Heat-exchange apparatus for insertion into a storage tank, and mounting components therefor

a technology of heat exchange apparatus and storage tank, which is applied in the direction of tubular elements, heat storage plants, stationary tubular conduit assemblies, etc., can solve the problems of accelerating wear and deterioration of pump components, affecting the smooth and safe operation of hydraulic-controlled attachments, and preventing engine start-up, etc., to achieve the effect of increasing the heat-radiating surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

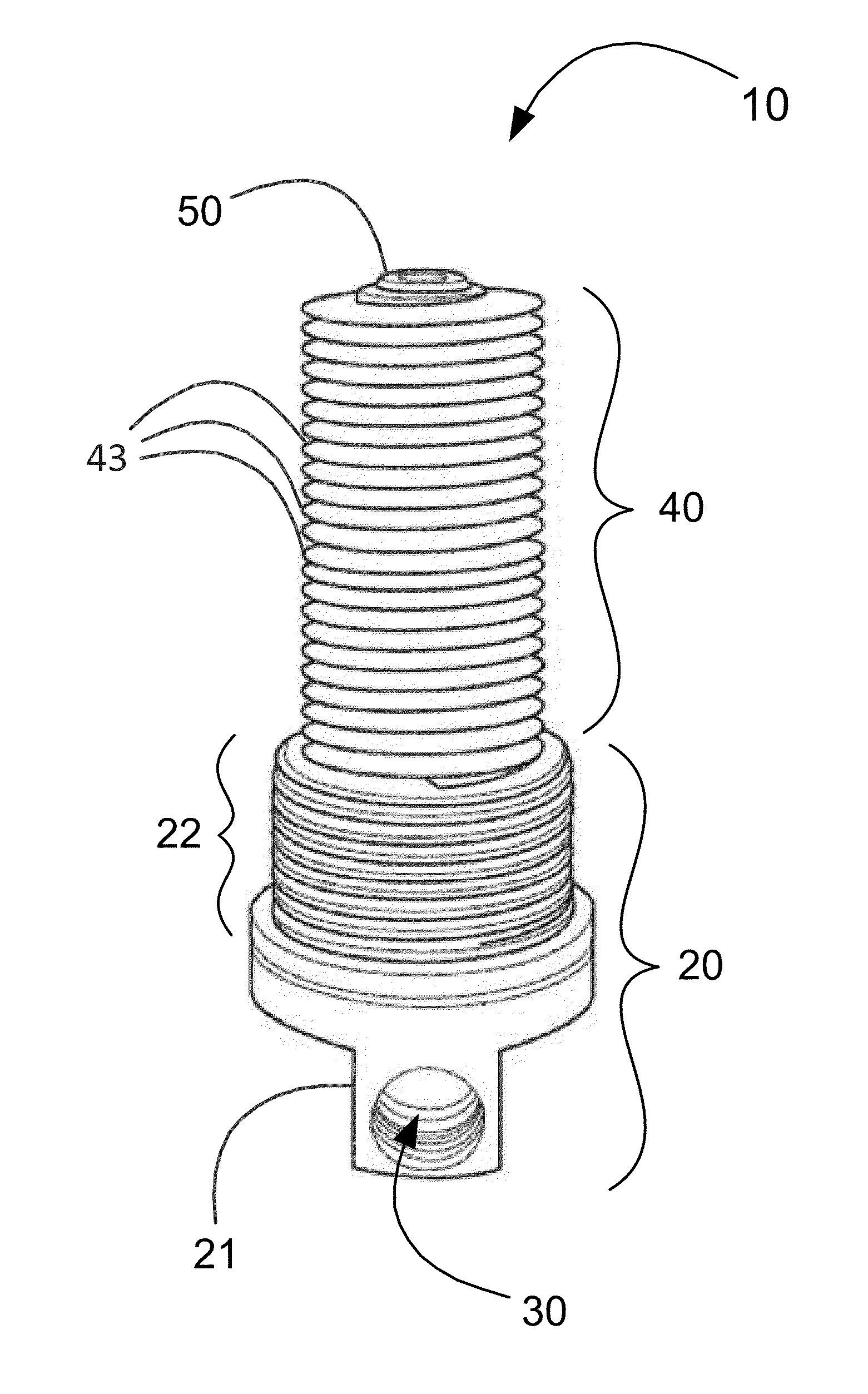

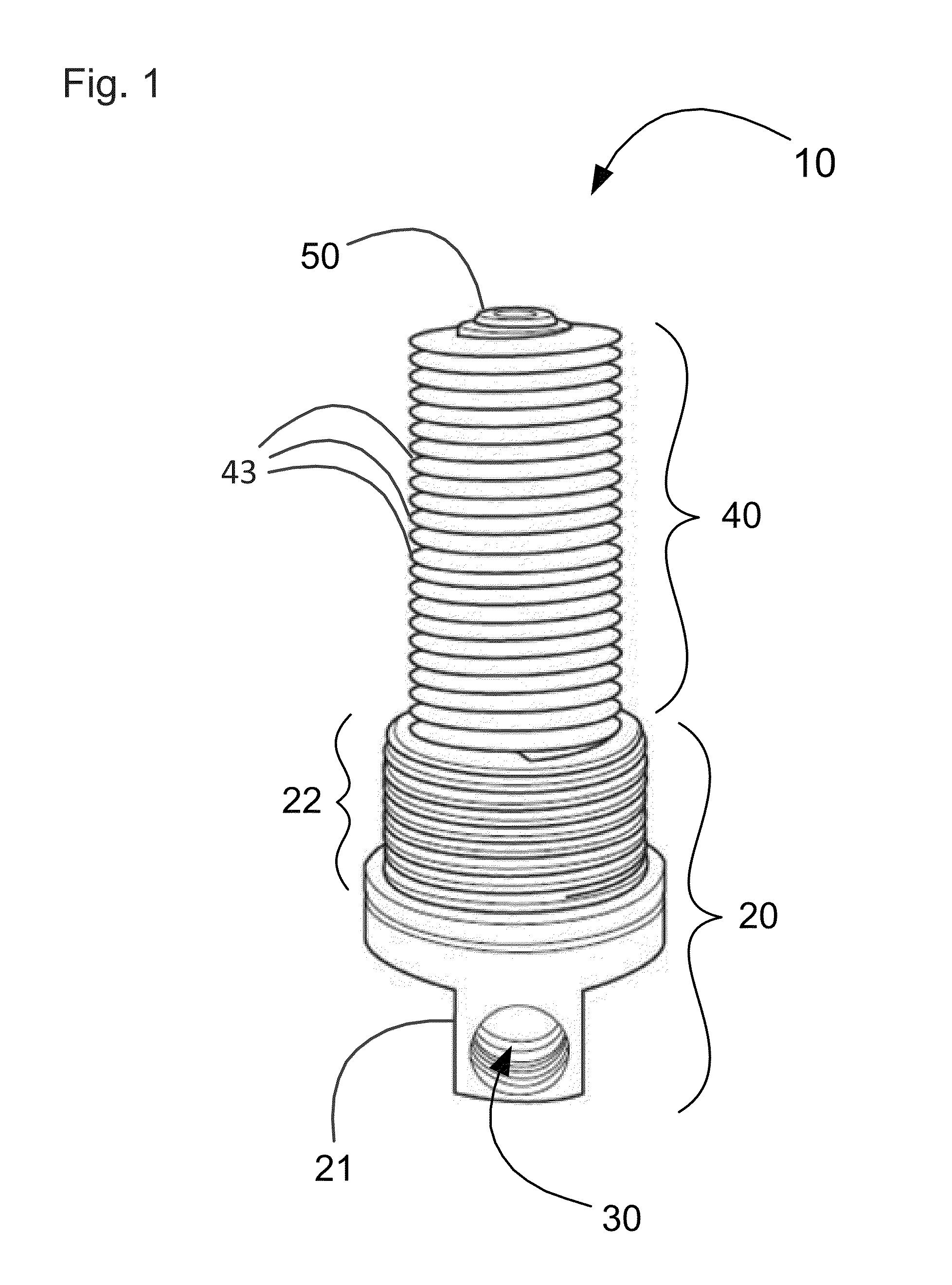

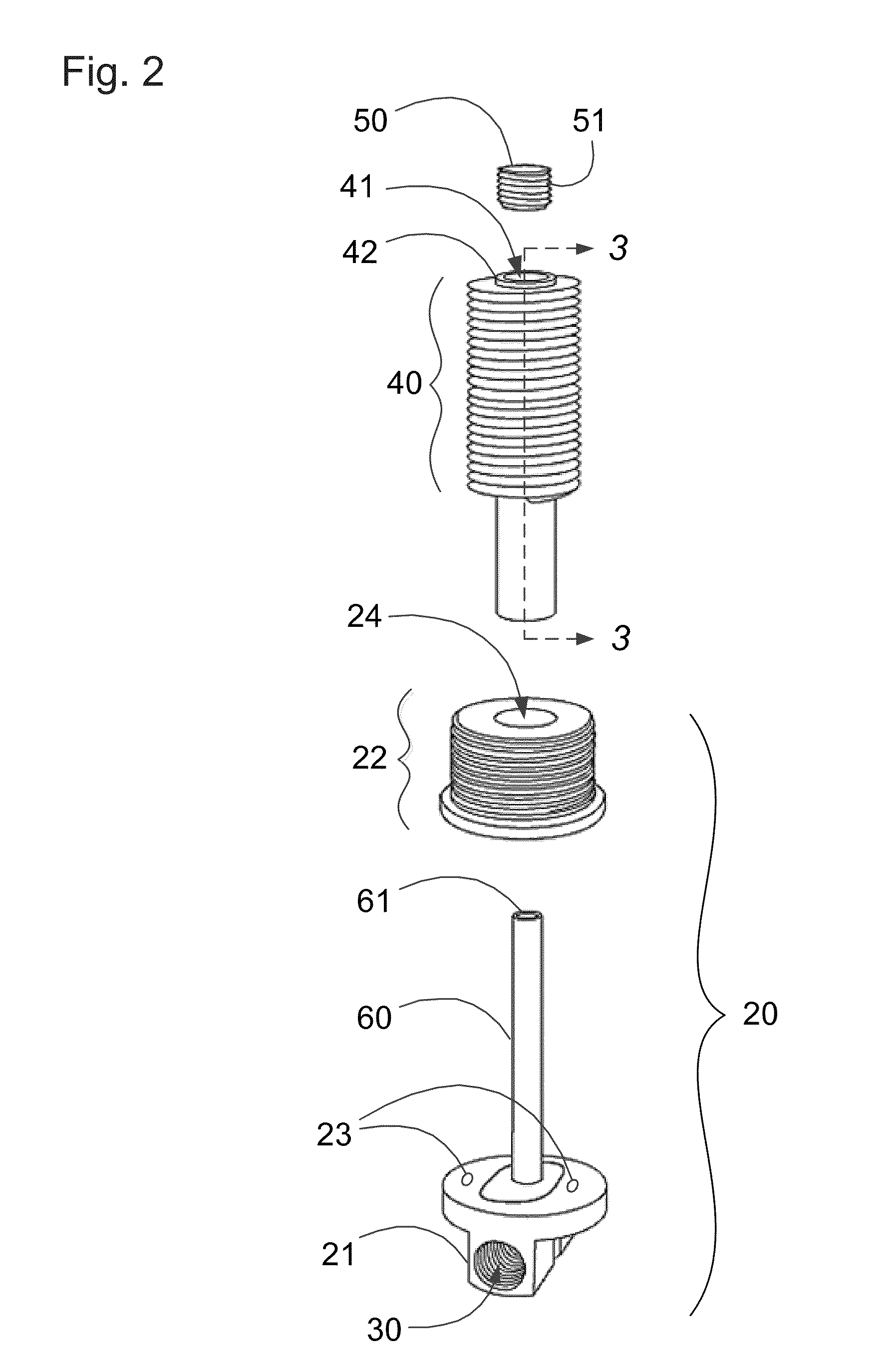

[0027]Exemplary embodiments of the present invention relate to a heat-exchange apparatus and to mounting components for sealingly engaging the heat-exchange apparatus with a storage tank wherein fluids may be stored.

[0028]An embodiment of the present invention relates to a heat-exchange apparatus comprising a heat-exchanging component, a coupling manifold interconnectable to a fluid supply and configured to engage with the heat-exchanging component, and a hollow, elongate, flow-directing element that delivers fluid to the heat-exchanging component.

[0029]The heat-exchanging component preferably comprises a void into which the flow-directing element delivers fluid. The void may be of any suitable size provided the flow-directing element can fit therein. Preferably the void is at least about 2 mm, more preferably at least about 5 mm, in diameter. Preferably the void is less than about 100 mm, more preferably less than about 50 mm, in diameter.

[0030]In a preferred embodiment the heat-ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com