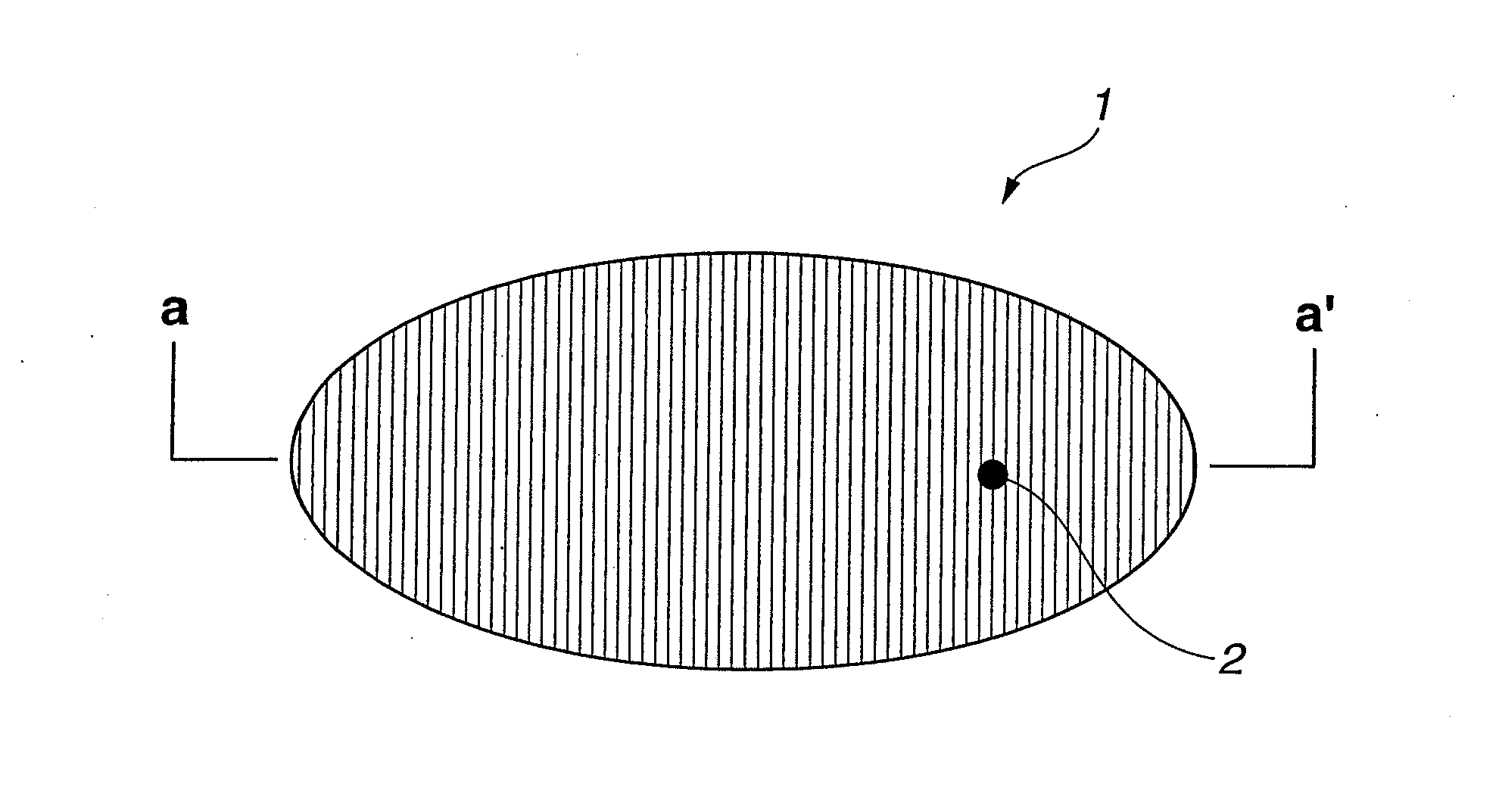

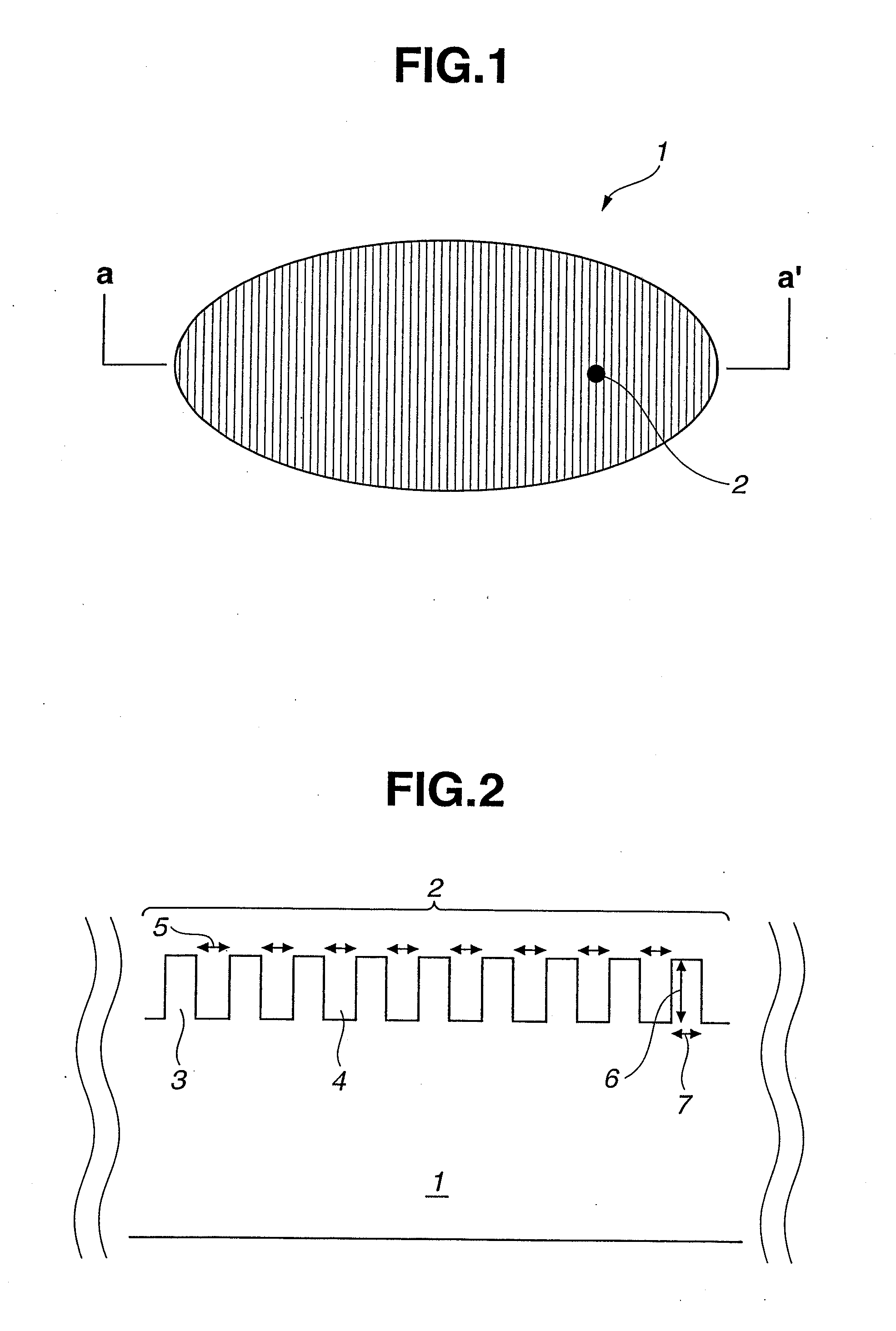

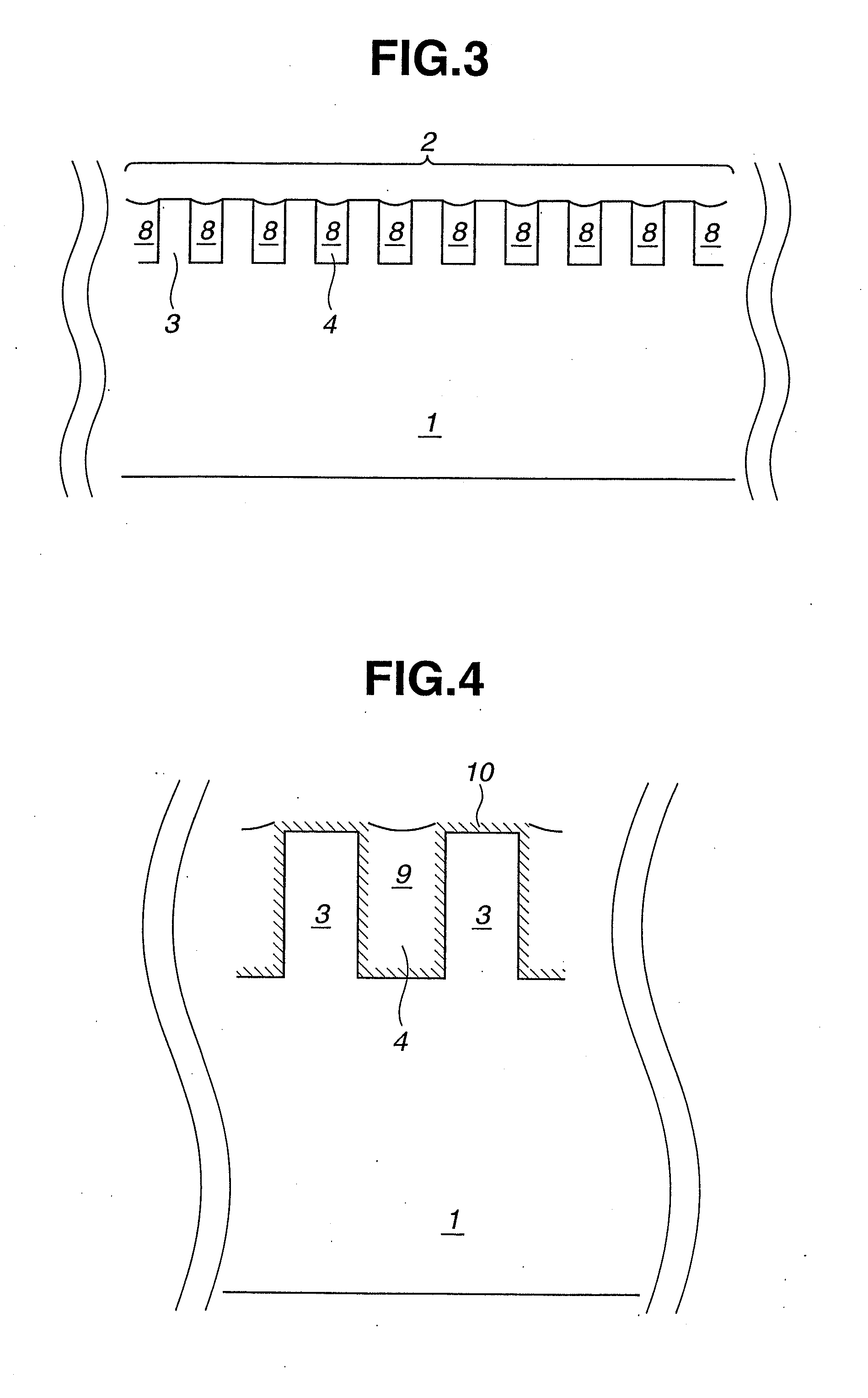

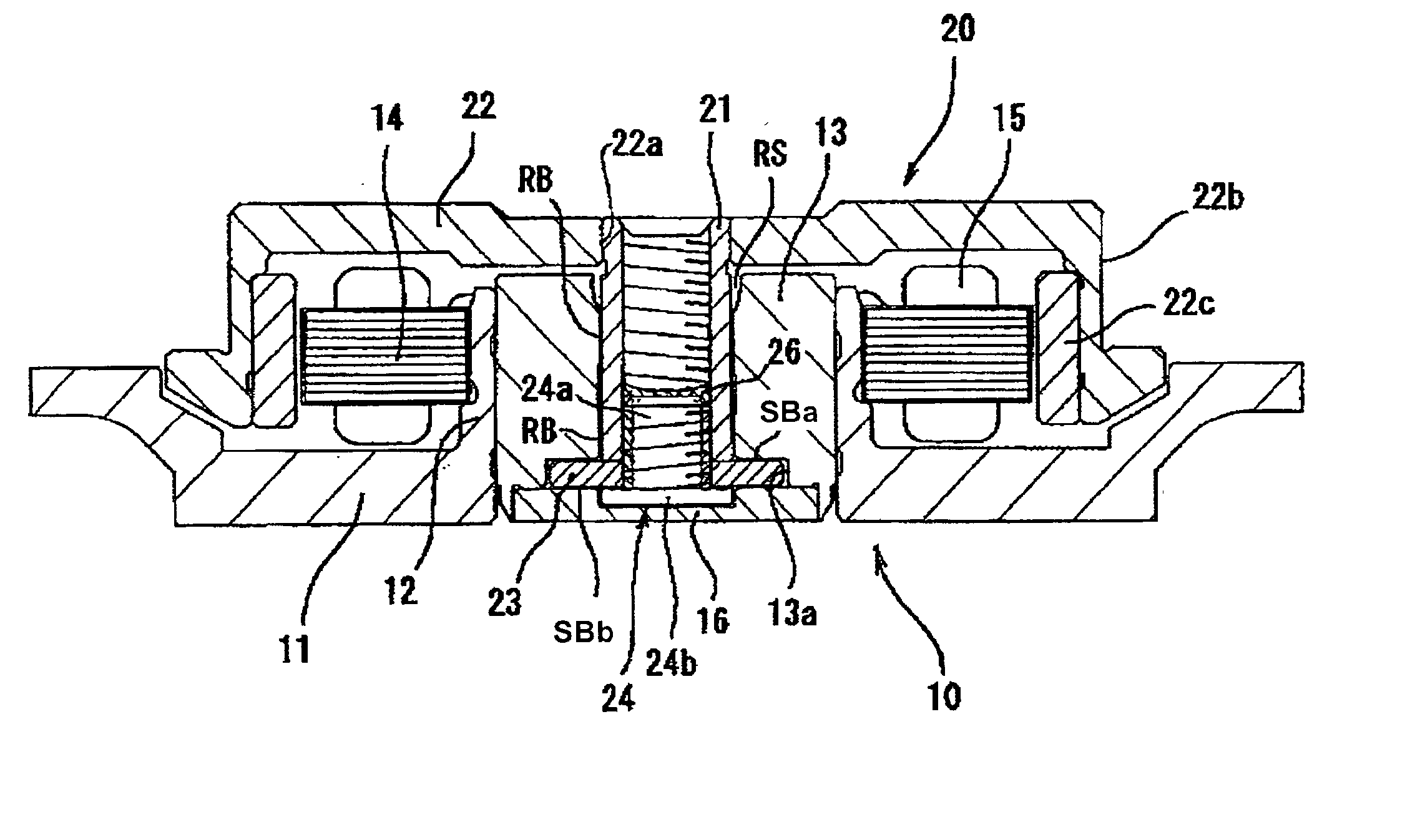

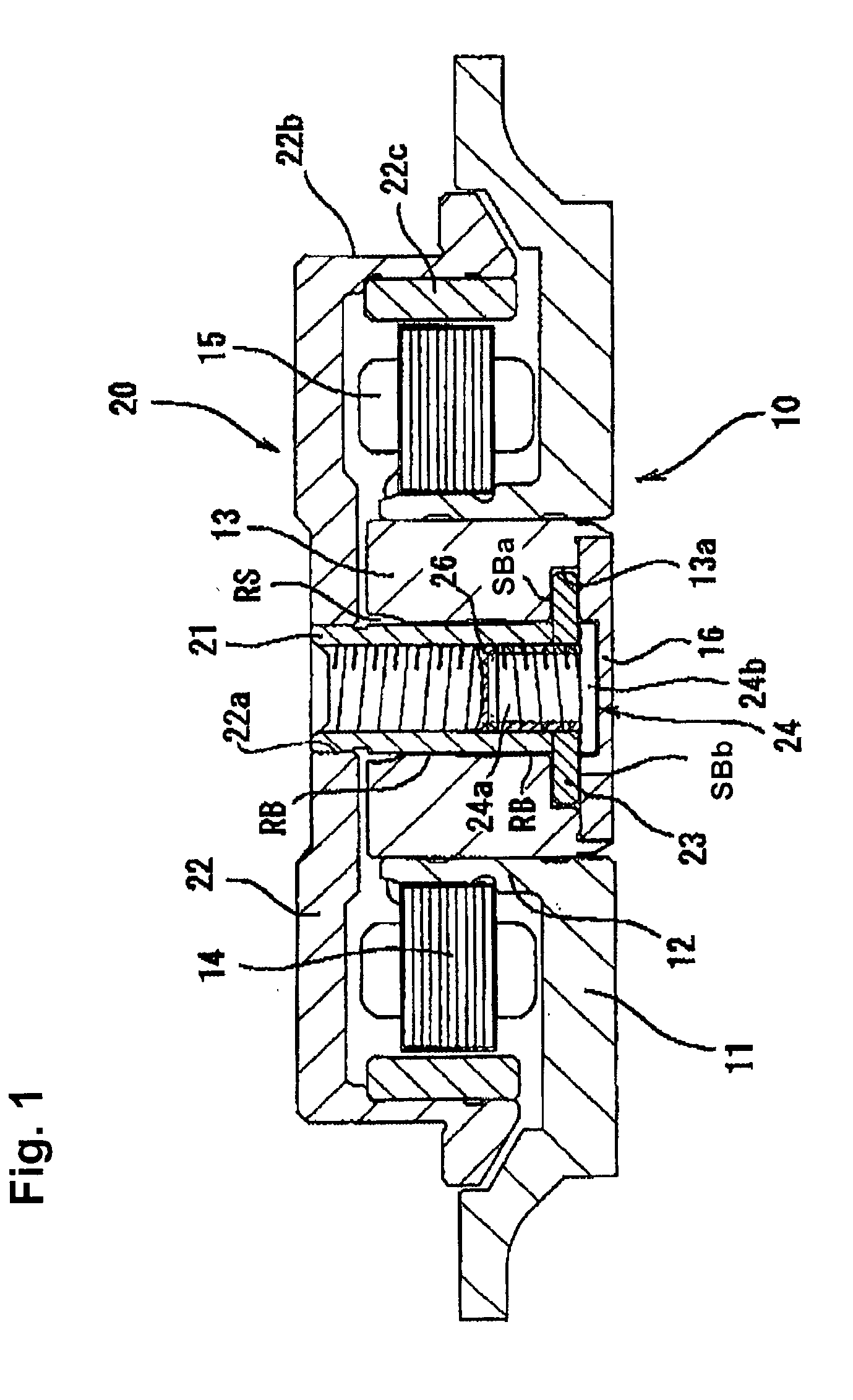

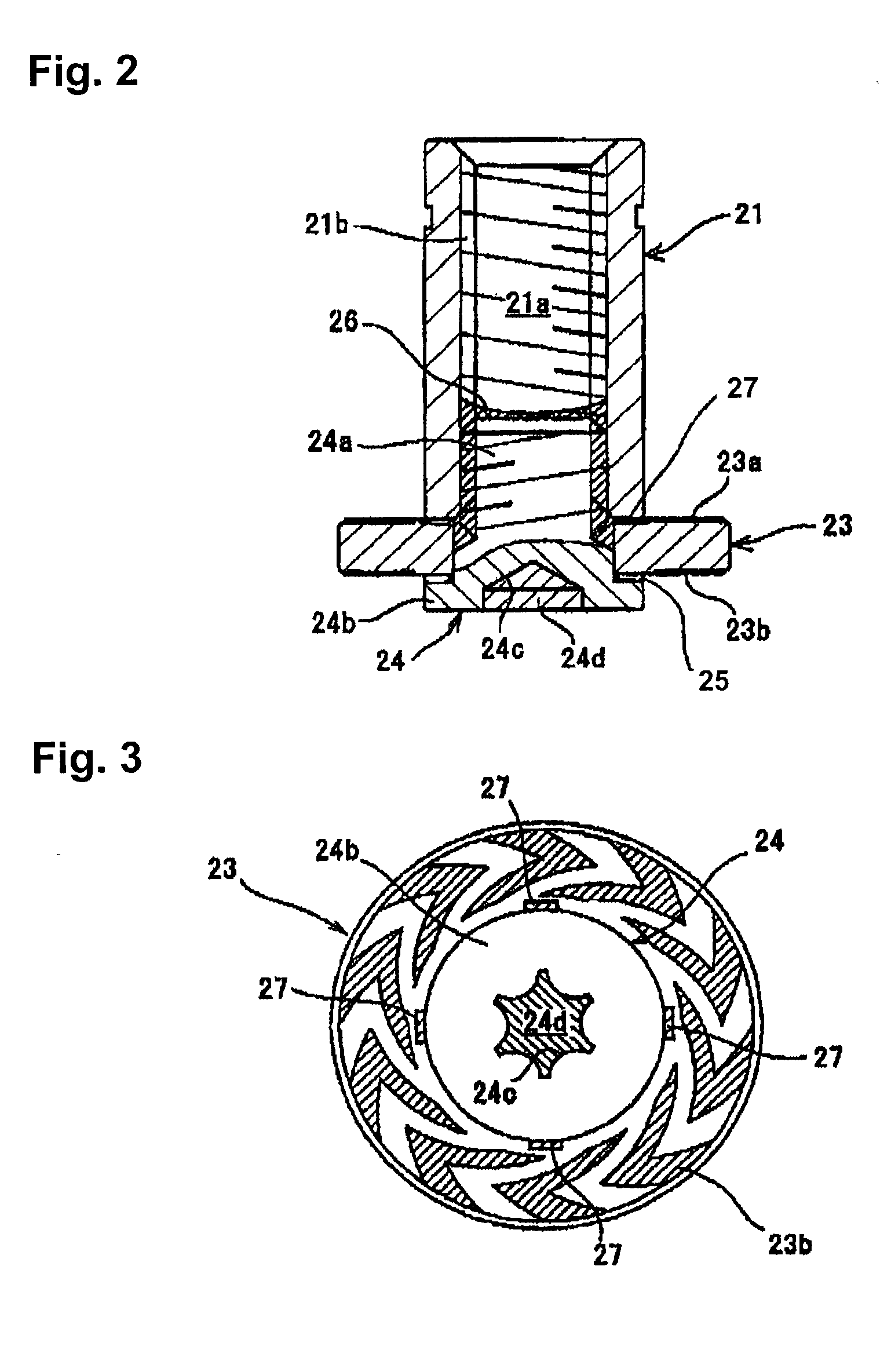

Method for manufacturing shaft member and method for manufacturing dynamic pressure bearing device

InactiveUS20030024099A1High bonding strengthReduce capillary forceShaftsBearing componentsAdhesiveEngineering

A method for manufacturing a dynamic pressure bearing device is provided. The dynamic pressure bearing device includes a bearing member and a shaft member rotatably disposed with respect to one another, and a thrust plate mounted on the shaft member and a counter plate fixed to the bearing member disposed opposite to one another to compose a thrust dynamic pressure bearing section. According to the method, a through hole that communicates with both ends of the shaft member in an axial direction thereof is formed in the shaft member, and a female screw section is formed in an inner wall section of the through hole such that screw members can be screwed from the both ends of the through hole of the shaft member. One of the screw members is screwed in the through hole of the shaft member from one end of the shaft member. The screw member has a screw head section and a male screw section extending from the screw head section for threaded engagement with the female screw section. Prior to screwing the screw member in the through hole of the shaft member, the thrust plate is interposed in the axial direction between the screw head section of the screw member and the one end of the shaft member, and the thrust plate is fixed to the shaft member by tightening the screw member. An adhesive is injected to fill gaps in a screw engagement section between the male screw section of the screw member and the female screw section of the shaft to prevent lubrication fluid from leaking through the screw engagement section, wherein the adhesive has a viscosity of 5 Pa.s or higher after the coating.

Owner:SANKYO SEIKI MFG CO LTD

Method of Preparing Liquid Chemical for Forming Protective Film

InactiveUS20170062203A1Reduce capillary forceGood for persistenceSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneOrganic solvent

[Problem] To provide a method for preparing a protective film-forming liquid chemical, in a method for producing a wafer having at its surface an uneven pattern and containing silicon element at least at a part of the uneven pattern. The liquid chemical forms a water-repellent protective film on the uneven pattern of the wafer and improves a cleaning step which tends to induce a pattern collapse, and particularly provides a good persistence (pot life) of the improving effect.[Solution] A method for preparing a liquid chemical for forming a water-repellent protective film, the liquid chemical being for forming a water-repellent protective film at the time of cleaning the wafer at least on surfaces of recessed portions of the uneven pattern, the liquid chemical containing a nonaqueous organic solvent, a silylation agent, and an acid or base. The method for preparing a liquid chemical for forming a water-repellent protective film is characterized by including:a dehydrating step for adjusting a water content of the nonaqueous organic solvent to 200 mass ppm or less; anda mixing step for mixing the nonaqueous organic solvent, the silylation agent, and the acid or base after the dehydrating step.

Owner:CENT GLASS CO LTD

Liquid chemical for forming protecting film

ActiveUS9228120B2Improve waterproof performanceReduce capillary forceOrganic detergent compounding agentsNon-ionic surface-active compoundsTrimethylsilyl trifluoromethanesulfonateCompound a

Disclosed is a liquid chemical for forming a water-repellent protecting film at least on a surface of a recessed portion of an uneven pattern at the time of cleaning a wafer having a finely uneven pattern at its surface and containing silicon at least a part of the uneven pattern. This liquid chemical contains a silicon compound A represented by the general formula: R1aSi(H)bX4-a-b and an acid A, the acid A being at least one selected from the group consisting of trimethylsilyl trifluoroactate, trimethylsilyl trifluoromethanesulfonate, dimethylsilyl trifluoroactate, dimethylsilyl trifluoromethanesulfonate, butyldimethylsilyl trifluoroactate, butyldimethylsilyl trifluoromethanesulfonate, hexyldimethylsilyl trifluoroacetate, hexyldimethylsilyl trifluoromethanesulfonate, octyldimethylsilyl trifluoroactate, octyldimethylsilyl trifluoromethanesulfonate, decyldimethylsilyl trifluoroacetate and decyldimethylsilyl trifluoromethanesulfonate.

Owner:CENT GLASS CO LTD

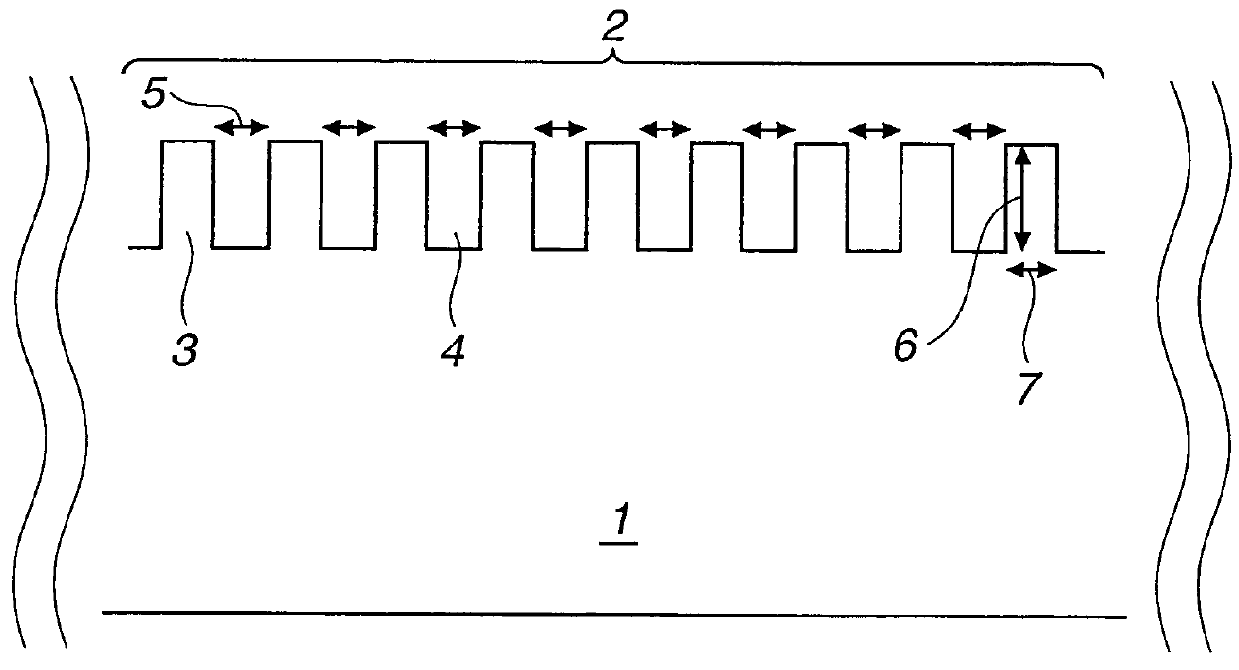

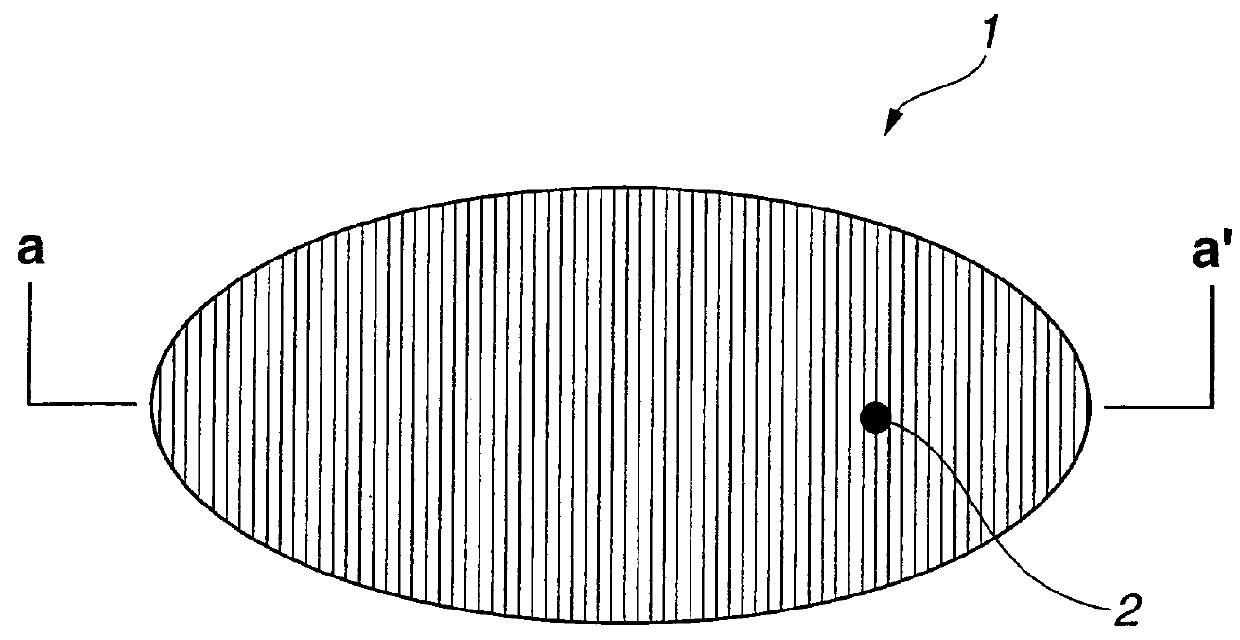

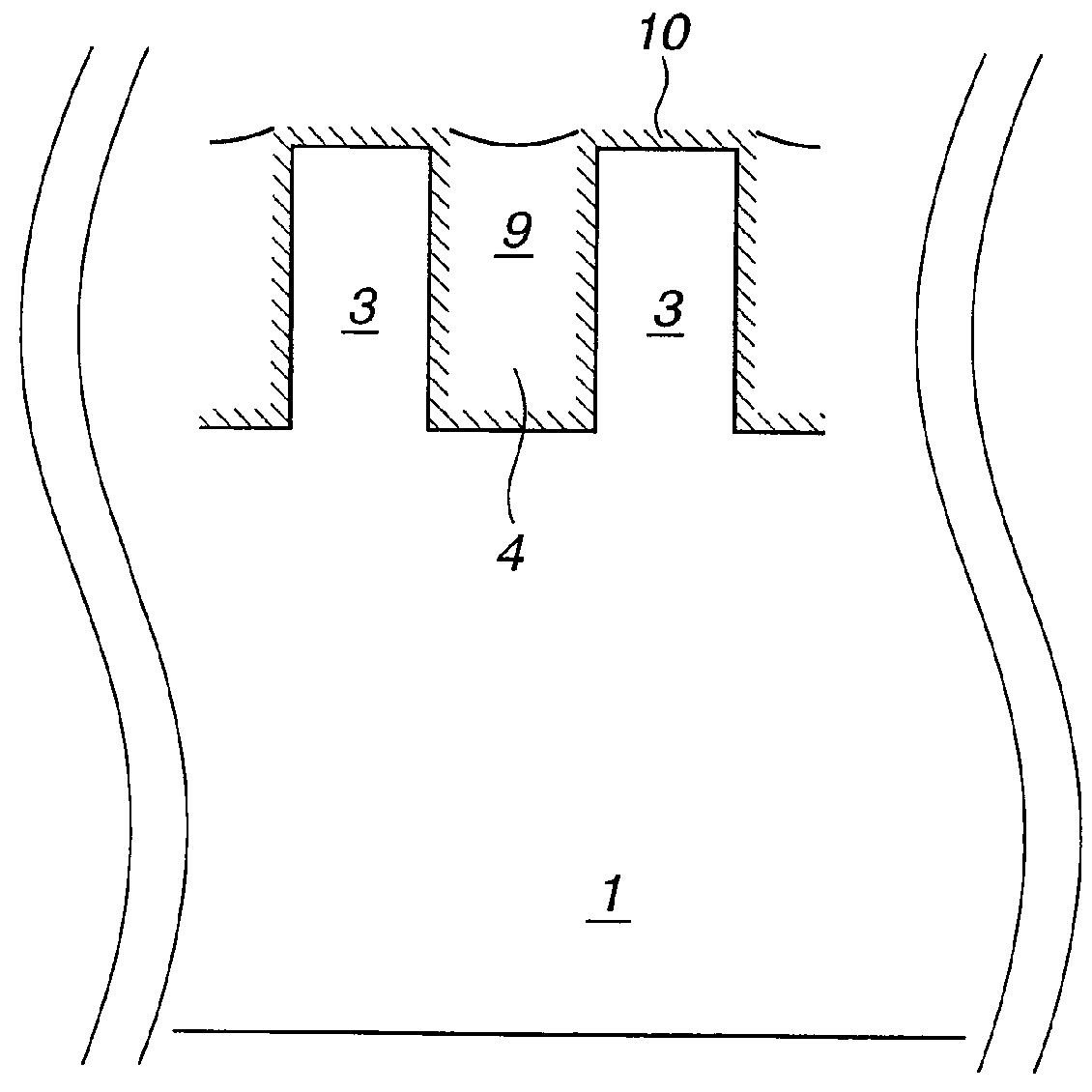

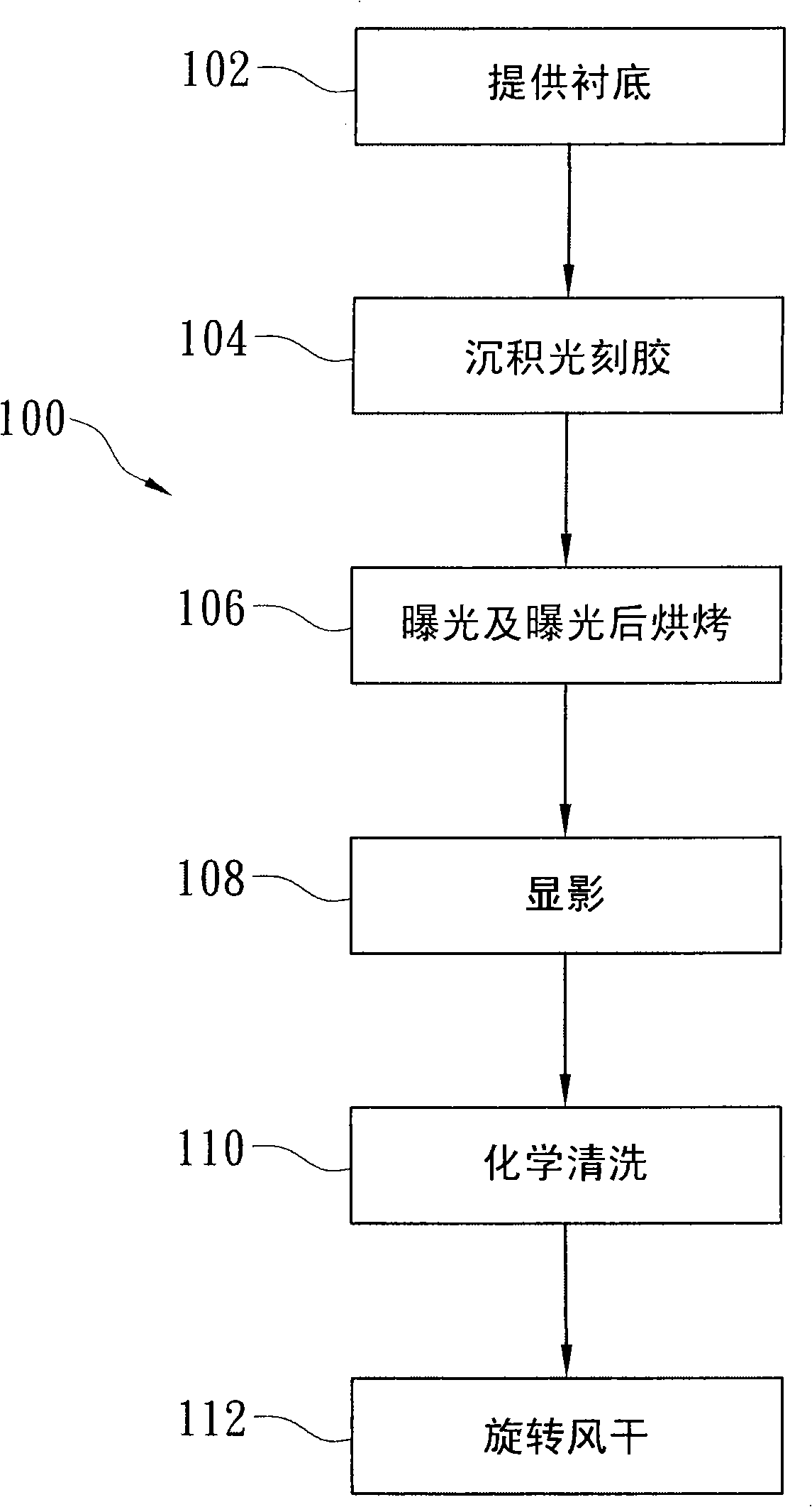

Photolithography process including a chemical rinse

ActiveCN101303970AReduce surface tensionReduce capillary forceSemiconductor/solid-state device manufacturingPhotosensitive material processingAlcoholLithography process

The present disclosure provides a plurality of methods of performing a lithography process. In one embodiment, a substrate including a layer of photoresist is provided. The layer of photoresist is exposed. The exposed layer of photoresist is developed. A chemical rinse solution is applied to the developed photoresist. The chemical rinse solution includes an alcohol base chemical. The substrate is spun dry.

Owner:TAIWAN SEMICON MFG CO LTD

Ink repellent coating on charge device to improve printer runability and printhead life

An ink jet printhead includes a drop generator having an attached orifice structure forming a jet array adapted to use ink jet fluids with a charge device disposed opposite the jet array forming a gap. The charge device includes a dimensionally stable, non-porous substrate layer having a high load to deflection ratio, one or more electrically conducting leads bonded to the substrate layer, an insulating protective layer disposed over the electrically conducting lead, and a non-wetting polymer coating compatible with the ink jet fluids disposed on the insulating protective layer. The coating reduces the capillary forces that hold liquid in the gap between the orifice structure and the charge device.

Owner:EASTMAN KODAK CO

High thermal insulation clothing material and preparation method thereof

ActiveCN110216936AWith skin-friendly fabricAvoid breakingSynthetic resin layered productsClothingsThermal insulationAramid

The invention discloses a high thermal insulation clothing material and a preparation method thereof. The high thermal insulation clothing material comprises an inner layer, a surface layer and an interlayer, wherein the interlayer is a polyimide fiber fabric, a composite aerogel material, and a camel fiber fabric from outside to inside, the composite aerogel material comprises quartz fiber and amodified aerogel, and the modified aerogel is prepared by gelation of a reinforcement material and an alcohol sol, wherein the reinforcement material is formed by nano-silica, graphene and aramid fiber pulp meal. The beneficial effects are as follows: graphene, aramid fiber pulp meal, and nano-silica free particles are used as support skeletons and the reinforcement material to match with a nano-network structure of an aerogel, and thus heat preservation thermal insulation performance, compressive strength, flexibility, elasticity and stability of the aerogel are improved; and the aerogel is compounded with the polyimide fiber fabric and the camel fiber fabric with the thermal insulation function, the breakage and particle shedding phenomenon of the composite aerogel is effectively avoided, and the heat preservation thermal insulation performance and comfort property of the heat preservation layer are further improved.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

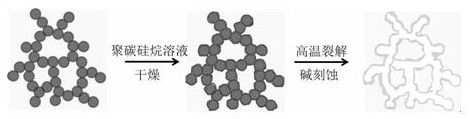

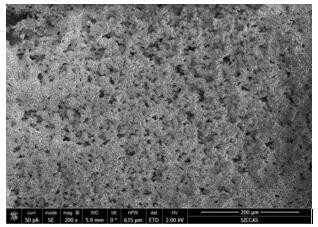

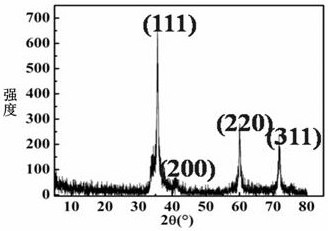

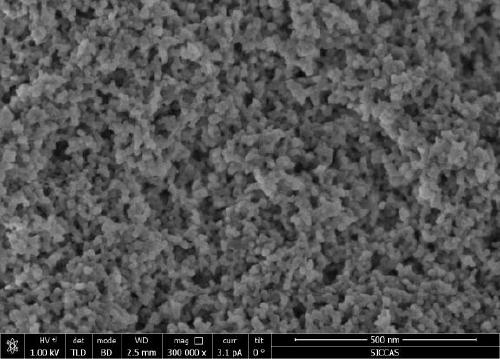

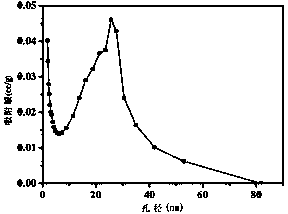

Preparation method of high-temperature-resistant ultralow-density silicon carbide nanotube aerogel

InactiveCN111807368ALow densityReduce capillary forceCarbon compoundsAerogel preparationCarbide siliconAlkoxy group

The invention discloses a preparation method of high-temperature-resistant ultralow-density silicon carbide nanotube aerogel. The preparation method of the aerogel comprises the following specific steps: (1) dissolving alkyl trialkoxy silane, dialkyl dialkoxy silane and hexadecyl trimethyl ammonium bromide in deionized water to obtain a transparent solution, wherein the molar ratio of alkyl trialkoxy silane to dialkyl dialkoxy silane to hexadecyl trimethyl ammonium bromide to deionized water is 1: (0.1-1): (0.1-0.5): (40-80); according to the preparation method disclosed by the invention, thepoly alkyl siloxane gel with a macroporous structure is obtained by utilizing phase separation of alkyl siloxane in a sol-gel process in a water system, the capillary force in a normal-pressure process can be greatly reduced by the macroporous structure, a low-density aerogel block can be obtained under normal-pressure drying, and the preparation method is simpler.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

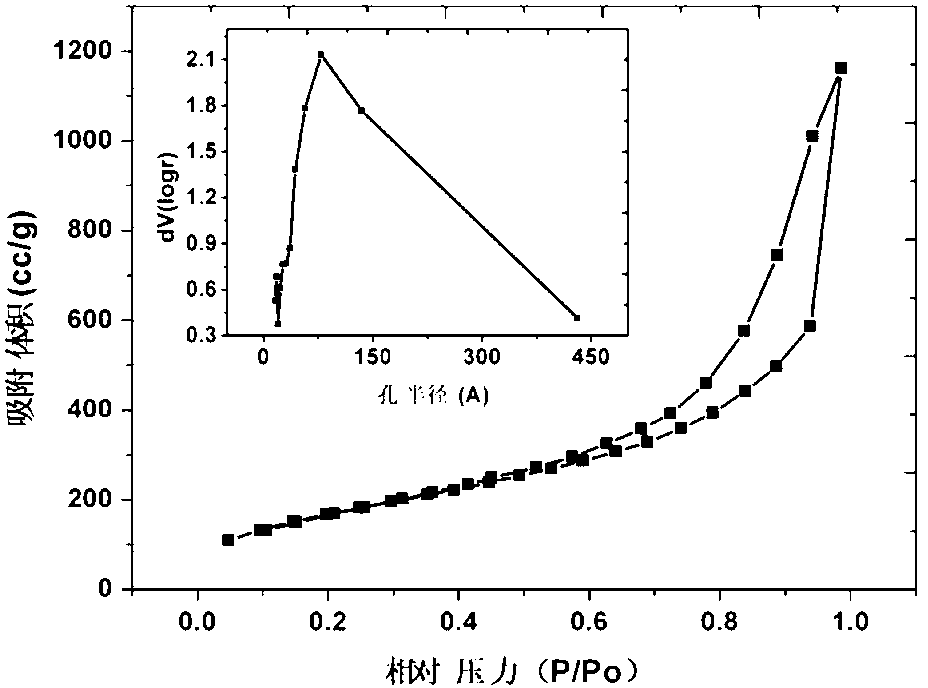

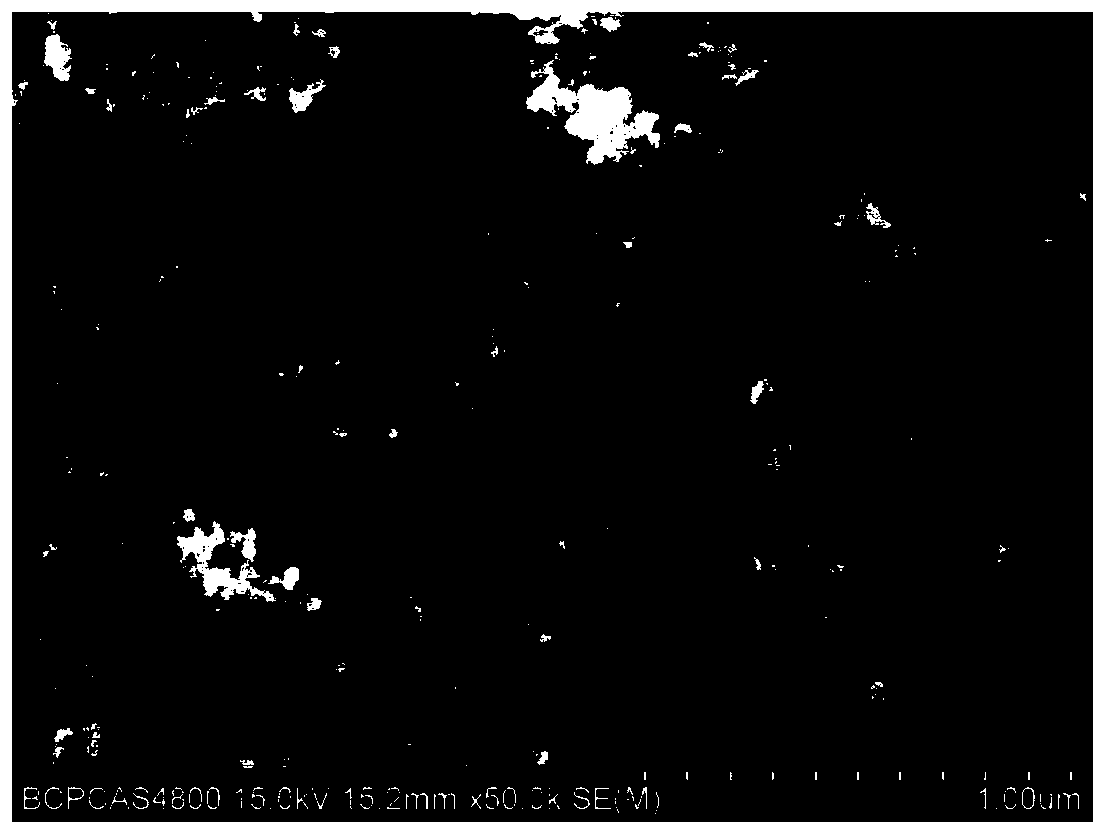

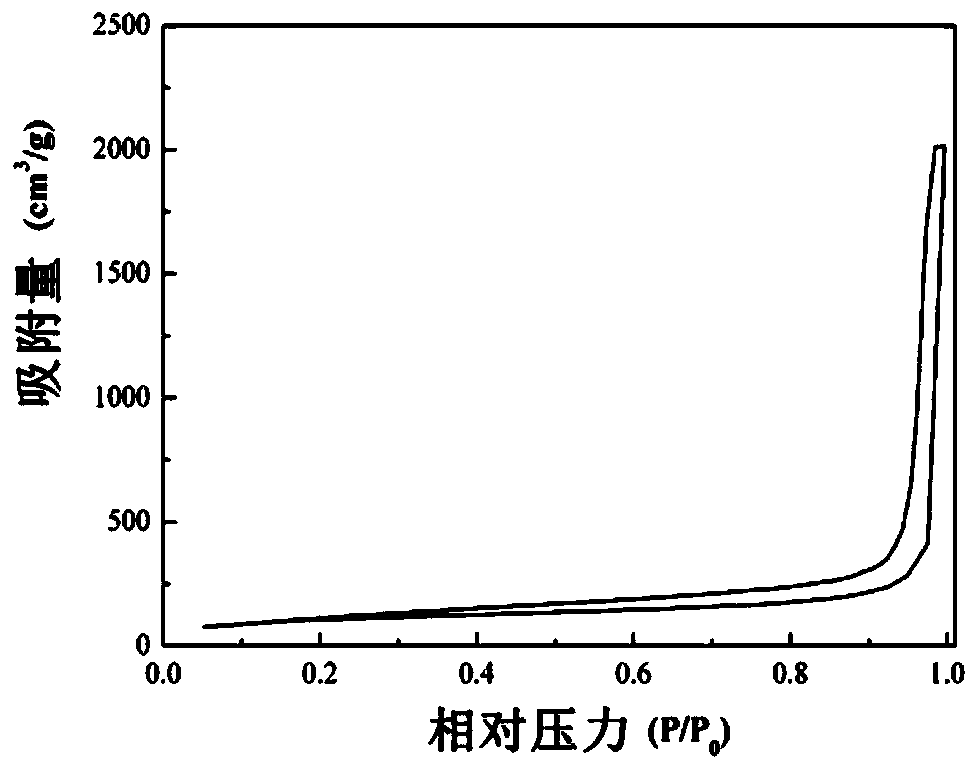

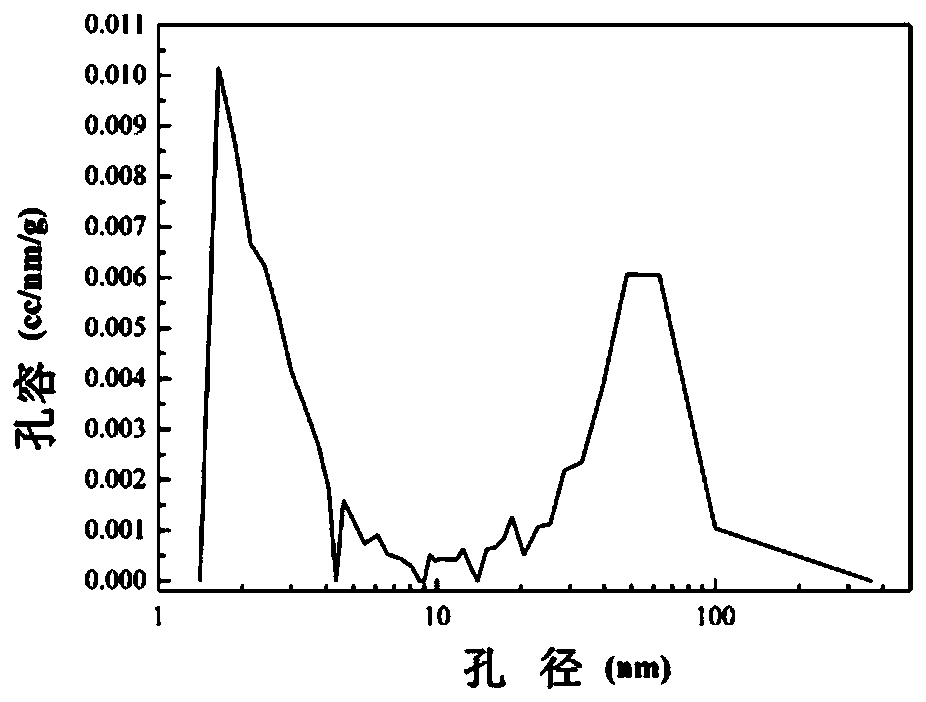

Method for preparing silicon dioxide aerogel by sublimation method

InactiveCN109650395ALow densityReduce capillary forceMaterial nanotechnologySilicon compoundsVacuum sublimationVolumetric Mass Density

The invention discloses a method for preparing silicon dioxide aerogel by a sublimation method. The method comprises the following steps of (1) dissolving a sublimation substance in an alcohol-water solvent to obtain a transparent solution; (2) adding a silicon source and a alkali catalyst into the solution in step (1), uniformly mixing and standing to form gel, and then aging the gel; (3) carrying out vacuum sublimation on the aged gel in step (2) to remove the sublimation substance so as to obtain the silicon dioxide aerogel. According to the method, the sublimation substance can plug the gaps of the gel, plays a role in enhancing the network structure of the gel, and can reduce the shrinkage of the gel; solvent exchange and gel surface modification process are not needed in the preparation process, so that a large amount of organic solvents are saved, and the preparation efficiency of the silicon dioxide aerogel is greatly improved. The silicon dioxide aerogel prepared by the methodis of a nano-pore structure and has the advantages that the pore diameter distribution is 1-200 nanometers; the BET specific surface area is as high as 300-1000 m2 / g<1>, the density is 0.05-0.65 g / cm<3>, and the thermal conductivity is 0.01-0.08 W / m<1> / k<1>.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

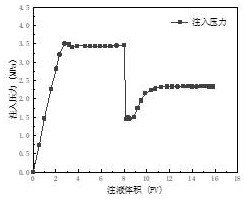

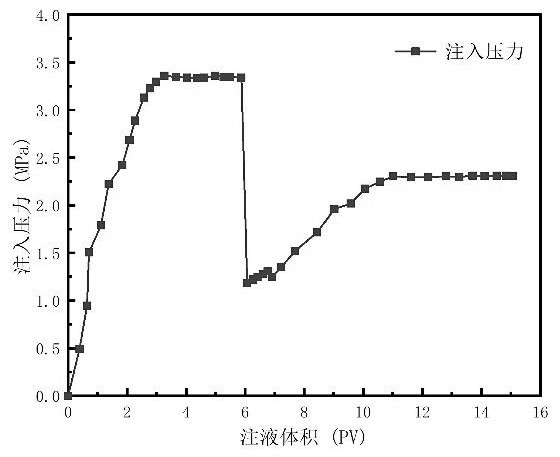

Ultra-low permeability reservoir decompression and augmented injection system and preparation method

InactiveCN111849444AReduce water injection pressureGood blood pressure effectDrilling compositionActive agentPhysical chemistry

The invention provides an ultra-low permeability reservoir decompression and augmented injection system and a preparation method. The system is prepared from the following components in percentage byweight: 0.10-0.20% of a surfactant, 0.20-0.30% of an anti-swelling agent, 0.05-0.10% of an anti-scaling agent and the balance of formation water. The decompression and augmented injection system has good compatibility with formation water, and is suitable for formation water with different mineralization degrees; the oil-water interfacial tension can be effectively reduced, and the wettability ischanged; clay expansion can be obviously inhibited; scale formation can be effectively inhibited, and the scale inhibition rate is high; and the system can be stored and used for a long term.

Owner:PETROCHINA CO LTD

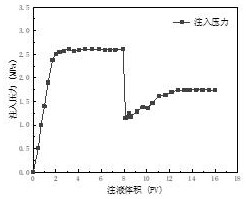

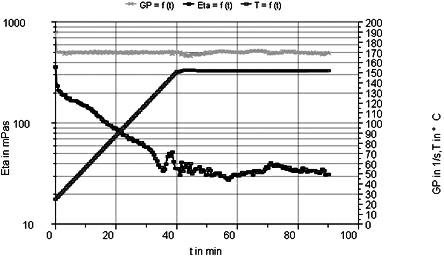

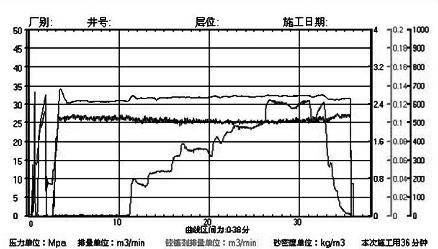

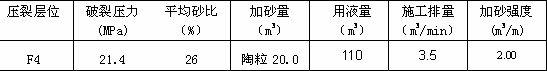

Large-scale transformed low-residue fracturing fluid

The invention relates to a large-scale transformed low-residue fracturing fluid. The fracturing fluid disclosed by the invention is prepared by mixing the following components in percentage by weight: 0.18-0.50% of thickener, 0.06-0.16% of surface active agent, 0.05-0.1% of emulsion breaker, 0.3-0.9% of clay stabilizer, 0.02-0.18% of fungicide, 0.02-0.09% of defoaming agent, 0.00066-0.09% of gel breaker, 0.0002-0.0009% of gel breaking catalyst, and the balance of water, and according the components, a low-residue fracturing fluid adapted to oil layers at different temperatures can be formed. The low-residue fracturing fluid disclosed by the invention has the advantages of temperature resistance, shearing resistance, good rock stability, low leakoff of the fracturing fluid, and high efficiency of the fracturing fluid, has the characteristics of low residue and strong sand suspending capacity in oil layers and artificial cracks, and capability of achieving an effect of rapid field preparation, and solves the problem of large-scale fracturing transformation on low-permeability difficult-to-recovery reserves.

Owner:PETROCHINA CO LTD +1

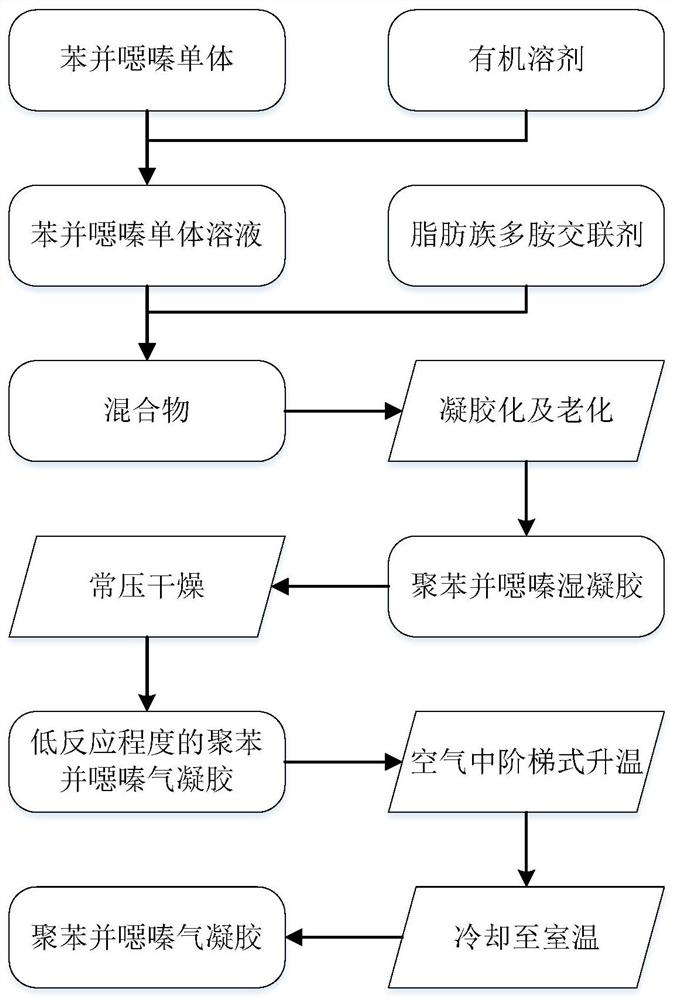

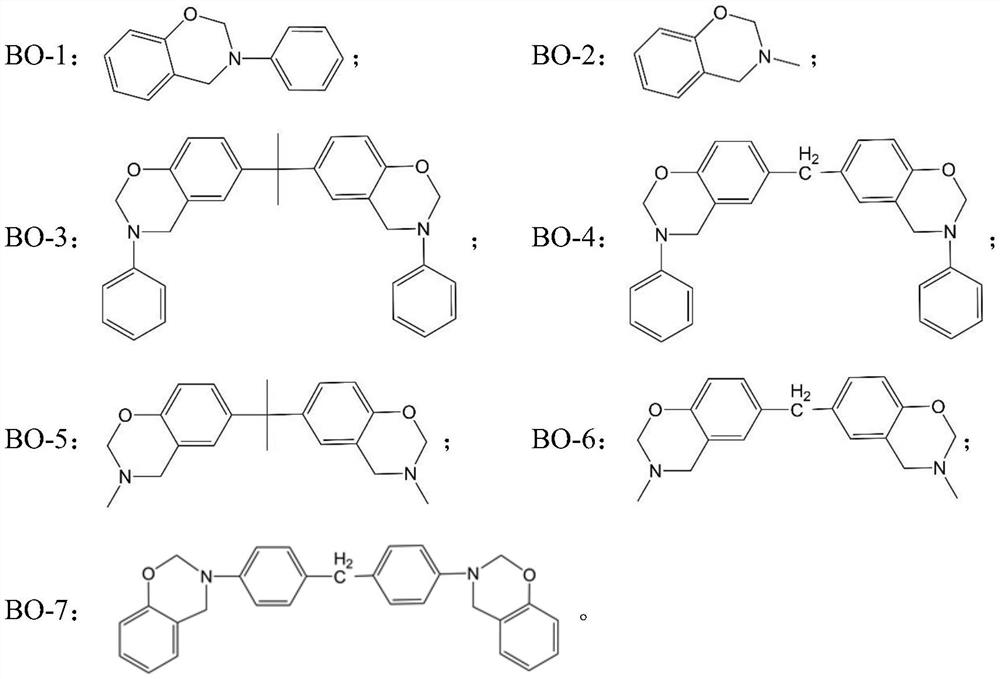

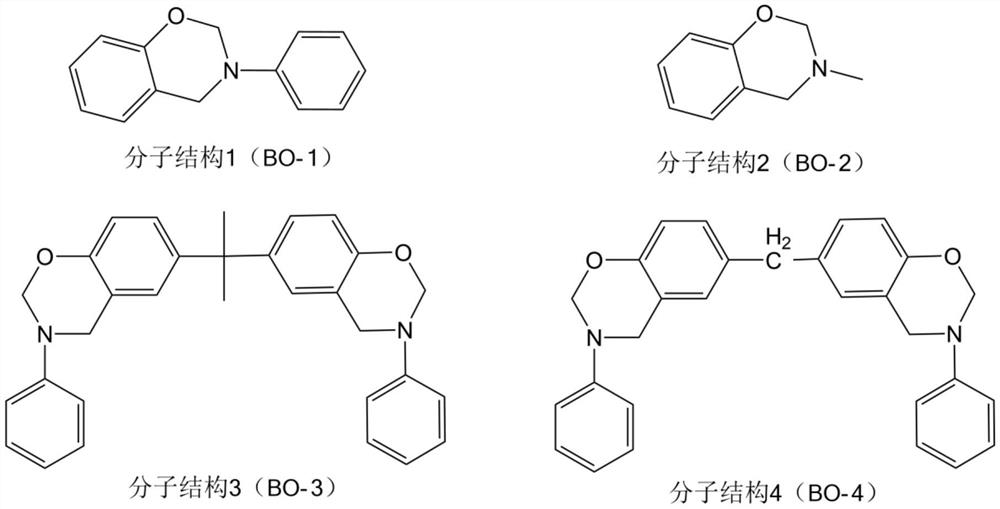

Polybenzoxazine aerogel and preparation method thereof

The invention discloses polybenzoxazine aerogel and a preparation method thereof, and belongs to the technical field of aerogel materials. The preparation method comprises the steps of: dissolving a benzoxazine monomer in an organic solvent to obtain a benzoxazine monomer solution; adding an aliphatic polyamine cross-linking agent, mixing well, pouring the solution into a mold, heating for a gelation reaction, and aging to obtain polybenzoxazine wet gel; then carrying out normal pressure drying to obtain polybenzoxazine aerogel with a low reaction degree; and heating to 200 DEG C in air in a stepped manner, preserving heat for 2-12 hours at each temperature section, and cooling to room temperature to obtain polybenzoxazine aerogel. The linear shrinkage rate of the aerogel can be reduced, and the aerogel is good in thermal stability and easy to form.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com