Graphite-copper composite material, heat sink member using same, and method for producing graphite-copper composite material

A composite material and manufacturing method technology, applied in the field of graphite-copper composite material manufacturing, can solve the problem of high thermal expansion rate and achieve the effect of high thermal conductivity and stable thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

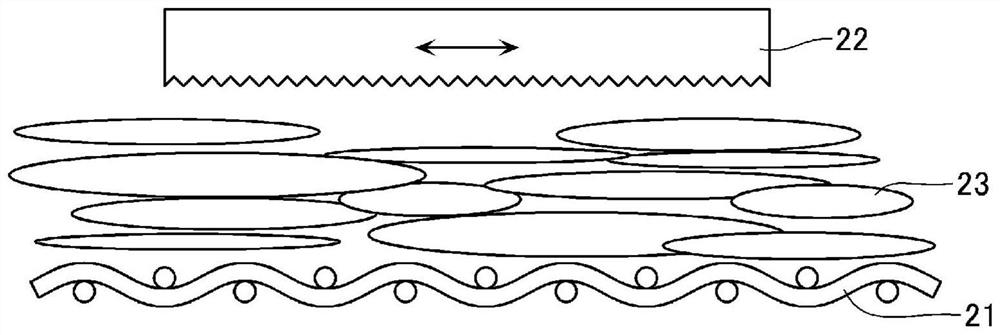

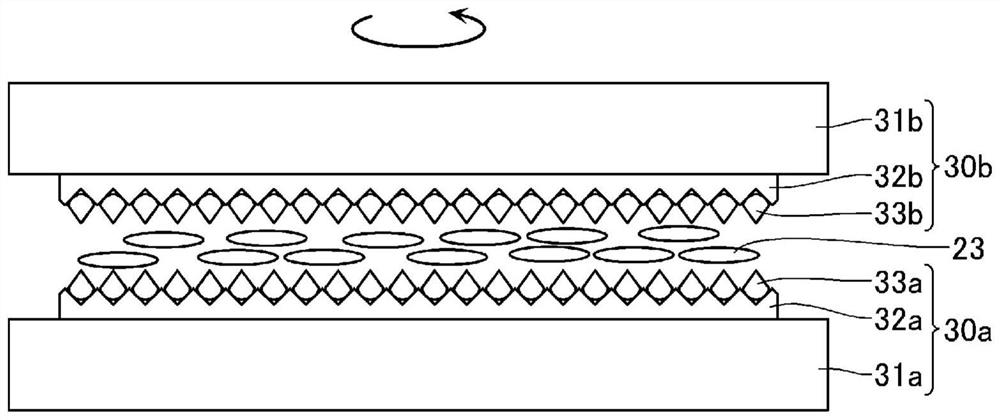

[0071] by reference figure 2 By the method described, pretreatment (thinning) was performed on commercially available graphite particles, and scaly graphite particles having a thickness of 50 μm or less were obtained. The mesh size of the sieve 21 was about 53 μm, and the grindstone 22 used corundum or natural diamond as abrasive grains. The obtained scaly graphite particles were dried with a dryer. On the other hand, as copper particles, copper particles having a median particle diameter of 1.5 μm were prepared.

[0072] 15.33 g of flaky graphite particles after pretreatment and drying were mixed with 15.19 g of copper particles so that the volume fraction of sintered copper was 20% to obtain molding raw materials. These powders were accommodated in a 250 mL eggplant-shaped flask together with 50 mL of toluene as a solvent, and were desolvated and mixed with an evaporator.

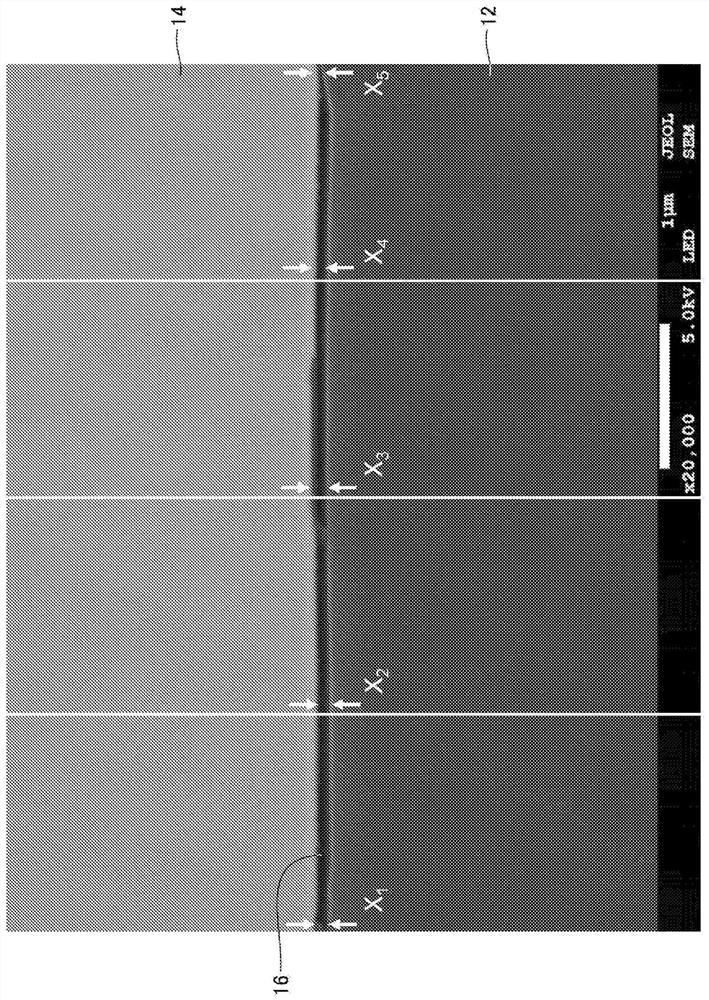

[0073] 3 g of the molding raw material was put into a SUS mold having a diameter of 30 mm, and the p...

Embodiment 2

[0079] A composite material of Example 2 was produced in the same manner as in Example 1, except that the molding raw material was changed so that the volume fraction of copper after sintering was 16%.

Embodiment 3

[0081] A composite material of Example 3 was produced in the same manner as in Example 1, except that the molding raw material was changed so that the volume fraction of copper after sintering was 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com