Patents

Literature

835 results about "Prosthetic limb" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A prosthesis (also called a prosthetic limb, artificial limb, or limb "replacement"—though natural limbs are irreplaceable) is an artificially made substitute for a limb lost through a congenital defect (present at birth), accident, illness, or wartime injury.

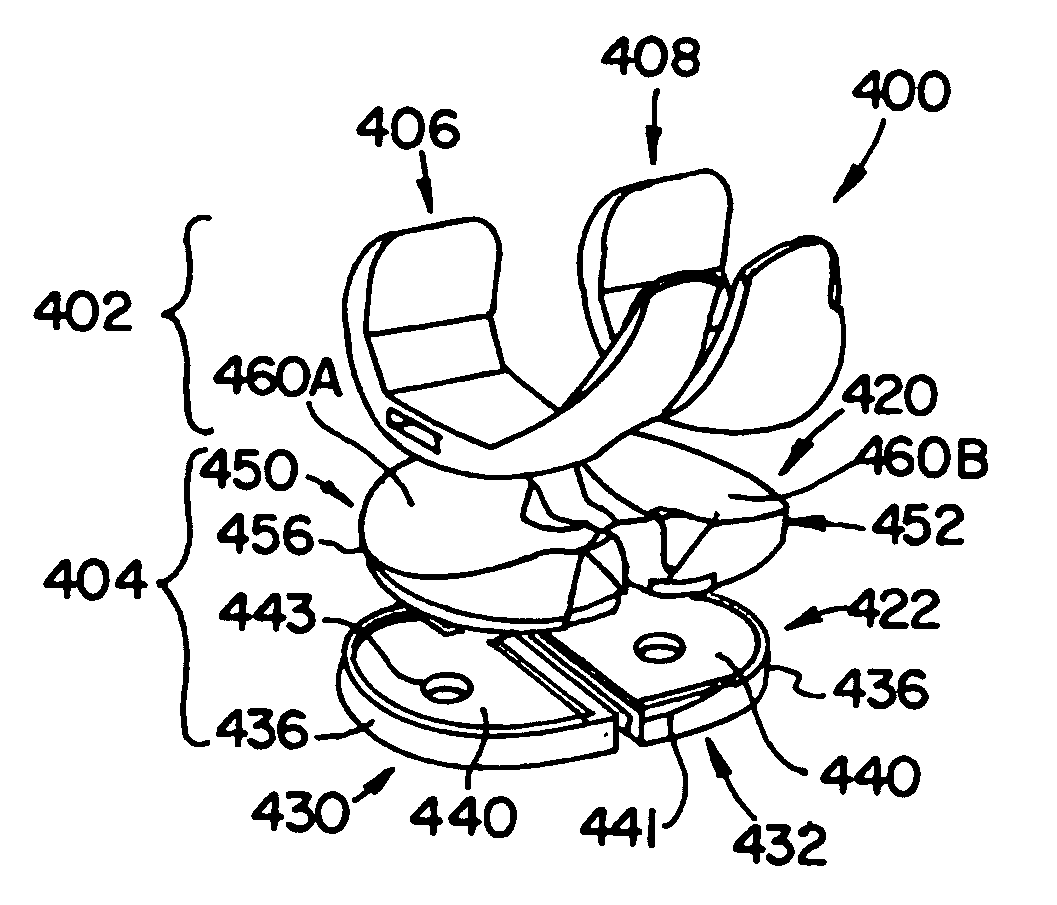

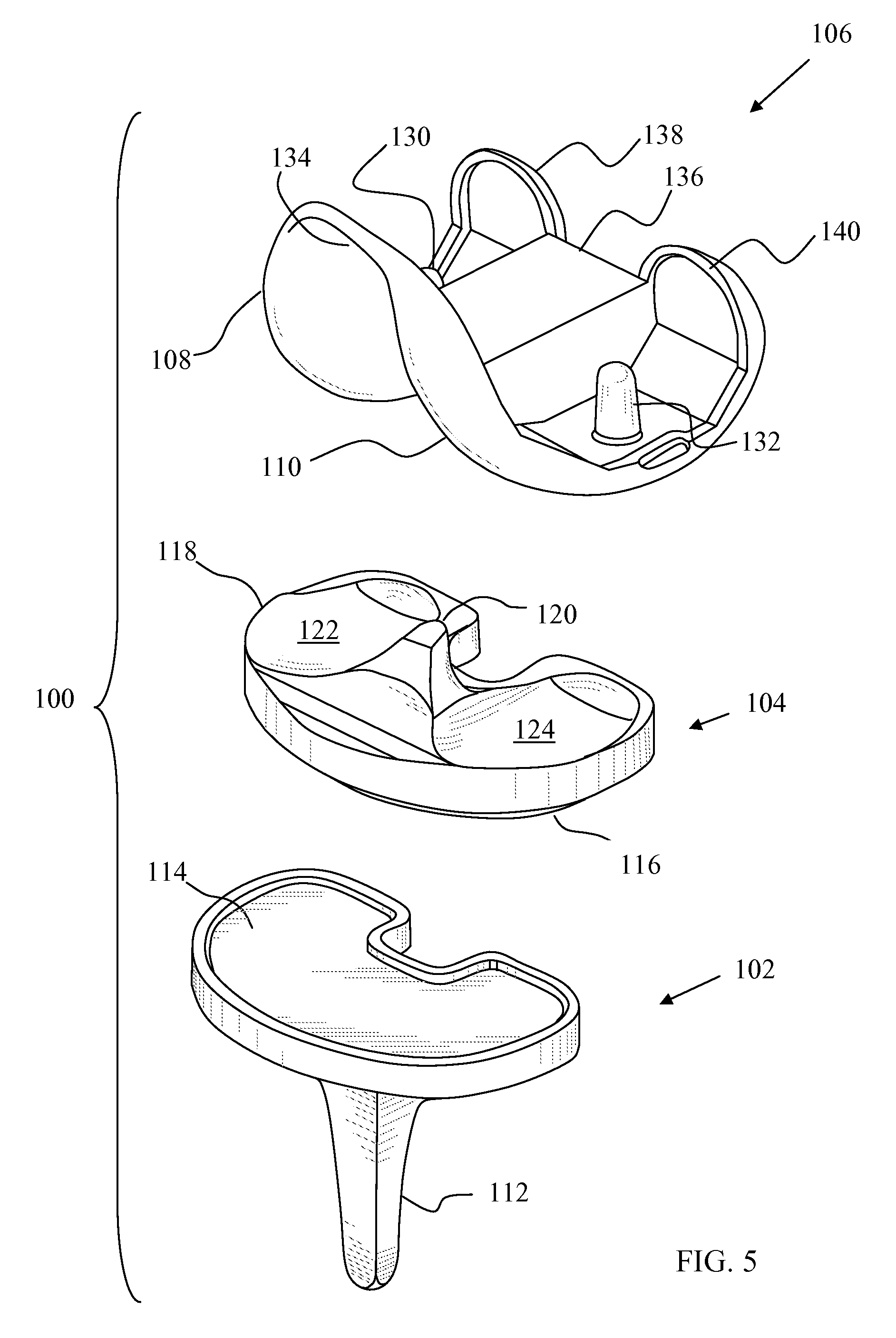

Modular knee prosthesis

A modular prosthetic knee system used to replace the natural knee. The system includes a femoral knee prosthesis and a tibial knee prosthesis. Both prostheses are formed of modular components that are connectable in-vivo to form the prosthetic knee system. The femoral knee prosthesis includes two separate components, a lateral condyle and medial condyle; and the tibial knee prosthesis includes a multiple separate components, a medial baseplate, a lateral baseplate, a medial insert, and a lateral insert. The medial and lateral baseplate are connectable to form a complete baseplate with the medial and lateral inserts connectable to the complete baseplate.

Owner:ZIMMER TECH INC

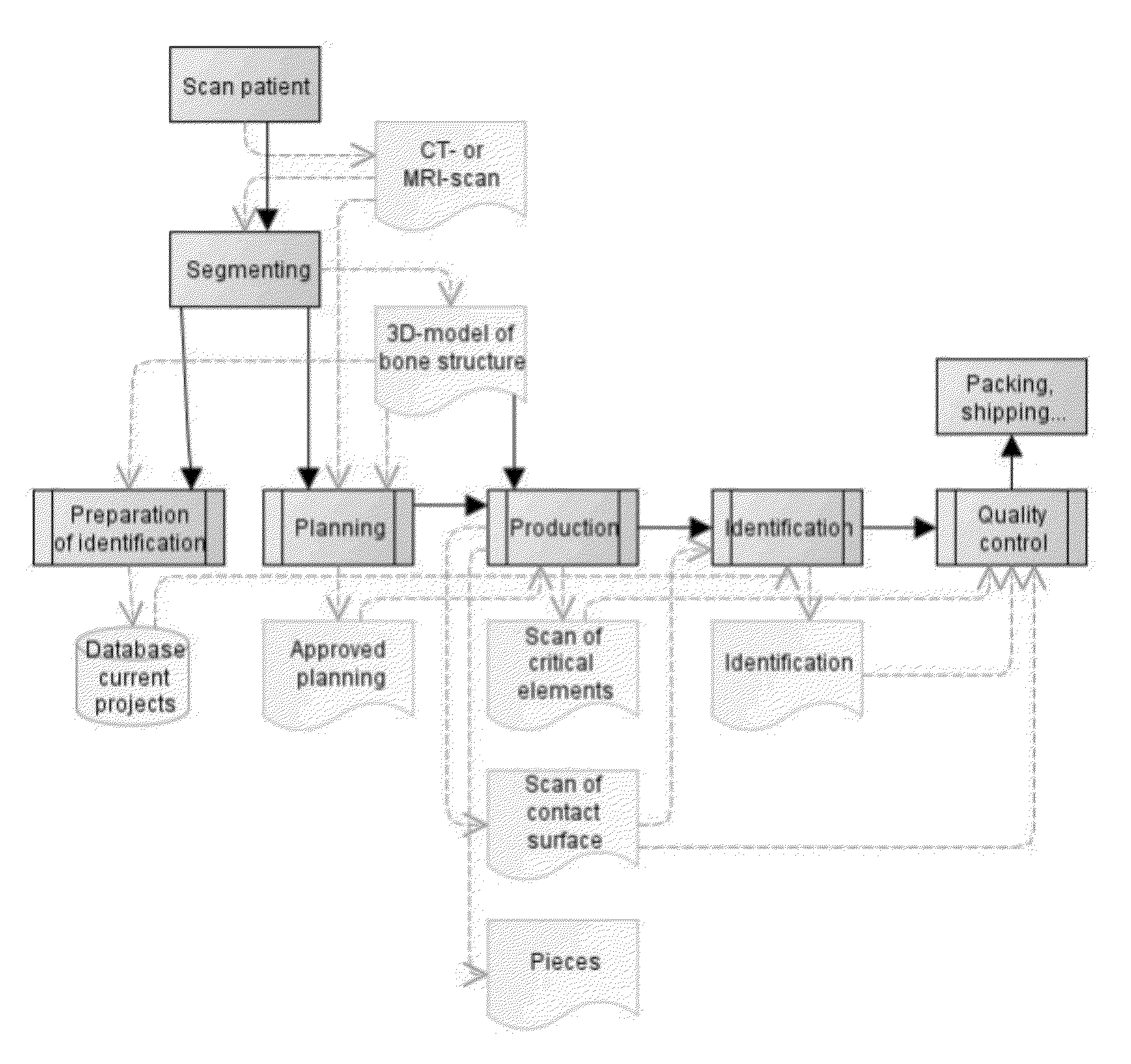

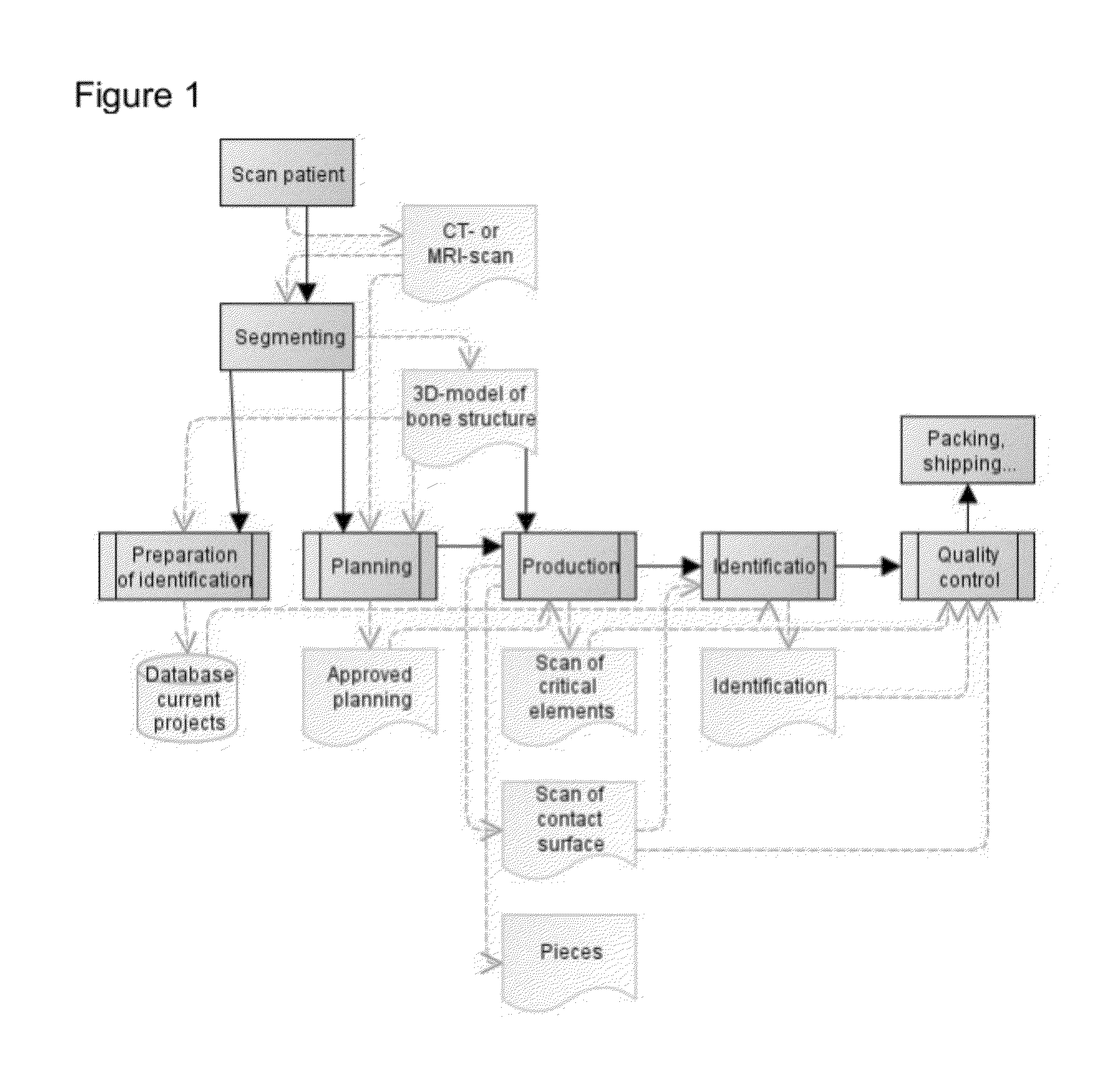

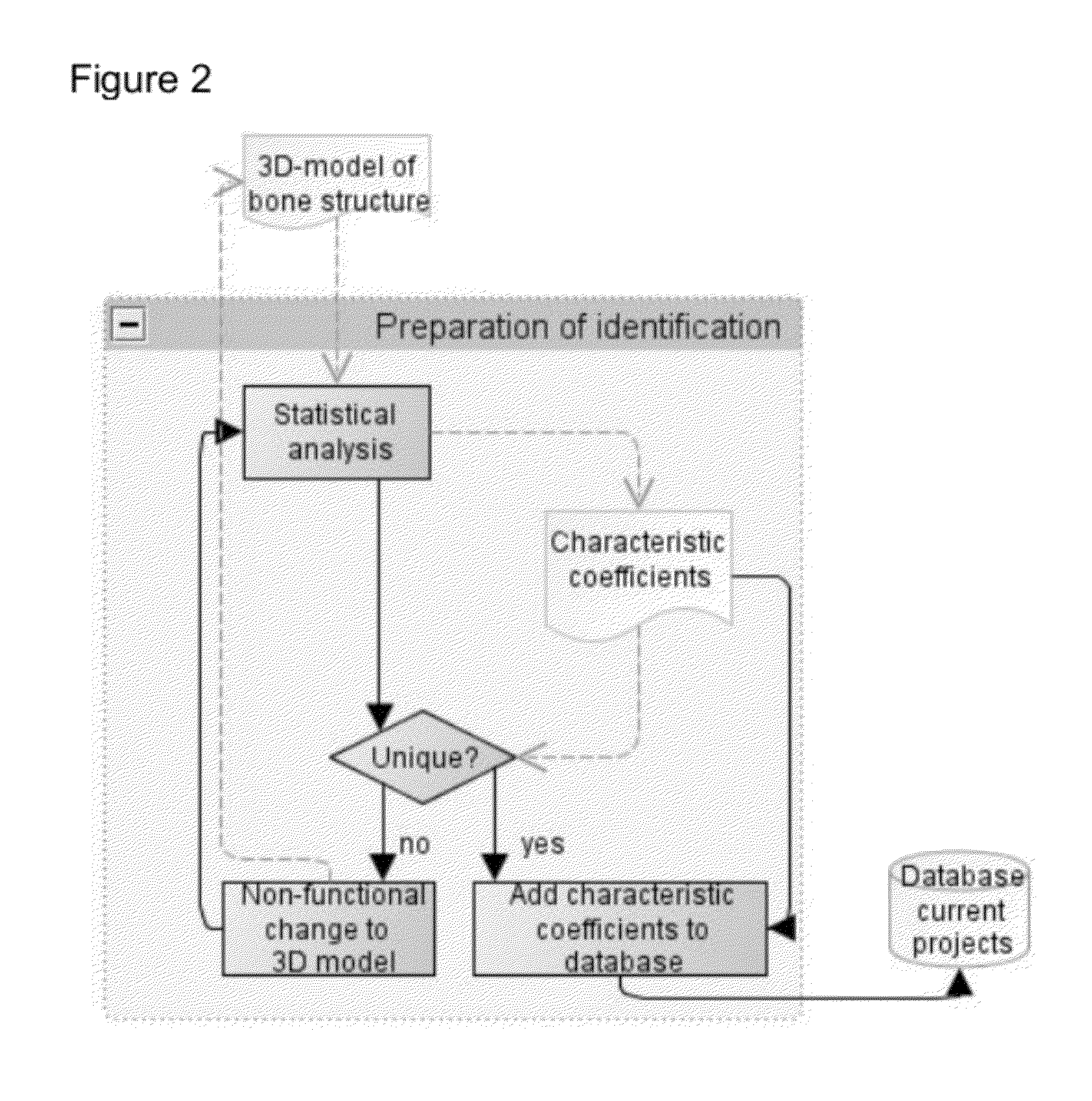

Additive manufacturing flow for the production of patient-specific devices comprising unique patient-specific identifiers

InactiveUS20120116203A1Many timesSpeed up the processMedical simulationAdditive manufacturing apparatusProsthesisMedical device

Owner:MATERIALISE NV

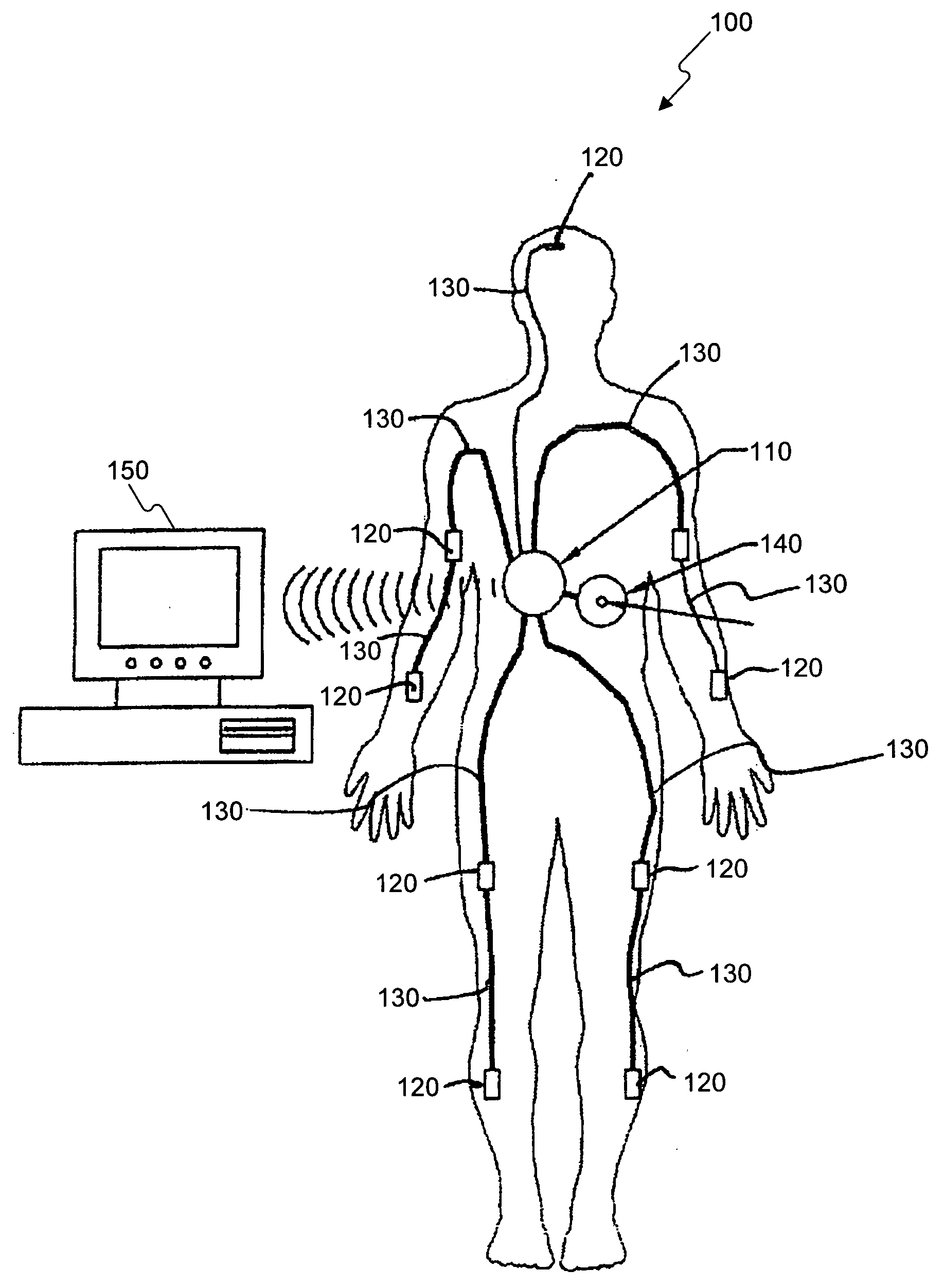

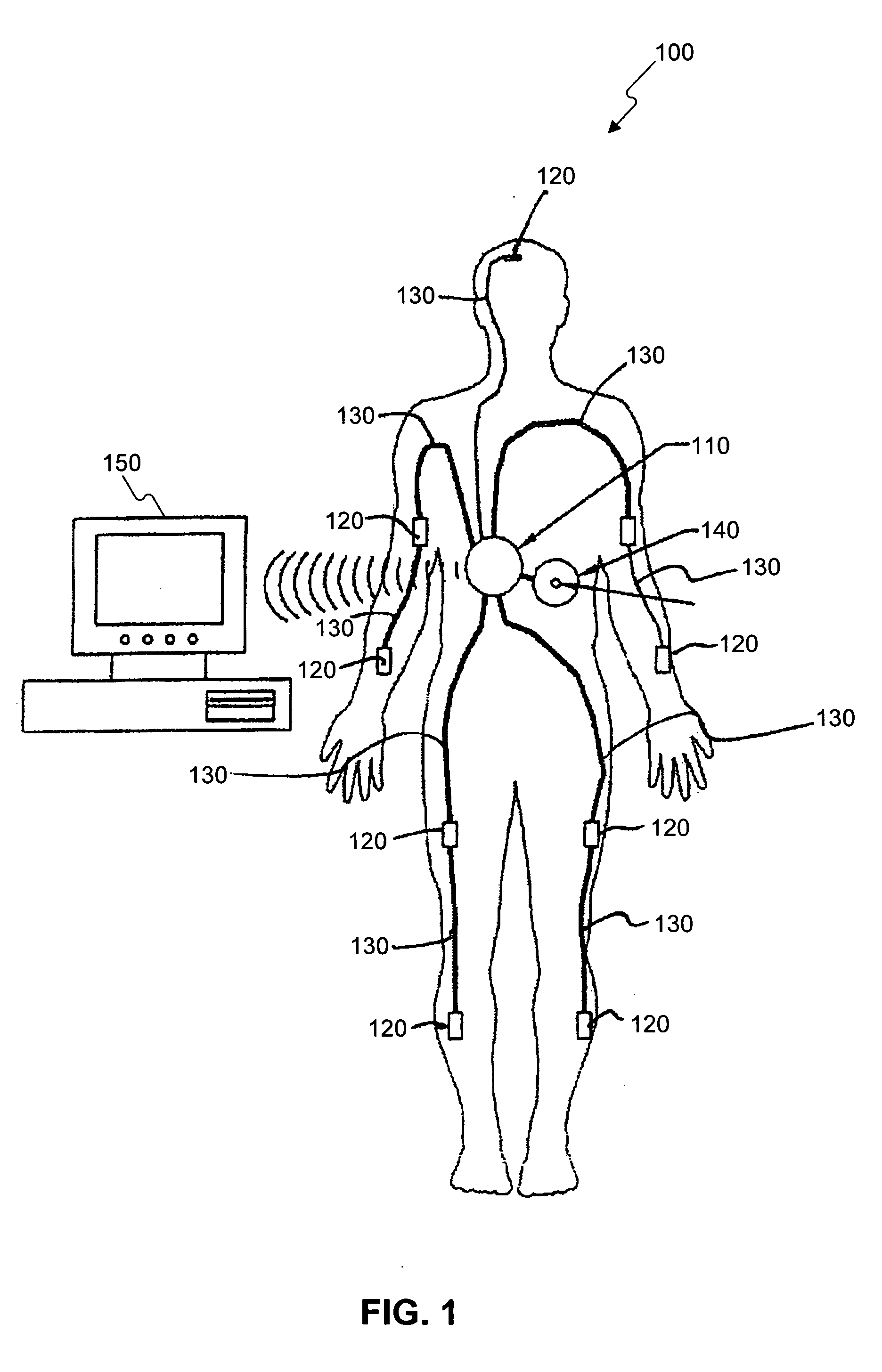

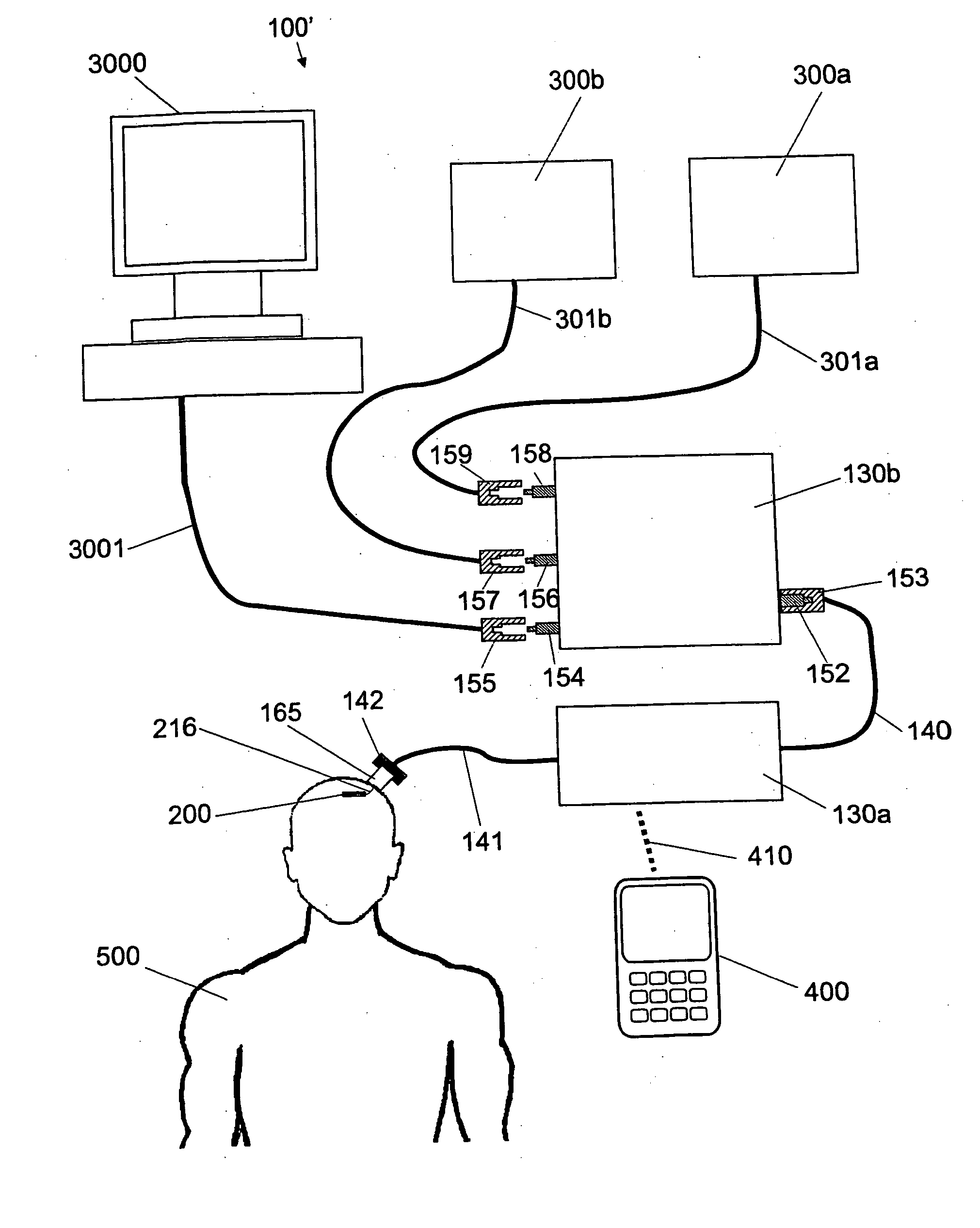

Agent delivery systems and related methods under control of biological electrical signals

InactiveUS20050113744A1Input/output for user-computer interactionHead electrodesControl signalSignaling system

Systems and methods are disclosed for detecting neural, biological, or other electrical signals generated within a patient's body and processing those signals to generate a control signal that may control the delivery of a biologic, therapeutic, or other agent, such as a drug. Embodiments include a system having a sensor implanted in a patient's brain to detect neural signals used to control delivery of a drug to the patient. The system may also control an internal and / or external device, such as a prosthetic limb, and control delivery of a drug to increase the performance of the system and / or the controlled device.

Owner:CYBERKINETICS

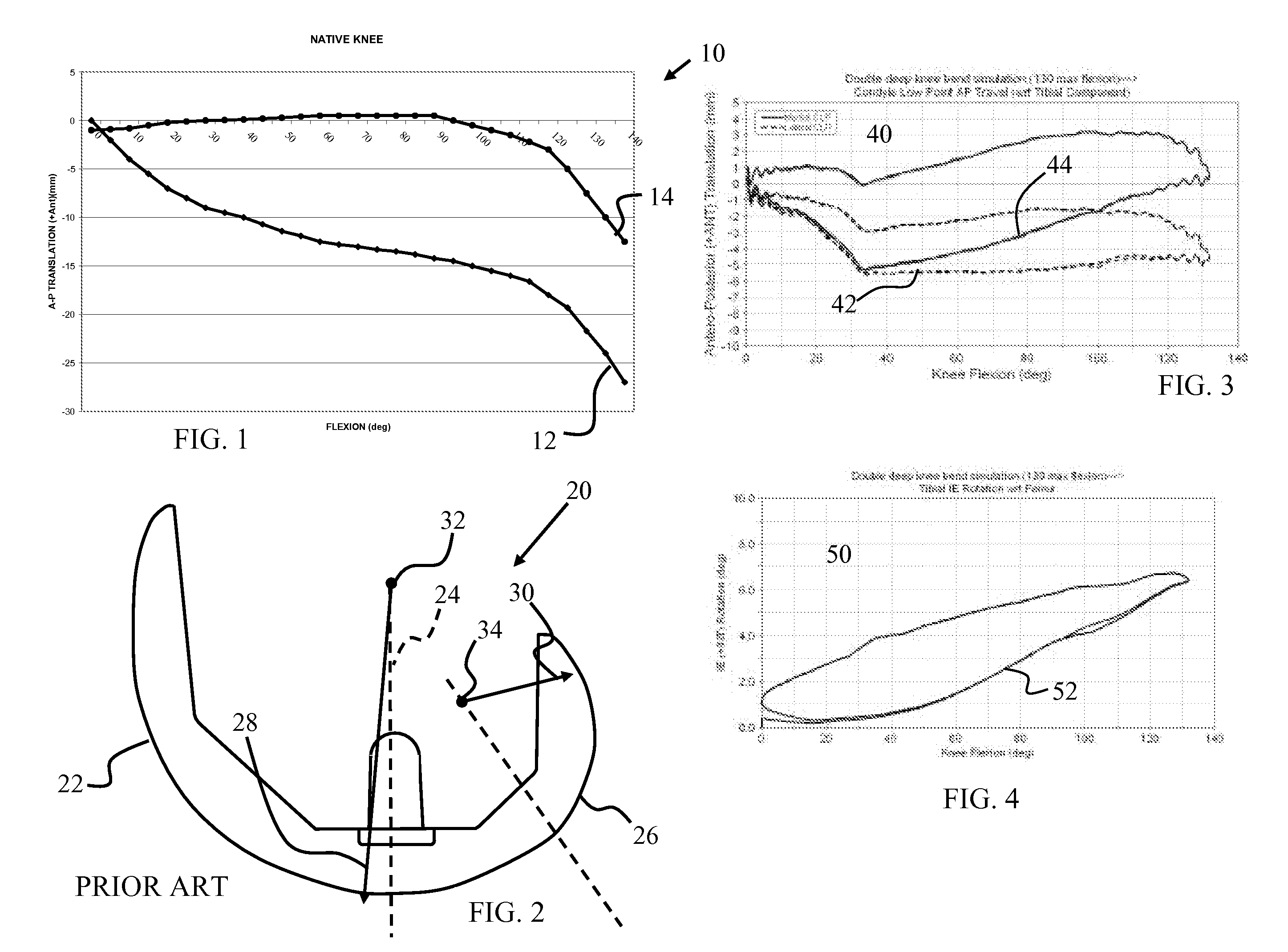

Knee prostheses with enhanced kinematics

A knee replacement system includes a proximal tibial posterior camming portion defined by a first radius of curvature with a first origin in a first medio-lateral plane, a distal tibial posterior camming portion defined by a second radius of curvature with a second origin in a second medio-lateral plane, an anterior femoral camming portion of a posterior cam defined by a third radius of curvature with a third origin in the first medio-lateral plane, and a posterior femoral camming portion of the posterior cam and defined by a fourth radius of curvature with a fourth origin in the second medio-lateral plane, wherein the second origin is closer to the lateral tibial portion than the first origin, or the fourth origin is closer to the medial femoral portion than the third origin.

Owner:DEPUY (IRELAND) LTD

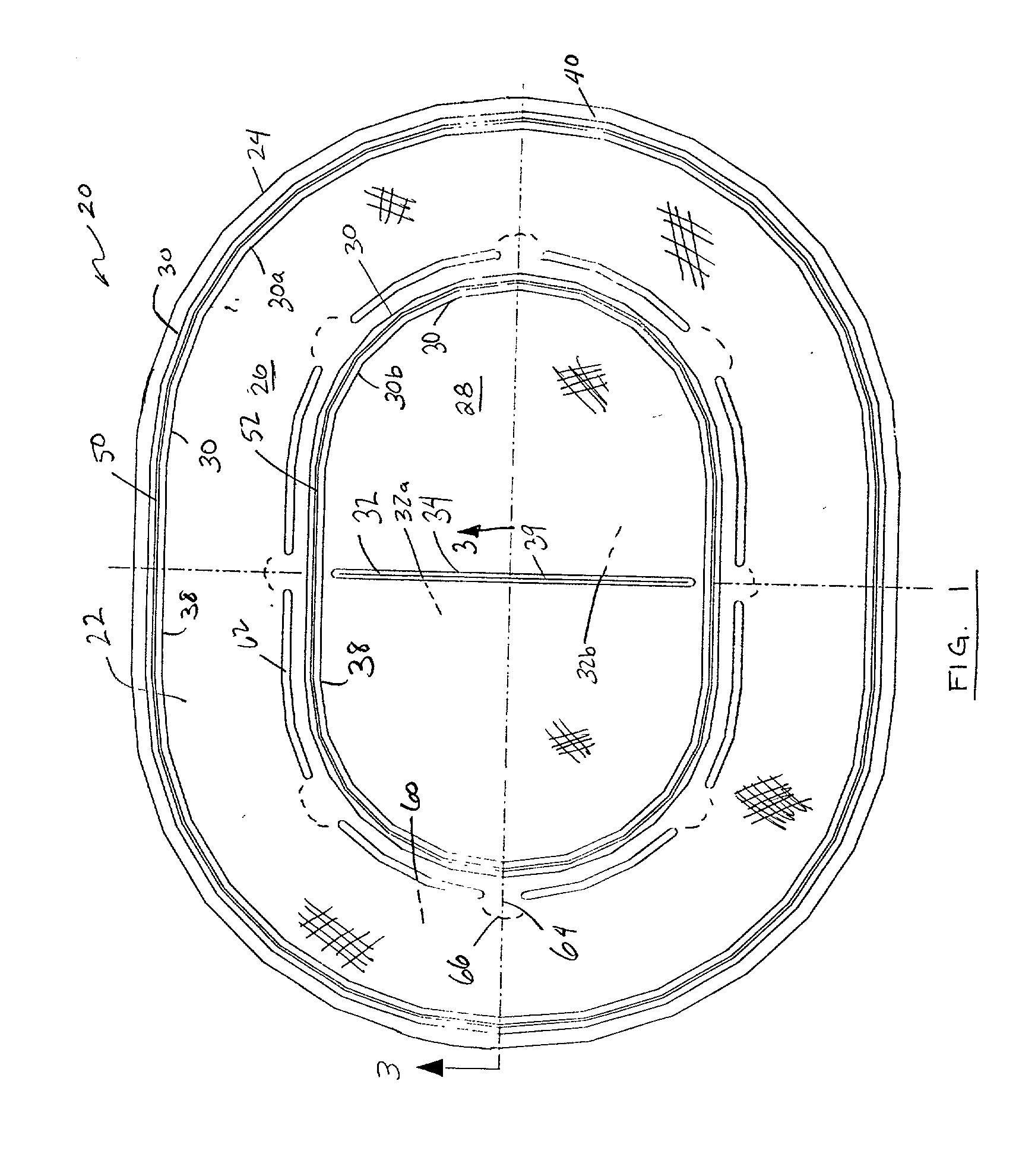

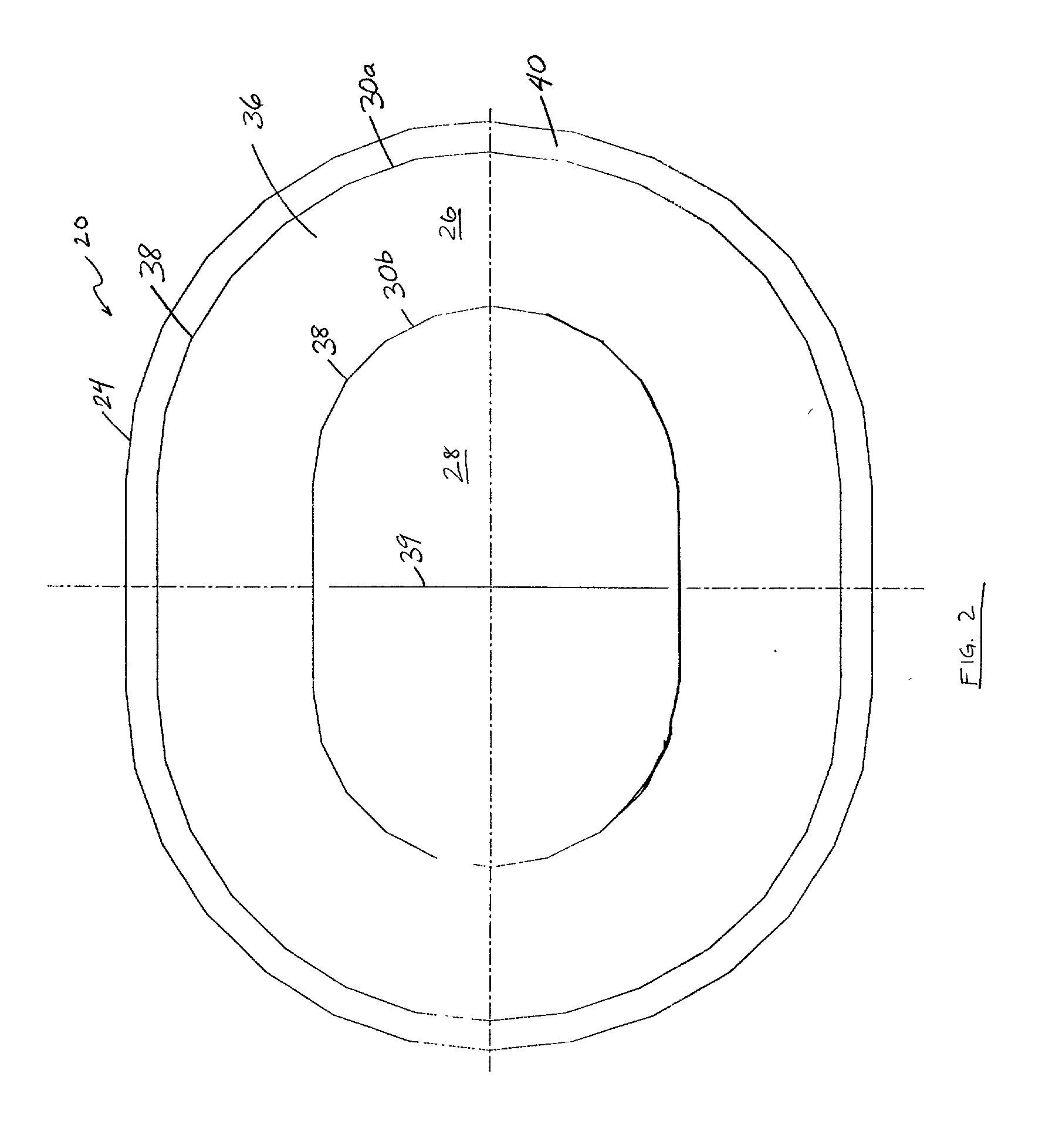

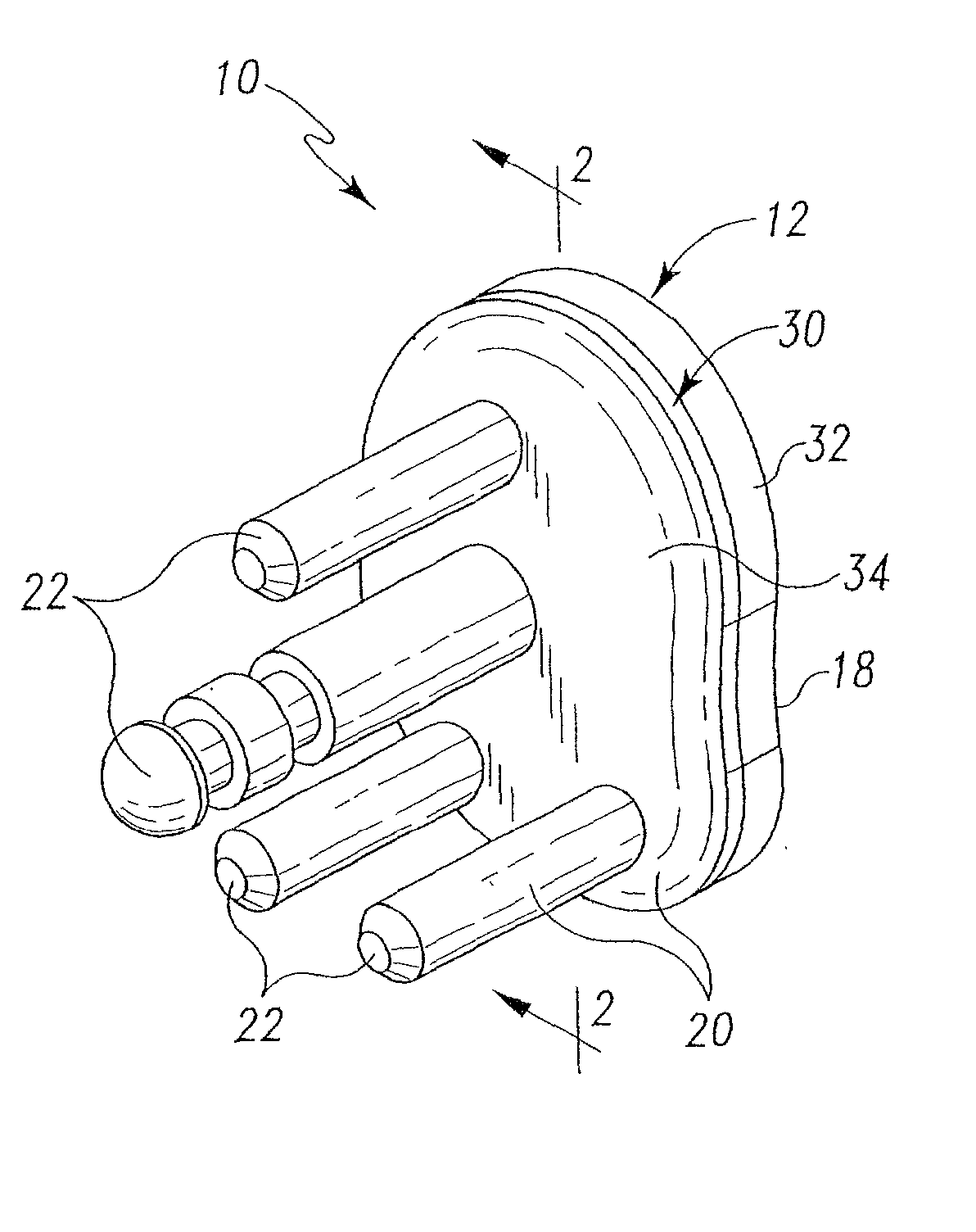

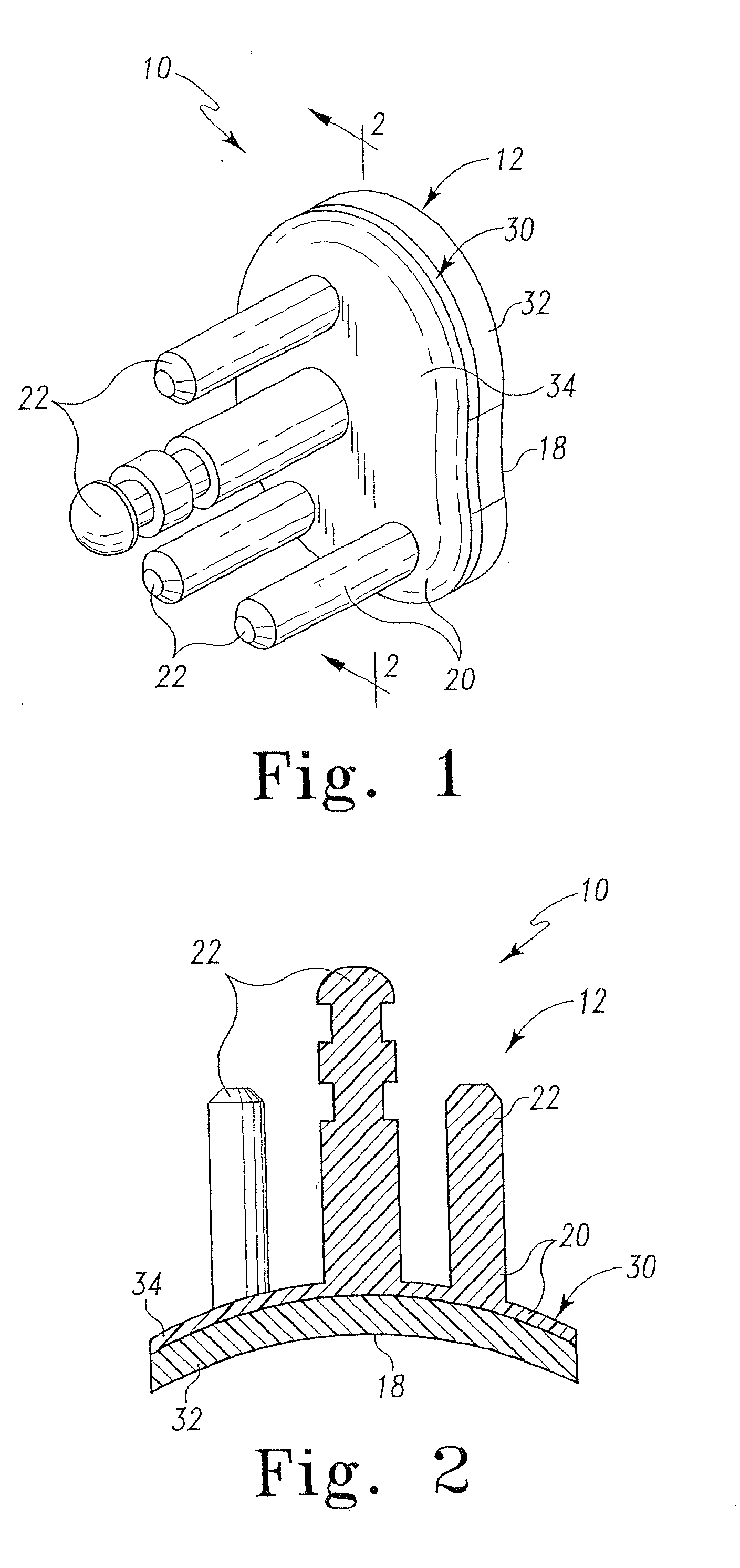

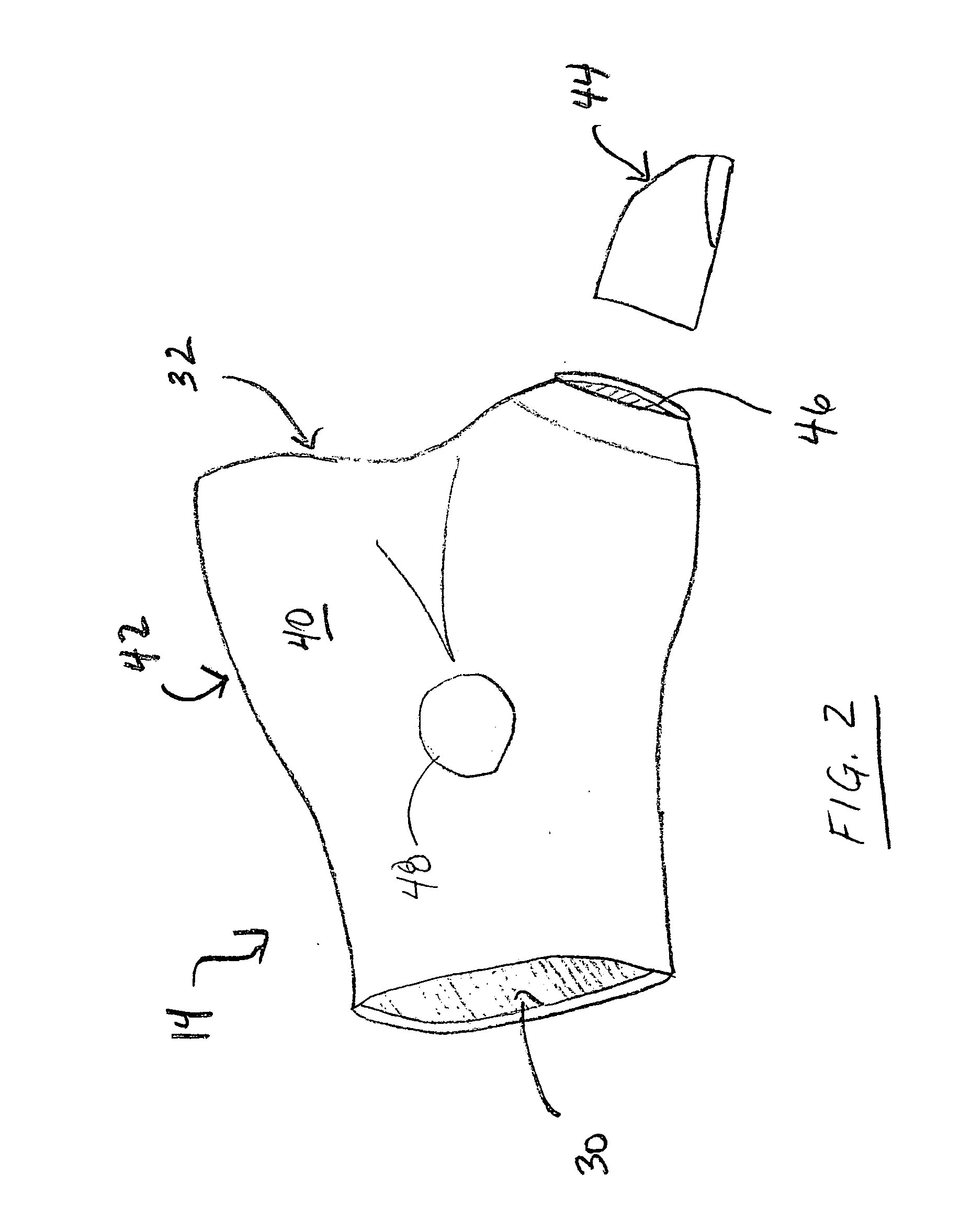

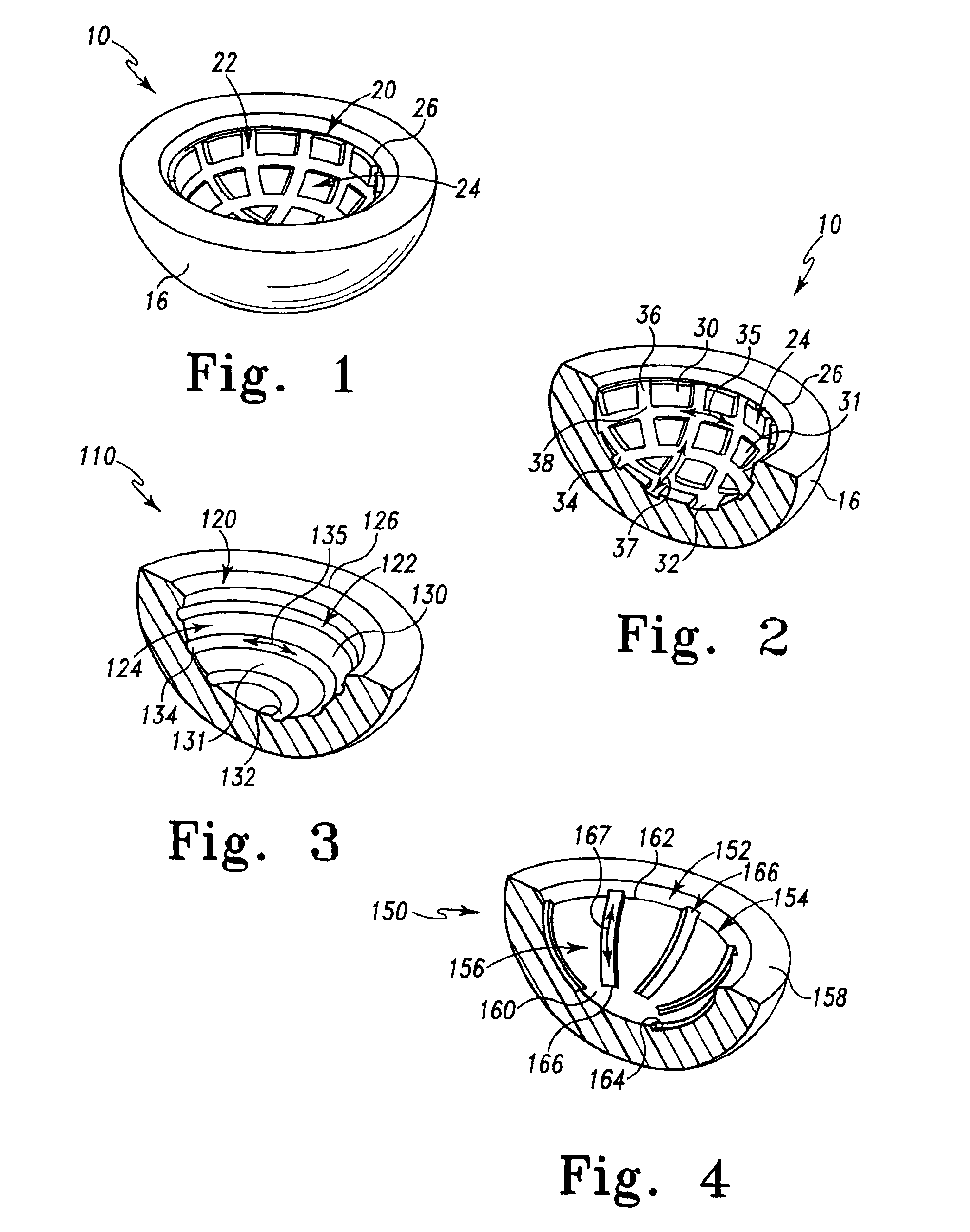

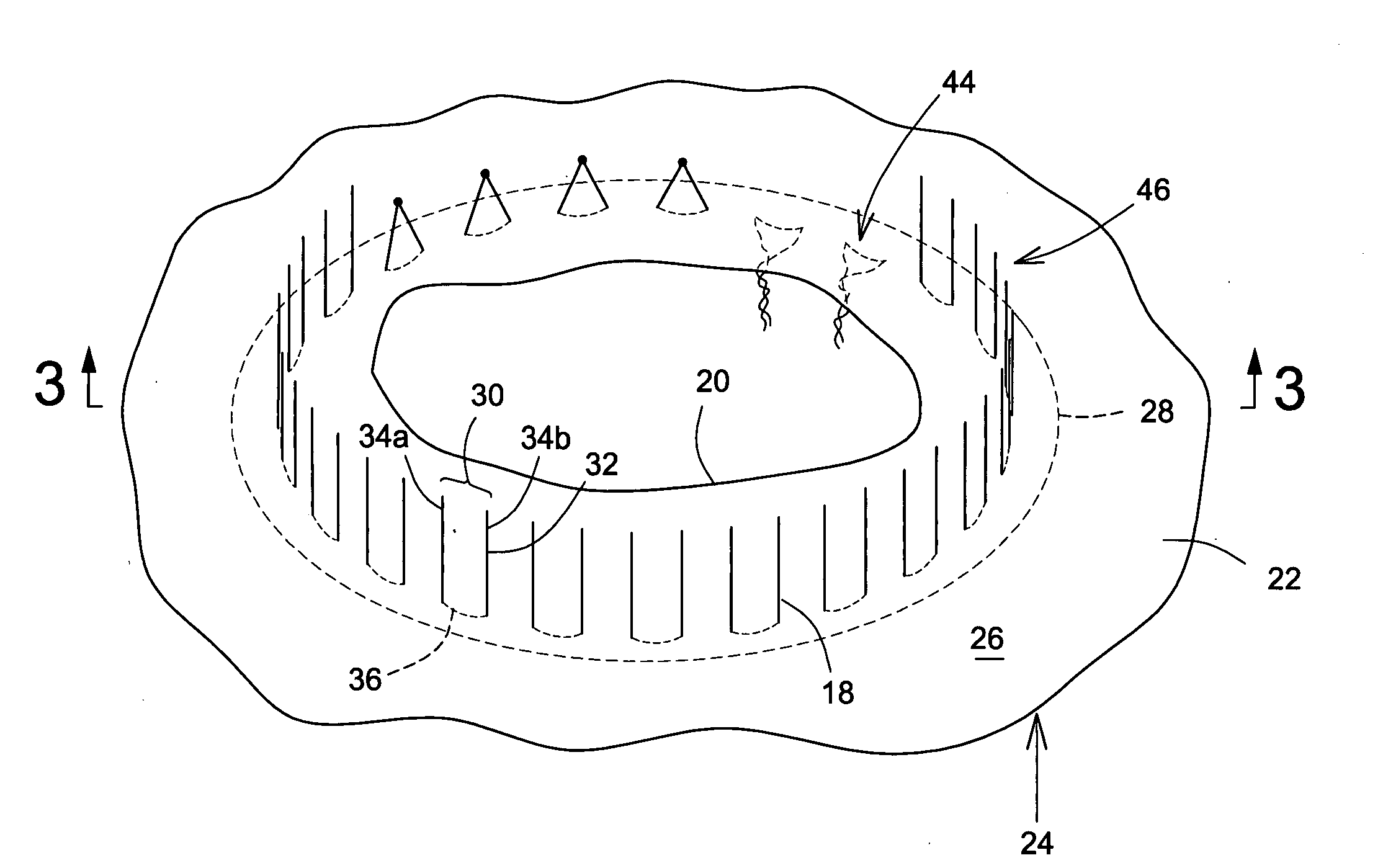

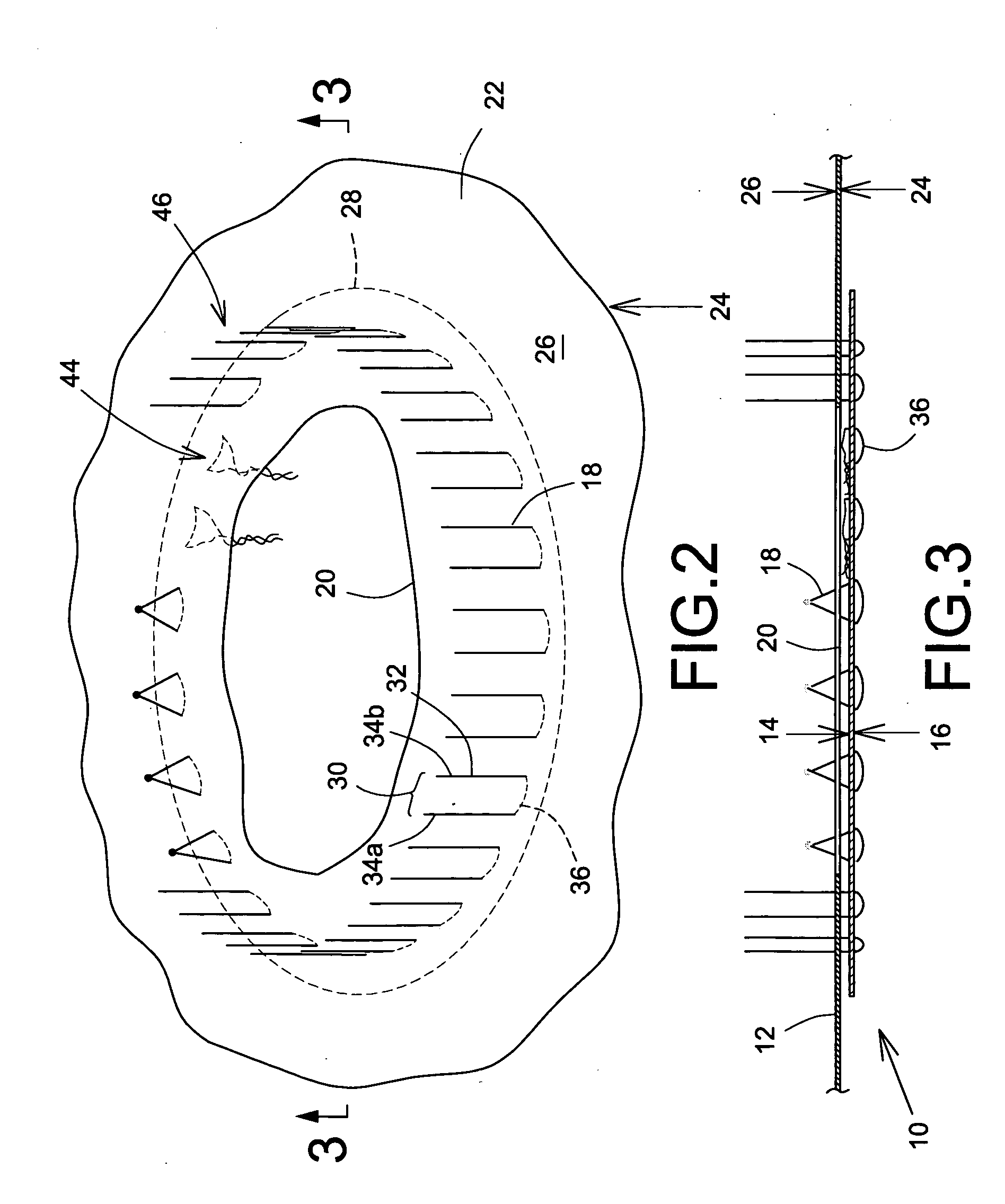

Implantable prosthesis

ActiveUS20040087980A1Avoid it happening againHelp positioningLigamentsMusclesProcedure LocationWeakness

An implantable prosthesis for repairing an anatomical defect, such as a tissue or muscle wall hernia, including an umbilical hernia, and for preventing the occurrence of a hernia at a small opening or weakness in a tissue or muscle wall, such as at a puncture tract opening remaining after completion of a laparoscopic procedure. The prosthesis includes a patch and / or plug having a body portion that is larger than a portion of the opening or weakness so that placement of the body portion against the defect will cover or extend across that portion of the opening or weakness. At least one tether, such as a strap, extends from the patch or plug and may be manipulated by a surgeon to position the patch or plug relative to the repair site and / or to secure the patch or plug relative to the opening or weakness in the tissue or muscle wall. The tether may be configured to extend through the defect and outside a patient's body to allow a surgeon to position and / or manipulate the patch from a location outside the body. An indicator may be provided on the tether as an aid for a surgeon in determining when the patch or plug has been inserted a sufficient distance within the patient. A support member may be arranged in or on the patch or plug to help deploy the patch or plug at the surgical site and / or help inhibit collapse or buckling of the patch or plug. The patch or plug may be configured with a pocket or cavity to facilitate the deployment and / or positioning of the patch or plug over the opening or weakness.

Owner:DAVOL

Implantable prosthesis

An implantable prosthesis for an anatomical defect, such as a tissue or muscle defect, that promotes tissue or muscle growth into the prosthesis and subsequently strengthens the area of the defect. At least one pocket and preferably two concentric pockets may be provided to aid with manipulating the prosthesis. Where two pockets are used, a barrier or partition exists between the pockets and the outer pocket allows manipulation of the outer periphery. The incidence of postoperative adhesions between a portion of the prosthesis and tissue, muscle or organs may be minimized with the use of a barrier layer. Reinforcing members may be attached to portions of the prosthesis to aid in positioning and deployment in the area of desired coverage without rendering the prosthesis unduly difficult to implant or uncomfortable for the patient. Typically, two concentric members are employed. Further, the prosthesis is constructed to allow it to be provisionally held in place at desired locations by openings in the pockets that allow access for a stapler or sewing device.

Owner:DAVOL

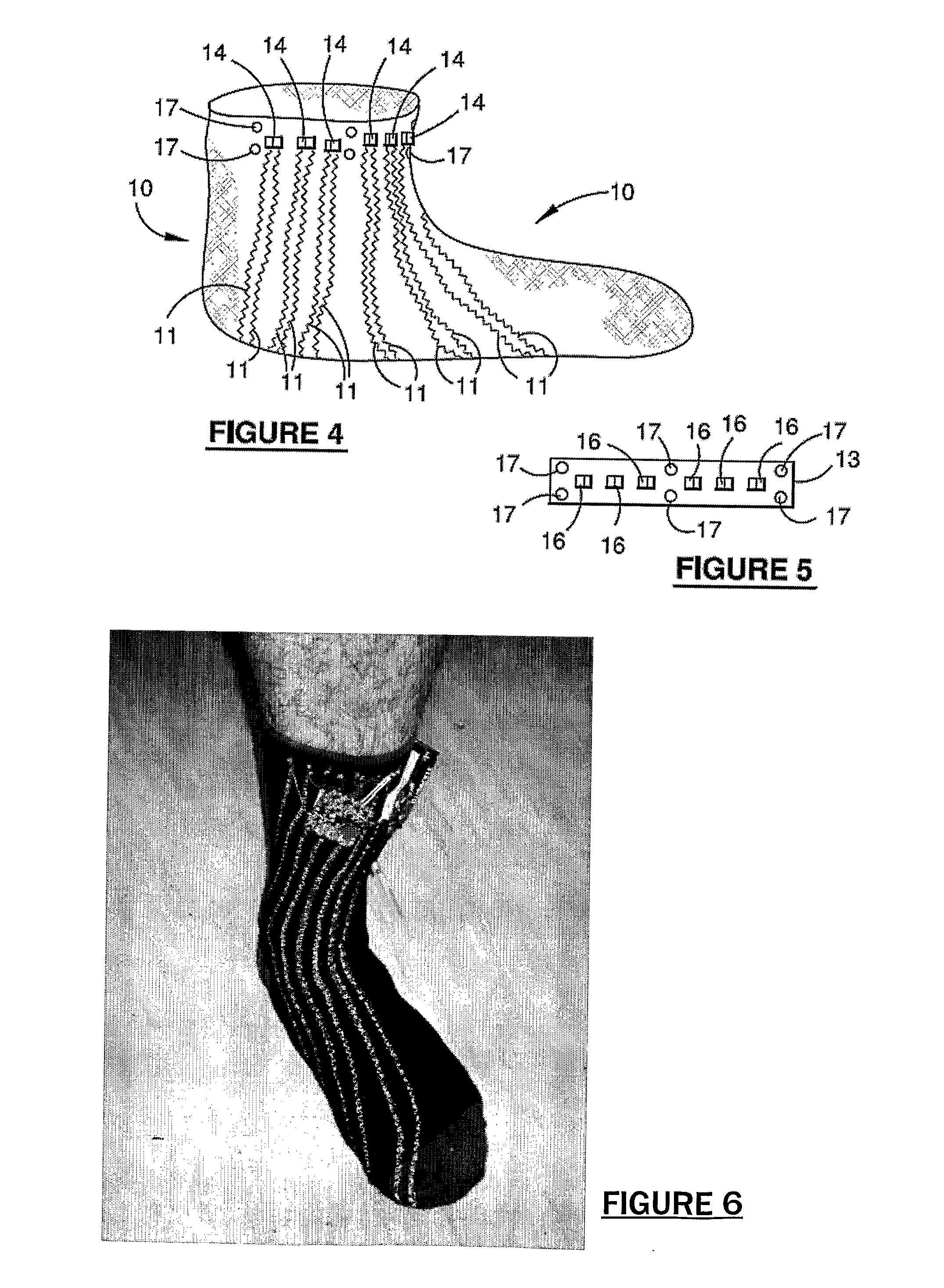

System, garment and method

ActiveUS20110015498A1Level of customizationSame compressionPerson identificationSensorsButtocksExternal pressure

The present invention relates to a system and garment that incorporates sensors that can be used for measuring or monitoring pressure or forces in feet, the stumps of limbs of an amputee that are fitted with prosthetic devices, or any other parts of the body that are subject to forces such as the buttock while seated or when external pressure inducing devices are employed, such as for example, pressure bandages. The invention also relates to a method to monitor or diagnose any foot or limb related activity for recreational, sporting, military or medical reasons and is particularly aimed at the treatment of neuropathic or other degenerating conditions.

Owner:SENSORIA

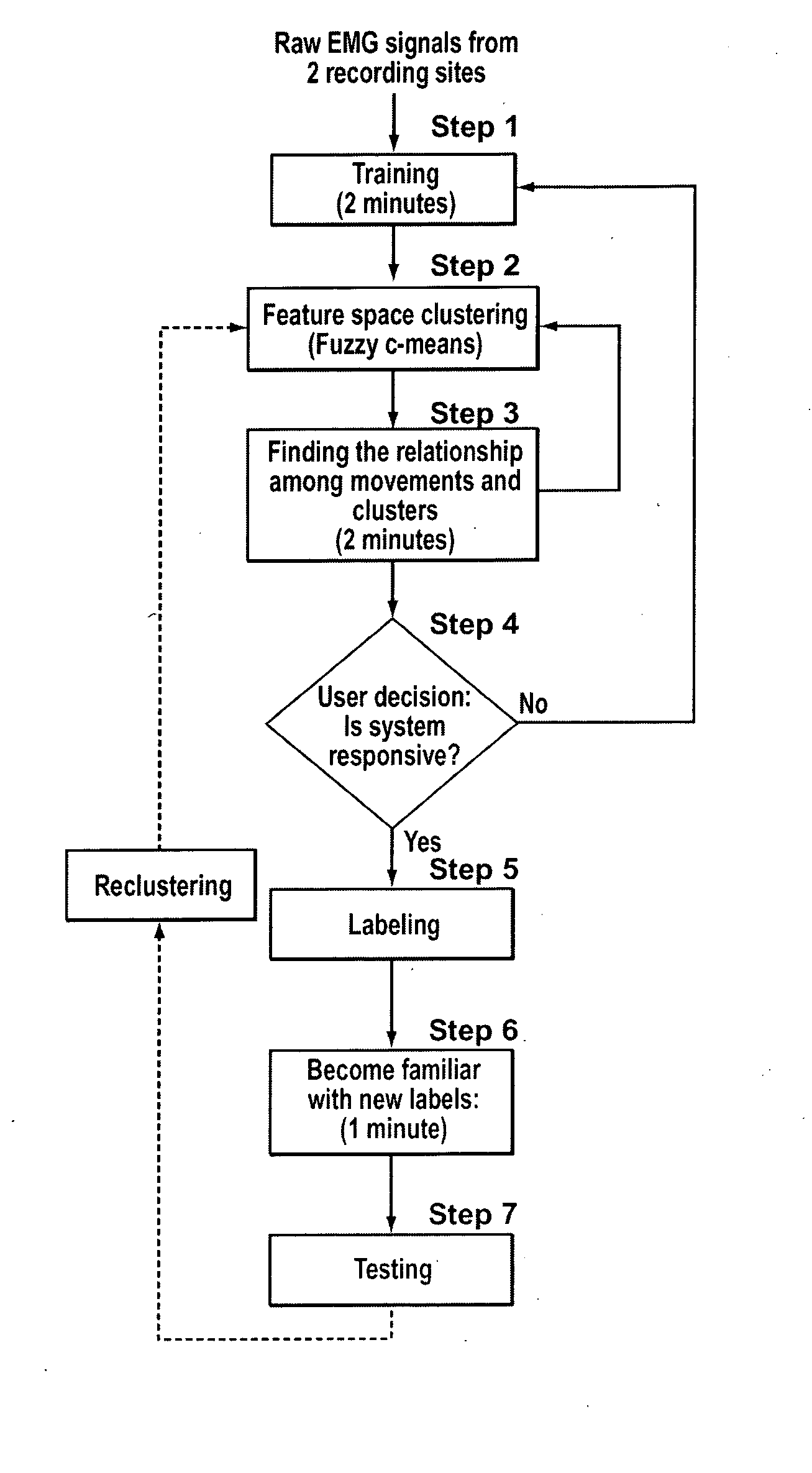

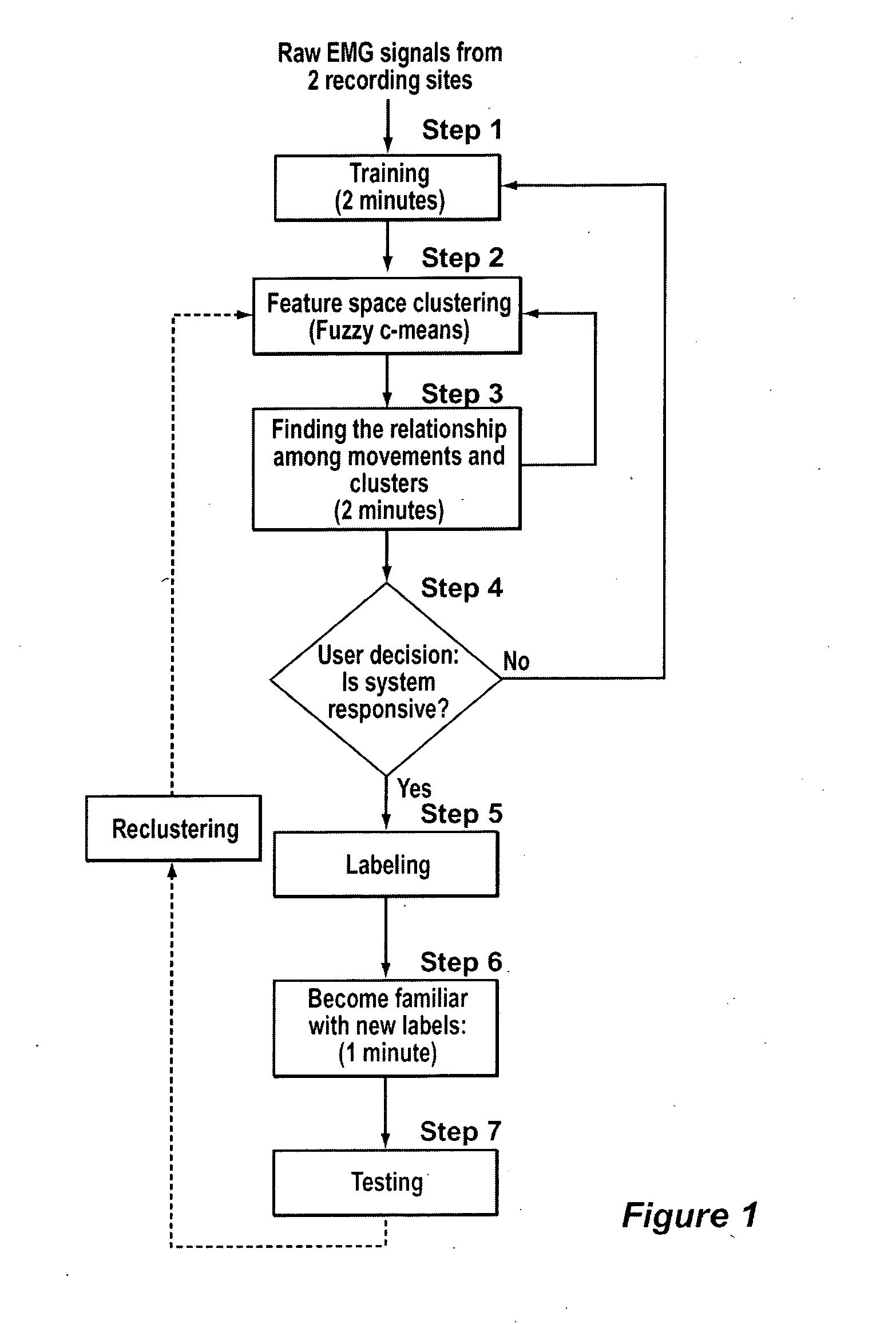

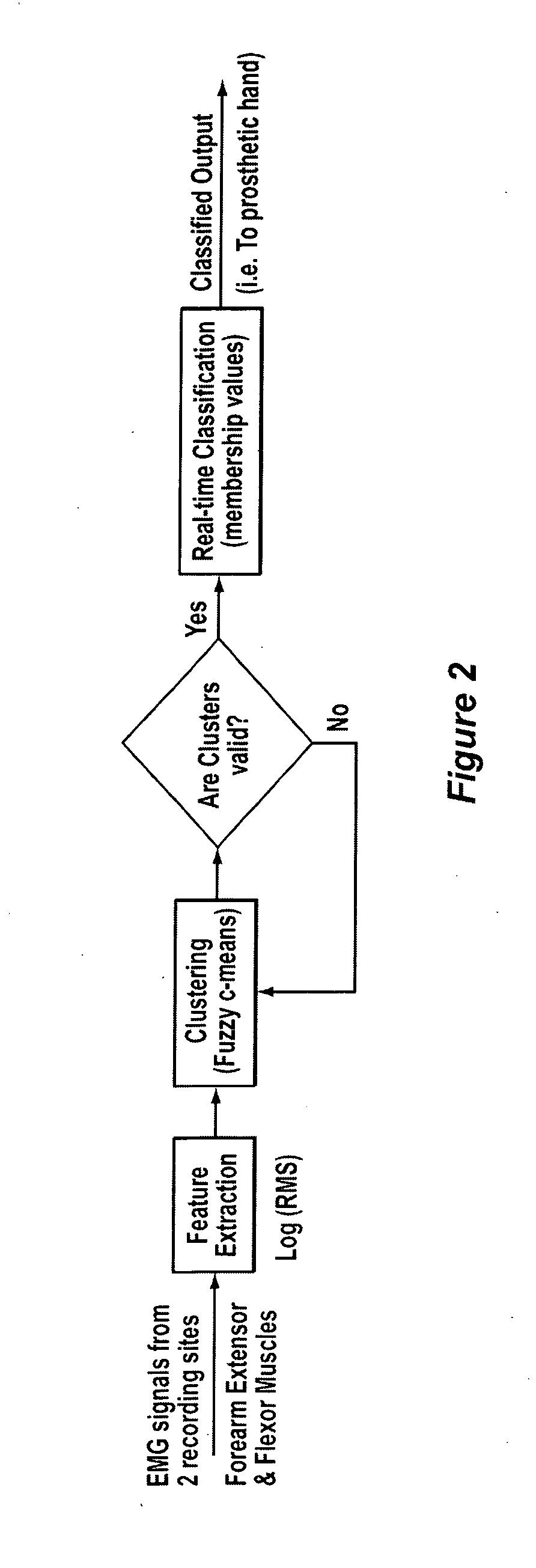

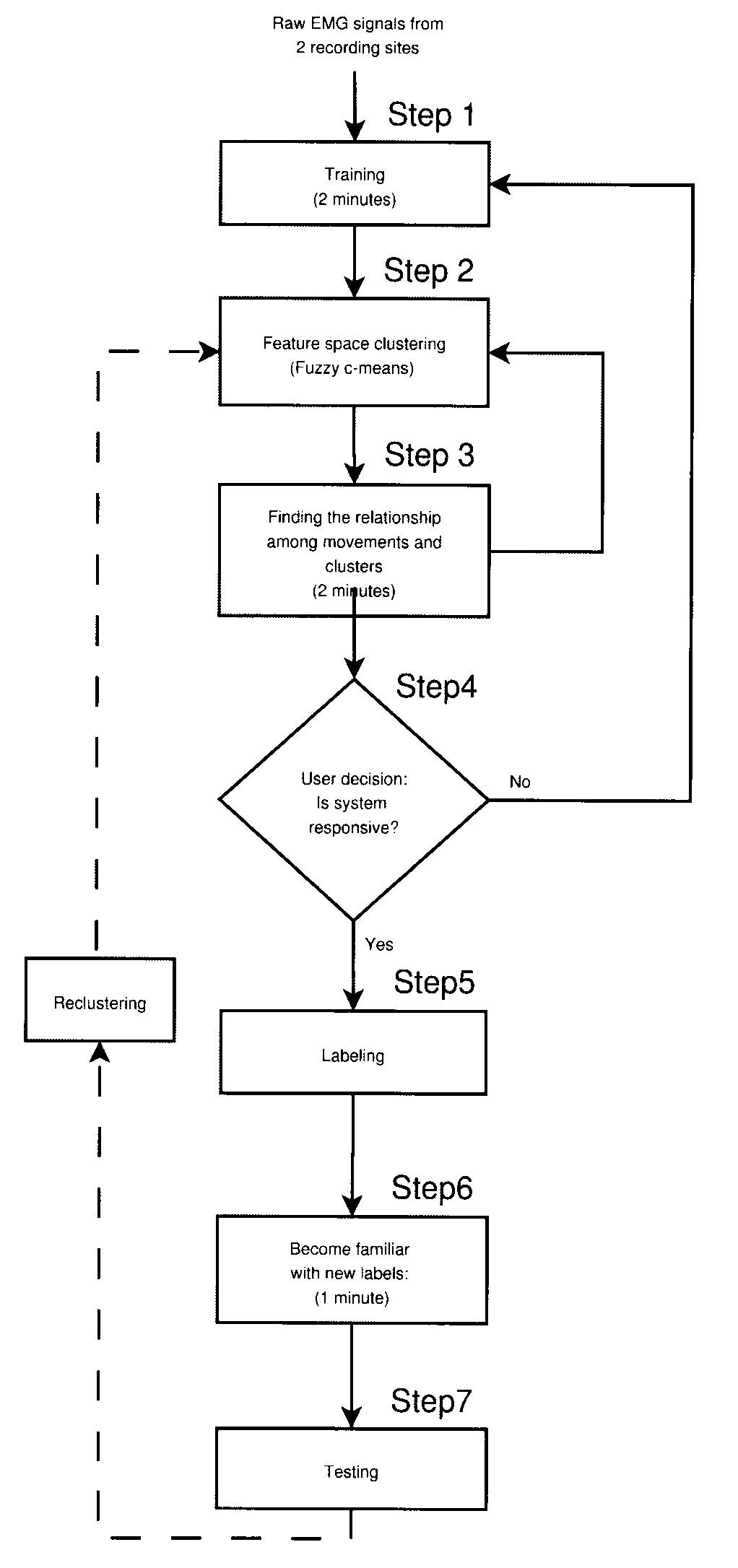

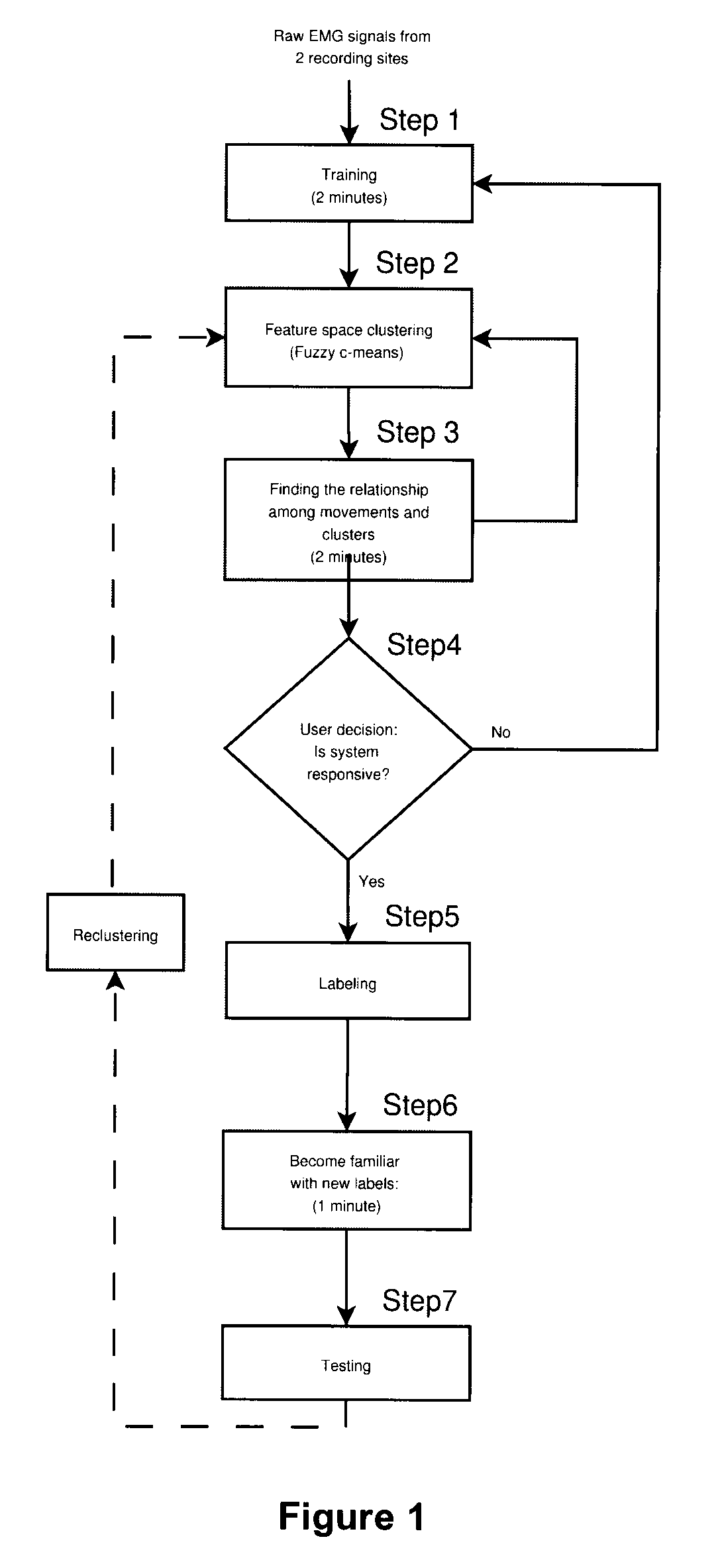

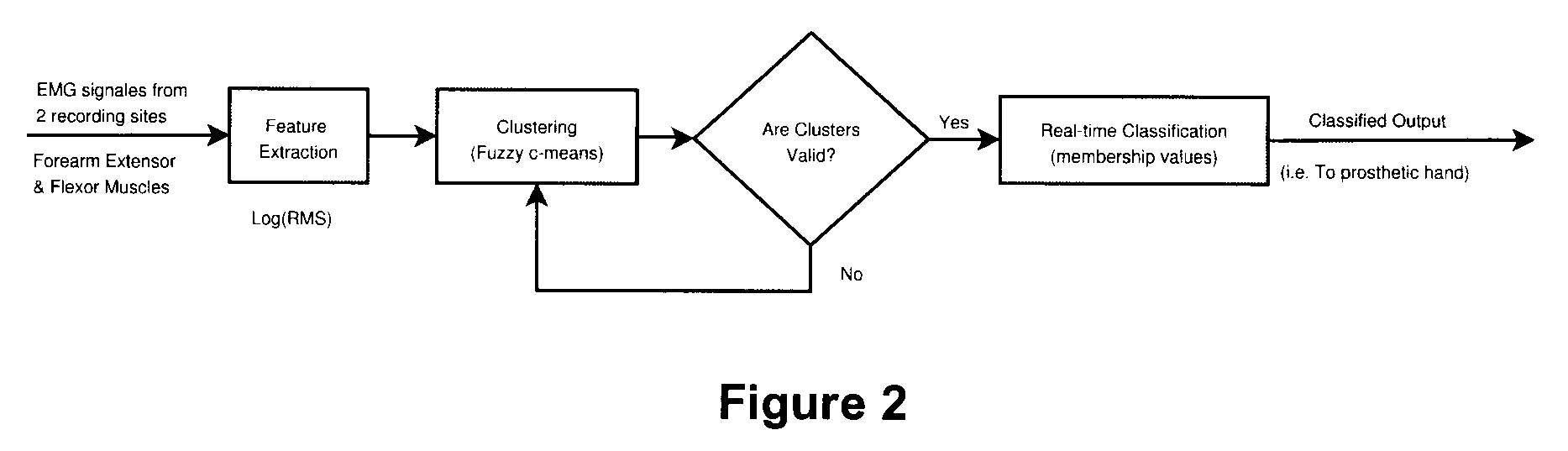

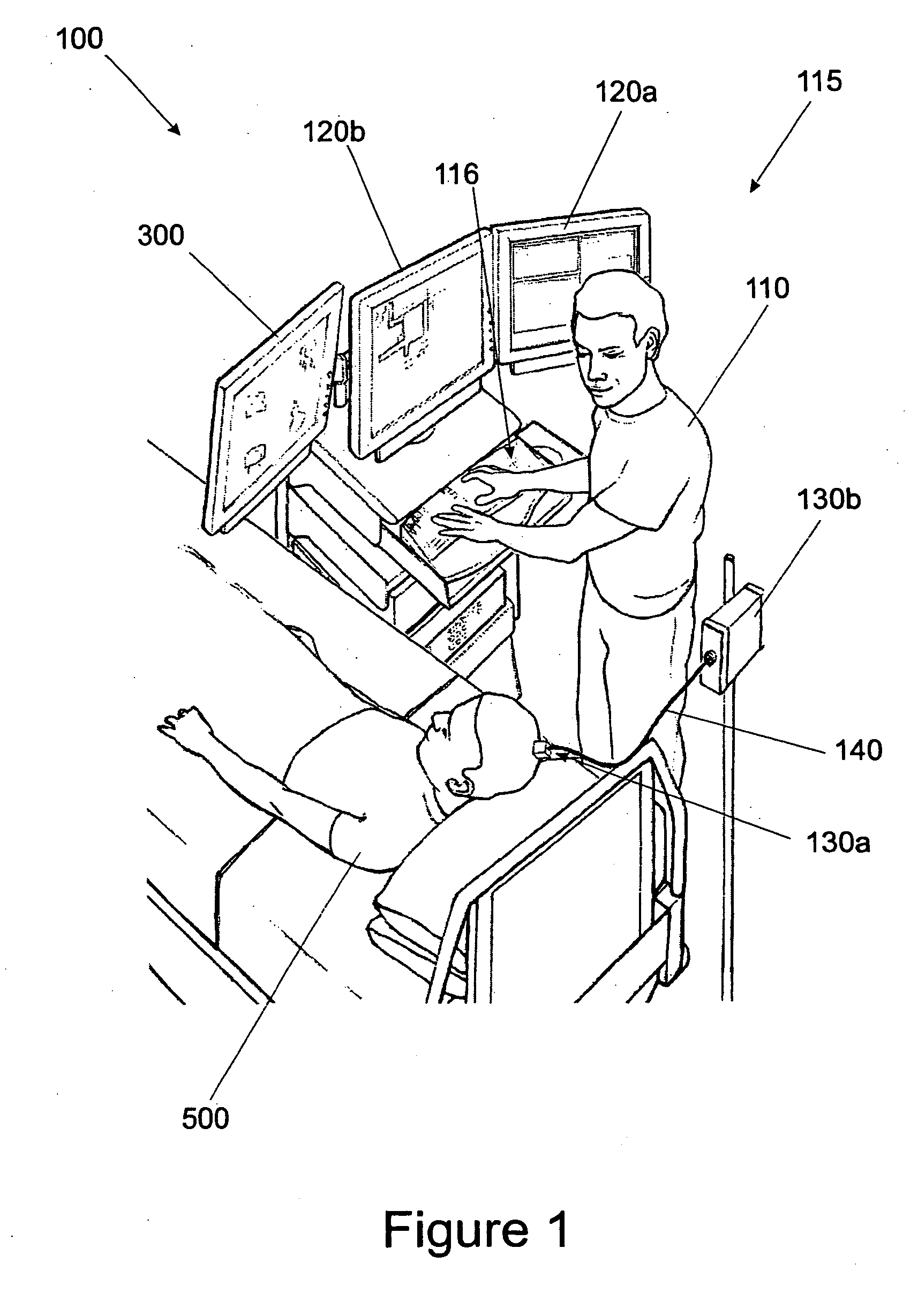

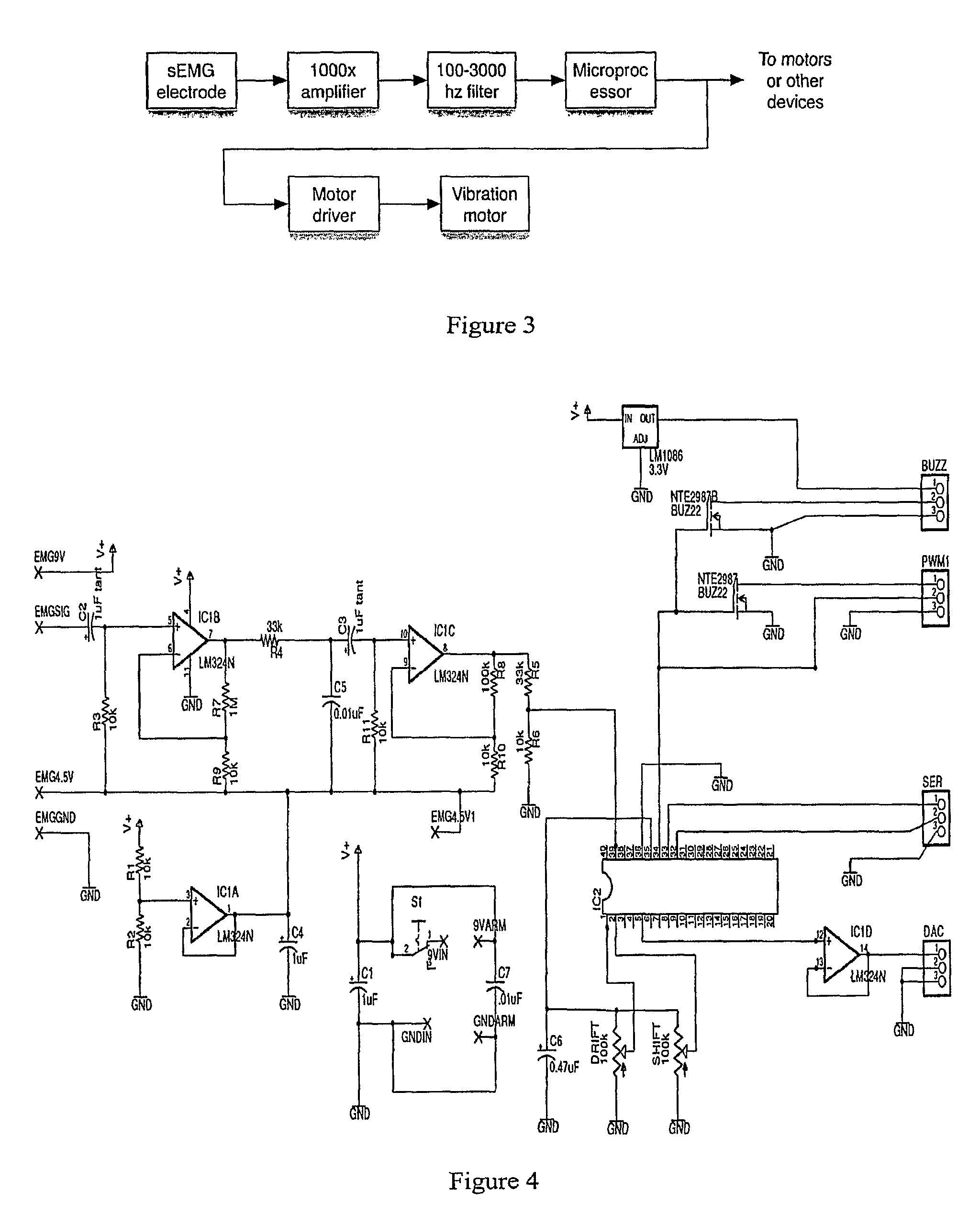

Method, system and apparatus for real-time classification of muscle signals from self-selected intentional movements

InactiveUS20080058668A1Improve abilitiesEasy to operateMedical data miningElectromyographyMuscle contractionSelf training

A new method, system and apparatus is provided that enables muscle signals that correspond to muscle contractions to be mapped to one or more functions of an electronic device such as a prosthetic device or gaming apparatus. Muscle signals are classified in real-time from self-selected intentional movements. A self-training protocol allows users to select and label their own muscle contractions, and is operable to automatically determine the discernible and repeatable muscle signals generated by the user. A visual display means is used to provide visual feedback to users illustrating the responsiveness of the system to muscle signals generated by the user.

Owner:HOLLAND BLOORVIEW KIDS REHABILITATION HOSPITAL

Control device and system for controlling an actuated prosthesis

A method and a control system are used for determining a portion of locomotion and a phase of locomotion portion in view of controlling an actuated prosthesis in real time. The method comprises receiving a data signal from a plurality of main artificial proprioceptors, obtaining a first and a second derivative signal for each data signal, obtaining a third derivative signal for at least one of the data signals, using a set of first state machines to select one state among a plurality of possible states for each artificial proprioceptor with the corresponding data and derivative signals, generating the phase of locomotion portion using the states of the main artificial proprioceptors; and using a second state machine to select the portion of locomotion among a plurality of possible portions of locomotion using events associated to the data signals. It is particularly well adapted for an actuated, above-knee leg prosthesis.

Owner:NATIONAL BANK OF CANADA

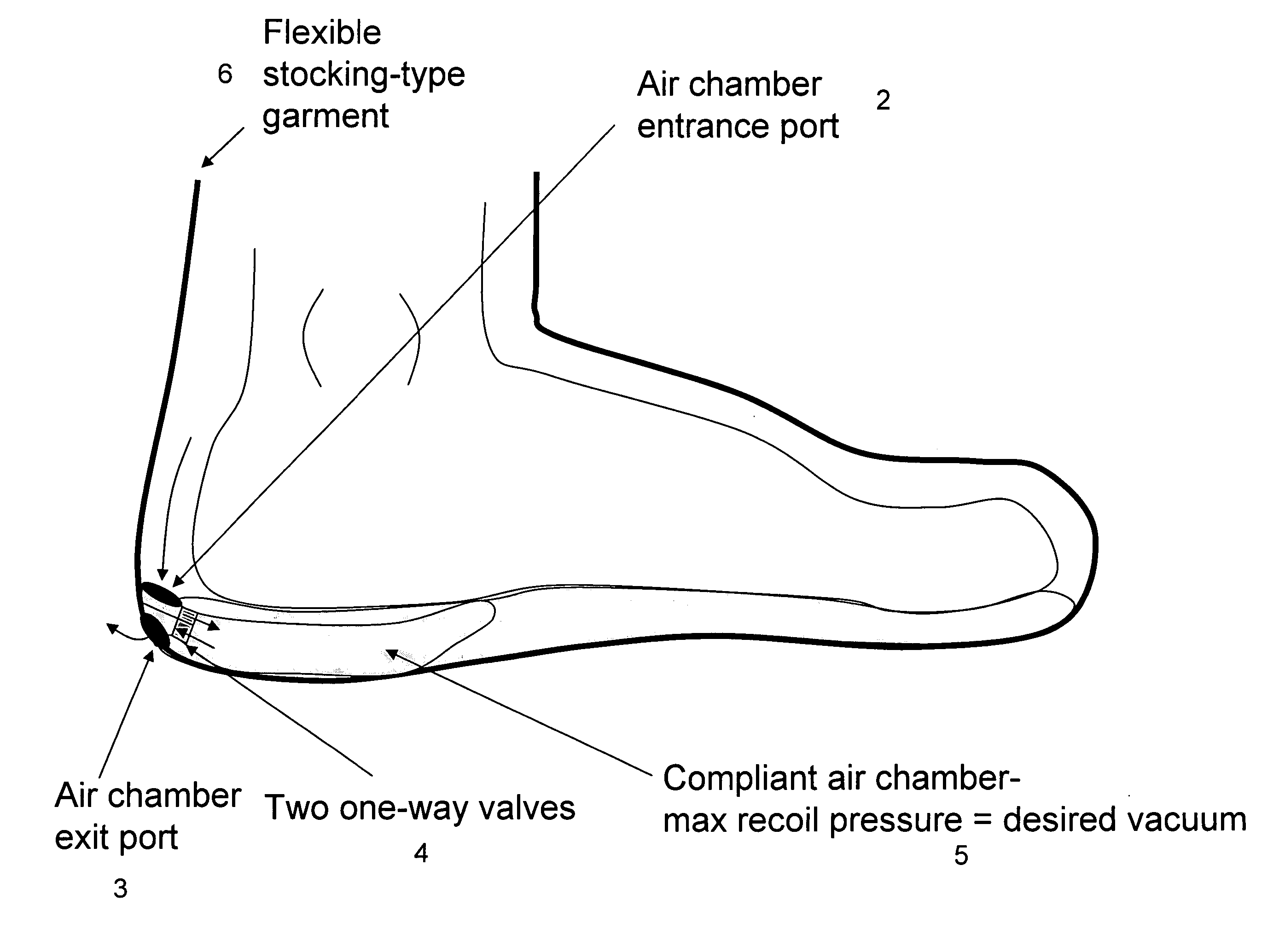

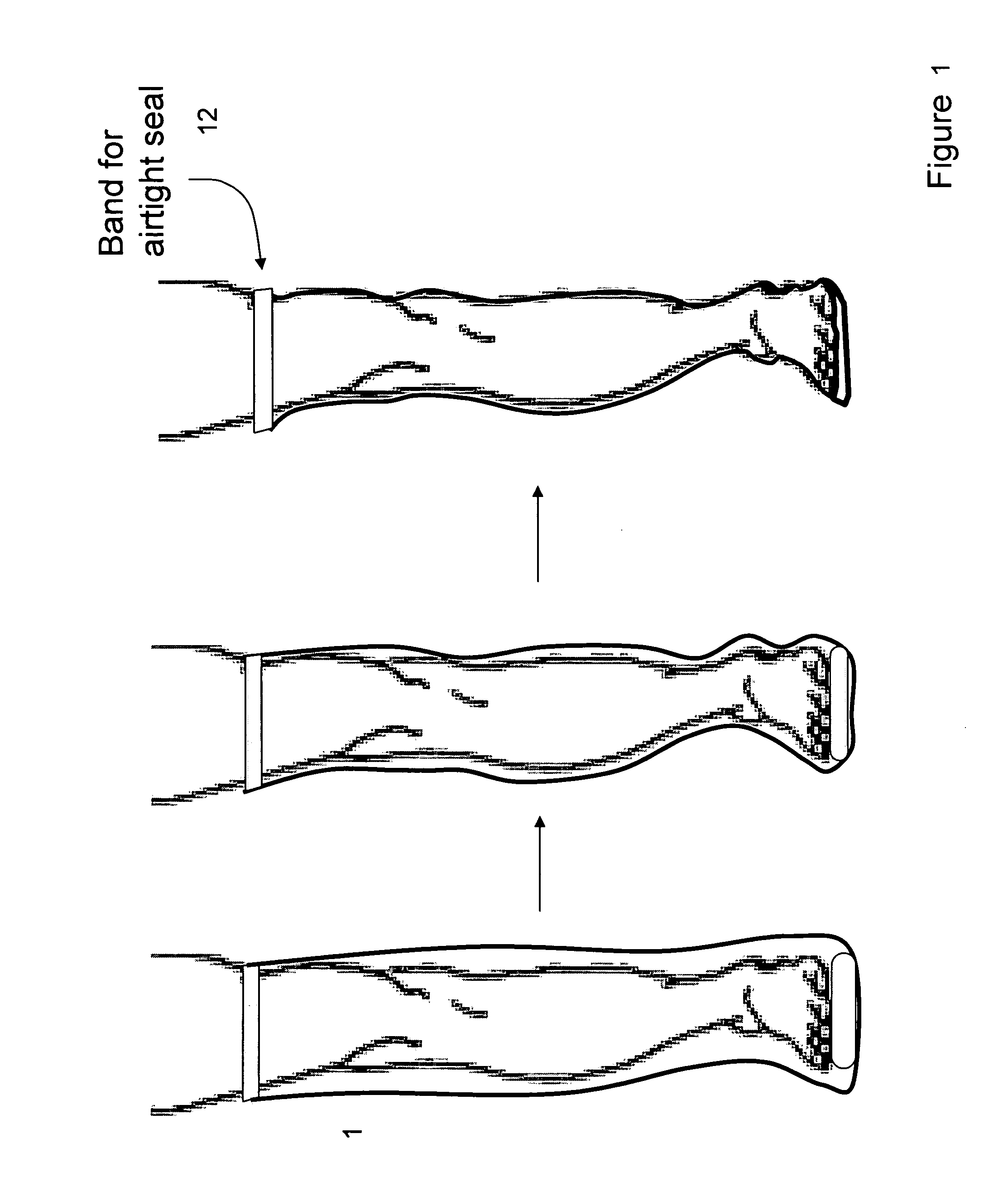

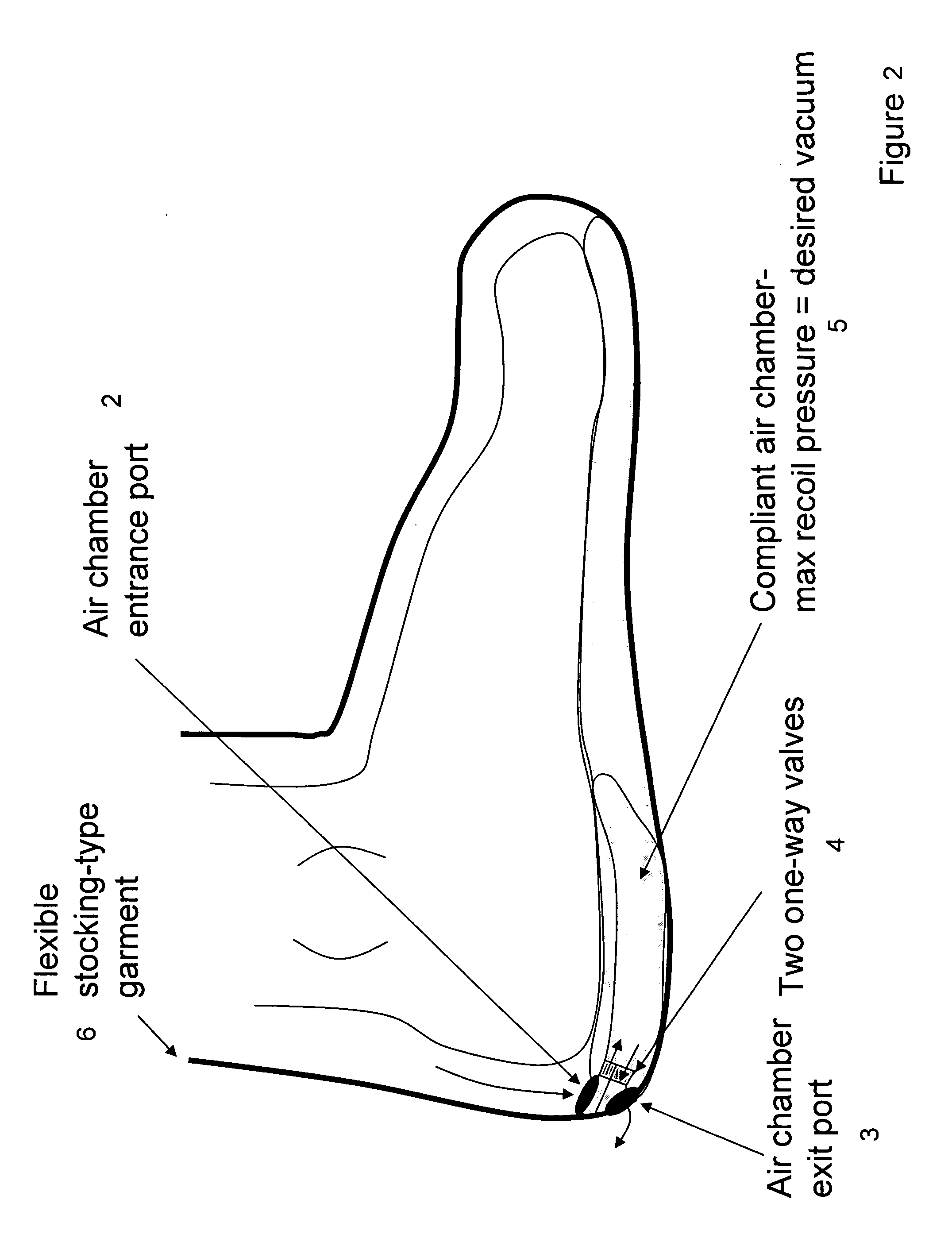

Method and apparatus for negative pressure therapy

InactiveUS20070167884A1Cost reductionRequirement be decreaseBlood stagnation preventionPneumatic massageEdemaVenous thromboembolic disease

Devices that employ external compression stocking-type garments in the treatment of edema, chronic wounds, deep venous thrombosis prevention or claudication all share a number of significant limitations. These include the frequent need for custom fitting to assure an appropriate fit, vigilant maintenance to assure a continued “good fit,” limited compliance with proper use by patients and difficulty of application. There is a large body of evidence demonstrating that patients often decline to wear the compressive stockings as prescribed or in the form that would be most beneficial because they find these devices to be difficult to put on and take off. Building on the limitations of existing therapies, and distilled lessons learned from the field of prosthetics and wound healing, the present invention employs vacuum-assisted negative pressure to provide compression and help pump fluid from the tissues of affected limbs. The device is embodied in the form of a flexible stocking-like garment that will utilize a pumping mechanism to generate negative pressure around the limb and thus create vacuum compression that will mobilize fluid in a limb and increase venous return to the heart. Through the use of a circumferential wrap, the present invention provides a major advance in both the distribution of vacuum and the securing of the device over the limb.

Owner:THERANOVA LLC

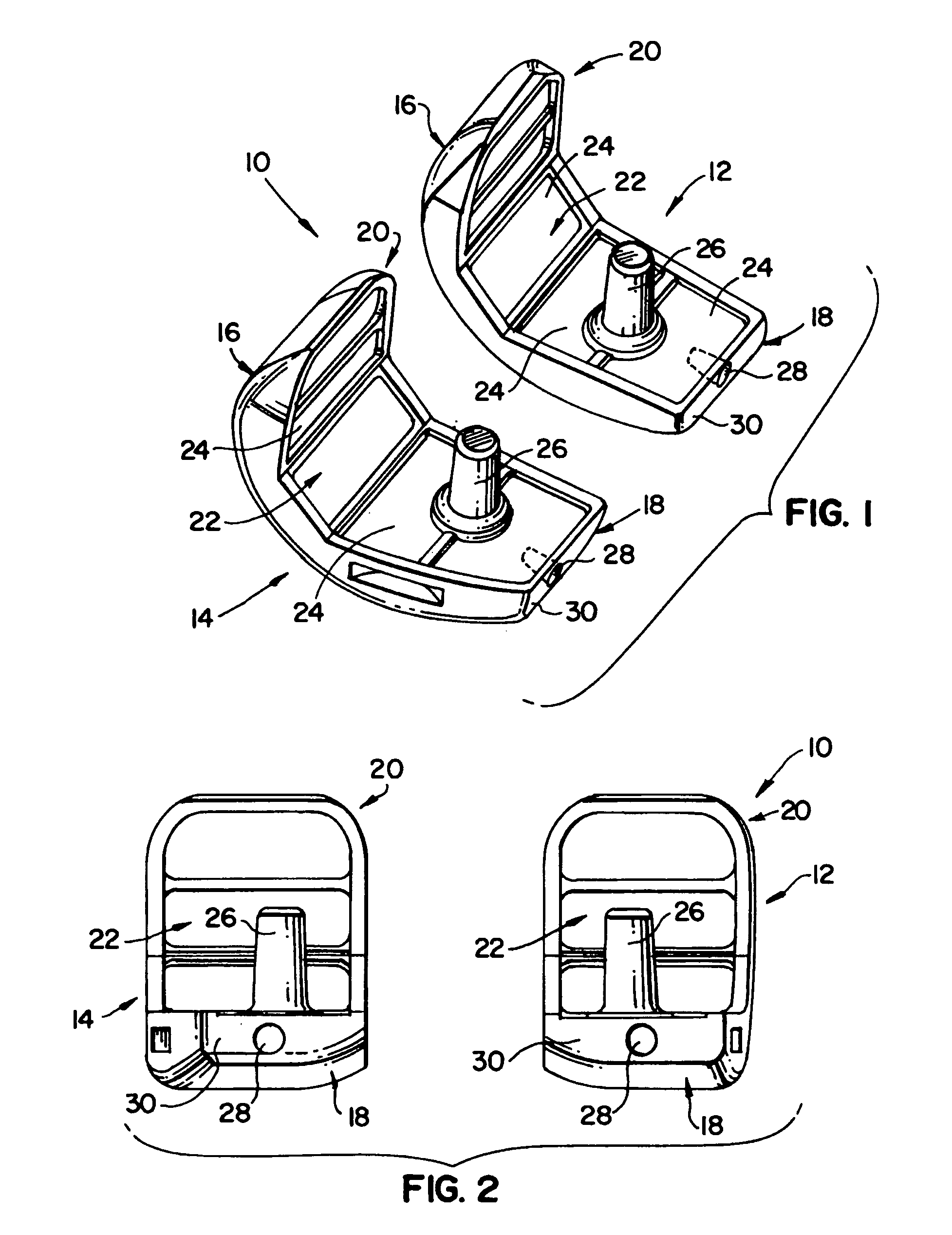

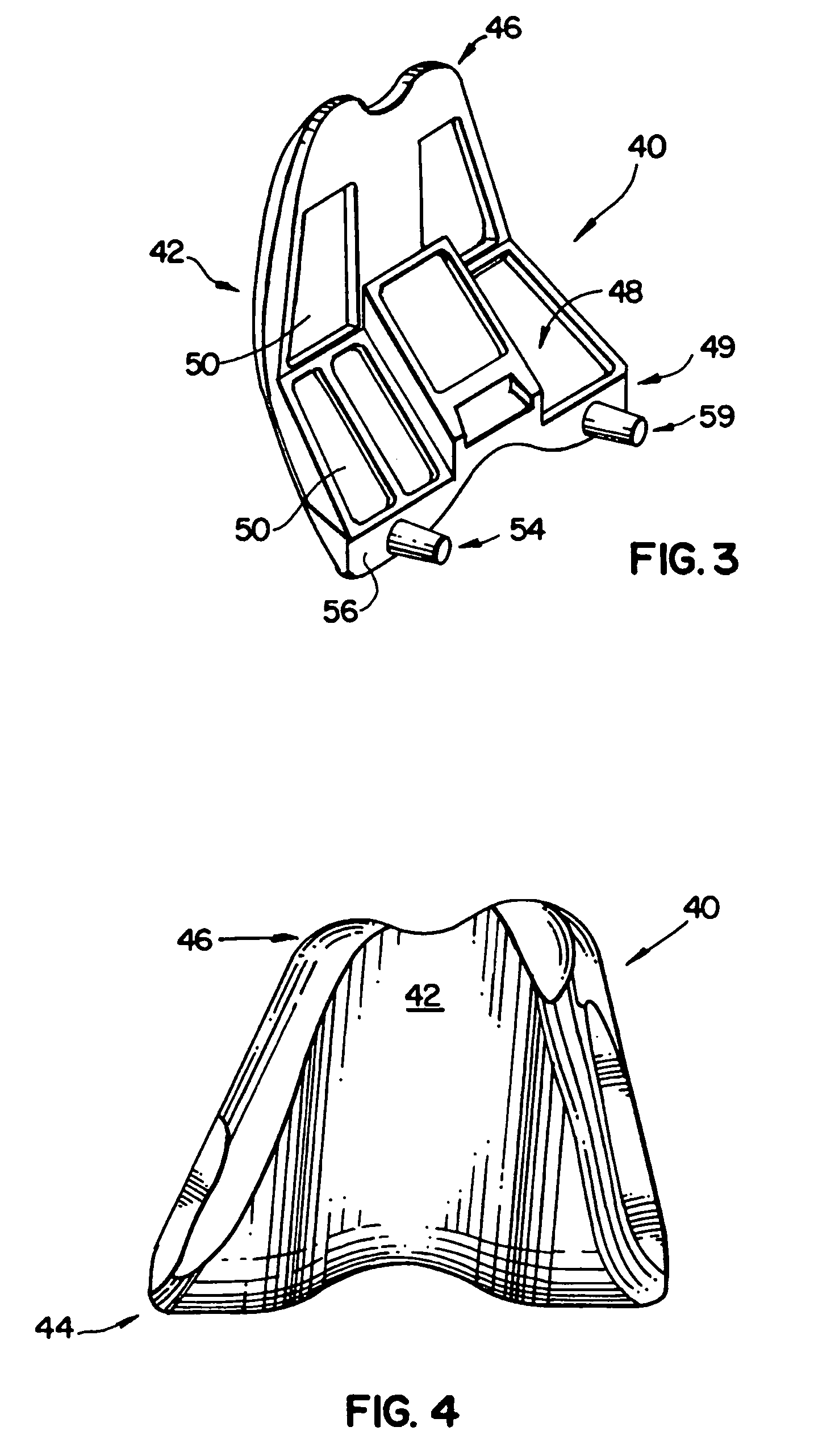

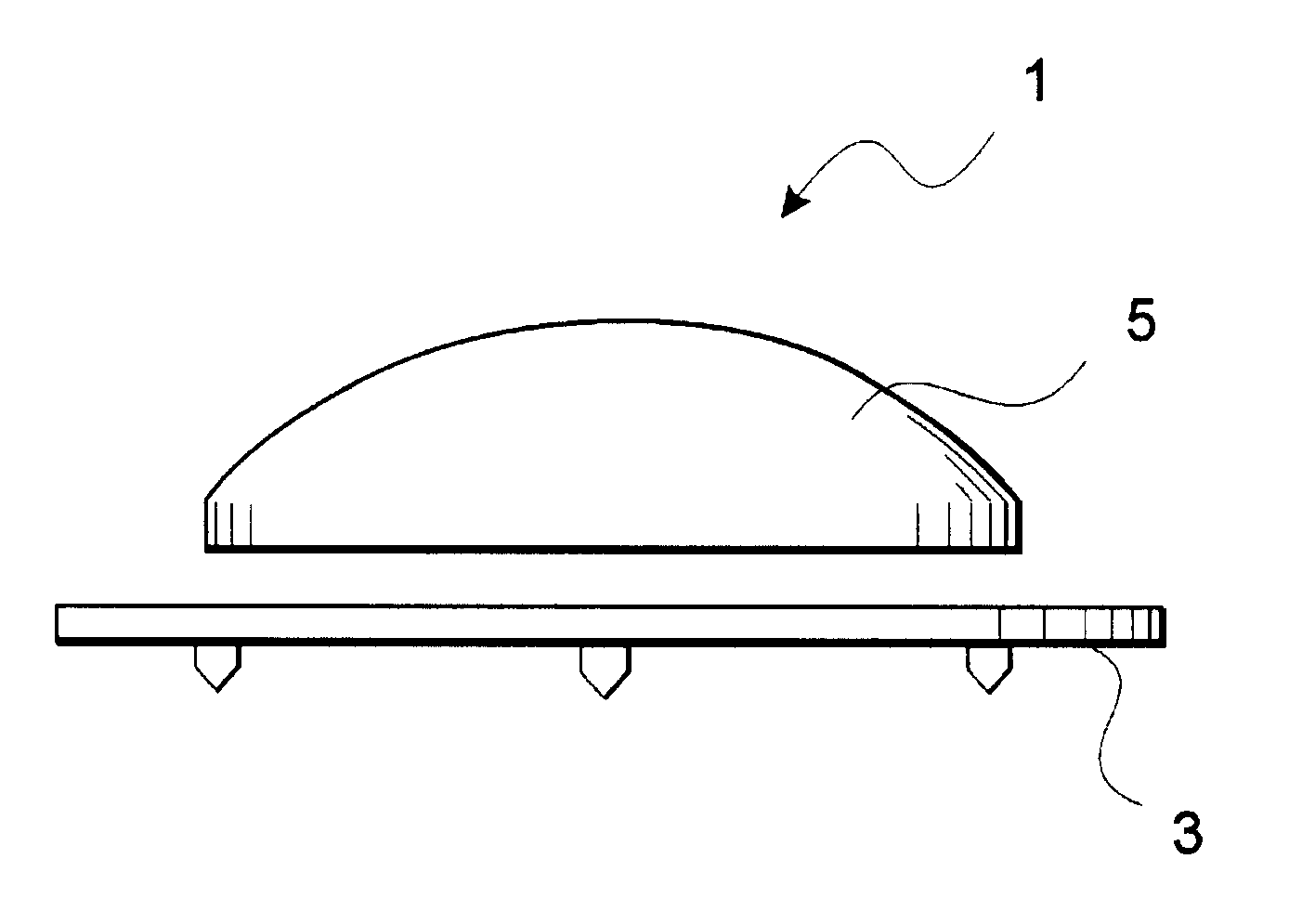

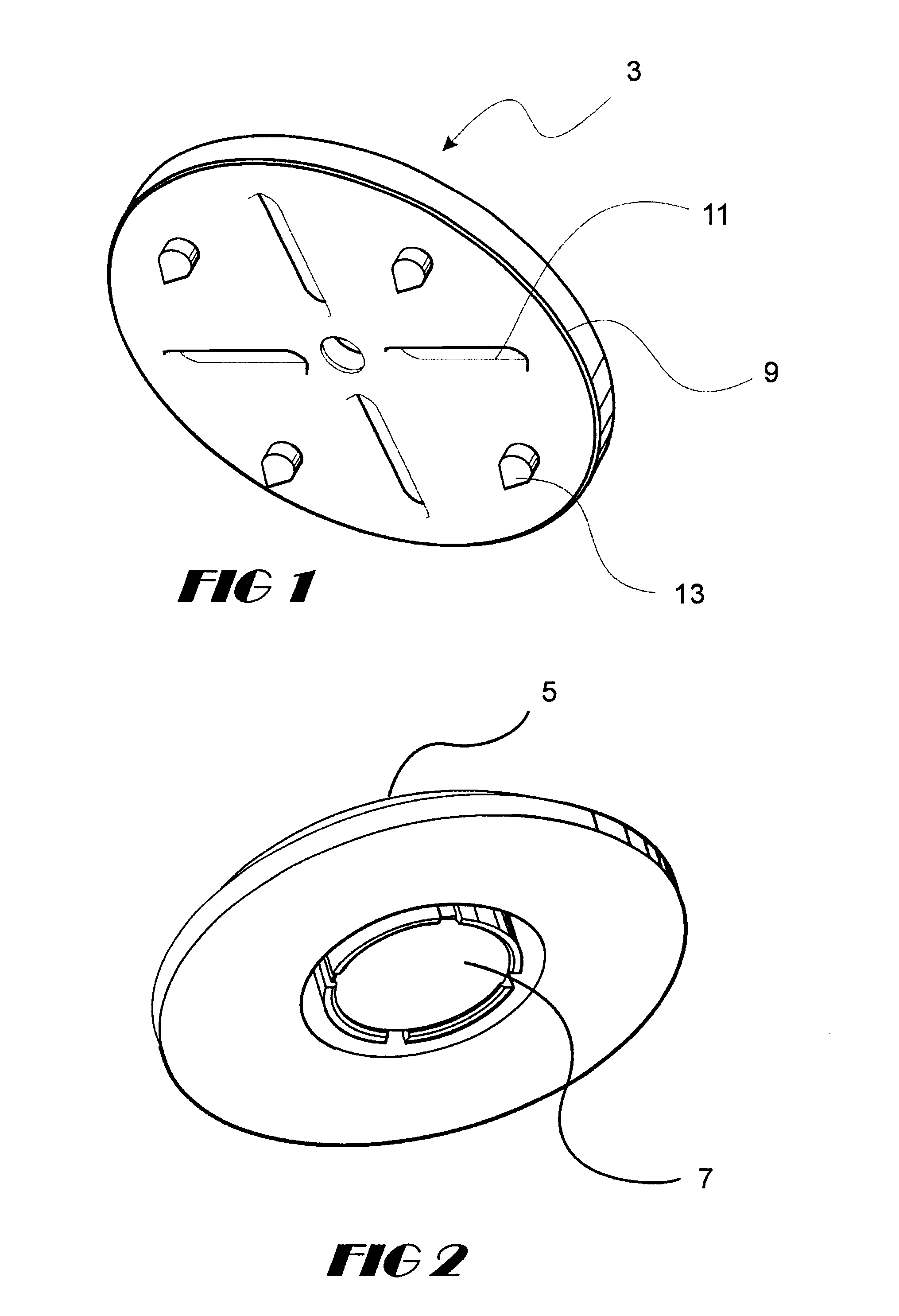

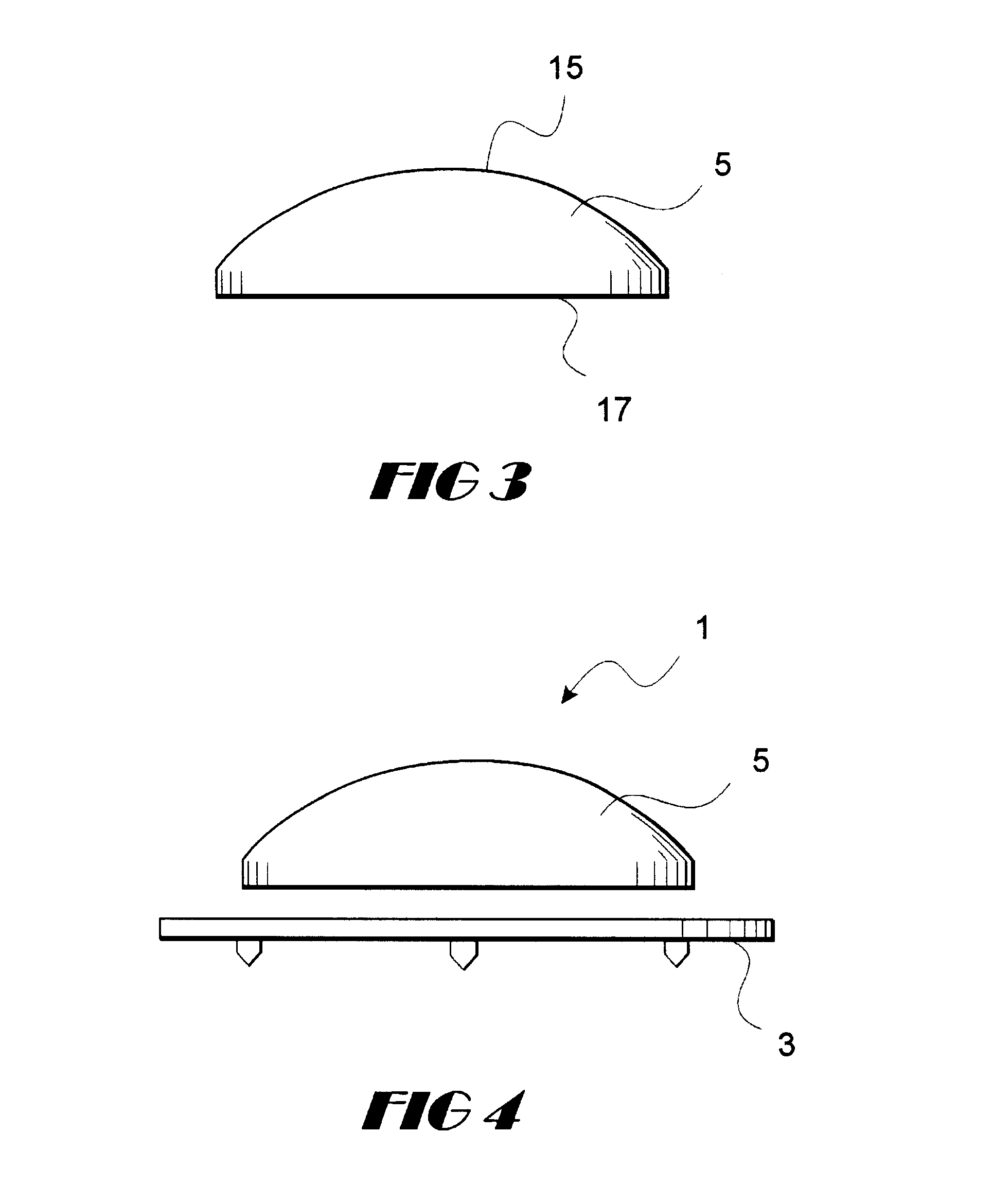

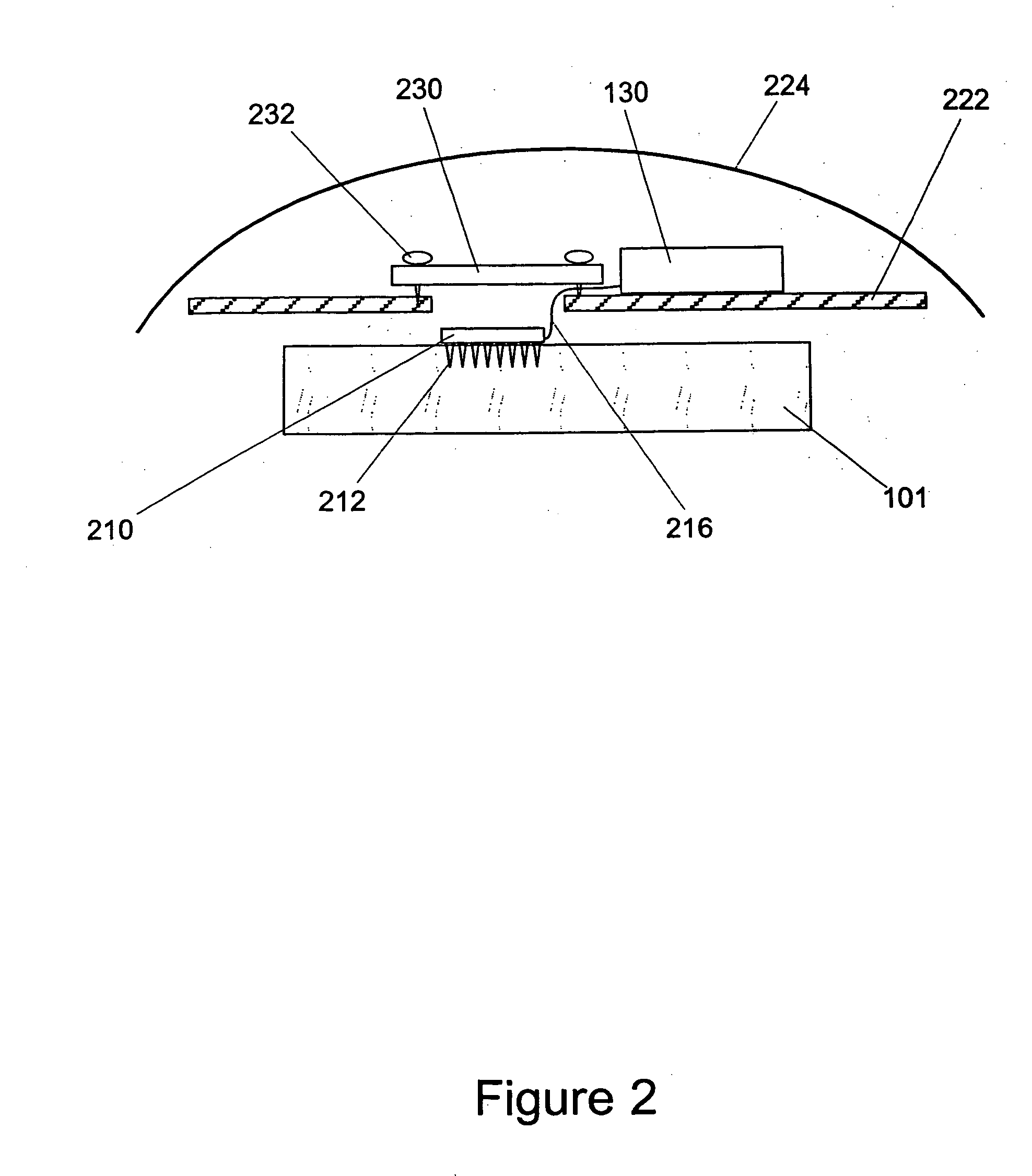

Patellar alignment device

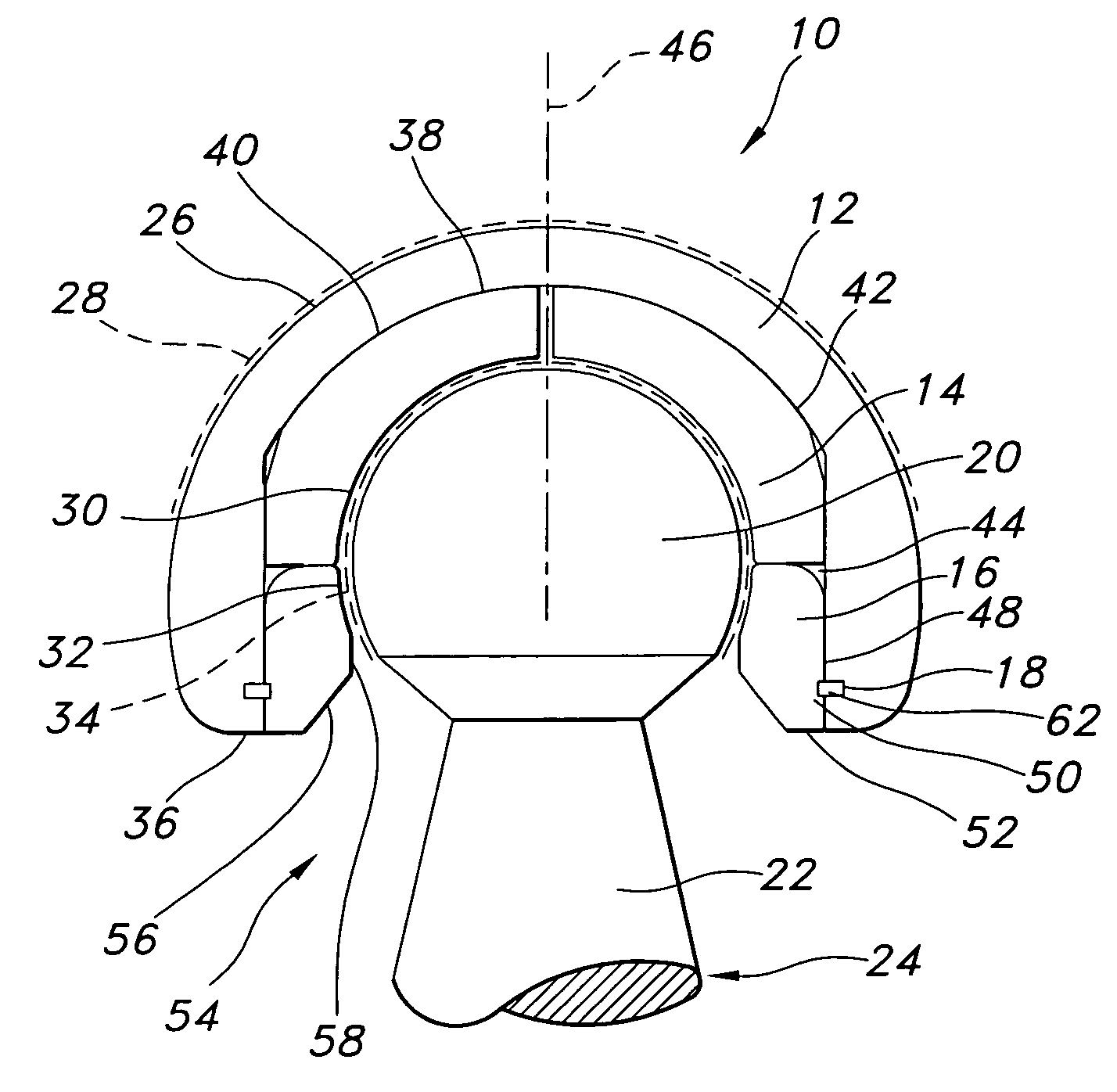

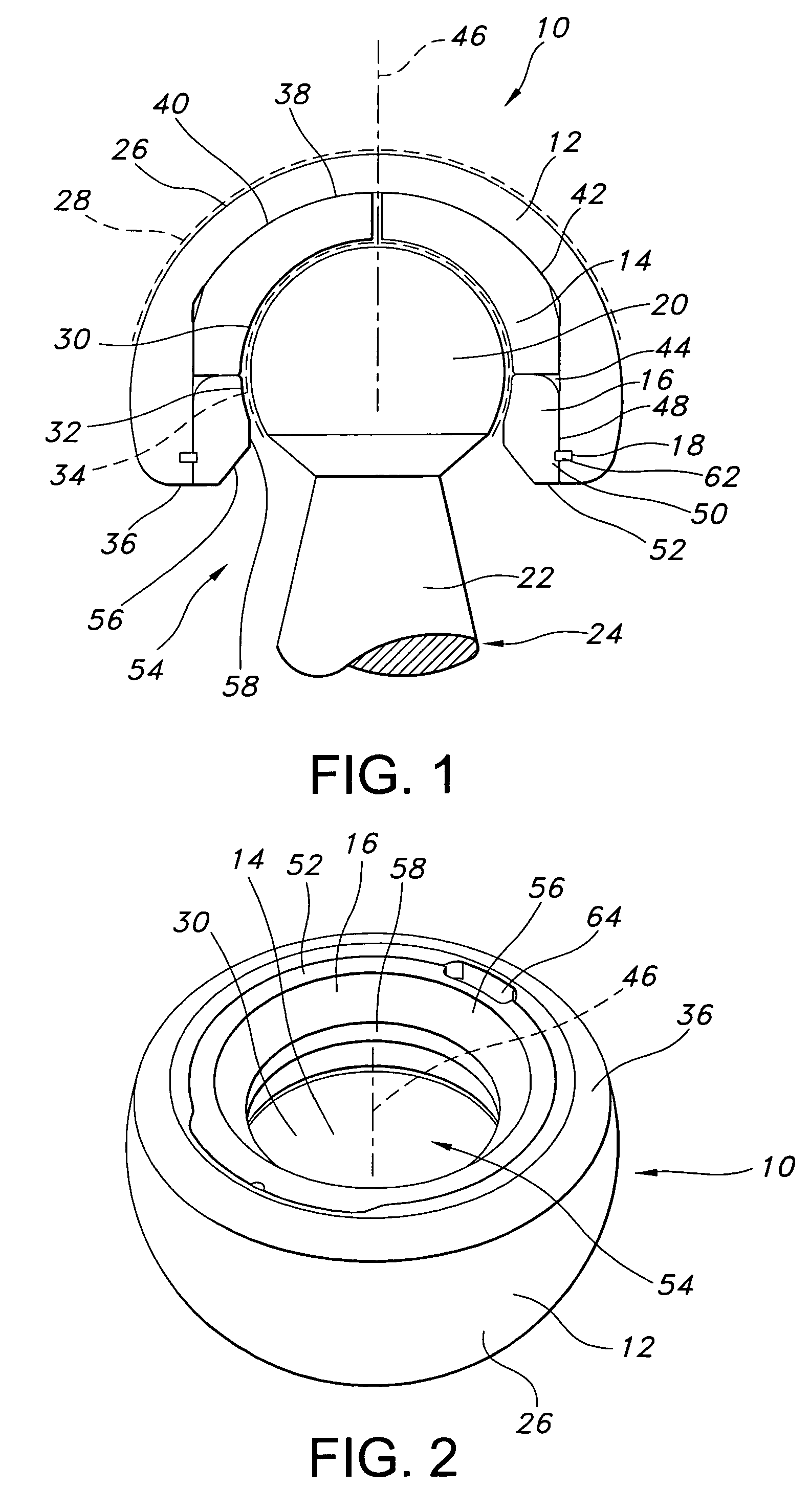

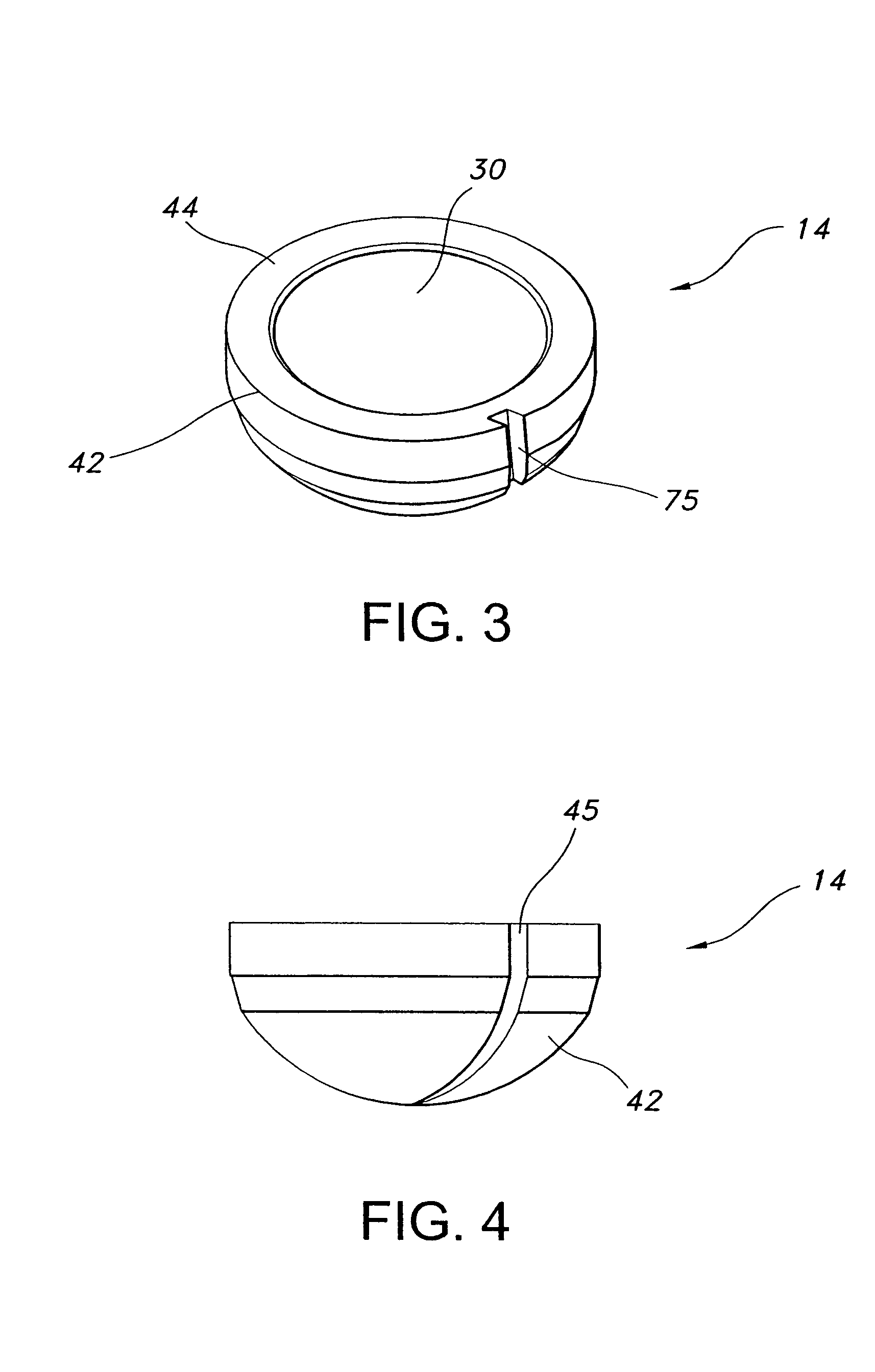

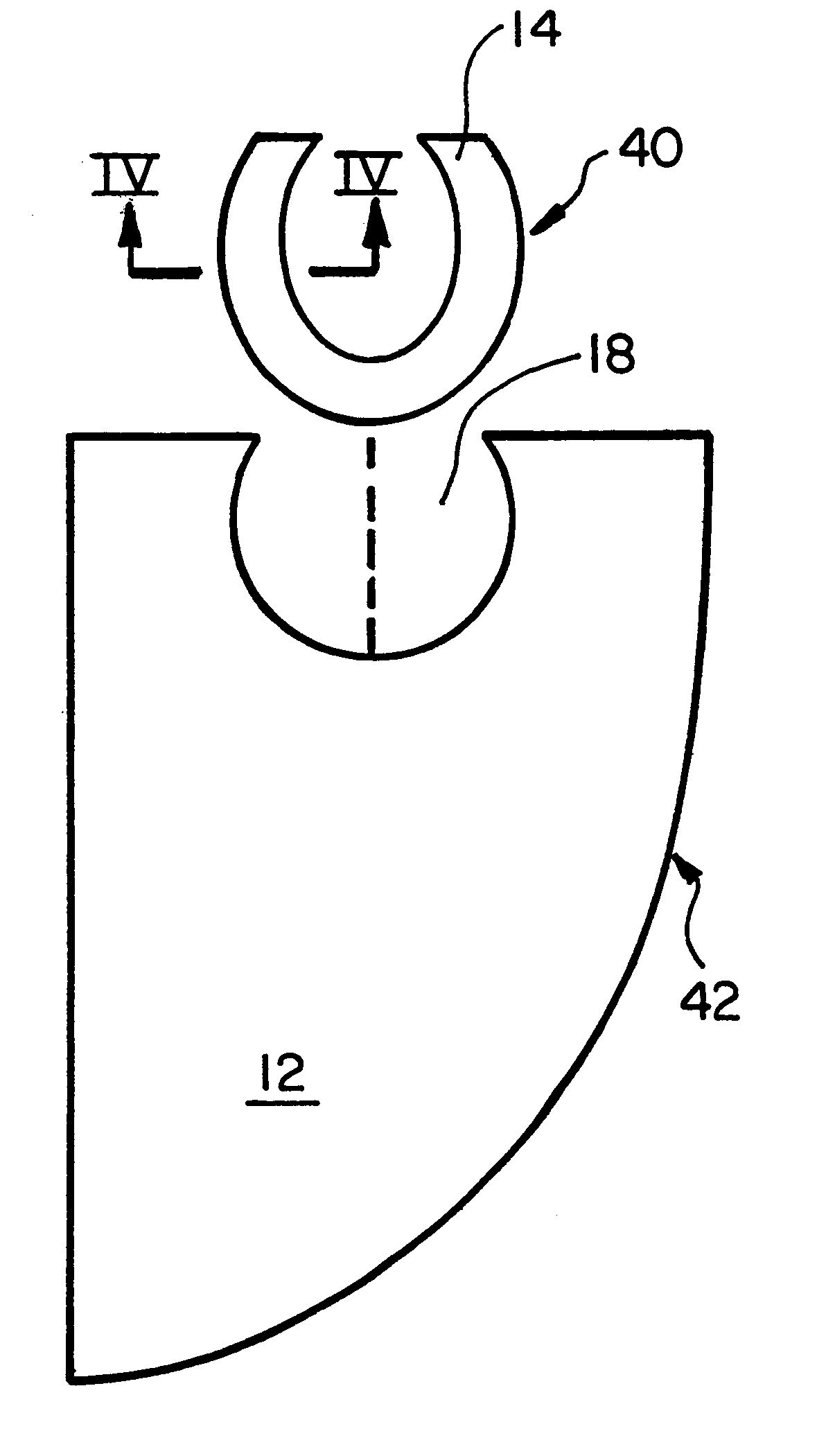

InactiveUS6589248B1Accurately locate proper positionReduce performanceDiagnosticsJoint implantsPatella prosthesisEngineering

A patellar alignment device for determining the position of a patella prosthesis. The device comprises two components-a baseplate and a mobile component which is preferably magnetically attached to the baseplate. During a surgical procedure to replace the knee, the baseplate is temporarily attached to the back of the patella. The baseplate may contain spikes or prongs to secure it to the patella. The baseplate further includes a series of slots for marking the patella. The mobile component resembles a patella and is placed on the baseplate. The patella with the alignment device in place is then placed in position on the knee and trialed. Because the mobile component is free to move on the baseplate, it finds the position that is most amenable to a natural knee movement. The alignment device is then exposed and the patella is marked at the position of the mobile component. Since the baseplate contains a series of slots, the patella can be easily marked at several locations around the mobile component. The entire patella alignment assembly is then removed and the final prosthetic device can be inserted at the marked location.

Owner:HUGHES JOE L

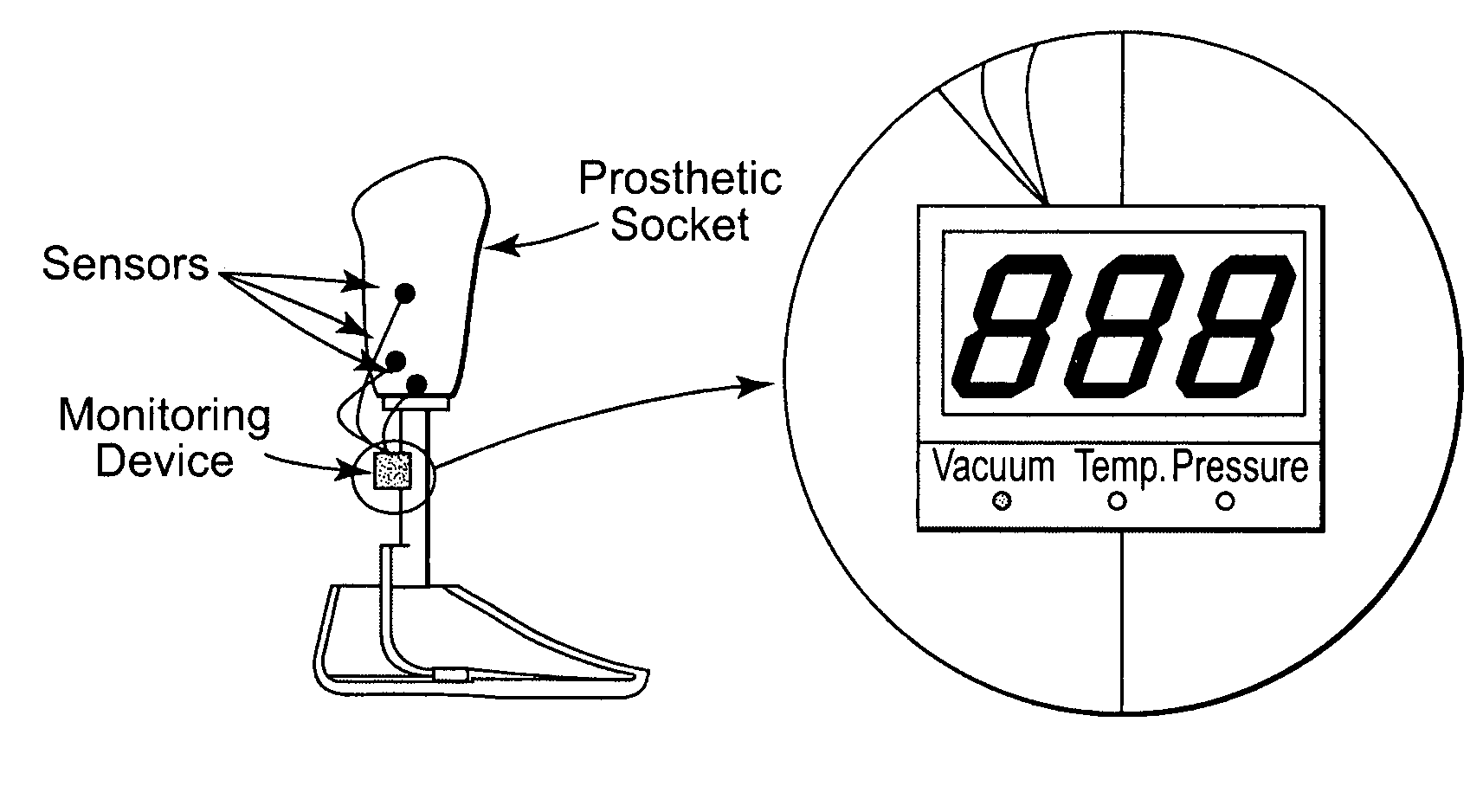

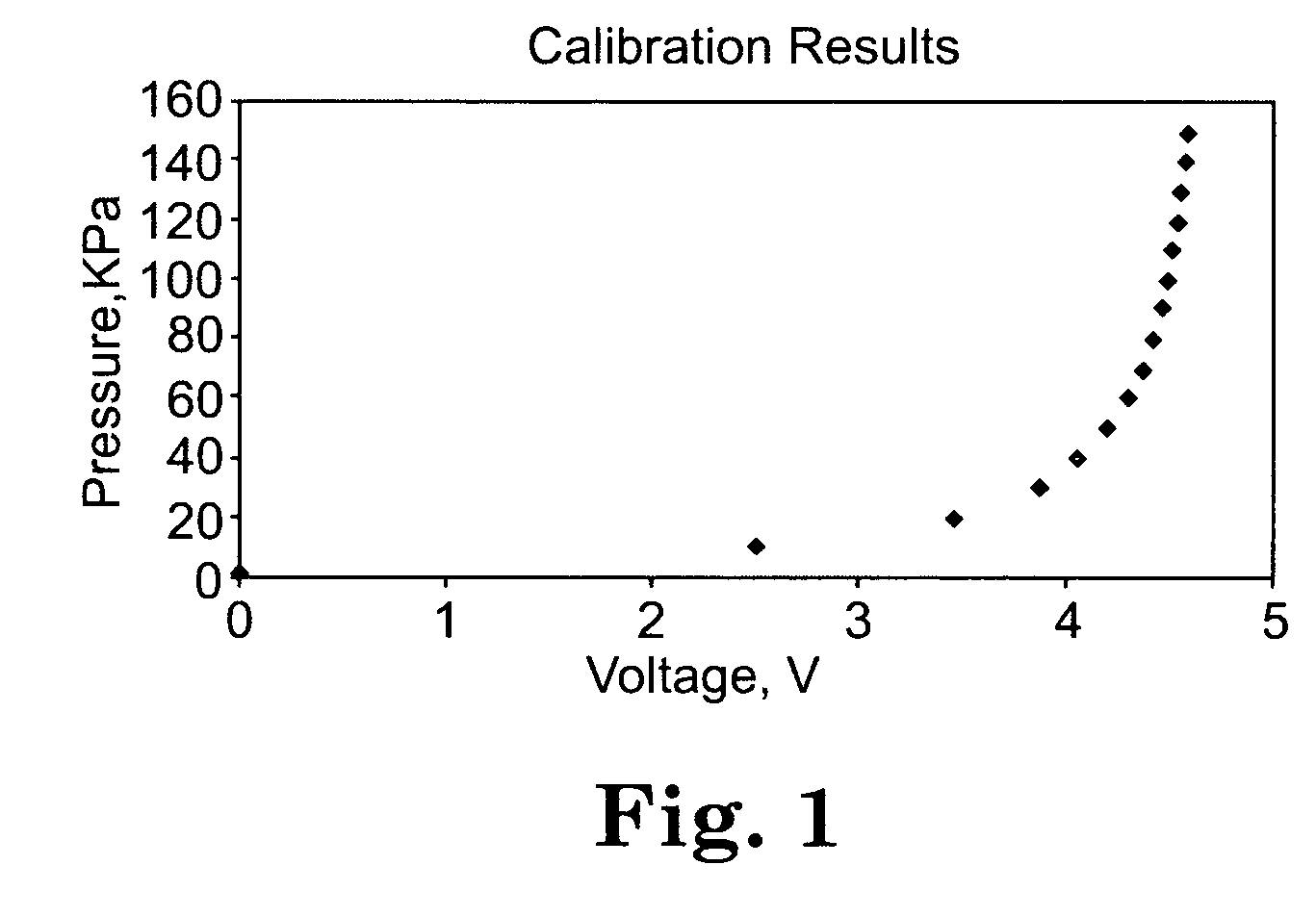

Pressure/temperature monitoring device for prosthetics

An apparatus and method for monitoring aspects of a socket of a prosthetic limb having a residual limb contained therein. The apparatus includes and the method uses sensors for measuring one or more of pressure, force, temperature, moisture, and vacuum and one or more devices for displaying sensor values to the wearer, setting sensor limits, and / or sounding an audible alarm when a sensor limit is exceeded.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

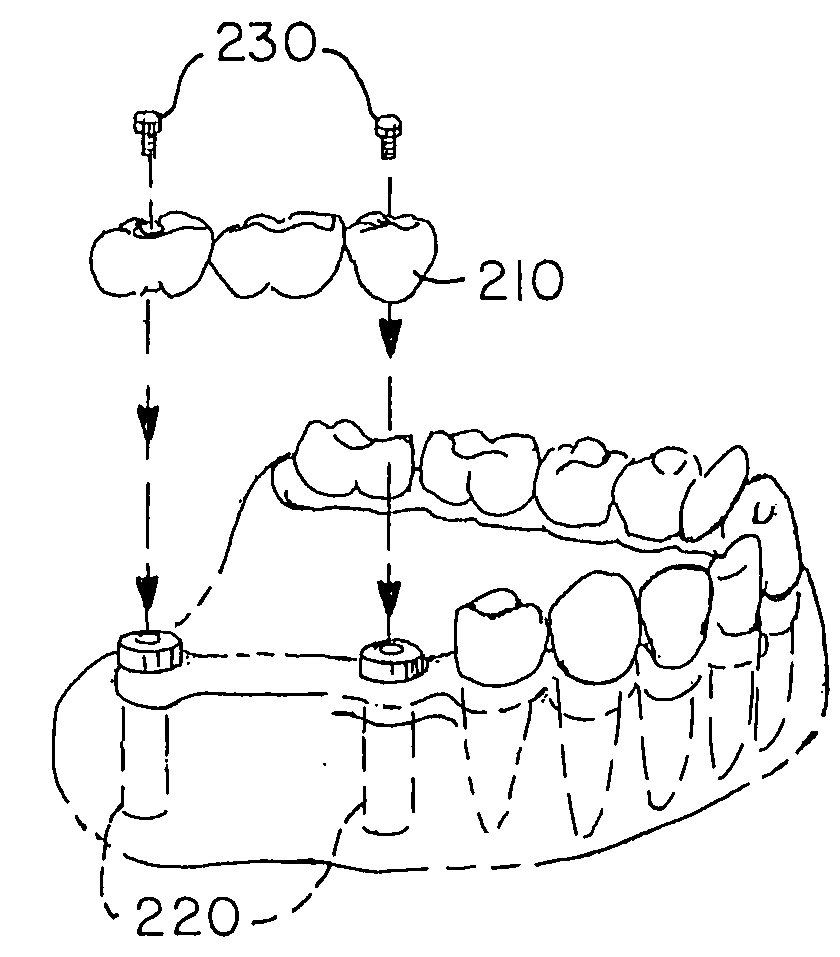

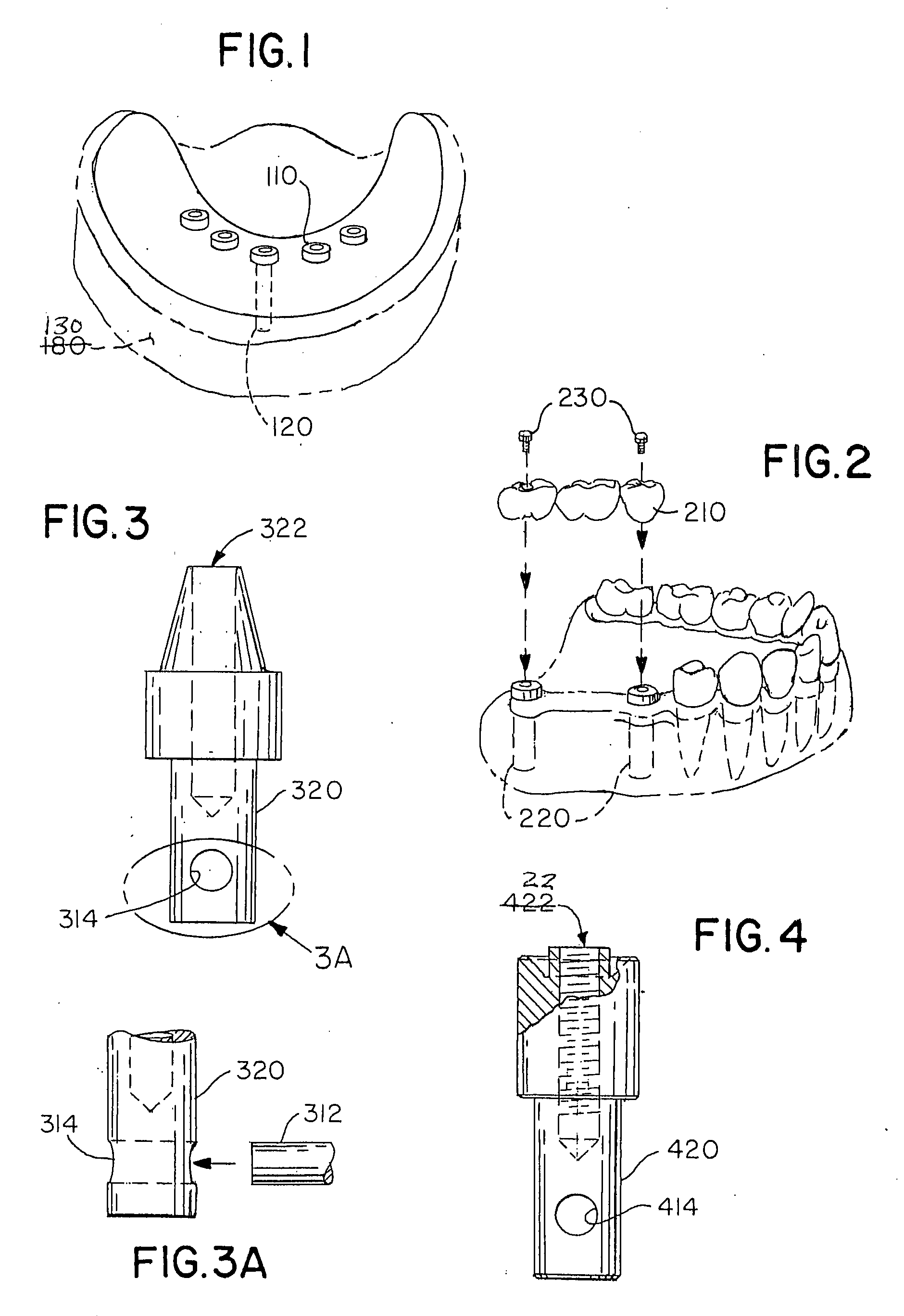

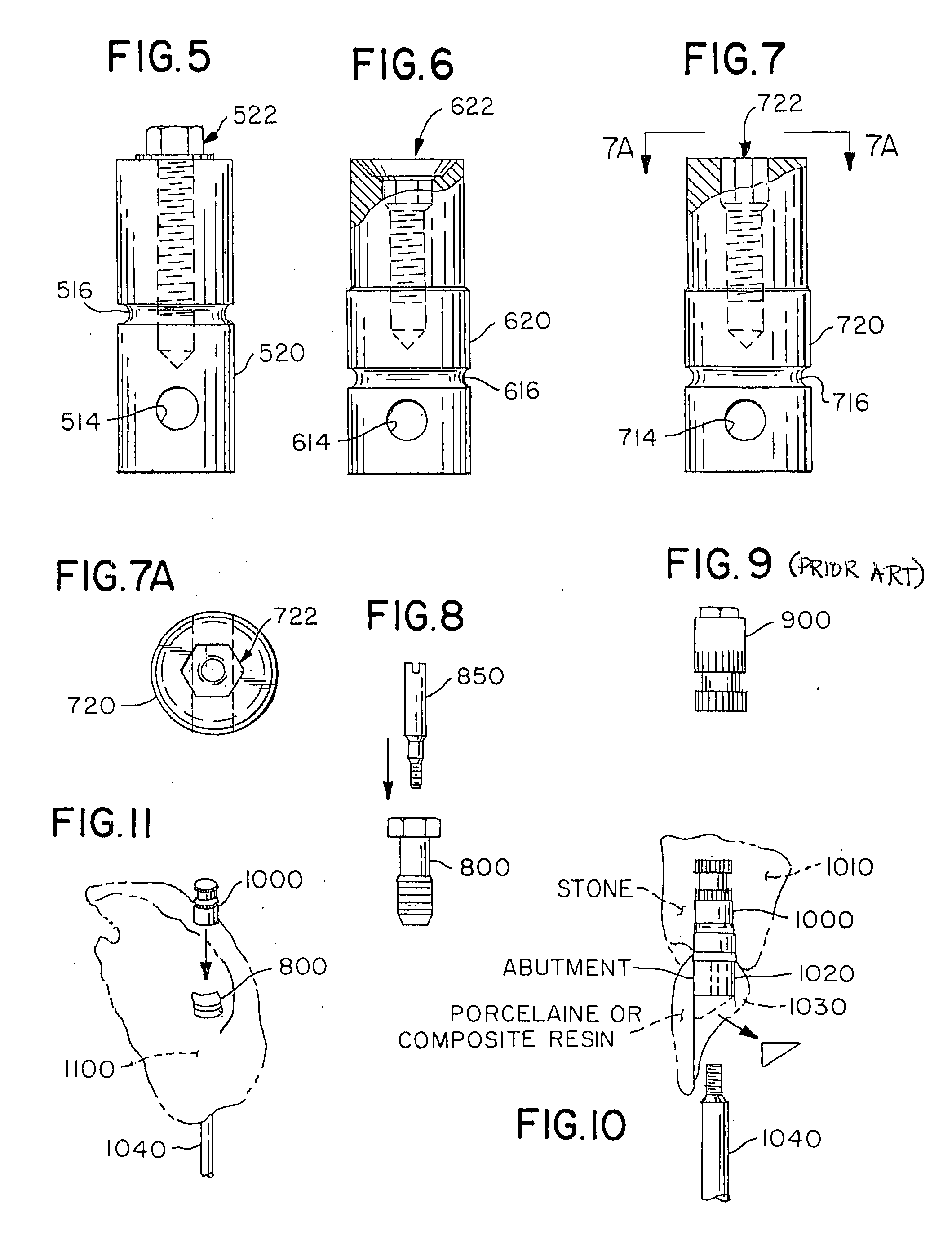

Accurate analogs for prostheses using computer generated anatomical models

ActiveUS20080124676A1Improve actionDental implantsAdditive manufacturing apparatusComputer generationEar prosthesis

Pre-surgical planning for cranial and facial reconstruction includes preparing a computer generated jaw or skull model for determining a locational position for a dental implant, a surgical bone implant to repair missing bone in the cranium, install ear prostheses, and / or install nose prostheses. The computer generated jaw or skull model is made from medical imagery and computer aided design. A surgical guide is prepared with oversize holes in registration with analogs for the dental or surgical bone implants to be inserted at the locational positions determined by a dentist or surgeon in the jaw or cranial skull model. The surgical guide is fitted atop each analog, and the surgical guide is bonded to the jaw or skull model at a predetermined angle of the analog in the jaw or skull. The surgical guide is removed from the model attached to the law or skull of a patient for accurate drilling during the dental or surgical procedure for insertion of the implants into the jaw or skull of the patient.

Owner:CLM ANALOGS LLC

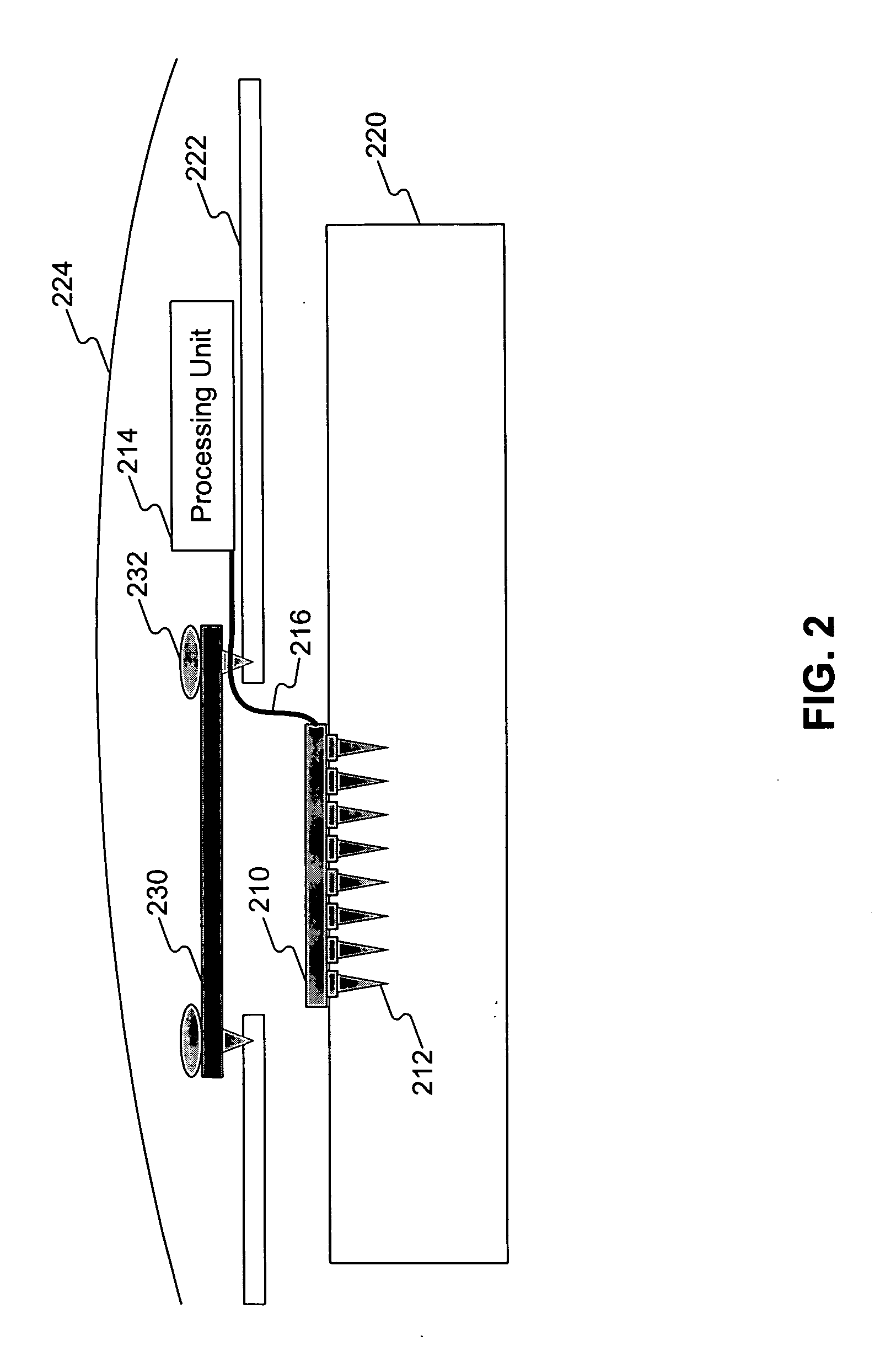

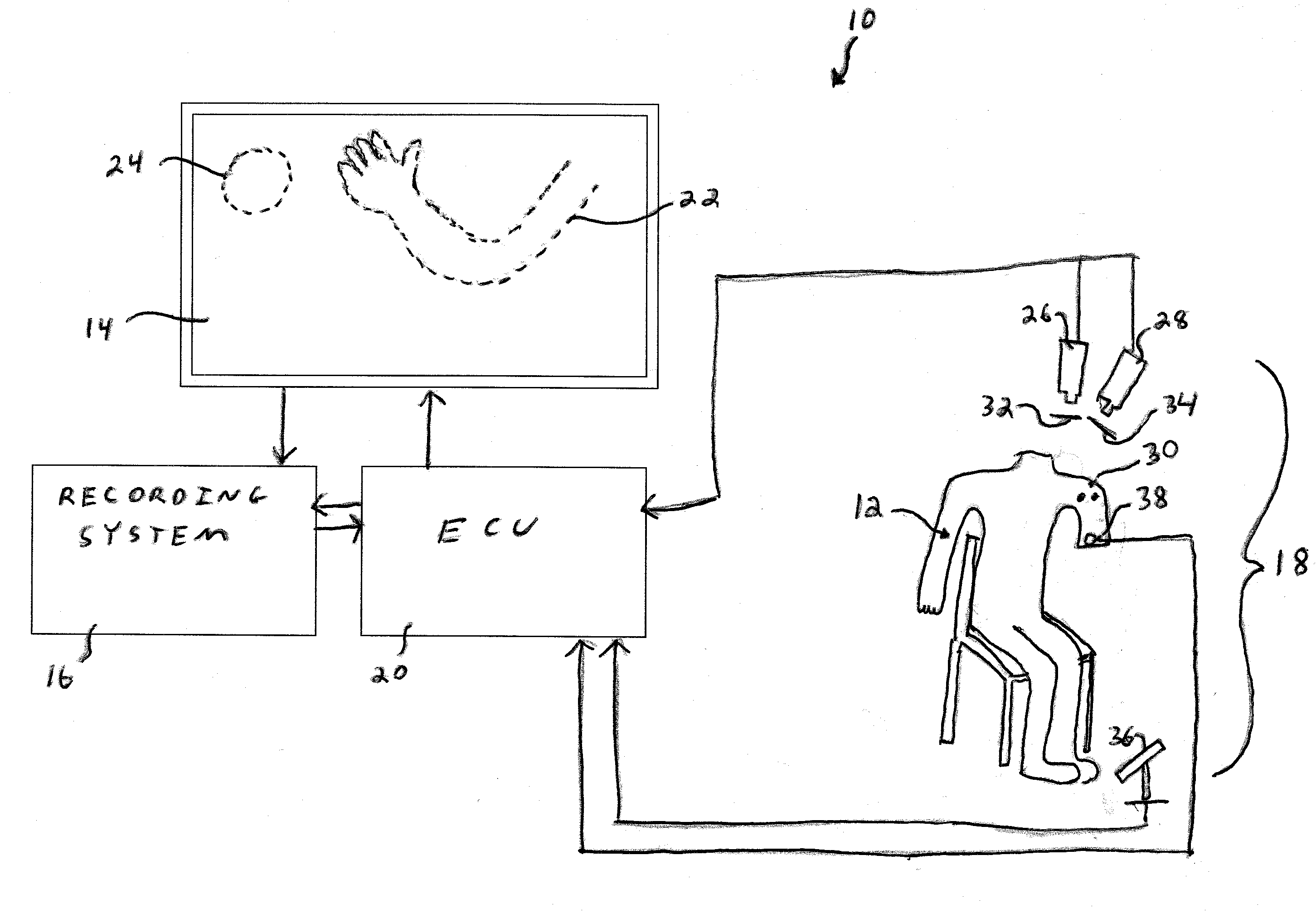

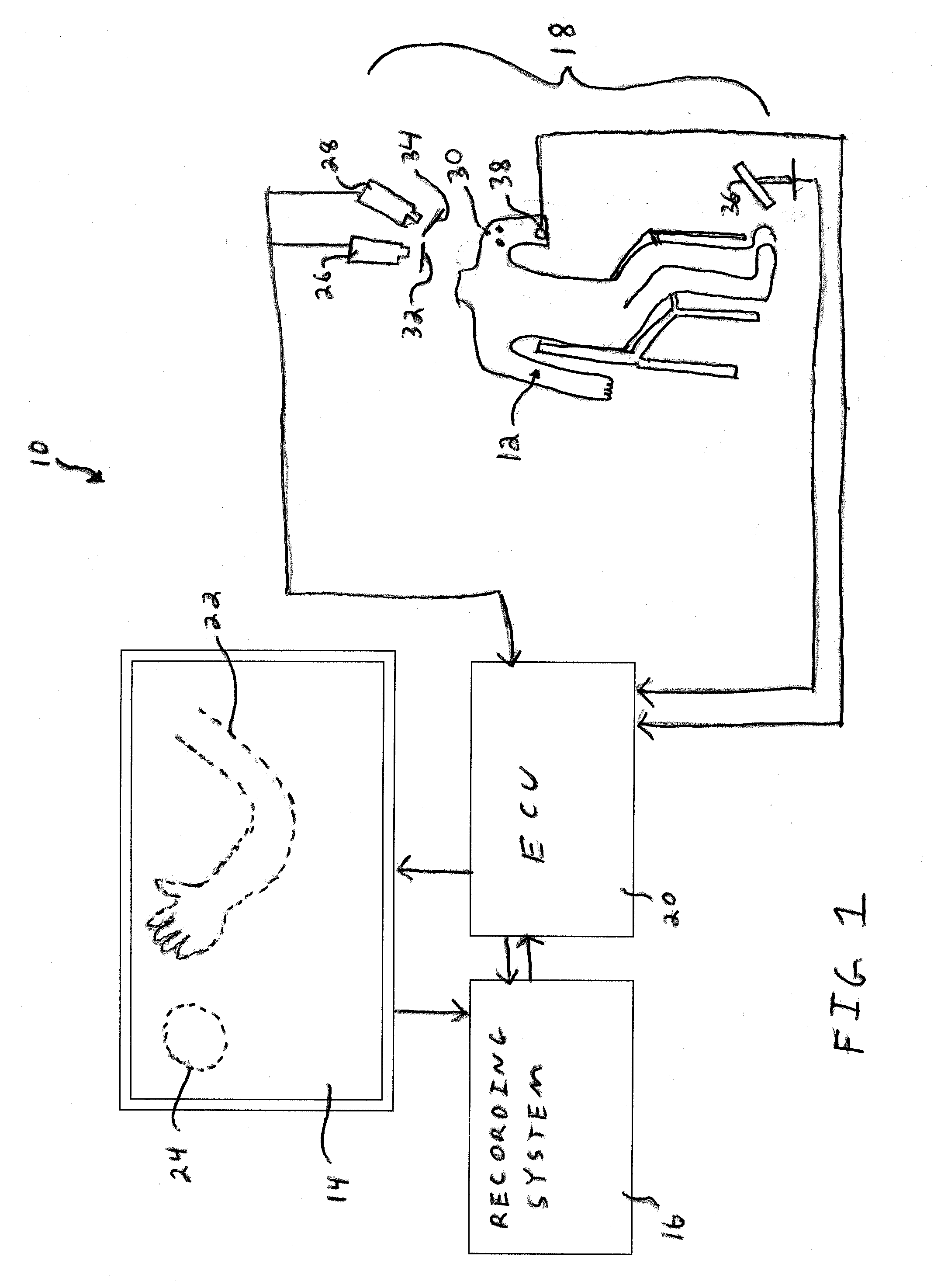

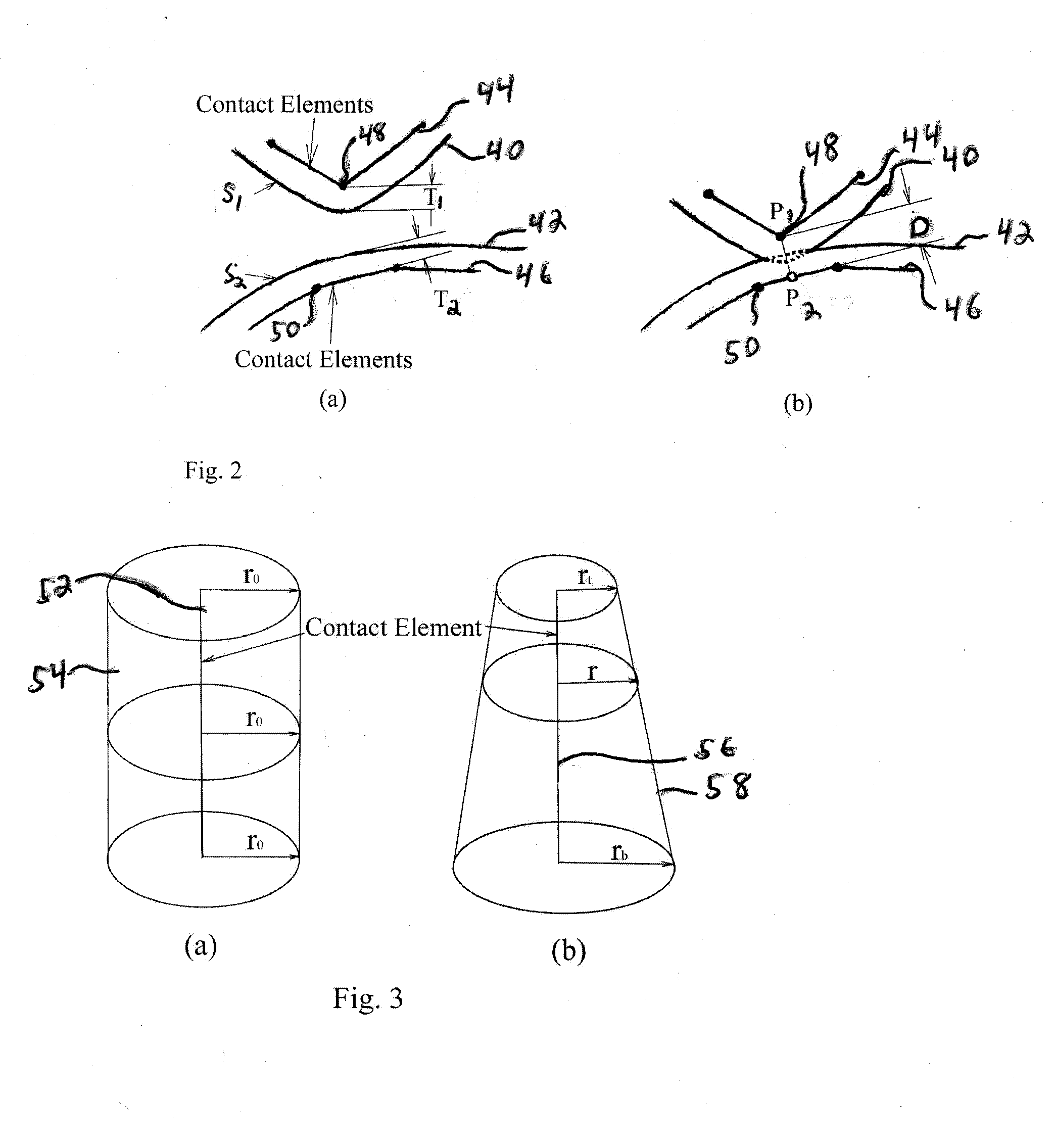

Virtual Prosthetic Limb System

ActiveUS20120004579A1Effective simulationImproves design and evaluationMedical simulationElectromyographyControl signalDisplay device

A system for configuring a prosthetic limb for use by a living being is provided. The system includes an electronic control unit (ECU) configured to receive a control signal generated in response to a command from the living being and to generate a plurality of virtual bodies on a display including members of a virtual prosthetic limb and at least one virtual object. The ECU is further configured to control movement of at least one member of the virtual limb responsive to the control signal, to determine a contact force between first and second virtual bodies of the plurality of virtual bodies upon engagement between the first and second bodies caused by movement of one of the one member of the virtual limb and the at least one virtual object and to adjust a position of at least one of the first and second bodies responsive to the contact force.

Owner:LUO GANGMING +1

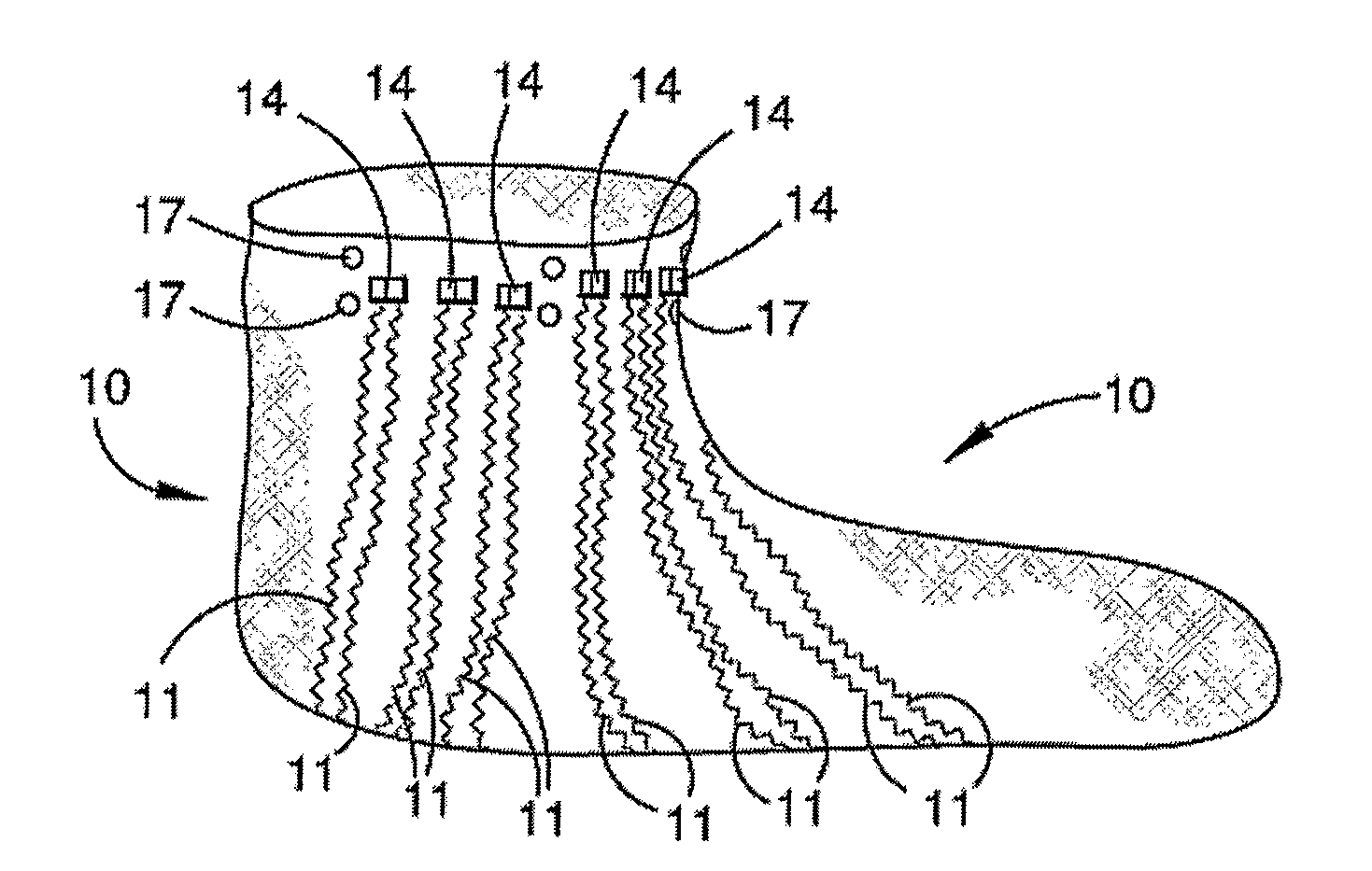

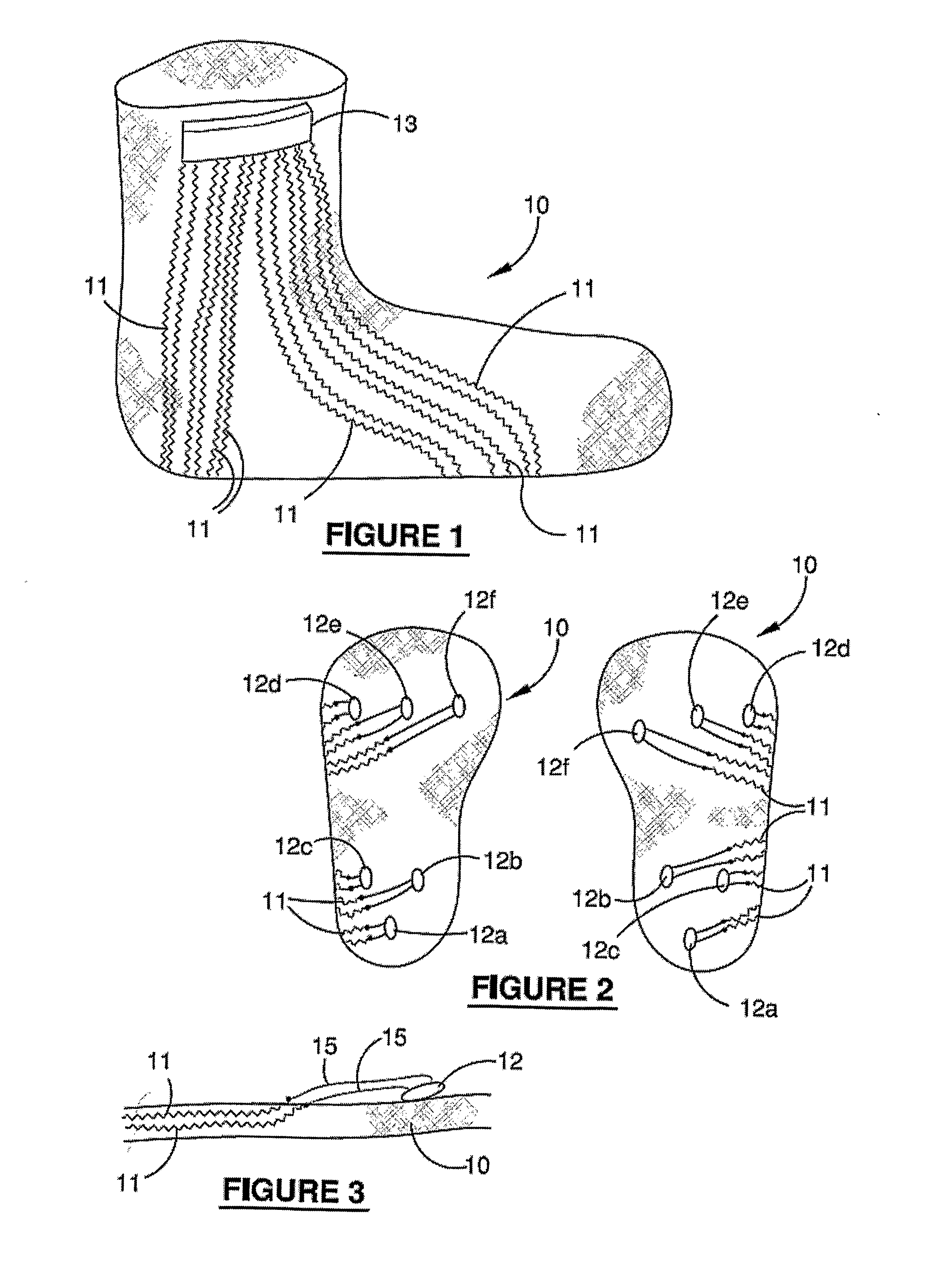

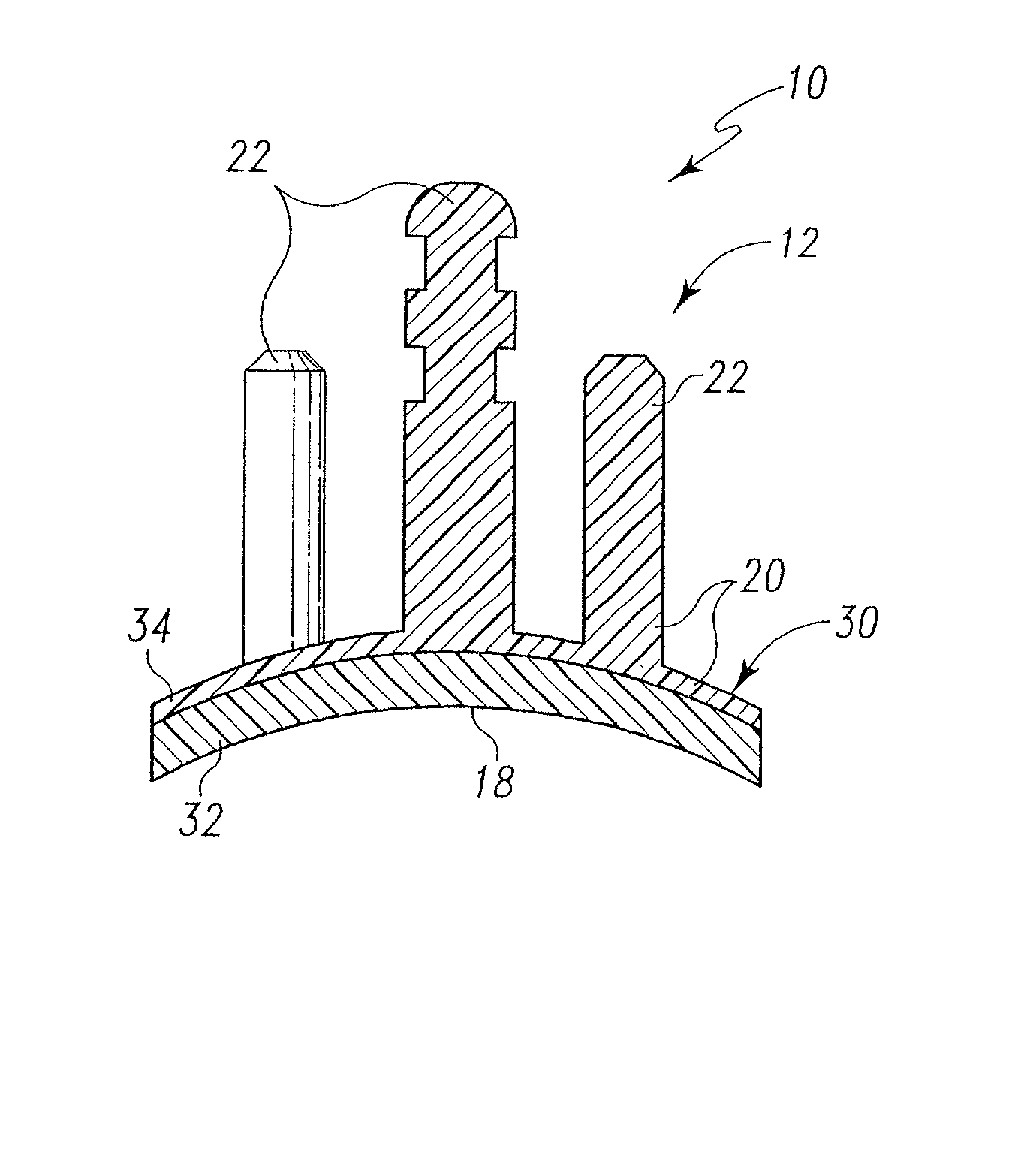

Modular prosthetic sockets and methods for making same

ActiveUS20130123940A1Improve fitAdd dimensionArtificial legsMetal working apparatusBiomechanicsModularity

The invention relates to a prosthetic socket for a residual limb of the lower extremity or upper extremity of an individual person. The residual limb has particular dimensions and anatomical contours; the prosthetic socket has dimensions and contours that fit the dimensions and contours of the residual limb. The prosthetic socket may also fit in a manner that is biomechanically particularly appropriate for the individual. The prosthetic socket is an assembly of components from groups of components that include (a) struts arranged longitudinally with respect to the residual limb, (b) proximal brim members arranged proximally to the struts and connected thereto; and (c) distal socket members disposed at the distal base of the prosthetic socket. The socket components within these groups may be modular in that they can vary with respect to dimensions and / or contours, and yet have common connecting features that permit assembly of the components together to form the prosthetic socket.

Owner:LIM INNOVATIONS

Method, system and apparatus for real-time classification of muscle signals from self -selected intentional movements

InactiveUS20100293115A1User training can be minimizedImprove performanceMedical data miningElectromyographyMuscle contractionSelf training

A new method, system and apparatus is provided that enables muscle signals that correspond to muscle contractions to be mapped to one or more functions of an electronic device such as a prosthetic device or gaming apparatus. Muscle signals are classified in real-time from self-selected intentional movements. A self-training protocol allows users to select and label their own muscle contractions, and is operable to automatically determine the discernible and repeatable muscle signals generated by the user. A visual display means is used to provide visual feedback to users illustrating the responsiveness of the system to muscle signals generated by the user.

Owner:HOLLAND BLOORVIEW KIDS REHABILITATION HOSPITAL

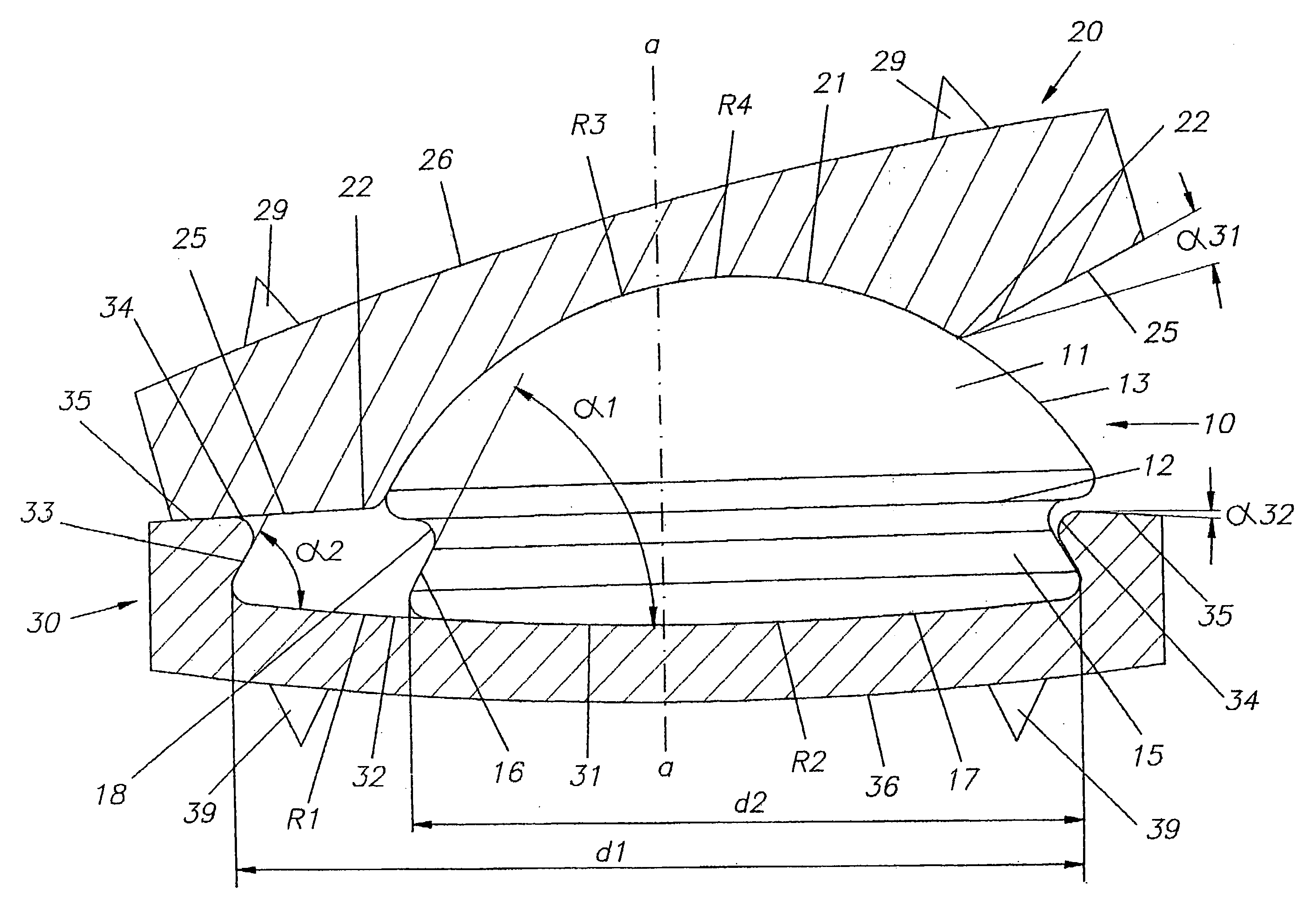

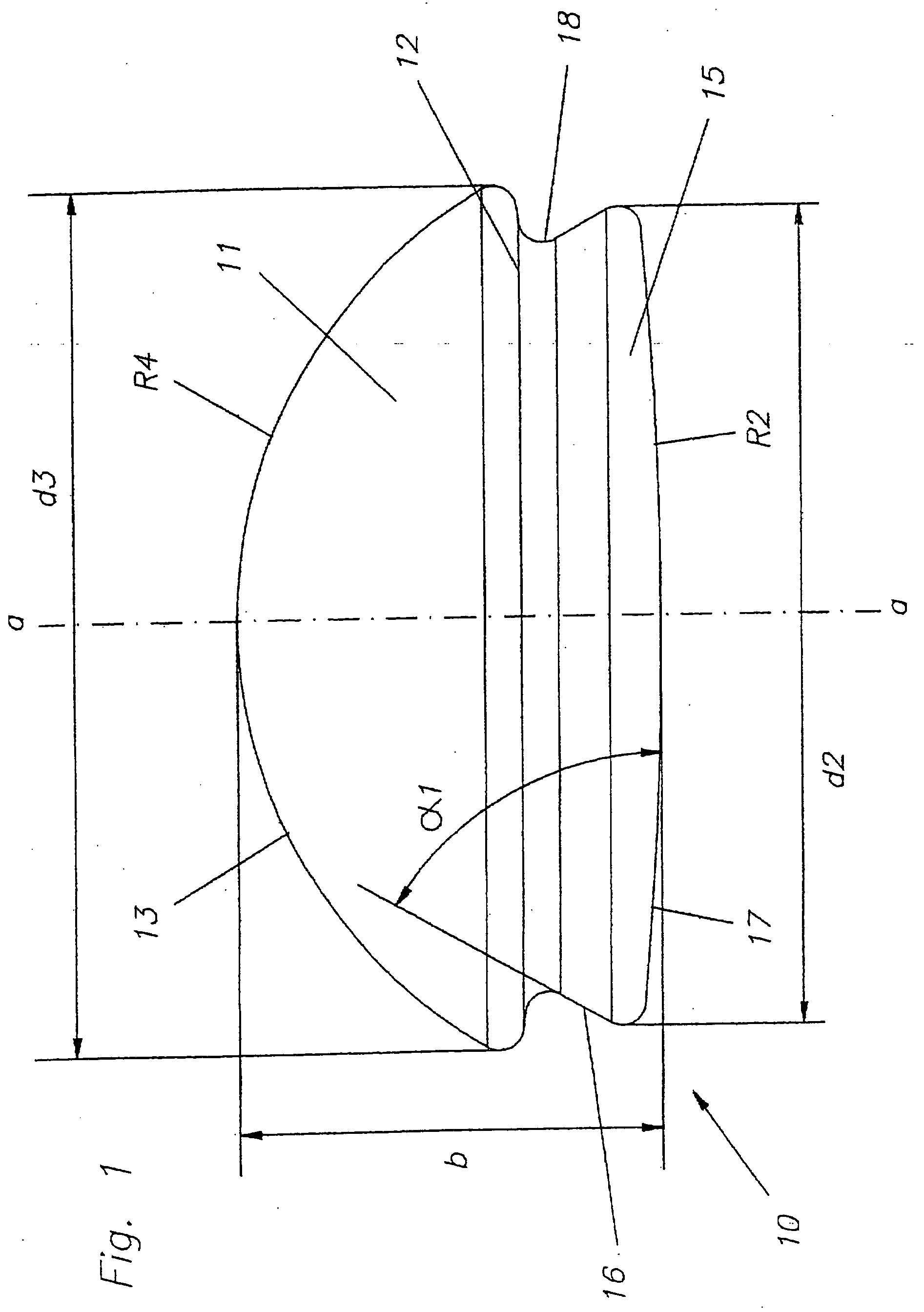

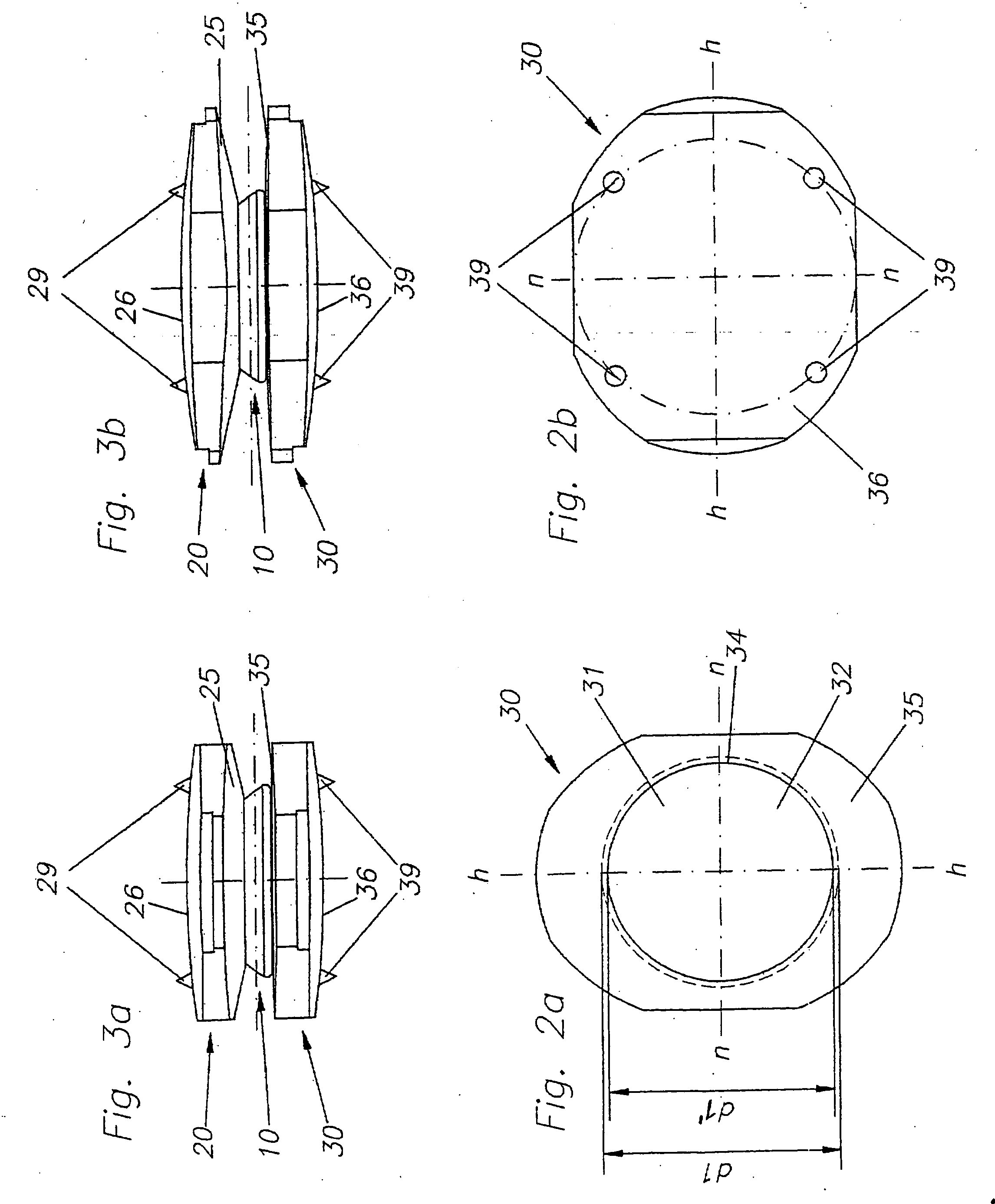

Intervertebral prosthesis

InactiveUS20060069437A1Improve distributionAvoid damageSpinal implantsProsthesisBiomedical engineering

The invention concerns an intervertebral prosthesis comprised of a first prosthetic end plate (20) and a second prosthetic end plate (30) as wall as a prosthetic core (10) located between the first prosthetic end plate (20) and the second prosthetic end plate (30), wherein the first prosthetic end plate (20) has a hemispherical shaped recess (21) with a radius (R3), in which a hemispherical segment (11) of the prosthetic core (10) engages, and wherein the second prosthetic end plate (30) has an essentially planar recess (31), in which an essentially flat segment (15) of the prosthetic core (10), connected to the hemispherical segment (11), engages, wherein the essentially flat segment (15) of the prosthetic core (10) is slideably moveable in the essentially planar recess (31).

Owner:WEBER HELMUT

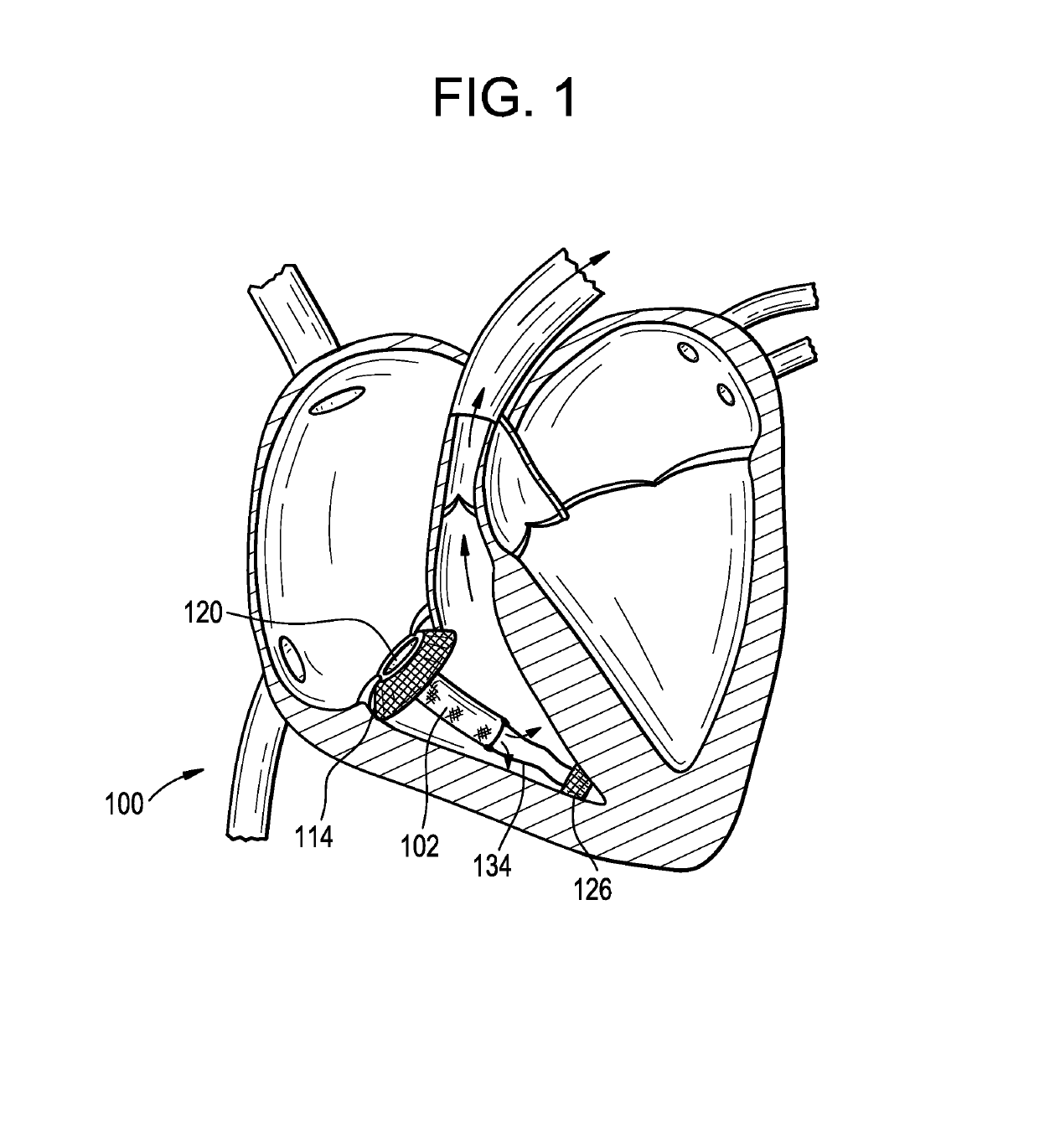

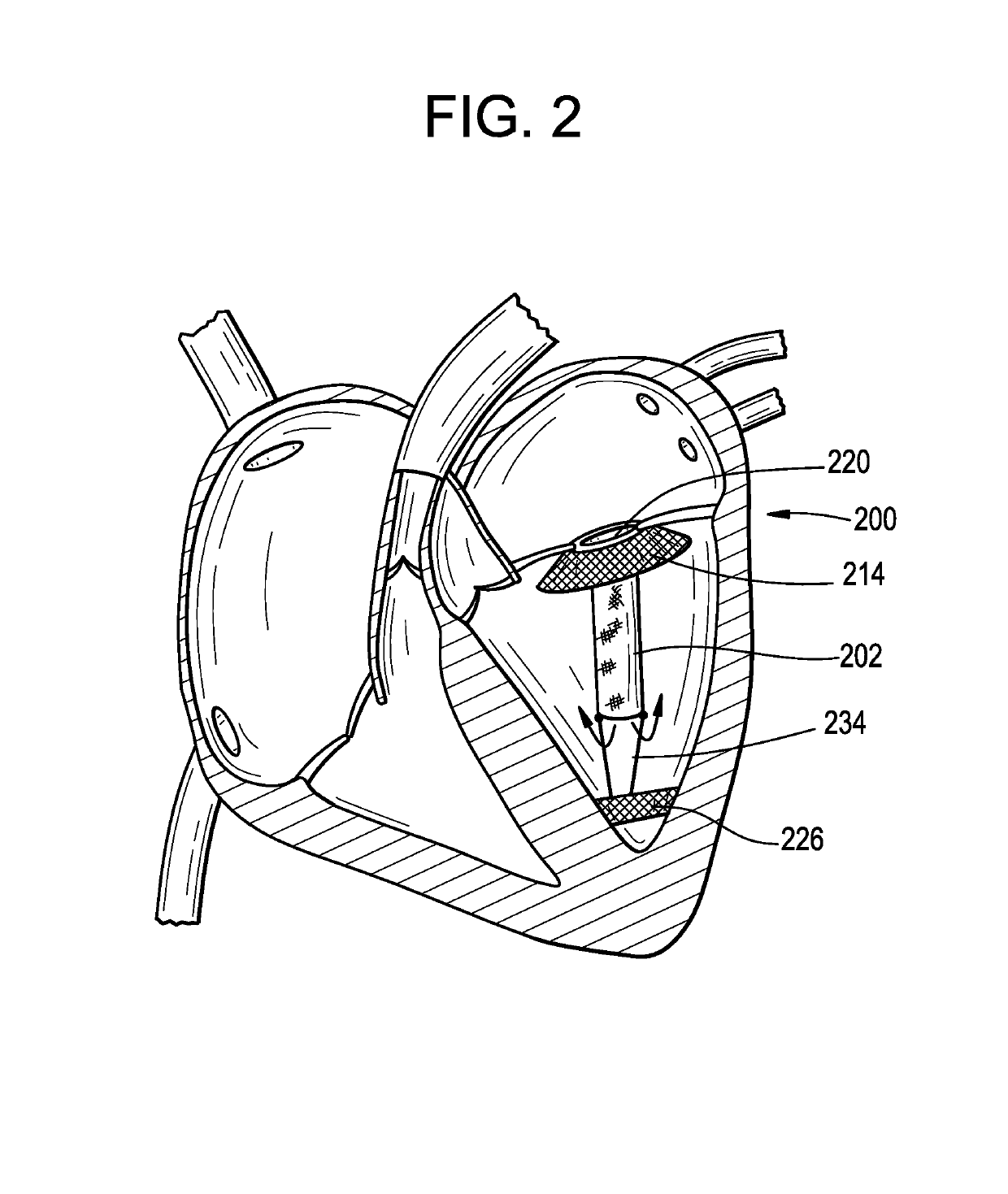

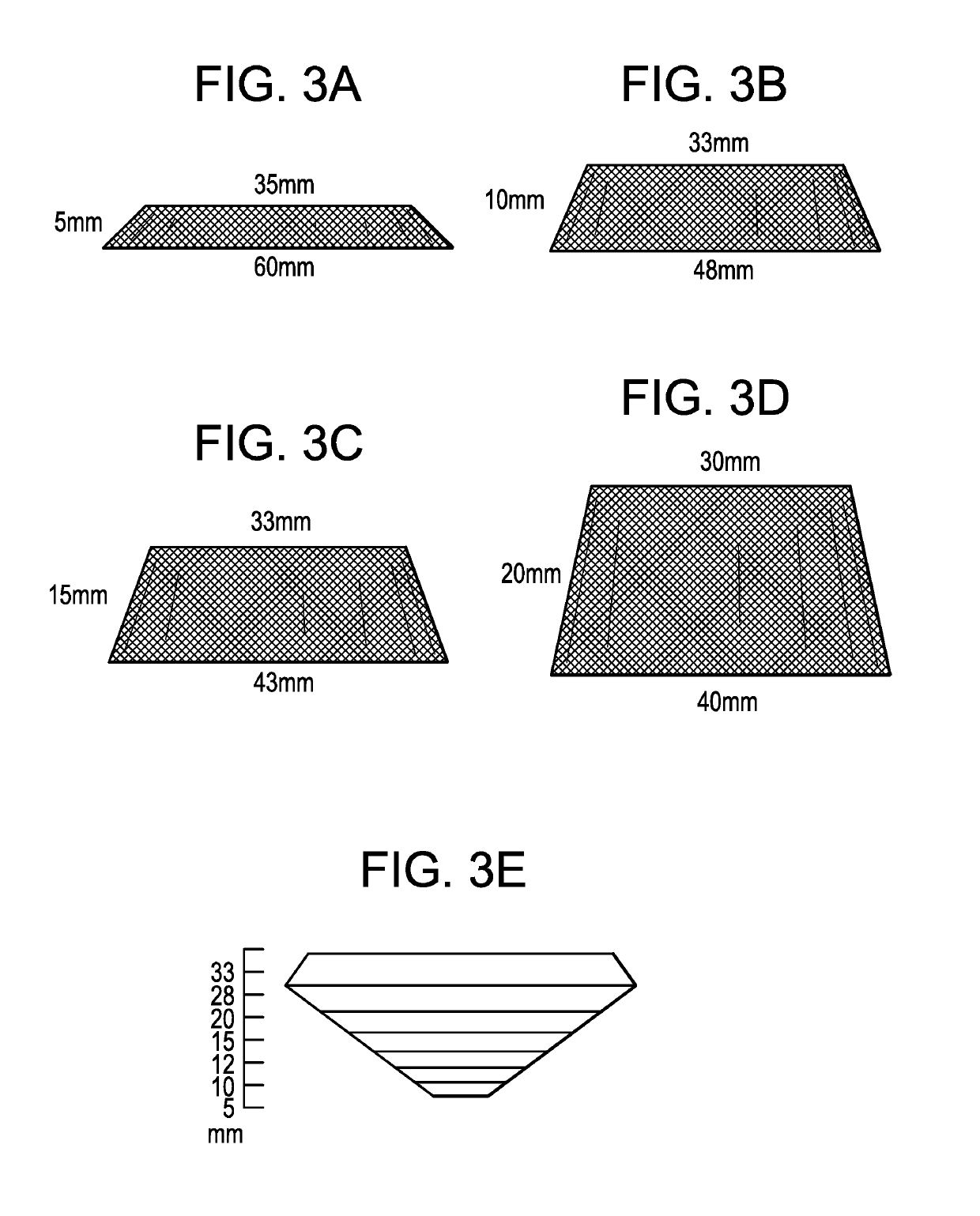

Pressure differential actuated prosthetic medical device

The invention relates to a medical prosthesis, and in particular a heart valve substitute comprising a pliant tubular conduit mounted on a resilient annular frame and tethered to a non-perforating anchor within the right or left ventricle of the heart, wherein the pliant tubular conduit is a reciprocating mechanical member that is compressed by pressurized working fluid within the ventricle during systole.

Owner:VDYNE INC

Neural interface system and method for neural control of multiple devices

A system and method for a neural interface system with a unique identification code includes a sensor including a plurality of electrodes to detect multicellular signals, an processing unit to process the signals from the sensor into a suitable control signal for a controllable device such as a computer or prosthetic limb. The unique identification code is embedded in one or more discrete components of the system. Internal and external system checks for compatibility and methods of ensuring safe and effective performance of a system with detachable components are also disclosed.

Owner:BRAINSGATE LTD

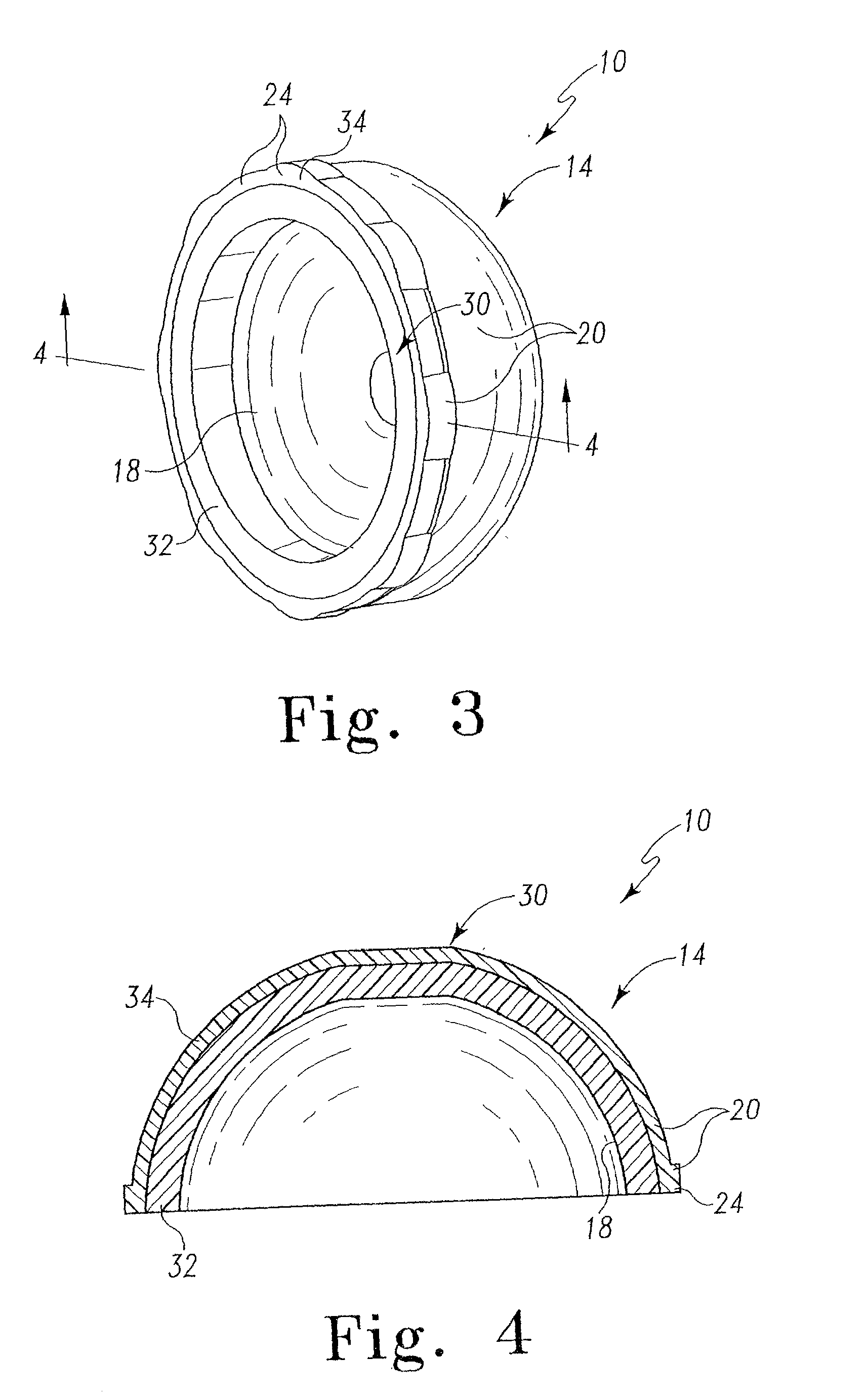

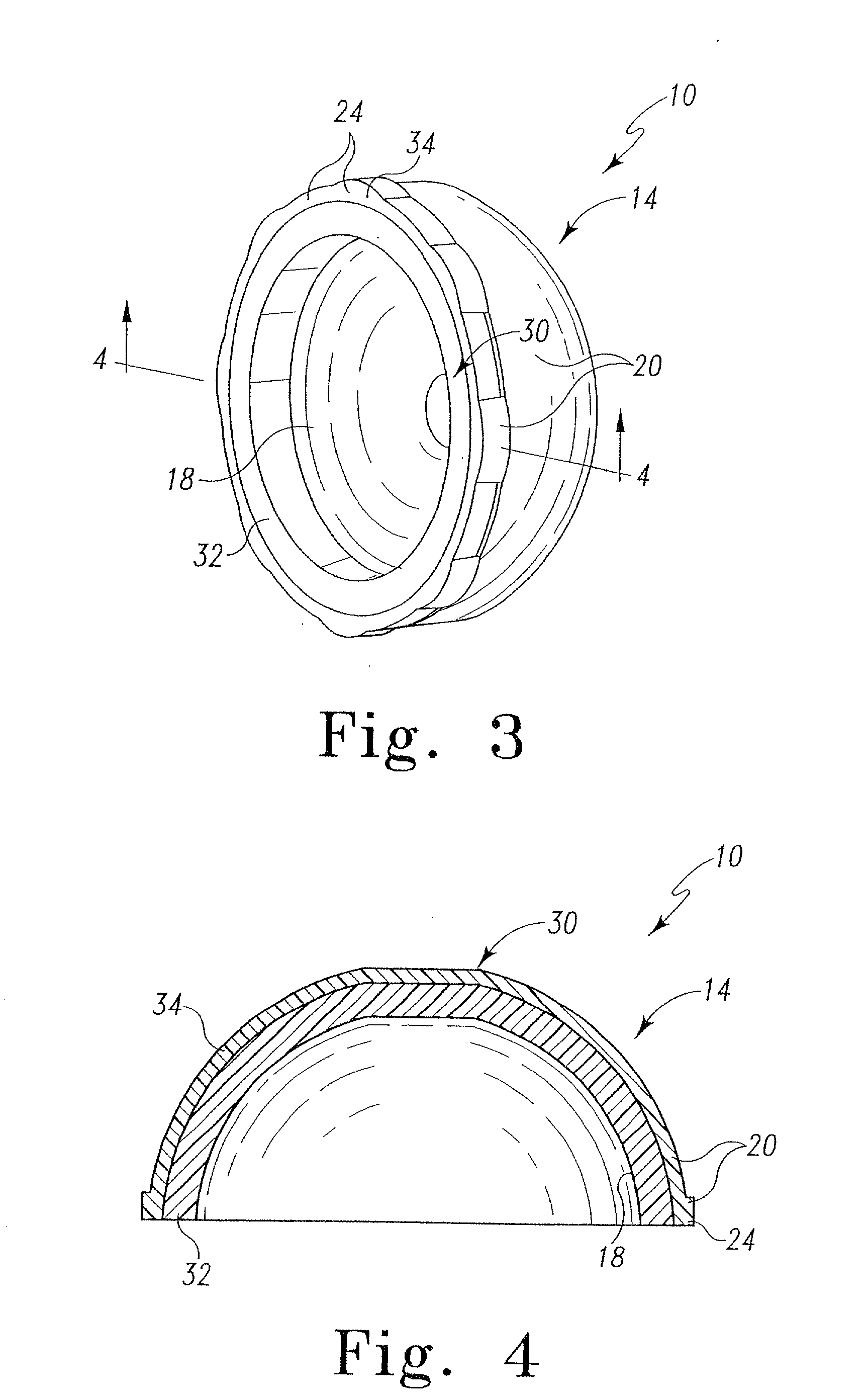

Composite prosthetic bearing having a crosslinked articulating surface and method for making the same

InactiveUS20030144741A1Easy to wearImprove oxidation resistanceBone implantSynthetic resin layered productsProsthesisCrosslinked polymers

An implantable prosthetic bearing is constructed of a composite material having a first layer and second layer. The first layer has an articulating surface defined therein, whereas the second layer has a engaging surface defined therein for engaging either another prosthetic component or the bone itself. The first layer of the implantable prosthetic bearing is constructed of crosslinked polymer such as UHMWPE, whereas the second layer of the implantable prosthetic bearing is constructed of polymer such as UHMWPE that is either non-crosslinked or crosslinked to a lesser degree than the first layer. In such a manner, the first layer possesses mechanical properties which are advantageous in regard to the articulating surface (e.g., enhanced wear and oxidation resistance), whereas the second layer possesses mechanical properties which are advantageous in regard to the engaging surface (e.g., high ductility, toughness, and creep resistance). A method of making a prosthetic bearing is also disclosed.

Owner:DEPUY SYNTHES PROD INC

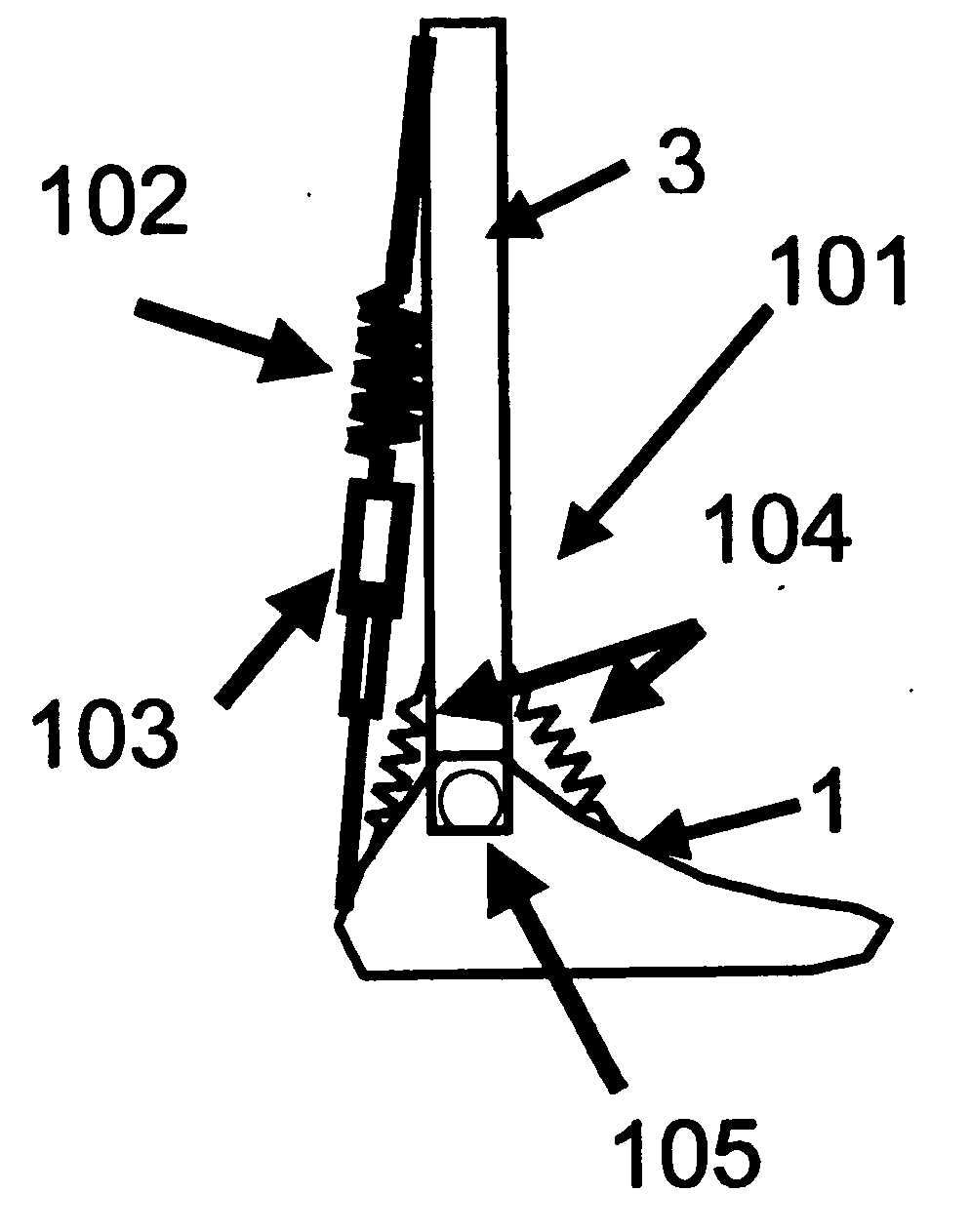

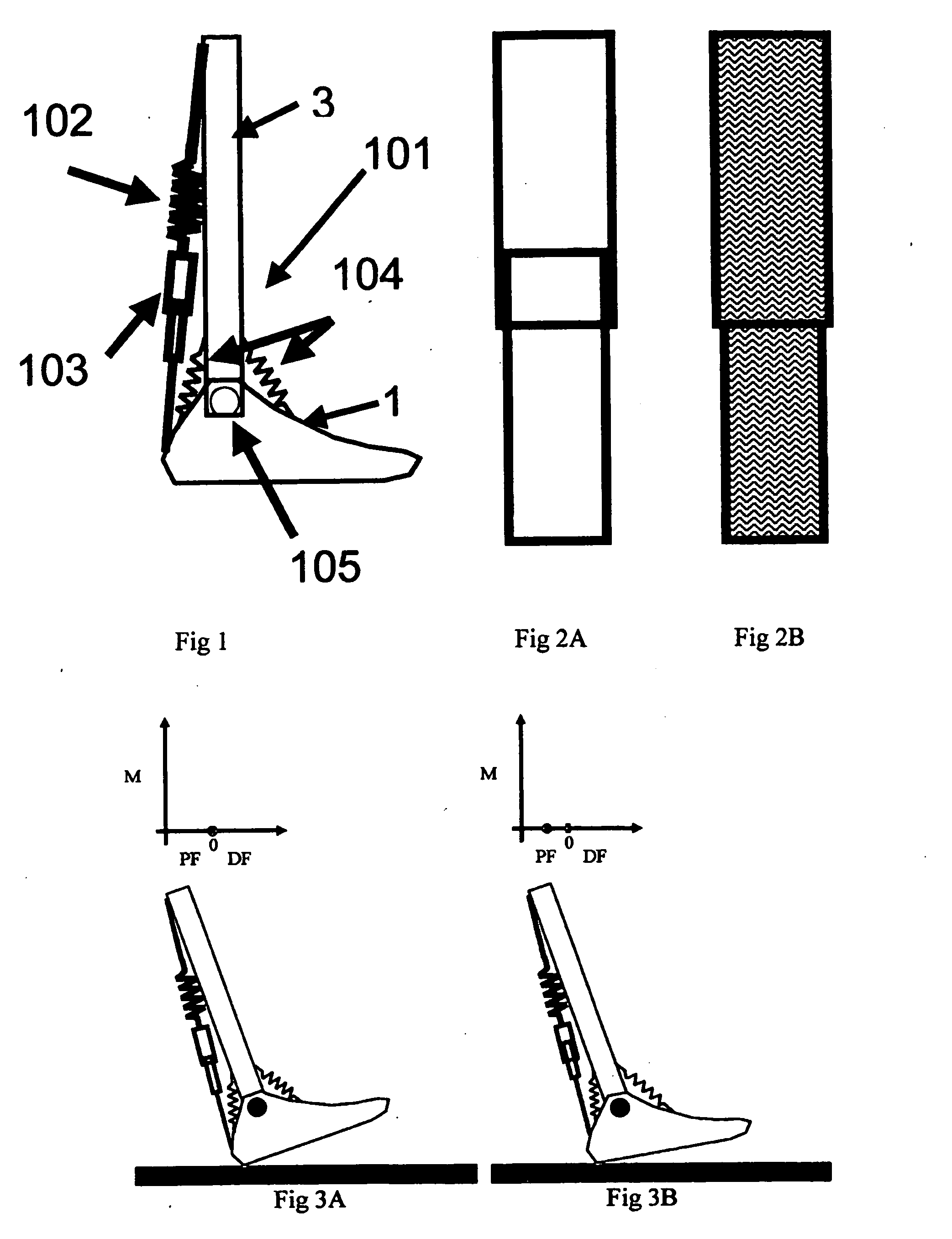

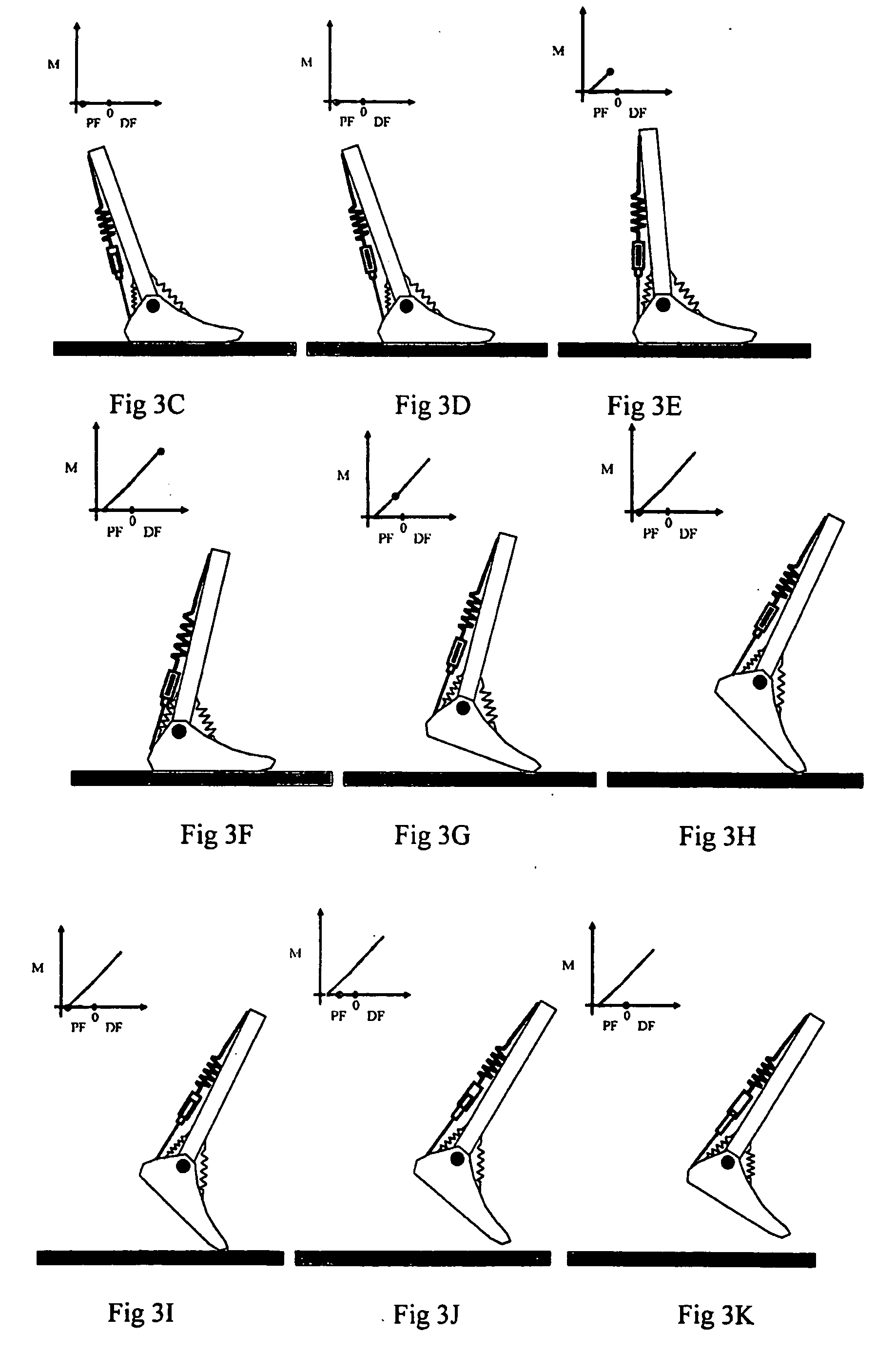

Equilibrium-point prosthetic and orthotic ankle-foot systems, devices, and methods of use

ActiveUS20100185301A1Reduce and prevent likelihoodWeaken energyArtificial legsDiseasePhysical medicine and rehabilitation

The present invention relates to a system for use in rehabilitation and / or physical therapy for the treatment of injury or disease. The system can enable an amputee to proceed over any surface without overbalancing. In particular the system is self-adapting to adjust the torque moment depending upon the motion, the extent of inclination, and the surface topography.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

Prostheses

InactiveUS6986792B2Reduce wearIncreasing or at least not compromising ability of the shell/linerJoint implantsFemoral headsFemoral stemWear resistance

Bipolar prostheses which include various structures and other techniques for optimizing material wear and mechanical strength properties. Such prostheses feature, for example, improved resistance to polyethylene wear while also reducing potential for dislocation of the femoral stem from the prosthesis. Such techniques and structures include varying wear resistance and mechanical strength treatment in various components of the prostheses or portions of those components as desired to improve, accentuate or optimize wear performance and dislocation reduction, locking ring structural features, structures for retaining locking rings in the bipolar prosthesis shell, and structures for limiting or reducing movement or rotation of locking rings and liners in bipolar prosthesis shells.

Owner:SMITH & NEPHEW INC

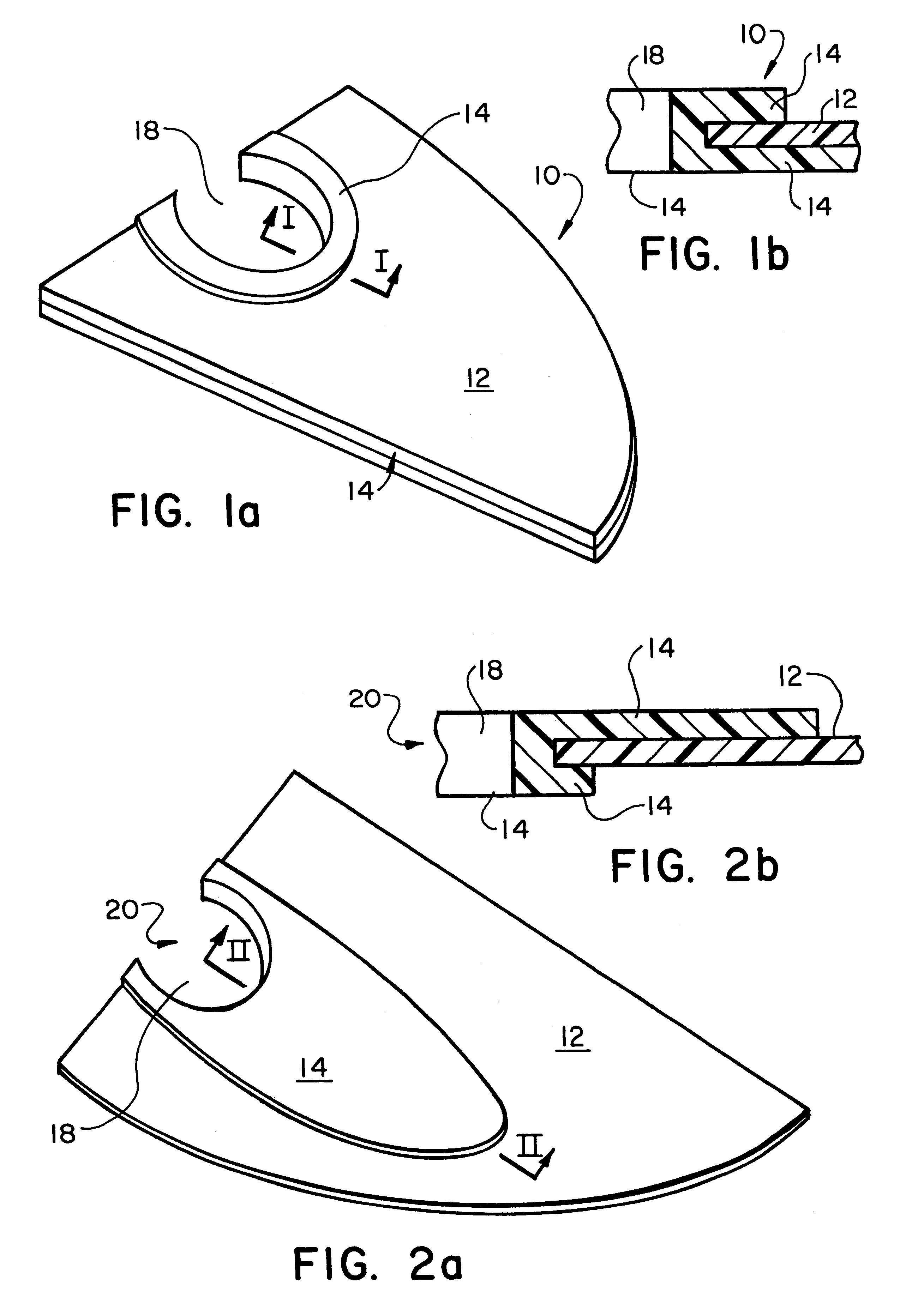

Hernia prosthesis

A prosthesis and a method for repairing a tissue or muscle wall defect, such as an inguinal hernia, near a cord-like structure, such as the spermatic cord. The prosthesis comprises a layer of repair fabric having a cord opening therethrough that is adapted to receive the cord-like structure when the prosthesis is implanted at the repair site. The prosthesis also includes a cord protector that is attachable to the repair fabric at the opening to isolate the cord-like structure from the fabric in proximity to the opening. The repair fabric may be formed from a material which is susceptible to the formation of adhesions with sensitive tissue and organs. The cord protector may be formed from material which inhibits the formation of adhesions with sensitive tissue and organs. The cord protector may overlie a portion of at least one of the first and second surfaces of the repair fabric. The cord protector may extend substantially farther away from the opening edge on one of the first and second surfaces than on the other of the first and second surfaces. The cord protector may be configured as an insert that is separate from and attachable to the repair fabric. Alternatively, the cord protector may be integral with the repair fabric to form a composite prosthesis.

Owner:CR BARD INC +1

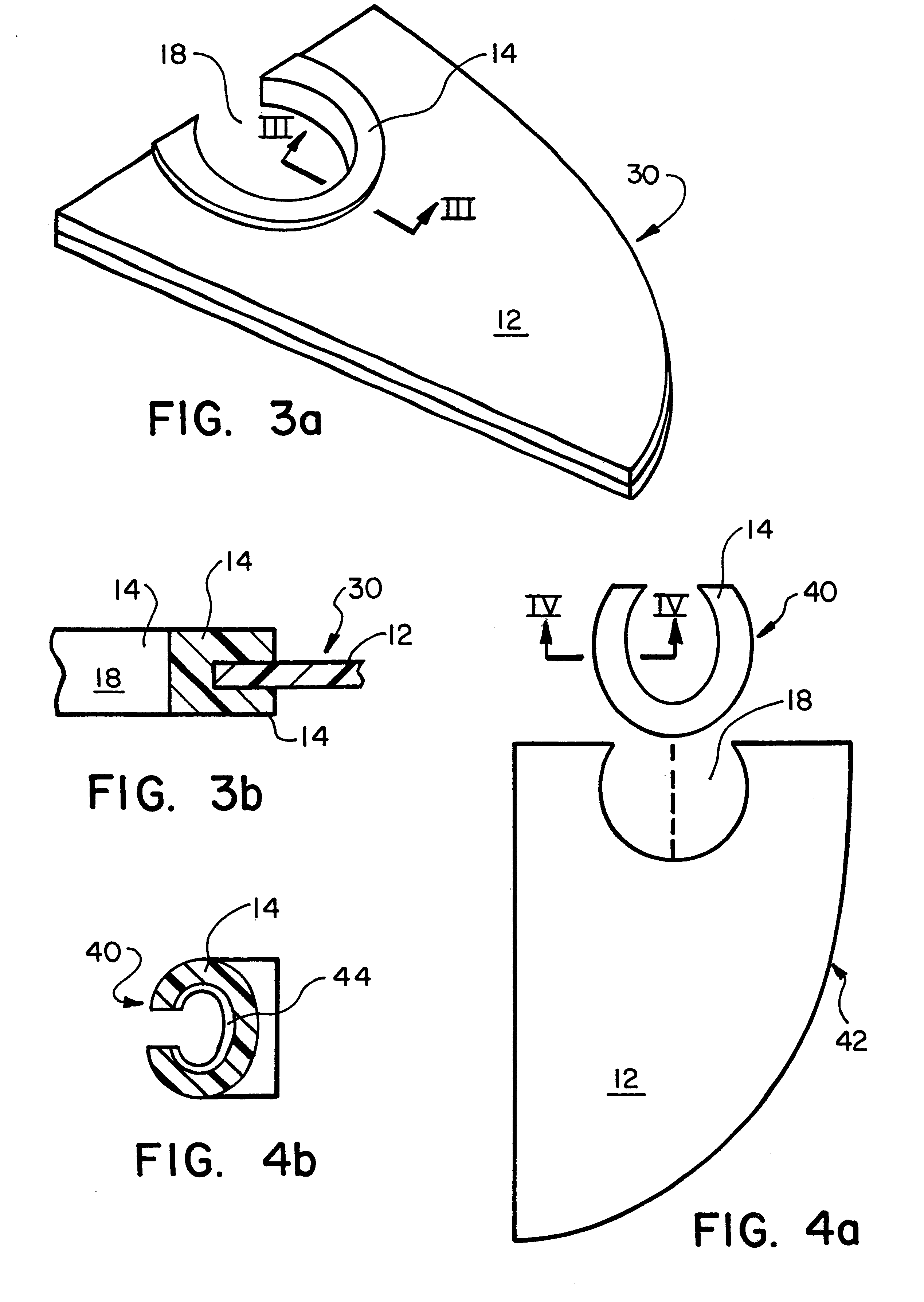

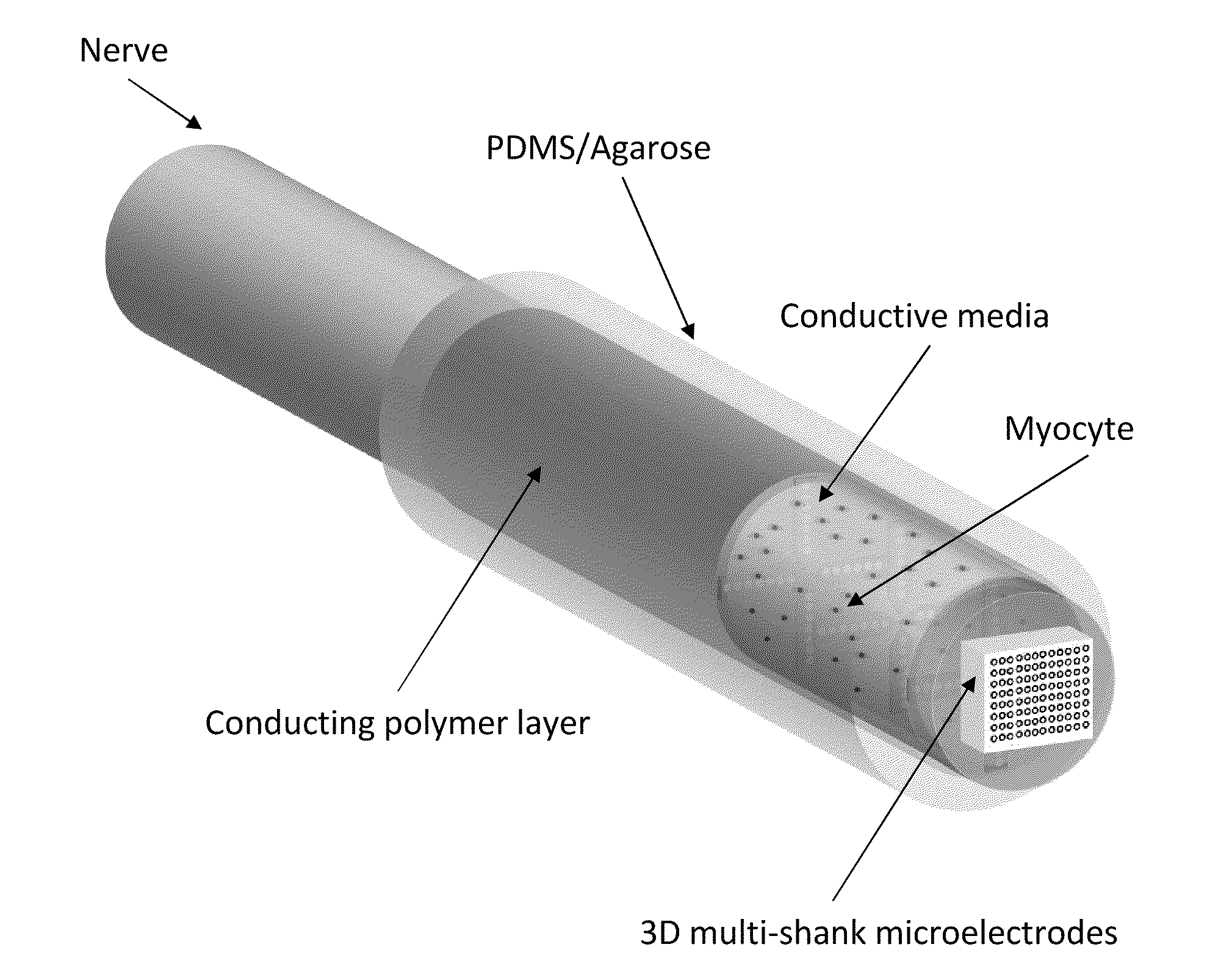

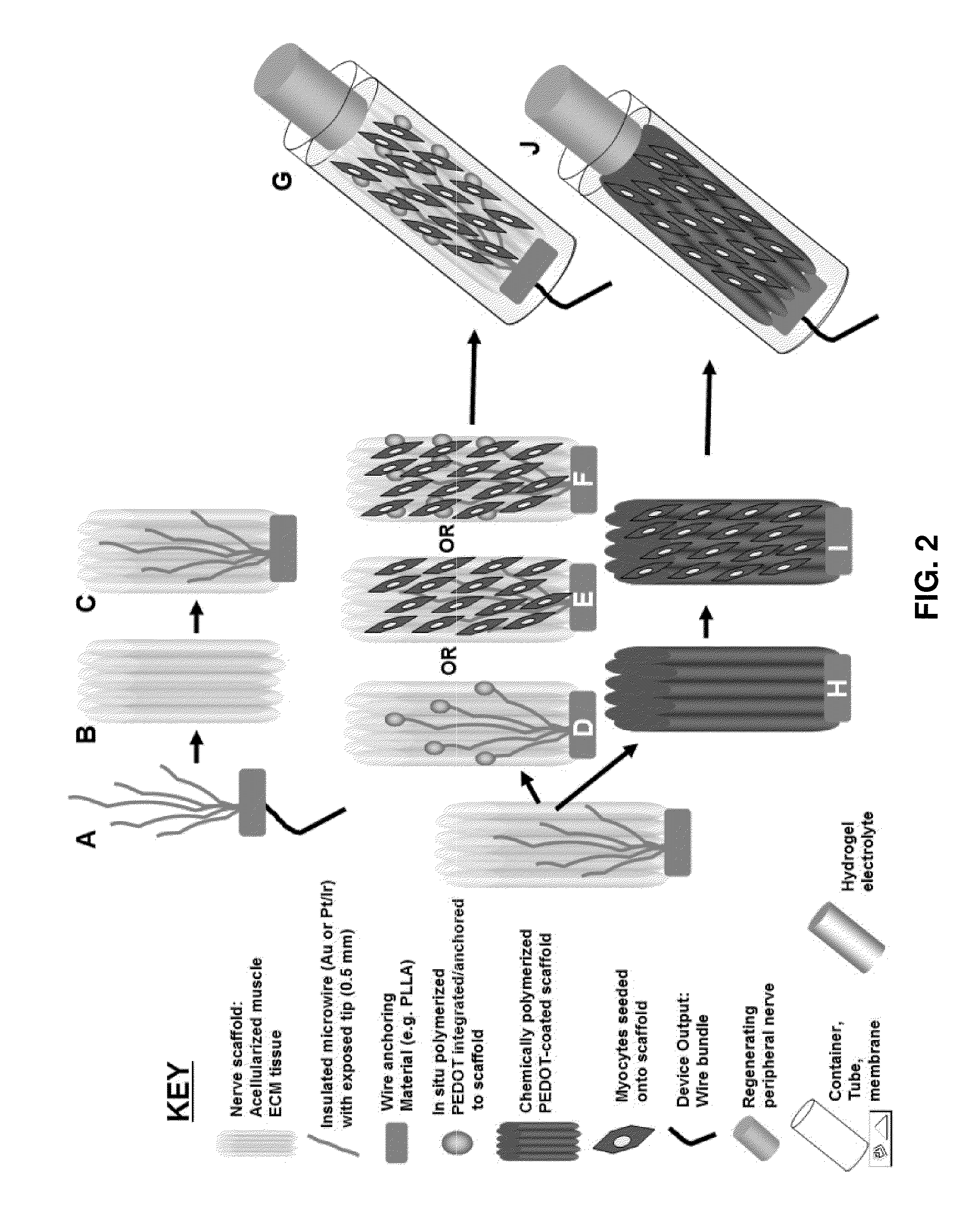

Hybrid bioelectrical interface device

InactiveUS20090292325A1Lack of directionalityGood handling characteristicsSpinal electrodesHead electrodesElectricityNervous system

A hybrid bioelectrical interface (HBI) device can be an implantable device comprising an abiotic component operable to transmit charge via electrons or ions; a biological component interfacing with the neural tissue, the biological component being sourced from biologic, biologically-derived, or bio-functionalized material; and a conjugated polymer component that together provide a means to chronically interface living neural tissue with electronic devices for extended durations (e.g. greater than 10 years). In some embodiments, conjugated polymers provide a functional electrical interface for charge transfer and signal transduction between the nervous system and an electronic device (e.g. robotic prosthetic limb, retinal implant, microchip).

Owner:RGT UNIV OF MICHIGAN

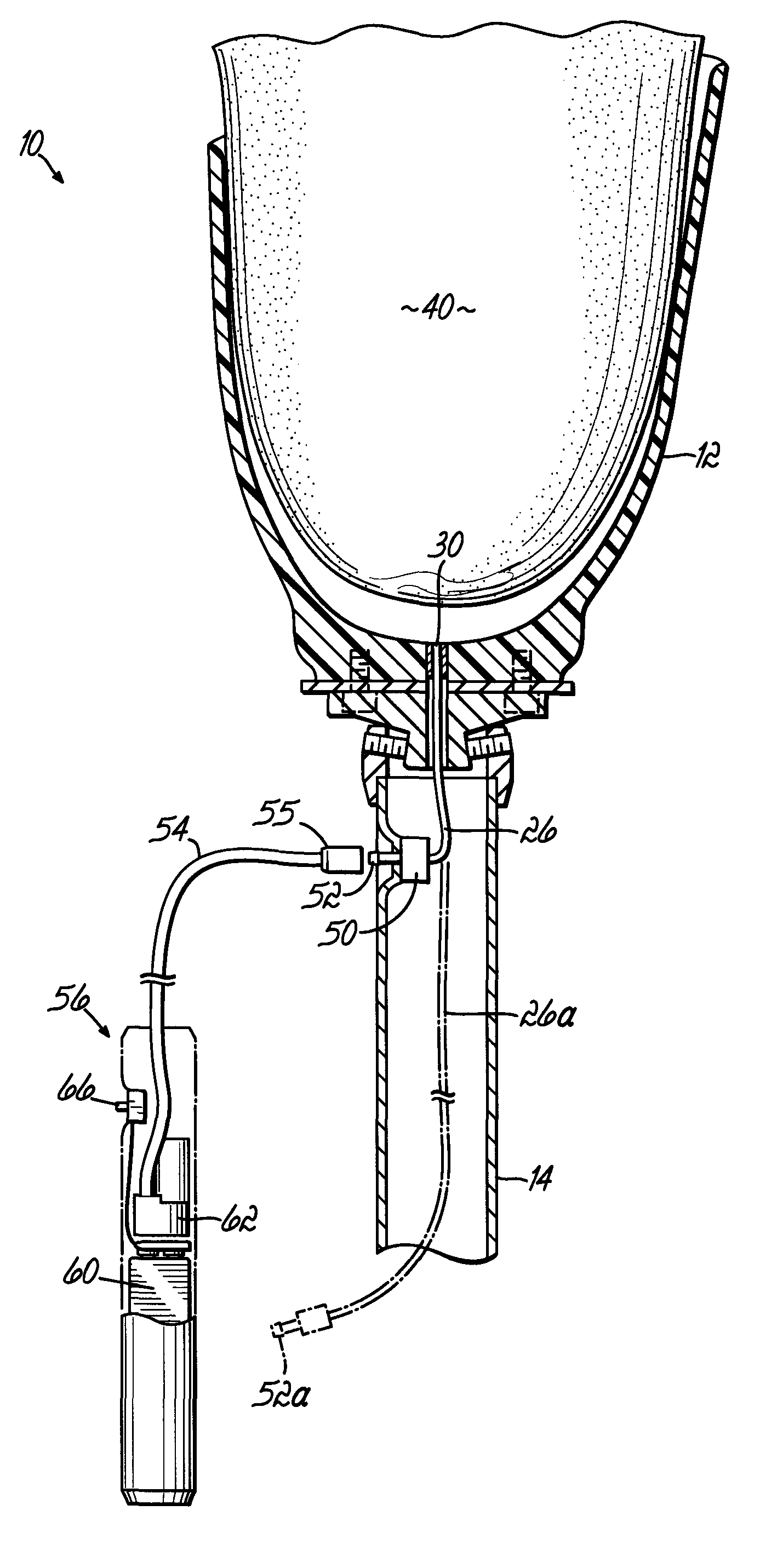

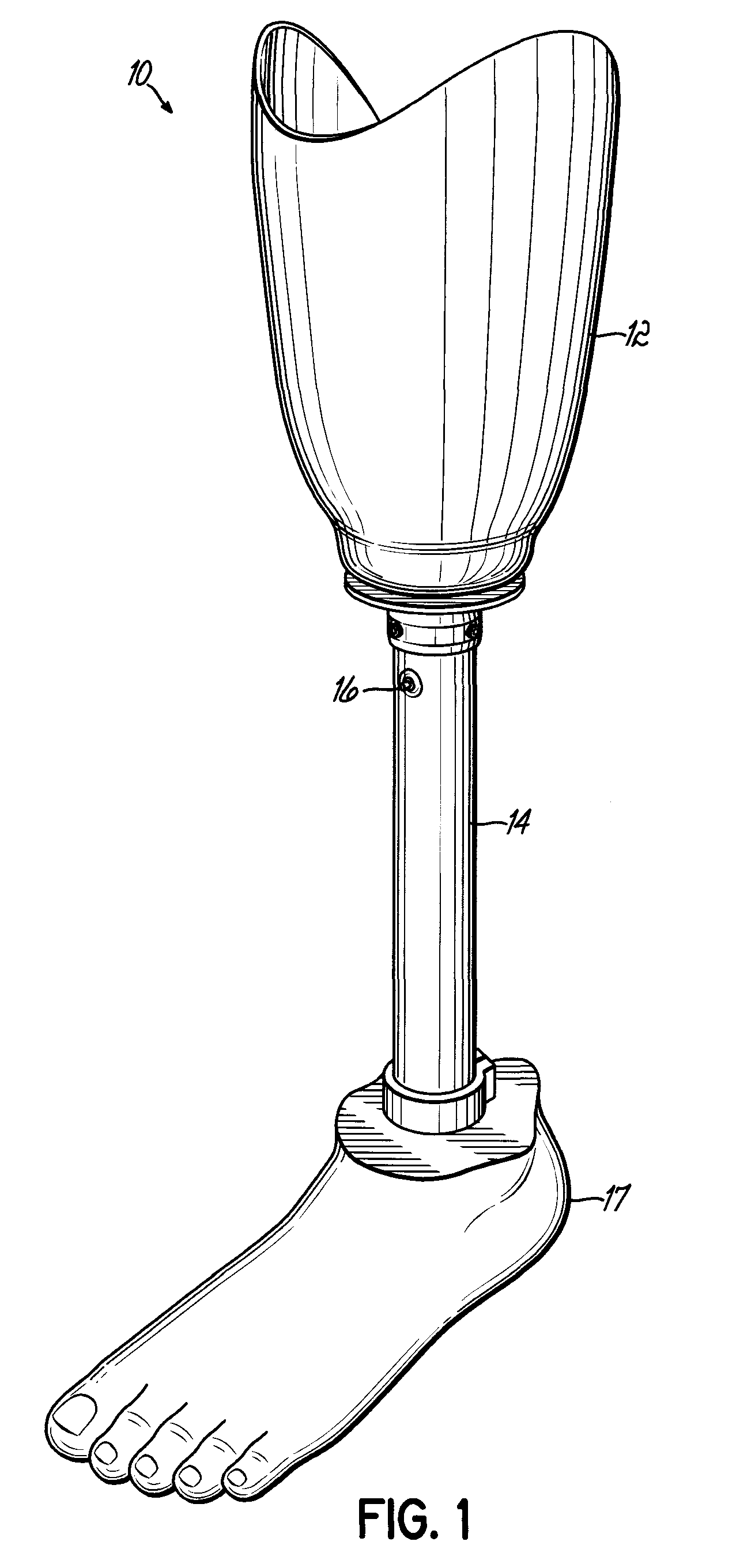

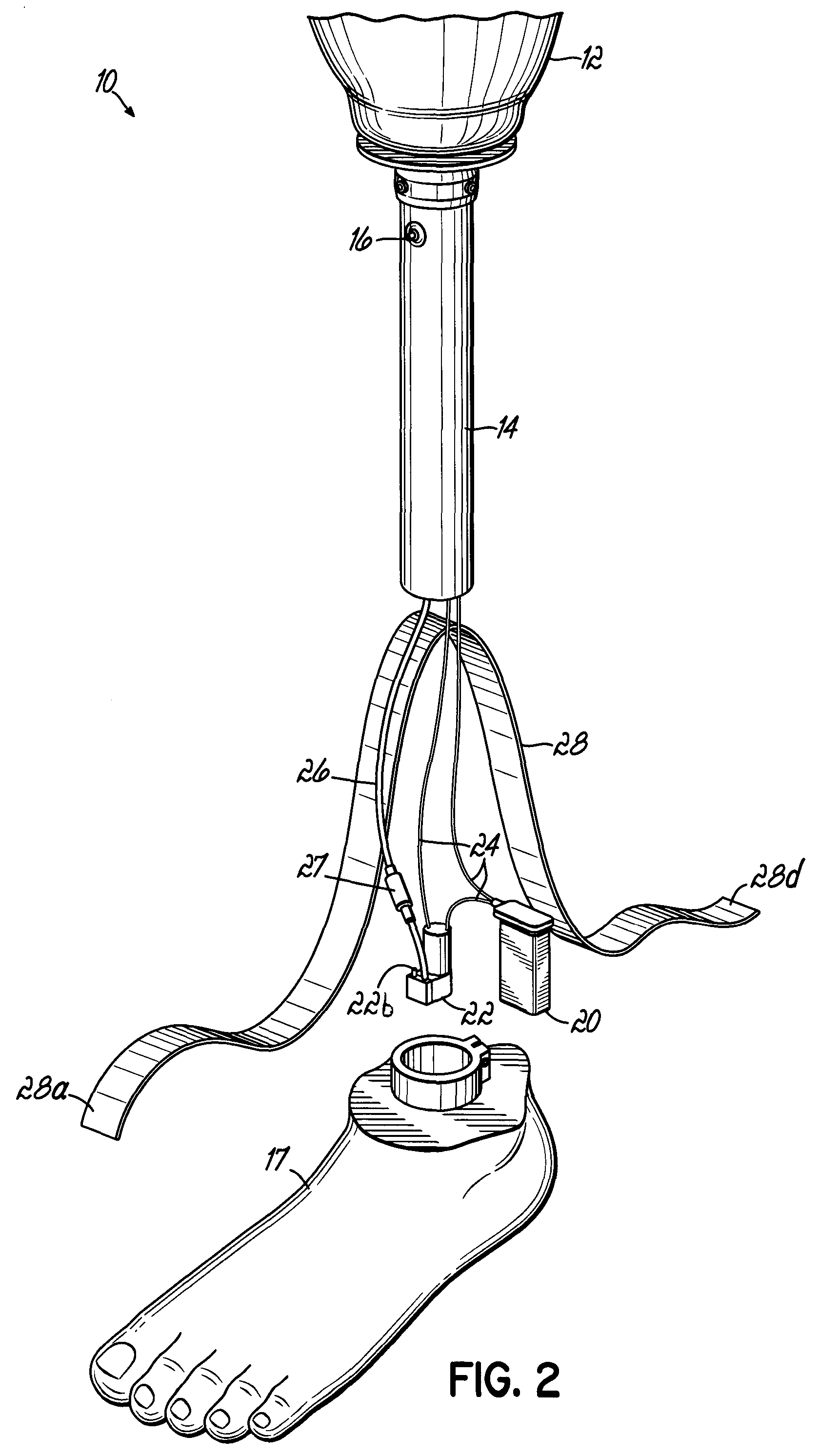

Prosthetic device utilizing electric vacuum pump

Evacuation devices for evacuating the socket of a prosthetic limb, and prosthetic limb systems employing such vacuum devices. The evacuation devices each preferably include at least an electrically powered vacuum pump and a power source. Such evacuation devices can be attached at various locations on or in a prosthetic limb. Because the electrically powered pump does not require manual manipulation to create vacuum, it is substantially easier to use than a manual pump. Due to the small size and small power source required by such an electrically powered pump, an evacuation device may be readily incorporated into a prosthesis.

Owner:WILLOWWOOD GLOBAL LLC

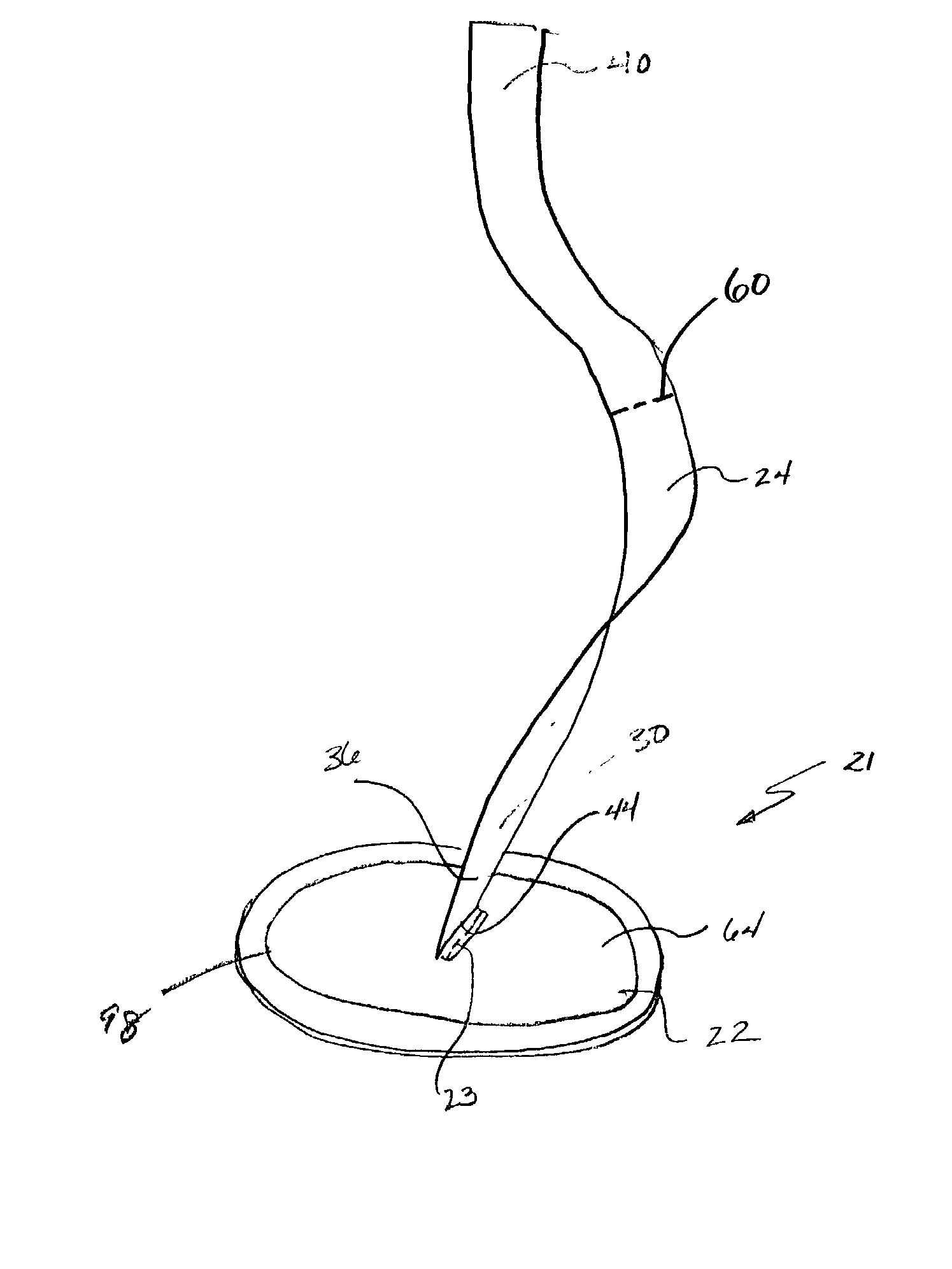

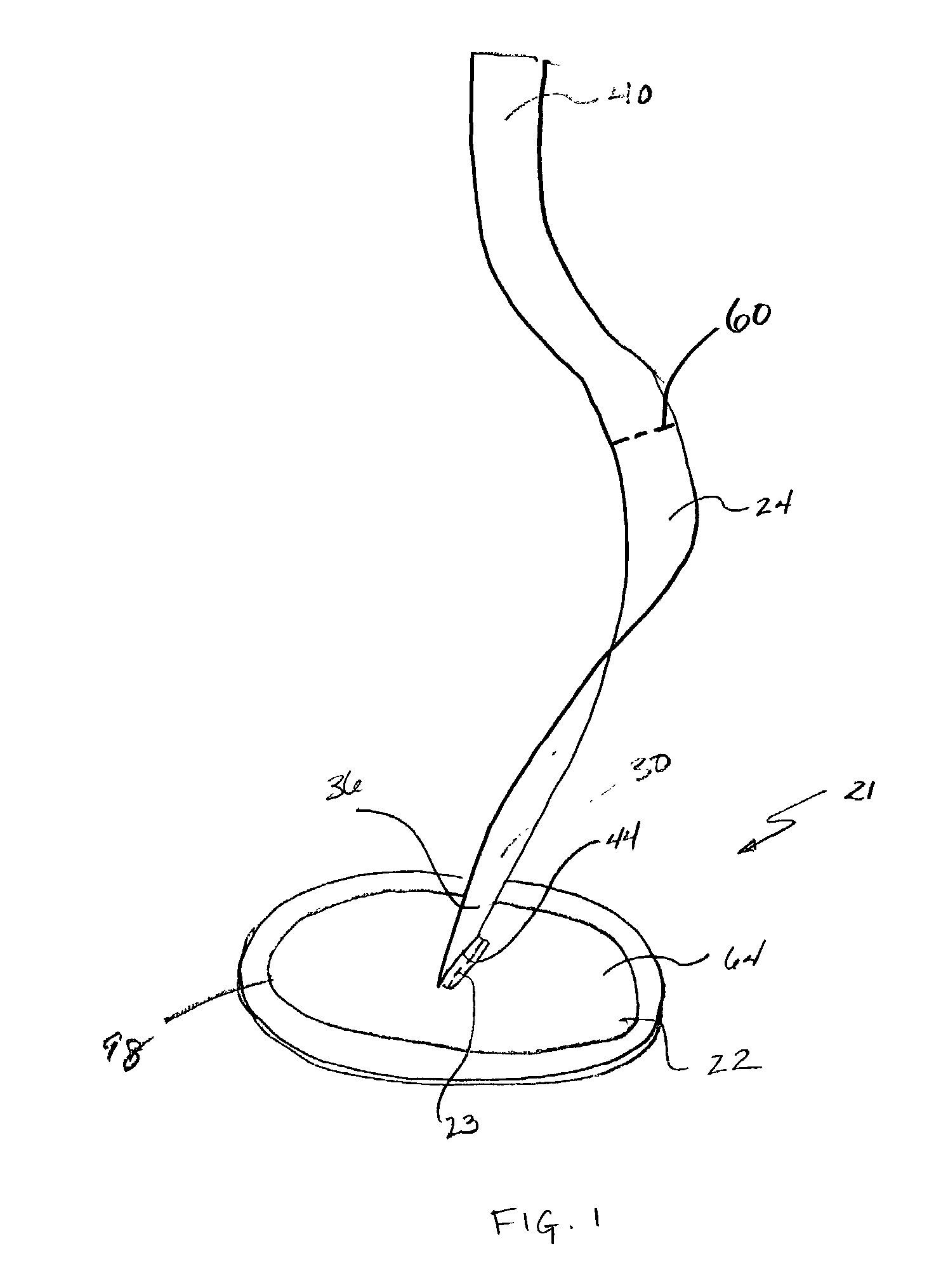

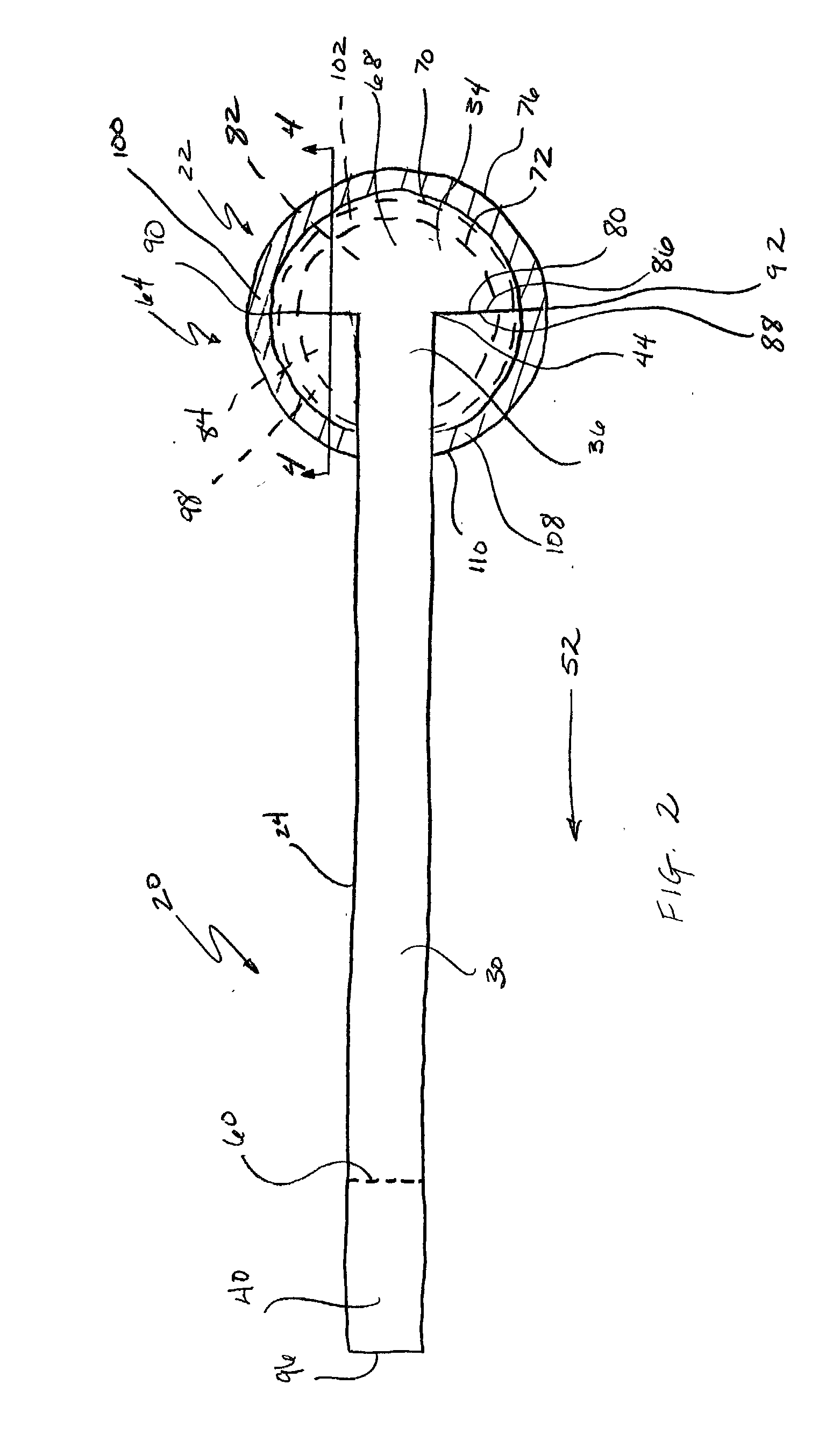

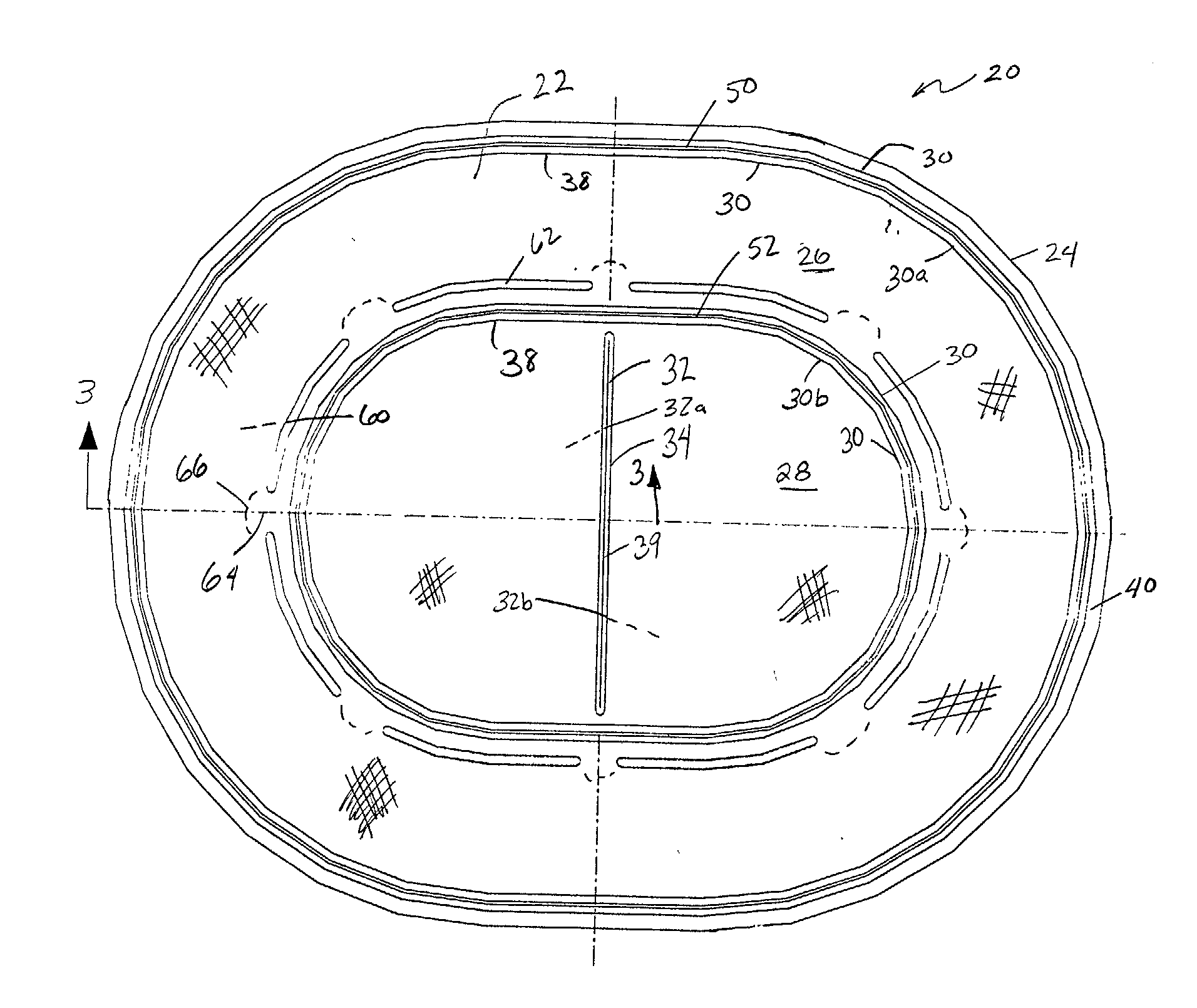

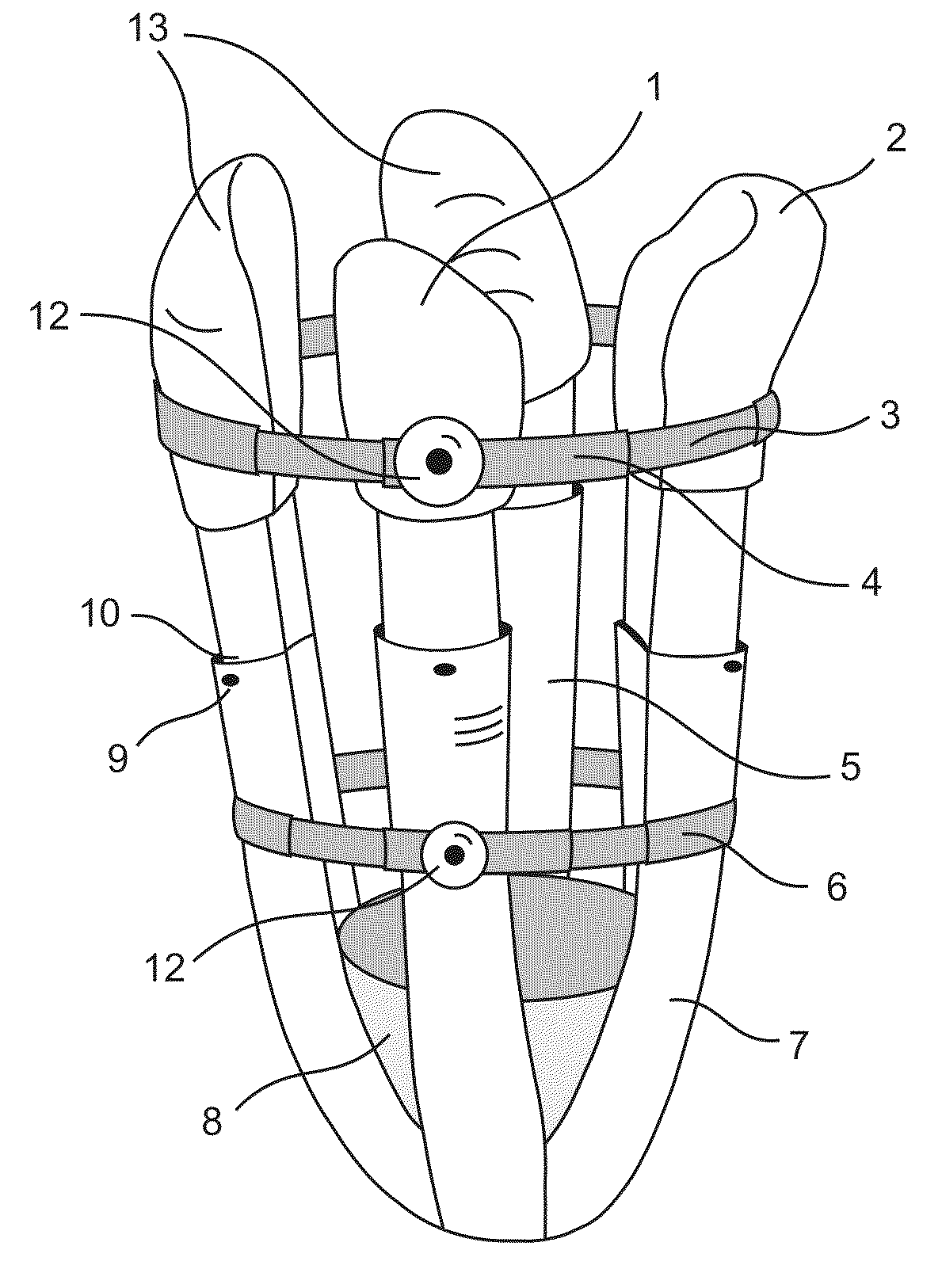

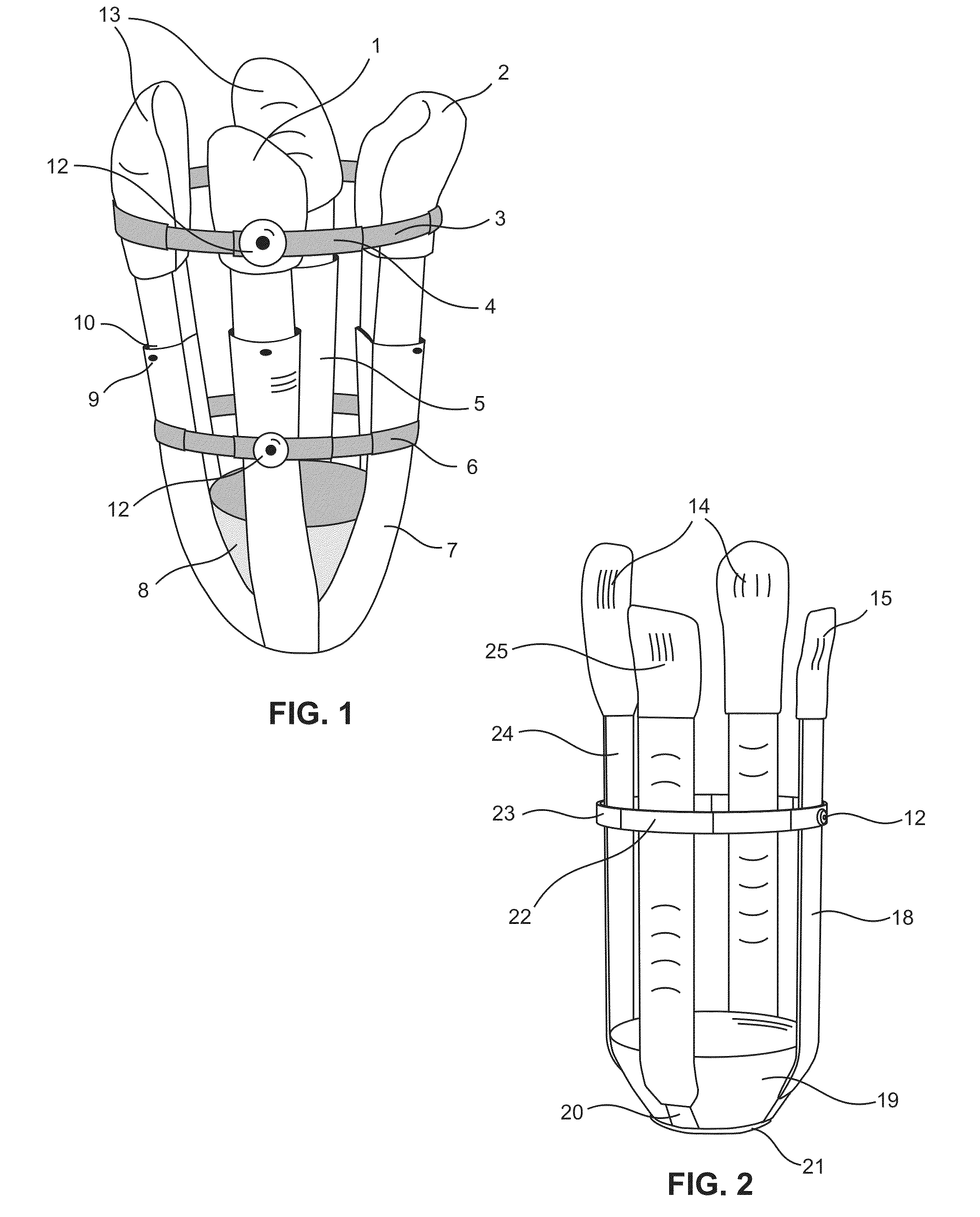

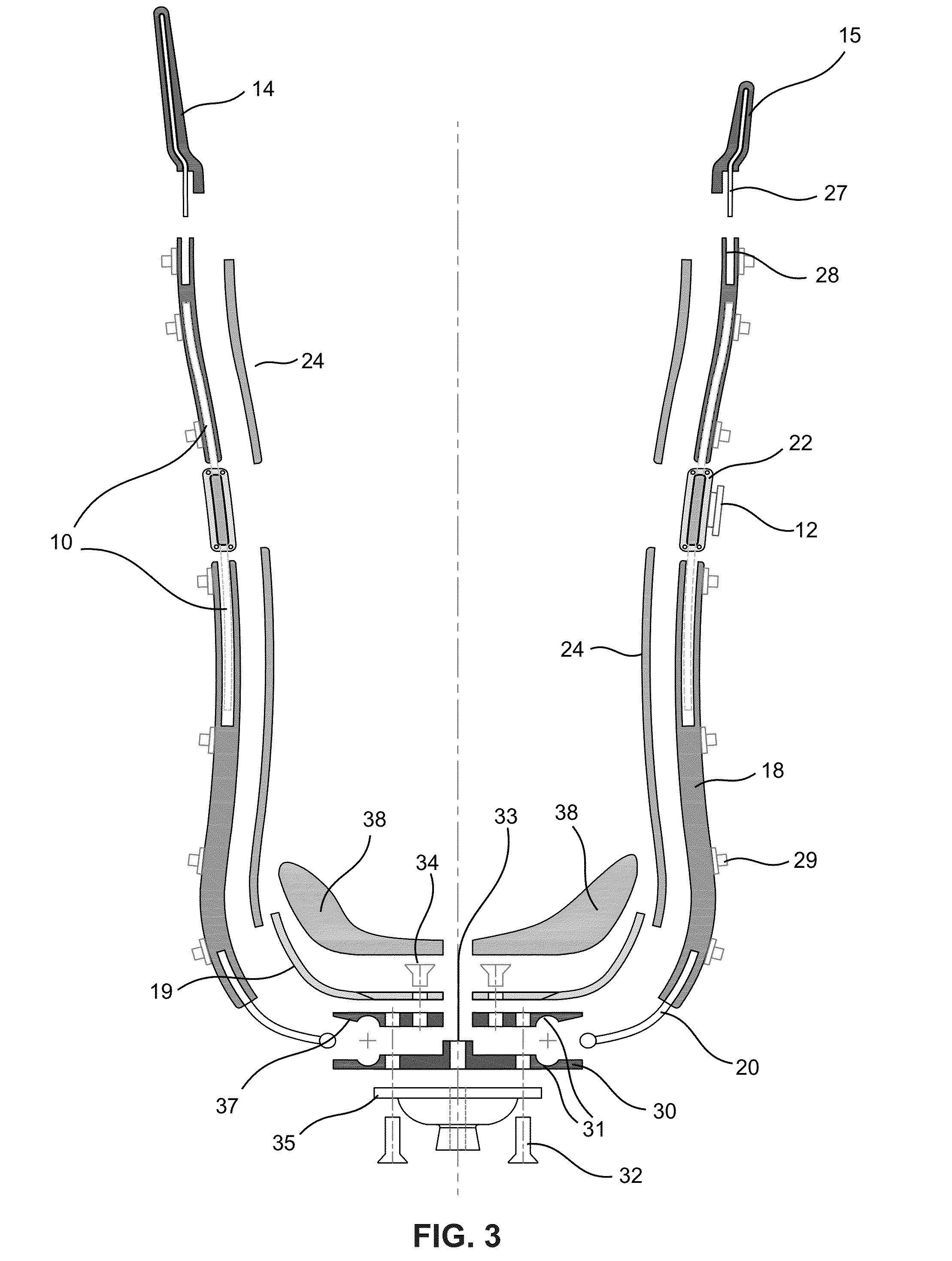

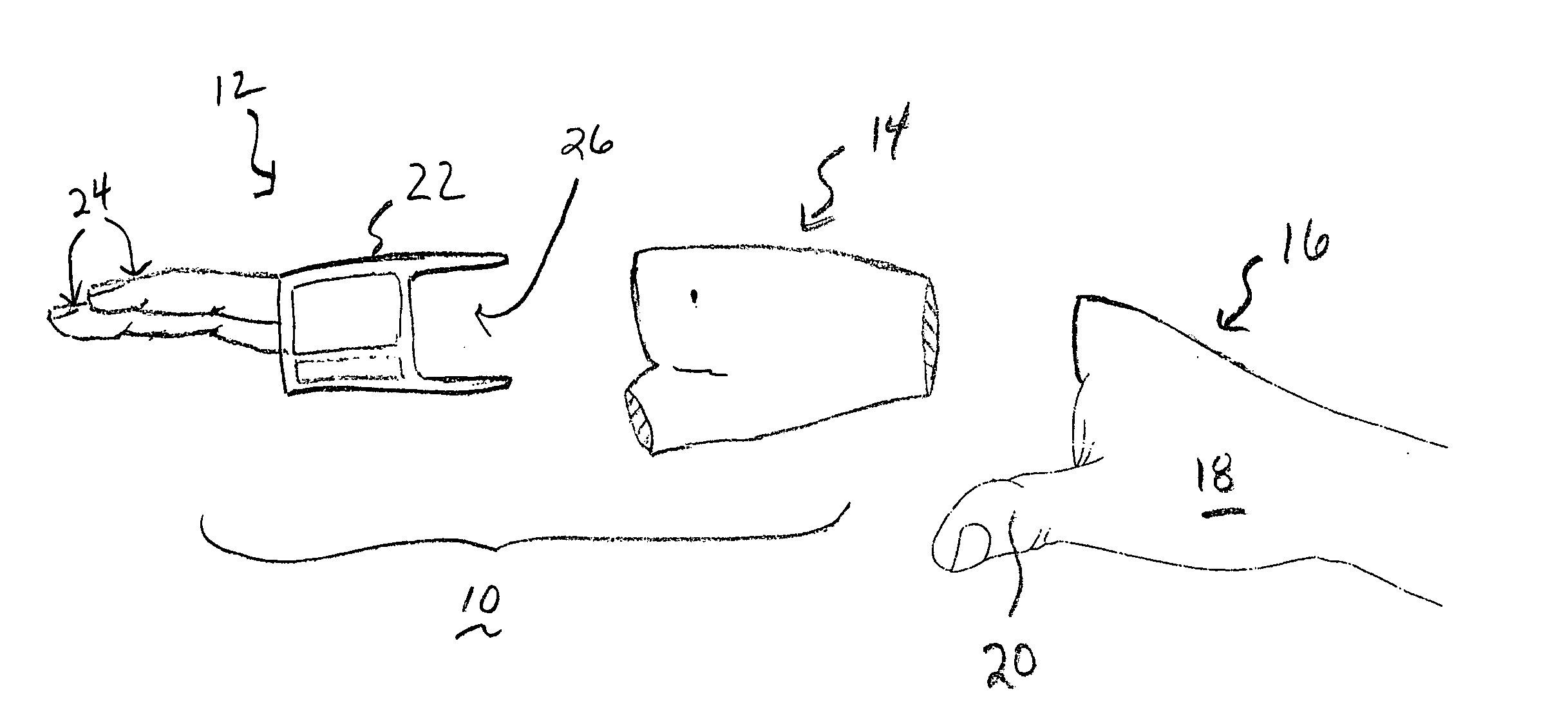

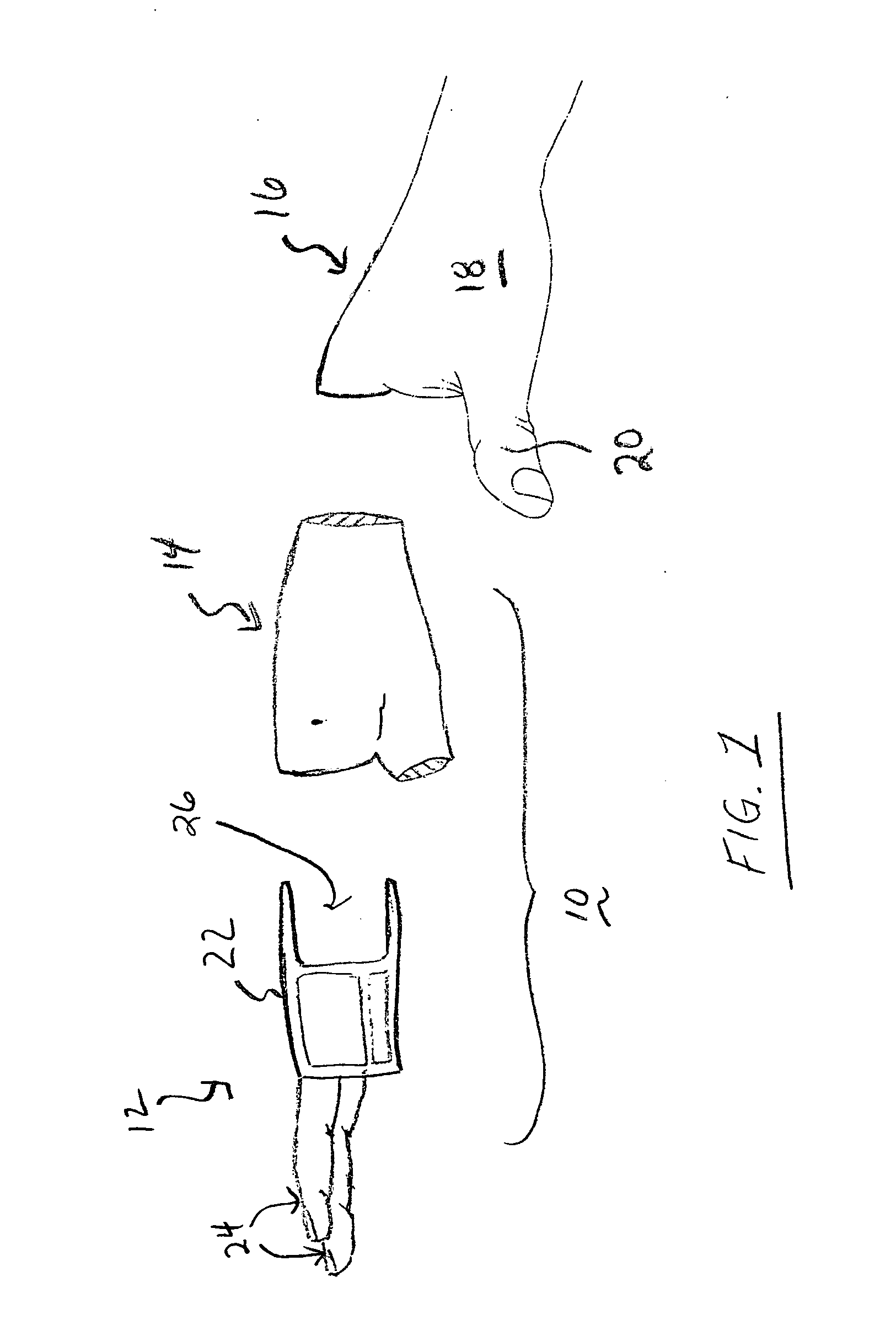

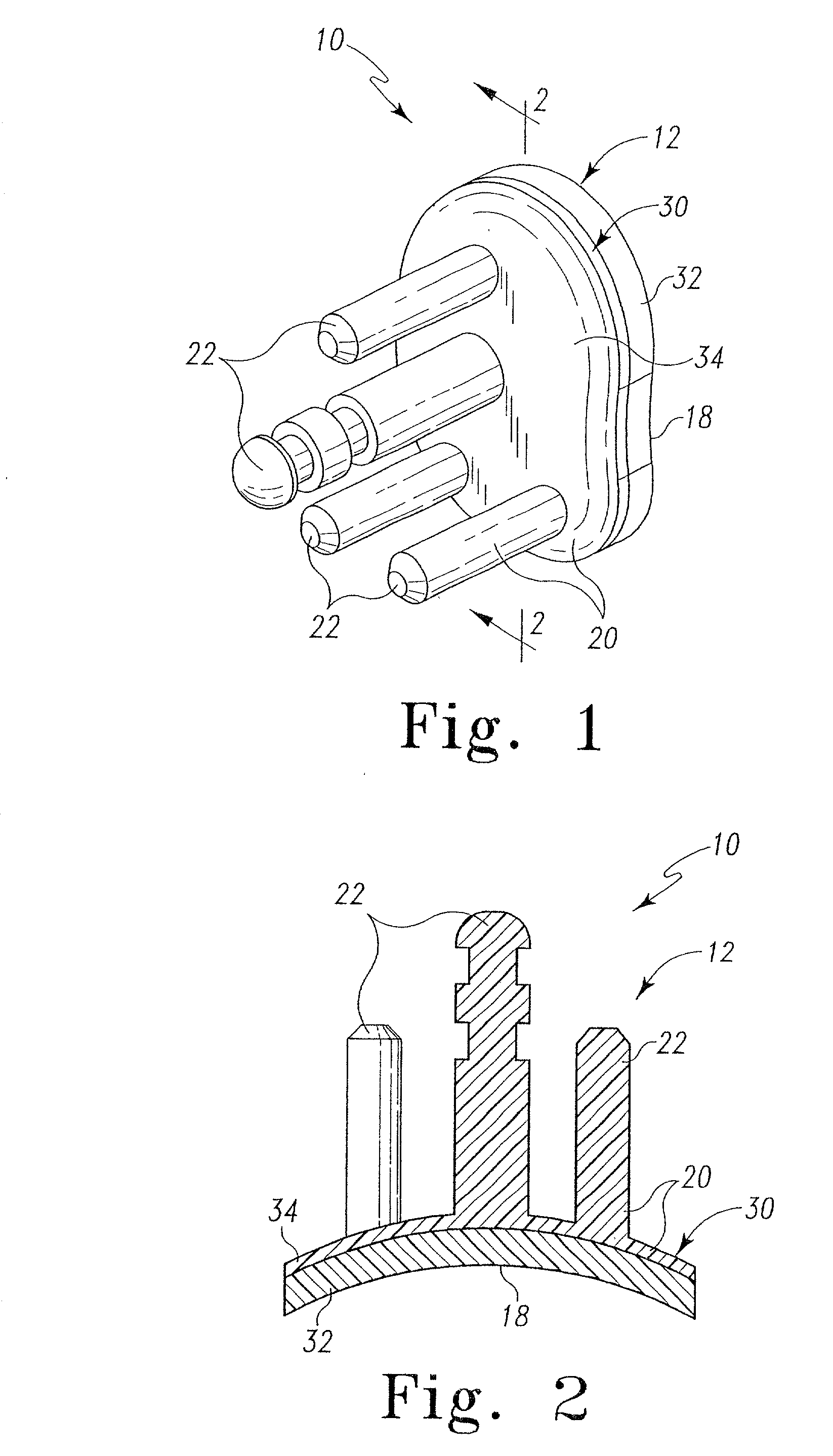

Partial hand prosthesis

A prosthetic device (12) and liner (14) form a prosthetic system (10) that can substantially mimic the cosmetic and functional qualities of a human hand. A harness (22) is adapted to fit about a remnant portion (16) of a hand (18). The harness has an opening (26) for accommodating the liner (14). A moveably mounted opposition member (24) is supported by the harness (22) and sensors (60, 62) positioned about the harness (22) detect a force exerted by an area (40) in proximity to the hypothenar eminence of remnant portion. Once a force is detected by either sensor (60, 62) a signal is communicated to a controller (70) which activates a motor (100) causing motion of the opposition member (24).

Owner:ADVANCED ARM DYNAMICS OF TEXAS

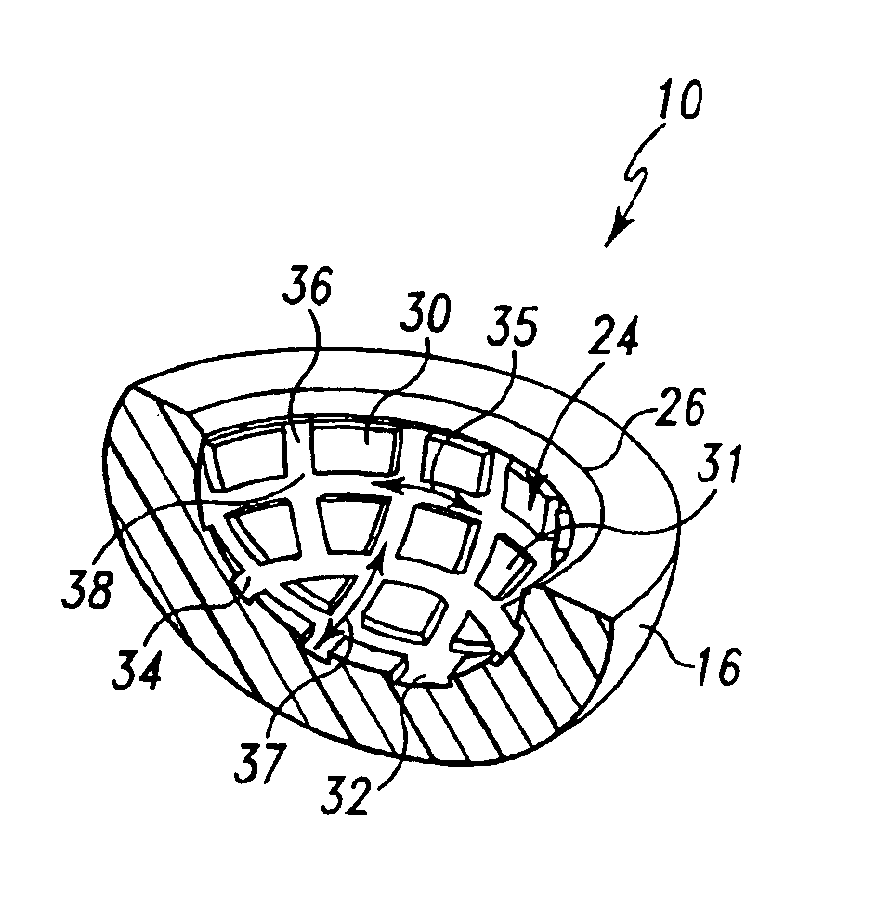

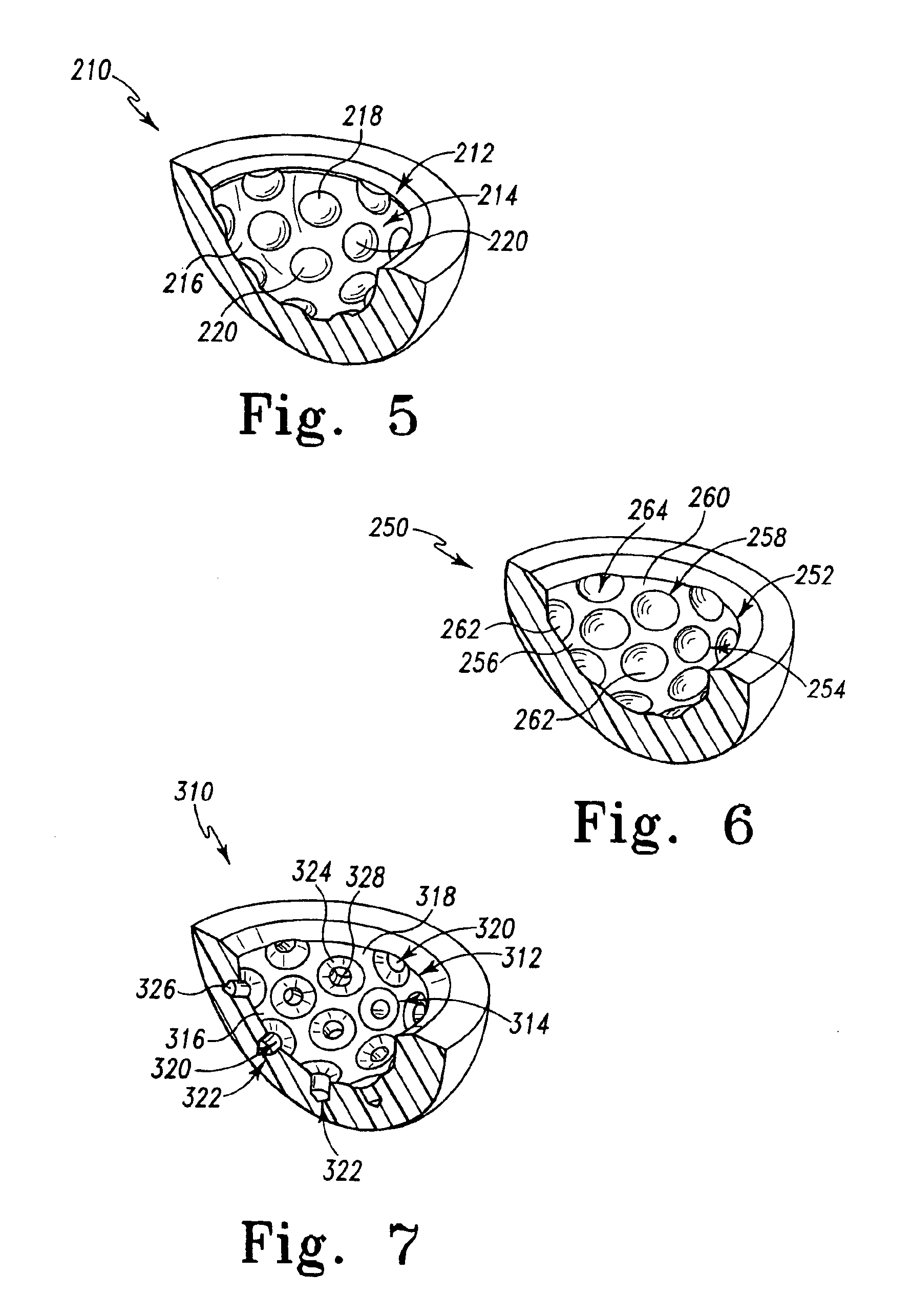

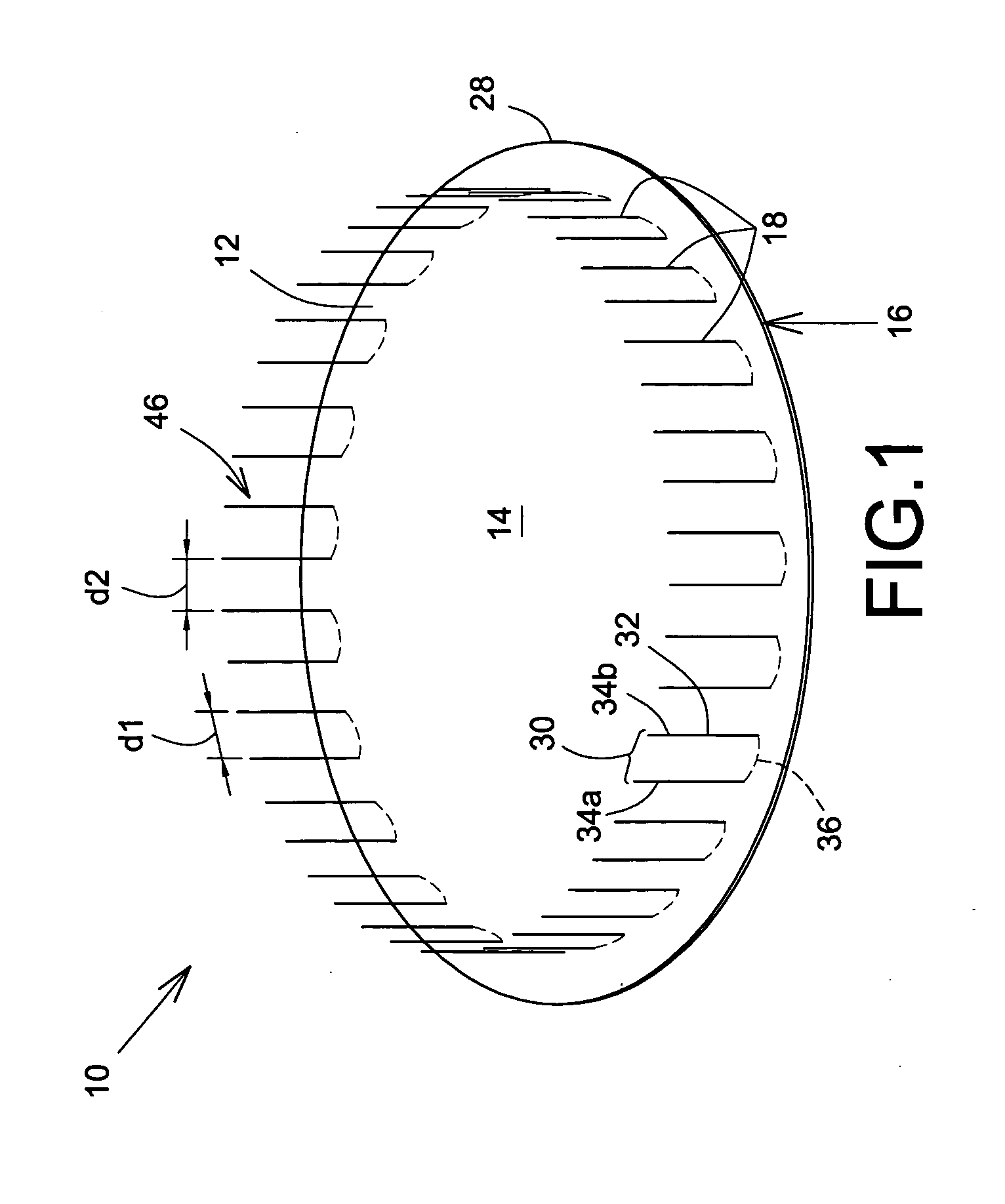

Prosthetic joints having reduced area bearing surfaces and application thereof to a range of sizes of prosthetic joints

InactiveUS6866685B2Reduce frictional torqueReduce wearWrist jointsAnkle jointsRange of motionProsthesis

A prosthetic component is configured to have intentional interruptions in an articulating face thereof. The intentional interruptions are configured to yield an optimum contact area or bearing surface, particularly with regard to low wear and greater lubricity through the application of lubrication and contact mechanics theory for the particular prosthetic component. Such optimization is applied to a wide range of prosthetic component sizes of the particular prosthetic component. The optimum range of percentage area of relief or interruptions, defined as a percentage of a baseline uninterrupted bearing surface area to be removed by the features of the interrupted bearing surface configuration is from 0.3% to 73.7% for hard-on-hard bearing components and from 5.7% to 83.2% for polyethylene-on-hard bearing components. The range for both hard-on-hard and polyethylene-on-hard implants translates to a relieved area ranging from 0.3% to 31.9% of the area of the entire articulating surface, depending on the size of the implant. For both hard-on-hard and polyethylene-on-hard bearing combinations, optimally decreasing the contact area or bearing surface by interruptions in the articulating surfaces will allow for the benefits of larger diameter prosthetic components with an increased range of motion and decreased potential for dislocation, and the low frictional torques and lower wear of smaller diameter components.

Owner:DEPUY ORTHOPAEDICS INC

Composite prosthetic bearing constructed of polyethylene and an ethylene-acrylate copolymer and method for making the same

Owner:DEPUY SYNTHES PROD INC

Prosthetic repair patch with integrated sutures

InactiveUS20080167519A1Repair be simplify and accelerateReduce riskProsthesisWound clampsProsthetic patchProsthesis

A prosthetic repair patch has a sheet and a plurality of sutures integrated there with. The sheet, with first and second sheet surfaces, completely under covers a hernia in the abdominal tissue of a patient with the first sheet surface adjacently abutting a first surface of the tissue that faces away from a person installing the patch. The sutures are connected to the sheet in a spaced apart configuration from one another and each has a longitudinal end thereof that extends from the first sheet surface. Each suture end is adapted to extend through the tissue for locally abutting the first sheet surface to the first tissue surface and to extend from an opposite second surface of the tissue for attachment with another suture end thereat for local fastening of the sheet to the tissue. The present invention also discloses a method of under covering a hernia with the repair patch.

Owner:ST GERMAIN PASCAL

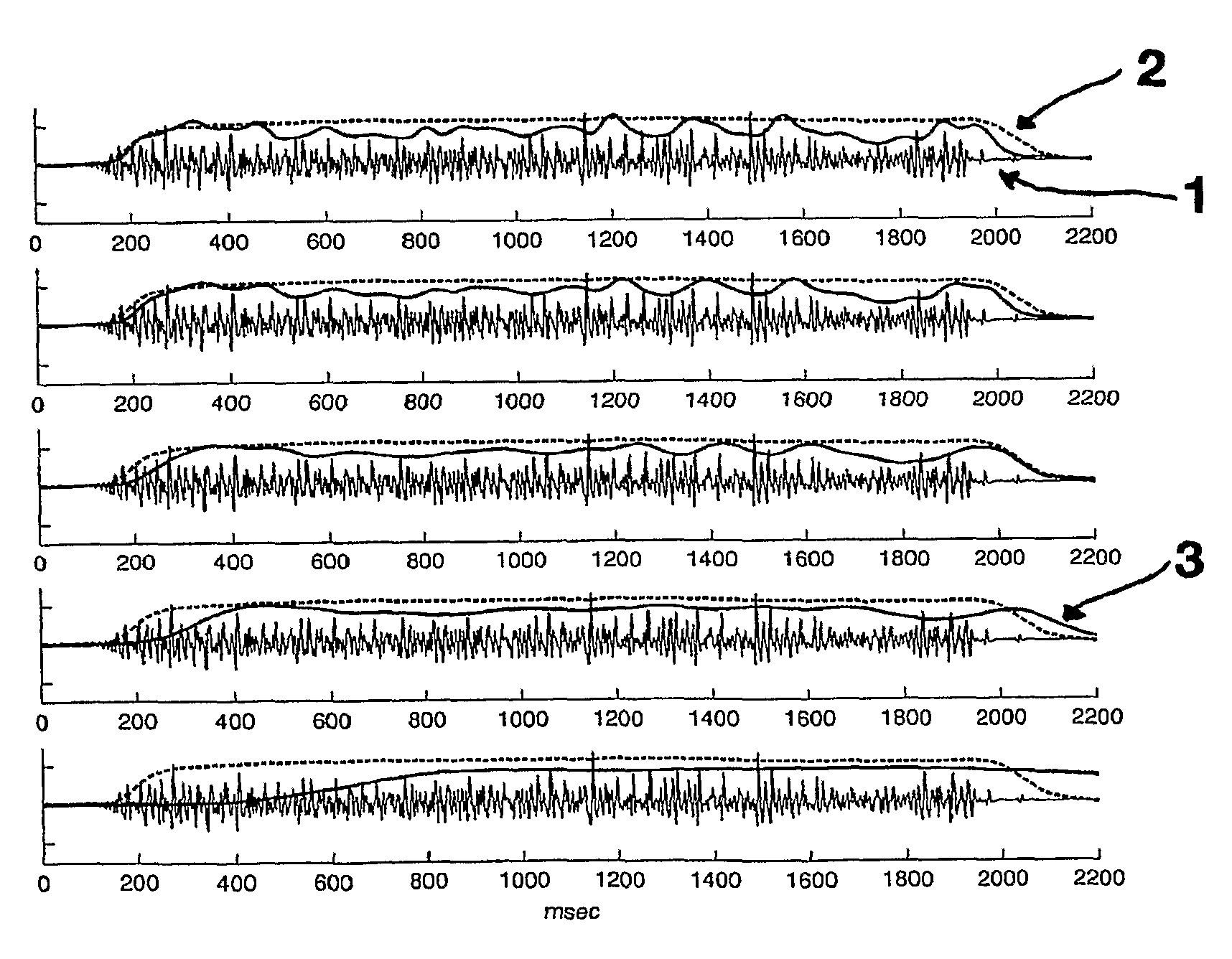

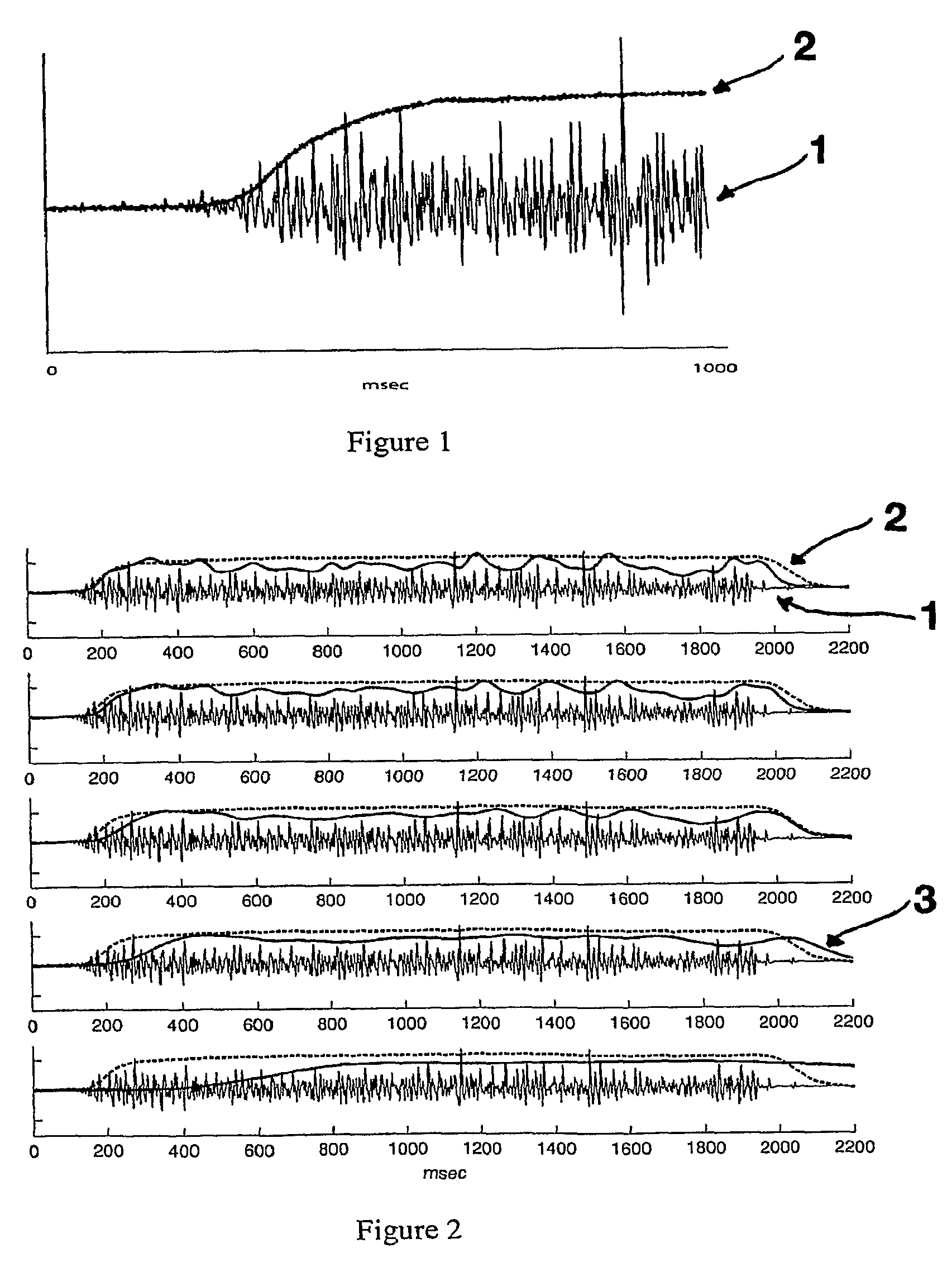

Systems and methods for estimating surface electromyography

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com