Patents

Literature

370results about How to "Increase heat conduction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

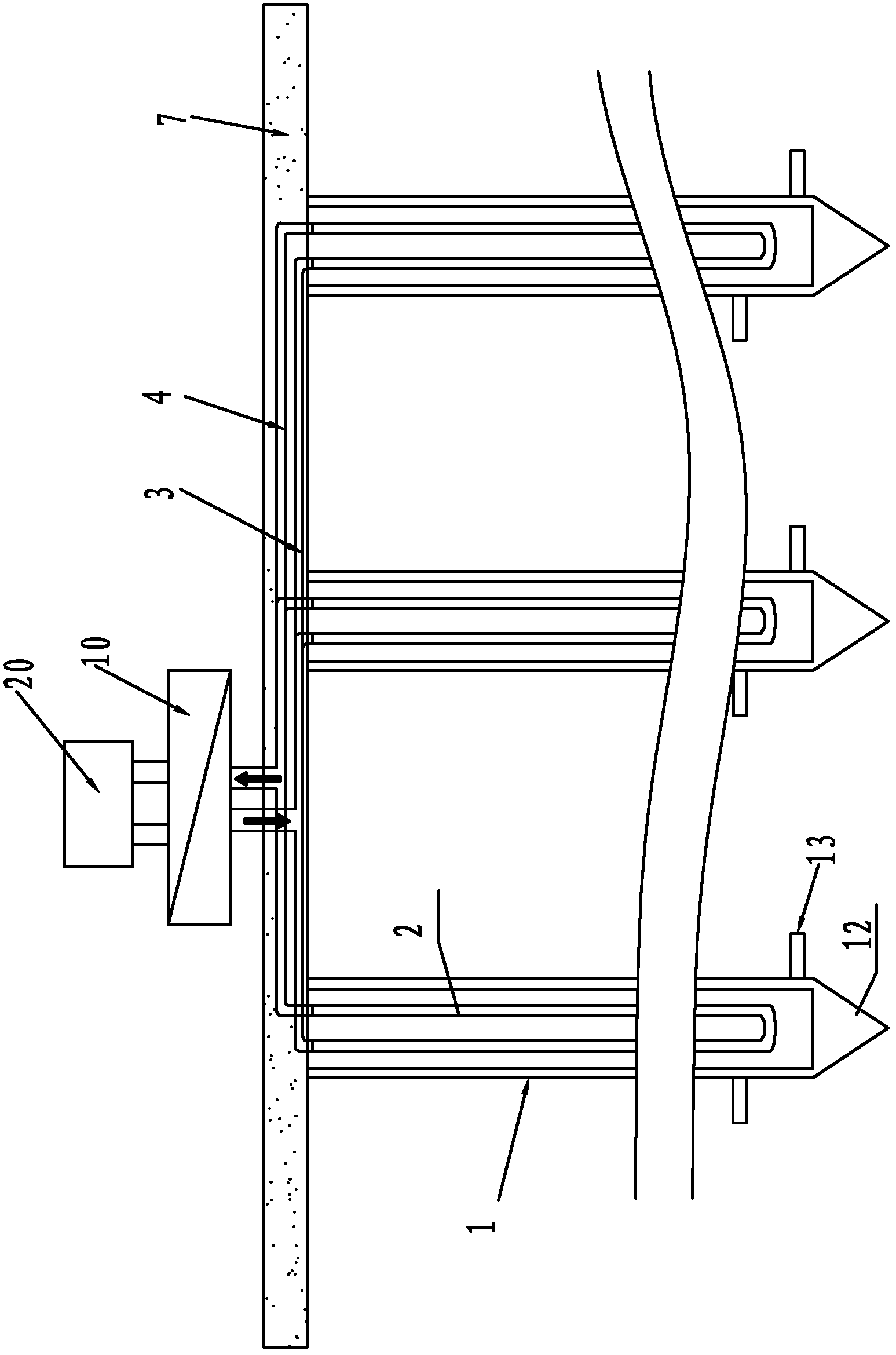

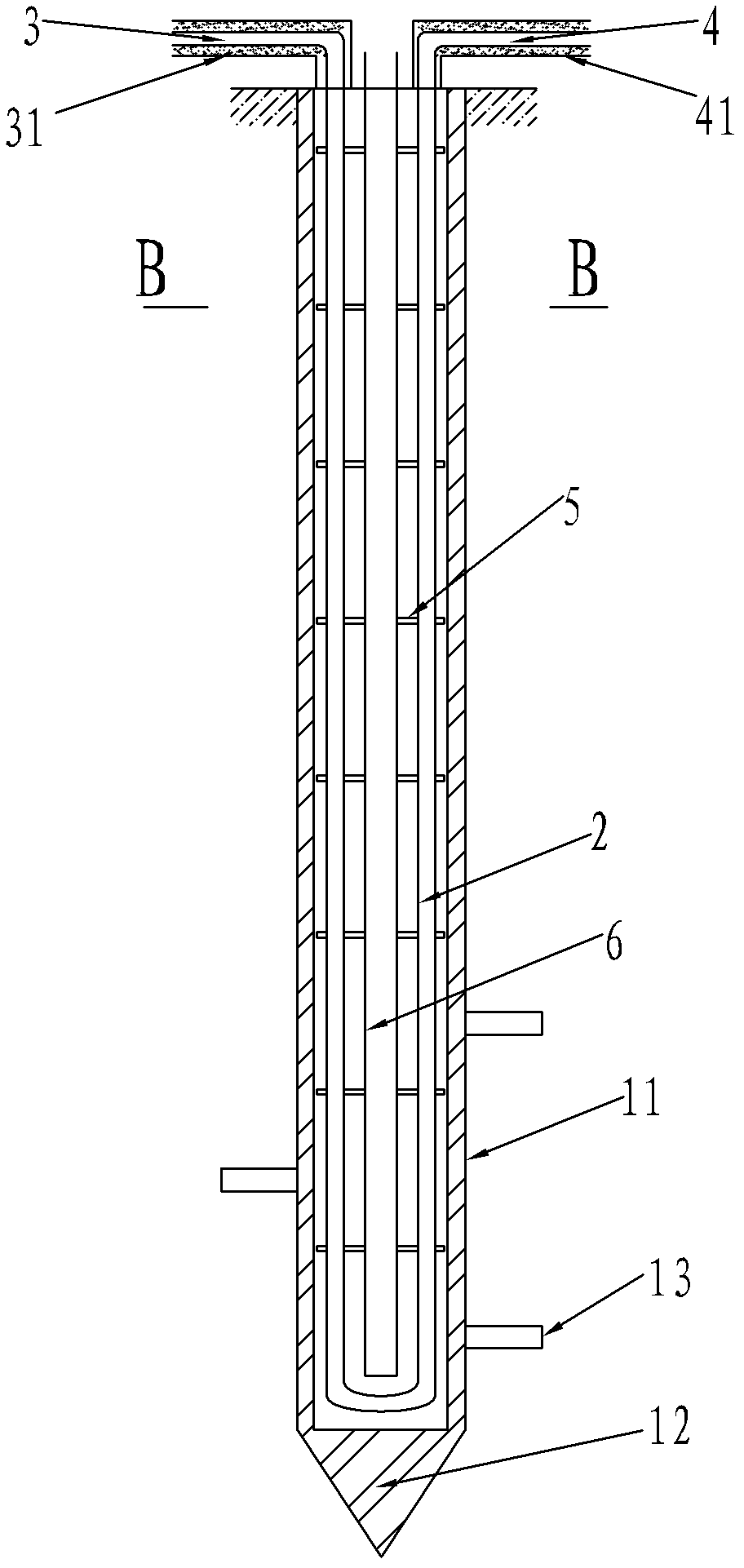

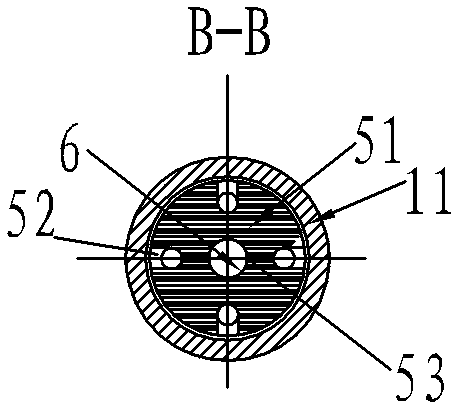

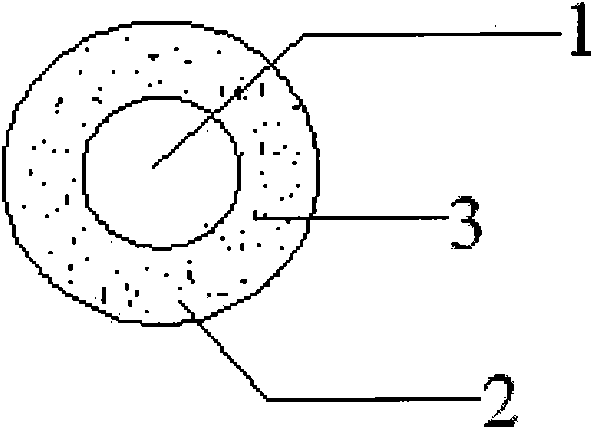

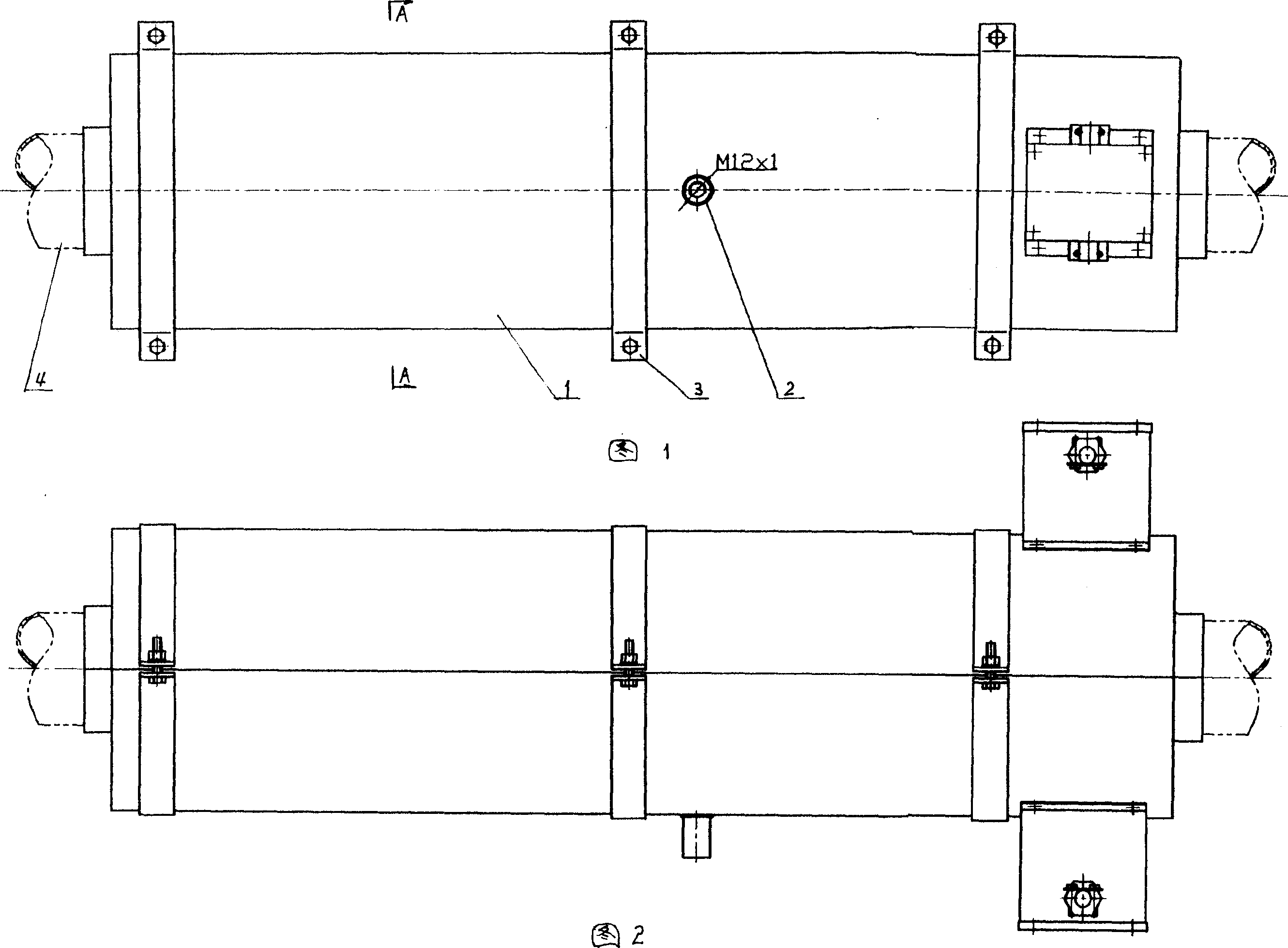

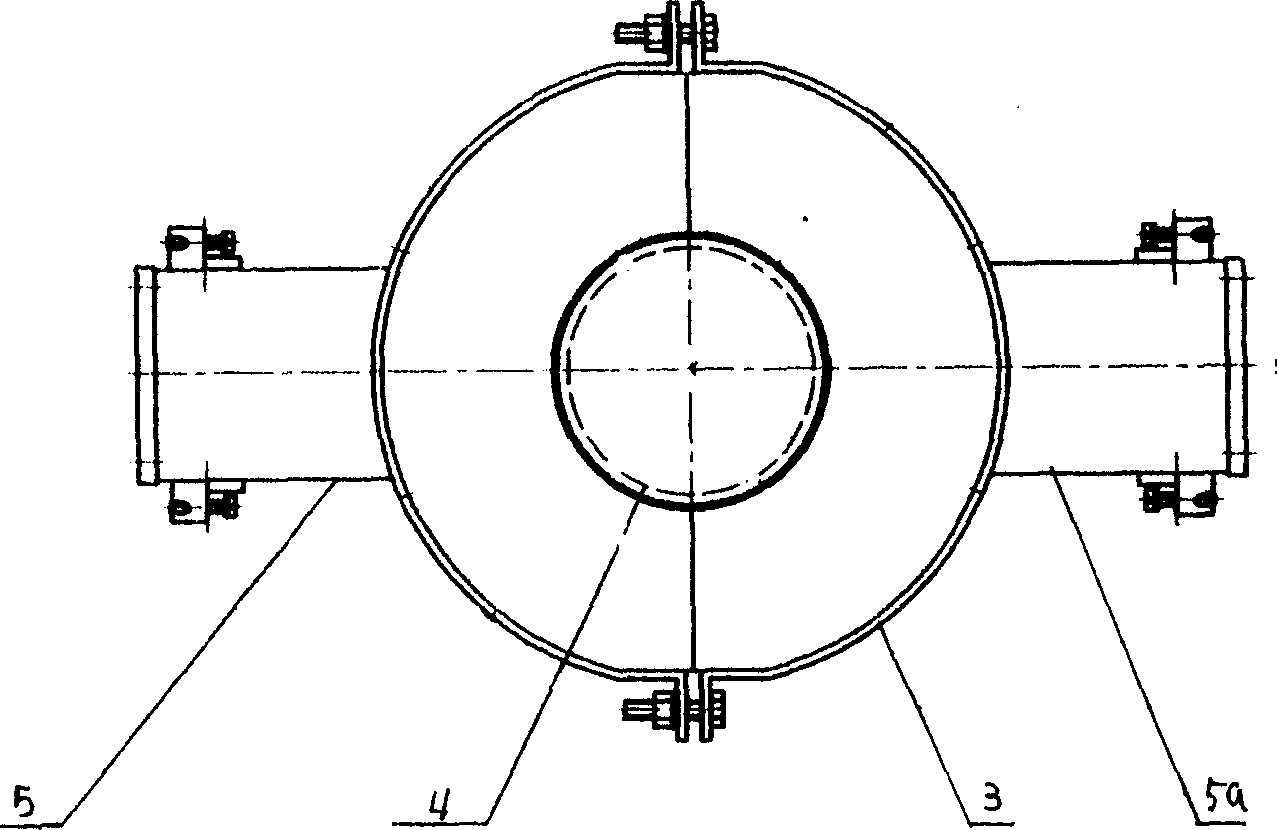

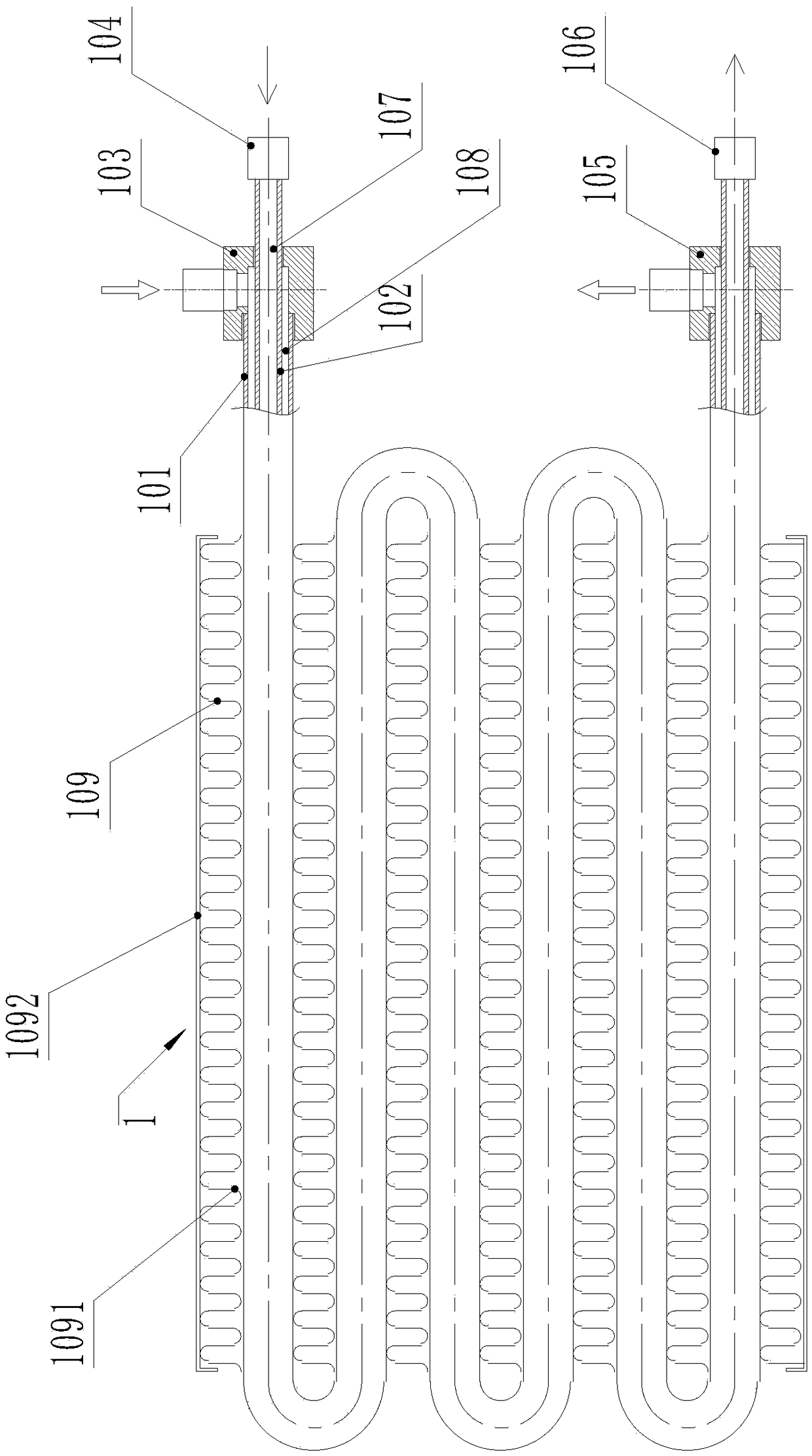

Precession-type backfill grouting ground source thermal energy conversion precast pile device and method for embedding precast pile device into stratum

InactiveCN102587365AConvenient closed loop conversionImprove bearing capacityHeat pumpsBulkheads/pilesThermal energyGeothermal heat pump

The invention discloses a precession-type backfill grouting ground source thermal energy conversion precast pile device, which comprises a plurality of precession-type backfill grouting prefabricated screw piles respectively embedded into pile holes, wherein a vertical heat exchanger is embedded in each screw pile; the inlet end and the outlet end of each vertical heat exchanger respectively extend out of an opening at the upper end of the screw pile to be respectively connected with a horizontal liquid-feeding collecting pipe and a horizontal liquid outlet collecting pipe in a bearing platform or a cushion layer; centring brackets are arranged at an interval of 1-3 m along the length direction of each vertical heat exchanger; each precession-type backfill grouting prefabricated screw pile comprises a hollow pile core, wherein the bottom of the pile core is provided with a cone-shaped pile head; a screw blade is arranged on the position far away1-3m from the lower part of the outer wall of the pile core; and a post grouting reinforcing layer is poured between the middle upper part of the outer wall of the pile core and a pile hole wall. The precession-type backfill grouting ground source thermal energy conversion precast pile device comprises a plurality of precession-type backfill grouting prefabricated screw piles, and the vertical heat exchanger is embedded in each screw pile; the pile foundation construction and the ground source heat pump construction are integrated so as to avoid a drilling and pipe-laying program of a ground source heat pump system on the ground, greatly lower the front-end investment cost and save the land use area; and the post grouting reinforcing layer is poured between the middle upper part of the outer wall of the pile core and the pile hole wall so as to enlarge a heat conduction area, improve the heat conduction performance and simultaneously improve the pile body bearing capacity.

Owner:CHINA JINGYE ENG +2

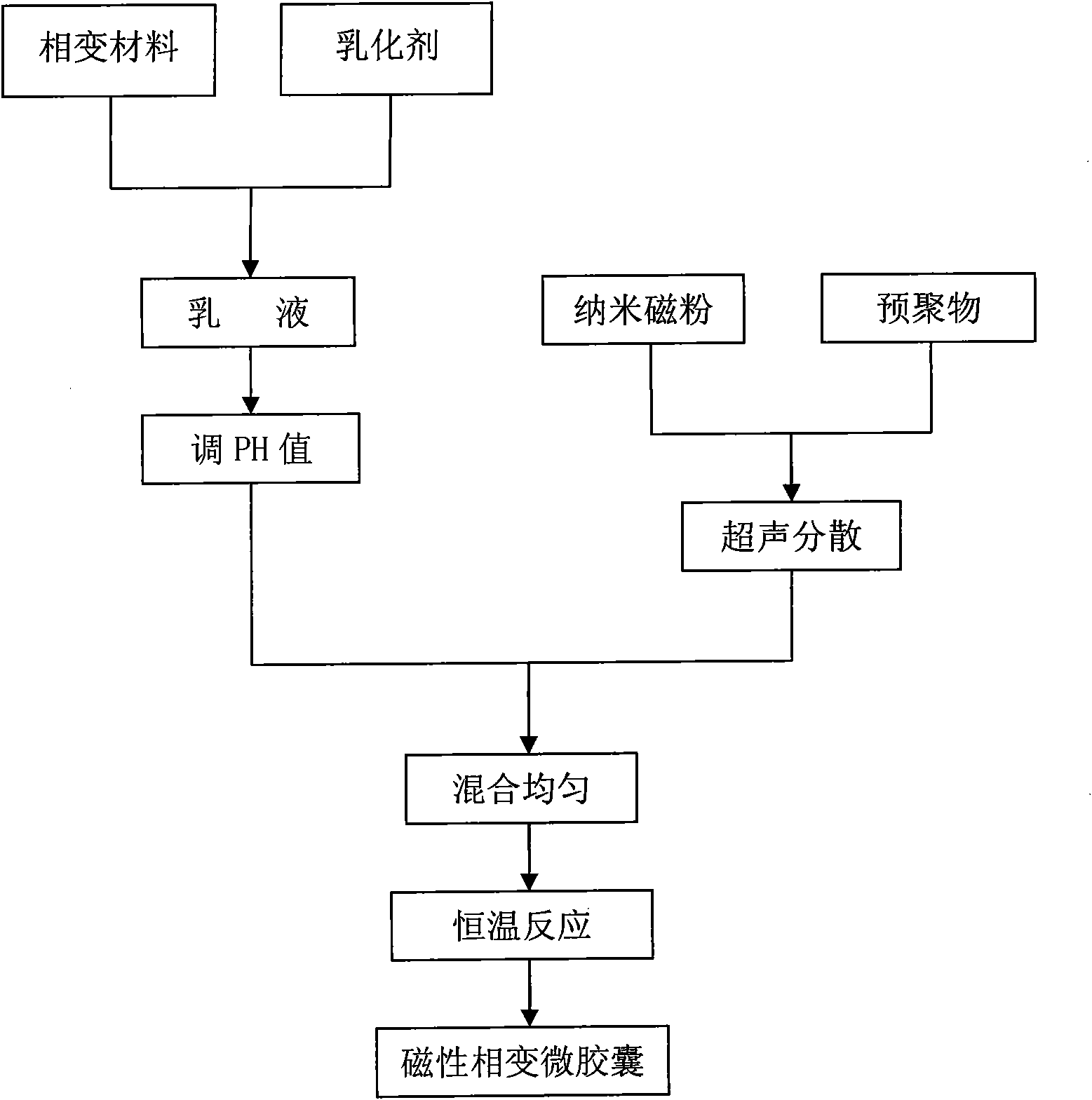

Magnetic phase transition microcapsule and preparation method thereof

InactiveCN101574637AReduce consumptionEasy to controlHeat-exchange elementsMicroballoon preparationUltrasonic dispersionFORMALDEHYDE SOLUTION

The invention discloses a magnetic phase transition microcapsule and a preparation method thereof. Nanometer magnetic powder is filled in a microcapsule material to form a shell, and a core material is wrapped in the shell. The magnetic phase transition microcapsule is prepared by the following steps: firstly, adding urea to a formaldehyde solution to dissolve or adding melamine to the formaldehyde solution, or adding the urea to the formaldehyde solution and adding melamine after fully dissolving the urea; then, reacting under stirring at a constant temperature to obtain a prepolymer solution; adding the nanometer magnetic powder to the prepolymer solution and dispersing the solution under ultrasound; dissolving an emulsifying agent in the water, adding an organic phase transition material and cutting and emulsifying the organic phase transition material at a high speed to prepare an emulsion; and uniformly mixing the emulsion and the prepolymer solution after ultrasonic dispersion and reacting under stirring at the constant temperature to obtain the magnetic phase transition microcapsule. The magnetic phase transition microcapsule has magnetism and can reach specific parts under the guide of an external magnetic field while the magnetic phase transition microcapsule is applied to a latent heat type functional fluid so as to control the flow of the fluid.

Owner:NANJING UNIV OF SCI & TECH

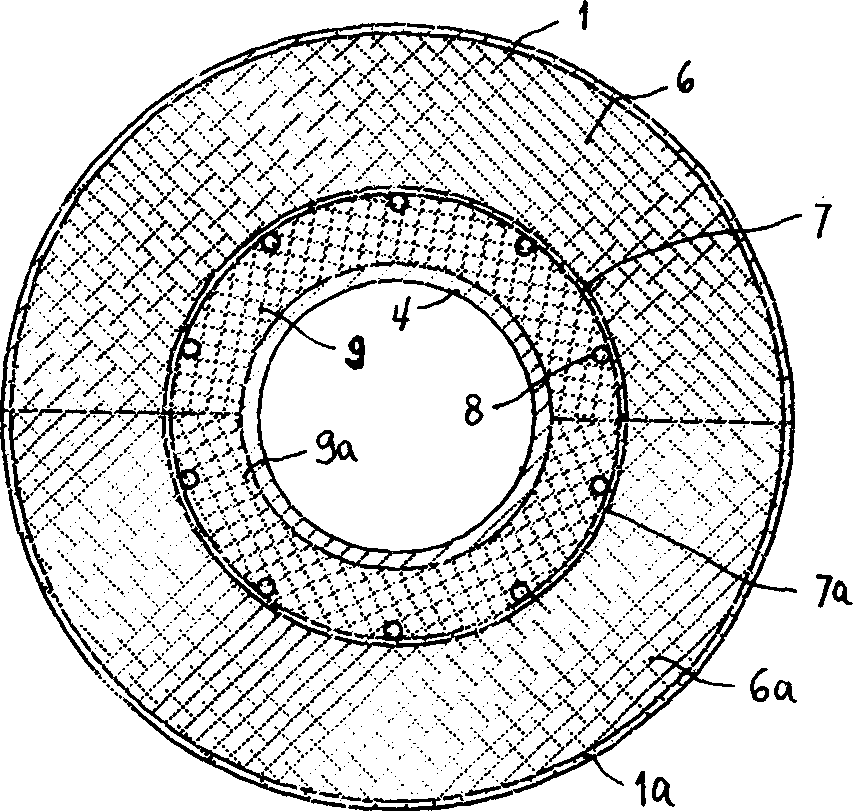

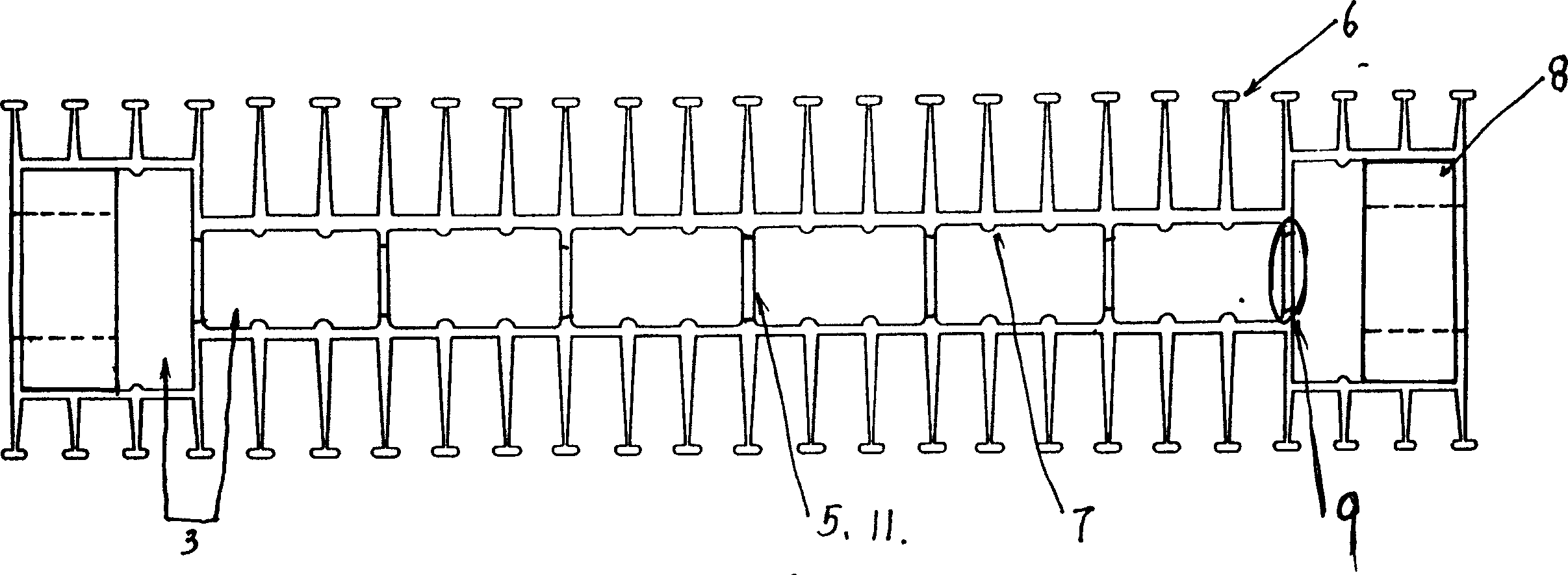

Electric heater for pipeline

InactiveCN1908499AImprove efficiencyIncrease heat conduction areaPipe heating/coolingPipeline systemsElectric heatingEngineering

An electric heater for pipeline is an electric heater used for heating the pipeline or the medium therein. A temperature control unit is composed of a SCM and a temperature sensor, also has two bush-shape metal endoconches. On the inwall side of the two metal endoconches is fixed with an electric heating pipe, also has two bush-shape molding heat-conducting layers made of heat conducting materials used in shrinking on the pipeline. The outerwall side of the molding heat-conducting layers is joint with the inwall side of two metal endoconches. Also provided are two bush-shape molding insulating layers joint with the outerwall side of the two metal endoconches, two bush-shape shell on the external surface of the two molding insulating layers. Also provided are the fixed links joining the heating module on the pipeline. The invention has the advantages of high thermal efficiency, convenient to assemble and disassemble and is widely used in a variety of pipeline heating occasions.

Owner:成都市兴岷江电热电器有限责任公司

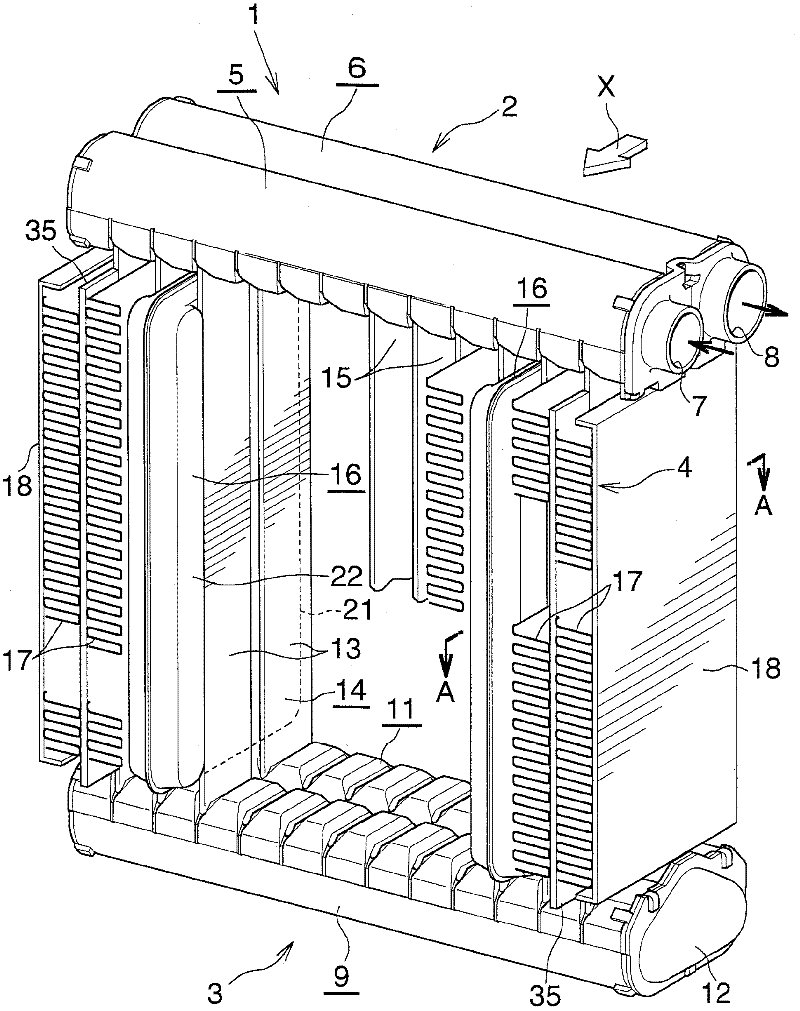

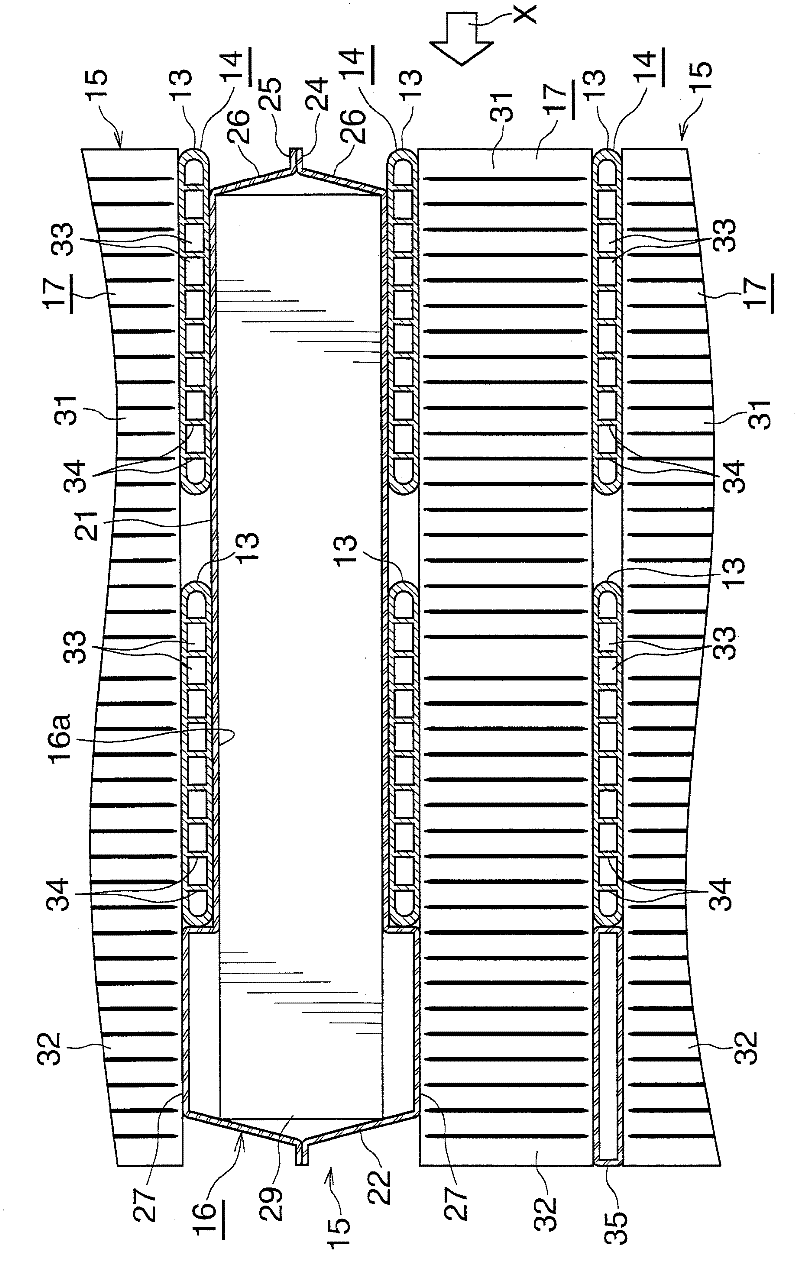

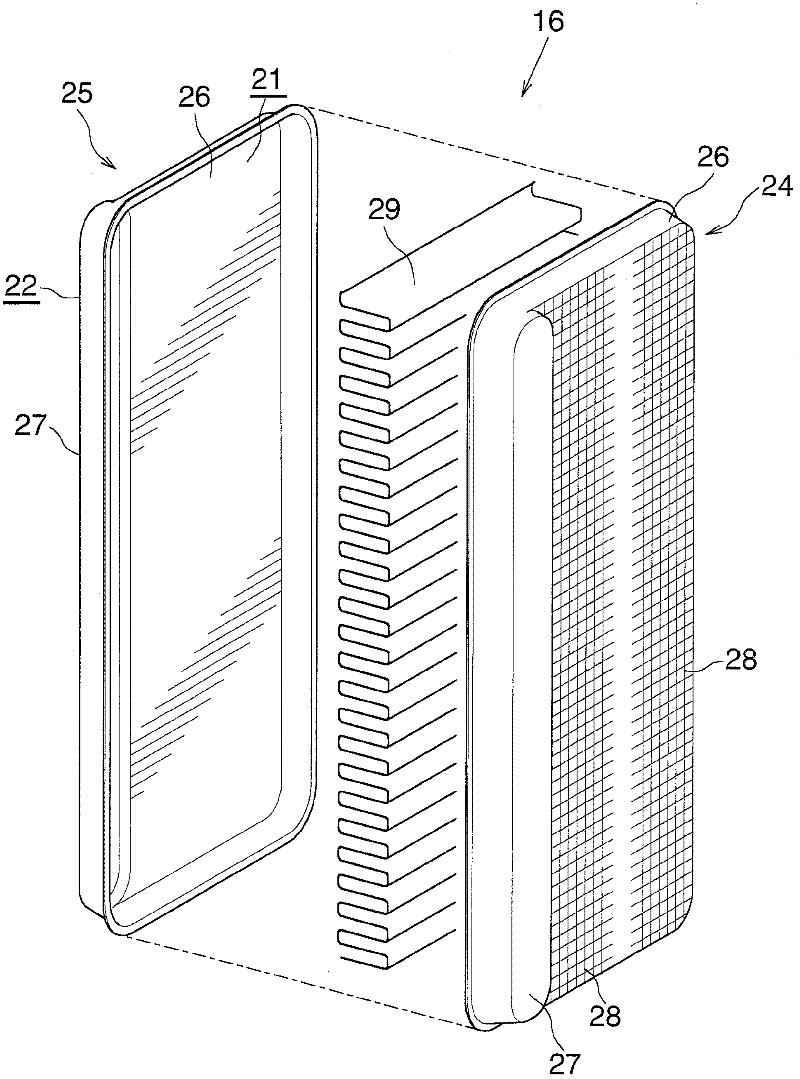

Evaporator with cool storage function

ActiveCN102374705AReduce the pass areaInhibit the increase in ventilation resistanceHeat storage plantsEvaporators/condensersCool storageFront edge

An evaporator with a cool storage function includes a cool storage material container disposed at least one of air-passing clearances formed between adjacent refrigerant flow tubes, and fins disposed in air-passing clearances on opposite sides of the cool storage material container. The cool storage material container includes a container body portion joined to the corresponding refrigerant flow tubes, and an outward extending portion which extends from the front edge of the container body portion and projects frontward in relation to the refrigerant flow tubes. Each of the fins has a fin body portion joined to the corresponding refrigerant flow tubes, and an outward extending portion which extends from the front edge of the fin body portion body and projects frontward in relation to the refrigerant flow tubes. The outward extending portions of the fins are brazed to opposite sides of the outward extending portion of the cool storage material container.

Owner:MAHLE INT GMBH

Heat management and energy recycling system and method for battery module group of electric vehicle

ActiveCN109962317AGood high temperature heat dissipationGood low temperature heating abilitySecondary cellsHeat managementAutomotive battery

The invention provides a heat management and energy recycling system and method for a battery module group of an electric vehicle. The system comprises a thermoelectric power generation module, a cooling and heating module and an electronic control module, wherein the thermoelectric power generation module is connected with the battery module; the battery module is used for recycling heat emittedby the battery module and supplying power to the outside. The cooling and heating module is connected with the thermoelectric power generation module, is used for providing cooling liquid for the thermoelectric power generation module to produce temperature difference, and is also used for achieving the cooling or temperature heating of the battery module. The electronic control module is connected with the thermoelectric power generation module and the cooling and heating module, and is used for achieving dynamic control over temperature difference power generation and cooling and heating. When the temperature of the battery module is high, too high, low and too low, the electronic control module is used for achieving control over the temperature difference power generation module and thecooling and heating module, and the high-temperature heat dissipation capacity and the low-temperature heat preservation capacity of the battery module are greatly improved.

Owner:SHANDONG UNIV

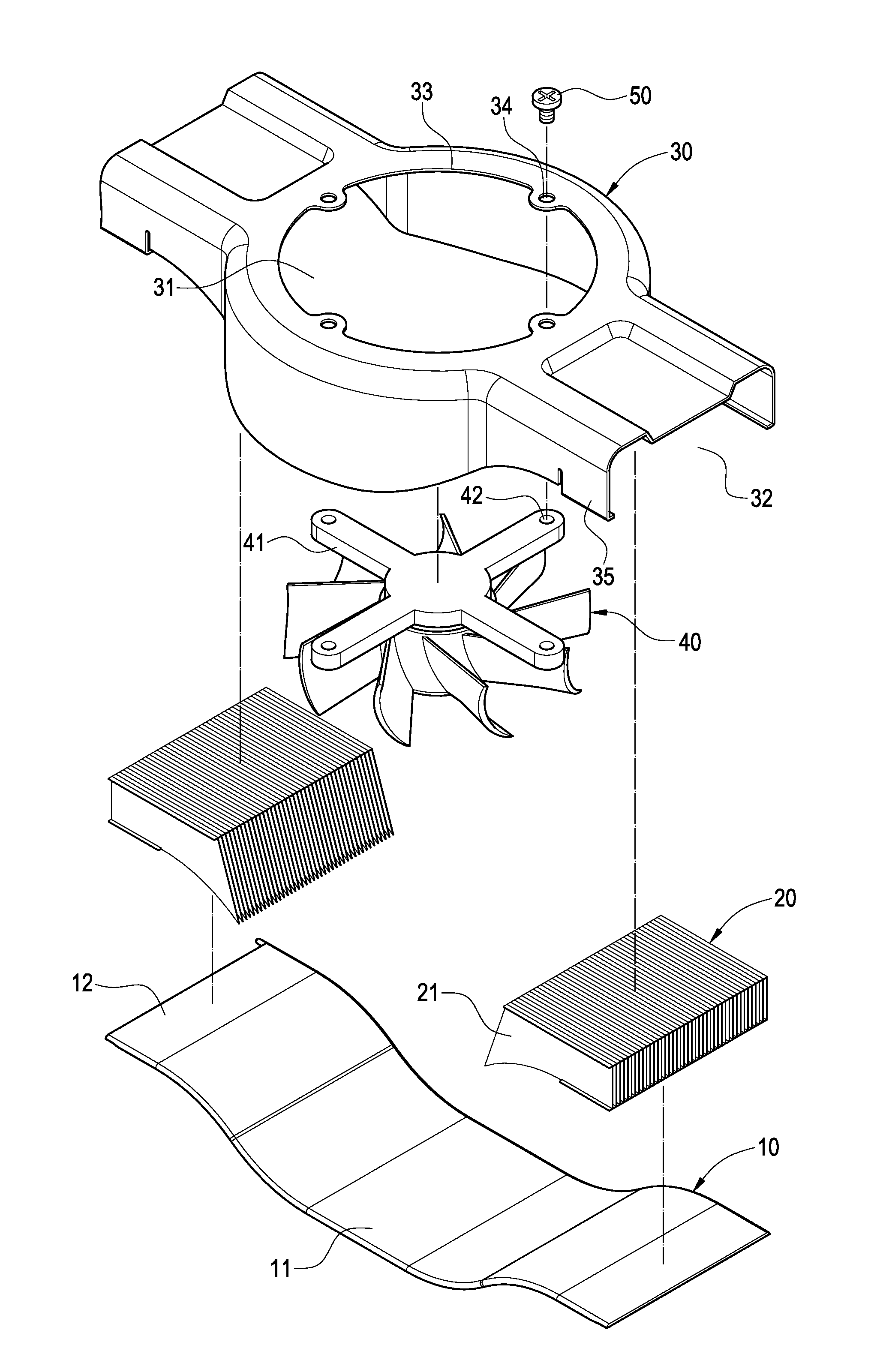

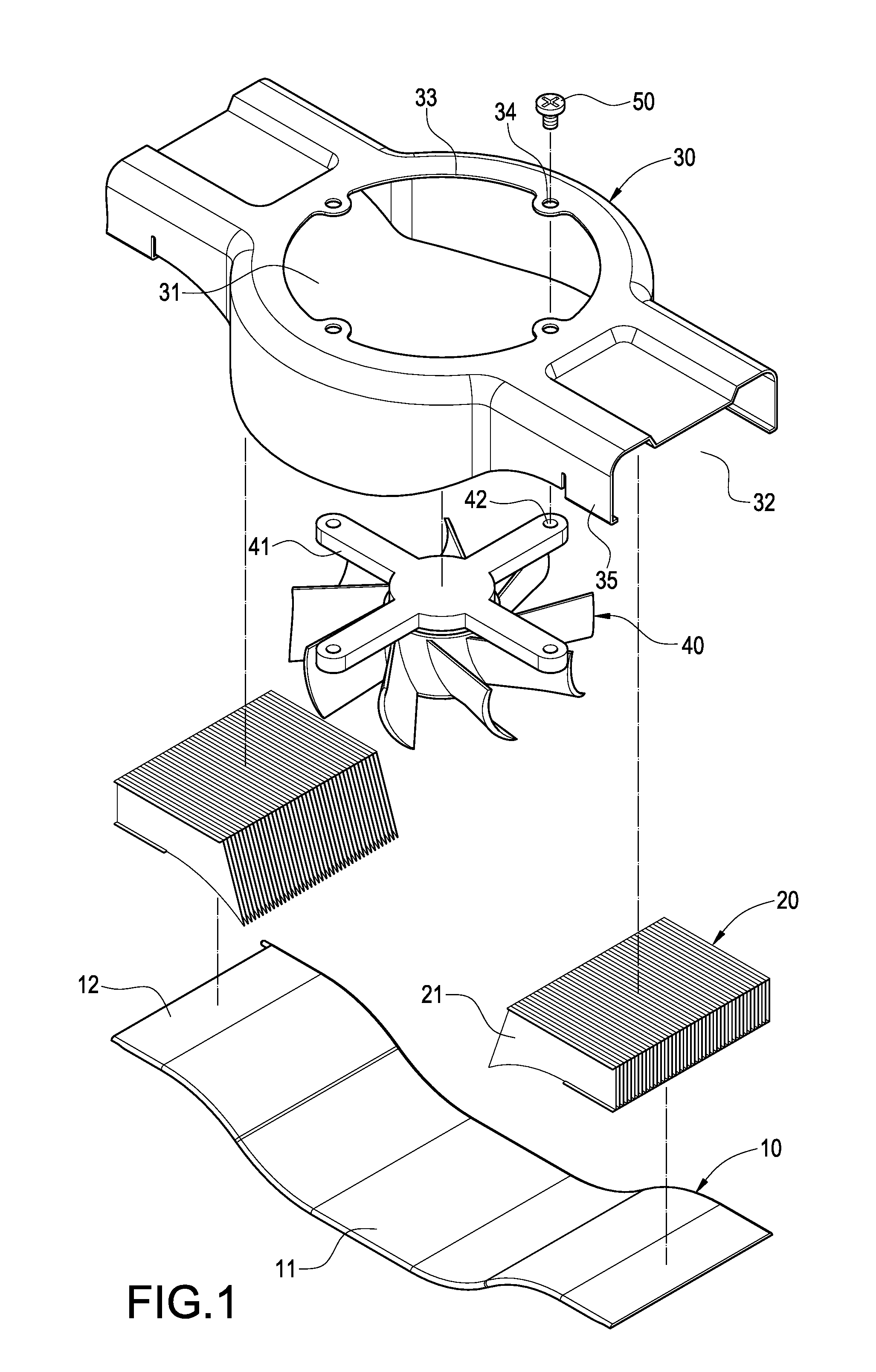

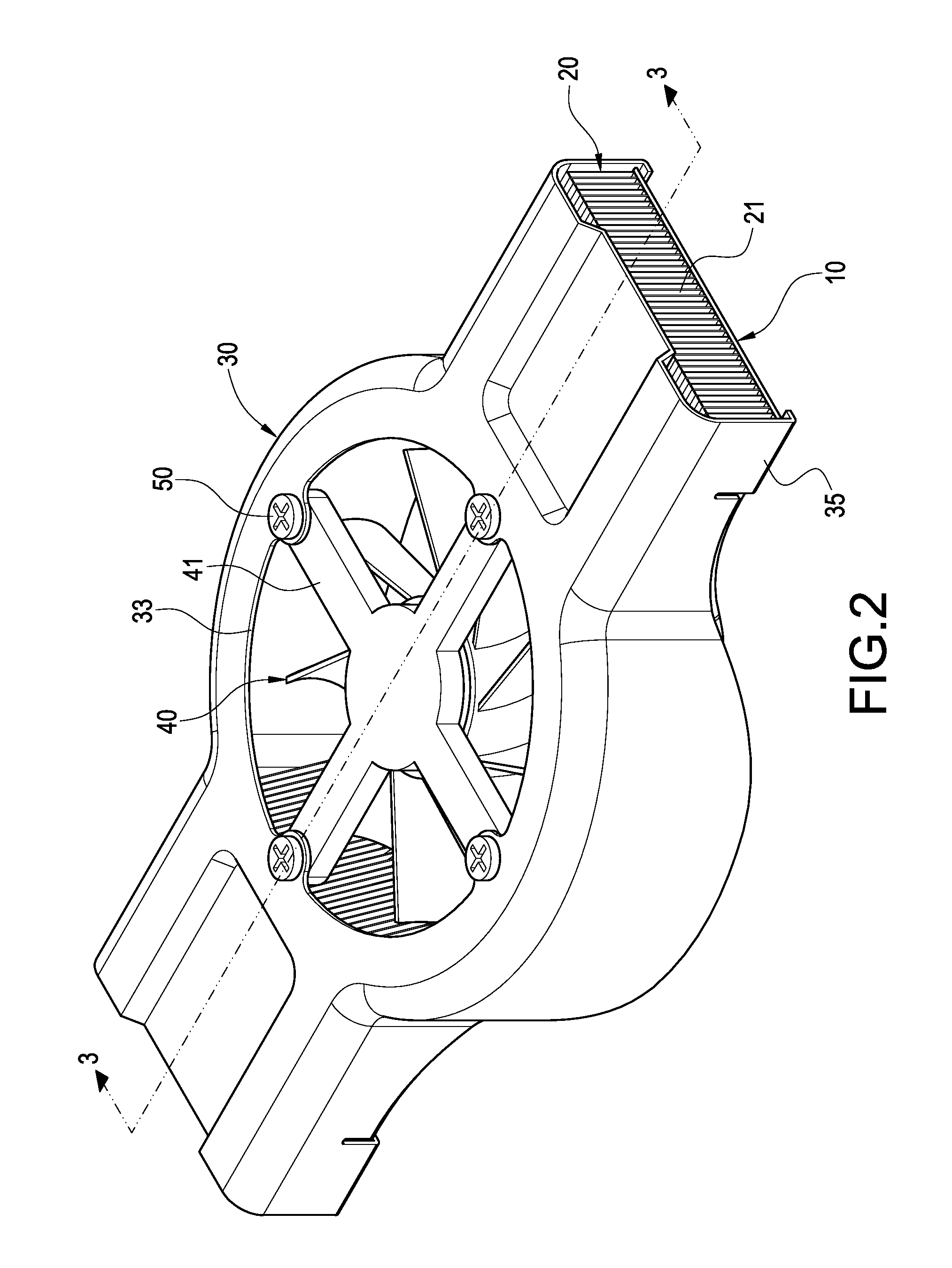

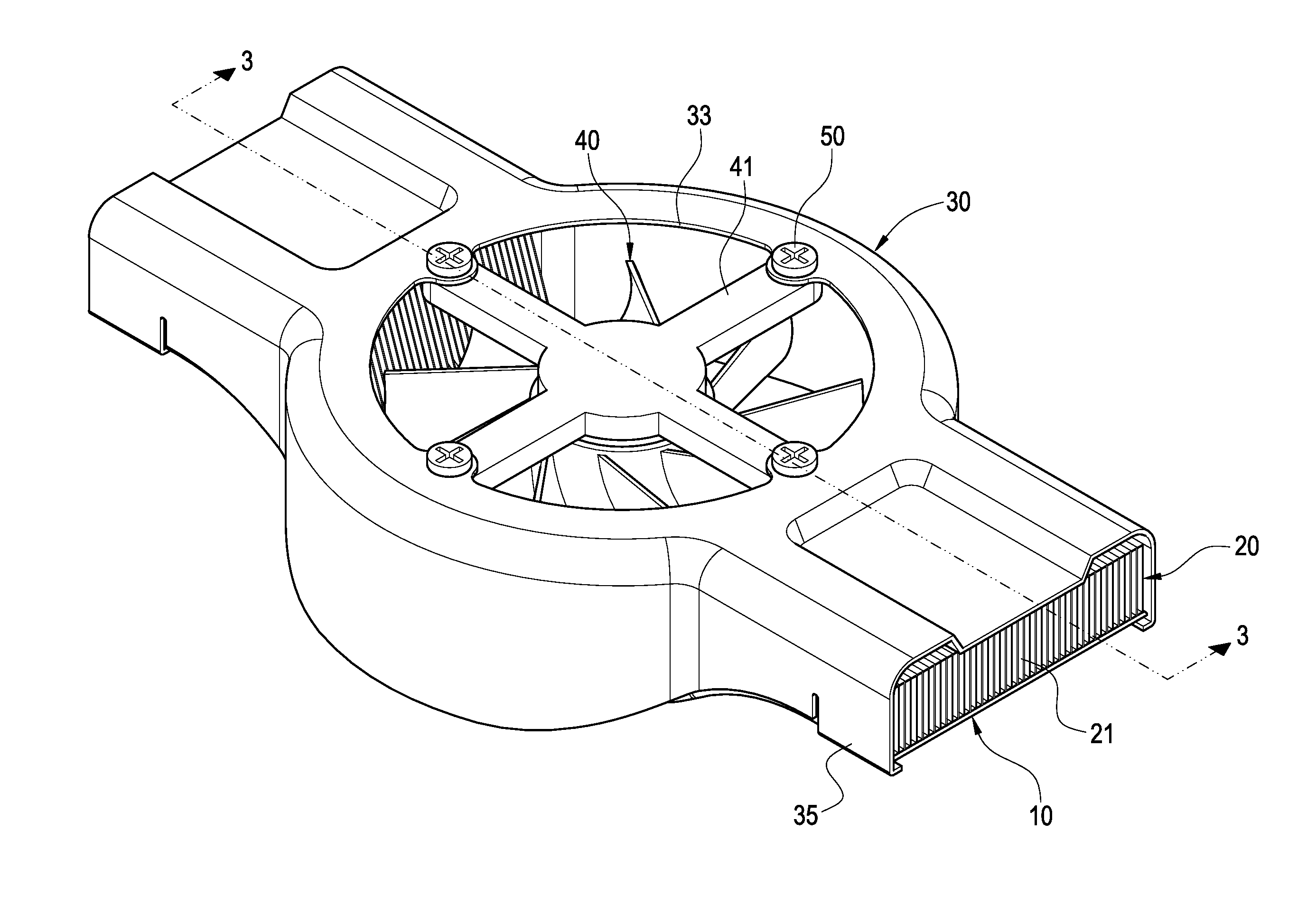

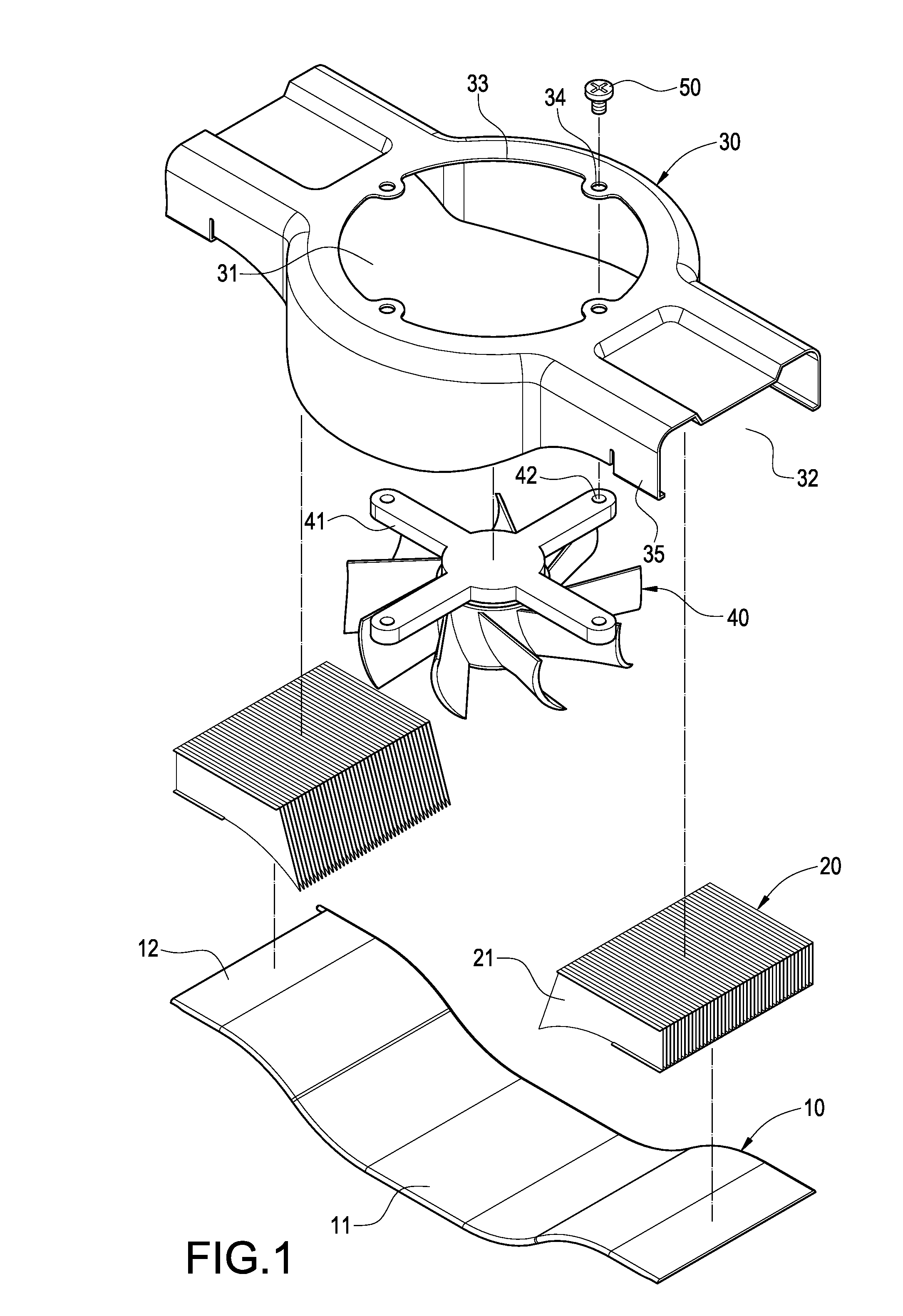

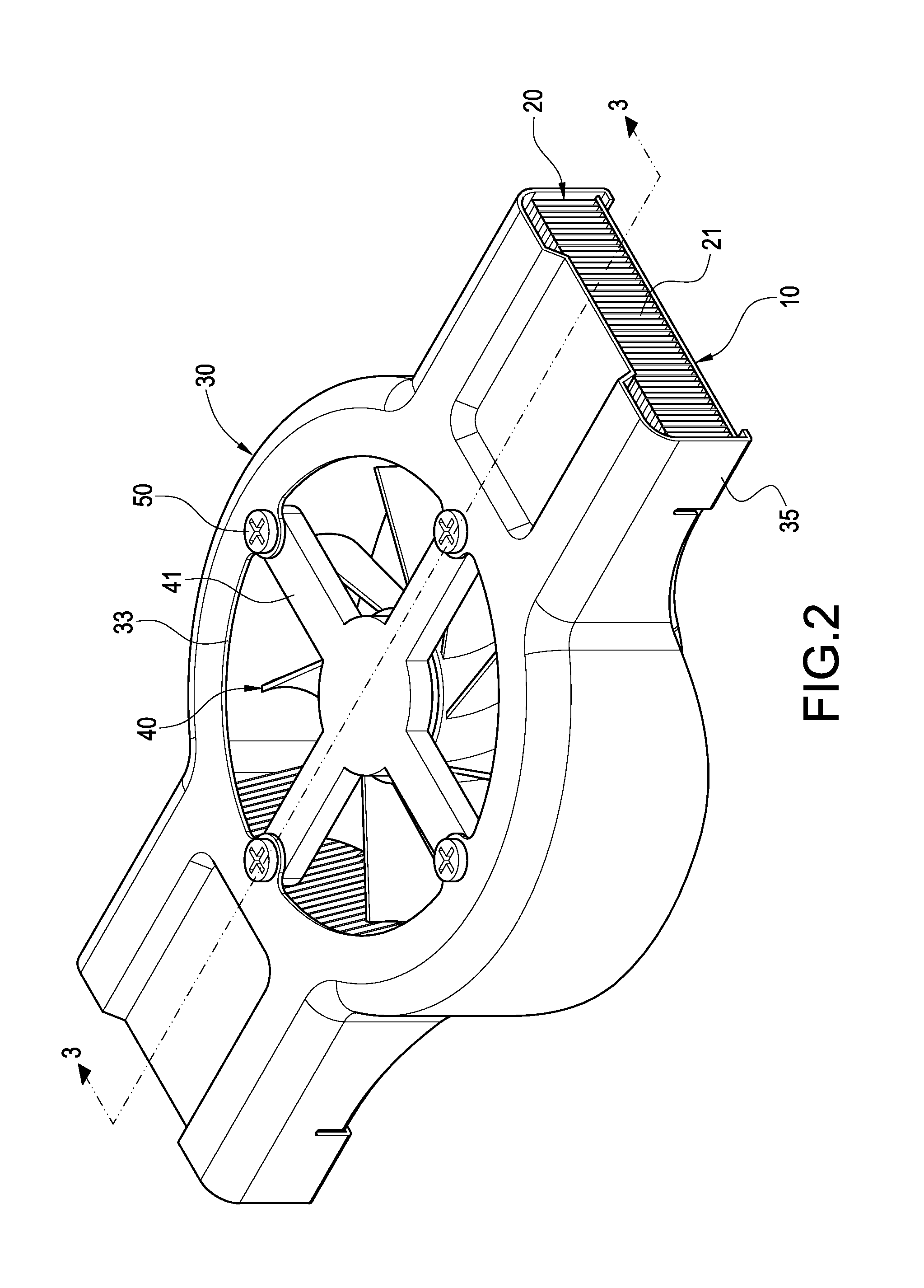

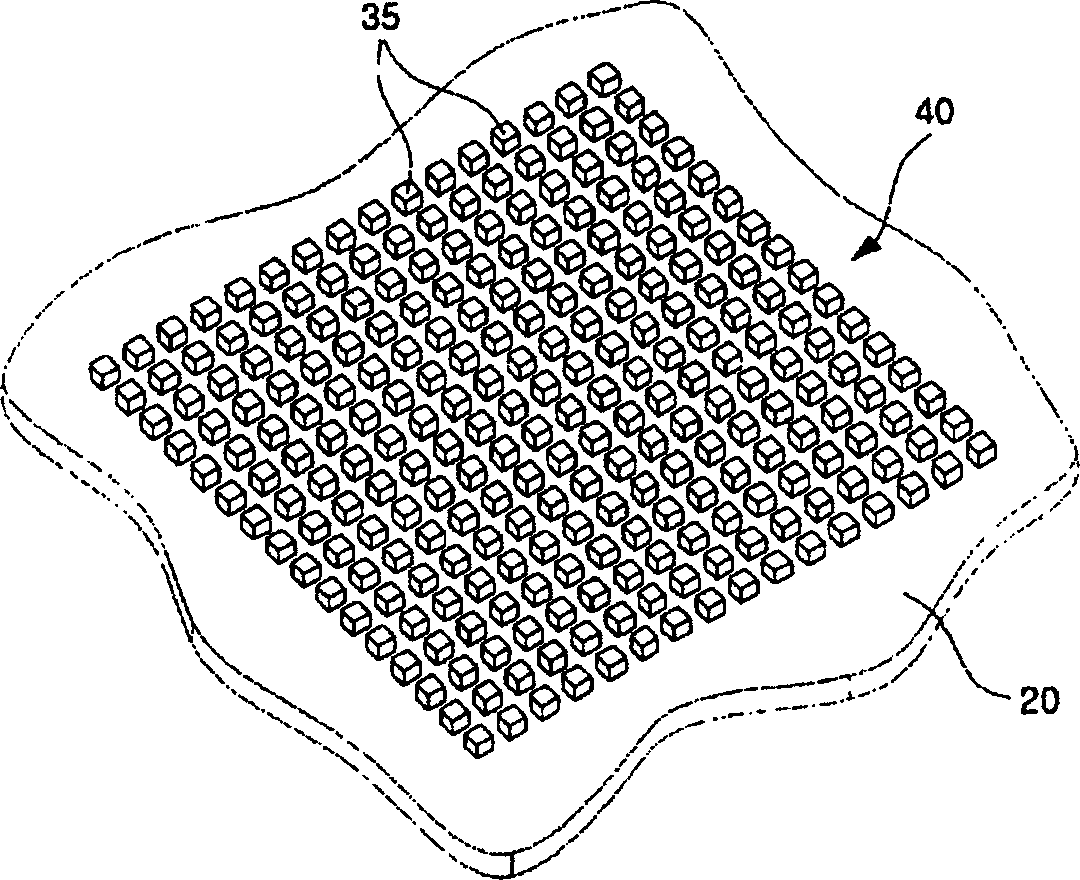

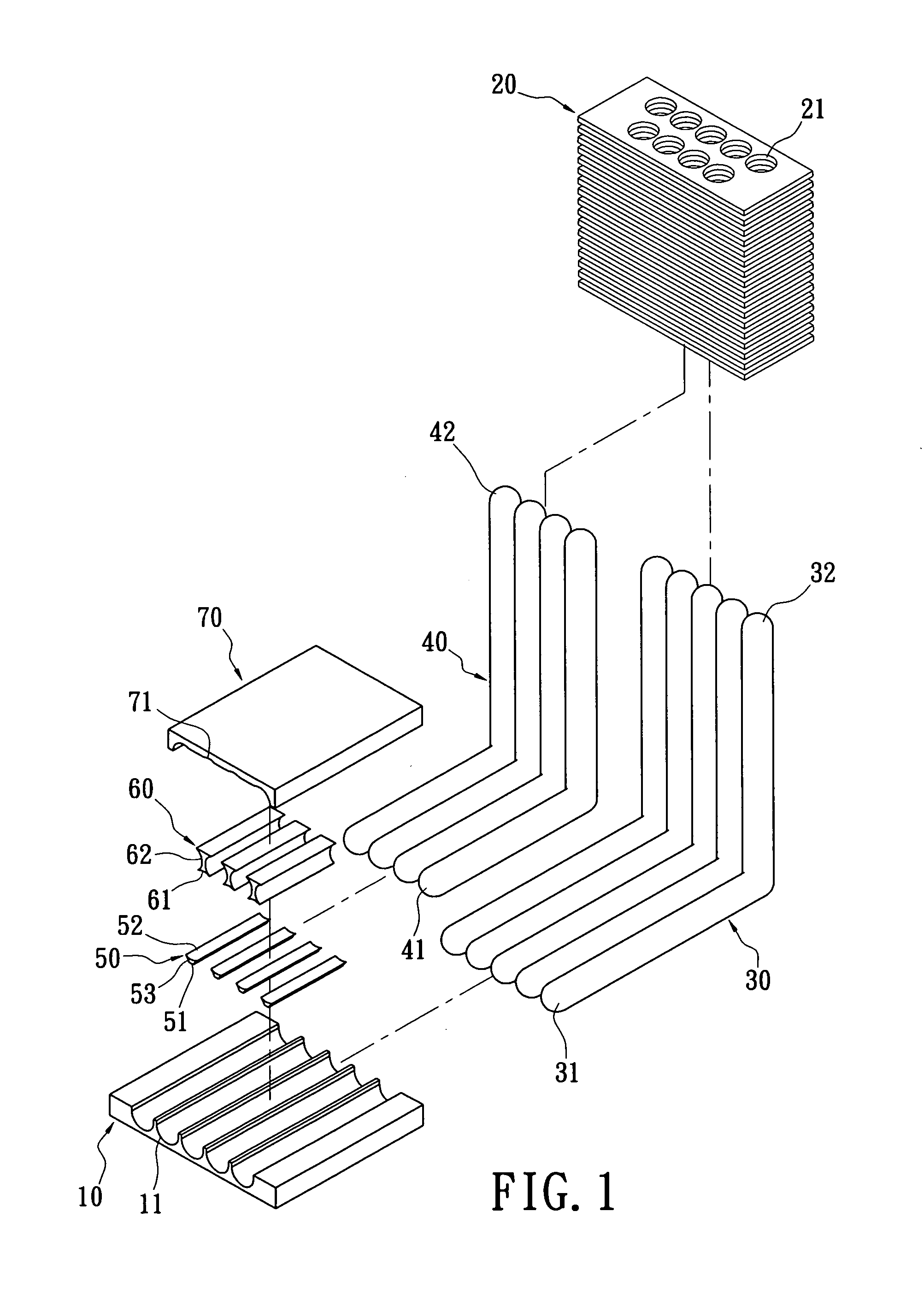

Heat dissipation device

ActiveUS7684187B1Improve cooling efficiencyIncrease heat conduction areaDomestic stoves or rangesDigital data processing detailsEngineeringHeat sink

A heat dissipation device includes a vapor chamber, a heat dissipating fins assembly, a cover and a fan. The vapor chamber is configured to a bent shape. The heat dissipating fins assembly is adhered to a partial surface of the vapor chamber. The cover is connected to the vapor camber. A flow passage is defined between the vapor chamber and the cover. The heat dissipating fins assembly is positioned in the flow passage. The cover defines an opening communicating to the flow passage. The fan is arranged facing to the opening of the cover and other partial surface of the vapor chamber. Therefore, the heat dissipating efficiency can be greatly improved.

Owner:CELSIA TECH TAIWAN INC

Spiral-body-enhanced metal-based or polymer-based composite and preparation method

ActiveCN105803241AIncrease binding areaAvoid breakingVacuum evaporation coatingSputtering coatingGas phaseCarbon nanotube

The invention provides a spiral-body-enhanced metal-based or polymer-based composite and a preparation method. The composite is formed by distributing an array formed by a plurality of spiral enhancing bodies in a metal matrix and combining the surface-modified spiral enhancing bodies with the metal matrix in a metallurgical manner. The metal matrix is made of frequently-used electronic packaging metal materials such as Al, Cu and Ag. The spiral enhancing bodies are formed by depositing diamond on a spiral-body-shaped substrate through a chemical vapor deposition method to obtain lining supporting diamond spiral bodies, and graphene or carbon nanotubes grow in the direction perpendicular to the surface to obtain a spiral diamond heat conductor structure with a vertical-array graphene wall or a carbon nanotube forest on the surface. The high-heat-conductivity composite is obtained by distributing the spiral enhancing bodies in the metal matrix to form an array and adding enhancing particles to further improve the heat conductivity. The composite can be used as electronic packaging, heat sink materials and the like, and the packaging problems of high-temperature, high-frequency and high-power electronic devices are solved.

Owner:CENT SOUTH UNIV

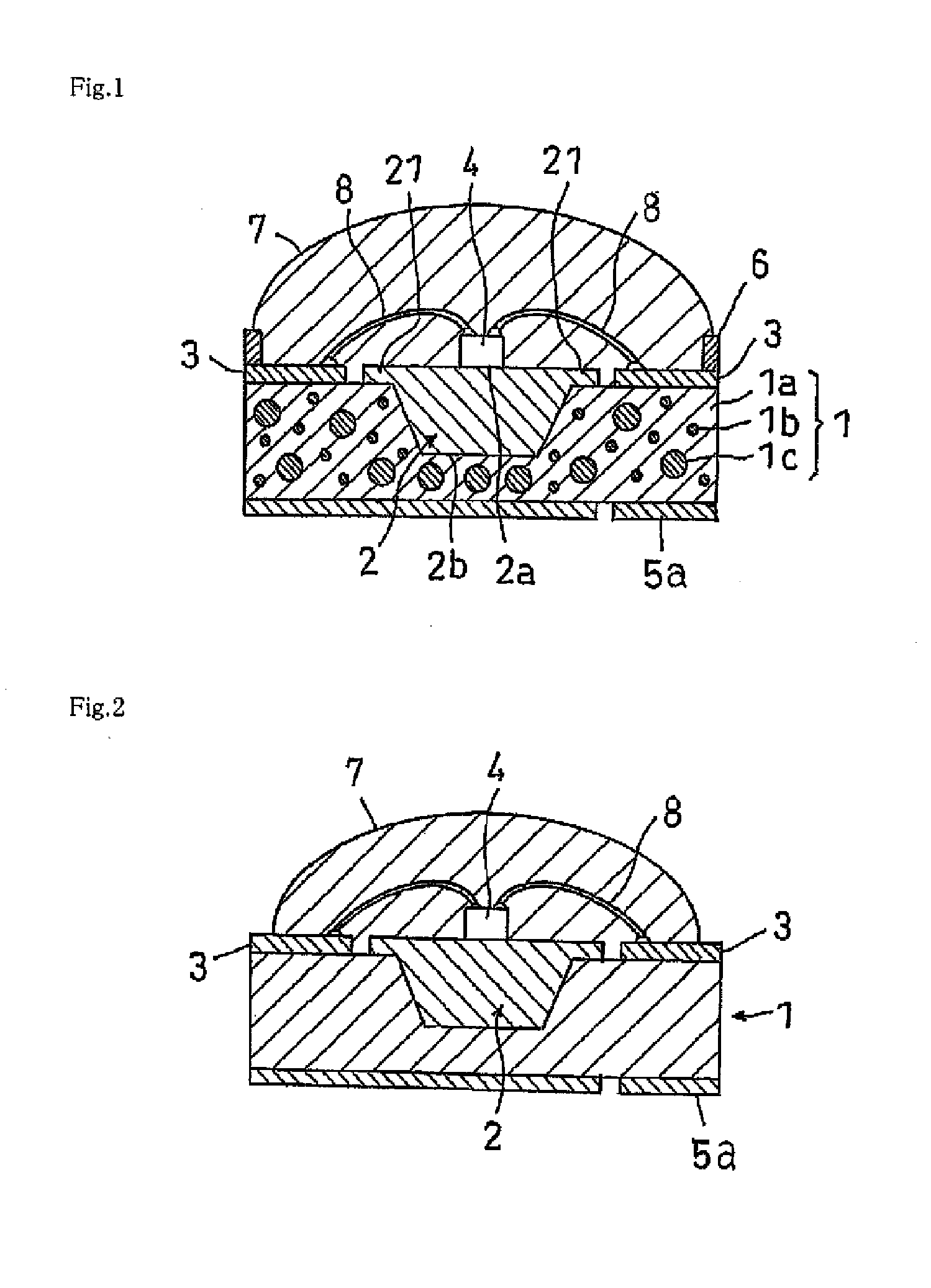

Method for manufacturing substrate for light emitting element package, and light emitting element package

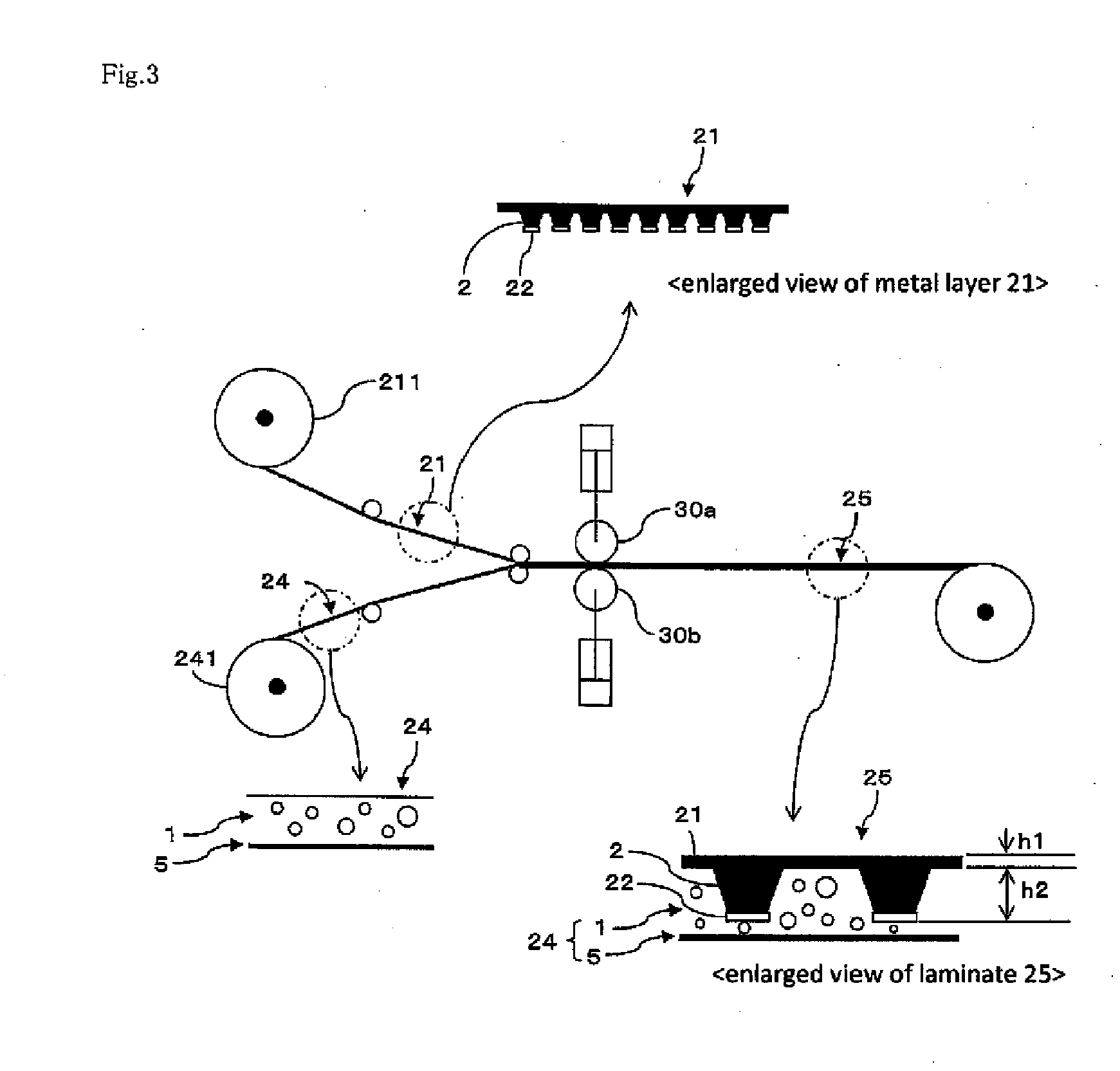

InactiveUS20110311831A1Improve thermal conductivityEasy to carryPrinted circuit aspectsSolid-state devicesOptoelectronicsMetal

A method for manufacturing a substrate for a light emitting element package provided with a thick metal section formed under a mounting position of a light emitting element, having a lamination step of laminating and integrating a laminate having an insulating adhesive agent which is composed of a resin containing heat conductive fillers and has a heat conductivity of 1.0 W / mK or more and a metal layer member, with a metal layer member having a thick metal section while drawing out each member.

Owner:DENKA CO LTD

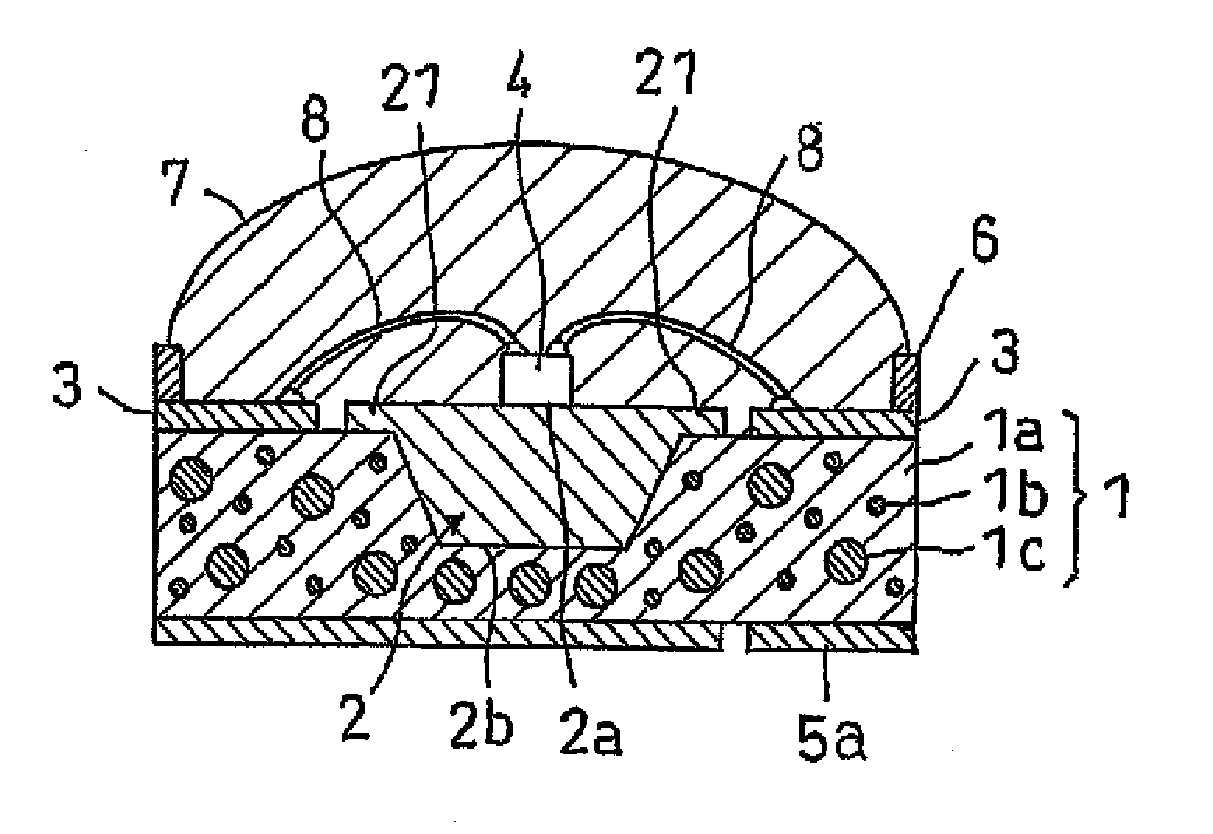

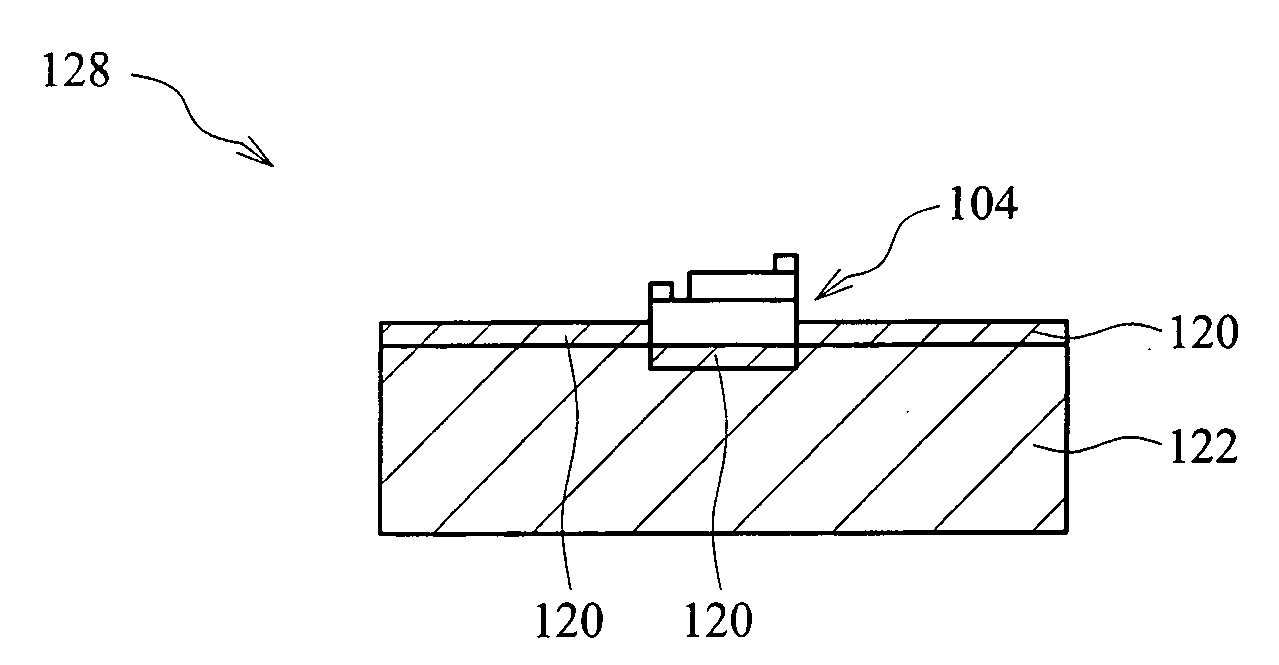

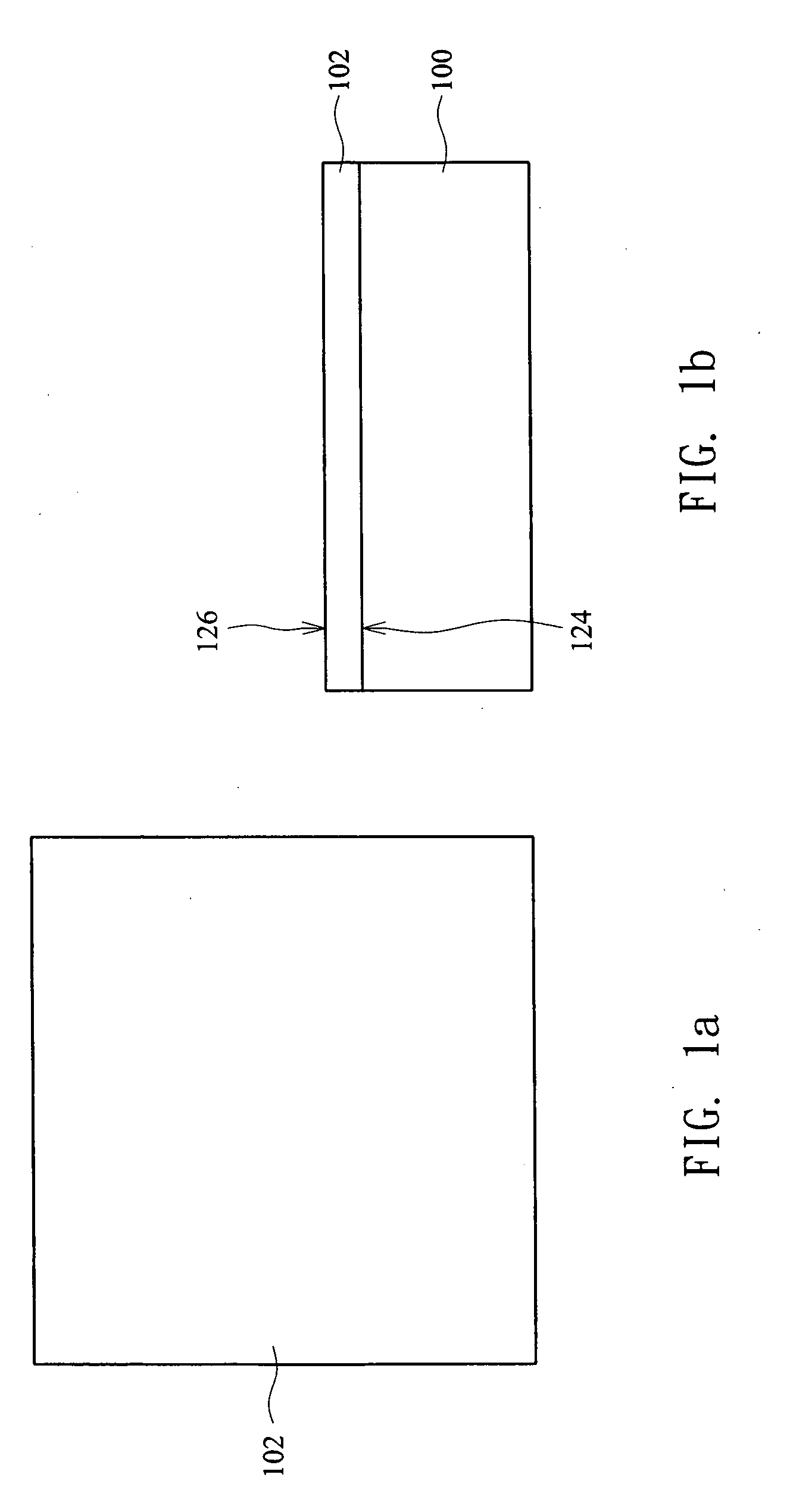

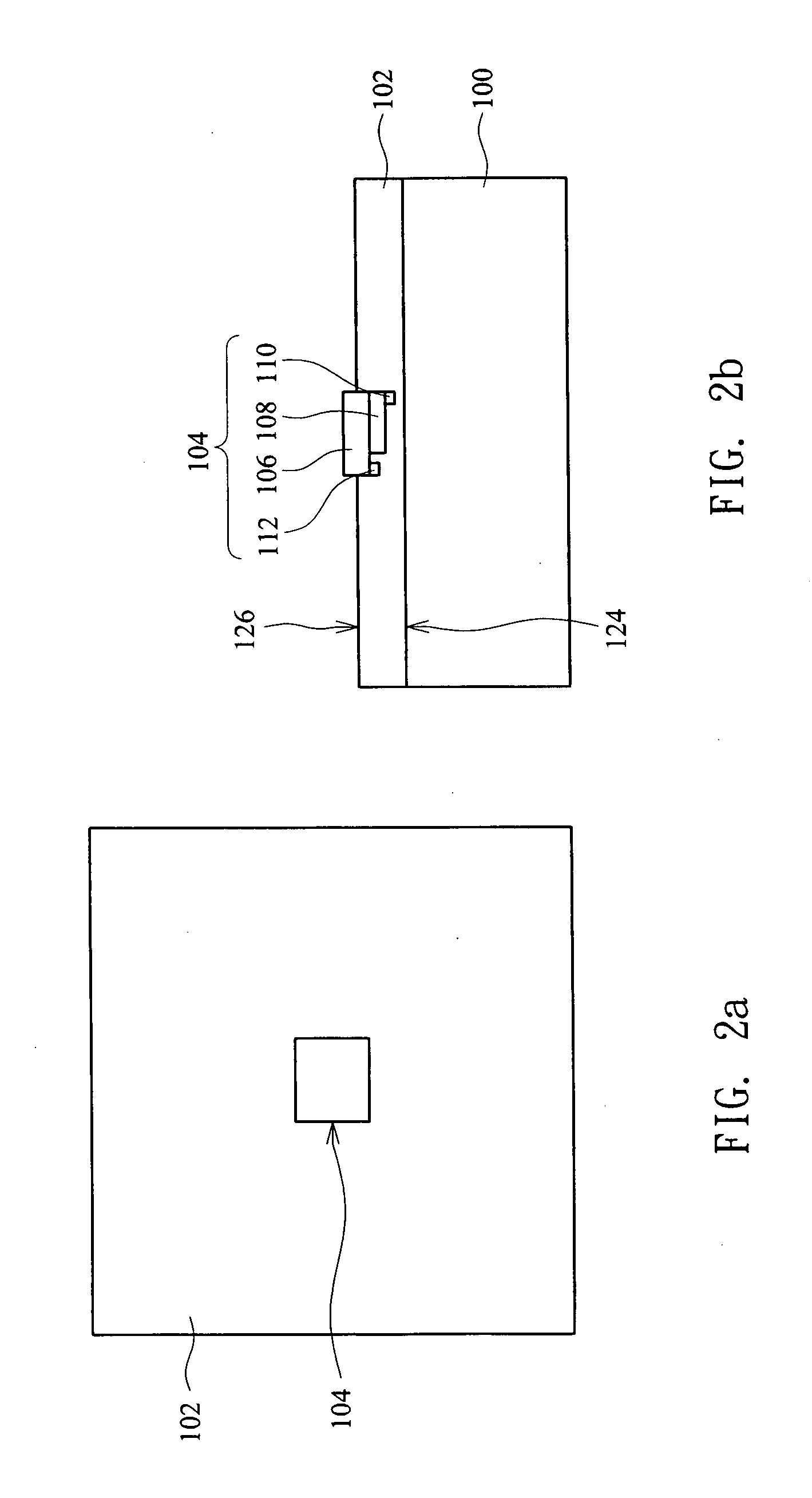

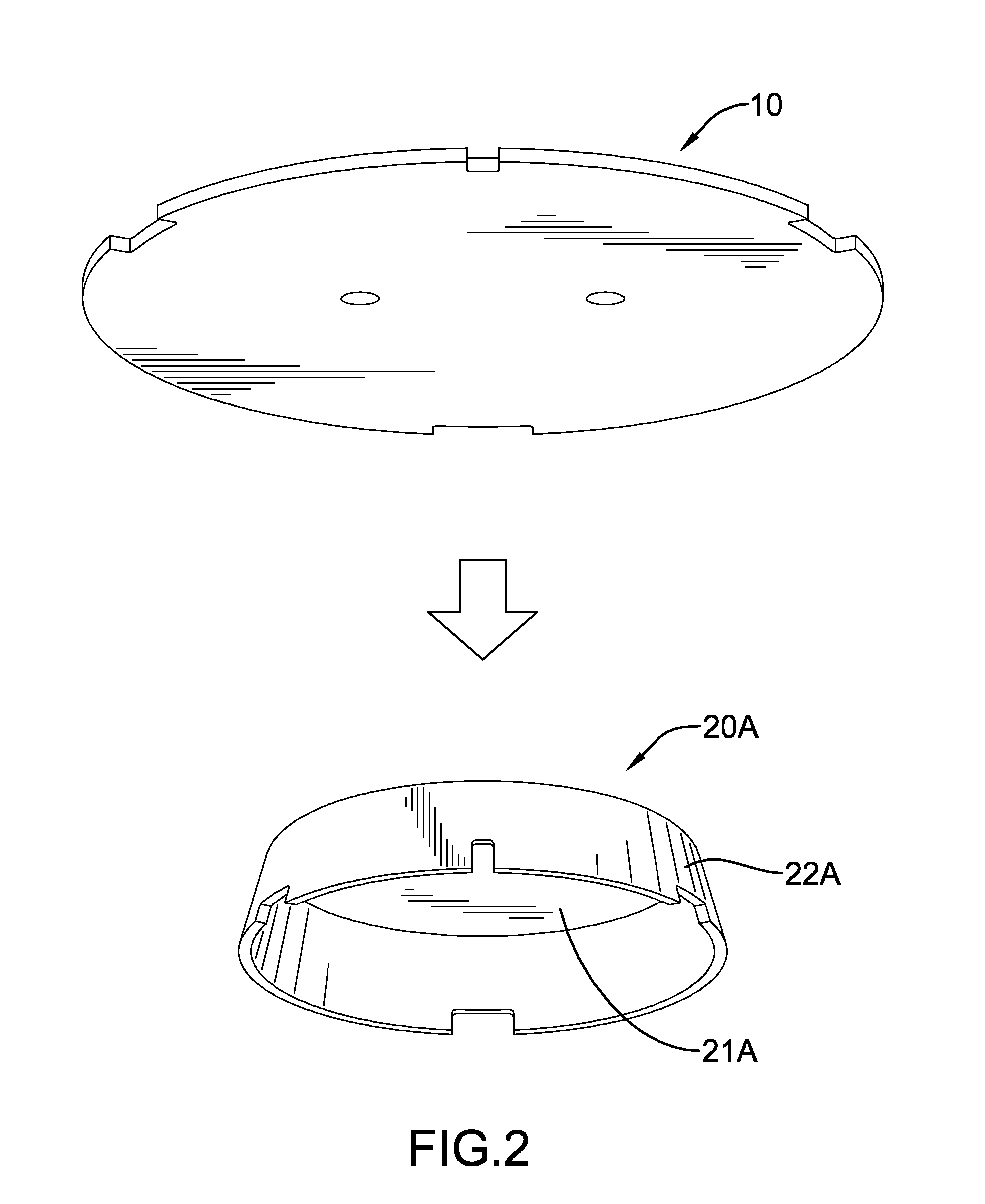

Light-emitting device and process for manufacturing the same

InactiveUS20070121327A1Improve efficiencyImprove cooling effectLighting heating/cooling arrangementsSemiconductor devicesThin metalHeat sink

A light-emitting device and a process for manufacturing the same are described. The light-emitting device comprises: a thin metal layer including a first surface and a second surface on opposite sides; a metal heat sink directly formed and closely connected to the second surface of the thin metal layer; and a light-emitting chip deposed on a portion of the first surface of the thin metal layer, wherein the thin metal layer directly contacts and is closely connected with the light-emitting chip.

Owner:NAT CHENG KUNG UNIV

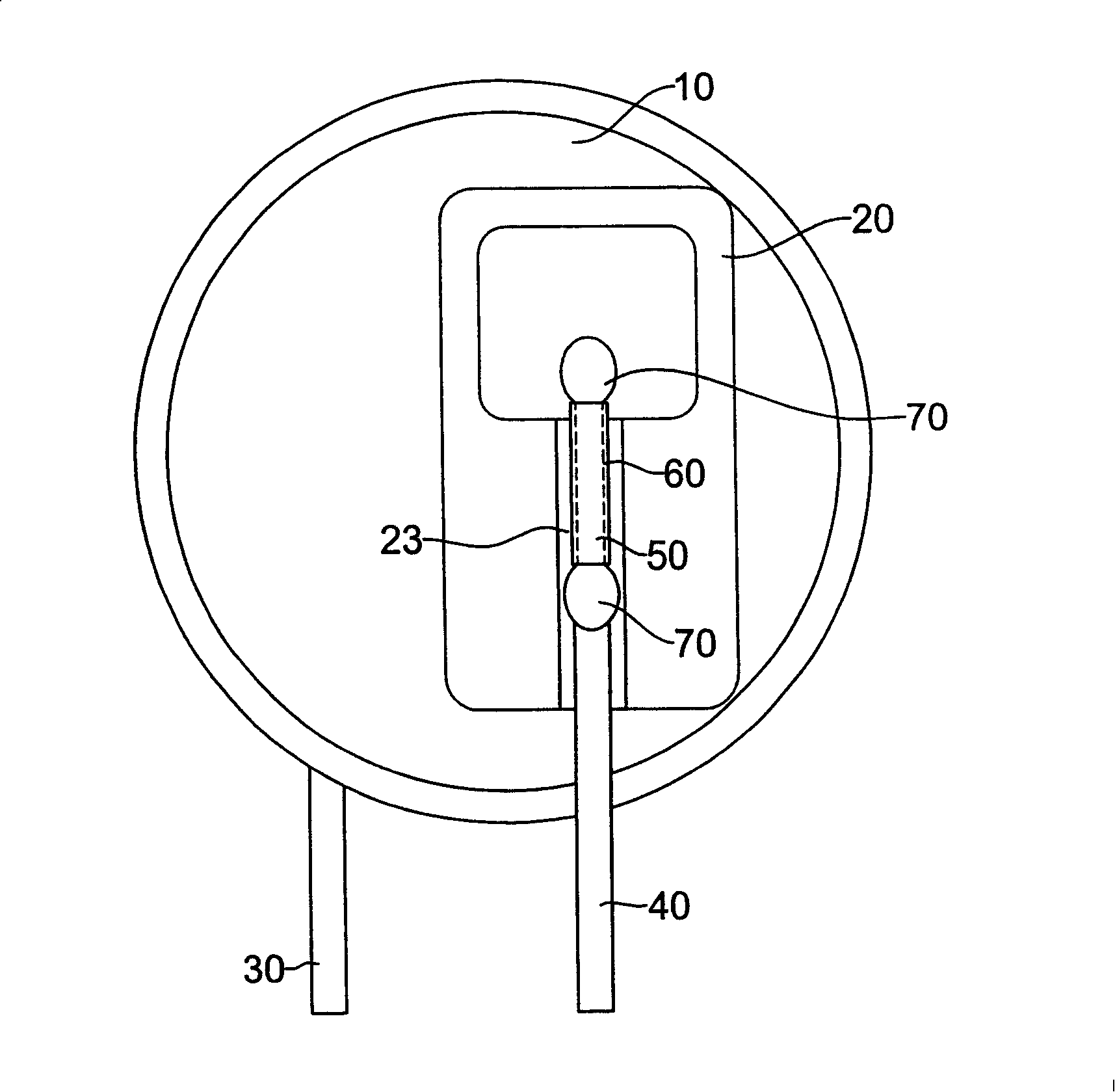

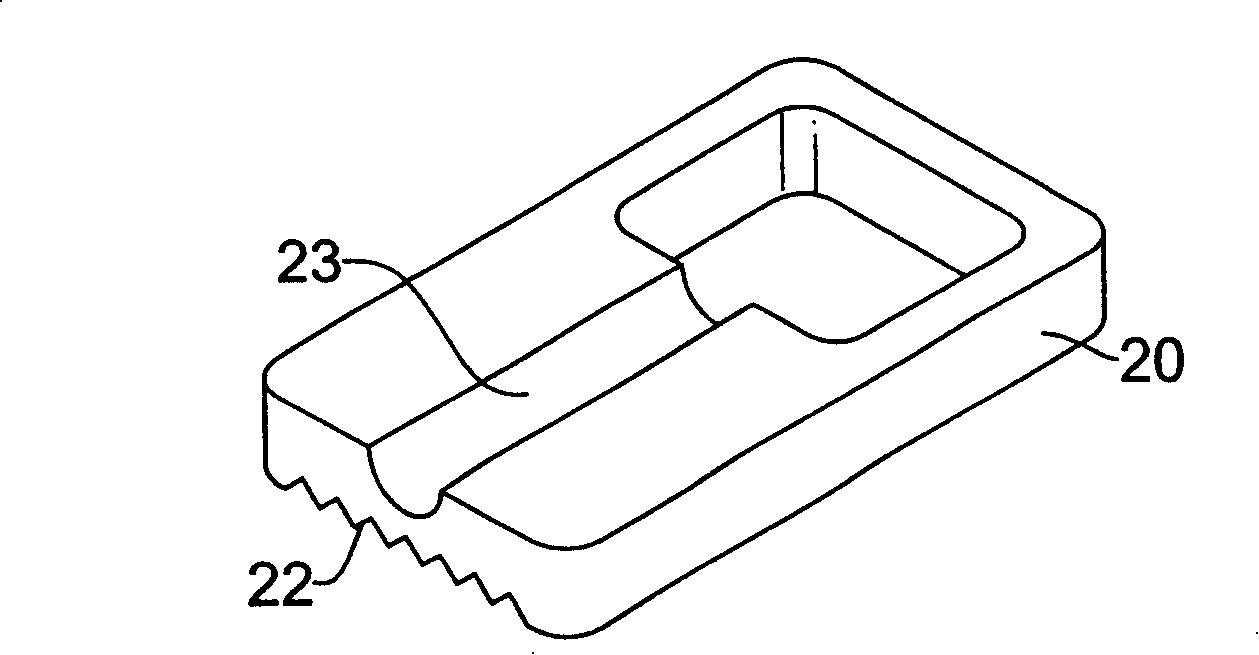

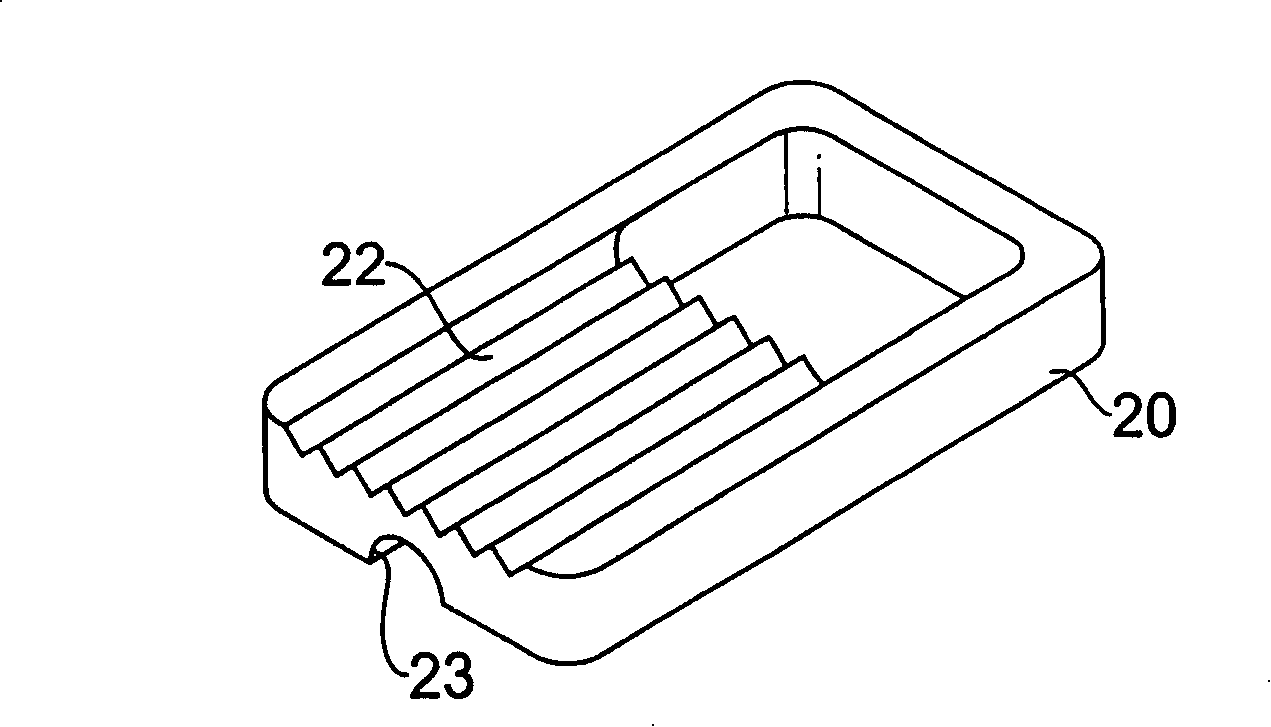

Voltage dependent resistor with hot protection function

InactiveCN101202137AIncrease heat conduction areaProtection from damageOvervoltage protection resistorsResistor detailsVaristorElectricity

The invention relates to a heat-protective varistor which has simple and compact structure, high reaction speed and wide application range and self failure protection function. An insulation bracket is arranged on a main body of the varistor component, and a heat fuse and a contact pin are mutually and electrically connected and are arranged on the insulation bracket. When the main body is affected by various excessive voltages to result in an abnormal temperature rising, the heat conduction area can be enlarged with the help of the insulation bracket so as to quickly transmit heat to the heat fuse and then the temperature of the heat fuse rises in virtue of the excessive heat; once the temperature is above a melting point the fuse forms a melted liquid state. A plurality of grooves are arranged on the insulation bracket, and the capillary force generated by the grooves can further promote the melted liquid fuse to diffuse quickly. And the quick melting-diffusion and separation of the heat fuse can reflect the excessive heat state in time to avoid the burning of the main body, so as to reach the aim of cutting the circuit in time to protect the electronic components of a current loop from being damaged.

Owner:THINKING ELECTRONIC IND CO LTD

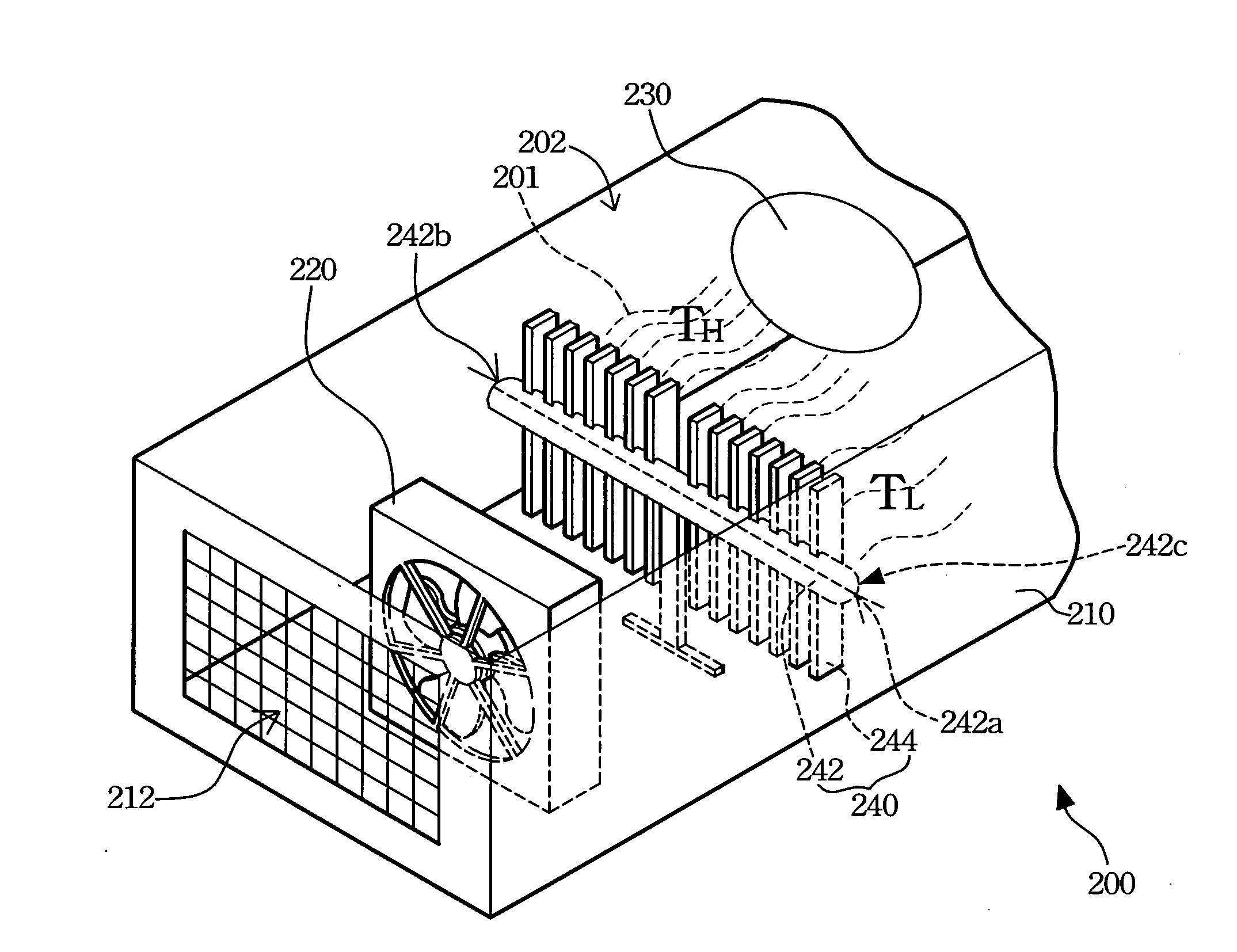

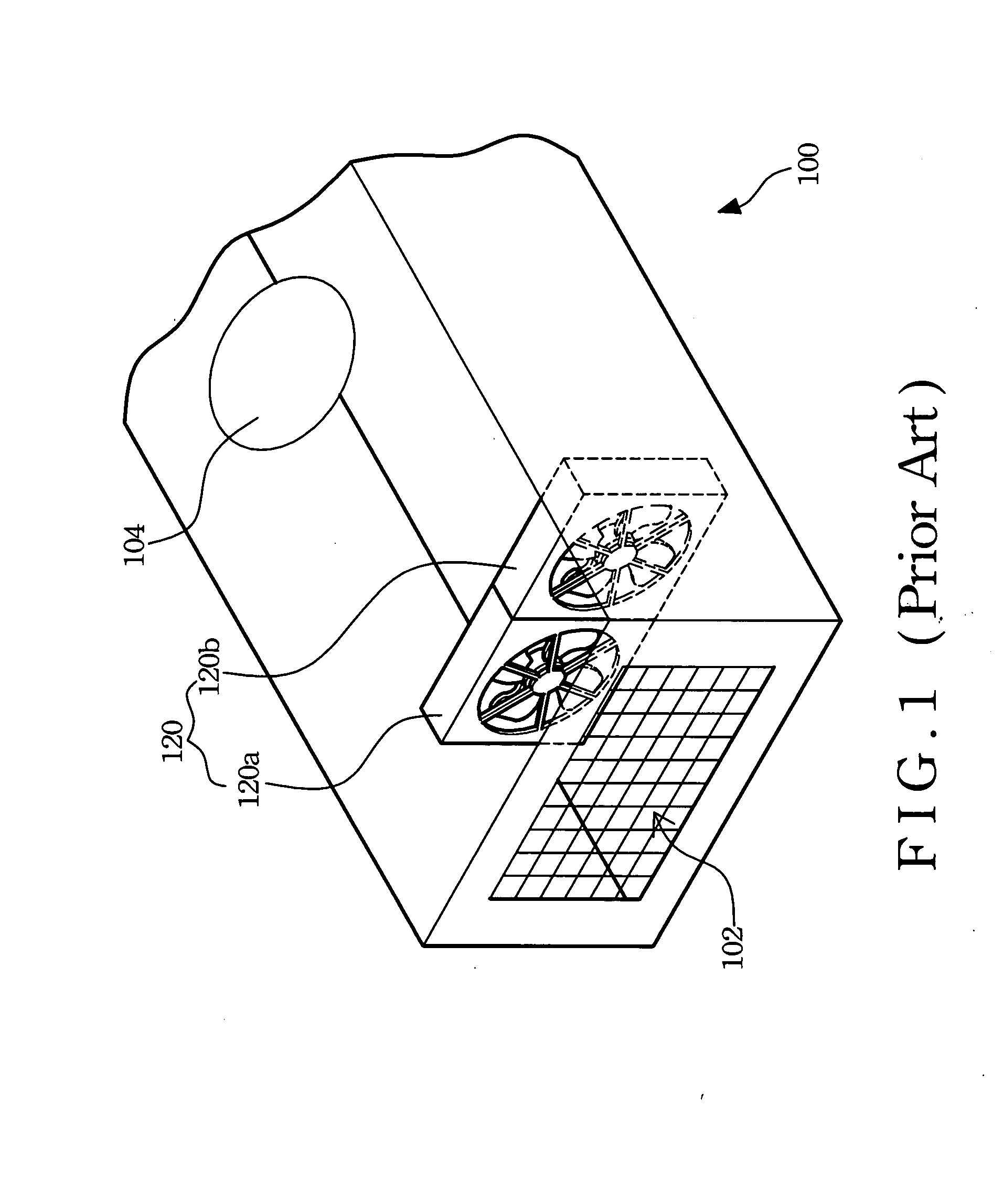

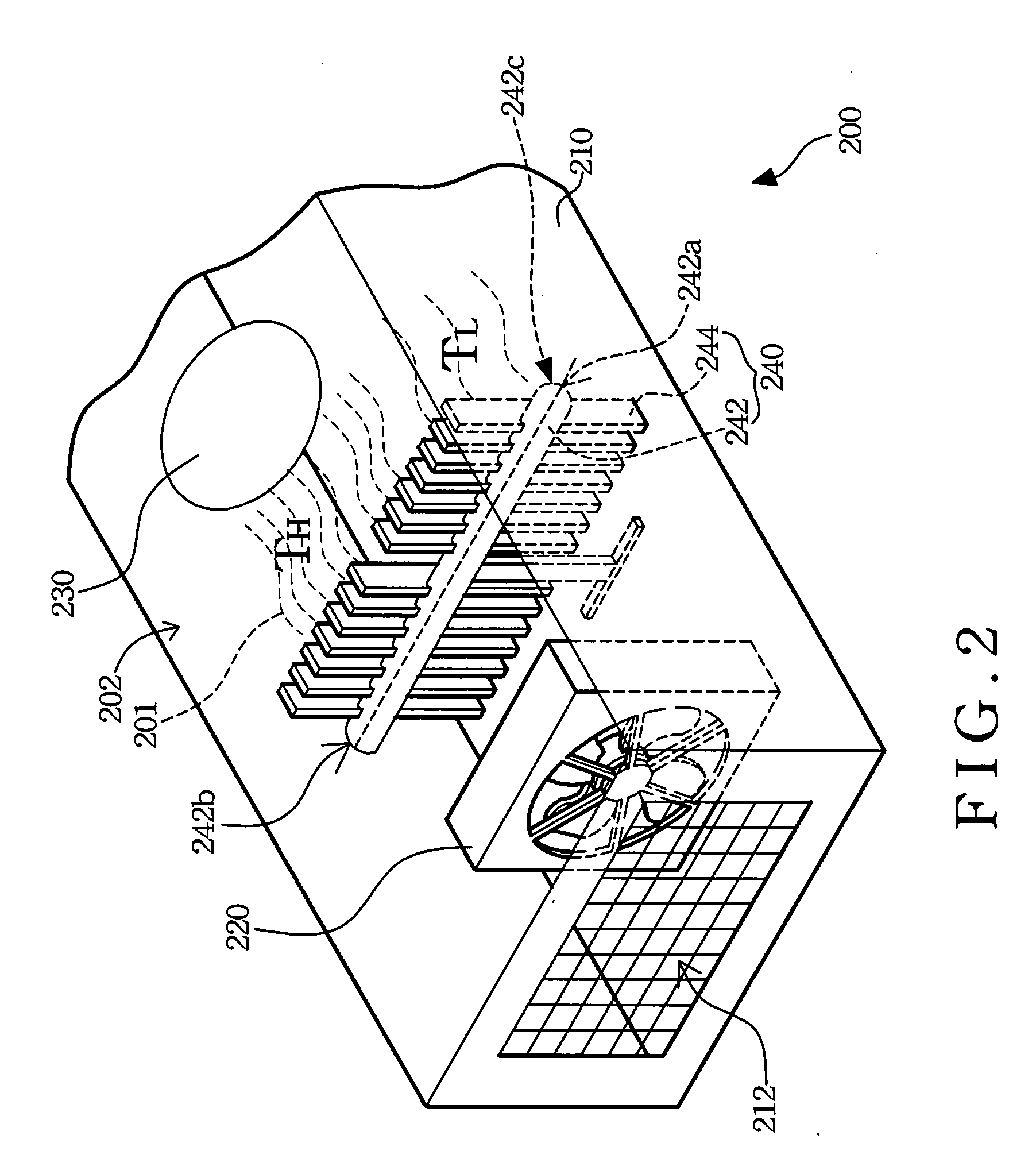

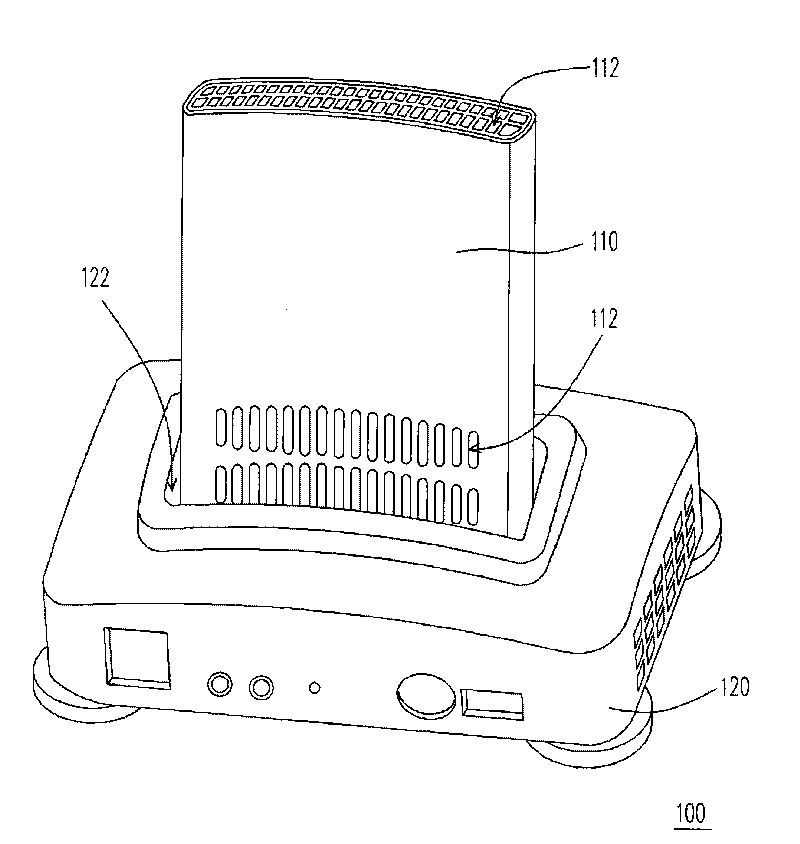

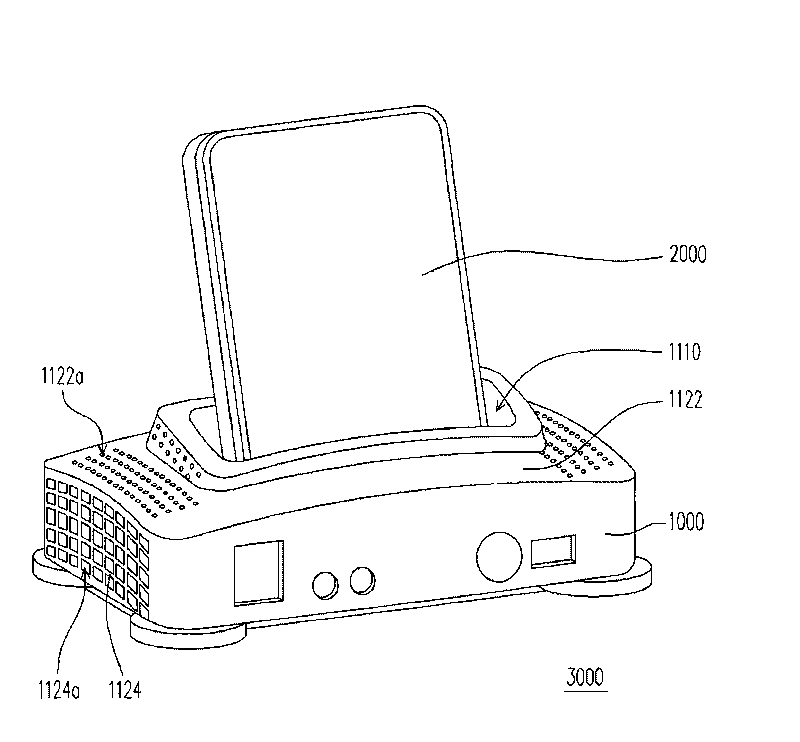

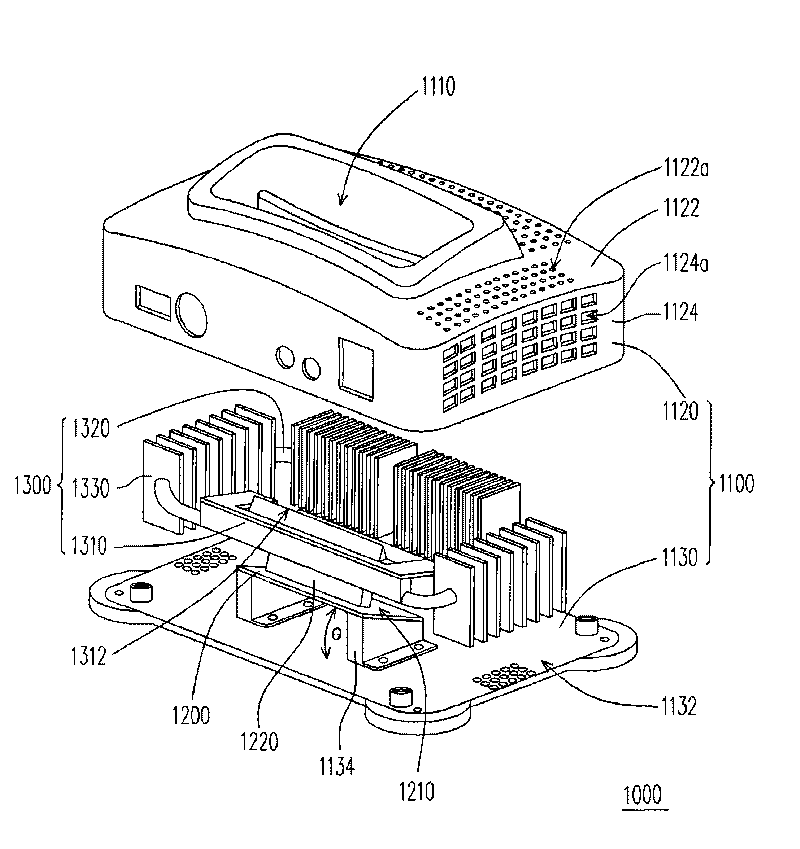

Heat dissipation device

ActiveUS20100067194A1Improve cooling efficiencyIncrease heat conduction areaDomestic stoves or rangesDigital data processing detailsEngineeringHeat sink

A heat dissipation device includes a vapor chamber, a heat dissipating fins assembly, a cover and a fan. The vapor chamber is configured to a bent shape. The heat dissipating fins assembly is adhered to a partial surface of the vapor chamber. The cover is connected to the vapor camber. A flow passage is defined between the vapor chamber and the cover. The heat dissipating fins assembly is positioned in the flow passage. The cover defines an opening communicating to the flow passage. The fan is arranged facing to the opening of the cover and other partial surface of the vapor chamber. Therefore, the heat dissipating efficiency can be greatly improved.

Owner:CELSIA TECH TAIWAN INC

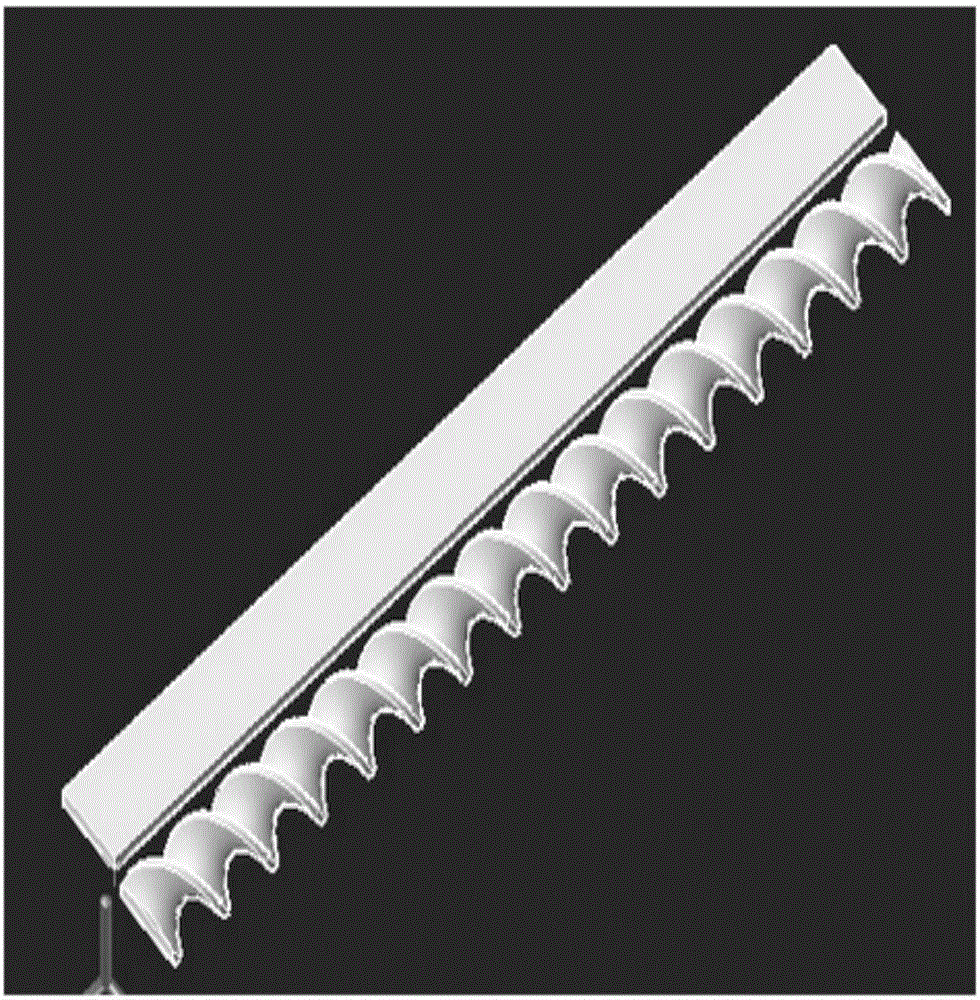

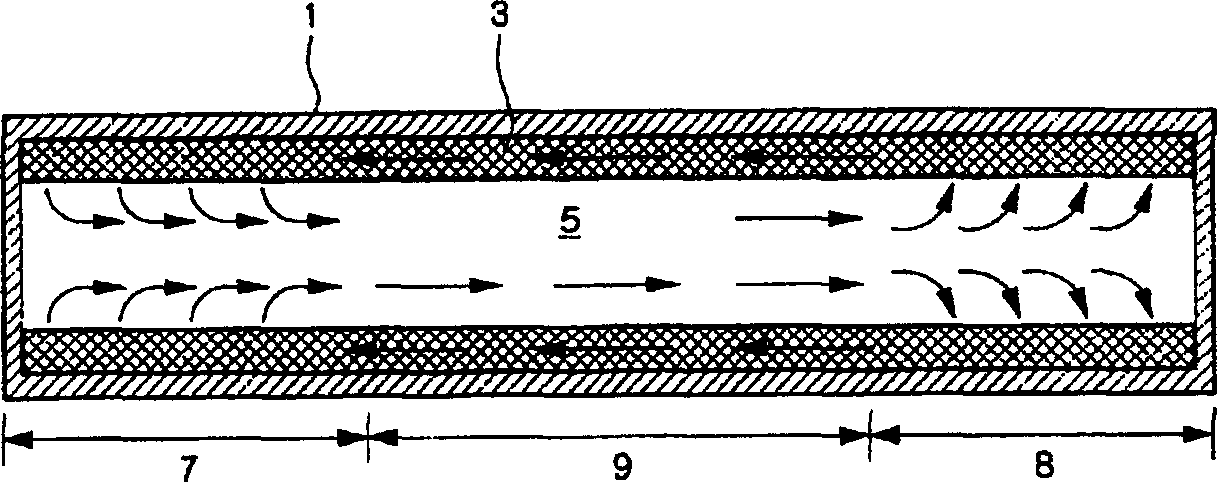

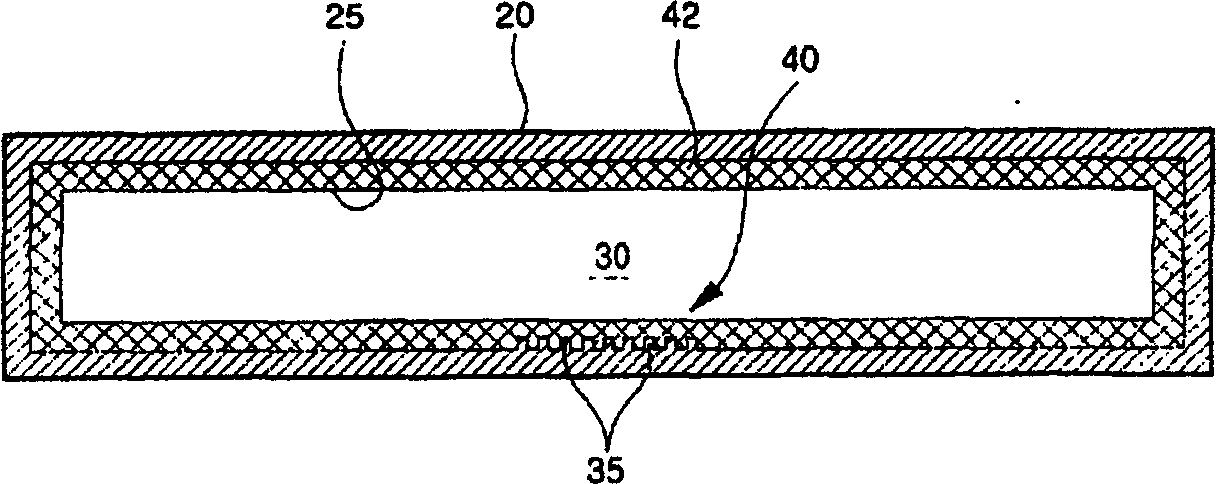

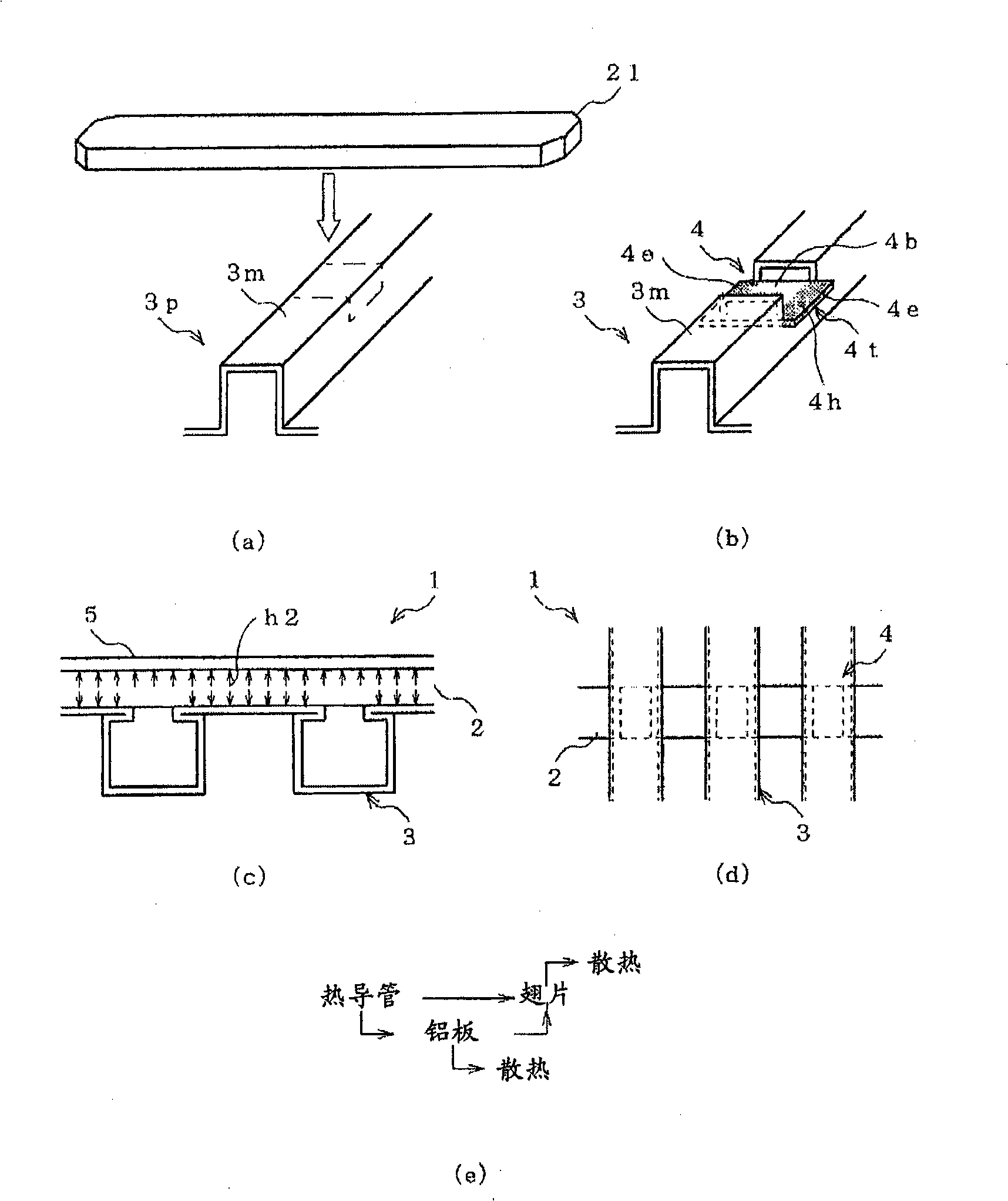

Heat pipe

InactiveCN1786647AIncrease heat conduction areaImprove thermal efficiencyIndirect heat exchangersEngineeringHeat pipe

The invention relates to heat pipe. It is set evaporating part and condensing part. It includes the following structure: circulation fluid storage space, box type shell, capillary structure in shell inner wall, passage supplied for gas state circulation fluid to flow, and heat exchange unsmooth in the evaporating part. It has the advantages that it can maximize exchange area to relatively increase heat exchange efficiency; it can prevent bubble to increase heat exchange efficiency when the phase of the heat tube is changed.

Owner:LEJIN ELECTRONICS KUNSHAN COMPUTER CO LTD

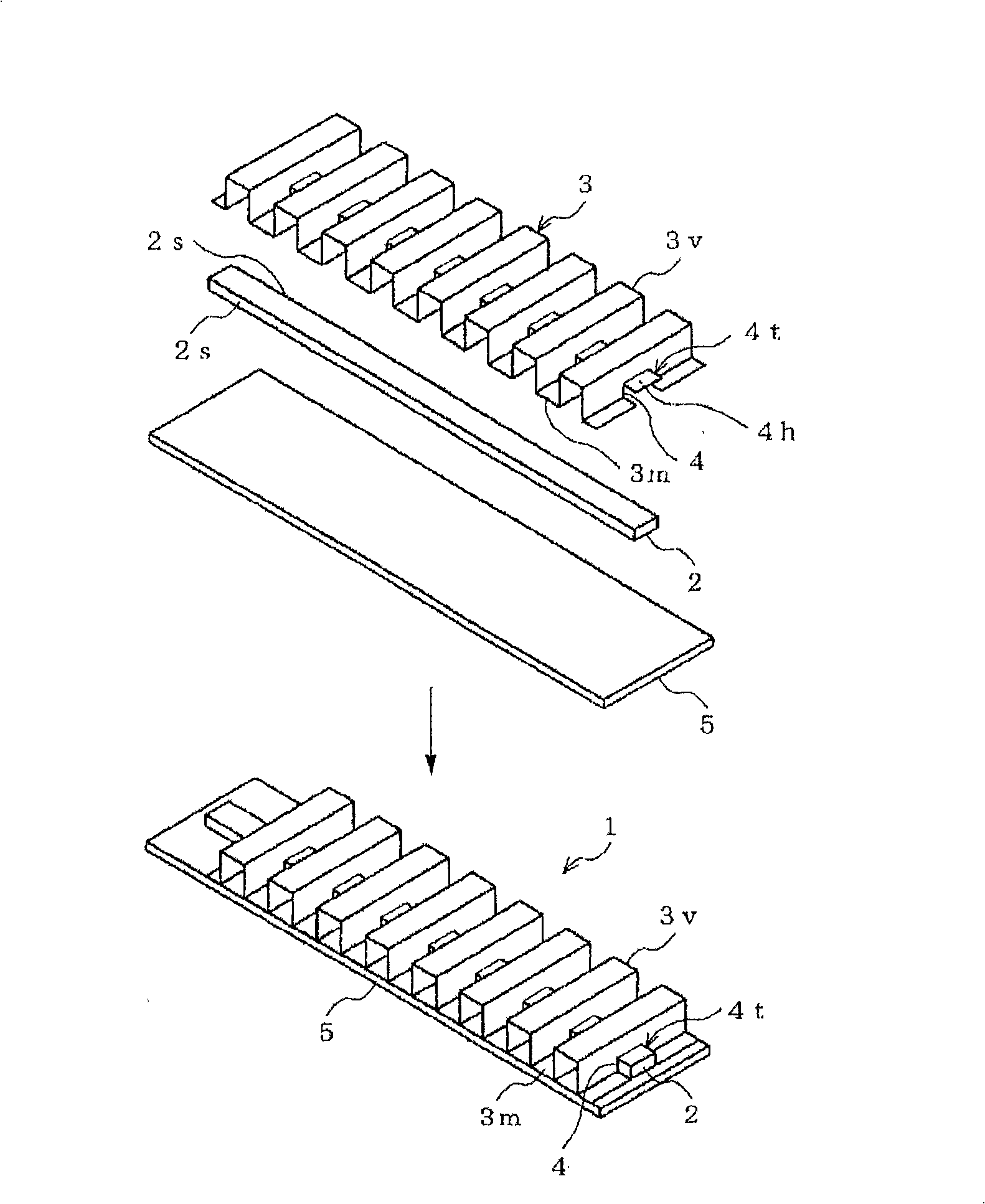

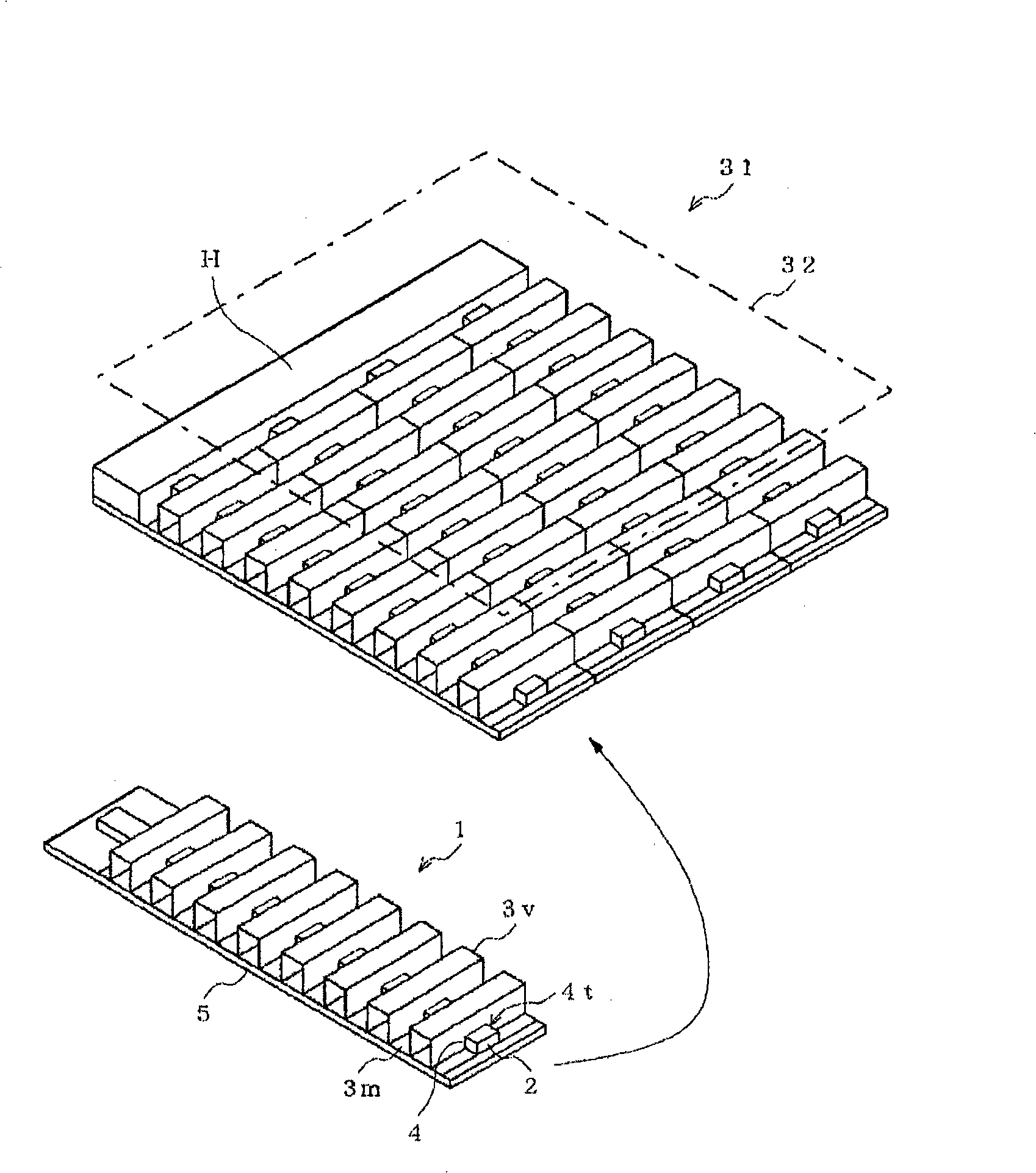

Heat sink and method of making same

InactiveCN101309577AEasy to manufactureLow costSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

Owner:HITACHI CABLE MEC TECH LTD

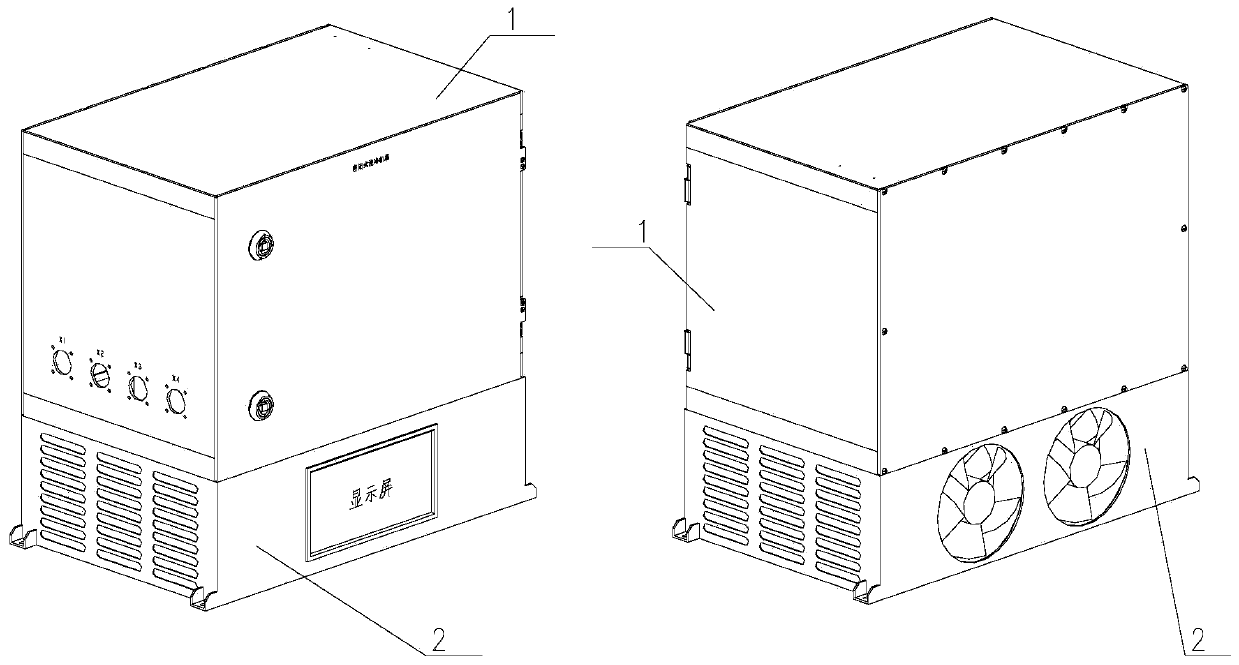

Selective catalytic reduction (SCR) urea heating/cooling system and method

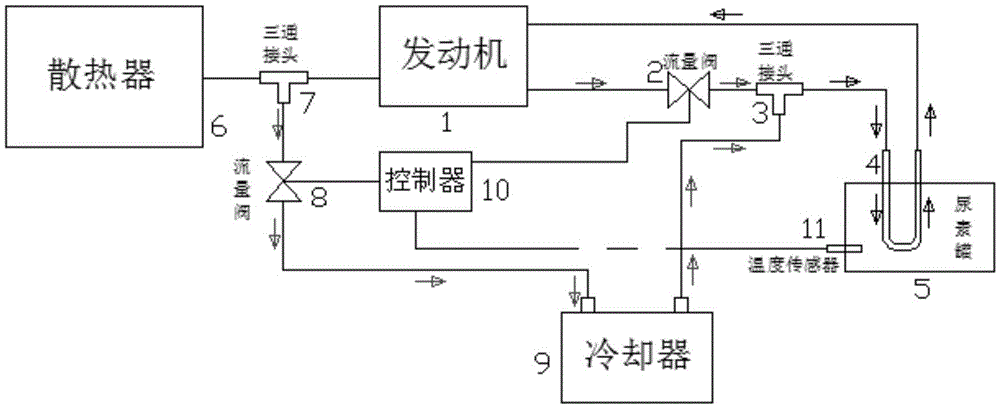

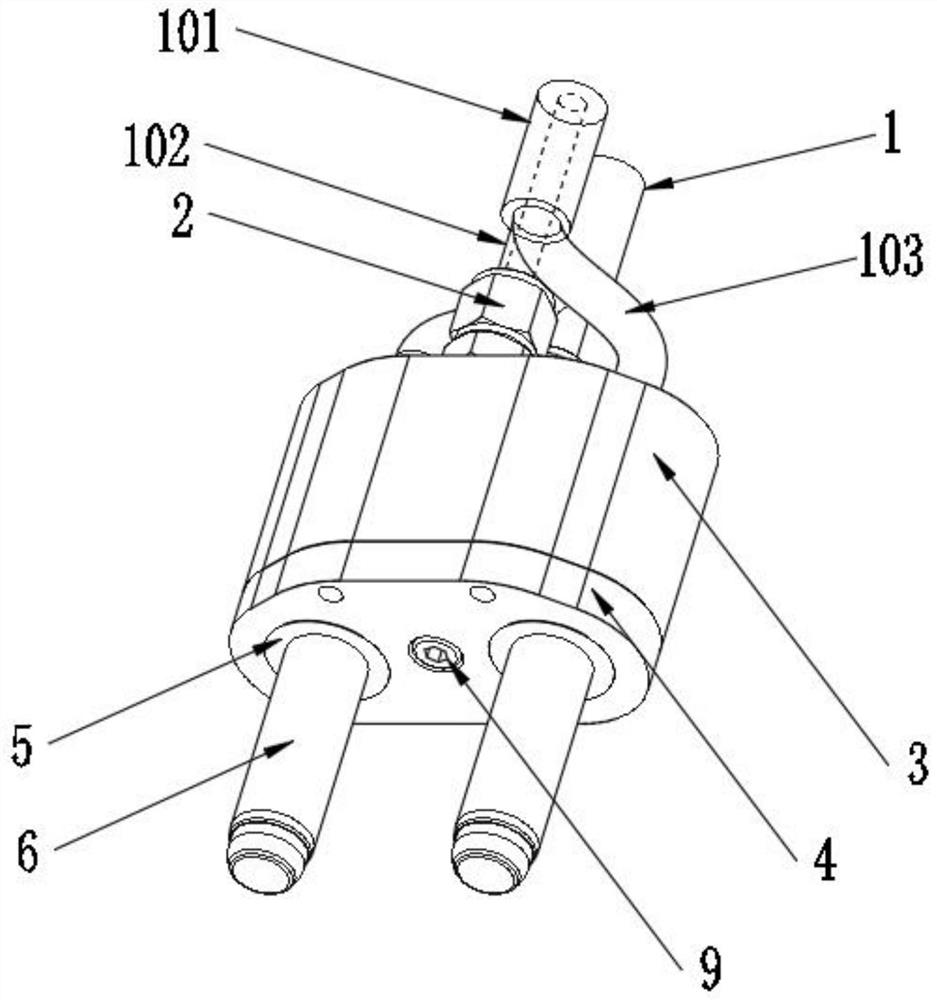

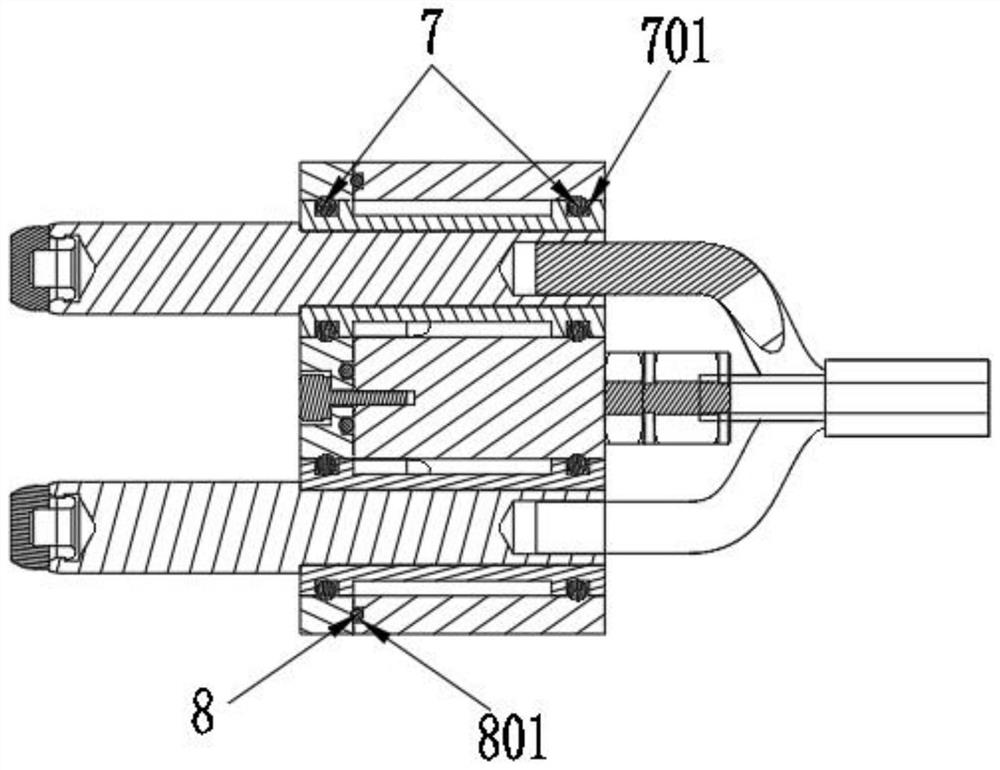

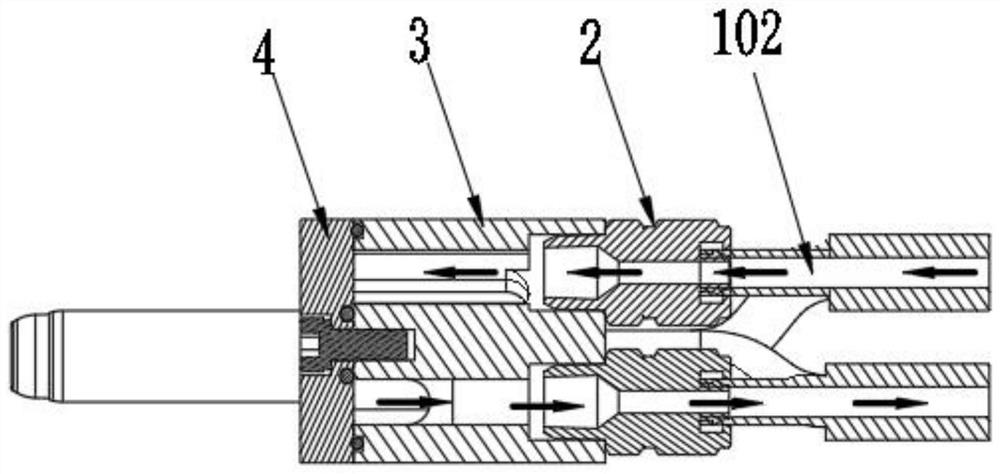

ActiveCN105626203AEnsure emissionsLow costInternal combustion piston enginesExhaust apparatusWater dischargeWarm water

The invention relates to the field of tail gas treatment of engineering machinery, in particular to a selective catalytic reduction (SCR) urea heating / cooling system and method. The system comprises an engine and a radiator and further comprises a heating and cooling pipe disposed in a urea tank. The heating and cooling pipe is provided with a first water inlet port and a first water outlet port. The engine is provided with a second water inlet port and a second water outlet port. The radiator is provided with a third water inlet port and a third water outlet port. In addition, the second water outlet port is connected with the third water inlet port in a communicating mode, and the third water outlet port is connected with the second water inlet port in a communicating mode, so that heat dissipation is performed on the engine. The first water inlet port is connected with the second water outlet port and the third water inlet port in a communicating mode, and the first water outlet port is connected with the second water inlet port, so that urea is heated through hot water discharged from the engine and the urea is cooled through warm water discharged from the radiator. By means of the scheme, control can be performed according to the real-time temperature of the urea, so that the urea works at the appropriate temperature all the time, and the emission performance of a machine is guaranteed.

Owner:SANY HEAVY MACHINERY

Non-contact liquid cooling system for high-power charging and liquid cooling method thereof

PendingCN112566472AImprove thermal conductivityReal-time heat exchangeModifications by conduction heat transferElectric vehicle charging technologyThermodynamicsElectrical conductor

The invention discloses a non-contact liquid cooling system for high-power charging and a liquid cooling method of the non-contact liquid cooling system, the non-contact liquid cooling system comprises a liquid cooling cable, a cable built-in pipeline is arranged in the center of the liquid cooling cable, a quick connector is arranged at the rear end of the cable built-in pipeline, and the cable built-in pipeline is coated with a cable conductor. A cable outer insulating layer is arranged on the outer side of the cable conductor, a power terminal is connected to the rear end of the cable conductor in a pressing mode, the quick connector is fixedly installed on a liquid cooling cavity, and an insulating heat conduction piece is arranged in the liquid cooling cavity. According to the non-contact liquid cooling system for high-power charging and the liquid cooling method of the non-contact liquid cooling system, heat generated on the power terminals during charging is transmitted to and exchanged to the cooling liquid through the insulating heat conduction piece, the rapid circulating cooling liquid transmits heat, the cooling is rapid, a non-contact mode is adopted, the cooling liquid is safer, the short-circuit risk is eliminated, and through the I-shaped design of the insulating heat conduction piece, the heat dissipation is more comprehensive and effective.

Owner:WEIHAI HONGLIN ELECTRIC POWER TECH CO LTD

Projector with an equalizing temperature module

A projector comprises a case, an illuminant heat source, a thermal module, and an equalizing temperature module. The equalizing temperature module is disposed between the illuminant heat source and the thermal module. When the fluid flows from the illuminant heat source to the equalizing temperature module, the fluid flows through a relative high temperature region more than that of flowing through a relative low temperature region. The equalizing temperature module at least comprises a heat pipe and a plurality of heat sinks. The heat pipe has a first end located in the relative low temperature region and a second end located in the relative high temperature region. The heat pipe transfers heat from the relative high temperature region to the relative low temperature region by a cold fluid in the heat pipe. The plurality of heat sinks are disposed on the heat pipe to increase the area of heat conduction. The projector can uniform the fluid temperature by means of the equalizing temperature module so as to increase life time and reliability of the thermal module.

Owner:BENQ CORP

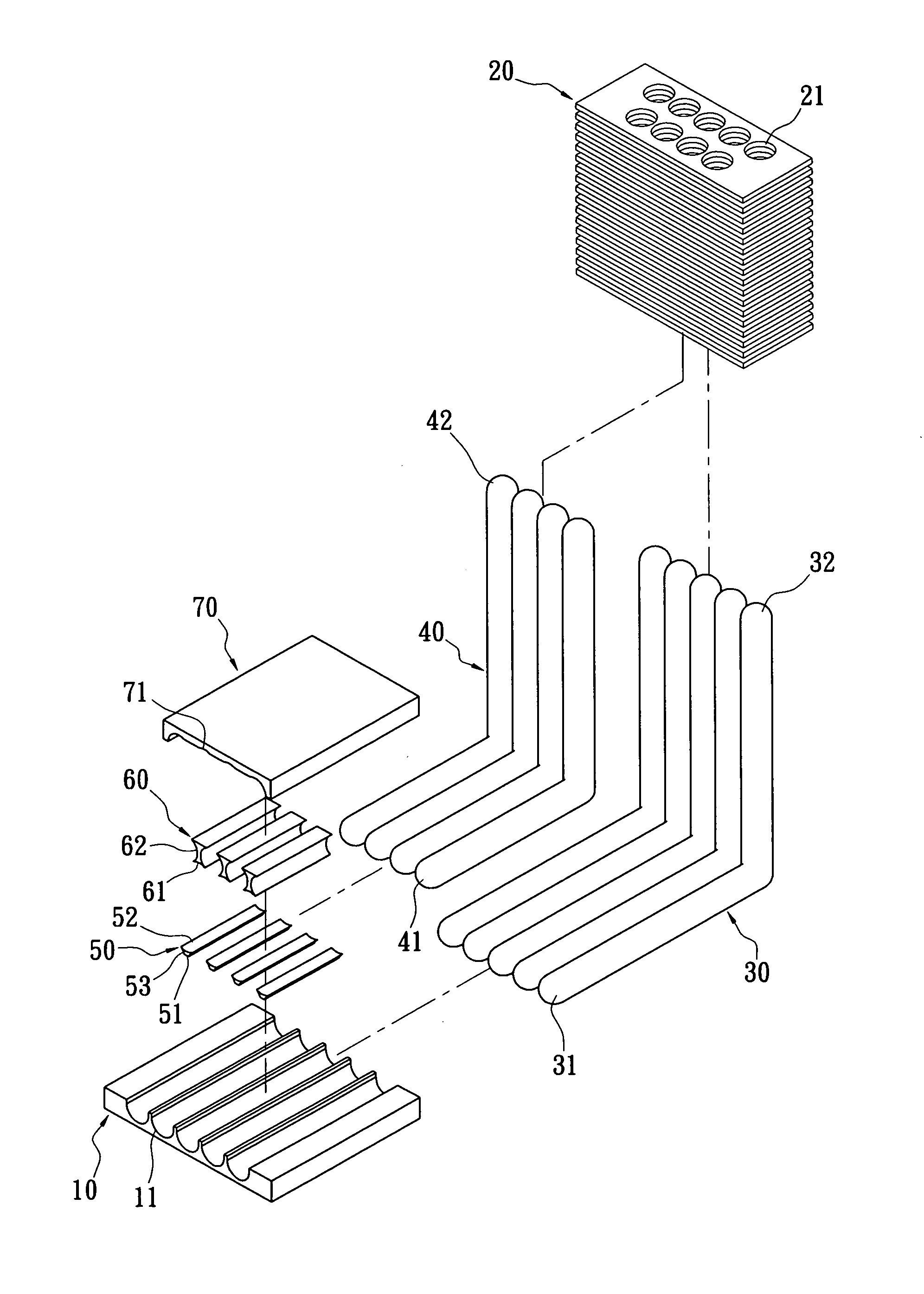

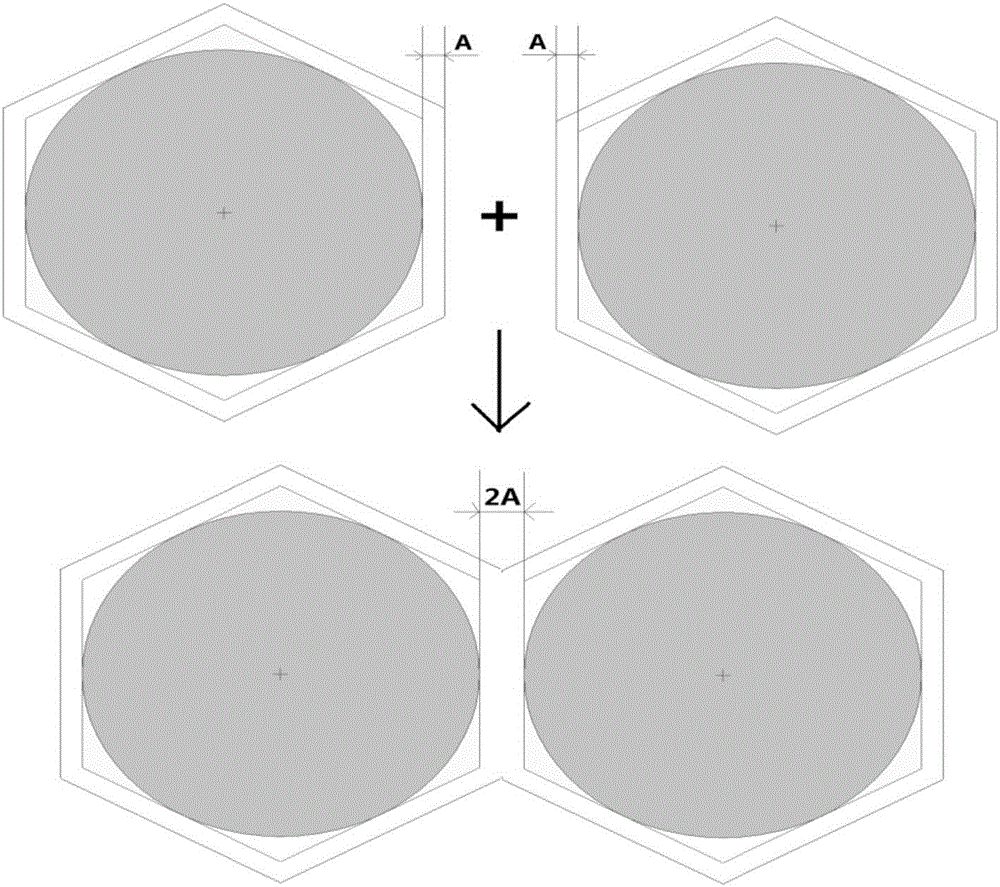

Cooling apparatus

InactiveUS20090151899A1Improve cooling efficiencyIncrease heat conduction areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

A cooling apparatus includes a base, a plurality of first heat pipes, a plurality of second heat pipes, a plurality of first heat conducting columns and a plurality of second heat conducting columns. Each of the first heat pipes and the second heat pipes respectively has a heat-absorbing terminal. The heat-absorbing terminals of the first heat pipes are disposed on the base spaced at intervals. The heat-absorbing terminals of the second heat pipes are stacked above the heat-absorbing terminals of the first heat pipes spaced at intervals. Each of the first heat conducting columns is installed between the heat-absorbing terminals of the two adjacent first heat pipes. Each of the second heat conducting columns is installed between the heat-absorbing terminals of the two adjacent second heat pipes. Thereby, the heat conducting area is increased within the base, and the cooling efficiency of the cooling apparatus is enhanced.

Owner:COOLER MASTER CO LTD

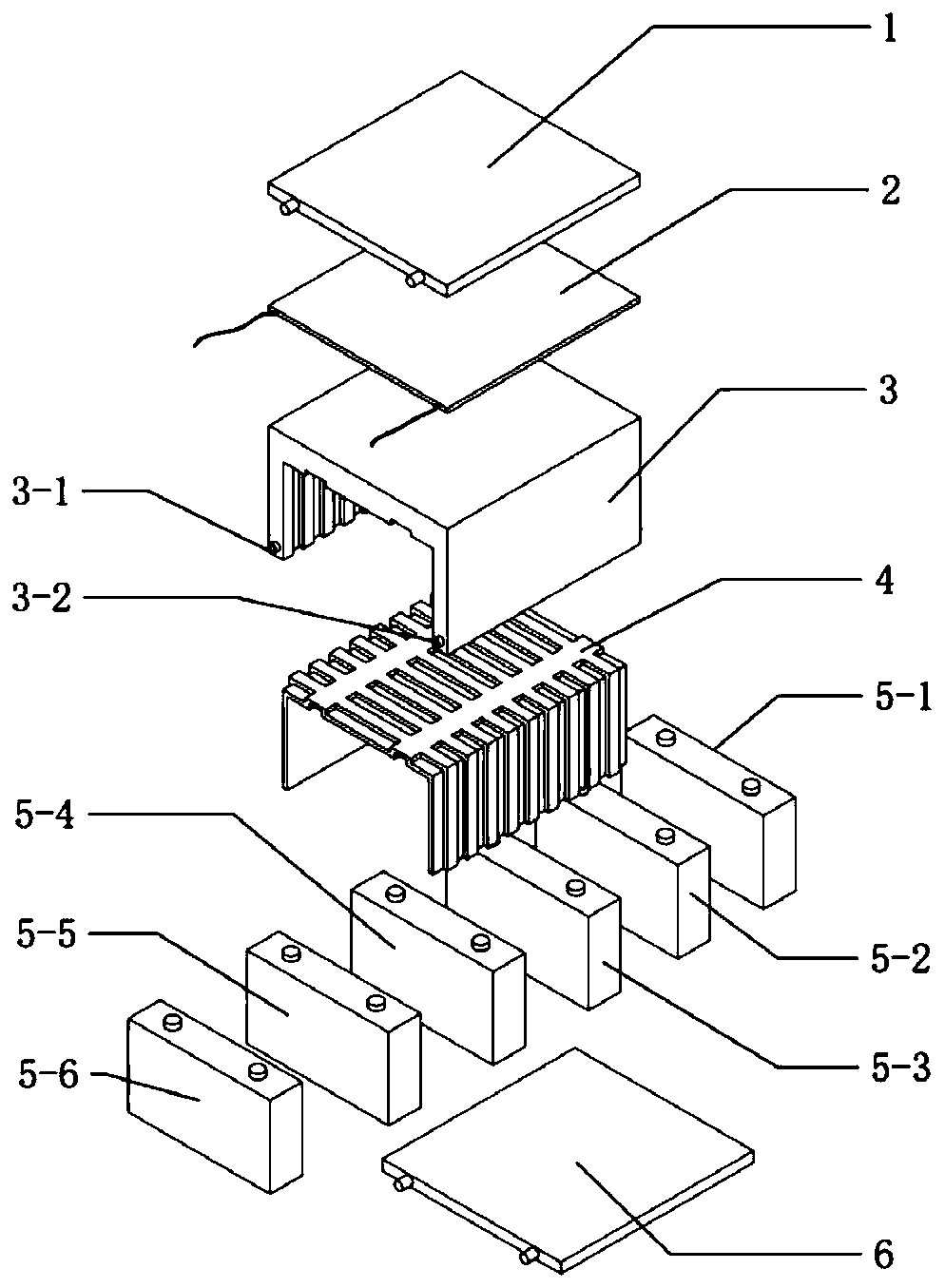

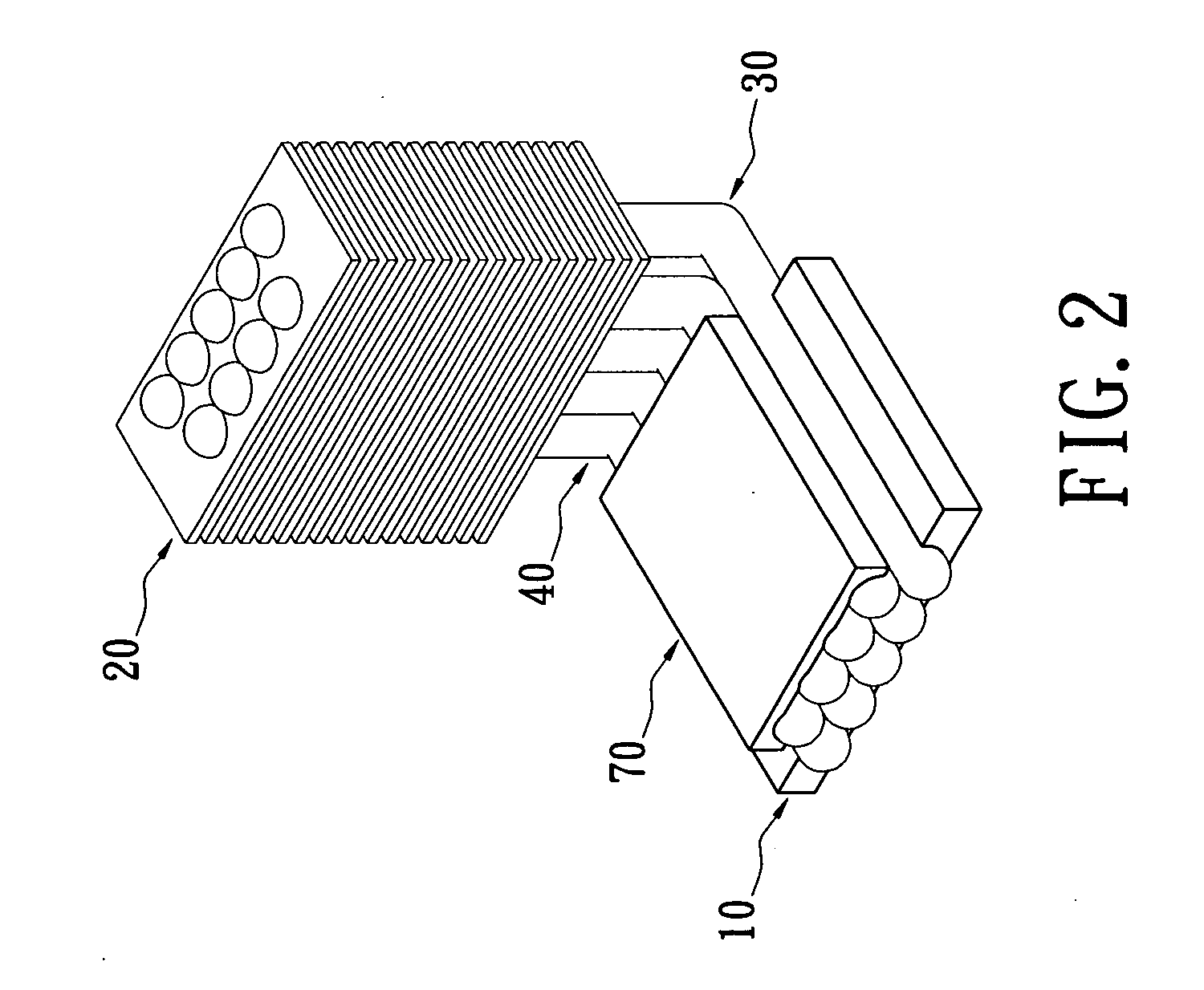

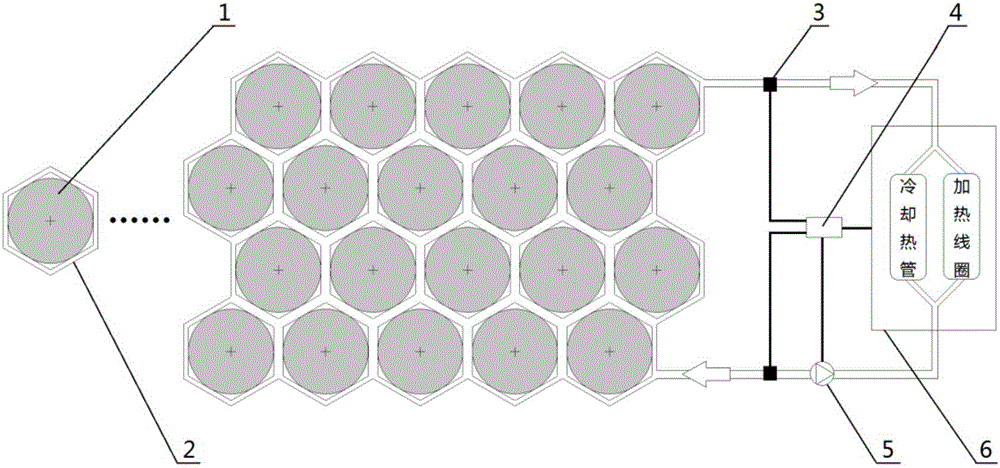

Thermal management system for batteries

PendingCN106374163ANot easy to squeeze and deformGuaranteed uptimeSecondary cellsElectrical batteryHeat conducting

The invention provides a thermal management system for batteries. A battery module comprises a plurality of batteries and a hexagonal honeycomb heat-conducting material hollow structure, wherein the batteries are internally tangentially embedded into the hexagonal honeycomb heat-conducting material hollow structure; channels are arranged between adjacent hexagons of the hexagonal honeycomb heat-conducting material hollow structure; the channels form a passage; the passage is filled with a heat exchange medium; the passage is connected with a heating and cooling device; the passage is provided with a thermocouple; the heating and cooling device and the thermocouple are connected with a controller separately; and the controller controls the heating and cooling device to heat or cool the battery module according to the temperature fed back by the thermocouple. According to the thermal management system for the batteries, the batteries have relatively good safety, and the operation stability of the batteries is improved.

Owner:GREE ELECTRIC APPLIANCES INC

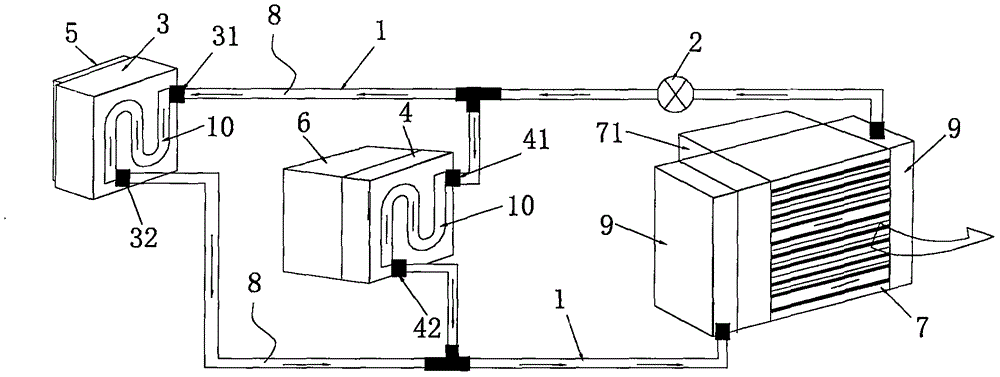

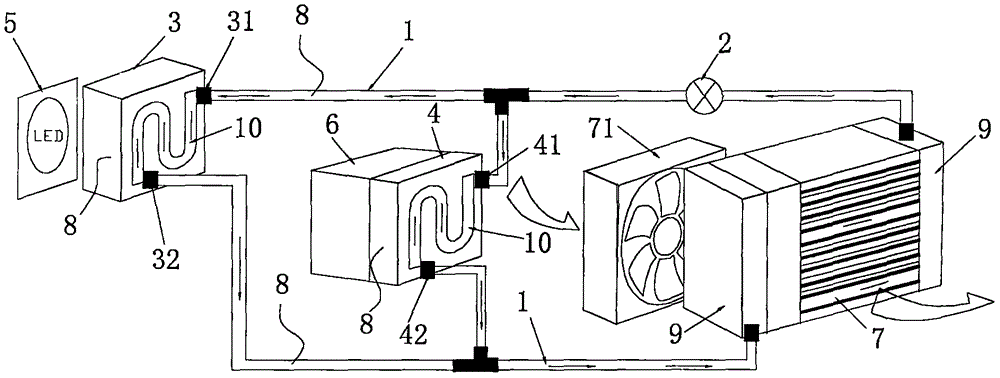

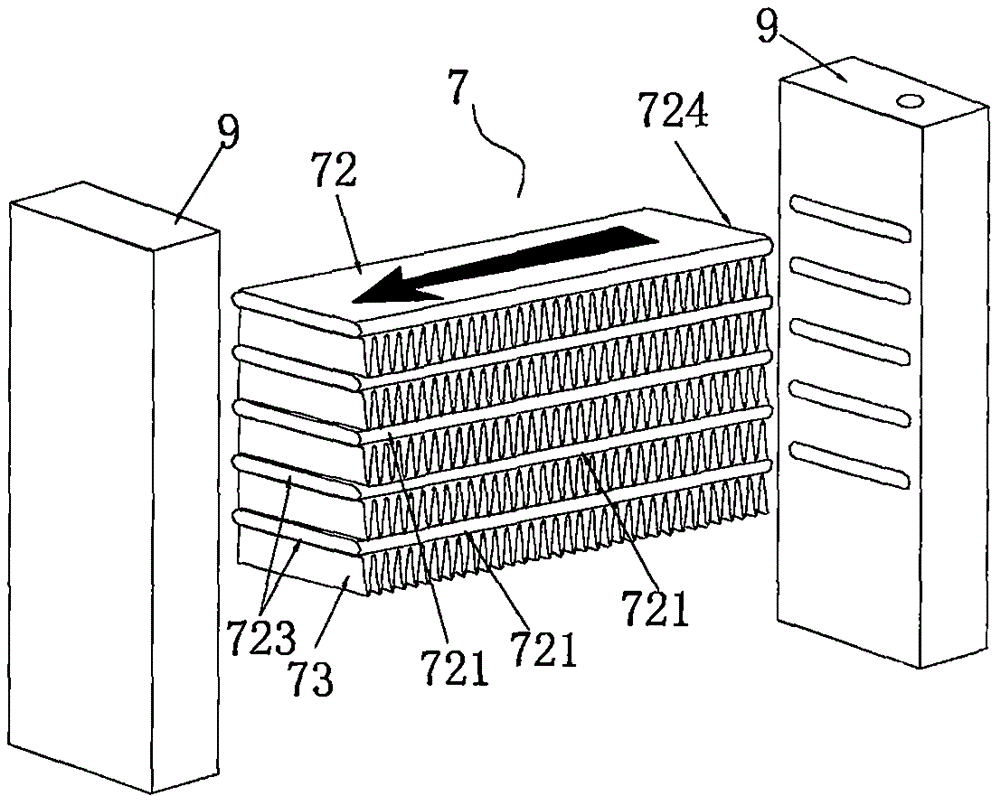

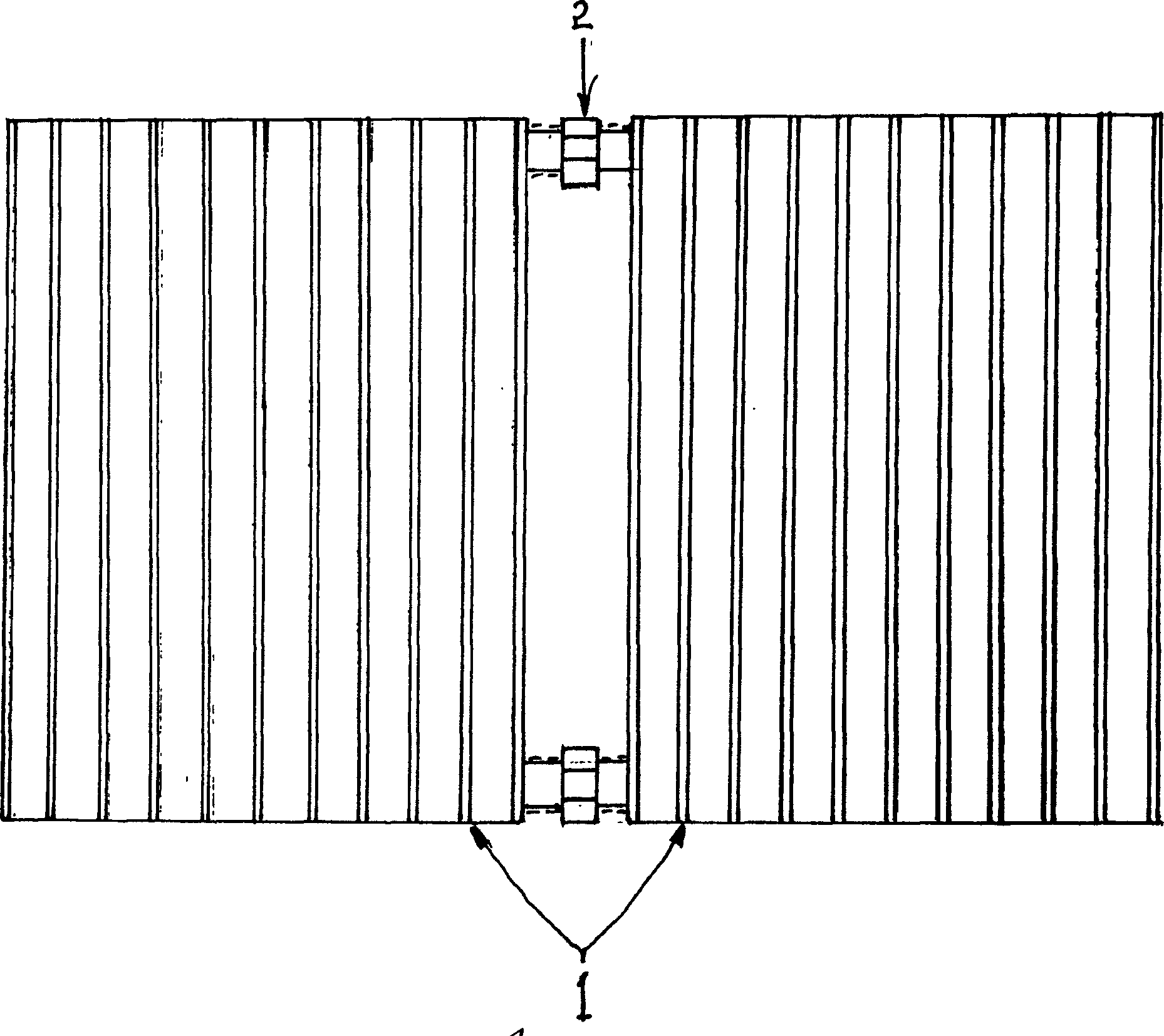

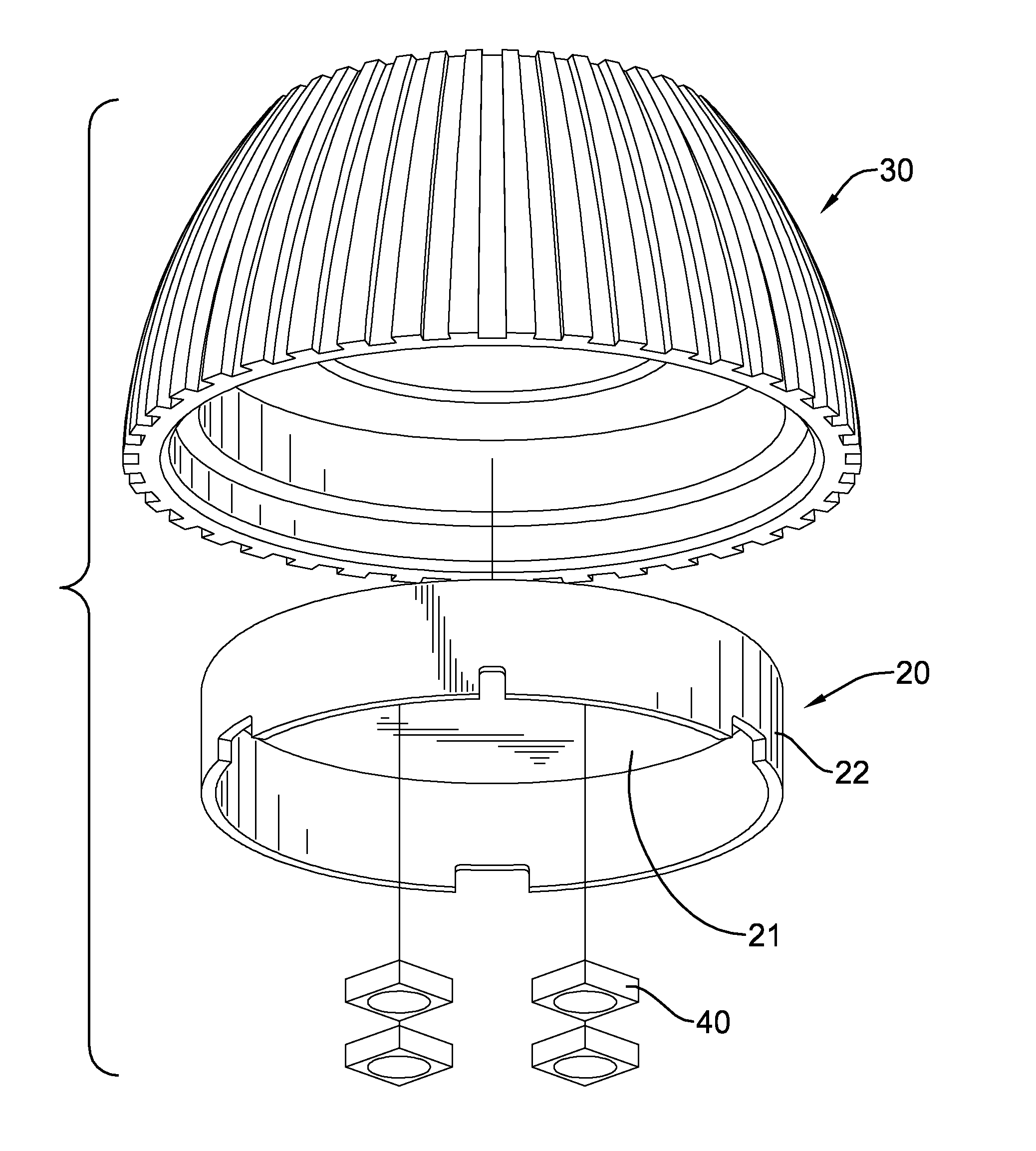

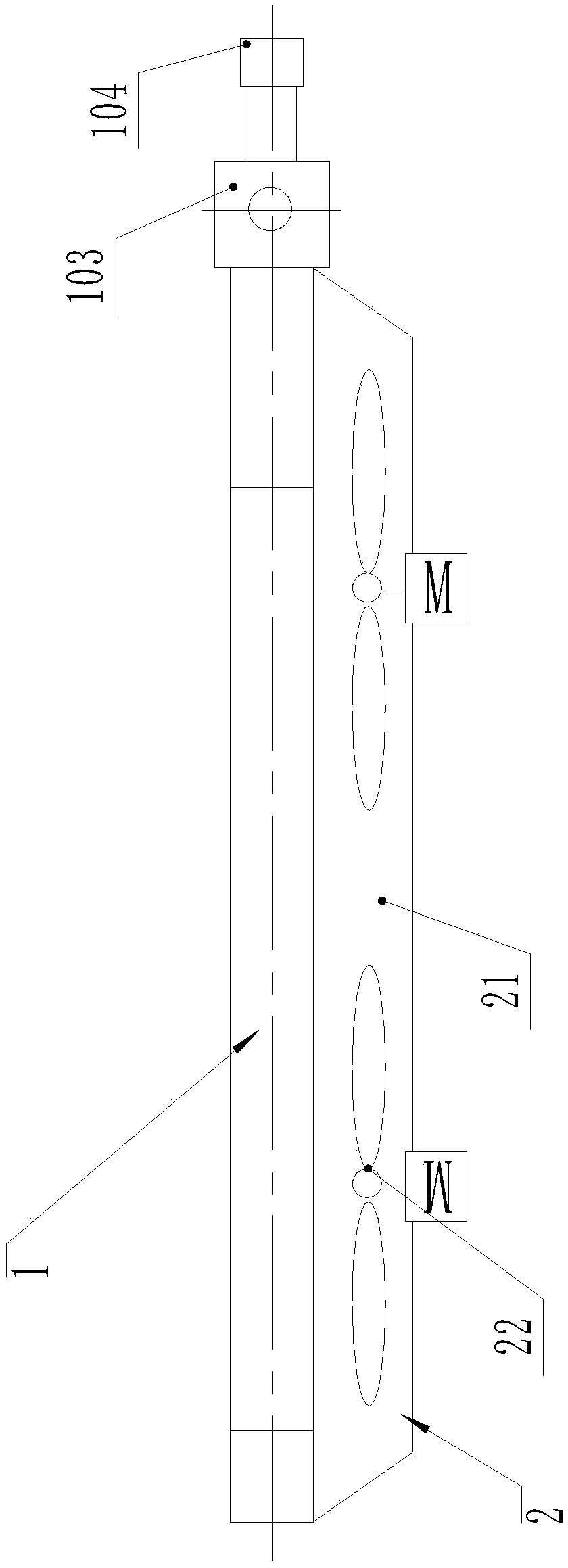

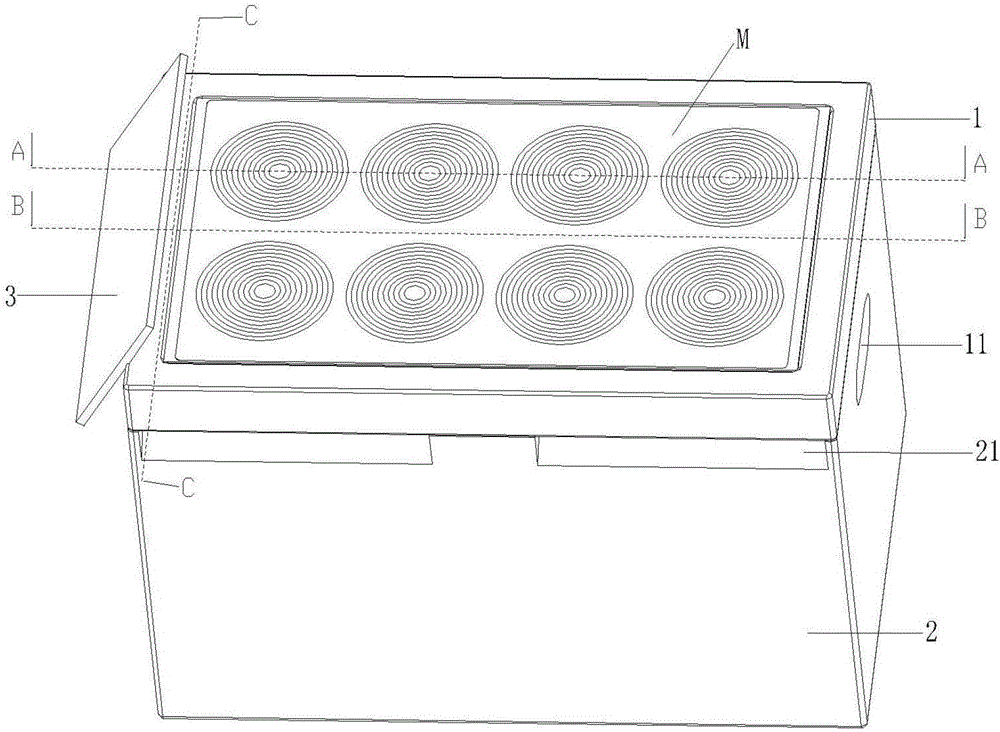

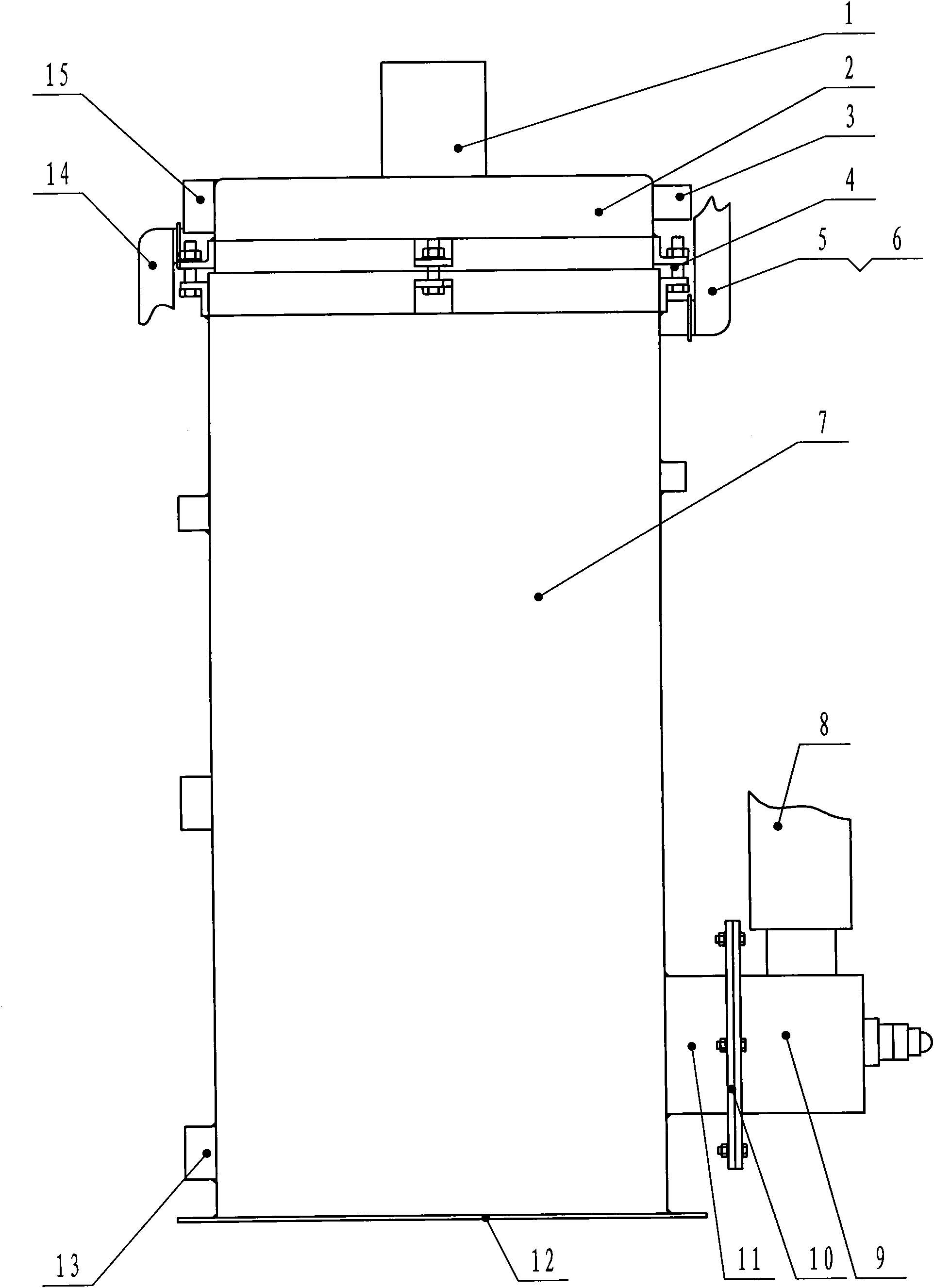

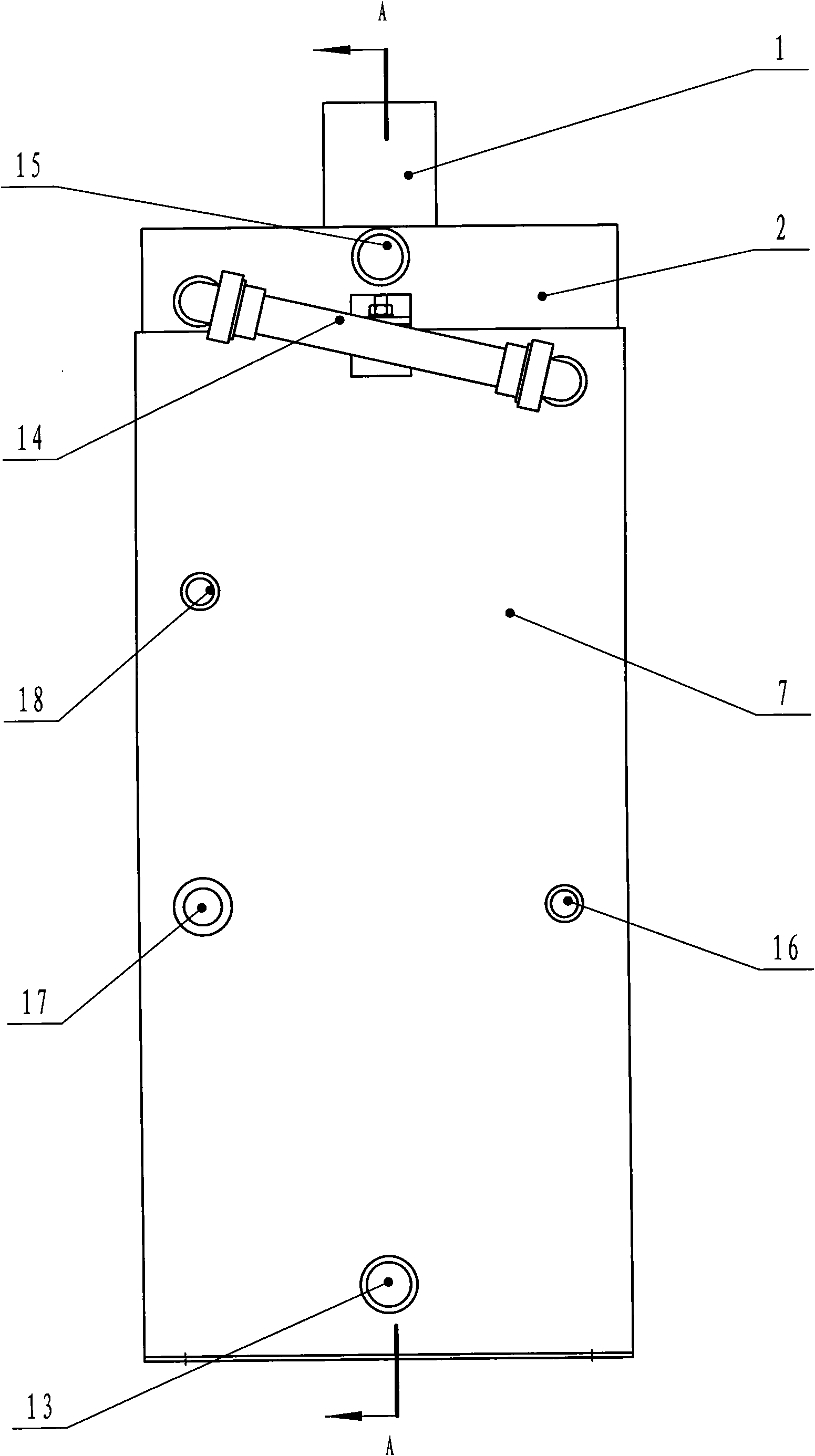

Cooling system of LED (Light Emitting Diode) lamp

InactiveCN106122797AImprove lighting effectsQuality improvementLighting heating/cooling arrangementsLighting safety devicesCooling effectEngineering

The invention relates to a heat dissipation system for an LED lamp, comprising a circulation pipe (1) and a pump (2), and also includes an LED heat dissipation module (3) and a power supply heat dissipation module (4), the LED heat dissipation module (3) ) is a fluid cooling device for the LED lamp (5), and the power cooling module (4) is a fluid cooling device for the LED lamp power module (6); the circulation pipe (1) is connected to the LED cooling module (3) and the power supply A heat dissipation module (4); the pump (2) is installed on the circulation pipe (1), so that the fluid in the circulation pipe (1) passes through the LED heat dissipation module (3) and the power supply heat dissipation module (4) to form a circulating type flow, thereby simultaneously realizing the heat dissipation and cooling functions of the LED lamp (5) and the power module (6). The invention not only effectively guarantees the heat dissipation effect of the whole LED lamp equipment, improves the lighting effect and quality of the LED lamp, but also prevents the power module from being damaged by heat, so that the service life can be effectively prolonged.

Owner:麦健文

Radiator suitable for aluminium alloy cavity nickel coated anti-corrosion

InactiveCN1912522AIncrease heat conduction areaAchieve connectionHeat exchanger casingsCoatingsChemical platingMetallic Nickel

A radiator suitable to carry out Ni anticorrosion on internal cavity of aluminium alloy is prepared as setting T shaped radiation fin on two surfaces of radiation plate of aluminium alloy, setting connection water channel on top and bottom connection units, inserting aluminium alloy seal cover into internal cavity at two ends of said radiation plate and applying argon arc welding to weld them together, reserving internal thread at two ends for connecting with two said connection units and water inlet and outlet as well as using chemical plating to plate Ni-P anticorrosion at internal cavity of said radiation plate.

Owner:李建新

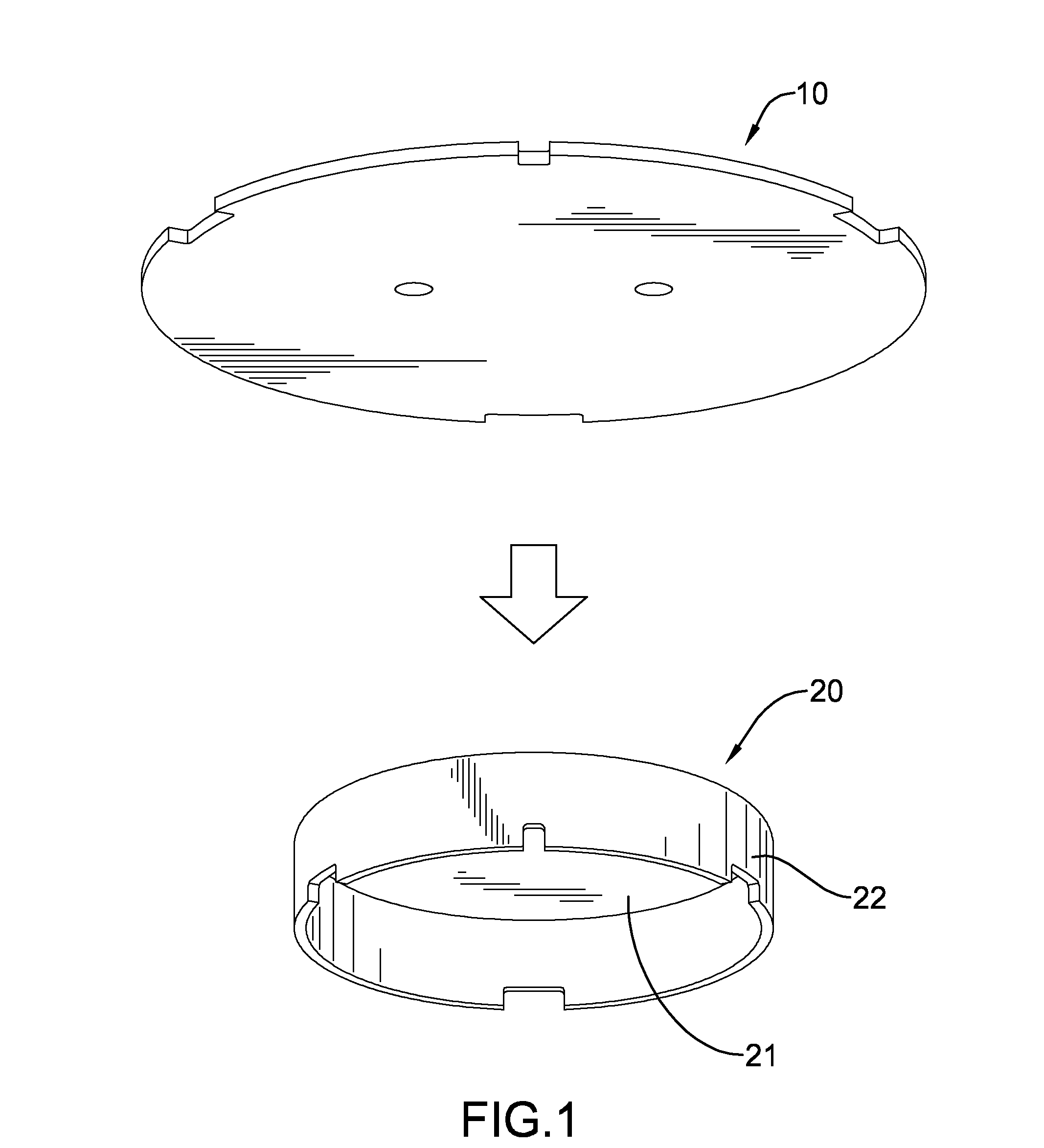

Manufacturing method of a heat conductive device for a light-emitting diode

InactiveUS20120311849A1Improve thermal efficiencyFast heat conductionPoint-like light sourceWave amplification devicesHeat conductingEngineering

A manufacturing method of heat conductive device for an LED has steps of forming a heat sink and an engagement recess in the heat sink by cold forge, punching a heat-conducting disc to form an LED carrier having a mounting portion and a heat-conducting wall formed around the mounting portion, soldering multiple LEDs on the LED carrier, and heating the heat sink to thermally expand the heat sink and assembling the LED carrier and the heat sink so that the heat-conducting wall is assembled with the engagement recess and further chilling the heat sink to thermally retract and tightly hold the LED carrier. The manufacturing method increases contact area and reduces air gaps between the LED carrier and the heat sink to effectively enhance the heat-conducting efficiency of the LED carrier so that the LEDs are operated at a suitable operating temperature to secure a prolonged life duration.

Owner:PAN JIT INT

New energy automobile water-cooled condenser

PendingCN108709342AFast coolingLess power consumptionEvaporators/condensersTubular elementsThermal energyNew energy

The invention discloses a new energy automobile water-cooled condenser which comprises a condenser body and a draught fan assembly. The condenser body comprises an outer pipe and an inner pipe which are fixedly installed in a sleeve manner, a refrigerant flowing channel is formed in an inner cavity of the inner pipe, a water flowing channel is formed in a space between the inner pipe and the outerpipe, the two ends of the outer pipe are provided with a water inlet connector and a water outlet connector, the two ends of the inner pipe are provided with a refrigerant inlet connector and a refrigerant outlet connector, the water inlet connector and the water outlet connector both communicate with the water flowing channel, the refrigerant inlet connector and the refrigerant outlet connectorboth communicate with the refrigerant flowing channel, heat conduction fins are arranged outside the outer pipe, and the draught fan assembly is arranged on one side of the condenser body to be used for blowing air to or sucking air from the condenser body. By means of the water-cooled condenser, the inner pipe and the outer pipe which are installed in the sleeve manner are used for achieving heatexchange between medium water and a high temperature refrigerant, heat in the high temperature refrigerant is conveniently recovered, utilization of thermal energy in a new energy automobile is morereasonable, and the aim of energy saving is achieved.

Owner:苏州赛普瑞新能源科技有限公司

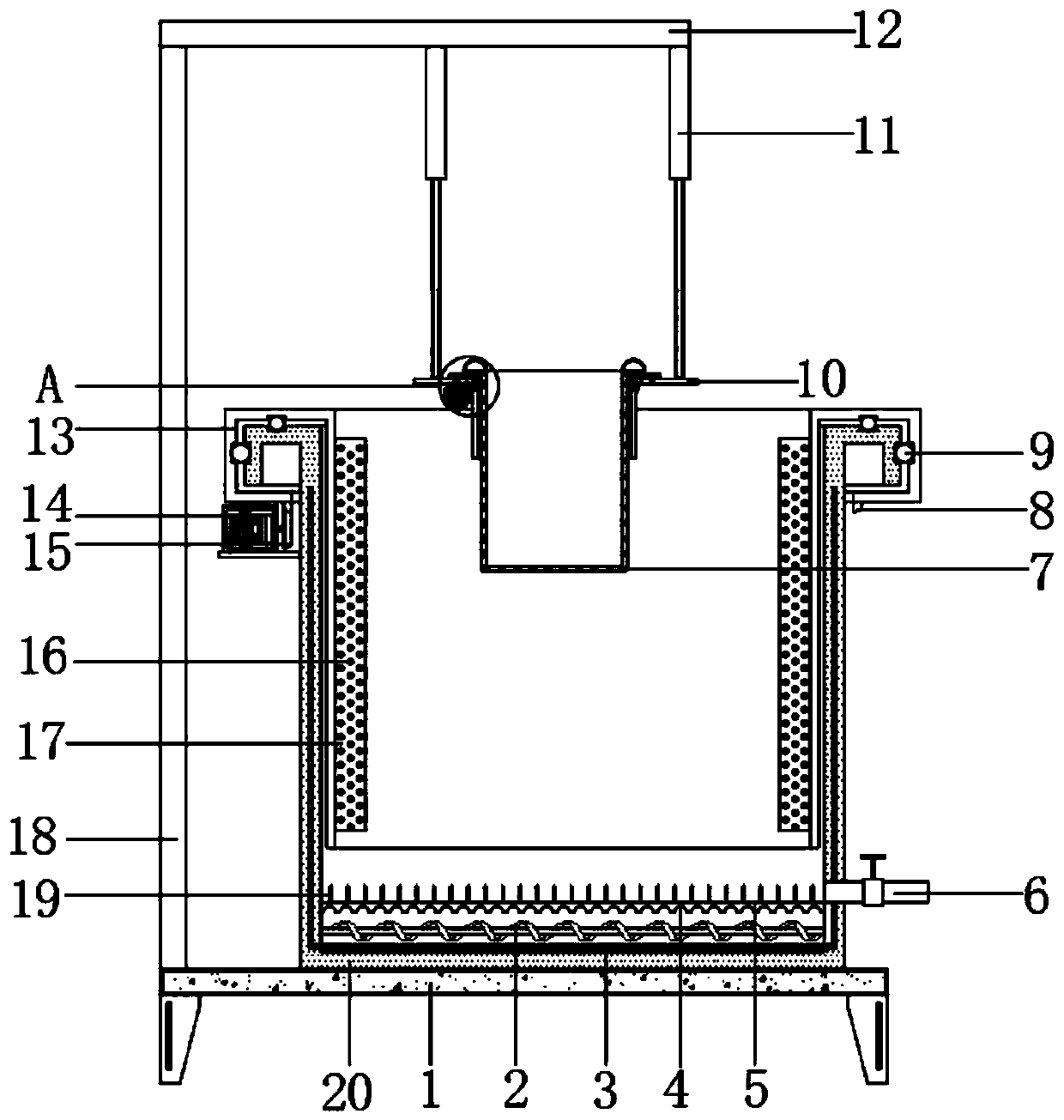

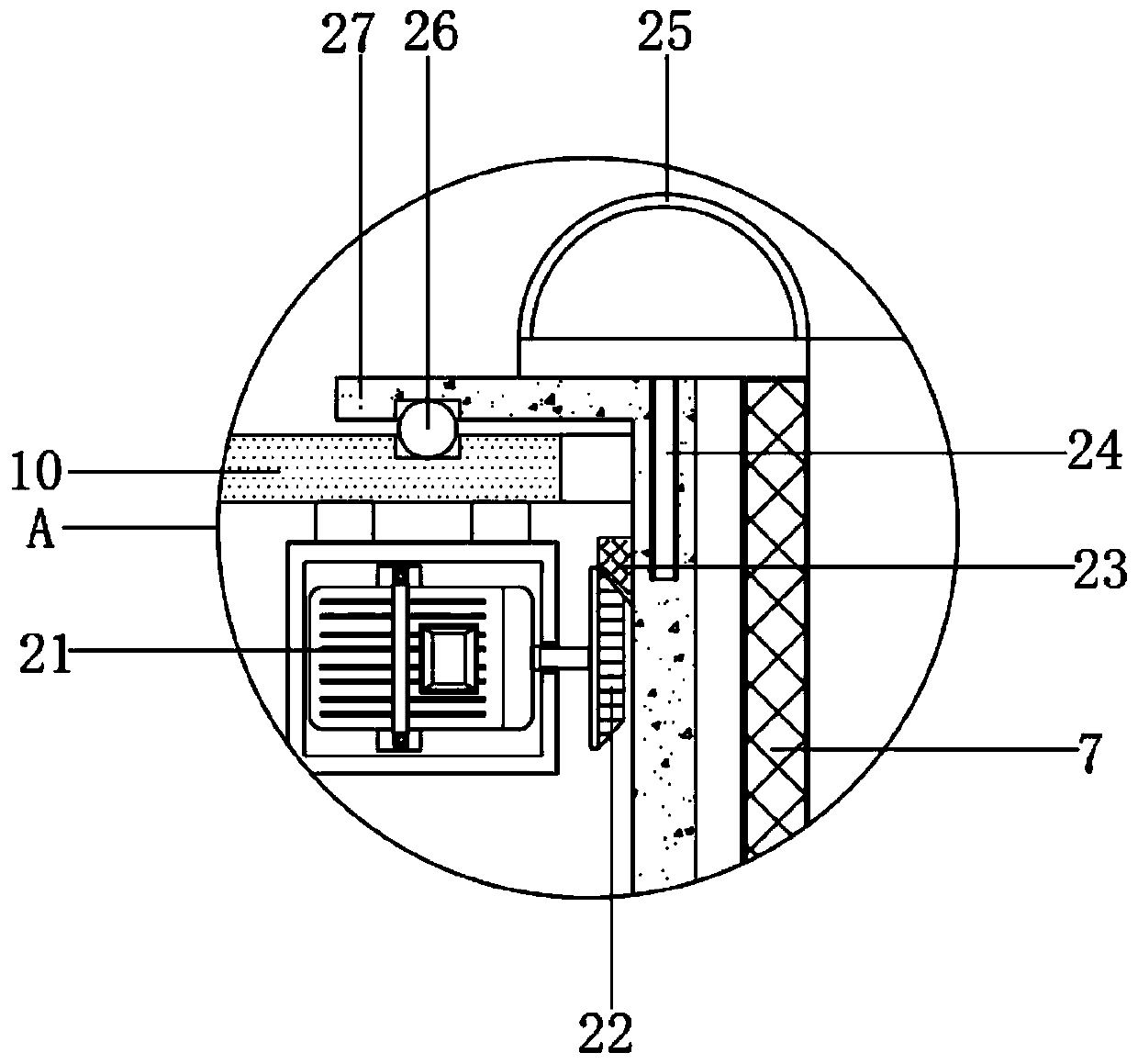

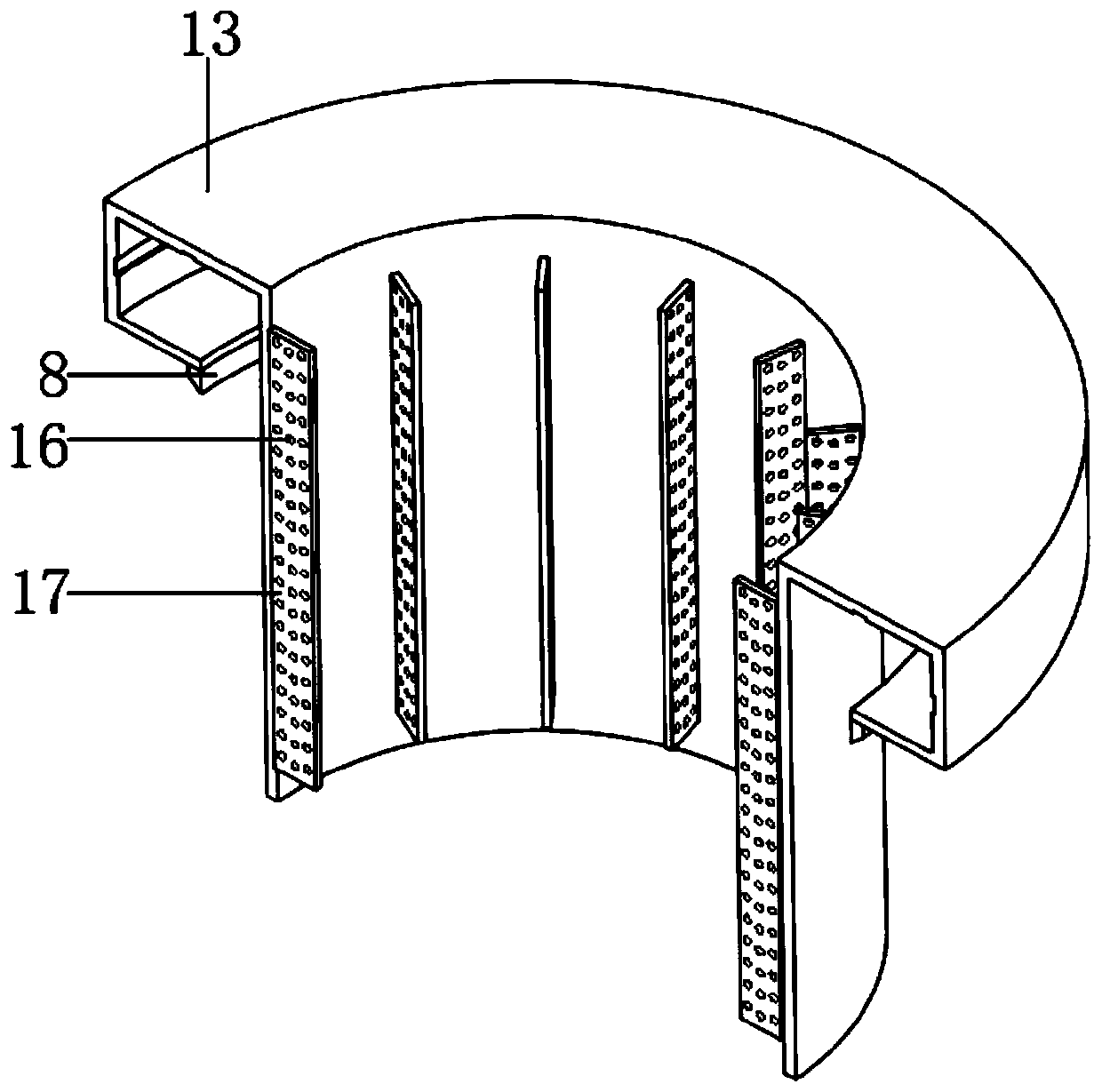

Cleaning and deoiling device for mechanical parts

ActiveCN111136057AImprove solubilityQuick mixDrying solid materials without heatCleaning using liquidsElectric machineryCleansing Agents

The invention belongs to the technical field of machining of mechanical parts, in particular to a cleaning and deoiling device for mechanical parts. For solving the problems that a traditional cleaning and deoiling device for mechanical parts is simple in design and common in deoiling effect, the scheme is provided: the cleaning and deoiling device comprises a top plate and a base, support legs are welded at four corners of the bottom of the base, a cleaning box is fixed on the outer wall of the top of the base through bolts, a heating bottom plate is welded at the bottom end of the cleaning box, and a heating cavity is formed by the opposite sides of the heating bottom plate and the cleaning box. Through mutual cooperation of a stepping motor, a first driving conical gear, a first drivingconical gear ring, a first annular groove and a first ball, a wall plate can be driven to rotate according to a certain frequency, the effects of accelerating cleaning agent mixing and improving cleaning efficiency are achieved, when the stepping motor stops rotation at fixed time, cleaning liquid impacts the wall plate due to inertia, by means of the arrangement of drain holes, convection of cleaning fluid is effectively improved, and the cleaning effect is further improved.

Owner:ZHUZHOU HUAXIN PRECISION IND

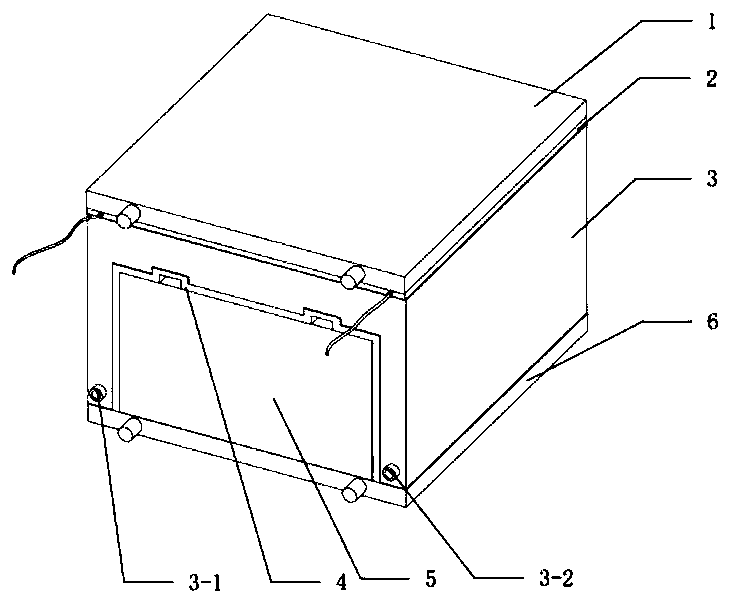

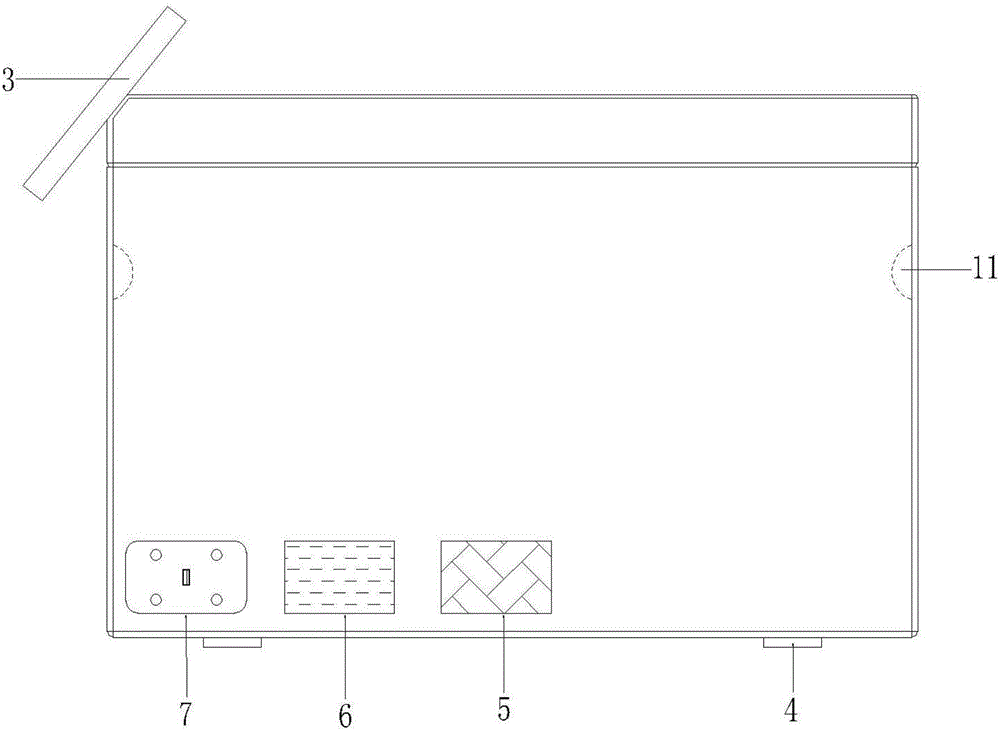

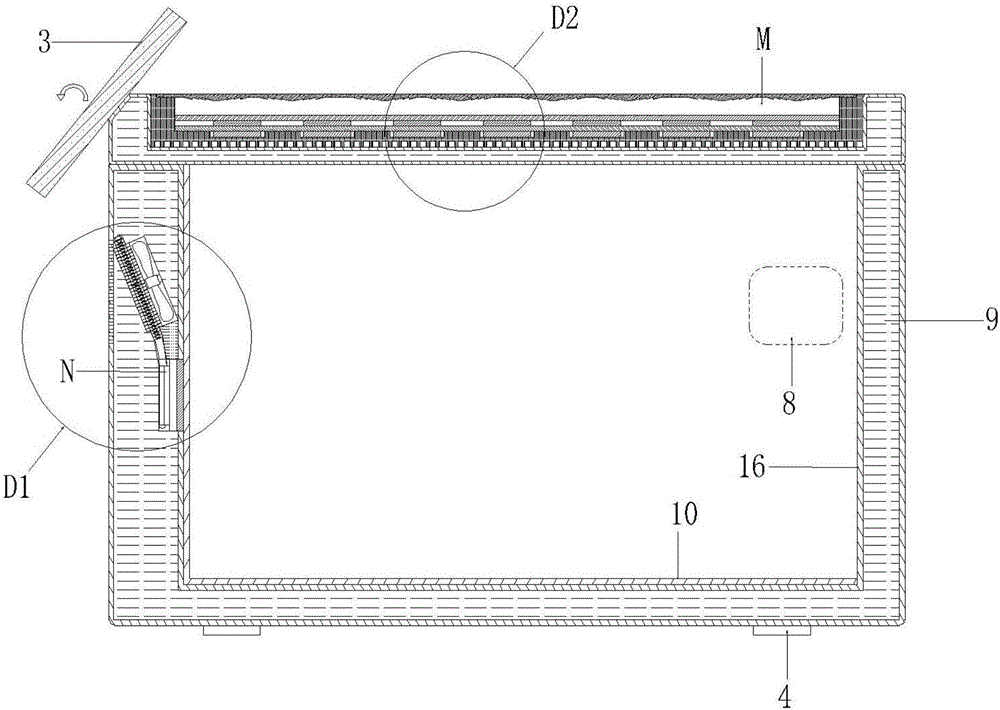

Solar thermoelectric power generation movable refrigerator

InactiveCN106766494AImprove utilization efficiencyRealize recovery and power generationLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

A solar thermoelectric power generation movable refrigerator comprises a refrigerator body. A solar thermoelectric power generation device is arranged on the surface of the refrigerator body. A refrigerating device is arranged in the refrigerator body. A semiconductor thermoelectric power generation slice is directly or indirectly fixed to the surface of a heat source in the solar thermoelectric power generation device and / or the refrigerating device. The solar thermoelectric power generation movable refrigerator has the beneficial effects that a solar thermoelectric power generation module carries out photovoltaic power generation through the solar energy and further carries out power generation through the temperature difference, and the utilization efficiency of the solar energy is improved. The thermoelectric power generation chip is fixed to the hot end of a condenser or a semiconductor chilling plate, and therefore recycling power generation of surplus heat is achieved.

Owner:ZHEJIANG GEMCORE TECH

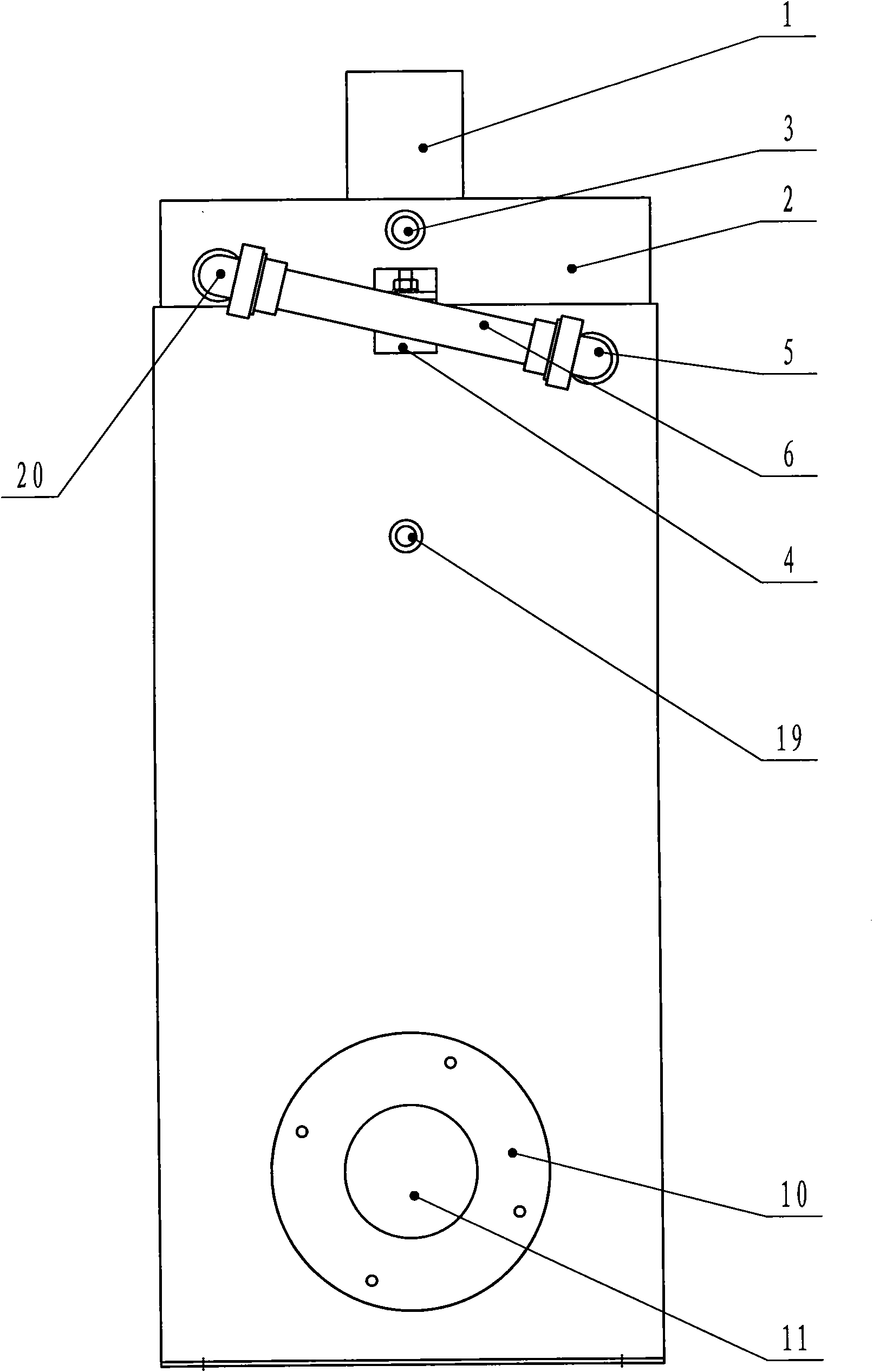

Vertical gas fired boiler

InactiveCN102022821ALow gas consumptionIncrease heat conduction areaWater heatersBoiler furnaceHearth

The invention relates to a vertical gas fired boiler, comprising a chimney, a smoke venting cover, an outer boiler furnace, water jackets, a fire tube, hearths and a boiler door tube, wherein the chimney is welded on the smoke venting cover; the smoke venting cover is installed at the top of the outer boiler furnace; an upper hearth is formed between the lower part of the smoke venting cover and each of an upper side plate and an upper embossed plate; the outer boiler furnace is internally provided with the fire tube; a lower hearth is positioned in an inner boiler furnace; the boiler door tube is communicated with the lower hearth; the gap between the periphery of the inner boiler furnace and the outer boiler furnace forms a lower interlayer water jacket; an upper interlayer water jacketis communicated with the upper part of a water containing cavity; and the lower part of the water containing cavity is communicated with the lower interlayer water jacket. The vertical gas fired boiler is characterized in that the fire tube is internally provided with a water tube, the upper hearth is internally provided with an upper horizontal water tube, the lower hearth is internally providedwith a lower horizontal water tube, the upper end of the water tube is welded on the through hole of the upper horizontal water tube, and the lower end of the water tube is welded on the through holeof the lower horizontal water tube. A water interlayer and a horizontal water tank can also be arranged on the smoke venting cover. The vertical gas fired boiler has large heat exchange area and highthermal efficiency.

Owner:曲沃县秀水炉业有限公司

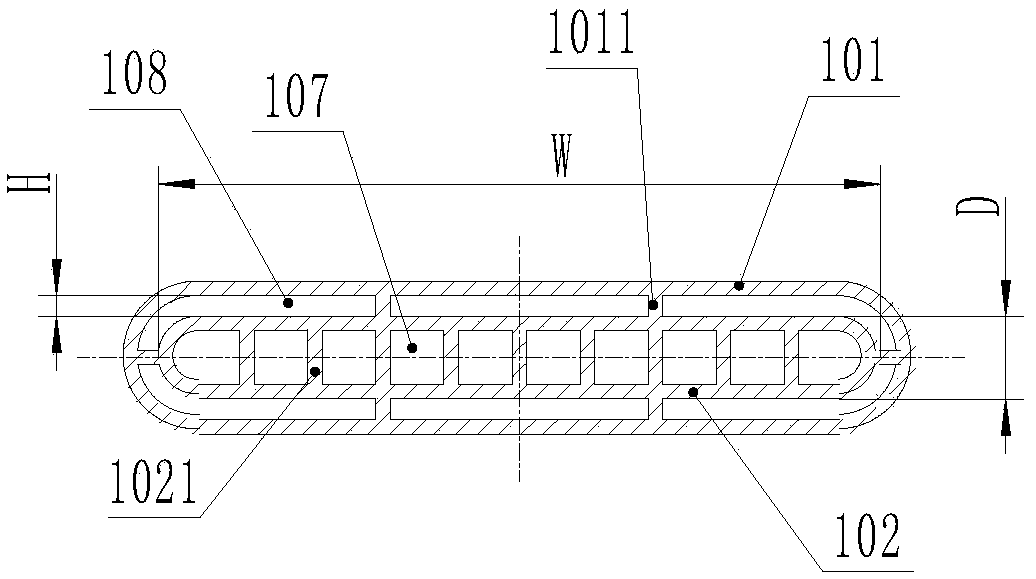

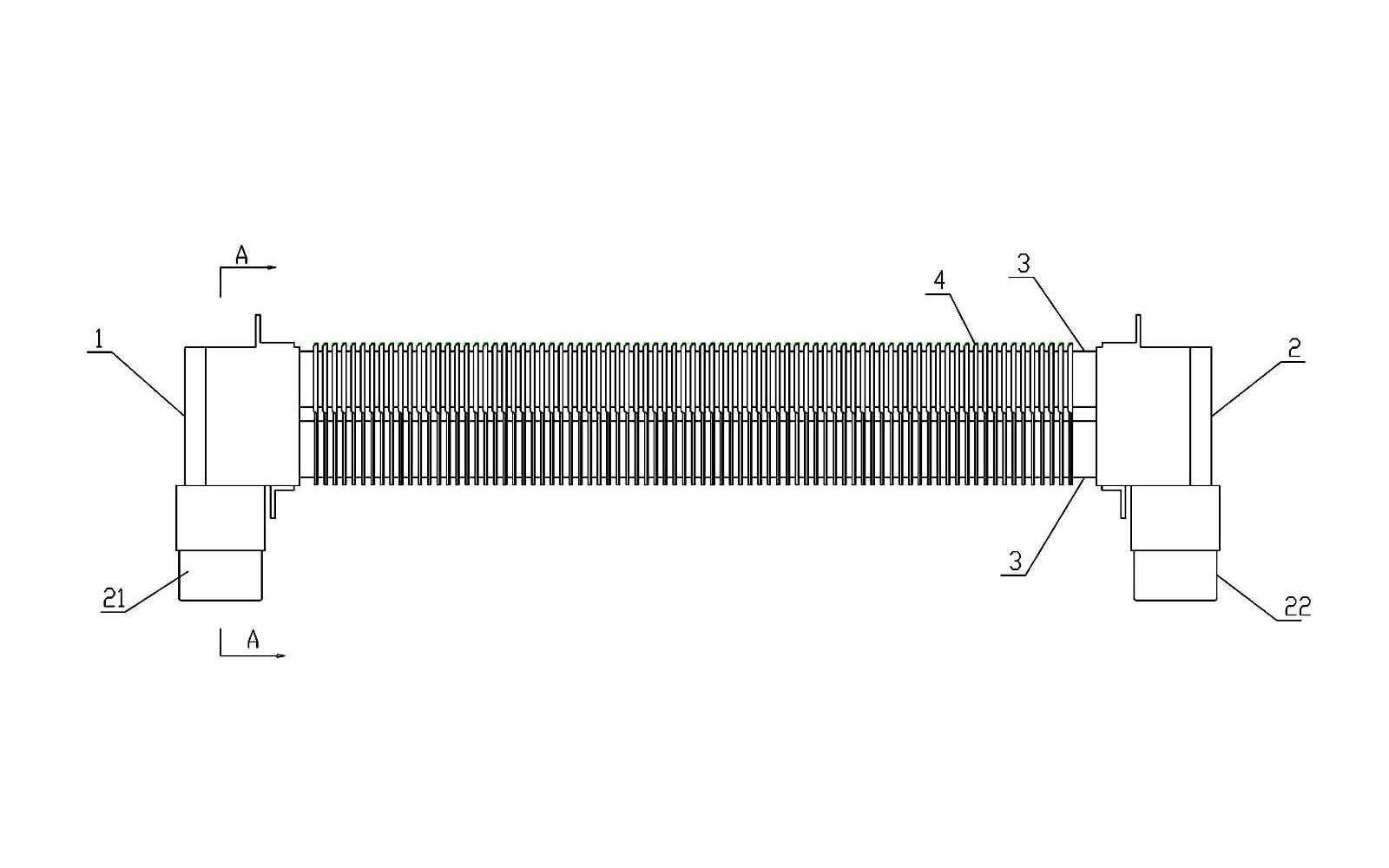

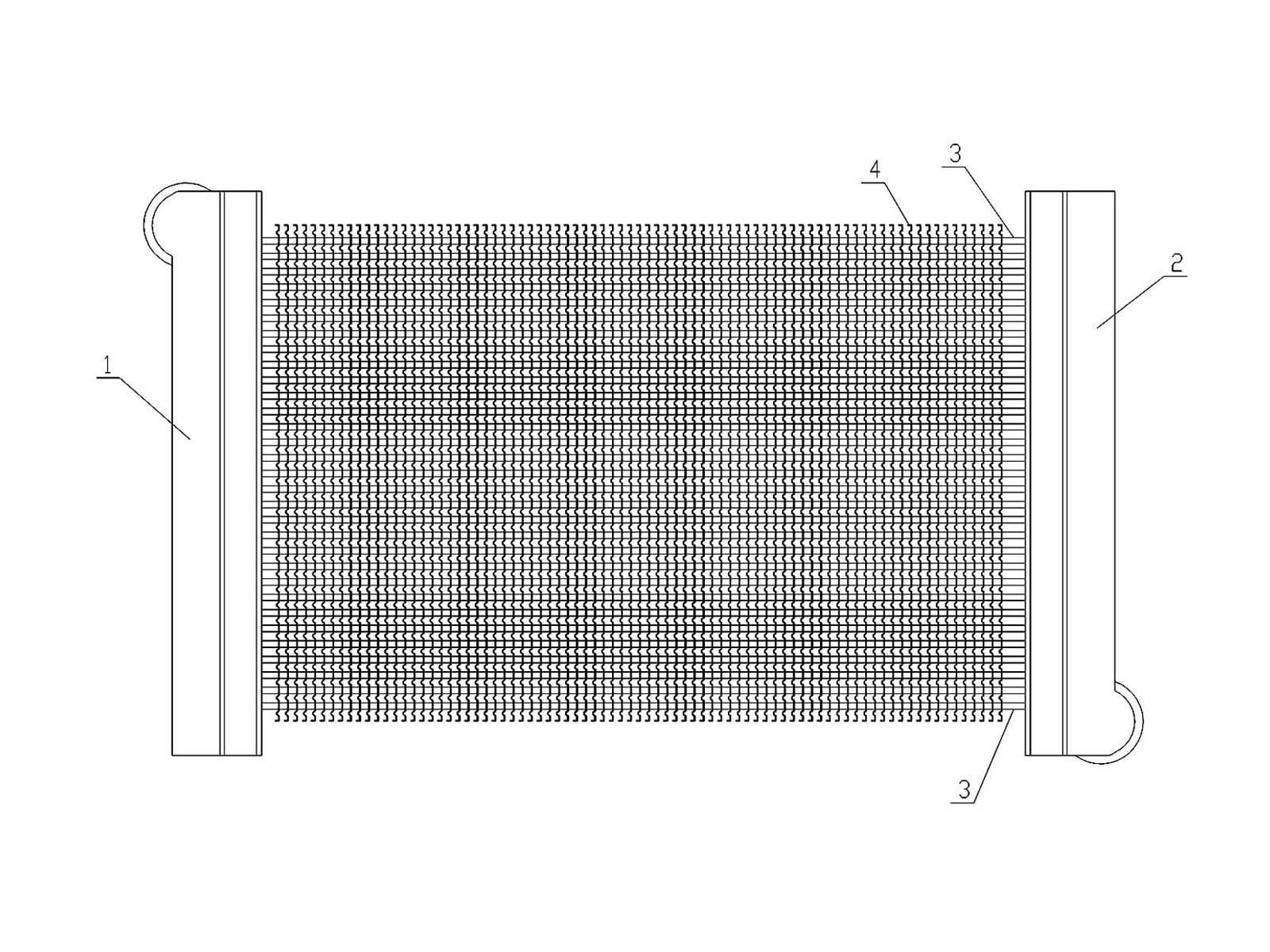

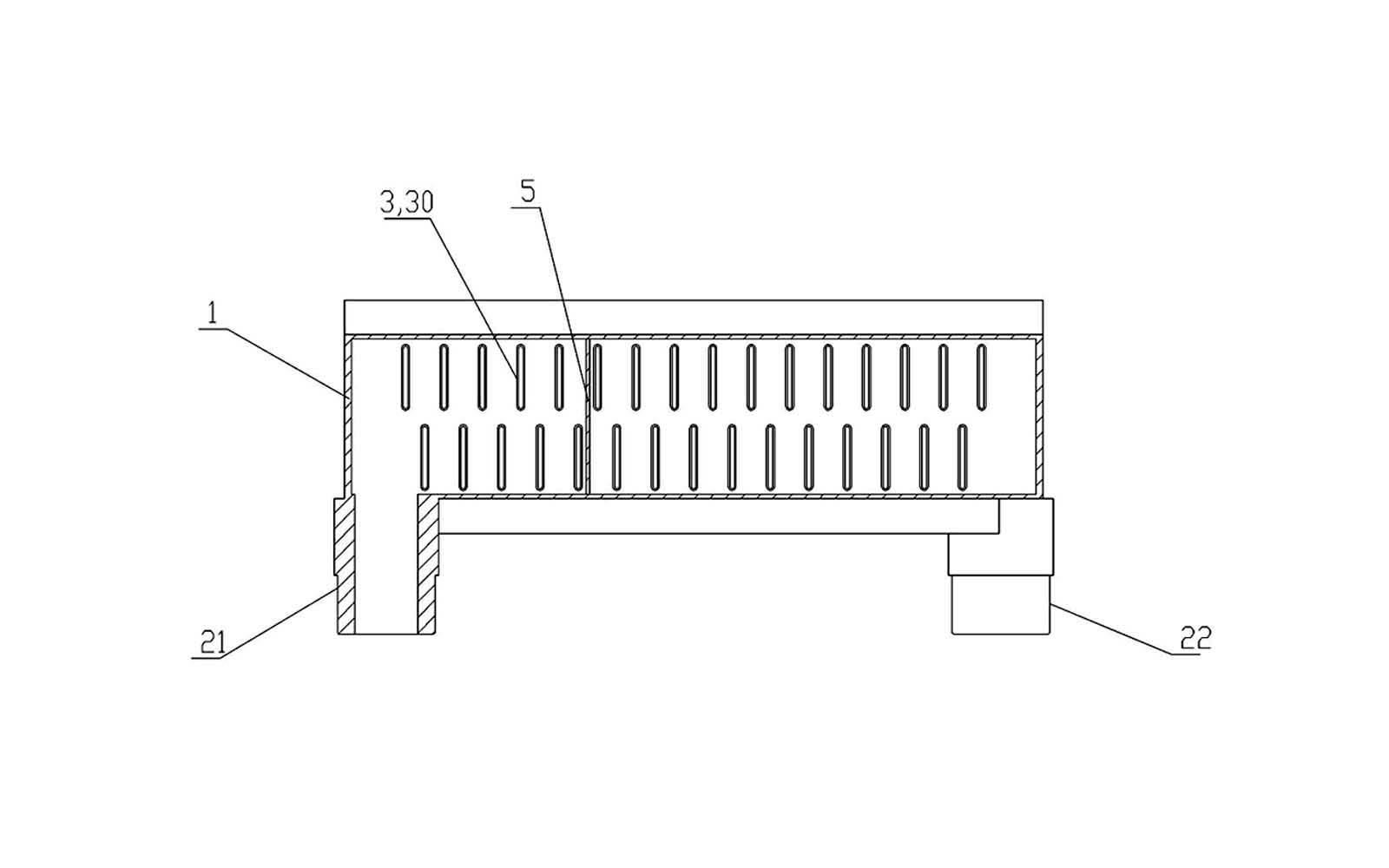

Fin-and-tube main heat exchanger for gas heating water heater and manufacturing method thereof

InactiveCN102278899AIncrease heat conduction areaIncrease manufacturing costFluid heatersSoldering apparatusHeat transfer tubeHeat transfer efficiency

Owner:GUANGZHOU DEVOTION HOME ENVIRONMENT TECH CO LTD

Electronic device

InactiveCN101742833AGood lookingReduce volumeDigital data processing detailsCooling/ventilation/heating modificationsEngineeringMechanical engineering

Owner:JIAXING JINRISHENG TOOLS CO LTD

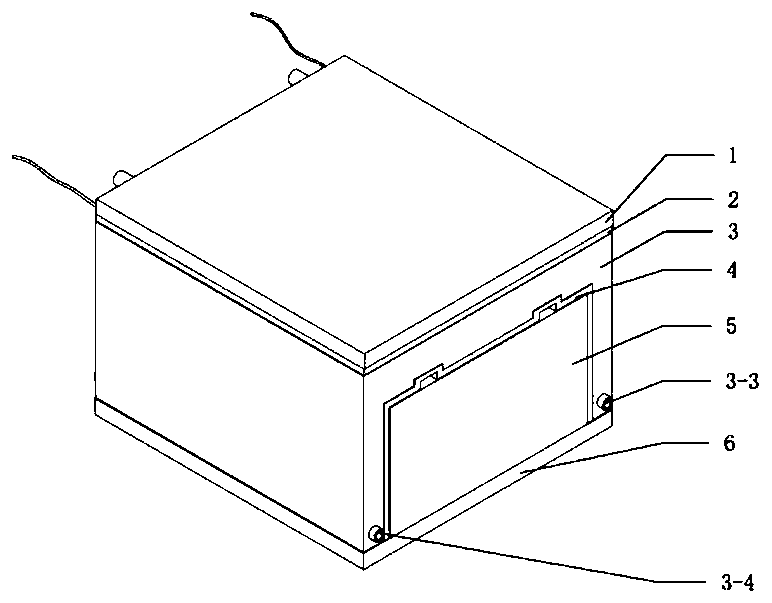

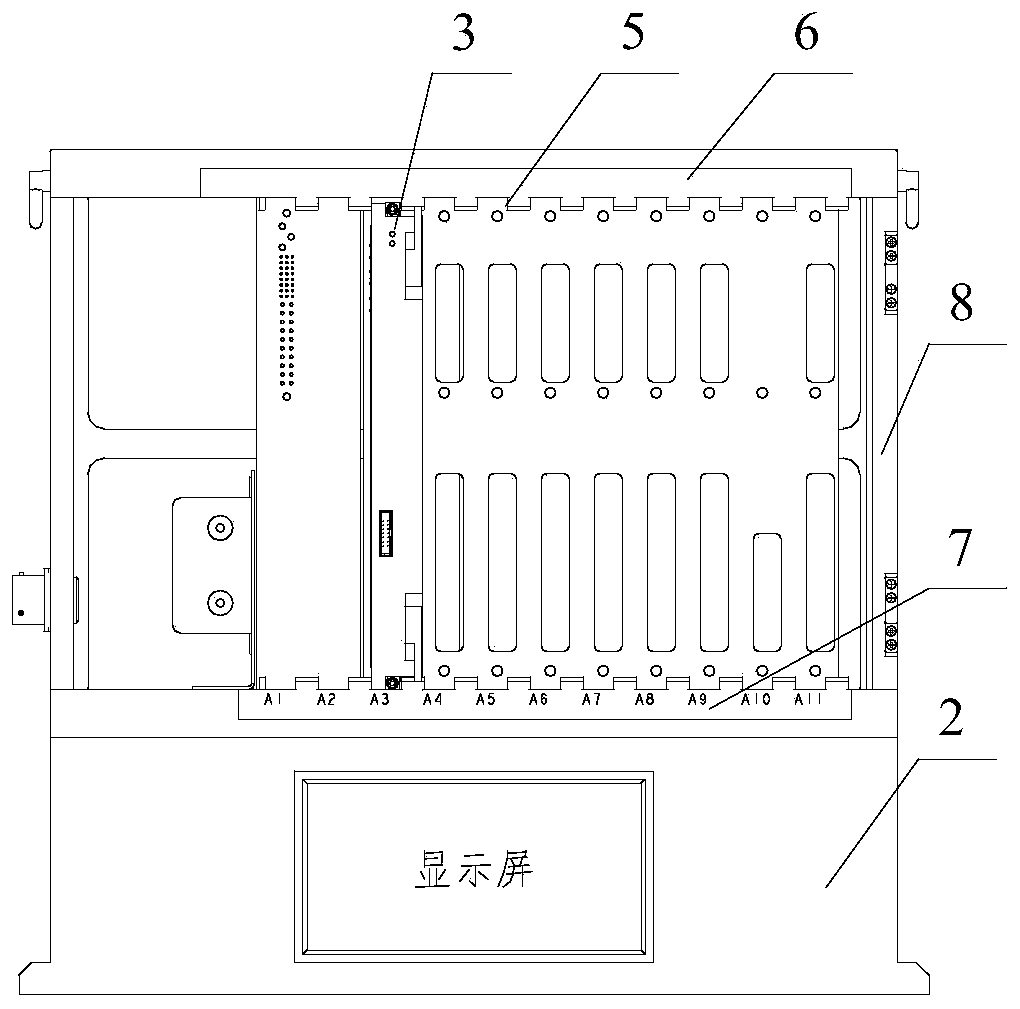

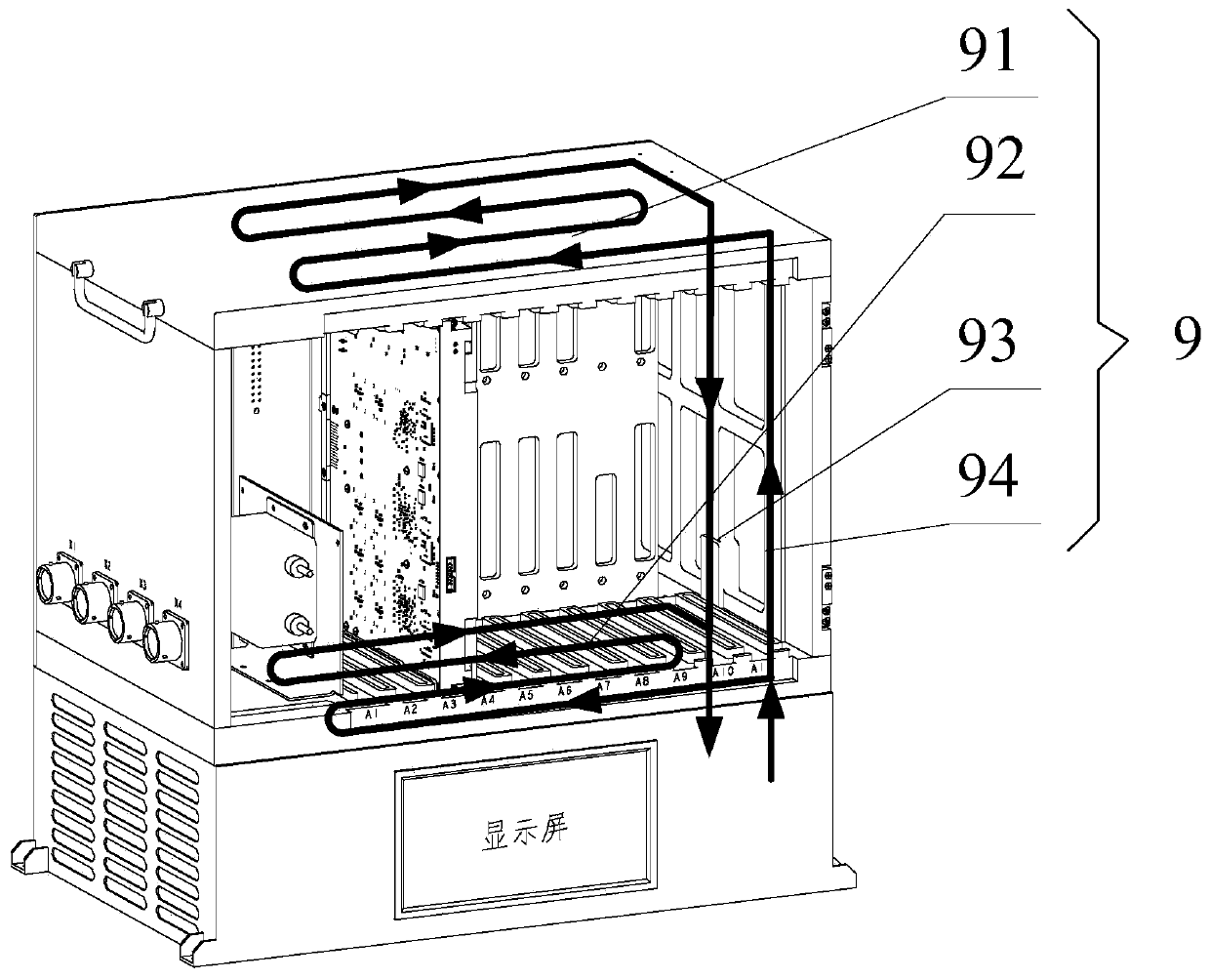

Integrated liquid cooling machine box based on two-phase heat transfer and two-phase heat transfer method thereof

InactiveCN110213942AImprove heat transfer efficiencyGood isothermModifications using liquid coolingSingle phaseIntegrated circuit

The invention relates to an integrated liquid cooling machine box based on two-phase heat transfer and a two-phase heat transfer method thereof. The integrated liquid cooling machine box comprises a machine box shell, a two-phase liquid cooling source and a plug-in cold guide plate, wherein flow channels which are communicated with each other are arranged in the top wall and the bottom wall of themachine box shell; the upper end and the lower end of the plug-in cold guide plate are fixedly connected with the top wall and the bottom wall of the machine box shell respectively, and are used forfixing electronic plug-in components; the two-phase liquid cooling source is fixedly connected with the machine box shell; and each flow channel has a flow channel inlet and a flow channel outlet which are communicated with the two-phase liquid cooling source through pipelines. The two-phase liquid cooling source is fixedly connected with the machine box shell and does not need to depend on an external liquid cooling source. The two-phase liquid cooling source is adopted, and a working medium is subjected to liquid state and gaseous state conversion in a pipeline system; the cooling working medium absorbs the heat of electronic equipment in the flow channels and is changed from the liquid state into the gaseous state, so that heat exchange efficiency is far higher than that of single-phasefluid heat exchange; and the cooling working medium phase change is performed in an isothermal process, so that the isothermal performance of the top wall and the bottom wall of the machine box shellis superior to that of the single-phase fluid heat exchange.

Owner:BEIJING INST OF RADIO MEASUREMENT

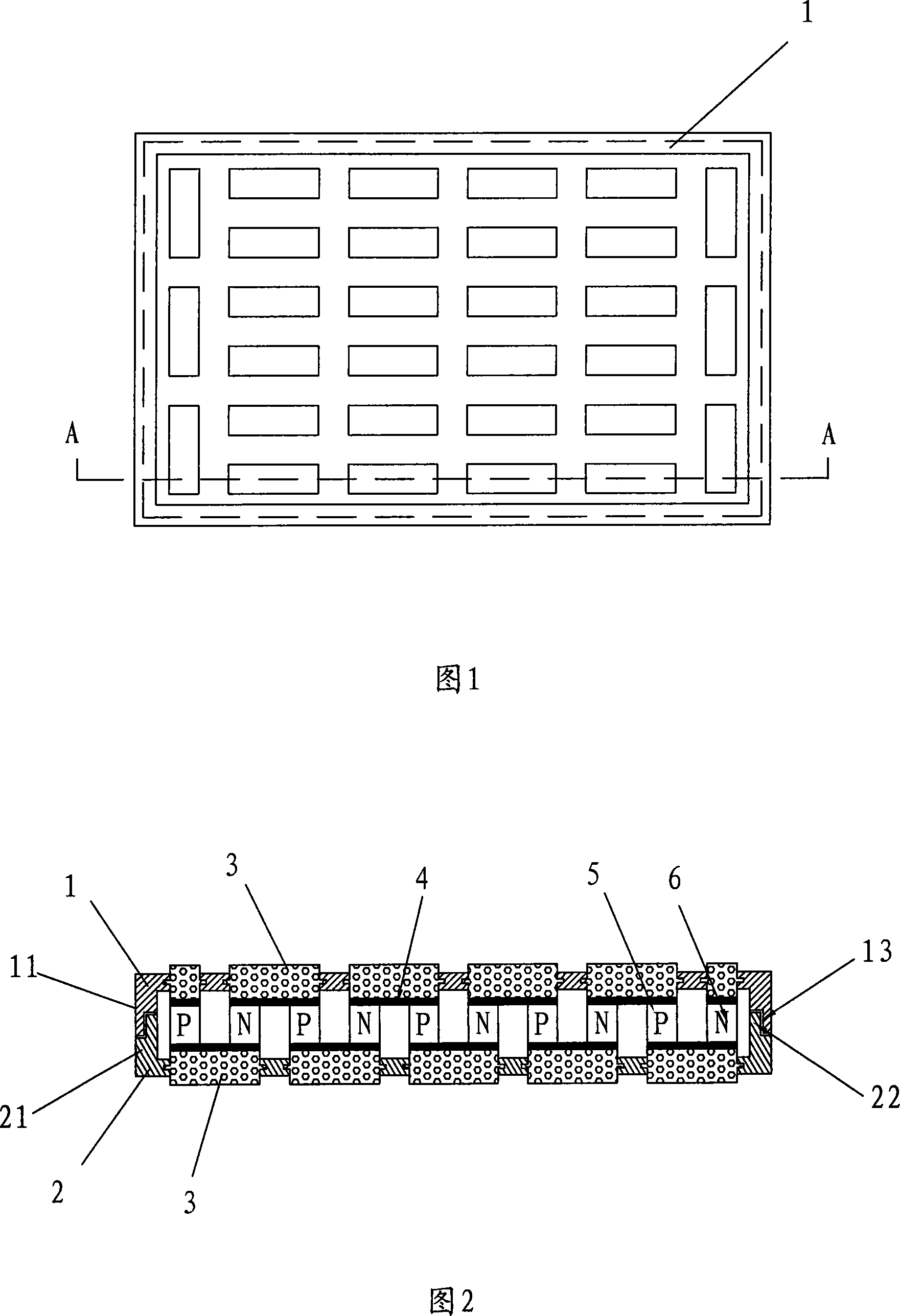

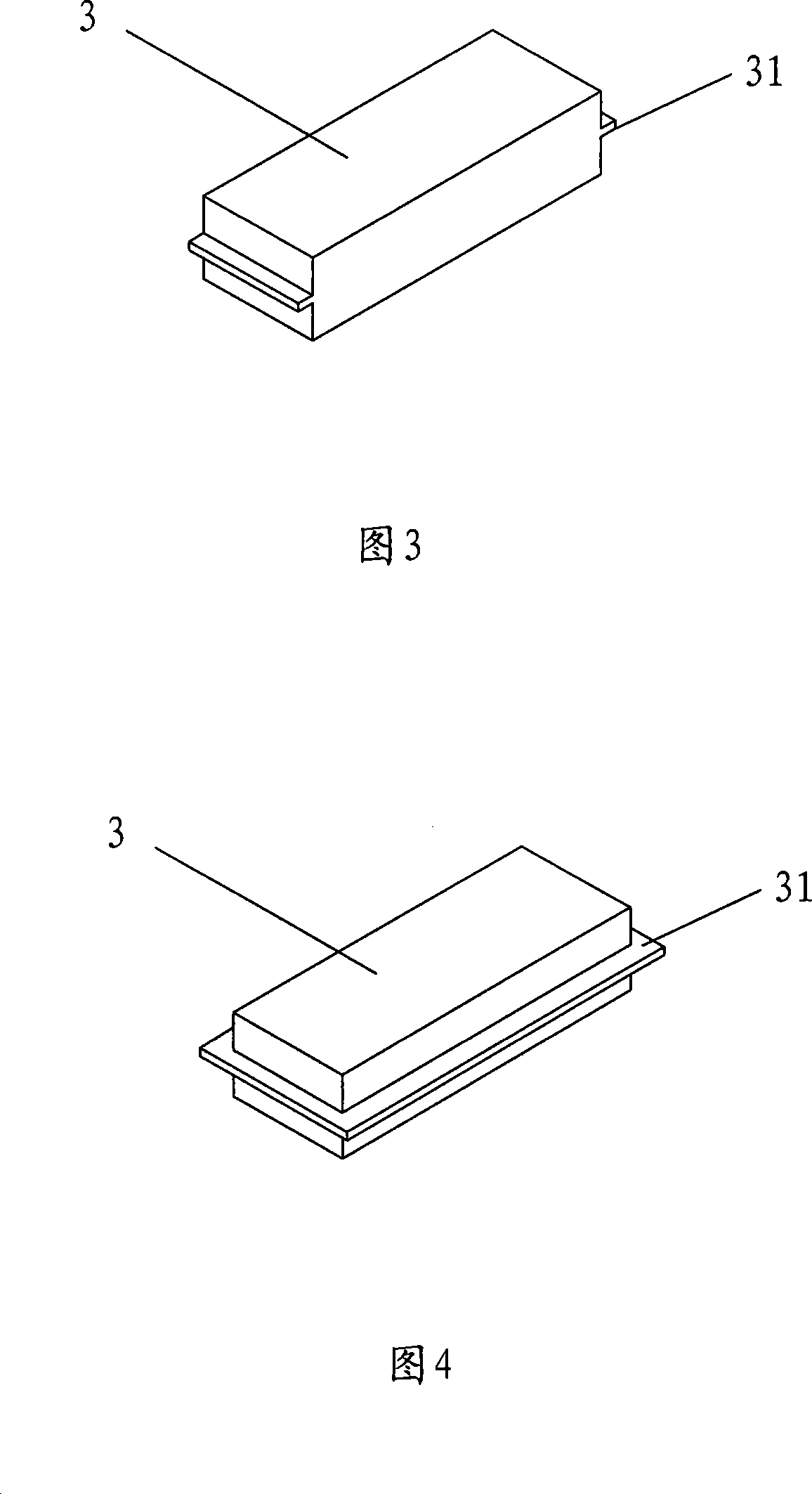

An improved electric cooling and heating component driven by semiconductor temperature difference

InactiveCN101188269ASimple processReduce processThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentState of artHigh rate

The invention relates to an improved electric cooling and heating component which is induced by the temperature difference of a semiconductor, and the component comprises a conductive plate, a metal guide vane, a P-type mould, an N-type mould and a solder layer between the metal guide vane and the P-type mould and the N-type mould. The conductive plate is classified into the hot and cold end conductive plates. The invention is characterized in that the hot and cold end conductive plates which consist of plastic and the metal guide vane are respectively injected to be a mold or die-casted into an integral body. The metal guide vane extends out of the surfaces of the hot and cold end conductive plates. The hot and cold ends of the conductive plates are connected together to form a sealed space. The structure is adopted that the metal guide vane and the hot and cold ends of the conductive plates are respectively injected to be the mold or die-casted into the integral body, and compared with the prior art, the invention has the advantages of simple technology and decreased process. The metal guide vane is directly contacted with a hot and cold end radiator. The problem that the thermal conductivity of the ceramic is poor and the thermal efficiency is low in the prior art are overcome, thereby the invention has the advantages of simple technology, high rate of the finished product, extensive area of the thermal conductivity and excellent performance of the thermal conductivity.

Owner:宋晓葵

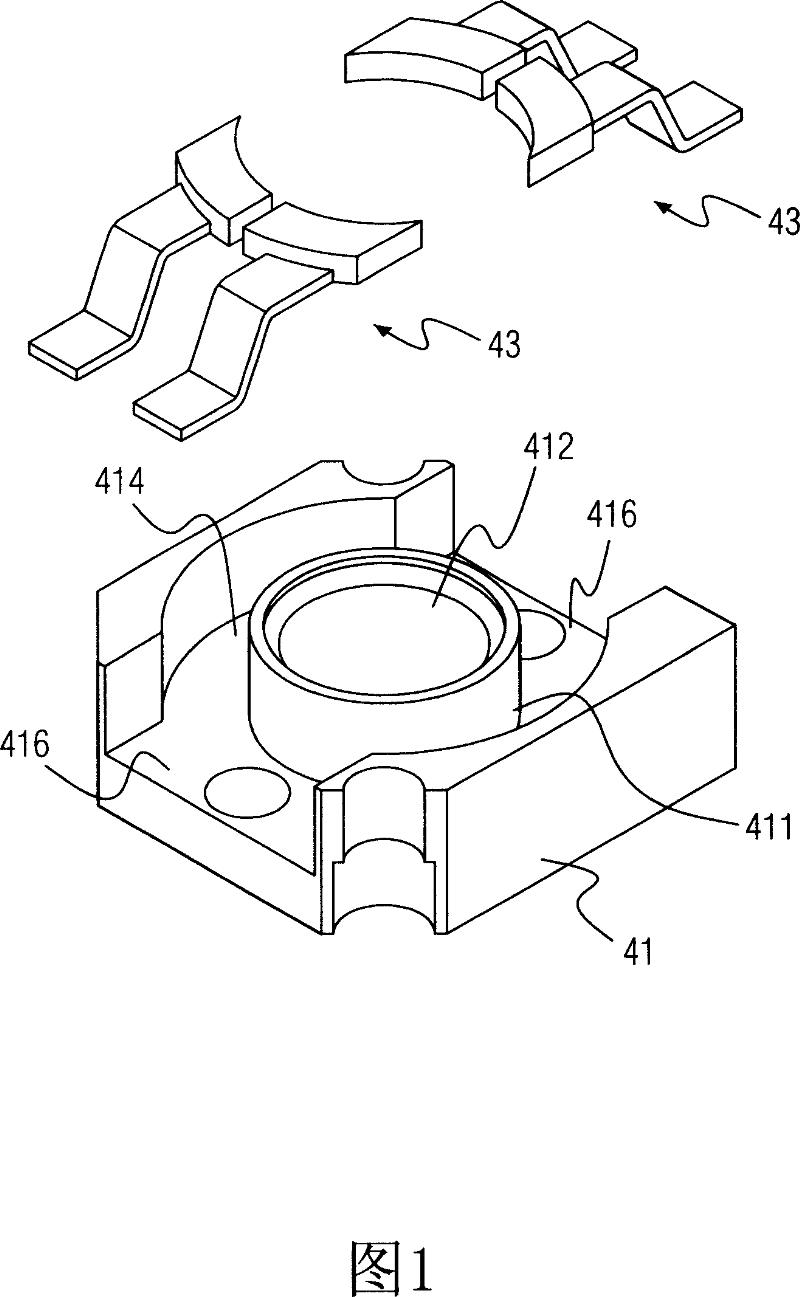

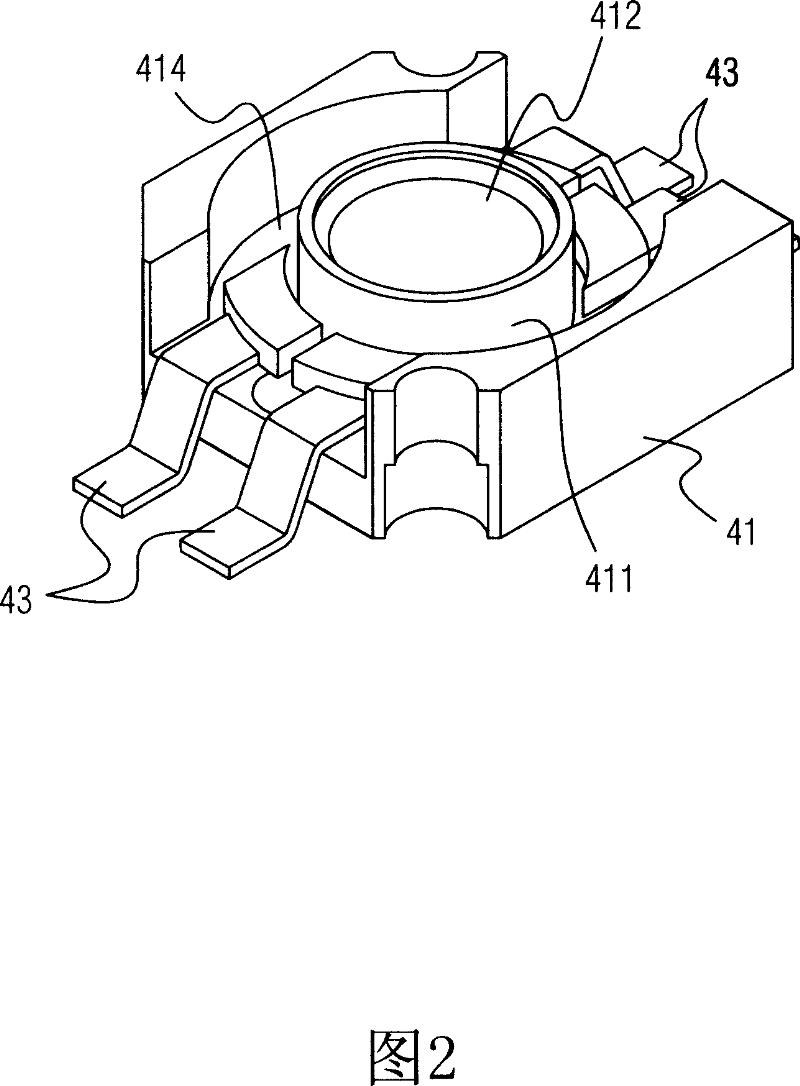

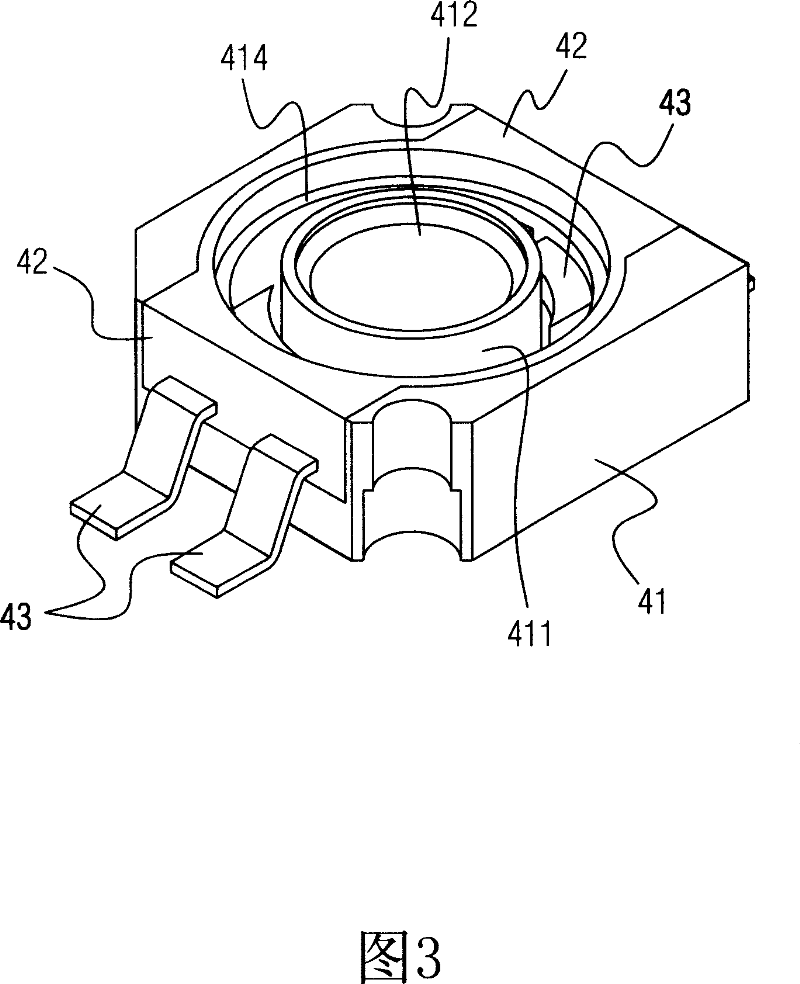

Seat structure of diode illuminating device and method for manufacturing diode illuminating device

InactiveCN101043062AAchieve progressive effectImprove package reliabilitySolid-state devicesSemiconductor devicesHeat conductingEngineering

The invention discloses a seat structure and manufacturing method of diode irradiance device, thereinto the irradiance device includes seat structure, diode chip, light getting layer and lens, the seat structure possesses heat-conducting noumenon, plastic insulator and lead rack. Thereinto the plastic insulator is combined with the heat-conducting noumenon via the first mould, and then it is produced via the heat-conducting noumenon or the first sprue of the first mould in effluence moulding mode and the lead rack is coated in the plastic insulator. The lens are produced by combining the heat-conducting noumenon which is after connection from diode chip to lead rack and coating of light getting layer with the second mould.

Owner:TOP CRYSTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com