Patents

Literature

56results about How to "Low linear shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic fiber

InactiveUS7887917B2Low shrinkageEasy to manufactureGlass/slag layered productsWoven fabricsFiberThermal insulation

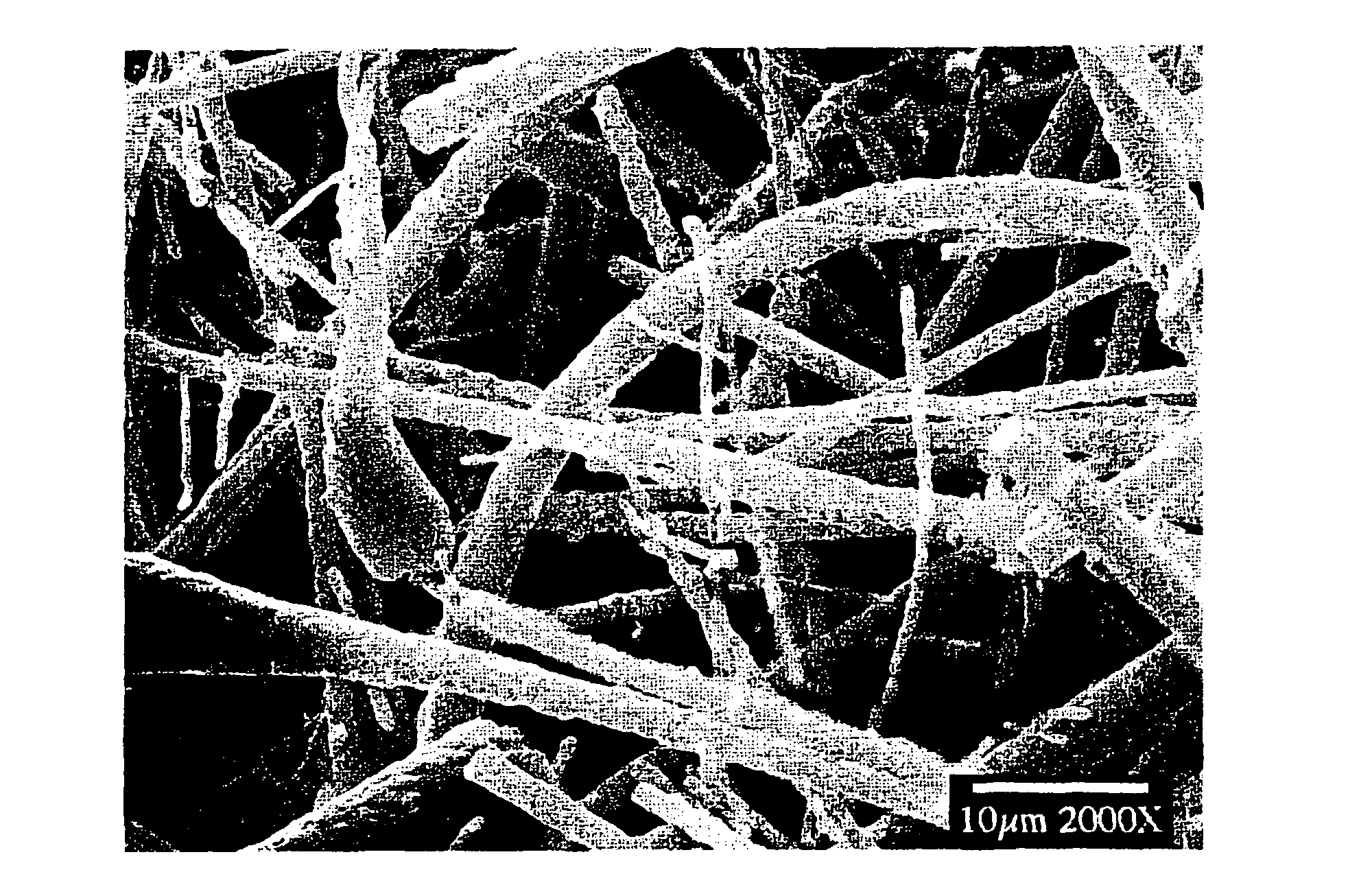

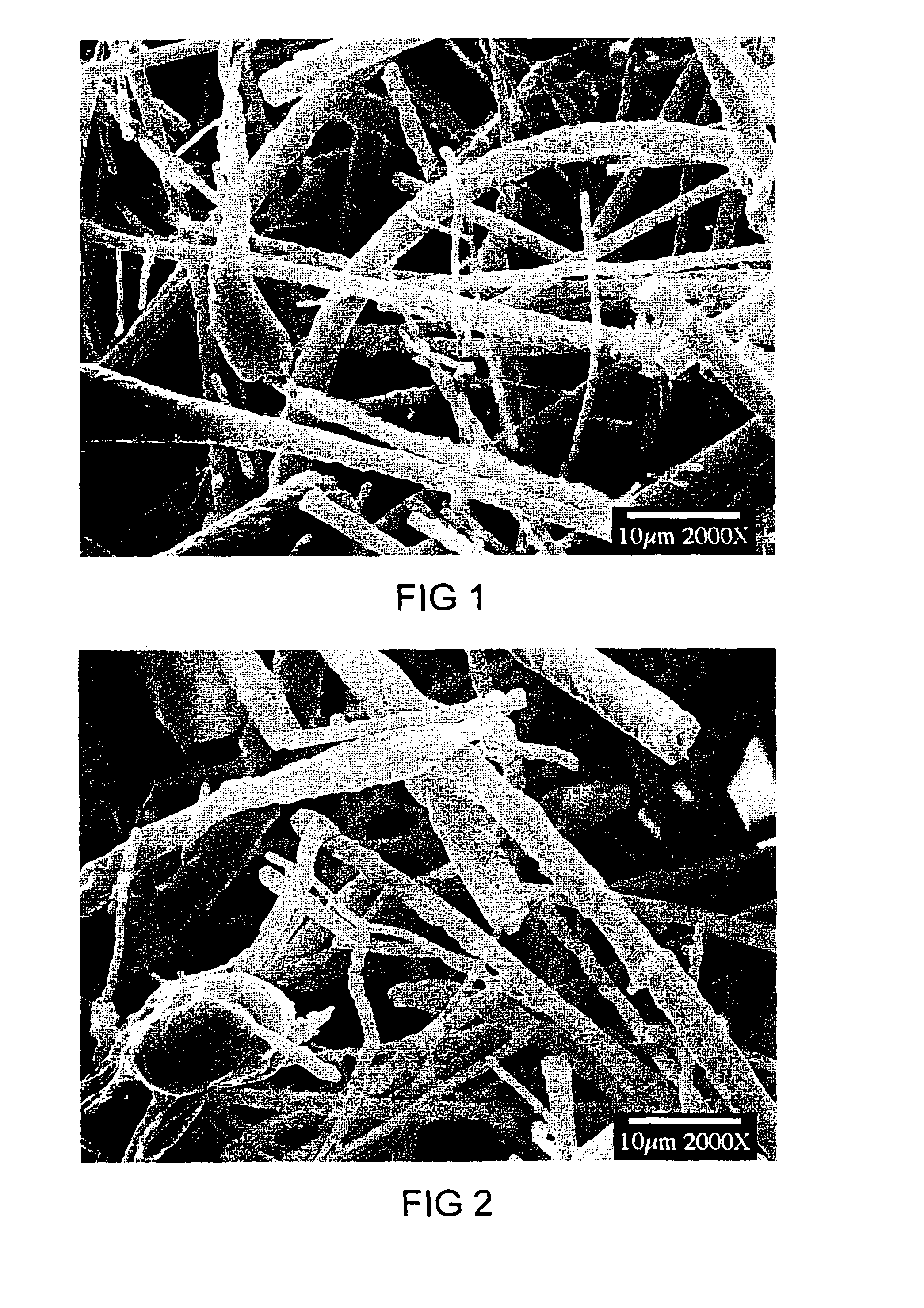

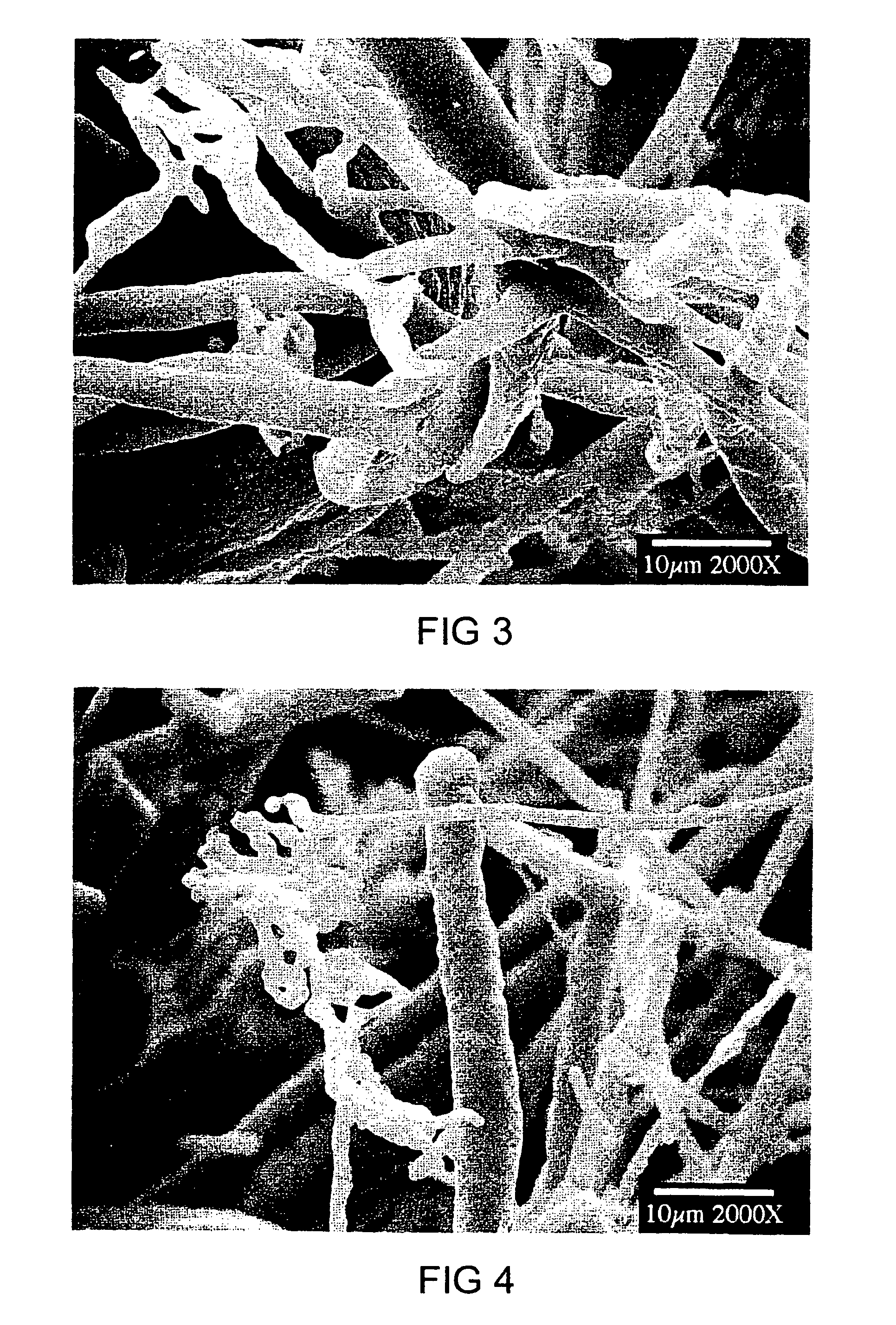

Provided are inorganic fibers containing calcium and alumina as the major fiber components. According to certain embodiments, the inorganic fibers containing calcia and alumina are provided with a coating of a phosphorous containing compound on at least a portion of the fiber surfaces. Also provided are methods of preparing the coated and non-coated inorganic fibers and of thermally insulating articles using thermal insulation comprising the inorganic fibers.

Owner:UNIFRAX I LLC

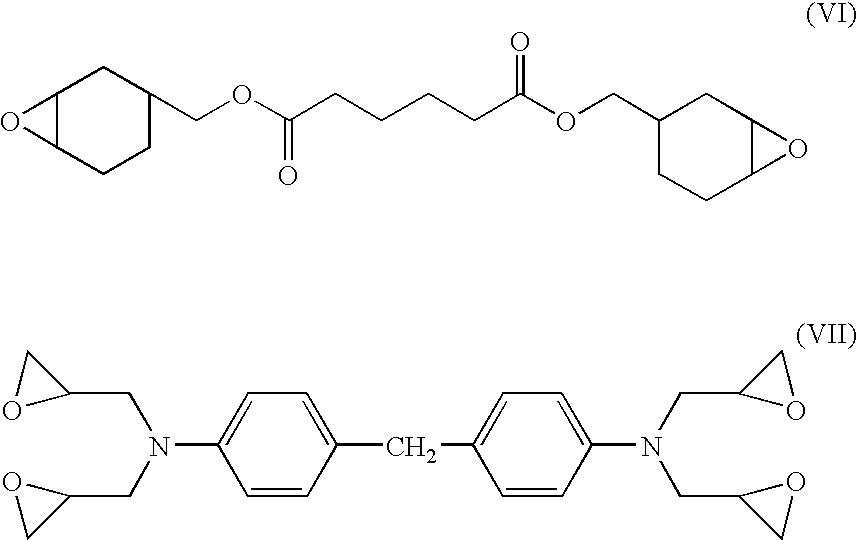

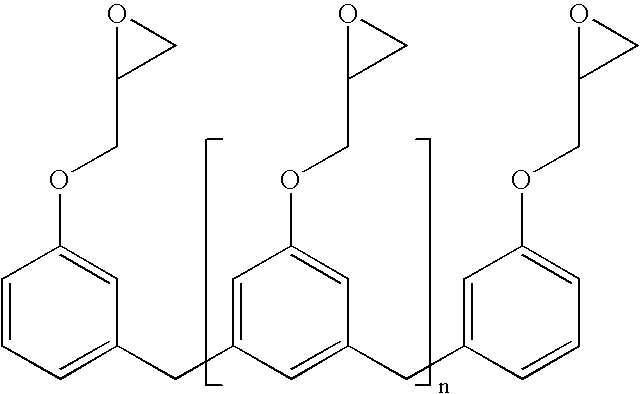

Hardenable reaction resin system

InactiveUS20070191513A1Low linear shrinkageHigh elongationMaterial nanotechnologyPrinted circuit aspectsNanoparticlePolymer chemistry

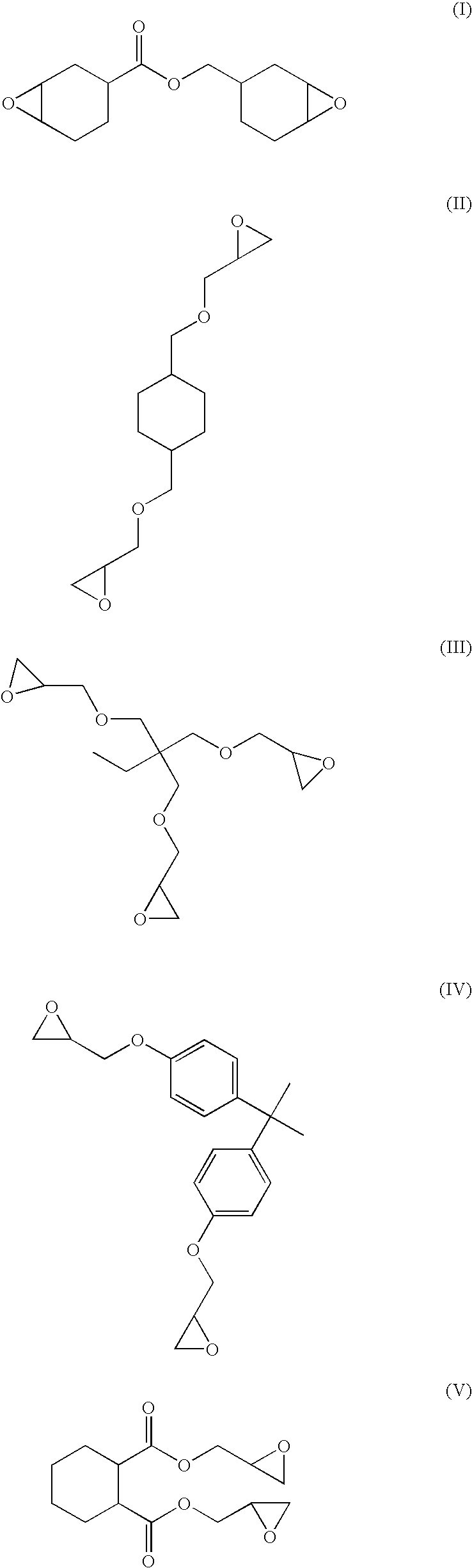

A hardenable reaction resin system, in particular a casting compound, laminating resin, or impregnating resin, which is to be processed as a two-component compound and contains a resin component, a mineral filler, and polymer particles dispersed in the resin component. The filler includes nanoparticles.

Owner:ROBERT BOSCH GMBH

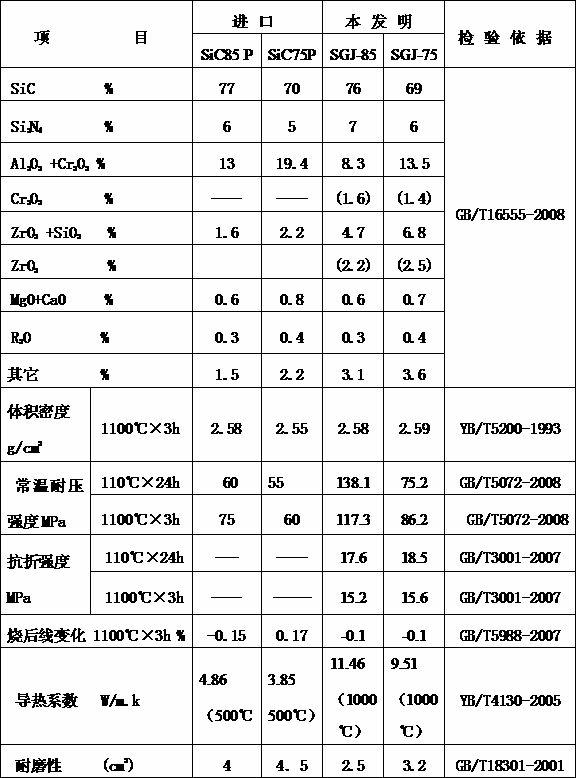

Silicon carbide ramming material high in abrasion resistance and application thereof

The invention relates to a silicon carbide ramming material high in abrasion resistance, which comprises the following components in part by weight: 55-78 parts of superfine silicon carbides, 5-15 parts of alpha type silicon nitrides, 5-10 parts of zirconium corundum, 1-7 parts of aluminum oxide powder and silicon dioxide powder, 9-13 parts of aluminum chromium phosphates, 0.5-5 parts of coagulation accelerators, 0-2.5 parts of iodine bismuth oxyiodide tannates and 0.3-0.7 parts of anti-explosion fibers, wherein the mixture of active rho-aluminum oxide and magnesium oxide is taken as the coagulation accelerators, and the diameter of the anti-explosion fibers is 1.5-2.5 microns. The silicon carbide ramming material high in abrasion resistance, which is provided by the invention, is high instrength after being naturally dried, is excellent in abrasion resistance at high temperature, is high in heat transfer coefficient, is low in linear contractibility rate and is long in service life.

Owner:上海皕涛耐火材料有限公司

Wax-containing 3D printing light-cured cast resin and preparation method thereof

InactiveCN109880272ALow viscosityImprove mechanical propertiesAdditive manufacturing apparatusMechanical propertyDefoaming Agents

The invention discloses wax-containing 3D printing light-cured cast resin and a preparation method thereof. The wax-containing 3D printing light-cured cast resin comprises the following components inparts by weight: 30-80 parts of oligomer resin, 15-60 parts of a reactive diluent, 1-10 parts of a photoinitiator, 1-10 parts of micro-powder wax, 0.1-5 parts of an organic pigment, 0.01-2 parts of adispersing agent, 0.1-5 parts of a defoaming agent and 0.1-5 parts of a flatting agent. The wax-containing 3D printing light-cured cast resin disclosed by the invention has the multiple advantages oflow viscosity, excellent mechanical property, low ash content, small linear shrinkage rate and the like, and can effectively ensure the dimensional precision and clean and smooth appearance of a casting. The invention provides the light-cured material with high printing precision, rapid casting and stable performance for the field of 3D printing and casting, greatly expands the advantages of a laser rapid prototyping technology in the field of casting, and remarkably improves the market competitiveness of products.

Owner:HANS LASER TECH IND GRP CO LTD

Low-temperature semiwhite porcelain and manufacturing method thereof

The invention discloses a low-temperature semiwhite porcelain and a manufacturing method thereof, belonging to the technical field of ceramics. The blank of the low-temperature semiwhite porcelain comprises the following raw materials in parts by mass: 30-40 parts of Longyan clay, 25-35 parts of Gangxi kaolin raw ore, 20-28 parts of flint, 7-12 parts of feldspar, 2-9 parts of talcum and 5-10 parts of dolomite. The low-temperature semiwhite porcelain can be quickly fired at the low temperature of 1000 DEG C, and can be discharged out of the kiln only by 7-8 hours from firing to cooling. The linear shrinkage is low and can be kept at 12% or below. The low-temperature semiwhite porcelain has high hardness and excellent whiteness (85% or above), and has comparable whiteness with light-weight porcelain. The low-temperature semiwhite porcelain has low water absorptivity (which can be kept at 3% or below and can reach the porcelain industry standard), has the advantages of high strength excellent high temperature resistance and excellent microwave resistance, can be subjected to 180-DEG C drying oven testing more than twice, and can pass the microwave oven and dishwasher performance test. The low-temperature semiwhite porcelain has wide applicability, and can be widely used for producing medium / high-grade domestic ceramics.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

High-strength and high-toughness anti-alumina magnesium alloy material for 5G mobile phone middle plate and preparation method thereof

The invention discloses a high-strength and high-toughness anti-alumina magnesium alloy material for a 5G mobile phone middle plate and a preparation method thereof, and relates to an aluminum alloy material. The high-strength and high-toughness anti-alumina magnesium alloy material for the 5G mobile phone middle plate and preparation method thereof aims to solve the technical problem that in theprior art, when an alloy material for a mobile phone middle plate is smelted, and the alloy material is easy to oxidize and form oxide inclusions. The high-strength and high-toughness anti-alumina magnesium alloy material for the 5G mobile phone middle plate comprise the following chemical elements of, in percentage by mass, 2.0-5.5% of Si, 5.5-12.0% of Mg, 0.60-1.20% of Mn, 0.01-0.35% of Ti, 0.001%-0.04% of Be, 0.01-0.30% of Ce, less than or equal to 0.40% of Fe, less than or equal to 0.50% of inevitable impurities and the balance aluminum. the preparation method comprises the following stepsof melting a pure aluminum ingot, adding silicon, manganese and a titanium additive, so that the pure aluminum ingot is alloyed; (2) adding aluminum beryllium and an aluminum-cerium alloy, and melting to obtain an alloy melt; (3) adding a pure magnesium ingot, completely melting, and refining by using a sodium-free refining agent in an argon atmosphere. According to the invention, and the alloy material is mainly applied to a mobile phone middle plate.

Owner:范卫忠

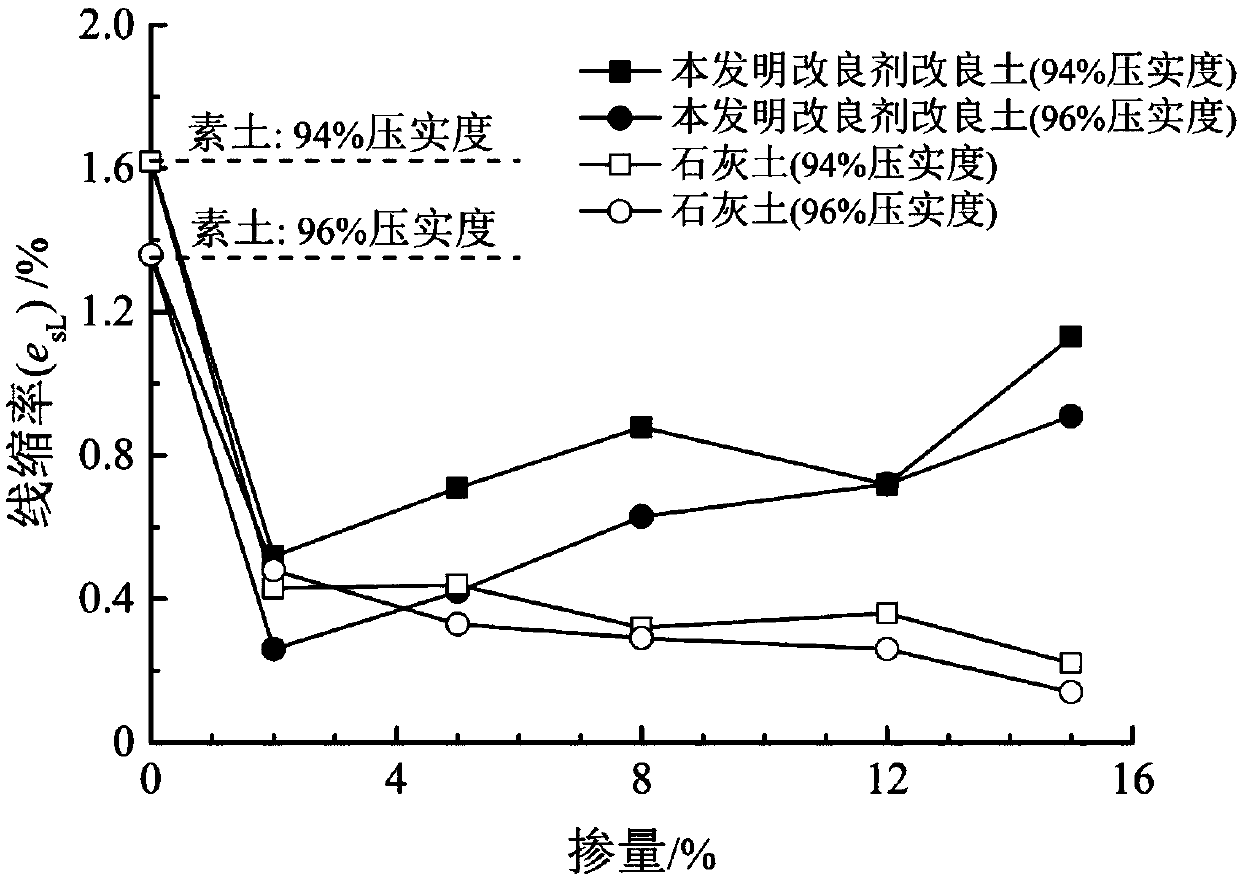

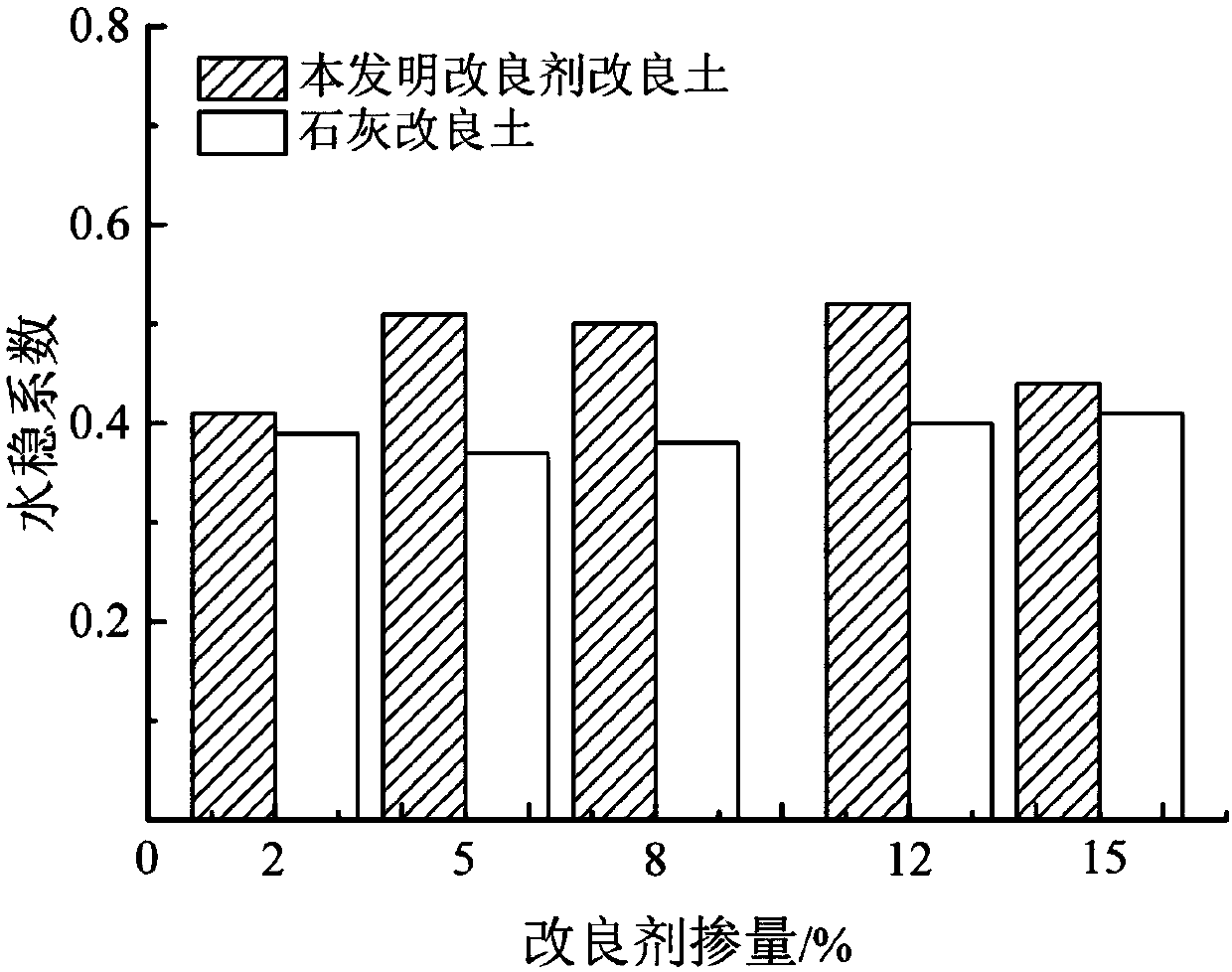

Expanded soil improver based on industrial organic solid wastes, and application of expanded soil improver

InactiveCN107603636AImproved shrinkage propertiesLow linear shrinkageBuilding constructionsOrganic fertilisersSwelling ratioSlag

The invention discloses an expanded soil improver based on industrial organic solid wastes, and application of the expanded soil improver. The expanded soil improver is prepared from the following components by mass percent: 70-76% of lignin, 12-15% of calcium chloride and 12-15% of coal ash. The expanded soil improver is evenly mixed with expanded soil, and the mixture is compacted and molded andis then cured to a prescribed age. The preparation of the expanded soil improver comprises the following steps: 1, carrying out spray-drying on industrial pulping and papermaking waste liquid to obtain the lignin; 2, drying waste carbide slag of acetylene manufacturing plants in the air so as to enable the water content of the waste carbide slag to be reduced to 10% or below, then mixing the dried waste carbide slag with waste hydrochloric acid, and carrying out a reaction under the condition of heating so as to obtain the calcium chloride; 3, evenly mixing the lignin, the calcium chloride and the coal ash with grade F so as to obtain the expanded soil improver. The free swelling ratio of the expanded soil improved by using the expanded soil improver is obviously reduced; the expanded soil improver is environmentally friendly and low in price, thus being wide in application prospect; the application method of the expanded soil improver is simple, economical and high in operability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Basalt fiber and preparation method thereof

ActiveCN110078378ASimple processReduce manufacturing costGlass making apparatusMolten stateElectric arc furnace

The invention relates to basalt fiber and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: uniformly mixing the following raw materials: 52.0 to 67.0 percent by weight of basalt, 28.0 to 43.0 percent by weight of waste talc, 1.5 to 4.5 percent by weight of genthite and 0.3 to 3.3 percent by weight of aluminum oxide to obtain a mixed material; and placing the mixed material into a resistance furnace or an electric-arc furnace, heating into a molten state and performing thread throwing to obtain the basalt fiber. The basalt comprises the following chemical components: more than or equal to 45.5 percent by weight of SiO2, more than or equal to 13.7 percent by weight of Al2O3, more than or equal to 10.9 percent by weight ofMgO, more than or equal to 9.6 percent by weight of CaO, less than or equal to 11.2 percent by weight of Fe2O3 and FeO and less than or equal to 3.5 percent by weight of Na2O and K2O); and the waste talc comprises the following chemical components: more than equal to 57.9 percent by weight of SiO2, more than or equal to 28.5 percent by weight of MgO, less than or equal to 2.3 percent by weight ofNa2O and K2O) and less than or equal to 4.7 percent by weight of IL. The basalt fiber and the preparation method thereof have the characteristics of resource recoverability, environmental friendliness, simple process and low production cost; and the prepared basalt fiber has small thread shrinkage rate, low heat conductivity and high use temperature.

Owner:MORGAN KAILONG (JINGMEN) THERMAL CERAMICS CO LTD

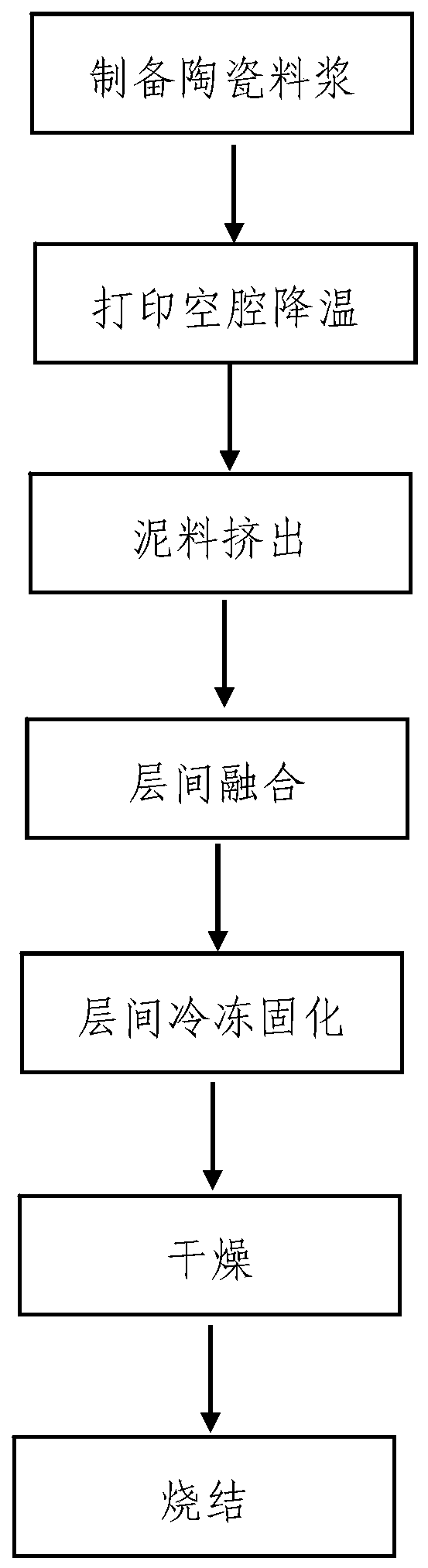

Three-dimensional freezing printing method of ceramic components

ActiveCN110815491AAchieve wholenessHigh bonding strength between layersAdditive manufacturing apparatusCeramic shaping apparatusPolyethylene glycolPolyvinyl alcohol

The invention relates to a three-dimensional freezing printing method of ceramic components. The method comprises the following steps that (1) ceramic powder, silica sol, polyethylene glycol and polyvinyl alcohol are subjected to ball milling to obtain a ceramic slurry; (2) a printing cavity of a 3D printing device is cooled to minus 10 DEG C to minus 60 DEG C, and then the ceramic slurry is usedfor printing; the wet mud material extruded from nozzles is bonded to a printing base plate to form a first layer of mud material; printing is continuously conducted, the wet mud material extruded from the nozzles continuously form a second layer of mud material, a third layer of mud material.., and an Nth layer of mud material on the first layer of mud material; and the formed mud layers are gradually fused, and when printing is carried out to by 4-10 layers, the inner mud material layers and the interlayers are gradually frozen and solidified to obtain a green body; and (3) the green body isfreeze-dried and then heated and sintered to obtain the ceramic component. According to the printing method, the integrity of the printed ceramic can be realized, and the bonding strength between thelayers is improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

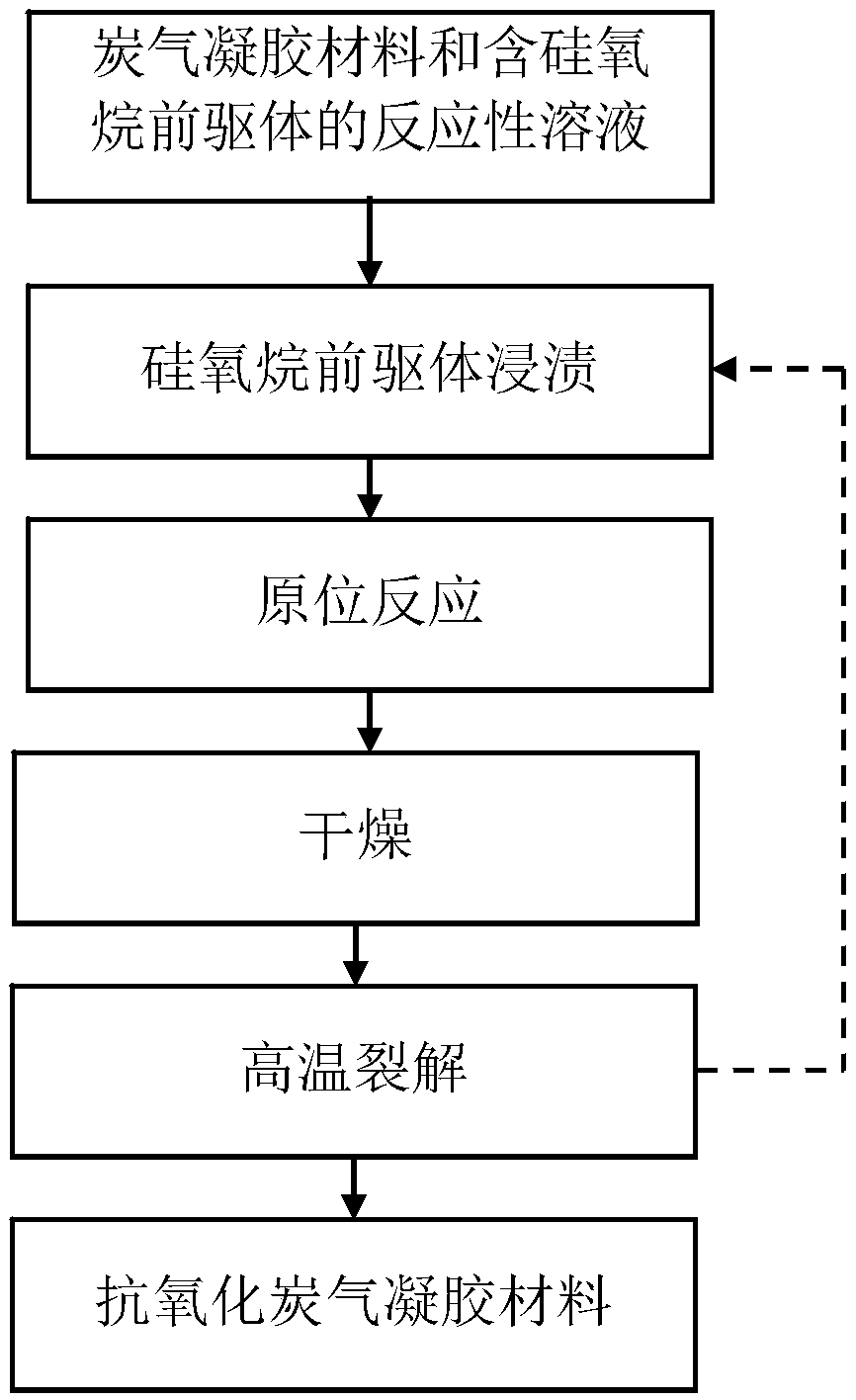

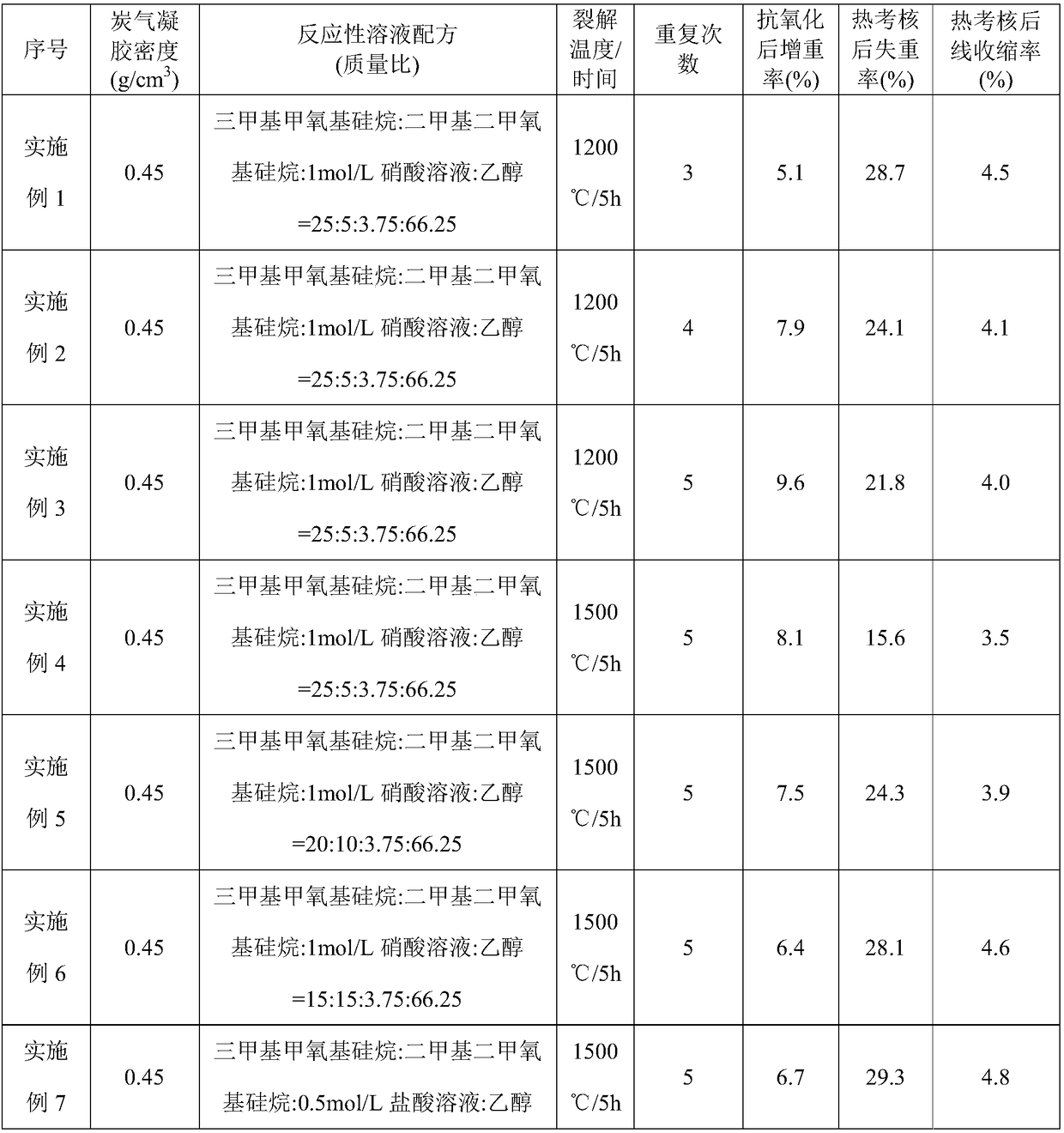

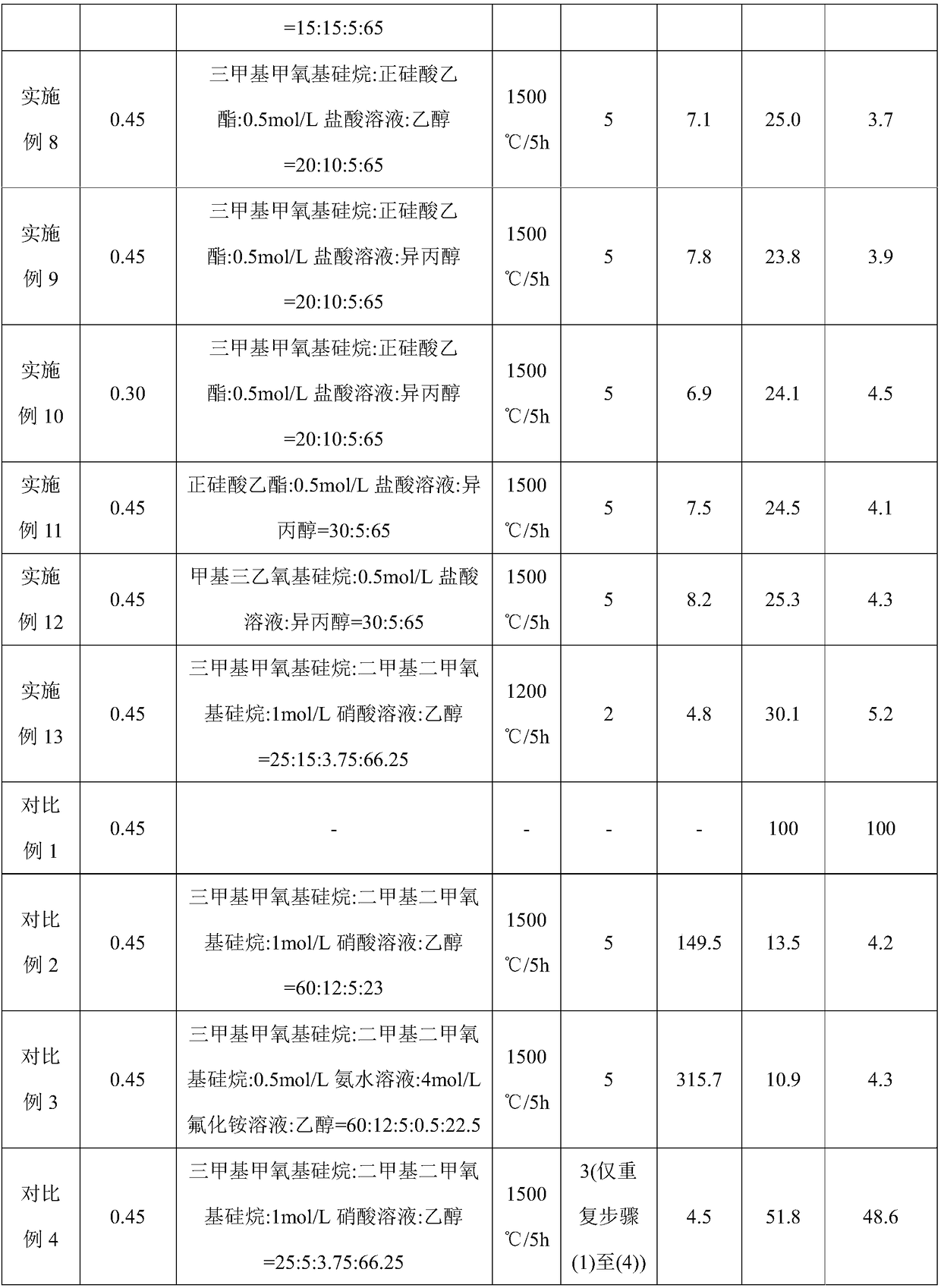

Antioxidative carbon aerogel material and preparation method thereof

ActiveCN109179373AImprove antioxidant capacityReduce weight lossCarbon preparation/purificationAerogel preparationThermal conductivityIn situ reaction

The invention provides a method of preparing an antioxidative carbon aerogel material. The method comprises the following steps: providing a carbon aerogel material and a reactive solution containinga siloxane precursor; impregnating the carbon aerogel material by using the reactive solution; carrying out an in-situ reaction on the siloxane precursor on the surface of the carbon aerogel particlesunder the enclosed condition to generate an antioxidative precursor film; drying the carbon aerogel material; pyrolyzing the carbon aerogel material at high temperature; and repeating step (2) to step (5) to obtain the antioxidative carbon aerogel material. The invention also provides an antioxidative carbon aerogel material prepared by the above method. The oxidation resistance of the carbon aerogel material can be improved with a low weight gain rate. Thereby, under the precondition of no significant increase in the weight of the carbon aerogel, oxidation resistance of the carbon aerogel isremarkably enhanced, and the carbon aerogel material with low thermal conductivity and high oxidation resistance is obtained. The method of the invention also has advantages of simple process and strong applicability.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

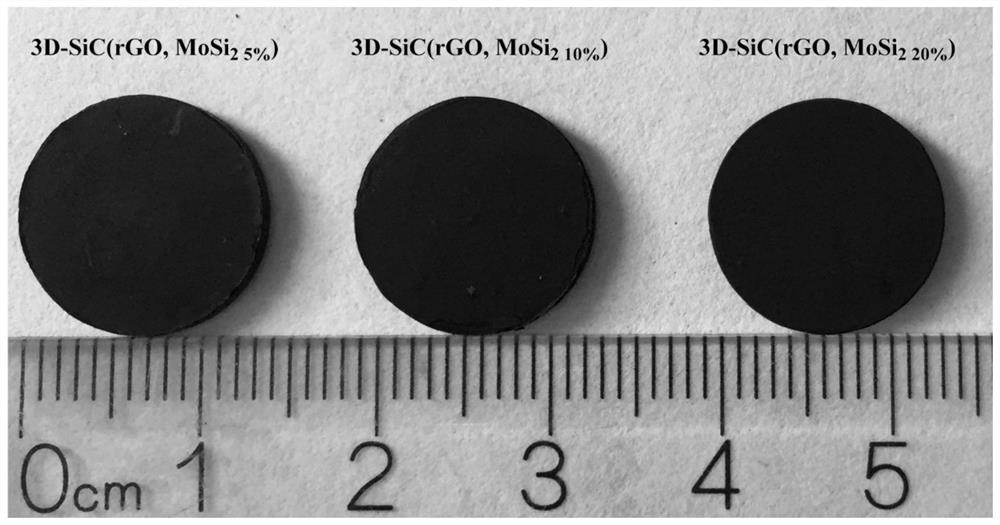

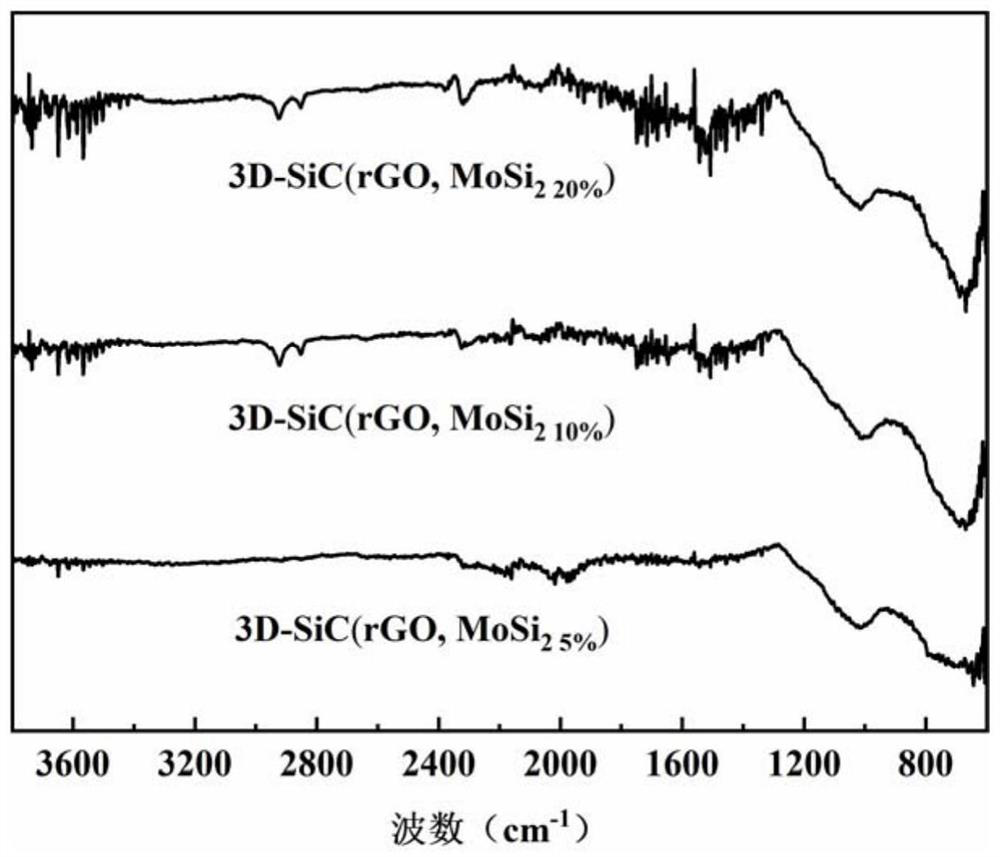

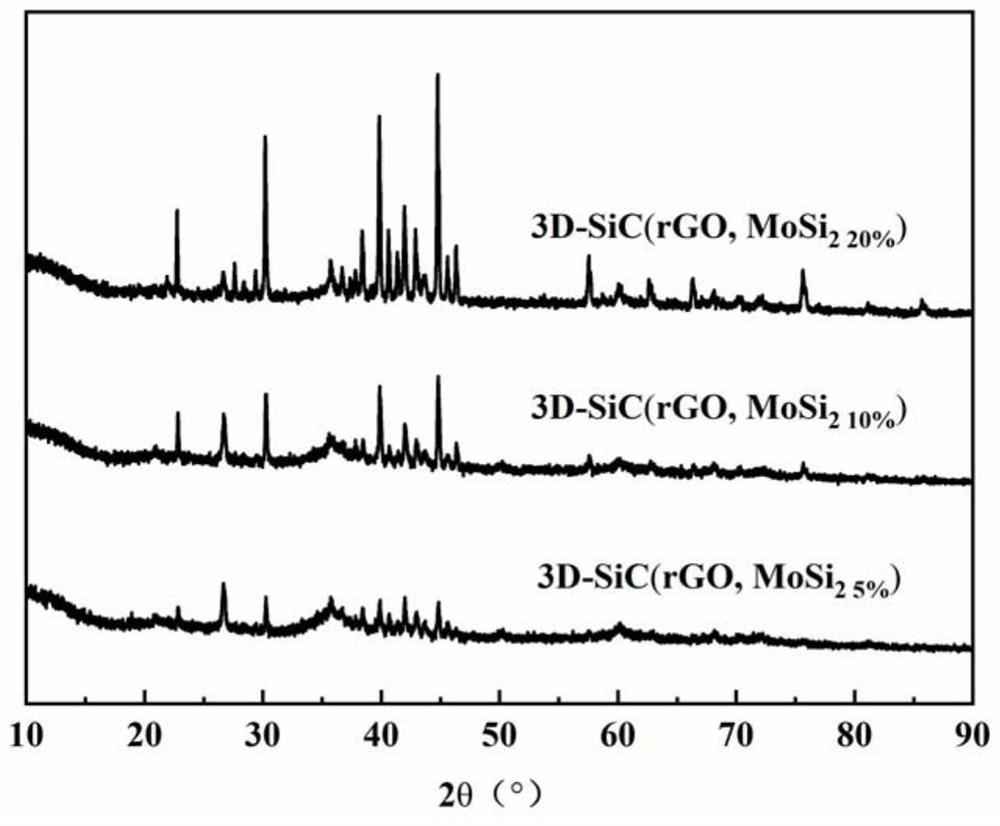

Molybdenum disilicide/silicon carbide three-dimensional polymer precursor ceramic and preparation method thereof

The invention discloses molybdenum disilicide / silicon carbide three-dimensional polymer precursor ceramic and a preparation method thereof, belonging to preparation of ceramic materials. The preparation method comprises the following steps: putting precursor PVG powder into a graphite paper boat and carrying out high-temperature cracking under the protection of an inert atmosphere; mixing MoSi2, cracked SiC(rGO)p ceramic particles and the precursor PVG powder to form a MoSi2 / SiC(rGO)p / PVG mixture, carrying out ball milling and uniform mixing in an alcohol medium, and then drying the MoSi2 / SiC(rGO)p / PVG mixture in an oven; and loading the mixture into a mold for compression molding, conducing demolding to obtain a biscuit, putting the biscuit into an inert atmosphere tube furnace for high-temperature sintering, and conducting cooling along with the furnace to obtain black molybdenum disilicide / silicon carbide three-dimensional polymer precursor ceramic, namely 3D-SiC(rGO, MoSi2x) nanometer composite block ceramic for short, wherein x is the mass fraction of silicon carbide in the whole biscuit. The obtained ceramic is high in heat conductivity and electric conductivity and good in formability and component uniformity; and the preparation method is simple and economical in process.

Owner:中科德胜(常州)电子科技有限公司

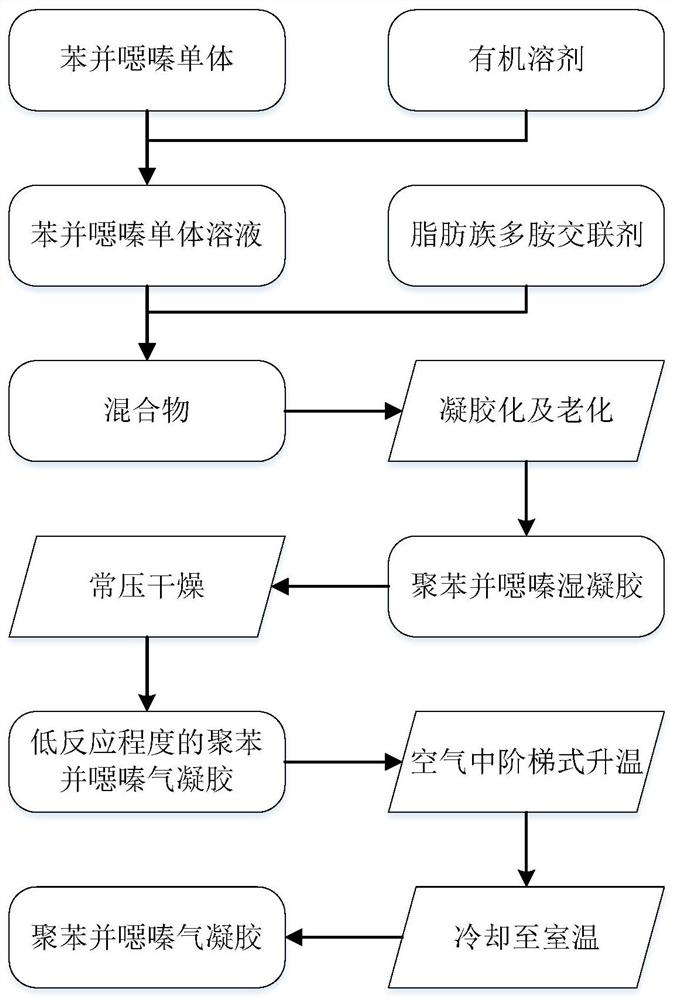

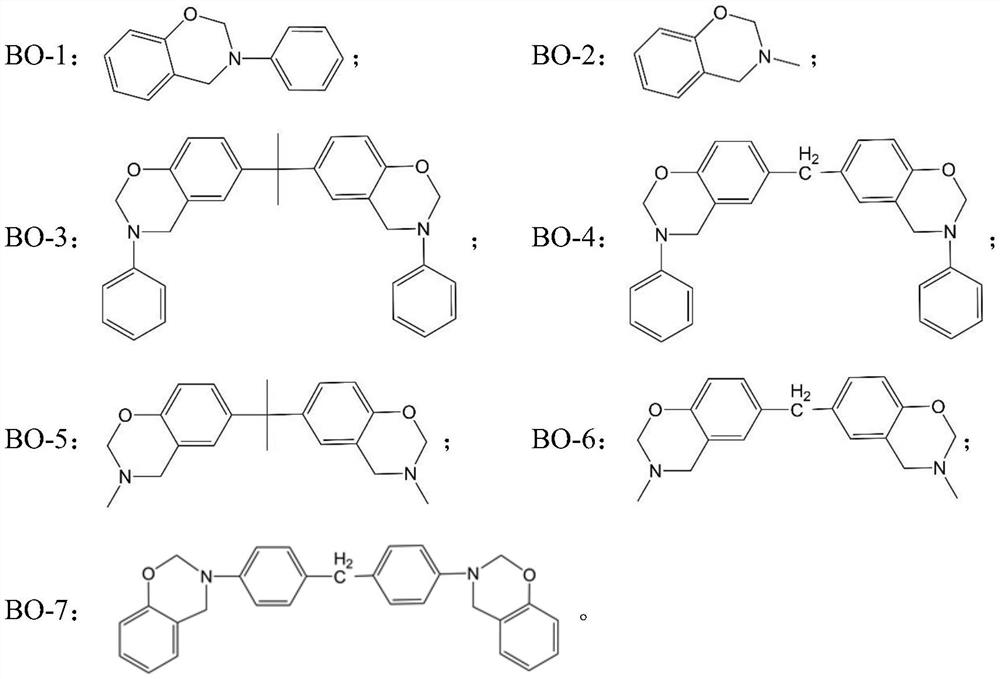

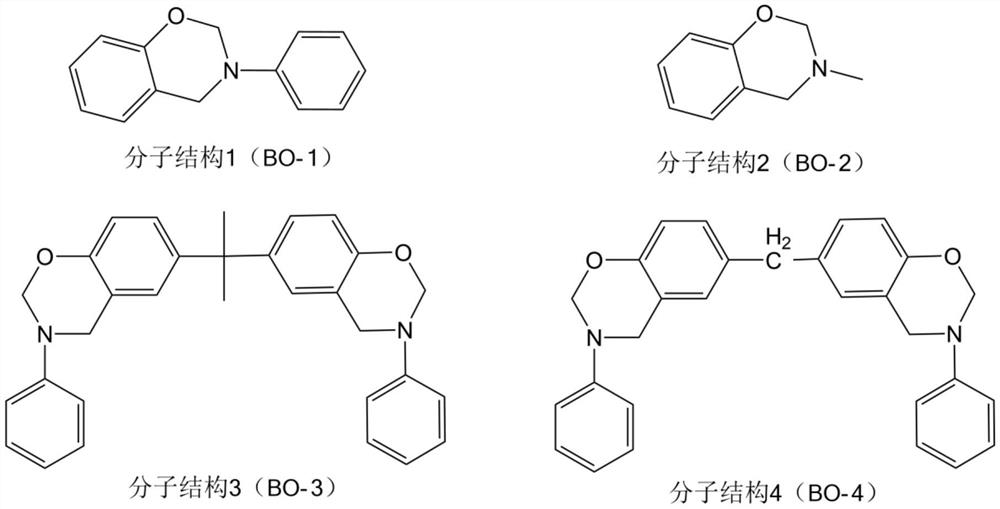

Polybenzoxazine aerogel and preparation method thereof

The invention discloses polybenzoxazine aerogel and a preparation method thereof, and belongs to the technical field of aerogel materials. The preparation method comprises the steps of: dissolving a benzoxazine monomer in an organic solvent to obtain a benzoxazine monomer solution; adding an aliphatic polyamine cross-linking agent, mixing well, pouring the solution into a mold, heating for a gelation reaction, and aging to obtain polybenzoxazine wet gel; then carrying out normal pressure drying to obtain polybenzoxazine aerogel with a low reaction degree; and heating to 200 DEG C in air in a stepped manner, preserving heat for 2-12 hours at each temperature section, and cooling to room temperature to obtain polybenzoxazine aerogel. The linear shrinkage rate of the aerogel can be reduced, and the aerogel is good in thermal stability and easy to form.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

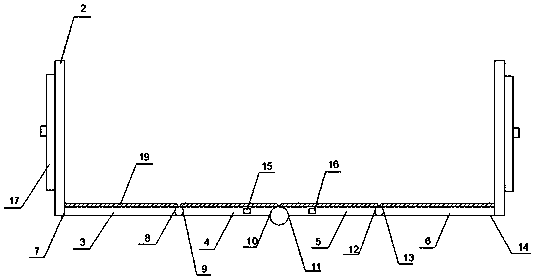

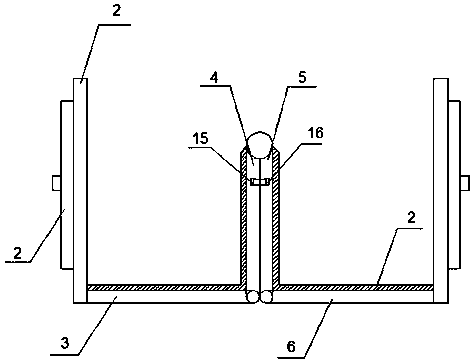

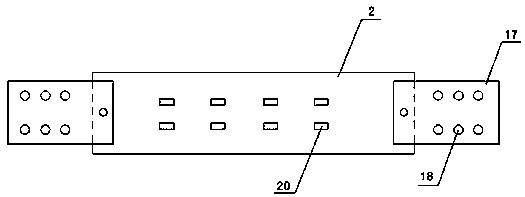

High-heat-dissipation air-ventilation tray type cable bridge

Owner:JIANGSU HUAQIANG ELECTRIC EQUIP

Grinding material for precision casting

ActiveCN1325566CHigh drop melting pointImprove heat resistanceFoundry moulding apparatusMINERAL WAXCasting mold

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

Precisive ornament casting moulding material

ActiveCN101074320BHigh drop melting pointImprove heat resistanceFoundry moulding apparatusParaffin waxMINERAL WAX

Owner:CHINA PETROLEUM & CHEM CORP +1

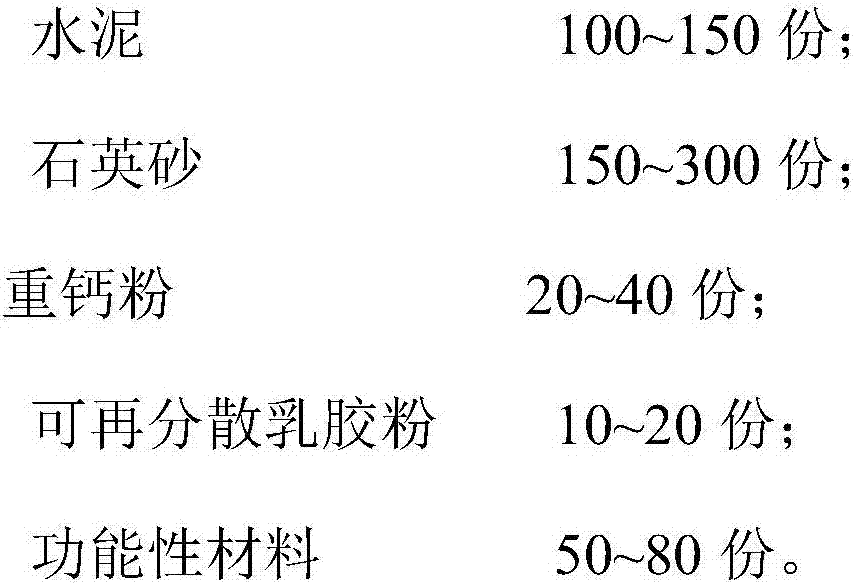

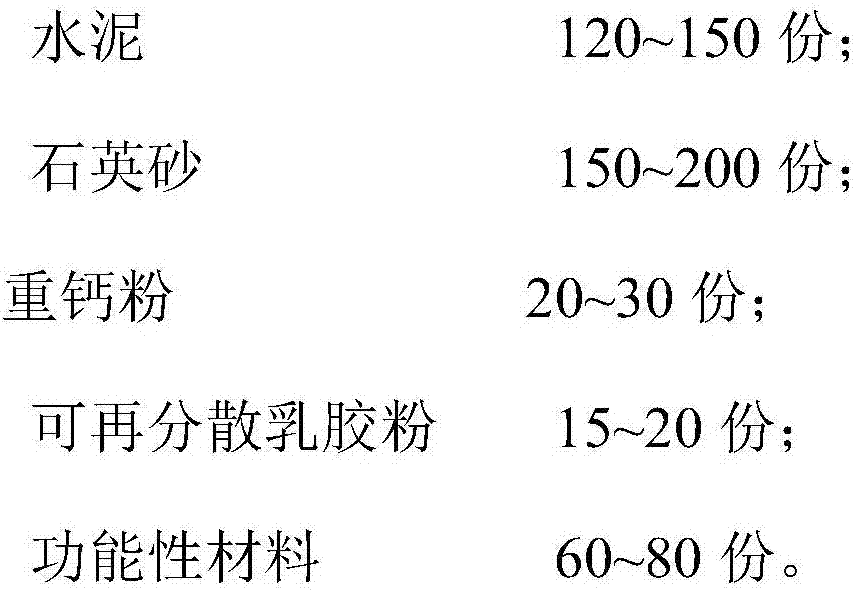

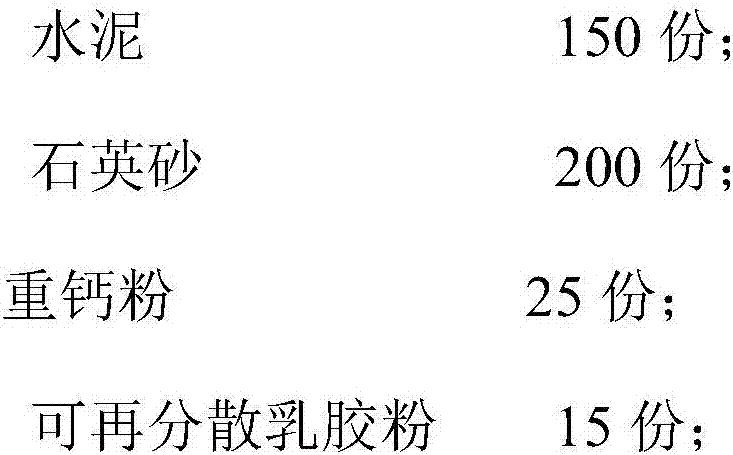

Micro-expanded fireproof heat-insulating mortar and preparation method thereof

The invention relates to the technical field of preparation of mortar, and particularly discloses micro-expanded fireproof heat-insulating mortar and a preparation method thereof. The micro-expanded fireproof heat-insulating mortar contains the following components in parts by weight: 100-150 parts of cement, 150-300 parts of quartz sand, 20-40 parts of heavy calcium powder, 10-20 parts of redispersible powder and 50-80 parts of functional material; the functional material contains the following components in parts by weight: 30-50 parts of glass bead, 30-50 parts of vermiculite, 10-20 parts of lignin and 5-10 parts of graphite powder. All the components are selected from non-toxic components, thus being environment-friendly and pollution-free; the prepared micro-expanded fireproof heat-insulating mortar can be prevented from generating cracks due to shrinkage in drying, and has excellent anti-cracking property; in addition, the micro-expanded fireproof heat-insulating mortar is good in heat-insulating property, and high in strength and flame-retardant degree.

Owner:清远肆柒柒新材料科技有限公司

Preparation method of porous high-strength mullite refractory raw material

The invention discloses a preparation method of a porous high-strength mullite refractory raw material and belongs to the technical field of refractory raw materials. The preparation method comprisesthe specific steps that raw bauxite and a pore-forming agent are used as raw materials, water accounting for 10-40wt% of the raw materials is added, mixed grinding is carried out for even mixing, thenforming is carried out, and thus a refractory raw material green body is obtained; the green body is baked in an electrothermal blowing drying box with a baking condition of 110 DEG C for 24 hours, then the dried green body is put into a sintering furnace, the temperature is kept at 1,550 DEG C for 3 hours, heating is carried out with the heating rate of 3 DEG C.min<-1>, in-situ reaction sintering is carried out at high temperature, and thus a mullite crystal is generated; and the sintered mullite crystal is taken out of the furnace, cooled and then subjected to graded crushing, and thus theporous high-strength mullite refractory raw material is obtained. The preparation method has the advantages that the prepared porous high-strength mullite refractory raw material is small in pore size, even in pore diameter distribution, small in volume density, low in thermal conductivity, good in thermal stability, low in linear shrinkage rate and high in compression strength.

Owner:TONGDA REFRACTORY TECH CO LTD

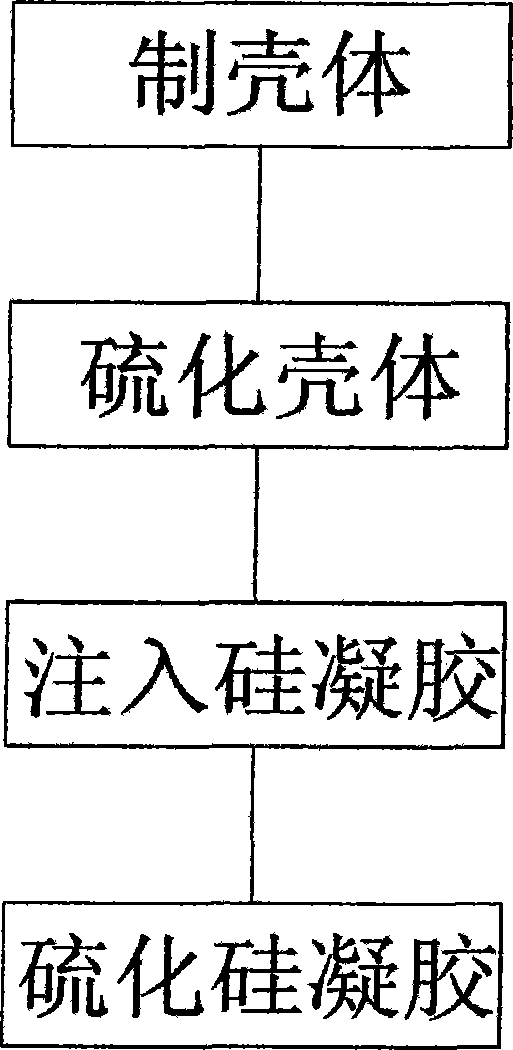

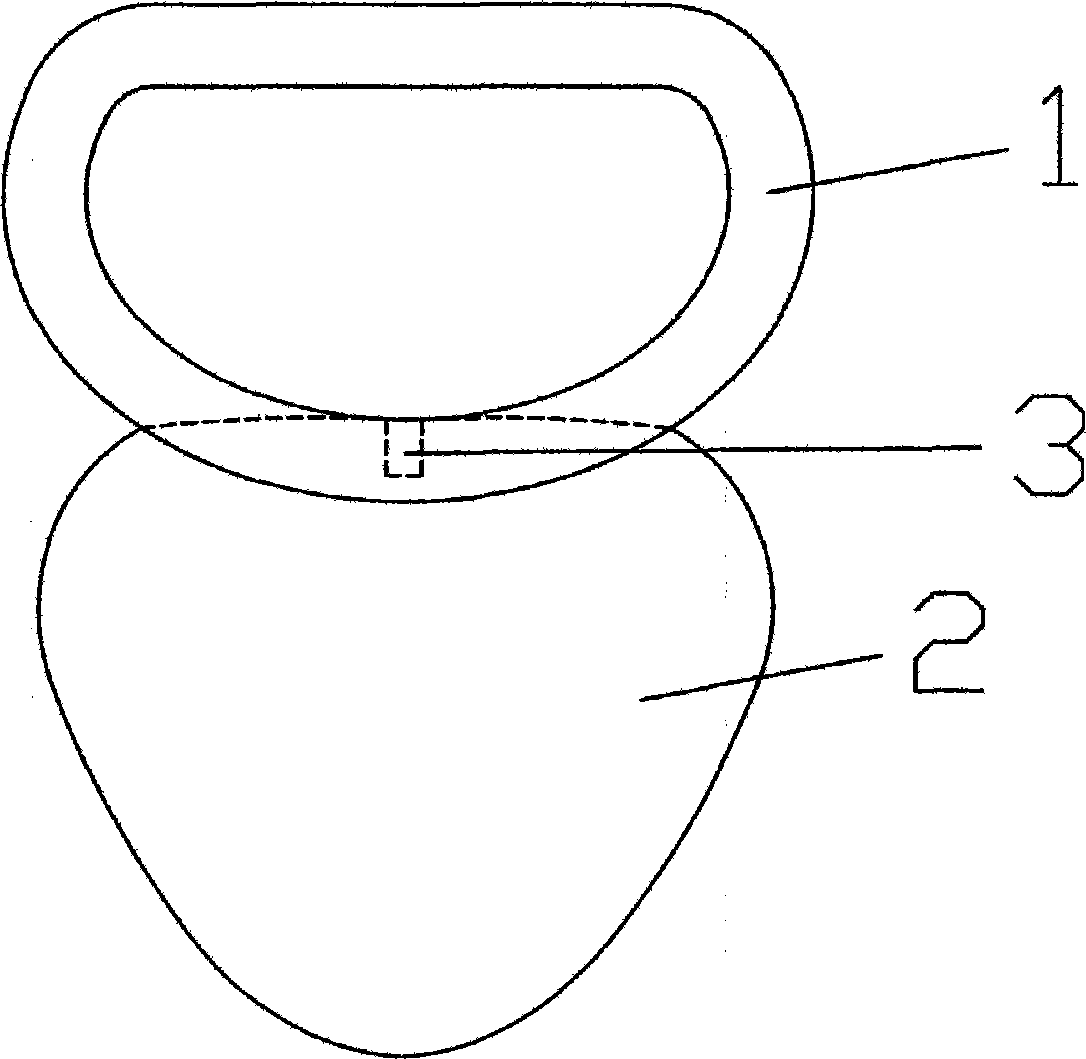

Silica gel gutta-percha and manufacturing technology thereof

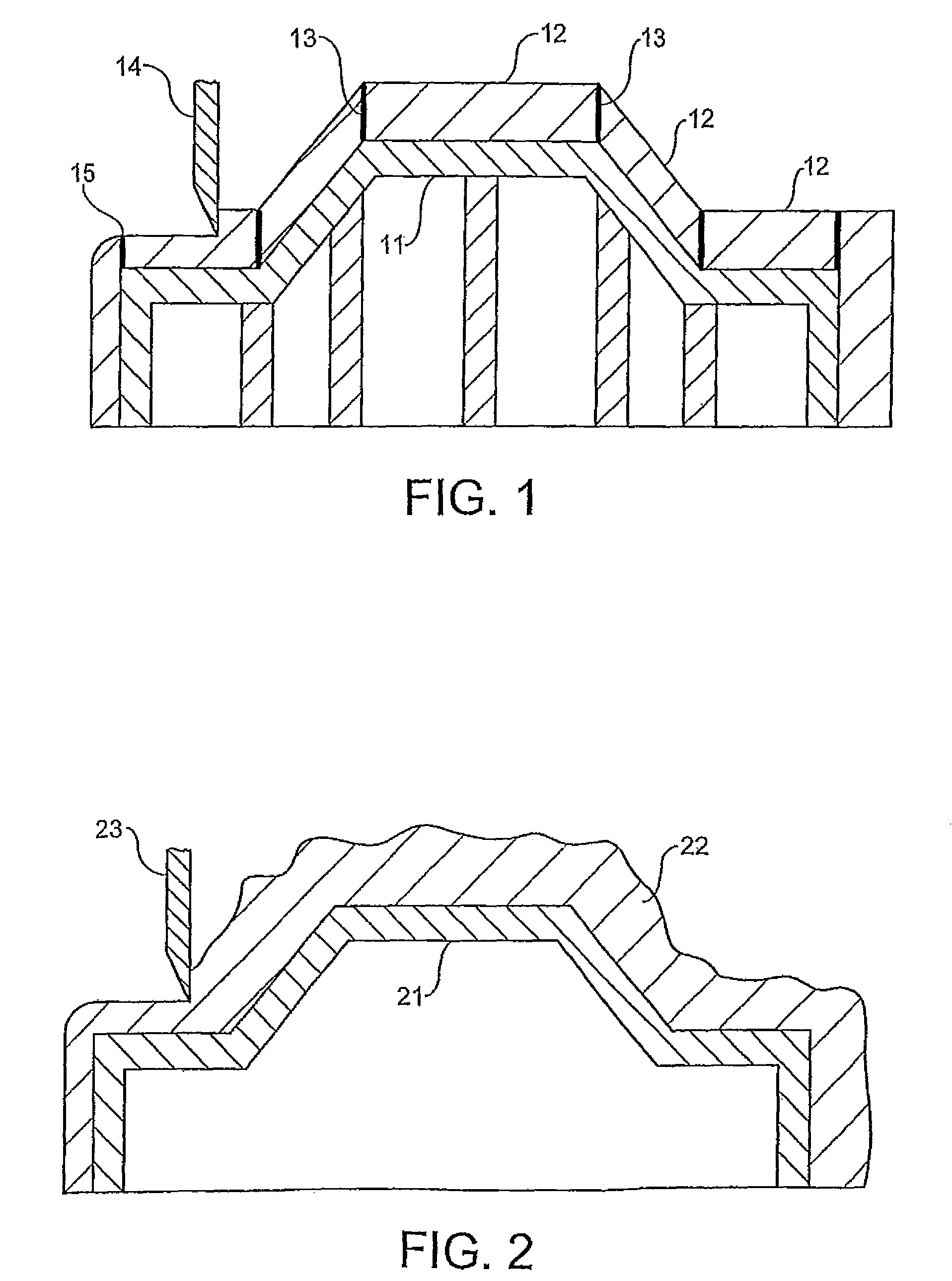

ActiveCN103862613ADoes not cause outflowFeatures SoftBaby-comfortersManufacturing technologyGutta-percha

The invention discloses silica gel gutta-percha and a manufacturing technology thereof. The technology at least comprises the steps of pouring a silica gel material into a mold to prepare a silica gel shell (1) with an injection opening (3); vulcanizing the silica gel shell (1); injecting silica gel into the silica gel shell (1) through the injection opening (3), and sealing the injection opening (3); and vulcanizing the silica gel. The silica gel gutta-percha comprises a gutta-percha body and a handheld part (2), wherein the gutta-percha body comprises the silica gel shell (1) with the injection opening (3) and the silica gel injected into the silica gel shell (1); the handheld part (2) and the silica gel shell (1) are made of the same silica gel and are integrally formed. The silica gel gutta-percha disclosed by the invention has comfortable mouth feeling and is safe to use.

Owner:中山市高亚硅胶制品有限公司 +1

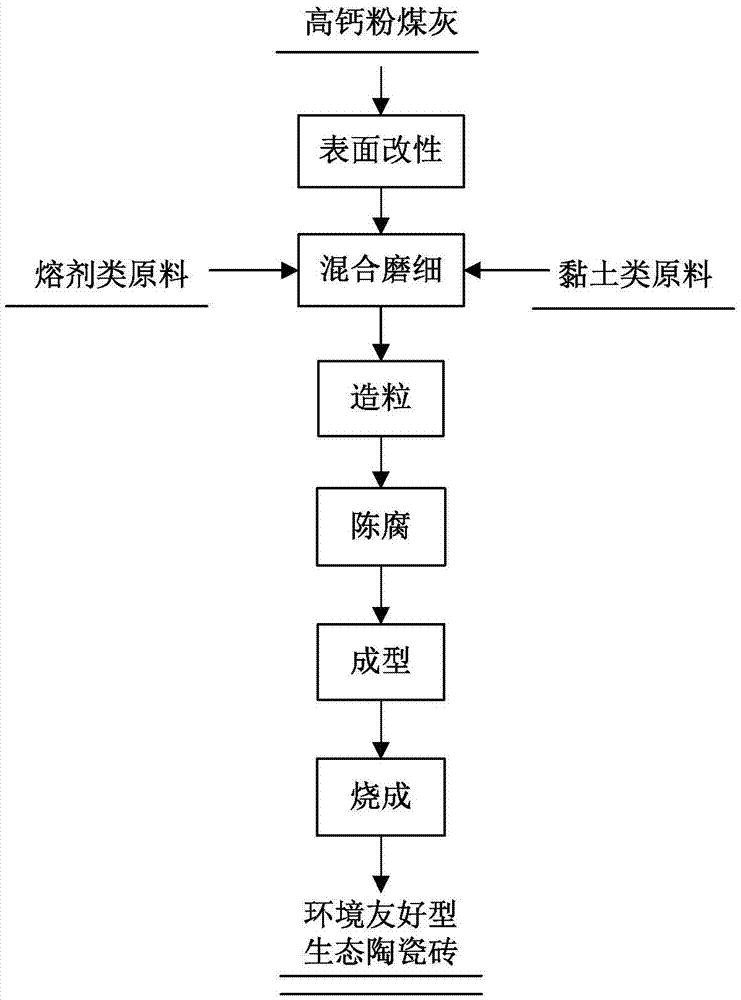

Method for low-temperature firing of ceramic brick by using high-calcium fly ash

InactiveCN106977176AImprove plasticitySolve the problem of low green strengthCeramic materials productionClaywaresBrickThermal insulation

The invention discloses a method for preparing a ceramic brick by using fly ash. The method comprises: 1) adding high-calcium fly ash to a 40-150 g / L soluble alkali solution system, and carrying out a reaction; 2) filtering the slurry obtained after the reaction in the step 1), and washing, wherein the obtained filtration residue is surface modified high-calcium fly ash; 3) grinding the surface modified high-calcium fly ash, clay and a flux raw material; 4) granulating; 5) molding the spherical powder obtained in the step 4), and drying to obtain a ceramic brick billet; and 6) heating the ceramic brick billet, carrying out thermal insulation, and cooling to prepare the ceramic brick. The ceramic brick of the present invention has the low temperature firing characteristic.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low-shrinkage blended wax material and preparation method thereof

ActiveCN113881241AReduce contentMeet the dimensional accuracy requirementsFoundry moulding apparatusParaffin waxMolten state

The invention discloses a low-shrinkage blended wax material and a preparation method thereof, and relates to the technical field of precision investment casting. The preparation method comprises the steps: heating and melting rosin and paraffin, adding a grain refiner, a viscosity modifier, a flexibilizer and a heat stabilizer into liquid wax, placing in a reaction kettle, and uniformly mixing to prepare the novel reusable special blended wax. The special novel blended wax has the advantages of small linear shrinkage rate, small expansion coefficient within softening temperature, low heat capacity, sufficient strength and hardness, small viscosity in a molten state, small residual ash content, low content of low-temperature volatile matters, good chemical stability, fine grain structure, repeated use and the like. The prepared special novel blended wax can meet the size precision requirements and surface quality requirements of various complex precision castings and has wide market application prospects, and meanwhile, the preparation method is simple, low in cost, high in applicability, capable of being repeatedly used and capable of being used for large-scale production.

Owner:NANJING TIANSHI NEW MATERIAL TECH +1

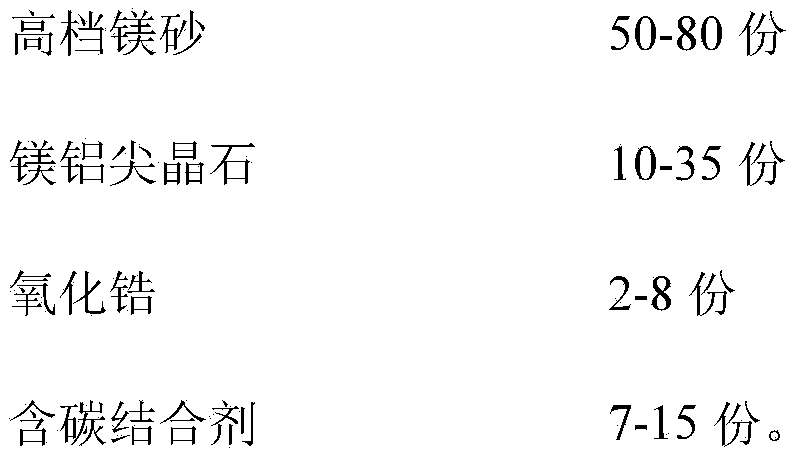

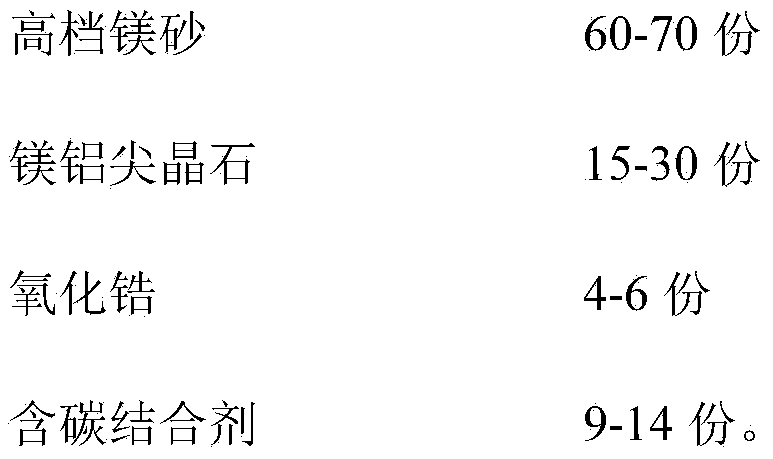

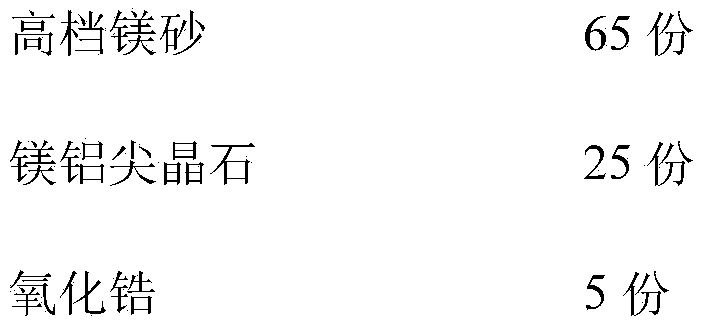

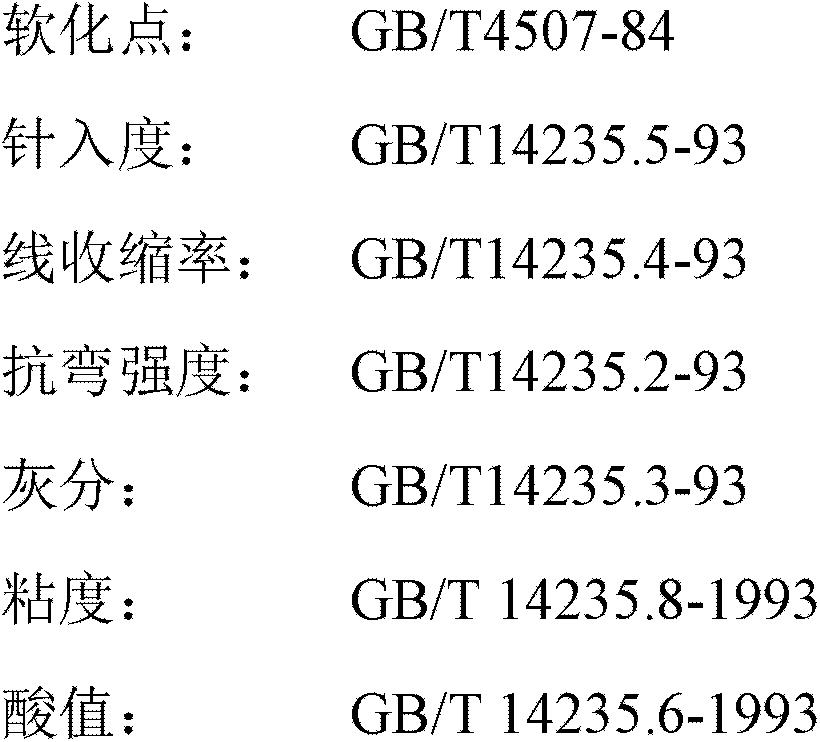

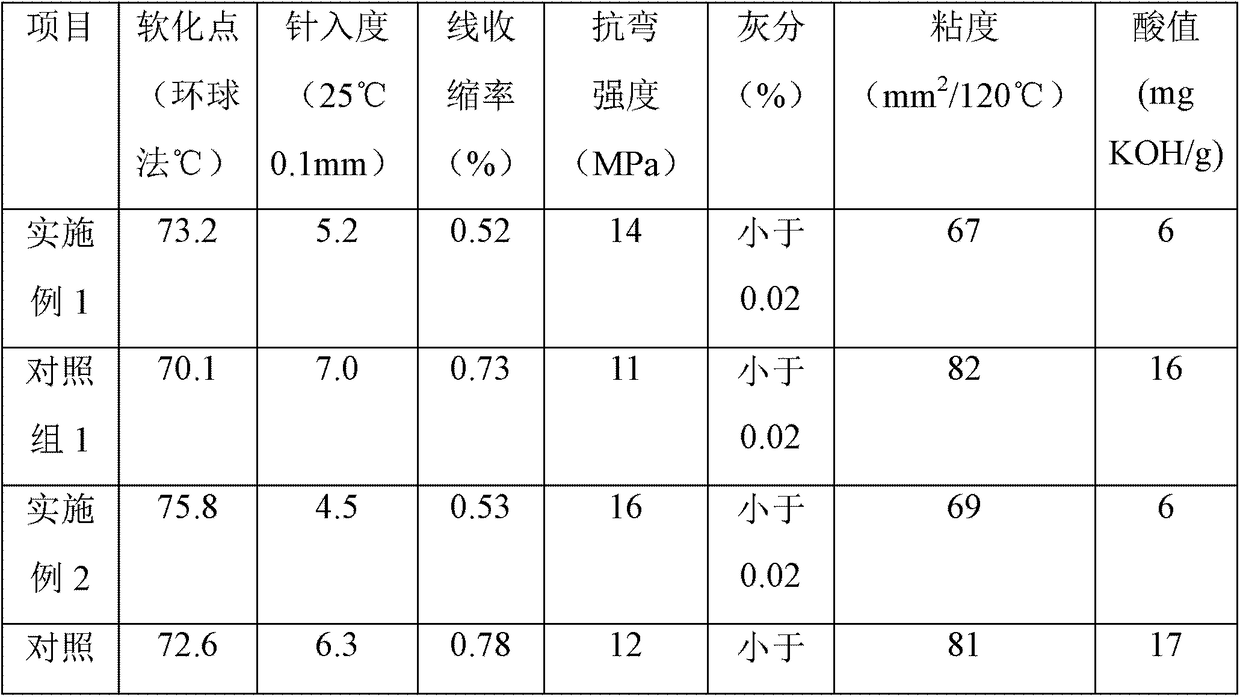

Magnesium-zirconium spinel ramming material for furnace bottom

ActiveCN104108944ALow linear shrinkageGood high temperature performanceMagnesium AluminateWork safety

The invention discloses a magnesium-zirconium spinel ramming material for a furnace bottom. The ramming material is prepared from the following raw materials in parts by weight: 50-80 parts of high-grade magnesia, 10-35 parts of magnesium aluminate spinel, 2-8 parts of zirconium oxide and 7-15 parts of carbon-contained binding agent. The ramming material can be used for improving the filling condition of a triangle area part at the furnace bottom and providing a certain protection for a furnace shell in a high-temperature state, so that the furnace life is prolonged, and the working safety is favorably realized.

Owner:LIAONING ZHONGMEI HLDG

Investment casting wax based on graphite oxide modified rosin and preparation method thereof

ActiveCN106084806BReduce penetrationImprove bending strengthFoundry moulding apparatusNatural resin chemical modificationParaffin waxHigh surface

The invention relates to the field of casting wax, in particular to a graphite oxide-modified rosin-based investment casting wax and a preparation method thereof. The graphite oxide-modified rosin-based precision casting wax of the present invention has a component of 20% by mass fraction ~30% modified rosin, 50%~65% paraffin, 5%~10% tackifier, 5%~10% PE wax and 0%~3% montan wax, the total content of each component is 100%; Among them, the components of the modified rosin are primary rosin, graphite oxide, zinc oxide and pentaerythritol, the quality of graphite oxide is 5% to 8% of the quality of primary rosin, and the quality of zinc oxide is 5% of the quality of primary rosin. 0.3% to 0.5%, the quality of pentaerythritol is 5% to 8% of the quality of the primary rosin; the softening point of the modified rosin is 98°C to 103°C, and the acidity value is 15KOH / g to 25KOH / g. The precision casting wax of the invention has small needle penetration, small linear shrinkage, high bending strength and small ash content, and can better meet the requirements of high dimensional accuracy and high surface quality of precision castings.

Owner:DONGGUAN UNIV OF TECH

Filling type investment casting pattern material with high filler content and preparation method of filling type investment casting pattern material

InactiveCN112920611ALow shrinkageHigh dimensional accuracyFoundry moulding apparatusWaxInvestment casting

The invention provides a filling type investment casting pattern material with high filler content. The filling type investment casting pattern material comprises the following components in percentage by weight: 20%-50% of petroleum wax, 10%-40% of tackifying resin, 5%-10% of vegetable wax, 0%-5% of a high-molecular polymer, 30%-50% of a solid filler and 0%-8% of a dispersing agent. The prepared investment casting pattern material is high in solid filler content, small in linear shrinkage rate, high in size precision and good in processing property.

Owner:苏州泰尔航空材料有限公司

Precision casting modulated wax

InactiveCN110814279ALow linear shrinkageReduce the probability of subsidenceFoundry moulding apparatusPolymer scienceMicrocrystalline wax

The invention belongs to the technical field of precision casting, and particularly relates to a precision casting modulated wax. The precision casting modulated wax comprises the following raw materials of, in parts by mass, 44 to 46 parts of microcrystalline wax, 2.5 to 3.5 parts of candelilla wax, 34 to 36 parts of carnauba wax, 3.5 to 4.5 parts of ethylene-vinyl acetate copolymer, and 12 to 14parts of pure monomer resin. The modulated wax is applied to the precision casting industry, and has the characteristics of strong stability, high strength and difficulty in deformation, low gray scale and reduced pollution to metal casting, easy demolding and easy to melt and flow out of a shell with a wax mold when demoulding, and being capable of effectively improving the production efficiencyin the precision casting process.

Owner:襄阳市立强机械有限公司

A kind of basalt fiber and preparation method thereof

ActiveCN110078378BSimple processReduce manufacturing costGlass making apparatusElectric arc furnaceChemical composition

Owner:MORGAN KAILONG (JINGMEN) THERMAL CERAMICS CO LTD

Flam resistant silicone rubber beneficial to demolding and preparation method thereof

The invention discloses a flam resistant silicone rubber beneficial to demolding and a preparation method thereof. The flam resistant silicone rubber comprises the following formula materials in partsby mass: 100 parts of mixed silicone rubber, 0 to 100 parts of aluminum hydroxide, 0 to 100 parts of silicon dioxide, 1 to 50 parts of iron oxide, 0 to 5 parts of a plasticizer, 0 to 5 parts of a vulcanization accelerator, and 0 to 1 part of a release agent. The flam resistant silicone rubber can ensure that the problems of roll sticking and mold sticking cannot occur on the basis that the flameresistance reaches UL94V-0, and further has the advantages that the preparation technology is simple, the cost is low, the molding efficiency is high, the defective percentage is low, and the flam resistant silicone rubber halogen-free and environmentally friendly.

Owner:广州科系维新材料有限公司

Method of making models

InactiveUS7994235B2Controlling the heat produced during the reactionHigh hardnessCoatingsEpoxyLow density

A method of a seamless model free of bond lines. The method includes the sequential steps of providing a substructure having an exposed outer surface, applying a modelling paste to a structure support in the form of a continuous layer, curing the applied modelling paste, and machining the cured layer of modelling paste to the desired contour. The modelling paste a low density curable composition prepared from thixotropic epoxy or polyurethane containing microballoons.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Strong adhesive

The invention discloses a strong adhesive, which is prepared from macromolecular synthetic latex with extremely high adhesion, special hydraulic coagulation-promoting powder and various aids according to a scientific and reasonable formula. The strong adhesive has the characteristics that a construction process is simple, and the adhesive is strongly bonded with media such as cement mortar, concrete, a stone and a ceramic material, is quickly bonded and solidified, is low in linear shrinkage, is flame-retardant, does not sag when vertically applied, and does not hurt the skin of a constructor after being contacted with the skin for a long time, and the like; and the adhesive has obvious effects of reducing the shipping weight of ship materials, improving construction performance and protecting the body of the constructor, is suitable for laying various ceramic finish materials on wet cabins such as a kitchen, a catering room and a toilet on a superstructure of a ship, and is also suitable for a civil building.

Owner:启东安升润液设备有限公司

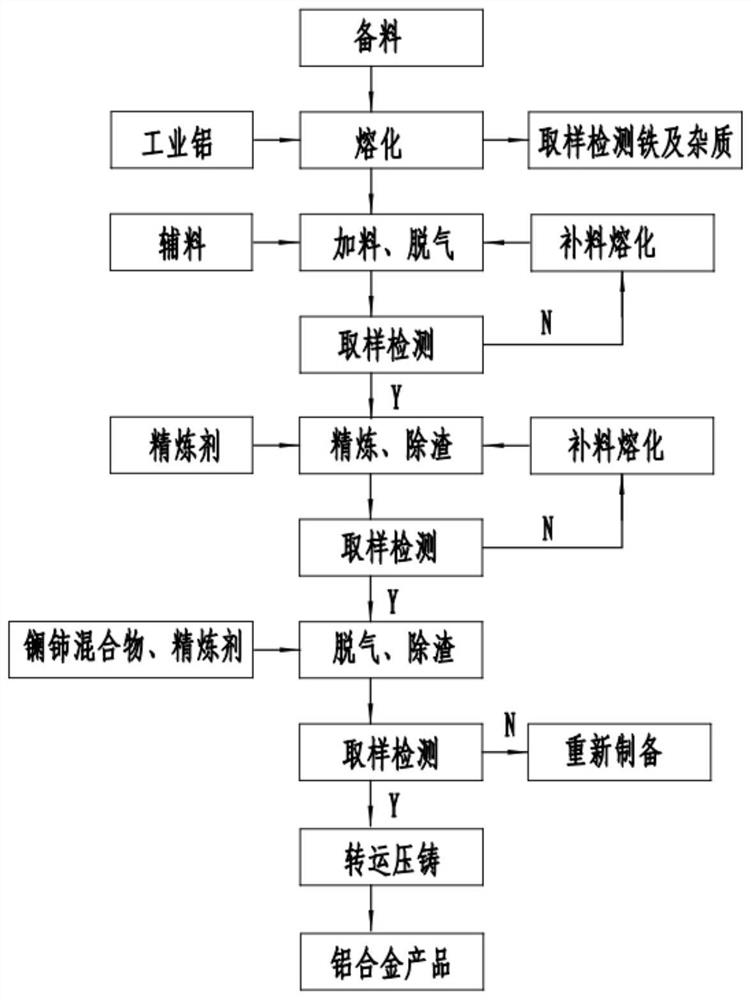

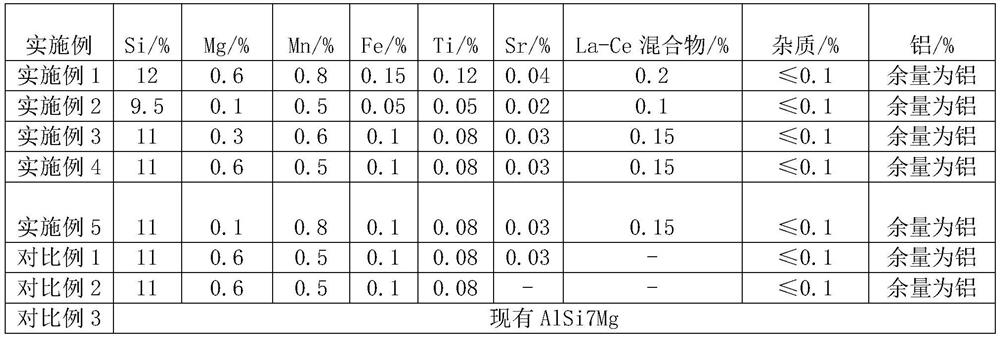

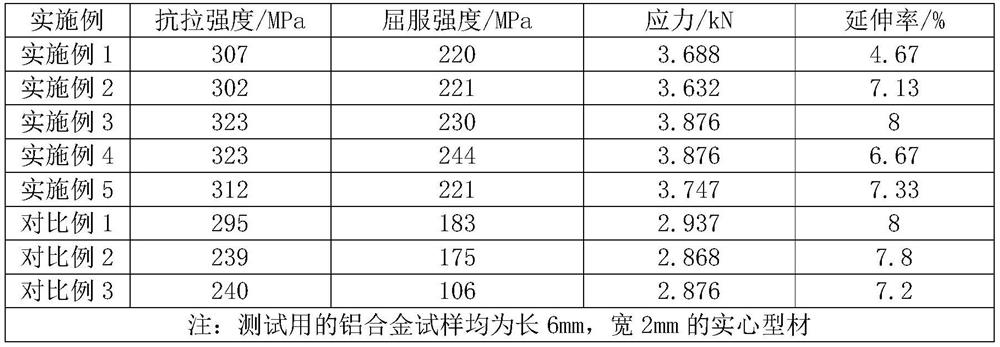

High-yield-strength aluminum alloy and preparation method thereof

The invention relates to the technical field of aluminum alloy materials, and discloses a high-yield-strength aluminum alloy and a preparation method thereof.The high-yield-strength aluminum alloy comprises, by mass, 9.5%-12% of silicon, 0.5%-0.8% of manganese, 0.1%-0.6% of magnesium, smaller than or equal to 0.15% of iron, smaller than or equal to 0.12% of titanium, 0.02%-0.04% of strontium, 0.1%-0.2% of lanthanum-cerium mixture (the ratio of lanthanum to cerium is 7: 3) and the balance aluminum and inevitable impurities, and the total amount of the impurities is smaller than or equal to 0.1%. According to the scheme, by increasing the silicon content, the wear resistance of the aluminum alloy is improved while the hardness of the aluminum alloy is guaranteed; and meanwhile, different types of rare earth elements are added, alloy components and structures are optimized, harmful impurity elements are purified through the rare earth, grains are refined, the purpose of refined grain strengthening is achieved, and therefore the yield strength and wear resistance of the aluminum alloy are improved.

Owner:CHONGQING YUJIANG DIE CASTING +1

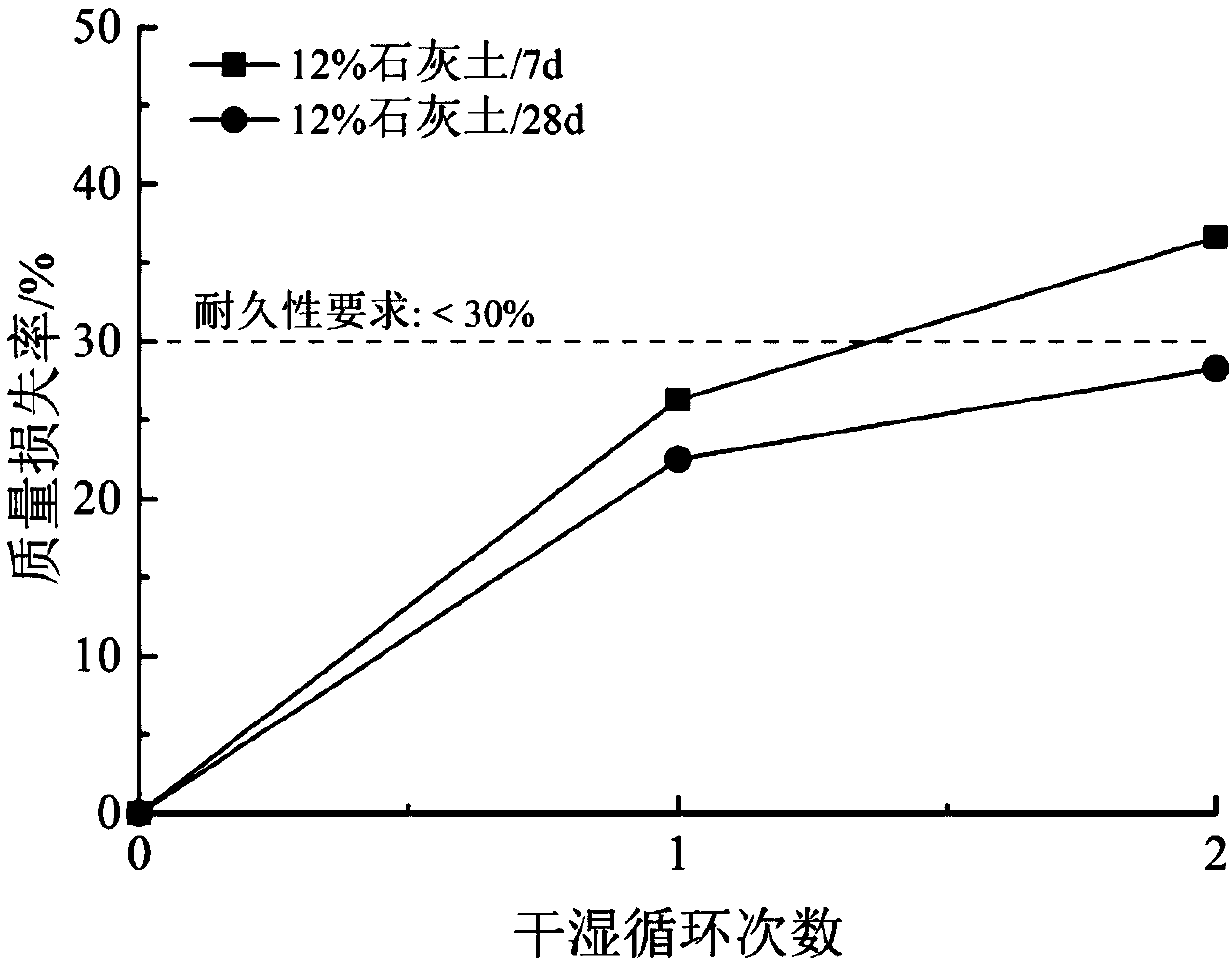

Method for determining lime mixing amount ratio in expansive soil

The invention discloses a method for determining a lime mixing amount ratio in expansive soil, relates to the technical field of civil engineering, and aims at solving the problems that in the relatedart, the expansive soil is improved through the lime, and after lime metering exceeds a certain value, the mechanical index and the water stability of the lime stabilized soil are reduced, and the method comprises the following steps that S1, taking the expansive soil and the lime; S2, preparing an EDTA standard titer line according to the water content controlled by construction; S3, taking 3-6%of lime, and uniformly mixing with the lime to obtain a mixed soil sample; S4, culturing bacillus megaterium liquid and preparing cementing liquid; S5, adding diluted 60-80% bacillus megaterium liquid into the mixed soil sample, uniformly stirring, and standing for 2 hours; S6, after 2 hours, sucking out the bacillus megatherium liquid, adding 60-80% of cementing liquid, continuing to solidify, uniformly stirring, and standing for 22 hours; and S7, sucking out the bacillus megaterium liquid and the cementing liquid, and repeating the steps S4 and S5 seven times.

Owner:ROAD & BRIDGE INT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com