High-performance thermal conductive silicone rubber and preparation method thereof

A thermally conductive silicone rubber and high-performance technology, applied in the field of high-performance thermally conductive silicone rubber and its preparation, can solve problems such as easy sticking to rollers, mold sticking, poor processing performance, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

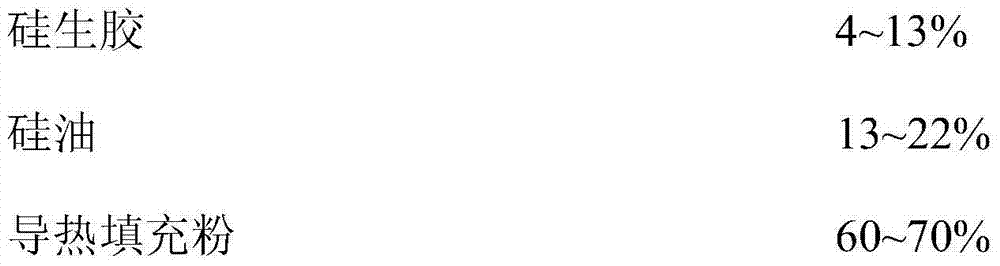

[0068] A high-performance heat-conducting silicone rubber of the present invention comprises the following raw materials in mass percentage:

[0069]

[0070] The thermally conductive filling powder of the present embodiment comprises the following raw materials in mass percentage:

[0071] Aluminum Oxide 30%

[0072] Aluminum nitride 70%.

[0073] The particle size of aluminum oxide in this embodiment is 10 nm, and the particle size of aluminum nitride is 100 nm.

[0074] The silica gel in this embodiment is methyl vinyl silica gel.

[0075] The silicone oil in this embodiment is vinyl silicone oil.

[0076] The coupling agent in this embodiment is a silane coupling agent.

[0077] The release agent in this embodiment is a fluorine internal release agent.

[0078] A preparation method of high-performance heat-conducting silicone rubber, comprising the following processing steps:

[0079] Step A, weighing various materials according to the formula, and placing them in...

Embodiment 2

[0085] A high-performance heat-conducting silicone rubber of the present invention comprises the following raw materials in mass percentage:

[0086]

[0087]

[0088] The thermally conductive filling powder of the present embodiment comprises the following raw materials in mass percentage:

[0089] Aluminum Oxide 40%

[0090] Aluminum Nitride 60%.

[0091] The particle size of aluminum oxide in this embodiment is 20 nm, and the particle size of aluminum nitride is 70 nm.

[0092] The silica gel in this embodiment is methyl vinyl silica gel.

[0093] The silicone oil of this embodiment is ethyl silicone oil.

[0094] The coupling agent in this embodiment is a chromium complex coupling agent.

[0095] The release agent in this embodiment is a silicon-based internal release agent.

[0096] A preparation method of high-performance heat-conducting silicone rubber, comprising the following processing steps:

[0097] Step A, weighing various materials according to the fo...

Embodiment 3

[0103] A high-performance heat-conducting silicone rubber of the present invention comprises the following raw materials in mass percentage:

[0104]

[0105]

[0106] The thermally conductive filling powder of the present embodiment comprises the following raw materials in mass percentage:

[0107] Aluminum Oxide 50%

[0108] Aluminum Nitride 50%.

[0109] The particle size of aluminum oxide in this embodiment is 40 nm, and the particle size of aluminum nitride is 85 nm.

[0110] The silica gel in this embodiment is methyl vinyl silica gel.

[0111] The silicone oil in this embodiment is phenyl silicone oil.

[0112] The coupling agent in this embodiment is a titanate coupling agent.

[0113] The release agent in this embodiment is a wax internal release agent.

[0114] A preparation method of high-performance heat-conducting silicone rubber, comprising the following processing steps:

[0115] Step A, weighing various materials according to the formula, and placin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com