Vertical gas fired boiler

A gas-fired boiler and vertical technology, which is applied in the field of vertical gas-fired atmospheric hot water boilers, can solve the problems of large gas consumption, small heat exchange area, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

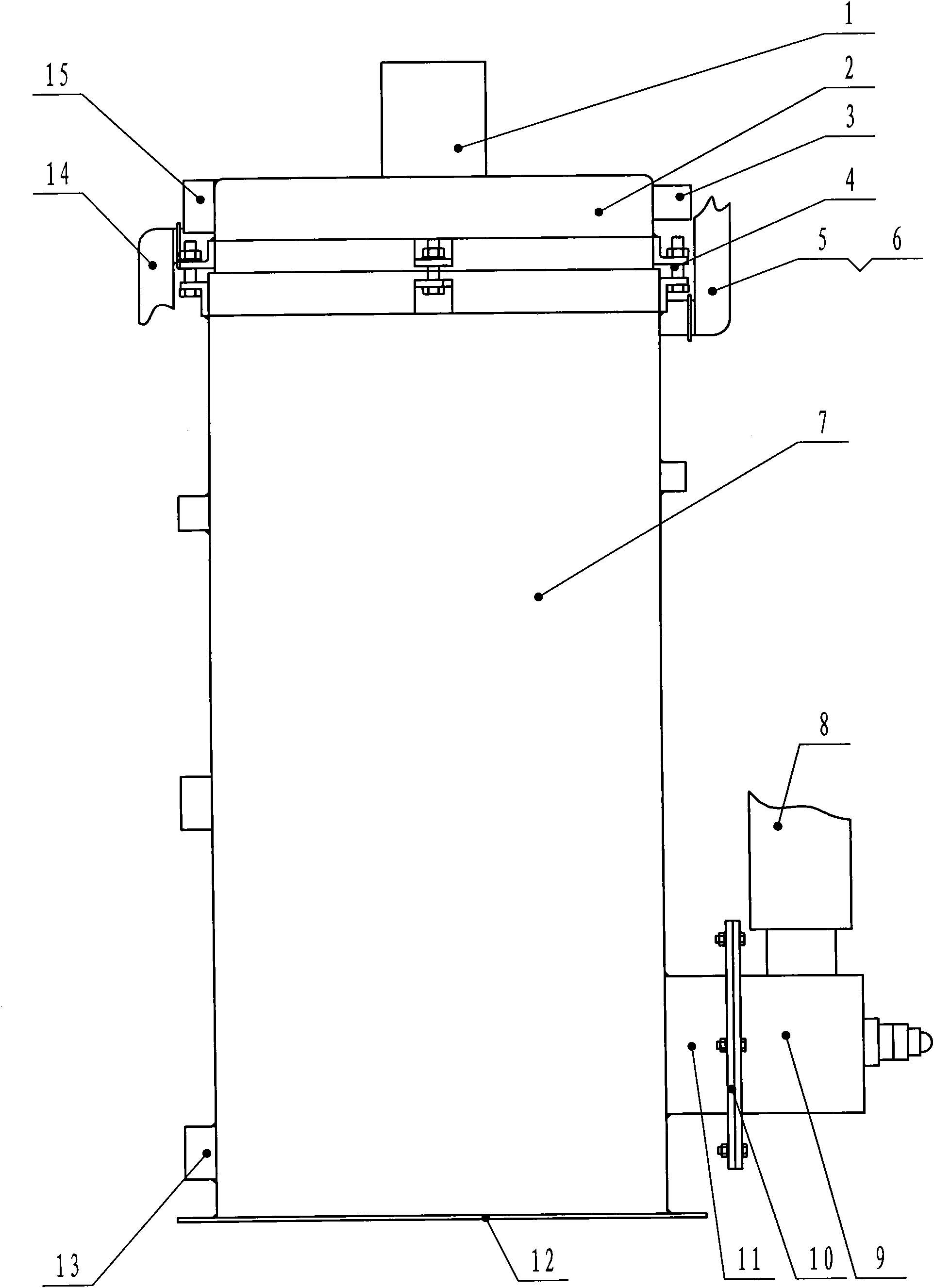

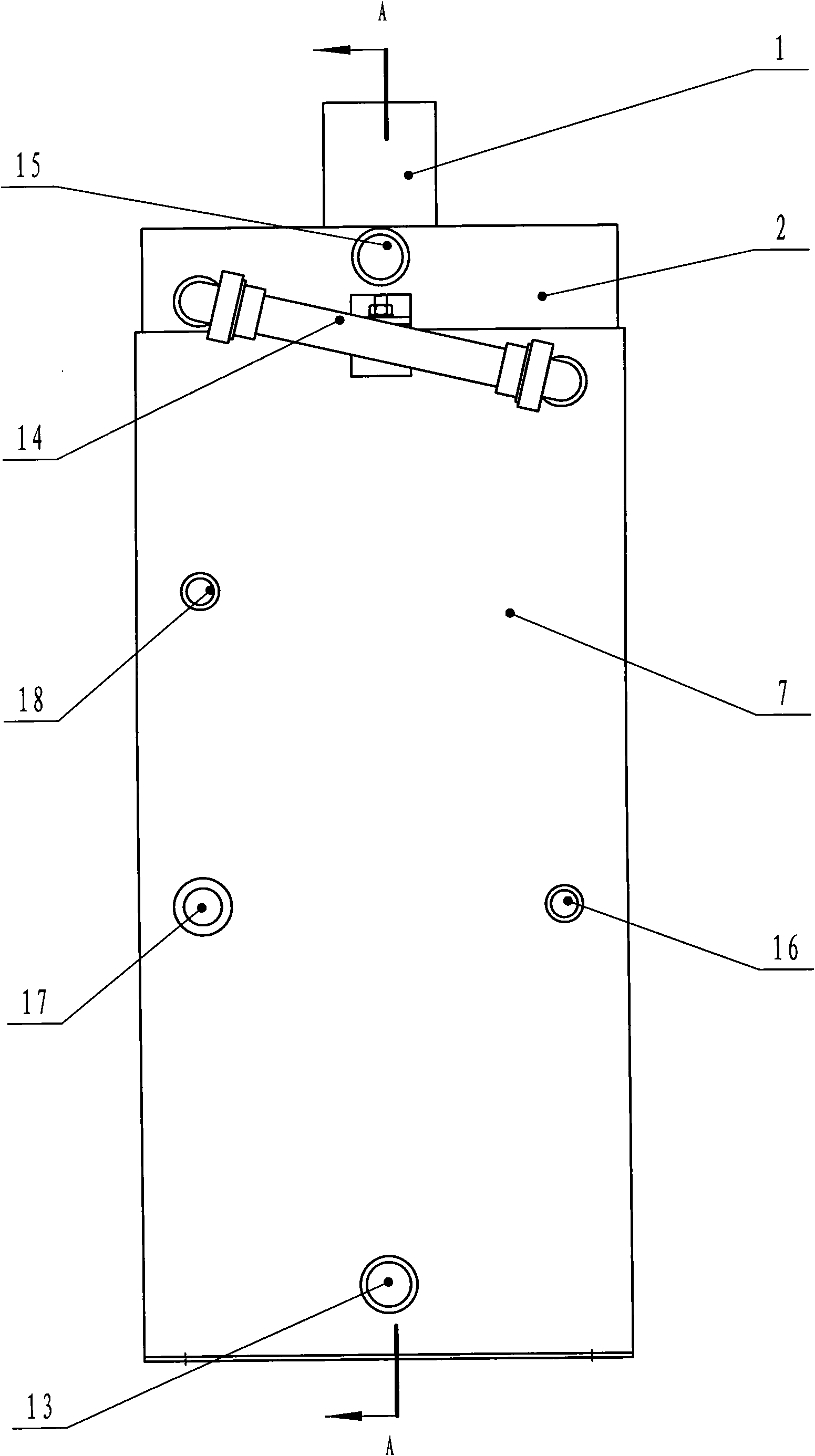

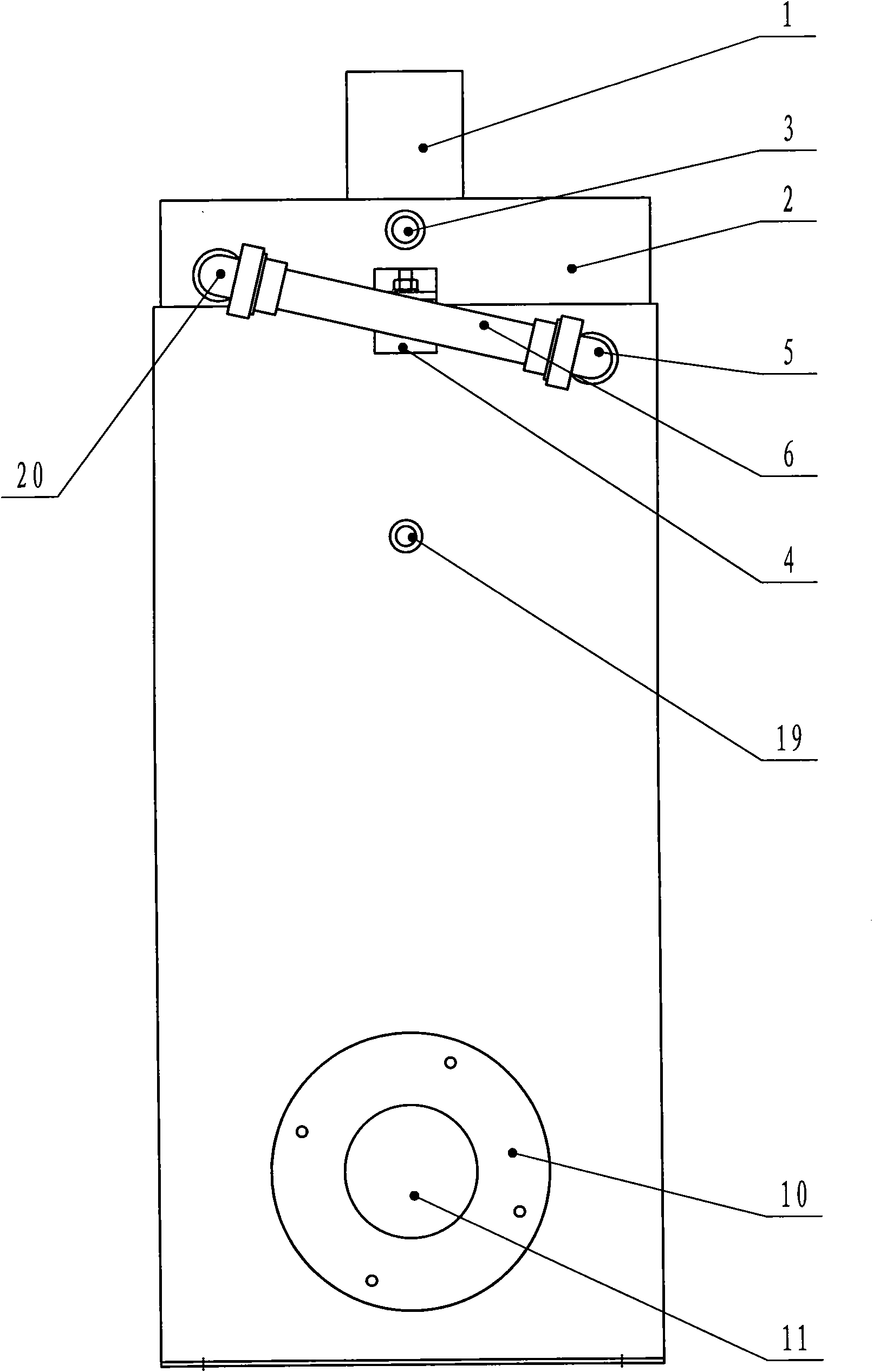

[0045] figure 1 , figure 2 , image 3 and Figure 4The described vertical gas boiler includes a chimney 1, a smoke exhaust cover 2, a furnace outer tank 25, a water chamber 24, a fire tube 34, a furnace and a furnace door pipe 11, the chimney 1 is welded on the smoke exhaust cover 2, and the smoke exhaust cover 2 Be installed on the top of the outer bladder 25 and be fastened together by fasteners, the return pipe 13 and the furnace door pipe 11 are fixed at the outer bladder 25, and the outer bladder 25 is the base 12. Four upper side plates 37 forming a circle are welded inside the outer furnace bladder 25, the interval between the outer furnace bladder 25 and the upper side plates 37 constitutes the upper interlayer water jacket 22, and the upper end of the upper interlayer water jacket 22 is closed. The upper flower plate 23 of the distribution through hole is welded under the upper side plate 37 in the outer furnace 25, and the upper furnace 21 is formed between the s...

Embodiment 2

[0053] The structure of this embodiment is simpler than that of Embodiment 1, and it is easier to popularize. It just installs the water pipe in the fire pipe of the existing vertical gas boiler, see Figure 10 . It includes a chimney 58, a smoke exhaust cover 59, an outer furnace bladder 69, a water chamber 70, a fire pipe 85, a furnace 81 and a furnace door pipe 74. The chimney 58 is welded on the smoke exhaust cover 59, and the smoke exhaust cover 59 is installed outside the furnace The top of the gallbladder 69 is fastened together by fastening bolts 63 and hexagonal nuts 64, and there is an insulating material 60 between the outer casing and the inner casing of the smoke exhaust cover 59. Backwater pipe 78 and furnace door pipe 74 are fixed at outer furnace 69, and base 75 is under the outer furnace 69. Four upper side plates 67 are welded on the inner side of the outer bladder 69, the interval between the outer bladder 69 and the upper side plate 67 constitutes an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com