Stainless steel cup stamping die

A stamping die and stainless steel technology, applied in the field of stainless steel cup stamping die, can solve the problems of affecting the qualified rate and delicate feeling of stainless steel cups, reducing rod pressure and roller grinding polishing degree, and increasing the loss of shaving and white forming parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

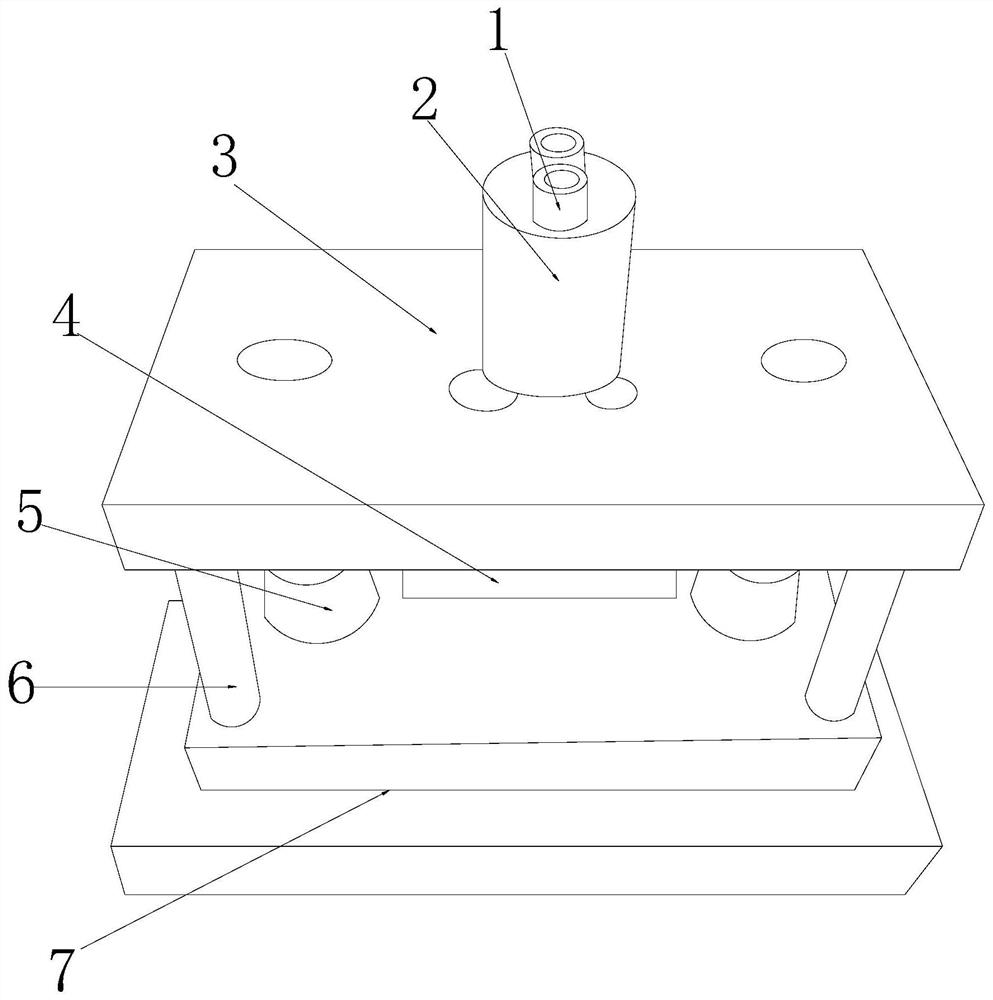

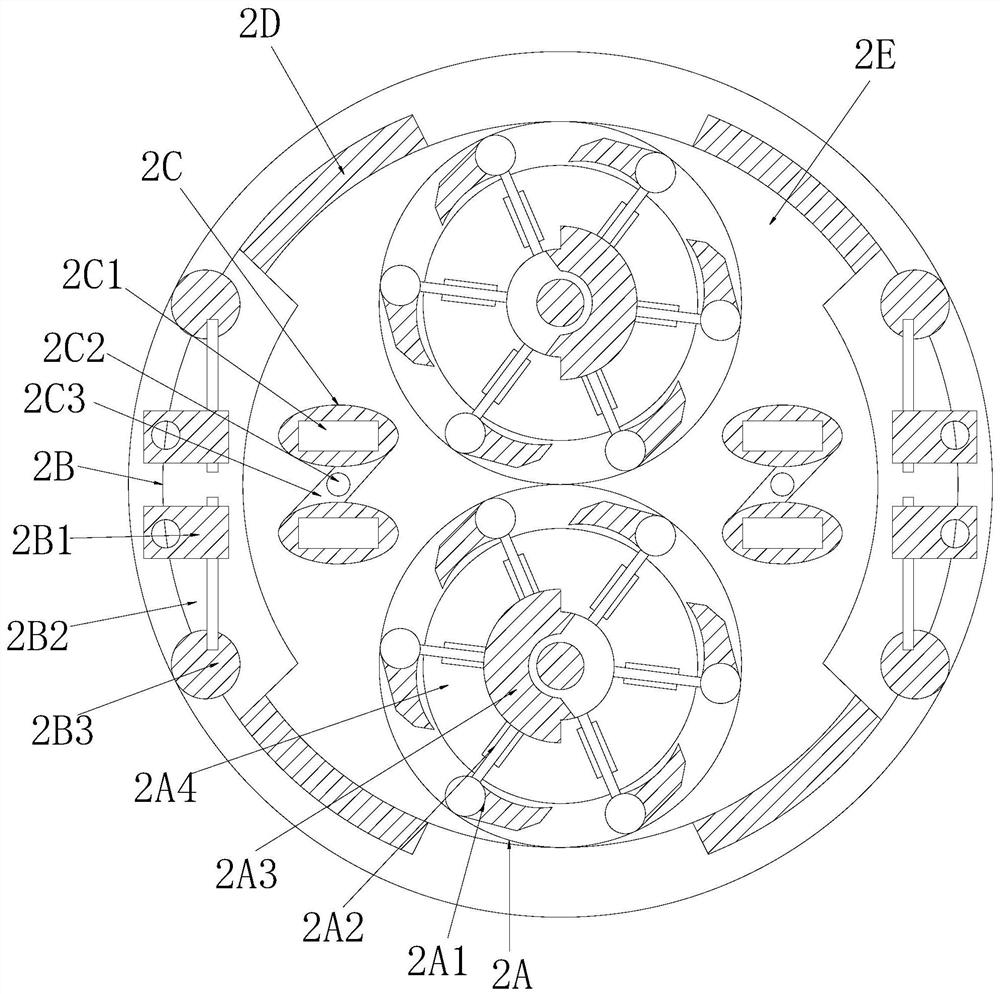

[0032] see Figure 1-Figure 6 , the present invention provides a stainless steel cup stamping die, its structure includes: short cap 1, pressure roller clamp cylinder 2, upper parting panel 3, threaded ring splint 4, clamping wheel seat 5, spring tube 6, base The liner block 7, the pressure roller clamp cylinder 2 is inserted on the top of the upper parting panel 3 and is perpendicular to each other, the short sleeve cap 1 is installed on the top of the pressure roller clamp cylinder 2, the thread The ring splint 4 is closely attached to the bottom surface of the upper parting panel 3 and is on the same level. The clamping wheel seat 5 is provided with two and is respectively attached to the left and right sides of the top surface of the base liner plate 7. The base The liner block 7 is mechanically connected to the upper parting panel 3 through the spring tube 6, and the pressure roller clamp cylinder 2 is provided with a sash paddle roller 2A, a spring core clamp column plat...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a stainless steel cup stamping die, other aspects are the same as in Embodiment 1, the difference is:

[0040] see figure 2 The folding pad base 2C is composed of an ellipsoidal frame groove pad 2C1, a torsion shaft wheel 2C2, and a slanted fin plate 2C3. On both sides, the torsion wheel 2C2 is installed inside the slanted fin plate 2C3 and is on the same vertical plane, and presses the slanted fin plate 2C3 through the ellipsoidal frame groove pad 2C1 to form the effect of knuckle cushioning and load-bearing operation.

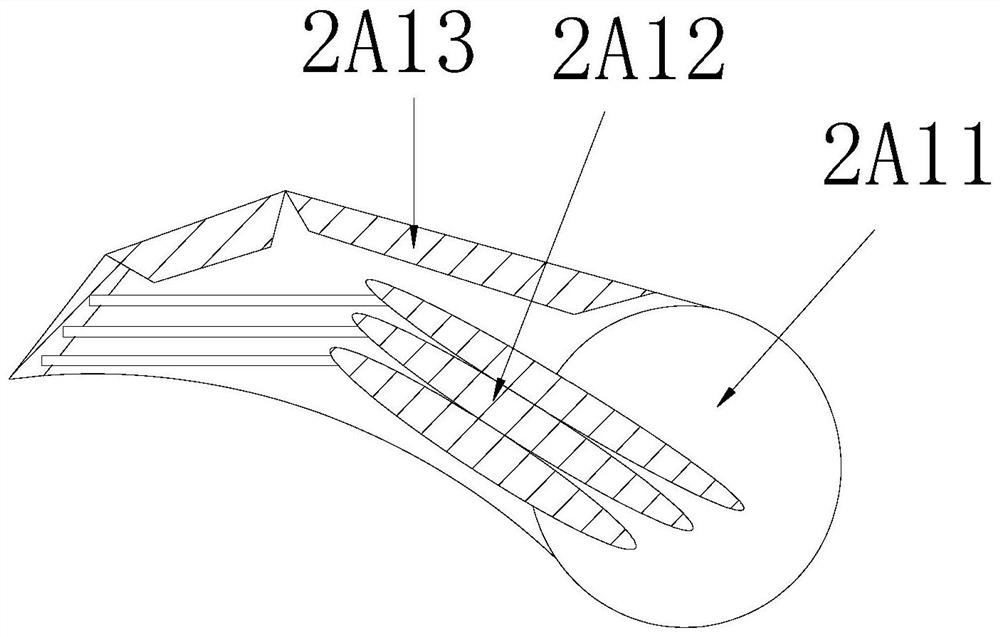

[0041] see Image 6 , the ellipsoidal frame groove pad 2C1 is made up of a cushion ball rod frame 2C11, a double ball strut 2C12, and an ellipsoidal frame groove body 2C13, and the pad ball rod frame 2C11 is installed inside the ellipsoidal frame groove body 2C13, and the There are four double-ball struts 2C12, which are respectively inserted on the left and right sides of the ellipsoidal fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com