Once-through hot water boiler

A technology for a hot water boiler and a furnace body, which is applied in the field of boilers, can solve the problems of insufficient utilization of flue gas waste heat, short flue gas circulation time, low heat exchange efficiency, etc., so as to maintain stability and heat exchange efficiency, and improve heat Effect of improving exchange efficiency and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

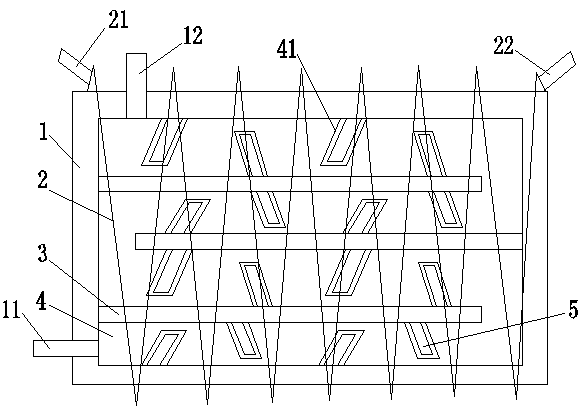

[0020] The present invention comprises a furnace body 1, the furnace body 1 is provided with a coil pipe 2 wound on the outer wall of the furnace body 1, and the coil pipe 2 is provided with a liquid inlet 21 and a liquid outlet 22;

[0021] The furnace body 1 is provided with a plurality of partitions 3 arranged axially along the furnace body 1 and parallel to each other, and the partitions 3 divide the furnace body 1 into several connected flue gas chambers 4 sequentially in the radial direction;

[0022] The furnace body 1 is provided with a smoke inlet 11 and a smoke outlet 12, the smoke inlet 11 is arranged on the outermost flue gas cavity 4 on one side, and the smoke outlet 12 is arranged on the other side On the outermost flue gas chamber 4;

[0023] A plurality of baffles 41 are arranged in each of the flue gas chambers 4 to isolate the flue gas chambers 4 into several interconnected areas.

[0024] The baffles 41 are inclined at a certain angle with the partition 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com