Patents

Literature

55 results about "O-ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface.

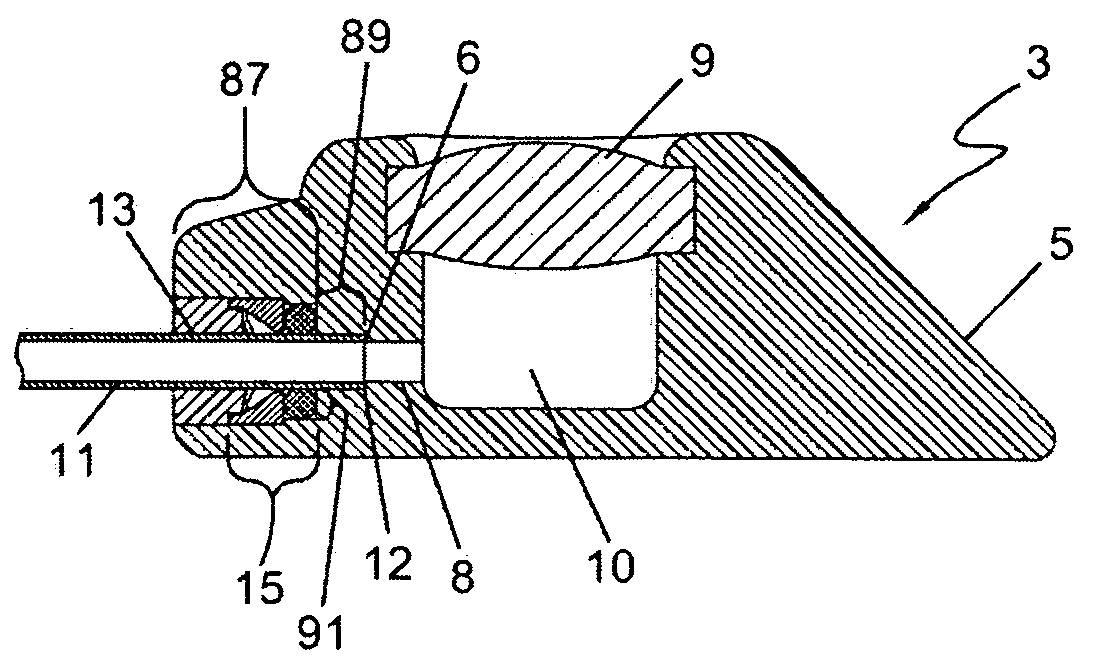

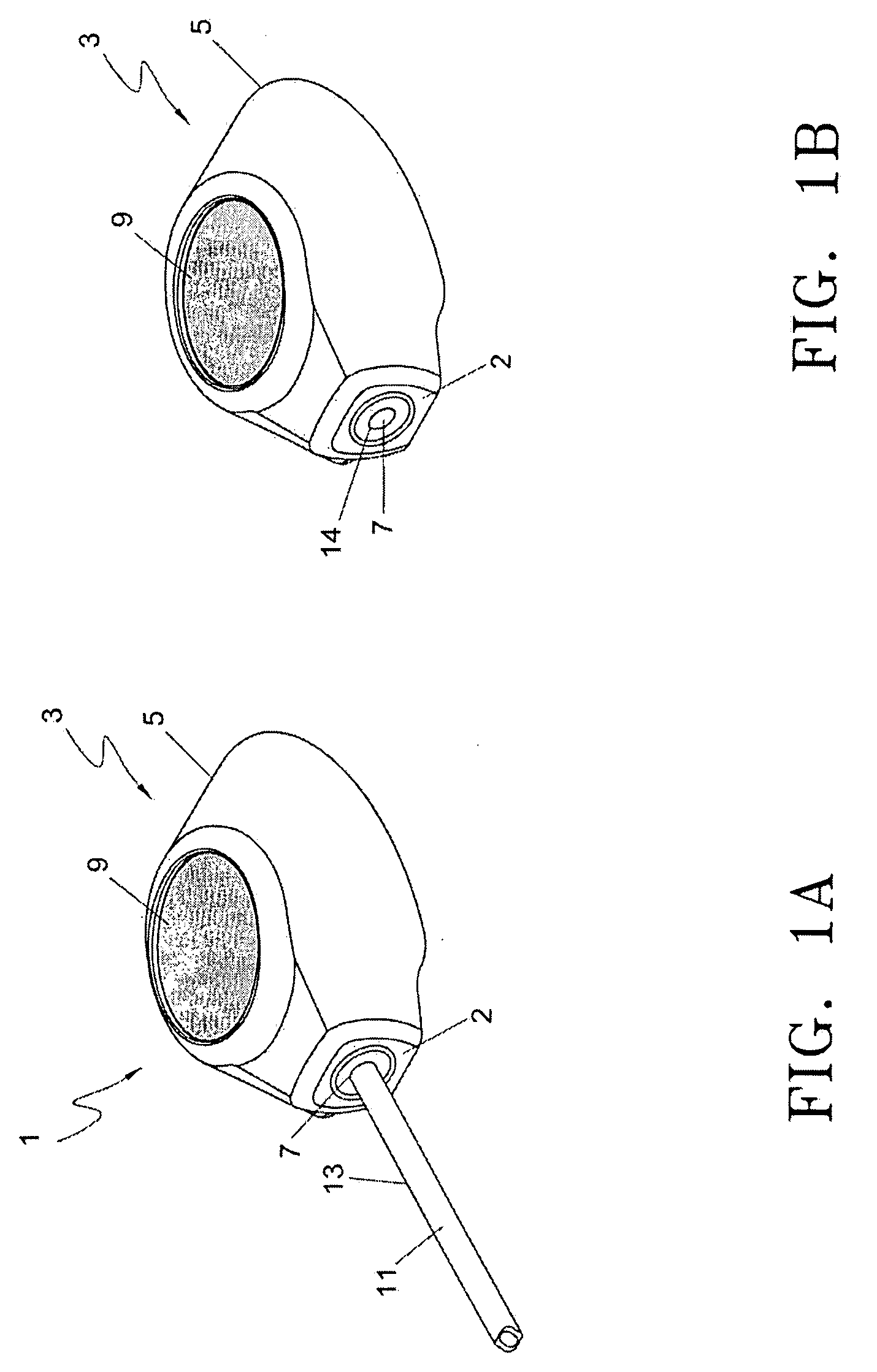

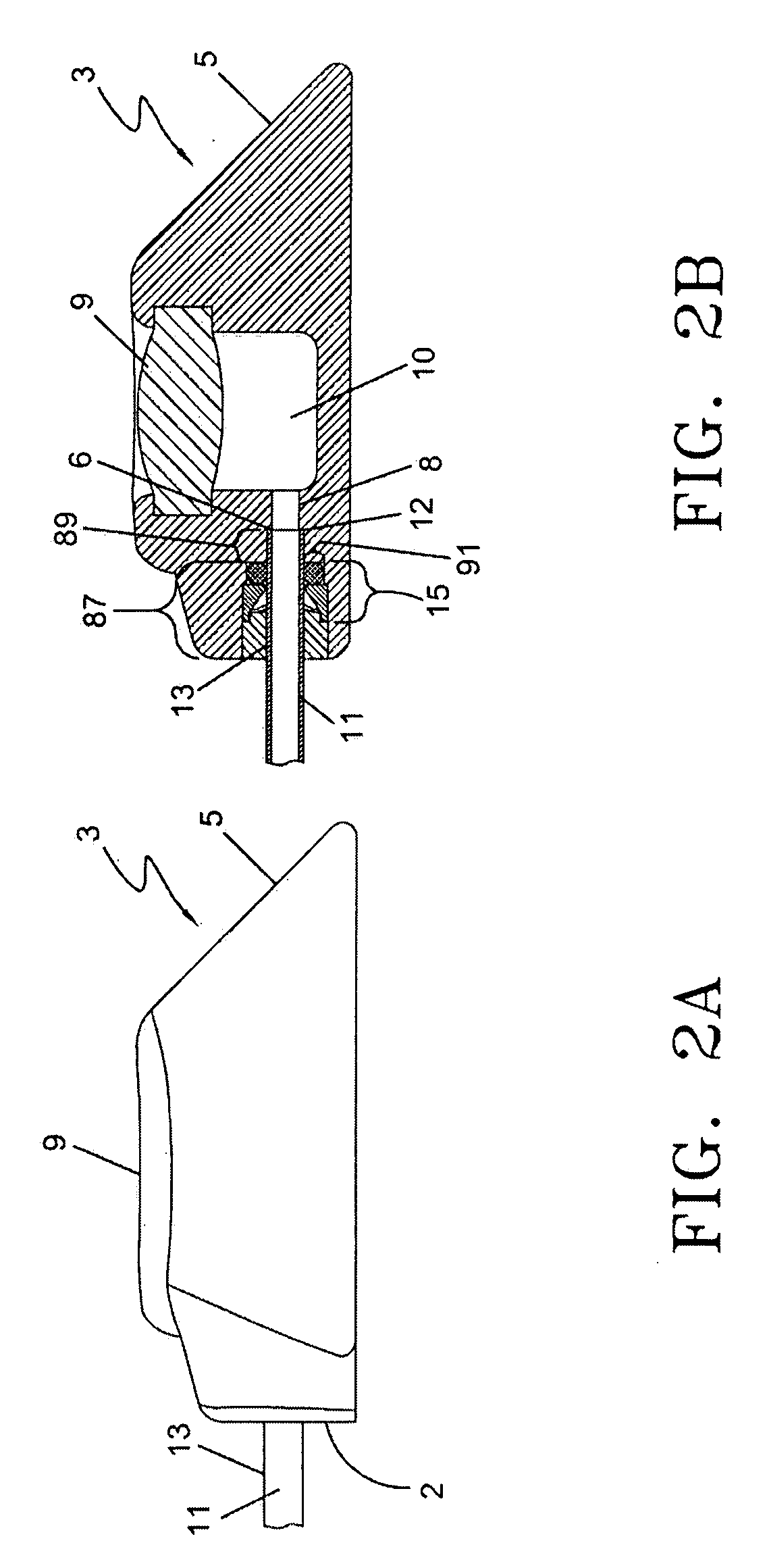

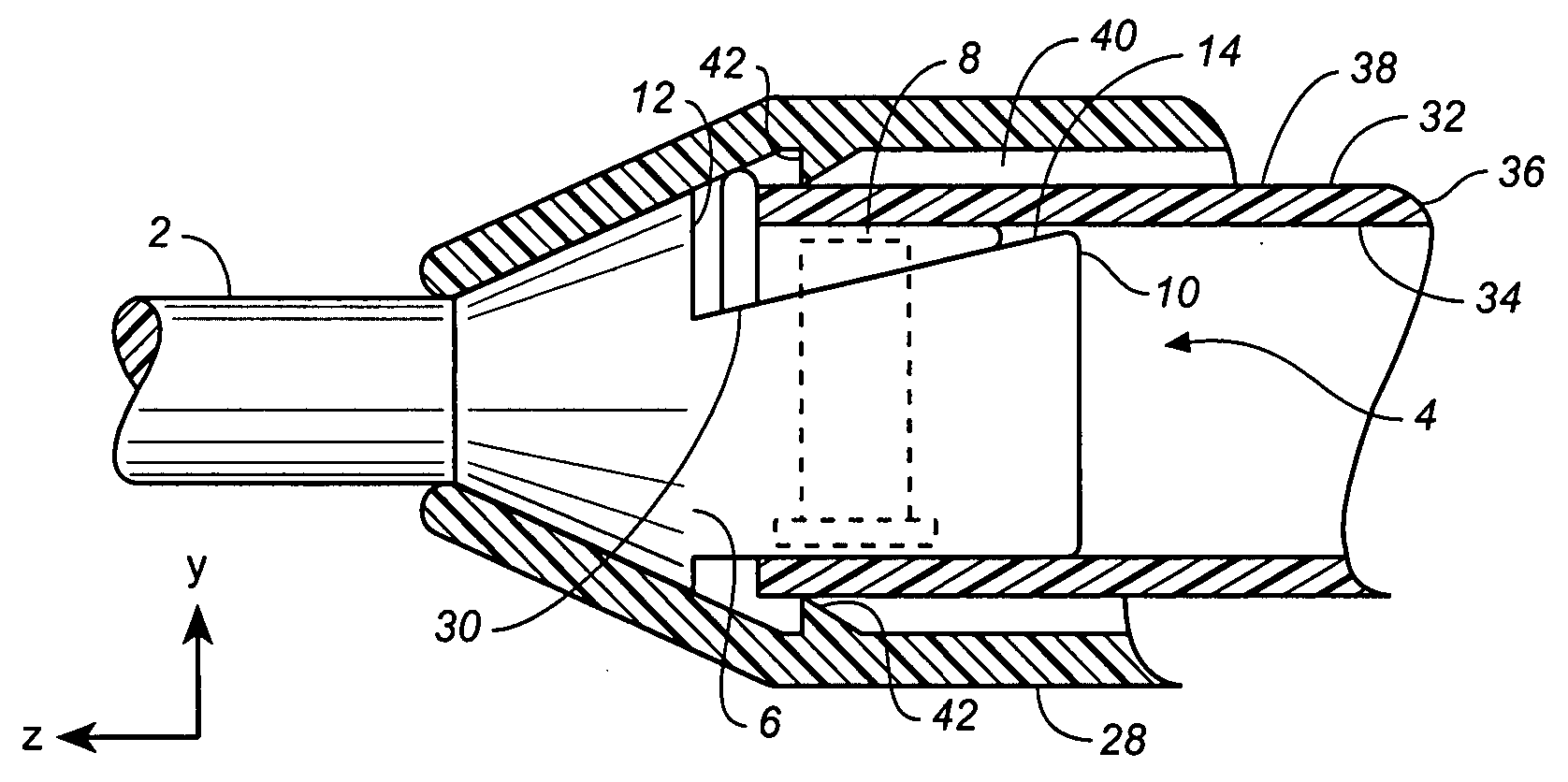

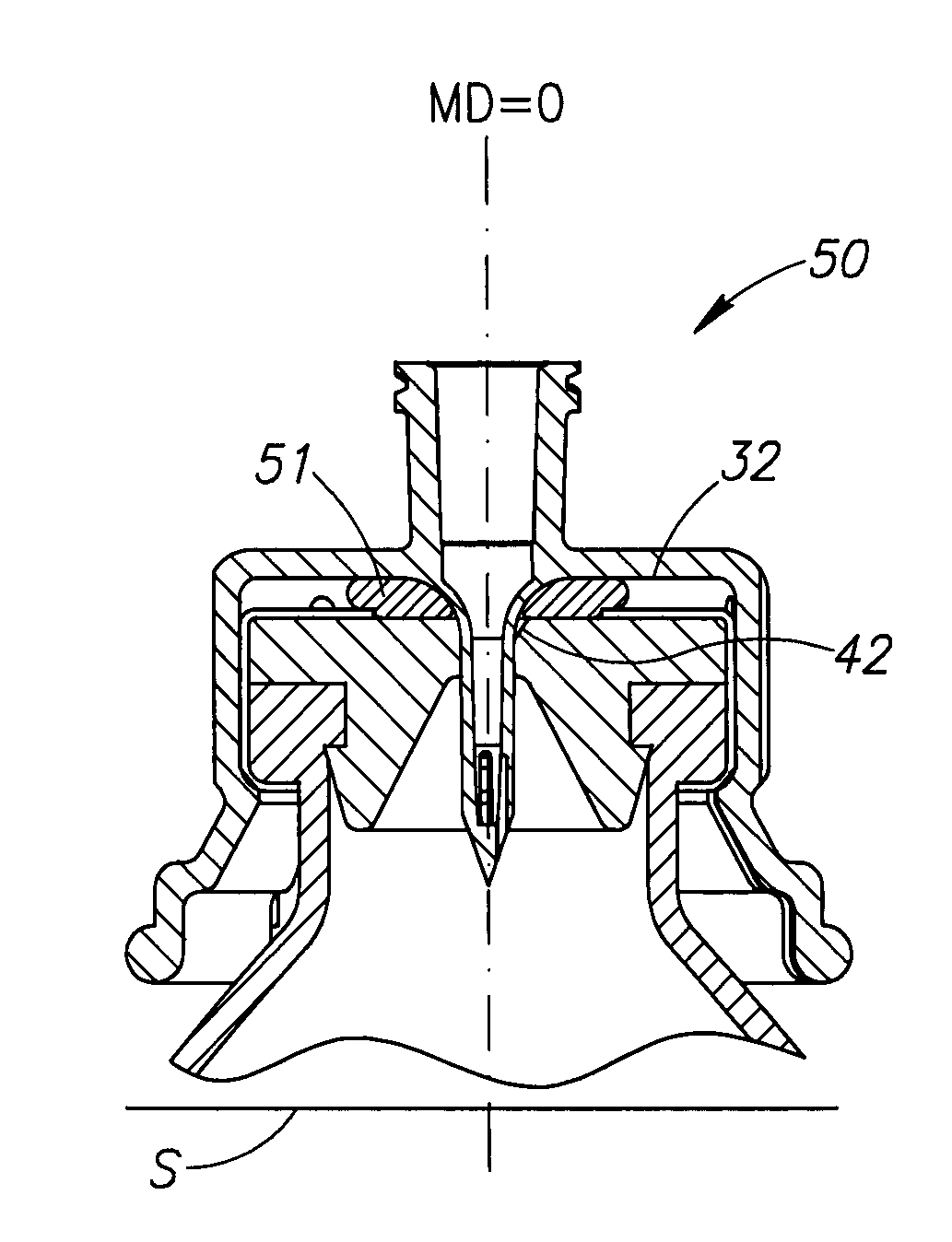

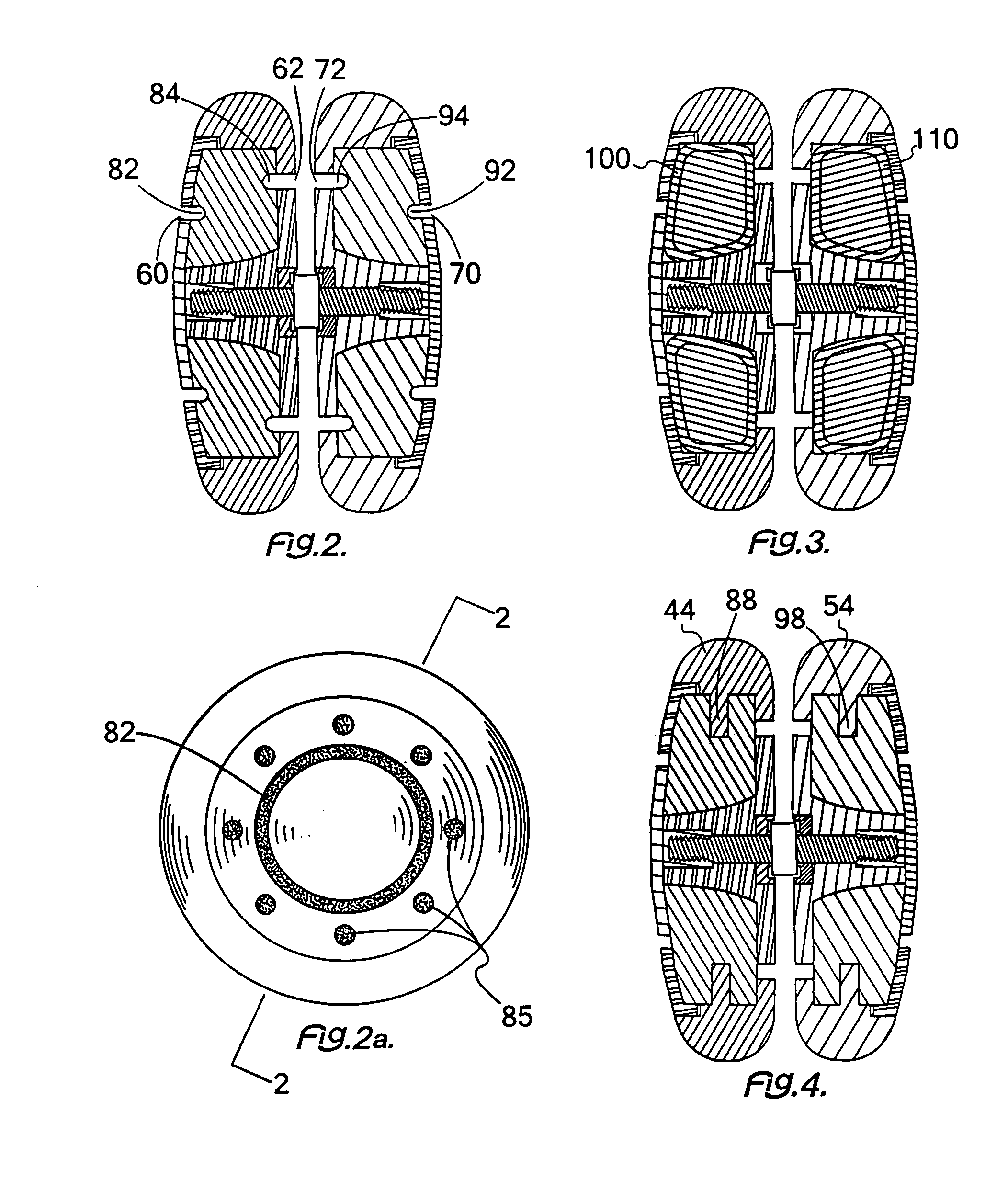

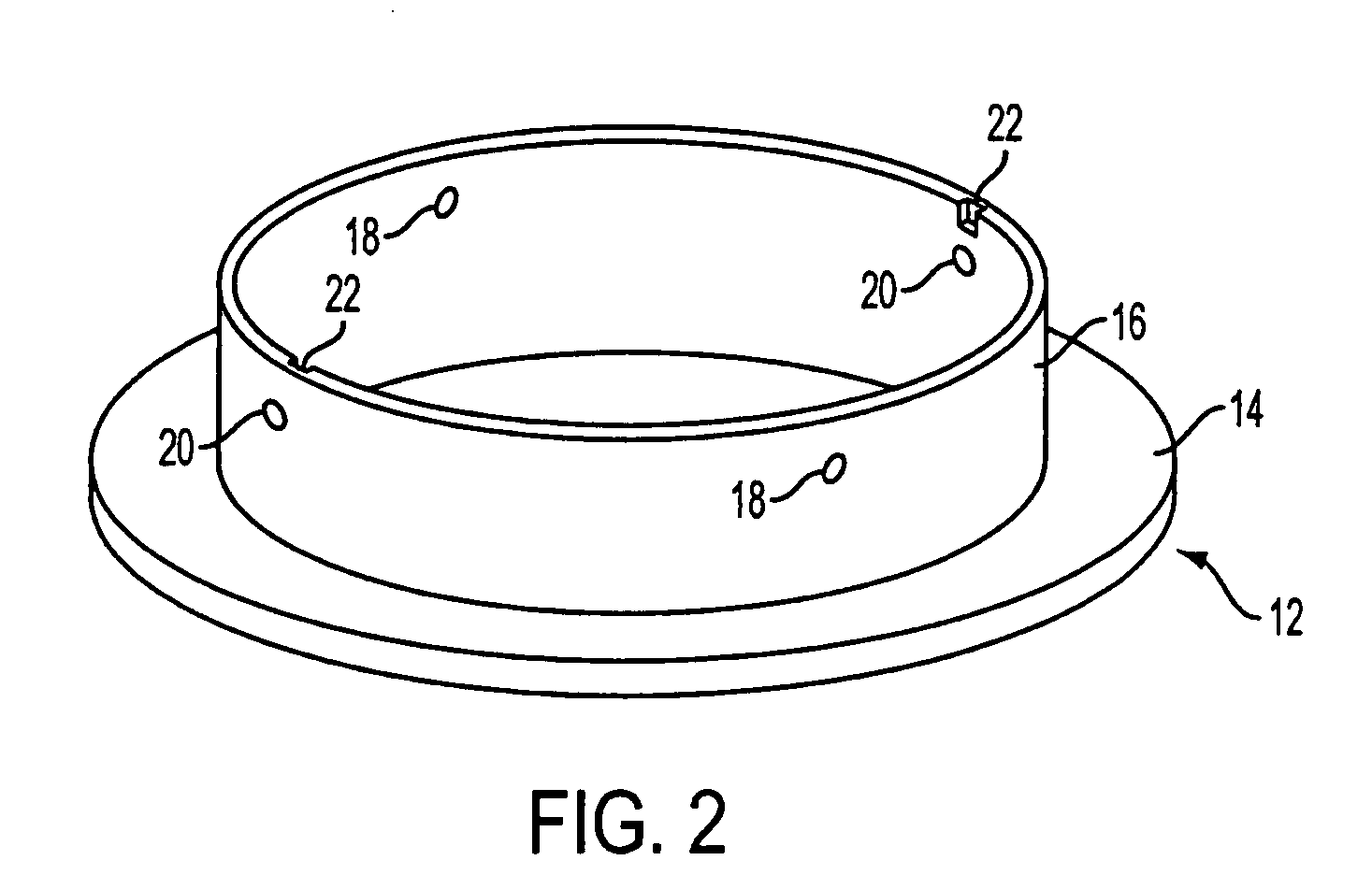

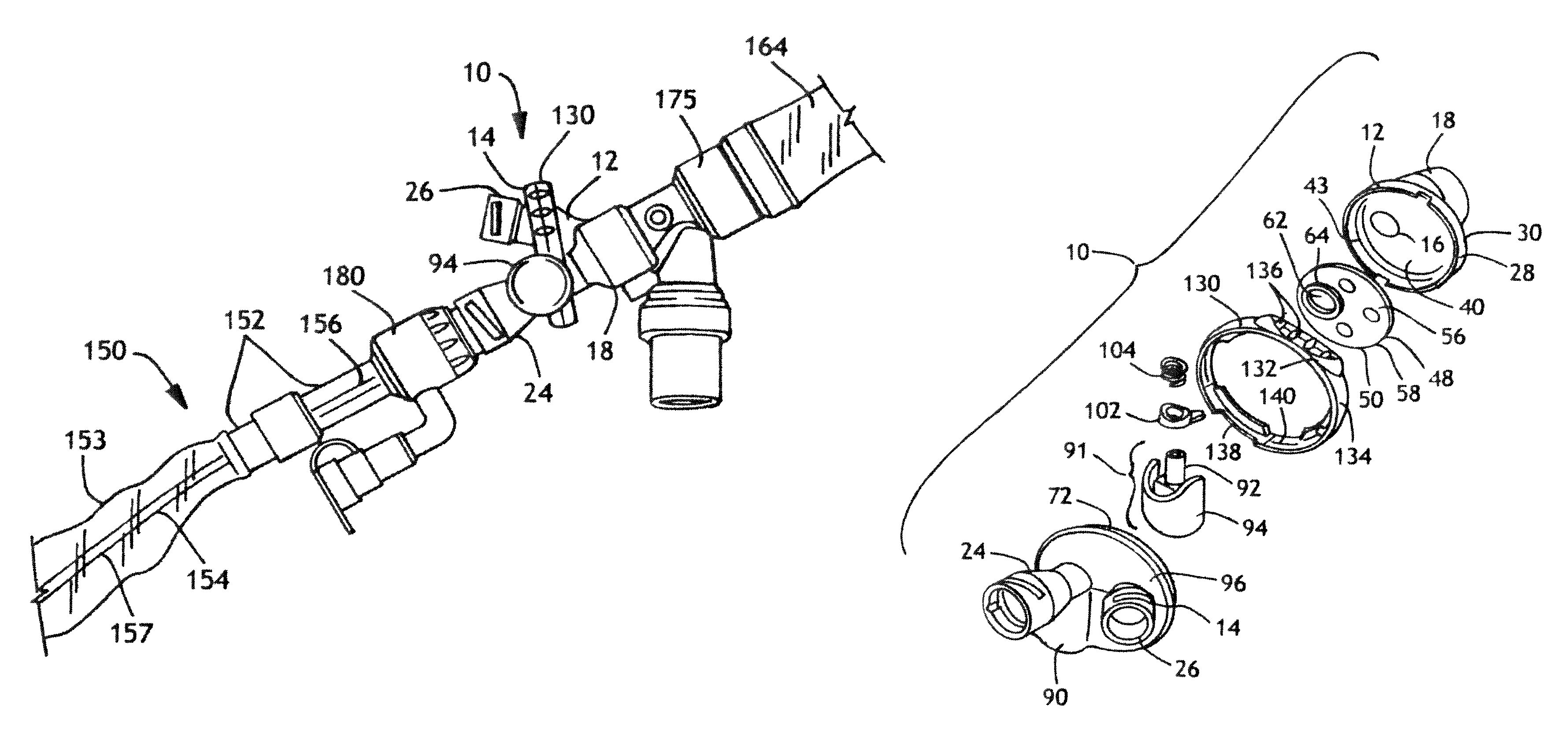

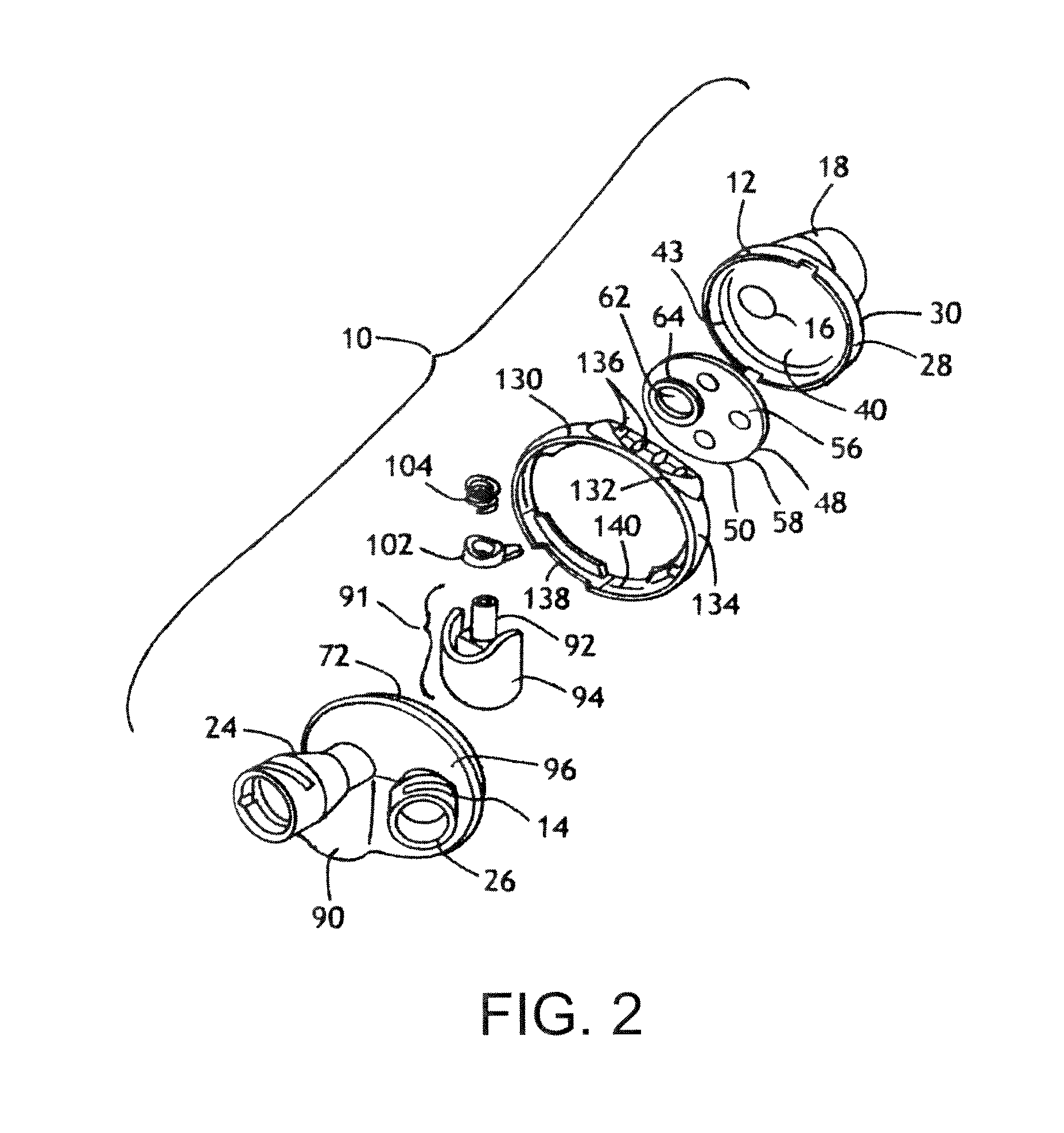

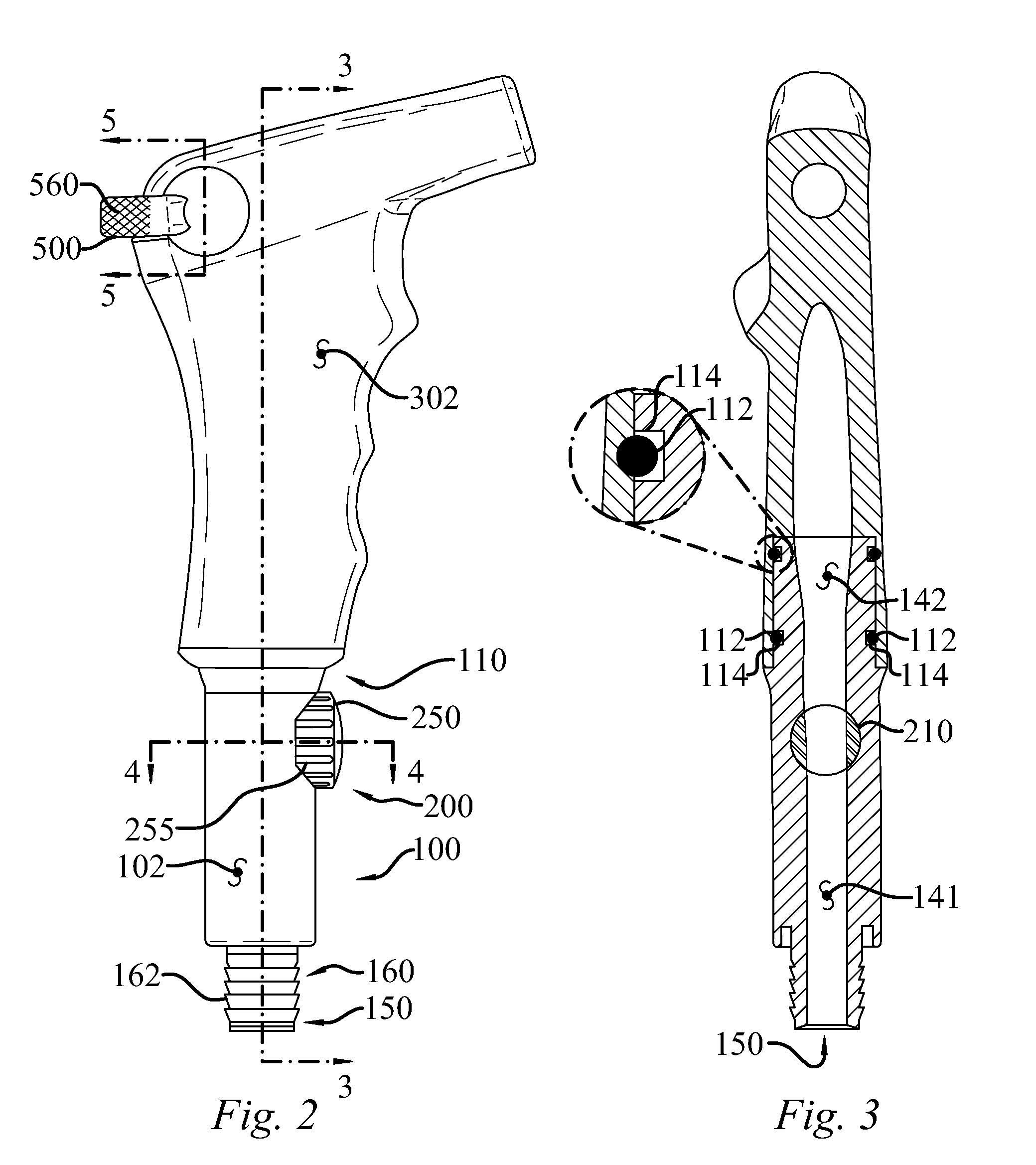

Vascular Access Port with Catheter Connector

An implantable vascular access port assembly that has a septum, a reservoir, and a catheter connector assembly for use in connecting a catheter with the vascular access port. The catheter connector assembly has an O-ring, an O-ring seal, a locking ring, and a catheter connection plug, which components are located in secured adjacent relationship to one another, respectively, in the vascular access port. The catheter connector assembly securely locks the catheter inside of the vascular access port without compromising the lumen cross-sectional area and can withstand high pressures.

Owner:ANGIODYNAMICS INC

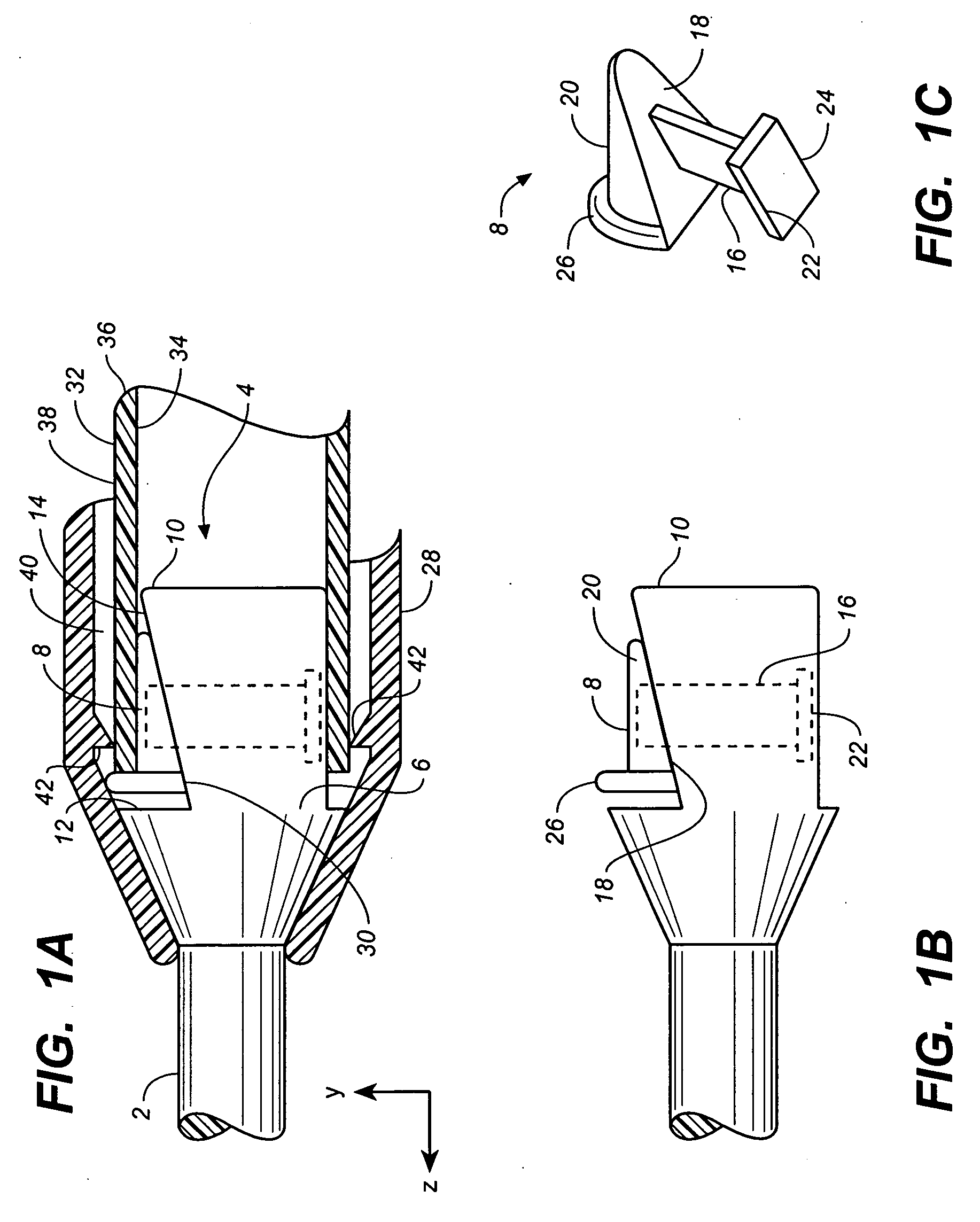

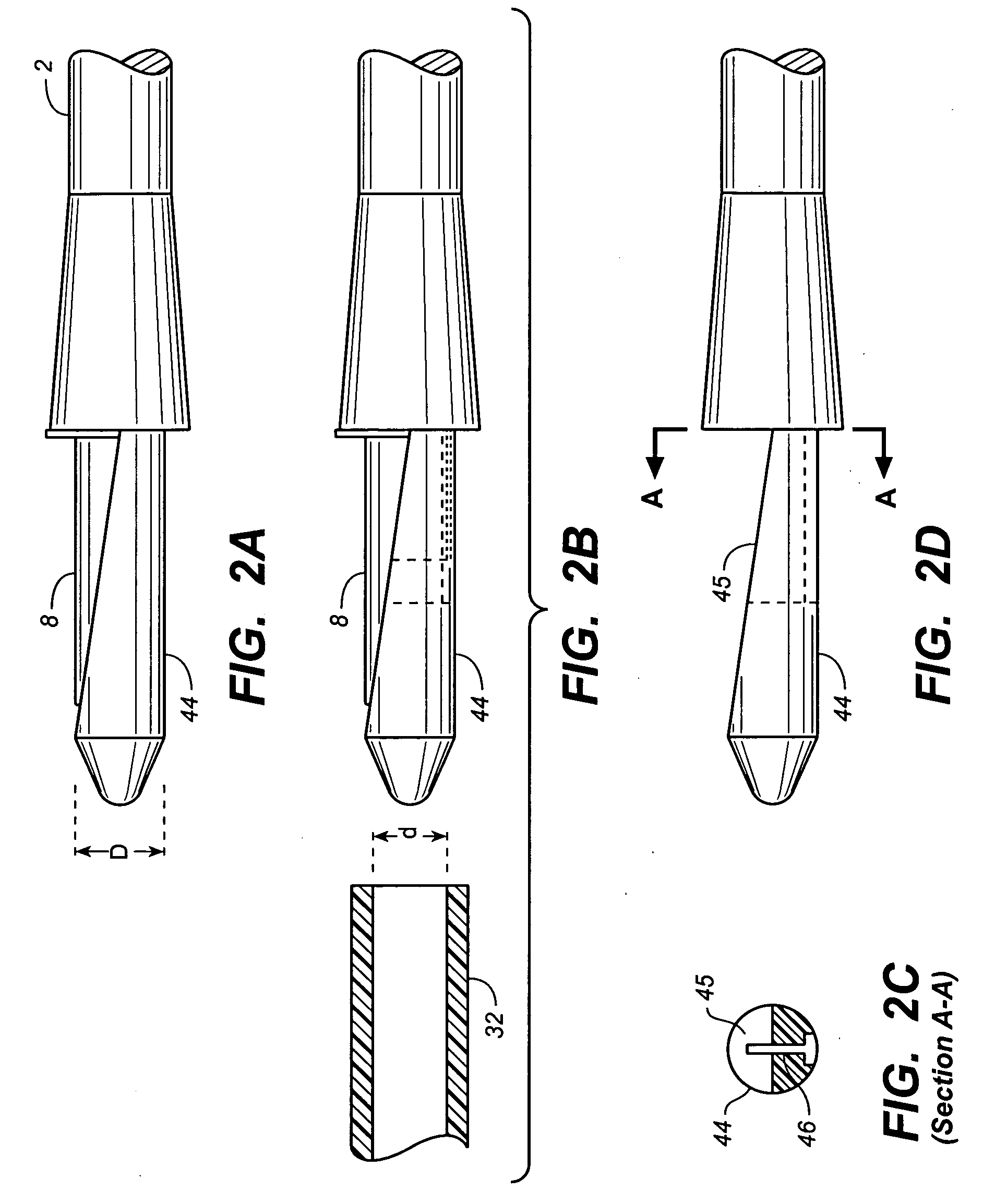

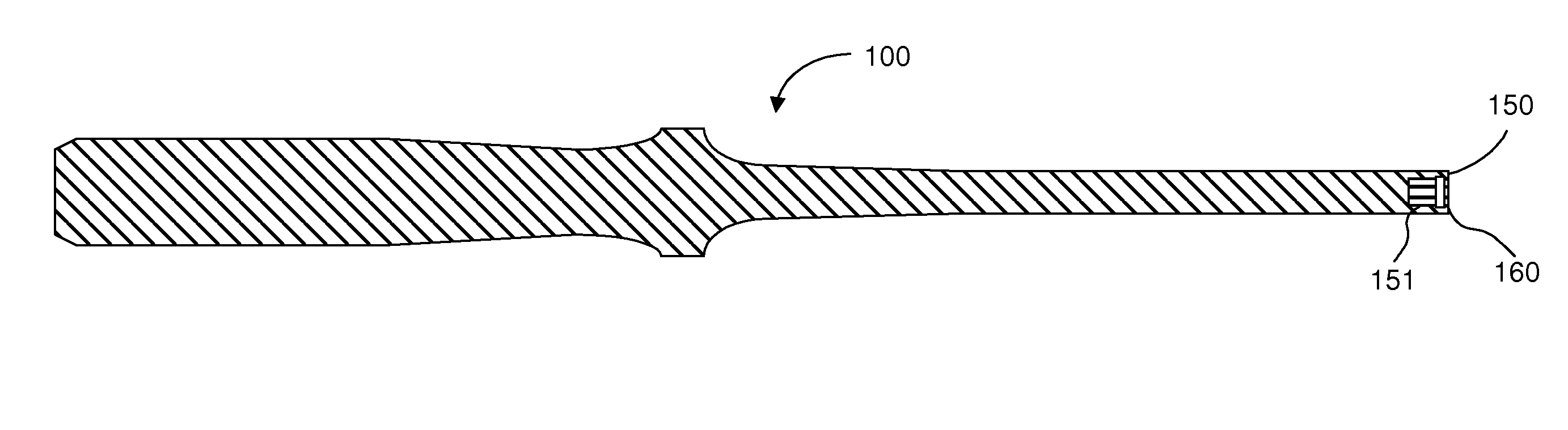

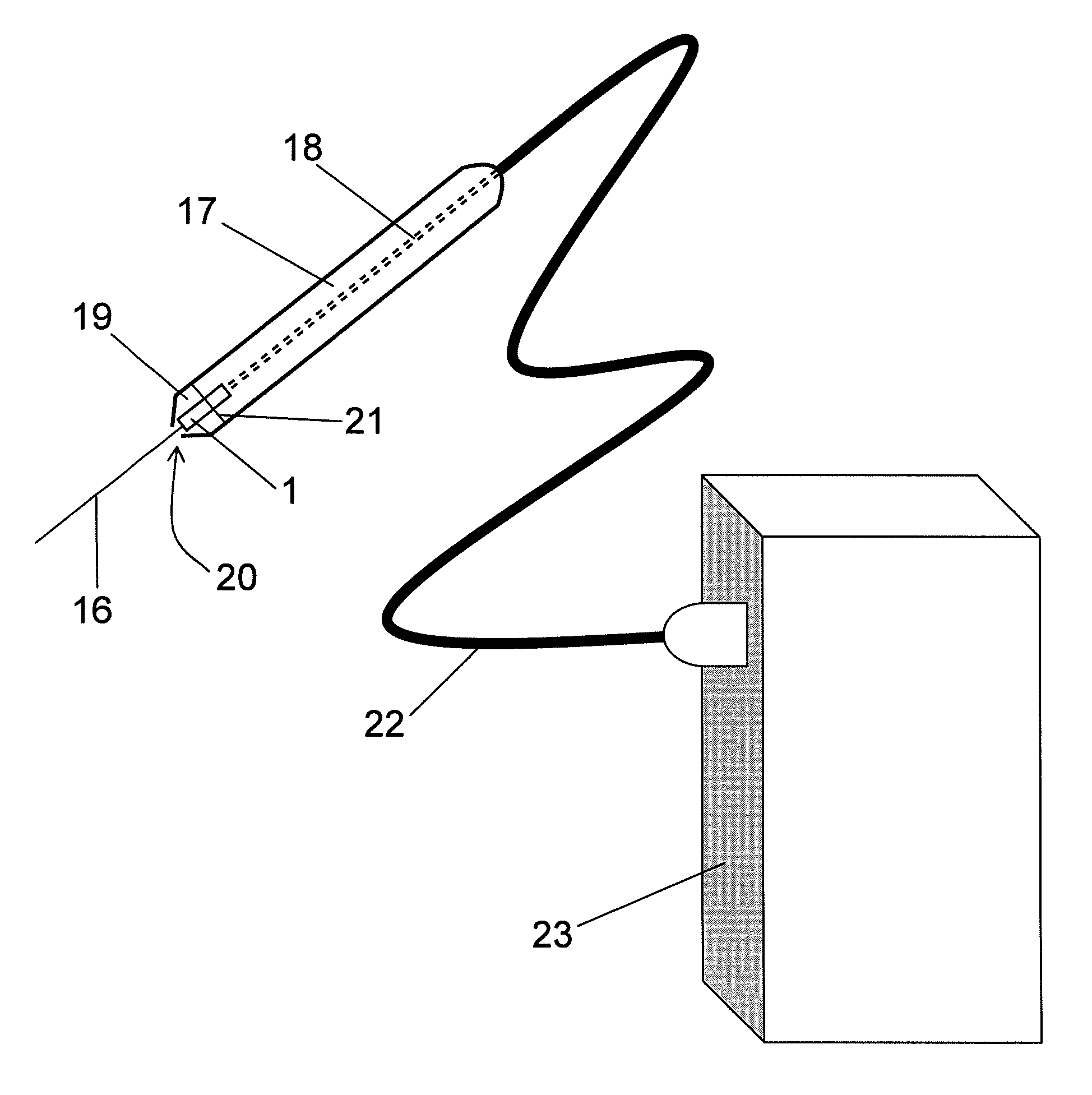

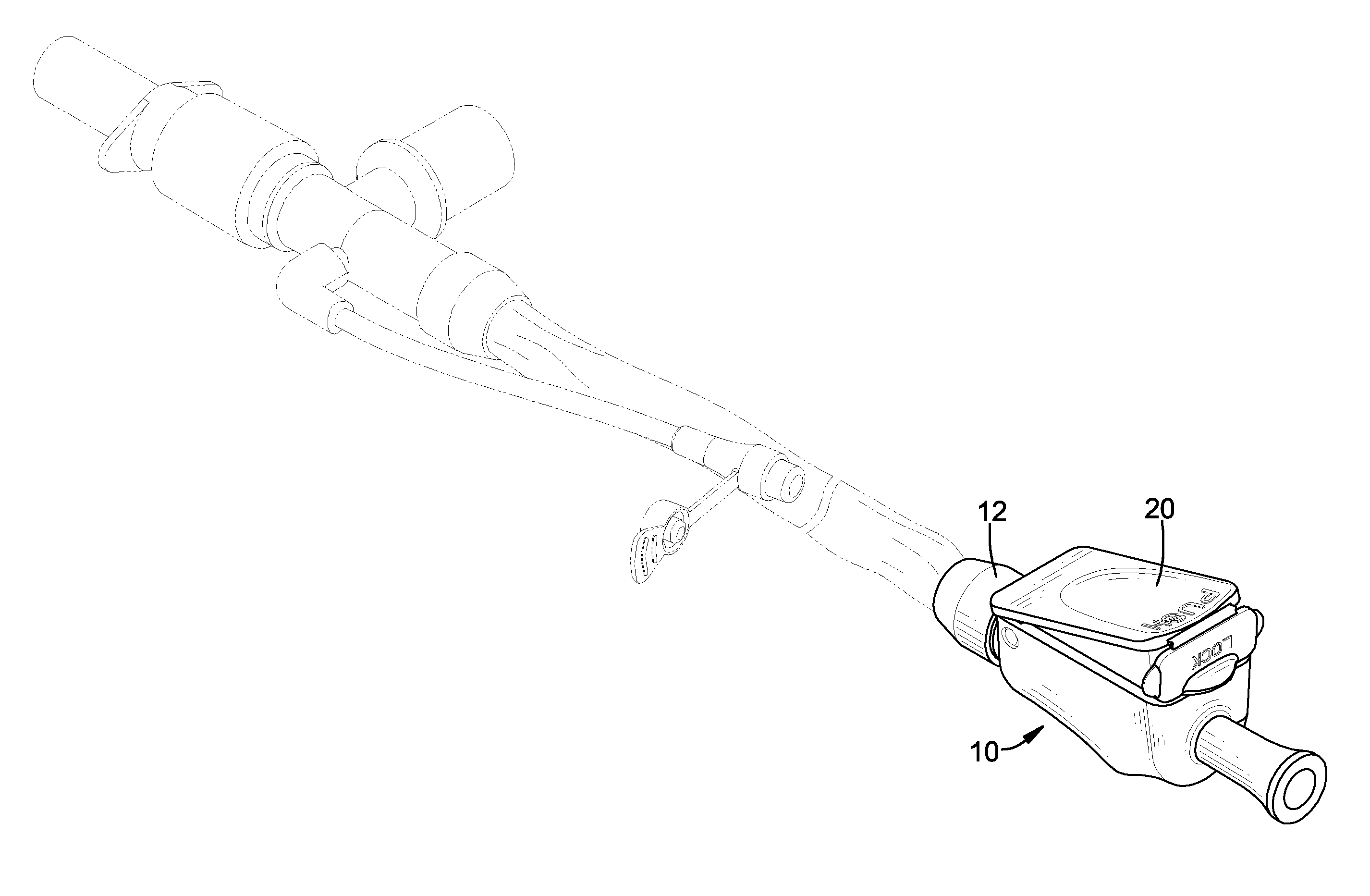

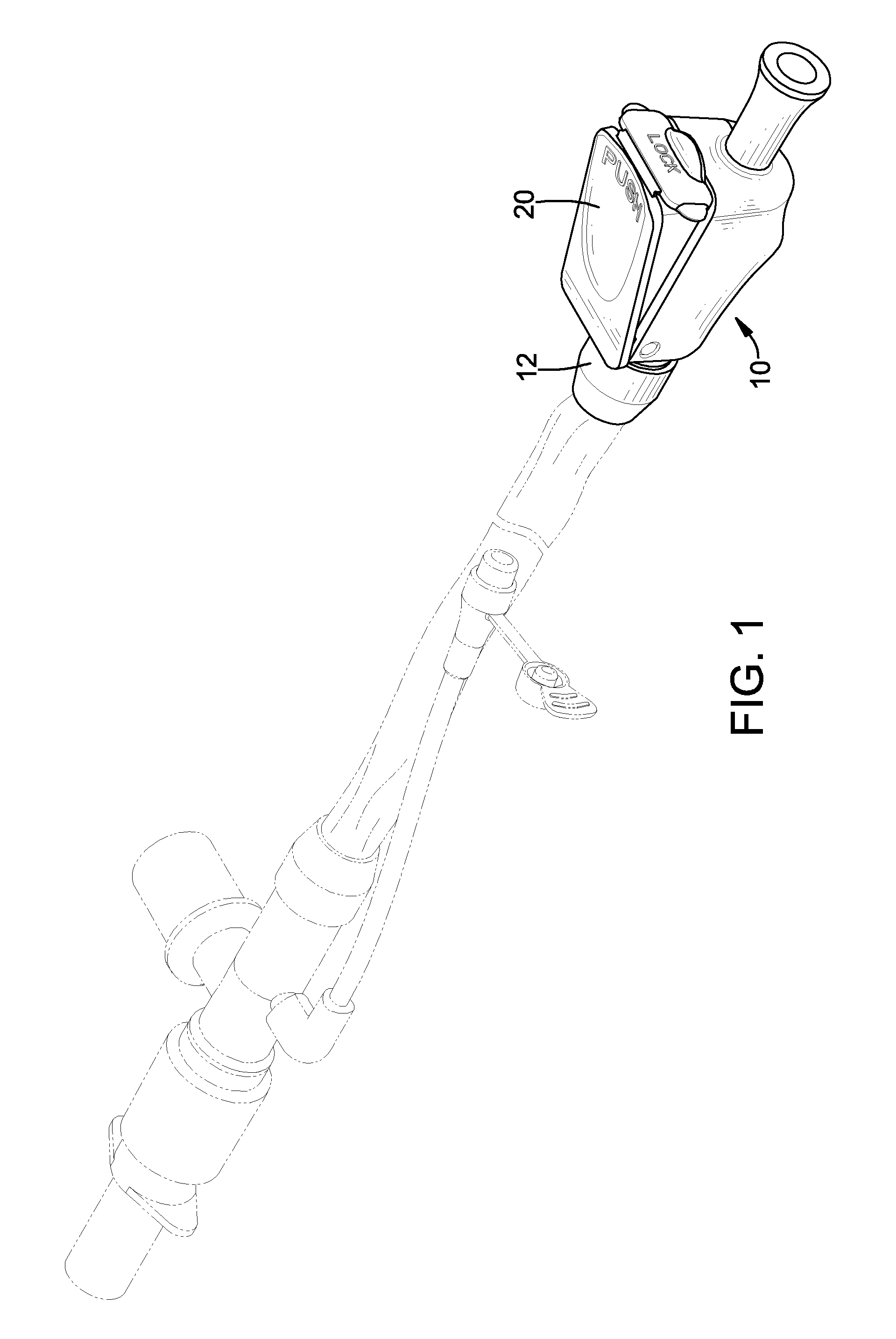

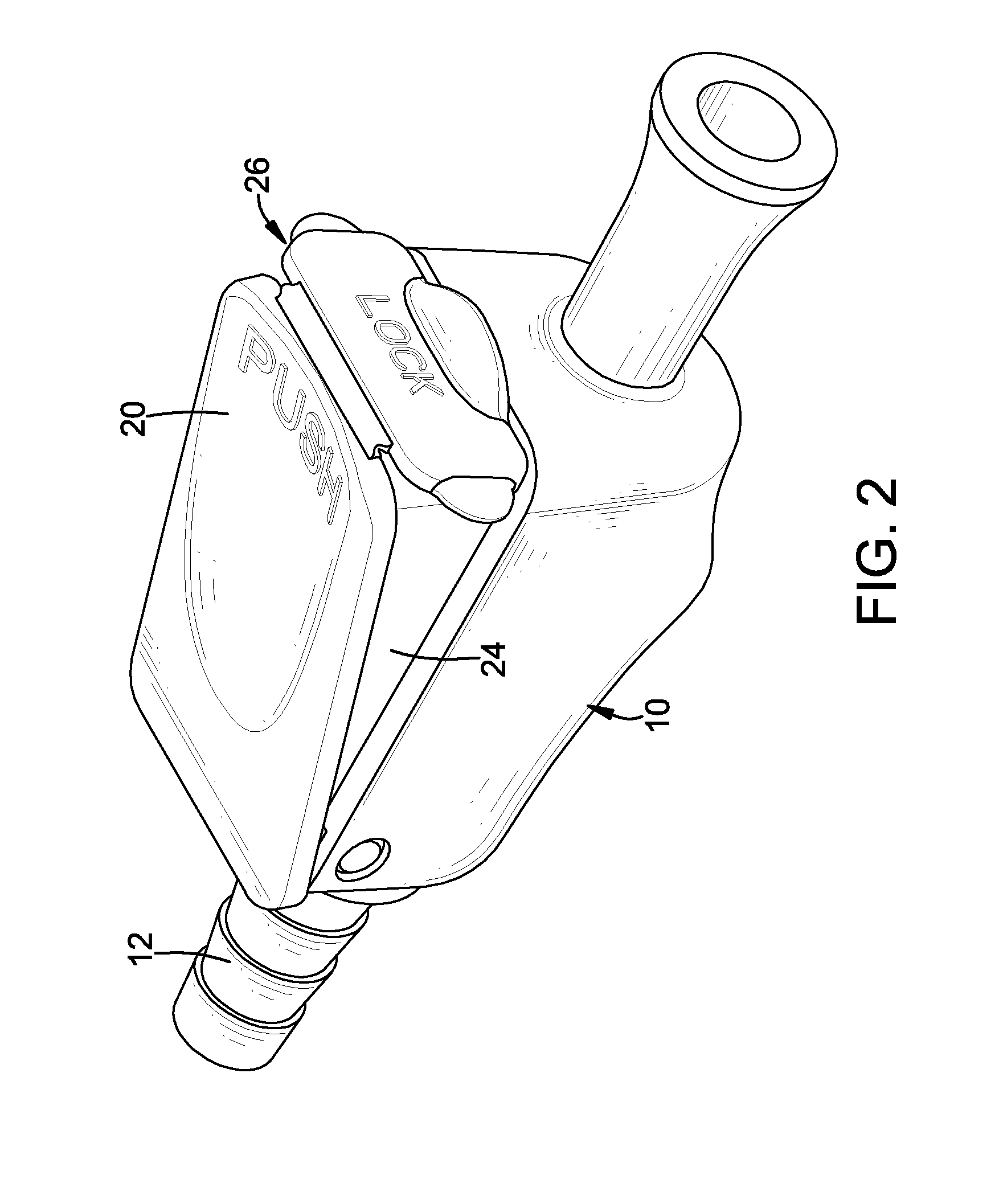

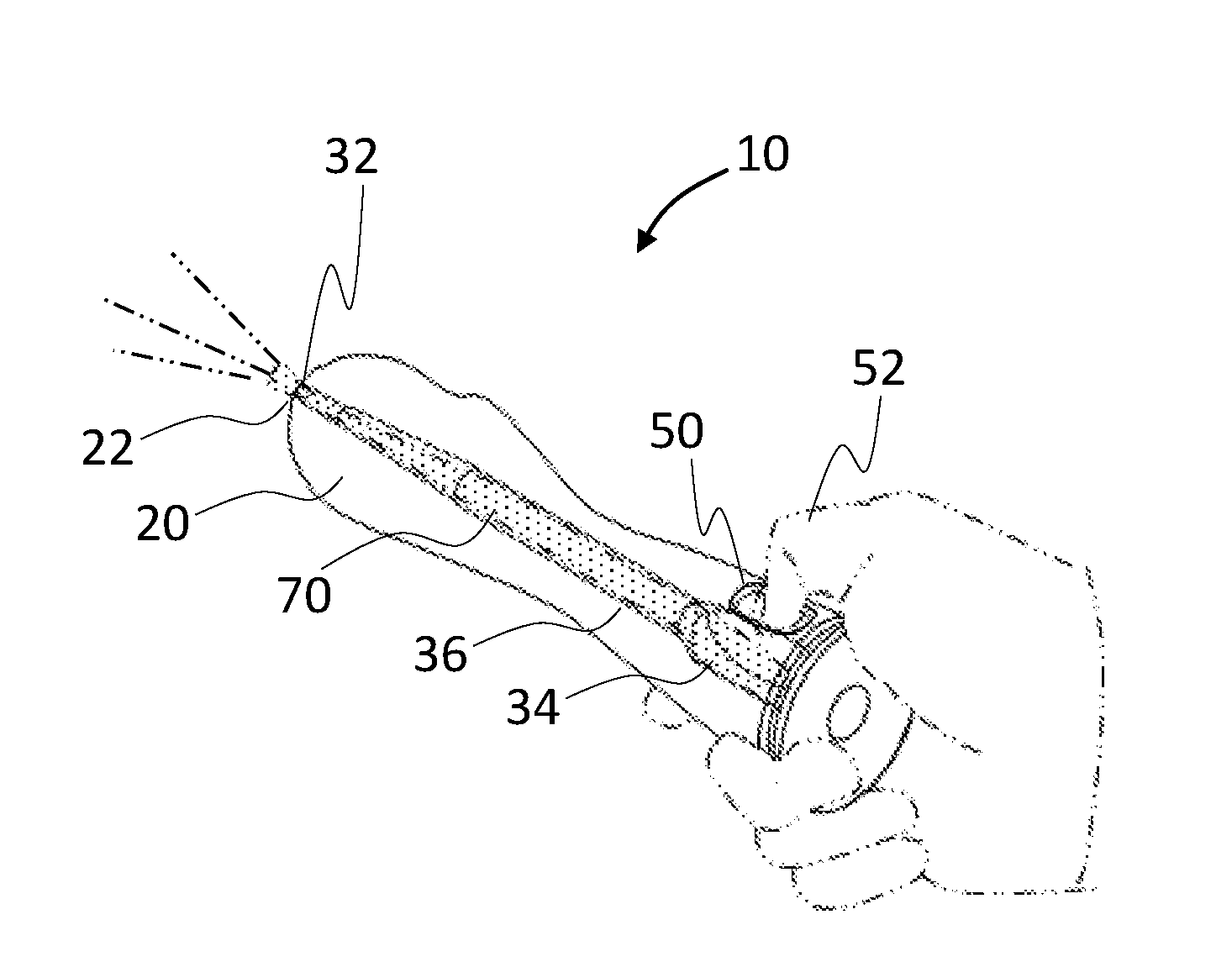

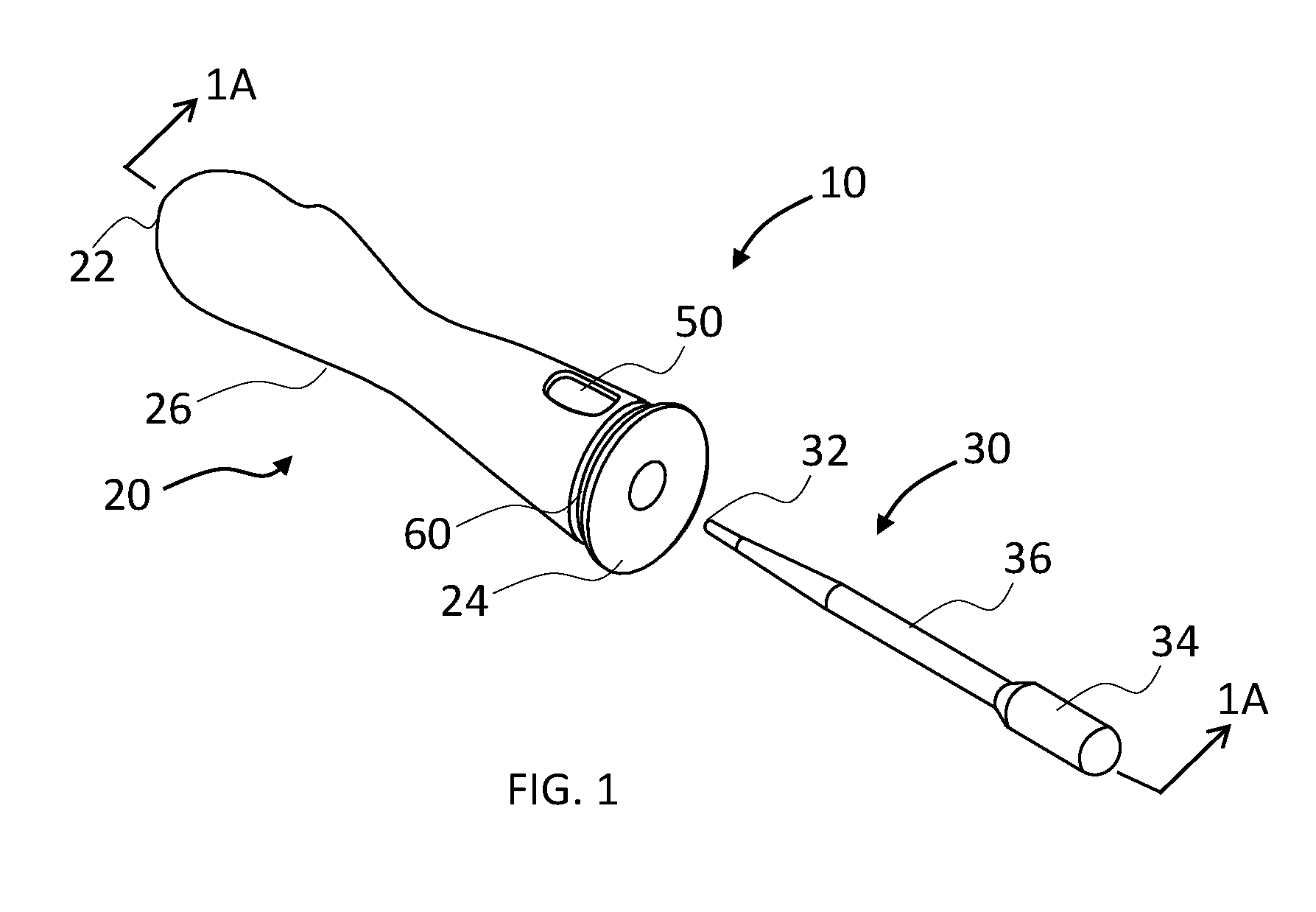

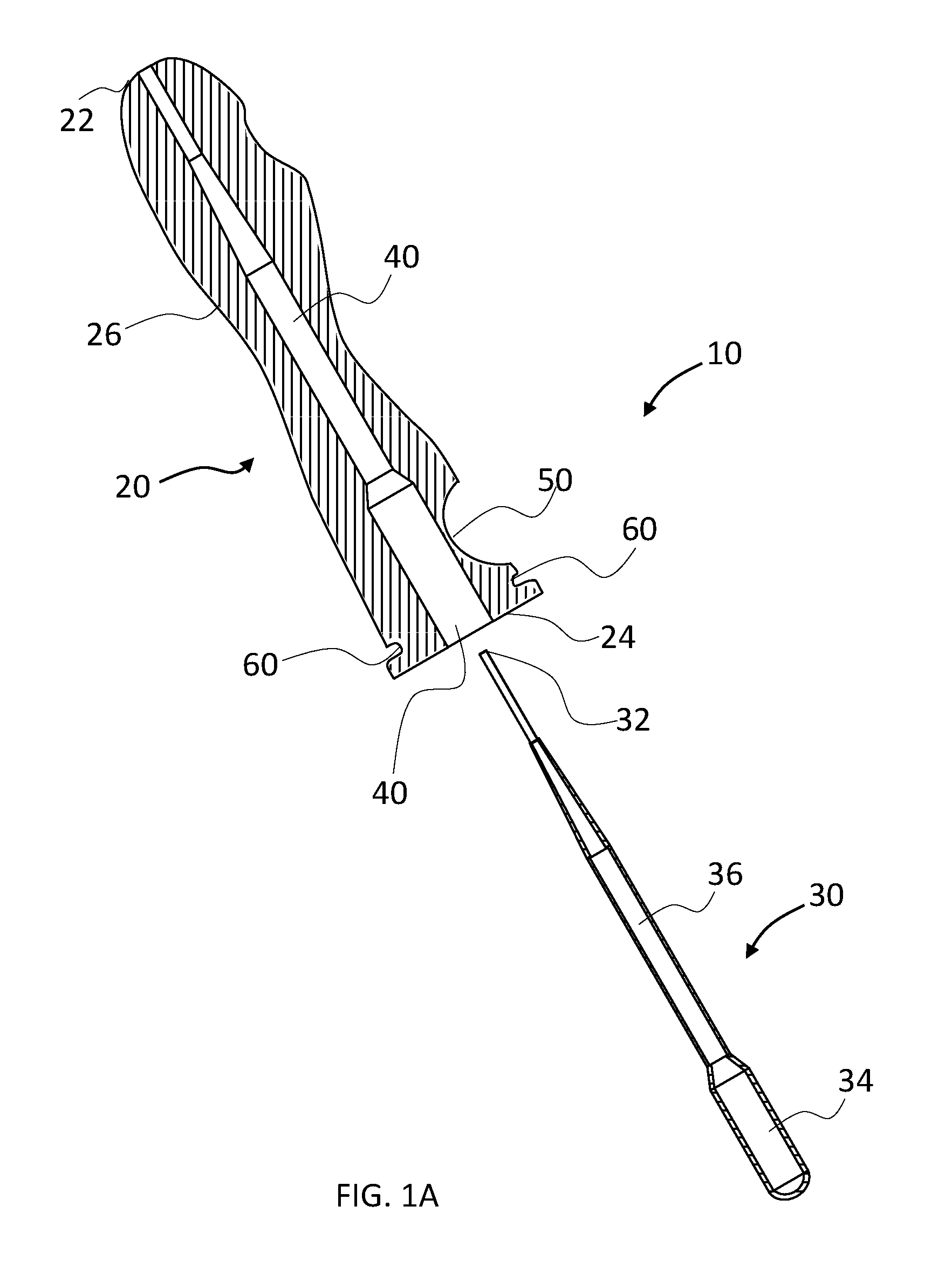

Tunneler with an expandable attachment mechanism

ActiveUS20060135949A1Relieve pressureMinimizing abrasionSurgical needlesBlunt dissectorsO-ringCatheter device

A tissue tunneler including an expandable attachment mechanism for securing a catheter. In one variation, the tissue tunneler comprises an elongate tunneler with a protrusion extending from the proximal end of the tunneler. An expansion mechanism is provided on the protrusion for insertion into the catheter. An oversleeve slidably disposed over the elongated tunneler may be provided to engage the expansion mechanism and trap the catheter between the oversleeve and the expansion mechanism. In another variation, the expansion mechanism may comprise of an expandable O-ring configured to engage an inner surface within a catheter.

Owner:CR BARD INC

Fluid transfer devices with sealing arrangement

The present invention is directed toward fluid transfer devices including a vial adapter having a top wall and a cannula with a cannula tip, and an elastic O-ring like sealing element sealingly encircling the cannula and initially disposed towards the cannula tip and spaced apart from the top wall, the sealing element being brought into initial contact with the vial stopper subsequent to the cannula tip contacting the vial stopper at a puncture site and thereafter being slidingly urged towards the top wall and continuously sealing the puncture site during snap fit mounting the vial adapter on the vial.

Owner:WEST PHARM SERVICES IL LTD

Prosthetic coupling device

InactiveUS7033400B2Additive manufacturing apparatusRopes and cables for vehicles/pulleyO-ringCoupling

Owner:CURRIER MARK R

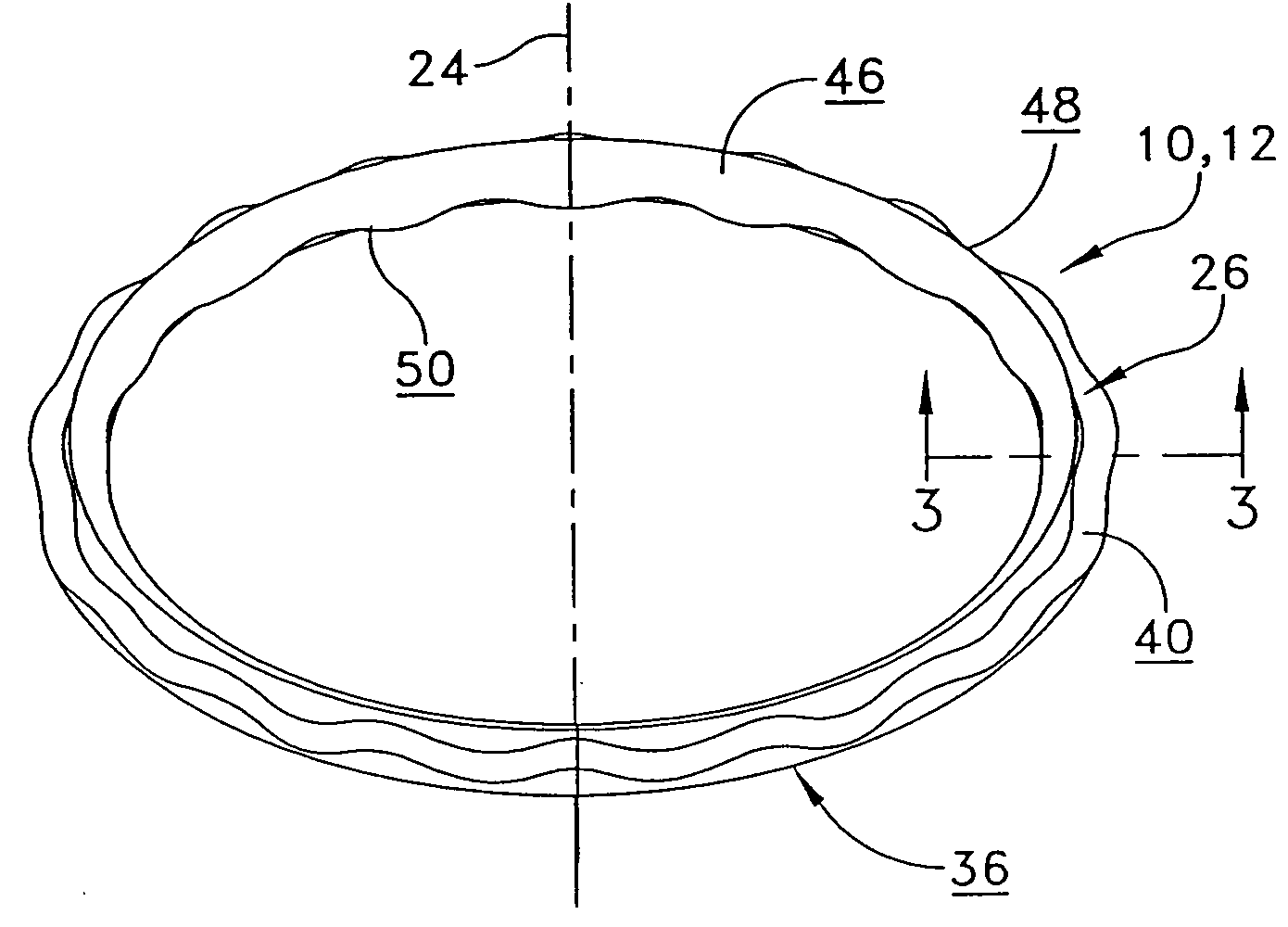

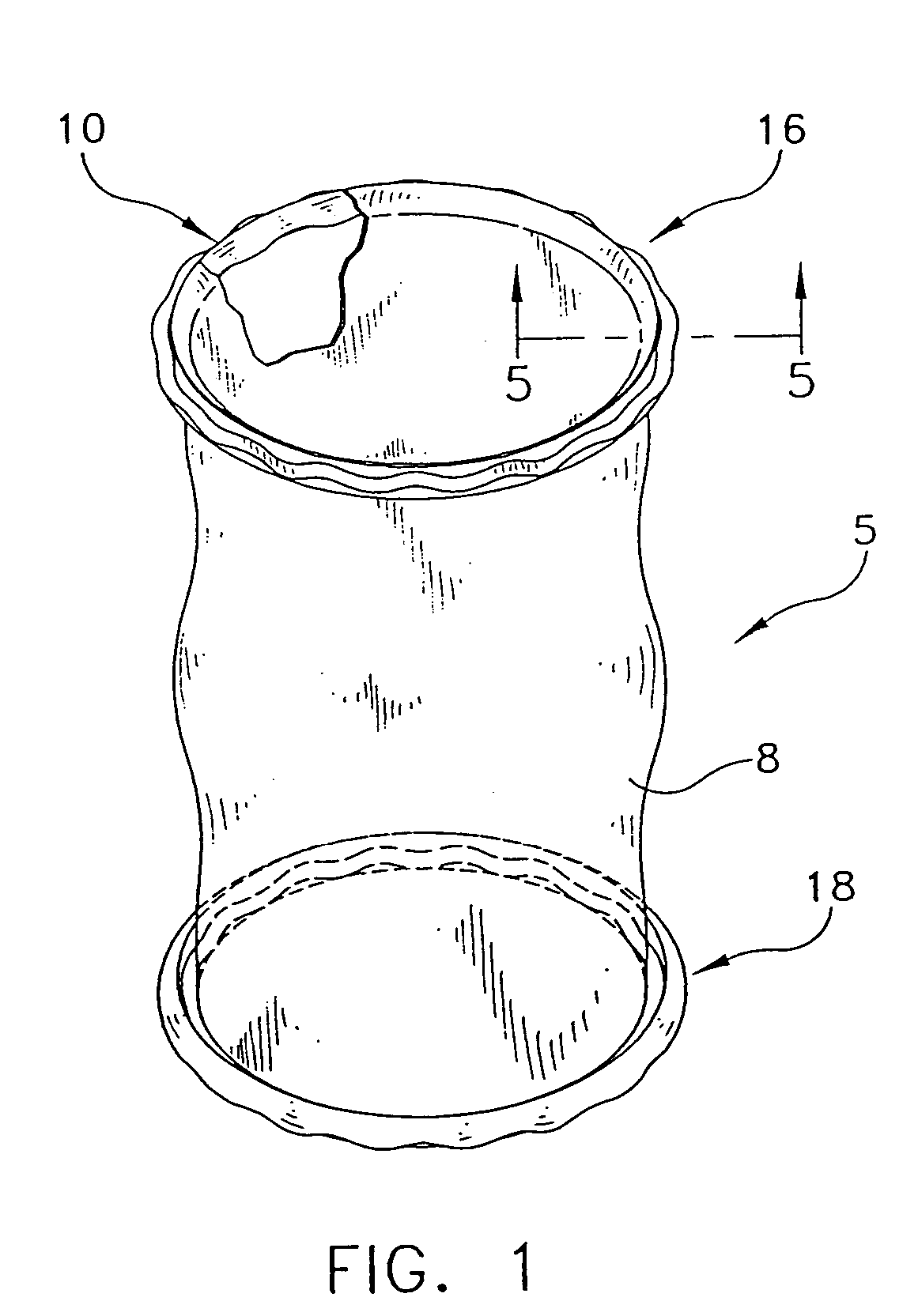

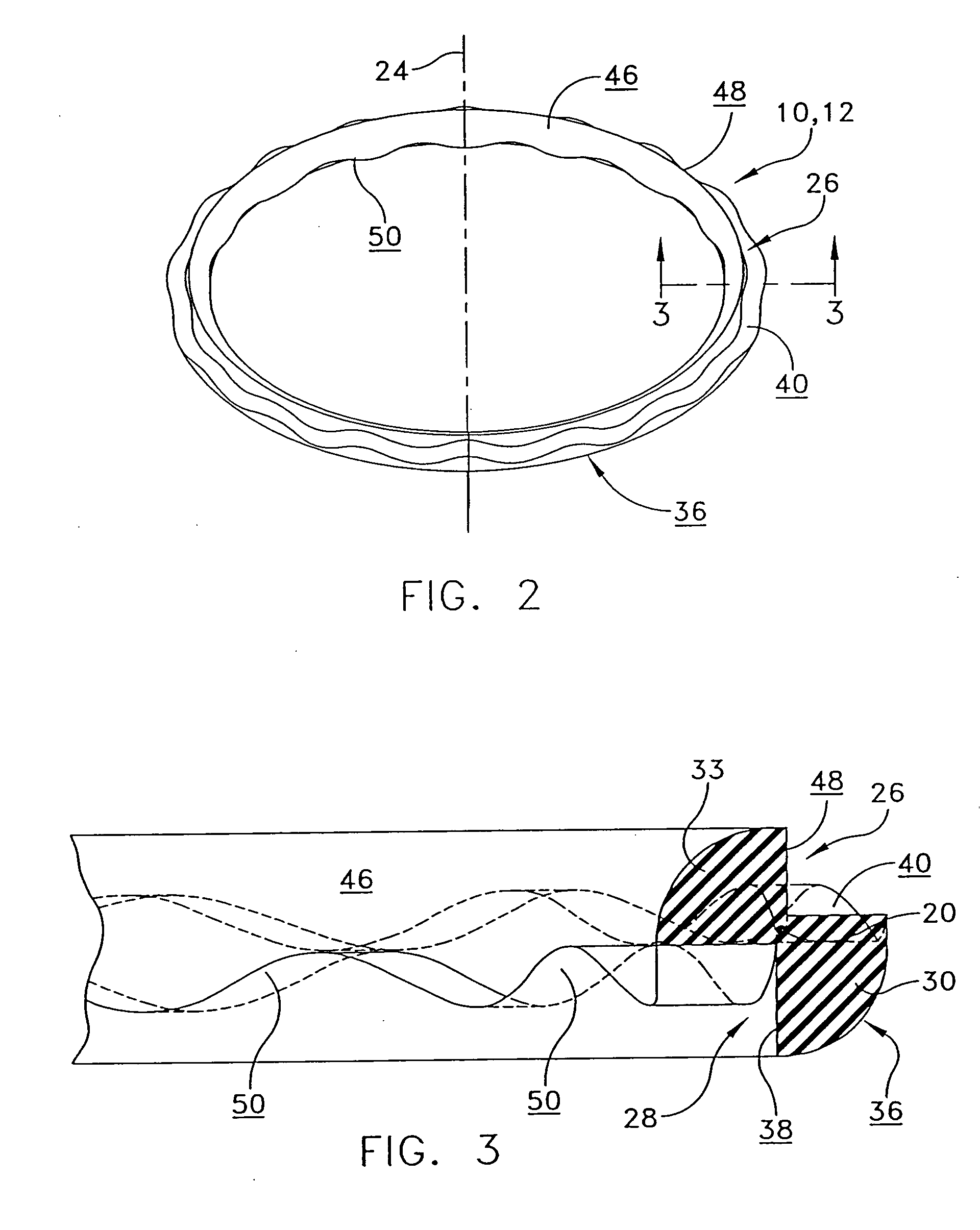

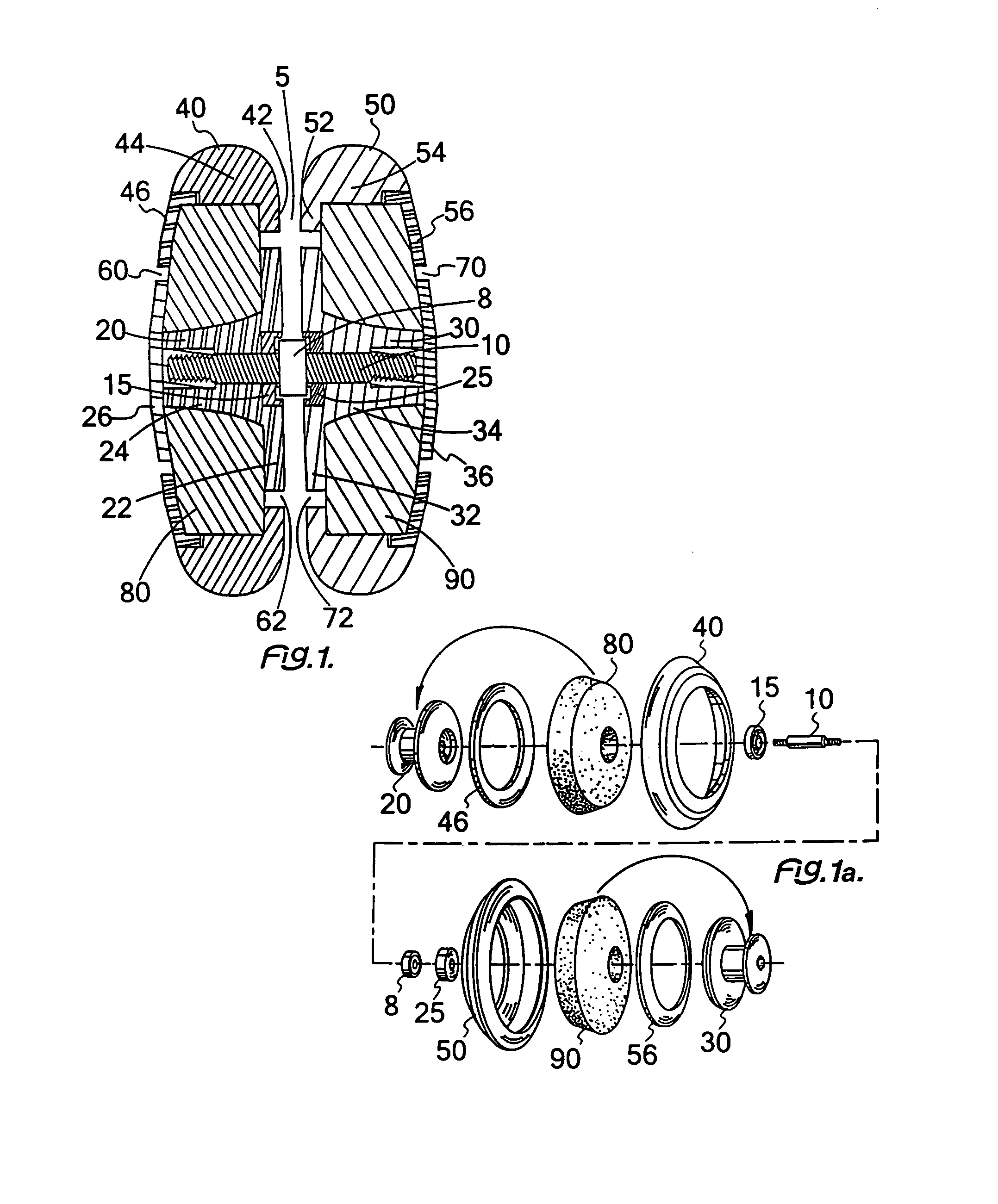

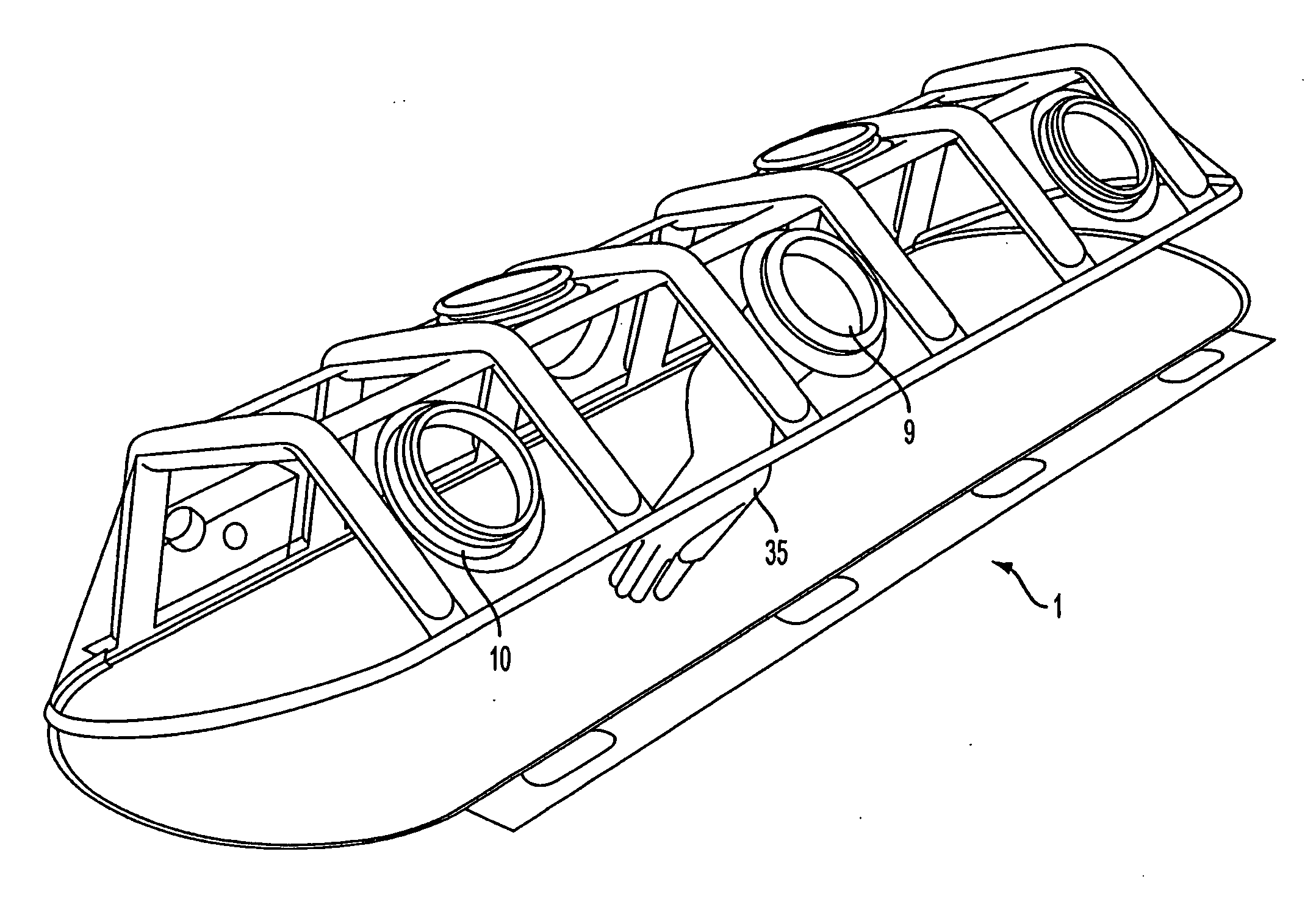

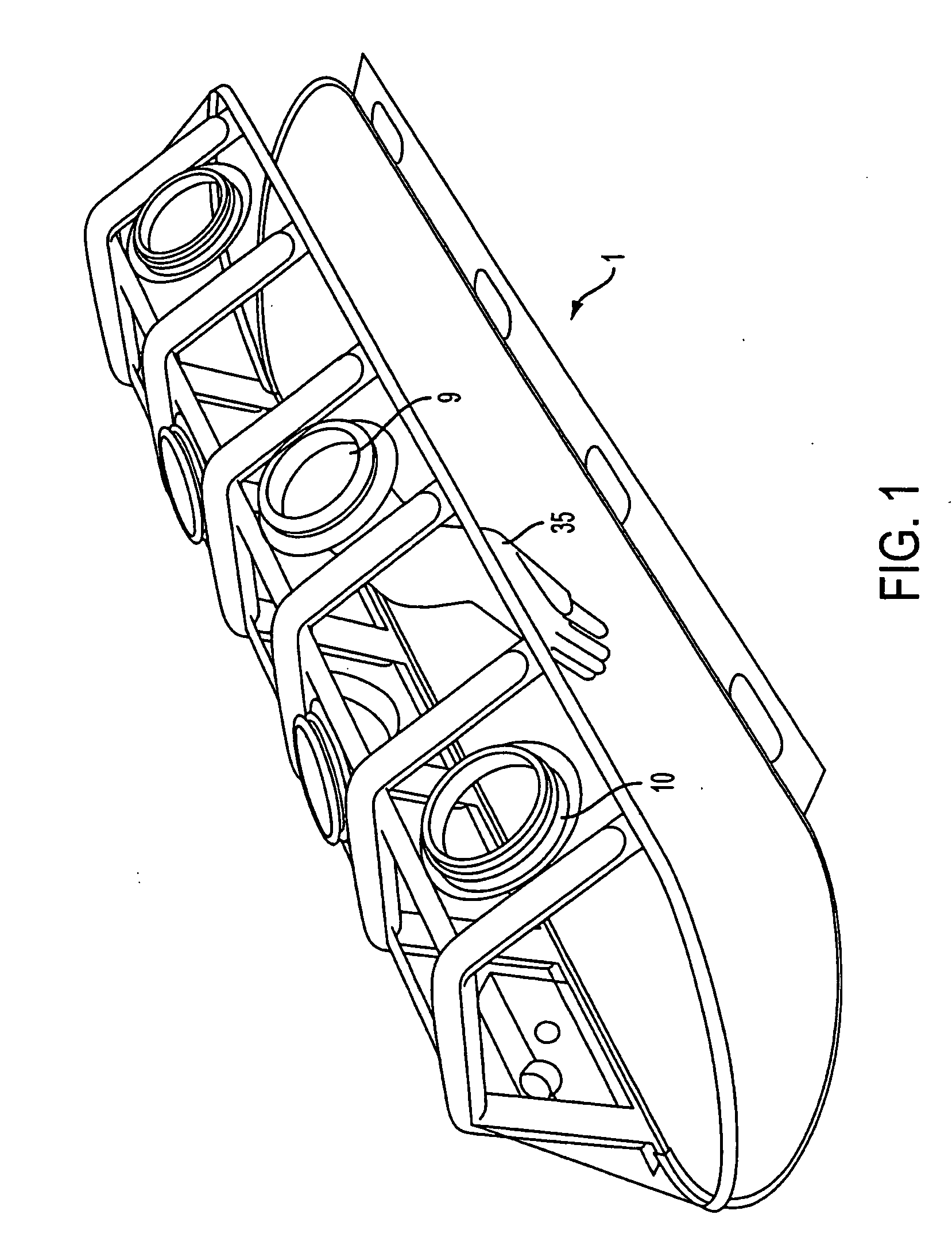

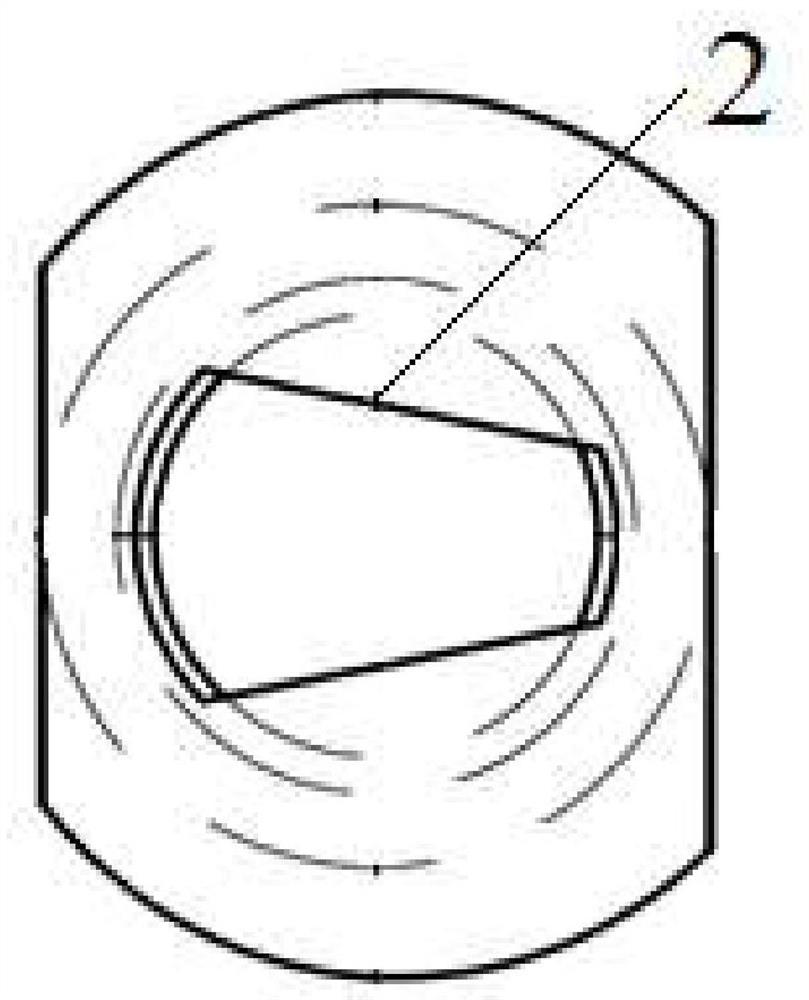

O-ring for incrementally adjustable incision liner and retractor

An O-ring is provided for use in an adjustable surgical wound protector having a solid cross-section including a cross-sectional center that is spaced from a central longitudinal axis and a resilient configuration for squeezing into an oblong shape that is insertable into a surgical incision. At least one recess is defined in the O-ring that is selectively sized and shaped to enable a snap-action rolling of the O-ring about the cross-sectional center in predetermined increments. The recess may comprise various cross-sectional shapes, such as, at least one circumferential groove, a plurality of circumferentially positioned recesses, or be shaped such that the O-ring comprises a cruciform cross-section. An improved incrementally adjustable apparatus for protecting an incised wound from exposure to bacterial and other harmful contaminants is also provided including a pair of resilient O-rings connected to opposite ends of an impermeable pliable sleeve. One of the O-rings is formed to engage the inner edge of the wound with a portion of the sleeve above the wound capable of being rolled onto the other ring to draw the remaining sleeve portion contiguous with the sides of the wound.

Owner:MCT II LLC

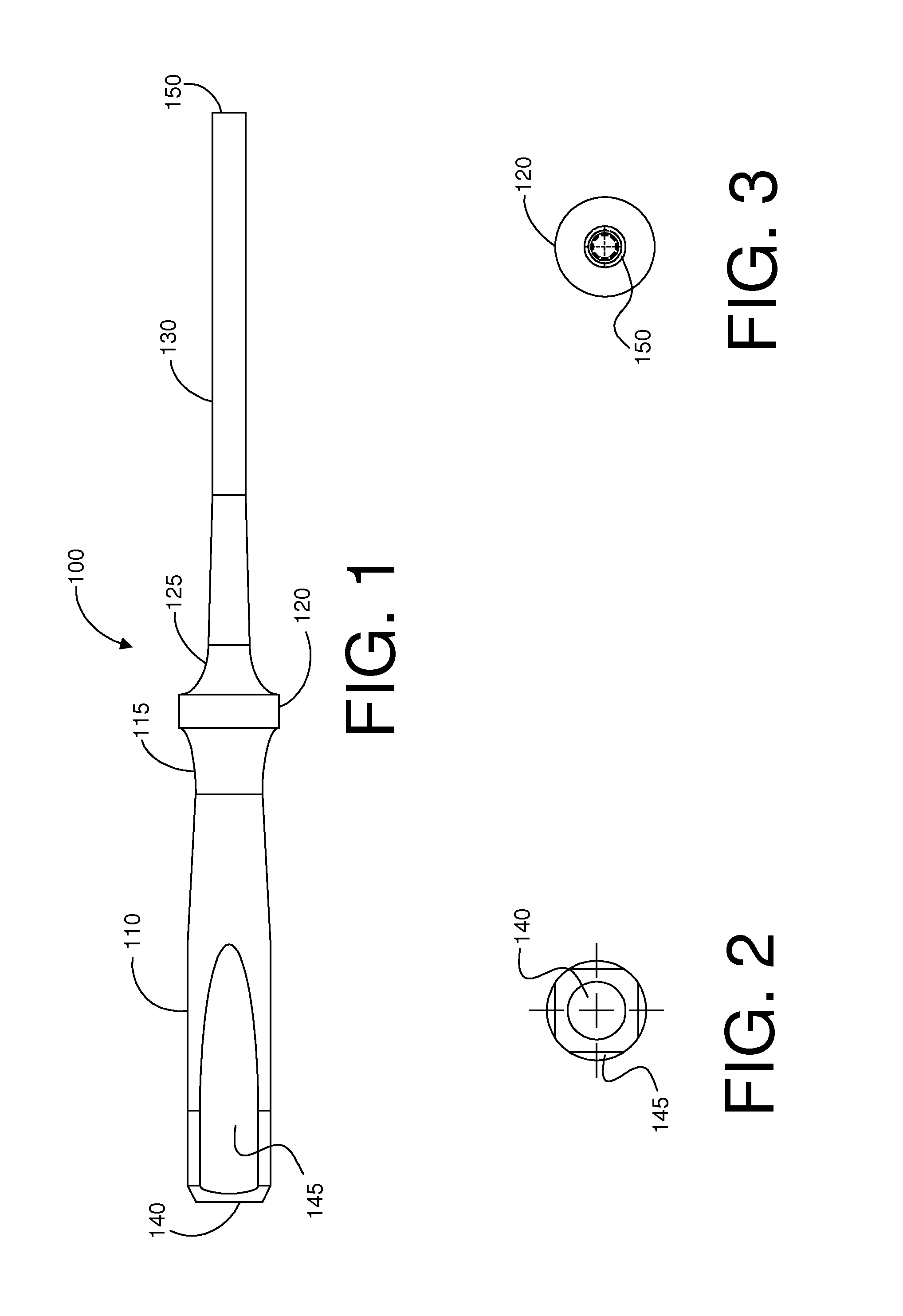

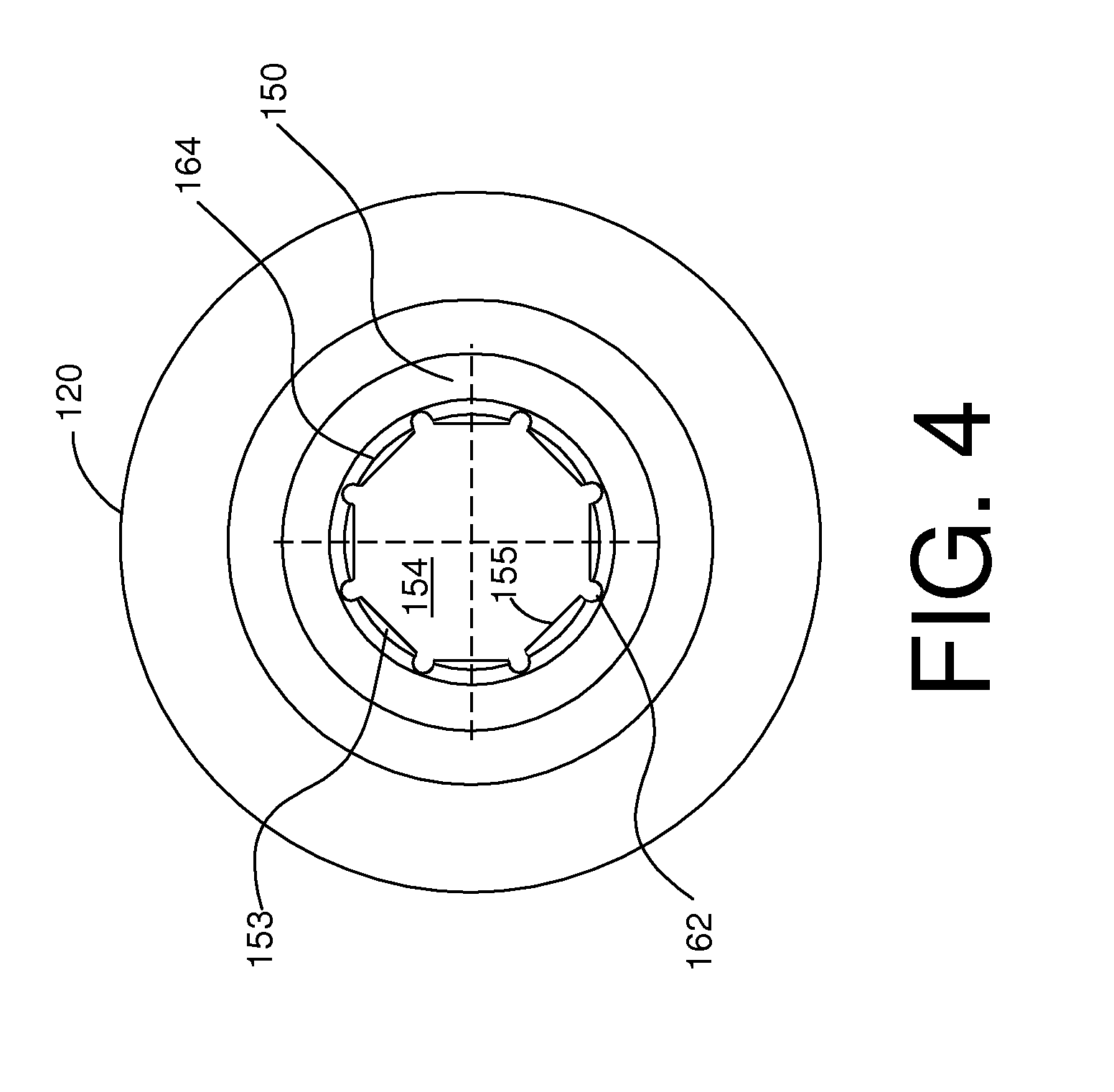

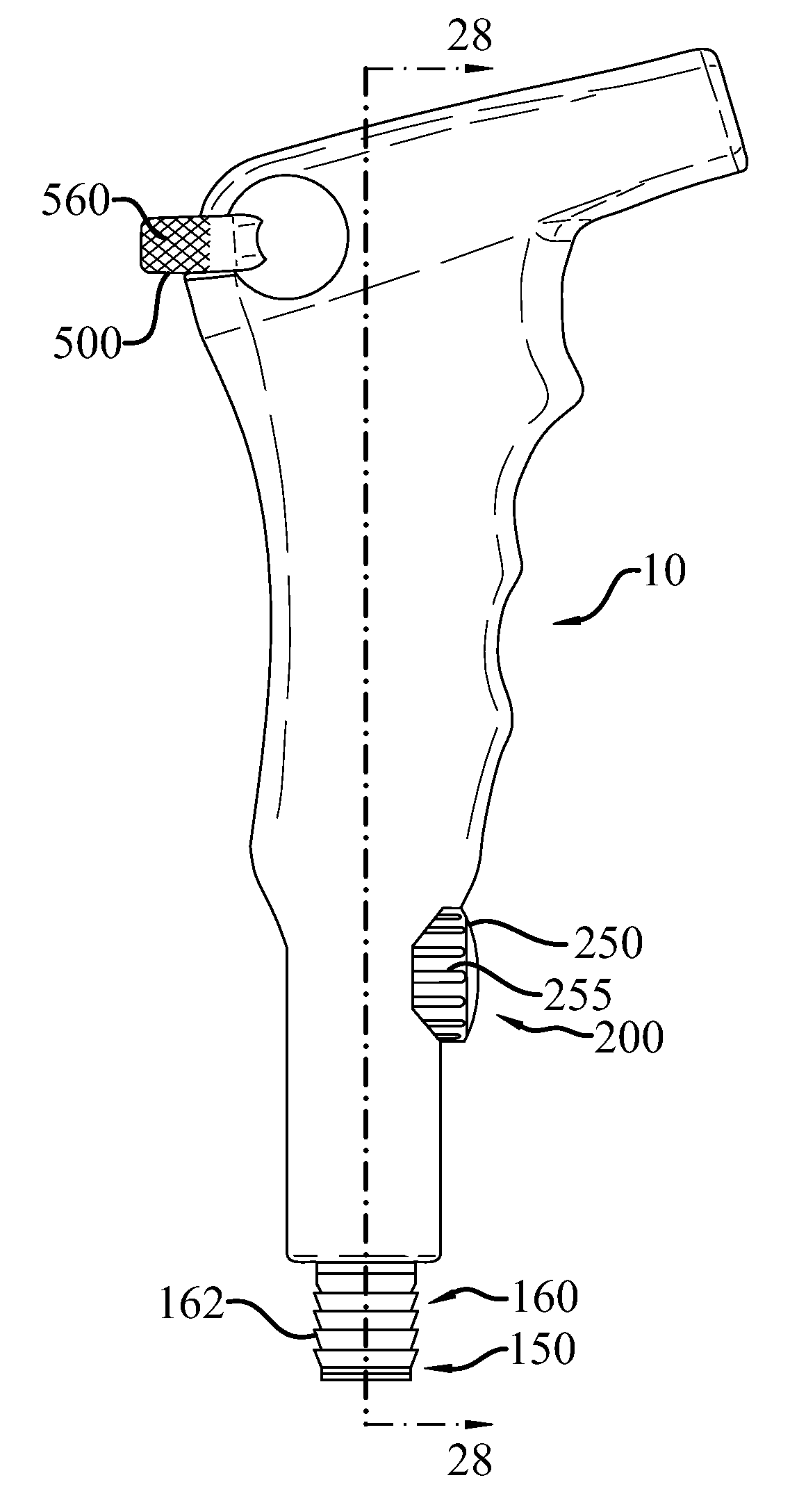

Dental implant driver and carrier removal system

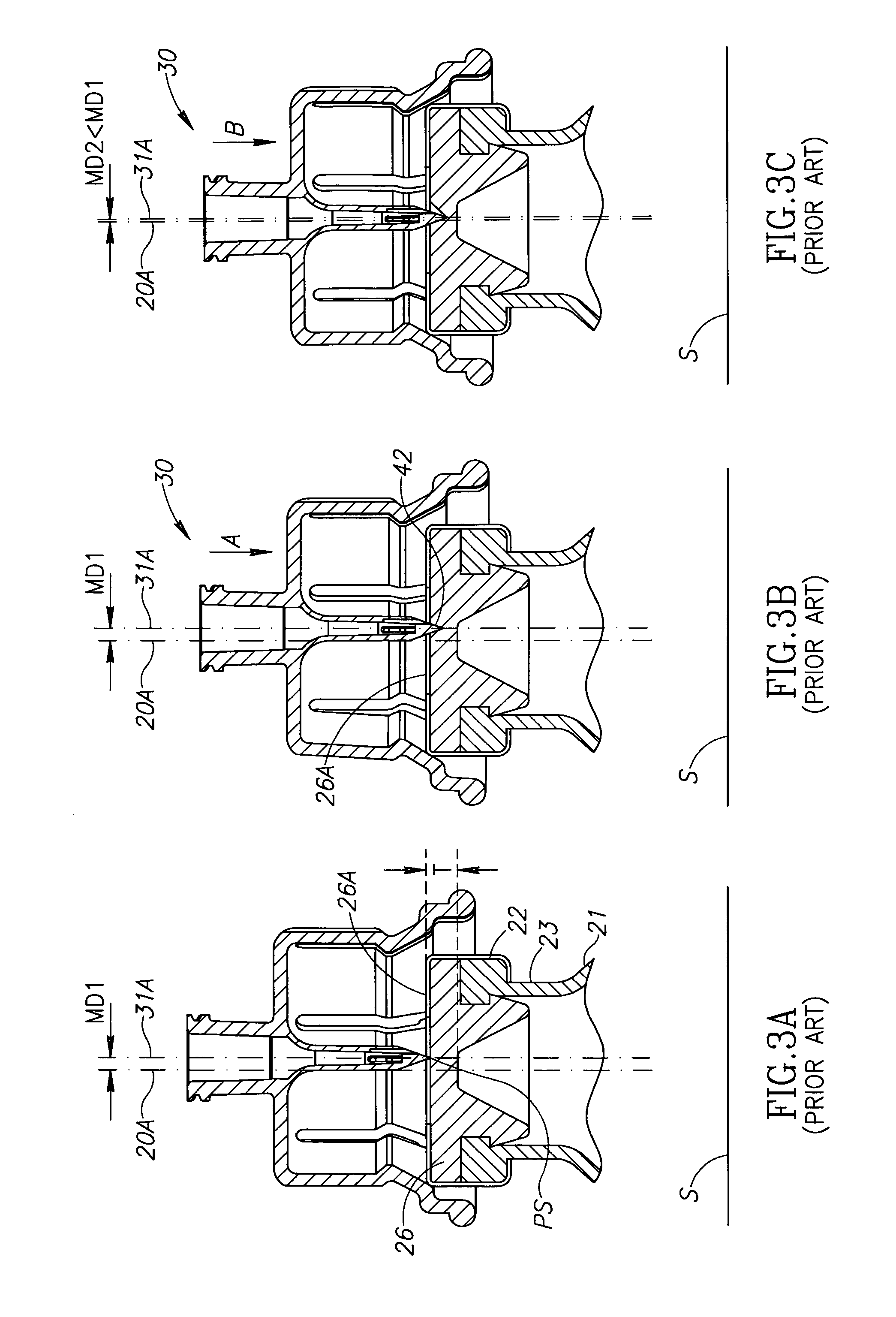

InactiveUS20110143316A1Good tactile feedbackEasy and fast processingDental implantsDental toolsO-ringOsteotomy

The present invention is directed to a tool package for use with bone and / or dental implant systems. The tool package includes of two mating tools. The first tool is designed to engage an implant and carrier assembly and place the implant into the osteotomy. Once the implant is fully seated, the first tool is removed. The second tool is placed over the implant to hold the implant securely in place. The first tool is reintroduced through the second tool to engage and remove the implant carrier. The first tool may function like screwdriver except that the tip is able to mate with and positively engage the octagonal implant carrier head and plastic o-ring catch. The first tool drives the implants into place, and also mates with the second tool to remove the implant carrier.

Owner:DESIGNED DENTAL SYST

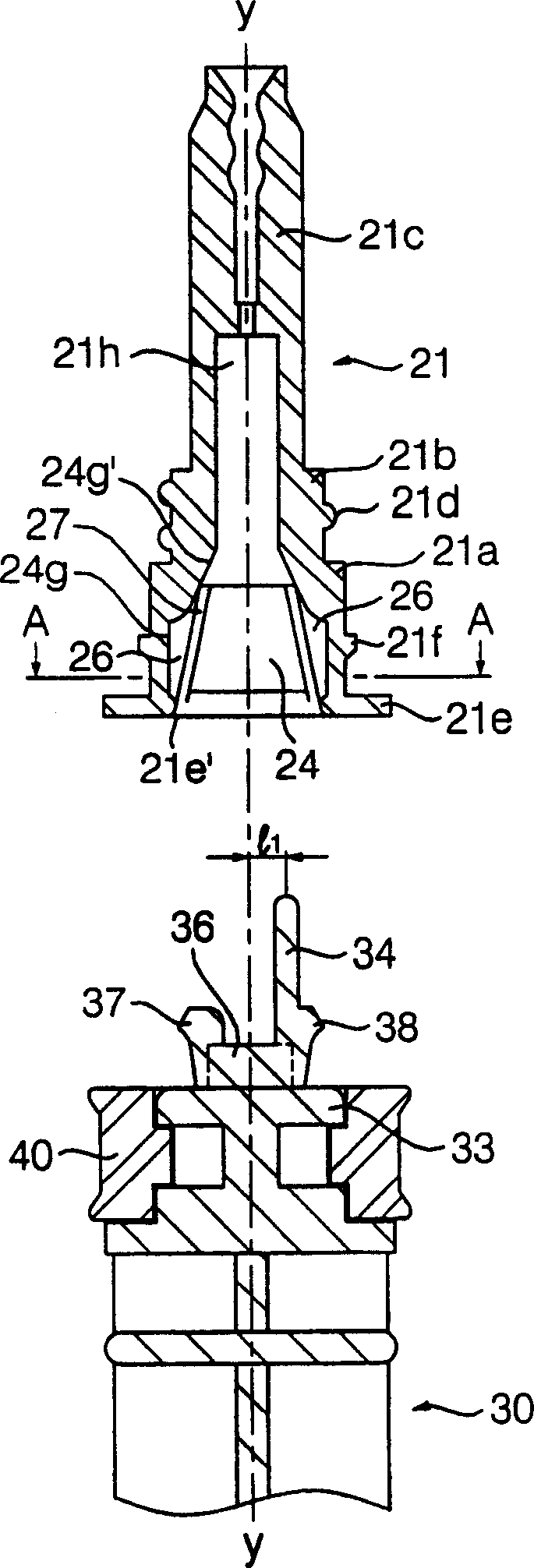

Disposable nozzle

InactiveUS20100286636A1Safe and reliableLow costMedical applicatorsFluid jet surgical cuttersO-ringClean wounds

The present invention relates to a disposable nozzle for inserting into a hand piece for treating and cleaning wounds by means of a highly focused high-pressure micro water jet. The disposable nozzle comprises a cylindrical nozzle body having a centrally traversing orifice body duct, which is laterally closed, as well as a cylindrical orifice with a centrally traversing orifice duct. The orifice is disposed in a recess that is centrally arranged in the frontal terminal region of the nozzle body at the front side in such a manner that both ducts adjoin to each other in a coaxial manner. An O-ring is disposed in the recess between the nozzle body and the orifice in a clamping manner, wherein the O-ring centrally retains the orifice in the nozzle body.

Owner:MEDAXIS

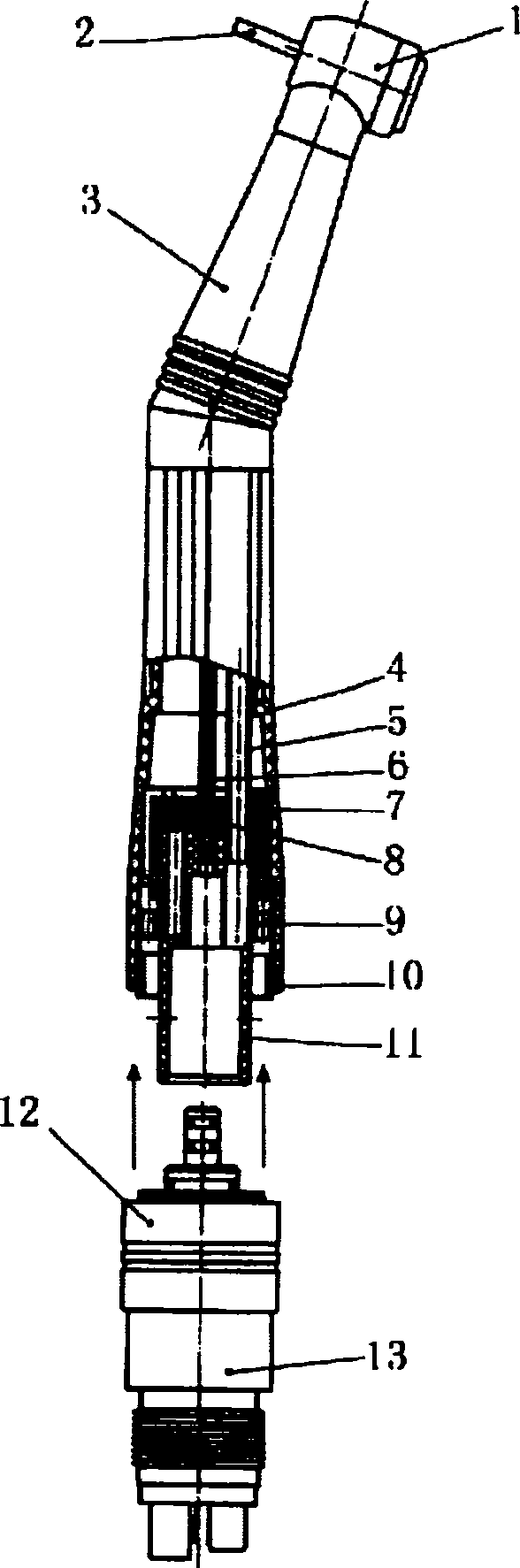

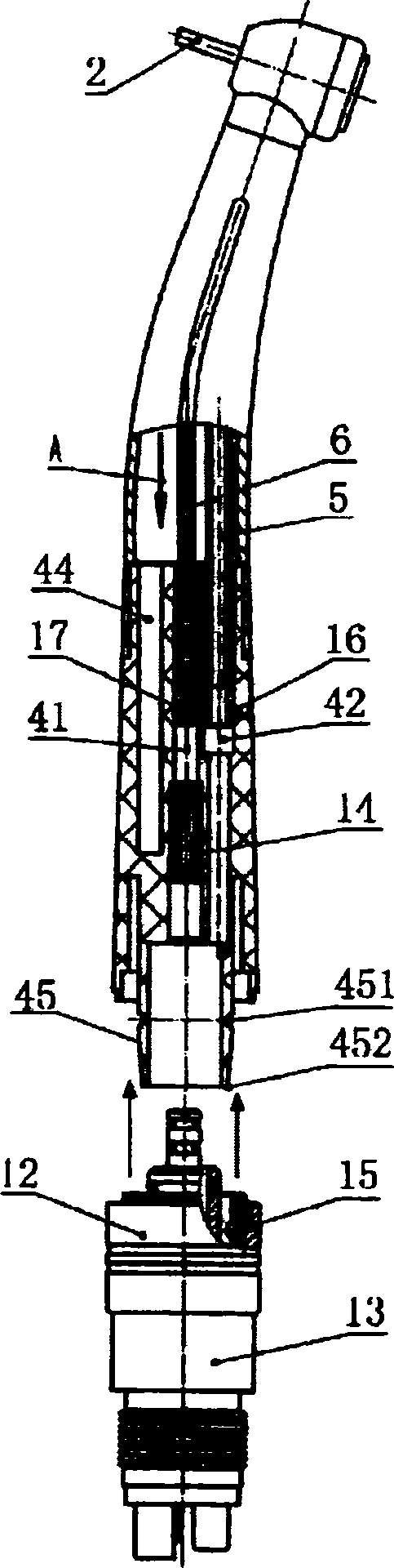

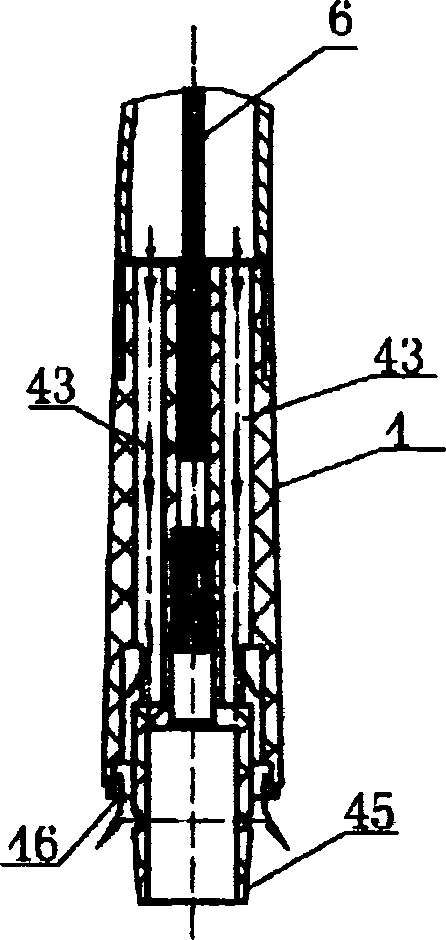

Disposable high speed turbine dental drill hand piece

InactiveCN1887236ASolve the trouble of assemblySimple structureDental toolsBoring toolsO-ringEngineering plastic

The disposable high speed turbine dental drill hand piece has one handle made of molded engineering plastic, and the handle has one integrated back part for connection to the dental drill hand piece and the other end made into tail structure suitable for connecting with water pipe and air pipe easily. The handle features its front part in inserting structure with O-ring for sealing the air pipe and water pipe union. The back part of the handle may be in different sizes for fast connection to water pipe and air pipe of different sizes. The handle may have one non-return valve installed to avoid back flow of water. The handle has light weight, high strength, easy manufacture and installation and low cost and is suitable for use in disposable high speed turbine dental drill hand piece.

Owner:BEIJING NORTH POLE DENTAL HANDPIECE

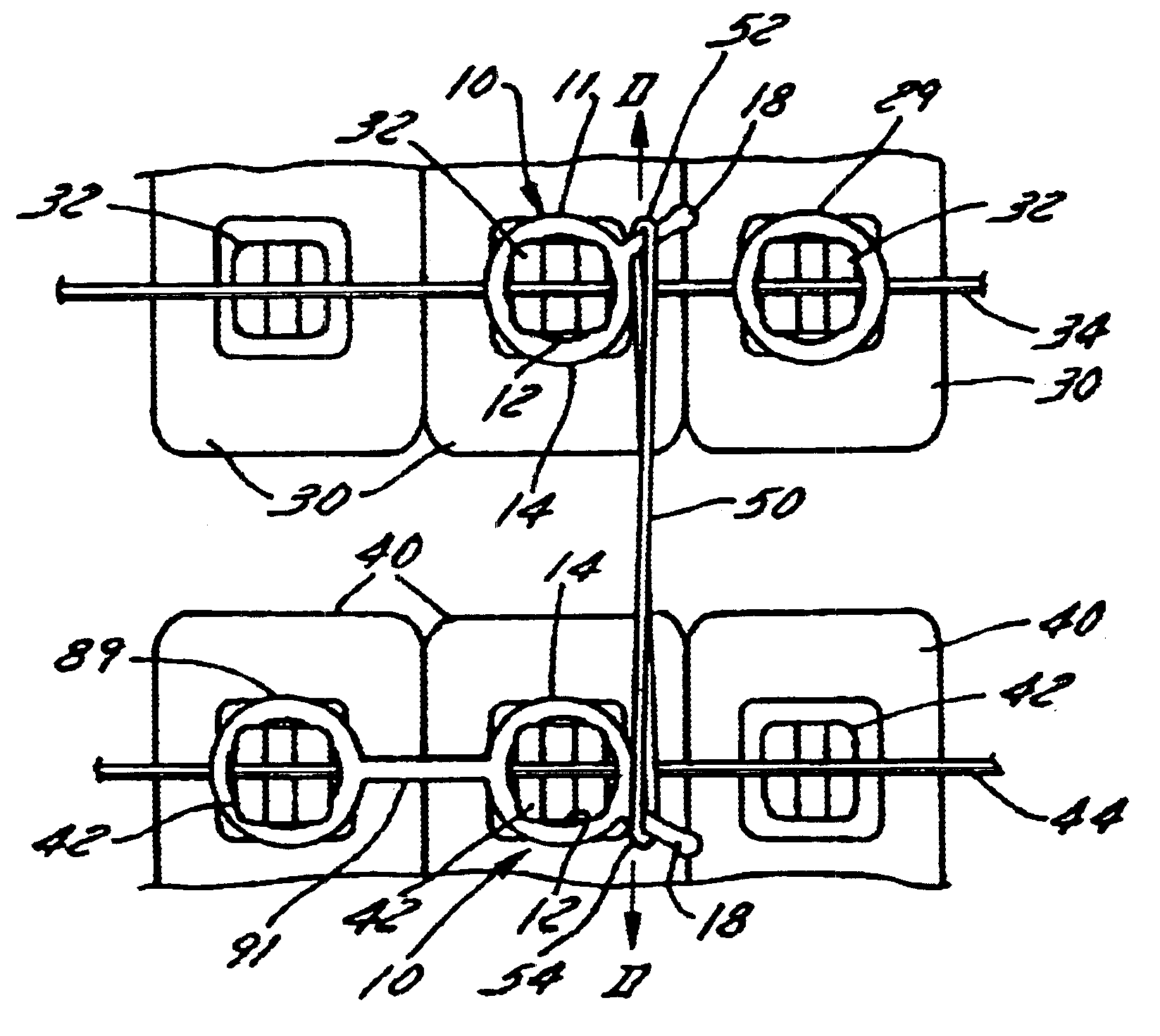

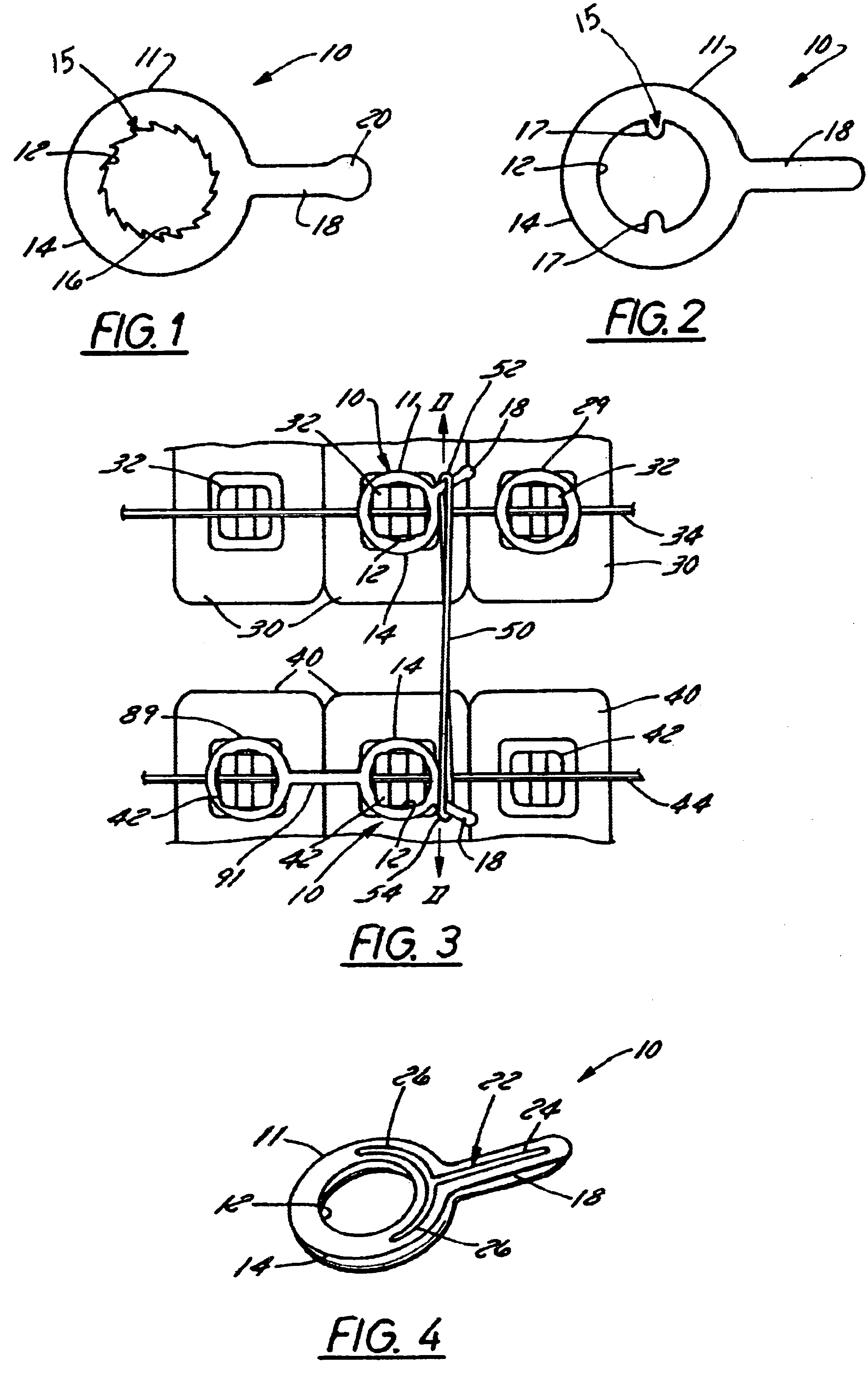

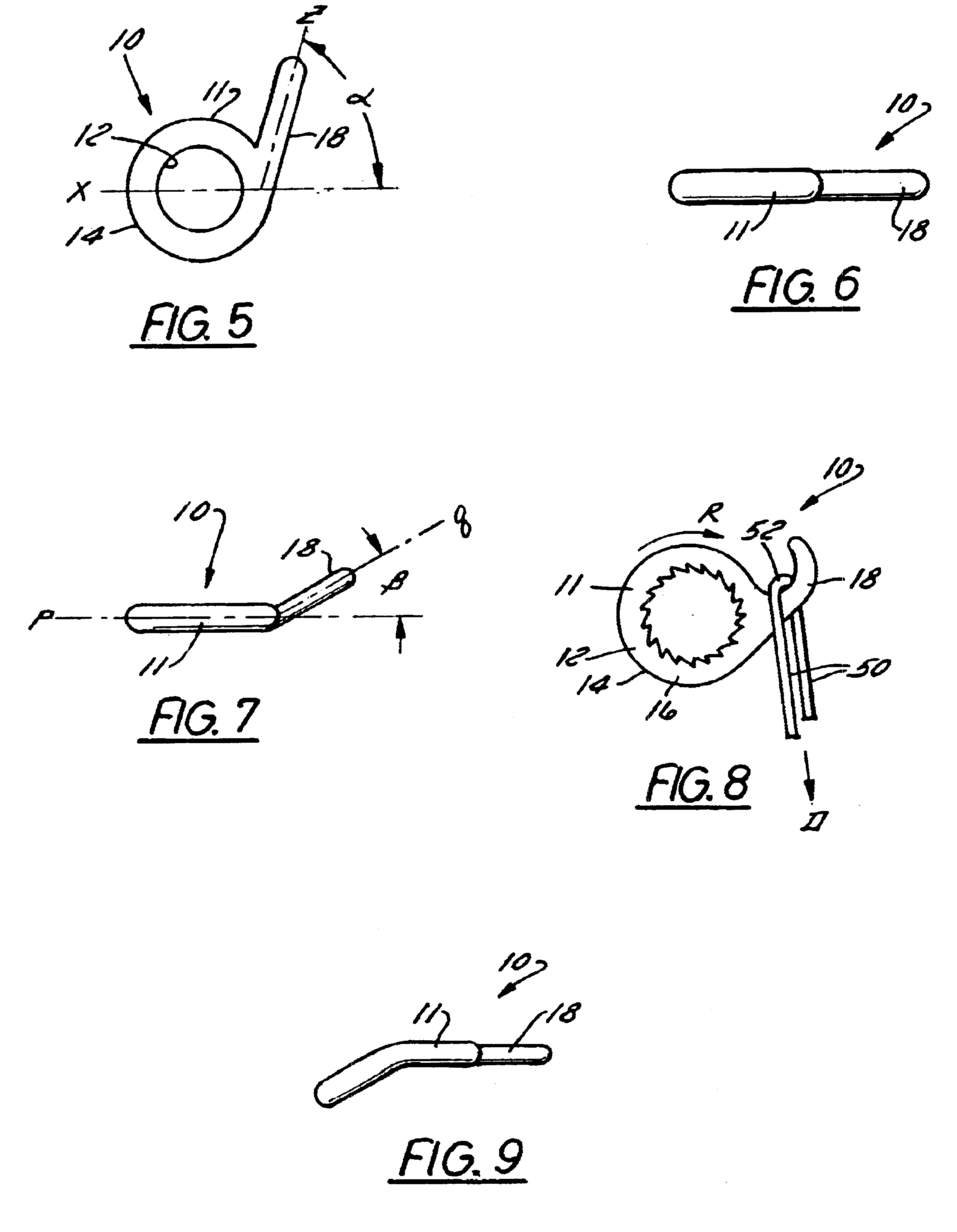

Orthodontic ligature and method of use

A generally elastic orthodontic ligature in the shape of an O-ring is provided with a semi-rigid retaining arm for the general purpose of attaching a rubber band between teeth. The retaining arm is integral with the O-ring although the two may be made of different materials. The O-ring may have projections therein for preventing rotation of the ligature during use, and the projections may include unidirectional barbs. Further, variations in the angle or shape of the arm may be provided as desired.

Owner:HOLZHAUER DANIEL A

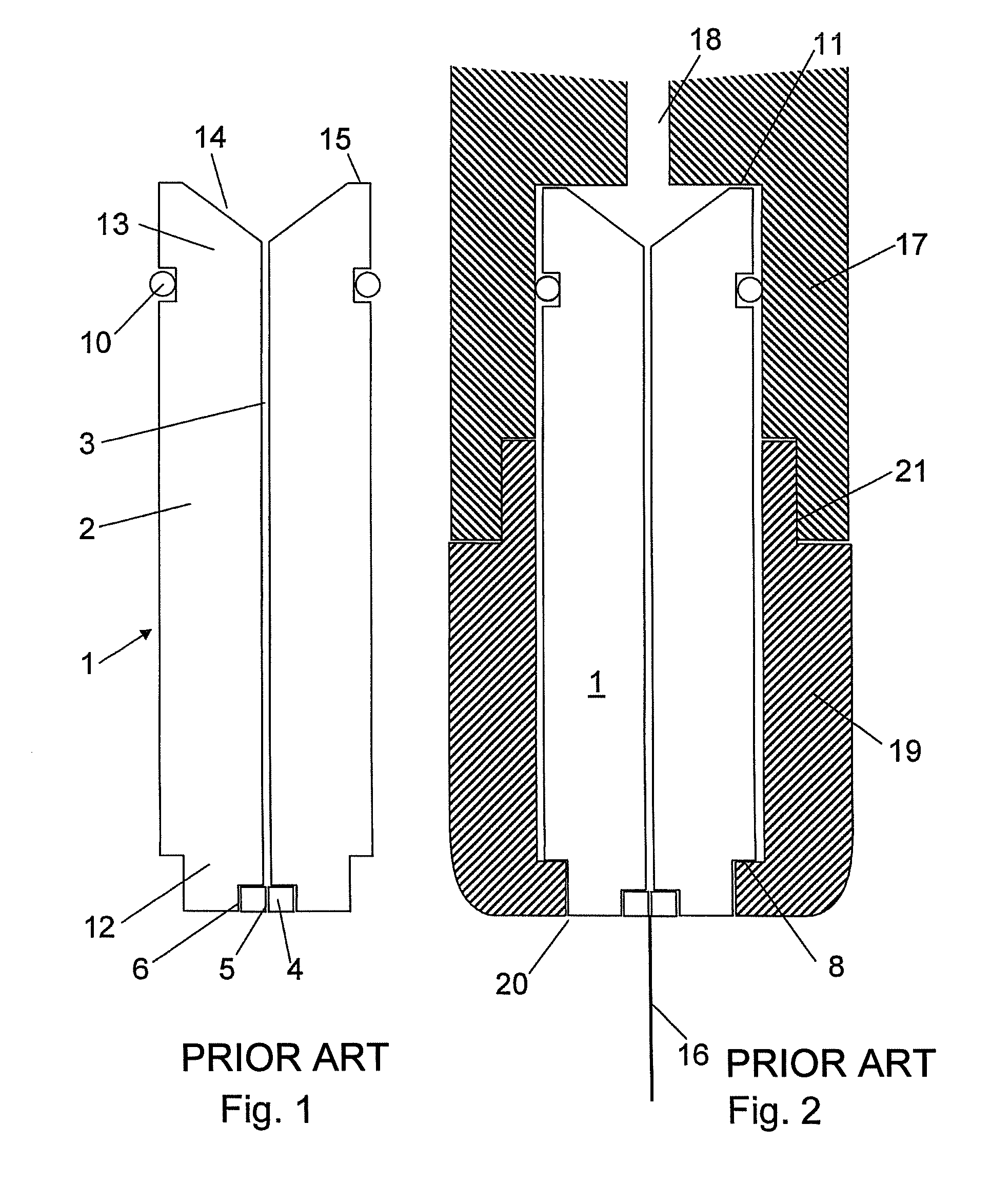

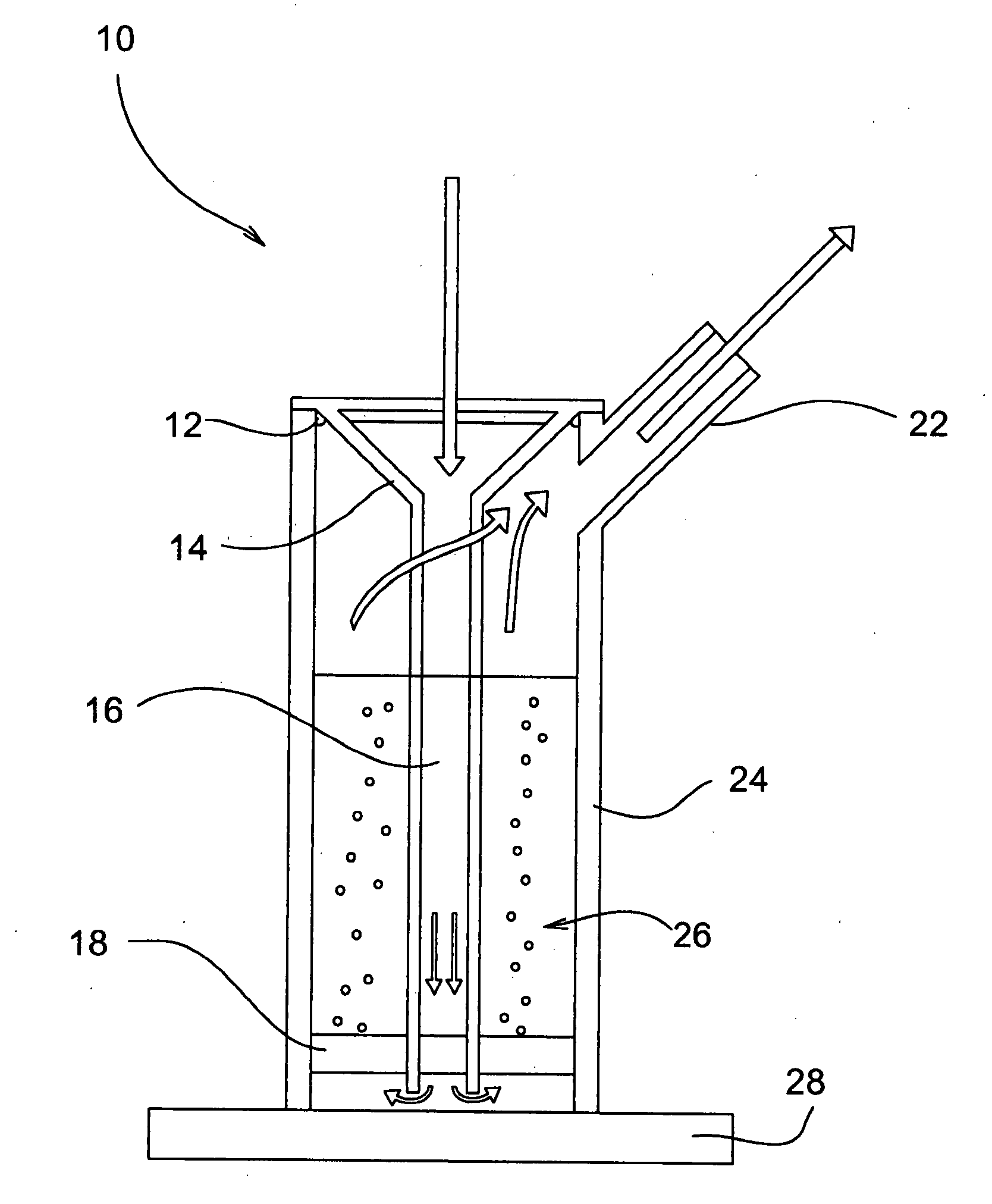

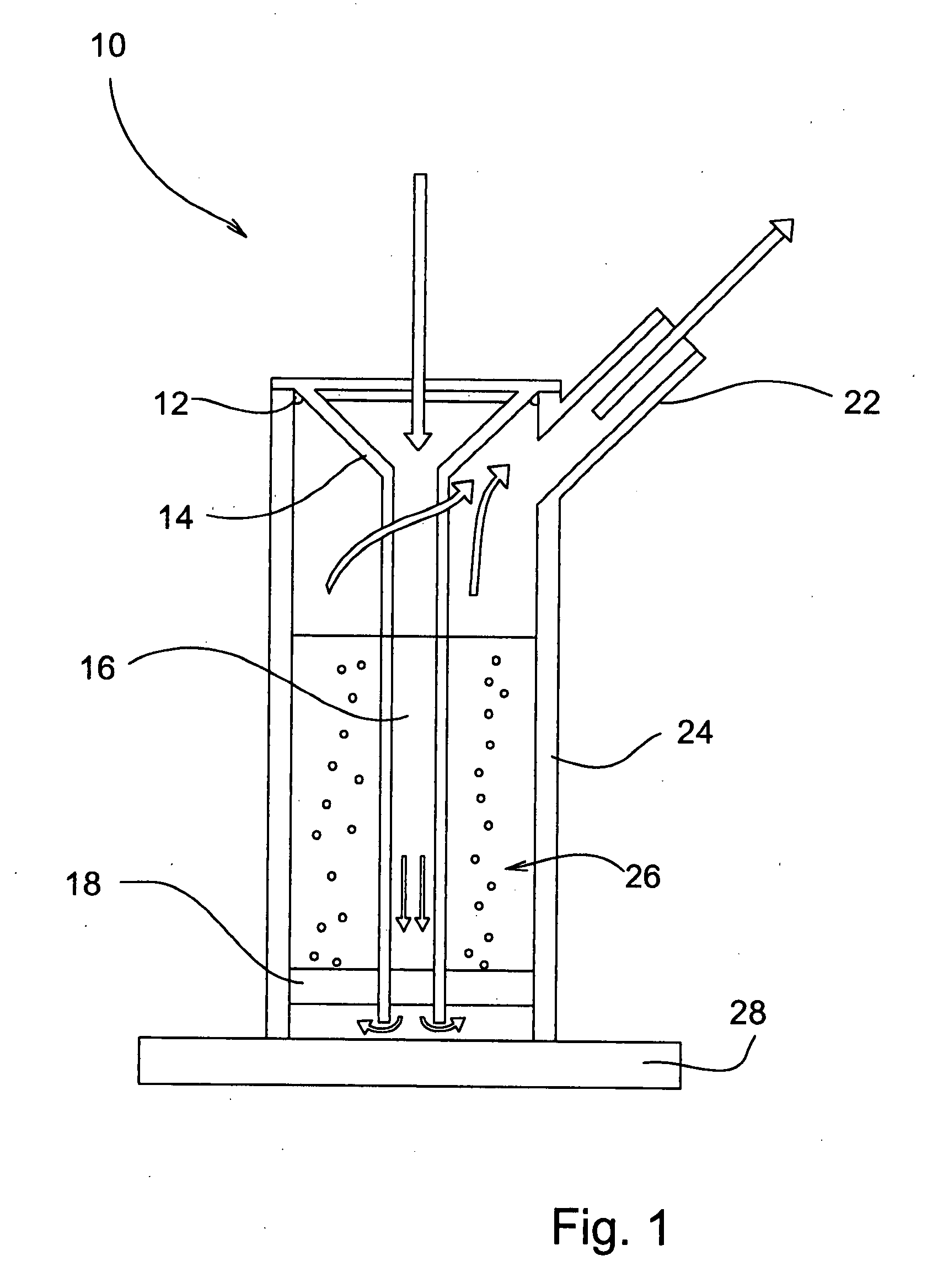

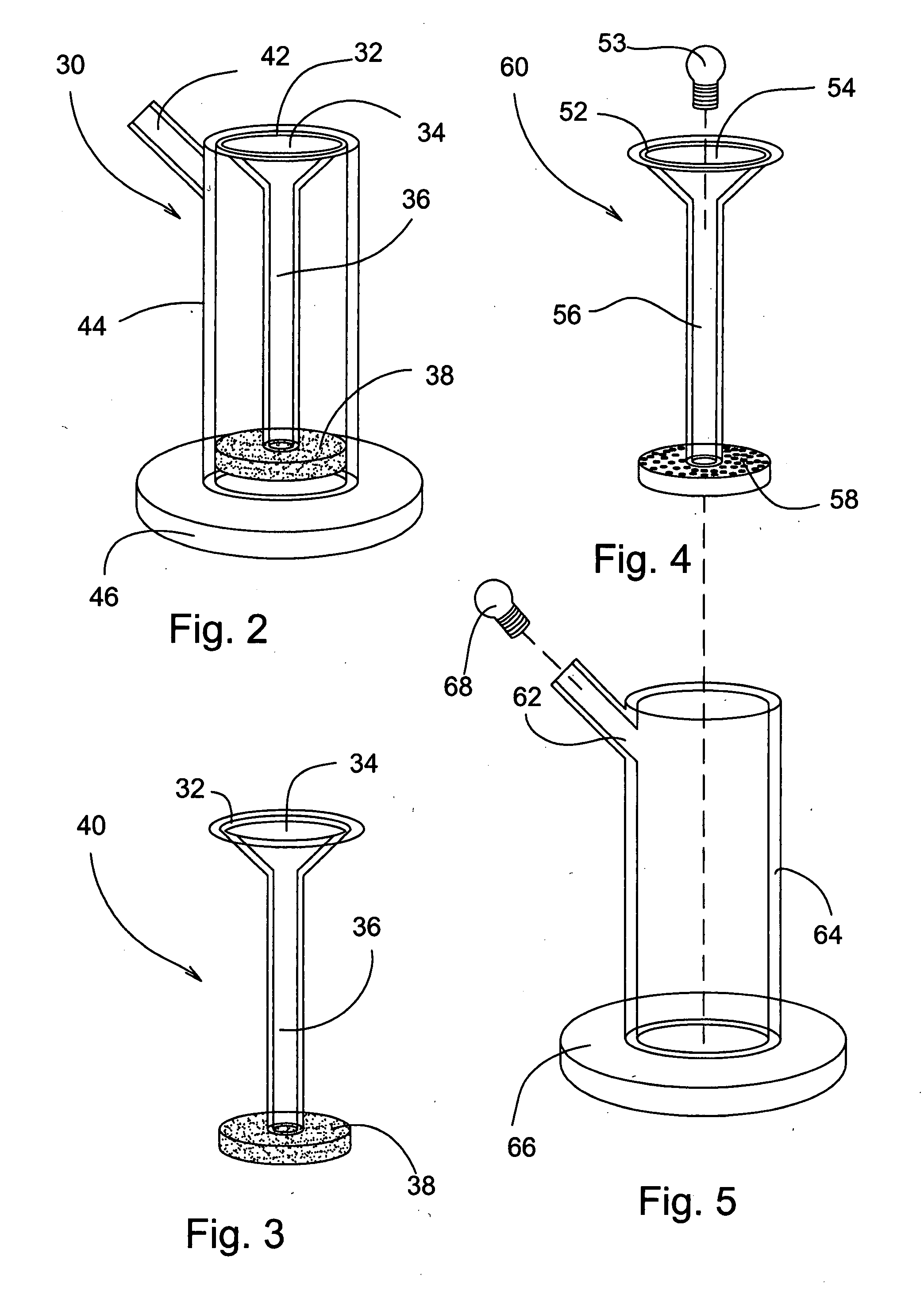

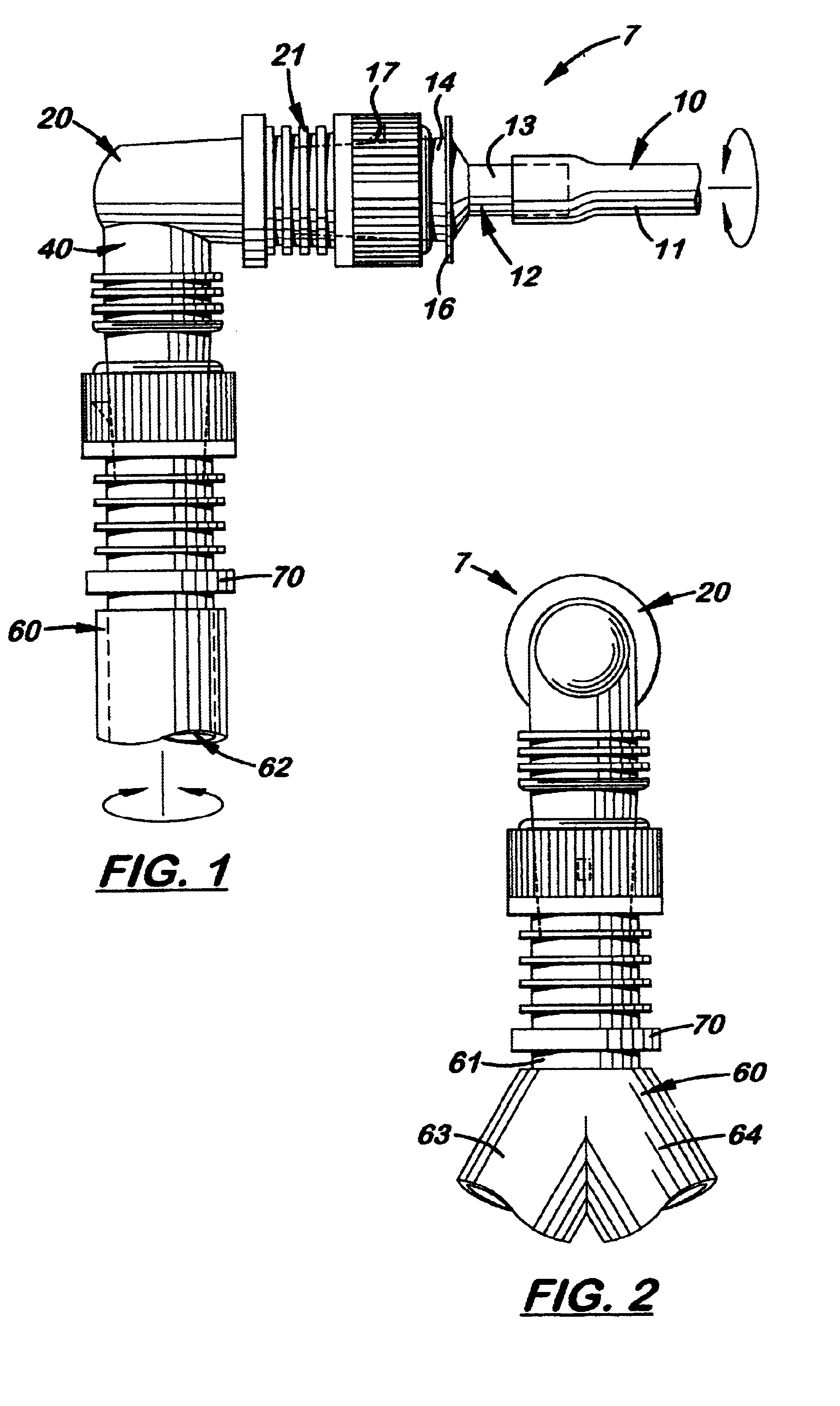

Inhaler vaporizer

An inhaler vaporizer consists of two parts, the first part consisting of a funnel with a top portion, a “Y” portion and a disc portion made of a porous material or a non-porous material with a multiplicity of small holes. This part is inserted into a main body portion consisting of a main body, mouthpiece and base. The internal “Y” portion is sealed to the main body portion by an O-ring. Ethyl alcohol is poured into the main body of the inhaler vaporizer, and air is drawn into the inhaler vaporizer by applying suction through the mouthpiece. This air is drawn into the “Y” cone, passes through the “Y” stem tubular portion to the bottom of the body portion of the inhaler vaporizer. The air is drawn through the alcohol, vaporizing the alcohol in the process and is then inhaled through the mouthpiece into the mouth, throat, and lungs where it interacts with affected tissue.

Owner:SVEHAUG OSWALD C +1

Partly Disintegrating Plug for Subterranean Treatment Use

Owner:BAKER HUGHES INC

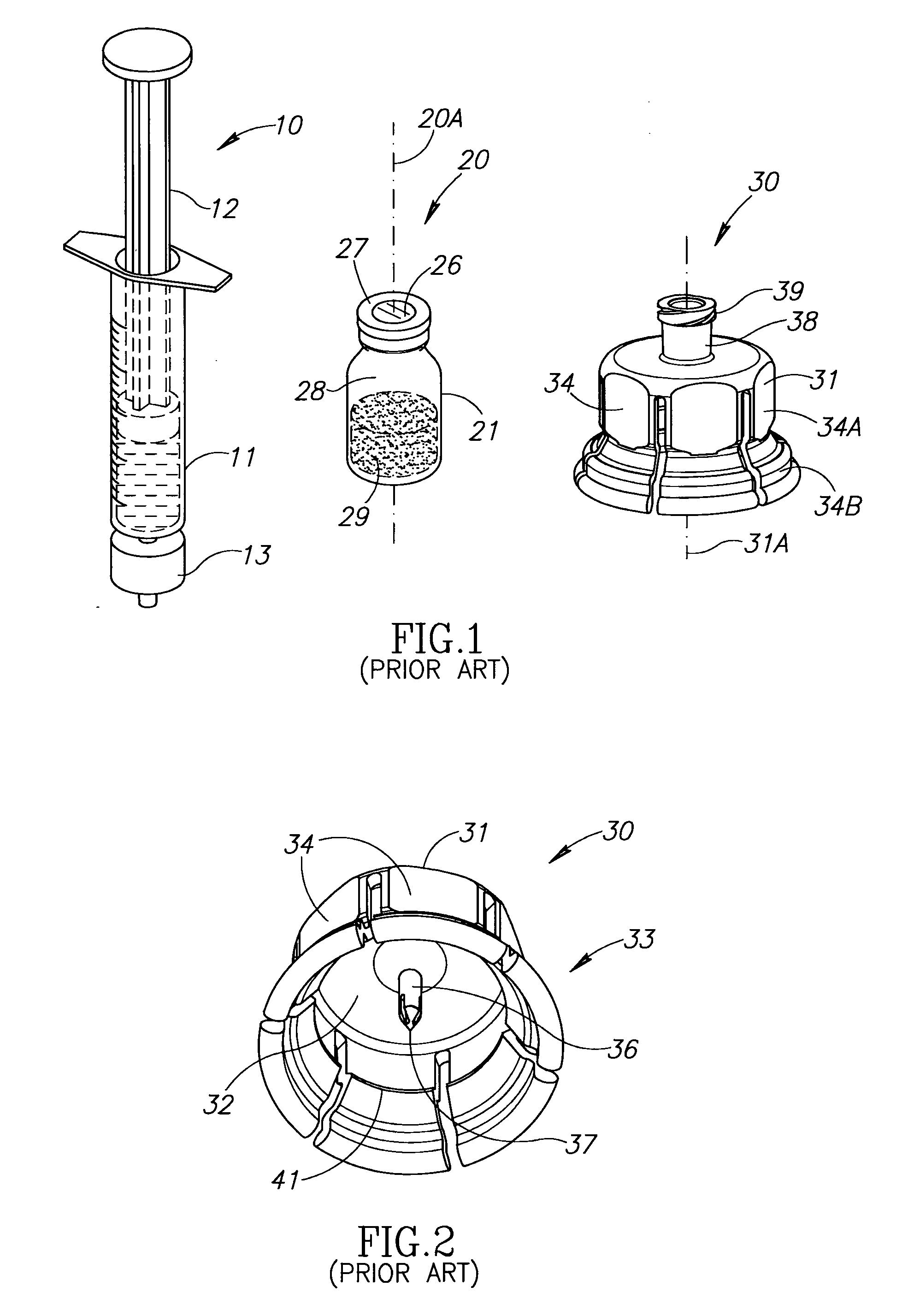

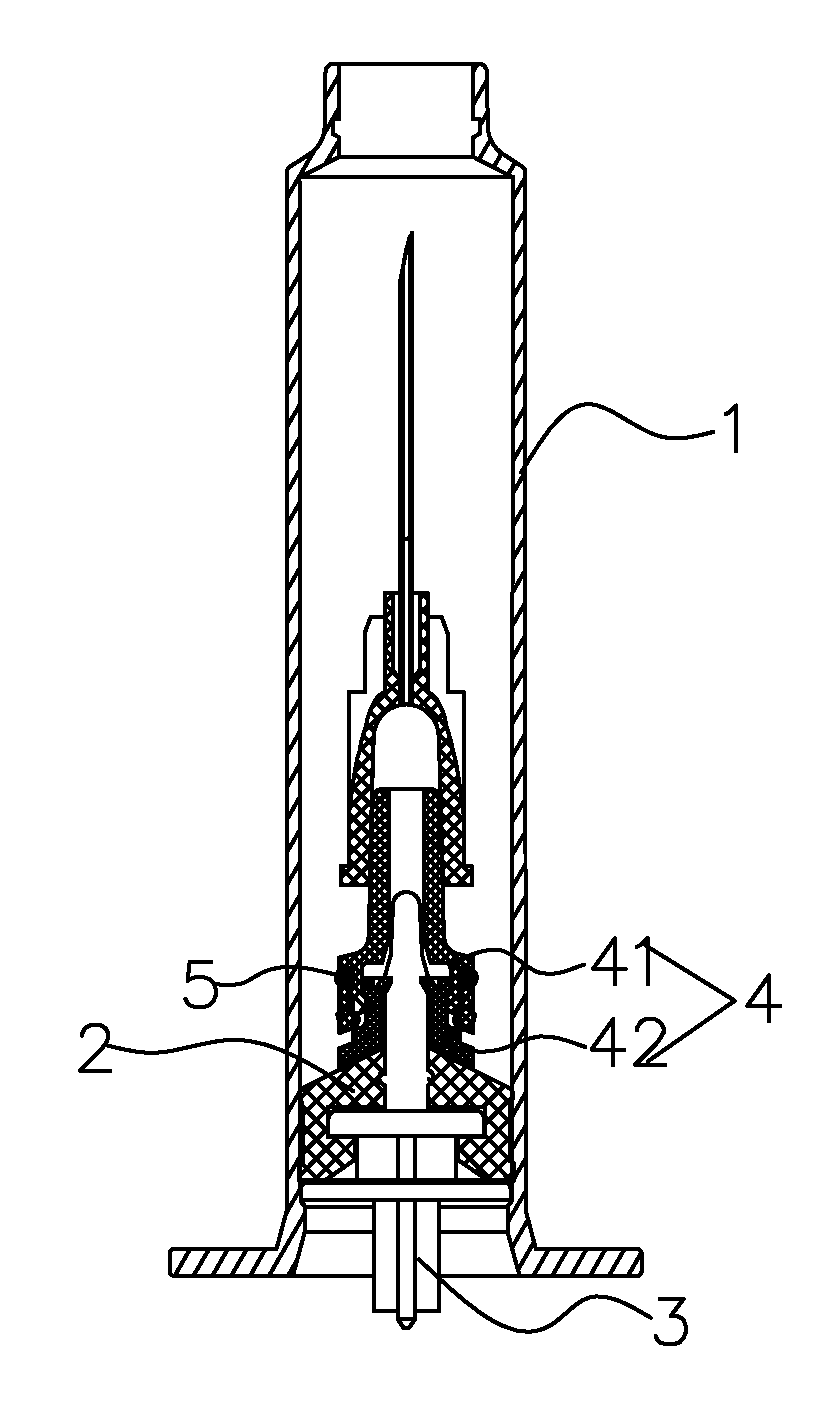

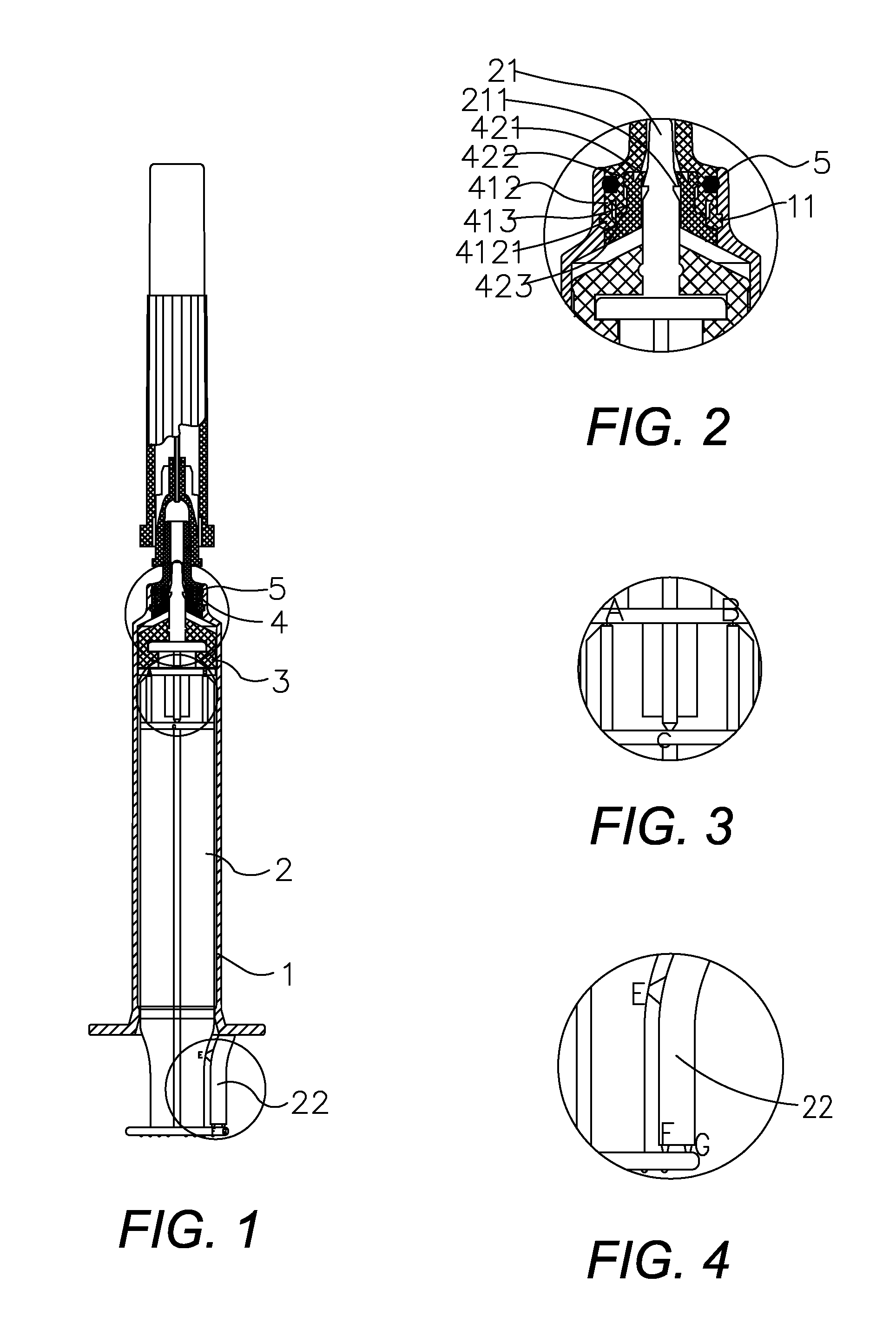

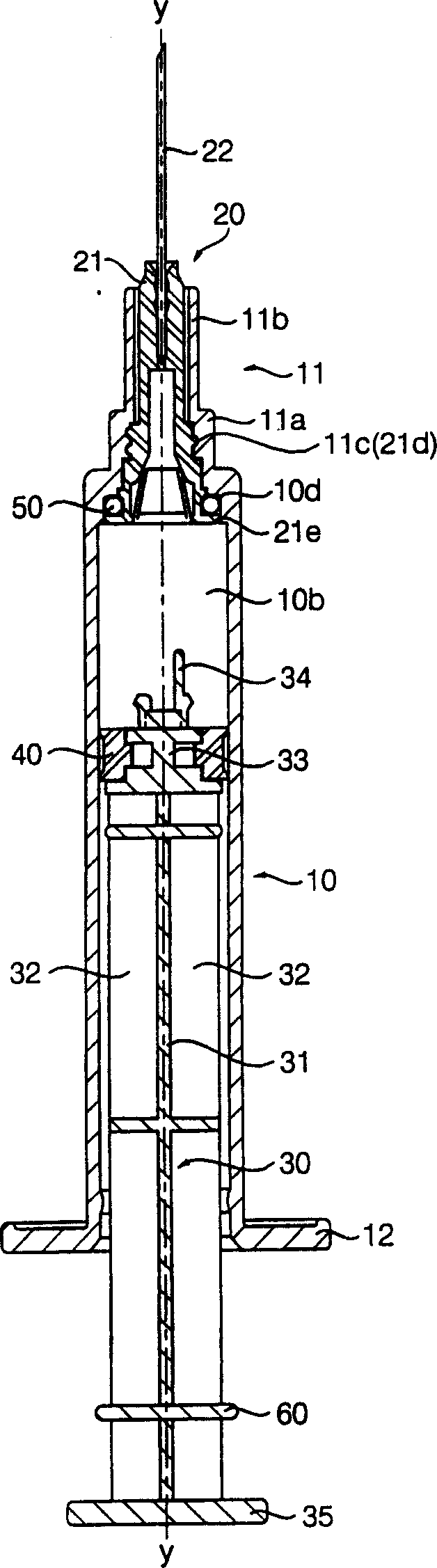

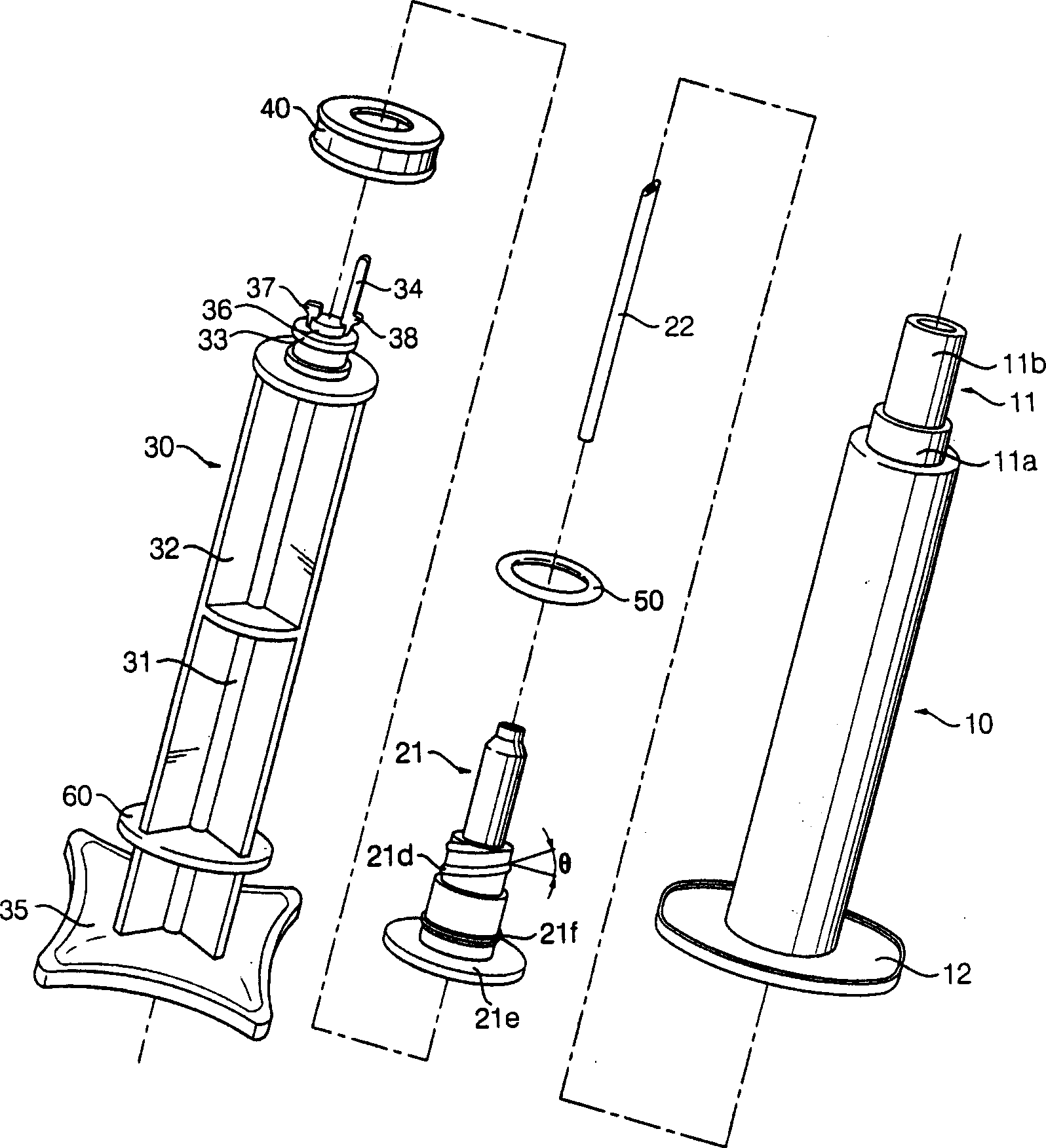

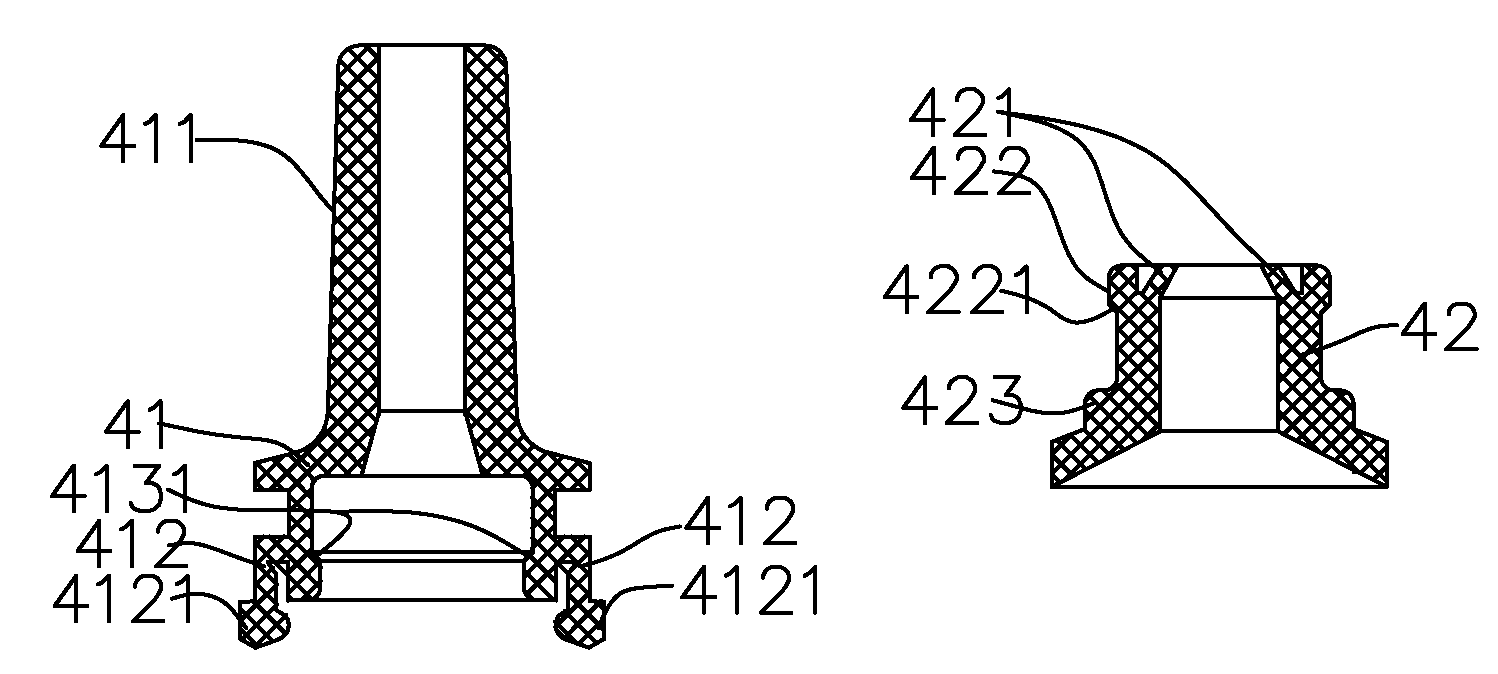

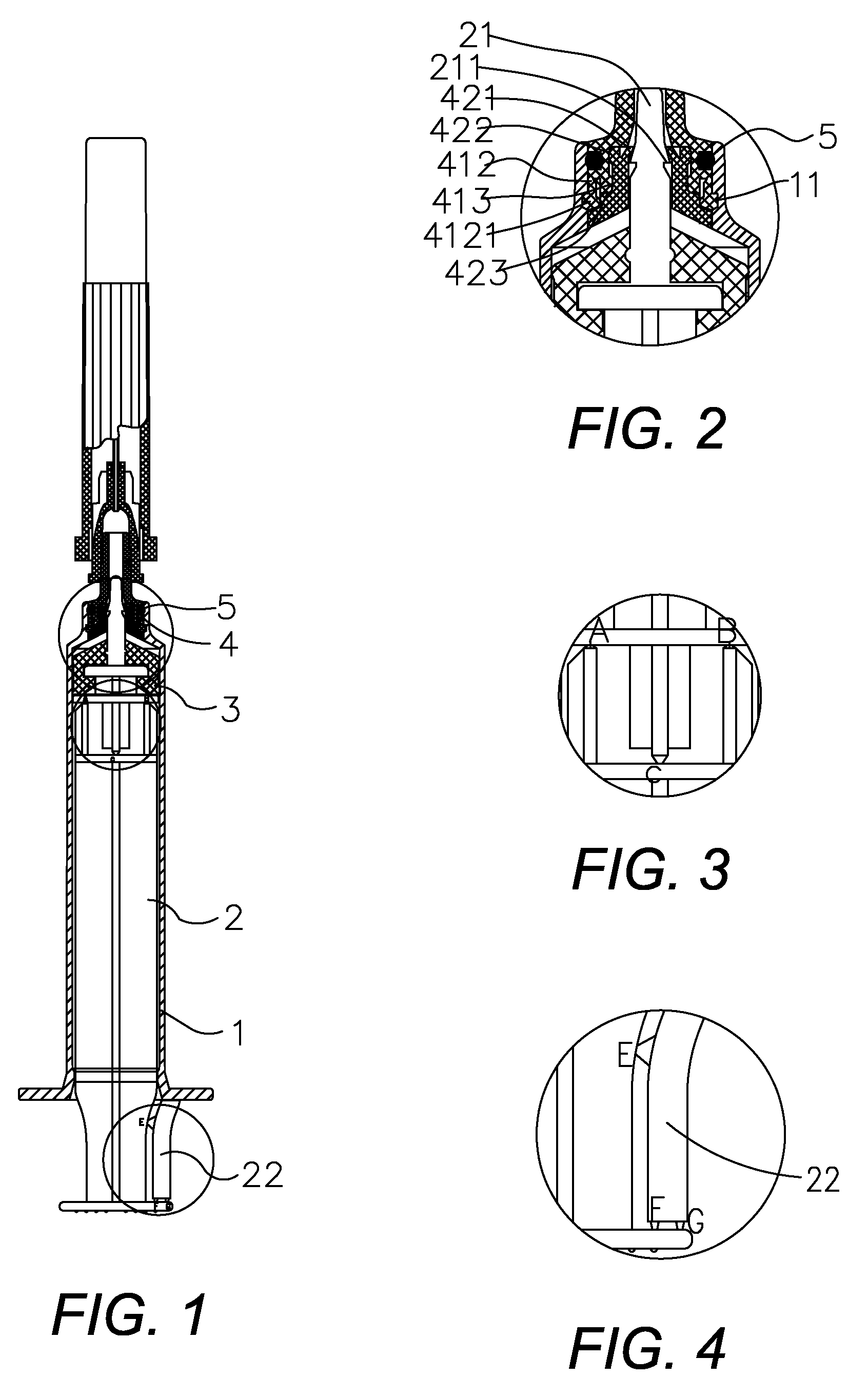

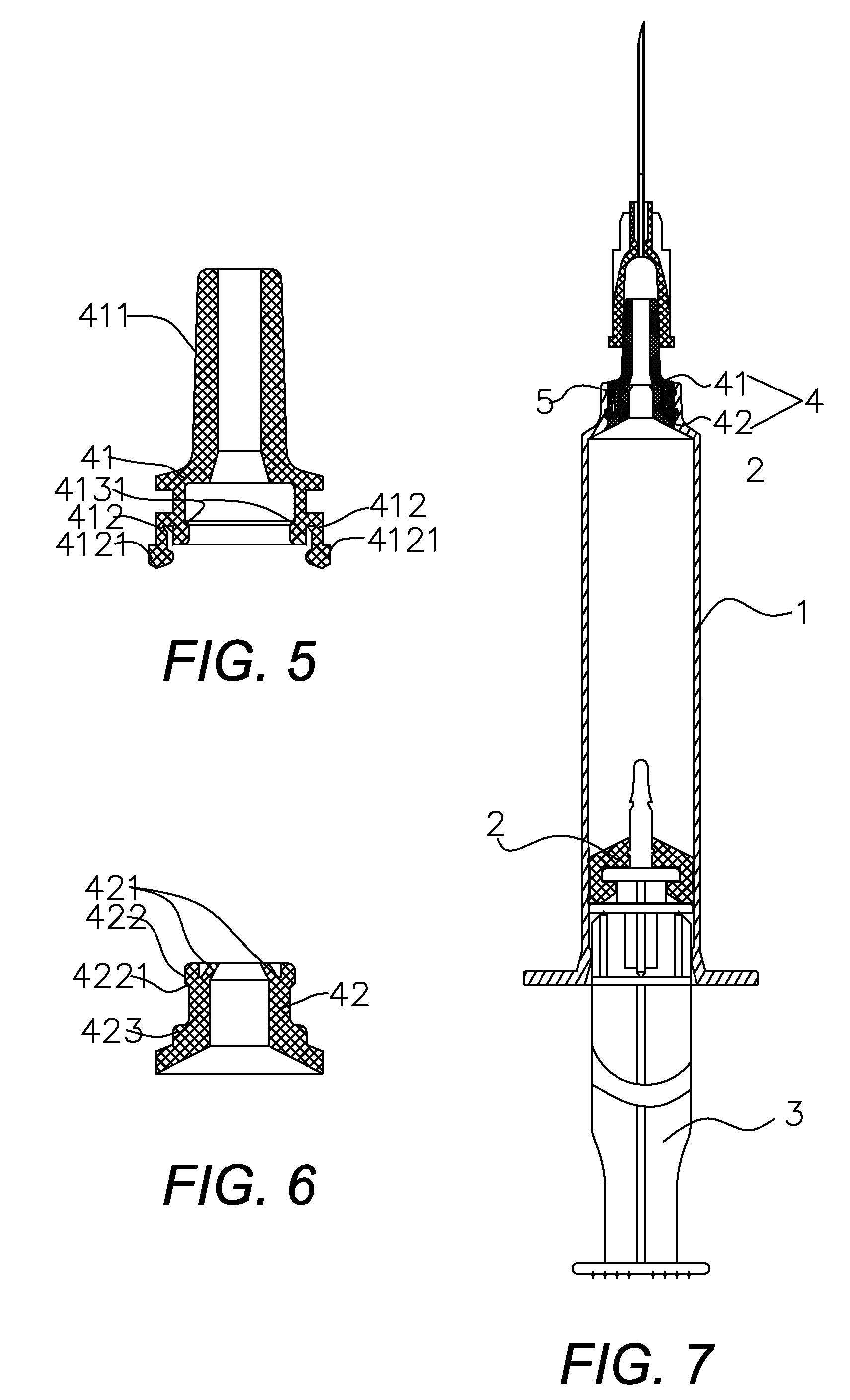

Safety Self-Destroying Disposable Syringe

ActiveUS20080132837A1Relieve painSimple structureInfusion syringesIntravenous devicesO-ringSafety syringe

The present invention provides a safety self-destroying disposable syringe, which consists of a hollow tube, a plunger fitting into the inside of the hollow tube and a rubber piston attached on the tip end of the plunger, and a needle holder attached on the front end of the hollow tube, wherein said needle holder is comprised of a cone base and a seat; said cone base has a Roll cone for fitting into the needle, and a circular base for fitting into the inside of the hollow tube, there are several O-rings attached on the contacting surface between them; there is a locating ring-groove built on the inside wall of the hollow tube approaching the front end for catching up the needle holder; said plunger has a conical head built on the front end, and said conical head has a circular barb built on the middle portion. The safety syringe provided by the present invention can be withdrew into the inside of the tube, and also suit to match to diversity of standard needles for replacing, it also has simple structure, easy manufacturing and convenient use with high safeness features.

Owner:SOL MILLENNIUM MEDICAL LTD

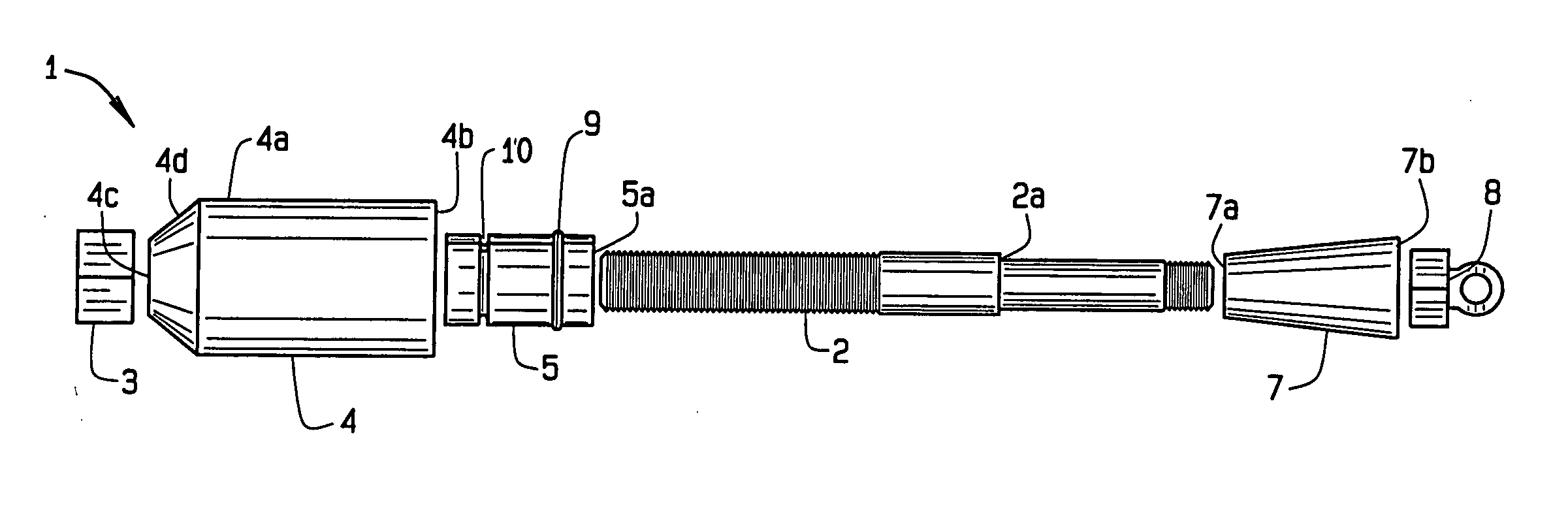

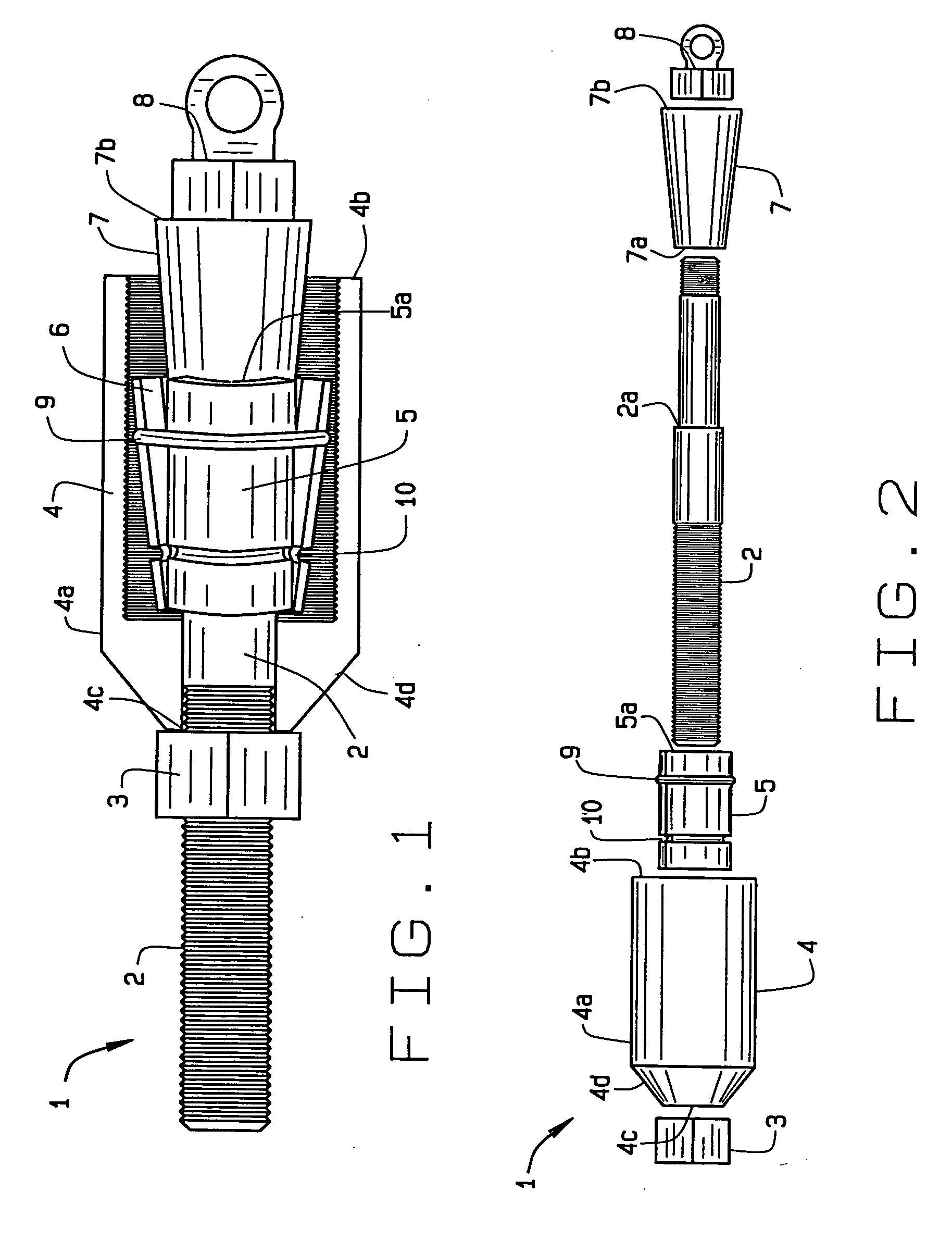

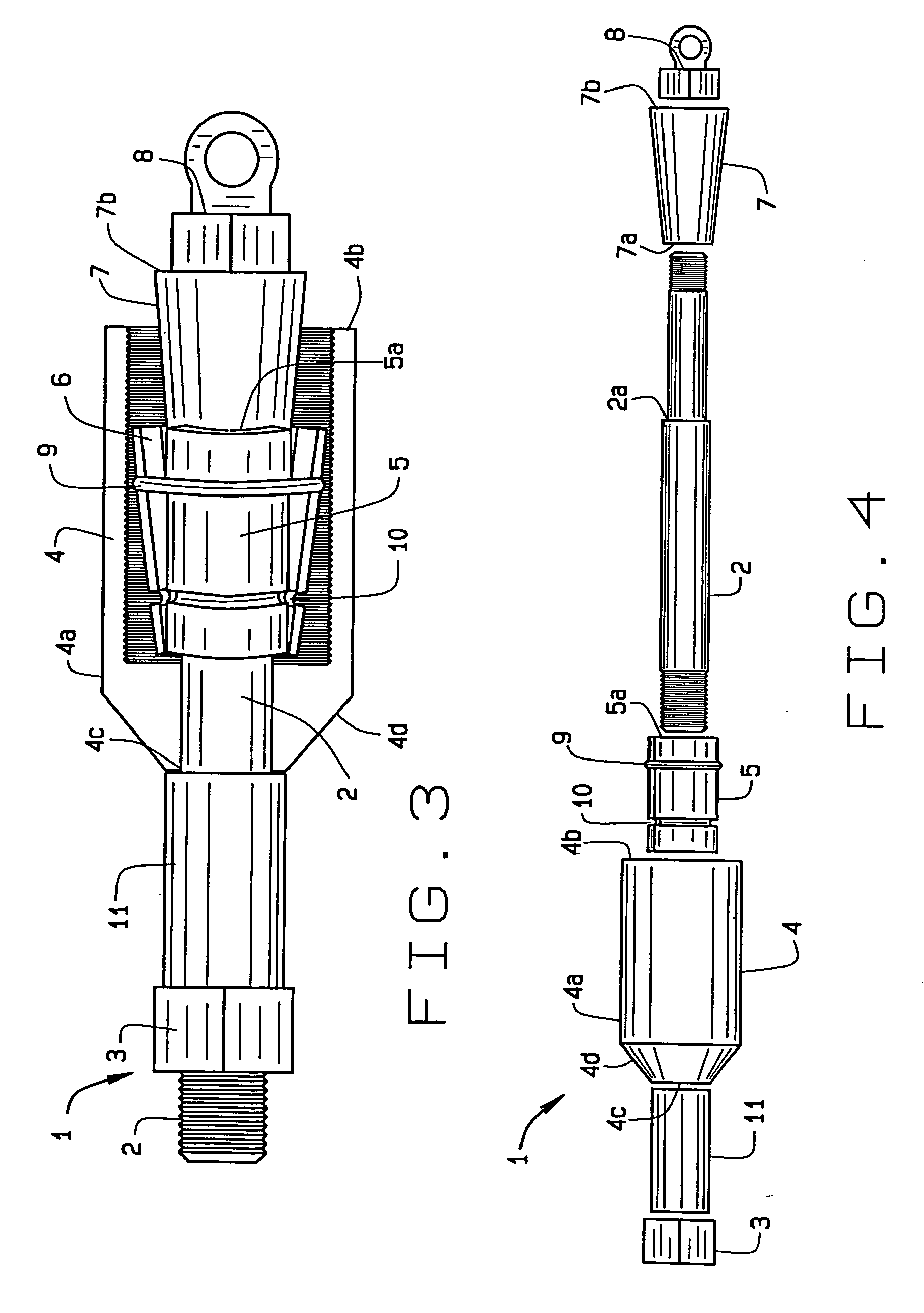

Pipe pulling device

InactiveUS20060018717A1Easy to assembleLow costPipe supportsPipe laying and repairEngineeringMechanical engineering

A pipe pulling device secures to the end of a pipe, with wedge action, for pulling by equipment. The device has a shaft, a housing upon the shaft, one or more wedges, a cone, nuts, eye nuts, O rings, and a sleeve, all arranged coaxially. First the nut is placed upon the shaft, then the housing is oriented forward. The forward end of the housing has a beveled edge to assist in passage through soil. The contractor then places a wedge of three vanes upon the shaft within the housing. A hollow cone upon the shaft contacts the wedge. An eye nut then secures the assembled parts upon the shaft. In use, a contractor tightens the nut rearward thus pulling the cone forward and expanding the wedge. The Is wedge expands to grasp the pipe between the housing and the wedge. The contractor can then pull the pipe through soil.

Owner:HUNCOVSKY JEFFERY W

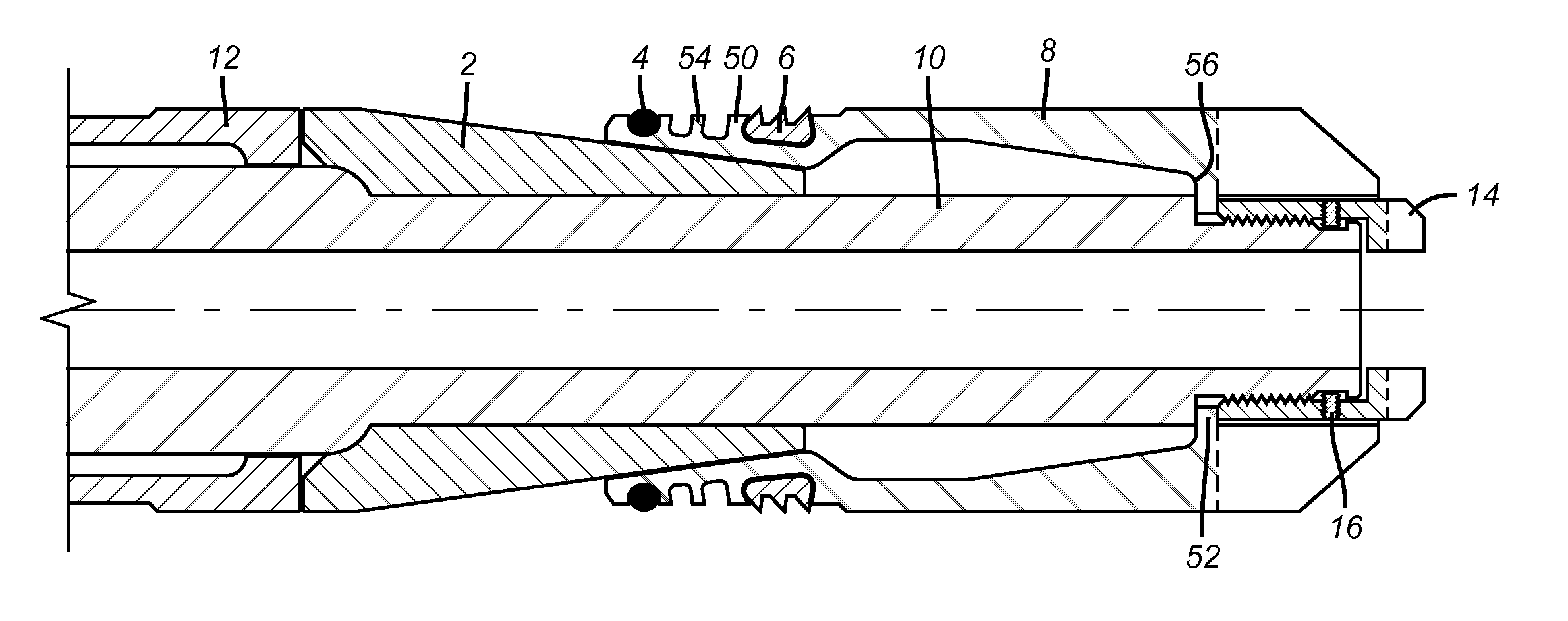

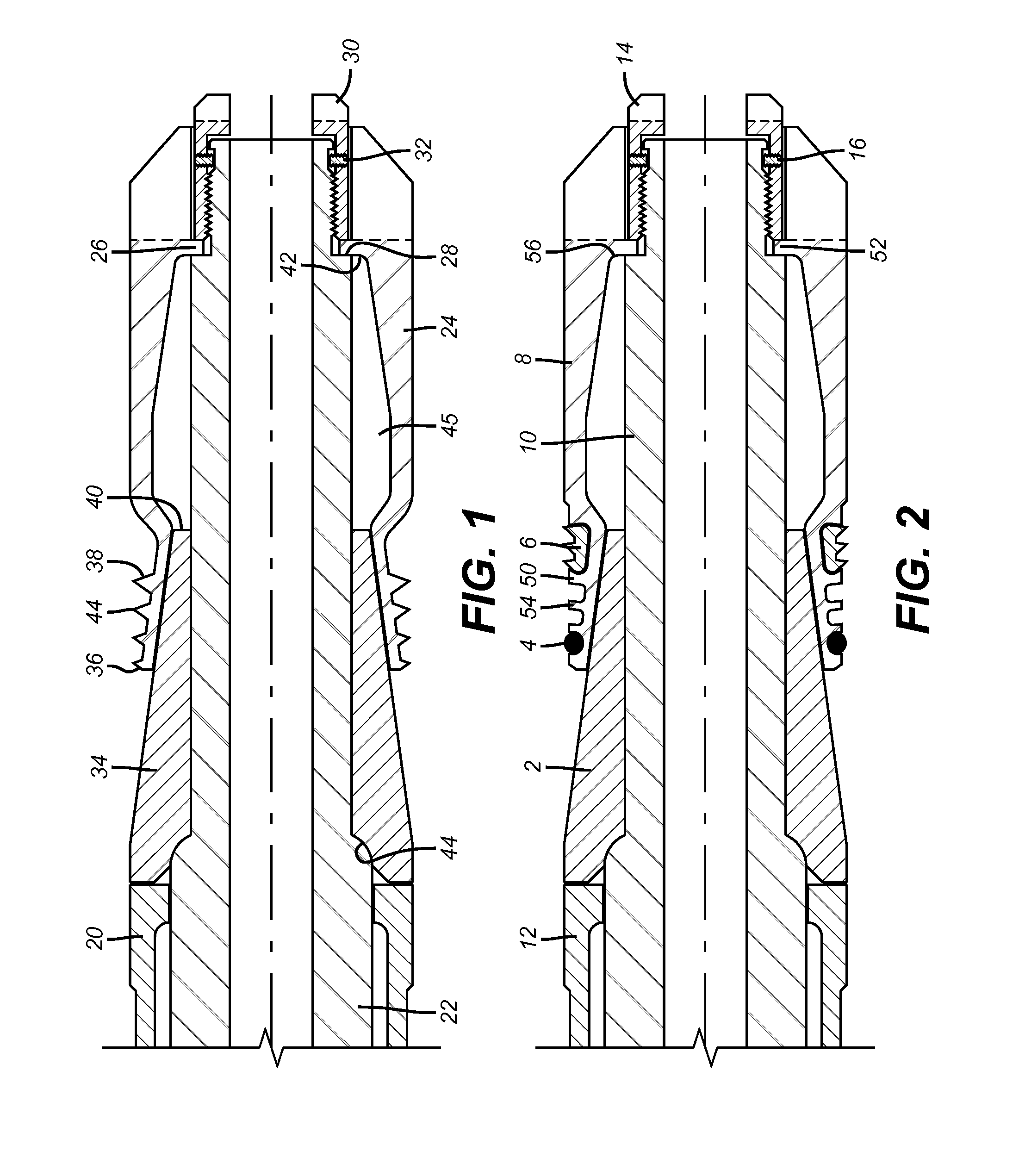

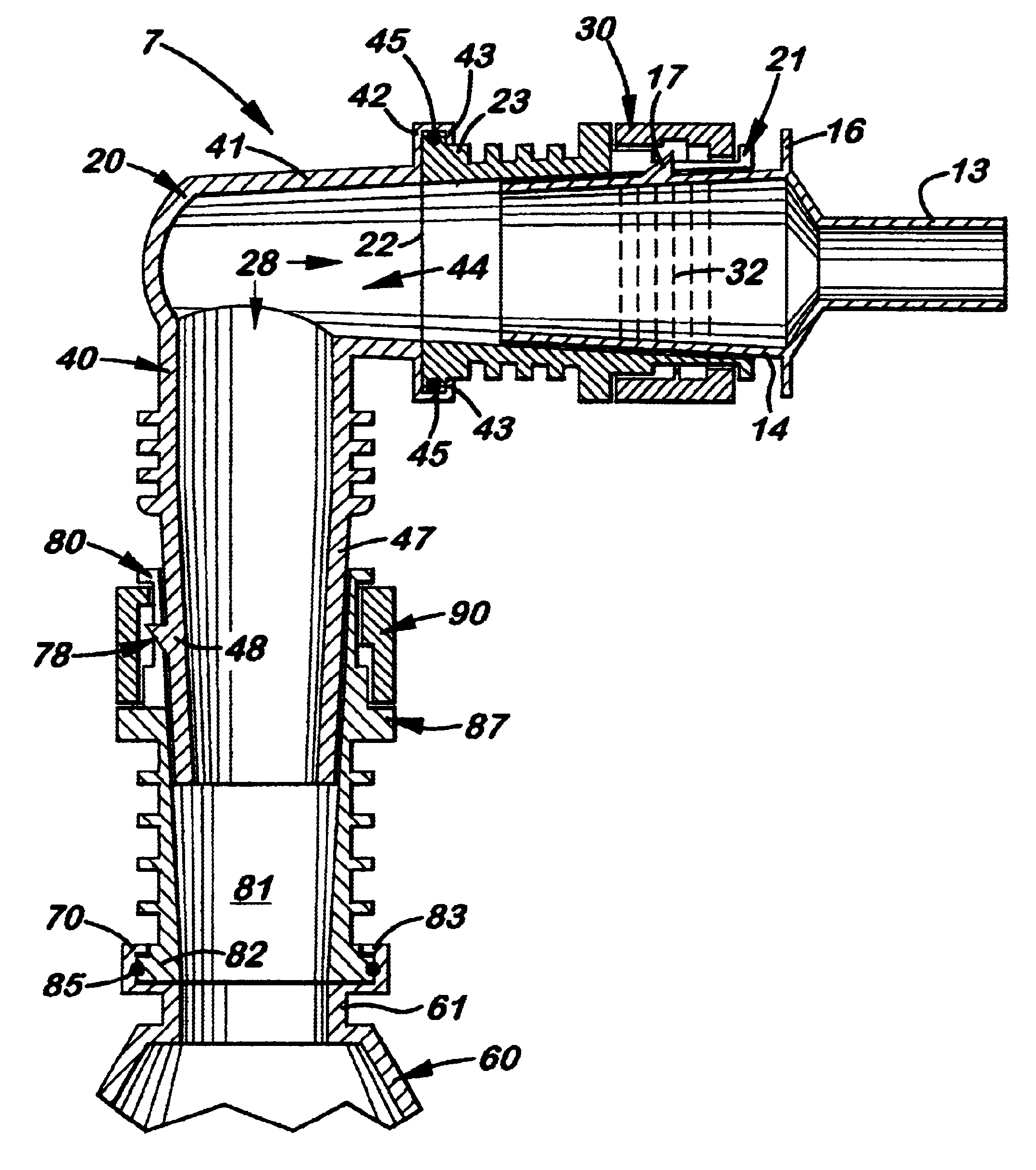

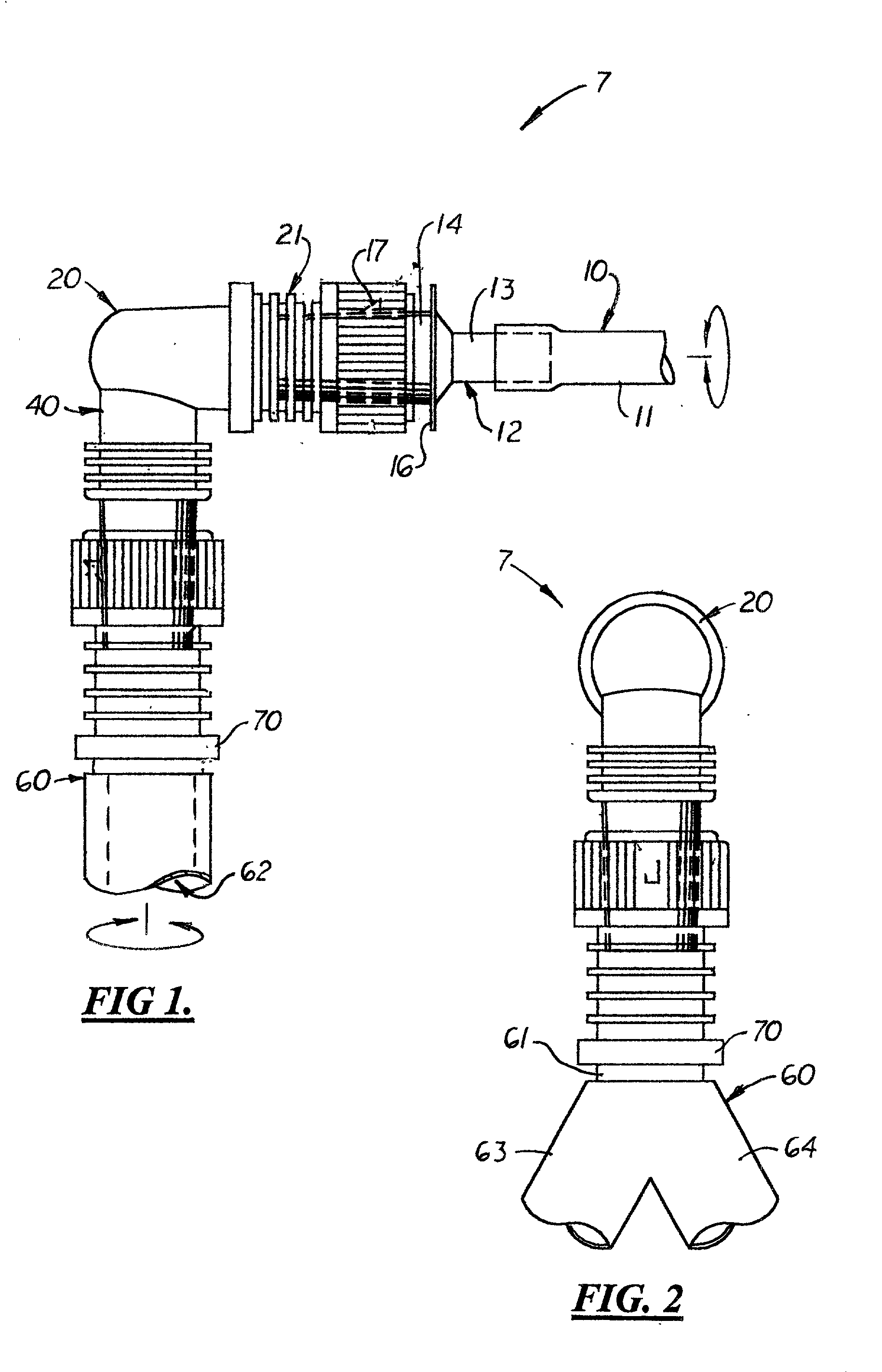

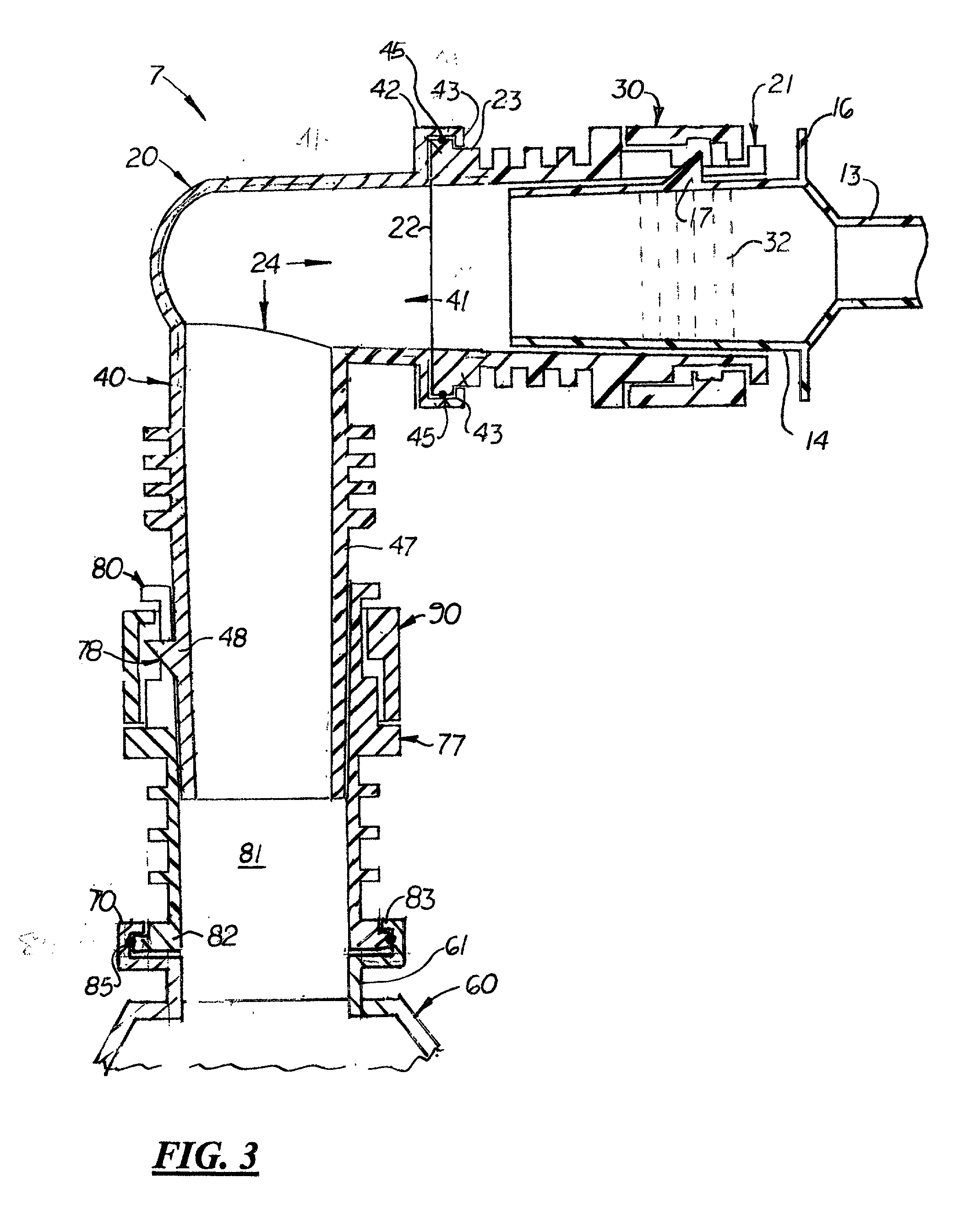

Ventilation tube connection system

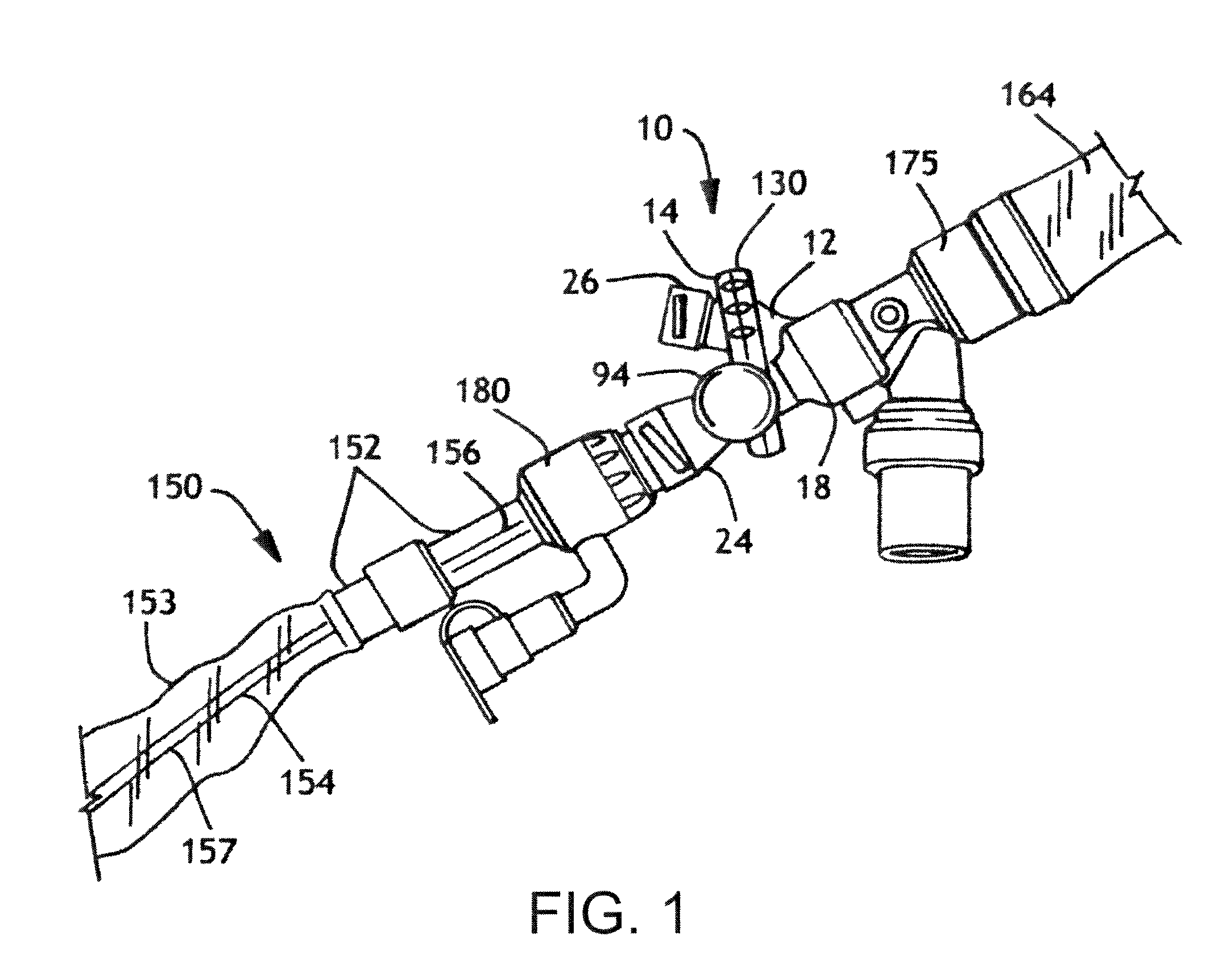

InactiveUS6668825B2Reduce forceImprove patient comfortTracheal tubesRespiratory apparatusVentilation tubeSystems design

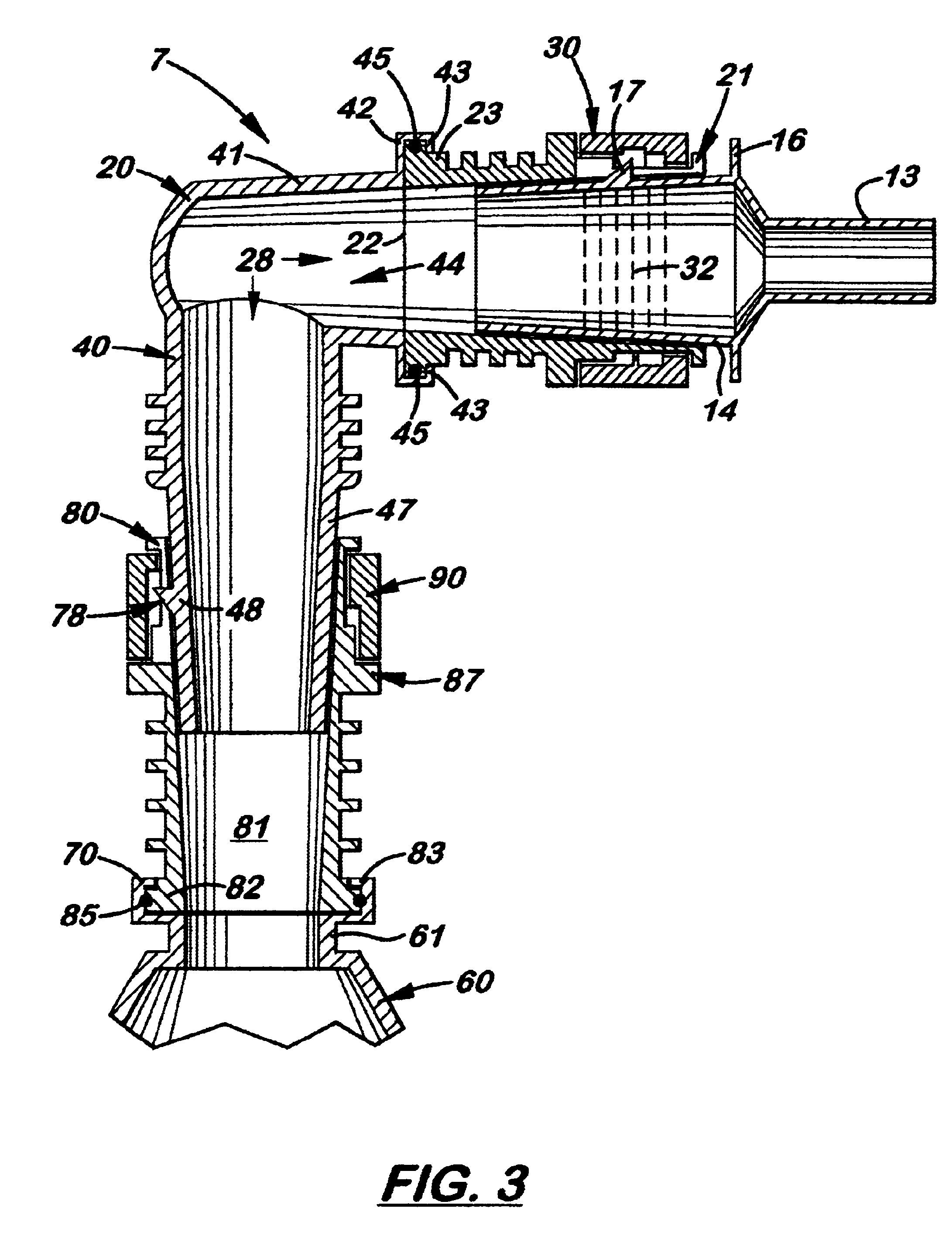

An improved modified ventilation tube system designed to improve patient comfort and prevent accidental "pop off" incidents that often occur with standard endotracheal and ventilation tubes. The system includes a modified endotracheal tube that includes a cylindrical-shaped end adapter, an L-shaped elbow connector with a rotating leg member and a fixed leg member, and a modified ventilation tube. The rotating leg member is perpendicularly aligned on one end of the fixed leg member and slidingly receives the end adapter on the modified endotracheal tube. Disposed around the rotating leg member is a first rotating collar that securely fixes the end adapter to the rotating leg member. The fixed leg member includes a long leg section that slidingly connects to a rotating coupler attached to the modified ventilation tube. A second rotating collar is disposed around the rotating coupler to selectively attach the fixed leg member to the rotating coupler. When the system is assembled, the rotating leg member and rotating coupler are able to selectively rotate over the ends of the elbow connector and the modified ventilation tube, respectively, thereby reducing forces exerted thereon. Optional O-rings are disposed inside each joint to provide airtight seals.

Owner:BISON CREEK INNOVATIONS

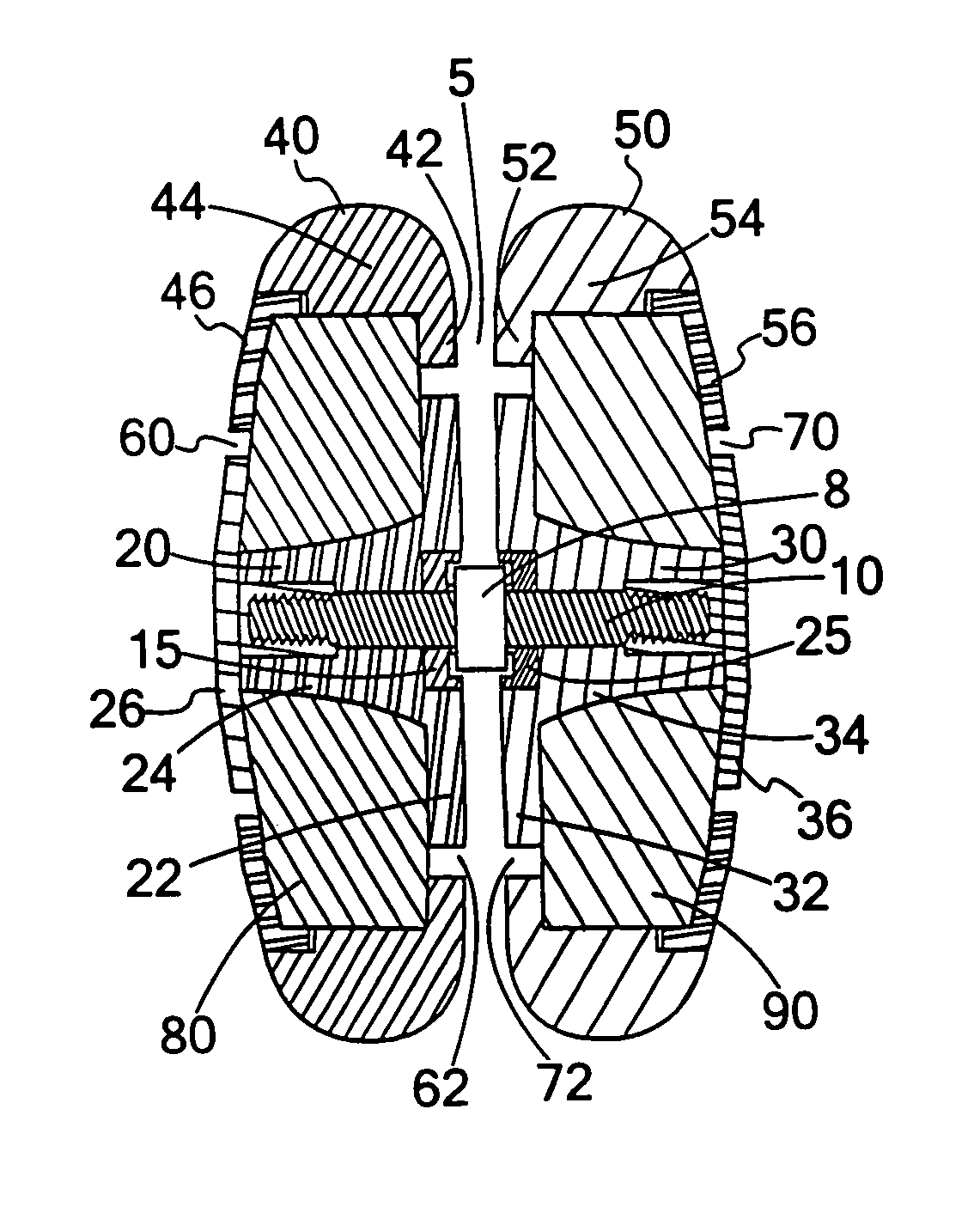

Yo-yo with shock suppression system

A yo-yo wherein each half body has three essential elements: a axle / hub assembly, a rim, and an interior space containing flexible, compressible material, such as an elastomer or a bladder filled with gas, liquid, or gel. The axle / hub assembly and the rim contain the flexible, compressible material but are not rigidly in contact with each other. In this way a shock to the rim and vibrations to the string are suppressed and dampened by the flexible, compressible material. For greater flexibility and shock damping, there could be cavities (grooves or holes) in the elastomer material or for greater lateral stability, the rim could overlap the gaps between it and the axle / hub assembly. There could also be containment / alignment walls extending into the flexible, compressible material or O-rings in gaps between the rim and the axle / hub assembly.

Owner:VANKUIKEN JACK C

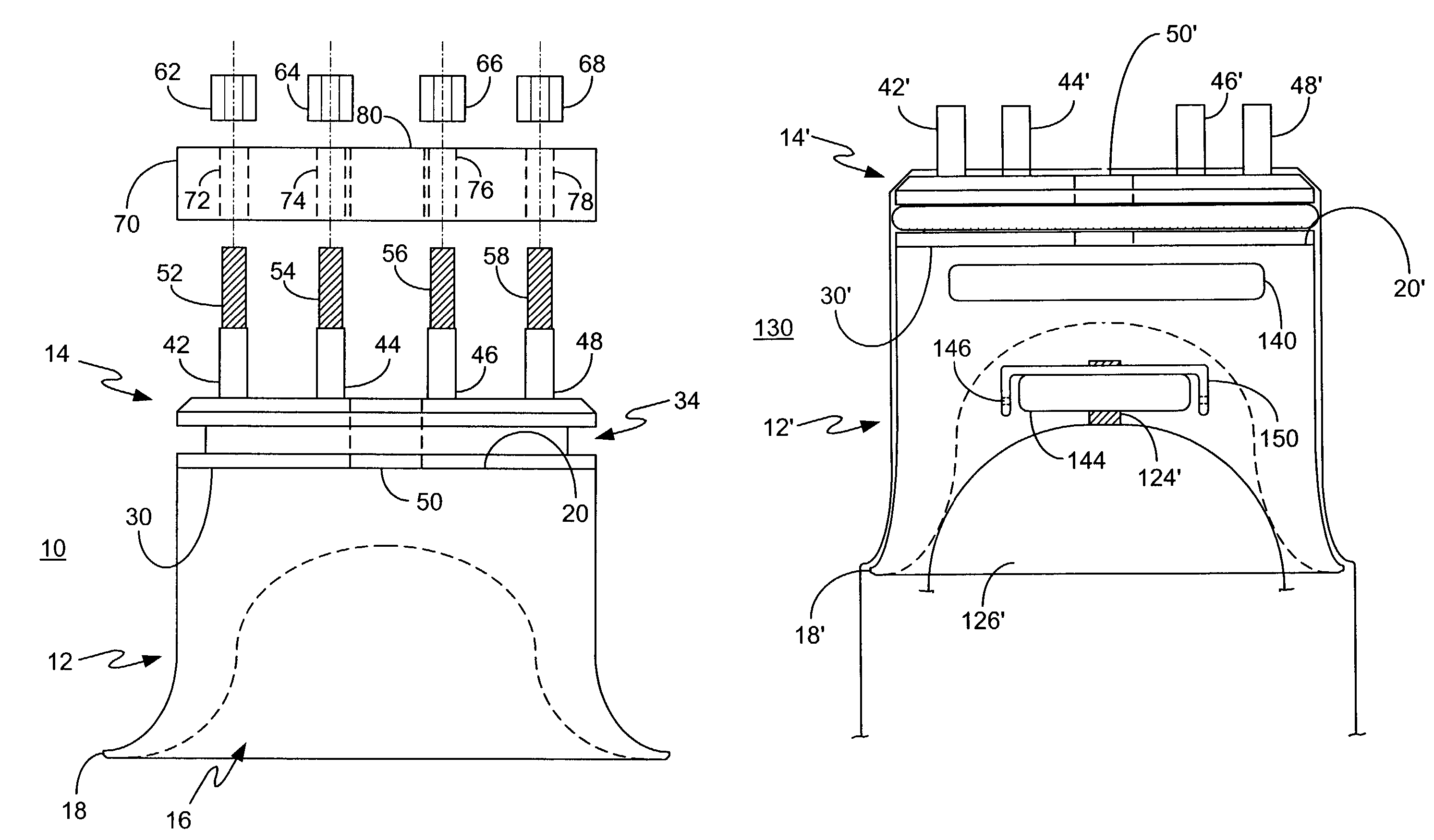

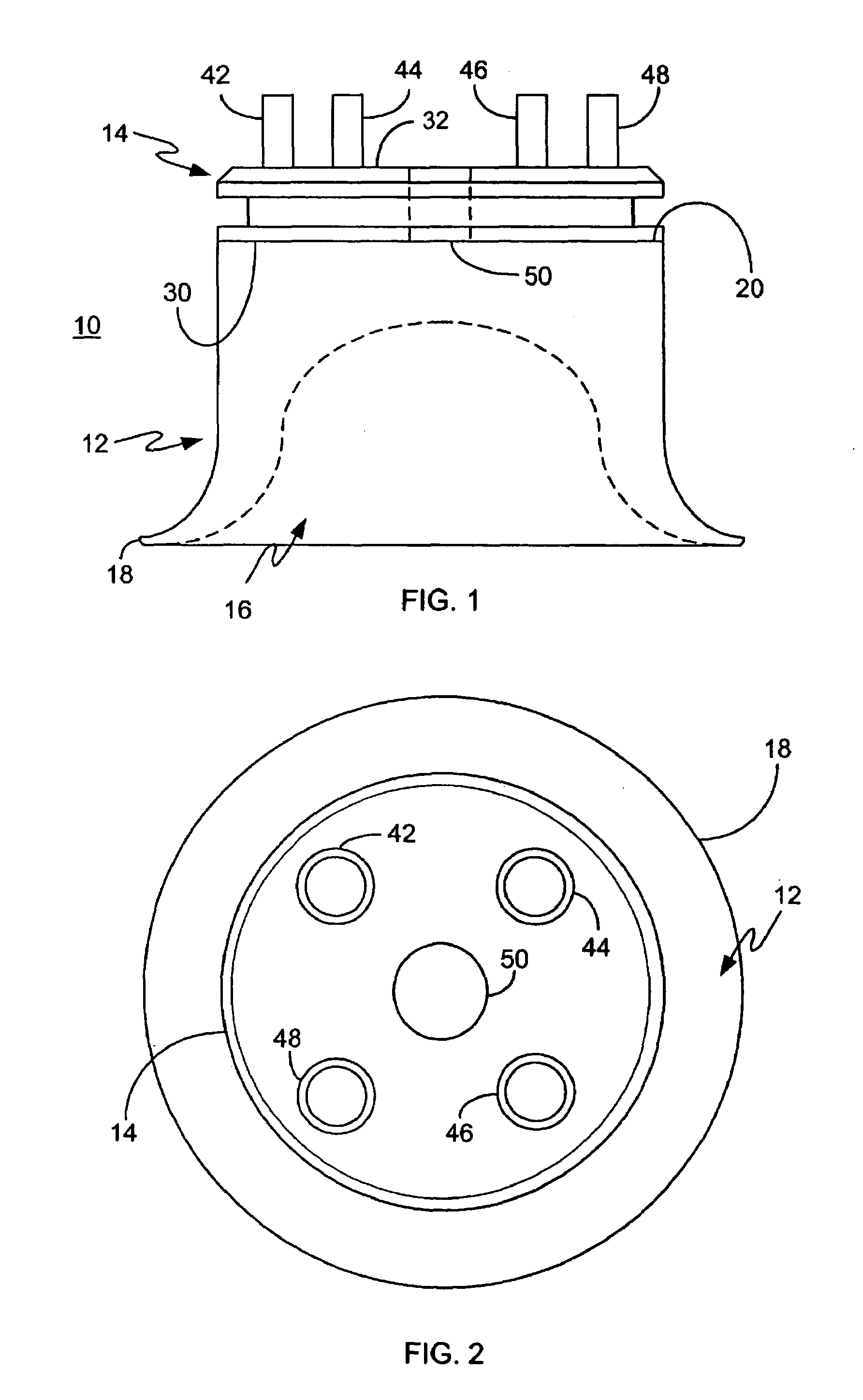

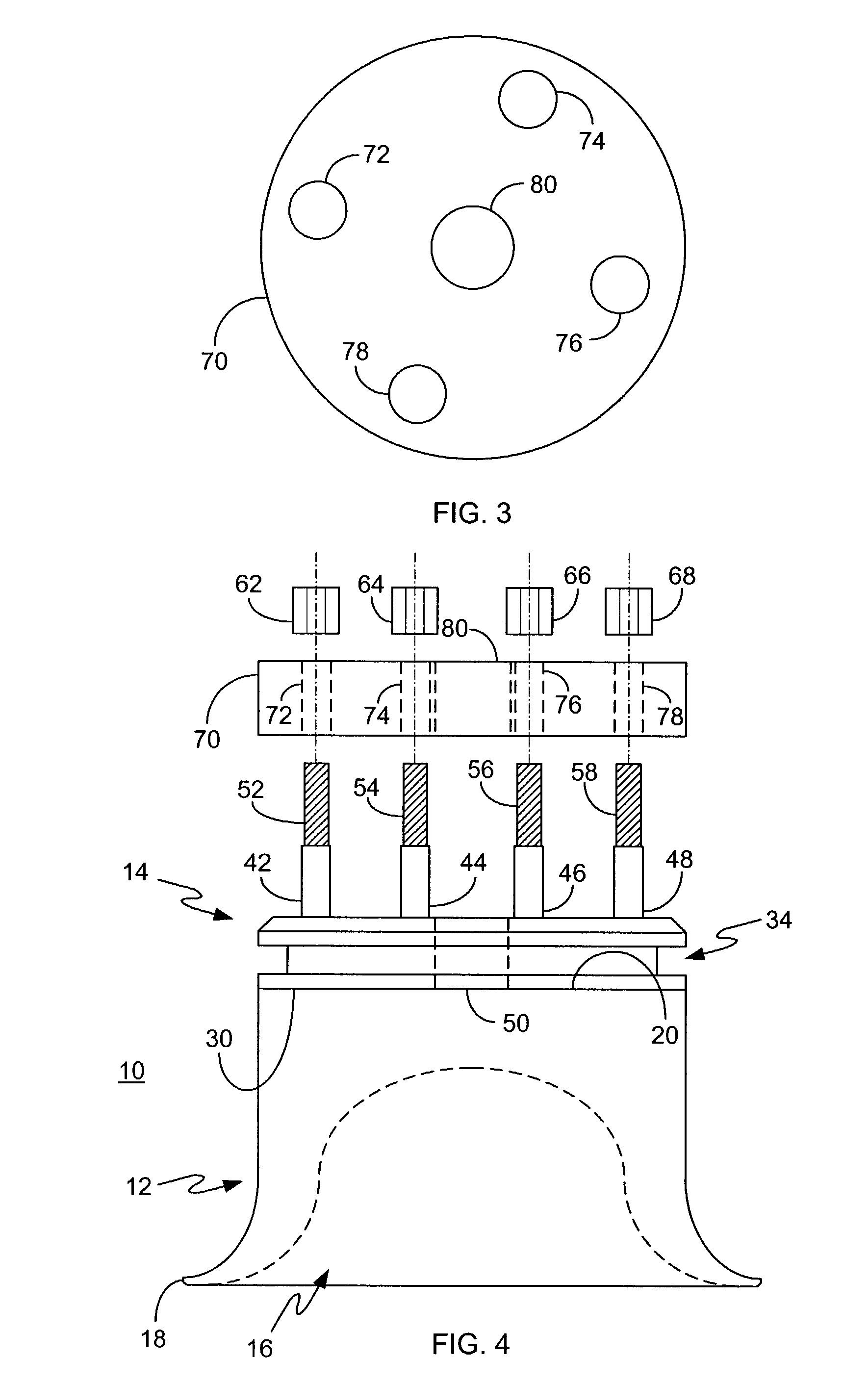

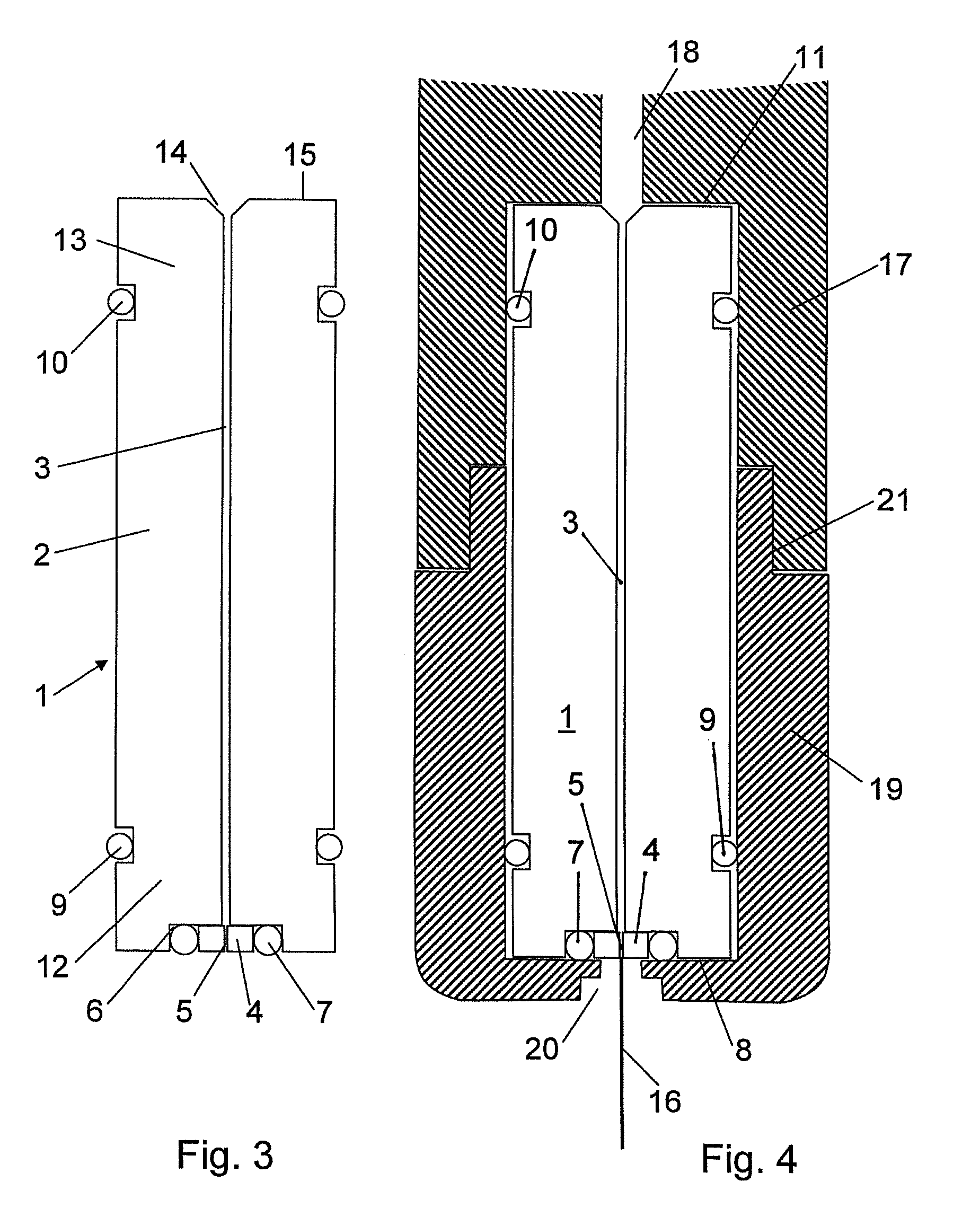

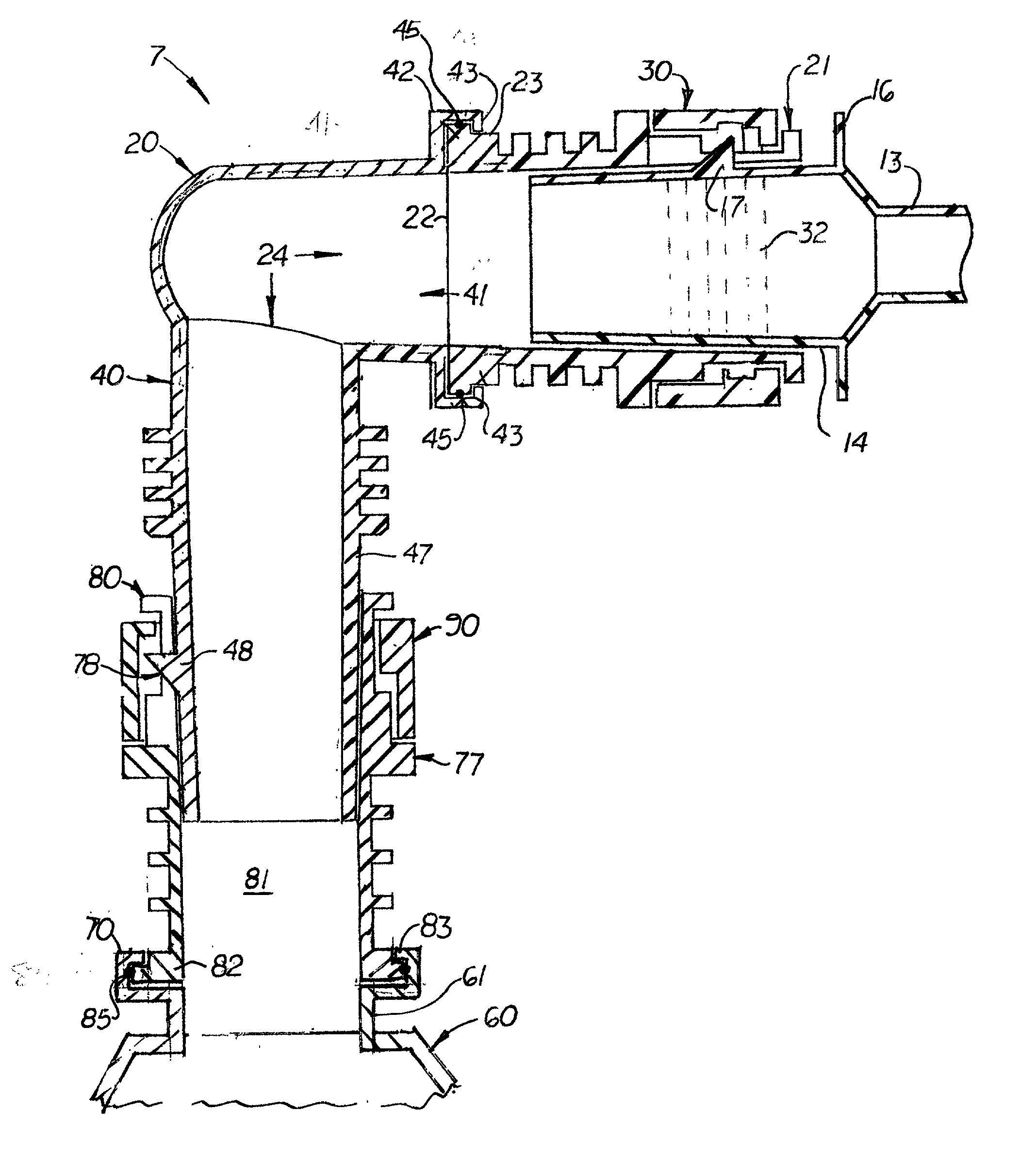

Modular port system and replacement method thereof

A chemical or biological containment apparatus having a seal to contain contaminants in an inside thereof from passing to an outside, including an outer envelope; a port disposed in the envelope, the port including an outer portion having a circumferential portion extending away from the envelope and a flange extending from the circumferential portion and attached to the envelope, and an inner portion. The inner portion includes a circumferential surface corresponding to the circumferential portion, a plurality of grooves formed in the circumferential surface, and a plurality of O-rings respectively received in the grooves to form the seal with the outer portion.

Owner:ALION SEIENCE & TECH CORP

Ventilation tube connection system

InactiveUS20030106558A1Improve comfortPreventing accidental "poTracheal tubesInhalatorsVentilation tubeSystems design

An improved ventilator connection tube system designed to improve patient comfort and prevent accidental "pop off" incidents that often occur with standard endotracheal and ventilation tubes. The system includes a modified endotracheal tube that includes a cylindrical-shaped end adapter, an L-shaped elbow connector with a rotating leg member and a fixed leg member, and a ventilator connection tube. In the preferred embodiment, the rotating leg member is perpendicularly aligned on one end of the fixed leg member and slidingly receives the end adapter on the modified endotracheal tube. Disposed around the rotating leg member is a first rotating collar that securely fixes the end adapter to the rotating leg member. The fixed leg member includes a long leg section that slidingly connects to a rotating coupler attached to the ventilator connection tube. A second rotating collar is disposed around the rotating coupler to selectively attach the fixed leg member to the rotating coupler. When the system is assembled, the rotating leg member and rotating coupler are able to selectively rotate over the ends of the elbow connector and the ventilator connection tube, respectively, thereby reducing forces exerted thereon. Optional O-rings are disposed inside each joint to provide airtight seals.

Owner:BISON CREEK INNOVATIONS

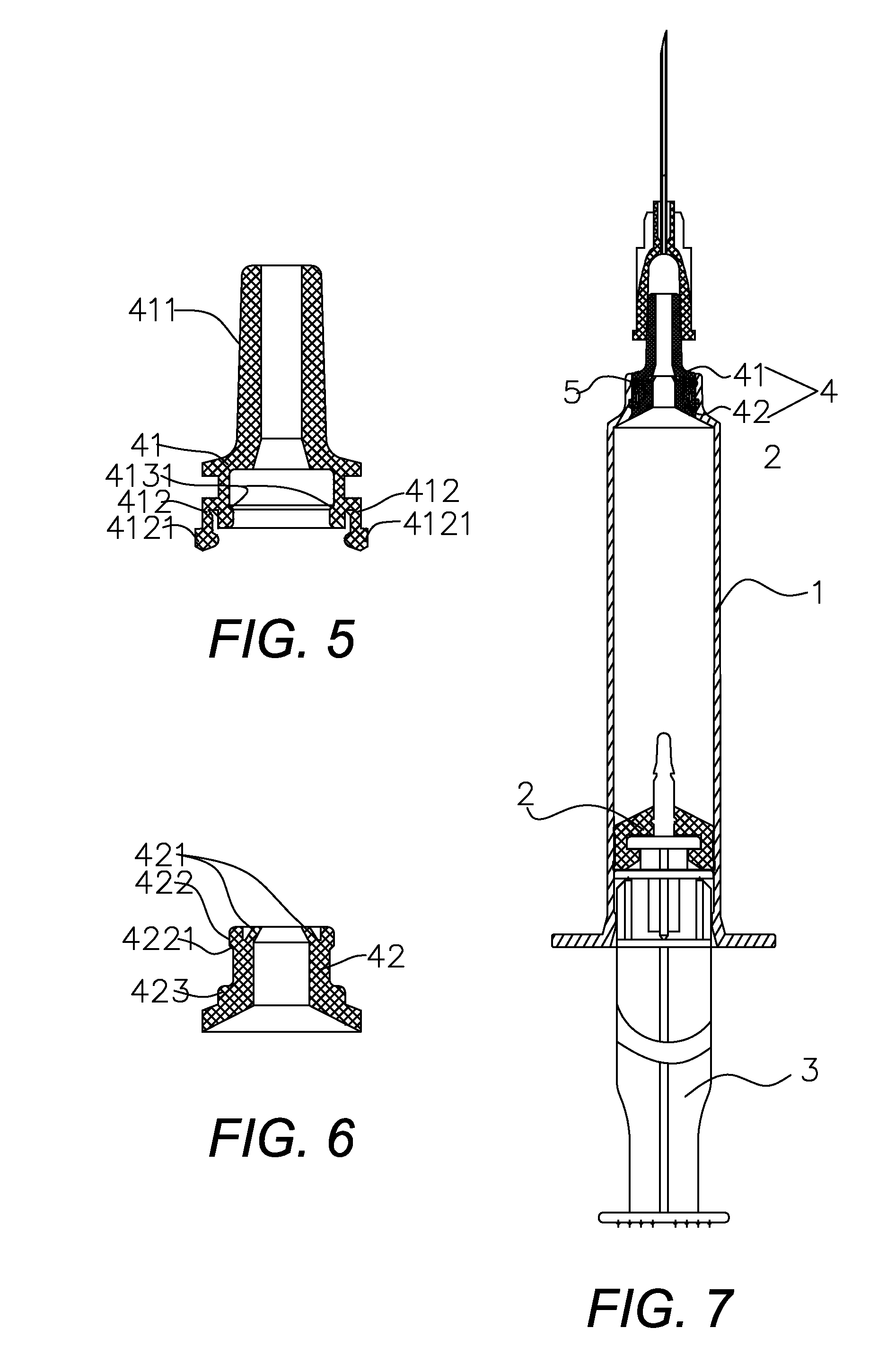

Safety syringe

InactiveCN1512899ASolve mobile instabilityReliable returnAmpoule syringesPharmaceutical containersO-ringEngineering

Disclosed herein is a safety syringe. According to the safety syringe of the present invention, an adapter connected to an injection needle is threadedly coupled with the neck of a cylinder while interposing an O-ring therebetween. Thus, the movement of the injection needle is effectively prevented while in use, and thus the injection needle can be pricked accurately at a desired position of the patient's body. Since the adapter is formed with grooves, whereas a plunger is formed with two protrusions positioned diametrically opposite to each other so as to be inserted into the grooves, the adapter is rotated and then moved downwardly in accordance with the successive rotation and downward movements of the plunger after the adapter is released from the neck of the cylinder. The plunger is formed at its upper surface with a vertical rod extending upwardly from an eccentric position, whereas the adapter is defined with a conical cavity. The upper end of the rod is inserted into the cavity while being bent inwardly. When the injection needle is withdrawn into the cylinder, the injection needle is firmly tilted in a lateral direction due to the strong restoring force of the rod so that it can be collapsed simply against the inner surface of the cylinder. In addition, a circular plate is formed at a certain lower position of the plunger. The circular plate enables the user's fingers gripping the safety syringe not to come into contact with the plunger to be entered into the cylinder, thereby achieving the sanitary use of the safety syringe.

Owner:SEZ

Manual switch for a closed suction tube

A manual switch has a body, a button, a valve rod and a biasing member. The body has a valve mount having multiple holding ribs. The valve rod is mounted slidably in the valve mount, is pressed by the button and has a valve rod, a mounting tube and an O-ring. The rod body has an outer diameter smaller than the inner diameter of the valve mount. The mounting tube is mounted securely around the rod body and has an outer diameter being equal to the inner diameter of the valve mount and an outer surface abutting with the holding ribs in the valve mount. The O-ring is mounted around the rod body and abuts with the inner surface of the valve mount to provide a sealing effect to the valve rod and the valve mount.

Owner:CHANG TI LI

Safety self-destroying disposable syringe

ActiveUS7637890B2Simple structureImprove securityInfusion syringesIntravenous devicesO-ringSafety syringe

Owner:SOL MILLENNIUM MEDICAL LTD

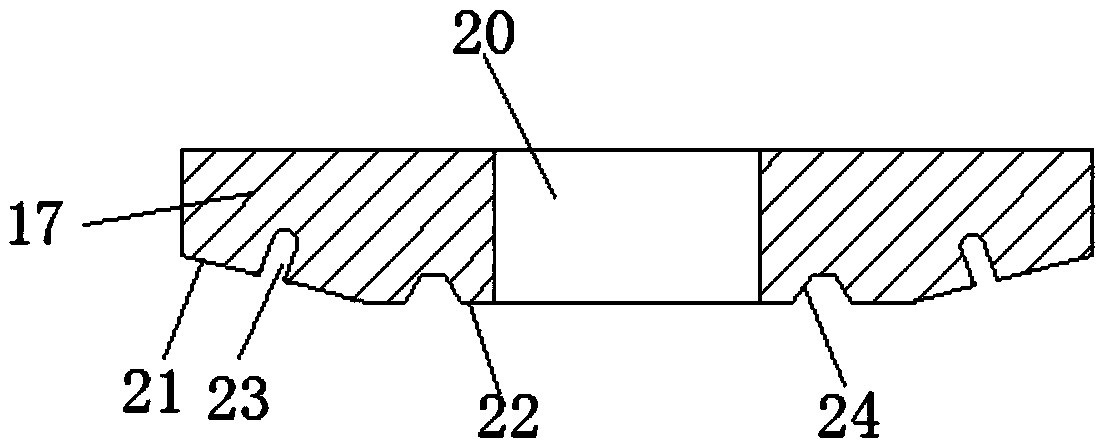

Overmolded manifold O-ring

A respiratory access assembly includes a distal plate having one port and cuff and an axially aligned proximal plate including a first port and first cuff and a second port and second cuff. The distal plate is configured to move relative to the proximal plate. The respiratory access assembly includes an actuator, which has a plurality of predetermined positions. The actuator includes a blocking portion that controls the movement of the plates. The blocking portion moves slidably within an O-ring that prevents loss of pressure from the artificial airway system. The O-ring may be molded in place using an injection molding process, thus ensuring good adhesion to the disk.

Owner:AVENT INC

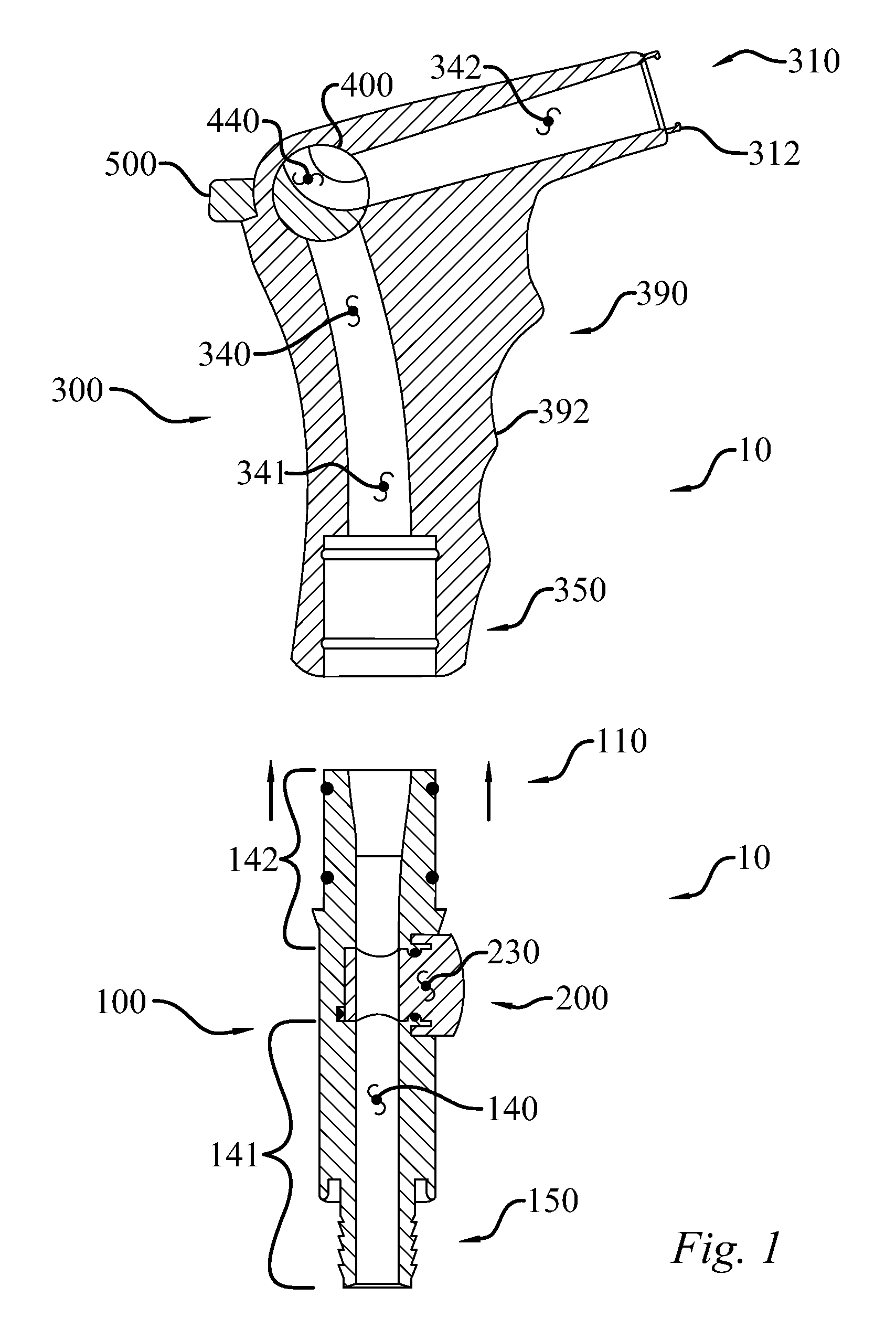

Sterilizable vacuum handpiece

InactiveUS20100249703A1Good conditionOvercomes shortcomingIntravenous devicesSuction drainage systemsBucket HandleO-ring

A sterilizable vacuum handpiece that may include a base unit reversibly coupled to a handle unit, having a central vacuum passage connecting proximal and distal ends. A hand-removable base unit valve may divide a base unit vacuum passage and a hand-removable handle unit valve may separate a handle unit vacuum passage, in adjustable fluid communication with each other. The valves may be retained within bores and counter-bores, and may achieve fluid-tight fit with O-rings retained within the valves. The valves may have vacuum passages with surface areas greater than or equal to a least diameter of the vacuum passage containing the valve. In at least one embodiment, the handle valve is releasably retained by the opposing ends of a “bucket-handle” shaped controller. Alternatively, the handpiece may be formed as a single combined unit, where the terms base unit and handle unit refer only to regions of an otherwise unified structure.

Owner:CLIFF JOHN A

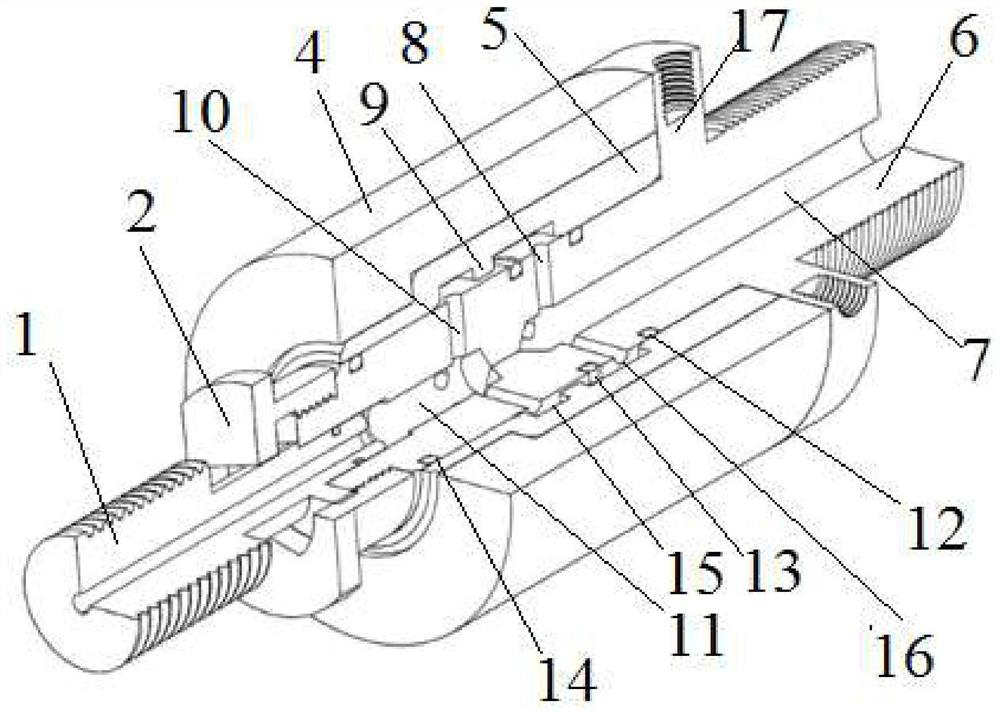

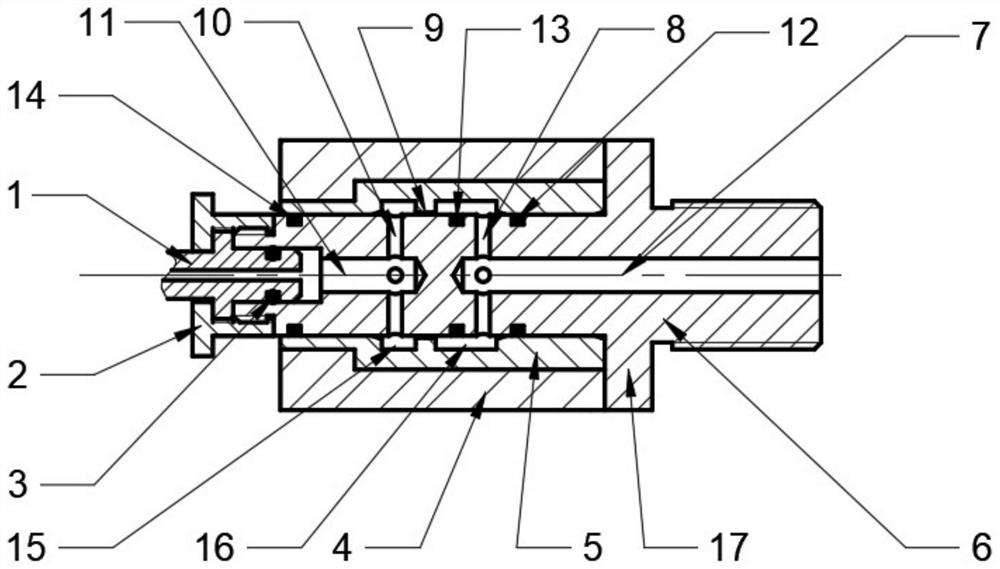

Large-flow automatic vent valve for supercavitation aircraft

ActiveCN112303310ALarge ventilation flowImprove air flowWatercraft hull designAeration devicesO-ringStructural engineering

The invention discloses a large-flow automatic vent valve for a supercavitation aircraft. The large-flow automatic vent valve comprises a valve seat, a first axial vent hole is formed in one end of the valve seat in the axial direction, and a second axial vent hole is formed in the other end of the valve seat in the axial direction. A first radial vent hole communicating with the first axial venthole and a second radial vent hole communicating with the second axial vent hole are formed in the valve seat in the radial direction, a valve sleeve sleeves the valve seat, a first annular groove anda second annular groove are formed in the valve sleeve, and the first annular groove communicates with the second annular groove. The distance between the first annular groove and the second annulargroove is smaller than the distance between the first radial vent hole and the second radial vent hole. When the supercavitation aircraft is launched, the supercavitation aircraft can be automaticallystarted by means of inertia. According to the large-flow automatic vent valve for the supercavitation aircraft, the working mode of "fixing a valve element and moving the valve sleeve" is adopted, the situation that the compression amount of an O ring is suddenly increased is avoided, and the problems of clamping stagnation, "ring cutting" and the like in the opening process can be solved; and anannular gap between the valve sleeve and the valve element is adopted as a throttling opening, and the large enough ventilation flow can be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Artificial Insemination Dildo

InactiveUS20160374724A1Assist developmentAvoid spreadingGenitals massageVeterinary instrumentsO-ringPipette

a sexual stimulation and insemination apparatus, comprises a shaft having a tip, a base, and an elongated cylindrical body extending therebetween; a disposable plastic transfer pipette having an open tip, liquid-holding-chamber, and a pipe extending therebetween; a tunnel formed inside the shaft extending from the tip to the base, wherein the tunnel is in a shape of the disposable plastic transfer pipette, and wherein the disposable plastic transfer pipette can be inserted into or removed out of the tunnel; a button, wherein the button is a depressed area formed on the elongated cylindrical body and is located relatively above the liquid-holding-chamber of the disposable plastic transfer pipette when the disposable plastic transfer pipette is inserted in the tunnel; and an O-ring groove formed circumferentially on elongated cylindrical body of the shaft next to the base of said shaft, wherein said O-ring groove is radially smaller than said elongated cylindrical body.

Owner:WREN DIONE ARLEE

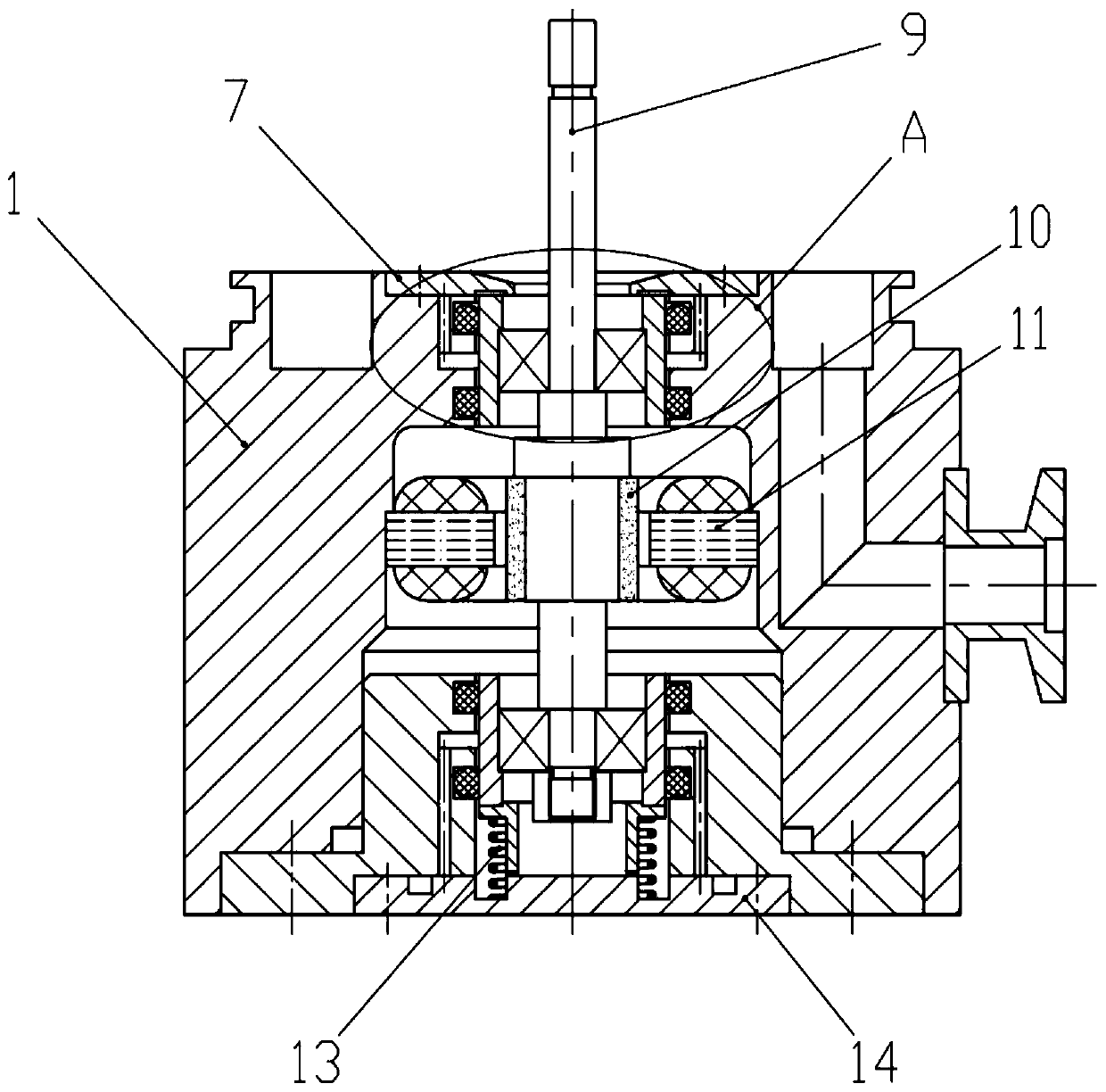

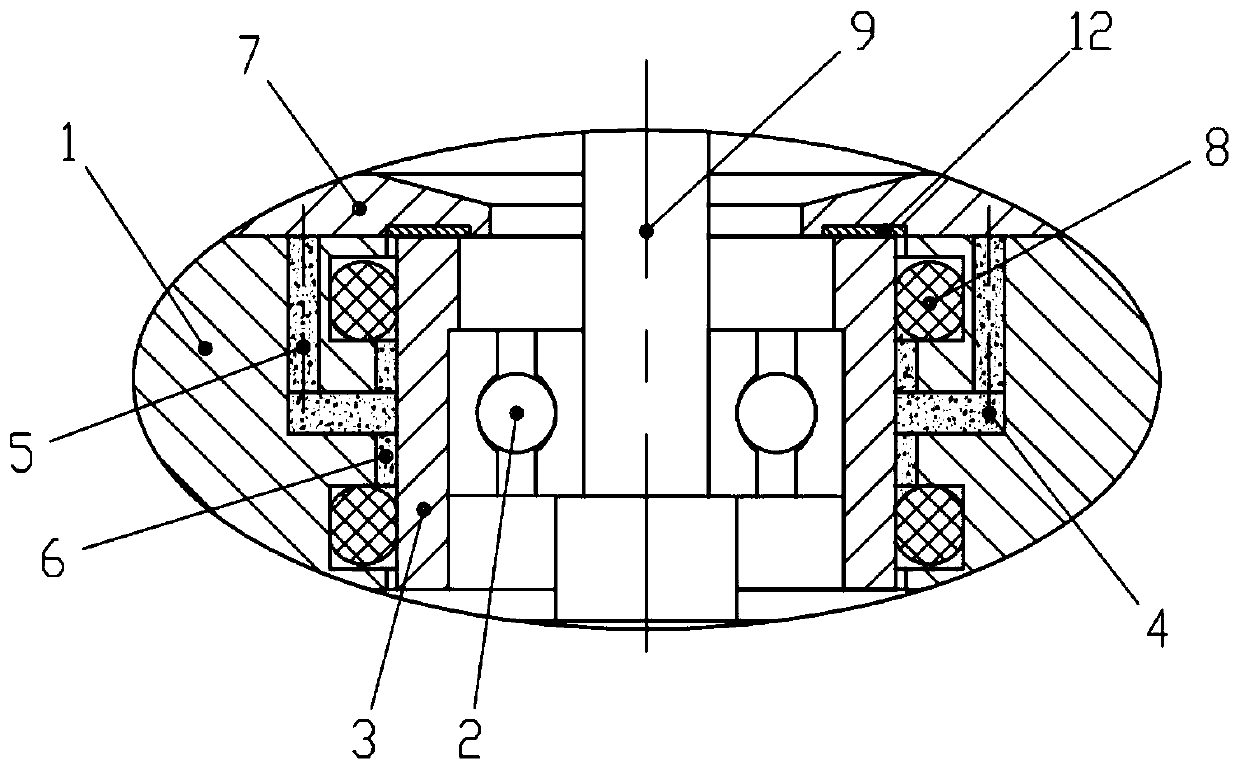

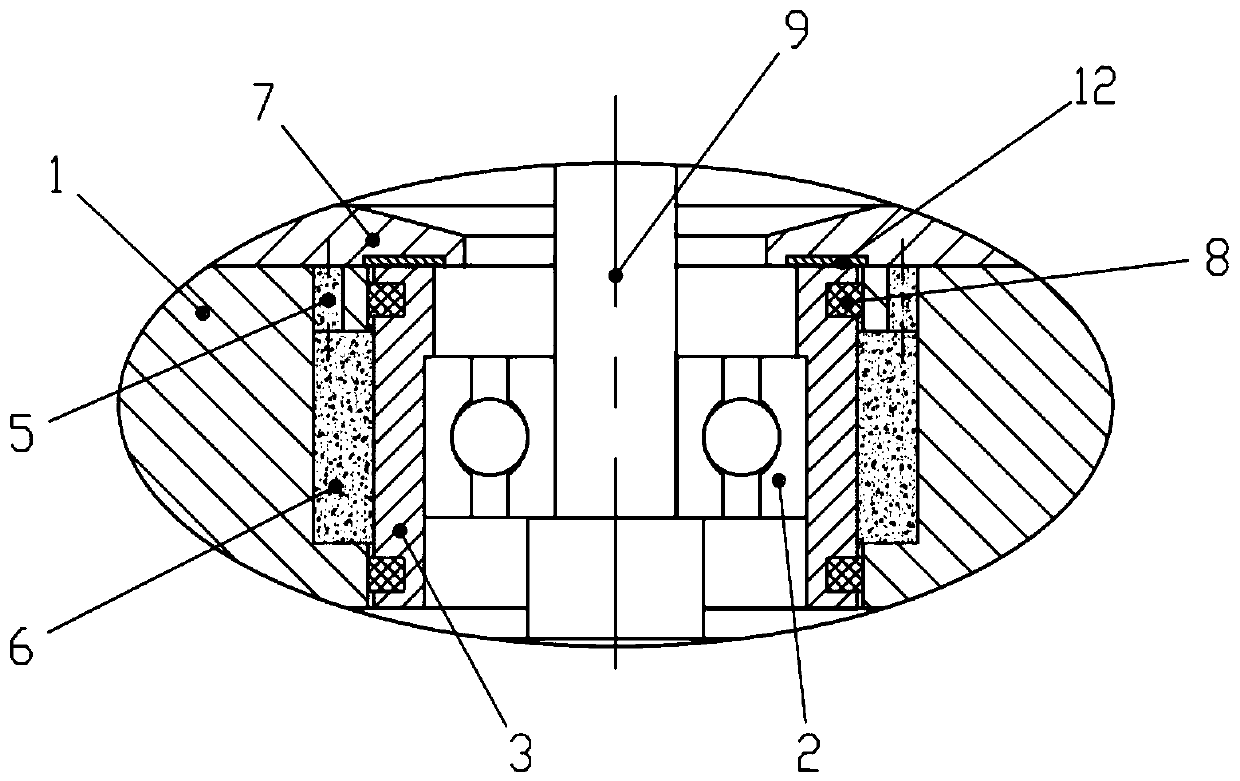

Bearing mounting structure and heat-conducting grease filling method

PendingCN111102233AIncrease heat conduction areaAvoid overheating and burningPump componentsPumpsPillow block bearingO-ring

The invention relates to the technical field of molecular pumps, in particular to a bearing mounting structure and a heat-conducting grease filling method. The bearing mounting structure comprises a bearing with a bearing bush and a bearing seat, wherein the bearing is supported by an upper damping O ring and a lower damping O ring in the radial direction in a damping mode, an annular cavity is formed between the double layers of damping O rings as well as between the outer wall of the bearing bush and the inner wall of the bearing seat, the annular cavity communicates with grease injection holes through an annular groove, and heat-conducting grease is injected through the grease injection holes to fill the annular cavity. By means of the structure, reliable and efficient heat conduction is formed between the bearing and the bearing seat, the bearing mounting structure can efficiently transfer heat generated by high-speed rotation of the bearing to the bearing seat and dissipate the heat to the outside, the bearing can be prevented from being burnt due to overheating, the service life of the bearing is prolonged, and the heat-conducting grease filling method has the advantage of facilitating naked eye observation, and can ensure that the annular cavity is filled with the heat-conducting grease.

Owner:KYKY TECH

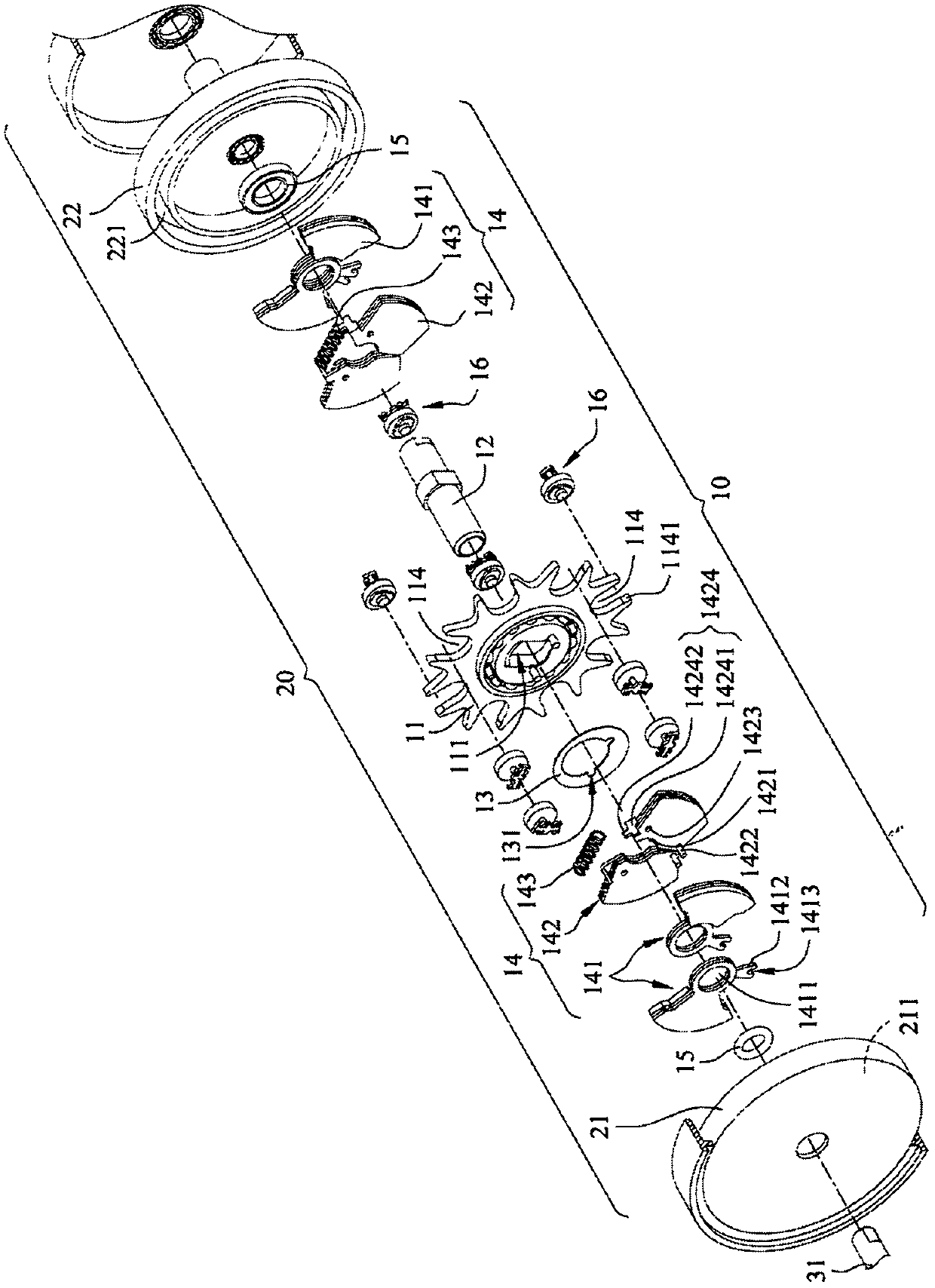

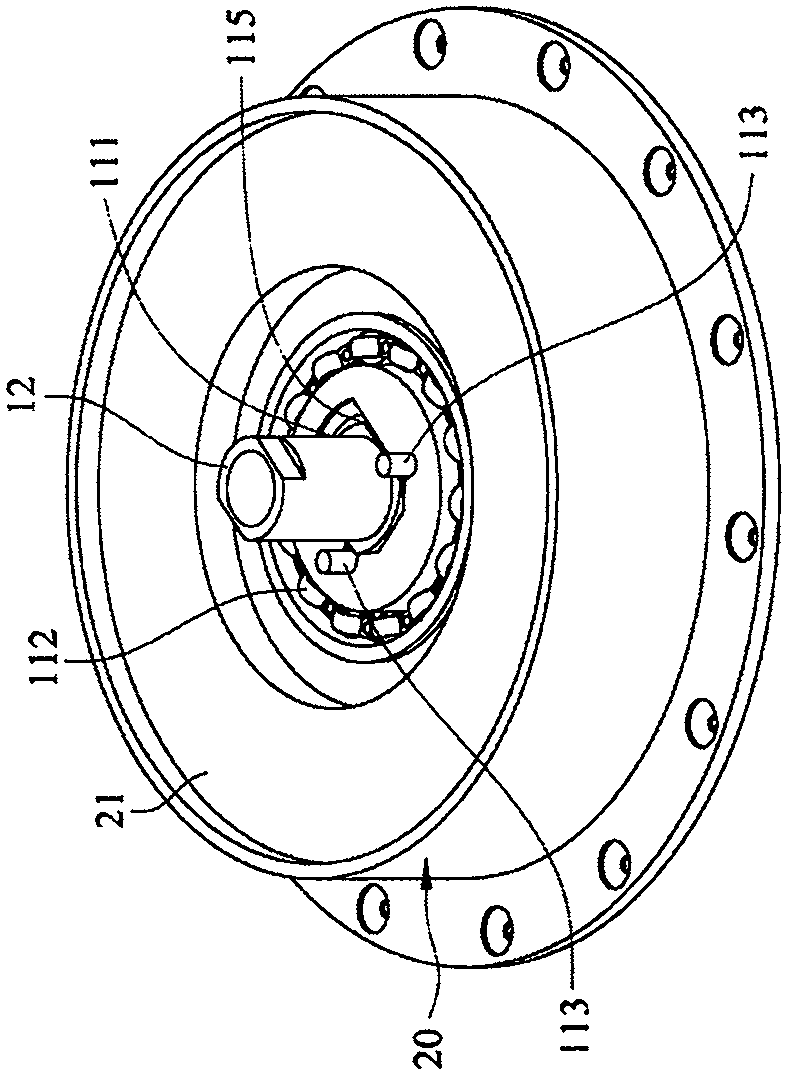

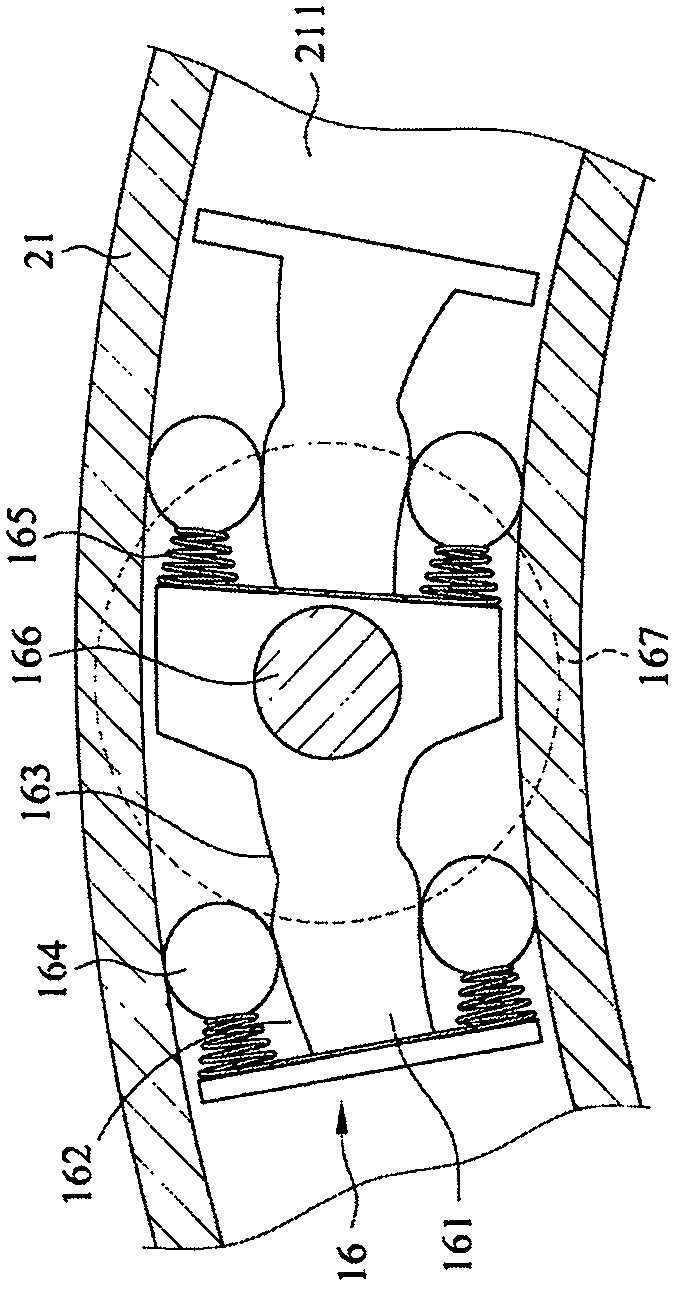

Speed change device with coaxial connecting rod rolling disc

PendingCN107763181AIncrease torqueImprove enduranceGearing detailsFriction gearingsO-ringEngineering

The invention relates to a speed change device with a coaxial connecting rod rolling disc. The speed change device comprises a speed changer shell containing a body. The body comprises the coaxial connecting rod rolling disc, a force-input shaft, a centrifugal piece, a plurality of counterweight assemblies, a plurality of O rings and a plurality of sliding block assemblies. When the speed change device conducts actuation, the force-input shaft serves as a force applying point of the lever principle, the equal sliding block assemblies serve as weight points, and the arm of force is equal to thedistance between the force-input shaft and each equal sliding block assembly; the equal sliding block assemblies are arranged at the tail end of the connecting rod rolling disc, therefore, compared with the prior art, the arm of force is increased, the bearing force of the weight points is improved, the turning force of the speed change device is increased under the same motor force, and accordingly the motor force is saved; and in addition, U-shaped grooves for containing the equal sliding block assemblies are formed in the tail end of the connecting rod rolling disc, so that machining is easy during manufacturing, and the cost can be reduced.

Owner:陈鹏宇

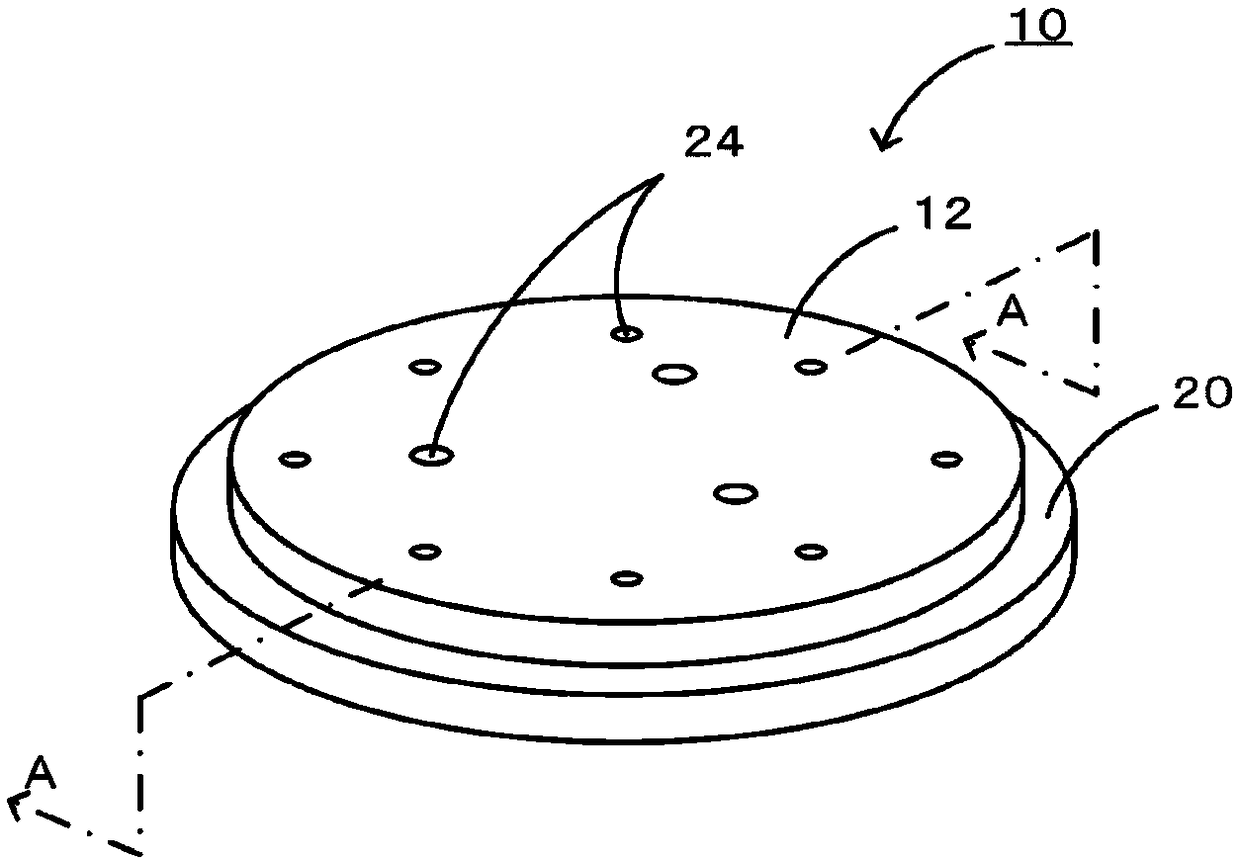

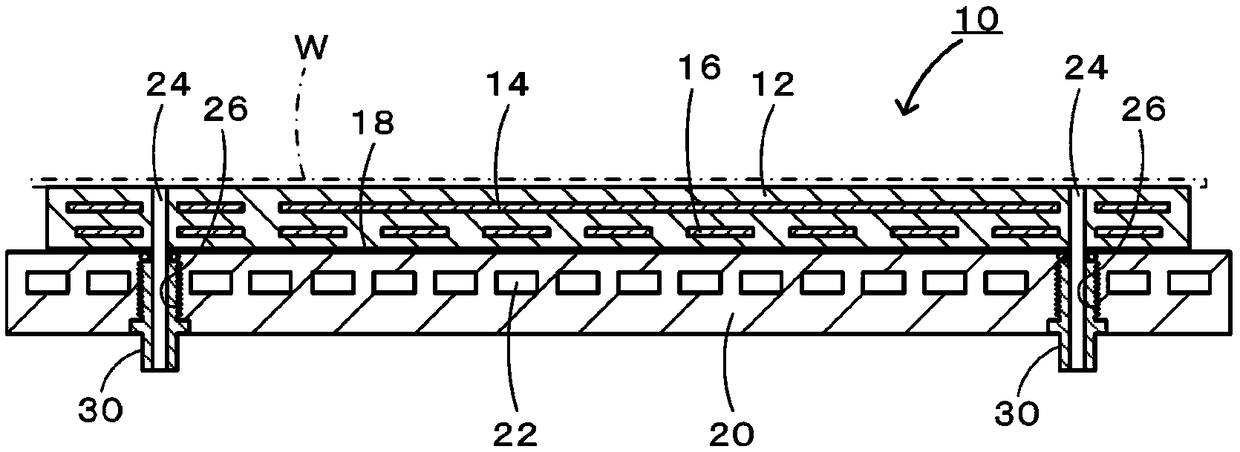

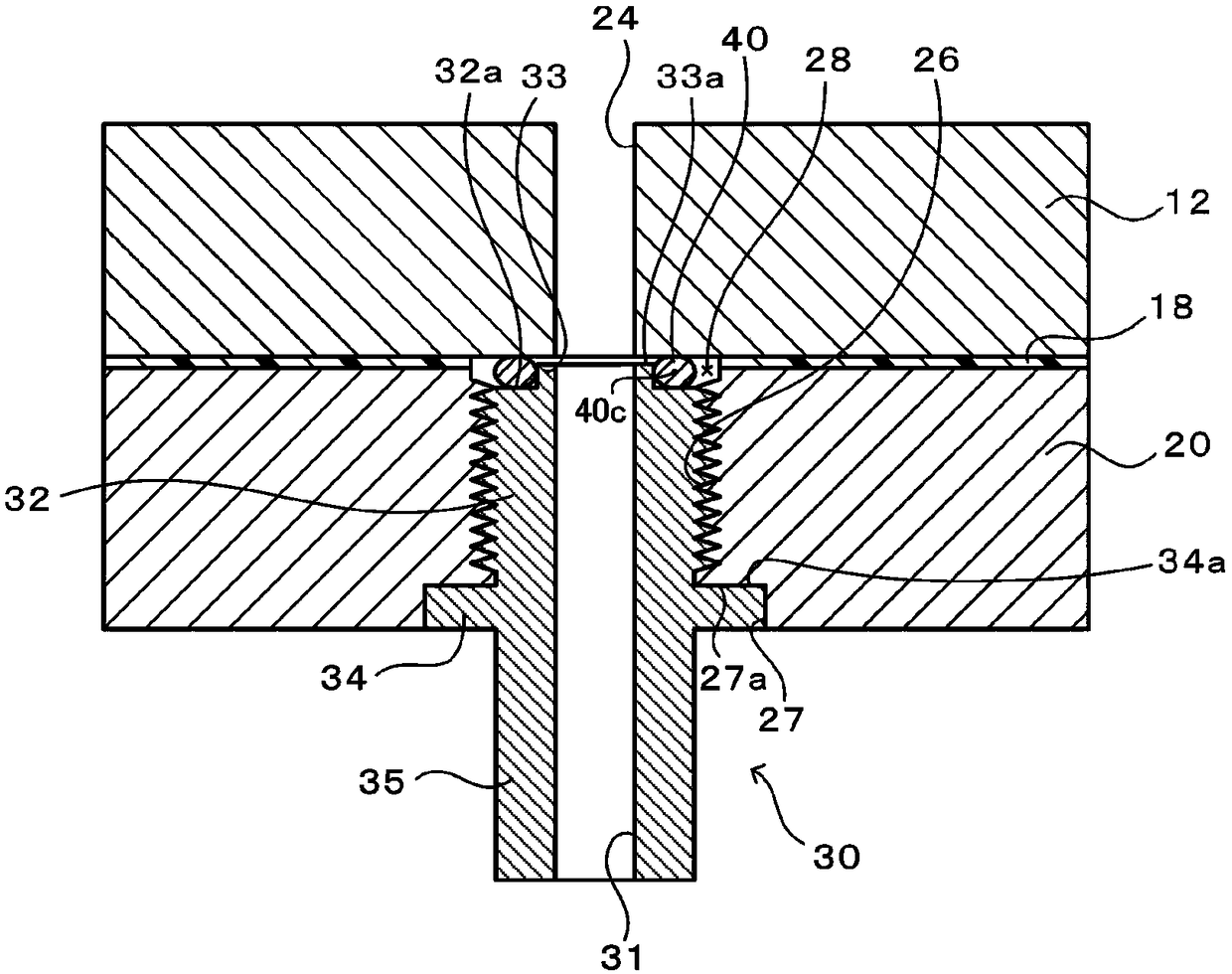

Susceptor for wafer

ActiveCN109478531APrevent looseningElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorWafering

Owner:NGK INSULATORS LTD

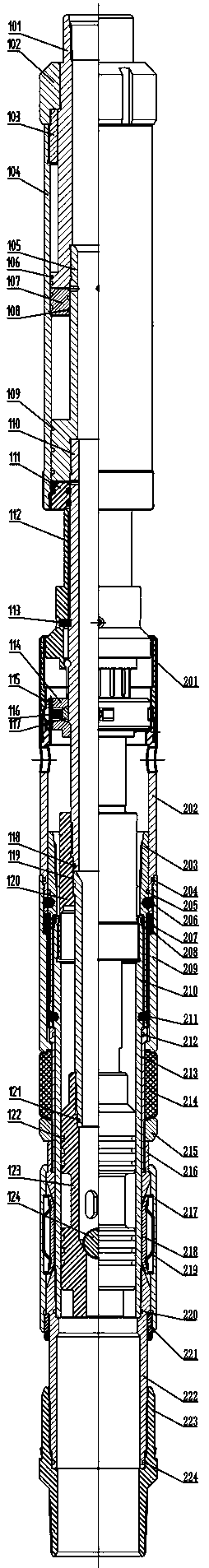

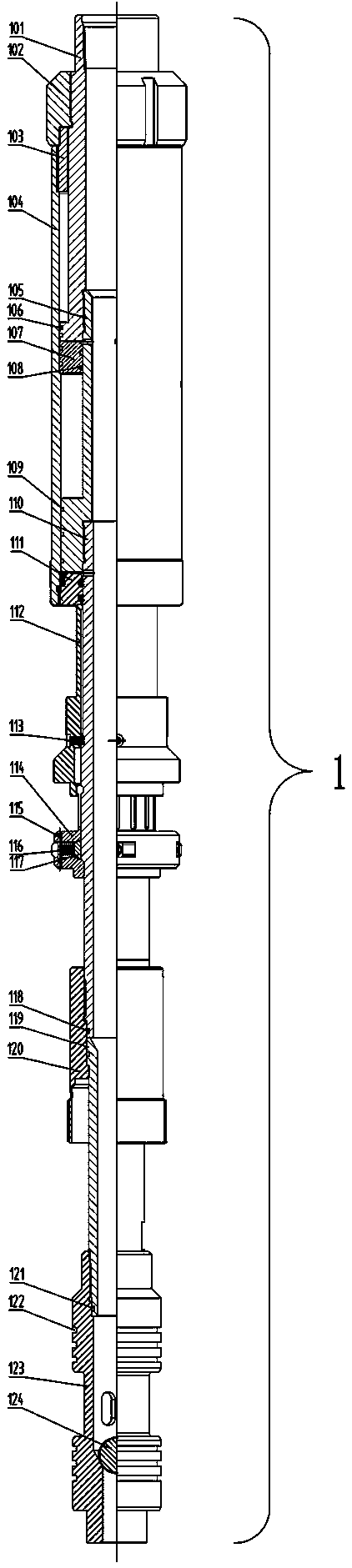

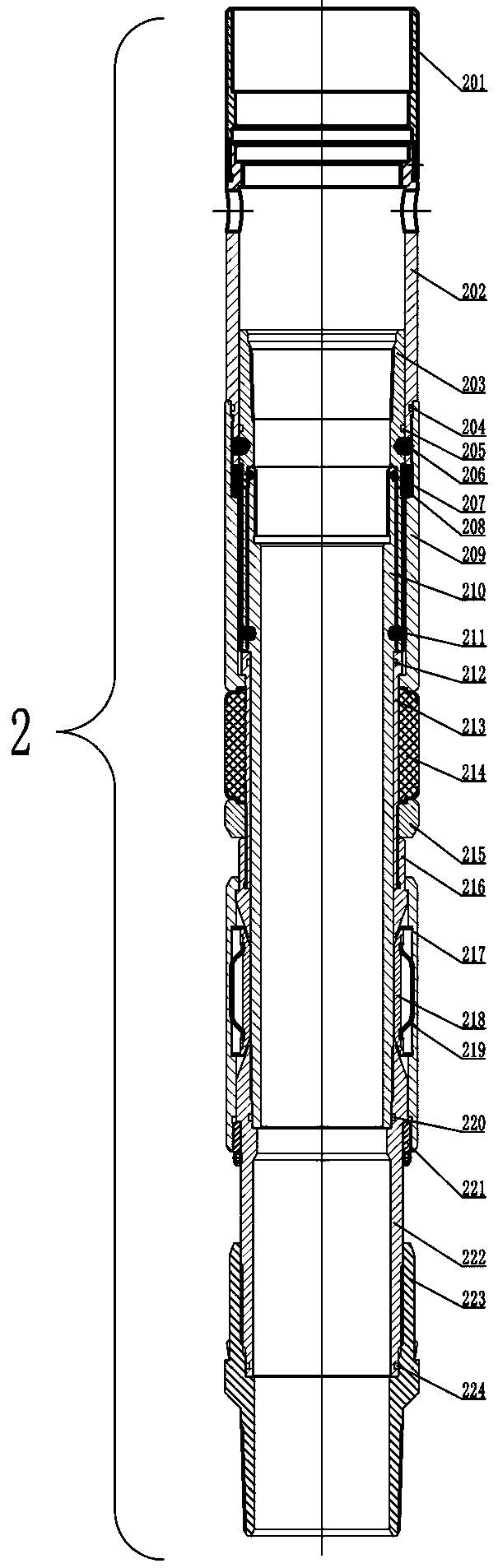

Hydraulic releasing packer preventing midway setting and method

PendingCN111075388AMechanical shock does not affectDoes not affect the secondary start pinSealing/packingO-ringScrew thread

The invention relates to a hydraulic releasing packer preventing midway setting and a method. According to the technical scheme of the hydraulic releasing packer preventing midway setting, a releasingportion and a stay-well portion are included, and the lower portion of the releasing portion is sleeved with the stay-well portion, and connecting into a whole is achieved through a releasing ring and a center pipe; a releasing thread of the releasing ring is a left hand thread; the exterior of a pressure relief pipe and an inner hole of the center pipe are in sliding seal fit with each other through a sealing O ring; and a lock block and a step hole are in limiting cooperation connection. The hydraulic releasing packer preventing midway setting has the beneficial effects that firstly, an elastic sleeve mechanical self-locking midway setting preventing mechanism solves the midway setting problem caused by the mechanical force; secondly, a double-stage starting pin improves the capacity ofresisting hydraulic pressure causing midway setting; thirdly, a pressure relief pipe sliding seal mechanism achieves oil sleeve annulus hydraulic examining seal; and fourthly, a mechanical back off and hydraulic double releasing mechanism guarantees reliable releasing, the measure reliability is guaranteed from tripping in of the packer to completing of the whole function, the measure success rate of the packer is increased, and the low-grade reservoir development benefits are improved.

Owner:SHANDONG BOSAITE PETROLEUM TECH CO LTD

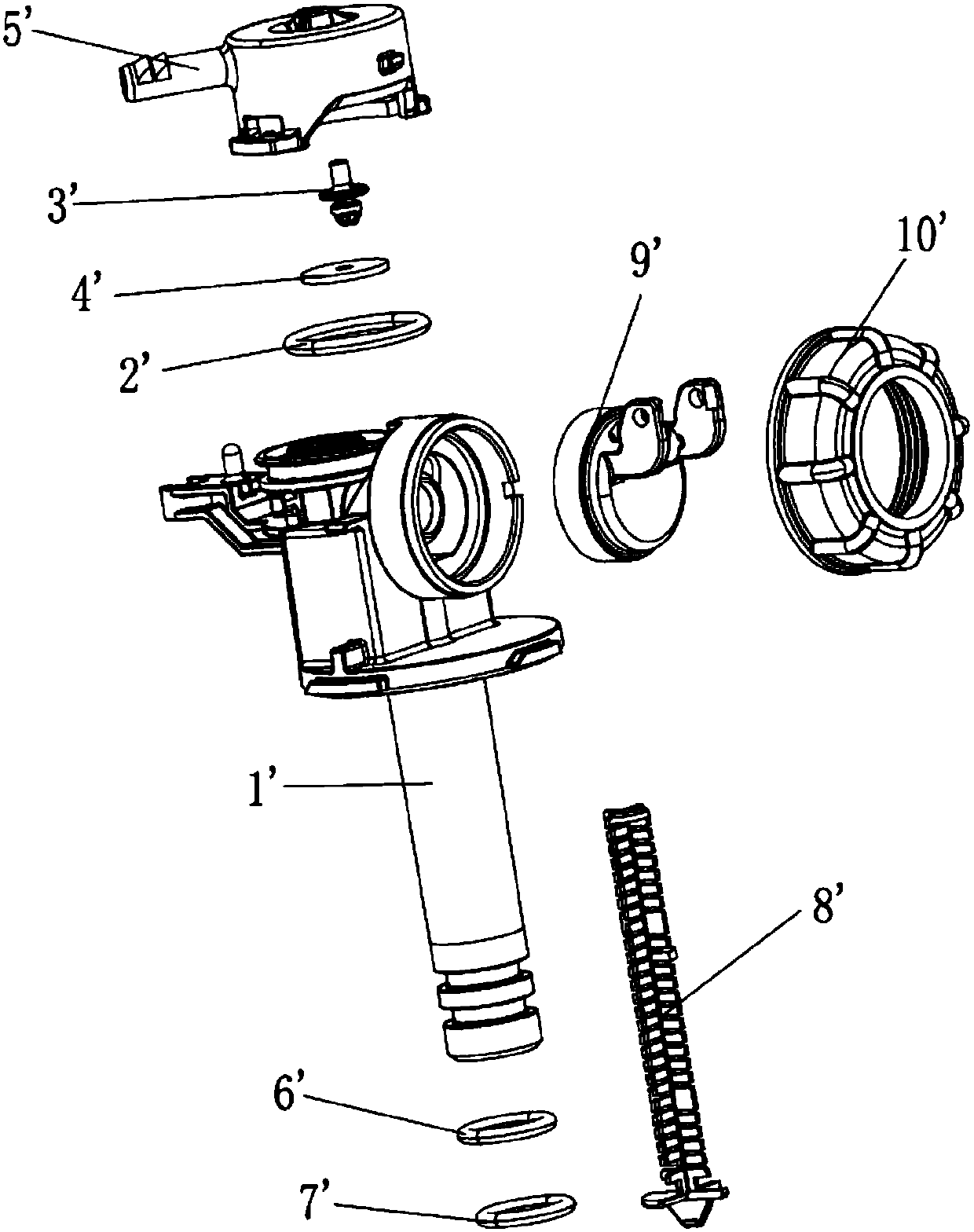

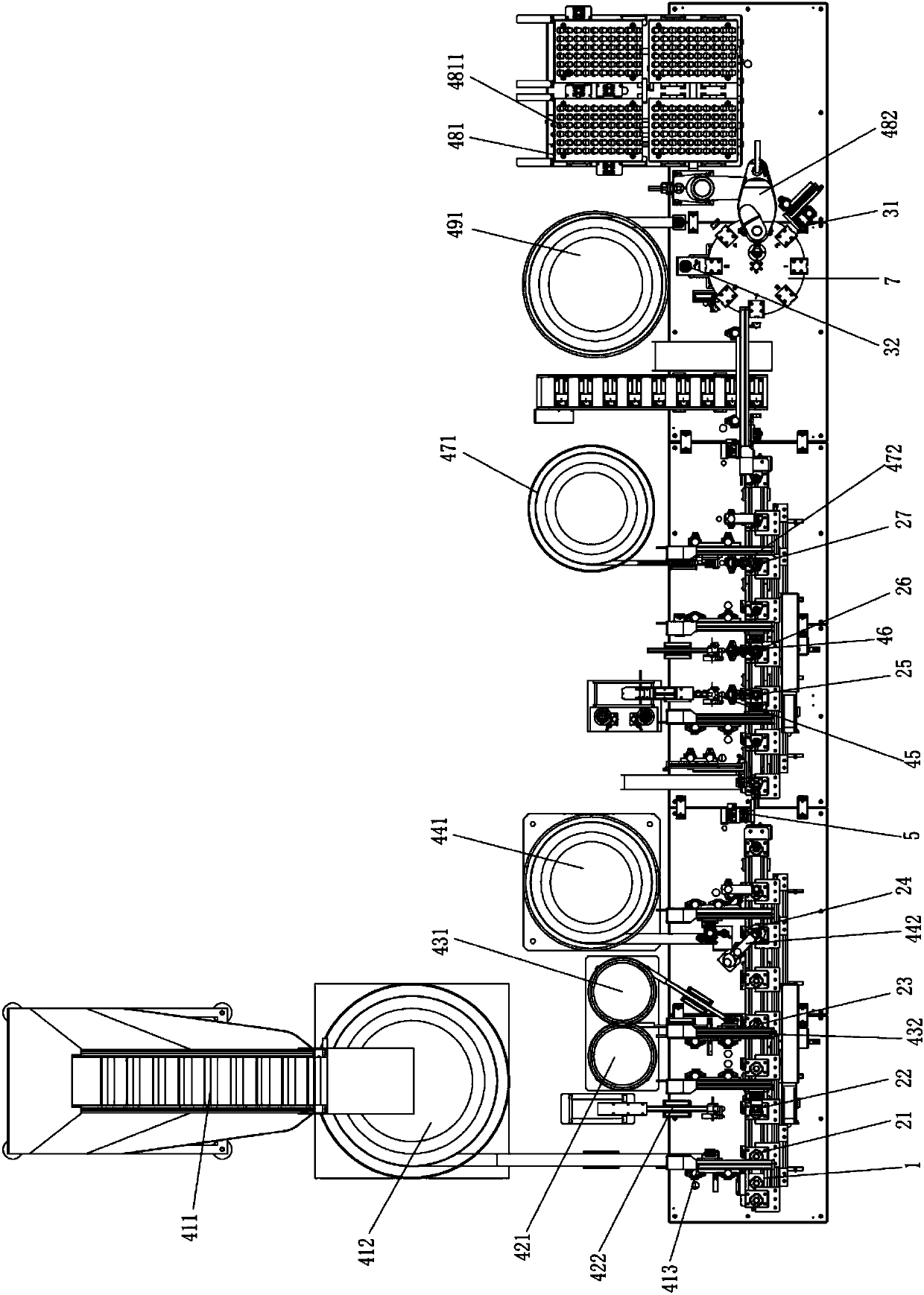

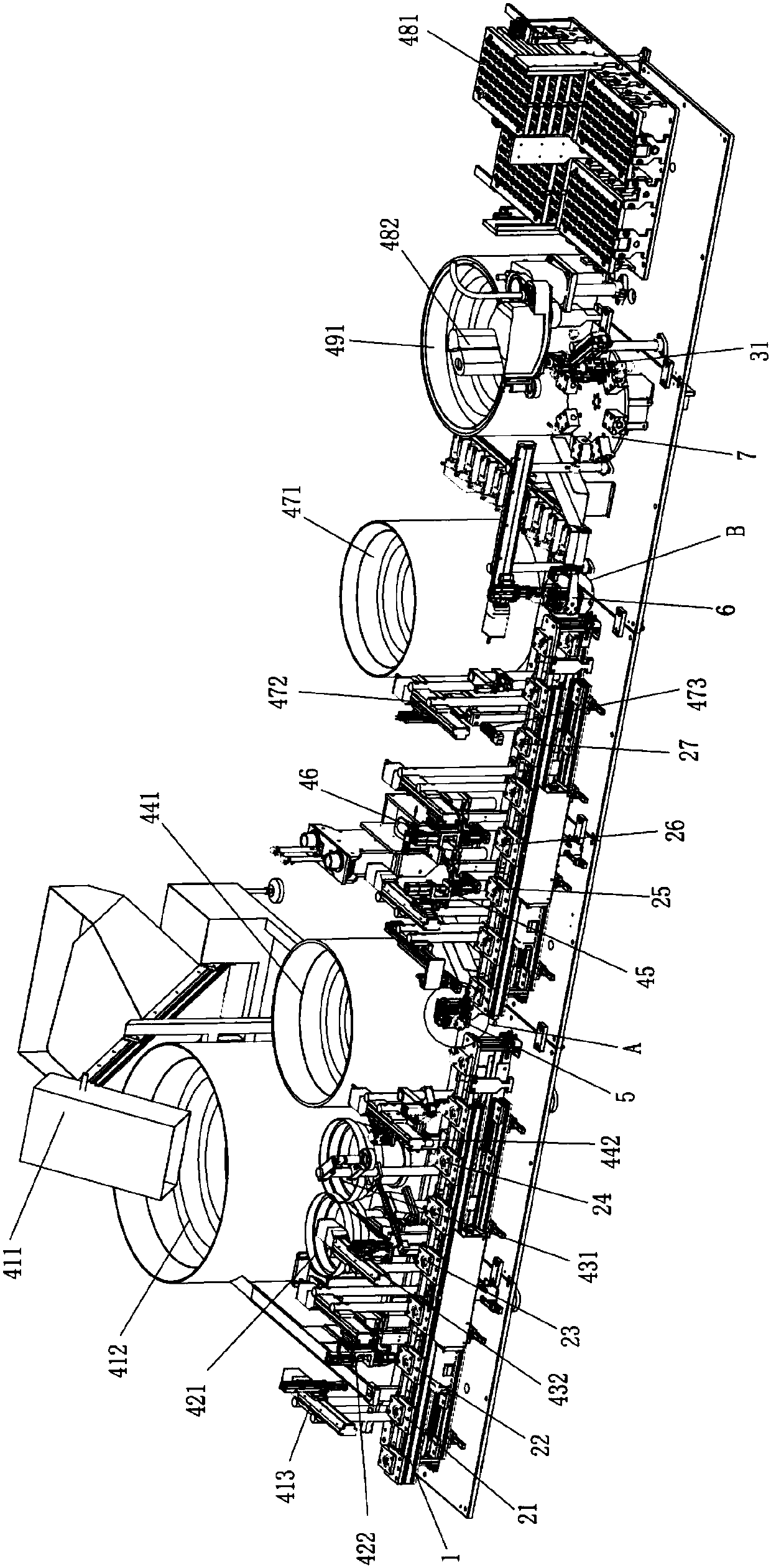

Production equipment for assembling closestool water inlet valves

The invention discloses production equipment for assembling closestool water inlet valves. The production equipment comprises a station conveying track, longitudinal assembly assembling stations, transverse assembly assembling stations and feeding mechanisms. The longitudinal assembly assembling stations are arranged on the station conveying track in a spaced manner and sequentially comprise the valve body station, the large-size O ring assembling station, the piston body and anti-siphon rubber pad assembling station, the water replenishment cover assembling station, the first small-size O ring assembling station, the second small-size O ring assembling station and the filter assembling station. The transverse assembly assembling stations are arranged at the rear ends of the longitudinal assembly assembling stations and comprise the water stop cover assembly assembling station and the nut assembling station. The feeding mechanisms are arranged to correspond to the longitudinal assemblyassembling stations and the transverse assembly assembling stations. By means of the production equipment, all assemblies are assembled automatically on the assembling stations according to the set assembling sequence; and the production equipment has the beneficial effects of being high in assembling speed and work efficiency and precise in assembling.

Owner:厦门讯诺科技股份有限公司

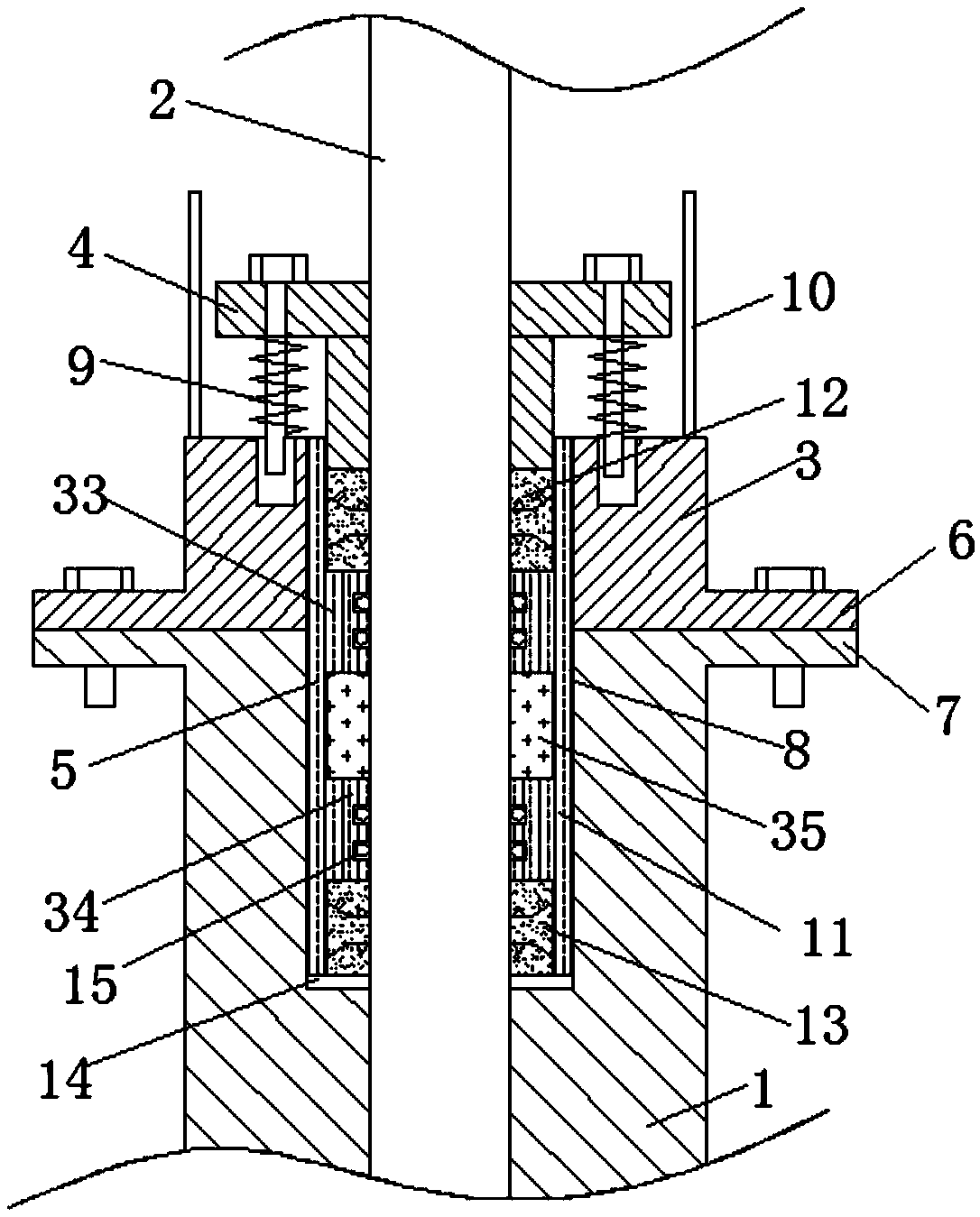

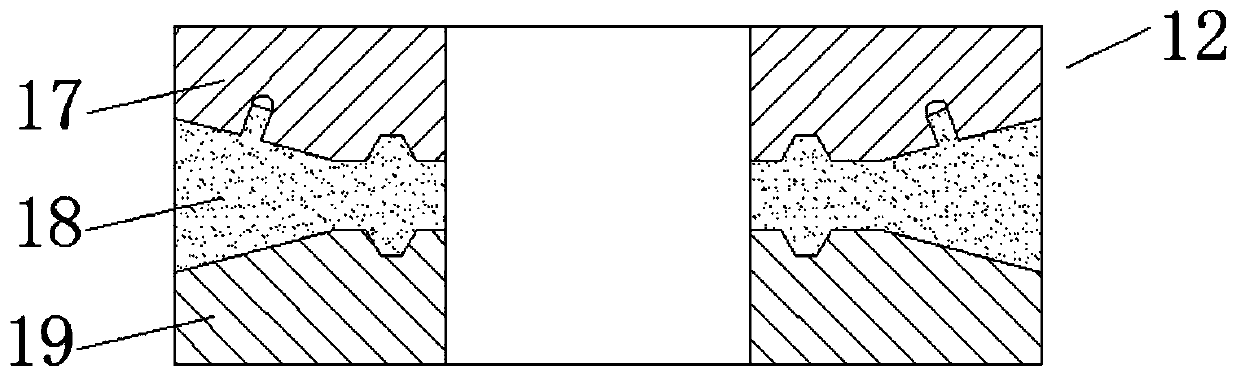

Valve packing sealing structure

The invention provides a valve packing sealing structure. The valve packing sealing structure is simple in structure and good in airtightness; by arranging a scale, the compression amount of a packingassembly is reasonably controlled, and the situations that the packing assembly is compressed insufficiently, and consequentially, a valve medium is leaked in the packing position, or the packing assembly is compressed excessively, consequentially, friction force between a valve rod and packing components is excessively large, and a valve is difficult to open and close are avoided; an upper packing group, an intermediate packing group and a lower packing group form multiple seals, the airtightness of packing is improved, and accordingly, the reliability and airtightness of the valve are improved; through the structures including a first packing ring, a second packing ring and a third packing ring, the sealing reliability is further improved, compression force of a gland in the vertical direction is changed into axial force and radial force by means of ring-shaped inclined surfaces, the deformation of the packing groups is increased, and the packing groups are pressed and attached to the valve rod; and through O-rings in a first ring-shaped protrusion and a second ring-shaped protrusion, the sealing reliability is further improved.

Owner:建湖县坤腾机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com