Heat exchanger

a technology of heat exchanger and heat exchanger body, which is applied in the direction of heat exchange apparatus safety devices, lighting and heating equipment, and stationary conduit assemblies, etc., can solve the problems of large downtime of the apparatus with which the heat exchanger is used, the difficulty of assembly of the heat exchanger from its individual parts, and the difficulty of pre-assembly fastening type, etc., to achieve the effect of convenient manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As alluded to previously, the heat exchanger of the present invention is ideally suited for vehicular use as, for example, a vehicular radiator or charge air cooler. However, no limitation to vehicular use, or to a radiator, or charge air cooler is intended because those skilled in the art will recognize that the heat exchanger of the invention may be used in a variety of environments and for a variety of purposes. For example, the same could be utilized in a heating system for a building, or the like. In any event, no limitation to a particular environment of use or to a particular use is intended except insofar as expressly stated in the appended claims.

[0035] With the foregoing in mind, several embodiments of the invention will now be described.

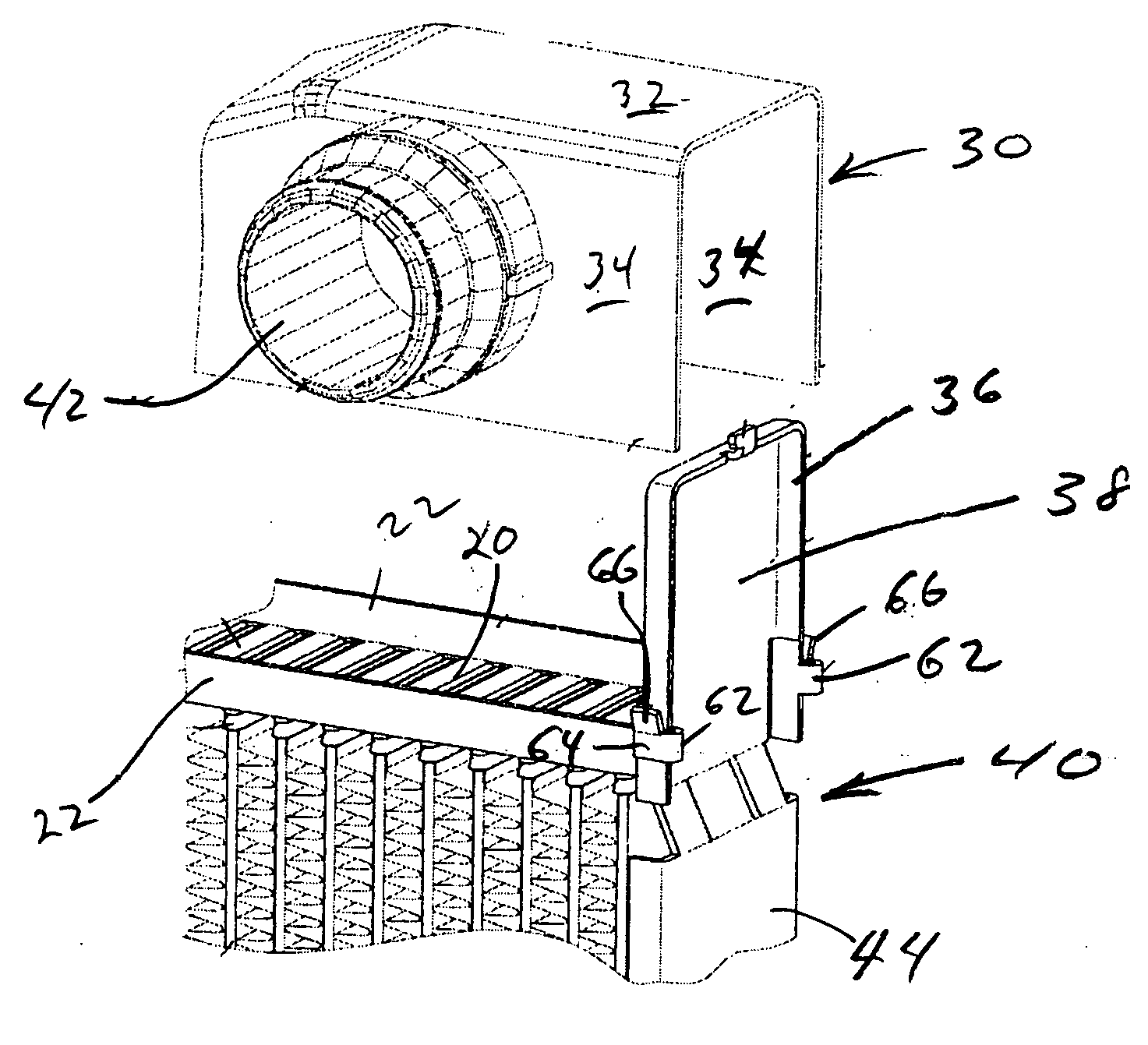

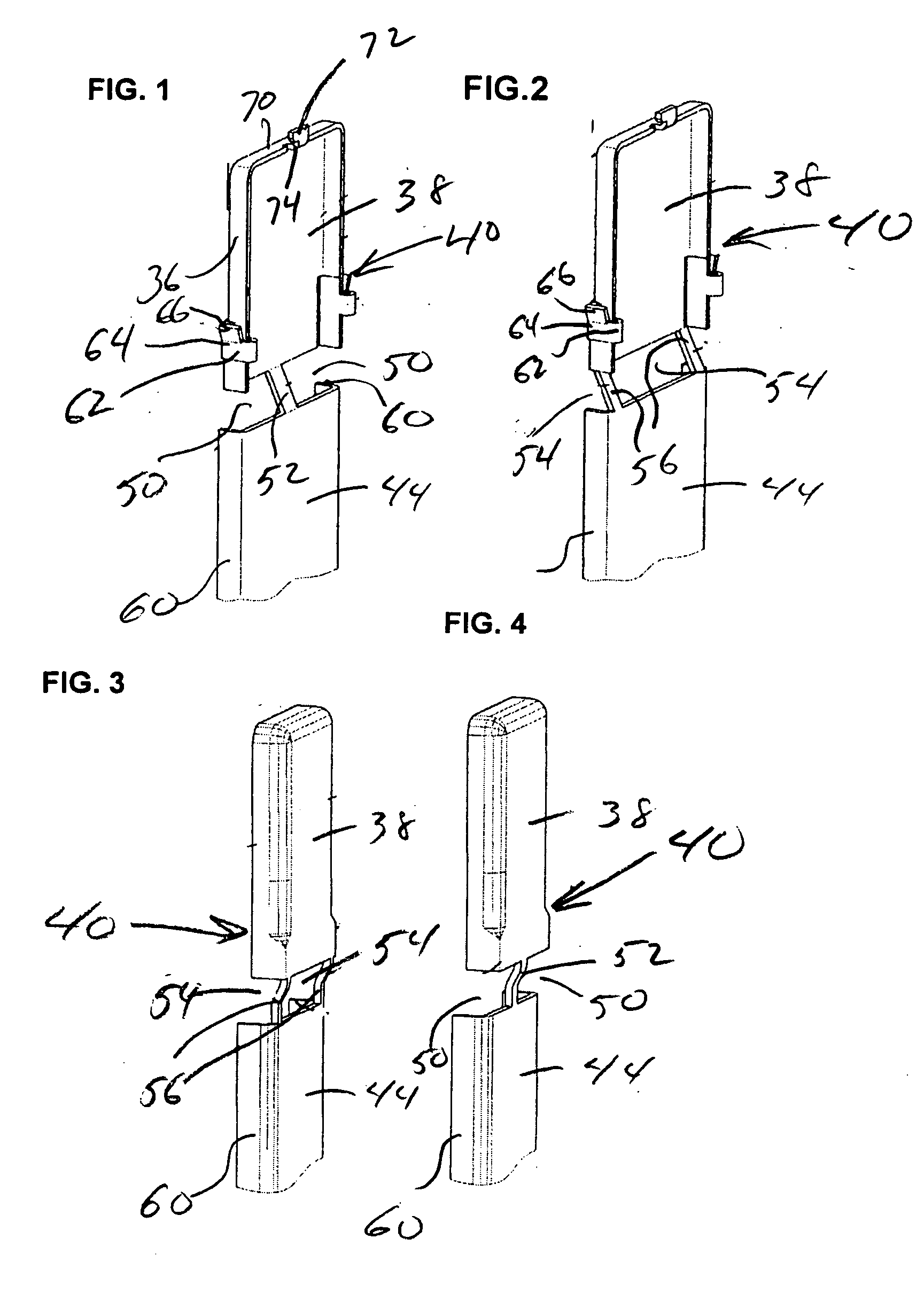

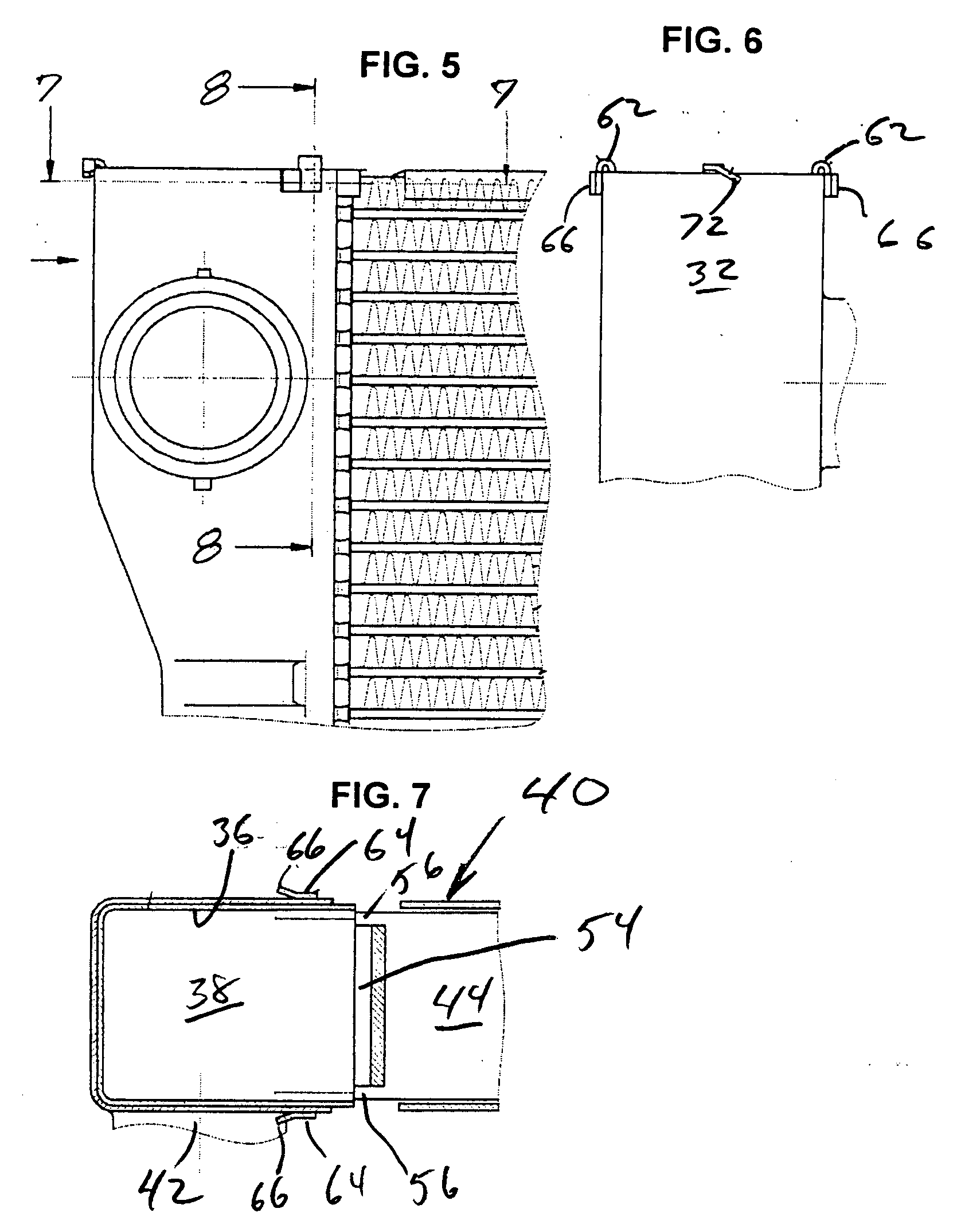

[0036] Turning first to FIGS. 8, 9, and 10, a typical heat exchanger embodying the invention is shown fragmentarily. The same includes two, spaced, parallel header plates 20 (only one of which is shown) having upturned side edges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com