Flam resistant silicone rubber beneficial to demolding and preparation method thereof

A technology of silicone rubber and mixing silicone rubber, applied in the field of silicone rubber, can solve the problems of long vulcanization time, slow vulcanization speed, long molding process, etc., achieve obvious synergistic effect of flame retardant, reduce linear shrinkage rate, and improve elongation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

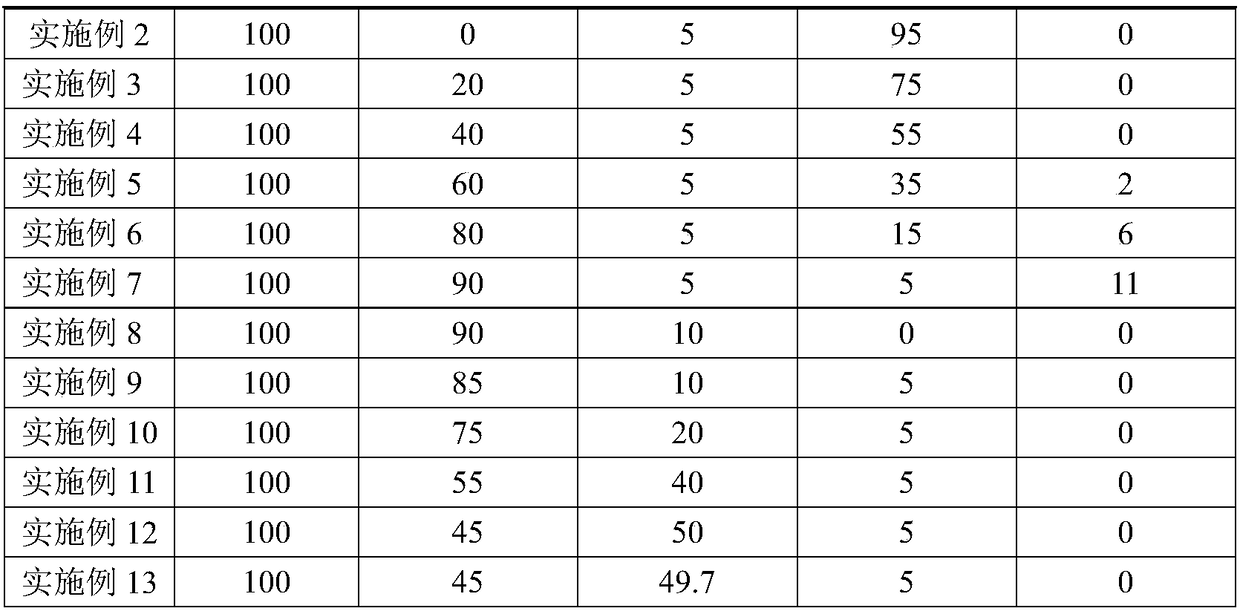

Examples

Embodiment 1

[0035] A kind of flame-retardant silicone rubber that is beneficial to demoulding. The raw materials are calculated in parts by mass: 100 parts of kneaded silicone rubber, 98 parts of aluminum hydroxide, 0 parts of silicon dioxide, 2 parts of iron oxide, and 3 parts of plasticizer , 0.3 parts of vulcanization accelerator, 0.3 parts of release agent.

[0036] Iron oxide is Fe 2 o 3 .

[0037] The vulcanization accelerator is a hydrosilyl functional vulcanization accelerator.

[0038] The plasticizer is hydroxy silicone oil.

[0039] The release agent is zinc stearate.

[0040] A kind of preparation method of the flame-retardant silicone rubber that is beneficial to demoulding, comprises the steps:

[0041] S1 taking materials, weighing and mixing raw materials such as silicone rubber, aluminum hydroxide, silicon dioxide, ferric oxide, mold release agent and vulcanization accelerator in proportion;

[0042] S2 kneading, which is divided into 5 times and put into the kneade...

Embodiment 2

[0053] A kind of flame-retardant silicone rubber that is beneficial to demoulding. The raw materials are calculated in parts by mass: 100 parts of kneaded silicone rubber, 95 parts of aluminum hydroxide, 0 parts of silicon dioxide, 5 parts of iron oxide, and 3 parts of plasticizer , 0.3 parts of vulcanization accelerator, 0.3 parts of release agent. Other specific implementations are all the same as in Example 1.

Embodiment 3

[0055] A kind of flame-retardant silicone rubber that is beneficial to demoulding. The raw materials are calculated in parts by mass: 100 parts of kneaded silicone rubber, 75 parts of aluminum hydroxide, 20 parts of silicon dioxide, 5 parts of iron oxide, and 3 parts of plasticizer , 0.3 parts of vulcanization accelerator, 0.3 parts of release agent. Other specific implementations are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com