Rotary air preheater dust-blocking-prevention synergy sealing method and system

A technology of air preheater and sealing system, applied in heat exchanger sealing devices, combustion methods, heat exchange equipment, etc., can solve the problems of low heat transfer efficiency, low-temperature corrosion, high air leakage rate, etc., and achieve lower exhaust gas temperature, Reduce air leakage rate and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

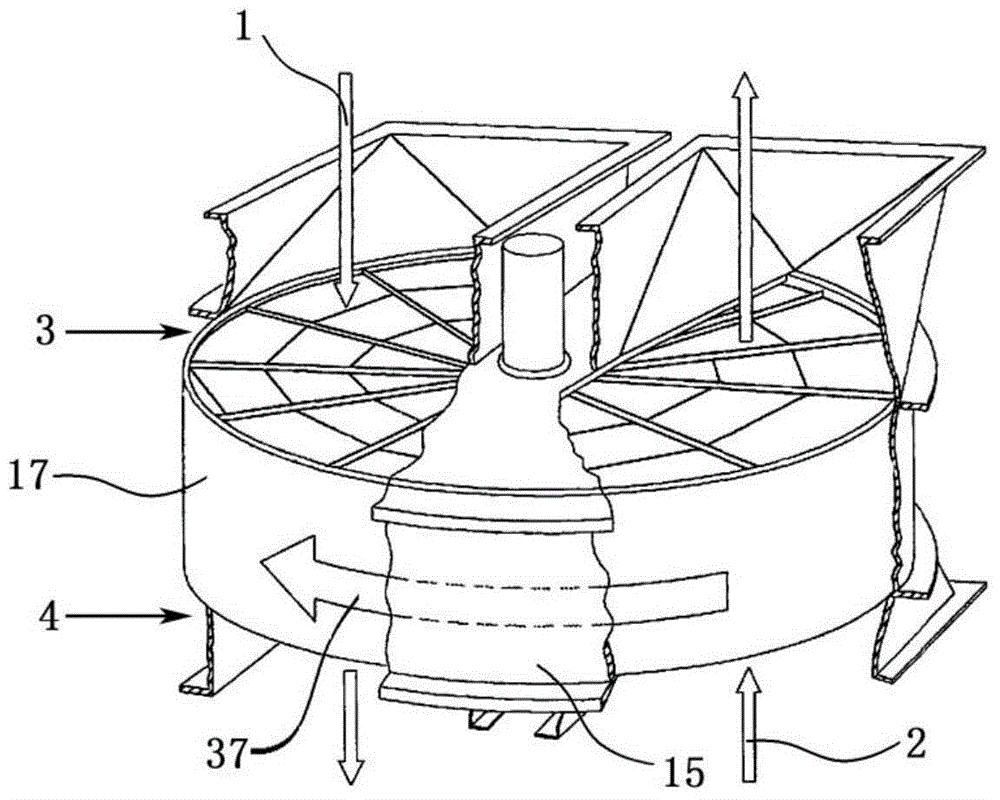

[0081] Almost all large utility boilers are equipped with rotary air preheaters to reduce exhaust gas temperature and improve boiler efficiency. A typical rotary air preheater such as figure 1 As shown, the preheater rotates slowly with the heat exchange element through the continuously rotating rotor, and the hot flue gas and cold air flowing into the preheater complete the heat exchange. Specifically, the heat exchange element absorbs heat from the hot flue gas on the flue gas side, and through the rotation of the rotor, the heated heat exchange element continuously transfers energy to the cold air coming in from the air side, thereby heating the air.

[0082] The flue gas and air of the preheater flow in opposite directions. Therefore, the inlet of the cold air and the outlet of the cooled flue gas are at one end of the preheater, generally the lower end, which is called the cold end; while the inlet of the hot flue gas And the heated air outlet is at the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com