Patents

Literature

329results about "Spacing means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat and mass exchanger

ActiveUS7269966B2Additional exchangeEfficient exchangeSpacing meansDomestic cooling apparatusEngineeringContinuous flow

Owner:AIL RES

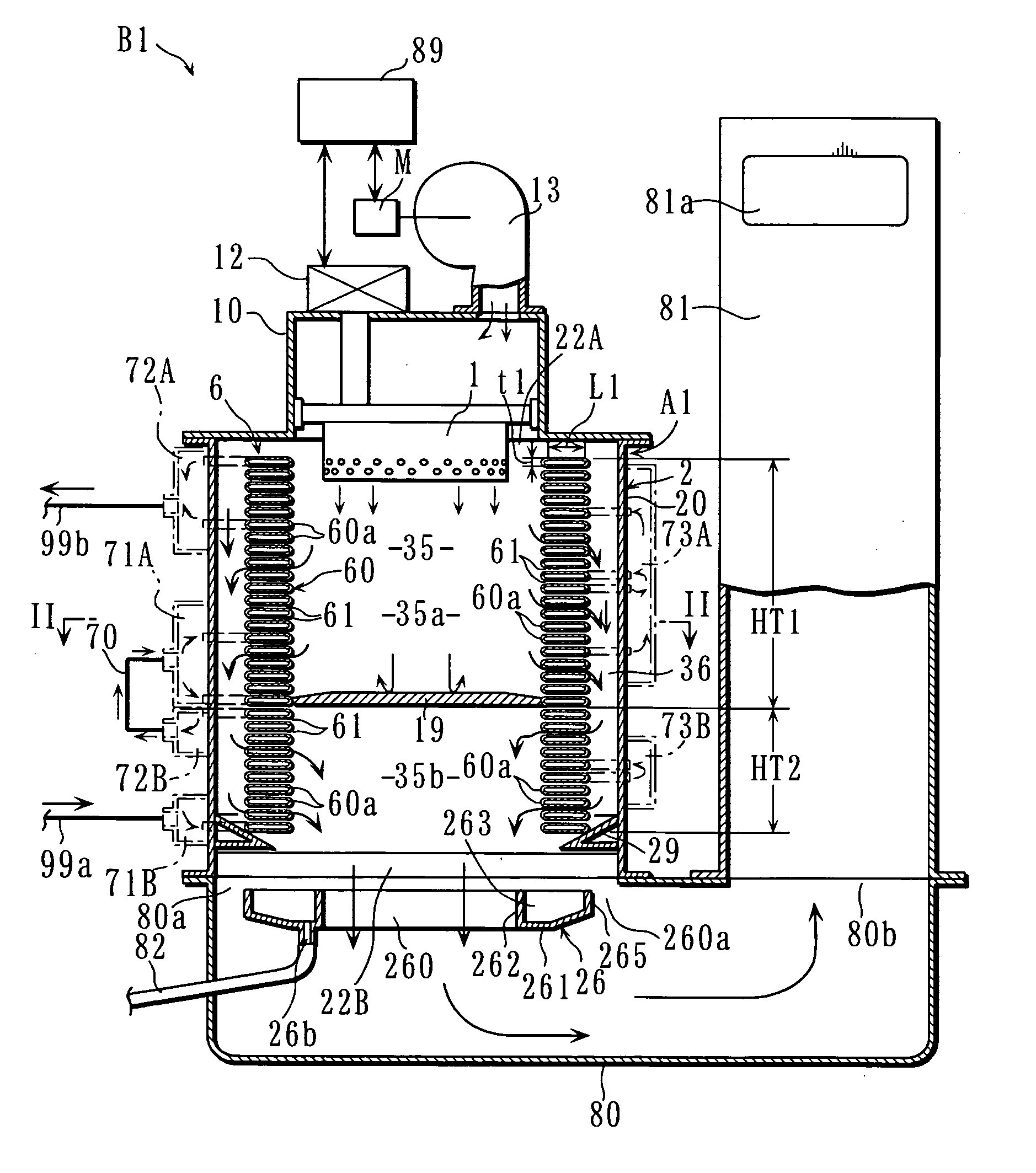

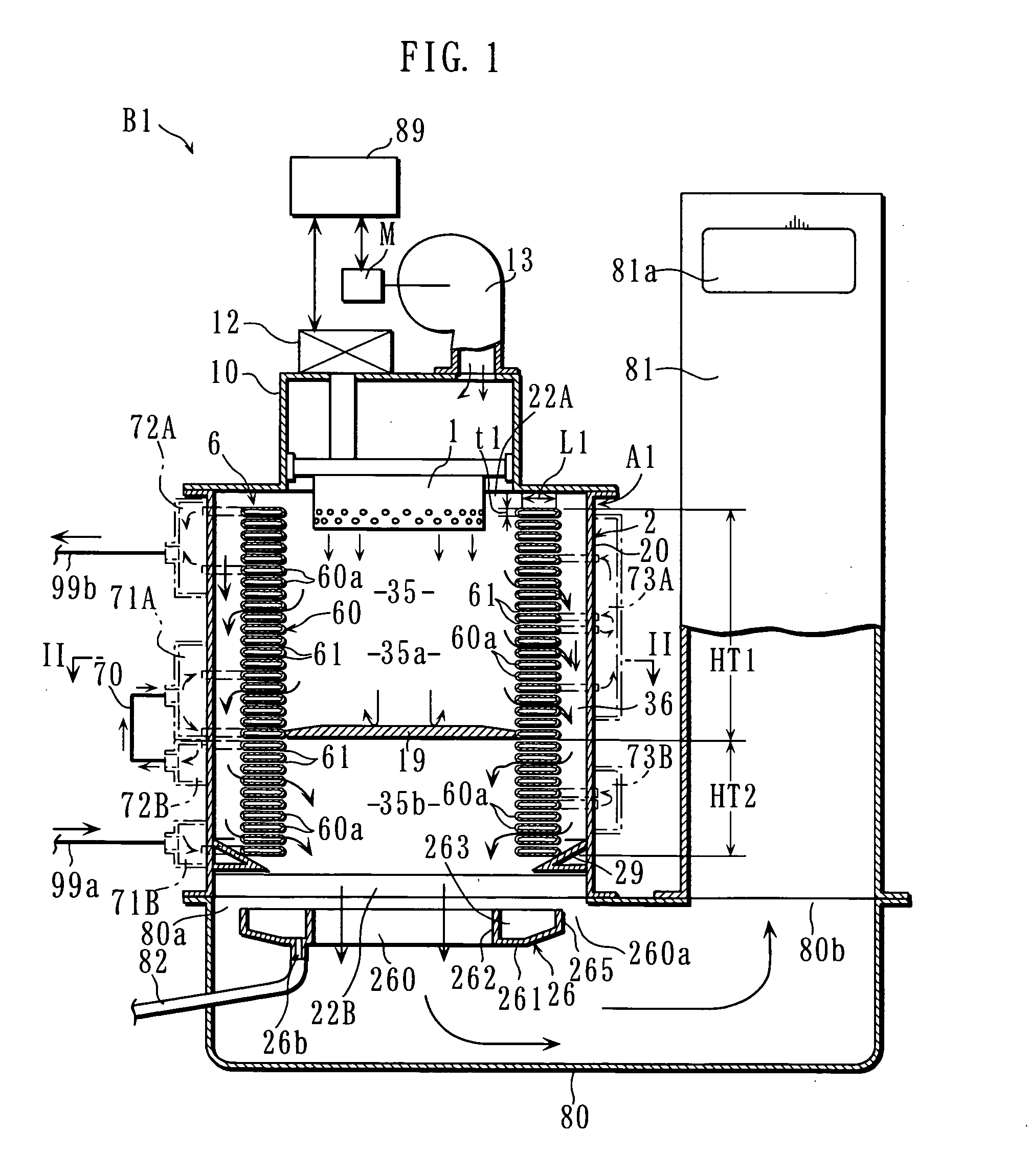

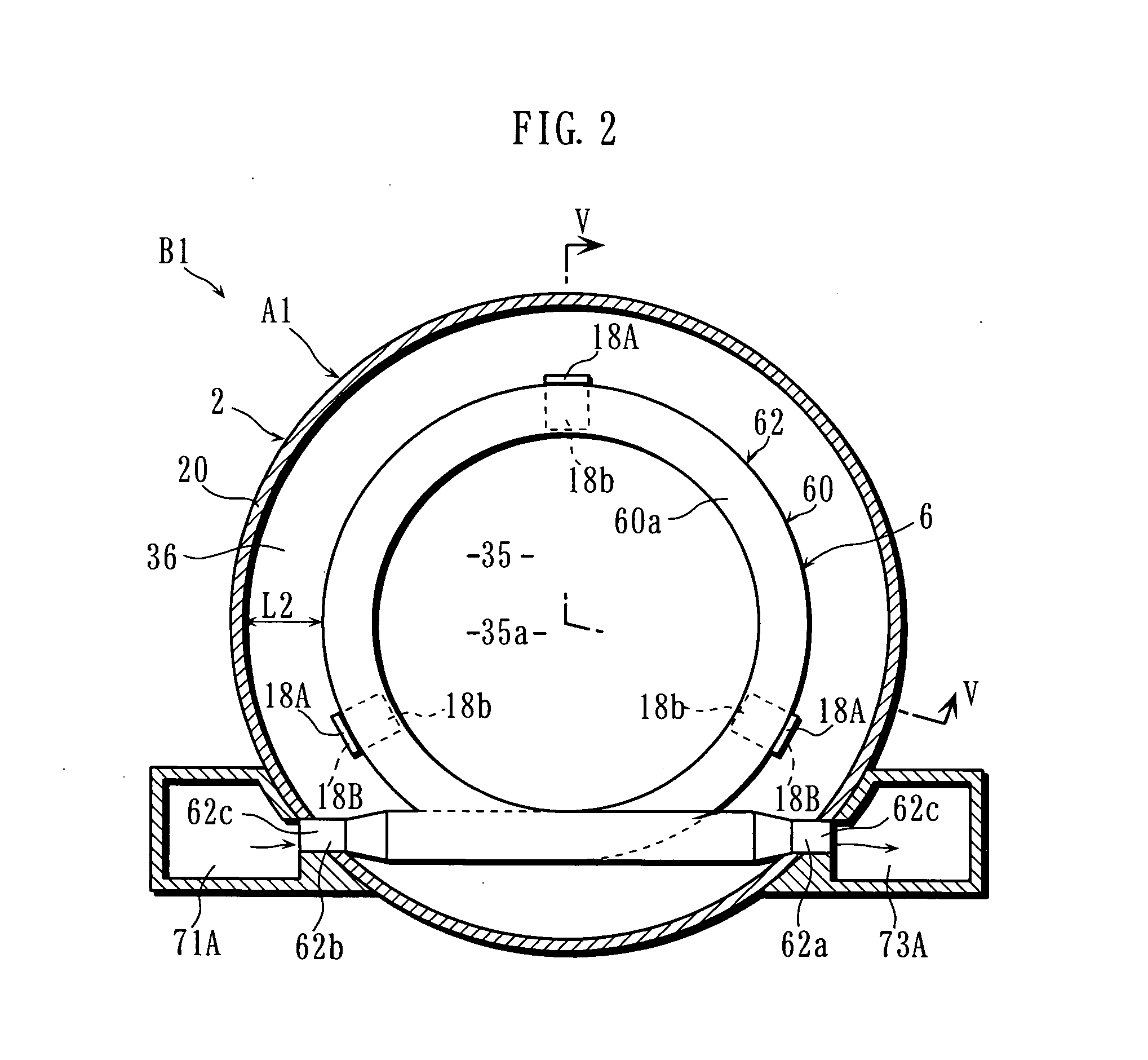

Heat Exchanger and Water Heater

A heat exchanger A1 includes a partition 19 partitioning the space 35 surrounded by a coiled tube 60 at an axially intermediate portion of a housing 2 into a first and a second regions 35a and 35b and partitioning the coiled tube 60 into a first and a second heat exchanging portions HT1 and HT2. The combustion gas supplied to the first region 35a flows to a combustion gas path 36 by passing through a clearance 61 of the first heat exchanging portion HT1 and then passes through a clearance 61 of the second heat exchanging portion HT2. With this structure, the amount of heat recovery is increased, and the heat exchange efficiency is enhanced while simplifying the overall structure of the heat exchanger A1 and reducing the size of the heat exchanger.

Owner:NORITZ CORP

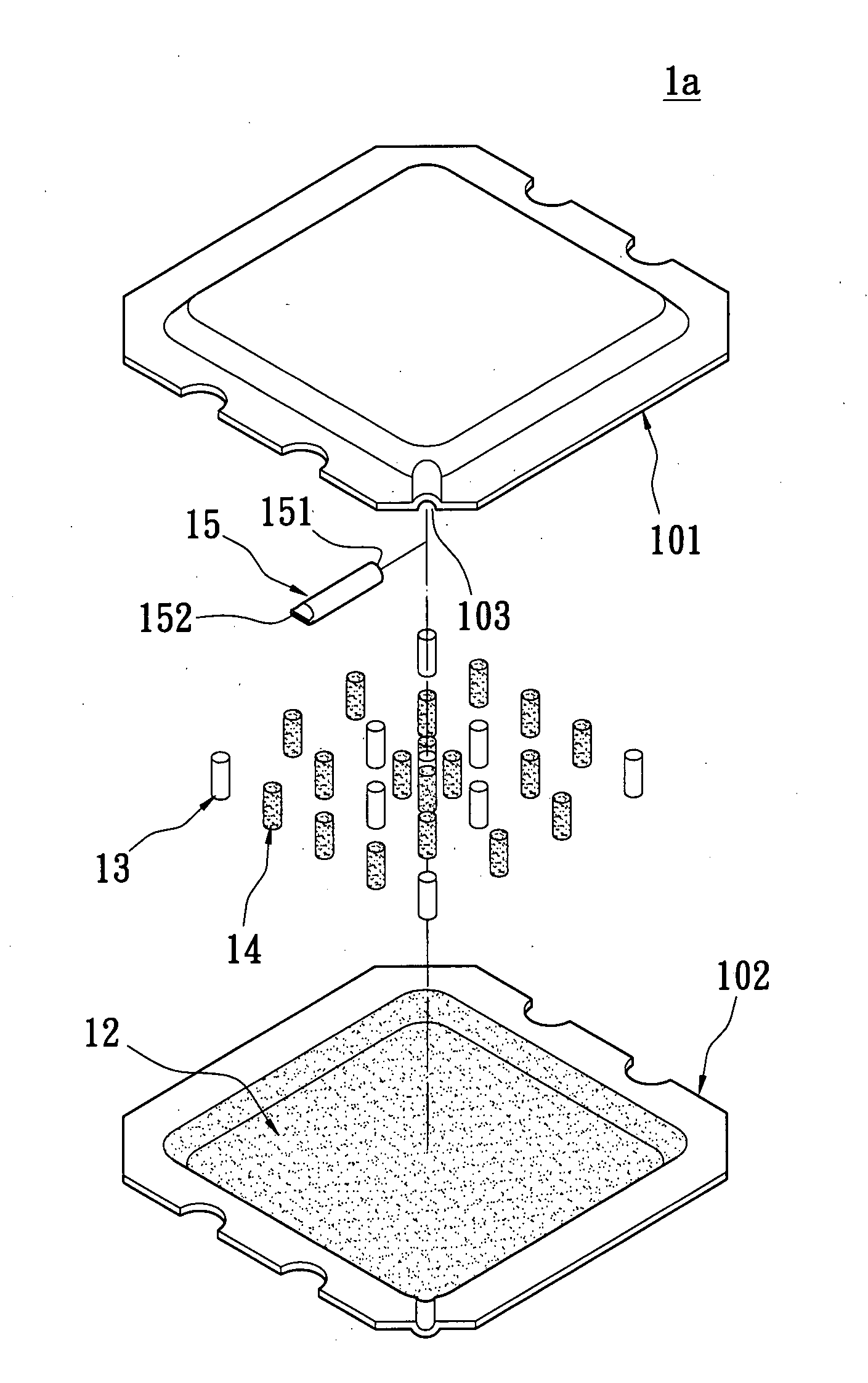

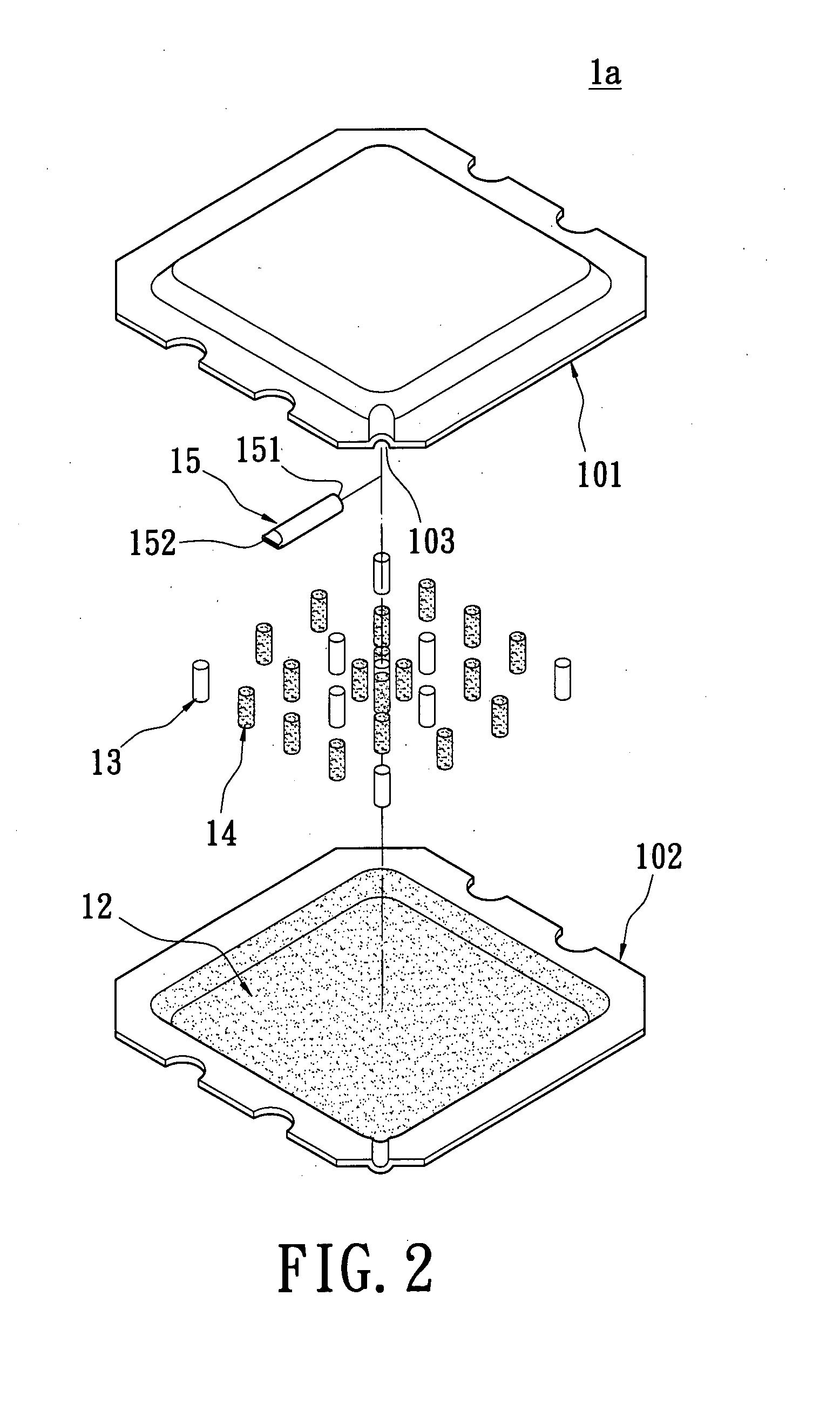

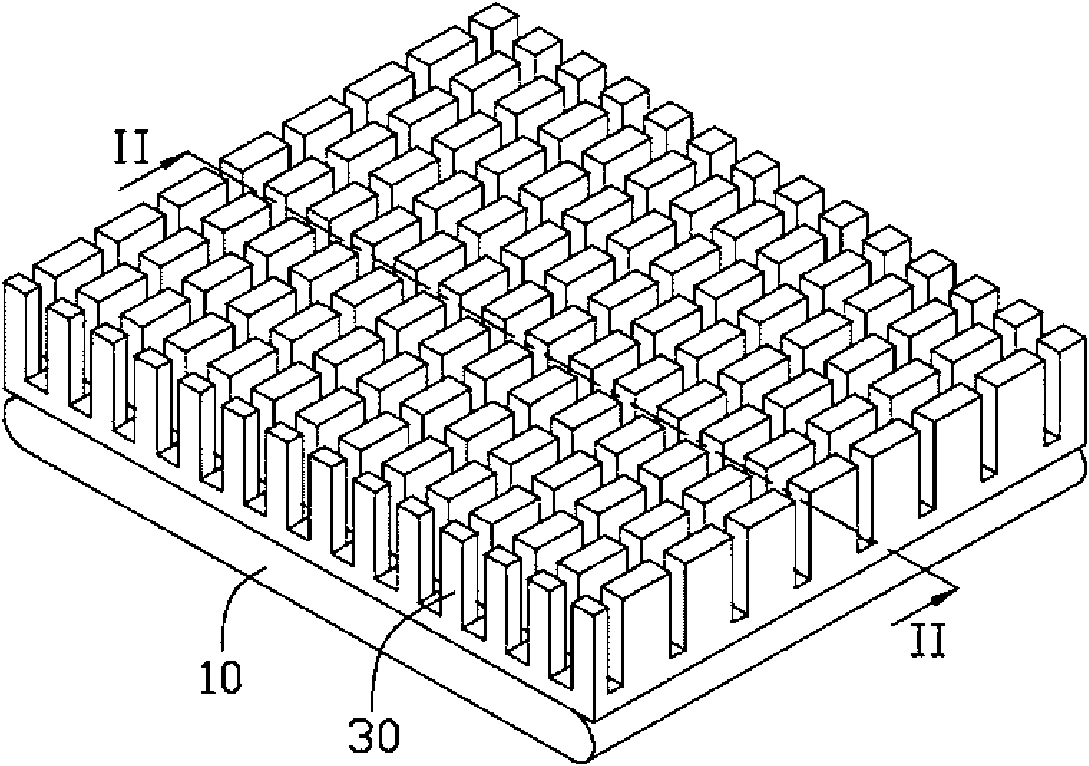

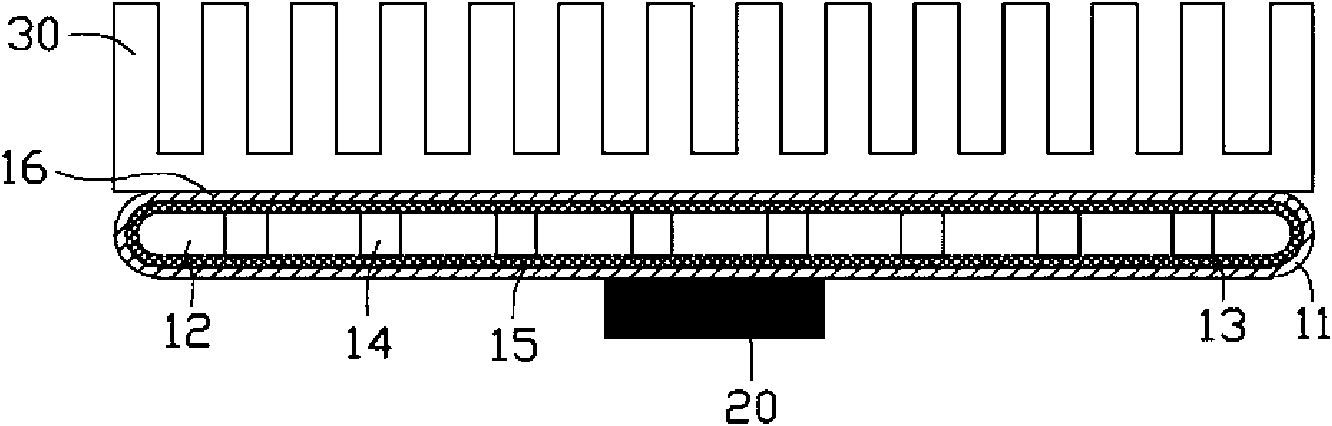

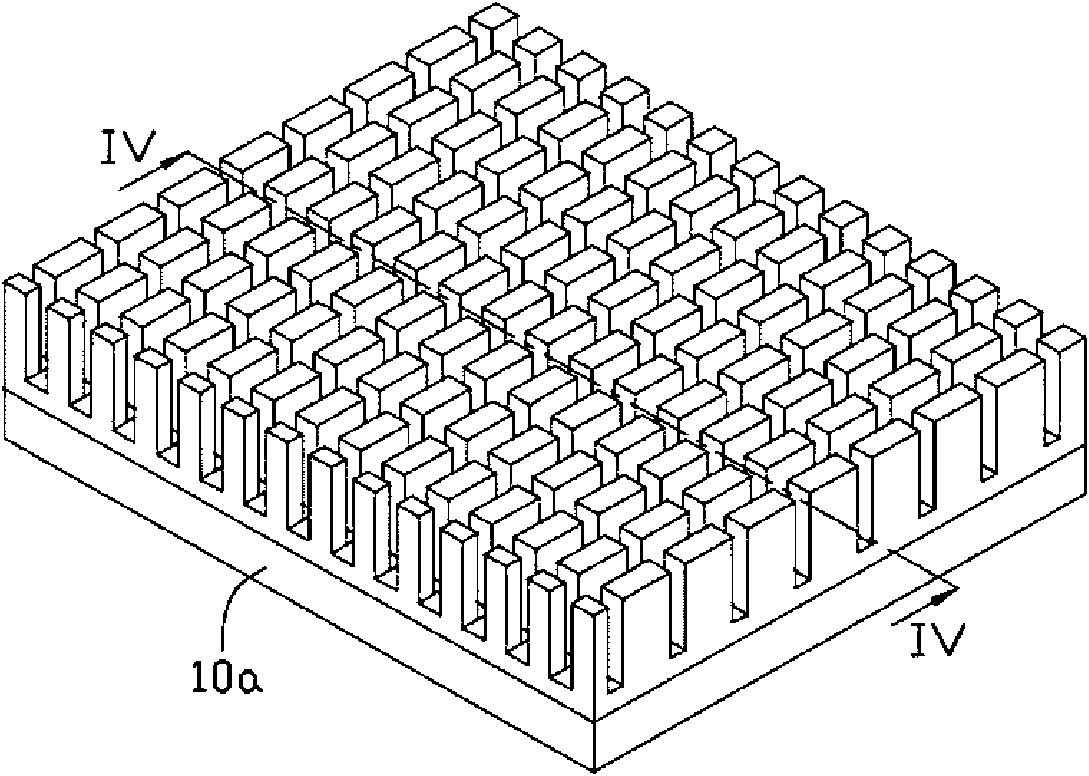

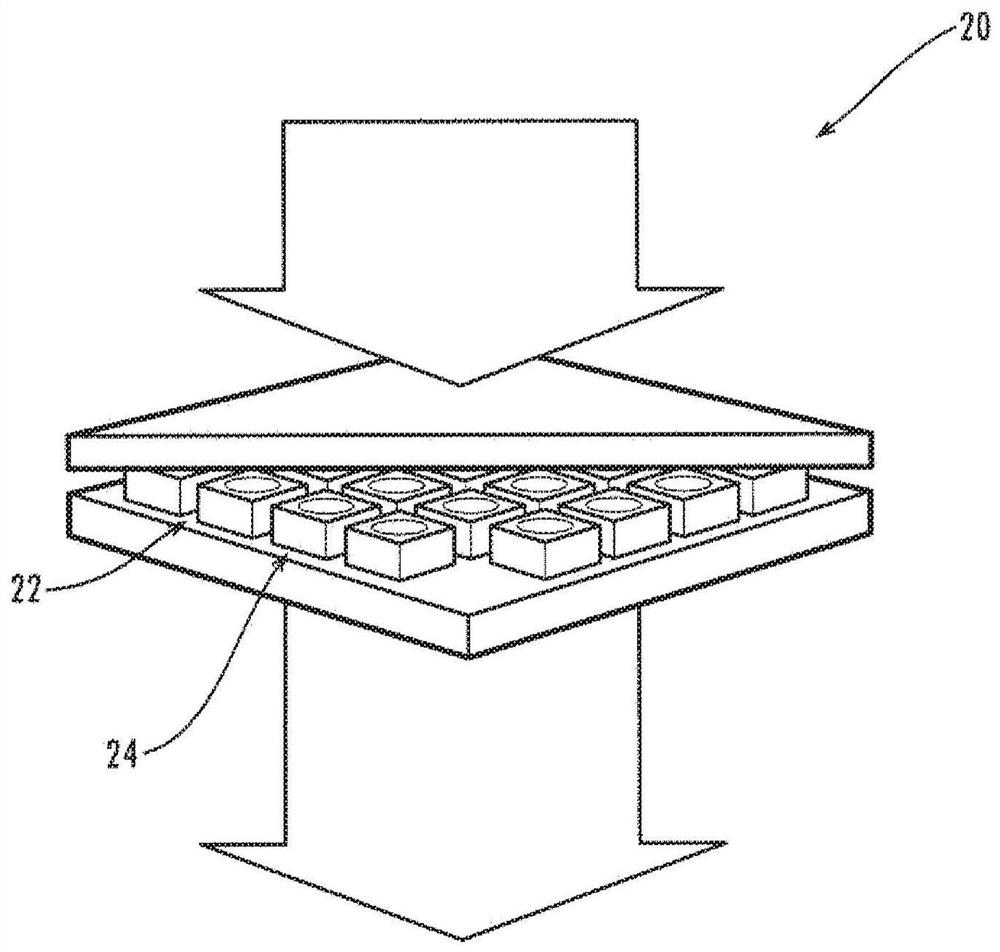

Vapor chamber structure and method for manufacturing the same

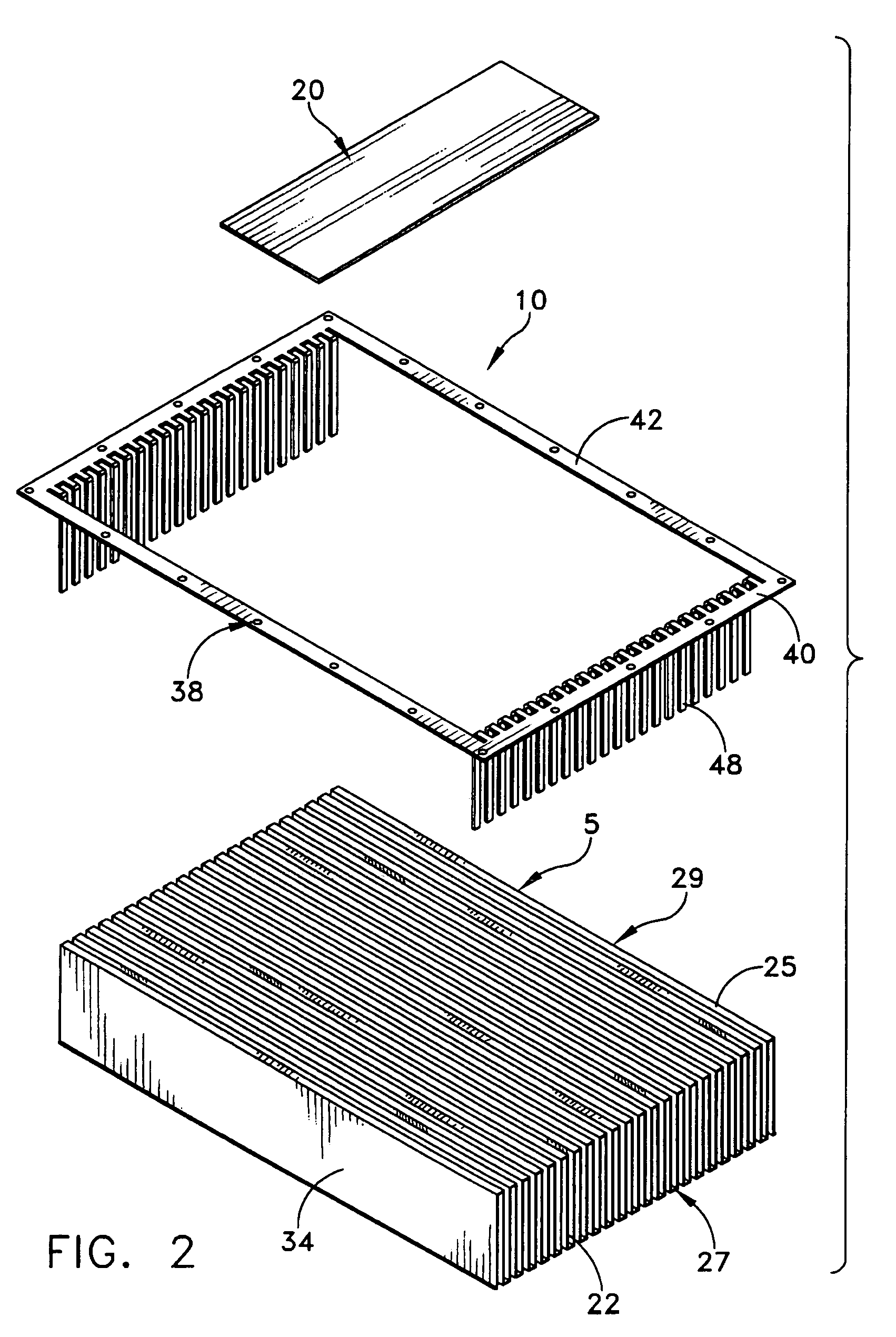

InactiveUS20090040726A1Improve structural strengthImprove sealingSpacing meansReinforcing meansWorking fluidEngineering

A vapor chamber structure includes a casing, a working fluid, a wick layer, a plurality of structure strengthening bodies, and a plurality of backflow accelerating bodies. The casing has an airtight vacuum chamber. The working fluid is filled into the airtight vacuum chamber. The wick layer is formed on a surface of the airtight vacuum chamber. The structure strengthening bodies are respectively arranged in the airtight vacuum chamber for supporting the casing. The backflow accelerating bodies are respectively arranged in the airtight vacuum chamber for increasing the backflow velocity of the working fluid. Therefore, the present invention can maintain the completeness of the vapor chamber structure and increase the backflow velocity of the working fluid due to the match of the structure strengthening bodies and backflow accelerating bodies. Because the backflow velocity of the working fluid is increased, the heat-transmitting efficiency is increased.

Owner:THERMAL TECH

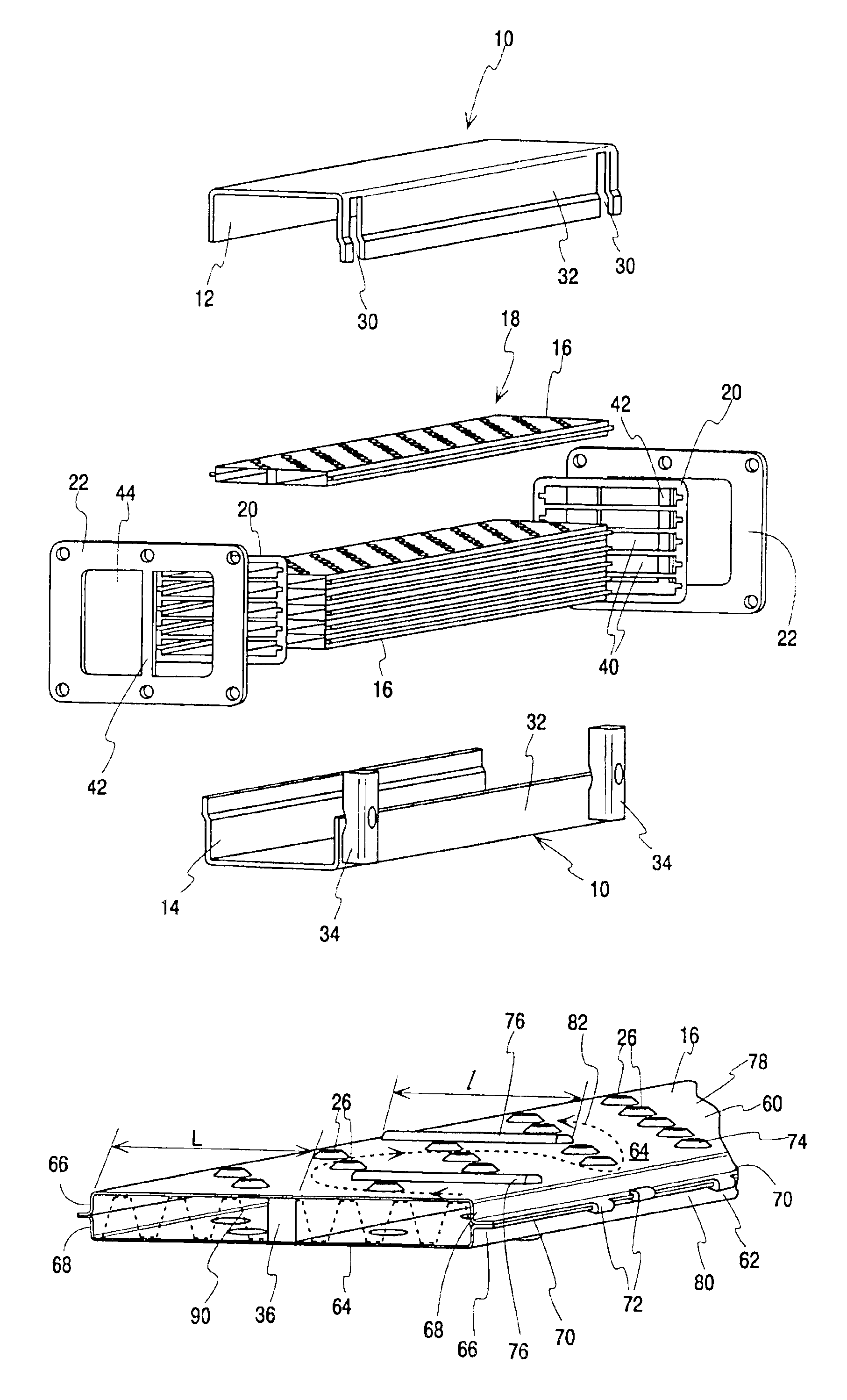

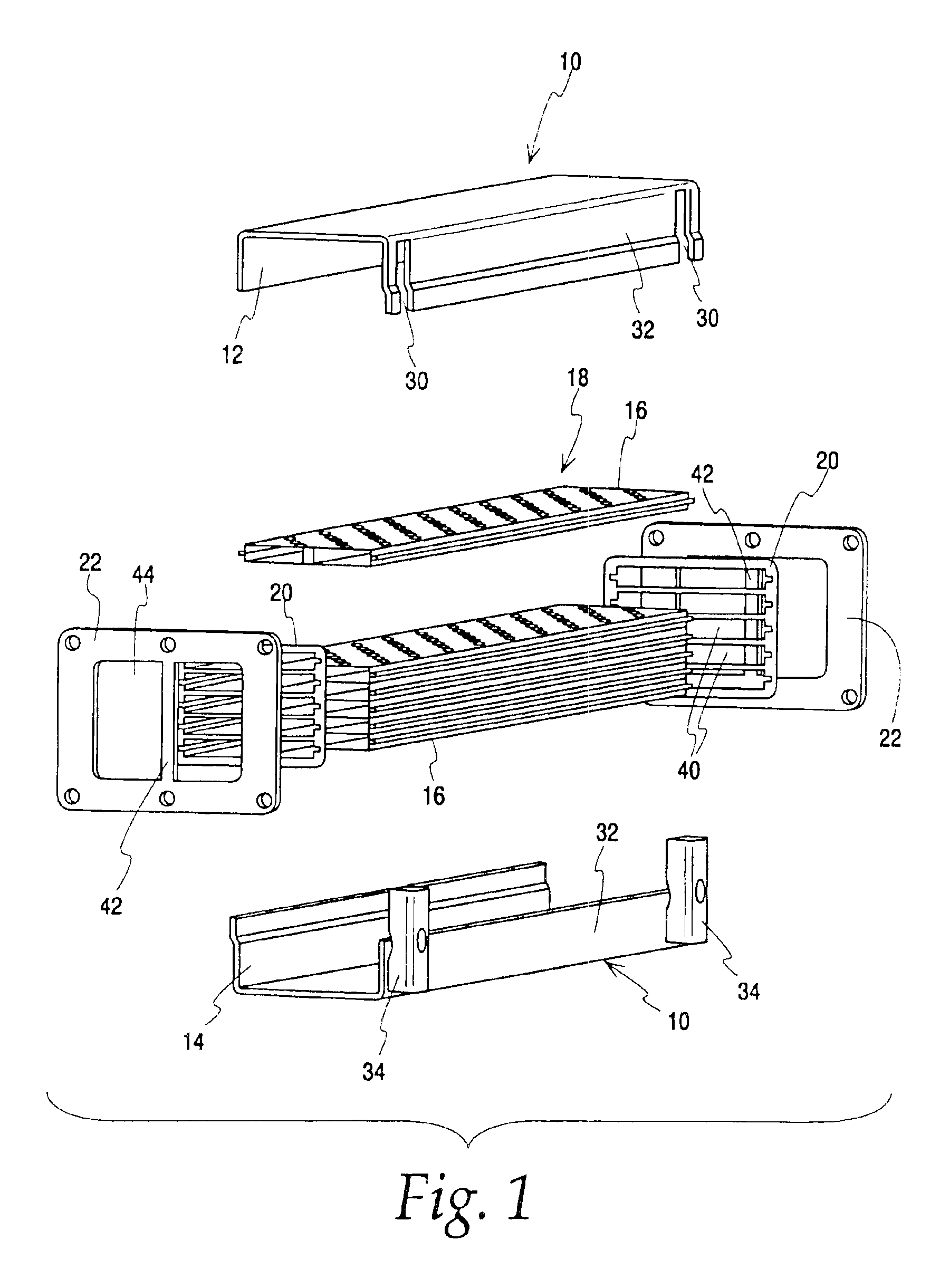

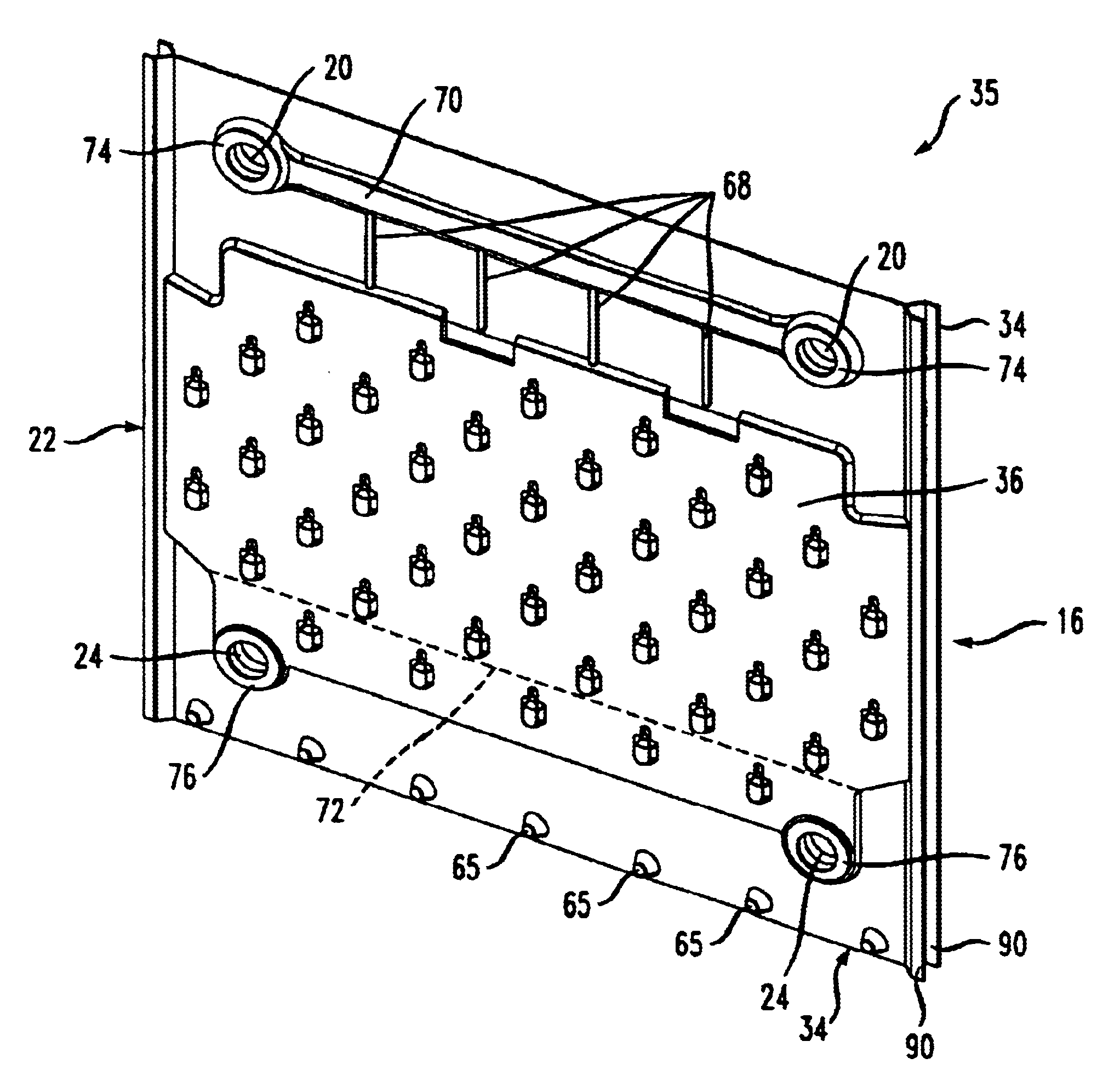

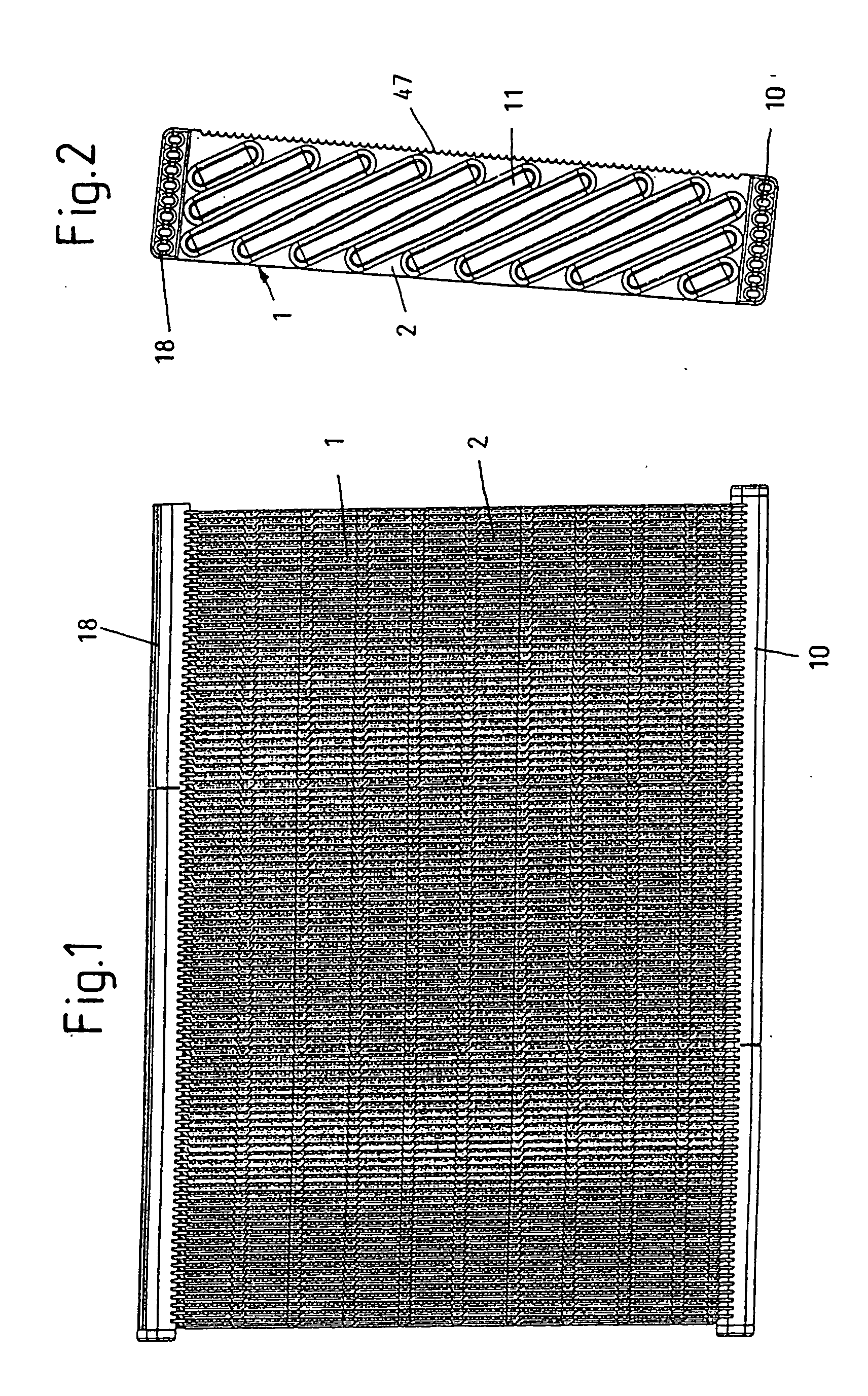

Heat exchanger

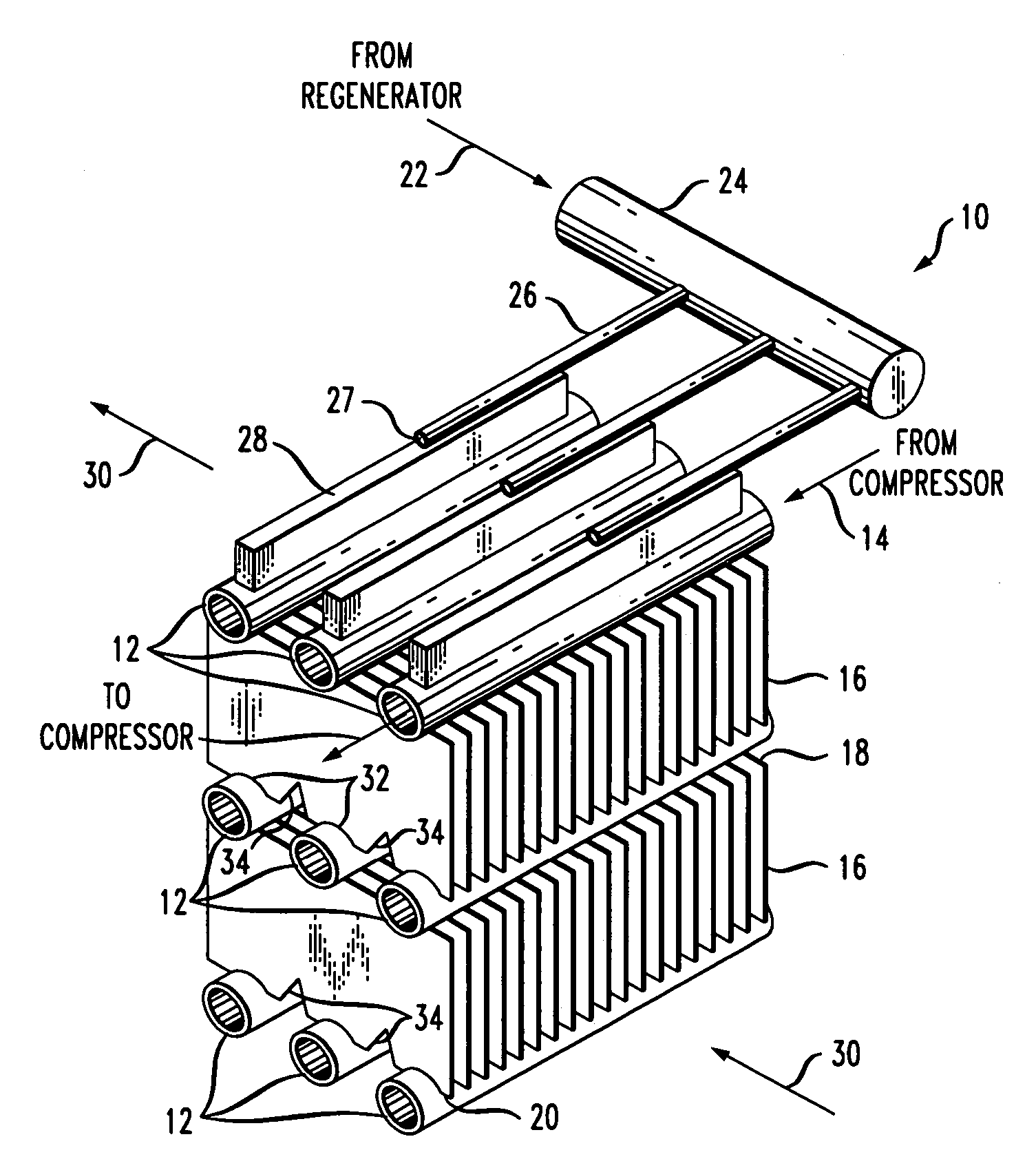

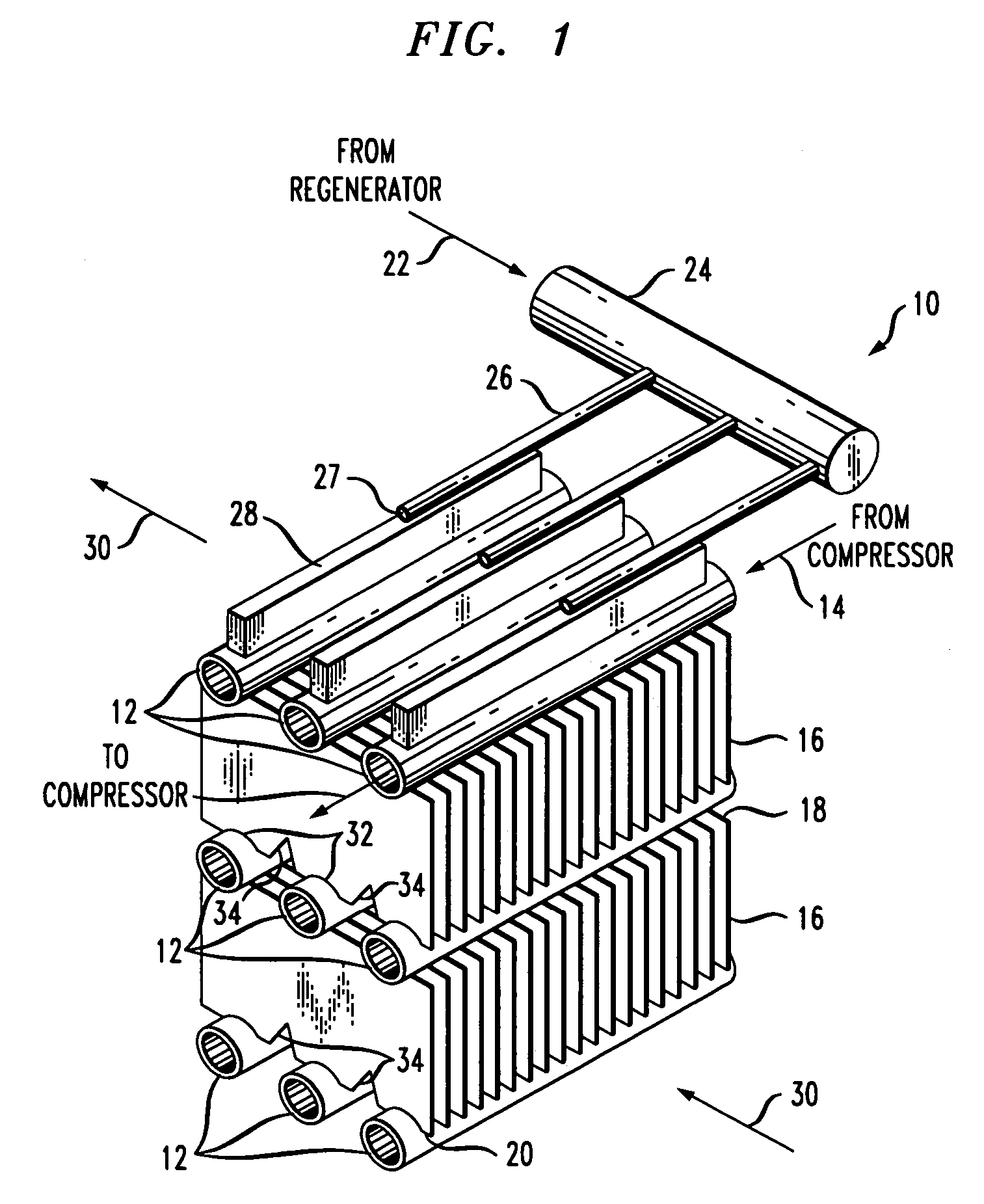

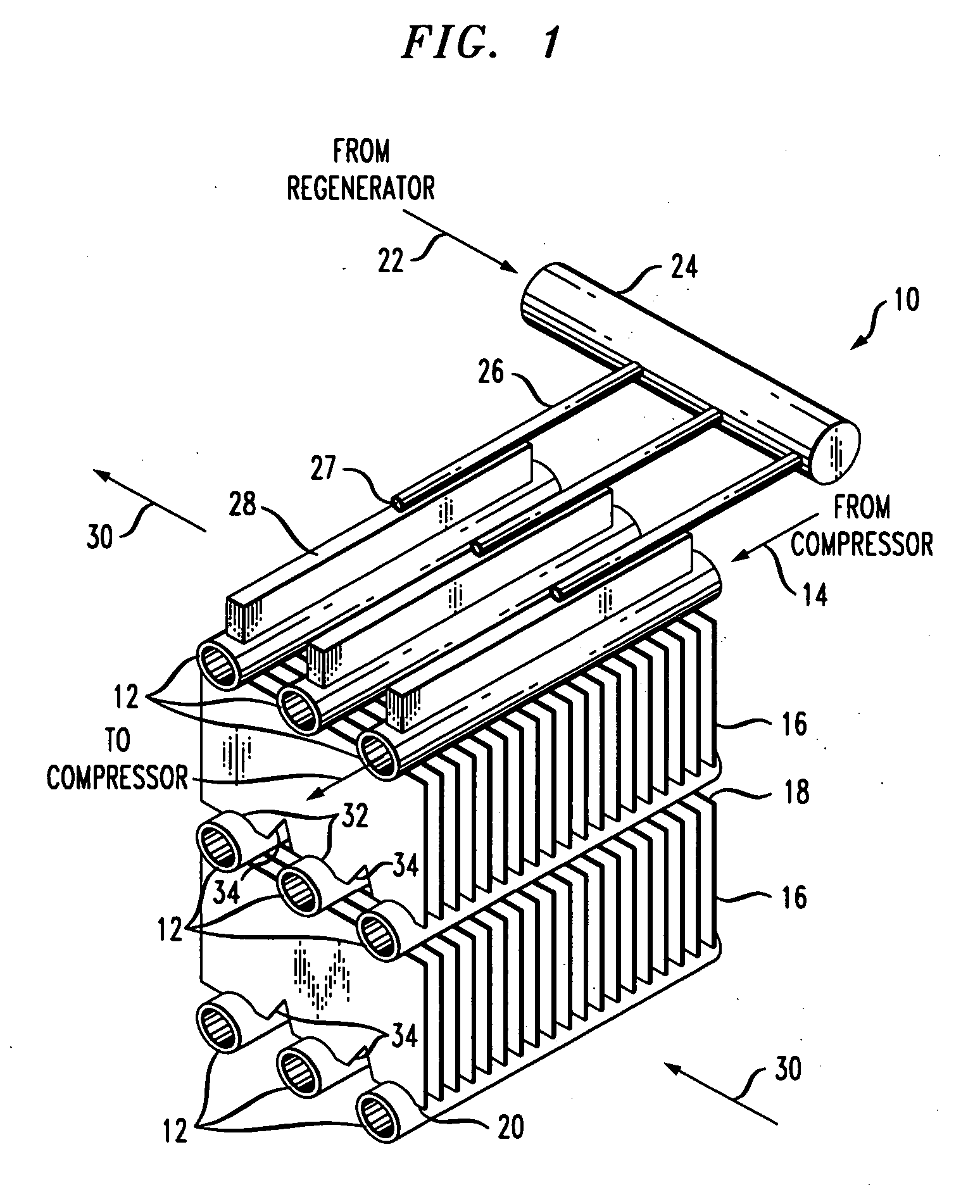

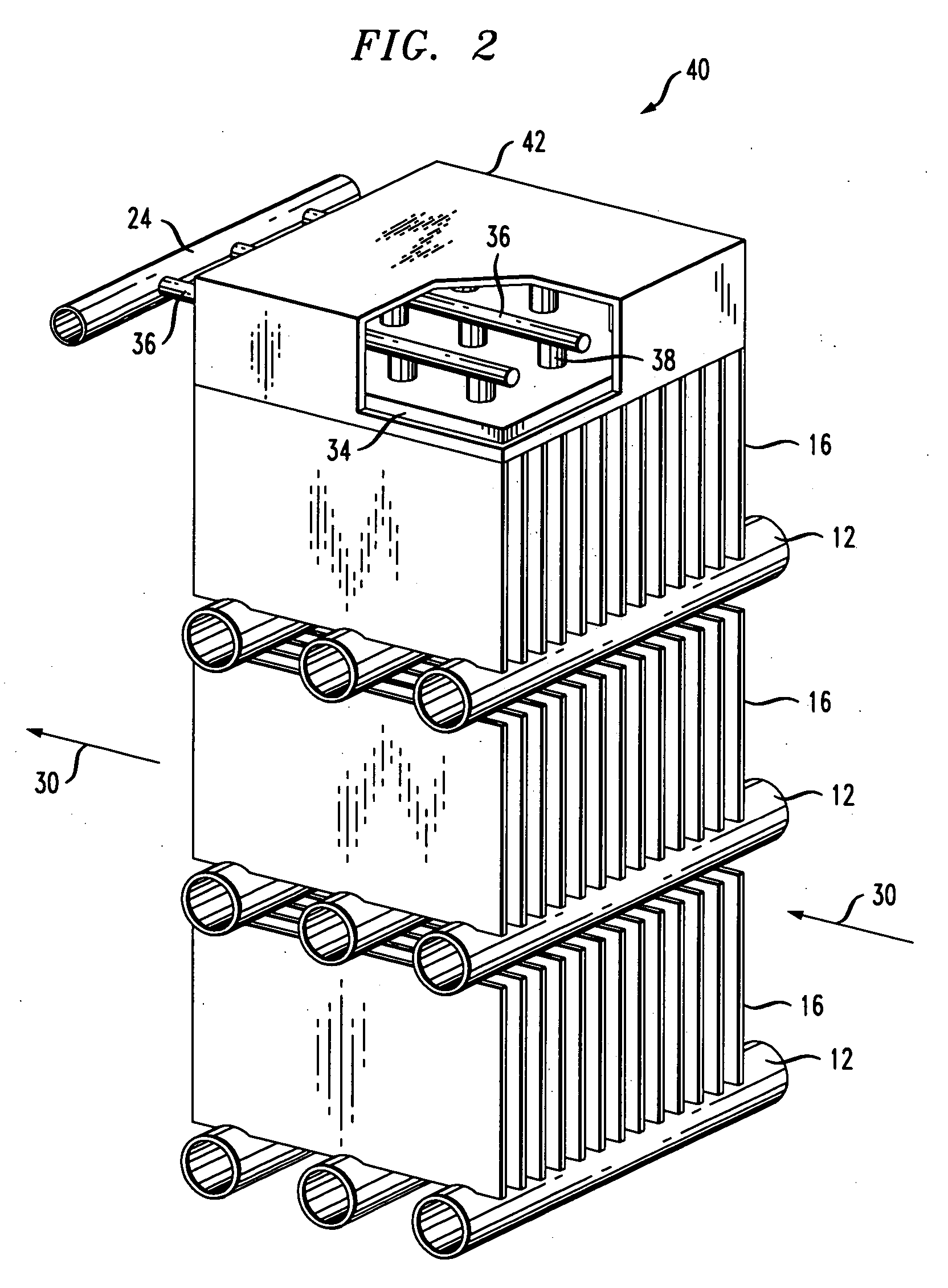

An economically manufactured heat exchanger is provided and includes a plurality of elongated, straight, flat tubes (16), each formed of two identical halves (78,80) joined to each other in mirror image fashion and each having opposed open ends and all arranged in a stack (18). At least one spacer wall (36) is disposed within each tube and extends generally from end to end thereof to define at least two side-by-side first fluid flow paths within a tube. An elongated housing (10) contains the stack and includes spaced headers (20,22) with each header including a tube slot for the adjacent end of each tube (16) in the stack (18). Spacers (26) in the stack separate adjacent tubes in the stack from one another and the spacers include ribs defining a serpentine flow path for a second fluid. An opening (30) is located in the housing (10) near each end thereof and is in fluid communication with the second fluid flow path (28).

Owner:MODINE MFG CO

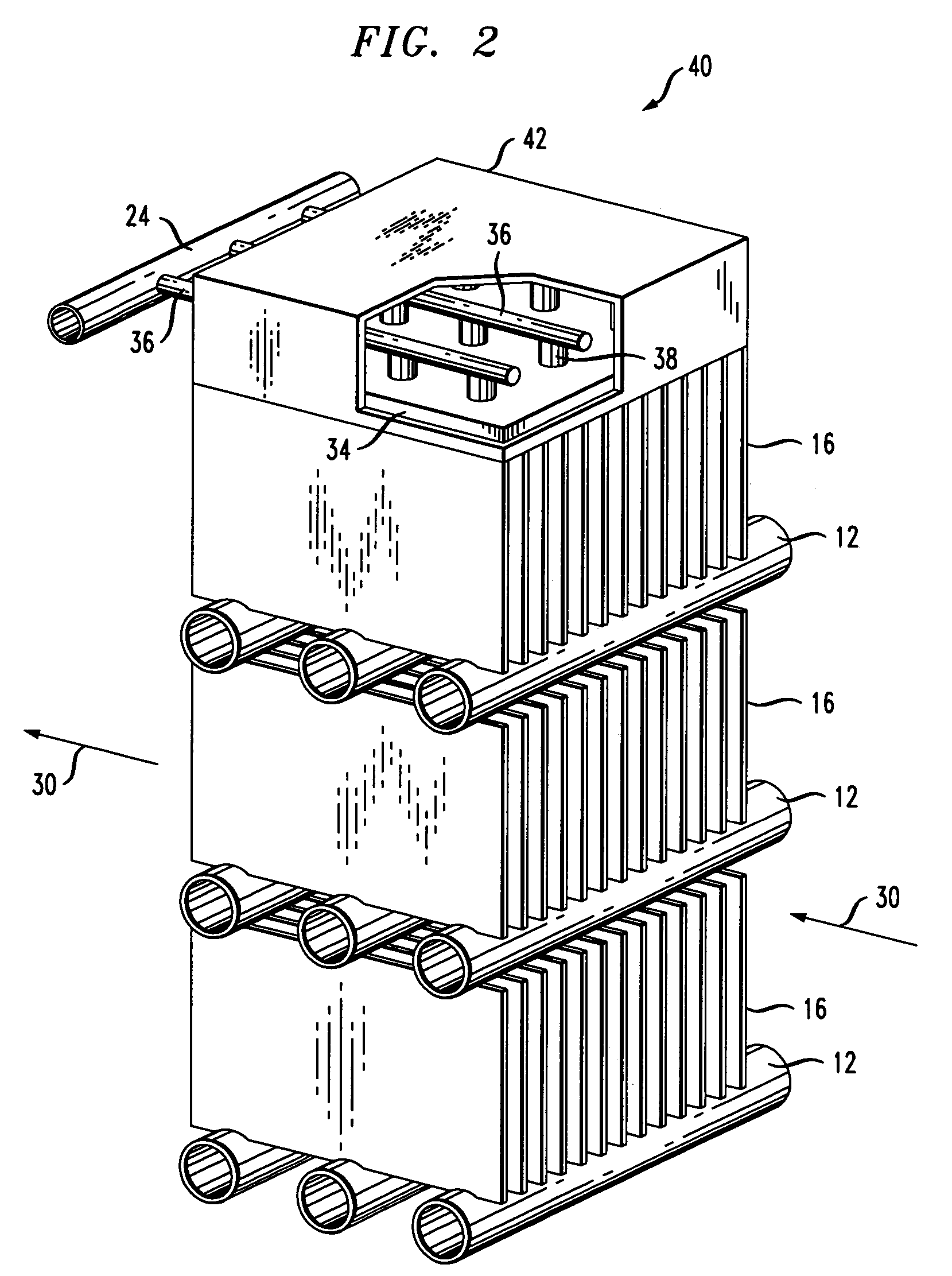

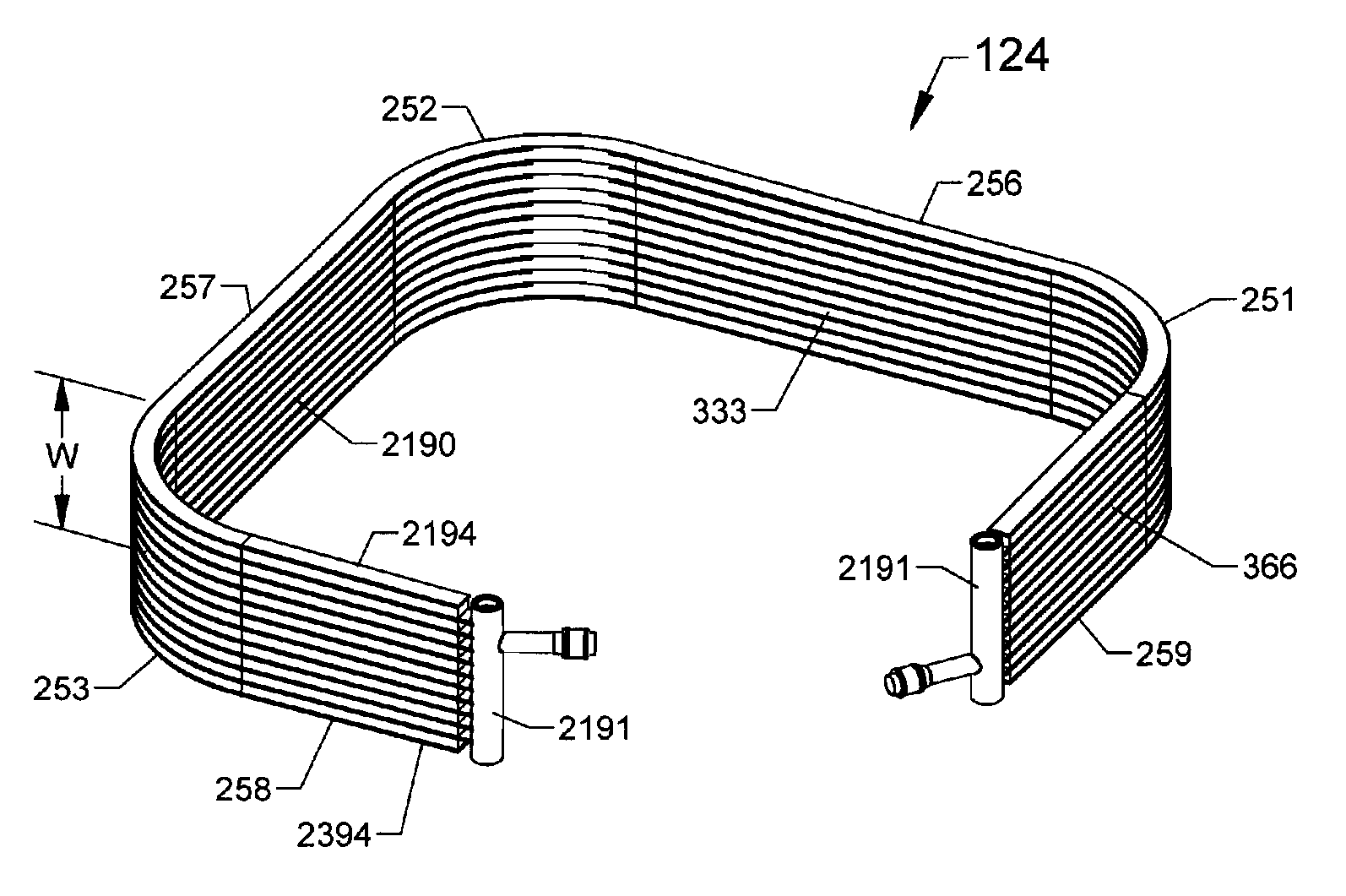

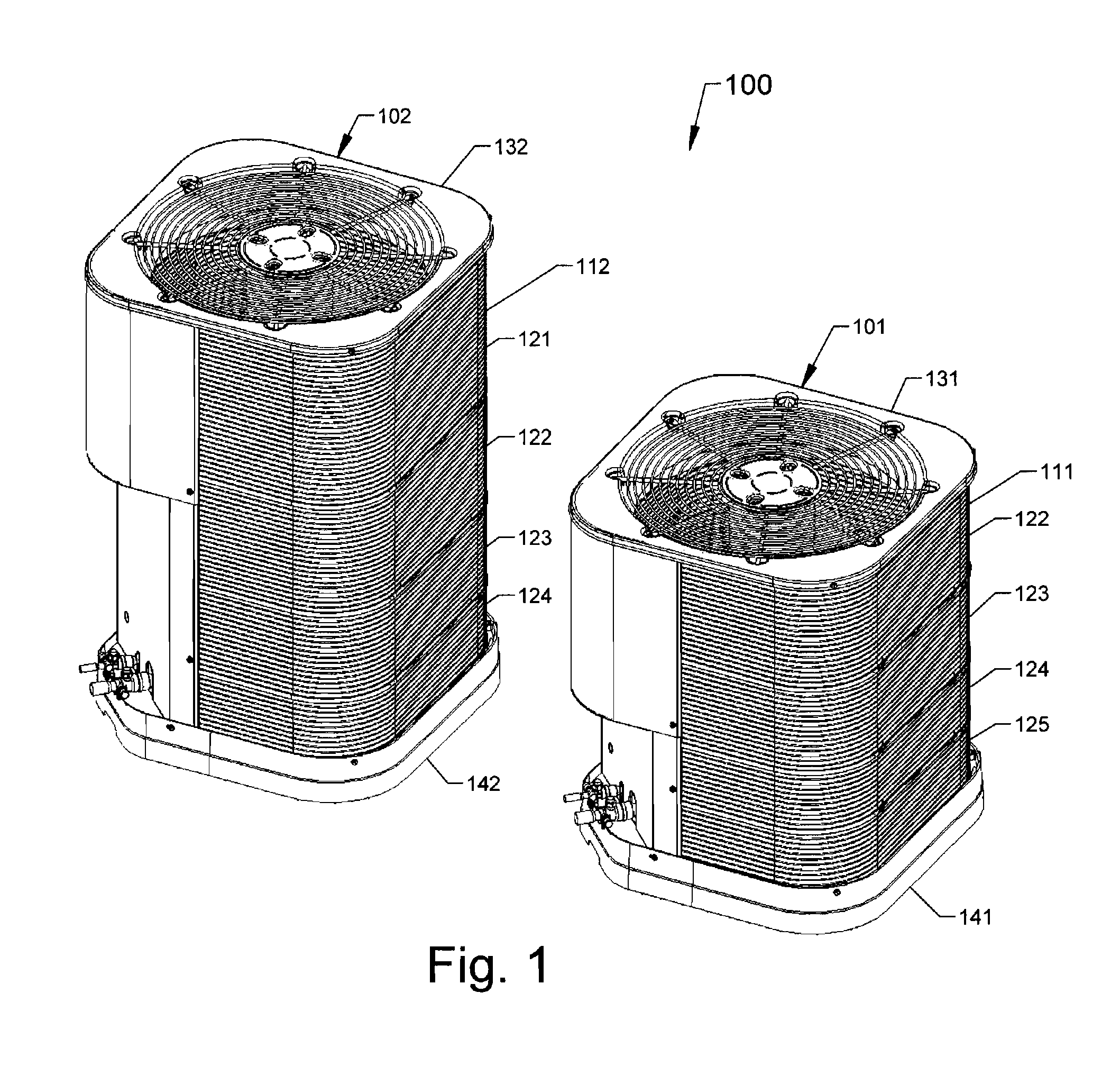

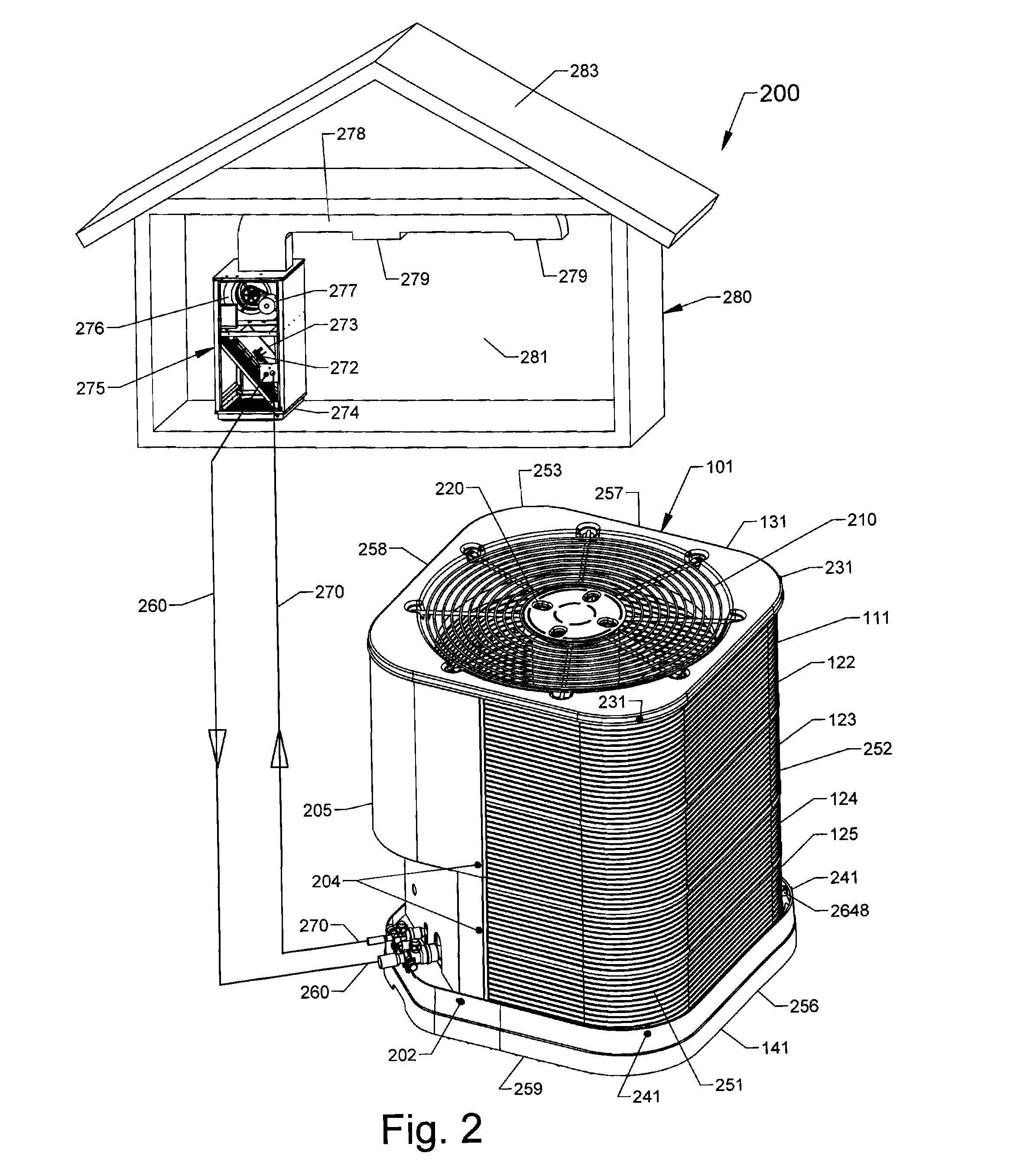

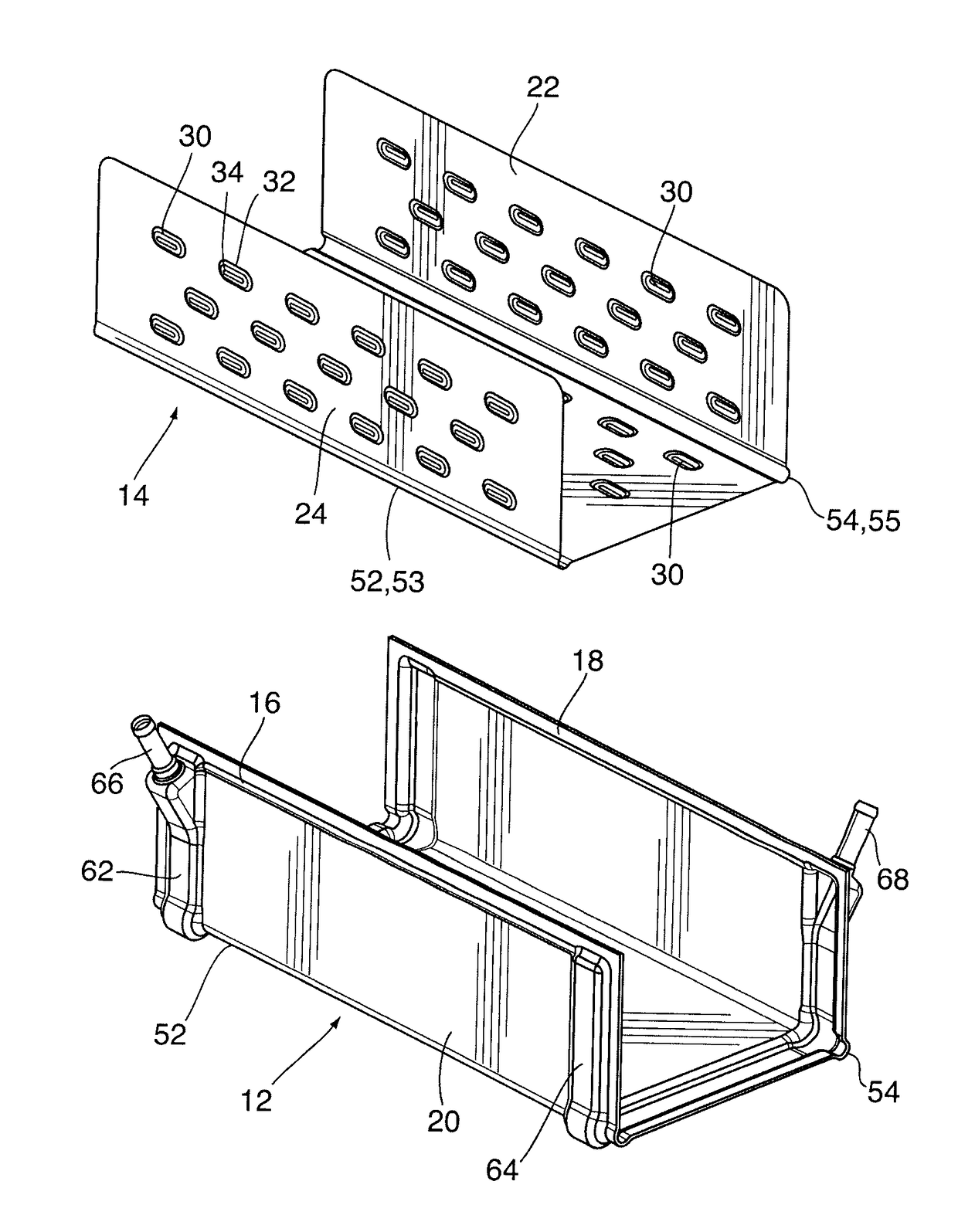

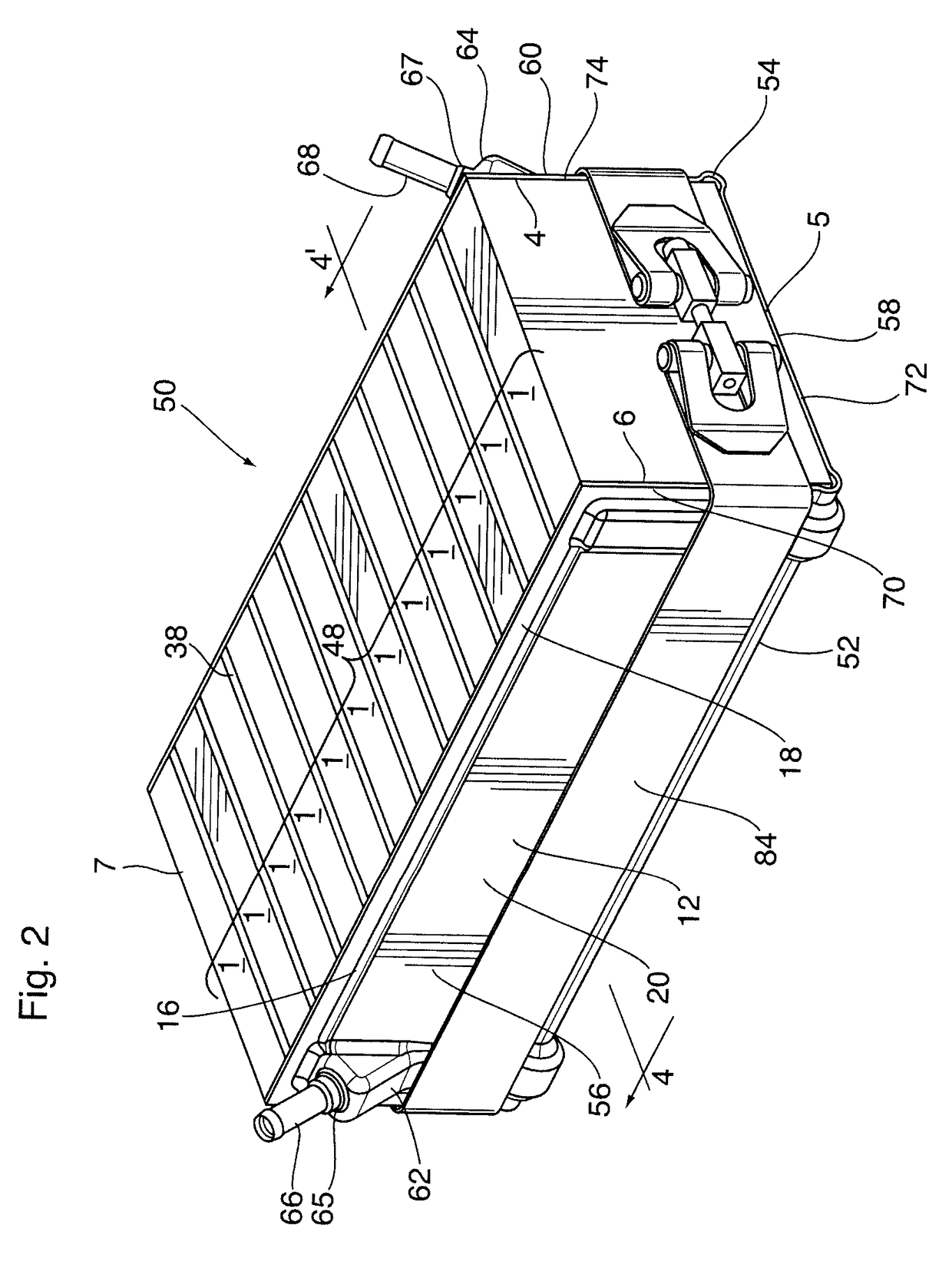

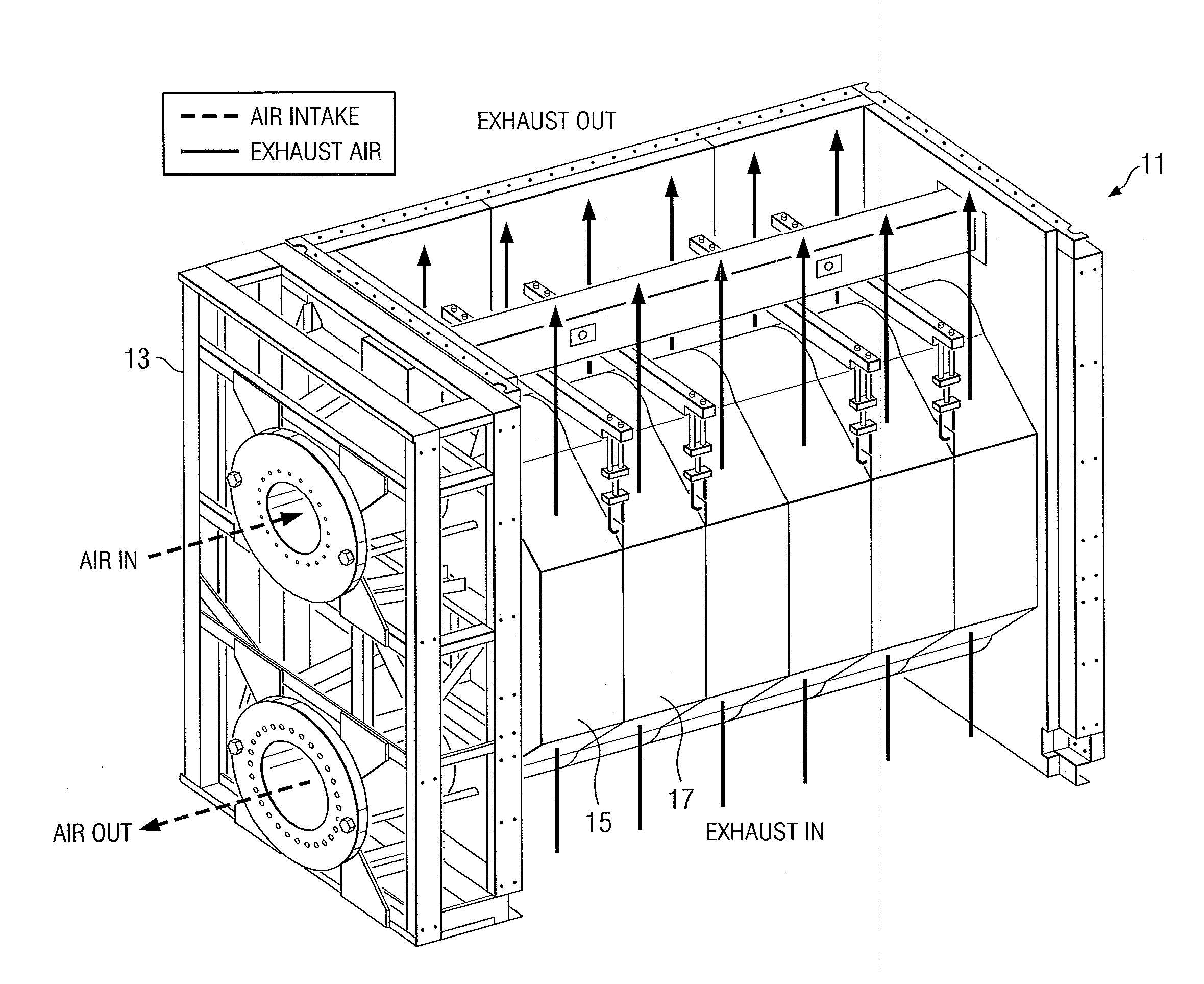

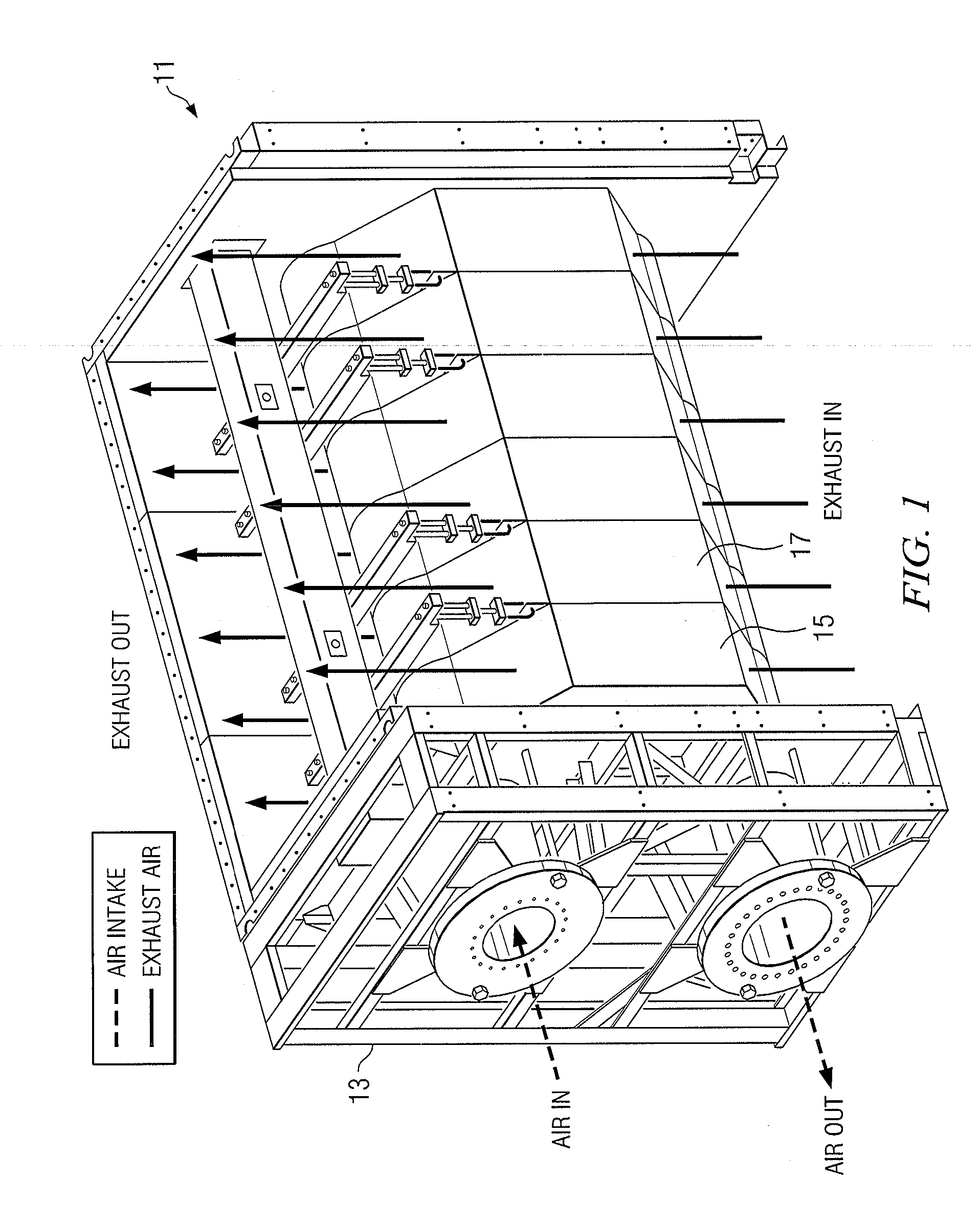

Air Conditioning Units with Modular Heat Exchangers, Inventories, Buildings, and Methods

InactiveUS20090084131A1Reduce the amount requiredEasy field replacementSpacing meansDomestic refrigeratorsComputer moduleEngineering

Air conditioning units, methods of manufacturing, inventories, and buildings wherein certain heat exchanger modules are combined to make air conditioning units. In some embodiments, different combinations of different size modules are used to produce air conditioning units having different capacities wherein some identical modules are used in different size units. Various heat exchanger assemblies include spacers between modules, bends formed after modules are assembled into heat exchanger assemblies, attachment rails at the ends of the modules, inactive multi-tubes at the top and bottom of the modules, copper tubing between aluminum modules to facilitate field replacement of individual modules, name plates that attach between modules, attachment clips or spacers that snap attach to the modules, or a combination thereof, as examples.

Owner:NORDYNE

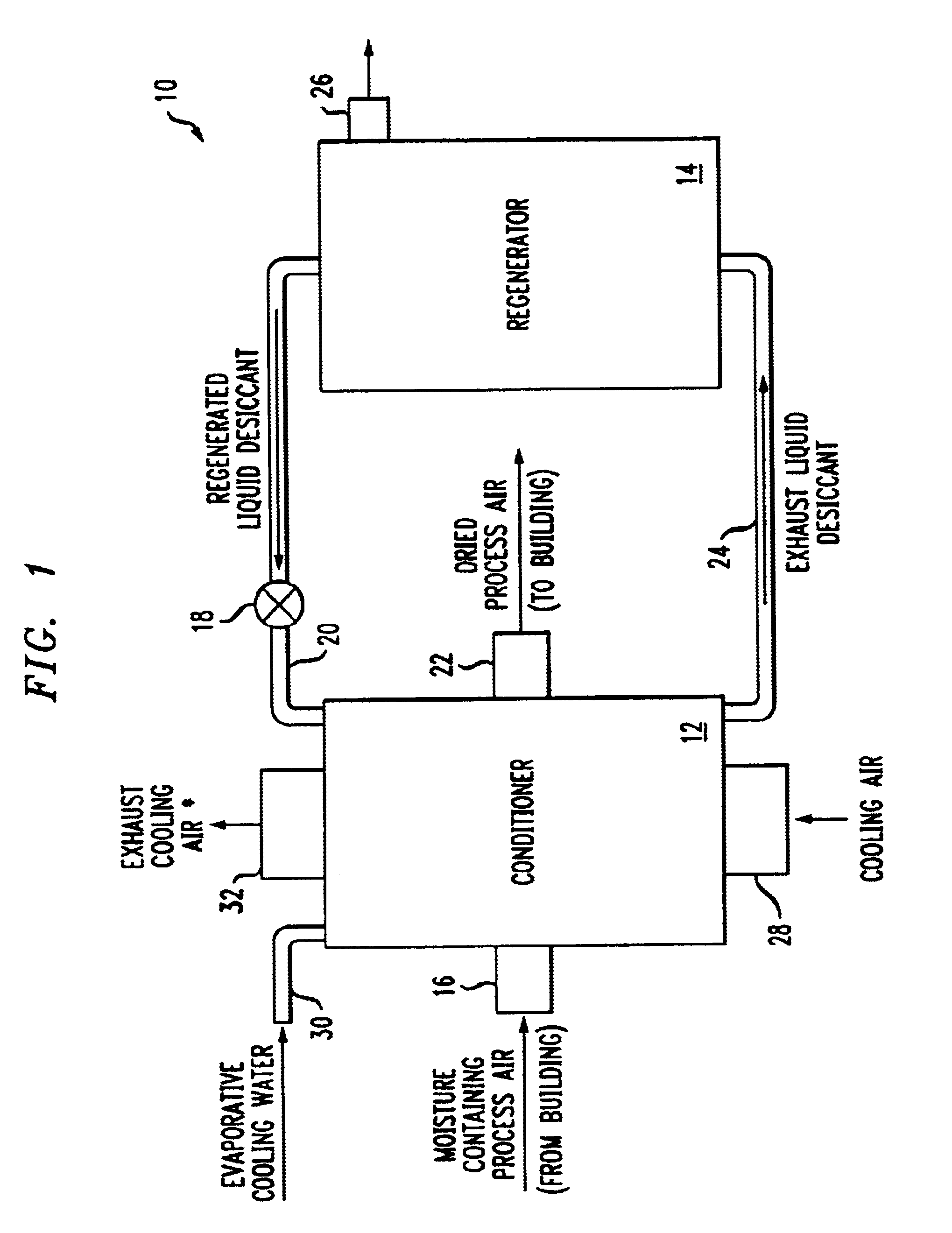

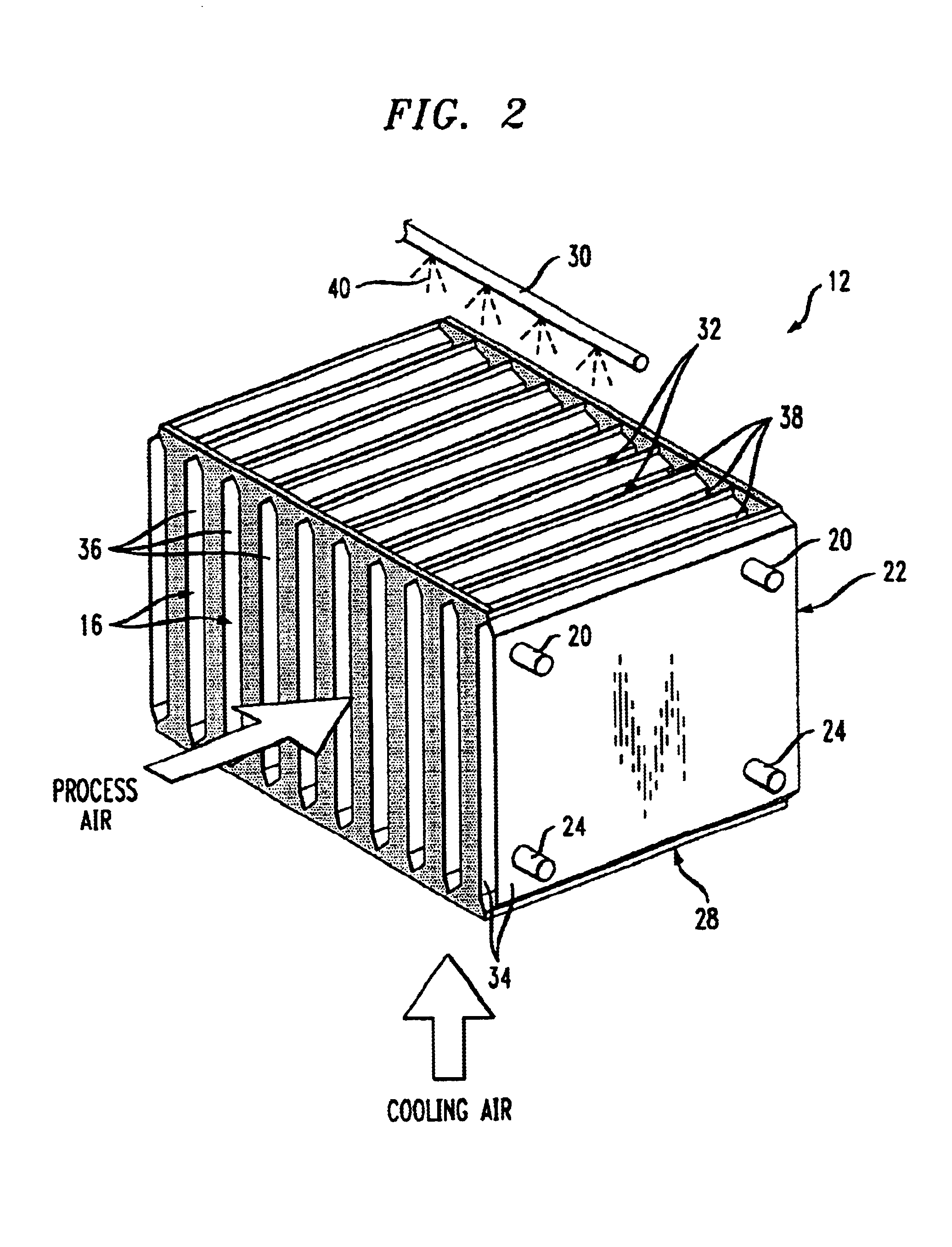

Heat and mass exchanger

ActiveUS20060156750A1Additional exchangeEfficient exchangeSpacing meansDomestic cooling apparatusEngineeringContinuous flow

A mass and heat exchanger includes at least one first substrate with a surface for supporting a continuous flow of a liquid thereon that either absorbs, desorbs, evaporates or condenses one or more gaseous species from or to a surrounding gas; and at least one second substrate operatively associated with the first substrate. The second substrate includes a surface for supporting the continuous flow of the liquid thereon and is adapted to carry a heat exchange fluid therethrough, wherein heat transfer occurs between the liquid and the heat exchange fluid.

Owner:AIL RES

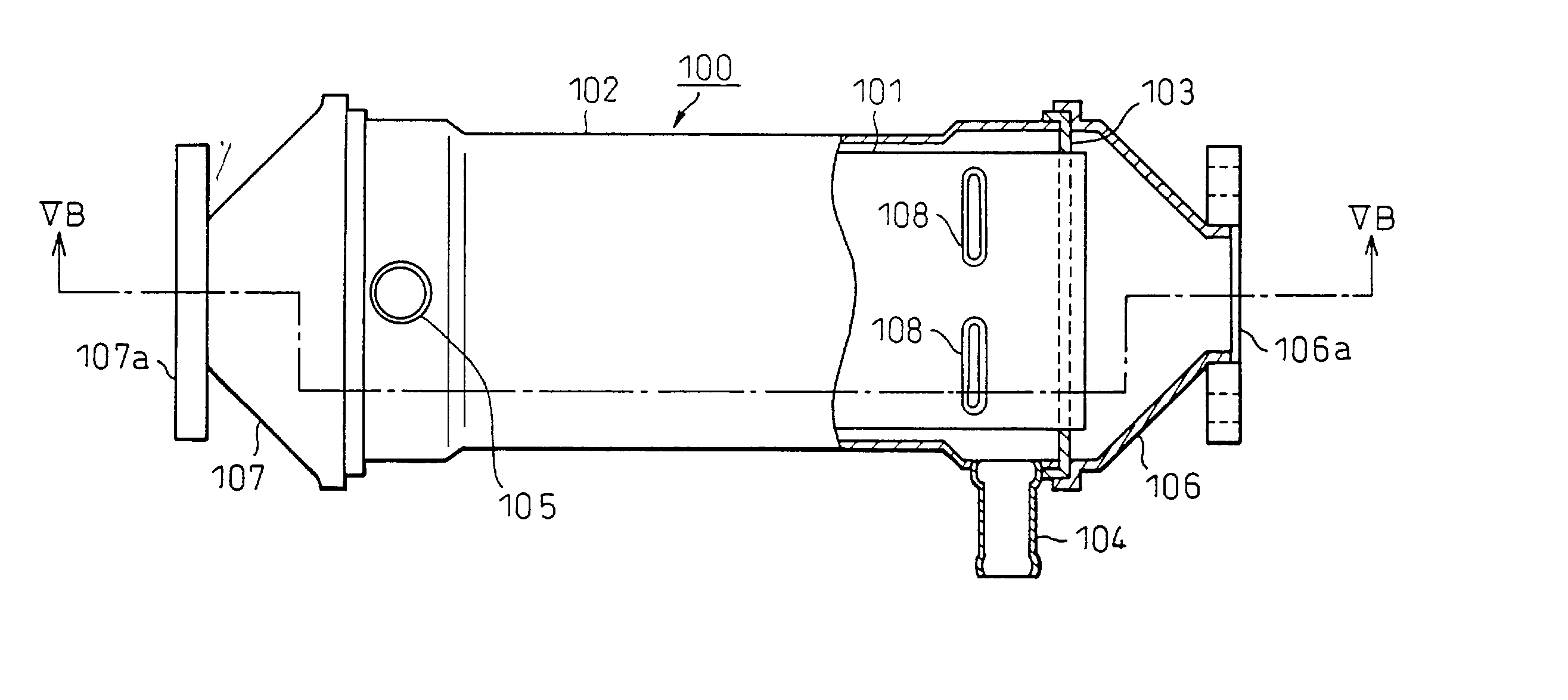

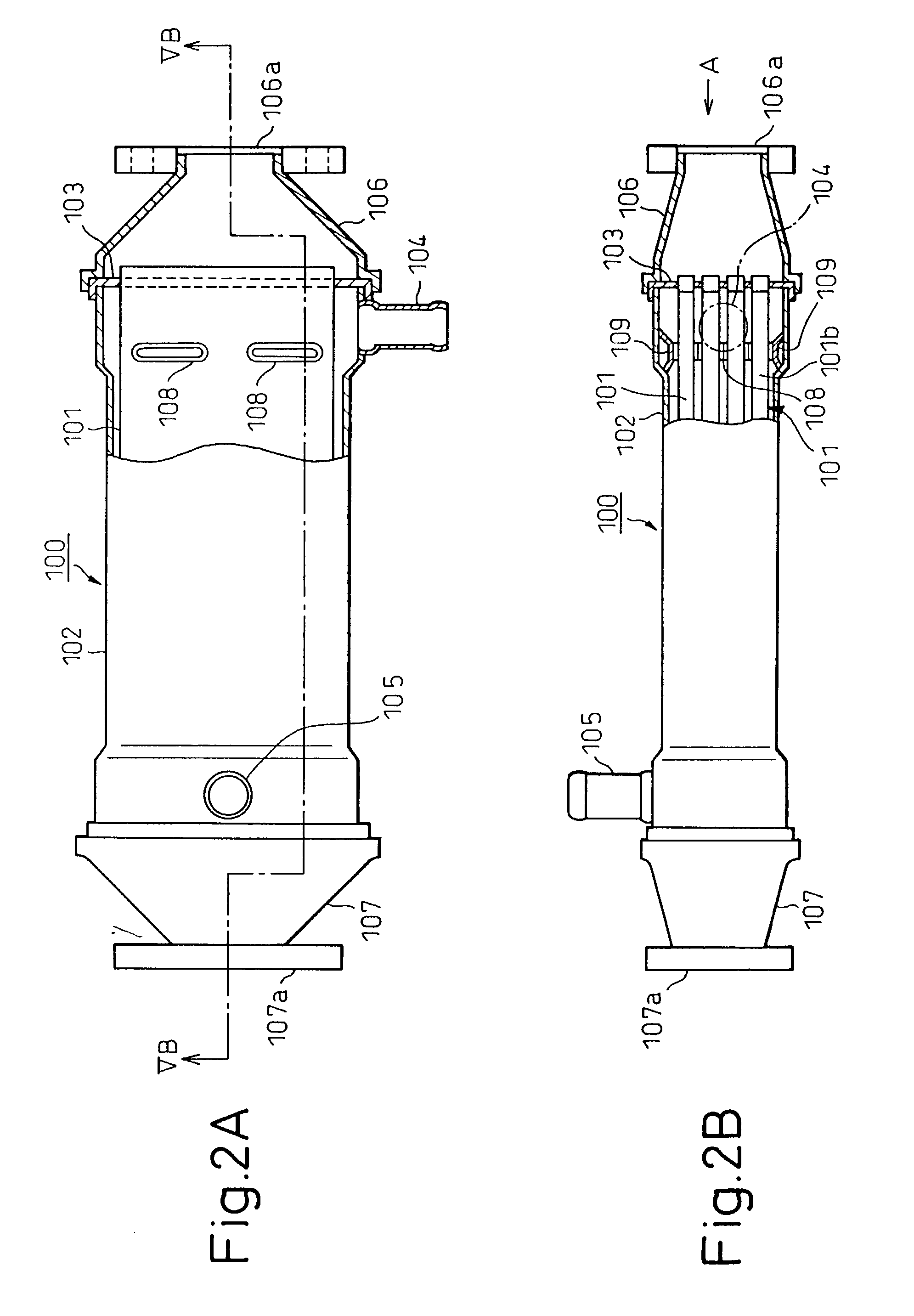

Exhaust gas heat exchanger

InactiveUS20030010480A1Spacing meansNon-fuel substance addition to fuelEngineeringMechanical engineering

A tube 101 is constituted by a pair of plates 111a, 111b which are fitted with each other in such a manner as to put an inner fin 101b between the plate 111a and the plate 111b. Differences in level 111c are formed on the second plate 111b, which fits inside, which differences in level each protrude inwardly by a distance equal to the thickness of the first plate 111a, whereby the outer wall surface of the tube 101 is made substantially level thereover. A gap which is formed between the outer wall surface of the tube 101 and a core plate, when the tube is passed through the core plate, can be as small as possible whereby the brazing properties can be improved.

Owner:DENSO CORP

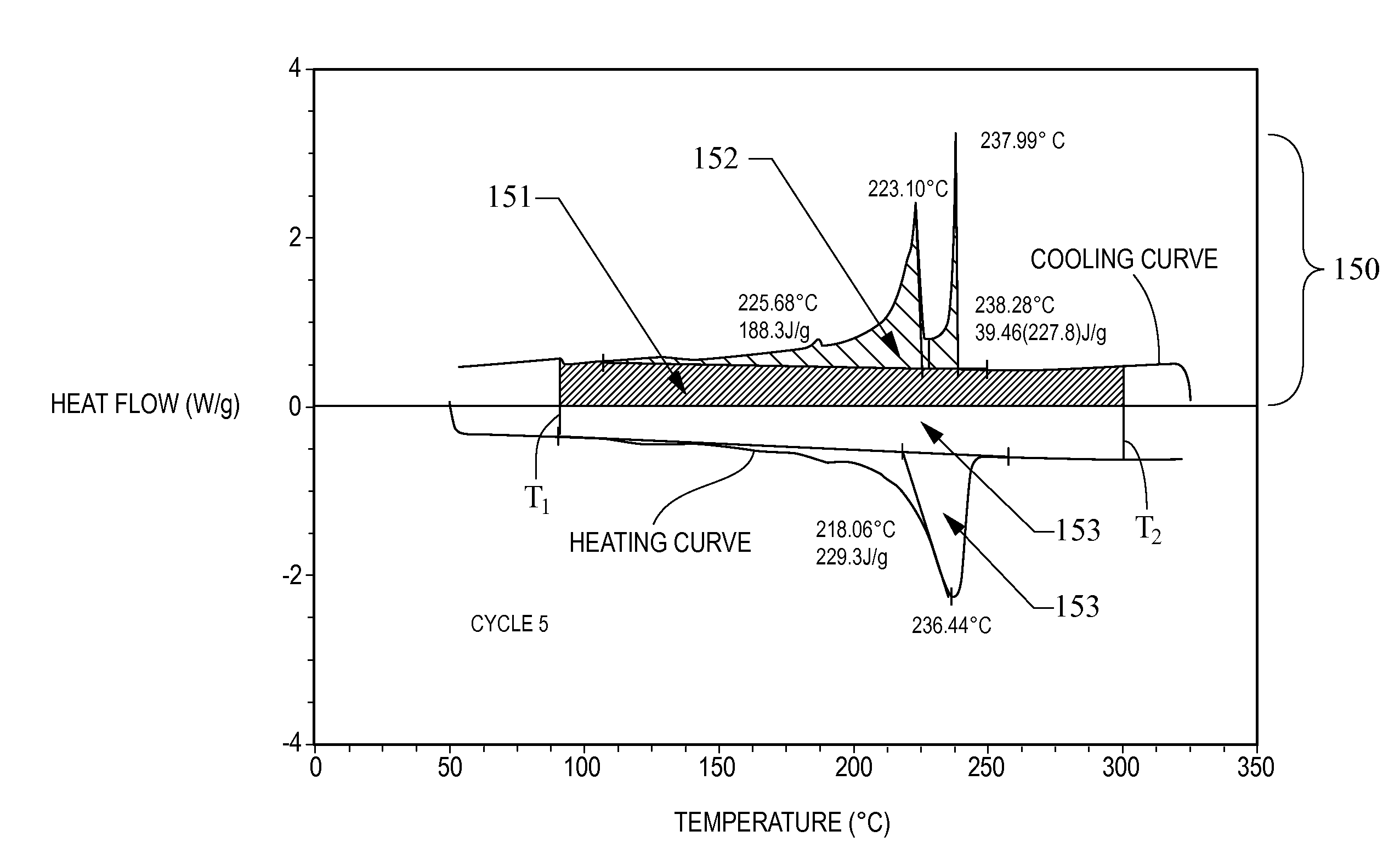

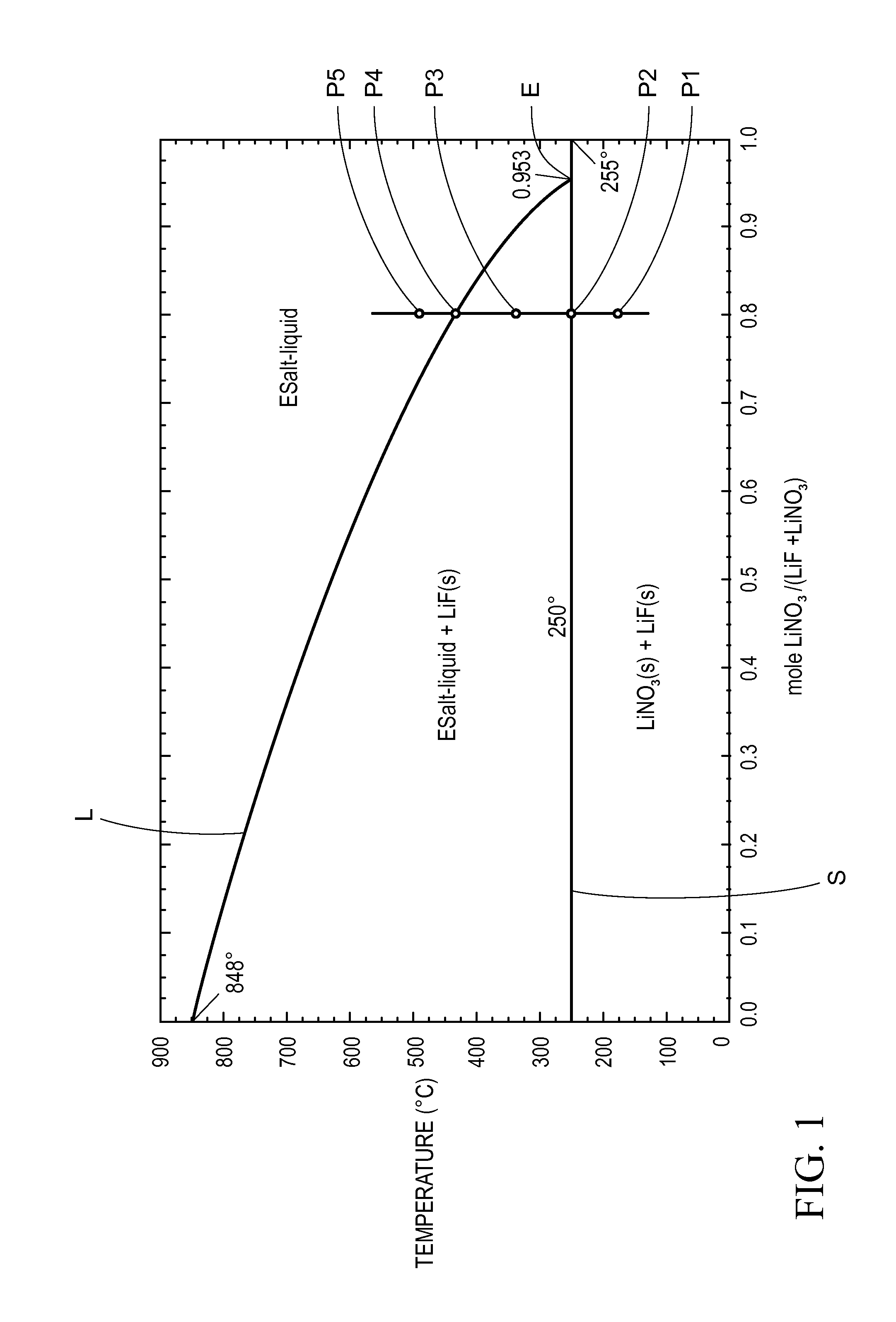

Thermal energy storage materials

A thermal energy storage material (TESM) system (and associated methods) that reproducibly stores and recovers latent heat comprising i) at least one first metal containing material including at least one first metal compound that includes a nitrate ion, a nitrite ion, or both; ii) at least one second metal containing material including at least one second metal compound; and iii) optionally including water, wherein the water concentration if any is present is less than about 10 wt. %; wherein the TESM has a liquidus temperature, TL, from about 100° C. to about 250° C.; and wherein the TESM exhibits a heat storage density from 300° C. to 80° C. of at least about 1 MJ / l; so that upon being used in a system that generates heat, at least a portion of the heat is captured and stored by the TESM and subsequently released for use, and the system is generally resistant to corrosion at temperatures of about 300° C.

Owner:DOW GLOBAL TECH LLC

Multi-sided heat exchangers with compliant heat transfer surfaces

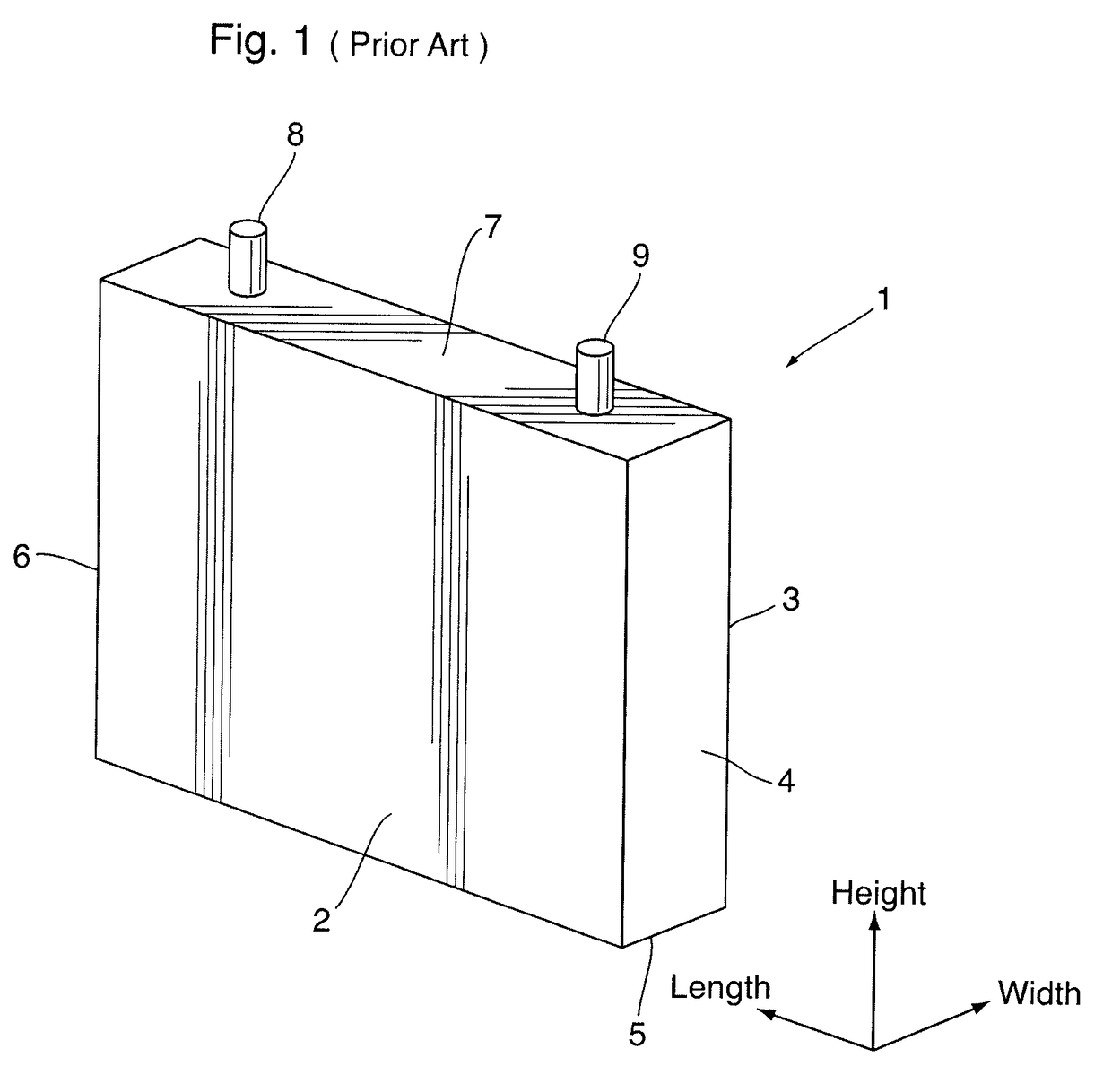

A heat exchanger for a battery has fluid-carrying panels and defines a multi-sided enclosure for enclosing at least two sides of the battery. The heat exchanger has first and second fluid-carrying panels defining first and second flow channels, where the first and second fluid-carrying panels are arranged at an angle to another. The heat exchanger may also include a third fluid-carrying panel defining a third flow channel, and being arranged at an angle to the second fluid-carrying panel. The heat exchanger has first and second plates sealingly joined together along their peripheries and defining a fluid flow passageway between their central fluid flow areas. The second plate may be compliant, its central fluid flow area being deformable away from the central fluid flow area of the first plate in response to a pressure of a fluid inside the fluid flow passageway.

Owner:DANA CANADA CORP

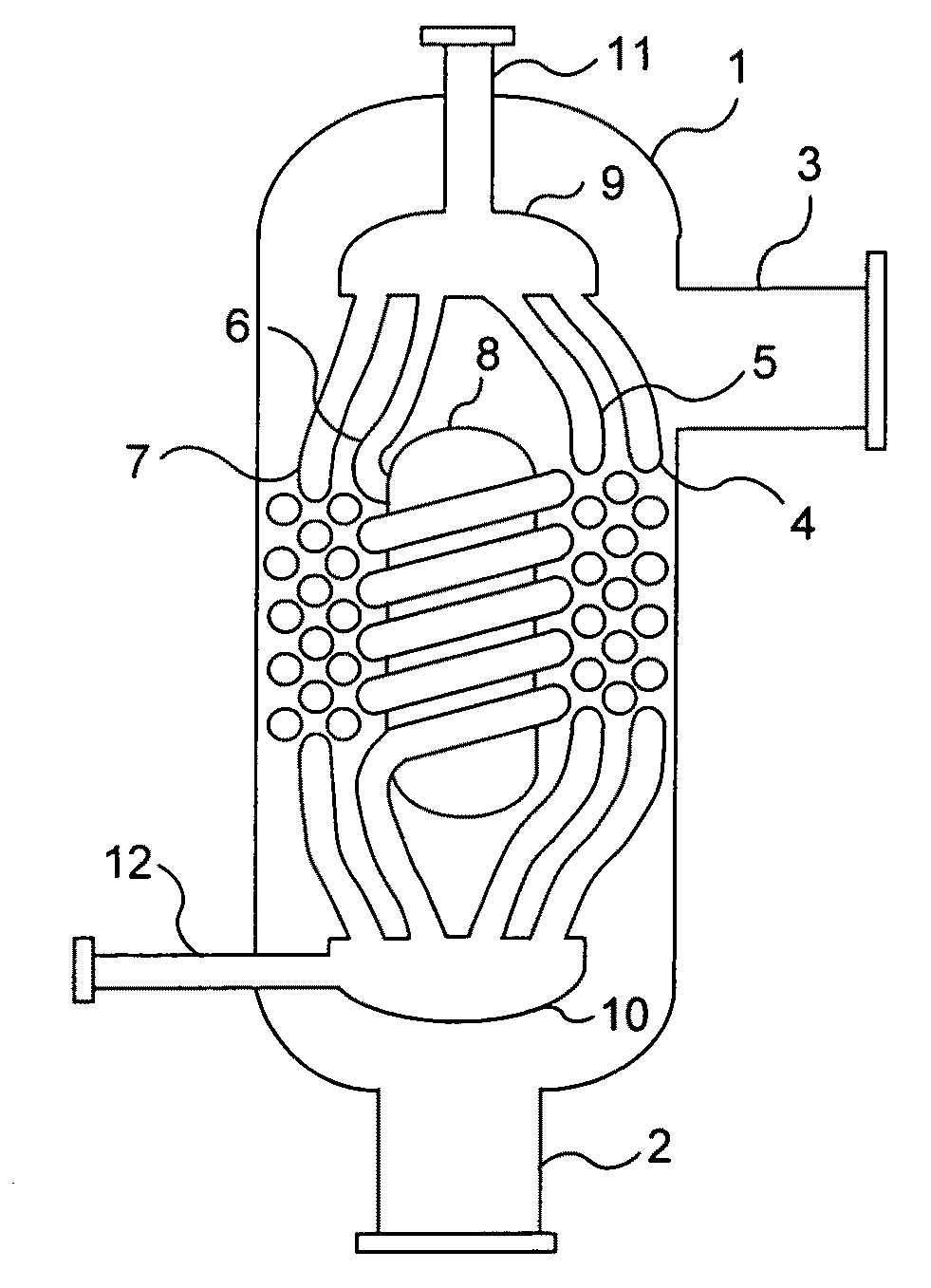

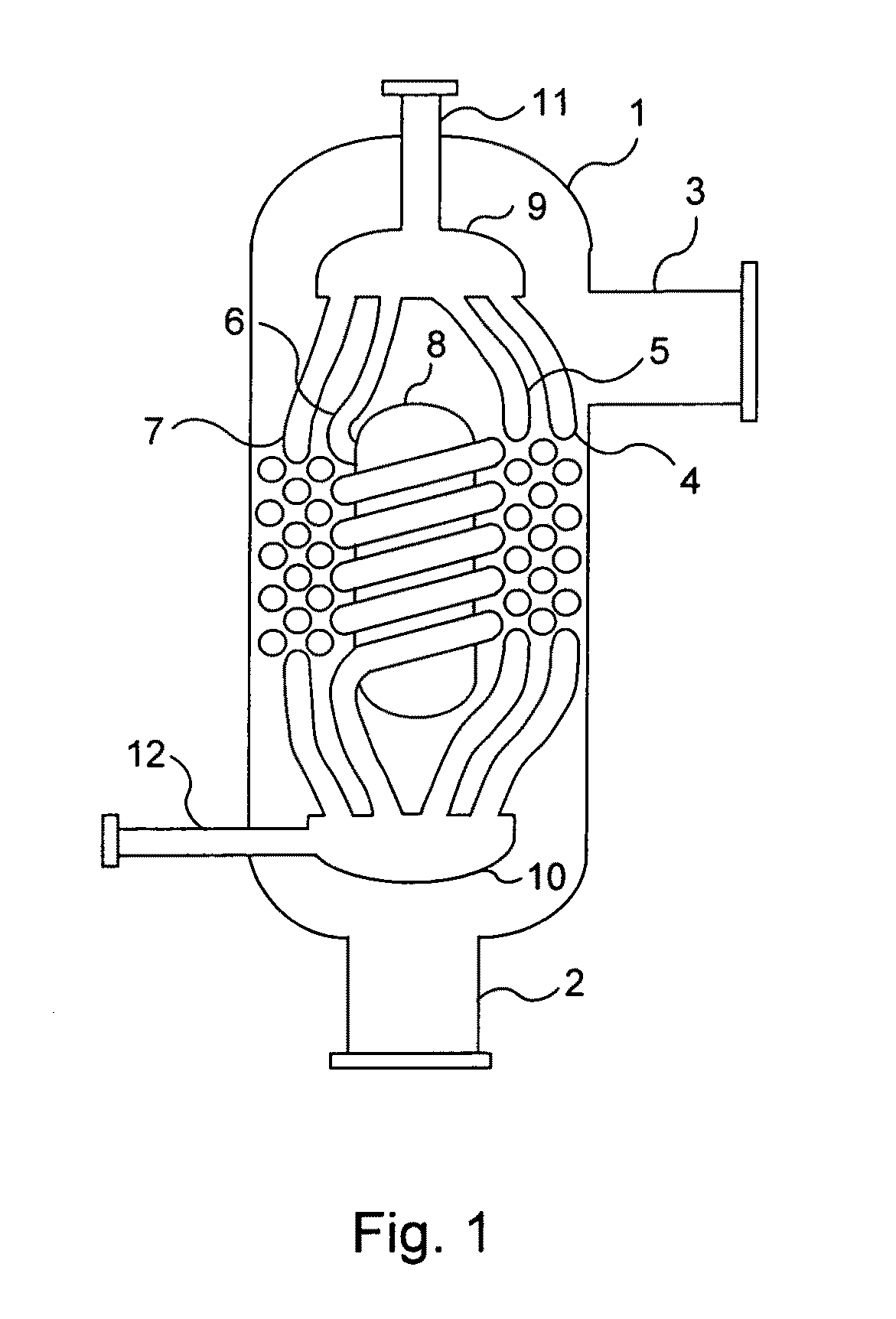

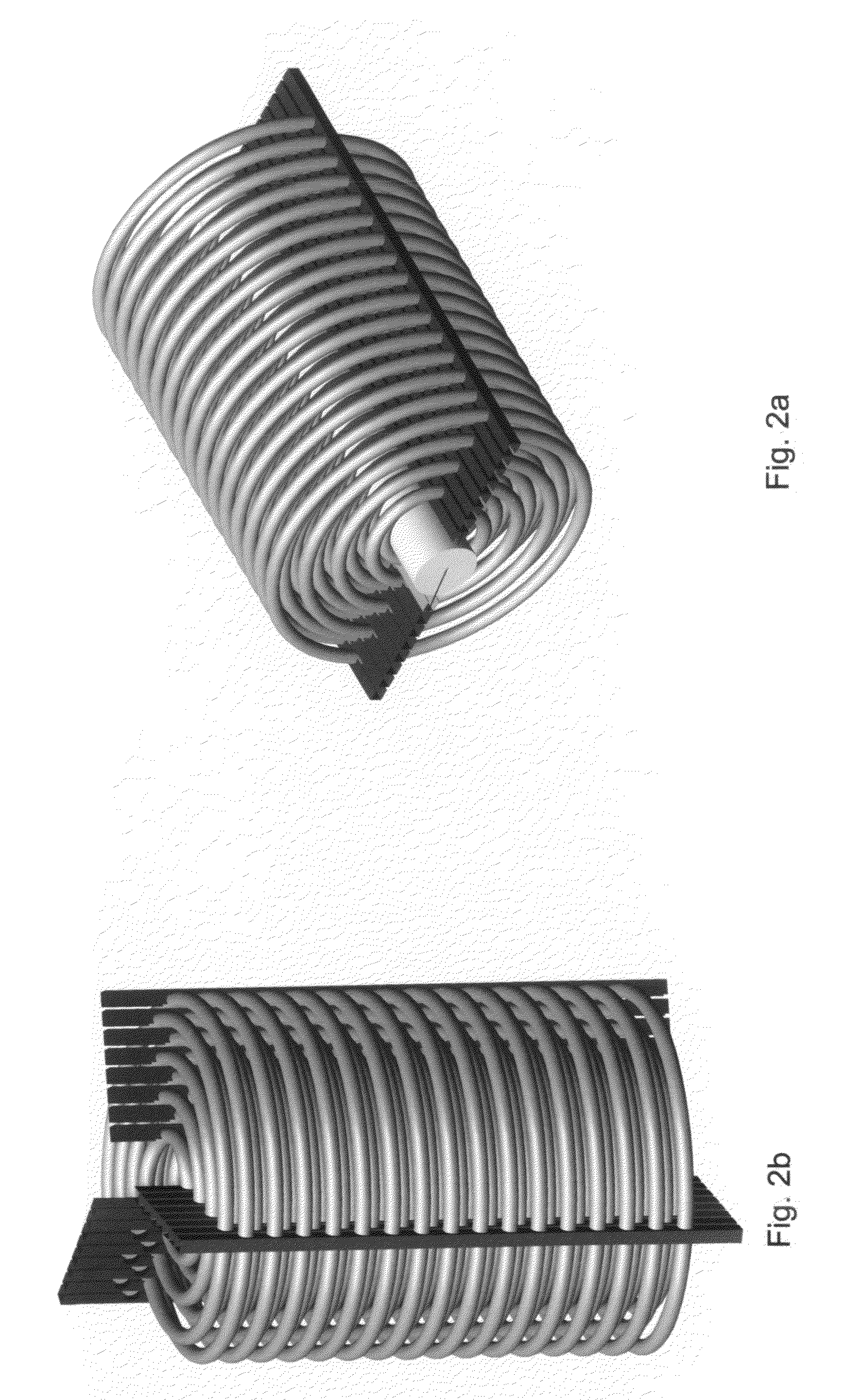

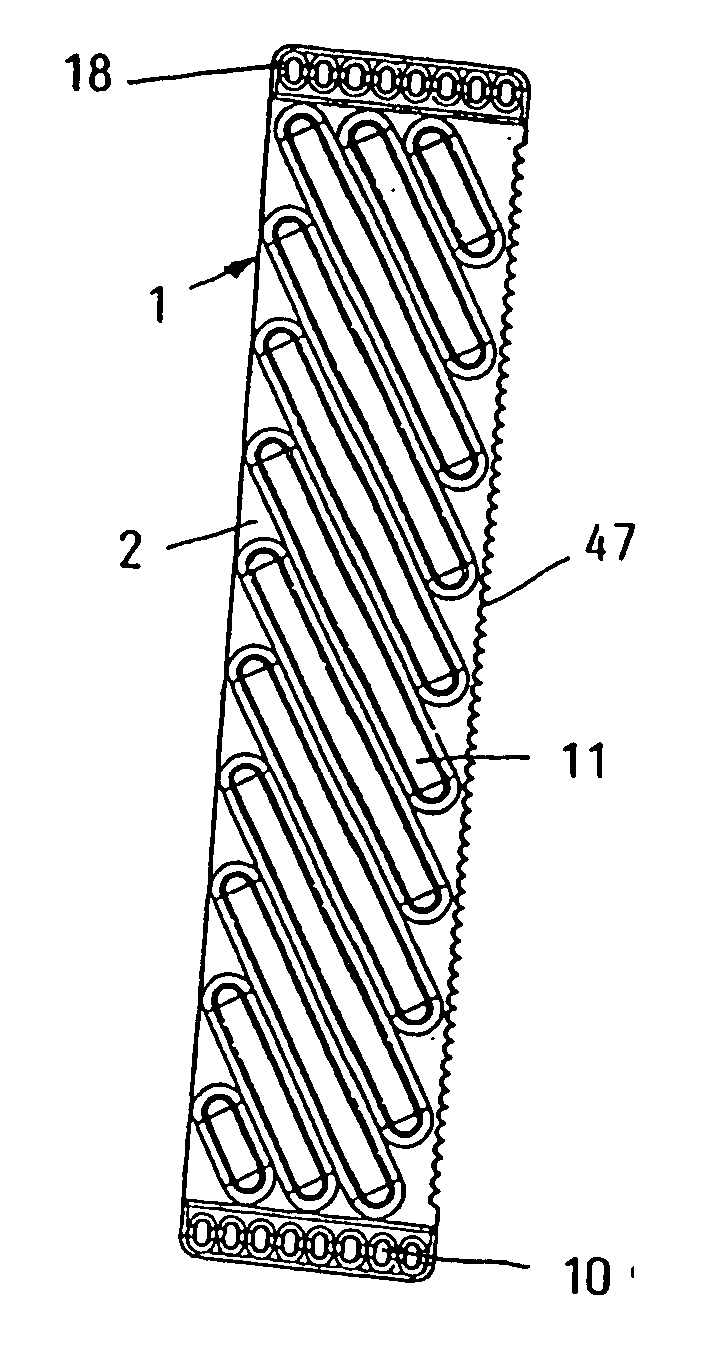

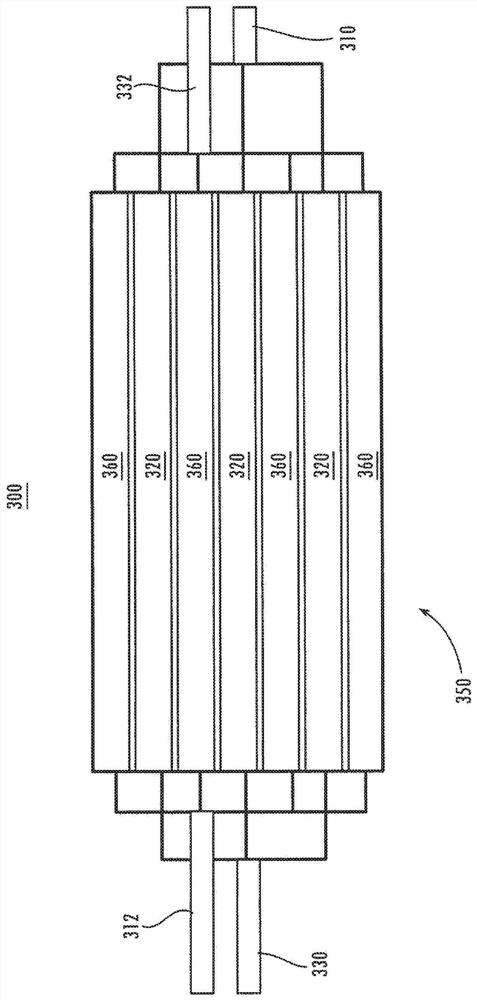

Multiple concentric cylindrical co-coiled heat exchanger

A compact shell and coil heat exchanger is disclosed that accommodates widely differing volumetric flowrates between the two fluids undergoing heat exchange. Multiple co-coiled helical coils of tubing are concentrically arranged, and coil spacers are provided which maintain the tubes in overall staggered alignment, as illustrated in FIG. 1. Uniformly high transfer coefficients are maintained throughout the bundle of coils via means for ensuring that the tube-side flow through the tubes of each coil, and the shell-side flow across each coil, are kept proportional to the tube surface area of each coil.

Owner:ERICKSON DONALD CHARLES

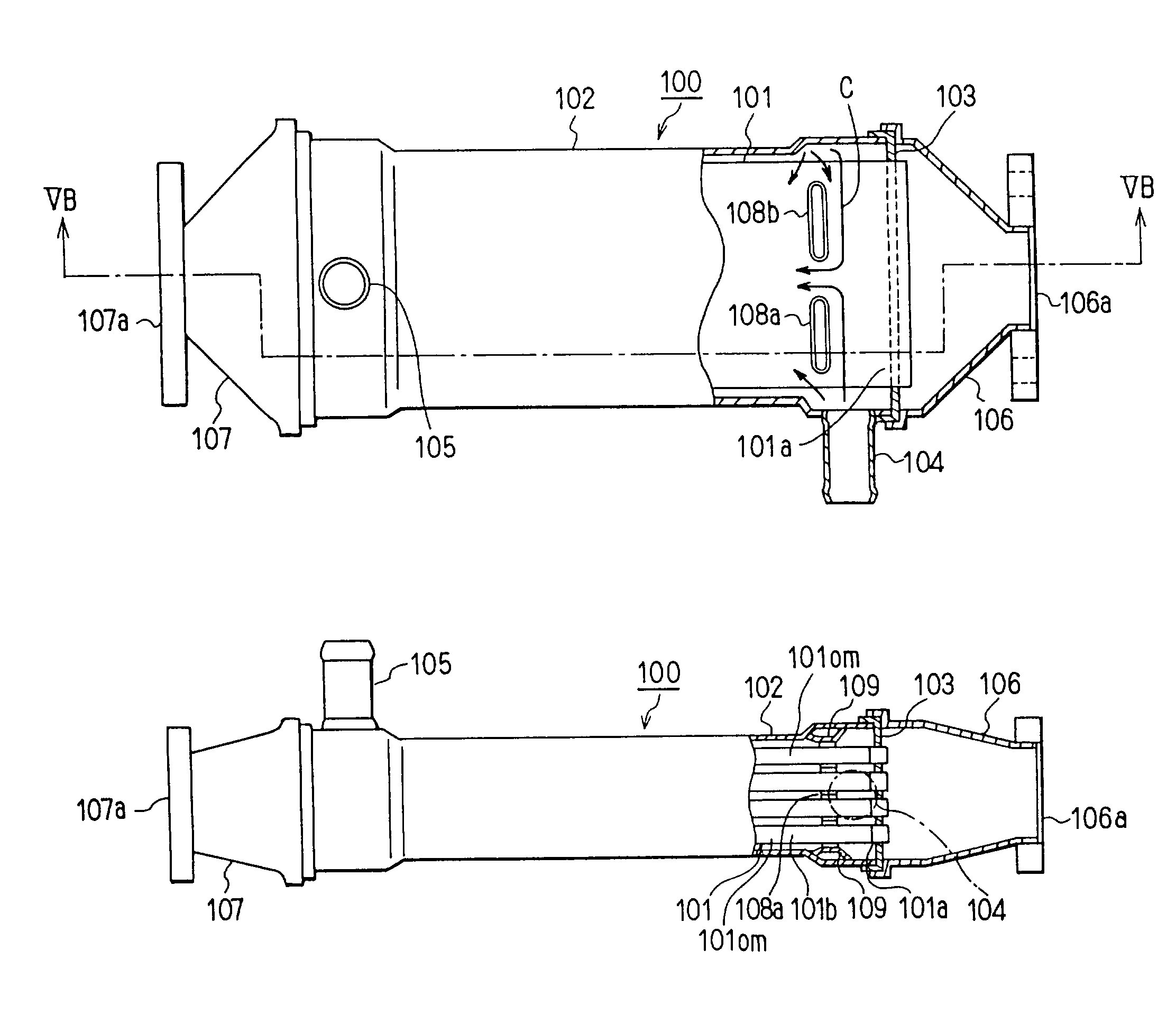

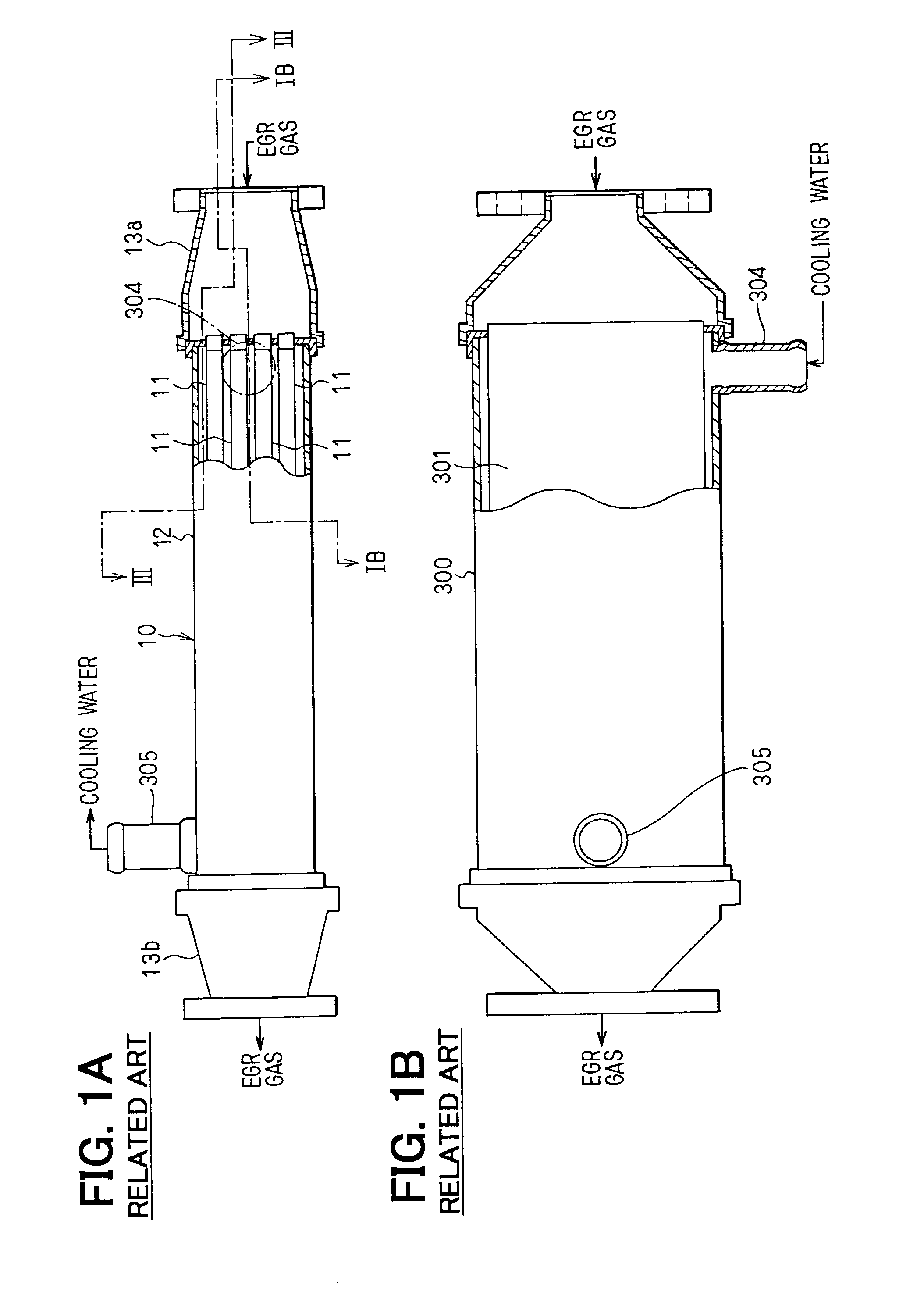

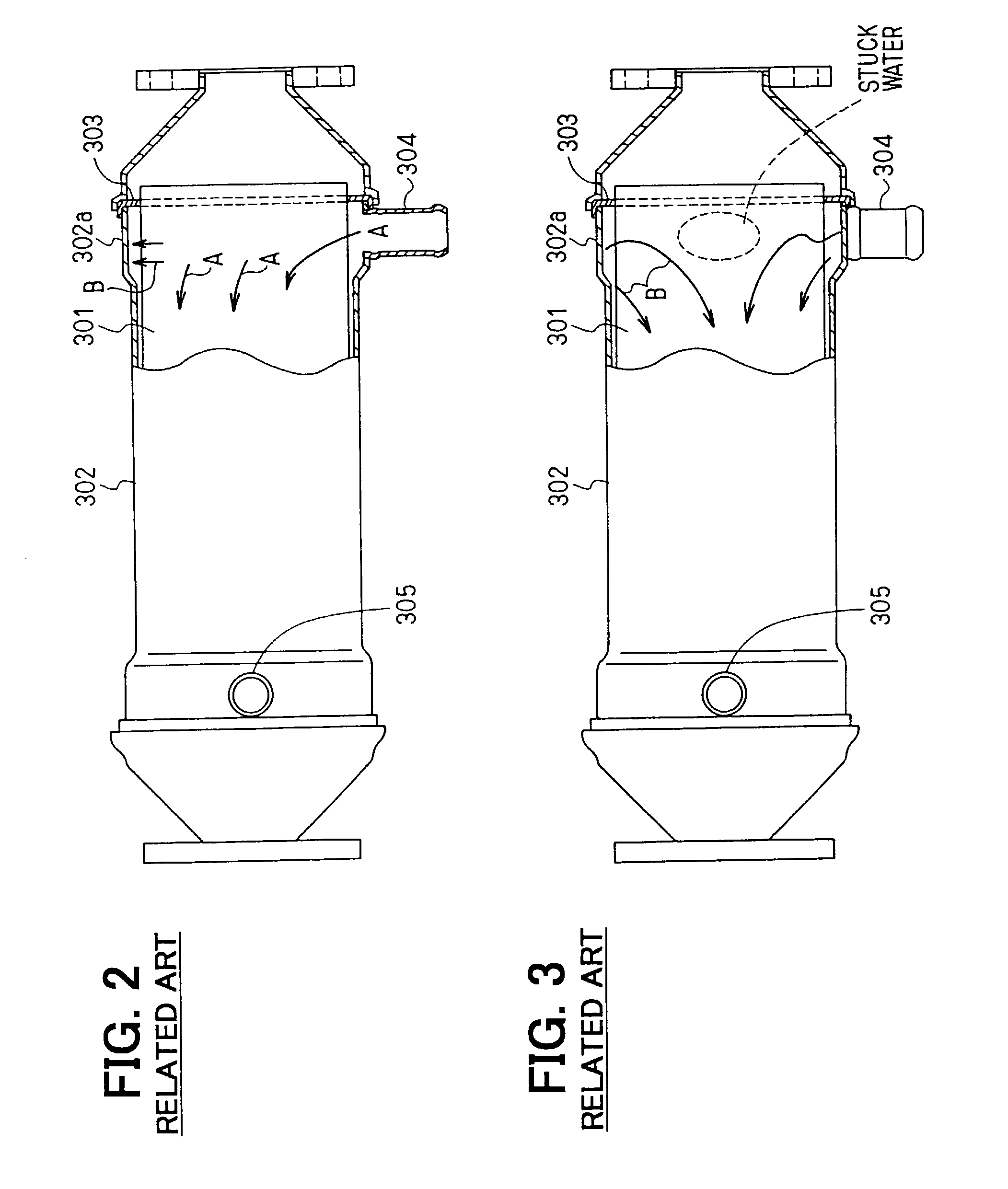

Exhaust gas heat exchanger

InactiveUS7077190B2Eliminating boilingReduce flow rateInternal combustion piston enginesRecuperative heat exchangersExhaust fumesWater flow

An exhaust gas heat exchanger has a tank, laminated exhaust gas tubes where the exhaust gas flows, a cooling water inlet pipe and a cooling water outlet pipe. The cooling water flows into the tank and flows through water passages between adjacent exhaust gas tubes and between an inner wall of the tank and an outermost exhaust gas tube. Ribs are formed on the exhaust gas tubes so as to lead the cooling water after colliding with an inner wall toward an upstream side of the exhaust gas tubes to prevent the cooling water from being stuck. Otherwise, spaces between an inner wall of a casing and the exhaust gas tubes are regulated to keep the flow rate of the cooling water in the casing so that the cooling water is prevented from being boiled locally by slow flow rate of the cooling water.

Owner:DENSO CORP

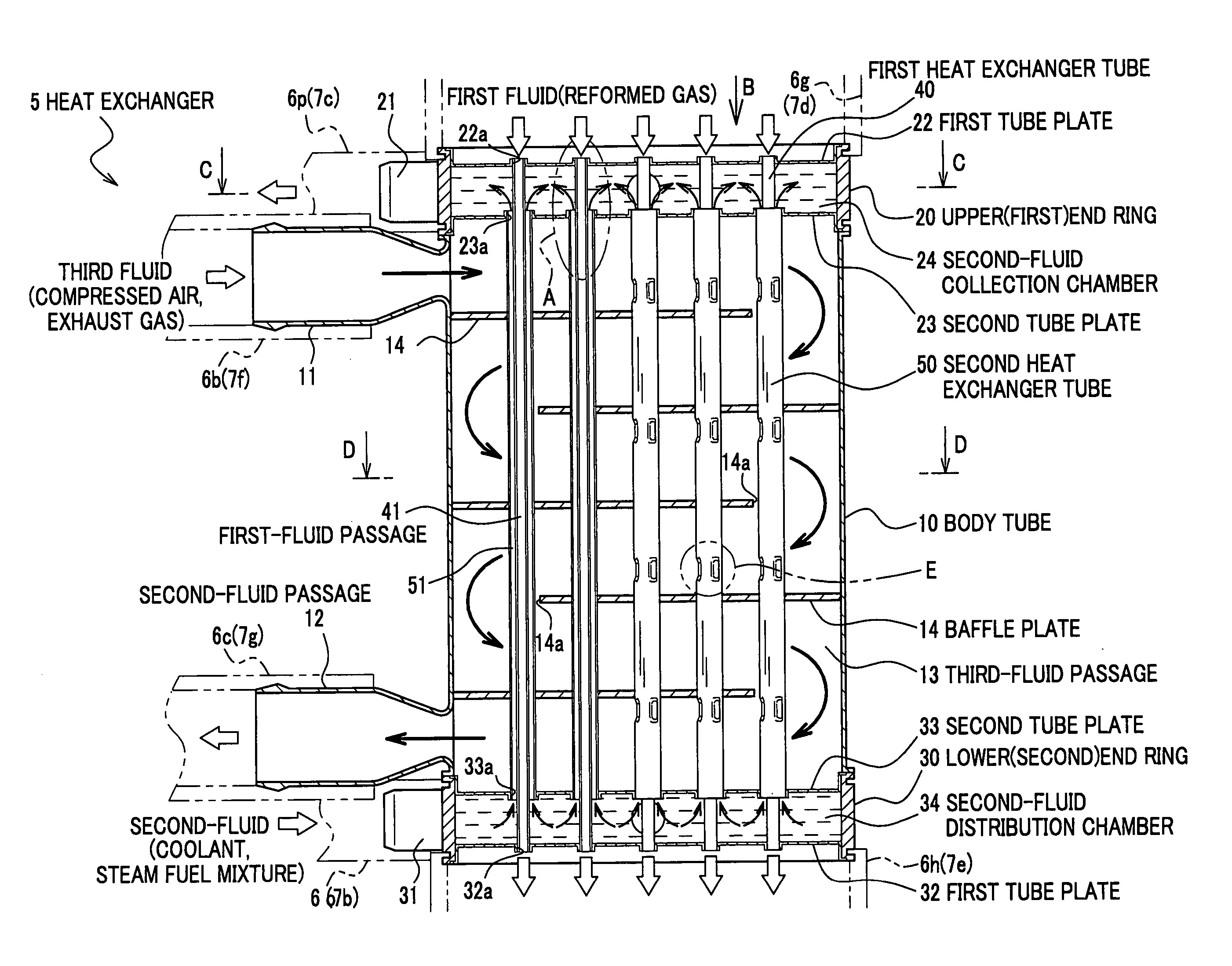

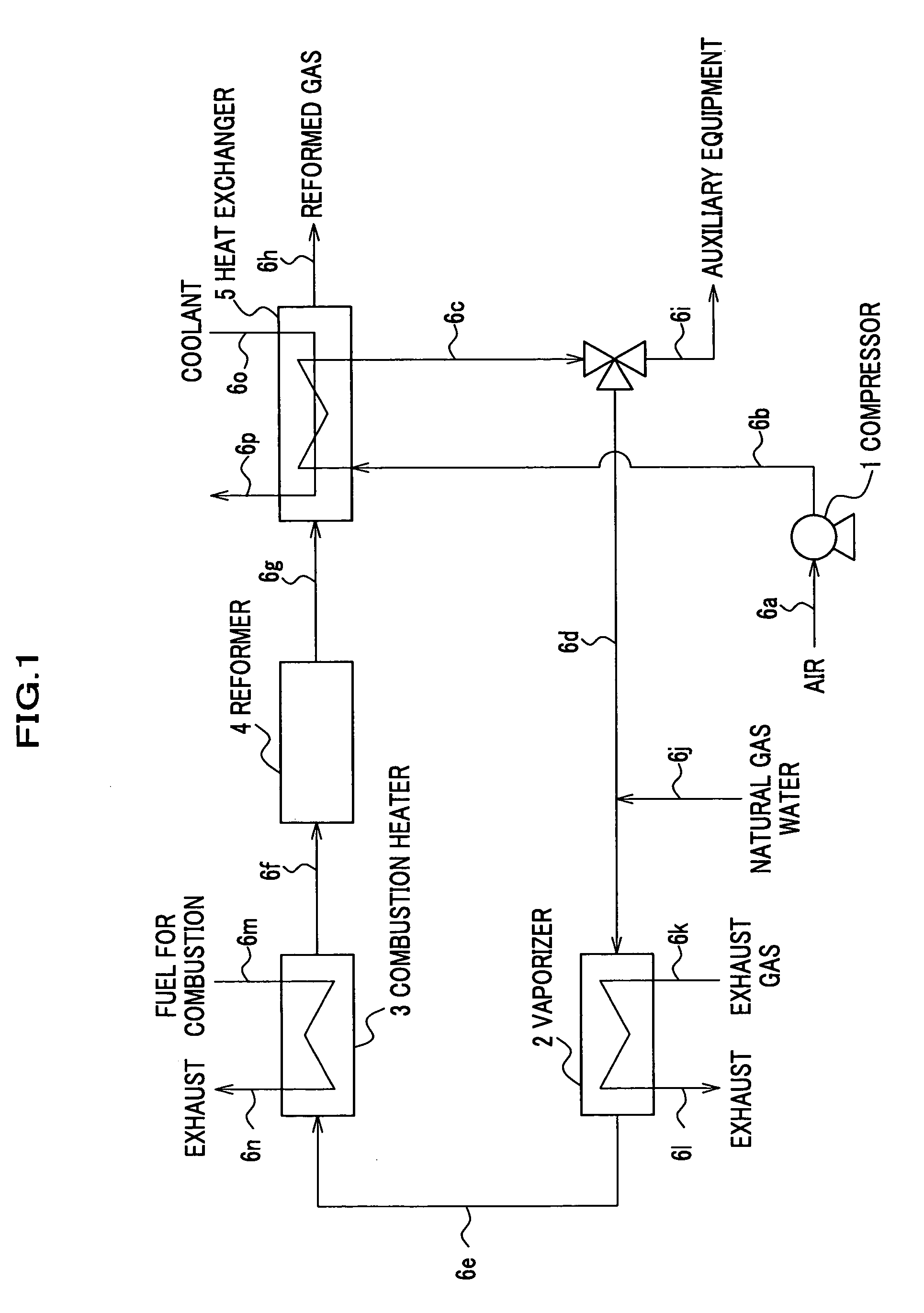

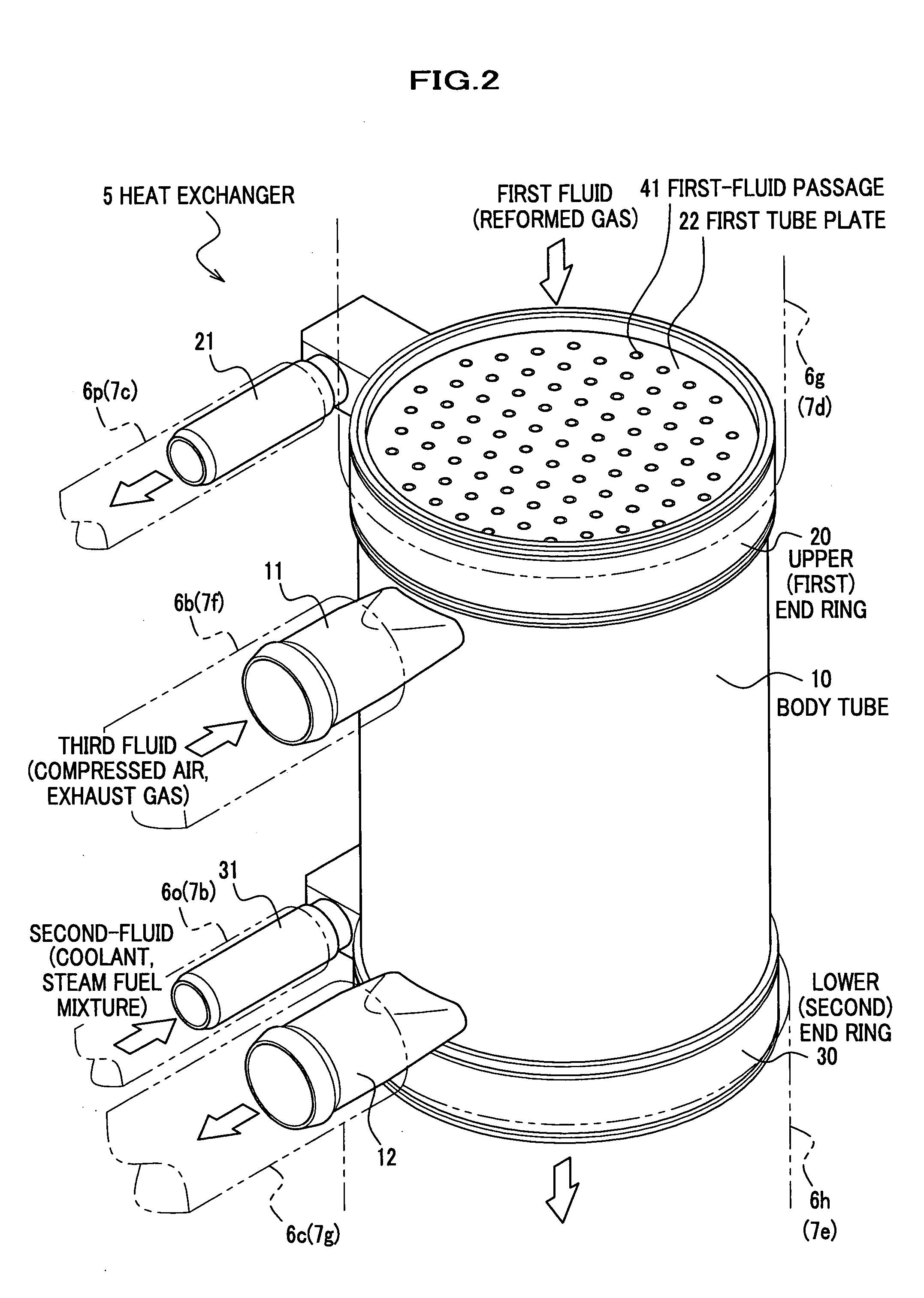

Heat exchanger

InactiveUS20050236145A1Improve heat exchange efficiencyLarge heat capacitySpacing meansHydrogenEngineeringHeat exchanger

End rings are coupled with upper and lower ends of a cylindrical body tube. A plurality of first heat exchanger tubes are fitted and held in holes provided in a pair of first tube plates. A plurality of second heat exchanger tubes are fitted and held in holes provided in a pair of second tube plates. The inside of each first heat exchanger tubes forms a first-fluid passage for carrying a reformed gas. The space defined between an outer wall of each first heat exchanger tube and an inner wall of the corresponding second heat exchanger tube forms a second-fluid passage for carrying a coolant. The space defined among an inner wall of the body tube and outer walls of the second heat exchanger tubes form a third-fluid passage for carrying compressed air.

Owner:HONDA MOTOR CO LTD

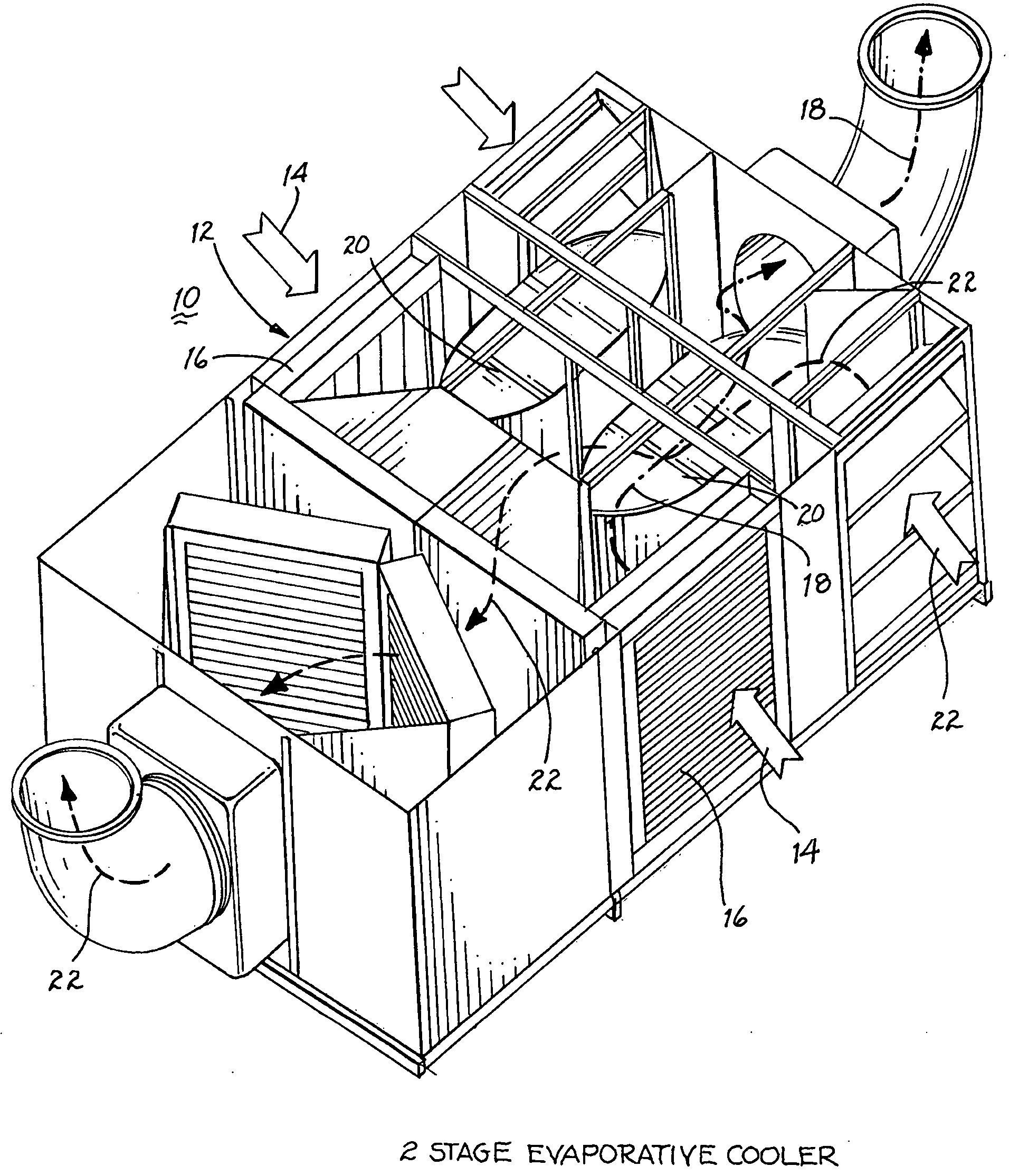

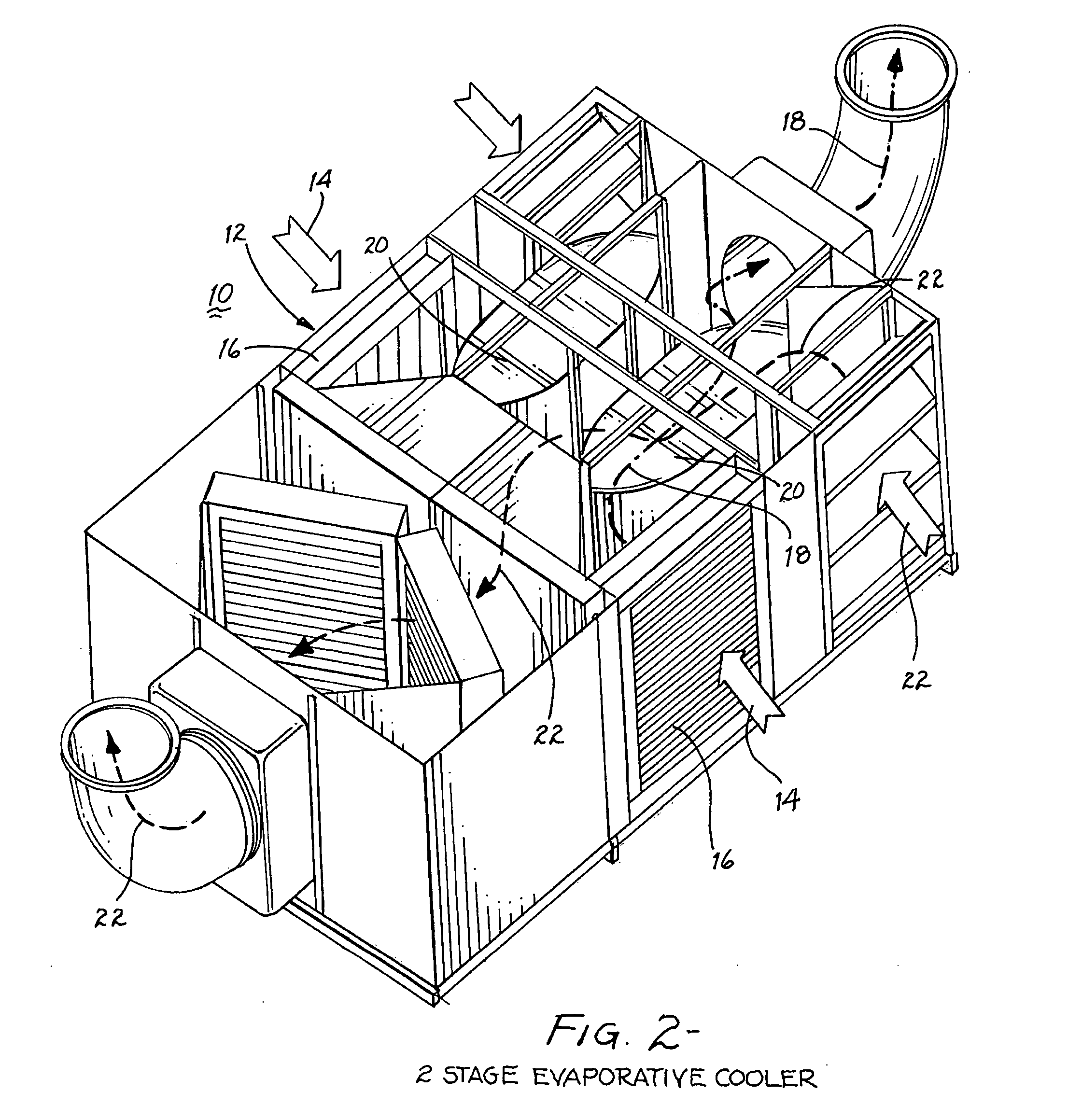

Air conditioning system

InactiveUS6848265B2Less complicated to fabricateLow costSpacing meansFree-cooling systemsContinuous flowEngineering

An air conditioner comprises a plurality of plates arranged in a successively stacked configuration with portions thereof having a spaced apart arrangement, and defining between successive adjacent pairs of plates at the spaced apart portions a first and second series of discrete alternating passages wherein a first air stream is passed through the first series of passages and a second air stream is passed through the second series of passages; and said stacked configuration of plates forming integrally therewith a liquid delivery means for delivering from a source a sufficient quantity of a liquid to the inside surfaces of the first series of fluid passages in a manner which provides a continuous flow of the liquid from a first end to a second end of the plurality of plates while in contact with the first air stream.

Owner:AIL RES

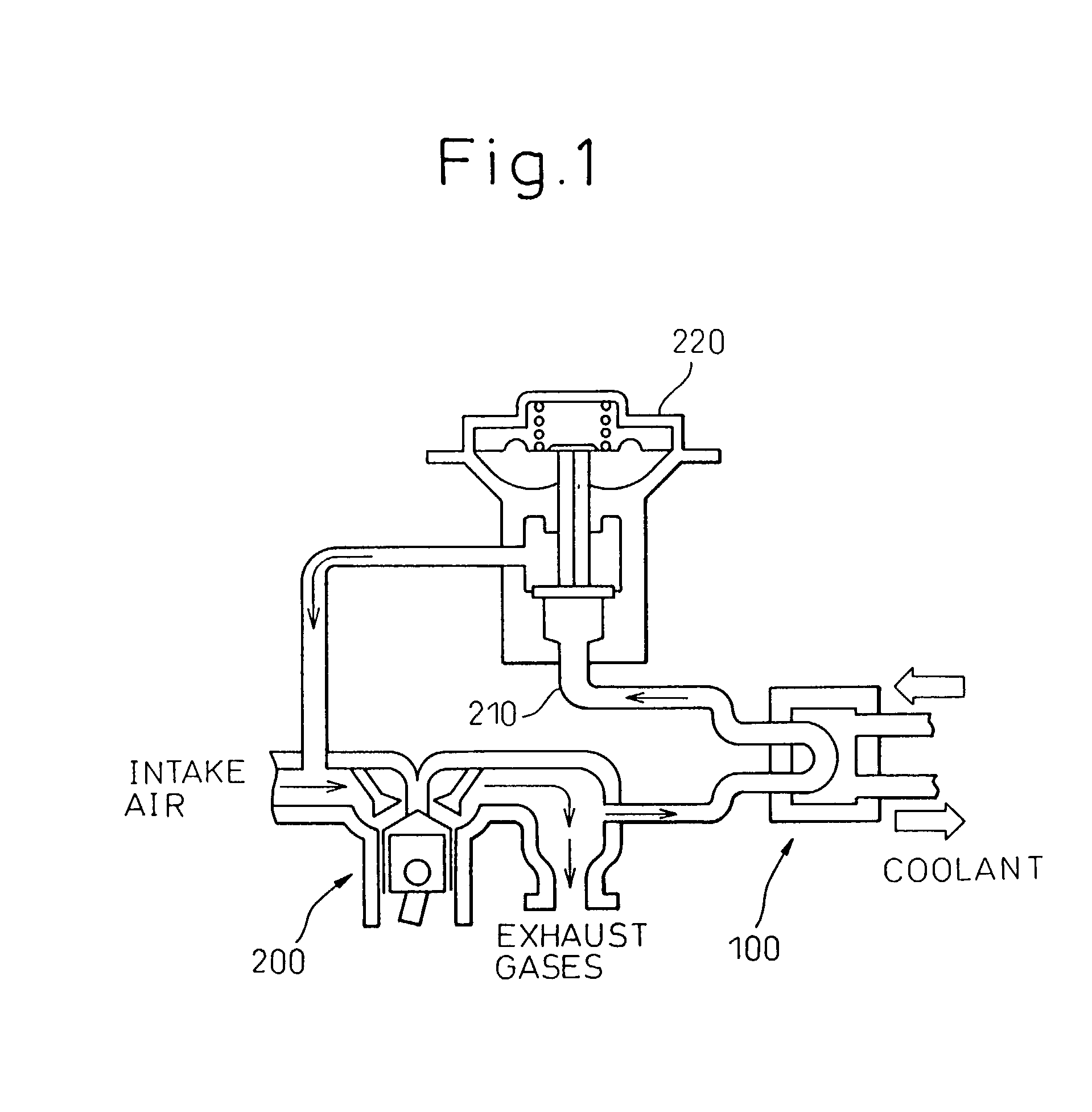

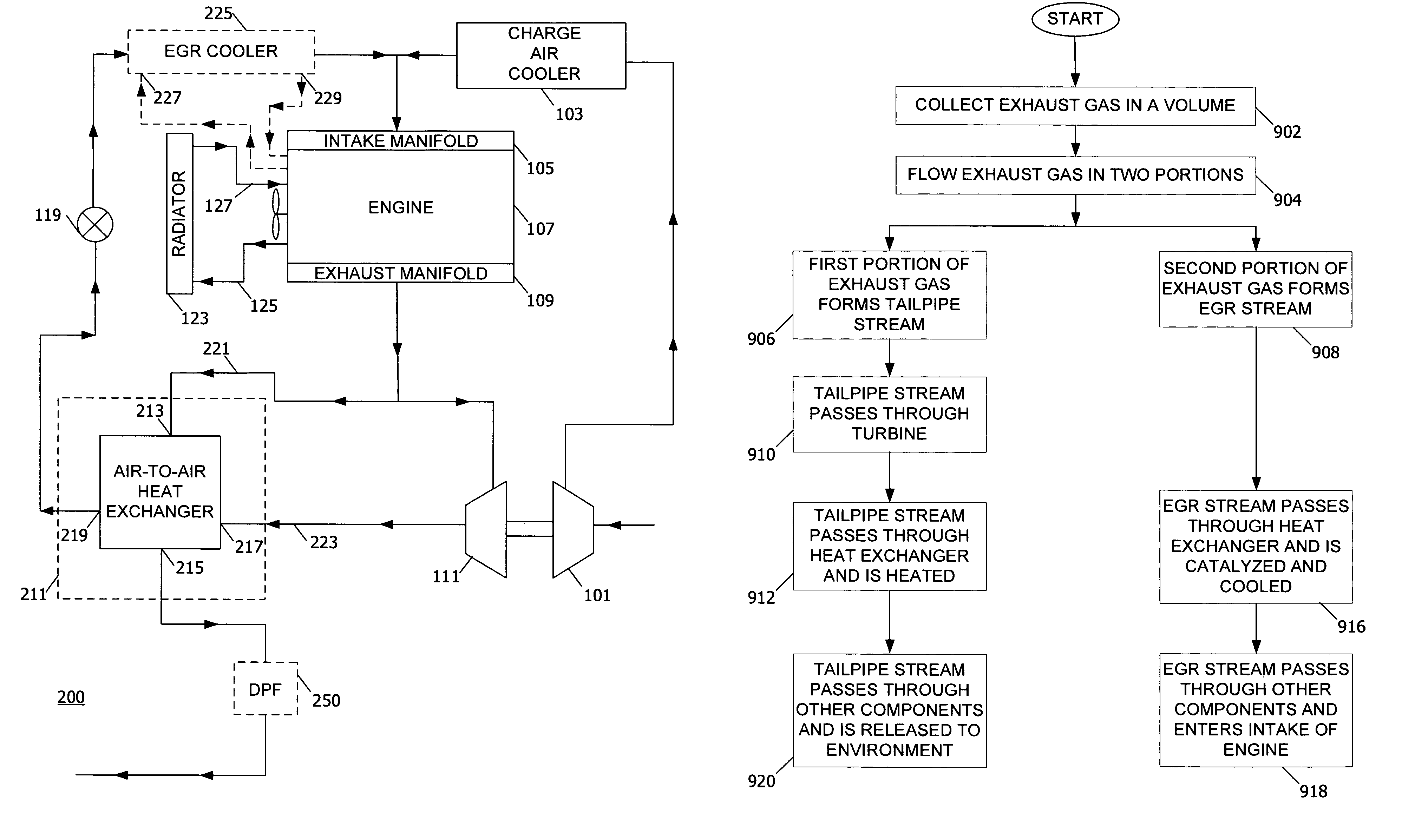

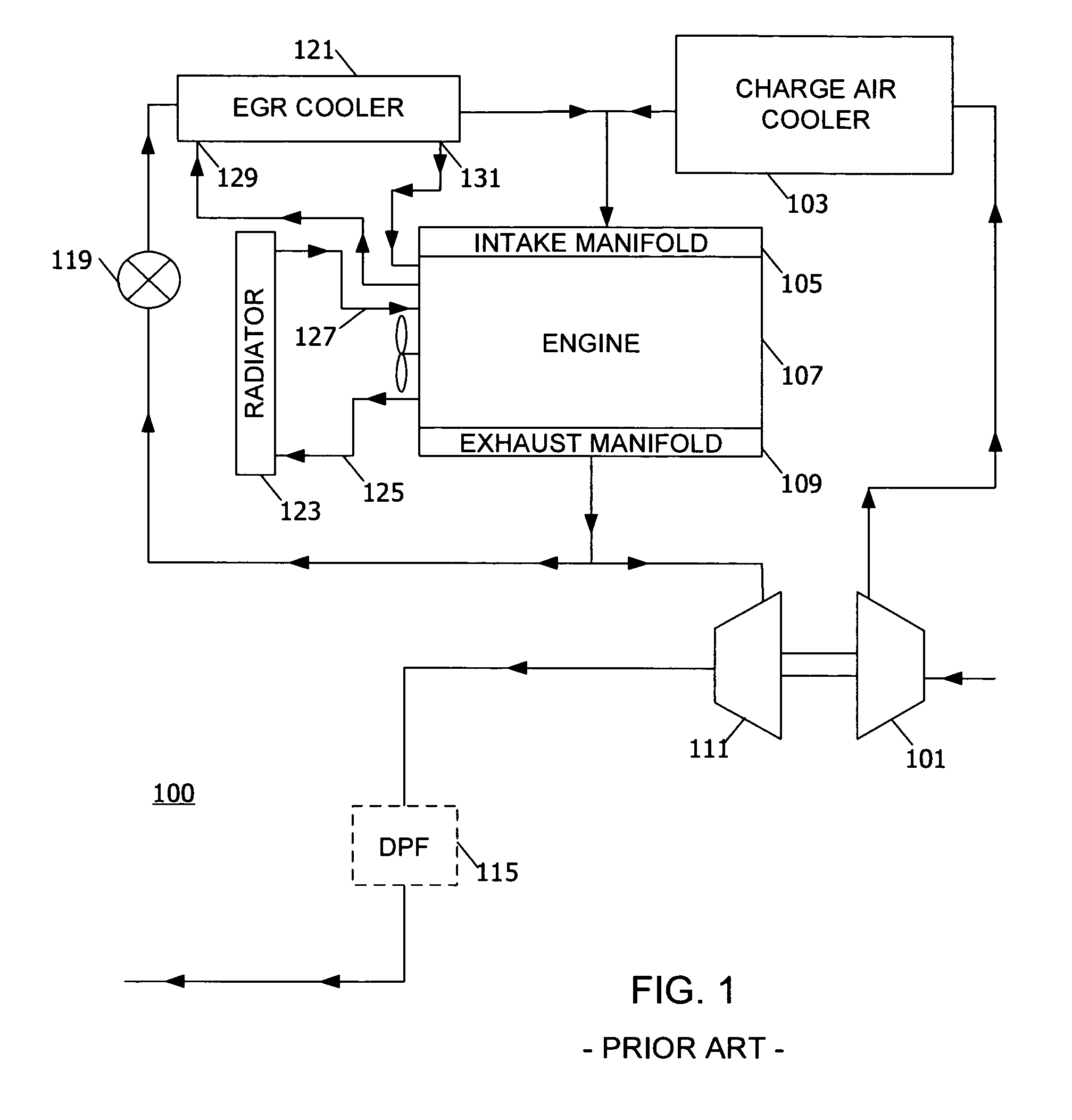

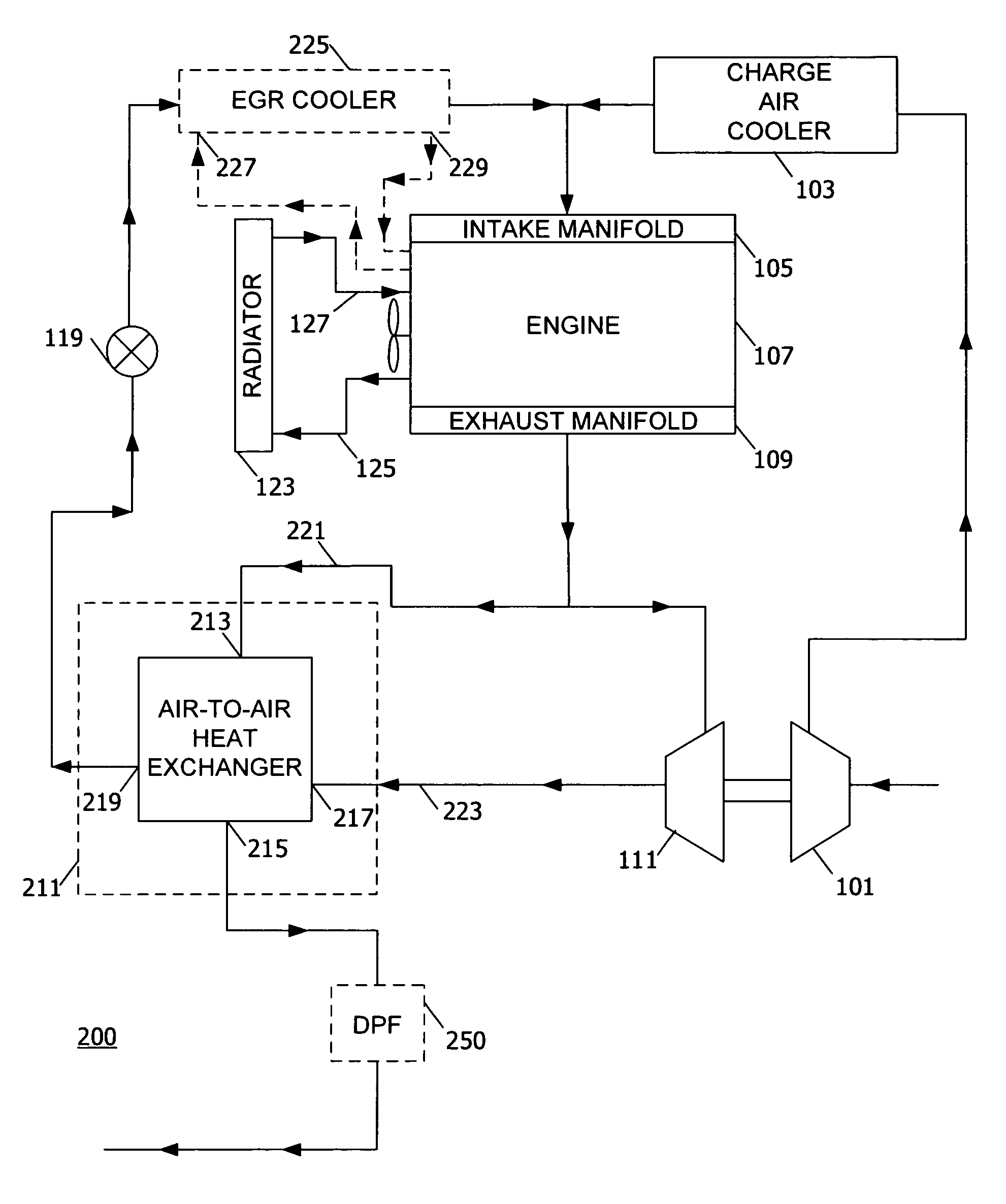

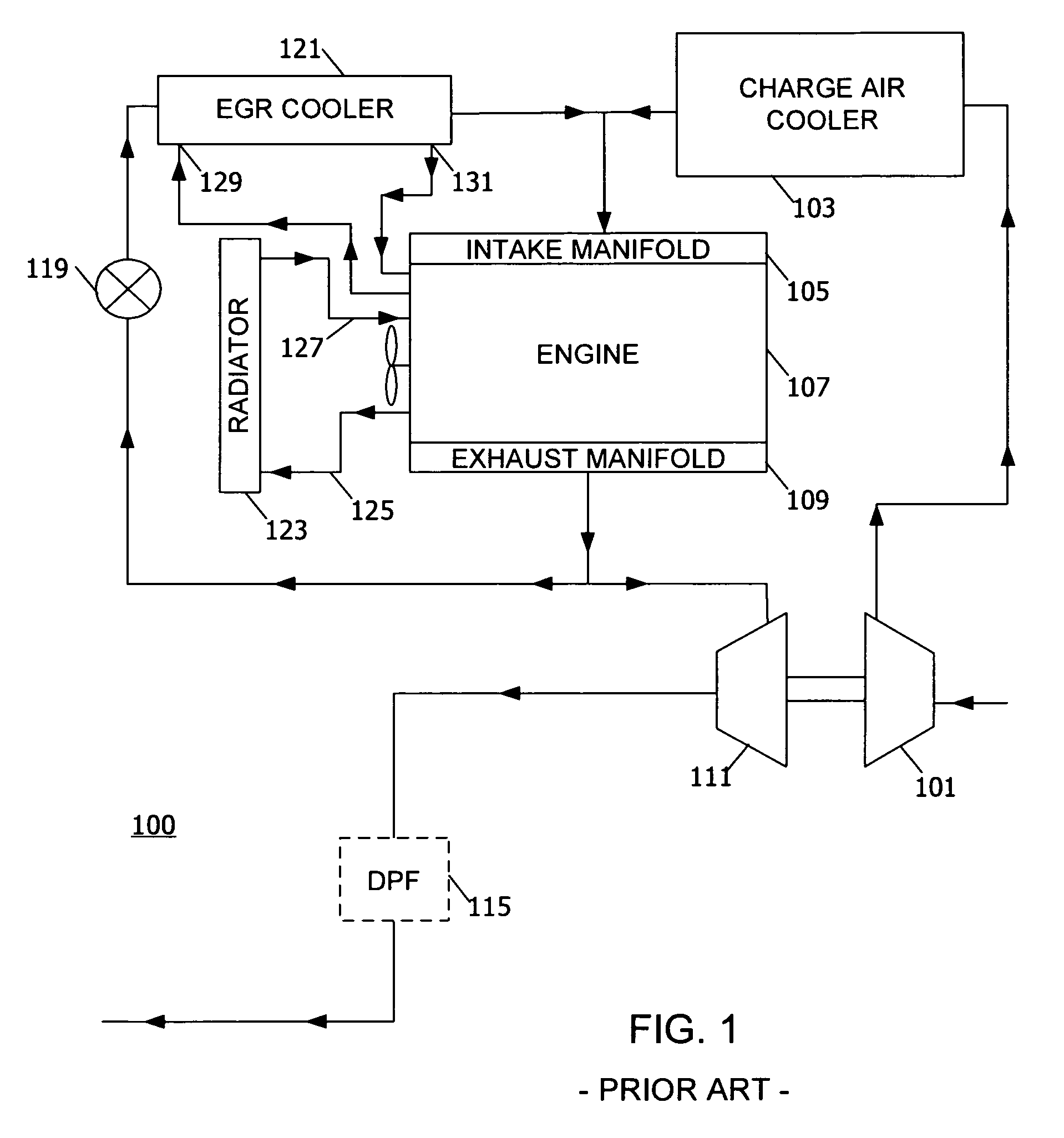

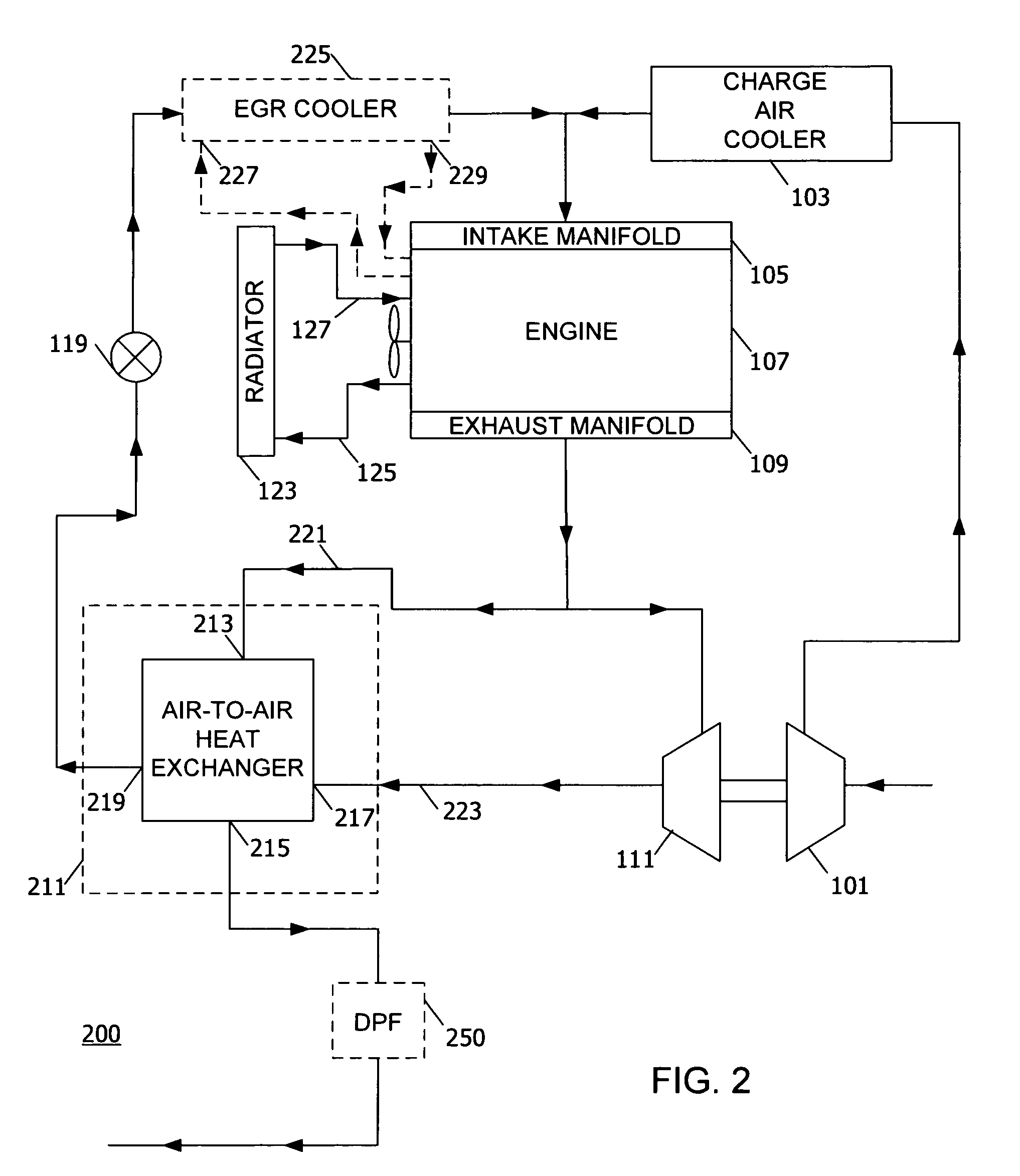

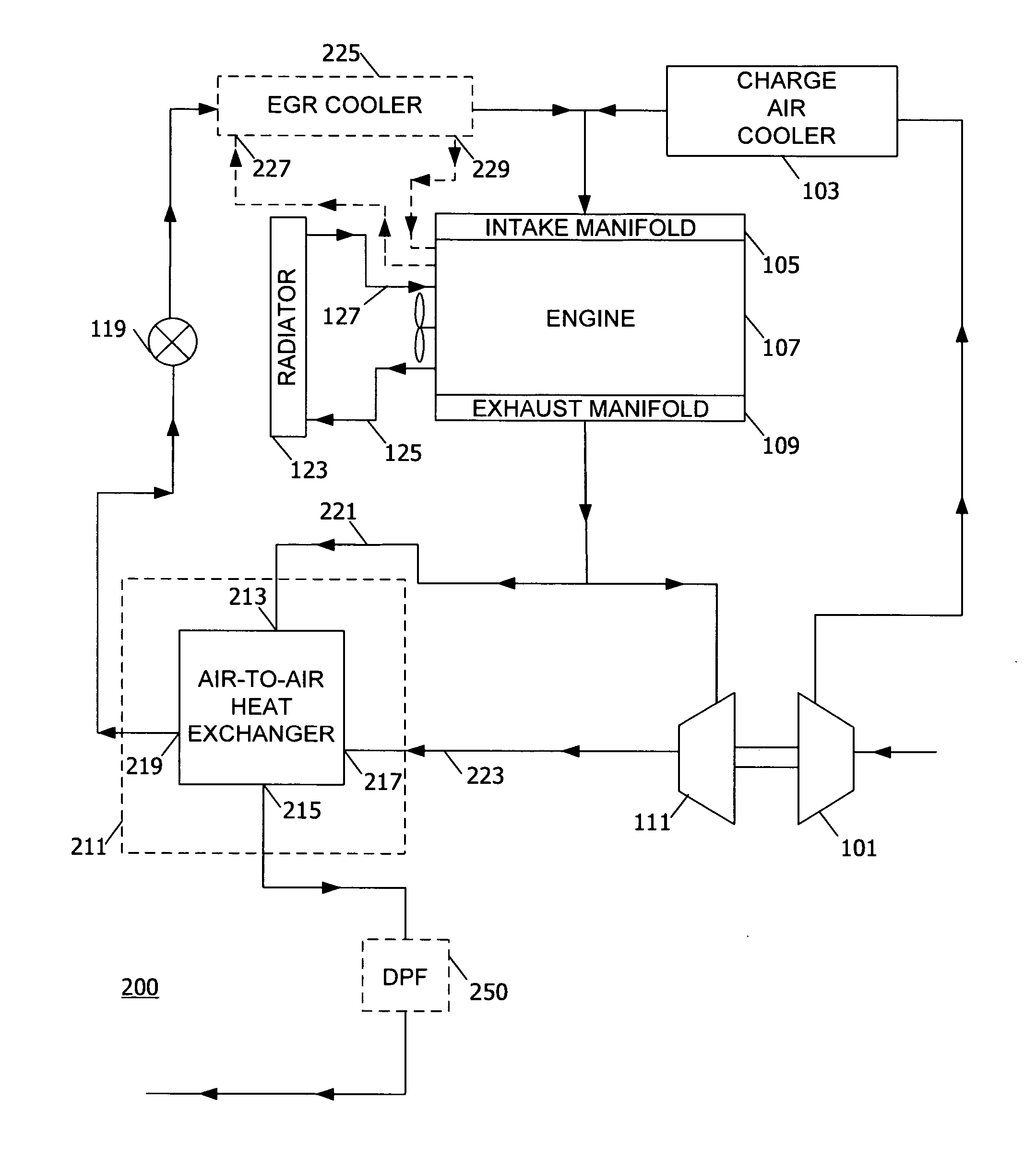

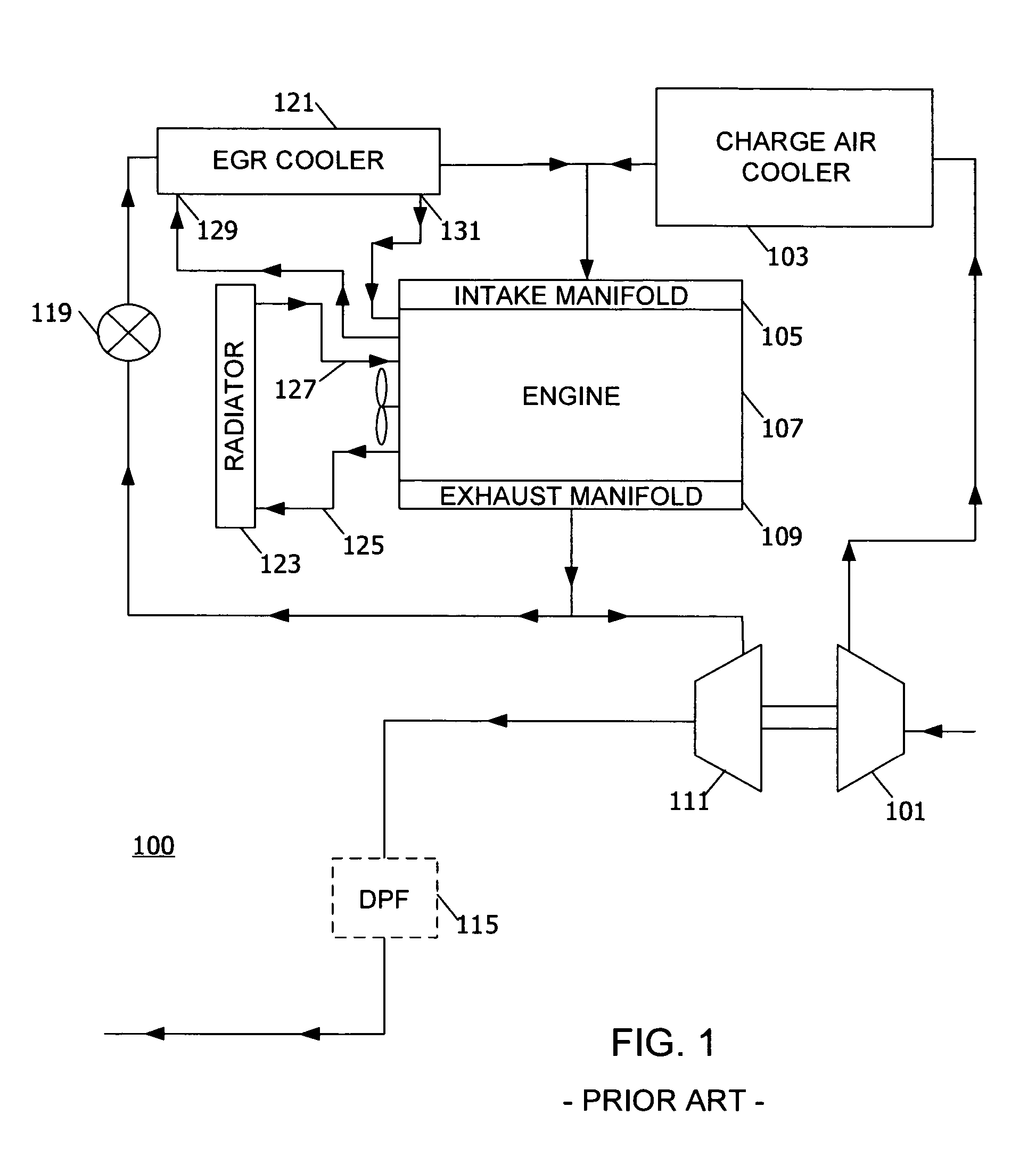

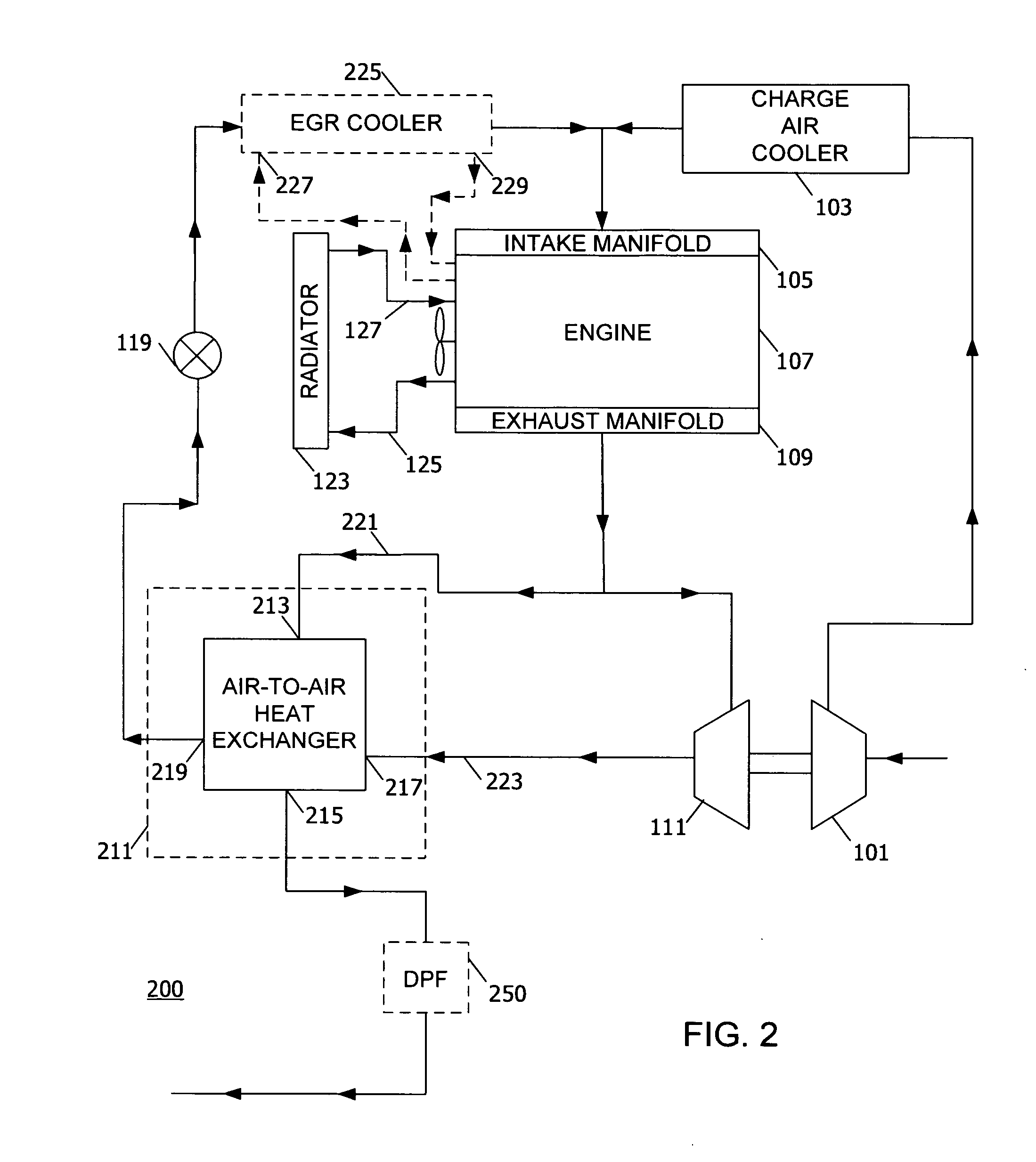

Oxidation catalyst coating in a heat exchanger

A method for an internal combustion engine includes the steps of collecting exhaust gas in a volume (902) and flowing exhaust gas out of the volume in a first and a second portions (904). The first portion forms a tailpipe gas stream (906), and the second portion forms an EGR gas stream (908). The tailpipe gas stream goes through a turbine (910). The EGR gas stream is catalyzed by an oxidizer coating in a heat exchanger, and thermal energy is transferred from the EGR gas stream to the tailpipe stream in the heat exchanger (916).

Owner:INT ENGINE INTPROP CO LLC

Uniform-temperature panel and manufacturing method thereof

InactiveCN101927426AHigh structural support strengthAct as a dense supportSpacing meansDigital data processing detailsUltimate tensile strengthMechanical engineering

A manufacturing method of a uniform-temperature panel comprises the following steps: providing an elongated hollow extruded section and cutting the section into a plurality of shells with accommodating cavities inside according to the preset dimension; forming capillary structure layers on the inner surfaces of the shells, corresponding to the accommodating cavities; vertically placing a plurality of support elements in the accommodating cavities of the shells, wherein two opposite ends of the support elements are respectively fixedly connected with the shells; sealing the accommodating cavities of the shells; and injecting liquid working media into the accommodating cavities from reserved liquid injection holes, vacuumizing and sealing the accommodating cavities. Compared with the prior art, the manufacturing method of the invention saves the production cost and is suitable for scale production and manufacturing because of adopting the elongated hollow extruded section and cutting the section into a plurality of shells according to the preset dimension. Meanwhile, the accommodating cavities of the uniform-temperature panel manufactured by the method accommodate a plurality of support elements and the support elements play a role of intensive support for the shells, thus improving the structural support intensity of the uniform-temperature panel.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

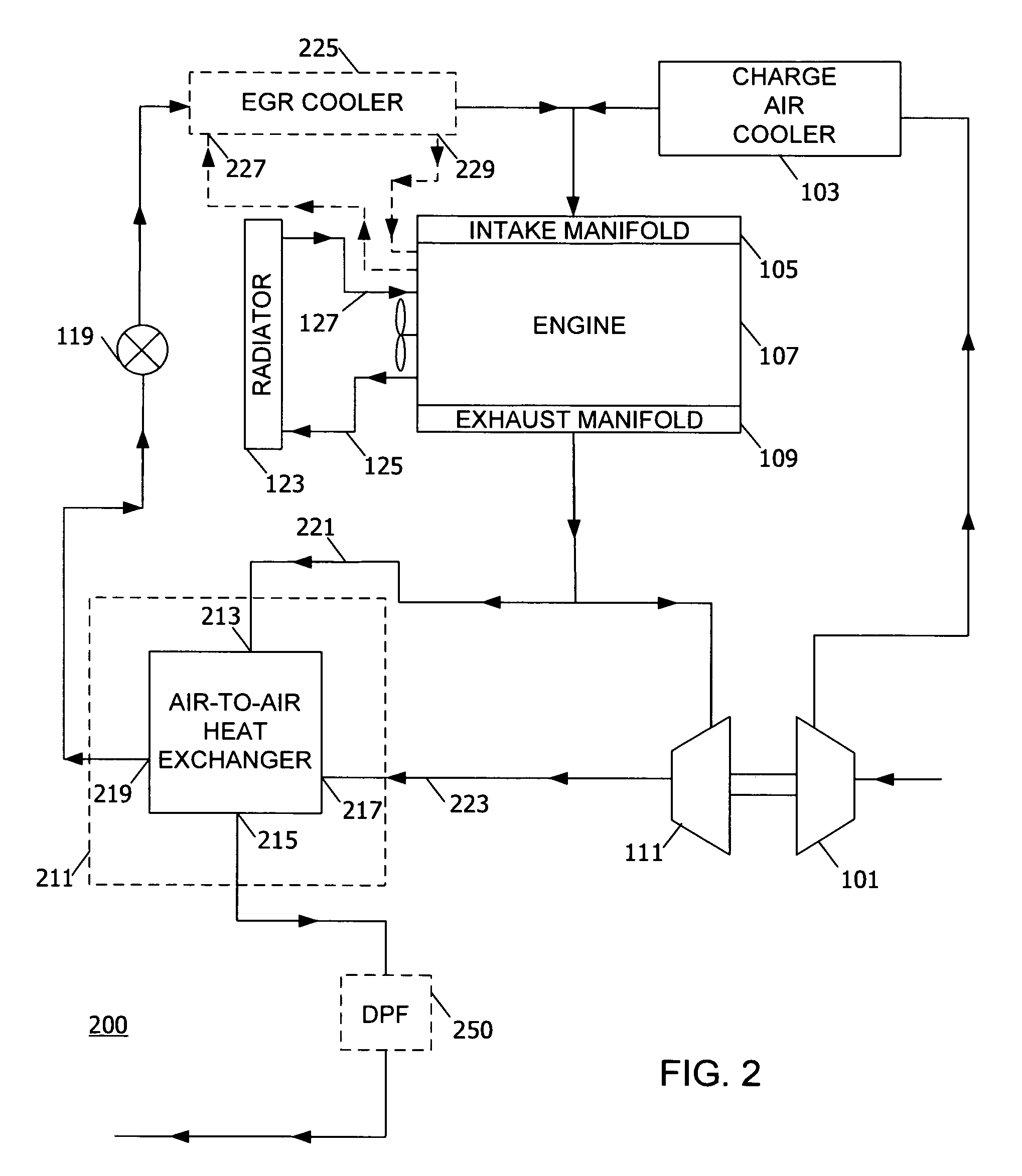

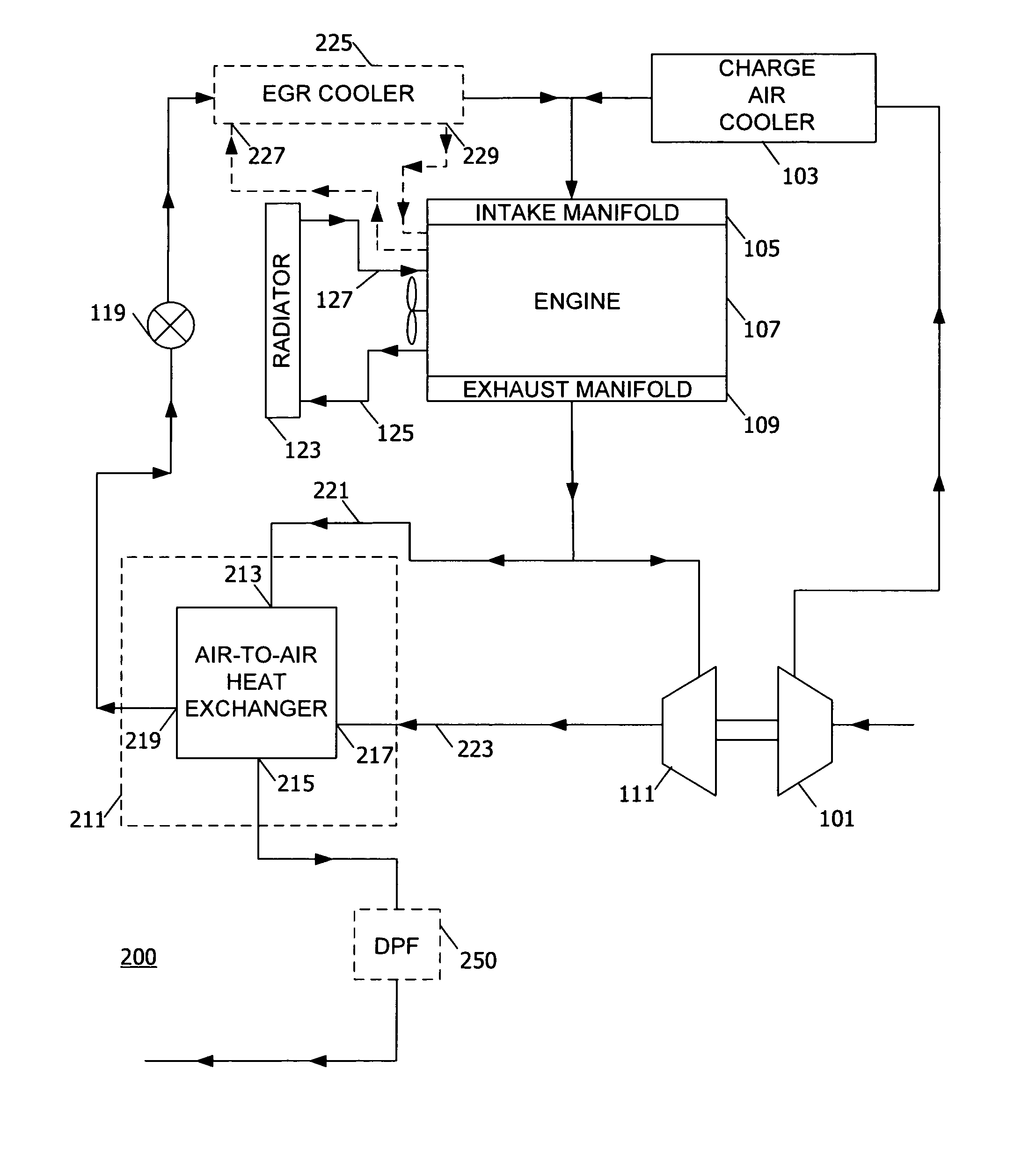

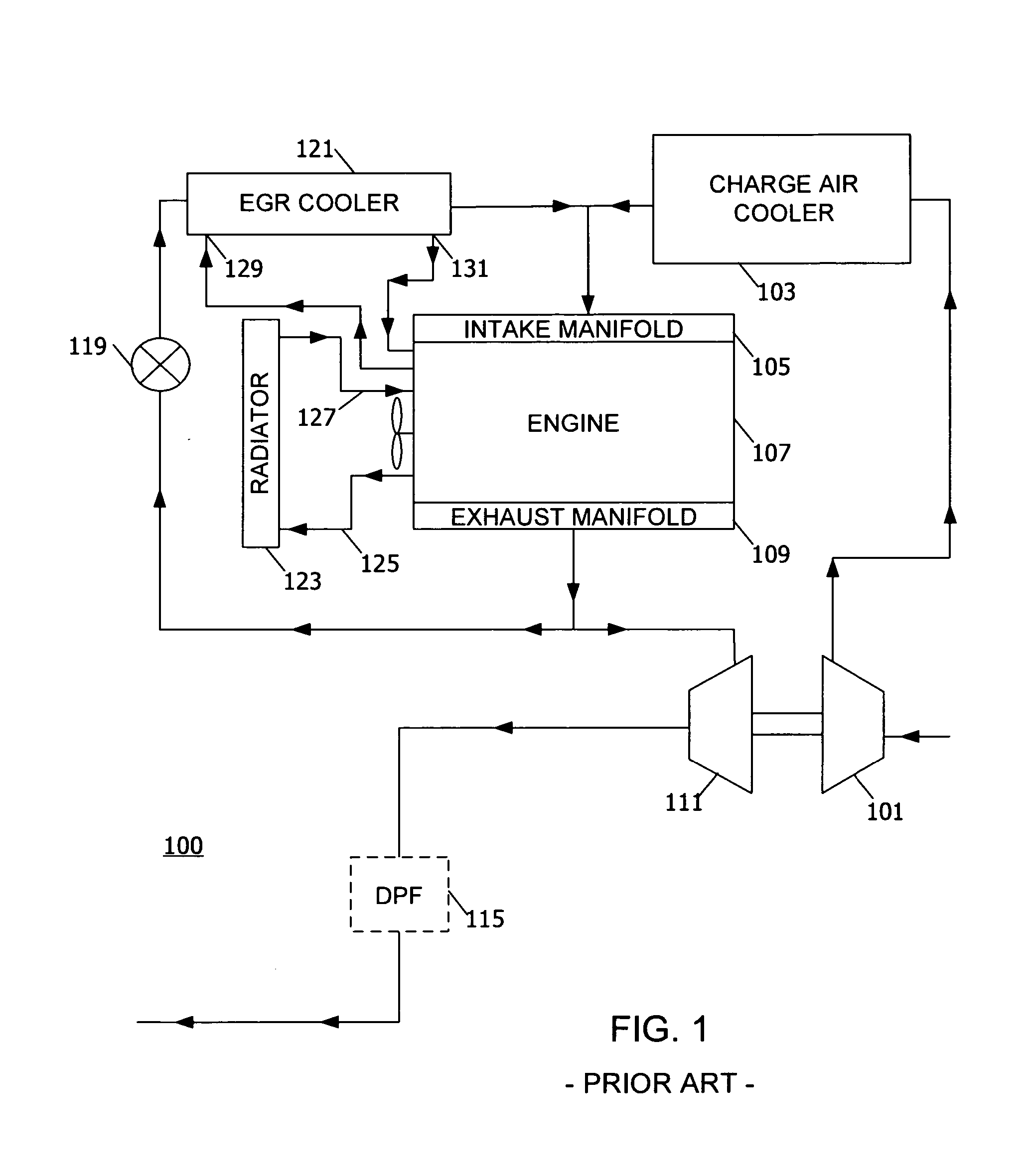

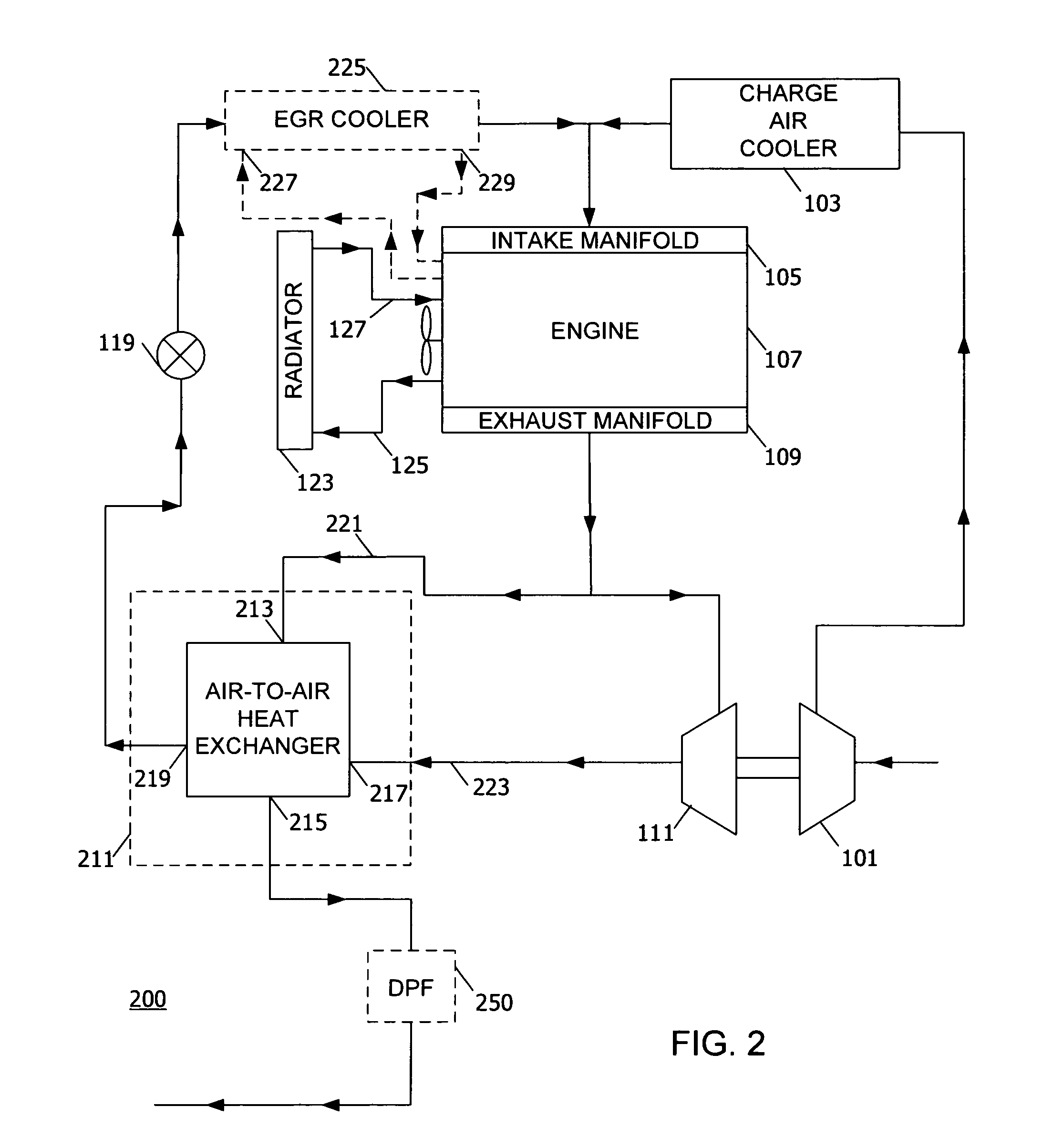

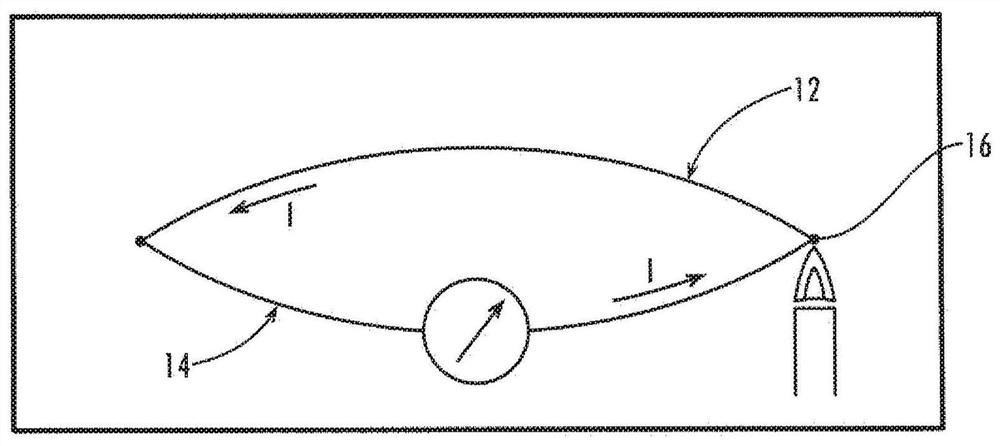

Heat exchanger method and apparatus

ActiveUS20070089716A1Spacing meansInternal combustion piston enginesThermal energyProcess engineering

A method for an internal combustion engine includes the steps of collecting exhaust gas in a volume (502) and flowing exhaust gas out of the volume in a first and a second portions (504). The first portion forms a tailpipe gas stream (506), and the second portion forms an EGR gas stream (508). The tailpipe gas stream goes through a turbine (510), and is heated in a heat exchanger (512). The heat exchanger transfers thermal energy out of the EGR gas stream (516) to heat the tailpipe gas stream. The EGR gas stream is recirculated into an intake of the internal combustion engine (518).

Owner:INT ENGINE INTPROP CO LLC

Heat exchanger for a motor vehicle air conditioning system

In an air / refrigerant heat exchanger, particularly for a motor vehicle air conditioning system, including a plurality of flat tubes arranged in closely spaced relationship so that a narrow flow passage for air is formed therebetween, the flat tubes include passages through which refrigerant is conducted in the longitudinal direction of the flat tubes and are provided on their outer surfaces with longitudinal parallel recesses and projections such that the flat tubes are wave-shaped the recesses and projections flattening out toward the narrow ends of the flat tubes and provide for narrow flat rectangular end sections.

Owner:OBRIST ENG

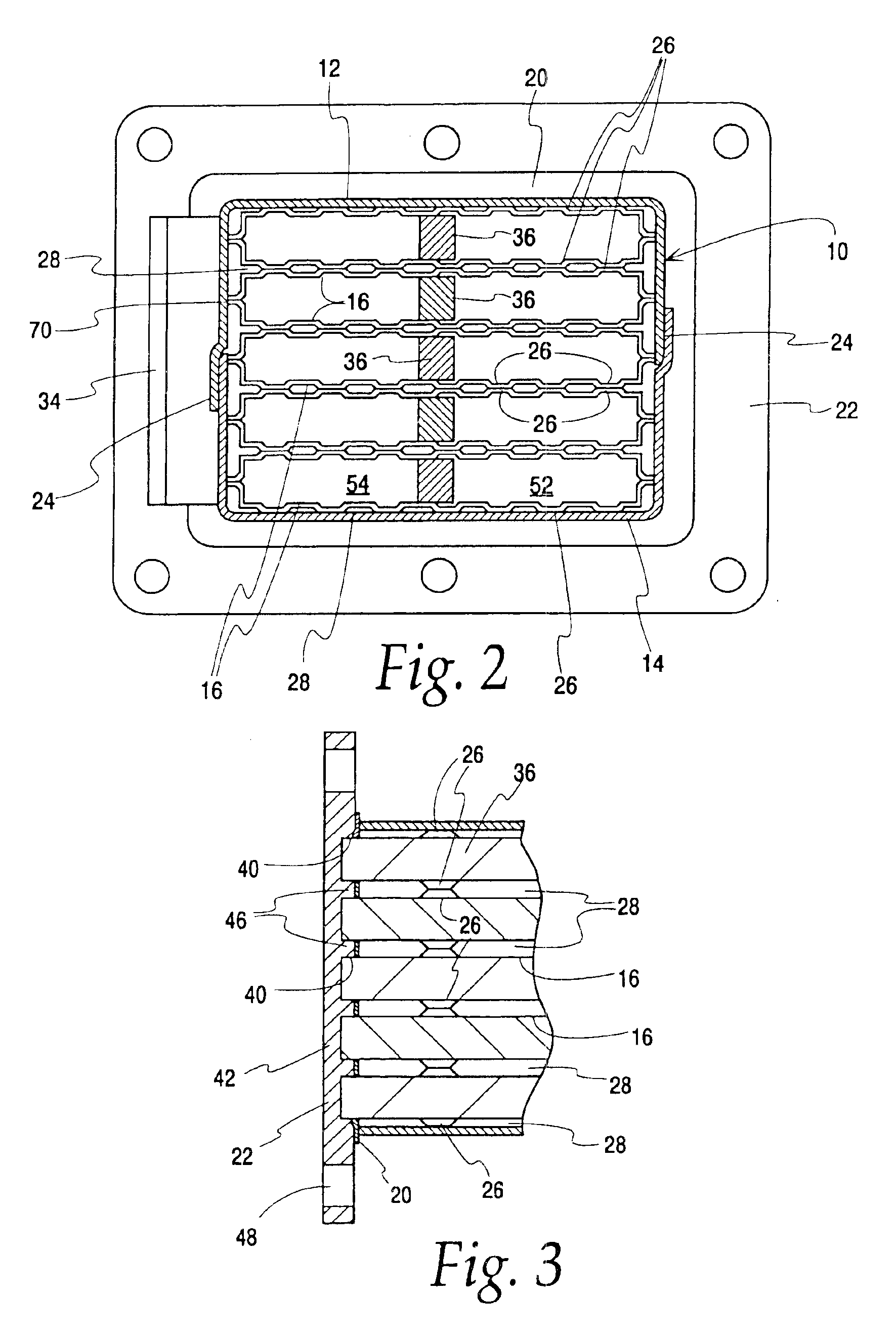

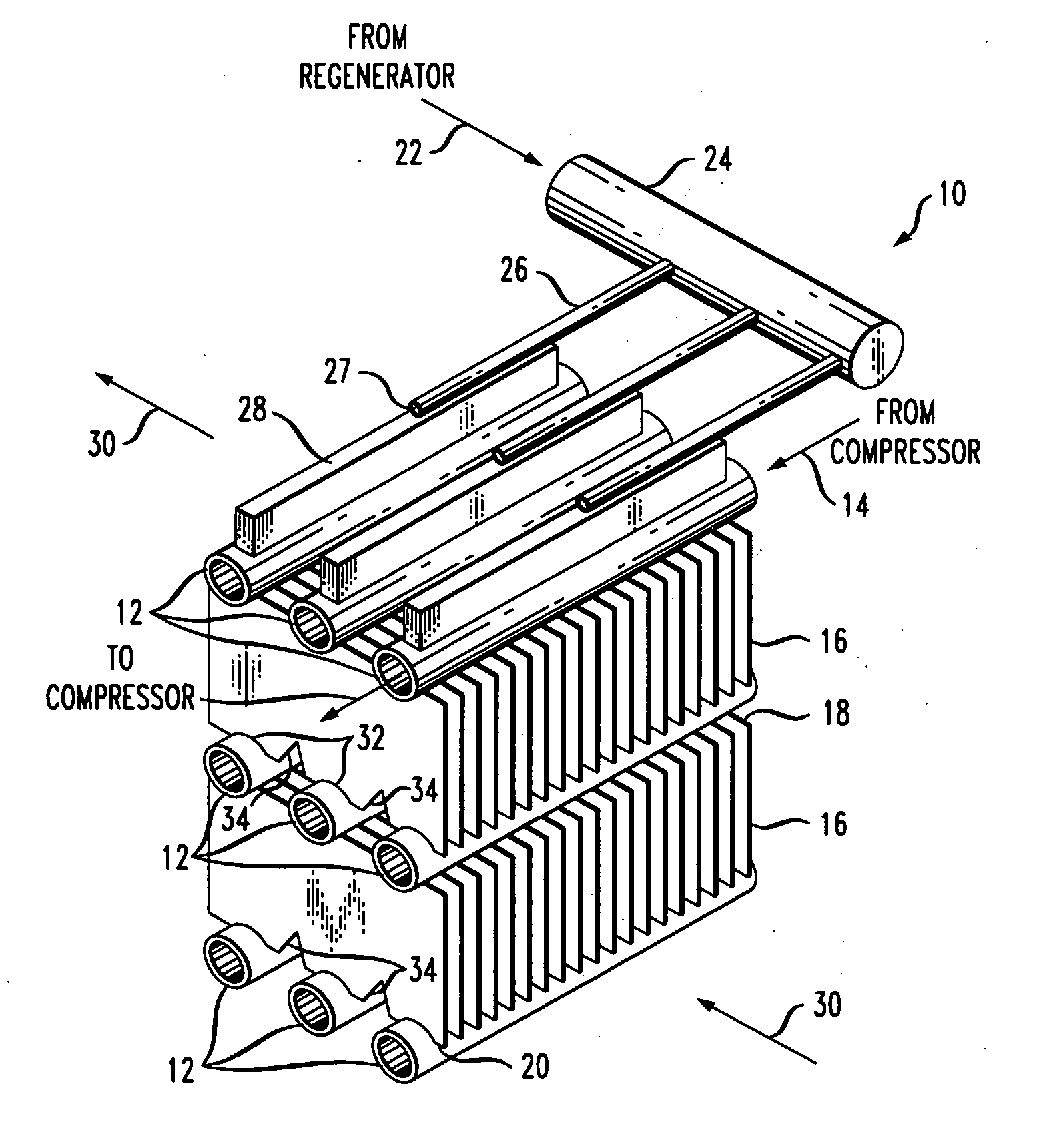

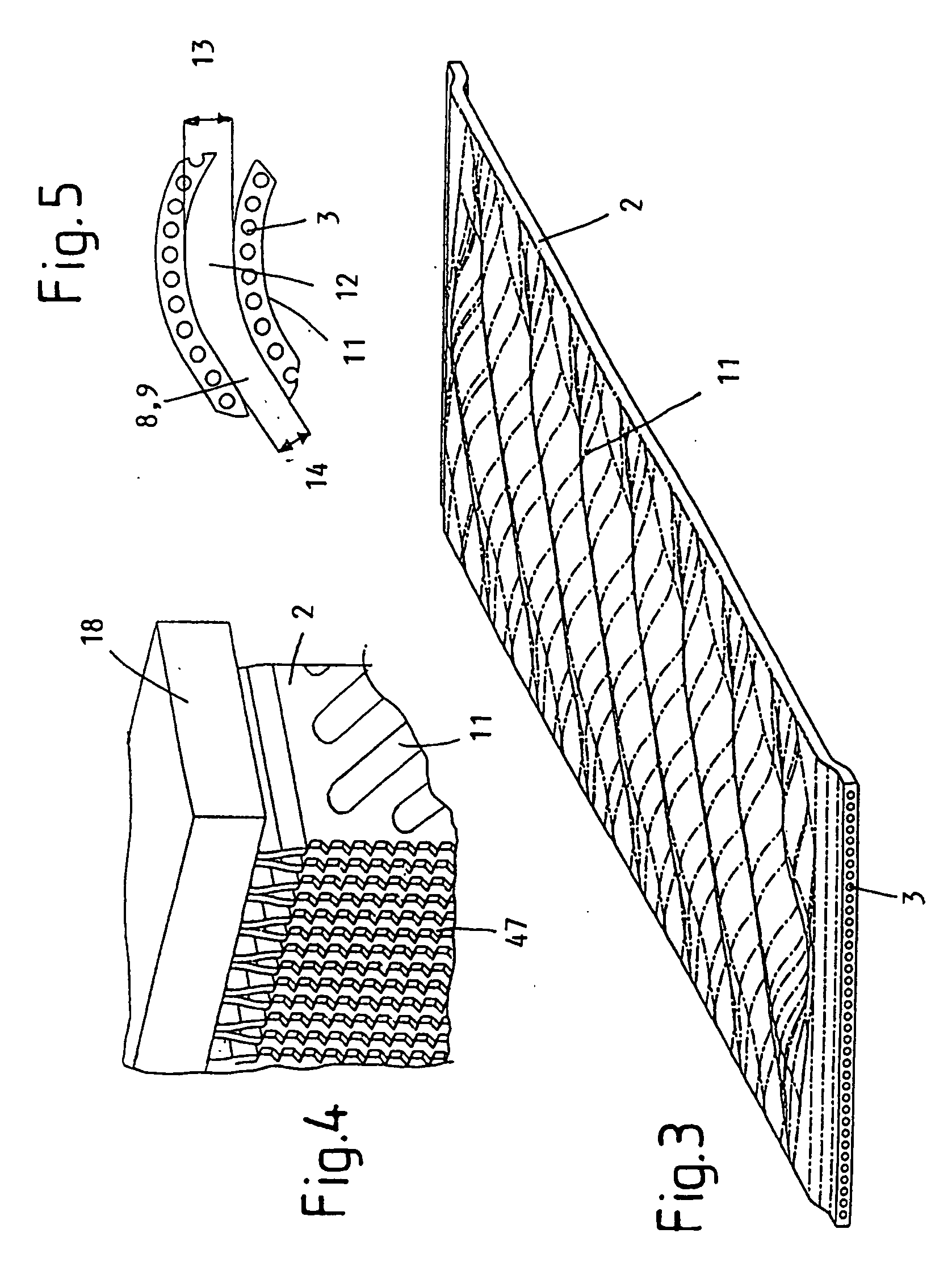

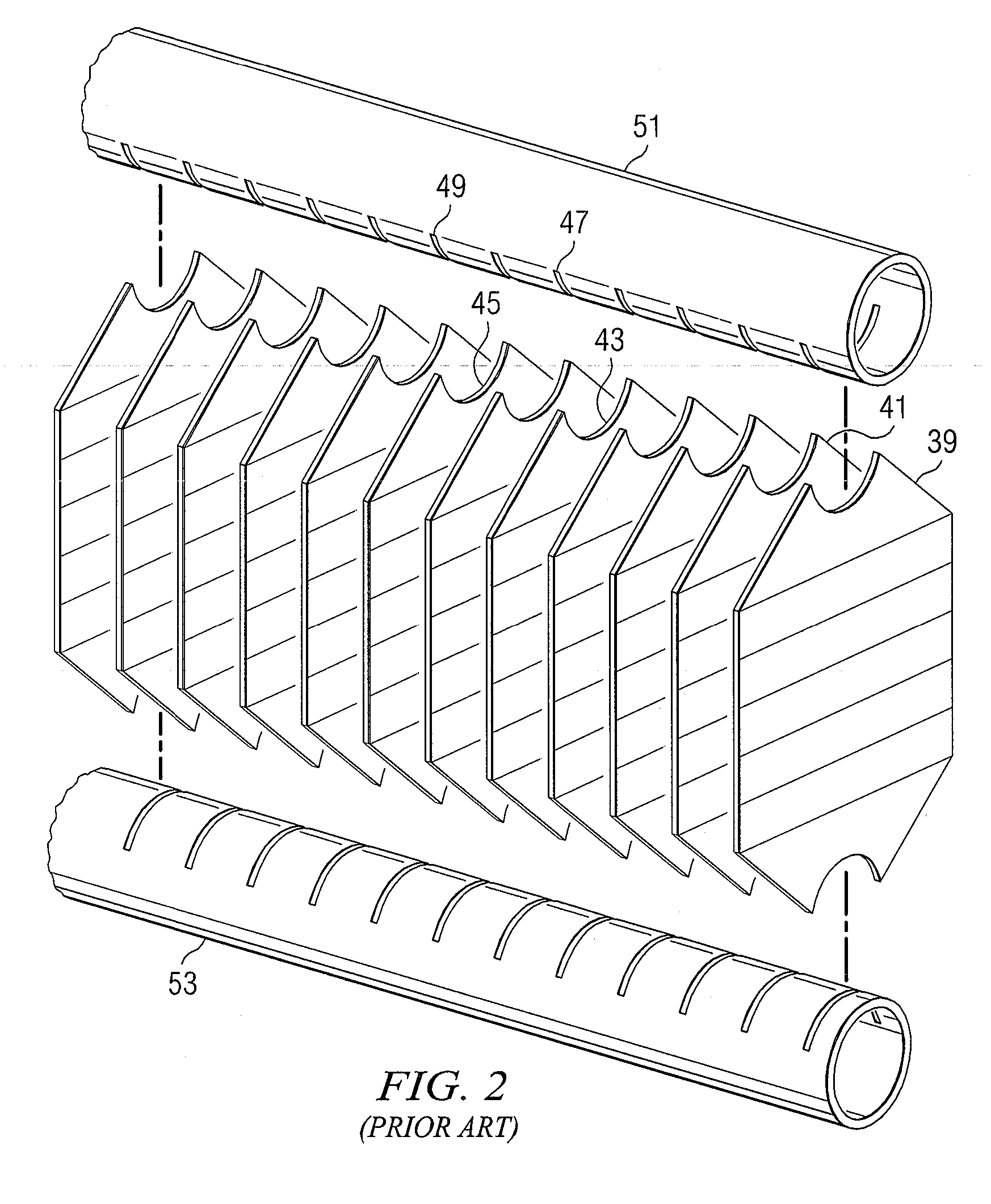

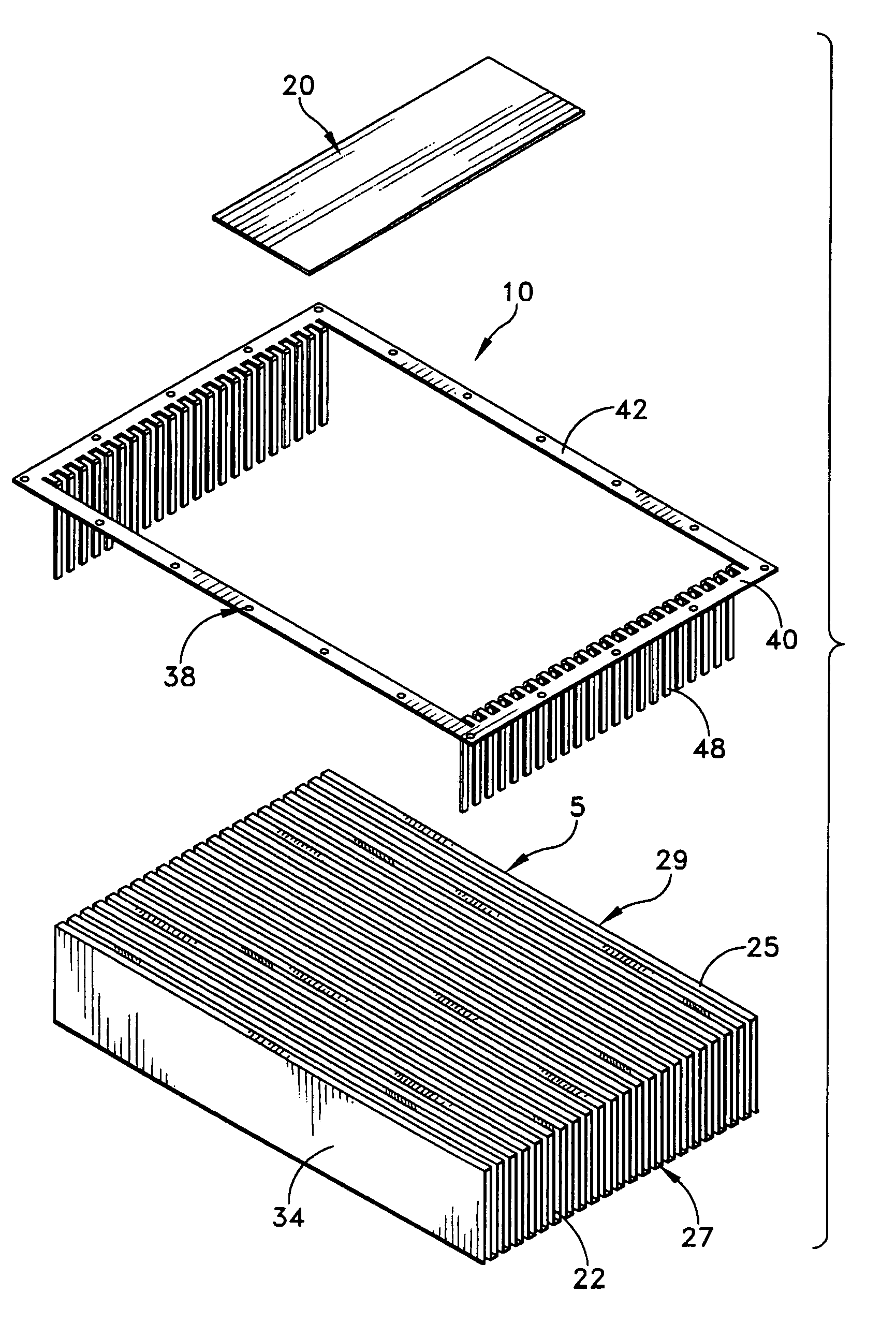

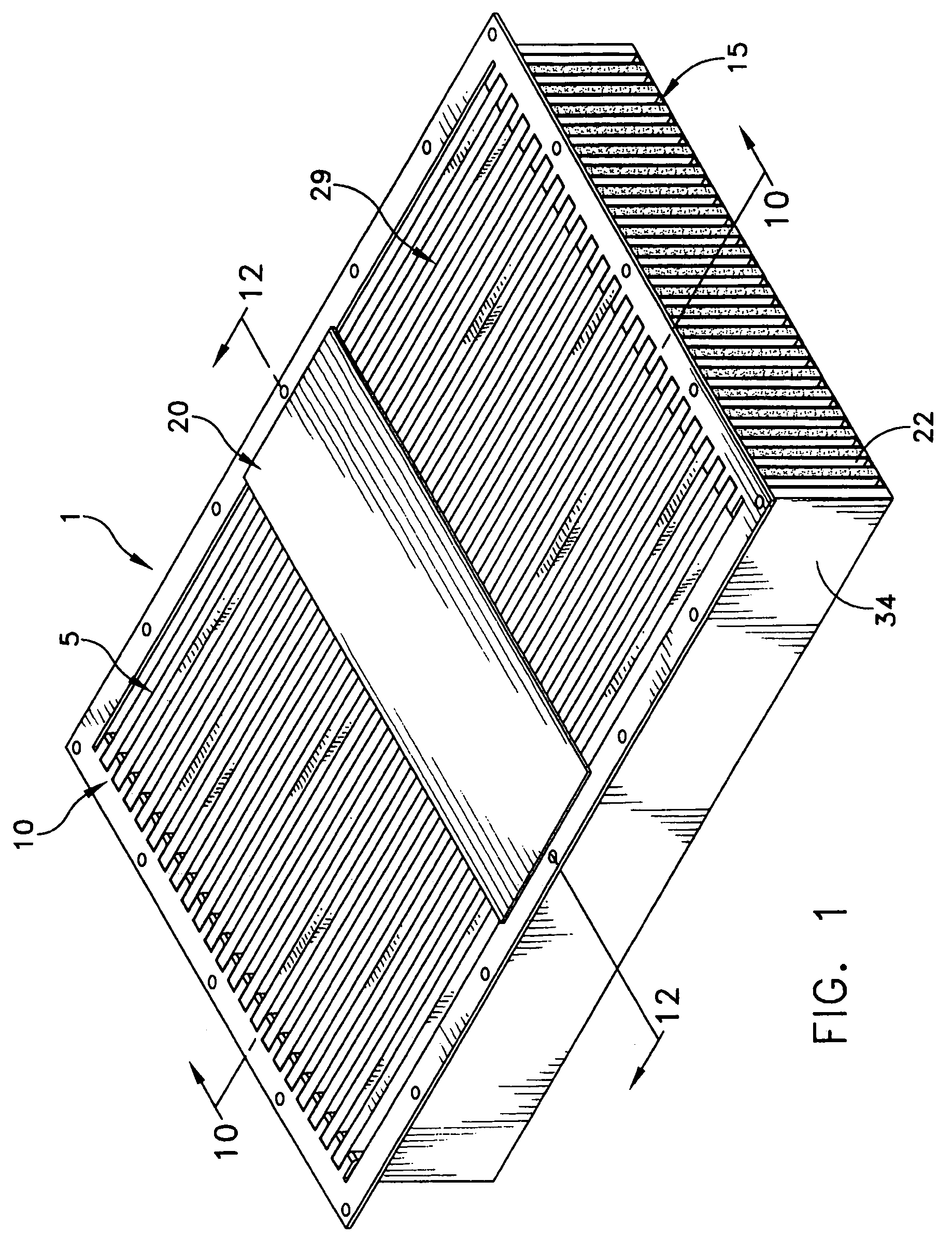

Gas Turbine Regenerator Apparatus and Method of Manufacture

A regenerator core for use in a gas turbine regenerator has integral manifold openings formed in the tube plates used to make up the core and has special reinforcing elements which provide high pressure containment in critical portions of the plate-and-fin heat exchanger construction. The reinforcing elements include a series of hoops of U-shaped cross section which are used to bridge the juncture lines of the heat exchanger manifolds. An outer channel region of the hoops is provided with a reinforcing strip of gusset material. The hoops with their reinforcing strips provide structural reinforcement in the region between the manifolds and the conventional side bar reinforcing members in the central core section.

Owner:MUND 2013 FAMILY TRUST +2

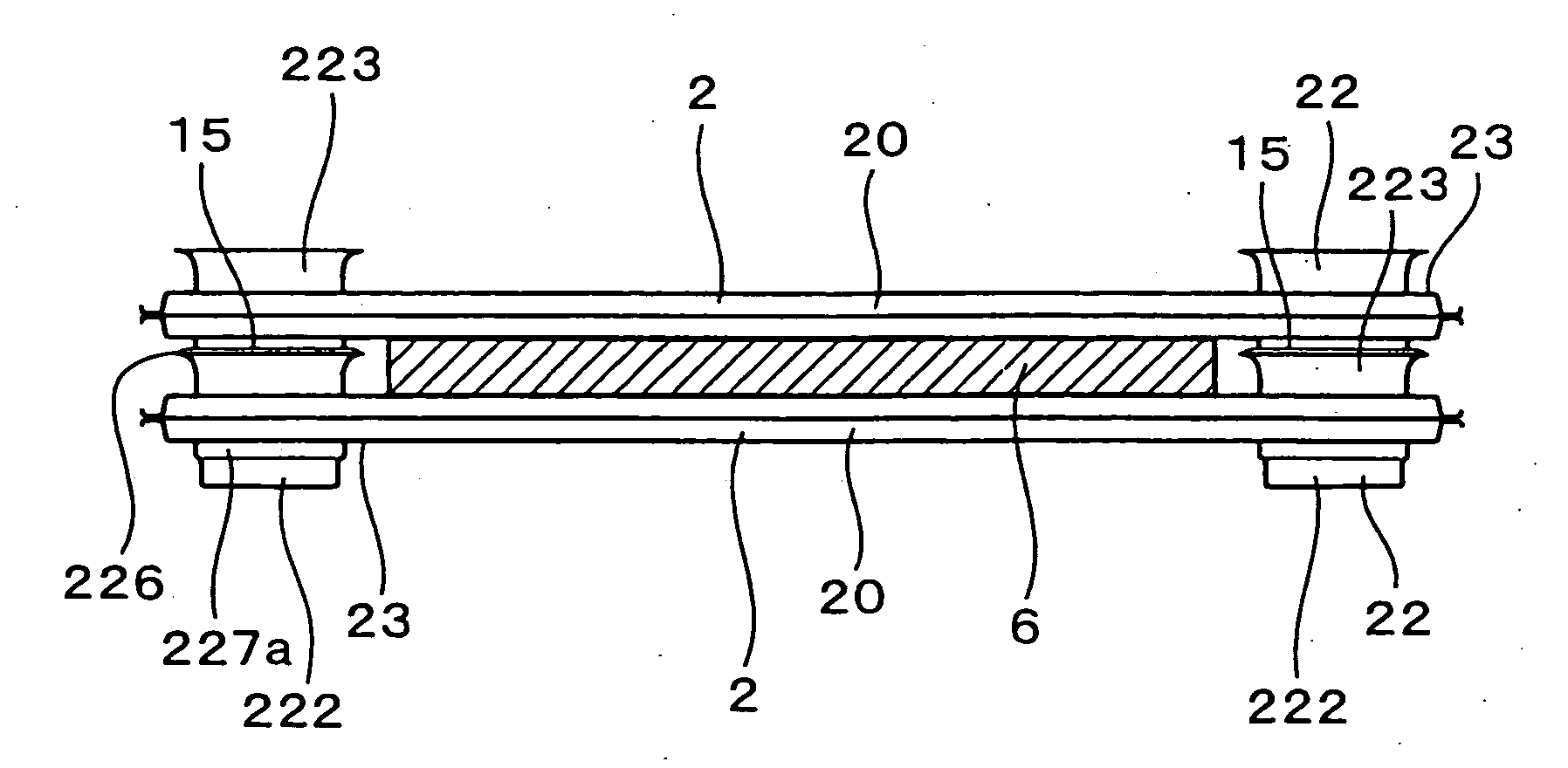

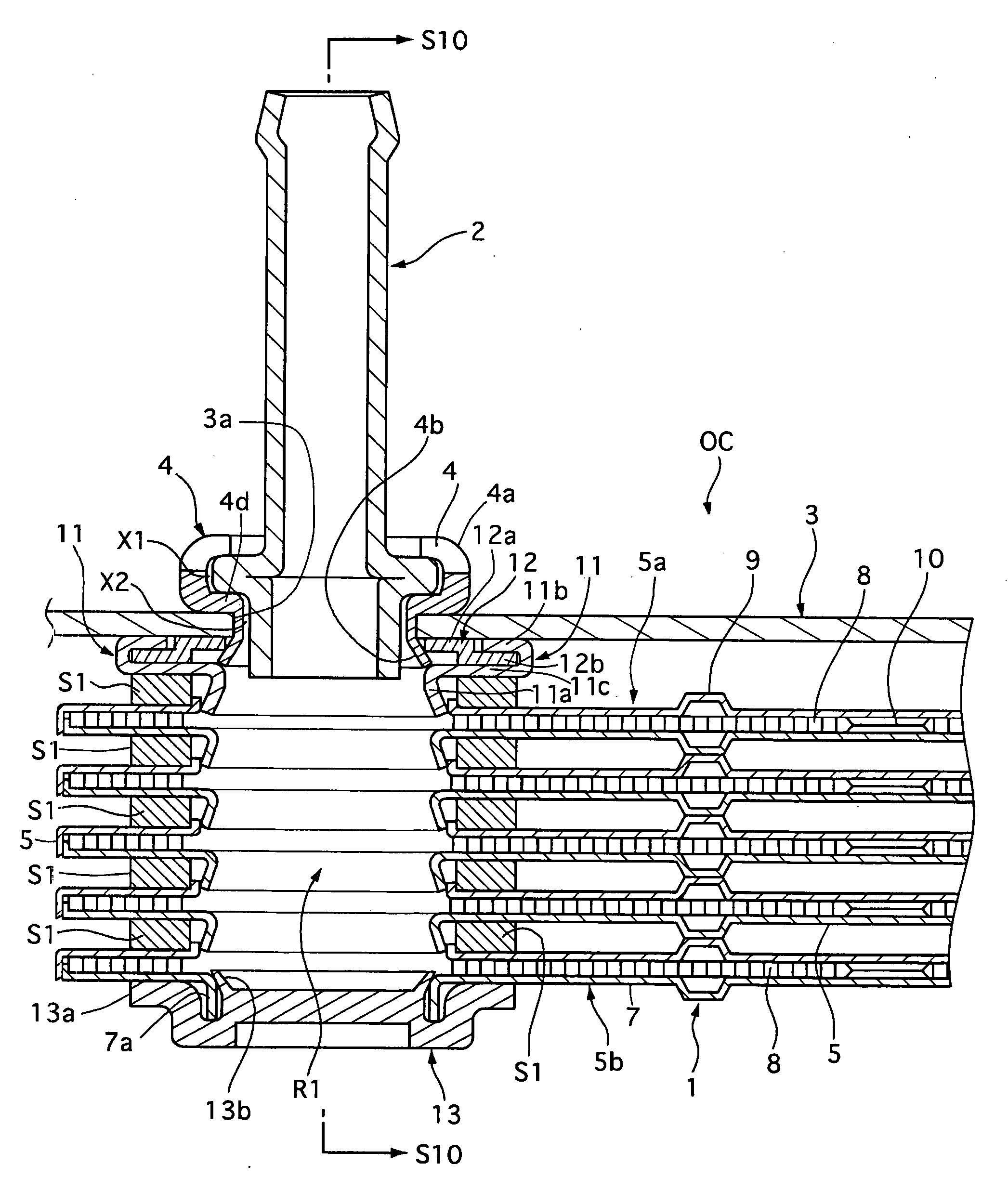

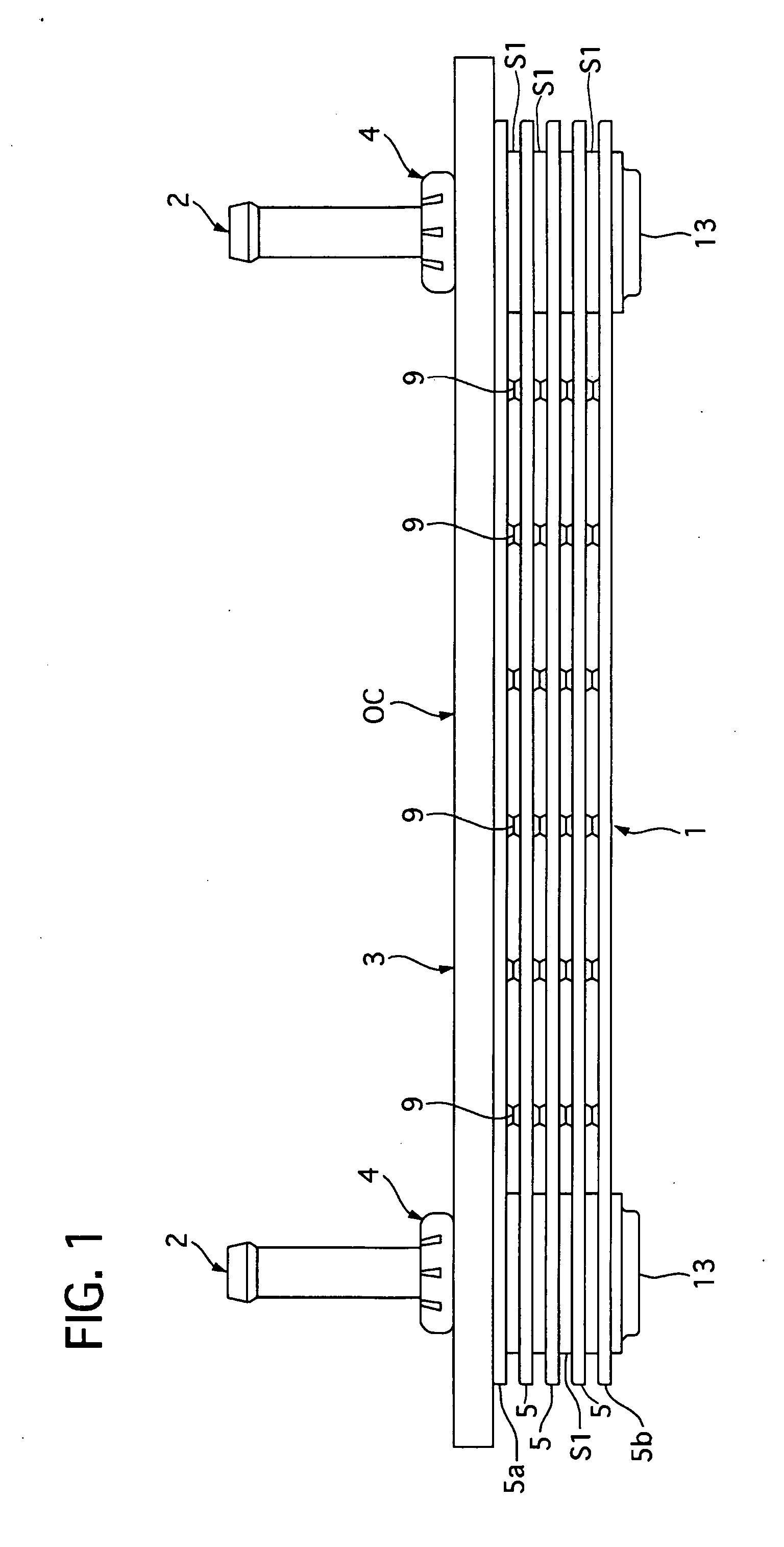

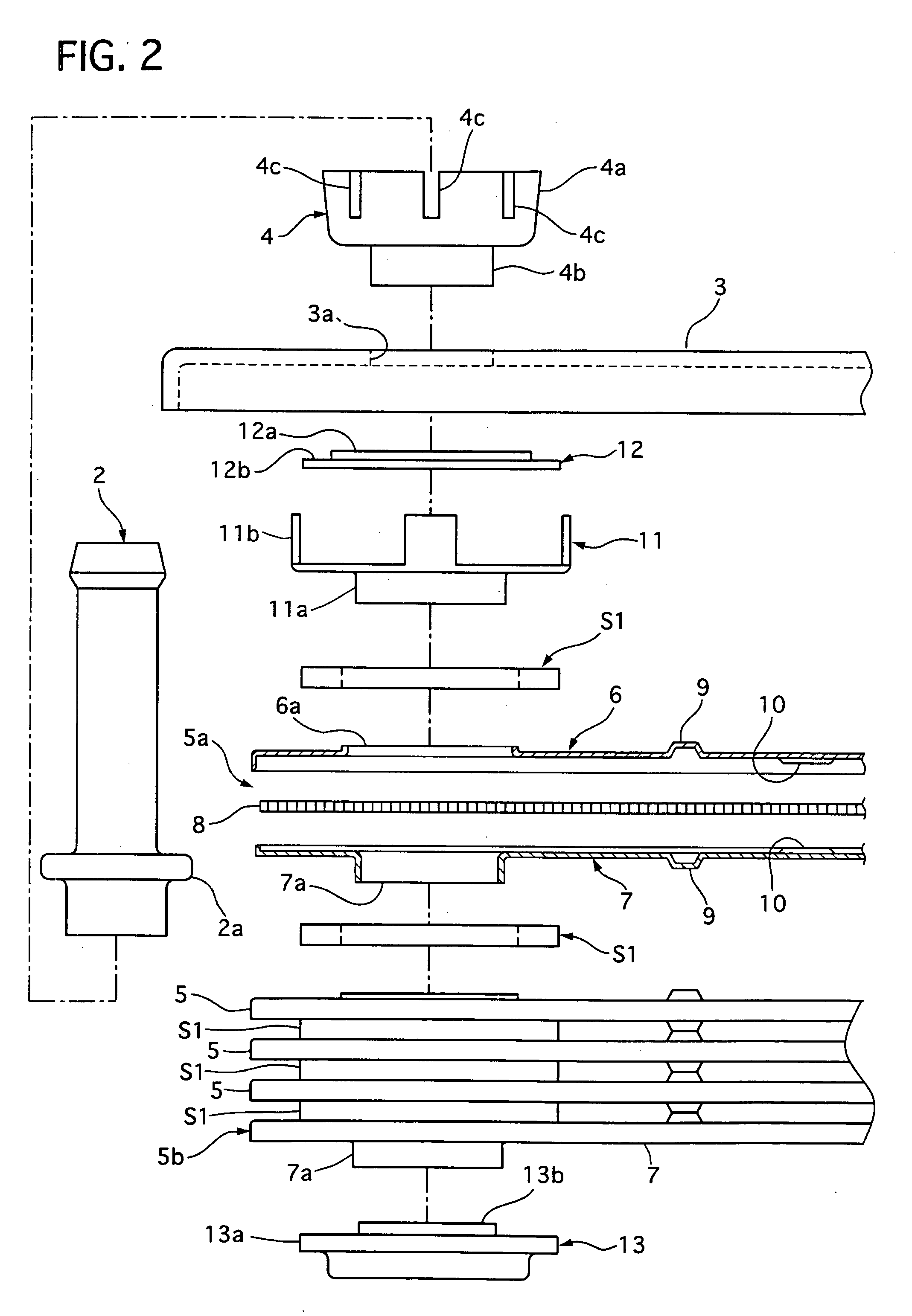

Heat exchanger unit and method of manufacturing the same

InactiveUS20070039717A1Easy to holdEasily and properly joinedSpacing meansSemiconductor/solid-state device detailsEngineeringHeat exchanger

A heat exchanger unit has tubes each having a body section and at least one of an inner pipe section and an outer pipe section extending from the body section and defining an opening at an end. Each of the inner pipe section and the outer pipe section has a first portion and a second portion adjacent to the first portion. The tubes are stacked such that the body sections are spaced from each other. Further, the inner pipe section is received in the outer pipe section such that the first portion of the inner pipe section overlaps the first portion of the outer pipe section, and the second portions of the inner and outer pipe sections are located on opposite sides of the overlapped first portions. The first and second portions of the inner pipe section have an outer diameter smaller than an inner diameter of the first and second portions of the outer pipe section.

Owner:DENSO CORP

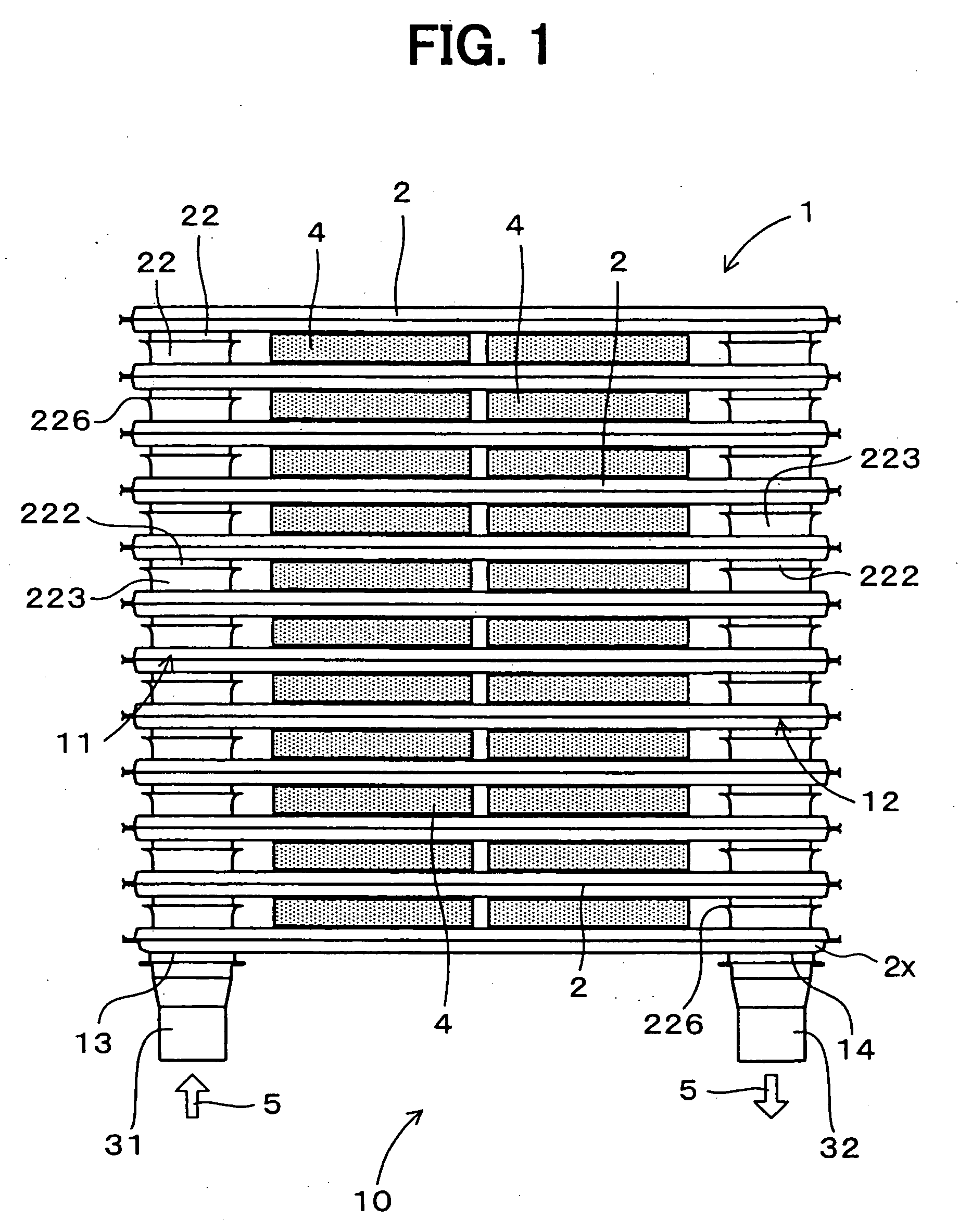

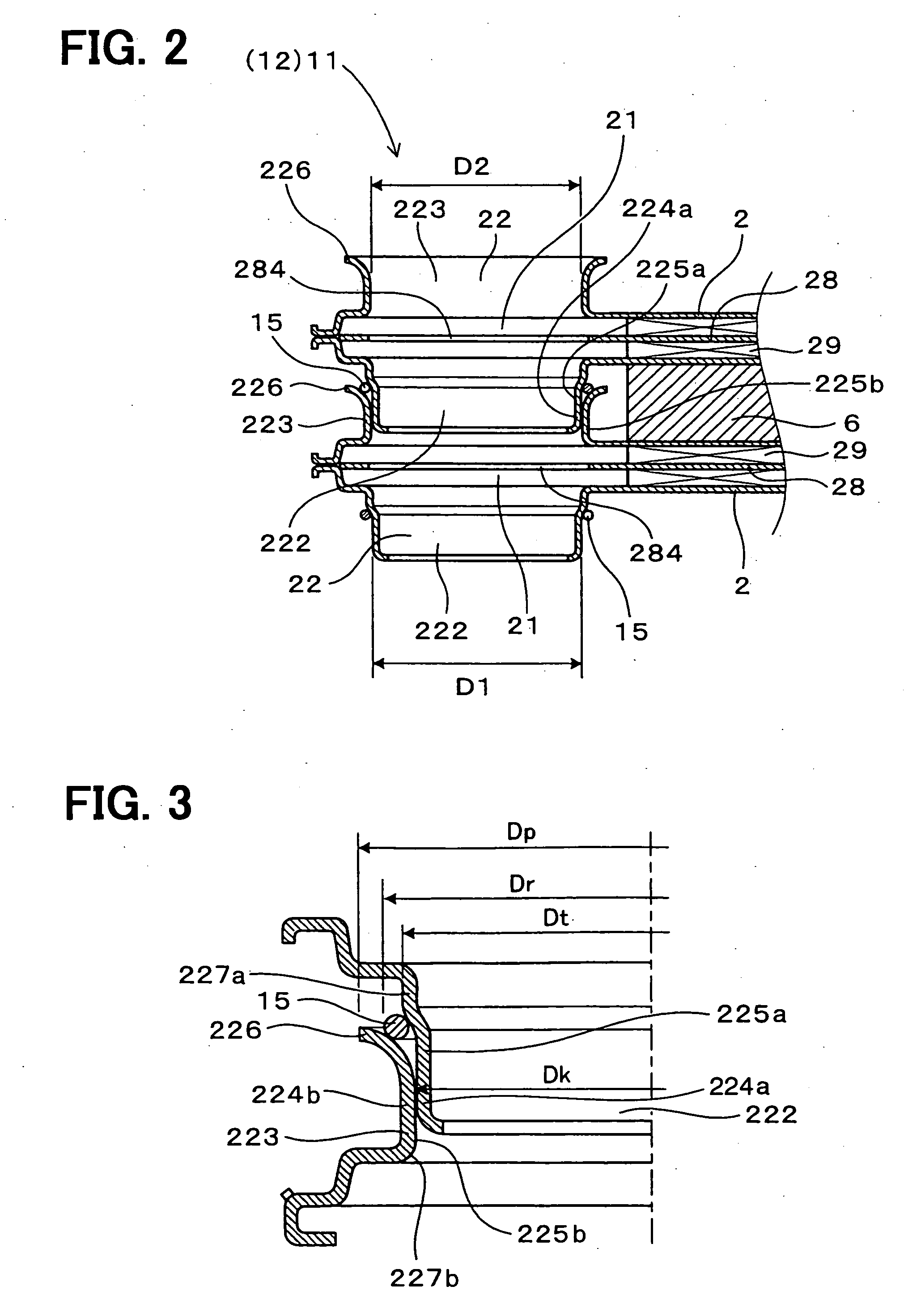

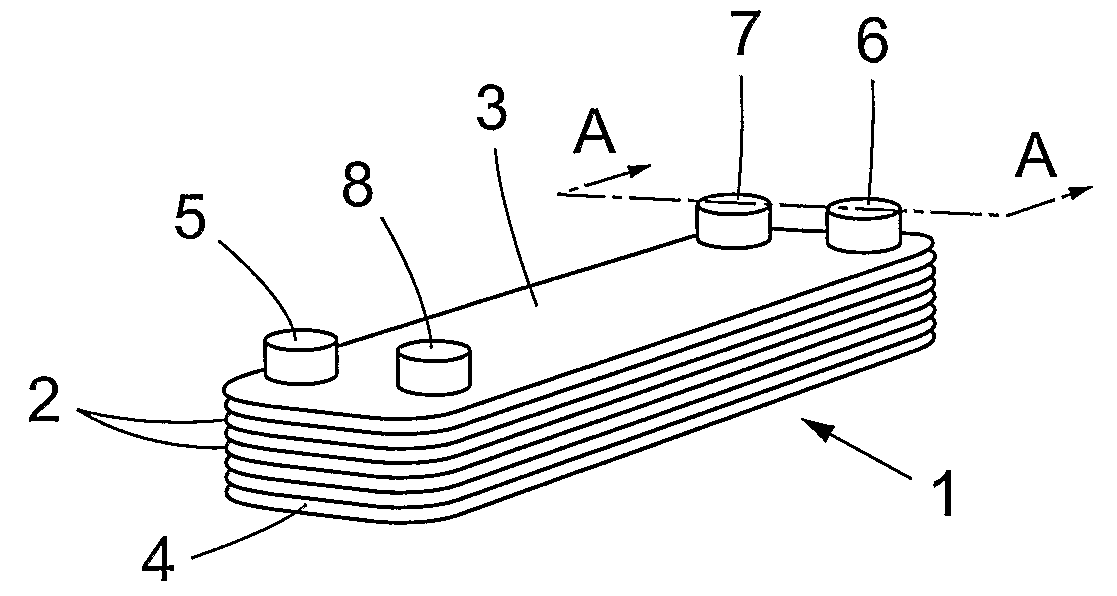

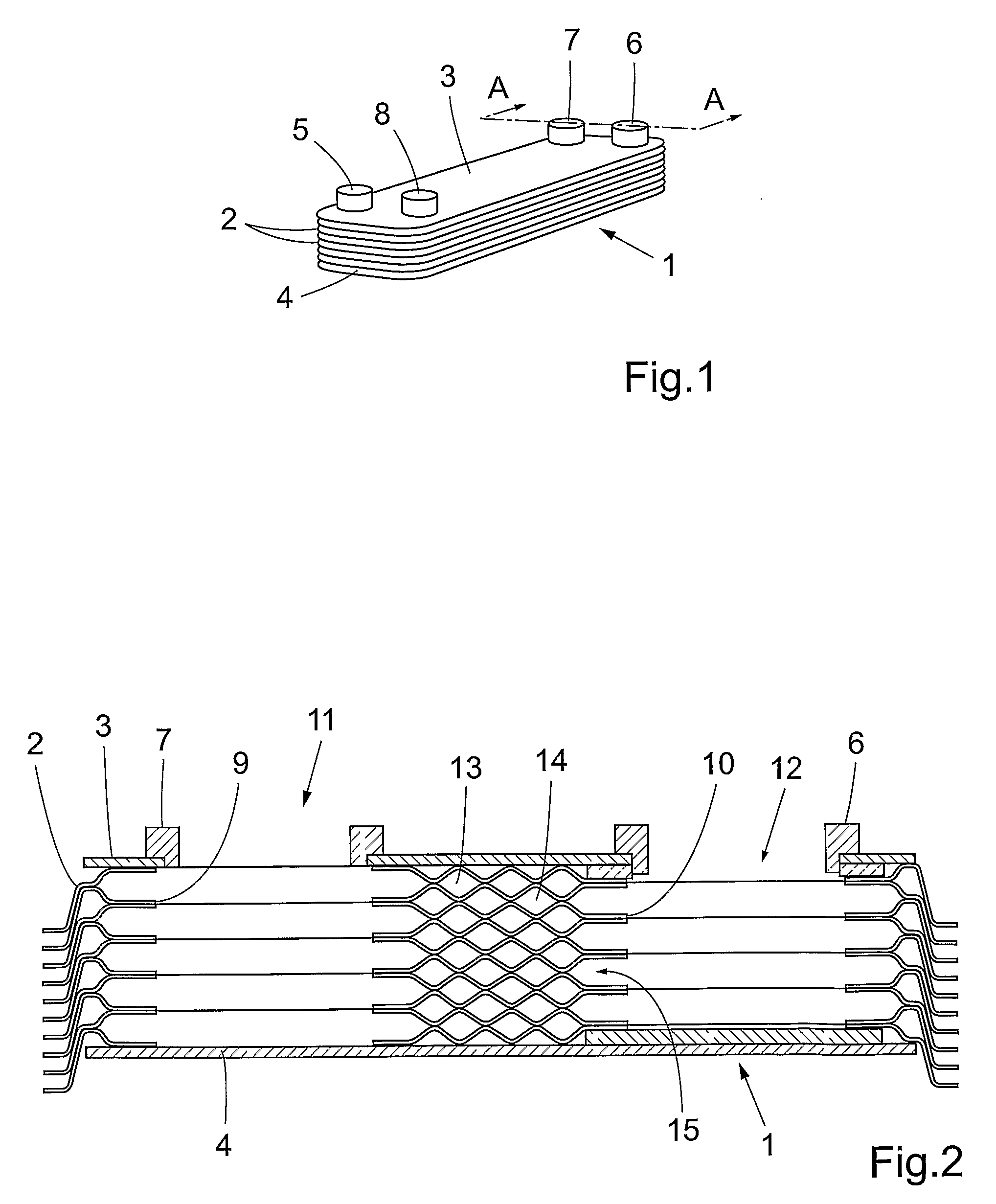

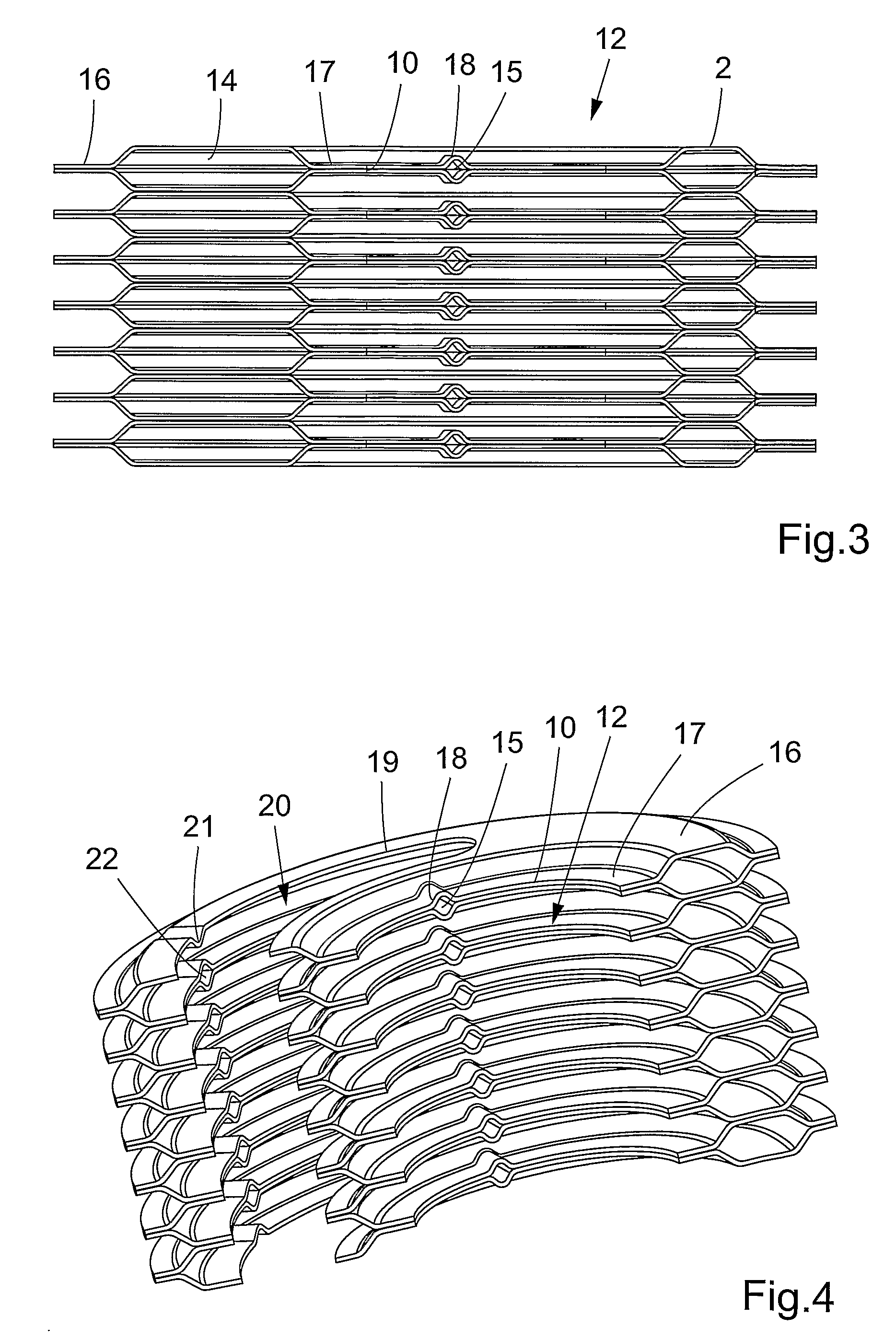

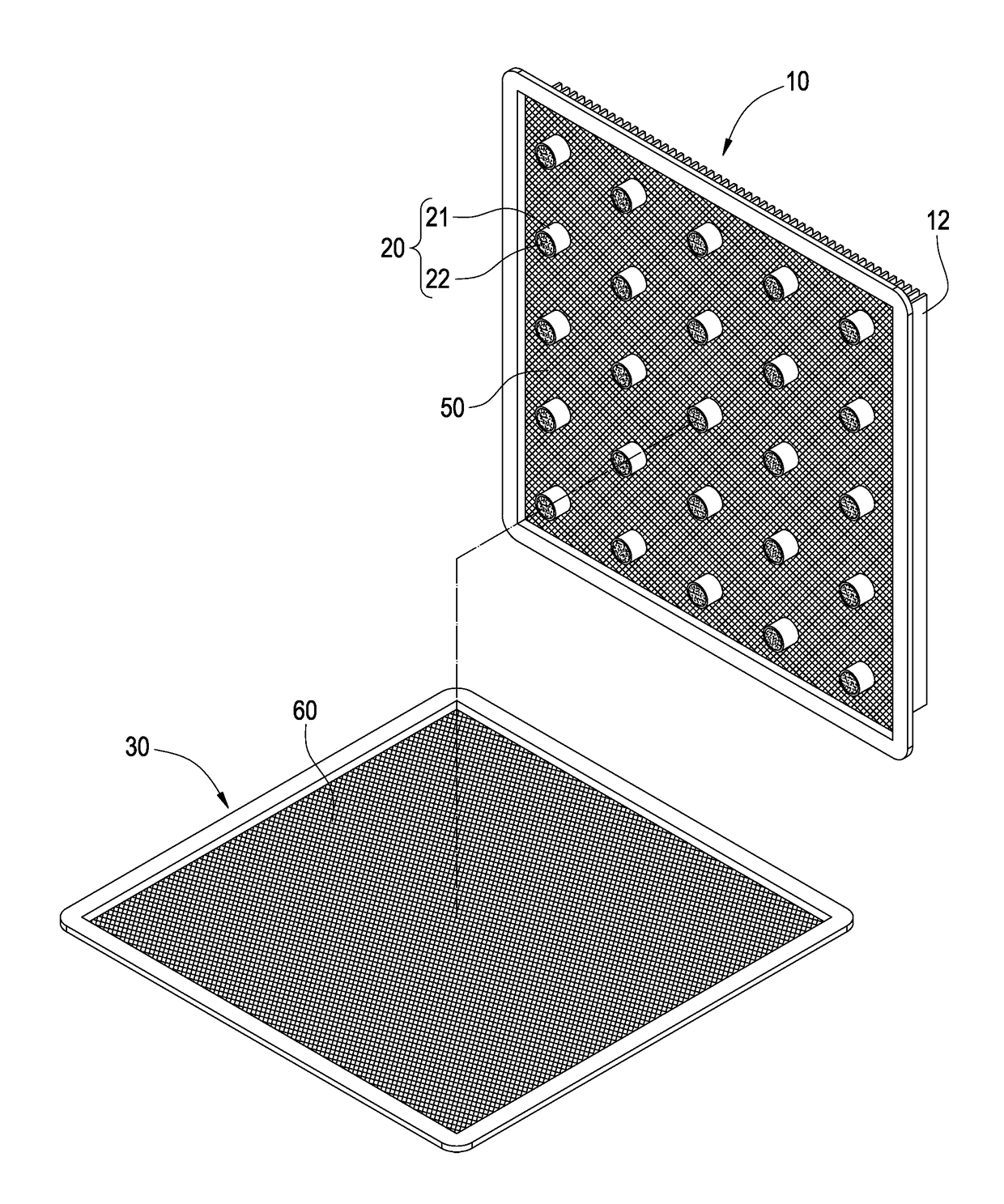

Plate Heat Exchanger

ActiveUS20080196874A1Easy and cost-effective to manufactureEasy and cost efficient to manufactureSpacing meansHeat exchanger casingsEngineeringMechanical engineering

The invention relates to a plate heat exchanger (1) having a package of heat transfer plates (2), which are provided with through inlet ports (10) forming an inlet channel (12) through the package, and between the heat transfer plates arranged sealing means, which together with the heat transfer plates in every other plate interspace delimit a first flow passage (14) for one fluid and in each of the remaining plate interspaces delimit a second flow passage (13) for a second fluid, wherein the inlet channel (12) communicates with each first flow passage (14) by way of a first inlet passage (15), and is sealed from communication with each second flow passage by the sealing means.

Owner:ALFA LAVAL CORP AB

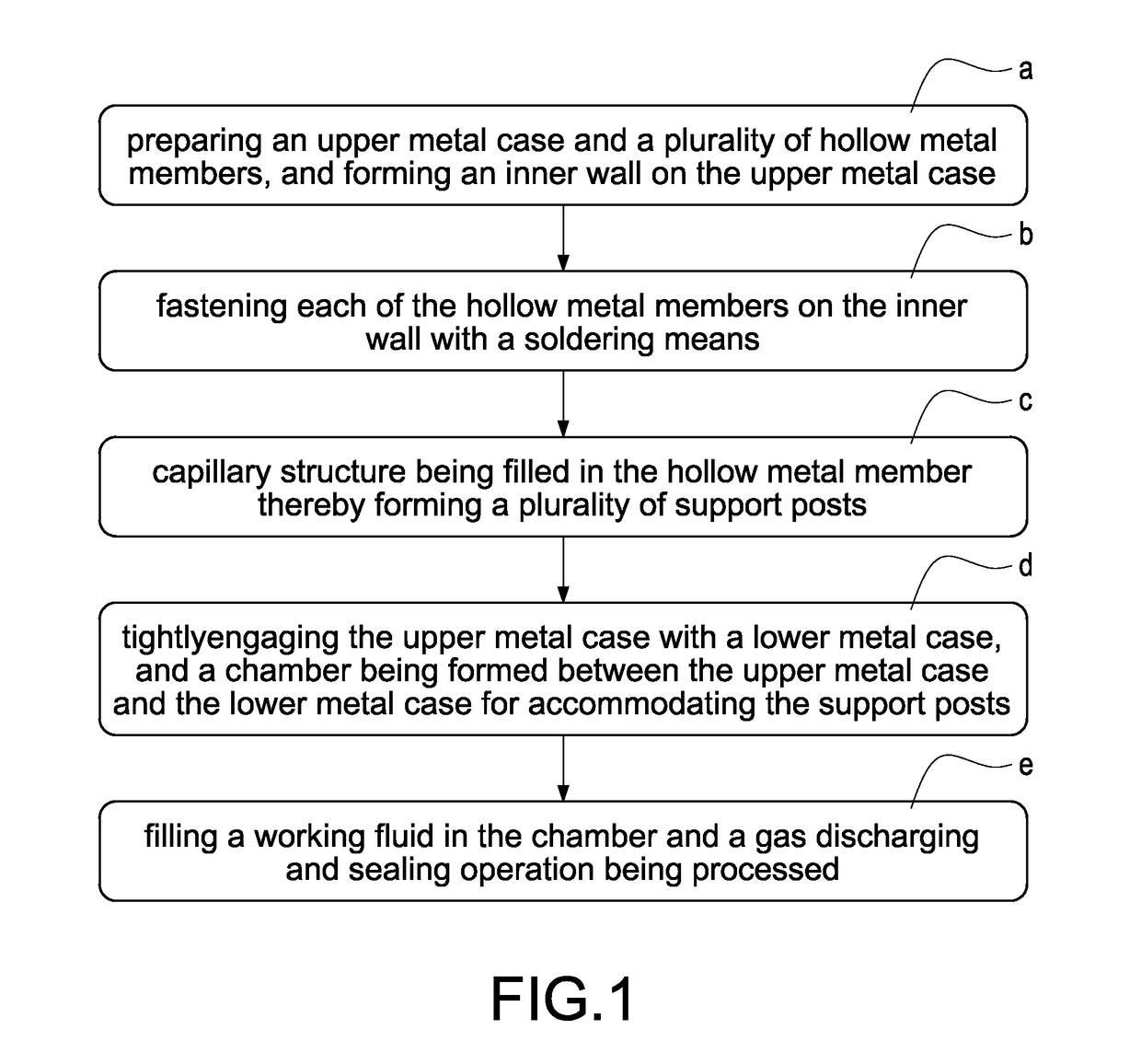

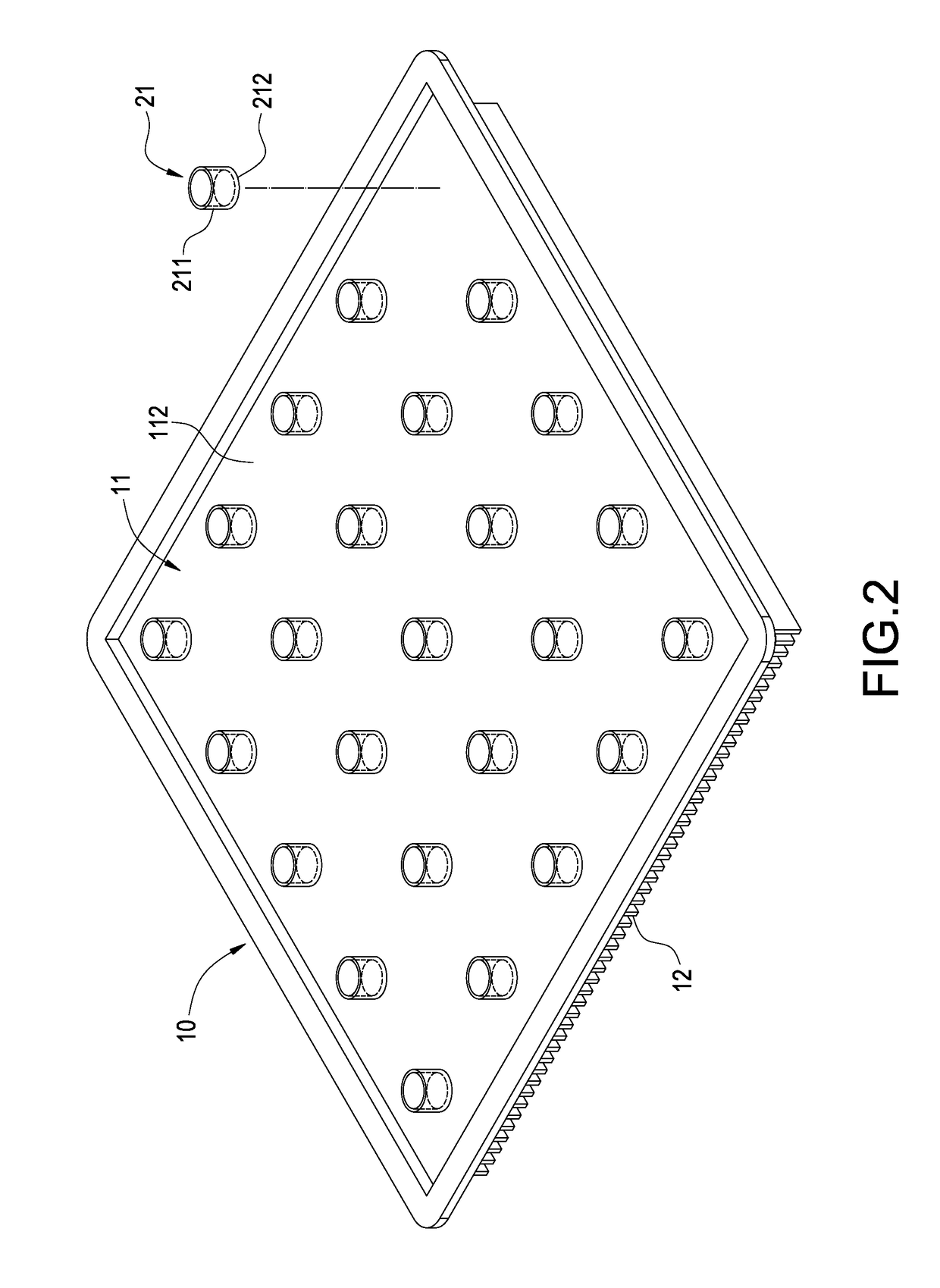

Vapor chamber and manufacturing method thereof

InactiveUS20170122672A1Work fasterIncrease return speedSpacing meansReinforcing meansWorking fluidManufacturing technology

In a vapor chamber and a manufacturing method thereof, the vapor chamber includes a lower metal case, an upper metal case, a plurality of support posts and a working fluid; the upper metal case is tightly engaged with the lower metal case, and a chamber is formed between the upper metal case and the lower metal case; the support posts are accommodated in the chamber and disposed between the upper metal case and the lower metal case, each of the support posts includes a hollow metal member and a capillary structure disposed inside the hollow metal member, and one end of the hollow metal member is soldered and fastened on the upper metal case; and the working fluid is filled in the chamber. Accordingly, advantages of simplifying manufacturing process, shortening manufacturing time and ensuring the quality of the vapor chamber to be stable can be achieved.

Owner:TAIWAN MICROLOOPS CORP

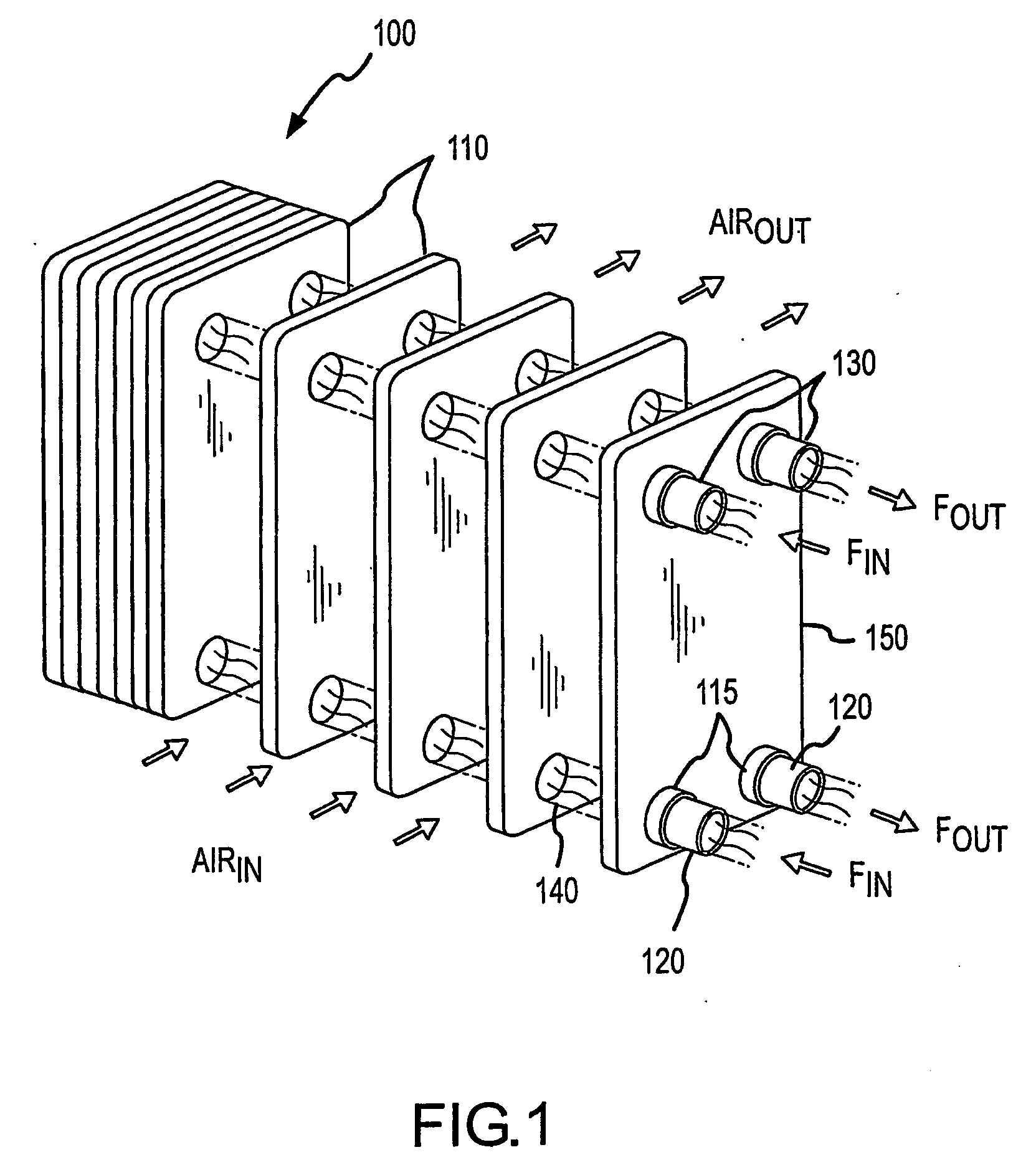

Air-to-air heat exchanger

An air-to-air heat exchanger, is provided that comprises a folded fin core formed from a continuous sheet of thermally conductive material that has been folded into alternating flat ridges and troughs; an insert overlay having an opening including two sets of uniform fingers, wherein each finger has a portion protruding into and essentially filling each trough on one surface of the folded fin core; an inset region between each finger portion and the end edges of each trough; a sealant within each inset region sealably attaching the insert overlay to the folded fin core; and an air flow divider plate. Heat exchanger components are also provided.

Owner:THERMAL

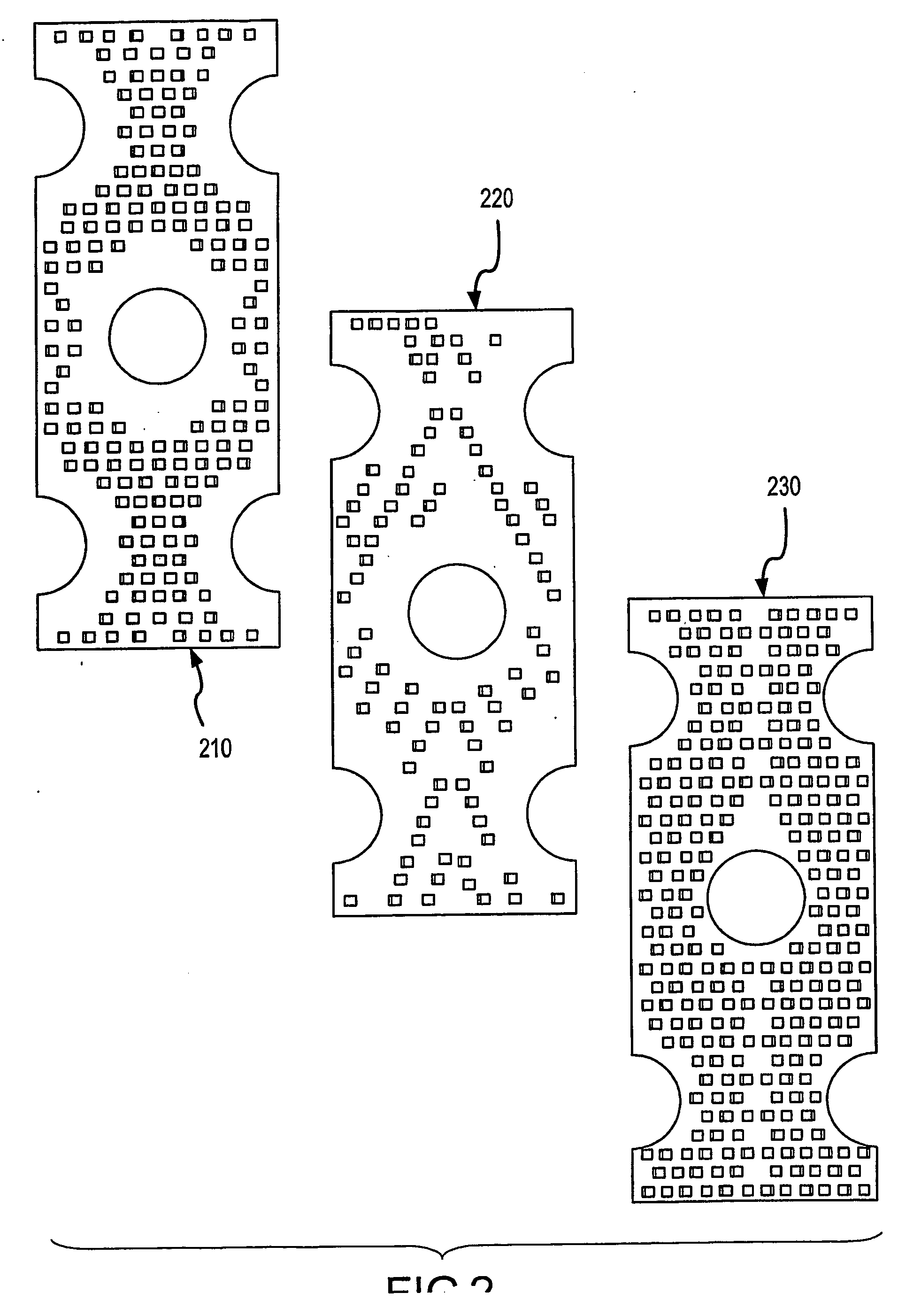

Air to air heat exchanger

InactiveUS20090114369A1Efficiently and cost-effectively exchange heatImprove pressure retaining capability and leak tightnessEnergy recovery in ventilation and heatingSpacing meansCounter flowParallel plate

A compact heat exchanger efficiently and cost-effectively exchanges heat from one gas stream to another through counter flow channels between parallel plates. Foam strips are incorporated to form the sides of the flow channels that allow channeling and directing the flow of air on each side of a plate heat transfer surface in patterns to maximize the heat exchanger's effectiveness and maintain the gap between heat transfer plates and form the pressure boundary at the edge of the heat exchanger. Clips are incorporated in strategic locations of each plate to locate and mechanically connect the plates to one another and to maintain the location of the foam strips. The heat transfer of the heat exchange surfaces are enhanced using rounded dimples and protrusions arranged such that these occur on the top and bottom of the flow channels.

Owner:AZ EVAP

Oil cooler

An oil cooler is contained in a radiator tank. It includes a connecting pipe having an enlarged diameter portion, a heat exchange part including elements and a communicating passage fluidically communicating the elements, and a pipe connector. The pipe connector has a first retaining portion seated on one side of a wall portion of the radiator tank to contain and fix at least a part of the enlarged diameter portion of the connecting pipe by caulking, and a second retaining portion inserted through a through-hole of the wall portion and an one end portion of the communicating passage to fix the heat exchanger part and the wall portion at the other side of the wall portion by caulking.

Owner:CALSONIC KANSEI CORP

Heat exchanger method and apparatus

A method for an internal combustion engine includes the steps of collecting exhaust gas in a volume (502) and flowing exhaust gas out of the volume in a first and a second portions (504). The first portion forms a tailpipe gas stream (506), and the second portion forms an EGR gas stream (508). The tailpipe gas stream goes through a turbine (510), and is heated in a heat exchanger (512). The heat exchanger transfers thermal energy out of the EGR gas stream (516) to heat the tailpipe gas stream. The EGR gas stream is recirculated into an intake of the internal combustion engine (518).

Owner:INT ENGINE INTPROP CO LLC

Oxidation catalyst coating in a heat exchanger

ActiveUS20070089717A1Spacing meansInternal combustion piston enginesThermal energyProcess engineering

A method for an internal combustion engine includes the steps of collecting exhaust gas in a volume (902) and flowing exhaust gas out of the volume in a first and a second portions (904). The first portion forms a tailpipe gas stream (906), and the second portion forms an EGR gas stream (908). The tailpipe gas stream goes through a turbine (910). The EGR gas stream is catalyzed by an oxidizer coating in a heat exchanger, and thermal energy is transferred from the EGR gas stream to the tailpipe stream in the heat exchanger (916).

Owner:INT ENGINE INTPROP CO LLC

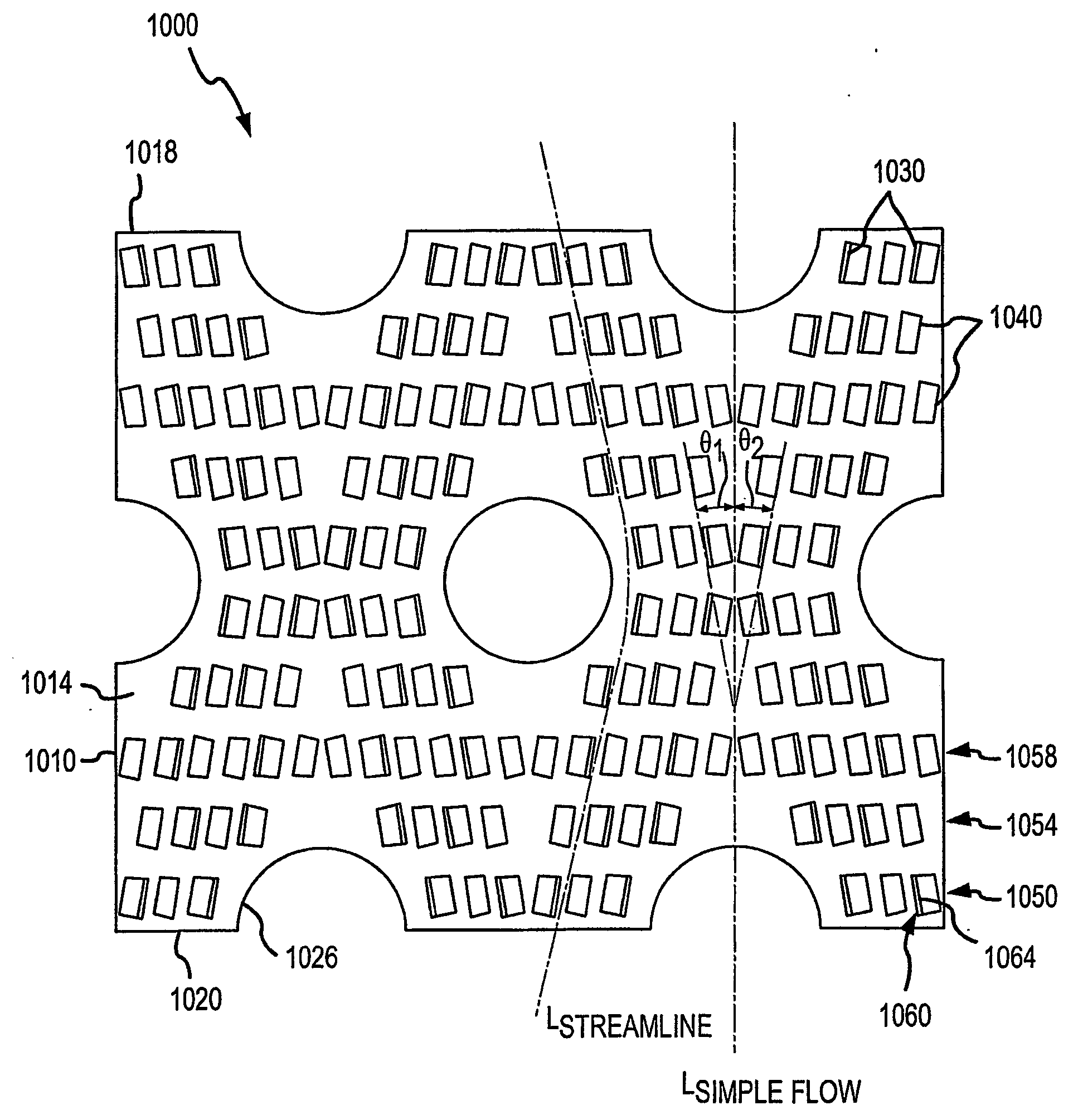

Tabbed transfer fins for air-cooled heat exchanger

InactiveUS20060169019A1Increase heat transfer rateMinimizing creationSpacing meansMechanical apparatusEngineeringHeat exchanger

Heat transfer fins (110), and heat exchangers (100) incorporating such fins (110), enhancing heat transfer with acceptable pressure drop increase. The fins (110) include tabs or secondary fins bent upward and downward from the fin body at a selected bend angle. All or a majority of the tabs are aligned with a simple flow path or with local flow paths for cooling air adjacent the fins (110) to minimize turbulence and pressure drop. The tabs are planar and generally aligned parallel to the simple flow path or local flow paths and are arranged so as to serve as a plurality of sites for starting new boundary layers by offsetting the tabs such that downstream tabs are not shadowed by upstream tabs. The tabs have a height sufficiently large to extend the tabs out into boundary layers on the fin (110). The tabs provide more uniform flow over fins (110) and shrink wake size behind tubes (120).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

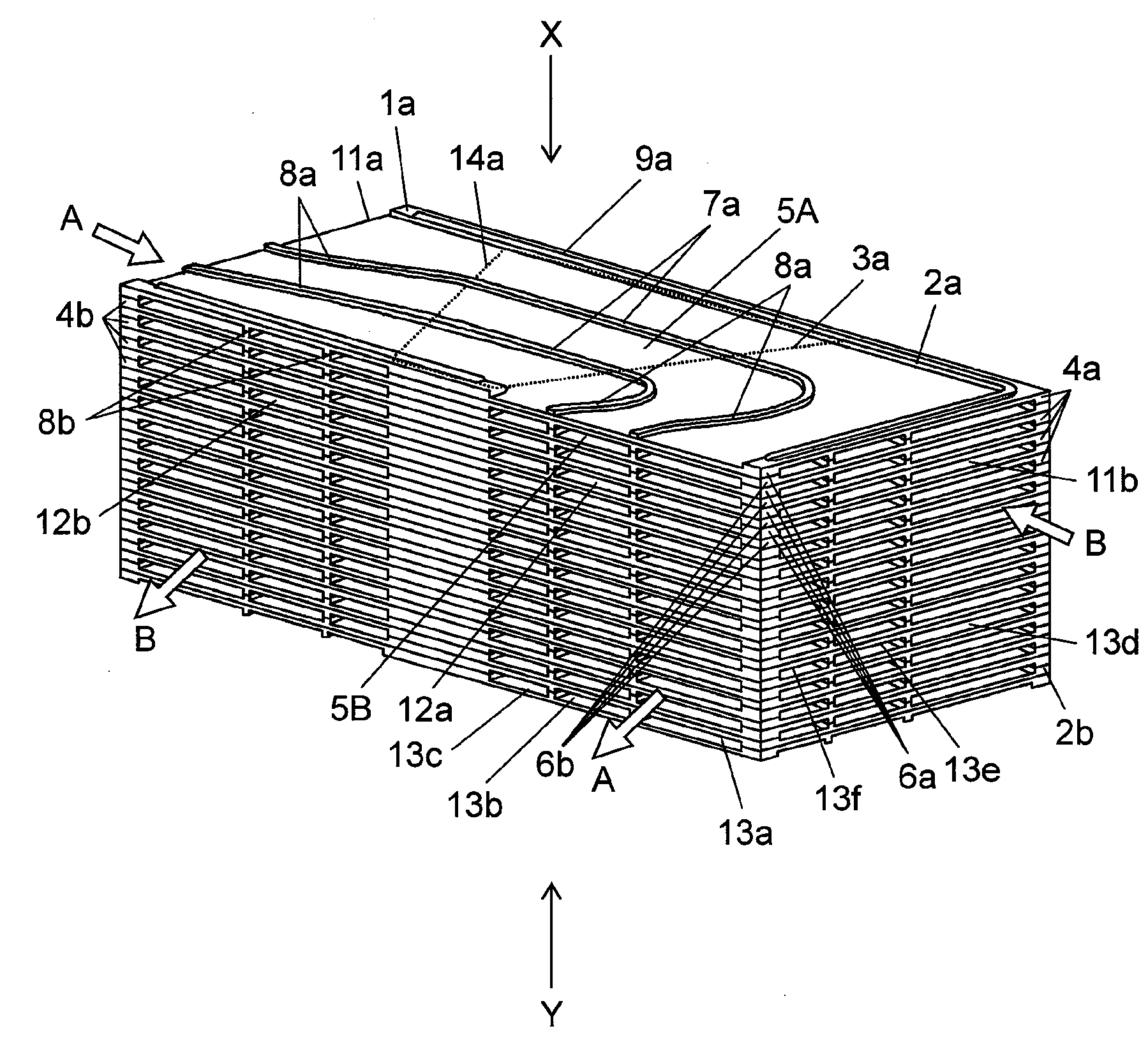

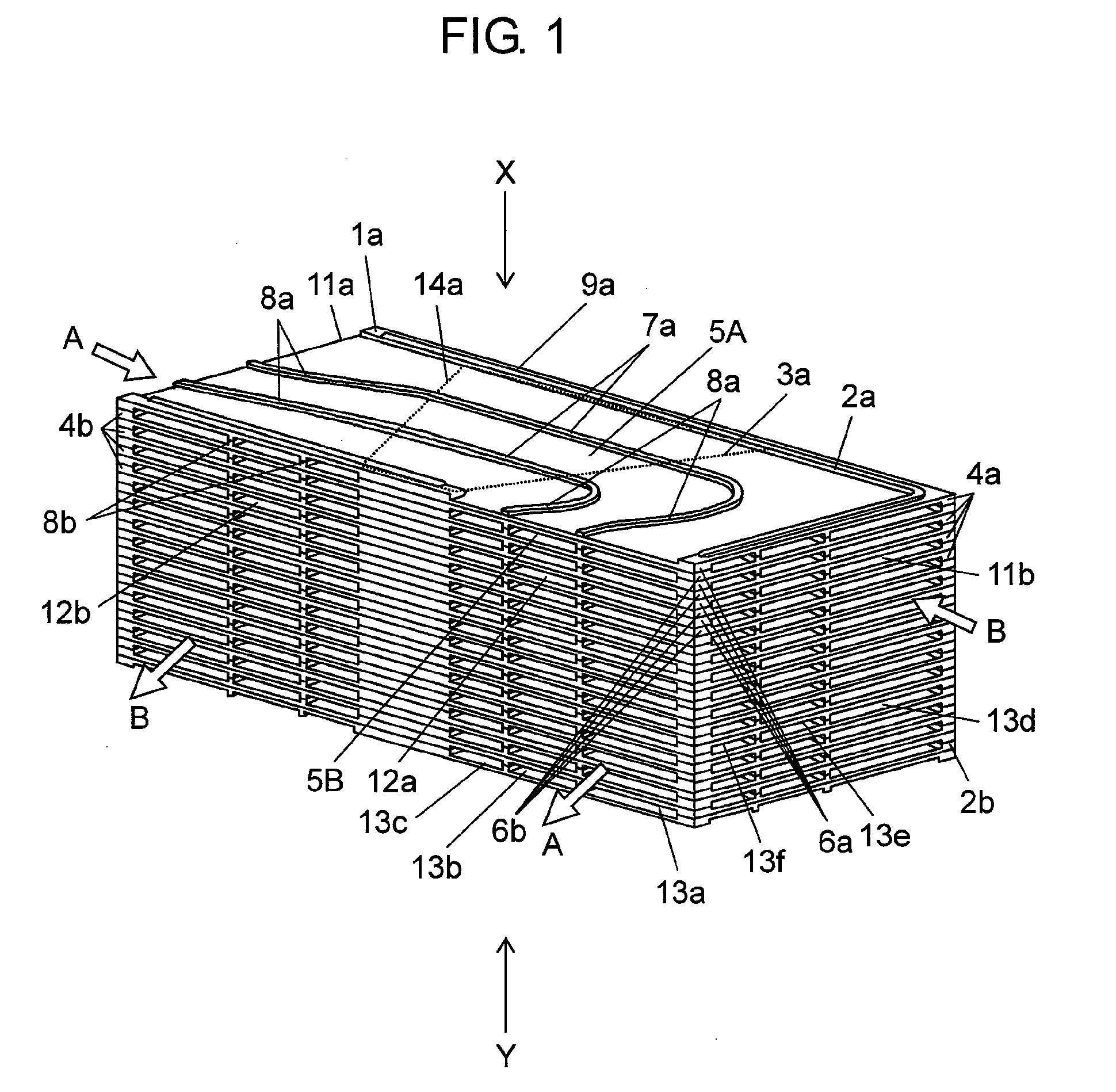

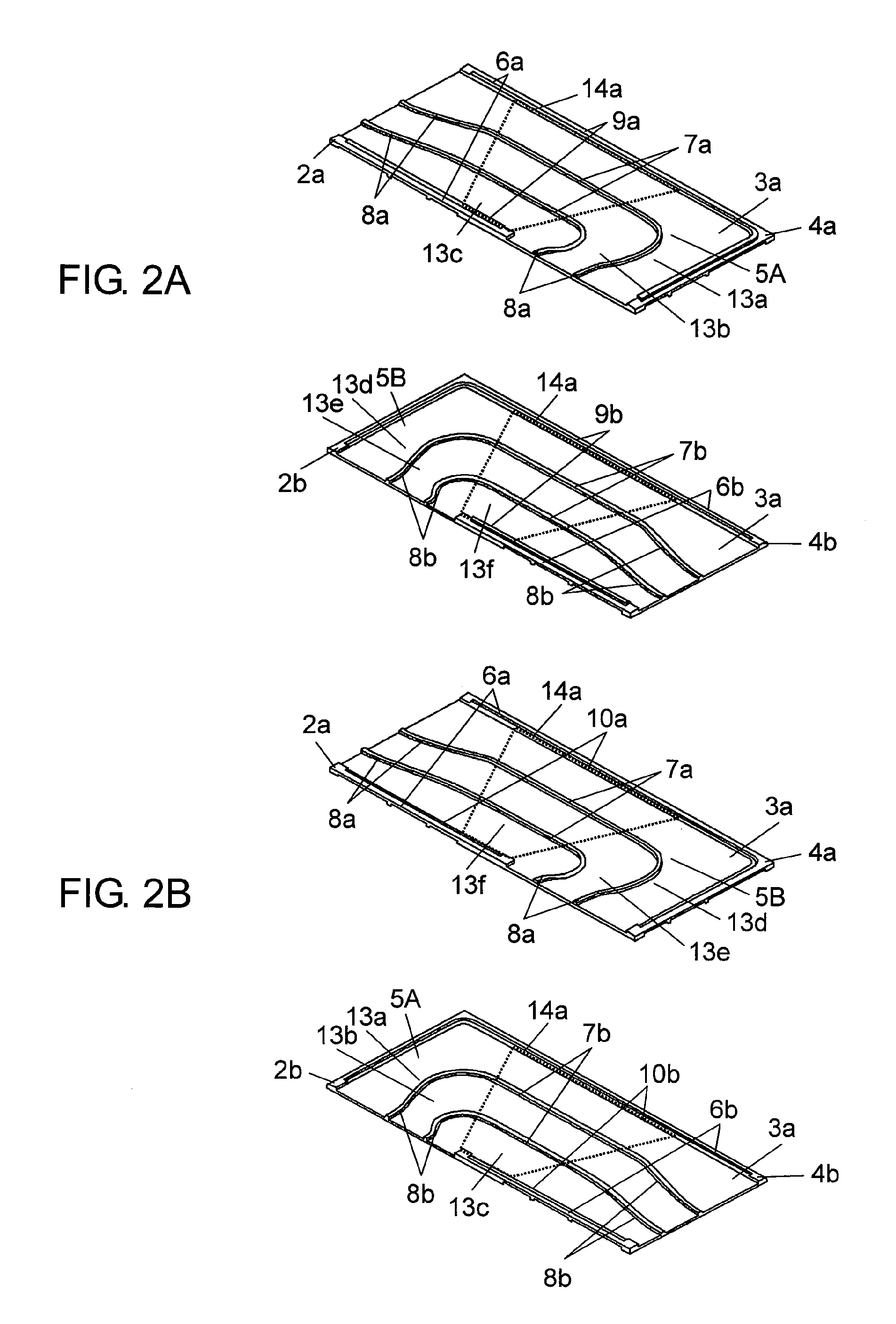

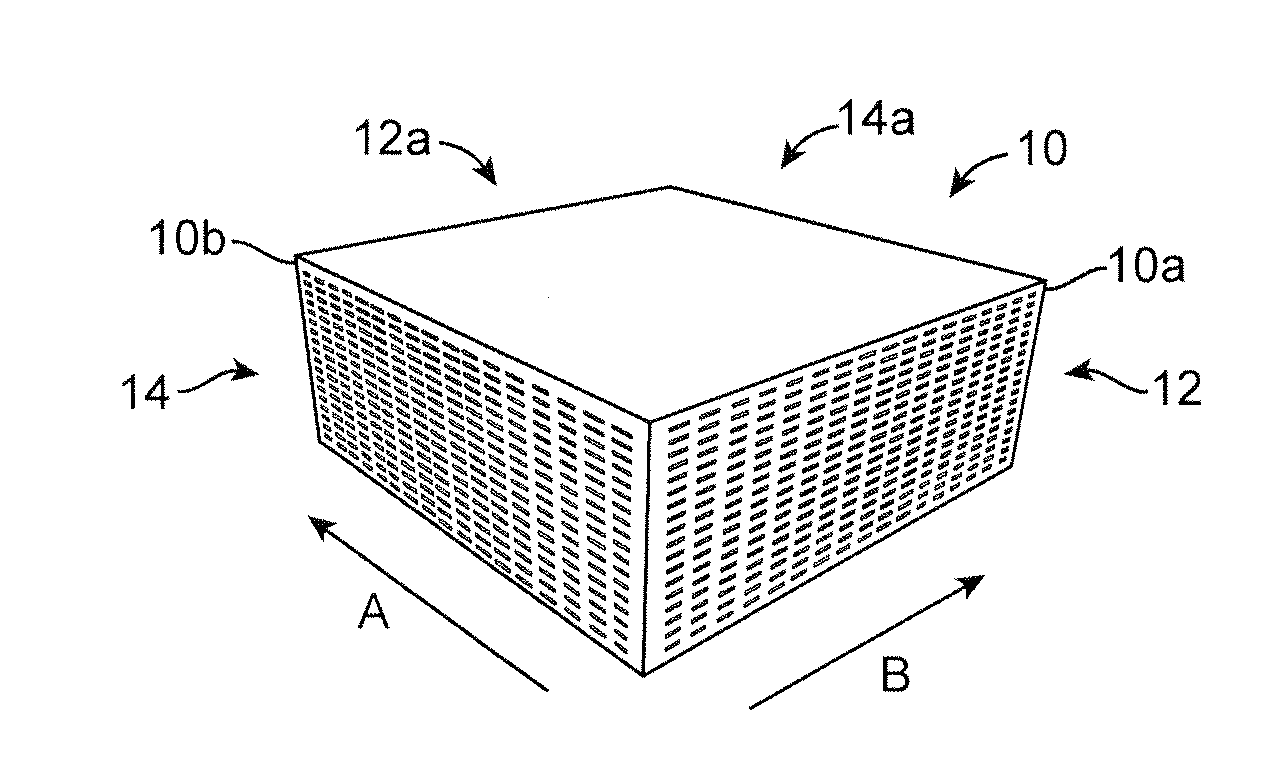

Heat exchanging element

InactiveUS20100071887A1Eliminate driftMaintain structural strengthEnergy recovery in ventilation and heatingSpacing meansEngineeringAir conditioning

A lamination type heat exchanging element for use in heat exchange type ventilators and other air conditioning devices eliminates drift in the air passages while maintaining its structural strength, thereby providing high heat exchange efficiency. The heat exchanging element also prevents airflow leakage due to peeling between heat exchanger plates and other components. To achieve this, rectification portions are provided which eliminate drift in the air passages due to different ventilation resistances of the flow channels caused by their different flow channel lengths generated by flow channel division portions, thereby forming a predetermined flow velocity distribution in the counterflow regions.

Owner:PANASONIC CORP

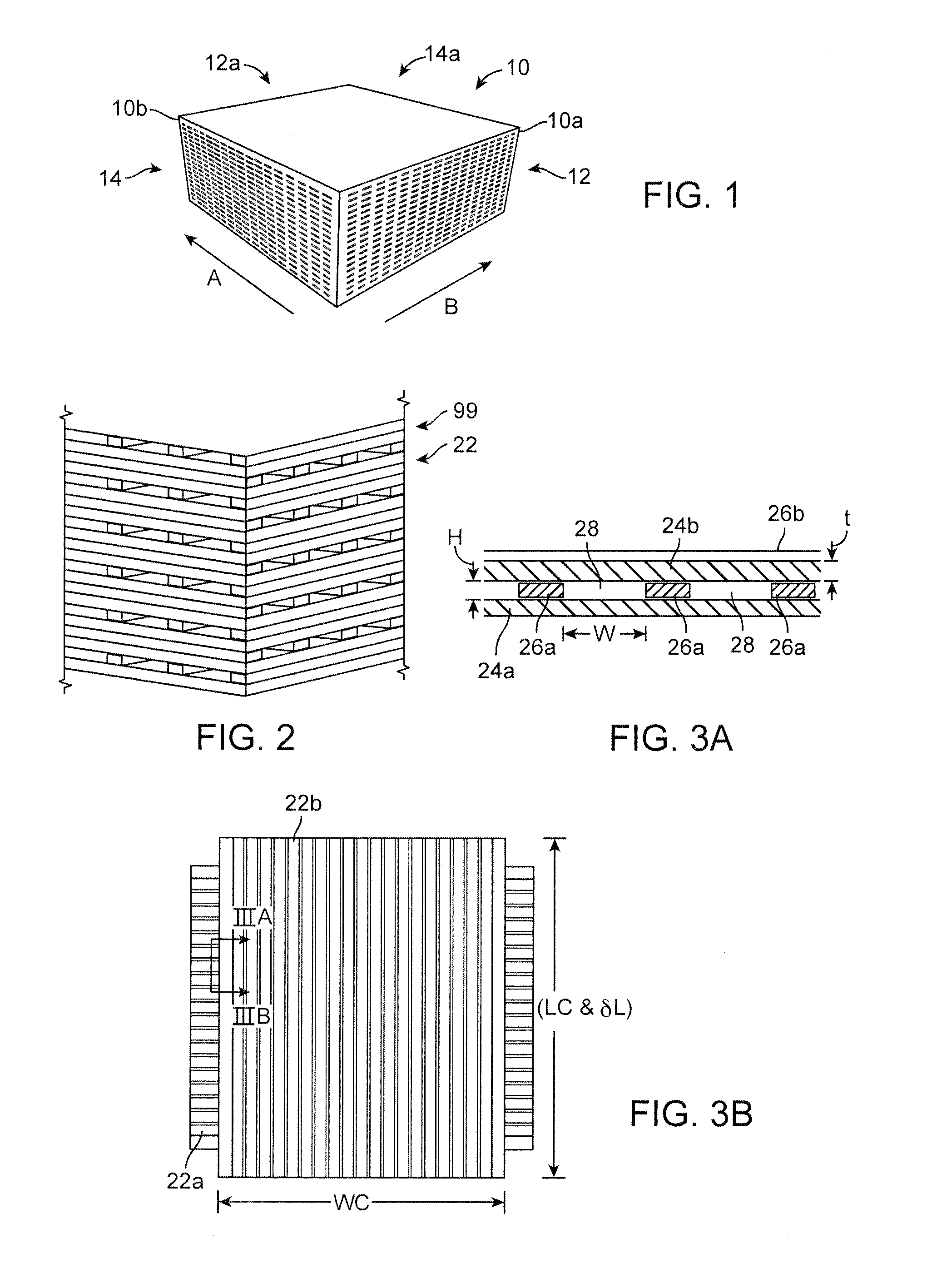

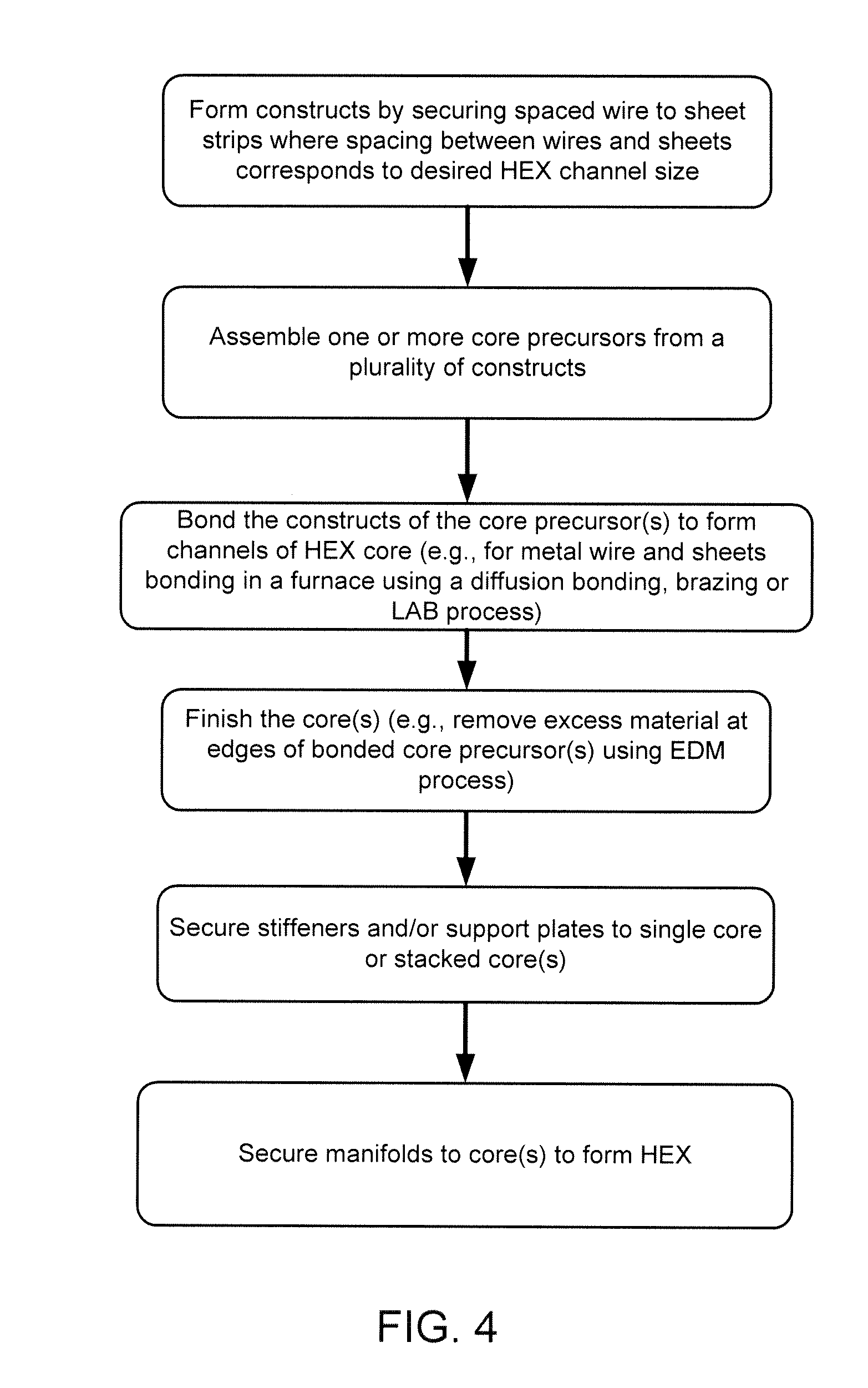

Microchannel Heat Exchangers and Reactors

InactiveUS20120261104A1Reduce manufacturing costIncrease useSpacing meansSoldering apparatusNuclear engineeringHeat exchanger

A method of making a core of, or a micro-channel heat exchanger includes making constructs from wire and sheet material. The constructs are then stacked together according to the desired orientation of the channels for the core. The stacked constructs are then bonded together to form the core.

Owner:ALTEX TECH

Systems and methods of generating electricity using heat from within the earth

PendingCN111837006AResolve dependenciesAvoid Excessive Construction CostsSpacing meansCollector components/accessoriesOrganic Rankine cycleEngineering

Systems and methods for producing energy from a geothermal formation are disclosed. A heat exchanger can be disposed within a well to absorb heat from a geothermal formation. The heat exchanger can besupported within the well using a high thermal conductivity material. The heat exchanger is connected to an organic Rankine cycle engine including a secondary heat exchanger and a turbine. The primary and secondary heat transfer fluids are chosen to maximize efficiency of the organic Rankine cycle.

Owner:HMFSF IP控股有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com