Fin-and-tube main heat exchanger for gas heating water heater and manufacturing method thereof

A main heat exchanger and gas heating technology, applied in the direction of indirect heat exchangers, heat exchanger types, manufacturing tools, etc., can solve the problems of small space volume, not easy to manufacture, and increased contact area of heat exchange tubes with flue gas, etc. To achieve the effect of expanding the heat conduction area and increasing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

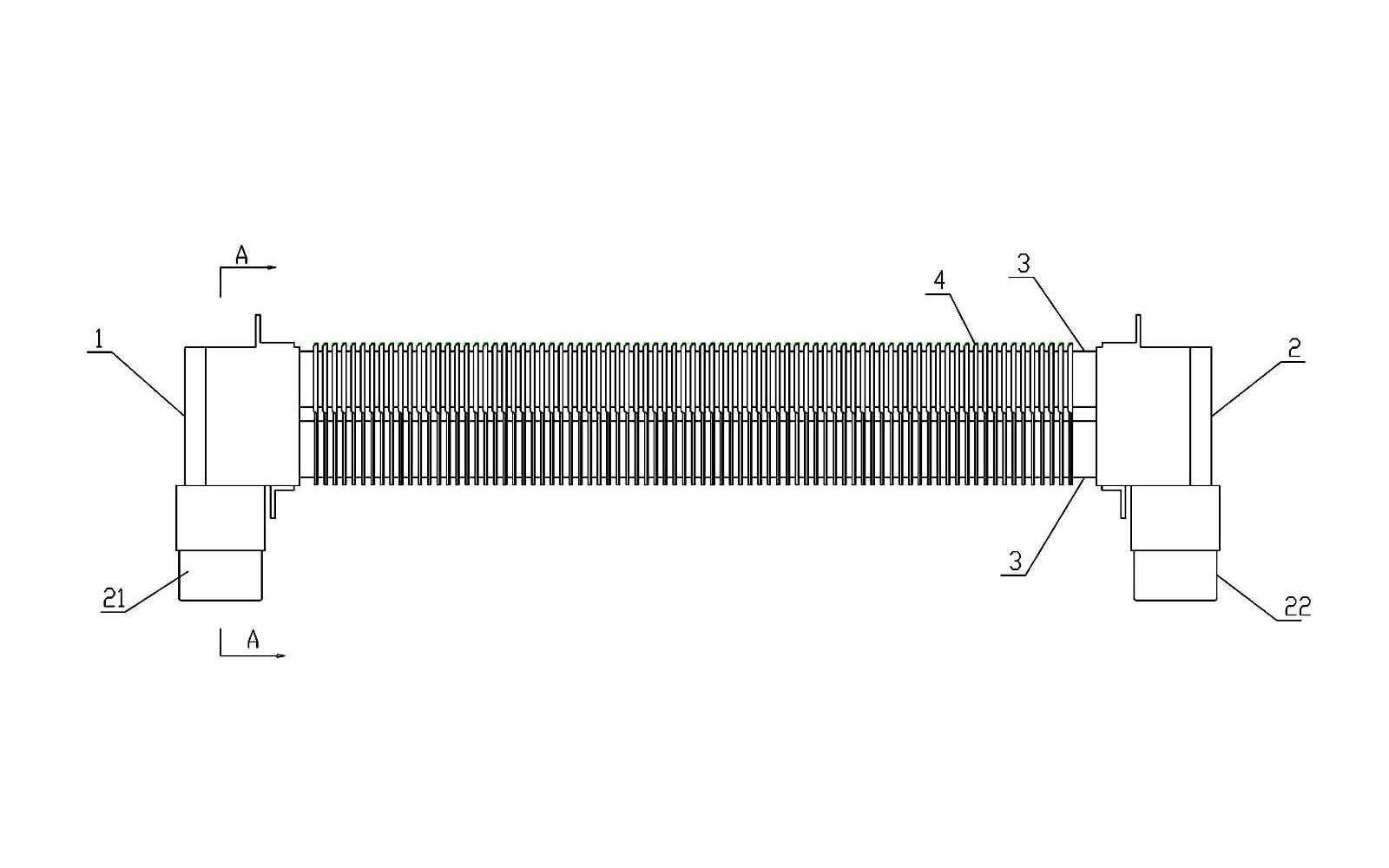

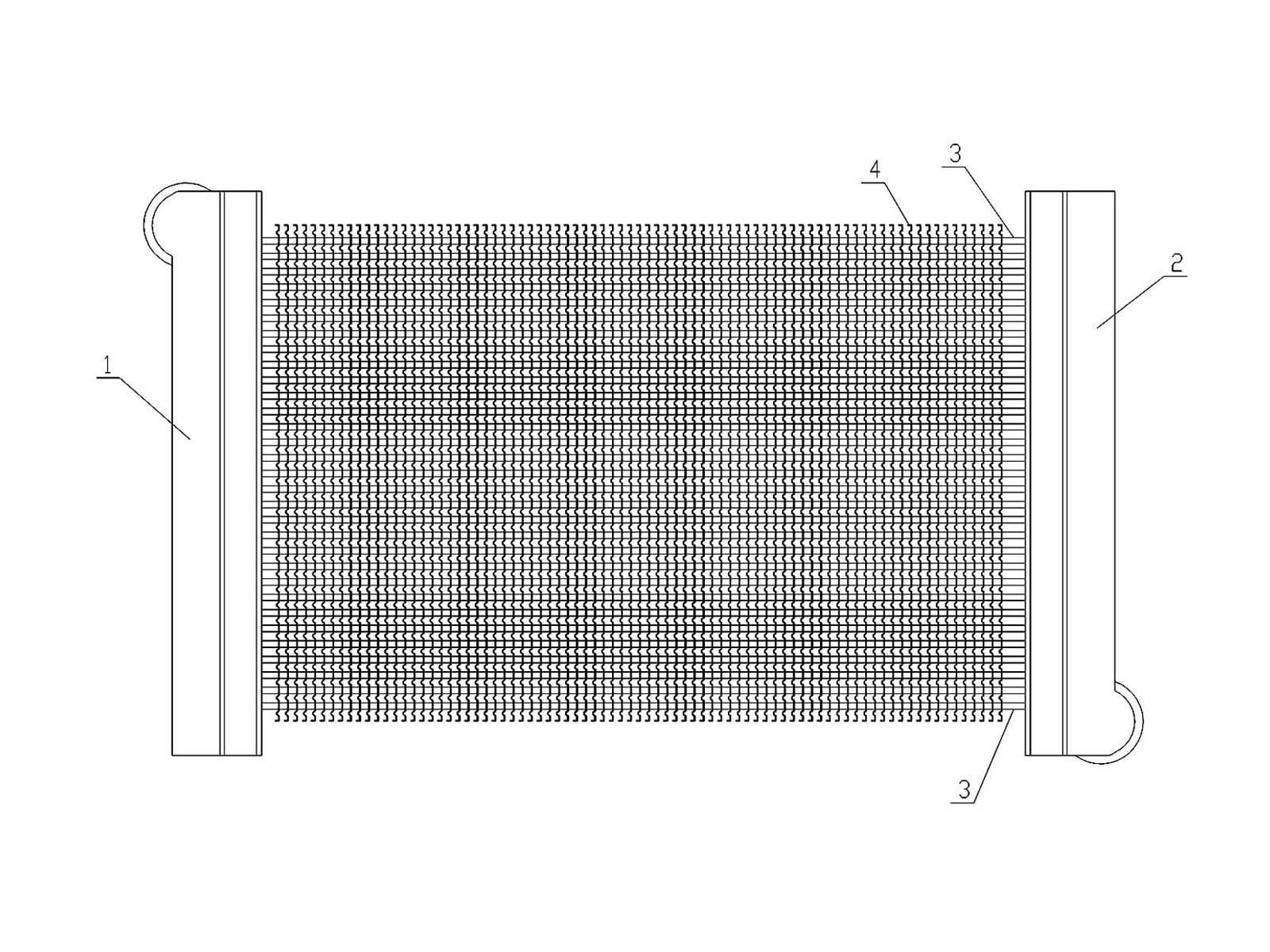

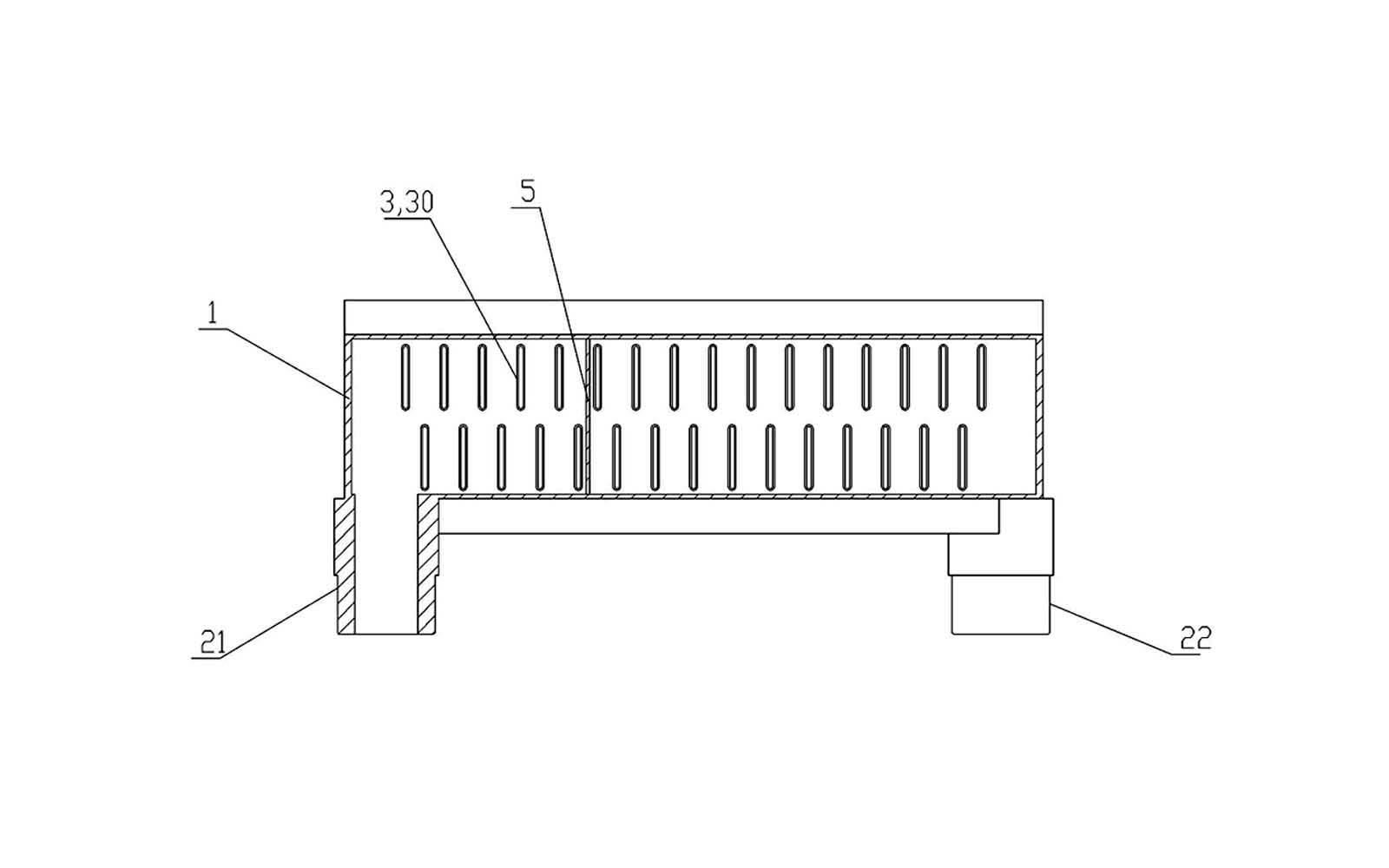

[0039] reference figure 1 —7. The fin-tube type main heat exchanger for gas-fired water heaters proposed by the present invention includes: a first water box 1, a second water box 2, a heat exchange flat tube 3 and fins 4, the first water The box 1 and the second water box 2 are paired to form a current collector; the first water box 1 has a water inlet and is externally connected with a water inlet connector 21; the second water box 2 is formed at a predetermined distance from the first water box 1 In the heat exchanger section, the second water box 2 of this embodiment has a water outlet and is externally connected to a water outlet connector 22; the water outlet and the water outlet connector 22 can also be provided on the first water box 1 as needed, and the first water box 2 and Each of the second water boxes 1 has a heat exchange flat tube insertion hole 30 corresponding to each other.

[0040] The heat exchange flat tube 3, the two ends of the heat exchange flat tube 3 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com