Patents

Literature

219results about "Closure means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat Exchanger

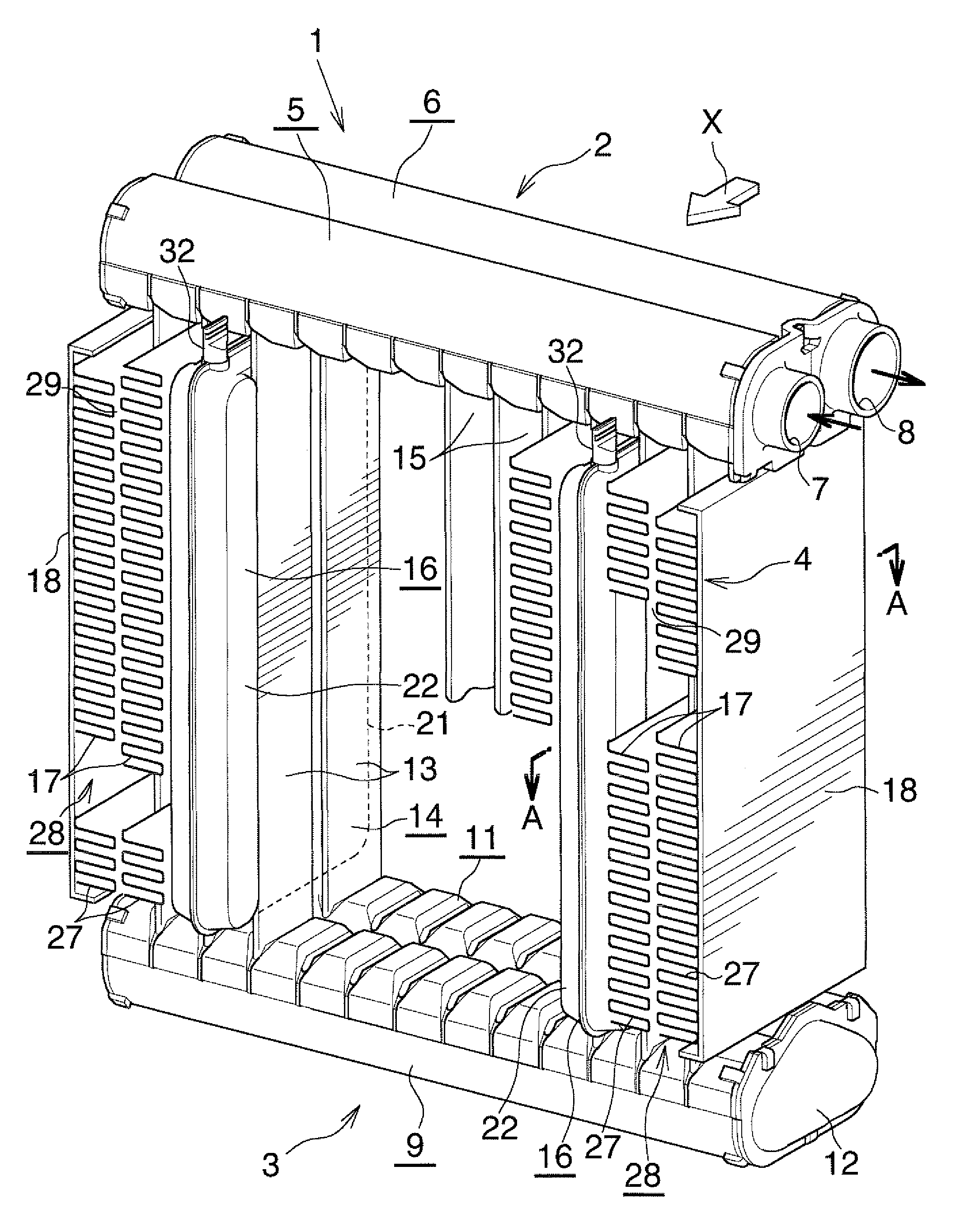

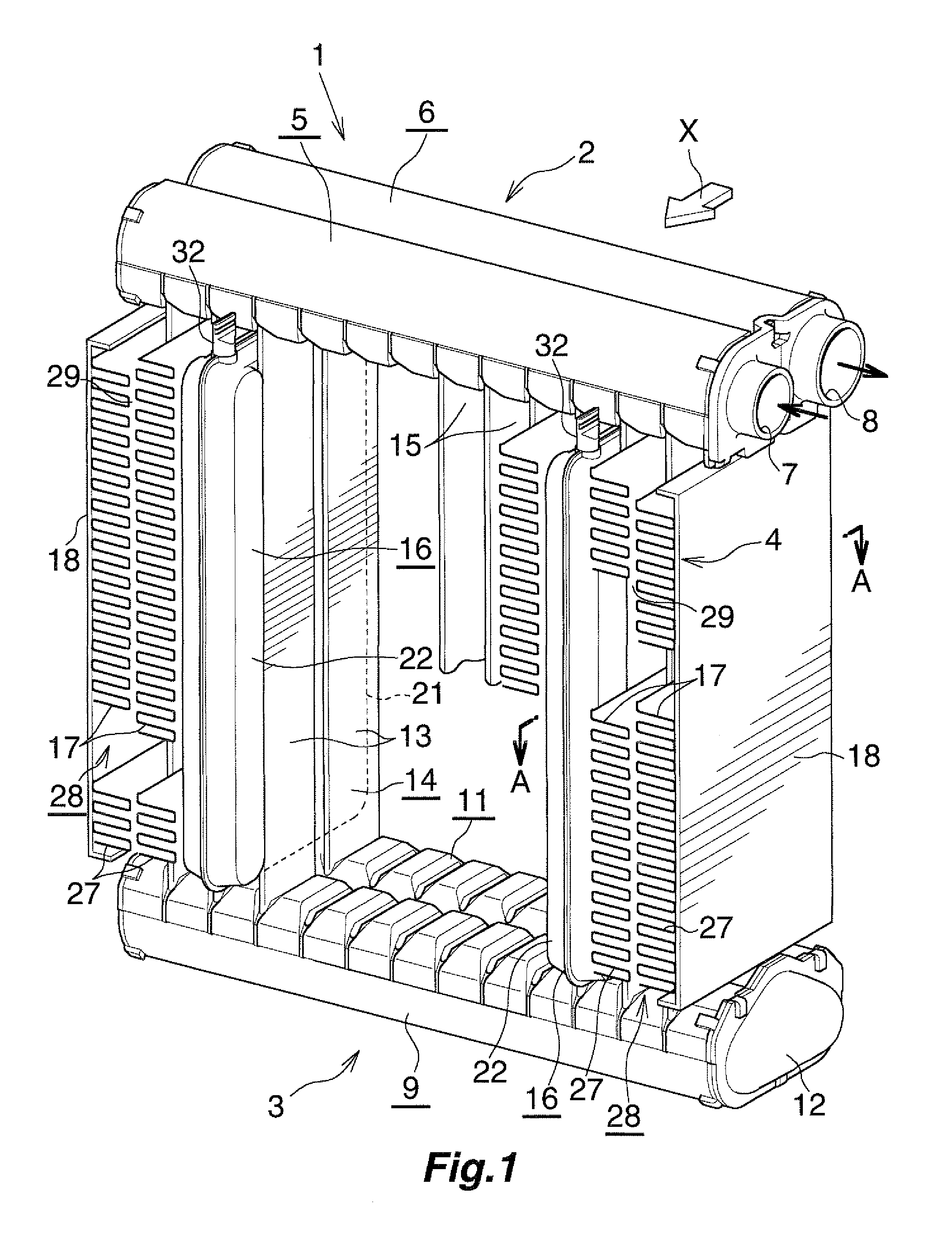

InactiveUS20080164014A1Improve performanceReduce in quantityInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringMechanical engineering

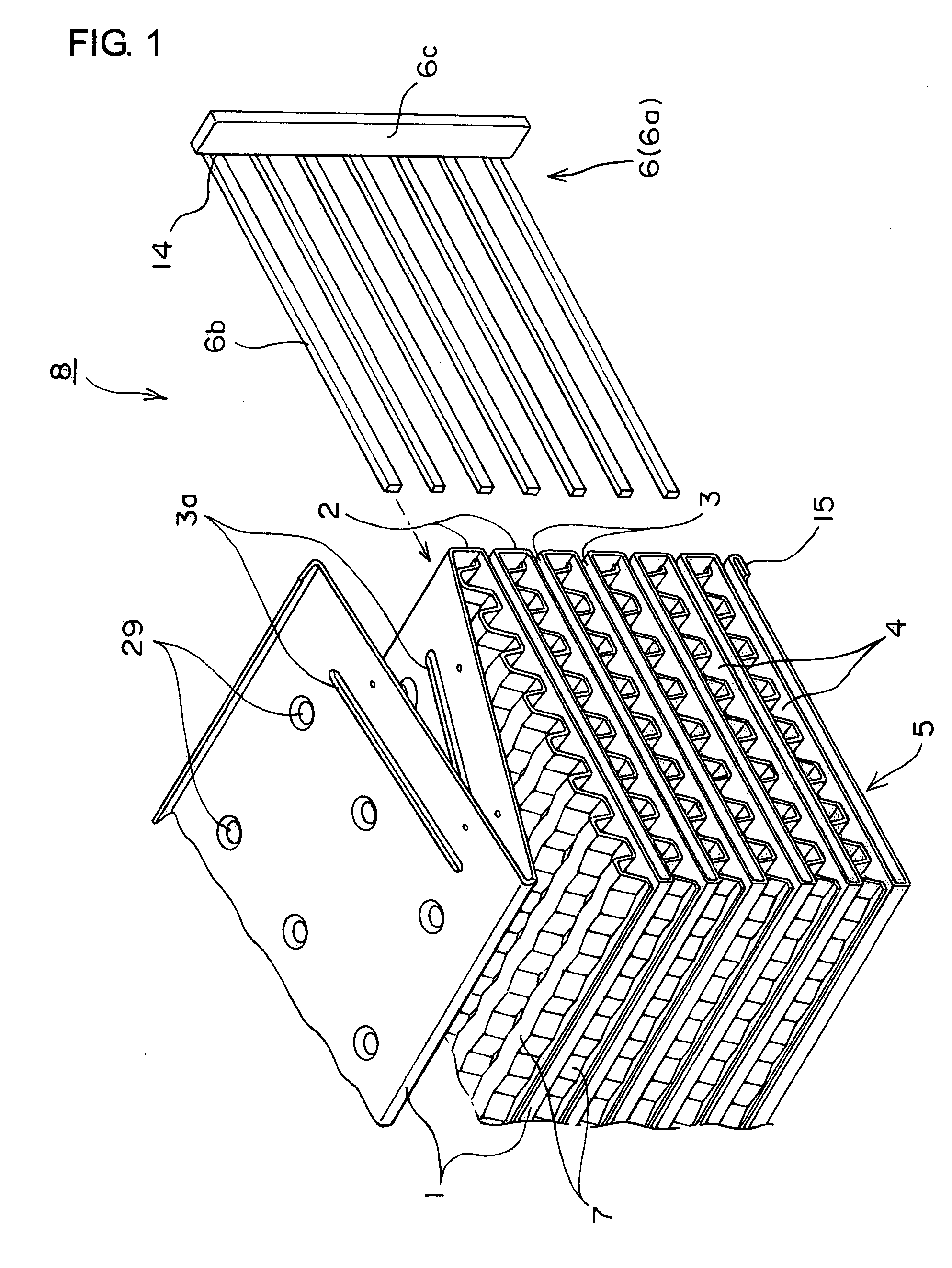

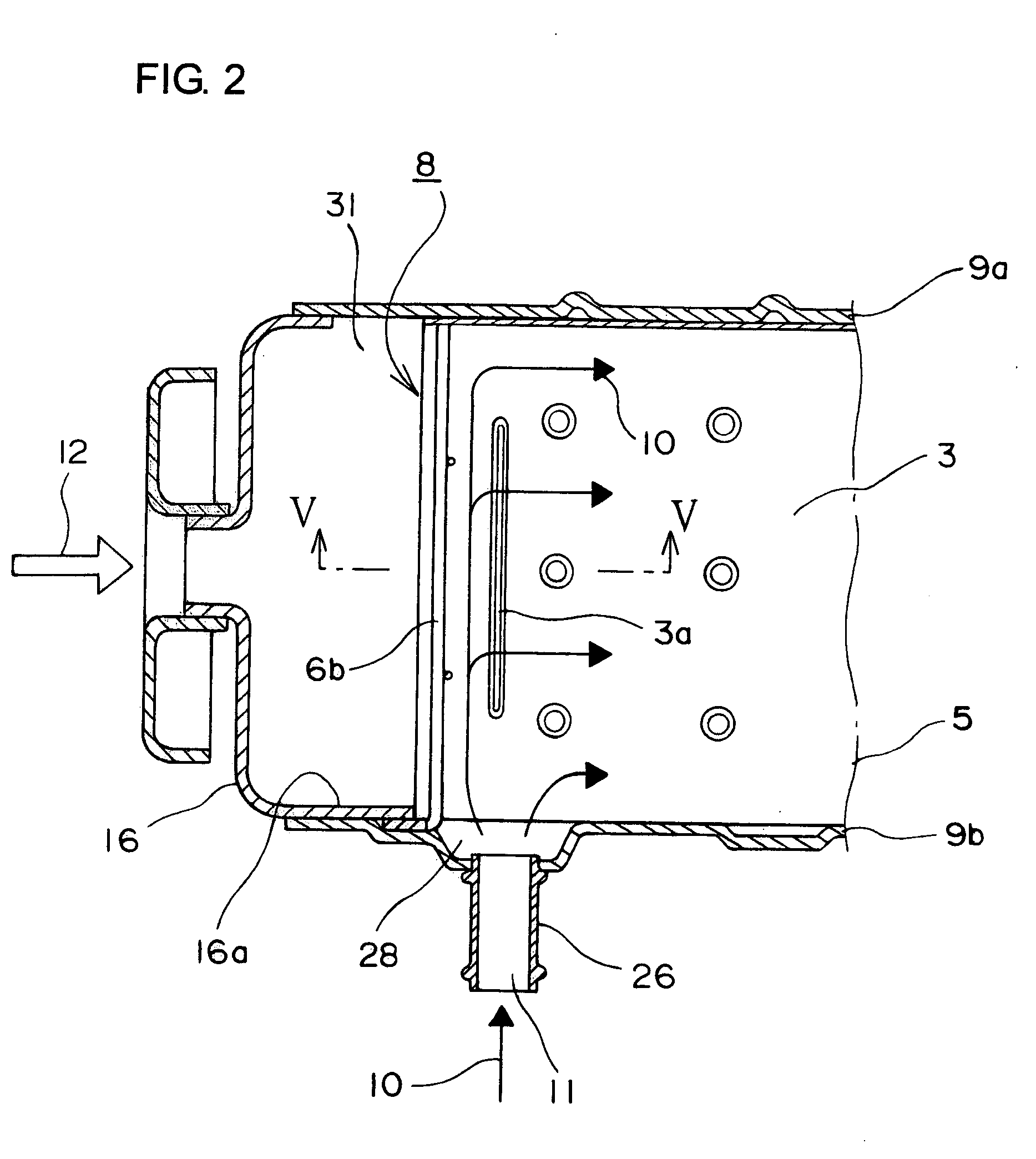

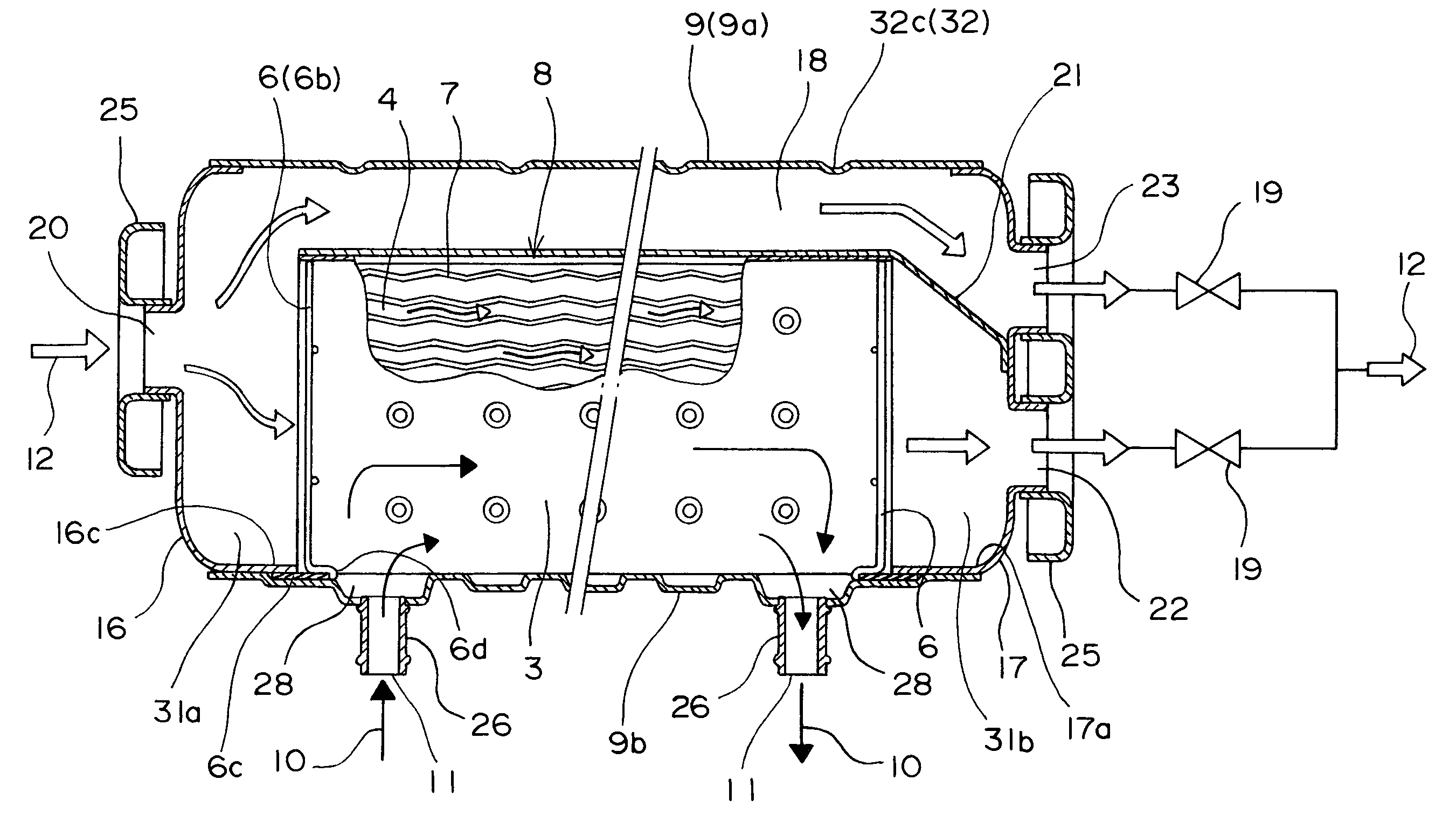

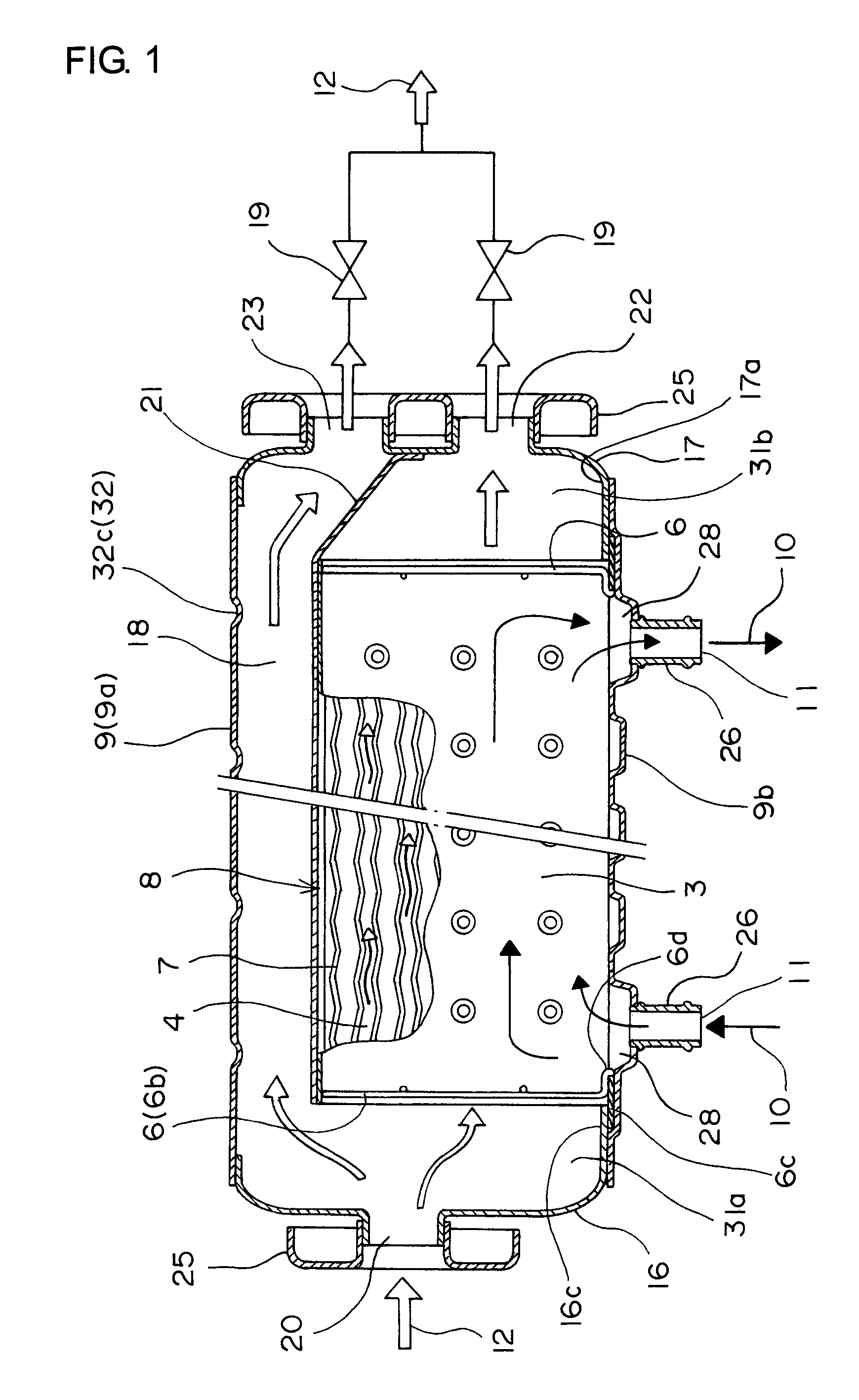

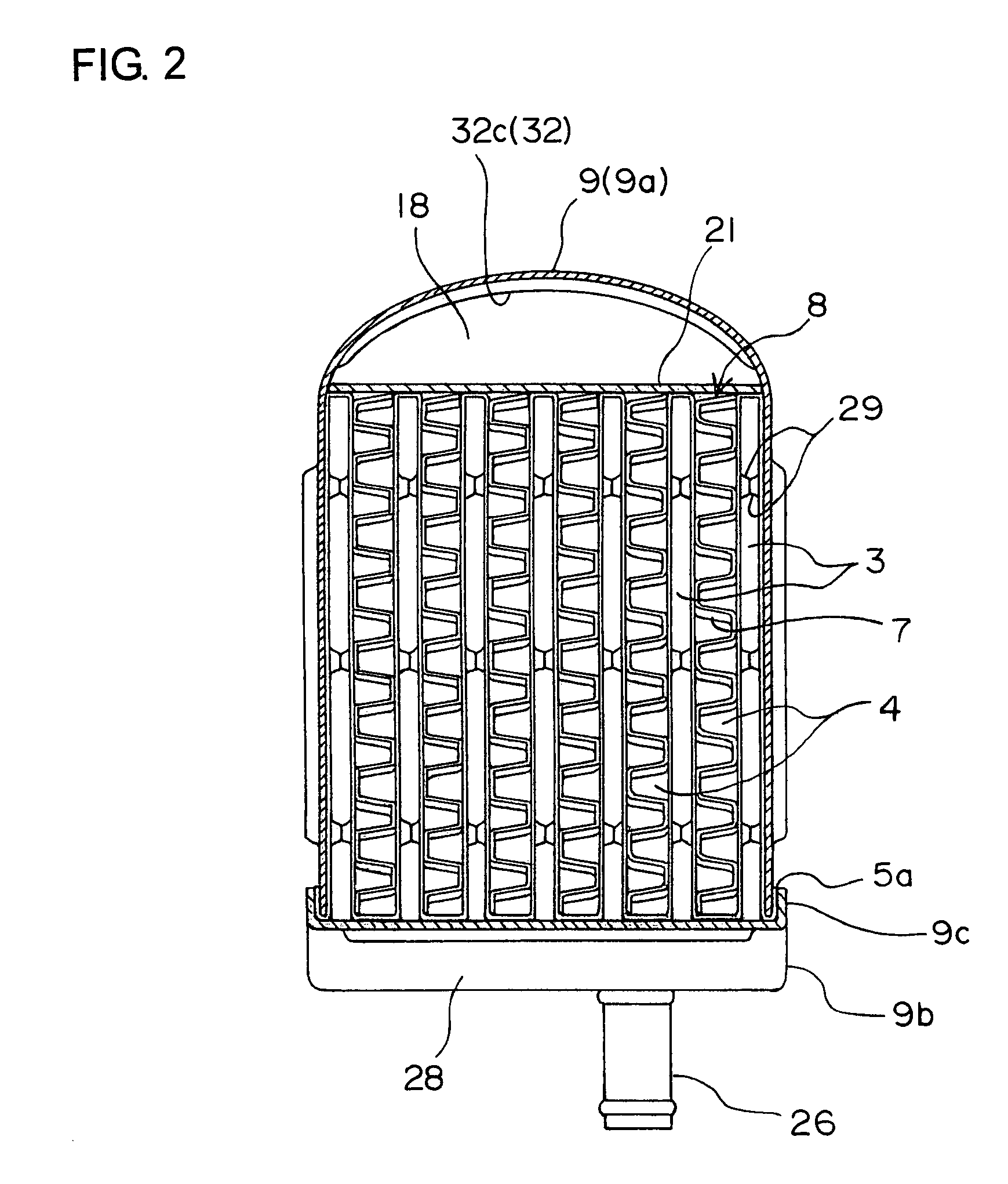

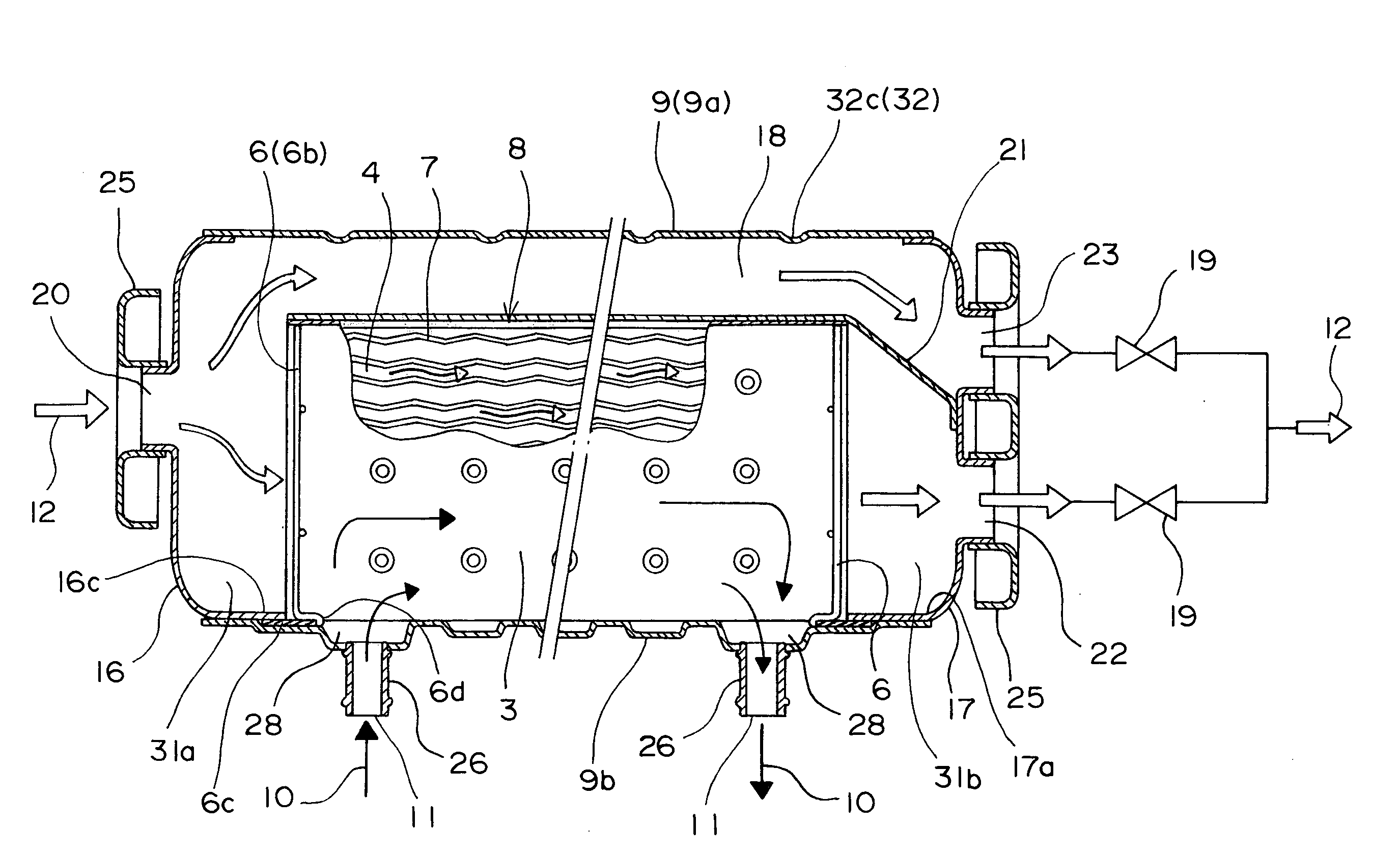

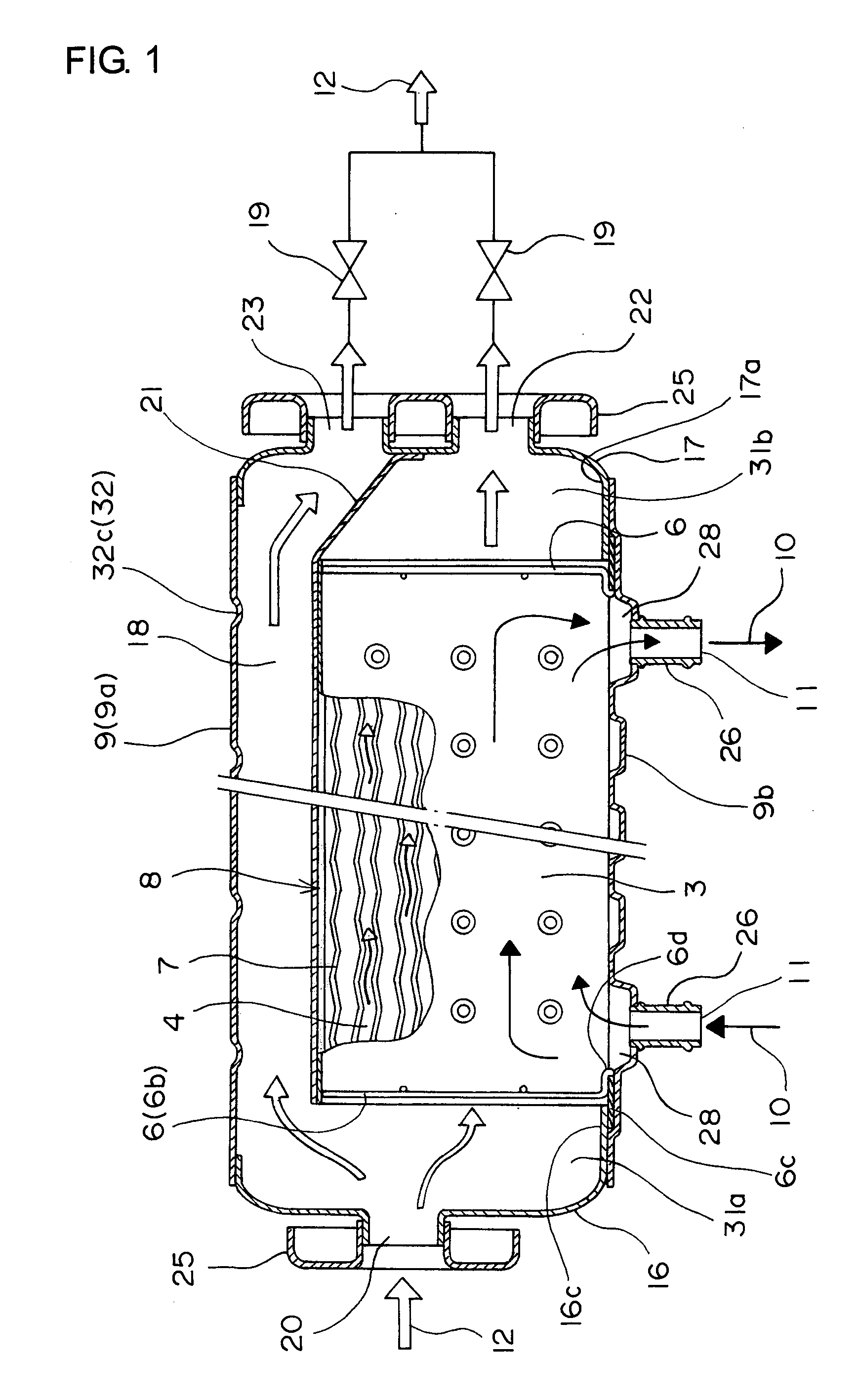

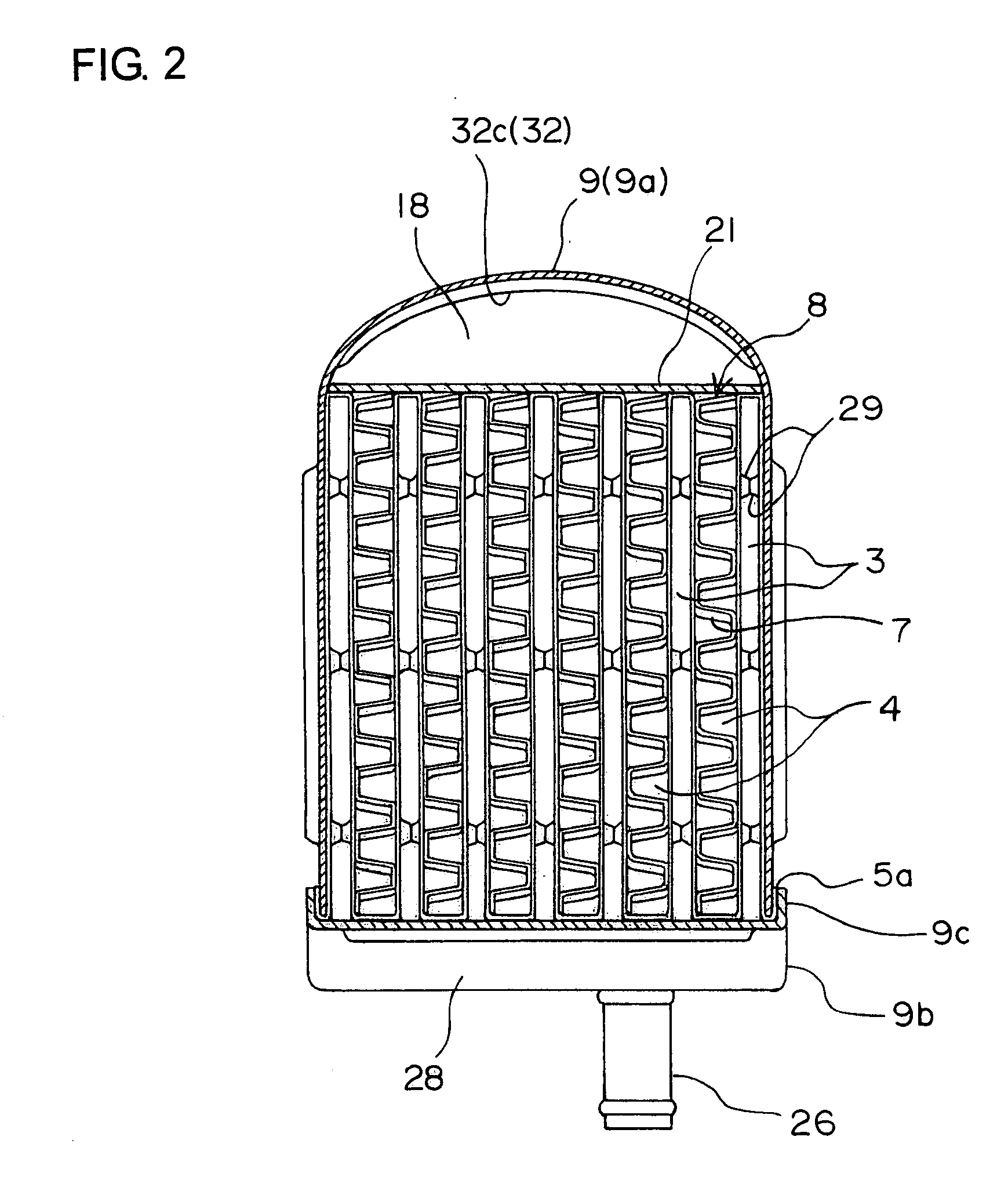

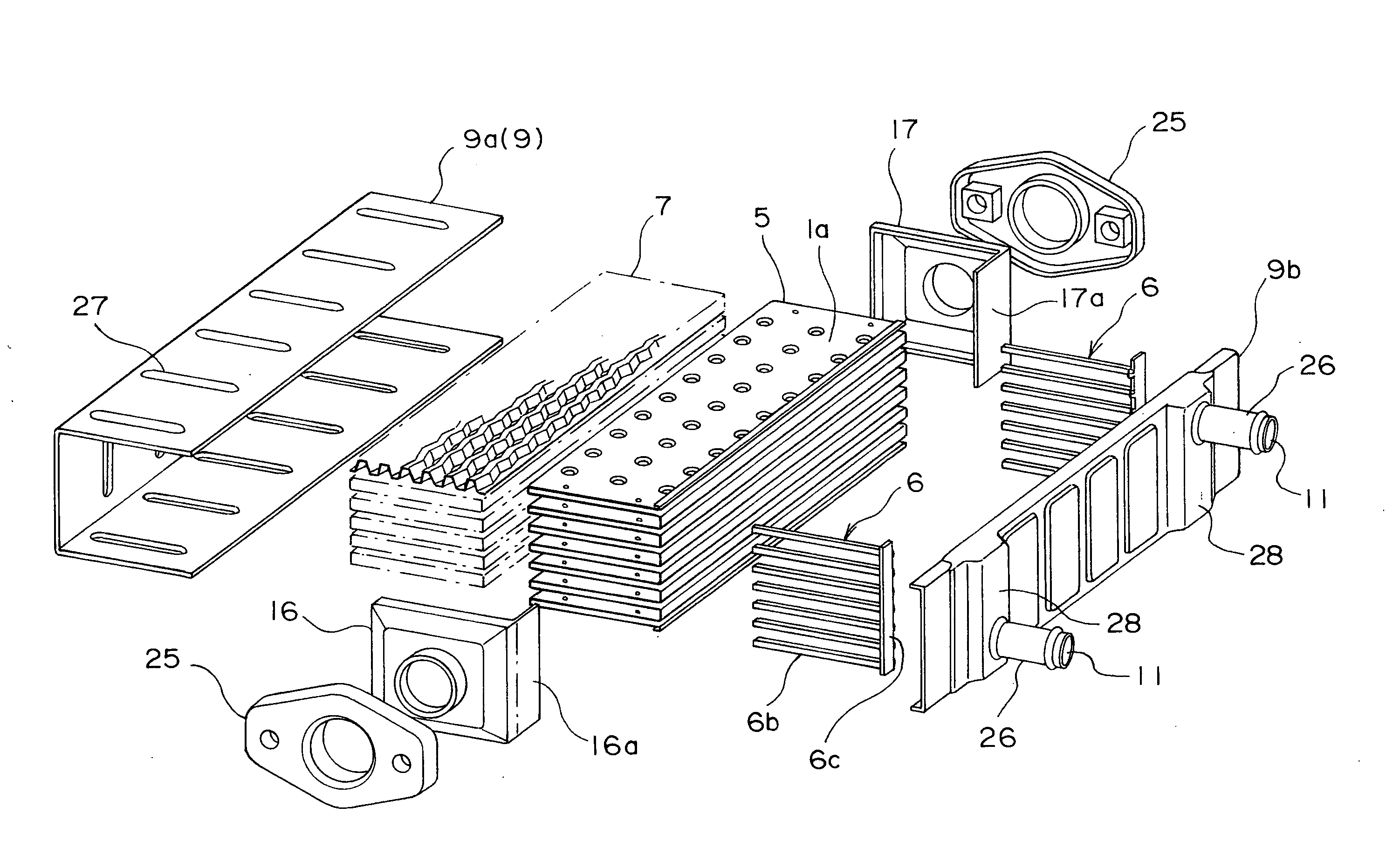

In a heat exchanger used for an EGR cooler or the like, in order to provide a heat exchanger that has a small number of parts, is assembled easily, can flow cooling water evenly at each part, and does not cause partial boiling, a strip-shaped metal plate is turned up and bent in a fanfold manner, flat first flow channels 3 and second flow channels 4 are formed alternately, both the ends of the first flow channels 3 are closed with slit blocks 6, projecting stripes 3a are bent and formed at the positions of ports 11 for the cooling water 10 in proximity to the slit blocks 6, and gaps 3c are formed between respective paired projecting stripes 3a.

Owner:T RAD CO LTD

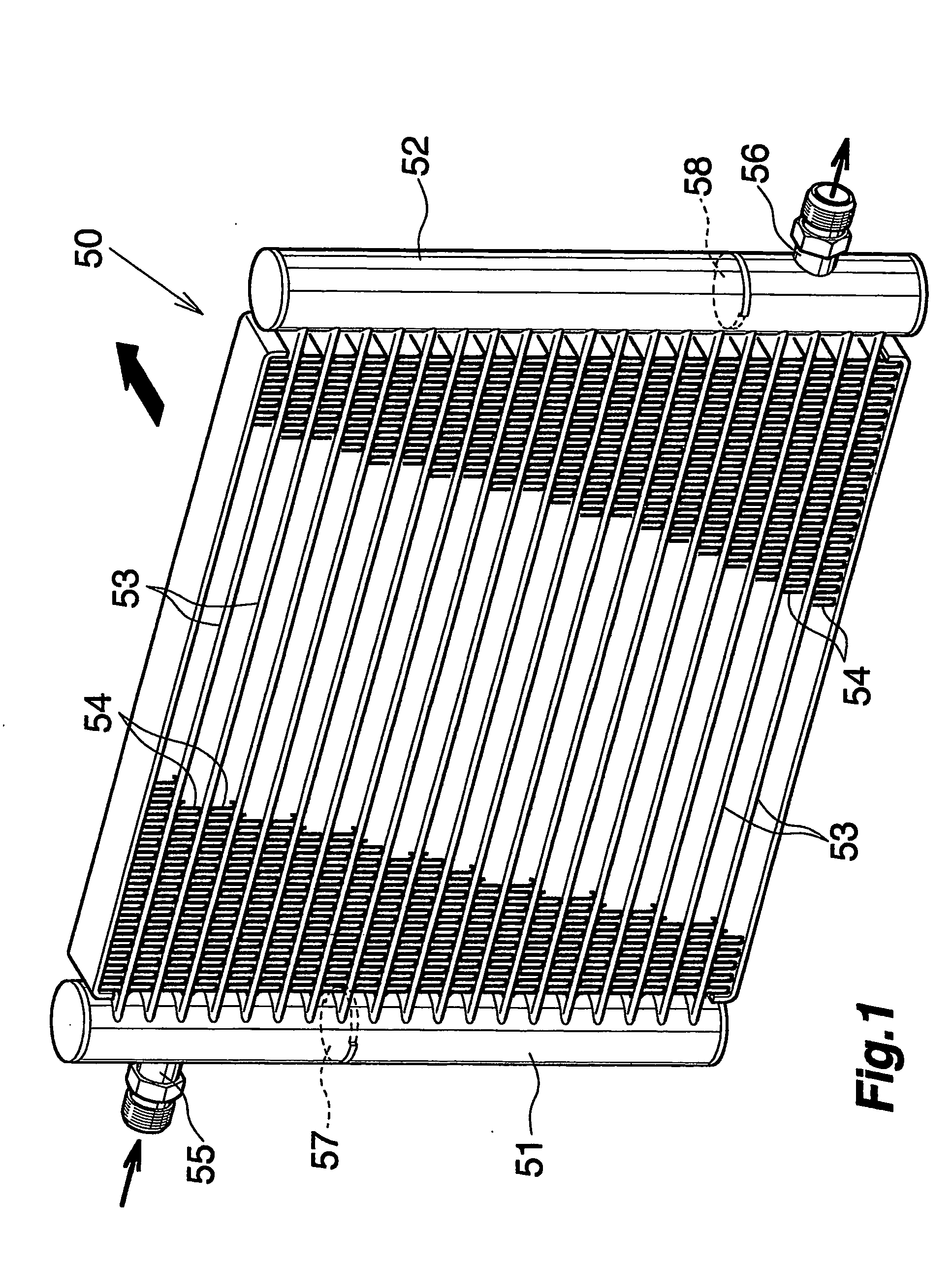

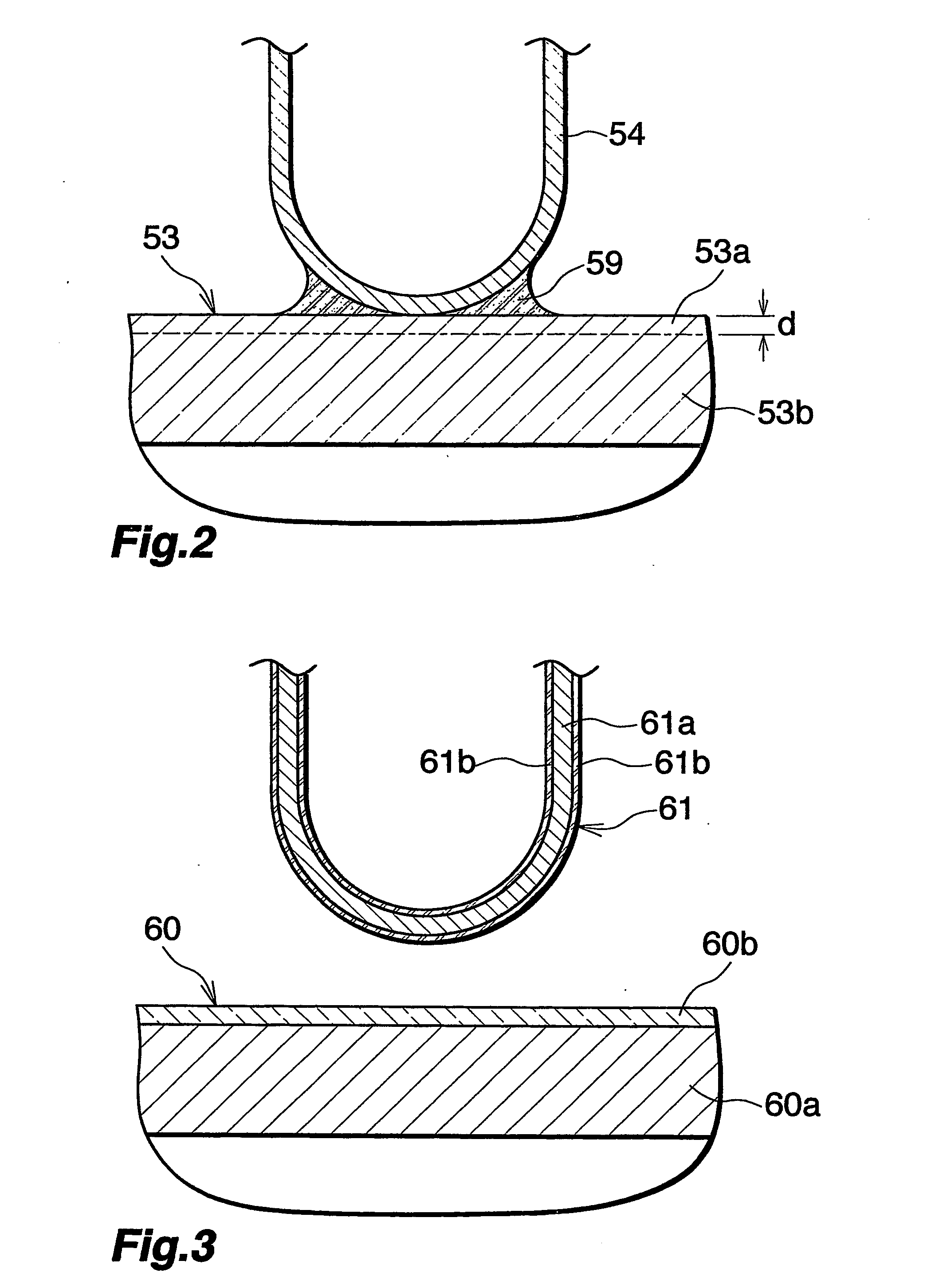

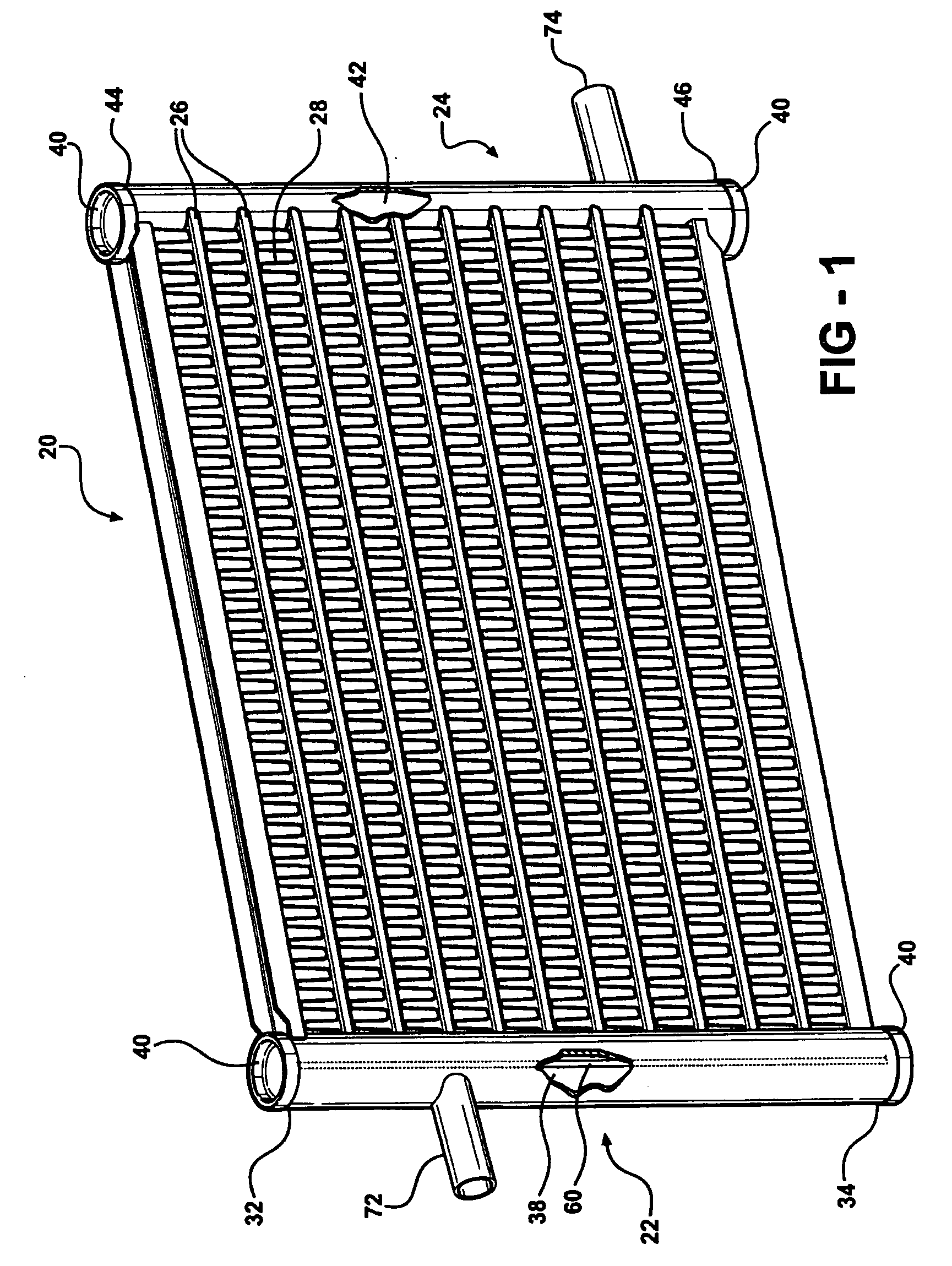

Heat exchanger, heat exchanger tube member, heat exchanger fin member and process for fabricating the heat exchanger

InactiveUS20060086486A1Separation of the fin from the heat exchange tube can be suppressedMaintain heat exchange efficiencyEvaporators/condensersSoldering apparatusSurface layerEngineering

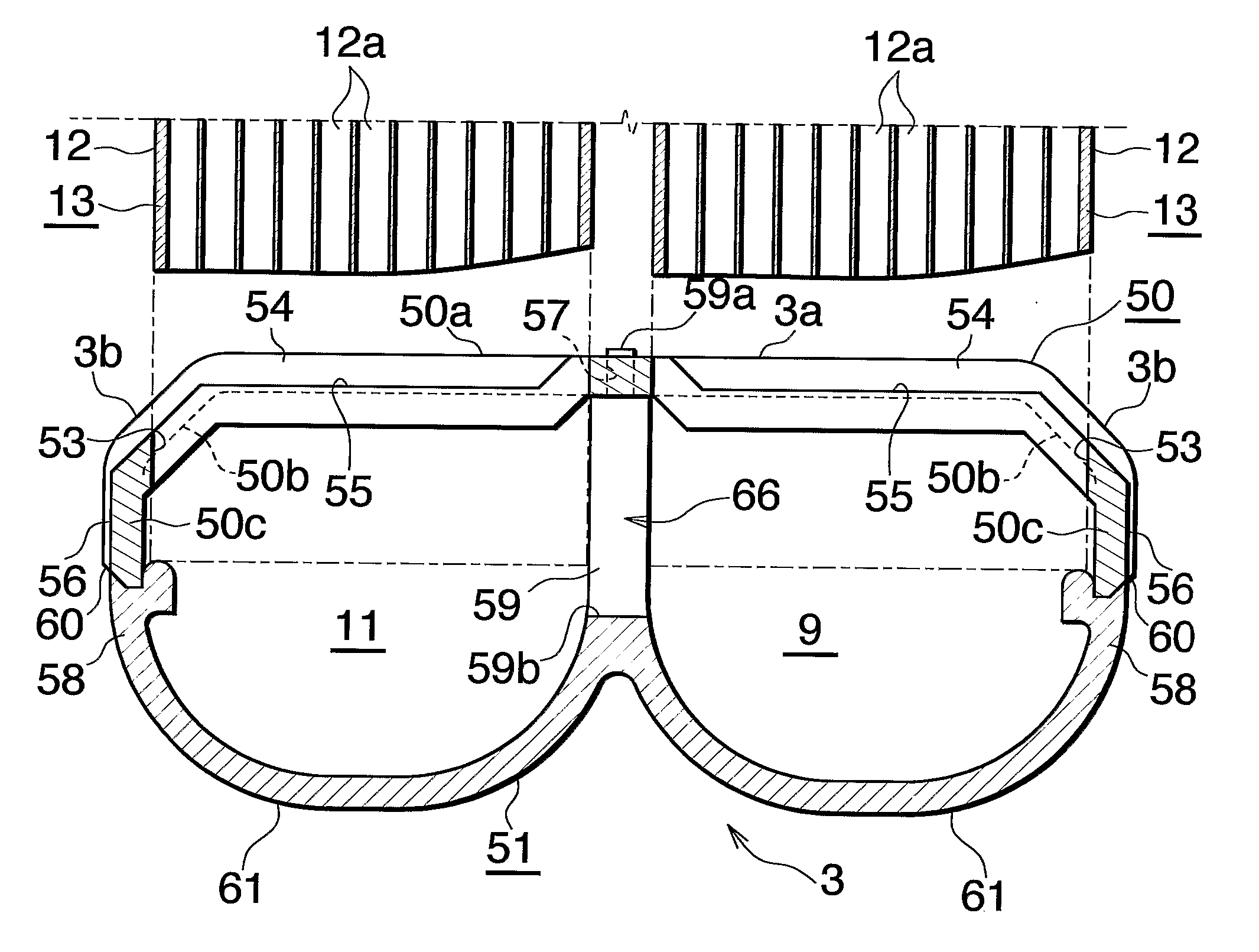

Suppose each of the refrigerant tubes 53 of a heat exchanger has a potential A at a surface layer portion 53 a of an outer periphery thereof and a potential B at a core 53 b of the tube 53 other than the surface layer portion 53 a thereof, each of the fins 54 has a potential C, and a fillet 59 formed at the brazed portion between the tube 53 and the fin 54 has a potential D. These potentials then have the relationship of A ?C ?D<B. The potential A of the surface layer portion 53 a of the outer periphery of the refrigerant tube 53 is -850 to -800 mV, the potential B of the core 53 b of the tube 53 is -710 to -670 mV, the potential C of the fin 54 is -850 to -800 mV, and the potential D of the fillet 59 is -850 to -800 mV.

Owner:SHOWA DENKO KK

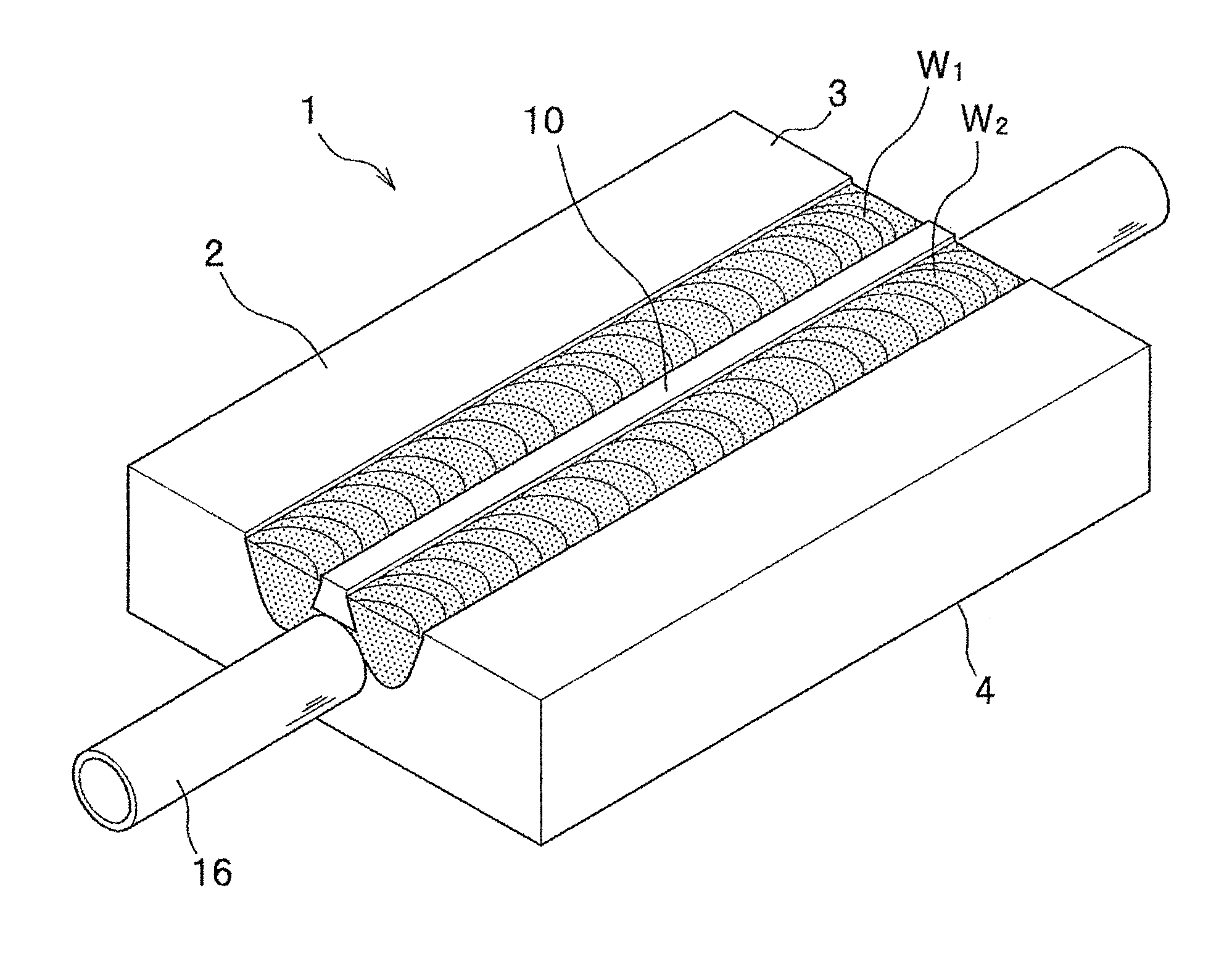

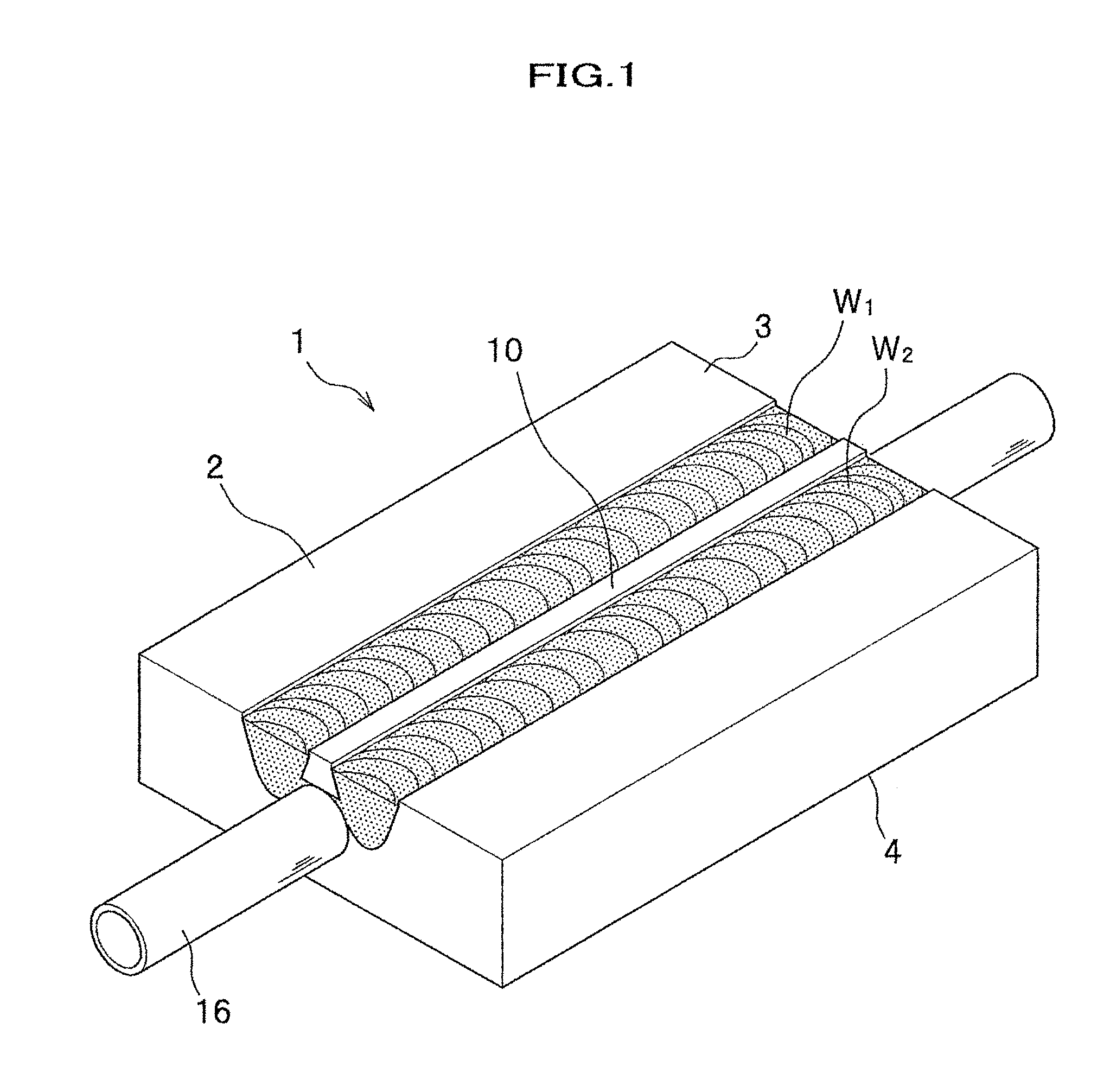

Heat transfer plate and method of manufacturing the same

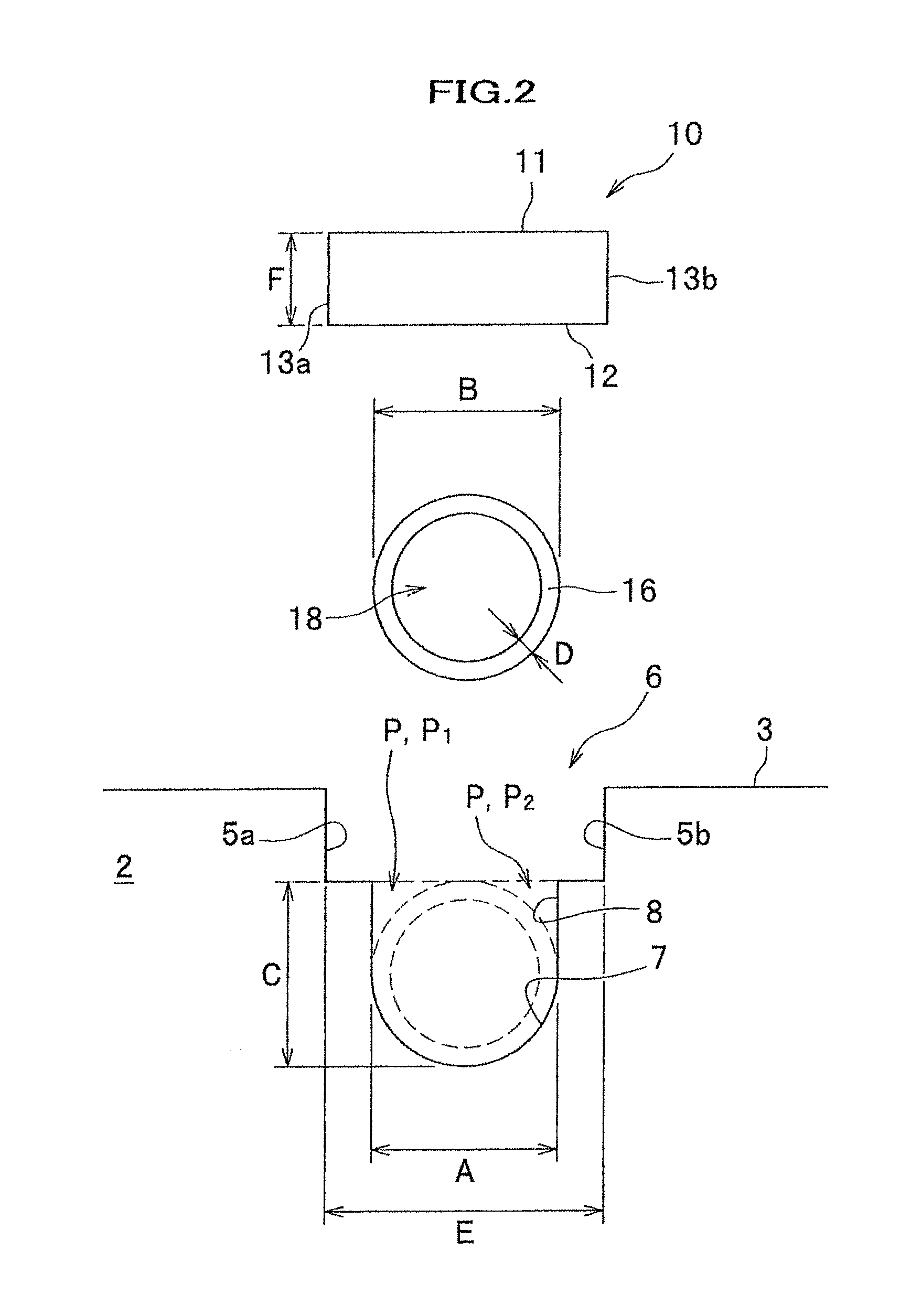

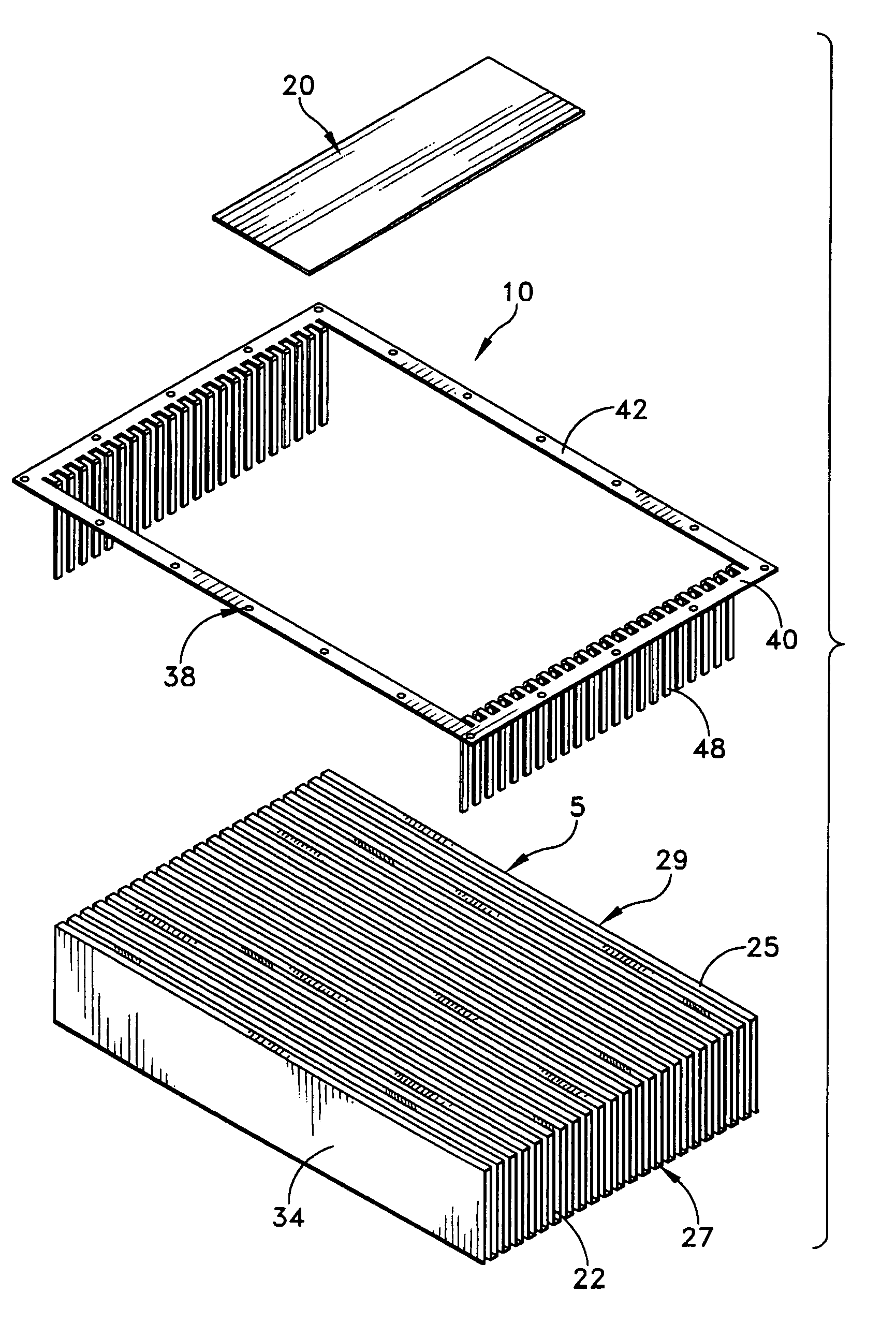

ActiveUS20100101768A1Improve thermal conductivityImprove heat exchange efficiencyClosure meansWelding/soldering/cutting articlesEngineeringMechanical engineering

A method of manufacturing a heat transfer plate (1) includes: an insertion process of inserting a heat medium pipe (16) in a concave groove (8) formed in a bottom face of a lid groove (6) open to an obverse (3) of a base member (2); a lid groove closing process of arranging a lid plate (10) in the lid groove (6); and a main joining process of moving a main joining rotation tool (20) along butt portions (V1, V2) between sidewalls (5a, 5b) of the lid groove (6) and side faces (13a, 13b) of the lid plate (10), wherein in the main joining process a plastic fluidizing material (Q), where the base member (2) and the lid plate (10) are fluidized due to frictional heat, is made to flow in air gap portions (P1, P2) formed around the heat medium pipe (16).

Owner:NIPPON LIGHT METAL CO LTD

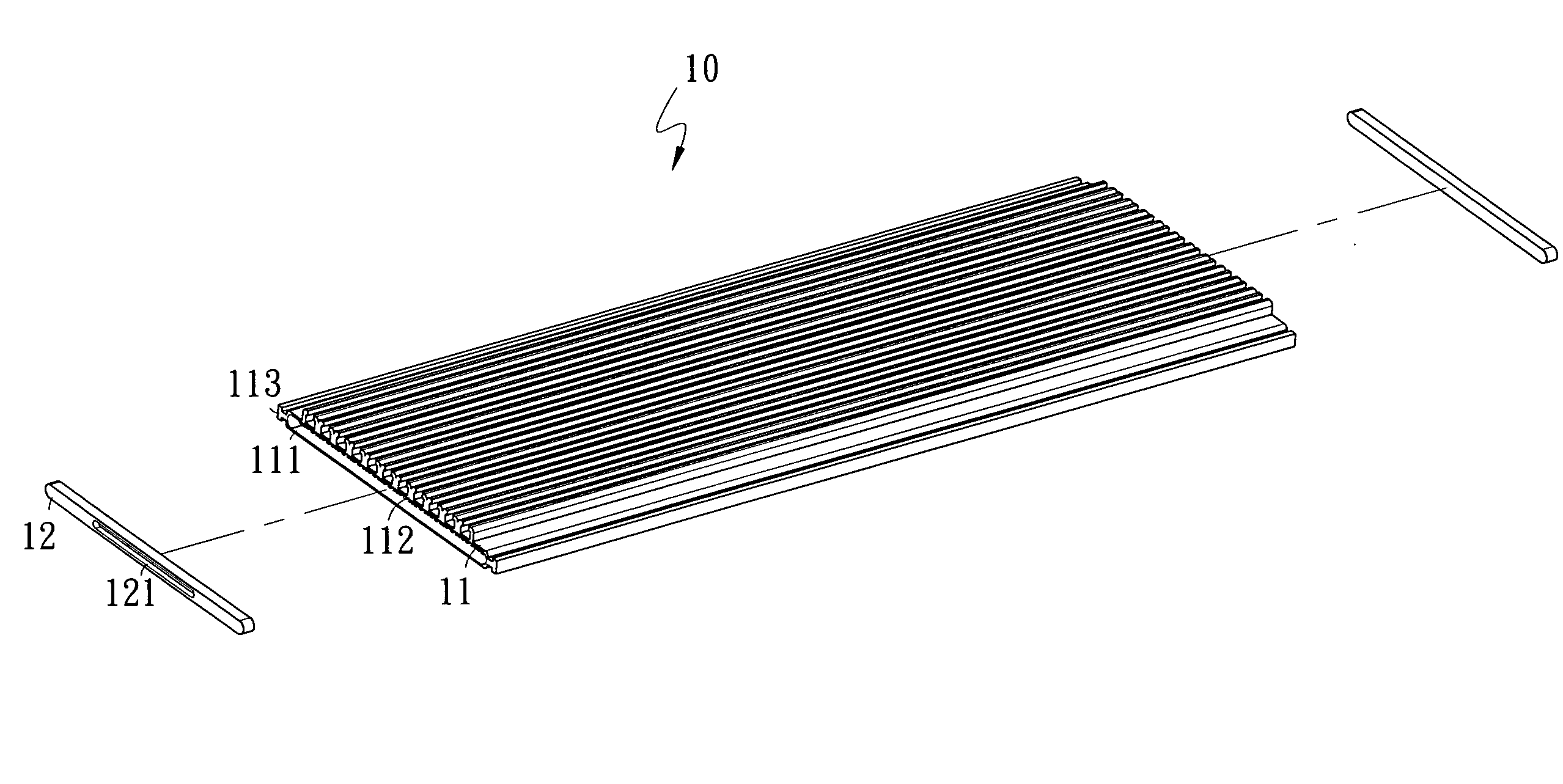

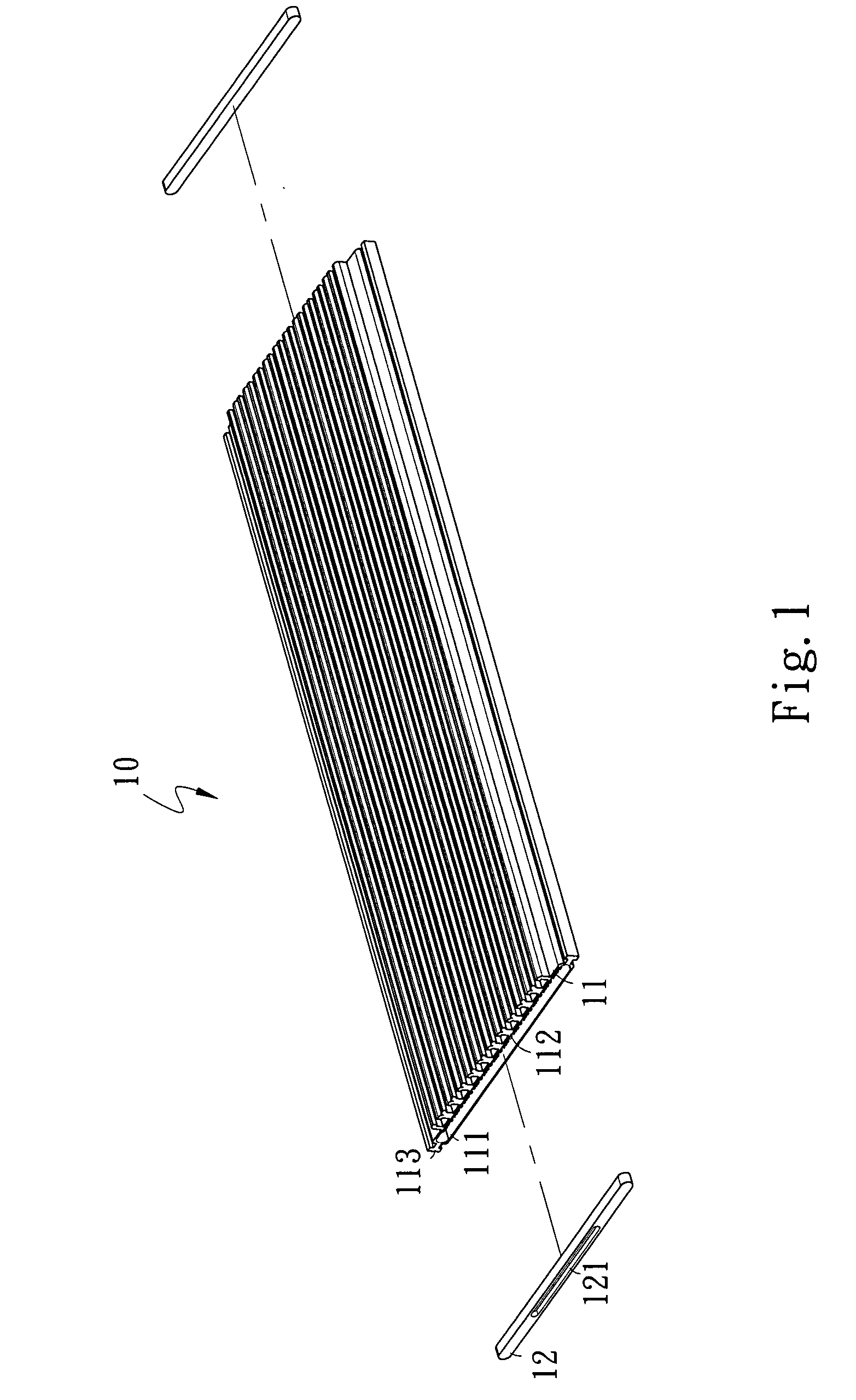

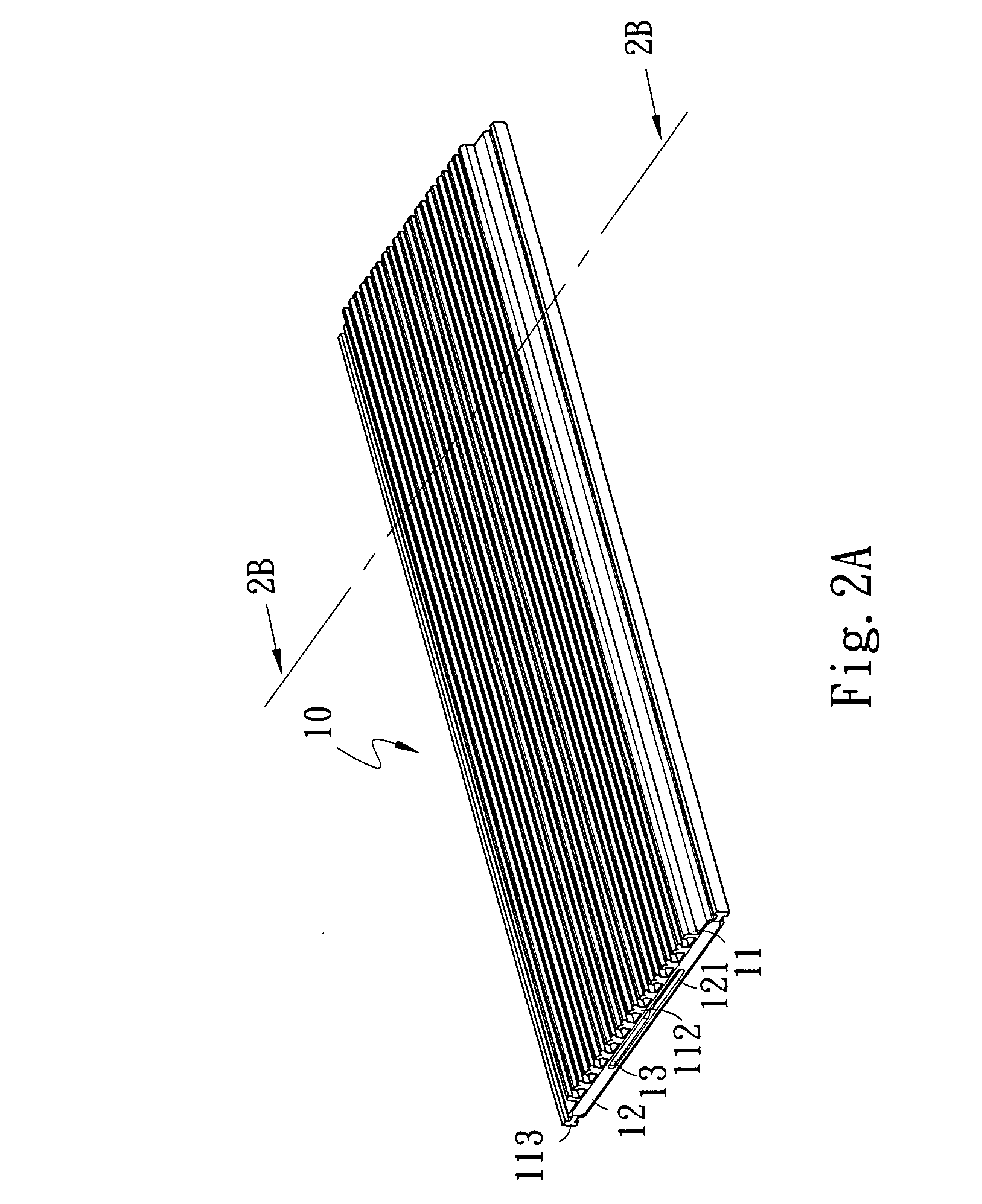

Heat plate

InactiveUS20080264611A1Solve the low heat dissipation efficiencyImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringAluminum extrusion

A heat plate mainly includes a hollow body and a plurality of caps. The hollow body is fabricated integrally by aluminum extrusion and has a hollow chamber inside. The hollow chamber has an inner side with a plurality of angular strips formed thereon to enhance heat dissipation efficiency and a plurality of spacing ribs to divide the hollow chamber into a plurality of housing space to hold a liquid to increase the heat dissipation efficiency. The hollow body has one surface with a plurality of sliding tracks formed thereon, a latch flute on the left side and right side to wedge in the sliding tracks of another heat plate to enhance the heat dissipation efficiency. The hollow body has another surface with a PCB circuit formed thereon. Electronic elements may be soldered on the PCB circuit to achieve optimal heat dissipation efficiency.

Owner:CHANG KUN JUNG +2

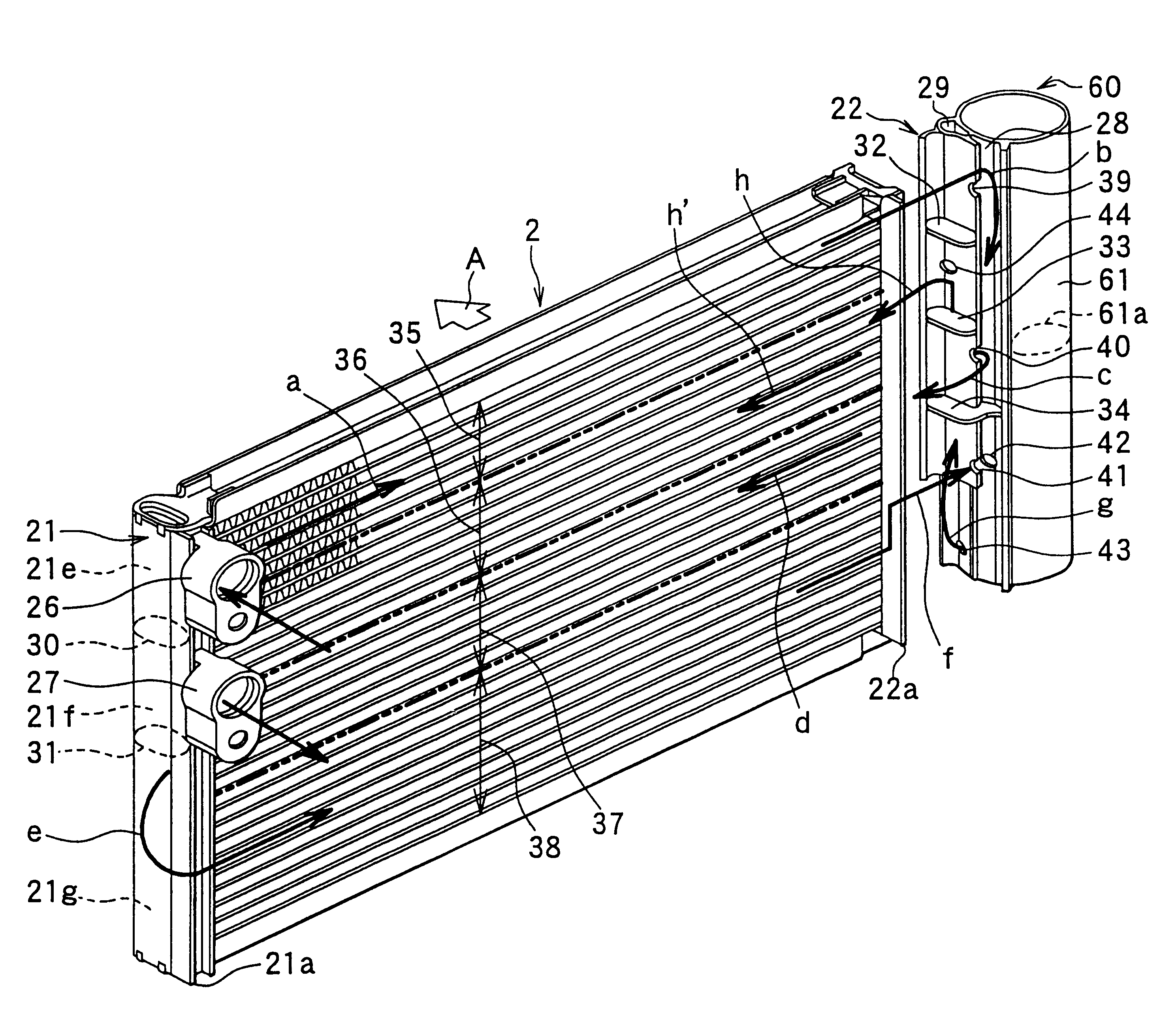

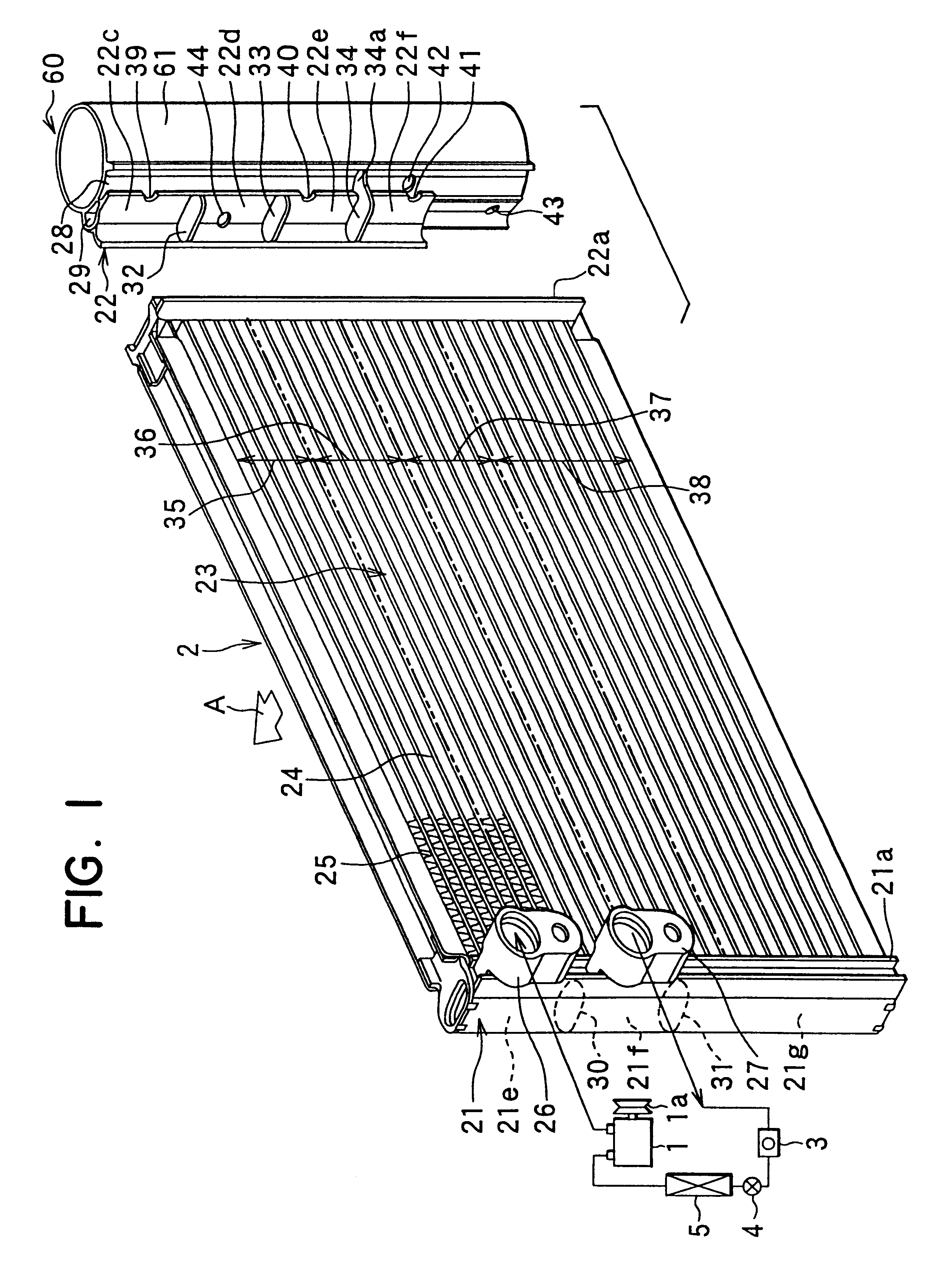

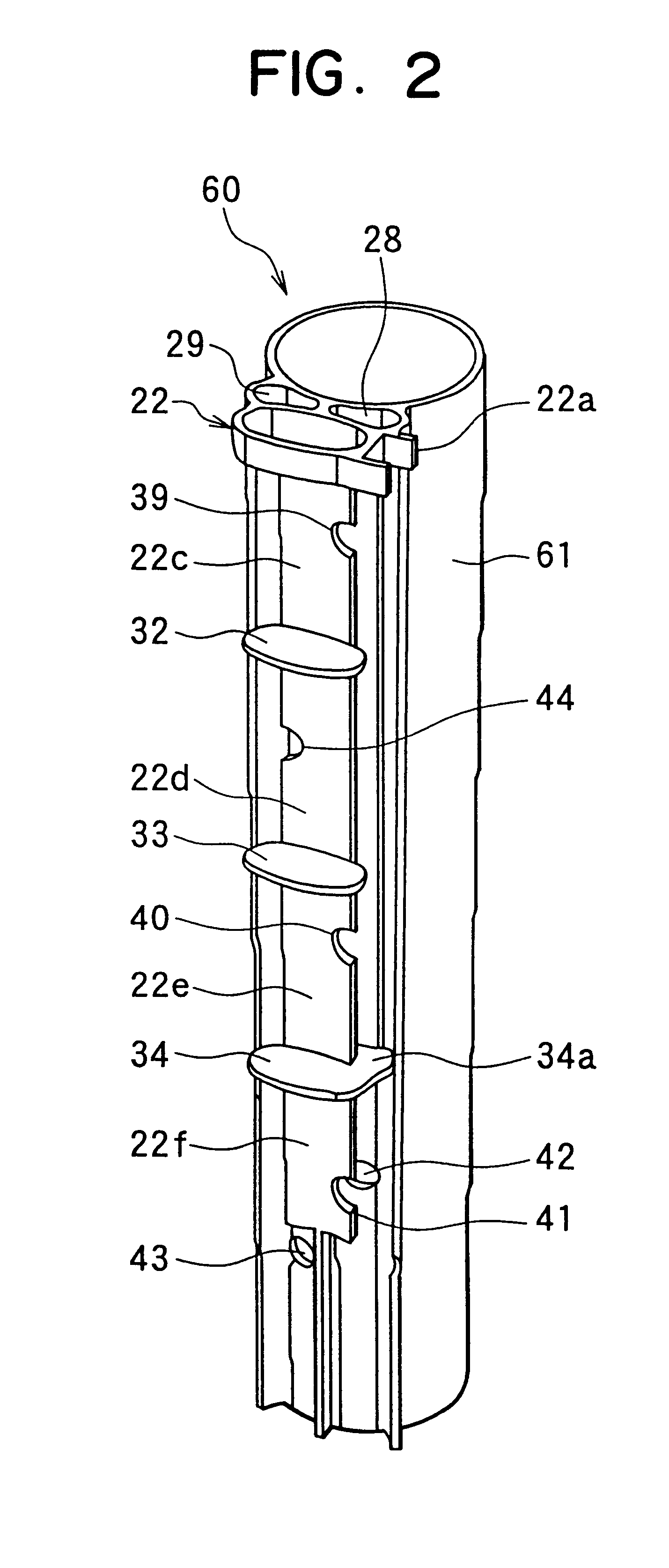

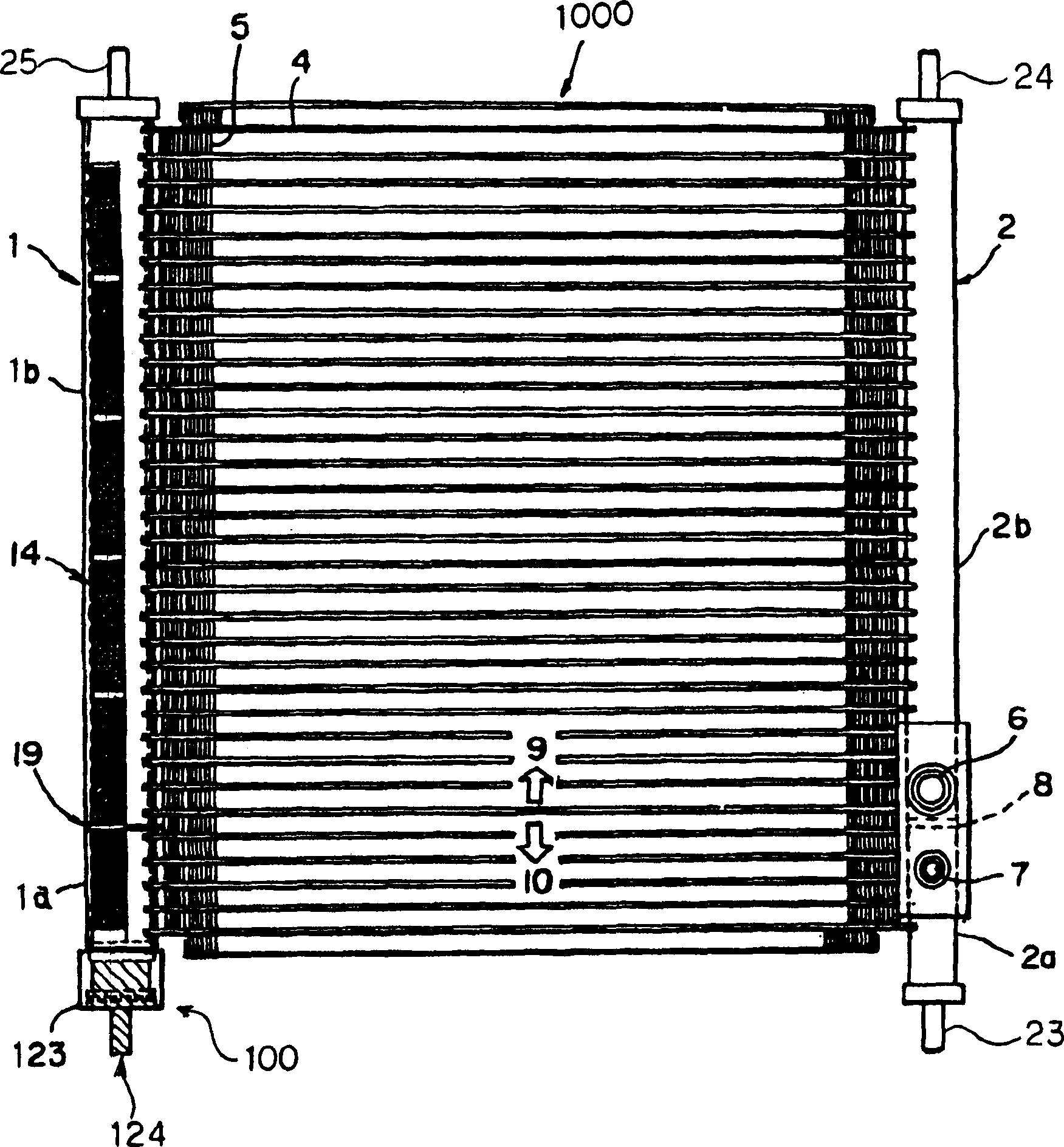

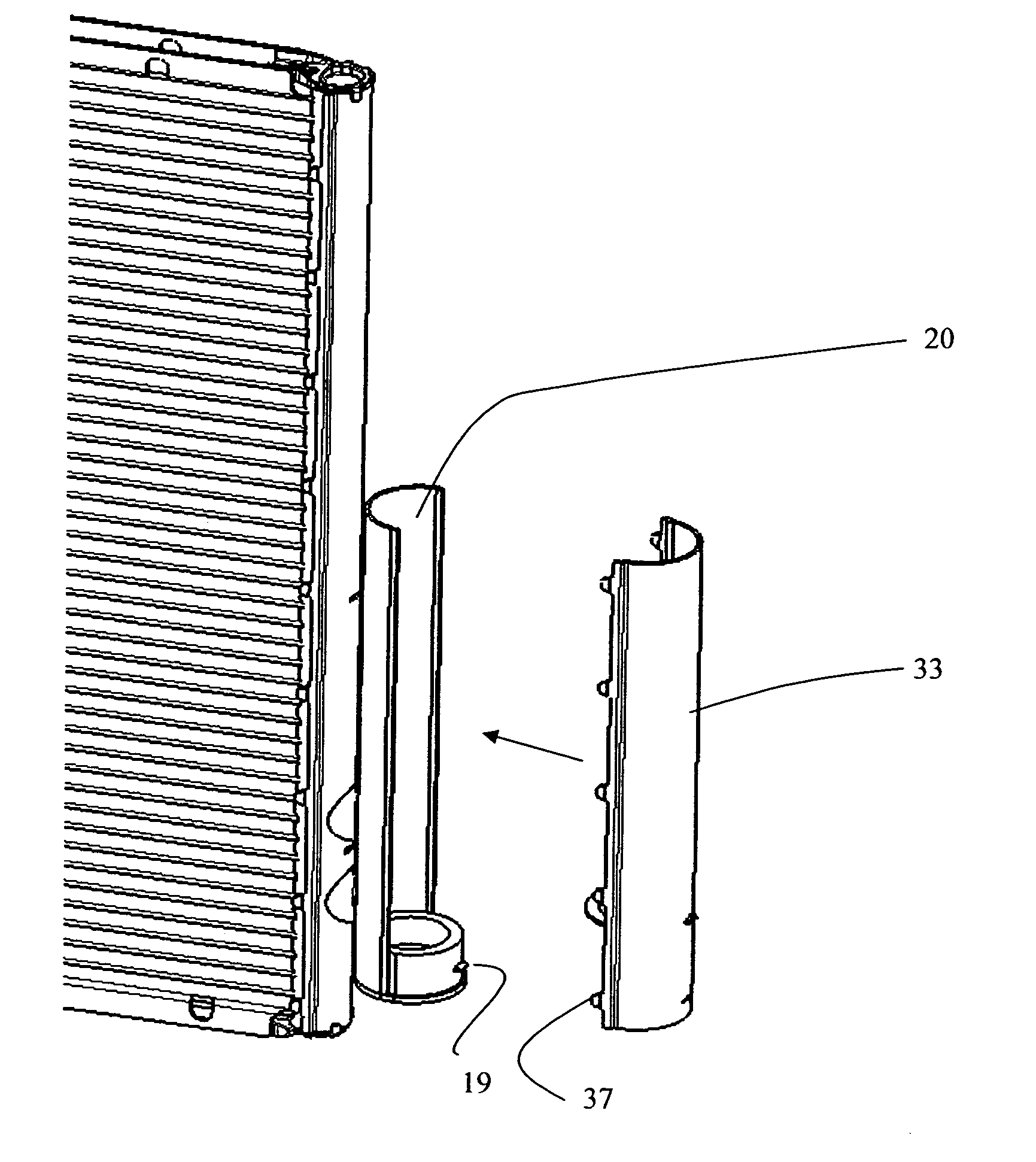

Receiver-integrated condenser

InactiveUS6397627B1Precise applicationPrecise punchingEvaporators/condensersClosure meansSuper coolingEngineering

In a receiver-integrated condenser, a super-cooling portion for cooling liquid refrigerant from a receiving unit is disposed between first and second condensing portions in a core portion in a vertical direction. Therefore, in an engine-idling, even when high-temperature air having passed through the receiver-integrated condenser is introduced again toward an upstream air side of the receiver-integrated condenser through a lower side of the receiver-integrated condenser, the high-temperature air is not introduced toward the arrangement position of said super-cooling portion, because the super-cooling portion is positioned at an upper side from the second condensing portion. Thus, super-cooling performance of refrigerant in the super-cooling portion of the core portion is prevented from being decreased even in the engine idling.

Owner:DENSO CORP

Header pipe evaporator for use in an automobile

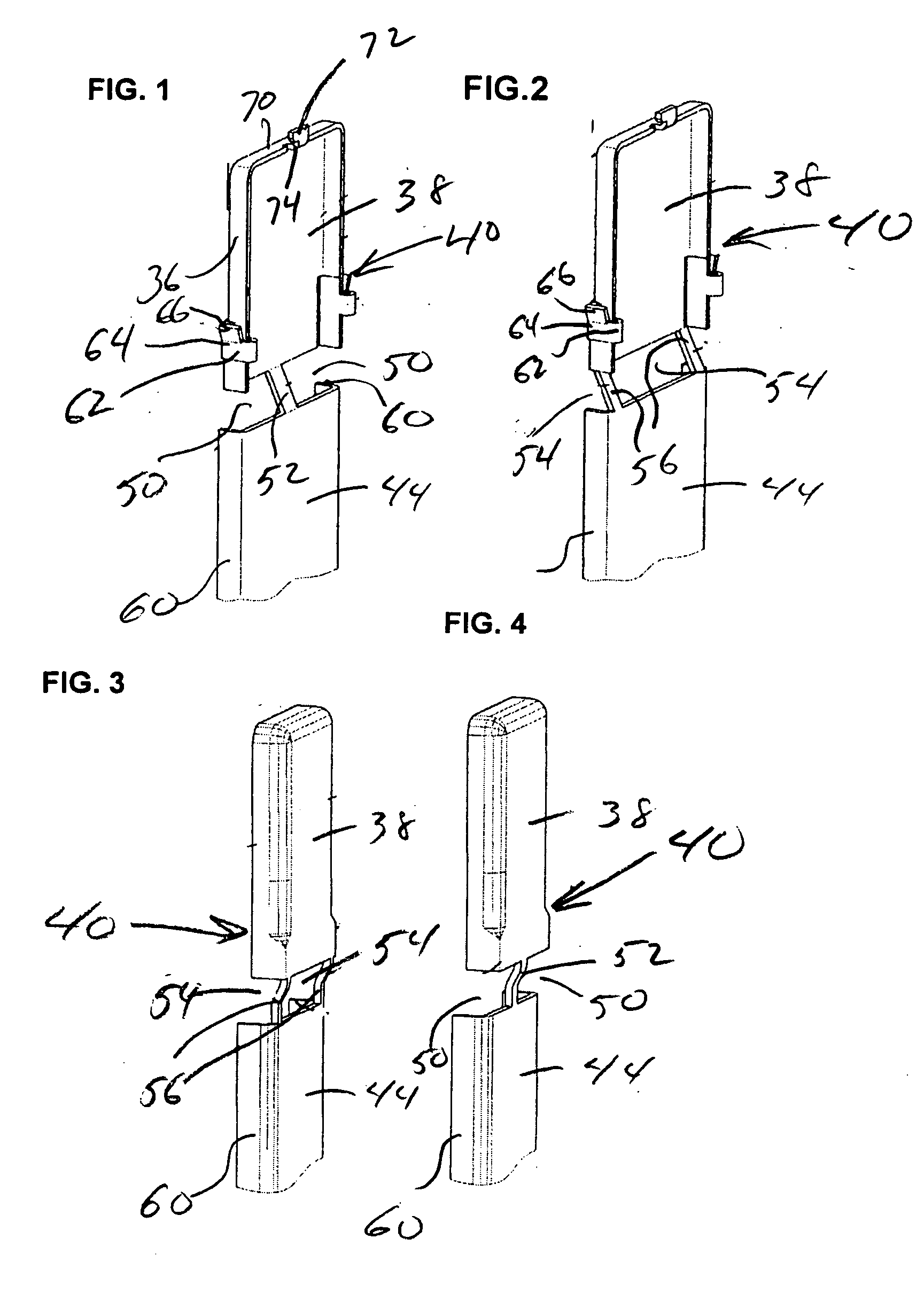

InactiveUS20050247443A1Reduce in quantityMinimize and prevent refrigerant leakageBuilding locksEvaporators/condensersEngineeringRefrigerant

The present invention relates to a header pipe for a vehicle evaporator capable of decreasing the number of assembling processes of a header pipe and minimizing / preventing a refrigerant leakage at a junction portion after elements are brazed for thereby achieving a simpler construction. In the present invention, a vehicle evaporator is provided with a header pipe, comprising a tank part and a header part forming an integral structure wherein a partition wall partitioning a refrigerant flow path space of the tank part, a partition plate for changing a refrigerant flow path at the tank part, and caps for covering the openings of both sides of the tank part are assembled in a structure.

Owner:MODINE KOREA

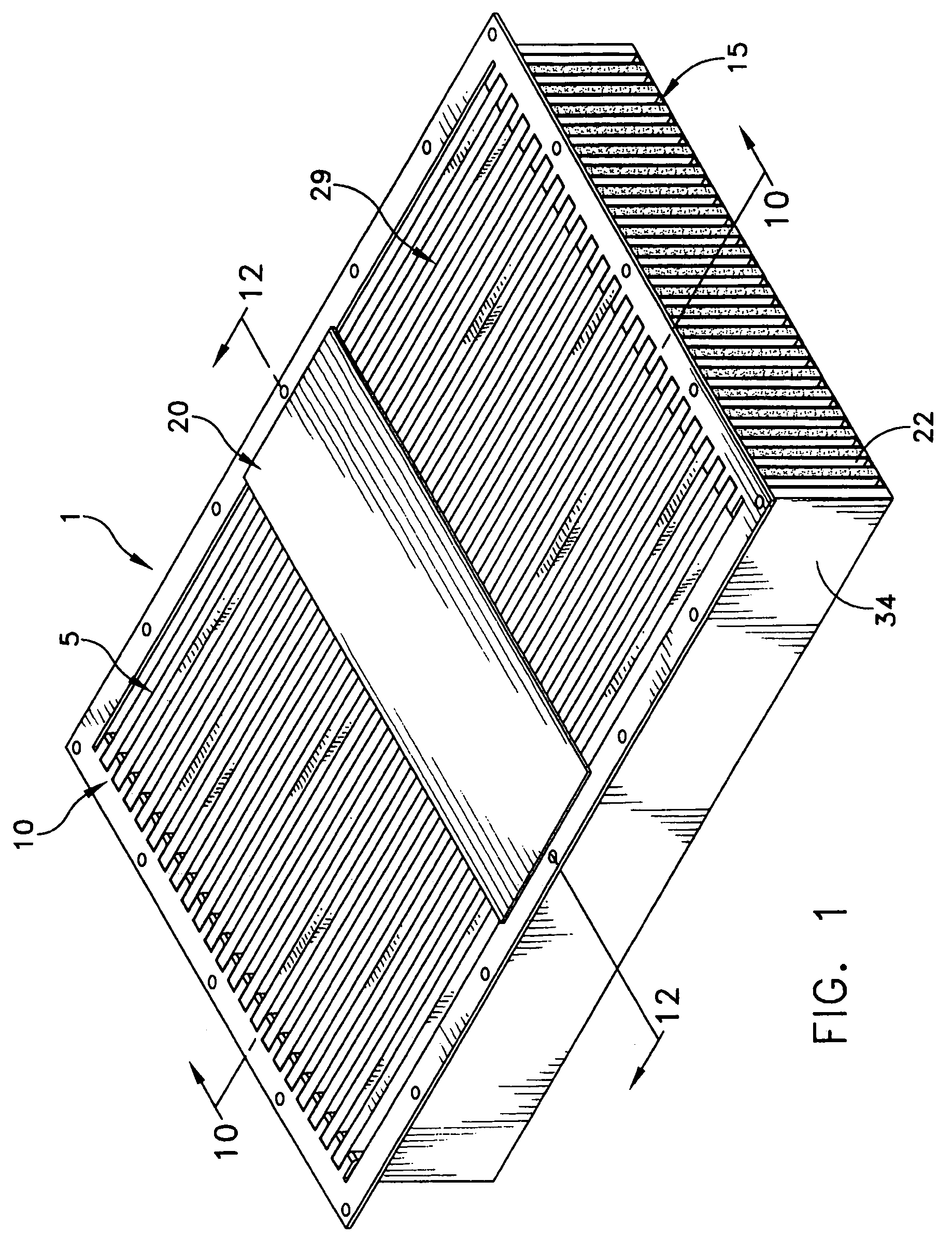

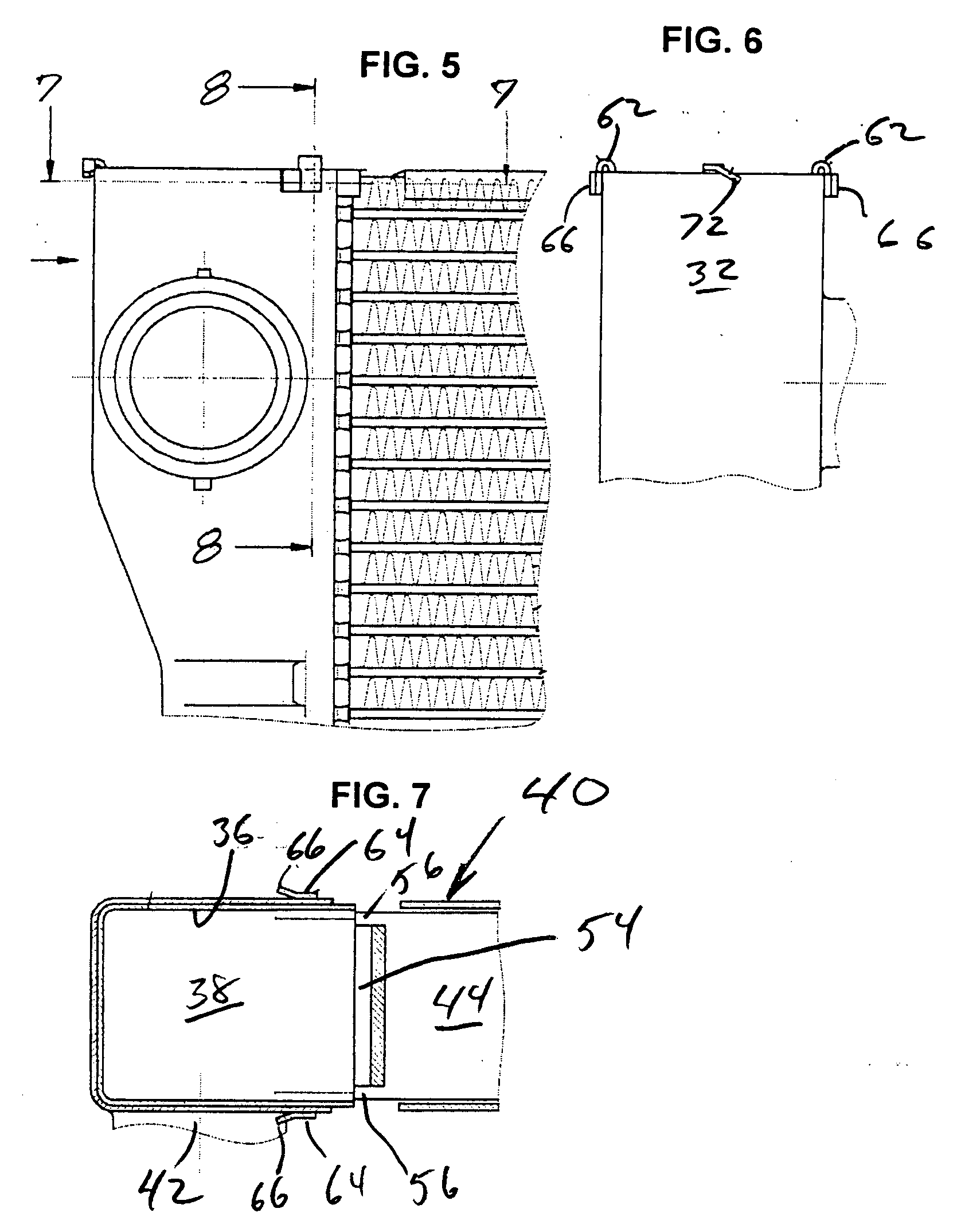

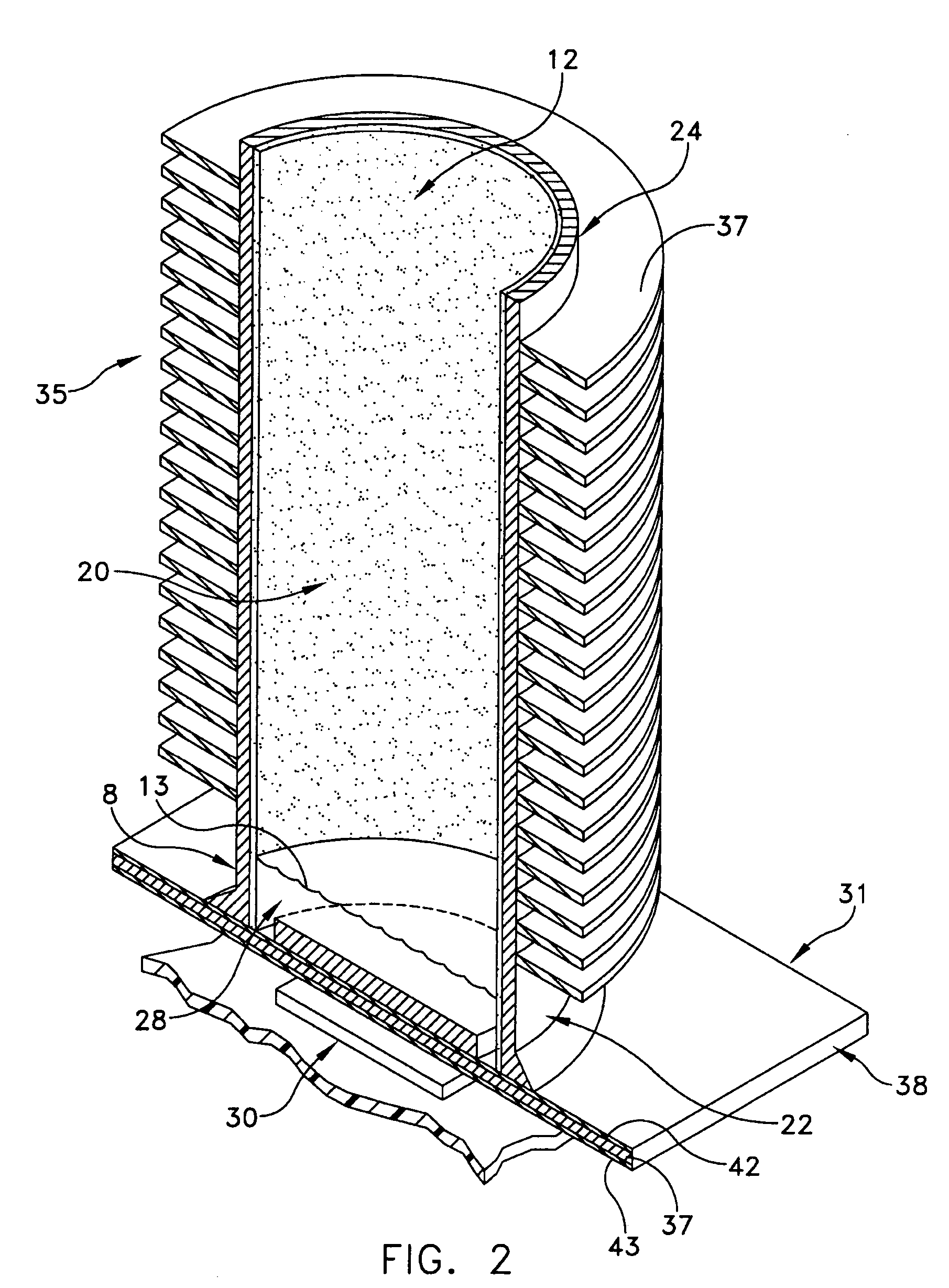

Air-to-air heat exchanger

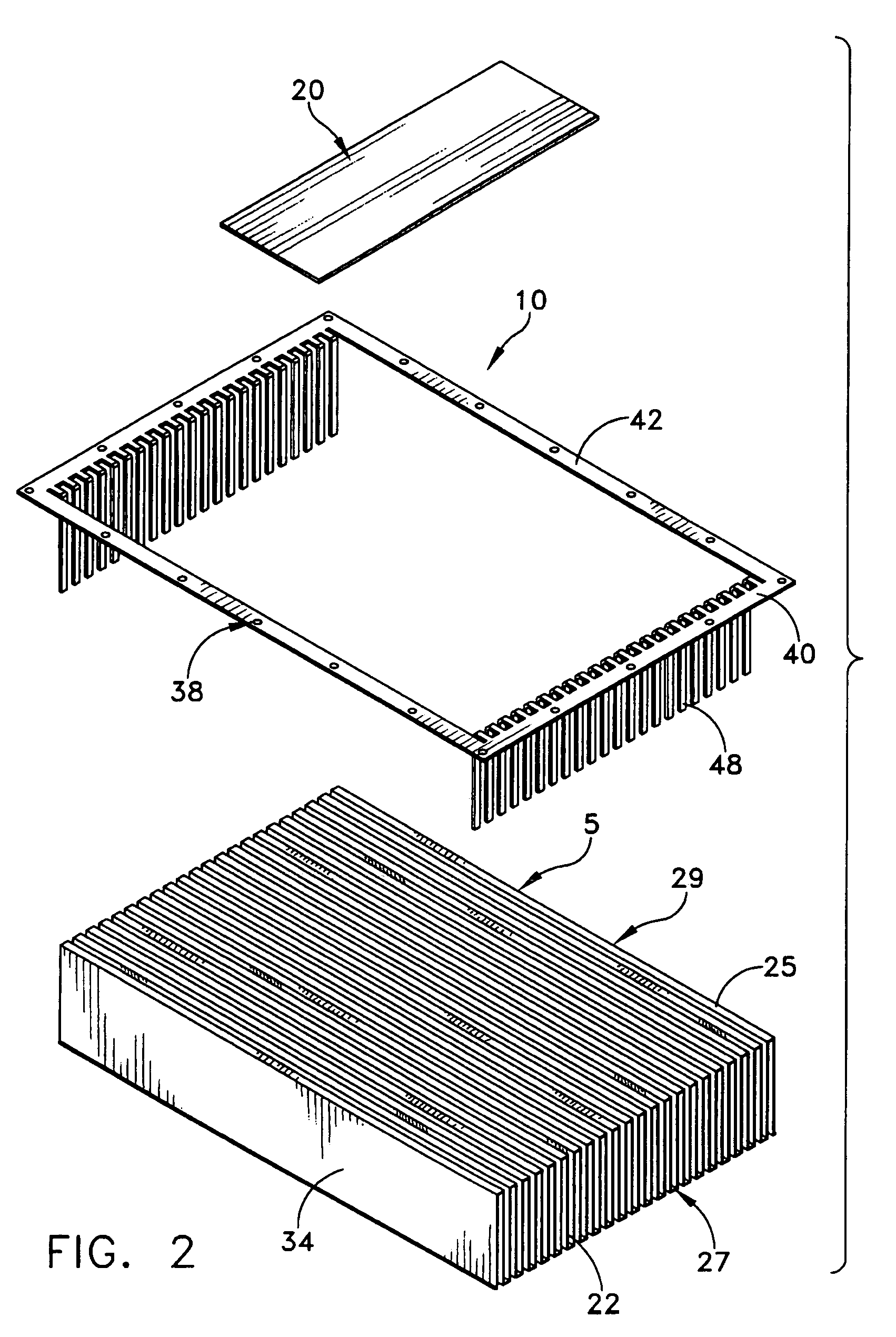

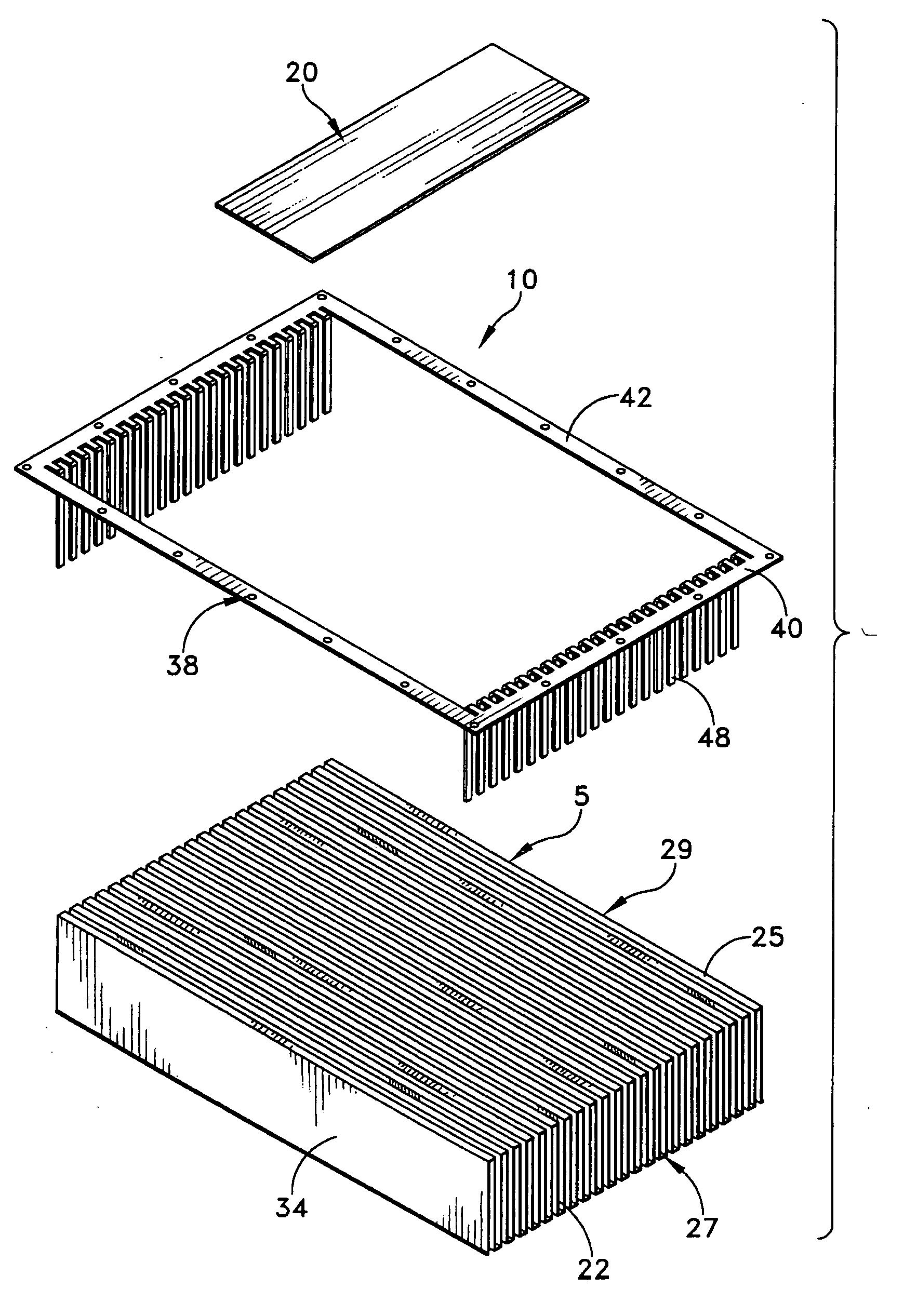

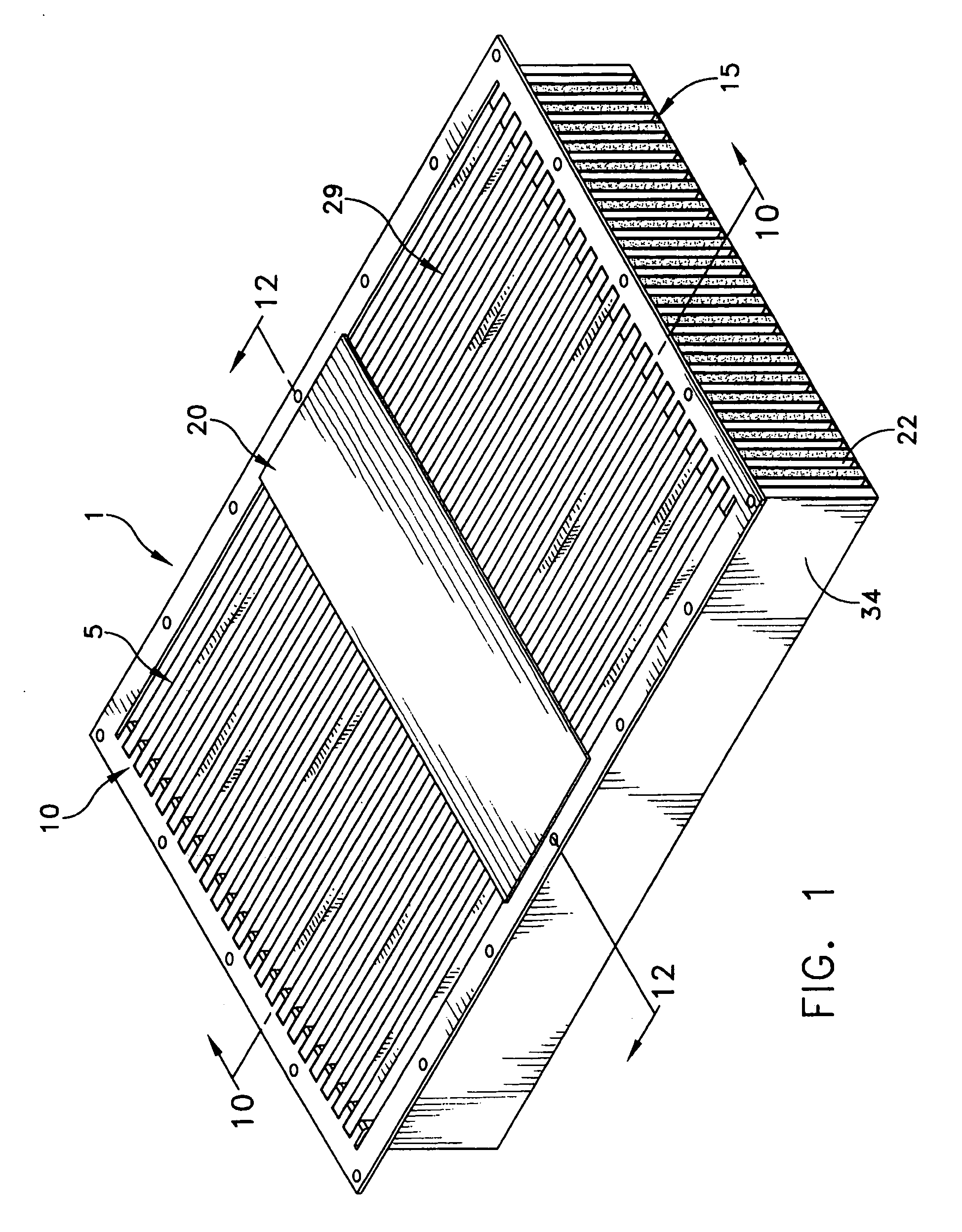

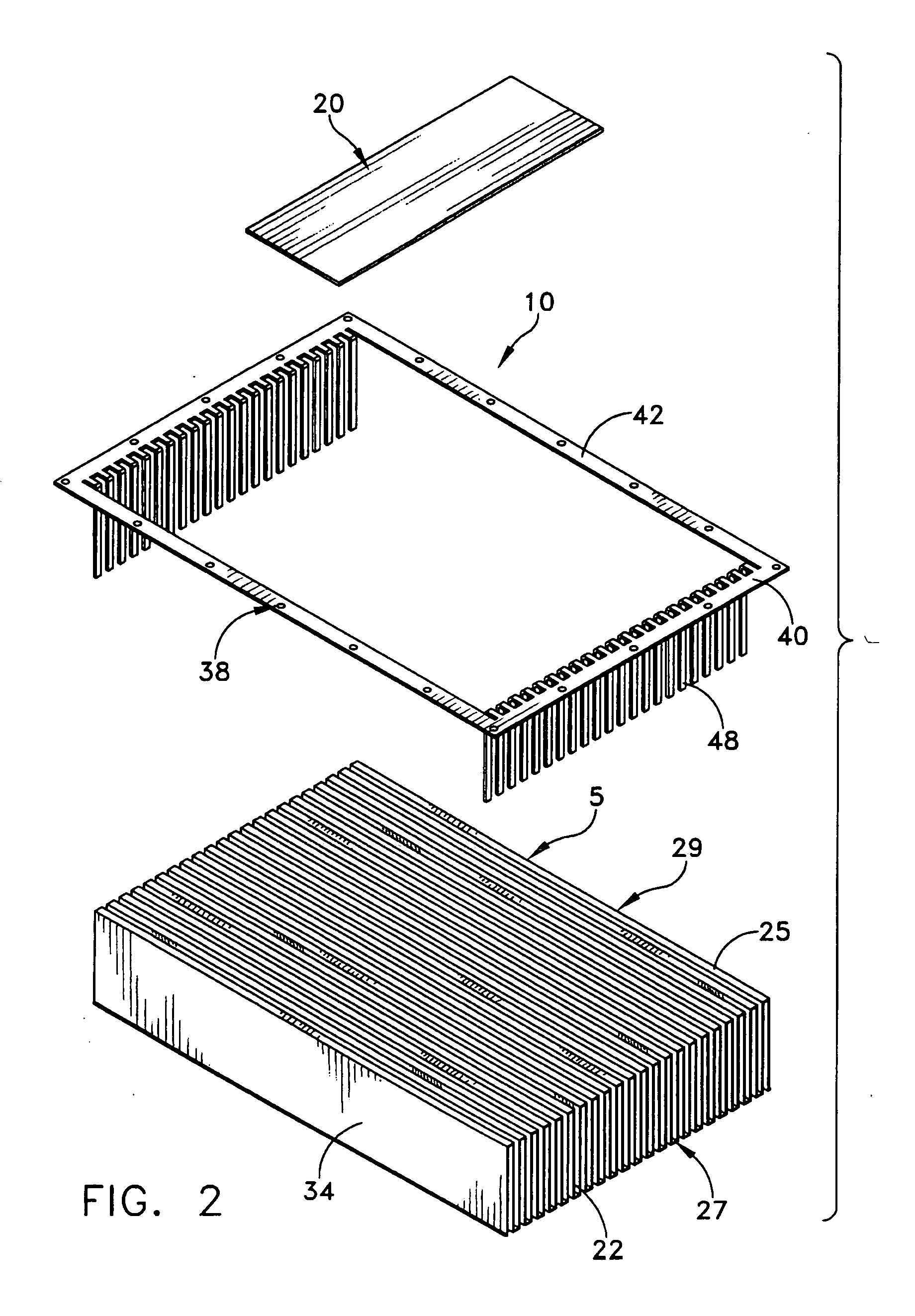

An air-to-air heat exchanger, is provided that comprises a folded fin core formed from a continuous sheet of thermally conductive material that has been folded into alternating flat ridges and troughs; an insert overlay having an opening including two sets of uniform fingers, wherein each finger has a portion protruding into and essentially filling each trough on one surface of the folded fin core; an inset region between each finger portion and the end edges of each trough; a sealant within each inset region sealably attaching the insert overlay to the folded fin core; and an air flow divider plate. Heat exchanger components are also provided.

Owner:THERMAL

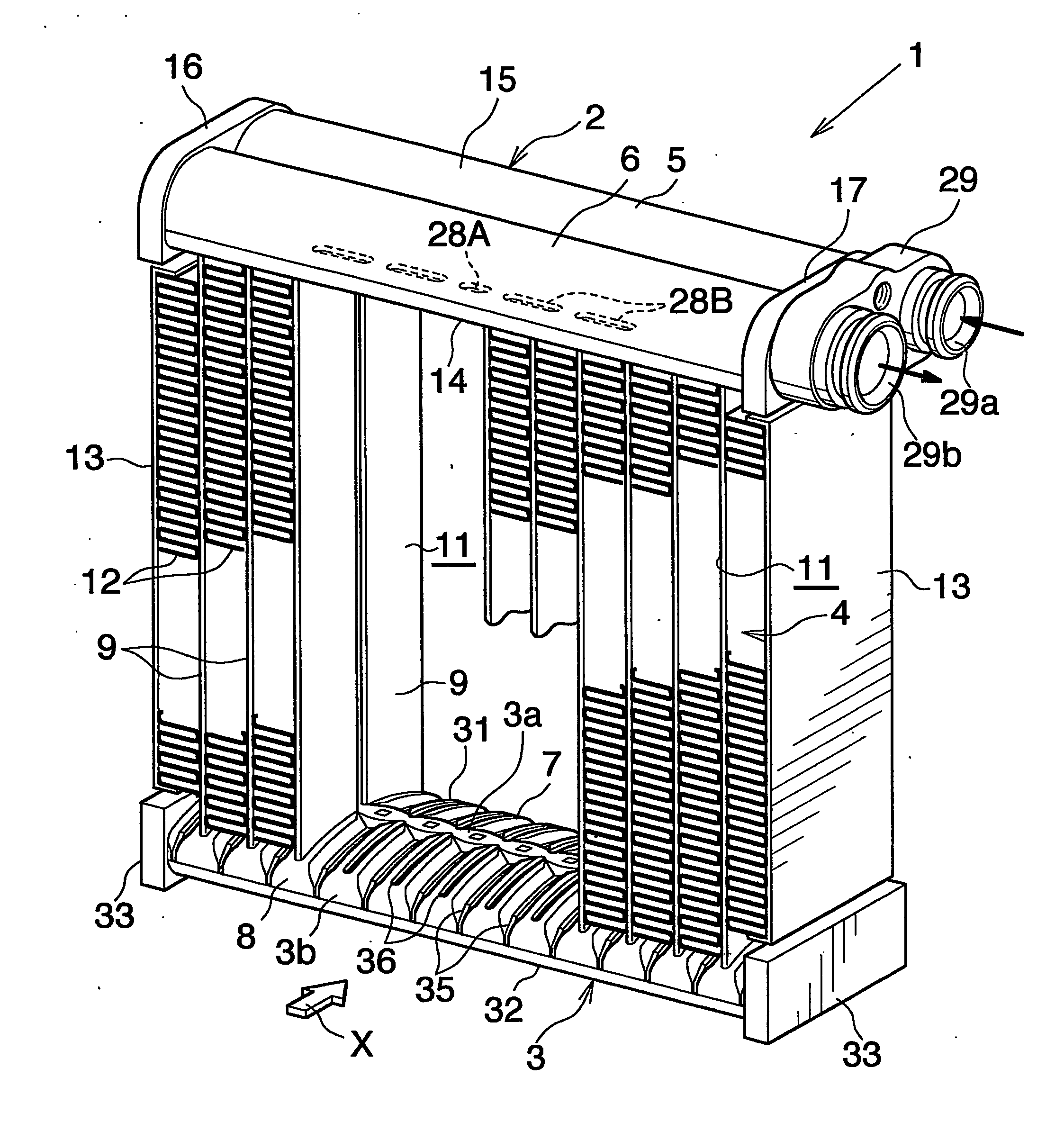

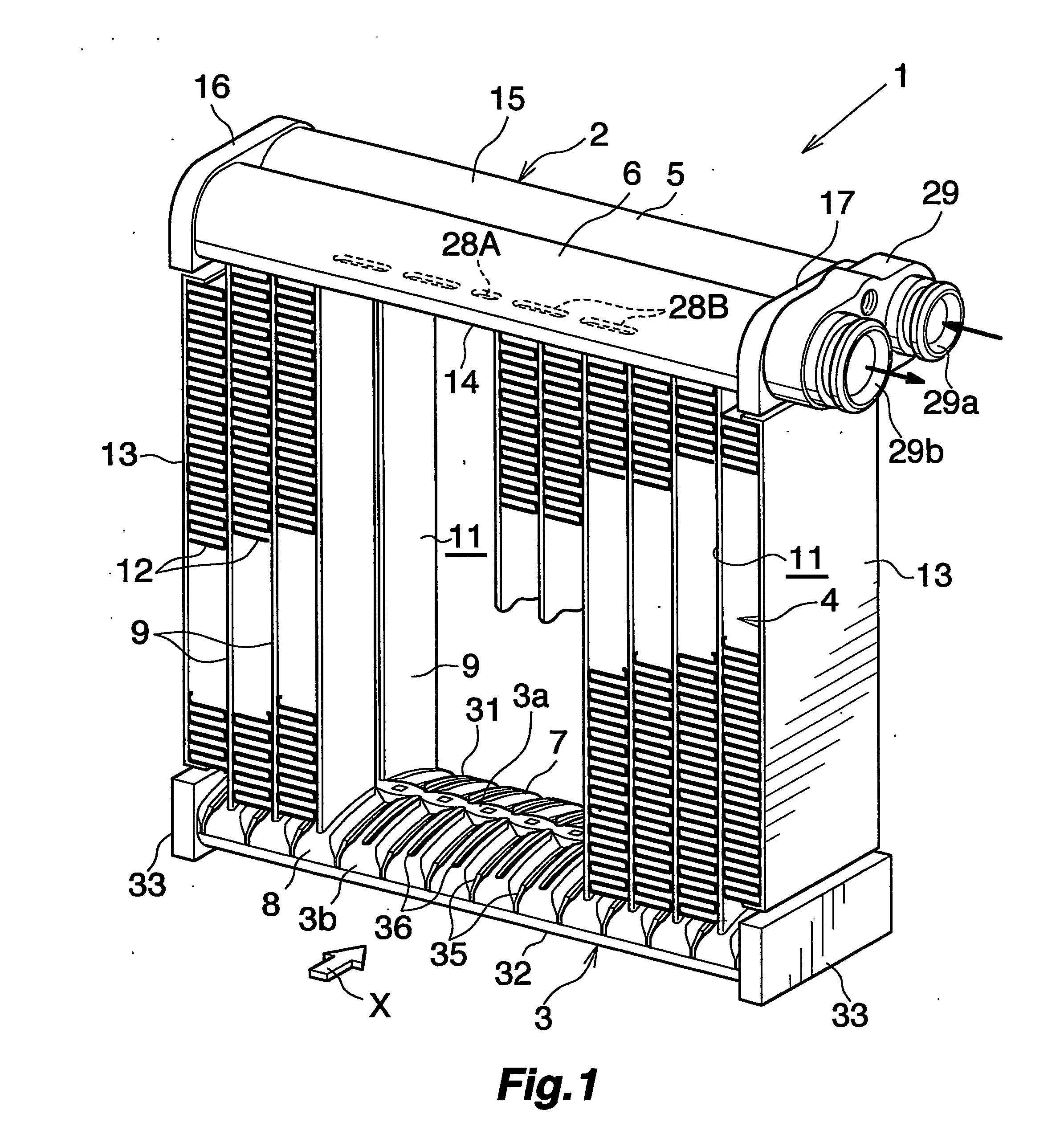

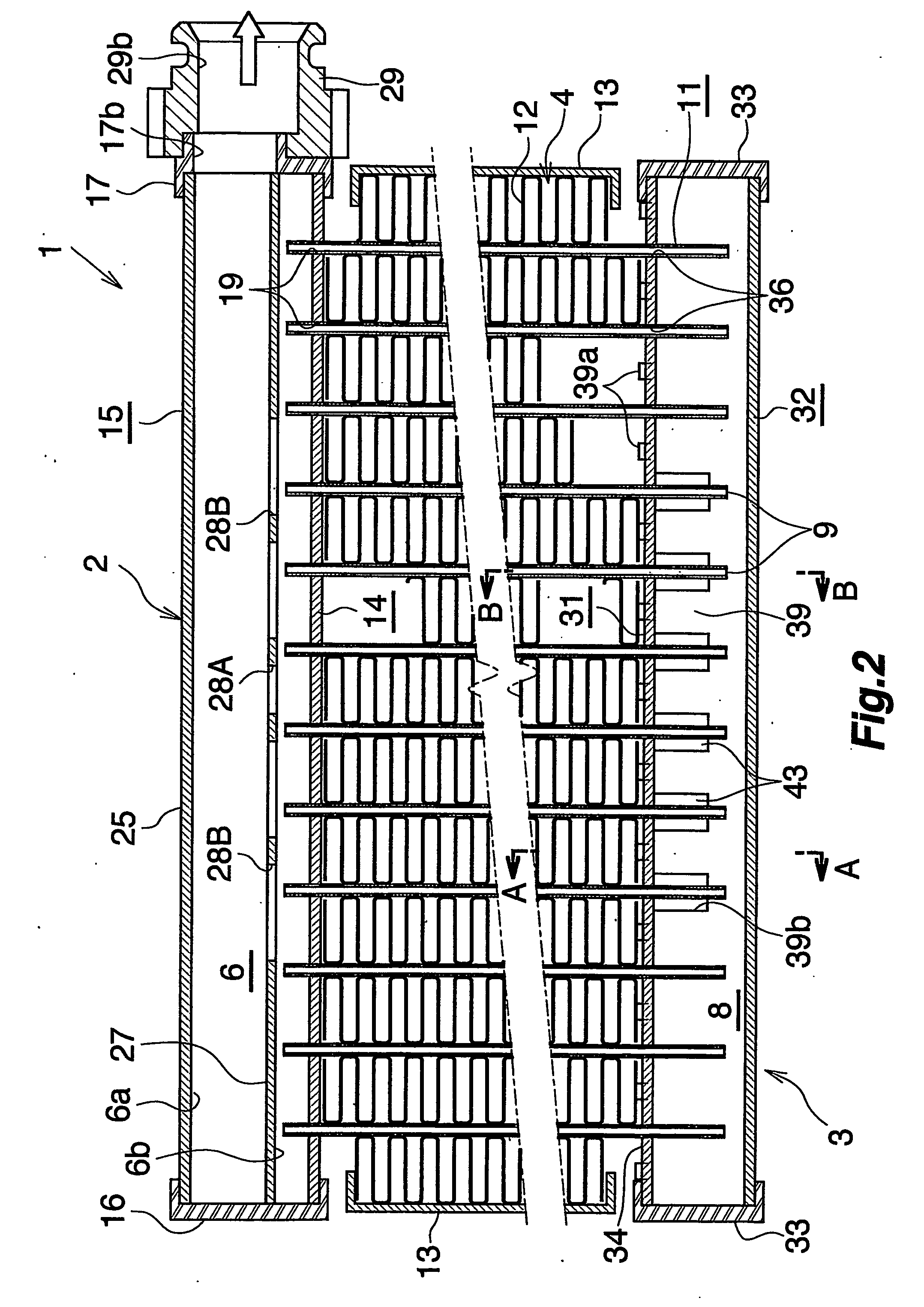

Heat exchanger

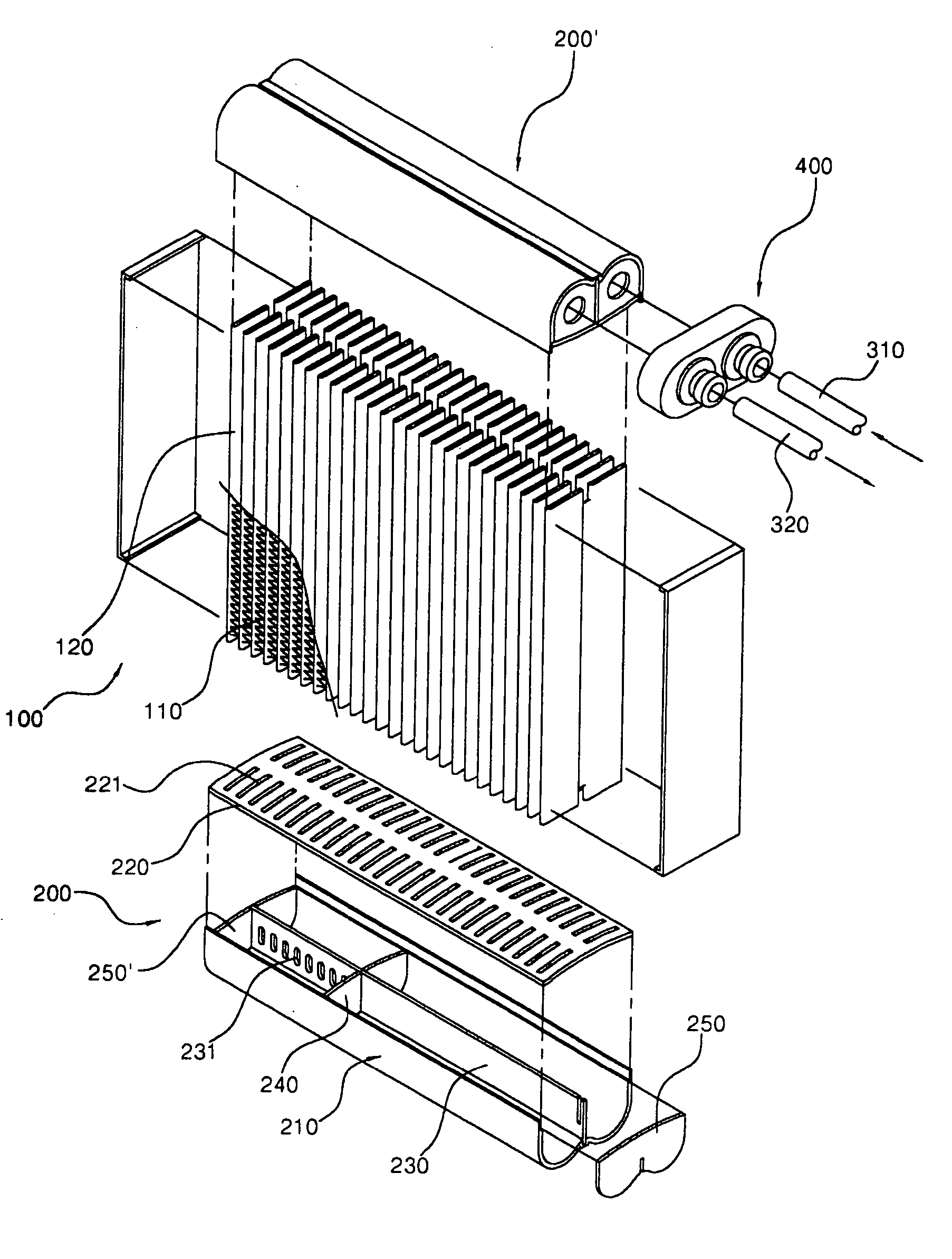

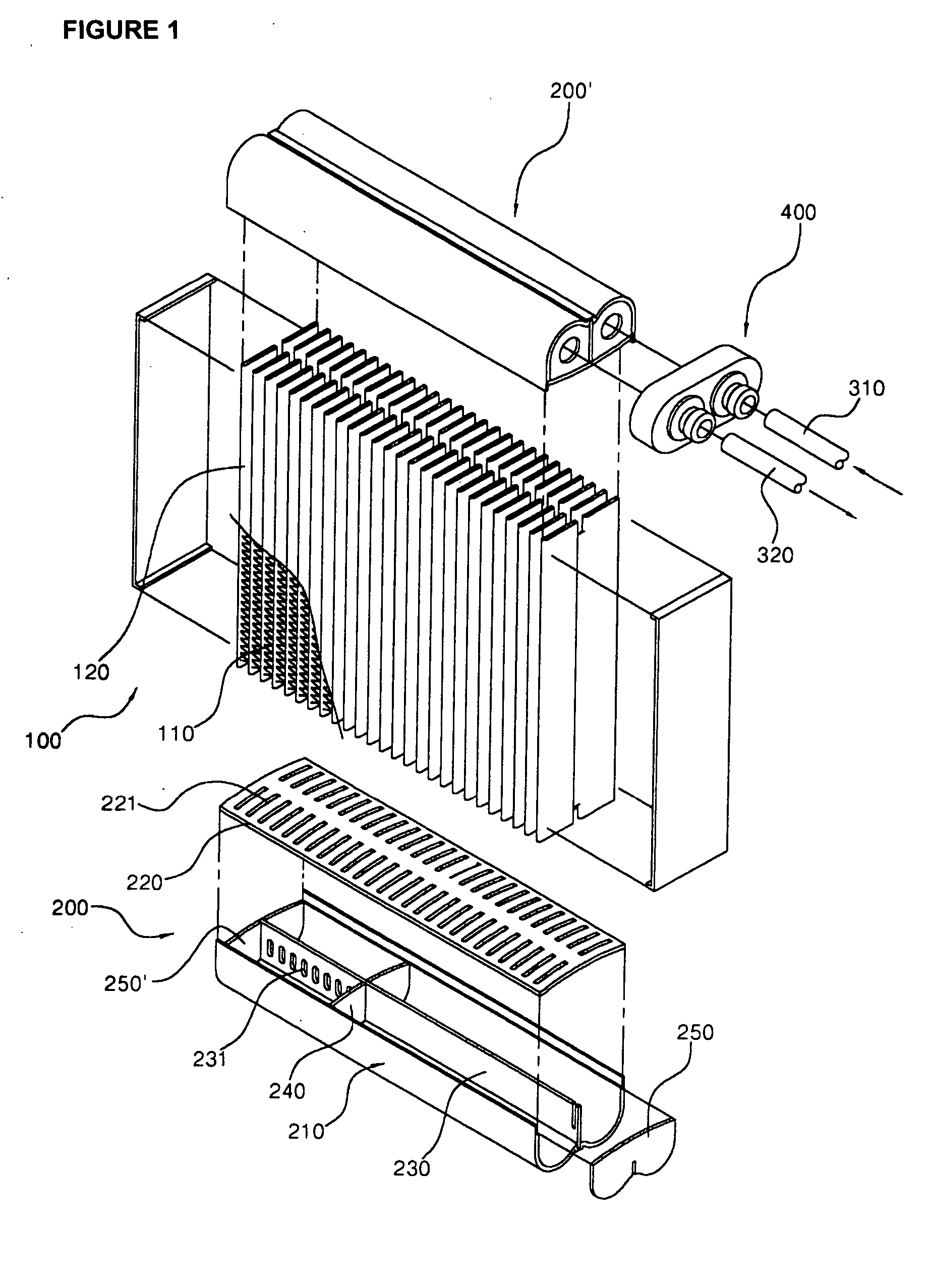

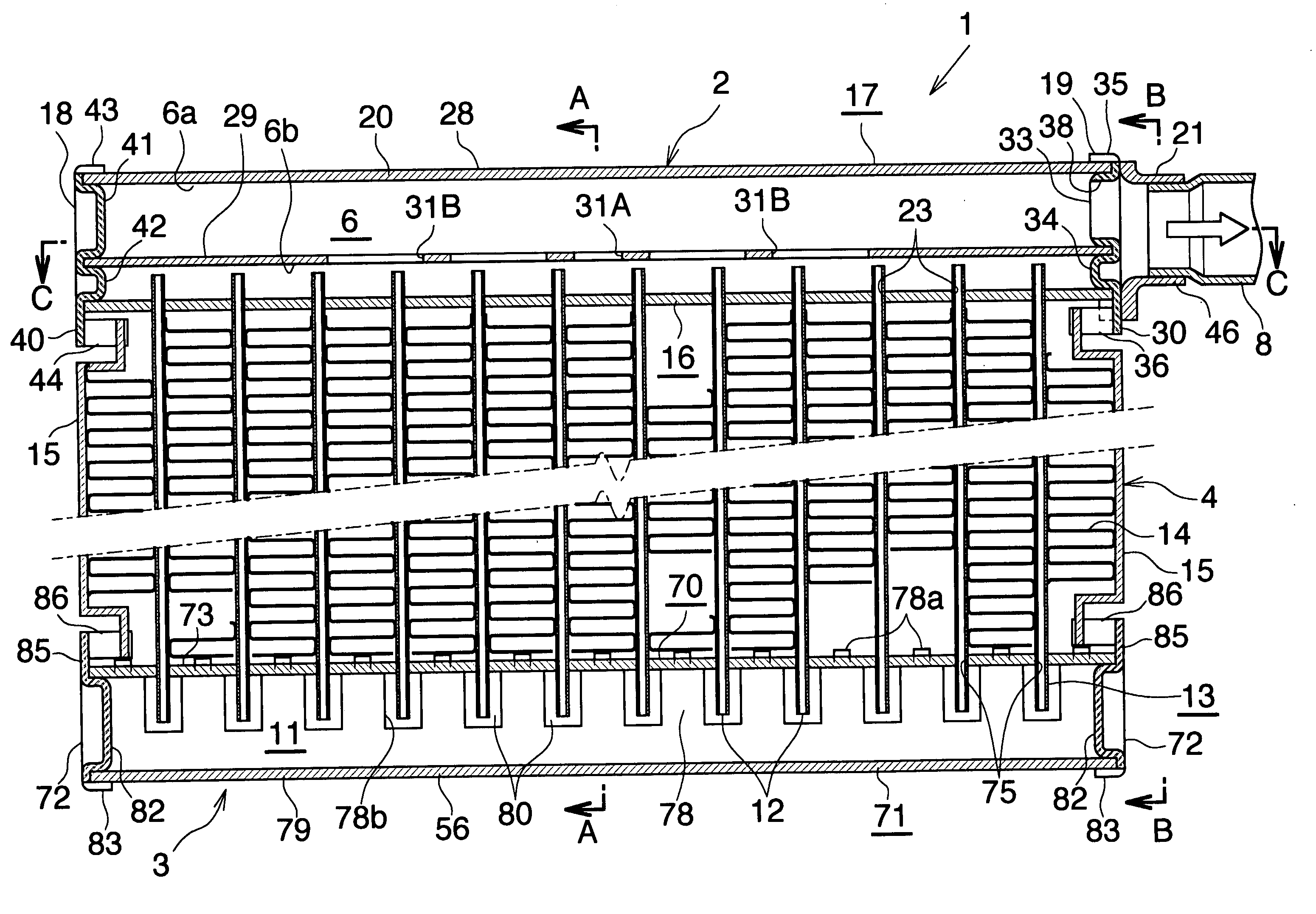

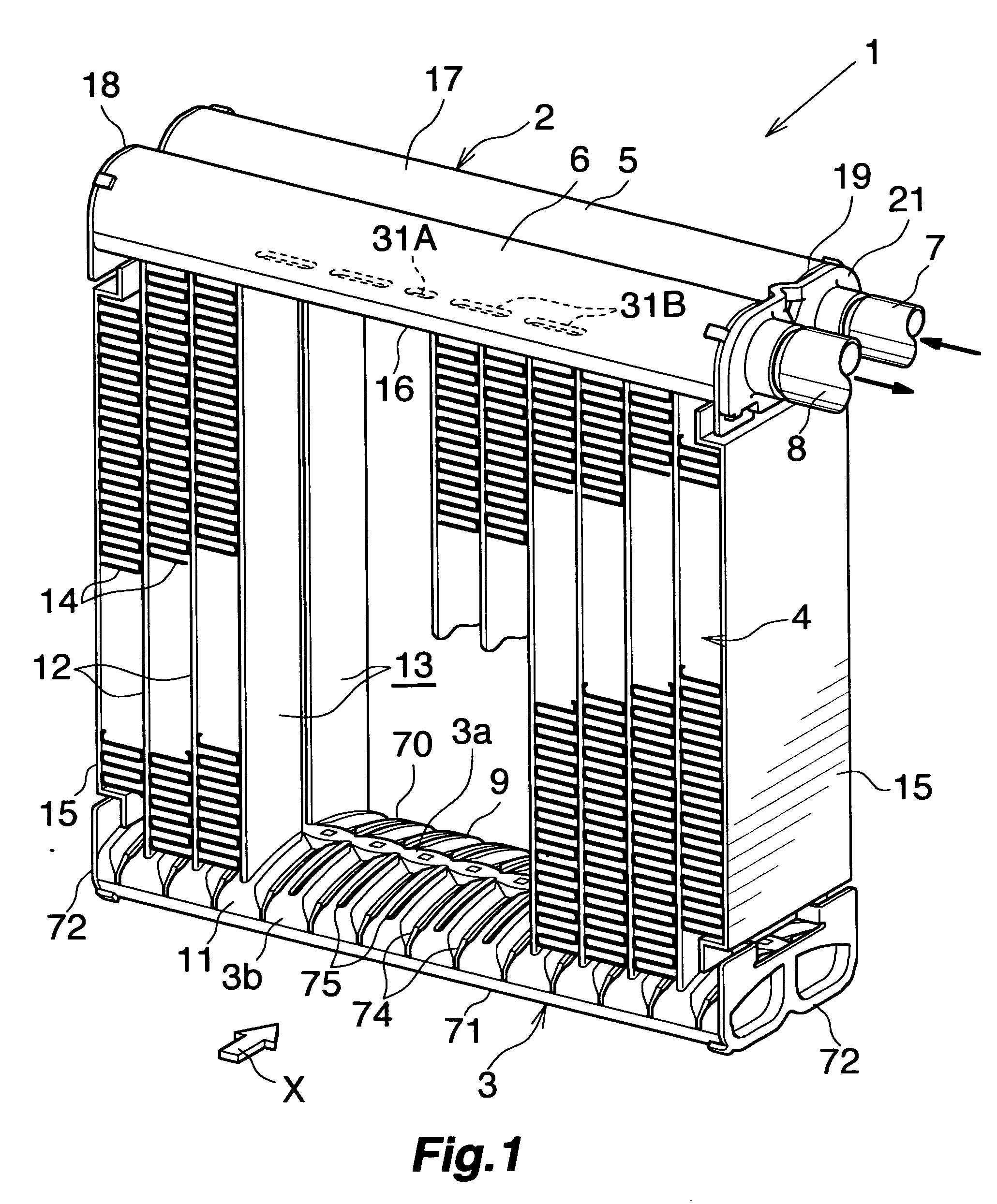

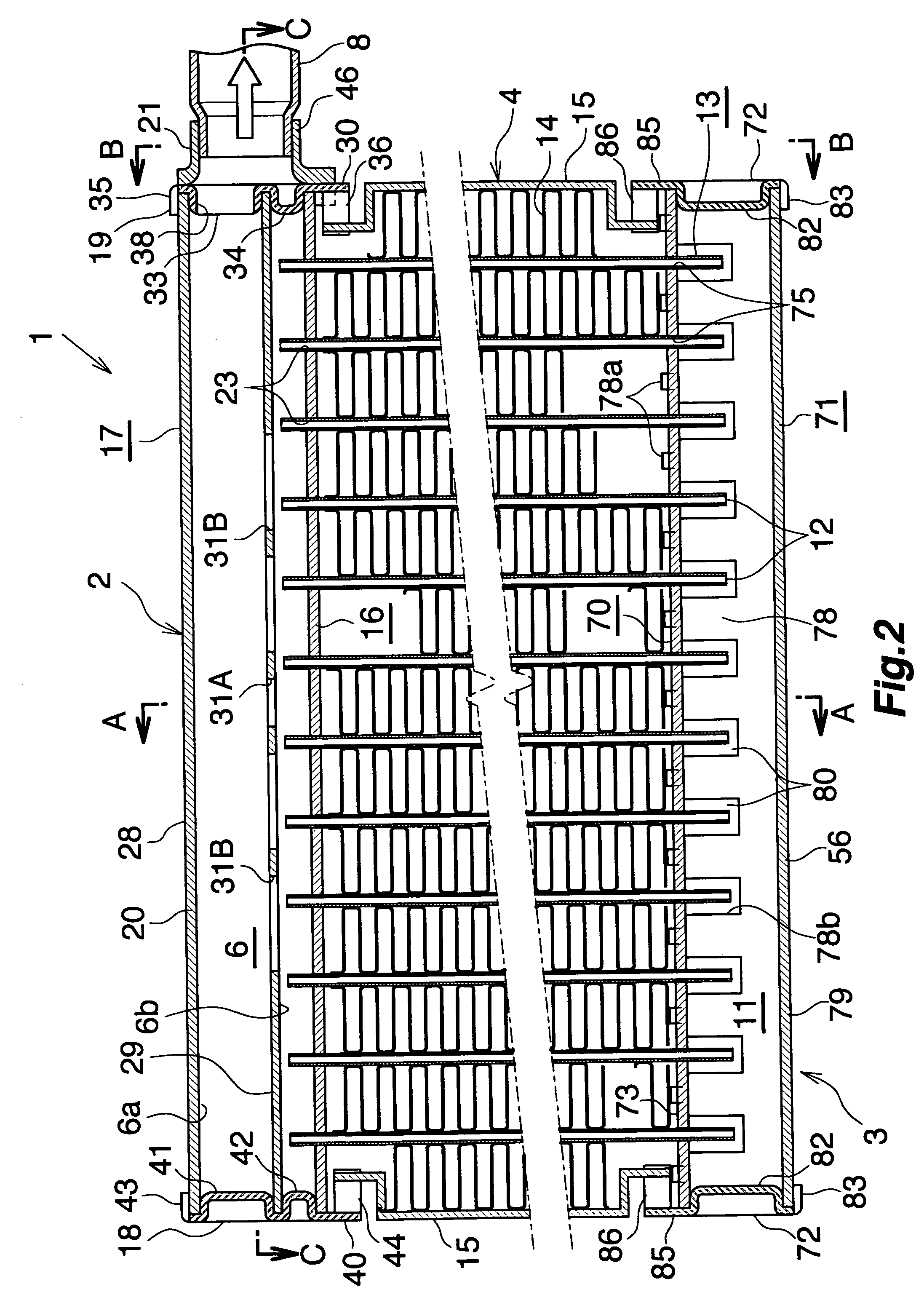

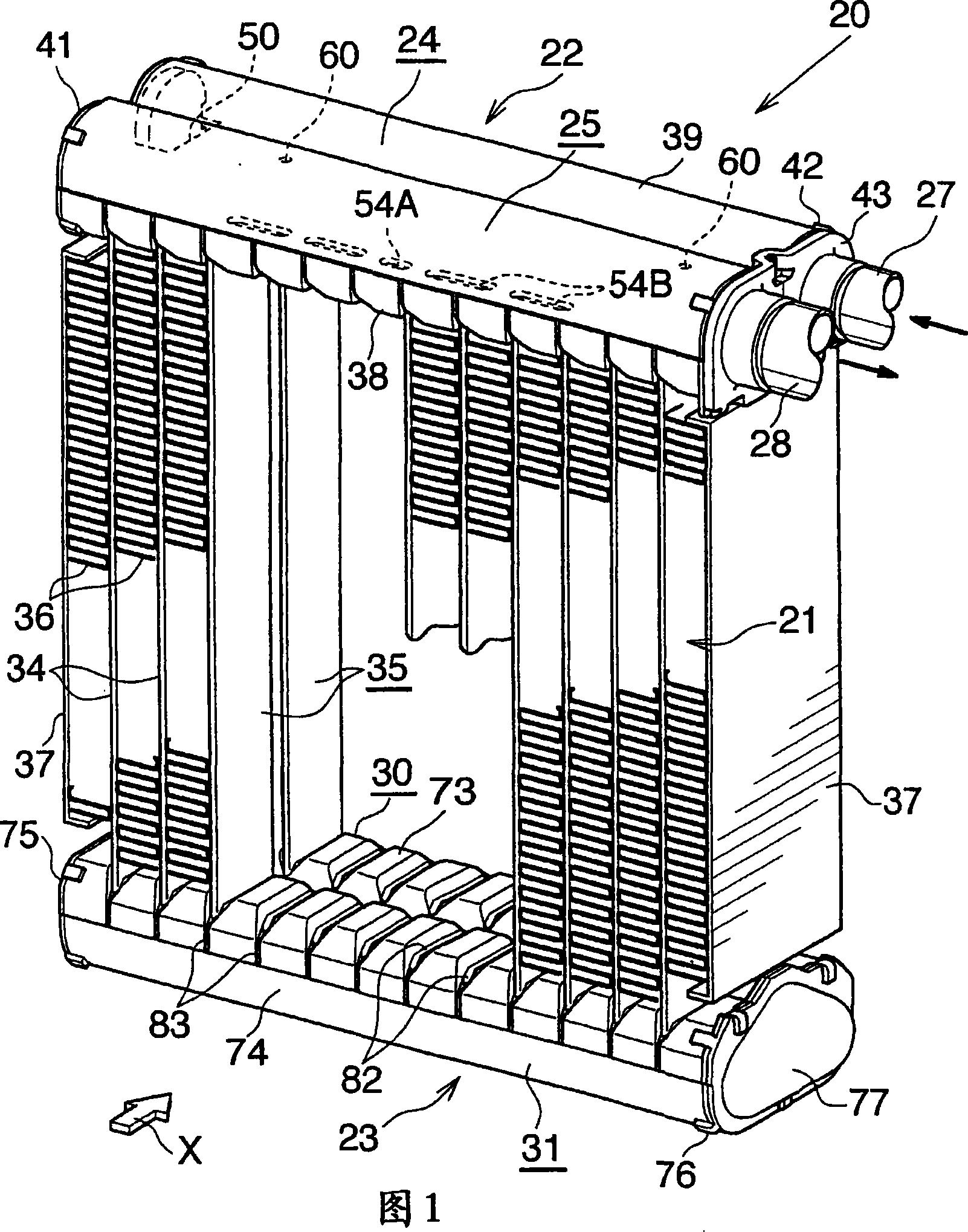

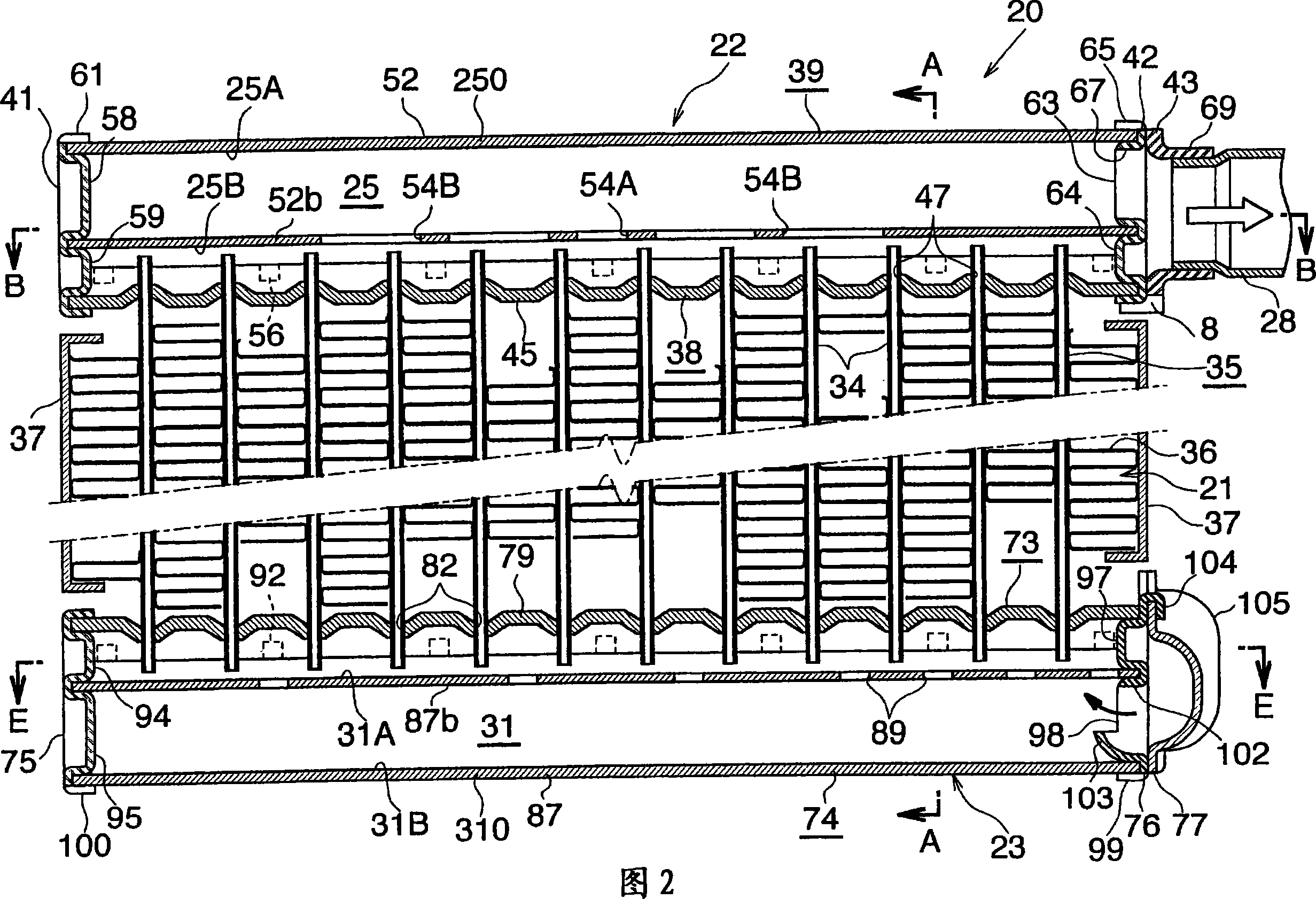

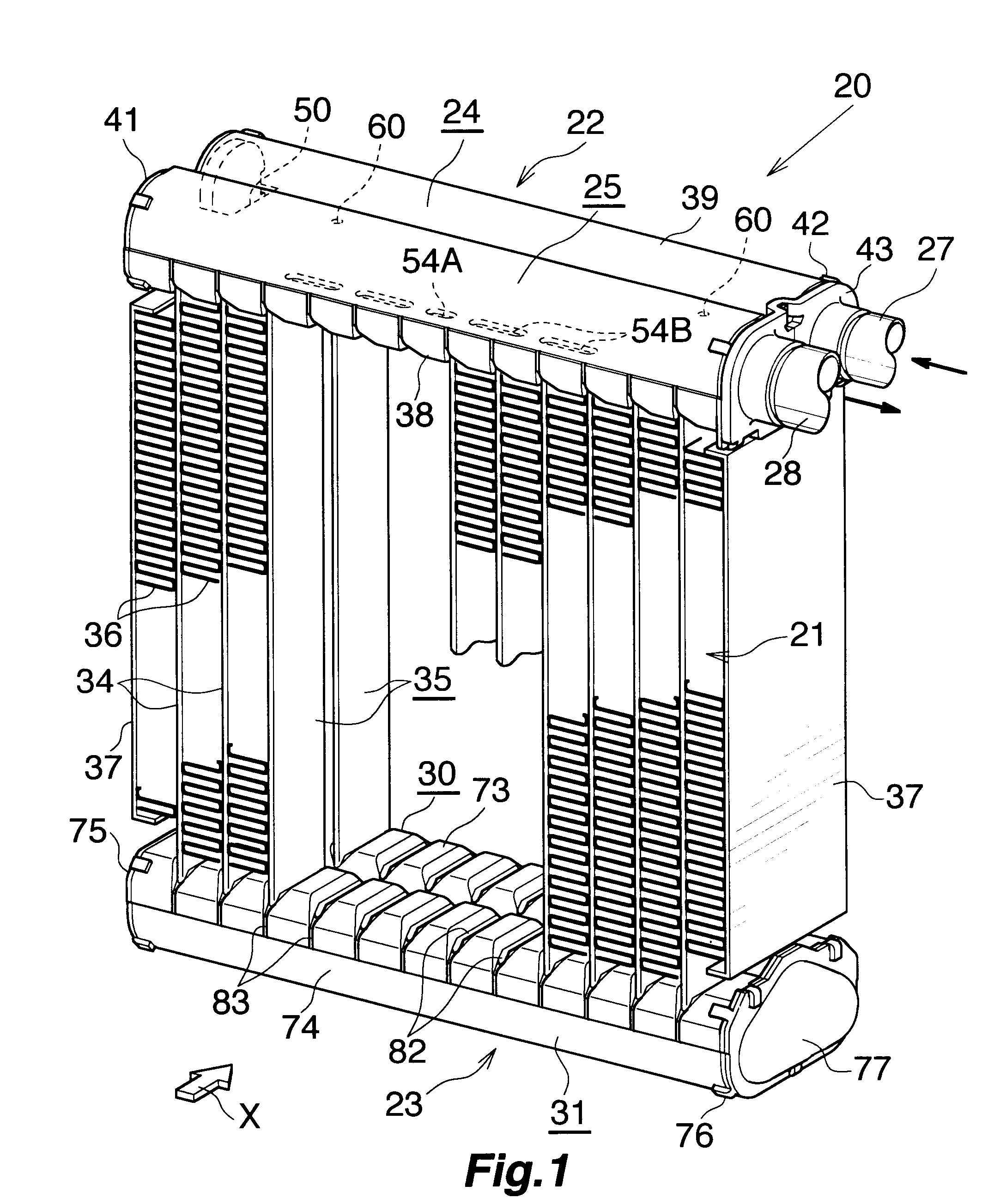

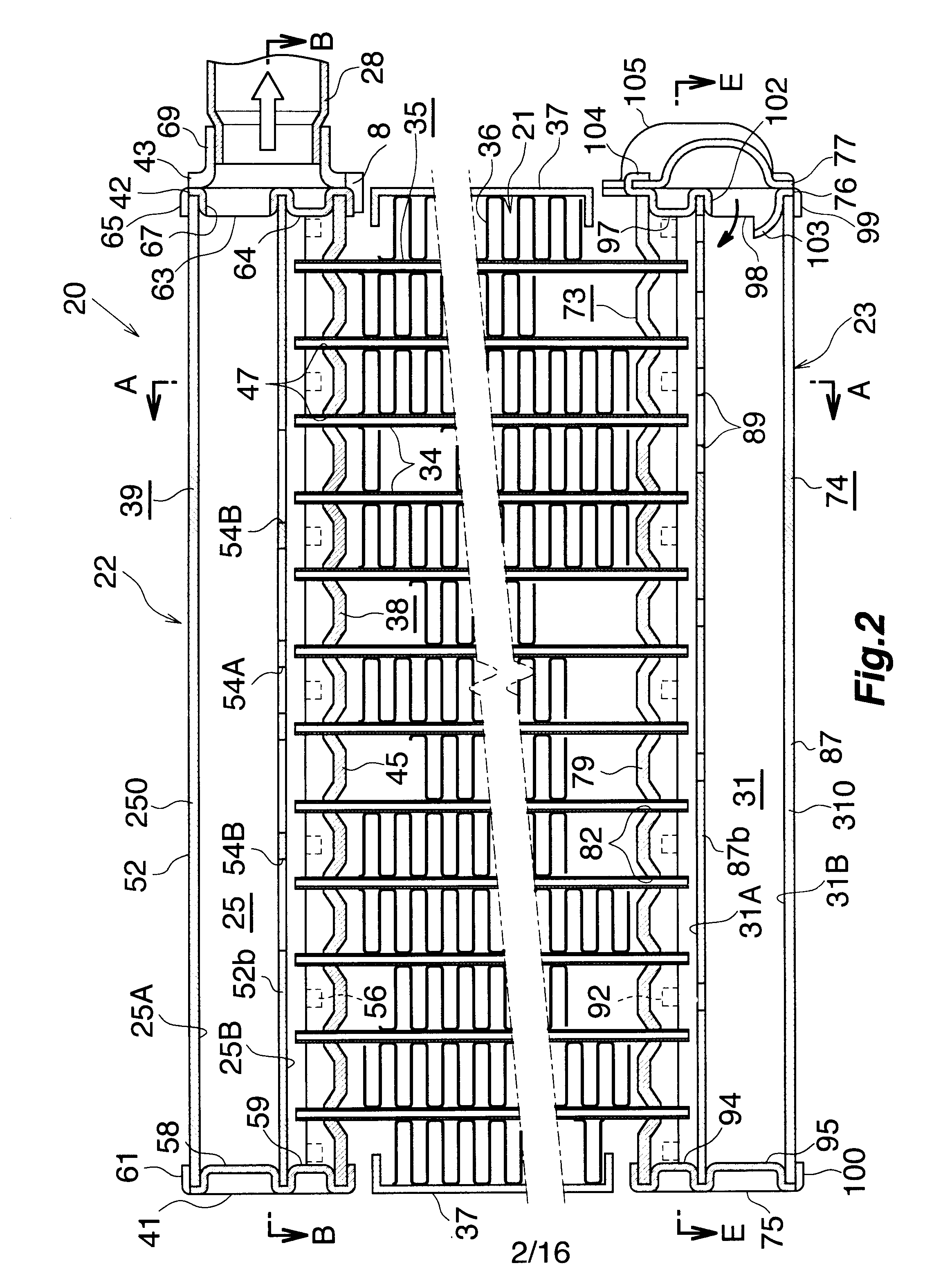

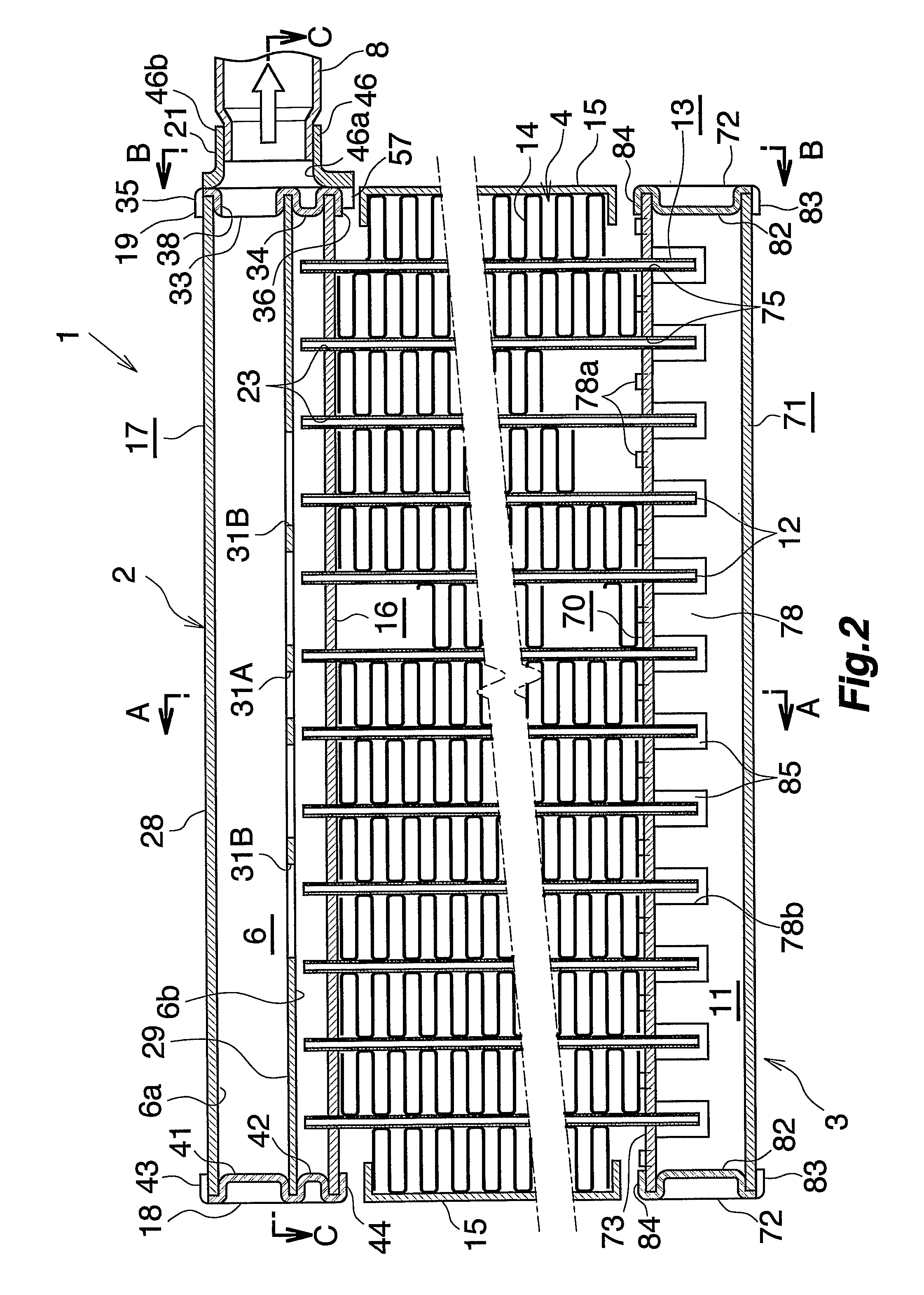

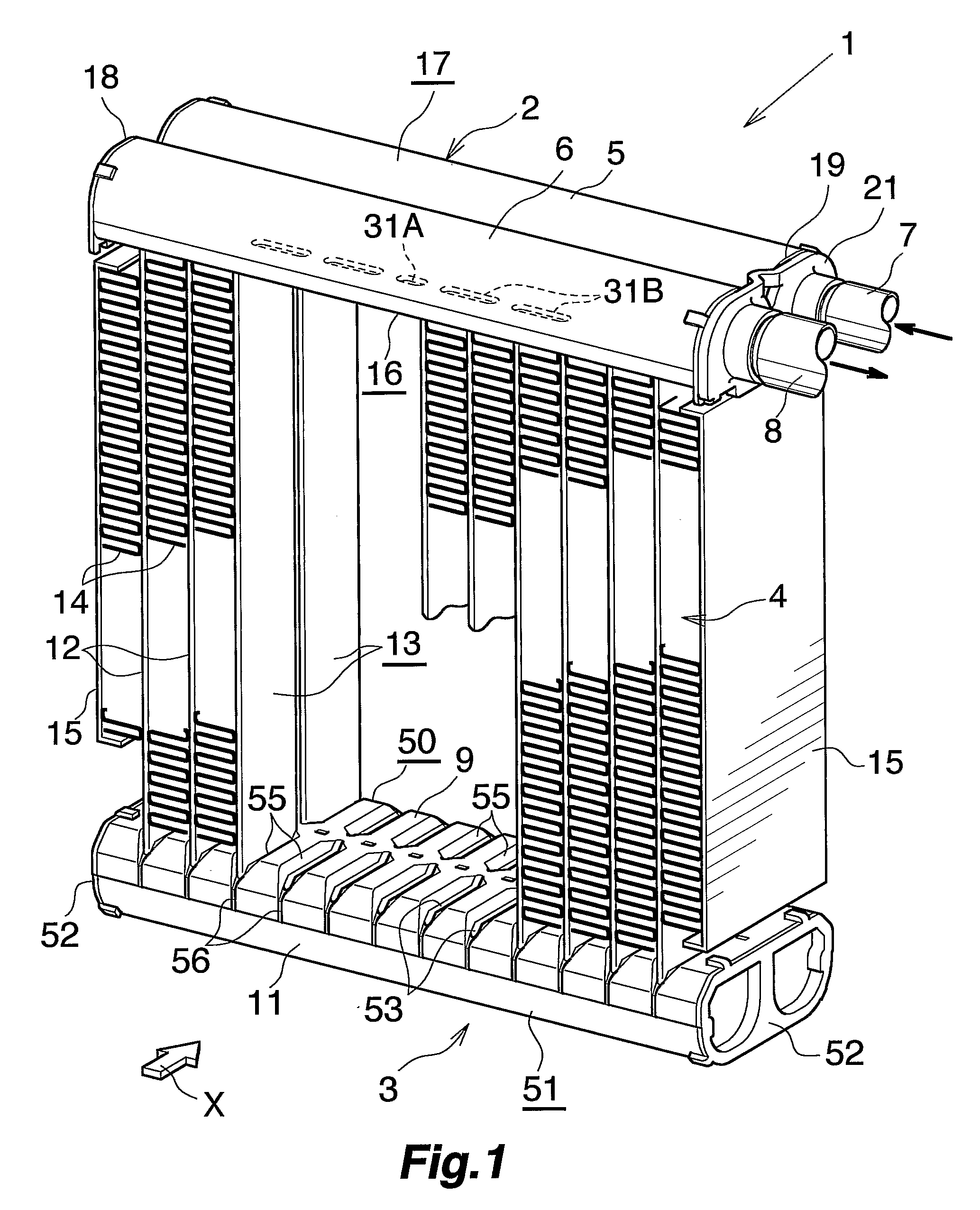

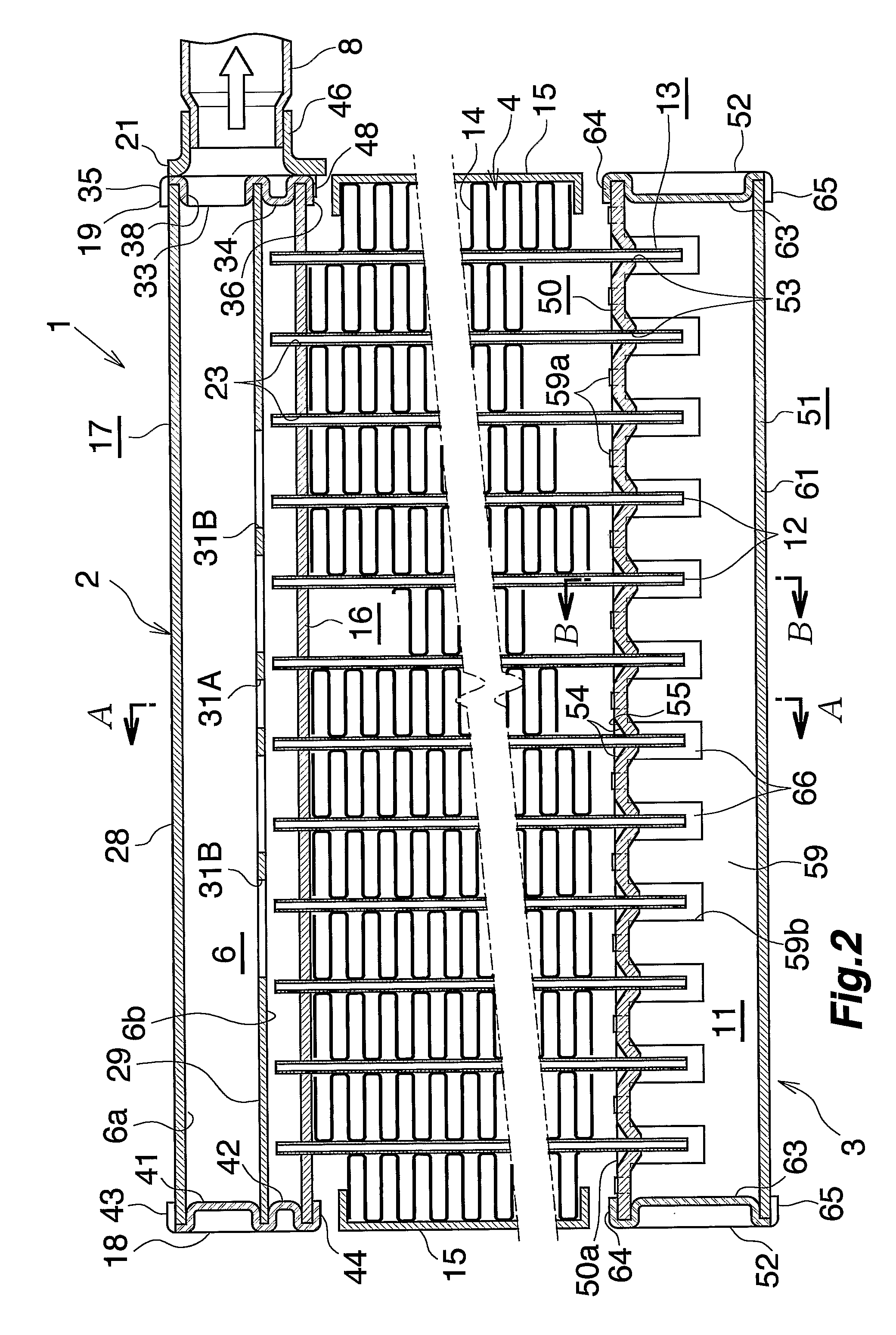

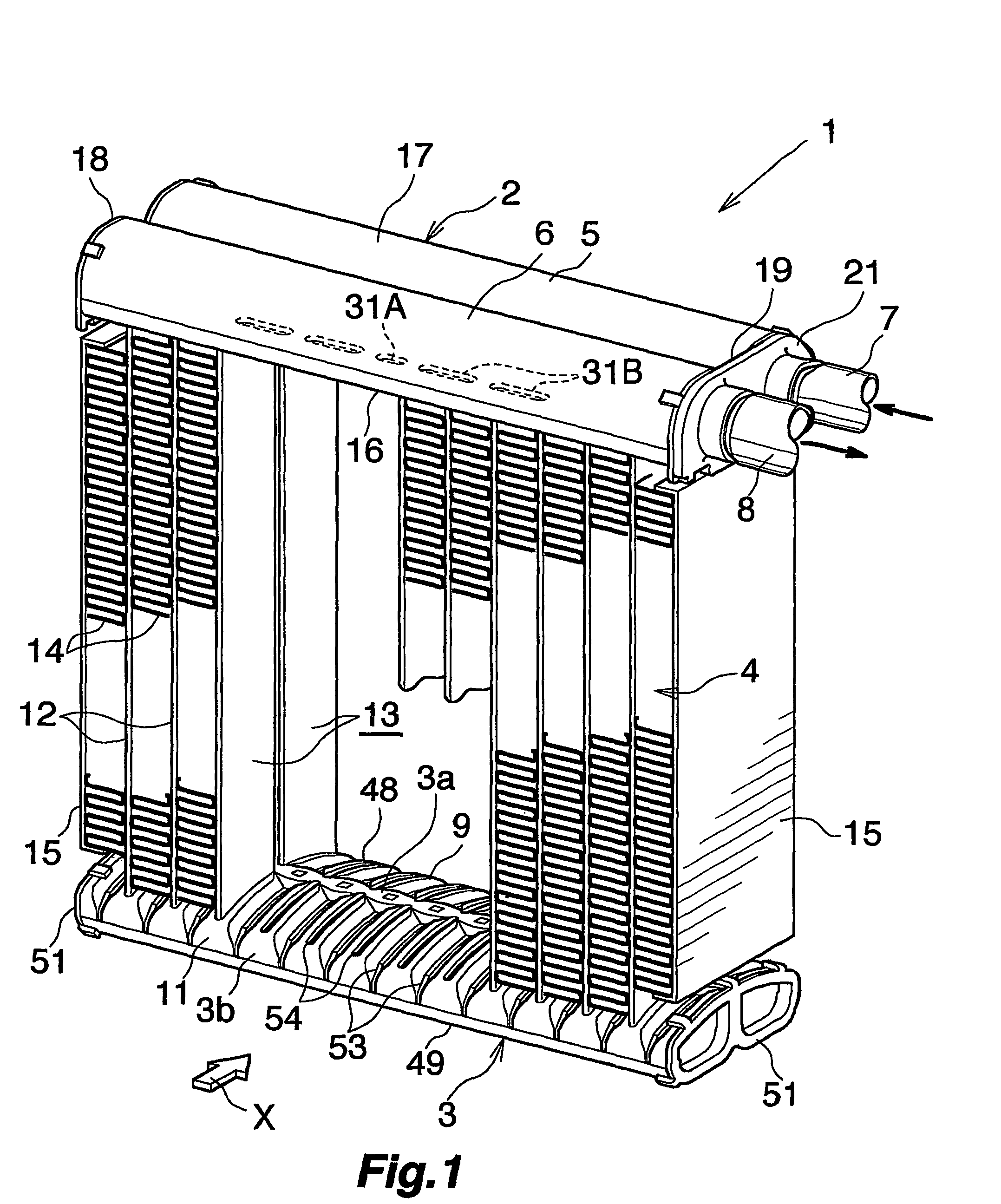

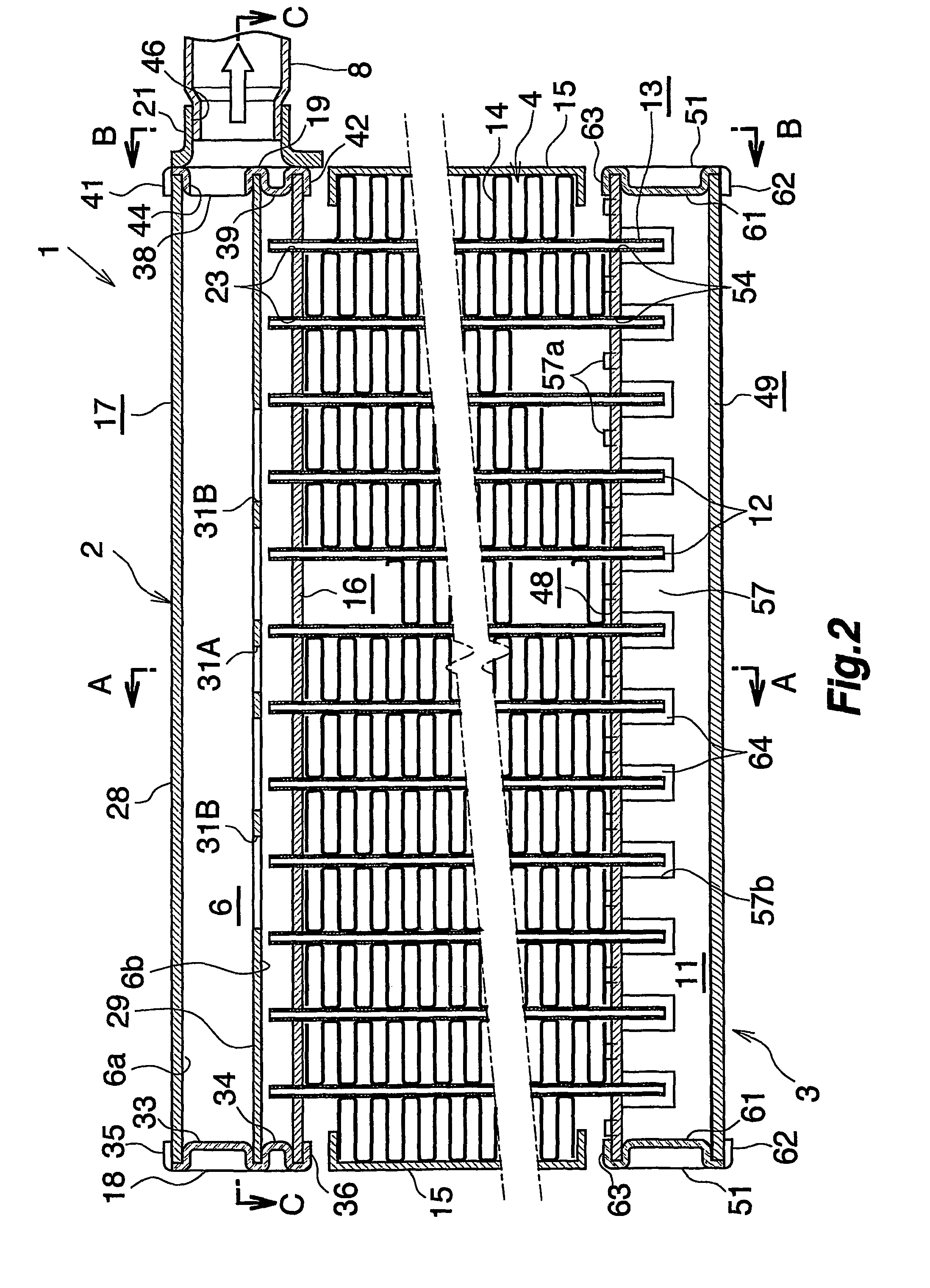

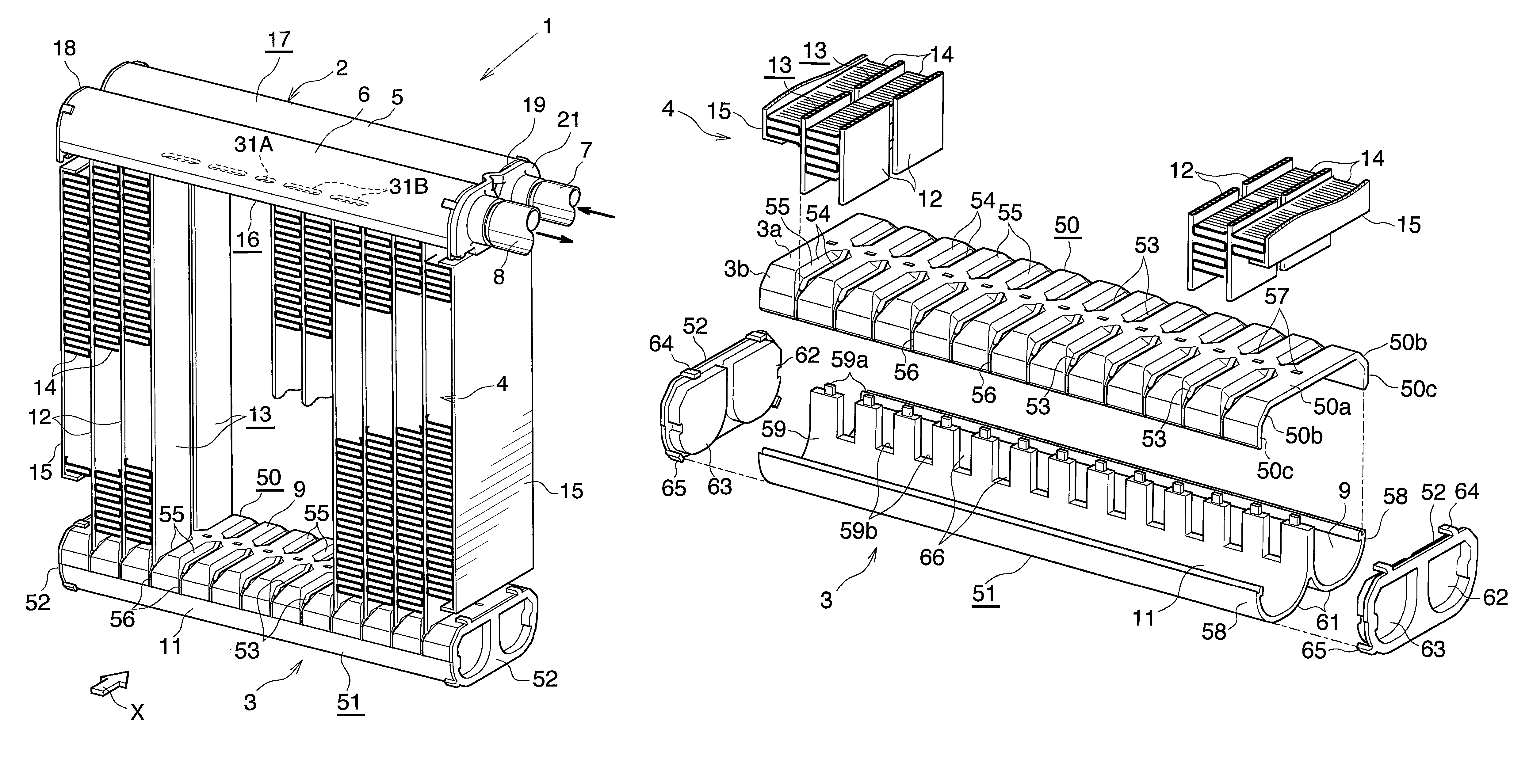

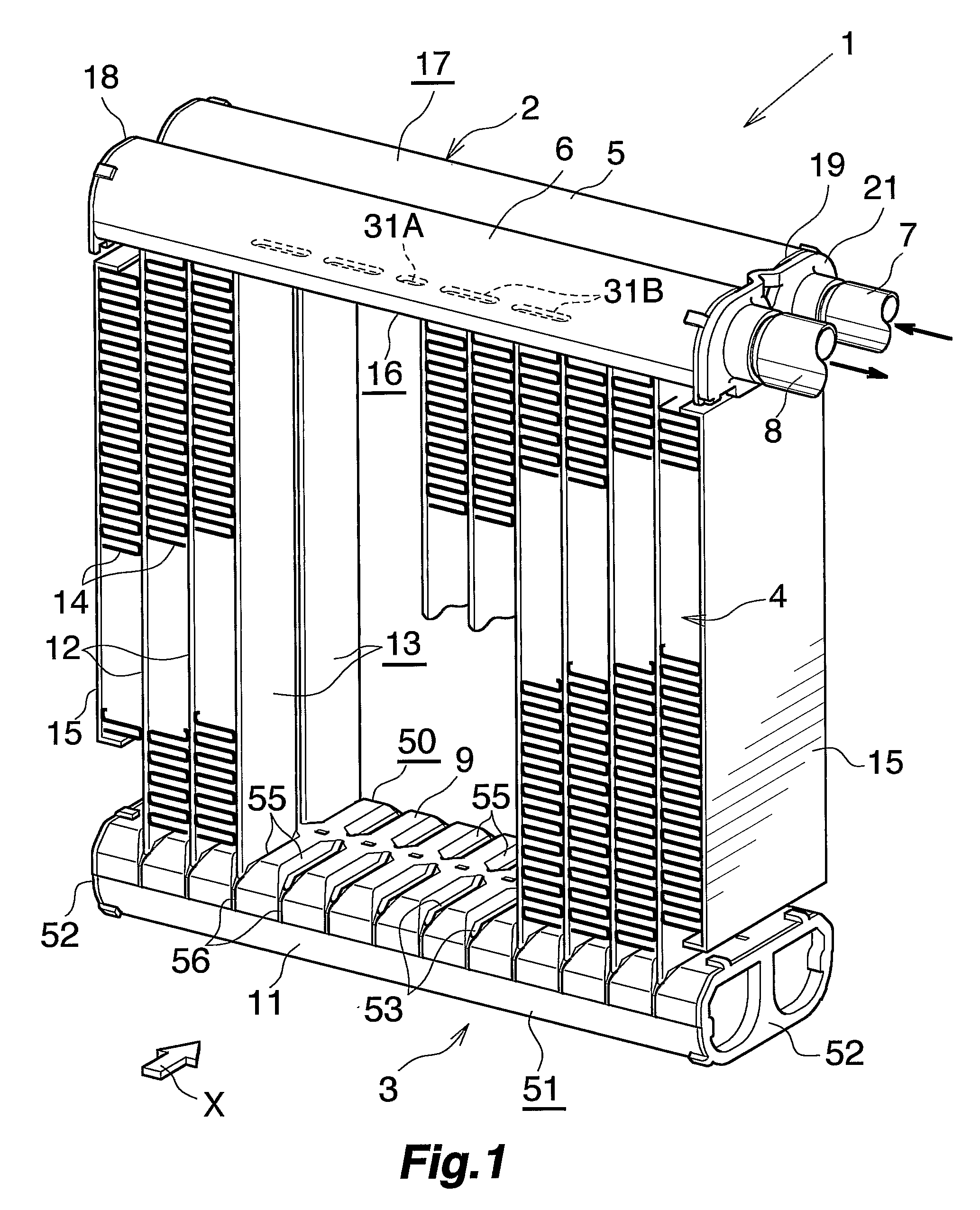

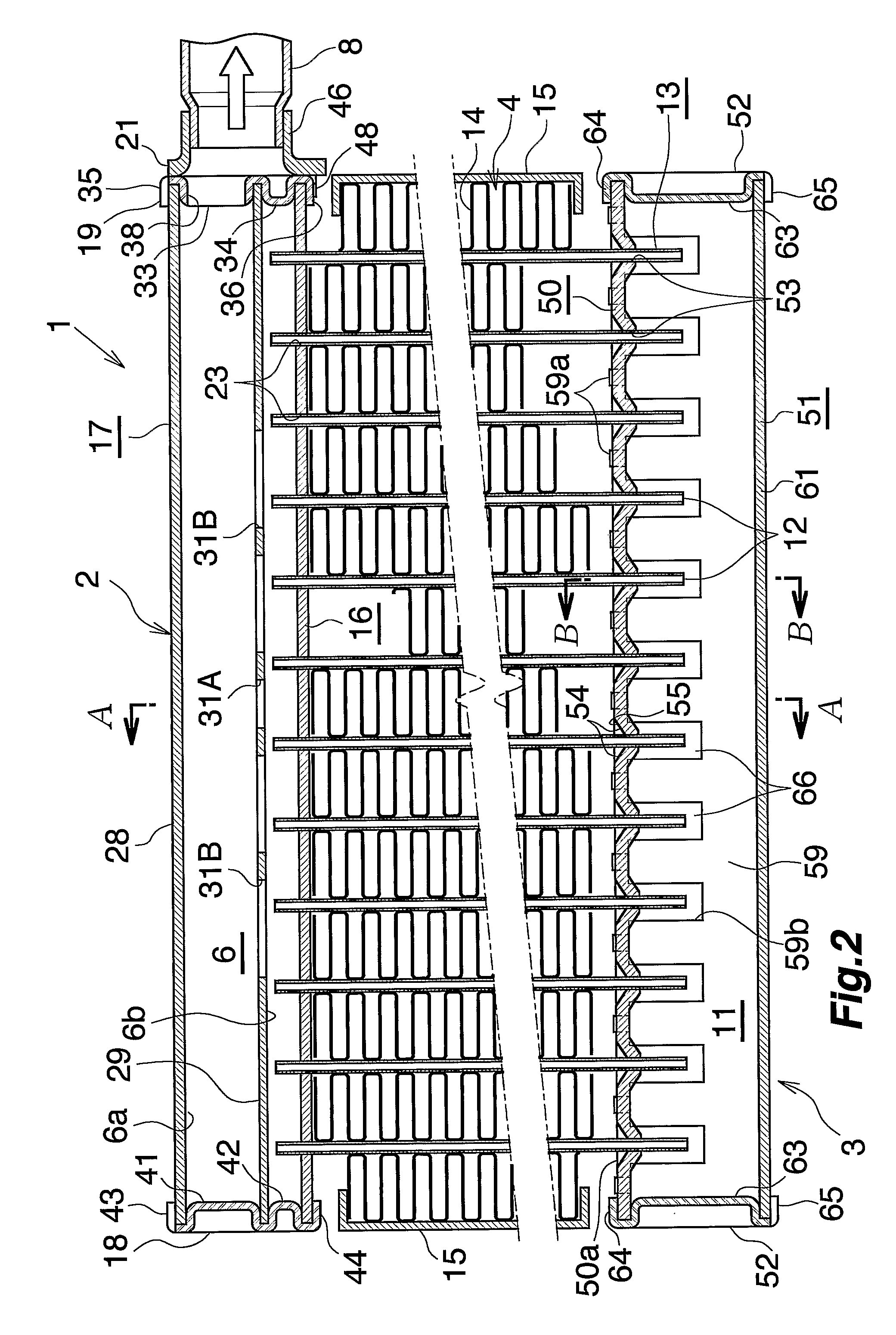

InactiveUS20070074861A1Reduced in number of componentEasy constructionEvaporators/condensersClosure meansPlate heat exchangerEngineering

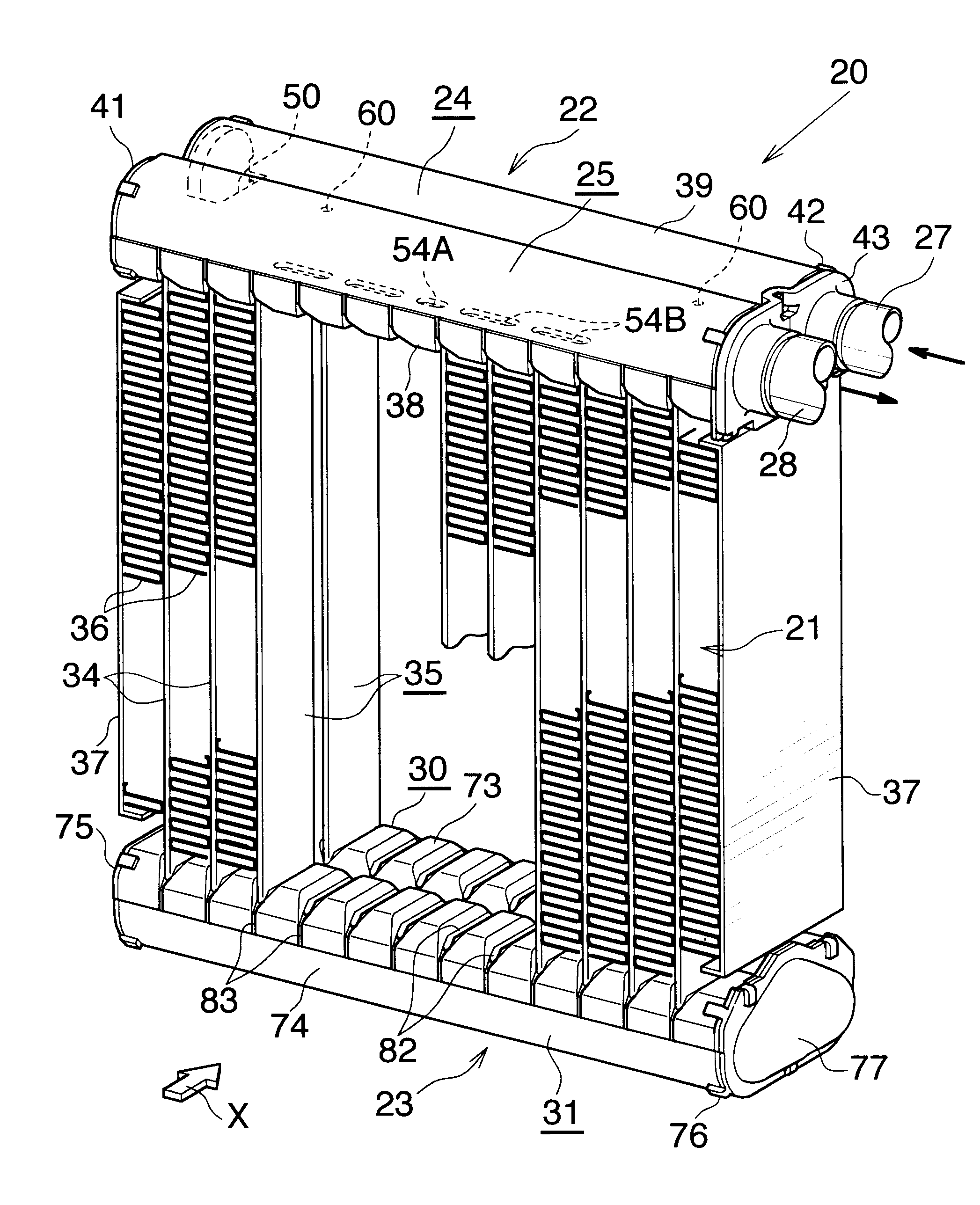

A heat exchanger comprising a heat exchange core 4 composed of tube groups 11 in the form of rows arranged in the direction of flow of air through the exchanger, each of the tube groups 11 comprising a plurality of heat exchange tubes 9 arranged at a spacing, a refrigerant inlet header 5 and a refrigerant outlet header 6 positioned at the upper end of the core 4 and having respective groups of heat exchange tubes joined thereto, and a refrigerant turn tank 3 disposed at the lower end of the core 4. The turn tank 3 has its interior divided by a partition wall 39 into a refrigerant inflow header 7 and a refrigerant outflow header 8. The heat exchange tubes 9 have lower end portions inserted in the headers 7, 8 and are joined to the headers 7, 8. Refrigerant passing holes 43 are formed in the partition wall 39. The heat exchange tubes 9 have their lower ends positioned below the lower ends of the holes 43. The heat exchanger is improved in heat exchange performance.

Owner:KEIHIN THERMAL TECH CORP

EGR cooler

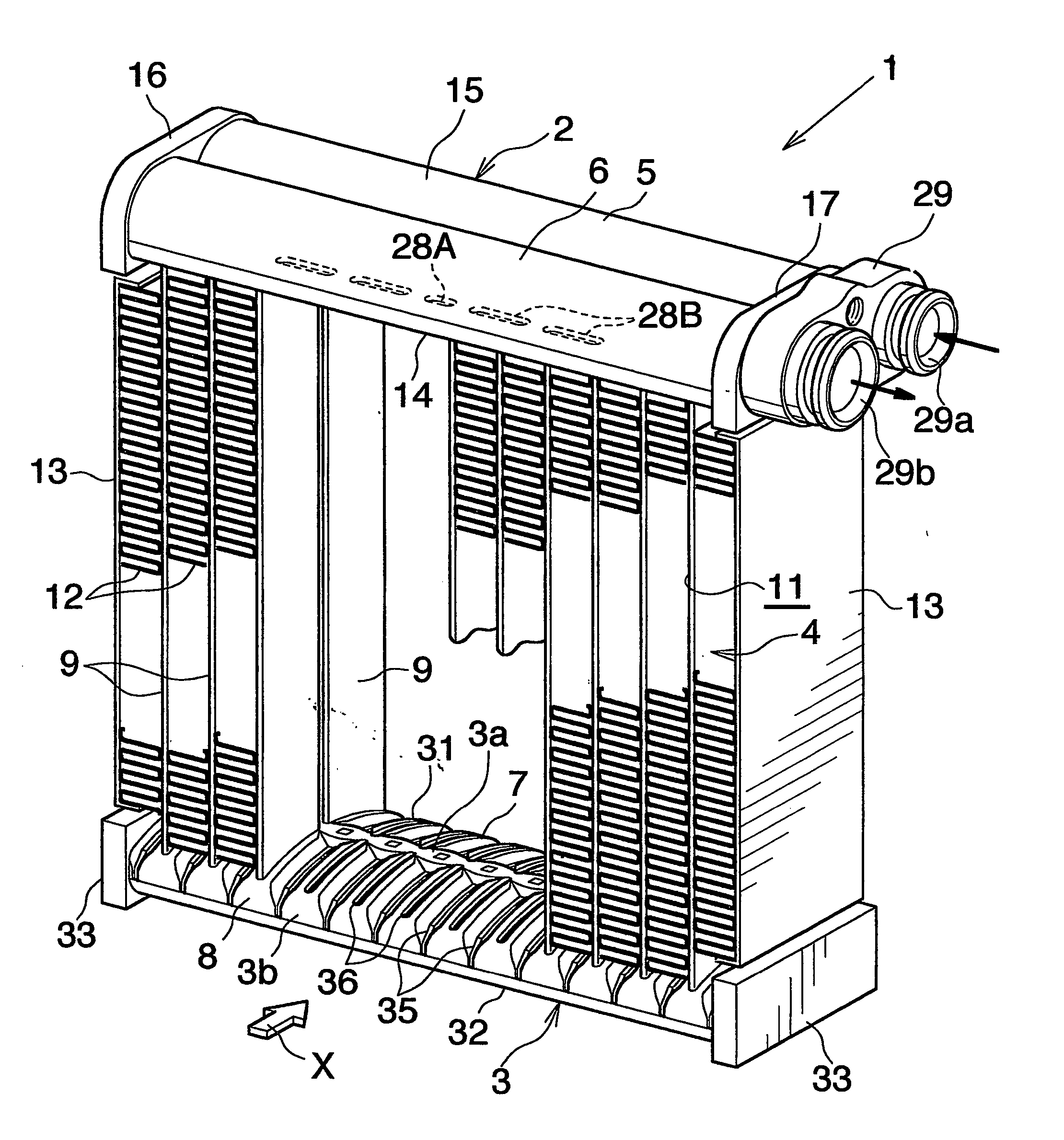

InactiveUS7661415B2Improve performanceImprove air tightnessNon-fuel substance addition to fuelRecuperative heat exchangersThin metalEngineering

A bypass duct portion is provided in a casing of an EGR cooler so that heat distortion is absorbed, and the EGR cooler body and a valve case are brazed / fixed together so as to improve strength of the valve case, whereby, the bypass duct portion is formed between an inner surface of the casing and the core, a switch is provided for switching and guiding the exhaust gas to either of the core or the bypass duct portion, and a number of outer ribs formed in the circumferential direction respectively are arranged side by side while being separated from each other in the longitudinal direction in the bypass duct portion of the casing to form a heat stress absorbing portion. Also provided is a cylindrical valve case that is integrally formed by deep drawing of a thin metal plate by a press machine, a pair of slits are provided at the rear end of the valve case, both edges of an intra-valve partition plate are inserted into the slits, support projection portions are provided on both faces of the both edge portions of the intra-valve partition plate, and the edge of the slit is supported by the support projection portion. An opening of the valve case is integrally brazed / fixed to an opening of a header portion of the casing.

Owner:T RAD CO LTD

Heat exchanger assembly

InactiveUS20080023183A1Maximum flexibilityReduce assemblyEvaporators/condensersClosure meansFuel tankEngineering

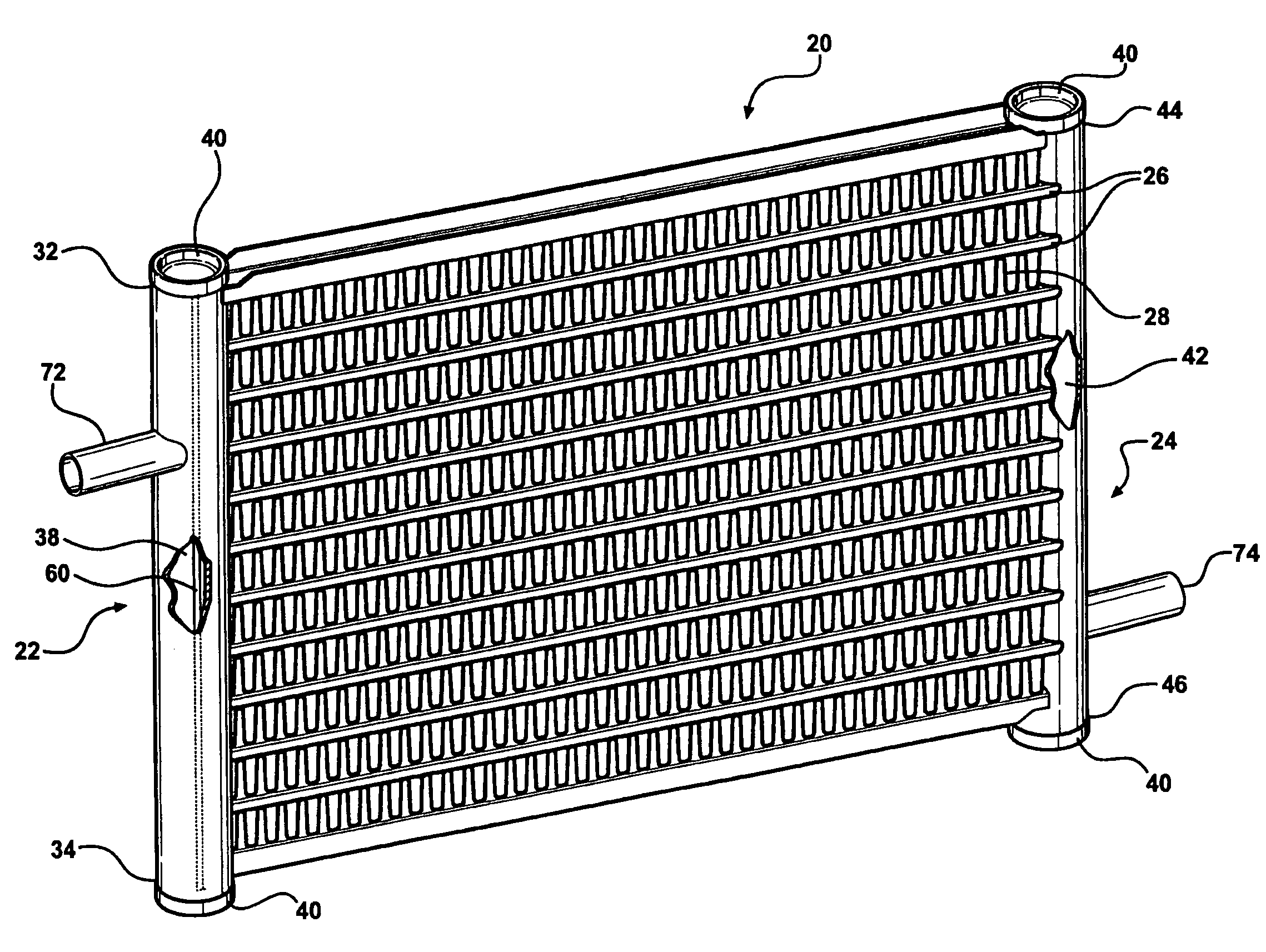

A heat exchanger assembly has a first manifold, a second manifold in spaced and substantially parallel relationship with the first manifold and a plurality of flow tubes fluidly connecting the manifolds for passing refrigerant between the manifolds. The first manifold includes a header and tank which are joined by their longitudinal edges to form a cavity. The tank is extruded and has an outer wall and an inner partition wall with a plurality of apertures which define a distribution chamber within the cavity. The distribution chamber is fluidly connected to the cavity. A method of manufacturing a manifold generally includes the steps of extruding the tank, cutting the tank to a predetermined length, forming a plurality of apertures in the inner partition wall, forming a plurality of openings in the header, joining the tank and the header, and joining the end cap to the tank and header.

Owner:DELPHI TECH INC

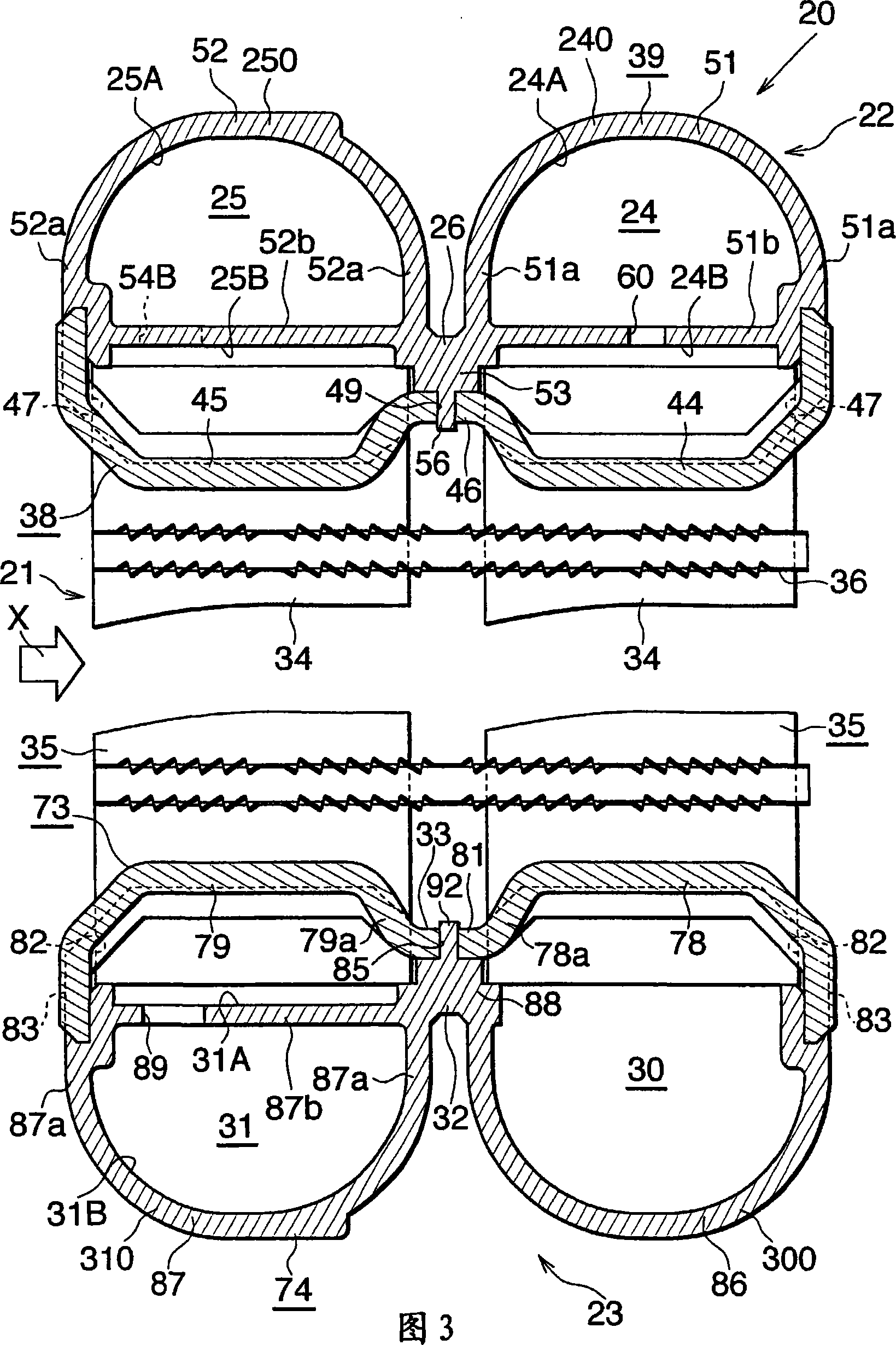

Egr Cooler

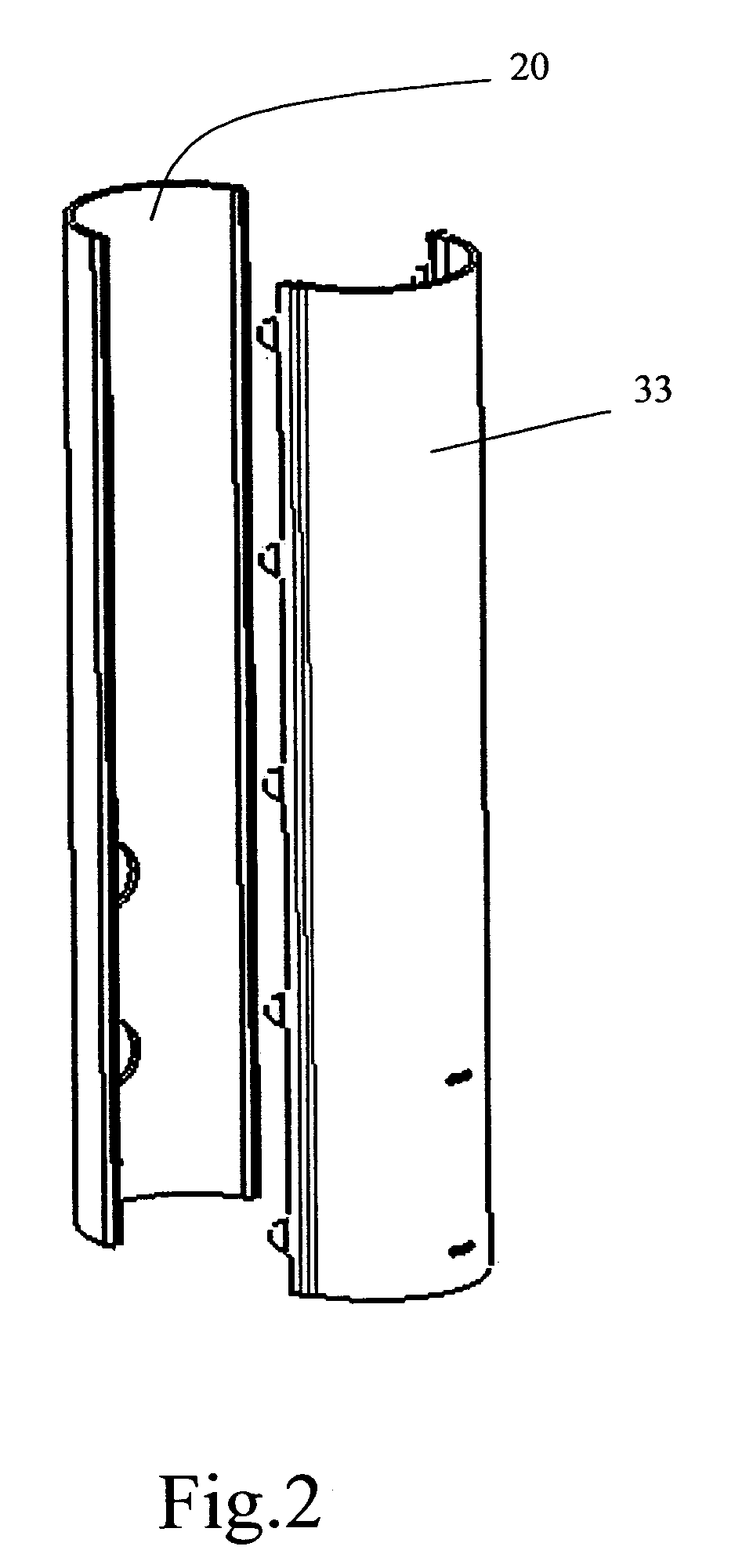

InactiveUS20070289581A1Easy to manufactureAvoid deformationInternal combustion piston enginesNon-fuel substance addition to fuelThin metalEngineering

A bypass duct portion is integrally provided in a casing of an EGR cooler so that heat distortion generated at a part of the casing when bypassing of an exhaust gas is rationally absorbed, and the EGR cooler body and a valve case are brazed / fixed all together so as to improve strength of the valve case, whereby, the bypass duct portion is formed between an inner surface of the casing and the core, a switch is provided for switching and guiding the exhaust gas to either of the core or the bypass duct portion, and a large number of outer ribs formed in the circumferential direction respectively are arranged side by side while being separated from each other in the longitudinal direction in the bypass duct portion of the casing so as to constitute a heat stress absorbing portion. And a cylindrical valve case is integrally formed by deep drawing of a thin metal plate by a press machine, a pair of slits are provided at the rear end of the valve case, both edges of an intra-valve partition plate are inserted into the slits, support projection portions are provided on both faces of the both edge portions of the intra-valve partition plate, and the edge of the slit is supported by the support projection portion. And an opening of the valve case is integrally brazed / fixed to an opening of a header portion of the casing.

Owner:T RAD CO LTD

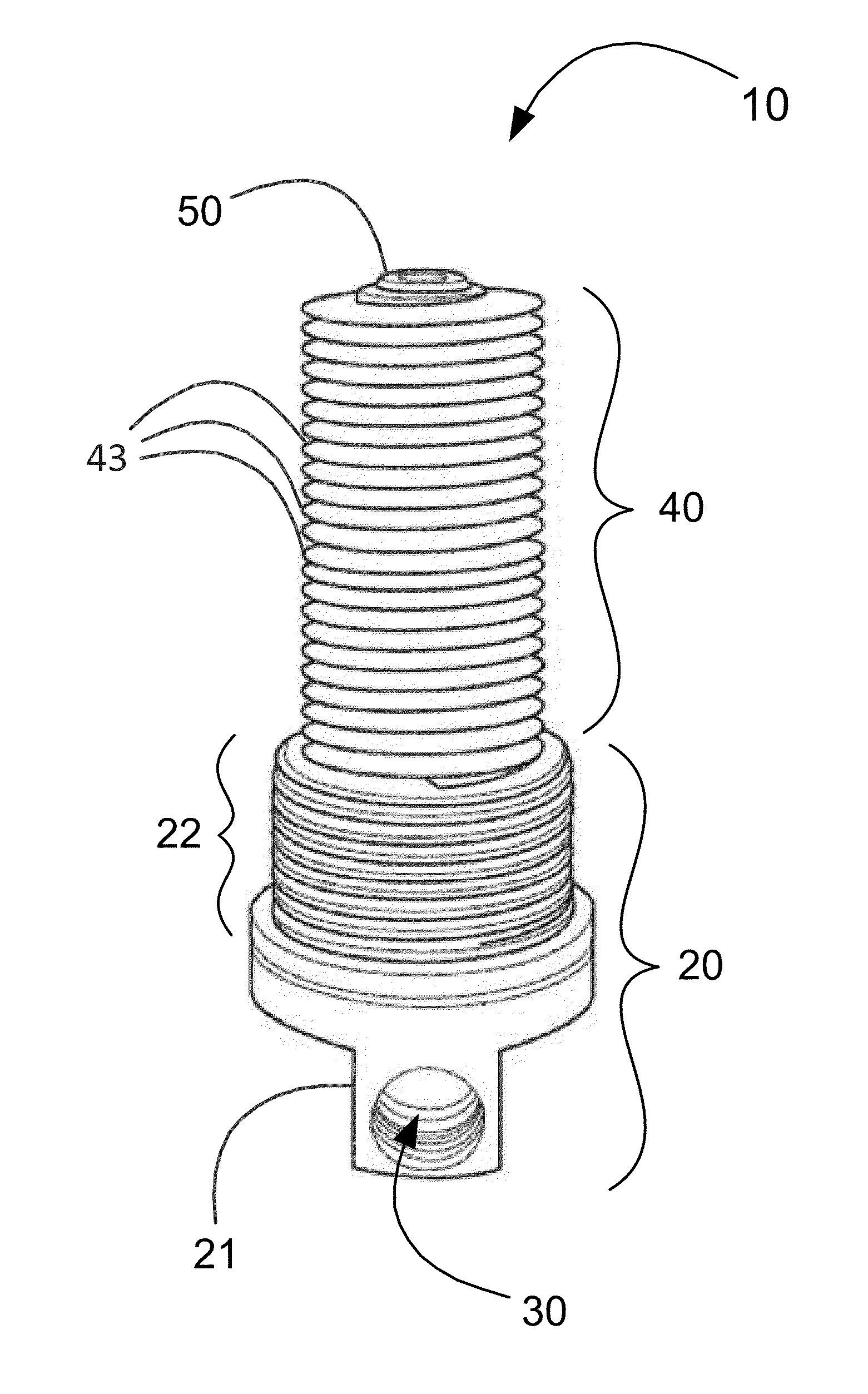

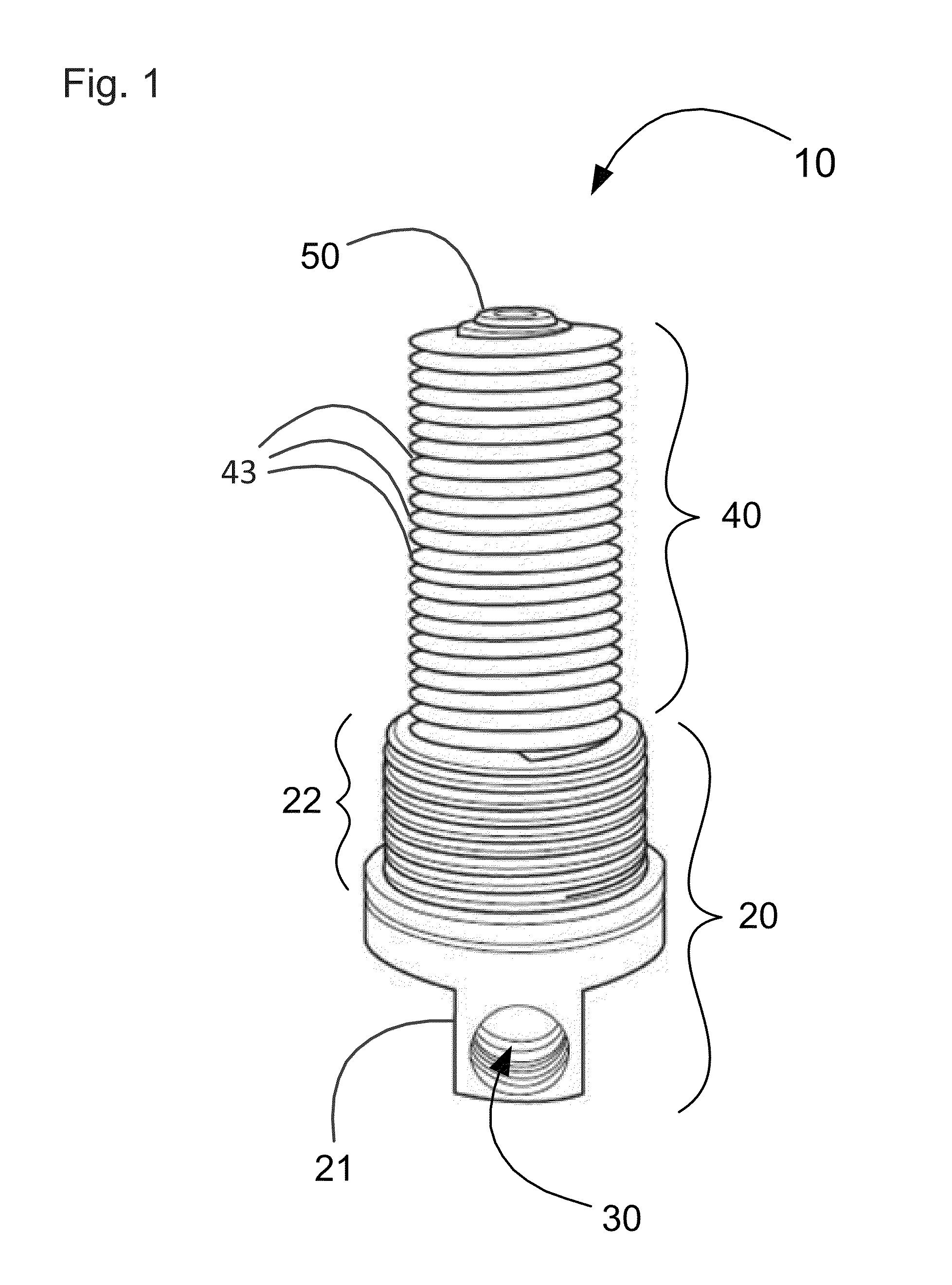

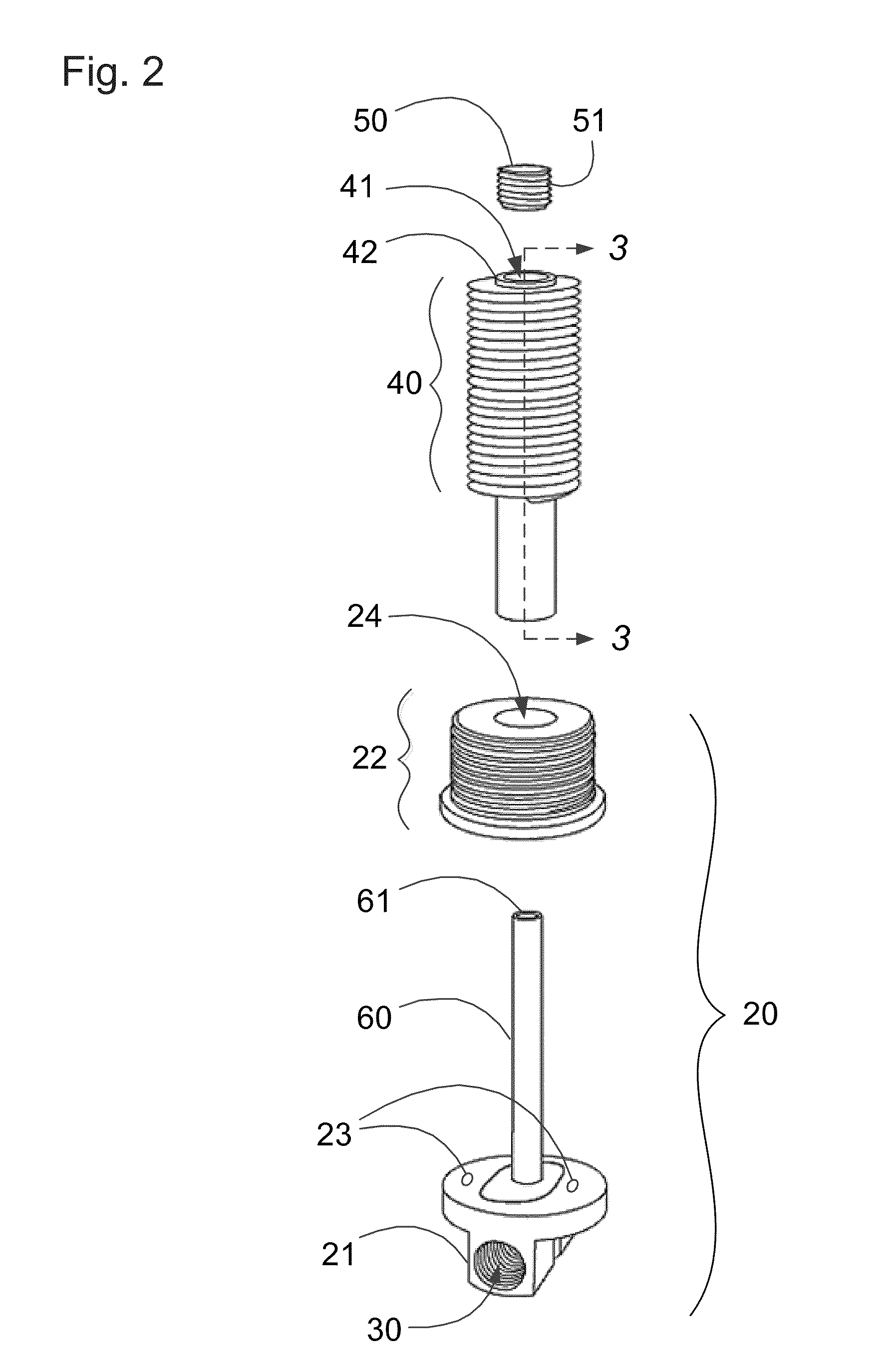

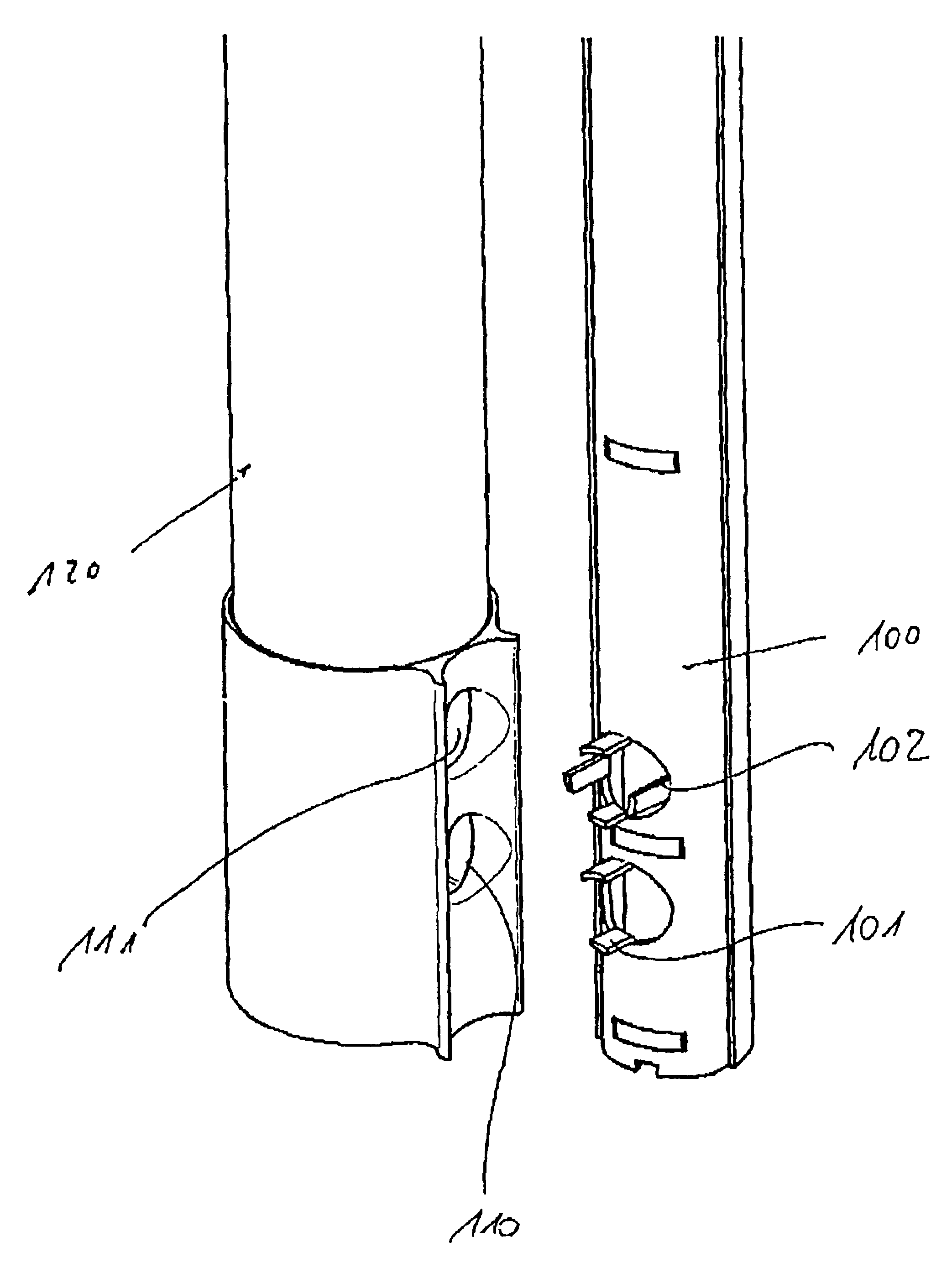

Irreversible plug assembly

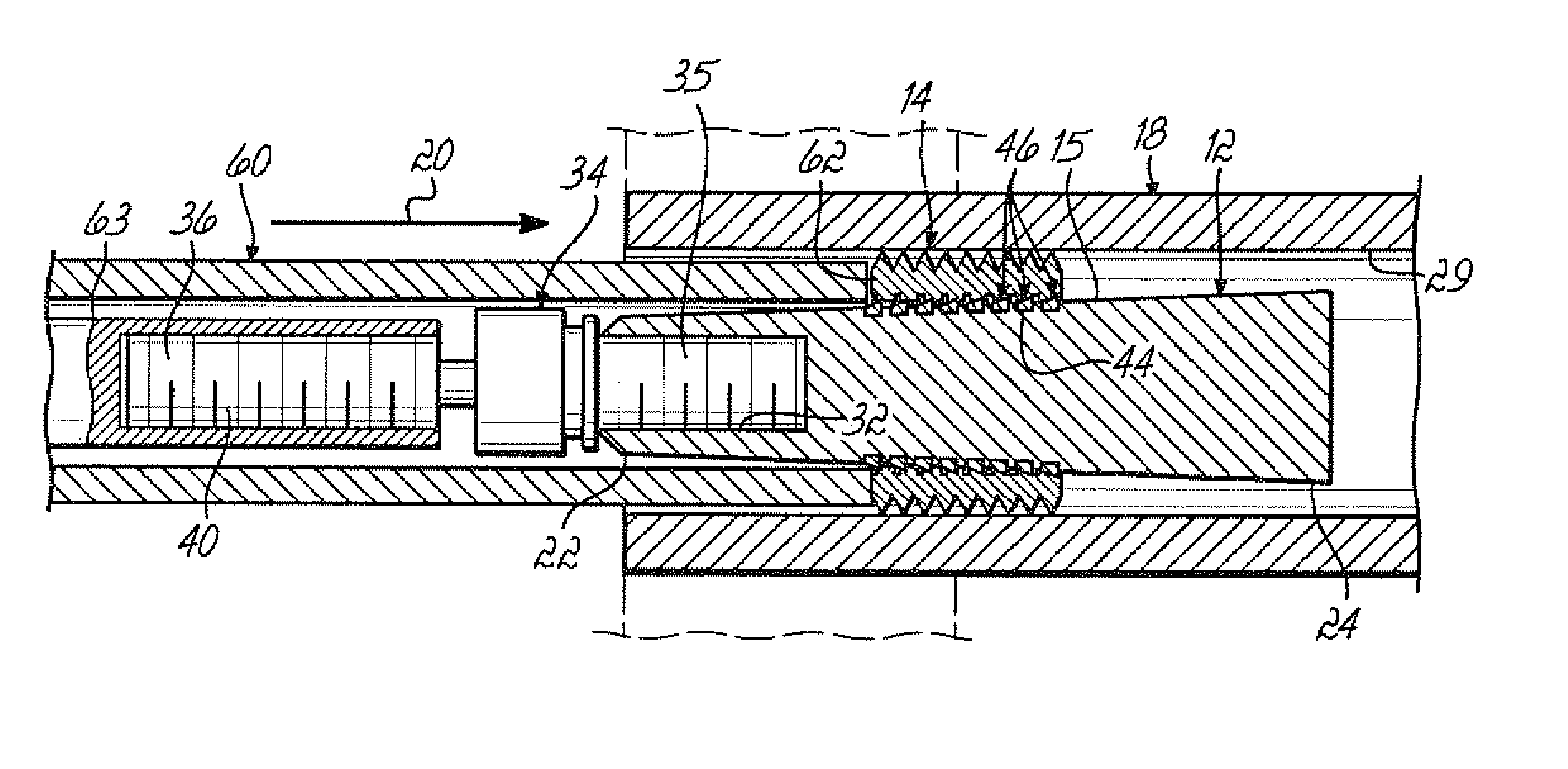

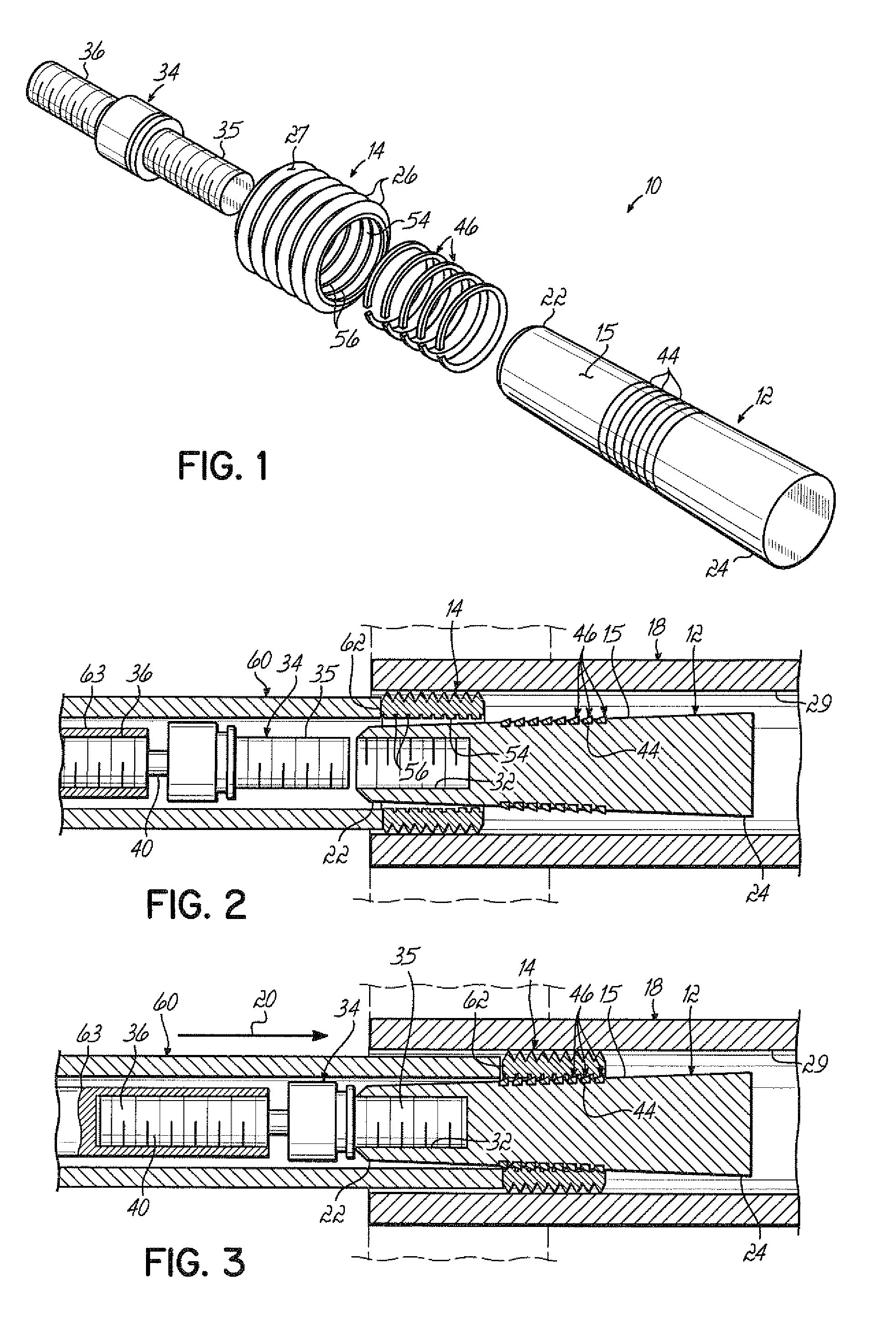

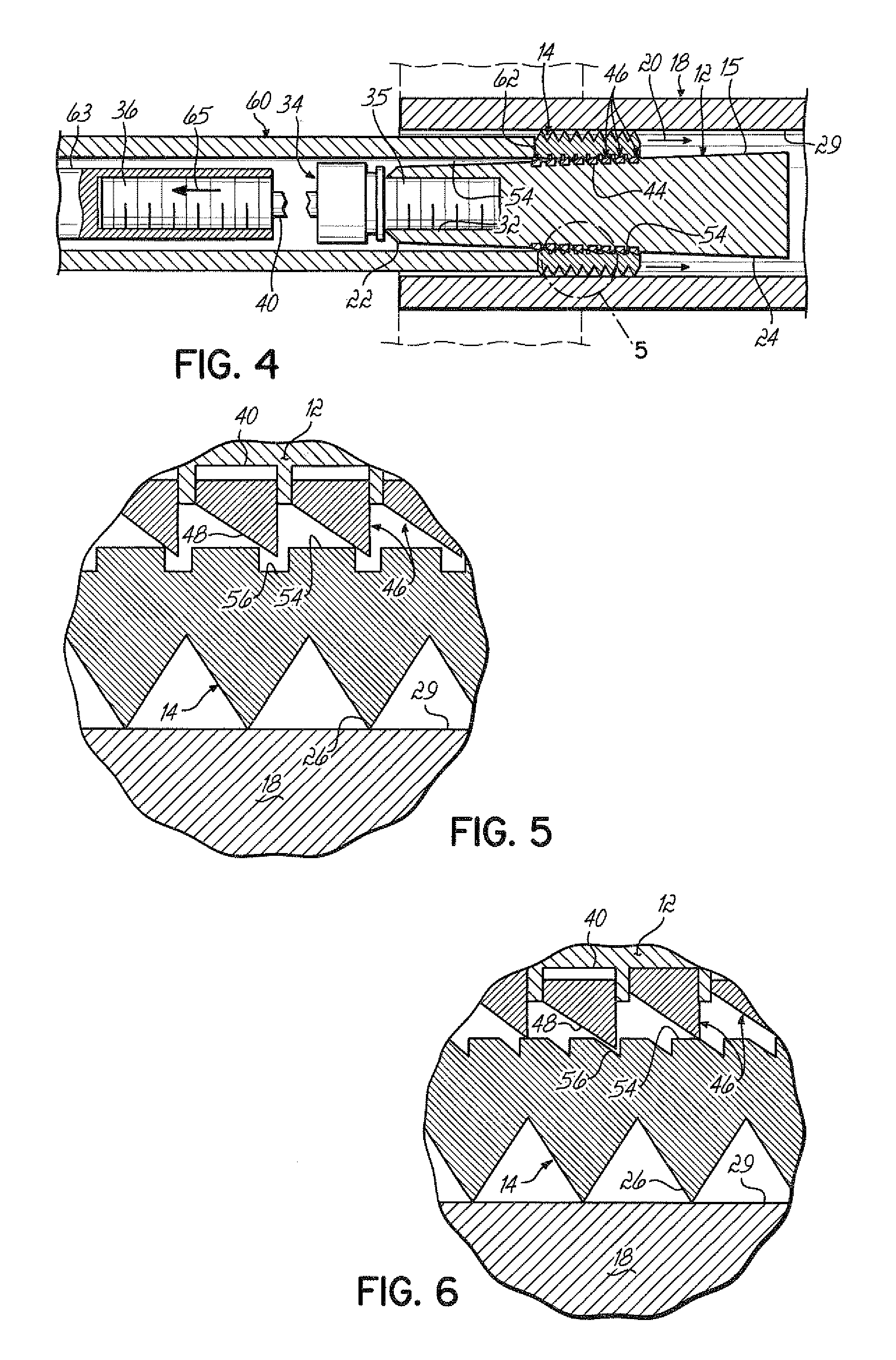

A plug assembly for a tube includes a tapered wedge and a sleeve. The sleeve fits over the wedge and is placed in a tube. Relative movement of the wedge and the sleeve causes the sleeve to expand and plug the tube. The exterior surface of the wedge and the interior surface of the sleeve include annular grooves. One or more compression rings in either the grooves in the sleeve or wedge permit motion of the sleeve relative to the wedge only toward the large diameter portion of the wedge. This prevents the sleeve from separating from the wedge after being installed in a tube.

Owner:DOUGLAS L HOLLAENDER ENTERPRISES

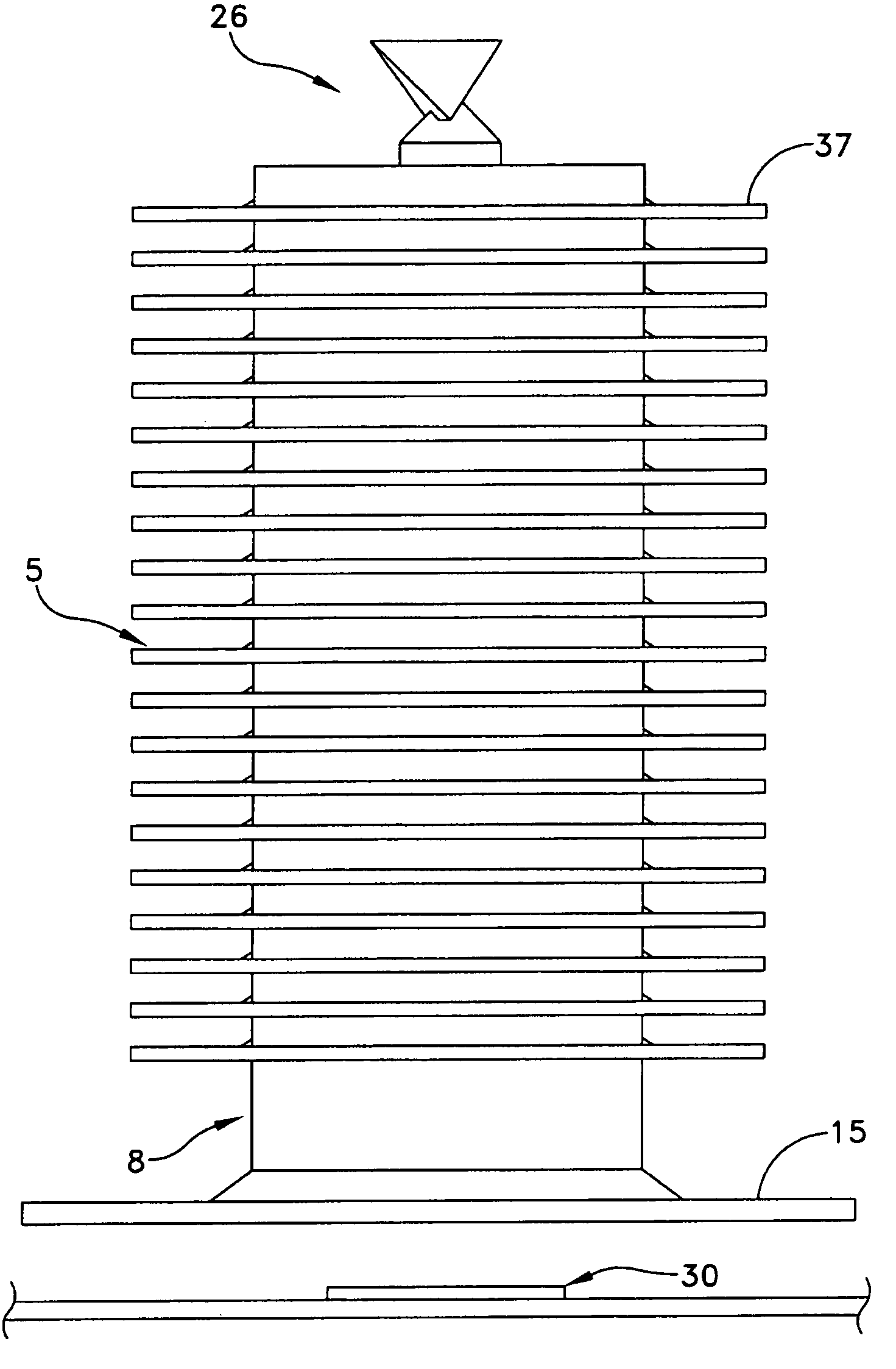

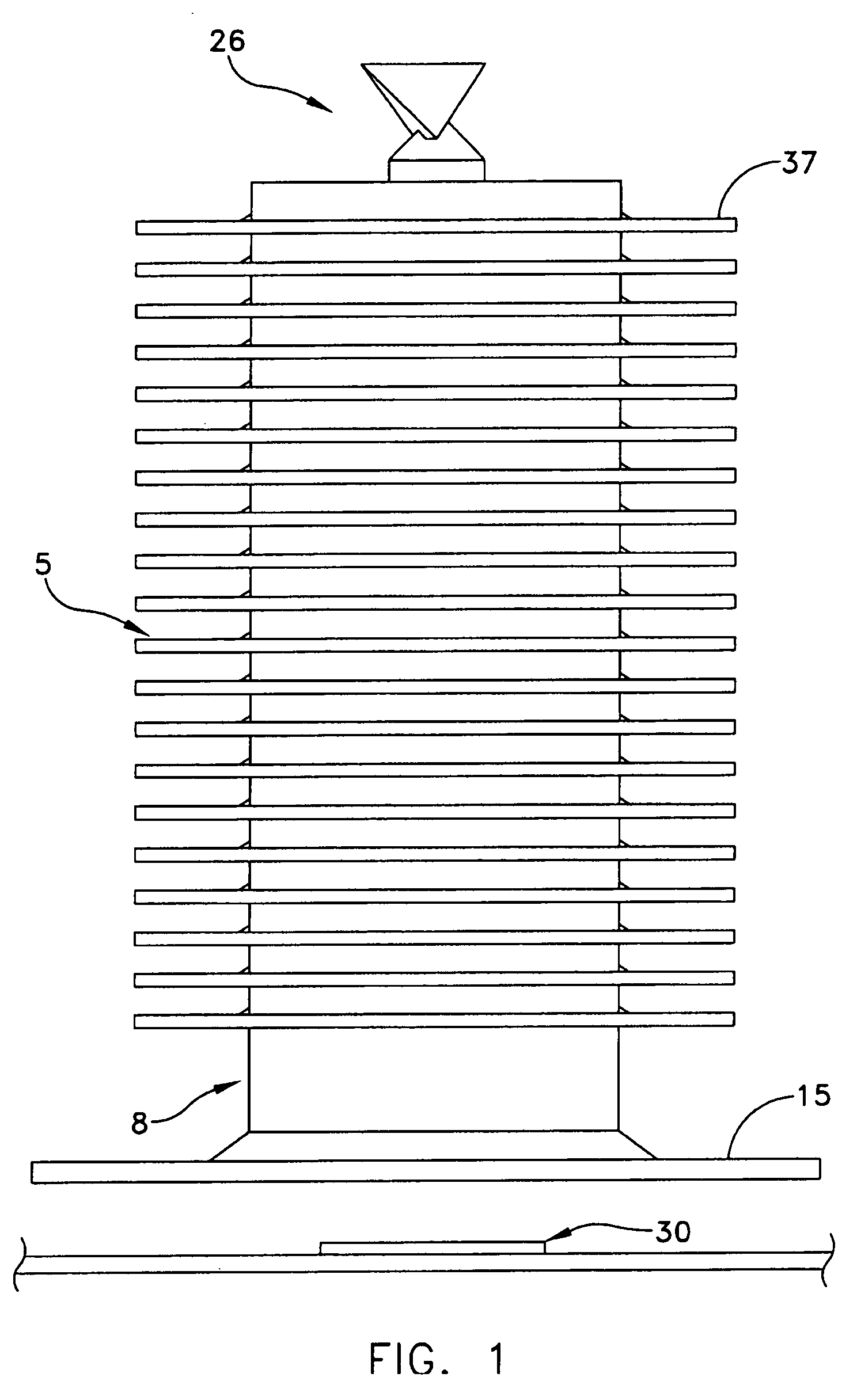

Heat Exchanger

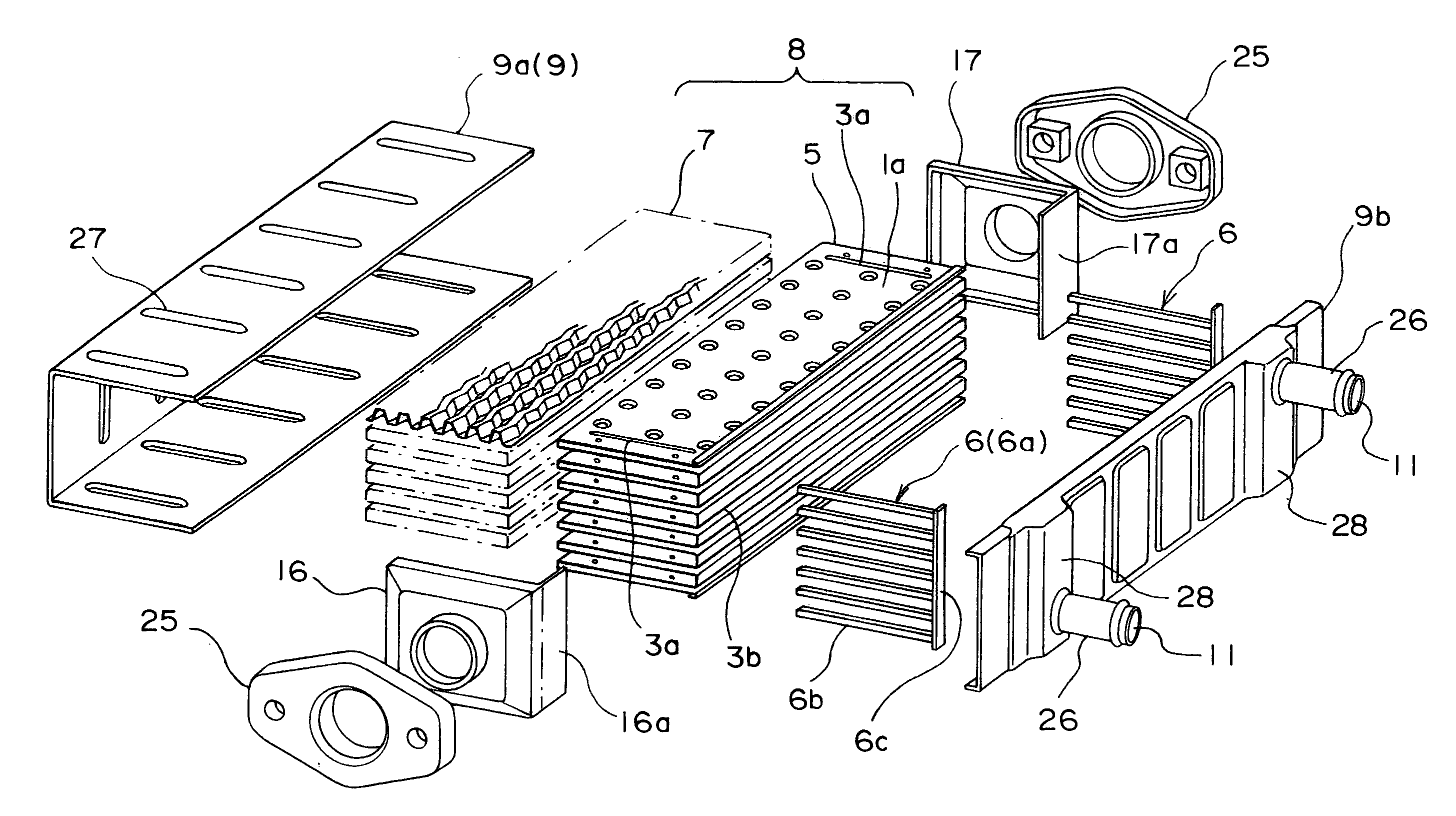

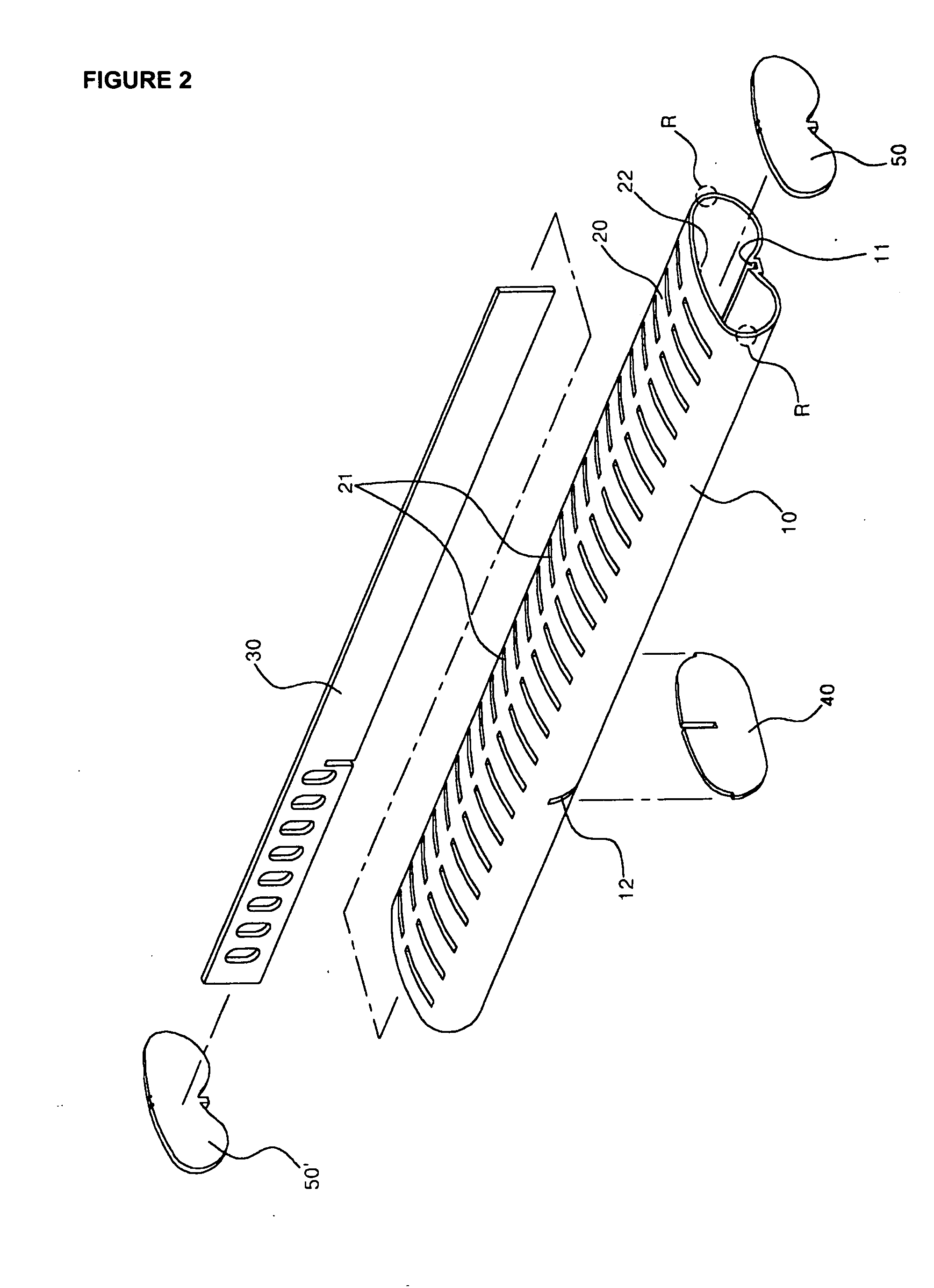

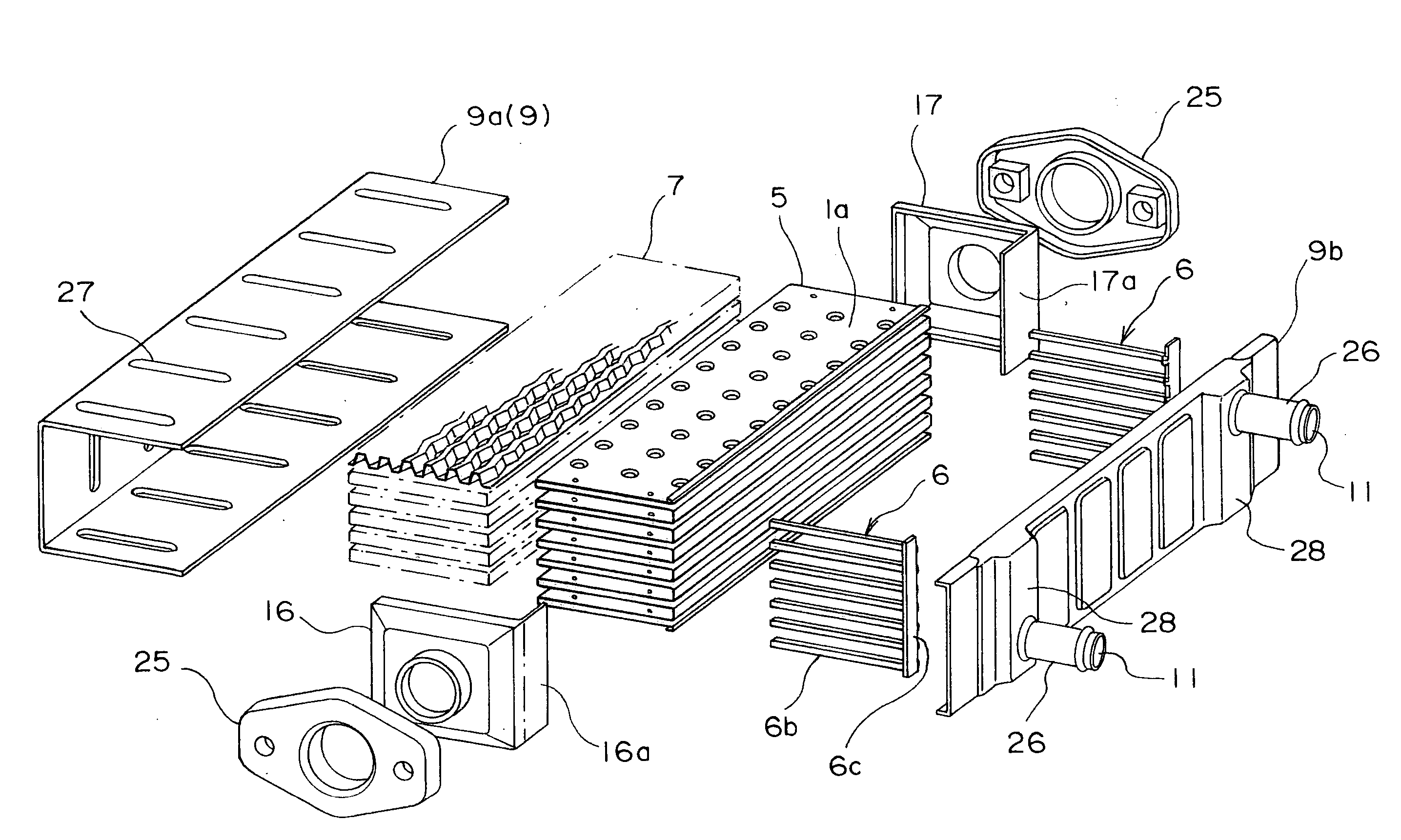

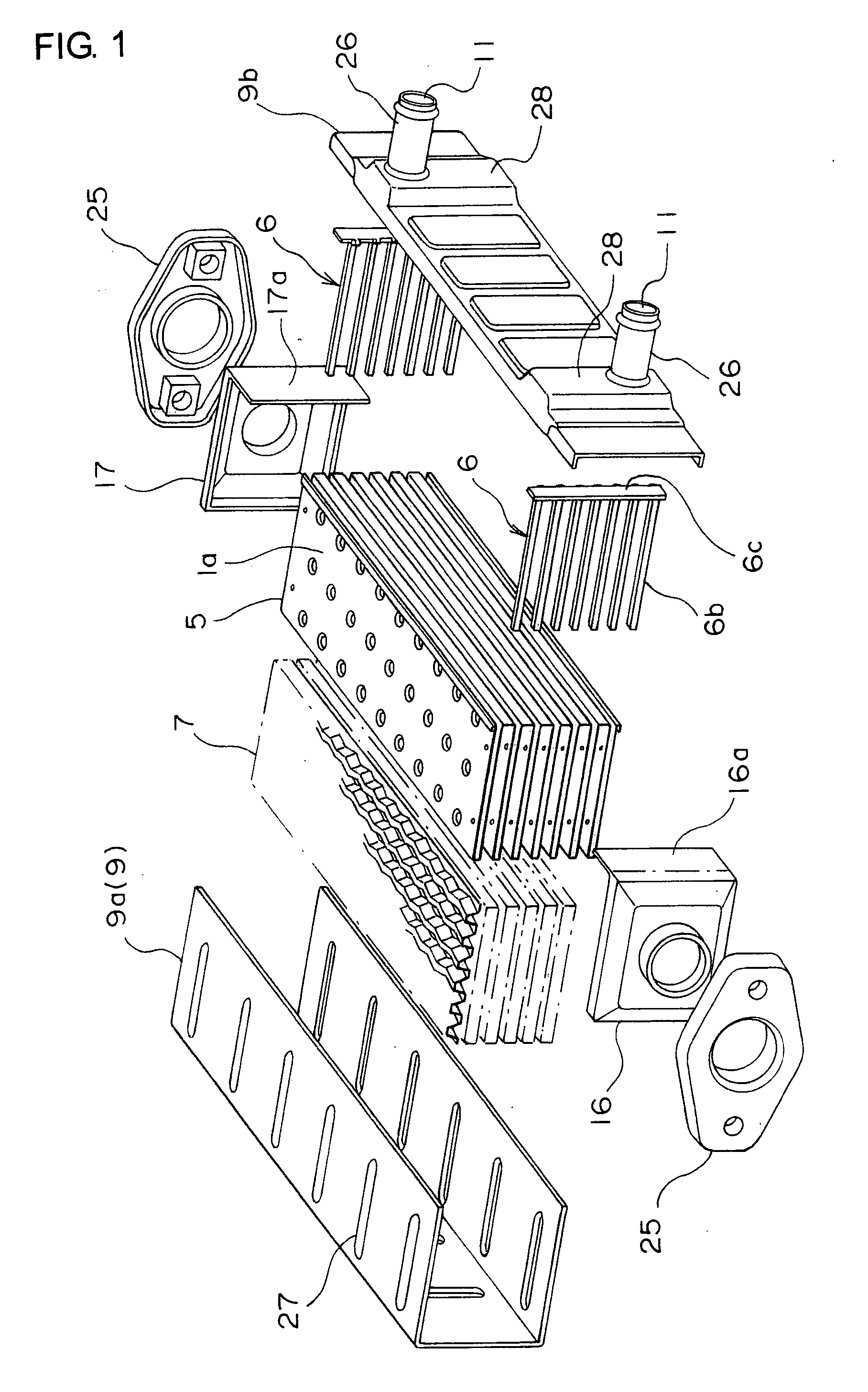

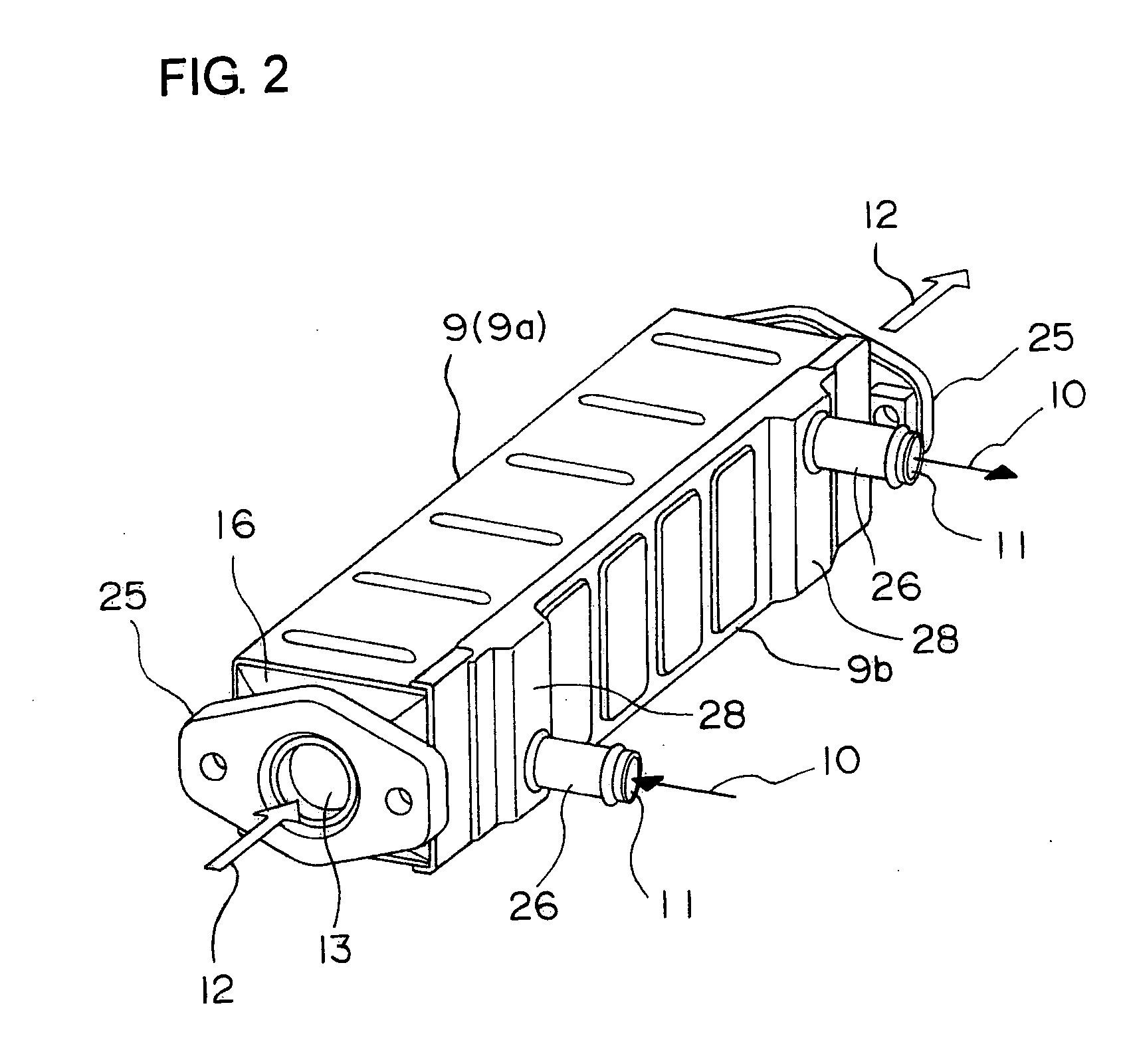

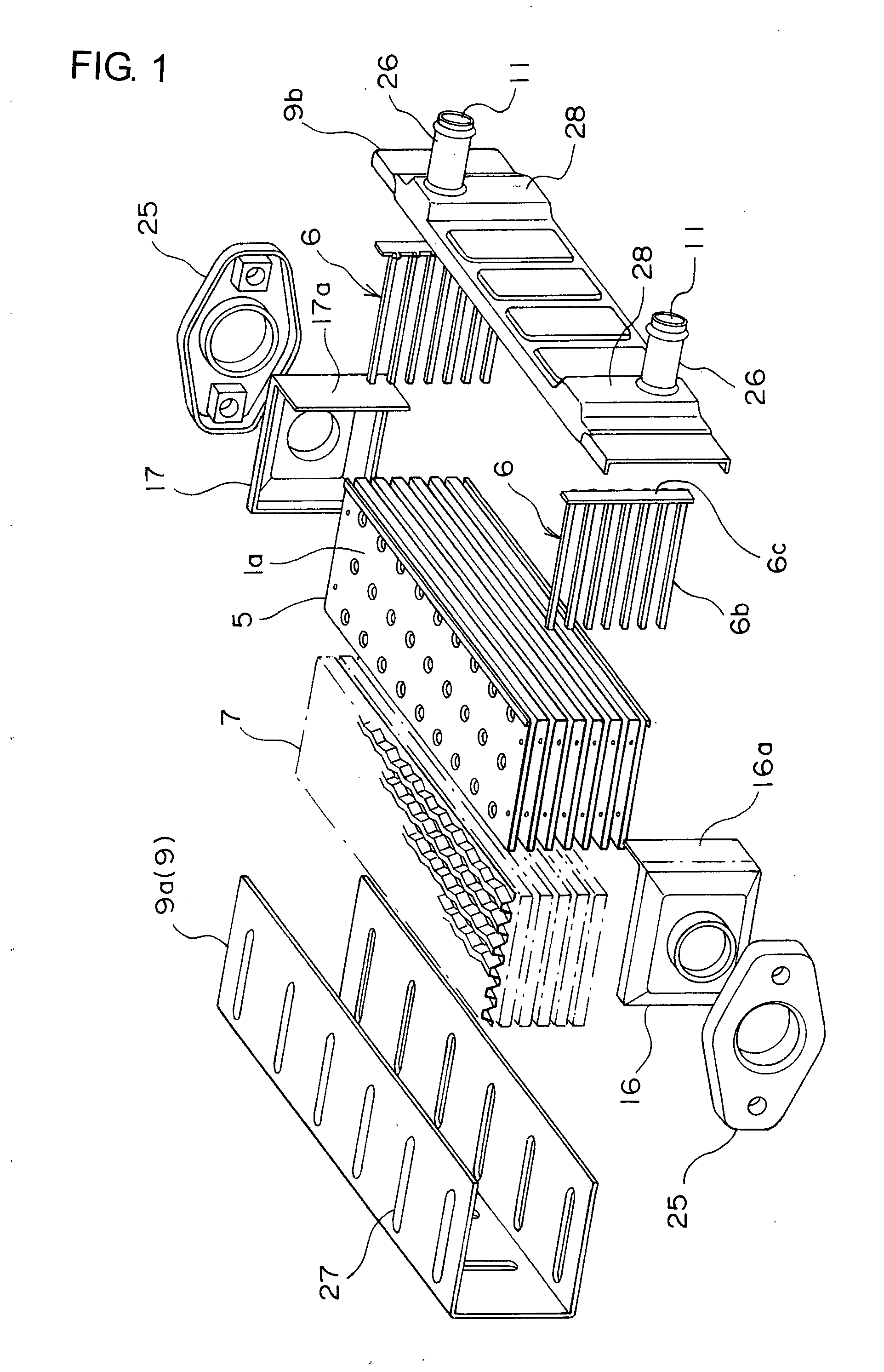

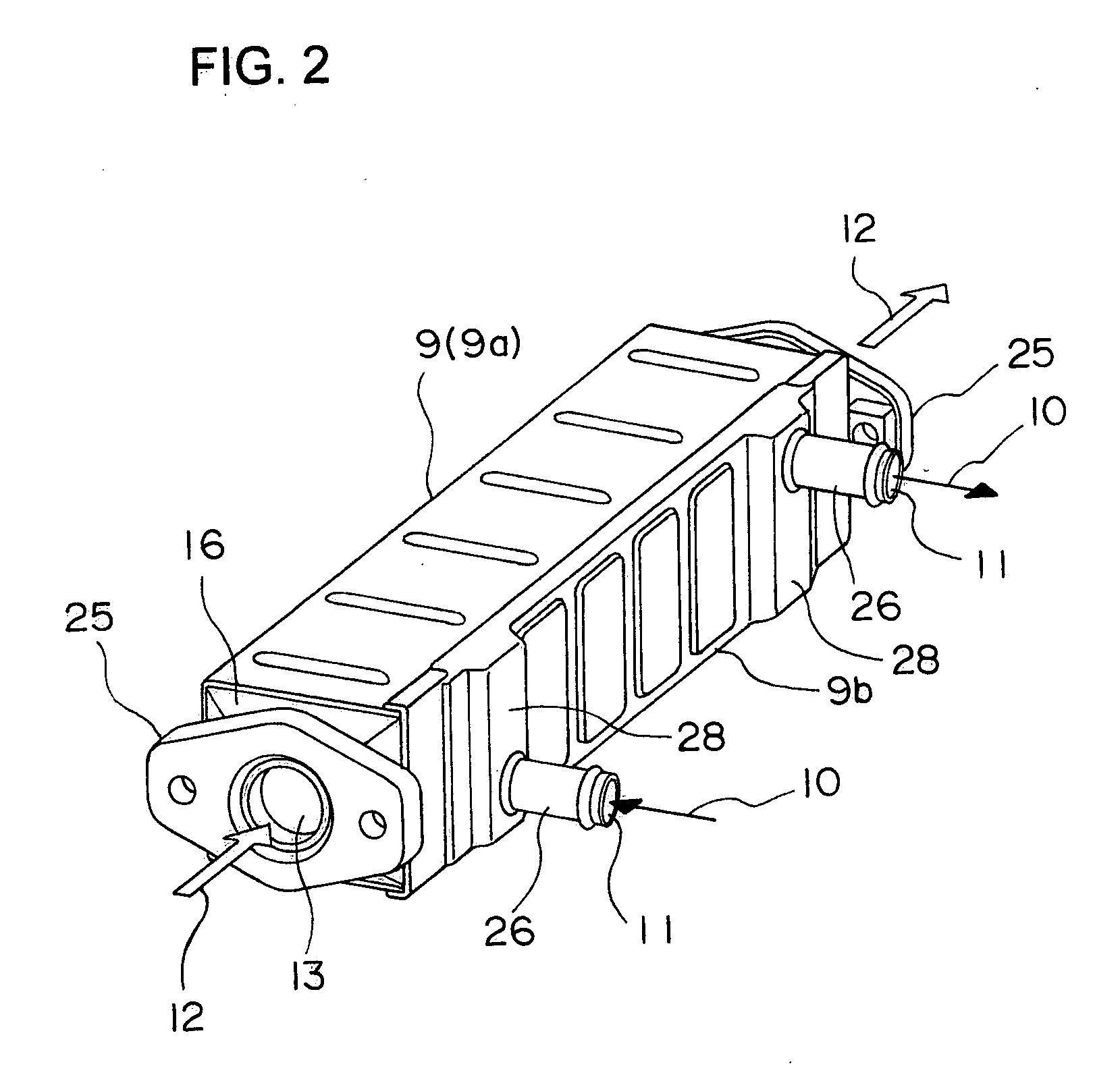

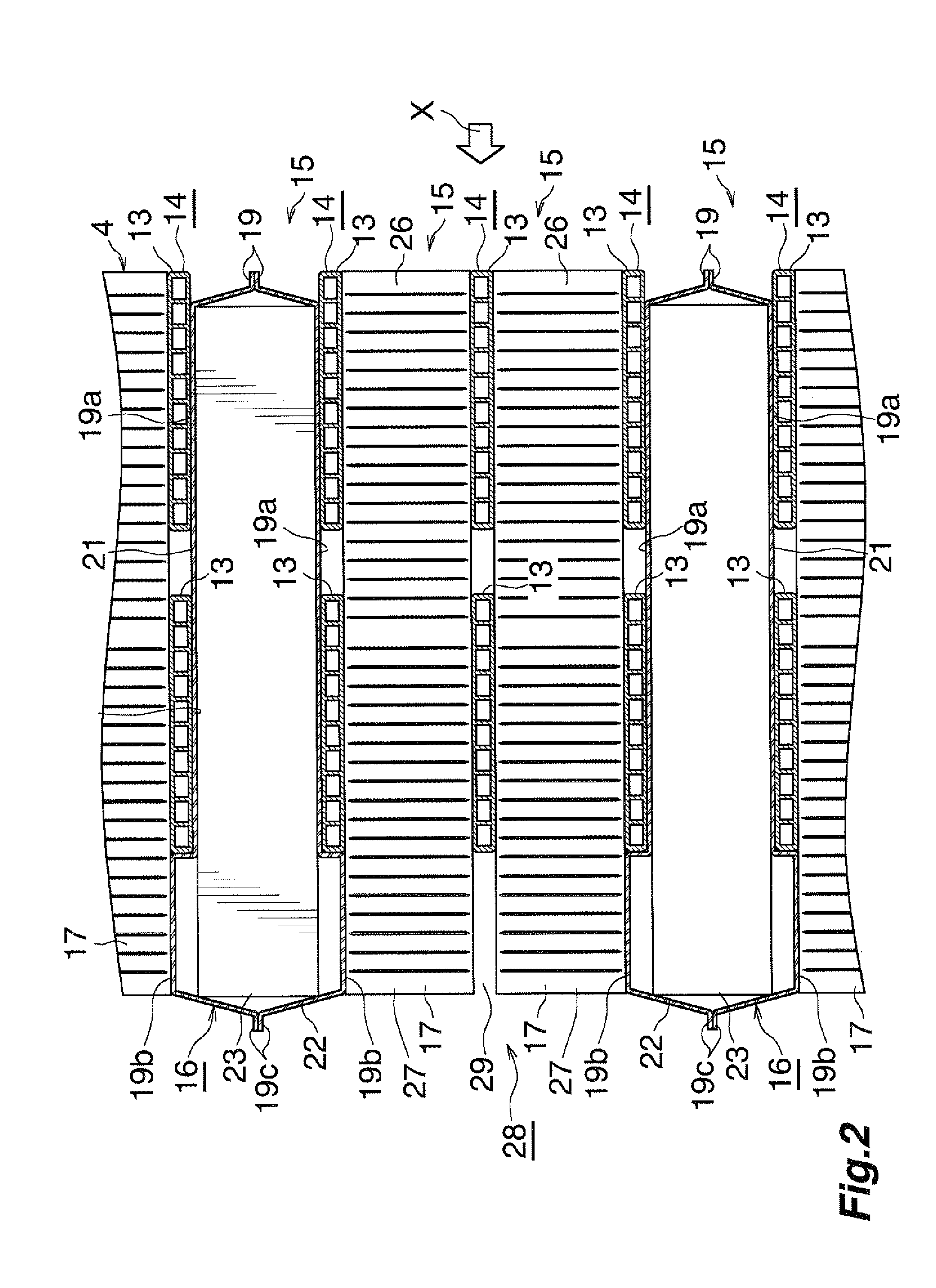

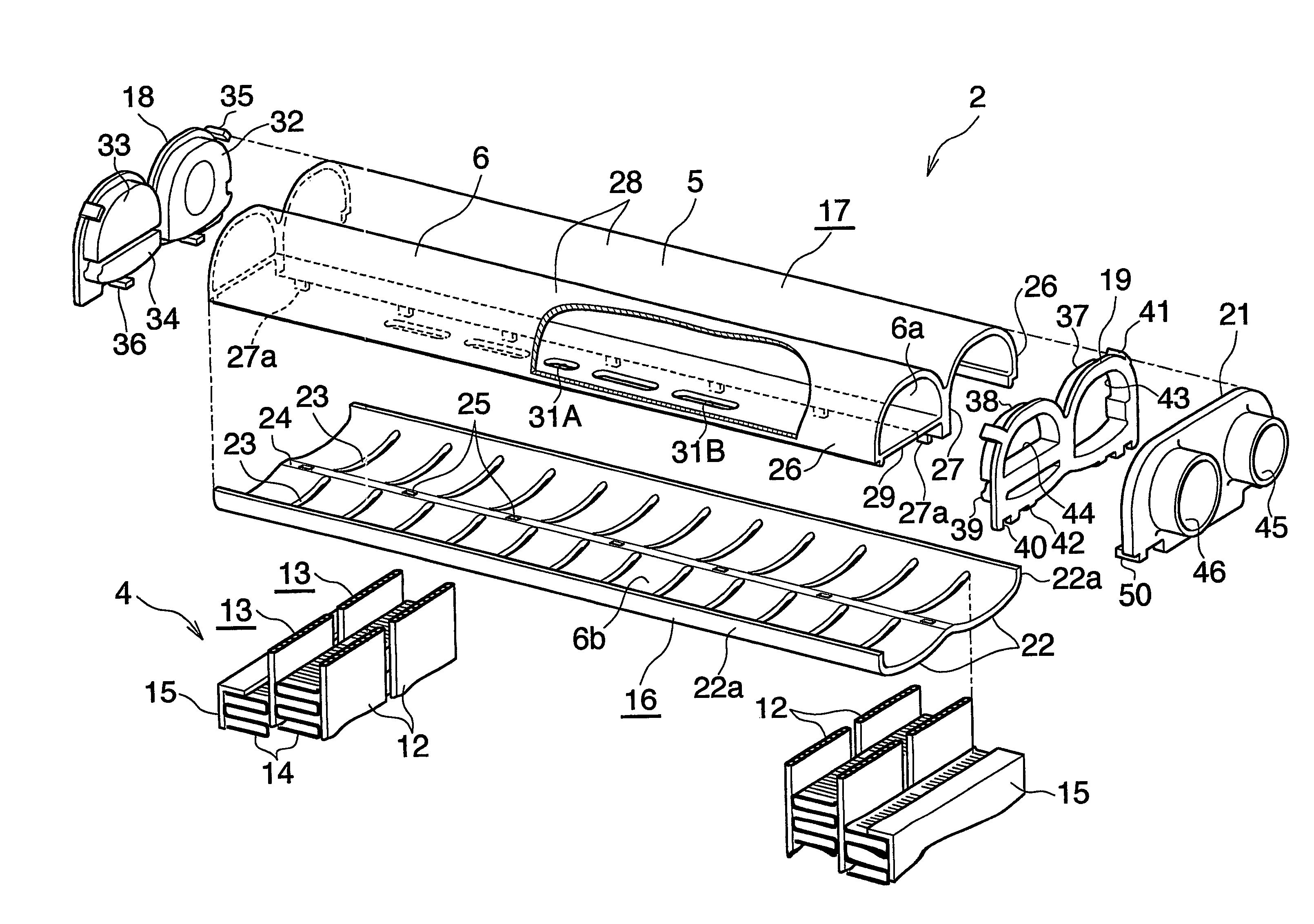

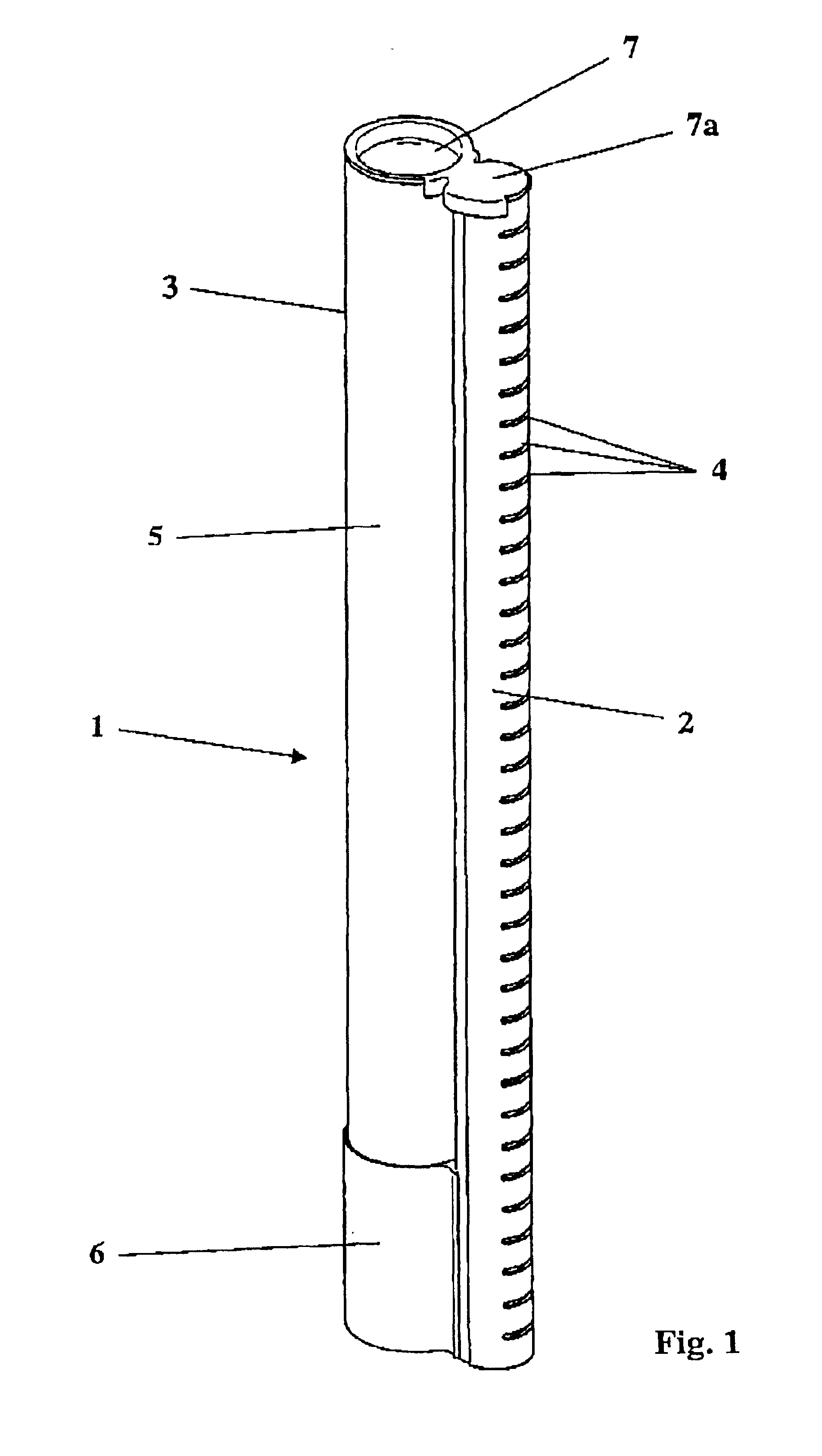

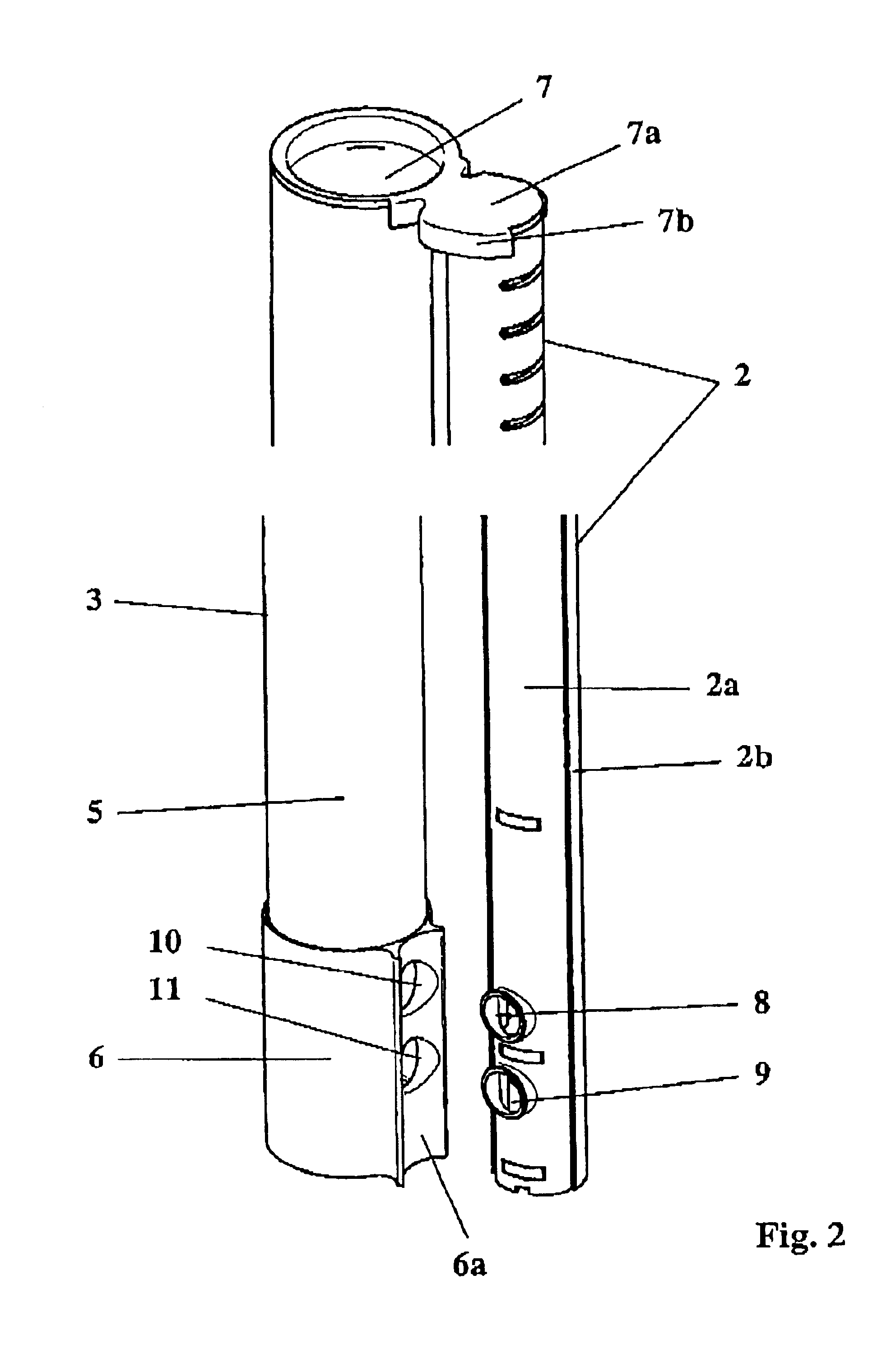

InactiveUS20080087409A1Speed up heat exchangeInternal combustion piston enginesNon-fuel substance addition to fuelBand shapeMechanical engineering

This invention is structured by: forming a core body by turning-up a strip-shaped metal plate in fanfold manner to create a large number of flat flow passages; blocking the individual flow passages at both ends thereof using the respective comb teeth of a pair of comb-state members; and fitting the casing to the core body, while providing inlet / outlet port of the fluid at a side face of the casing. The object of the invention is to establish uniform communication of the fluid in individual flat flow passages. As a means for achieving the object, a pair of header portions are provided at both end portions of the cylindrical casing, the inlet / outlet ports are provided at both edge portions of one side of the casing via a pair of small tank portions, the small tank portion at inlet side of the first fluid has a buffer plate arranged at a position closer to the outlet side of the first fluid between the core body and the inlet / outlet port, thereby allowing the first fluid to bypass the buffer plate in the small tank portion and to enter an end portion of the first flow passage from an edge opposite to the outlet.

Owner:T RAD CO LTD

Heat Exchanger

InactiveUS20080135221A1Easy to crackPrevent leakageInternal combustion piston enginesNon-fuel substance addition to fuelMechanical engineeringHeat exchanger

In a heat exchanger in which the number of parts is small, assembling is easy, bonded portions of each part are fewer and reliability of brazing is improved, a core body is constituted by turning up and bending a strip-shaped metal plate in a fanfold manner, and first flow passages and second flow passages are formed alternately in the thickness direction. Both ends of each of the first flow passages are blocked by each come tooth of a pair of comb-state members, and a fin is set within the second flow passages so as to constitute a core. And in the heat exchanger in which a cylindrical casing is fitted with the outer periphery of the core body, the comb-state member has its tooth base crossing perpendicularly with each of the comb tooth and a root of each comb tooth bent in the L-shape along the tooth base, the plane of the tooth base is brought into contact with a turned-up end edge, and each connection portion between the comb-state member and the core body is integrally brazed / fixed.

Owner:T RAD CO LTD

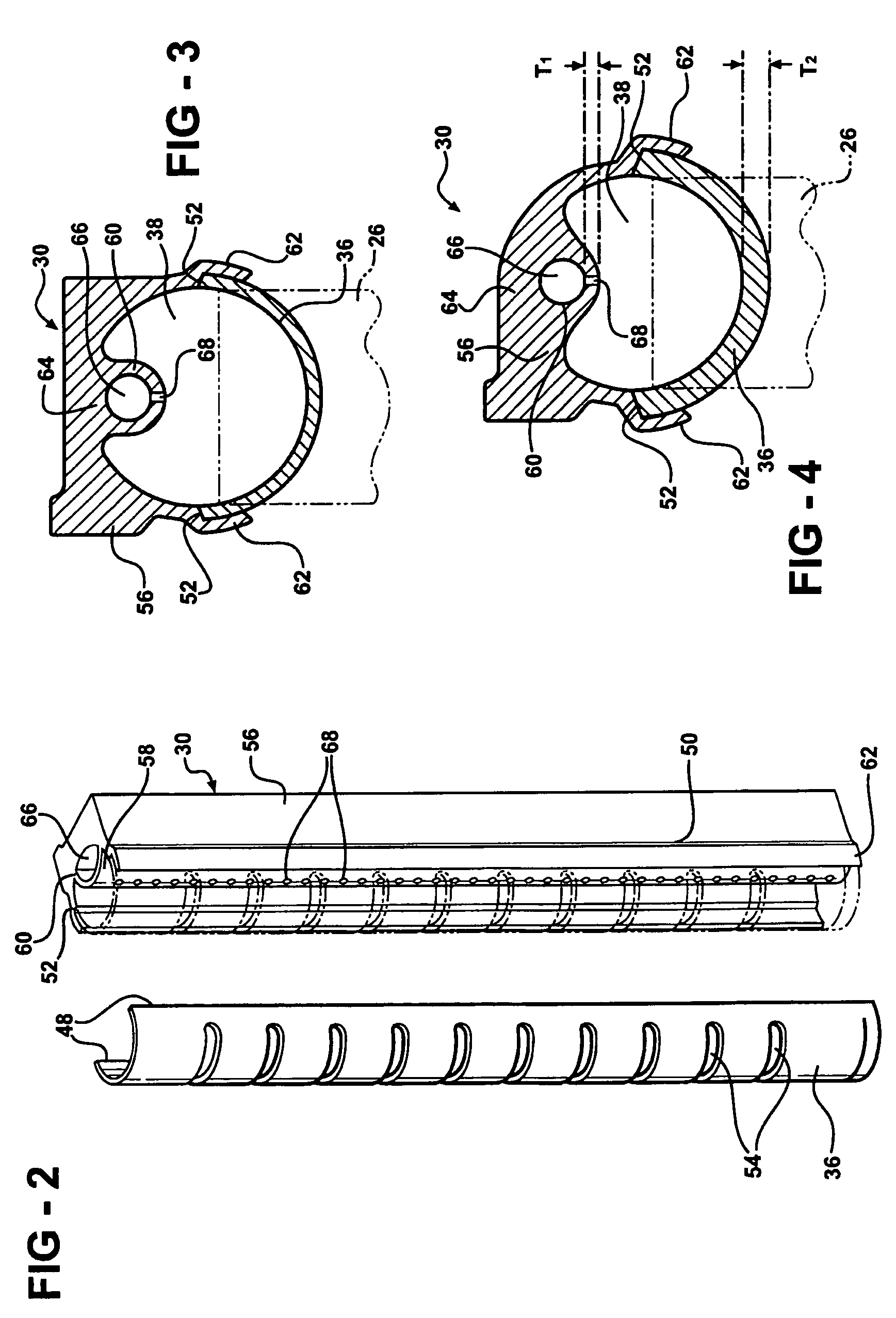

Heat exchanger with thermal storage function and method of manufacturing the same

ActiveUS20130284395A1Great degreeHeat storage plantsMetal-working apparatusPlate heat exchangerEngineering

A heat exchanger with a thermal storage function includes a plurality of heat exchange tubes, a plurality of thermal storage material containers, and a first thermal storage material charging member. A circumferential wall of the first thermal storage material charging member is deformed such that a collapsed portion is formed on the first thermal storage material charging member and the thermal storage material charging passage is closed and sealed. The collapsed portion of the first thermal storage material charging member includes a first collapsed part and a second collapsed part. A relation T2<T1≦2t is satisfied where “t” represents a thickness of the circumferential wall of an uncollapsed portion of the first thermal storage material charging member, “T1” represents a thickness of the first collapsed part, and “T2” represents a thickness of the second collapsed part.

Owner:MAHLE INT GMBH

Heat exchanger

InactiveUS20070044949A1Precise arrangementClosure meansStationary conduit assembliesEngineeringMechanical engineering

In manufacture of a heat exchanger, heat exchange tubes, fins, and header section bodies are arrange in an assembled condition. Projection pieces provided on caps of header sections are fitted into corresponding slits formed in side plates, thereby engaging end portions of the side plates with the caps. In this condition, the caps are arranged in such a manner as to bridge end portions of the header section bodies, and the side plates are arranged on the outer sides of the leftmost and rightmost fins. The heat exchange tubes and the fins, the heat exchange tubes and the header section bodies, the header section bodies and the caps, the side plates and the caps, and the side plates and the fins are respectively brazed together simultaneously. This method enables the side plates to be accurately arranged at respectively predetermined positions.

Owner:KEIHIN THERMAL TECH CORP

Deformable end cap for heat pipe

Owner:THERMAL

Heat exchanger

InactiveUS20050016717A1Easy to manufactureLess susceptible to failure and leakageSafety devices for heat exchange apparatusClosure meansEngineeringMechanical engineering

An improved heat exchanger includes an integral side piece / end cap structure for closing the ends of tanks and providing a side piece for each side of the heat exchanger and includes connecting strands between an end cap section and a side piece section that are weak, allowing the breakage thereof prior to excessive thermal stresses being placed on tube to the header joints. Also disclosed is the use of clips on end cap section and / or tank ends together with a tab on the end cap section which may be used to self-fixture of the components during assembly.

Owner:MODINE MFG CO

Heat exchange tube and evaporator

InactiveCN101082470AImprove liquid retention capacityImprove comfortEvaporators/condensersClosure meansTemperature differenceEngineering

An evaporator includes a plurality of flat heat exchange tubes extending in a vertical direction and arranged at intervals along a left-right direction with a width direction thereof coinciding with a front-rear direction. The heat exchange tube has a plurality of refrigerant channels arranged along the width direction. The evaporator satisfies a relation 0.558<=A<=1.235, where A is a value in pieces / mm obtained by dividing the number N of the refrigerant channels of the heat exchange tube by a width W of the heat exchange tube as measured in the front-rear direction. Also, the evaporator satisfies a relation 0.35<=Dh<=1.0, where Dh is an equivalent diameter in mm of the heat exchange tube. This evaporator can reduce the temperature difference between air discharged into a compartment when a compressor is turned ON and that when the compressor is turned OFF.

Owner:KEIHIN THERMAL TECH CORP

CTE-matched heat pipe

InactiveUS20050139995A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialThermal expansion

Heat sinks having a mounting surface with a coefficient of thermal expansion matching that of silicon are disclosed. Heat pipes having layered composite or integral composite low coefficient of expansion heat sinks are disclosed that can be mounted directly to silicon semiconductor devices.

Owner:THERMAL

Air-to-air heat exchanger

An air-to-air heat exchanger, is provided that comprises a folded fin core formed from a continuous sheet of thermally conductive material that has been folded into alternating flat ridges and troughs; an insert overlay having an opening including two sets of uniform fingers, wherein each finger has a portion protruding into and essentially filling each trough on one surface of the folded fin core; an inset region between each finger portion and the end edges of each trough; a sealant within each inset region sealably attaching the insert overlay to the folded fin core; and an air flow divider plate. Heat exchanger components are also provided.

Owner:THERMAL

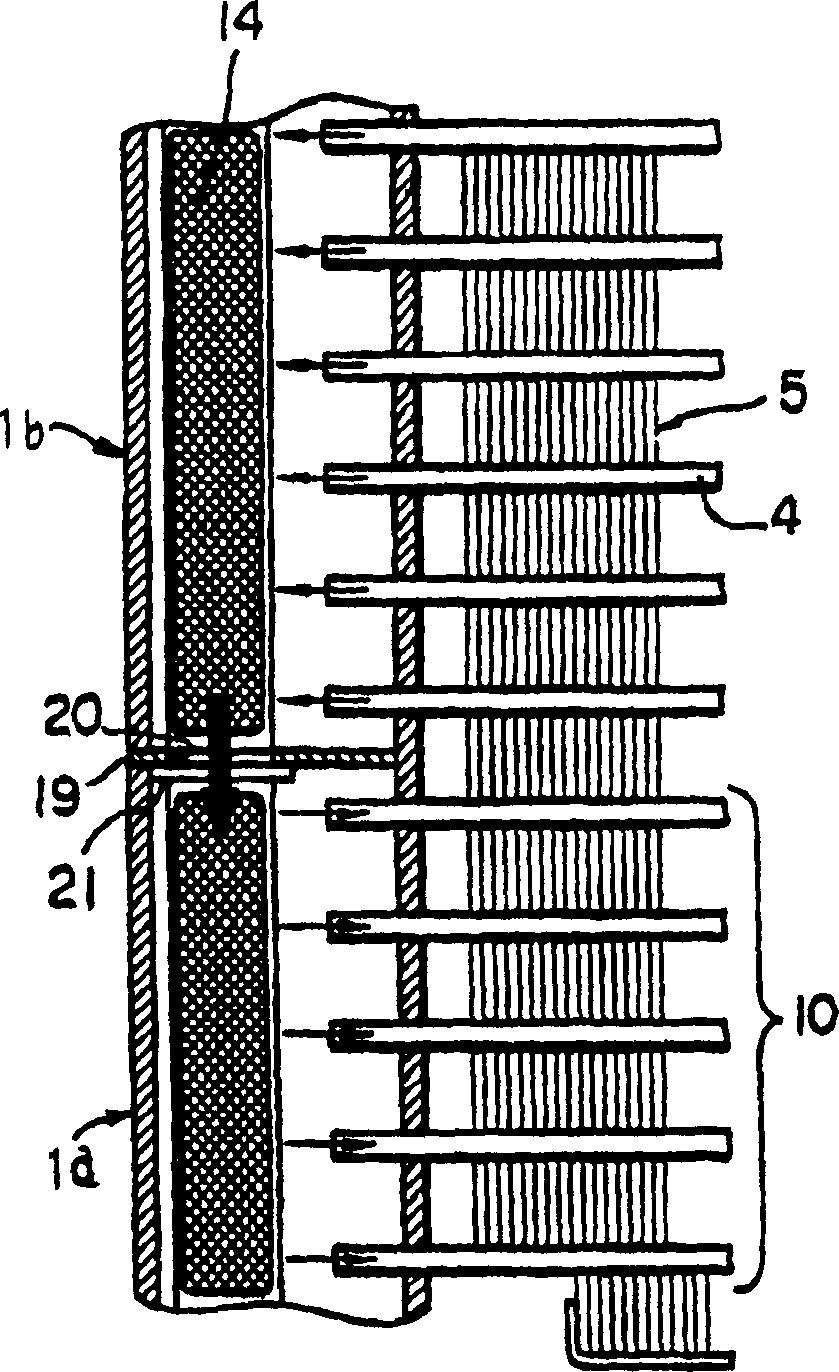

Heat exchange tube and evaporator

InactiveUS20070277964A1Reduce temperature differenceImproving retainabilityEvaporators/condensersClosure meansRefrigerantEvaporator

An evaporator includes a plurality of flat heat exchange tubes extending in a vertical direction and arranged at intervals along a left-right direction with a width direction thereof coinciding with a front-rear direction. The heat exchange tube has a plurality of refrigerant channels arranged along the width direction. The evaporator satisfies a relation 0.558≦A≦1.235, where A is a value in pieces / mm obtained by dividing the number N of the refrigerant channels of the heat exchange tube by a width W of the heat exchange tube as measured in the front-rear direction. Also, the evaporator satisfies a relation 0.35≦Dh≦1.0, where Dh is an equivalent diameter in mm of the heat exchange tube. This evaporator can reduce the temperature difference between air discharged into a compartment when a compressor is turned ON and that when the compressor is turned OFF.

Owner:SHOWA DENKO KK

Semifinished Joint Plate, Joint Plate, Process for Fabricating Joint Plate and Heat Exchanger

InactiveUS20070215331A1Reduce widthImprove uniformityAir-treating devicesEvaporators/condensersMechanical engineeringHeat exchanger

A semifinished joint plate 60 has a refrigerant inlet portion 45 and a refrigerant outlet portion 46 spaced apart in the front-rear direction. The semifinished plate 60 has an upwardly or downwardly extending slit 61 formed between the inlet portion 45 and the outlet portion 46, and slit width adjusting portions 62, 63 extending through the thickness of the plate 60, having a larger width than the slit 61 and communicating respectively with the upper and lower ends of the slit 61. A portion of the semifinished plate 60 above the upper adjusting portion 62 and a portion thereof below the lower adjusting portion 63 are bent to shorten the plate

Owner:KEIHIN THERMAL TECH CORP

Multiflow overcold condenser

A multi-flow subcooling condenser, comprising: a pair of headers, a plurality of flat heat transfer tubes connecting the pair of headers, and corrugated fins arranged alternately with the heat transfer tubes. The condenser includes a refrigerant condensing core section and a subcooling cooling core section. The lower part of one of the headers of the condenser, which serves as a liquid tank to collect liquid refrigerant for delivery to the subcooled cooling core section, also has a desiccant. A plug mechanism is provided to the end of the desiccant including the manifold, in the plug mechanism the plug can be arbitrarily fixed or removed, whereby the desiccant can be replaced.

Owner:SANDEN CORP

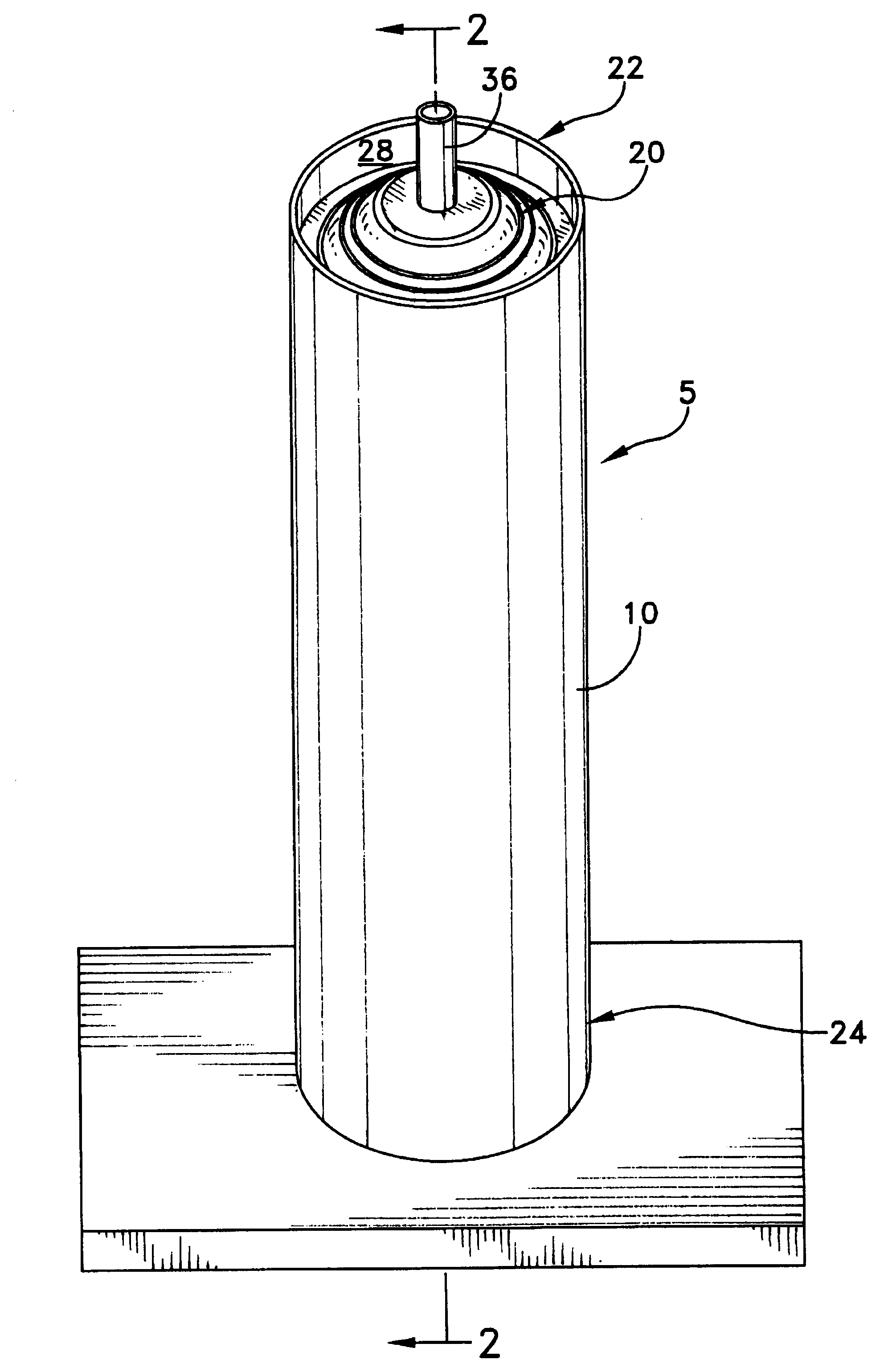

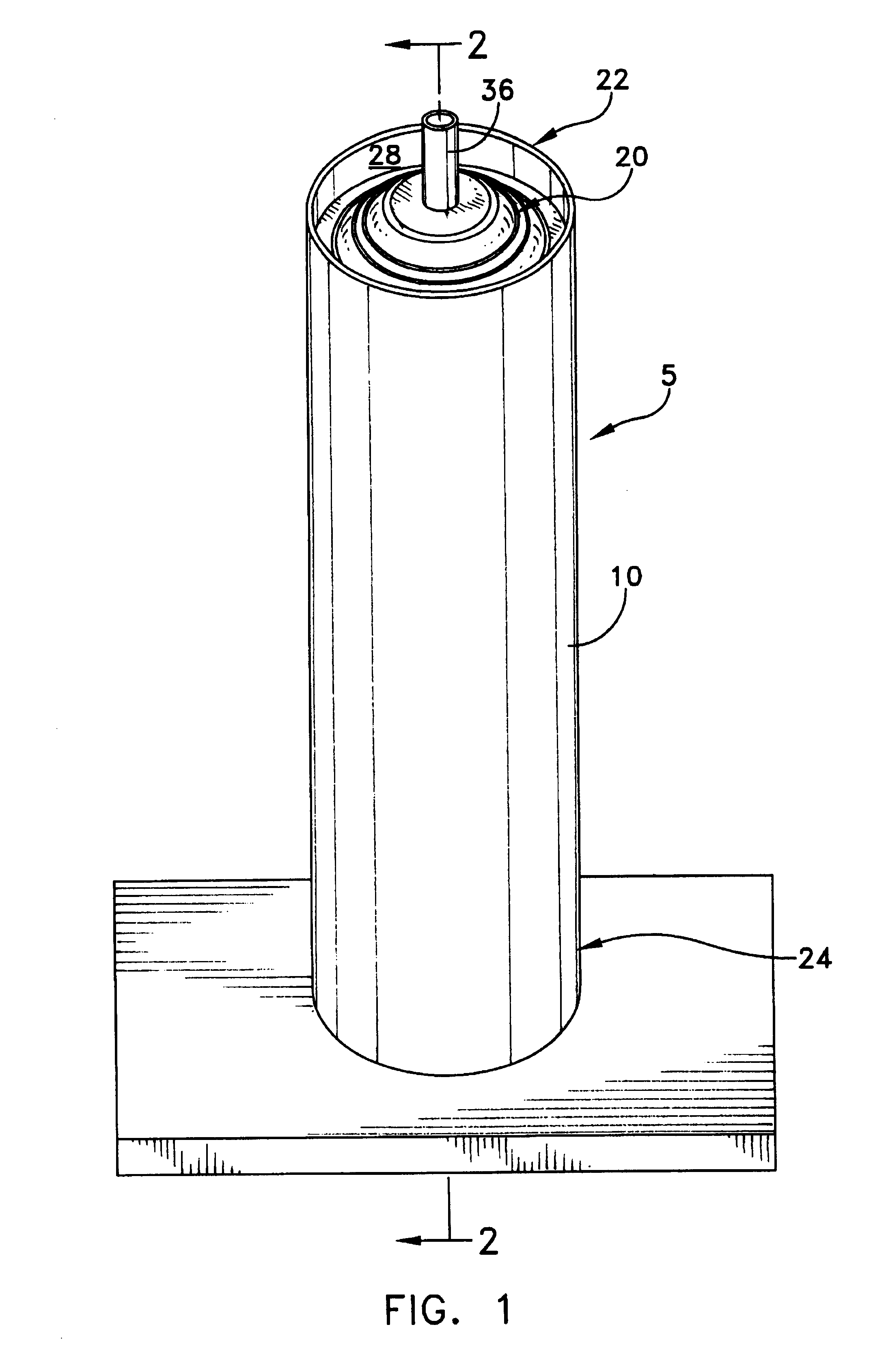

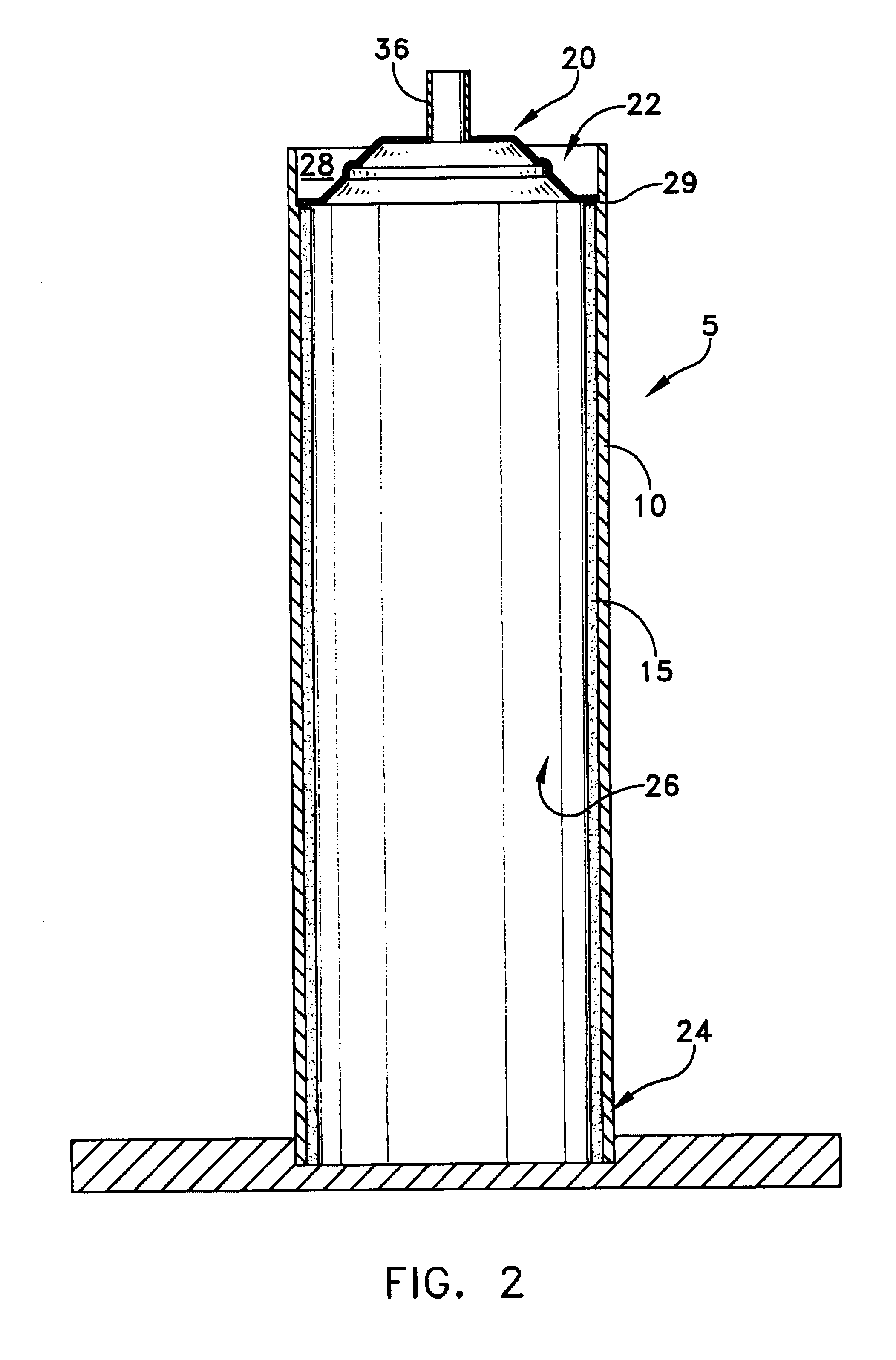

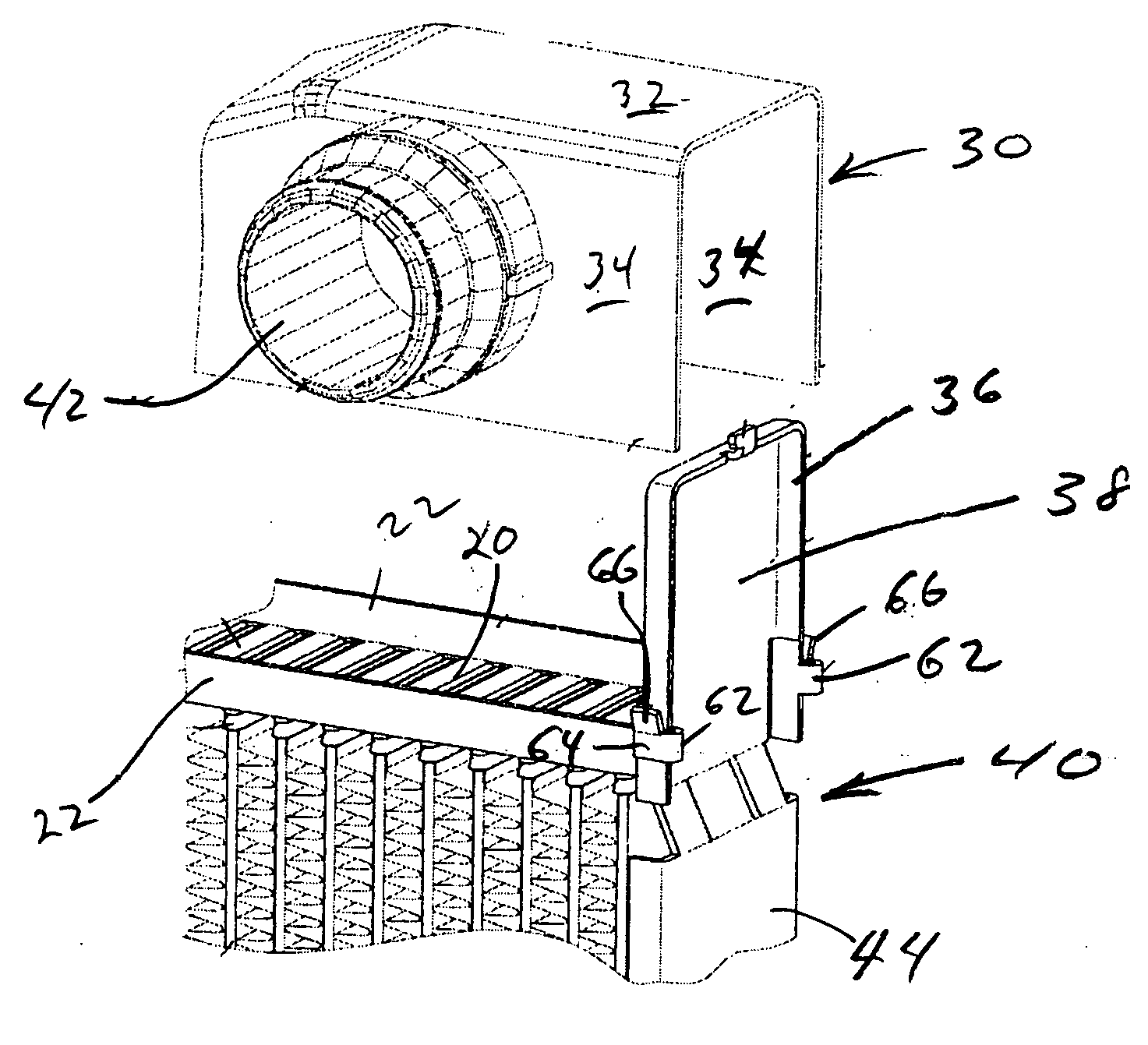

Heat-exchange apparatus for insertion into a storage tank, and mounting components therefor

A heat-exchange apparatus and a mounting component set for installation into storage tanks. The heat-exchange apparatus comprises a heat-exchanging component, a coupling manifold configured to engage with the heat-exchanging component, and a hollow, elongate, flow-directing element that delivers fluid to the heat-exchanging component. The mounting component set comprises an inner flange for engaging the inner wall of the storage tank, an outer flange for engaging the outer wall of the storage tank, and at least one gasket cooperable with one of the flanges. The heat-exchange apparatus sealably engages the outer flange such that the heat-exchanging component extends into the interior of the tank, and the coupling manifold is interconnectable to an external supply of heat-exchange fluid.

Owner:ARNOT ROGER

Heat exchanger

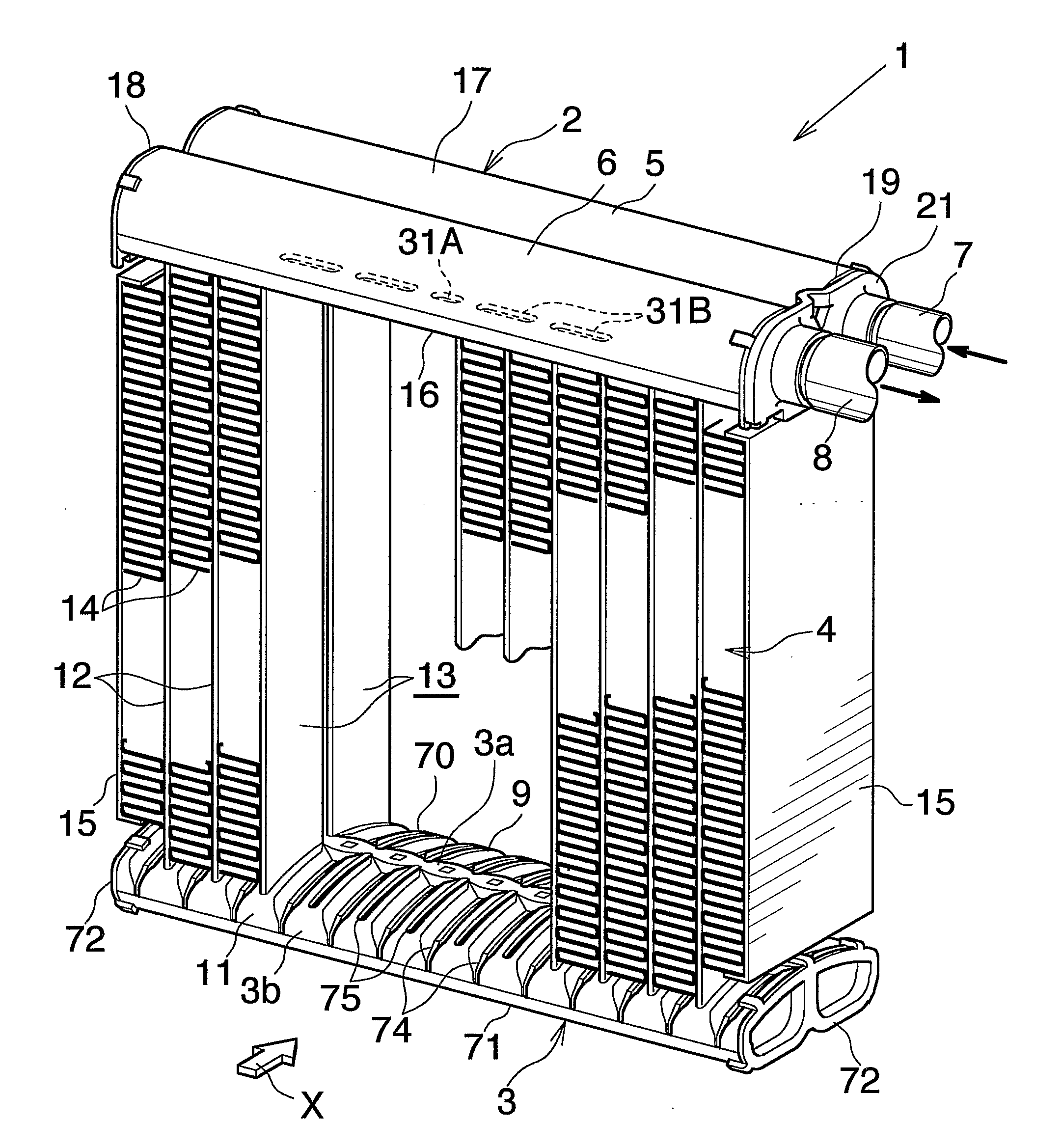

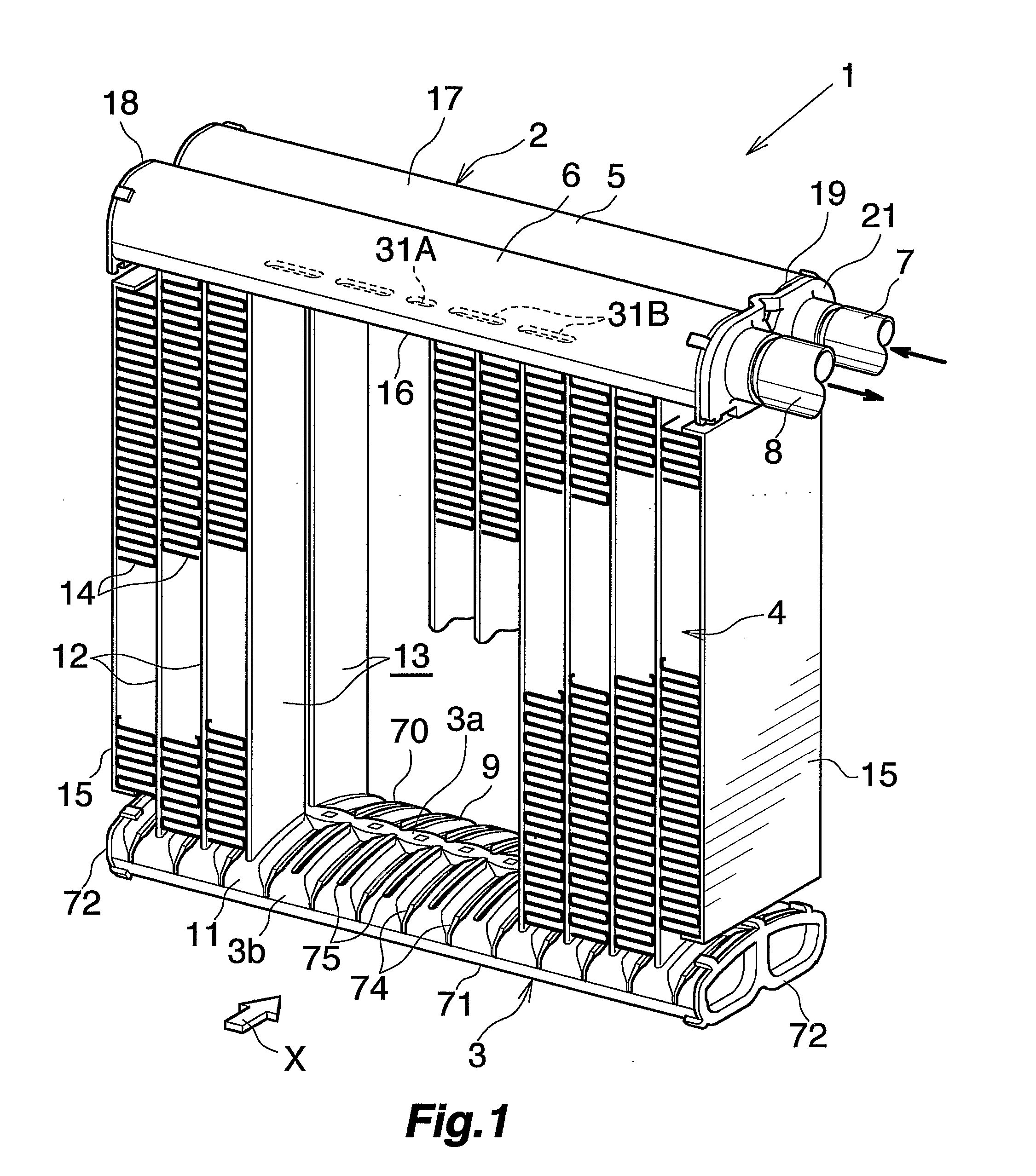

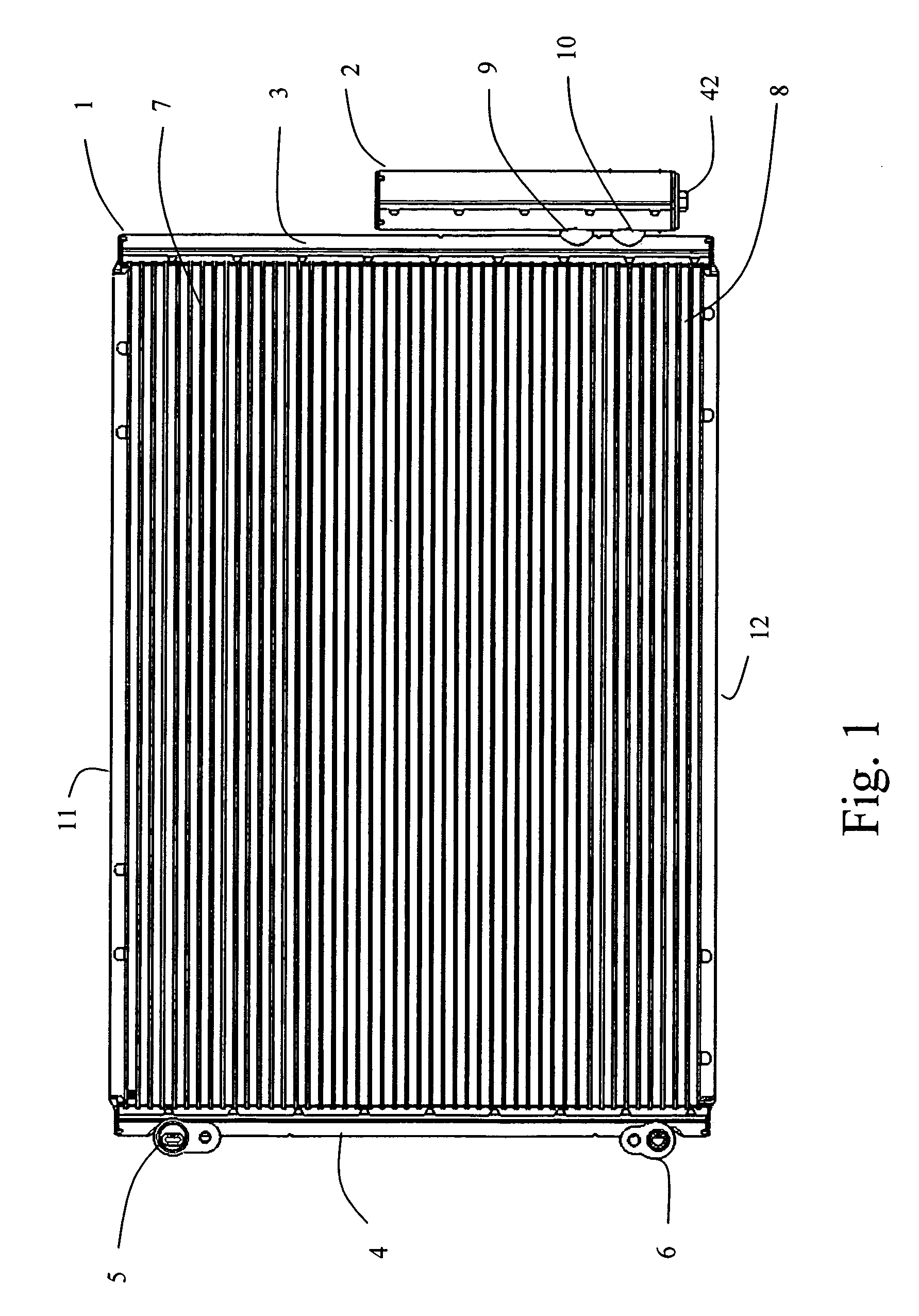

ActiveUS20070209386A1Easy to fallSimple processSafety devices for heat exchange apparatusEvaporators/condensersFuel tankEngineering

A heat exchanger for use as an evaporator includes a heat exchange core having a plurality of heat exchange tubes arranged in a left-right direction at a spacing, and a refrigerant turn tank as a lower tank disposed toward a lower end of the heat exchange core. The heat exchange tubes are inserted through respective tube insertion holes formed in the turn tank and joined to the tank, The turn tank has drain grooves each extending from a forwardly or rearwardly outer end of each of the tube insertion holes for discharging condensation water to below the turn tank therethrough. Each of the drain grooves has a bottom extending gradually downward as the bottom extends away from the tube insertion hole. When the exchanger is used as the evaporator, the top surface of the turn tank can be drained of water with an improved efficiency

Owner:MAHLE INT GMBH

Receiver tank for a condensor and method of manufacturing the same

InactiveUS20060123837A1Easy to manufactureLow costEvaporators/condensersMetal-working apparatusAutomobile air conditioningEngineering

The invention provides for a receiver tank for an automobile air conditioner condenser comprising: a first half having two openings for refrigerant inlet and outlet, a second half to be joined with the first half to form the receiver, at least one of the first or second half having means to join with the other half.

Owner:SUBROS

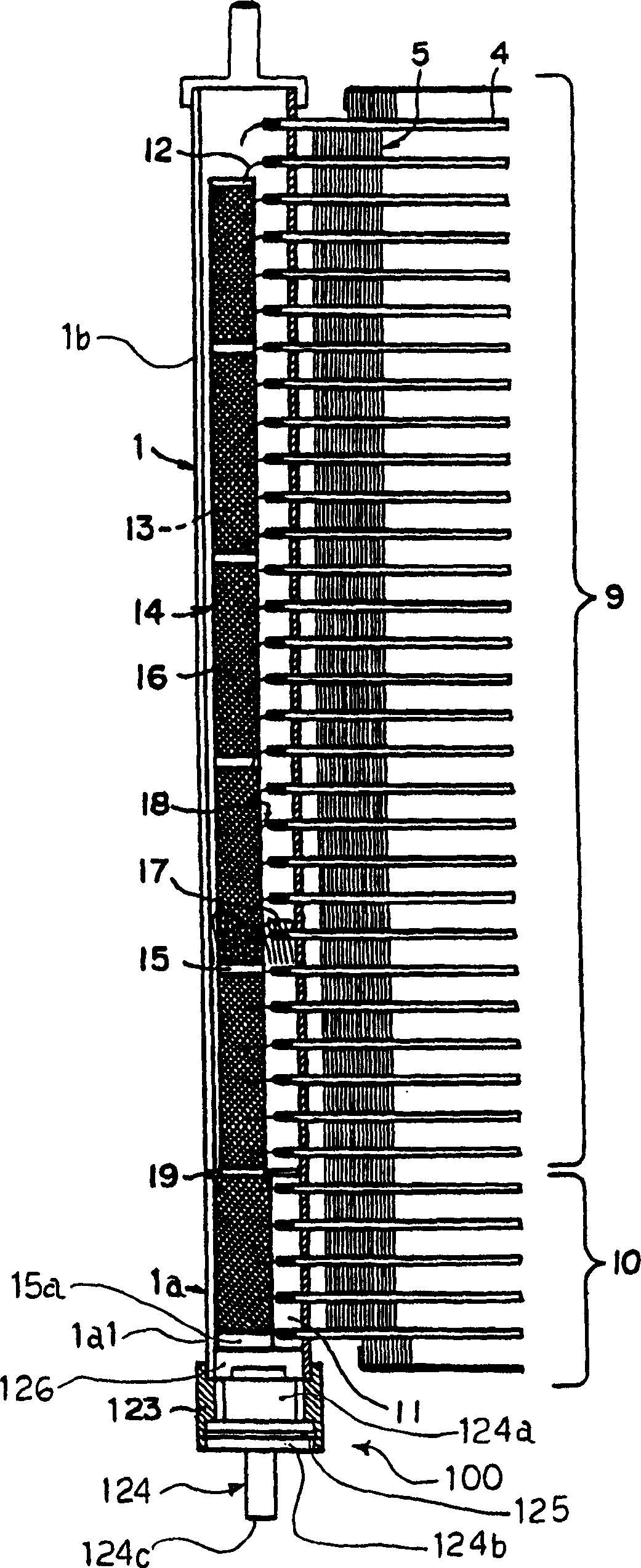

Evaporator and process for fabricating same

InactiveUS7886811B2Small heat capacityEasy to manufactureEvaporators/condensersSoldering apparatusRefrigerantEvaporator

An evaporator includes a refrigerant inlet header and a refrigerant outlet header arranged side by side in a front-rear direction, and a refrigerant circulating passage holding the headers in communication. The inlet and outlet headers are provided with caps forming refrigerant inlet and refrigerant outlet, the caps are joined to a pipe joint member having refrigerant inlet and outlet portions in communication with the refrigerant inlet and outlet, the caps or the pipe joint member is provided with a positioning lug which is projecting from its side edge toward the other one and which is fitted with a positioning recess formed in the other one, and the caps and the pipe joint member have flat surfaces to be contact with each other and are brazed such that the lug is engaged with the recess and that the flat surfaces are in contact with each other.

Owner:KEIHIN THERMAL TECH CORP

Heat exchanger with drain grooves

InactiveUS7971636B2Impairment of performance can be precludedImprove drainage efficiencySafety devices for heat exchange apparatusEvaporators/condensersPlate heat exchangerEngineering

A heat exchanger for use as an evaporator includes a heat exchange core having a plurality of heat exchange tubes arranged in a left-right direction at a spacing, and a refrigerant turn tank as a lower tank disposed toward a lower end of the heat exchange core. The heat exchange tubes are inserted through respective tube insertion holes formed in the turn tank and joined to the tank. The turn tank has drain grooves each extending from a forwardly or rearwardly outer end of each of the tube insertion holes for discharging condensation water to below the turn tank therethrough. Each of the drain grooves has a bottom extending gradually downward as the bottom extends away from the tube insertion hole. the exchanger is used as the evaporator, the top surface of the turn tank can be drained of water with an improved efficiency.

Owner:MAHLE INT GMBH

Heat exchanger

InactiveUS6851468B2Smooth connectionSimple methodEvaporators/condensersArc welding apparatusMobile vehiclePlate heat exchanger

The invention relates to a heat exchanger, in particular a refrigerant condenser, especially for a motor vehicle air-conditioning unit. The heat exchanger is comprised of a block of tubes and fins and of collecting tubes which are arranged on both sides and receive the ends of the tubes, and of a collector which is arranged parallel to a collecting tube. A method for manufacturing the heat exchanger is also disclosed.

Owner:BEHR GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com