Patents

Literature

1525results about "Heat exhanger sealing arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

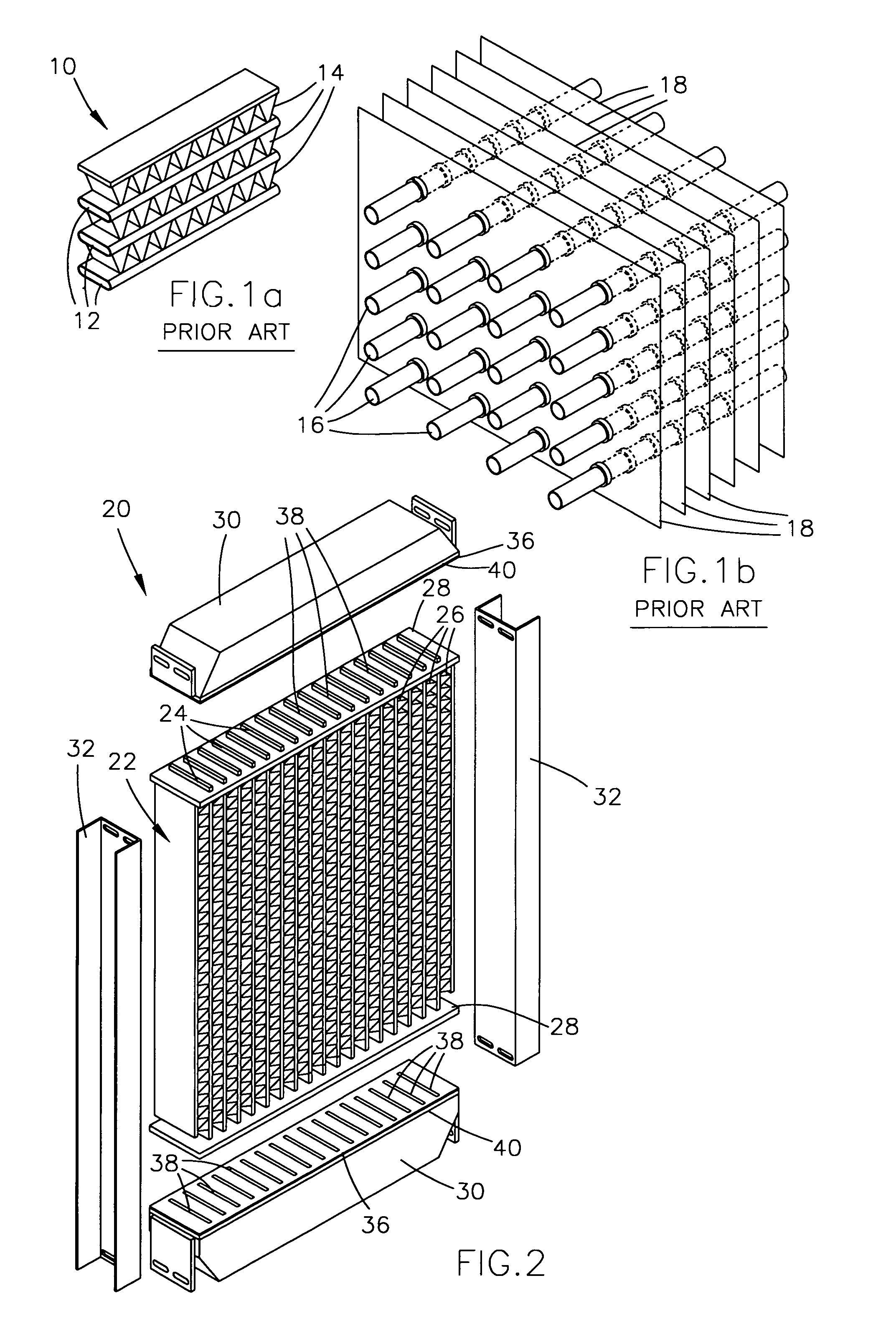

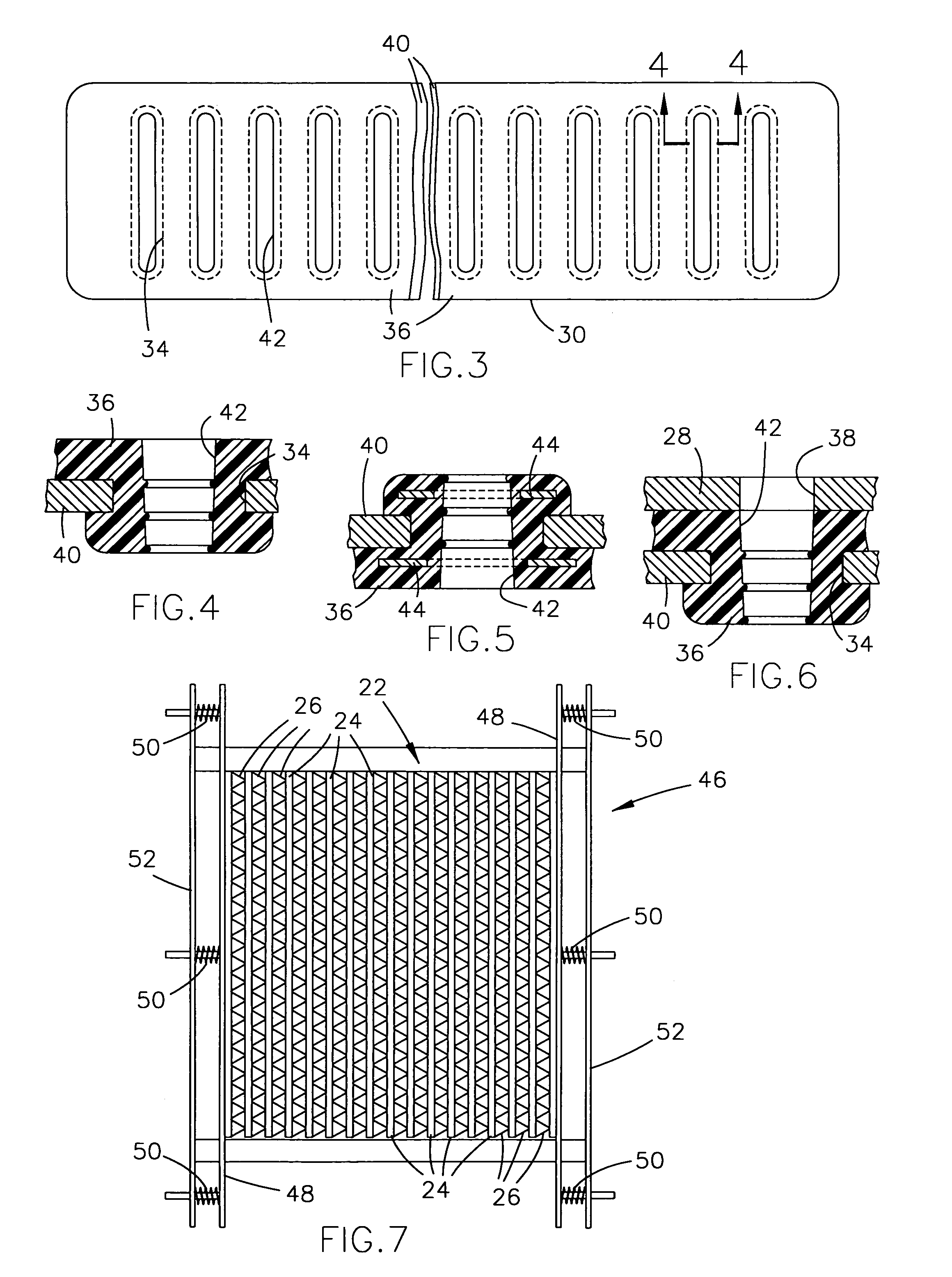

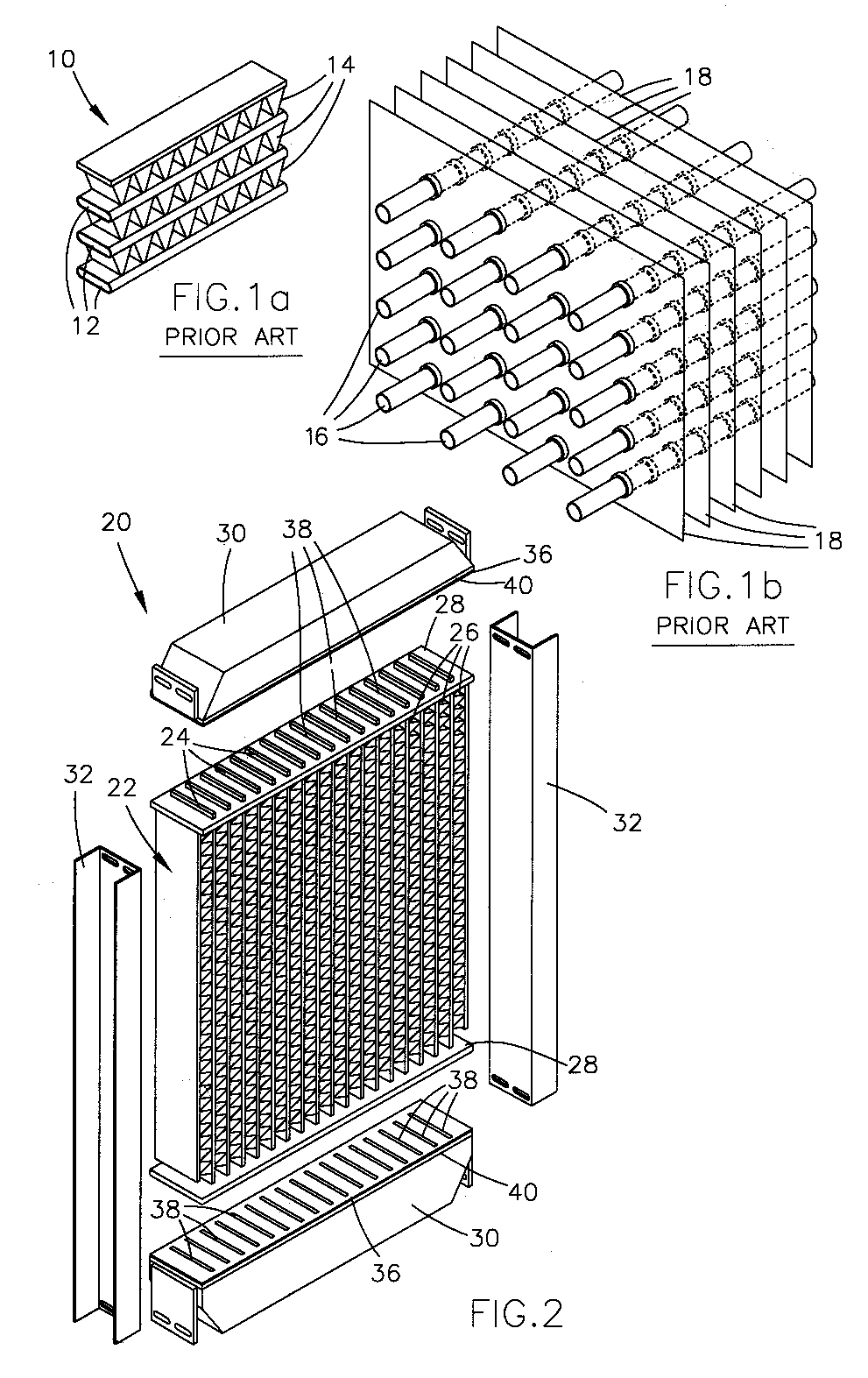

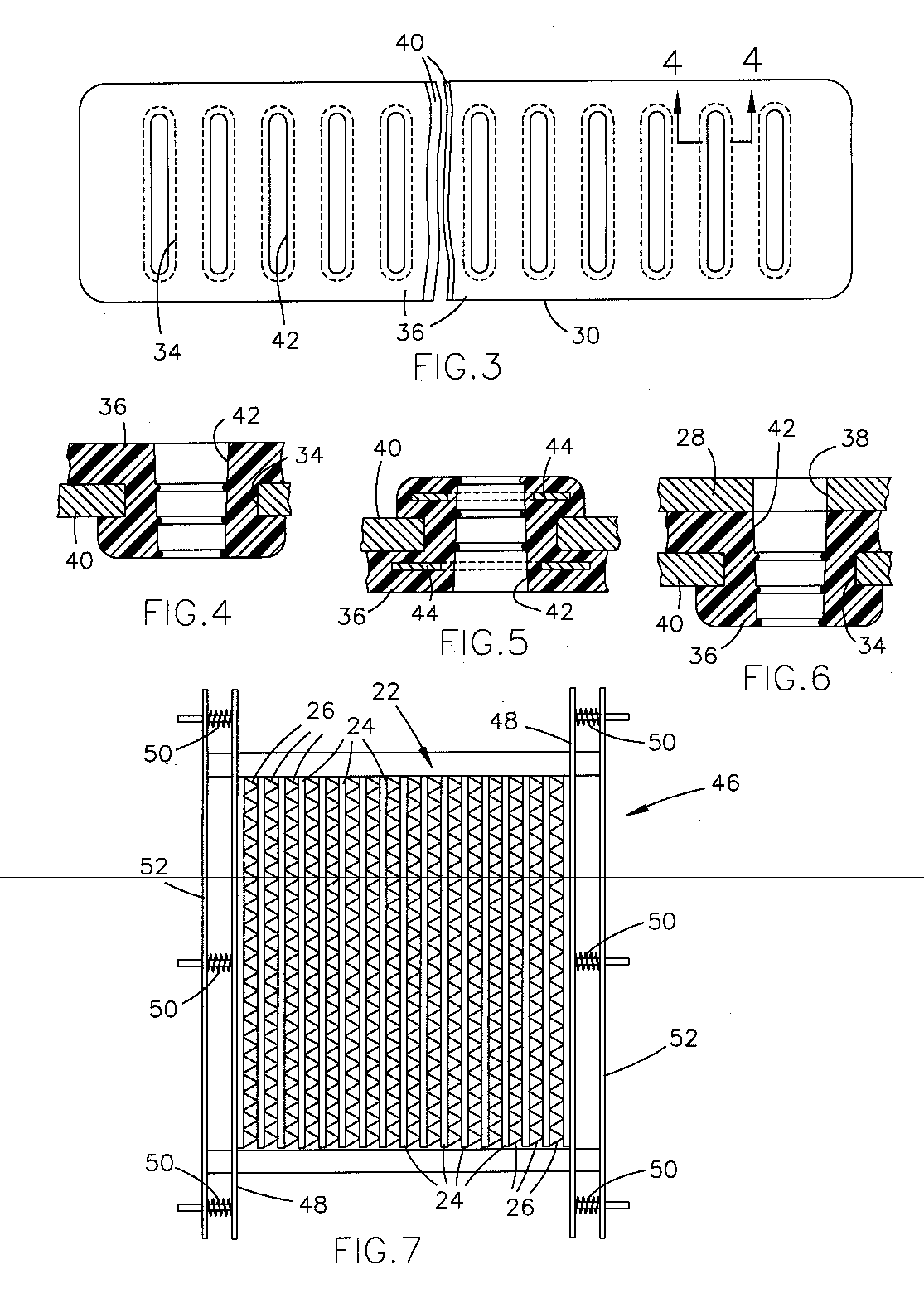

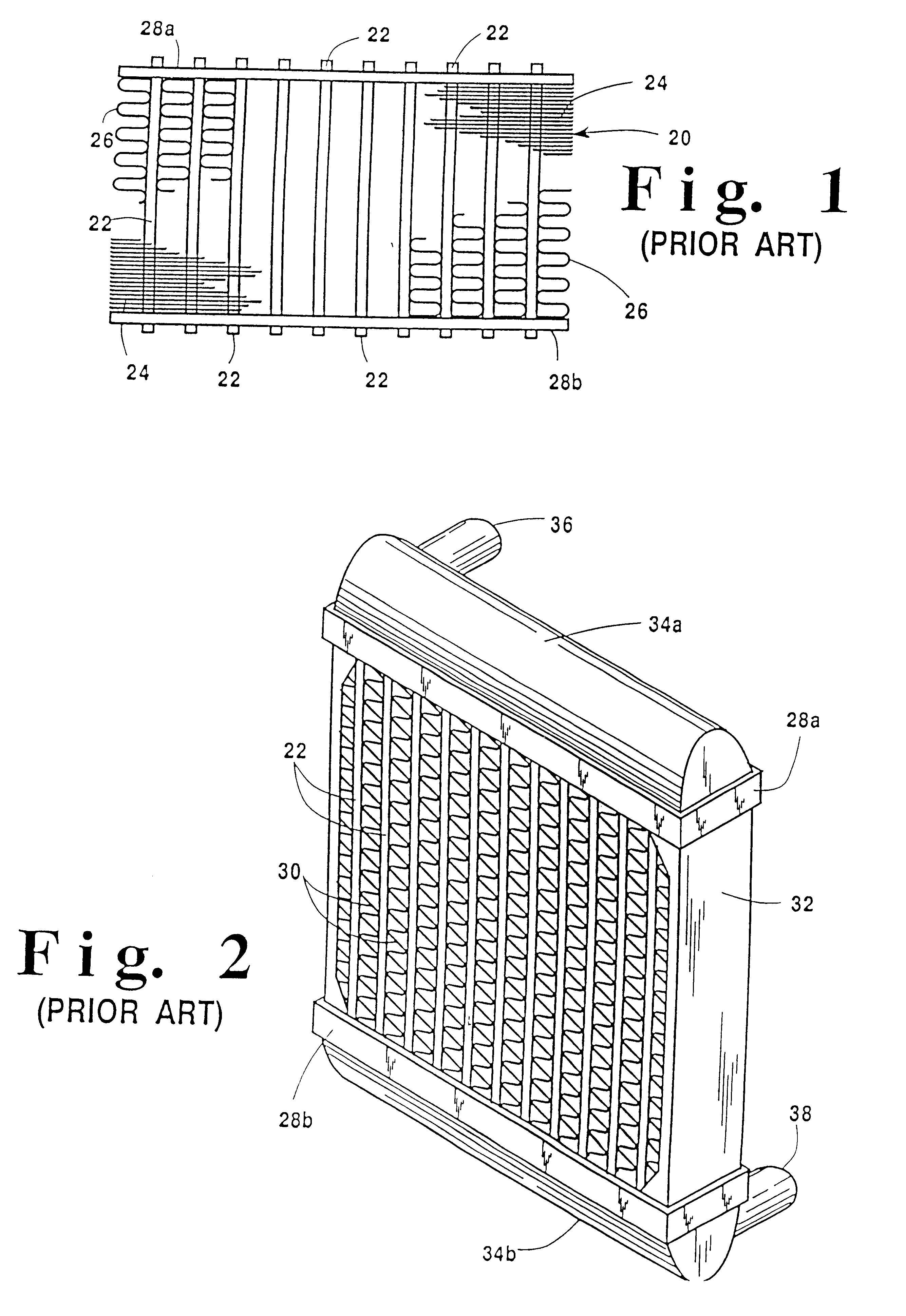

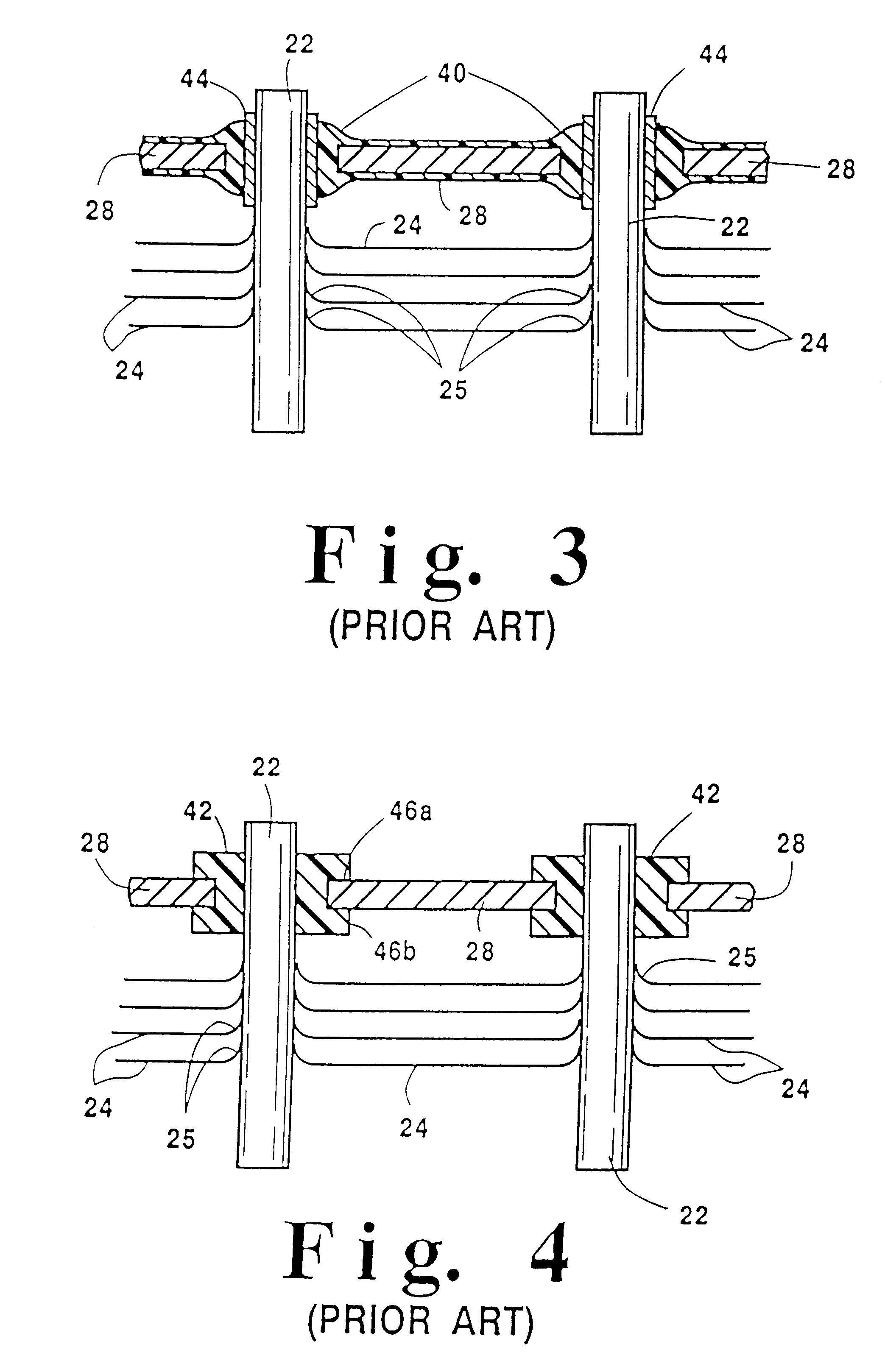

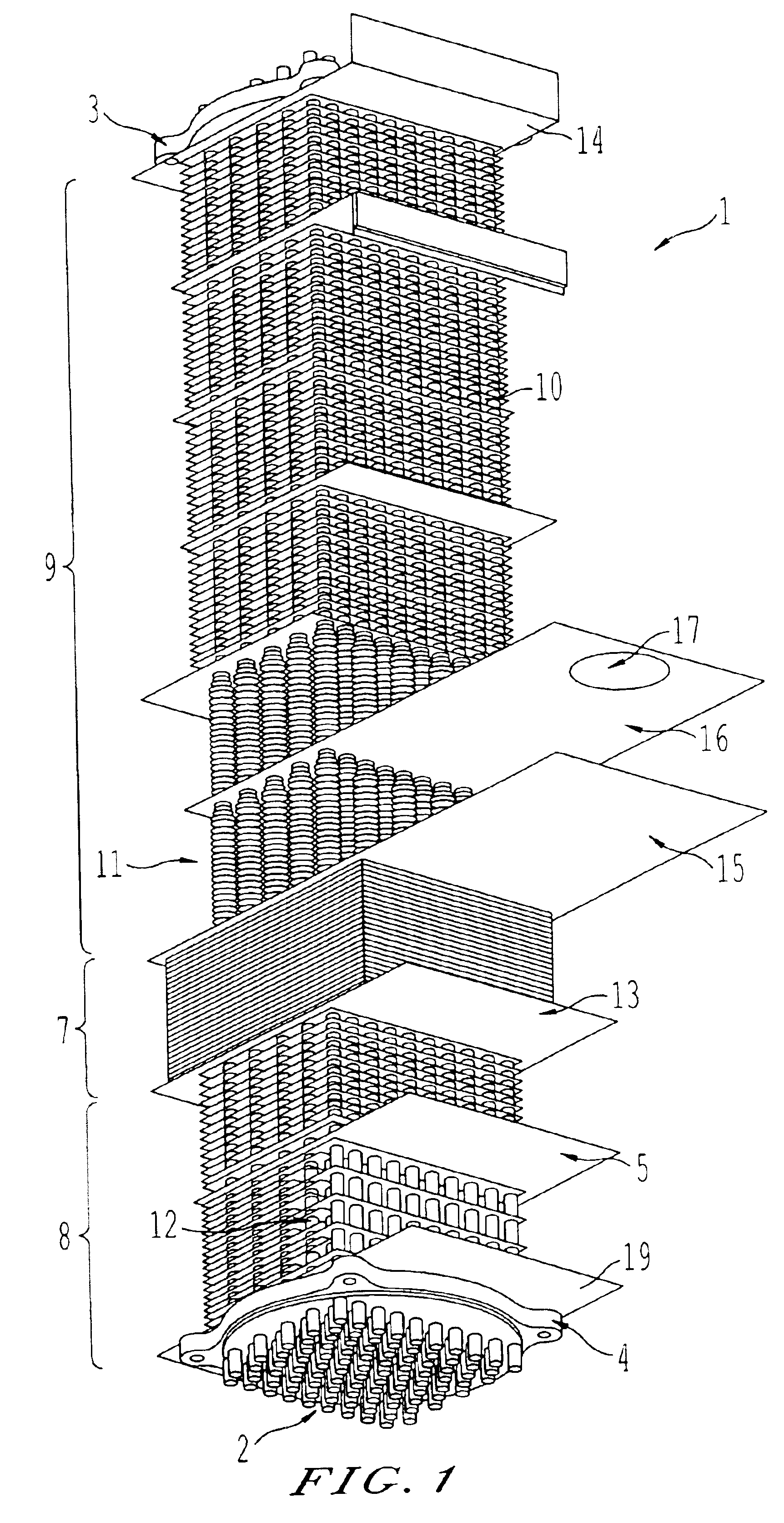

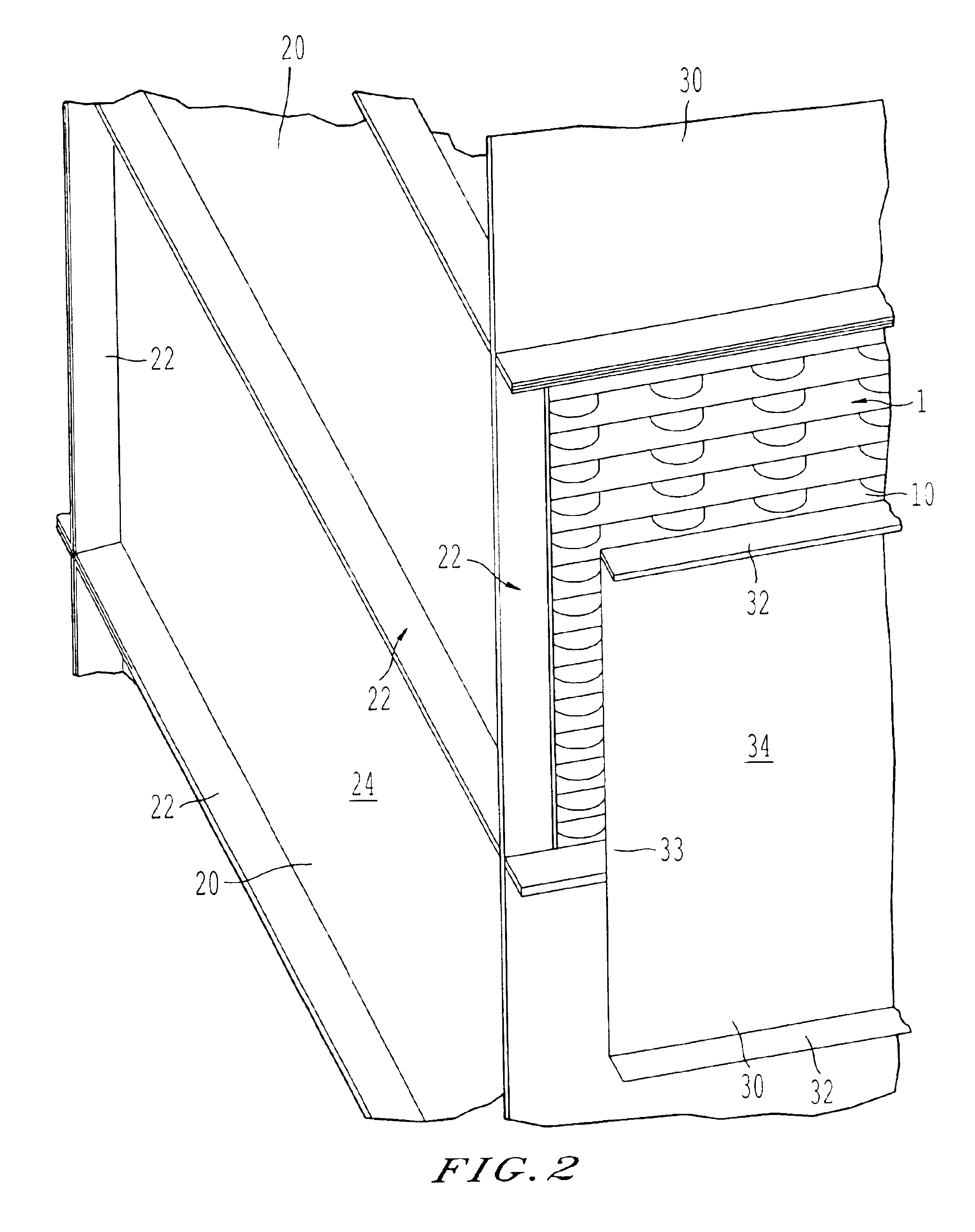

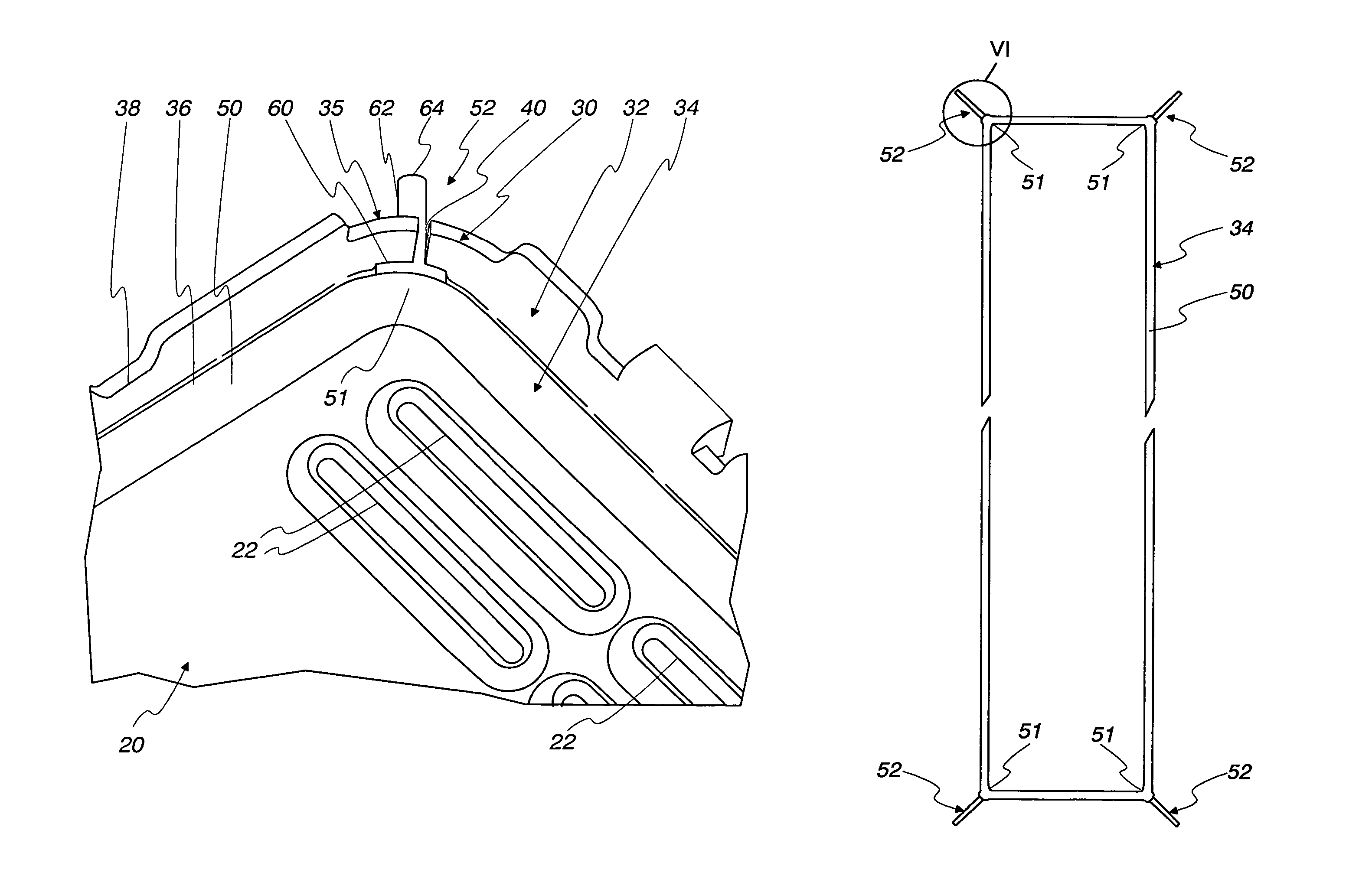

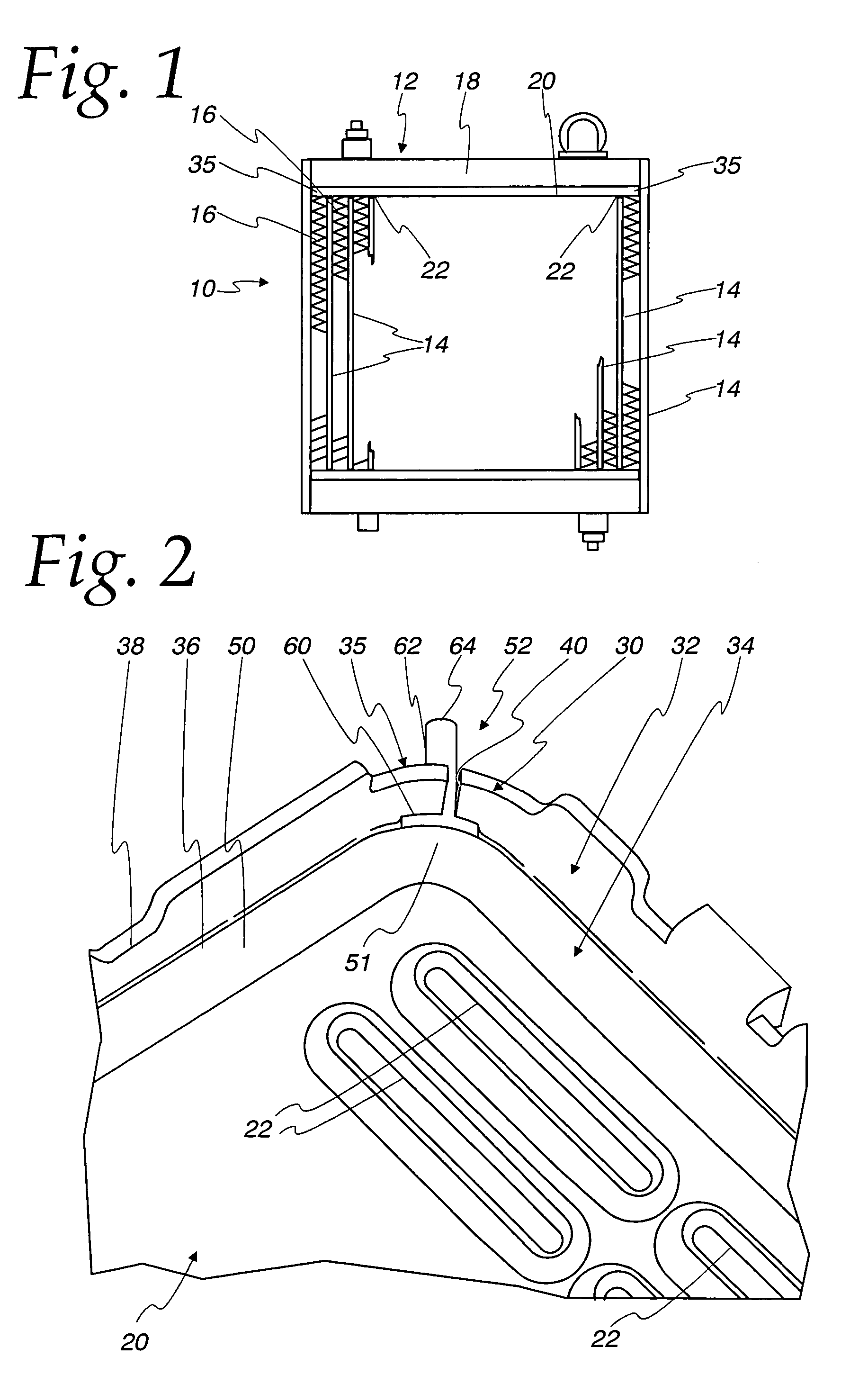

Modular heat exchanger having a brazed core and method for forming

InactiveUS7234511B1Improve heat transfer efficiencyReadily dismantled and rebuiltReinforcing meansSafety devices for heat exchange apparatusPosition toleranceNuclear engineering

An improved modular heat exchanger suitable for automotive applications, and particularly radiators for heavy duty equipment, and methods for forming the modular heat exchanger. The modular heat exchanger construction incorporates a brazed core assembly composed of flat-type cooling tubes and sinusoidal centers. The ability to use a brazed core assembly within a modular heat exchanger construction promotes enhanced heat transfer efficiencies associated with the use of flat tubes and sinusoidal centers, as compared to mechanically-joined round tubes and fins. The required positional tolerances of the tubes for mating with the remainder of the heat exchanger are maintained within the brazed core assembly by eliminating core shrinkage attributable to the use of clad aluminum alloy components to construct the core assembly. In two embodiments, core shrinkage is physical suppressed through the use of an expandable brazing fixture or the inclusion of sub-headers in the brazed core assembly. In a third embodiment, a clad slurry containing a braze alloy is deposited prior to brazing on a core assembly composed of unclad tubes and centers.

Owner:LESAGE PHILIP GEORGE

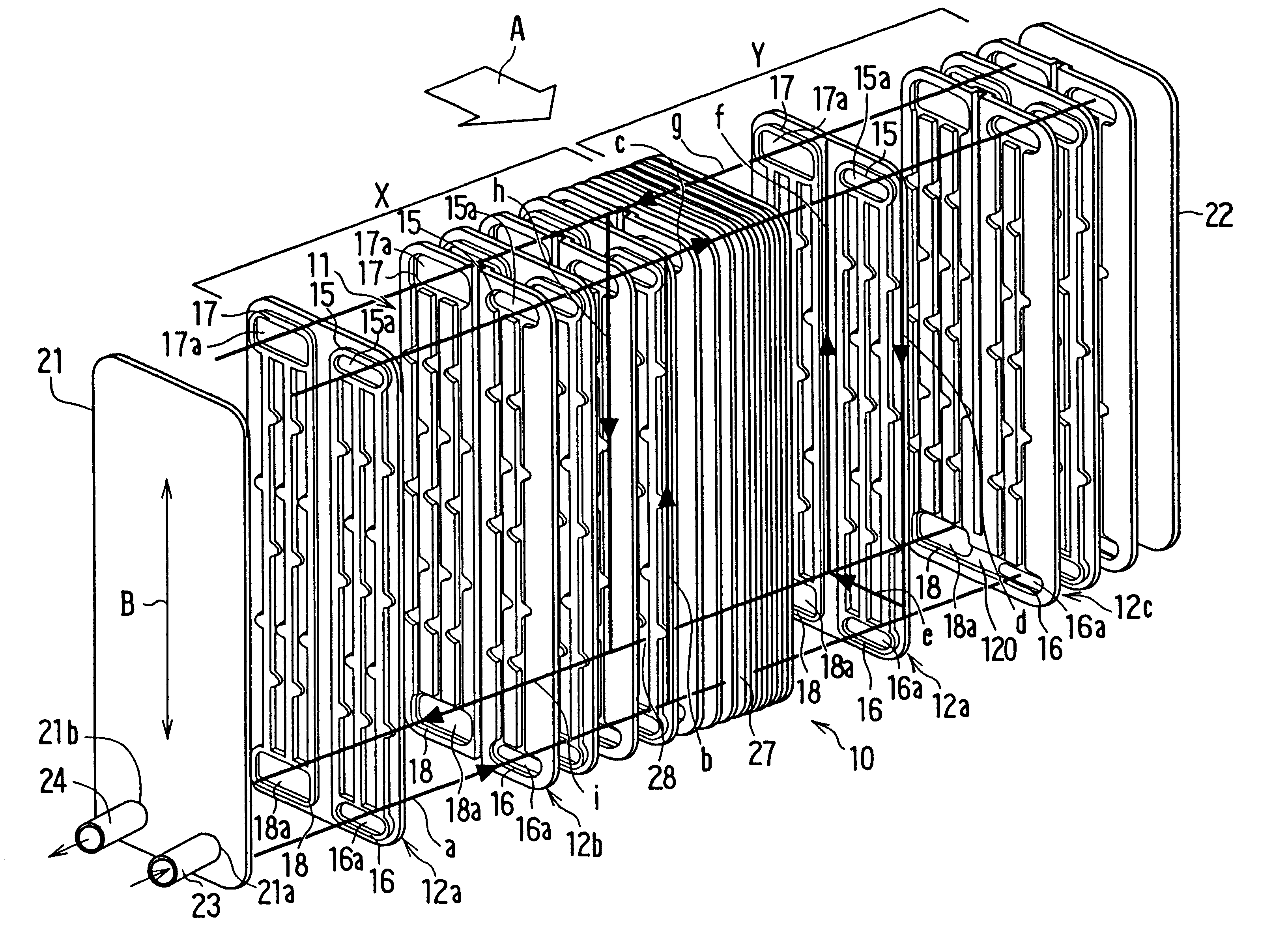

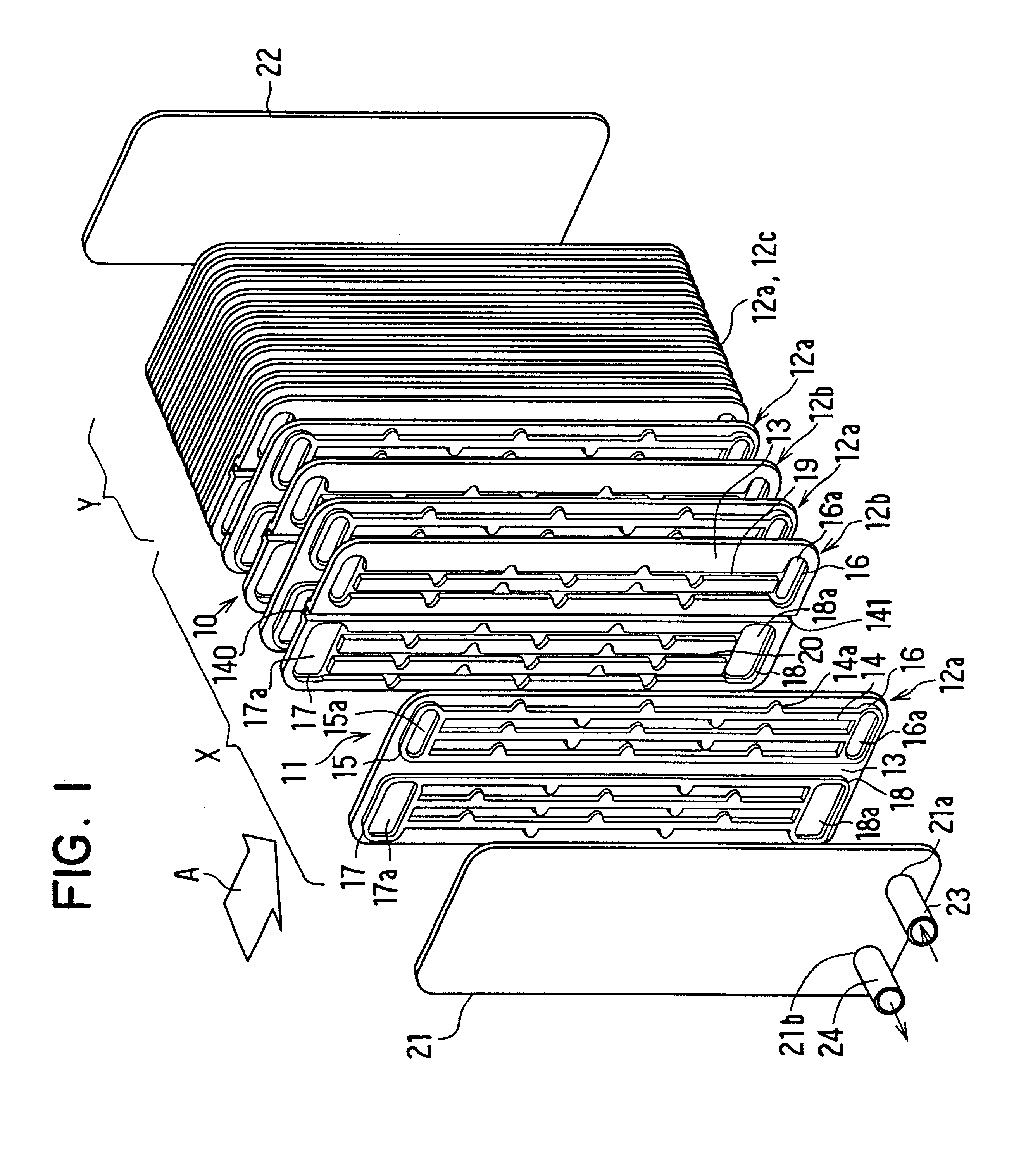

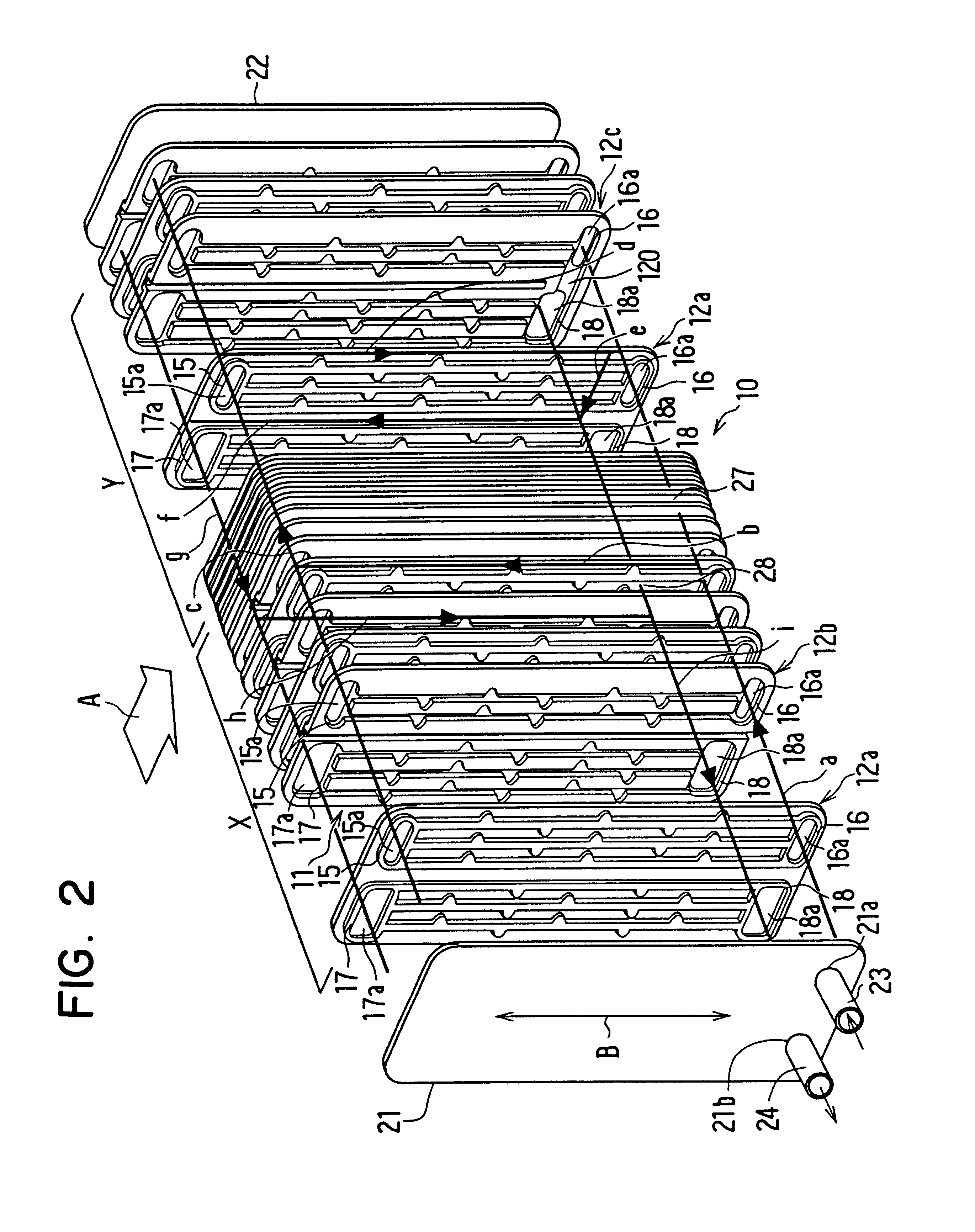

Heat exchanger only using plural plates

InactiveUS6401804B1Easy to detectCorrosion preventionStationary conduit assembliesEngineeringRefrigerant

Plural heat-exchanging plates for forming an evaporator have plural projection ribs. The projection ribs protrude toward outside of each pair of the heat-exchanging plates to form therein refrigerant passages through which refrigerant flows, and to form an air passage between adjacent pairs of the heat-exchanging plates. The projection ribs protrude from flat surfaces of the heat-exchanging plates toward the air passage to disturb a straight flow of air. The projection ribs are provided in each of the heat-exchanging plates to have a protrusion pitch (P1) between adjacent two, and the protrusion pitch is set in a range of 2-20 mm. Further, each of the heat-exchanging plates has a thickness of in a range of 0.1-0.35 mm, and a passage pitch (P2) between the refrigerant passages is in a range of 1.4-3.9 mm. Thus, in the evaporator formed by only using the plural heat-exchanging plates, a sufficient heat-exchanging performance can be obtained.

Owner:DENSO CORP

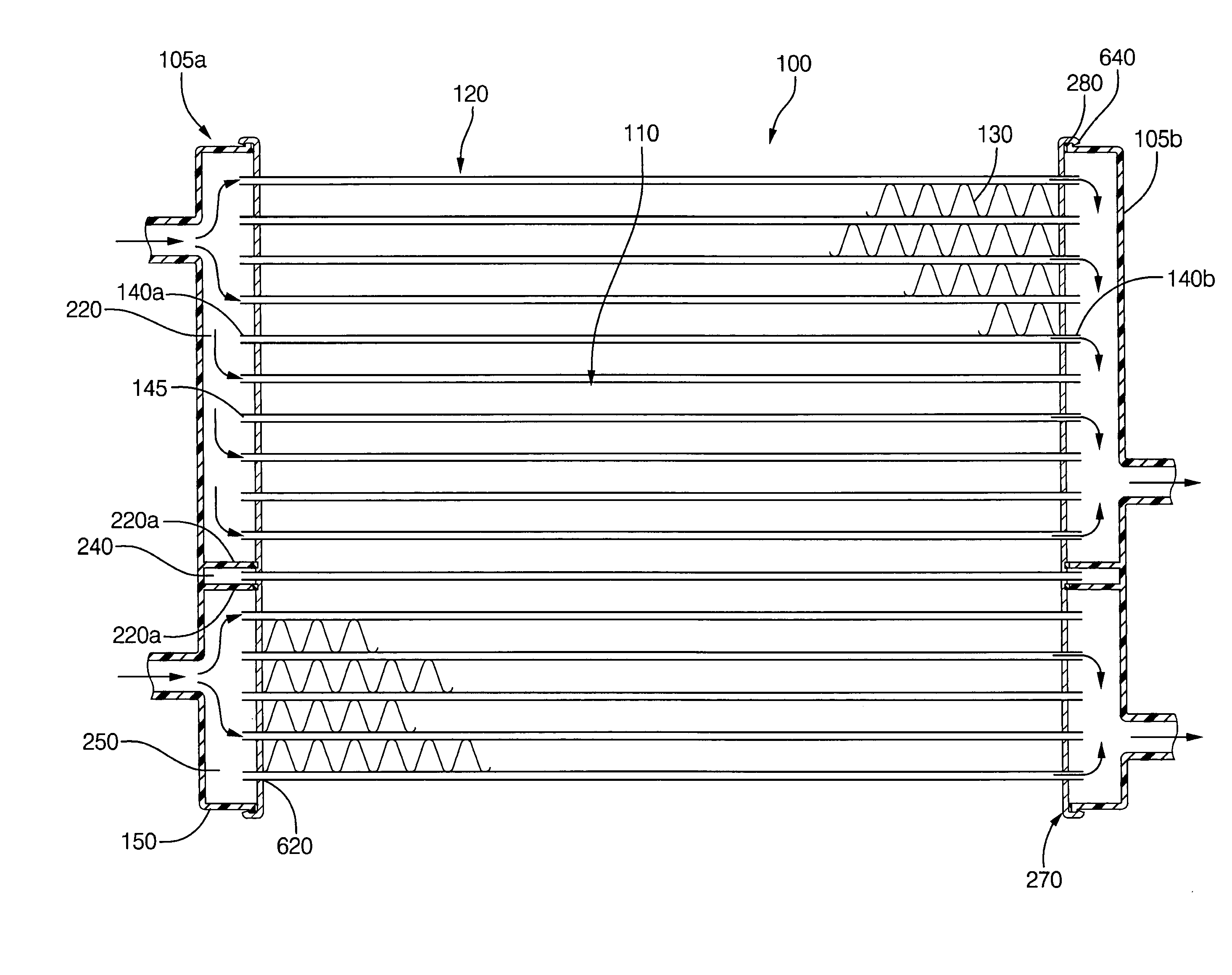

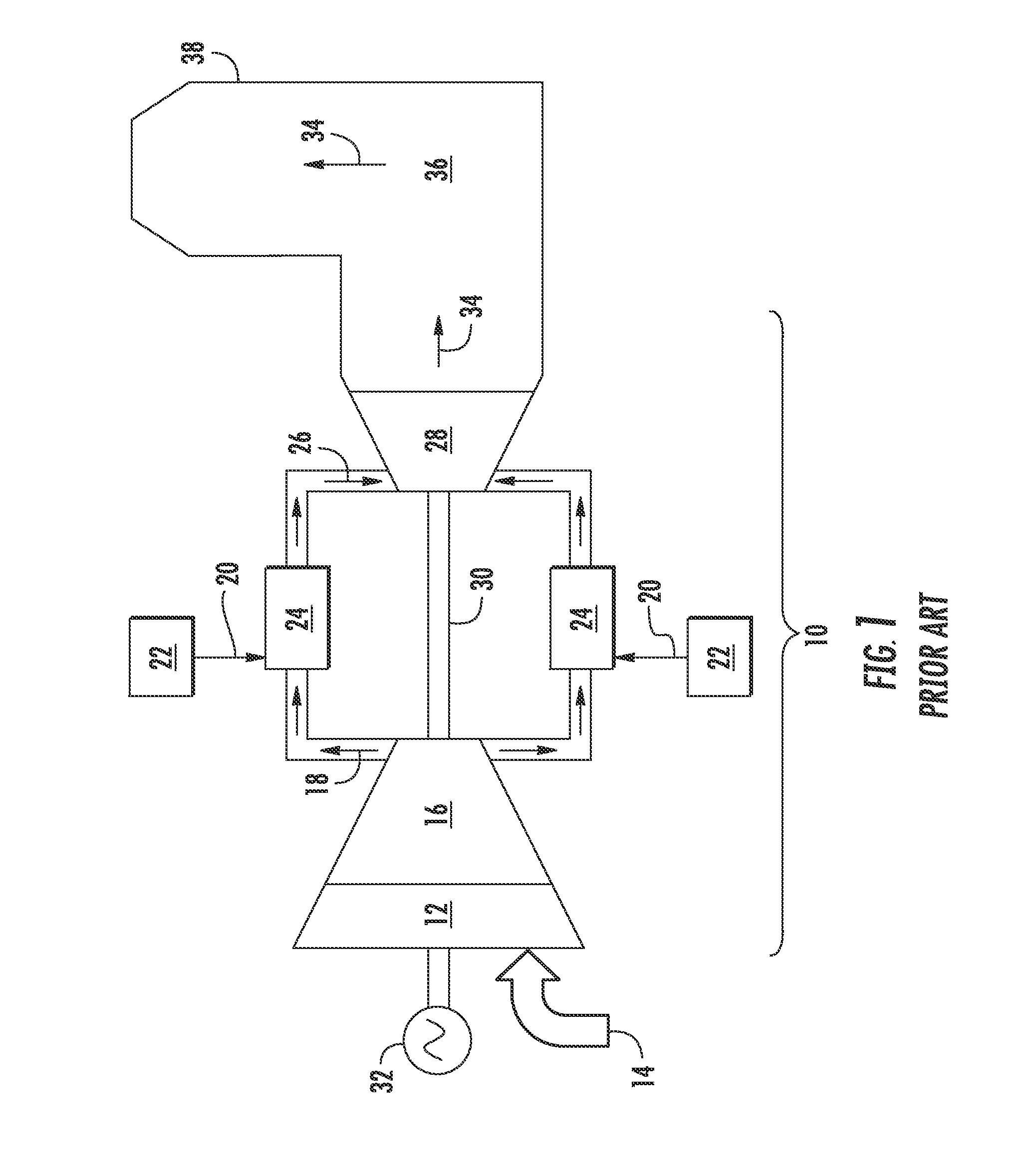

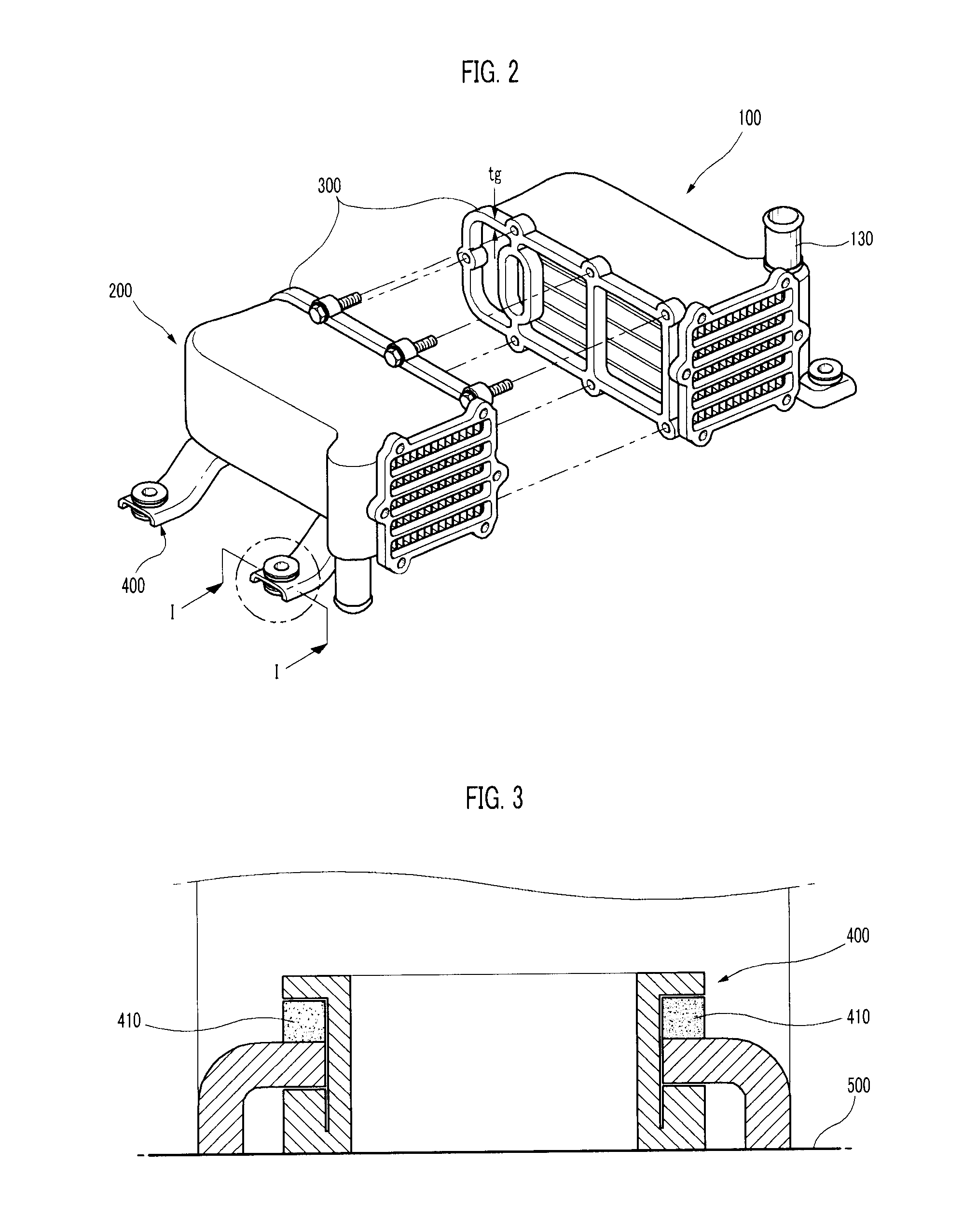

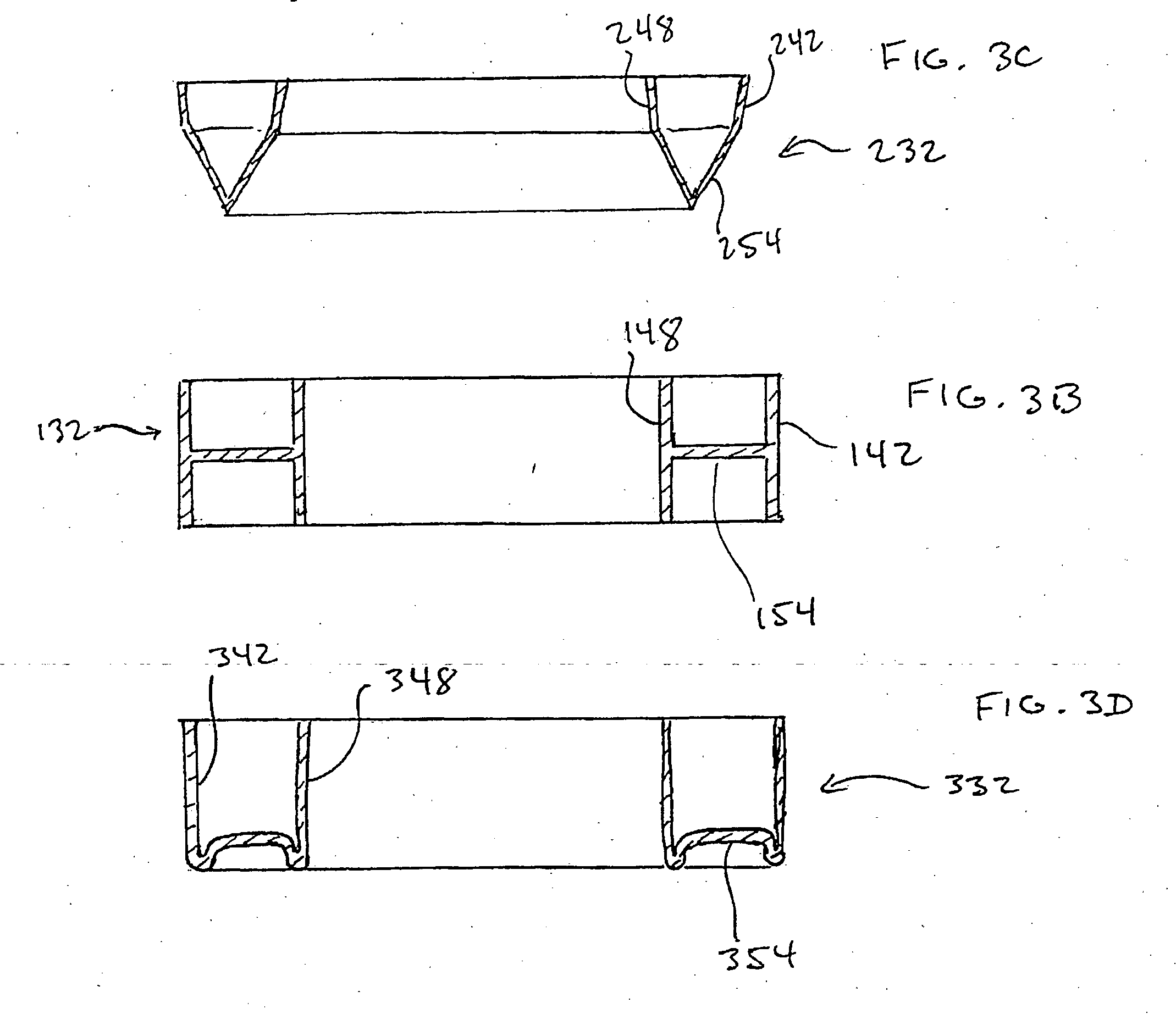

Combination heat exchanger having an improved end tank assembly

InactiveUS20080047687A1Increase the compression ratioRobust sealThermal insulationStationary conduit assembliesEngineeringCompression ratio

A combination heat exchanger comprising of a heat exchange core having a plurality tubes, wherein the core having at least one core end; an end tank having two side walls and two end walls, two bulkheads the cavity defining a least a first chamber, a second chamber, and a third chamber, a perimeter edge defined by exterior edges of said side walls, exterior edges of said two end walls, and exterior edges of said two bulkheads; a header plate engaged between said end tank and said core end; and a gasket between said perimeter edge and contact surface of said header plate, wherein the compression ratio of the gasket is varied along the contact surfaces of the perimeter edge and contact surface of the end plate.

Owner:MAHLE INT GMBH

Corrosion resistant fluid conducting parts, methods of making corrosion resistant fluid conducting parts and equipment and parts replacement methods utilizing corrosion resistant fluid conducting parts

ActiveUS20060027628A1Readily cold workedReduced corrosion resistanceWelding/cutting auxillary devicesHeat exhanger sealing arrangementFusion weldingReplacement method

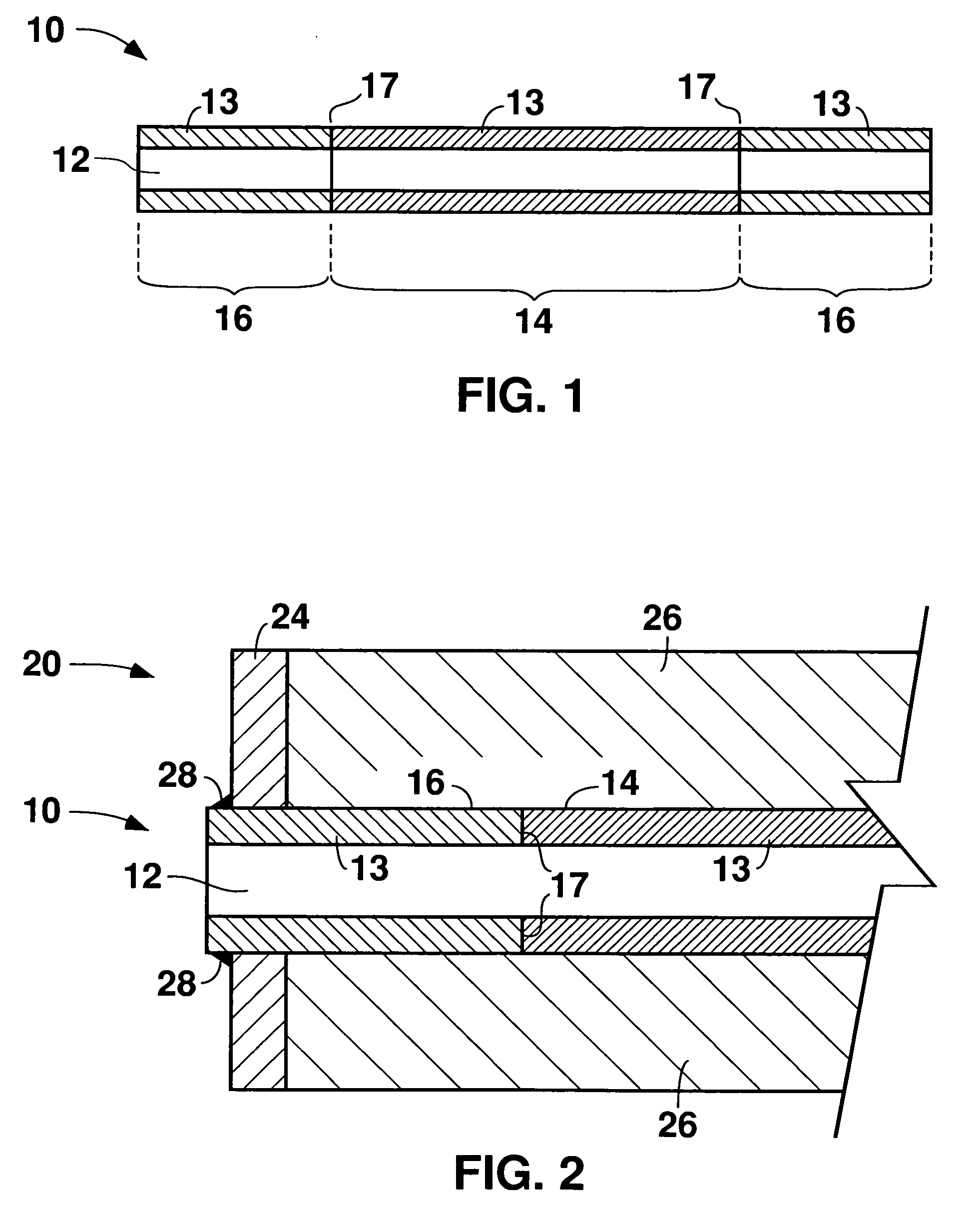

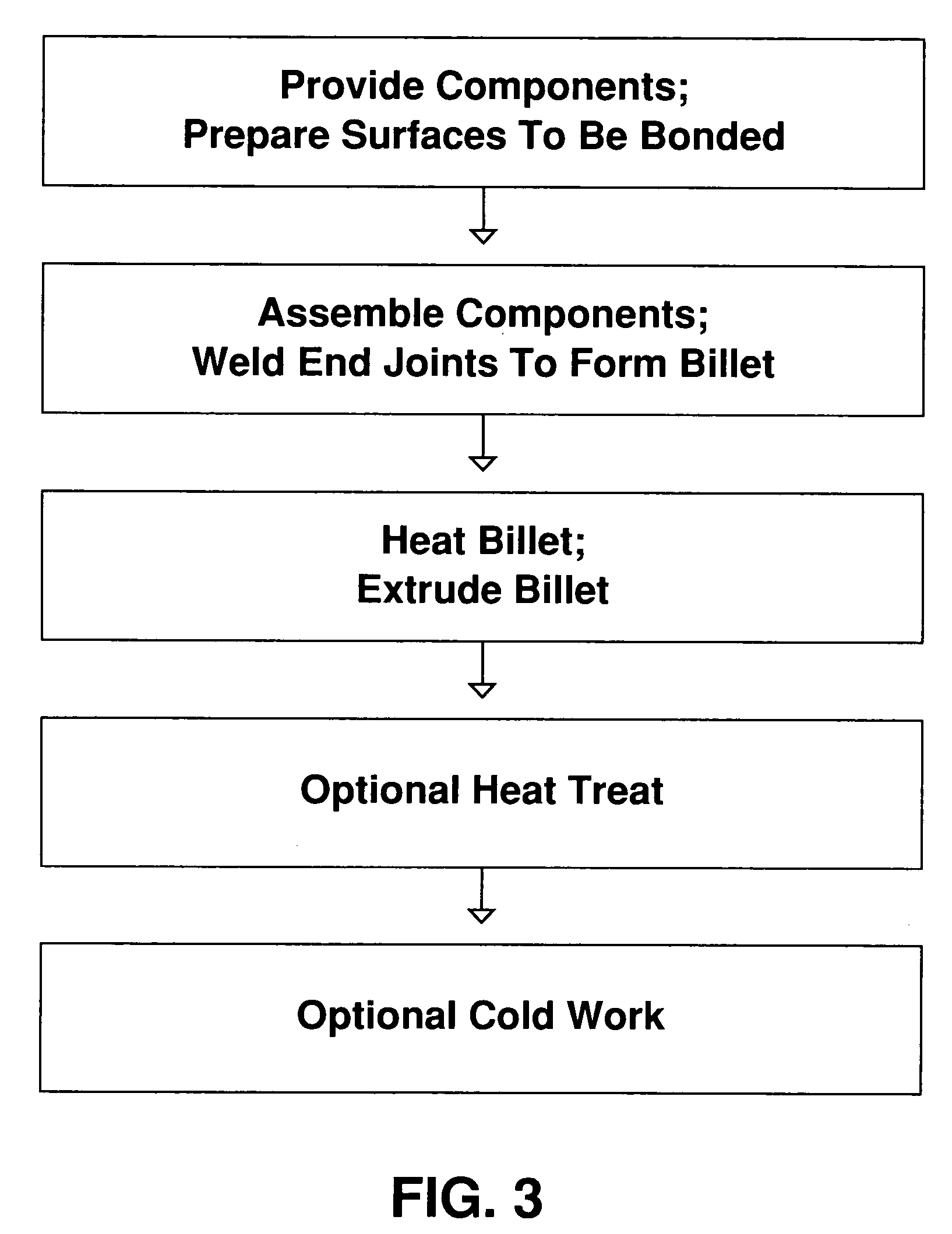

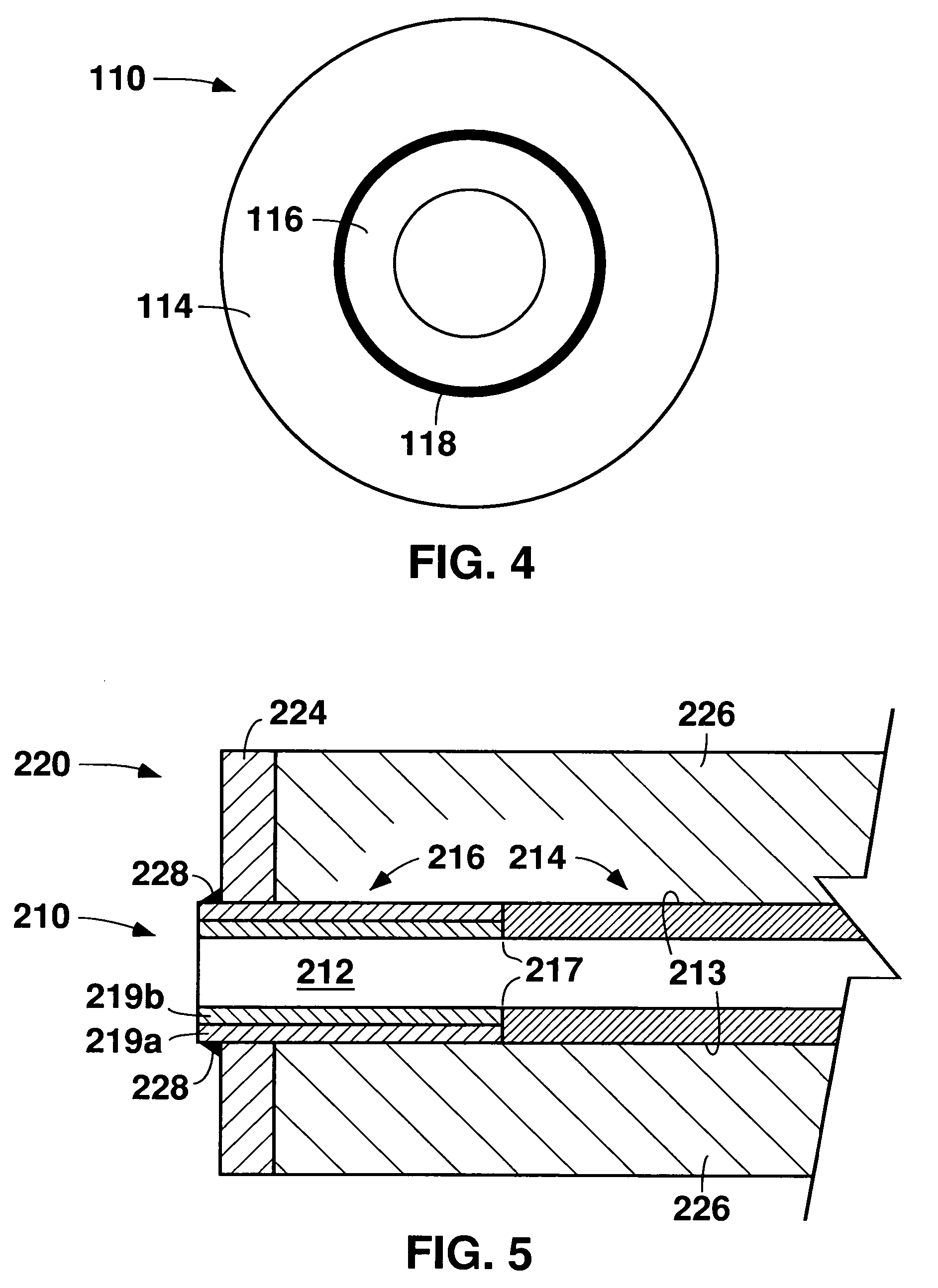

According to one aspect of the present disclosure, a part for an article of equipment includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The first region and the second region are either directly or indirectly joined by solid state welding to form a unitary fluid conducting part. According to another aspect of the present disclosure, a method for replacing at least one fluid conducting part of an article of equipment is disclosed wherein a replacement part is provided that includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The second material is substantially identical to the material of a region of the equipment on which the replacement part is mounted. The first and second regions are either directly or indirectly joined by solid state welding to form a unitary fluid conducting replacement part. The replacement part is secured to the article of equipment by a process comprising fusion welding the second material of the second region of the replacement part to the substantially identical material of the mounting region of the article of equipment.

Owner:ATI PROPERTIES LLC

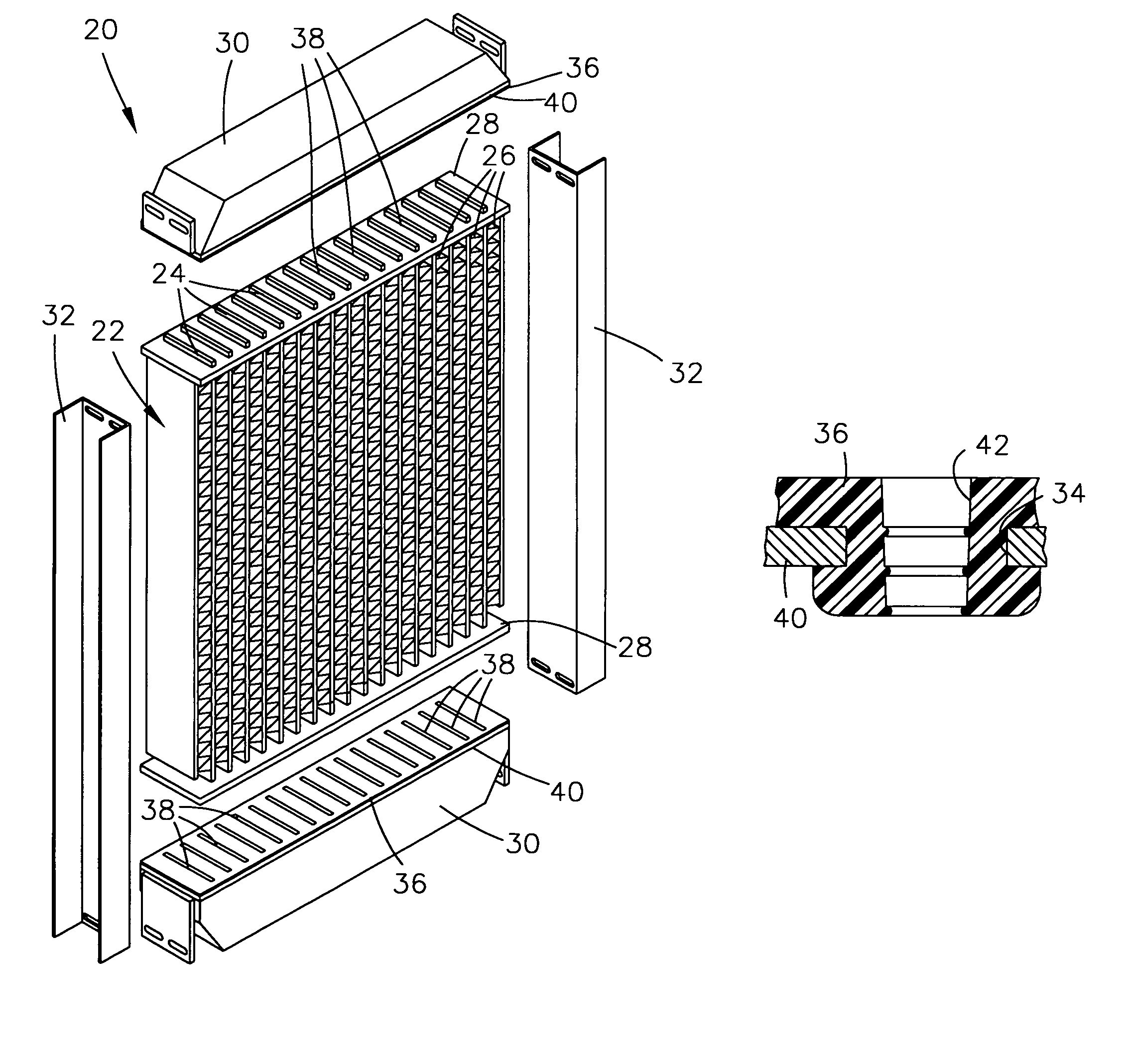

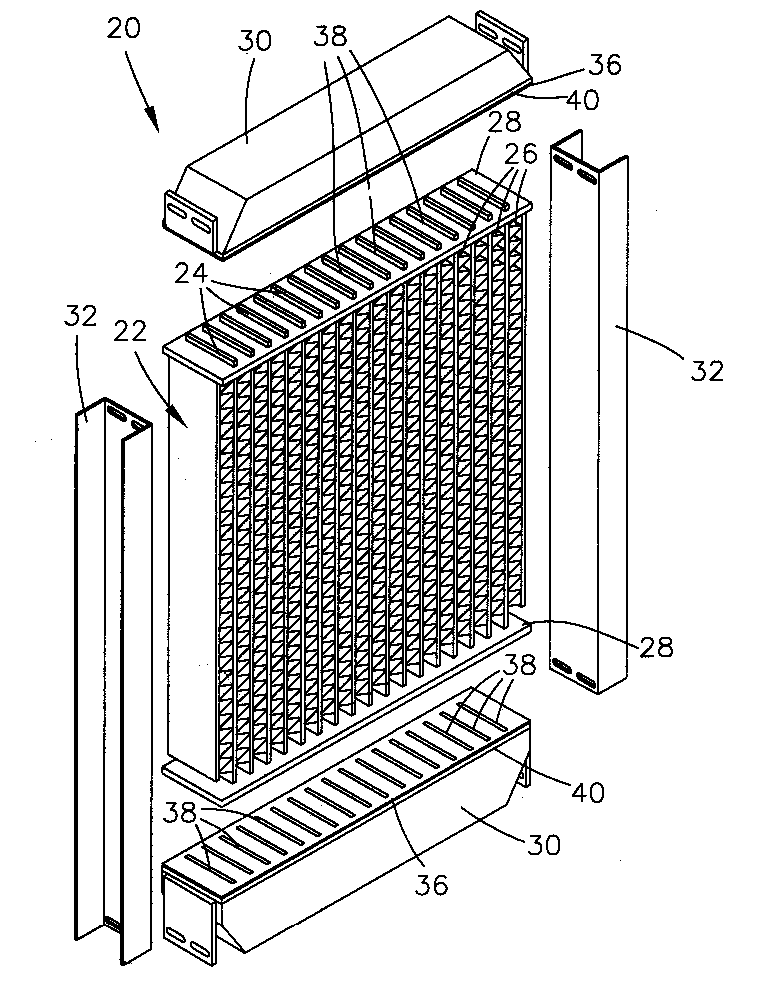

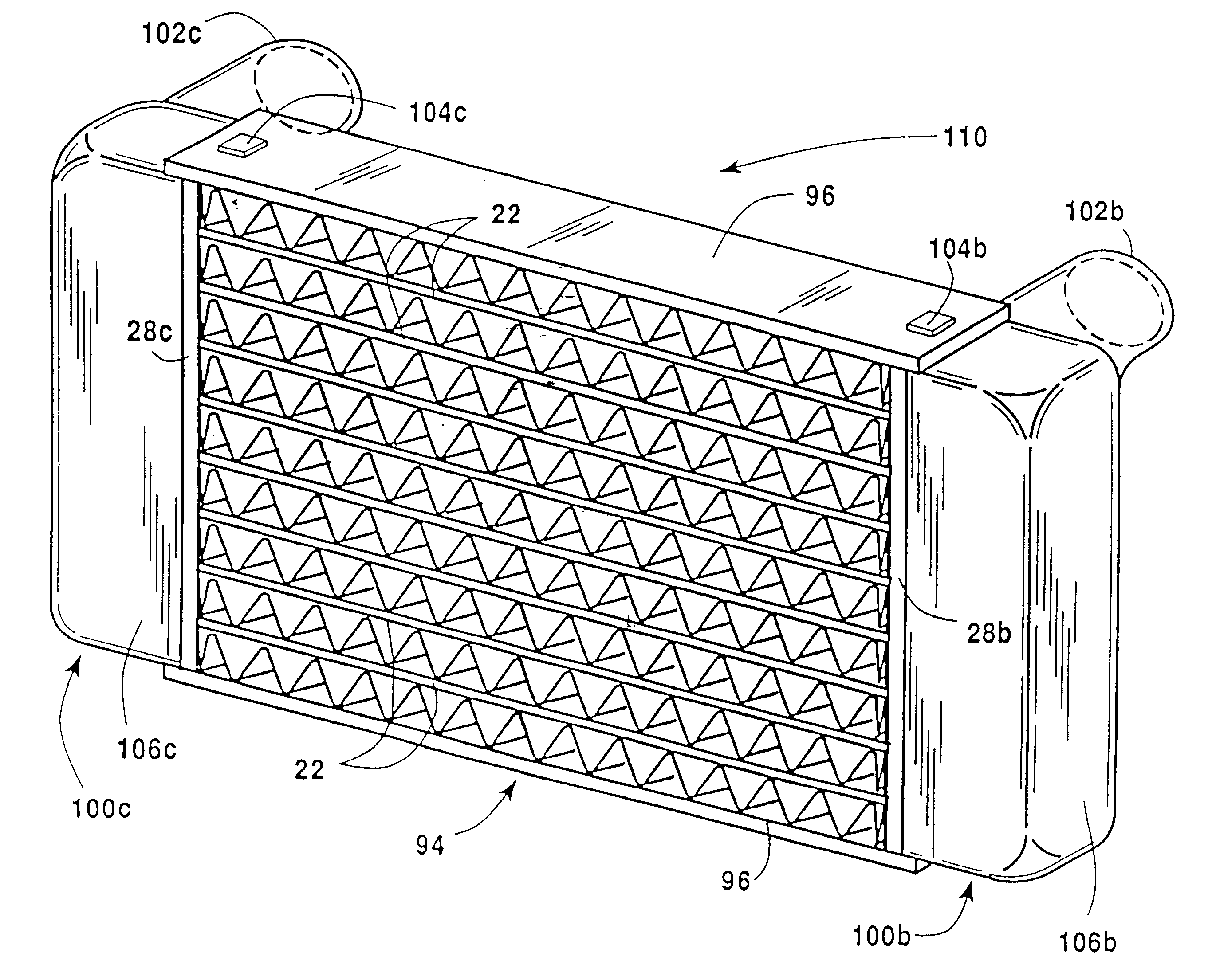

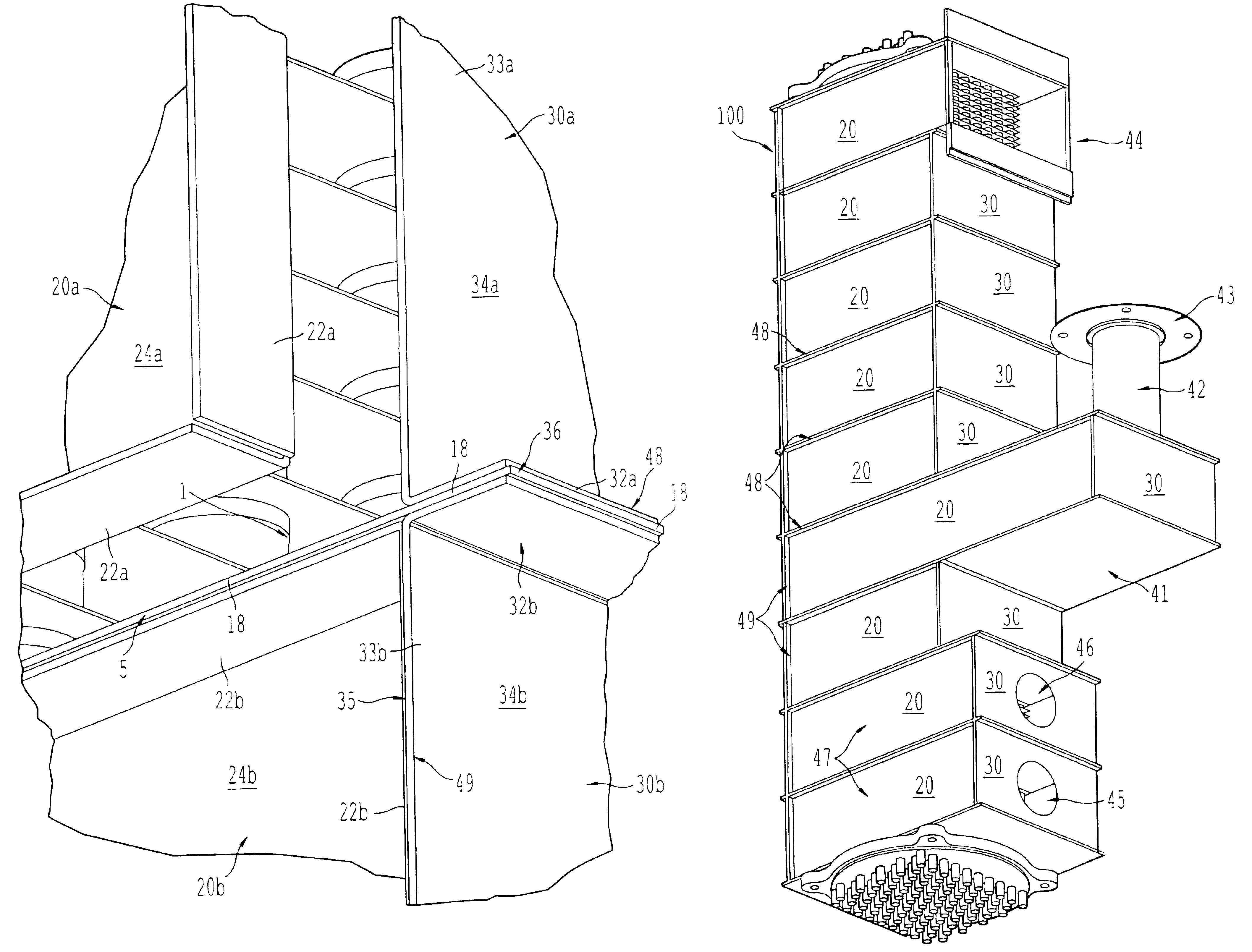

Modular heat exchanger having a brazed core and method for forming

InactiveUS20060196052A1Improve heat transfer efficiencyReadily dismantled and rebuiltReinforcing meansSafety devices for heat exchange apparatusPosition toleranceNuclear engineering

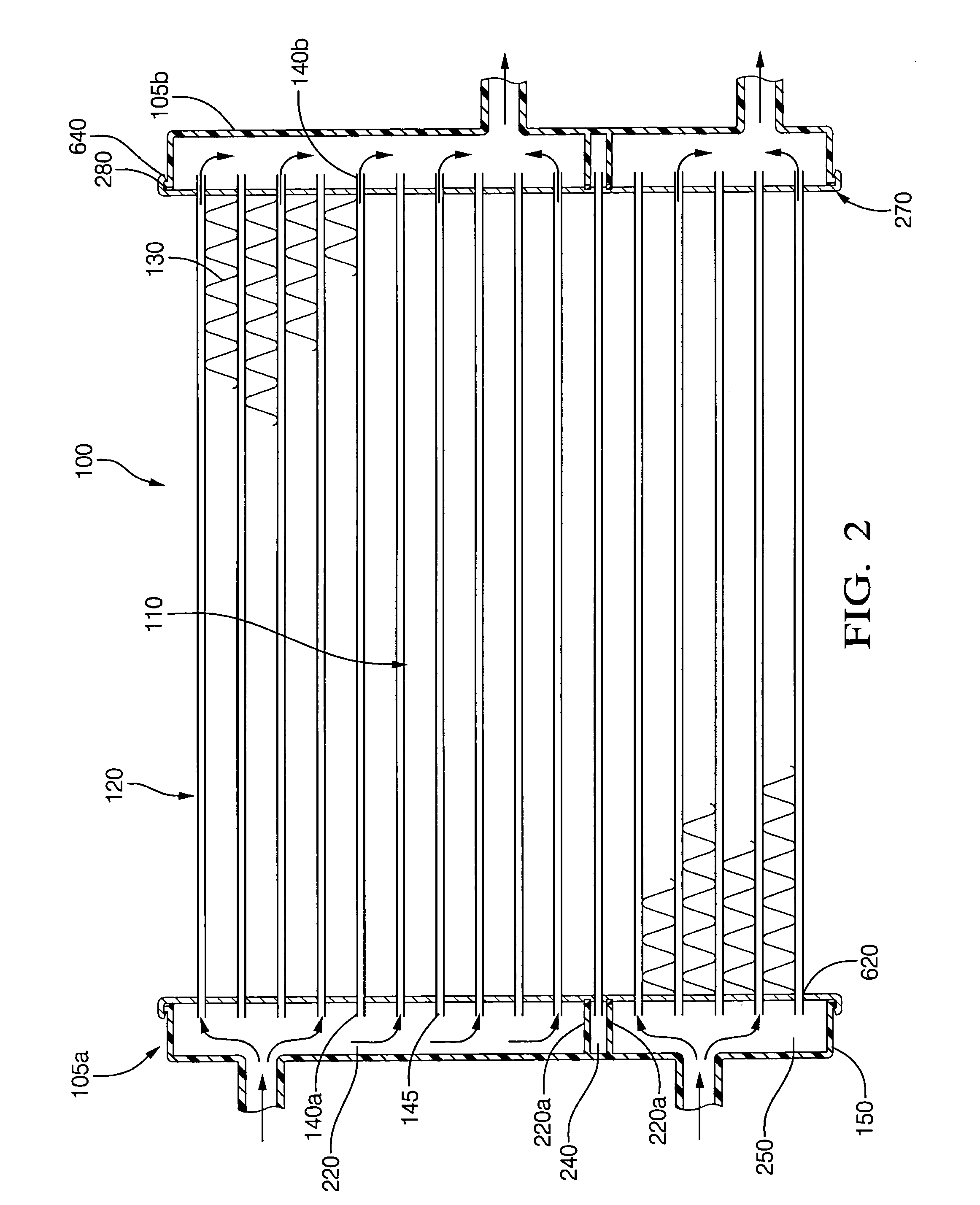

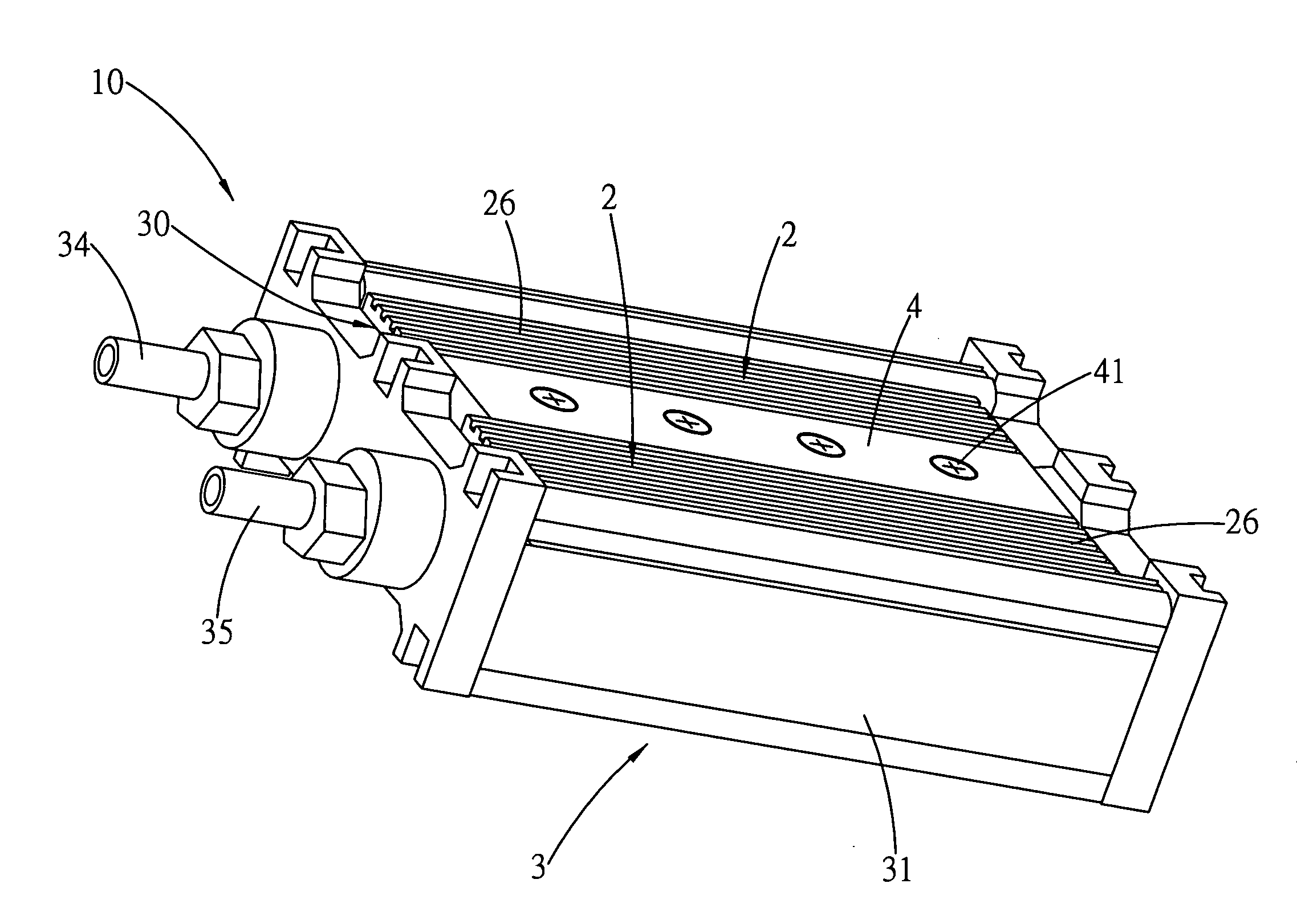

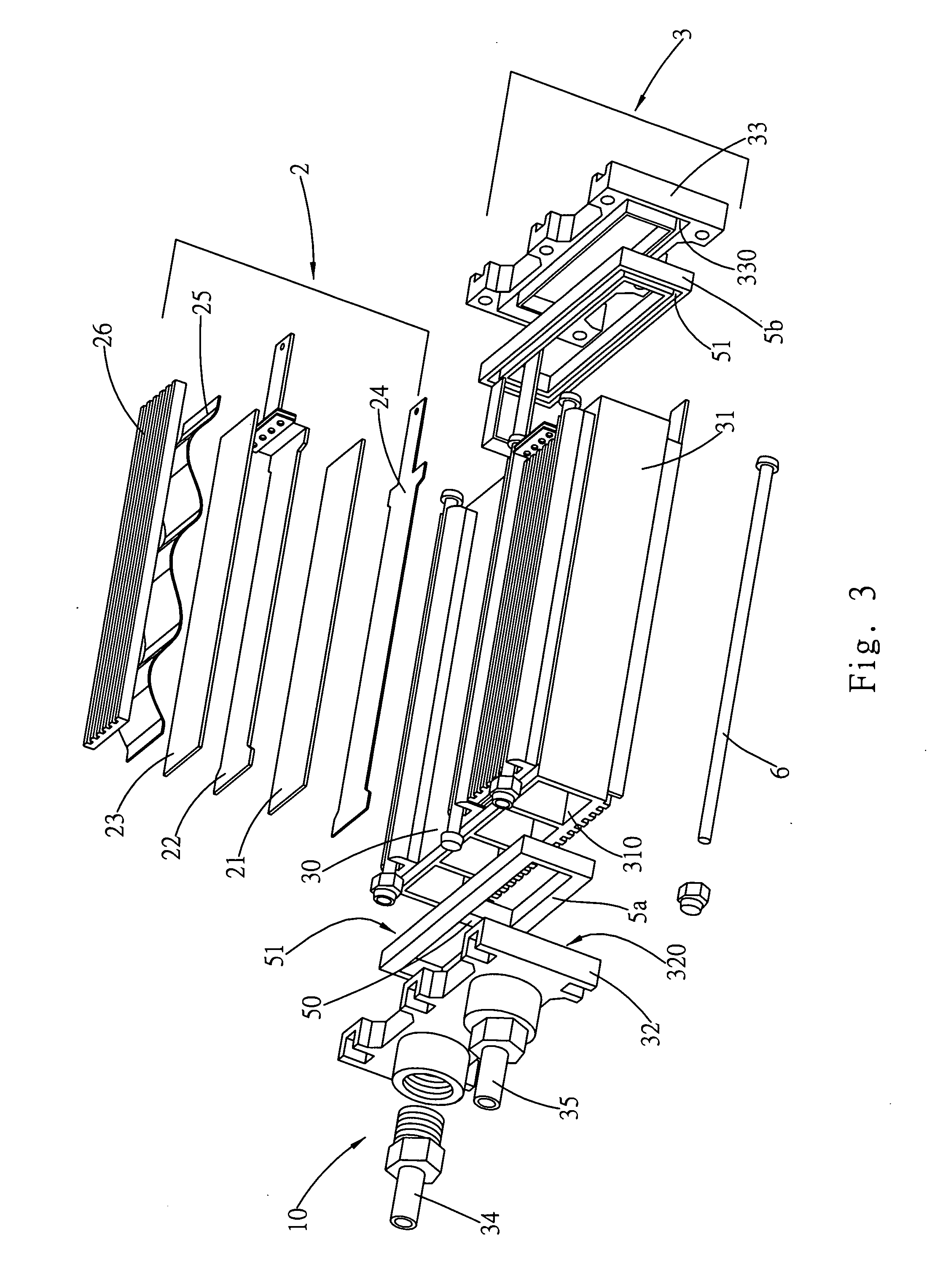

A modular heat exchanger suitable for automotive applications, and methods for forming the modular heat exchanger. The modular heat exchanger construction incorporates a monolithic brazed core assembly composed of flat-type cooling tubes and sinusoidal centers. The required positional tolerances of the tubes for mating with the remainder of the heat exchanger are maintained within the brazed core assembly by minimizing core shrinkage resulting from the brazing operation during which the tubes are brazed to the centers.

Owner:LESAGE PHILIP GEORGE

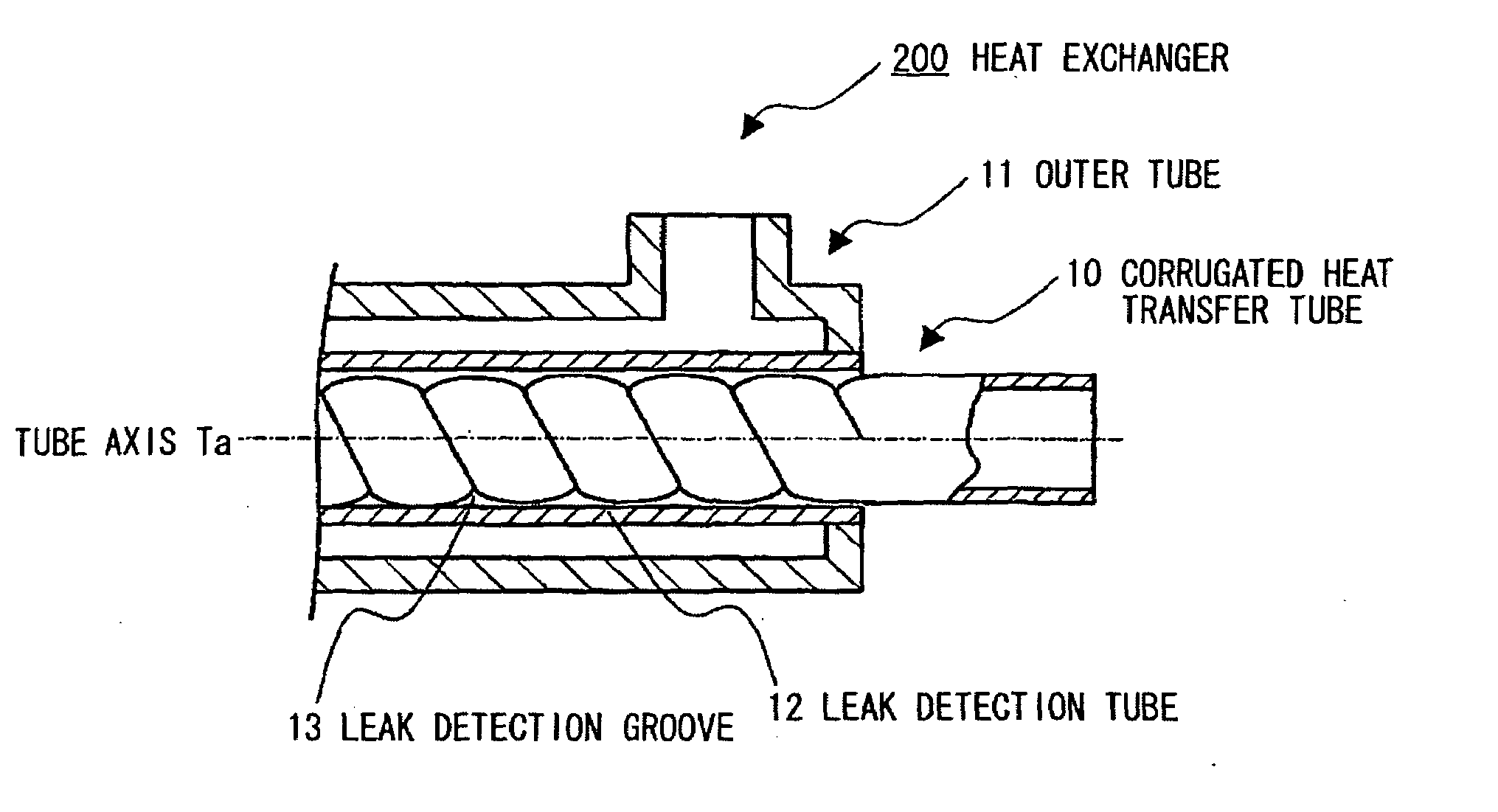

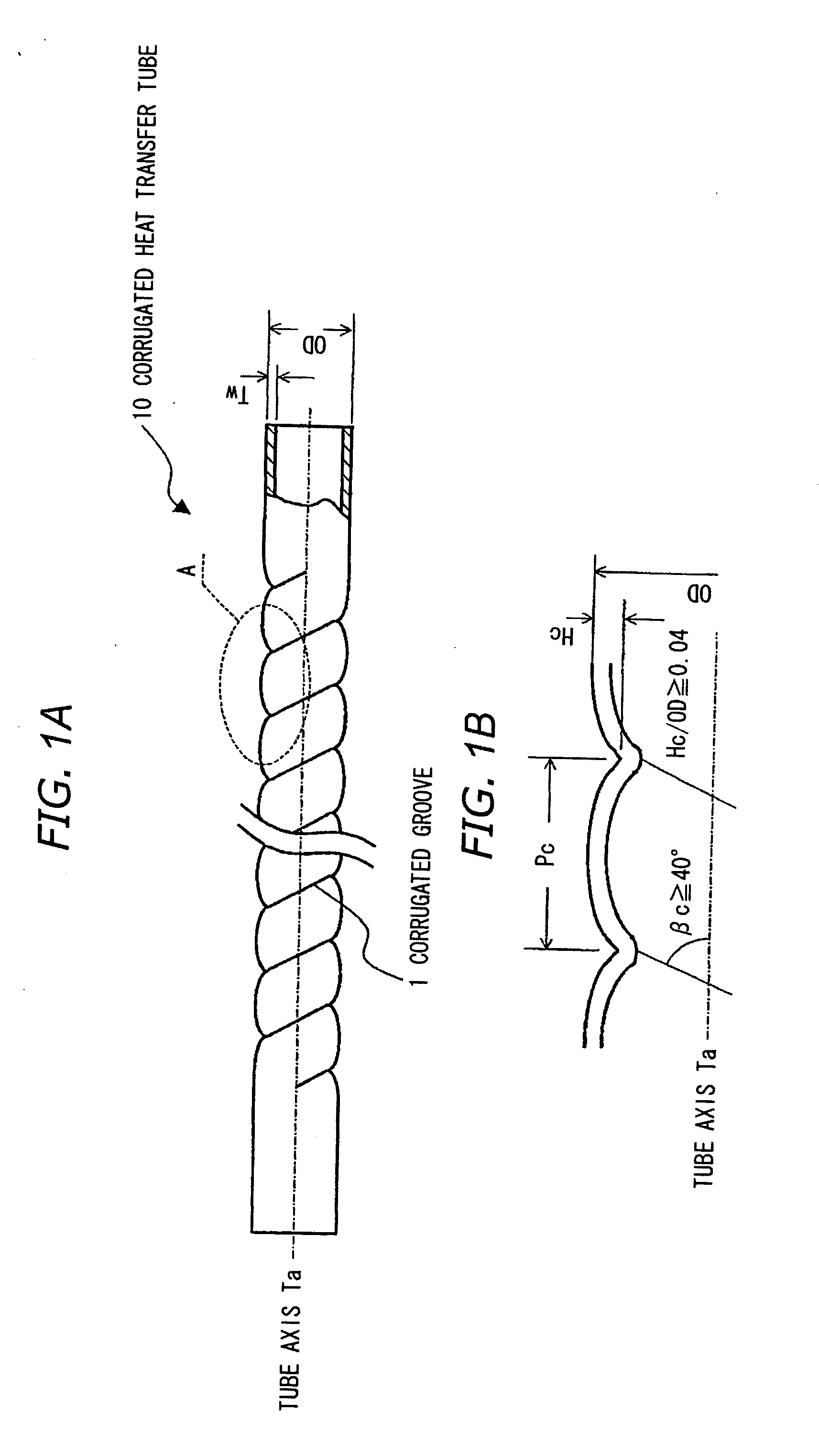

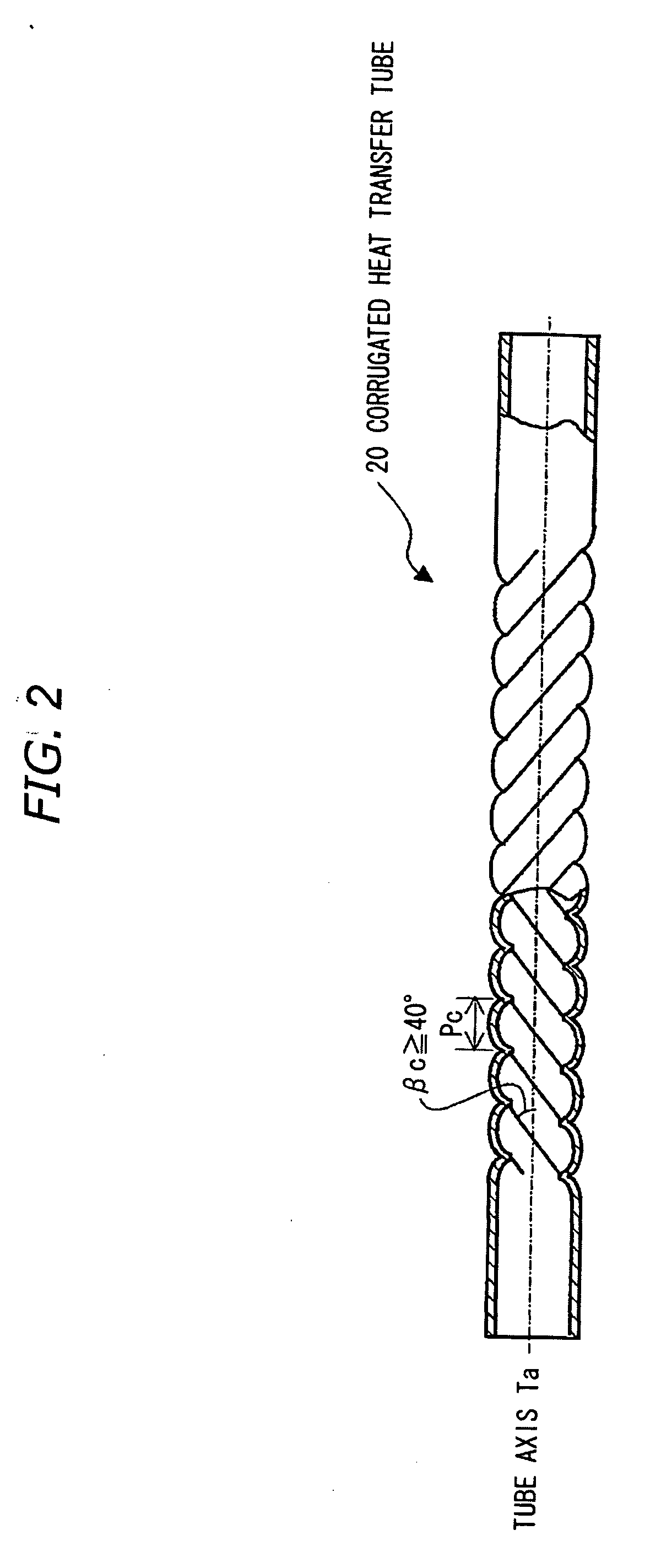

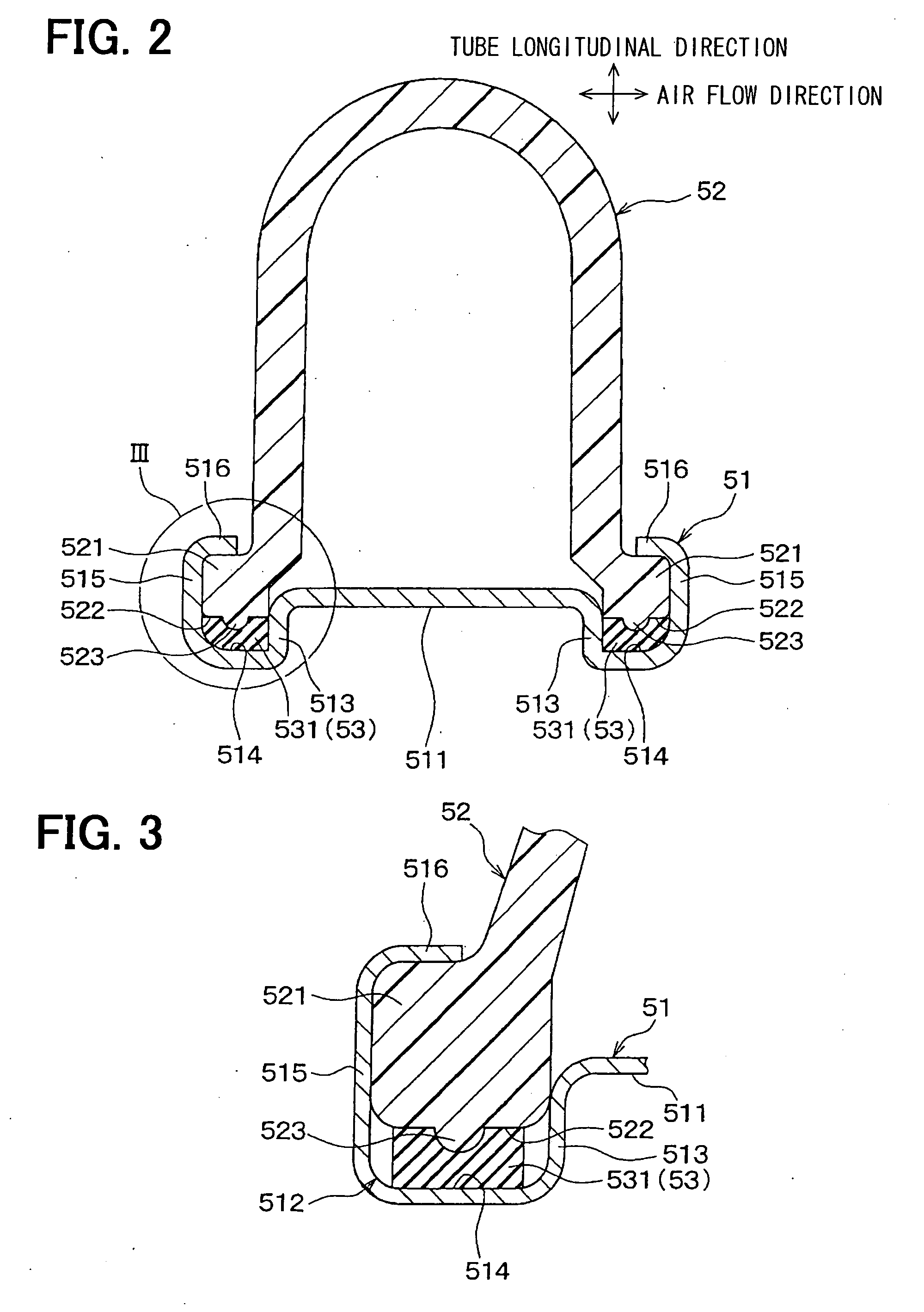

Heat transfer tube and heat exchanger using same

InactiveUS20070187067A1Improve heat transfer performanceImprove performanceHeat exhanger sealing arrangementStationary tubular conduit assembliesPlate heat exchangerEngineering

A heat transfer tube is formed with a corrugated water tube to be used in a heat exchanger, and satisfying 0.04≦Hc / OD, where Hc is the corrugated groove depth of the corrugated tube and OD is the corrugation outside diameter thereof.

Owner:HITACHI CABLE

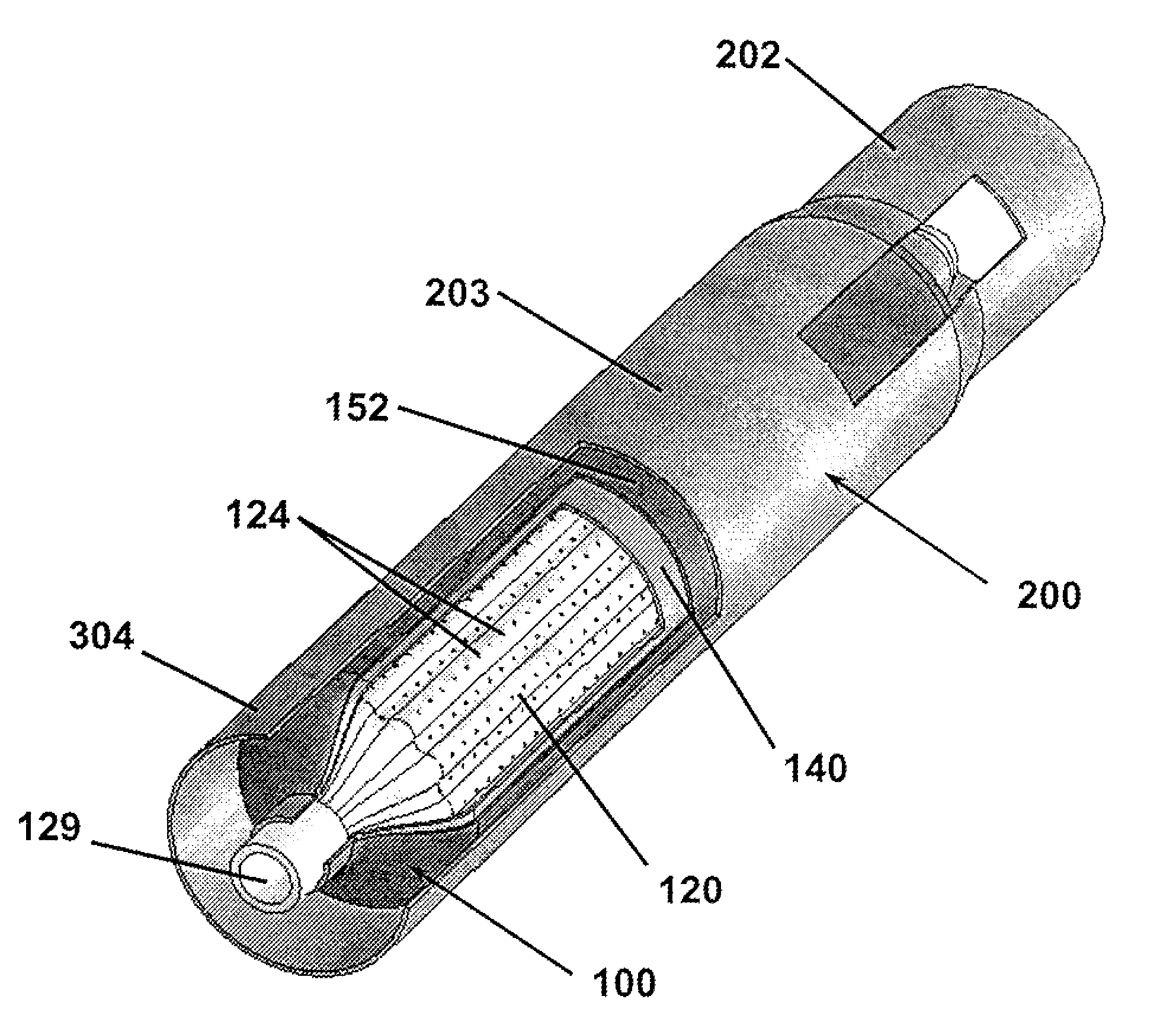

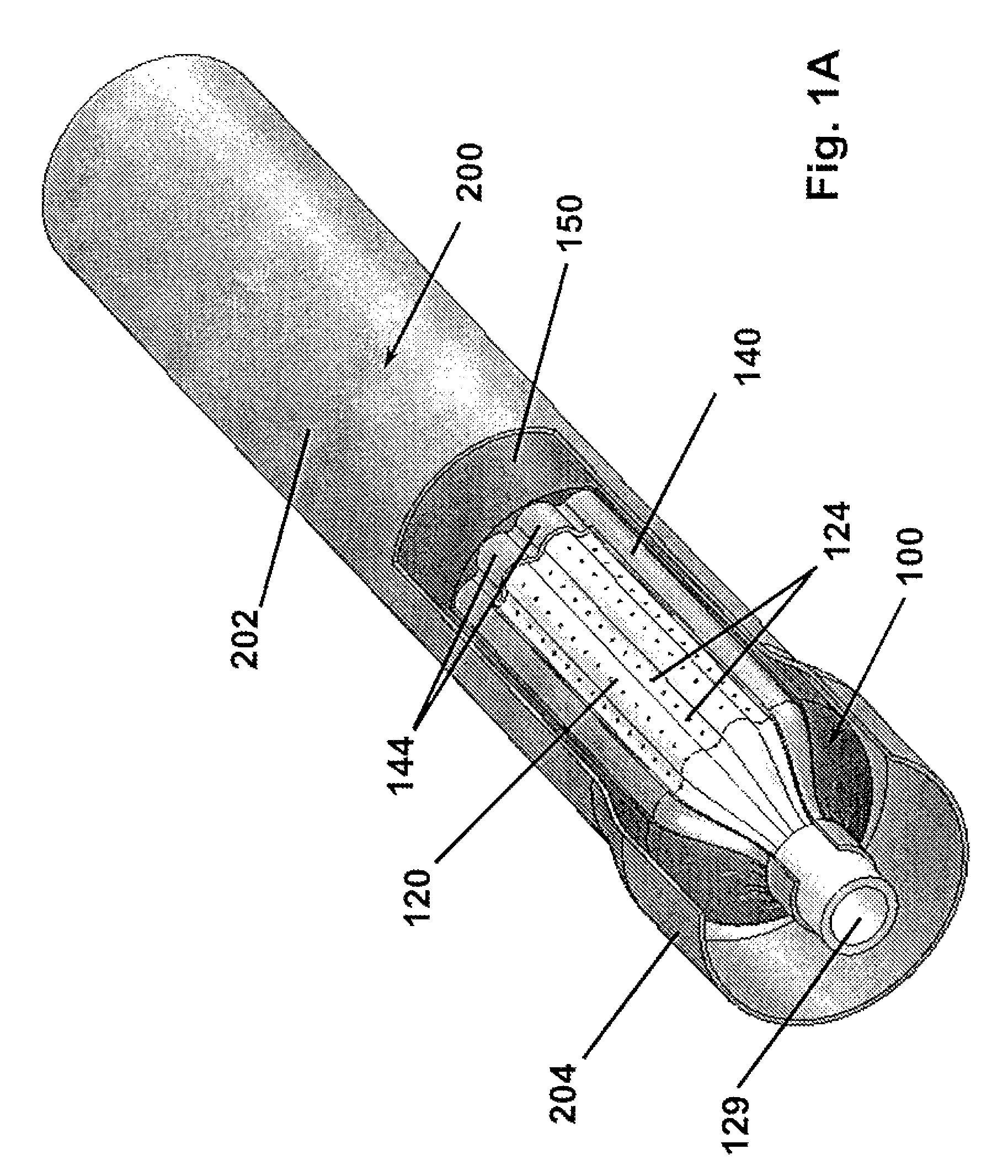

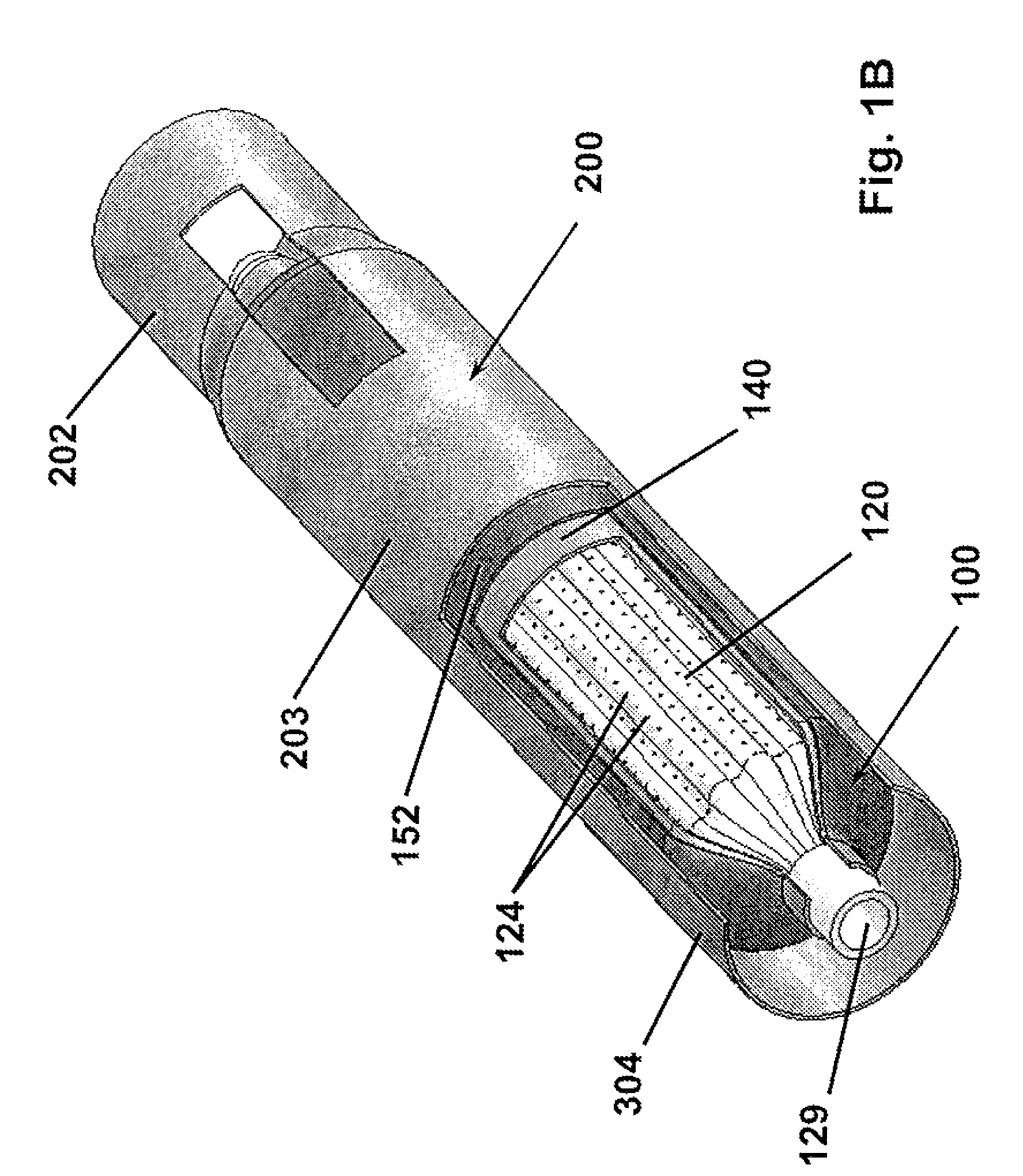

Tubular expansion device and method of fabrication

The invention comprises a device for expanding tubular members to a controlled diameter and its method of fabrication. The device includes an expandable bladder held in a convoluted form. After the device is inserted into a cylindrical tube to be evenly expanded, the bladder is expanded by hydraulic pressure to a controlled maximum diameter. It is then deflated so the device can then be moved to another location and reused. The bladder is formed from a flexible impervious material having integral reinforcing fibers. It is initially formed in a fully expanded configuration over a convoluted mandrel and a removable cylindrical shell. When the shell is removed vacuum or external pressure draws the bladder against the mandrel. The bladder is overmolded with a resilient cover to hold it in reduced form until pressurized. The bladder cover prevents the bladder from kinking during the expansion.

Owner:EXPANSION TECH

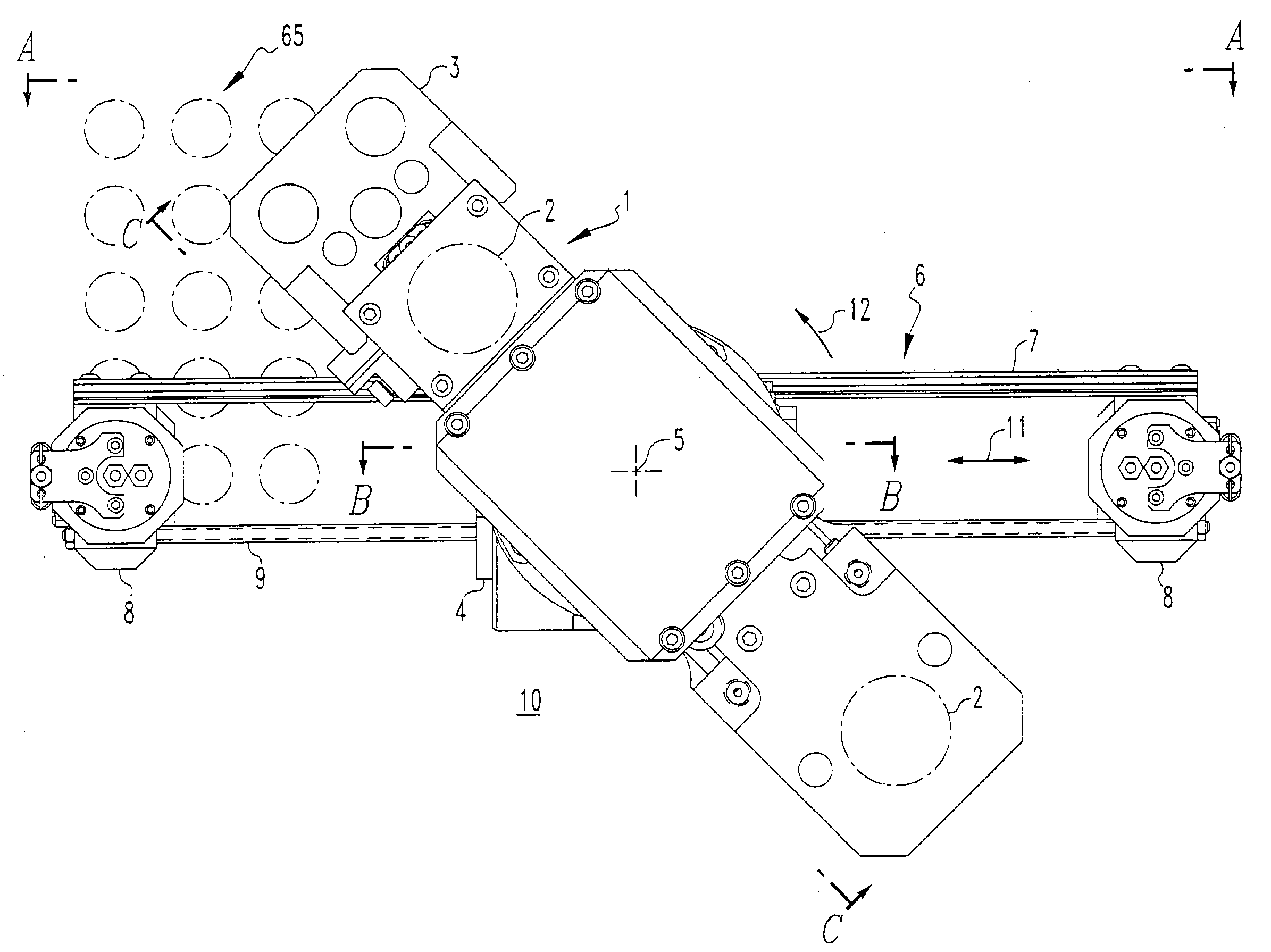

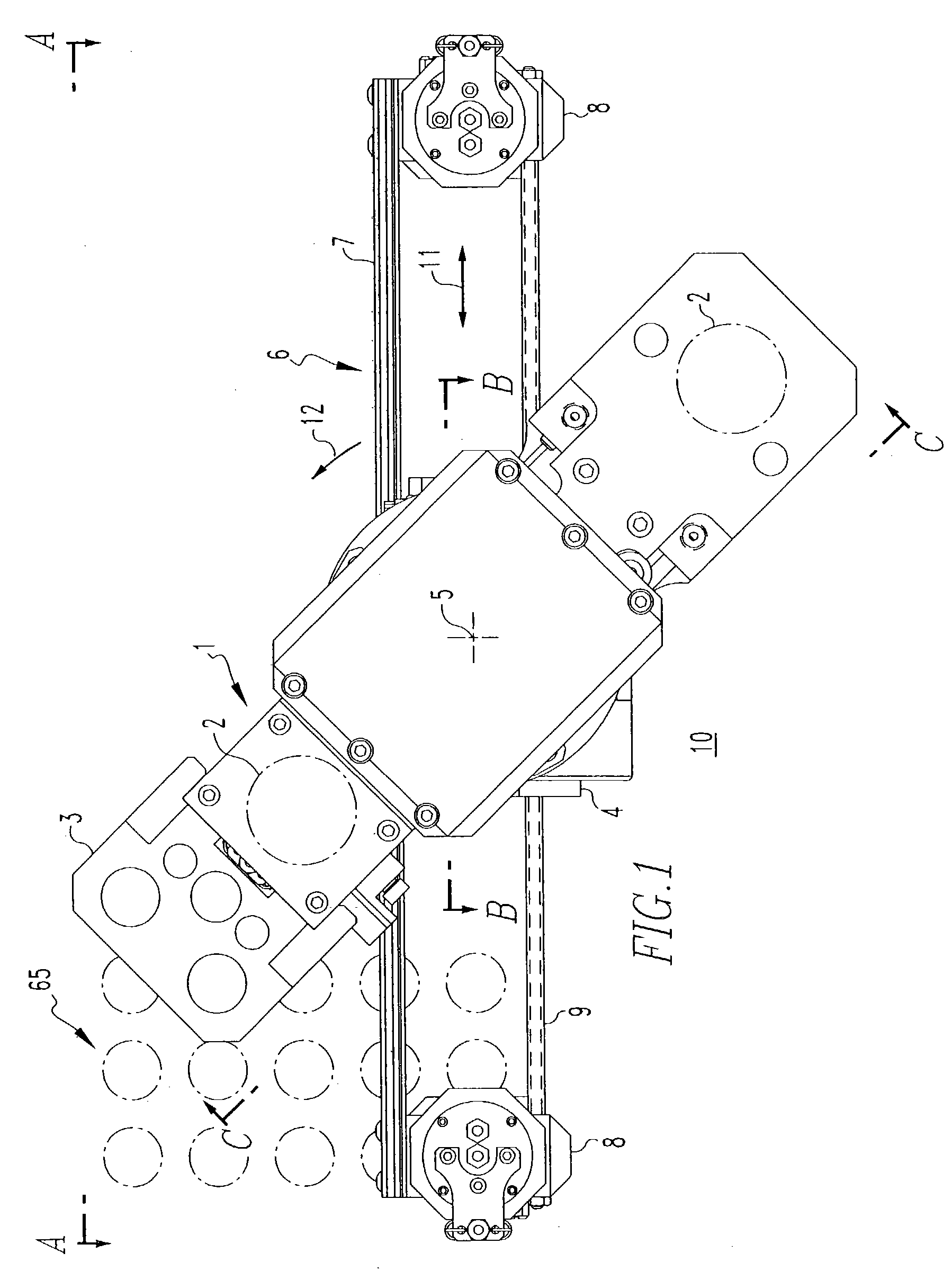

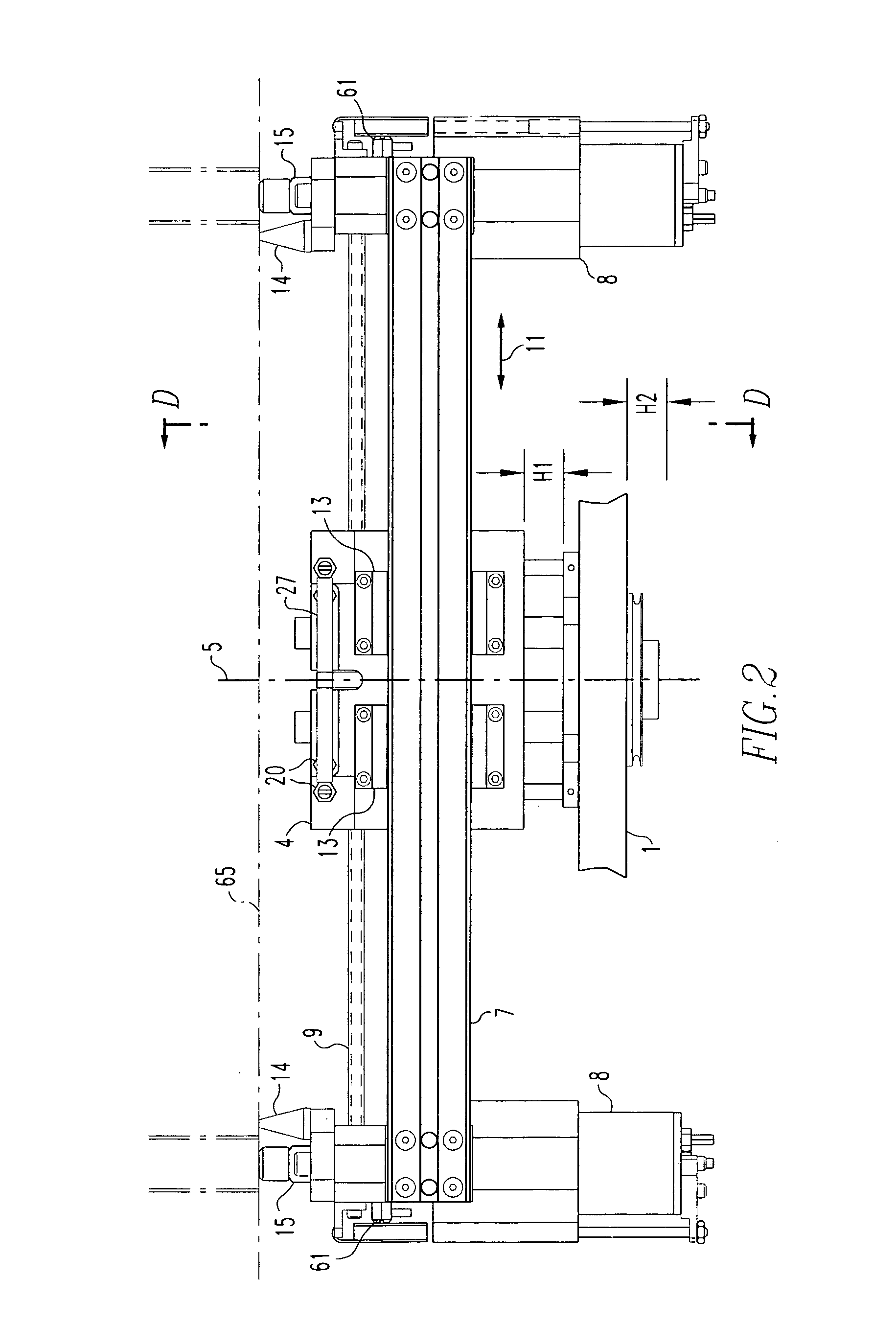

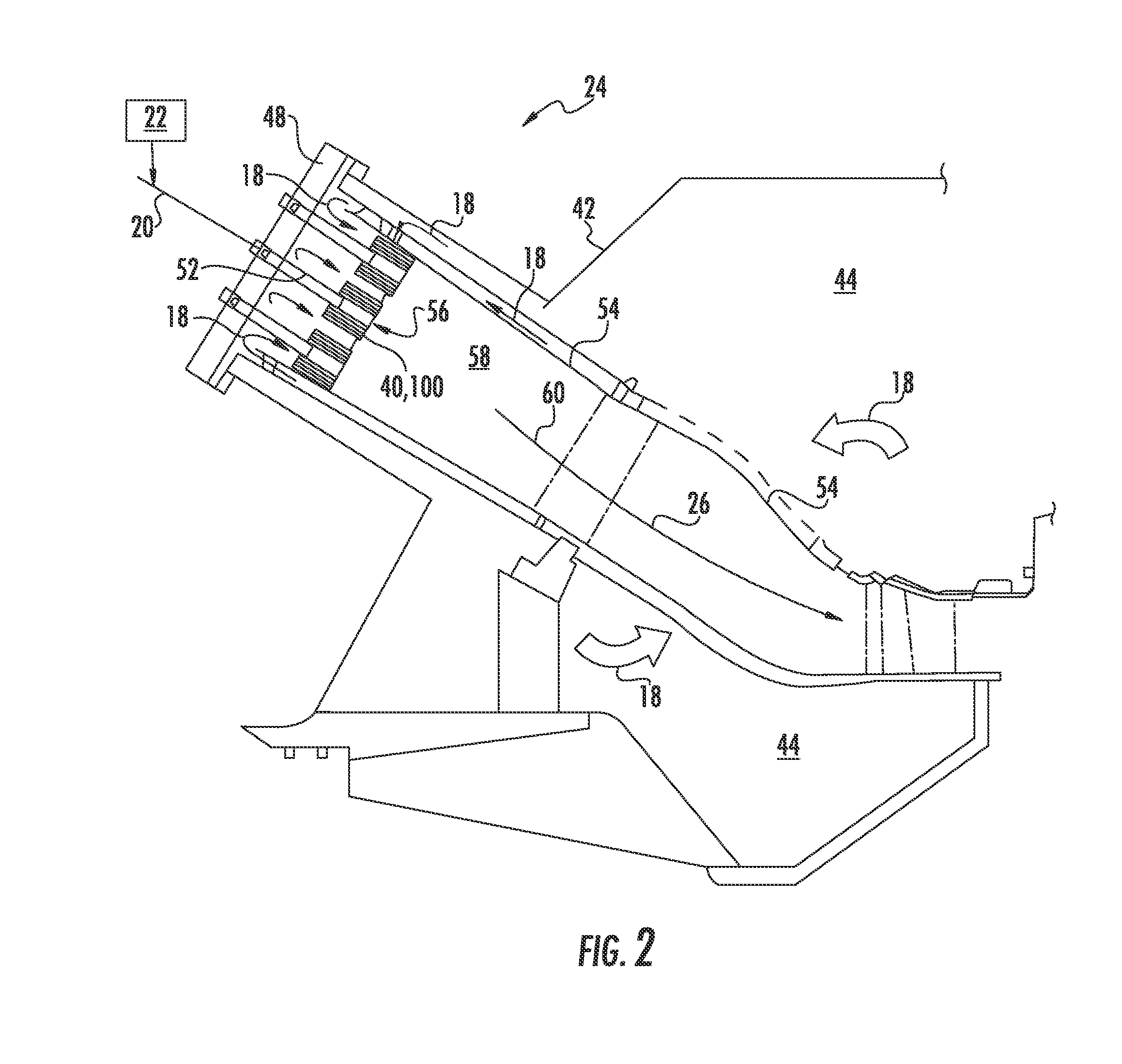

Miniature manipulator for servicing the interior of nuclear steam generator tubes

A manipulator for servicing tubes extending through a tube sheet having three major components: a base member, a block member, and a foot member. The base member has a holder for supporting tooling or inspection devices. The base member also has at least one gripper for releasably gripping a tube extending through the tube sheet. The block member is connected to the base member for linear movement and rotation relative to the base member. The foot member is connected to the block member for linear movement relative to the block member. The foot member has at least one, and preferably two grippers, for releasably gripping a tube extending through the tube sheet. The manipulator supports itself using the two sets of expandable and translatable grippers that anchor into the tube ends and can move from tube to tube by alternately engaging each set of grippers.

Owner:WESTINGHOUSE ELECTRIC CORP

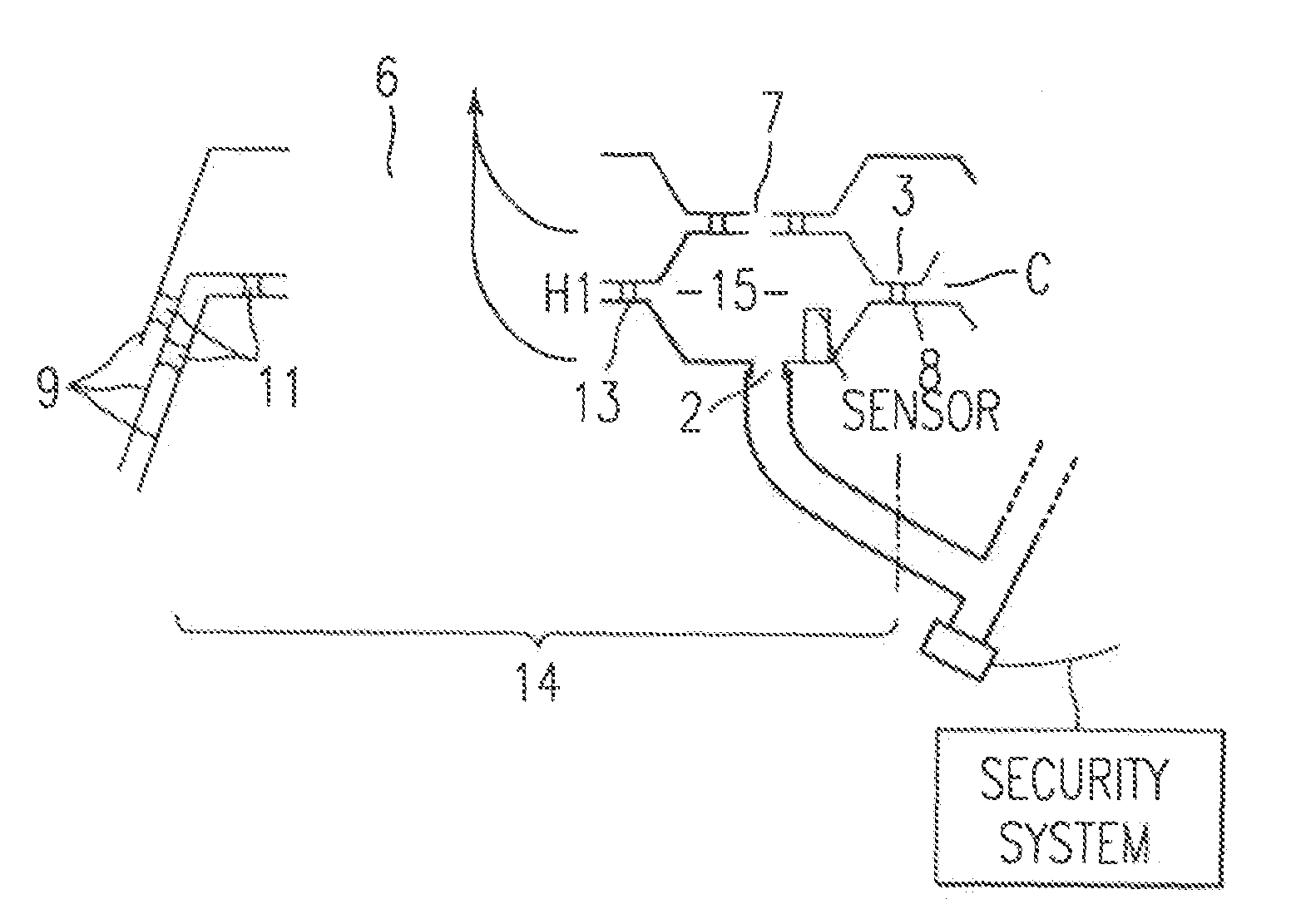

Heat exchanger with leakage vent

InactiveUS7337836B1Safety devices for heat exchange apparatusHeat exhanger sealing arrangementEngineeringMicro heat exchanger

A heat exchanger with a leakage vent. A fully brazed heat exchanger has an arrangement preventing the two media inside the heat exchanger from mixing in case of leakage. The heat exchanger includes plates having a pattern of grooves and inlet and outlet connections. The plates are placed in a pack and brazed together so as to form separate channels for two media between alternating pairs of plates. A separation zone is created around the connection so as so block off the medium that is not to reach the respective connection. The other medium can flow on by. A leakage vent to the exterior is provided in the separation zone so as to allow detection of any leakage.

Owner:DANFOSS AS

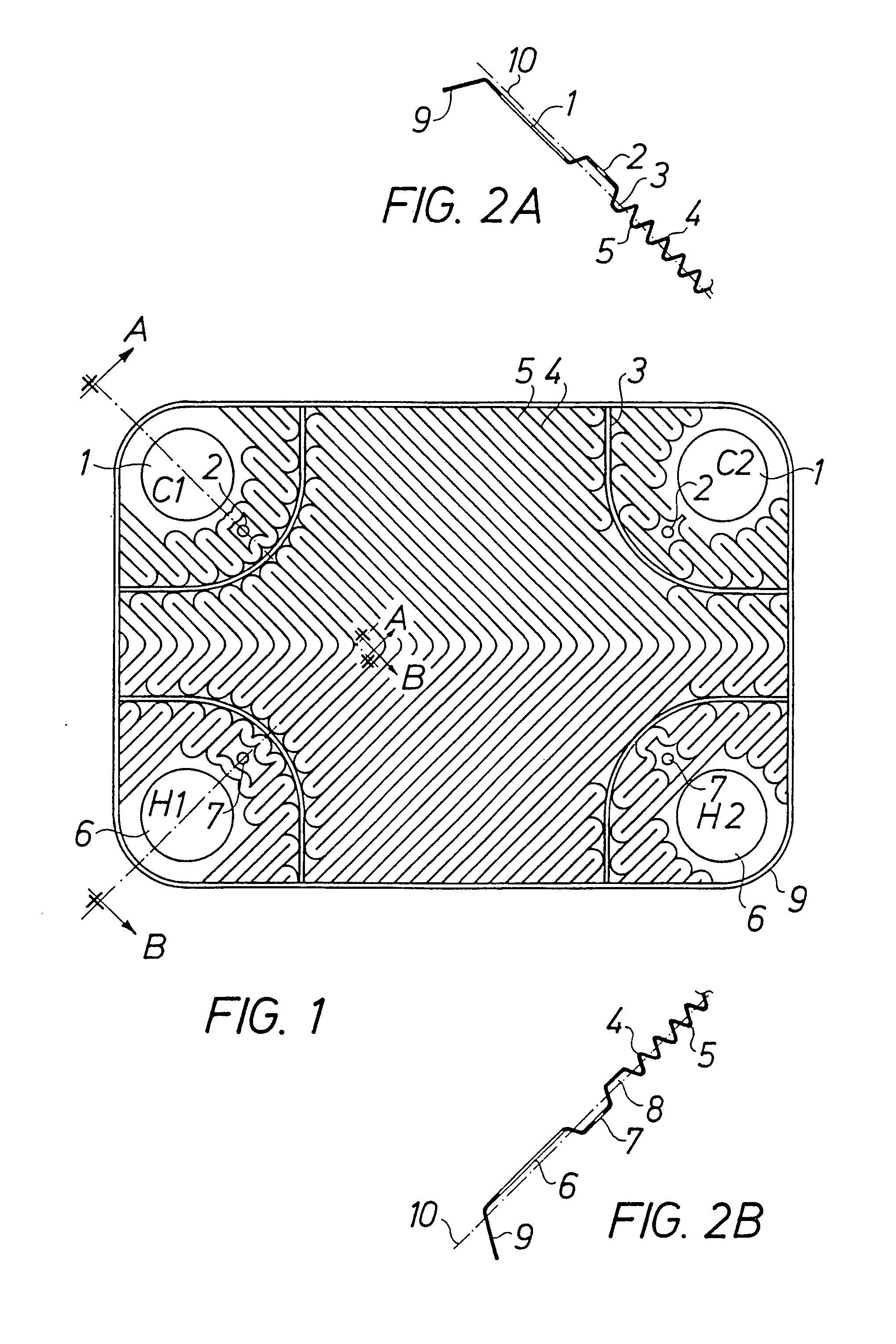

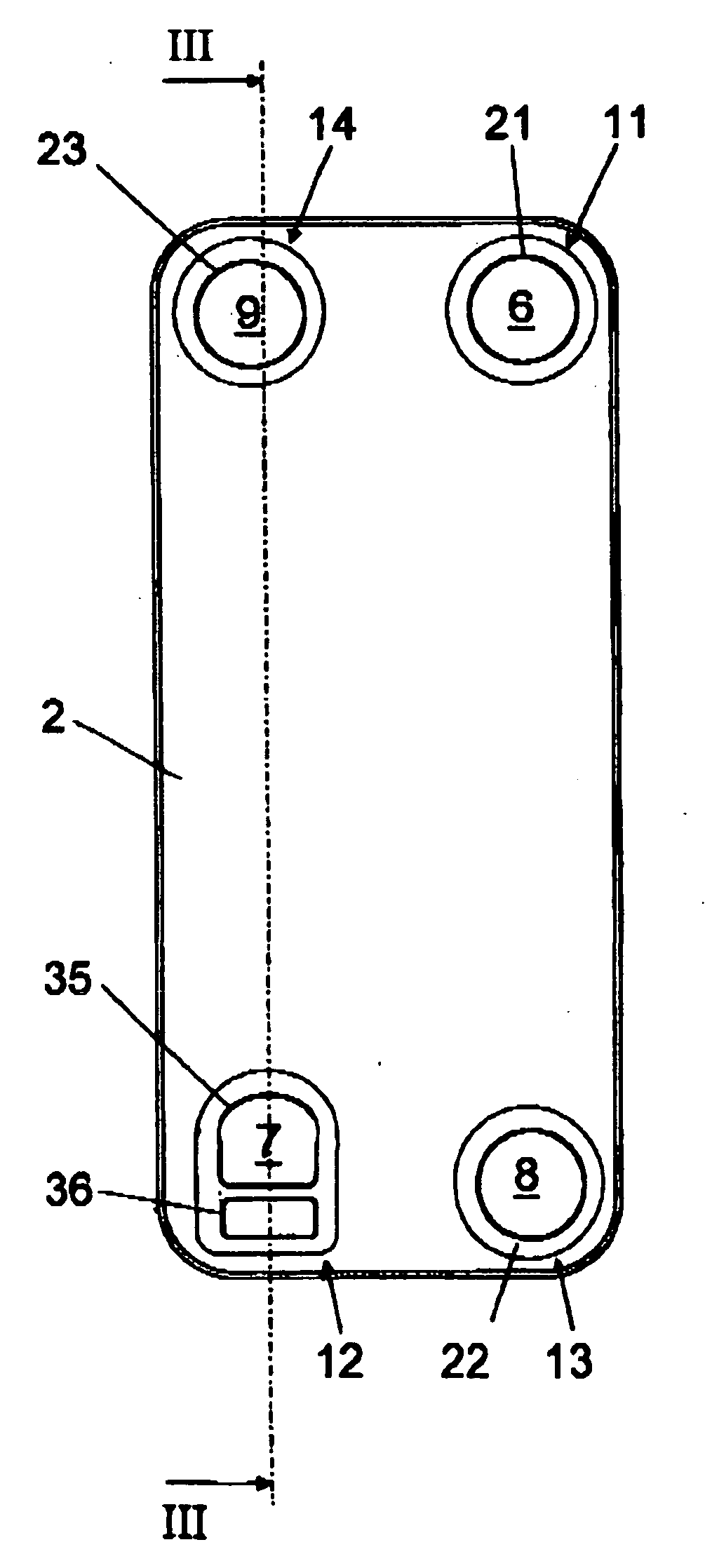

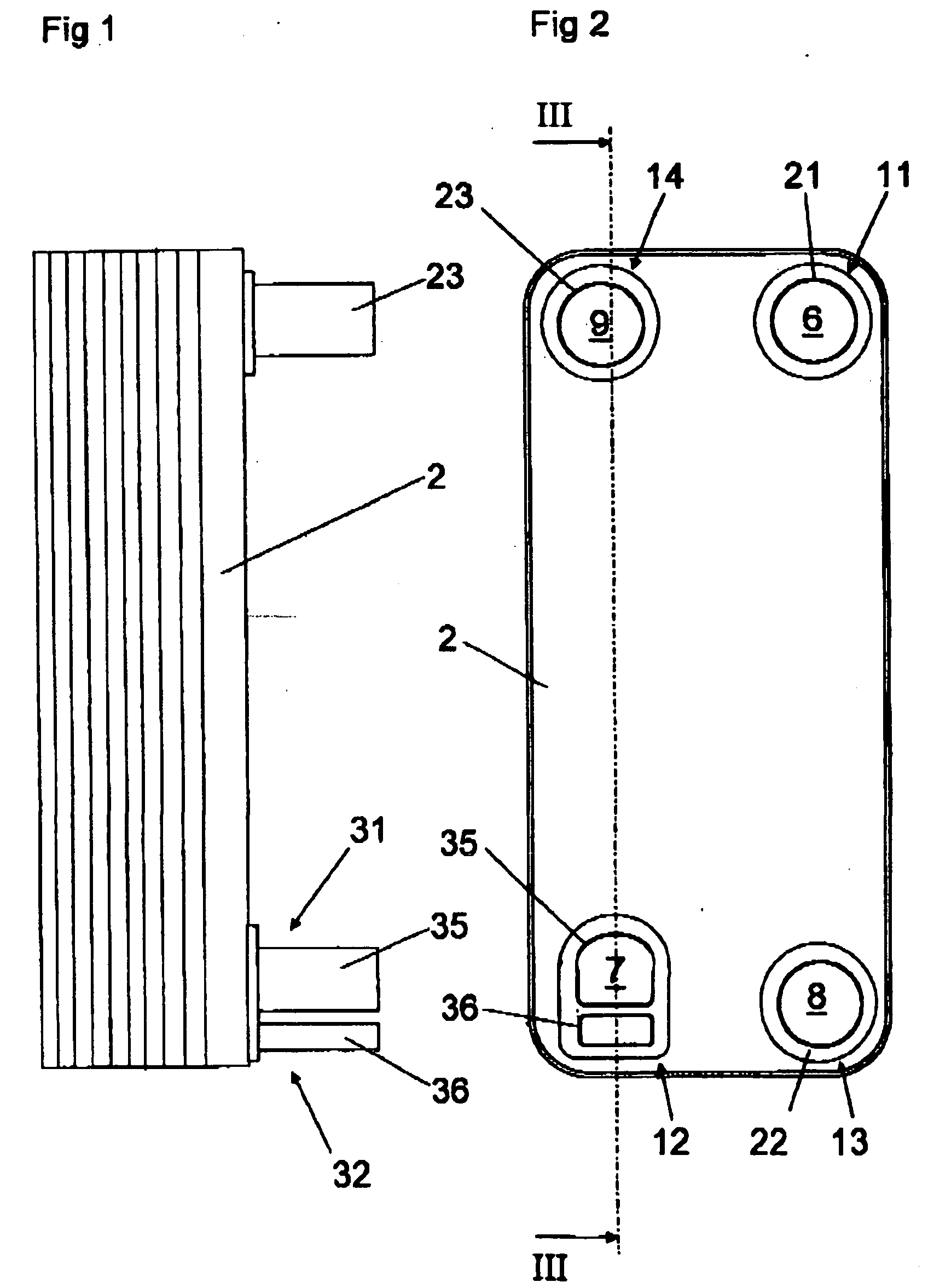

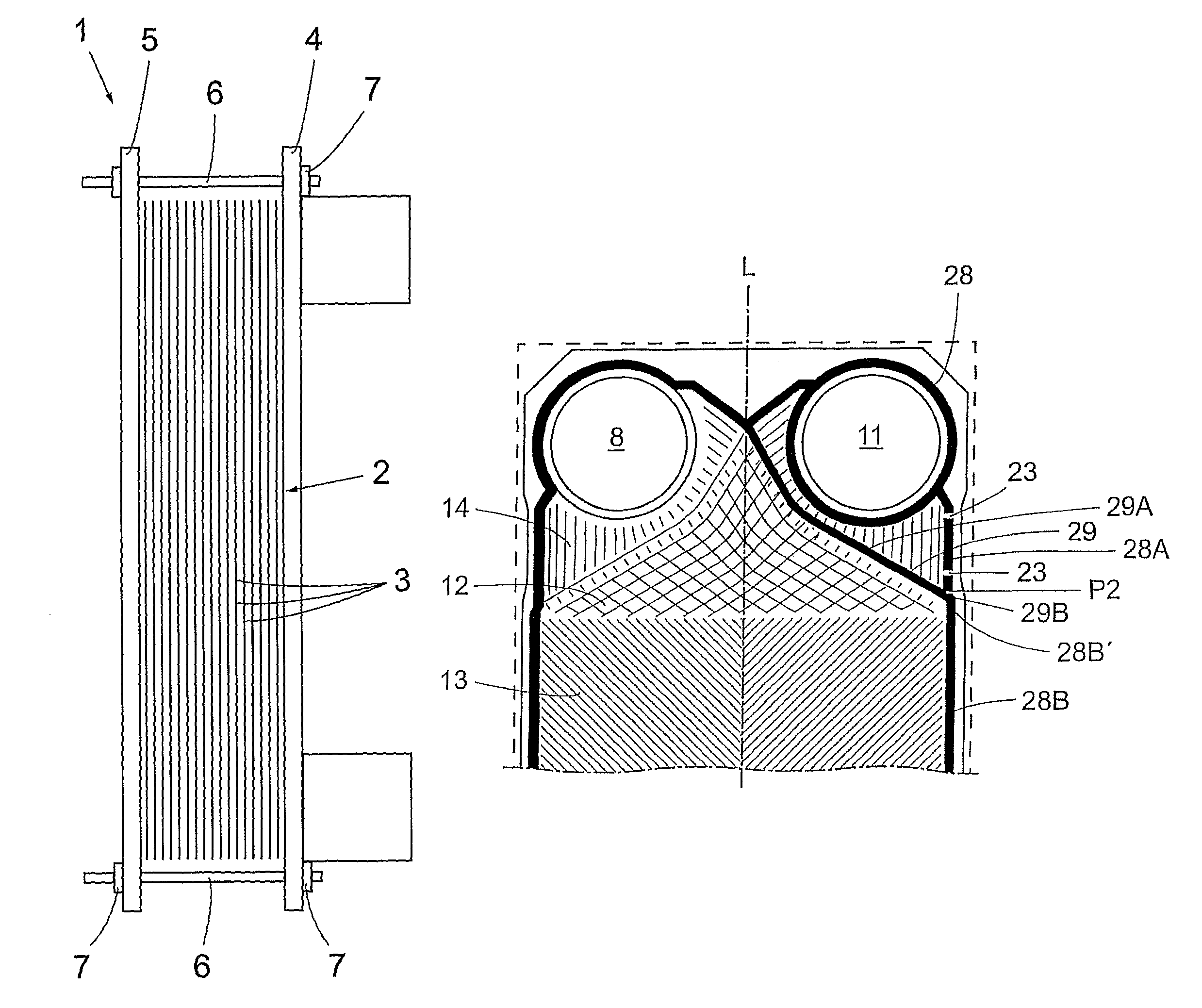

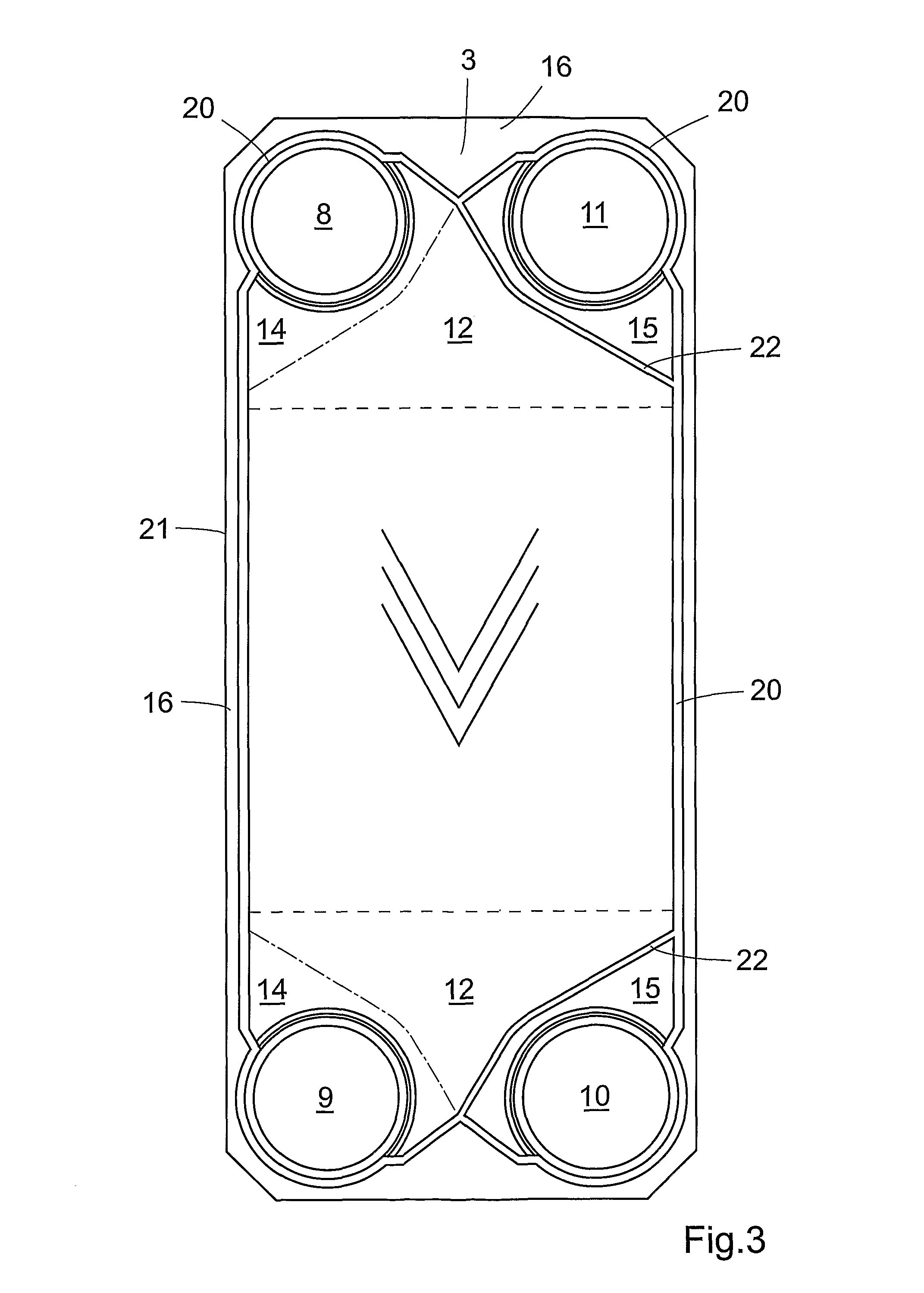

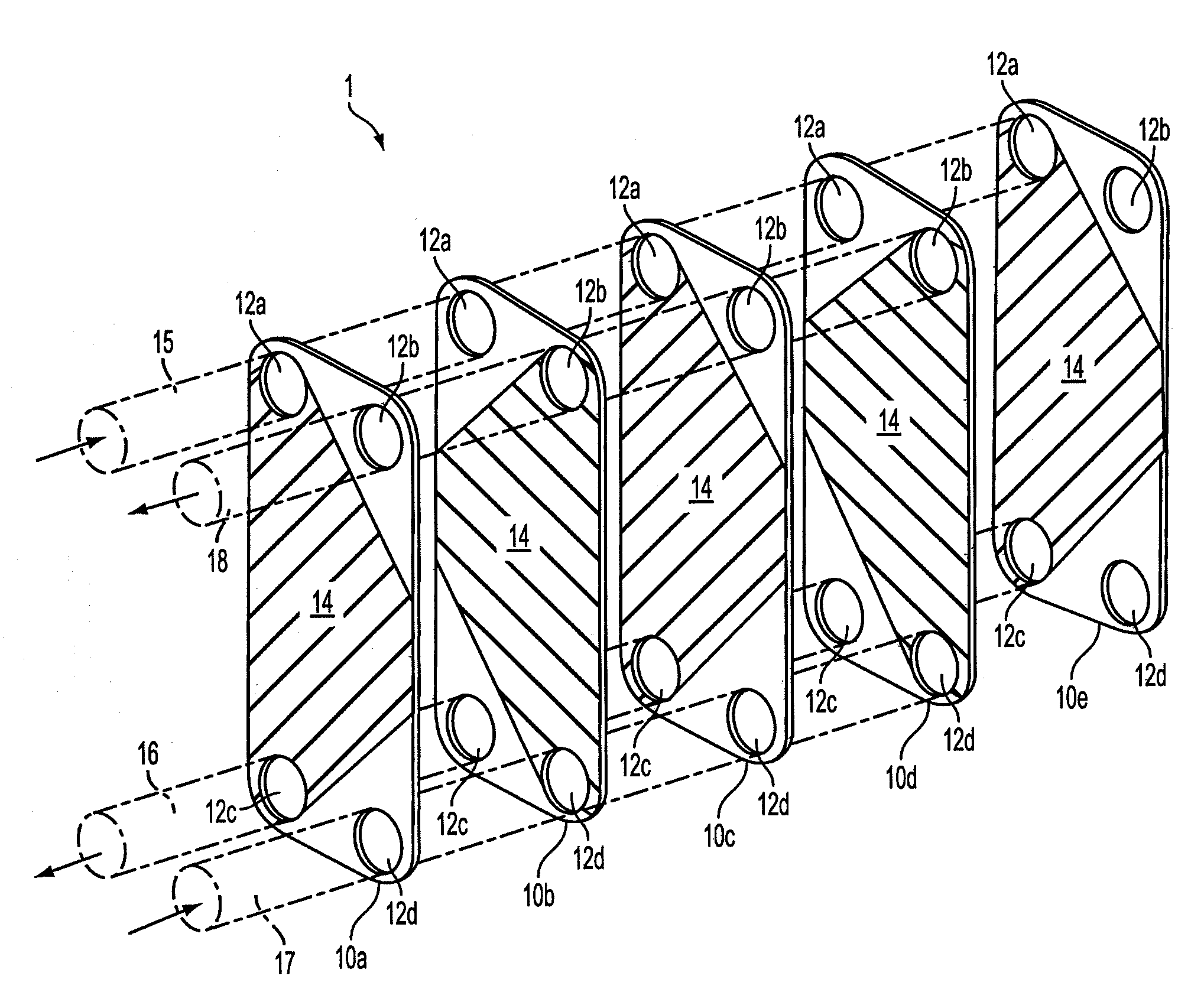

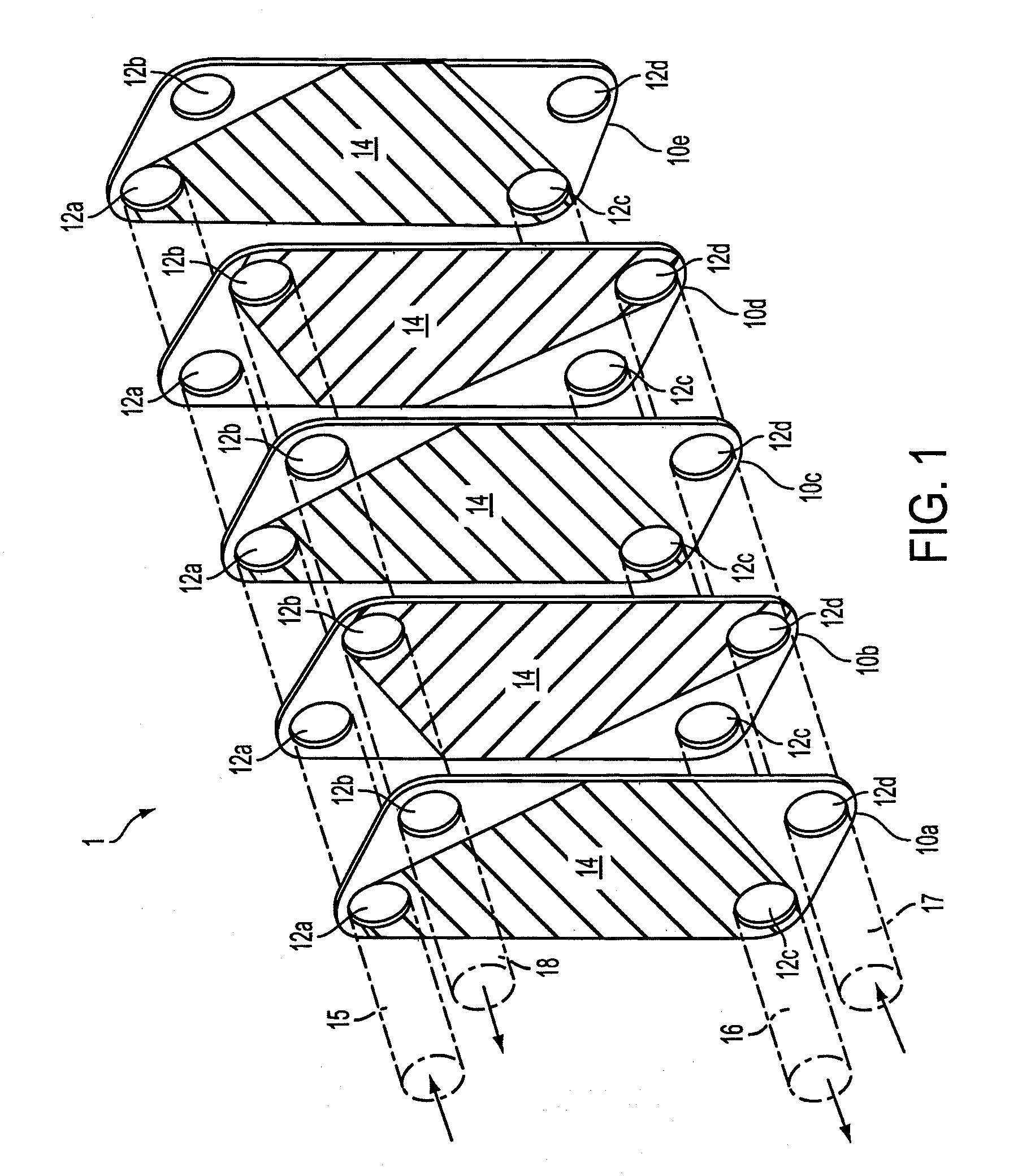

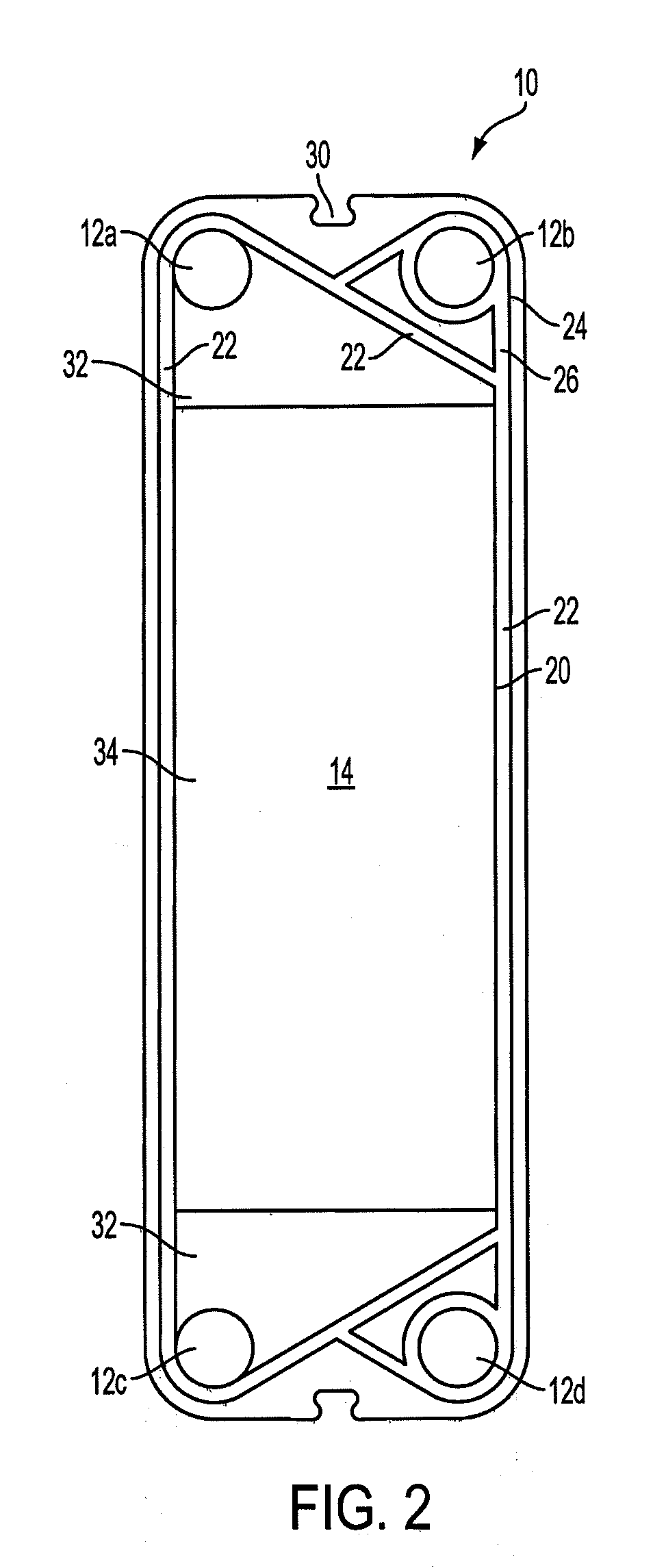

Plate heat exchanger device and a heat exchanger plate

InactiveUS20050211421A1Efficient separation of liquidAvoid mixingSafety devices for heat exchange apparatusEvaporators/condensersPlate heat exchangerProcess engineering

The invention refers to a device, including a plate package (2) of heat exchanger plates (1) which are provided beside each other to form a plate interspace between adjacent plates, and a heat exchanger plate. The plate interspaces form in an alternating order first passages (3) for a first medium and second passages (4) for a second medium for cooling of the first medium. Each heat exchanger plate has at least two portholes forming a first inlet port channel and a first outlet port channel (7), which extend through the plate package to a first inlet and a first outlet, respectively, for the first medium to and from the first passages (3). The first outlet forms a gas outlet (31) for discharge of a gas of the first medium and a liquid outlet (32) for discharge of liquid of the first medium. The liquid outlet (32) is separated from the gas outlet (31) for permitting separate discharge of the liquid and gas.

Owner:ALFA LAVAL CORP AB

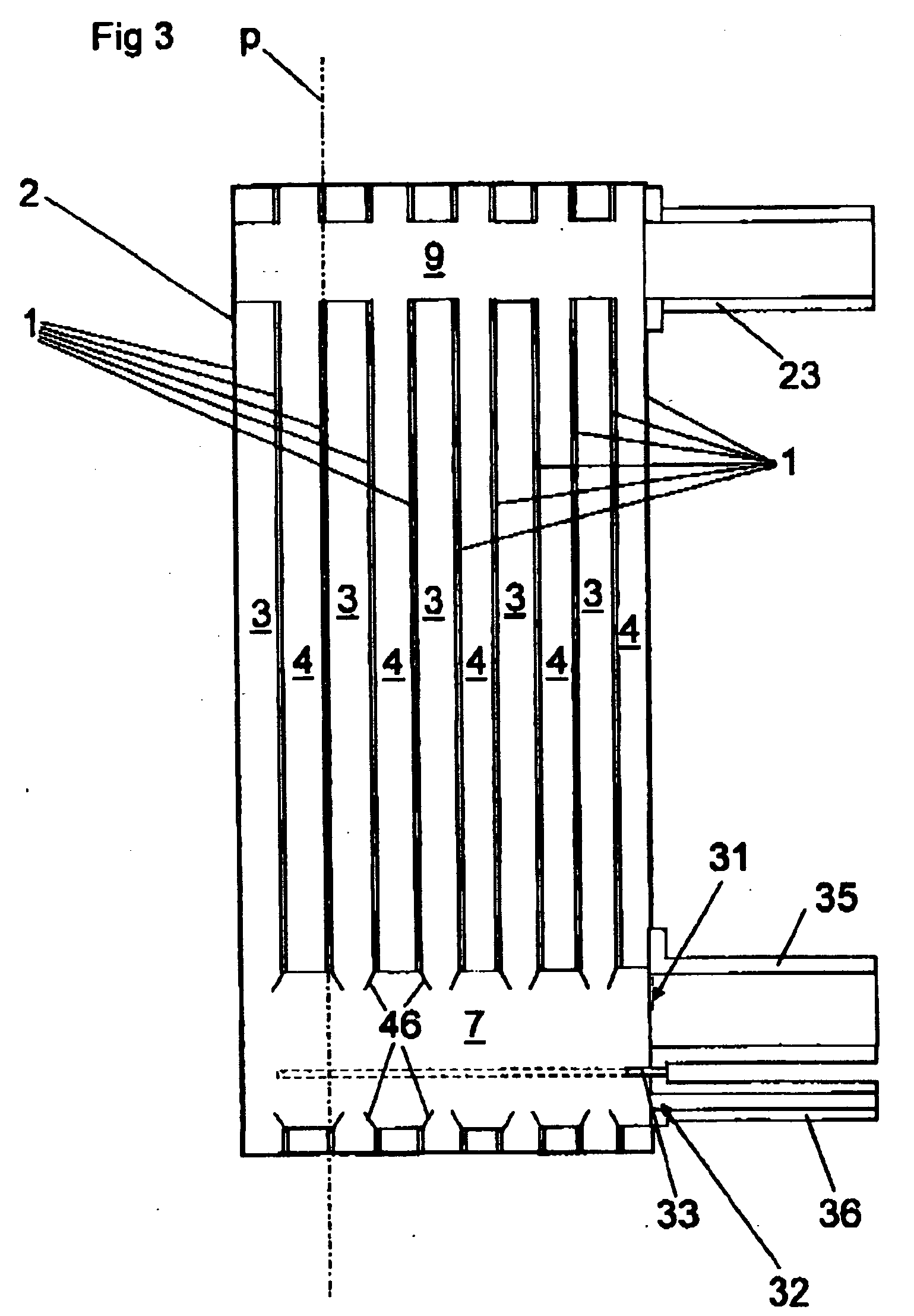

Plate and gasket for plate heat exchanger

ActiveUS8646517B2Optimal utilisationImprove performanceHeat exhanger sealing arrangementHeat exchanger casingsPlate heat exchangerEngineering

The invention relates to a heat exchanger plate for a plate heat exchanger, which plate has a number of ports, a distribution region, a heat transfer region, a first adiabatic region, a second adiabatic region and an edge area that extends outside the ports and the regions, which plate has a first gasket groove extending in the edge area outside the regions and around the ports, and a second gasket groove extending between the adiabatic region and the adjacent distribution region, whereby the gasket grooves are connected together to accommodate a gasket for sealing abutment against an adjacent heat exchanger plate in the plate heat exchanger. The invention further relates to a gasket for a heat exchanger plate and a plate heat exchanger having a package of heat exchanger plates and gaskets.

Owner:ALFA LAVAL CORP AB

Method for repairing a bundled tube fuel injector

A method for repairing a bundled tube fuel injector includes removing a portion of a pre-mix tube, aligning a tube tip with the remaining portion pre-mix tube and fixedly connecting the tube tip to the pre-mix tube. The method may further include removing an aft plate and an outer shroud from the bundled tube fuel injector so as to expose the pre-mix tube.

Owner:GENERAL ELECTRIC CO

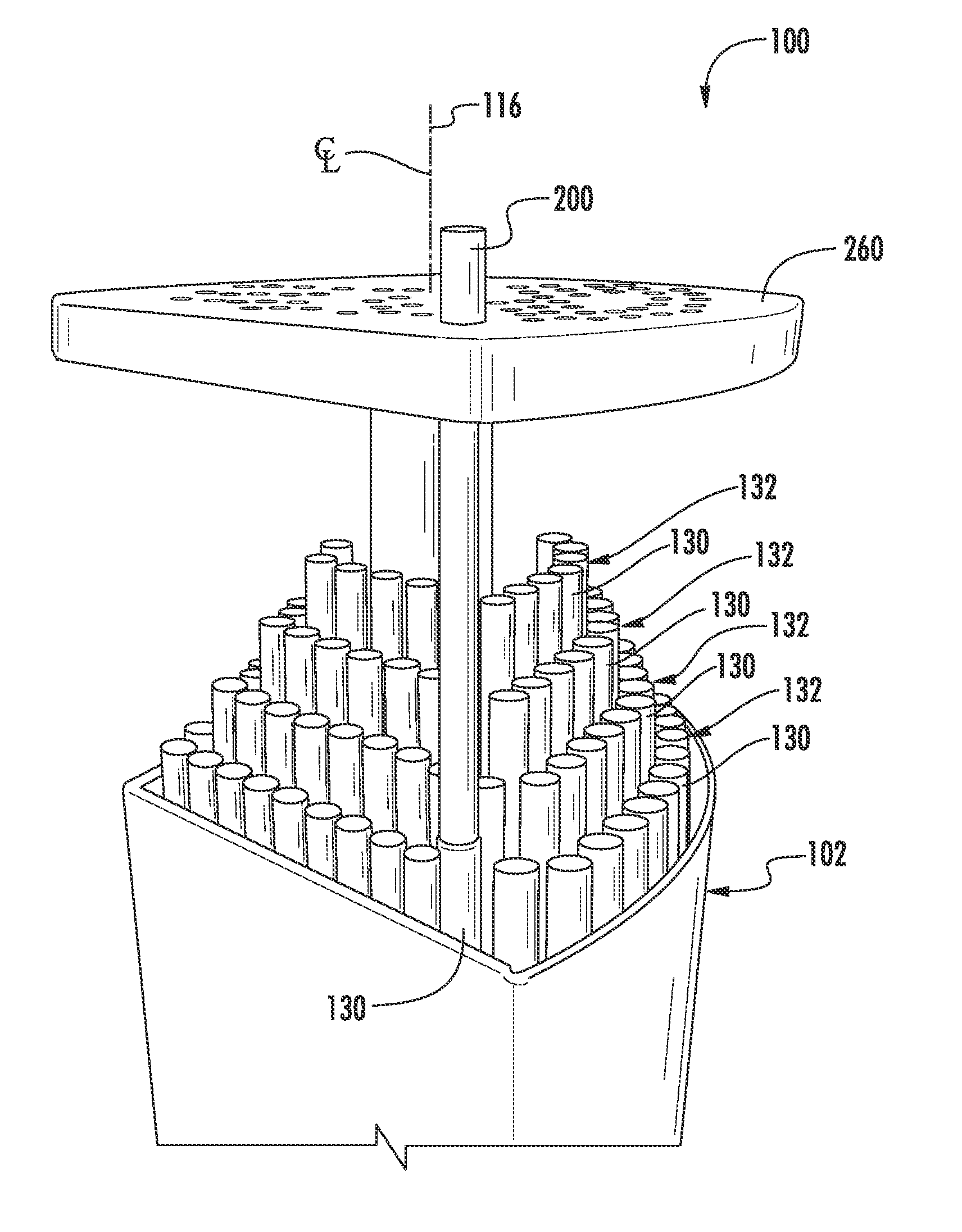

Heat radiator and power module

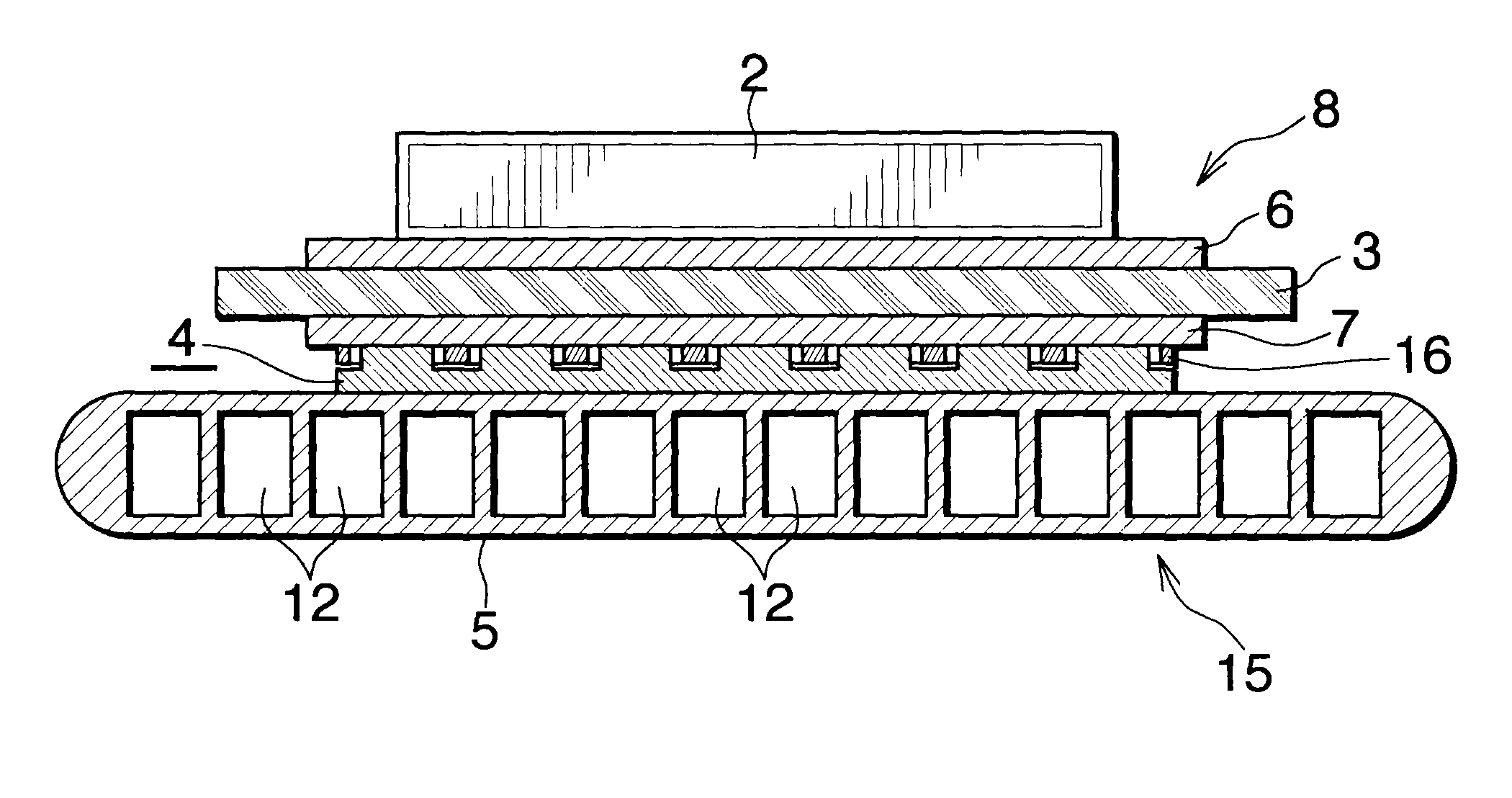

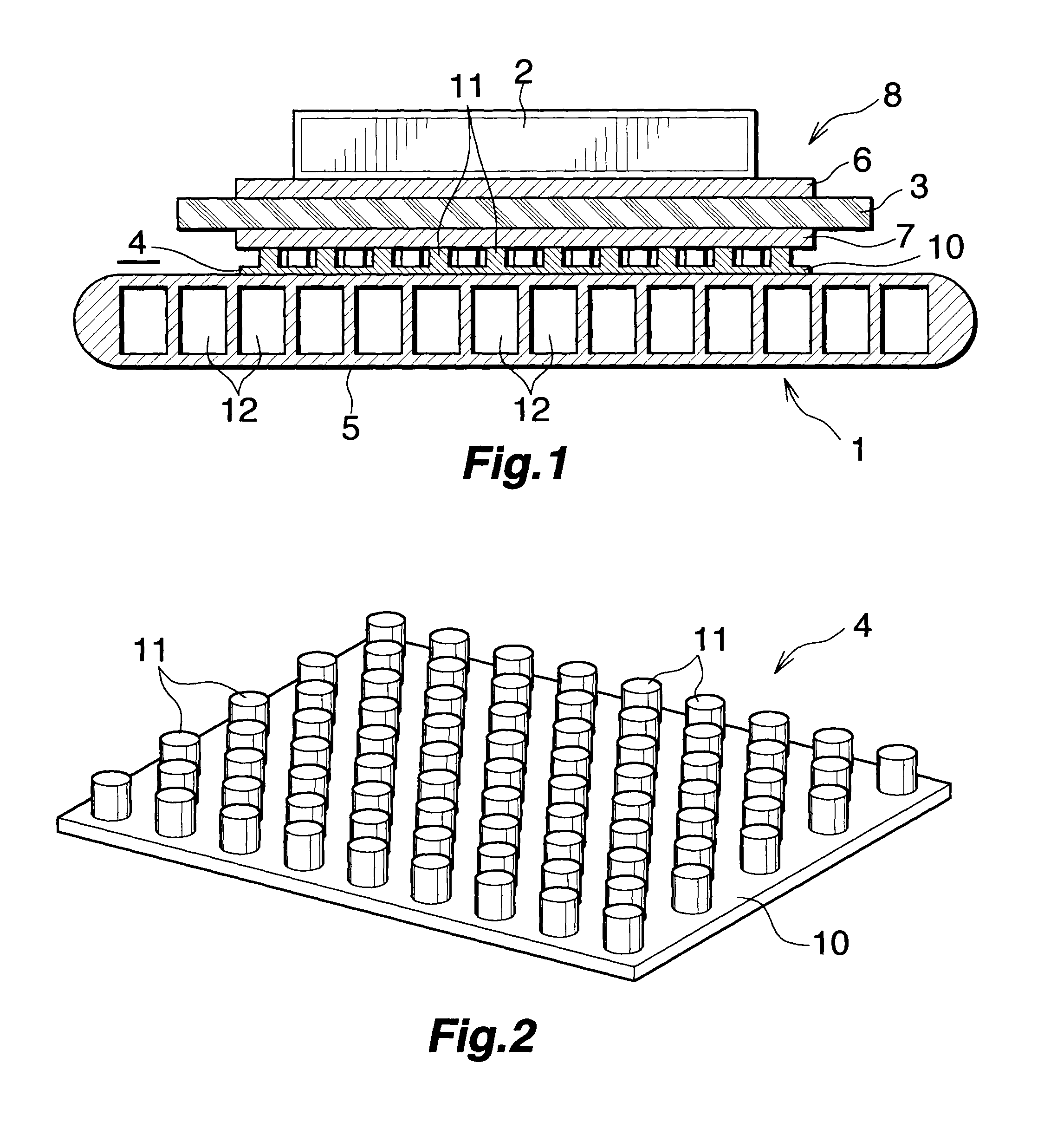

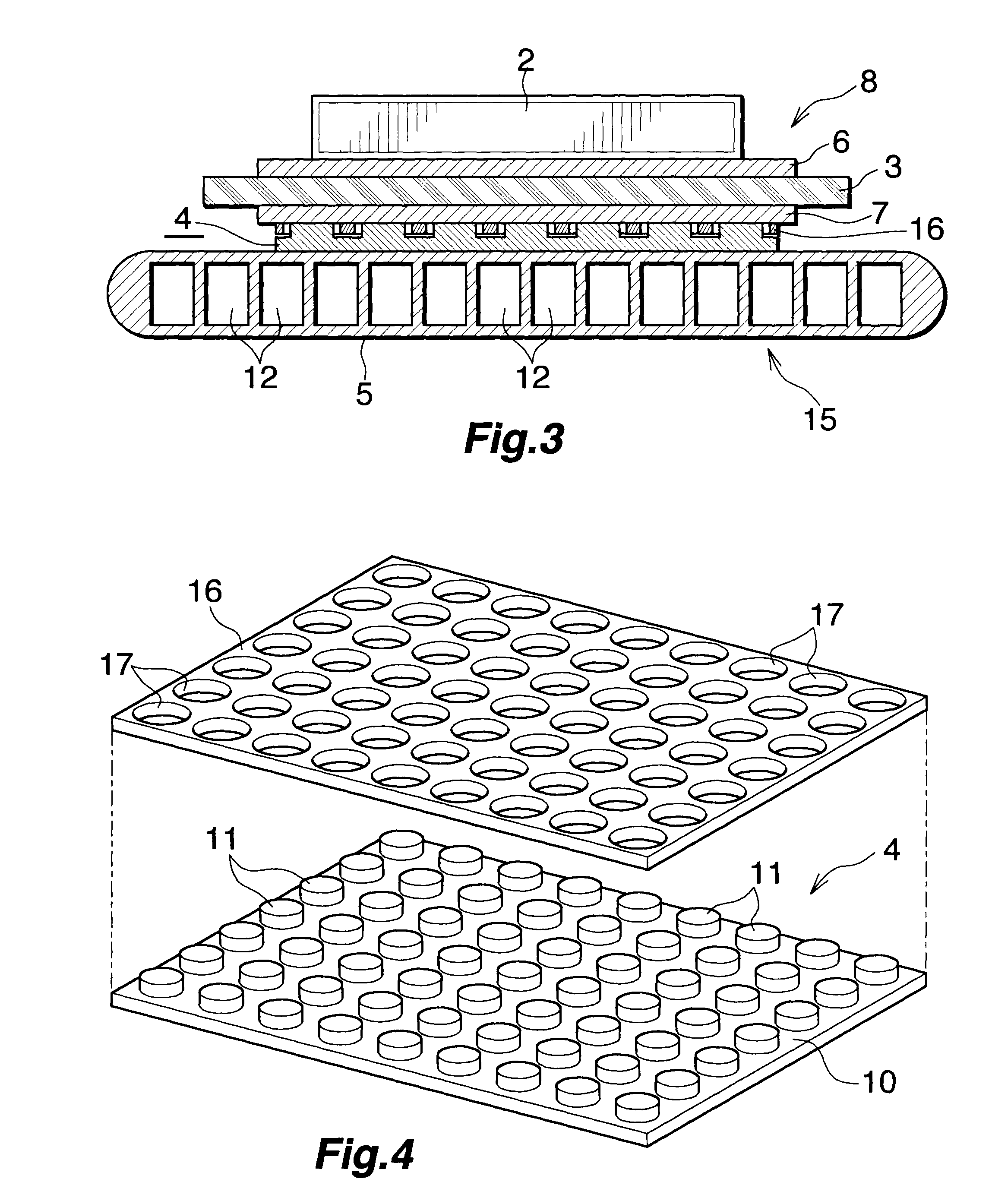

InactiveUS8198539B2Reduce material costsImprove thermal conductivityFinal product manufactureSemiconductor/solid-state device detailsEngineeringStress relaxation

A heat radiator 1 includes an insulating substrate 3 whose first side serves as a heat-generating-element-mounting side, and a heat sink 5 fixed to a second side of the insulating substrate 3. A metal layer 7 is formed on the second side of the insulating substrate 3 opposite the heat-generating-element-mounting side. A stress relaxation member 4 formed of a high-thermal-conduction material intervenes between the metal layer 7 of the insulating substrate 3 and the heat sink 5 and includes a plate-like body 10 and a plurality of projections 11 formed at intervals on one side of the plate-like body 10. The end faces of the projections 11 of the stress relaxation member 4 are brazed to the metal layer 7, whereas the side of the plate-like body 10 on which the projections 11 are not formed is brazed to the heat sink 5. This heat radiator 1 is low in material cost and exhibits excellent heat radiation performance.

Owner:TOYOTA IND CORP +1

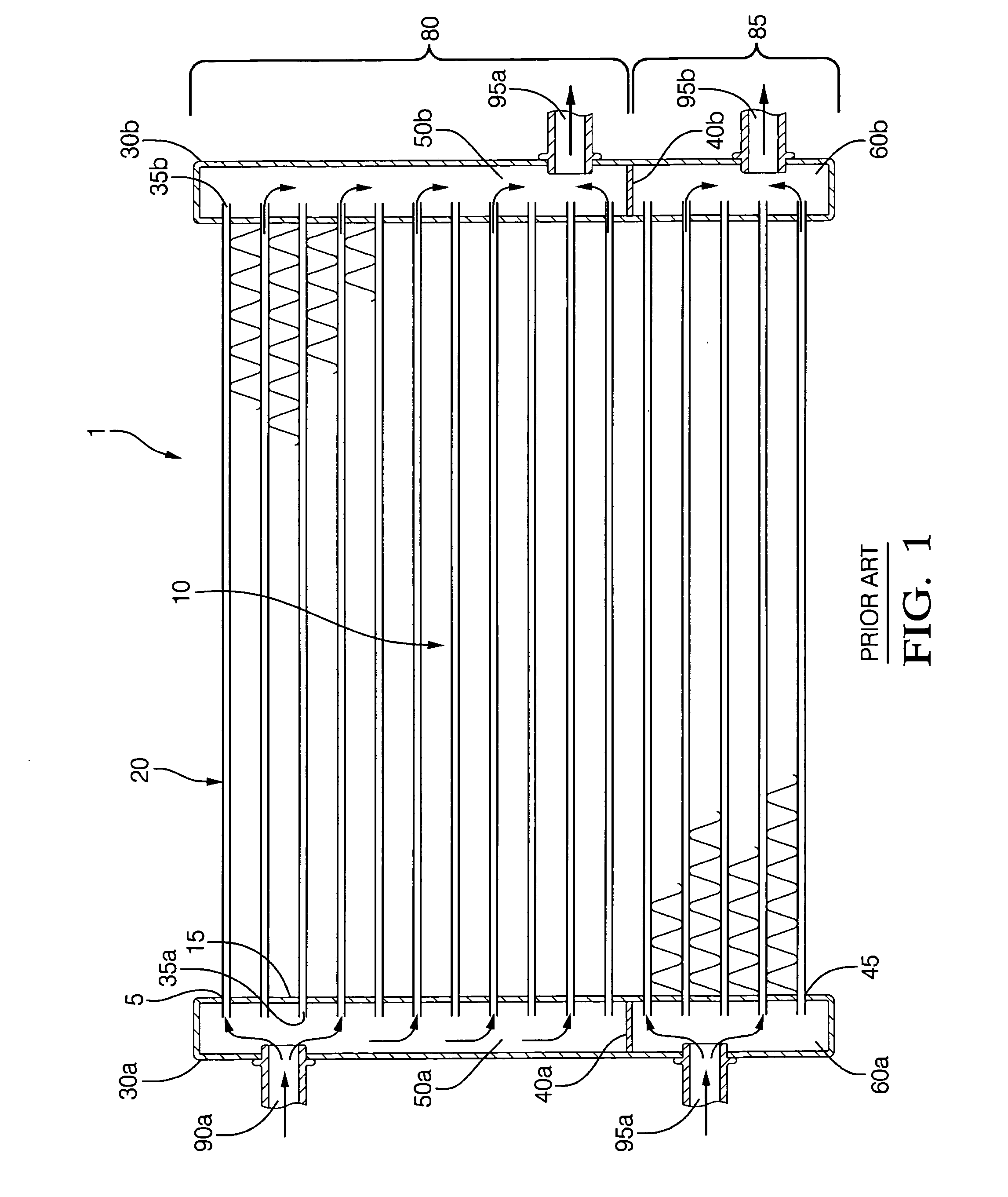

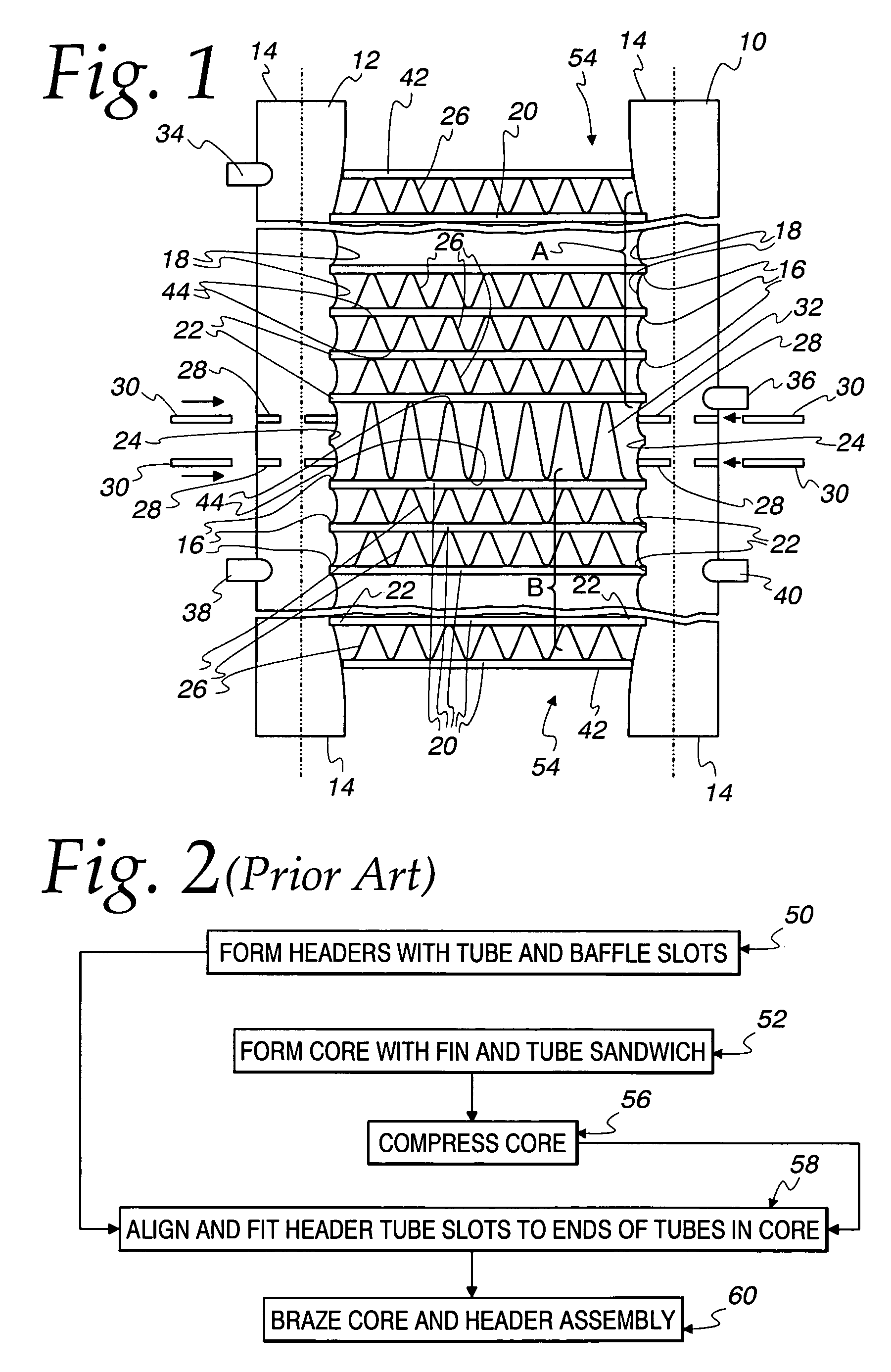

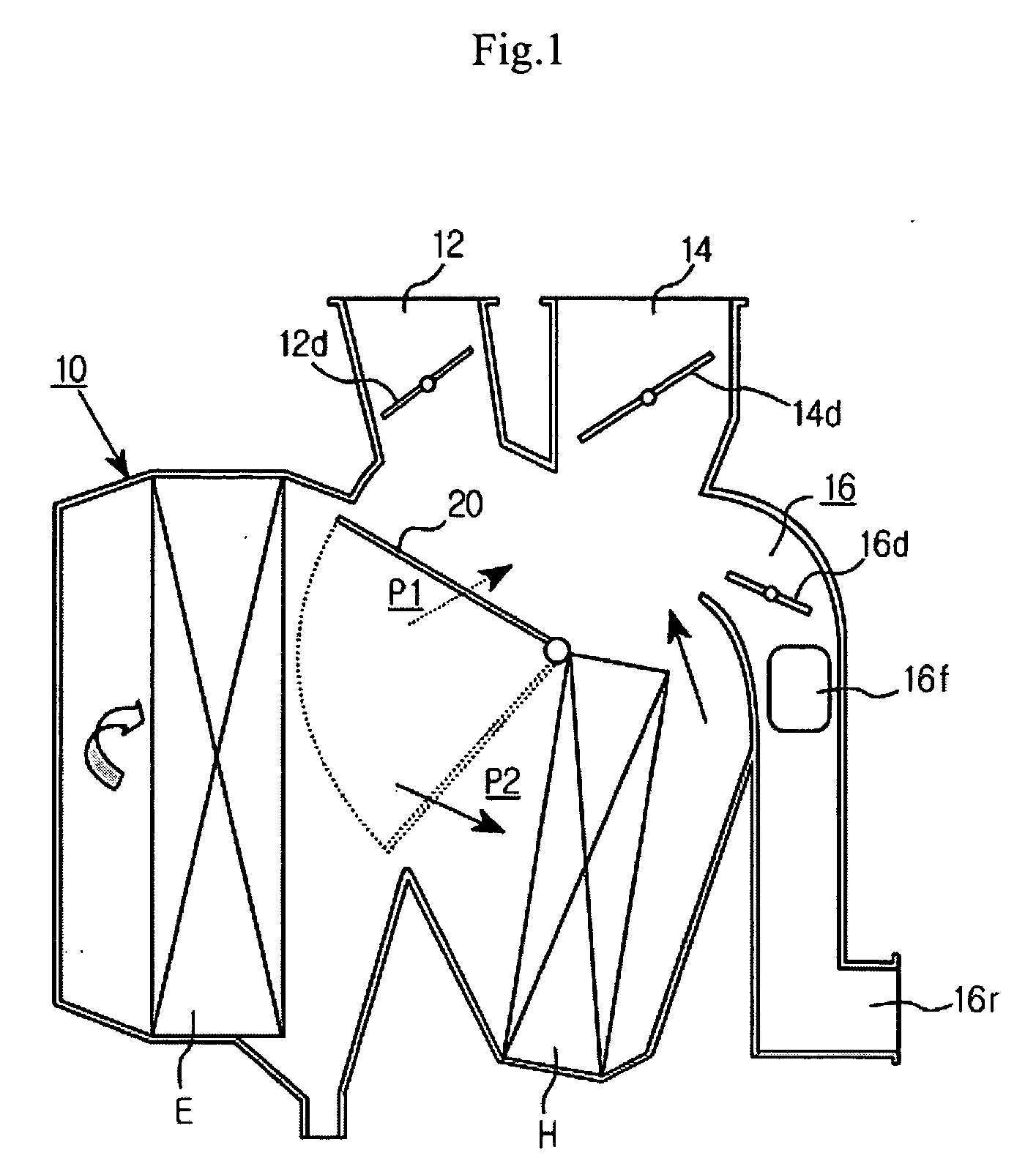

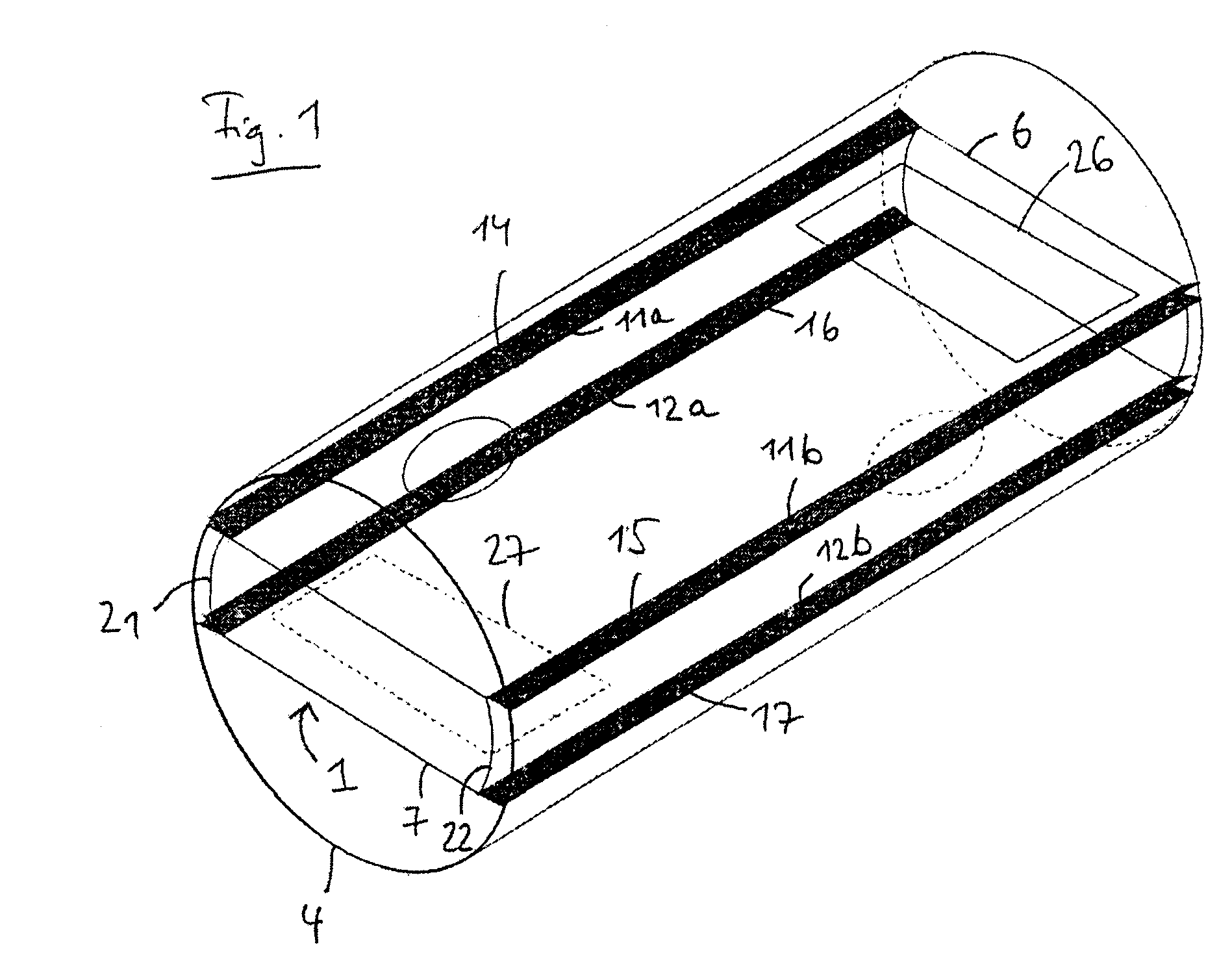

Multi-fluid heat exchanger and method of making same

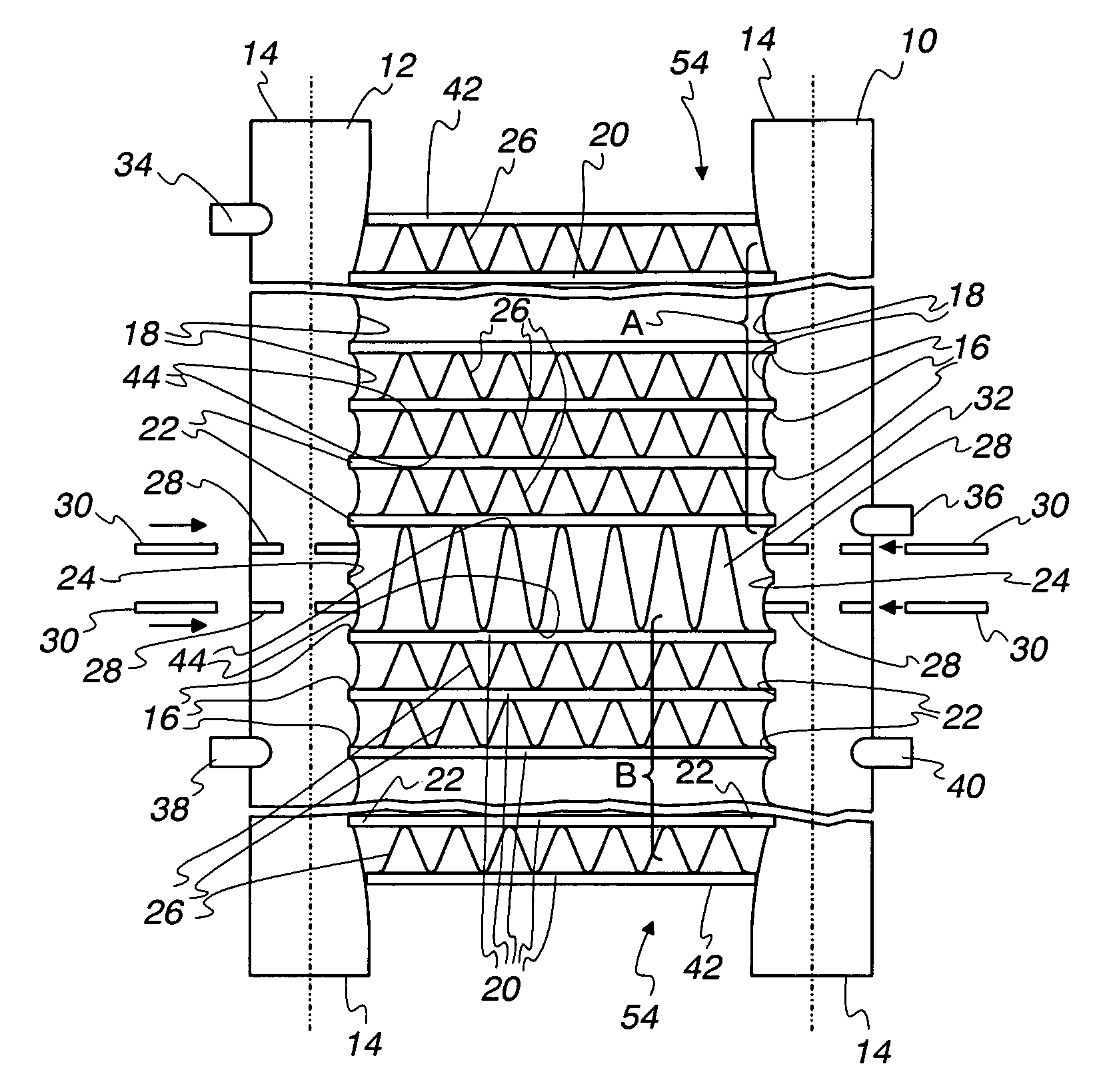

ActiveUS7096932B2Minimize the possibilityThermal insulationSafety devices for heat exchange apparatusPlate heat exchangerEngineering

A multi-fluid heat exchanger having separate fluid flow paths for two fluid streams to be heated or cooled by a third fluid stream includes first and second elongated, parallel tubular headers (10, 12), having opposed ends (14), generally uniformly spaced elongated tube slots (16) in each of the headers (10, 12) with the tube slots (16) in one header (10) facing-and aligned with the tube slots (16) and the other header (12), a plurality of flattened tubes (20) extending between the headers (10, 12) and having ends (22) received in aligned ones of the tube slots (16), one tube slot (24) in each header being unoccupied by any of the flattened tubes (20), the one tube slots (24) being aligned with each other and located at a predetermined location between the ends (14) of the headers (10, 12) and between two groups (A, B) of the flattened tubes (20) so there are two groups of the flattened tubes (20) on each side of the one tube slot (24), a pair of baffles (30) in each header (10, 12) with one on each side of the one tube slot (24) and fins (26, 32) extend between and are in heat transfer relation with at least the adjacent tubes (20) in each of the groups (A, B).

Owner:MODINE MFG CO

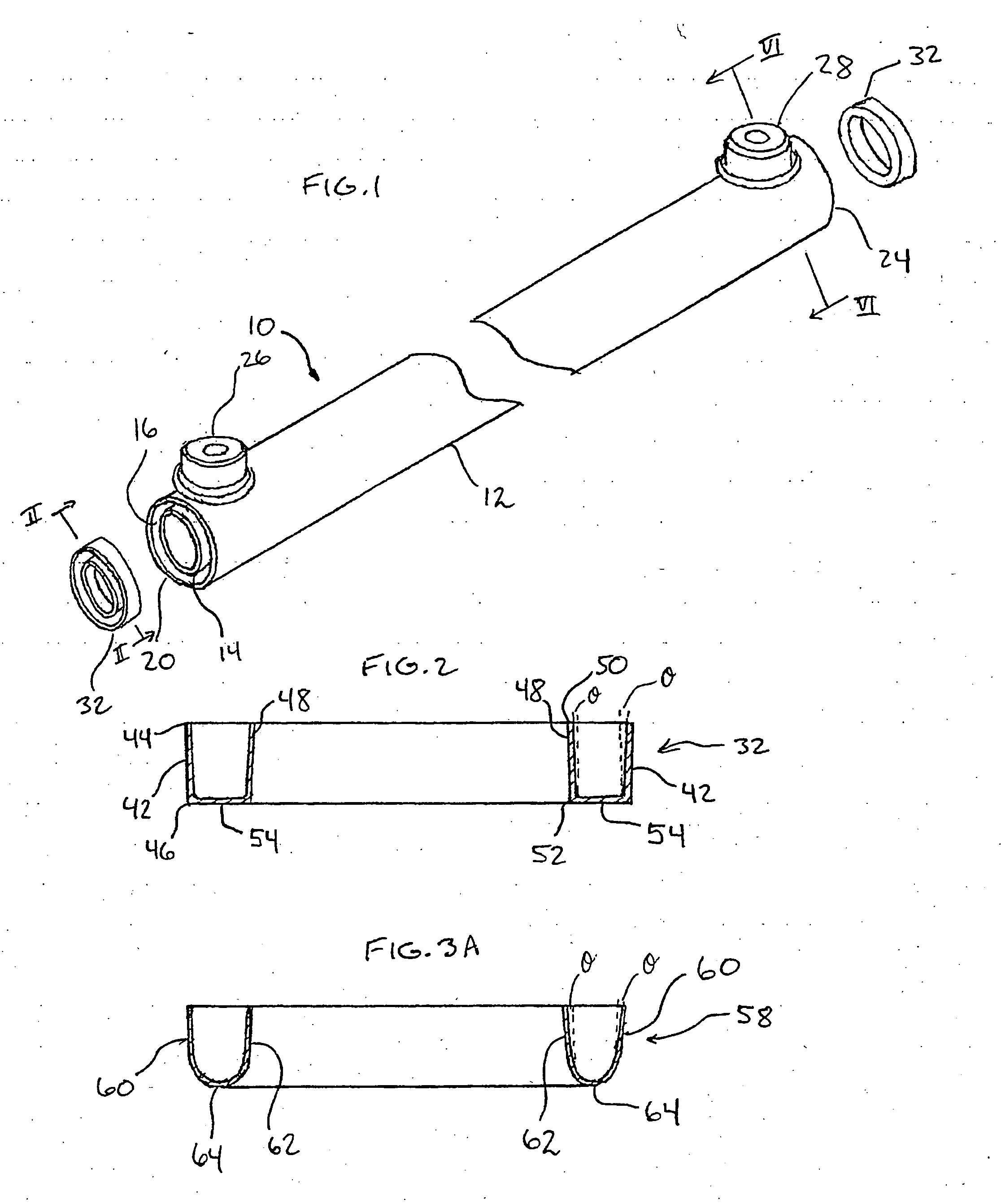

Heat exchanger assembly utilizing grommets and integral cast tanks

InactiveUS6330747B1Easy to manufactureEasy to assembleValve arrangementsInternal combustion piston enginesEngineeringGrommet

A heat exchanger comprises an as-cast combined header and tank having a header portion integral with a tank portion. The cast header and tank combination has a plurality of openings originally cast in the header portion of the combination and at least one opening originally cast in the tank portion of the combination for passage of coolant into or out of the cast header and tank combination. Tubes are received in and extends through the header portion openings, and resilient grommets seal the tubes to the header portion to prevent leakage around the tubes. In making the heat exchanger, there is provided an inner mold section and outer mold section corresponding respectively to the interior and exterior configurations of a desired combined header and tank having a header portion integral with a tank portion. The inner mold and outer mold sections are connected through the header and tank portion openings to support the inner mold section within the outer mold section and create a space therebetween corresponding to the configuration of the combined header and tank. The space is filled with molten metal and solidified to create the combined cast header and tank having the header portion integral with a tank portion. The outer mold section is removed and the inner mold section is removed from inside the cast header and tank through an opening in the header portion and / or through an opening in the tank portion. Following removal of the mold portions, the method may include inserting a tube from a heat exchanger core into an opening in the cast header portion and securing the tube therein.

Owner:VISTA PRO AUTOMOTIVE

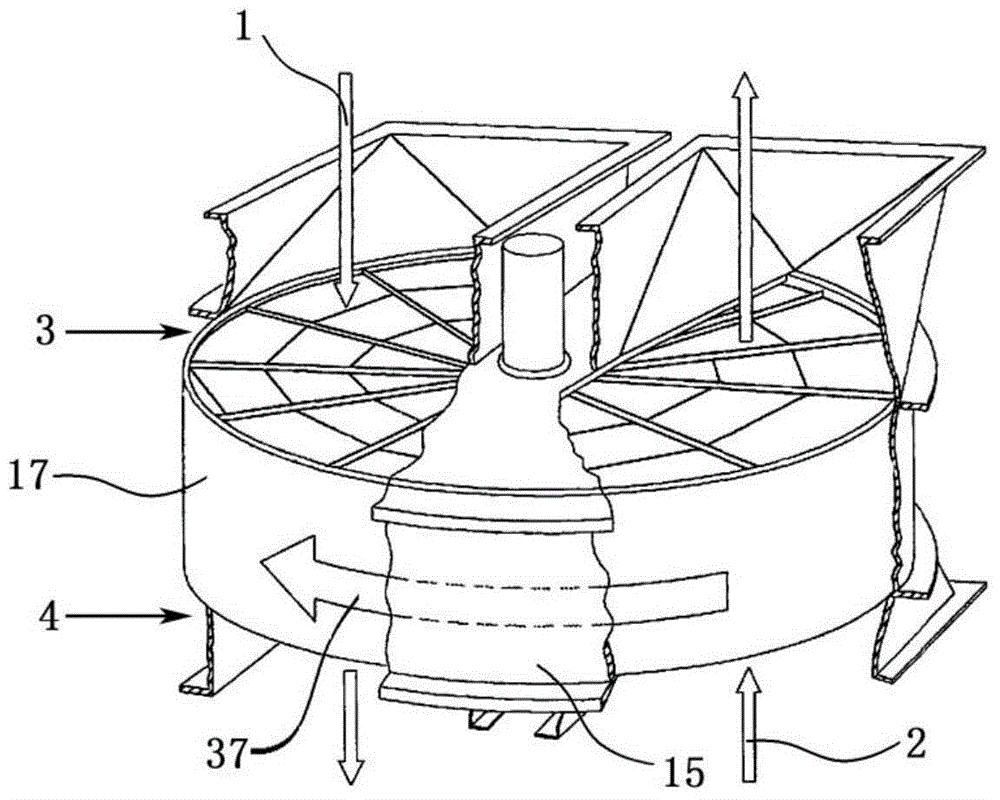

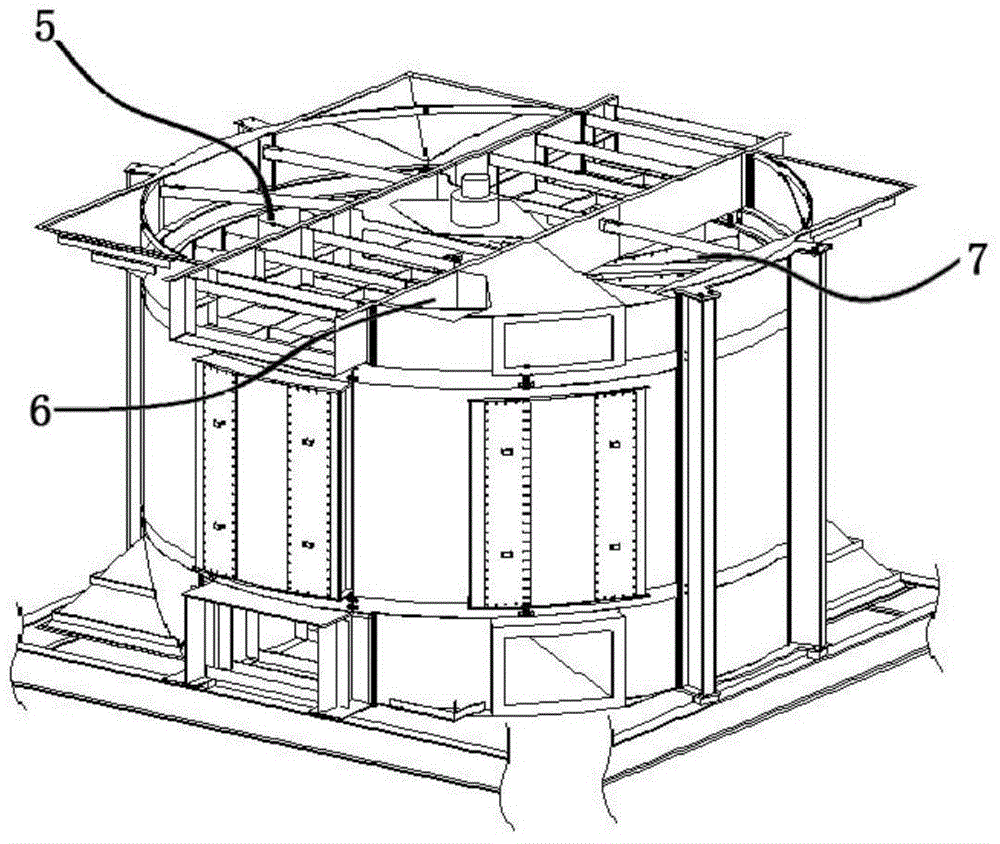

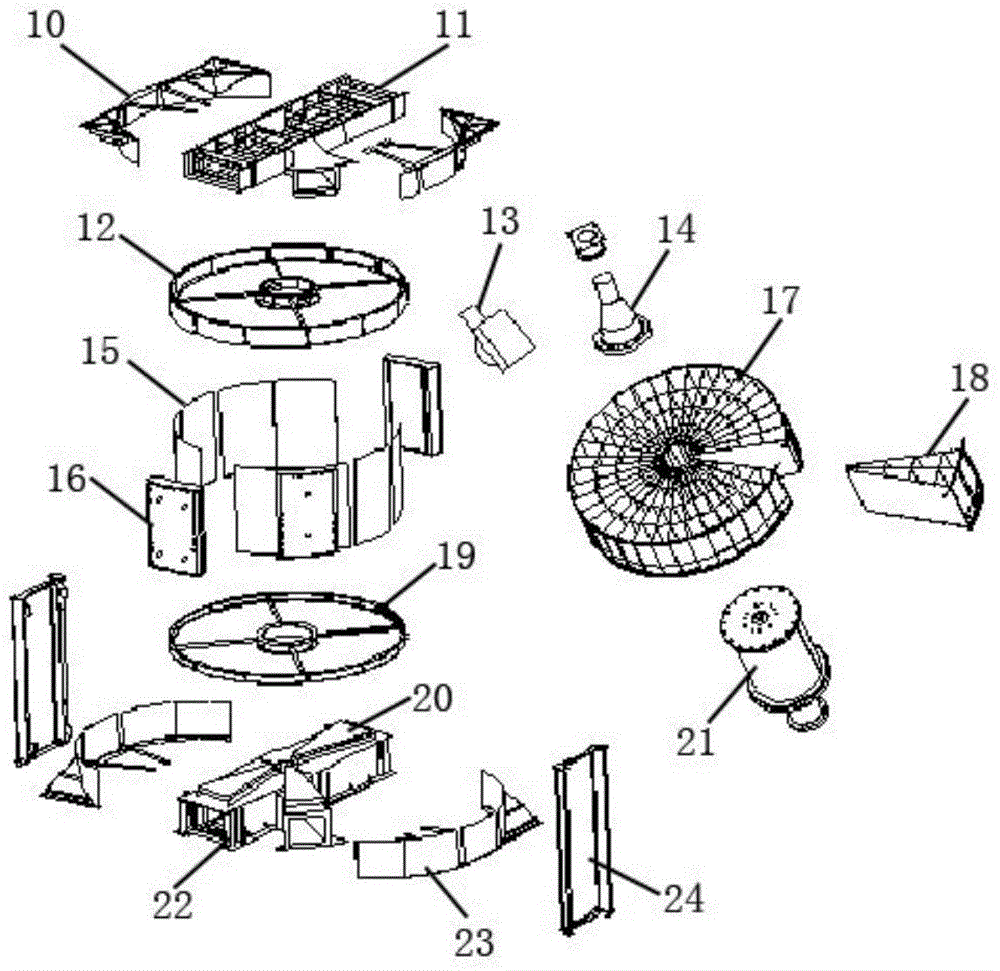

Rotary air preheater dust-blocking-prevention synergy sealing method and system

ActiveCN104949149AExtend your lifeEasy to implementCombustion processHeat exhanger sealing arrangementAir preheaterLiquid state

The invention discloses a rotary air preheater dust-blocking-prevention synergy sealing method and system. The dust-blocking-prevention synergy sealing method includes the steps that air leaked from the heat end is guided or extracted to the cold end from the heat end, and local heat exchange elements are purged and heated. The rotary air preheater dust-blocking-prevention synergy sealing system comprises a heat end primary air / smoke side sector sealing box, a heat end primary air / secondary air side sector sealing box and a cold end secondary air / smoke side sector sealing box, and further comprises a heat air leakage air flue; the heat end primary air / smoke side sector sealing box and the heat end primary air / secondary air side sector sealing box are each provided with an air inlet, one end of the heat air leakage air flue is in butt joint with the air inlets, and the other end of the heat air leakage air flue extends to a cold end secondary air highest-temperature module. By means of the rotary air preheater dust-blocking-prevention synergy sealing method and system, H2SO4 drops and liquid state NH4HSO4 are gasified while the air leaked from a preheater is reduced, and the aim of removing accumulated dust is achieved; the rotary air preheater dust-blocking-prevention synergy sealing method and system have the advantages of reducing the boiler smoke discharging temperature, restraining the accumulated dust of the preheater, reducing the air leakage rate, prolonging the service life of the heat exchange elements and the like.

Owner:南京博沃科技发展有限公司

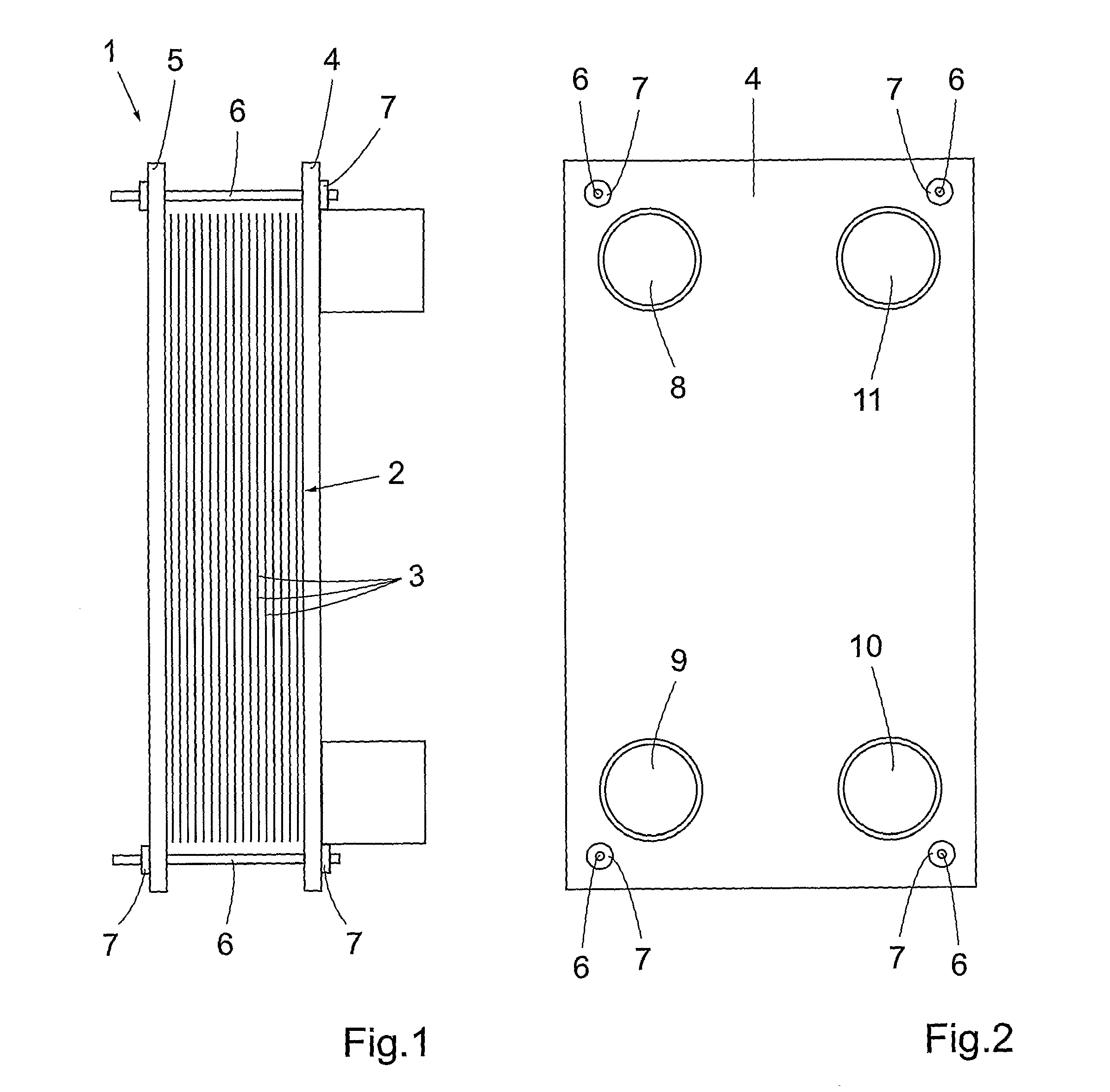

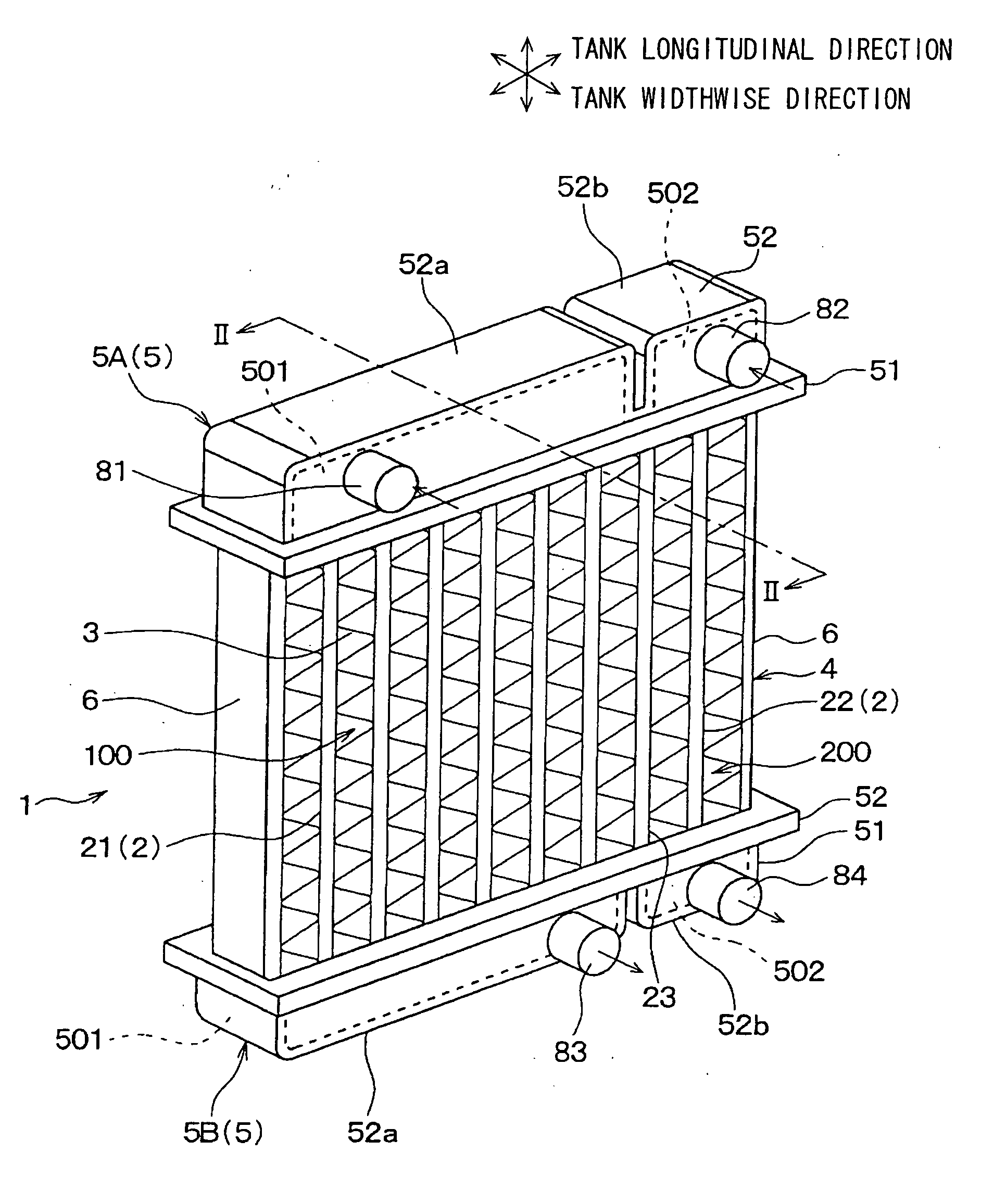

Heat exchanger

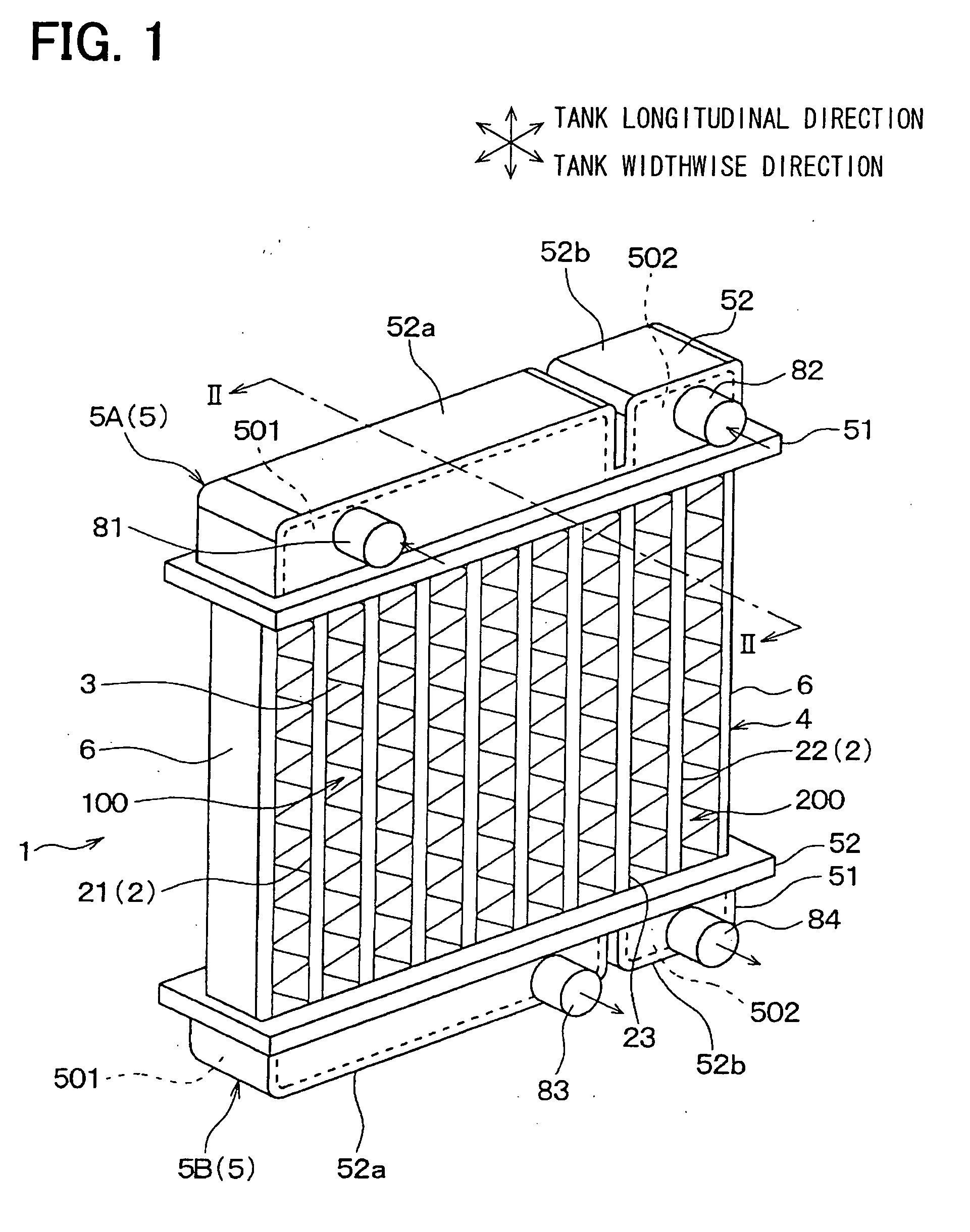

ActiveUS20110168372A1Uniform thicknessUniform thickness.InThermal insulationStationary conduit assembliesMechanical engineeringHeat exchanger

A heat exchanger has partitioning means for dividing a header tank such that a first space and a second space of a tank main body are arranged in a longitudinal direction of the header tank. An annular outer peripheral seal surface is provided around a tube bonding surface of a core plate of the header tank over an entire perimeter thereof and is provided with a gasket. A partitioning seal surface is provided to the tube bonding surface at a position corresponding to the partitioning means, and is provided with the gasket. The gasket seals between the core plate and the partitioning means. The partitioning seal surface is positioned on a plane identical with a plane of the outer peripheral seal surface. A part of the gasket, which is held by the core plate and the tank main body therebetween, has a uniform thickness.

Owner:DENSO CORP

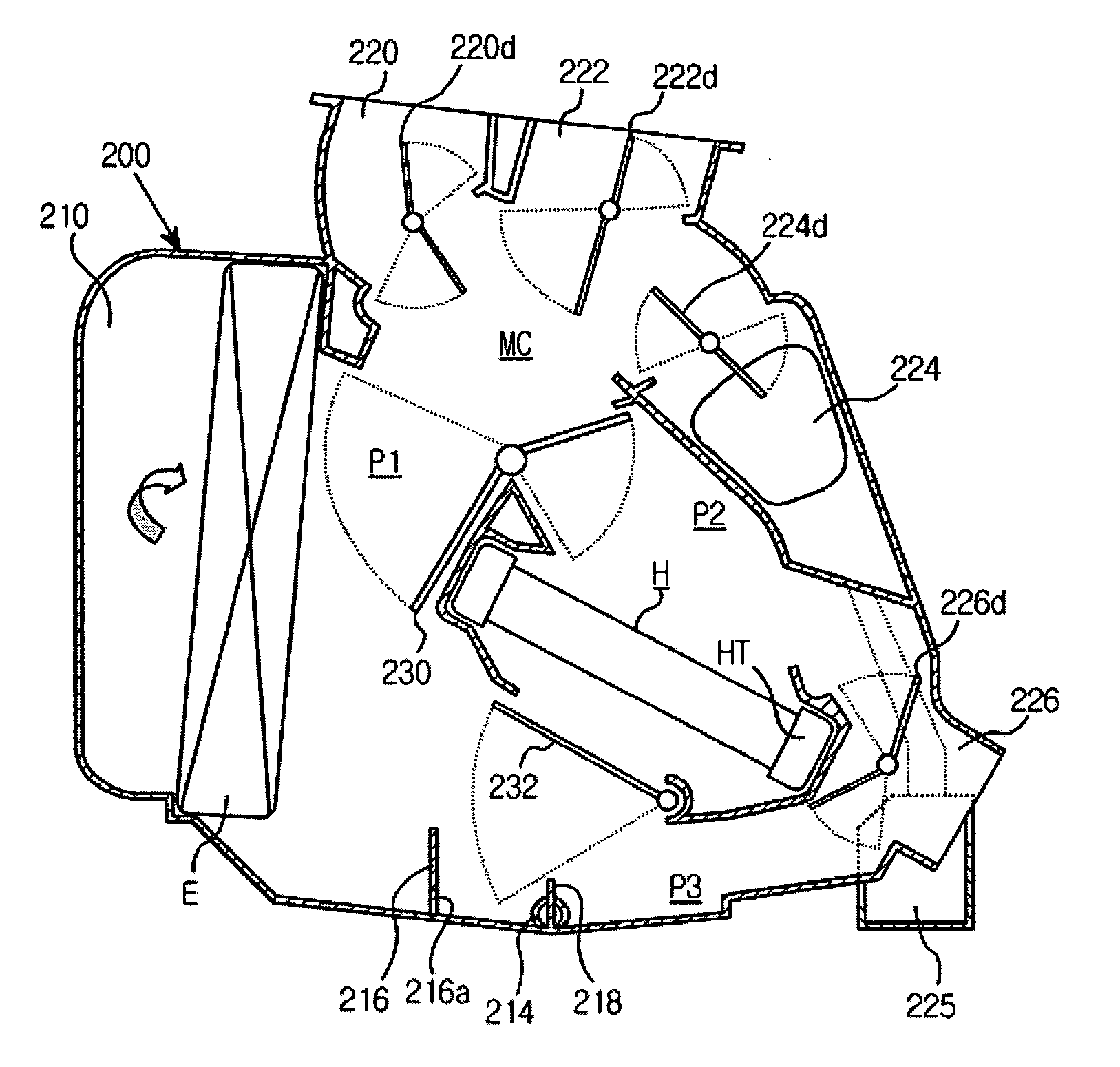

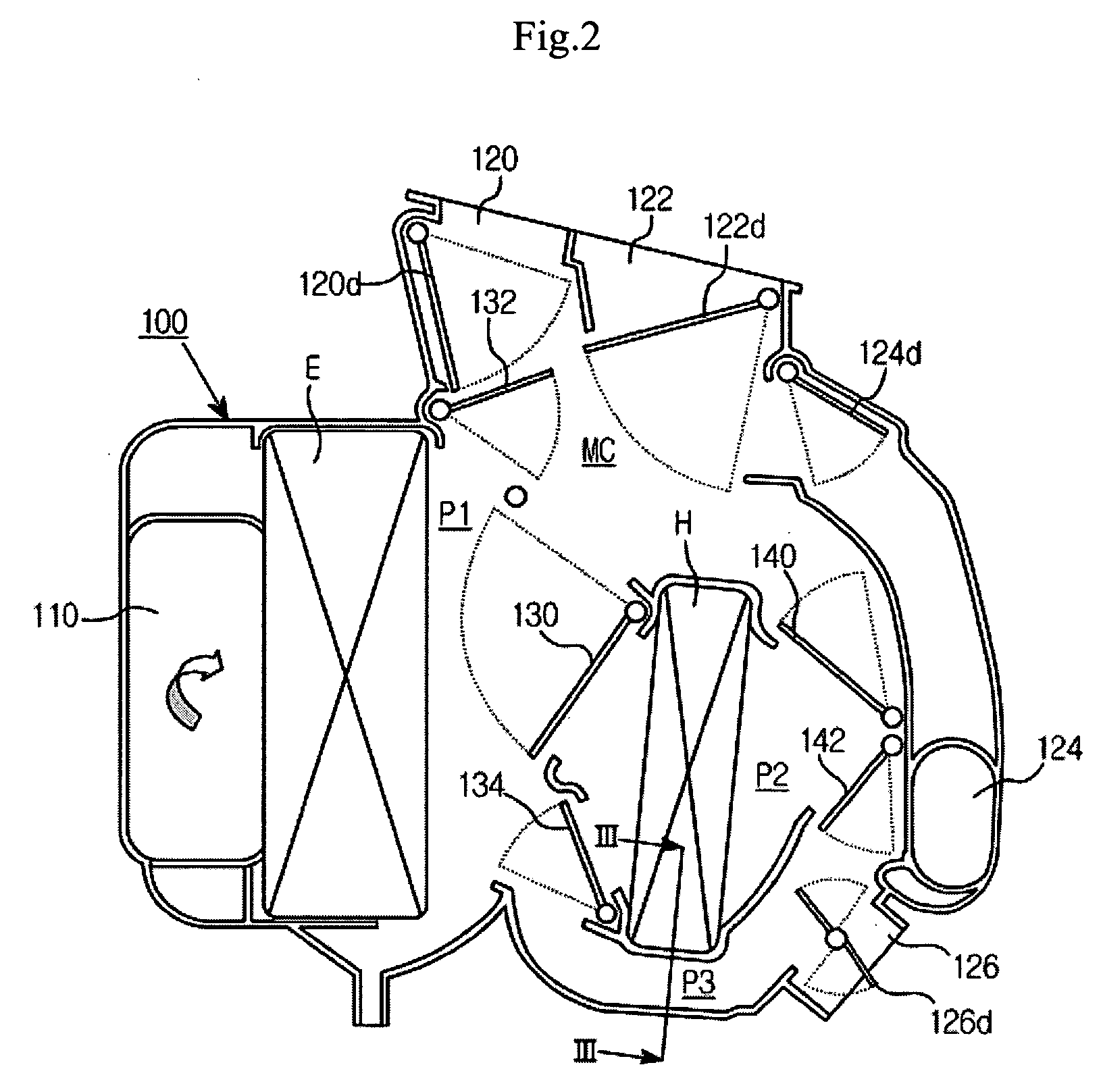

Air conditioner for vehicle

ActiveUS20060175050A1Effective preventionAir-treating devicesRailway heating/coolingCold airEngineering

A vehicle air conditioner casing has defrost, face, and front seat floor vents variably communicating with a mixing chamber. Air passageways in the casing include an evaporator and heater core. A rear seat console vent communicates with a warm air passageway including the heater core and a cool air passageway through a console side cool air bypass passageway on the casing bottom surface, under the heater core. A front seat temperature adjusting door adjusts variably opens cool air passageway outlets and the warm air passageway with respect to the mixing chamber. A rear seat main temperature adjusting door variably opens warm air passageway inlets and the console side cool air bypass passageway. A rear seat auxiliary temperature variably adjusts the openings of warm air passageway outlets and the console cool air bypass passageway with respect to the rear seat console vent.

Owner:HANON SYST

Heat exchanger housing and seals

A housing for a heat exchange apparatus including a fluid passageway partially defined by a baffle plate having an extended portion. The heat exchange apparatus further includes an array of fluid conduits extending through the fluid passageway. The housing includes a plurality of housing members each having a wall and at least one flange extending from the wall. The flanges of adjacent housing members are joined at a flange joint, and the flange joint is configured to fixedly receive the extended portion of the baffle plate. The apparatus also includes a plate member is provided within the fluid passageway and intumescent material fills a gap between the baffle plate and the plate member. Additionally, a second baffle plate is provided that defines a portion of a second fluid passageway, where a refractory gasket and a layer of intumescent material are provided between the first and second baffle plates.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Heat exchanger maintenance technique

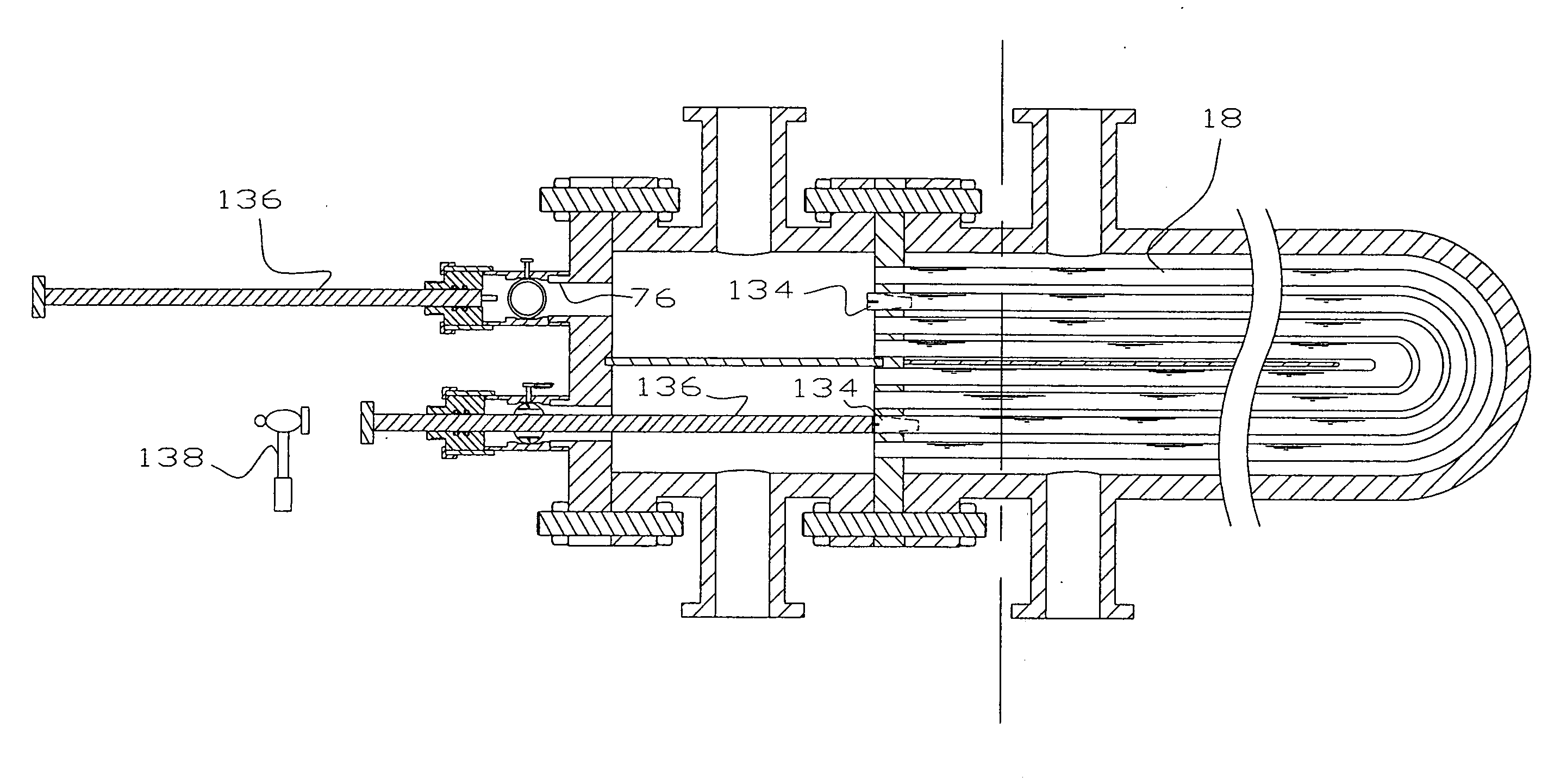

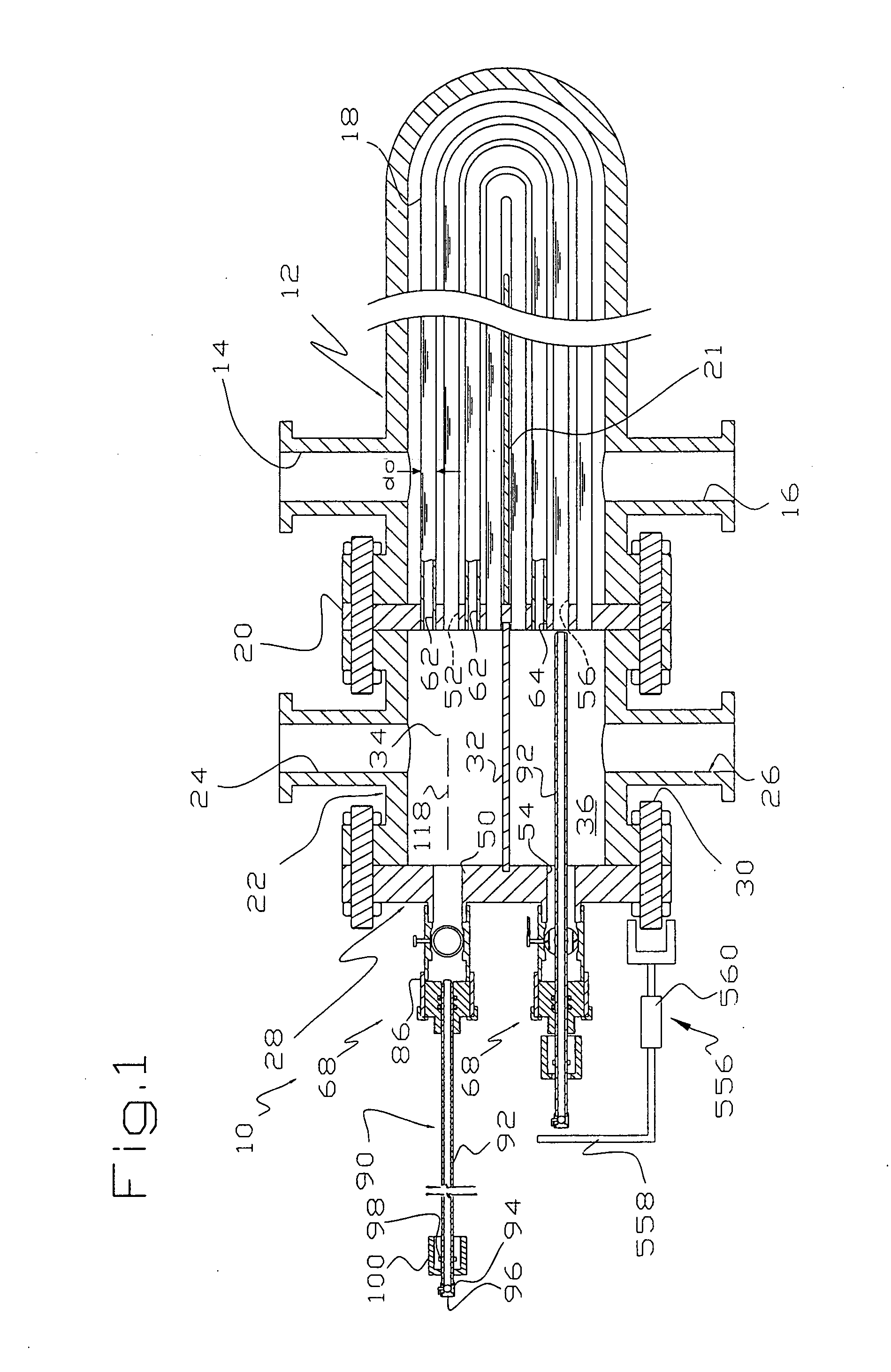

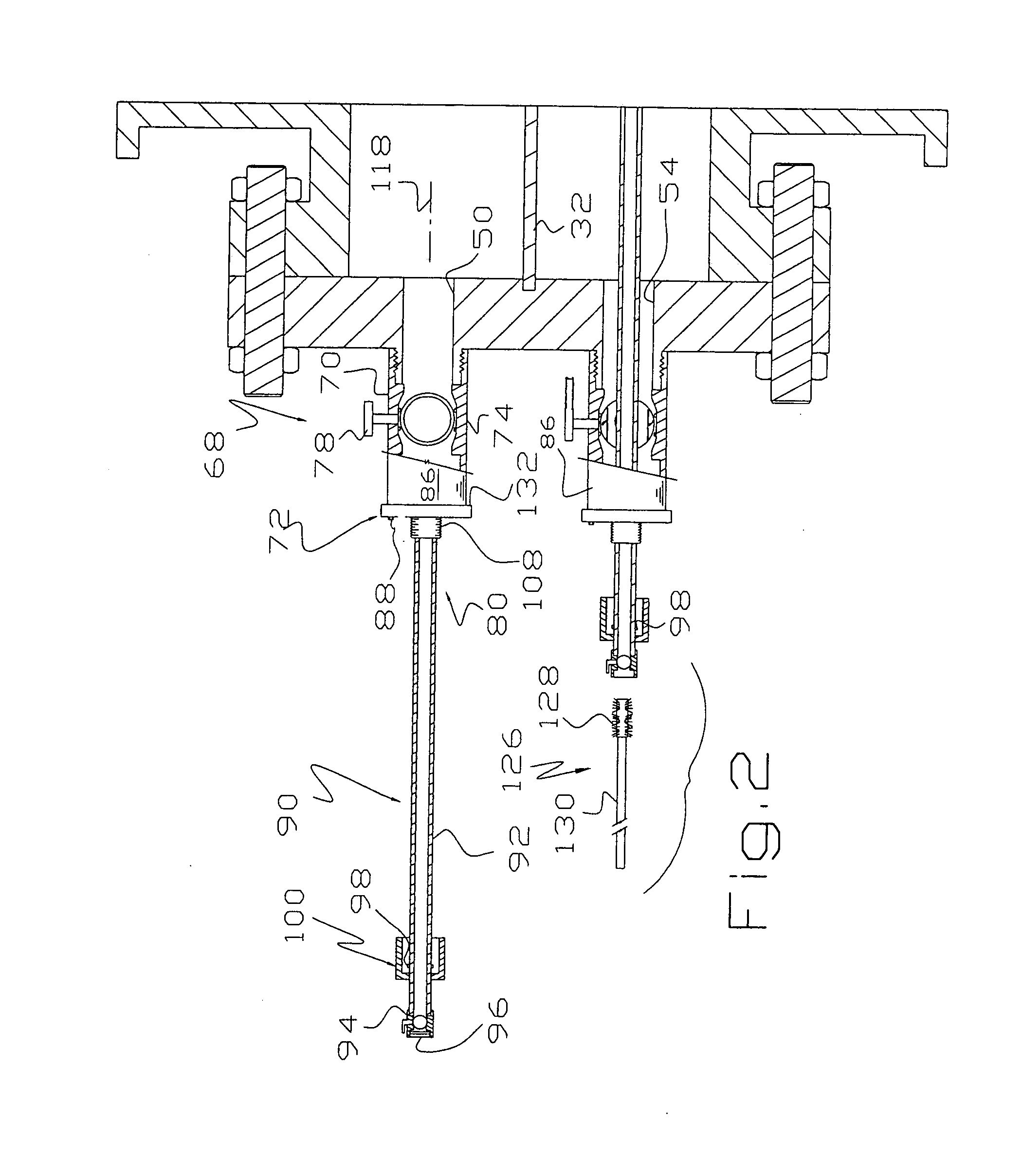

ActiveUS20110247786A1Large capacityMetal-working apparatusHeat exhanger sealing arrangementEngineeringMicro heat exchanger

A heat exchanger is cleaned, inspected and / or plugged while the heat exchange is in operation. In some embodiments, the heat exchanger comprises a channel cover having valve-seal assemblies allowing isolation tools to be inserted through the channel cover into sealing engagement with the ends of tubes to provide a flow path separate from the normal flow paths through the heat exchanger. Cleaning and / or inspecting can be done through the isolation tools and tubes that are leaking can be plugged through the valve-seal assemblies. In some embodiments, brushes are located inside the heat exchanger and can be independently advanced into cleaning relation with a large majority of the tubes.

Owner:DIXON CHRISTOPHER J +2

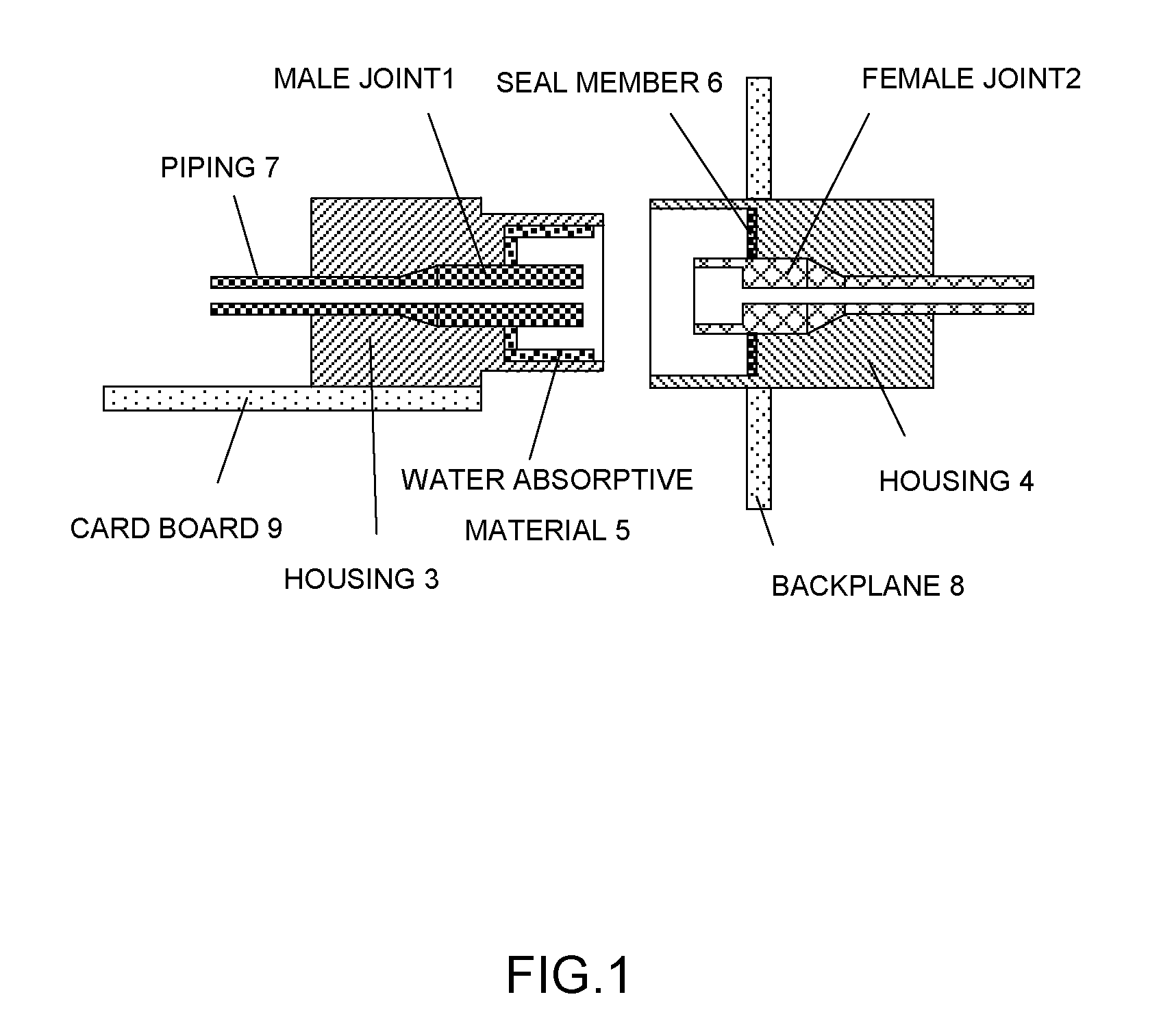

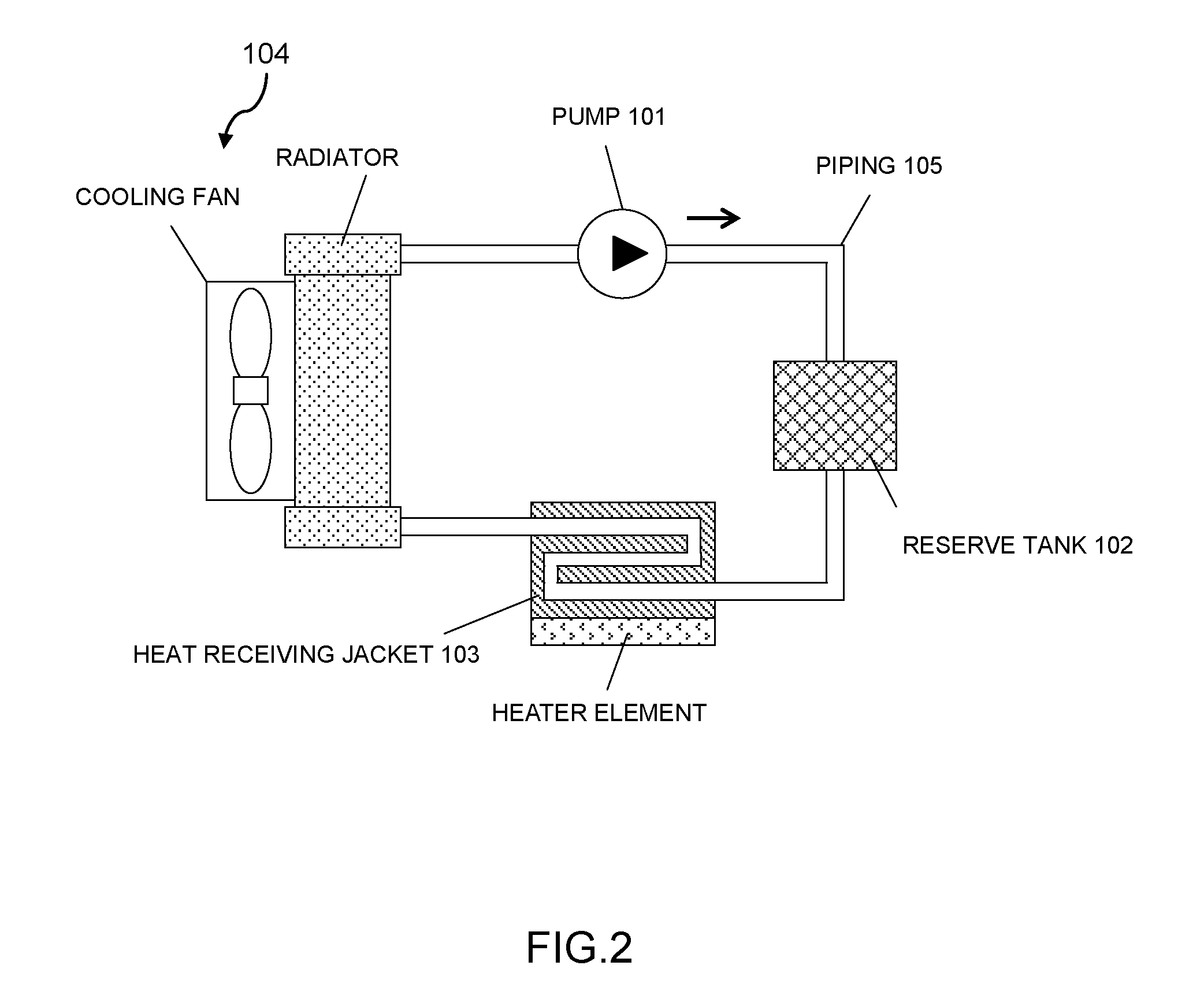

Liquid leakage prevention device, liquid leakage prevention method, and liquid cooling system

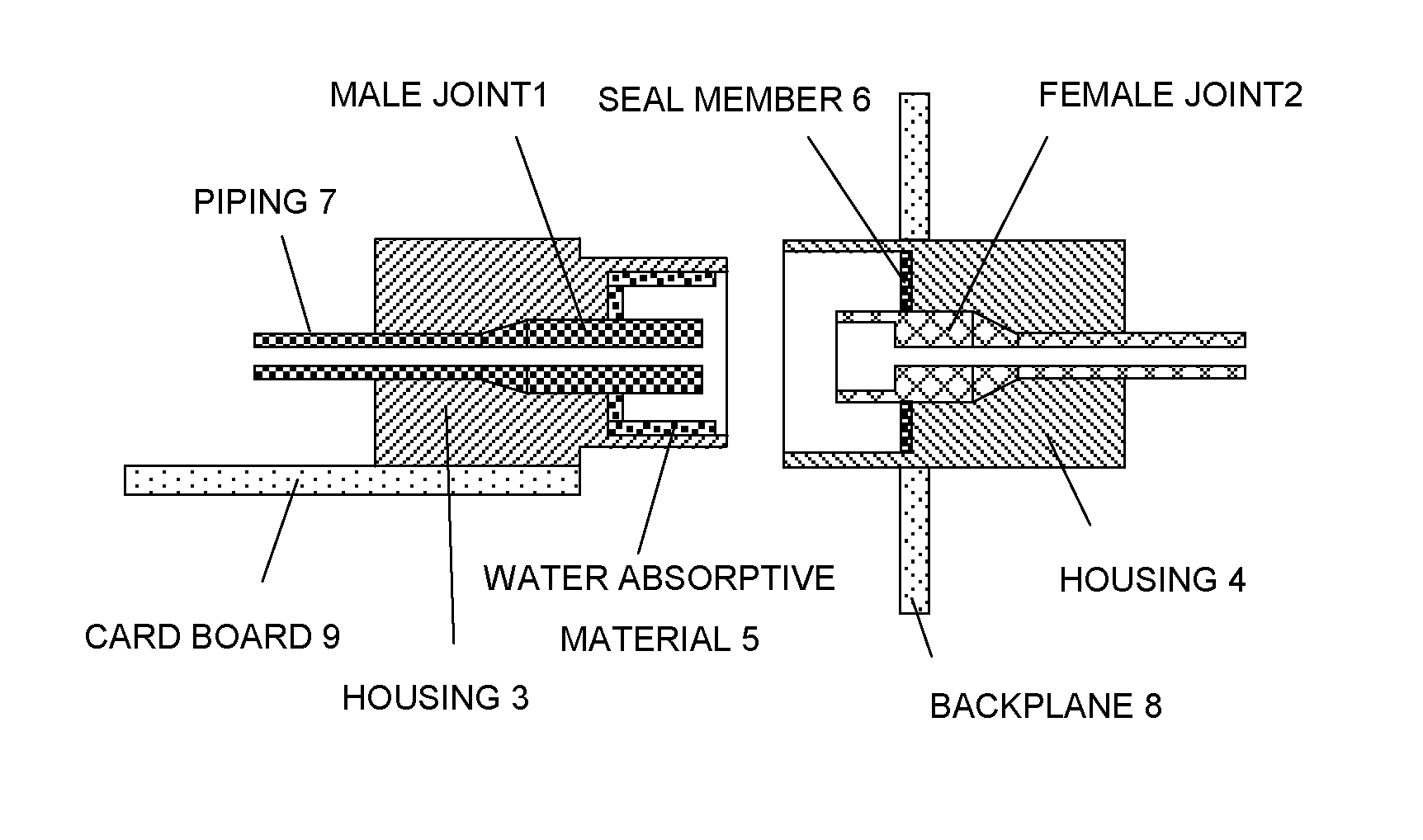

InactiveUS20130277008A1Pipe couplingsSemiconductor/solid-state device detailsLiquid cooling systemEngineering

In a liquid cooling system having a structure in which a joint is attached or detached while inserting or removing a card board, when a liquid is leaked from a connection portion of the joint, the leaked liquid confined within a housing is prevented from spilling out and scattering to surrounding electronic components when the card board is disconnected. The liquid cooling system includes male and female joints, and housings that fix those joints to each other. A water absorptive material is disposed on an inner wall of the housing of the male joint, and a seal member is disposed on an inner wall of the housing of the female joint. The liquid cooling system includes a liquid leakage detection function. When the liquid cooling system detects the liquid leakage, the liquid cooling system stops the operation of a pump, and prevents the liquid from being further leaked.

Owner:HITACHI LTD

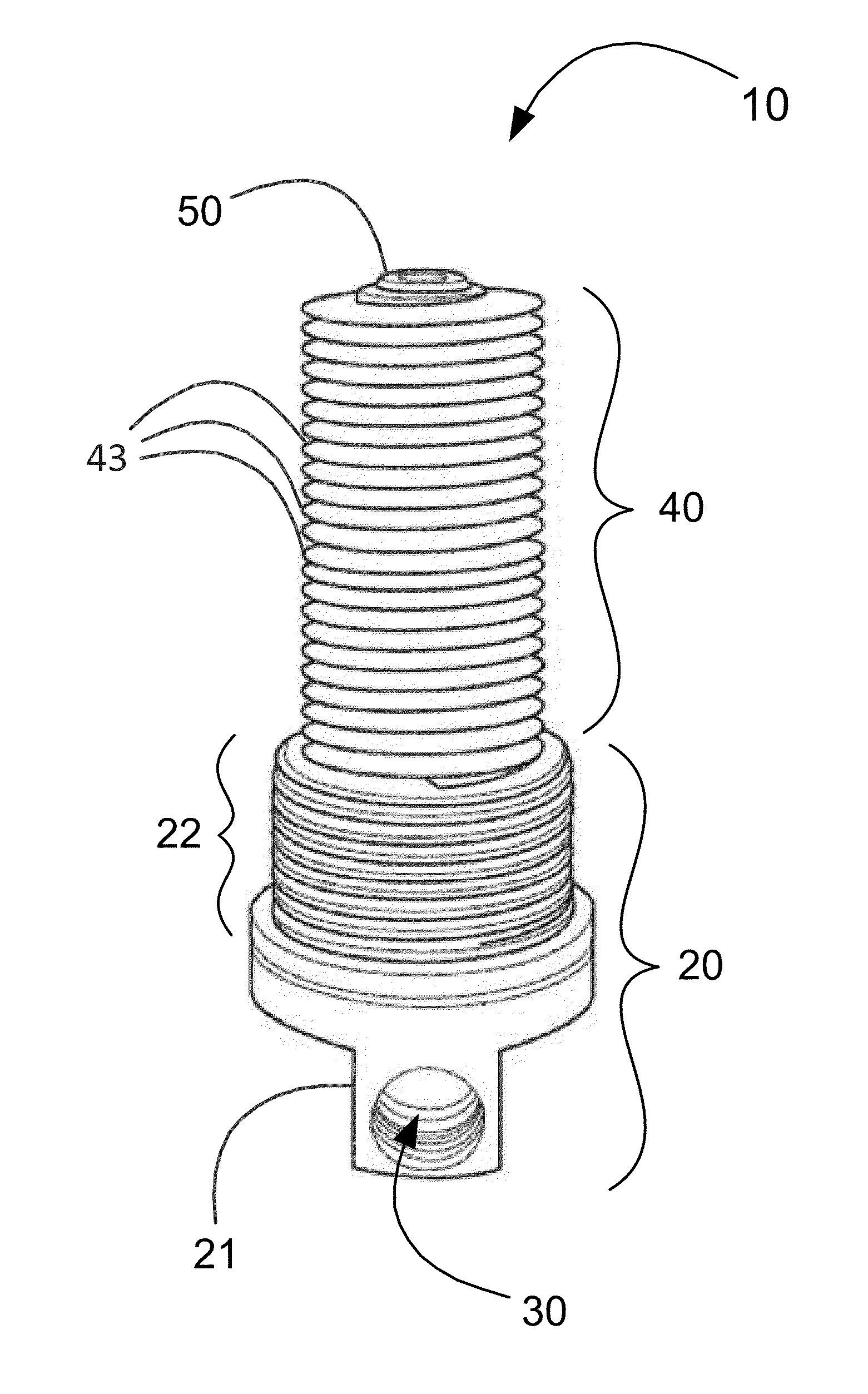

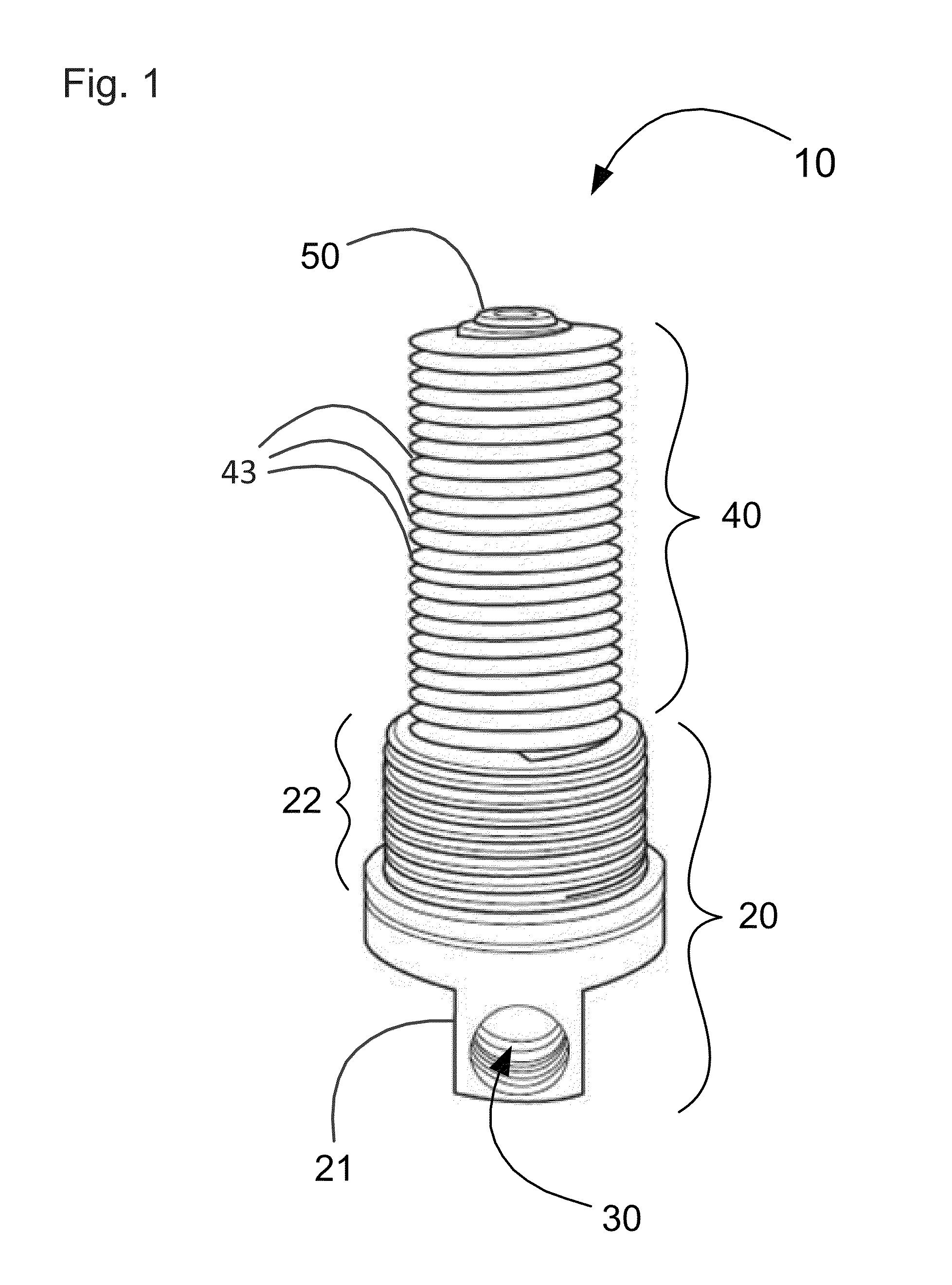

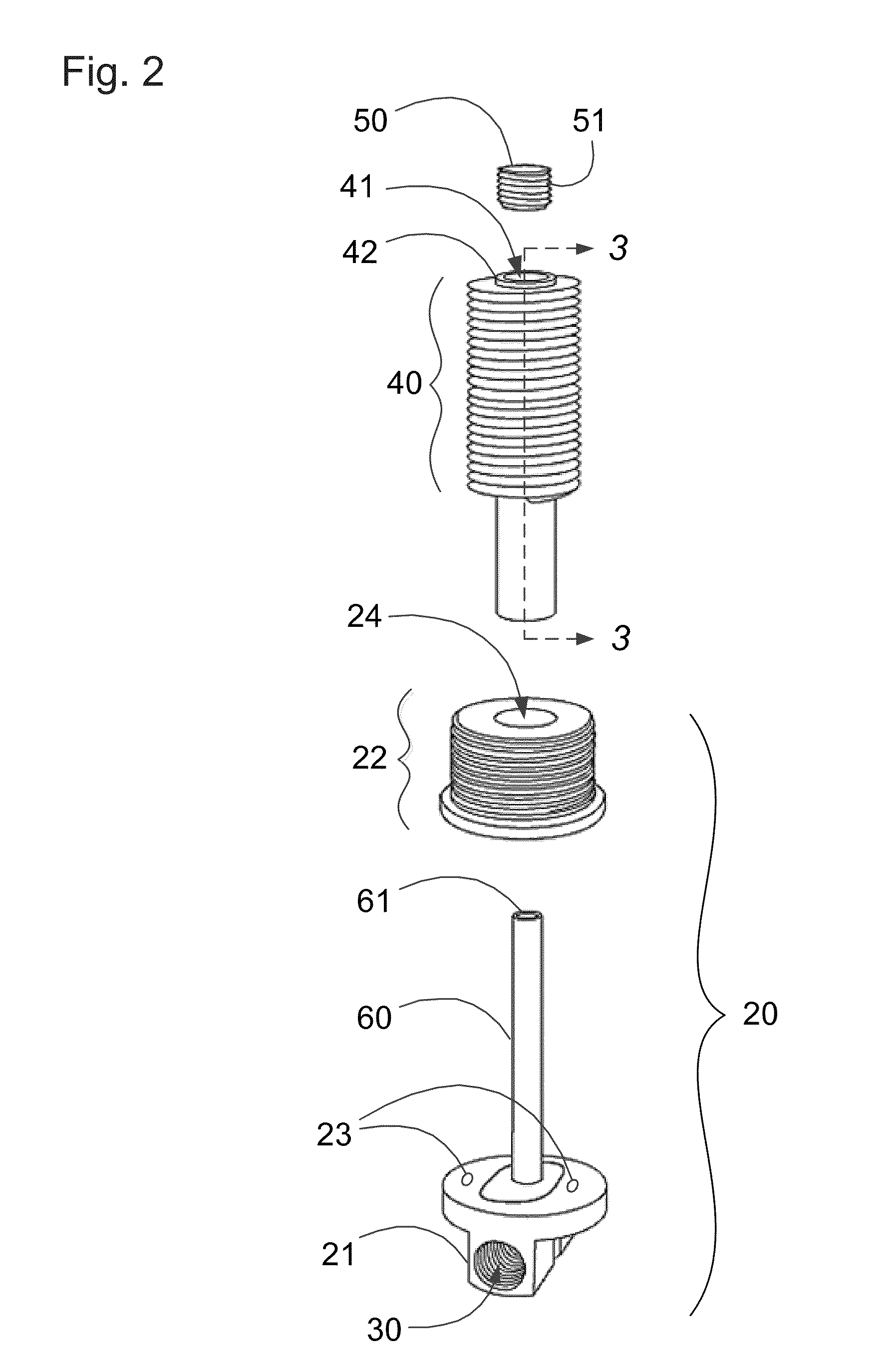

Elastomeric gasket in gasket well of heat exchanger

InactiveUS7156401B2Accurate locationEngine sealsStationary conduit assembliesPlate heat exchangerEngineering

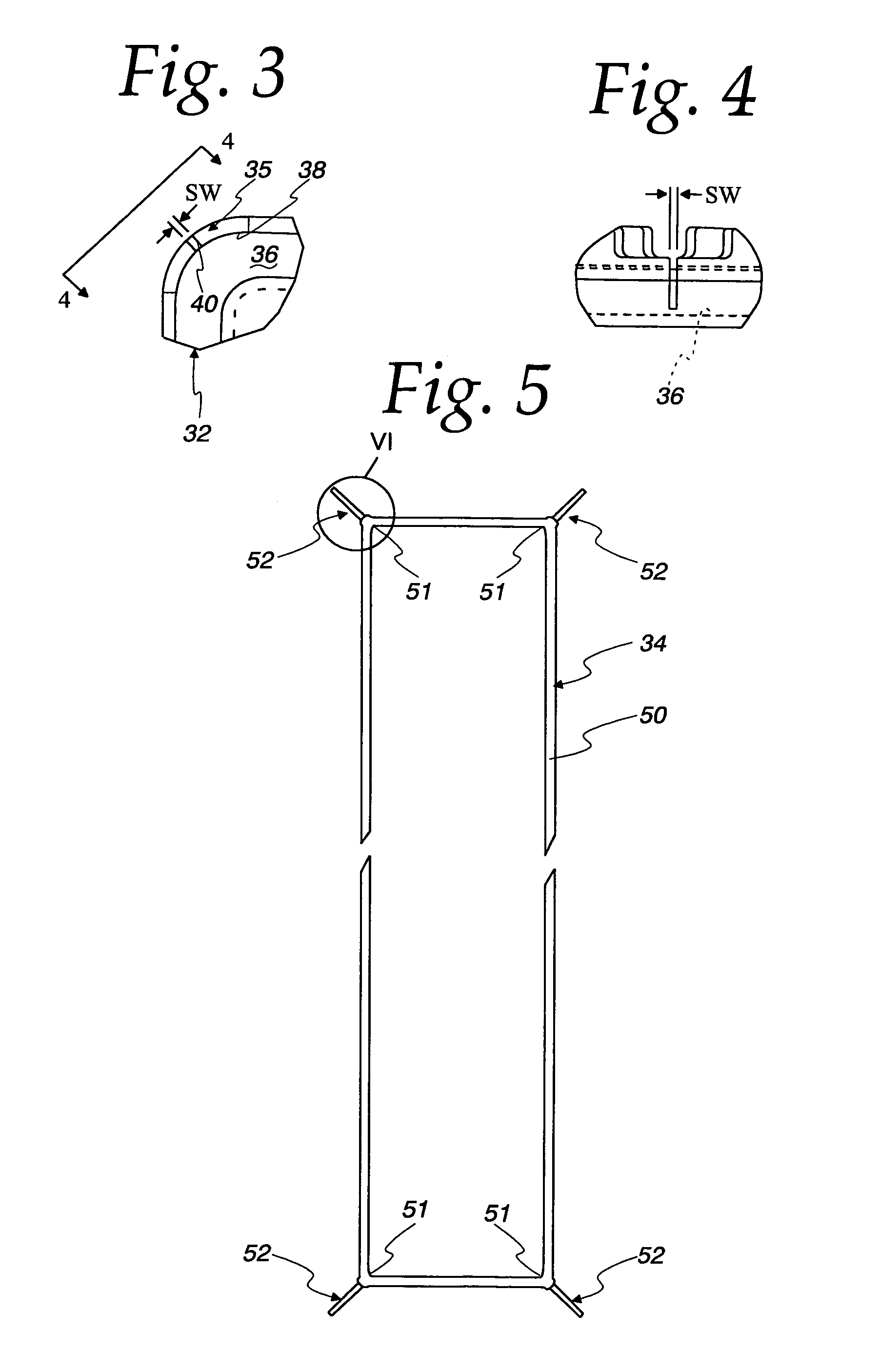

A gasket well / gasket combination (30) is provided, and may be particularly useful for use in a header / tank assembly (12) for a heat exchanger (10). The combination (30) includes a gasket well (32) defined by a base wall (36) and a side wall (38) extending upwardly from the base wall (36), with the side wall (38) including an upwardly opening slot (40) having a width (SW). The combination further includes an elastomeric gasket (34) shaped to be received in the gasket well (32) and compressed between the base wall (36) and a mating part to form a sealed connection. The gasket (34) includes a seal bead (50) and a locating feature (52) having a tab (62) extending outwardly from the seal bead (50) to a terminal end (64) of the tab (62), with the tab (62) having a transverse width that does not increase from the seal bead (50) to the terminal end (64). The transverse width is larger than the slot width (SW) with the tab (62) in an undeformed state. The gasket (34) is receivable in the gasket well (32) with the tab (62) pinched in the slot (40) across the transverse width to retain the gasket (34) in the gasket well (32).

Owner:MODINE MFG CO

Vehicular fluid heater

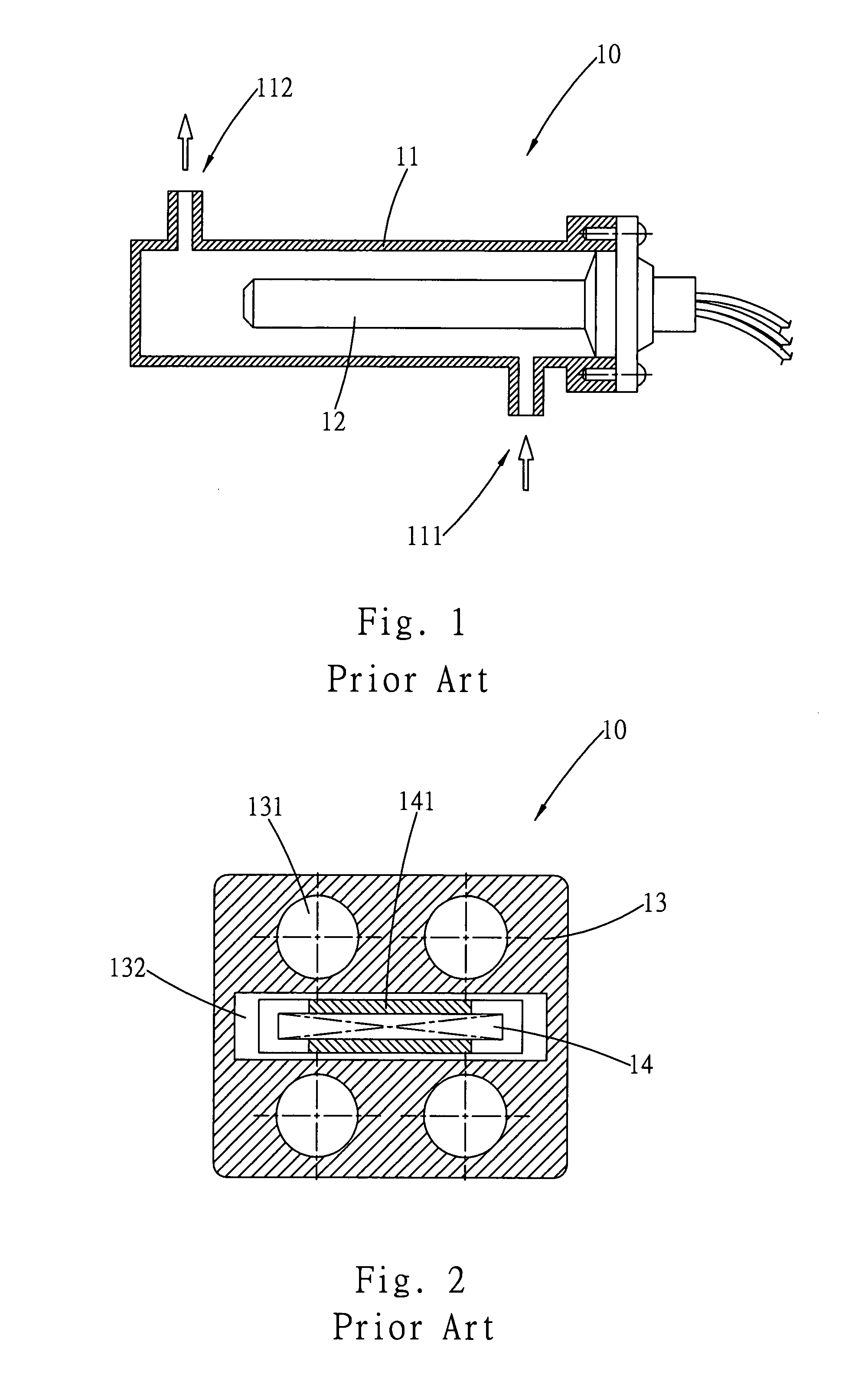

InactiveUS20110062137A1Good benefitImprove effectivenessDomestic stoves or rangesIndirect heat exchangersViscous liquidEngineering

A vehicular fluid heater is used to heat fluid for defrosting or cleaning a windshield, a head lamp, etc., and viscous fluid such as hydraulic oil, lubrication oil, etc. to reduce viscosity and improve performance, particularly during a cold condition. The heater is constructed by a plurality of laminated heating composites joined to heat conduction surfaces of a heat exchange vessel, which facilitates ease of production, maintenance, and heating power selection. A fluid field is defined by fluid pathways formed by a structural design that assembles the heat exchange vessel, and a front and a back seal panels disposed on the heat exchanger.

Owner:WU CHIA HSIUNG

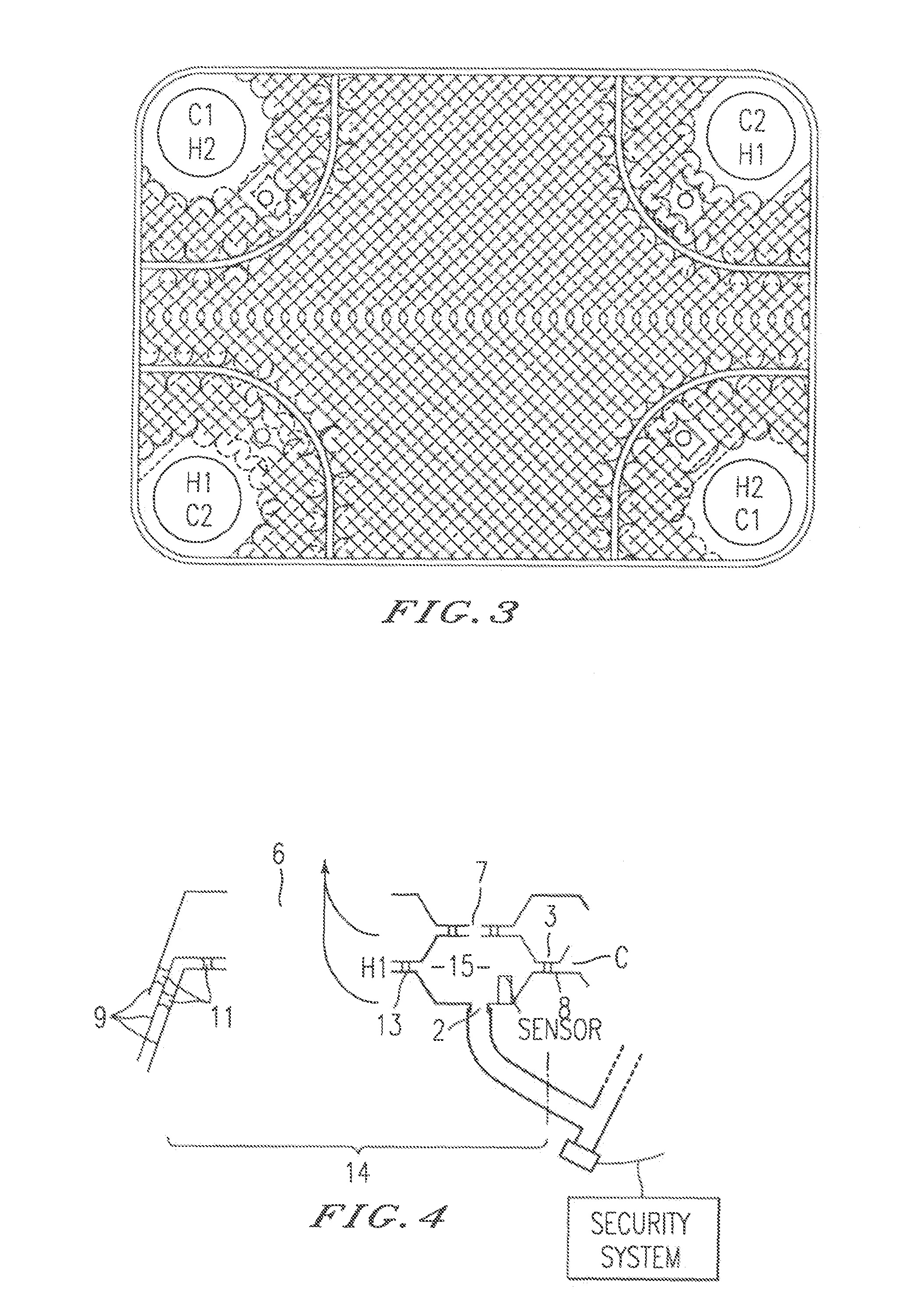

Double-walled plate heat exchanger

InactiveUS20100300651A1Avoid cross contaminationSafety devices for heat exchange apparatusHeat exhanger sealing arrangementPlate heat exchangerNuclear engineering

A double-walled plate heat exchanger and method of managing the same includes a first plate including a first skin, a second skin, at least two port holes, and a leakage escape path between the first and second skins for allowing leaked fluid to exit the double-walled plate heat exchanger, the leakage escape path being in contact with a leakage orifice in one of the skins, and an outer edge of the double-walled plate heat exchanger, the first plate further including a second plate in contact with the second skin.

Owner:APV NORTH AMERICA

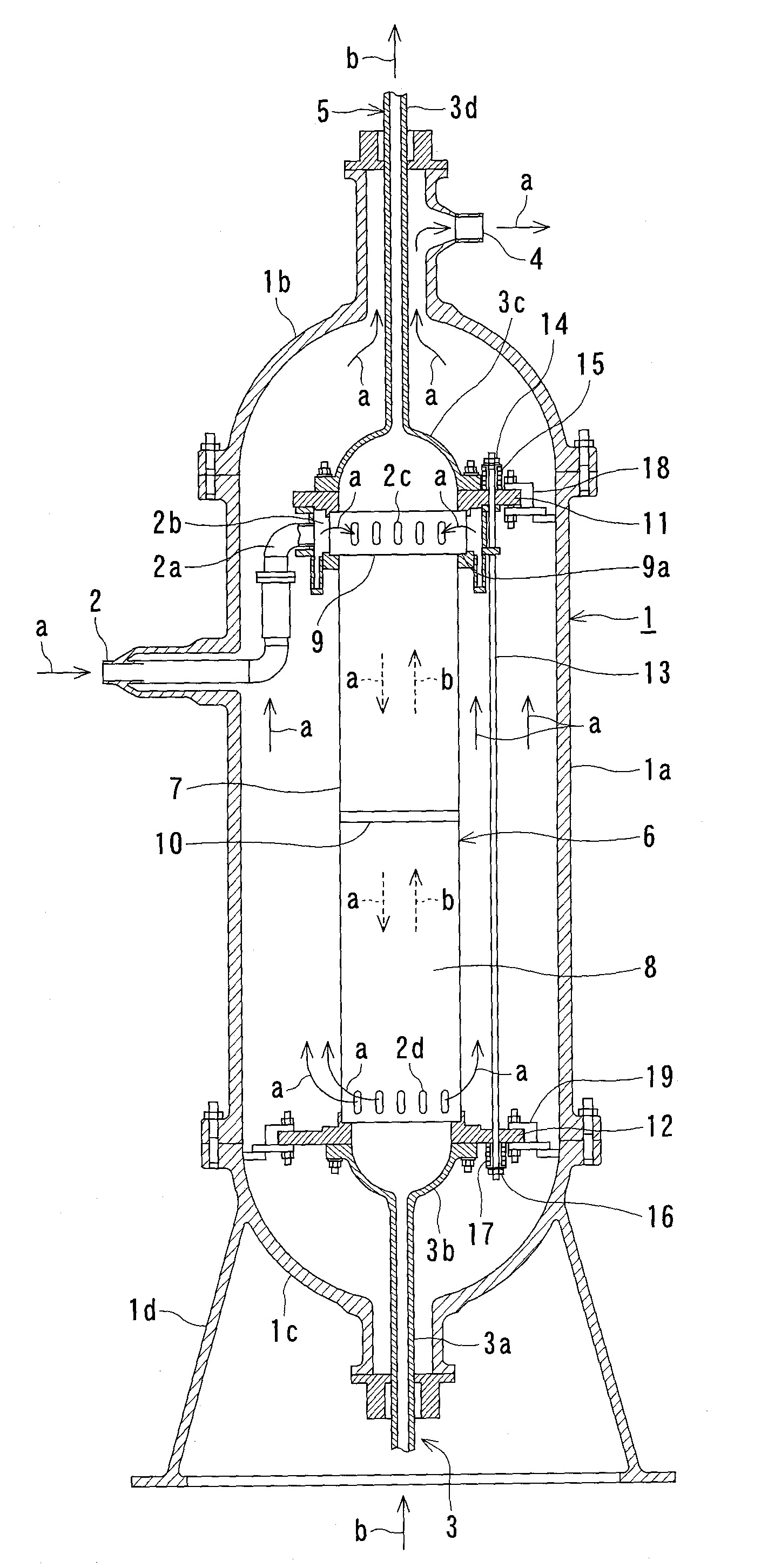

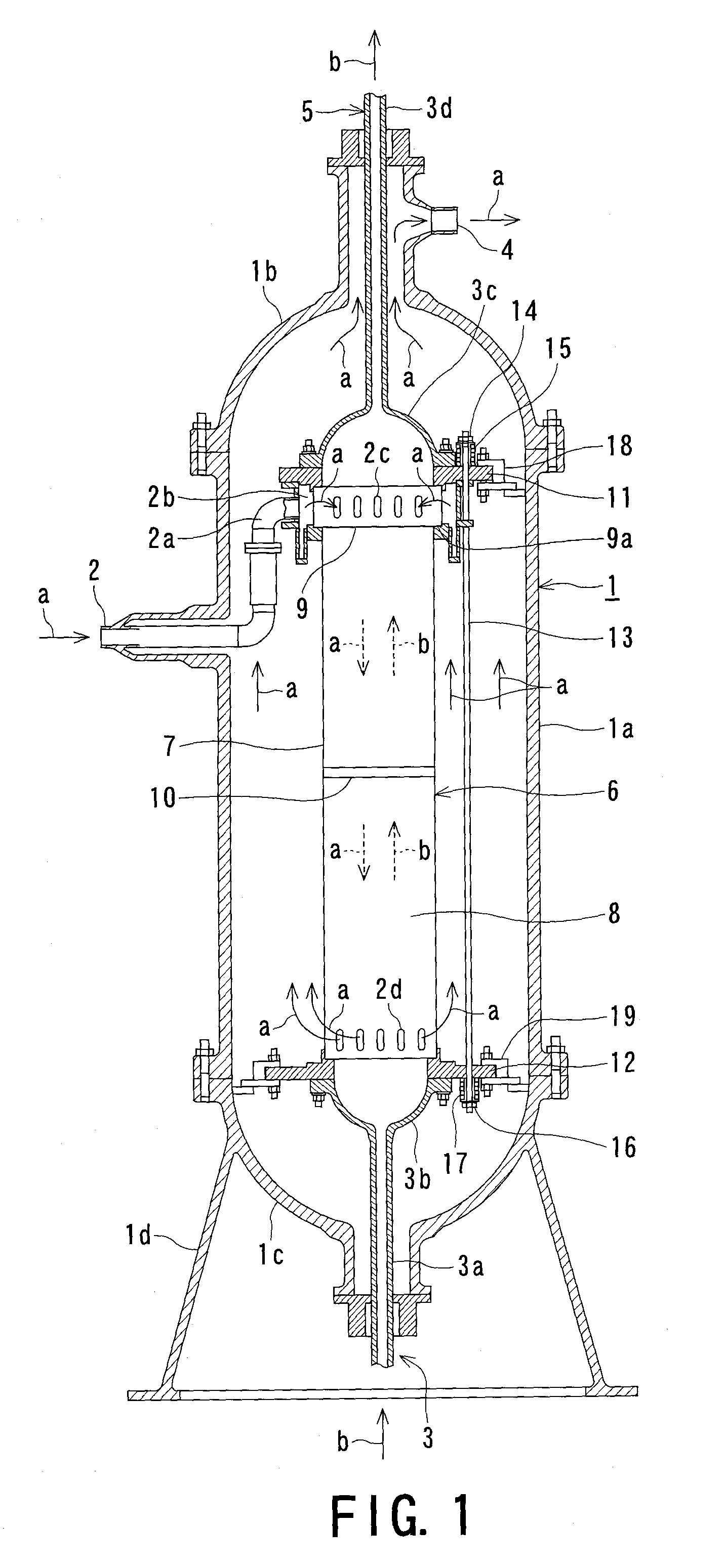

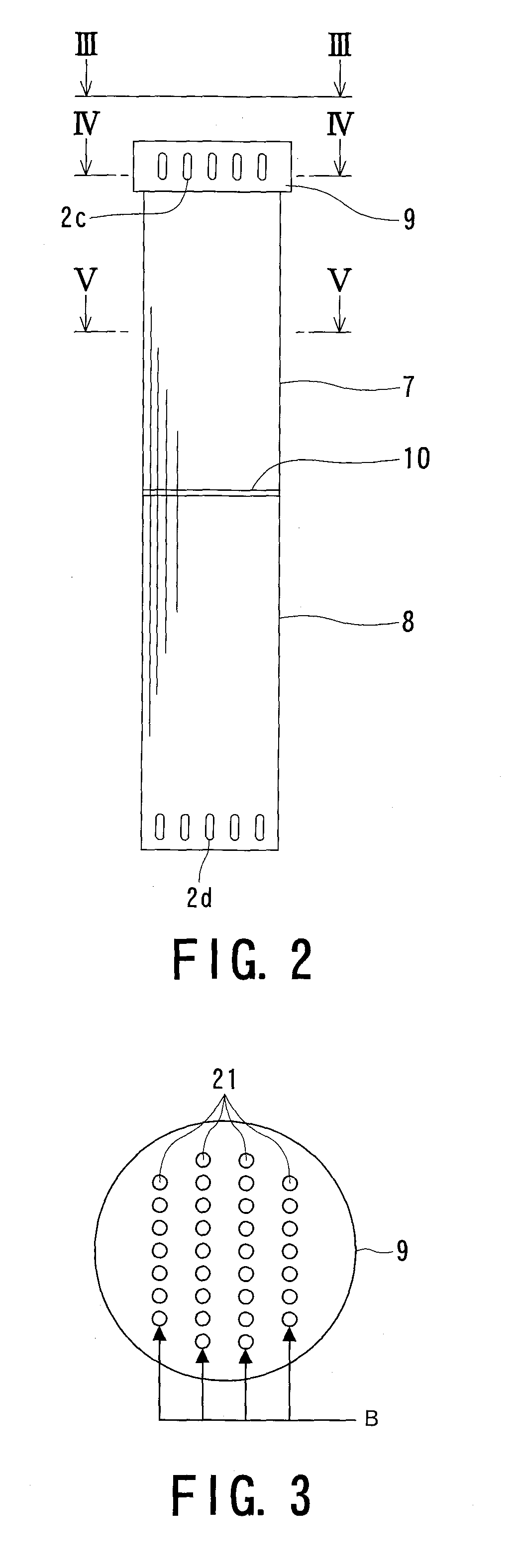

Ceramics heat exchanger

ActiveUS20090056924A1Improve heat exchange efficiencyImprove reliabilityNuclear energy generationSafety devices for heat exchange apparatusThermal expansionMaterials science

A ceramic heat exchanger includes a heat exchange section that heat-exchanges between two fluids A and B flowing opposite directions to each other. The heat exchange section includes ceramic blocks stacked one on top of another with a seal therebetween. The ceramic blocks have a plurality of parallel lines of flow channels, each line defined by the flow channels through which the same fluid flows, any two adjacent lines being defined by the flow channels through which the different fluids A and B flow respectively. Both ends in the stacking direction of the stack are bound to join and integrate the ceramic blocks with tightening means including end plates and a tie rod. A thermal expansion absorber is disposed on an external surface of the end plates for absorbing thermal expansion in the axial direction of the tie rod.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

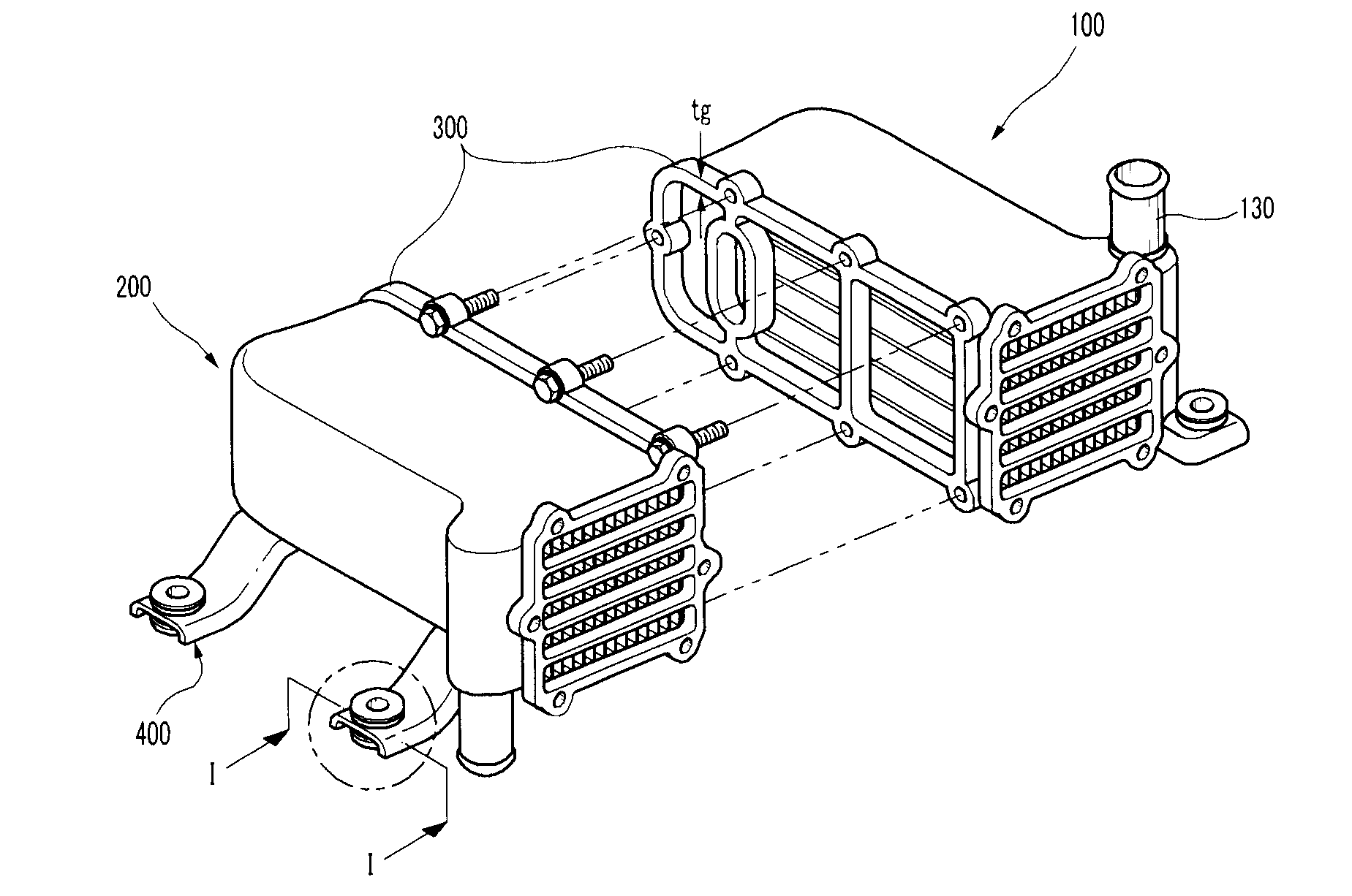

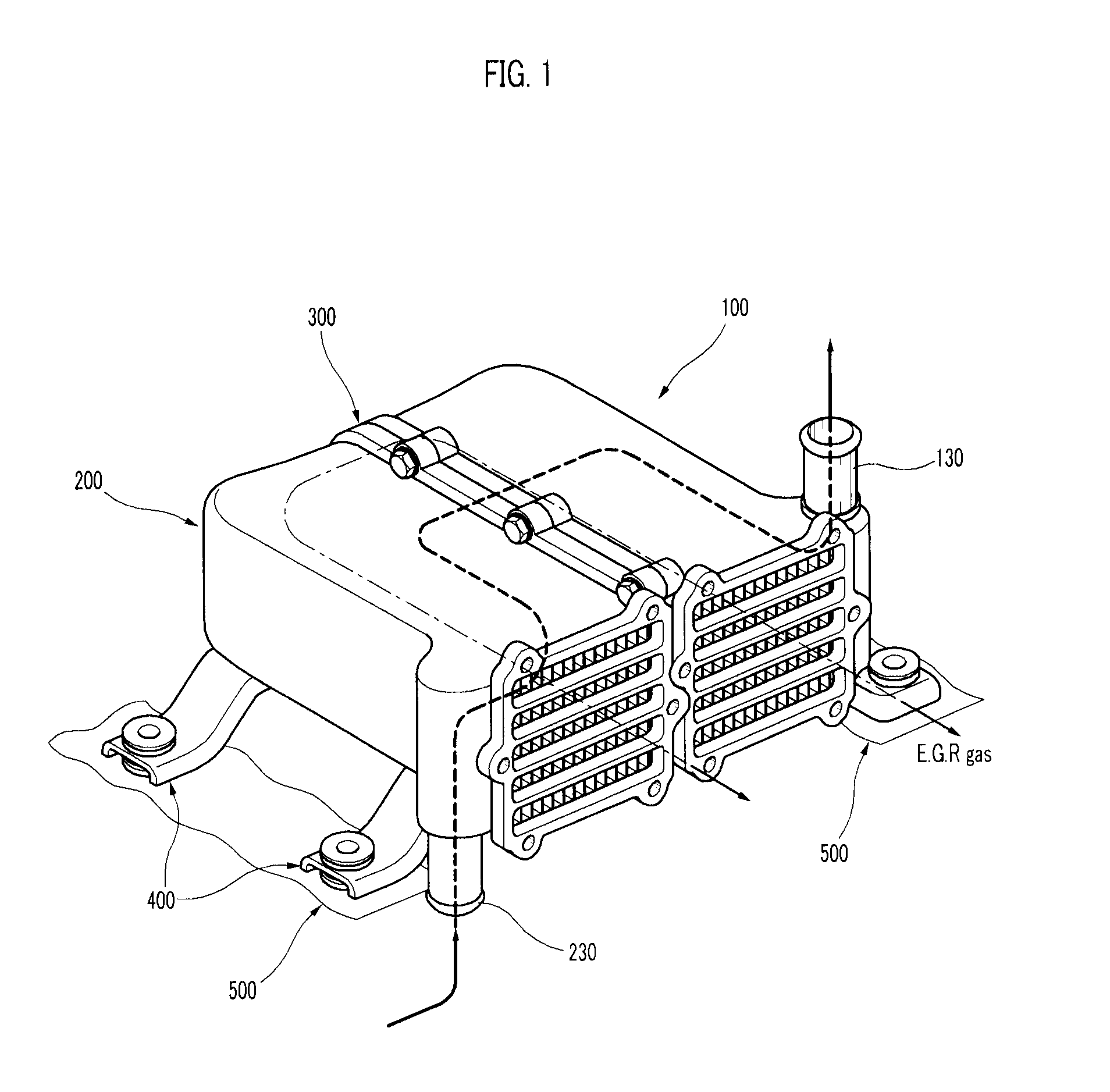

Cooling apparatus of exhaust gas recirculation system and method using the same

ActiveUS20080302094A1Non-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesEngineering

A cooling apparatus of an exhaust gas recirculation system includes a first cooling portion, made of a first material, that receives recirculation exhaust gas; and a second cooling portion, made of a second, different material, that receives the recirculation exhaust gas from the first cooling portion and exhausts the recirculation exhaust gas out of the apparatus. A cooling method of an exhaust gas recirculation system includes receiving a recirculation exhaust gas in a first cooling portion made of a first material; cooling the recirculation exhaust gas in the first coolant portion; receiving the recirculation exhaust gas in a second cooling portion made of a second, different material; and cooling the recirculation exhaust gas in the second coolant portion.

Owner:HYUNDAI MOTOR CO LTD +1

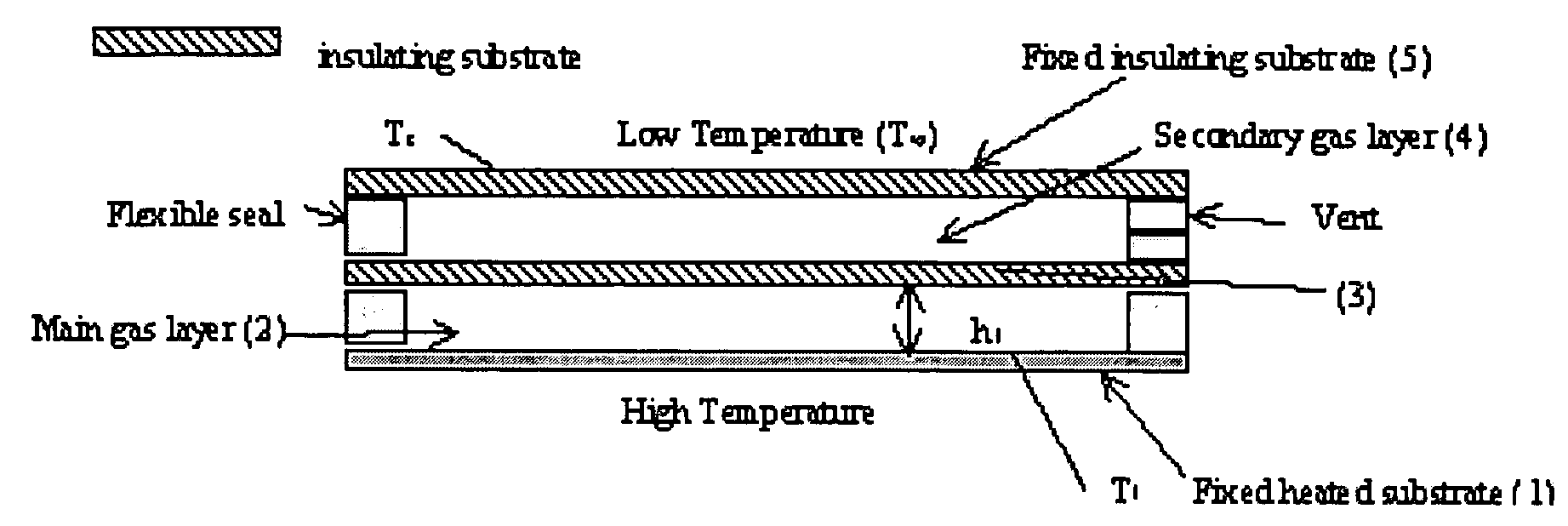

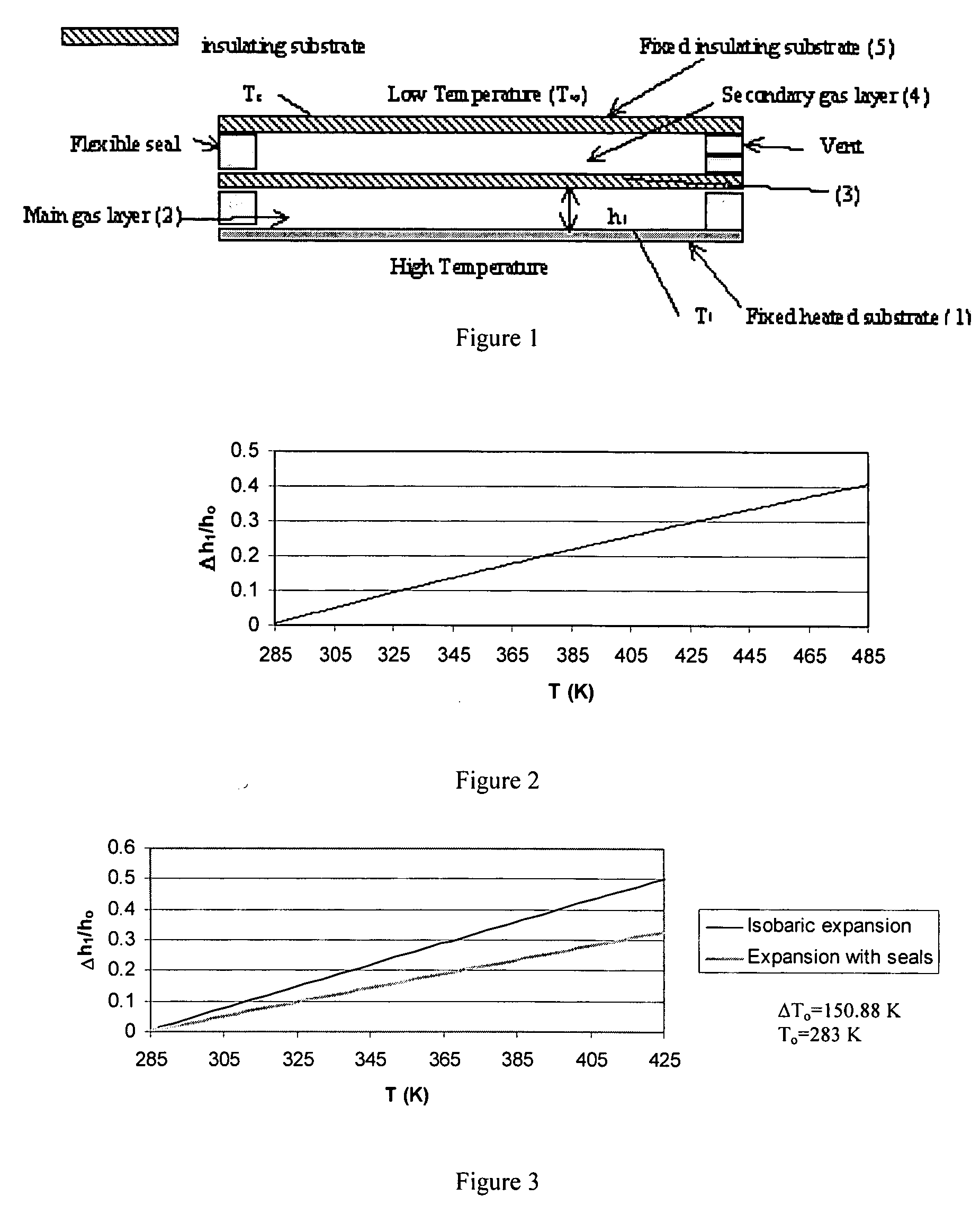

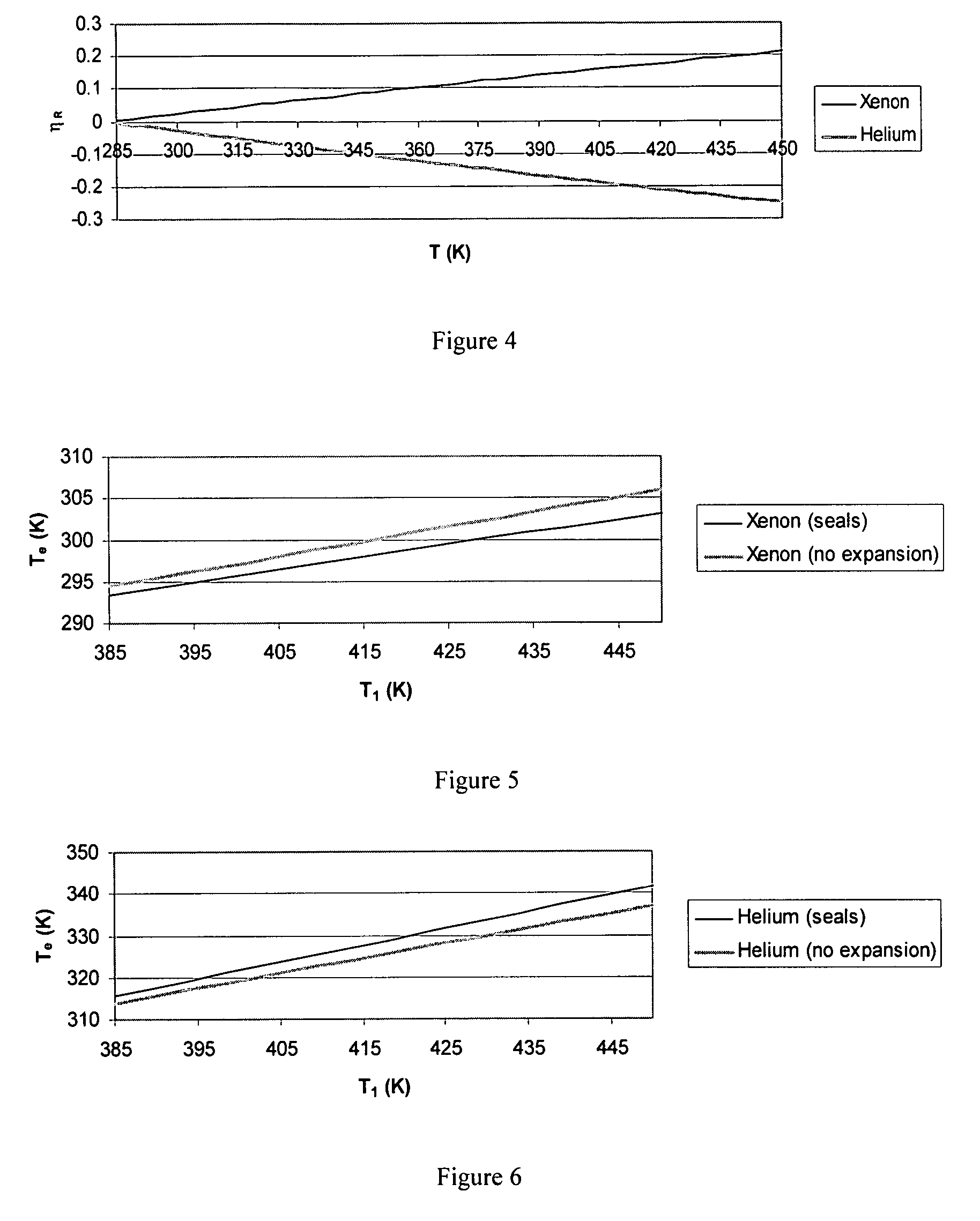

Methods and devices comprising flexible seals, flexible microchannels, or both for modulating or controlling flow and heat

InactiveUS20070084940A1Save heatReduce leakageMaterial nanotechnologyTemperature control without auxillary powerFluid layerEngineering

Disclosed herein are devices comprising at least one flexible seal, at least one flexible complex seal having at least one closed cavity containing a fluid, or a combination thereof. The devices may comprise at least one immobile and inflexible substrate and at least one mobile and inflexible substrate capable of movement due to the flexible seal, the flexible complex seal, or both. The flexible complex seals comprise at least one closed cavity comprising a fluid, such as a gas or a liquid. As disclosed, the presence or absence of heat will cause the mobile and inflexible substrate to move. The movement will increase or decrease the fluid amount or fluid flow rate in the primary fluid layer. Also disclosed are methods for enhancing the insulating properties of insulating assemblies.

Owner:RGT UNIV OF CALIFORNIA +1

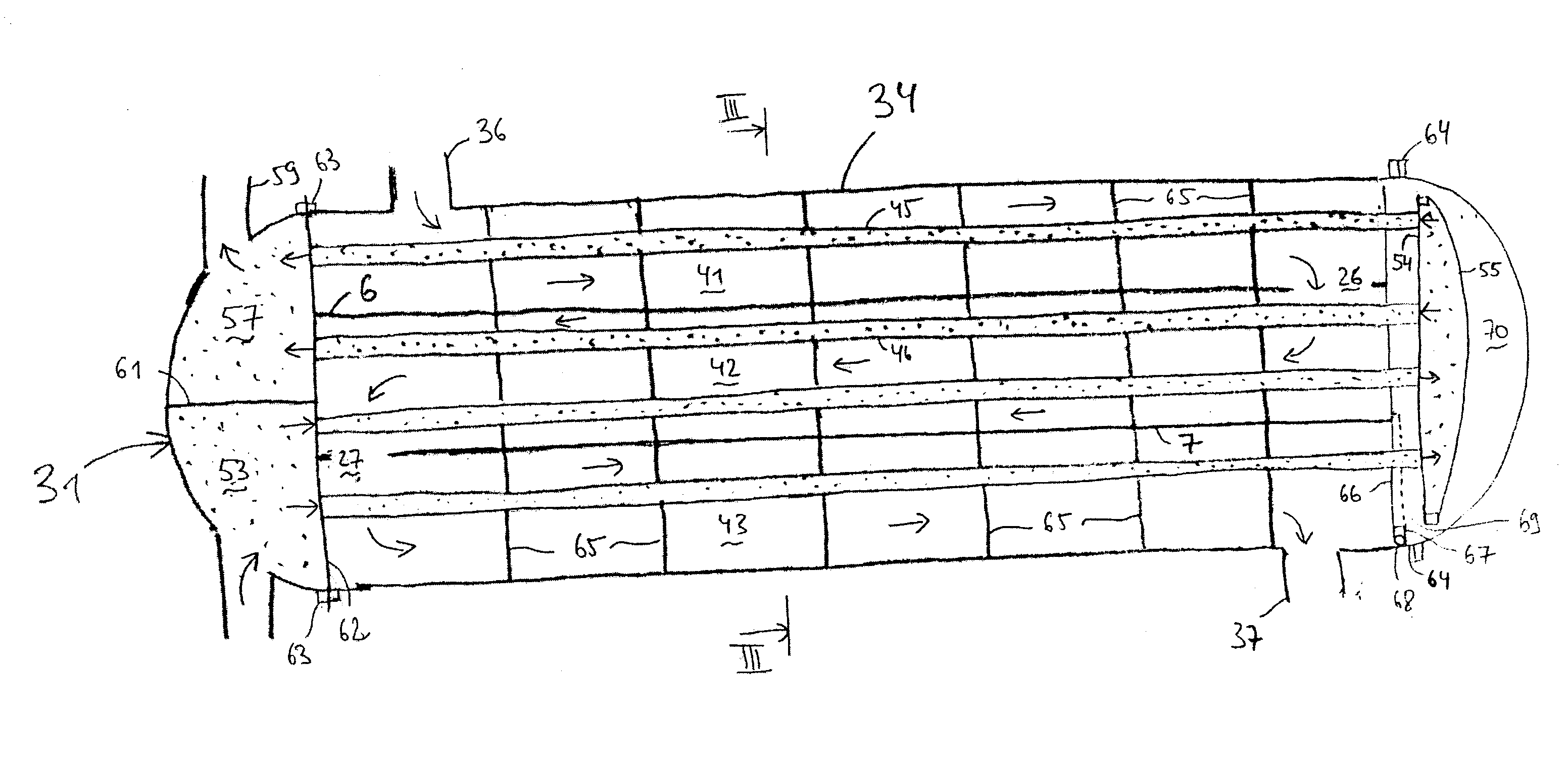

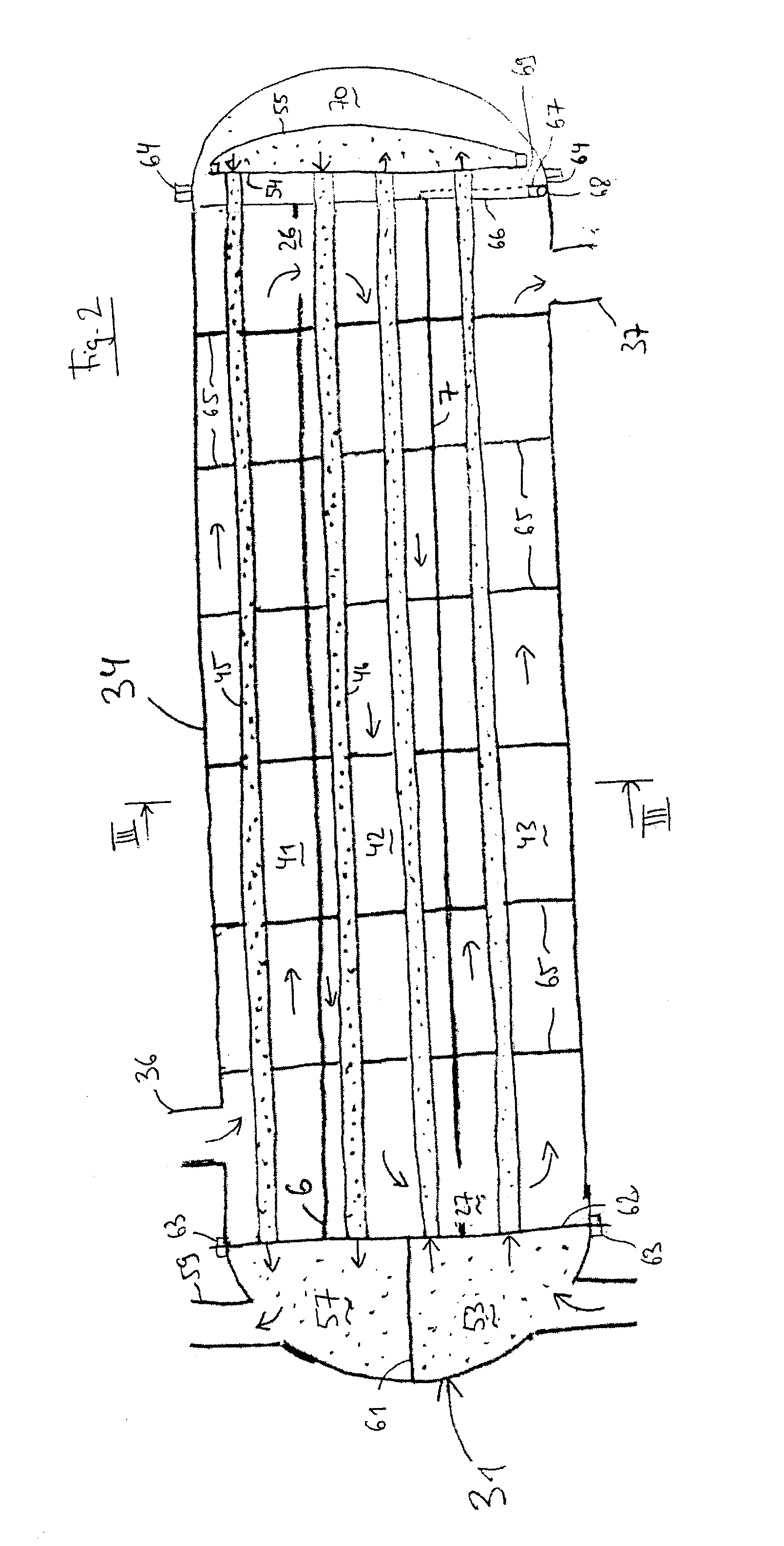

Assembly of baffles and seals and method of assembling a heat exhanger

ActiveUS20060289153A1Improve sealingHeat exhanger sealing arrangementHeat exchanger casingsDouble wallEngineering

An assembly of baffles and seals for mounting in a heat exchanger shell, comprising a plurality of longitudinal baffles; a plurality of longitudinal seals for sealingly engaging longitudinal rims of the longitudinal baffles against the heat exchanger shell after mounting, and further a wall member that is arranged to extend between longitudinal seals of adjacent longitudinal baffles so as to form a double wall with the heat exchanger shell after mounting. A method of assembling a heat exchanger, comprising providing a heat exchanger shell and an assembly of baffles and seals according to the invention; assembling the assembly of baffles and seals outside the heat exchanger shell and introducing the assembled arrangement into the heat exchanger shell so that each wall member forms a double wall with the heat exchanger shell.

Owner:BREMBANA & ROLLE

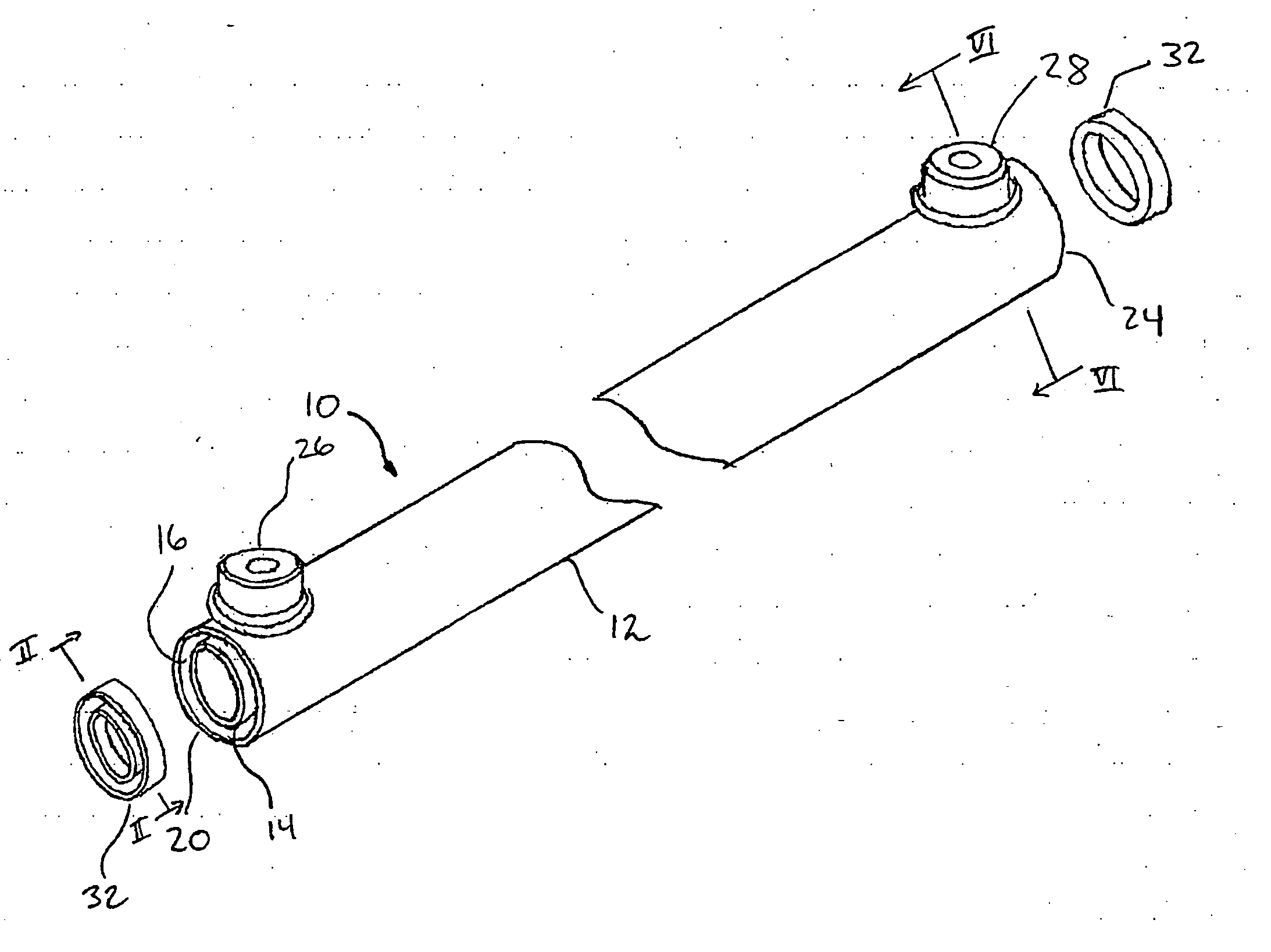

Concentric tube heat exchanger end seal therefor

InactiveUS20050155748A1Heat exhanger sealing arrangementHeat exchanger casingsEngineeringMechanical engineering

A concentric tube heat exchanger comprises an outer tube and a concentric inner tube, with an annular passageway between the tubes. The ends of the annular passageway are sealed by sealing members having axially extending inner and outer walls which are connected to one another and which are sealed to the respective outer and inner tubes. The sealing member walls are preferably connected by an integrally formed connecting wall. The walls of the sealing member are preferably resilient and diverge so as to form a friction fit with the tubes during assembly of the heat exchanger. The heat exchanger further comprises a turbulizer which comprises a plurality of rows of corrugations defining axially extending flow passages. Preferably, the corrugations have a top land width greater than a bottom land width so that the side walls of the corrugation are radially arranged in the annular passageway. Adjacent corrugations in each row are preferably offset relative to one another by an amount of from about 30 percent to about 40 percent.

Owner:DANA CANADA CORP

Heat-exchange apparatus for insertion into a storage tank, and mounting components therefor

A heat-exchange apparatus and a mounting component set for installation into storage tanks. The heat-exchange apparatus comprises a heat-exchanging component, a coupling manifold configured to engage with the heat-exchanging component, and a hollow, elongate, flow-directing element that delivers fluid to the heat-exchanging component. The mounting component set comprises an inner flange for engaging the inner wall of the storage tank, an outer flange for engaging the outer wall of the storage tank, and at least one gasket cooperable with one of the flanges. The heat-exchange apparatus sealably engages the outer flange such that the heat-exchanging component extends into the interior of the tank, and the coupling manifold is interconnectable to an external supply of heat-exchange fluid.

Owner:ARNOT ROGER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com