Heat exchanger for a motor vehicle air conditioning system

a heat exchanger and motor vehicle technology, applied in the direction of lighting and heating apparatus, tubular elements, stationary conduit assemblies, etc., can solve the problems of time-consuming and expensive soldering of the ribs of the tubes to the tubes, insufficient heat transfer surface area, and insufficient heat transfer heat transfer for air conditioning systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

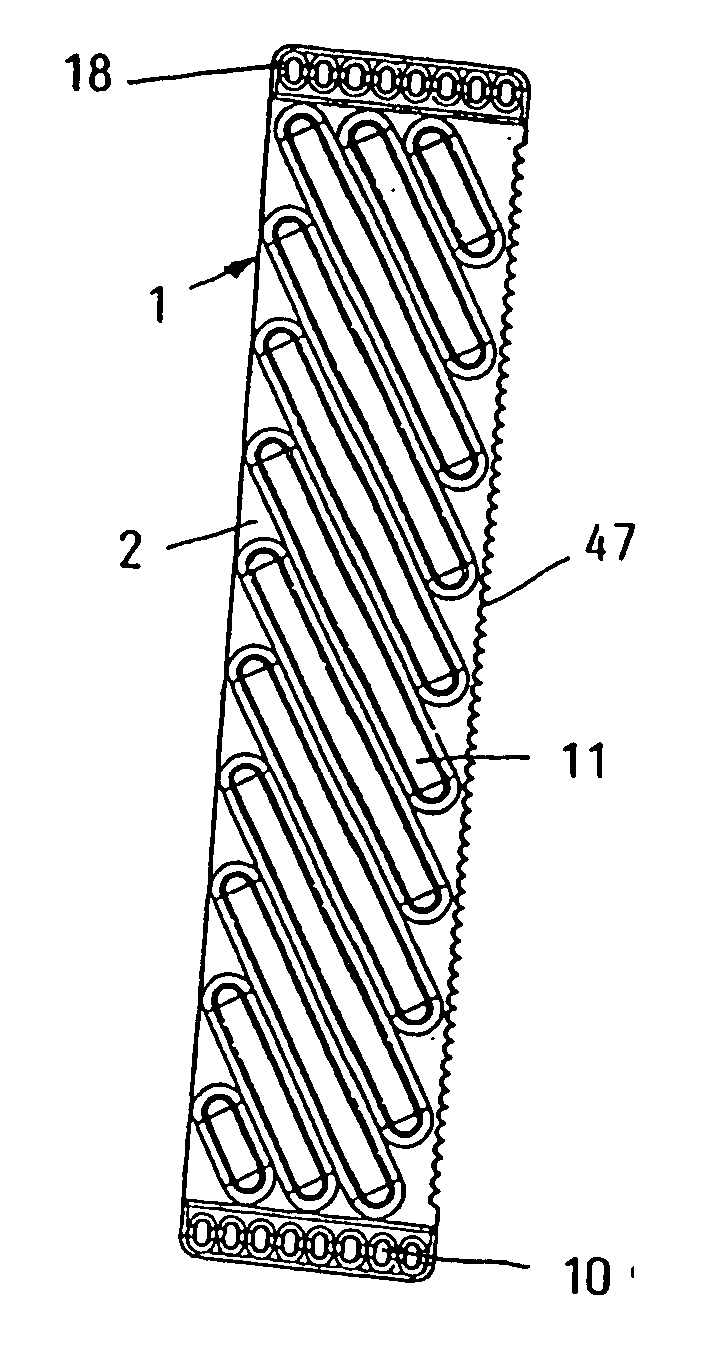

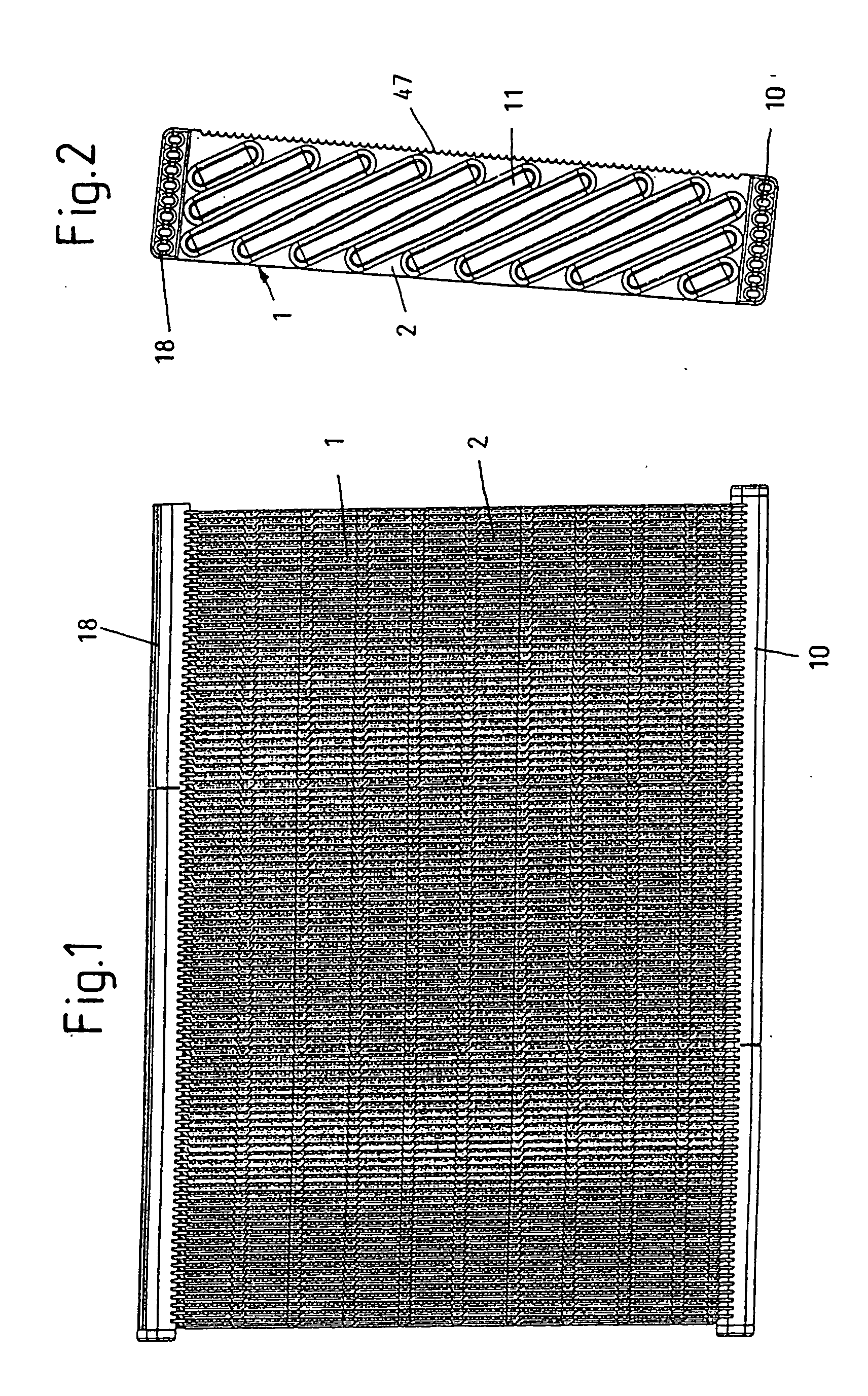

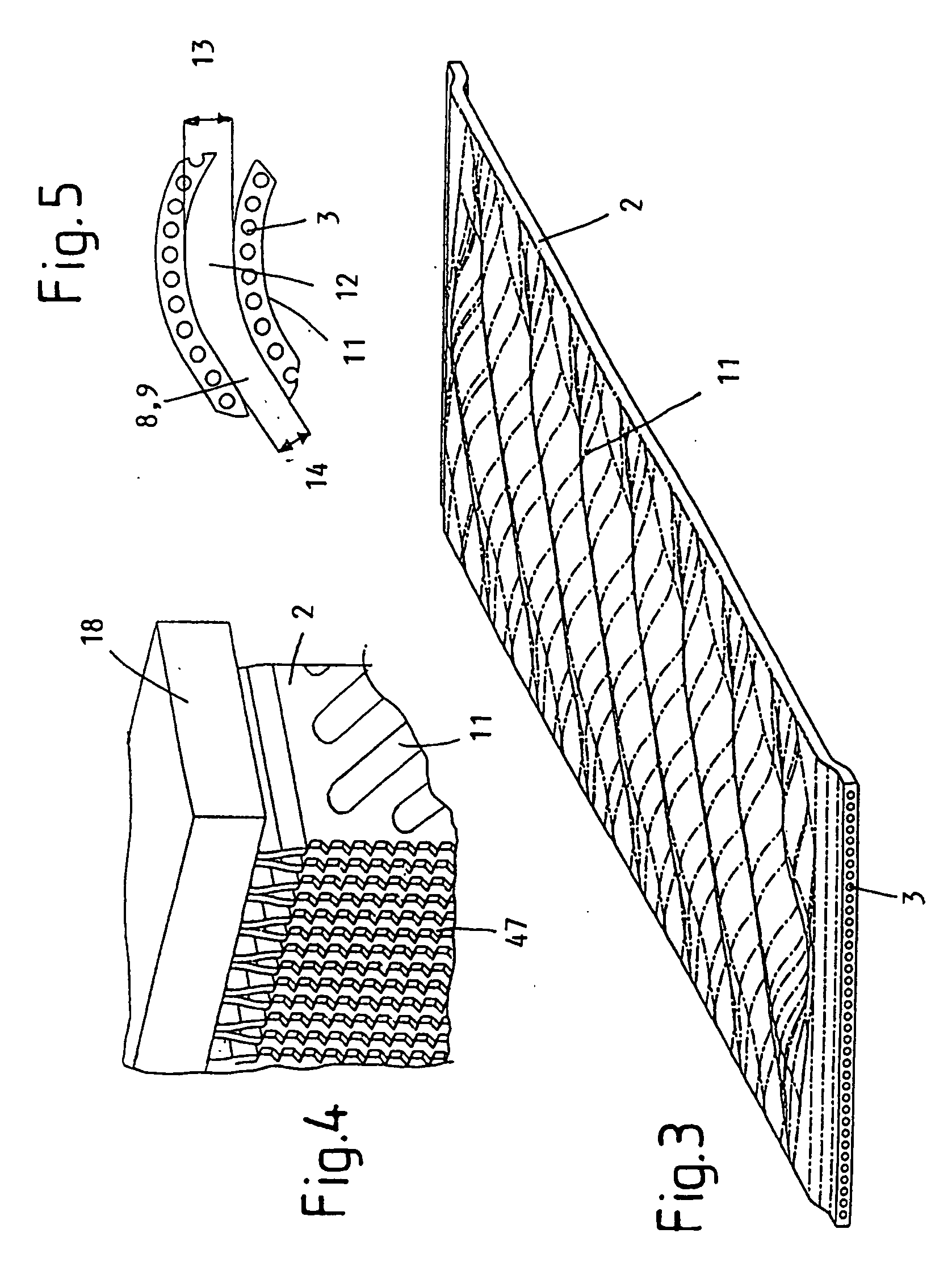

[0037] The heat exchanger according to the invention is provided mainly for installation in the air flow of a CO2 vehicle air conditioning system where, during cooling operation, it is used as an evaporator. To this end, it is installed in an air supply housing which also includes a blower. Consequently, the heat exchanger must be compact with dimensions of for example 235 mm width and 250 mm height. In order to ensure a heat exchange capacity corresponding to the desired performance of the air conditioning system a relatively large air-side heat exchange surface must be provided since, at this side, the heat transfer is only about one fifth of that at the inside surfaces of the heat exchange tubes which are in heat exchange contact with the operating medium of the air conditioning system such as condensing CO2. In modified embodiments, other refrigerants may be provided such as water, NH3, R404A, R407C, R410A, R22, SF6, etc.

[0038] The heat exchanger tubes generally are extruded fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| internal pressure | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com