Polybenzoxazine aerogel and preparation method thereof

A technology of polybenzoxazine and benzoxazine, which is applied in the field of polybenzoxazine airgel and its preparation, can solve the problem of high cost, low shrinkage of polybenzoxazine and the influence of polybenzoxazine Airgel application and other problems, to achieve the effect of suppressing collapse, solving the problem of large linear shrinkage and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

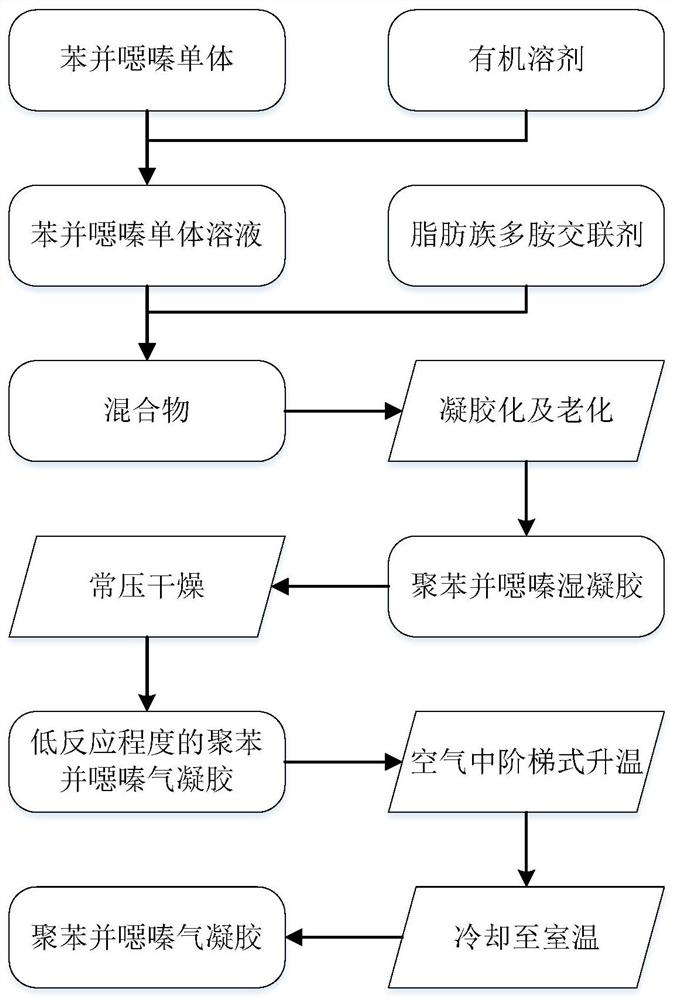

[0031] This embodiment adopts the preparation method proposed by the present invention to prepare polybenzoxazine airgel, such as figure 1 As shown, the steps are as follows:

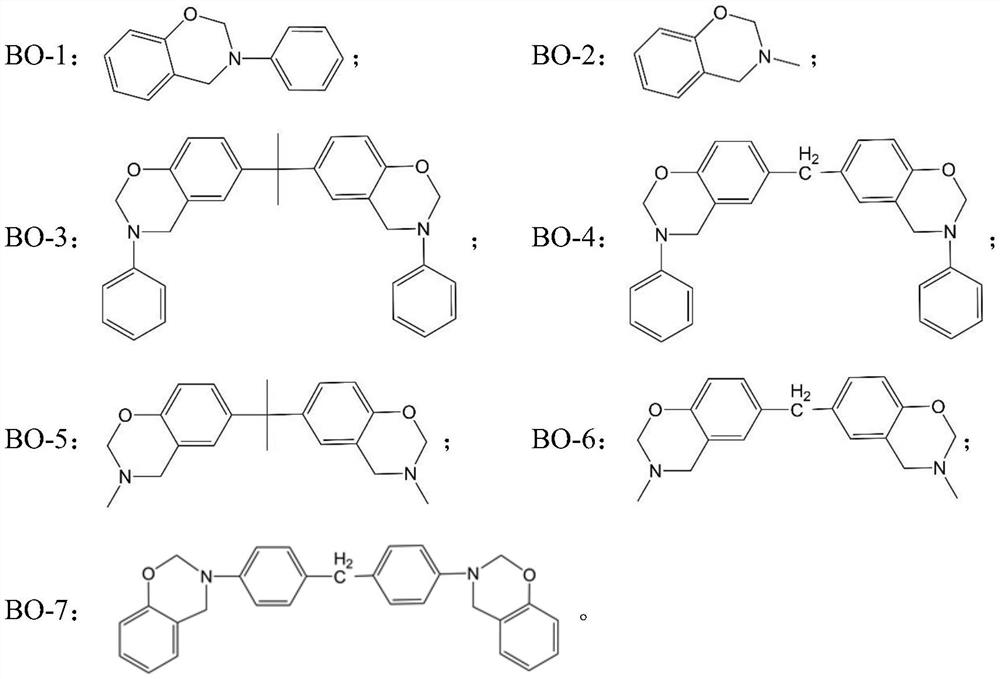

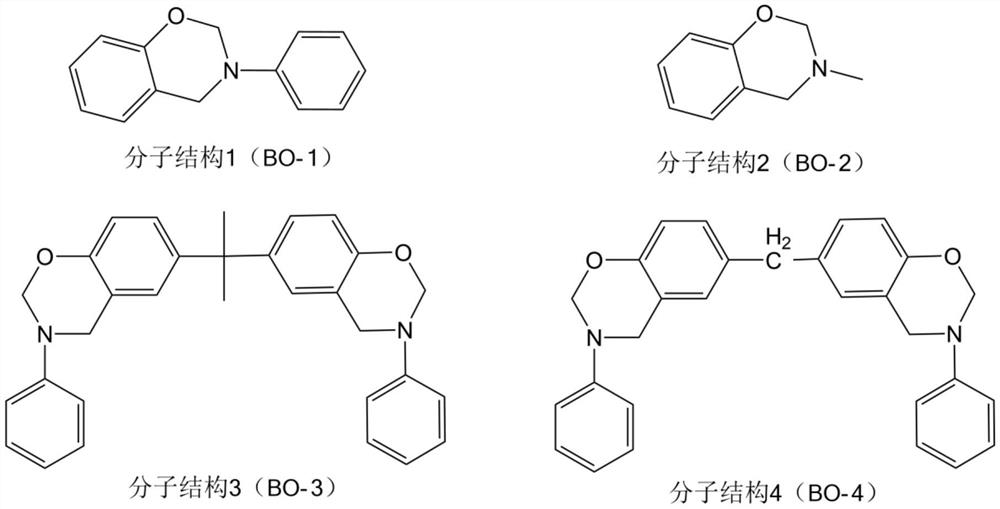

[0032] 1) 10g BO-1 was dissolved in 30g ethyl acetate to obtain a benzoxazine monomer solution.

[0033] 2) Add 0.5 g of triethylenetetramine cross-linking agent to the benzoxazine monomer solution, stir at 25°C for 5 minutes, pour into a mold, and age at 120°C for 8 hours to obtain polybenzoxazine wet gel.

[0034] 3) Cool the obtained polybenzoxazine wet gel at room temperature for 24 hours, and keep it warm at 100° C. for 12 hours to obtain polybenzoxazine airgel with a low degree of reaction.

[0035] 4) Heat the polybenzoxazine airgel with a low degree of reaction to 200°C stepwise in the air (step heating program: 140°C for 2h; 160°C for 2h; 180°C for 2h; 200°C for 2h) , to obtain polybenzoxazine airgel.

[0036] The test result data of the polybenzoxazine airgel obtained in this embodiment ar...

Embodiment 2

[0038] In this embodiment, the preparation method proposed by the present invention is used to prepare polybenzoxazine airgel, and the steps are as follows:

[0039] 1) Dissolve 10g BO-2 in 30g toluene to obtain a benzoxazine monomer solution.

[0040] 2) Add 0.2 g of triethylamine cross-linking agent to the benzoxazine monomer solution, stir at 25°C for 5 minutes, pour into a mold, and age at 100°C for 96 hours to obtain polybenzoxazine wet gel .

[0041]3) The obtained polybenzoxazine wet gel was cooled at room temperature for 72 hours, and kept at 120° C. for 24 hours to obtain polybenzoxazine airgel with a low degree of reaction.

[0042] 4) Heat the polybenzoxazine airgel with a low degree of reaction to 200°C stepwise in the air (step heating program: 140°C for 12h; 160°C for 12h; 180°C for 12h; 200°C for 12h) , to obtain polybenzoxazine airgel.

[0043] The test result data of the polybenzoxazine airgel obtained in this embodiment are listed in Table 1.

Embodiment 3

[0045] In this embodiment, the preparation method proposed by the present invention is used to prepare polybenzoxazine airgel, and the steps are as follows:

[0046] 1) Dissolve 10g BO-3 in 30g toluene and xylene to obtain a benzoxazine monomer solution.

[0047] 2) Add 0.8 g of ethylenediamine cross-linking agent to the benzoxazine monomer solution, stir at 25°C for 5 minutes, pour into a mold, and age at 110°C for 48 hours to obtain polybenzoxazine wet gel .

[0048] 3) The obtained polybenzoxazine wet gel was cooled at room temperature for 48 hours, and then kept at 110° C. for 18 hours to obtain polybenzoxazine airgel with a low degree of reaction.

[0049] 4) Heat the polybenzoxazine airgel with a low degree of reaction to 200°C stepwise in the air (the stepwise heating program is: 140°C for 8 hours; 160°C for 8 hours; 180°C for 8 hours; 200°C for 8 hours) , to obtain polybenzoxazine airgel.

[0050] The test result data of the polybenzoxazine airgel obtained in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com