Patents

Literature

182 results about "Prosthetic socket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

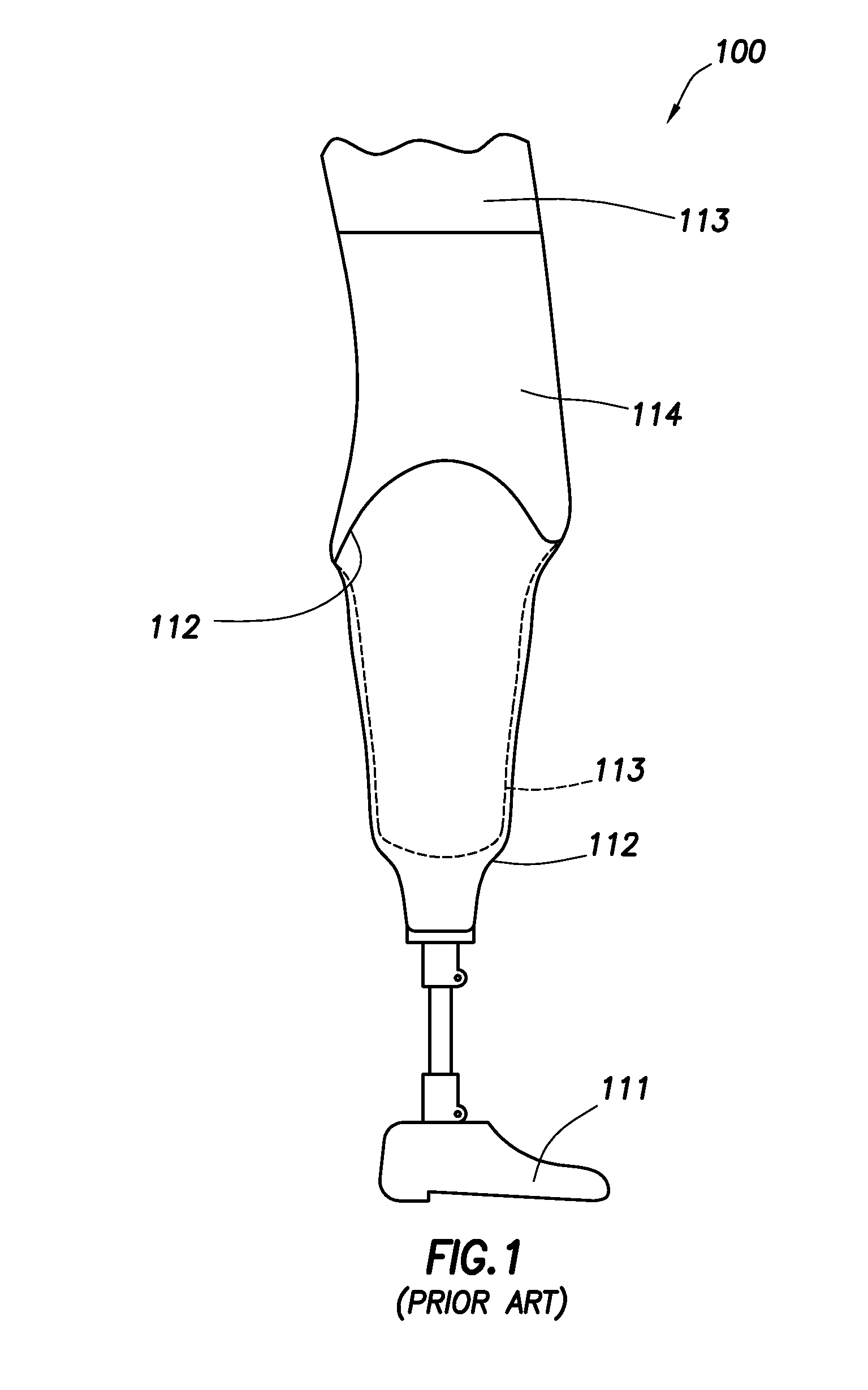

Prosthetic socket with self-contained vacuum reservoir

ActiveUS7427297B2Avoid substantial deflectionDomestic articlesProsthesisEngineeringLoad-bearing wall

Owner:OSSUR HF

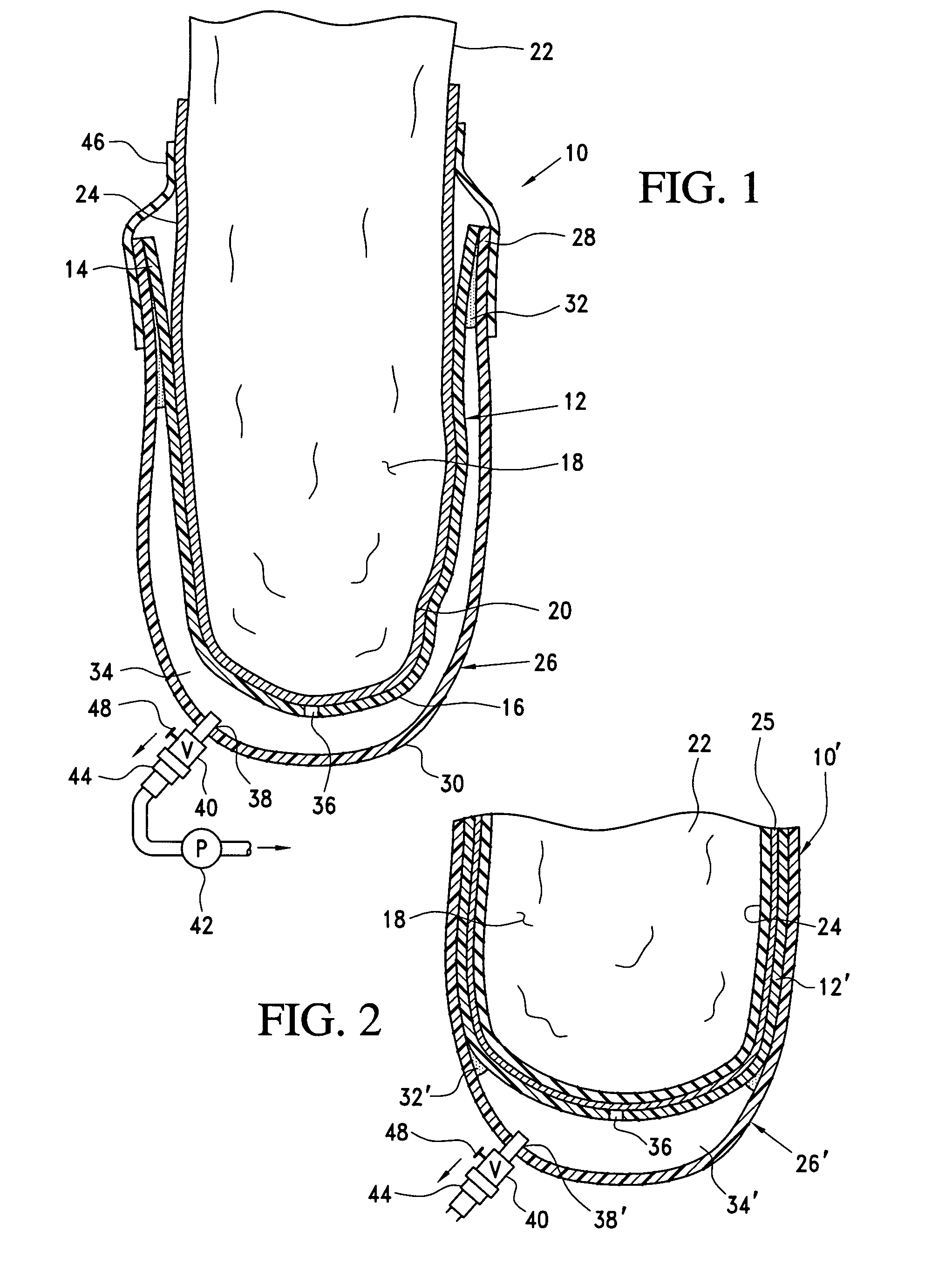

Seal arrangement for residual limb prosthetic socket

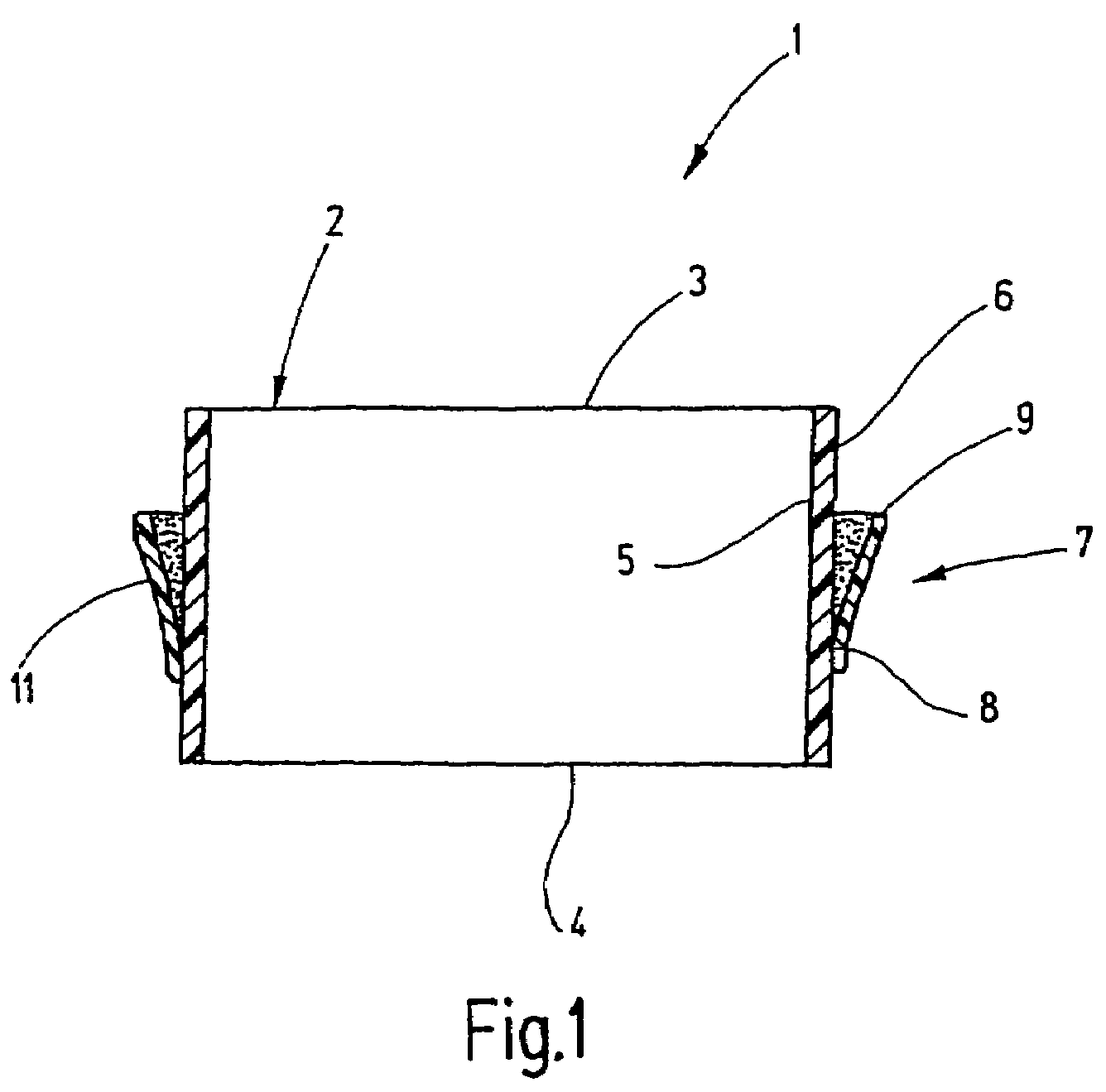

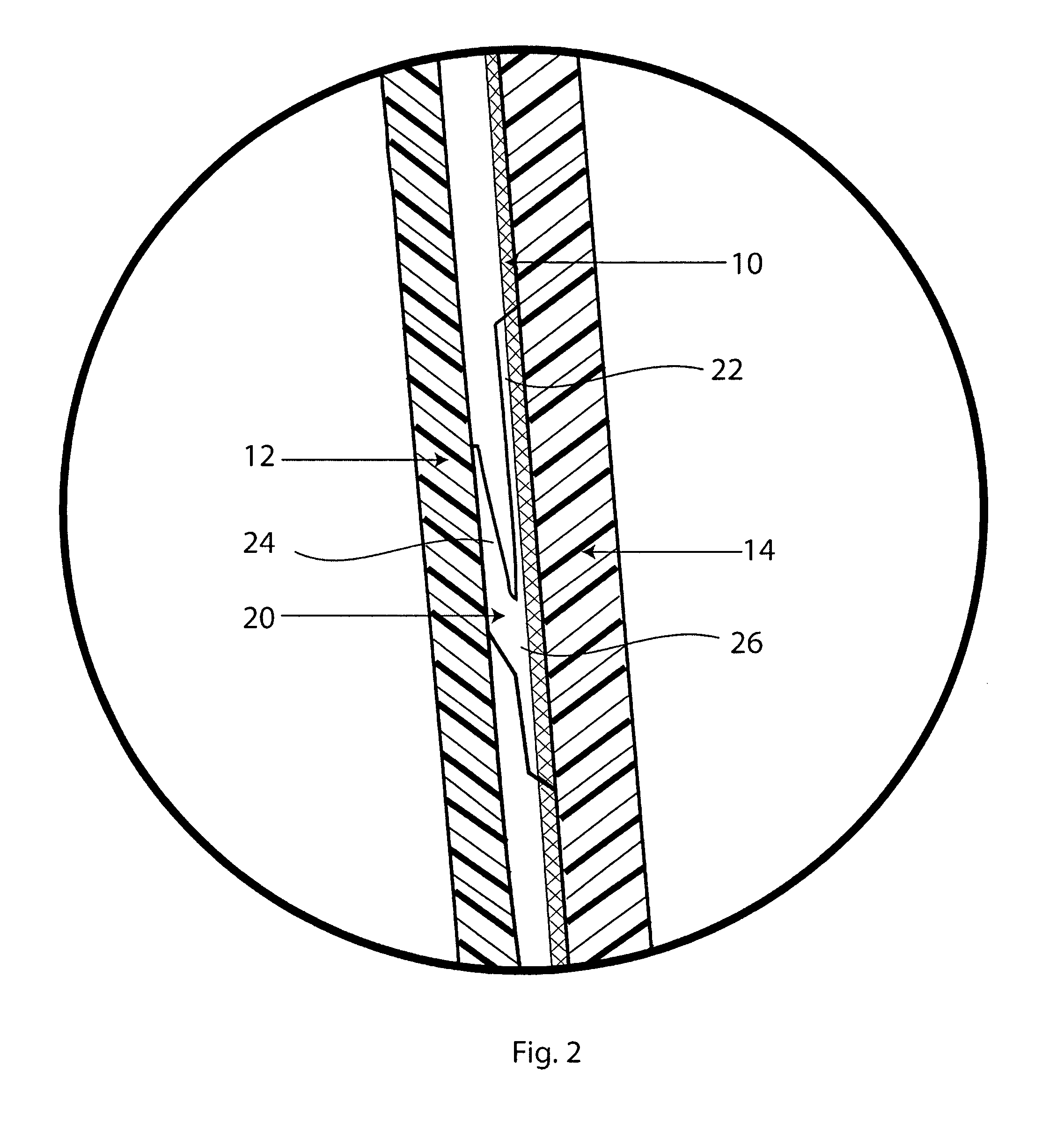

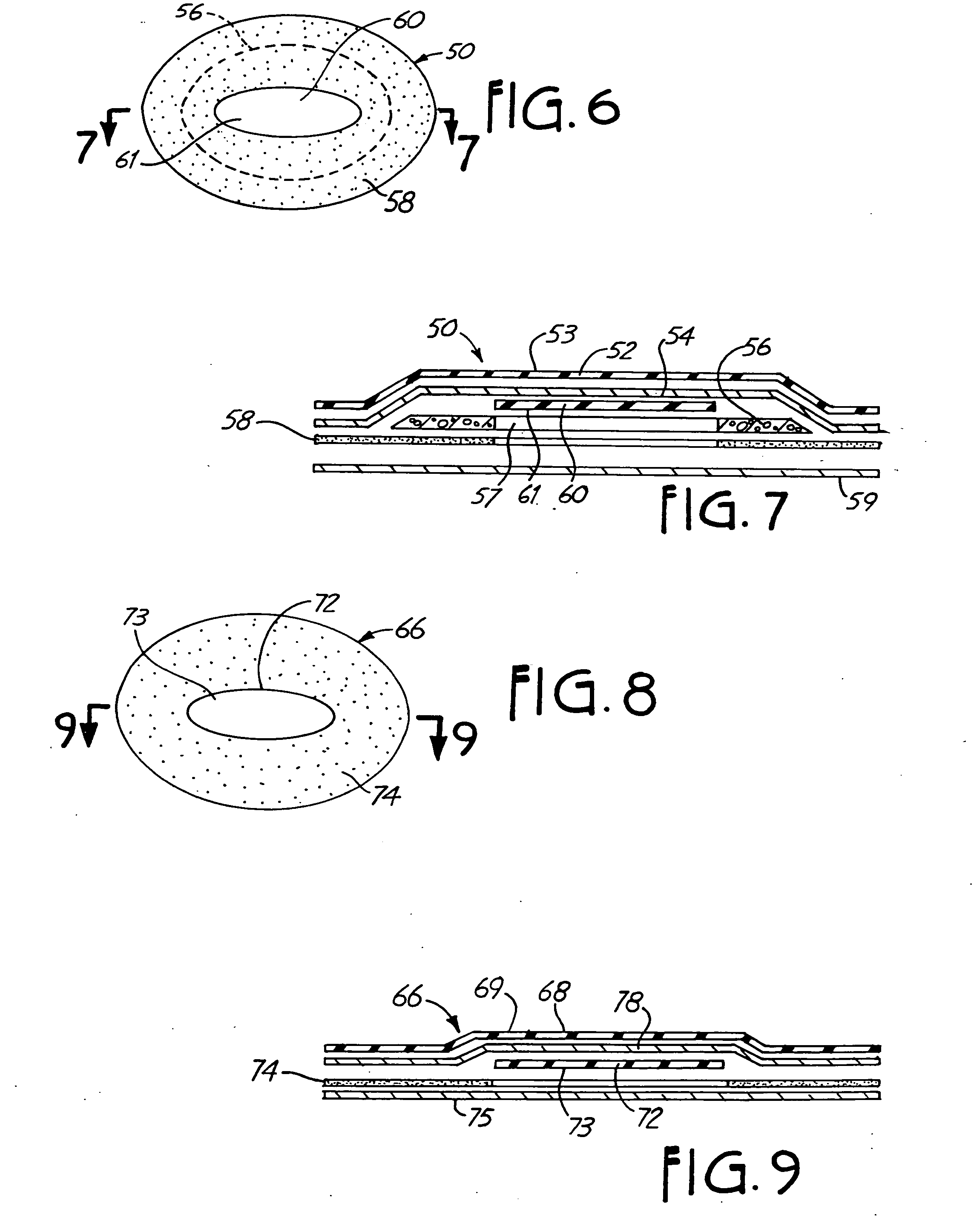

A prosthetic socket seal includes at least one radially projecting sealing lip which jointly with a base subtends an annular gap. This annular gap is vented on a proximal side by the external atmosphere, resulting in creation of a pressure gradient at the sealing lip that produces stronger compression of the sealing lip against the prosthetic socket with increasing partial vacuum on a distal side of the sealing lip.

Owner:KAUPTHING BANK

Sealing sleeve for sealing residual limb in a prosthetic socket

InactiveUS7169188B2Improve air tightnessEasy to compressAnkle jointsJoint implantsResidual limbProsthetic socket

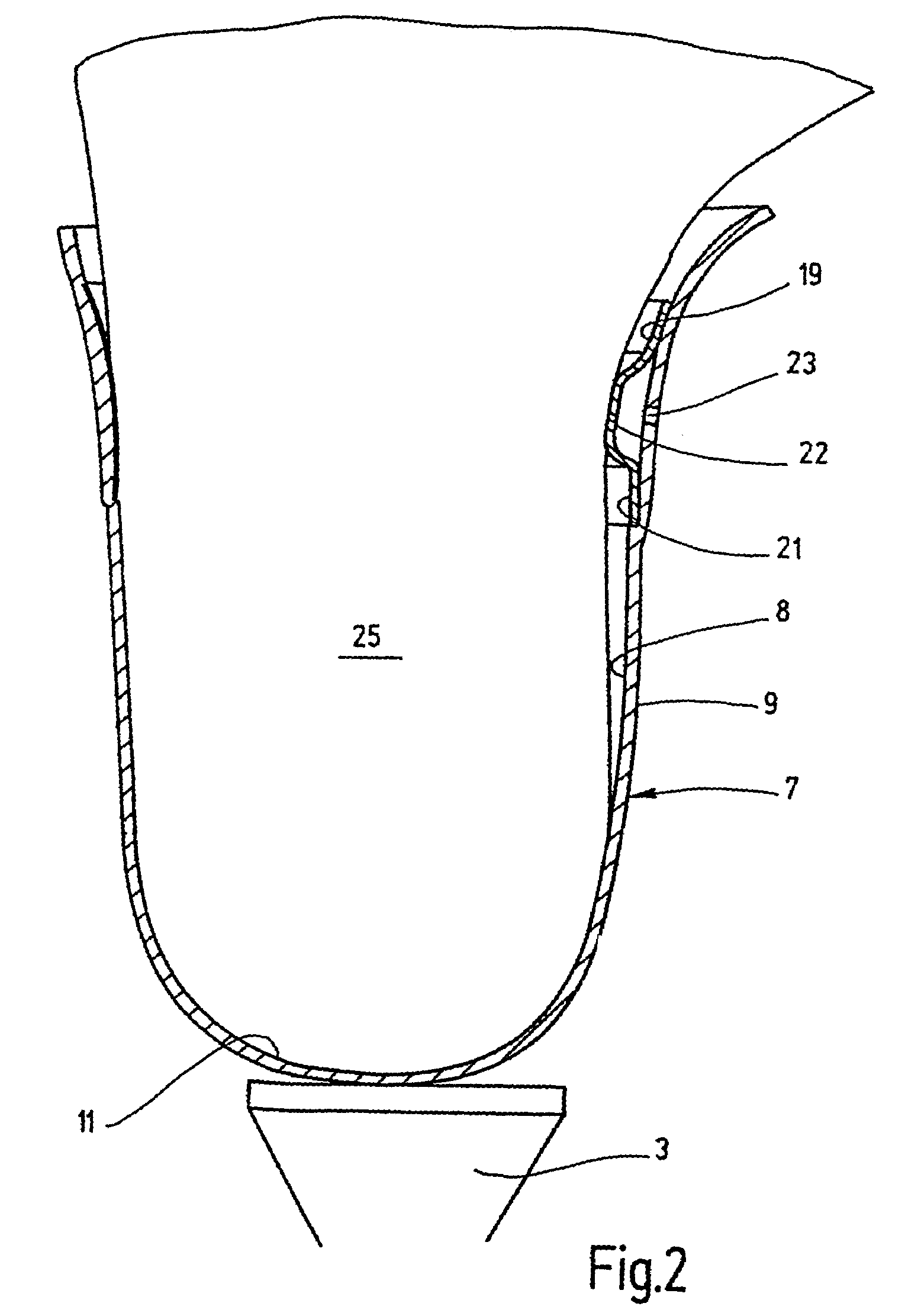

A prosthetic socket is fitted at a distance from its distal end with an annular chamber. This annular chamber is closed by a contour-conforming sealing wall facing the inner side of the prosthetic socket, said wall being designed to hermetically rest against the outer side of a residual limb. The space between the contour-conforming wall and the hard prosthetic socket is vented to atmosphere, whereby self-enhancing compression by the sealing wall against a residual limb arises when a partial vacuum arises in the distal prosthetic socket between the wall and the distal end. A liner having a sealing wall also is disclosed.

Owner:KAUPTHING BANK

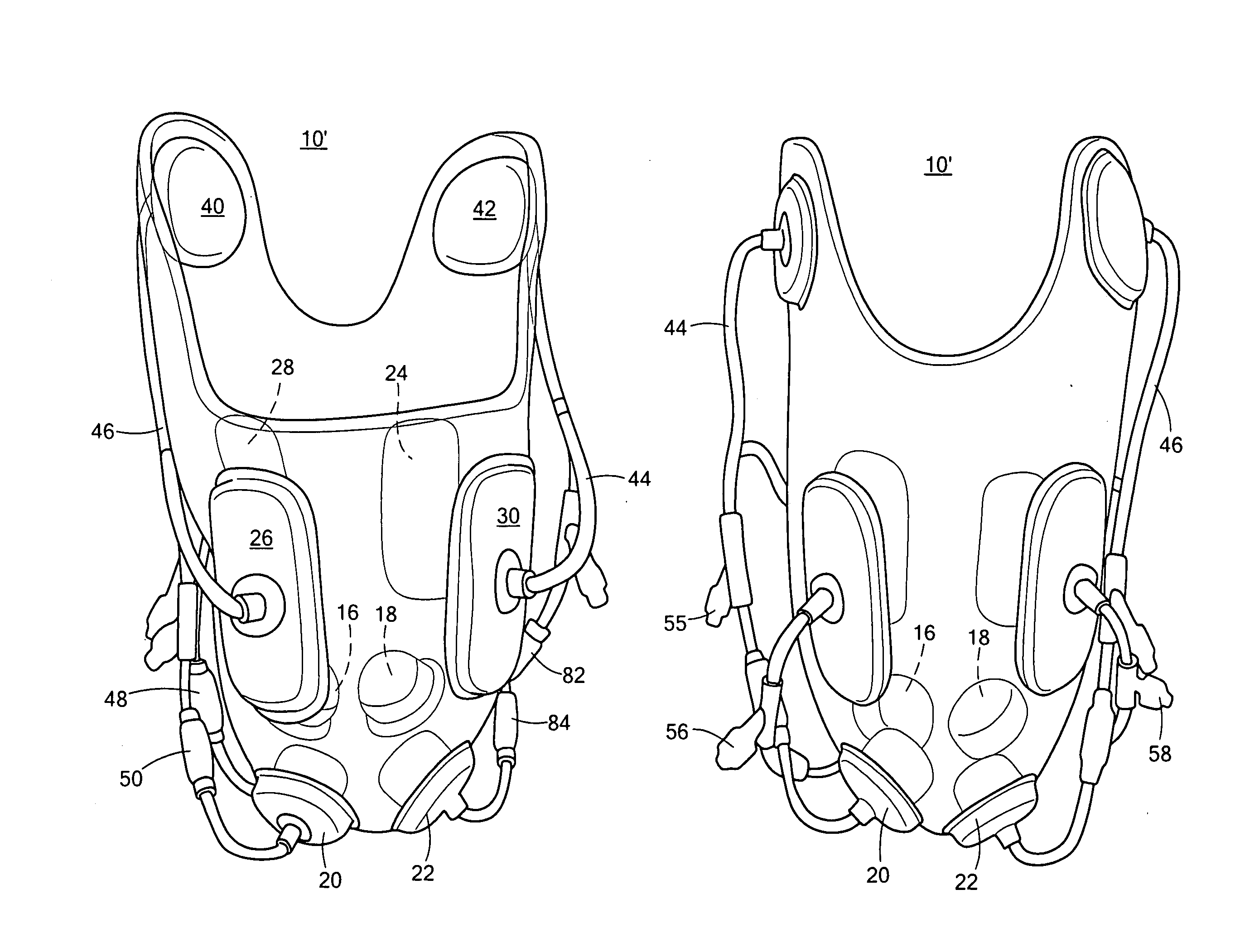

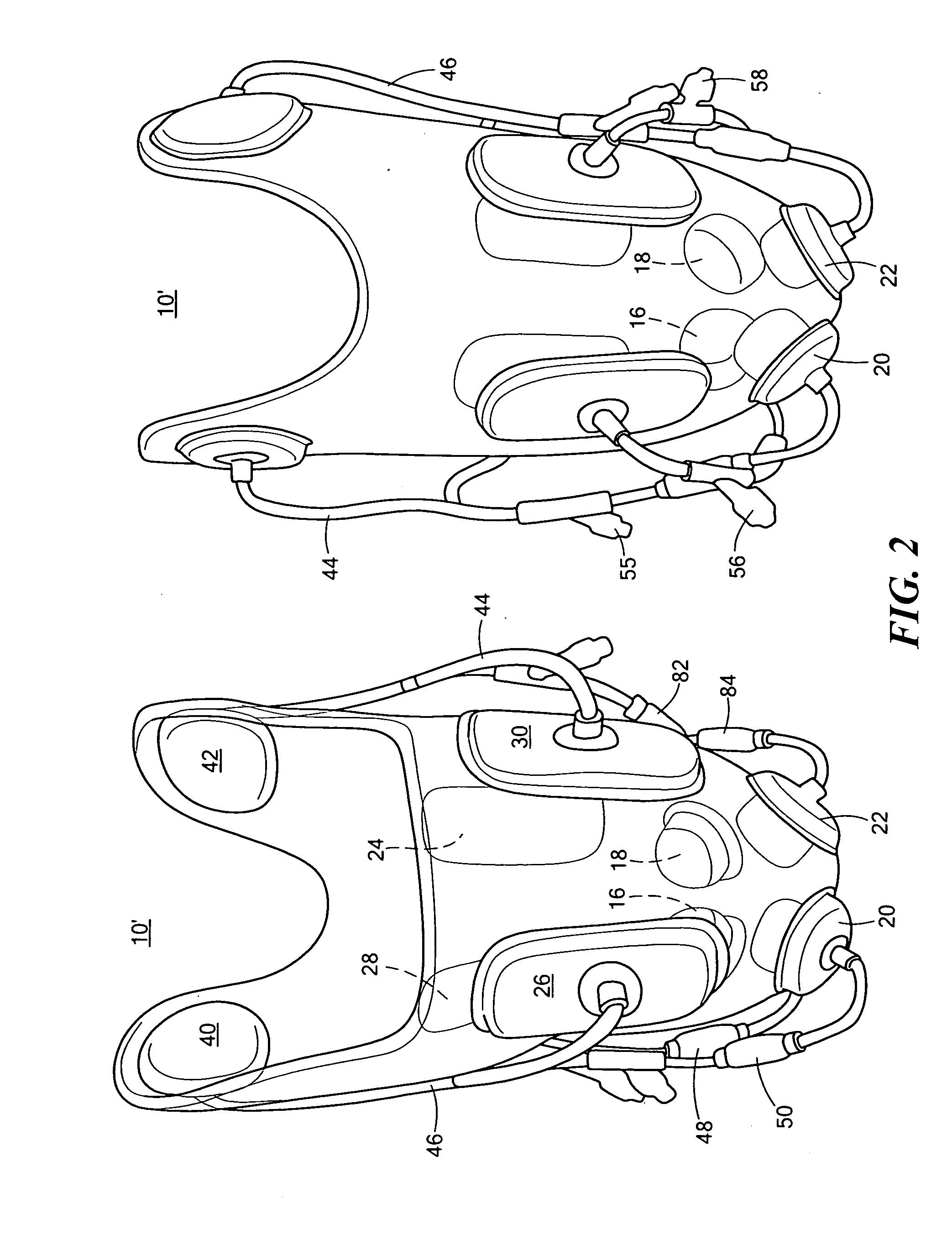

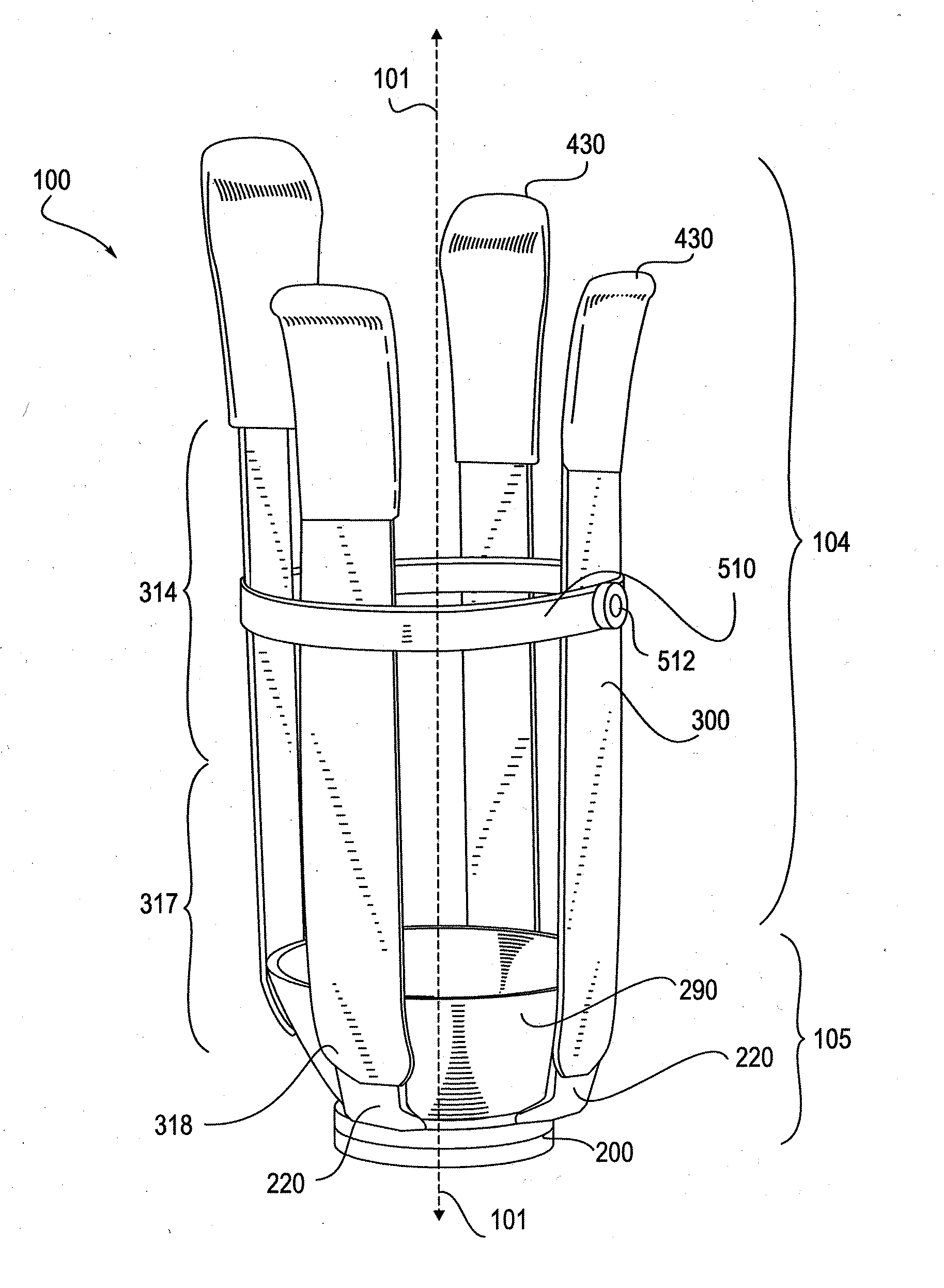

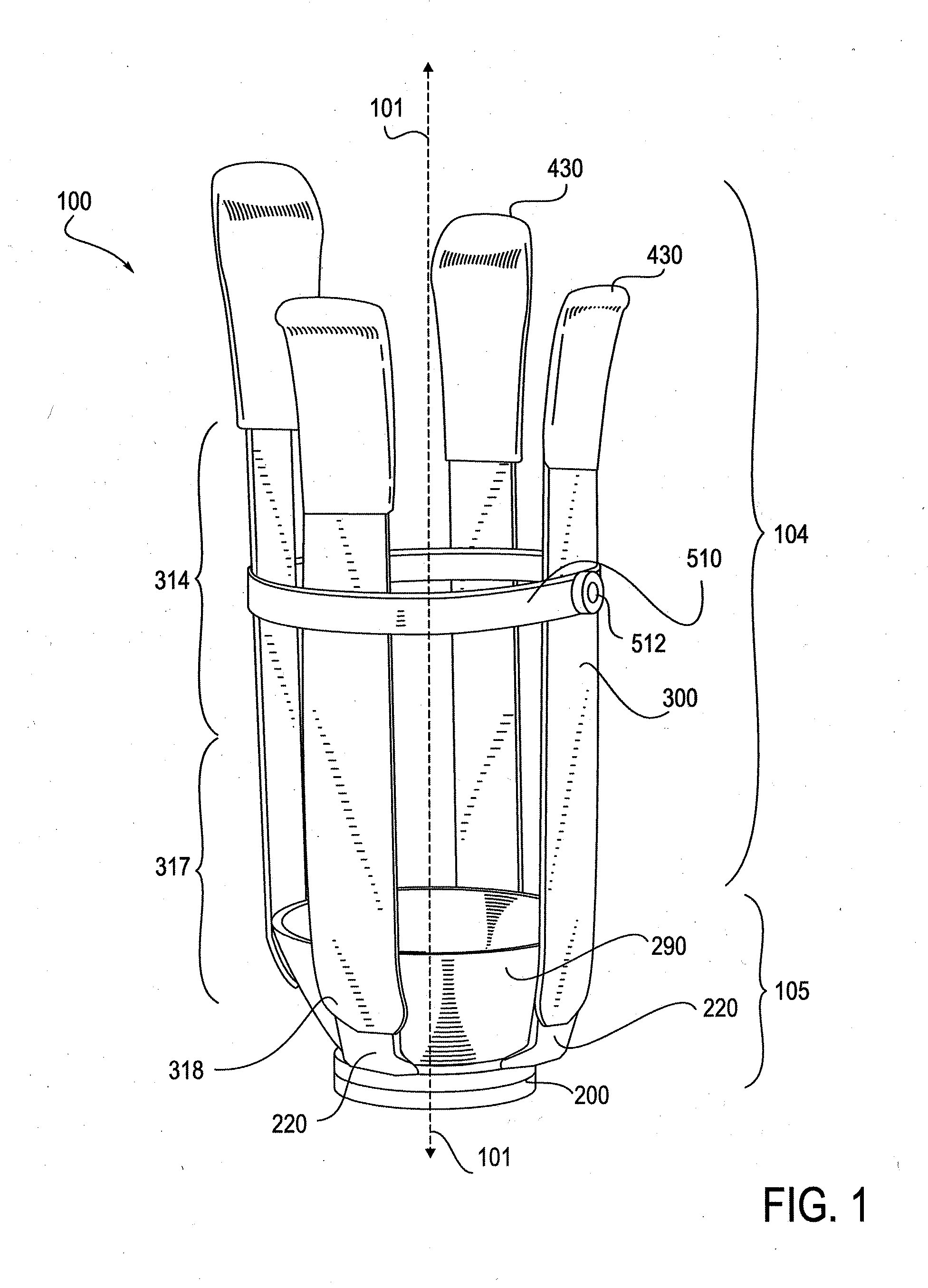

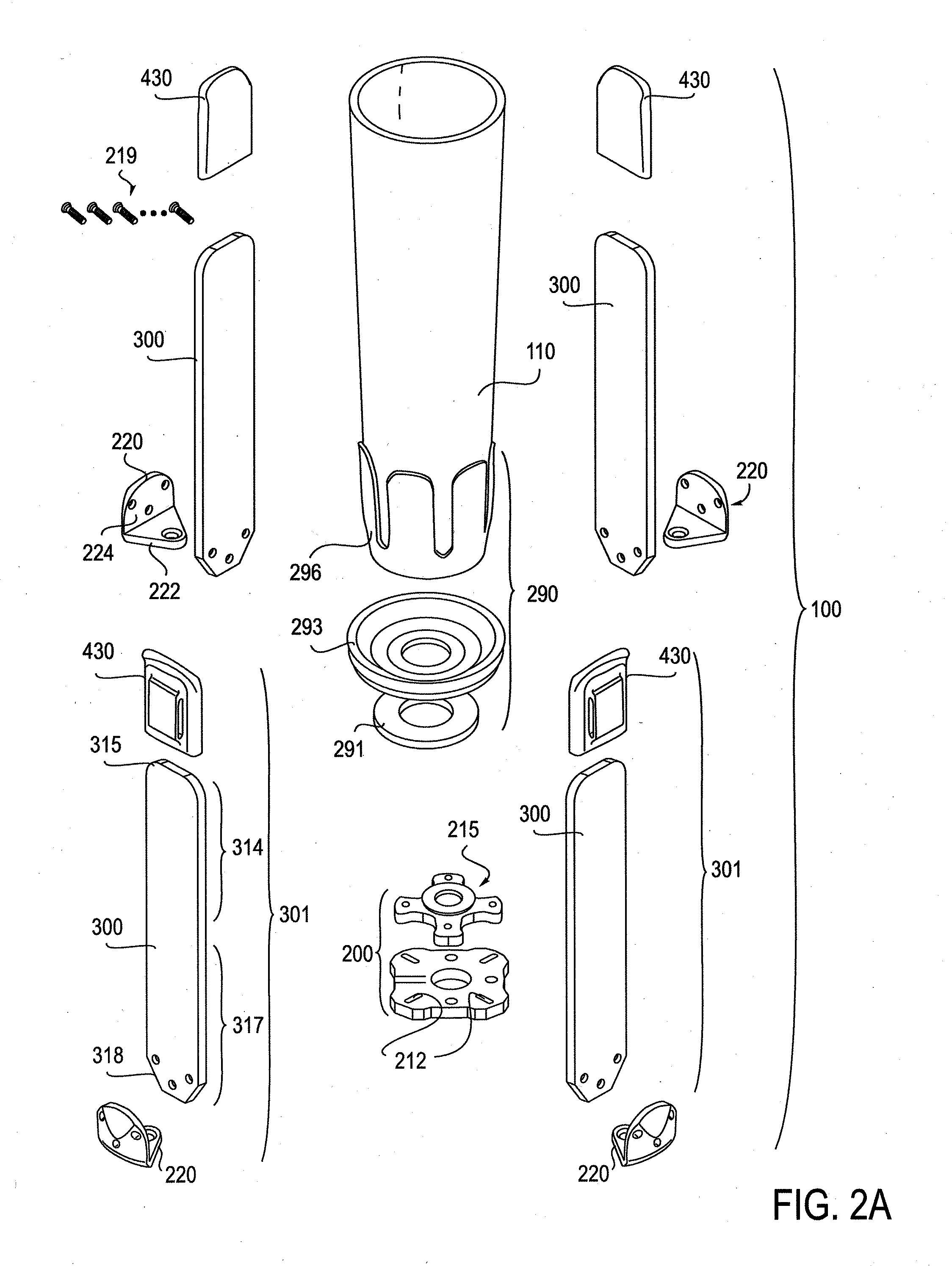

Modular prosthetic sockets and methods for making same

ActiveUS20130123940A1Improve fitAdd dimensionArtificial legsMetal working apparatusBiomechanicsModularity

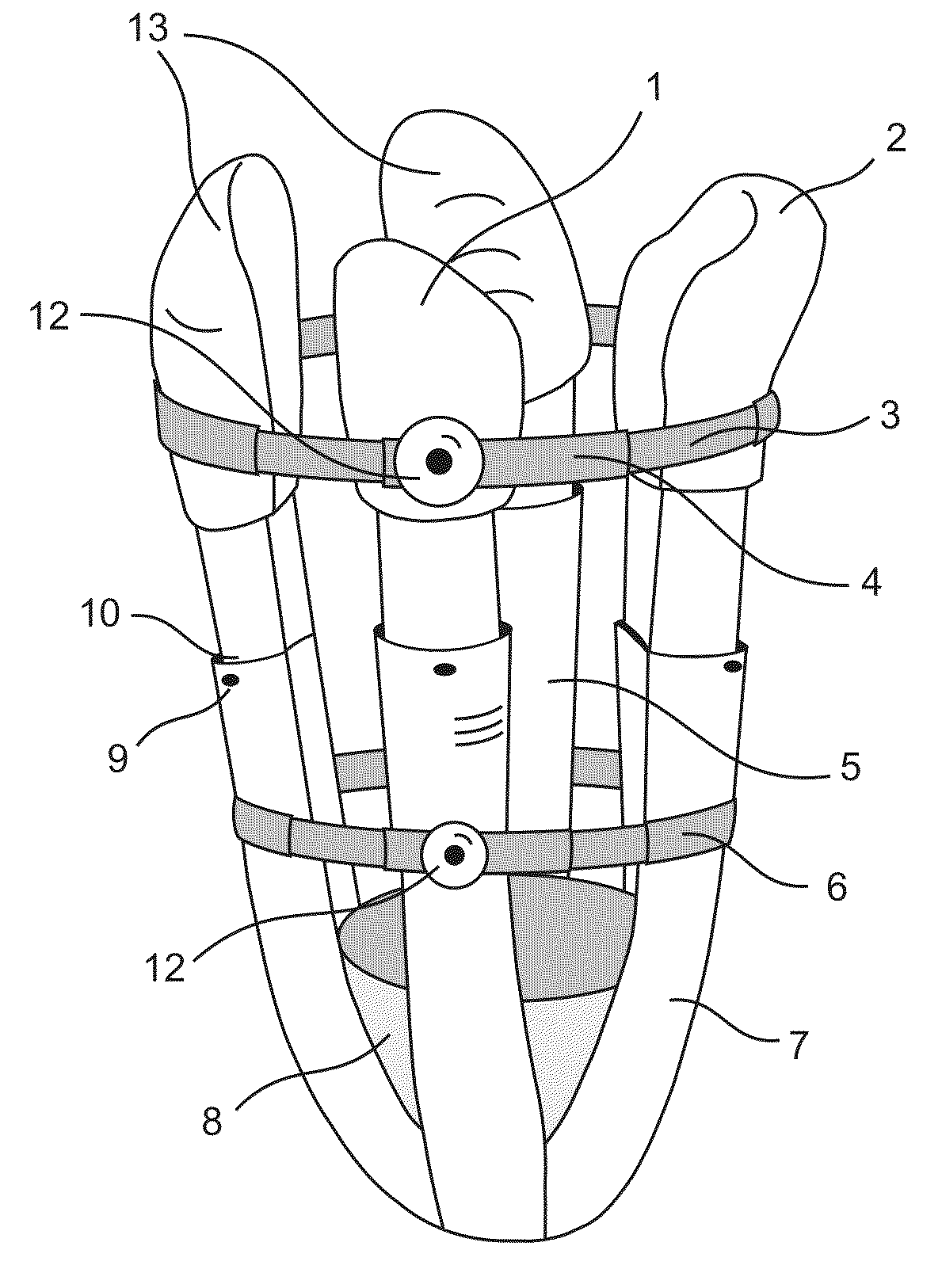

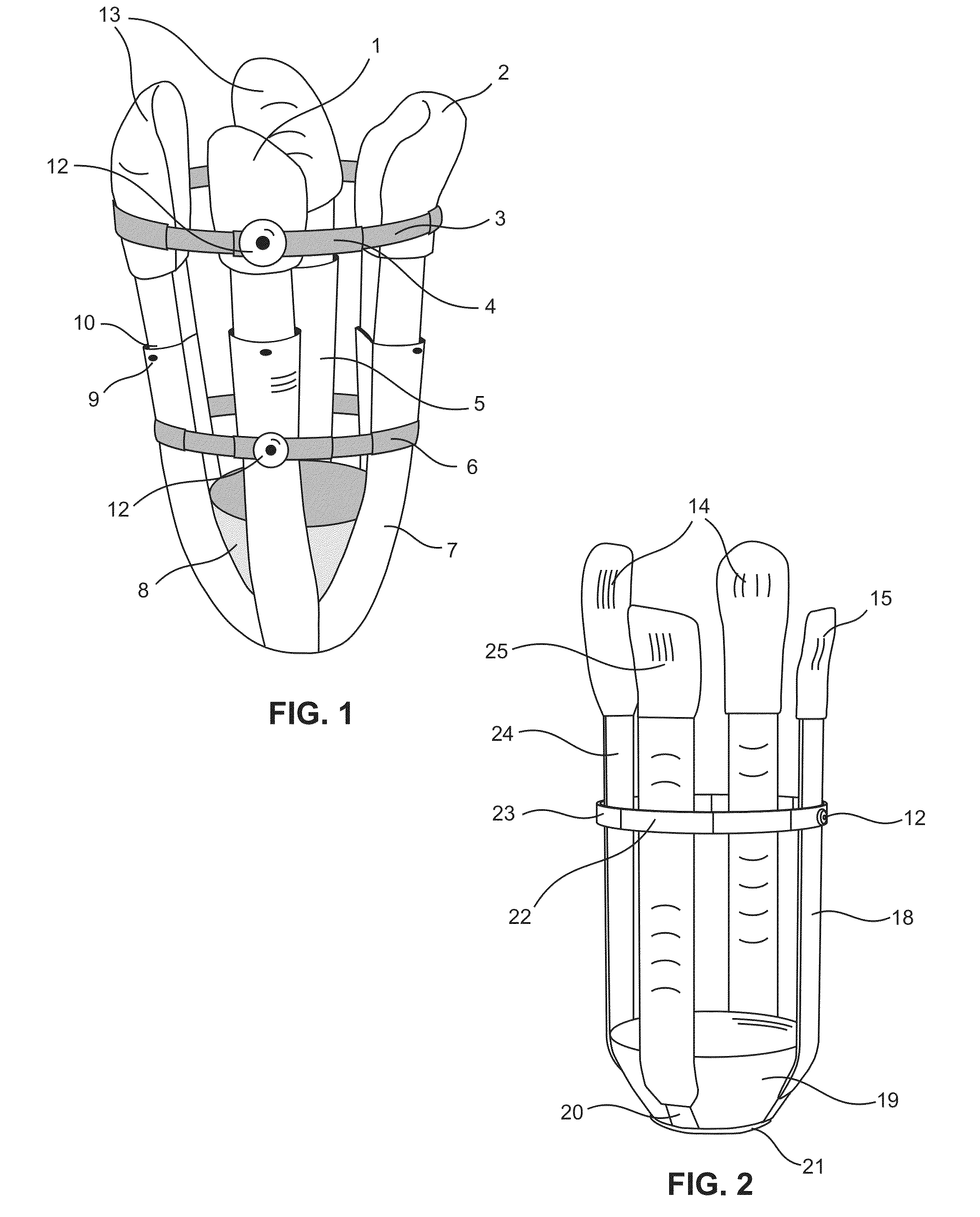

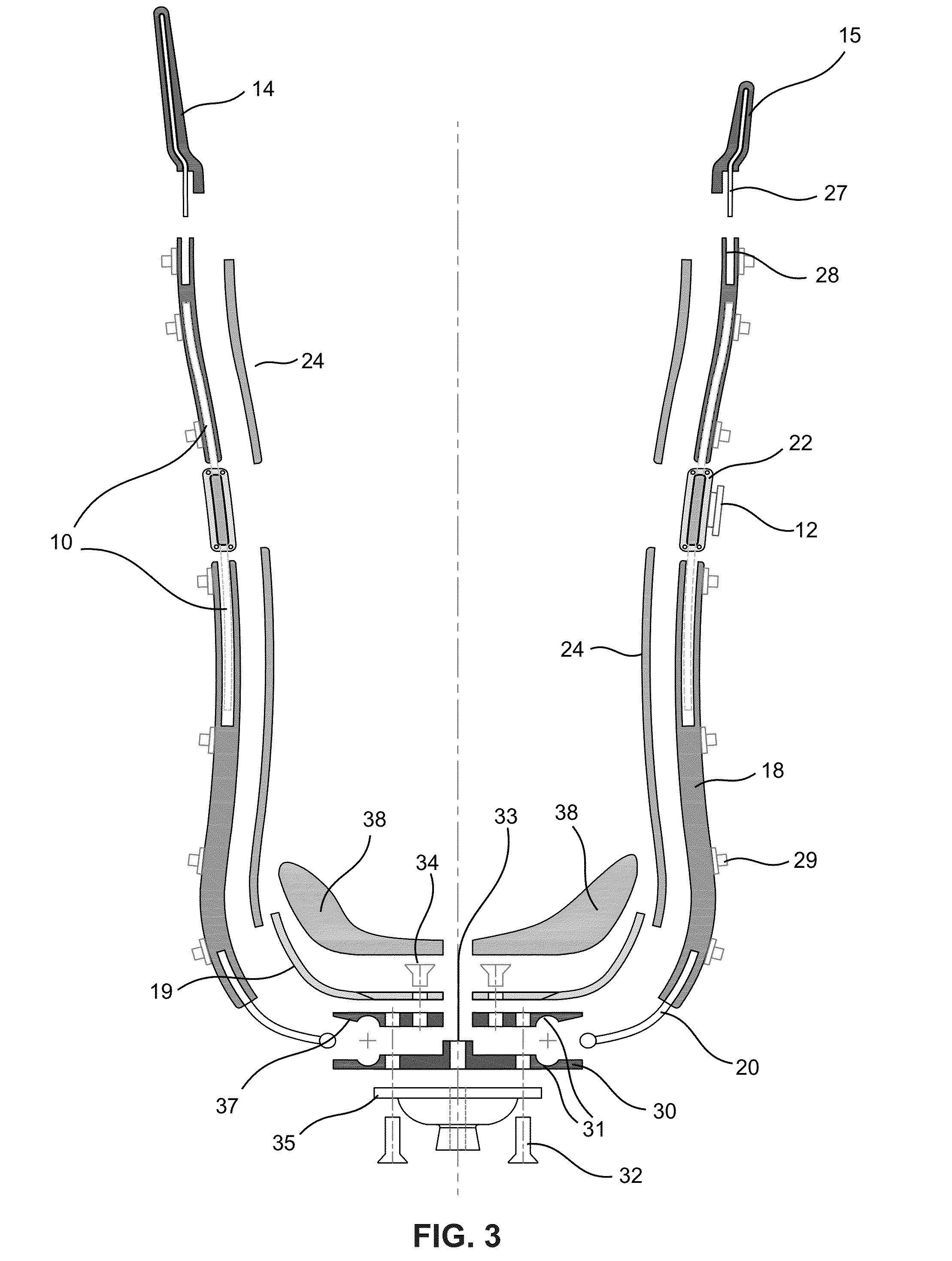

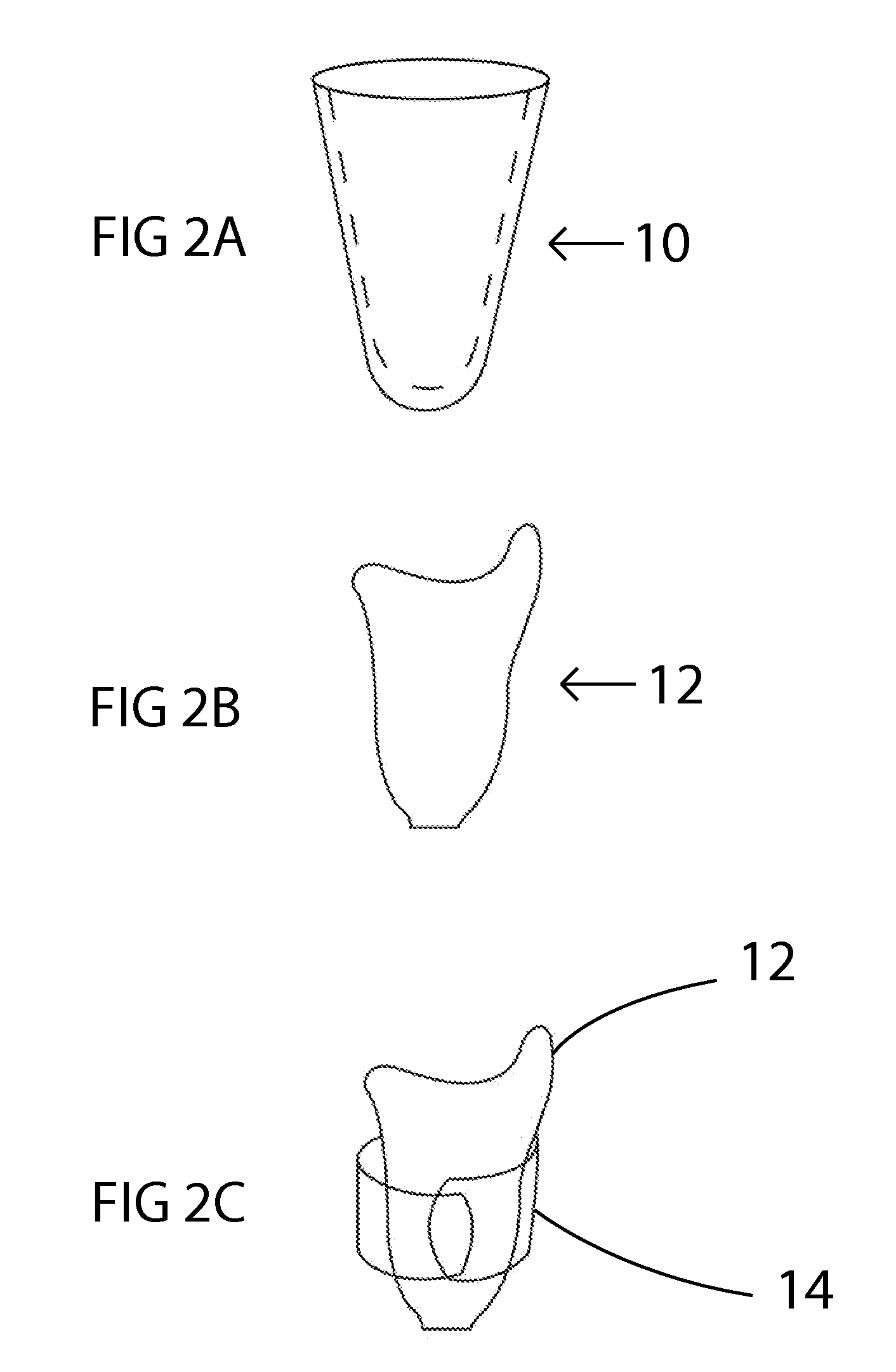

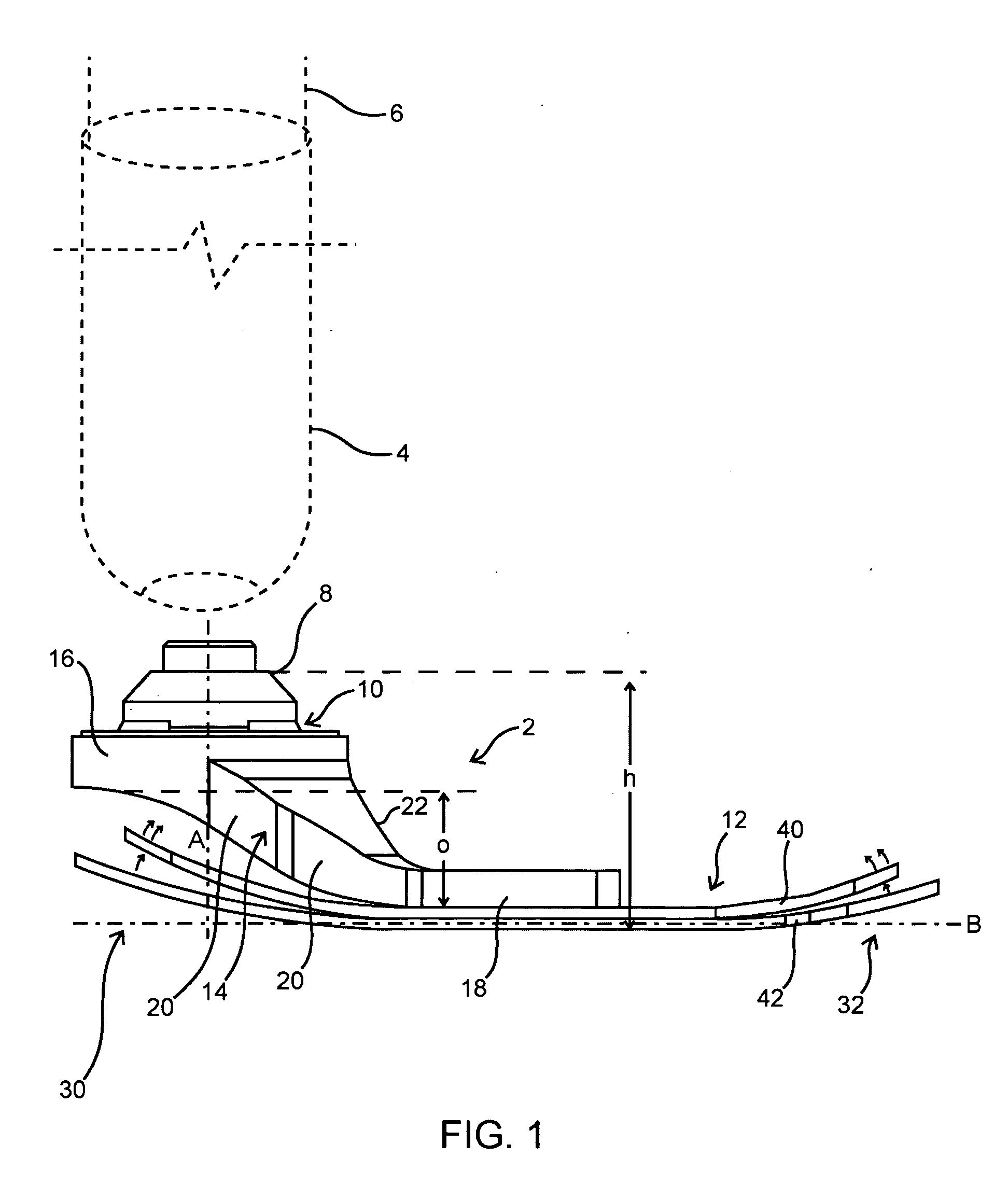

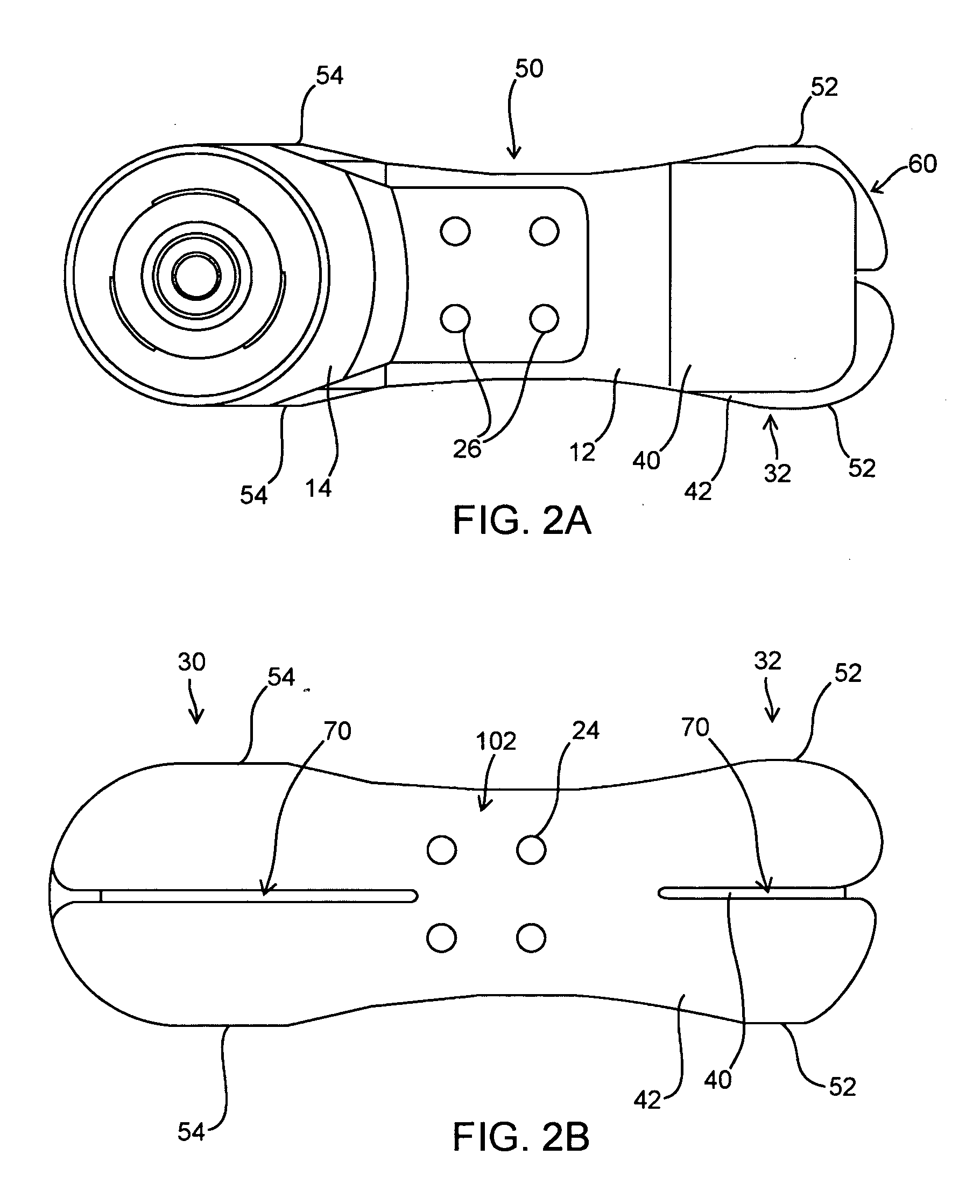

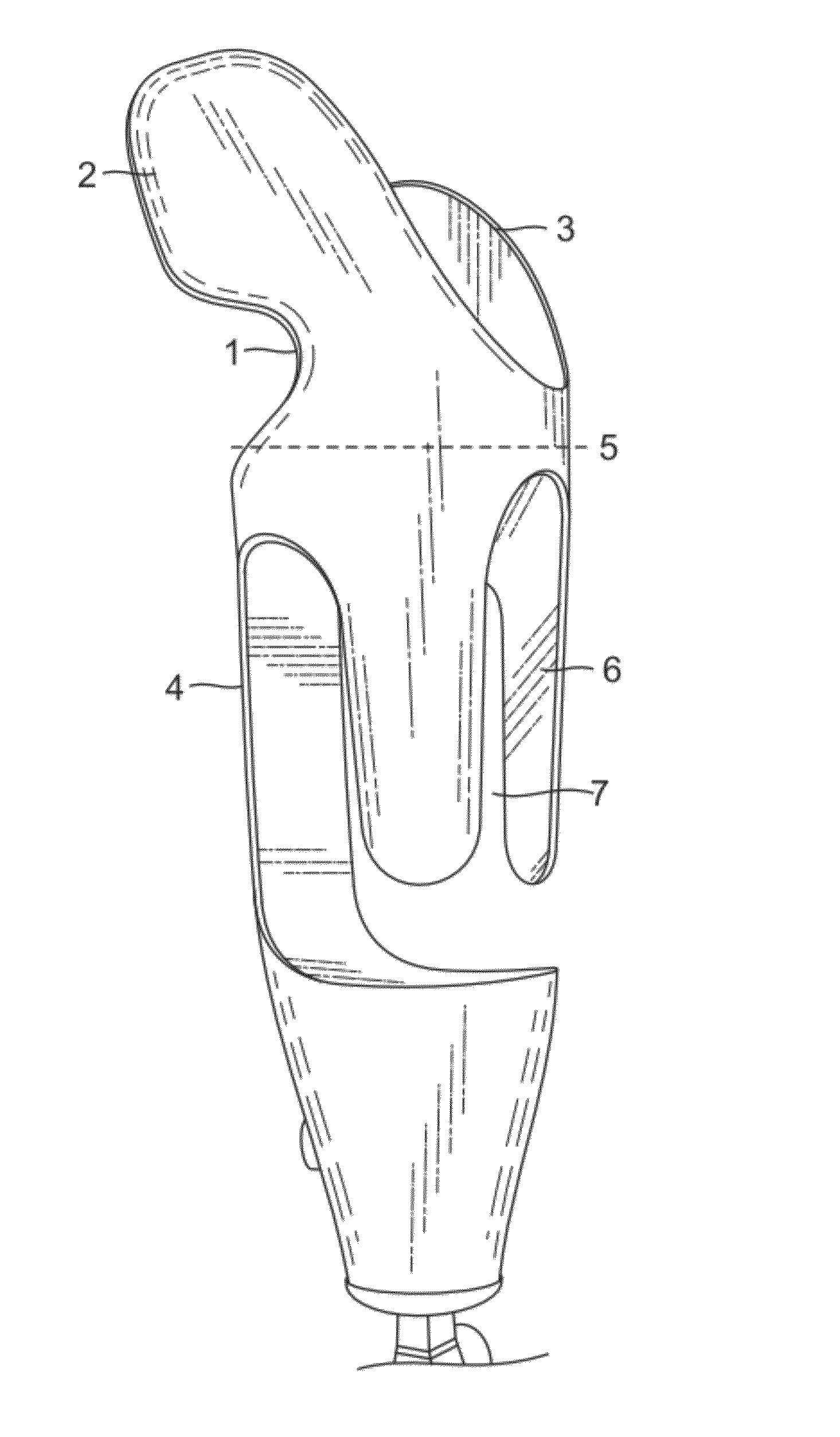

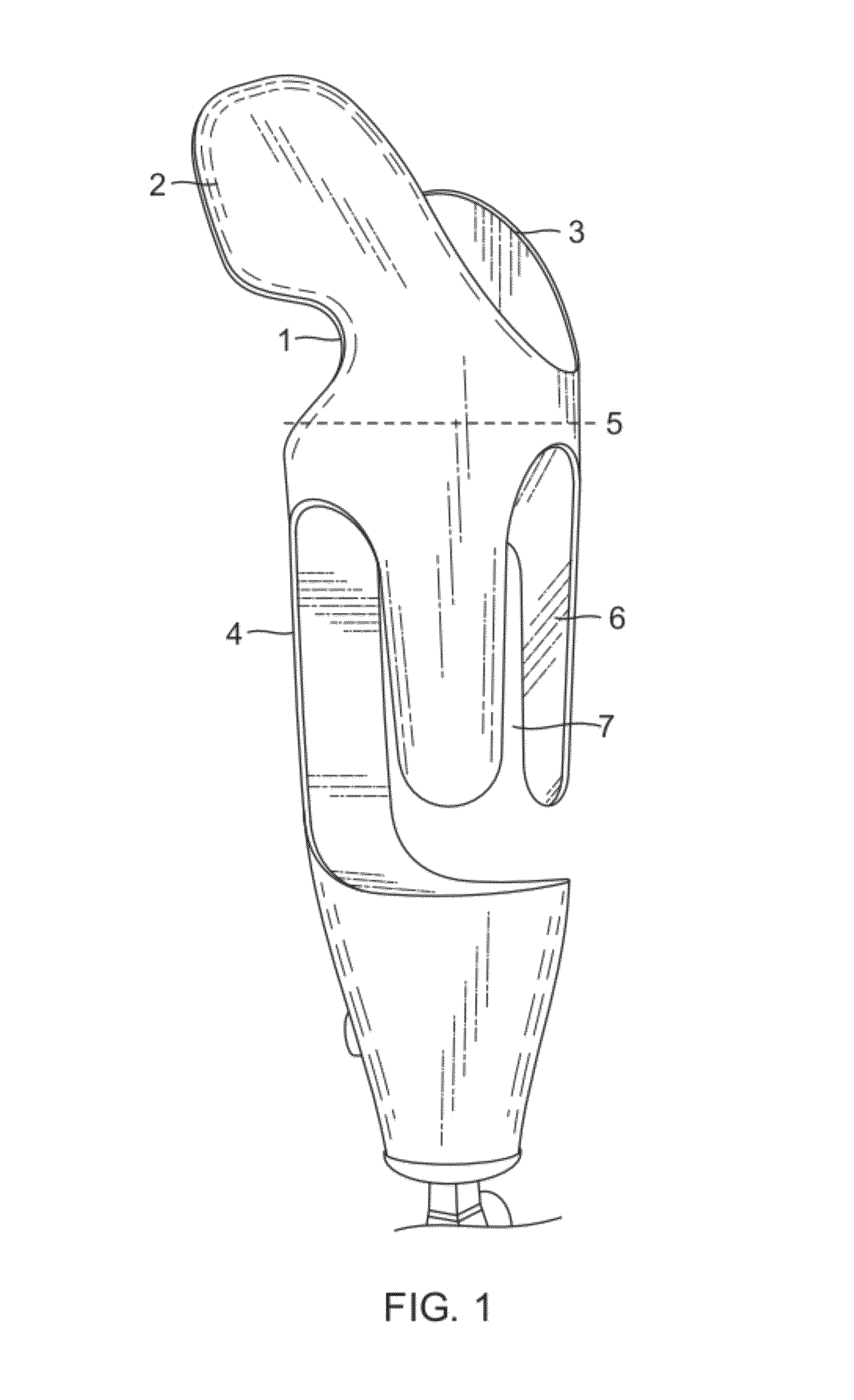

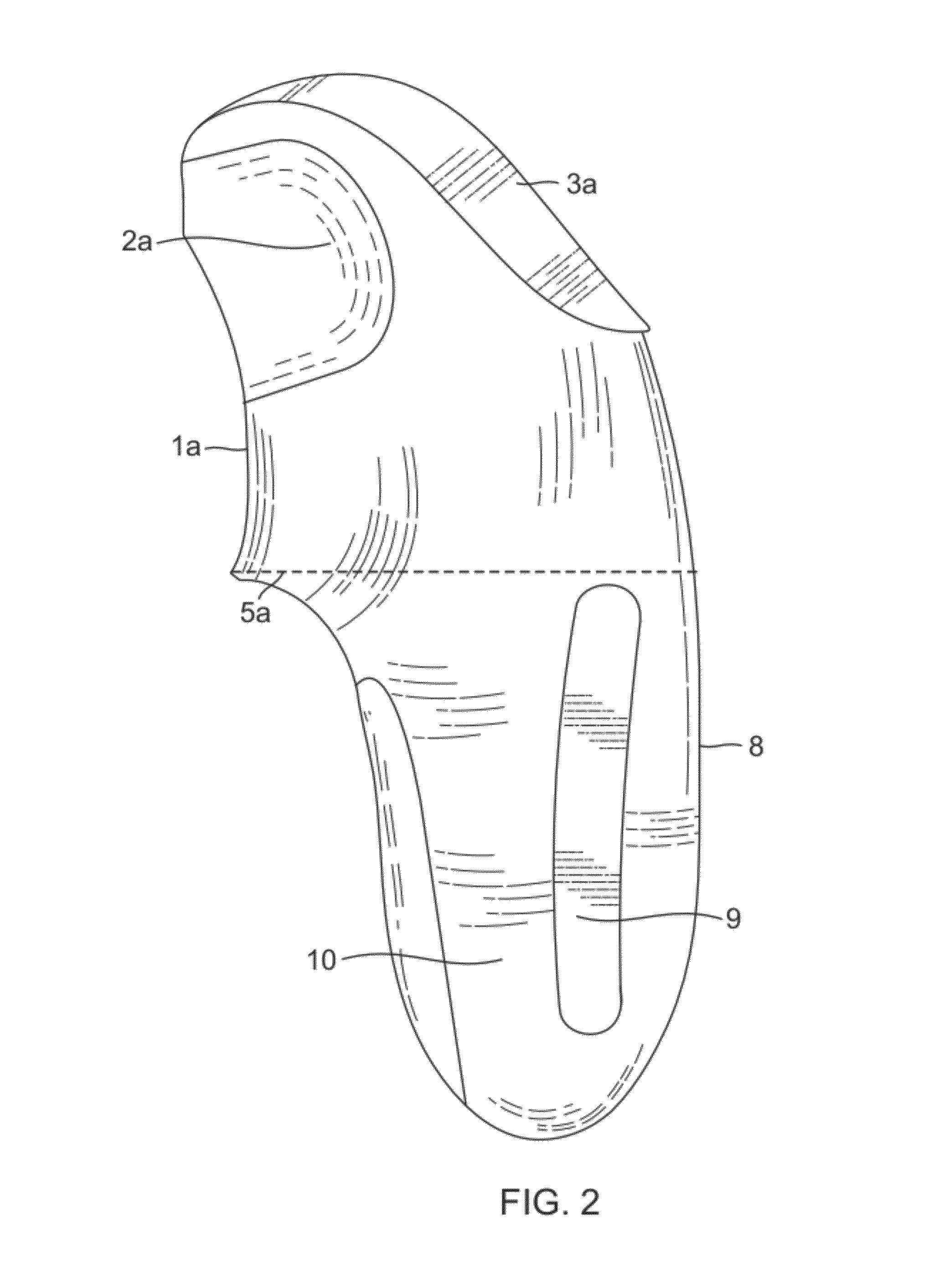

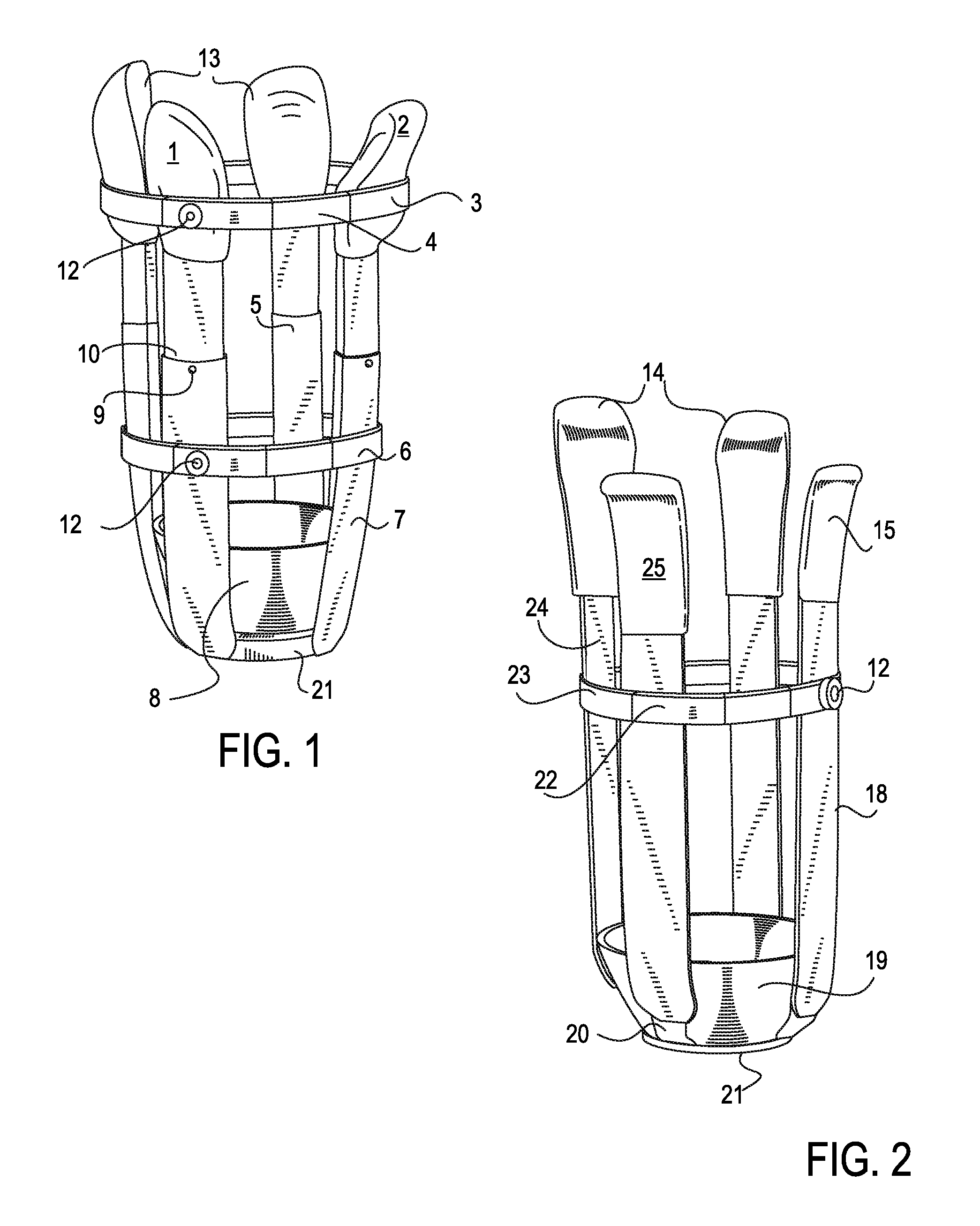

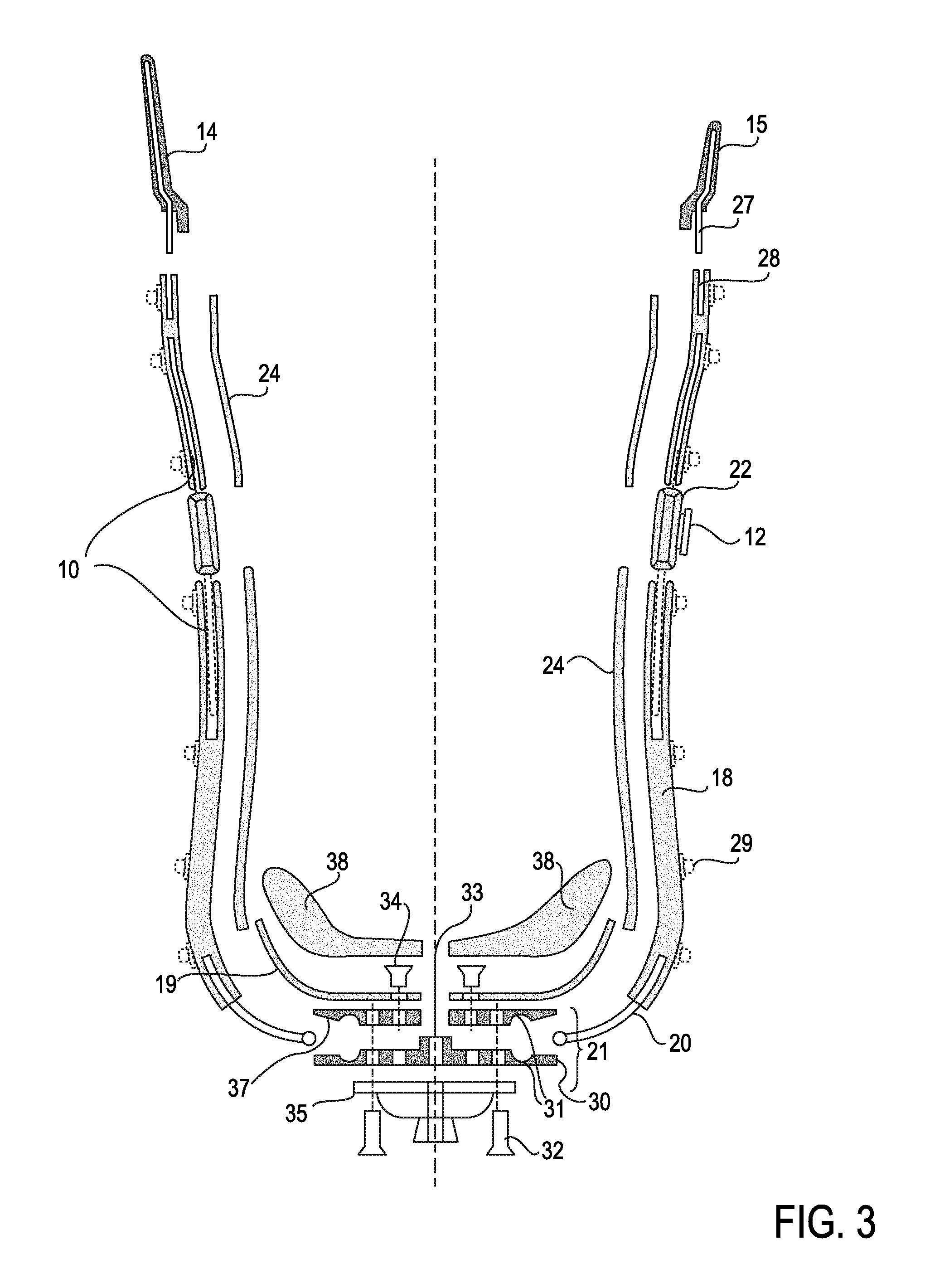

The invention relates to a prosthetic socket for a residual limb of the lower extremity or upper extremity of an individual person. The residual limb has particular dimensions and anatomical contours; the prosthetic socket has dimensions and contours that fit the dimensions and contours of the residual limb. The prosthetic socket may also fit in a manner that is biomechanically particularly appropriate for the individual. The prosthetic socket is an assembly of components from groups of components that include (a) struts arranged longitudinally with respect to the residual limb, (b) proximal brim members arranged proximally to the struts and connected thereto; and (c) distal socket members disposed at the distal base of the prosthetic socket. The socket components within these groups may be modular in that they can vary with respect to dimensions and / or contours, and yet have common connecting features that permit assembly of the components together to form the prosthetic socket.

Owner:LIM INNOVATIONS

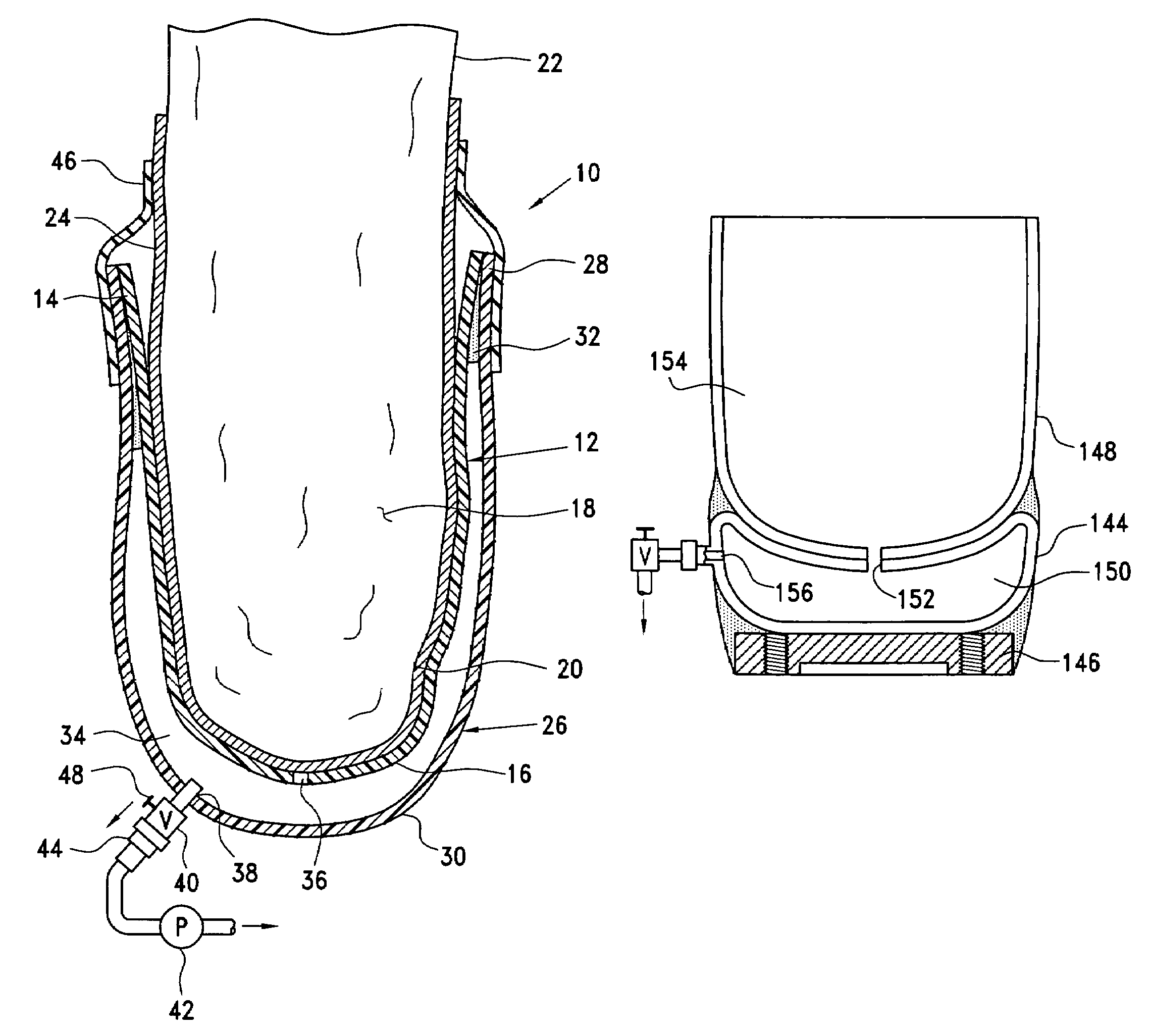

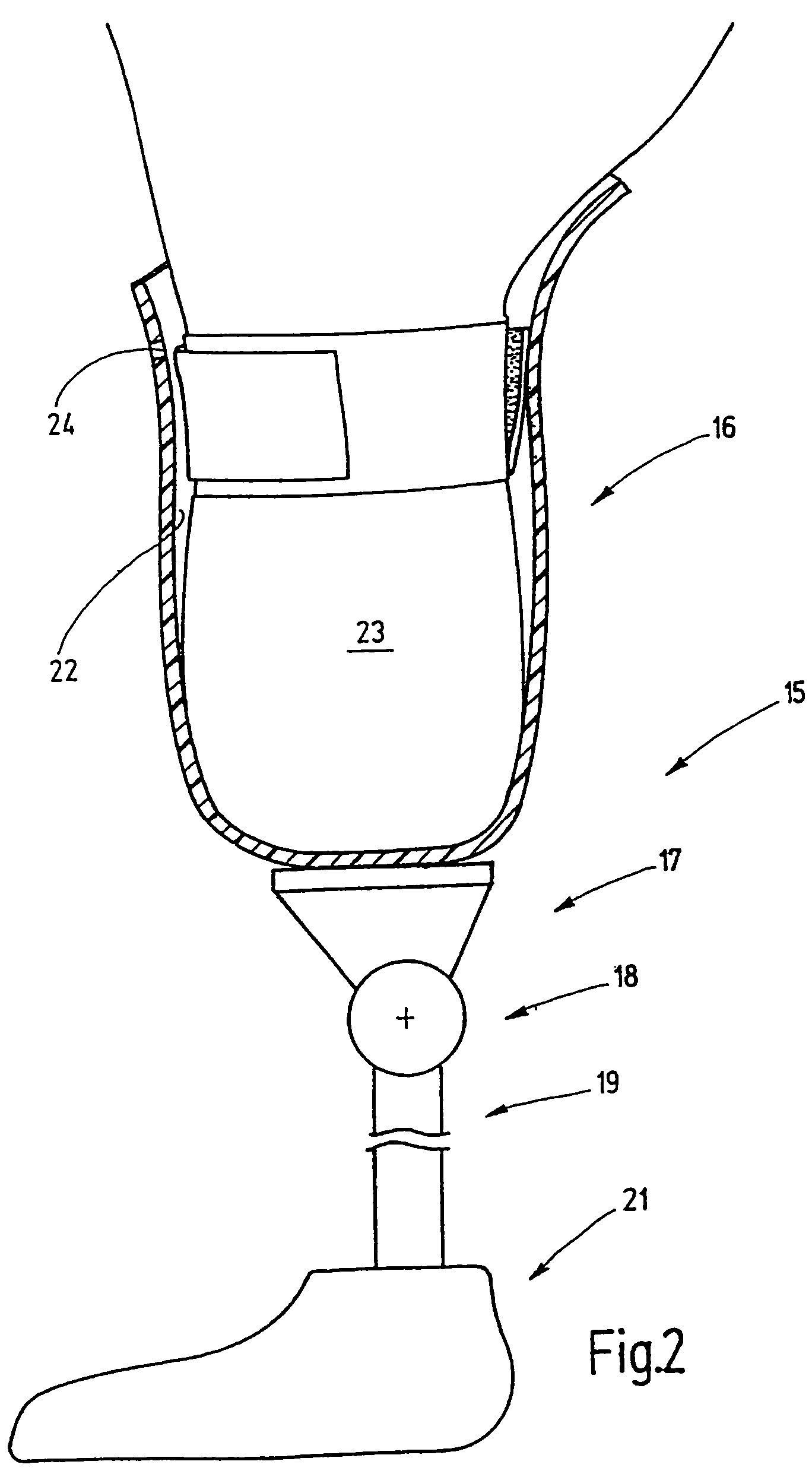

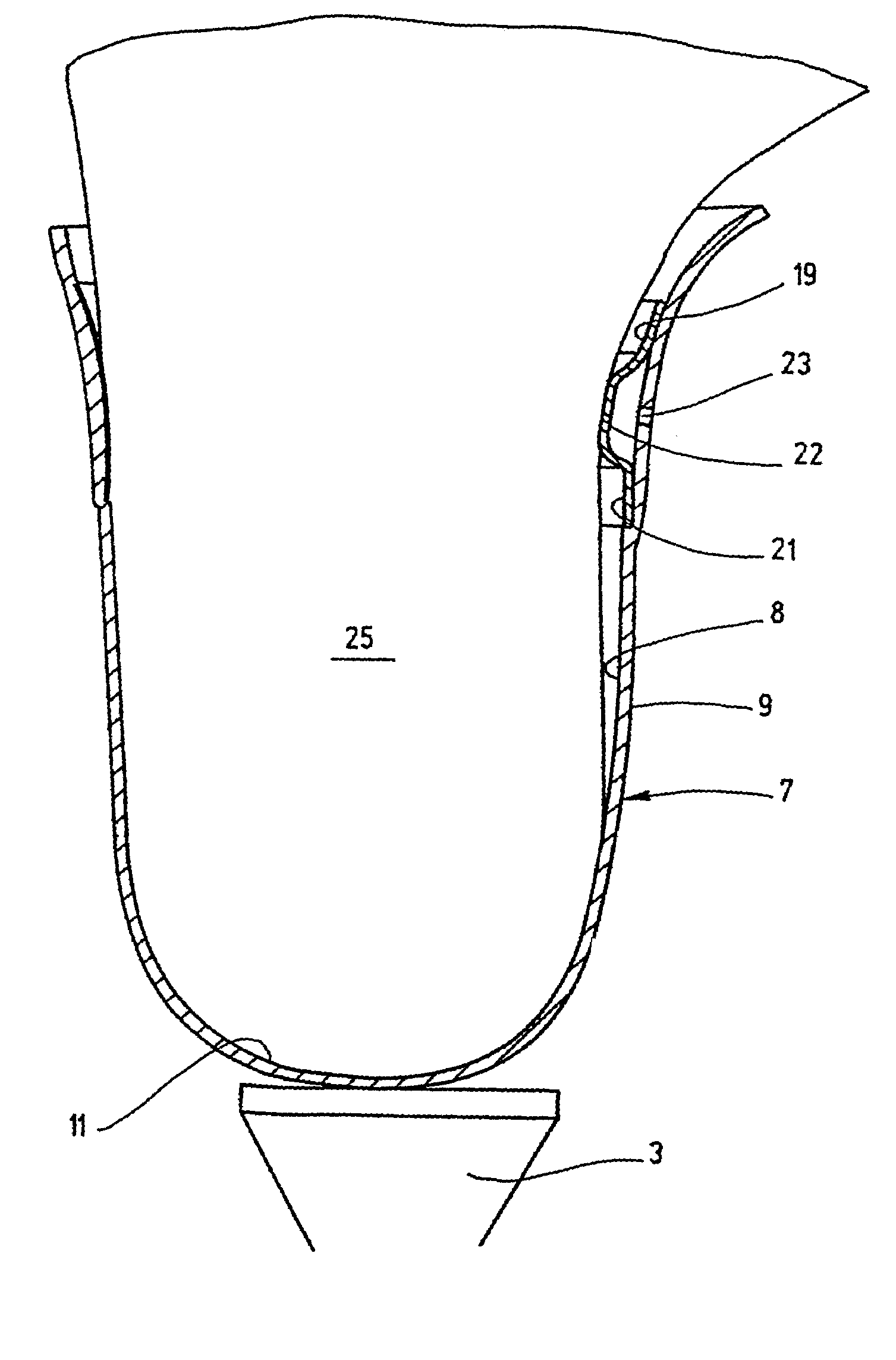

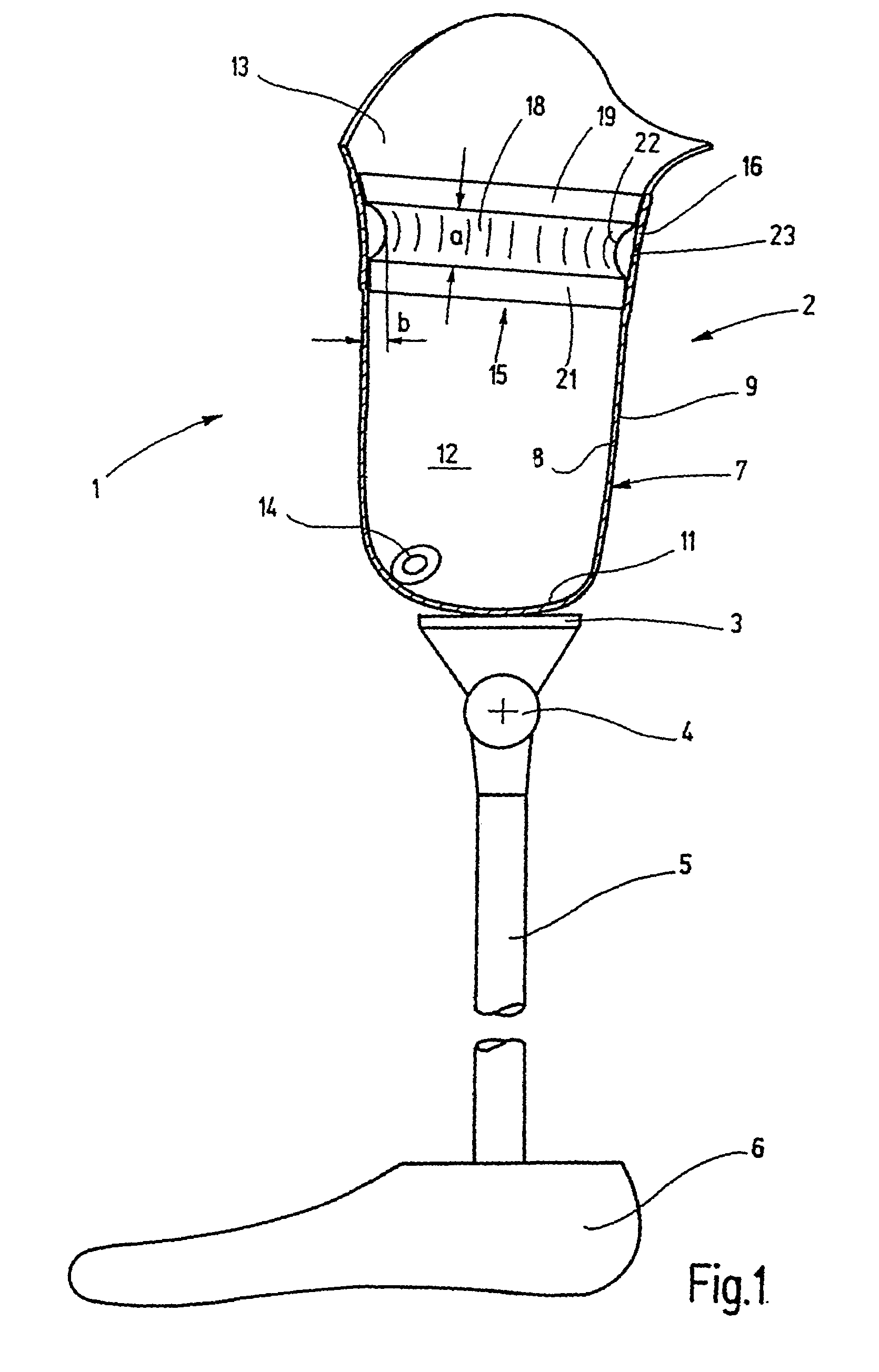

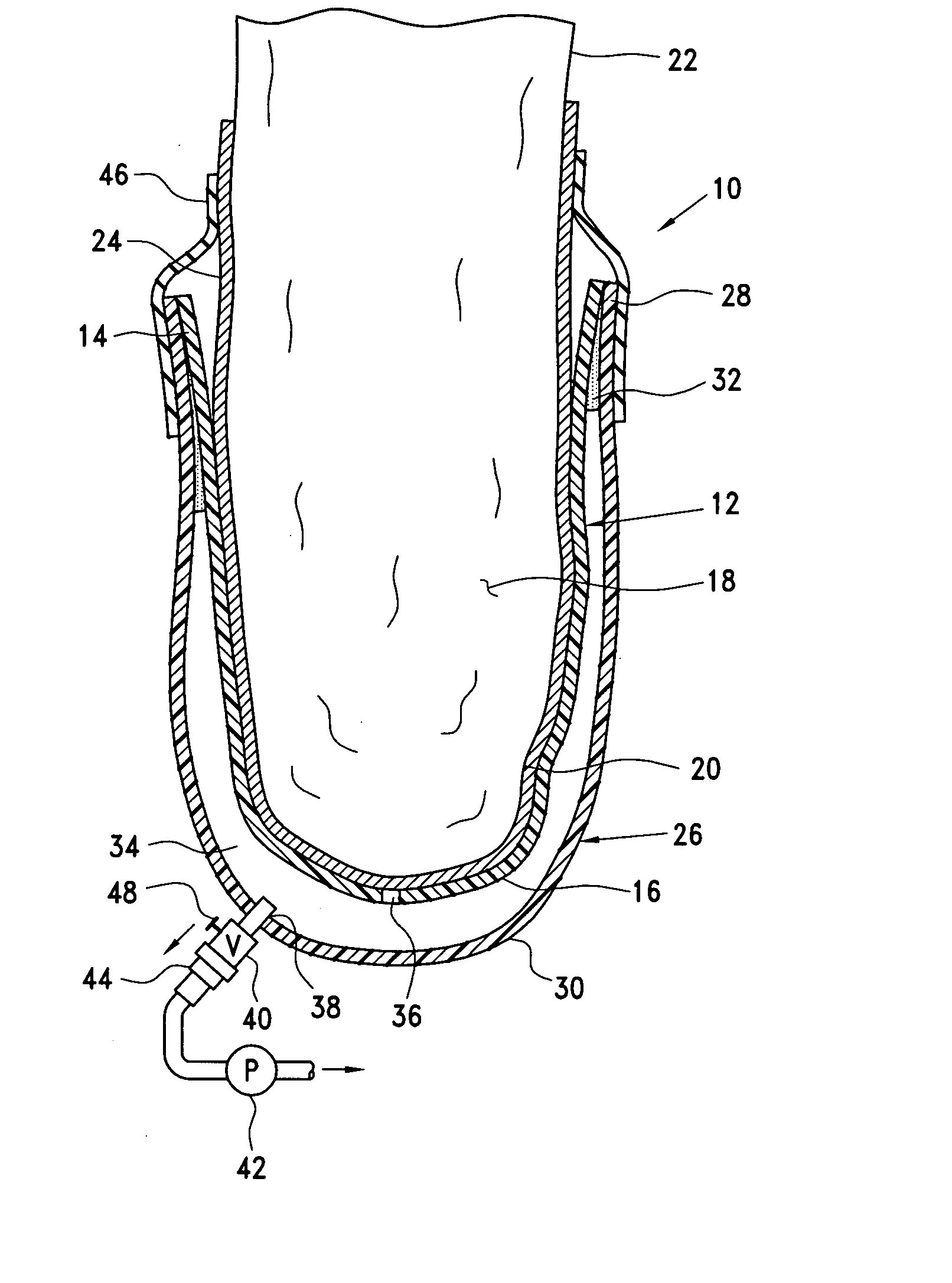

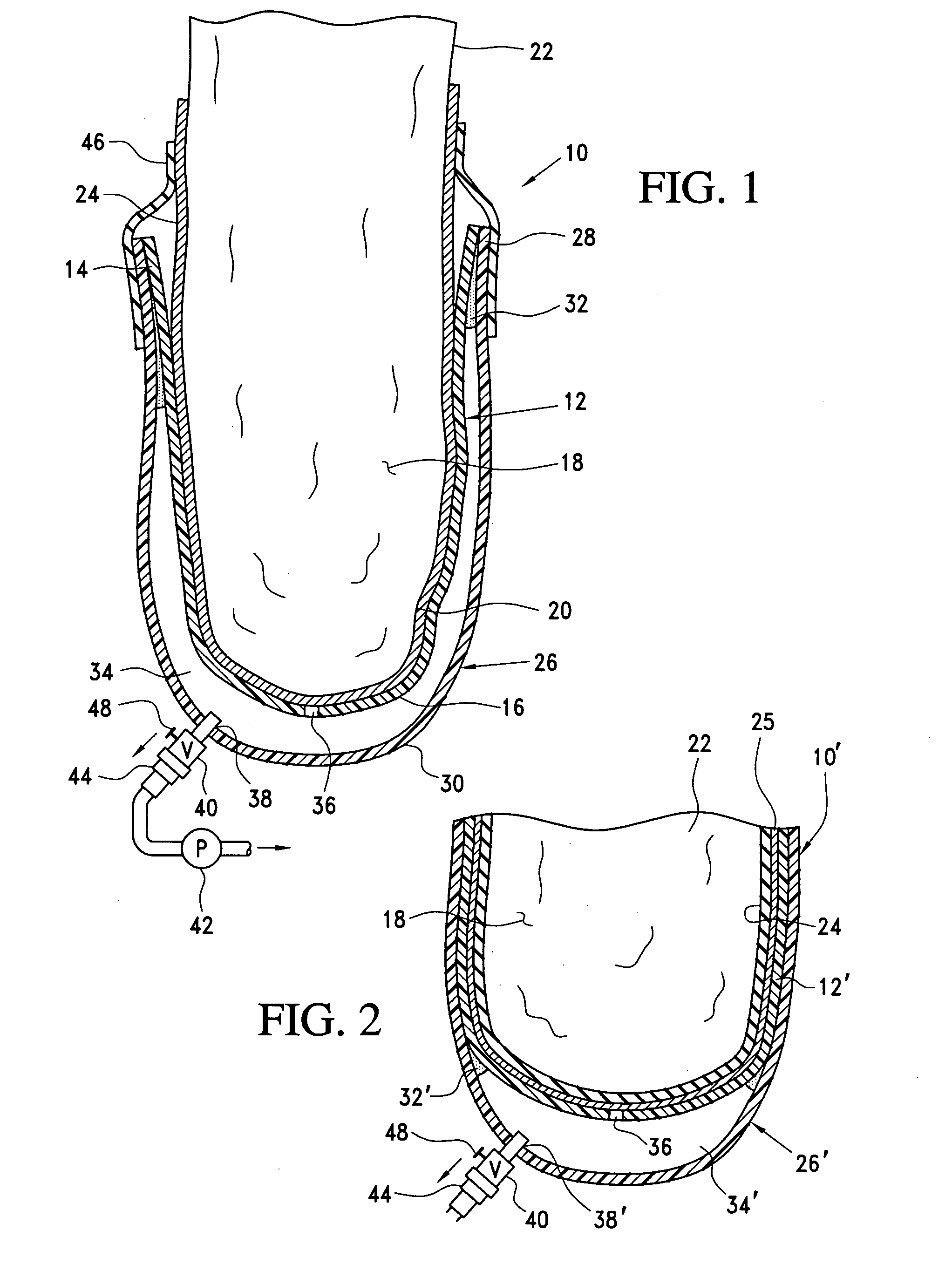

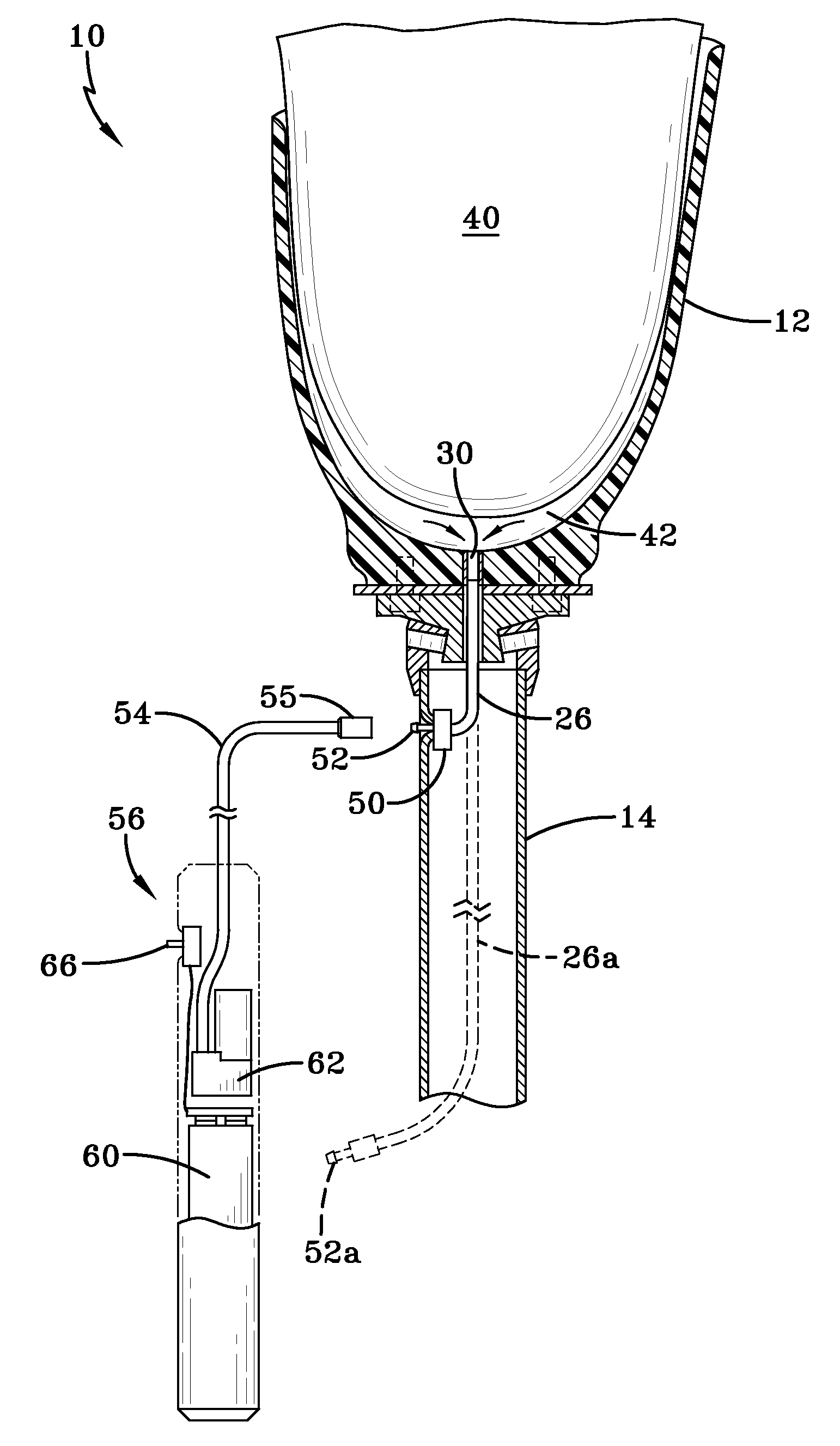

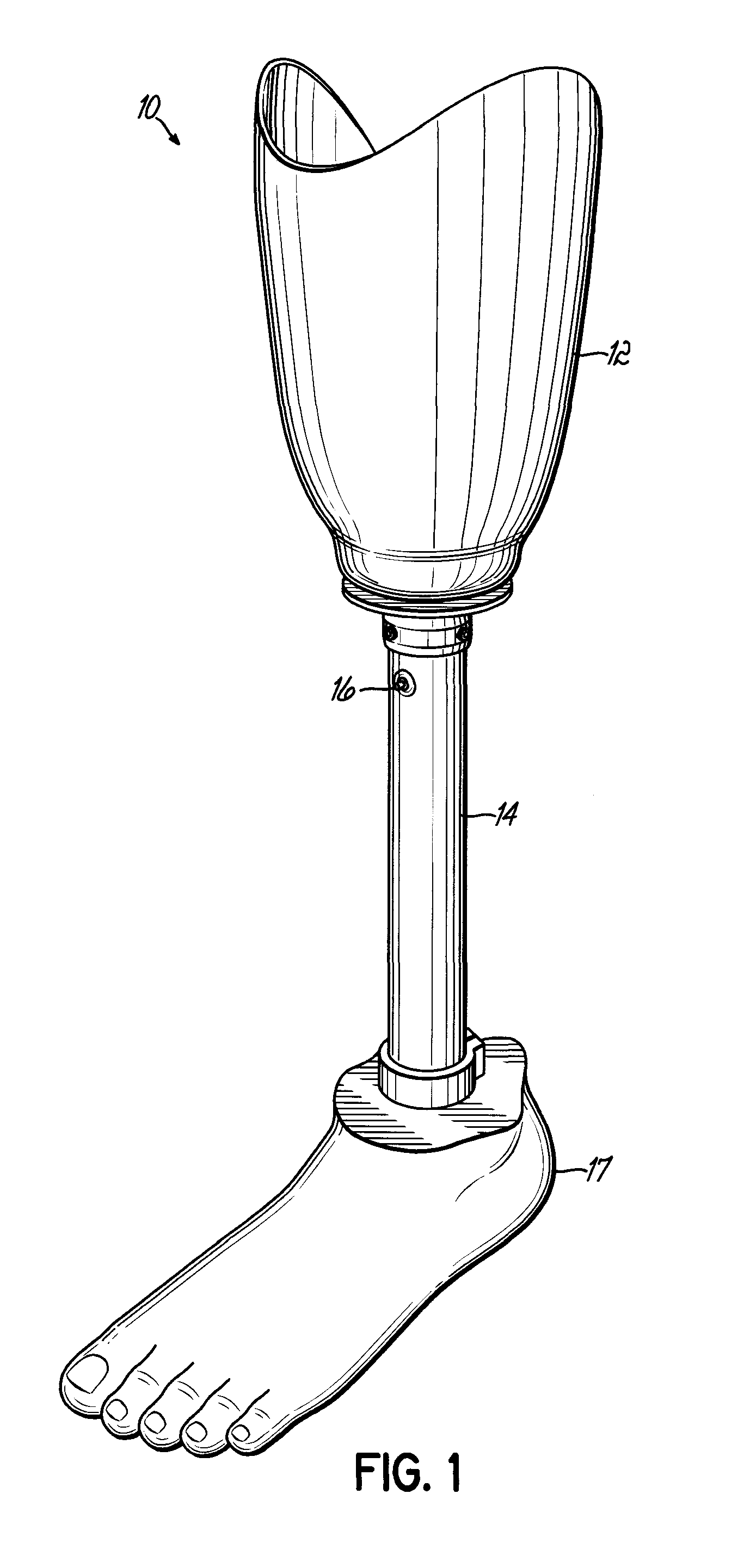

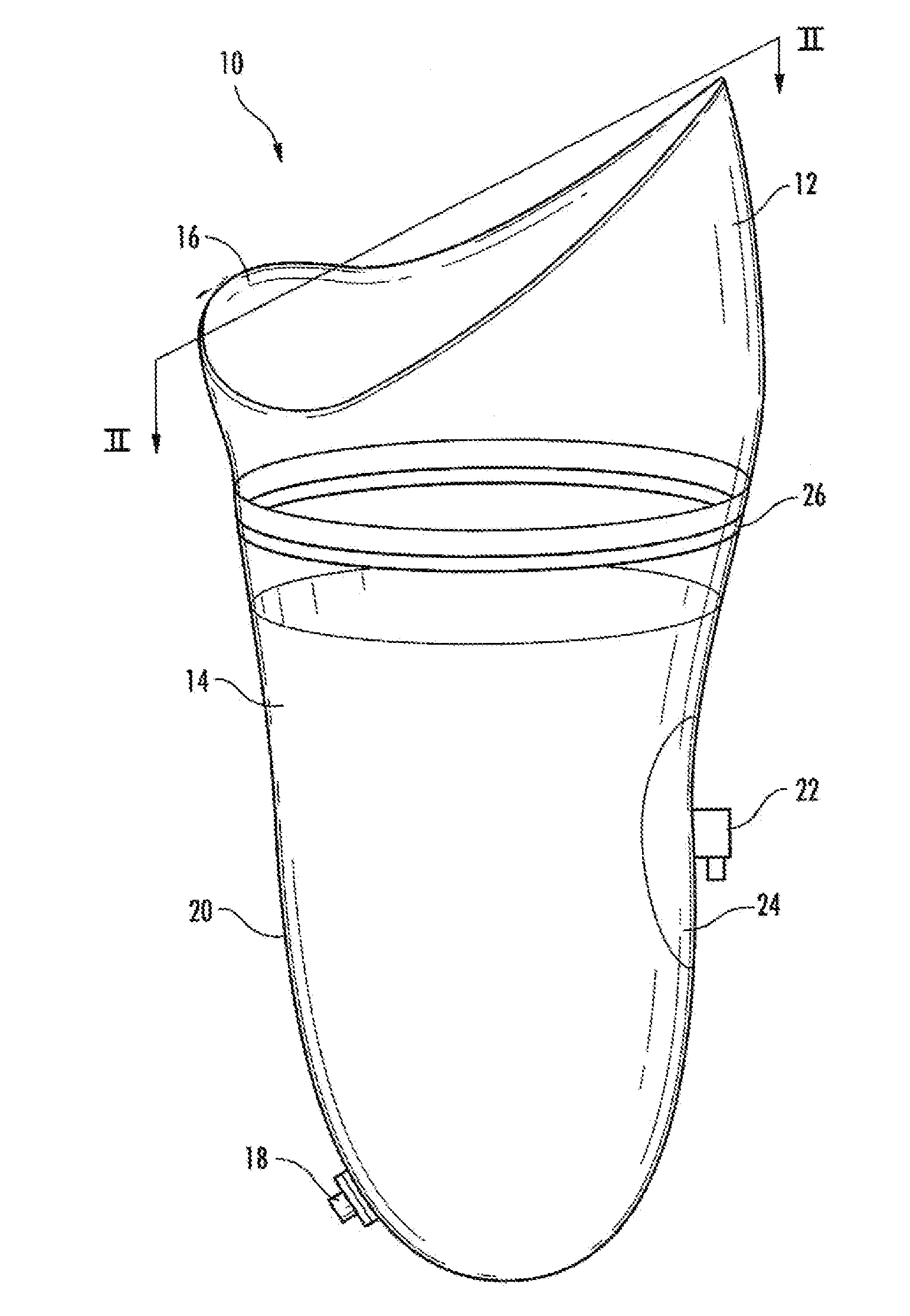

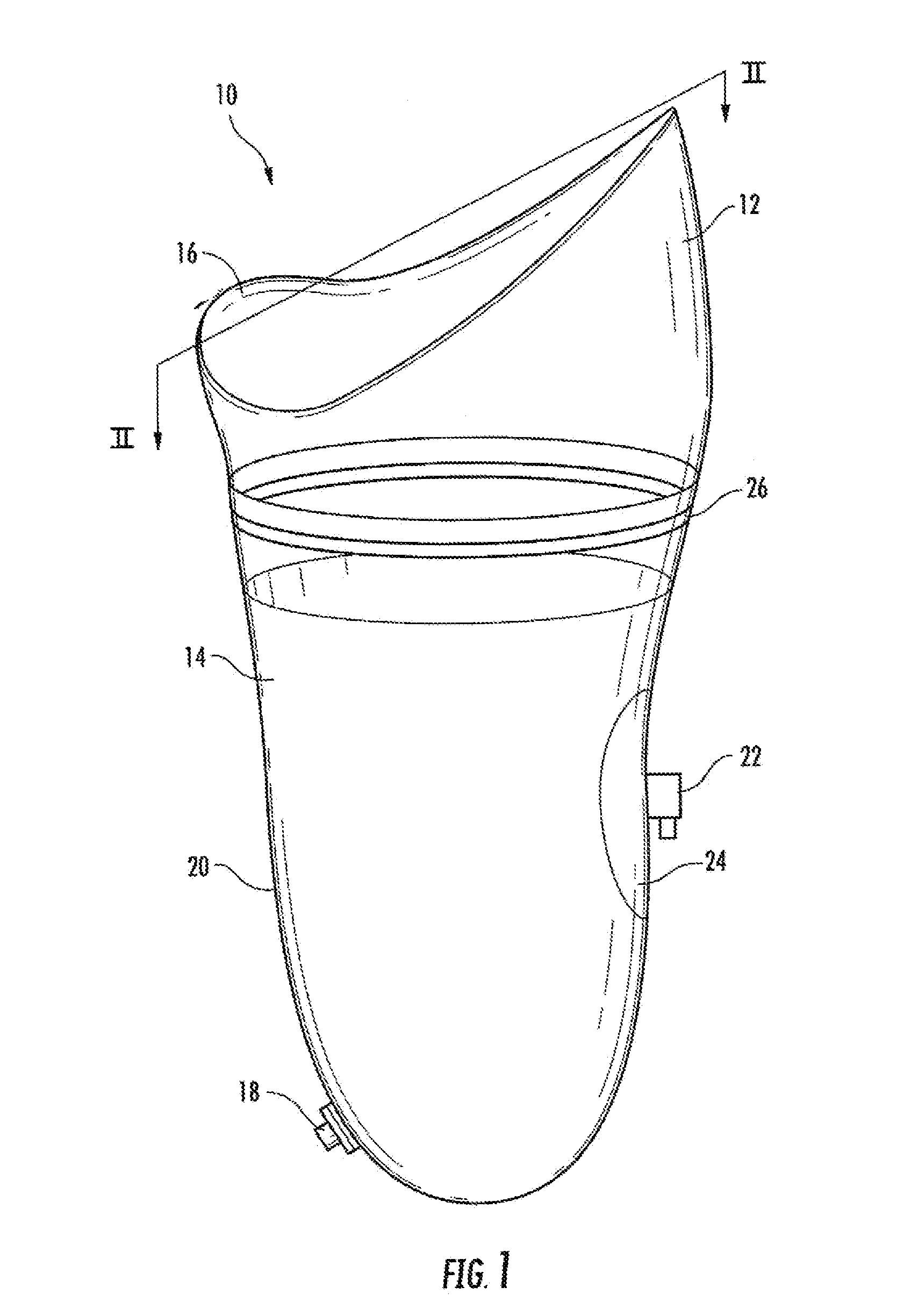

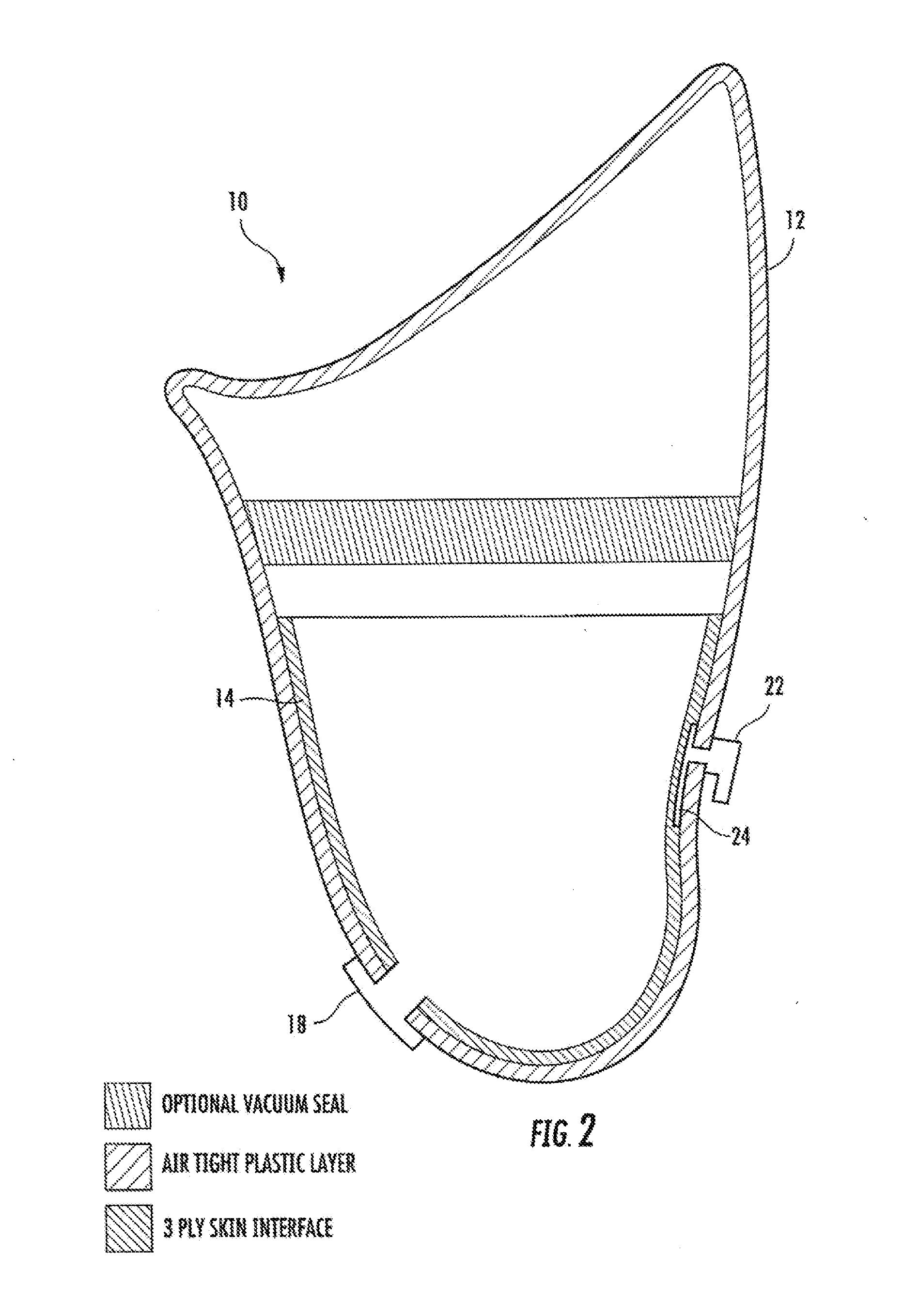

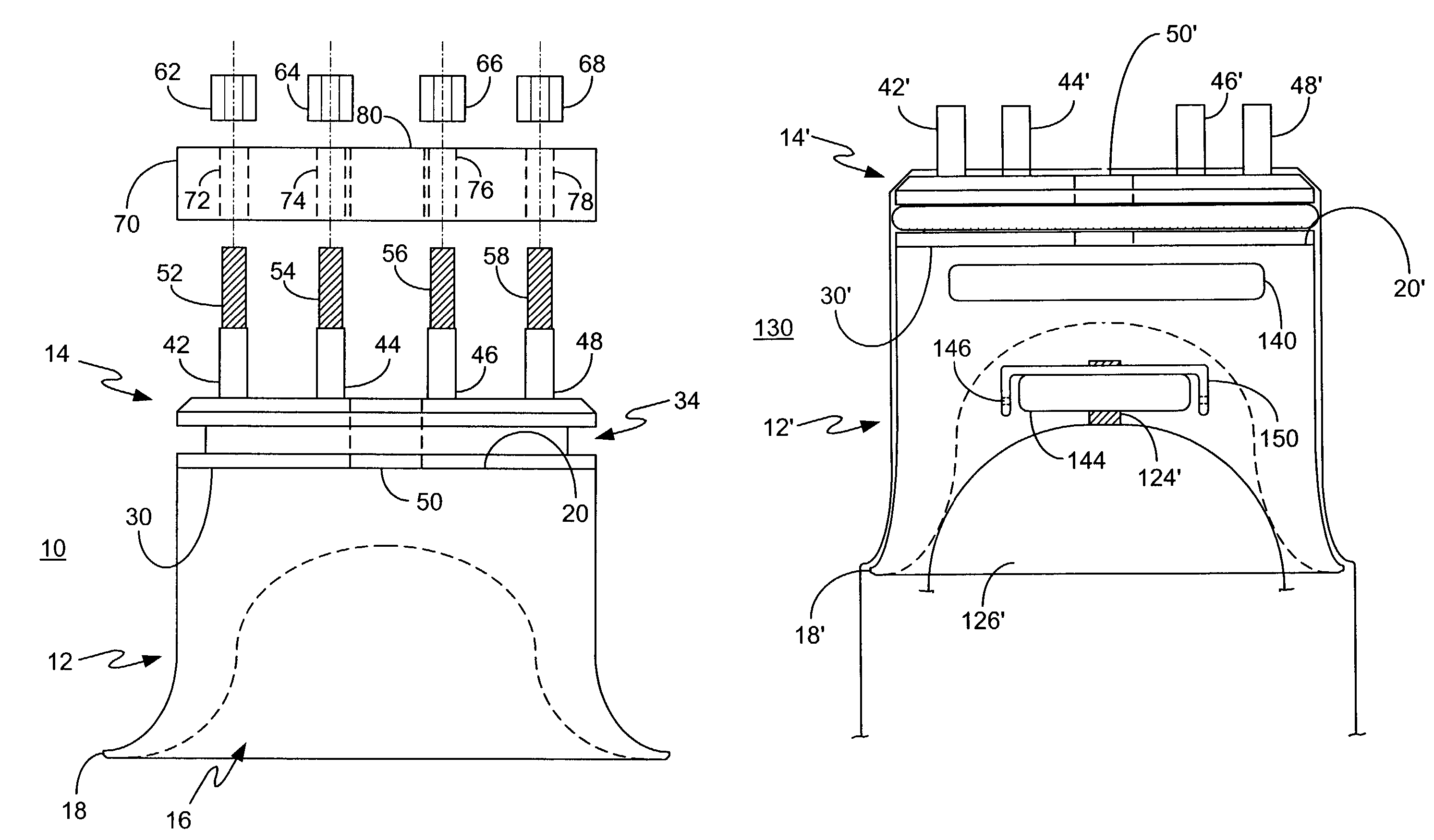

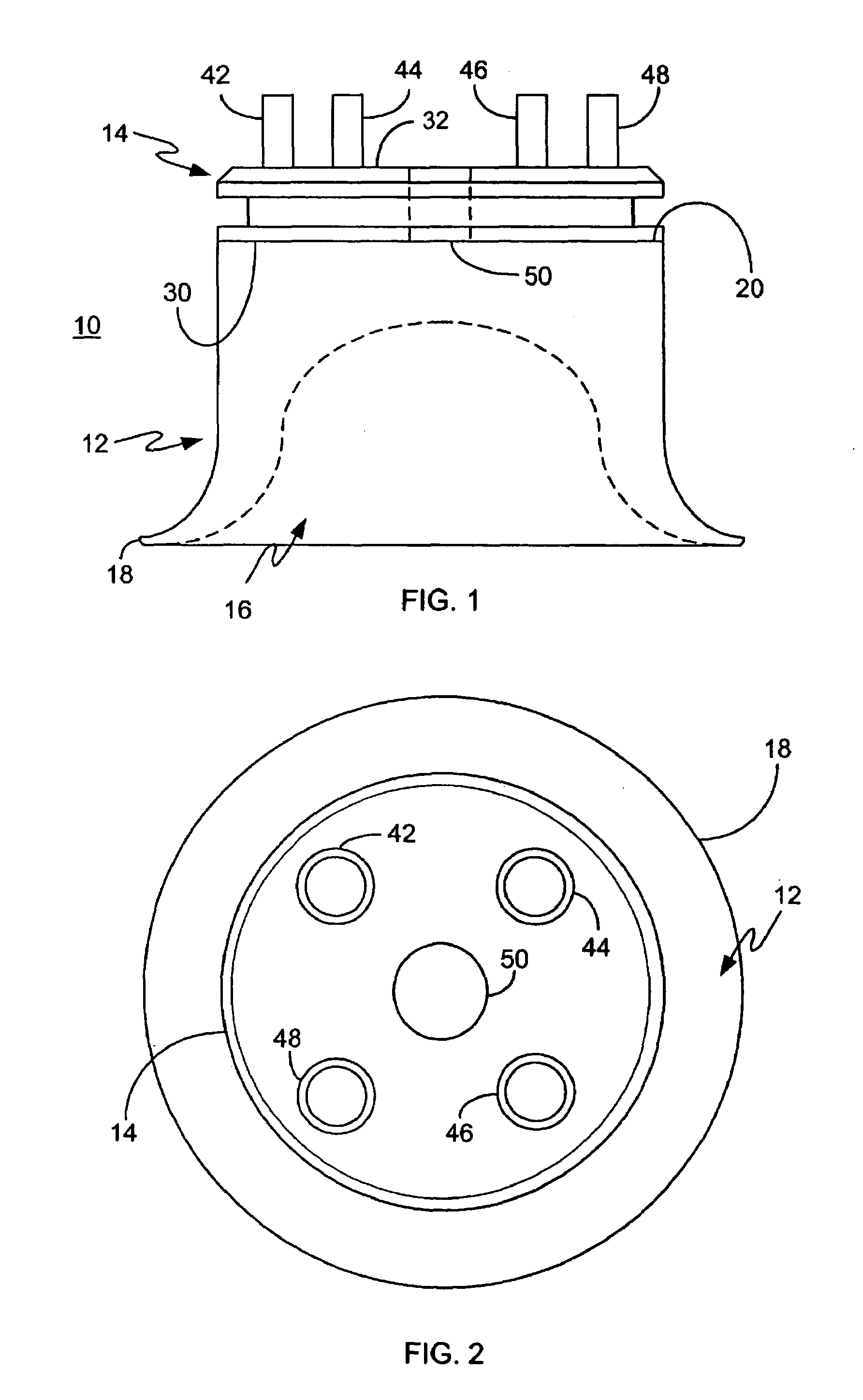

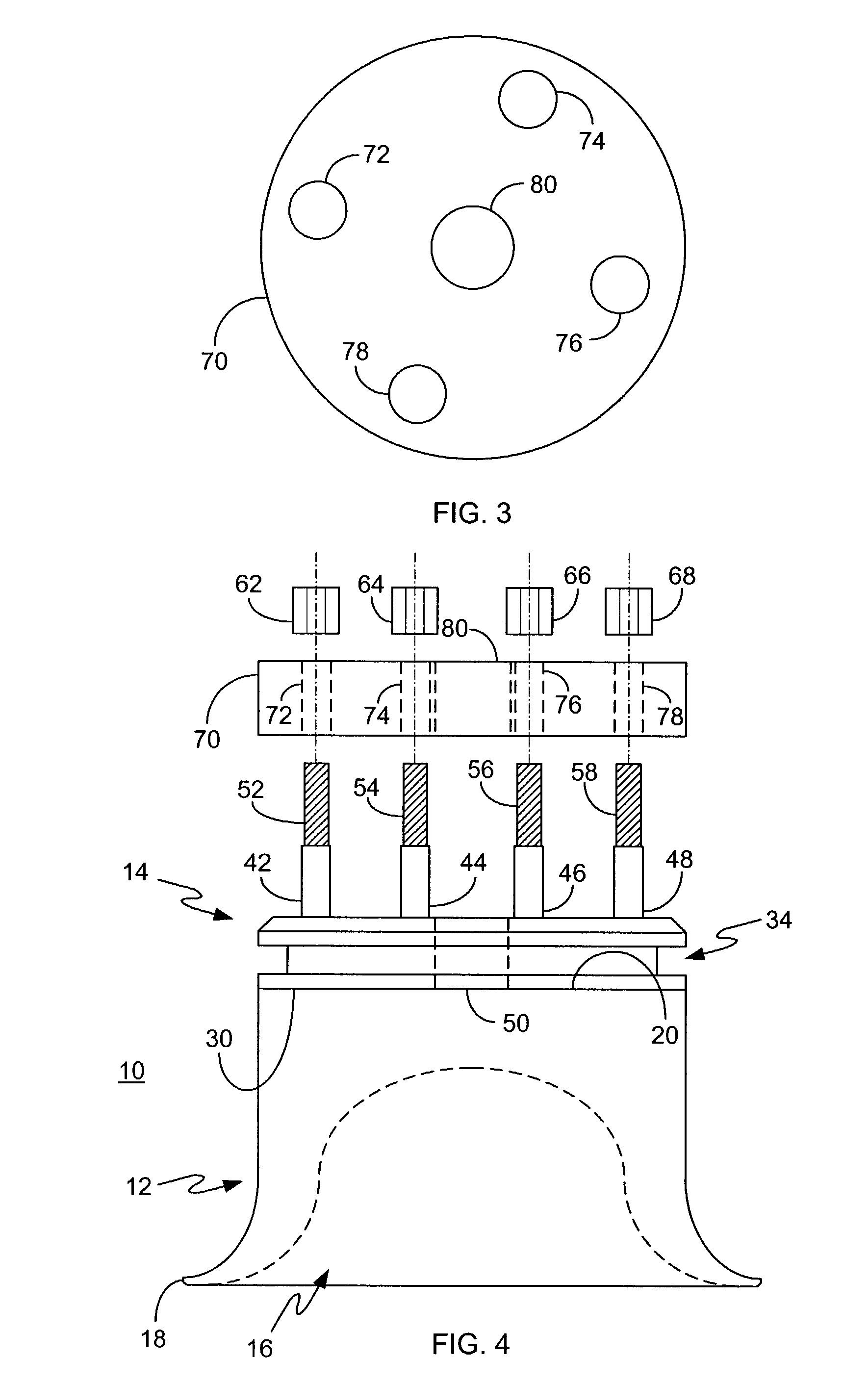

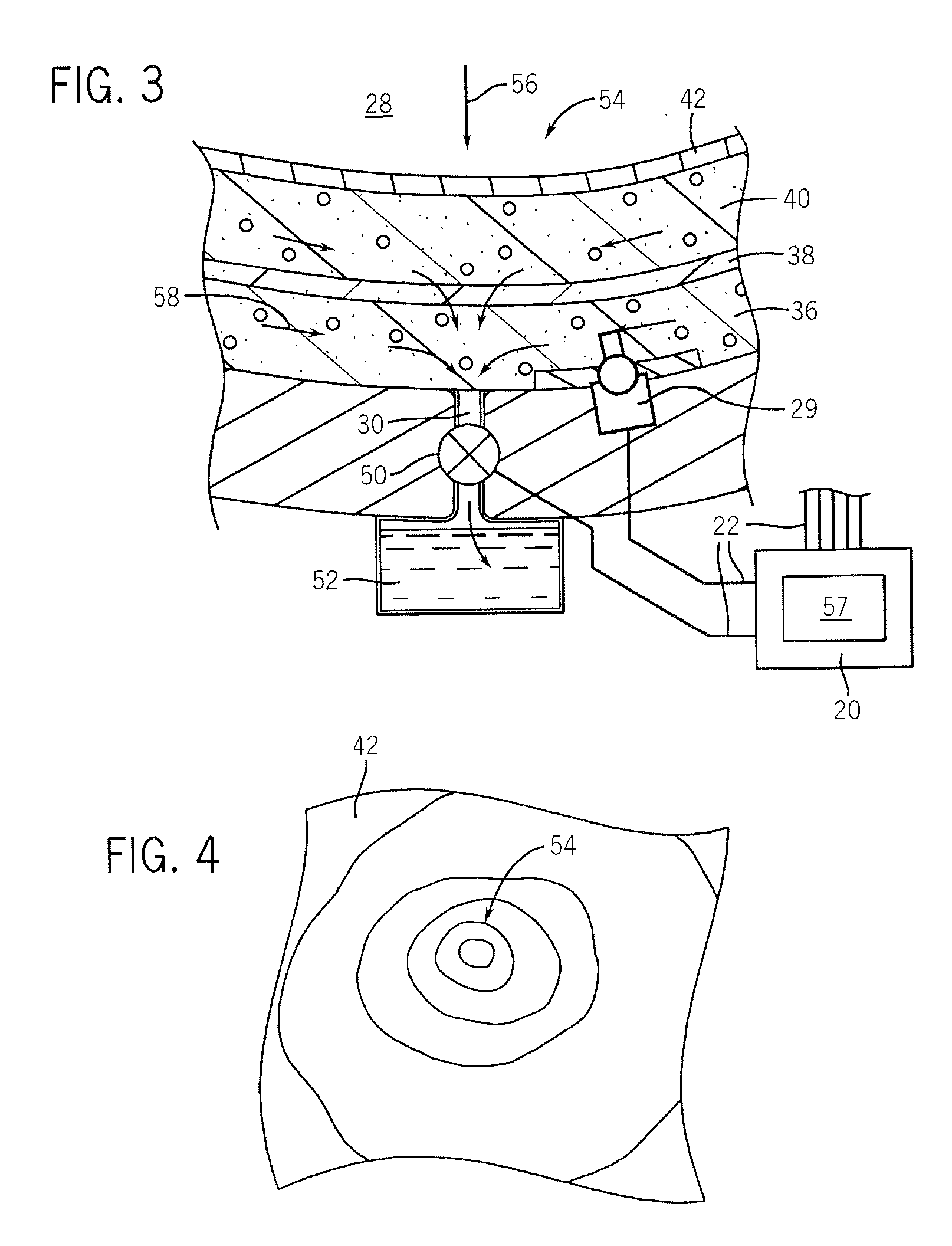

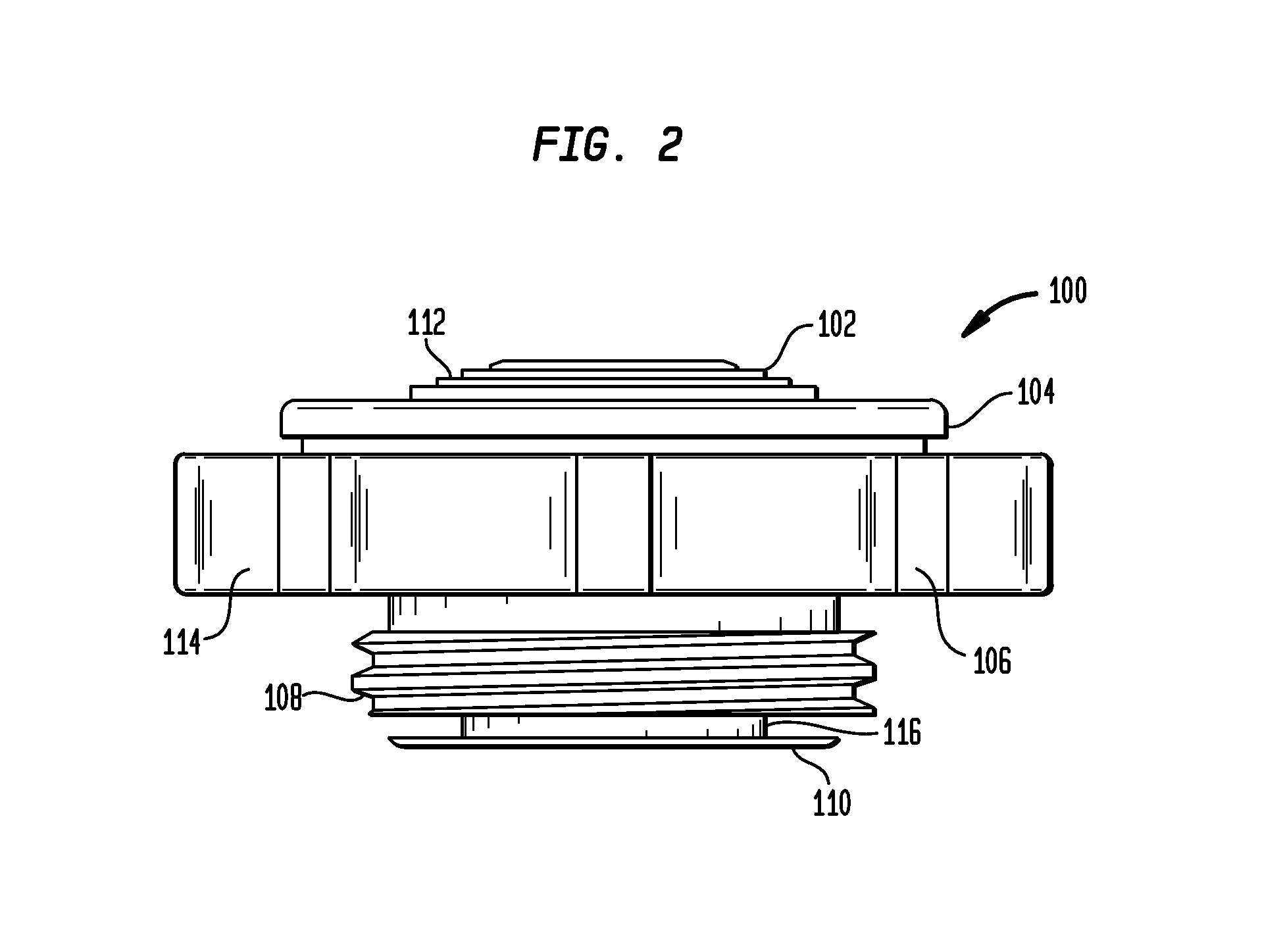

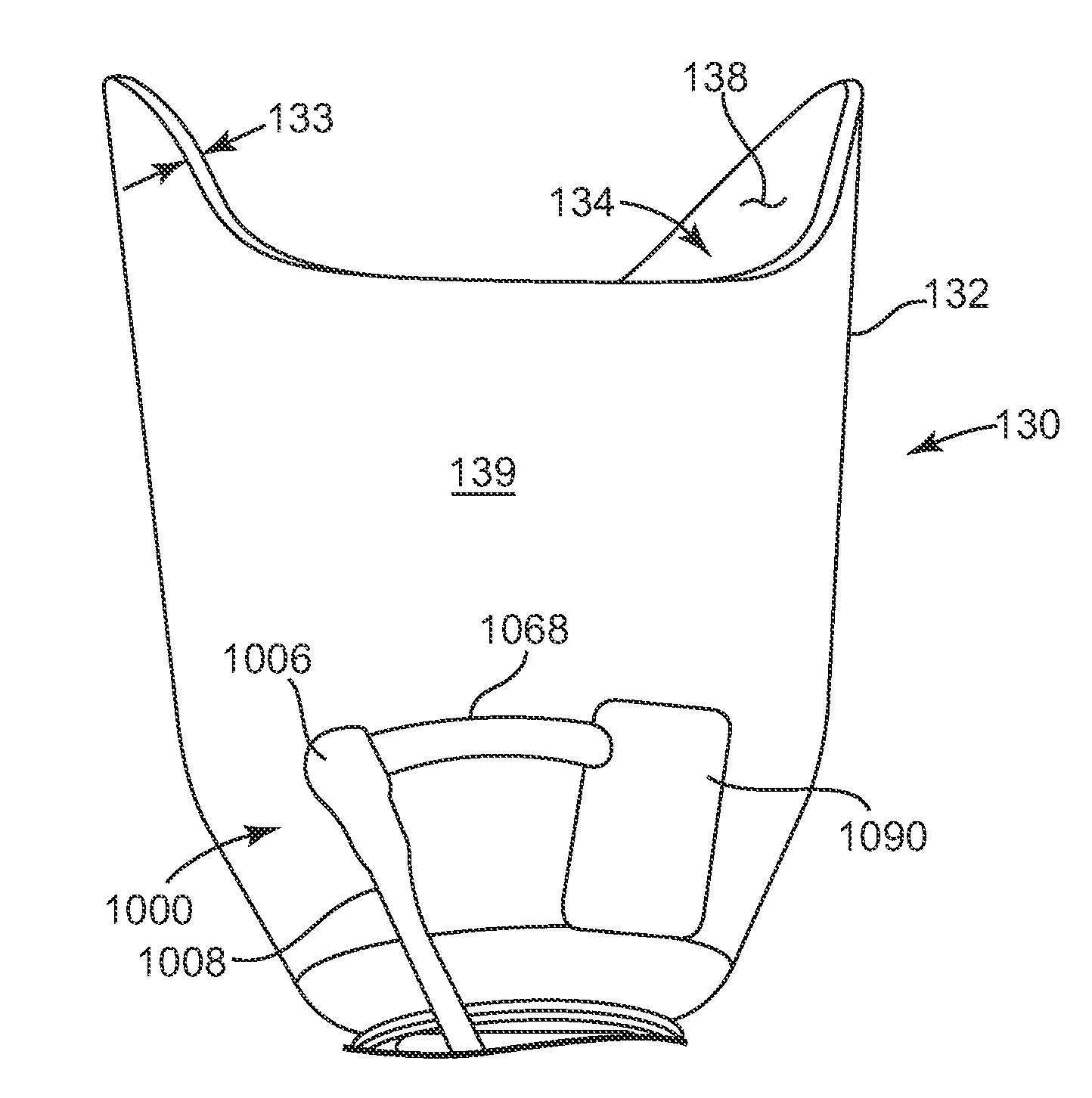

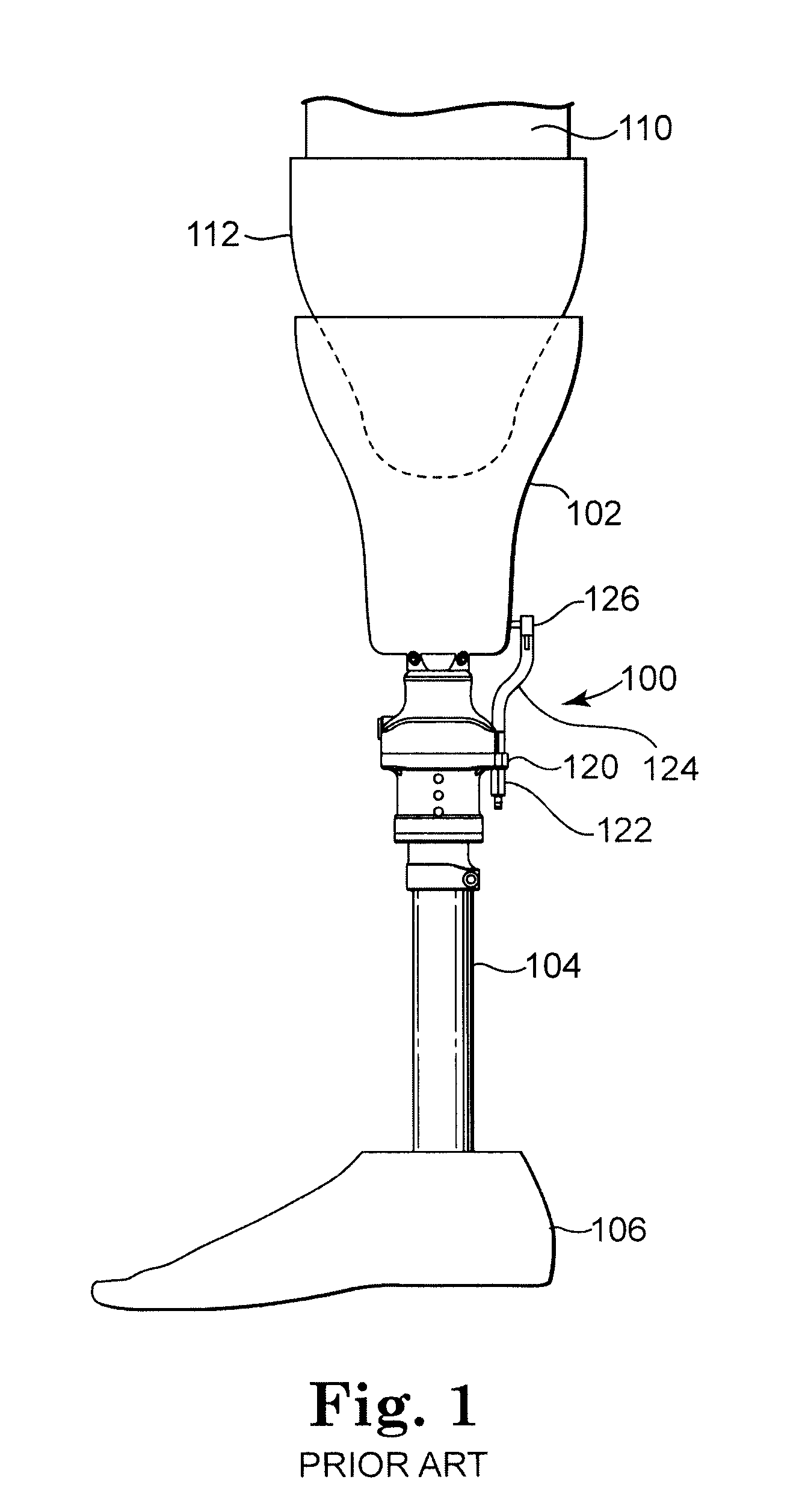

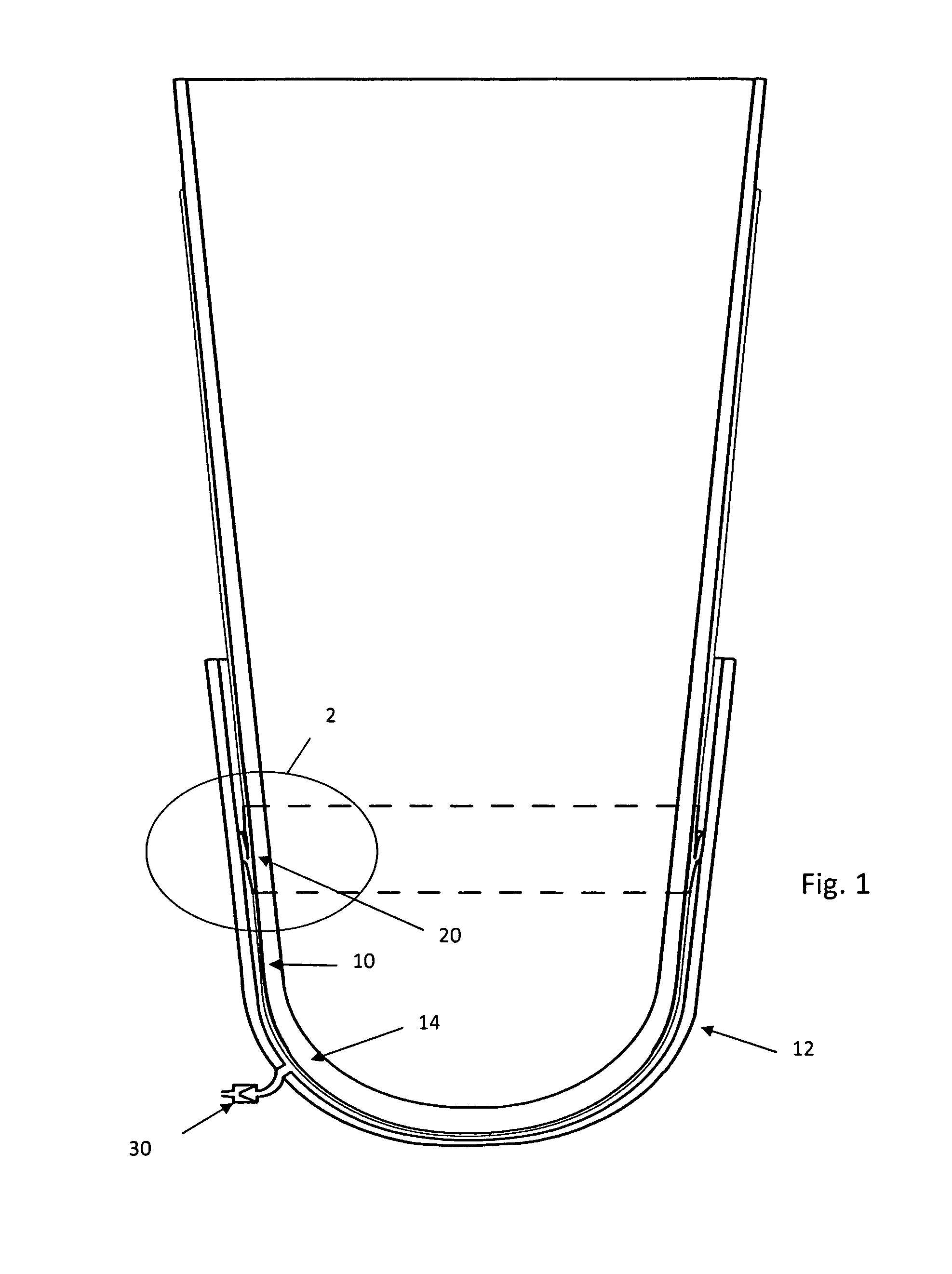

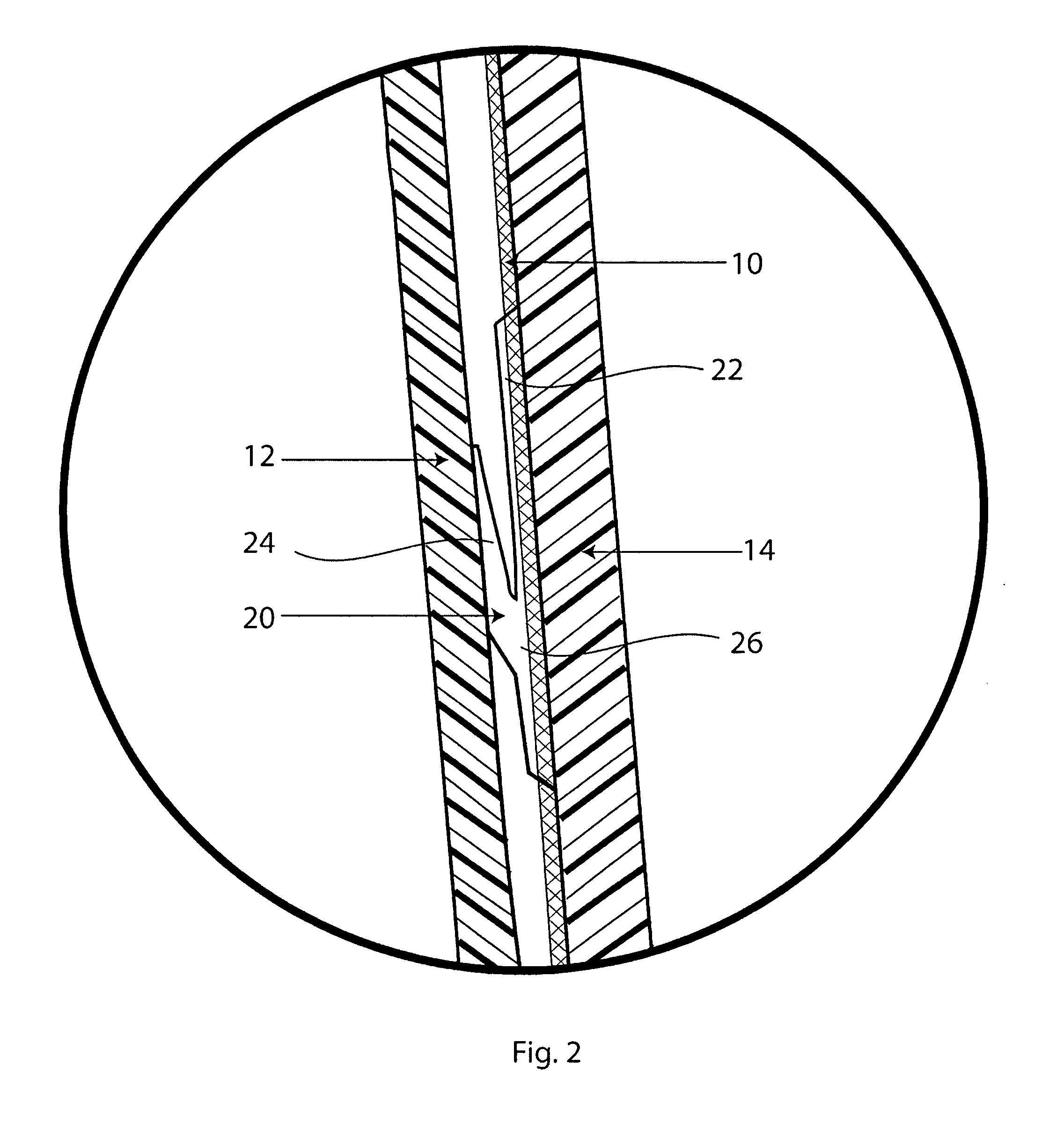

Prosthetic socket with self-contained vacuum reservoir

ActiveUS20040260403A1Avoid substantial deflectionDomestic articlesProsthesisEngineeringLoad-bearing wall

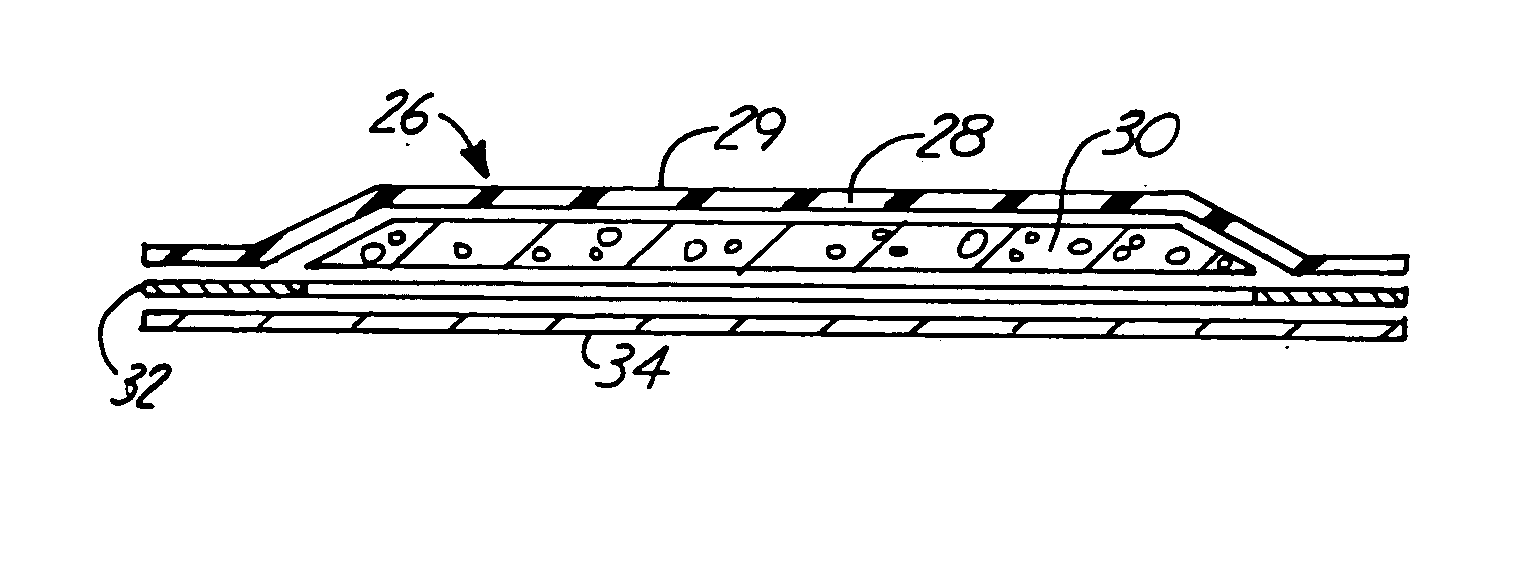

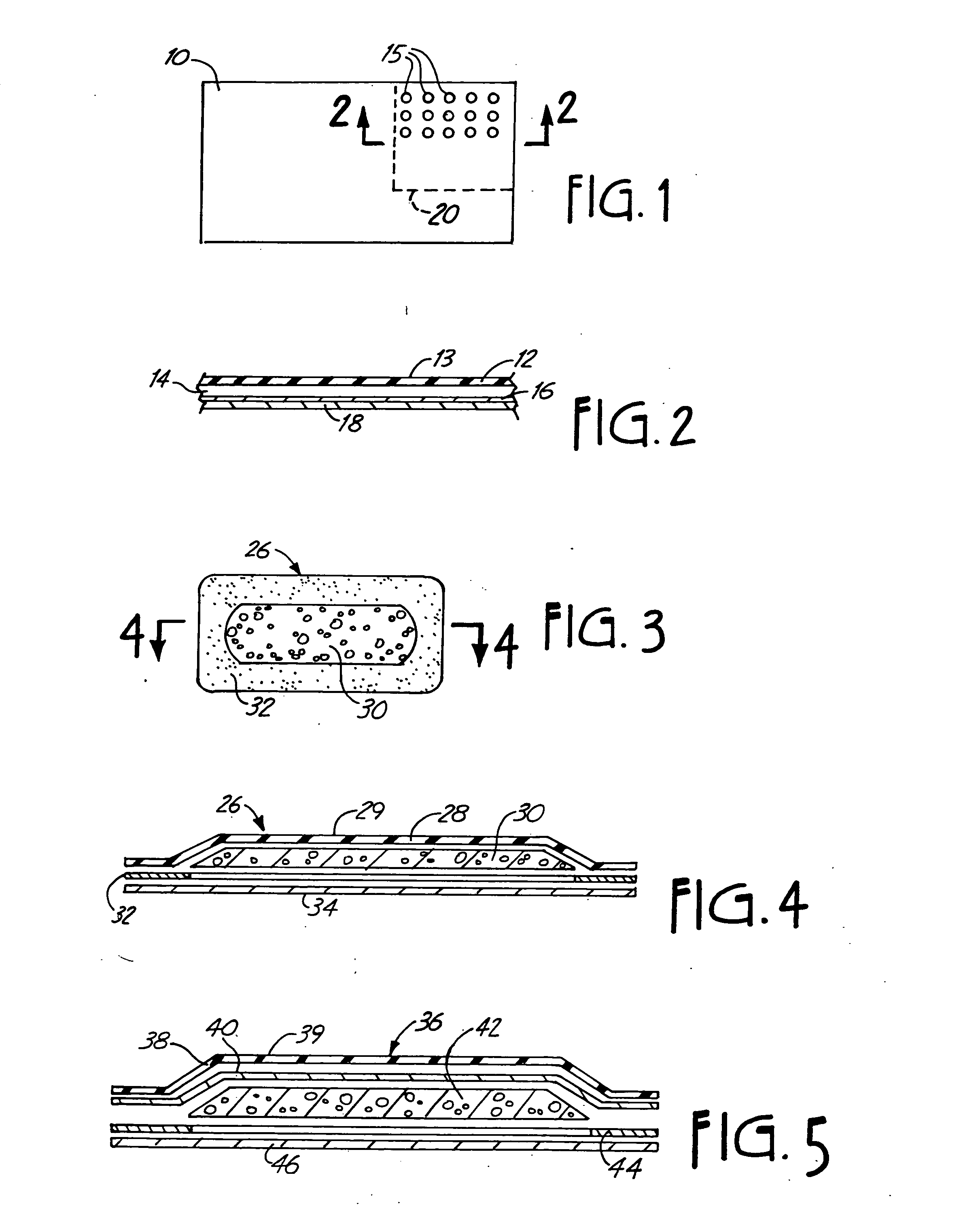

A prosthetic socket having a self-contained vacuum reservoir chamber includes a rigid, load-bearing inner socket member for receiving a residual limb and an outer, rigid, load-bearing wall section attached to the inner wall section in a manner providing a vacuum reservoir chamber between the inner wall and the outer wall section. The vacuum reservoir chamber communicates with the inner volume of the inner wall through a vacuum transfer port and the vacuum reservoir chamber may be evacuated via an evacuation port having an appropriate one-way check valve permitting withdrawal of air from the vacuum reservoir chamber while preventing ingress of air into the chamber. A method for making the prosthetic socket is disclosed.

Owner:OSSUR HF

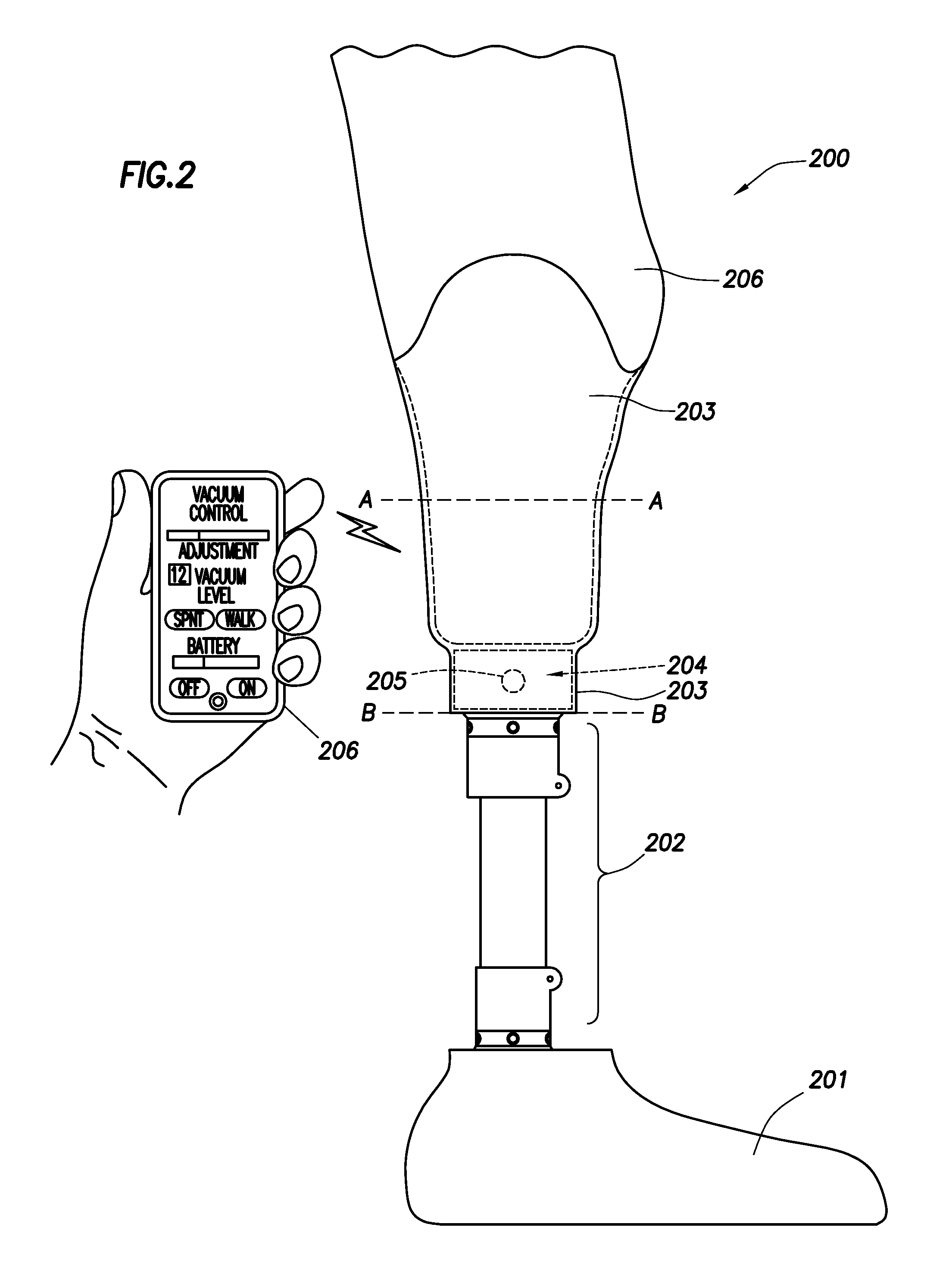

Intelligent prosthetic socket system with active user feedback interface and real time prosthesis diagnostics

An apparatus is provided for use with a prosthetic system. The apparatus includes a controller and a wireless smart device. The controller operates to gather data and derive prosthetic information from a plurality of sensors, and transmits the prosthetic information over a wireless radio link, where the controller and the plurality of sensors are disposed within the interior of a prosthetic socket. The wireless smart device is coupled to the controller via the wireless radio link, and receives the prosthetic information, and provides visual and audio representations of the prosthetic information to a user.

Owner:5280 PROSTHETICS

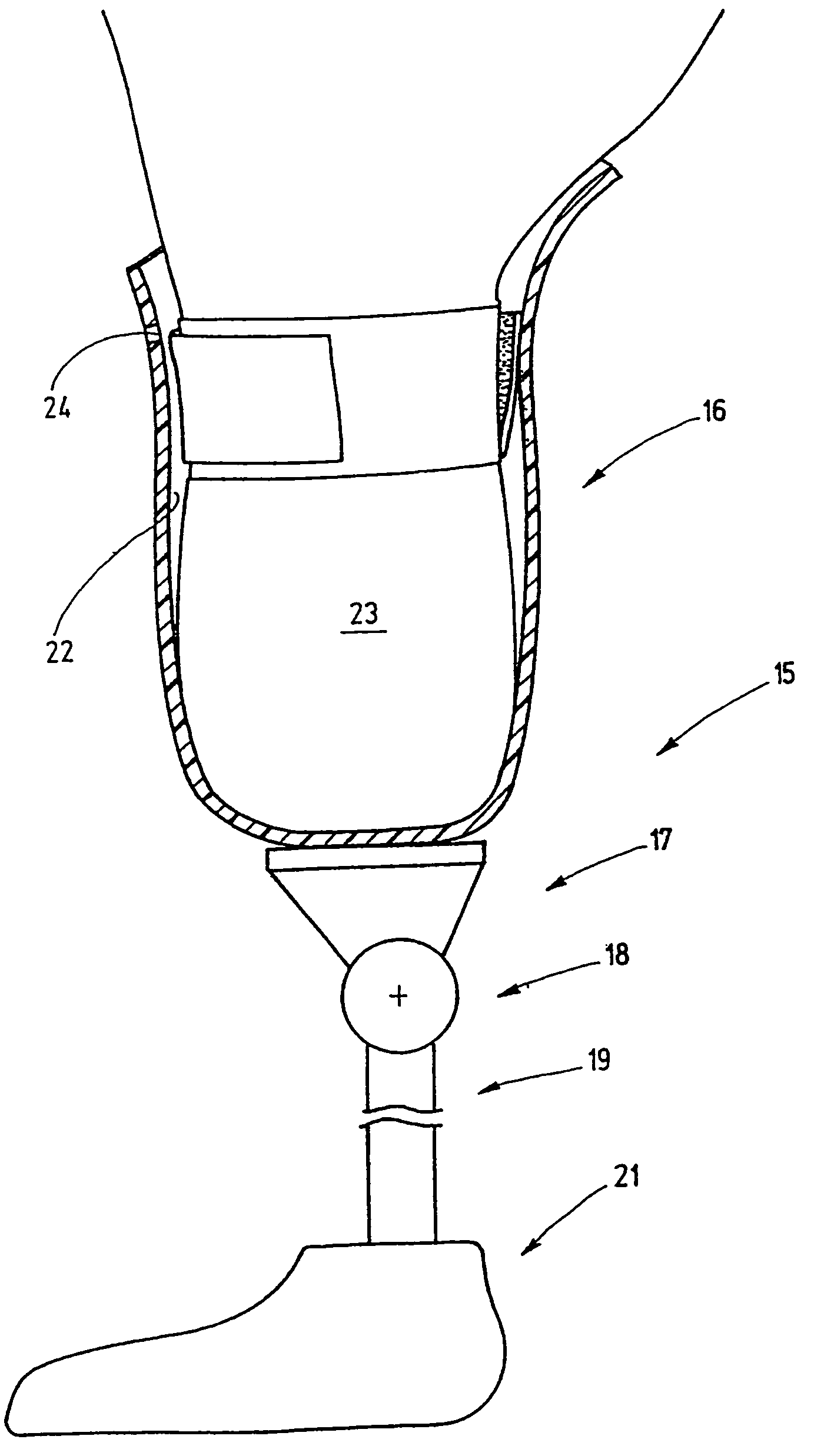

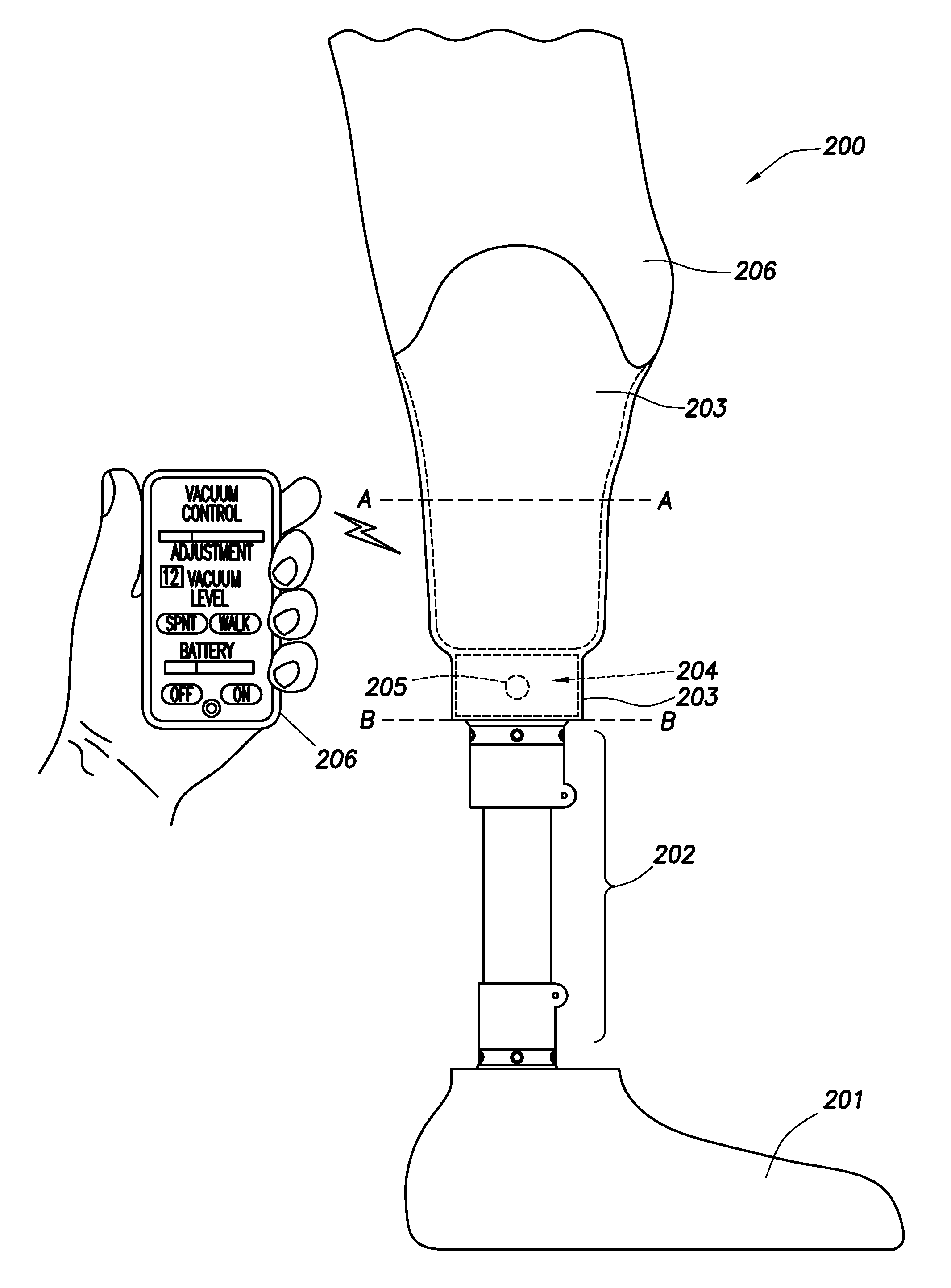

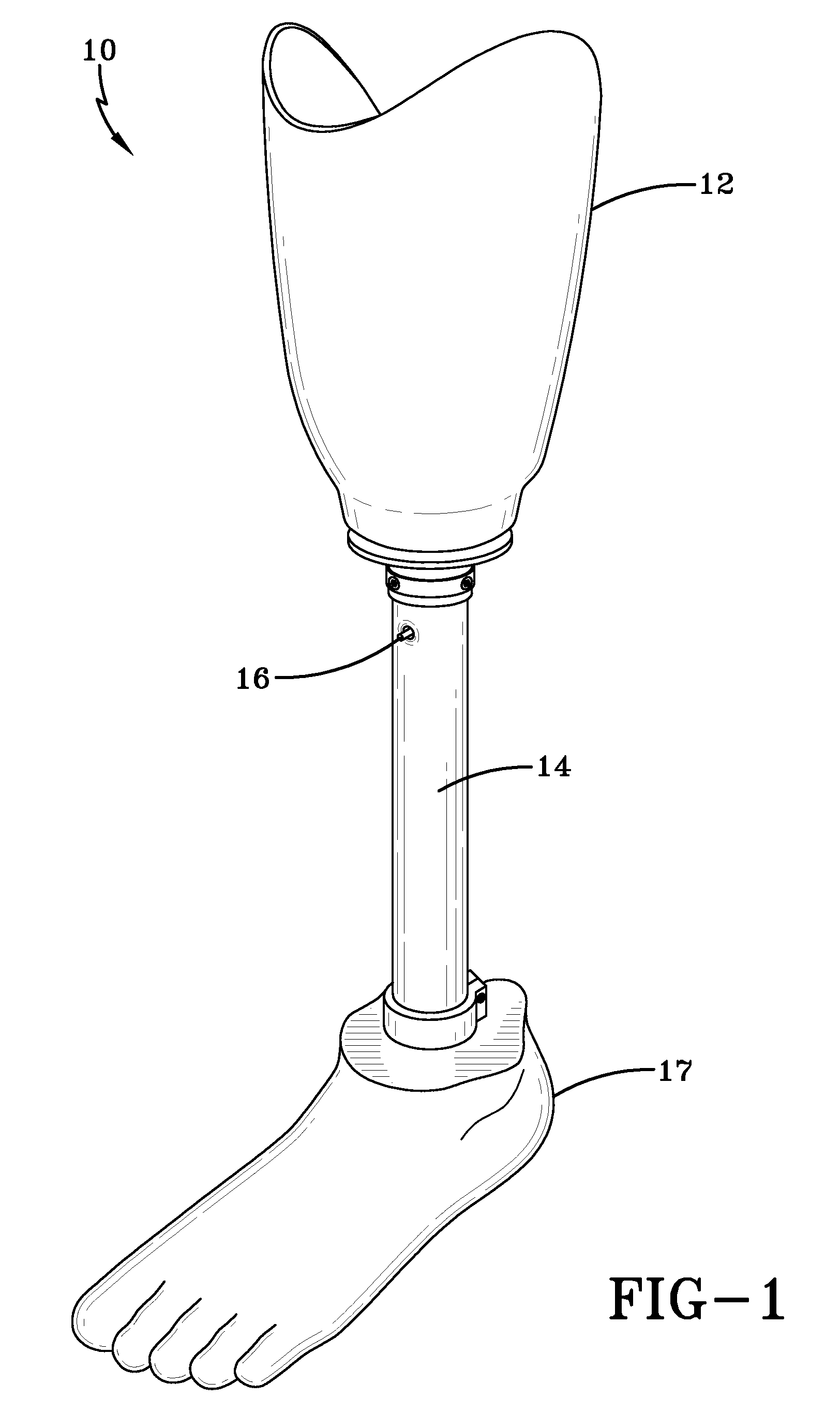

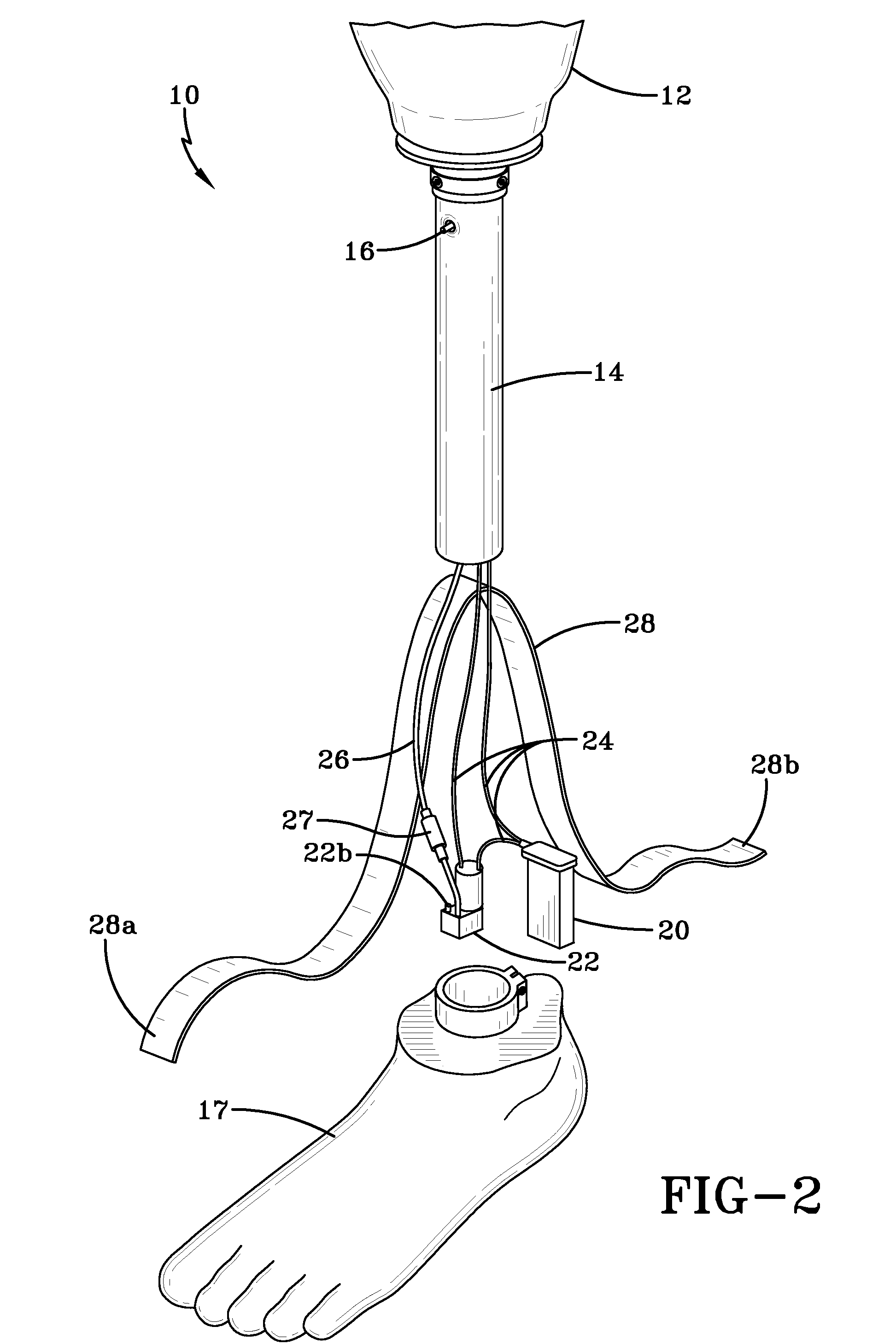

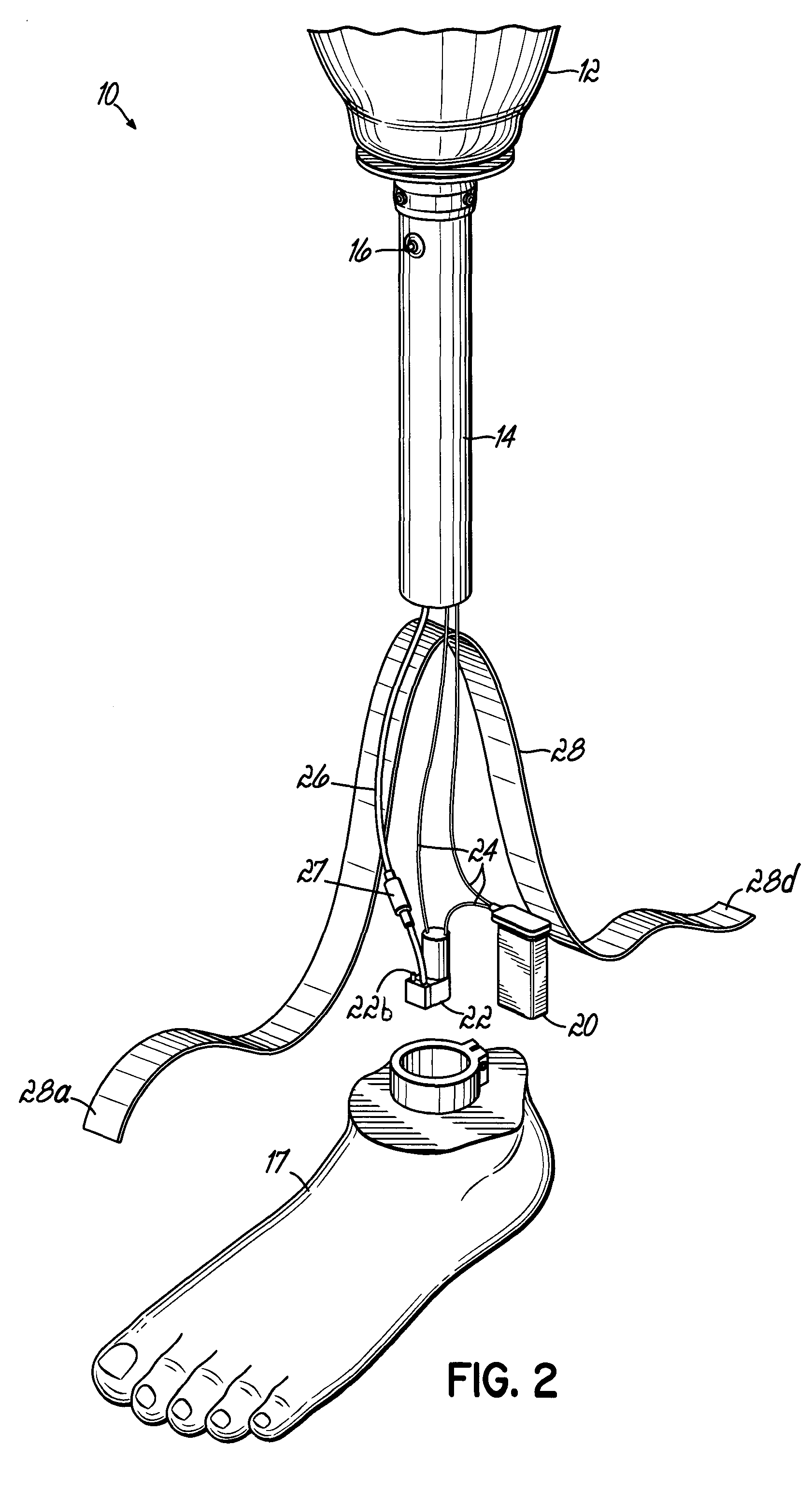

Prosthetic device utilizing electric vacuum pump

ActiveUS20080243266A1Easy to useReadily incorporated into/onto prosthesisArtificial legsArtificial handsControl systemVacuum level

Prosthetic devices having vacuum components operative to evacuate the interior of a prosthetic socket thereof, and control systems for use therewith. The evacuation devices preferably include at least an electrically powered vacuum pump and associated power source, and a vacuum accumulator connected to the vacuum pump. Associated control systems may be of various designs and may employ wired or wireless communication. Control of an evacuation device may be based on vacuum level, residual limb volume, residual limb motion, user activity level or other device parameters.

Owner:WILLOWWOOD GLOBAL LLC

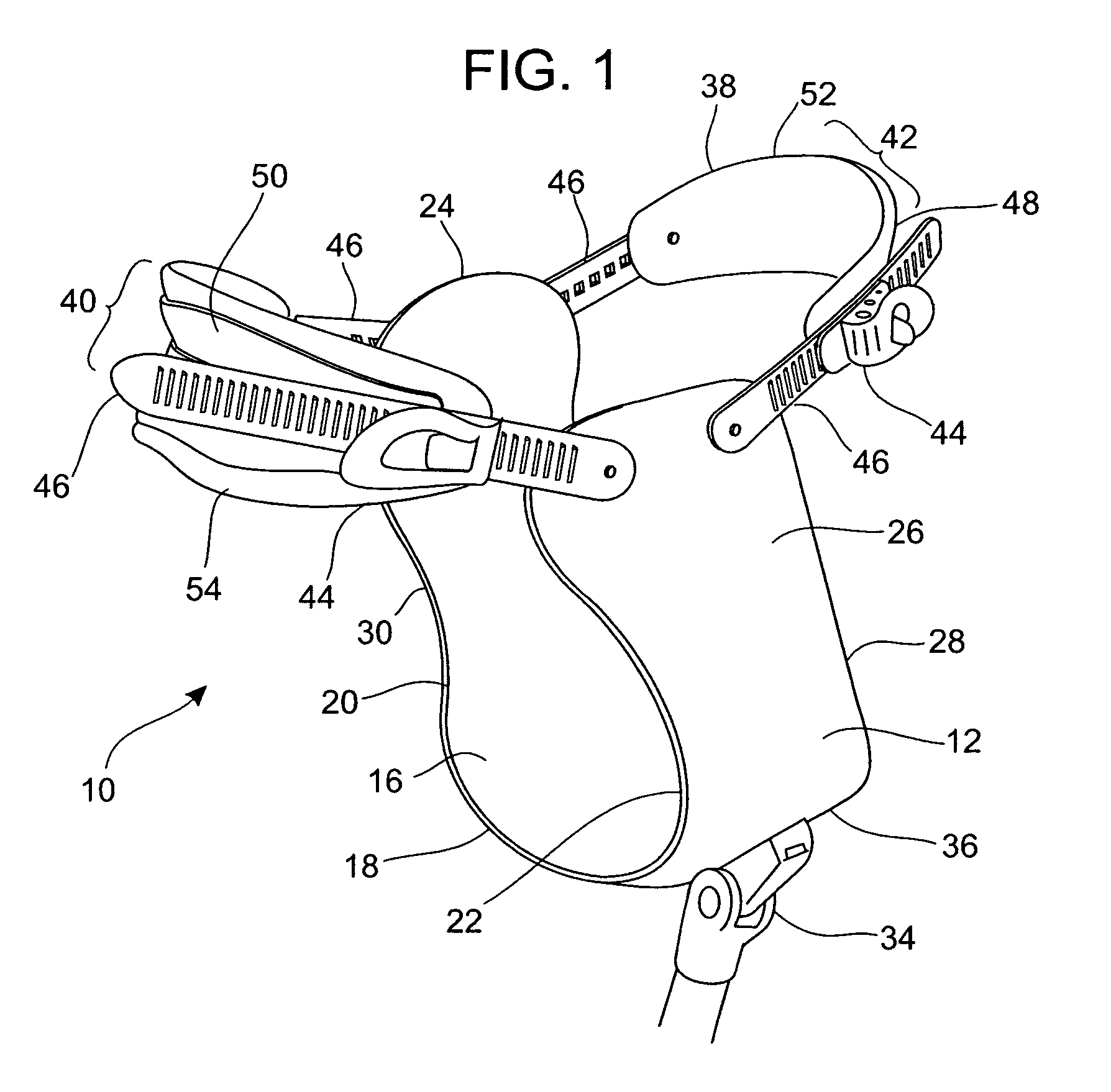

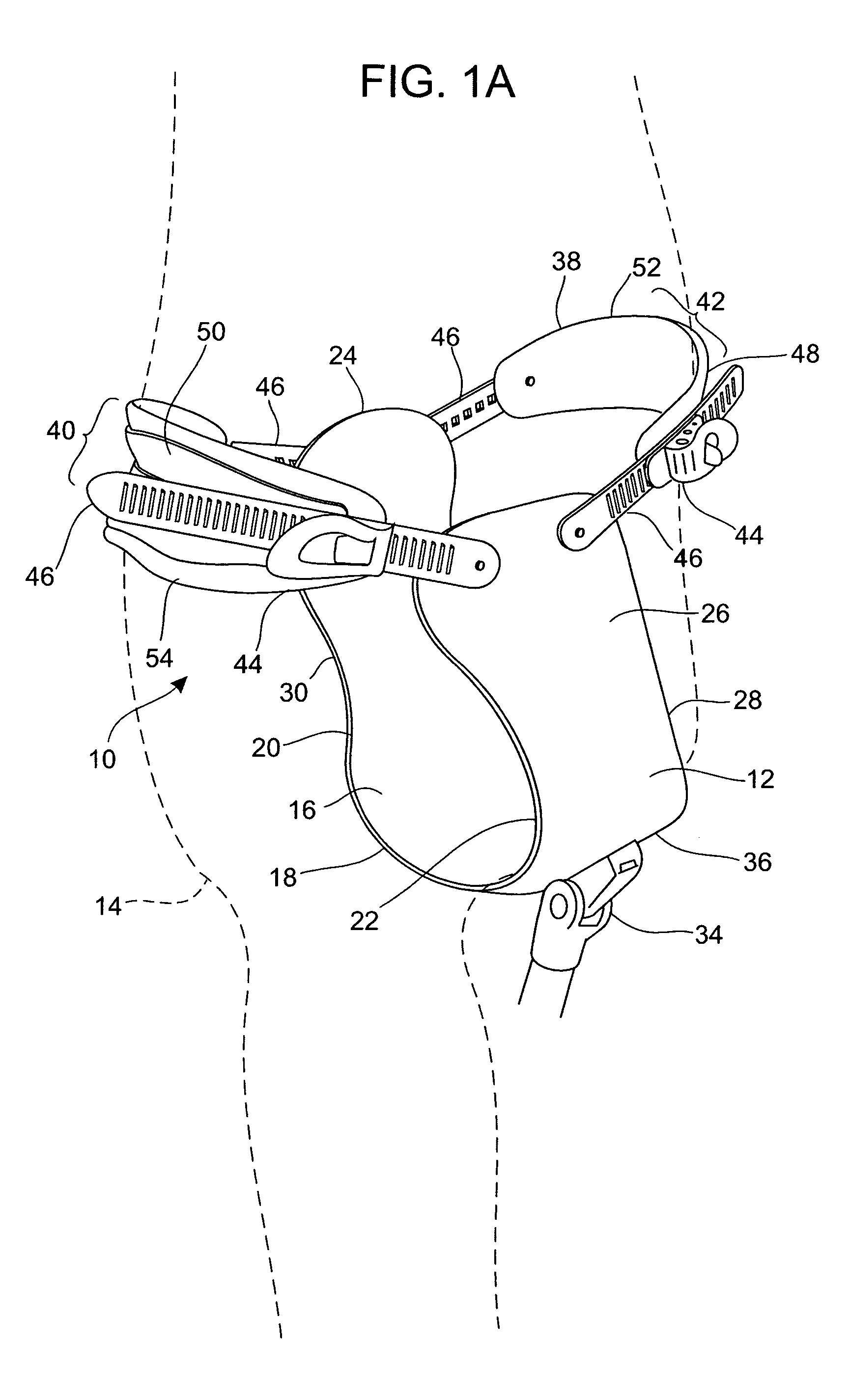

Active prosthetic socket

An active prosthetic socket including a prosthetic socket shaped to fit a residual limb. An active adjustment system is integrated with the prosthetic socket and is configured to dynamically adjust the fit of the active prosthetic socket to the residual limb of a user during ambulation or motion.

Owner:VIVONICS

Prosthetic device utilizing electric vacuum pump

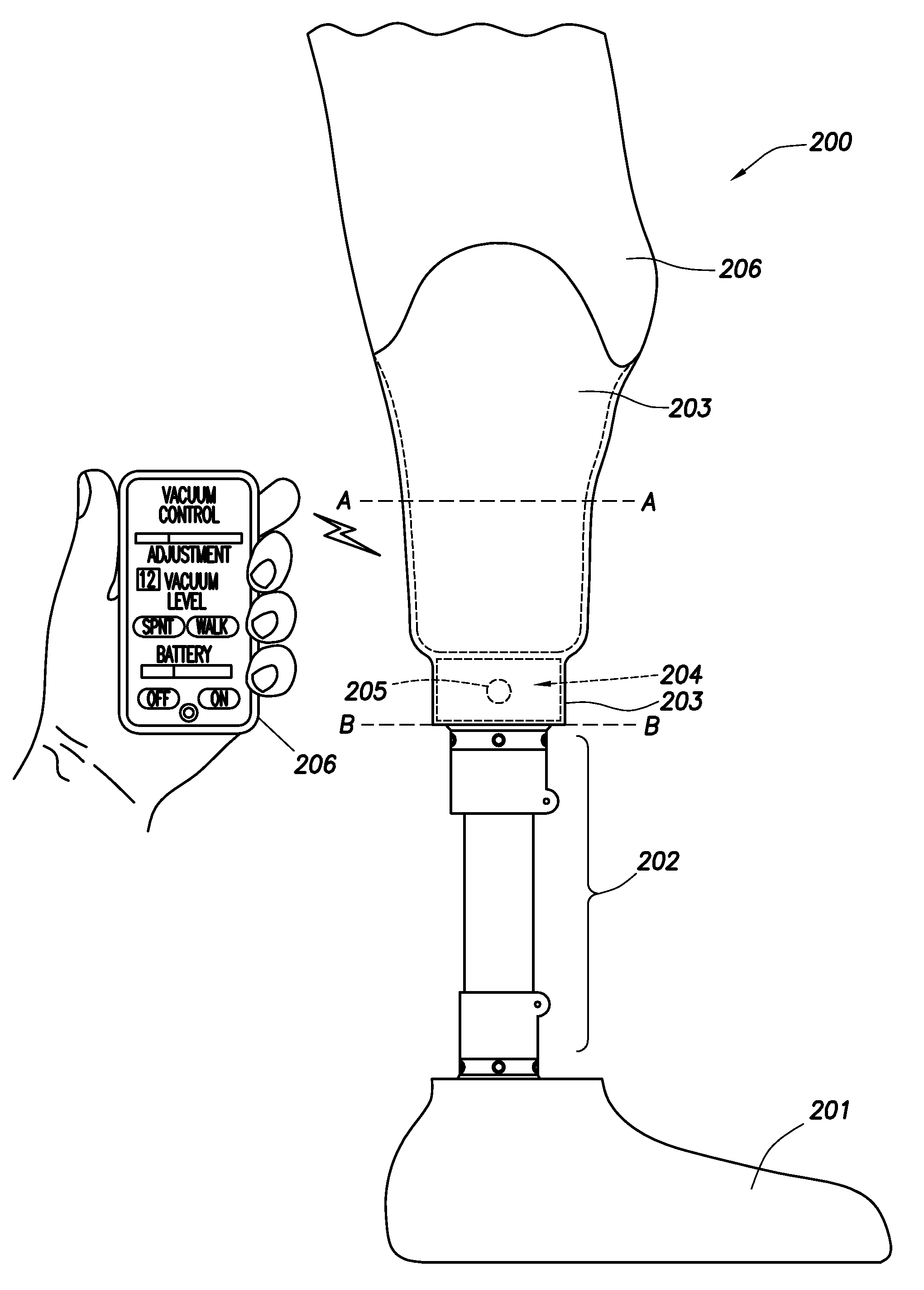

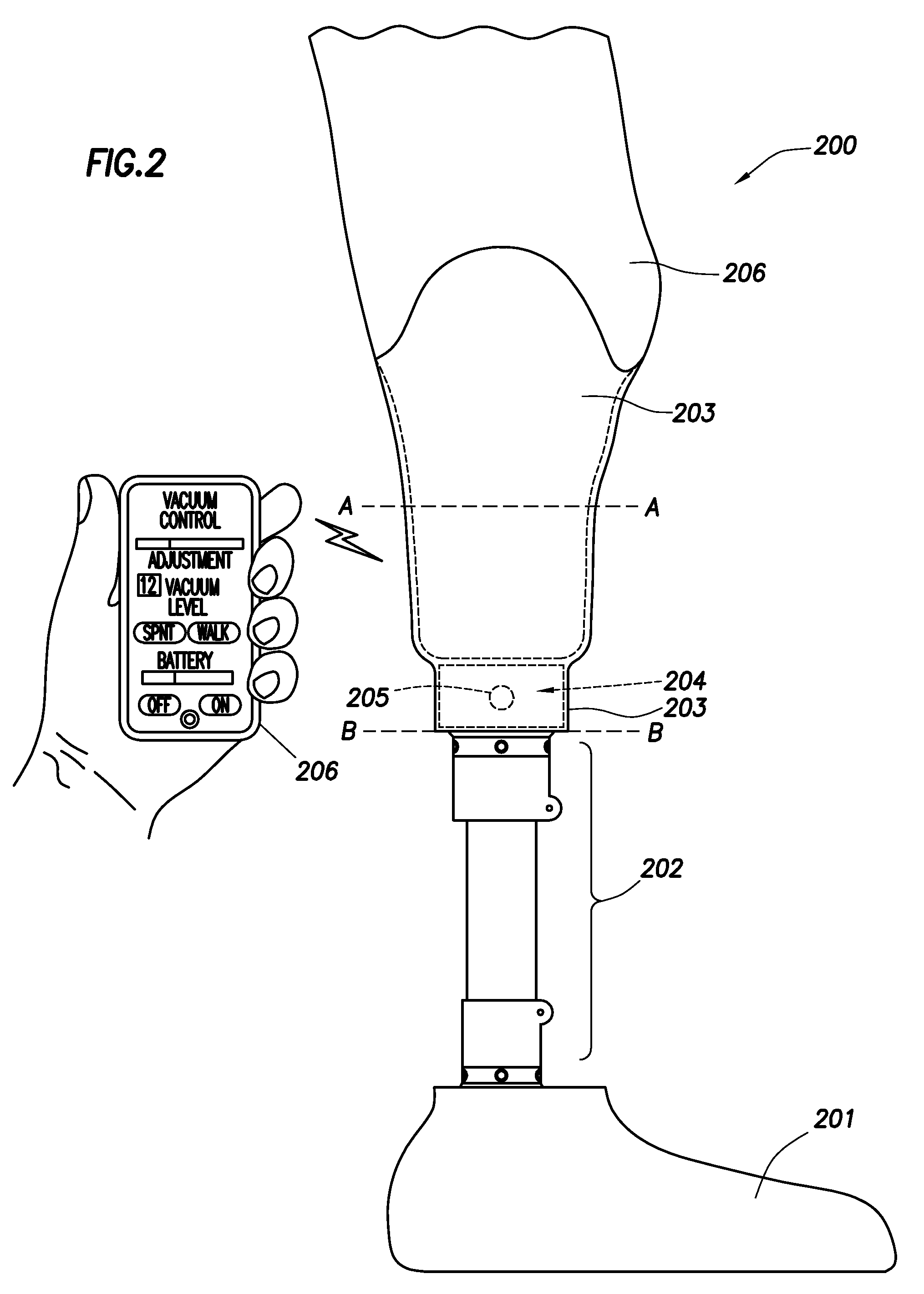

ActiveUS20070191965A1Easy to useReadily incorporated into/onto prosthesisArtificial legsArtificial handsControl systemHand held

A prosthetic device and prosthetic assembly operative to evacuate an interior of a prosthetic socket, and control systems for use therewith. The prosthetic device and prosthetic assembly employ evacuation devices for evacuating the socket. The evacuation devices preferably include at least an electrically powered vacuum pump and a power source, and are adapted for mounting to a universal adapter that is installed to the distal end of a prosthetic socket. Associated control systems may be of various design and may employ wired or wireless communication. When wireless communication is employed, a hand held controller may be used to remotely control operation of the evacuation device.

Owner:WILLOWWOOD GLOBAL LLC

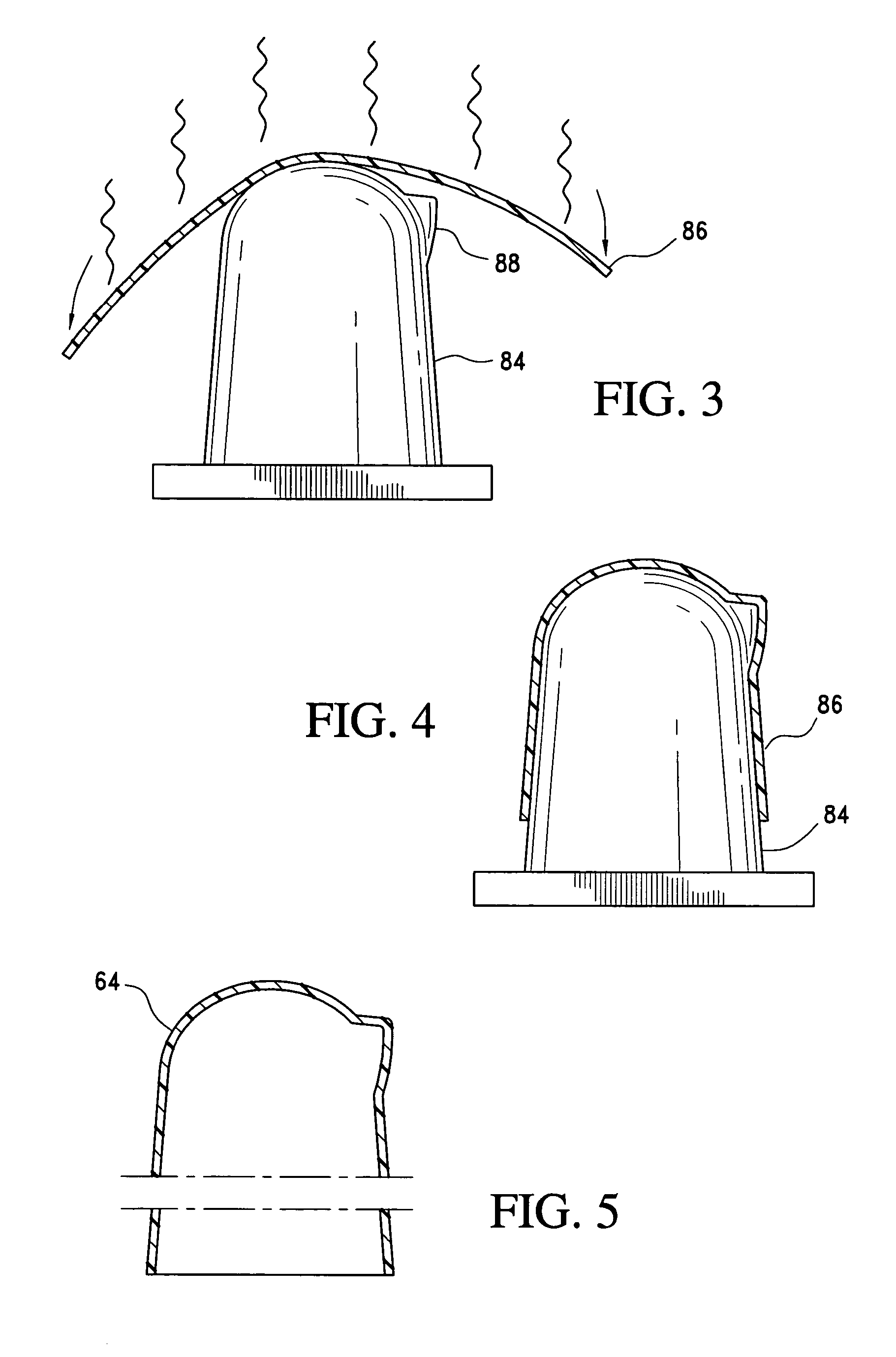

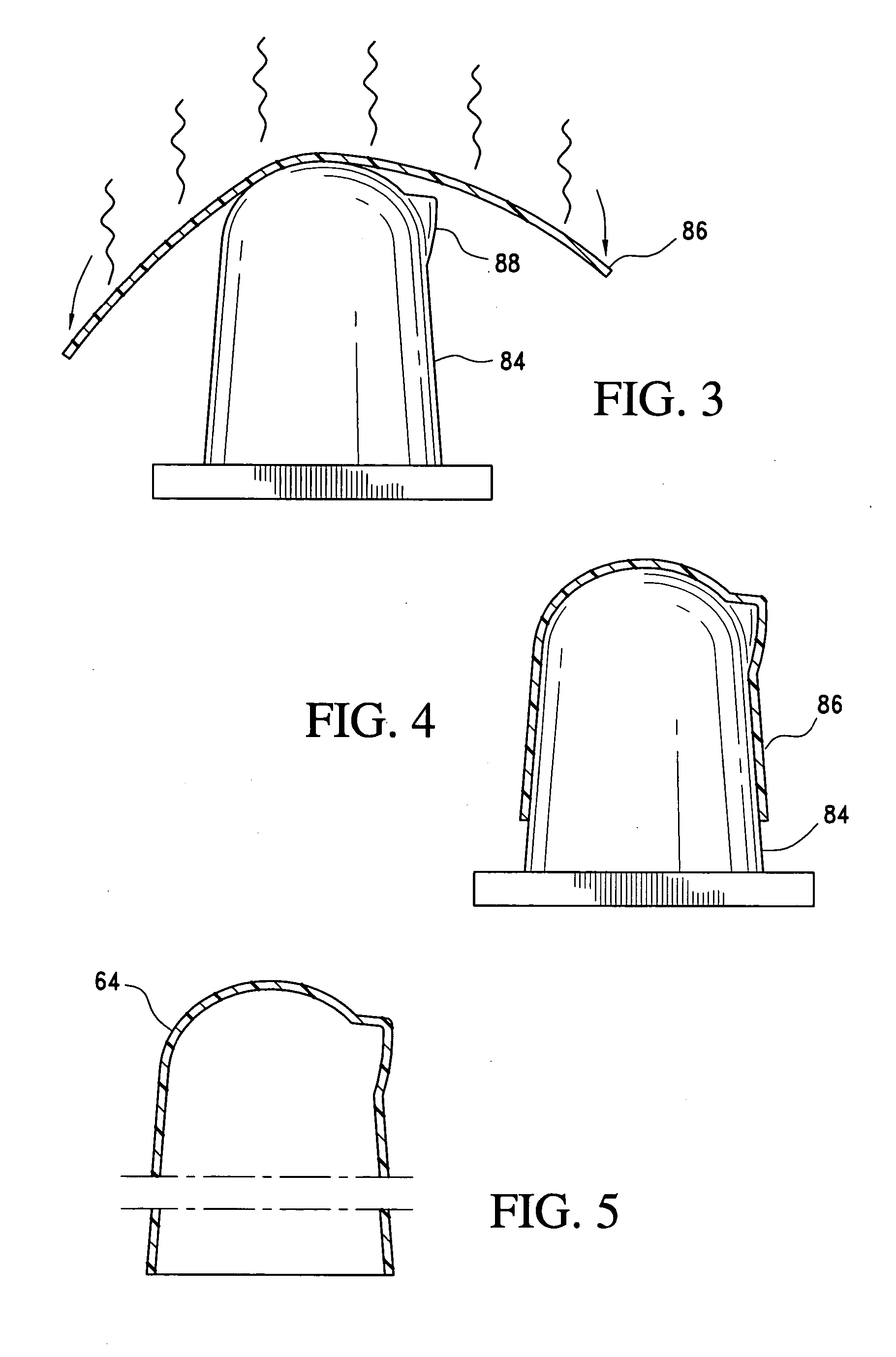

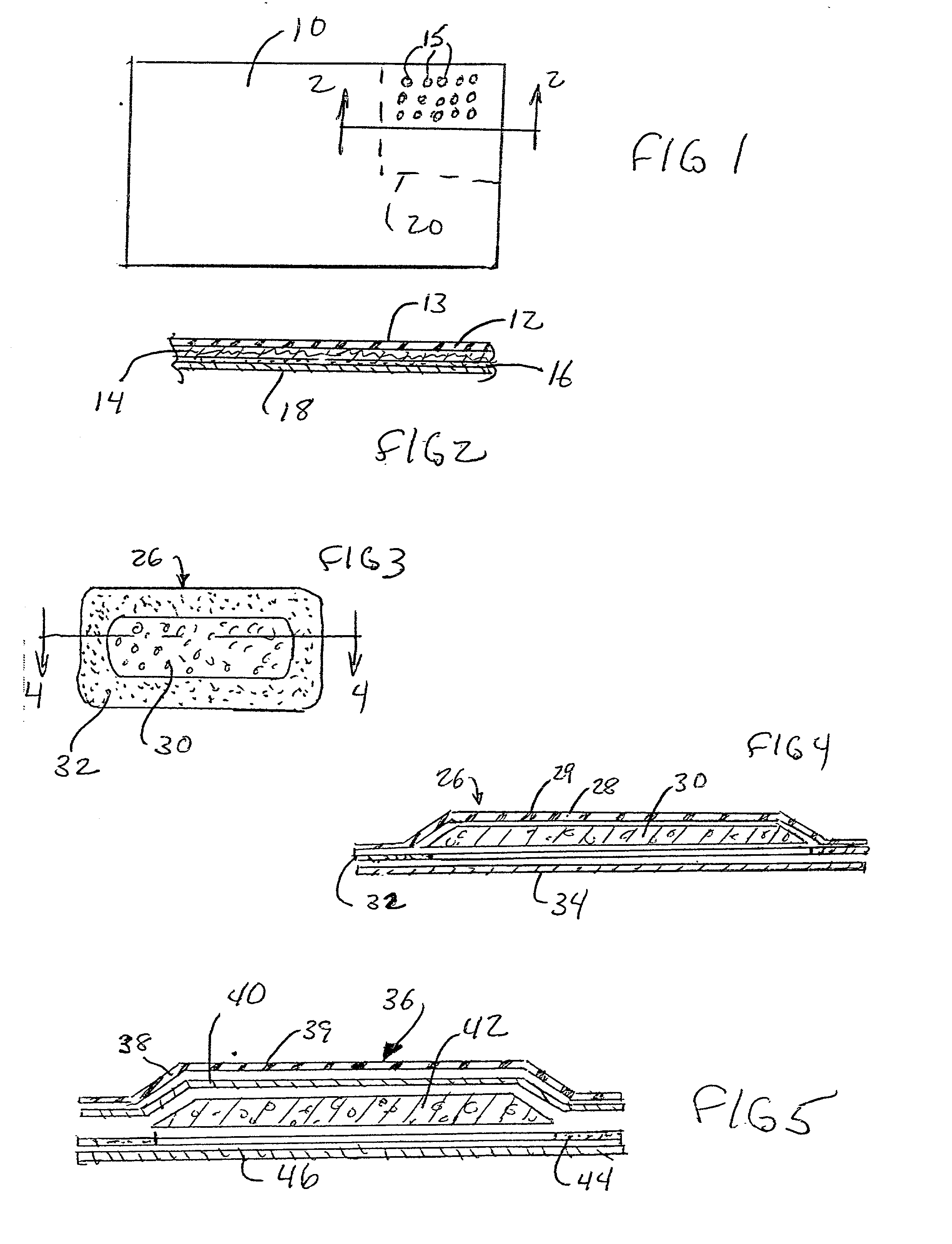

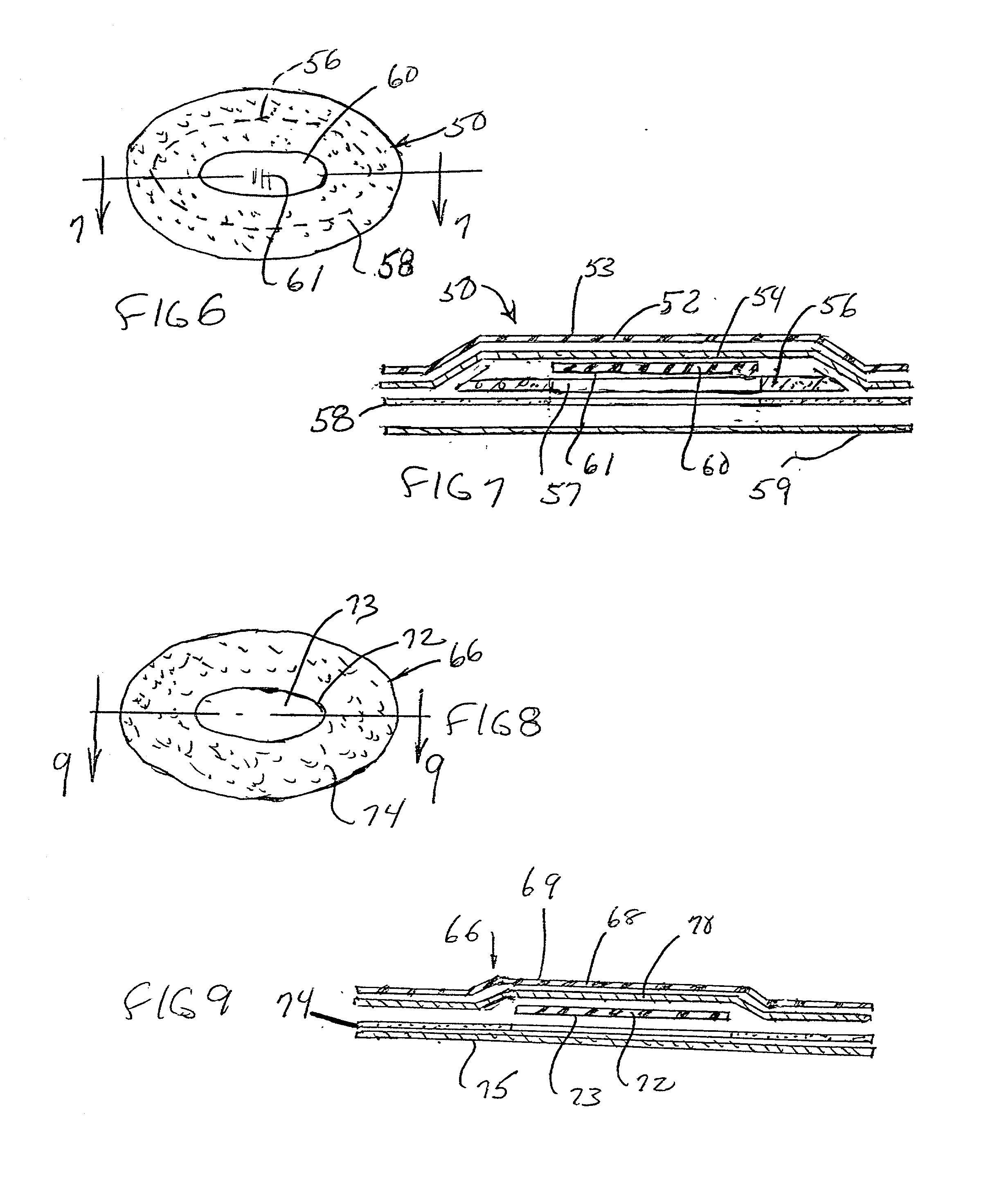

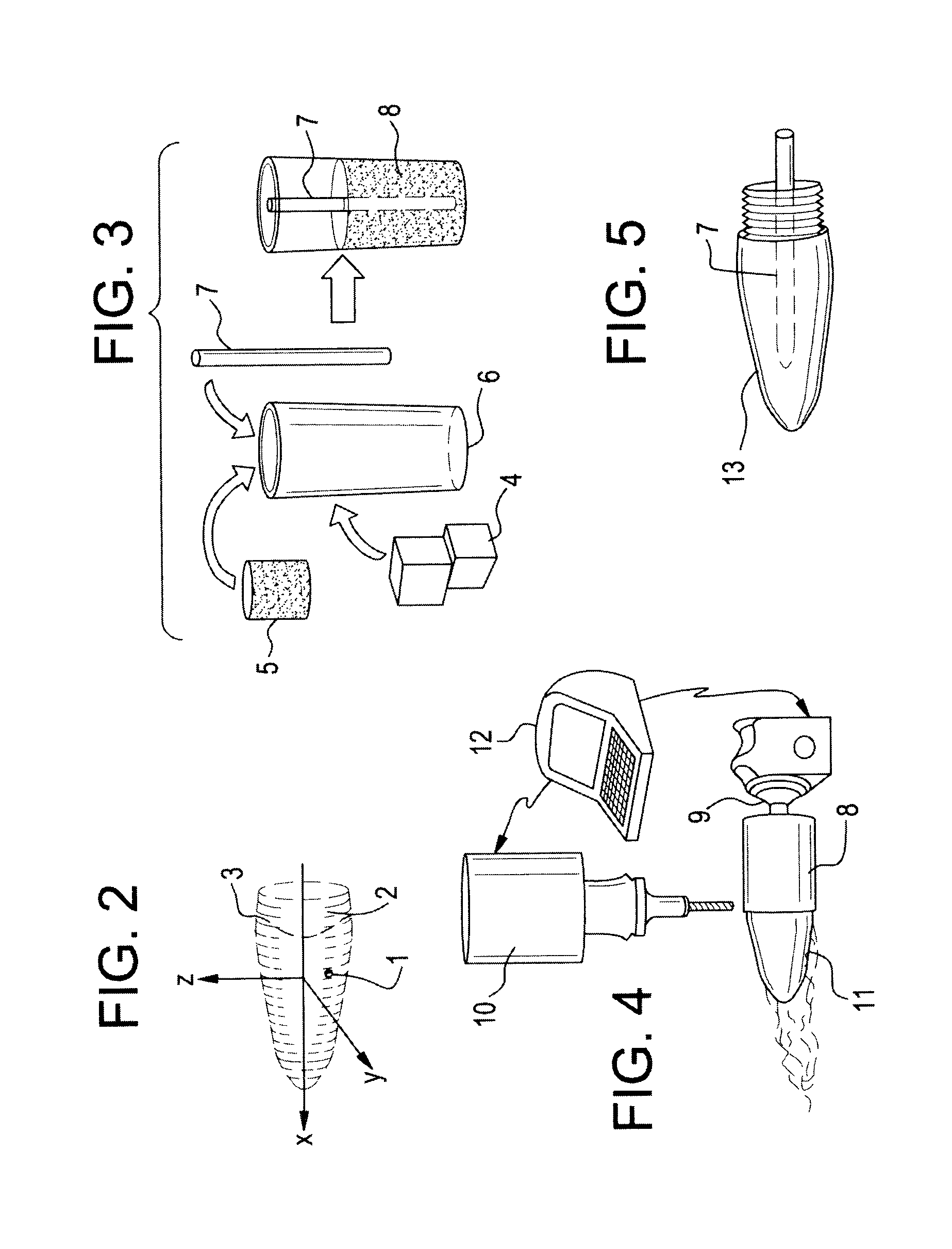

Direct contact moldable low temperature thermoplastic prosthetic devices

The present invention provides direct contact moldable low temperature thermoplastic prosthetic devices and method of making same. A direct contact moldable low temperature thermoplastic prosthetic socket preform that is formable between 50° Celsius and 80° Celsius wherein the socket preform can be direct contact molded on at least one appendage of a patient thereby forming a prosthetic socket and wherein the prosthetic socket is reformable after initial forming. The present invention also provides method of creating a direct contact moldable and reformable prosthetic socket.

Owner:QFIX SYSTEM LLC

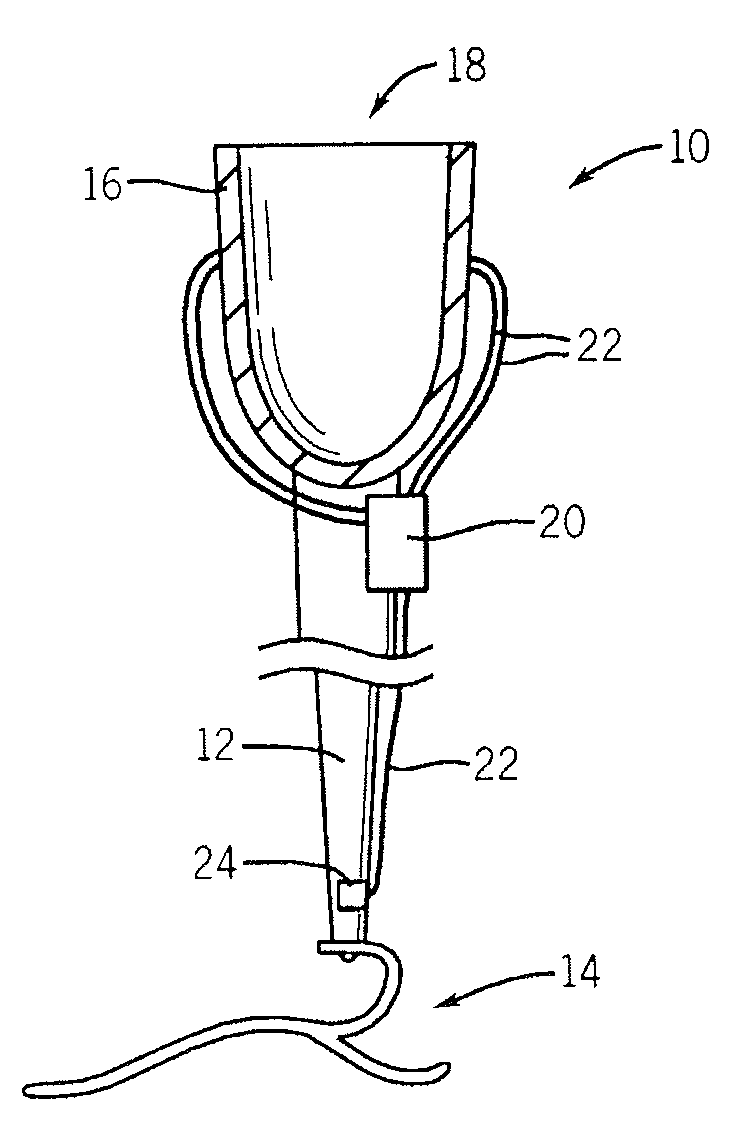

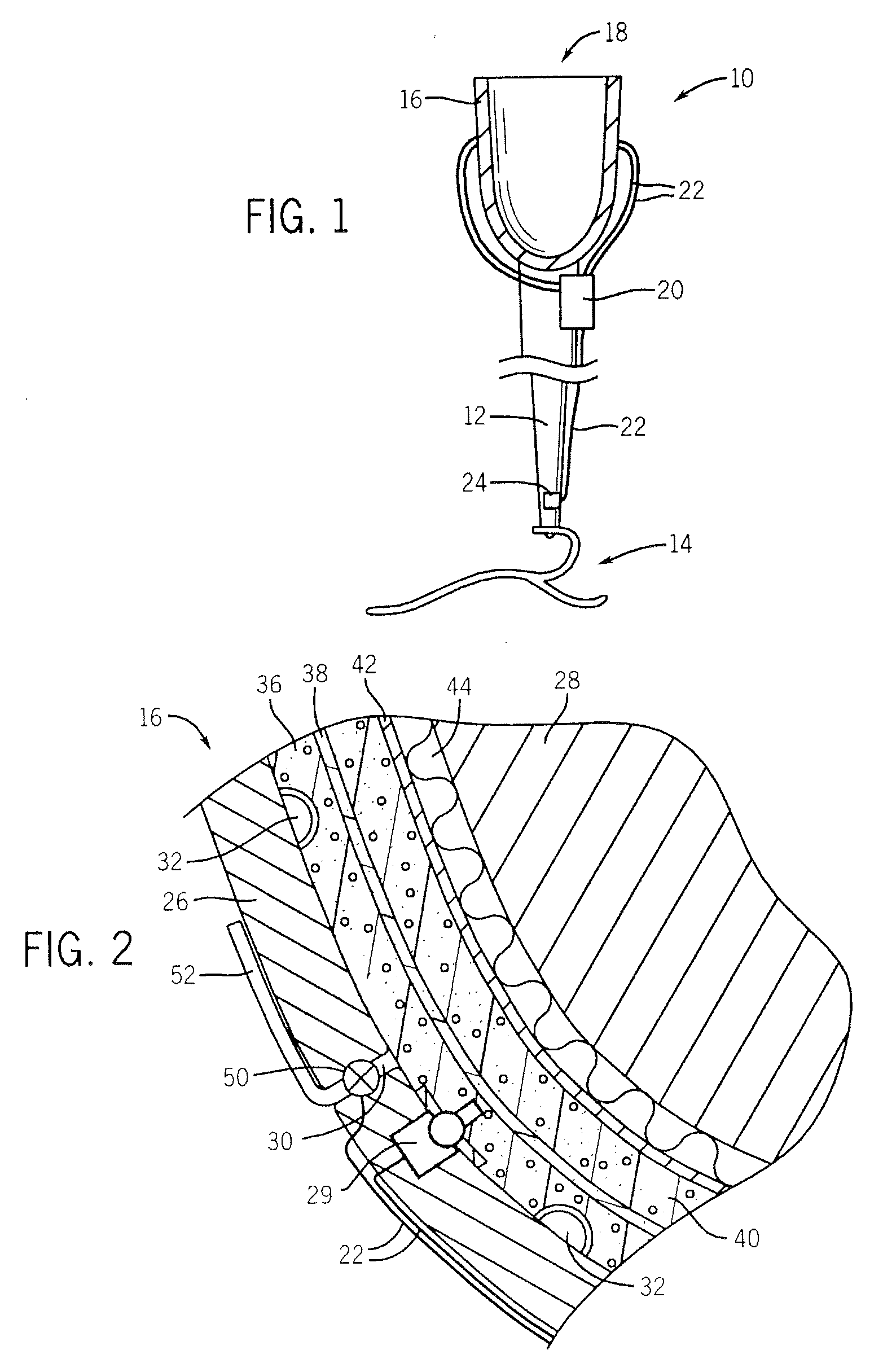

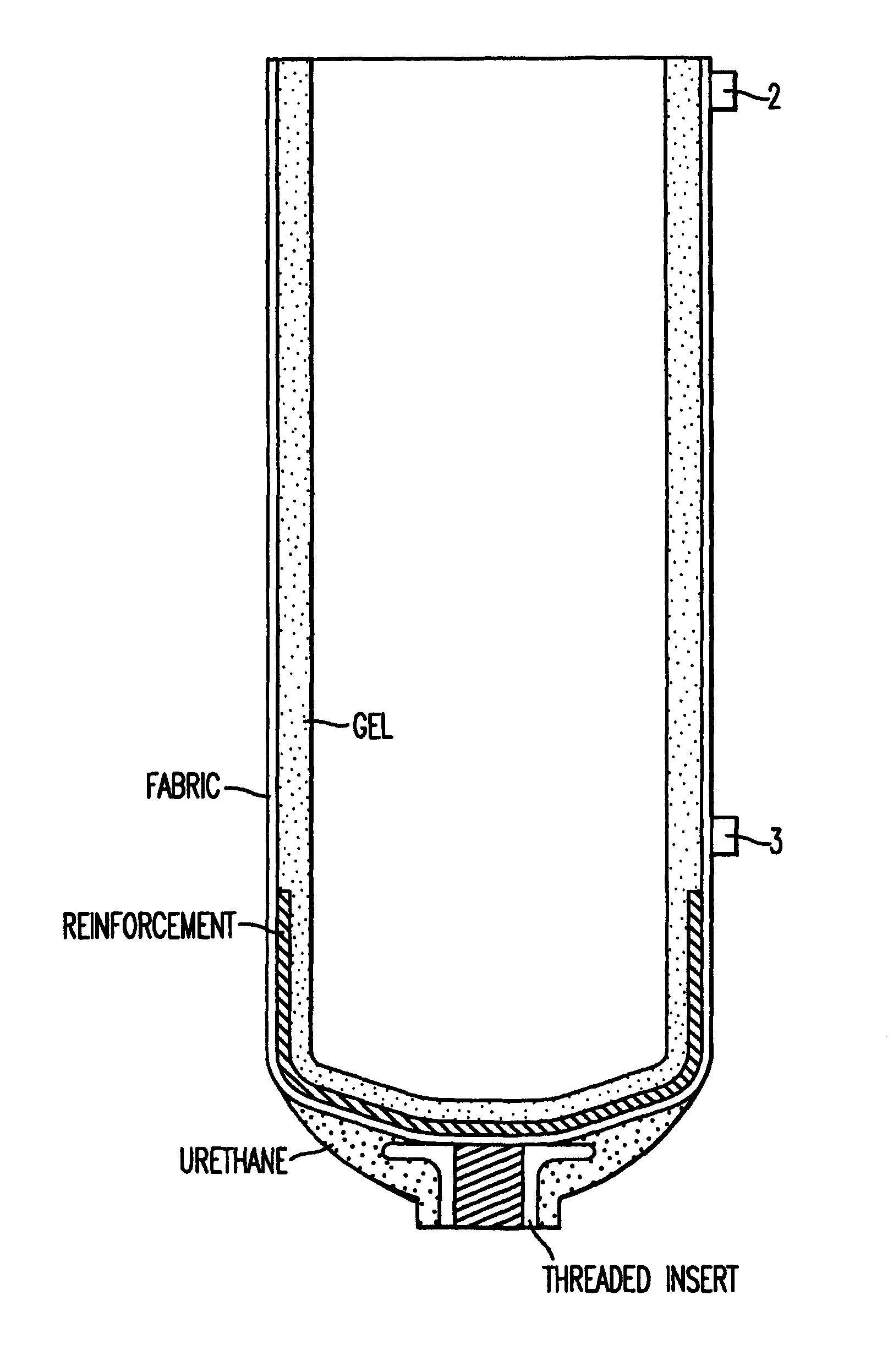

Prosthetic Socket Liner

A removable liner used in conjunction with a socket for a prosthetic device, in which a vacuum is wicked across the entire area of a porous fabric of the liner, is disclosed. The liner preferably includes a shaped-layer made from one of either a silicone or a urethane and has an exterior surface, an interior surface and a passage therein which opens at each of the two surfaces and connects to a valve of the socket. The liner further includes a first porous fabric covering at least a portion of the exterior surface of the shaped-layer including the corresponding opening of the passage, and a second porous fabric covering at least a portion of the interior surface of the shaped-layer including the corresponding opening of the passage. A vacuum source coupled to the liner, via the valve on the socket, draws a vacuum which is wicked across the entire surface of the first and second porous fabrics which interface with the socket and the user's residual limb, respectively. The vacuum secures the socket to the liner and the liner to the residual limb of the user.

Owner:SRT PROSTHETICS & ORTHOTICS LLC +1

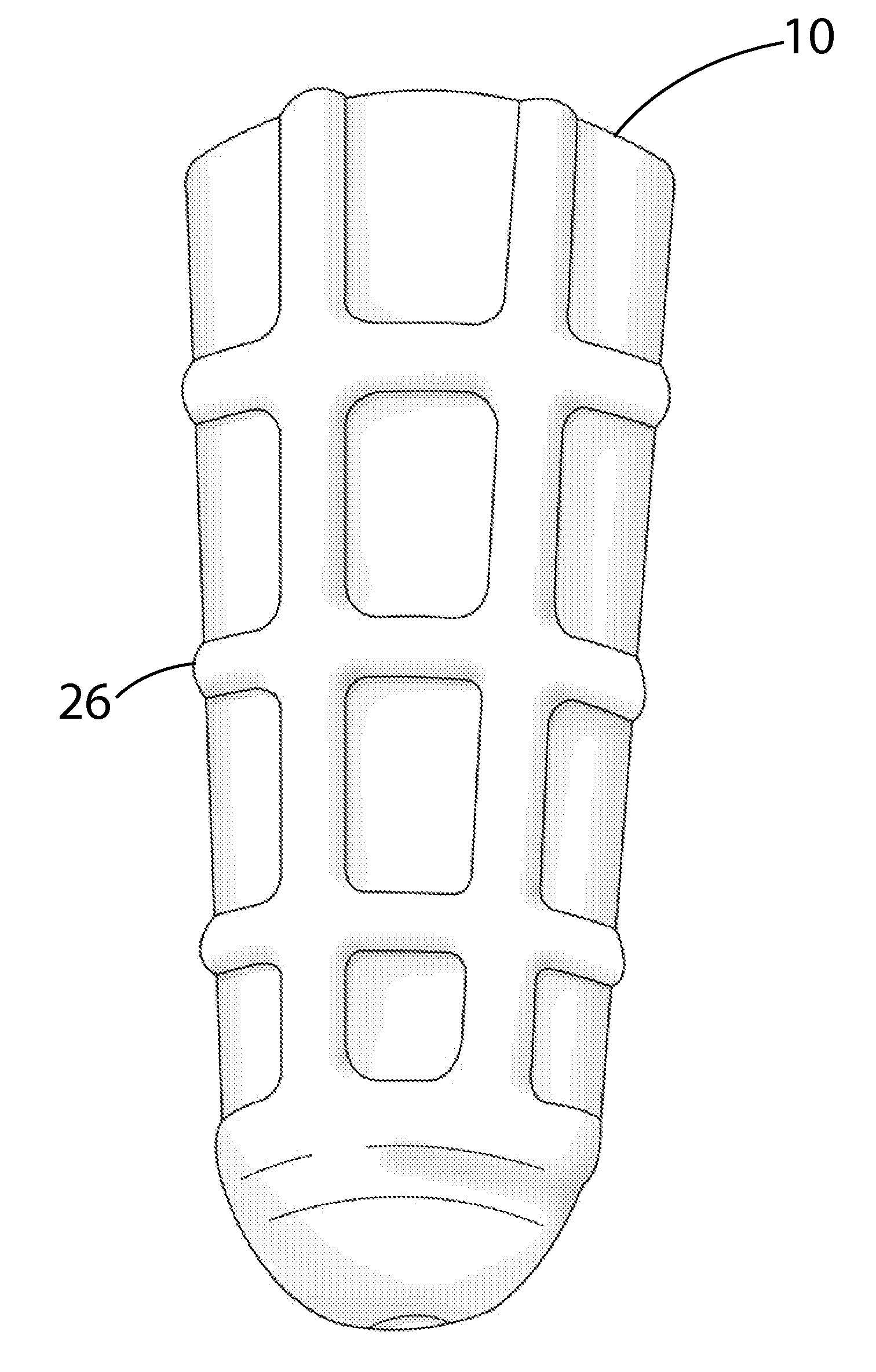

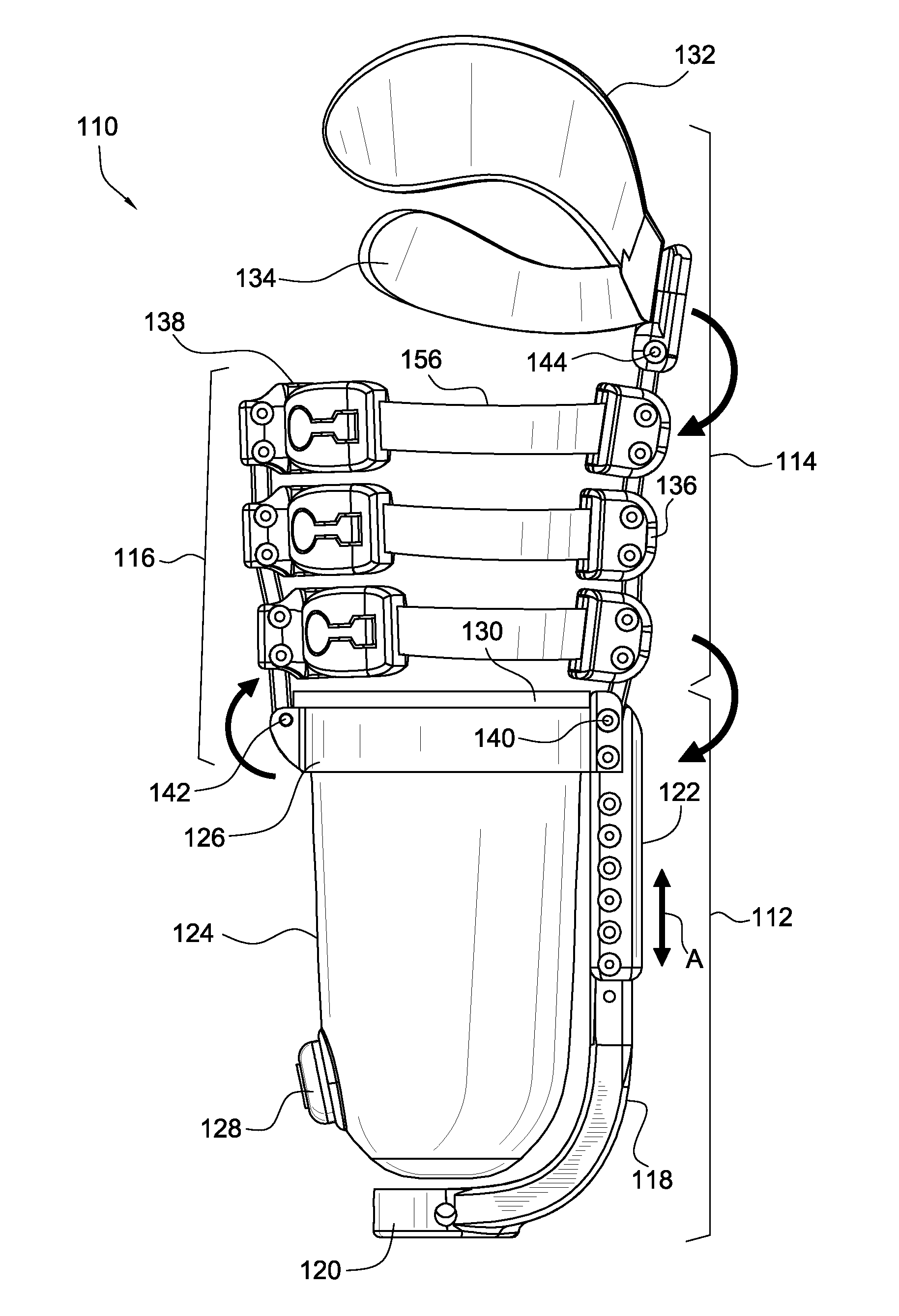

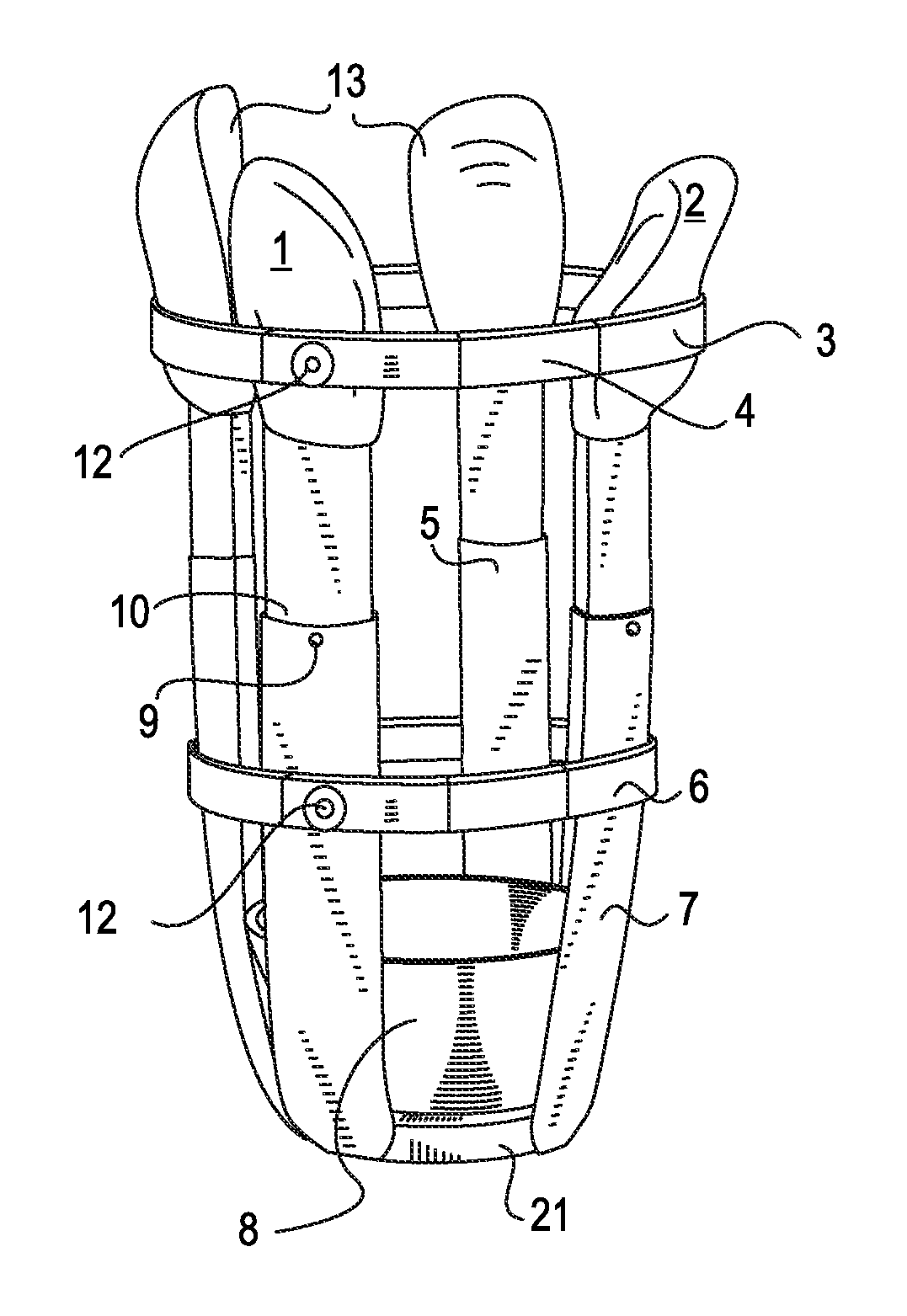

Adjustable socket system

ActiveUS20120101597A1Decrease pain, discomfort and soft tissue breakdownArtificial legsEngineeringProsthetic socket

An adjustable socket system is configured to accommodate a residual limb. The adjustable socket system has first and second opposed sides and includes a rigid first component arranged along the first side of the socket. An adjustable second component has a plurality of interconnected vertebrae elements connected to the first component and is arranged along the second side of the socket system. The adjustable prosthetic socket also has a base connector secured to the distal end area of the first component.

Owner:OSSUR HF

Prosthetic coupling device

InactiveUS7033400B2Additive manufacturing apparatusRopes and cables for vehicles/pulleyO-ringCoupling

Owner:CURRIER MARK R

Prosthetic foot

InactiveUS20050033451A1Facilitates iterative tuningNatural appearanceArtificial legsFeature completeEngineering

Features for a high performance prosthetic foot are provided in a package suitable for use with Symes and reverse-Symes amputees. The foot has a very low profile despite incorporating ankle-type torsional features complete with biasing. Other optional features are presented by way of a dual-rate padding spring system, that convincingly allow for both walking and running (together with related tasks like jumping) by way of a single prosthetic setup. Additional features may be provided in the padding springs directed toward more natural foot movement and response. The foot may be provided alone, in connection with a prosthetic socket and be bare or encased in order to appear more natural.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

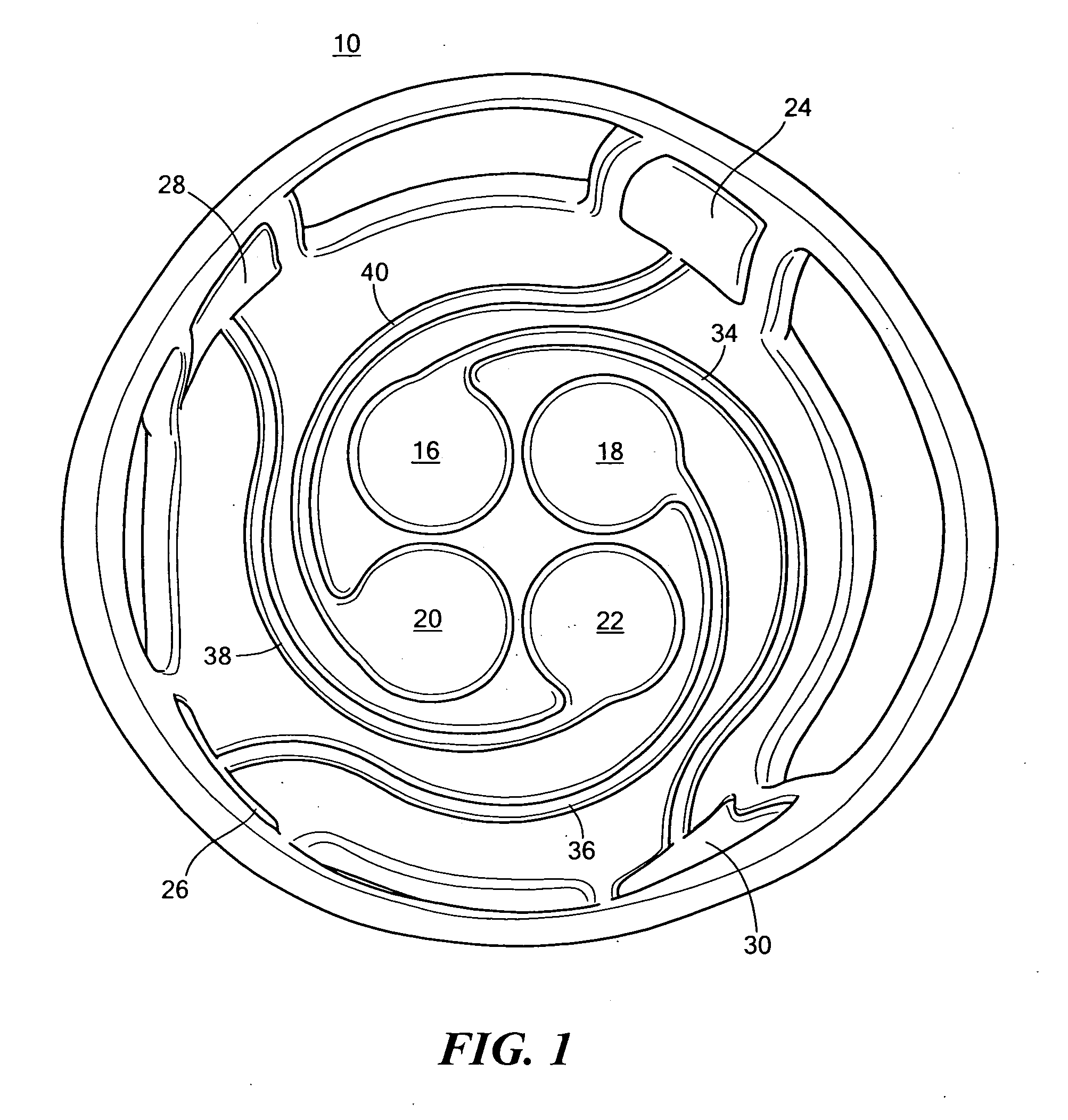

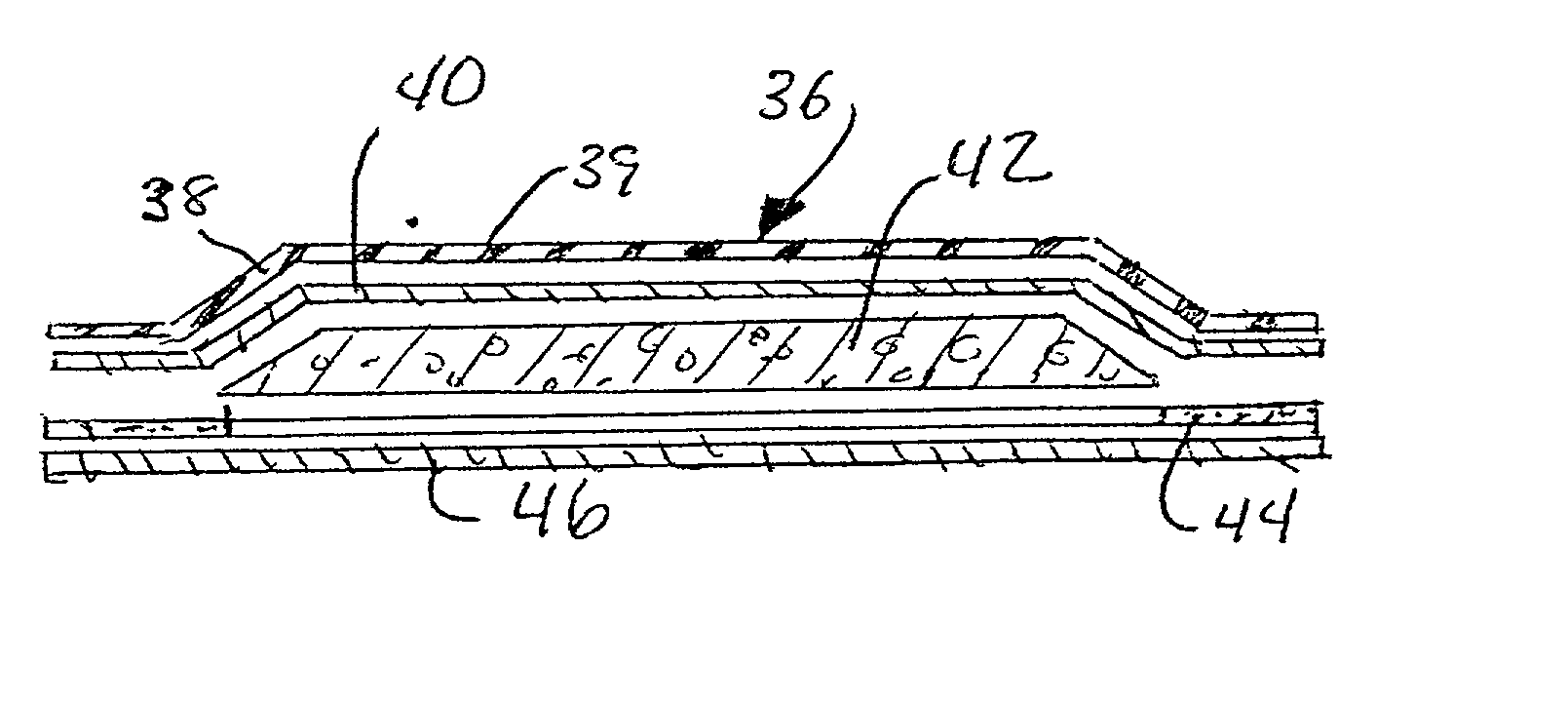

Prosthetic socket with real-time dynamic control of pressure points

An improved socket for a prosthesis uses a liner material providing fluid flow through a porous matrix whose local pressure is adjusted by a control system communicating with multiple valves and pressure sensors. Control of pressure in a viscoelastic material provides an improved trade-off between comfort and stability.

Owner:WISYS TECH FOUND

Method for use of a compression stabilized prosthetic socket interface

ActiveUS8323353B1Adjustable lengthIncrease the areaAdditive manufacturing apparatusDiagnostic recording/measuringProsthetic socketDevice prosthetic

A compression stabilized prosthetic socket for a patient having an amputated limb and a remaining portion includes a first socket portion for contacting a patient's remaining portion of a limb, and a second socket portion for attachment of a prosthetic device. The first socket portion has compression portions having a radius for compressing portions of the patient's remaining portion of a limb, and relief portions receiving any portions of the patient's remaining limb which bulge upon the compression applied by the compression portions. The relief portions may be formed as openings or as enlarged radius portions.

Owner:ALLEY RANDALL D MR

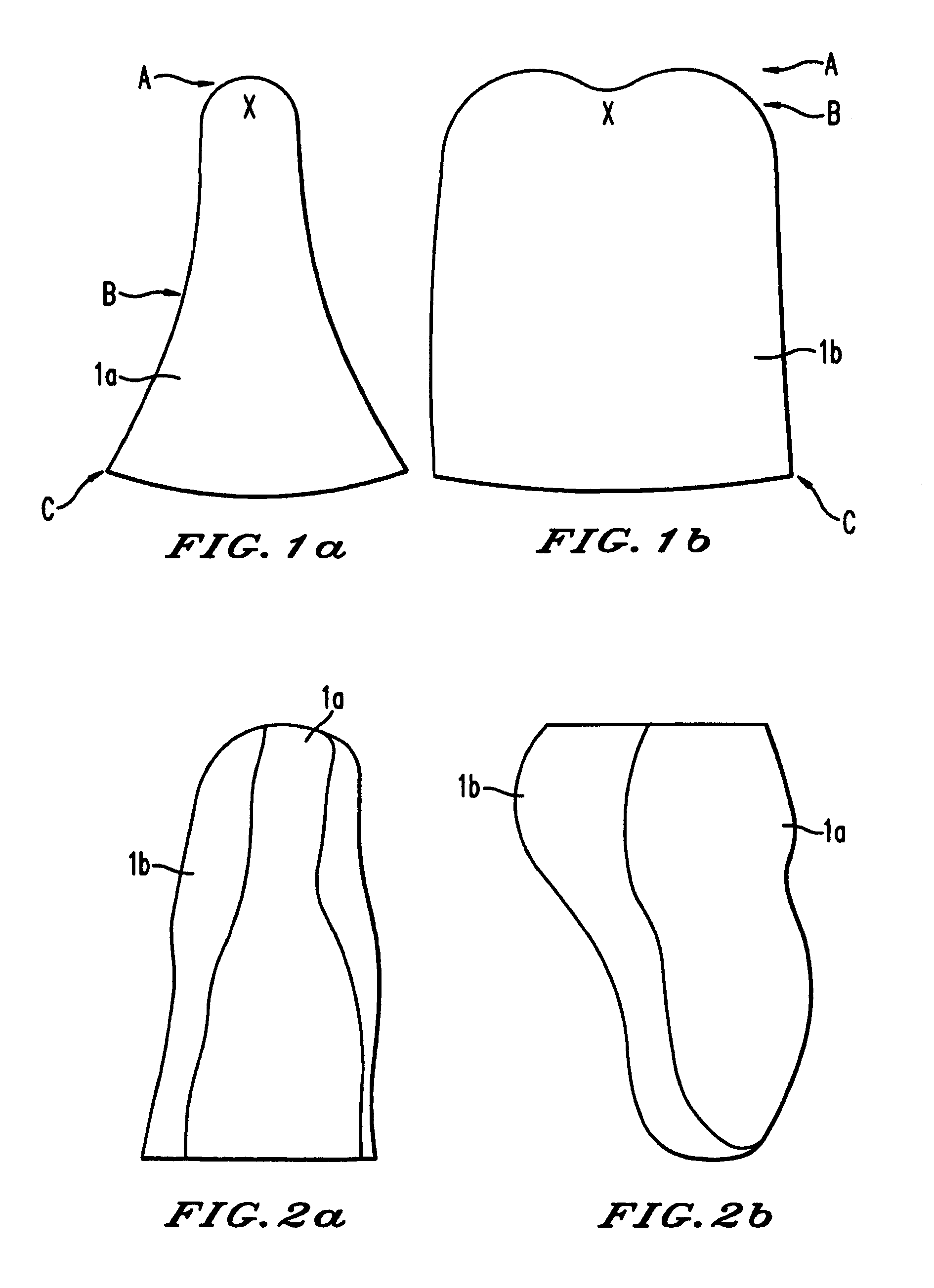

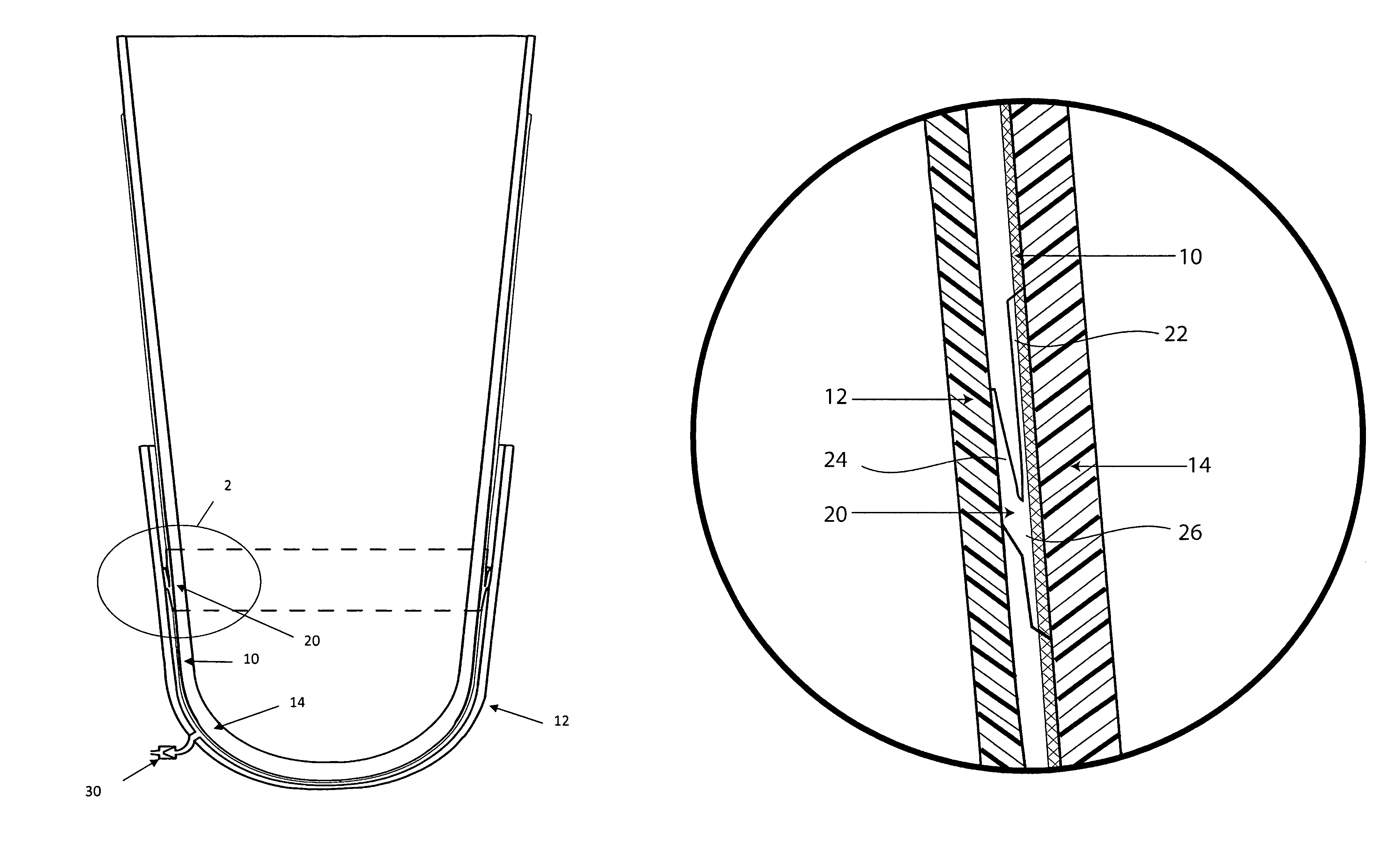

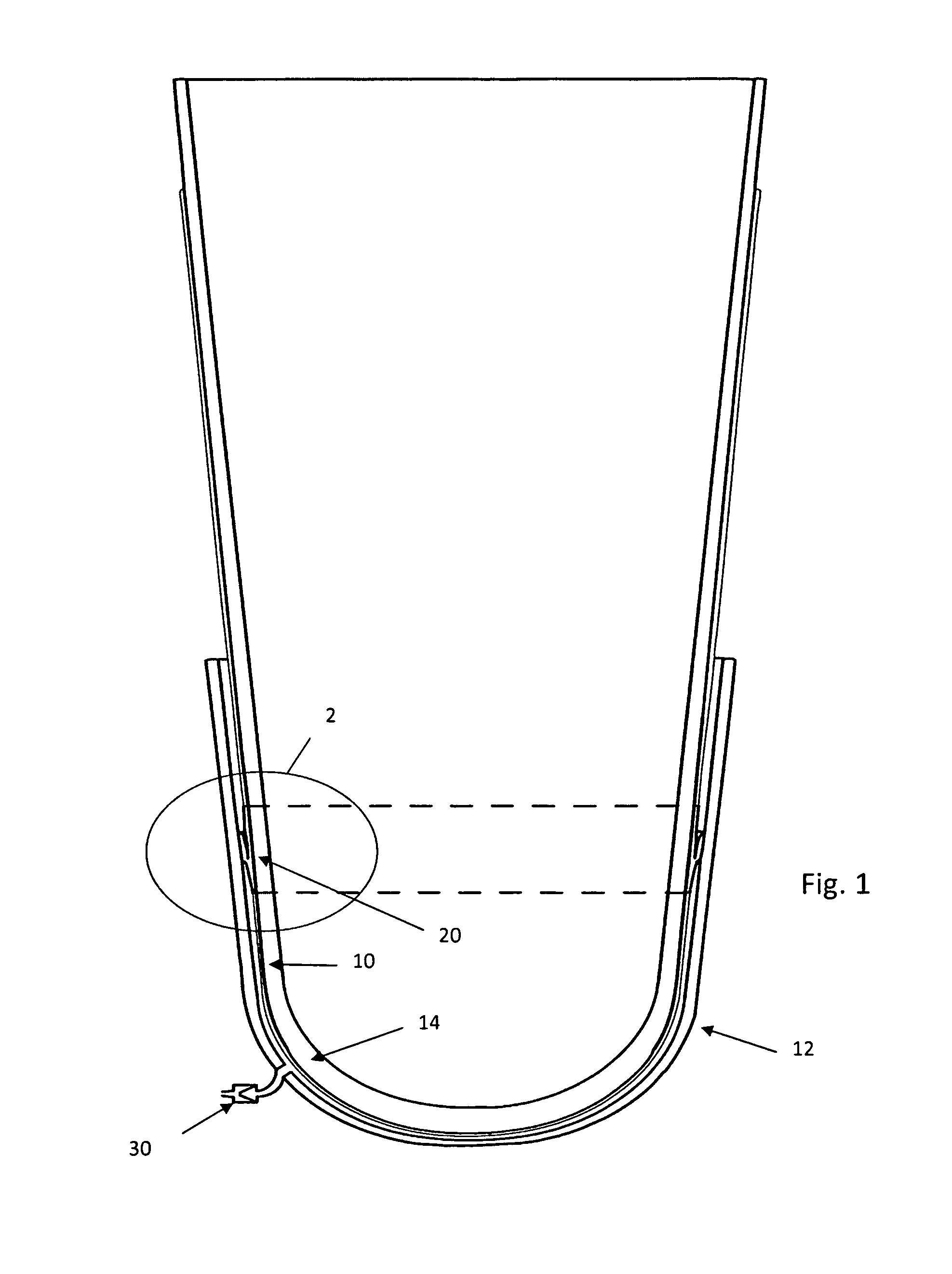

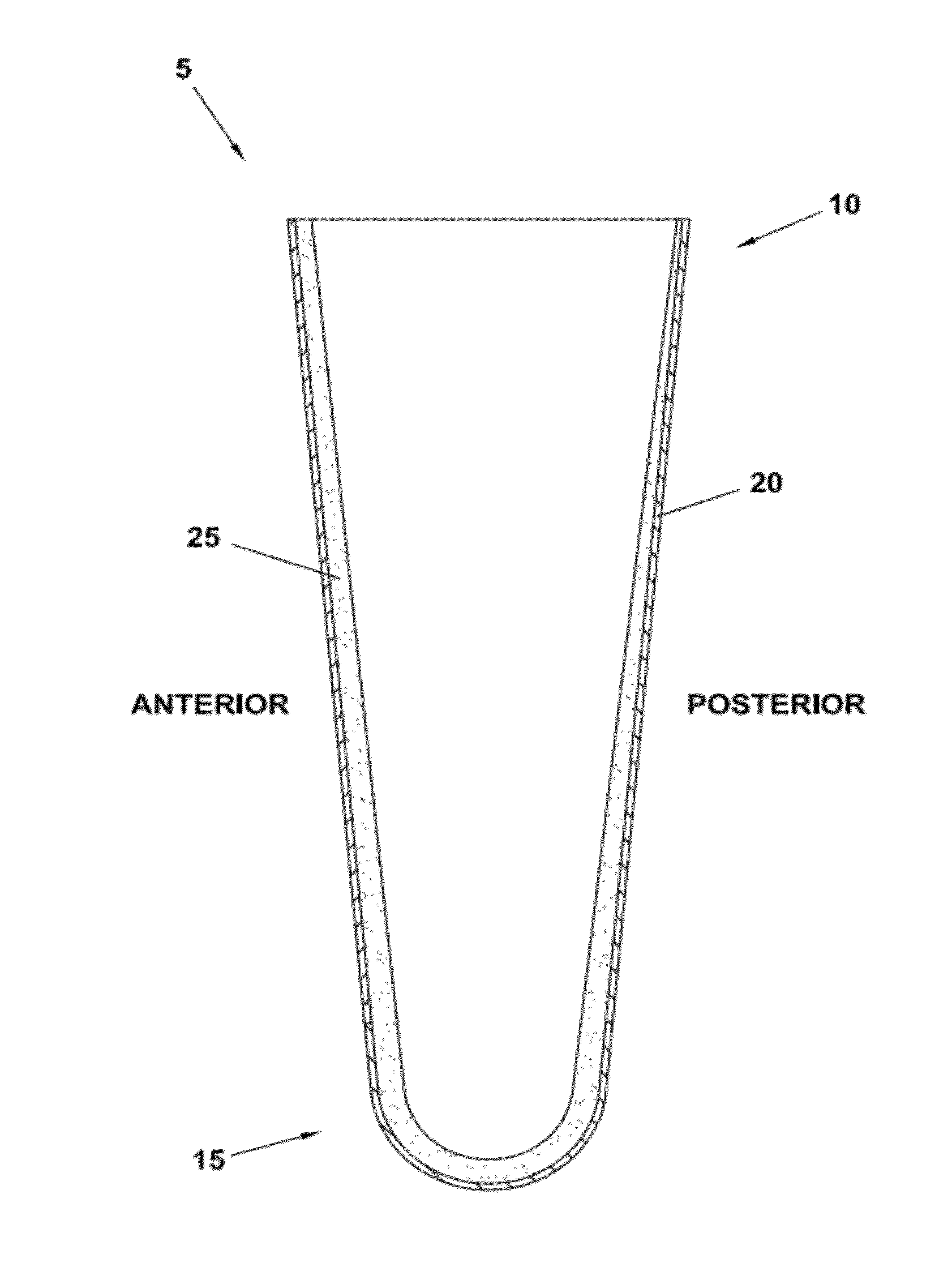

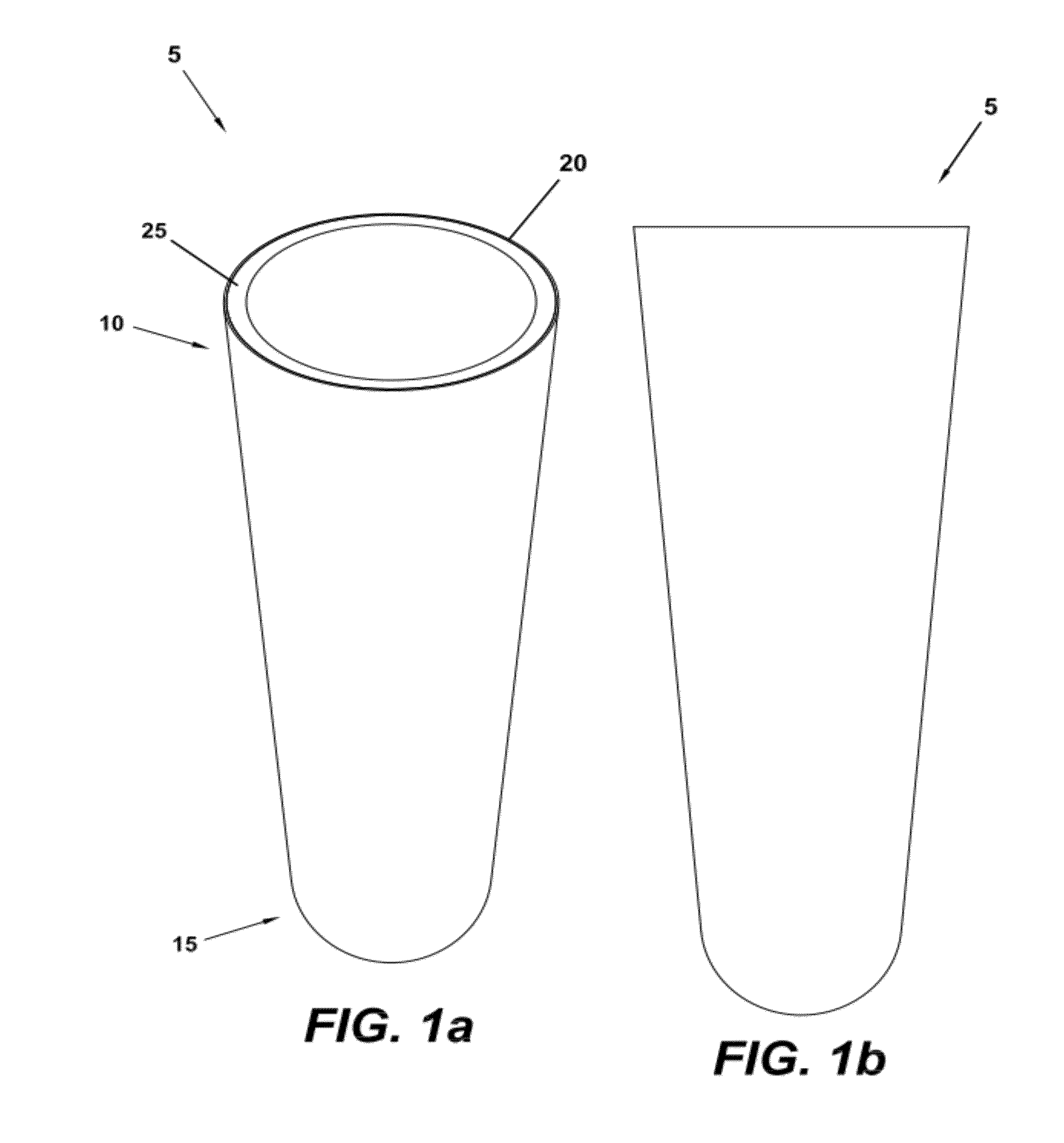

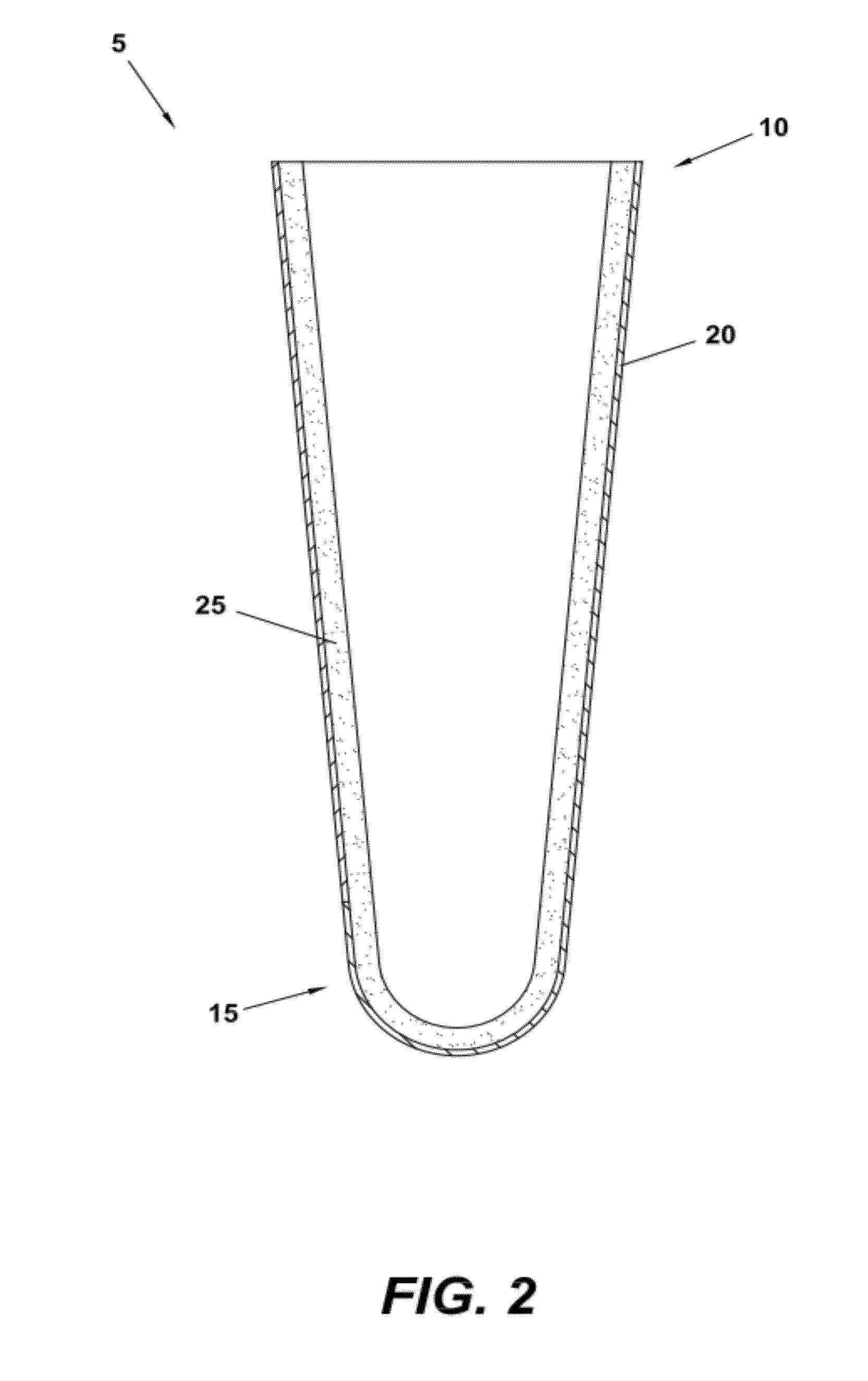

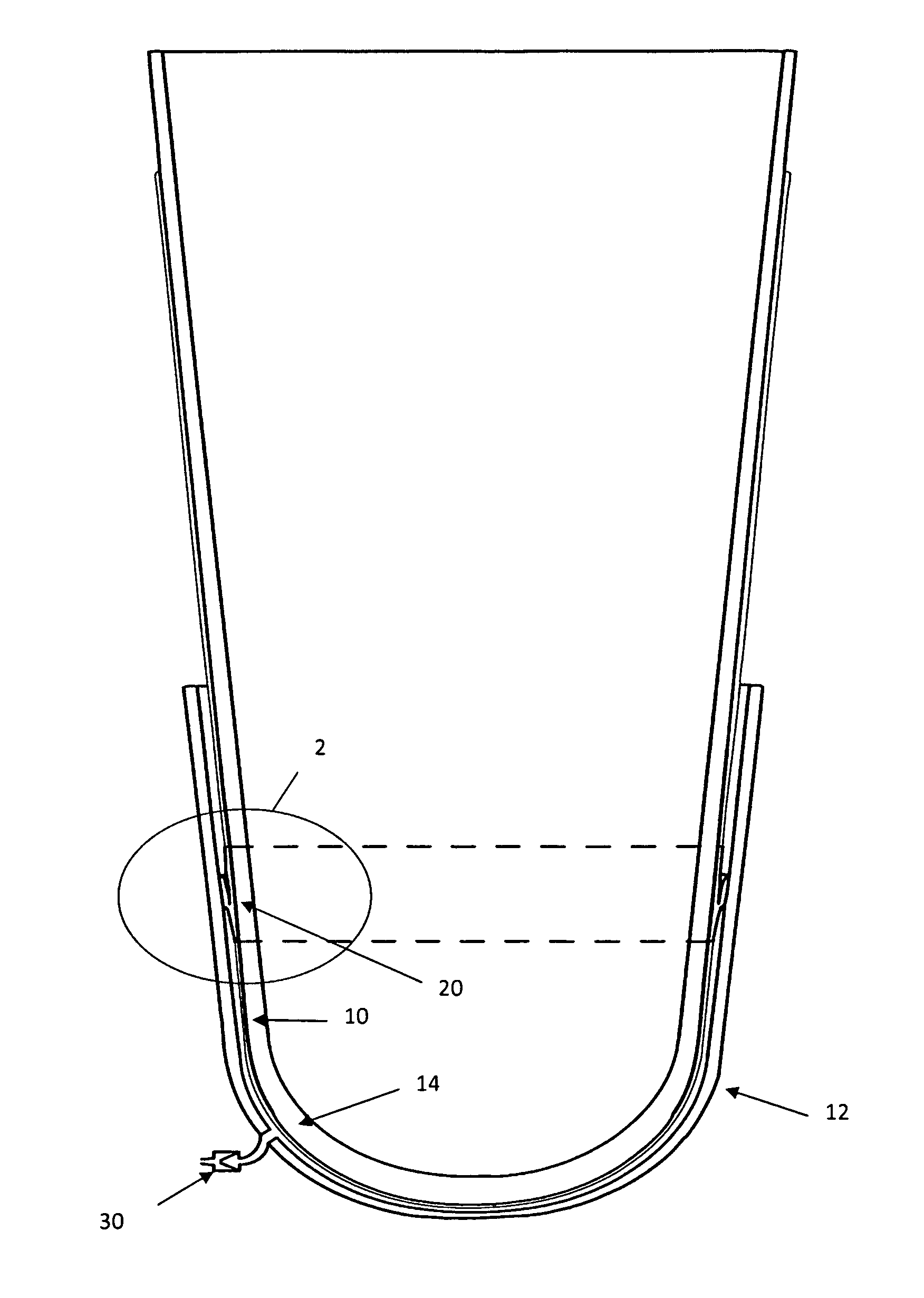

Prosthetic socket interface and assembly

A tube-sock shaped polymeric covering for wearing over an amputation stump. The covering has an open end for receiving the amputation stump and a closed end opposite the open end. The covering includes a docking means for attachment of an external device to the covering. The covering may also include one or more areas of reinforcing material that can be present in the form of a strip or rod, for example. The reinforcing material is comprised of a material that is less stretchable than the polymeric material forming the covering, and acts to reduce stretching and / or movement of the covering.

Owner:THE OHIO WILLOW WOOD CO INC

Self-adhering friction reducing liner and method of use

InactiveUS20020128580A1Easy to doMinimizing friction coefficientInsolesUpperCritical loadEngineering

A patch of low friction materials, such as a film of polytetrafluoroethylene is sized to provide an area of low friction support for a portion of a human body relative to an object such as a shoe or prosthetic socket. The patch can be lined with foam, or preferably, a stretch fabric so that it will fit around irregular contours of the shoe, or socket, or the skin itself. The patches reduce shear trauma in critical load areas. After identifying regions of high loads, the method comprises applying the patches as needed to avoid sores, calluses, blisters and abrasions.

Owner:CARLSON J MARTIN +1

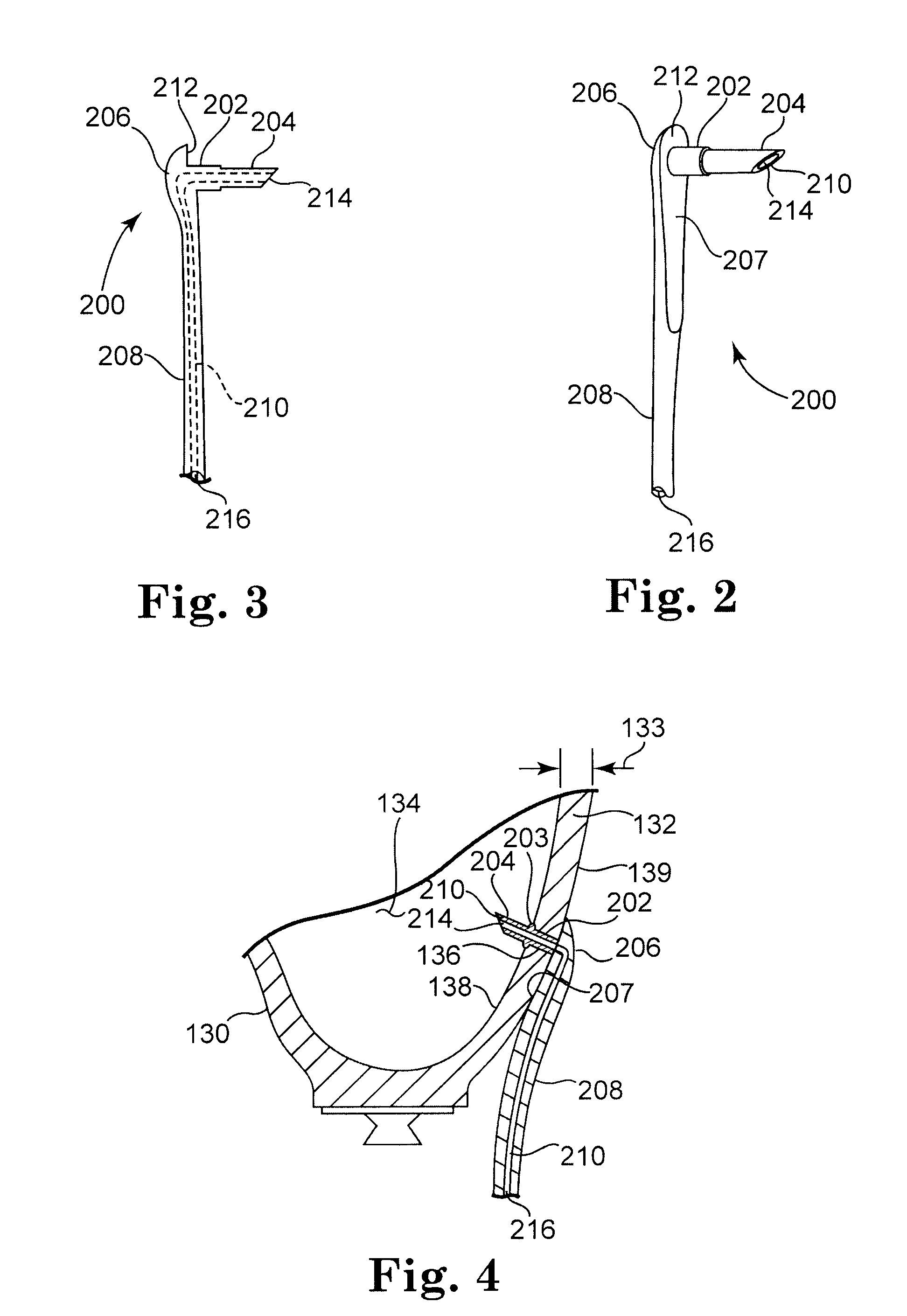

Sealing sheath for prosthetic liner and related methods

The sealing sheath is for use with a prosthetic socket and associated liner. The sealing sheath includes a textile tube for surrounding at least a portion of a liner that is configured to wear on a residual limb. An annular seal, e.g. an elastomeric or silicone seal, is positioned adjacent a proximal end of the textile tube and continuously extends from an inside of the textile tube configured to be adjacent the liner, through the textile tube to an outside thereof configured to be adjacent an inside of the prosthetic socket. The annular seal may include a first wing on an inside of the textile tube configured to be adjacent the liner, a second wing on an outside of the textile tube configured to be adjacent an inside of the prosthetic socket, and a base connecting lower ends of the first and second wings to define a v-shaped cross-section of the annular seal.

Owner:OSSUR AMERICAS

Intelligent prosthetic socket system with active user feedback interface and real time prosthesis diagnostics

An apparatus is provided for use with a prosthetic system. The apparatus includes a housing that is disposed within a prosthetic socket. The housing has a vacuum pump and a switch. The a vacuum pump is actuated to maintain a negative air pressure within the prosthetic socket. The switch is configured to allow a user to operate the vacuum pump.

Owner:5280 PROSTHETICS

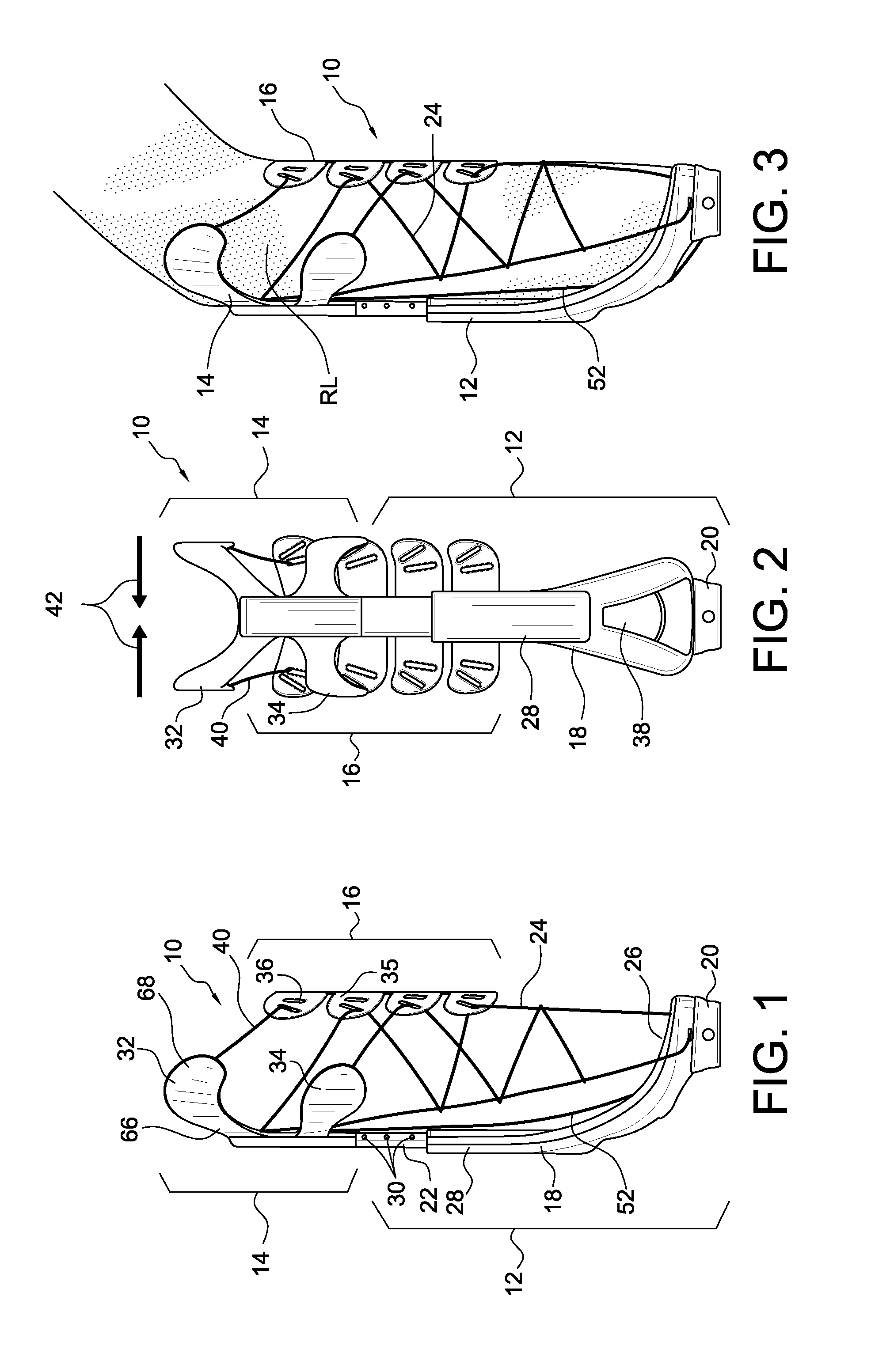

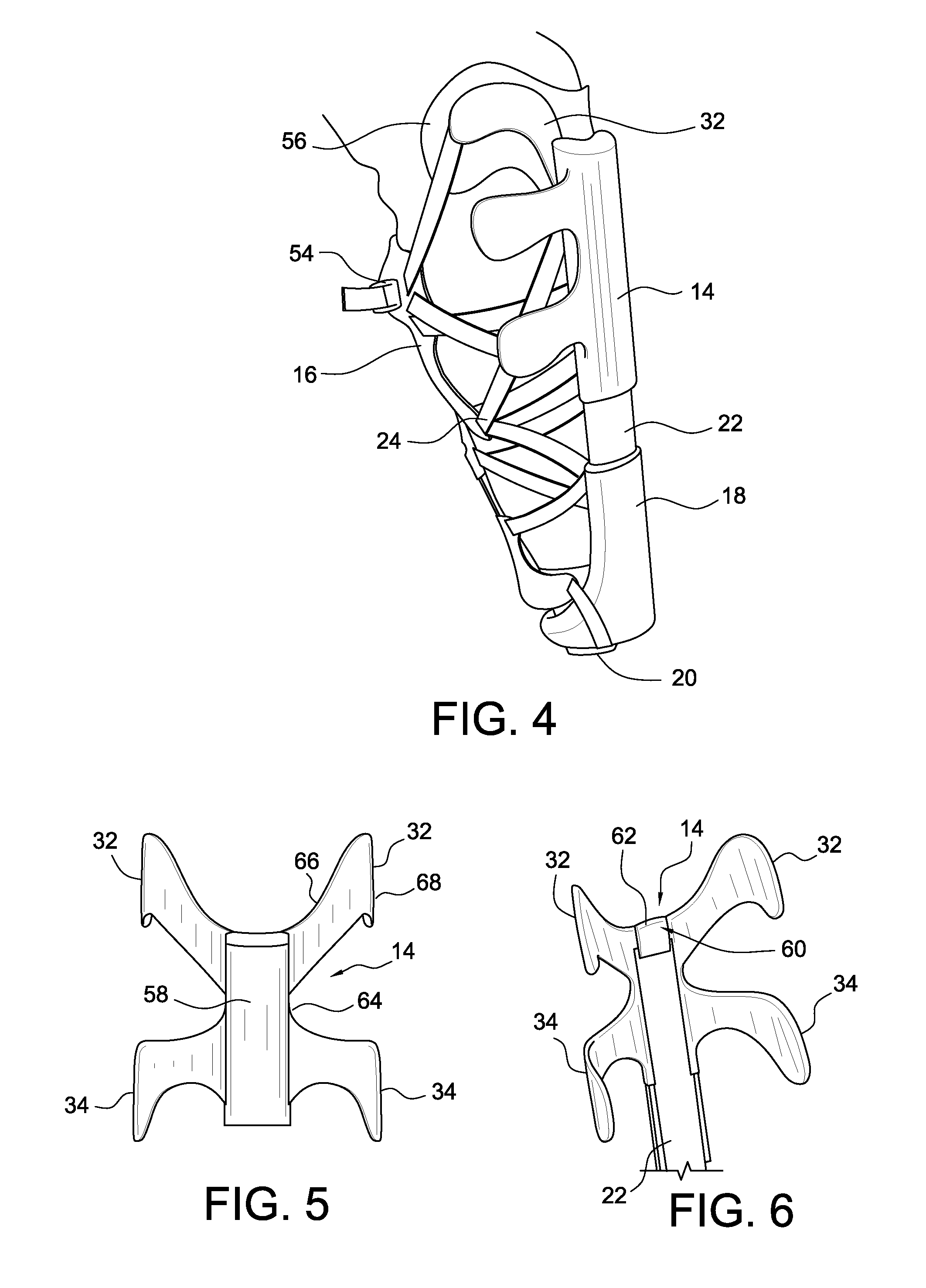

Modular prosthetic sockets and methods for making and using same

Owner:LIM INNOVATIONS

Modular prosthetic sockets and methods for making same

ActiveUS8978224B2Dimension demandShape demandMeasurement/indication equipmentsMetal working apparatusBiomechanicsModularity

The invention relates to a prosthetic socket for a residual limb of the lower extremity or upper extremity of an individual person. The residual limb has particular dimensions and anatomical contours; the prosthetic socket has dimensions and contours that fit the dimensions and contours of the residual limb. The prosthetic socket may also fit in a manner that is biomechanically particularly appropriate for the individual. The prosthetic socket is an assembly of components from groups of components that include (a) struts arranged longitudinally with respect to the residual limb, (b) proximal brim members arranged proximally to the struts and connected thereto; and (c) distal socket members disposed at the distal base of the prosthetic socket. The socket components within these groups may be modular in that they can vary with respect to dimensions and / or contours, and yet have common connecting features that permit assembly of the components together to form the prosthetic socket.

Owner:LIM INNOVATIONS

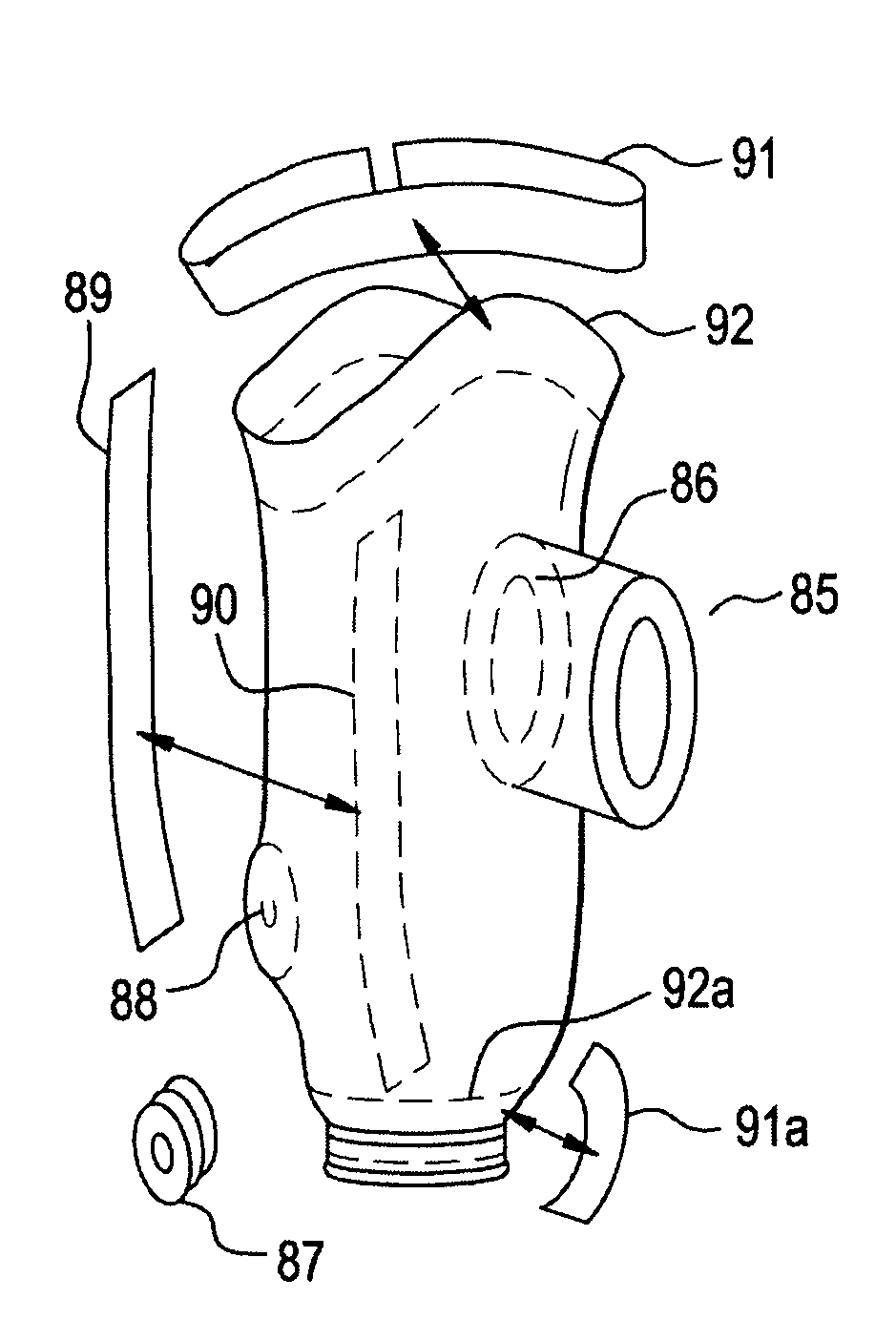

Apparatus and Methods for Facilitating Prosthesis Donning, Doffing, Retention, and Fit

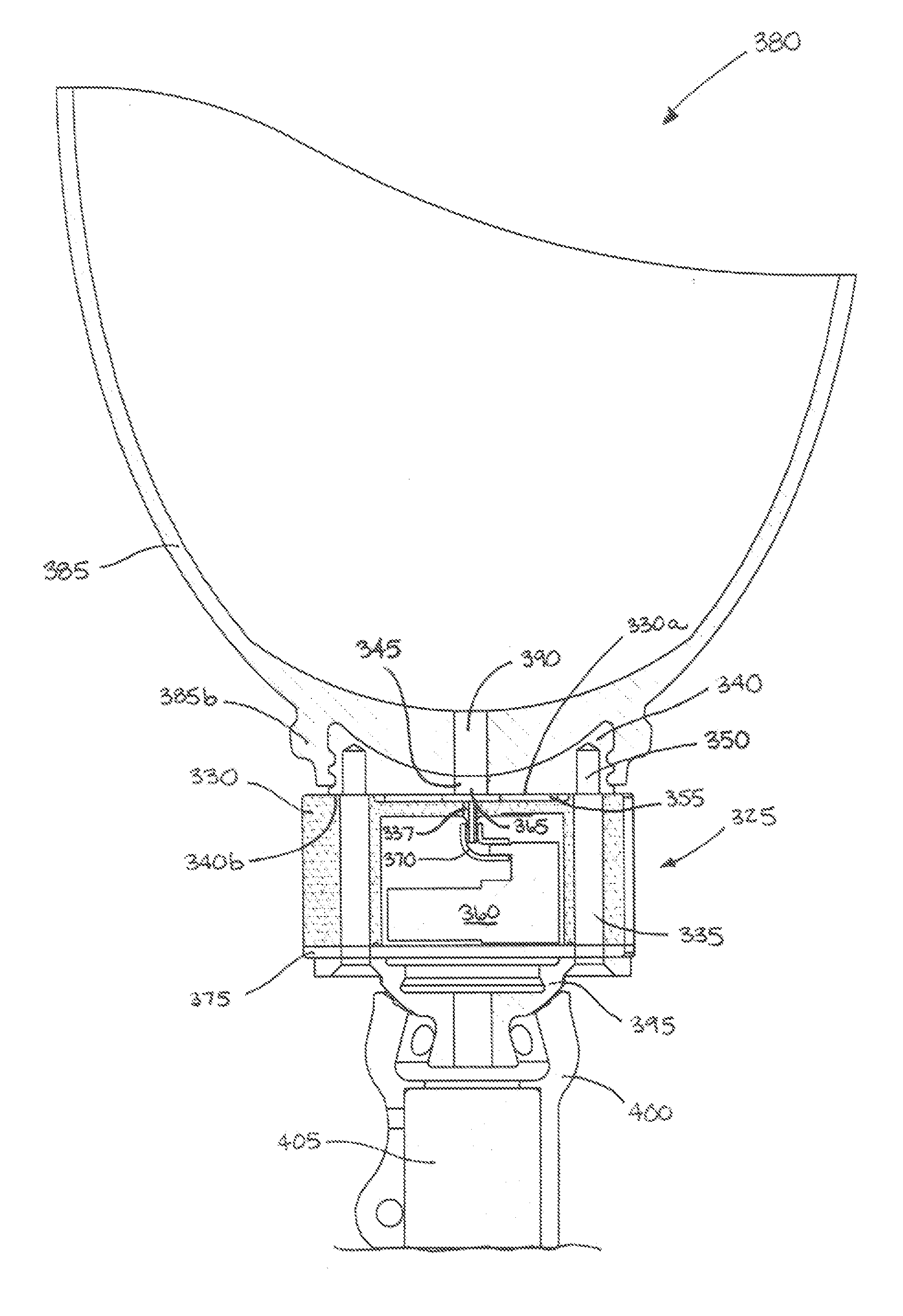

ActiveUS20100087931A1Operating means/releasing devices for valvesCheck valvesEngineeringResidual limb

Apparatus and methods for improved prosthesis donning, doffing, retention, and fit. A valve located in a prosthetic socket port includes a body, a core, a spring located partially within the core, a diaphragm, and a maintained operator. The operator includes a recess and a protrusion. The operator may be indexed to a displacement or vent position. When the operator is indexed to the displacement position, a tip of the core is pressed against the recess via the spring, and the diaphragm displaces any air that enters into the prosthetic socket when a load is applied to the residual limb. When the operator is laterally actuated, it is indexed to the vent position and the core tip moves from the recess to the protrusion. In this position, the diaphragm opens the socket cavity to the external atmosphere via valve vents, thereby facilitating prosthesis donning and doffing.

Owner:BOGUE DAVID ROBERT

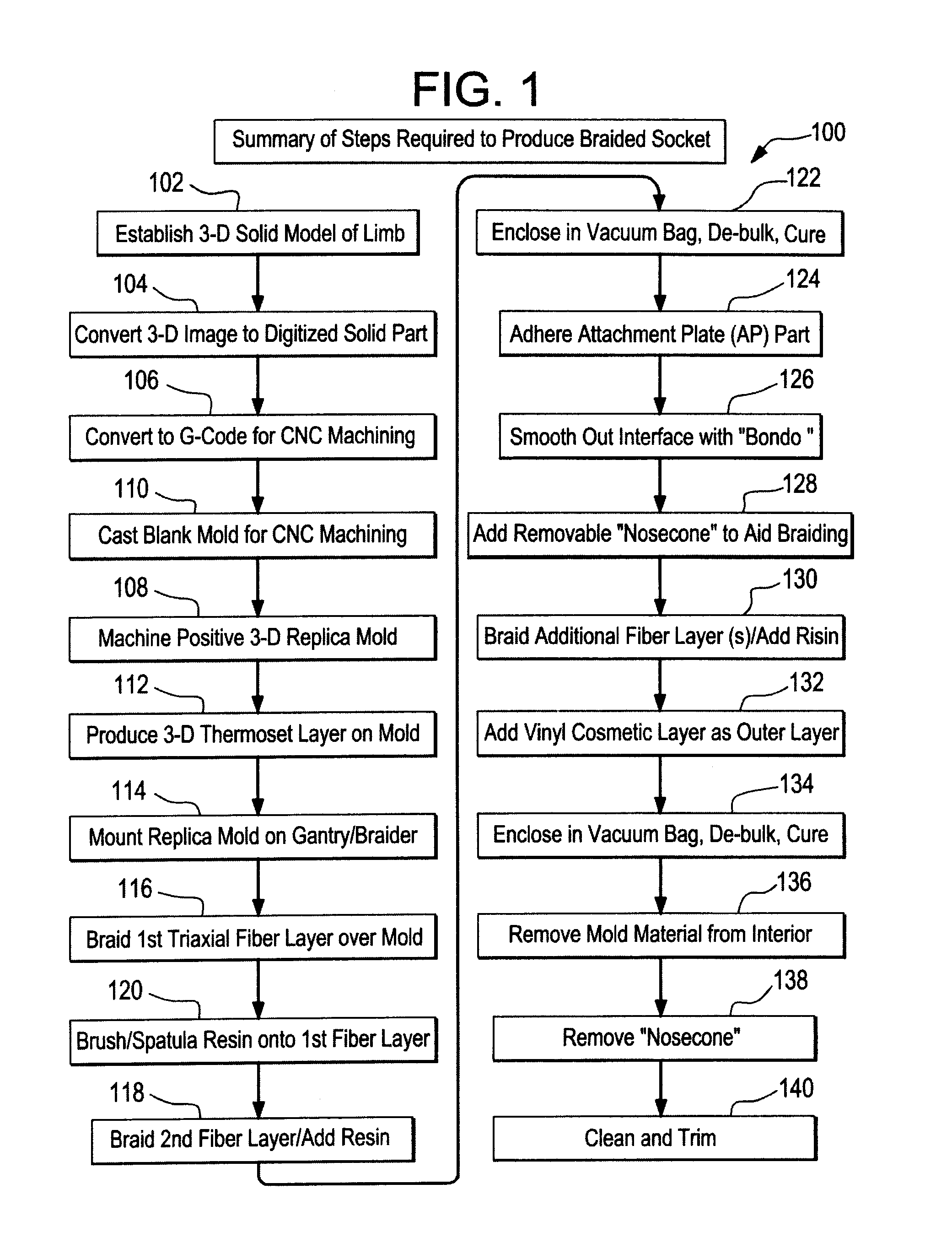

Braided prosthetic sockets with attachment plates and methods of manufacture

This invention provides new above knee (AK) and below the knee (BK) prosthetic sockets and implements specific manufacturing processes for the production of prosthetic sockets through the automated, computer controlled bi-axial and tri-axial braiding of sockets, over a mold or mandrel made of carved foam, plaster material or wax that is a replica of the patient's truncated limb, and is created by a Computer Aided Design (CAD) file controlling a Numerically Controlled (CNC) machine tool. This method of manufacture using aerospace fibers such as graphite or Kevlar, and high performance resins, is used to create a socket which is stronger and lighter weight than conventionally manufactured sockets. Braiding also allows incorporation of woven cloth, tapes and other reinforcements into the braiding process for added strength at selected areas. The method dramatically decreases the production time and cost of the prosthetic relative to conventional methods.

Owner:MENTIS SCI

Self-adhering friction reducing liner and method of use

A patch of low friction materials, such as a film of polytetrafluoroethylene is sized to provide an area of low friction support for a portion of a human body relative to an object such as a shoe or prosthetic socket. The patch can be lined with foam, or preferably, a stretch fabric so that it will fit around irregular contours of the shoe, or socket, or the skin itself. The patches reduce shear trauma in critical load areas. After identifying regions of high loads, the method comprises applying the patches as needed to avoid sores, calluses, blisters and abrasions.

Owner:TAMARACK HABILITATION TECH

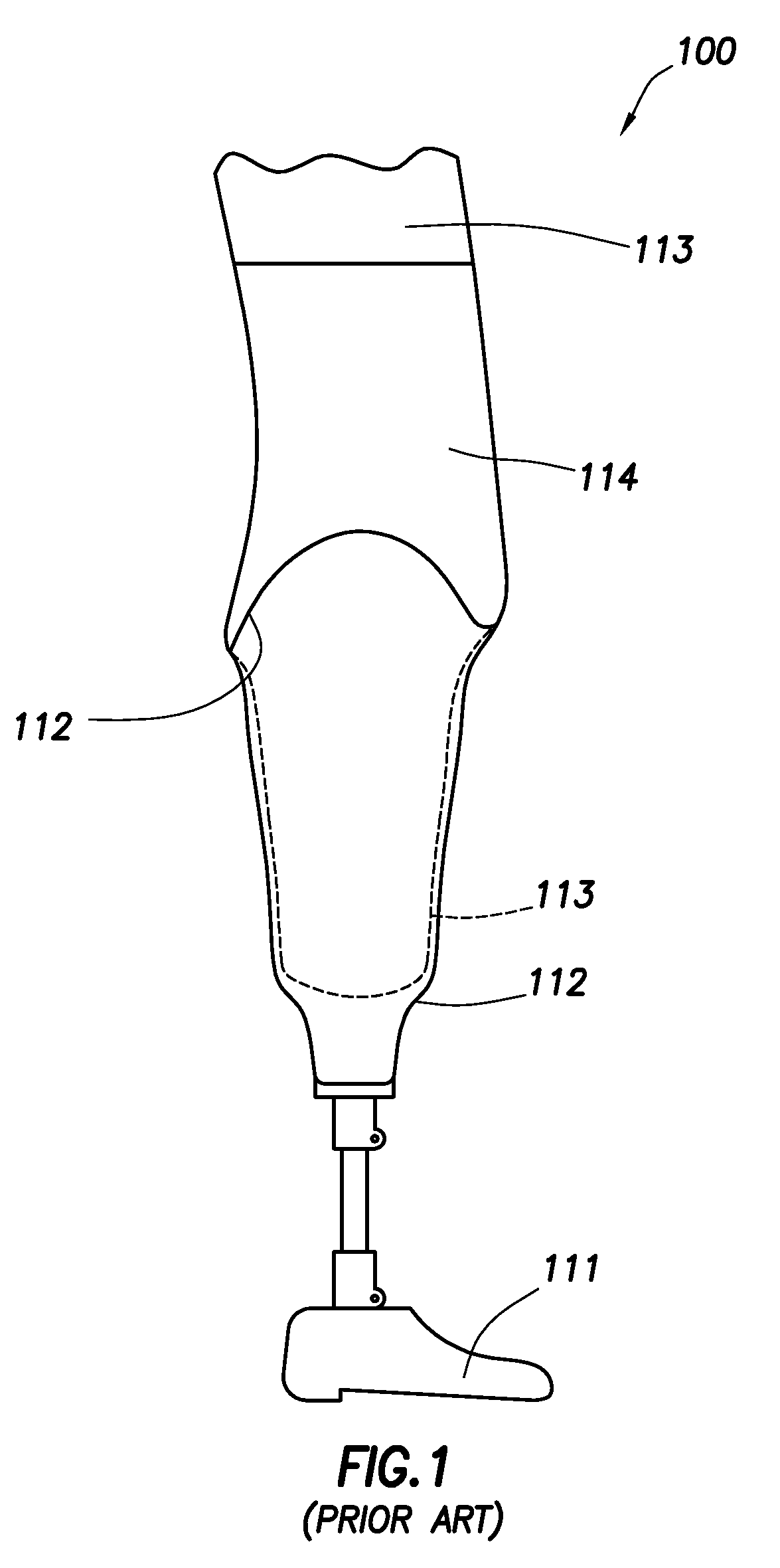

Anatomically configured hip level prosthetic socket system

InactiveUS7300466B1Increase the areaLess obtrusive trim linesArtificial legsEngineeringProsthetic socket

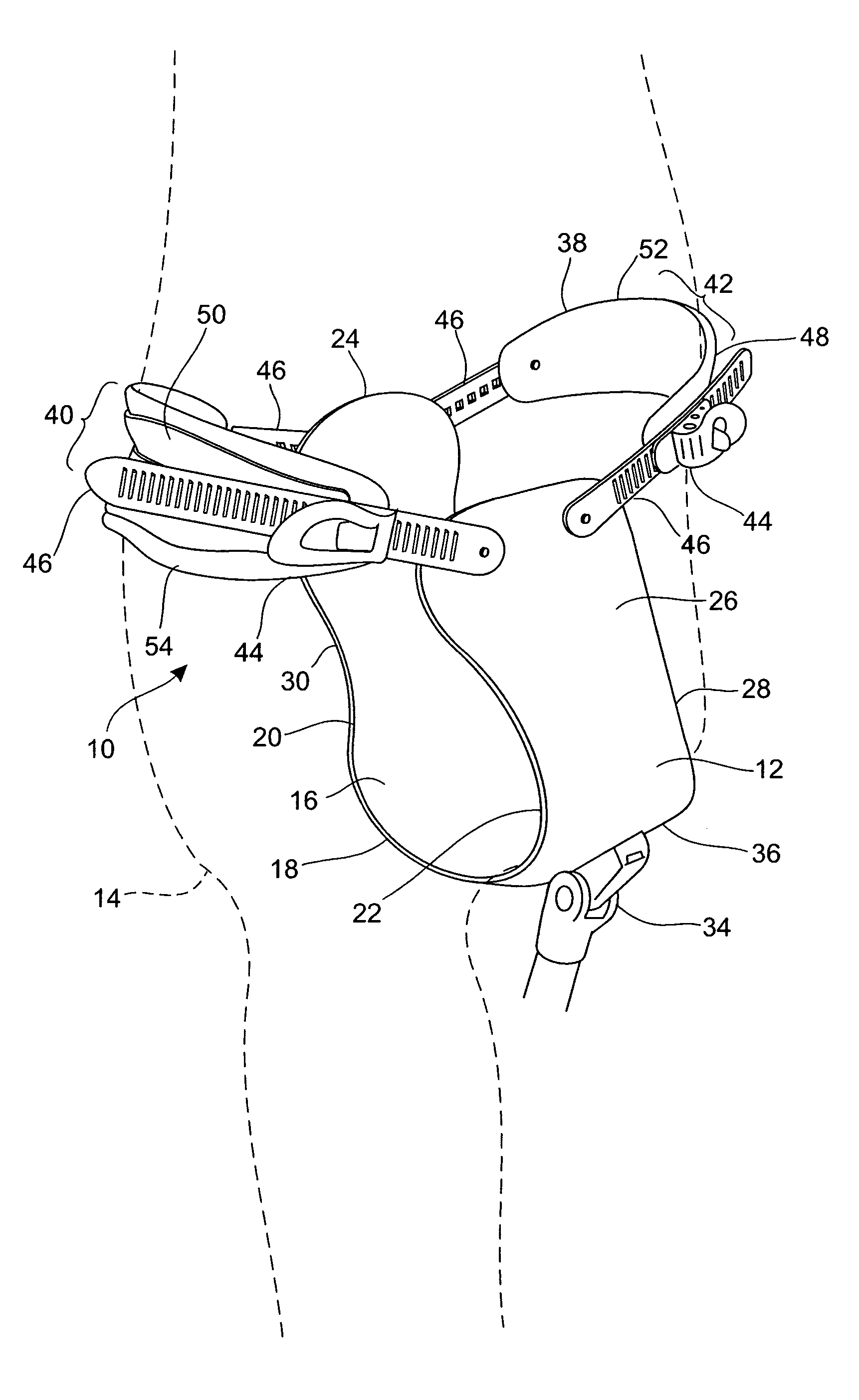

A prosthetic hip level socket system for a user's lower torso comprising a socket fitted to the individual user's lower torso having a mounting point for an attachment, a first strap attached to the socket and a second strap attached to the socket wherein the first strap and the second strap work in cooperation to support the socket on the iliac crests of the user's lower torso.

Owner:ORTHOCARE INNOVATIONS LLC

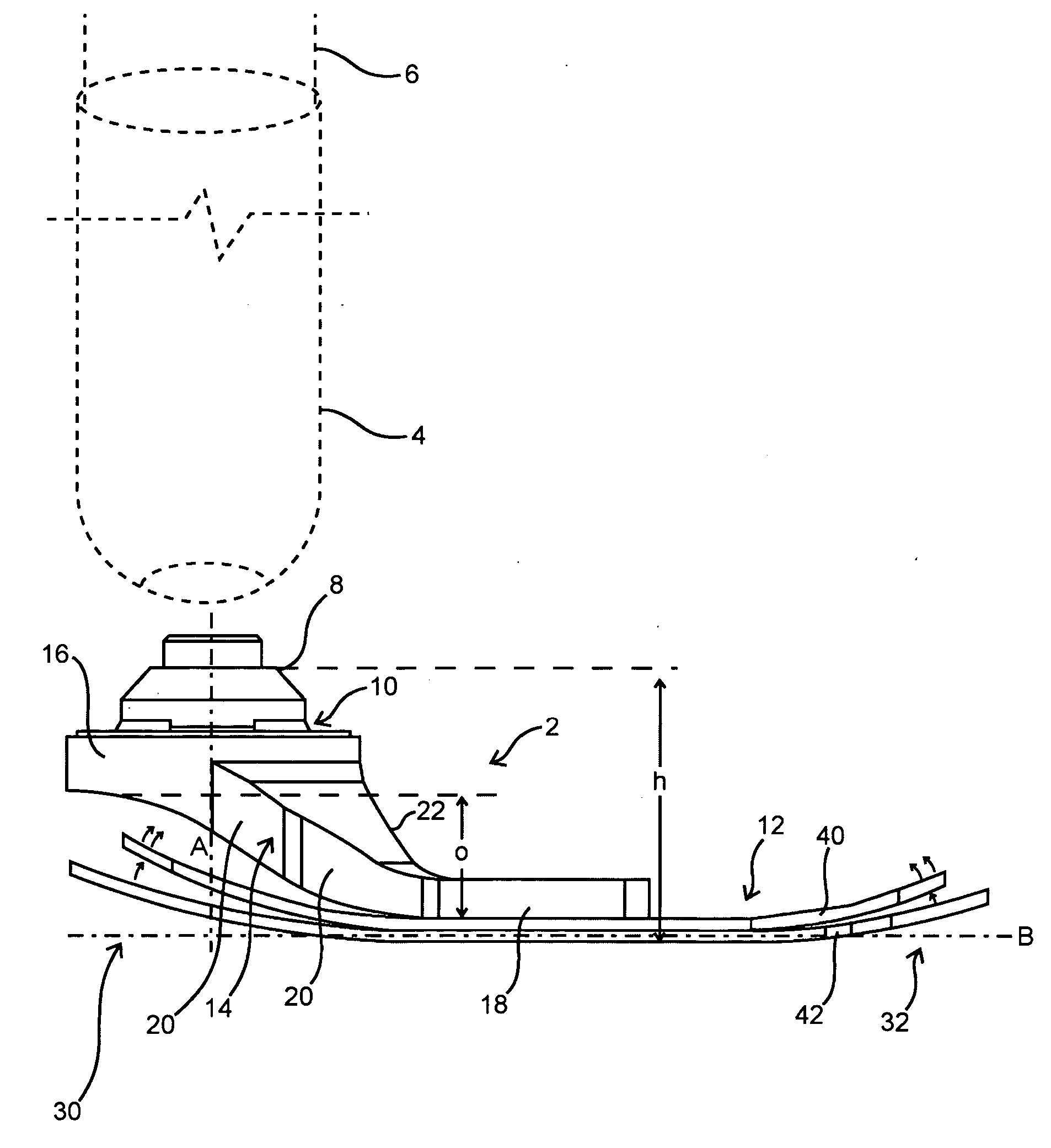

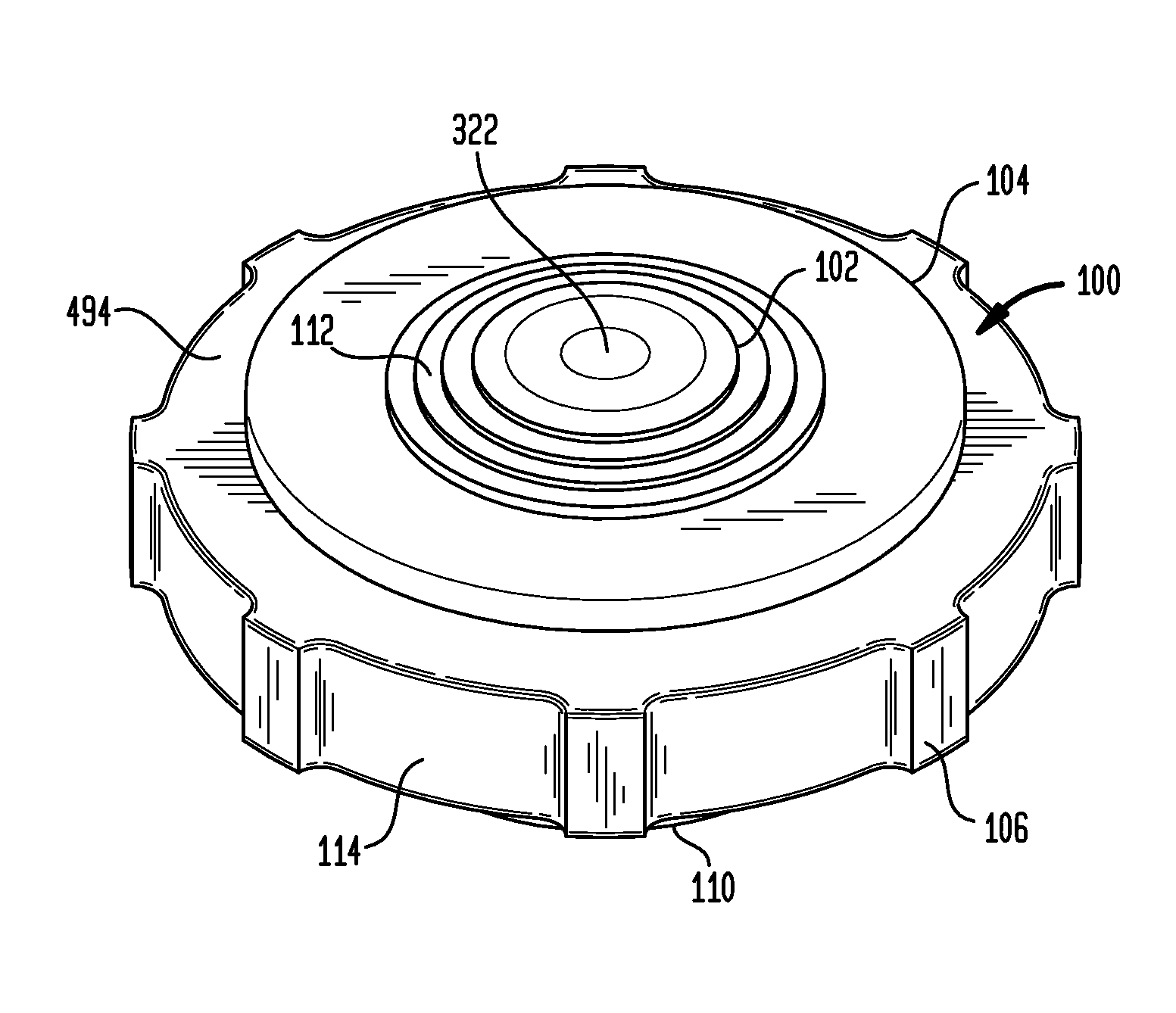

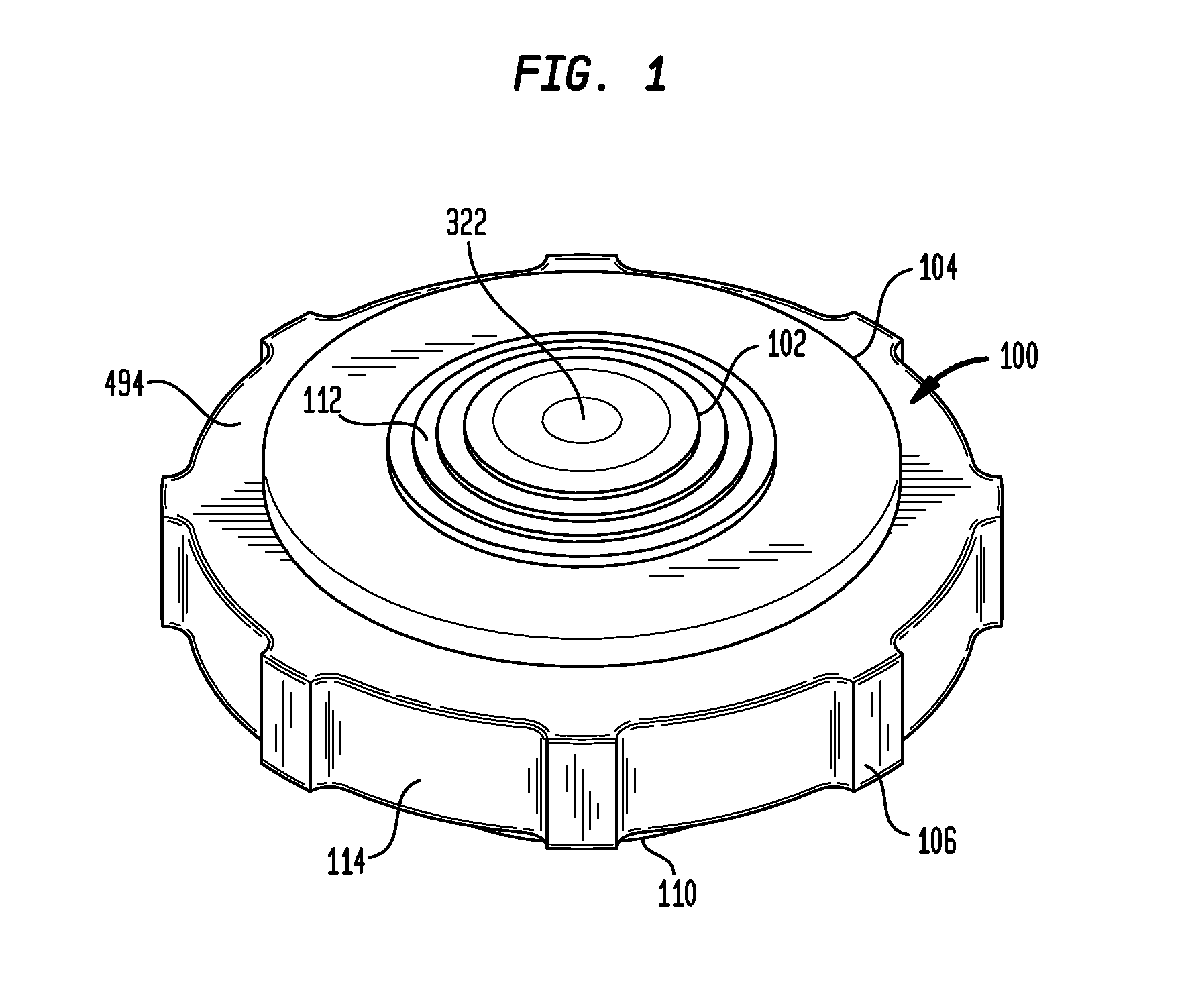

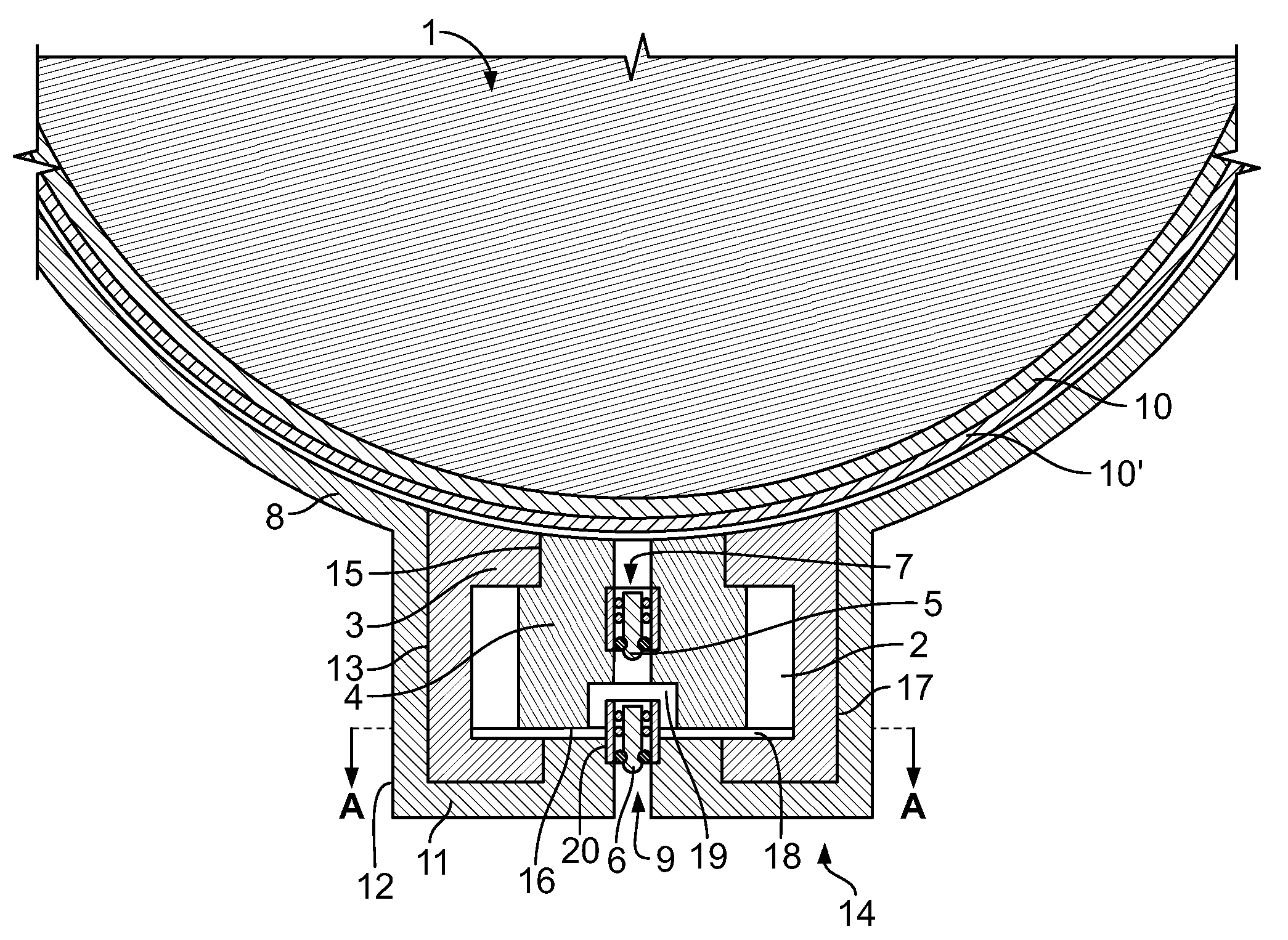

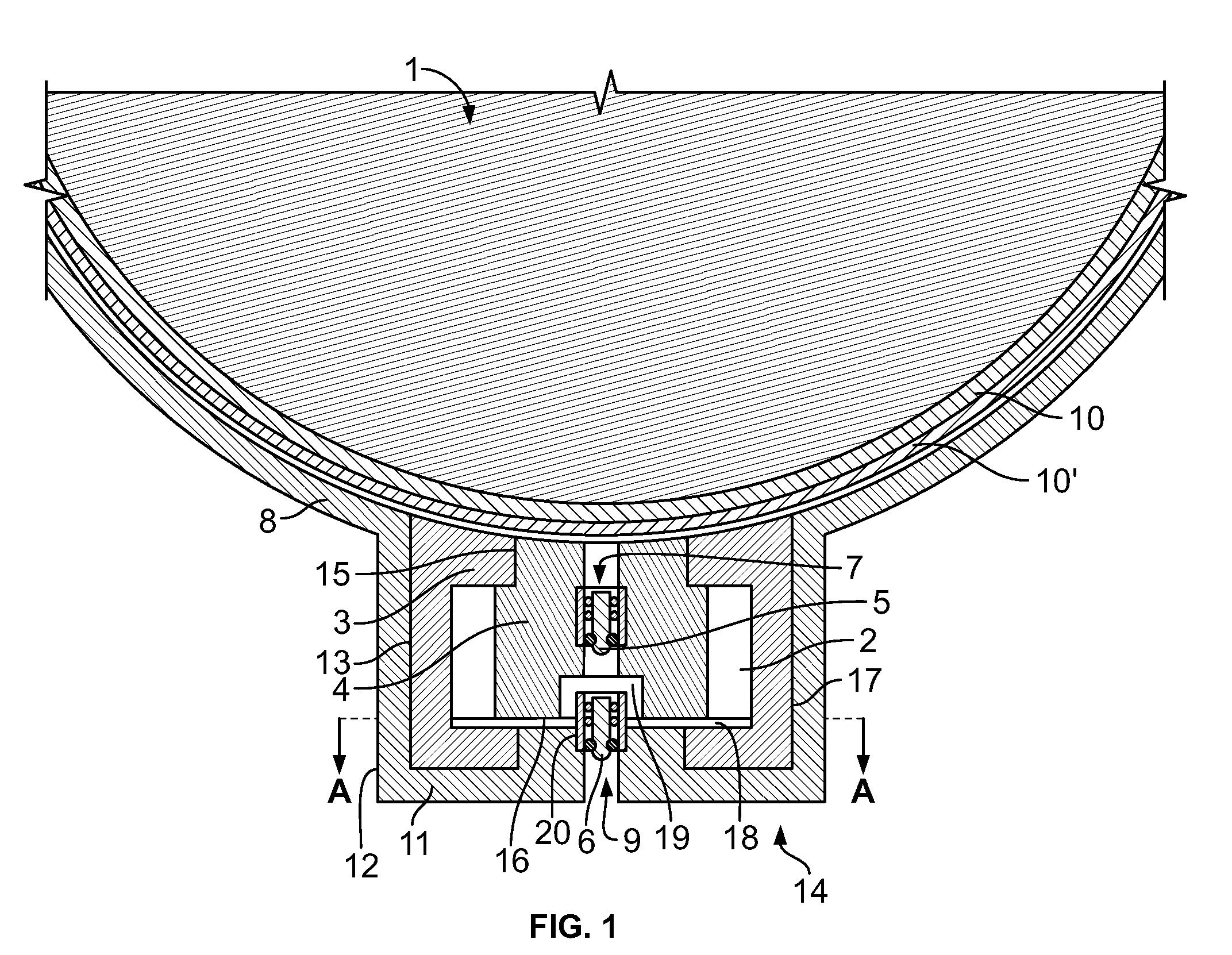

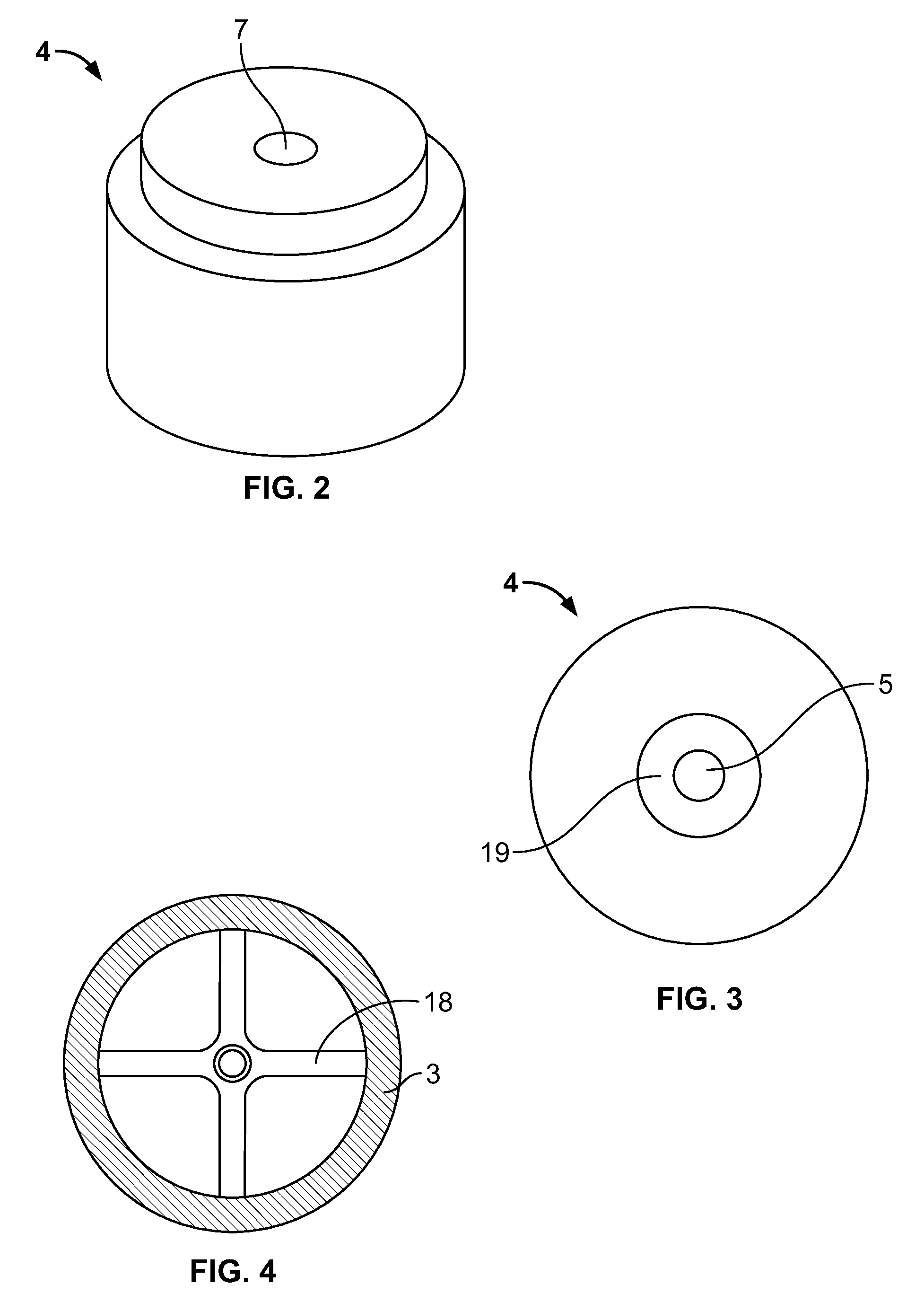

Valve integrated prosthetic expulsion pump

An air expulsion pump for a prosthetic socket adapted to be worn on a residual limb of an amputee. The pump includes an elastomeric housing which fits snugly in a well defined in the lower end of the socket. The pump is easy to install by simply sliding it into the well. The pump has an upper surface commensurate with the inside surface of the socket in that both surface have the same radius of curvature. The pump includes an elastomeric spring member and two check valves that together with the elastomeric housing exert a continuous vacuum within the prosthetic socket. When donned by the user, the pump provides continuous total contact between the socket and the residual limb of the user as the user ambulates.

Owner:ALPS SOUTH EURO

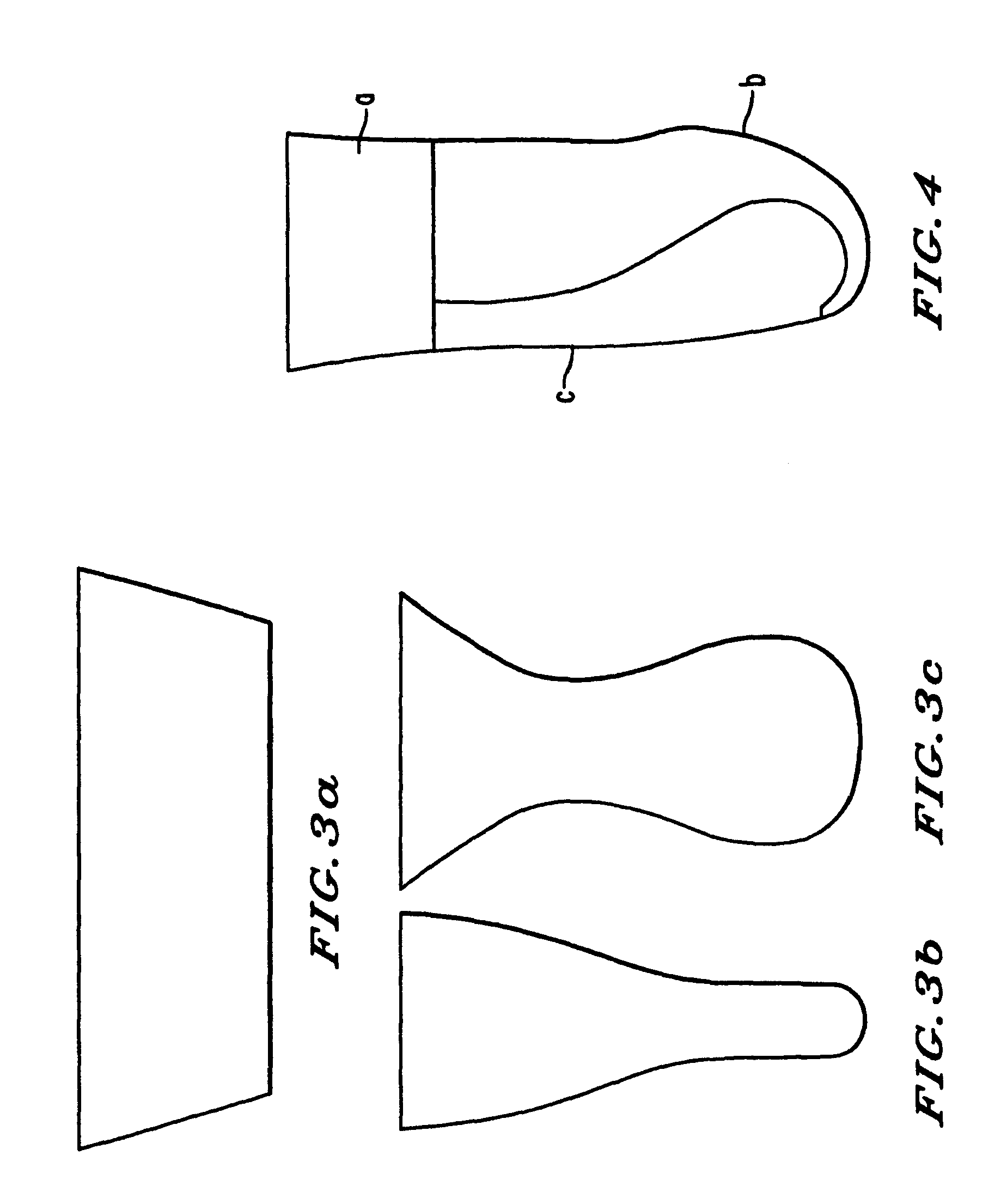

Fabric-covered polymeric prosthetic liner

InactiveUS20120253475A1Increase contactImprove comfortProsthesisThermoplastic elastomerResidual limb

A prosthetic cushion liner and cushion locking liner for use as a standalone interface between an amputee's residual limb and the interior of a prosthetic socket. The liners include a fabric covering having an open end for introduction of a residual limb and a closed end opposite said open end, and a cushioning block copolymer and plasticizing oil gel composition residing on only an interior surface of the fabric covering. The gel composition includes some amount of a Septon J-Series thermoplastic elastomer material. The cushion locking liner further includes a distally-located docking element for coupling the liner to the socket of a prosthesis.

Owner:THE OHIO WILLOW WOOD CO INC

Pneumatic connections for prosthetic socket

A connector for fluidly connecting the sealed interior of an artificial limb socket with a pressure source when the connector is mounted to the socket at a hole and an artificial limb including same. The connector includes a flexible elongated tubular section having a lumen, a flange coupled to one end of the elongated tubular section, the flange having a seal surface for sealingly abutting one of the socket wall surfaces around the hole, and a tubular portion adjacent to the flange and extending the lumen from the seal surface of the flange. Tubular portion has at least one section oversized relative to hole which provides a reasonable air-tight seal between the at least one section and an inner surface of the hole or the other of said socket wall surfaces around the hole and distant from the flange, when the tubular portion is received within the hole.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

Sealing sheath for prosthetic liner and related methods

The sealing sheath is for use with a prosthetic socket and associated liner. The sealing sheath includes a textile tube for surrounding at least a portion of a liner that is configured to wear on a residual limb. An annular seal, e.g. an elastomeric or silicone seal, is positioned adjacent a proximal end of the textile tube and continuously extends from an inside of the textile tube configured to be adjacent the liner, through the textile tube to an outside thereof configured to be adjacent an inside of the prosthetic socket. The annular seal may include a first wing on an inside of the textile tube configured to be adjacent the liner, a second wing on an outside of the textile tube configured to be adjacent an inside of the prosthetic socket, and a base connecting lower ends of the first and second wings to define a v-shaped cross-section of the annular seal.

Owner:OSSUR AMERICAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com