Heat pipe

A heat pipe and heat technology, applied in the field of heat pipes, can solve the problems of low thermal conductivity and reduced thermal conductivity, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the heat pipe of the present invention will be described in detail below with reference to the accompanying drawings.

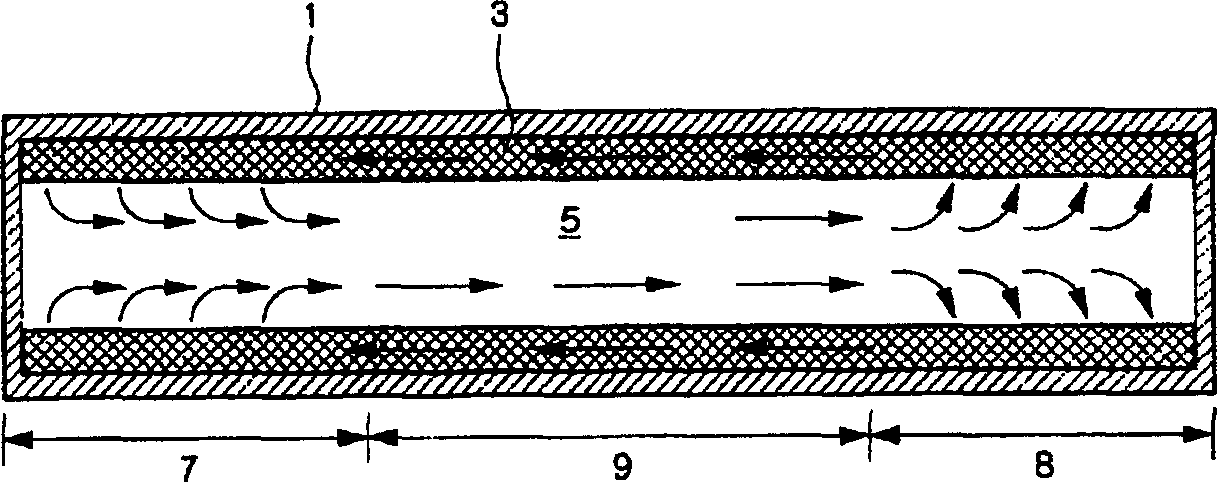

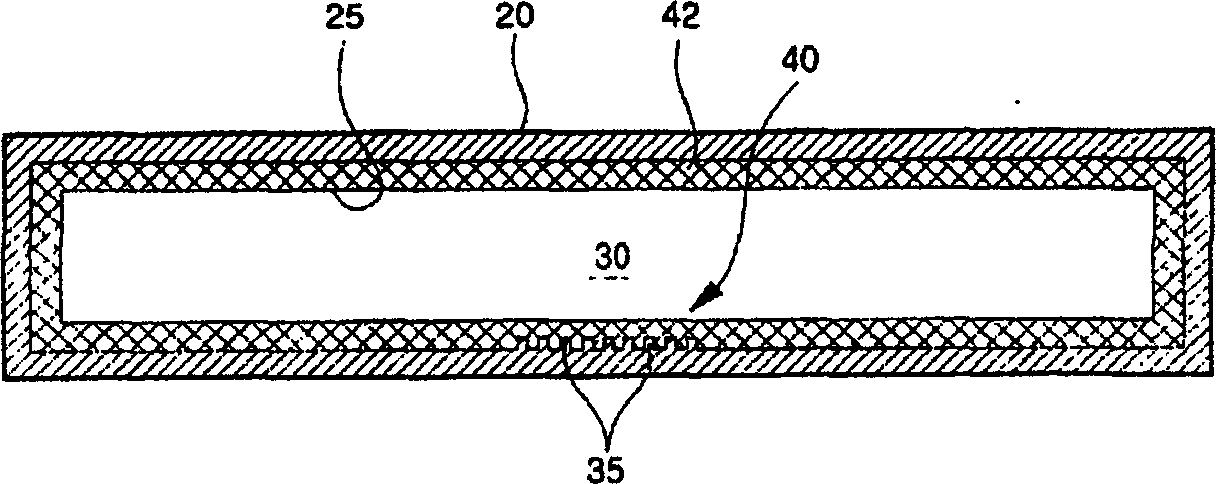

[0034] exist figure 2 The ideal working state of the heat management structure adopting the present invention is shown in a simplified cross-sectional view. exist image 3 A side view is used to show the composition of the middle part of the working state of the heat pipe of the present invention.

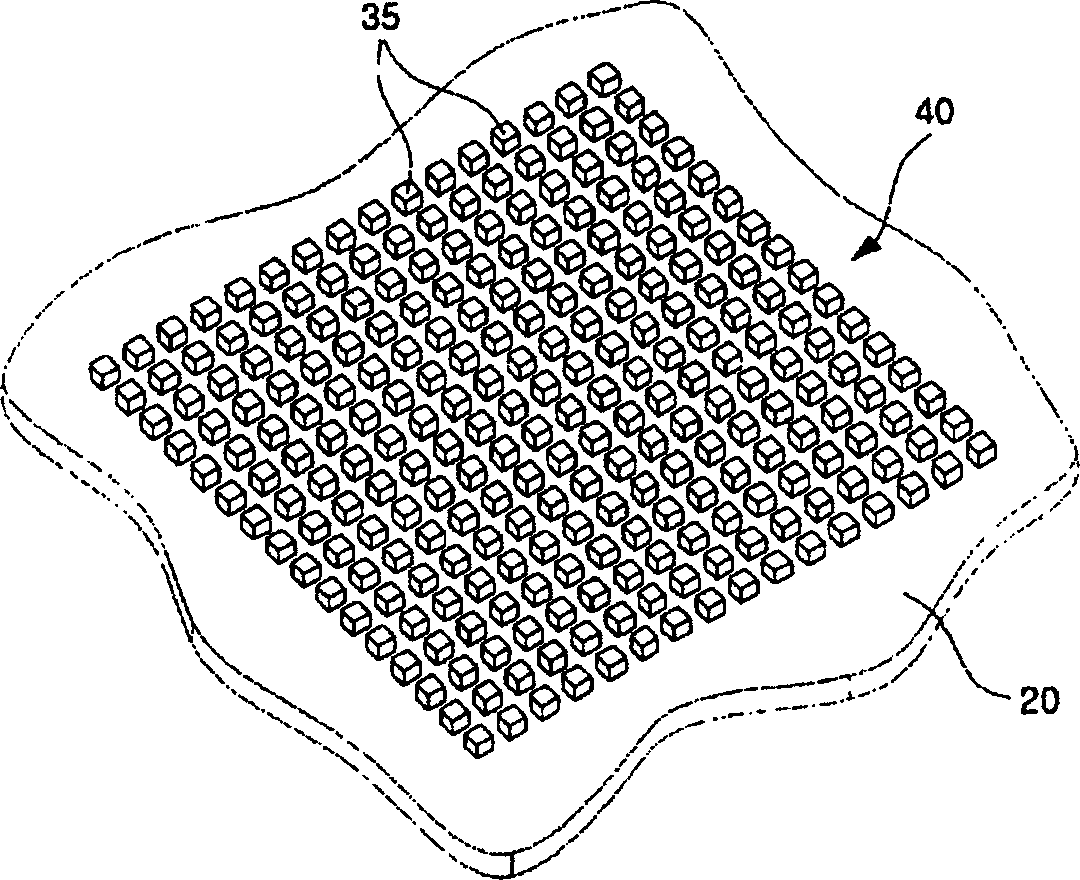

[0035] As shown in the figure, the appearance of the heat pipe is box-shaped. The box-shaped casing 20 of the heat pipe is in the shape of an oblate plate, and its cross section is in the shape of a circular tube or an oval tube. The box-shaped housing 20 is made of high-efficiency heat-conducting material. Metal materials such as copper or aluminum.

[0036] The inner wall of the box-shaped housing 20 is provided with capillary structures 25 . The capillary structure 25 is a porous structure capable of generating capillary force. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com