Patents

Literature

732 results about "Digital mockup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital MockUp or DMU is a concept that allows the description of a product, usually in 3D, for its entire life cycle. Digital Mockup is enriched by all the activities that contribute to describing the product. The product design engineers, the manufacturing engineers, and the support engineers work together to create and manage the DMU. One of the objectives is to have an important knowledge of the future or the supported product to replace any physical prototypes with virtual ones, using 3D computer graphics techniques. As an extension it is also frequently referred to as Digital Prototyping or Virtual Prototyping. These two specific definitions refer to the production of a physical prototype, but they are part of the DMU concept. DMU allows engineers to design and configure complex products and validate their designs without ever needing to build a physical model.

Methods, apparatus and computer program products that reconstruct surfaces from data point sets

ActiveUS7023432B2Quality improvementReduce noiseAdditive manufacturing apparatus3D-image renderingPoint cloudDigital mockup

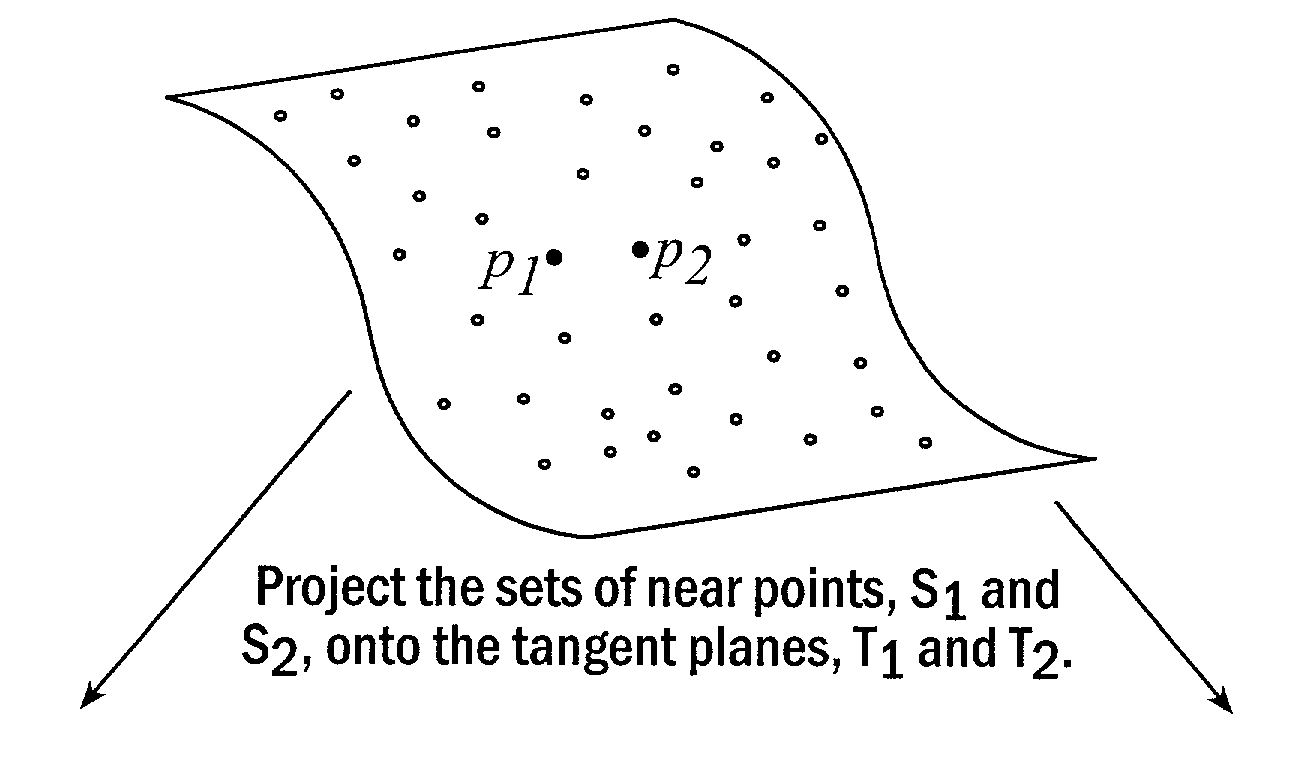

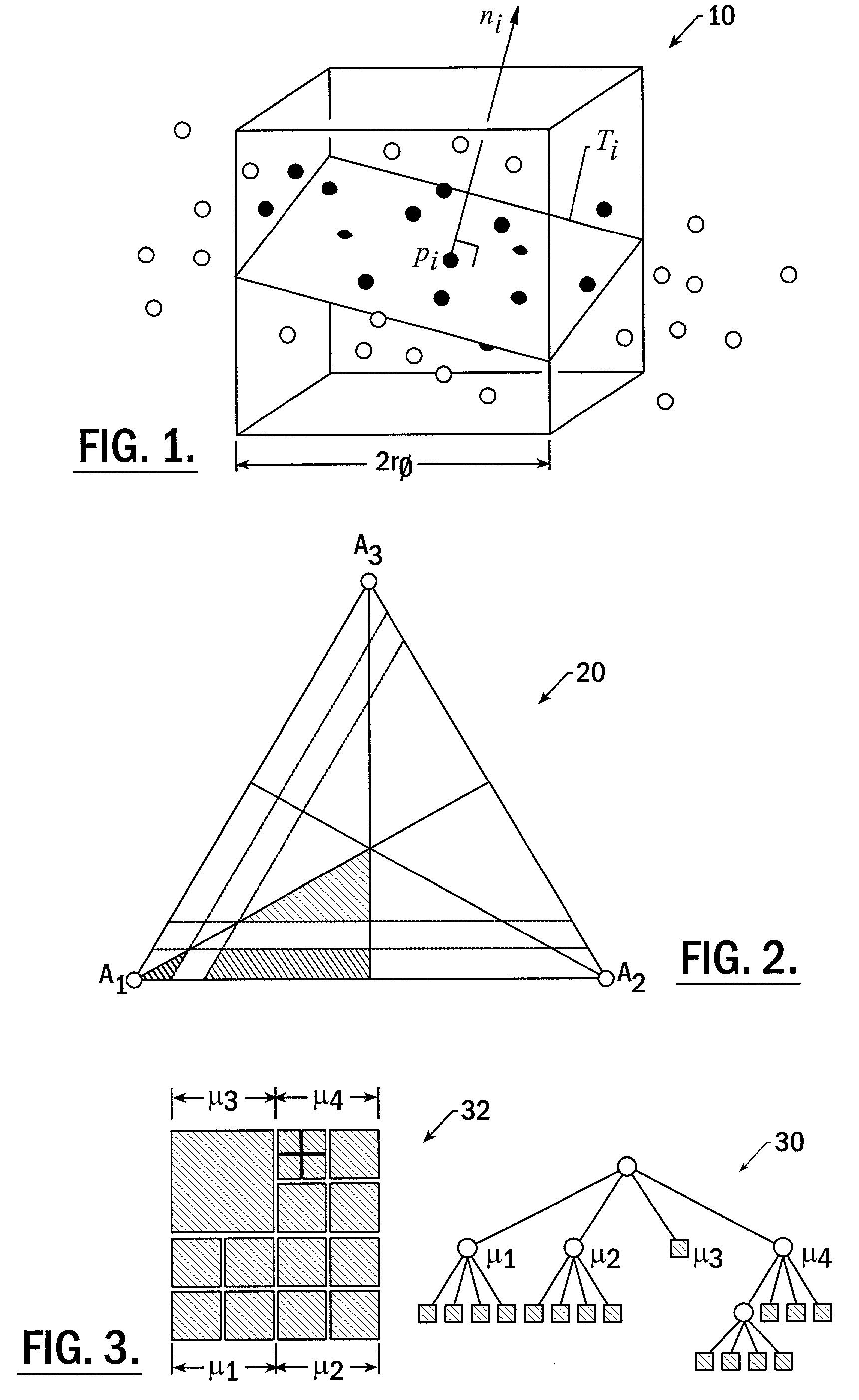

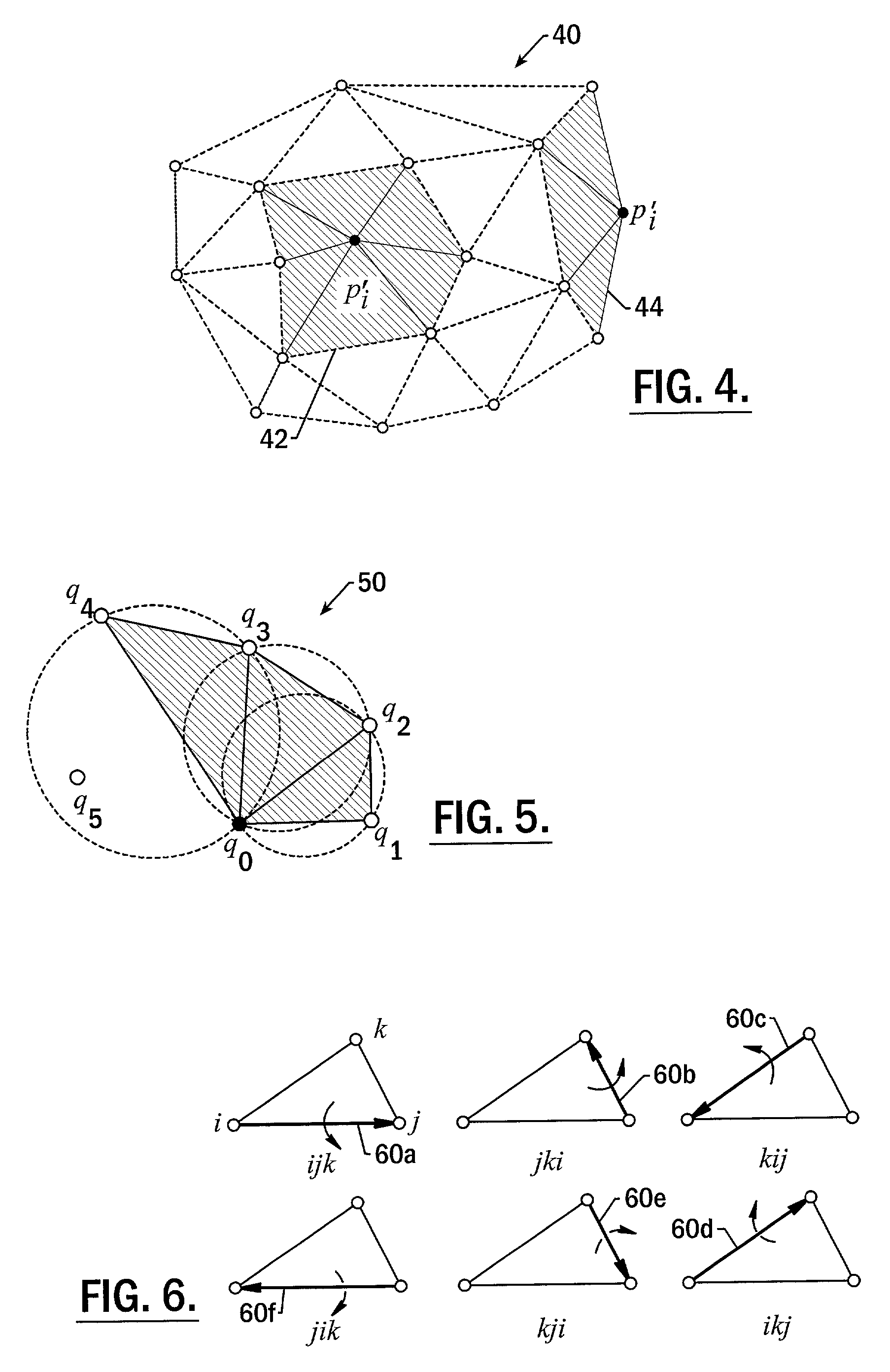

Methods, apparatus and computer program products provide efficient techniques for reconstructing surfaces from data point sets. These techniques include reconstructing surfaces from sets of scanned data points that have preferably undergone preprocessing operations to improve their quality by, for example, reducing noise and removing outliers. These techniques include reconstructing a dense and locally two-dimensionally distributed 3D point set (e.g., point cloud) by merging stars in two-dimensional weighted Delaunay triangulations within estimated tangent planes. The techniques include determining a plurality of stars from a plurality of points pi in a 3D point set S that at least partially describes the 3D surface, by projecting the plurality of points pi onto planes Ti that are each estimated to be tangent about a respective one of the plurality of points pi. The plurality of stars are then merged into a digital model of the 3D surface.

Owner:3D SYST INC

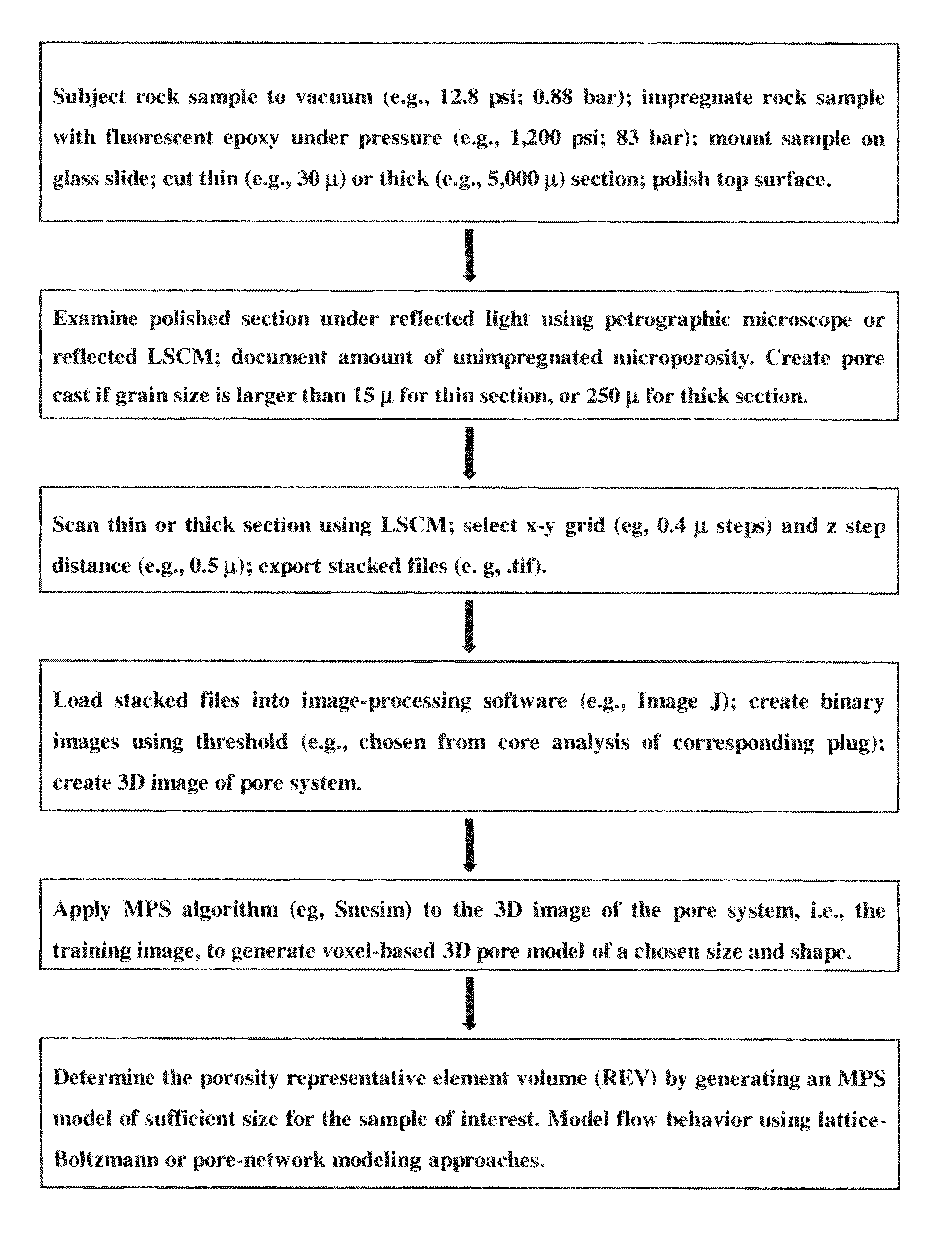

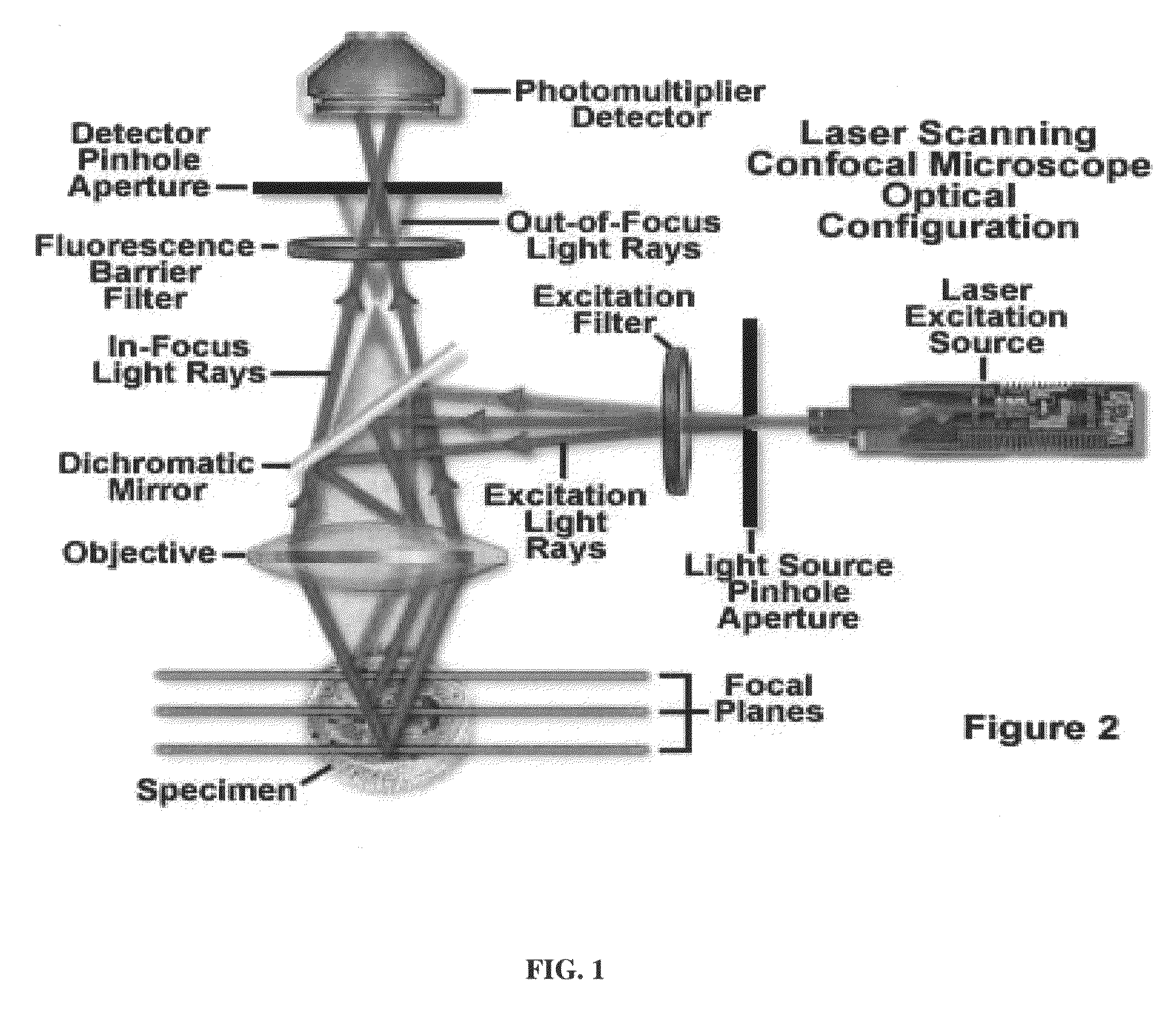

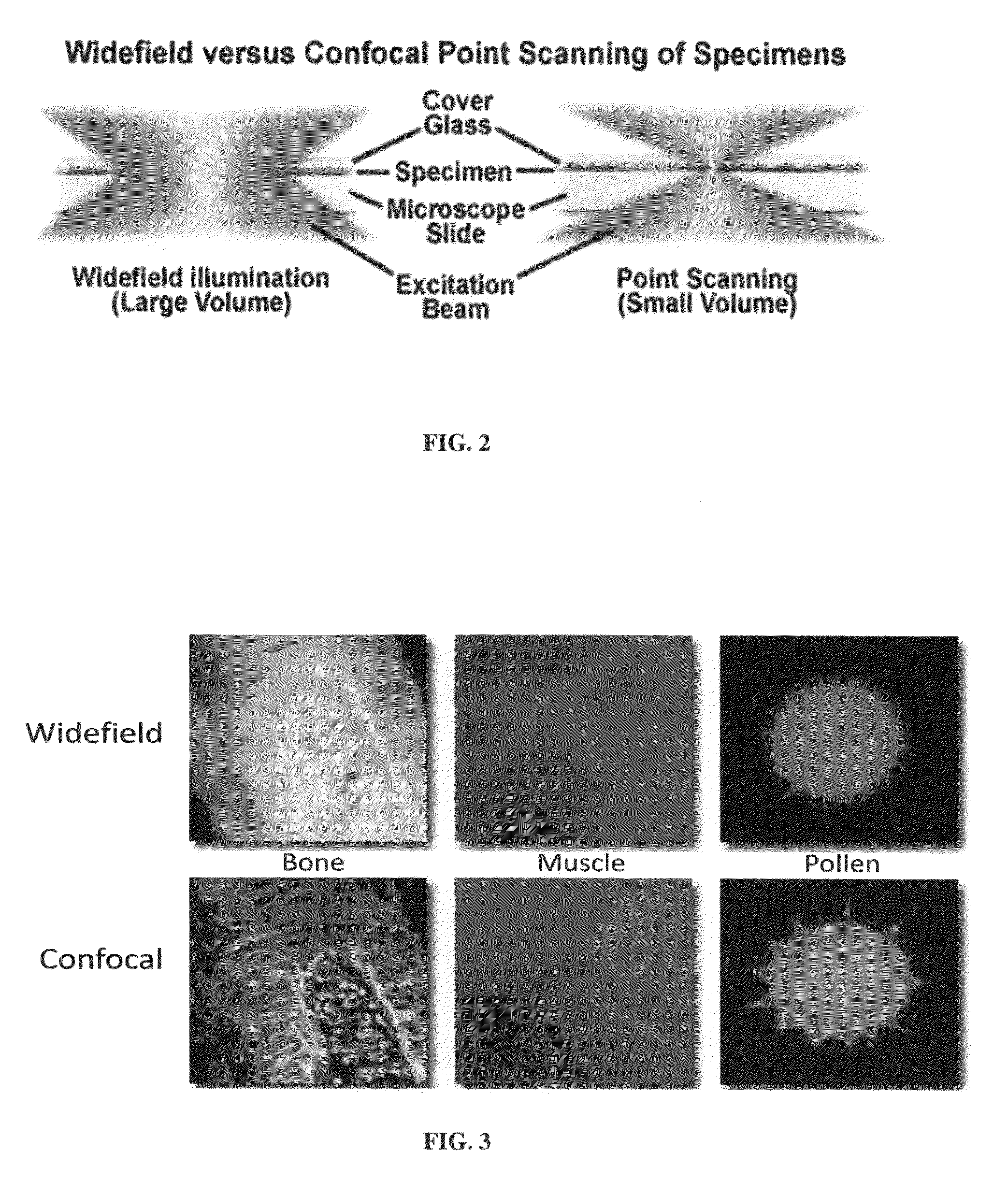

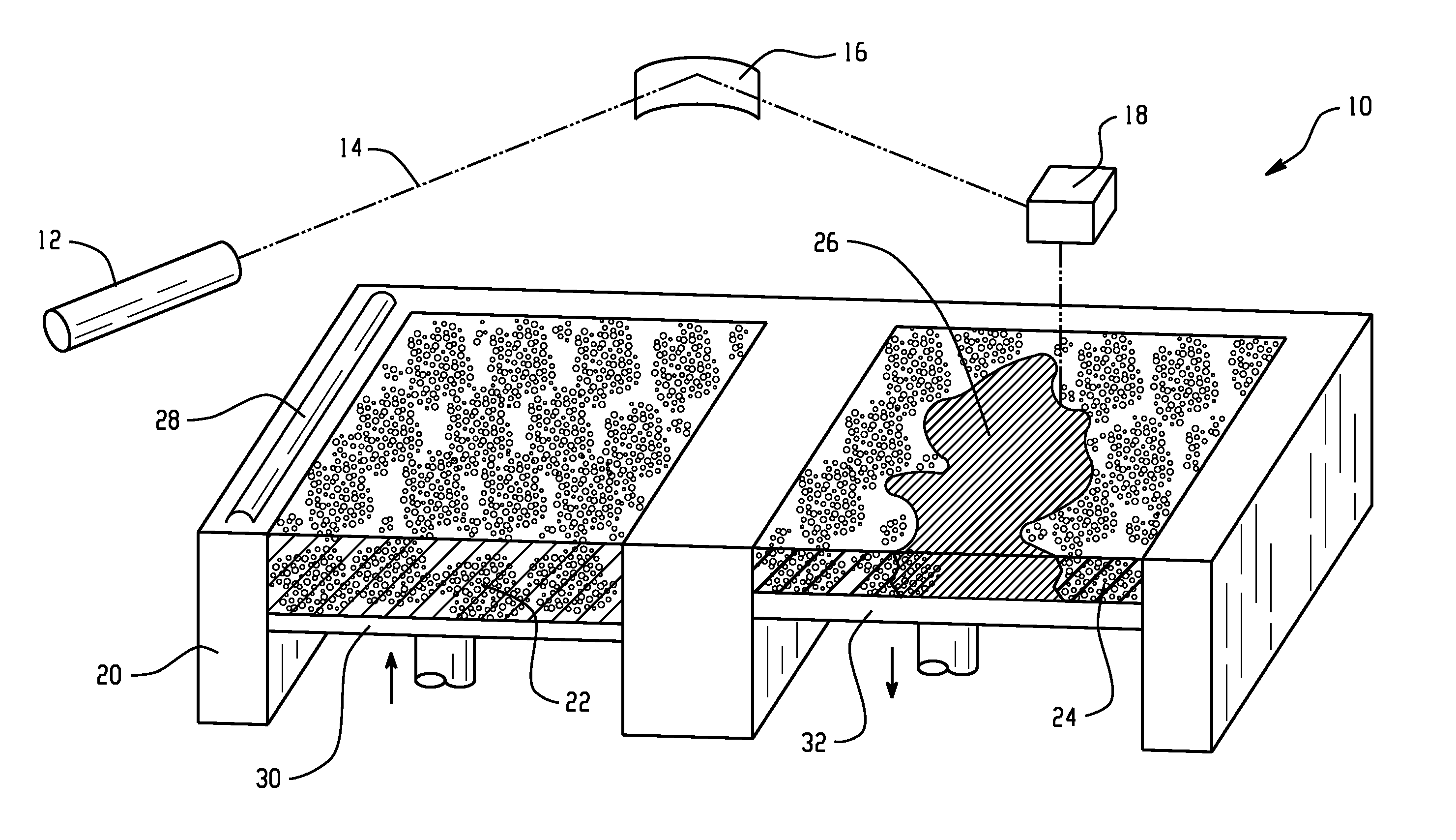

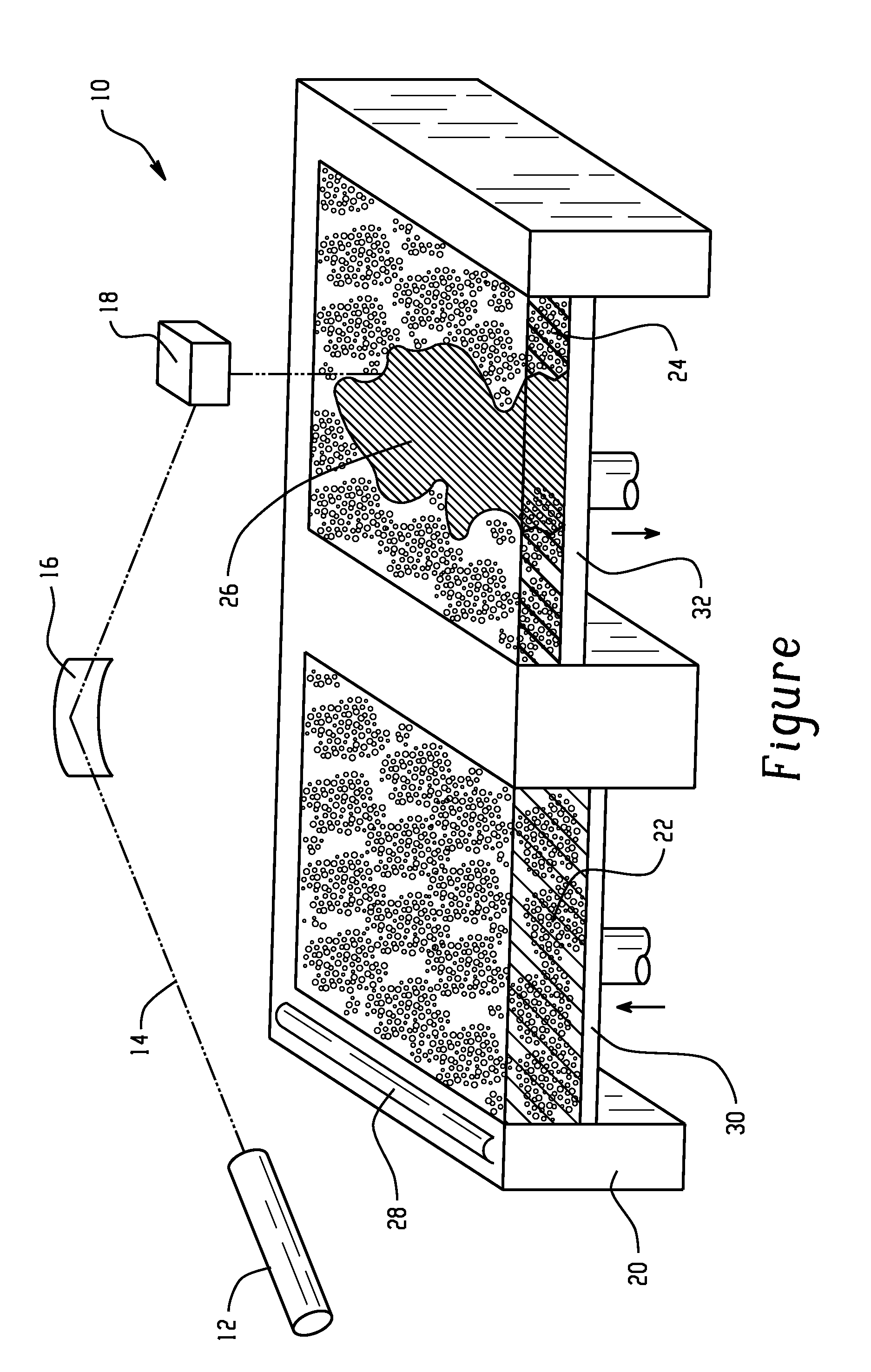

Method to build 3D digital models of porous media using transmitted laser scanning confocal mircoscopy and multi-point statistics

InactiveUS20110004447A1Reduce restrictionsReduce boundary effectsDigital computer detailsCharacter and pattern recognitionPorous mediumLaser scanning

Owner:SCHLUMBERGER TECH CORP

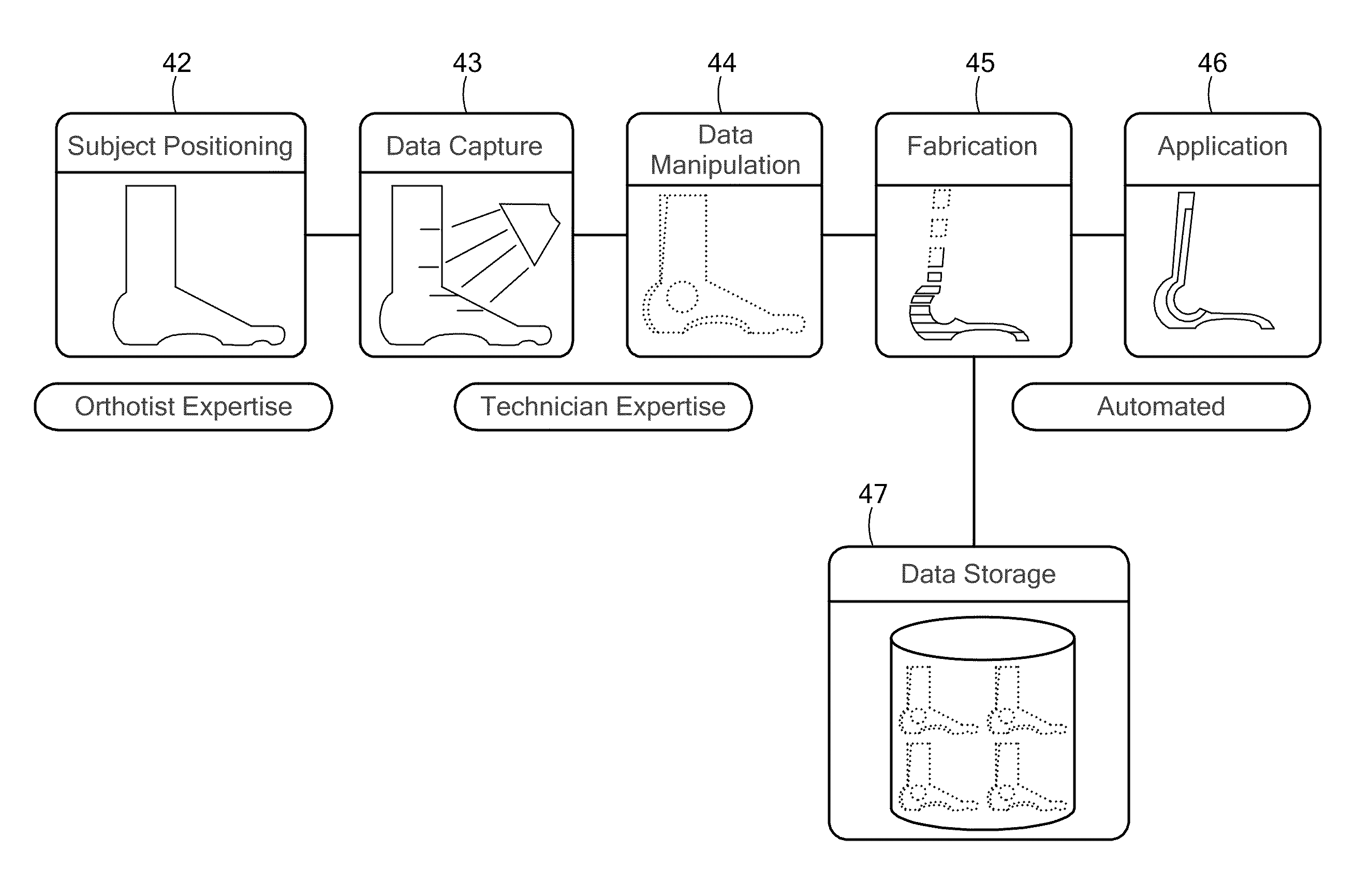

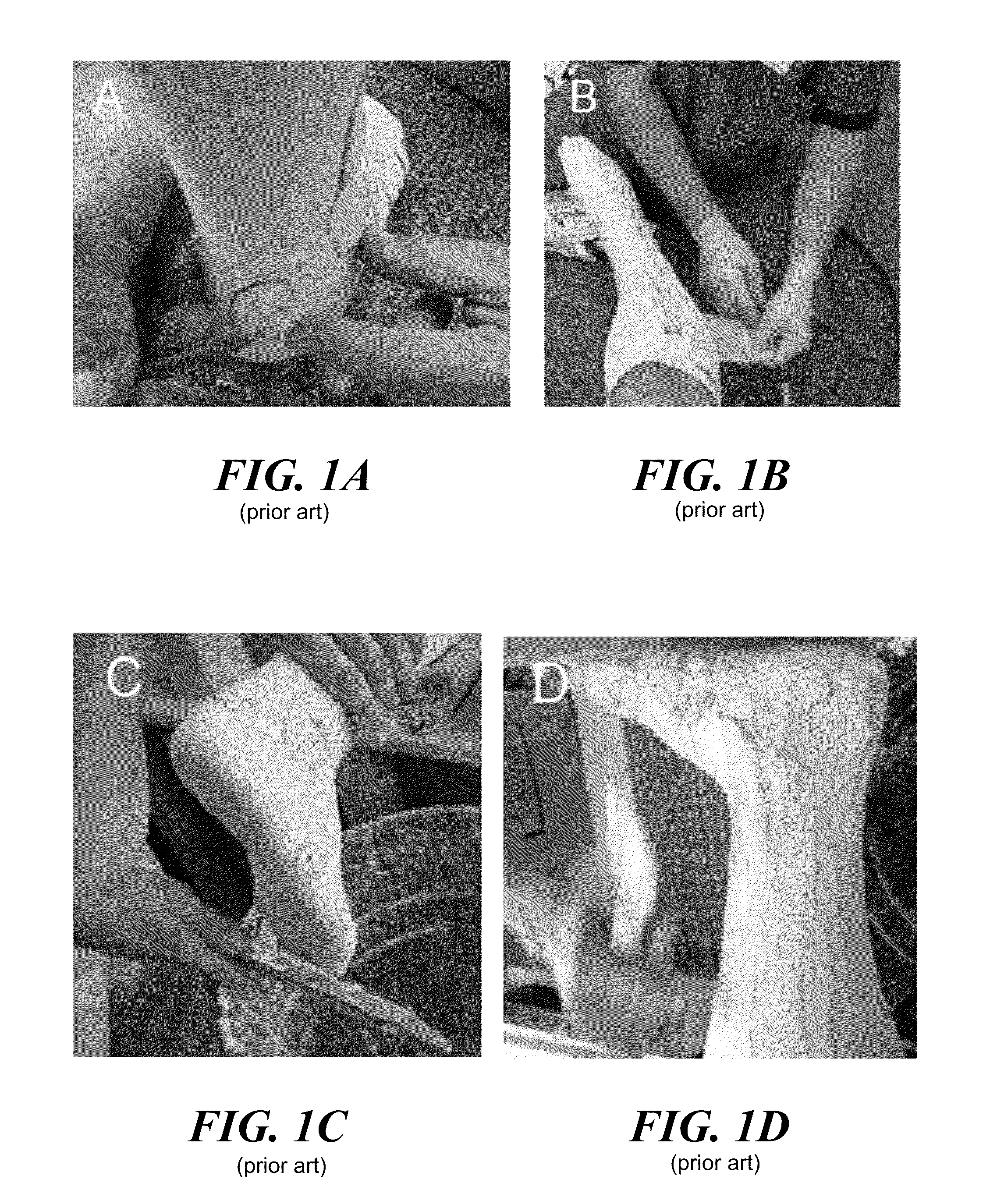

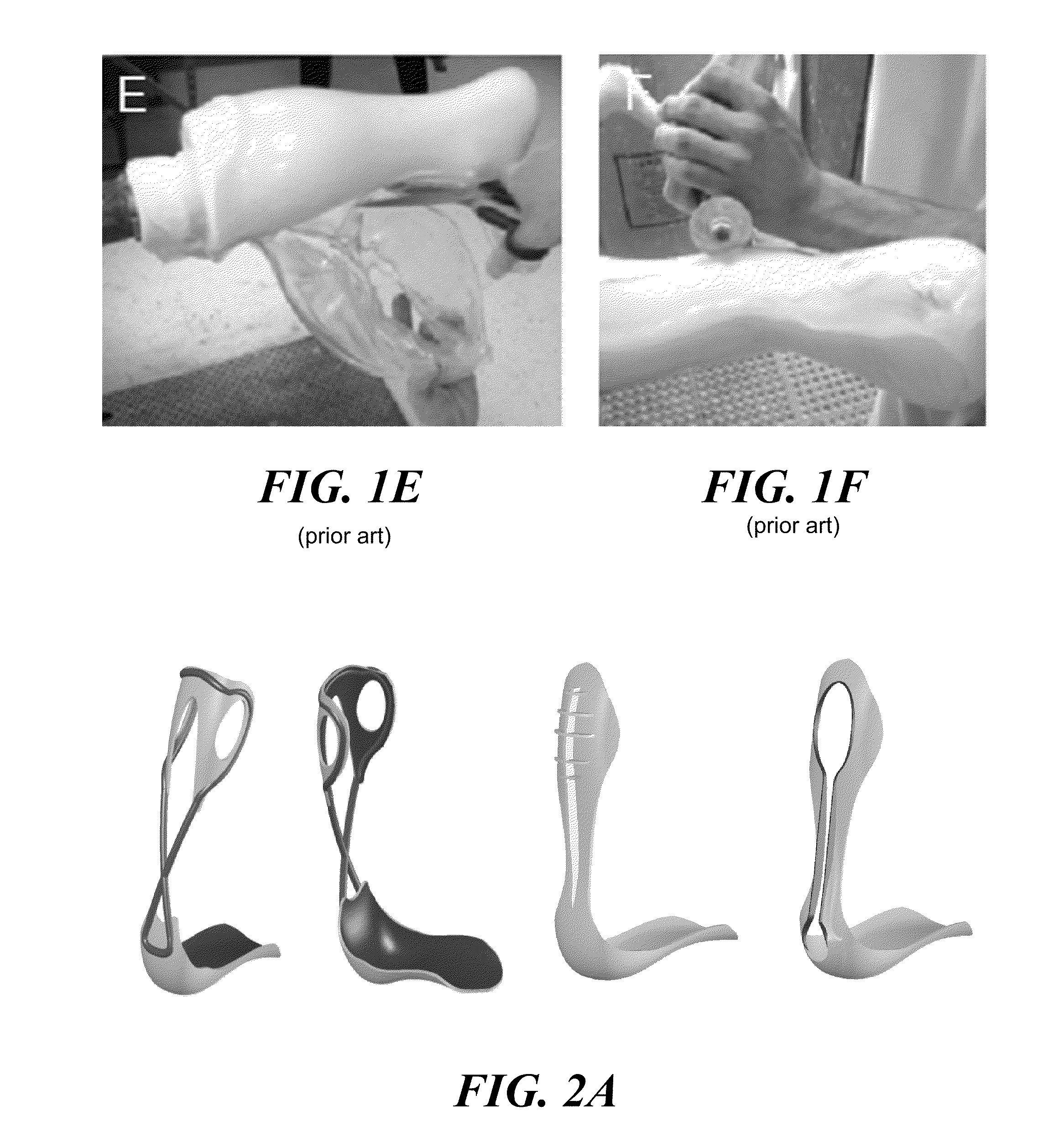

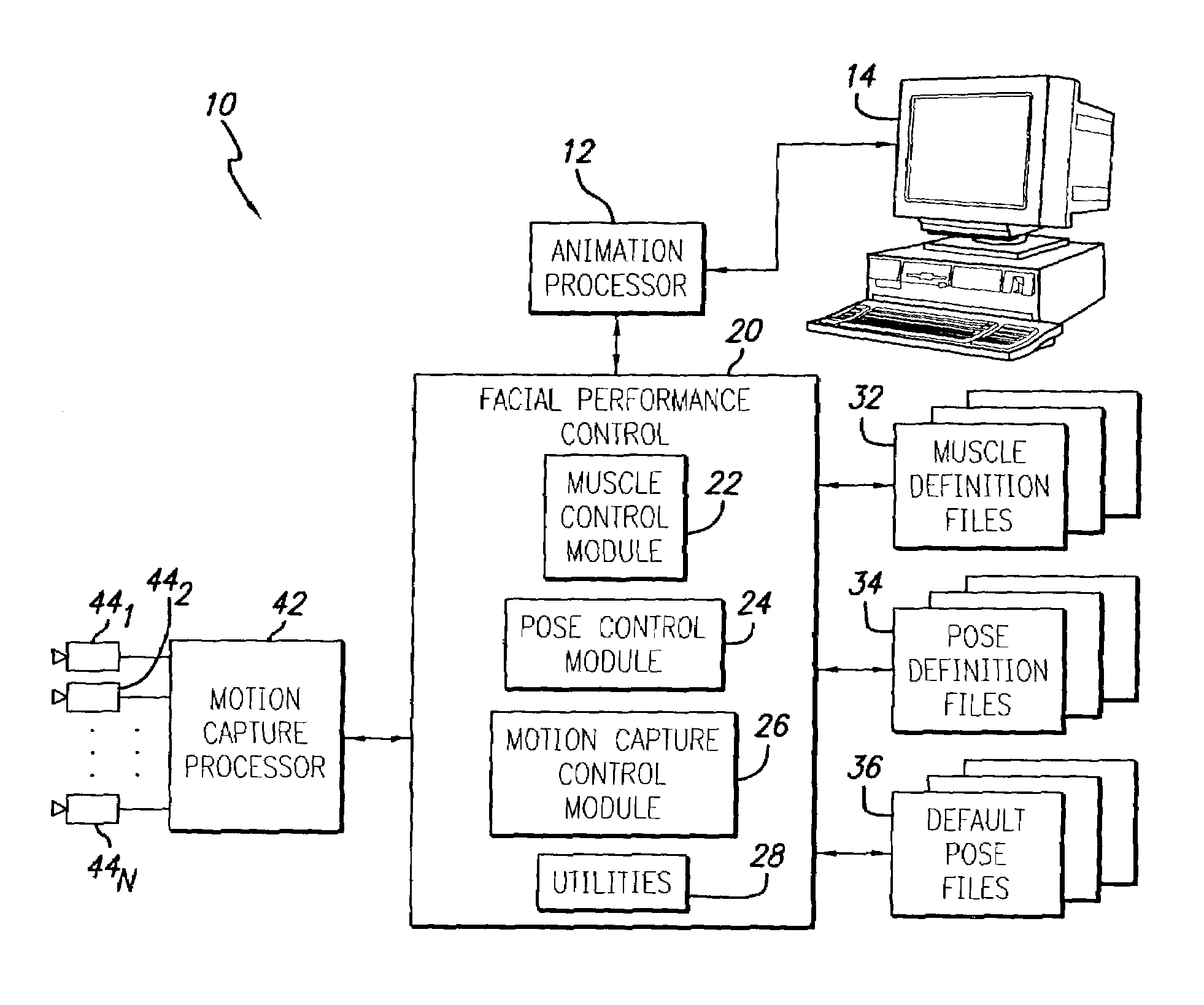

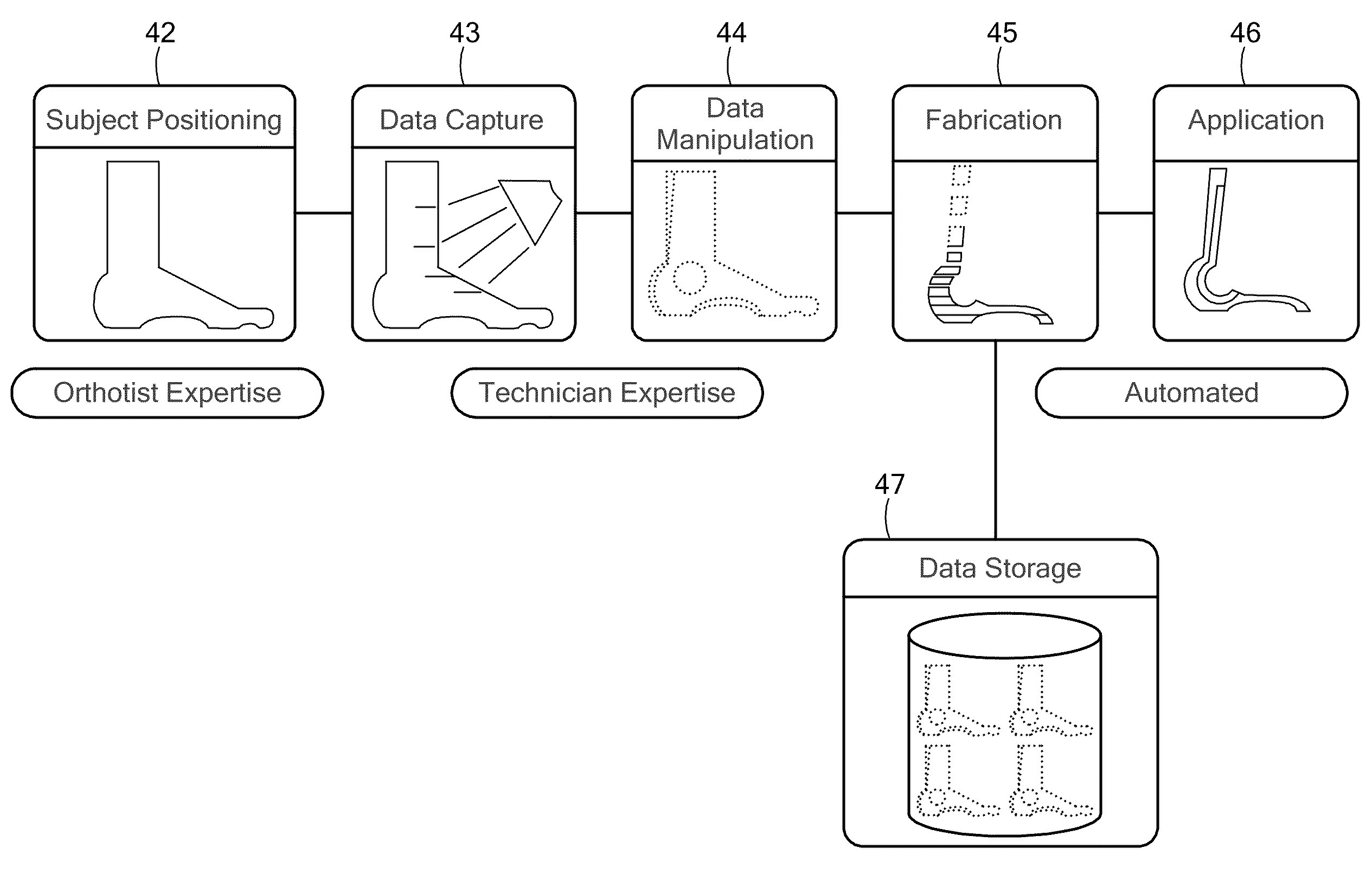

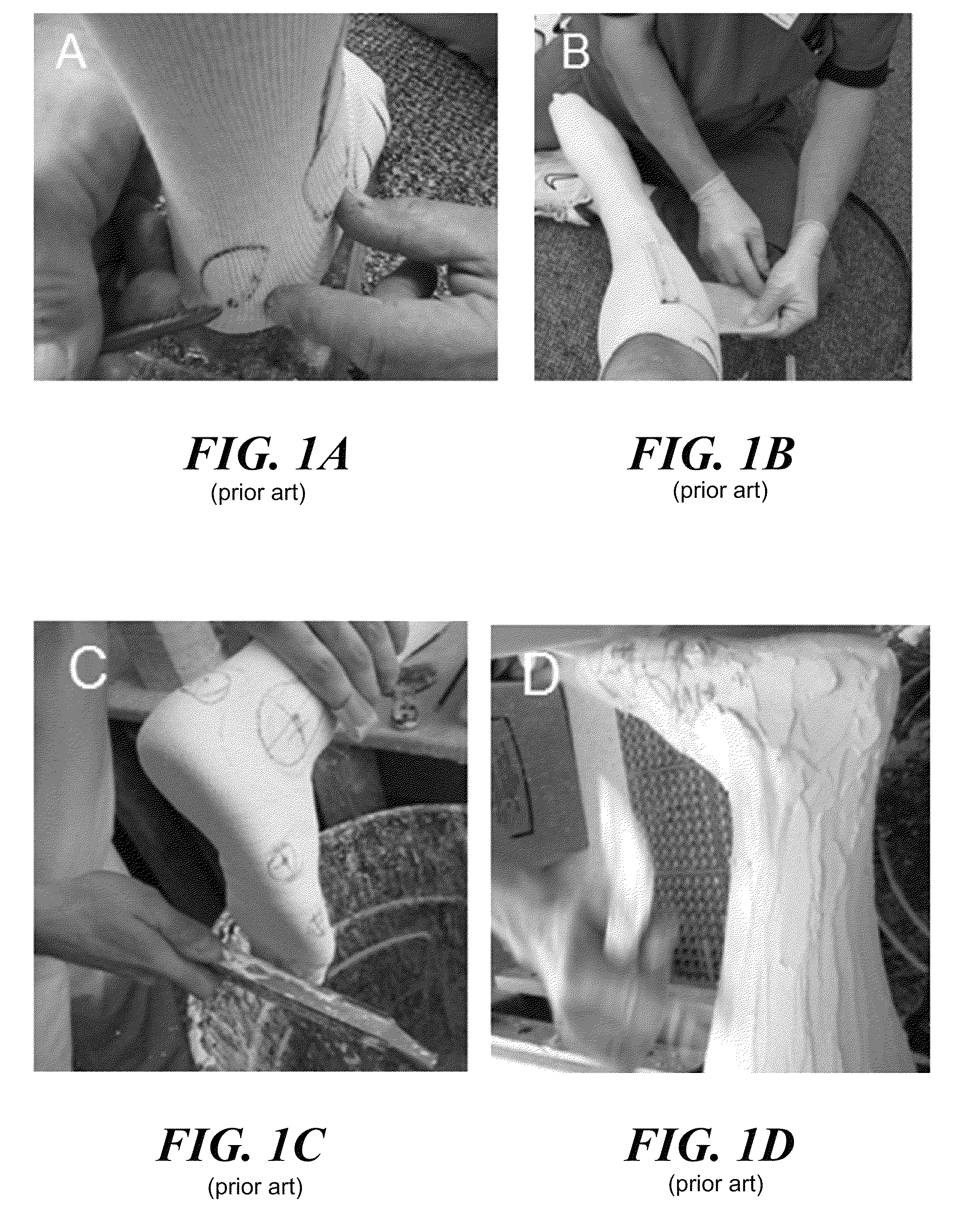

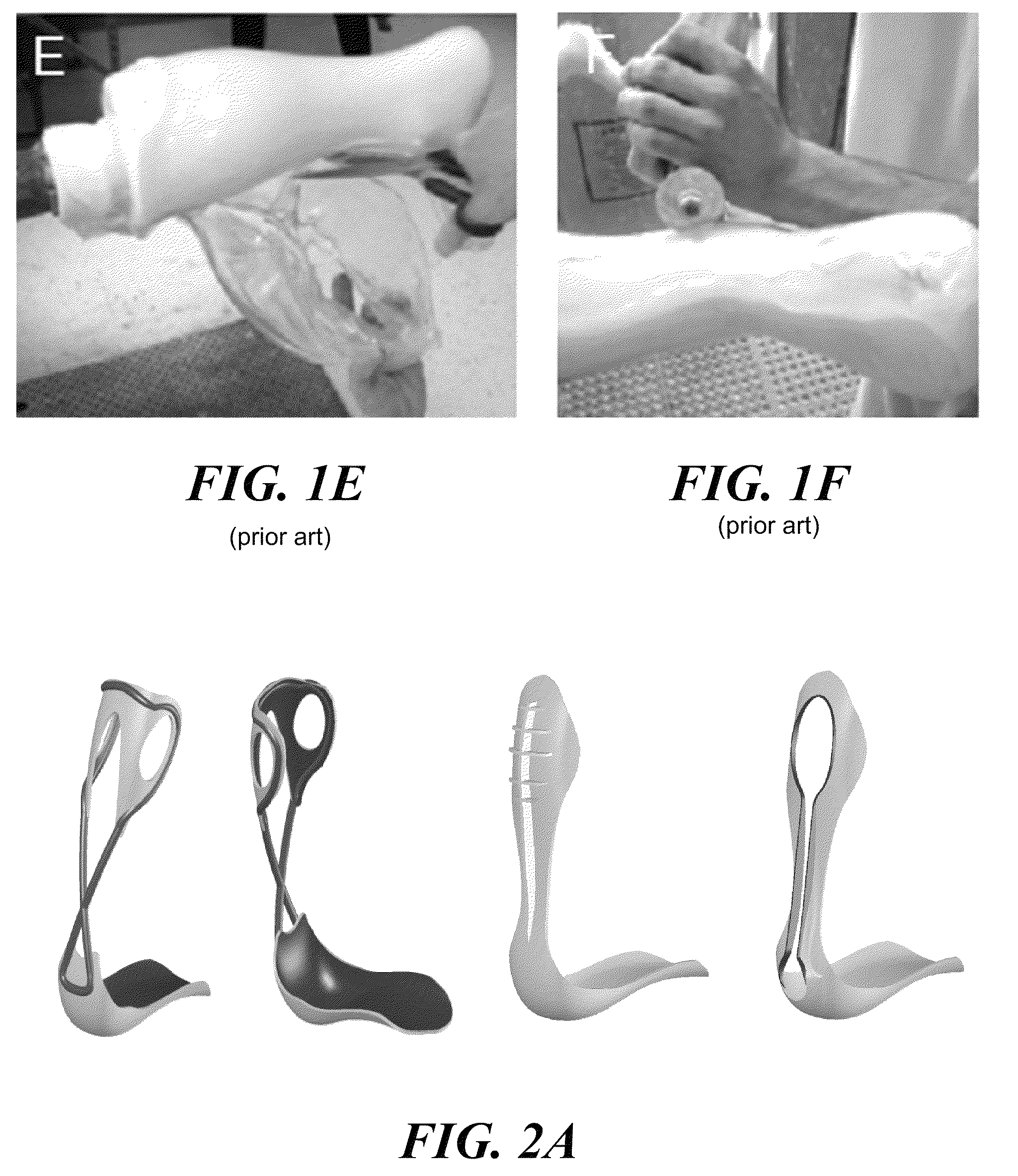

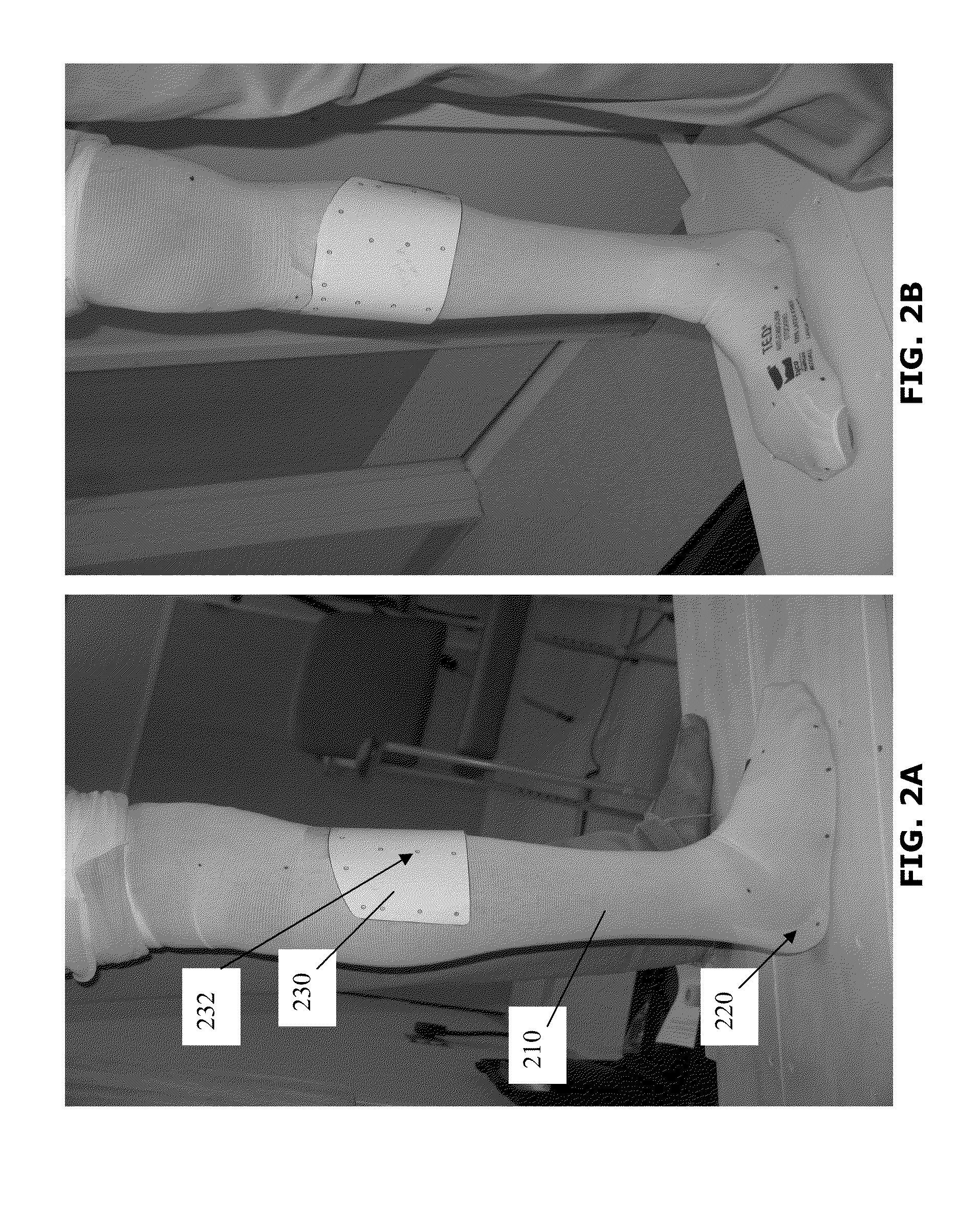

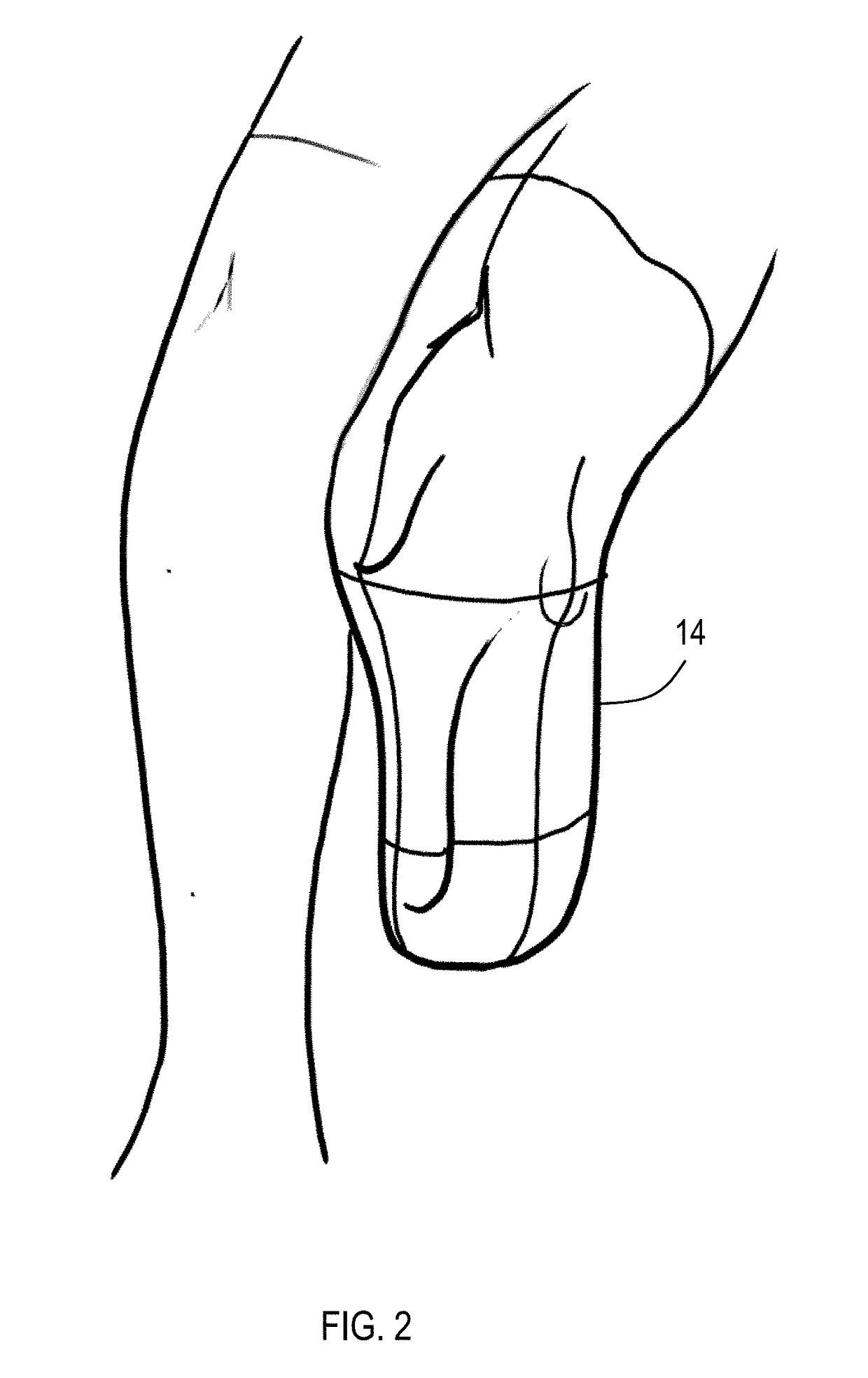

Patient specific ankle-foot orthotic device

The unique advantages of computer-controlled fabrication of a patient-specific orthotic device using an automated fabrication machine capable of following computer instructions to create 3D surface contours and new developments in non-invasive three-dimensional (3D) scanning have made it possible to acquire digital models of freeform surfaces such as the surface anatomy of the human body and to then fabricate such a patient-specific device with high precision. Such a patient-specific device brings significant improvement in patient-specific fit, comfort, and function of medical devices (and, in particular, to orthoses that require a close fit to the wearer's body to act effectively). The combination of these two technologies is ideally suited for the development of patient-specific orthotic devices.A patient specific ankle-foot orthotic device using this technology is disclosed. This exemplary device is used to help stabilize the ankle-foot region, for example, in patients with impaired gait.

Owner:TECHNEST HLDG +2

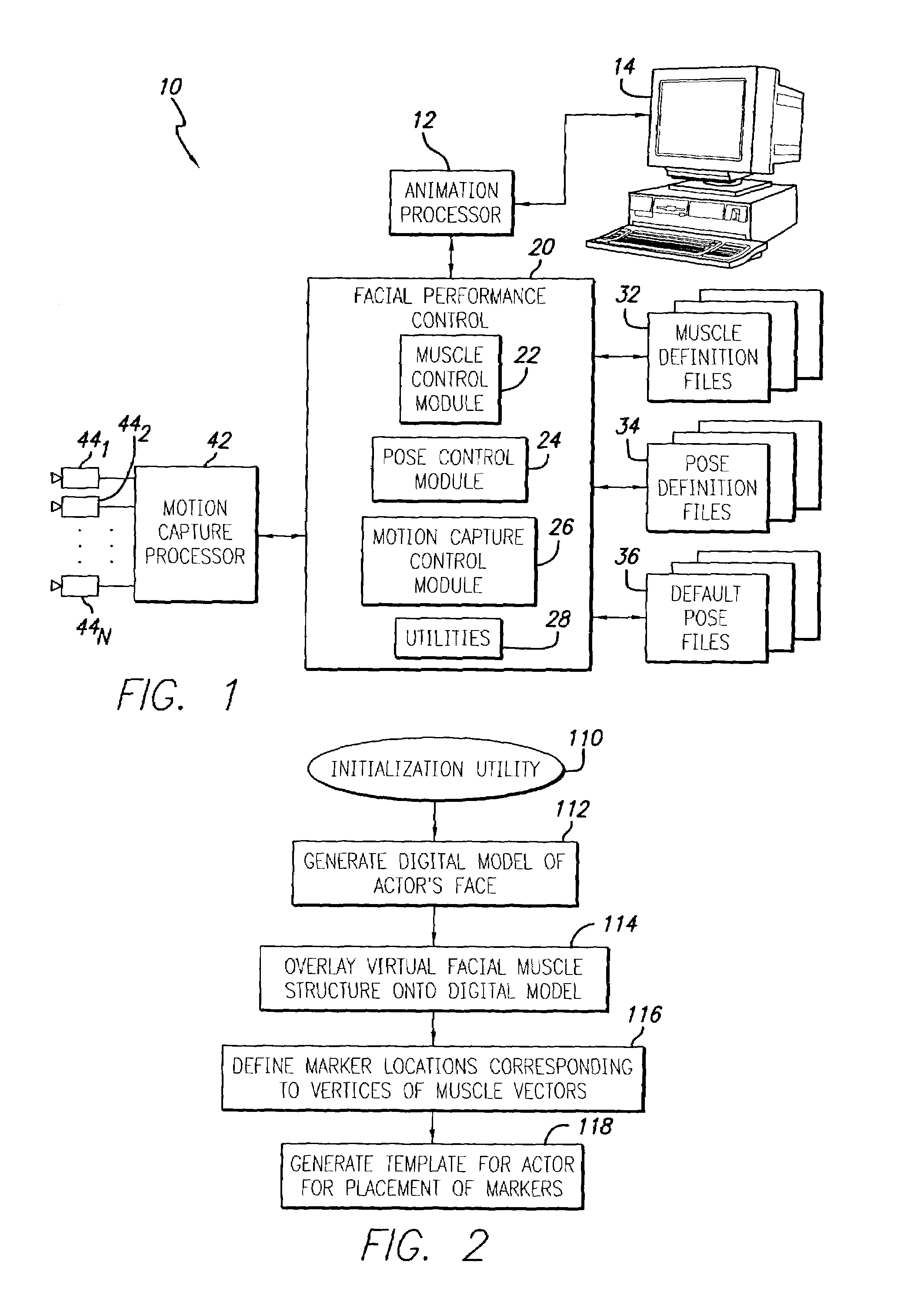

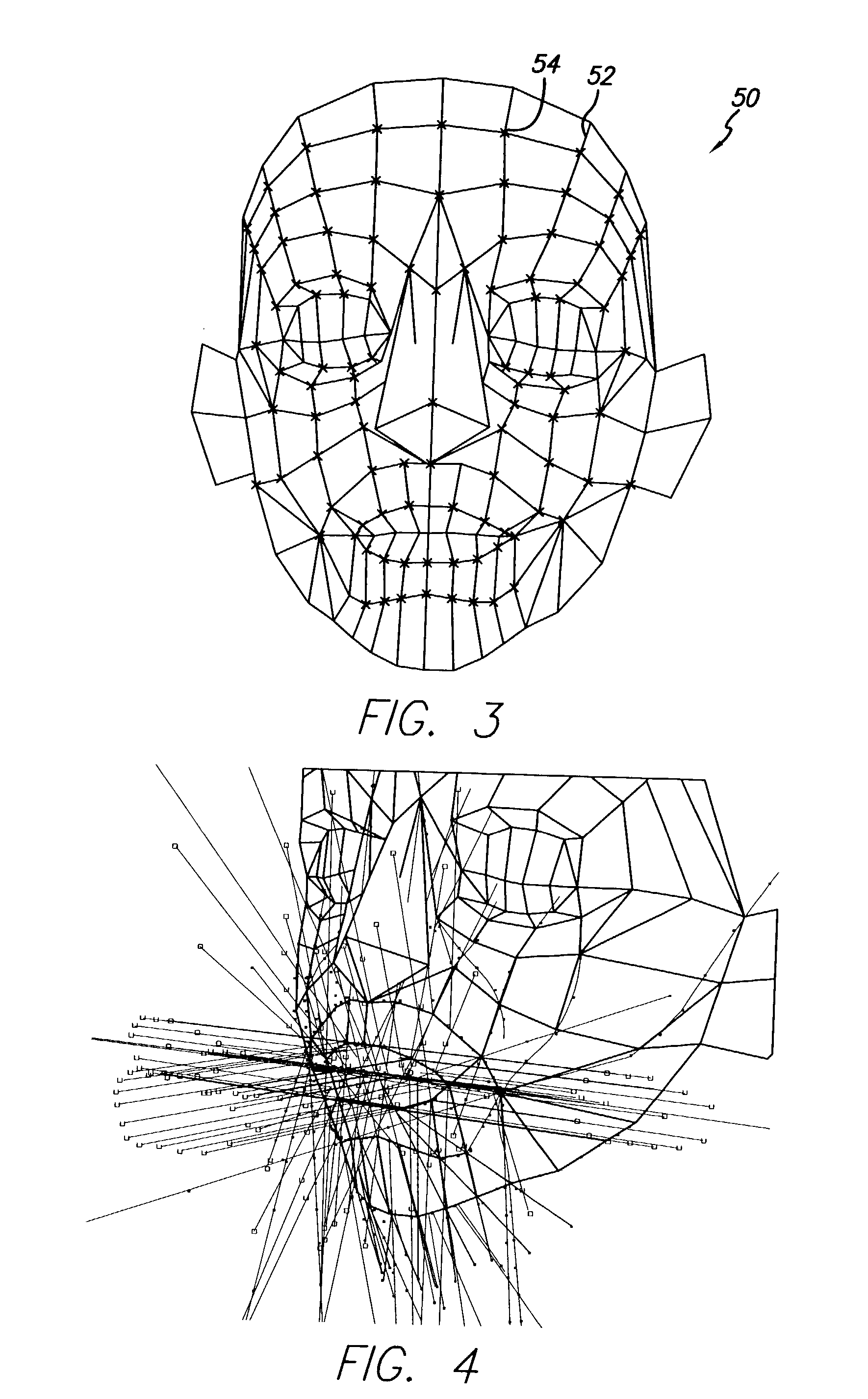

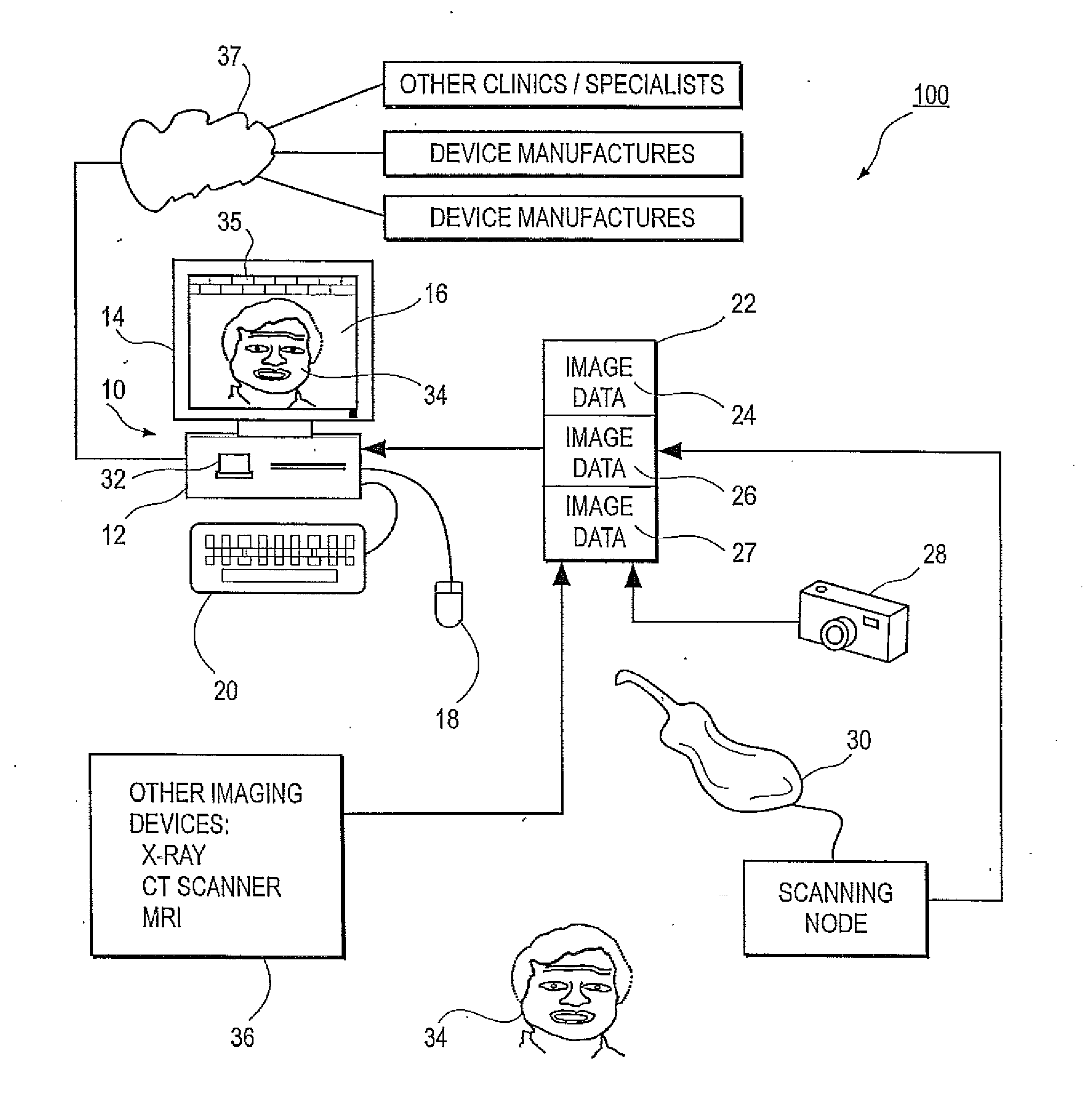

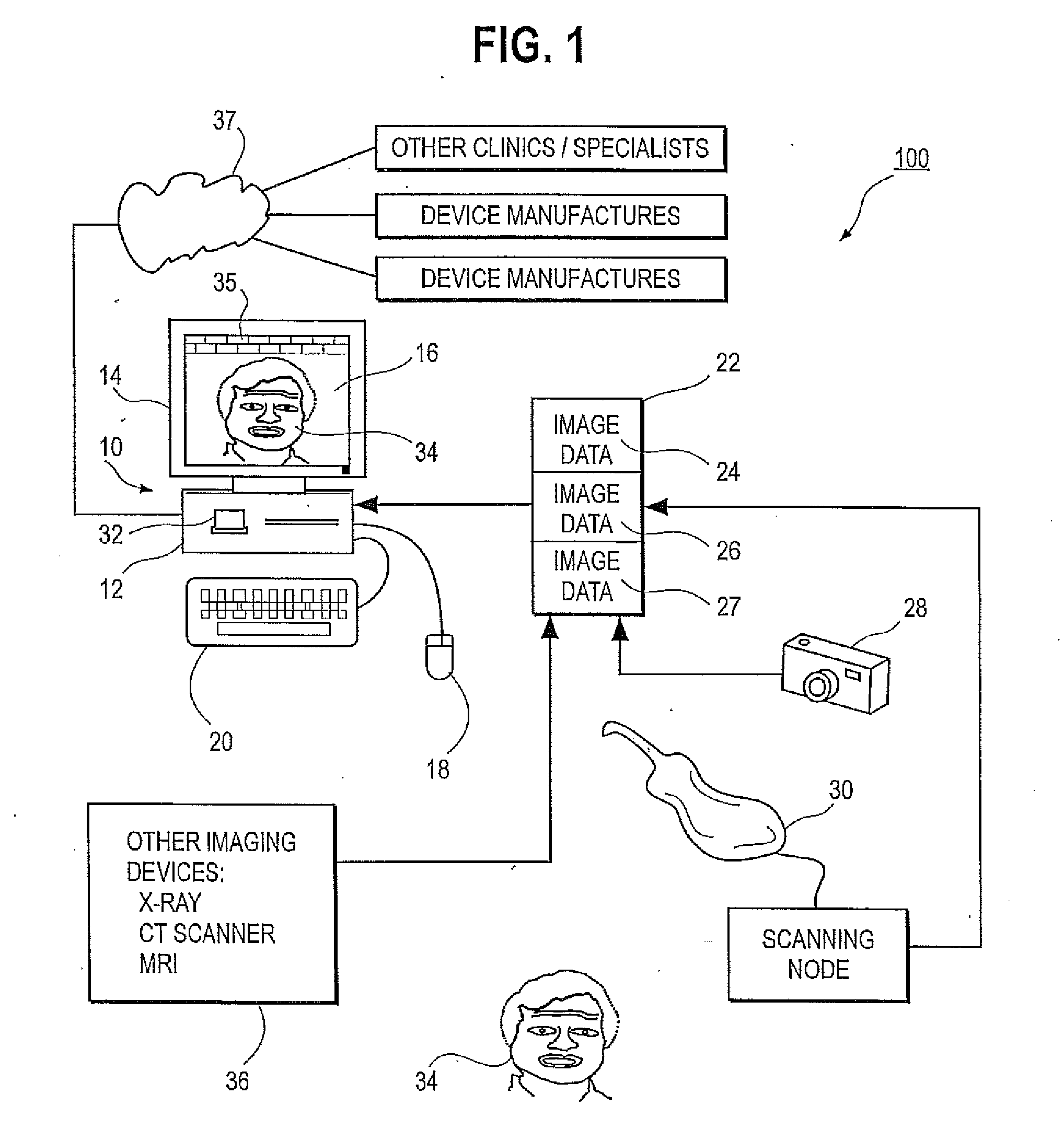

System and method for animating a digital facial model

InactiveUS7068277B2Highly realistic2D-image generationCathode-ray tube indicatorsGraphicsFacial movement

A system and method for animating facial motion comprises an animation processor adapted to generate three-dimensional graphical images and having a user interface and a facial performance processing system operative with the animation processor to generate a three-dimensional digital model of an actor's face and overlay a virtual muscle structure onto the digital model. The virtual muscle structure includes plural muscle vectors that each respectively define a plurality of vertices along a surface of the digital model in a direction corresponding to actual facial muscles. The facial performance processing system is responsive to an input reflecting selective actuation of at least one of the plural muscle vectors to thereby reposition corresponding ones of the plurality of vertices and re-generate the digital model in a manner that simulates facial motion. The muscle vectors further include an origin point defining a rigid connection of the muscle vector with an underlying structure corresponding to actual cranial tissue, an insertion point defining a connection of the muscle vector with an overlying surface corresponding to actual skin, and interconnection points with other ones of the plural muscle vectors.

Owner:SONY CORP +1

Generating three dimensional digital dention models from surface and volume scan data

A method and apparatus are disclosed enabling an orthodontist or a user to create an integrated three dimensional digital model of dentition and surrounding anatomy of an orthodontic patient from a three-dimensional digital model obtained using a scanner with a three-dimensional digital model obtained using a Cone Beam Computed Tomography (CBCT) or Magnetic Resonance Tomography (MRT) imaging devices. The digital data obtained from scanning as well as from CBCT imaging are downloaded into a computer workstation, and registered together in order to create a comprehensive 3-D model of the patient's teeth with roots, bones and soft tissues. The invention provides substantial improvement over the traditional two dimensional imaging modalities such as x-rays, photographs, cephalometric tracing for diagnosis and treatment planning

Owner:ORAMETRIX

Patient specific ankle-foot orthotic device

The unique advantages of computer-controlled fabrication of a patient-specific orthotic device using an automated fabrication machine capable of following computer instructions to create 3D surface contours and new developments in non-invasive three-dimensional (3D) scanning have made it possible to acquire digital models of freeform surfaces such as the surface anatomy of the human body and to then fabricate such a patient-specific device with high precision. Such a patient-specific device brings significant improvement in patient-specific fit, comfort, and function of medical devices (and, in particular, to orthoses that require a close fit to the wearer's body to act effectively). The combination of these two technologies is ideally suited for the development of patient-specific orthotic devices.A patient specific ankle-foot orthotic device using this technology is disclosed. This exemplary device is used to help stabilize the ankle-foot region, for example, in patients with impaired gait.

Owner:TECHNEST HLDG +2

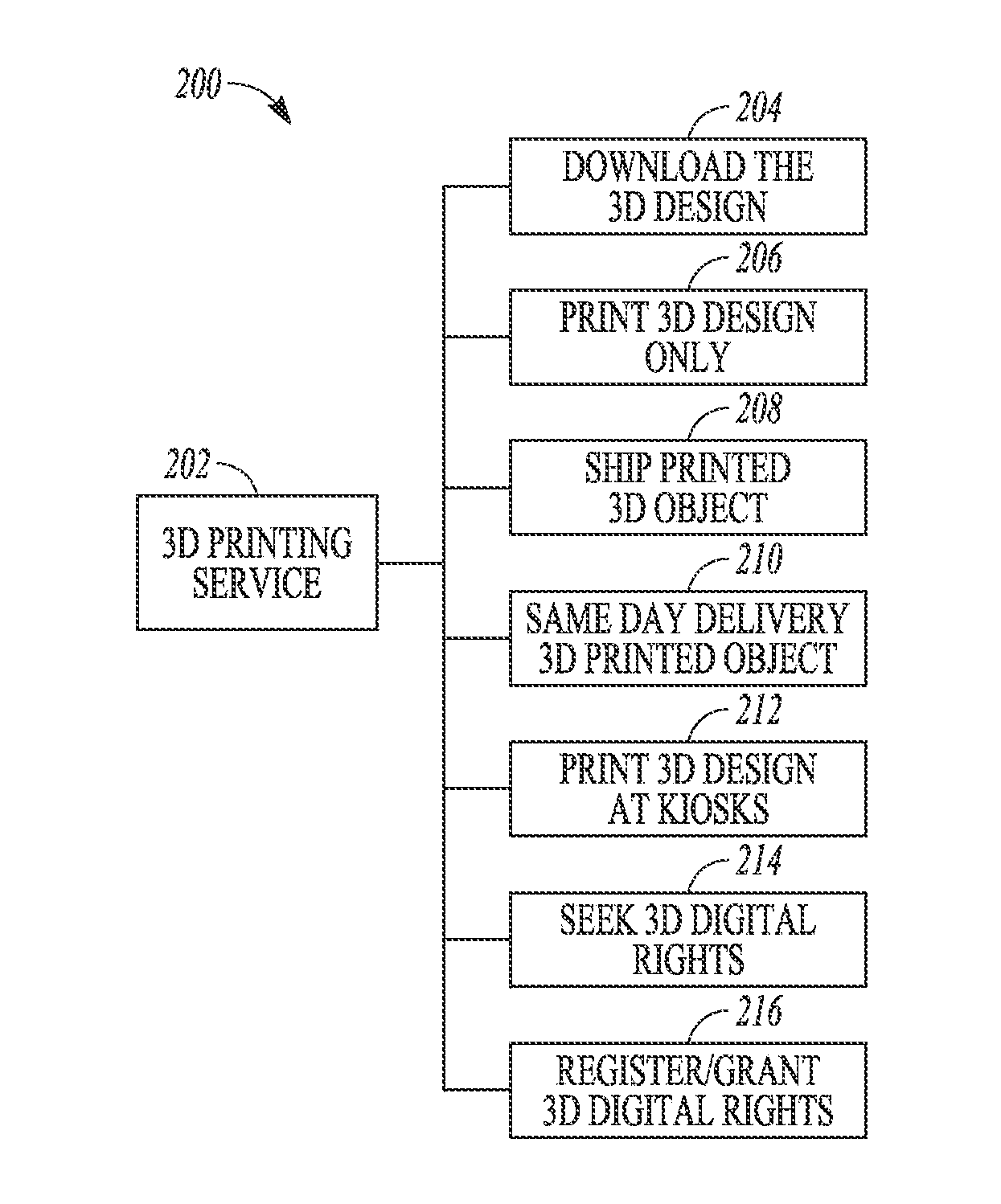

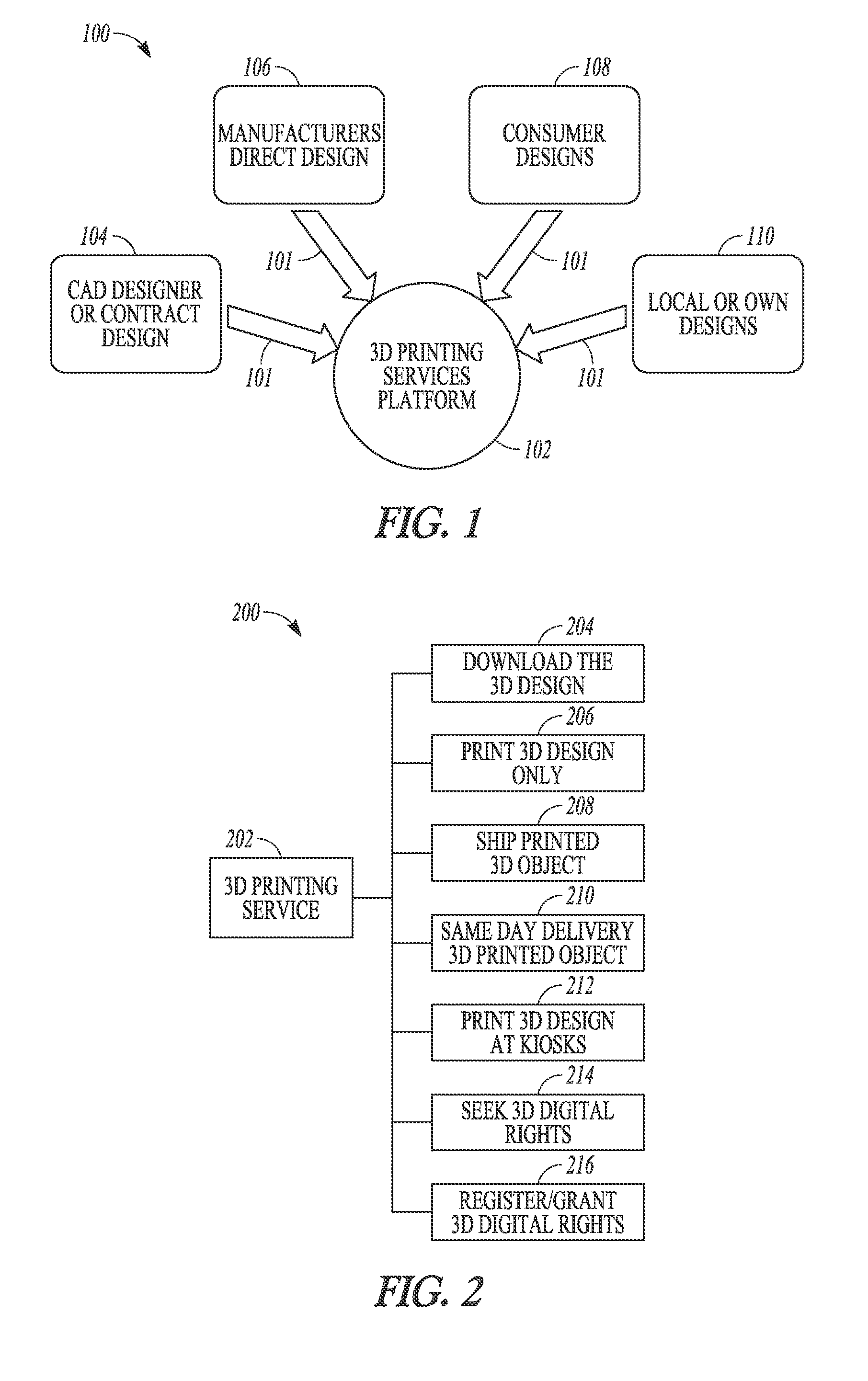

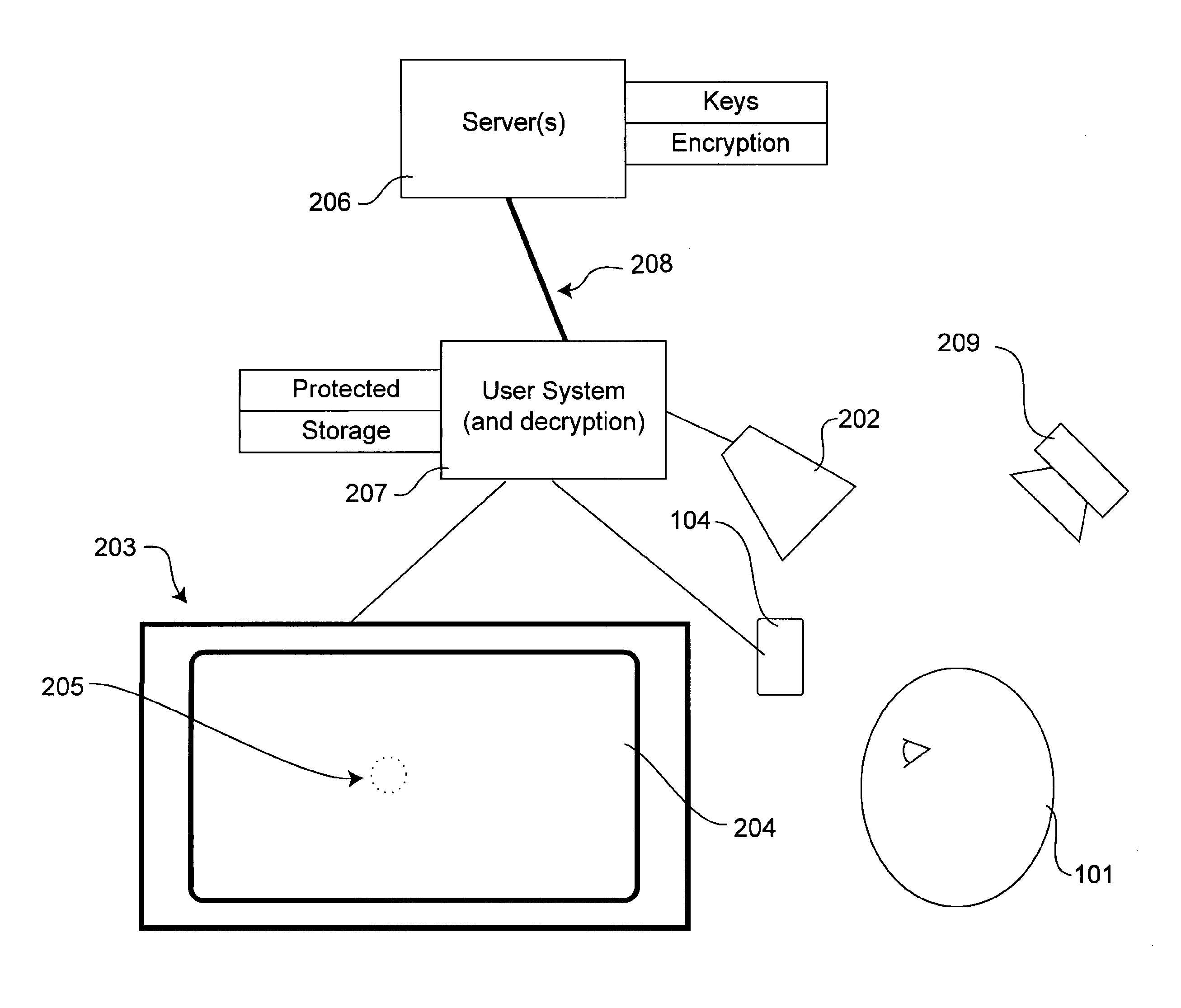

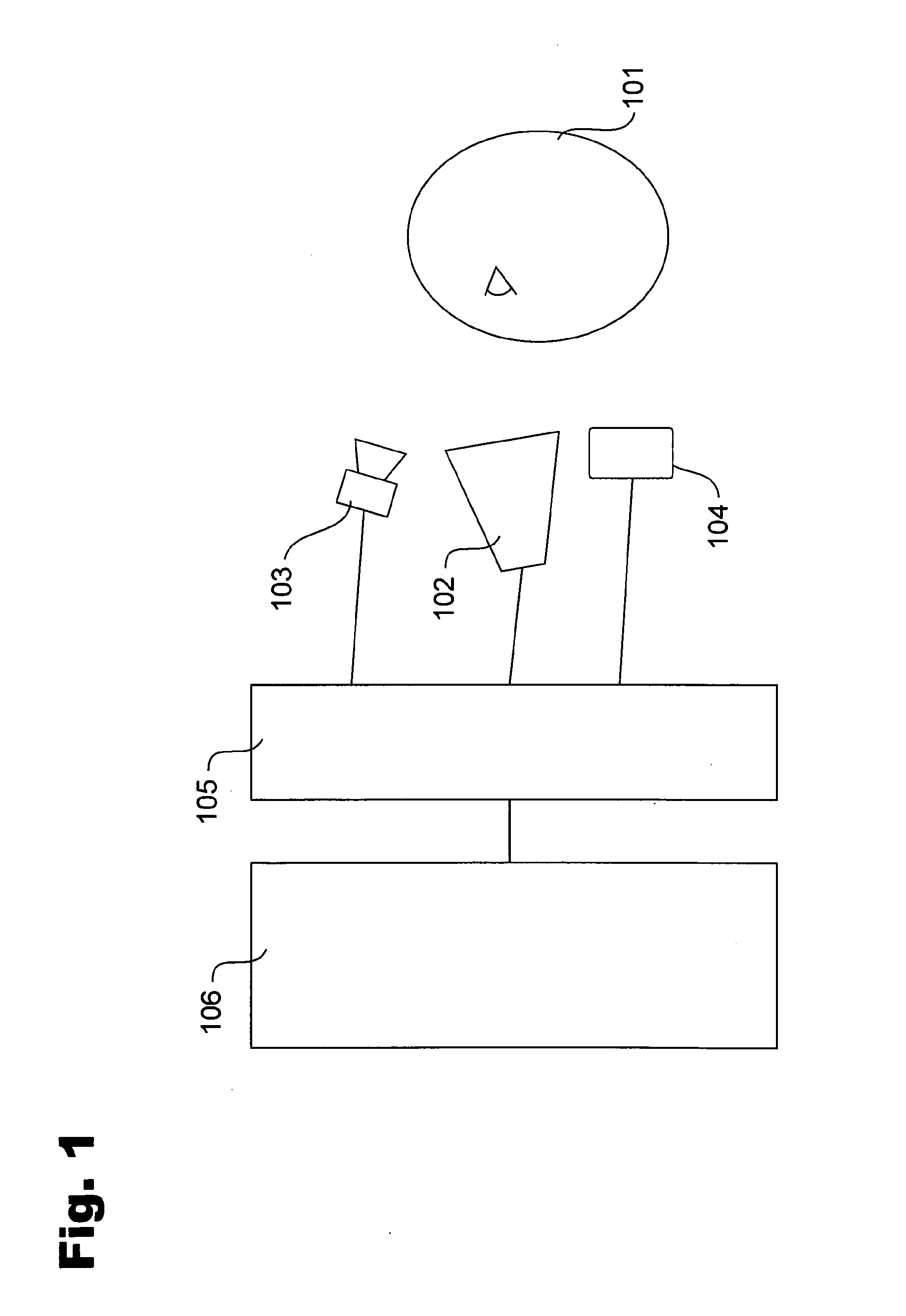

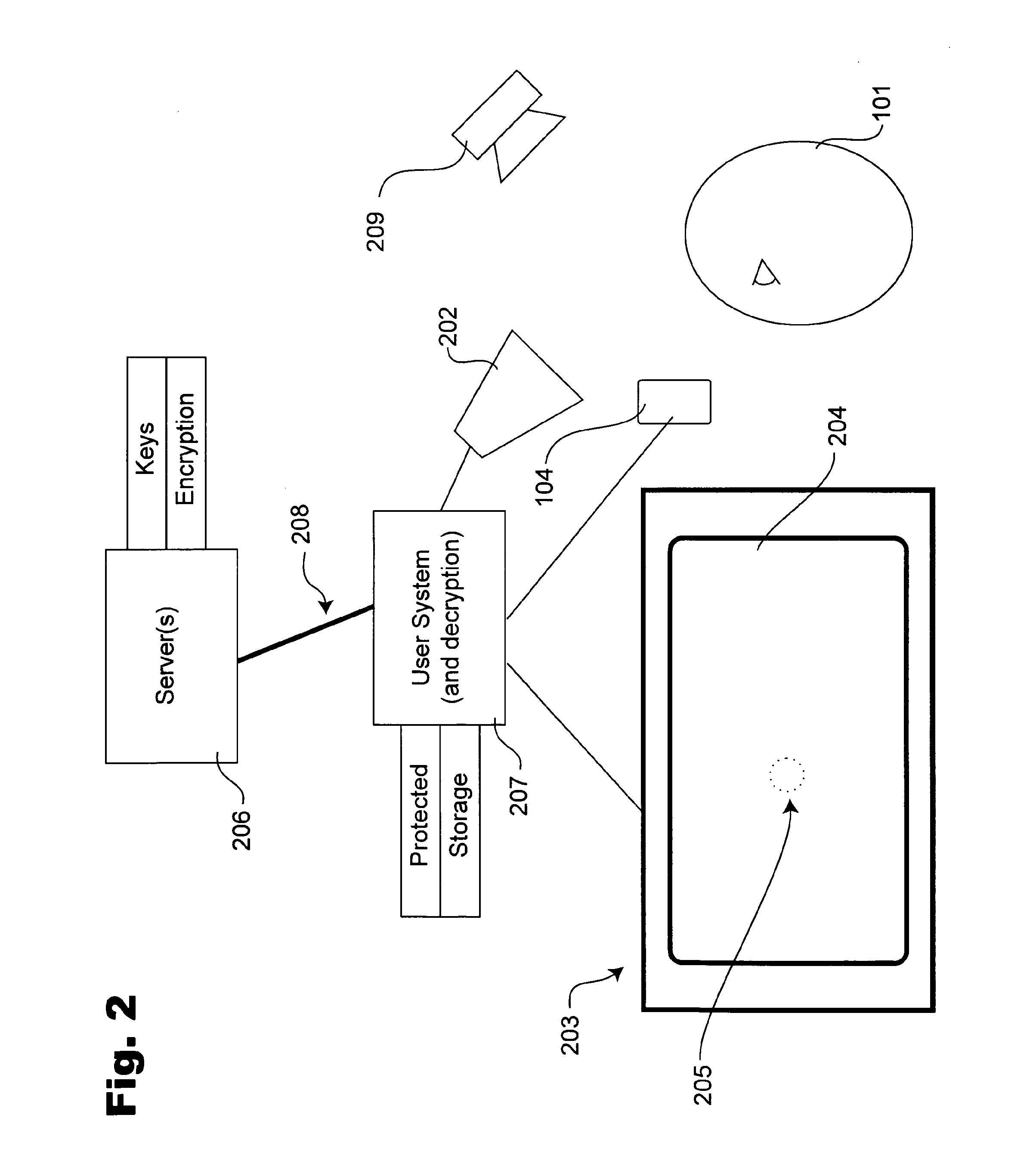

Digital rights and integrity management in three-dimensional (3D) printing

ActiveUS20160171354A1Programme controlAdditive manufacturing apparatusComputer printingComputer graphics (images)

Systems, methods and media for managing digital rights and pre-verification of structural integrity in three-dimensional (3D) printing are provided. In one example, a system comprises at least one module, executing on one or more computer processors, to receive a request from a user to print a 3D object by a 3D printer or printing service and receive a conditional authorization from an owner of digital rights in the 3D object to print the 3D object. The conditional authorization can include a printing specification or limitation. The at least one module pre-verifies, for structural integrity once printed by the 3D printer or printing service, a digital model on which the 3D object is based. In response to a received conditional authorization, the at least one module transmits instructions to the 3D printer or printing service to print the 3D object.

Owner:EBAY INC

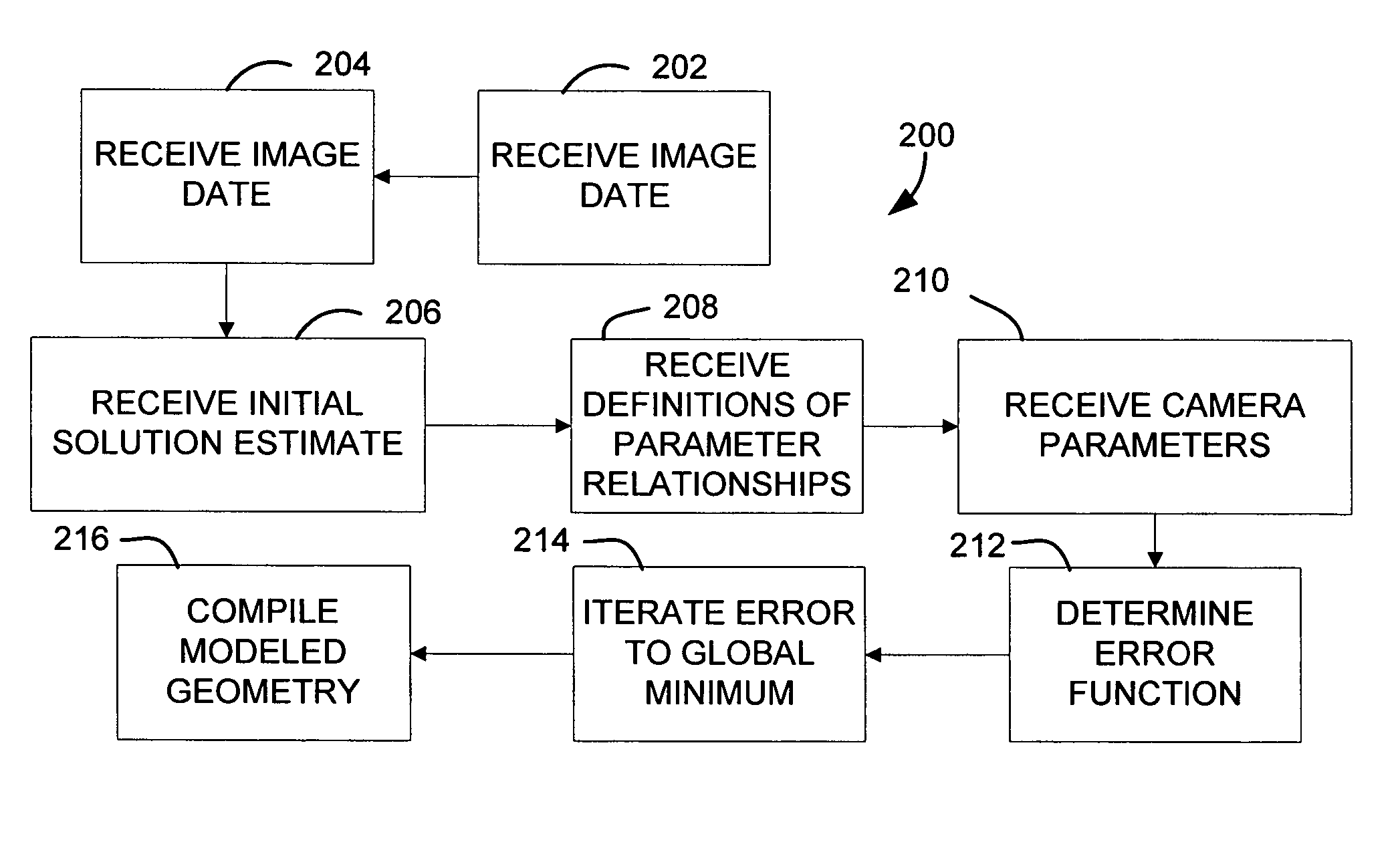

Reverse-rendering method for digital modeling

ActiveUS6990230B2Accurate reconstructionSimple calculationDetails involving processing stepsTelevision system detailsComputer graphics (images)Error function

A method for automatically or semi-automatically constructing a digital 3D model of a scene from photographic data and photogrammetry data includes defining an initial rough model as a solution estimate. A reverse rendering step includes a second-order solution method that employs automatic differentiation techniques to accurately compute derivatives of an error function. In an embodiment of the method, at least one camera is placed within the scene being constructed, and photographic data from this camera is used in the solution process.

Owner:WARNER BROS ENTERTAINMENT INC

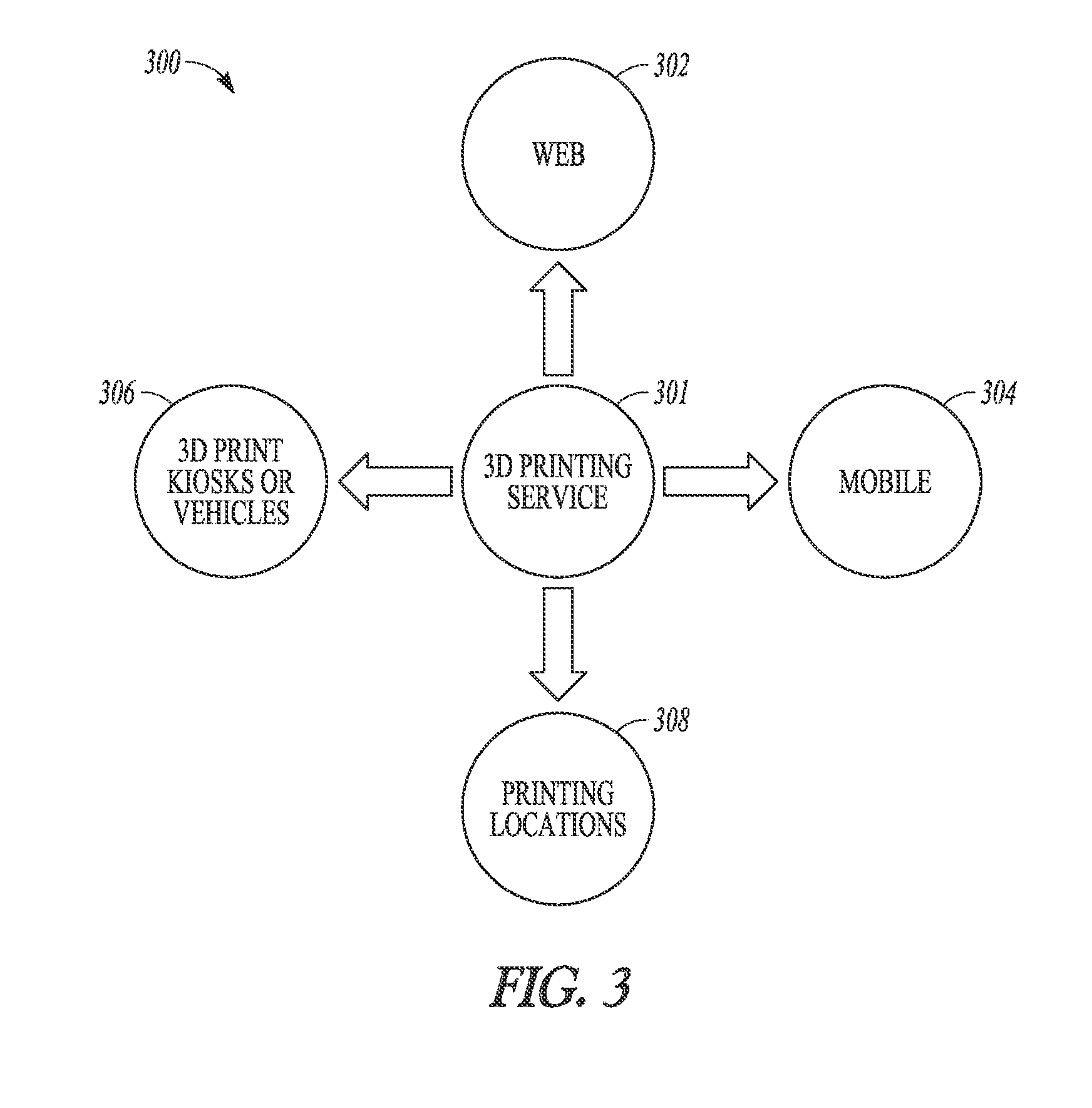

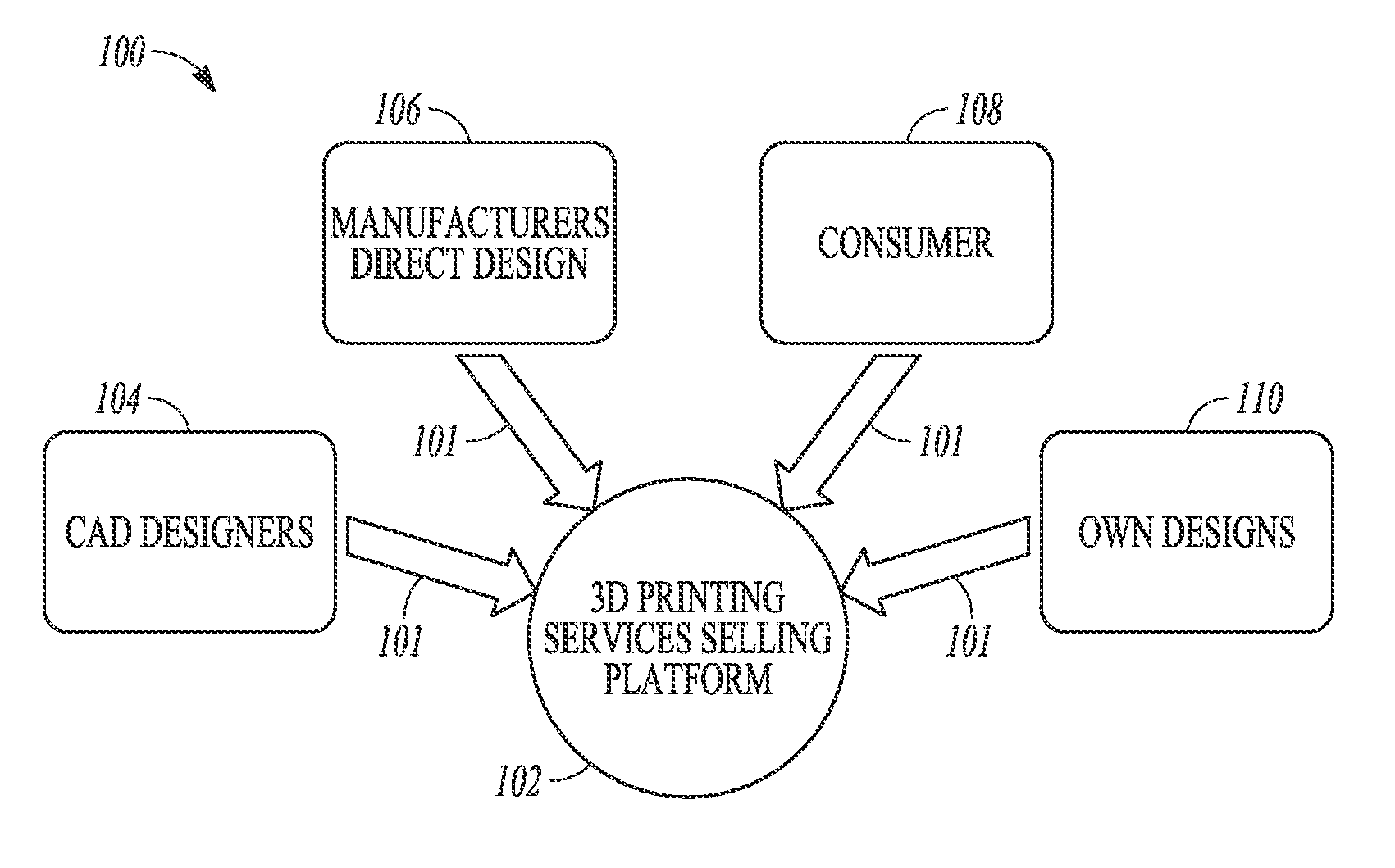

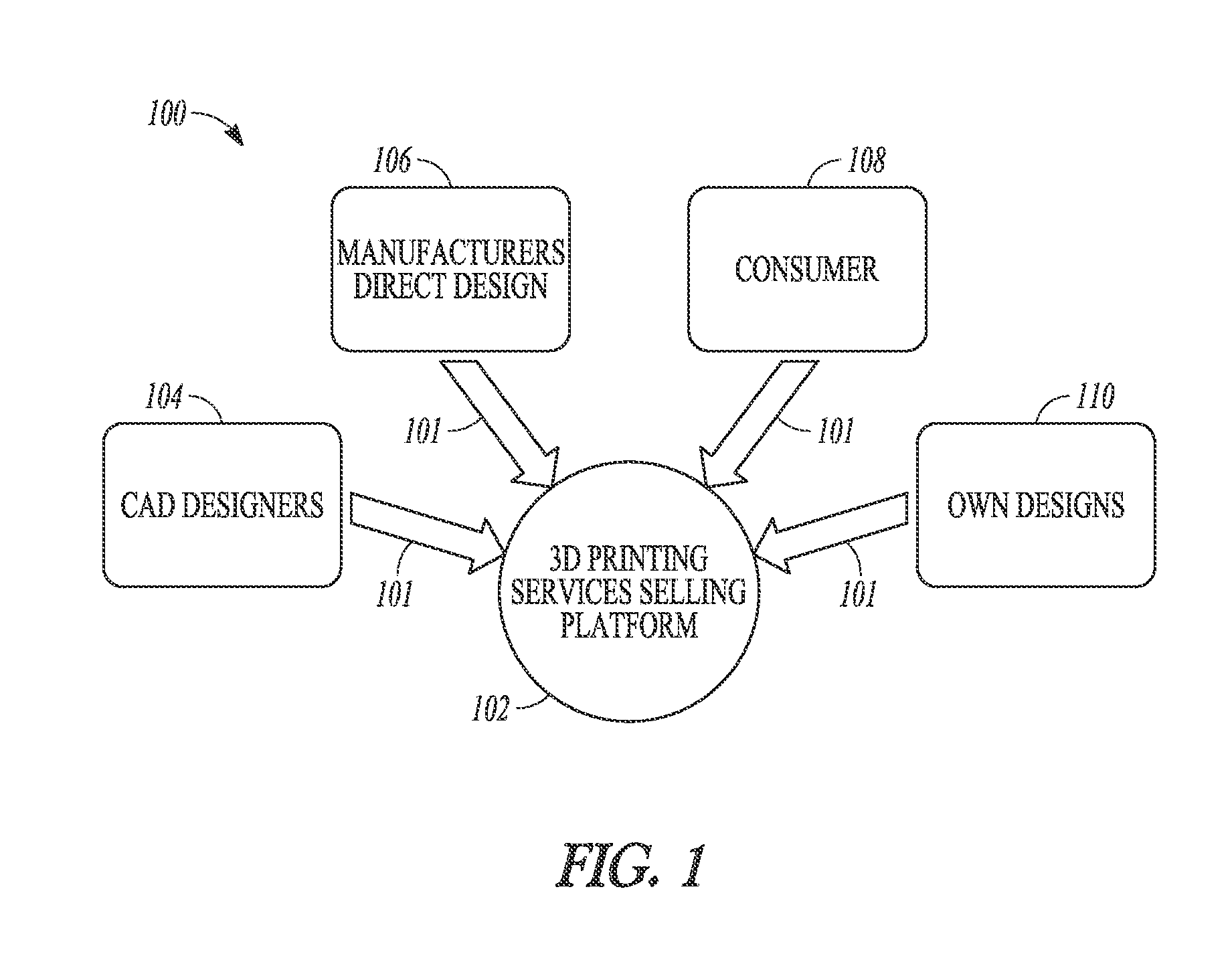

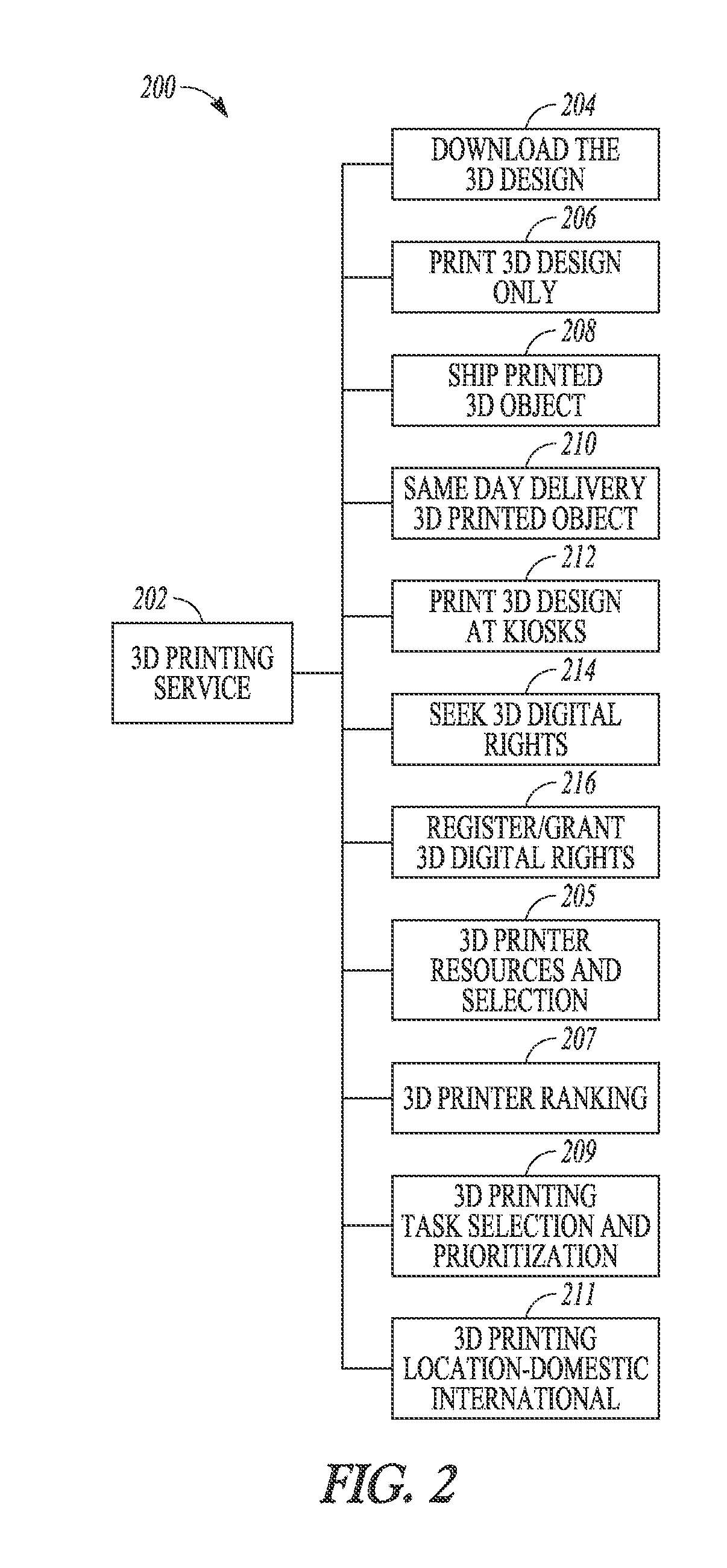

3D printing in marketplace environments

InactiveUS20150220748A1Facilitate authorizationImprove performanceDigital data processing detailsAnalogue secracy/subscription systemsConsumer unitDigital mockup

Systems, methods, and media for authorizing 3D printing services in a marketplace environment are provided. In one example, a system comprises a computing device that implements a 3D printing marketplace component. The marketplace component comprises a merchant unit, a transaction unit, a consumer unit, and a digital rights authorization unit which cooperatively act to receive a request from a consumer for a 3D printing task, rank a plurality of 3D printing service providers based on an availability or a suitability to fulfil the 3D printing task, and facilitate the authorization of performance of the 3D printing task based on a grant of digital rights associated with the digital model or object.

Owner:EBAY INC

Video copy prevention systems with interaction and compression

ActiveUS20100061553A1Optimization of detailsAttenuation bandwidthTelevision system detailsPulse modulation television signal transmissionInteractive contentImage resolution

Disclosed are systems and methods for providing video content while inhibiting the copying of that content for later viewing. Video images may be made difficult to copy for presentation at later times by the omission or addition of content developed in relation to the particular initial viewing. For instance, video information may be customized by omitting information that is not likely to be substantially perceived by the initial viewer but that is substantially likely to be perceived as missing by at least some other viewers. As another example, video information may be customized for a particular viewing instance so that it contains modified, selected or injected information that is likely to be perceived as non-disruptive or unnoticeable by the original viewer but that would be perceived as substantially noticeable and / or disruptive by some other viewers, including when parts of more than one such video information are combined in an effort to remove customization related to their respective original viewings. Various means and methods for accomplishing the forgoing in a variety of settings are disclosed including also for providing privacy related to what is viewed. In some examples higher-resolution images are provided for the region near the viewer's point-of-regard and lower resolution images are provided elsewhere, which also has the effect of reducing the bandwidth required. For interactive content rendered from digital models, a model for a central foveal region may be provide greater detail and have greater computational requirements than a model for a peripheral view, providing both economy / performance in rendering and protection against copying.

Owner:DIGITAL COMMUNITY LLC

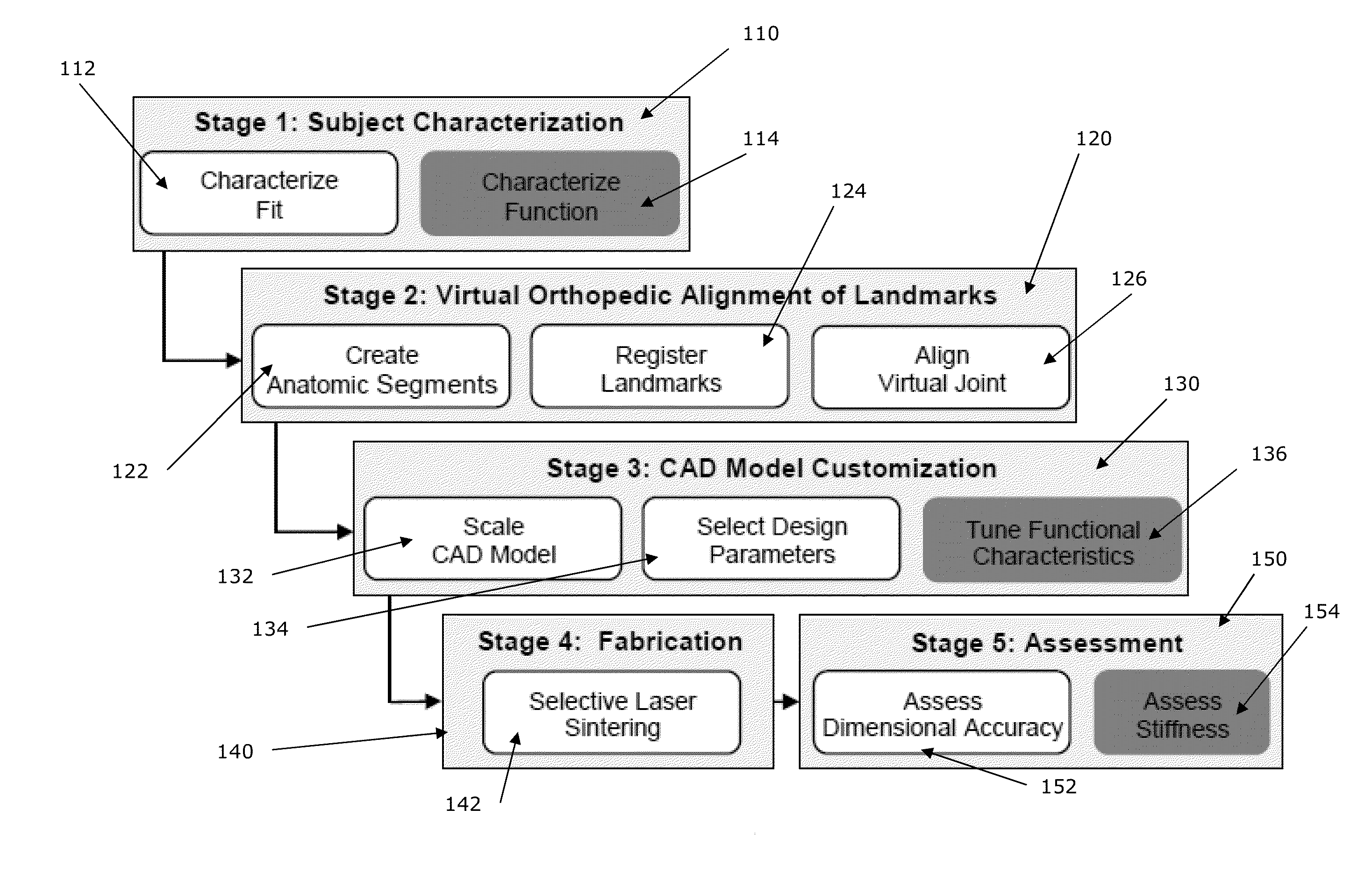

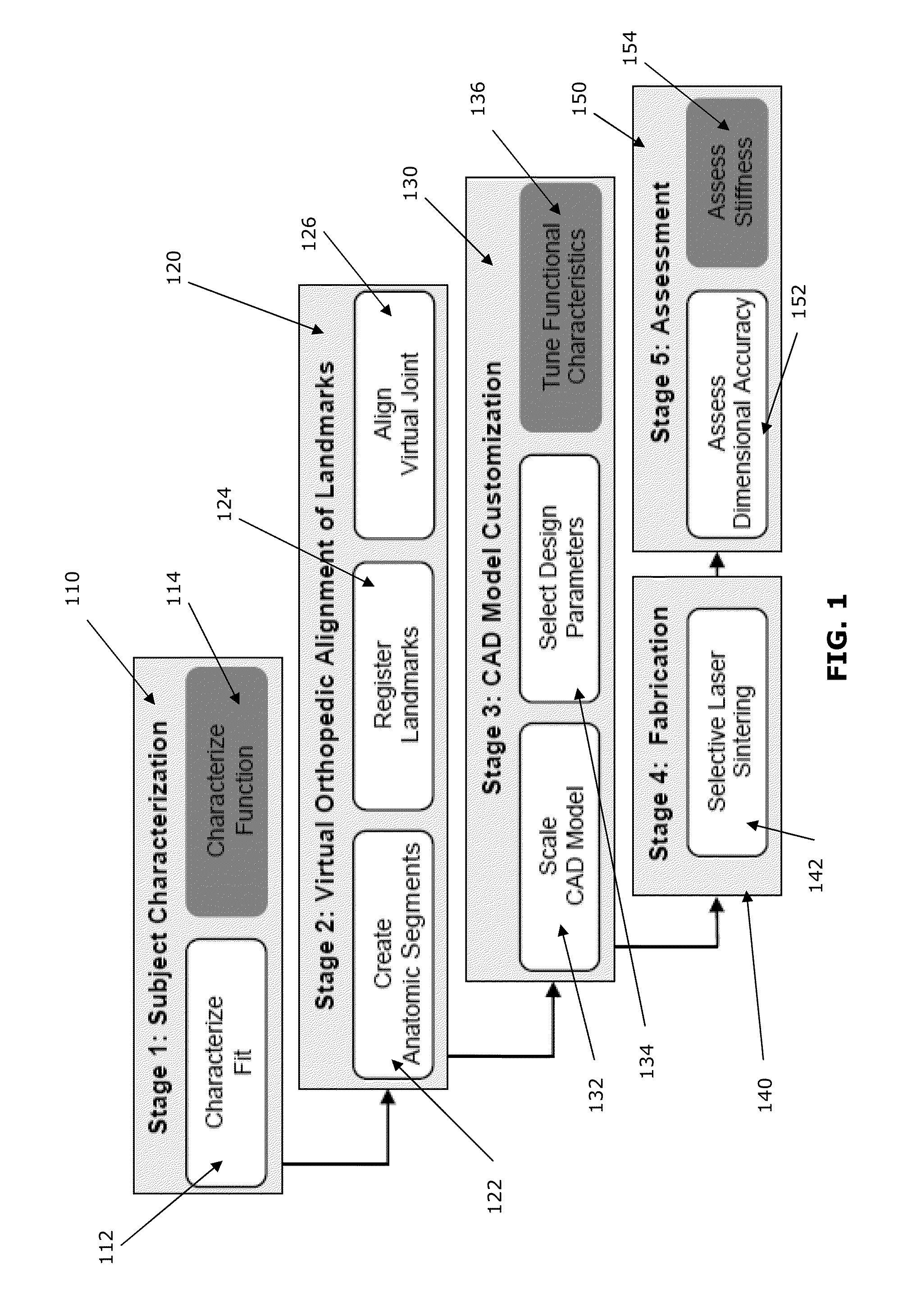

Process and System for Manufacturing a Customized Orthosis

InactiveUS20110082578A1Additive manufacturing apparatusCharacter and pattern recognitionDigital mockupComputer-aided

A process and system for fitting, customizing and manufacturing an orthosis for a subject. 3-dimensional coordinates for a plurality of landmarks corresponding to anatomical characteristics of the subject, means for attachment of the orthosis to the subject, and a reference plane are digitally acquired. Then, coordinates of one or more virtual landmarks corresponding to one or more anatomical joint centers or joint projection locations are calculated. The landmarks are clinically aligned in a reference position of one of the anatomical joint centers and a customized digital model of the orthosis is created using the clinically aligned landmarks. Finally, the orthosis is fabricated using a computer aided manufacturing process, based upon an output from the customized digital model.

Owner:UNIVERSITY OF DELAWARE

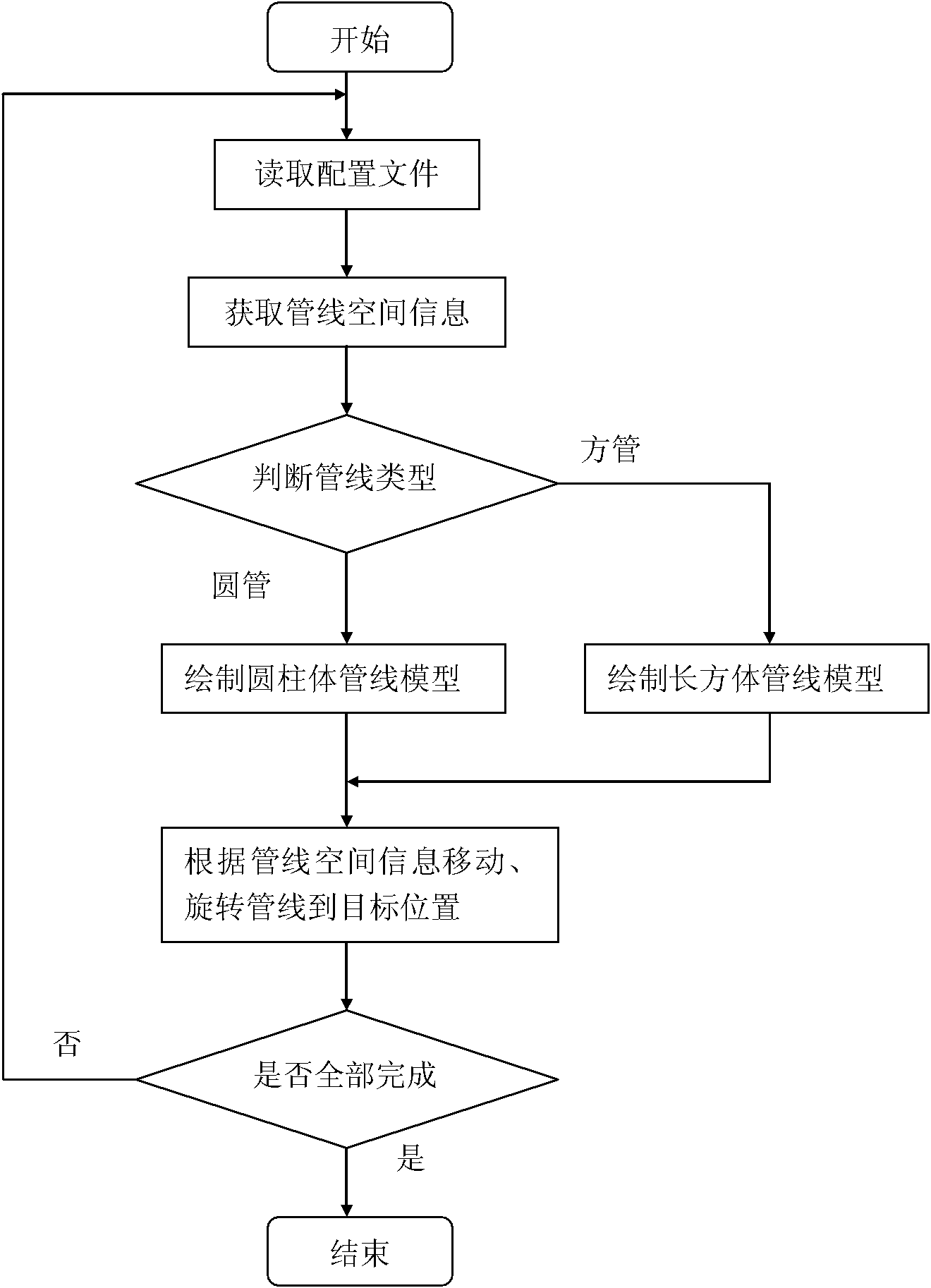

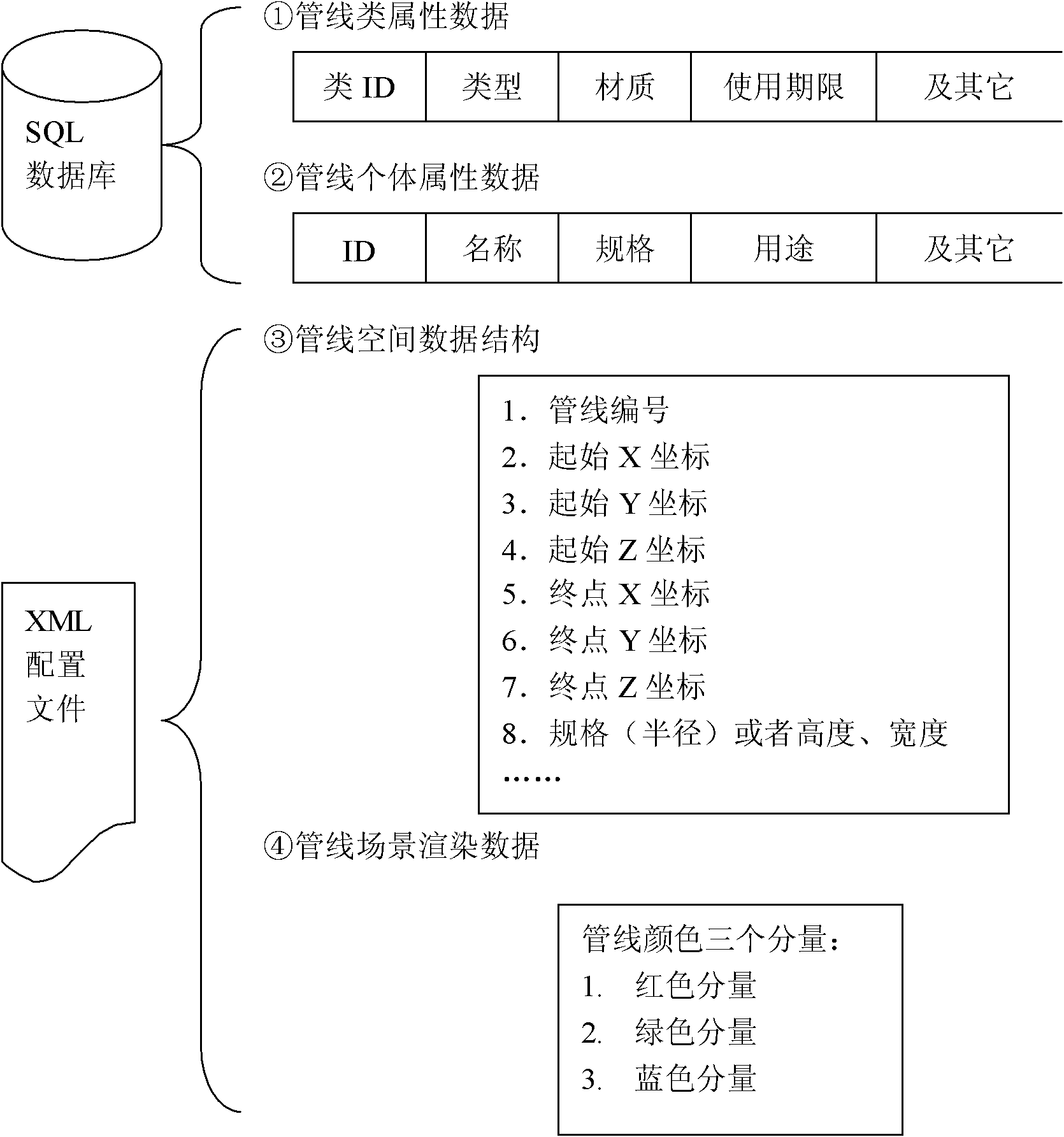

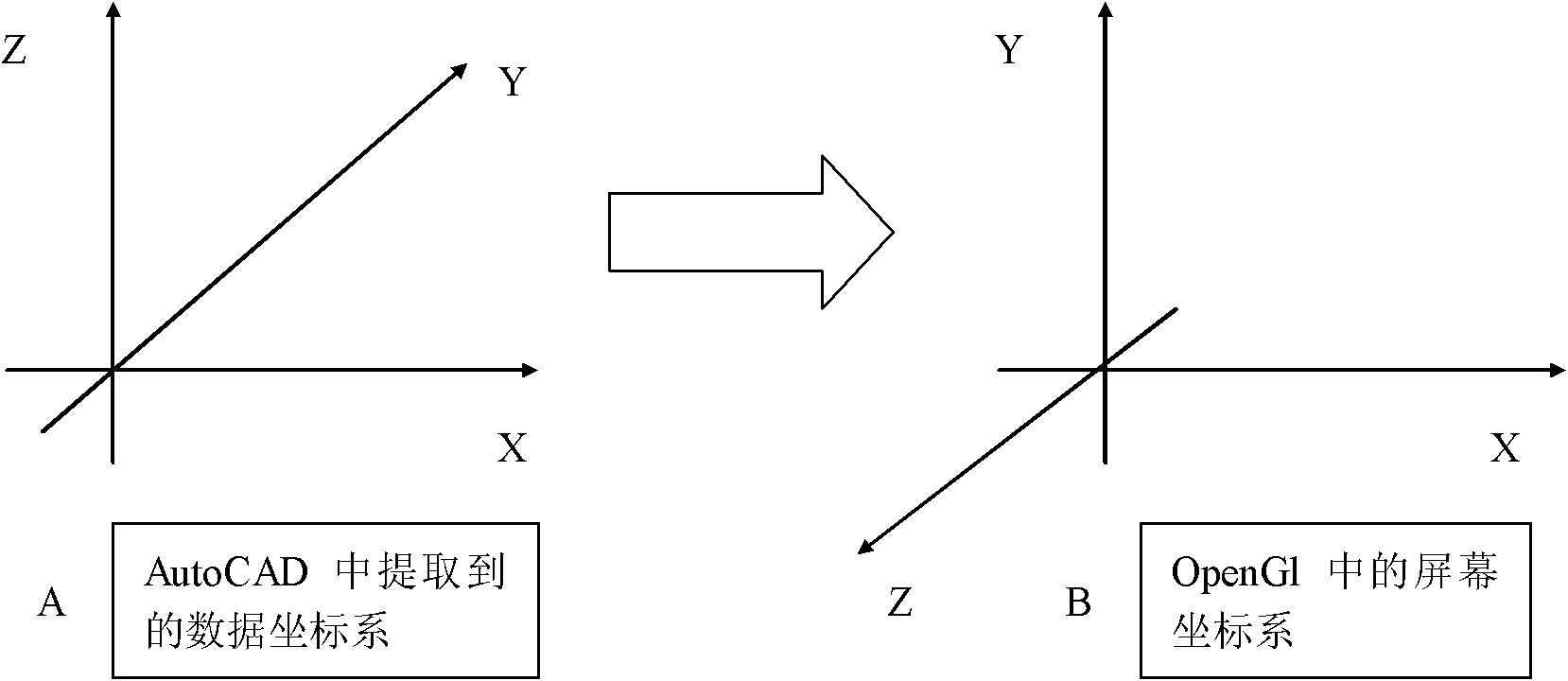

Method for three-dimensional visualization of comprehensive pipeline of metro

The invention discloses a method for three-dimensional visualization of a comprehensive pipeline of a metro. The method comprises the following steps of: firstly, extracting comprehensive pipeline data from a comprehensive pipeline drawing; and secondly, carrying out three-dimensional modelling according to the obtained comprehensive pipeline data, and carrying out three-dimensional dynamic displaying on the comprehensive pipeline. In the method for the three-dimensional visualization of the comprehensive pipeline of the metro, a modelling method has digital characteristics and can be edited in a three-dimensional visualization management system; data available for an established three-dimensional pipeline model comes from an auto computer aided design (CAD) drawing; the data is real and reliable; the position information of a three-digital pipeline model in a scene corresponds to the position information of a pipeline in the auto CAD drawing; and the three-dimensional pipeline model is configurable, changeable and manageable.

Owner:XIAN UNIV OF TECH

Material and method for preparing aluminum alloy structural member by using laser 3D (Three-Dimensional) printing technology

InactiveCN104759625AImprove performanceIncrease profitAdditive manufacturing apparatusComputer Aided DesignMaterial synthesis

The invention discloses a material and method for preparing an aluminum alloy structural member by using a laser 3D (Three-Dimensional) printing technology. Technologies such as a CAD (Computer Aided Design) three-dimensional entity model slicing technology, a digital programming technology and a laser quick forming technology and a material synthesis technology are combined integrally; under the condition that no any special mold or tool is used, multi-layer cladding accumulation is performed through quick melting and solidification of a laser beam on an aluminum alloy substrate by taking the powder of Al, Fe, Cu, Si, Ti, B, Mn, C and Ce according to the mass percentage of 80.0, 3.0, 2.0, 3.0, 4.0, 3.0, 1.5, 2.0 and 1.5 as a raw material; an aluminum alloy structural member with good comprehensive performance such as high performance, full compactness and high fatigue life is directly finished from a part digital model in one step. The method has the characteristics of low cost, short period and high material utilization rate, and is suitable for integrated quick forming manufacturing of large-sized and complex aluminum alloy structural members; the shapes and the sizes of the prepared parts are not limited, and the requirement on structural integration can be met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

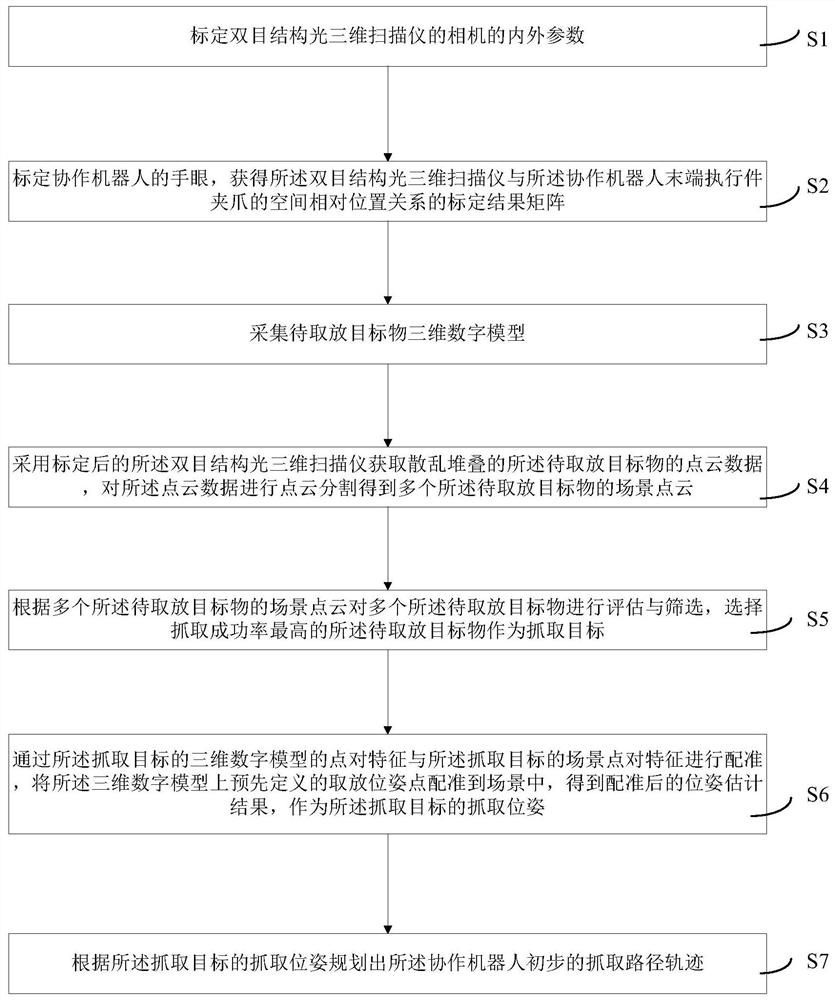

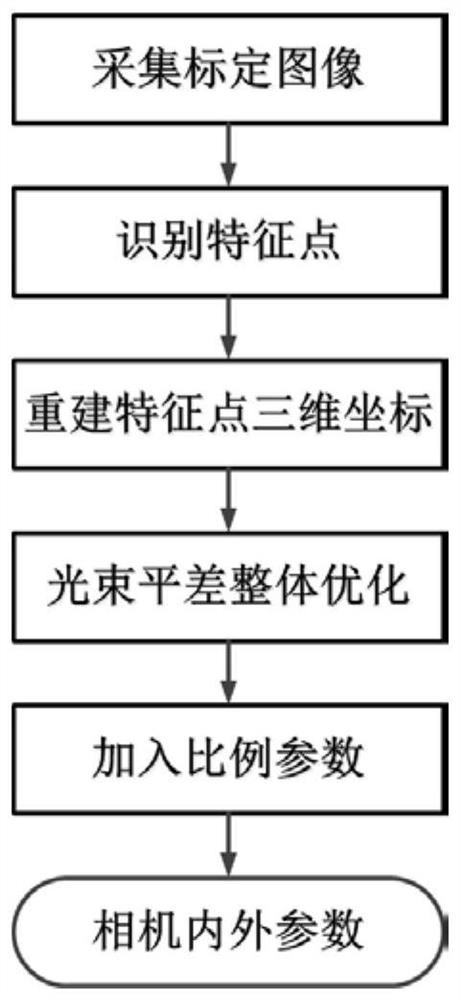

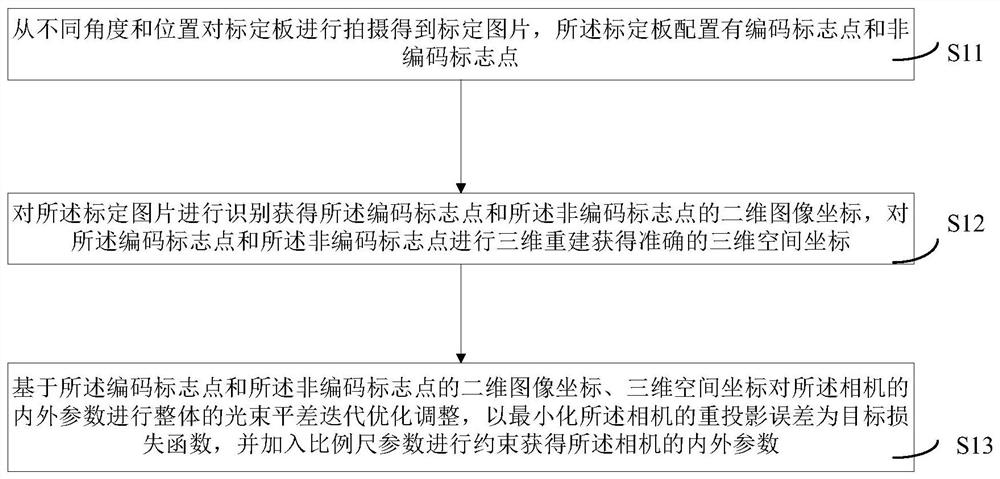

Visual 3D taking and placing method and system based on cooperative robot

ActiveCN112476434AImprove the quality of acquisitionGet fastProgramme-controlled manipulatorImage analysisPattern recognitionComputer graphics (images)

The invention provides a visual 3D taking and placing method and system based on a cooperative robot. The method comprises the steps that internal and external parameters of a camera of a binocular structured light three-dimensional scanner are calibrated; the hands and eyes of the cooperative robot are calibrated, and a calibration result matrix is obtained; a three-dimensional digital model of to-be-taken-and-placed target objects is collected; the calibrated binocular structured light three-dimensional scanner is adopted to obtain point cloud data of the to-be-taken-and-placed target objects which are stacked in a scattered mode, and the point cloud is segmented to obtain scene point clouds of the multiple to-be-taken-and-placed target objects; the to-be-taken-and-placed target object with the highest grabbing success rate is selected as a grabbing target according to the scene point clouds of the multiple to-be-taken-and-placed target objects; the three-dimensional digital model ofthe grabbing target and scene point pair features are registered, pre-defined taking and placing pose points are registered into a scene, and a registered pose estimation result is obtained and serves as a grabbing pose of the grabbing target; and a preliminary grabbing path track of the cooperative robot is planned. The target object can be accurately recognized, and the grabbing positioning precision is high.

Owner:新拓三维技术(深圳)有限公司

Preparation method of aesthetic all-zirconia restoration body

InactiveCN102579148ASmall coloring processGood aesthetic effectArtificial teethTooth PreparationsDigital mockup

The invention relates to a preparation method of an aesthetic all-zirconia restoration body. The process comprises the steps of: clinically making an impression and a model after tooth preparation, collecting the digital impression, establishing a digital model, designing the shape of the restoration body by being assisted with a computer, cutting into the shape of the restoration body by a digital control lathe, try-wearing on the model, adjusting the outline form, polishing, coloring, glazing, and completing the fabrication of final restoration body. The restoration body is colored by using a coloring zirconia porcelain piece; the coloring process is influenced little by personal factors; an all-zirconium-crown cutting end transparent handling liquid is used to handle the presintered tooth crown, so that the color and the transparence of the zirconia all-porcelain tooth change gradually, so that an ideal aesthetic effect is achieved. The preparation process is free of porcelain coating. The method has no porcelain fracture danger, and the operation is simple. The prepared tooth is few, so 1mm of preparation space is enough to use. The zirconia all-porcelain tooth has excellent biocompatibility, high strength, good transparence and glossiness, and natural and lifelike colors. CAD / CAM (Computer-Aided Design / computer-aided manufacturing) is used for designing and completing the processing, thereby ensuring the marginal adaption and precision of the zirconia all-crown porcelain tooth.

Owner:SHENZHEN UPCERA DENTAL TECH

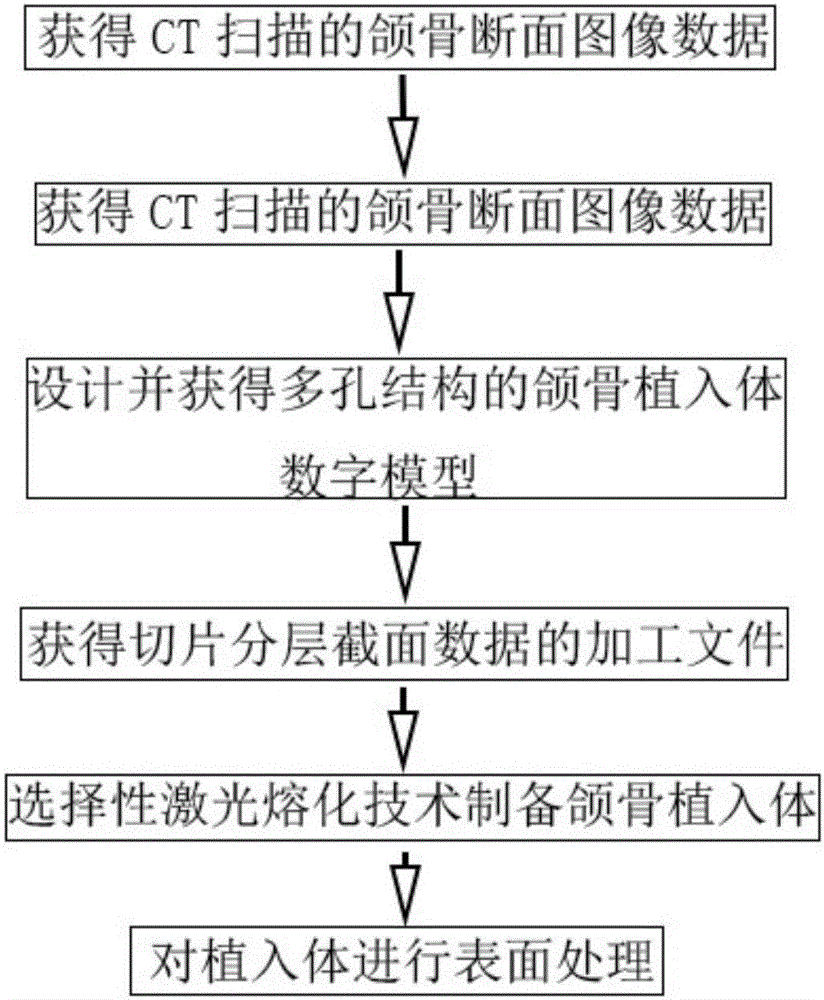

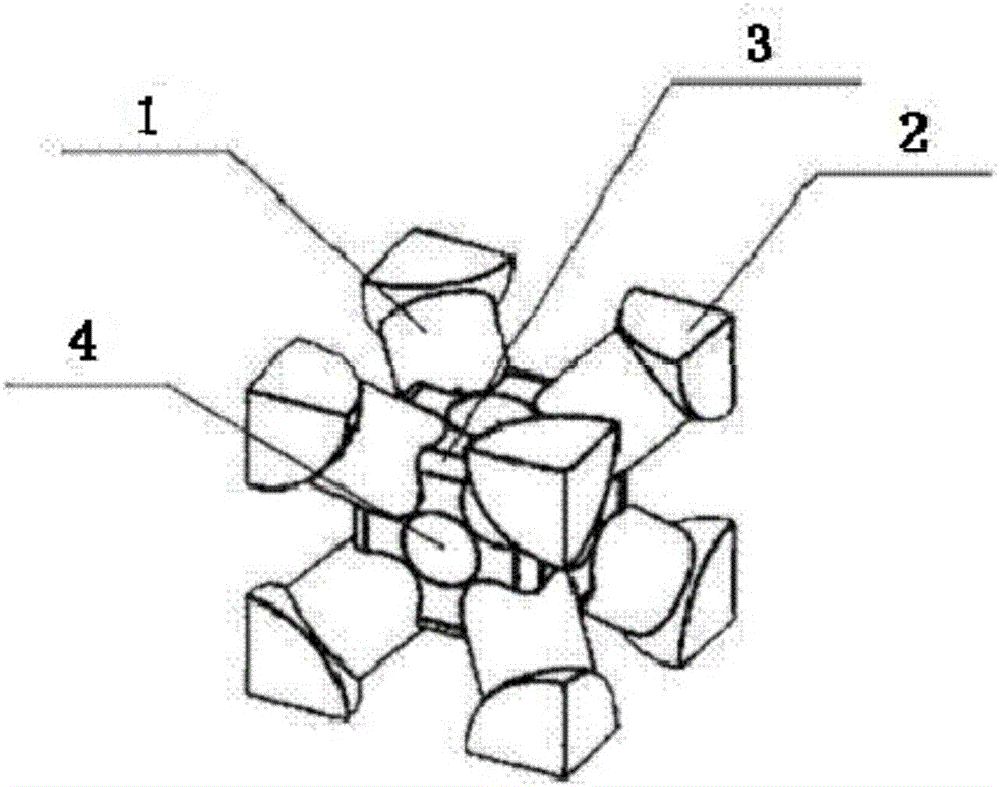

Low-elasticity-modulus titanium-based jawbone implant and preparation method thereof

InactiveCN104985183AMeet individual needsReduce concentrated stressBone implantStress concentrationPersonalization

The invention discloses a low-elasticity-modulus titanium-based jawbone implant and a preparation method of the implant. The preparation method mainly comprises the six steps that CT-scanned jawbone section image data are obtained; a rebuilt jawbone three-dimensional digital model is obtained; a jawbone implant digital model of a multi-hole structure is designed and obtained; a machining file of slice layered cross section data is obtained; the selective laser melting technology is adopted for preparing the jawbone implant; and surface treatment is carried out on the implant. The implant is used for treating a patient with jawbone defects, and the CAD digital design technology is used in the design of the implant; and jawbone repairing individualized design and multi-hole support structure design are combined, and through the selective laser melting technology, the low-elasticity-modulus titanium-based jawbone implant is prepared. The implant can meet the individual needs of the patient, and meanwhile can reduce the elastic modulus; and the problems of stress concentration and stress shielding of a traditional jawbone implant are solved, the preparation time is shortened, and the machining difficulty and the production cost are reduced.

Owner:东莞市唯信三维科技有限公司

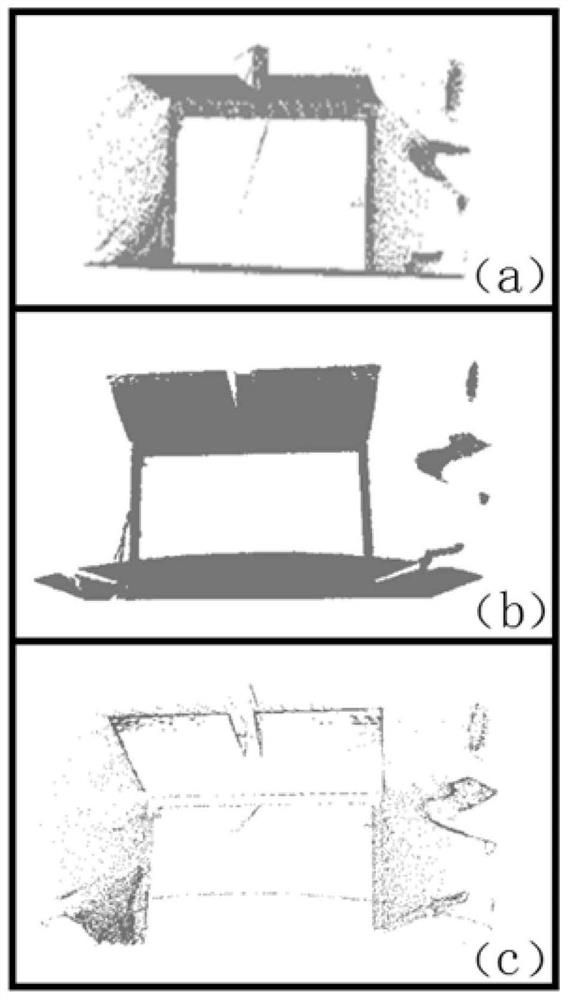

Three-dimensional entity model reconstruction method based on dense point cloud data

PendingCN111932671ALower acquisition costsAcquisition speed is fastImage enhancementImage analysisAlgorithmLaser scanning

The invention provides a three-dimensional entity model reconstruction method based on dense point cloud data. The dense point cloud data is acquired by a laser 3D scanner; 3D laser scanning can rapidly acquire three-dimensional coordinate data of the surface of a measured object in a large-area and high-resolution manner; a rapid and high-precision modeling method is matched, so that the characteristics of rapidness, non-contact, initiative, accuracy and the like are highlighted, data obtained in real time has the characteristics of high accuracy, high density and the like, reconstruction ofa three-dimensional model becomes more convenient, a digital model of an actual object can be created in the virtual world, and rapid and high-accuracy three-dimensional entity model reconstruction based on dense point cloud data is achieved; according to the semantic-based feature extraction method, a large amount of working time is saved, the semi-automatic mode is adopted for operation, the feature extraction precision and accuracy are effectively improved, the cost is greatly reduced, and the precision of the reconstructed three-dimensional solid model is obviously improved.

Owner:扆亮海

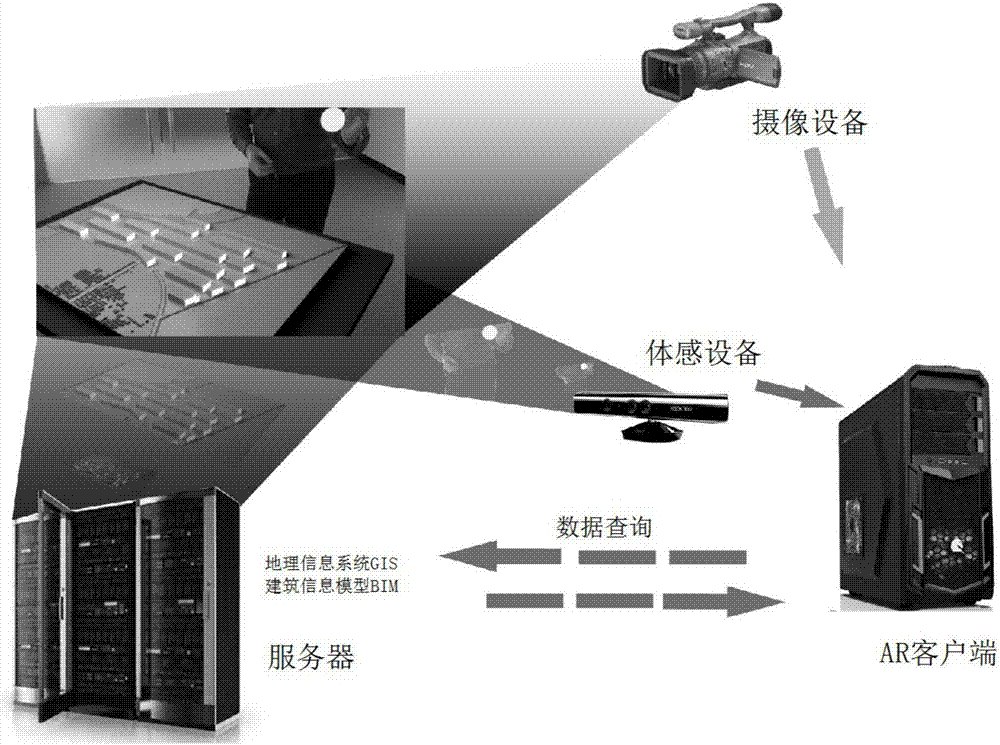

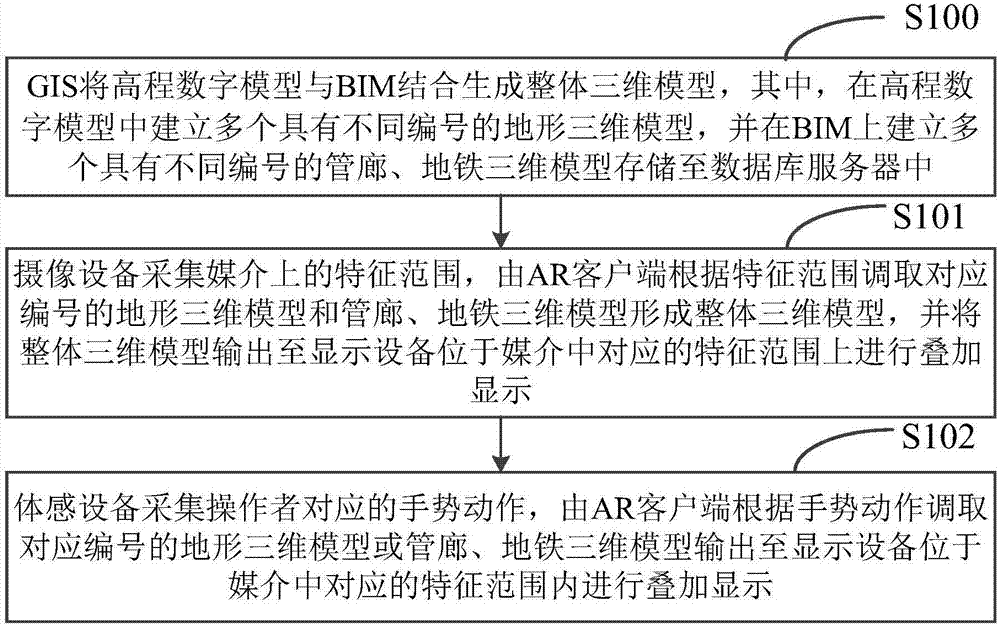

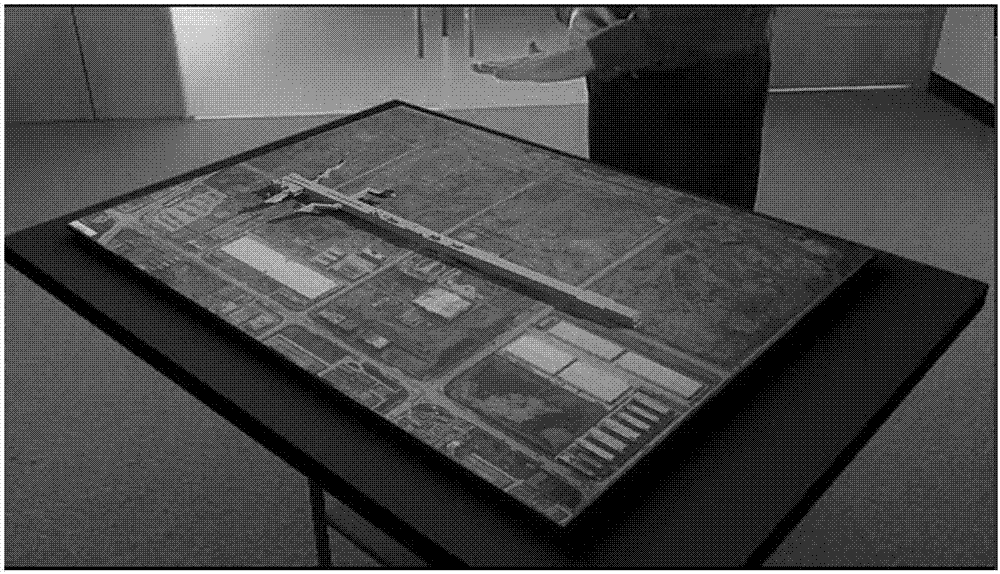

Interactive presentation method and system of GIS and BIM augmented reality in tubelane and subway construction

ActiveCN107037881AGood interactivityAvoid delays in communicationInput/output for user-computer interactionGraph readingTerrainThree dimensional model

The present invention discloses an interactive presentation method and system of GIS and BIM augmented reality in tubelane and subway construction. The method comprises: a GIS combines an elevation digital model with a BIM to generate a three-dimensional model, and establishes a terrain three-dimensional model on the elevation digital model, and establishes a tubelane-subway three-dimensional model on the BIM and stores the model into a database server; an imaging apparatus acquires a feature range on media, an AR client calls a terrain three-dimensional model and a tubelane-subway three-dimensional model with corresponding numbers according to the feature range to generate an overall three-dimensional model, and outputs the overall three-dimensional model into the corresponding feature range in a display device for overlapped display; and a sometosensory device acquires a corresponding gesture action of an operator, the AR client calls a terrain three-dimensional model and a tubelane-subway three-dimensional model with corresponding numbers according to the gesture action and outputs the terrain three-dimensional model and the tubelane-subway three-dimensional model into the corresponding feature range in the display device for overlapped display. The method and system disclosed by the present invention realize automatic identification and query of AR, and greatly improve working efficiency and quality.

Owner:广西七三科技有限公司

Method of manufacturing aluminum alloy articles

A method for making an article is disclosed. The method involves first generating a digital model of the article. The digital model is inputted into an additive manufacturing apparatus comprising an energy source. The additive manufacturing apparatus applies energy from the energy source to successively applied incremental quantities of a powder to fuse the powder to form the article corresponding to the digital model. The powder includes an aluminum alloy having 85.20-96.40 wt. % aluminum, 2.50-4.00 wt. % magnesium, 0.10-0.50 wt. % copper, 0.50-1.00 wt. % nickel, 0.50-5.50 wt. % zinc, 0-0.15 wt. % chromium, 0-3.00 wt. % titanium, 0-0.50 wt. % boron, and 0-0.15 wt. % other alloying elements, based on the total weight of the aluminum alloy.

Owner:HAMILTON SUNDSTRAND CORP

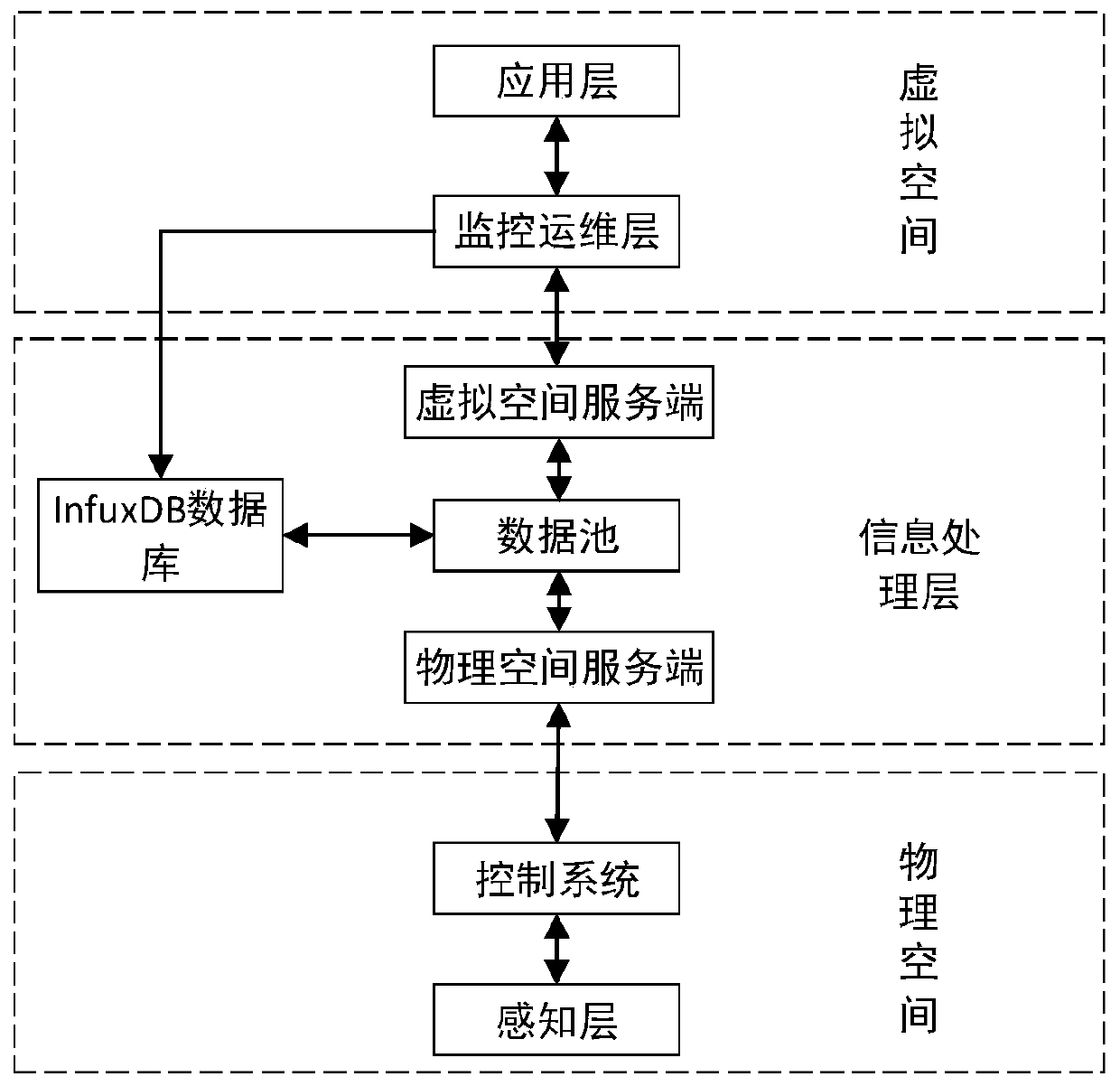

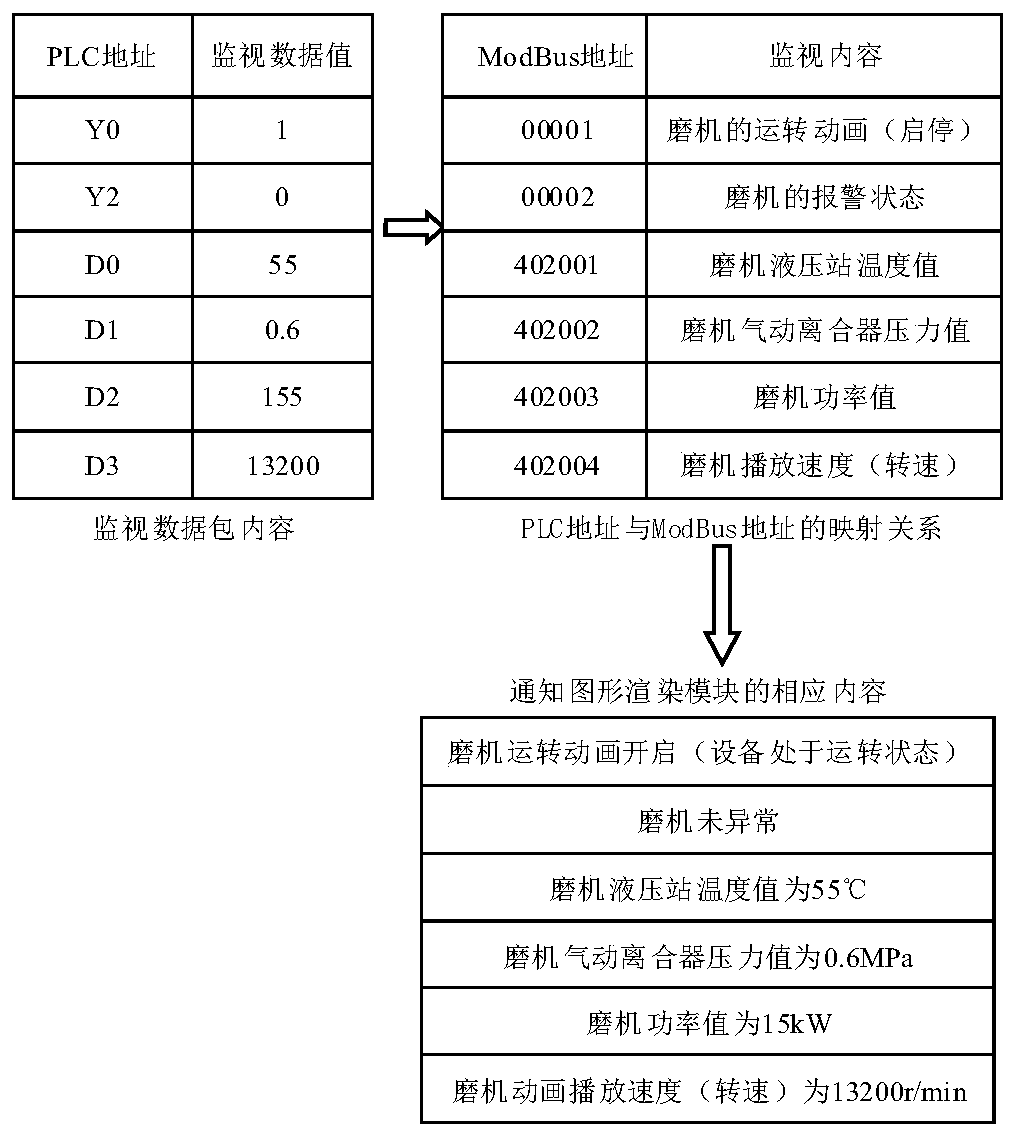

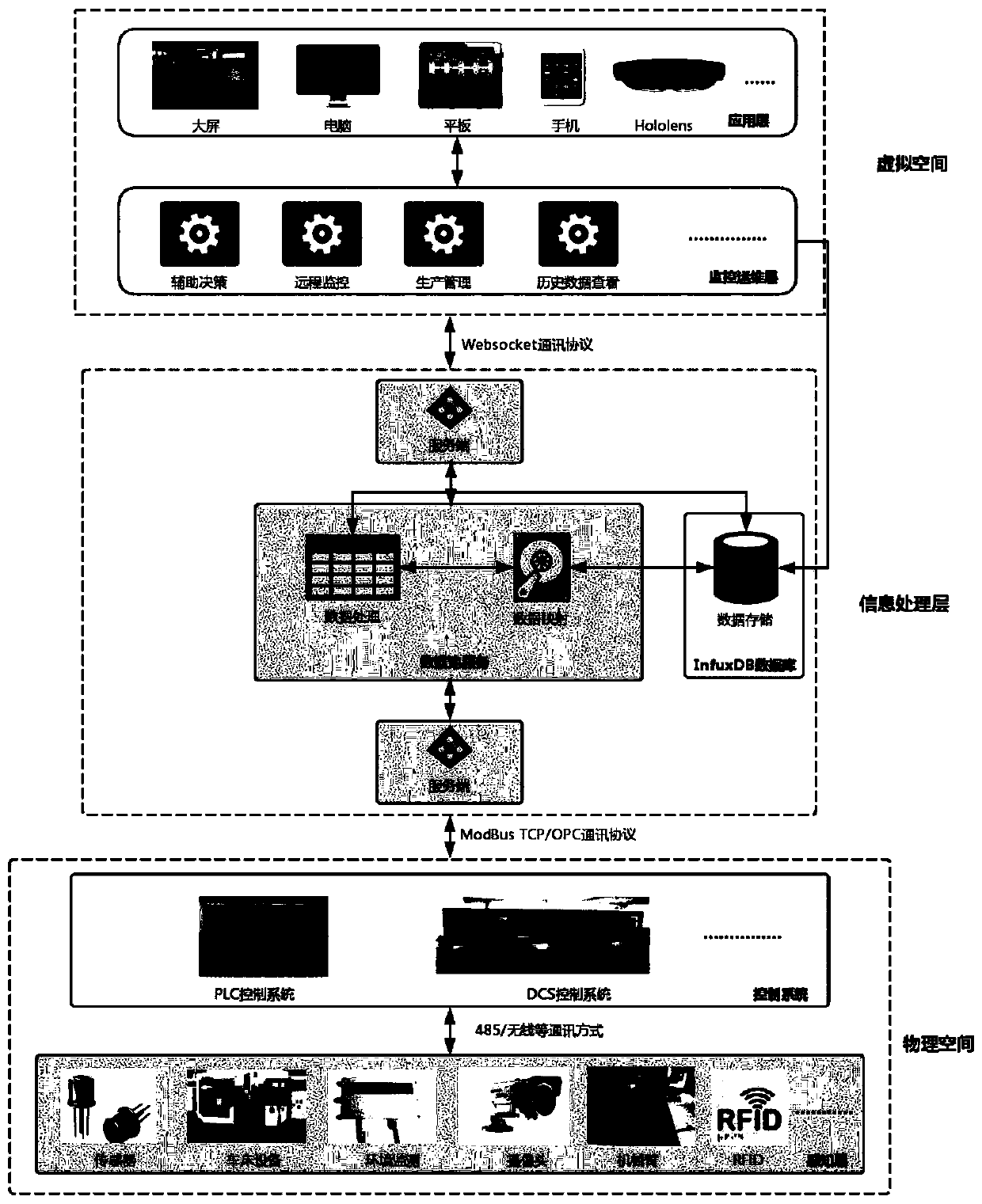

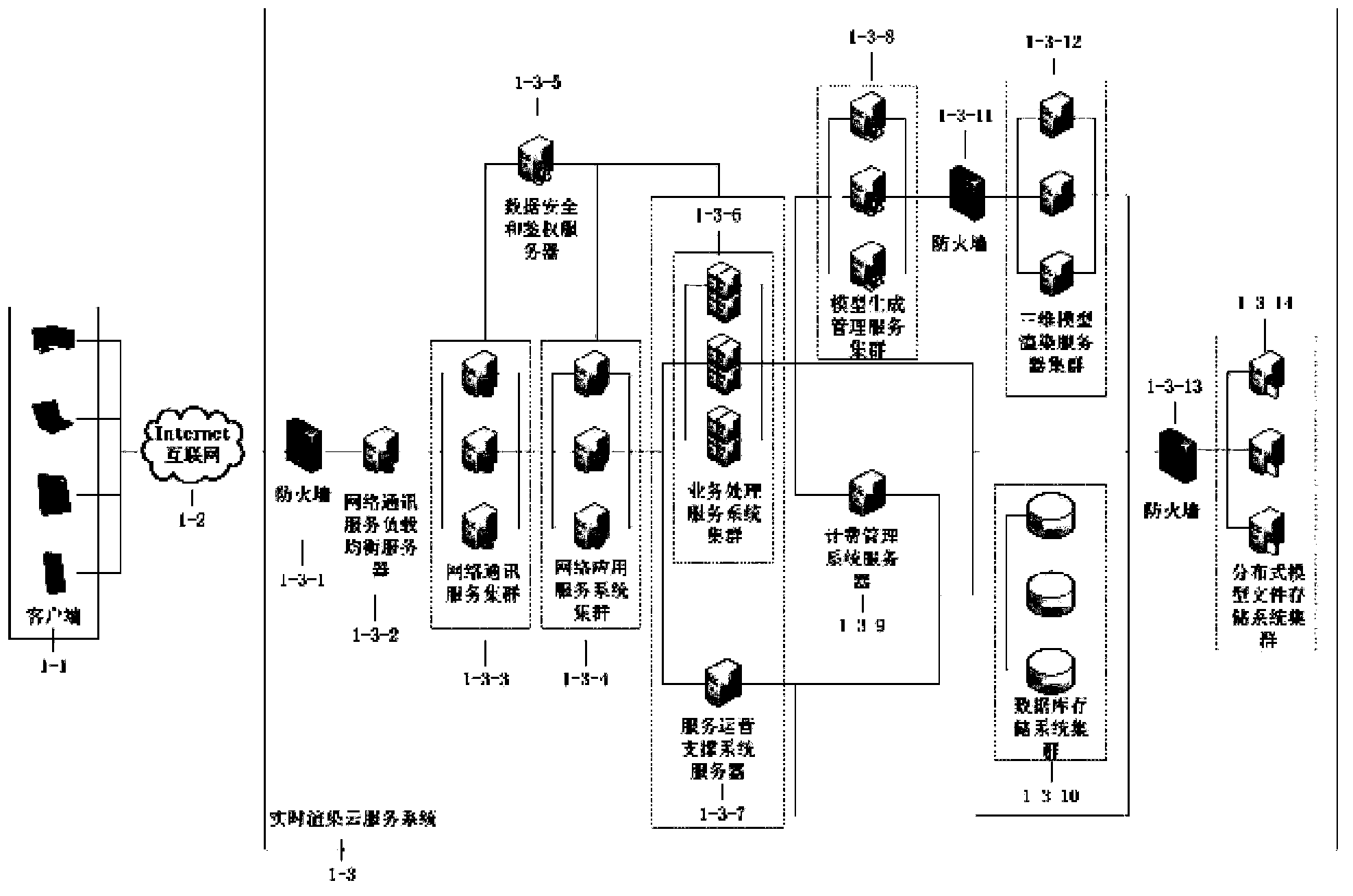

Real-time three-dimensional presentation system based on distributed sensing network

InactiveCN110320873AReal-time fast running statusAccurately grasp the running statusNetwork topologiesWireless network protocolsInformation processingPhysical space

The invention provides a real-time three-dimensional presentation system based on a distributed sensing network. The real-time three-dimensional presentation system comprises a physical space, an information processing layer and a virtual space, wherein the physical space is used for acquiring factory data, and transmitting the factory data to the information processing layer; the information processing layer is used for receiving the factory data, performing preprocessing and analytical calculation on the received factory data by a data pool in order to obtain processed factory data, and transmitting the processed factory data to the virtual space at the same time; and the virtual space is used for receiving the processed factory data, and performing modeling and scene reduction on the processed factory data through digital twin software in order to build a twin digital model of an industrial site. The real-time three-dimensional presentation system has the beneficial effects that thetechnical scheme is oriented to the global control of a factory, so that a user can rapidly and accurately comprehend the running state of equipment on the site in real time; the production process of an actual factory is controlled through a visual interaction interface; and equipment exceptions can be controlled and investigated immediately.

Owner:武汉魅客科技有限公司

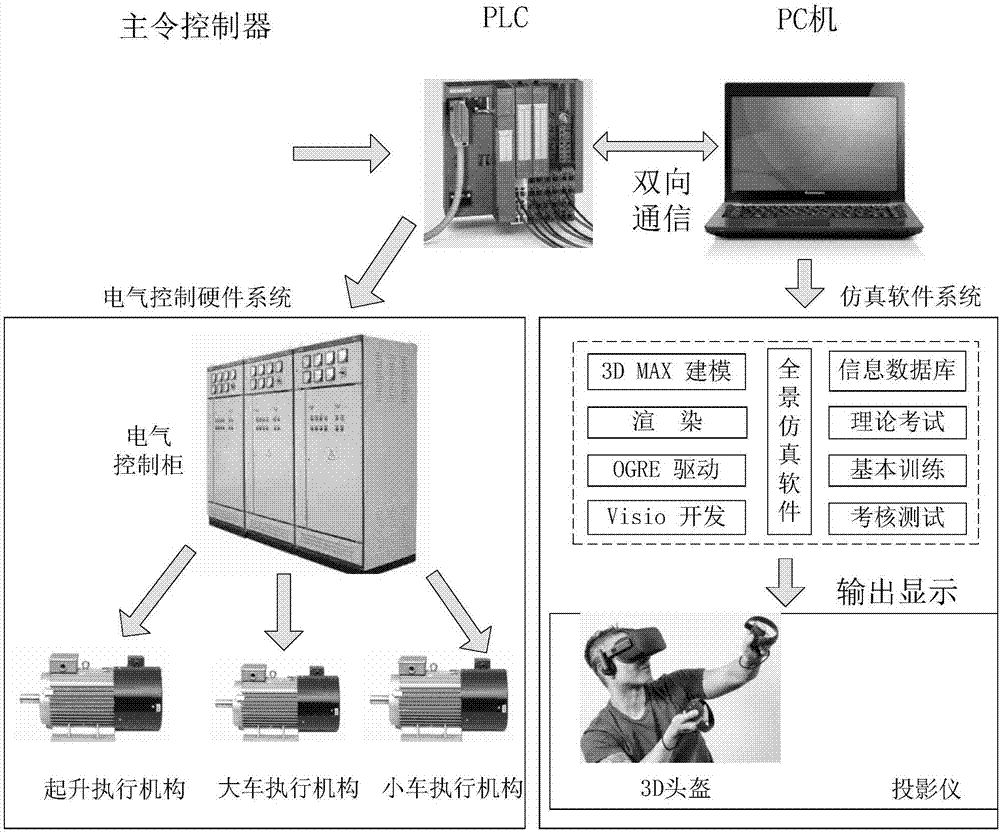

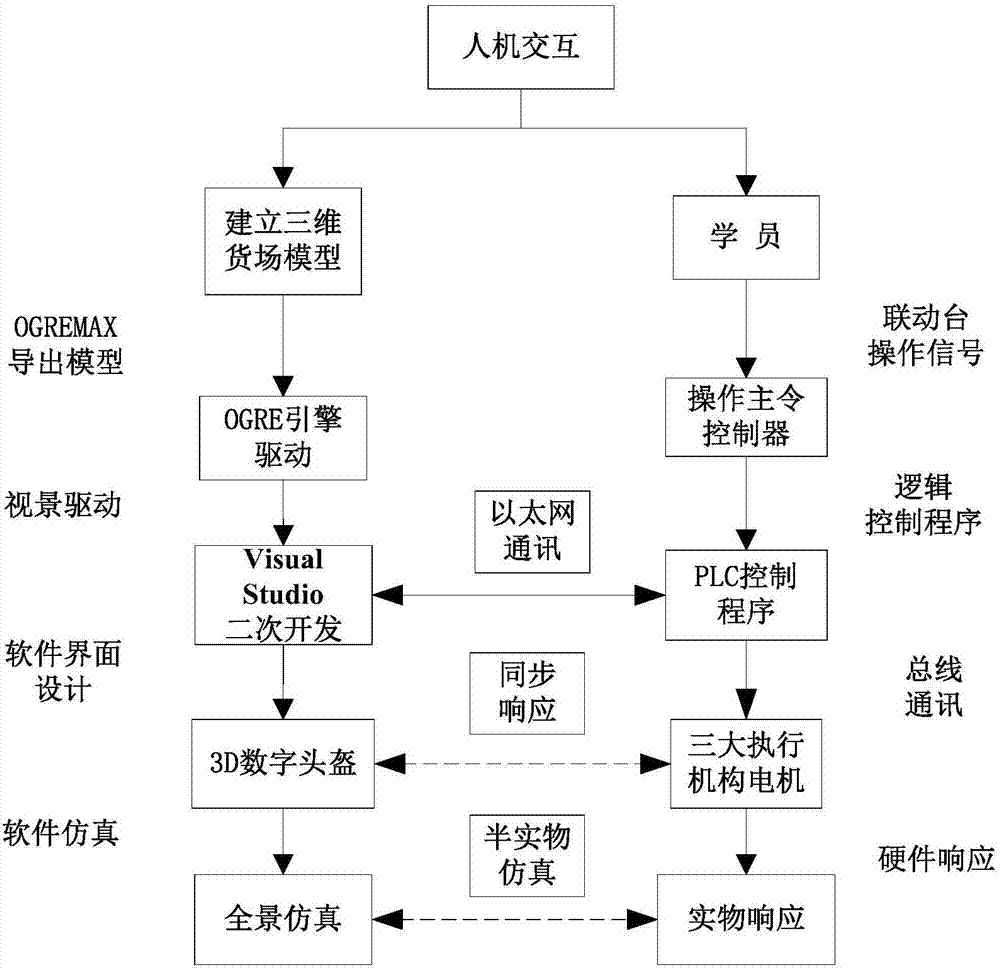

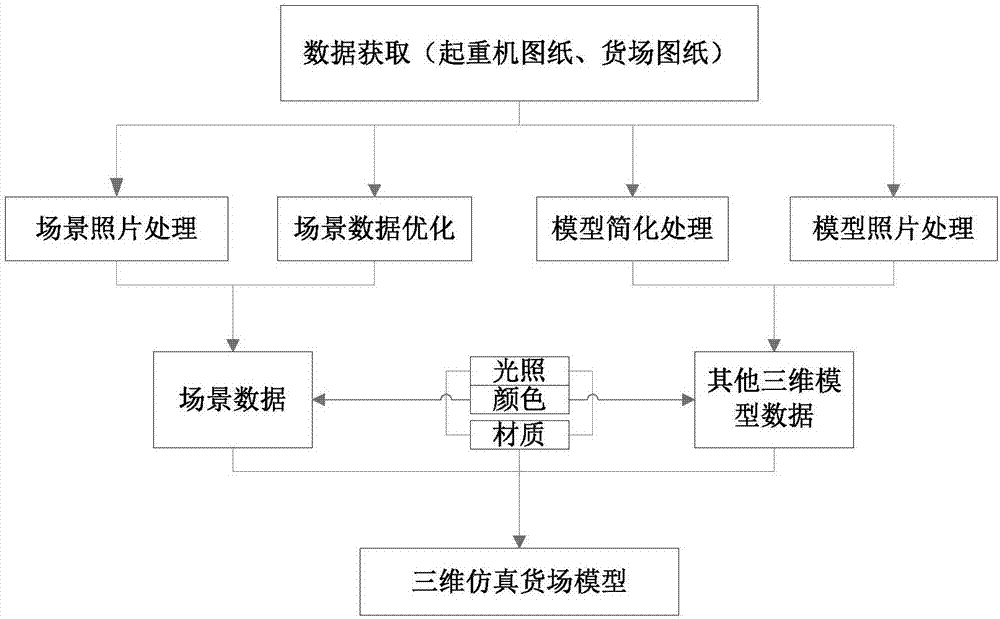

Container-door-type crane simulation operation panorama simulation system and method thereof

InactiveCN107331235AImprove training efficiencyImprove securityCosmonautic condition simulationsSimulatorsSoftware systemDigital mockup

The invention provides a container-door-type crane simulation operation panorama simulation system and a method thereof. The system comprises an electrical control hardware system and a panorama simulation software system. The electrical control hardware system comprises a crane operation linkage bench, a PLC control system, an electrical control cabinet, a driving motor, a 3D helmet system and a PC. The panorama simulation software system comprises a virtual three-dimensional modeling system, a virtual reality simulation software system, a three-dimensional virtual scene output display system, a student information recording database, a theory examination module, an operation training module and an evaluation system. A student operates a crane linkage bench and other external hardware, through using an Ethernet, operation command and the PC carry out bidirectional communication and a set of crane simulation digit model is established. A three-dimensional graph rendering engine is used to drive visual motion and a crane driver controls electrical equipment so that loading and unloading work panorama simulation operation training is performed on a container of a virtual environment. In the invention, training efficiency and training safety of a crane student are increased.

Owner:SOUTHWEST JIAOTONG UNIV

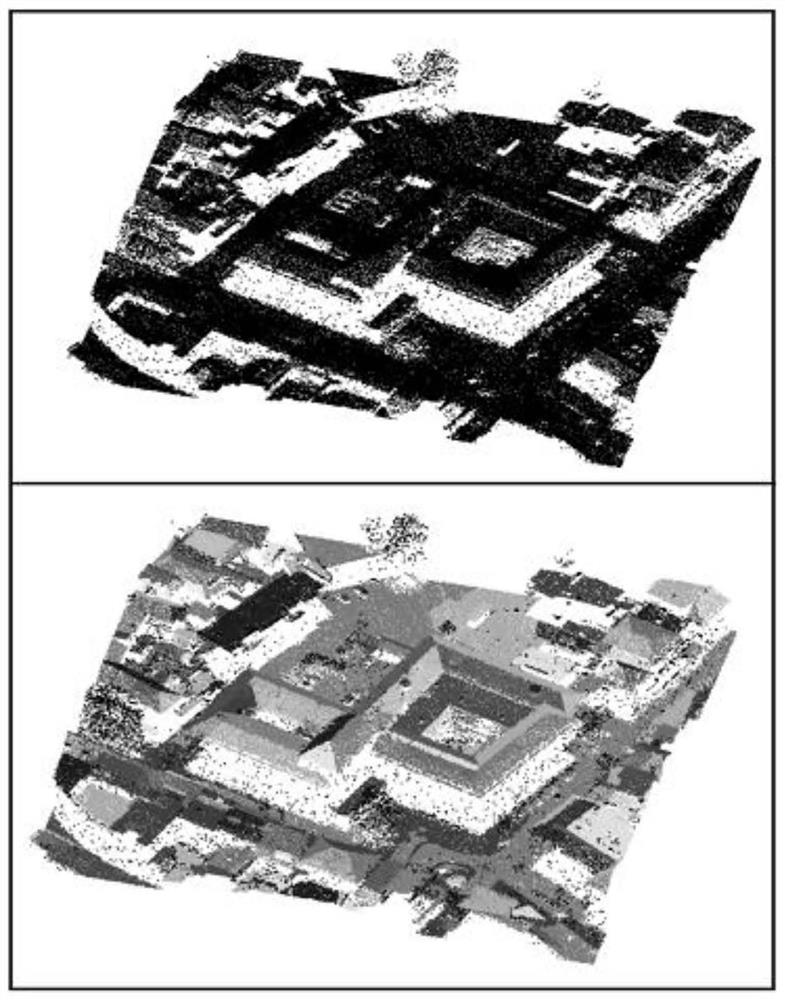

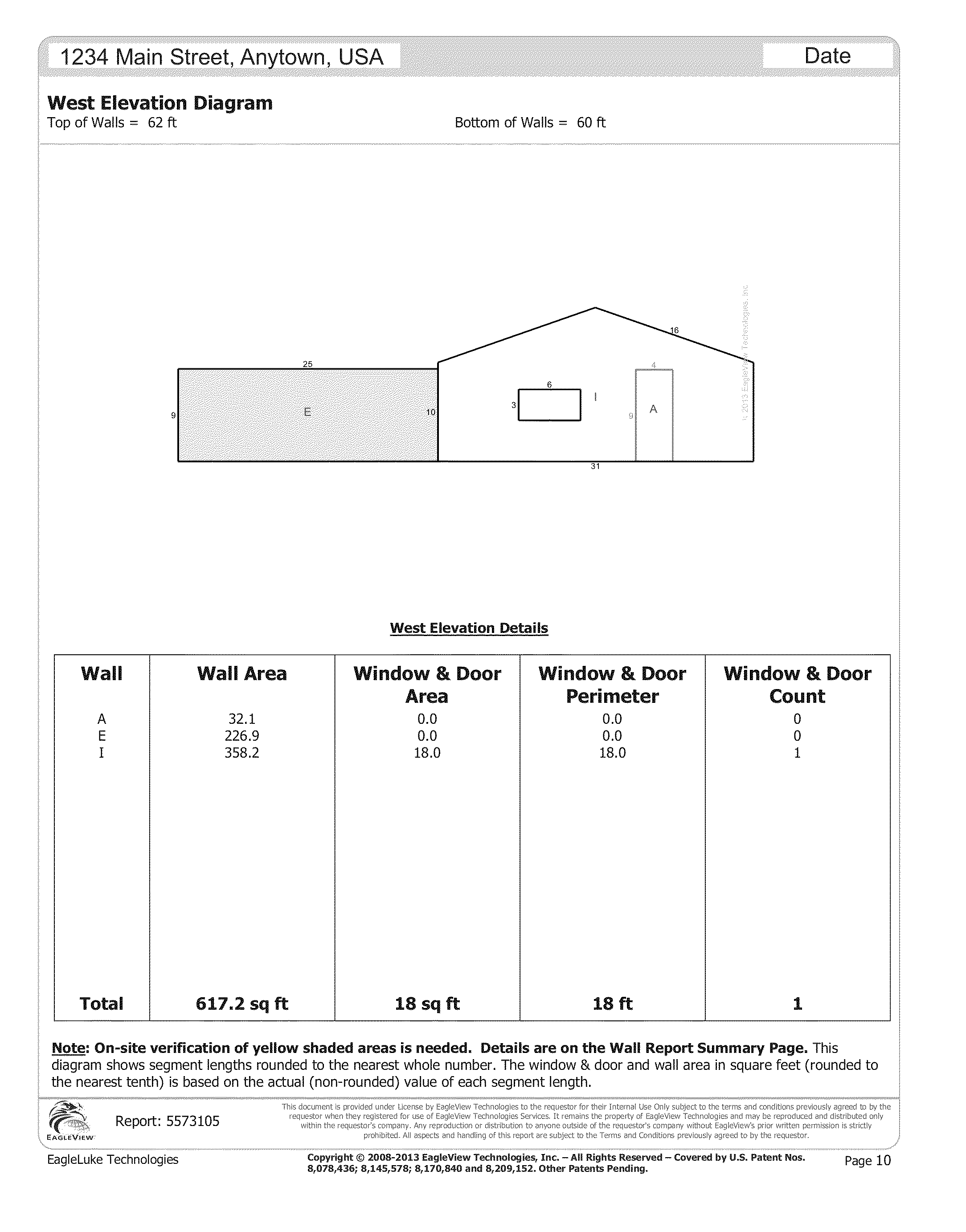

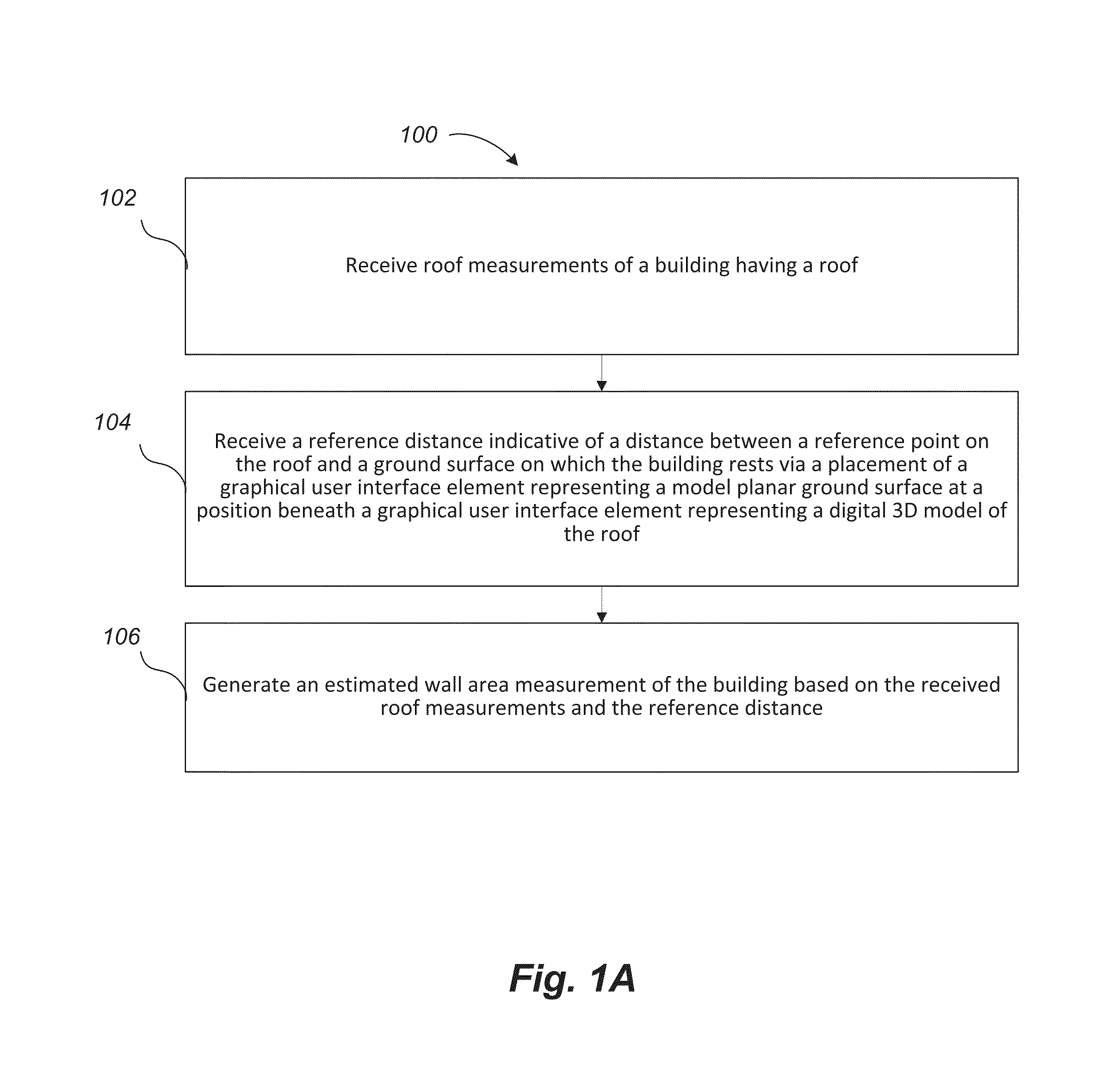

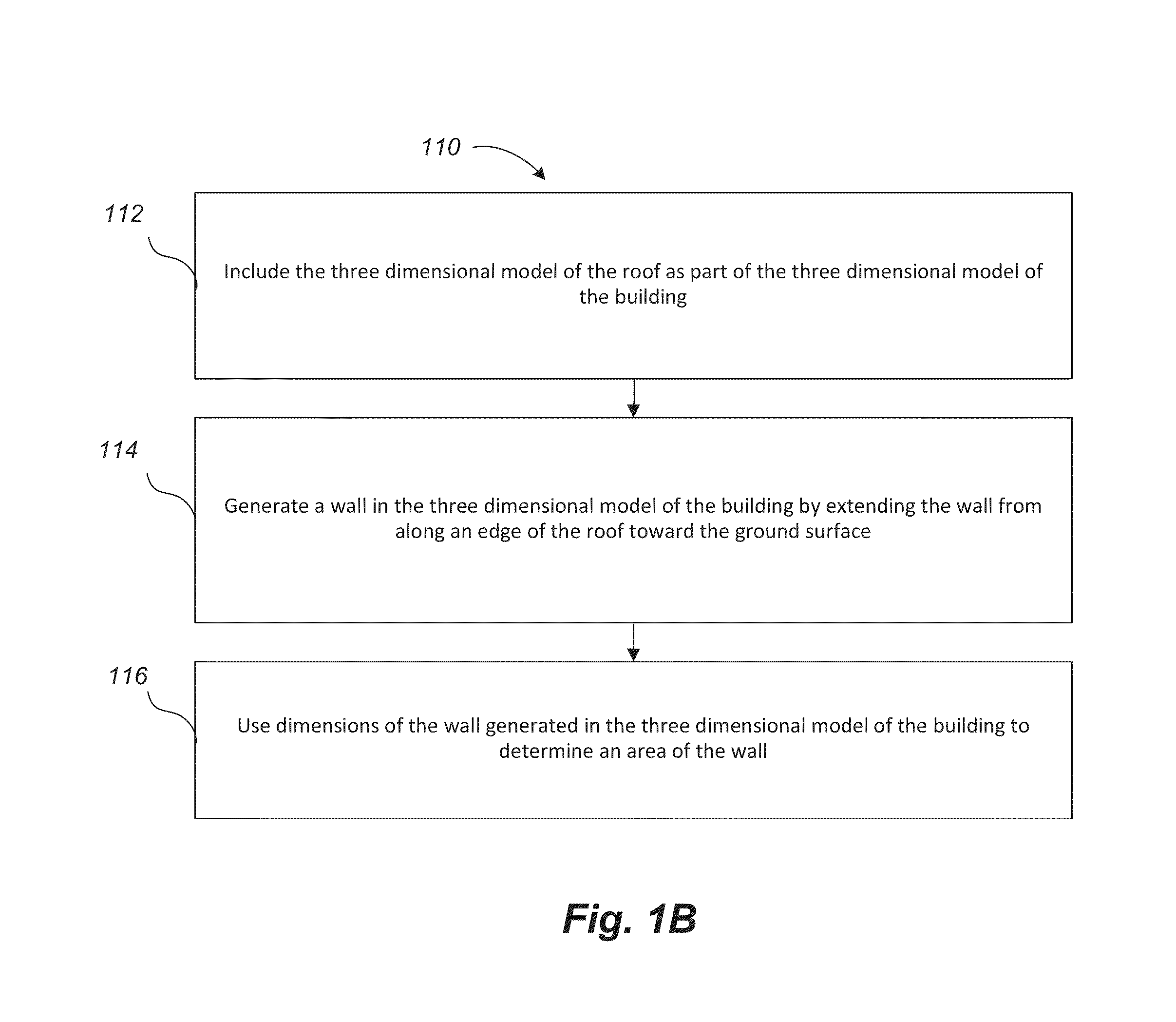

Systems and methods for estimation of building wall area

ActiveUS20140046627A1Mechanical area measurementsDigital computer detailsArchitectural engineeringStructural engineering

A wall area estimation system generates an estimated wall area measurement of a building based on the received roof measurements (e.g., those generated by, received from or found in a three-dimensional model of the roof) and a reference distance. The reference distance is a measurement indicative of a distance between the roof and a model ground surface placed on an image of the building where the walls of the building meet the ground. This reference distance may be used to determine how for down to extend the walls of the building (e.g., to a ground level) when building a three-dimensional digital model of the building to aid in generating wall area measurements. The resulting wall measurements, roof measurements, measurements of areas missing from the wall used to generate a wall estimate report, or a combined roof and wall estimate report including various different identifiers indicating the different features and measurements based on the three-dimensional model.

Owner:EAGLEVIEW TECH

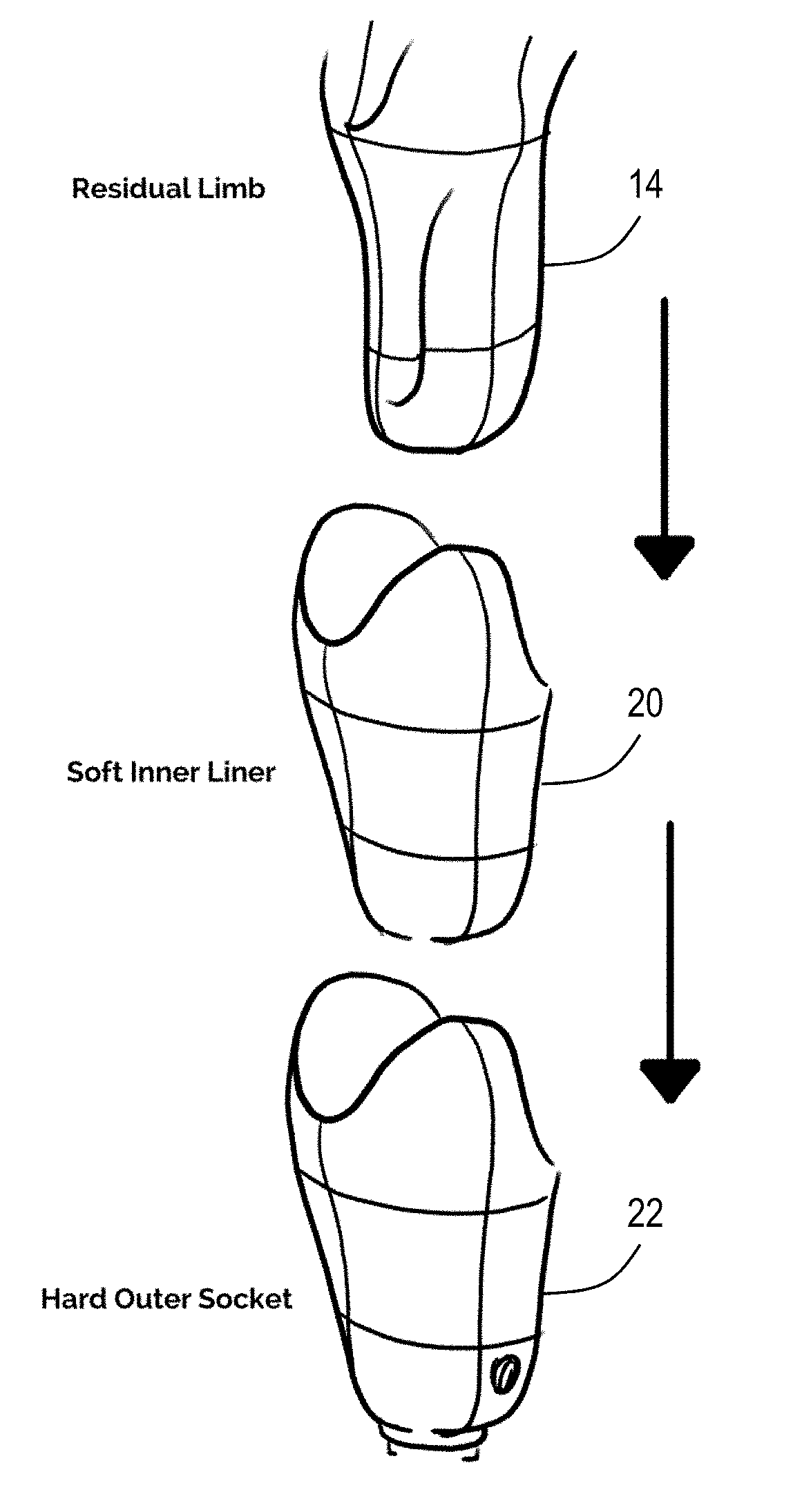

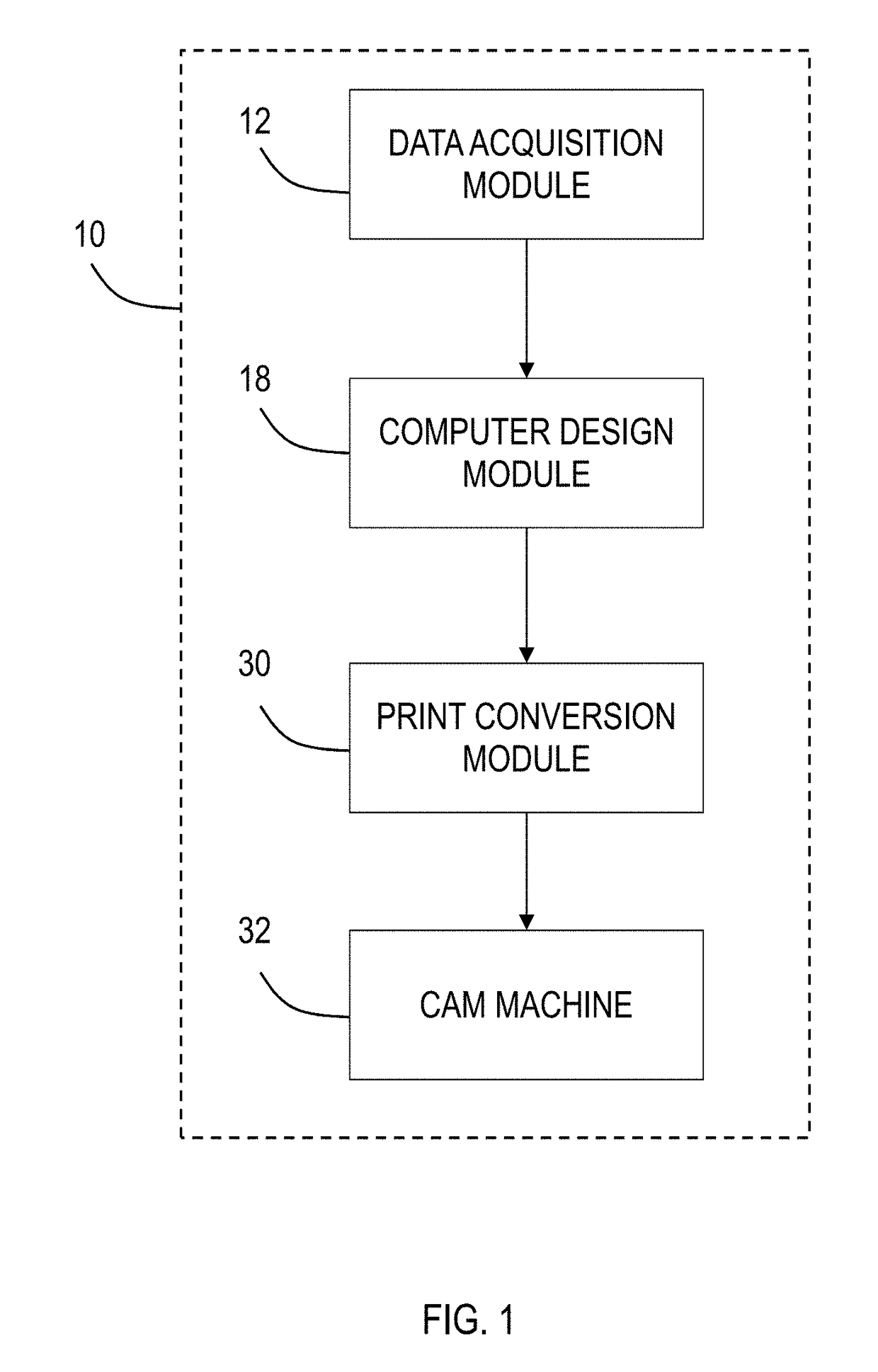

Prosthetic limb socket with variable harness

A system and method for producing a customized prosthetic socket based on a digital representation of a residual limb that is used to form a digital model of a prosthetic socket. The digital model is customized to alter its internal structure to produce differing areas of flexibility and support while maintaining the overall geometry of the model and without having to use different materials. The digital model is converted for use with a three-dimensional printing or manufacturing device and then used to print the customized socket.

Owner:PVA MEDICAL LLC

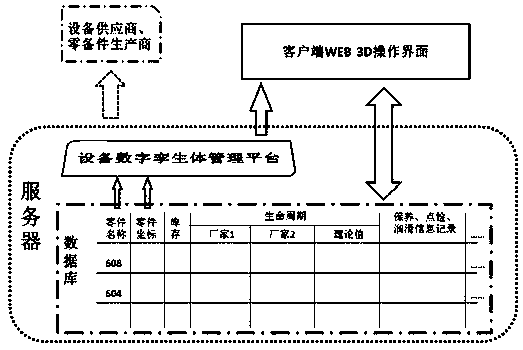

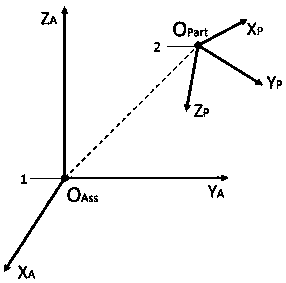

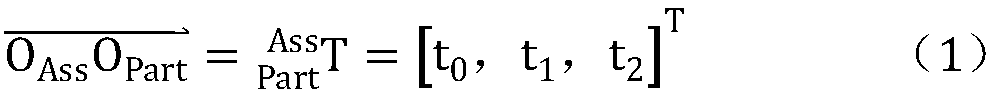

A method for component life cycle management based on equipment digital twin management platform

ActiveCN109146090AImplement life cycle managementAccurate predictive maintenanceData processing applicationsManufacturing computing systemsInterior spaceDigital line

The invention discloses a component life cycle management method based on a device digital twin management platform, belonging to the field of intelligent manufacturing management of equipment in industrial enterprises, the concrete steps of the component life cycle management method based on the equipment digital twin management platform are to establish a component digital twin model with the component origin inside the entity, take a part as an assembly, create a digital twin of the device, determine the spatial coordinates of the parts in the digital twin of the equipment, and add the physical properties of the parts with the spatial coordinate values of the parts located in the internal space of the digital twin of the equipment. As the user of the invention remotely accesses the digital model of the device store on the server by the client, by interacting with the database, the model library can distinguish the information of components under different working conditions, and thedatabase records the information of any maintenance and replacement of the components, so as to realize the life cycle management of the components of large-scale equipment.

Owner:HONGTA TOBACCO GRP

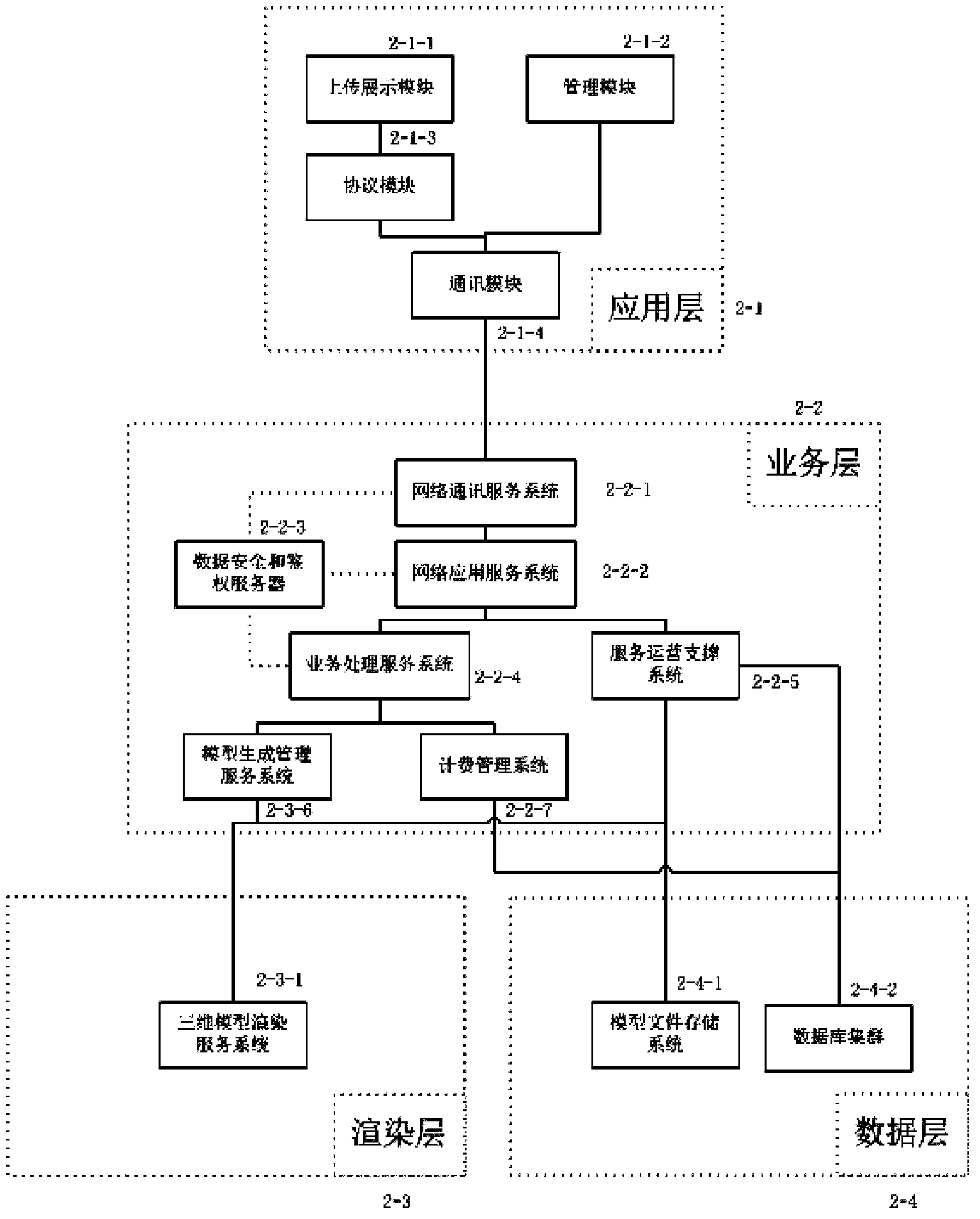

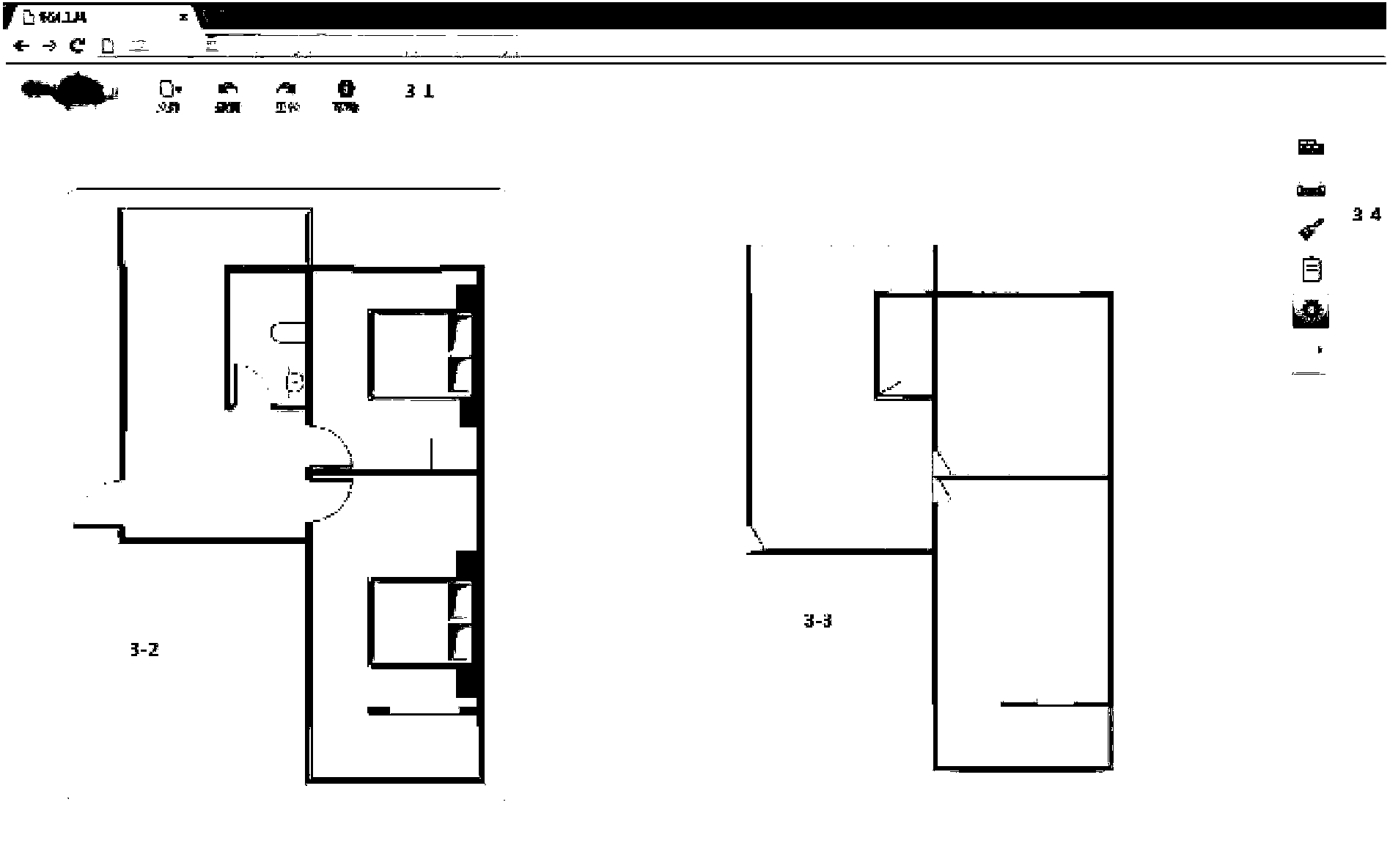

Implementation method and system for automatic generation and on-line interaction of three-dimensional digital model with planar space structure

ActiveCN103400415AChange generation methodTransmission3D modellingAutomatic Generation ControlStructure chart

The invention discloses an implementation method and system for automatic generation and on-line interaction of a three-dimensional digital model with a planar space structure based on a cloud computing frame. The method comprises the following steps: uploading a planar structure chart to a server at a client side; after receiving the planar structure chart by the server, analyzing and recognizing the chart, and then generating the three-dimensional model according to user settings. A user can perform operation of rotating and scaling the generated model to observe whether the model meets the requirement. The user can adjust the modeling process of a certain house model, and the positions, the heights and the styles of a wall and a window, and then the home model is regenerated by the server. The user can browse the home model in the system and various matched furniture. Through the adoption of the method and the system, an original three-dimensional model generation way is changed, the generated three-dimensional model can be in interaction with the user, and the user can match various furniture and browse from multiple angles.

Owner:JIANGSU CUDATEC TECH CO LTD

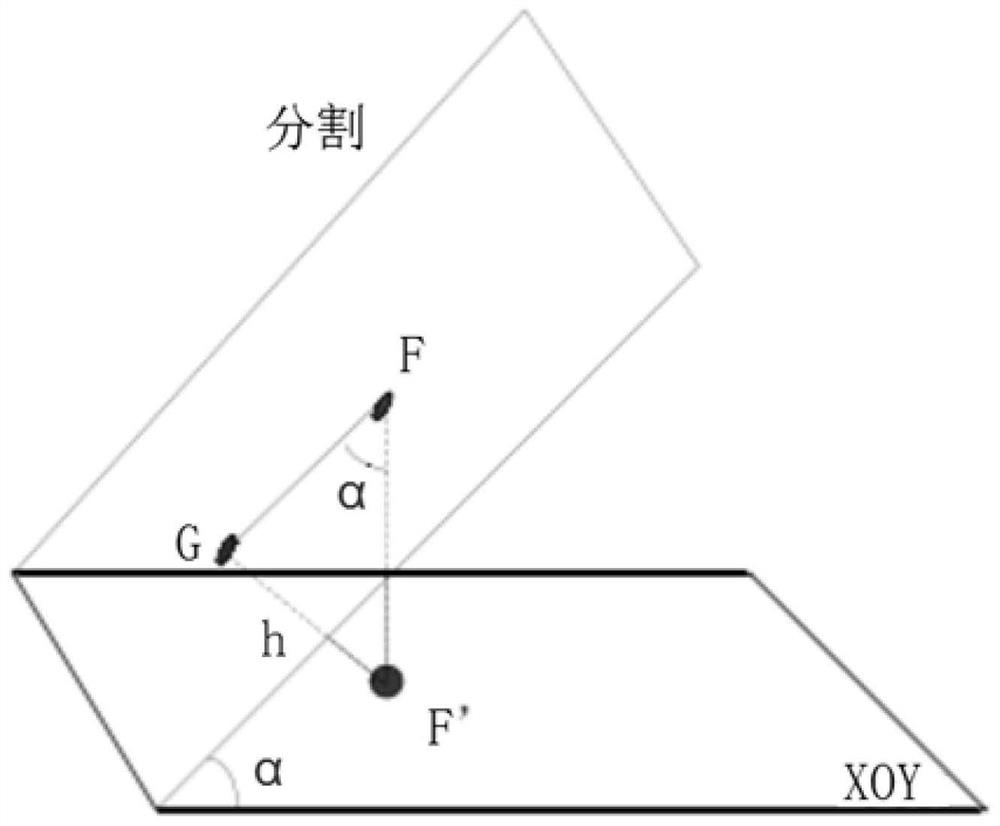

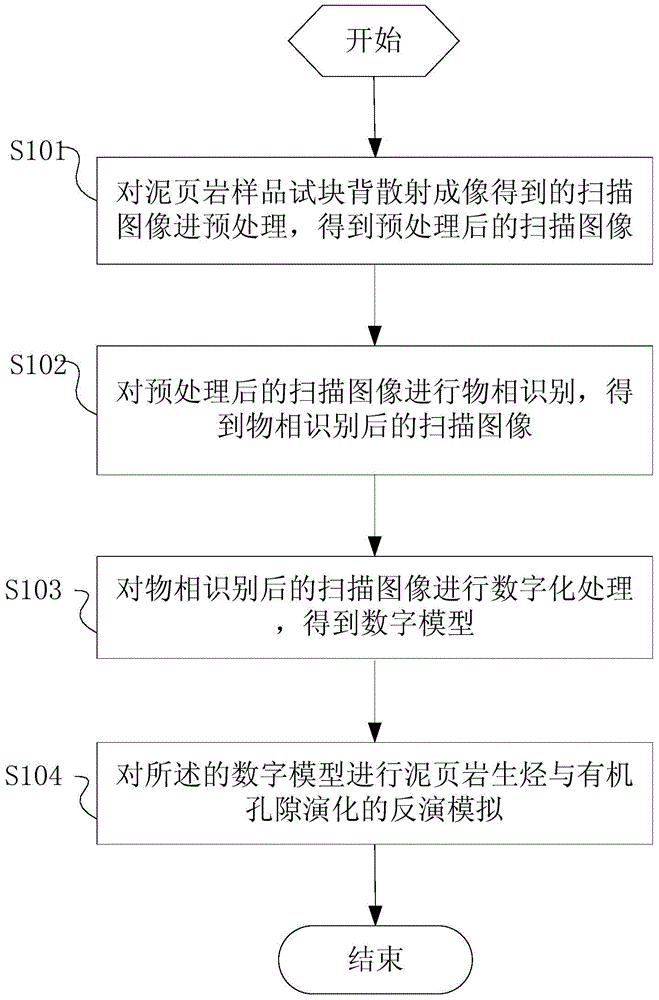

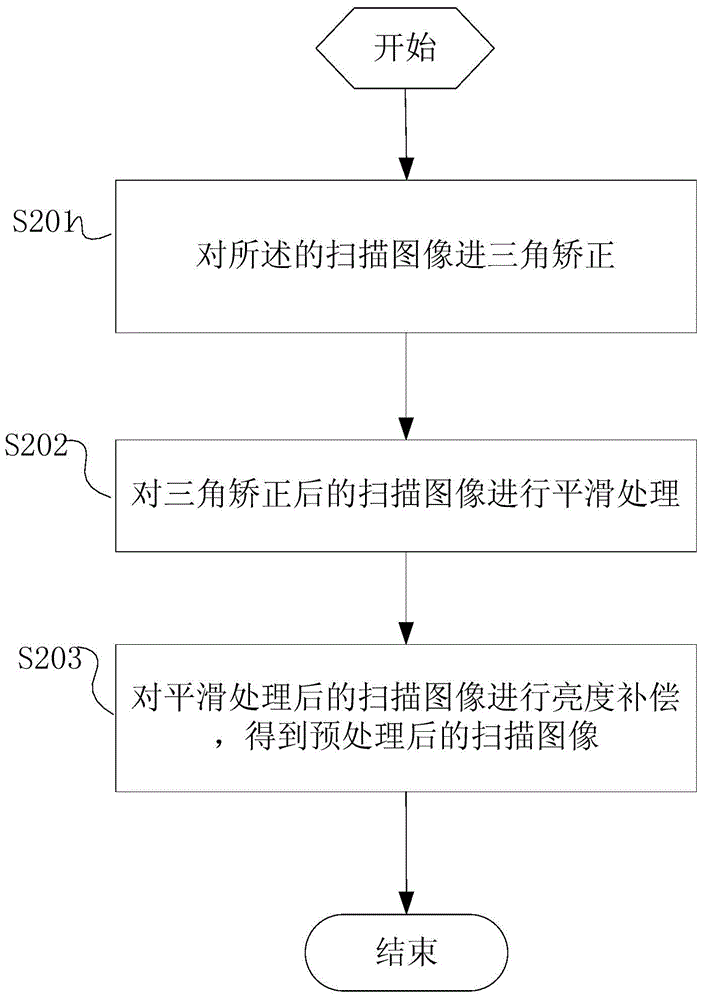

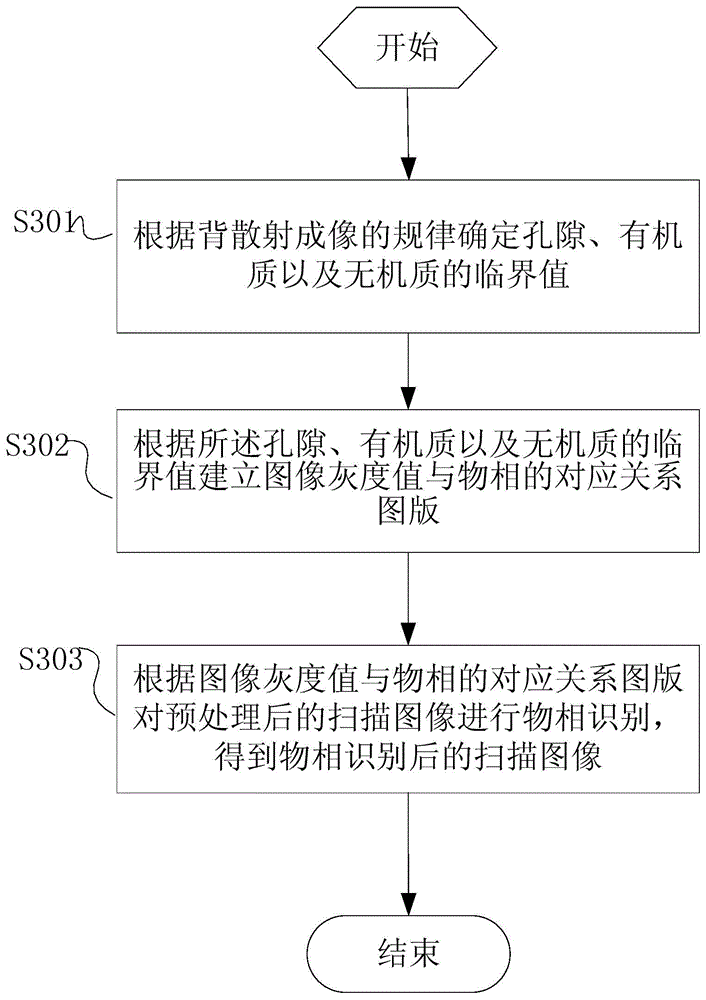

Simulation method and system of hydrocarbon generation of shale and organic pore evolution

The invention provides a simulation method and system of hydrocarbon generation of shale and organic pore evolution. The method includes the steps that a scanned image obtained by conducting back scattering imaging on a shale sample block is preprocessed to obtain a preprocessed scanned image; phase identification is conducted on the preprocessed scanned image to obtain a scanned image obtained after phase identification is conducted; digital processing is conducted on the scanned image obtained after phase identification is conducted so as to obtain a digital model; inverse simulation of hydrocarbon generation of the shale and organic pore evolution is conducted on the digital model. The microscopic rock structure characterization technology is used for establishing a model for shale thermal evolution simulation, then the hydrocarbon source rock thermal evolution process is simulated, the thermal evolution process can be represented quantitatively and visually, and powerful technical support can be provided for unconventional oil and gas resource research, especially shale oil research.

Owner:PETROCHINA CO LTD

3-d printing of porous implants

Computer implemented methods of producing a porous implant are provided including obtaining a 3D image of an intended tissue repair site; generating a 3D digital model of the porous implant based on the 3D image of the intended tissue repair site. The method also includes determining an implant material and an amount of a porogen to add to an implant material to obtain a desired porosity of the porous implant. The desired porosity is based on a combination of macropores, micropores and / or nanopores structures. The 3D digital model developed is stored on a database coupled to a processor, wherein the processor has instructions for combining the implant material with the porogen based on the stored 3D digital model and for instructing a 3D printer to produce the porous implant. A layered 3Dprinted porous implant prepared by the computer implemented method is also provided.

Owner:WARSAW ORTHOPEDIC INC

3-d printing of bone grafts

Computer implemented methods of producing a bone graft are provided. These methods include obtaining a 3-D image of an intended bone graft site; generating a 3-D digital model of the bone graft basedon the 3-D image of the intended bone graft site, the 3-D digital model of the bone graft being configured to fit within a 3-D digital model of the intended bone graft site; storing the 3-D digital model on a database coupled to a processor, the processor having instructions for retrieving the stored 3-D digital model of the bone graft and for combining a carrier material with, in or on a bone material based on the stored 3-D digital model and for instructing a 3-D printer to produce the bone graft. A layered 3-D printed bone graft prepared by the computer implemented method is also provided.

Owner:WARSAW ORTHOPEDIC INC

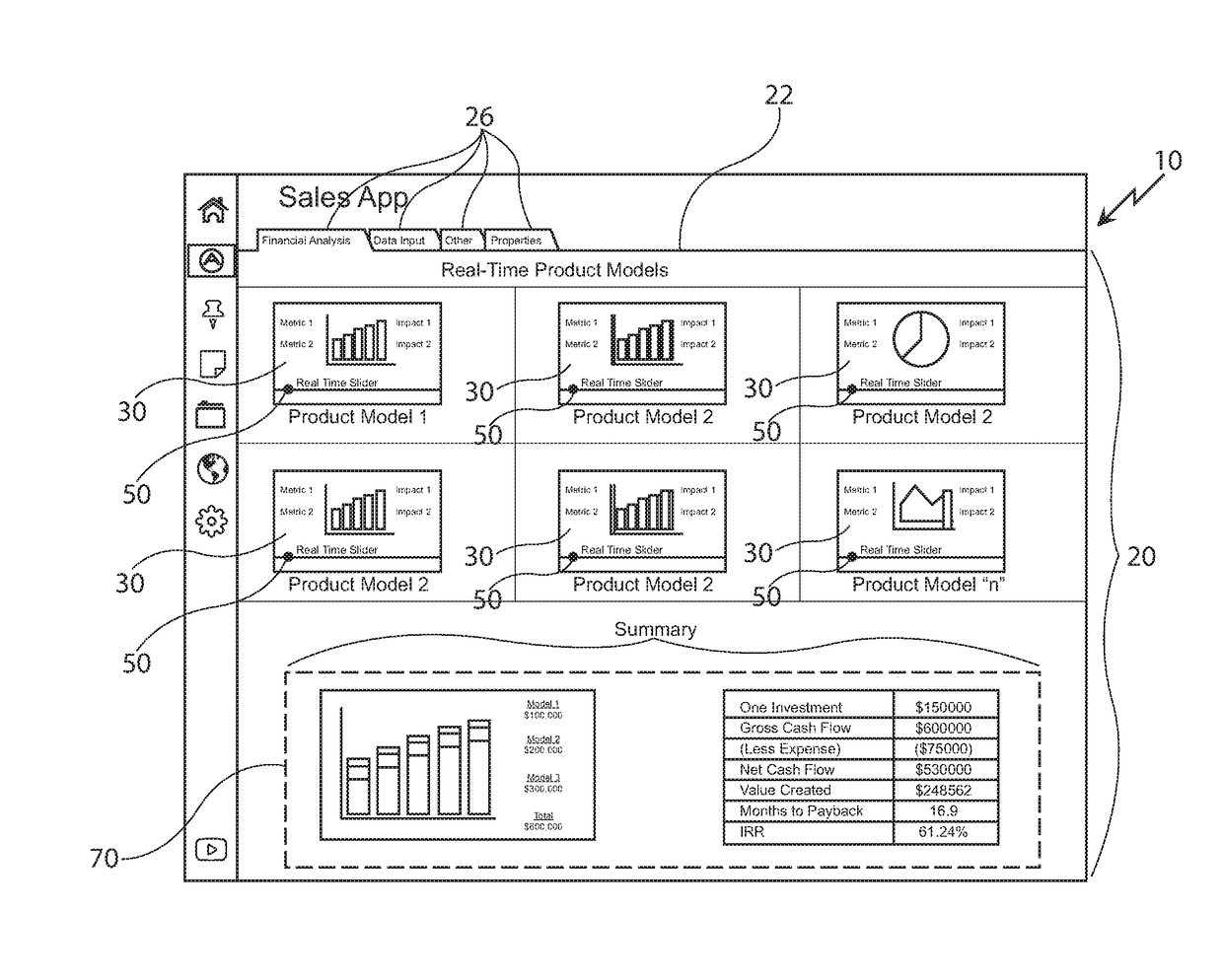

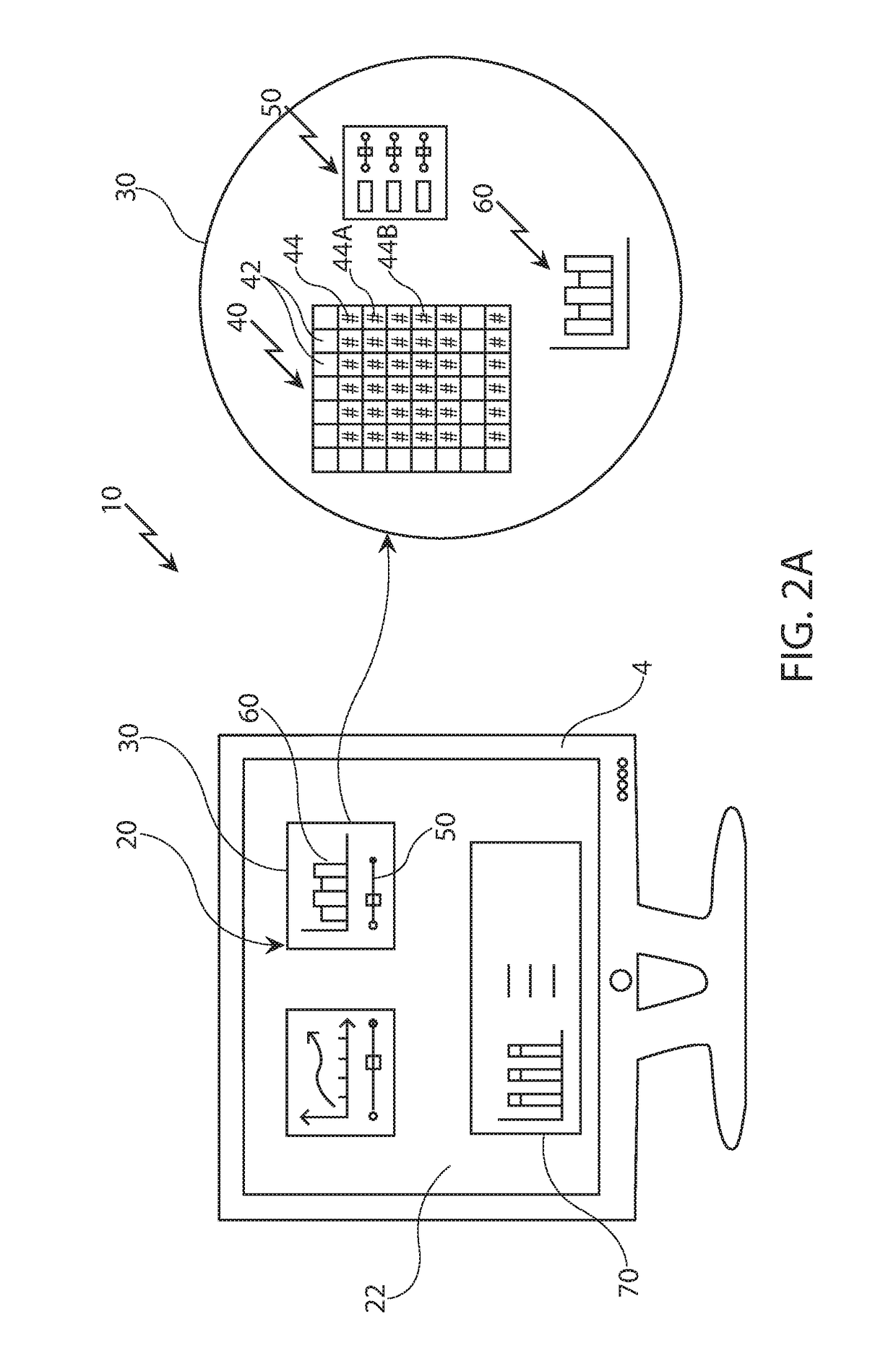

Method and system for dynamic data modeling for use in real-time computerized presentations

InactiveUS20170139894A1Market predictionsDrawing from basic elementsComputational scienceDigital data

A system and related method for dynamic data modeling for use in a real-time computerized presentation system includes a presentation engine having a visual interface. Computerized numerical models are each importable into the presentation engine. Each includes a data grid having data cells arranged by columns and rows, where numerical data values are stored within the data cells. At least one data input field controls a manipulation of a first numerical data value in a first data cell using a mathematical function applied to a second numerical data value in a second data cell. A numerical model display, displayable on the visual interface, is based on the first numerical data value and is changed in real-time based on the manipulation of the first numerical data value. A numerical model summary, displayable on the visual interface, combines numerical data from the computerized models imported into the presentation engine.

Owner:WELCH GLOBAL CONSULTING

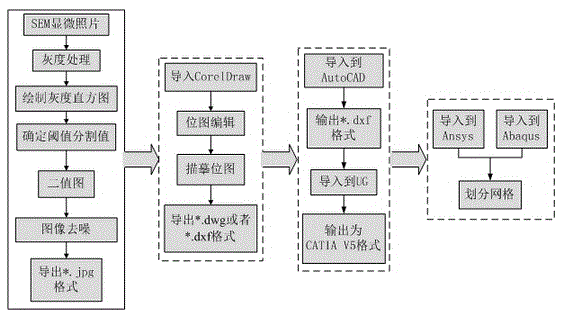

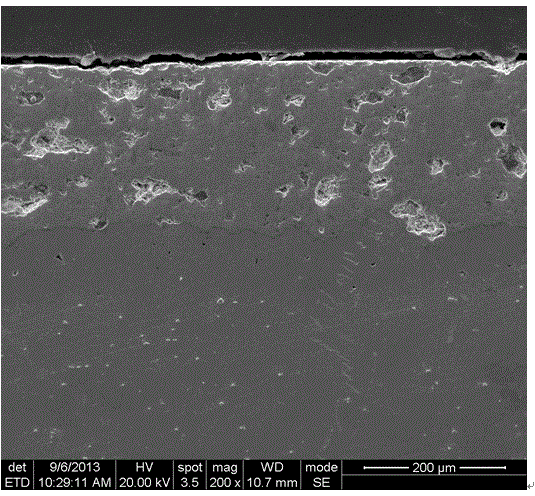

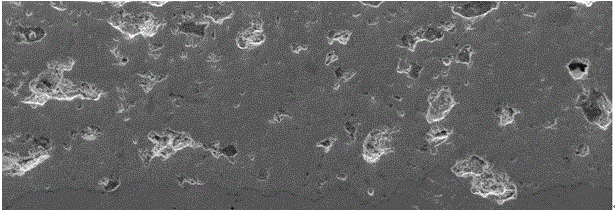

Finite element modeling method based on real material microstructure

InactiveCN104063902AHave pursuasive powerNoise suppressionImage enhancementImage analysisDigital signal processingElement model

The invention provides a finite element modeling method based on a real material microstructure. According to the method, various kinds of digital image technical processing are carried out on SEM scanned pictures, conversion from bitmaps to vector diagrams is achieved, and accordingly the real material microstructure can be mapped into a two-dimensional finite element model. By means of threshold segmentation, gray processing, binarization processing, repeated switch-off and switch-on operations and the technology converting the bitmaps into the vector diagrams, defects presented in the images or reinforcements are clearly segmented from a substrate, and besides attributes of the defects or the reinforcements can be respectively defined in finite element software. According to the method, a high-precision finite element model of the real material microstructure is built directly through the SEM pictures, a digital model is close to a real structure, and authenticity of the finite element model in the calculation process and in calculation results is improved. The method can be widely used in the field of optimization design field taking the defects and heterogeneous material performance judgment into consideration.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com