Patents

Literature

55results about How to "Meet the dimensional accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die in alloy blade precision forging process

InactiveCN102310154AImprove mechanical propertiesEasy to useForging/hammering/pressing machinesAlloyMechanical property

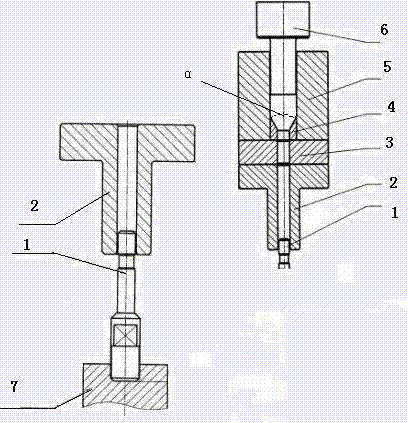

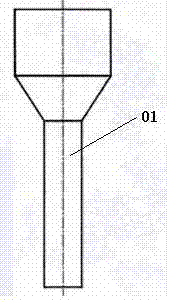

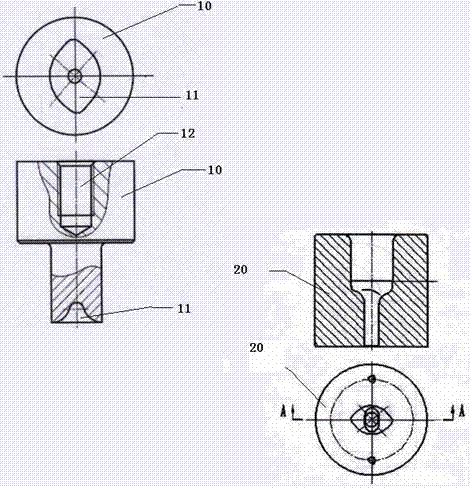

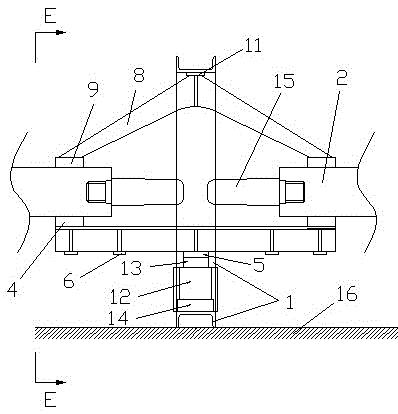

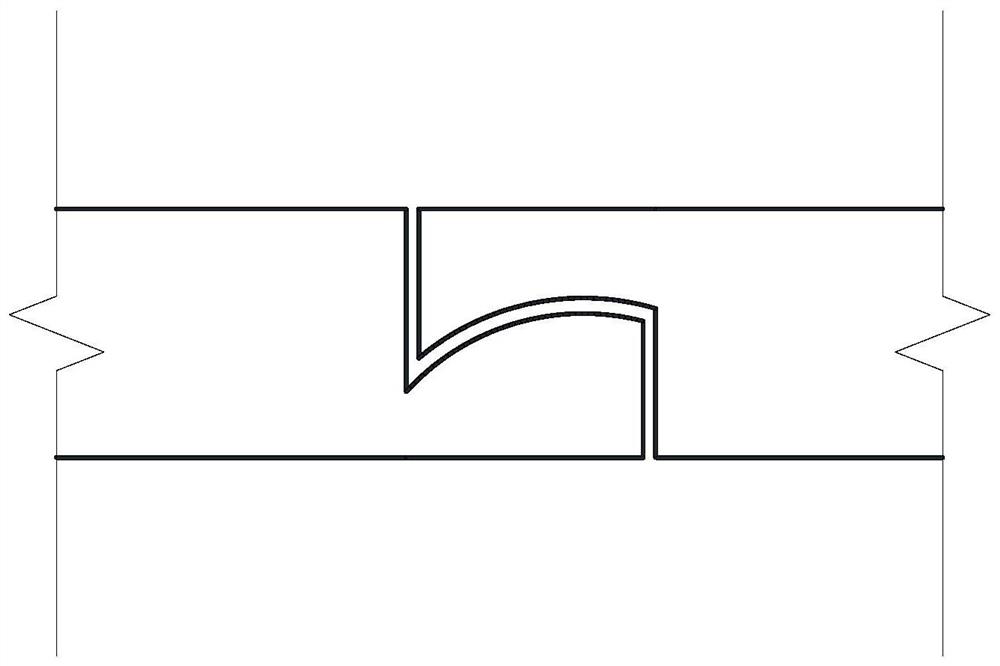

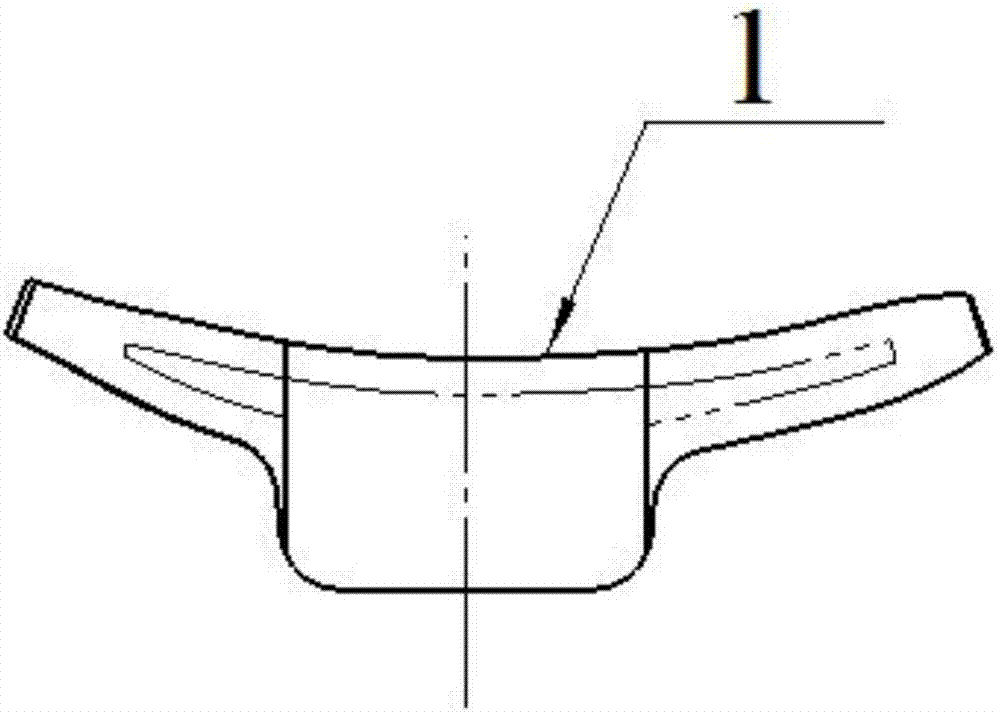

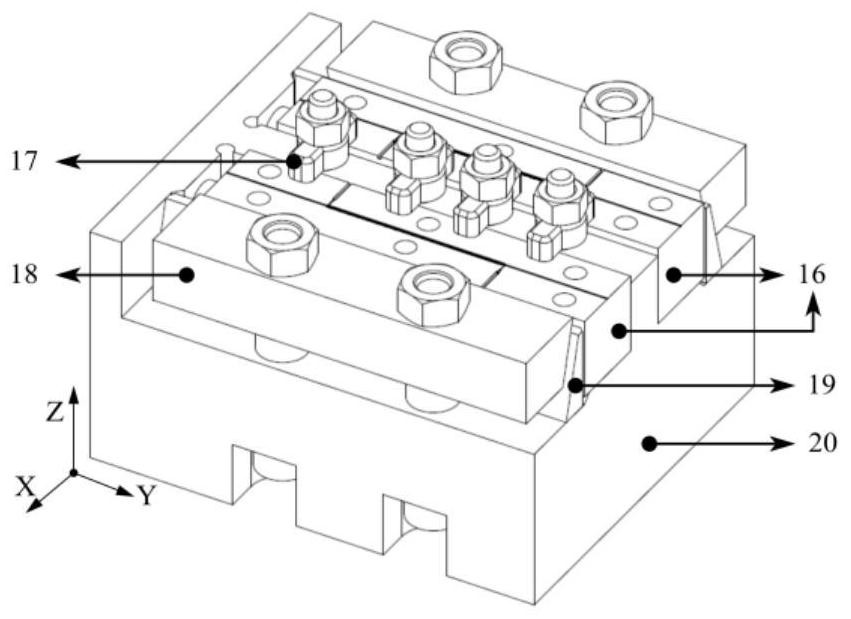

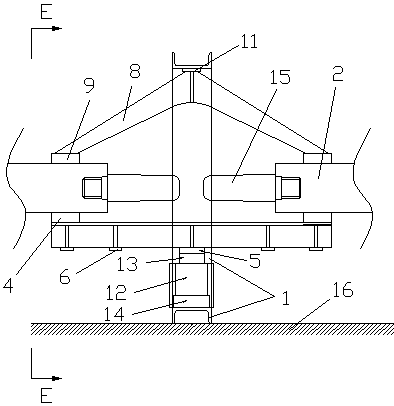

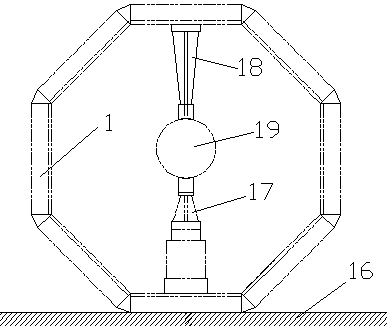

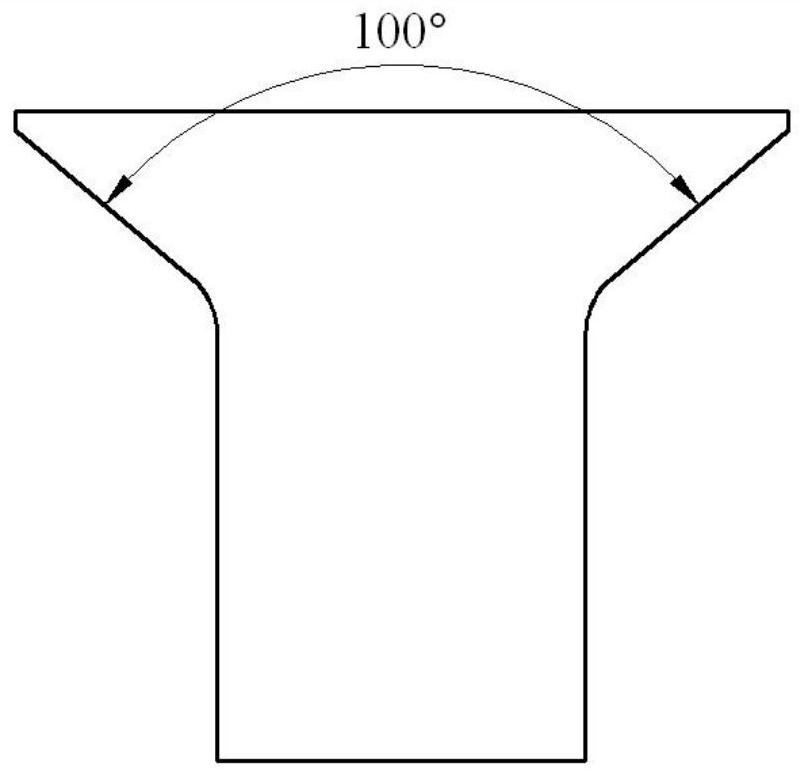

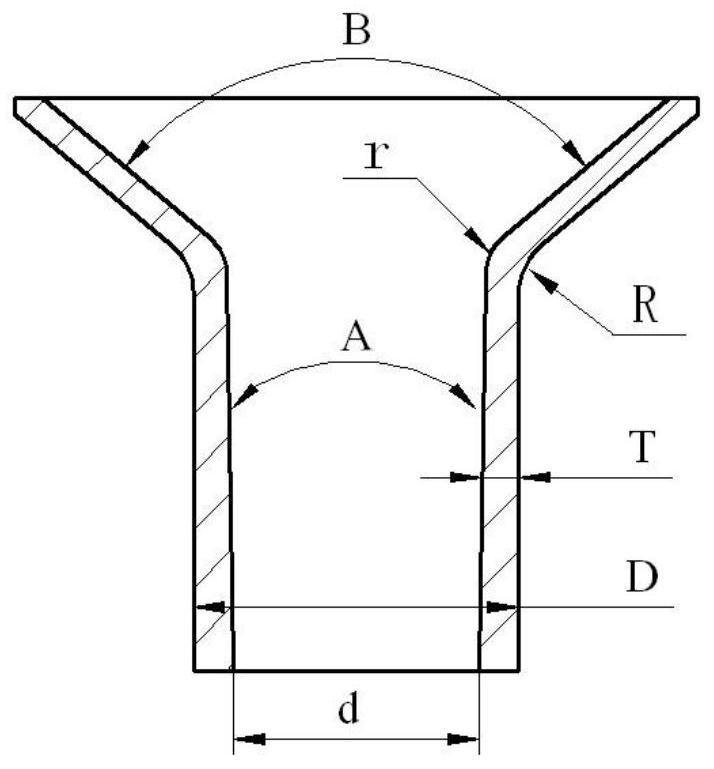

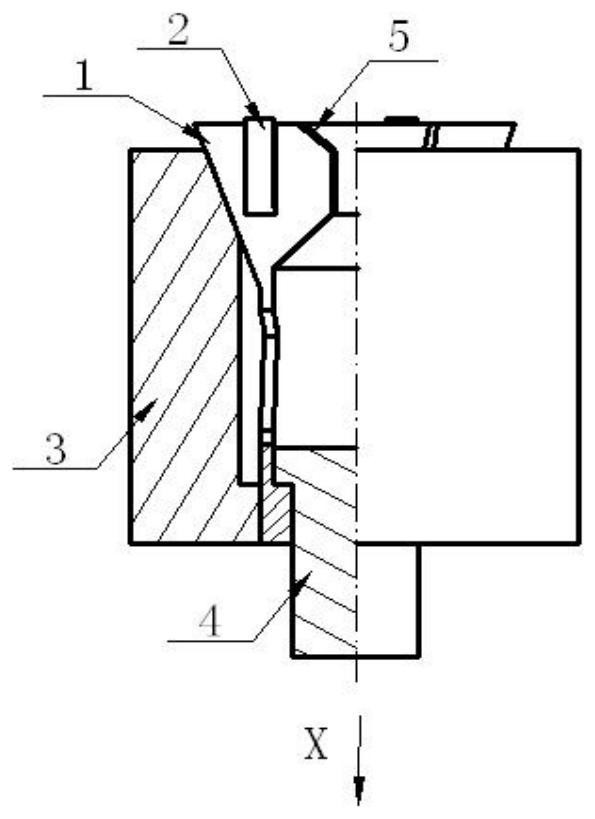

The invention provides a die in an alloy blade precision forging process, and particularly provides a rod squeezing die and a forging die. The die is characterized in that the rod squeezing die comprises an ejector rod (1), an ejector rod guide sleeve (2), a cushion block (3), an insert (4), a squeezing cylinder (5) and a punch head (6); and the forging die comprises a male die (10) and a female die (20). The blanking die squeezing die and forging die are adopted for blanking so as to realize precision forging with the blade singe-face allowance of 0.3-0.7mm, the requirements of a cold rolling process on processing allowance, size precision and surface quality of forge pieces are met, the metal streamline direction of a blade body is reasonable, and the mechanical properties and the use performance of the blade are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

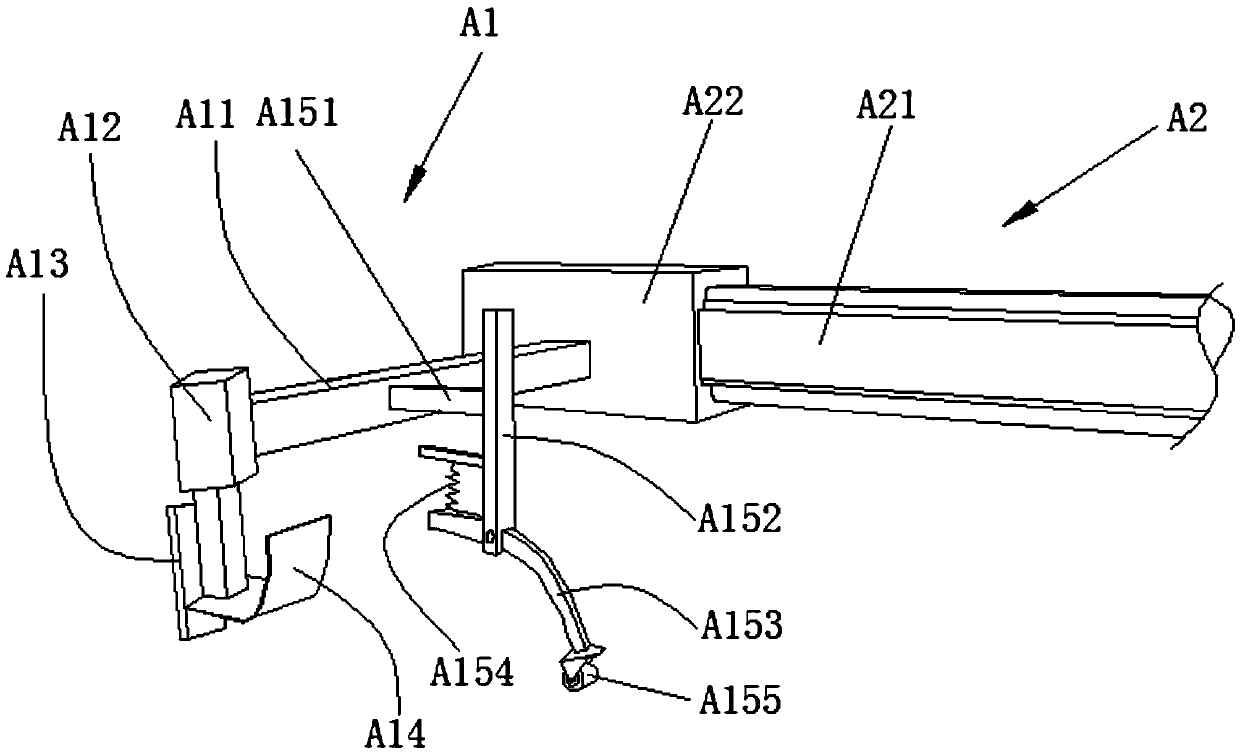

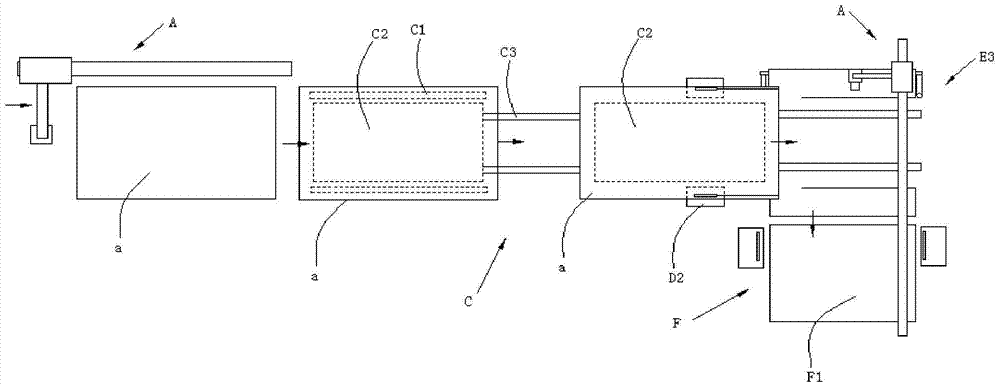

Full-automatic trimming machine

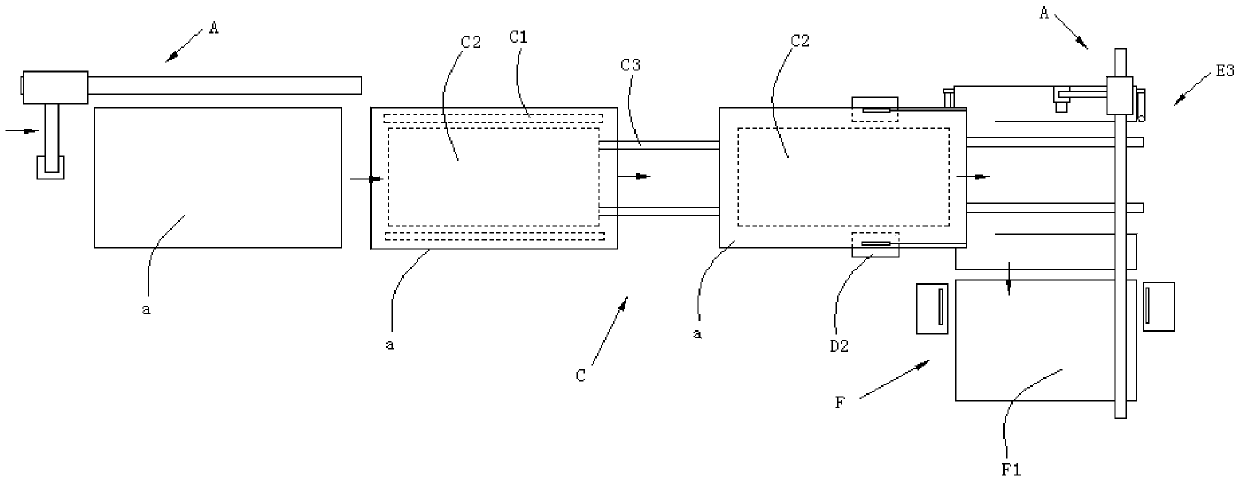

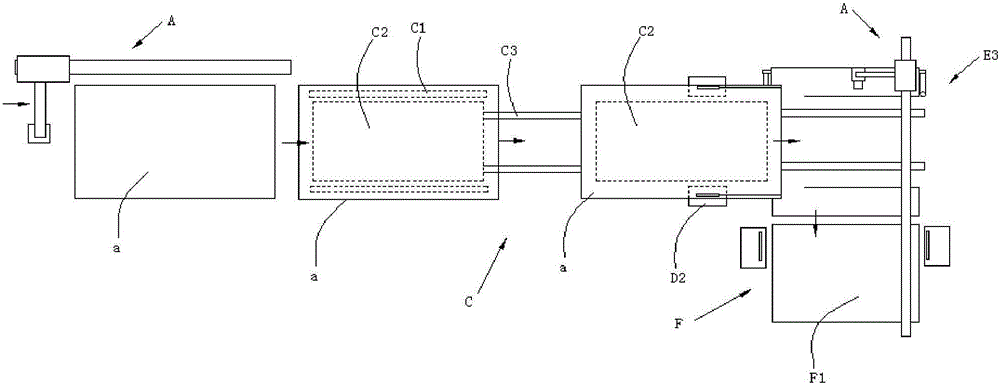

The invention provides a full-automatic trimming machine which comprises a feeding device, a long edge trimming device, a steering device and a short edge trimming device, wherein panels sequentially pass through the feeding device, the long edge trimming device, the steering device and the short edge trimming device; the long edge trimming device and the short edge trimming device are respectively positioned on the two adjacent sides of the steering device; and the horizontal-direction included angle of the long edge trimming device and the short edge trimming device is 90 degrees. Compared with the prior art, the trimming machine provided by the invention has the advantages that the structure is simple, the panel feeding is smooth, all the steps closely cooperate with each other, before the next step is carried out, the next work task is prepared in the precious step, the connection is close, and the working efficiency is high.

Owner:ANHUI ANSU WORLD HOME CO LTD

Adhesive electric machine magnetic strip and preparation method thereof

InactiveCN101000818APreventing sticking to each other is not desirableMeet performance requirementsManufacturing dynamo-electric machinesInductances/transformers/magnets manufacturePolymer scienceAdhesive

A adhesive magnetic strip of motor is prepared as forming bound magnetic strip of motor by 3-8 layer flattening and pressing process; forming internal layer by compositions in wt% as magnetic powder of 80-95%, polyethylene of 2-10%, plasticizer of 1-4%, stabilizer of 1-3% and coupling agent of 01-3%; forming two external layers by compositions in wt% as magnetic powder of 80-95%, polyethylene of 2-10%, hotmelt adhesive of 1-6%, stabilizer of 1-2% and coupling agent of 0.1-3%.

Owner:横店集团东磁有限公司

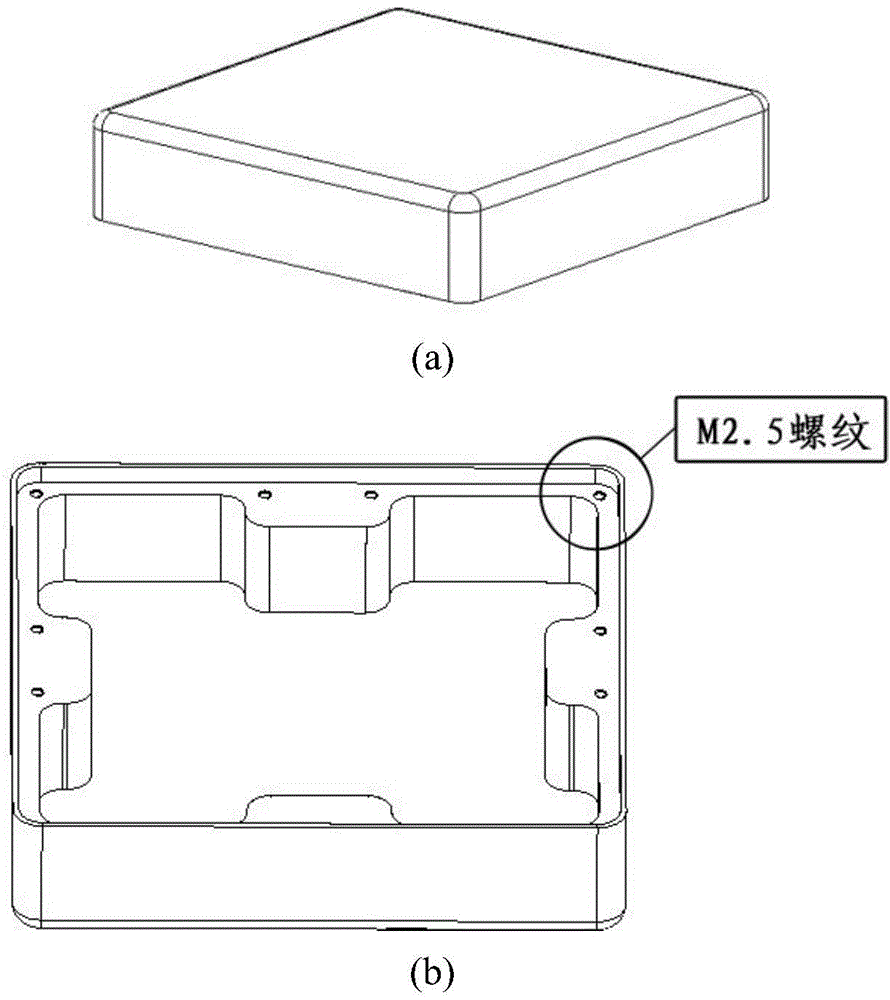

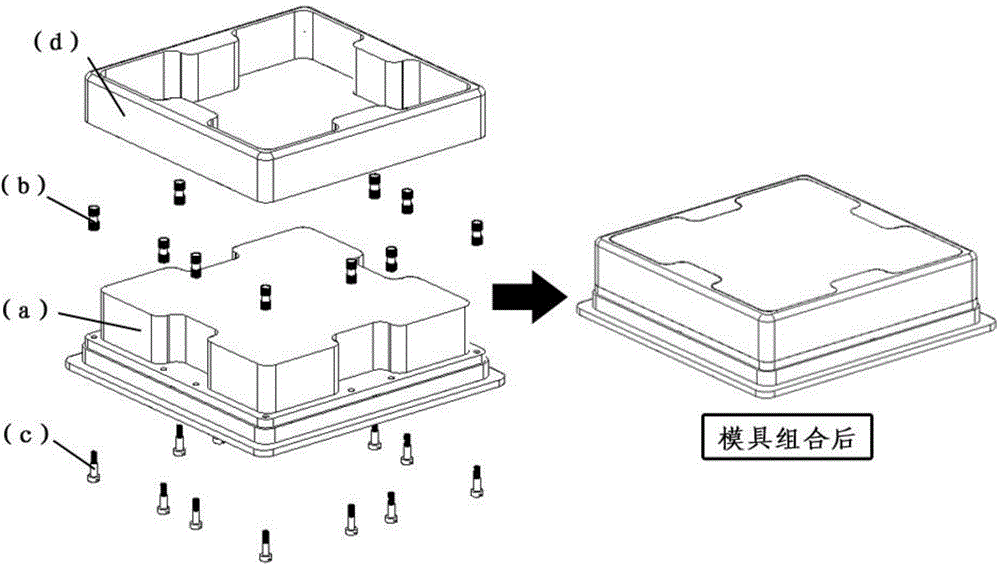

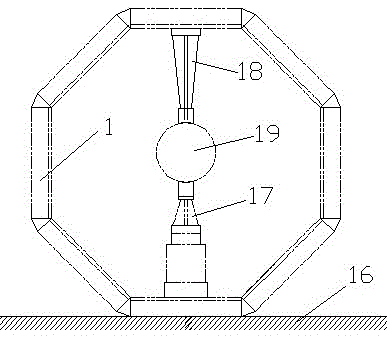

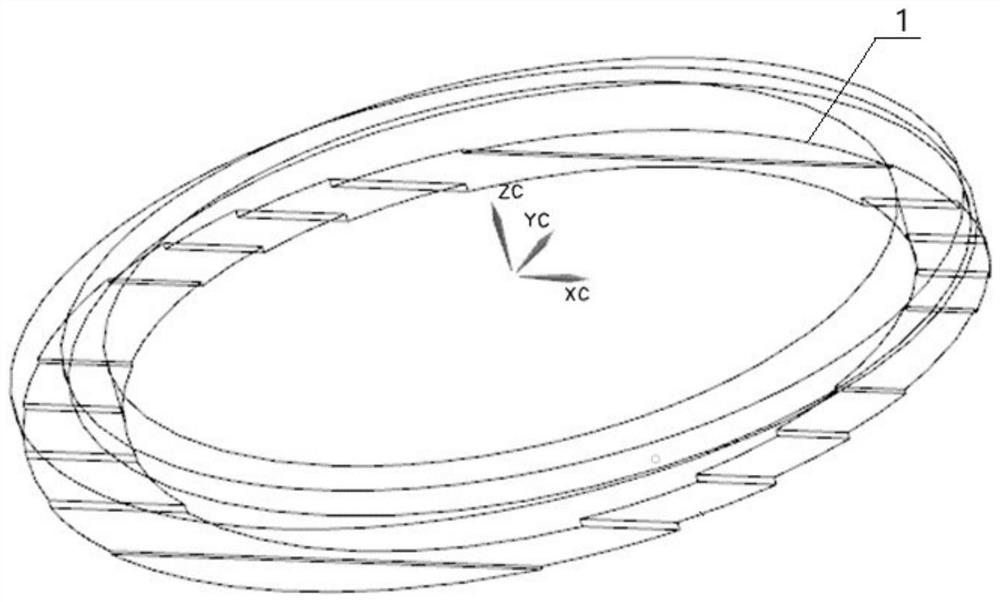

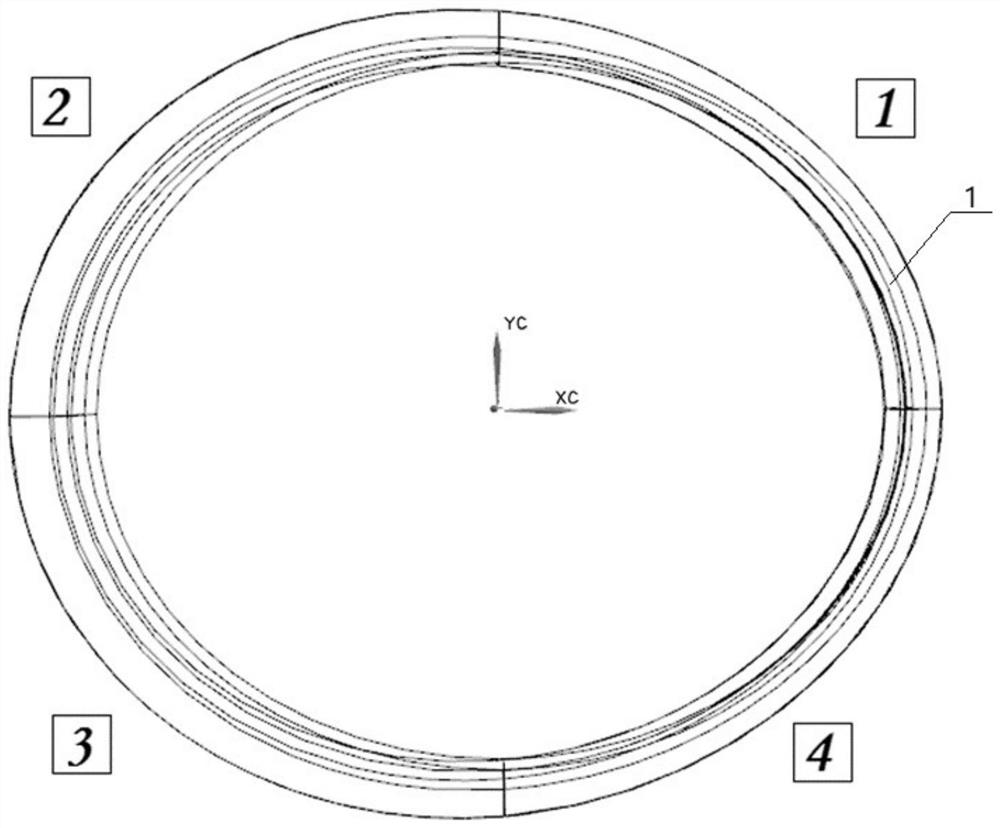

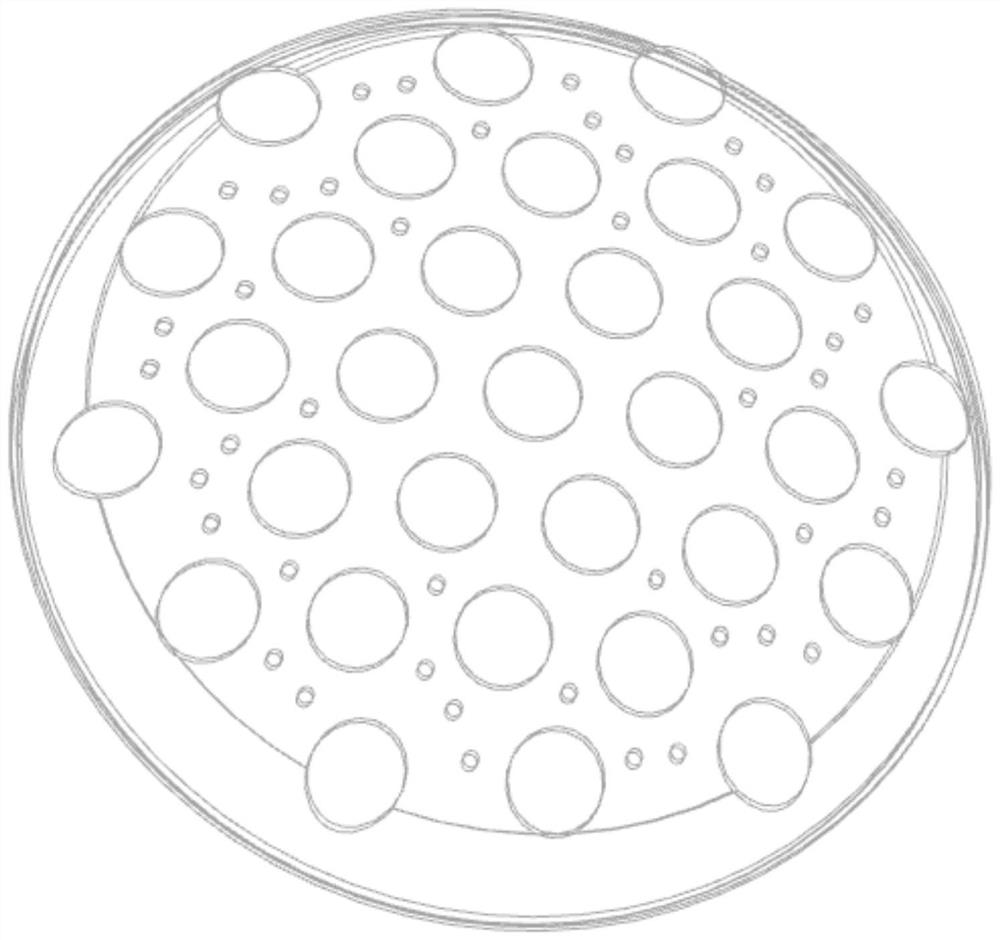

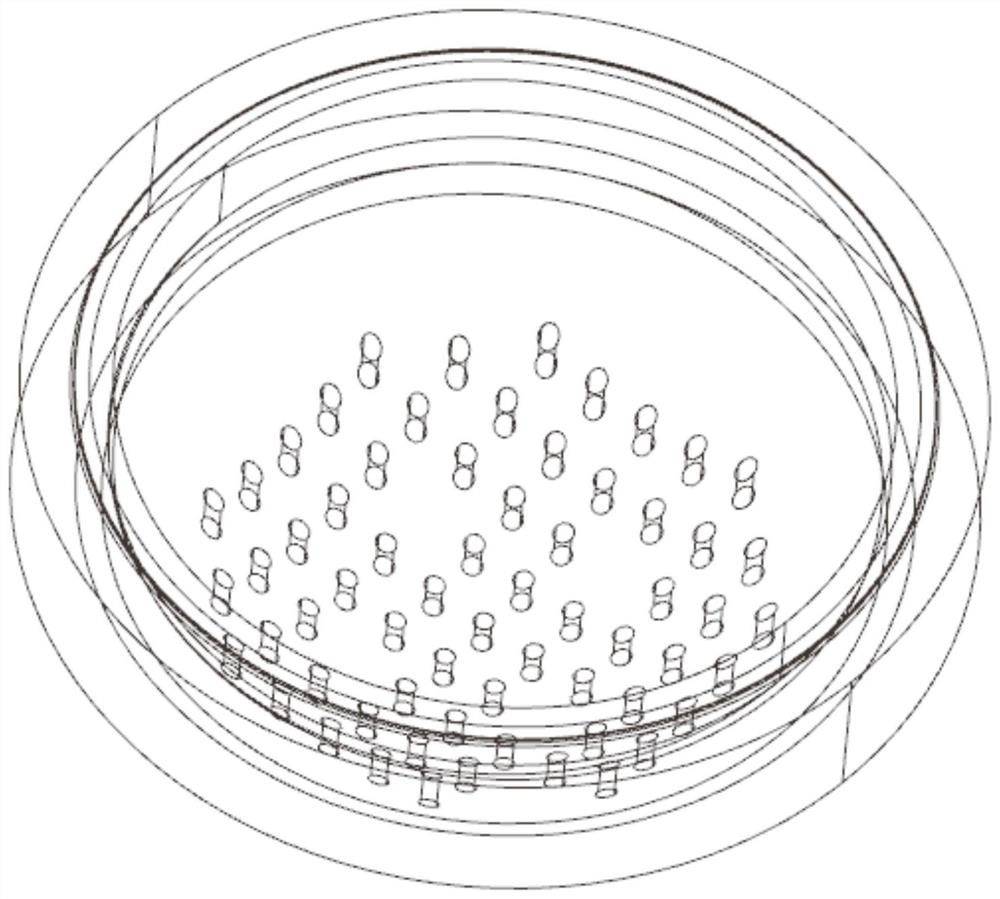

Integrated forming die and method for glass fiber reinforced plastic antenna housing

The invention relates to an integrated forming die and method for a glass fiber reinforced plastic antenna housing. The integrated forming die is composed of a main die (a), embedded circular nuts (b), special screws (c), a glass fiber reinforced plastic framework (d) and an outer die (e). A forming process comprises the following steps: (1) doing preparation work and assembling the dies; (2) preparing raw materials; (3) laying; (4) forming the antenna housing by an autoclave; and (5) releasing the dies and carrying out post-treatment. By adopting the integrated forming die, the embedded circular nuts (b) are synchronously glued and arranged in the forming process of the antenna housing and cracks caused by mechanical drilling when the embedding circular nuts are arranged by adopting a conventional method are avoided; drilling and secondary gluing procedures are eliminated, the operation difficulty is reduced and the splicing effect of the embedded circular nuts (b) is improved; and the main die (a) and the outer die (e) are combined so that the appearance quality requirements and the size precision requirements on the antenna housing are met when the antenna housing is formed and a manual polishing or machining procedure in a conventional forming method is eliminated.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

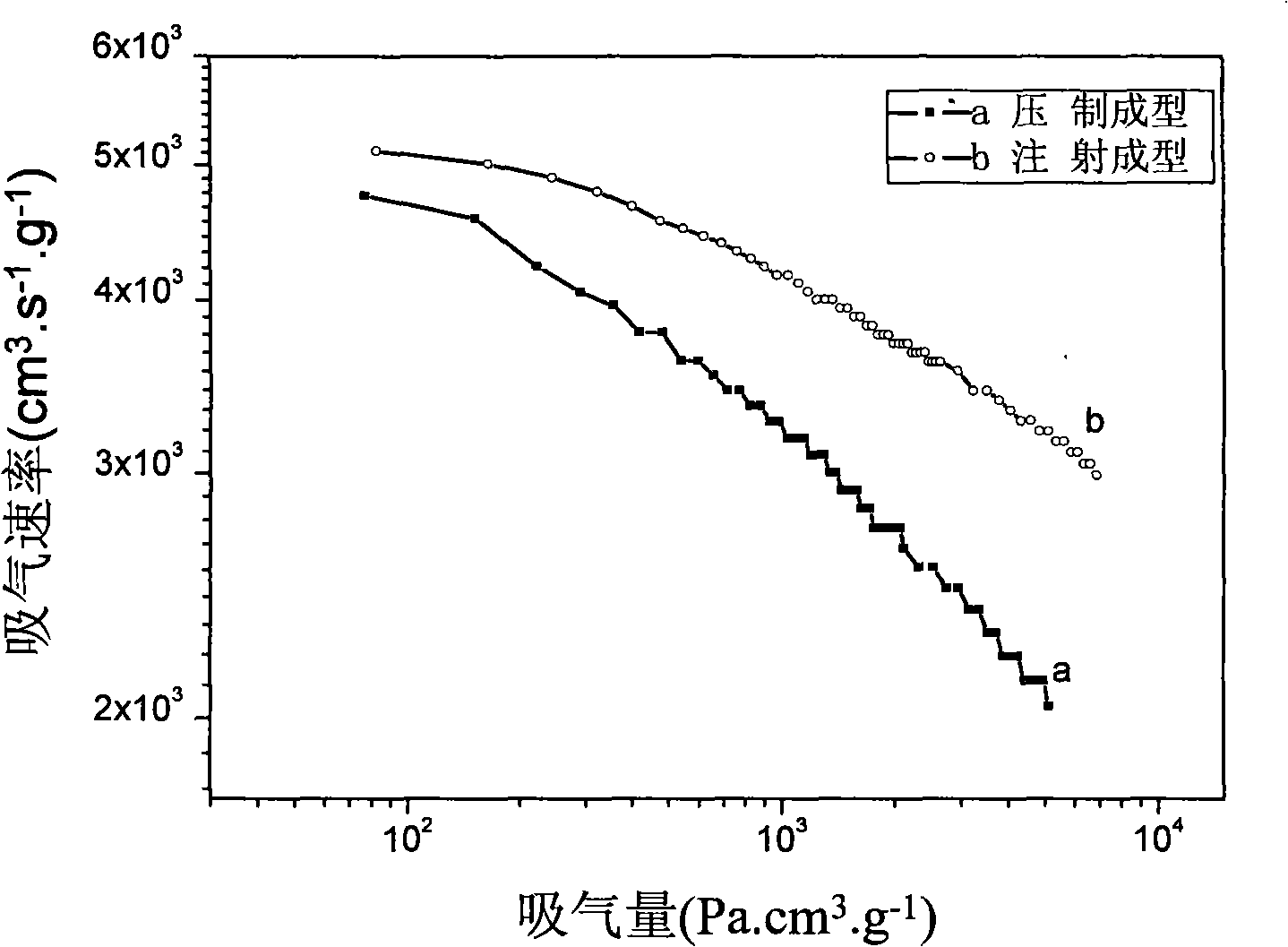

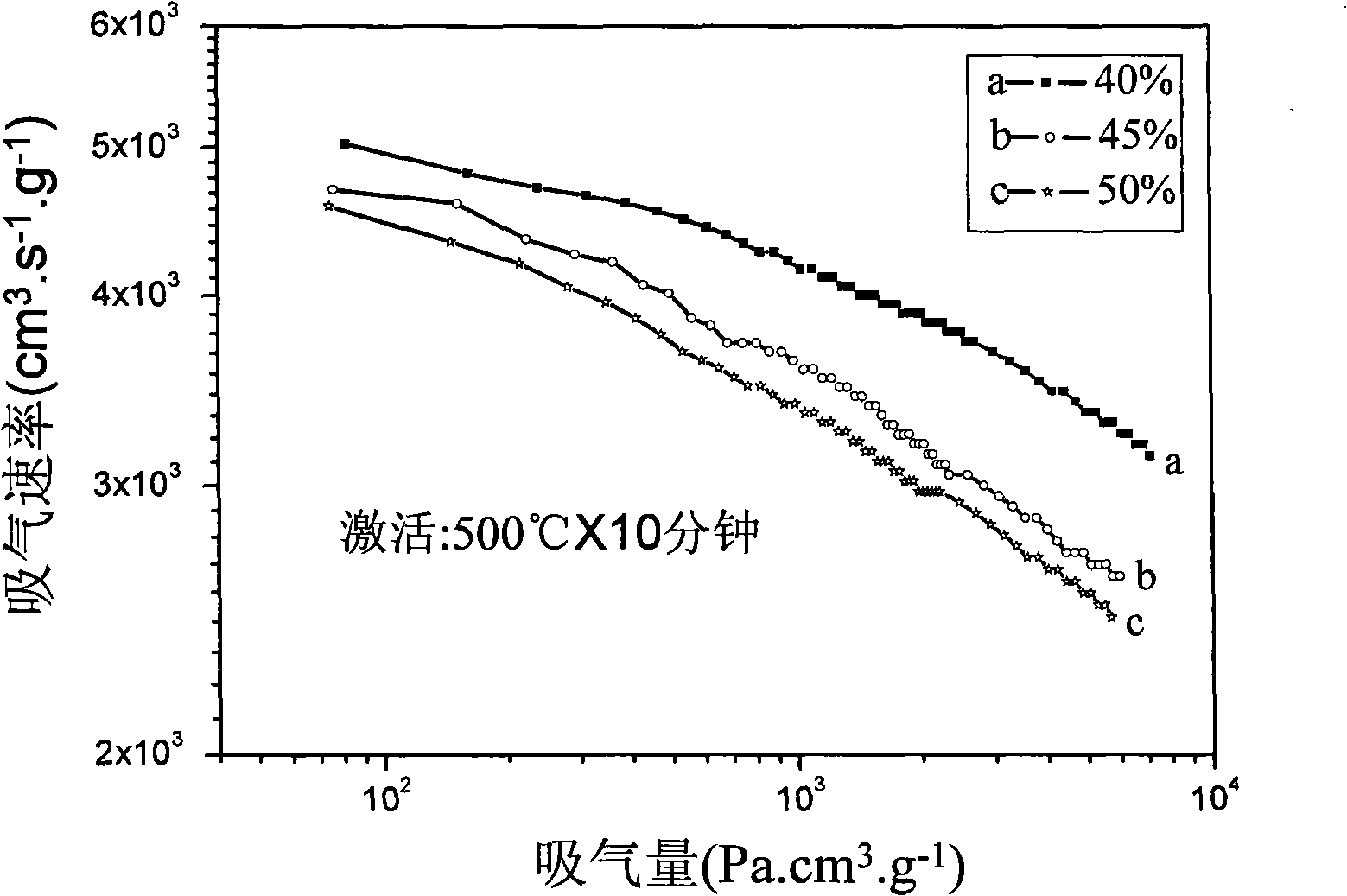

Method for preparing electric vacuum suction element molded by powder injection

ActiveCN101290851AMeet shape requirementsMeet the dimensional accuracy requirementsElectric discharge tubesTube/lamp vessel degassingElectricityPorosity

The invention provides a method for preparing an electric vacuum inspiration element by using powder injection molding, which belongs to the electric vacuum inspiration element manufacturing technical field. The preparation technology is as follows: Ti powder and Mo powder taken as raw materials are mixed in a mixer, the evenly-mixed raw material powder and adhesive are mixed according to the volume ratio, mixed in a mixing roll, cooled, then crushed into injection feedstock, and subject to the injection molding, two-step debinding process treatment is adopted to a blank formed by the injection molding, the blank formed by the injection molding undergoes solvent debinding and vacuum thermal debinding then, and finally vacuum sintering is carried out to the debound blank to prepare the vacuum inspiration element. The method has the advantages that: the method can prepare the inspiration elements with complicated shape and high dimension accuracy to meet the requirement of spaces with various shapes of various electric vacuum devices to the complicated shape and the dimension accuracy of the inspiration elements. The aperture and the degree of porosity of the product are evenly controlled, and the degree of porosity of the inspiration element can reach more than 50 percent.

Owner:GRIMAT ENG INST CO LTD

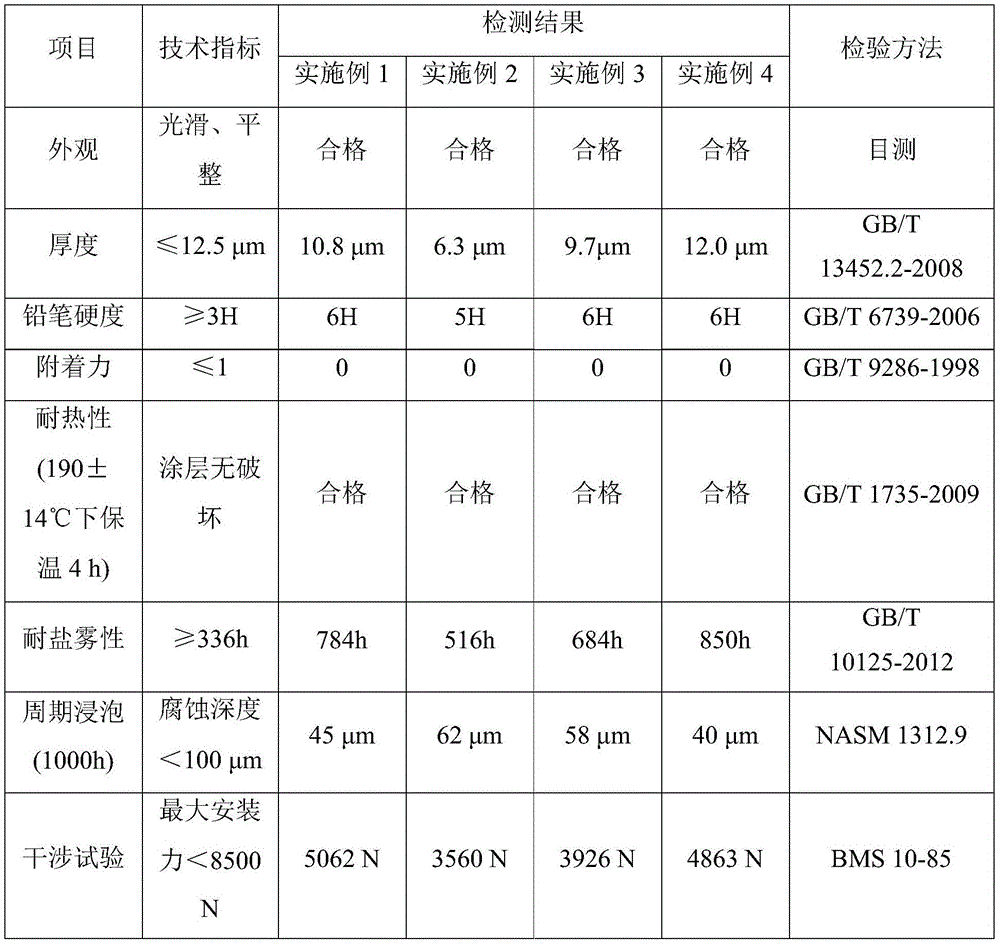

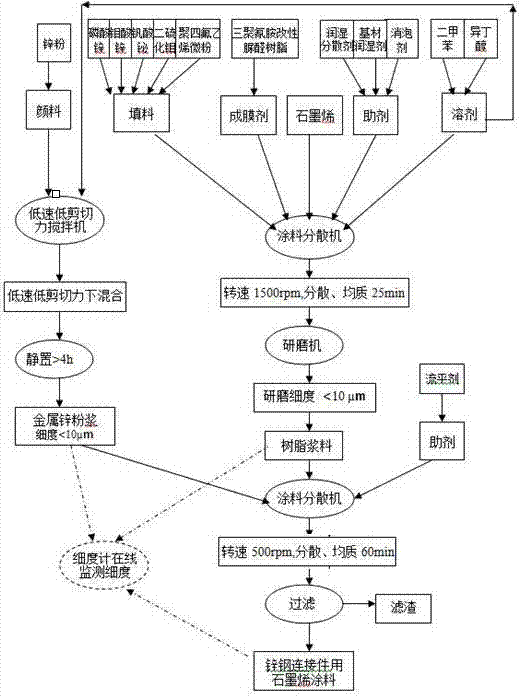

Graphene paint for steel fastening parts and preparation method of graphene paint

InactiveCN105585930ACorrosionReduce corrosionAnti-corrosive paintsFrictional coefficientMelamine formaldehyde resin

The invention discloses graphene paint for steel fastening parts and a preparation method of the graphene paint. The graphene paint is prepared from, by mass, 20-50 parts of urea formaldehyde resin, 1-10 parts of melamine-formaldehyde resin, 0.1-5 parts of graphene, 5-30 parts of aluminum paste, 5-30 parts of zinc powder, 2-10 parts of packing, 1-8 parts of an auxiliary and 10-70 parts of solvent. The paint can be applied to the surfaces of the steel fastening parts, a coating formed through heating curing has the advantages of being small in thickness, high in hardness, resistant to wear, good in adhesive force, low in frictional coefficient and excellent in corrosion resistance, therefore, corrosion of the steel fastening parts can be effectively delayed, and the service life of the steel fastening parts is prolonged.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

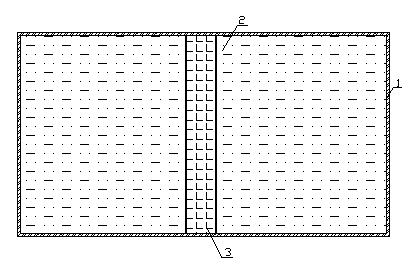

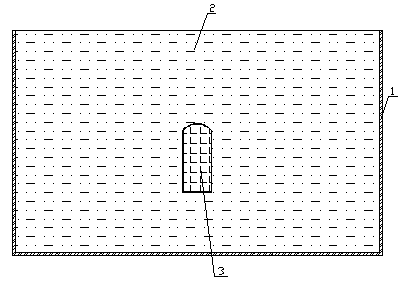

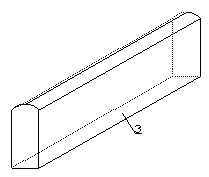

Shaping method for experimental grotto of earthquake simulated vibration platform model

InactiveCN103234724ASimple preparation processReduce distortionVibration testingShell moldingPolyvinyl chloride

The invention relates to a shaping method for an experimental grotto of an earthquake simulated vibration platform model. The method comprises the following steps of 1), manufacturing a wood mould with a grotto size consistent to an experimental request of a model, molding, additionally hardening and weighing a polystyrene foaming grotto model according to a model size, and wrapping a layer of polyvinyl chloride plastics on the surface of the grotto model; 2), drawing a grotto profile on a side wall in a model box according to a designed position for positioning, and fixing the borders of the grotto and the model box by the adoption of square wooden strips; 3), stuffing and symmetrically ramming around the grotto, and enabling the grotto model not to generate deviation; and 4), firstly digging the middle part of a grotto cross section, and then digging the edge and corner parts by utilizing the protection of plastic cloth on the outer layer of the model. By the adoption of the method, grottos with different shapes and sizes can be high-efficiently, simply and conveniently manufactured in model experiments, the accurate positioning of a grotto space is realized, the digging method is simple and convenient, and interference with model materials surrounding the grotto during the digging process is effectively reduced.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Casting technology of stainless steel casting

InactiveCN103586398AQuality improvementReduce roughnessFoundry mouldsFoundry coresPhosphateRefractory

The invention relates to a casting technology of a stainless steel casting. The stainless steel casting adopts quartz sand and alumina as fire-resistant materials, uses a modified phosphate as a binder, and is prepared and cast through pouring. The operation is simple and convenient, the production cost is low, the high-temperature strength of a roasted casting die is high, the quality of the cast casting is good, the requirement on size precision can be met, and the surface roughness of the casting is greatly lowered.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

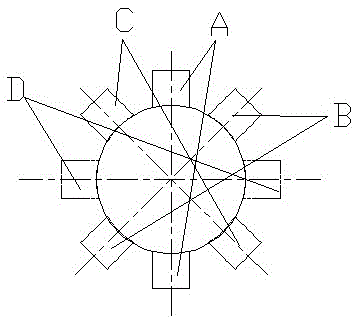

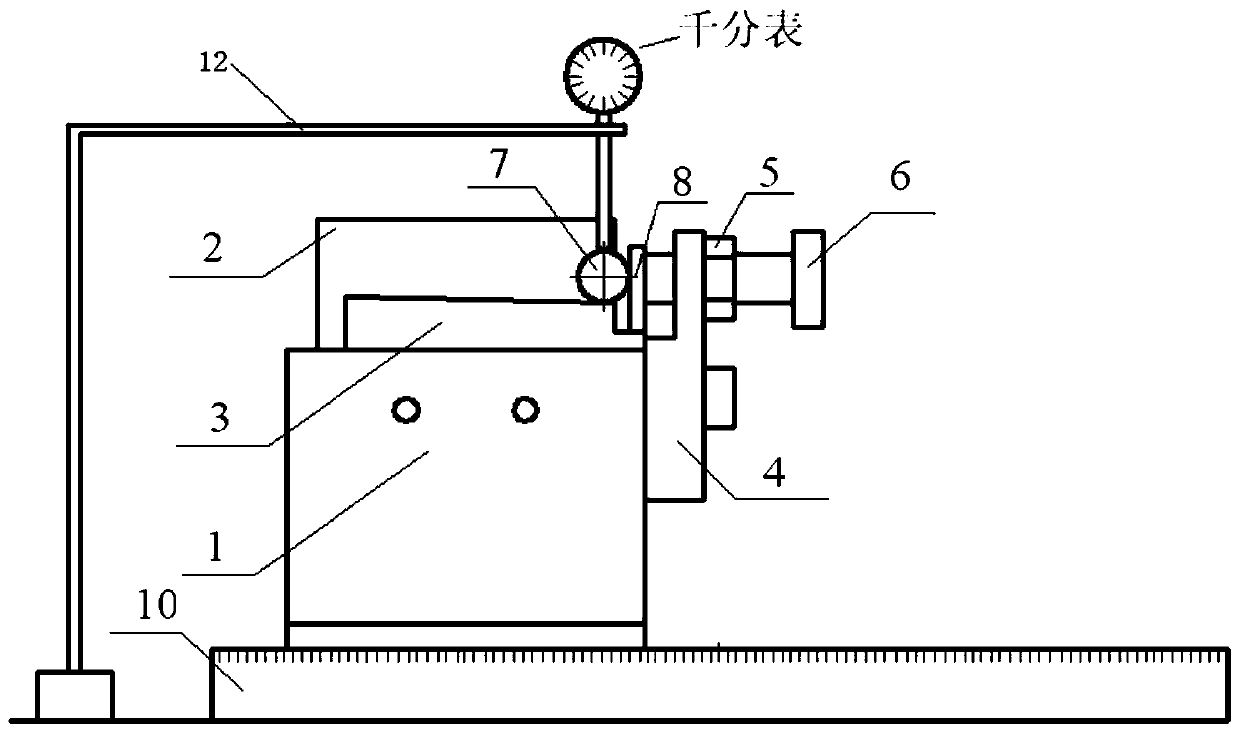

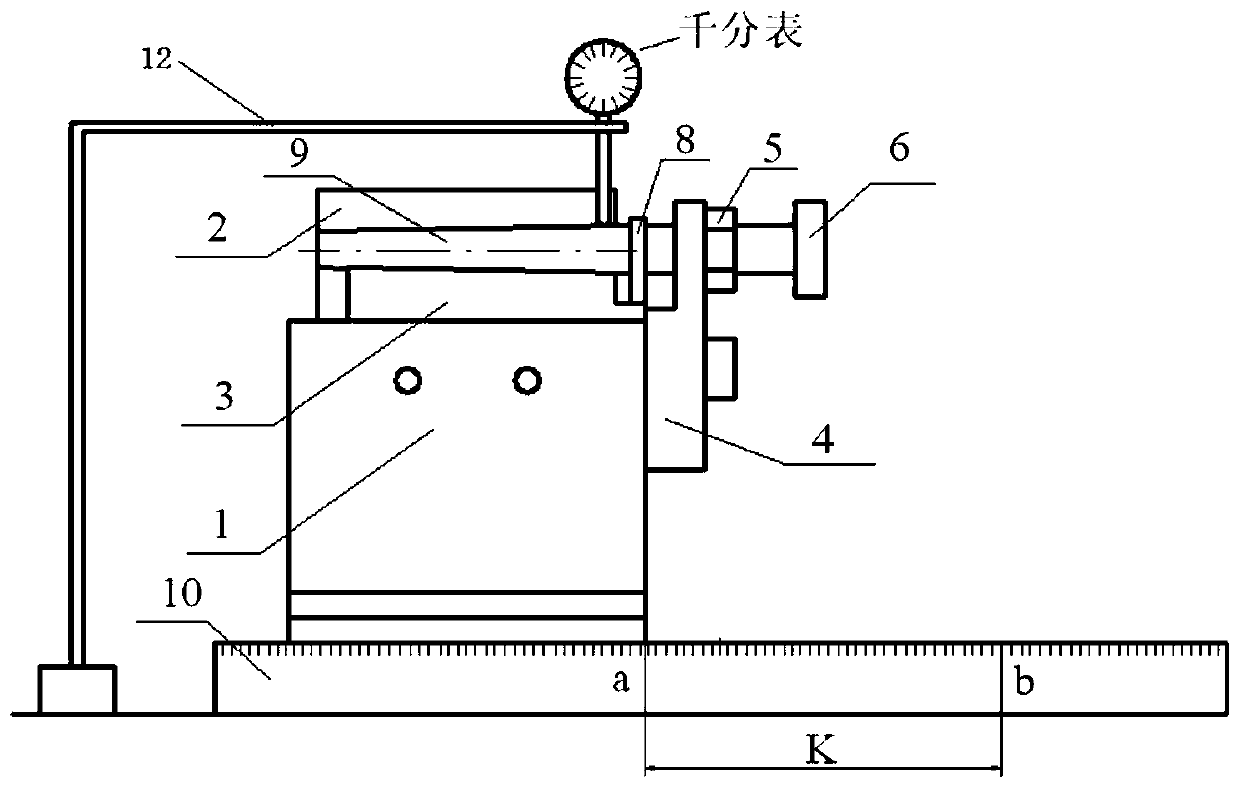

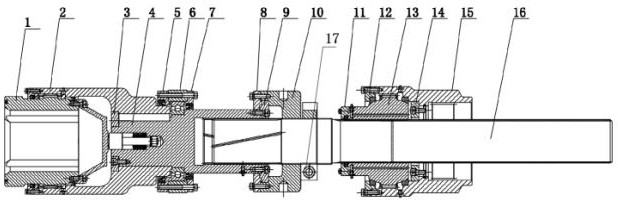

Device and method for measuring coaxiality of horizontal perforating punch of multi-directional die forging hydraulic press

ActiveCN105526850AExtended service lifeMeet the dimensional accuracy requirementsMechanical measuring arrangementsEconomic benefitsEngineering

A device and method for measuring the coaxiality of a horizontal perforating punch of a multi-directional die forging hydraulic press are provided. The device comprises: a measuring scale and a force application base; the measuring scale comprises a main scale and a secondary scale; the secondary scale is arranged upon two horizontal punch base parts, wherein two arc-shaped slide blocks of the secondary scale are in touch with the two horizontal punch base parts at corresponding positions; the main scale is arranged under the horizontal punch base parts and the lower part of a large base plate of the main scale is provided with a thin type hydraulic lifting jack; the bottom of the thin type hydraulic lifting jack is in touch with an inner plane of the force application base. The provided device for measuring coaxiality of a horizontal perforating punch of a multi-directional die forging hydraulic press has simple operation which is easy to learn, and high measurement accuracy which reaches 0.02mm theoretically; the measured data is easy to extract and is referential and can be referred to directly when adjusting; After the coaxiality error of the horizontal punch is adjusted and is qualified, not only the size accuracy requirement of forged pieces produced can be met, the outline size quality of products can be guaranteed, but also the service life of forging dies and especially the punch can be prolonged, and the economic benefit is obvious.

Owner:22MCC GRP PRECISION FORGING

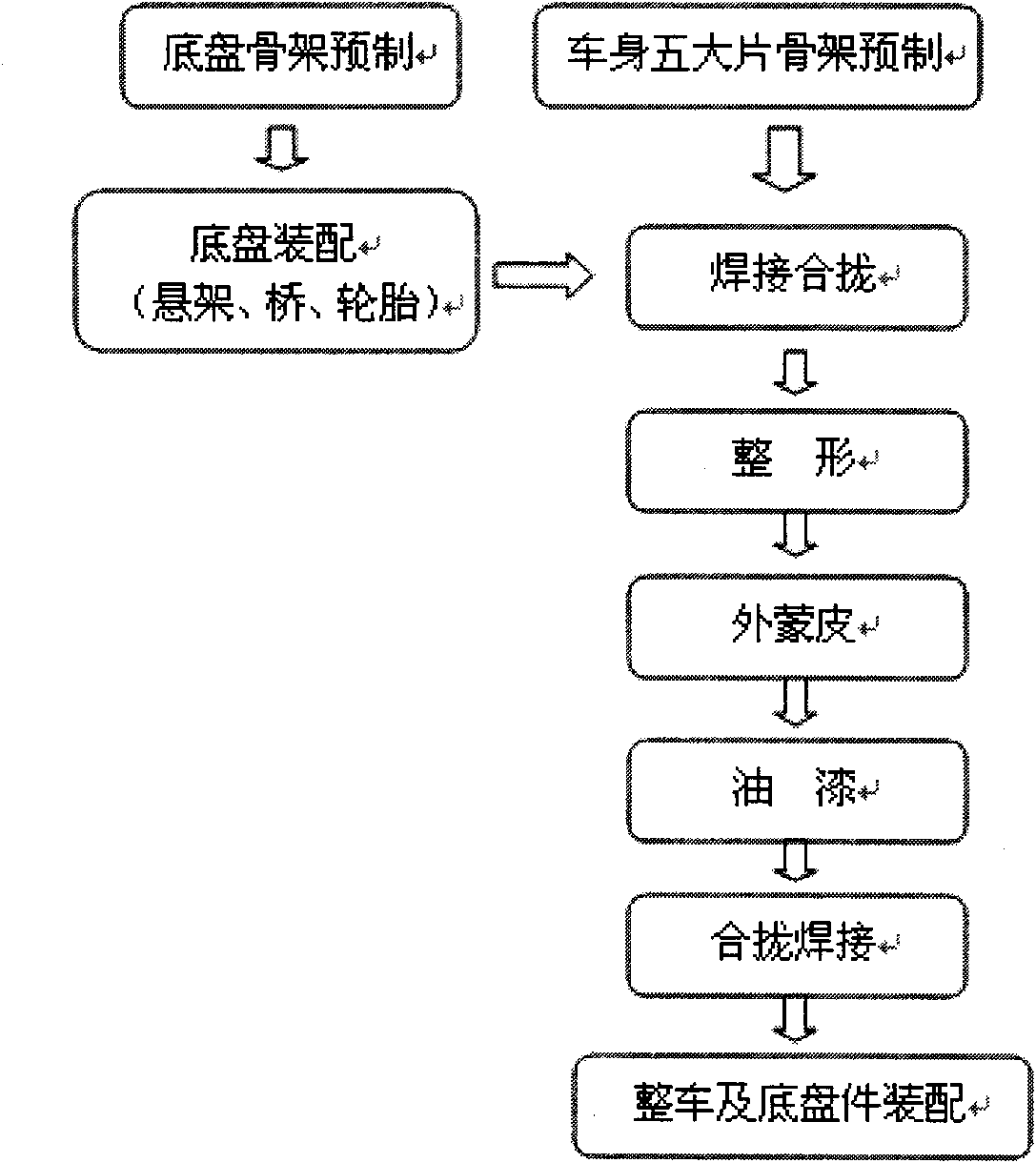

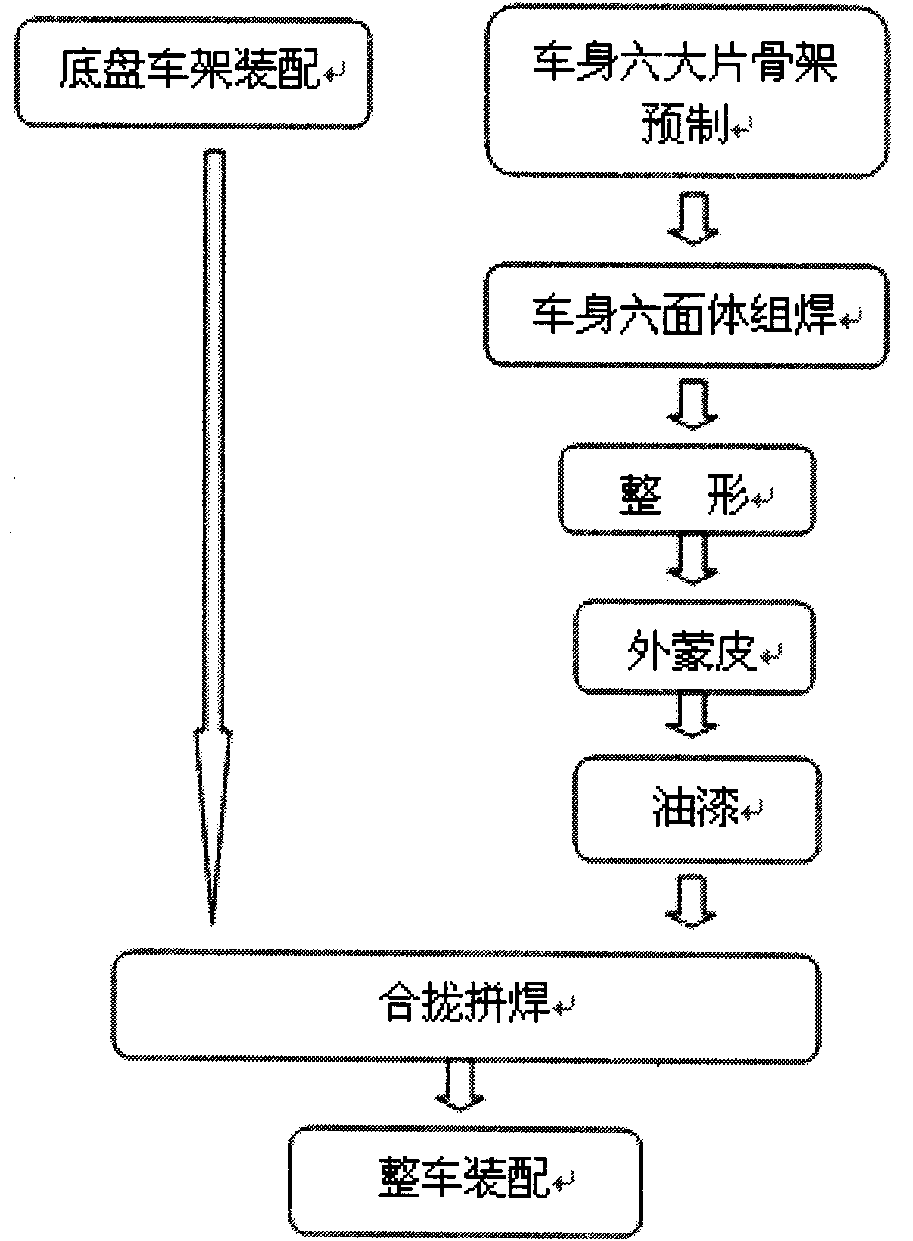

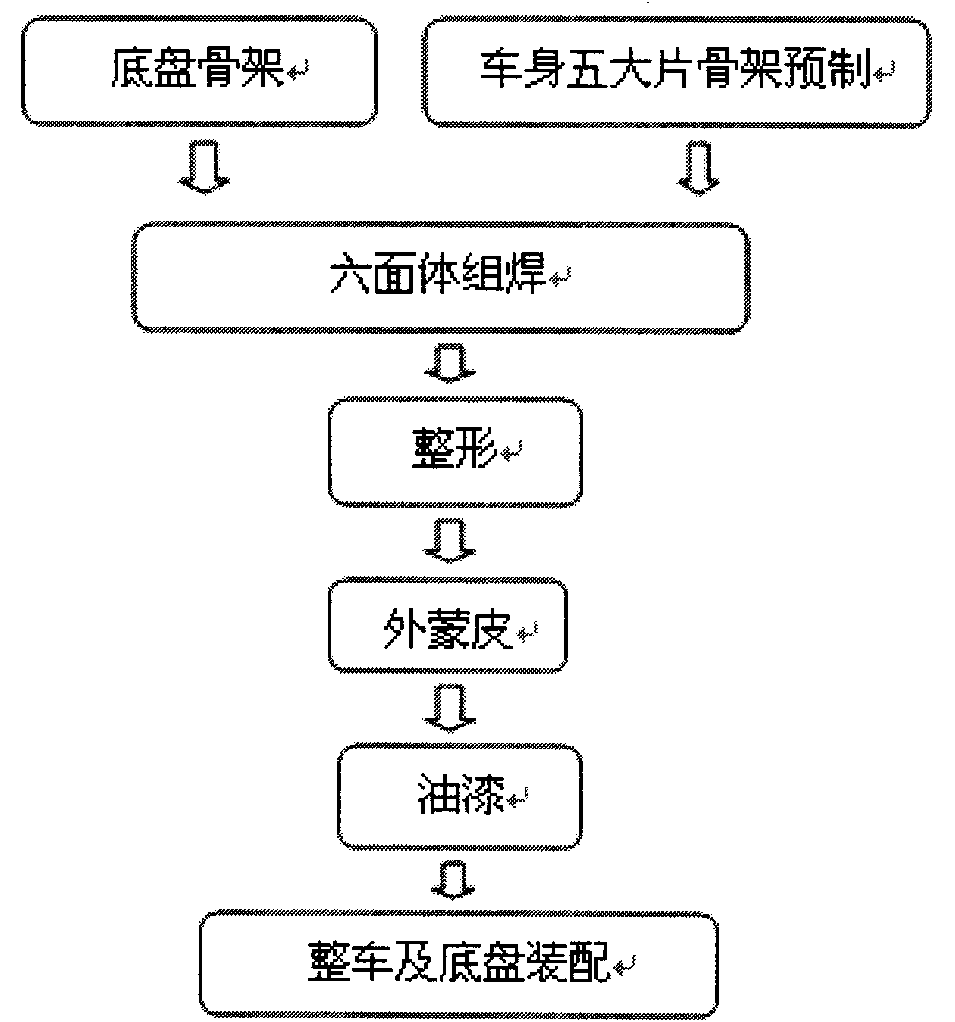

Skeleton assembly process of full-loading passenger car

InactiveCN102107692AGuaranteed accuracyMeet the dimensional accuracy requirementsVehiclesEngineeringWeld seam

The invention discloses a skeleton assembly process of a full-loading passenger car, which is characterized by comprising: after prefabricating the chassis skeleton, directly assembling a suspension rack, a bridge and tires, then welding and merging the prefabricated five skeletons of the car body with the assembled suspension rack, bridge and tires; and assembling the whole car and the chassis accessories via welded seam polishing, skeleton calibration, external covering and painting. Compared with the existing skeleton assembly process of the full-loading passenger car, the assembly process can be matched with the existing work position procedures without increasing apparatus investment in the prior art; and the difficulty in assembling the suspension and the bridge due to a small operation space in the prior art is reduced, the deformation of the chassis caused by non-uniform stress can be avoided, the precision of the sizes of the skeleton parts can be ensured, the assembly cost is lowered and the assembly efficiency the improved.

Owner:HENAN SHAOLIN AUTO

Water-based metal wire drawing liquid with good lubricating effect and preparation method thereof

InactiveCN104263486AMeet brightness requirementsMeet the dimensional accuracy requirementsLubricant compositionWater basedCoconut diethanolamide

The invention discloses a water-based metal wire drawing liquid with a good lubricating effect. The water-based metal wire drawing liquid is characterized in that the water-based metal wire drawing liquid is prepared from the following raw materials in parts by weight: 3-4 parts of sodium ricinoleate soap, 1-2 parts of coconut diethanolamide, 1.5-2 parts of polyepoxysuccinic acid, 5-7 parts of sulfurized lard oil, 3-4 parts of polyethylene glycol, 3-4.5 parts of sodium hydrogen carbonate, 3-5 parts of chlorinated paraffin, 3-4 parts of spindle oil, 2-4 parts of sodium carboxymethyl cellulose, 0.8-1.5 parts of sodium benzoate, 5-7 parts of additives and 900-950 parts of deionized water. The water-based metal wire drawing liquid disclosed by the invention has excellent lubricating performance and can meet the requirements of customers on brightness and dimensional precision at relatively low concentration; by adding the additives, the water-based metal wire drawing liquid has good wear resistance, dispersion, lubrication and film-forming property, is mutually matched with a surfactant, and can form a protective film on the surface of a metal to realize a corrosion inhibition effect. The water-based metal wire drawing liquid adopts a water-based formula, is good in cooling property and cleaning property, is easy to be moved after processing, and further ensures the cleanliness of a wire drawing operation environment.

Owner:ANHUI WANGDA COPPER DEV

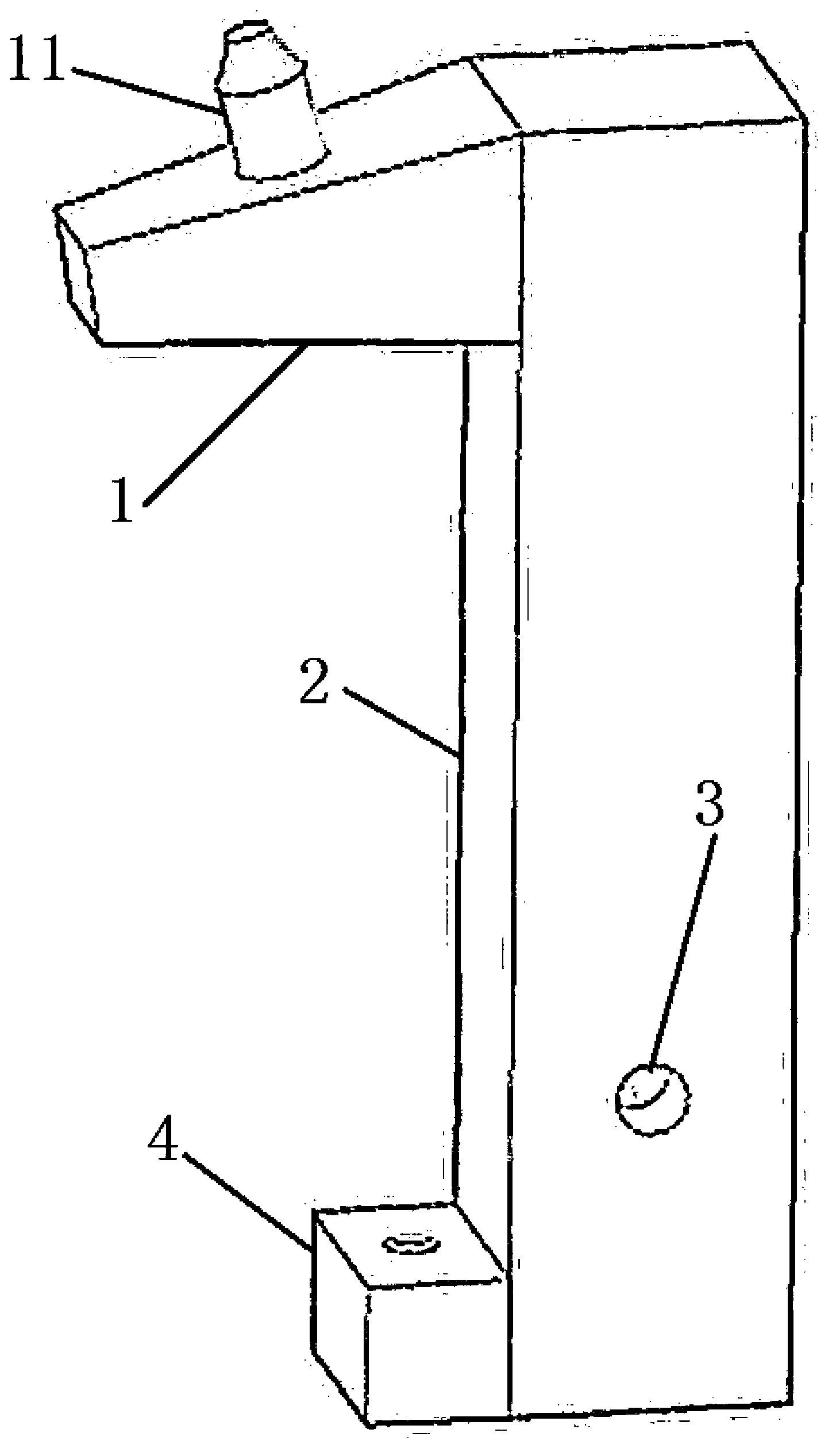

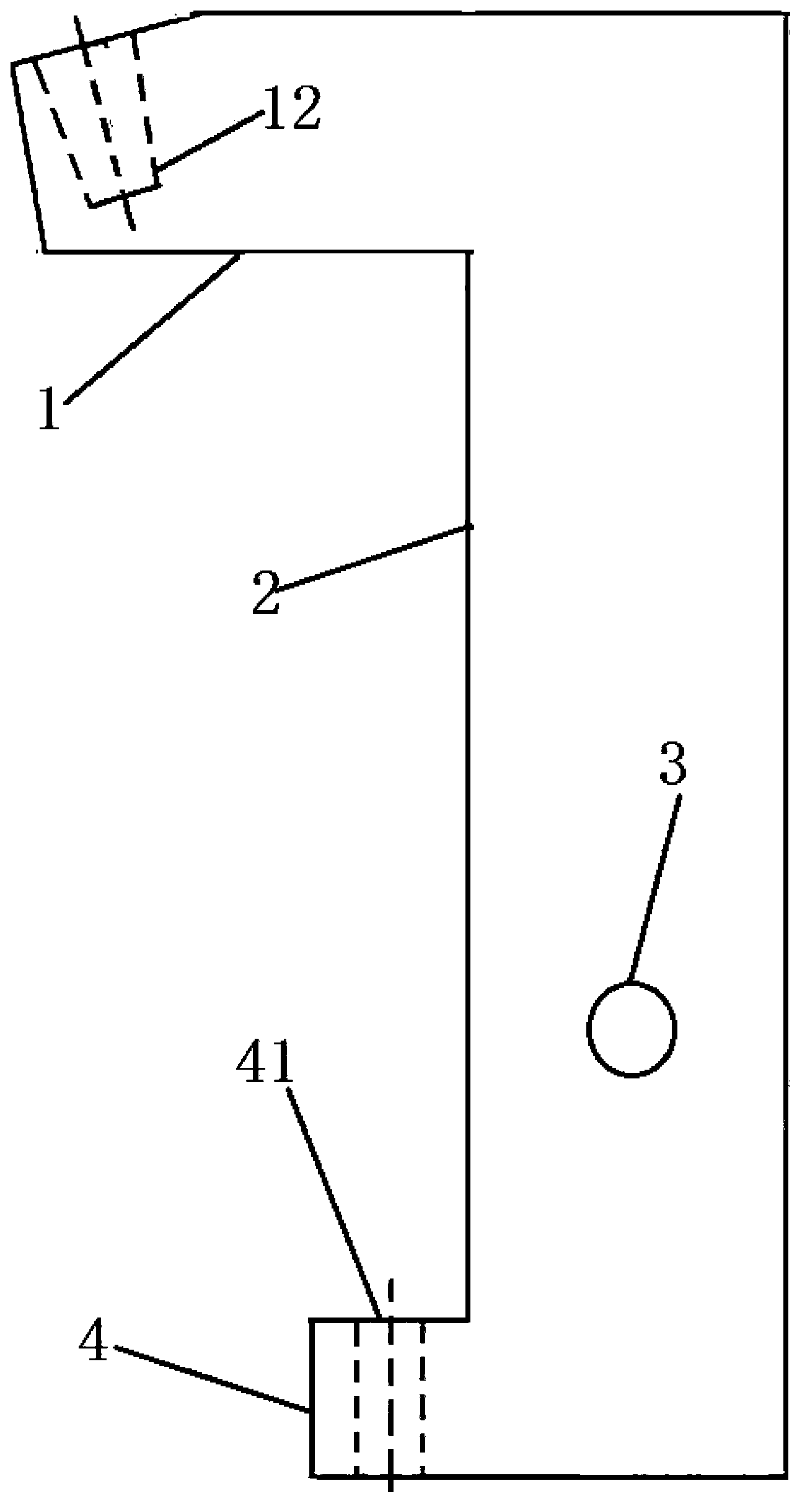

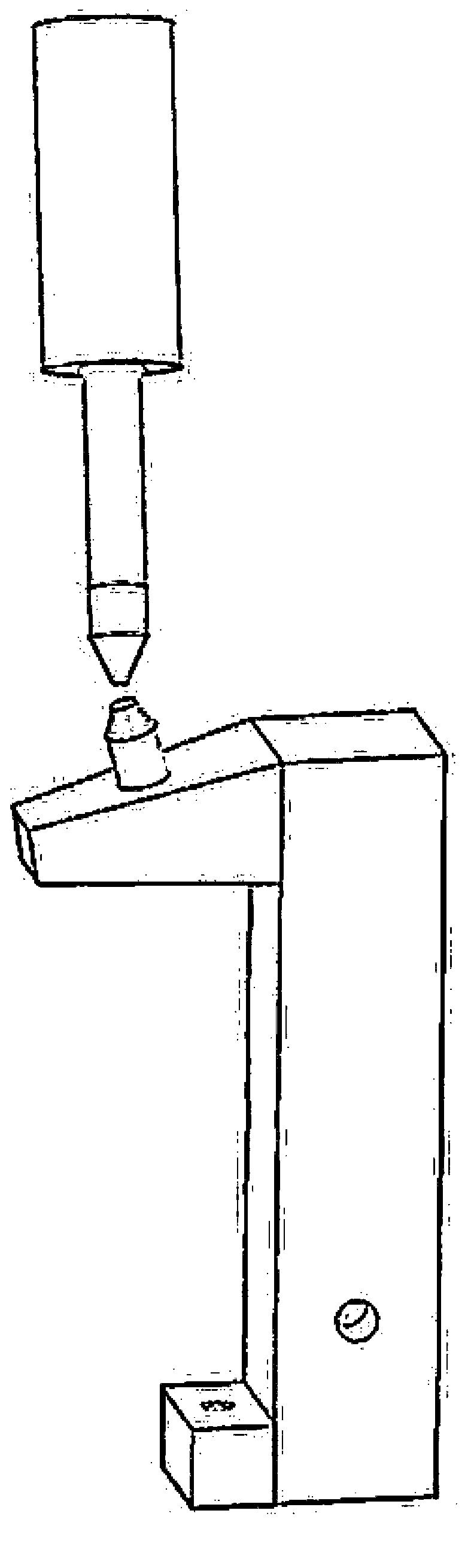

Fixed type projection welder and multi-section projection welding method

InactiveCN104209646AEffective use of equipment resourcesMeet the dimensional accuracy requirementsElectrode featuresSheet steelEngineering

The invention discloses a fixed type projection welder. The fixed type projection welder comprises a lower electrode base. The lower electrode base comprises an electrode head base and an electrode base body. The electrode head base is arranged on the top of the electrode base body. An included angle is formed by the upper surface of the electrode head base and the horizontal direction. An electrode head is arranged on the electrode head base. The electrode base body comprises a cooling water inlet and a cooling water outlet, and the inlet and the outlet are respectively formed in the surface of the electrode base body. The electrode base body is internally provided with a cooling water channel connected with the electrode head, the cooling water inlet and the cooling water outlet. A multi-section projection welding method comprises the following steps that firstly, an inversion medium-frequency direct current welding device is utilized, secondly, a small assembly component is welded with two points through a cantilever type spot welding machine via a maturely designed welding clamp, and thirdly, the fixed type projection welder is utilized for welding the rest of welding spots in a strengthened mode. According to the fixed type projection welder and the multi-section projection welding method, the requirement for the performance for welding a high-strength steel plate can be met, a traditional spot welding technology is replaced, and the requirements for size precision, welding and product size are met.

Owner:上海宝井钢材加工配送有限公司

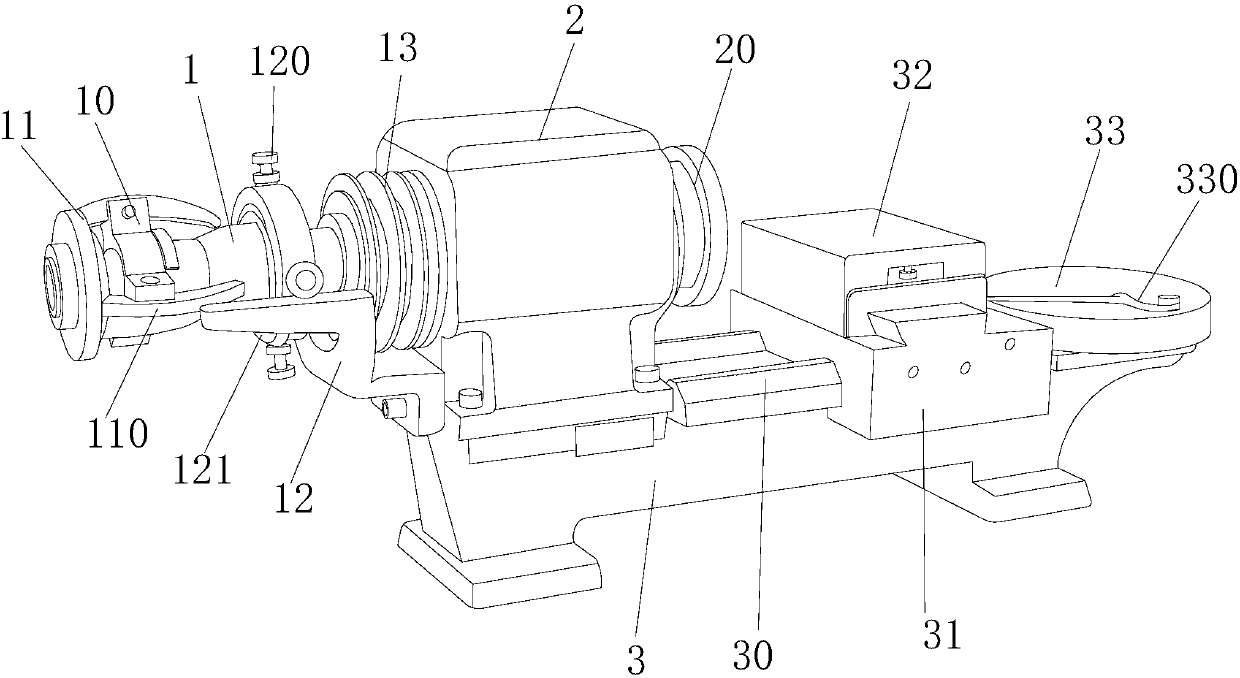

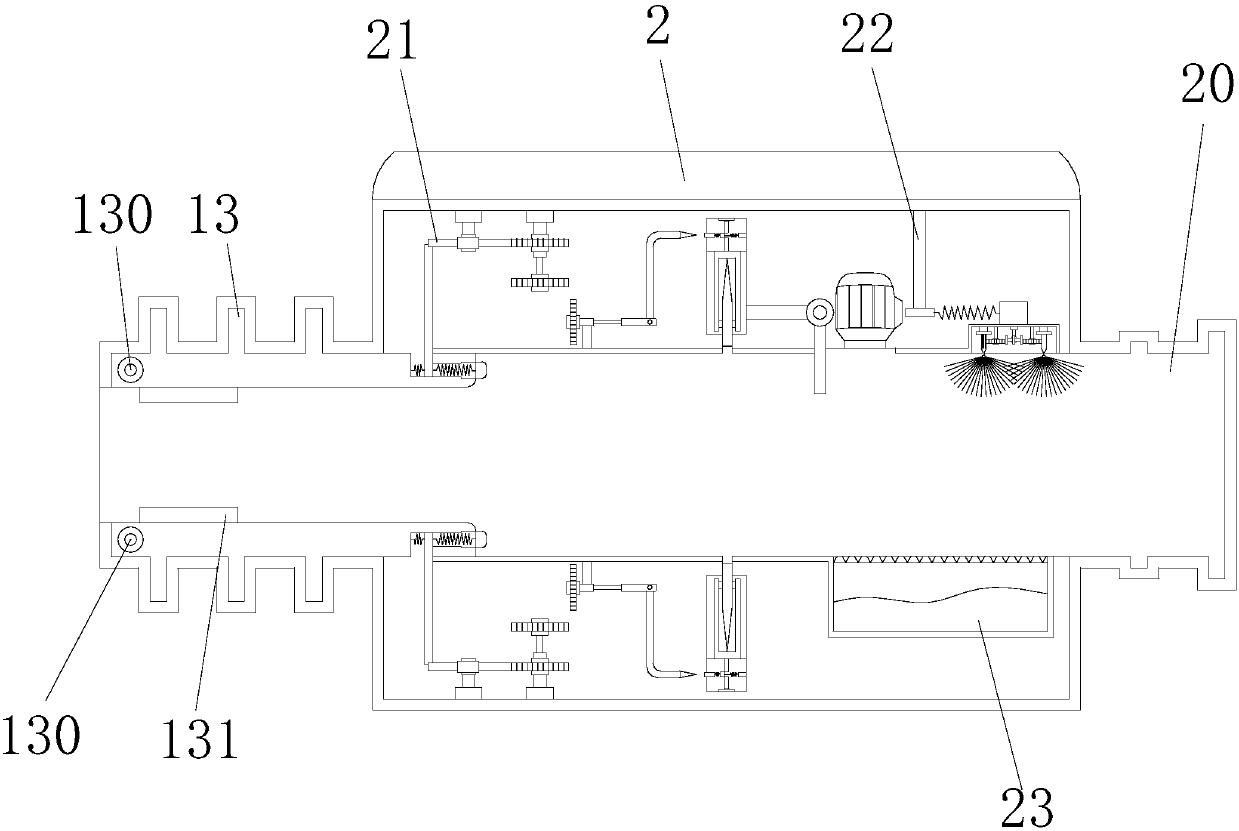

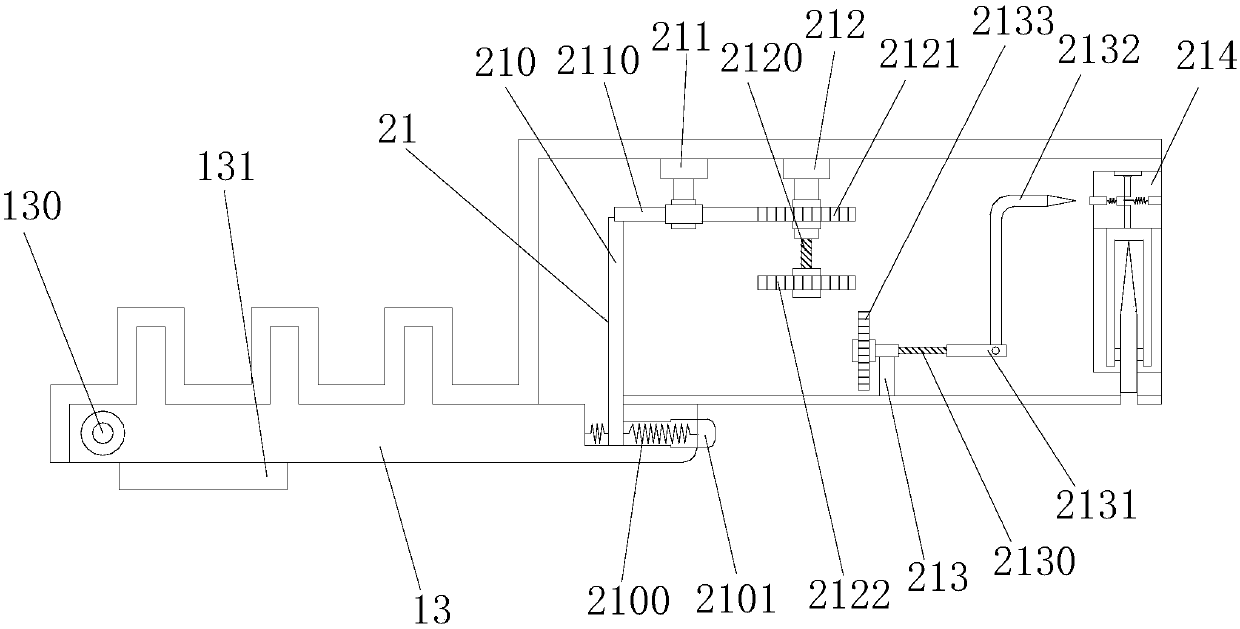

Meter lathe pipe cutting machine

ActiveCN107824806AMeet the dimensional accuracy requirementsMeet the precision requirementsTurning machinesEngineeringGuide tube

The invention discloses a meter lathe pipe cutting machine. The meter lathe pipe cutting machine structurally comprises a guide pipe fixing shaft, a transmission lathe head and a fixing supporting base; a connecting fixing rod is provided with a connecting rotating shaft and a rotating rod; an electrifying support is provided with a connecting contact block, a connecting wire and a controller; a brush cleaner is provided with cleaning brushes, brush fixing heads, threaded fixing rods and brush fixing bases; and the fixing supporting base is provided with a pipeline guide rail, a bottom supporting frame, a cutting supporting plate and a large disc. According to the meter lathe pipe cutting machine, in the using process of the equipment, a guide pipe can be automatically cut in the machiningprocess, the cutting length of the guide pipe is not required to be calculated through a fixed cutting mechanism, so that the working procedure is shortened, and therefore the problem that a tail part of a long pipe swings when the long pipe is cut on the meter lathe pipe cutting machine can be solved, the precision requirement of the required size of a short pipe can be met, the complicated working procedures can be omitted, the structure is simple, and the problem of waste in cost can be solved.

Owner:珠海市成辉自动化设备有限公司

High-efficiency copper wire drawing liquid with long usage life and preparation method thereof

The invention discloses a high-efficiency copper wire drawing liquid with long usage life, which is characterized by comprising the following raw materials by weight: 4-6 parts of polyoxyethylene alkanolamide, 2.5-4 parts of dimethyl acetamide, 4-5 parts of liquid paraffin, 2-3 parts of eleaostearic acid, 3.5-4.5 parts of deionized water-soluble phosphate ester, 1-2 parts of sodium benzoate, 2.5-3.5 parts of triethanolamine oleate, 1-2 parts of DL602 Casson antiseptic, 8-10 parts of silicon powder, 5-7 parts of auxiliary agent and 900-950 parts of deionized water. According to the invention, the added sodium benzoate and the DL602 Casson antiseptic have good anticorrosion effect, and odor and blackening condition of the wire drawing liquid can not be easily generated, and the added auxiliary agent has good antiwear, dispersion, lubrication and film forming ability. The high-efficiency copper wire drawing liquid has excellent lubrication performance, can satisfy the requirement of client brightness and size precision under low concentration, water base has good heat radiation effect, and the high-efficiency copper wire drawing liquid has the advantages of easy preservation and long usage life, and is suitable for copper wire drawing.

Owner:ANHUI TATSU PRECISION ALLOY

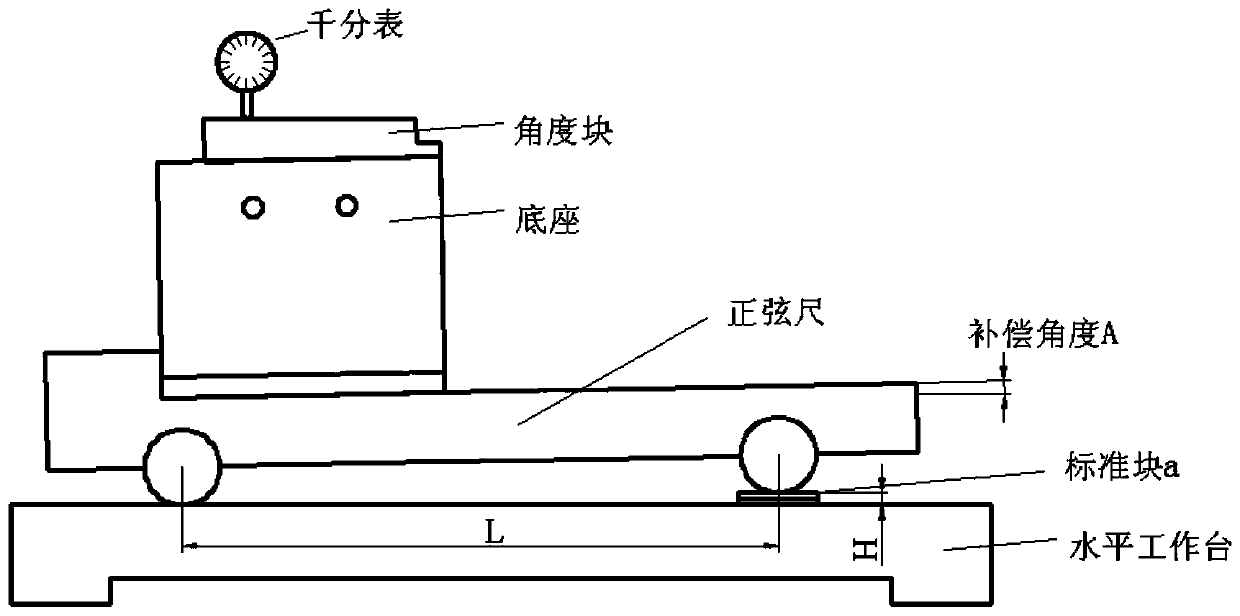

Device and method for detecting taper of conical bolt

ActiveCN110440679AEfficient detectionAccurate detectionAngles/taper measurementsMechanical diameter measurementsEngineeringWorkbench

The invention relates to a device and method for detecting taper of a conical bolt. The device comprises a horizontal ruler workbench, a base, a standard angle block and a dial indicator mounting frame; the base is movably arranged on the horizontal ruler workbench, a stop position adjusting structure is arranged on one side of the base, the dial indicator is arranged on the upper portion of the base through the dial indicator mounting frame, wherein the upper surface of the standard angle block is an inclined surface, the angle of the inclined surface is the same as the theoretical taper of the detected conical bolt; during detection, the detected bolt is placed on the upper end surface of the base through the standard angle block, the large-diameter end of the detected bolt is placed towards the stop position adjusting structure; the stop position adjusting structure is used for limiting the horizontal position of the large-diameter end; and the inclined surface of the standard angleblock is inclined towards the stop position adjusting structure, so that the center axis of the detected conical bolt is kept horizontal.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

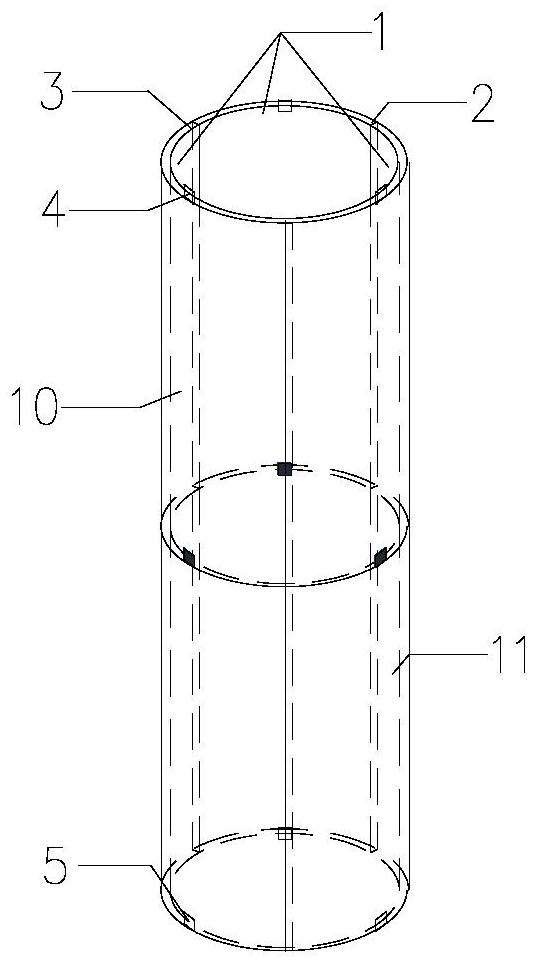

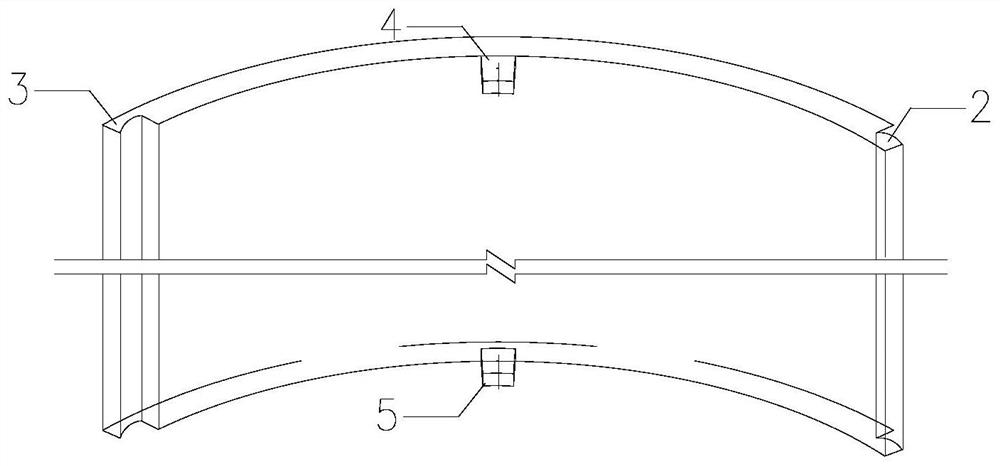

High-performance concrete cylindrical permanent formwork capable of being assembled and construction method thereof

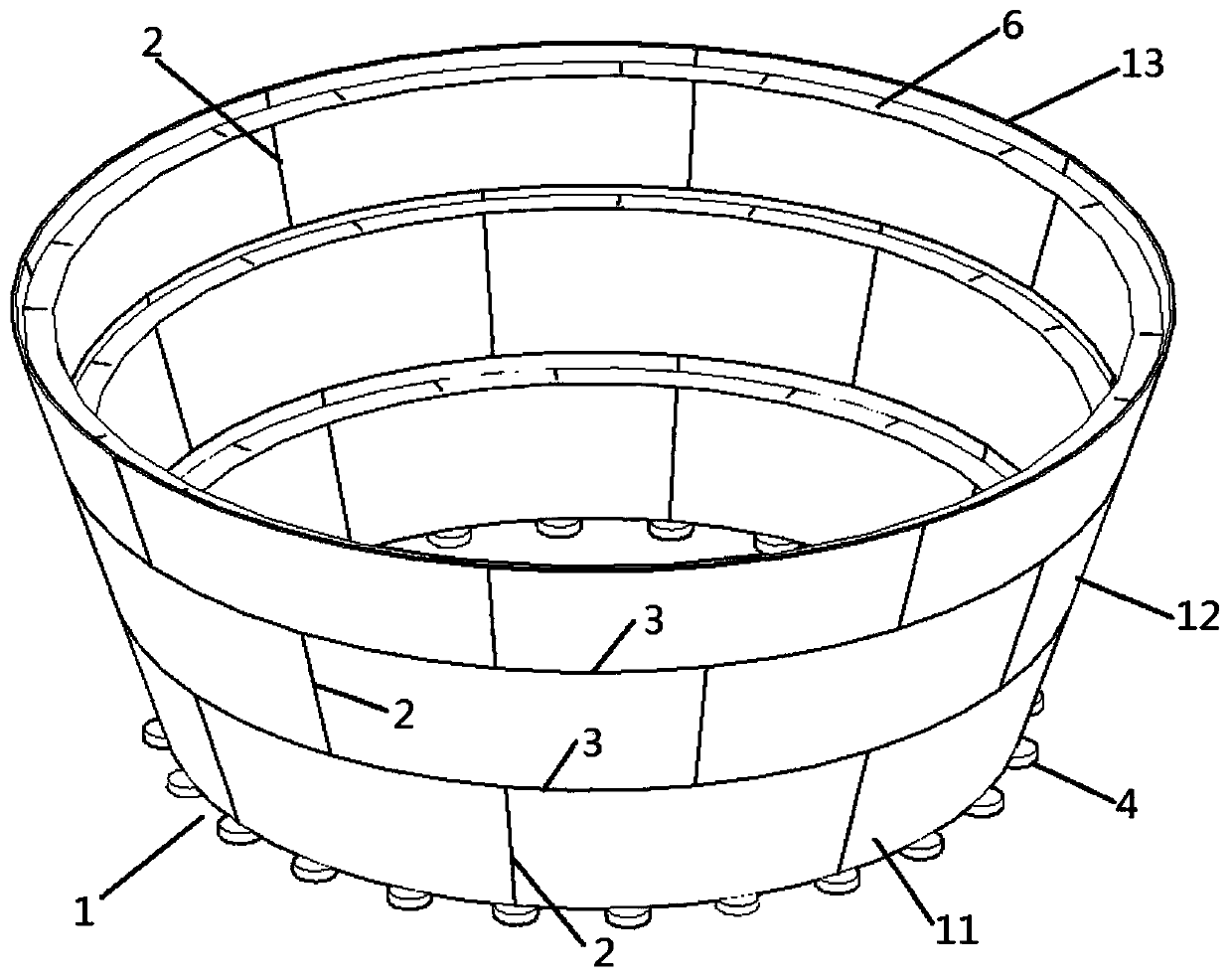

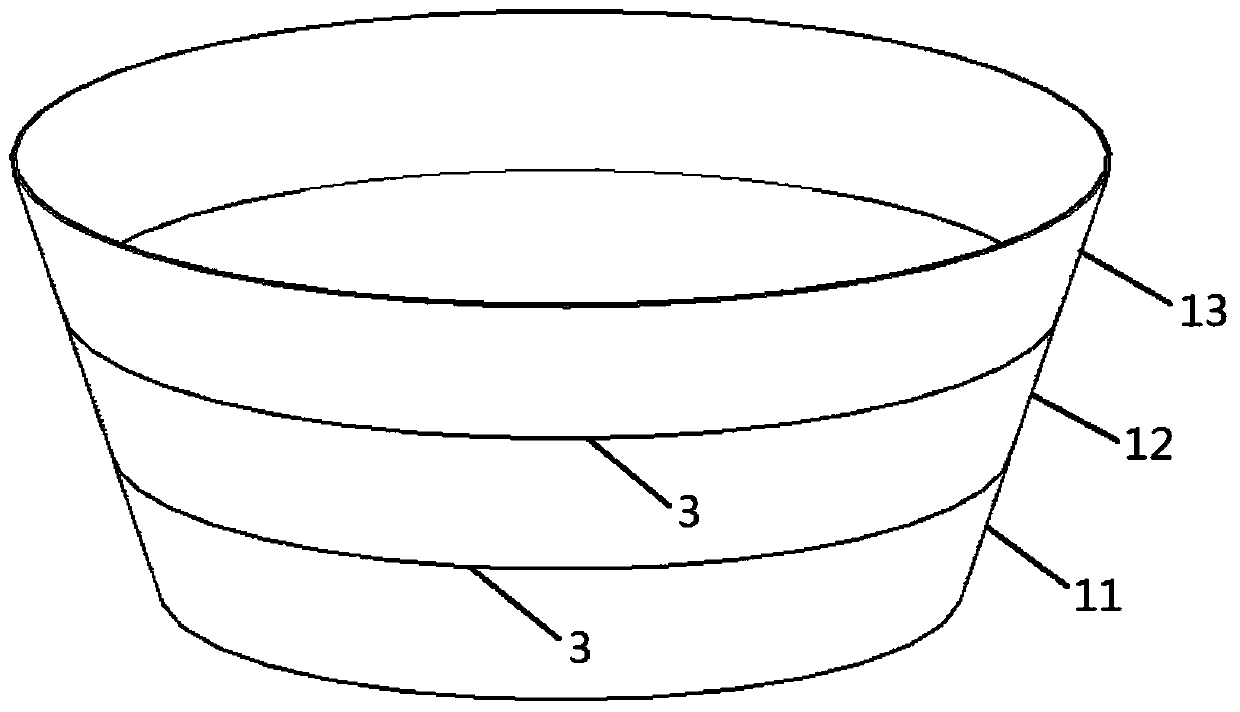

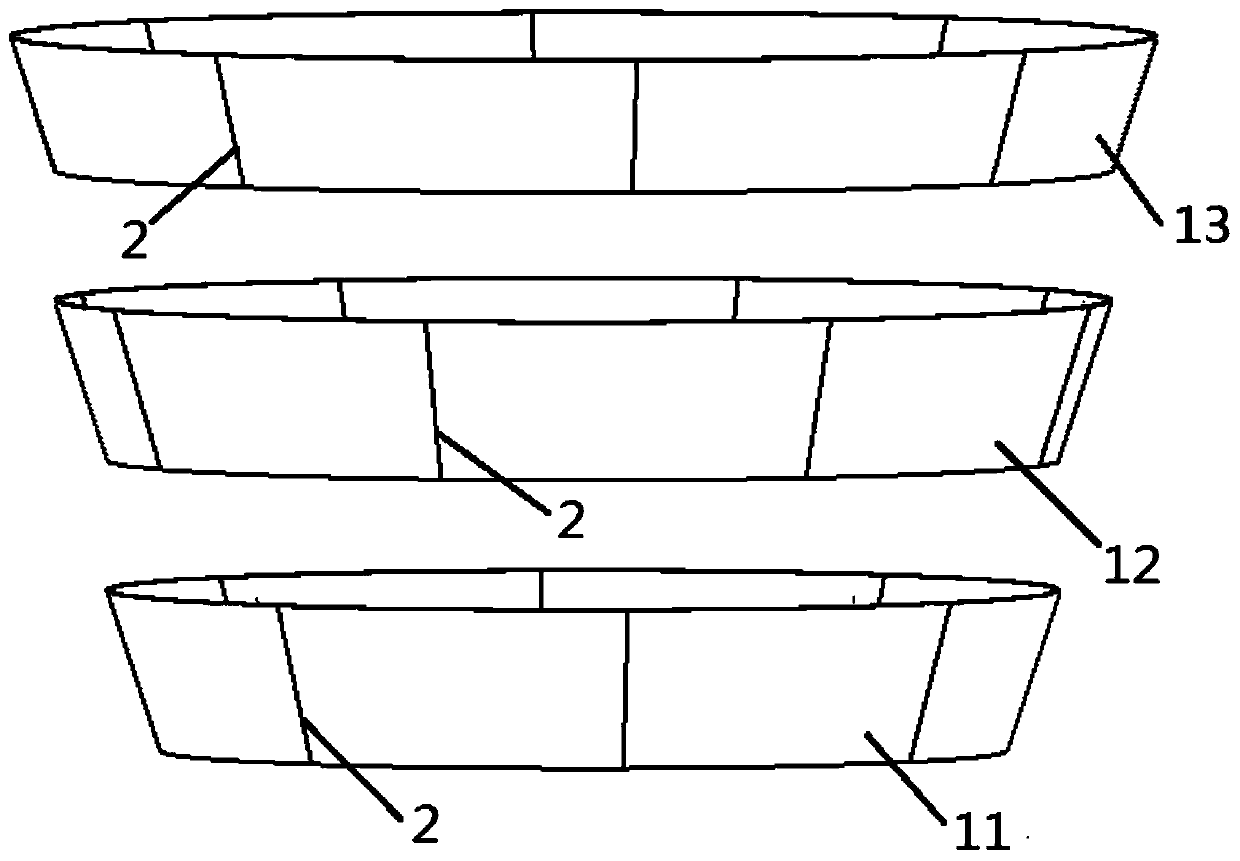

PendingCN113106851AGuaranteed validityGuaranteed durabilityBridge structural detailsBridge erection/assemblyMortise and tenonArchitectural engineering

The invention belongs to the technical field of bridge lower structure construction formworks, and relates to an ultra-high performance concrete splicable cylindrical permanent formwork and a construction method thereof, the formwork is made of ultra-high performance concrete, construction load generated when concrete is poured in the pouring formwork can be borne without arranging steel bars in the formwork. All the connecting structures and the standard plates are prefabricated together to guarantee effectiveness and durability of the connecting structures, self-locking cambered surface mortise and tenon structures are used, the stress requirement of the formwork is met, meanwhile, using of bolts is reduced, the construction speed is increased, the construction method that the prefabricated standard plates are adopted for assembling formwork segments is adopted, and the characteristic that ultra-high-performance concrete needs to be subjected to steam curing is met. The manufacturing quality of the standard plate is guaranteed through factory prefabrication, the standard plate is convenient to store and transport, site construction in the construction process is effectively reduced, the construction efficiency and the construction quality are guaranteed, and the formwork is suitable for post-disaster rapid reconstruction and repair engineering of the bridge substructure and has great application value and good economic benefits.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Dimension control process for single-point mooring cone structure prefabrication

ActiveCN111136429AMeet the dimensional accuracy requirementsAvoid reworkMeasurement devicesDimensional precisionSingle point mooring

The invention discloses a dimension control process for a single-point mooring cone structure prefabrication. The process comprises the following steps of dividing the cone into three sections, dividing each section into a multi-section arc plate, and drawing longitudinal seam and annular seam distribution diagrams; blanking, rolling and forming; drawing a ground sample datum line, arranging and leveling the prefabricated cushion pier; sequentially welding the first section, the second section and the third section from bottom to top according to requirements; and cutting off and polishing allthe supporting pieces are after welding is completed, and structural prefabrication of the single-point mooring cone is completed. According to the dimension control process for the single-point mooring cone structure prefabrication, one-time high-precision prefabricating construction of the cone structure can be achieved, the extremely high size precision requirement of the single-point mooringsystem is met, and the problem that the construction precision of the single-point mooring structure is too high and difficult to achieve is solved; and rework caused by size out-of-tolerance is avoided, waste of resources is reduced, and the construction cost is reduced.

Owner:OFFSHORE OIL ENG QINGDAO +1

Low-shrinkage blended wax material and preparation method thereof

ActiveCN113881241AReduce contentMeet the dimensional accuracy requirementsFoundry moulding apparatusParaffin waxMolten state

The invention discloses a low-shrinkage blended wax material and a preparation method thereof, and relates to the technical field of precision investment casting. The preparation method comprises the steps: heating and melting rosin and paraffin, adding a grain refiner, a viscosity modifier, a flexibilizer and a heat stabilizer into liquid wax, placing in a reaction kettle, and uniformly mixing to prepare the novel reusable special blended wax. The special novel blended wax has the advantages of small linear shrinkage rate, small expansion coefficient within softening temperature, low heat capacity, sufficient strength and hardness, small viscosity in a molten state, small residual ash content, low content of low-temperature volatile matters, good chemical stability, fine grain structure, repeated use and the like. The prepared special novel blended wax can meet the size precision requirements and surface quality requirements of various complex precision castings and has wide market application prospects, and meanwhile, the preparation method is simple, low in cost, high in applicability, capable of being repeatedly used and capable of being used for large-scale production.

Owner:NANJING TIANSHI NEW MATERIAL TECH +1

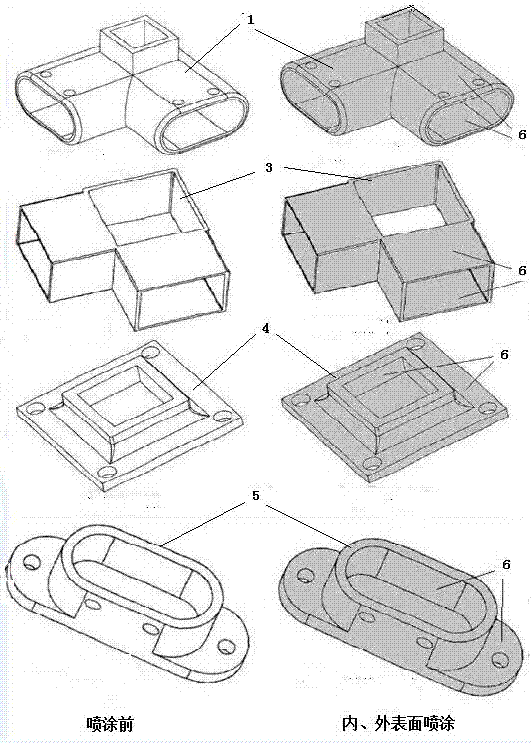

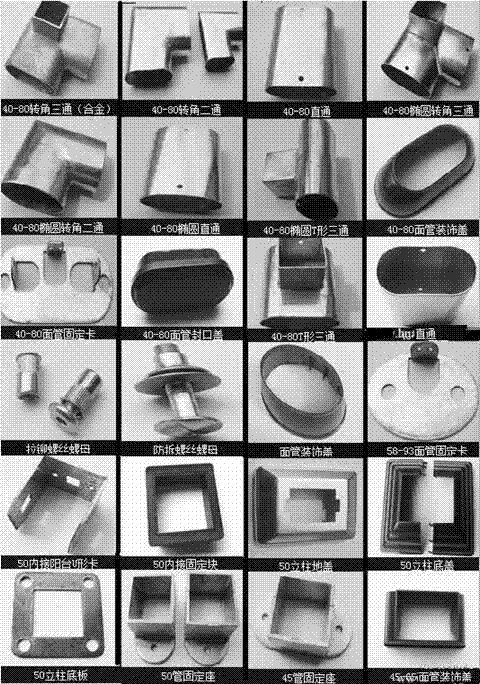

Zinc-steel fence connecting piece with surfaces sprayed with graphene coating

InactiveCN107313599AReduce performanceImprove performanceAnti-corrosive paintsBuilding material handlingConnection typeGraphene coating

A zinc-steel guardrail connector whose surface is sprayed with a graphene coating is characterized in that the prepared graphene coating suitable for the zinc-steel guardrail connector is applied on the outer surface of the zinc-steel guardrail connector or on the outer surface of the guardrail combined with the connector, Or the inner and outer surfaces of the connector, spray / brush the graphene coating with a thickness of 12µm±; for the connector that has been combined with the guardrail and is in use, spray the graphene paint with a thickness of 12µm± on its outer surface, or The outer surface of the combined guardrail is sprayed with a graphene coating with a thickness of 12µm±; for the new connecting piece that has not been combined with the guardrail, a graphene coating with a thickness of 12µm± is sprayed on the inner and outer surfaces; after testing, the thickness of the coating is only 12µm Under the condition of ±, a number of technical performances are superior to the existing surface-sprayed zinc-steel guardrail connectors.

Owner:湖南创新防护设施有限公司

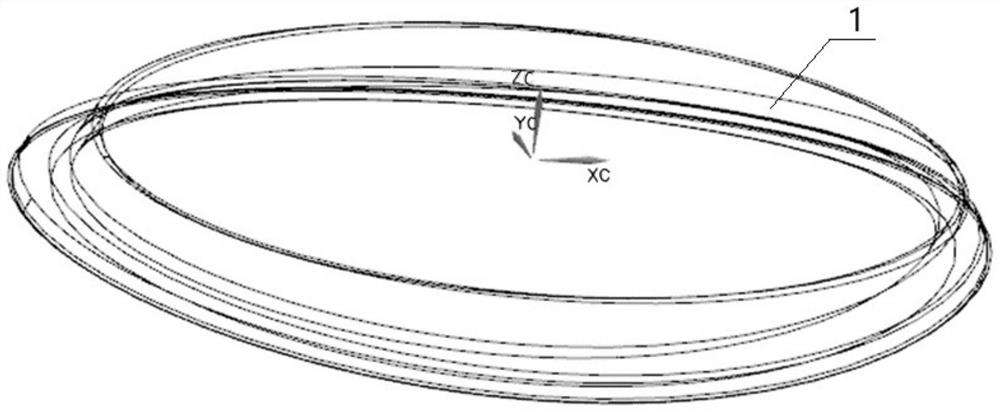

Method for machining spatial curved surface of large conical surface connecting pipe on three-axis linkage milling machine

ActiveCN112222497AUnable to processSimple processing methodMilling equipment detailsDigital mockupMachine

The invention provides a method for machining a spatial curved surface of a large conical surface connecting pipe on a three-axis linkage milling machine. The method comprises the following steps thata workpiece digital model is established and analyzed, a process scheme is formulated, and machining of the spatial curved surface of the large conical surface connecting pipe on the three-axis linkage milling machine through rough machining, semi-finish machining and finish machining. The invention provides a new segmentation method machining scheme, the problem that the complex spatial curved surface cannot be machined on the three-axis linkage milling machine is solved, and the segmentation method provides a new solution thought for machining of the complex curved surface; the angle milling head machining scheme adopted by the method solves the limitation of five-axis machine tool machining, the problems that a conventional machining method cannot meet the size requirement, the machining efficiency is low, and the machining cost is high are also solved; and more importantly, the angle milling head machining scheme provides a valuable solution for machining similar bidirectional internal corners, the surface quality of products is greatly improved, and meanwhile the machining efficiency is greatly improved.

Owner:CFHI DALIAN HYDROGENANT REACTOR +1

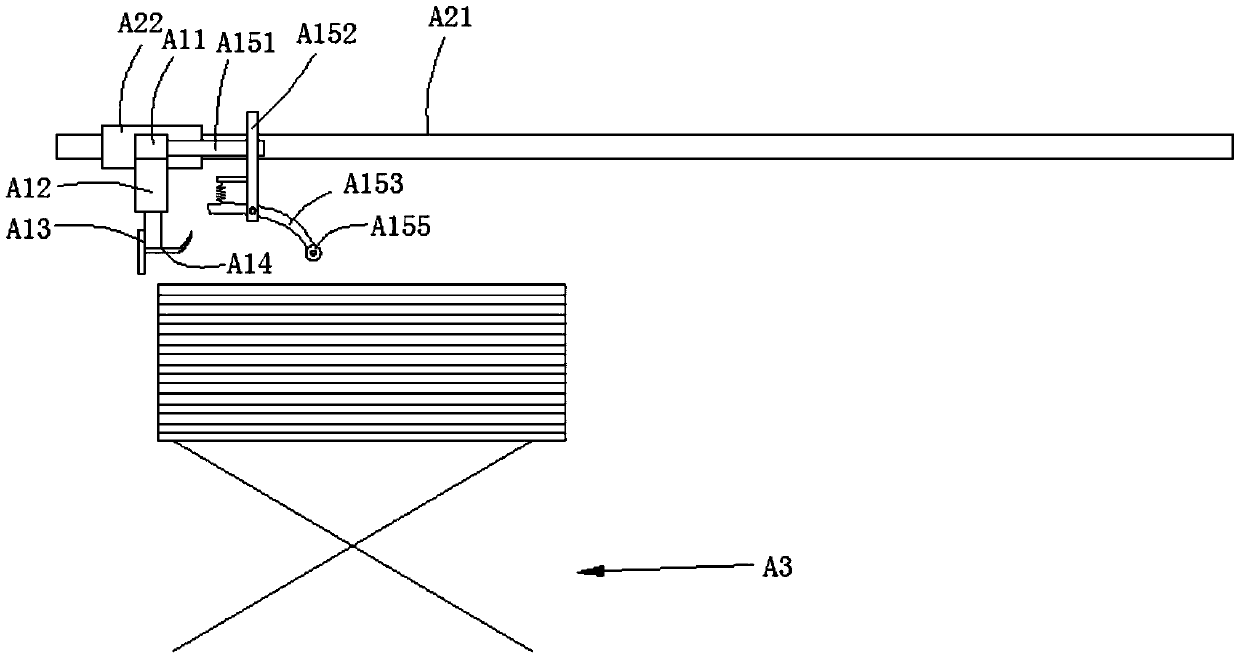

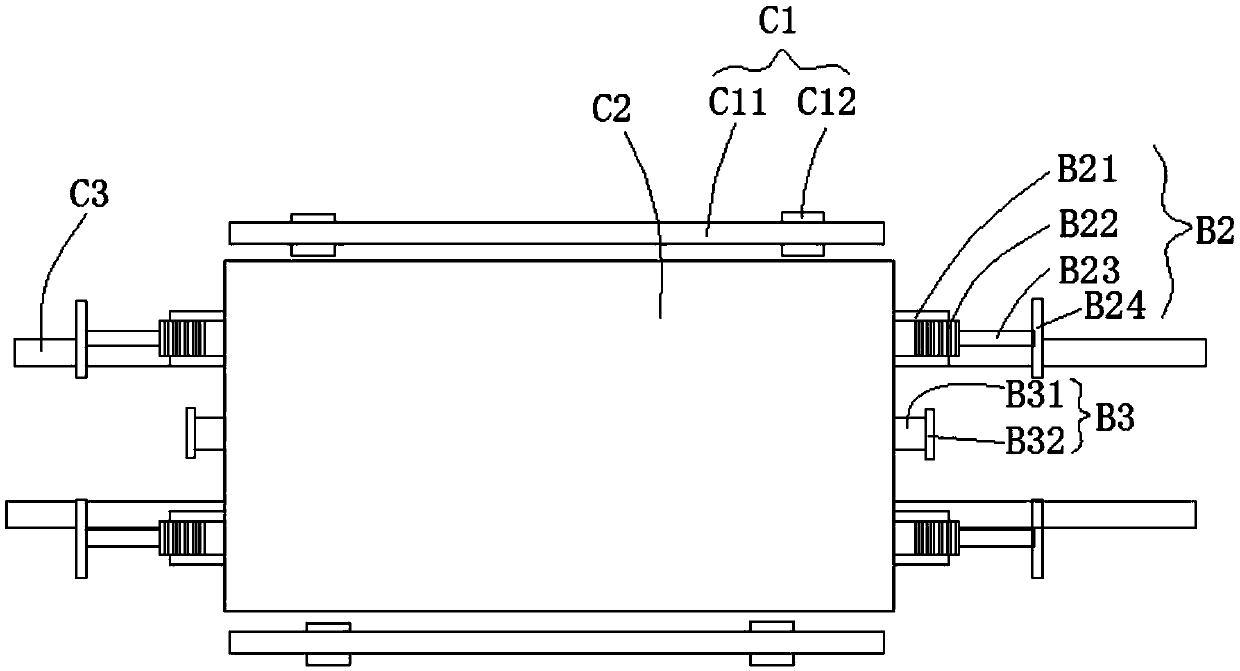

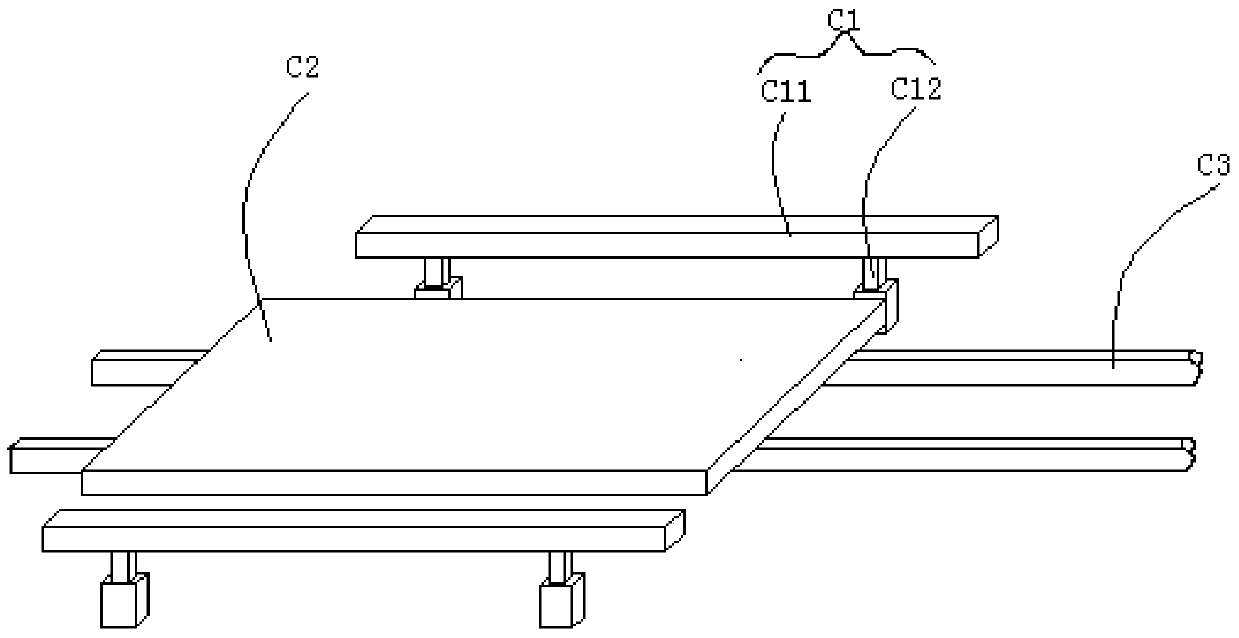

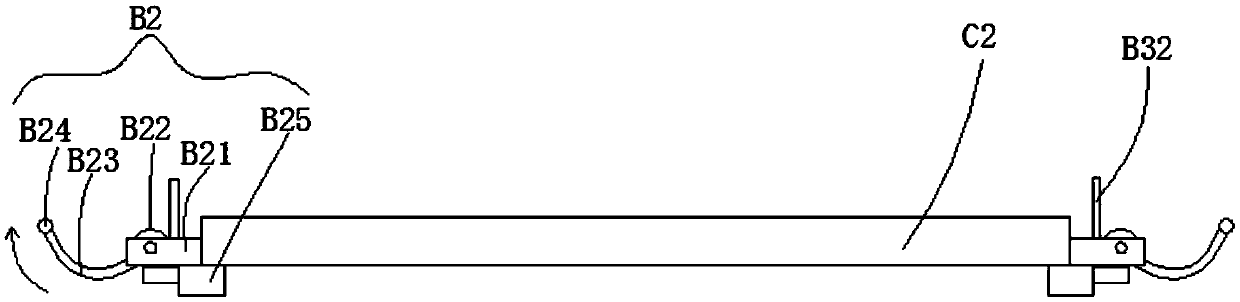

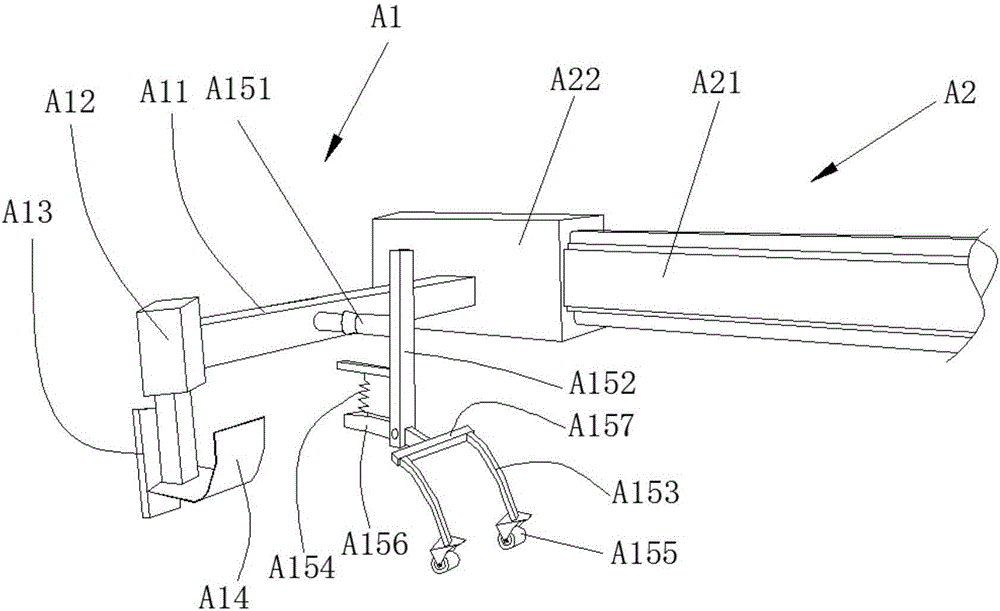

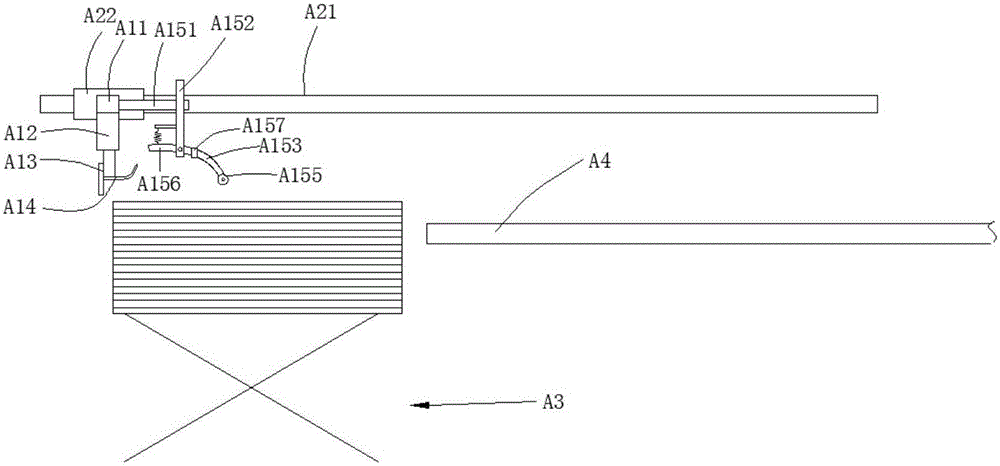

Panel moving mechanism of trimming machine

InactiveCN105500191AThe overall structure is compactSave powerGrinding feedersGrinding work supportsPower componentSurface level

The invention provides a panel moving mechanism of a trimming machine. The moving mechanism comprises a first panel bearing platform, a second panel bearing platform and a panel conveying mechanism, wherein the second bearing platform performs forward or backward motion on the conveying mechanism, and is positioned in the middle of the first bearing platform; the first bearing platform performs lifting motion; when the first bearing platform rises to the highest point, the upper surface of the first bearing platform is higher than the upper surface of the second bearing platform; when the first bearing platform drops to the lowest point, the upper surface of the first bearing platform is lower than the upper surface of the second bearing platform; pressure plate mechanisms are arranged on the second bearing platform; each pressure plate mechanism comprises a power component and a pressure plate device; the power components and the pressure plate devices are fixed to the second bearing platform; and each power component drives the corresponding pressure plate device to move. Compared with the prior art, the panel moving mechanism has the advantage that through the adoption of the vertical cooperation of the first bearing platform and the second bearing platform, the integral structure of the trimming machine is more compact.

Owner:ANHUI ANSU WORLD HOME CO LTD

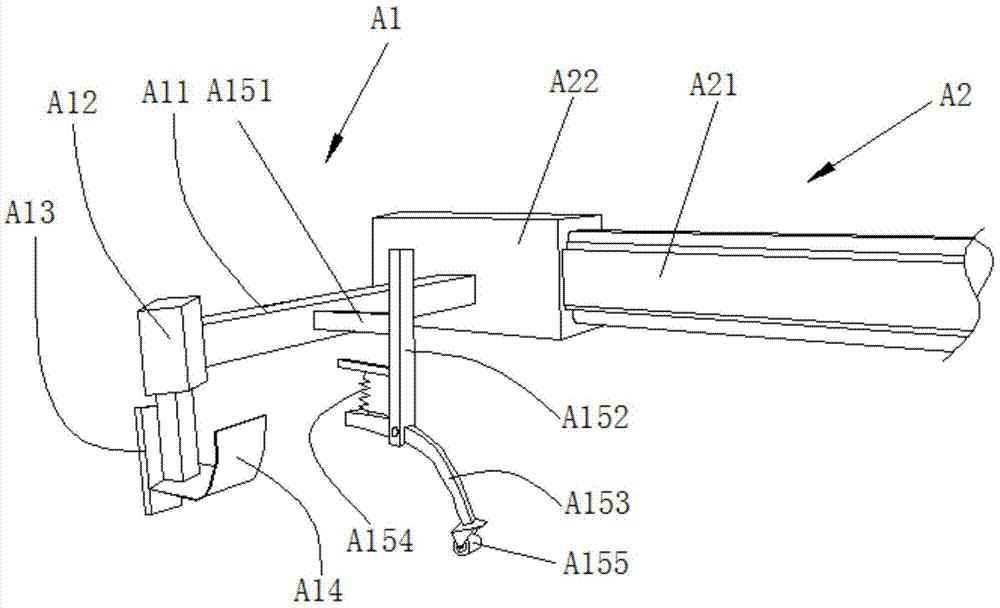

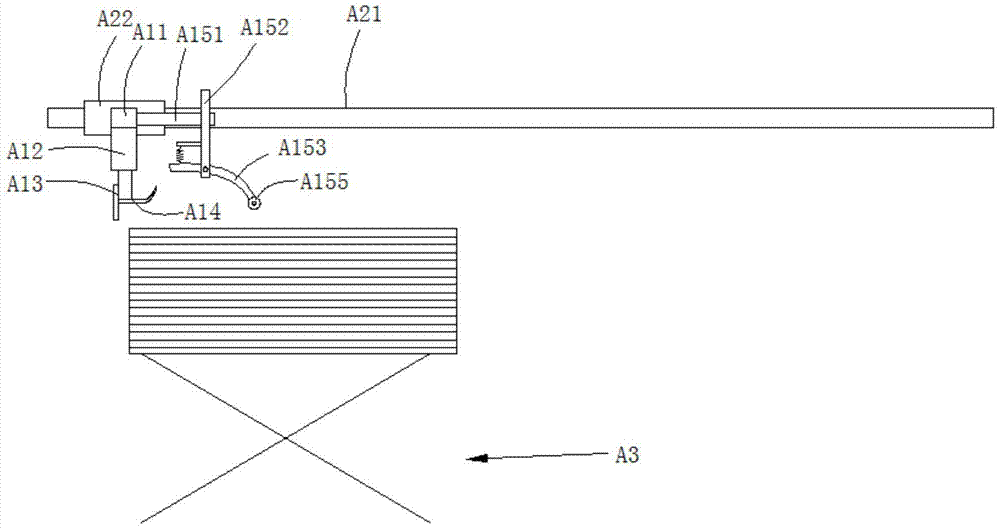

Long side sawing device of a sawing machine

ActiveCN105345140BCompact structureSimple structureMetal sawing devicesMetal working apparatusCircular sawEngineering

The invention provides a long-side sawing device of a sawing machine. The long-side sawing device includes a moving mechanism and a saw table; the two opposite sides of the moving mechanism are symmetrically provided with sawing tables, and the moving mechanism drives the board to pass through the sawing table to complete sawing. Side; the moving mechanism includes the first carrying platform, the second carrying platform and the conveying mechanism of the plate; the second carrying platform moves forward or backward on the conveying mechanism; the second carrying platform is in the middle of the first carrying platform; the first carrying platform acts as With lifting function. A plate pressing mechanism is also provided on the second carrying platform. A saw table includes a table top and a stand supporting the table top. There is a saw groove on the table. The circular saw is under the table, and a part of the saw blade of the circular saw passes through the saw groove from bottom to top and is exposed above the table. A platen device is also fixed on the table. Compared with the existing technology, the perfect cooperation between the moving mechanism and the saw table makes the board be sawed during the moving process, and the board is stable during the sawing process without displacement or floating.

Owner:ANHUI ANSU WORLD HOME CO LTD

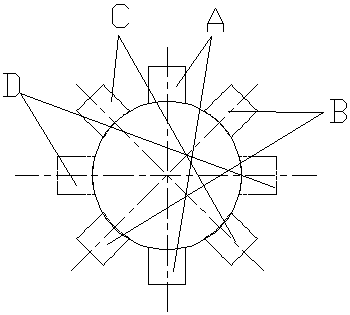

Method for designing blade blank for electrolytic machining

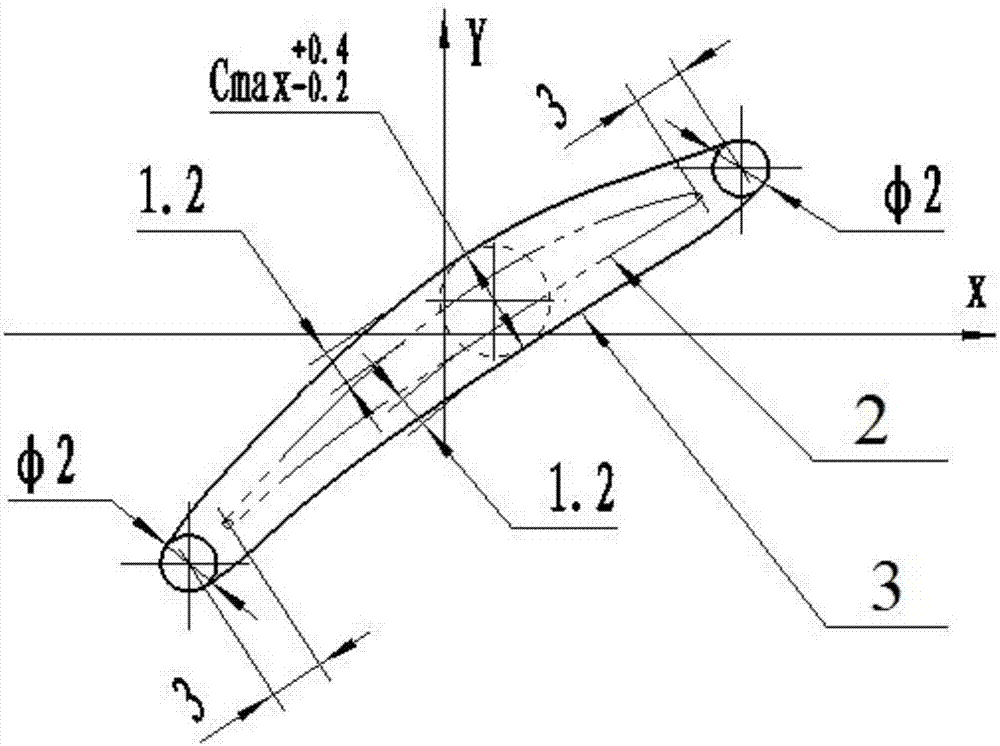

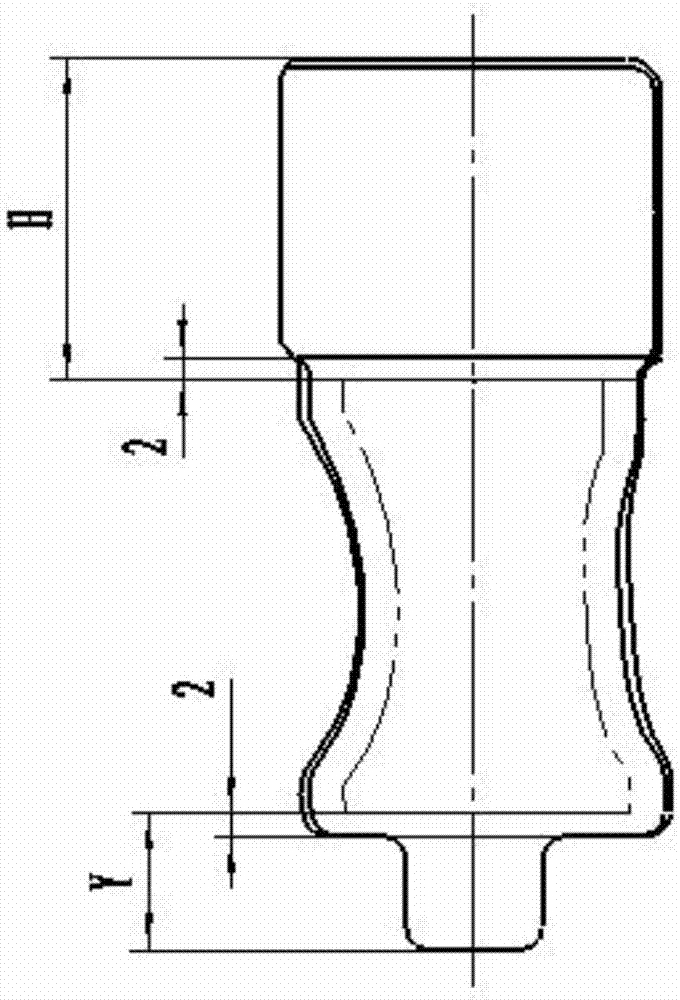

ActiveCN107962260AImprove processing efficiencyGood size consistencyElectrochemical machining apparatusLeading edgeElectrolysis

The invention aims at providing a method for designing a blade blank for electrolytic machining. A blade is a compressor stator blade without a mounting plate, and the blade blank is composed of the mounting plate, a blade body profile and a process boss. The blade blank is mainly designed from the following four aspects: (1) the design of the mounting plate, specifically, the mounting plate is added at the root of the blade; (2) the design of the process boss, specifically, the process boss is added at the tip of the blade; (3) the design of the theoretical allowance of the blade body profile, specifically, the single allowance of a blade body is designed to be 1.2mm, the allowance is added along the normal, and both the exhausting and leading edges of the blade body are phi 2mm and extend outwards for 3mm; and (4) the control of tolerance of the blade body profile, specifically, the control of tolerance of the blade body profile is designed as +0.4mm and -0.2mm. The blade blank designed by the method is used in electrolytic machining and can solve the problems of low production efficiency, easy deformation and poor precision in the traditional machining method.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for machining J-shaped grooves of series of pipe socket holes in thin-wall irregular spherical end socket

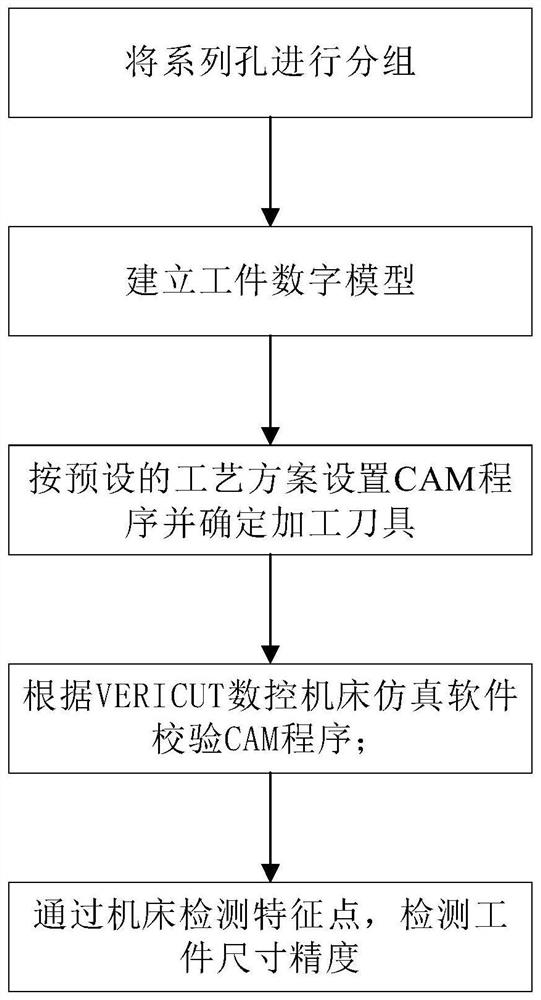

PendingCN114453836ASolve the problem of cumbersome processing proceduresMeet the dimensional accuracy requirementsTotal factory controlNumerical controlEngineering

The invention provides a machining method for J-shaped grooves of series pipe base holes in a thin-wall irregular spherical end socket. The machining method comprises the following steps that series holes are grouped; establishing a workpiece digital model according to the grouped series holes; a CAM program is developed according to a preset process scheme, and a machining tool is determined; checking the developed CAM program according to VERICUT numerical control machine tool simulation software; and detecting the dimensional accuracy of the workpiece by detecting the feature points through a machine tool. According to the method, the solution for machining the J-shaped groove in the irregular spherical surface is solved, the problem that the machining procedure of the J-shaped groove of a series of holes is tedious is solved, the final machining effect can meet all dimensional precision requirements of drawings, the surface quality of products is greatly improved, and meanwhile the machining efficiency is greatly improved.

Owner:CFHI DALIAN HYDROGENANT REACTOR +1

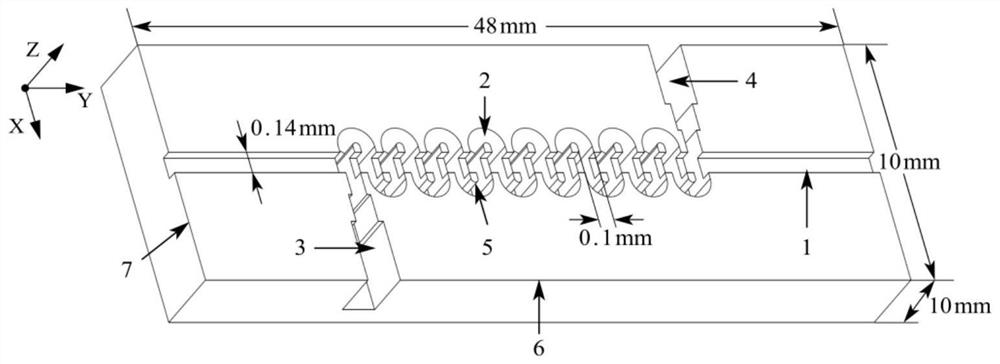

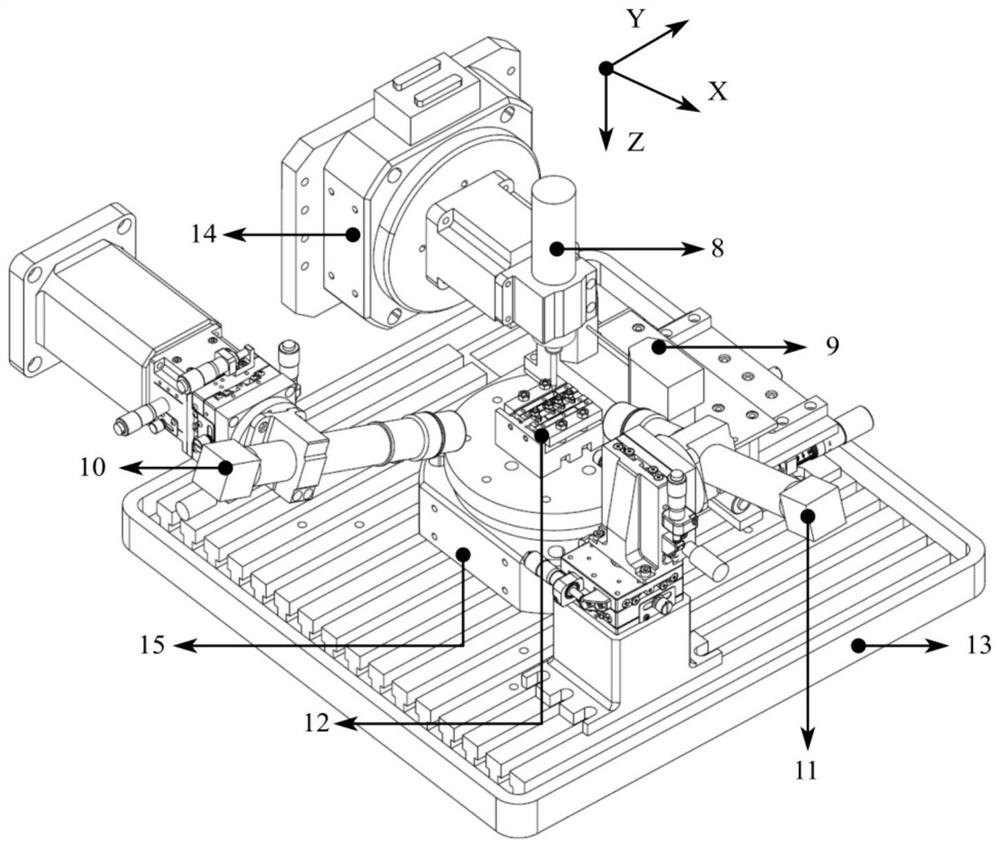

Technological method applied to guaranteeing micro-milling machining precision of folded waveguide slow-wave structure

ActiveCN112276177AGuaranteed dimensional accuracyGuaranteed shape and position accuracyMeasurement/indication equipmentsMilling equipment detailsWave structureMachined surface

The invention relates to a technological method applied to guaranteeing the micro-milling machining precision of a folded waveguide slow-wave structure. The technological method comprises the steps that the outer edge of a to-be-machined area of a workpiece blank is subjected to micro-milling machining, and an X-direction tool setting groove extending in the X-axis direction and a Y-direction toolsetting groove extending in the Y-axis direction are manufactured; after a tool is replaced in the micro-milling machining process, secondary tool setting of the tool in the X direction and the Y direction is correspondingly conducted with the X-direction tool setting groove and the Y-direction tool setting groove as the datum; and after the X-direction tool setting groove or / and the Y-directiontool setting groove is / are removed through micro-milling machining, secondary tool setting of the tool in the X direction or / and the Y direction is / are conducted based on the side wall of the machined surface at the corresponding position. According to the technological method applied to guaranteeing the micro-milling machining precision of the folded waveguide slow-wave structure, the accuracyof the relative position during micro-milling machining of the slow-wave structure can be guaranteed, and the micro-milling machining precision is improved.

Owner:HARBIN INST OF TECH

Adjustable underwater pipe clamp device

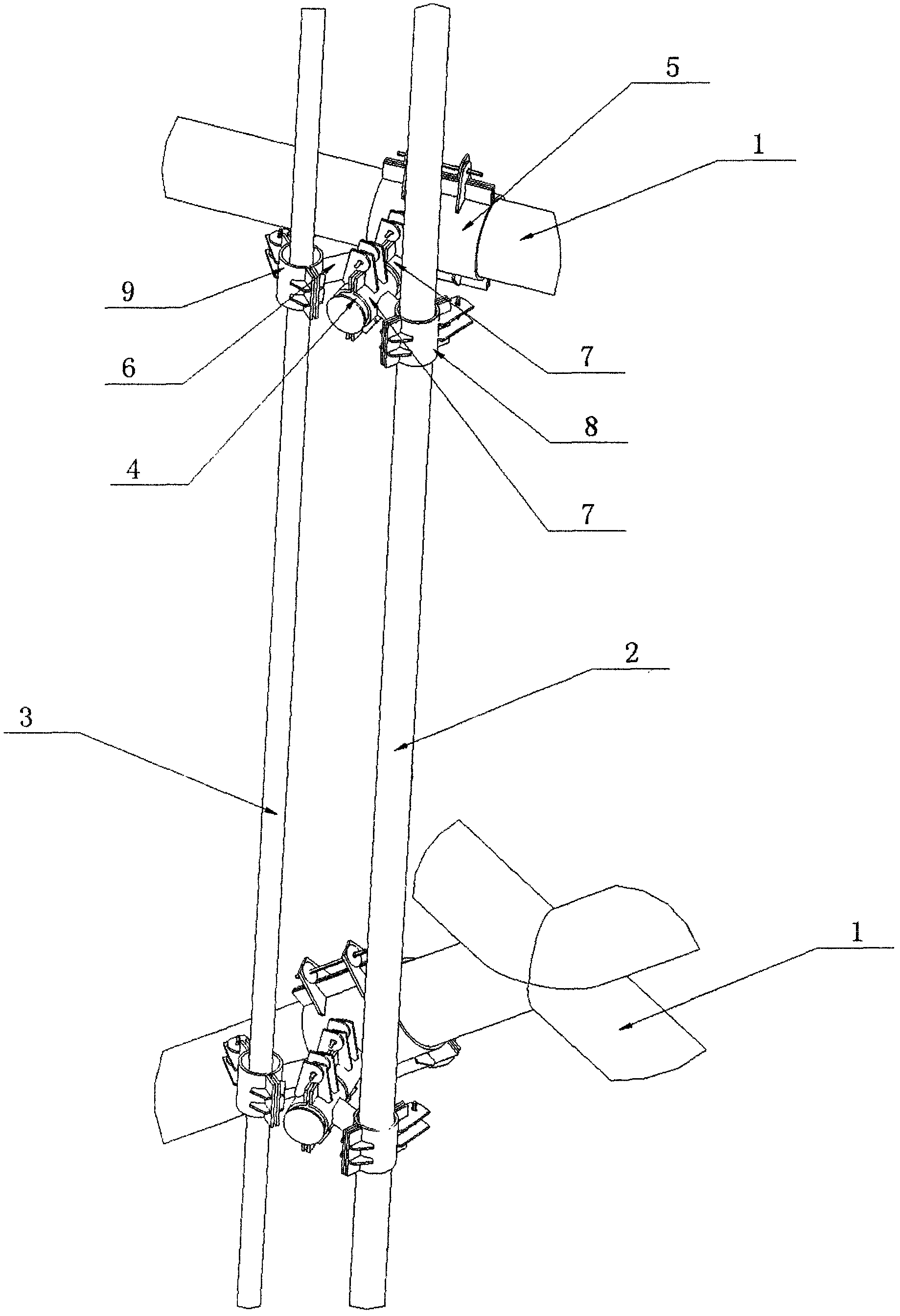

InactiveCN103256429AImprove offshore installation success rateShorten offshore construction periodArtificial islandsPipe supportsOffshore constructionArchitectural engineering

An adjustable underwater pipe clamp device comprises a main support pipe, a main support pipe clamp, two branch support pipes, two branch support pipe clamps, a cable protecting pipe clamp and a vertical pipe clamp, and is characterized in that the two branch support pipes and the two branch support pipe clamps are mounted on the main support pipe, the branch support pipes are connected with the vertical pipe clamp and a vertical pipe, the two branch support pipes are connected with the cable protecting pipe clamp and a cable protecting pipe, and the main support pipe is connected with a guide pipe frame structure rod and the main support pipe clamp. By 'one clamp for two pipes' mounting way, only one main pipe clamp is connected with the guide pipe frame structure rod, unoccupied positions on various horizontal structure rods of a guide pipe frame can be reasonably used. The main pipe clamp and the branch pipe clamps are adjustable, requirement for size accuracy is met, and offshore mounting success rate is increased. Integral offshore mounting of the vertical pipe and the cable protecting pipe can be realized, offshore construction period is effectively shortened, and mounting cost is greatly reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Threaded rib anchor rod steel bar hot rolling process and device

PendingCN114515756AMeet the dimensional accuracy requirementsHigh dimensional accuracyRolling mill drivesMetal rolling arrangementsEngineeringRebar

The invention discloses a thread rib anchor rod reinforcing steel bar hot rolling process which comprises the following steps: after a reinforcing steel bar is rolled into a circular material type in a rough and intermediate rolling stage, roller hole types adopted in a finish rolling stage are a flat rolling hole type, a vertical box hole type, a pre-splitting hole type, a splitting hole type, a flat oval hole type and a thread rib hole type in sequence; wherein the K1 roller phase connecting shaft adopts a crankshaft type connecting shaft. According to the inner inclined spline shaft sleeve, rotation of the roller end inner gear ring and the roller end outer gear shaft sleeve is achieved through the flat keys, so that a connected roller thread rib circular hole is driven to achieve micro-rotation, the requirement for rib size precision is met, produced thread rib anchor rod steel bars have excellent size precision, surface quality and rib precision, and the service life of the thread rib anchor rod steel bars is prolonged. The production efficiency can be effectively improved, and the rolling cost is reduced.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Measuring device and measuring method for coaxiality of horizontal punching punch of multi-directional die forging hydraulic press

ActiveCN105526850BExtended service lifeMeet the dimensional accuracy requirementsMechanical measuring arrangementsEconomic benefitsEngineering

A device and method for measuring the coaxiality of a horizontal piercing punch of a multi-directional die forging hydraulic press, comprising: a measuring ruler and a force application base; the measuring ruler includes: a main ruler and an auxiliary ruler; the auxiliary ruler is placed on the root of the horizontal punch, The arc-shaped slider is in contact with the corresponding position of the root of the horizontal punch; the main ruler is placed under the root of the horizontal punch, and a thin hydraulic jack is installed under the large bottom plate of the main ruler; the bottom of the thin hydraulic jack is in contact with the inner plane of the force base . The device for measuring the coaxiality of the horizontal perforating punch of the multi-directional die forging hydraulic press of the present invention is easy to operate and easy to learn, and the measurement accuracy is high, which can theoretically reach 0.02 mm; the measured data is easy to extract and has strong referenceability, which can be directly used as a reference for adjustment; After the adjustment of the coaxiality deviation of the horizontal punch is qualified, it can not only meet the dimensional accuracy requirements of forging production, ensure the quality of the product's shape and size, but also prolong the service life of the forging die, especially the punch, and the economic benefits are obvious.

Owner:22MCC GRP PRECISION FORGING

A tool for machining precision thin-walled bushings

ActiveCN111376066BPrecise clampingGuaranteed dimensional accuracyWork clamping meansPositioning apparatusPilot holeThin walled

The invention relates to a tool for machining precision thin-wall bushings. It includes an elastic ferrule, which is used to clamp the thin-walled bush; an outer jacket, which is set outside the elastic ferrule, and is used for clamping and guiding the elastic ferrule; the elastic ferrule includes an upper clamping part and The guide part is located at the lower end of the clamping part. There is a clamping hole inside the clamping part for placing the thin-walled bush and the axis of the clamping hole coincides with the axis of the thin-walled bush. The outer surface of the clamping part is gradually dimensioned along the X direction. Reduced outer tapered surface; the inside of the guide part is provided with a first guide hole, and a pull rod for pulling the elastic ferrule to move in the X direction is pierced in the first guide hole; the upper end of the outer sleeve is provided with a dimension along the X direction With the gradually reduced inner tapered surface, the invention can avoid the deformation of the bushing, and the use of an integral compound forming tool can ensure the stability and consistency of the inner wall size.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Full-automatic plate trimming machine

InactiveCN105729275ATacit cooperationCompact structureGrinding machinesGrinding feedersWork taskEngineering

The invention provides a full-automatic edge sawing machine for edge trimming of plates. The edge sawing machine includes a feeding device, a long edge sawing device, and a steering device; the plate passes through the feeding device, the long edge sawing device, and the steering device; the long-side sawing device and the short-side sawing device are respectively located on the two sides adjacent to the steering device, and the horizontal direction of the long-side sawing device and the short-side sawing device The angle is 90°. Compared with the prior art, the edge sawing machine provided by the present invention has a simple structure, smooth plate feeding, and each link cooperates closely. When the next link is working, the previous link starts to prepare for the next task, the connection is tight, and the work efficient.

Owner:ANHUI ANSU WORLD HOME CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com