Patents

Literature

902results about How to "Lower exhaust gas temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

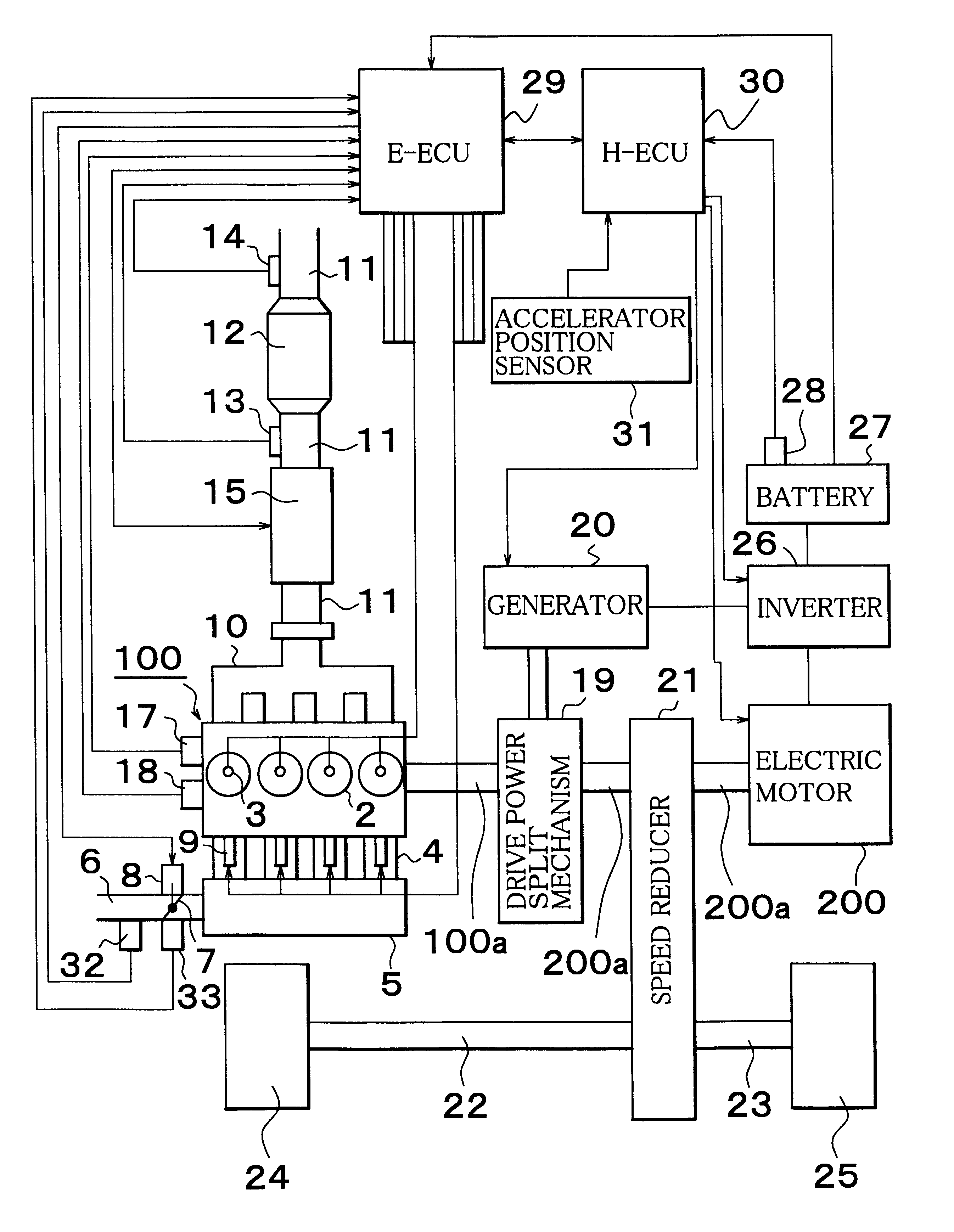

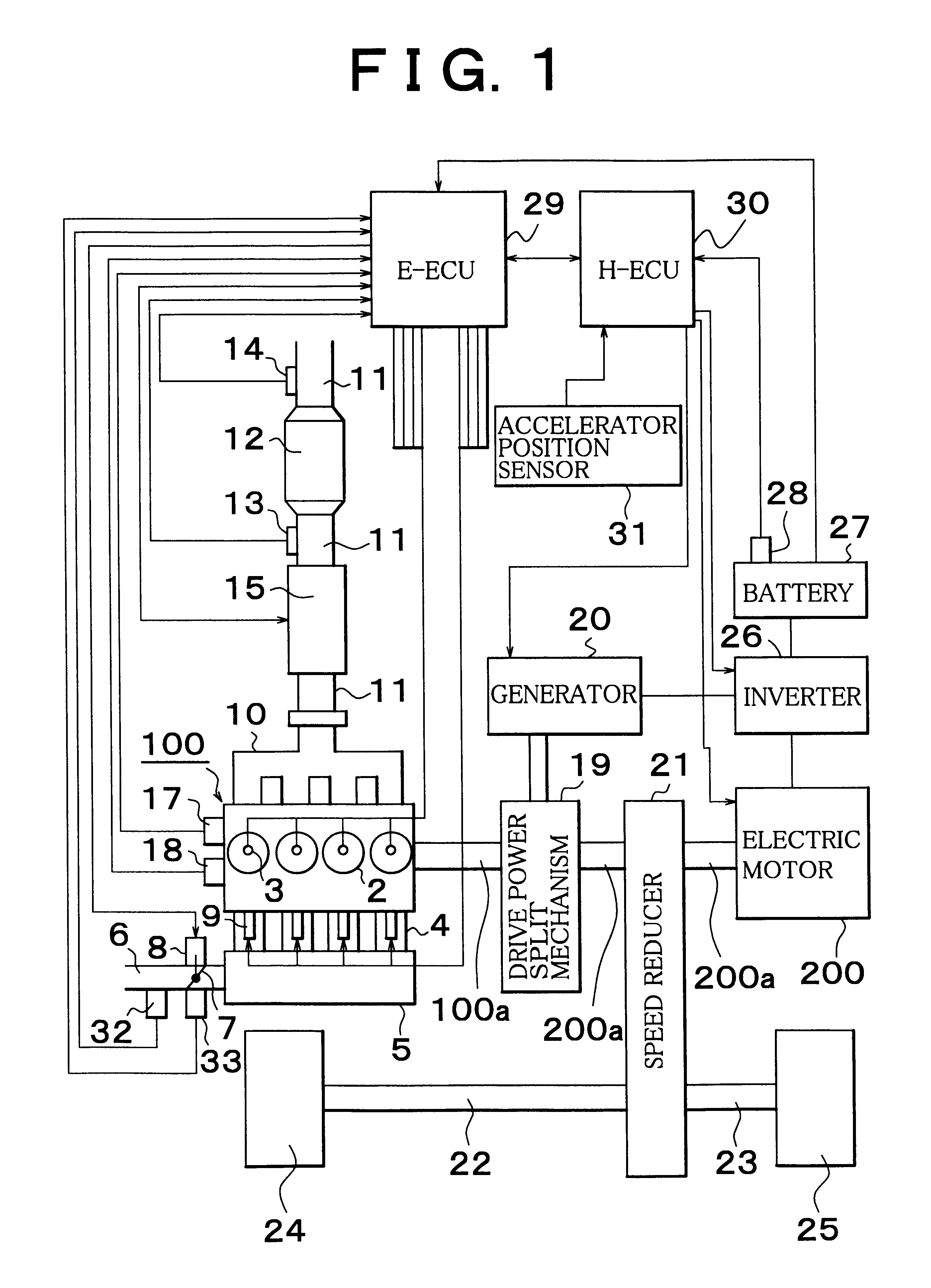

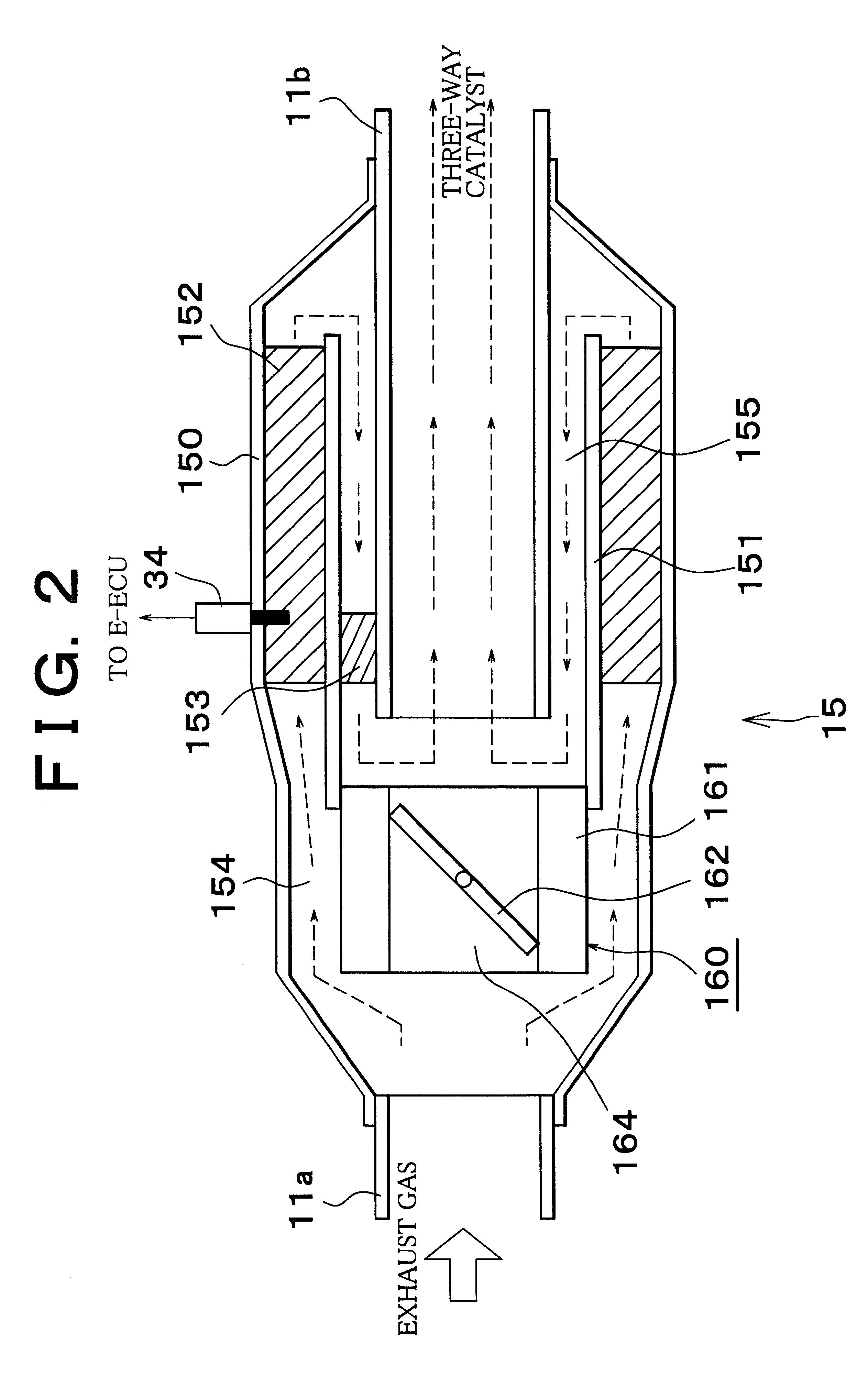

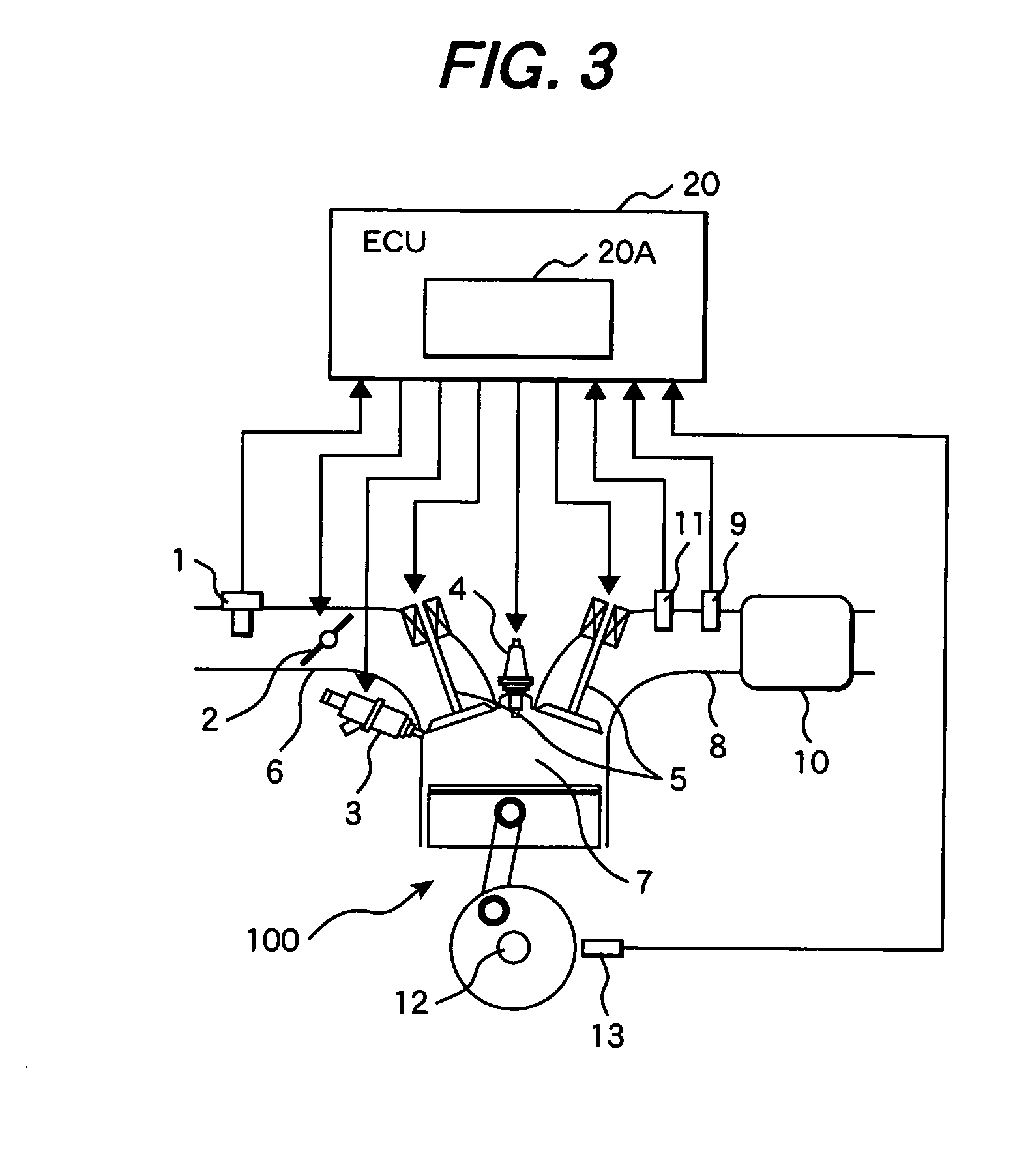

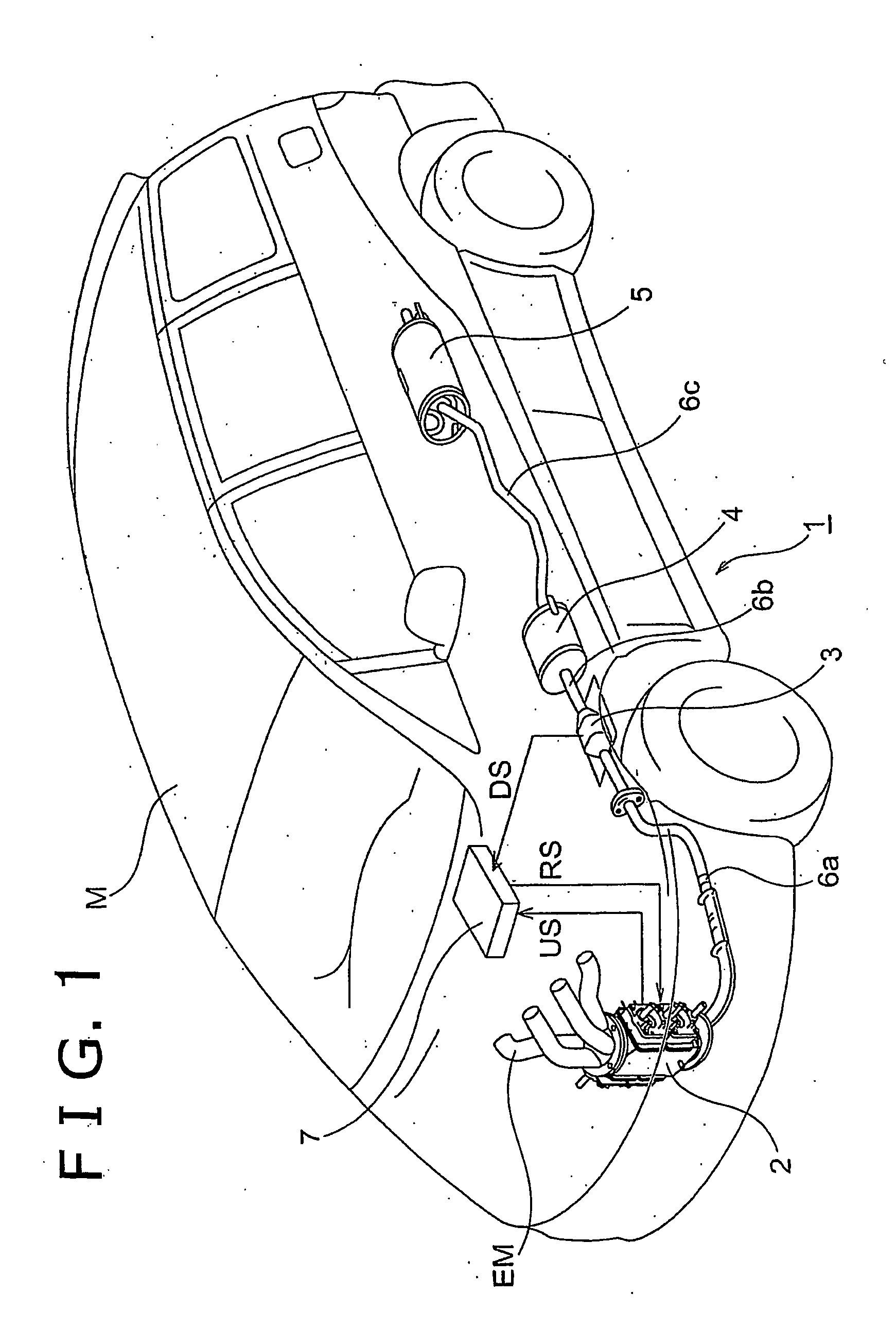

Exhaust gas emission control apparatus of hybrid vehicle

InactiveUS6327852B1Increase slowlyLower exhaust gas temperatureHybrid vehiclesElectrical controlSorbentExhaust fumes

An exhaust gas emission control apparatus is provided in an exhaust passage of a hybrid mechanism driven by an internal combustion engine and an electric motor. The apparatus has an adsorbent that adsorbs unburned fuel contained in exhaust gas when the temperature of the adsorbent is lower than a predetermined temperature, and that releases adsorbed unburned fuel therefrom when the temperature is at least the predetermined temperature. When the temperature of the adsorbent is lower than the predetermined temperature, the apparatus controls the hybrid mechanism to delay an increase in the temperature of the adsorbent.

Owner:TOYOTA JIDOSHA KK

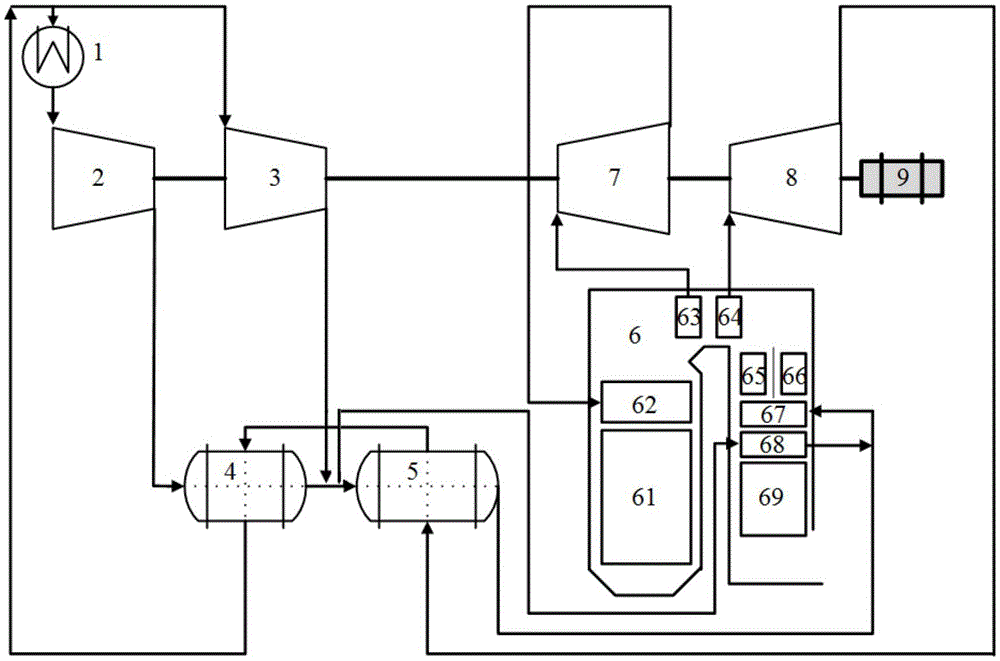

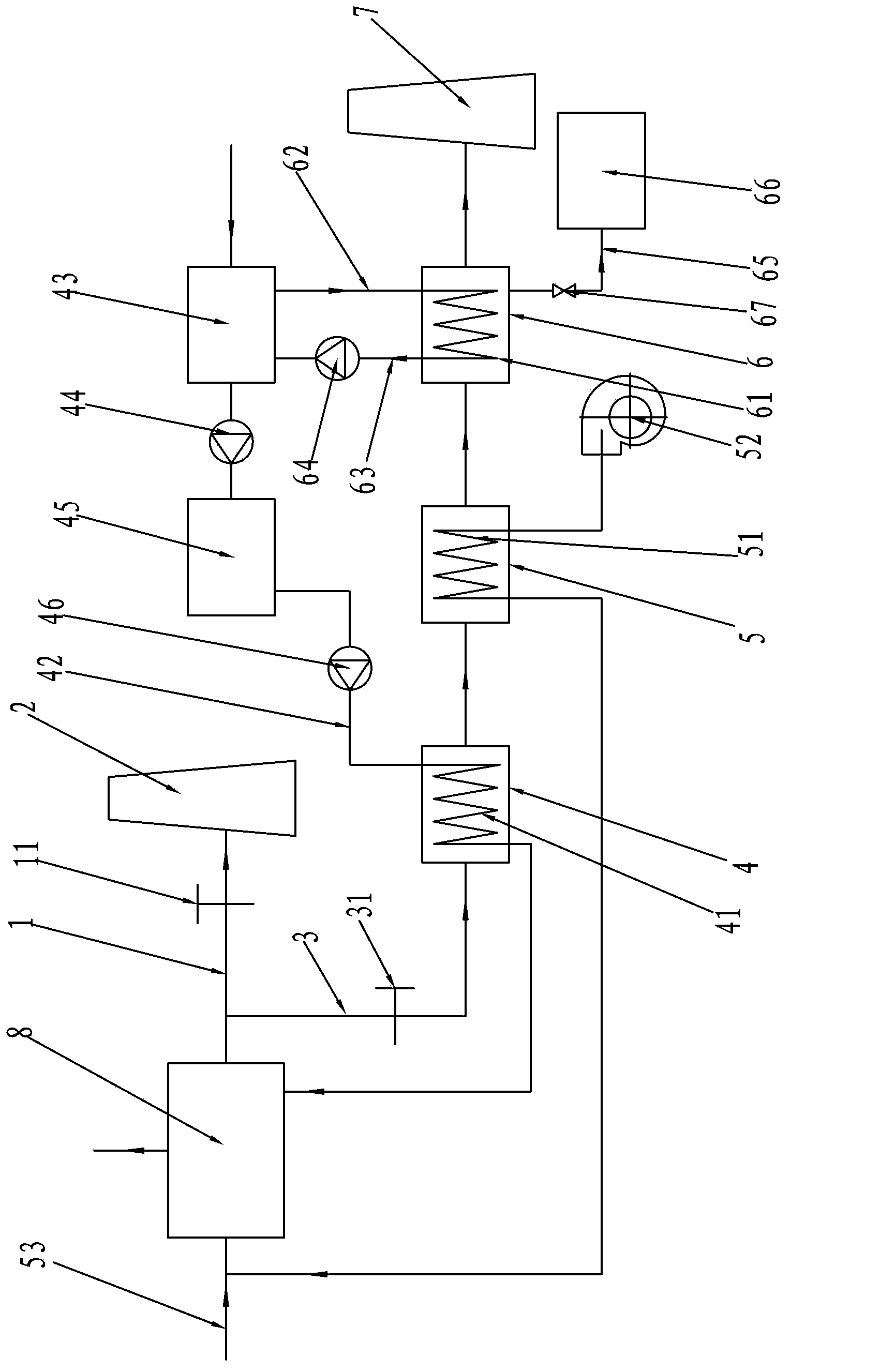

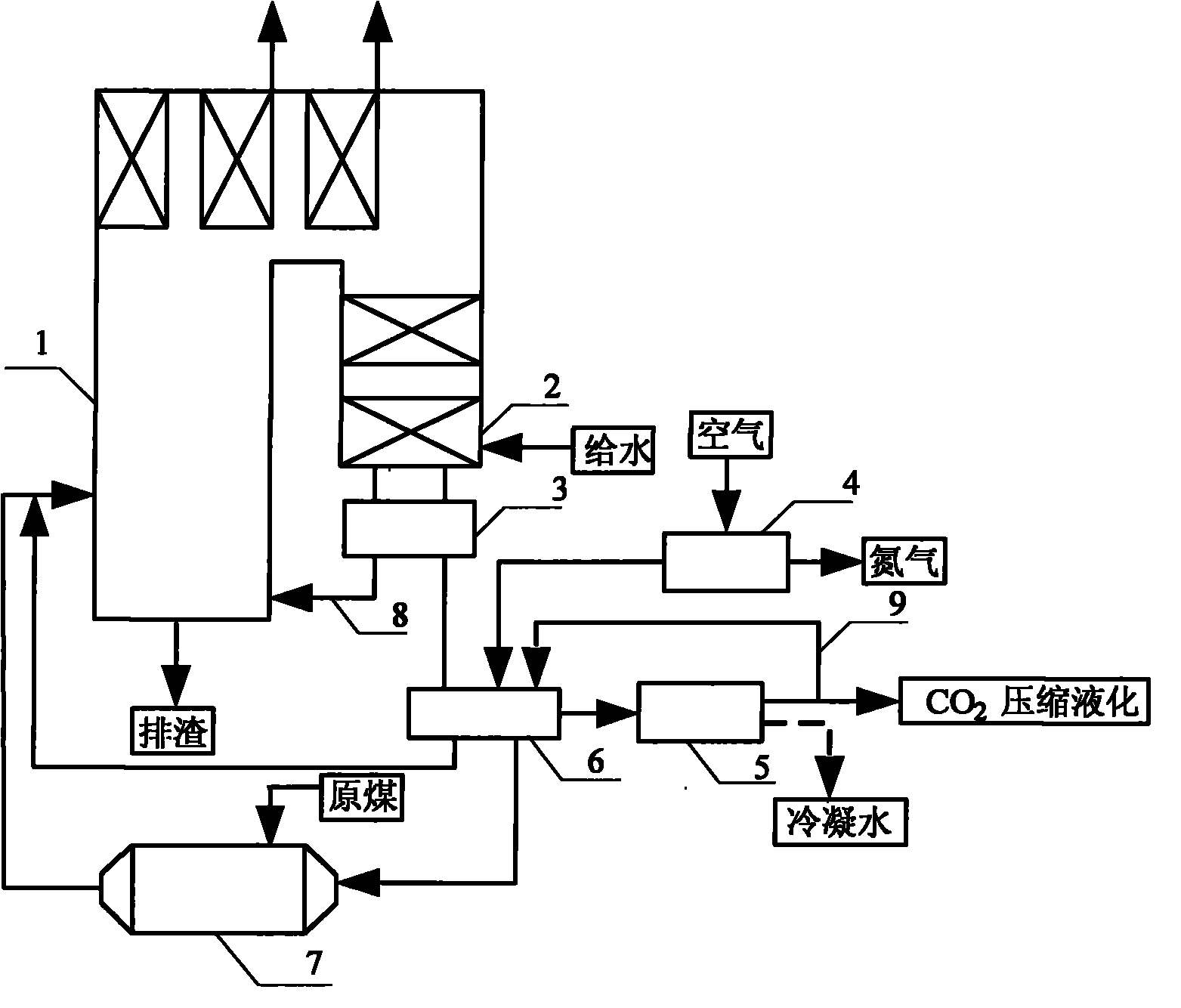

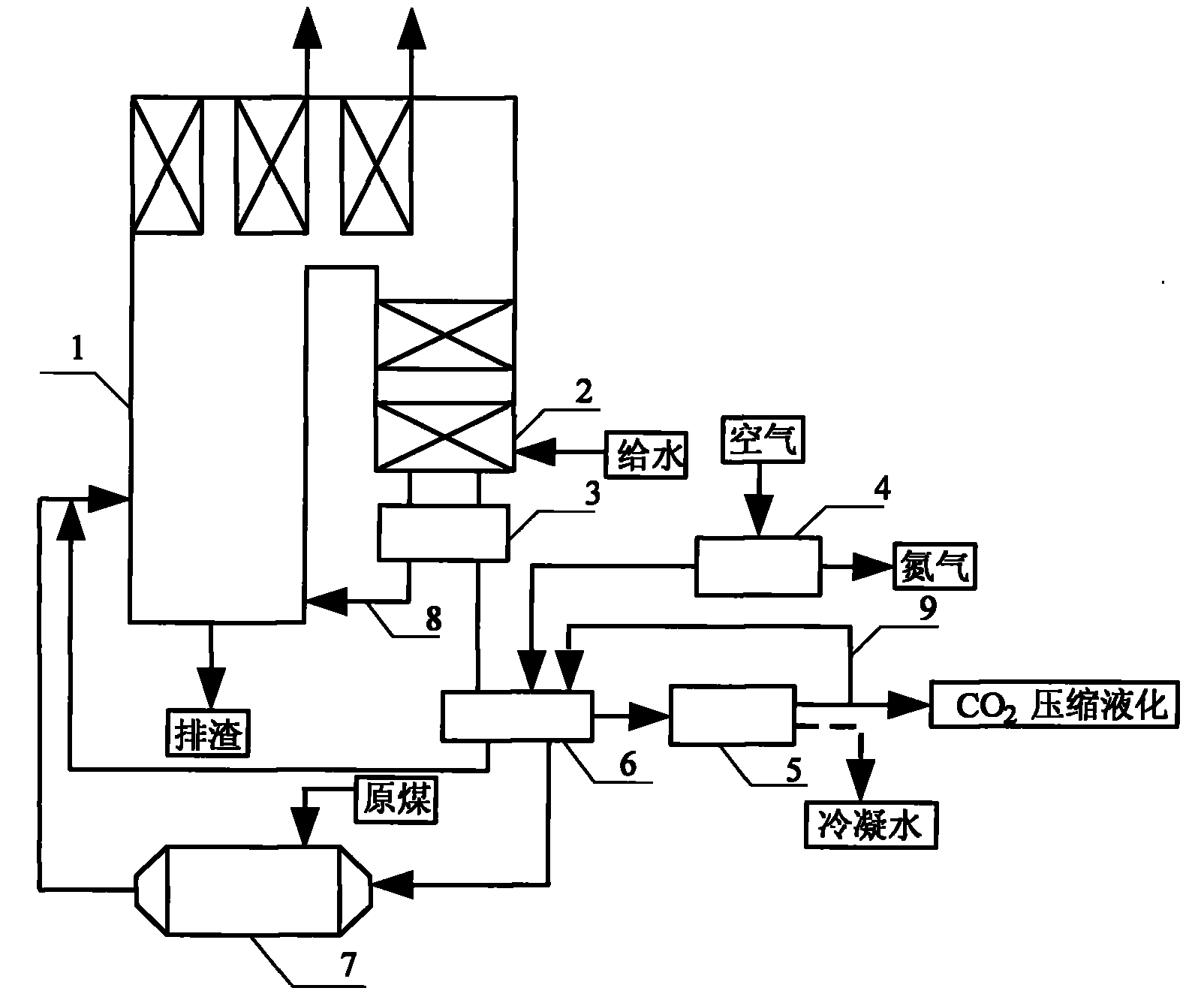

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

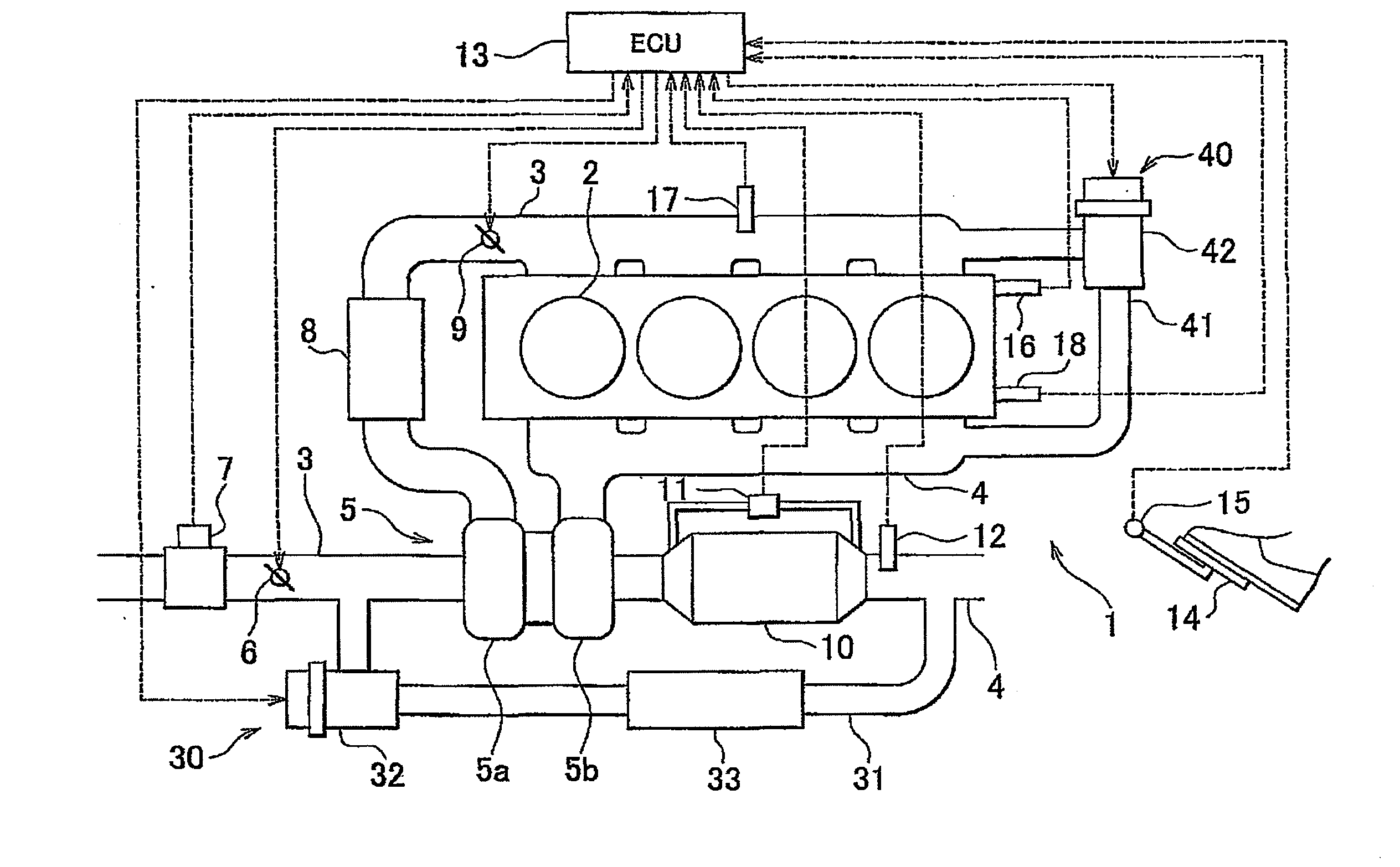

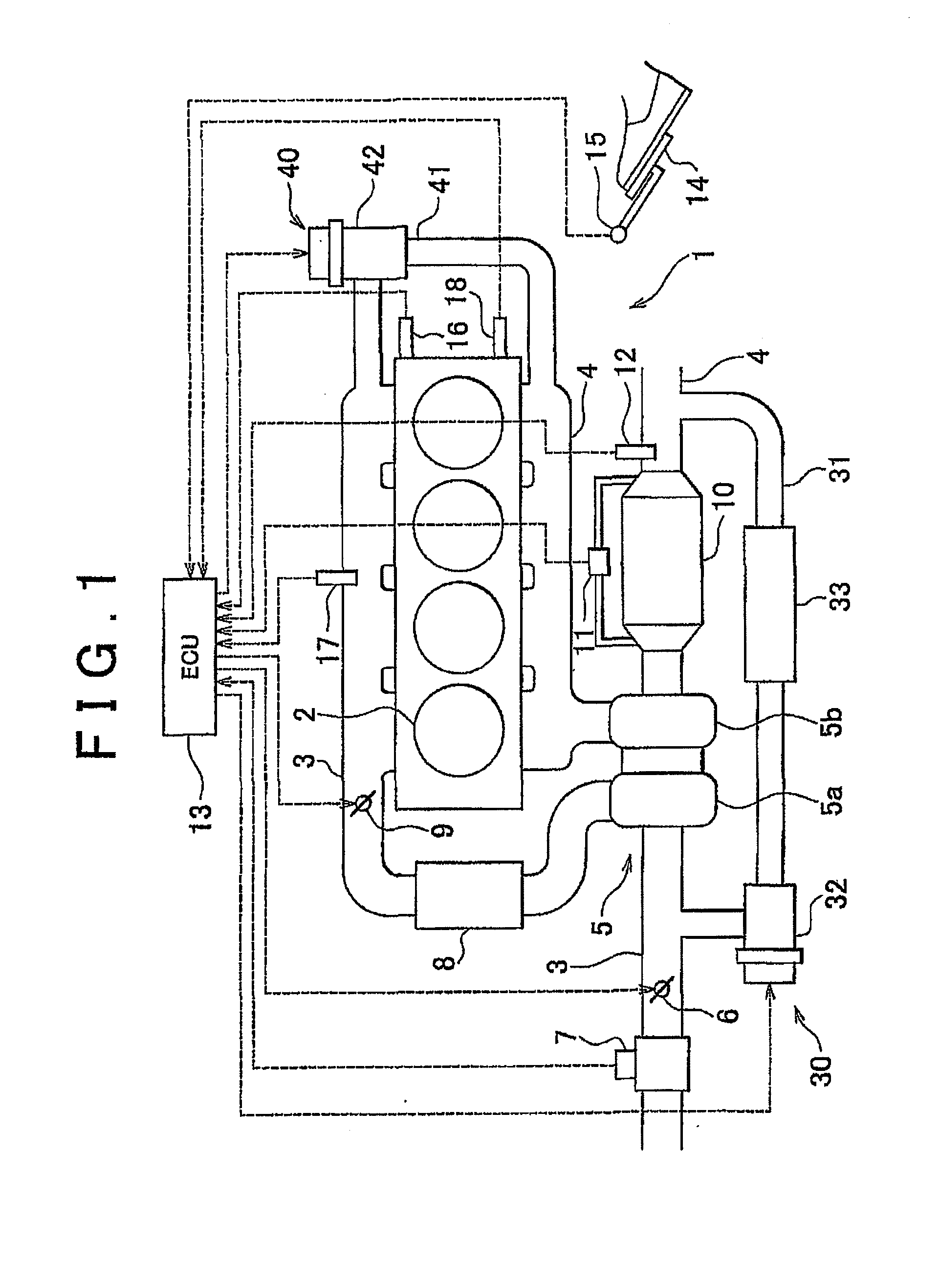

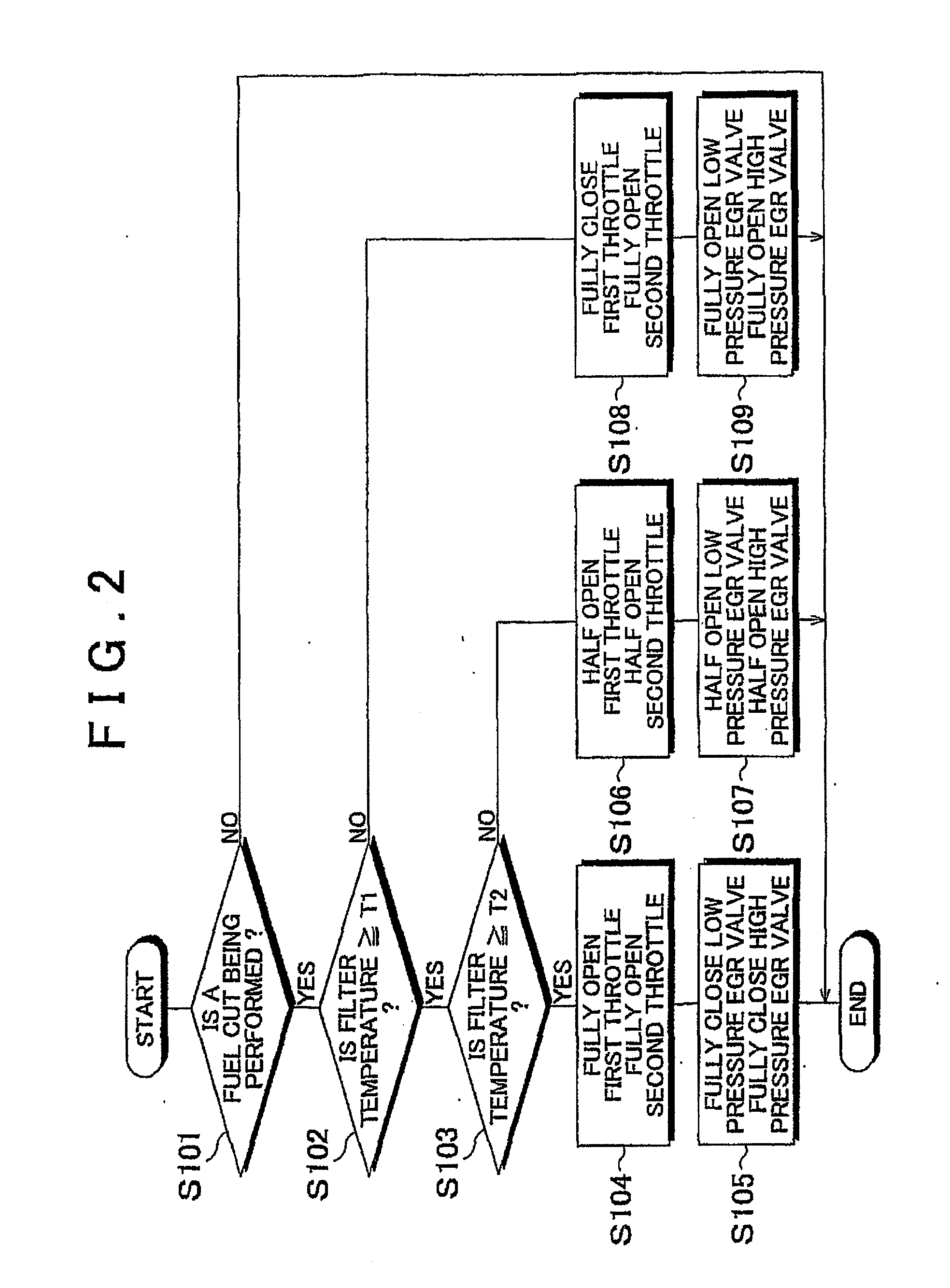

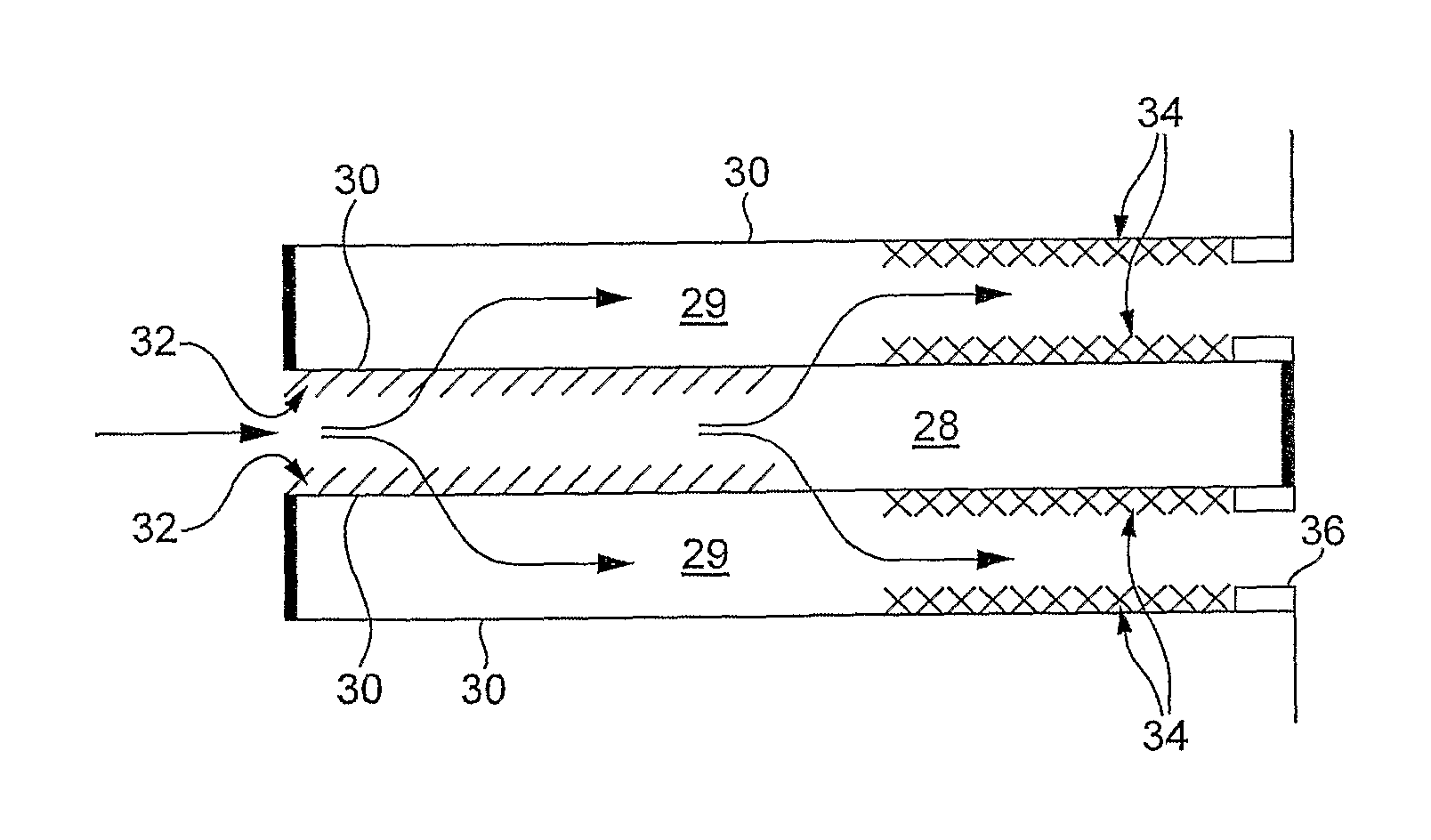

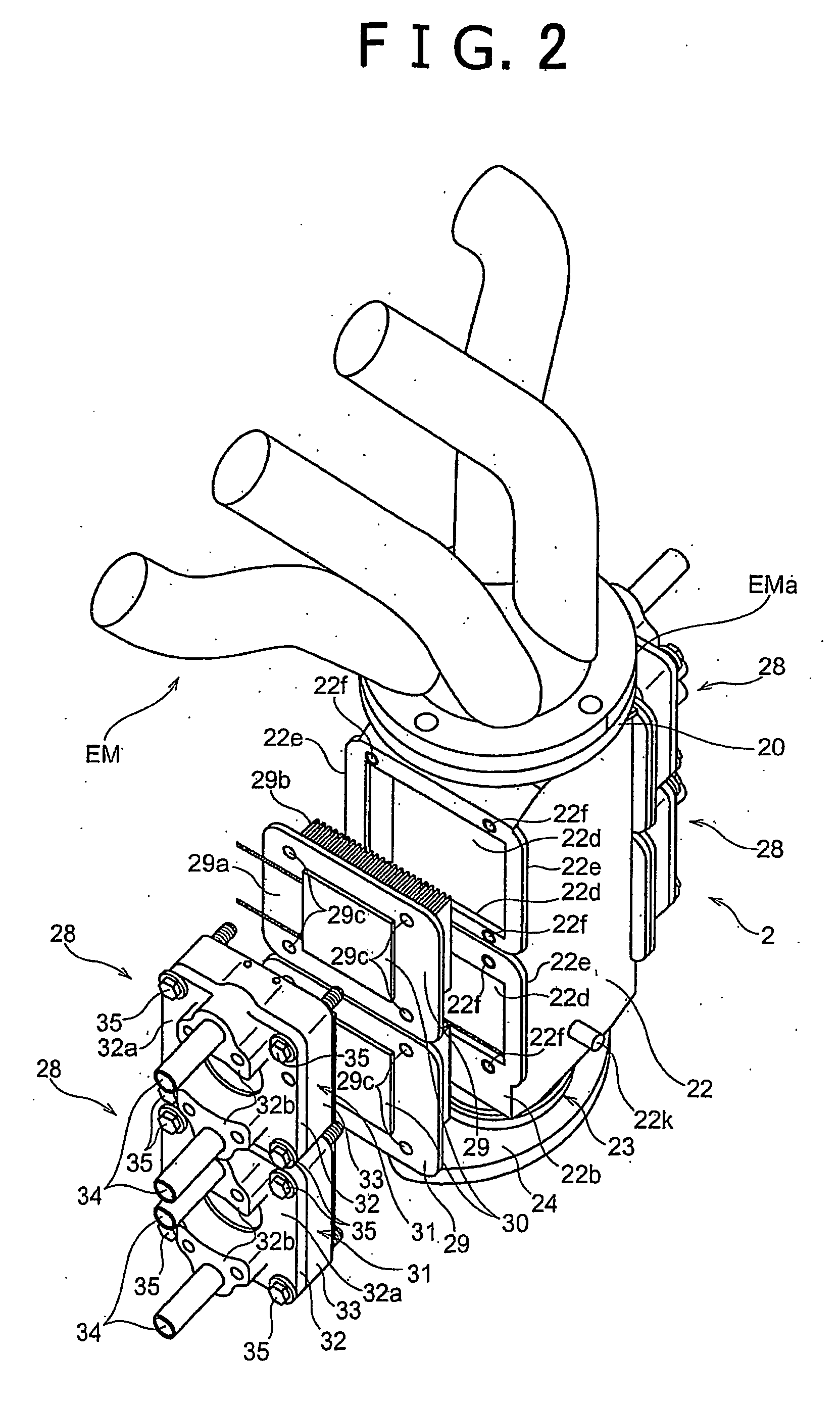

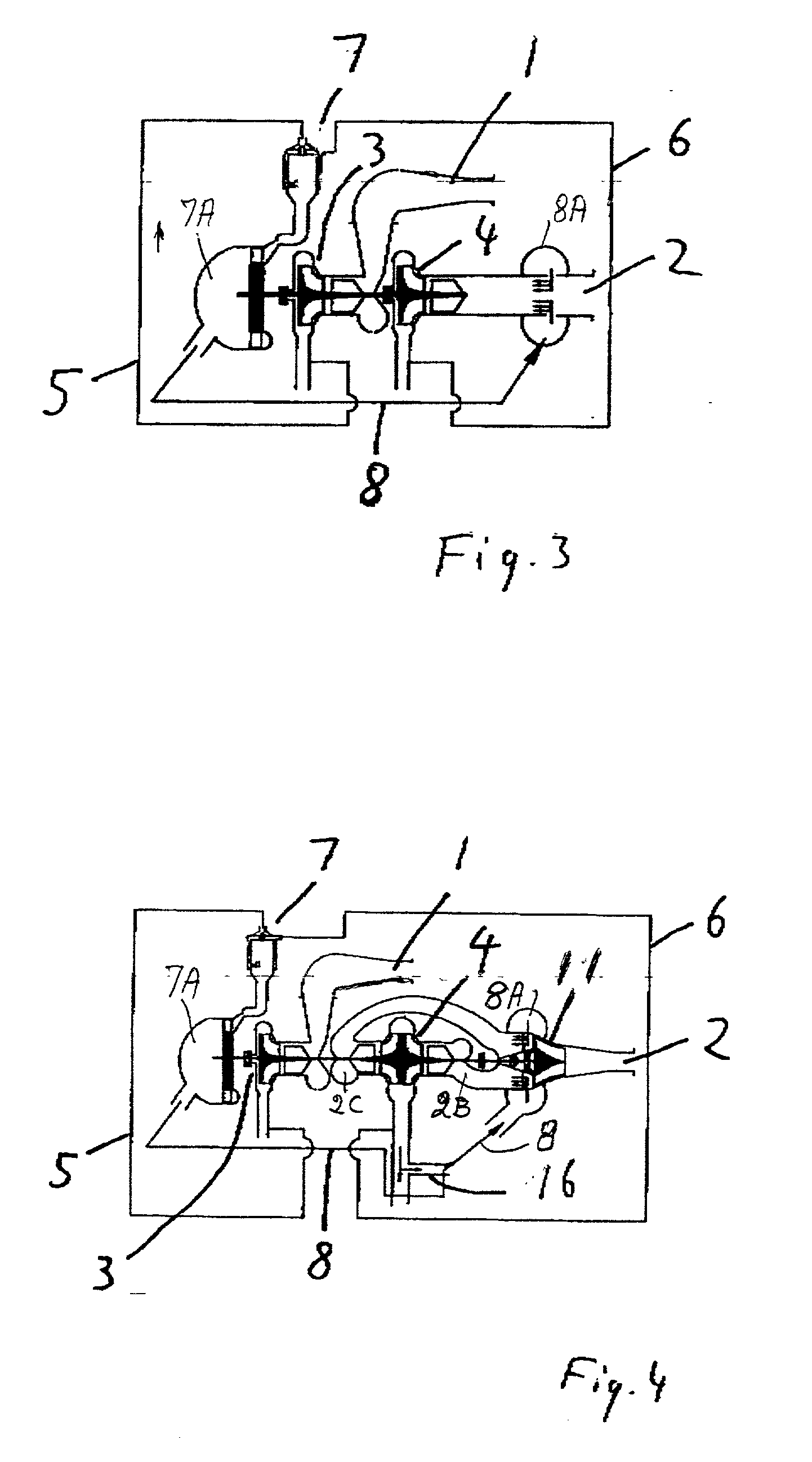

Exhaust Gas Recirculation Apparatus of an Internal Combustion Engine and Control Method Thereof

InactiveUS20080295514A1Reduce the amount requiredReduce the amount of solutionElectrical controlNon-fuel substance addition to fuelExternal combustion engineTurbocharger

An exhaust gas recirculation apparatus of an internal combustion engine includes a turbocharger provided with a turbine in an exhaust passage and a compressor in an intake passage, a low pressure EGR passage which connects the exhaust passage downstream of the turbine with the intake passage upstream of the compressor, a high pressure EGR passage which connects the exhaust passage upstream of the turbine with the intake passage downstream of the compressor; an exhaust gas control catalyst provided in the exhaust passage downstream of the turbine and upstream of the low pressure EGR passage; and EGR gas amount changing means for simultaneously changing amounts of EGR gas flowing through the low pressure EGR passage and the high pressure EGR passage such that a temperature of the exhaust gas control catalyst is within a target range.

Owner:TOYOTA JIDOSHA KK

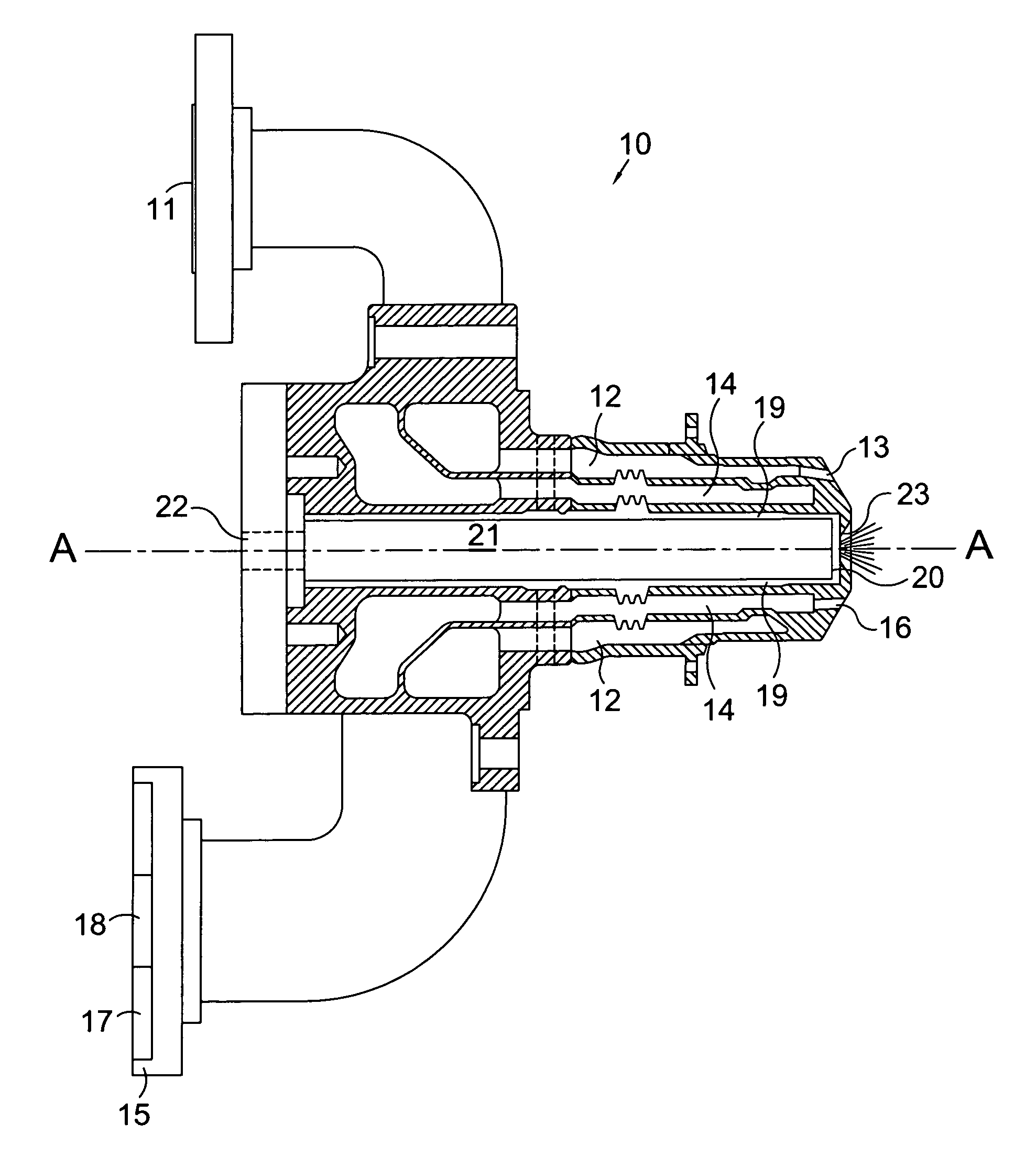

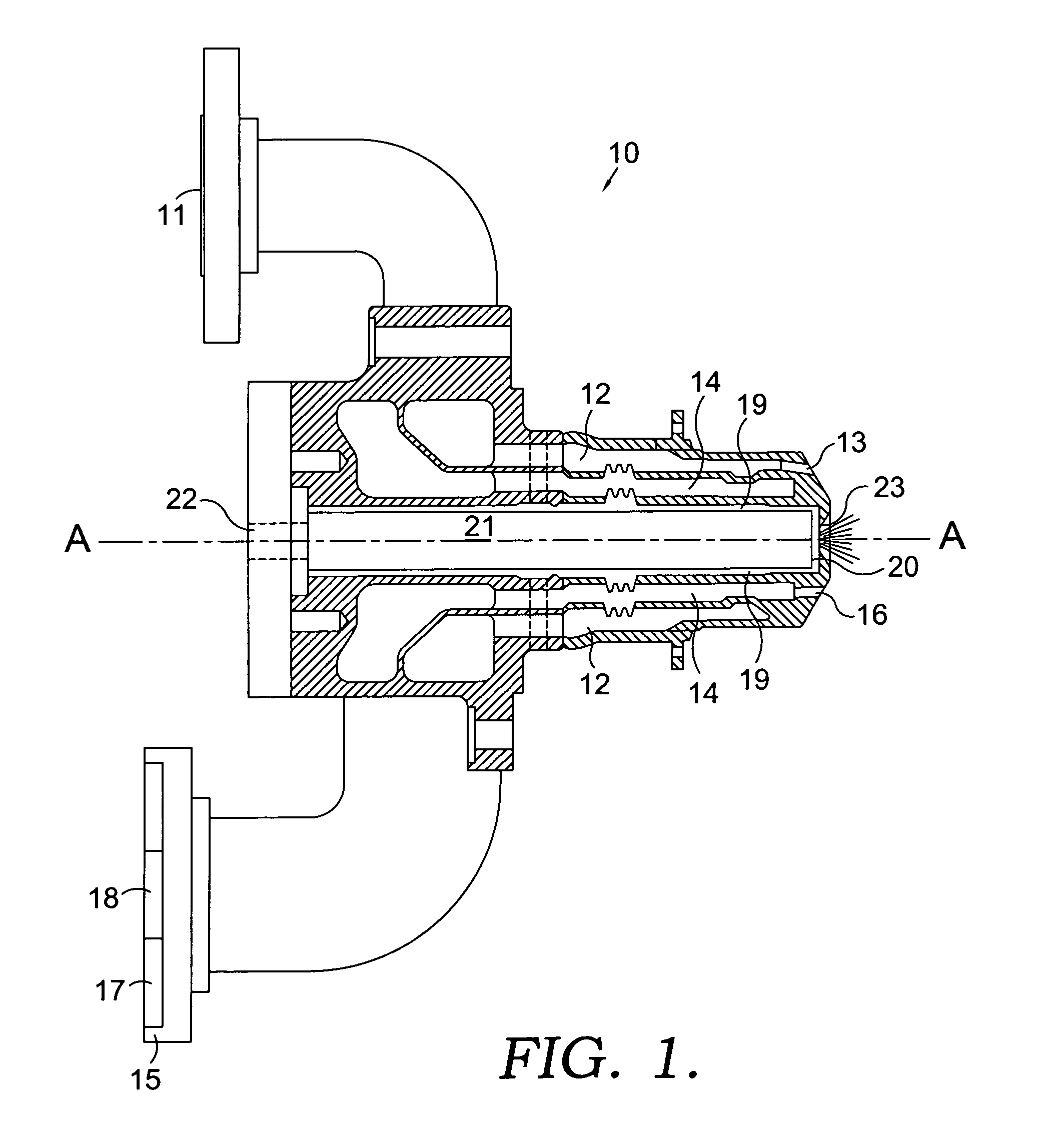

Exhaust system for a lean burn IC engine

InactiveUS20110179777A1Avoid and reduce pore blockageReduces and overcomes problemInternal combustion piston enginesDispersed particle separationNitric oxideEngineering

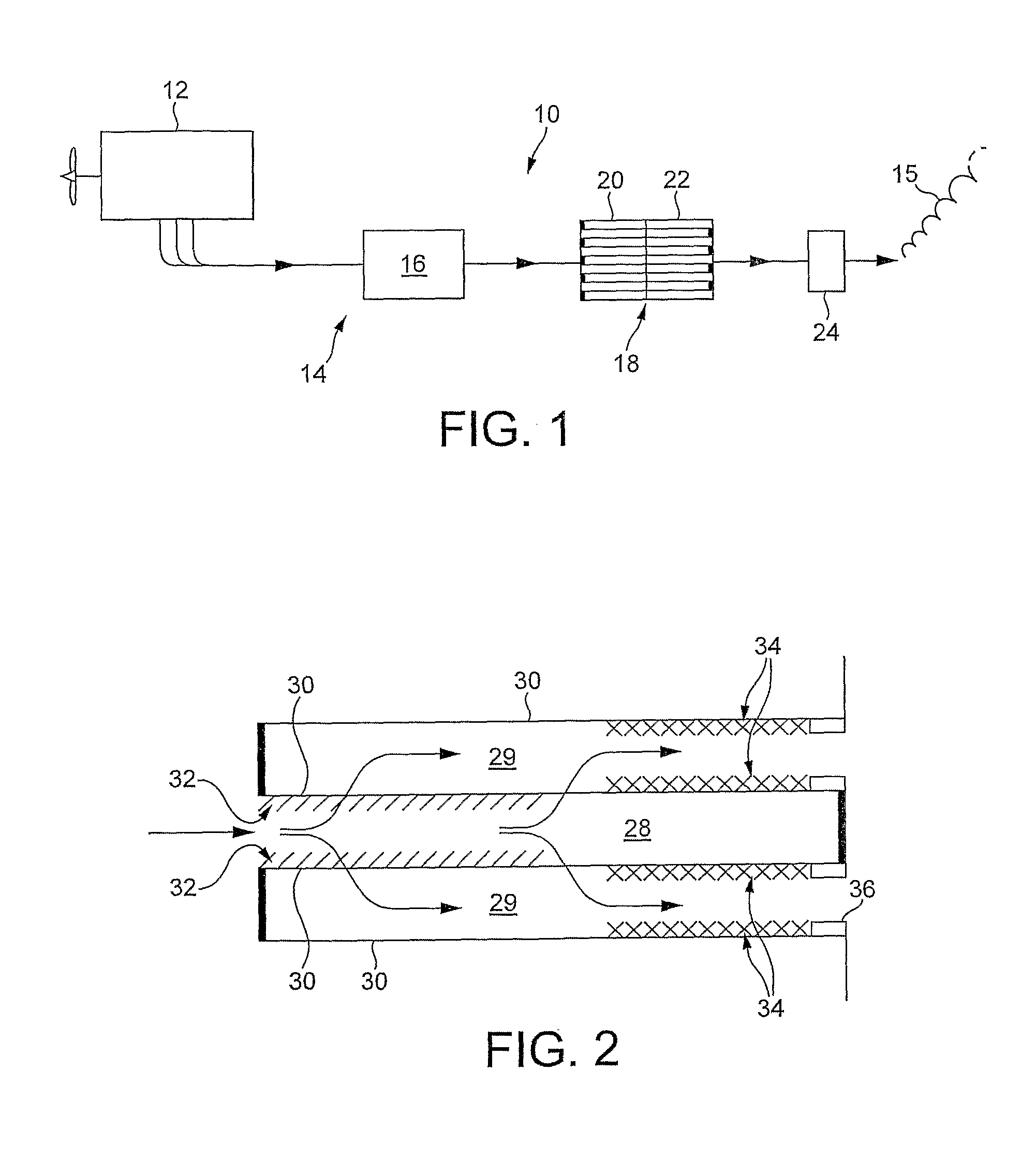

An exhaust system(10) for a lean-burn internal combustion engine (12) comprises a first substrate monolith (16) comprising a catalyst for oxidising nitric oxide (NO) comprising a catalytic oxidation component followed downstream by a second substrate monolith (18) which is a wall-flow filter having inlet channels and outlet channels, wherein the inlet channels comprise a NO x absorber catalyst (20) and the outlet channels comprise a catalyst for selective catalytic reduction (22) of nitrogen oxides with nitrogenous reductant.

Owner:JOHNSON MATTHEY PLC

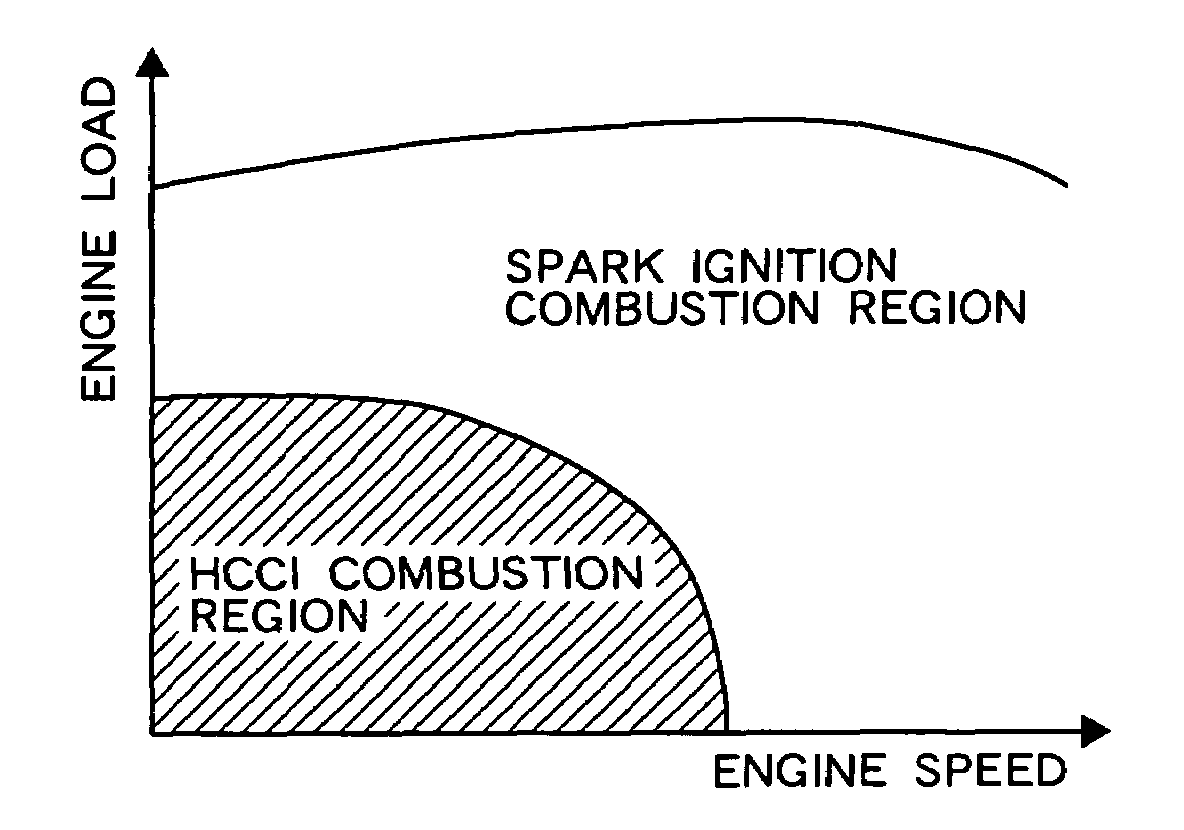

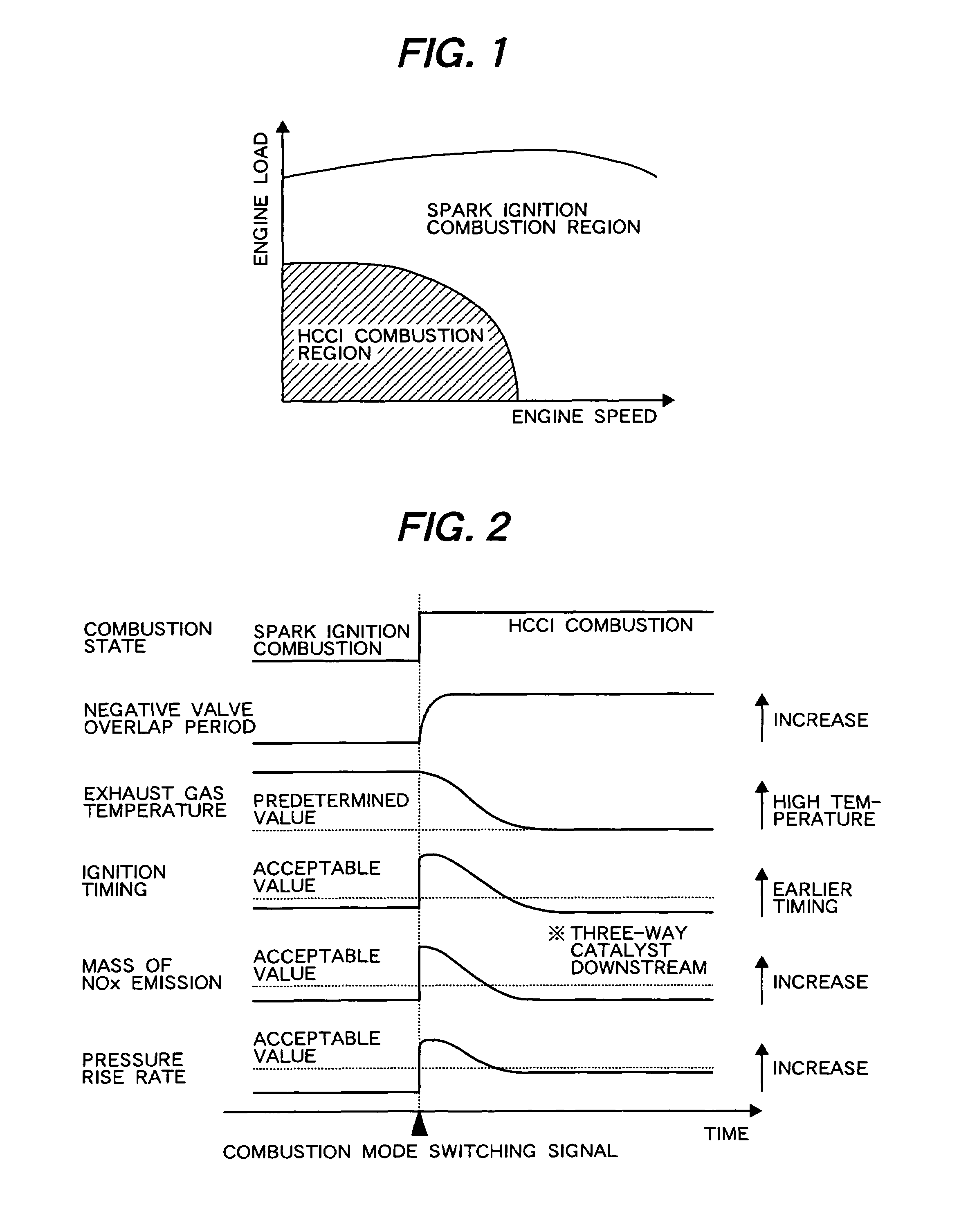

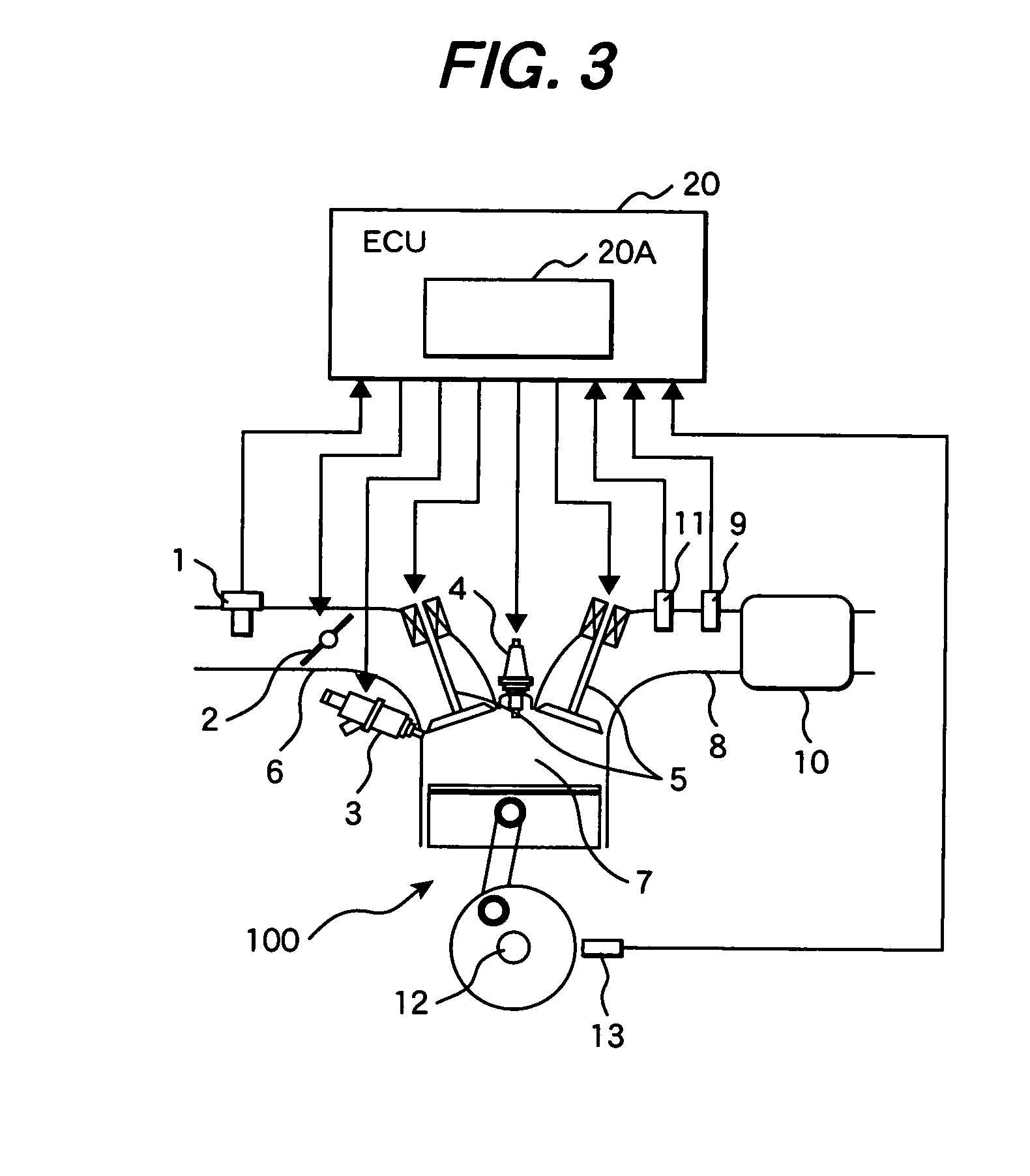

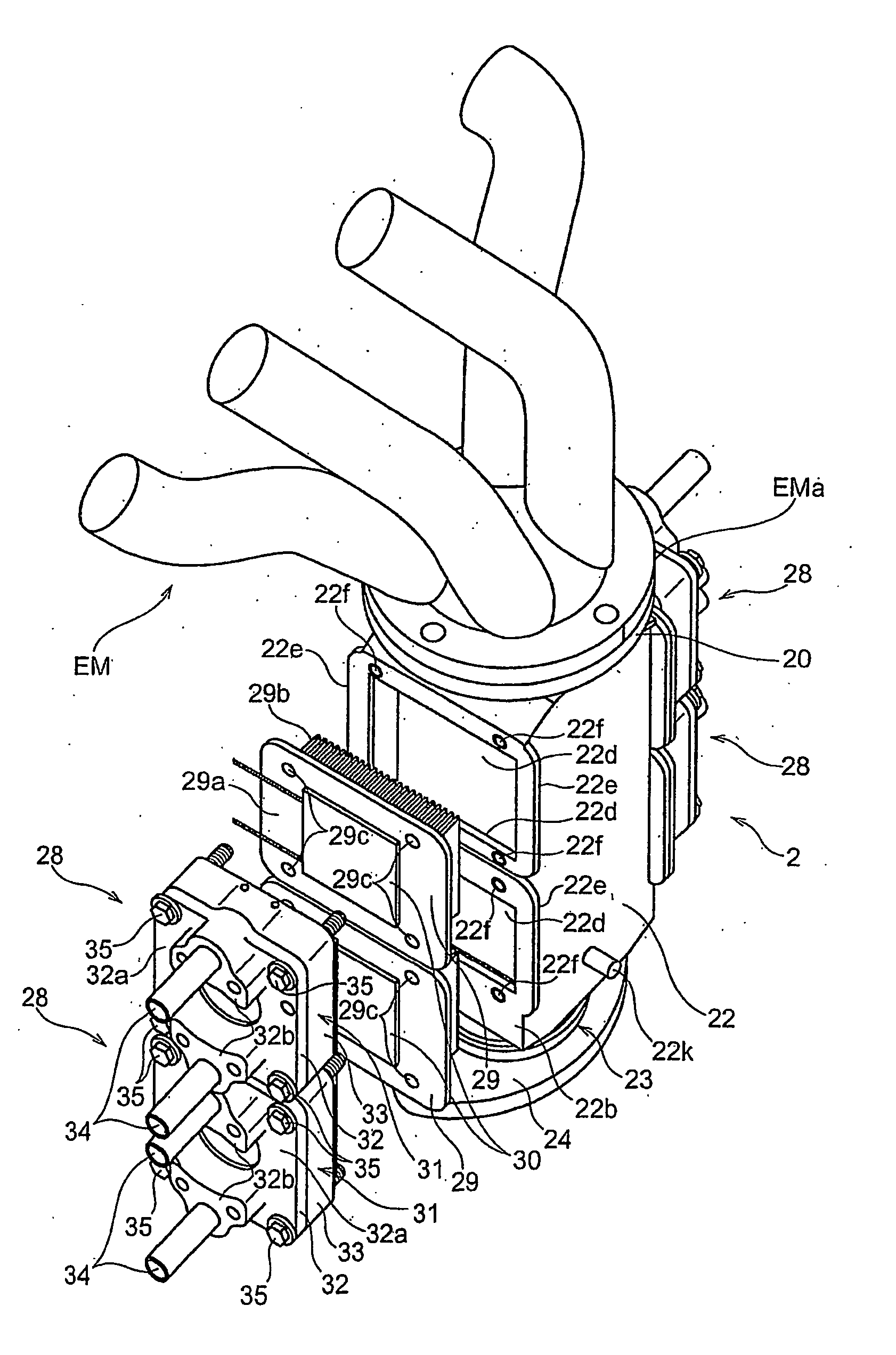

Controller for compression ignition engine

InactiveUS20070215095A1Increase blockingInhibit deteriorationElectrical controlNon-fuel substance addition to fuelHcci combustionControl theory

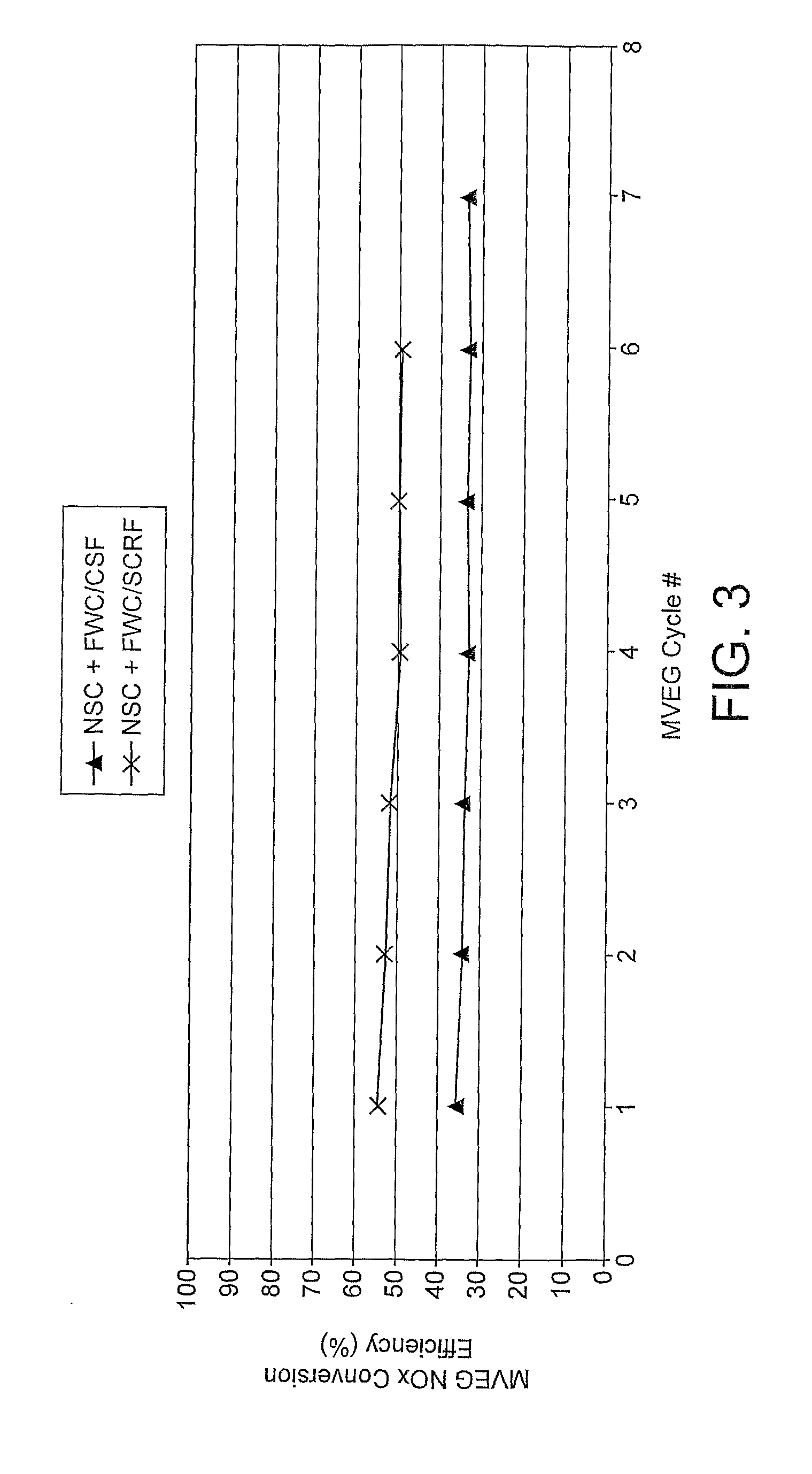

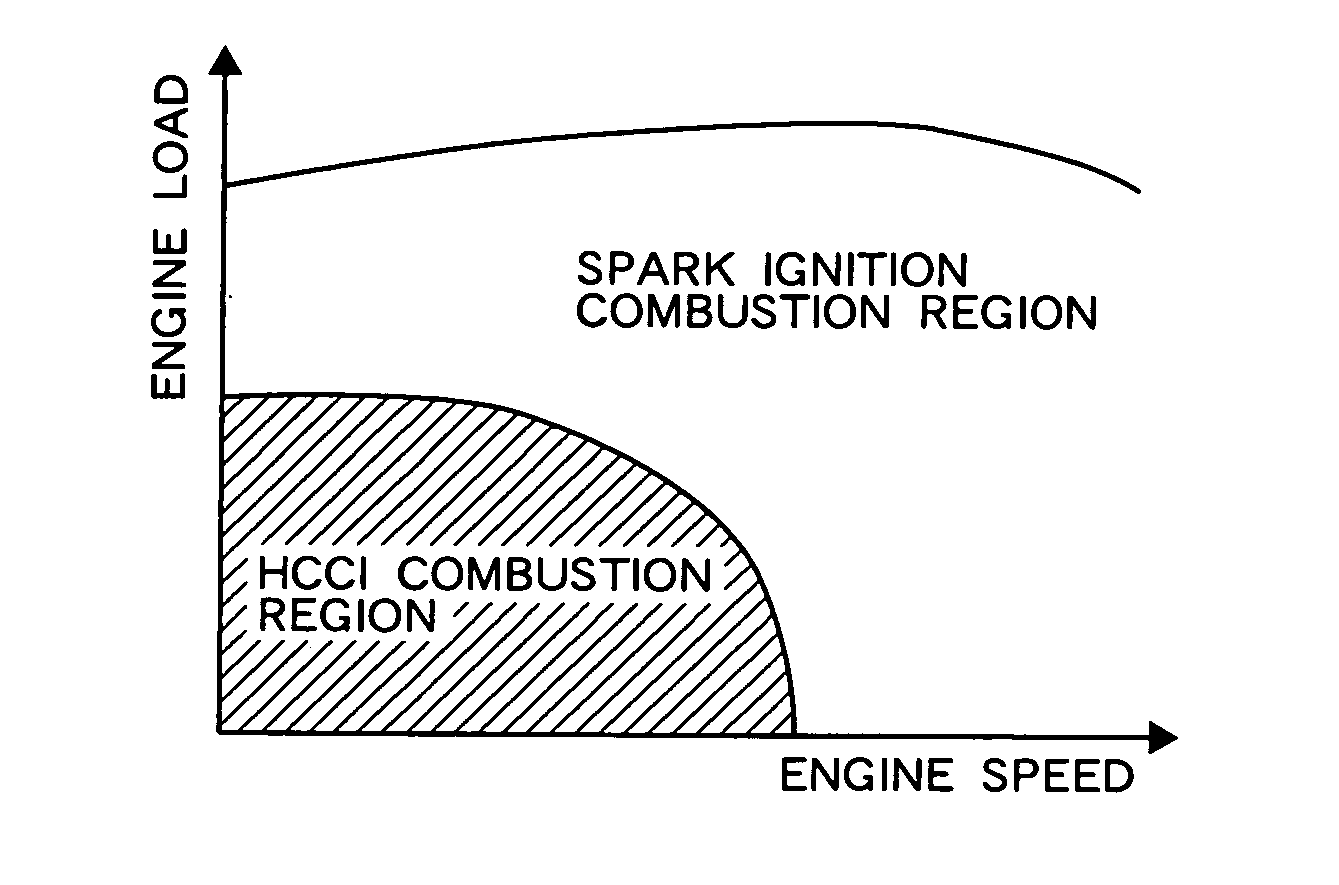

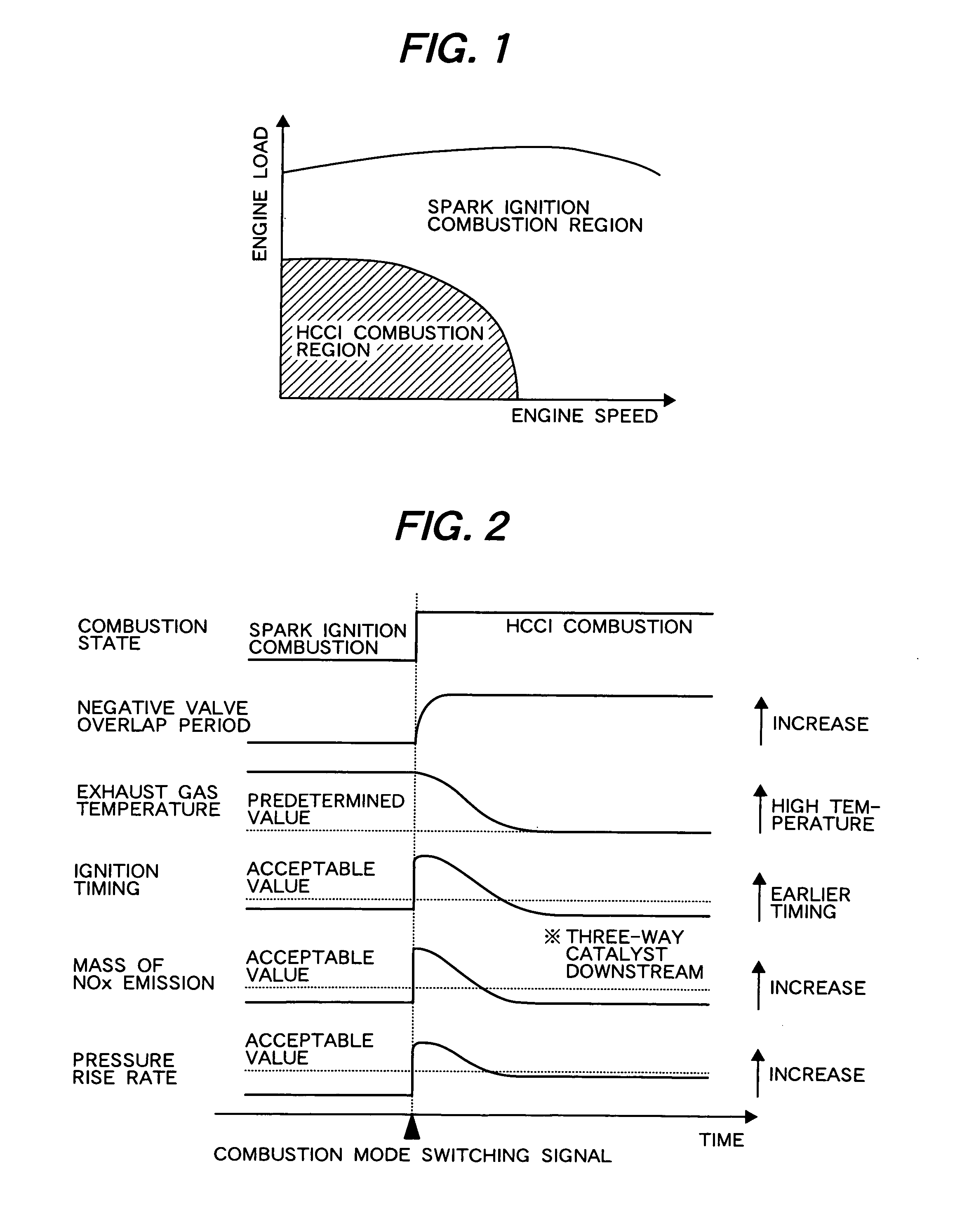

The controller includes combustion mode switching means for decreasing an exhaust gas temperature in the spark ignition combustion immediately before the combustion mode switching based on an estimated exhaust gas temperature immediately before the combustion mode switching, or for decreasing an EGR amount in the HCCI combustion immediately after the combustion mode switching.

Owner:HITACHI LTD

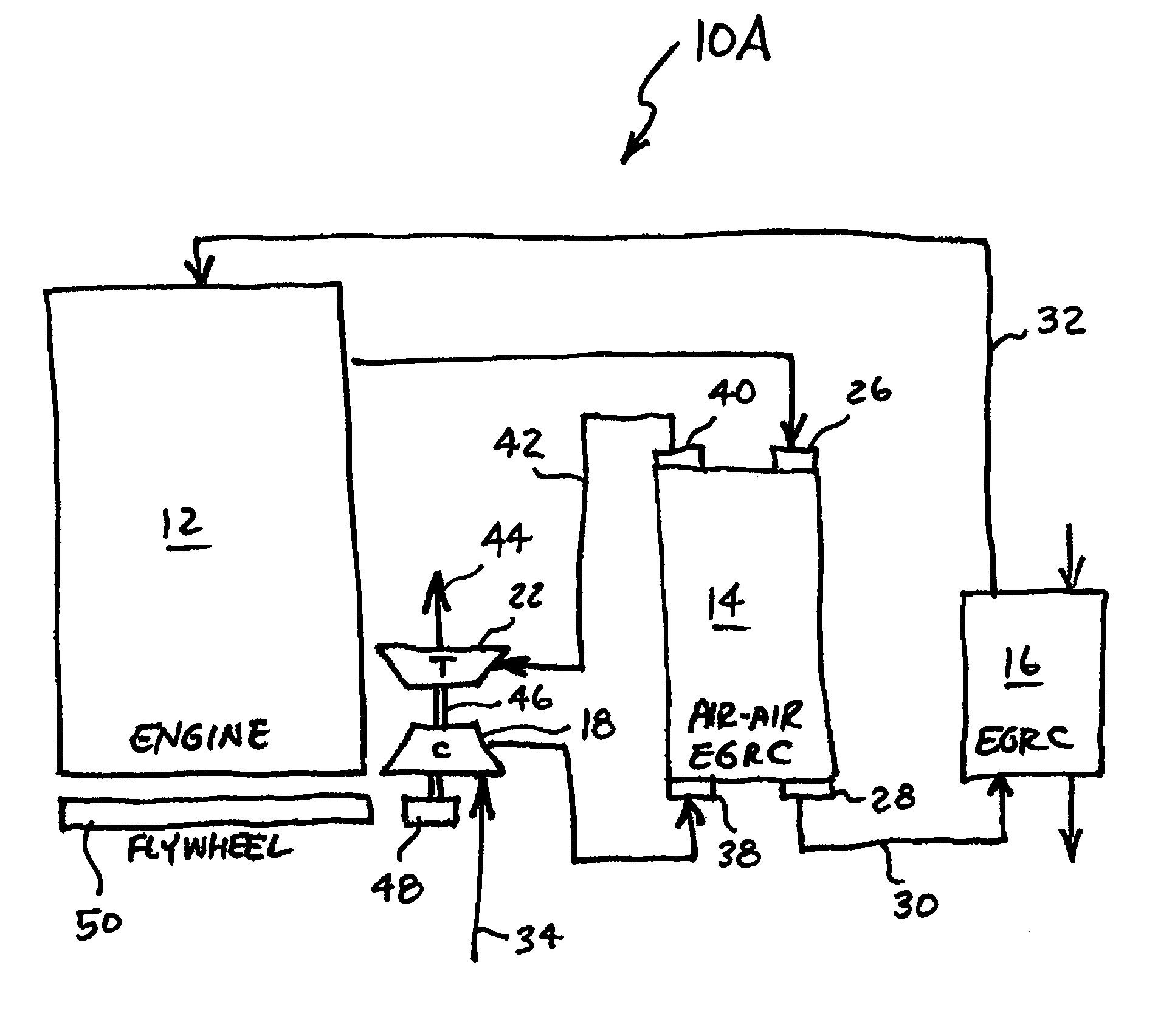

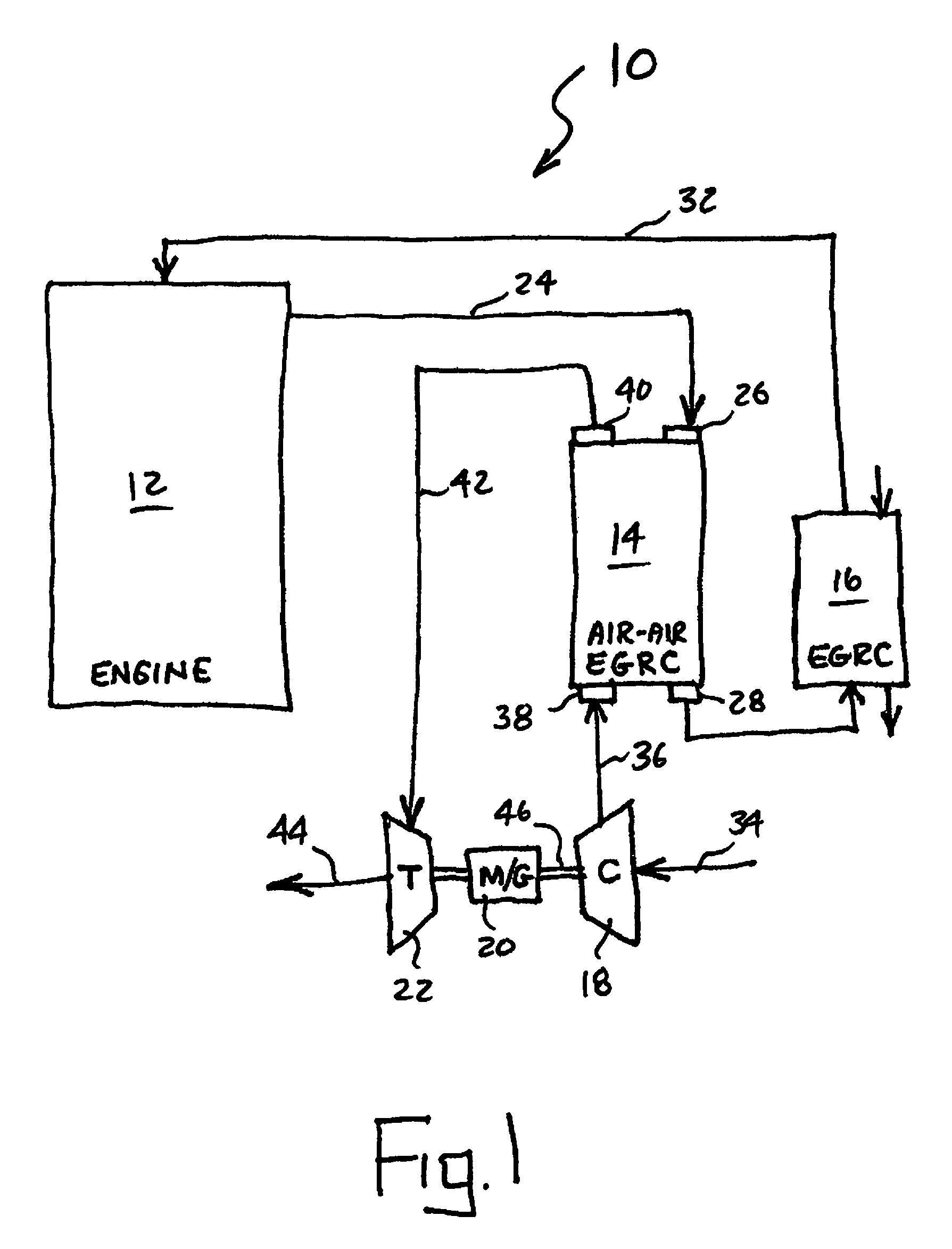

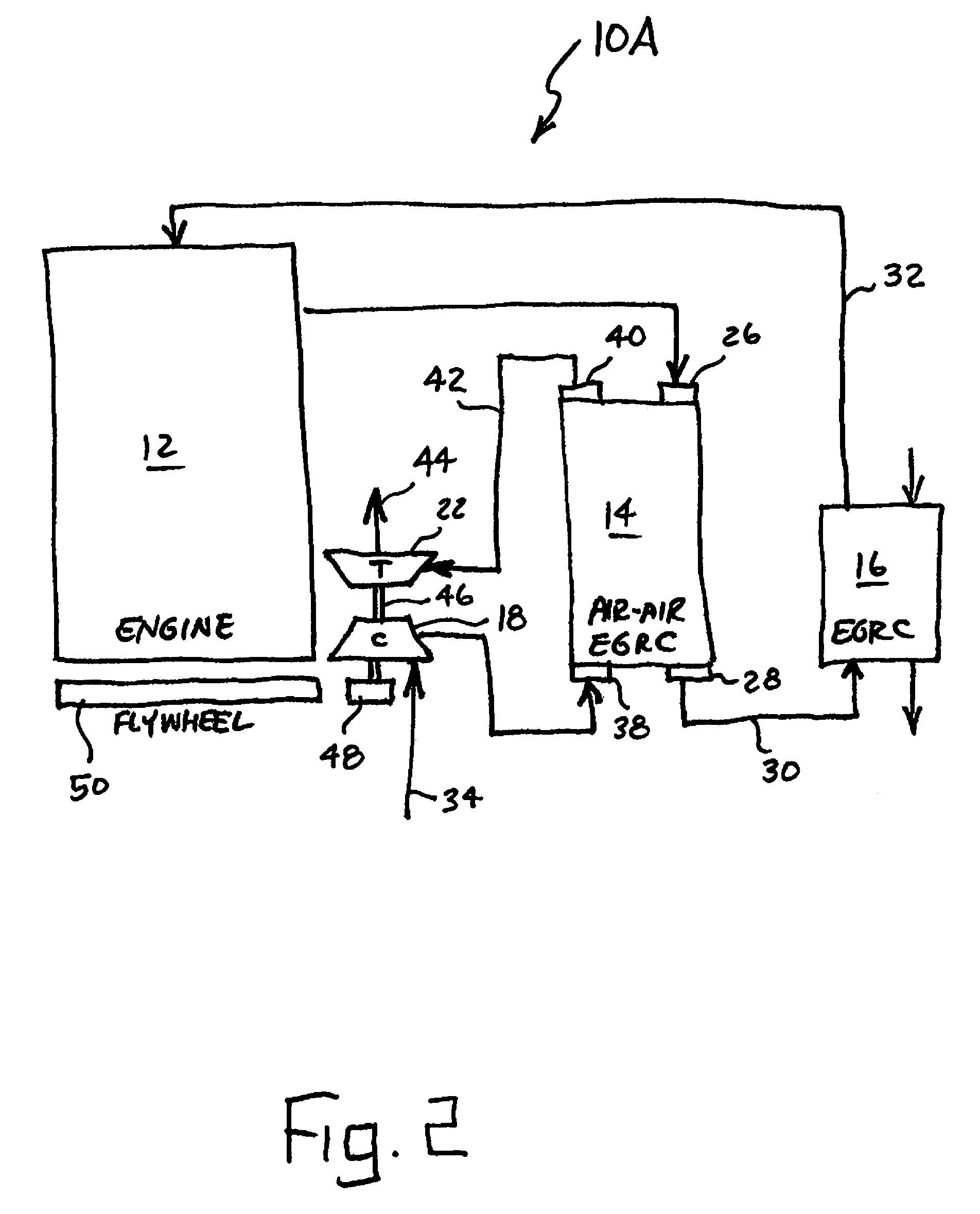

Open loop Brayton cycle for EGR cooling

ActiveUS7958873B2Lower exhaust gas temperatureReduce heat dissipationInternal combustion piston enginesNon-fuel substance addition to fuelBrayton cycleTurbine

A system for reducing the temperature of waste heat from a waste heat source of a vehicle engine, including an open loop Brayton cycle having a cooler, a compressor, a turbine, and a shaft coupling the compressor to the turbine. Waste heat and compressed air from the compressor flow through the cooler, thereby transferring heat from the waste heat to the compressed air and lowering the temperature of the waste heat. The heated and compressed air is expanded across the turbine, to cause rotation of the shaft, thereby powering rotation of the compressor. Excess power beyond that necessary to drive the compressor may be drawn off through a generator which has its rotor mounted on the same shaft as the compressor and turbine.

Owner:CUMMINS INC

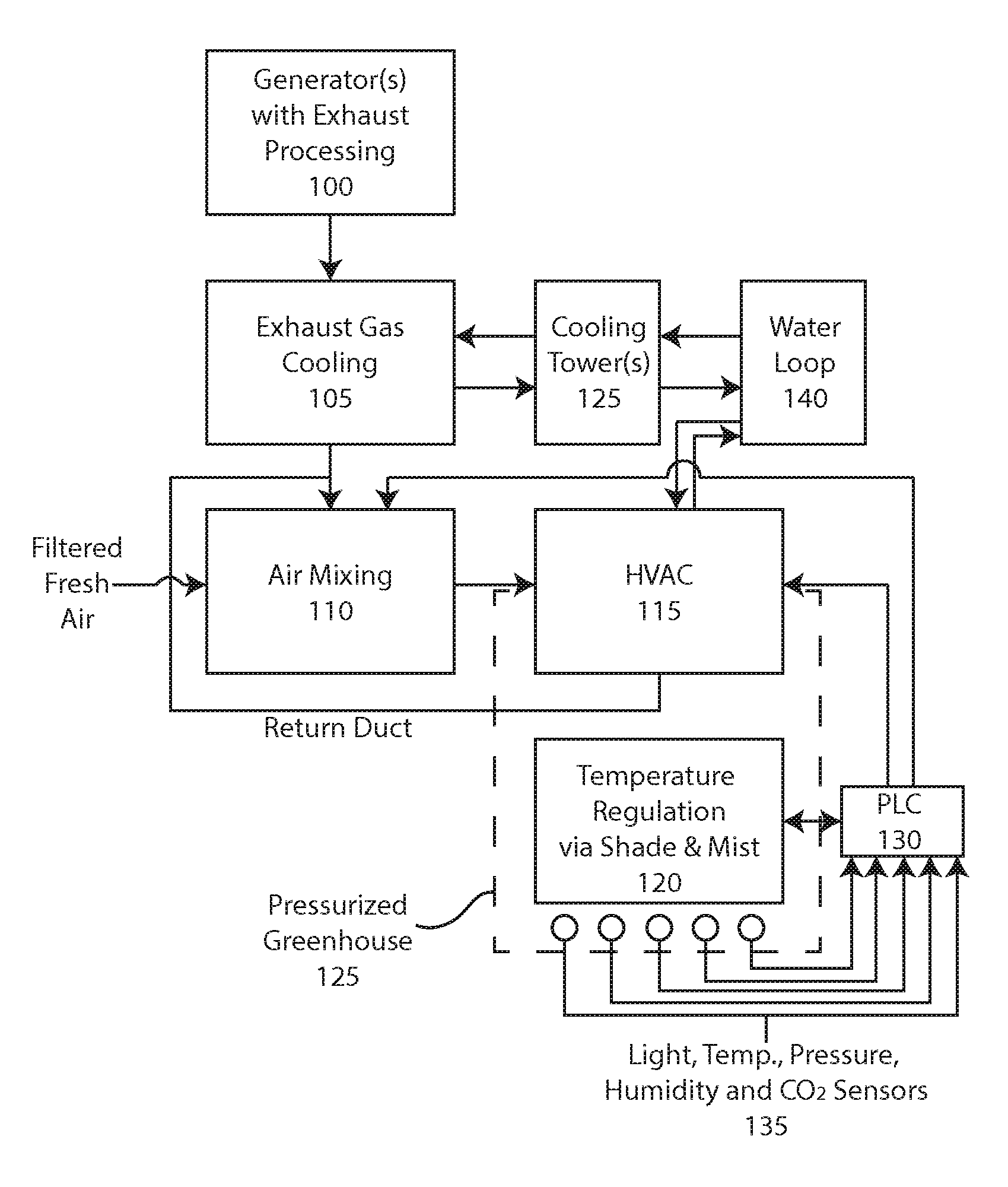

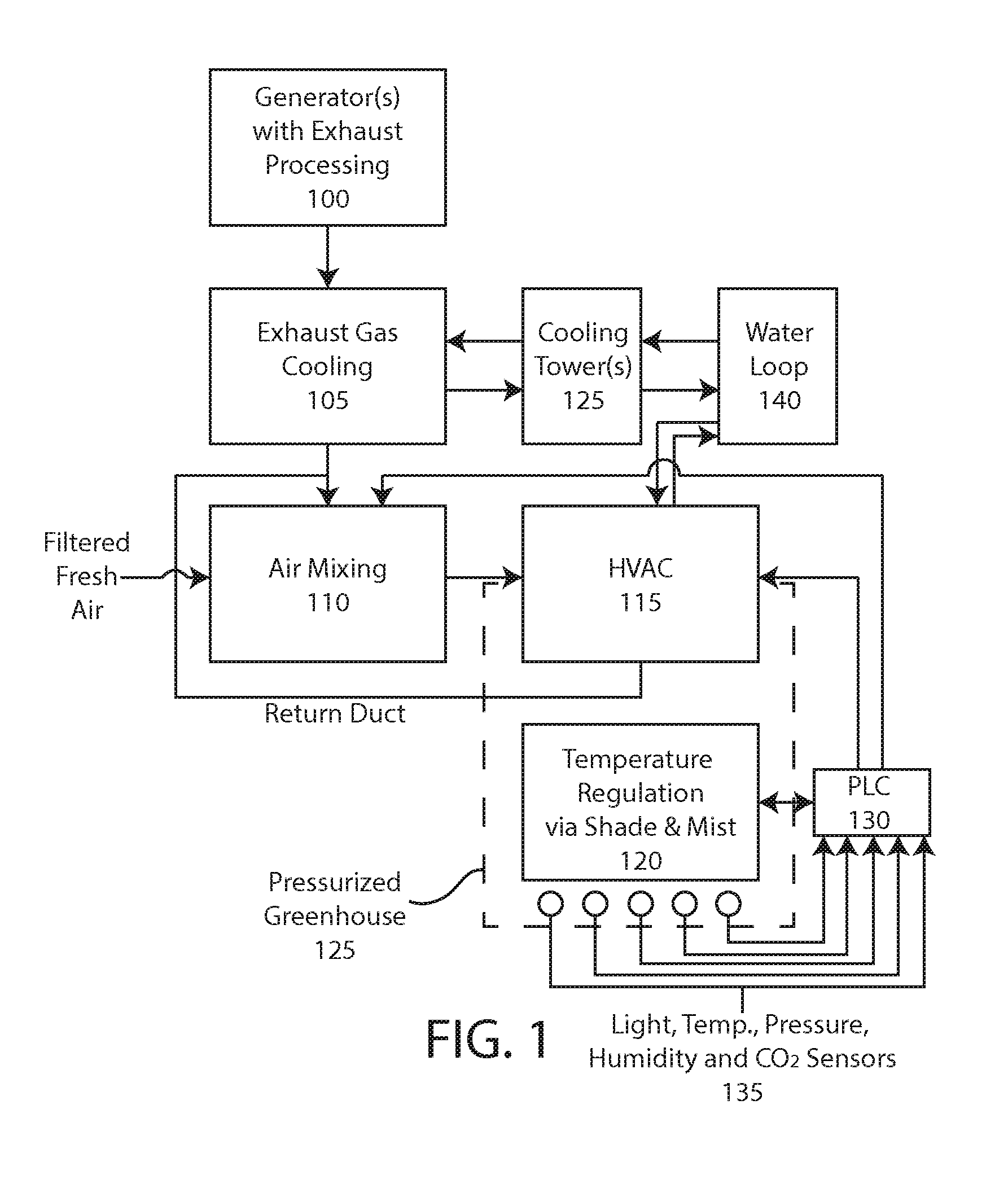

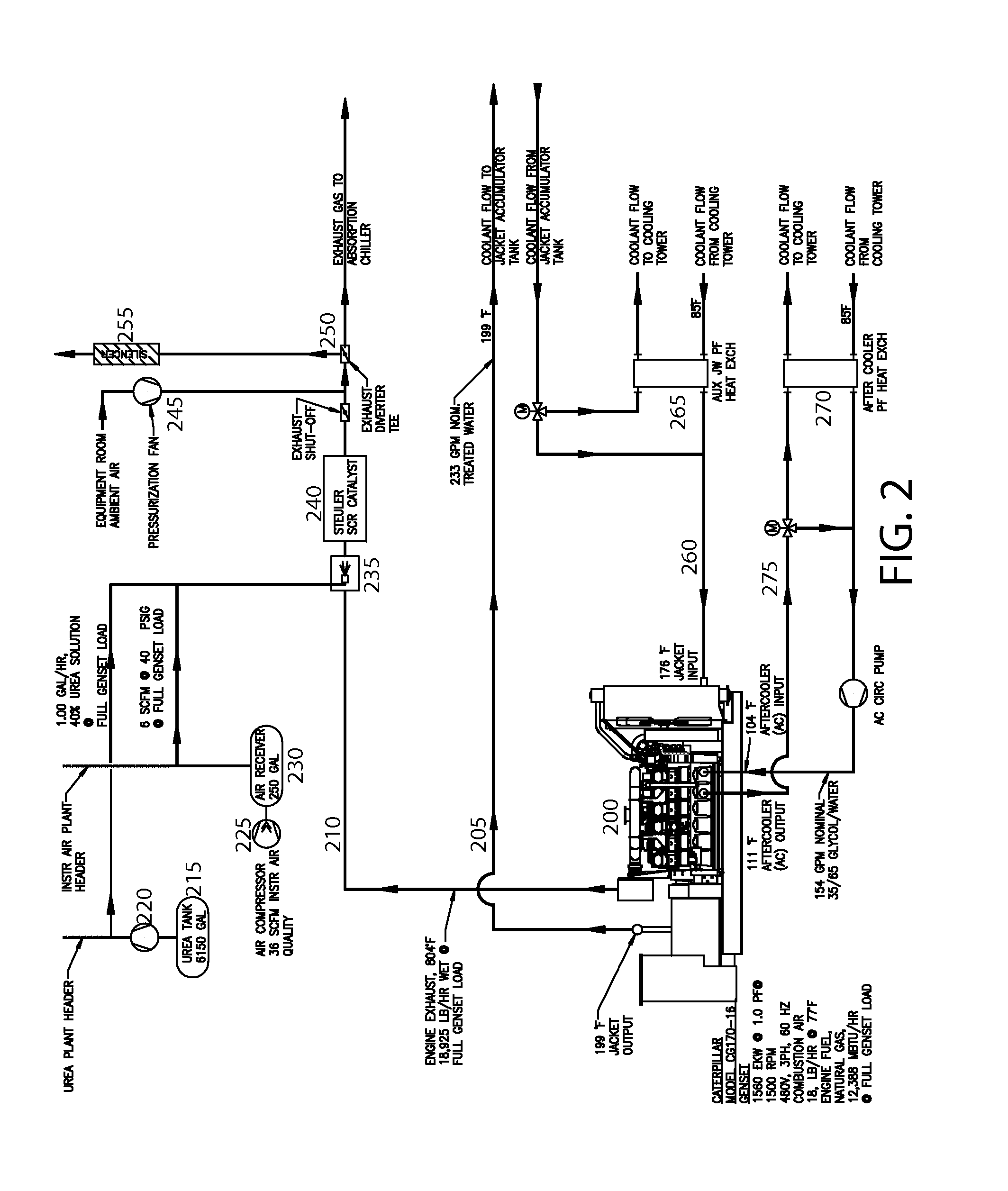

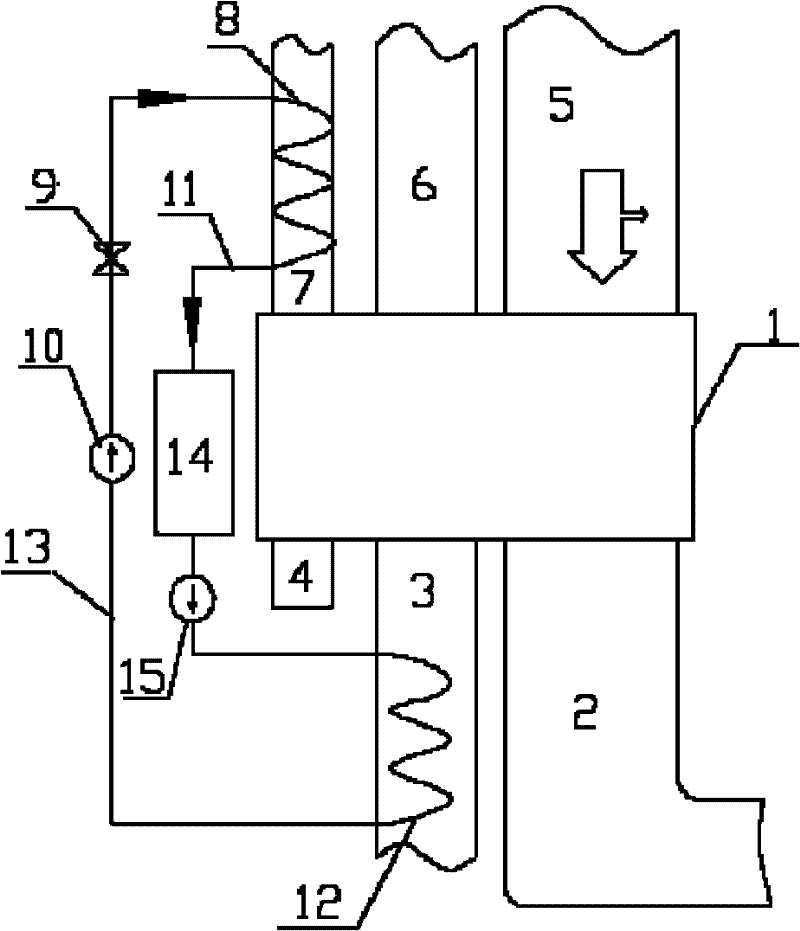

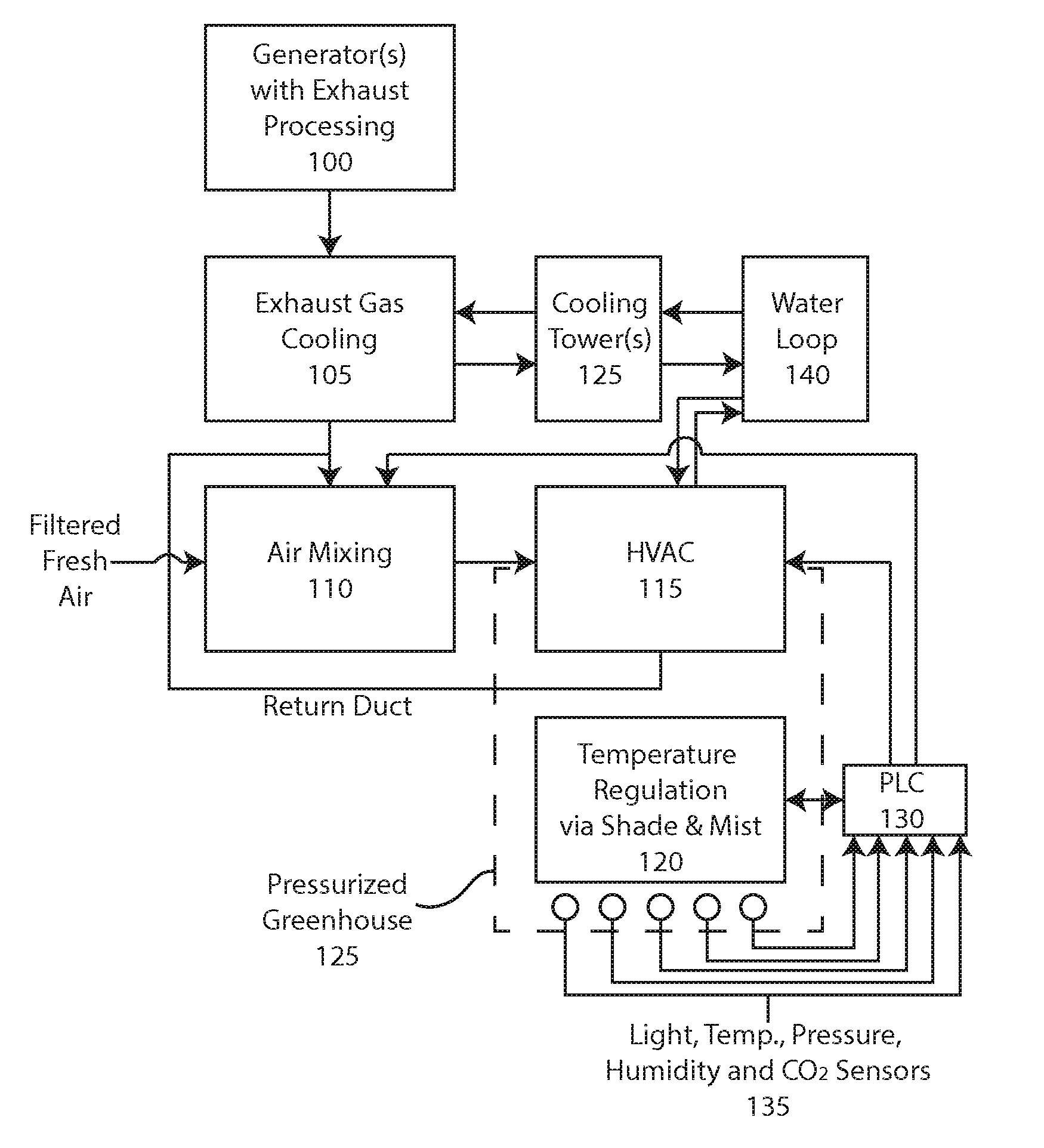

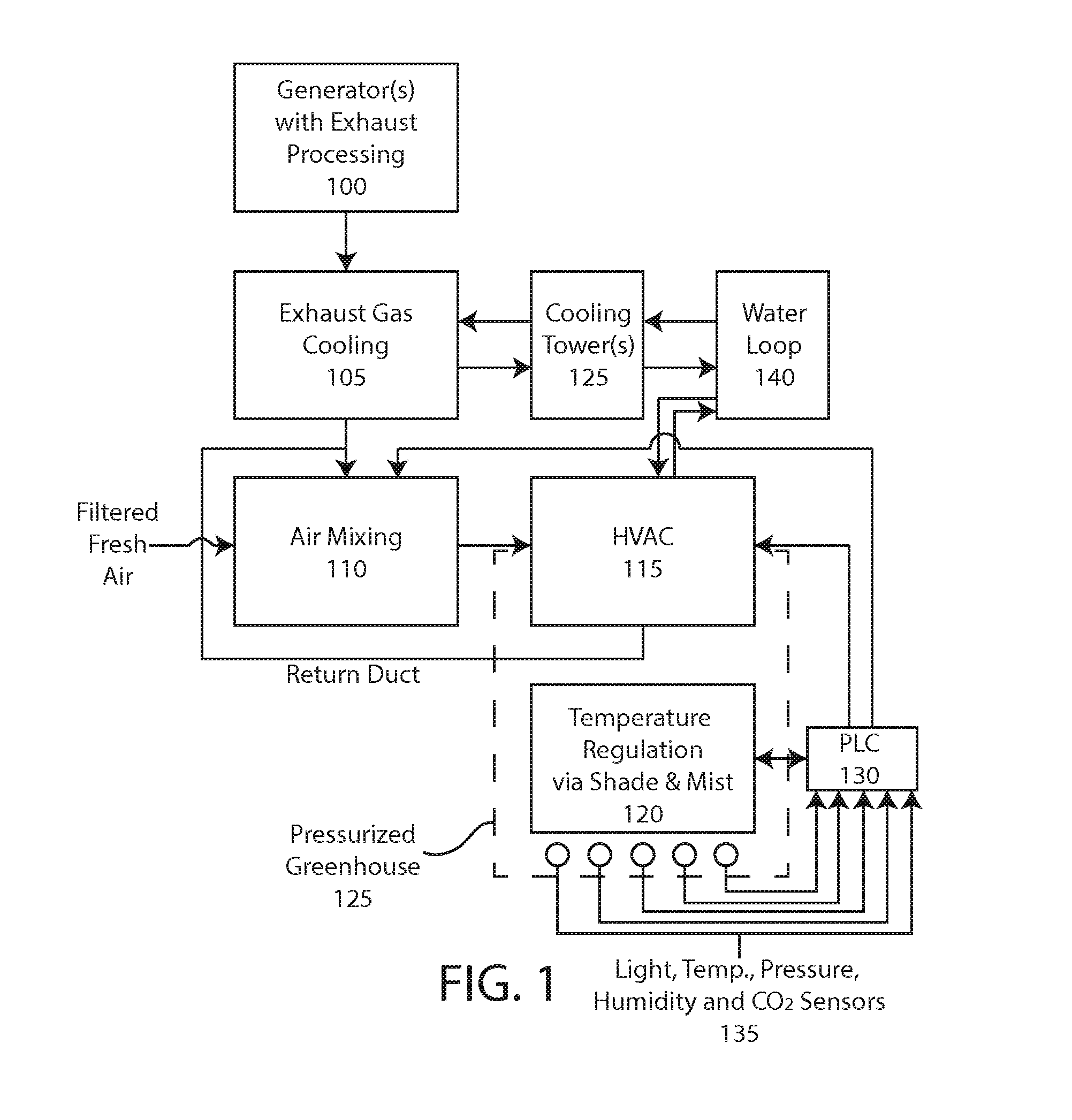

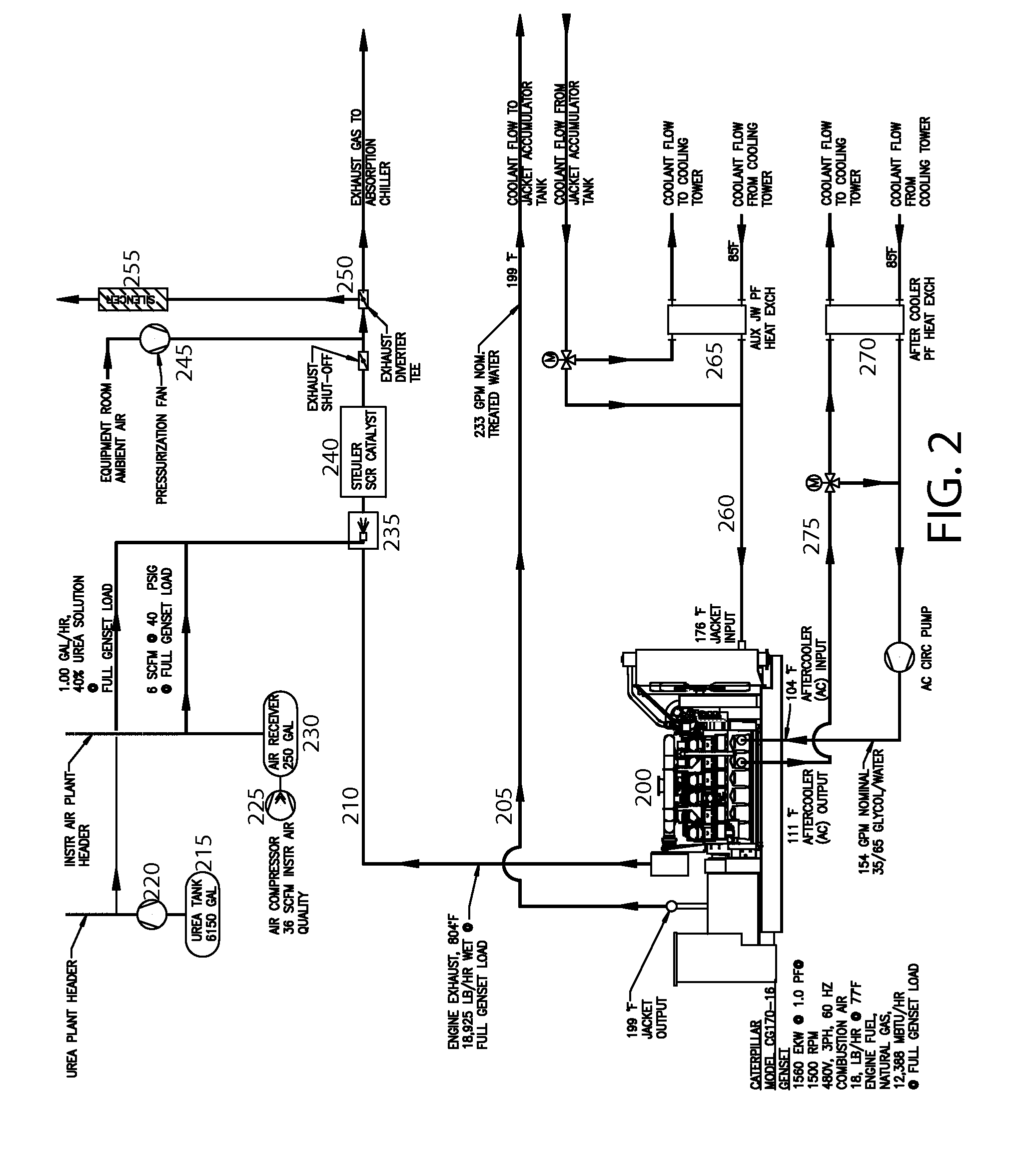

Climate control system and method for a greenhouse

ActiveUS20150282440A1Reduce pollutantsEasy to useClimate change adaptationGreenhouse cultivationGrowth plantControl system

A greenhouse environment control system generates a CO2-enriched air which is supplied to a greenhouse at a controlled temperature suitable for plant growth. An absorption chiller reduces temperature of a CO2-containing stream of processed gasses from an engine. A mixing and blending unit maintains CO2 at an acceptable concentration for enhanced plant growth and human occupation. An HVAC system modulates temperature and positively pressurizes the greenhouse with the CO2-enriched air to reduce risk of contaminant intrusion. Misting further controls temperature. Retractable shades regulate light supplied to plants and solar gain.

Owner:TROPOS TECH LLC

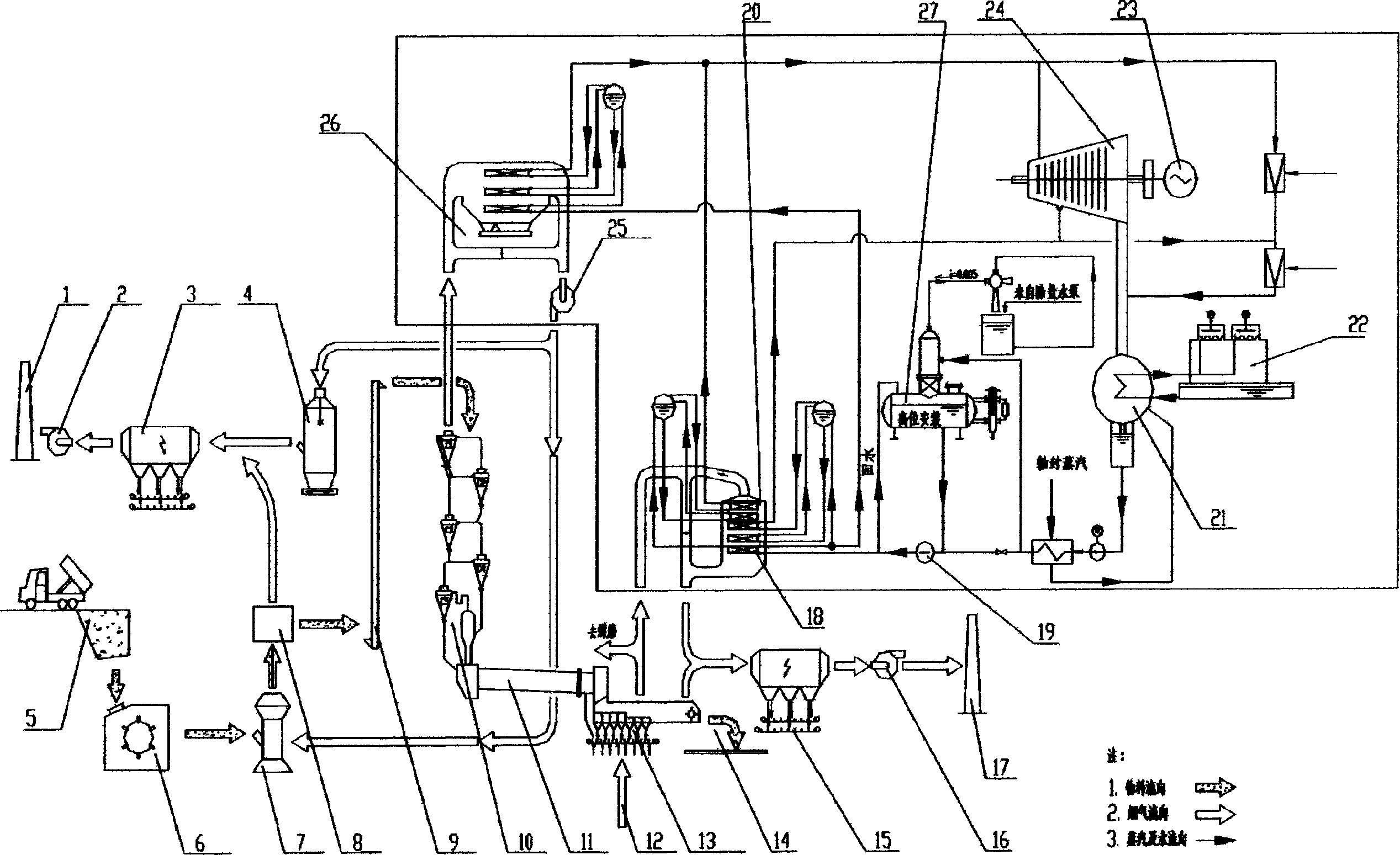

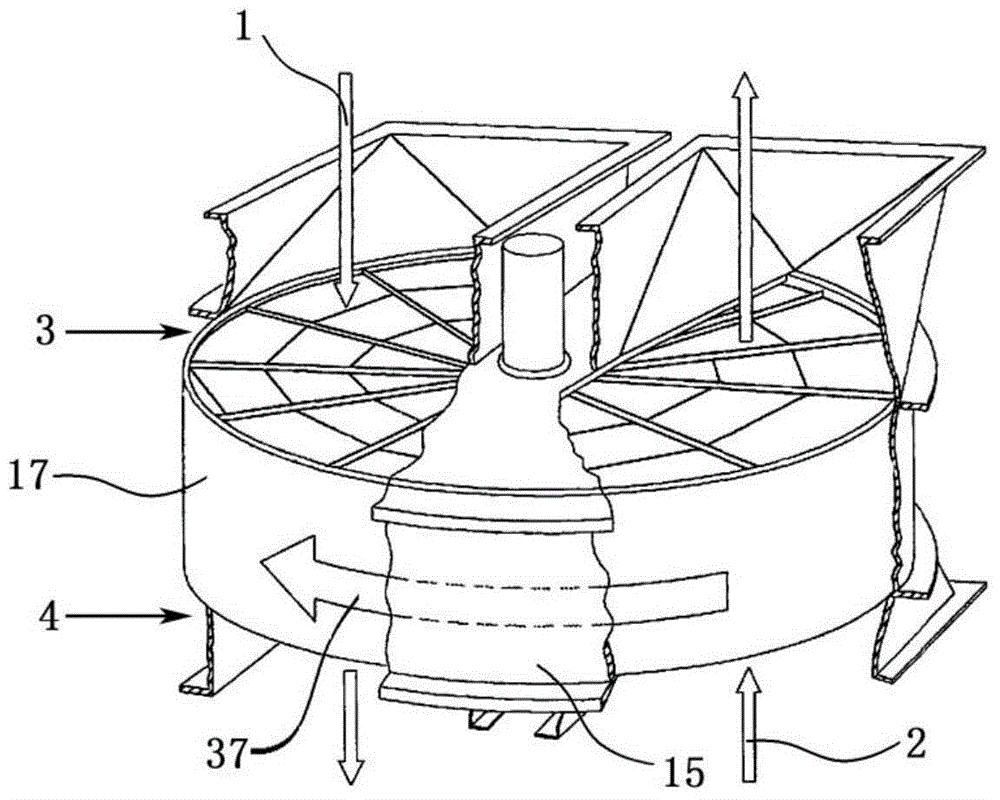

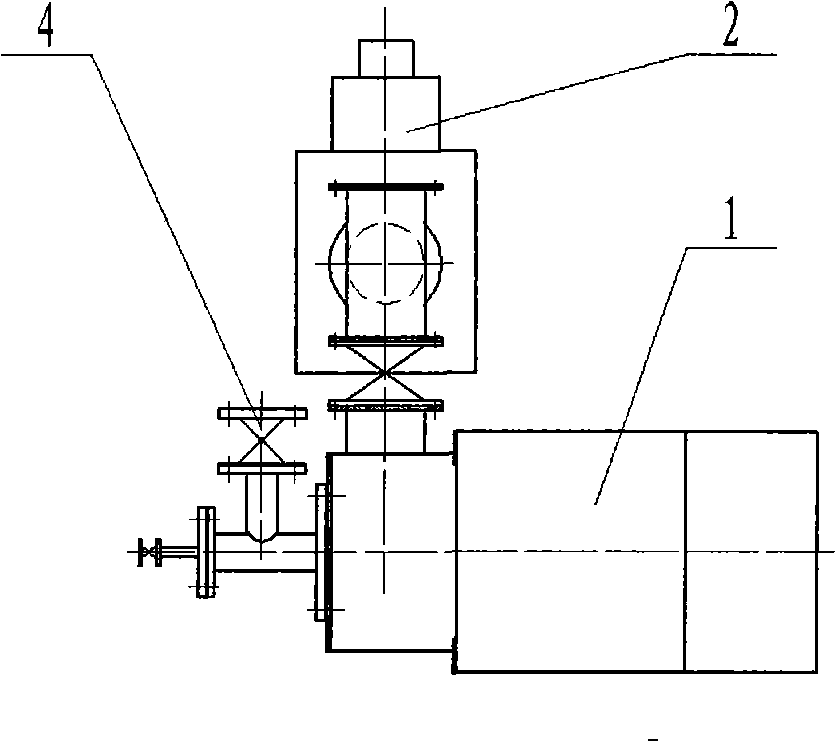

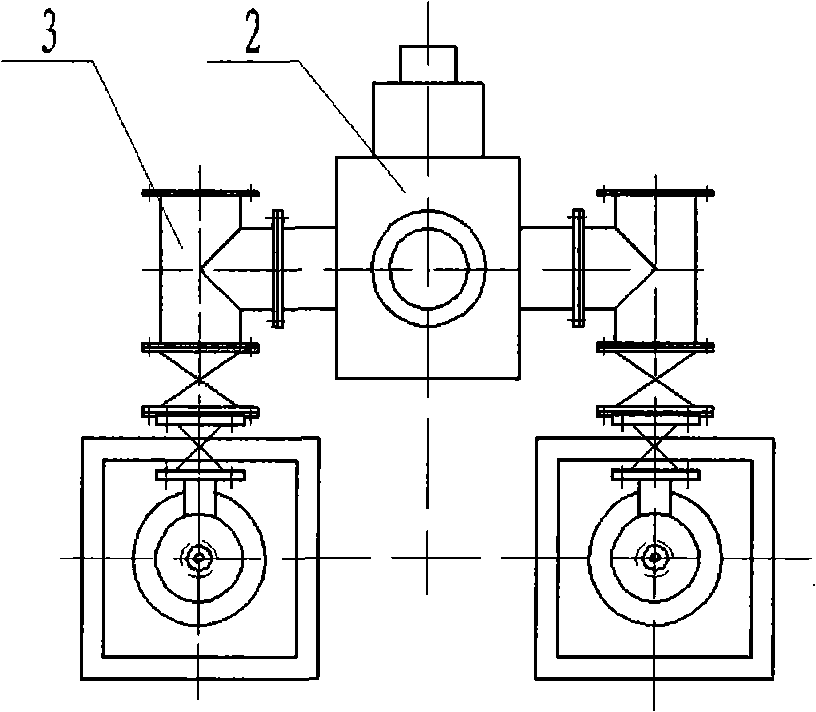

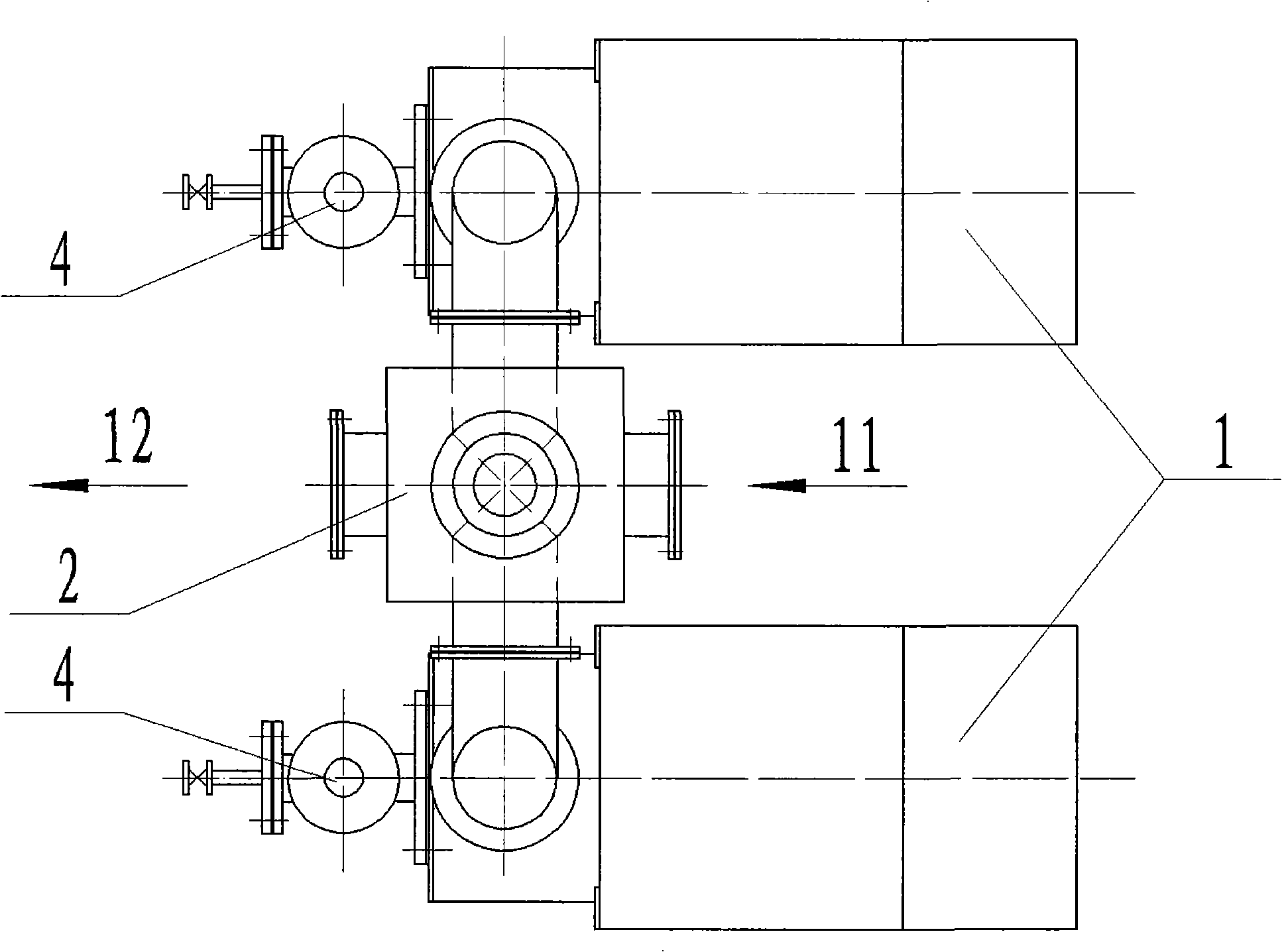

Generating set system of simple low temperature waste heat from large size cement manufacture line in dry method, and technical process

InactiveCN1601214AReduce heat pollutionConducive to environmental protectionIncreasing energy efficiencyClinker productionElectric generatorWaste heat

The invention is an electric generator system using low temperature afterheat of large-scale dry cement production line, which has two kiln head double-pressure afterheat boilers for heating, producing the whole low pressure steam and simultaneously producing partial high-pressure steam; a kiln tail afterheat boiler mainly for producing high pressure steam; the high pressure steam produced by the two afterheat boilers are mixed and then enter through pipeline into a steam -supply and -condensing steam turbine, and the low pressure steam enters in the steam turbine through steam supply pipeline; the blast steam at the tail of the turbine enters in a condenser, the condensed water enters in a vacuum deoxygenator through a condensed water pump and pipeline, the deoxygenated water in the deoxygenator is supplied through water supply pump into the boiler; the exhaust gas produced by a kiln tail preheater of cement production line is led in the kiln tail afterheat boiler through reformed pipeline.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Controller for compression ignition engine

InactiveUS7367310B2Inhibit deteriorationQuality improvementElectrical controlInternal combustion piston enginesHcci combustionControl theory

The controller includes combustion mode switching means for decreasing an exhaust gas temperature in the spark ignition combustion immediately before the combustion mode switching based on an estimated exhaust gas temperature immediately before the combustion mode switching, or for decreasing an EGR amount in the HCCI combustion immediately after the combustion mode switching.

Owner:HITACHI LTD

Exhaust system

InactiveUS20060053771A1Improve fuel efficiencyPrevent degradationInternal combustion piston enginesThermoelectric device with peltier/seeback effectThermal energyPulp and paper industry

An exhaust system (1) is provided with an exhaust passage that allows exhaust gas discharged from an internal combustion engine to pass therethrough, an exhaust emission control unit including a catalyst (2,3) such as a three-way catalyst (27) to purify the exhaust gas, and an exhaust heat collecting unit that converts thermal energy of the exhaust gas into electric energy. The exhaust passage (25) is formed in the center of the exhaust system provided with the exhaust emission control unit. By-pass passages (26) are formed at both sides of the exhaust passage (25) through which the exhaust gas flows without passing through the exhaust emission control unit. The exhaust heat collecting unit (29) is provided on the outer side of each of the by-pass passages (26).

Owner:TOYOTA JIDOSHA KK

Apparatus and method for improving combustion stability

InactiveUS7104069B2Reduce varianceReduce combustion dynamicBurnersContinuous combustion chamberGas turbinesEngineering

A fuel nozzle for use in a gas turbine combustor is provided having the capability of injecting multiple fuel types as well as steam for NOx reduction. Combustion dynamics within a combustor due to the mal-distribution of steam are controlled by the placement of a meterplate at the steam inlet, such that the meterplate reduces steam velocity and increases steam pressure drop. A higher pressure drop reduces the sensitivity of the combustion process to upstream steam supply variations. A method for providing uniform steam flow to a plurality of fuel nozzle assemblies about a gas turbine engine is also disclosed.

Owner:ANSALDO ENERGIA IP UK LTD

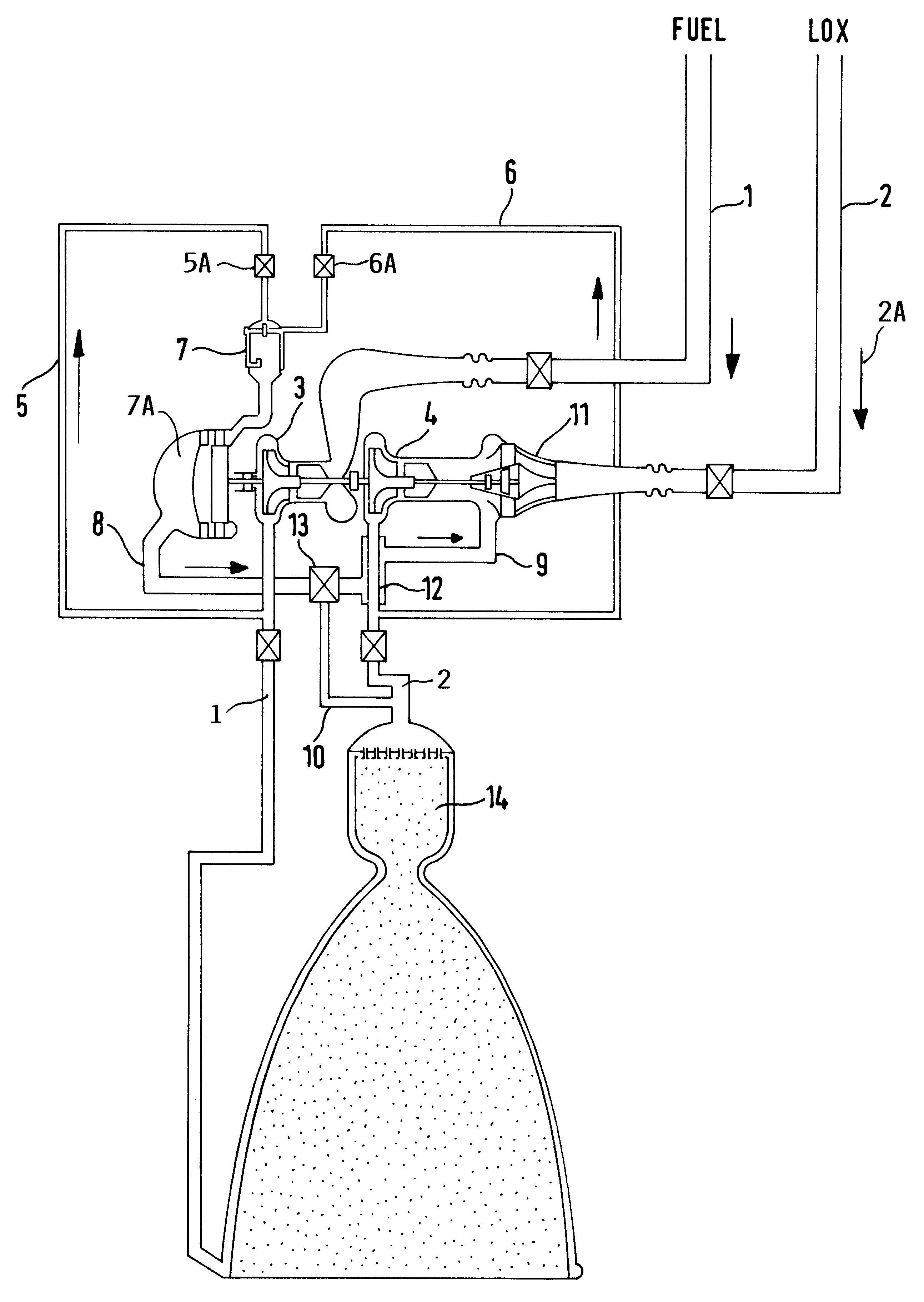

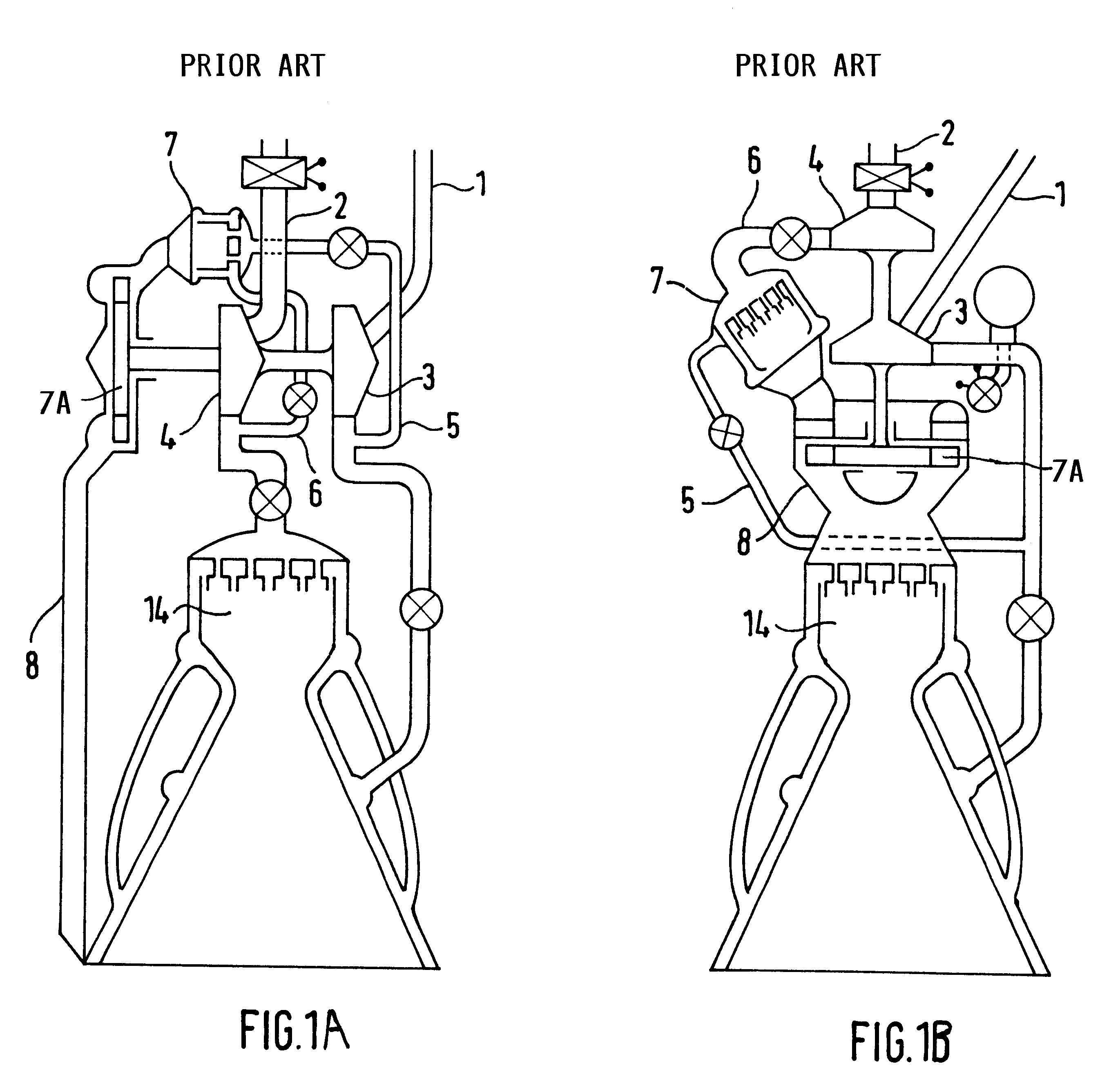

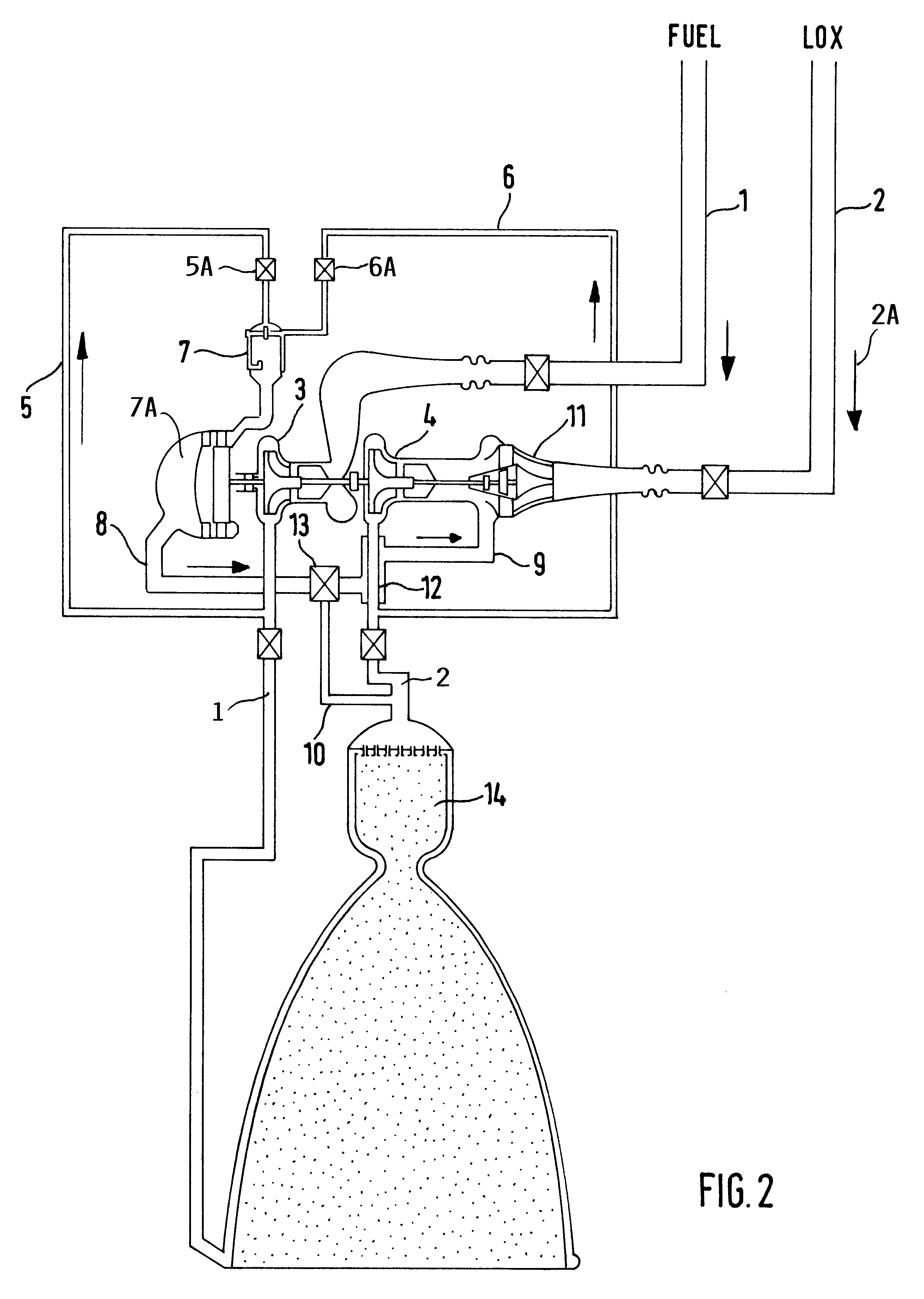

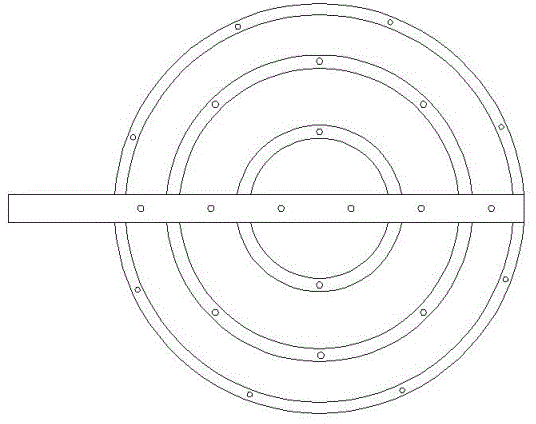

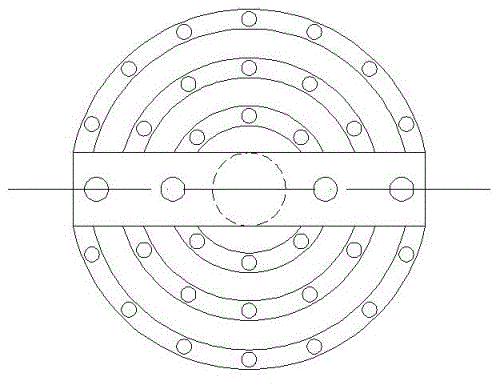

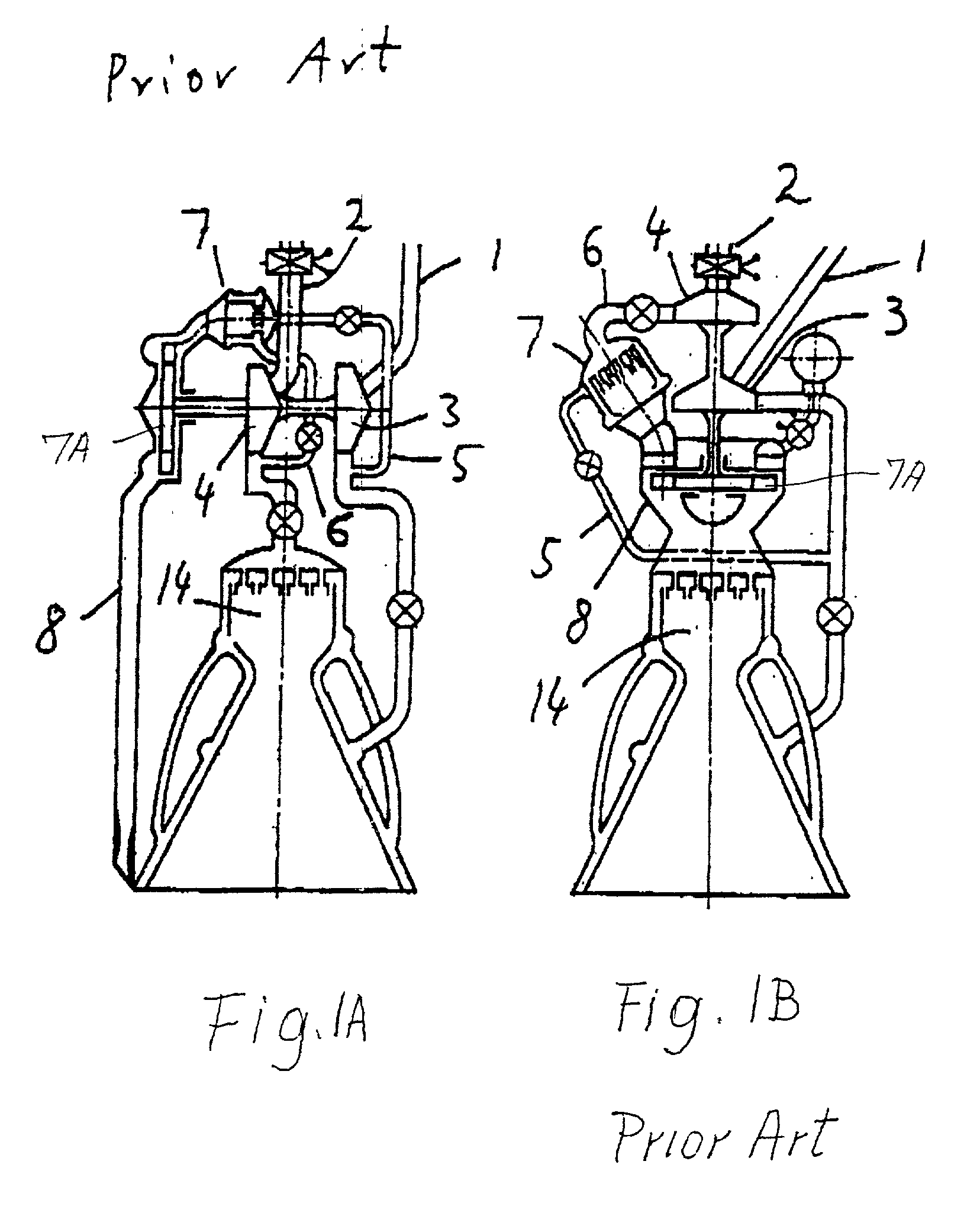

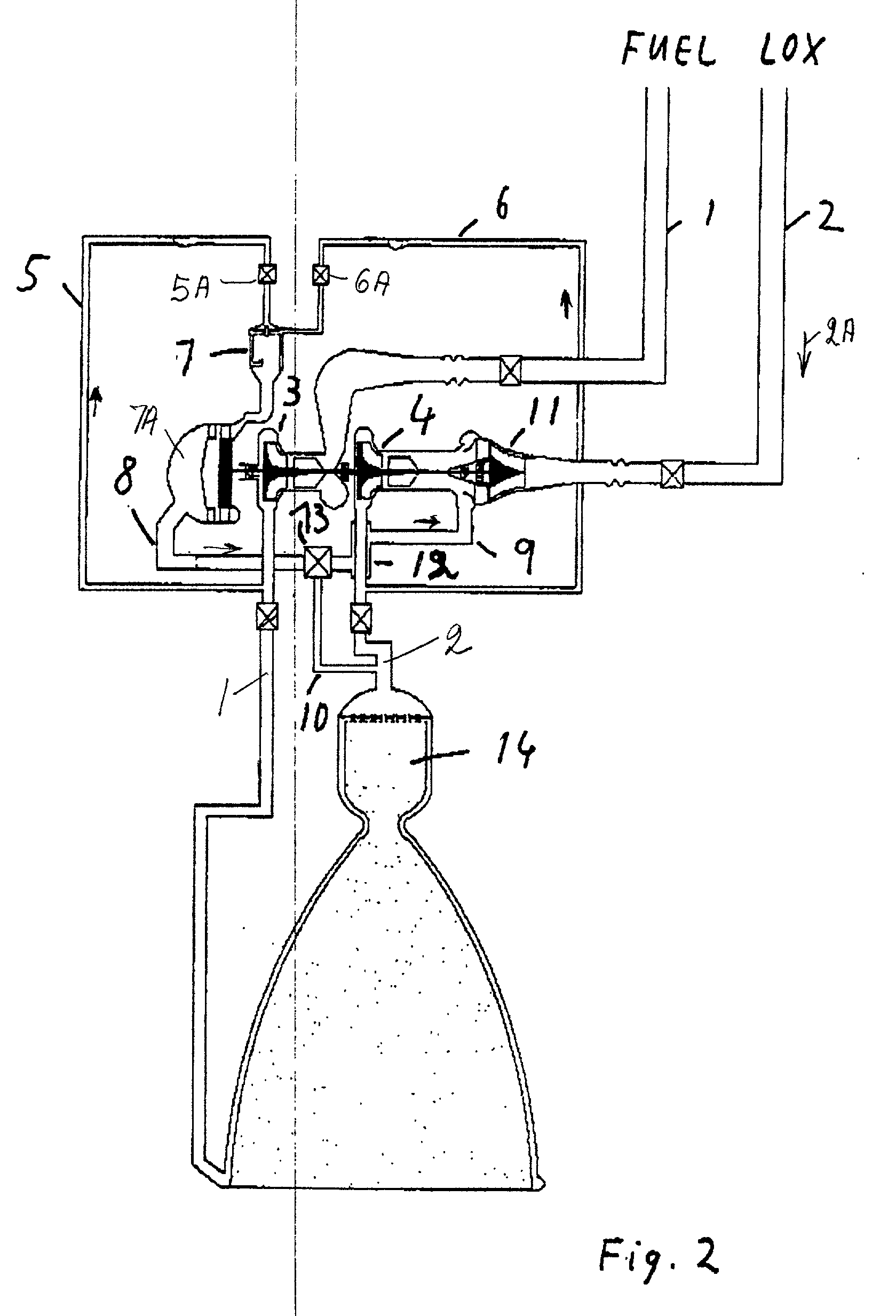

Liquid fuel rocket engine with a closed flow cycle

InactiveUS6470670B2Easy constructionReduce the temperatureRocket engine plantsCombustion chamberProduct gas

A liquid fuel rocket engine with a closed direct auxiliary flow cycle has a combustion chamber connected to each liquid fuel source through a respective main liquid fuel supply line. A turbo pump is provided in each main fuel supply line. The turbo pump is driven by a gas generator which is connected to a first bypass fuel supply line for supplying fuel to the gas generator. An exhaust gas duct (8, 9, 10) leads from the gas generator into at least one main fuel supply line for feeding gas generator exhaust gas into the main fuel supply line upstream of the turbo pump.

Owner:ASTRIUM GMBH

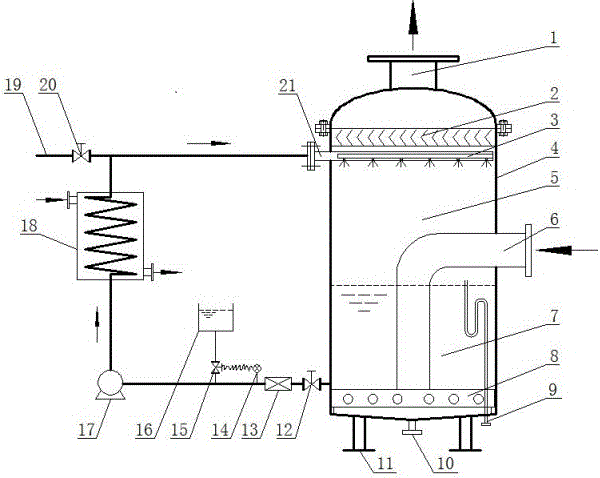

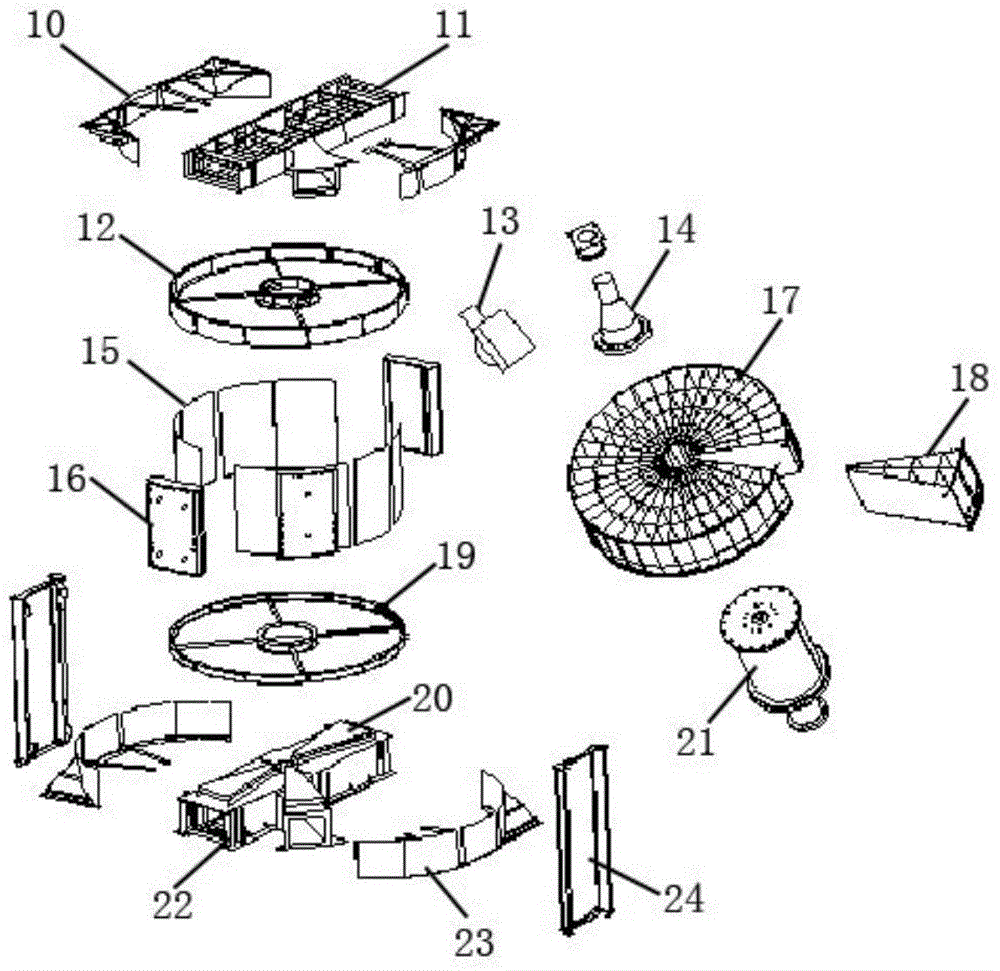

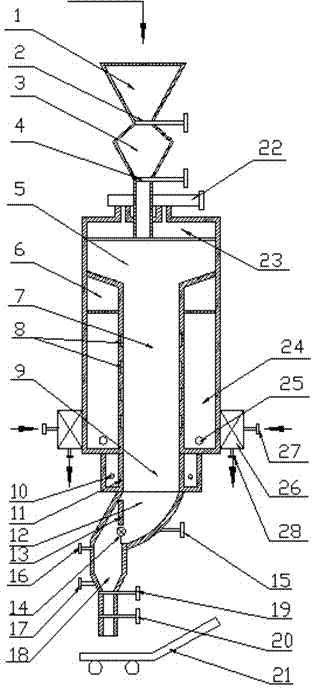

Heat supplying device for smoke purification and waste heat recovery

InactiveCN104791823AEvenly distributedReduce resistanceCombustion technology mitigationWater heatersThermal engineeringWaste heat recovery unit

The invention discloses a heat supplying device for smoke purification and waste heat recovery. The heat supplying device comprises a direct contact type waste heat recovery device and a circulating water system and is characterized in that the direct contact type waste heat recovery device comprises a bubbler, a smoke inlet pipe, an overflow pipe, a cylinder, a bubbling section, a spraying section, a sprayer, a water inlet pipe, a demister and a smoke exhaust pipe. The high temperature smoke enters cooling water in the bubble form through the bubbler and carries out direct contact type heat and mass transfer in the bubbling section; smoke discharged from the cooling water enters the spraying section and is in direct contact with the cooling water sprayed out of the sprayer again to transfer heat and mass; the cooling water absorbing heat enters the circulating water system, and a heat medium is heated through a heat exchanger in the circulating water system so as to supply heat outwards; the purified and cooled smoke is exhausted from a chimney at the upper portion of the cylinder. Two-section type direct contact of the smoke and the cooling water is adopted in the heat supplying device to transfer heat and mass, so that the smoke is fully cooled and completely purified, and the heat supplying device is suitable for smoke purification and waste heat recovery of all gas thermal engineering equipment.

Owner:ZHENGZHOU UNIV

Liquid fuel rocket engine with a closed flow cycle

InactiveUS20010015063A1Easy constructionReduce the temperatureRocket engine plantsCombustion chamberProduct gas

A liquid fuel rocket engine with a closed direct auxiliary flow cycle has a combustion chamber connected to each liquid fuel source through a respective main liquid fuel supply line. A turbo pump is provided in each main fuel supply line. The turbo pump is driven by a gas generator which is connected to a first bypass fuel supply line for supplying fuel to the gas generator. An exhaust gas duct (8, 9, 10) leads from the gas generator into at least one main fuel supply line for feeding gas generator exhaust gas into the main fuel supply line upstream of the turbo pump.

Owner:ASTRIUM GMBH

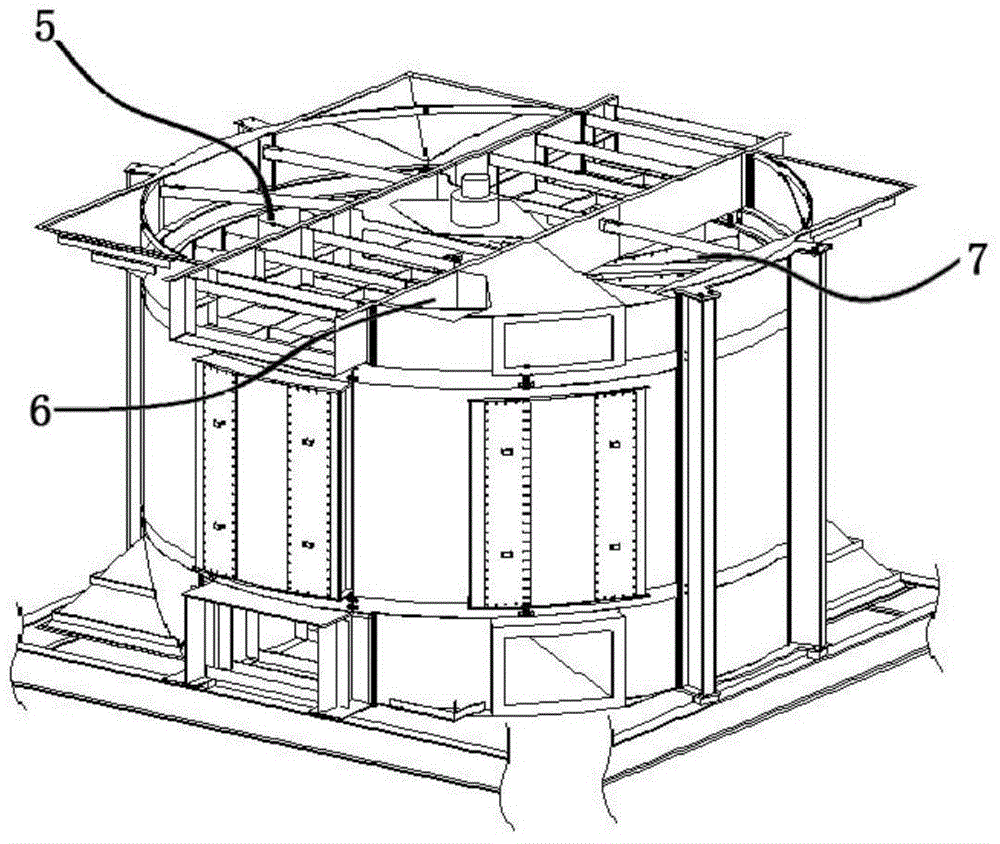

Rotary air preheater dust-blocking-prevention synergy sealing method and system

ActiveCN104949149AExtend your lifeEasy to implementCombustion processHeat exhanger sealing arrangementAir preheaterLiquid state

The invention discloses a rotary air preheater dust-blocking-prevention synergy sealing method and system. The dust-blocking-prevention synergy sealing method includes the steps that air leaked from the heat end is guided or extracted to the cold end from the heat end, and local heat exchange elements are purged and heated. The rotary air preheater dust-blocking-prevention synergy sealing system comprises a heat end primary air / smoke side sector sealing box, a heat end primary air / secondary air side sector sealing box and a cold end secondary air / smoke side sector sealing box, and further comprises a heat air leakage air flue; the heat end primary air / smoke side sector sealing box and the heat end primary air / secondary air side sector sealing box are each provided with an air inlet, one end of the heat air leakage air flue is in butt joint with the air inlets, and the other end of the heat air leakage air flue extends to a cold end secondary air highest-temperature module. By means of the rotary air preheater dust-blocking-prevention synergy sealing method and system, H2SO4 drops and liquid state NH4HSO4 are gasified while the air leaked from a preheater is reduced, and the aim of removing accumulated dust is achieved; the rotary air preheater dust-blocking-prevention synergy sealing method and system have the advantages of reducing the boiler smoke discharging temperature, restraining the accumulated dust of the preheater, reducing the air leakage rate, prolonging the service life of the heat exchange elements and the like.

Owner:南京博沃科技发展有限公司

Particulate matter oxidation catalyst and filter

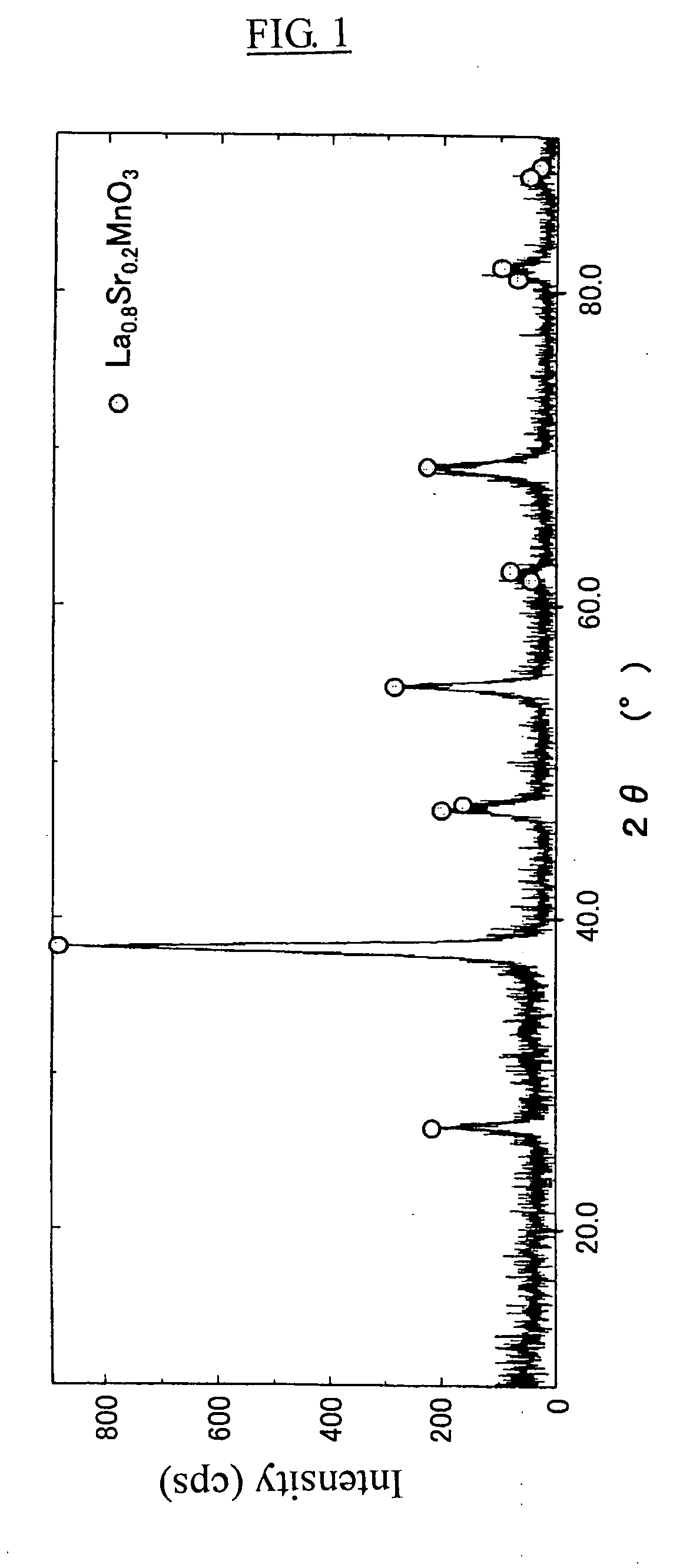

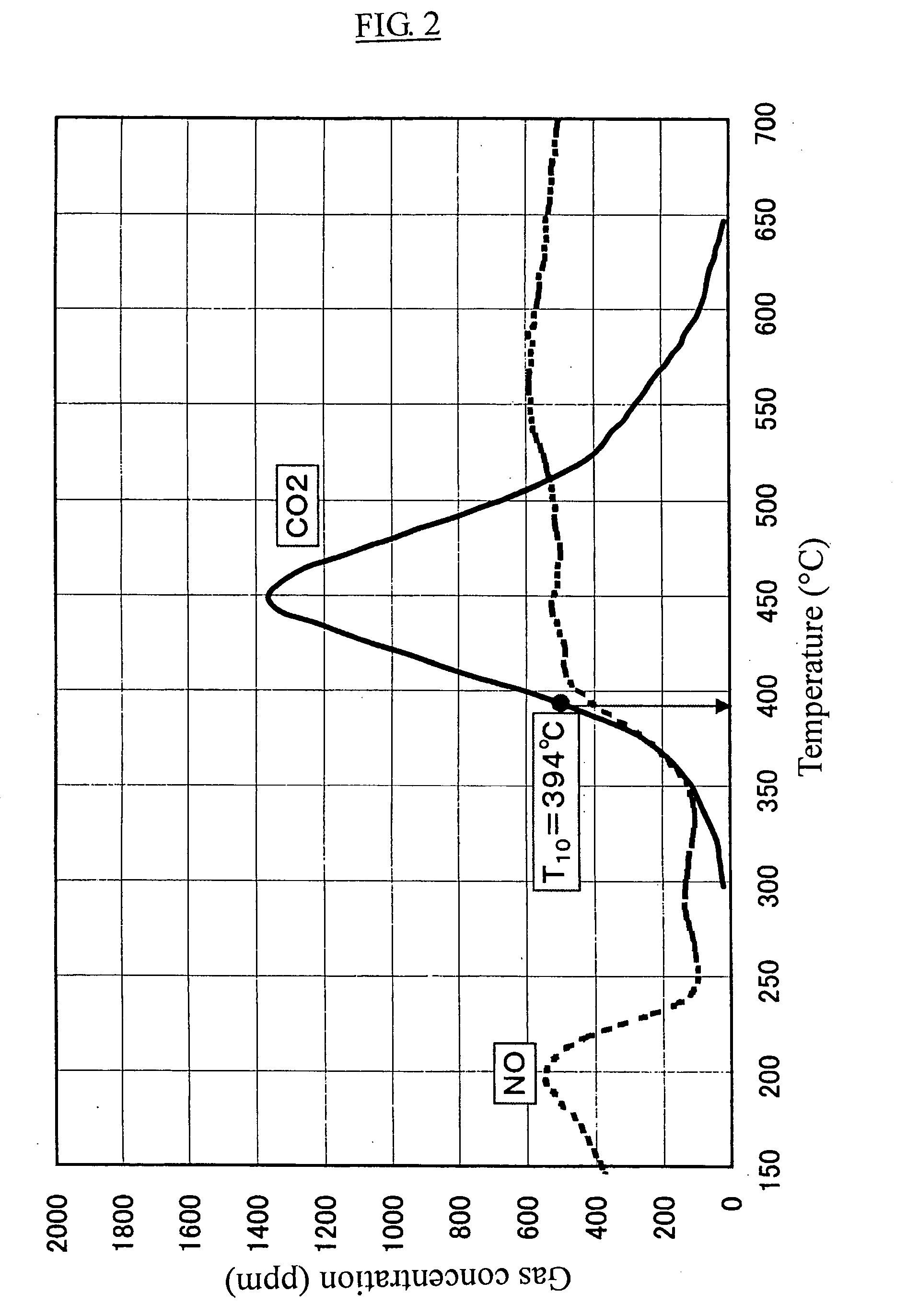

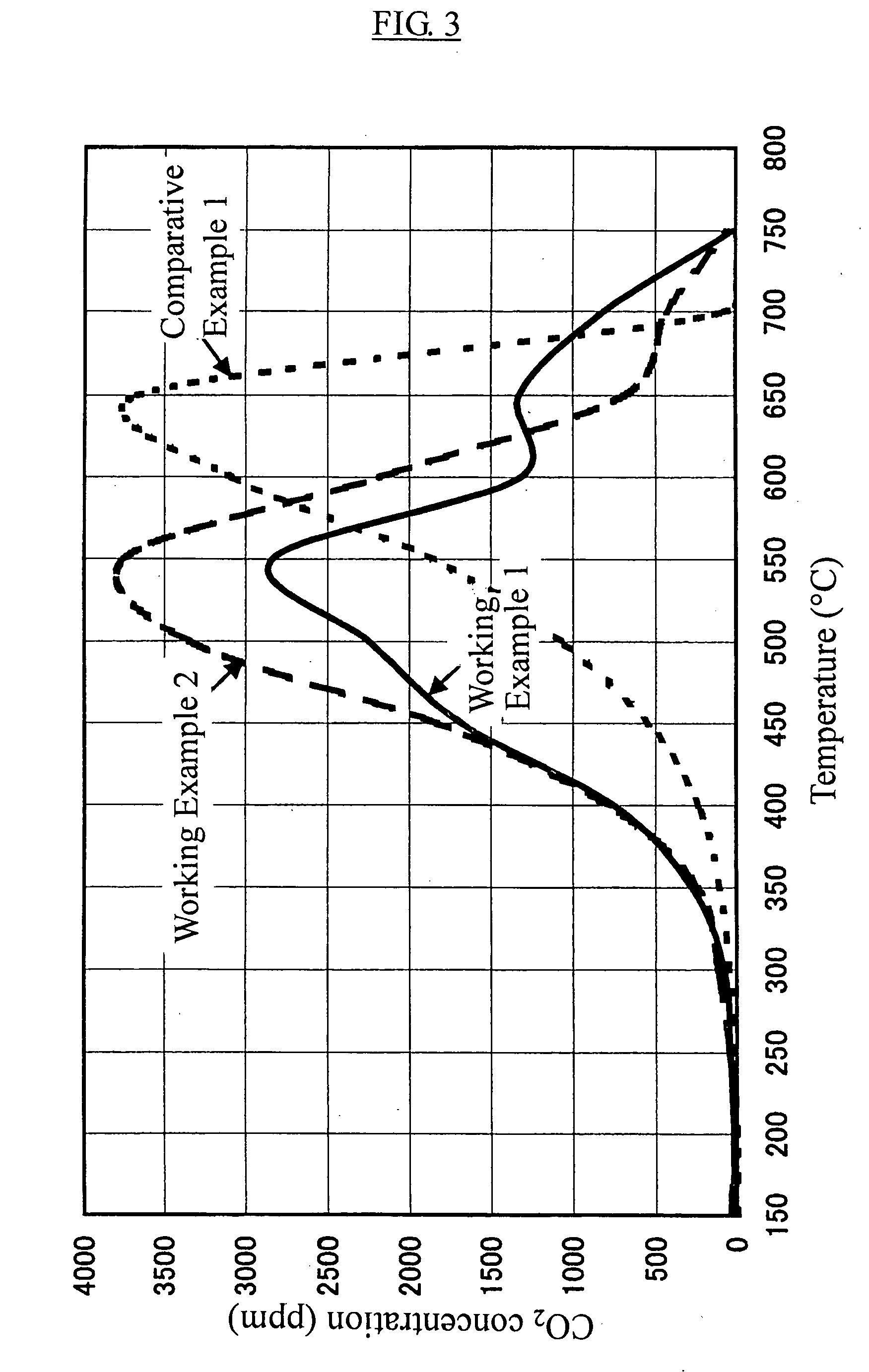

InactiveUS20070105715A1Increased durabilityReduce the amount requiredCombination devicesGas treatmentStructural formulaDiesel particulate filter

This is a catalyst suitable for a diesel particulate filter (DPF) that traps particulate matter (PM) present in diesel engine exhaust, being a diesel engine exhaust gas particulate matter oxidation catalyst using a perovskite-type composite oxide that has an NO adsorption domain over the range of 200-450° C. This catalyst induces low-temperature combustion of PM but does not use noble metals so it is inexpensive and its constituent materials are not volatile at exhaust gas temperatures so it has superior durability. The perovskite-type composite oxide contains essentially no Na and is represented by the structural formula RTO3, where R comprises one or more elements selected from a group made up of La, Sr, Ba, Ca and Li, and T comprises one or more elements selected from a group made up of Mn, Fe, Co, Cu, Zn, Ga, Zr, Mo, Mg, Al and Si.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

System for reducing discharge smoke temperature of power station boiler

InactiveCN102252339AReduce the temperatureIncrease temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a system for reducing discharge smoke temperature of a power station boiler and belongs to the technical field of waste heat recovery, and the system is characterized that a heat transfer pipeline is arranged in the hot primary air pipeline of the boiler, the two ends of the heat transfer pipeline are respectively connected with a water inlet pipeline and a water outlet pipeline, the other ends of the water inlet pipeline and the water outlet pipeline are connected to a heater on the secondary air inlet air flue of an air pre-heater; and simultaneously a bypass flue is additionally arranged, thus the original smoke is divided into two paths, one path of the original smoke is sent into the air pre-heater through the original flue, and the other path of the originalsmoke is sent into a low-pressure high-temperature economizer through the bypass flue. The hot primary air is utilized to heat the cold secondary air, thereby improving the air temperature of a secondary air inlet; the primary air temperature is controlled by changing the quantity of a cooling medium in the heat transfer pipeline, thereby reducing the amount of the cold primary air doped in a coal pulverizing system; and a method of increasing the amount of the smoke in the bypass flue is adopted, thereby reducing the temperature of the discharge smoke. On the premise of ensuring the temperature of the secondary air, the surplus heat of the primary air is recycled, thus the coal consumption of the boiler and the heat rate of a steam turbine are reduced, and the economical efficiency of a power plant is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

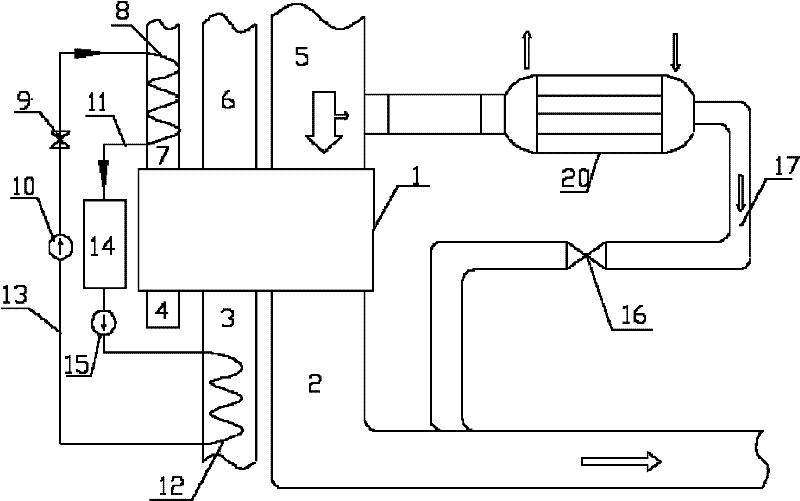

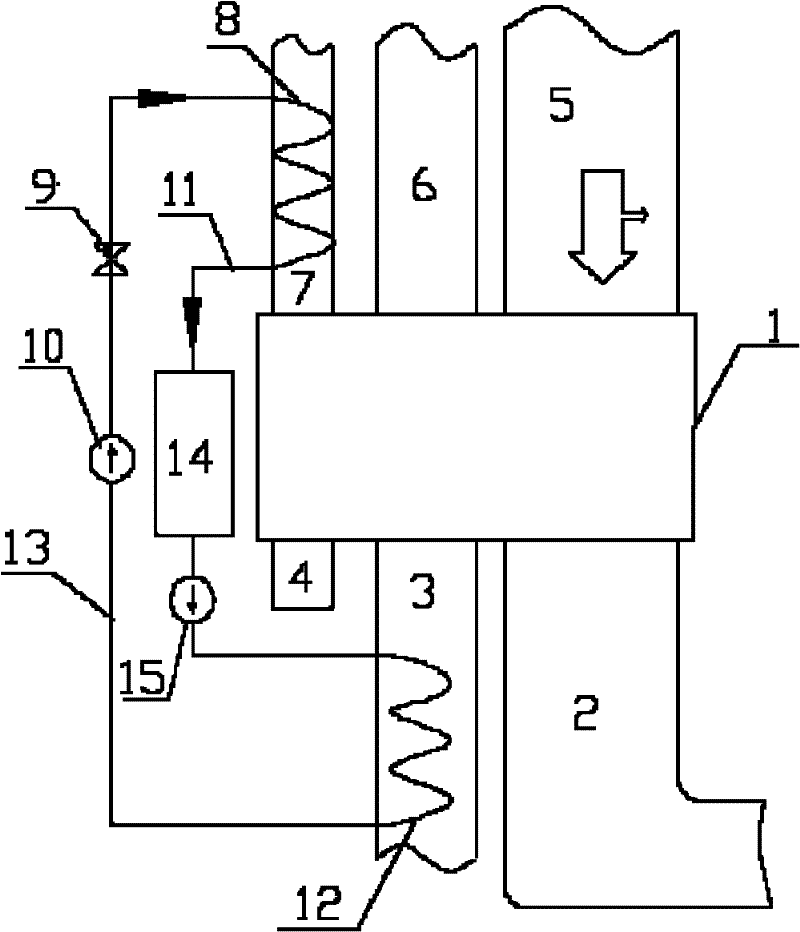

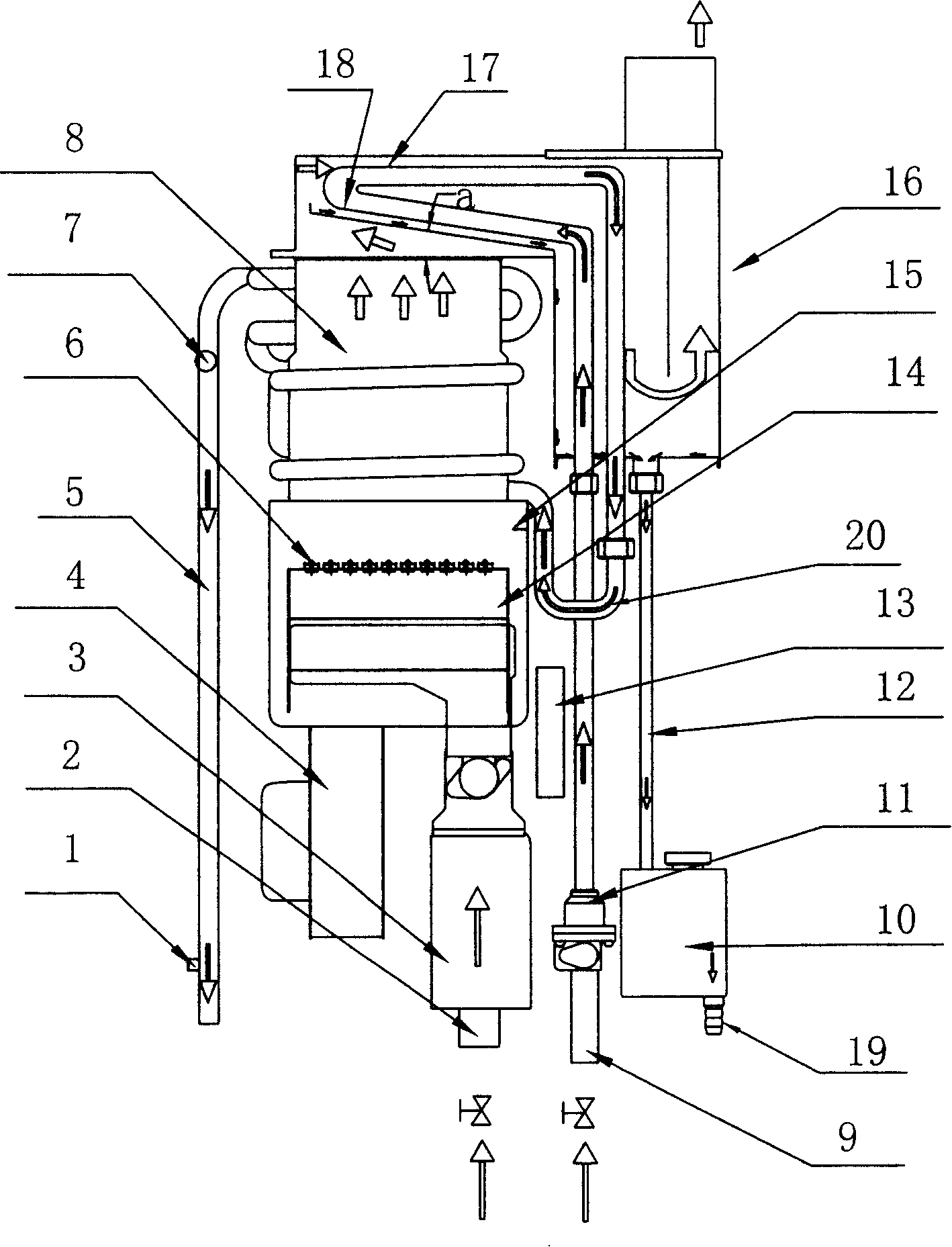

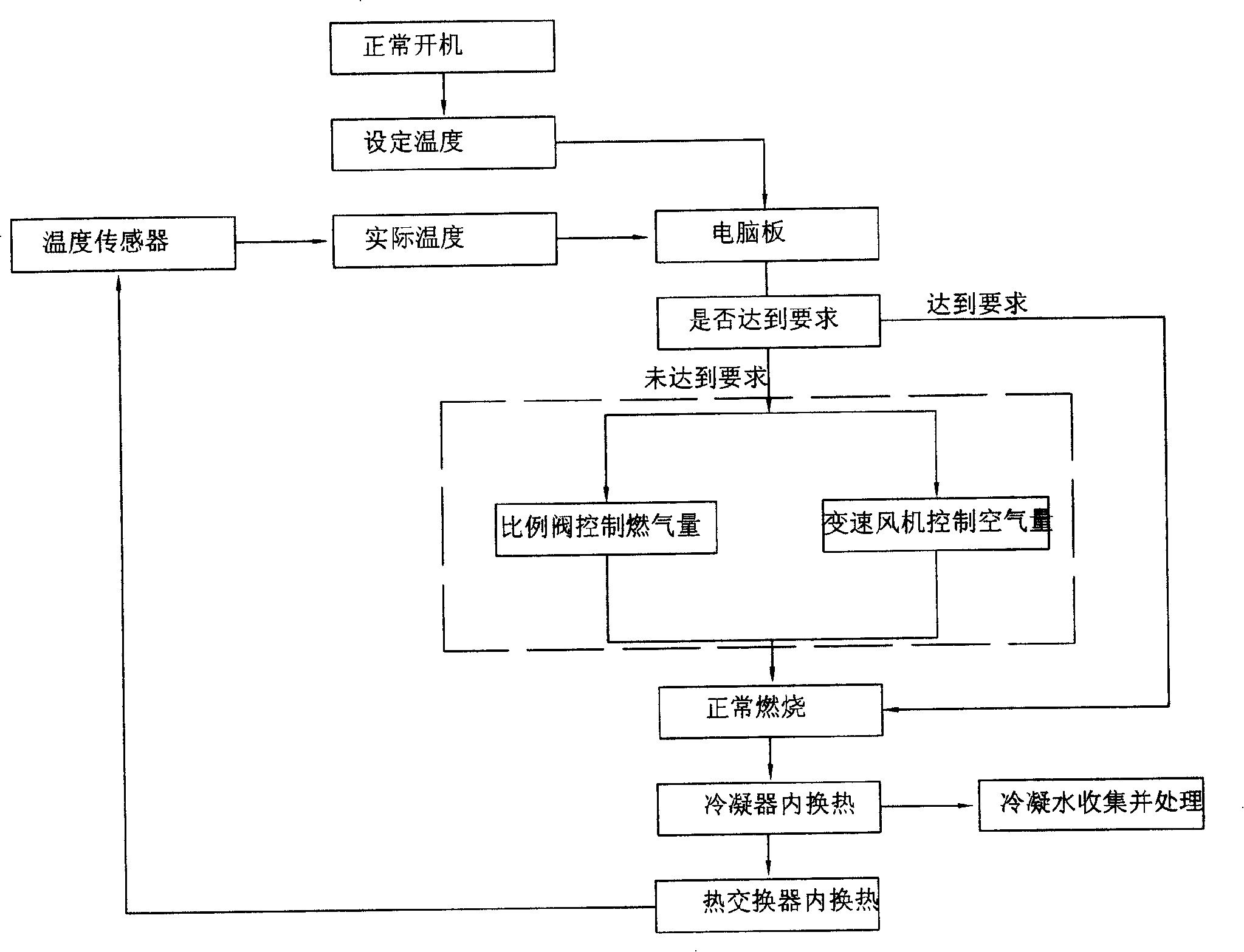

Condensing type constant temperature gas water heater

The invention discloses a condensing constant temperature gas water heater, comprising a gas distribution device, an inflamer unit and a flame induction system which are arranged on the upper part of the gas distribution device, a cold water inlet pipeline and a water flow sensor which is connected with the cold water inlet pipeline, a gas inlet pipeline, a hot water outlet pipeline, a condenser which is arranged on the upper part of the heater and is provided with a pipe coil and a main heat exchanger which is communicated with a mild water outlet pipe of the condenser, wherein, the lower part of the condenser is communicated with a condensed water processor through a condensed water drain pipe and is communicated with a regulation and control part for adjusting the temperature and the gas amount as well as the amount of wind; the regulation and control part comprises a computer board, a hot water temperature sensor which is in electric connection with the computer board, an over temperature controller, a frequency conversion fan and a gas proportional valve. The invention is based on a forced exhaust type heater and is provided with an independent stainless steel sylphon bellowss pipe coil type heat exchanger outside and realizes the complete separation of the primary heat exchange, the secondary heat exchange and the collection of condensed water. Moreover, the thermal efficiency is up to more than 96 percents, the exhaust temperature is reduced to about 100 DEG C, the infection of condensed water on the main heat exchanger is effectively reduced, and the service life of the heater is guaranteed.

Owner:HAIER GRP CORP +1

Thermal storage type oxygen-enriched combusting method and device

InactiveCN101280916AEasy to replaceCompact structureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFour-way valveEngineering

The invention discloses a heat accumulation type oxygen-enriched combustion method and apparatus, gas and oxygen or other gases are intensively mixed at oxygen mixing showerhead of the heat accumulation type oxygen-enriched combustor, and are sprayed into a mix gas duct arranged at center of a heat accumulation chamber, the intensively mixed gas is mixed again with combustion air pre-heated to 900-1000 DEG C at the showerhead of the combustor to combust; according to the invention, the heat accumulation type oxygen-enriched combustion apparatus comprises two heat accumulation type oxygen-enriched combustors, each of which comprises a heat accumulation chamber, a heat storage, mixture gas duct and a combustor showerhead, the heat accumulation chamber communicates with an air chamber, the air chamber communicates with a four-way valve, the oxygen mixing showerheads are separately arranged on ends of gas duct and oxygen duct. The method and device, employing the invention, have compact conformation, energy conservation, also can use low-calorie fuels as combustion air, can remarkably reduce exhaust smoke level and reduce smoke discharging temperature.

Owner:TIANJIN SAIYANG INDAL FURNACE

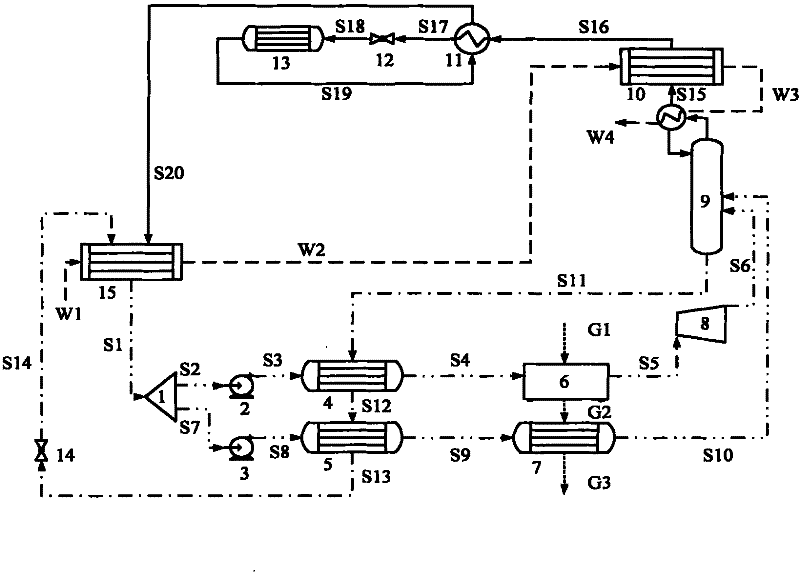

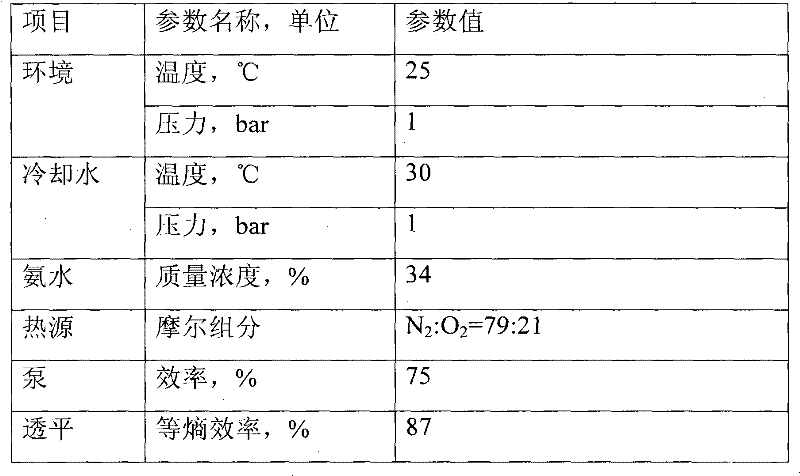

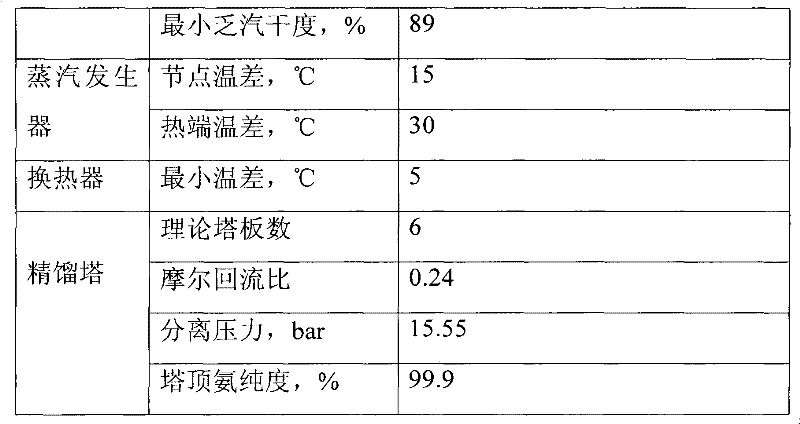

Mixed working medium thermal circulating system and method for power and refrigeration cogeneration

ActiveCN102242985AAchieve the goal of energy saving and emission reductionReduce irreversible lossClimate change adaptationEnergy efficient heating/coolingEvaporationCogeneration

The invention discloses a mixed working medium thermal circulating system and method for power and refrigeration cogeneration. In the system, an ammonia and water mixture is utilized as a working medium, and the middle / low temperature heat is utilized as a heat source. The method comprises the following steps: heating the ammonia water working medium to obtain superheated steam; introducing the superheated steam into a turbine to do work; introducing the exhaust steam of the turbine into a rectification tower to supply heat for the rectification process; introducing the ammonia generated by the rectification tower into an evaporator after condensing, undercooling and throttling; throttling a dilute solution subjected to waste heat recovery, introducing the throttled dilute solution into aabsorber, mixing with the ammonia from the evaporator and condensing; and introducing a heat source into a steam generator firstly, and then introducing the heat source into a waste heat solution heat exchanger. The steam generator adopts the ammonia water strong solution as the working medium, the variable temperature evaporation feature of the ammonia water strong solution is well matched with the temperature of the heat source, thus the irreversible loss of the heat exchange process in the steam generator is reduced; simultaneously the exhaust steam of the turbine directly enters into the rectification tower to supply the rectifying heat without condensation, thus the irreversible loss caused by the variable temperature condensation of the ammonia water working medium is avoided; and the mixed type heat transfer is adopted, thus the irreversible loss of the heat exchange process is reduced.

Owner:江苏中国科学院能源动力研究中心 +1

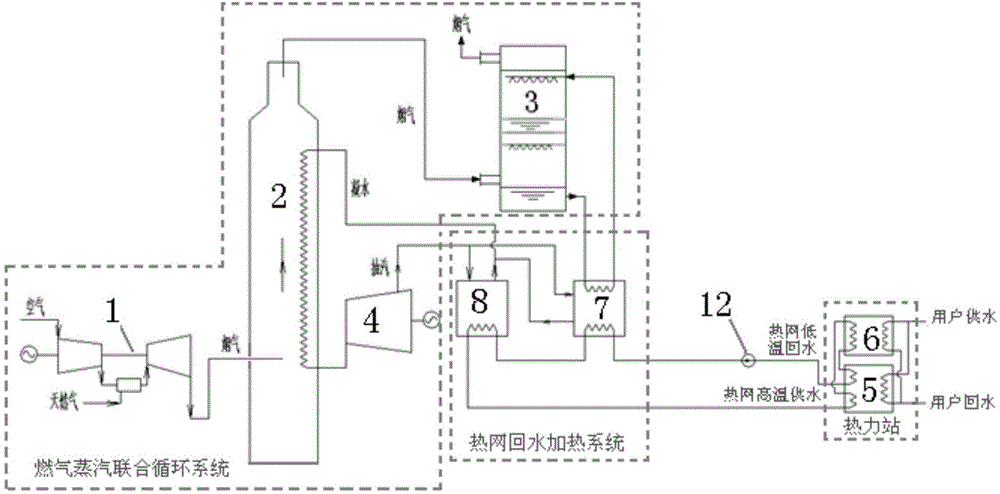

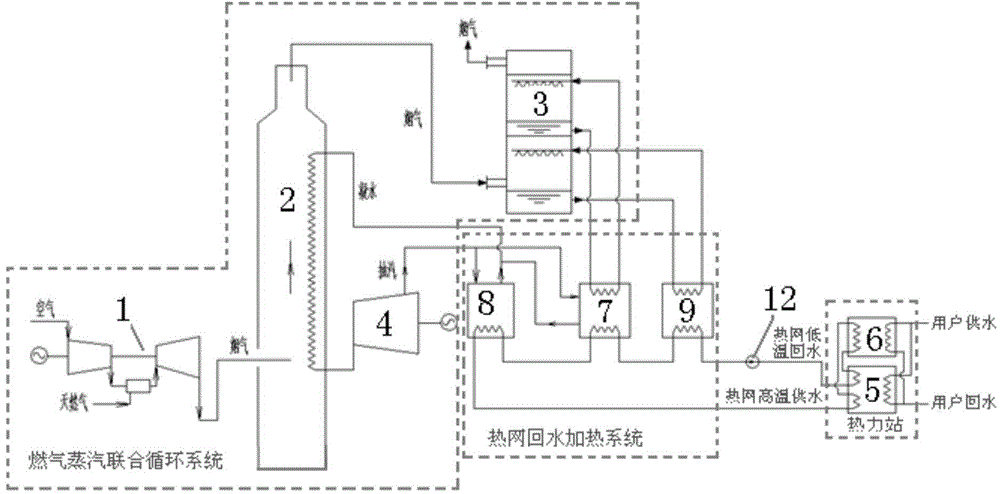

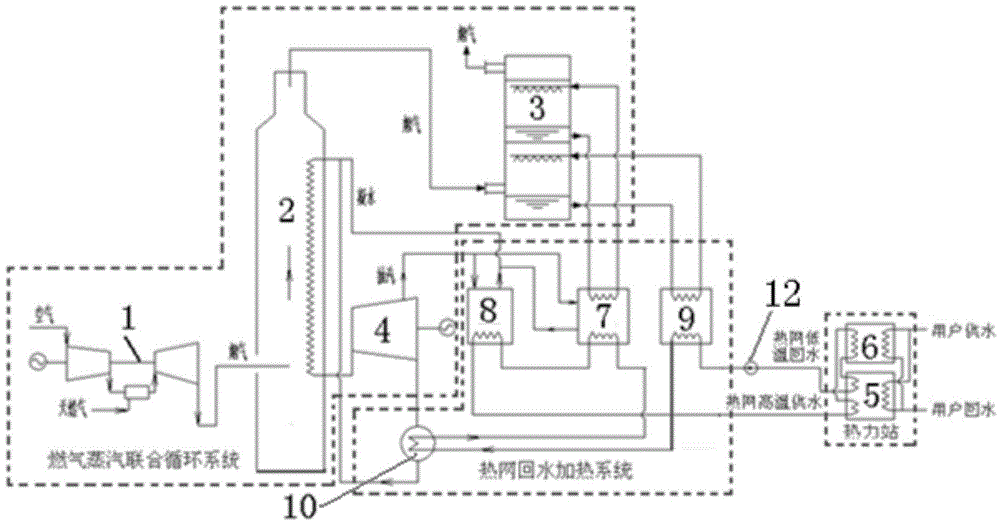

Gas steam combined cycle central heating device and heating method

InactiveCN104534539AReduce pollutionReduce wasteInternal combustion piston enginesRecuperative heat exchangersFlue gasRecuperator

The invention relates to a gas steam combined cycle central heating device and heating method. The device comprises a gas steam combined cycle system, a heat supply network backwater heating system and a thermal station, and the gas steam combined cycle system is connected with the thermal station through the heat supply network backwater heating system; the gas steam combined cycle system comprises a gas turbine, a waste heat boiler, a direct contact flue gas condensing heat exchanger and a steam turbine; the gas turbine is connected with the waste heat boiler, and the waste heat boiler is connected with the direct contact flue gas condensing heat exchanger and the steam turbine; the thermal station comprises a hot water absorption heat pump and a water-water heat exchanger; the heat supply network backwater heating system comprises a steam absorption heat pump used for recovering flue gas waste heat and a steam-water heat exchanger; the steam absorption heat pump used for recovering the flue gas waste heat is connected with the steam-water heat exchanger, the direct contact flue gas condensing heat exchanger, the waste heat boiler, the steam turbine and the thermal station, and the steam-water heat exchanger is connected with the waste heat boiler, the steam turbine and the thermal station. The gas steam combined cycle central heating device and heating method can be widely applied to the industry of recycling waste heat of power plants.

Owner:TSINGHUA UNIV

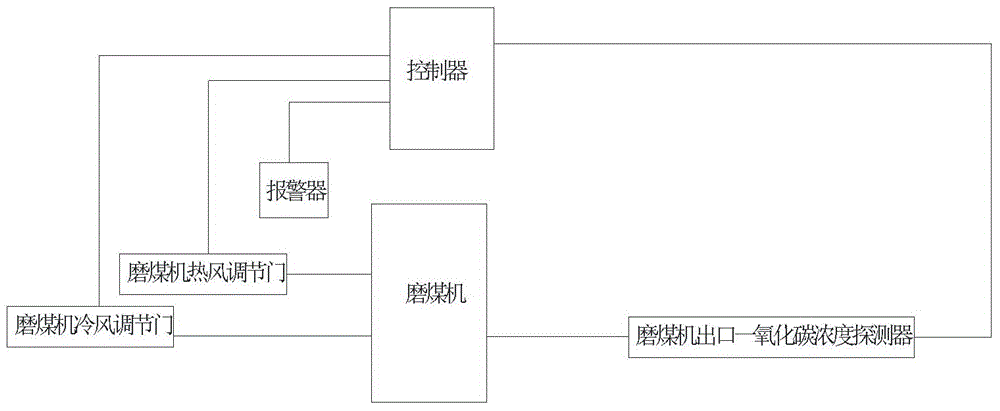

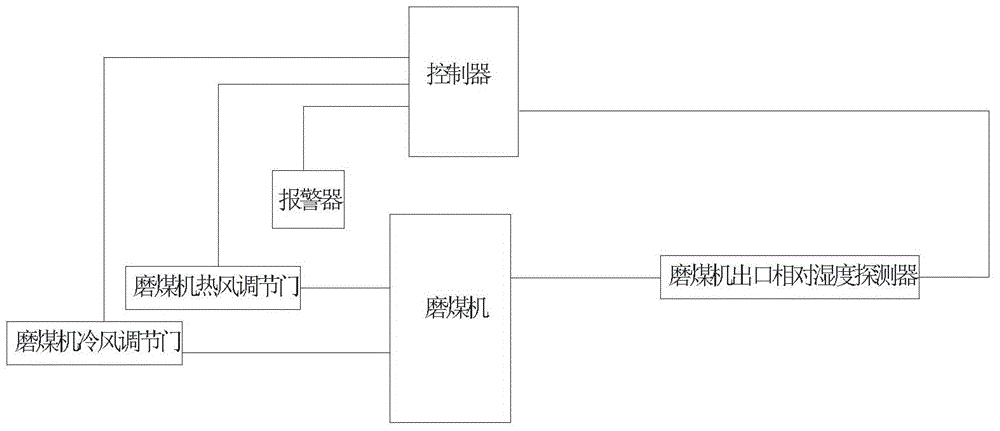

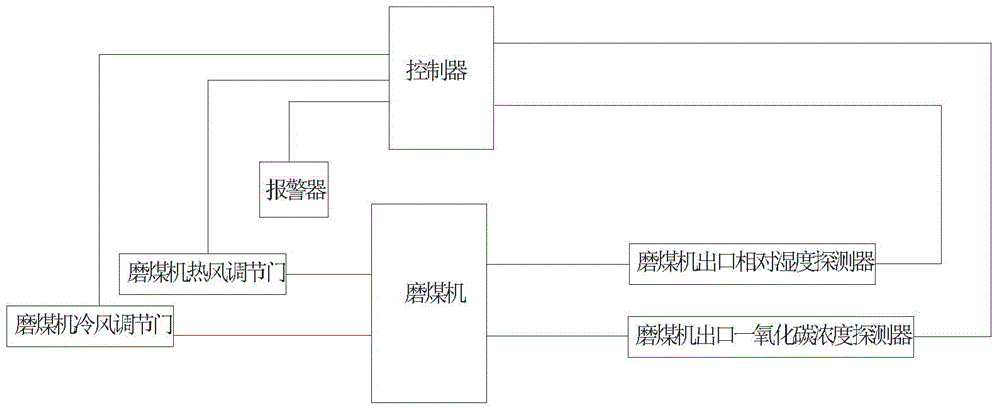

Control system and control method for outlet temperature of novel coal mill

ActiveCN104801416ARaise the outlet temperatureIncrease the level of automationGrain treatmentsLump/pulverulent fuel preparationTemperature controlCombustion

The invention discloses a control system and control method for outlet temperature of a novel coal mill. The control system comprises a controller, a coal mill outlet temperature detector and a coal mill hot air damper, wherein the coal mill outlet temperature detector is mutually connected with the controller; the controller is connected to the coal mill hot air damper. Compared with an existing control method, the control method disclosed by the invention can overcome the defects existing in an existing coal mill outlet temperature control method that a coal mill outlet temperature upper limit value is only set aiming at specific coal, the frequent change of the quality of coal supplied by the coal mill cannot be adapted, and a coal mill outlet temperature running value is low. According to the control system and the control method disclosed by the invention, the automatic level of coal mill operation can be improved, the outlet temperature of the coal mill is effectively improved, the power consumption generated during coal milling of the coal mill is reduced, and the carbon content of a product after pulverized coal combustion can be reduced.

Owner:SOUTHEAST UNIV

Gas-fired boiler afterheat recovering system and recovering method

InactiveCN103438427ARaise the water temperatureLower exhaust gas temperatureLiquid degasificationAir preheaterEngineering

The invention discloses a gas-fired boiler afterheat recovering system and a gas-fired boiler afterheat recovering method. A bypass flue is parallelly connected onto a main flue, a bypass flue butterfly valve, a boiler coal economizer, an air preheater and a condensing type heat exchanger are sequentially and serially connected onto the bypass flue, the bypass flue is communicated with a bypass chimney, a water inlet of a heat exchange pipe of the boiler coal economizer is connected with a water tank through a water supply pipeline, a water outlet of the heat exchange pipe is communicated with a boiler through a pipeline, an air inlet of a heat exchange pipe of the air preheater is communicated with a fan through a pipeline, an air outlet is communicated with a boiler combustion-supporting air inlet pipe through a pipeline, a water inlet of a heat exchange pipe of the condensing type heat exchanger is communicated with the water tank through a descending pipe, and a water outlet is communicated with the water tank through an ascending pipe. The gas-fired boiler afterheat recovering system and the gas-fired boiler afterheat recovering method have the advantages that the structure is simple and compact, the size is small, the boiler smoke discharge temperature is lowered to 40 to 50 DEG C, in addition, all recovered heat is used for a boiler system, the boiler smoke discharge temperature is greatly lowered, the boiler heat efficiency is greatly improved up to more than 100 percent, and the goal of greatly improving the utilization rate of energy sources is reached.

Owner:TIANJIN NUONENGDA ENERGY TECH

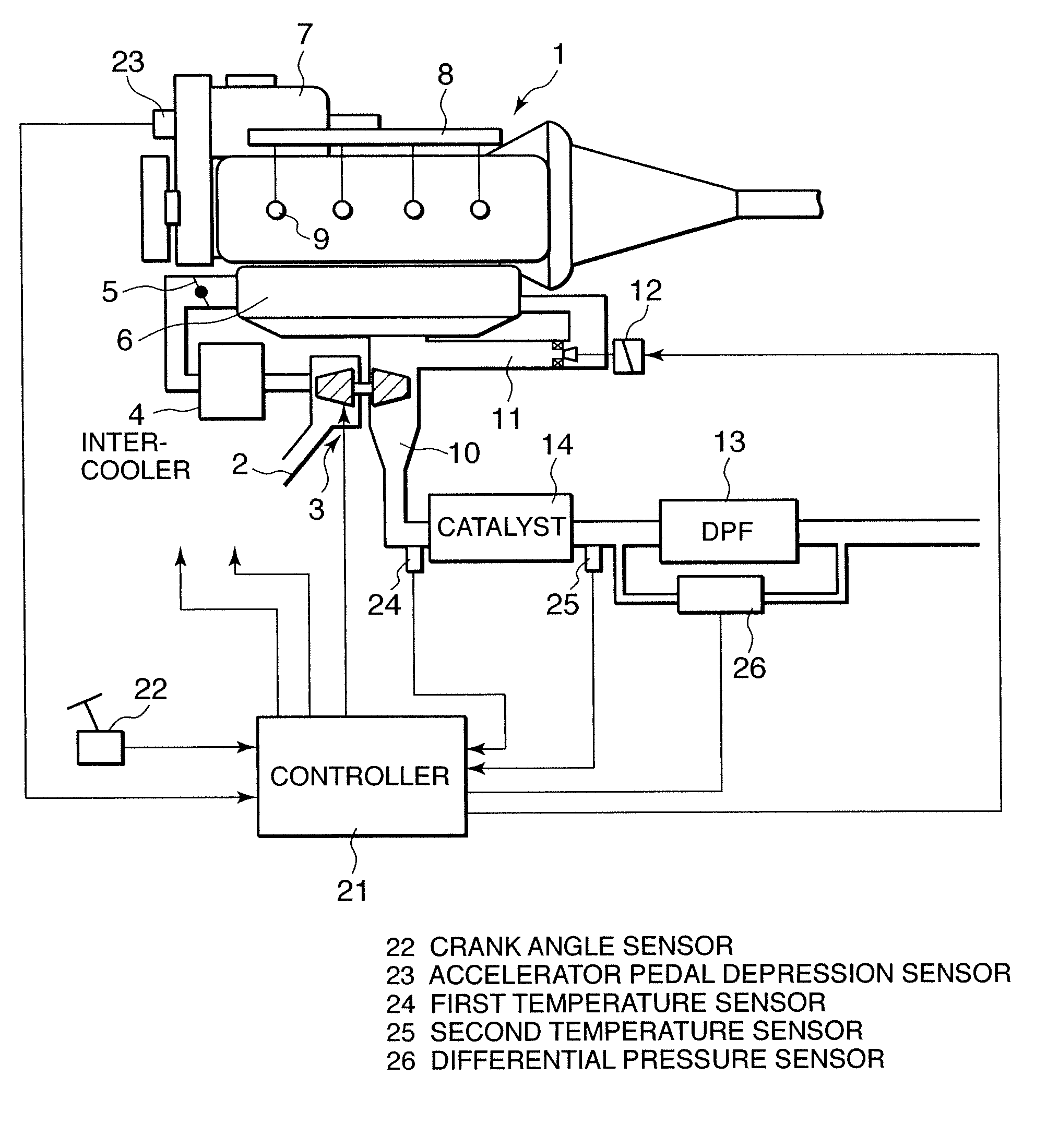

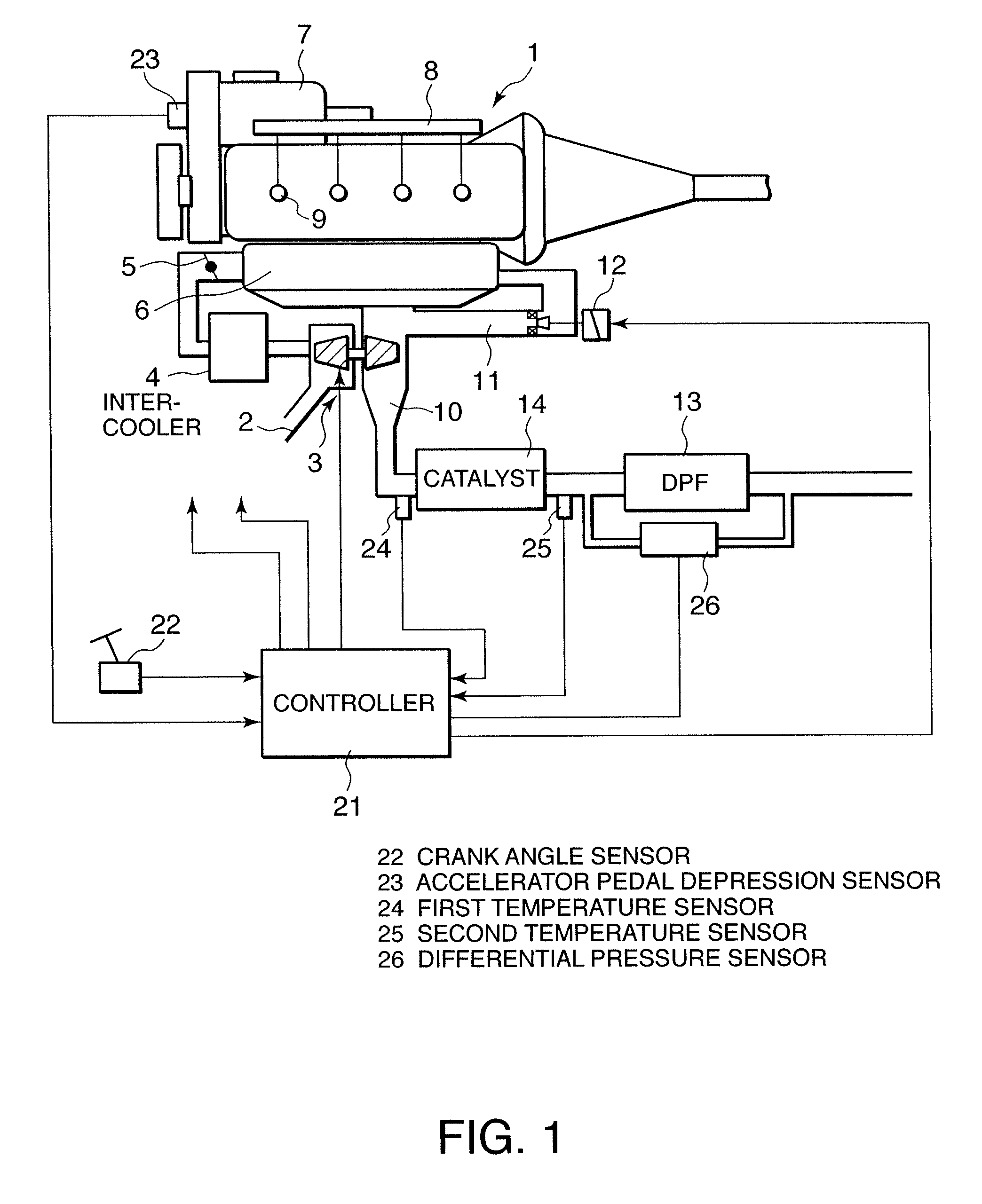

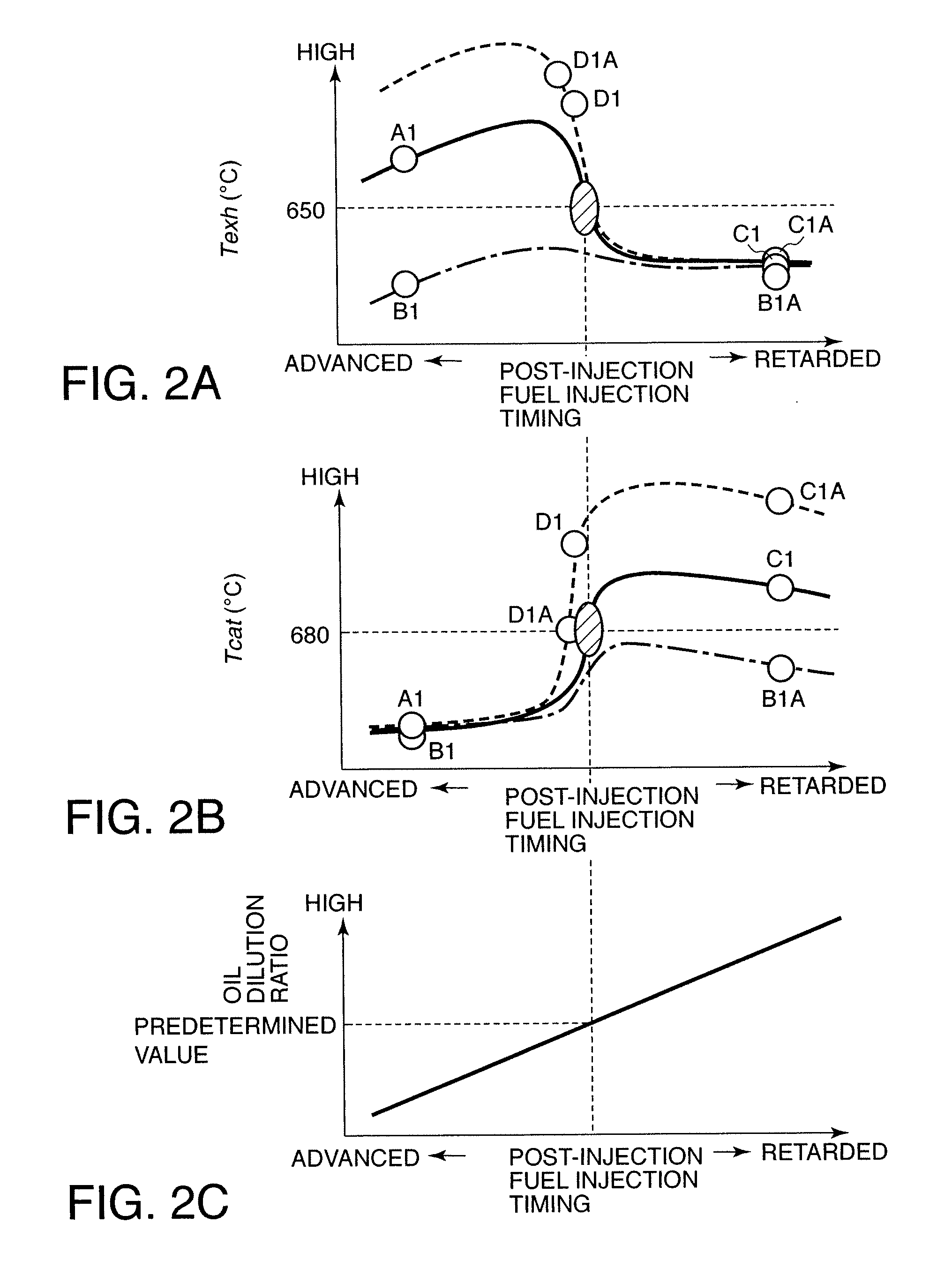

Particulate matter trap filter regeneration temperature control for internal combustion engine

InactiveUS20090133387A1Lower exhaust gas temperatureElectrical controlInternal combustion piston enginesTemperature controlParticulates

An internal combustion engine (1) comprises a fuel injector (9), a filter (13) which traps particulate matter in exhaust gas, and a catalyst (14) which oxidizes unburnt fuel or carbon monoxide in the exhaust gas on the upstream side of the filter (13). When regeneration of the filter (13) is required, a controller (21) determines a post-injection fuel injection timing and a post-injection fuel injection amount of the fuel injector (9) on the basis of an upstream exhaust gas temperature (Texh) and a catalyst temperature (Tcat) (S16, S17, S19, S20, S22, S23, S25, S26, S28), thereby optimizing the regeneration temperature condition of the filter (13).

Owner:NISSAN MOTOR CO LTD

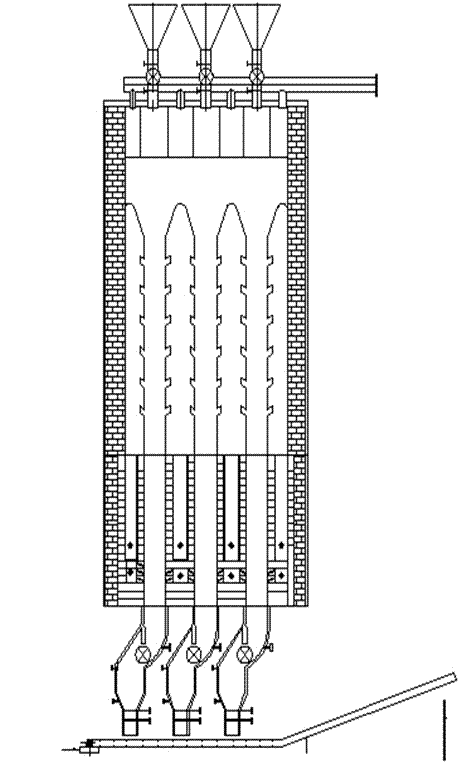

HY type dry distillation furnace

ActiveCN103923676ASolve the problem of low utilization efficiencyImprove utilization efficiencyIndirect and direct heating destructive distillationEnergy inputCombustion chamberHeat carrier

The invention discloses an HY type dry distillation furnace which is characterized by comprising a plurality of dry distillation subunits, wherein each dry distillation subunit comprises a charging device, an oil gas discharge device, a dry distillation device, a heating device and a coke discharge device; materials are subjected to dry distillation by using a combined radiation heat exchange and convection heat exchange mode in the furnace; gas generated in a dry distillation process is used as a dry distillation heat source, and the dry distillation heat can be self-balanced; the materials are directly heated by virtue of radiation of a furnace wall of a combustion chamber, and a heat carrier does not need to be subjected to secondary heating and long-distance conveying; a dry distillation gas outputting device is arranged in the furnace, so that the gas in the furnace flows smoothly; coke is discharged by a dry method. The dry distillation furnace is high in heat utilization efficiency, low in outlet gas quantity, low in water consumption, high in oil yield and large in daily treatment capacity capable of being more than 6,000 tons, and is suitable for low and medium-temperature dry distillation of the materials such as oil sand, oil shale, coal and the like, and suitable for oil refining and dry distillation of large particle materials and small particle materials of less than 15mm.

Owner:辽宁智越建设有限公司

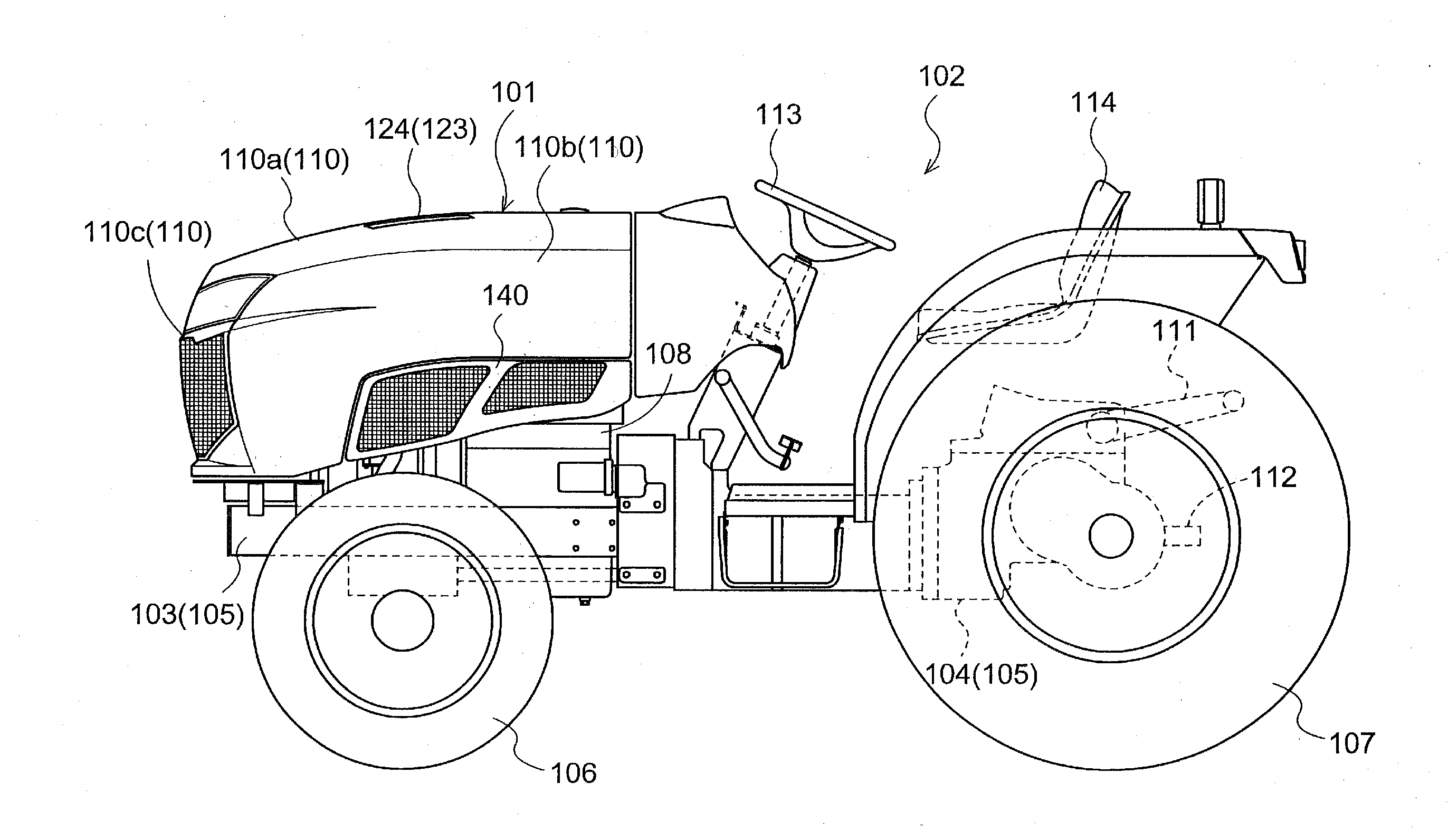

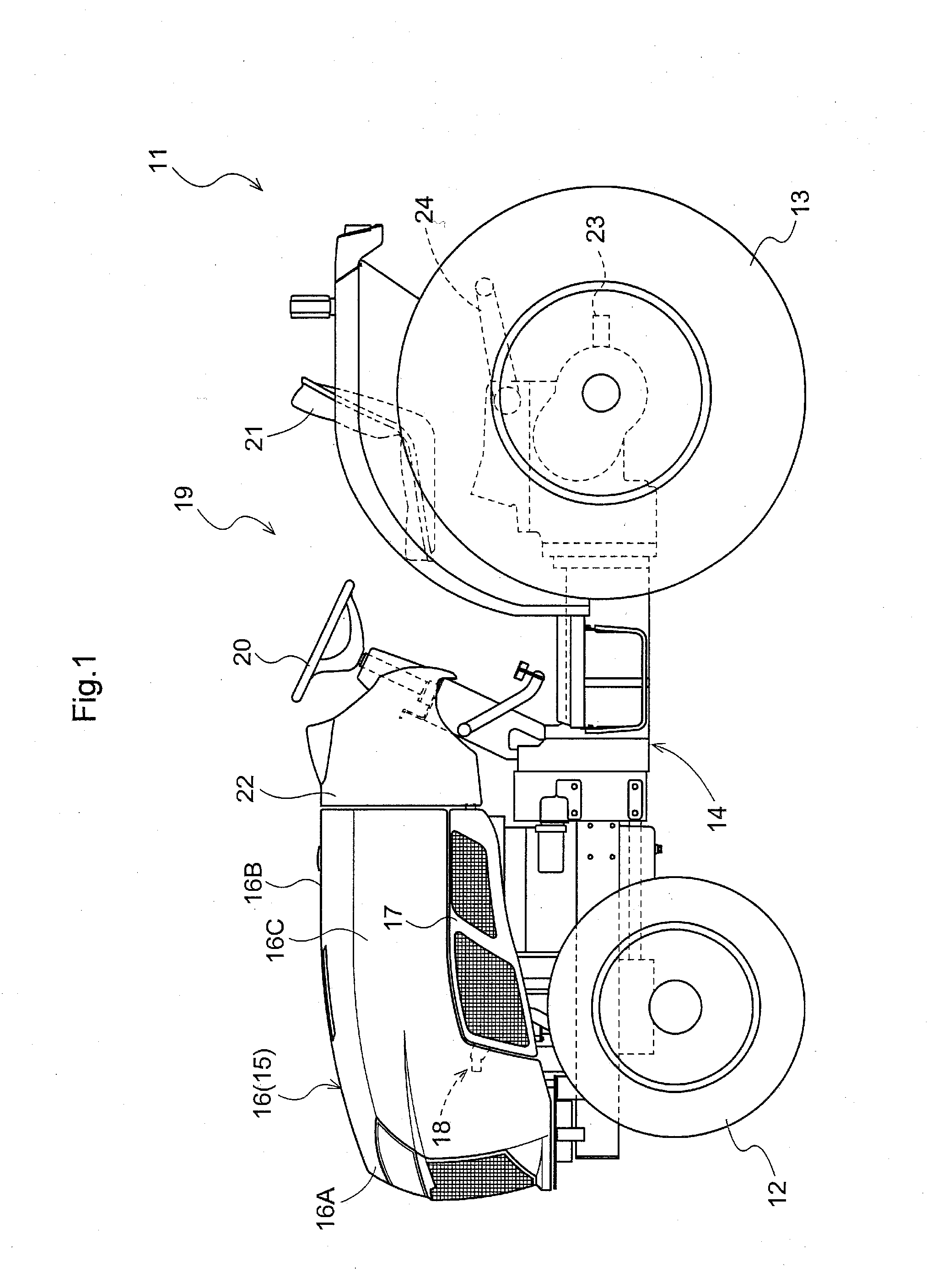

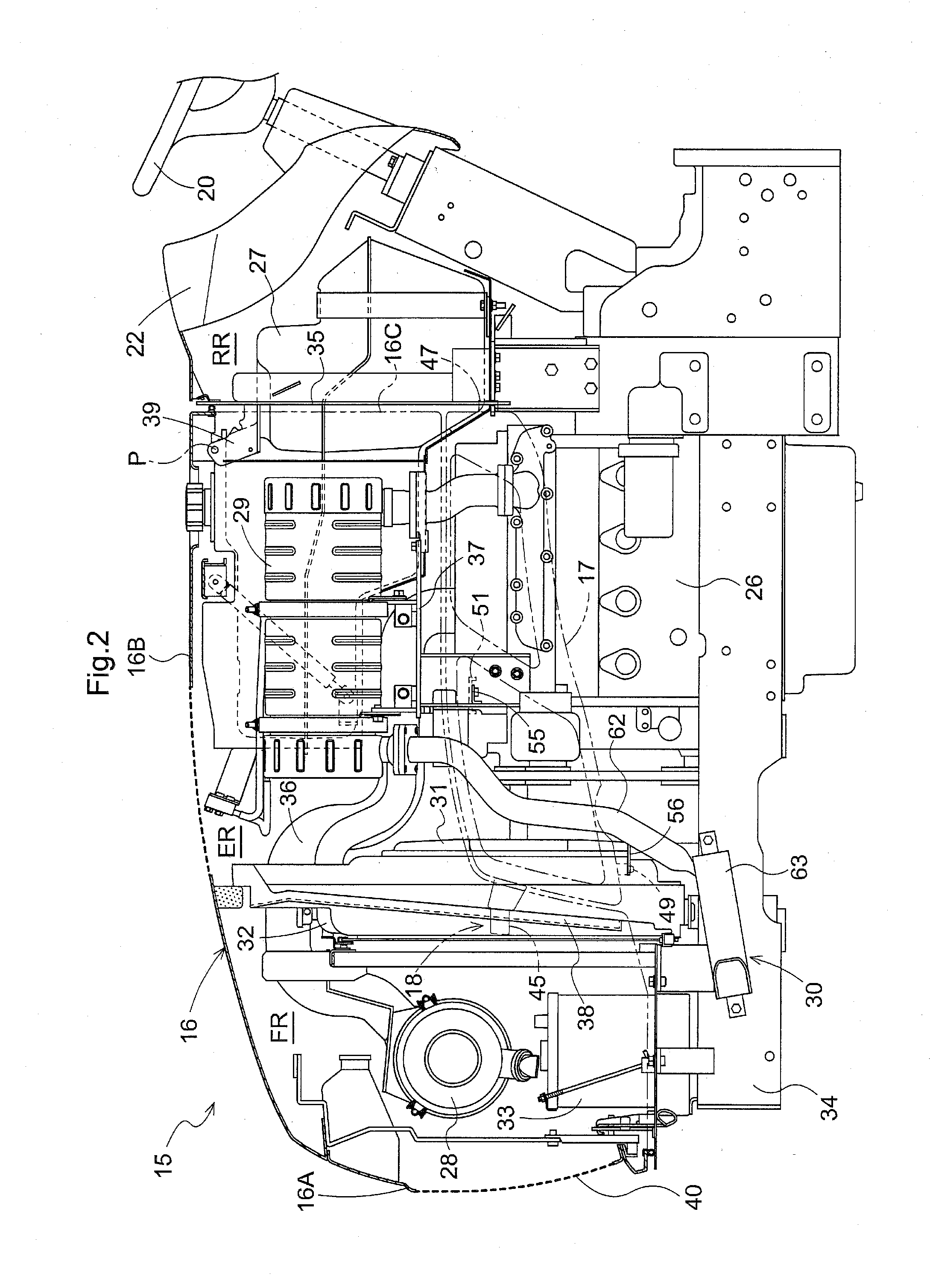

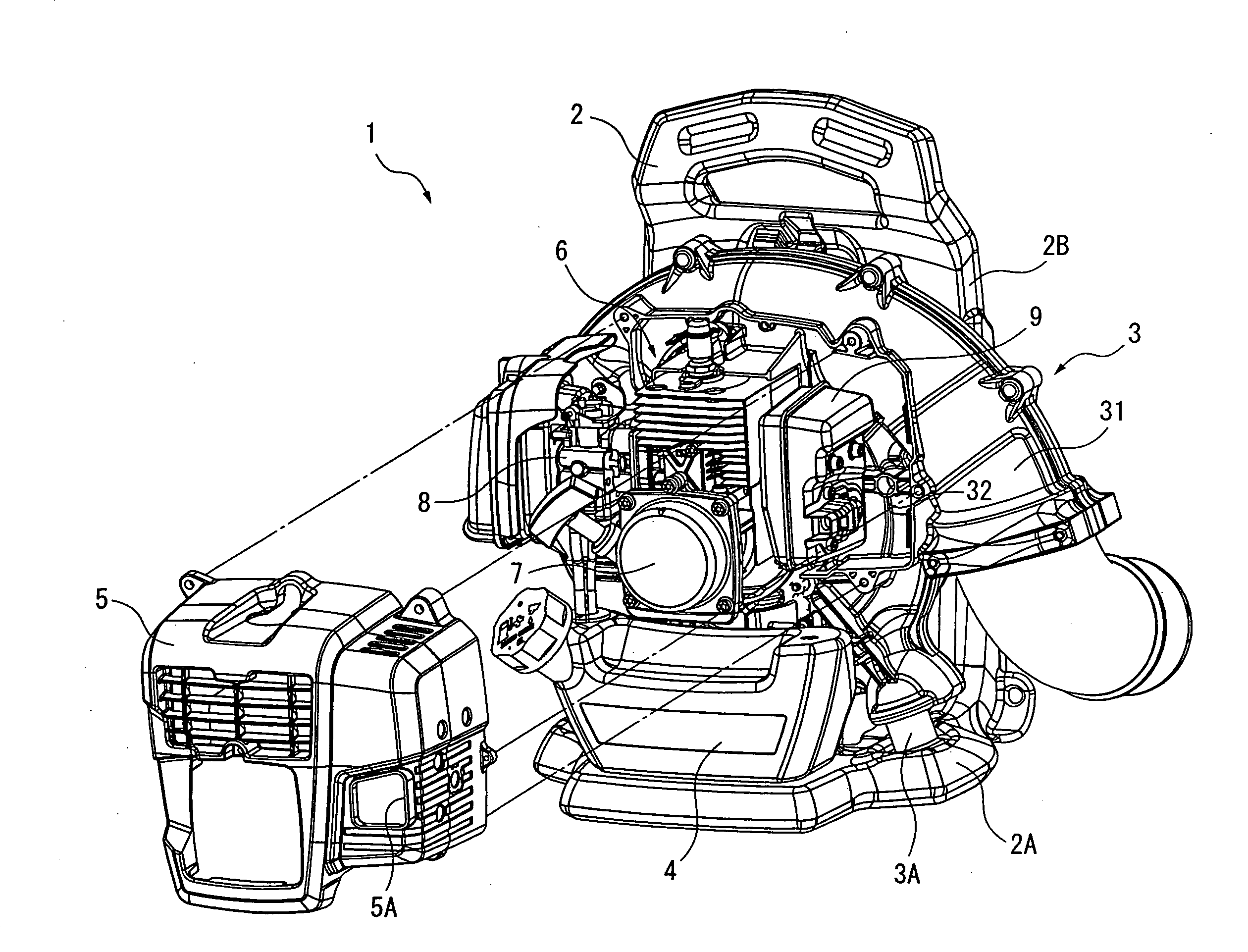

Working Vehicle

ActiveUS20140251713A1Increase temperatureLower exhaust gas temperatureSuperstructure subunitsVehiclesEngineeringMechanical engineering

A working vehicle includes a traveling machine assembly, a drive unit, a bonnet configured to cover the drive unit, and a cover provided below the bonnet and configured to be removably attached to the traveling machine assembly, including a main body portion extending in a longitudinal direction of the traveling machine assembly, a first male engagement portion provided at a front end portion of the main body portion, a second male engagement portion provided at a rear end portion of the main body portion, and a third male engagement portion provided at a lower end portion of the main body portion.

Owner:KUBOTA LTD

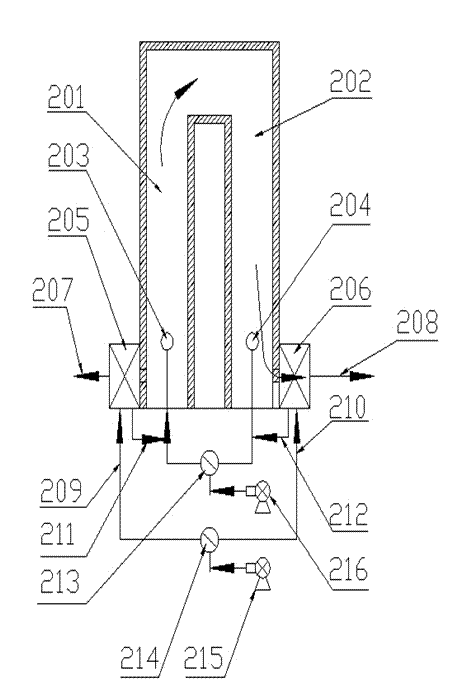

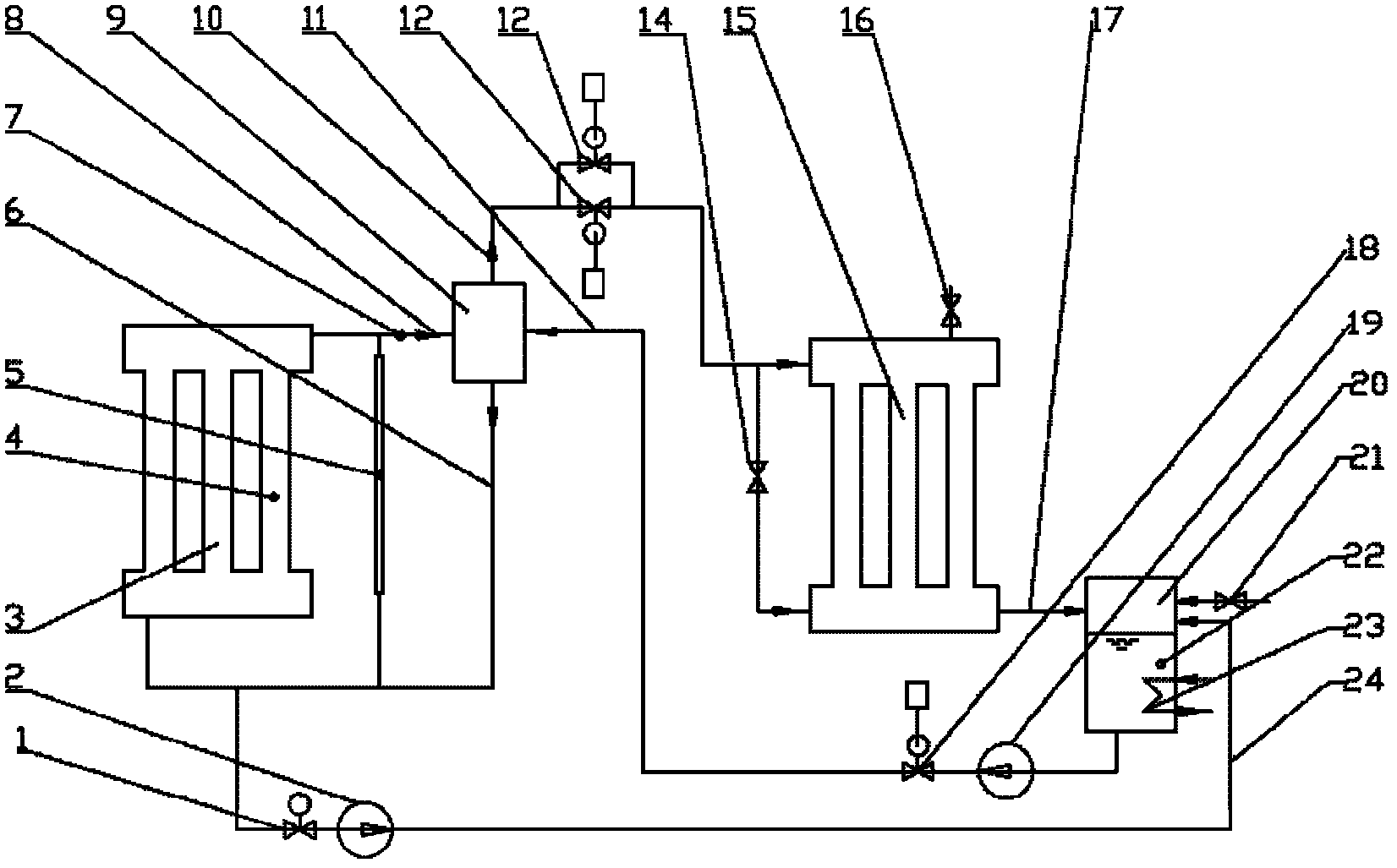

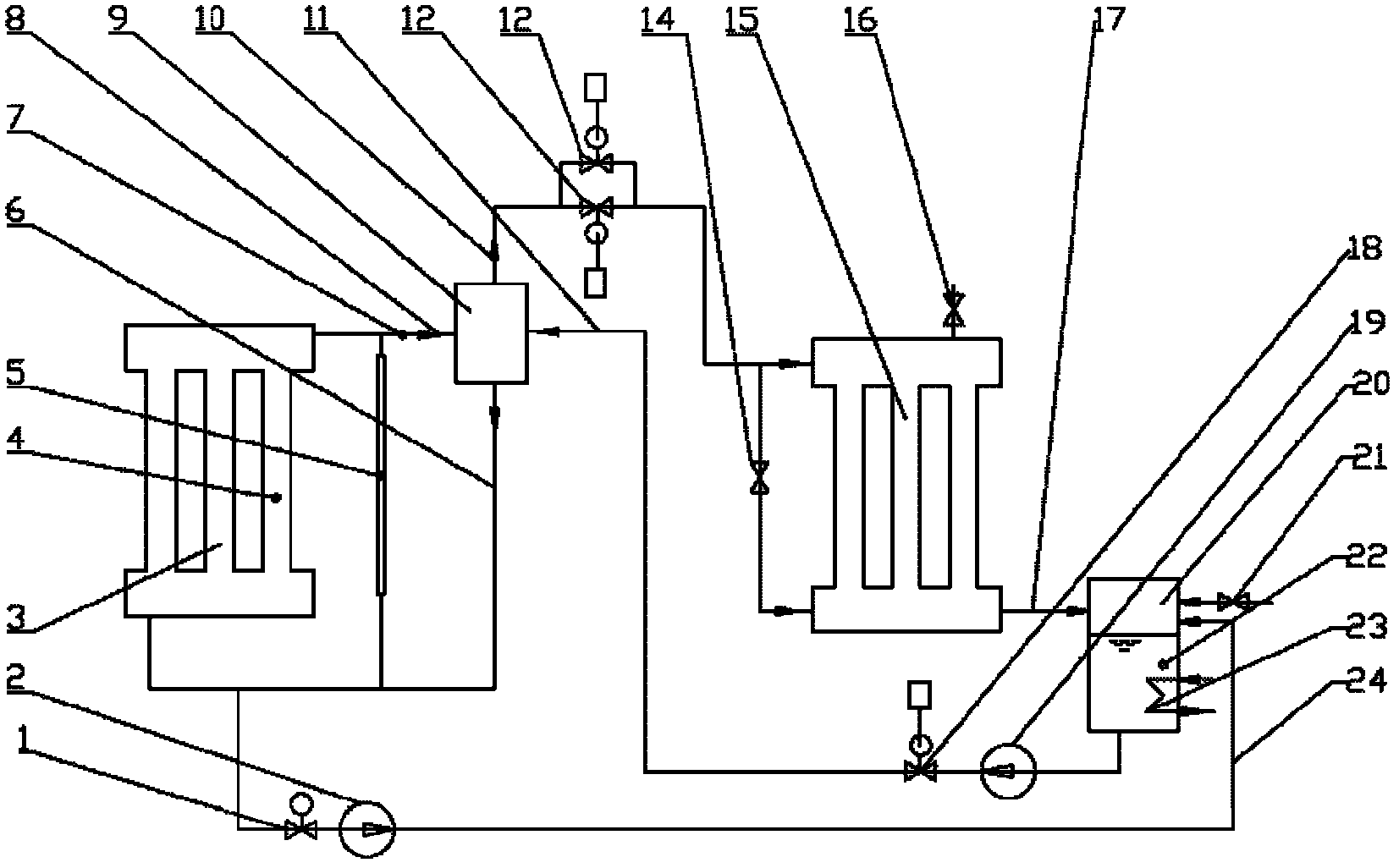

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersEngineeringLiquid storage tank

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

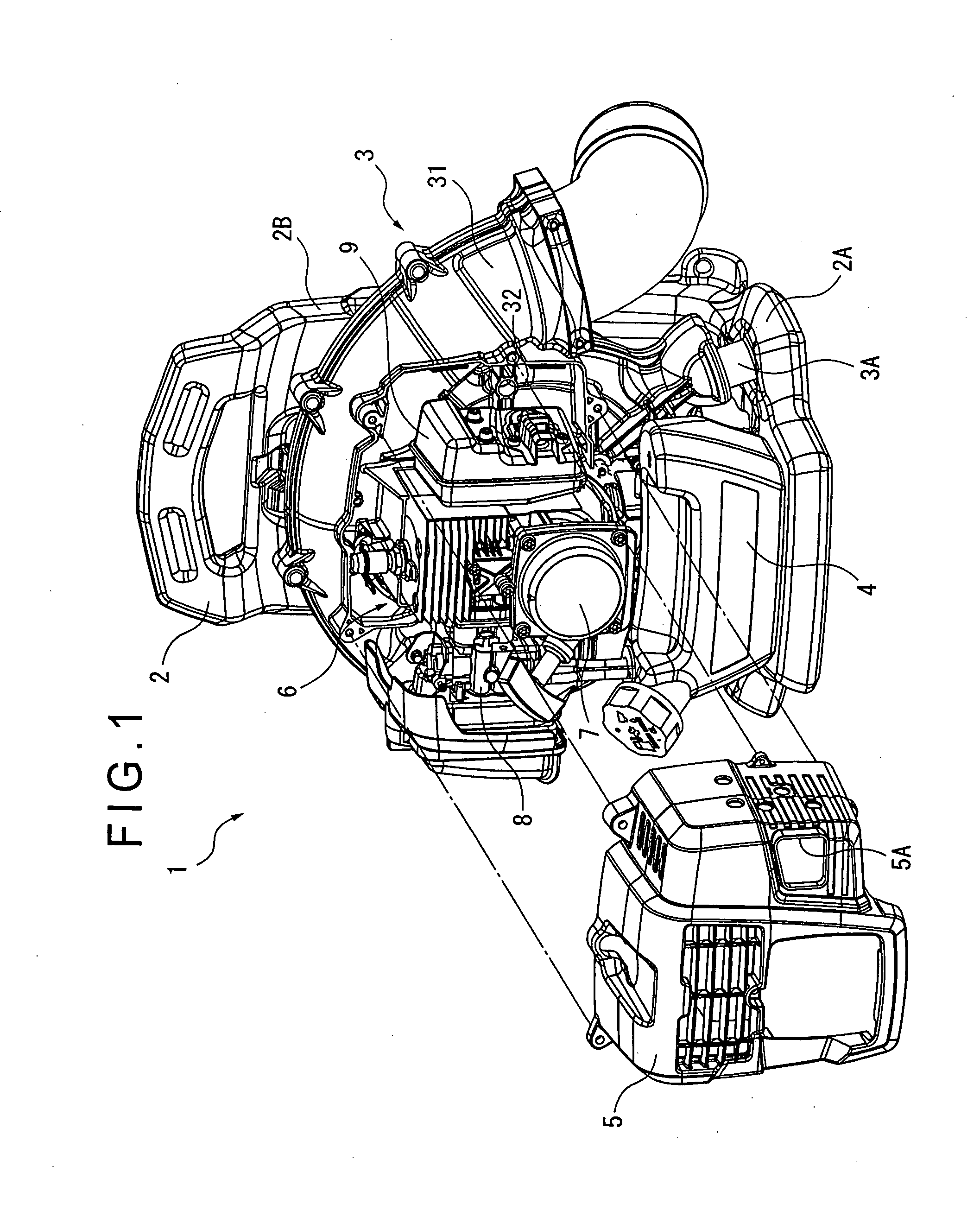

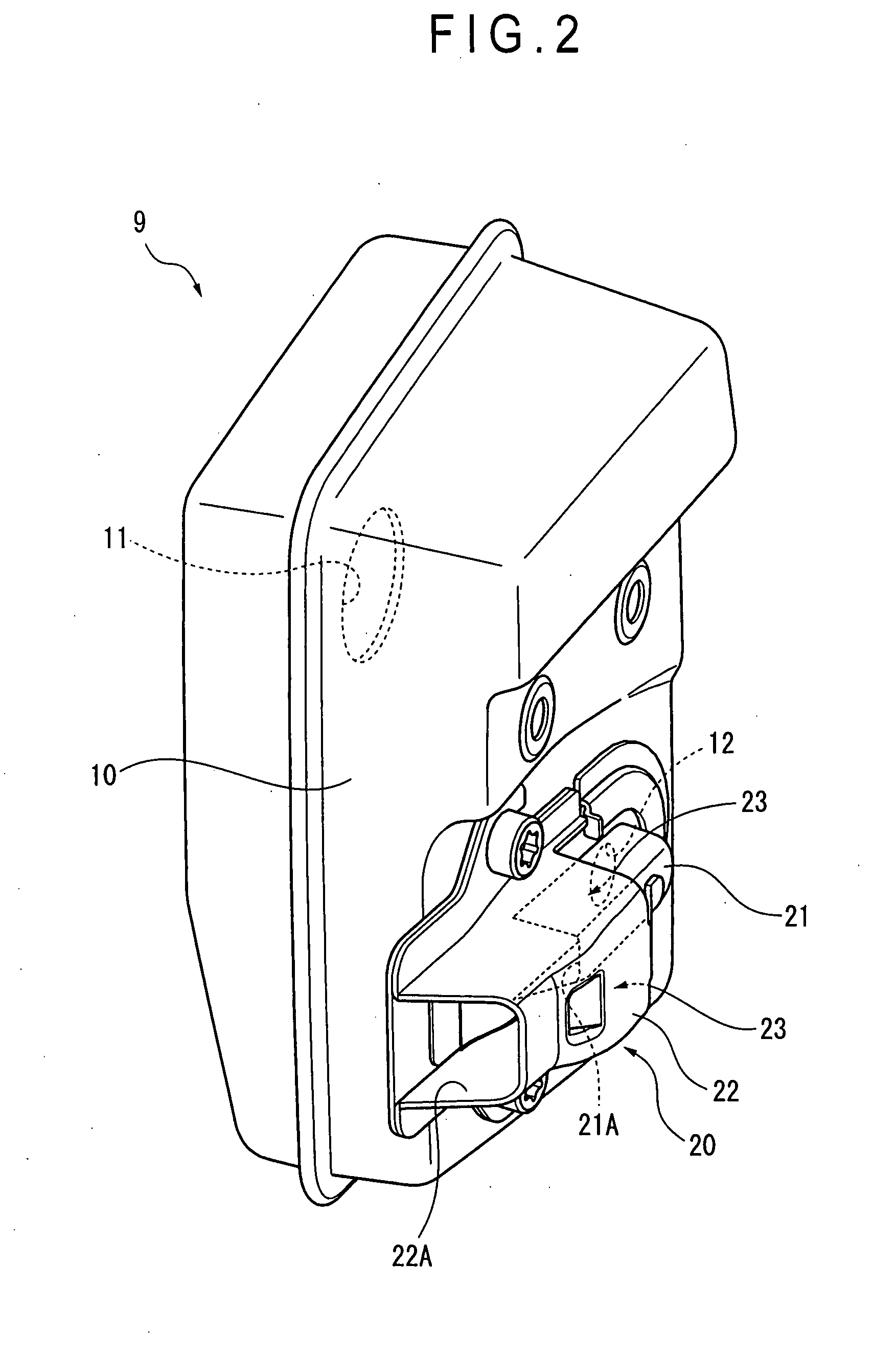

Engine blower

InactiveUS20090038106A1Improve spraying effectPromote lowerExhaust apparatusSuction cleanersEngineeringMuffler

An engine blower includes a muffler (9) provided to an engine and a volute case (31) accommodating a fan driven by the engine. On a muffler main body (10) of the muffler (9), an exhaust-gas guide member (21) covering an exhaust-gas outlet port and a cover hood (22) covering the exhaust-gas guide member (21) on the side of the outlet port are provided. Between the exhaust-gas guide member (21) and the cover hood (22), an outside-air introduction gap (23) is formed, through which outside air is introduced into the cover hood (22) by ejector effects. A blow-off port (32) for blowing off a part of pressure air in the volute case (31) to the outside-air introduction port (23) is only provided at a position substantially on a back side of the outside-air introduction gap (23).

Owner:HUSQVARNA ZENOAH

System adopting high concentration CO2 flue gas as coal dust drying medium in boiler

InactiveCN101893370AInitial temperature adjustmentIncrease working temperatureDrying gas arrangementsHigh concentrationCoal dust

The invention relates to a system adopting a high concentration CO2 flue gas as a coal dust drying medium in a boiler and belongs to the technical field of energy technology application and CO2 capture. The flue gas which is dehydrated and heated to a certain temperature and contains over 95 percent of CO2 is used as the drying medium for coal dust pulverizing. The drying medium is an inert gas with low oxygen content so as to solve the problem of easy explosion of a coal pulverizing system when hot air is used as the drying medium and improve the operational safety of the coal pulverizing system. Meanwhile, compared with the temperature of the hot air, the initial temperature of the drying medium can be greatly improved so as to reduce the power consumption of a coal mill, improve the fineness of coal dust, improve combustion efficiency, reduce the exhaust gas temperature and improve the heat efficiency of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Climate control system and method for a greenhouse

ActiveUS9161498B1Reduce pollutantsEasy to useClimate change adaptationGreenhouse cultivationGrowth plantControl system

A greenhouse environment control system generates a CO2-enriched air which is supplied to a greenhouse at a controlled temperature suitable for plant growth. An absorption chiller reduces temperature of a CO2-containing stream of processed gasses from an engine. A mixing and blending unit maintains CO2 at an acceptable concentration for enhanced plant growth and human occupation. An HVAC system modulates temperature and positively pressurizes the greenhouse with the CO2-enriched air to reduce risk of contaminant intrusion. Misting further controls temperature. Retractable shades regulate light supplied to plants and solar gain.

Owner:TROPOS TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com