Multiflow overcold condenser

A multi-flow, condenser technology, used in subcoolers, evaporators/condensers, refrigerators, etc., to solve problems such as size constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

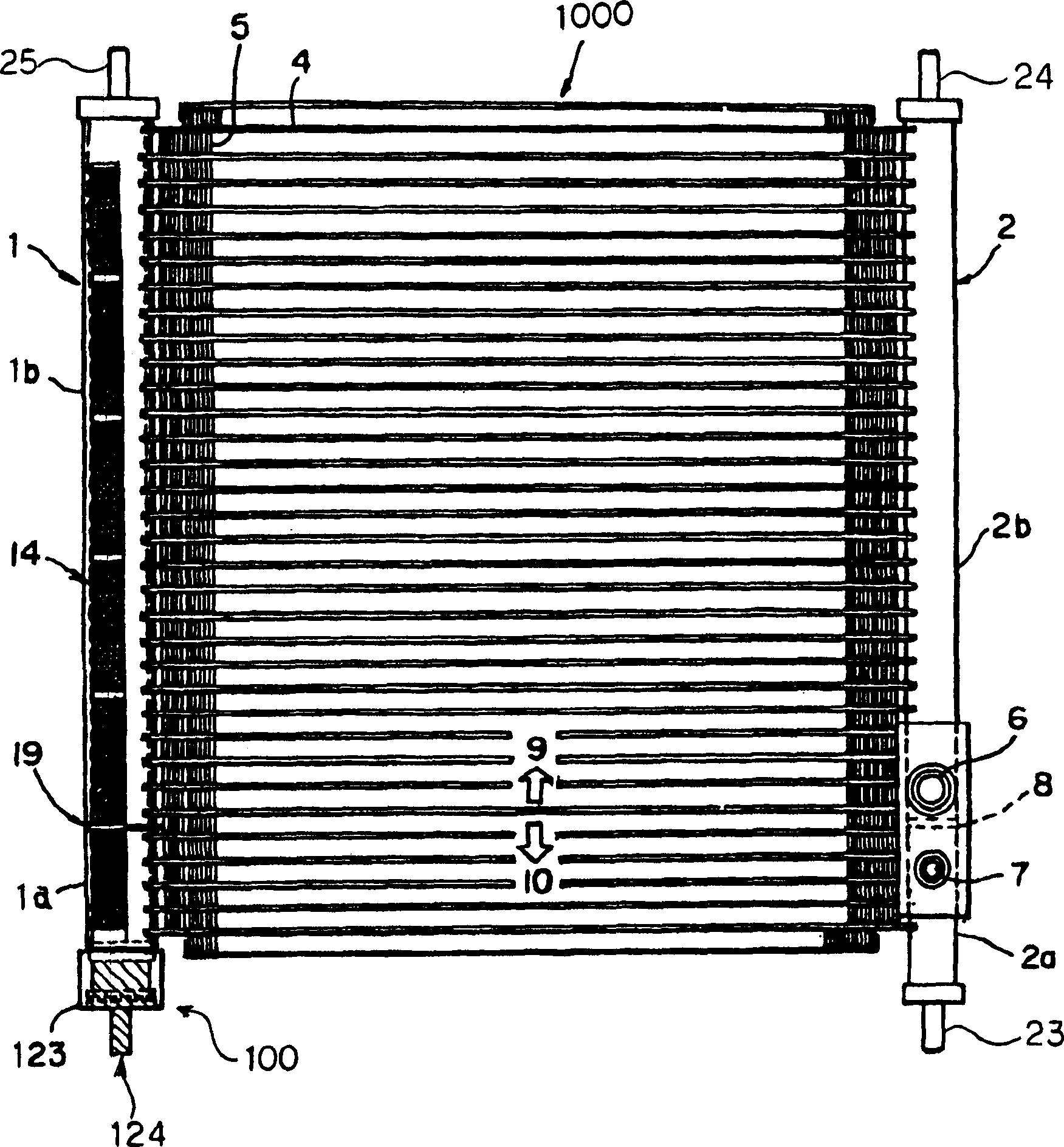

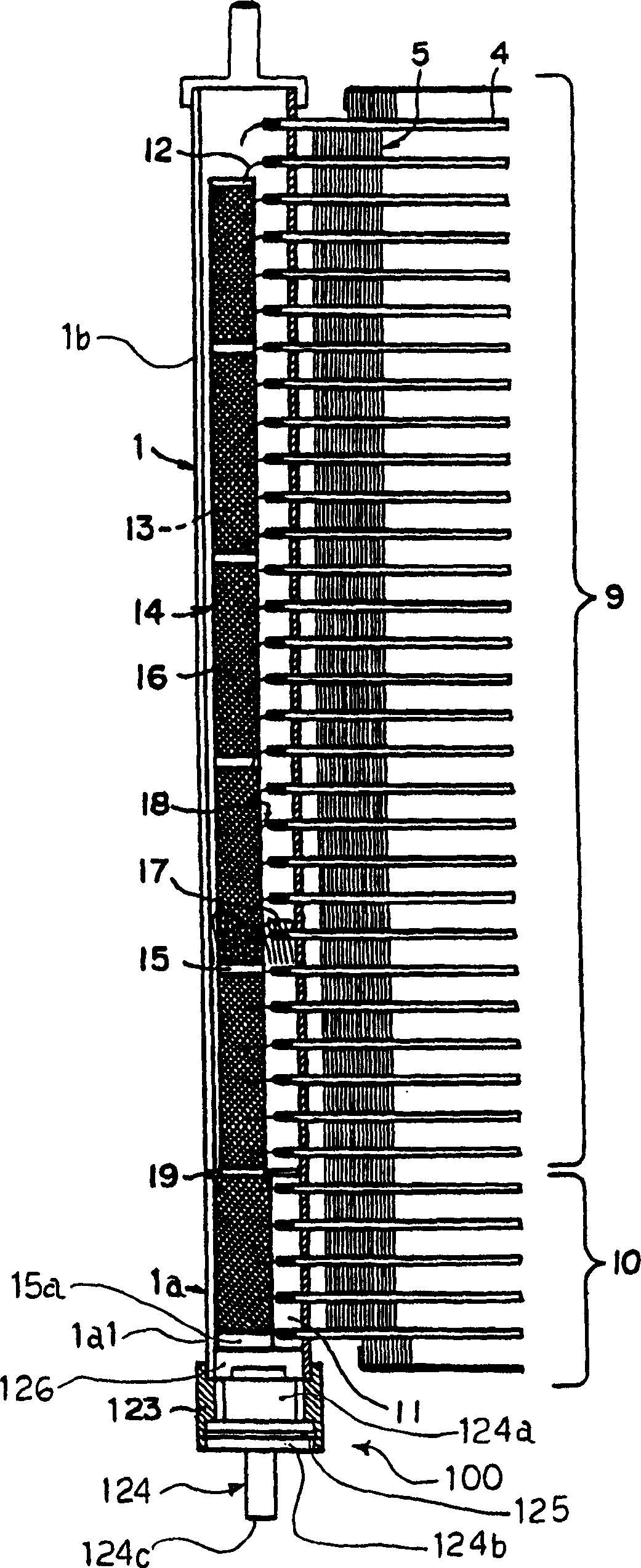

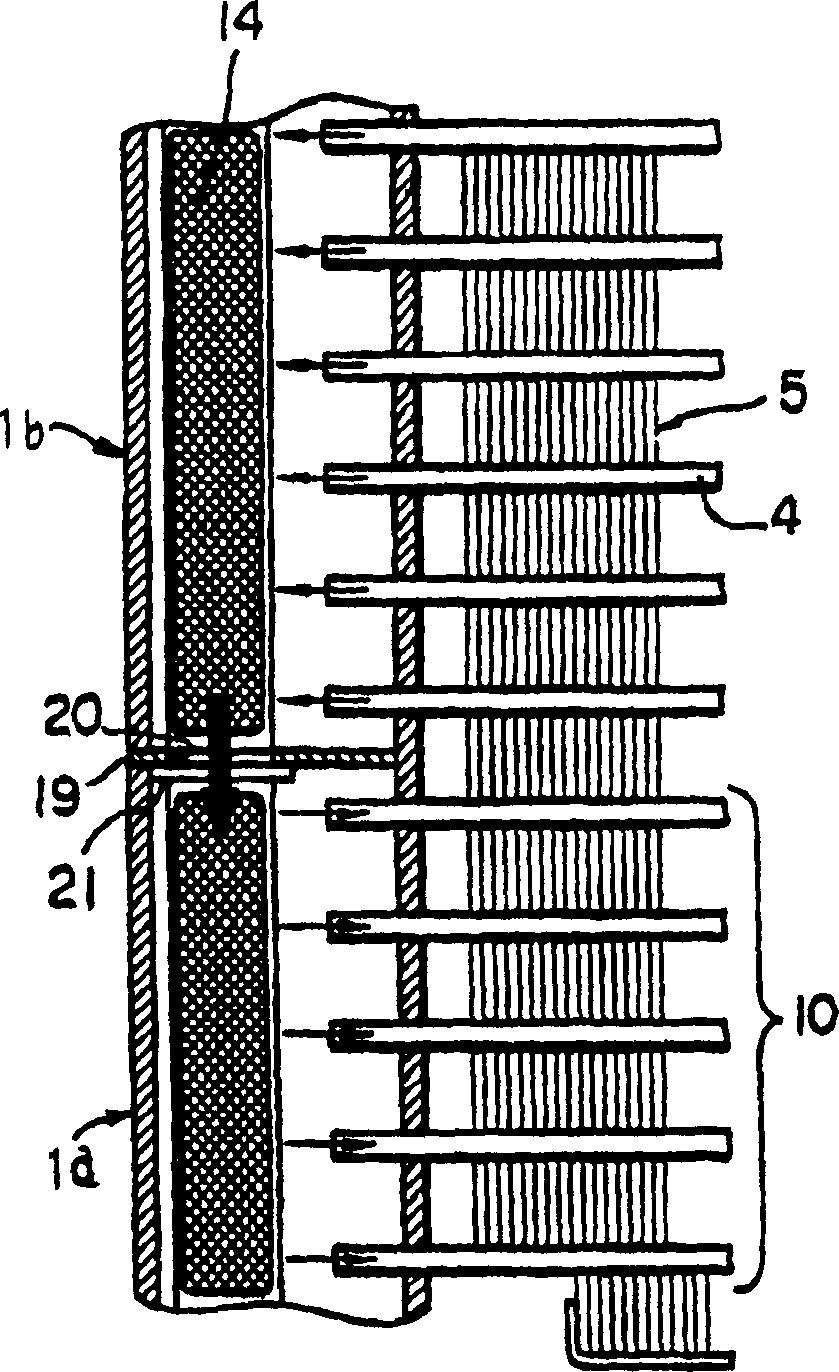

[0067] figure 1 Shown is a multi-flow type sub cool condenser (multi-flow type sub cool condenser) according to the first embodiment of the present invention. Hereinafter, the multi-flow subcooling condenser is referred to as condenser for short. The condenser 1000 mainly includes a first header 1, a second header 2, a plurality of flat heat transfer tubes 4 and a plurality of corrugated fins 5. The first header 1 and the second header 2 are connected to each other through a plurality of heat transfer tubes 4. A plurality of heat transfer tubes 4 and a plurality of corrugated fins 5 are alternately stacked. The first header 1 is divided into an upper pipe portion 1b and a lower pipe portion 1a by a partition 19. The second header 2 is divided into an upper tube portion 2b and a lower tube portion 2a by a partition 8. The inlet pipe 6 is connected to the second header 2 near the upper portion of the partition 8. The refrigerant flows into the upper pipe portion 2b of the second h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com