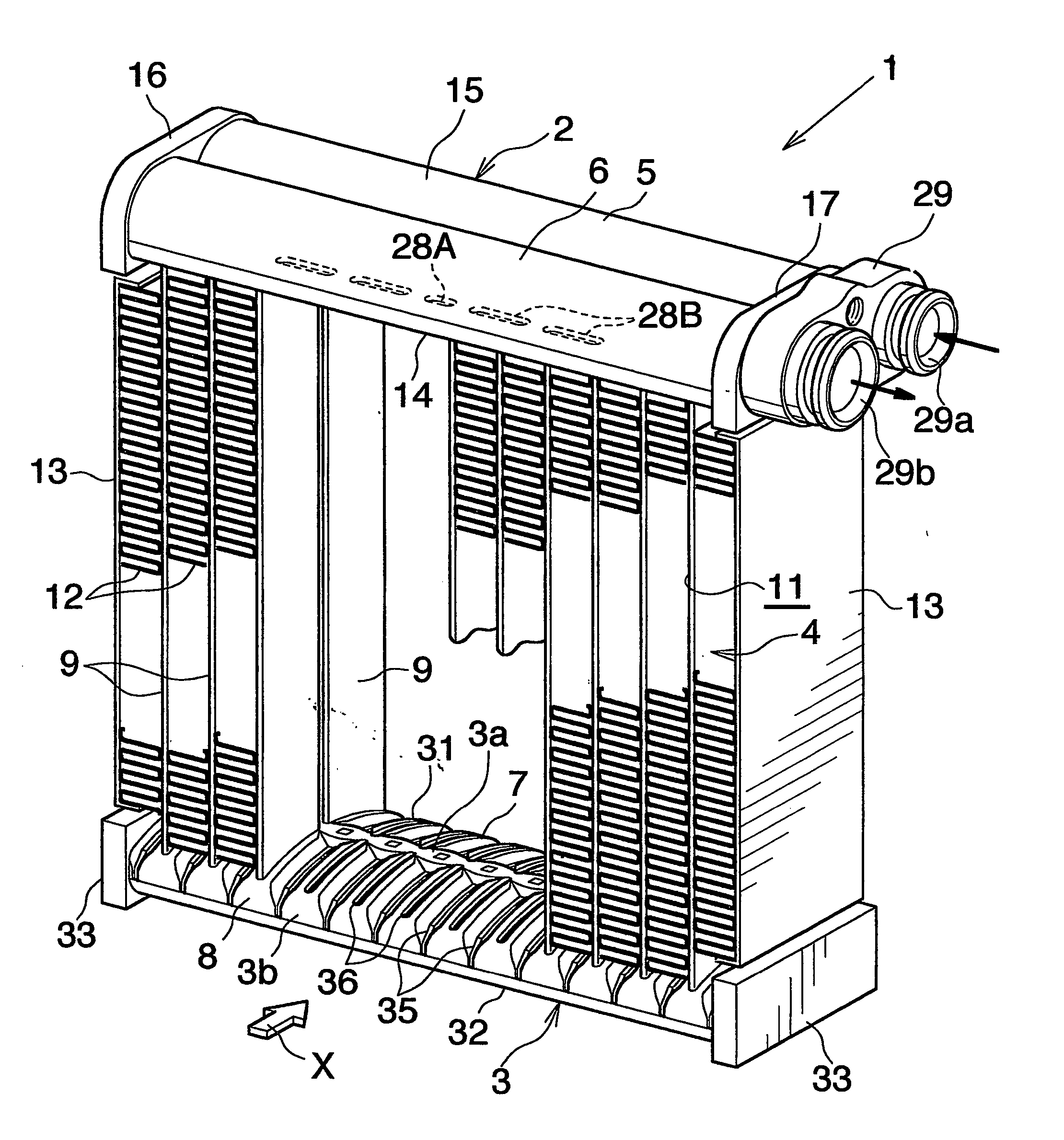

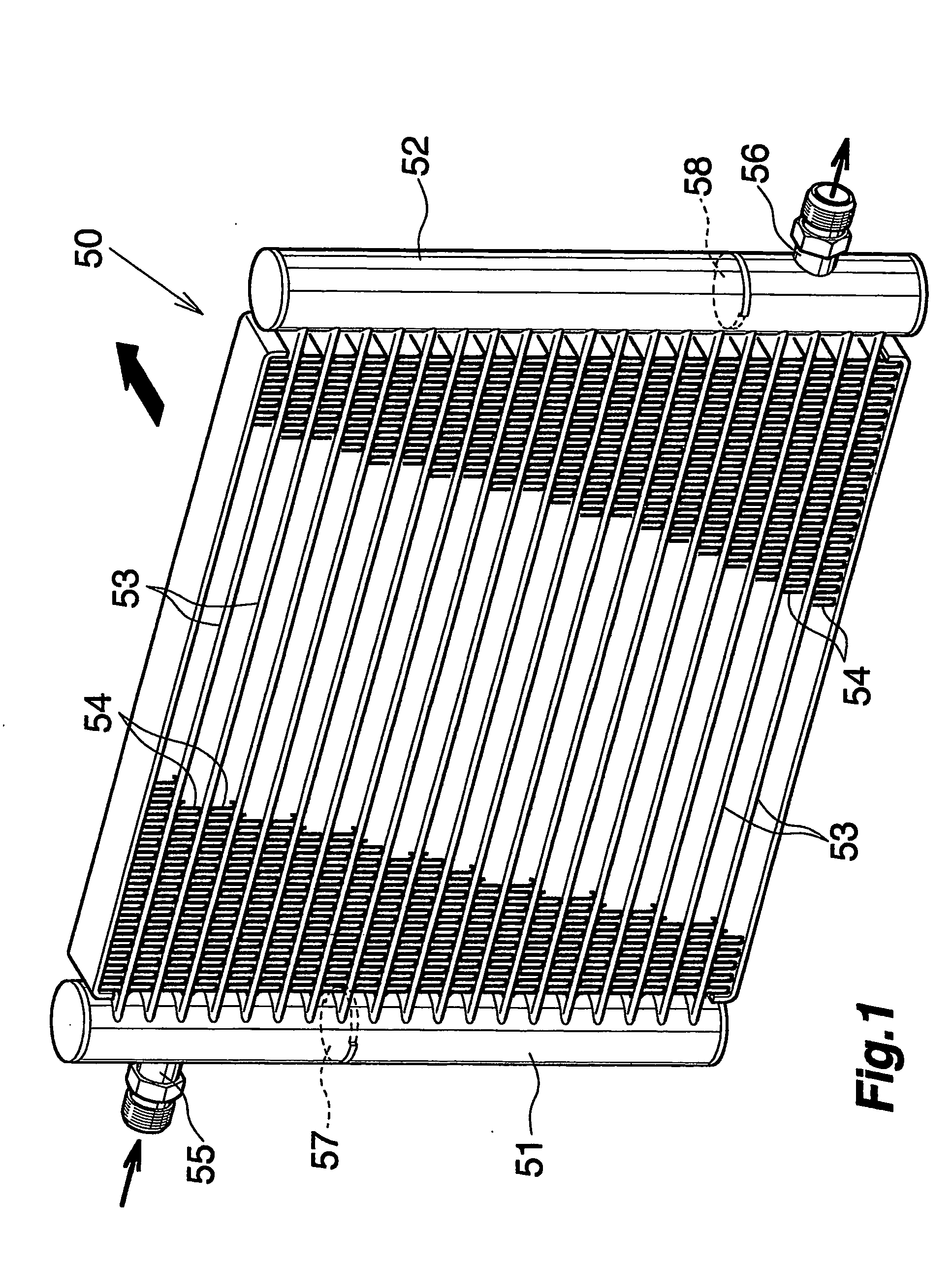

Heat exchanger, heat exchanger tube member, heat exchanger fin member and process for fabricating the heat exchanger

a heat exchanger and fin technology, applied in the field of heat exchanges, can solve the problem of low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

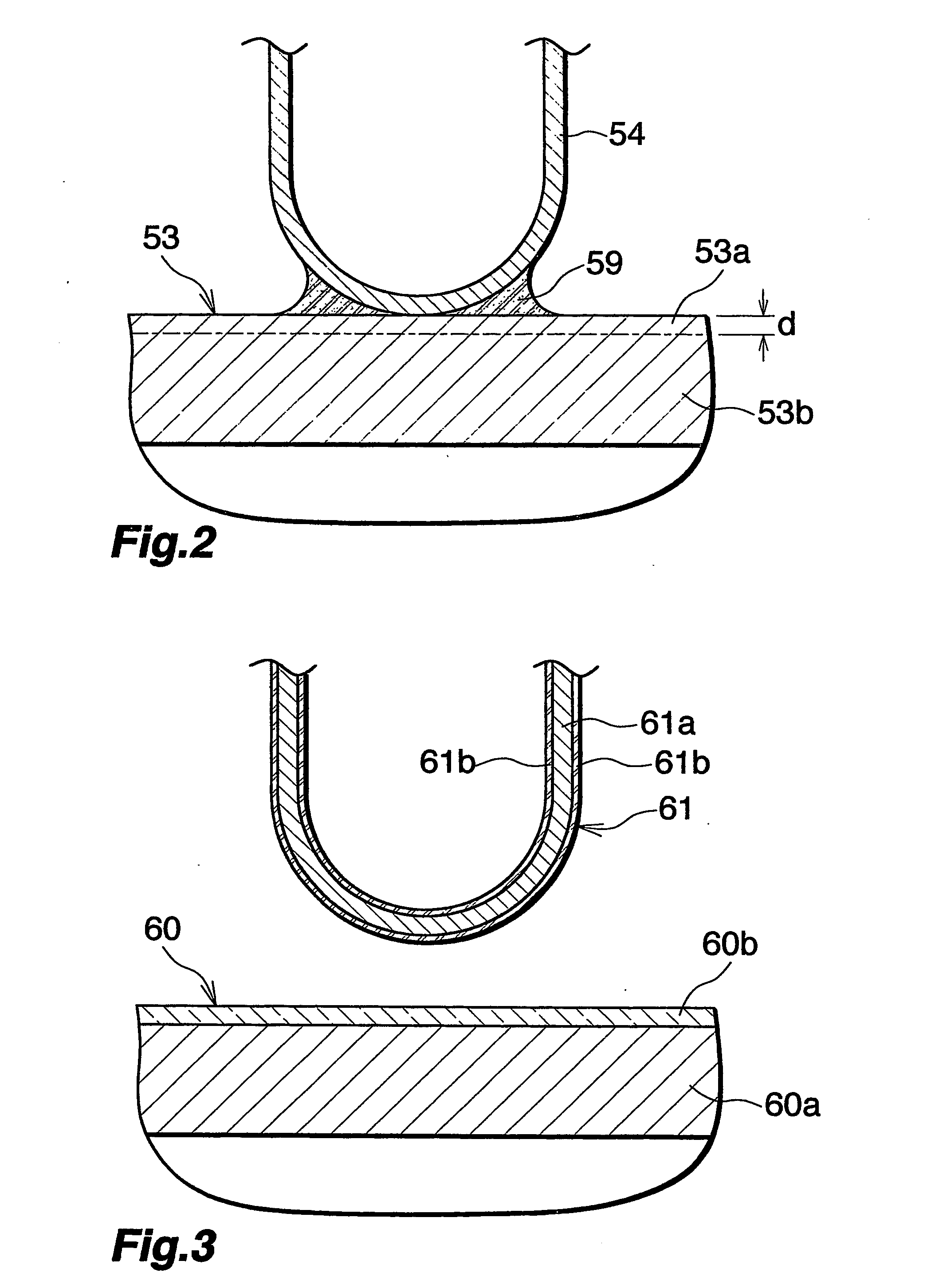

[0056] Refrigerant tube members 60 were produced each by extruding an alloy having the composition shown in Table 1 into a tubular main body 60a and forming a Zn spray layer 60b in an amount of 4 g / m2 over the entire outer peripheral surface of the main body 60a. Also produced were corrugated fin members 61 each comprising a core 61a and a cladding 61b covering each of opposite surfaces of the core 61a, the core and the cladding having the respective compositions shown in Table 2. In the corrugated fin member 61, the cladding ratio of the cladding 61b on one surface of the core 61a was 10%. Also prepared were suitable header members.

TABLE 1Exam-Composition (mass %)pleAlCuMnSiFeMgCrZnTiEx. 1Bal.0.490.290.060.150.010.010.01Comp.Bal.0.150.020.100.210.010.01Ex. 1Comp.Bal.0.400.190.050.170.010.010.010.01Ex. 2

[0057]

TABLE 2Composition (mass %)AlSiFeCuMnMgZnTiExam-CoreBal.0.350.171.21.1ple 1Clad-Bal.8.80.160.30.10.02dingComp.CoreBal.0.350.201.21.2Ex. 1Clad-Bal.8.90.201.2dingComp.CoreBal.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com