INS (Inertial Navigation System) film-coated cavity for automotive trim

A technology for automobile interior decoration and lamination, applied in the field of automobile interior decoration assembly, can solve the problems of abnormal assembly noise, uneven gap, surface difference, etc., and achieve the effect of good practicability, reduction of processes, and reduction of welding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

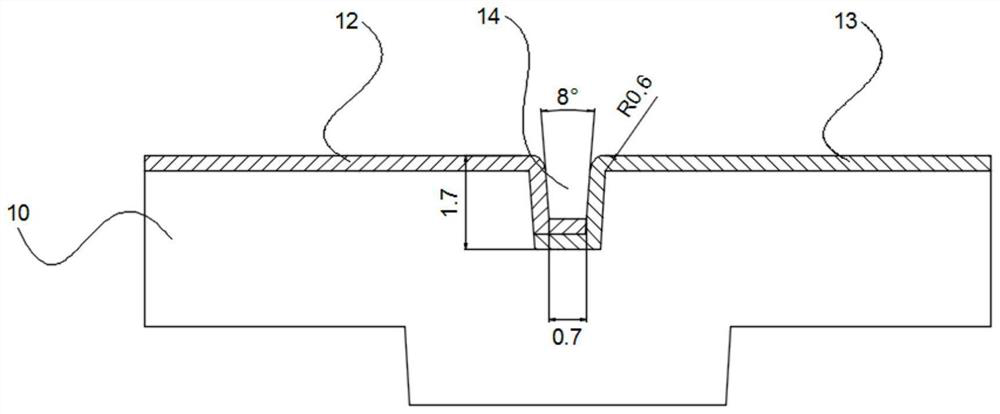

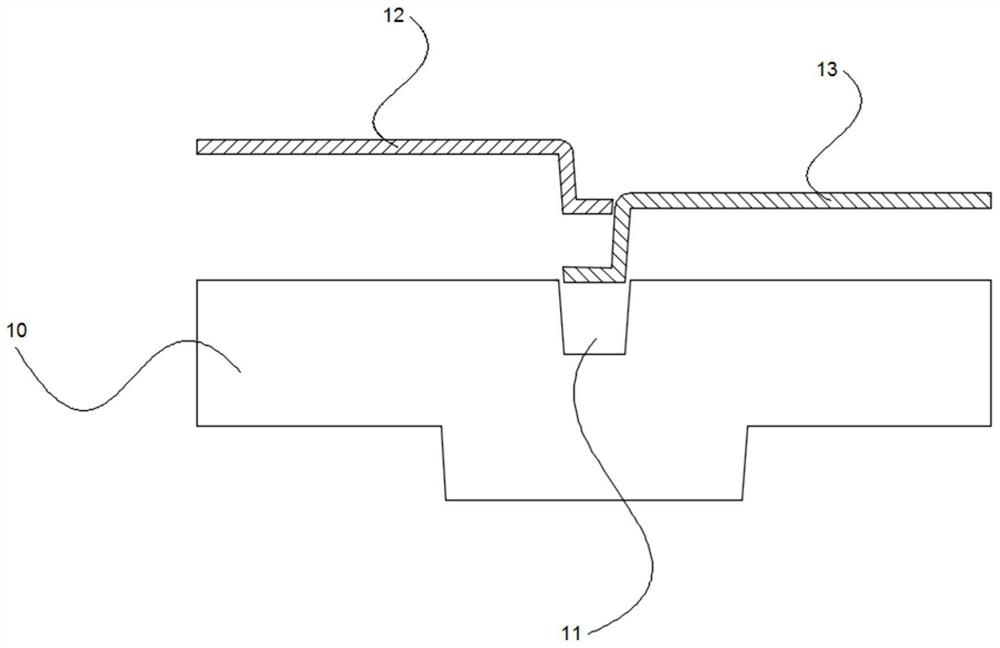

[0031] A INS coating cavity for automotive interior, including processing panel 10, first INS diaphragm 12, and second INS diaphragm 13, and a groove 11 is provided with a groove 11, the groove. 11 The longitudinal section of the longitudinal section is inverted, the first INS diaphragm 12 and the second INS diaphragm 13 located at the top of the machining panel 10, and one end of the first INS diaphragm 12 and the second INS diaphragm 13. A process slot 14 is formed between the groove 11 and bonded to the groove 11, and the first INS diaphragm 12 and the second INS diaphragm 13 are formed, and the first INS diaphragm in the groove 11 is formed. 12 The end is covered with the top of the end of the second INS diaphragm 13.

[0032] When the first INS diaphragm 12 and the second INS diaphragm 13 are used, the first INS diaphragm 12 and the second INS diaphragm 13 are provided on the machining panel 10 and are sent to the injection mold, and the plastic bag. The top portion of the fi...

Embodiment 2

[0034] This embodiment is optimized on the basis of Example 1, such as Figure 1 - Figure 2 As shown, the groove 11 is bent by a machining panel 10.

[0035] The groove 11 of the processing panel 10 is composed of stamping, avoiding the use of tool slots and reduces the process.

[0036] The other portions of the present embodiment are the same as in Example 1, so it will not be described again.

Embodiment 3

[0038] This embodiment is optimized on the basis of Example 1 or 2, such as figure 1 As shown, the inclination angle of the process tank 14 is a, height h, a width D, and the inclined angle A is 6 ° -8 °, the height H ranges from 1.7 mm to 2.5 mm, The width D ranges from 0.7 mm to 0.9 mm;

[0039] Among them, the optimization is that the inclination angle A is 6 °, the height H is 1.7 mm, and the width D is 0.7 mm. The inclination angle A ranges from 6 ° -8 °, the height H ranges from 1.7 mm to 2.5 mm, and the range D is 0.7mm to 0.9mm, and the above parameters are set, which makes the appearance of the injection molded product meet the requirements, and easy The product is removed from the first INS diaphragm 12 and the second INS diaphragm 13 without sticking.

[0040] The other portions of the present embodiment are the same as those of the above-described Embodiment 1 or 2, so it will not be described again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com